Patents

Literature

241results about How to "Difficult to manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

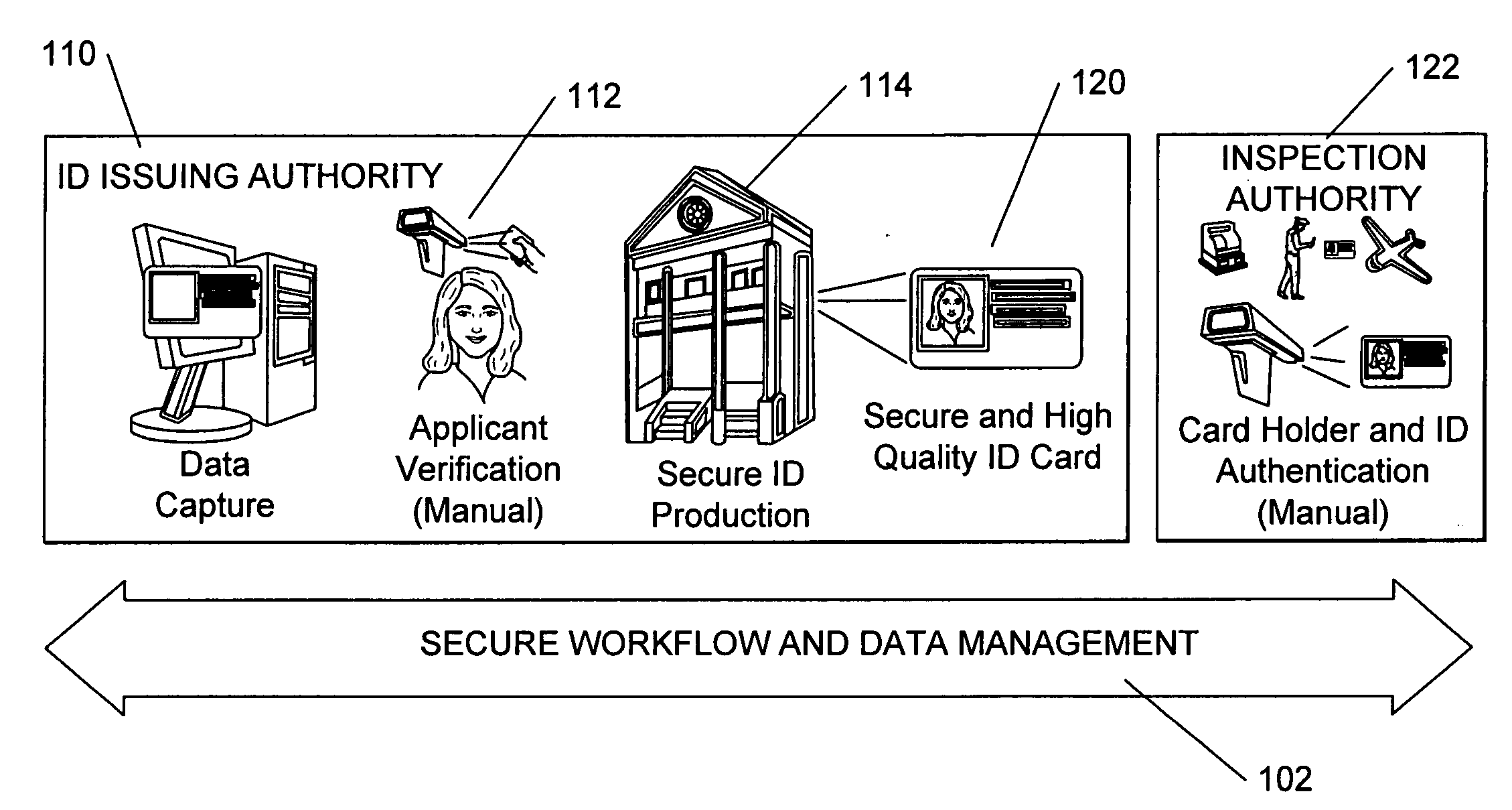

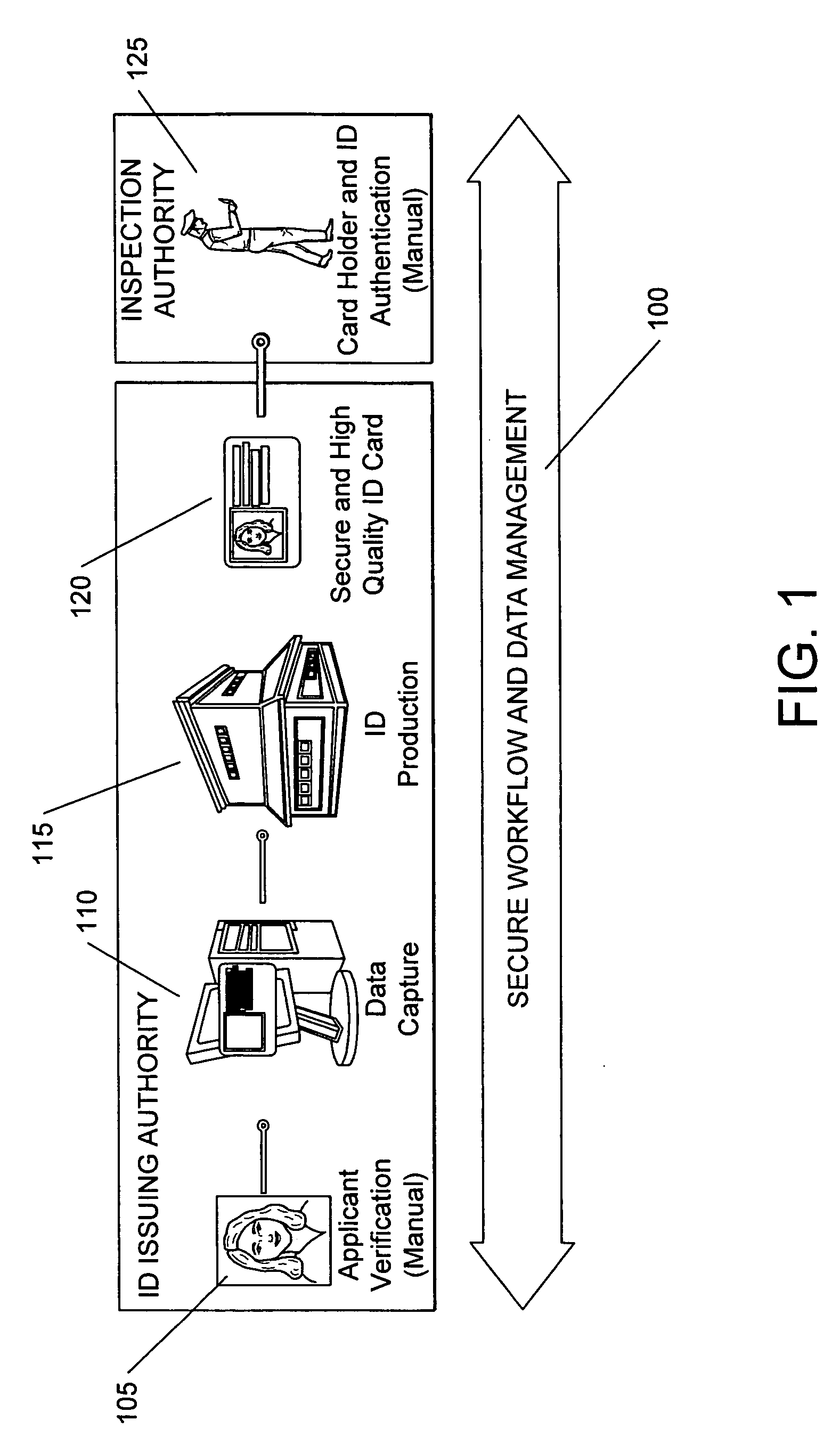

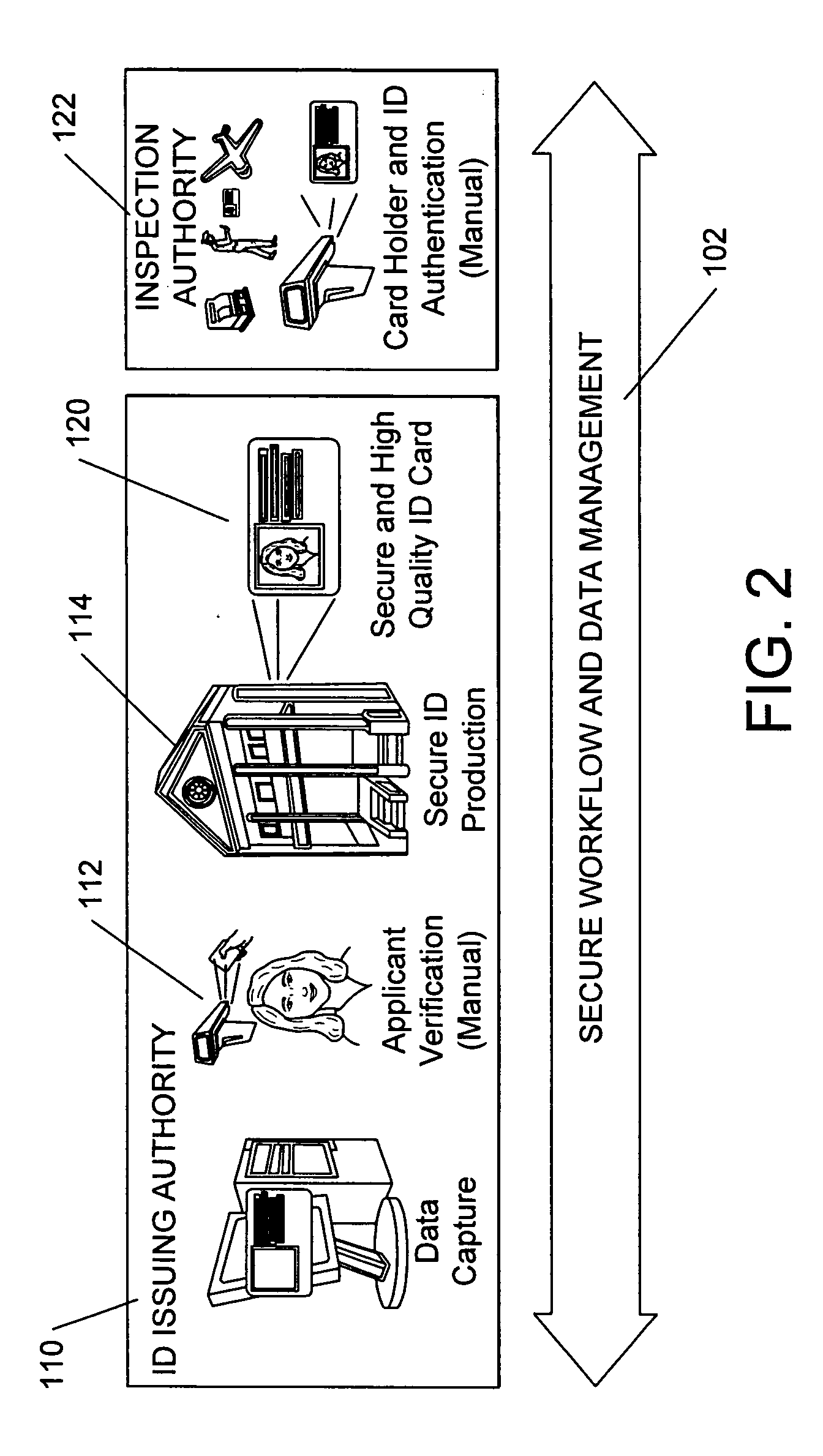

Systems and methods for document verification

InactiveUS20060157559A1Absence in detectionEliminate needAcutation objectsCo-operative working arrangementsPhysical securityPaper document

A method for issuing a credential includes scanning in documents (e.g., breeder or ID documents) used to verify the applicant of the credential and creating data records including the image of the documents. As a means to reduce fraud, these data records are linked to the credential and to the issuer location, operator and time and place of issuance. If the document includes machine readable information, the method automatically reads the machine readable information from the document and uses at least part of the machine readable information from the document to pre-populate a form used to create a credential, such as an identification document. The method includes applying a transformation to the image of the document that enables protection against fraudulent use. The transformation secures the image of the document from tampering and / or enables tracking of the use of the document image to deter fraud. A method of verifying a credential comprises reading a physical security feature attribute on the credential, reading a logical attribute on the credential, and comparing information from the physical security feature with the logical storage element on the credential to verify the credential.

Owner:DIGIMARC CORP

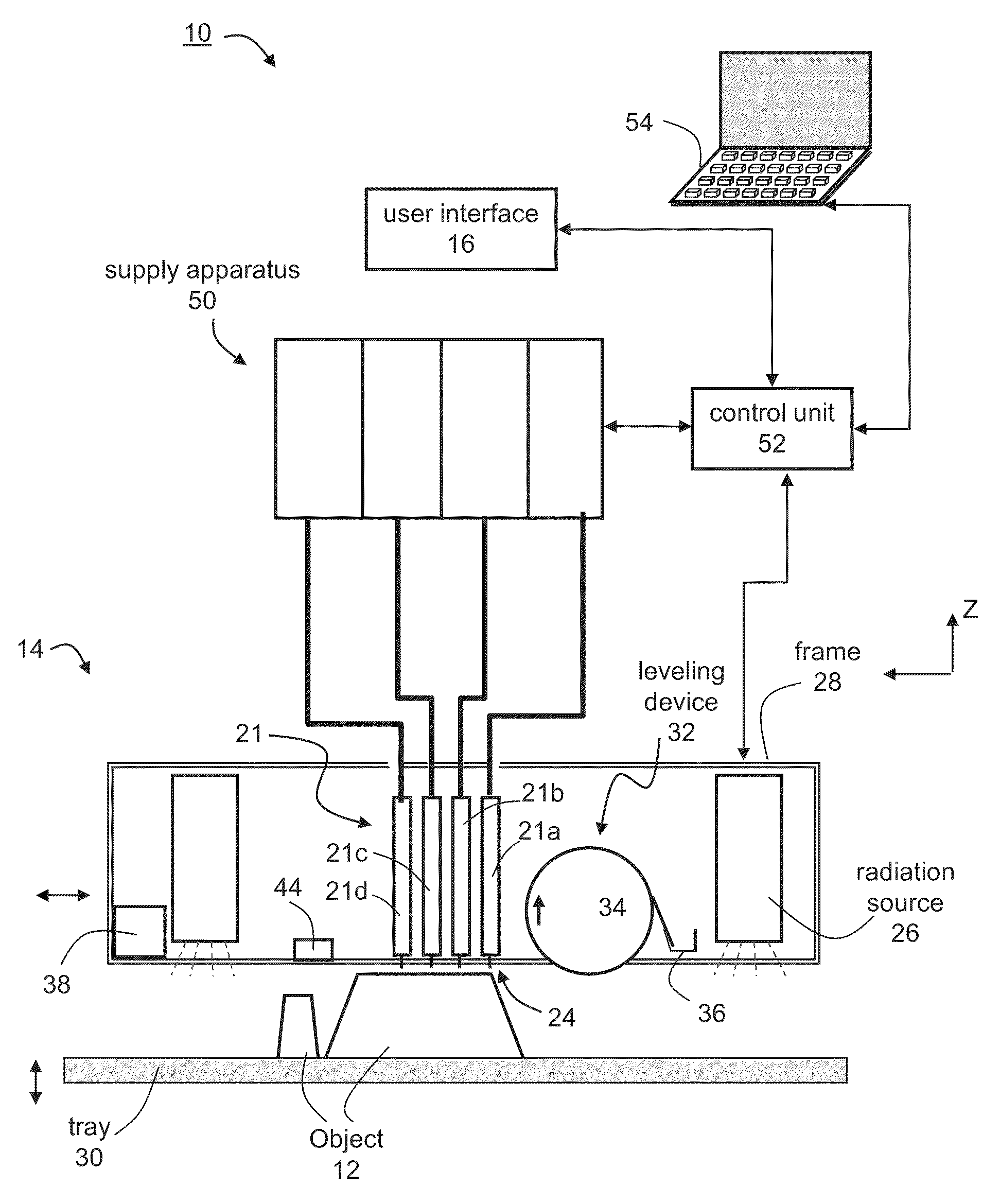

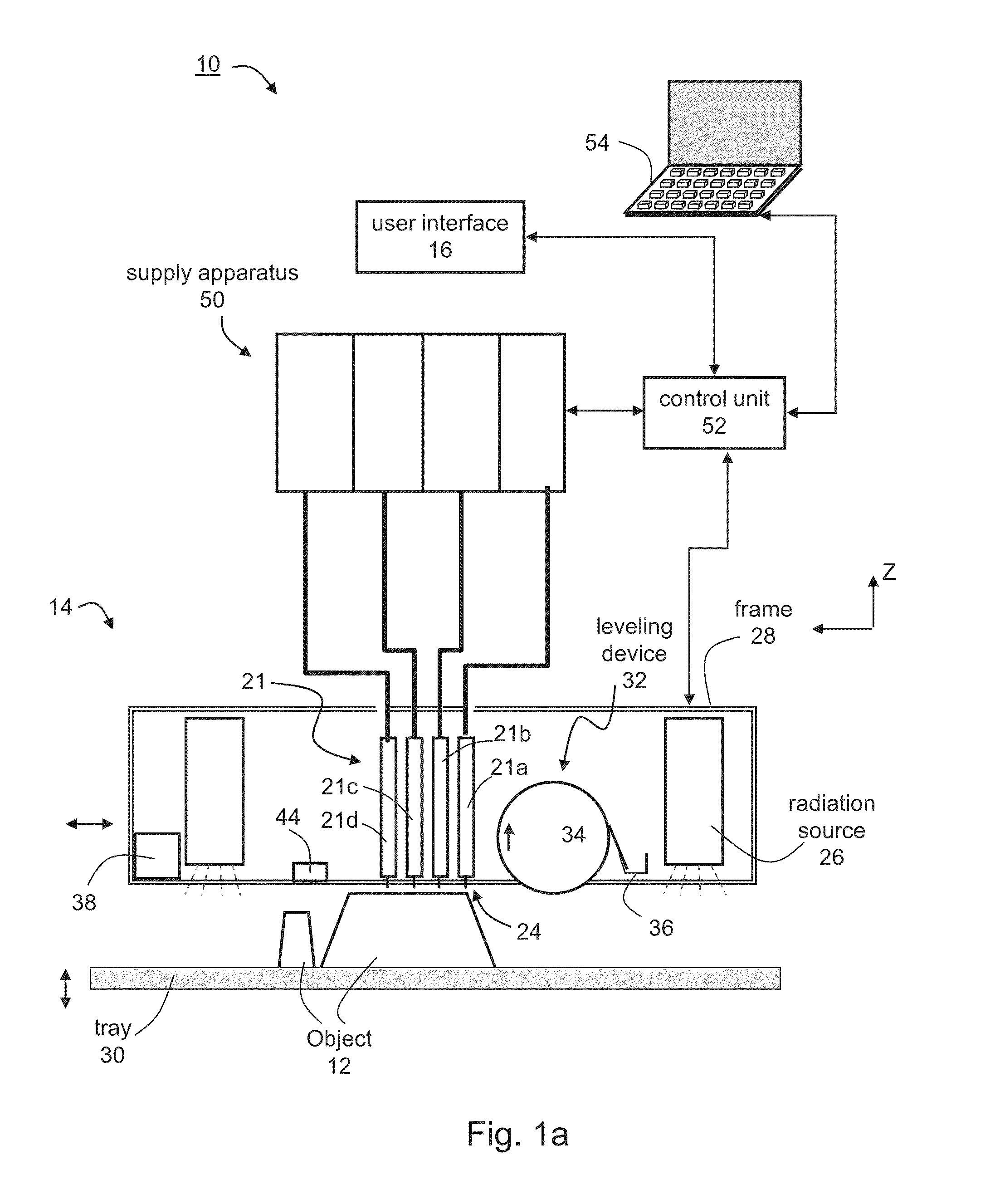

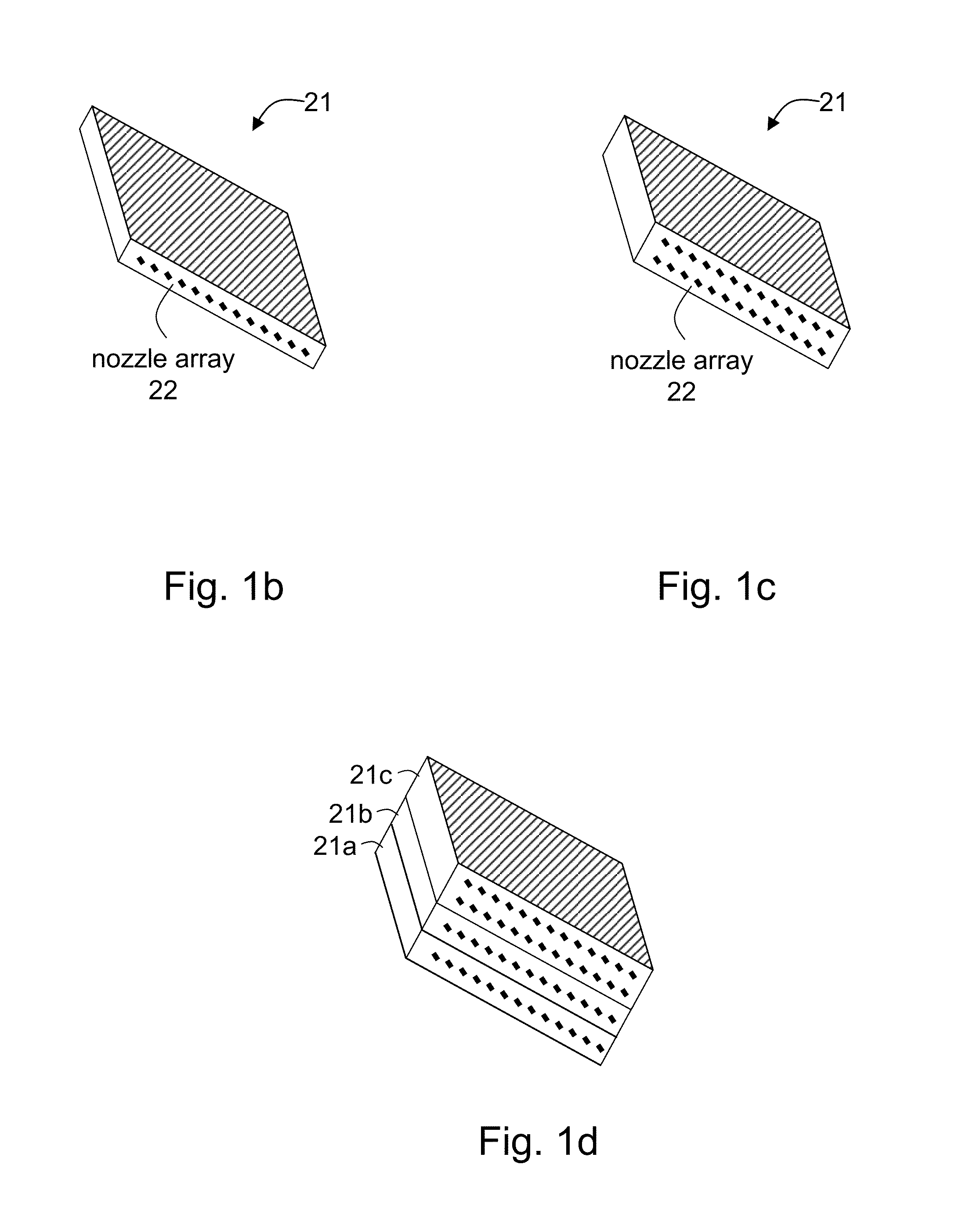

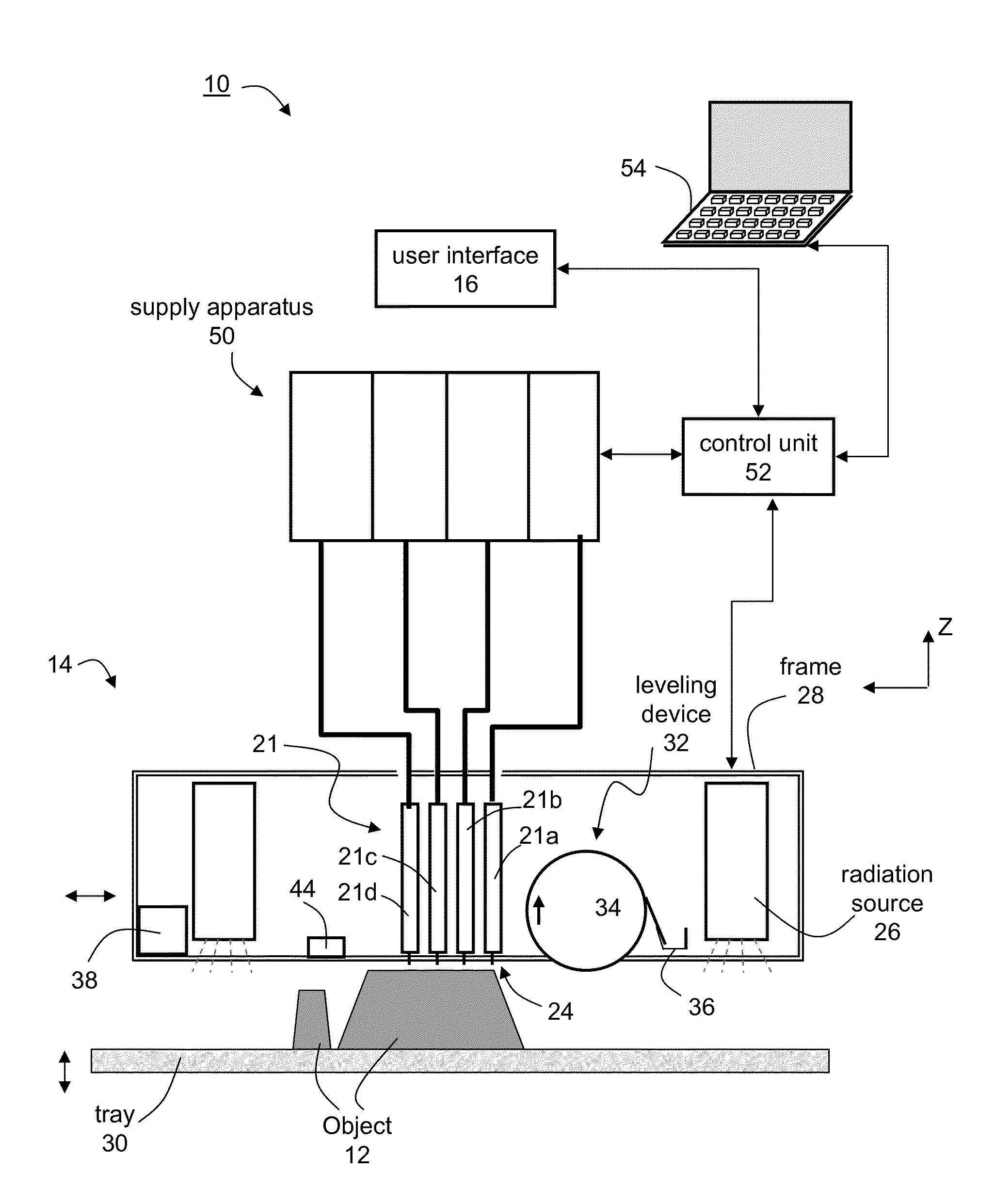

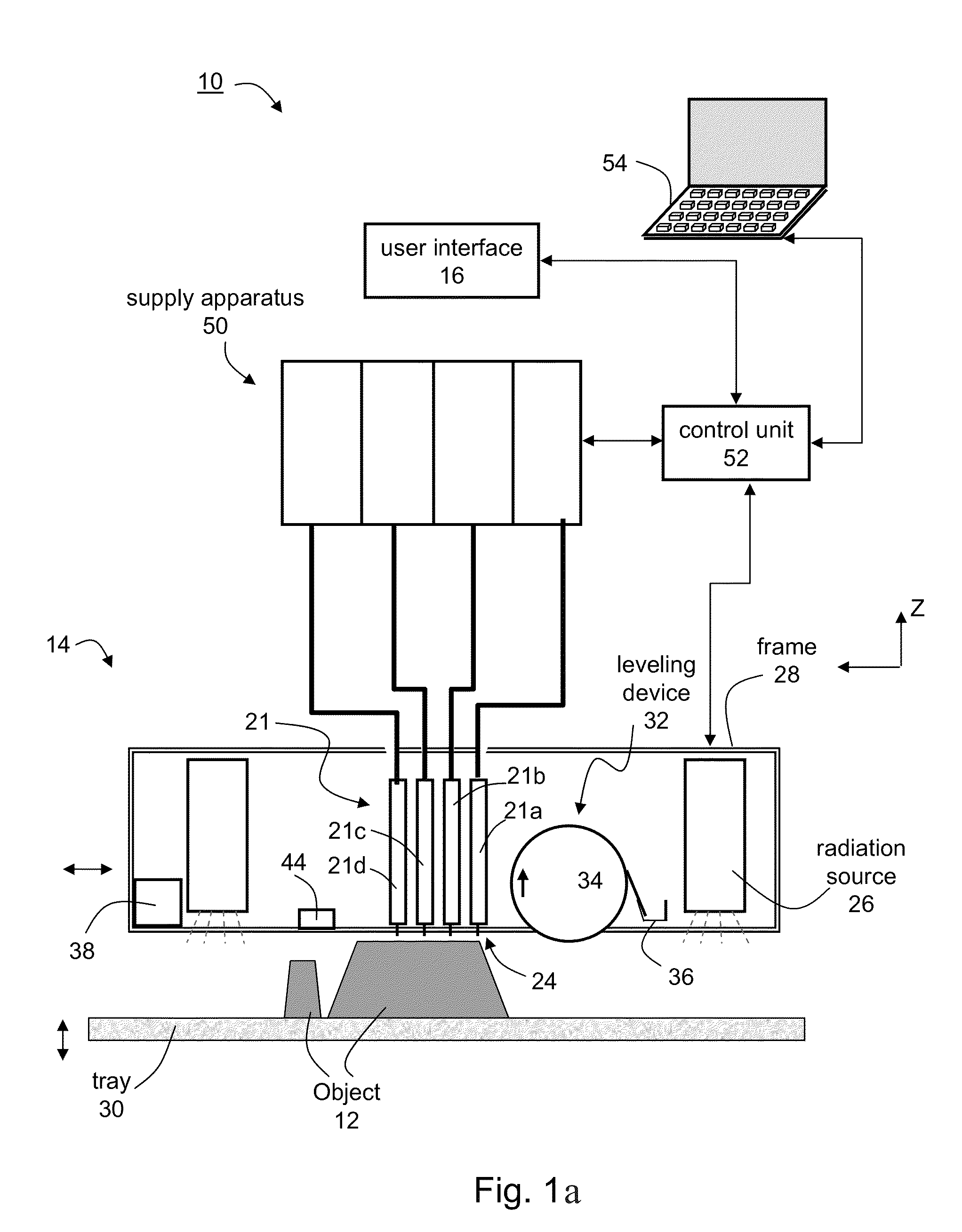

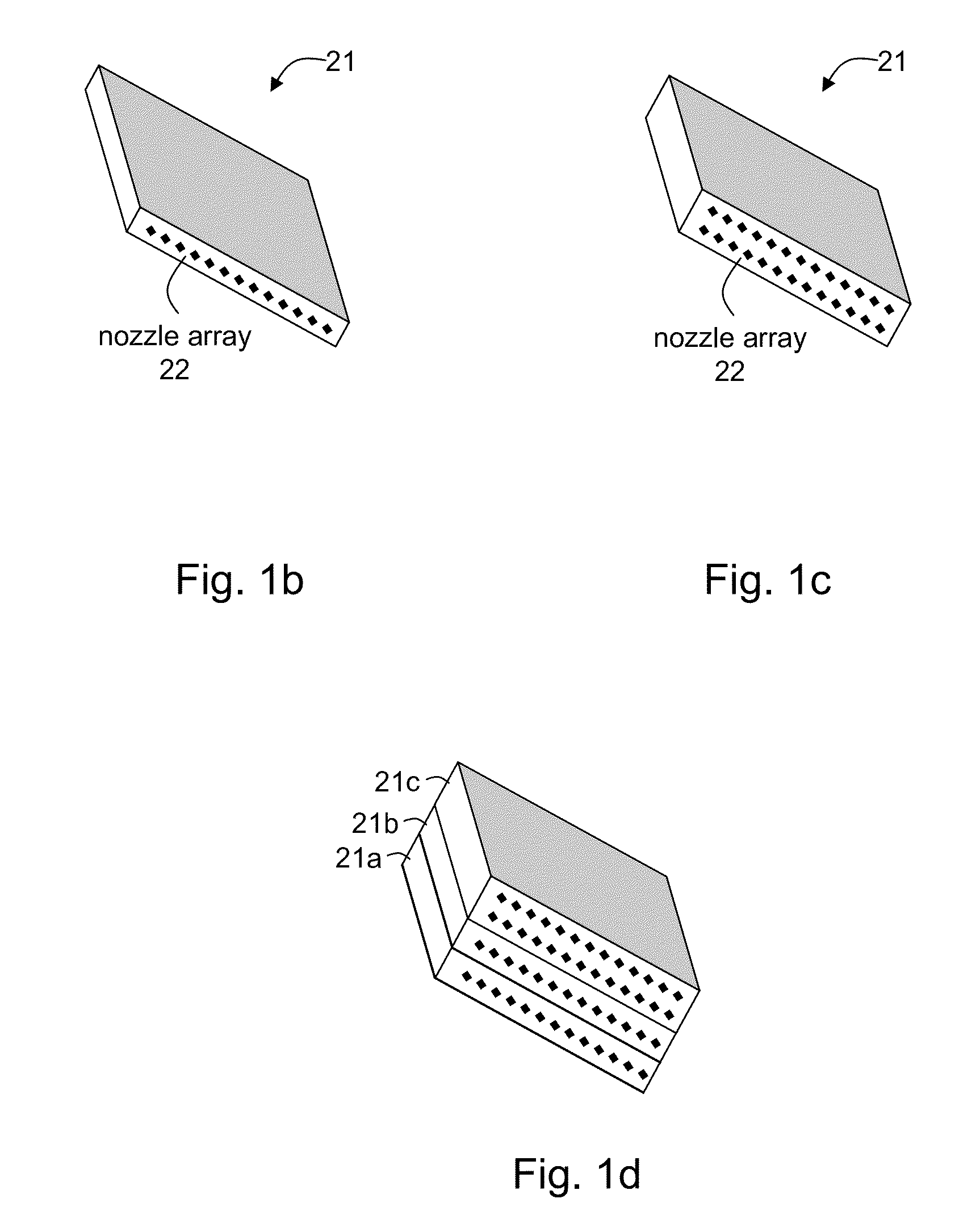

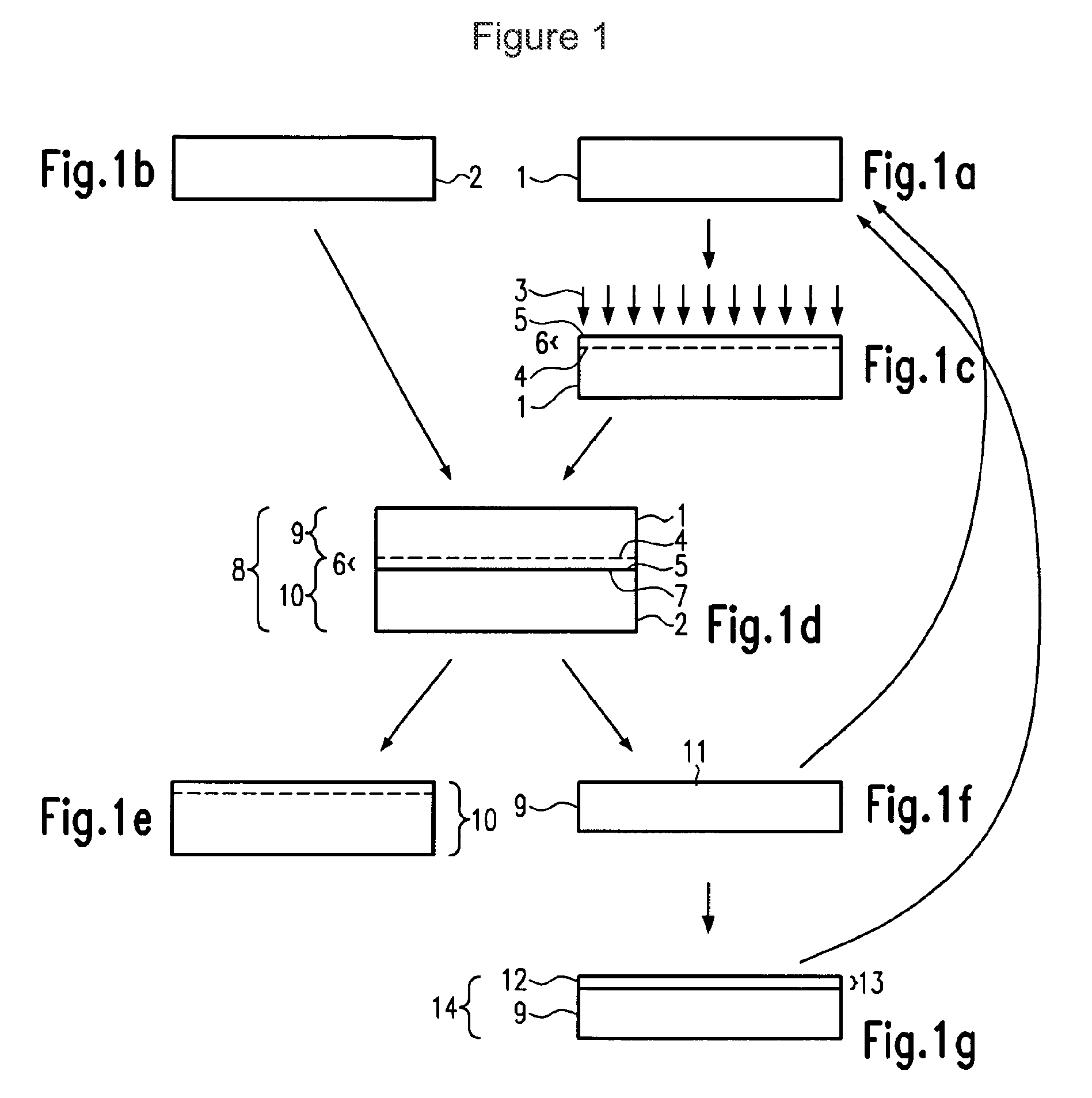

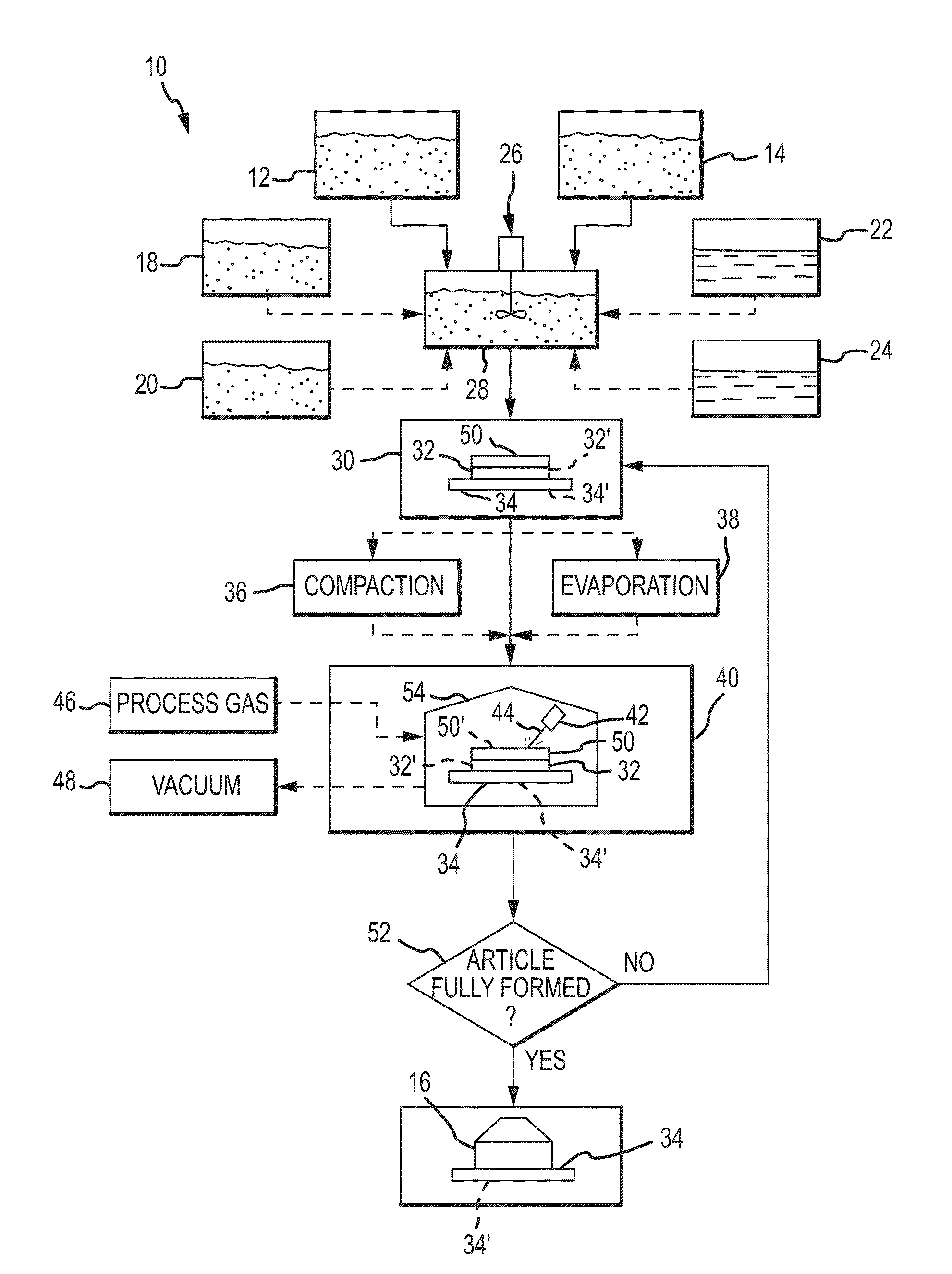

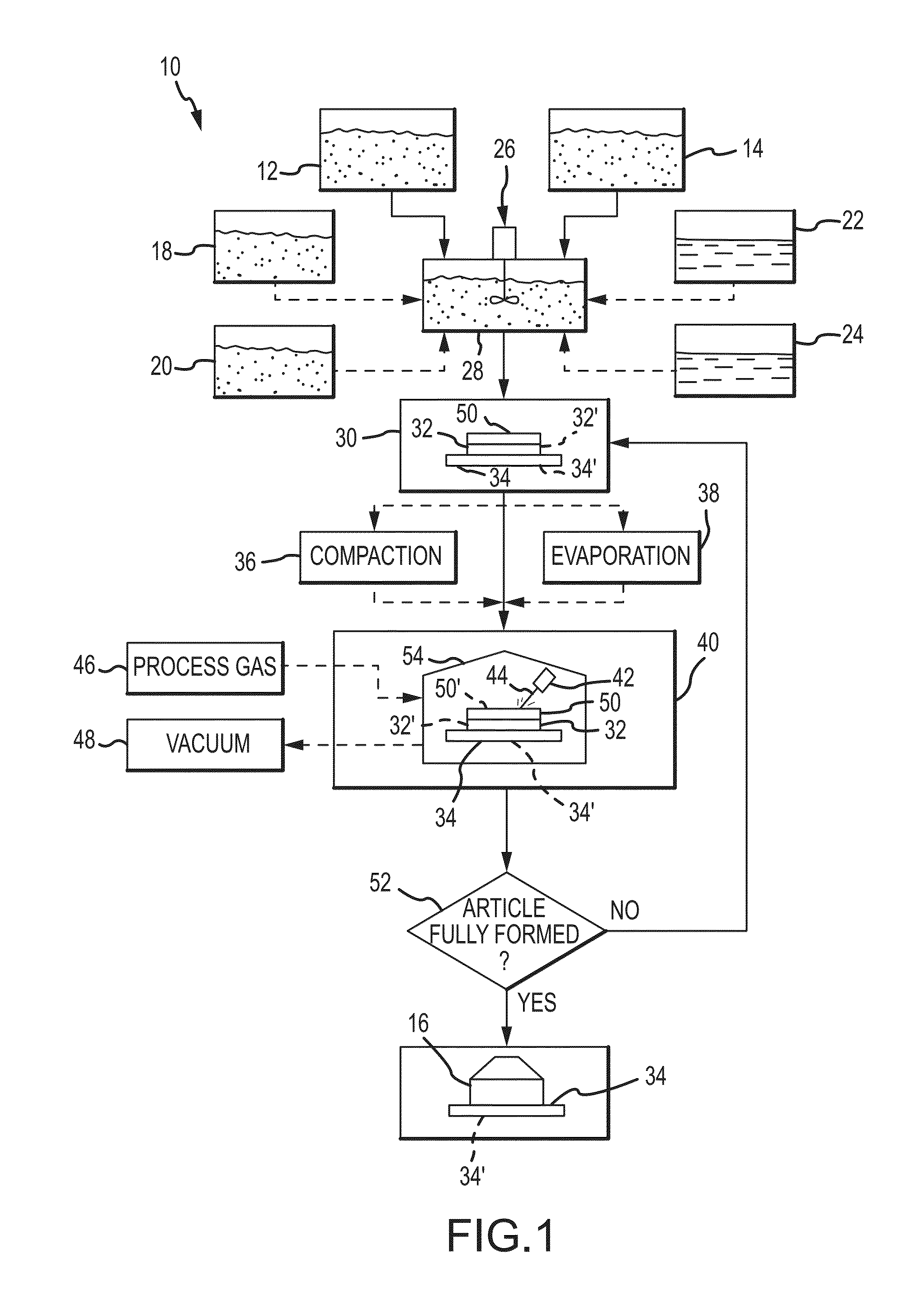

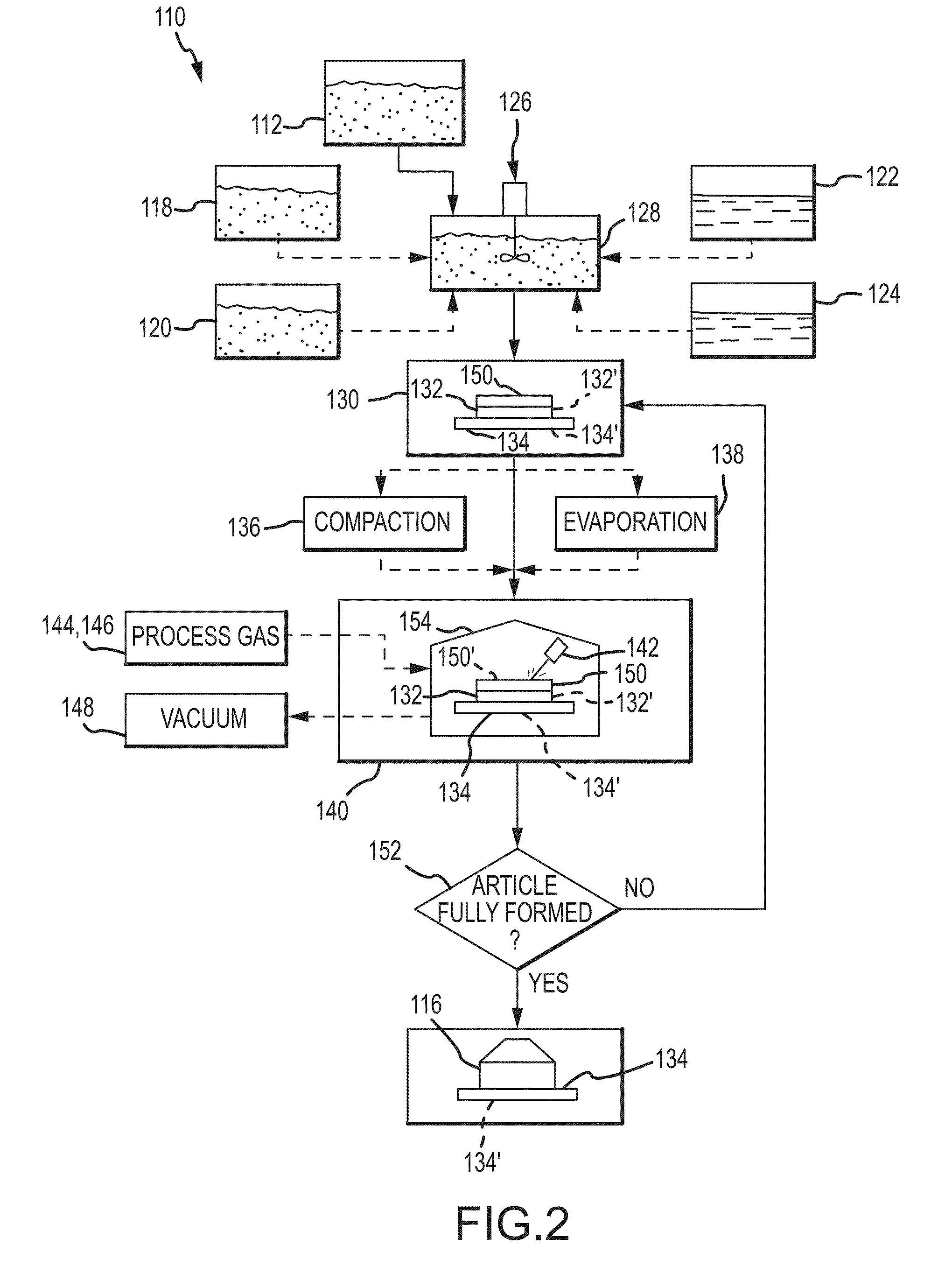

Solid freeform fabrication using a plurality of modeling materials

ActiveUS9031680B2Easy to burnImprove shrinkageAdditive manufacturing apparatusAdditive manufacturing with liquidsOperation modeSolid freeform fabrication

A system and methods for solid freeform fabrication of an object is disclosed. The system comprises a solid freeform fabrication apparatus having a plurality of dispensing heads, a building material supply apparatus configured to supply a plurality of building materials to the fabrication apparatus, and a control unit configured for controlling the fabrication apparatus and the supply apparatus based on an operation mode selected from a plurality of predetermined operation modes.

Owner:STRATASYS LTD

Solid freeform fabrication using a plurality of modeling materials

ActiveUS20130073068A1Easy to burnImprove shrinkageAdditive manufacturing apparatusAdditive manufacturing with liquidsOperation modeSolid freeform fabrication

Owner:STRATASYS LTD

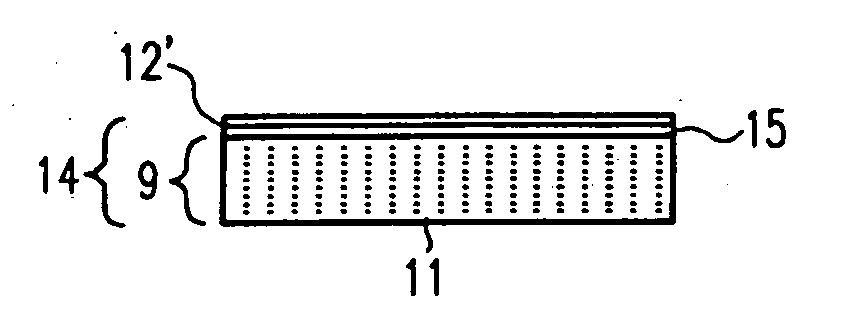

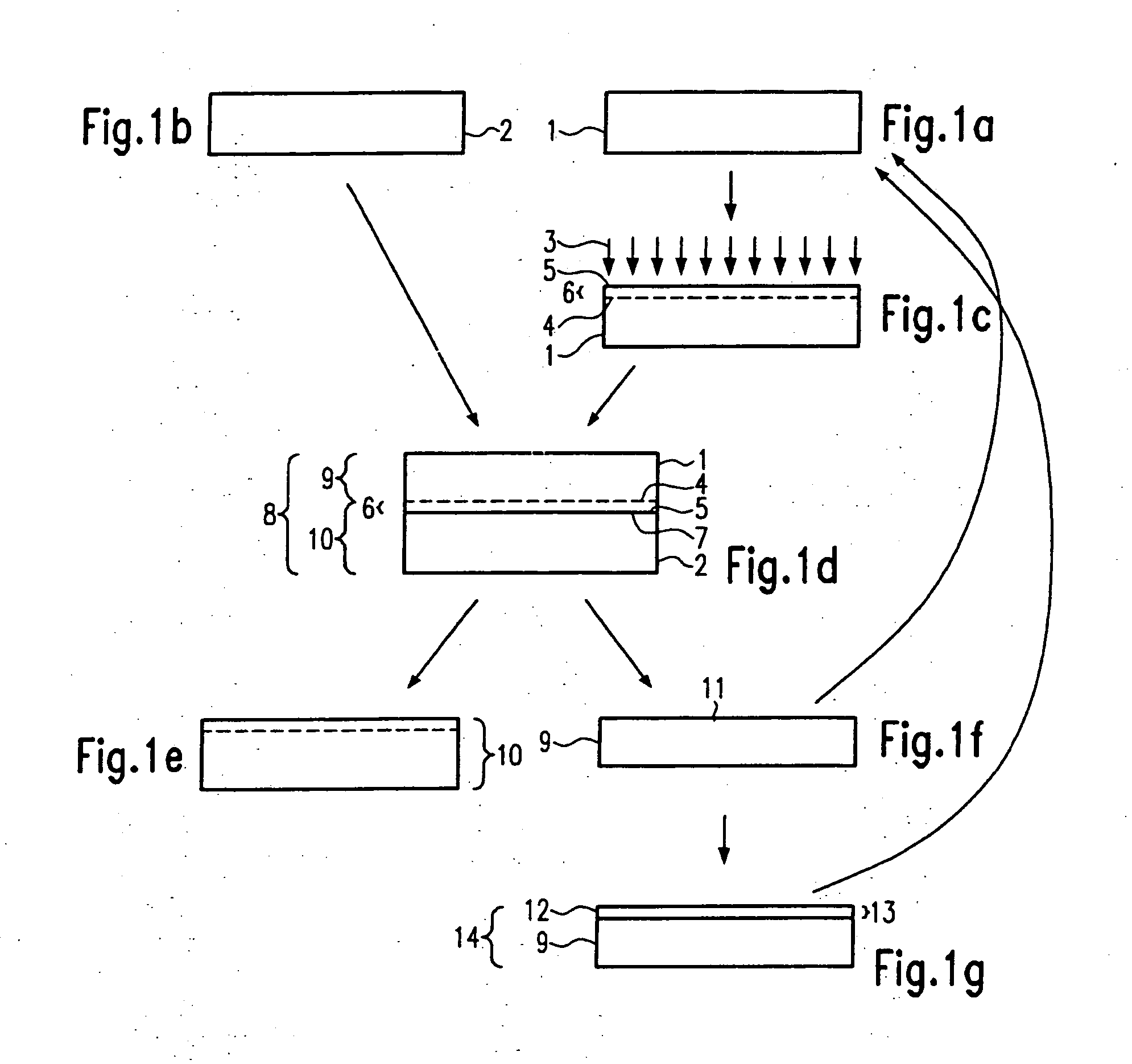

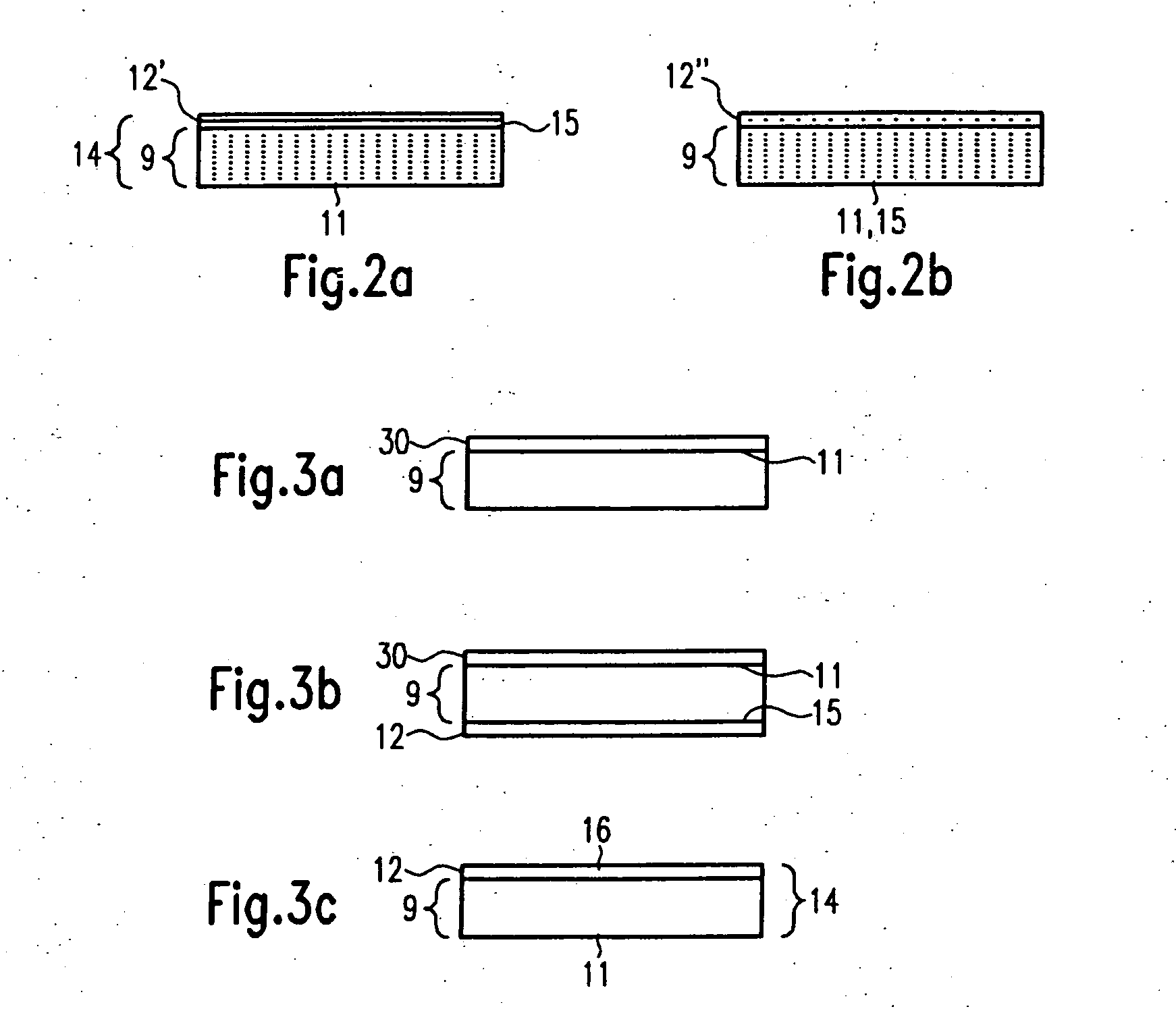

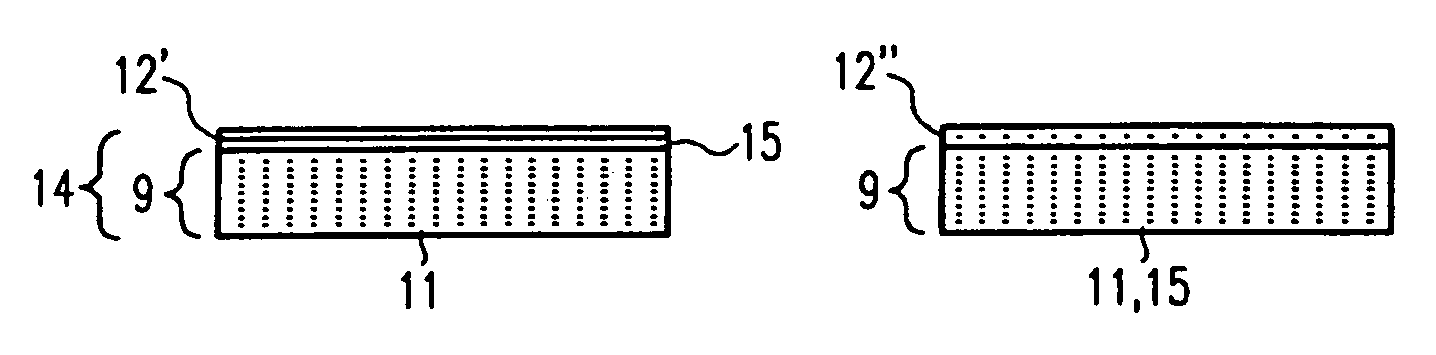

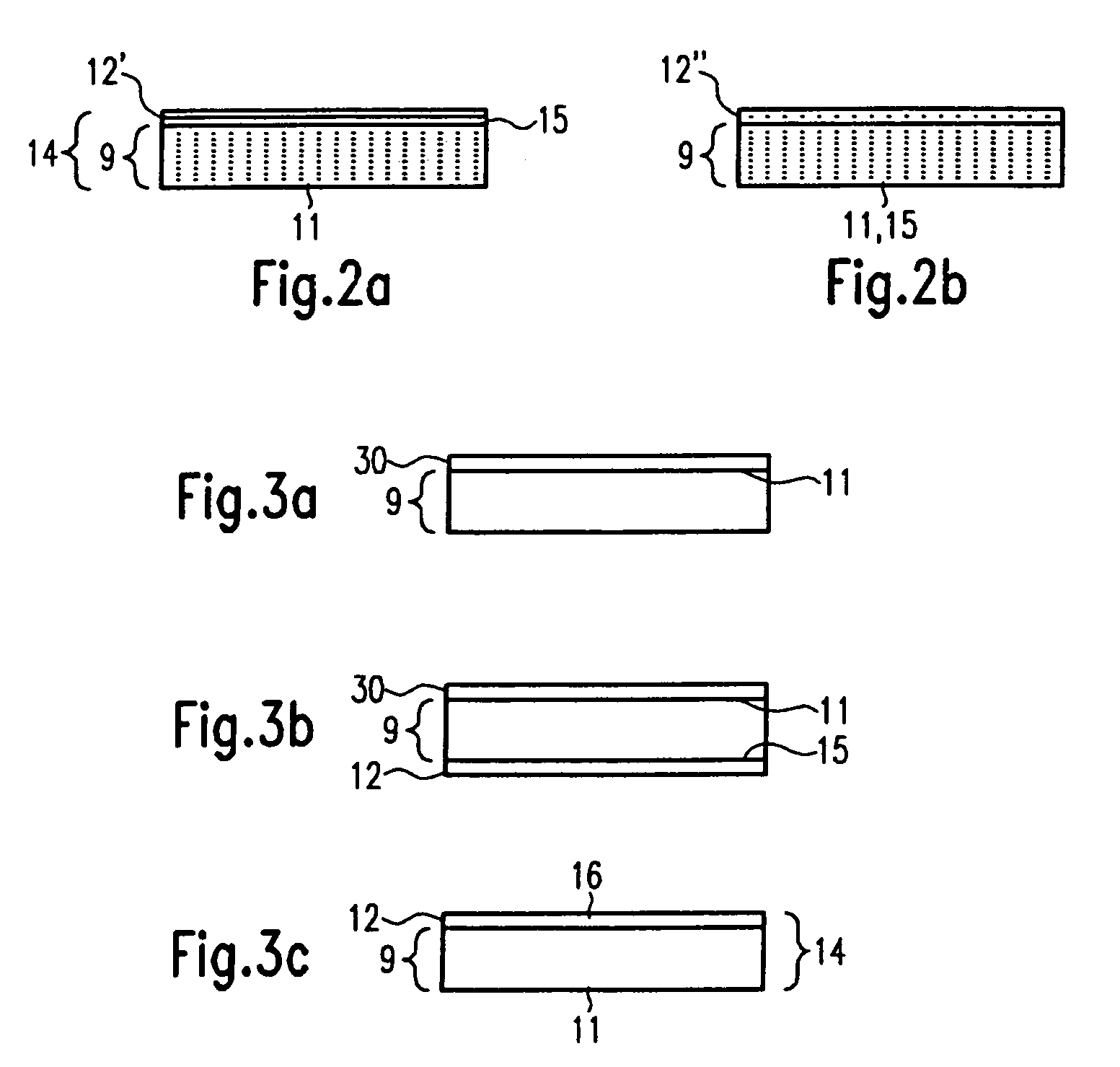

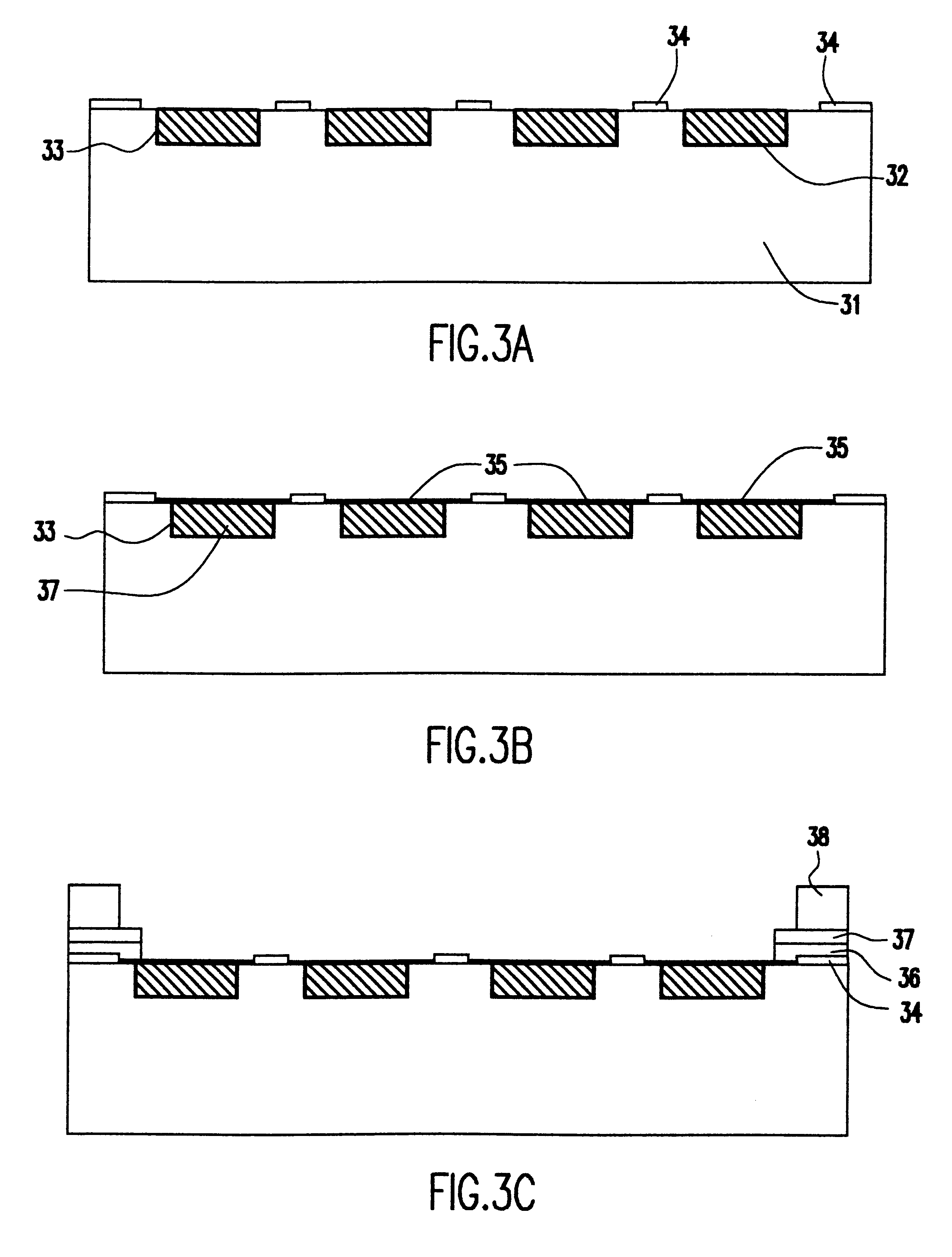

Methods for fabricating compound material wafers

ActiveUS20060099776A1Increasing the thicknessOvercome problemsSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsSubstrate surface

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

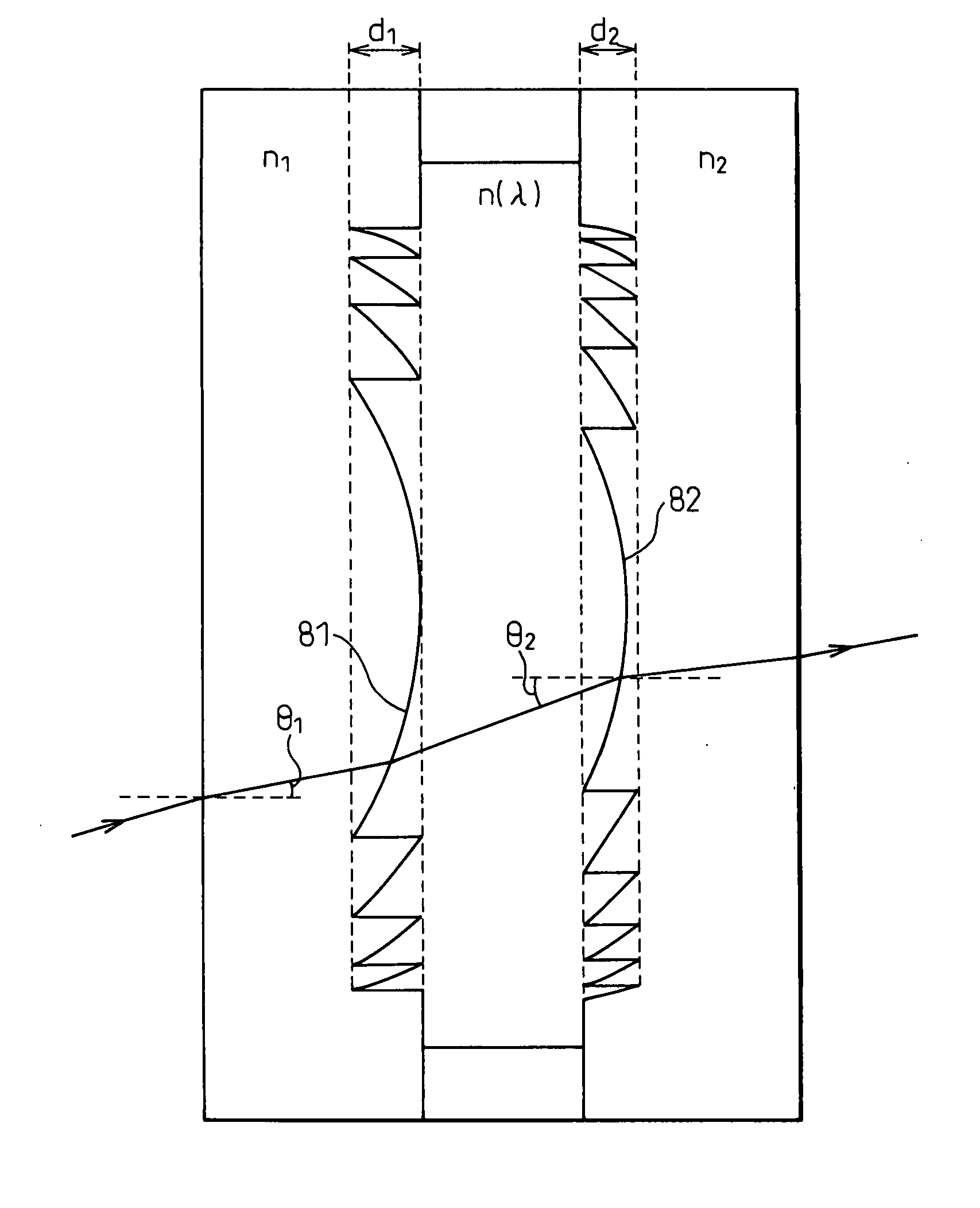

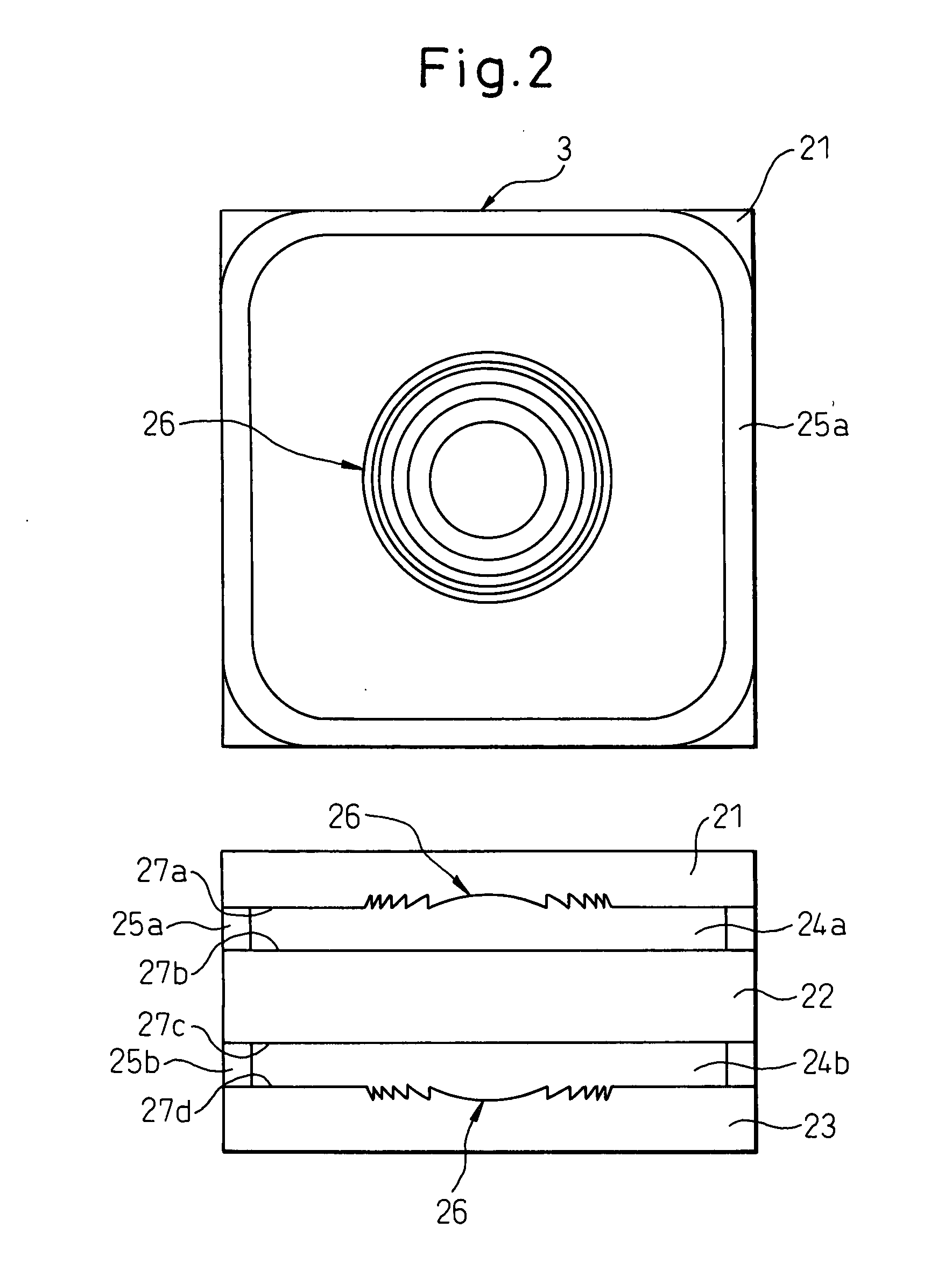

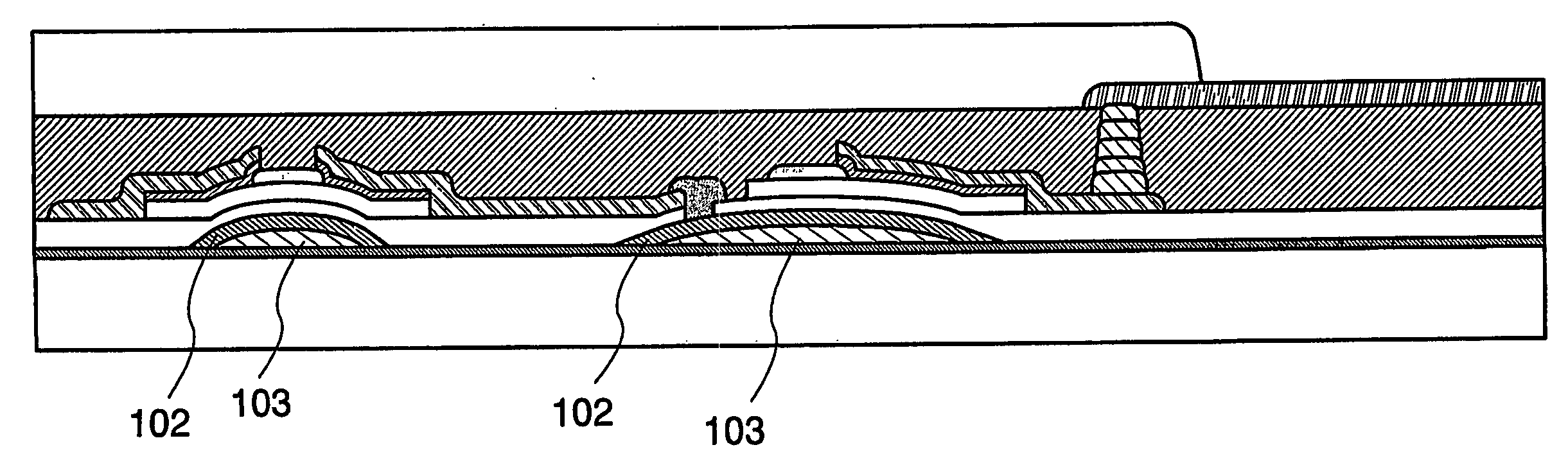

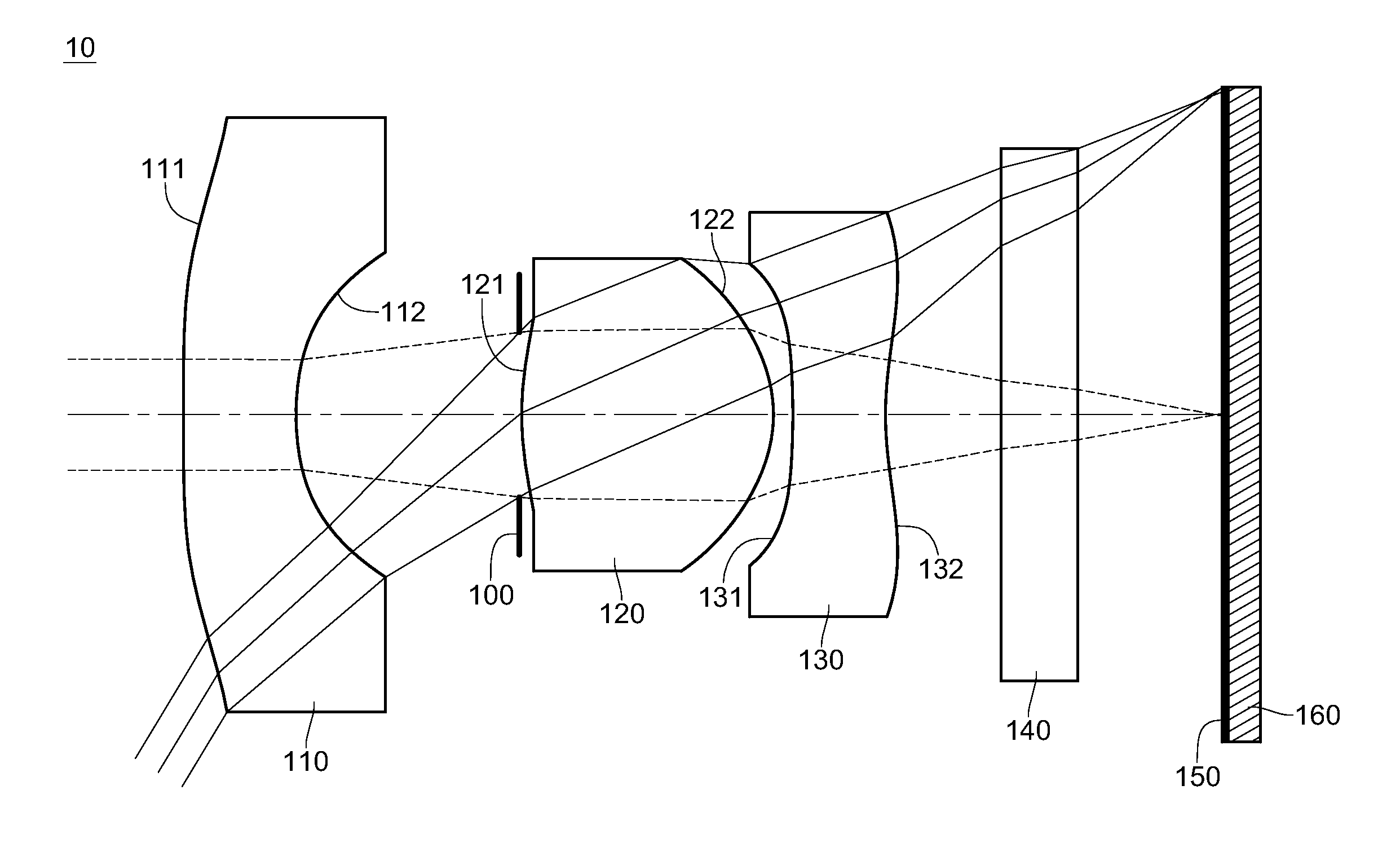

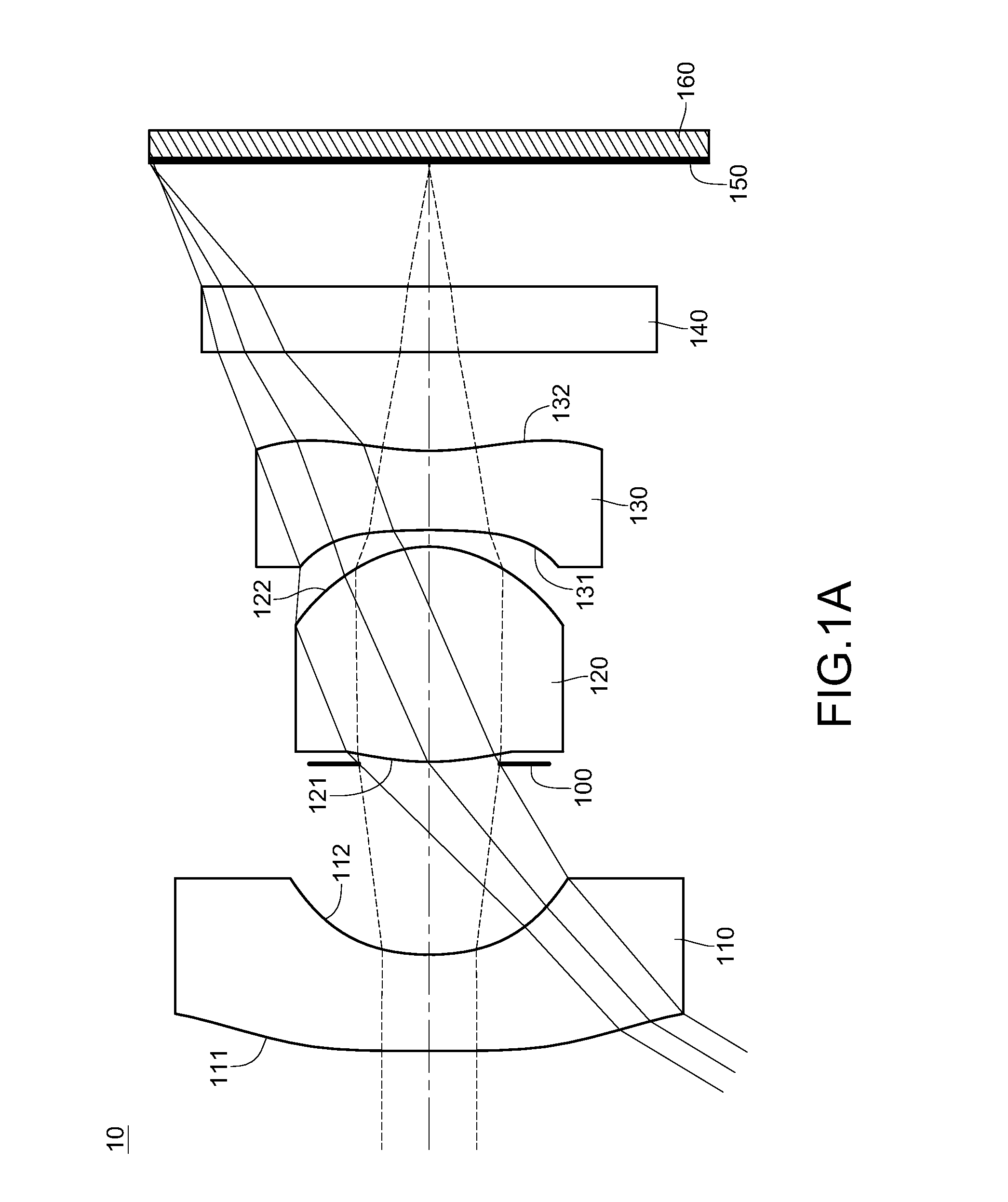

Liquid crystal lens and imaging lens device

The present invention provides an imaging lens device, which has a widely extended focusing range and exhibits good resolution over the entire focusing range. The imaging lens device comprises a liquid crystal lens for focusing an object at a prescribed distance, comprising a liquid crystal layer, a first transparent substrate disposed adjacent to one surface of the liquid crystal layer and having a first electrode and having Fresnel lens surface formed on the boundary with the liquid crystal layer, a second transparent substrate disposed adjacent to the other surface of the liquid crystal layer and having a second electrode; a controller for changing the refractive index of the liquid crystal layer for extraordinary ray by changing electric voltage applied between the first electrode and the second electrode; and an imaging element for taking an image of the object. The liquid crystal lens functions as a diffractive optical element for an extraordinary ray when the liquid crystal layer has a prescribed refractive index for an extraordinary ray incident upon the liquid crystal layer.

Owner:CITIZEN WATCH CO LTD

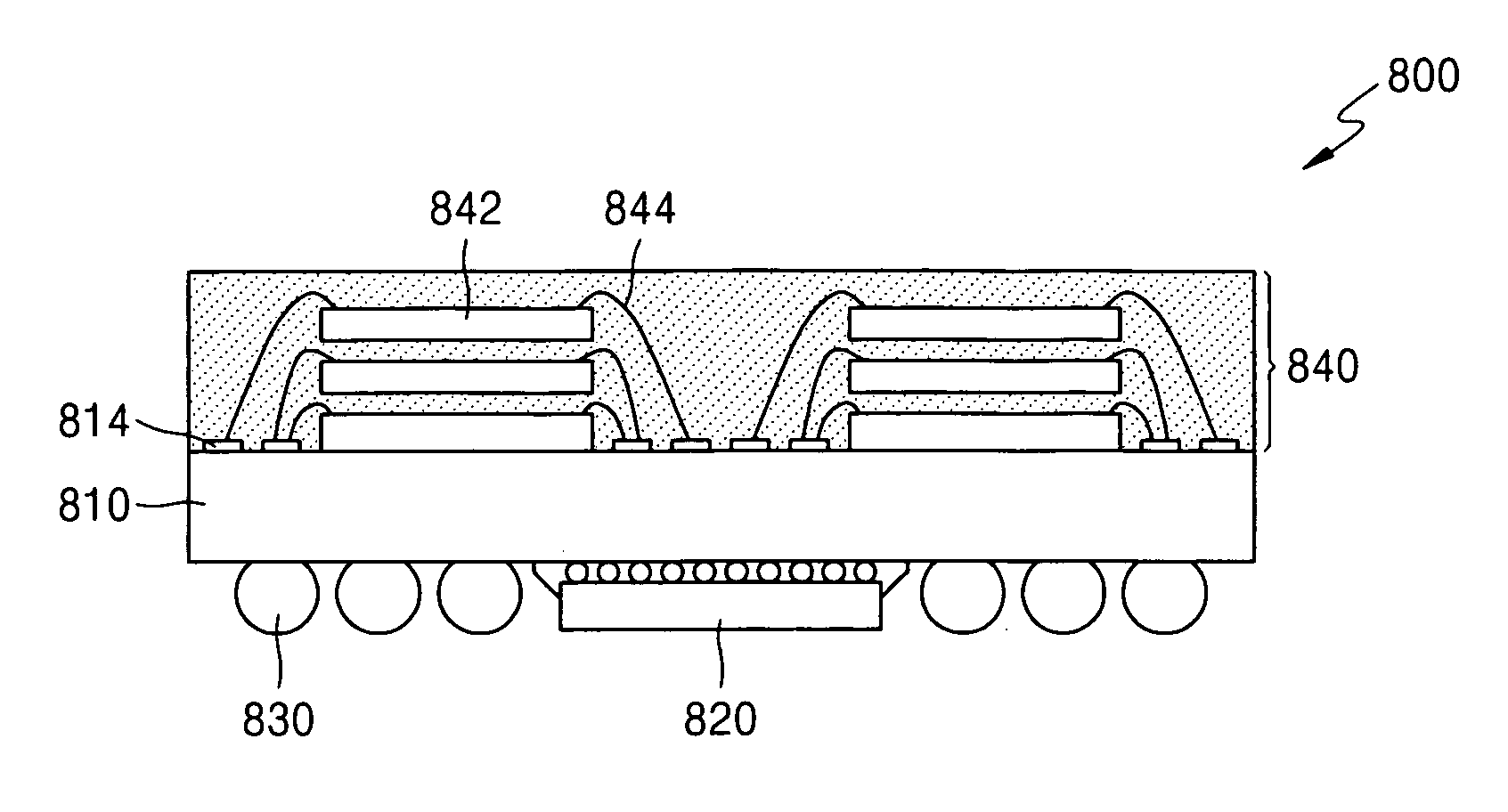

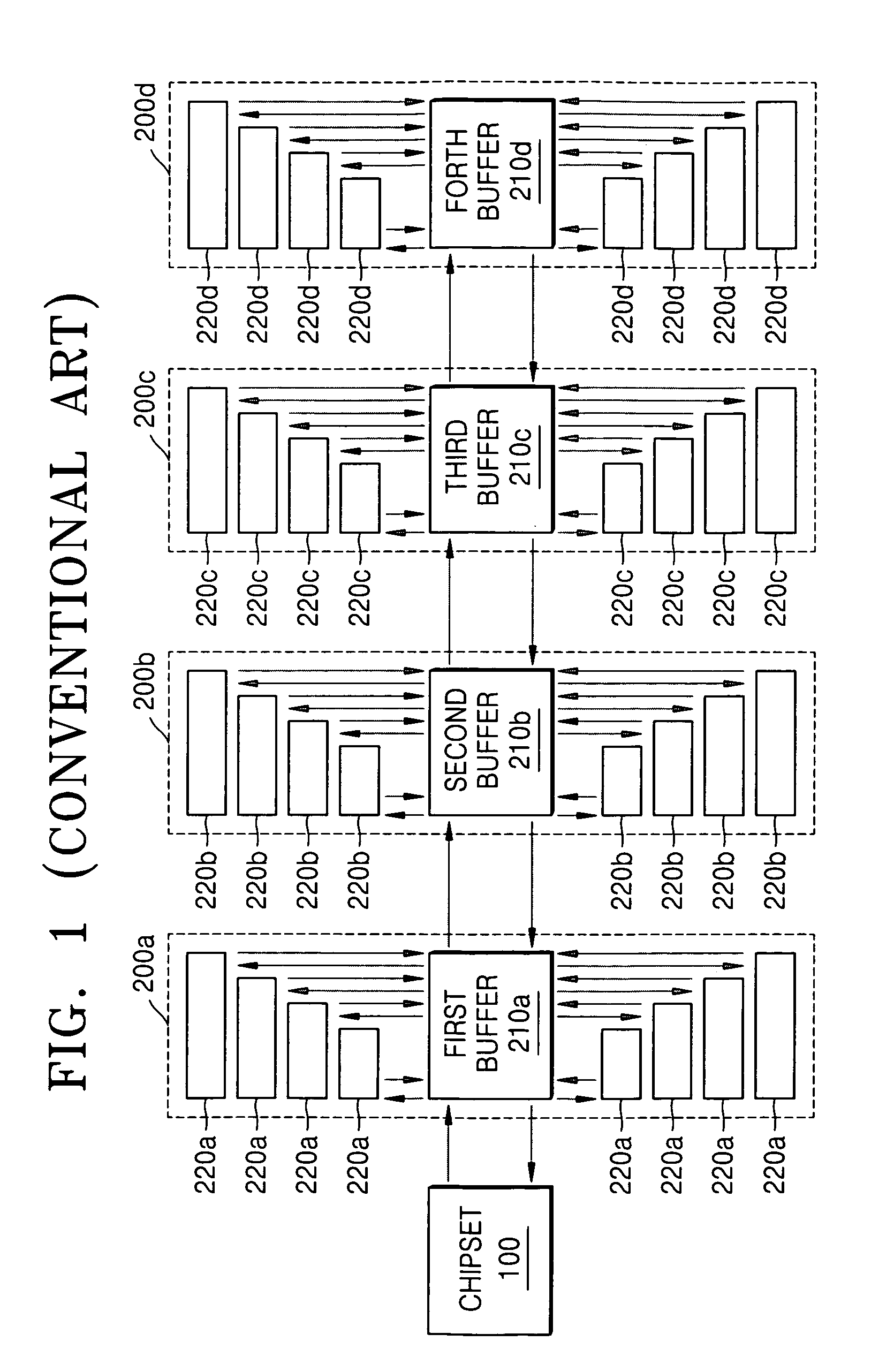

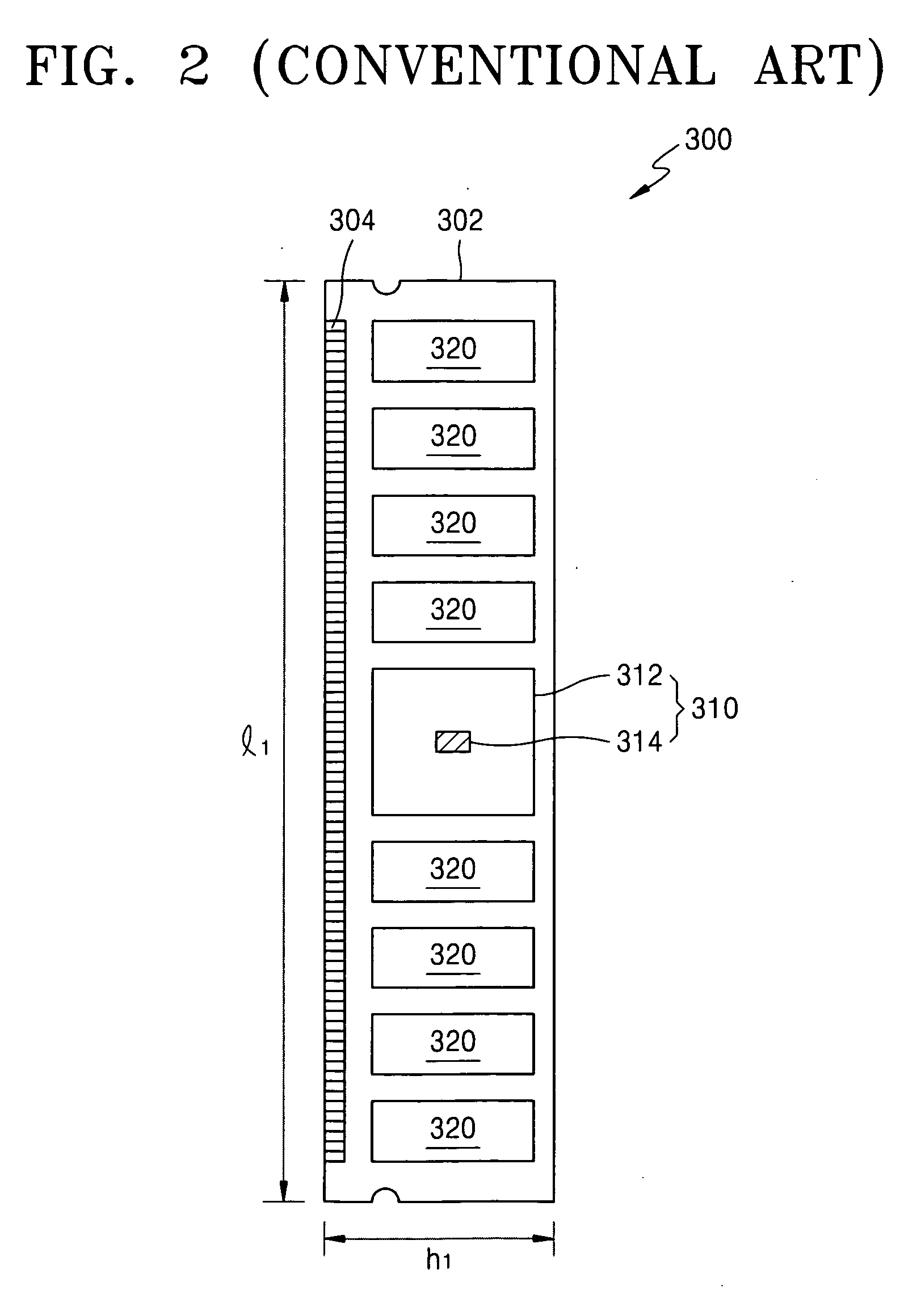

Semiconductor device package having buffered memory module and method thereof

ActiveUS20050224948A1Excellent electrical propertiesReduce distanceSemiconductor/solid-state device detailsPrinted circuit aspectsMemory chipDevice material

A method and apparatus of fabricating a semiconductor device are disclosed. The semiconductor device may include a buffer chip package having a buffer chip mounted on a buffer chip substrate and at least one memory package mounted on the buffer chip substrate, wherein the at least one memory package may include a plurality of memory chips. Further, the buffer chip package may have a plurality of external connection terminals.

Owner:SAMSUNG ELECTRONICS CO LTD

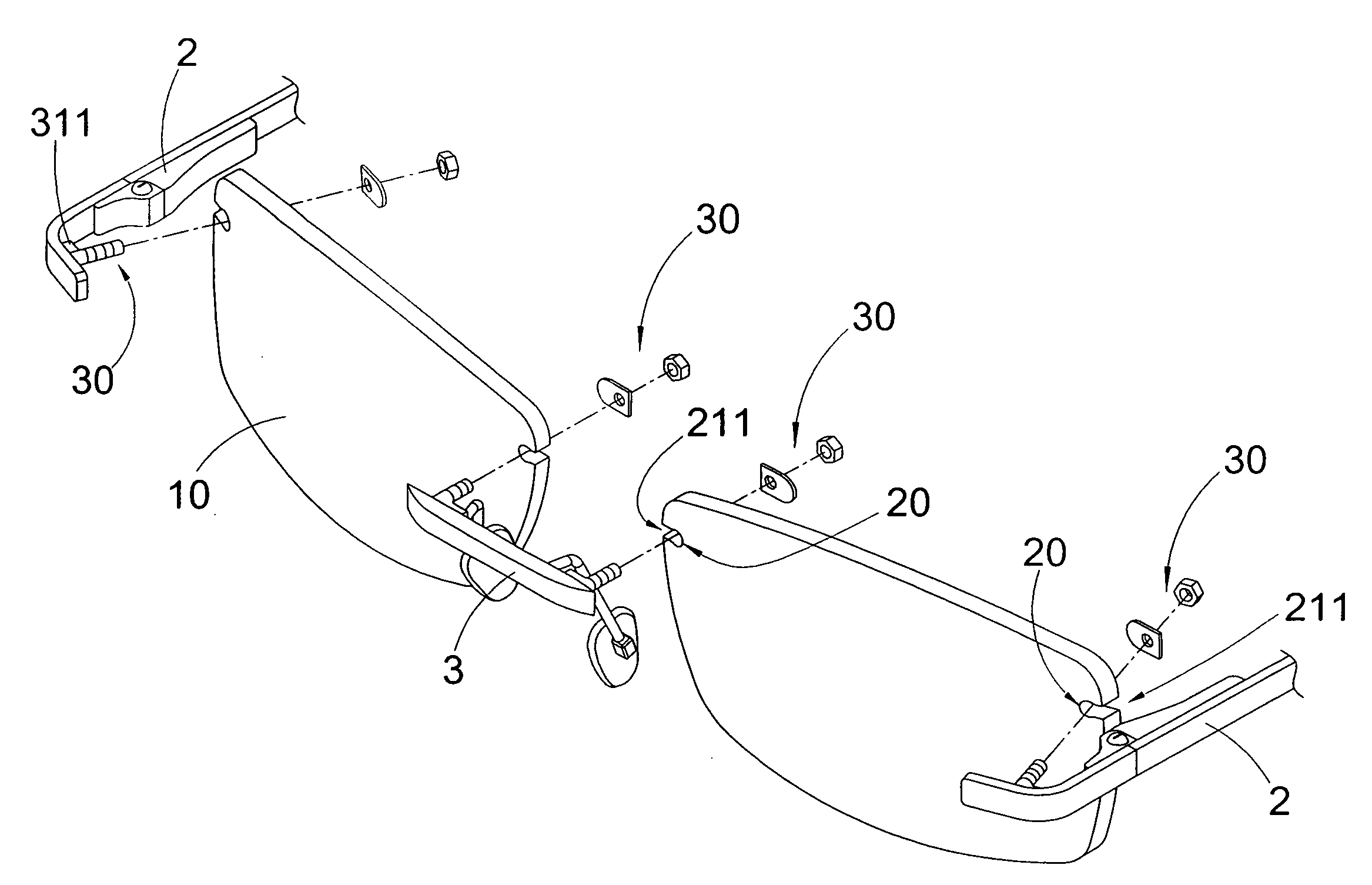

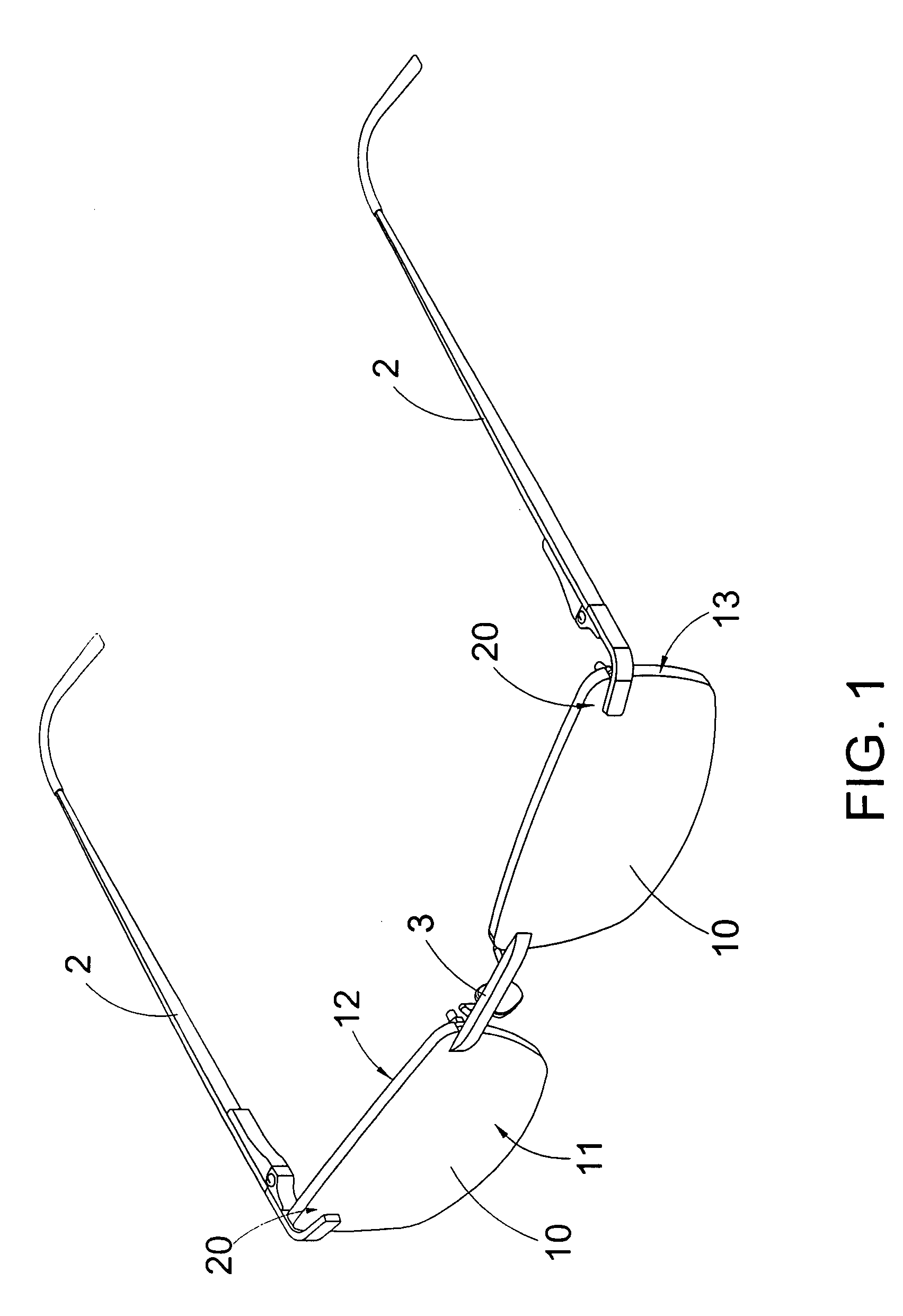

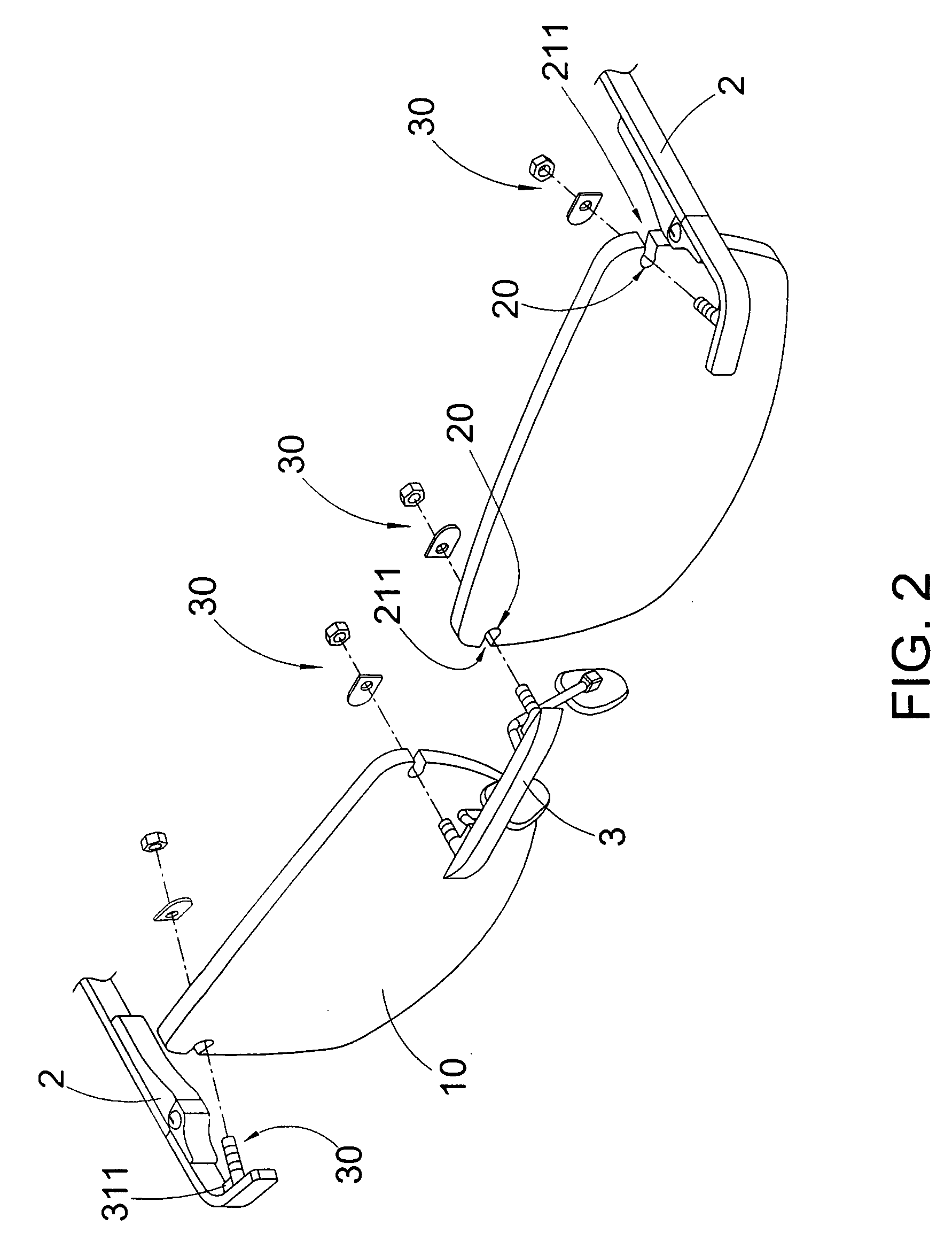

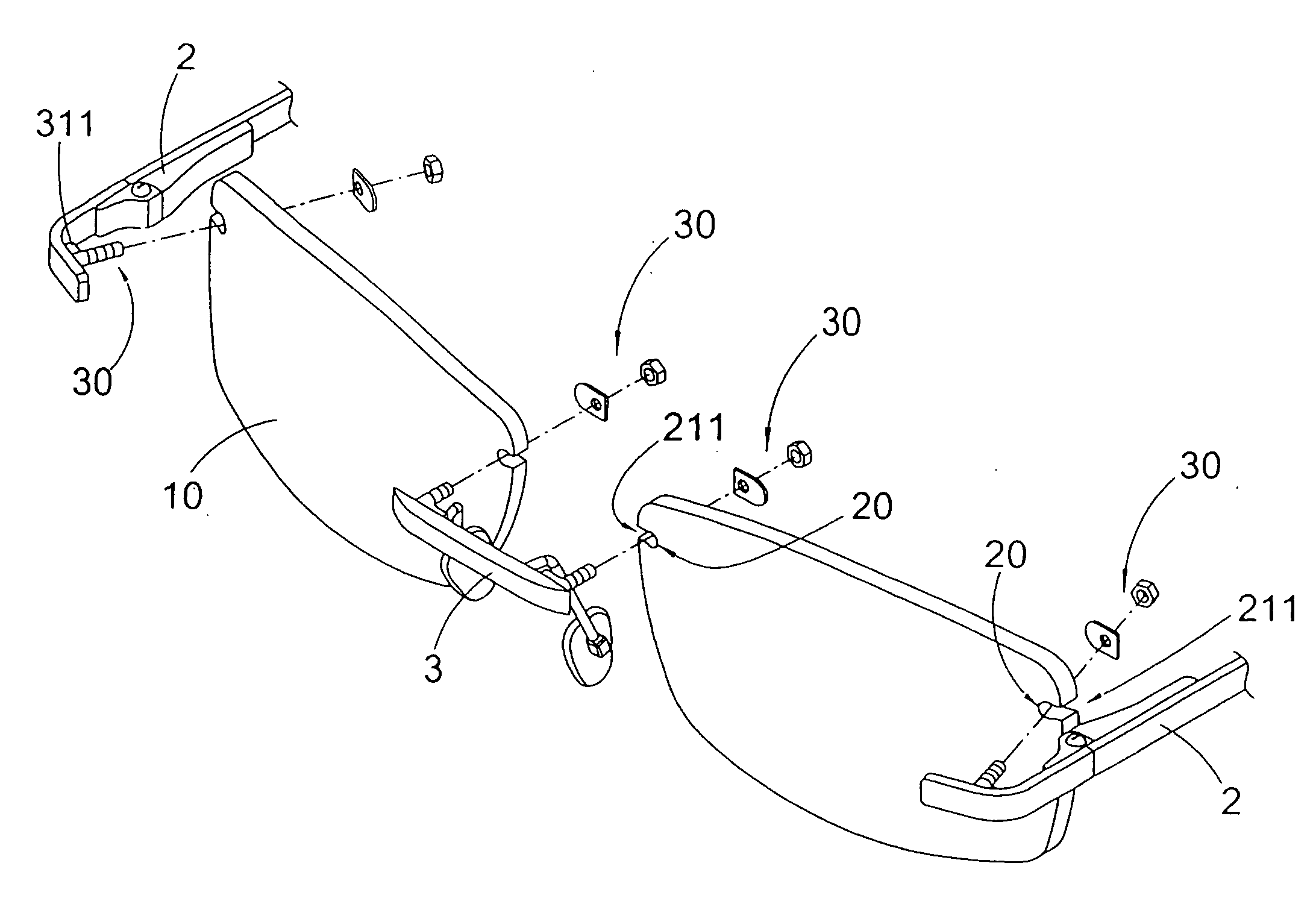

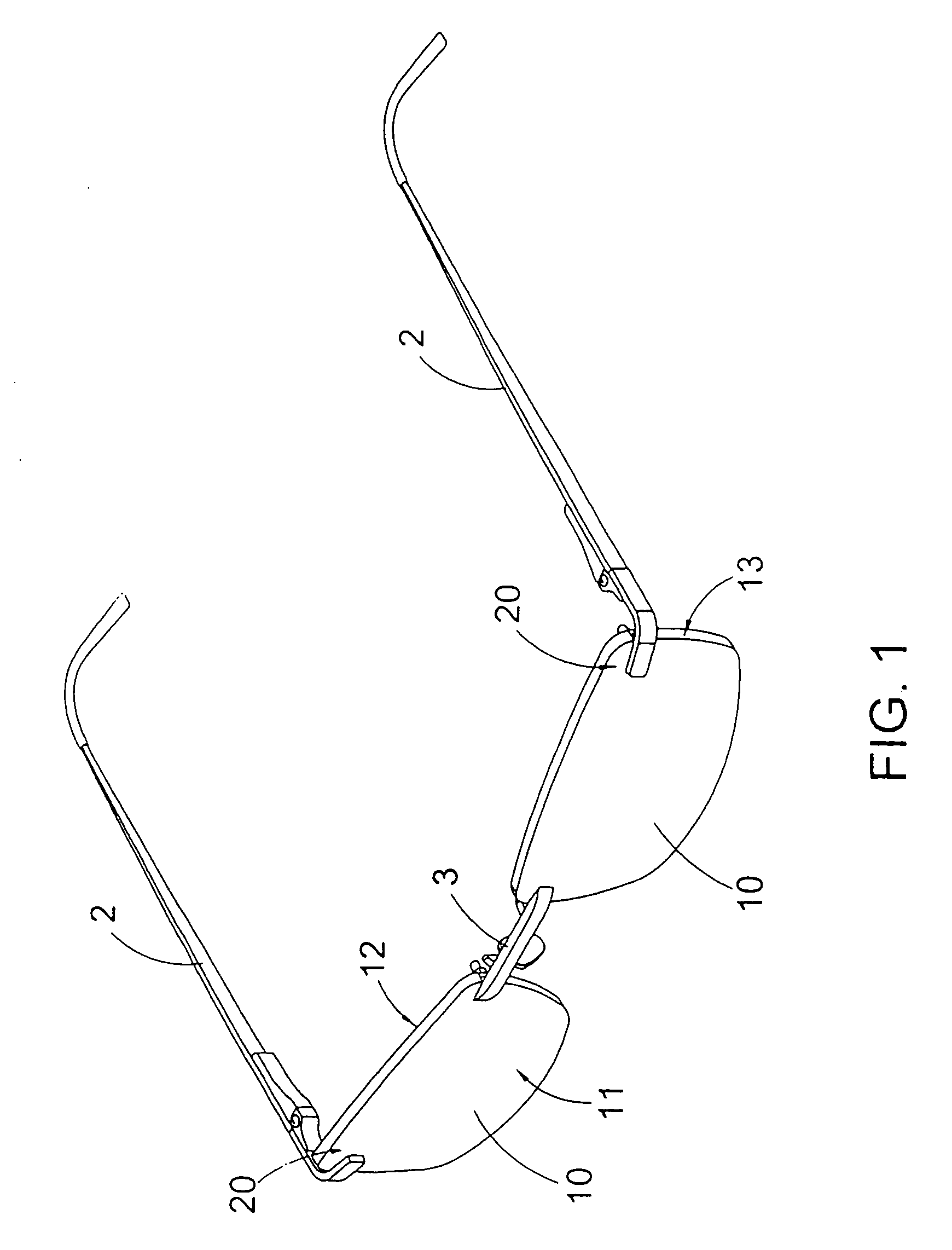

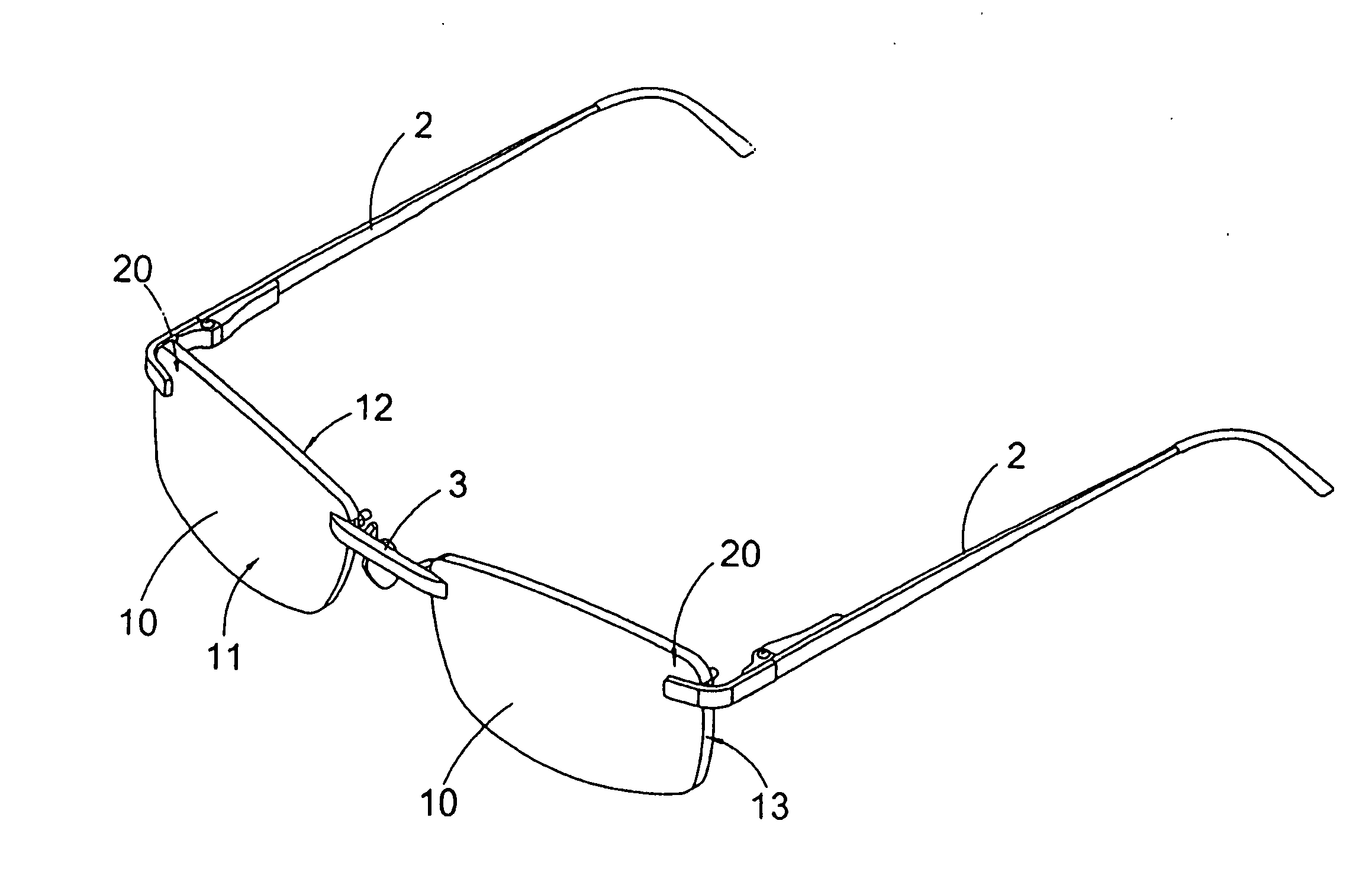

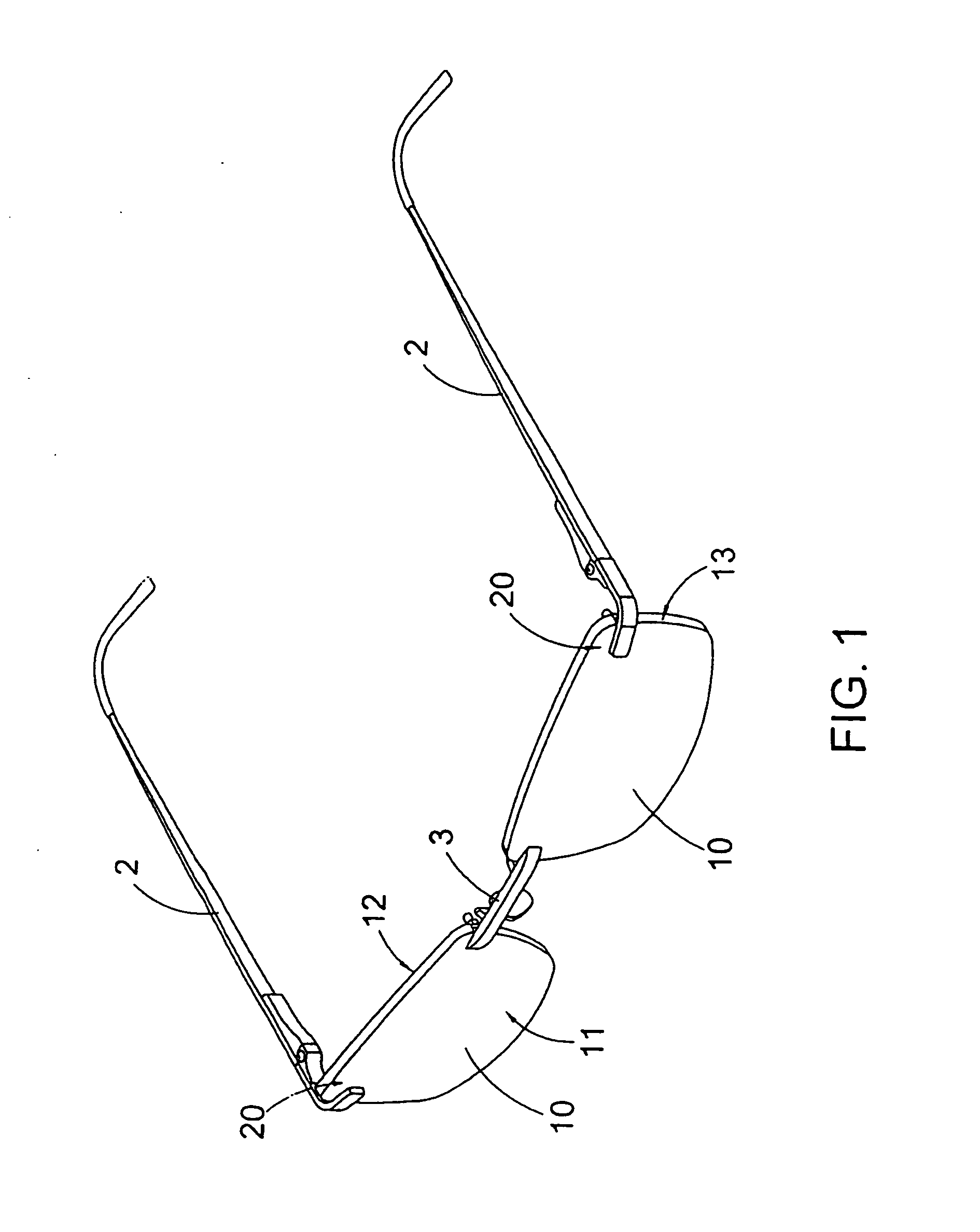

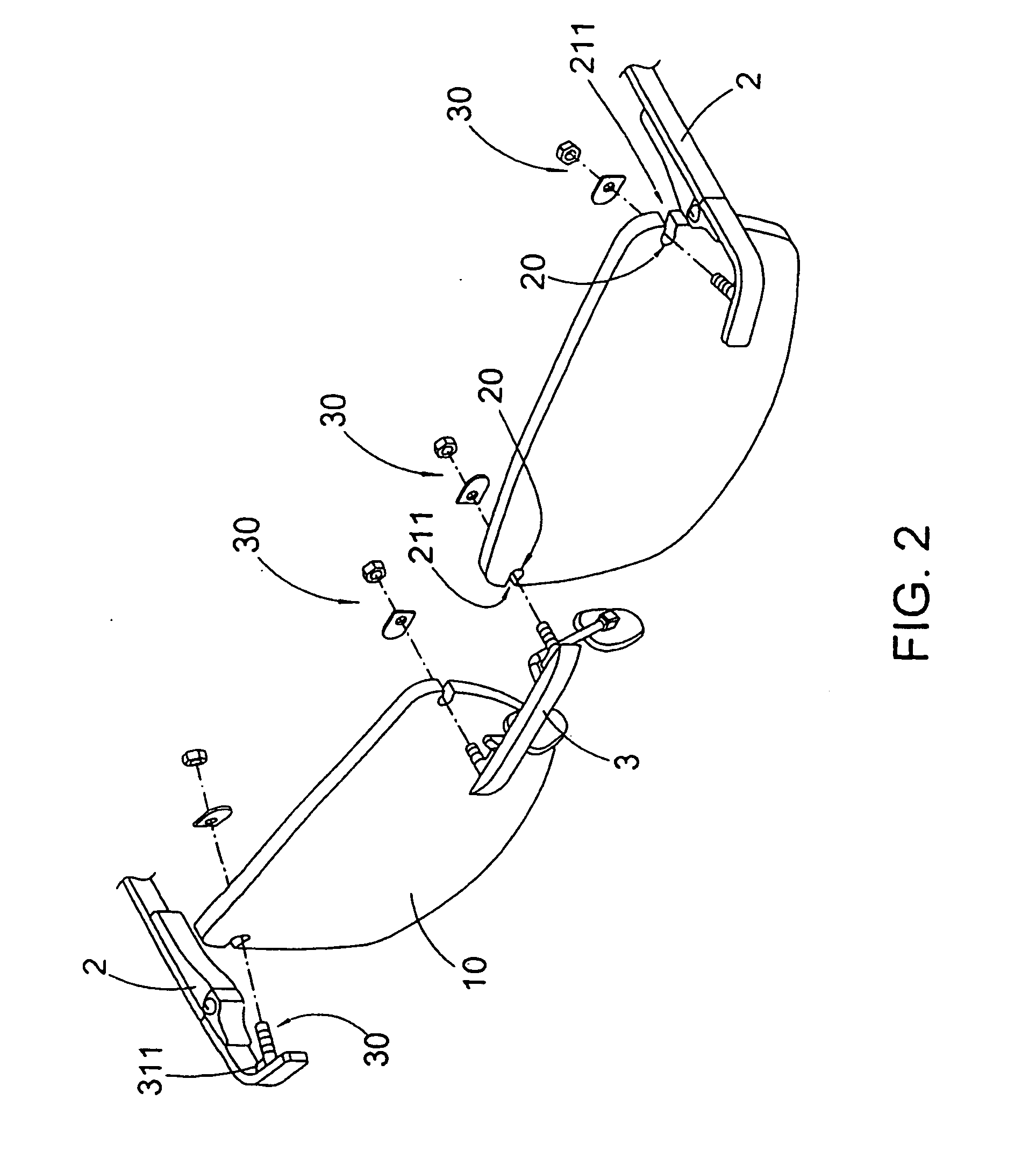

Rimless spectacles

InactiveUS20080198323A1Difficult to manufactureImprove manufacturing efficiencyLens assembliesLens plateElectrical and Electronics engineering

Owner:DONGGUAN JI SHENG OPTICAL

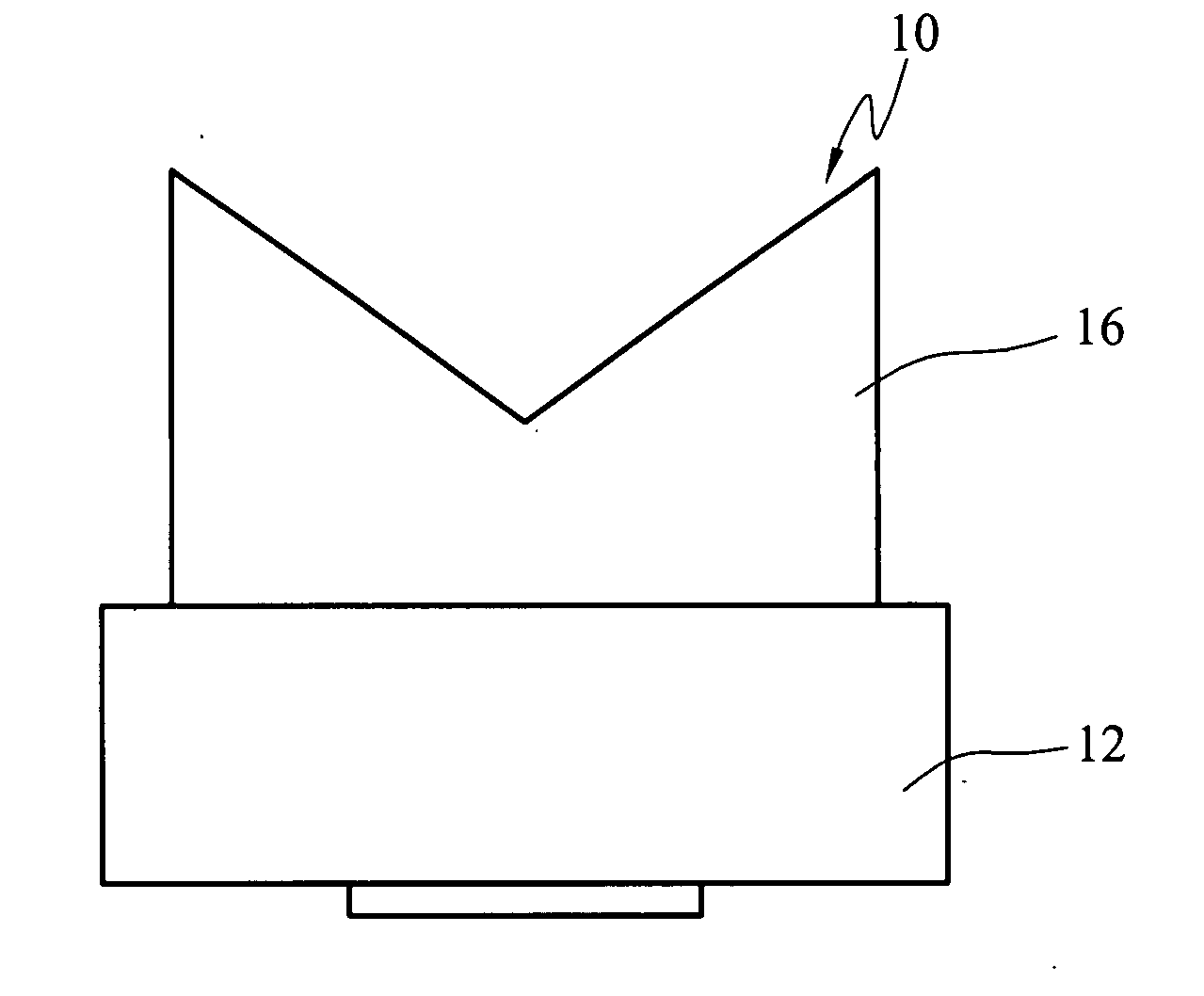

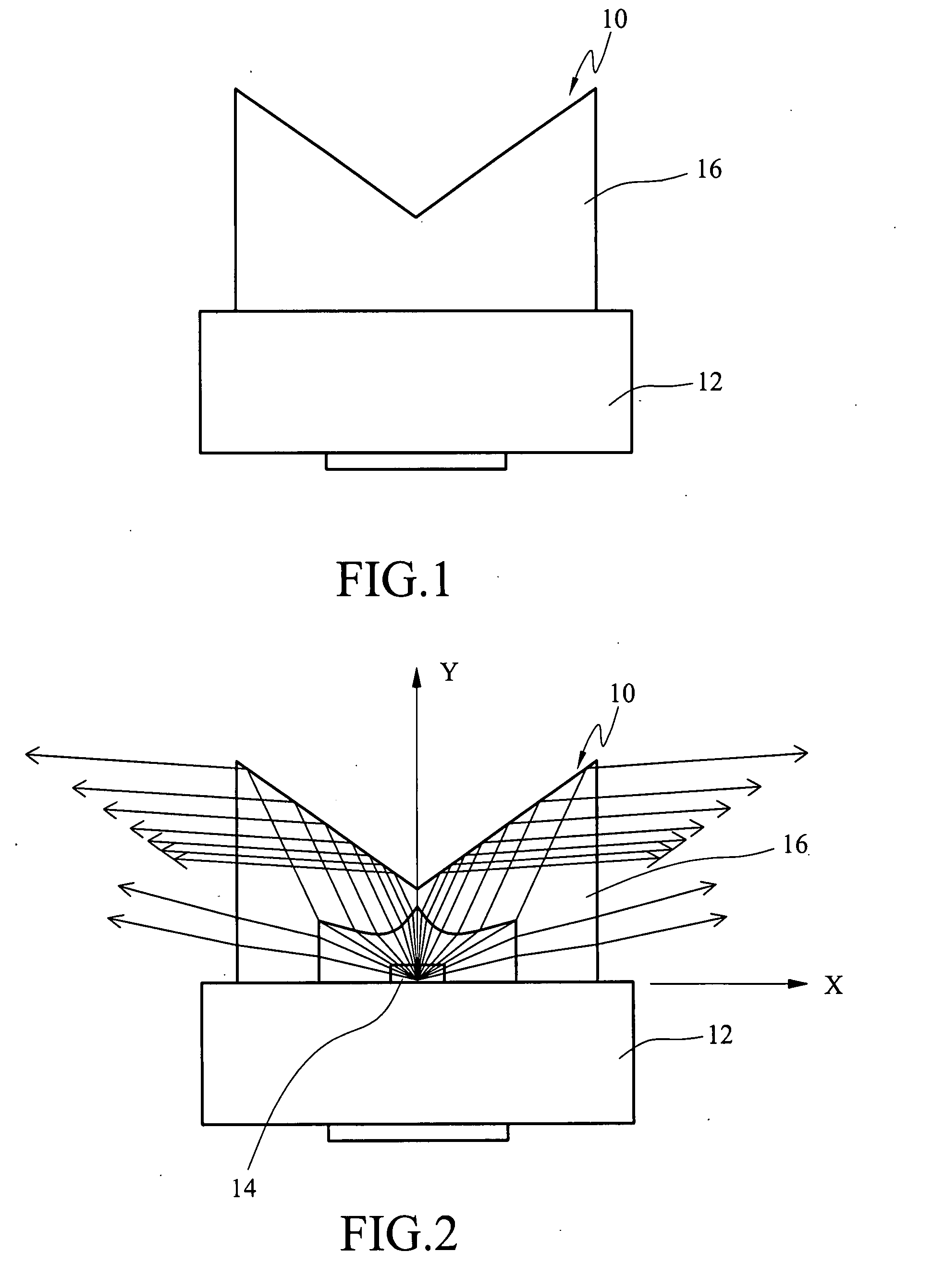

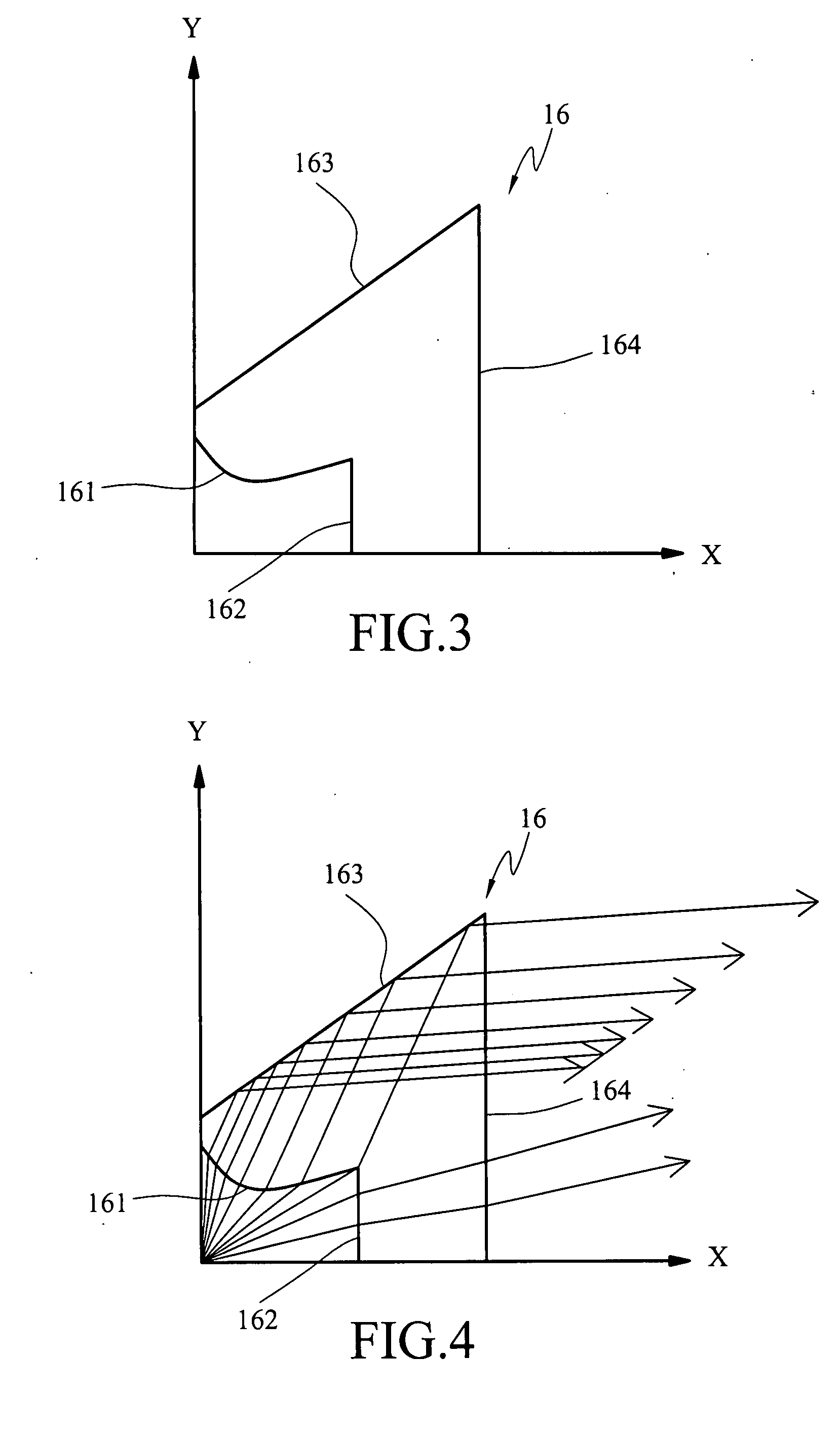

Lens cap and light emitting diode package structure using the same

InactiveUS20080151551A1Improve lateral luminous efficiencyReduce light leakagePoint-like light sourceCondensersLight-emitting diodePoint light source

A lens cap and an LED package structure using the same are provided. The lens cap includes a cap body made of a transparent material for being covered on a point light source. The cap body includes a first incident surface, which is a curved surface raised on a inner side of the cap body and refracts light emitted by the point light source into the cap body. A reflective surface is formed the outer side of the cap body and is opposite to the first incident surface, wherein the reflective surface reflects the light refracted by the first incident surface. A light-transmitting surface is formed on the outer side of the cap body, and the light reflected by the reflective surface is projected onto the light-transmitting surface to exit the cap body. Thus, the light is emitted towards the lateral of the lens cap along a horizontal direction.

Owner:IND TECH RES INST

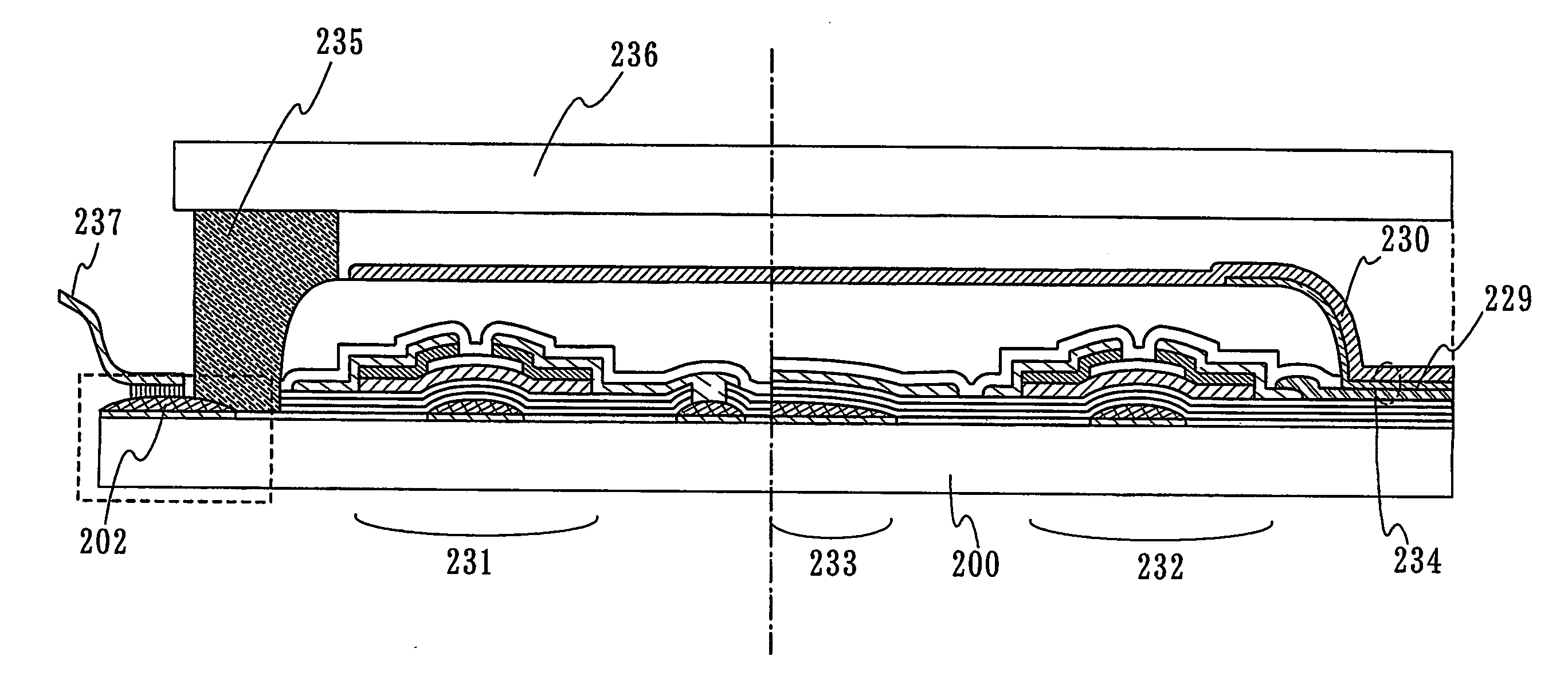

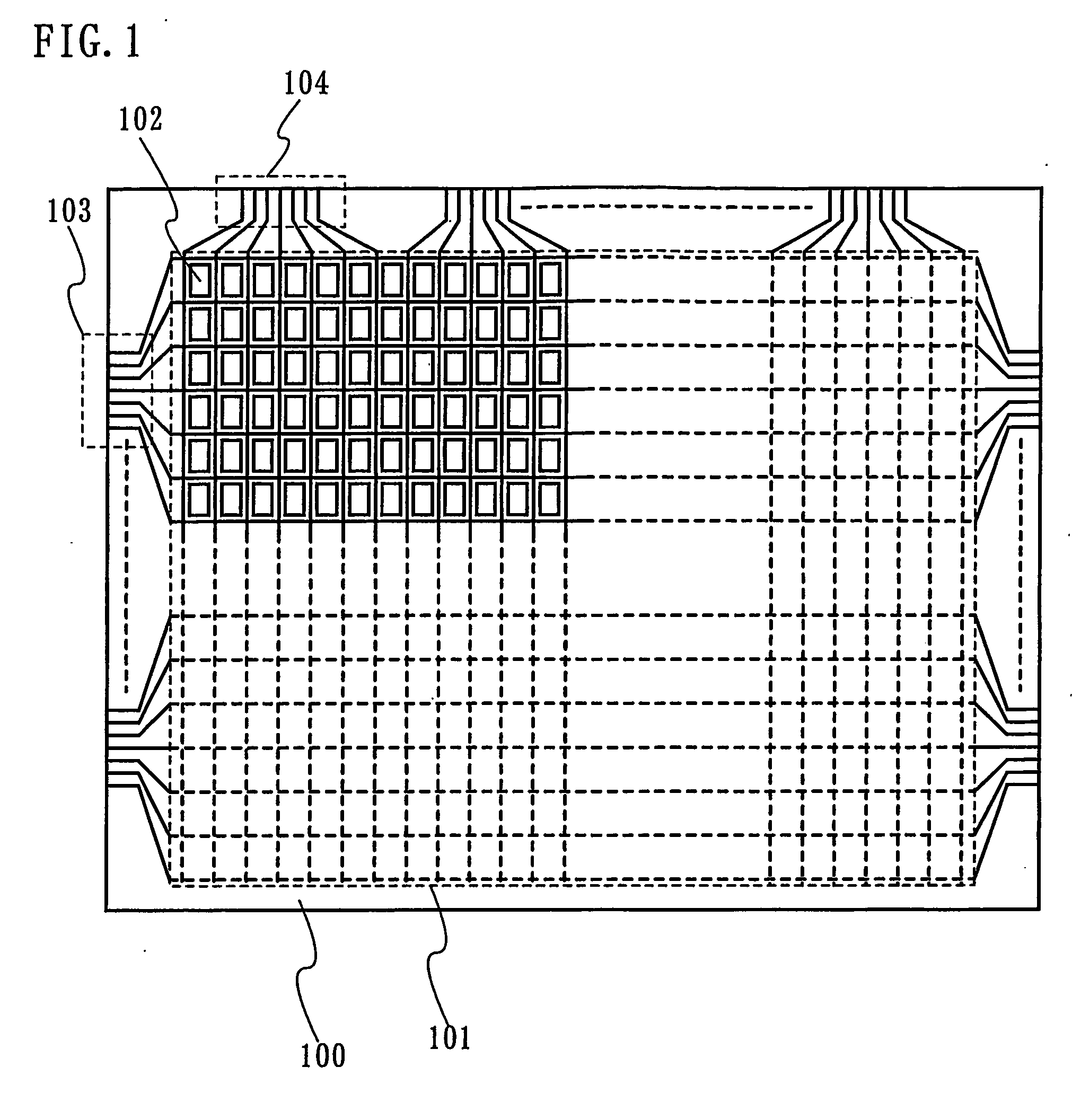

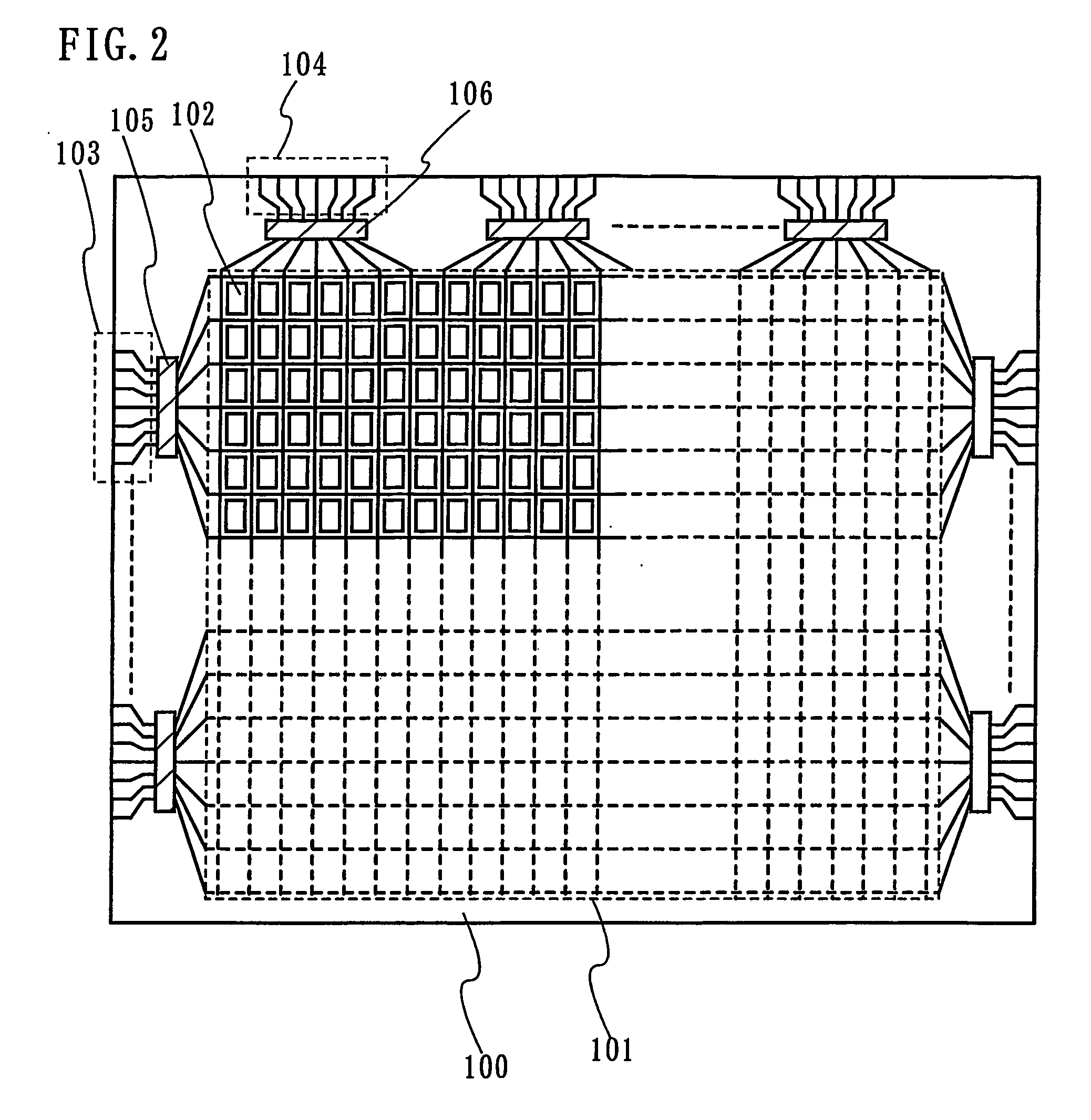

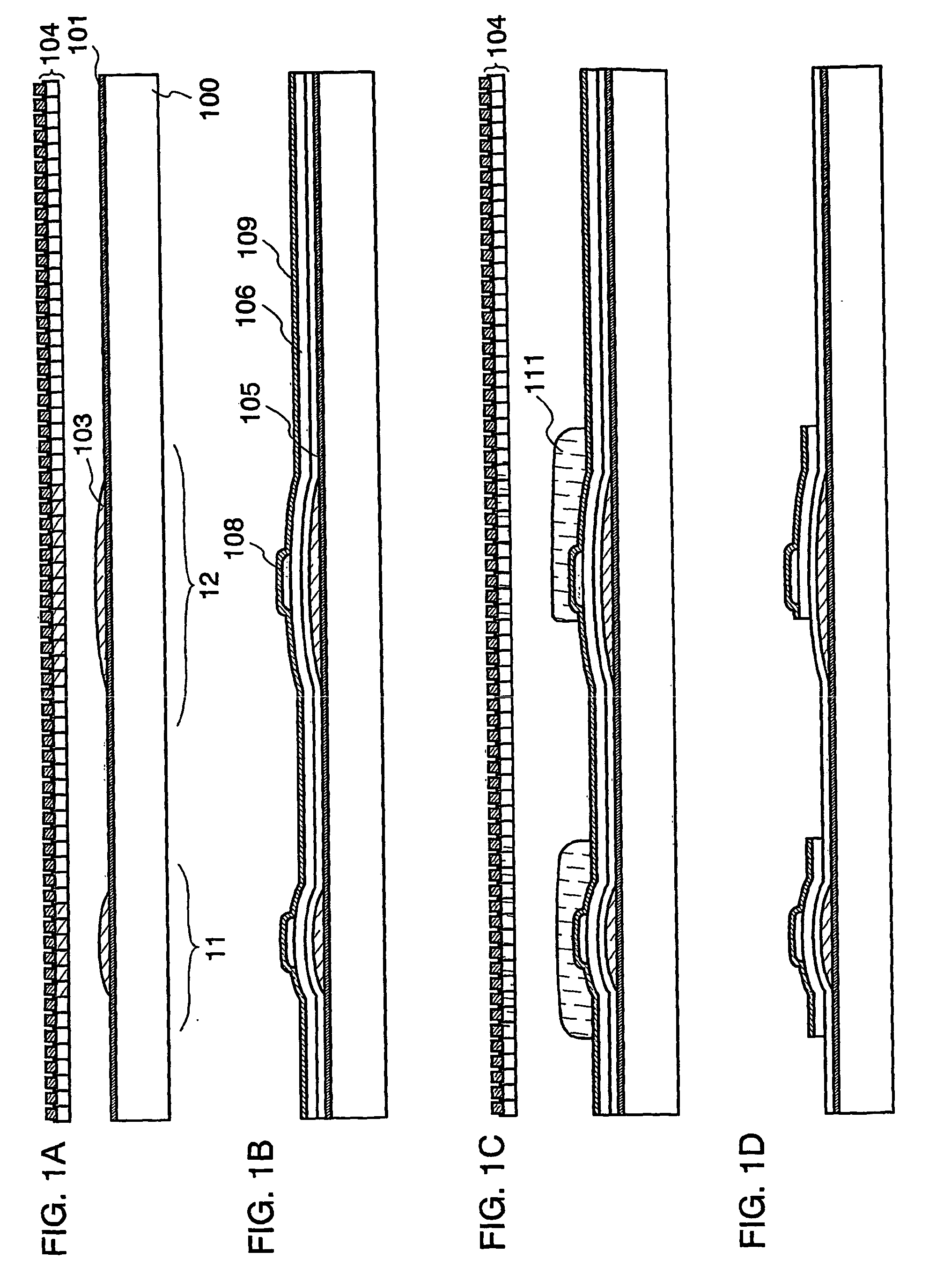

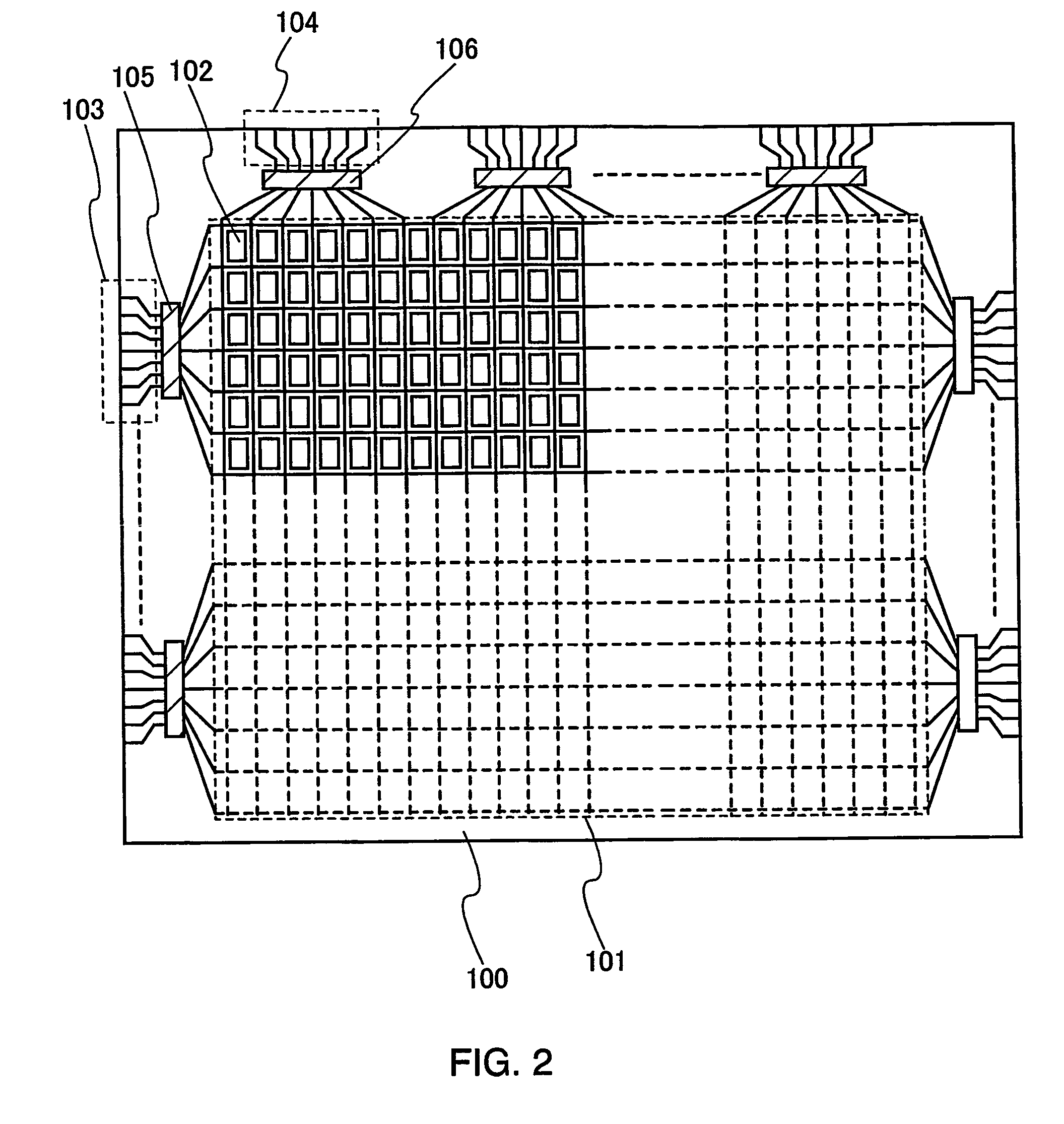

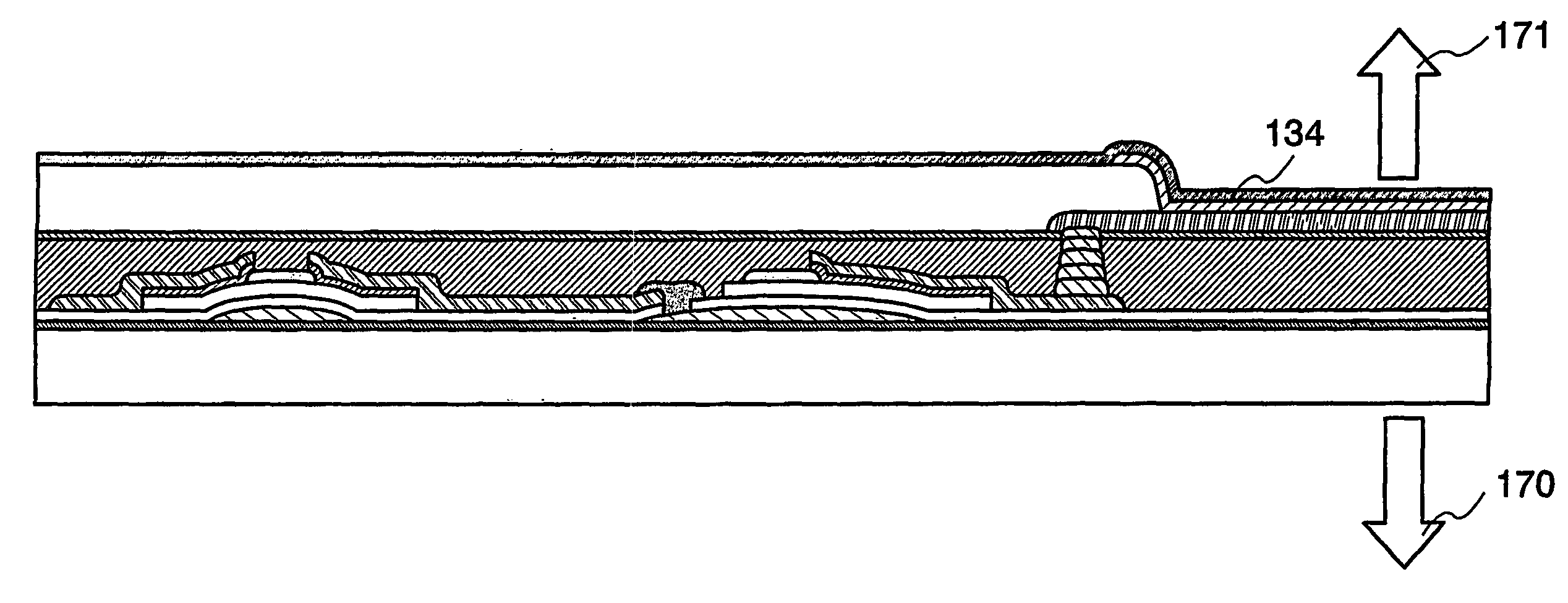

Display device and method for manufacturing the same, and television receiver

InactiveUS20070051958A1Inhibit deteriorationImprove material efficiencySolid-state devicesSemiconductor/solid-state device manufacturingTelevision receiversDisplay device

According to the present invention, which is a display device in which a light-emitting element where an organic substance generating luminescence referred to as electroluminescence or a medium including a mixture of an organic substance and an inorganic substance is sandwiched between electrodes is connected to a TFT, the invention is to manufacture a display panel by forming at least one or more of a conductive layer which forms a wiring or an electrode and a pattern necessary for manufacturing a display panel such as a mask layer for forming a predetermined pattern is formed by a method capable of selectively forming a pattern. A droplet discharge method capable of forming a predetermined pattern by selectively discharging a droplet of a composition in accordance with a particular object and by forming a conductive layer or an insulating layer is used as a method capable of selectively forming a pattern.

Owner:SEMICON ENERGY LAB CO LTD

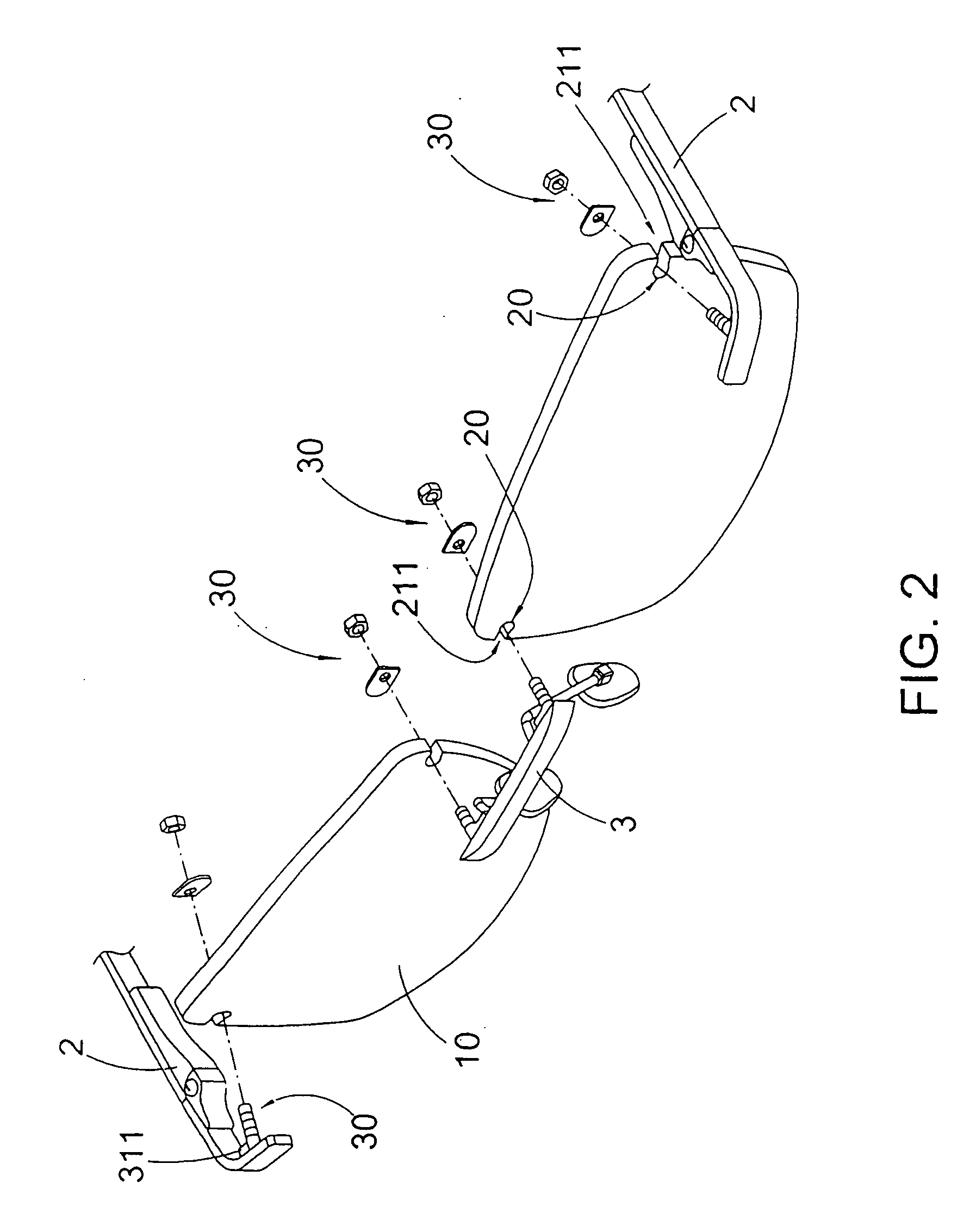

Spectacles

InactiveUS20110013134A1Difficult to manufactureImprove production efficiencySpectales/gogglesLens assembliesEngineeringElectrical and Electronics engineering

Owner:SIU YU +1

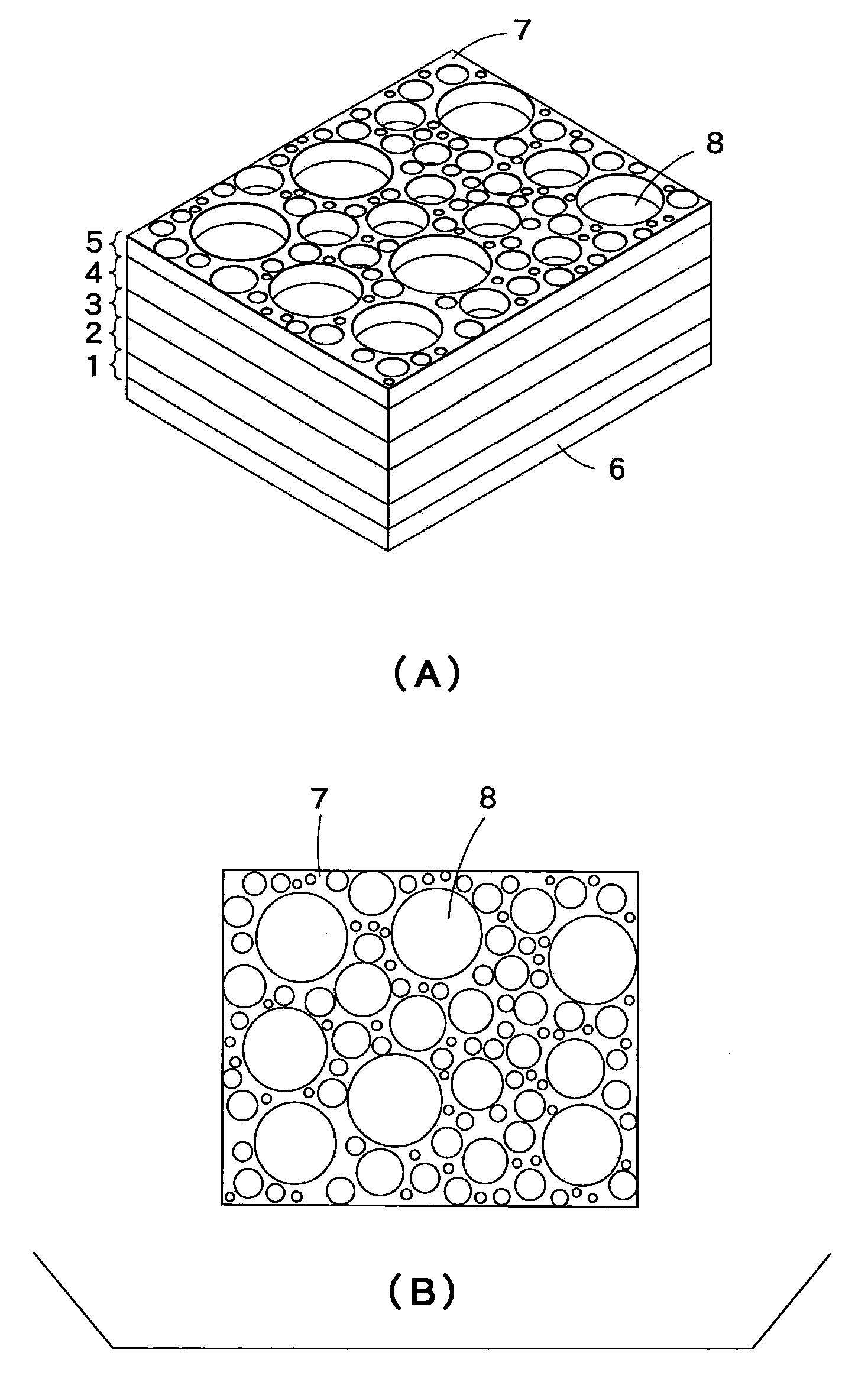

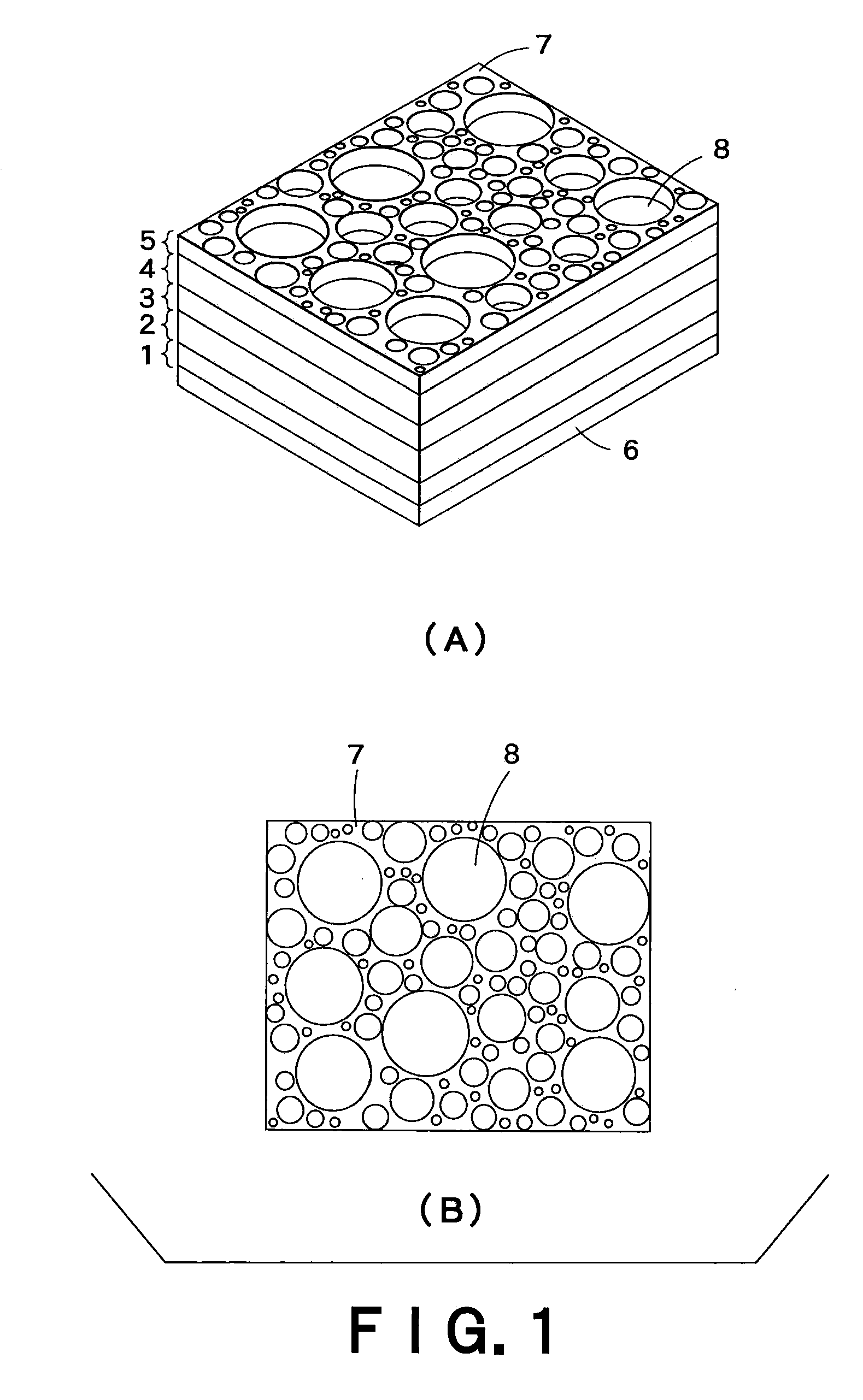

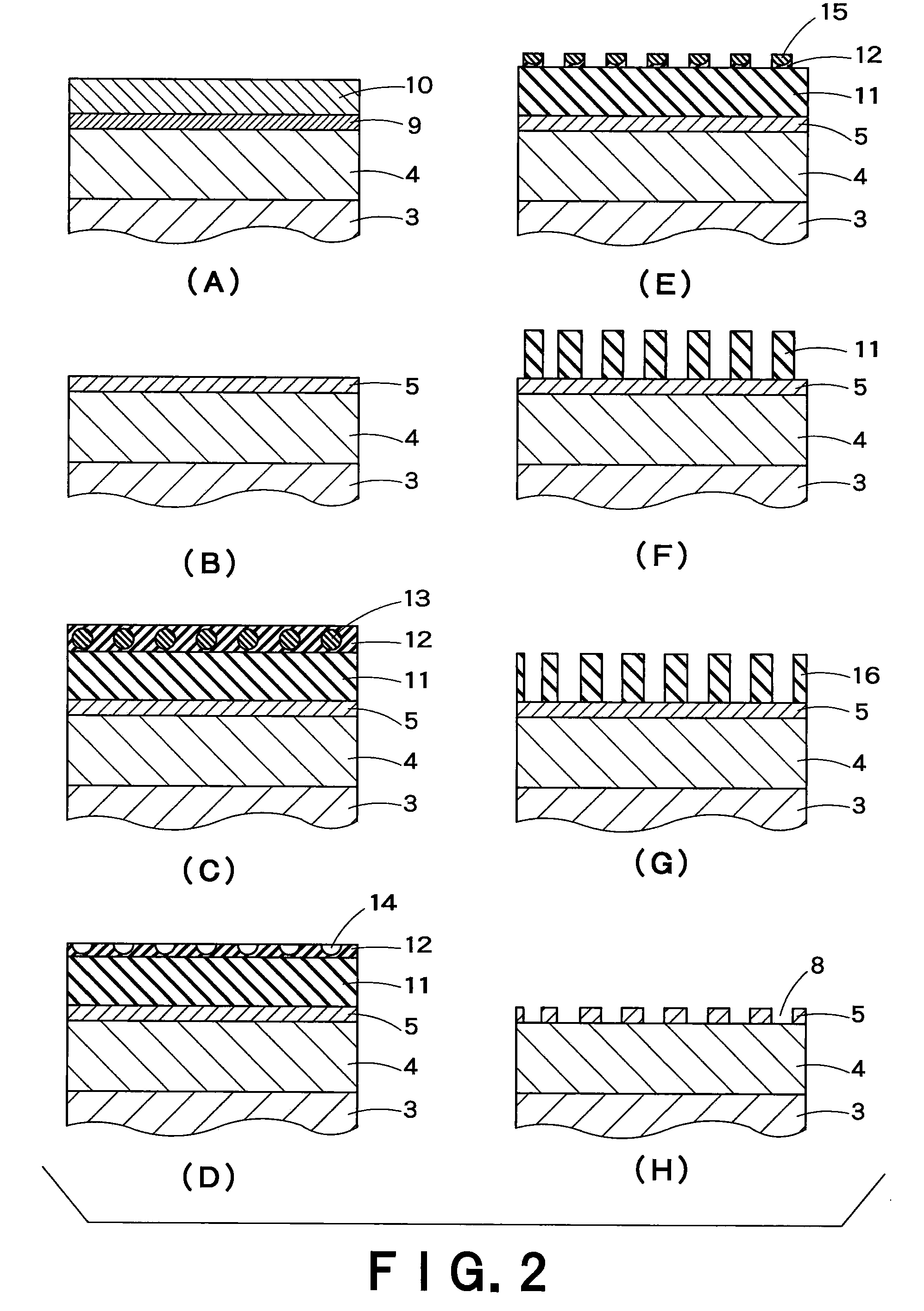

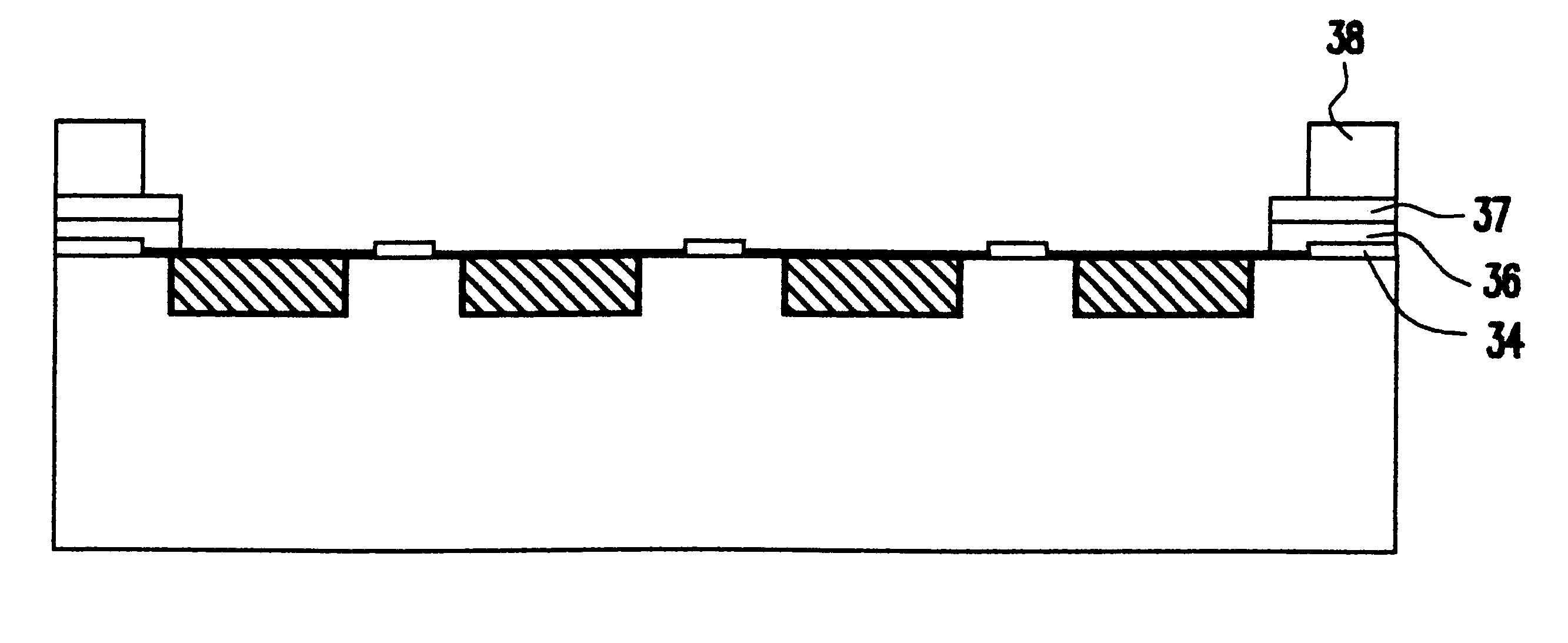

Semiconductor light-emitting element and process for production thereof

InactiveUS20090242925A1Difficult to manufactureSuitable for manufactureSemiconductor/solid-state device manufacturingSemiconductor devicesOhmOhmic contact

The present invention provides a semiconductor light-emitting element comprising an electrode part excellent in ohmic contact and capable of emitting light from the whole surface. An electrode layer placed on the light-extraction side comprises a metal part and plural openings. The metal part is so continuous that any pair of point-positions in the part is continuously connected without breaks, and the metal part in 95% or more of the whole area continues linearly without breaks by the openings in a straight distance of not more than ⅓ of the wavelength of light emitted from an active layer. The average opening diameter is of 10 nm to ⅓ of the wavelength of emitted light. The electrode layer has a thickness of 10 nm to 200 nm, and is in good ohmic contact with a semiconductor layer.

Owner:KK TOSHIBA

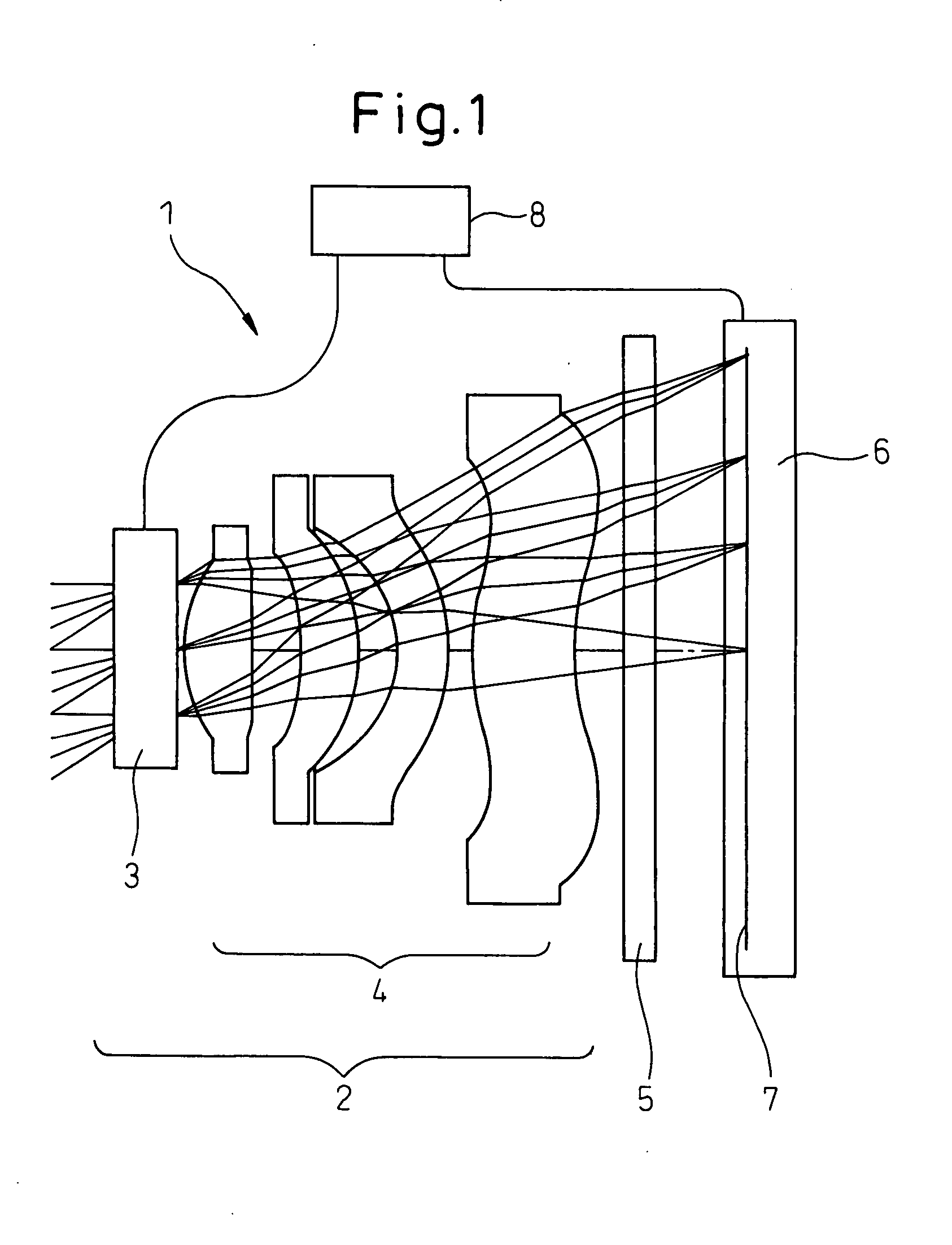

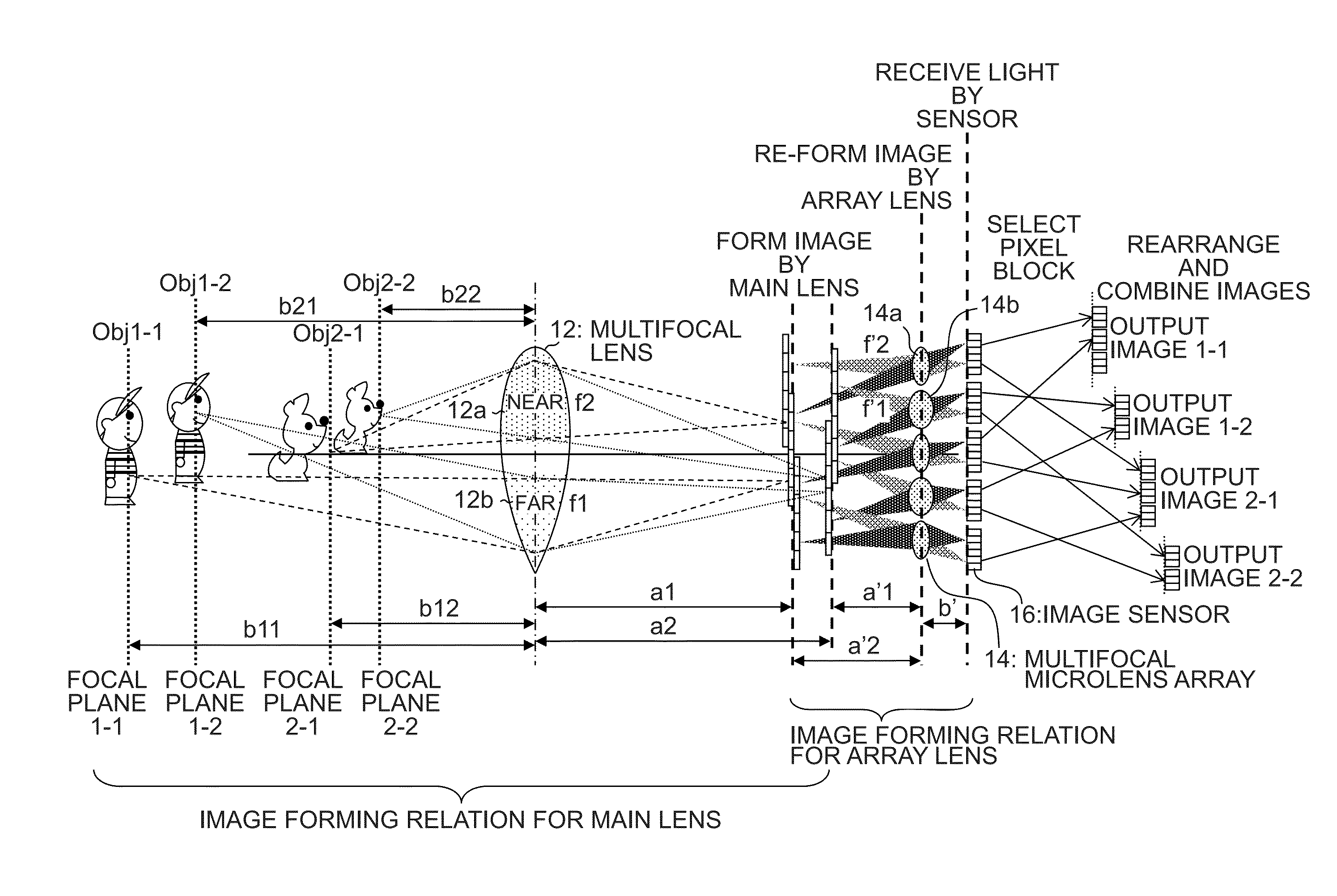

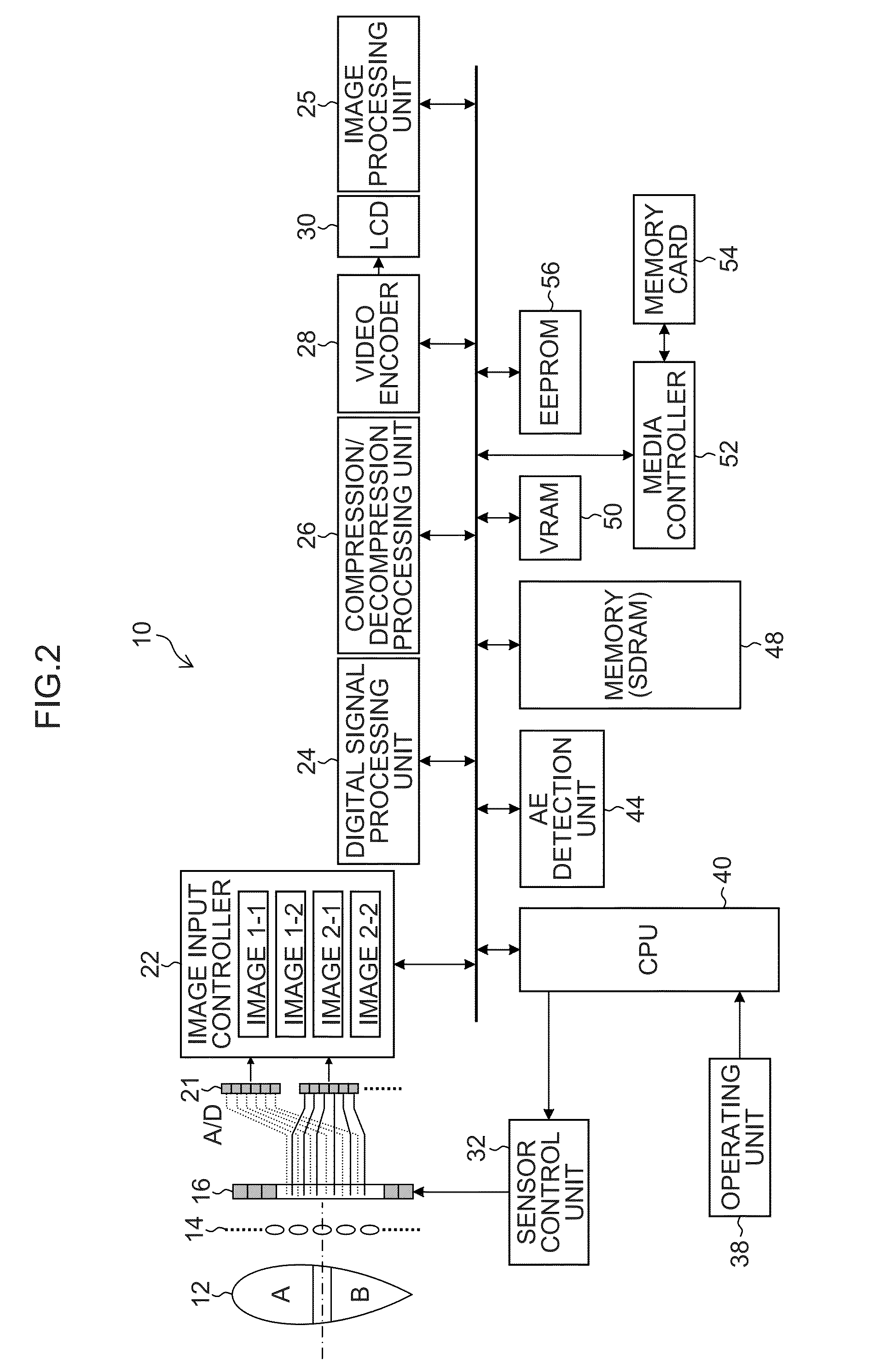

Imaging device

ActiveUS20150156478A1Increase the number ofDifficult to manufacturePrismsSolid-state devicesImaging equipmentMicrolens

An imaging device includes a multifocal main lens having different focal distances for a plurality of regions, an image sensor having a plurality of pixels configured of two-dimensionally arranged photoelectric converting elements, a multifocal lens array having a plurality of microlens groups at different focal distances disposed on an incident plane side of the image sensor, and an image obtaining device which obtains from the image sensor, a plurality of images for each of the focal distances obtained by combining the multifocal main lens and the plurality of microlens groups at different focal distances.

Owner:FUJIFILM CORP

Spectacles

InactiveUS20140333887A1Difficult to manufactureImprove production efficiencyLens assembliesEngineeringElectrical and Electronics engineering

Owner:SIU YU +1

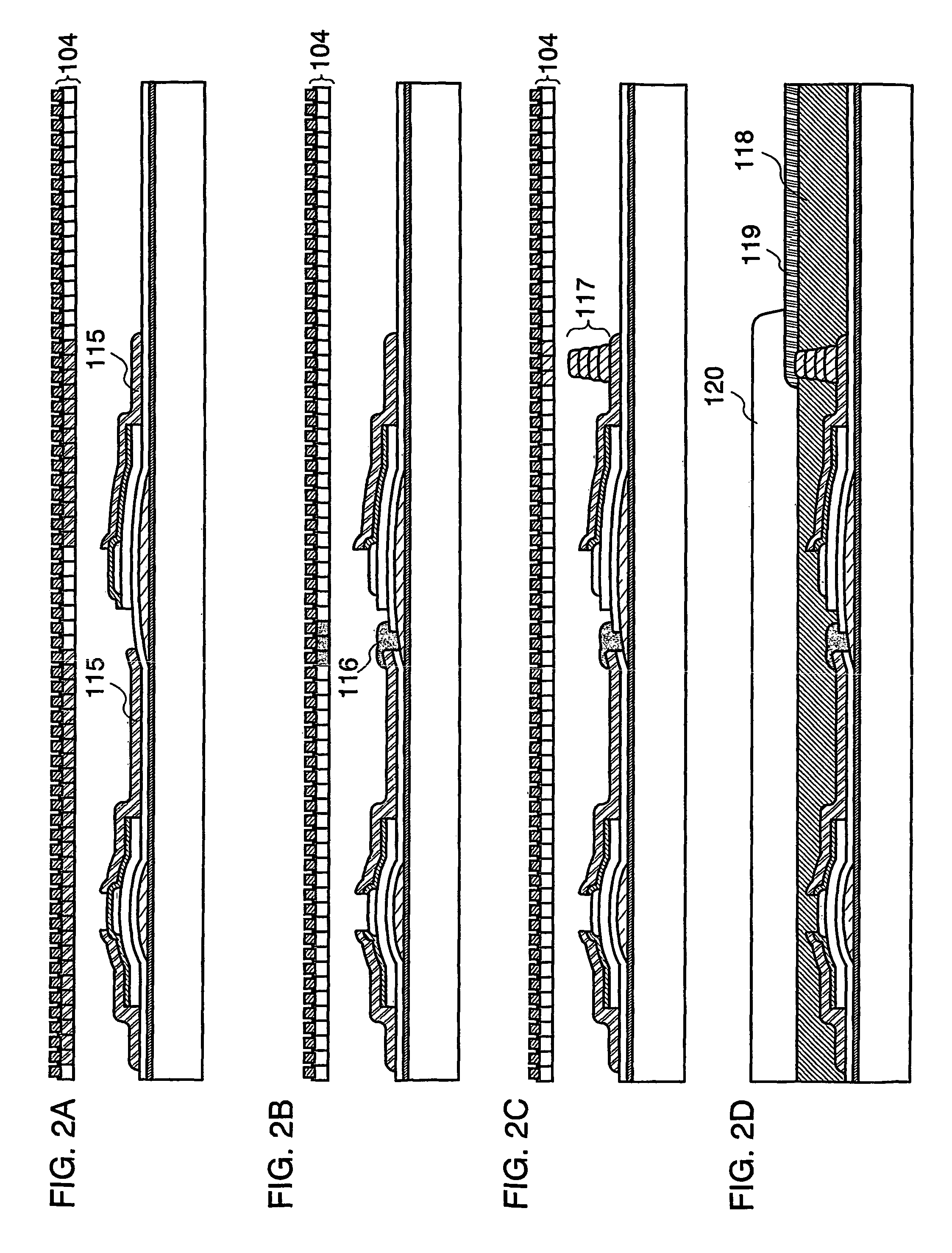

Display device and method for fabricating the same

InactiveUS20070120471A1Low costBig investmentTransistorLiquid surface applicatorsManufacturing technologyDisplay device

It is an object of the invention to provide a display device which can be manufactured by a simplified manufacturing process by which the efficiency in the use of material is improved. It is a further object of the invention to provide a manufacturing method of the display device. It is another object of the invention to provide a fabrication technology for improving adhesion of a pattern. In view of the above problems, according to the present invention, a pattern is formed by a droplet discharge method. Particularly in the invention, base pretreatment is performed before / after a pattern is formed by a droplet discharge method. As a result of such base pretreatment, adhesion of a pattern can improved, and the pattern may be made finer.

Owner:SEMICON ENERGY LAB CO LTD

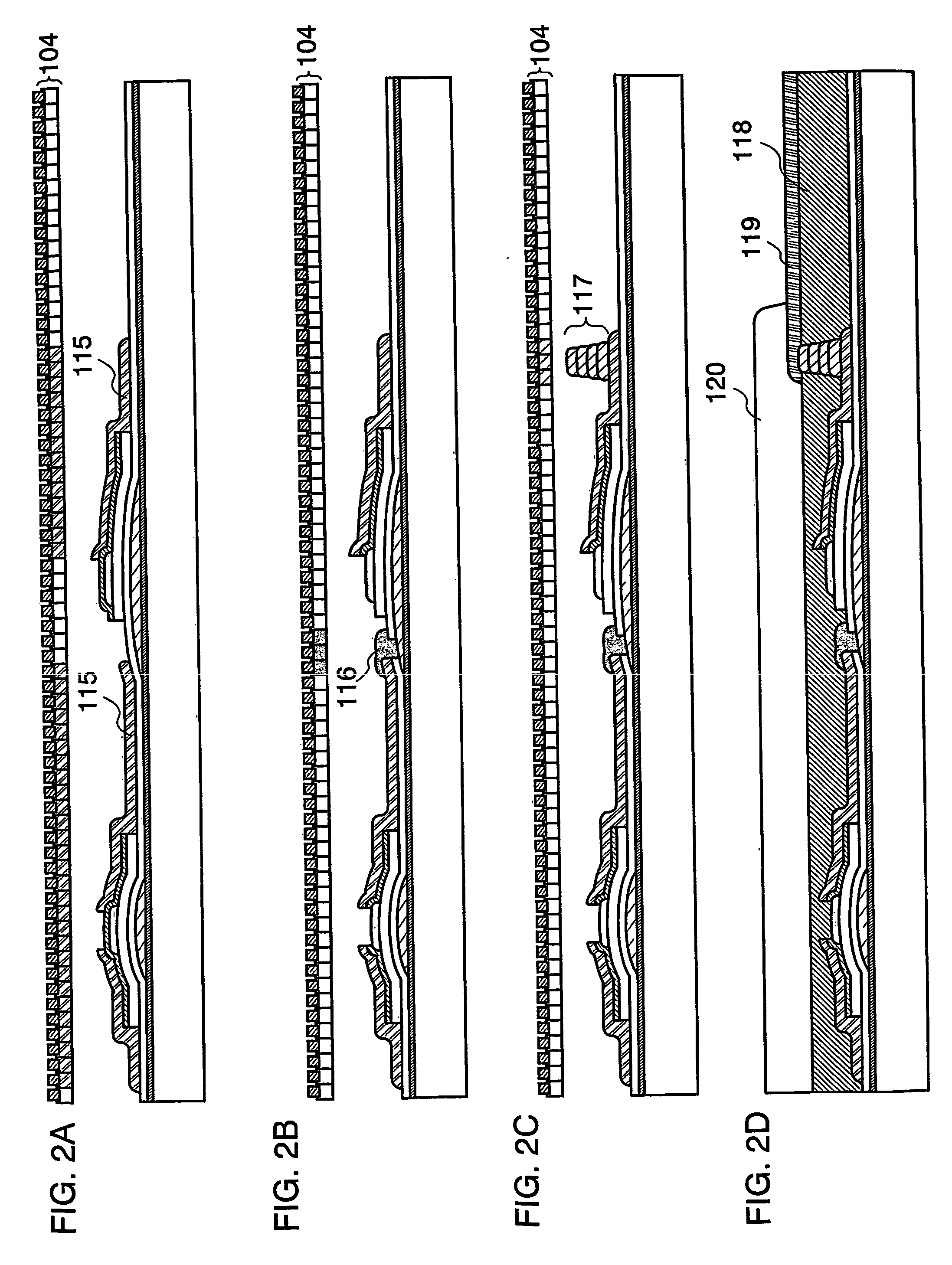

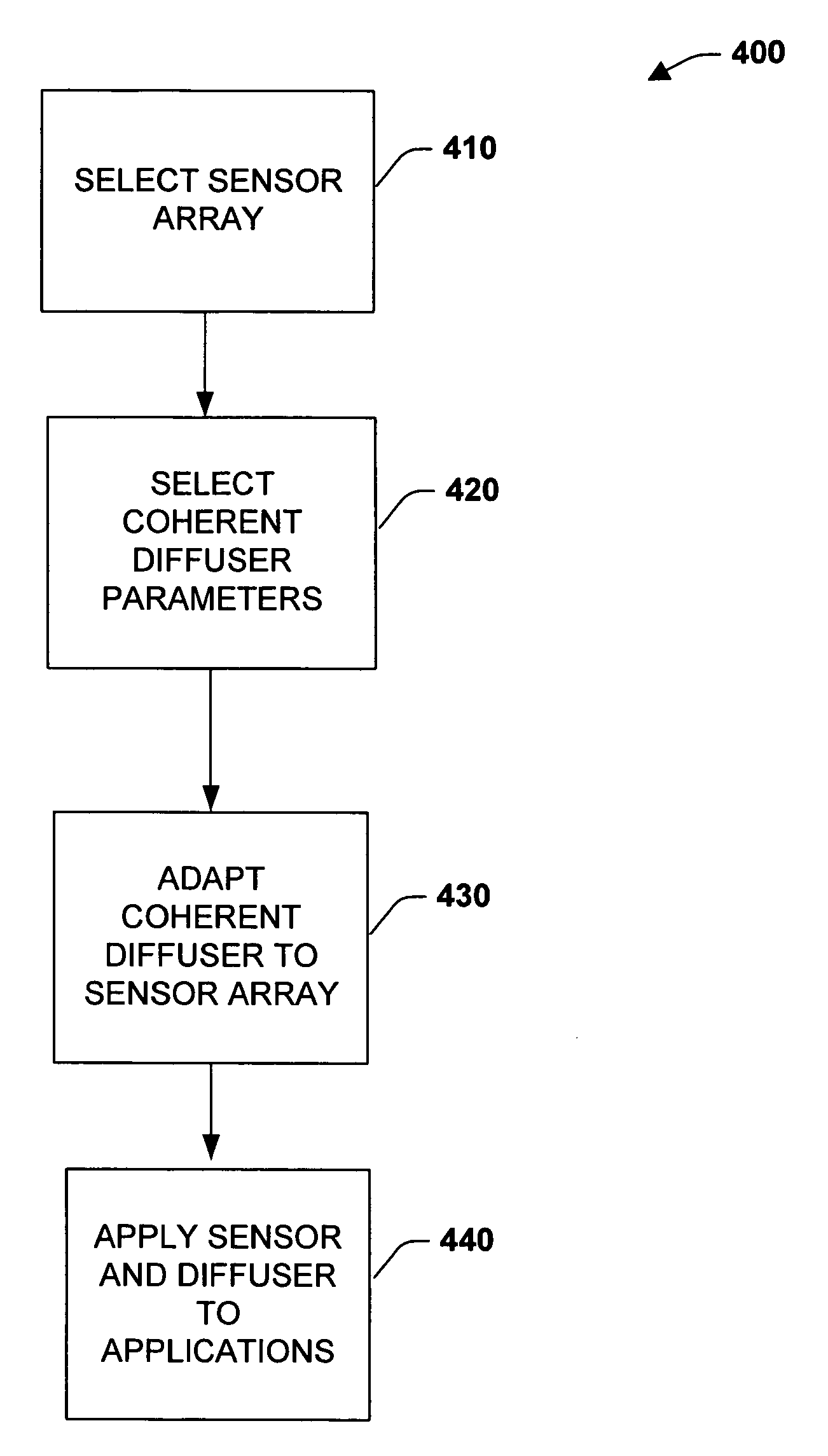

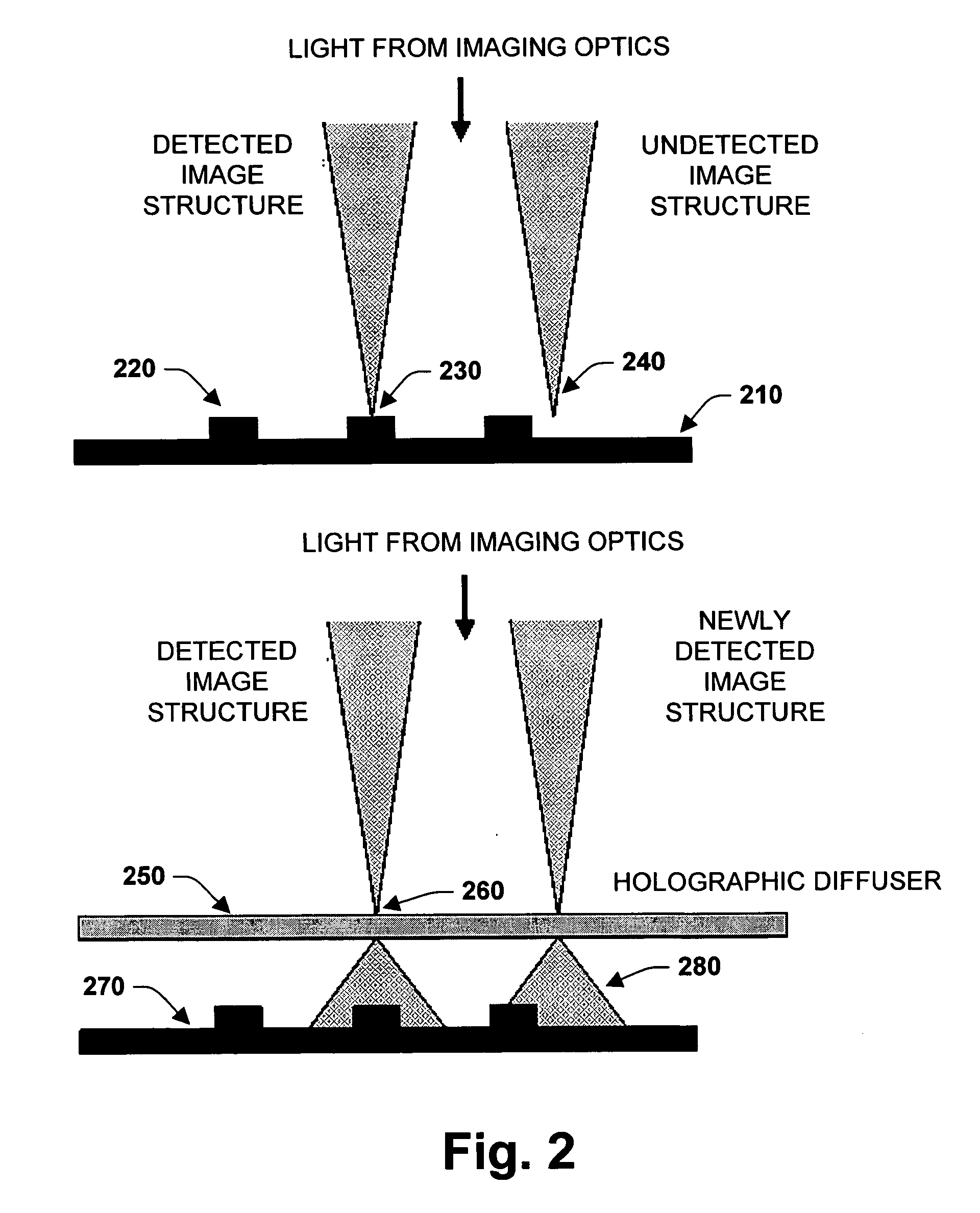

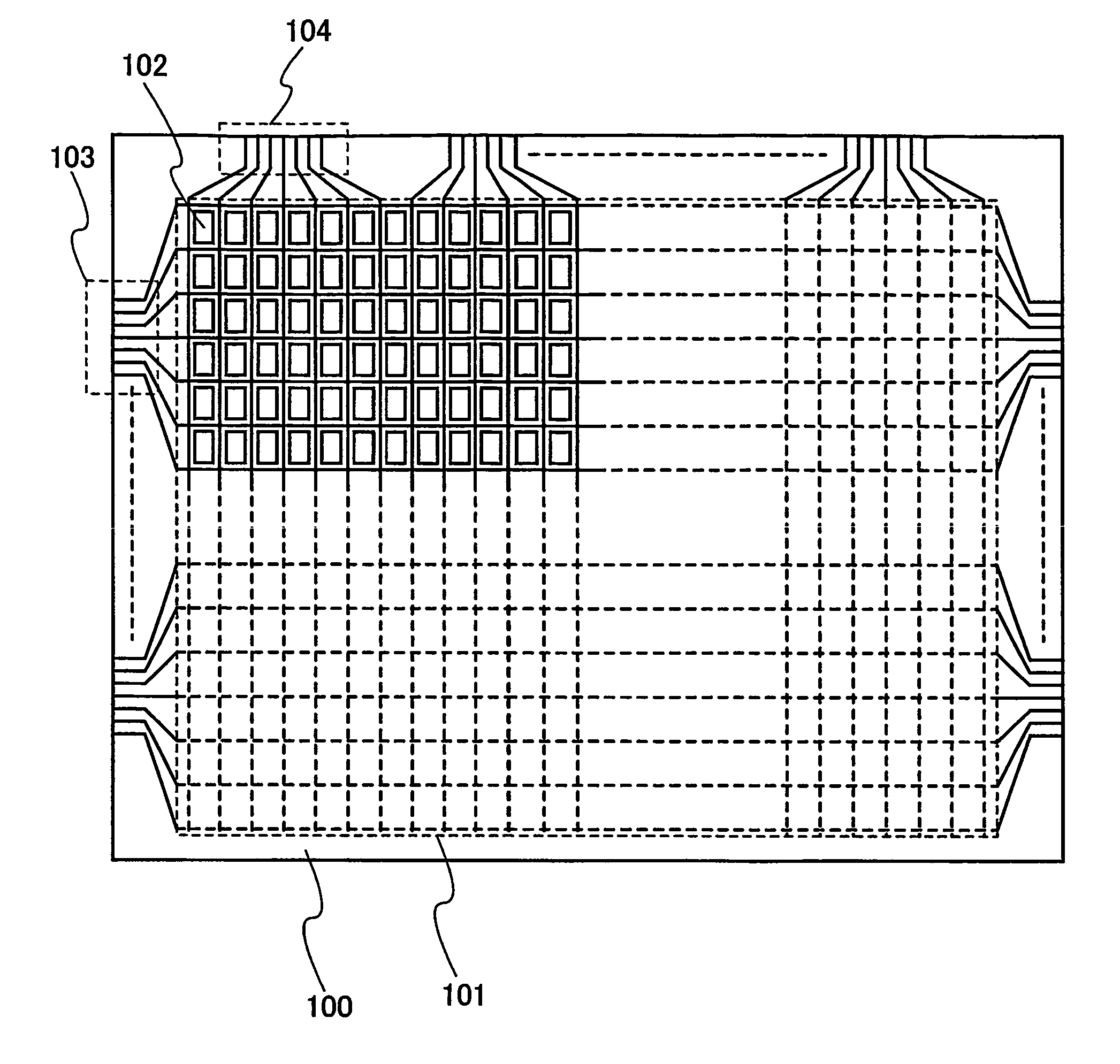

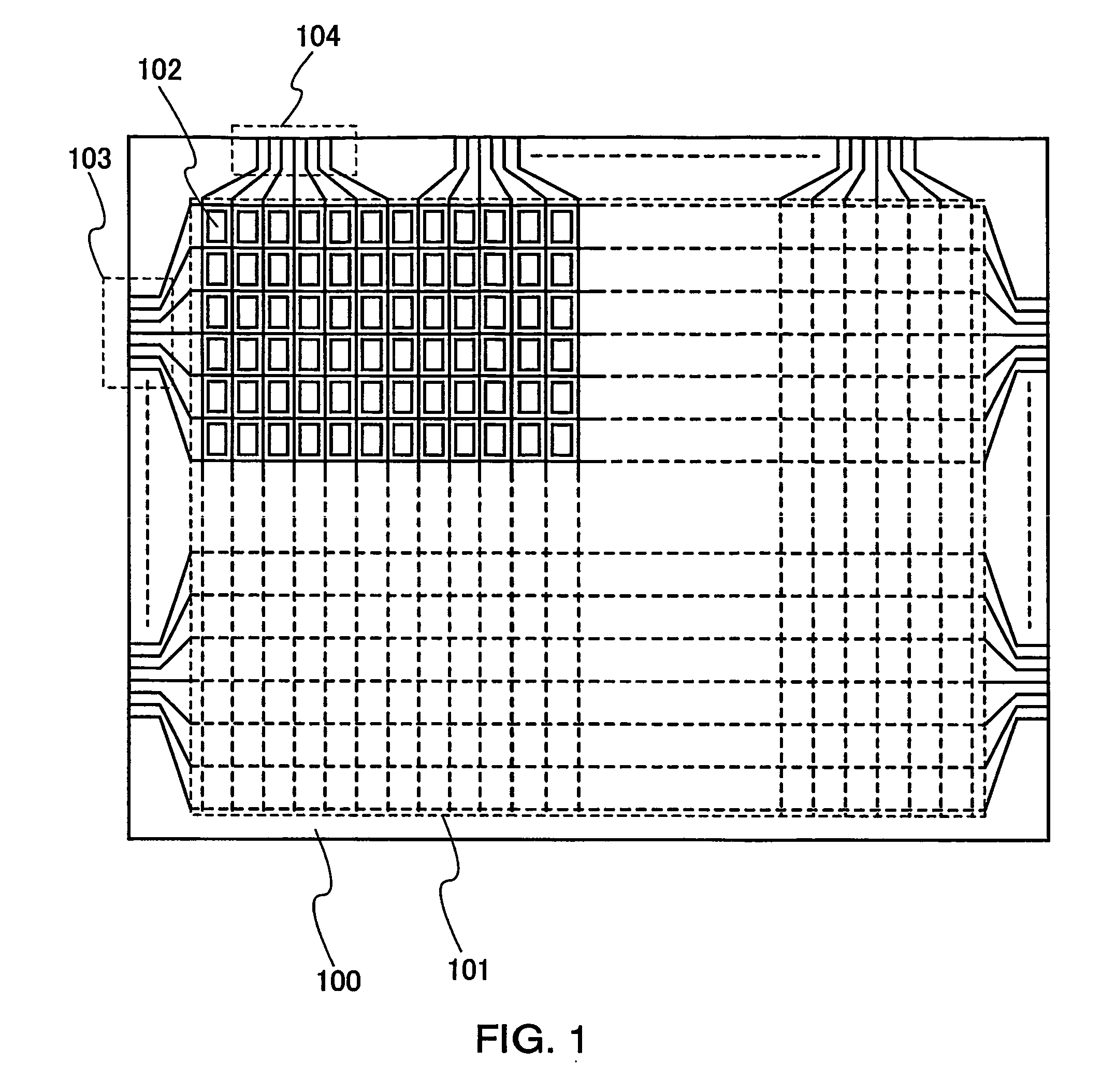

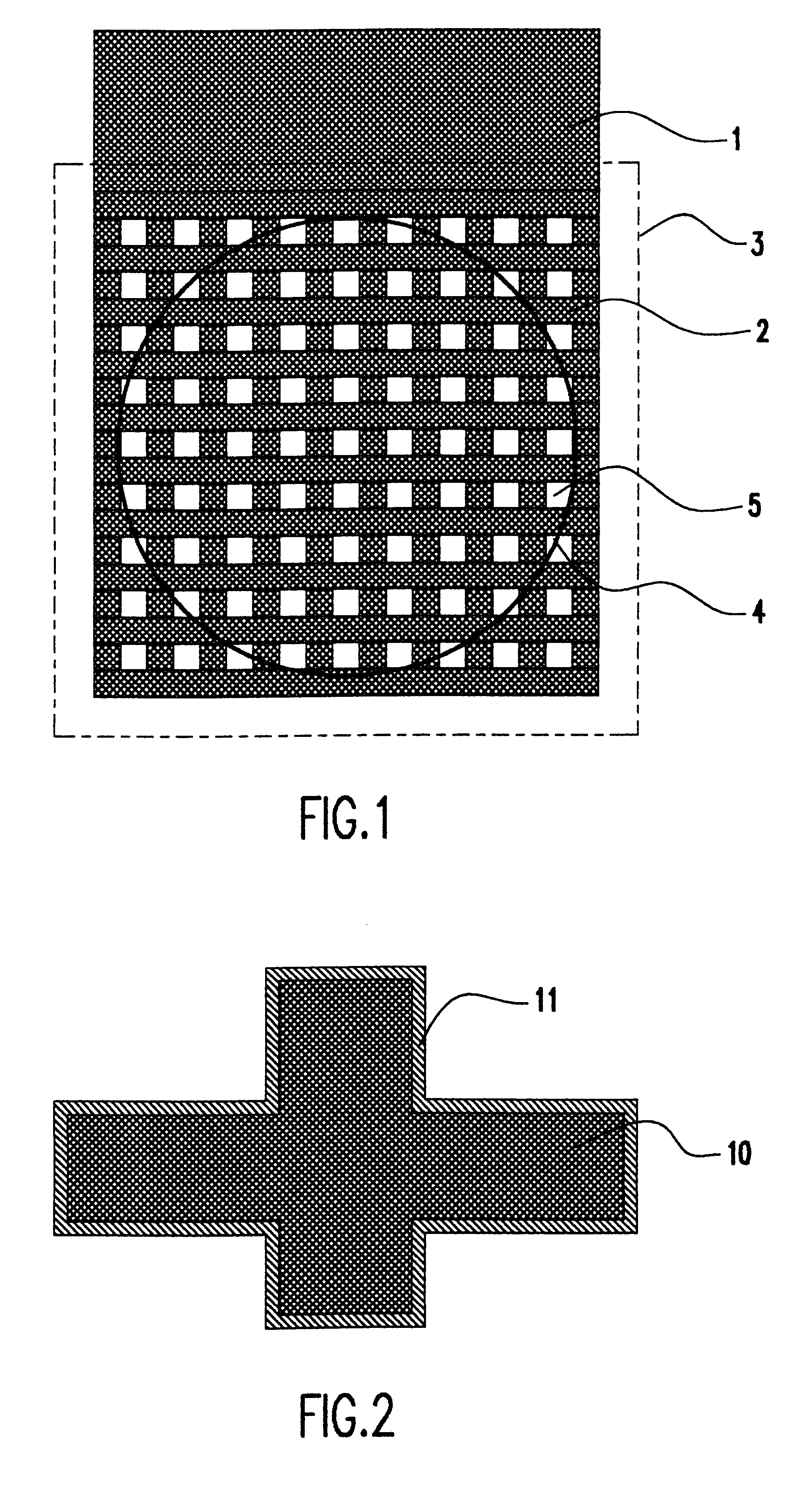

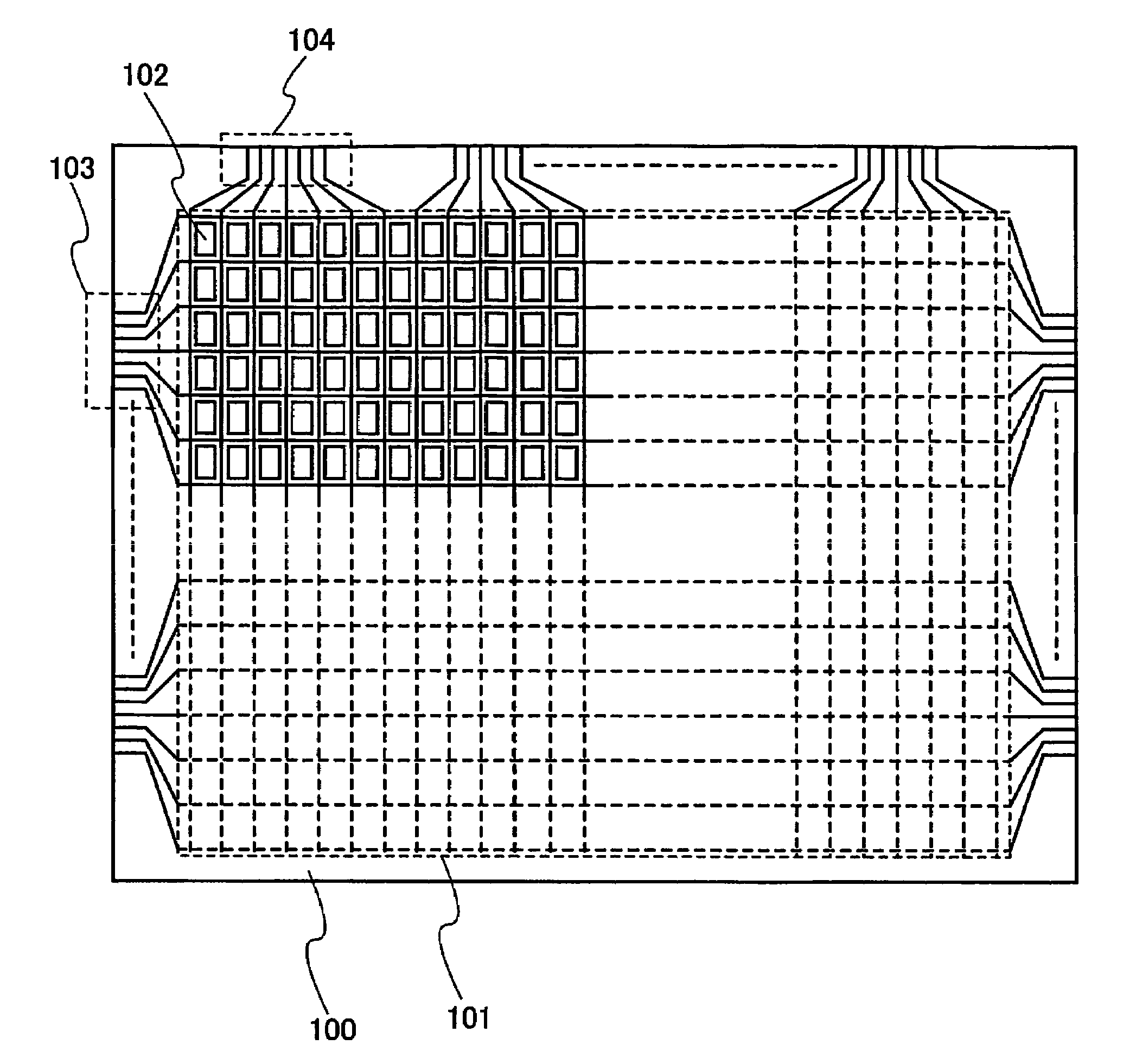

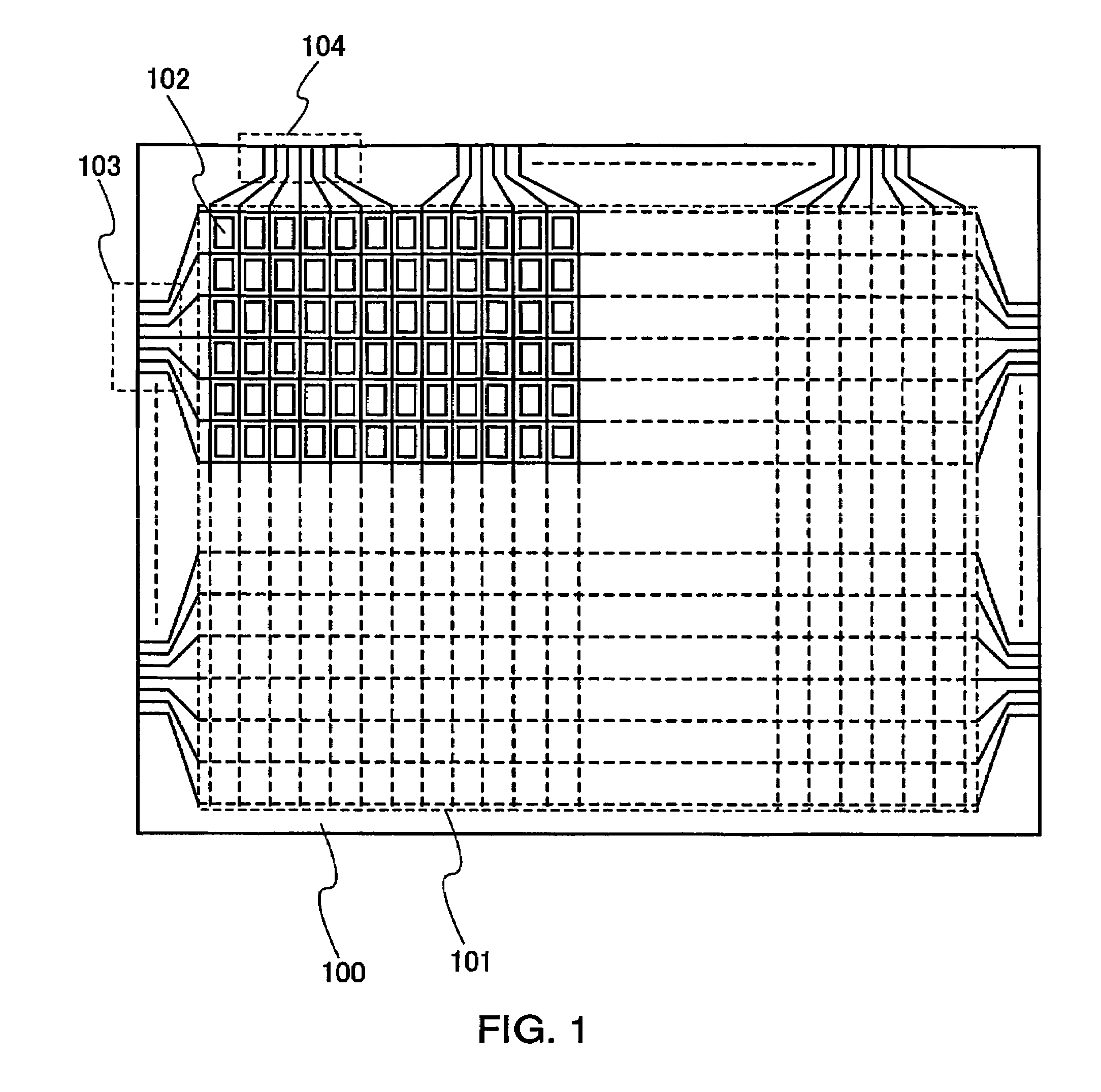

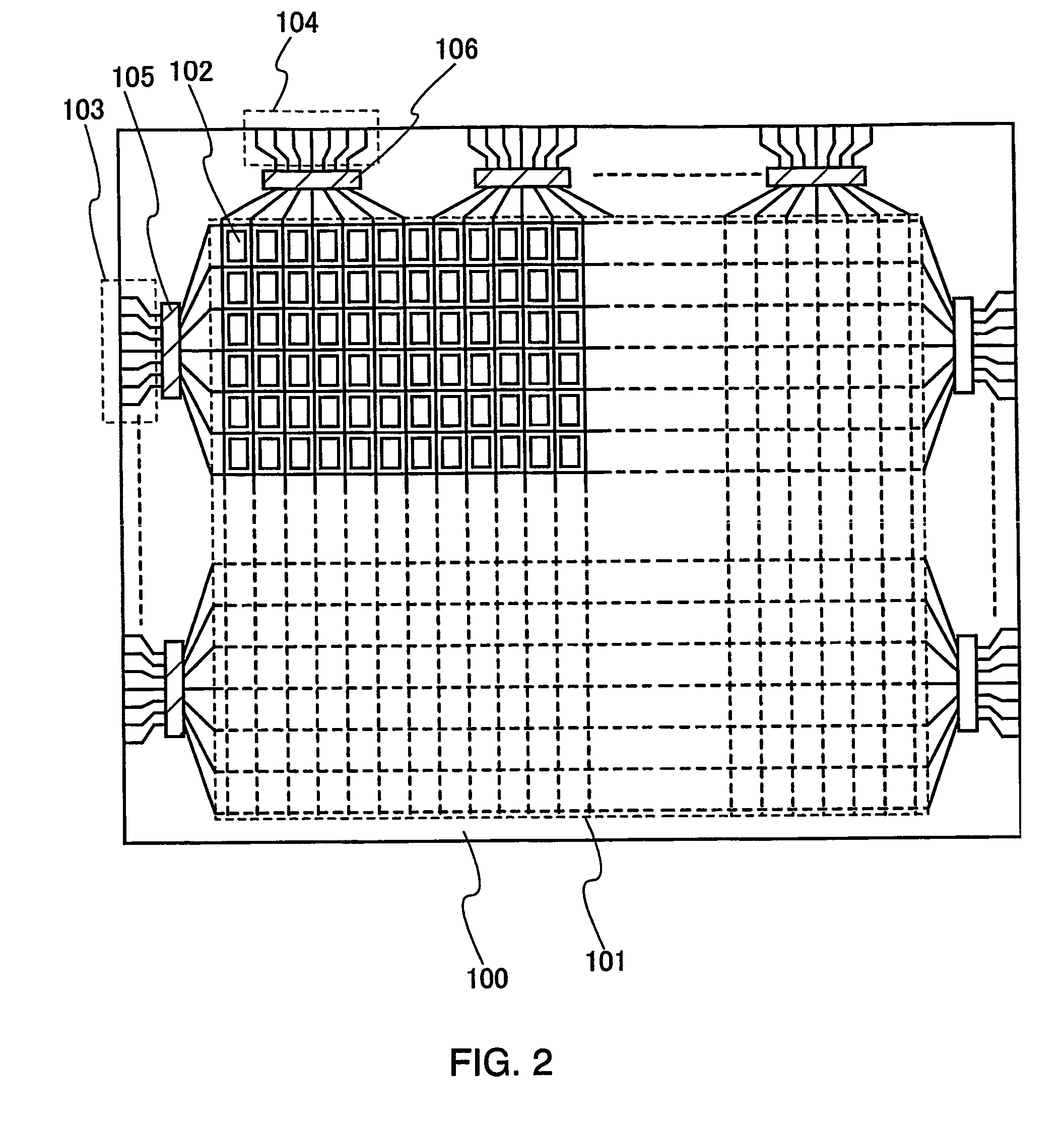

Increasing fill-factor on pixelated sensors

InactiveUS20060244851A1Improve fill factorKeep resolutionTelevision system detailsTelevision system scanning detailsFill factorElectromagnetic radiation

Disclosed are systems, devices, and methodologies that facilitate increasing the effective fill-factor of digital sensors. In general, fill-factor relates to the active area or photosensor region of the sensor with respect to the inactive area / deadzone or space between pixels. By increasing the effective fill-factor, transmission of optical information is increased to the sensor while mitigating information loss between pixels. A digital camera may contain a sensor that is responsive to electromagnetic radiation and a coherent scattering medium between the sensor and a lens that diffuses the electromagnetic radiation with respect to the sensor in order to increase the effective fill-factor.

Owner:CARTLIDGE ANDREW G +3

Recycling the reconditioned substrates for fabricating compound material wafers

ActiveUS7531428B2Difficult to manufactureSolid-state devicesSemiconductor/solid-state device manufacturingMetallurgySubstrate surface

Owner:SOITEC SA

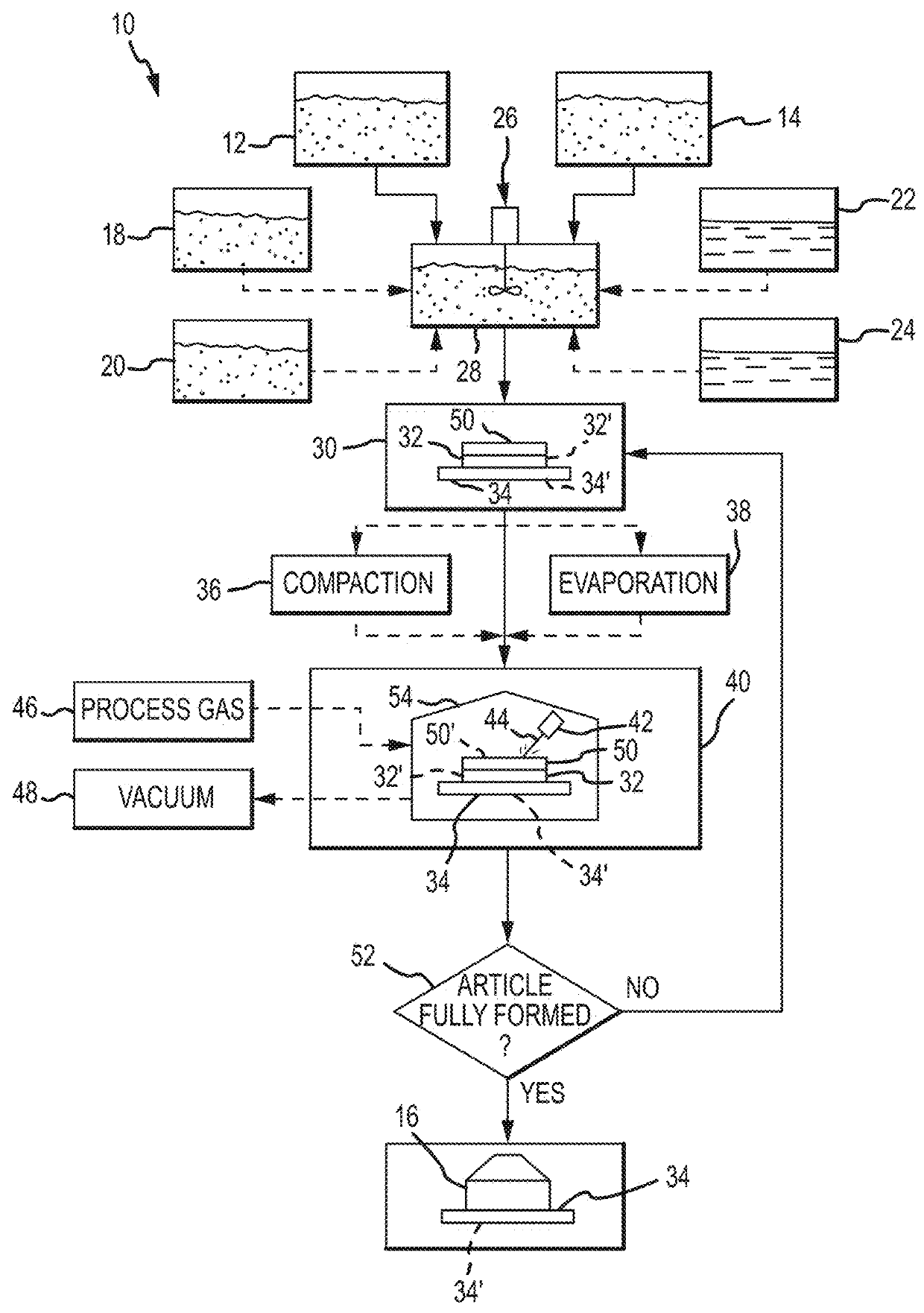

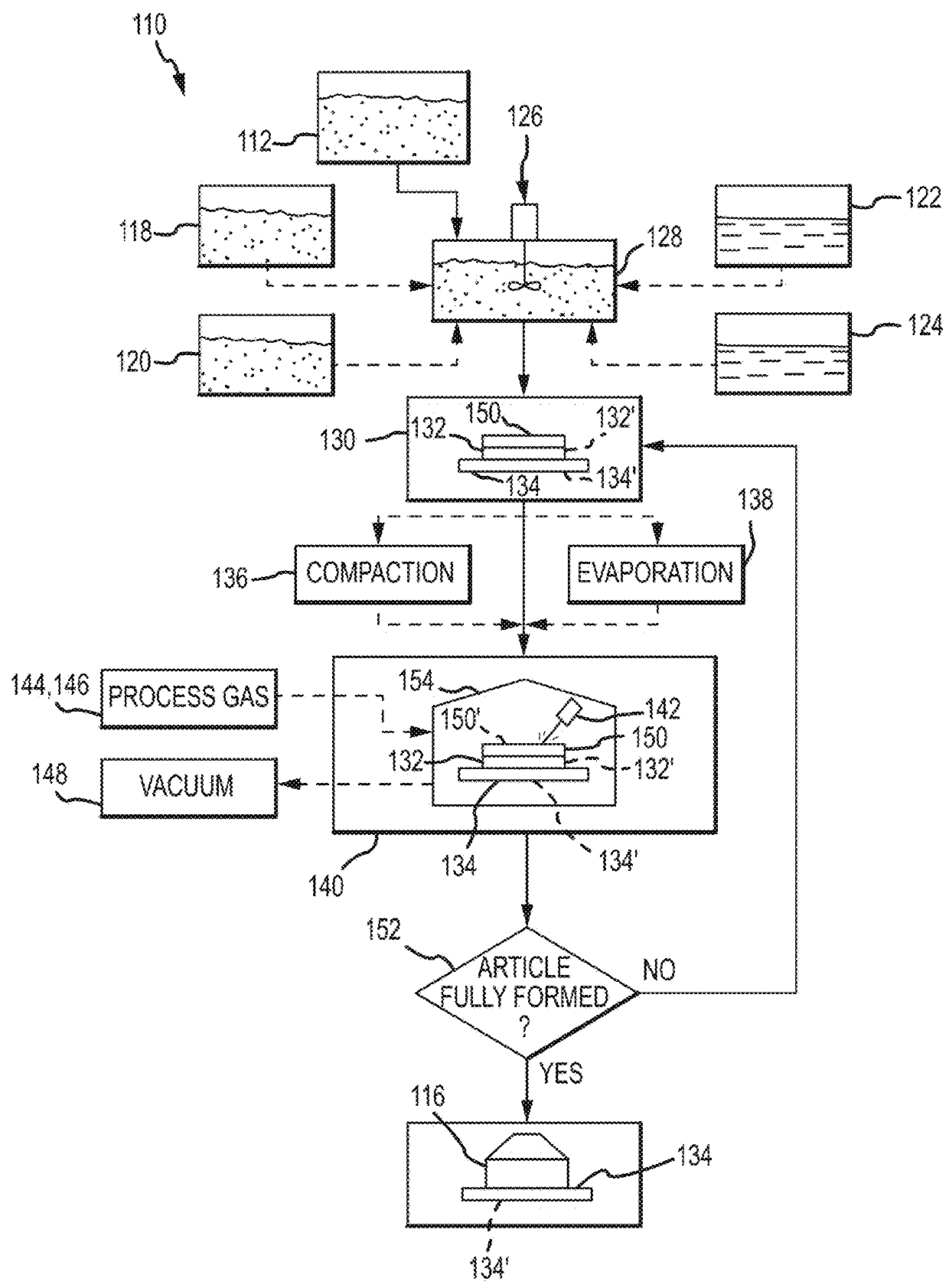

Additive manufacturing of metal alloys and metal alloy matrix composites

ActiveUS20180161874A1High strengthPrevent partial lowAdditive manufacturing apparatusTitanium carbideMetal alloyNucleation

An additive manufacturing method of producing a metal alloy article may involve: Providing a supply of a metal alloy in powder form; providing a supply of a nucleant material, the nucleant material lowering the nucleation energy required to crystallize the metal alloy; blending the supply of metal alloy powder and nucleant material to form a blended mixture; forming the blended mixture into a first layer; subjecting at least a portion of the first layer to energy sufficient to raise the temperature of the first layer to at least the liquidus temperature of the metal alloy; allowing at least a portion of the first layer to cool to a temperature sufficient to allow the metal alloy to recrystallize; forming a second layer of the blended mixture on the first layer; and repeating the subjecting and allowing steps on the second layer to form an additional portion of the metal alloy article.

Owner:ELEMENTUM 3D INC

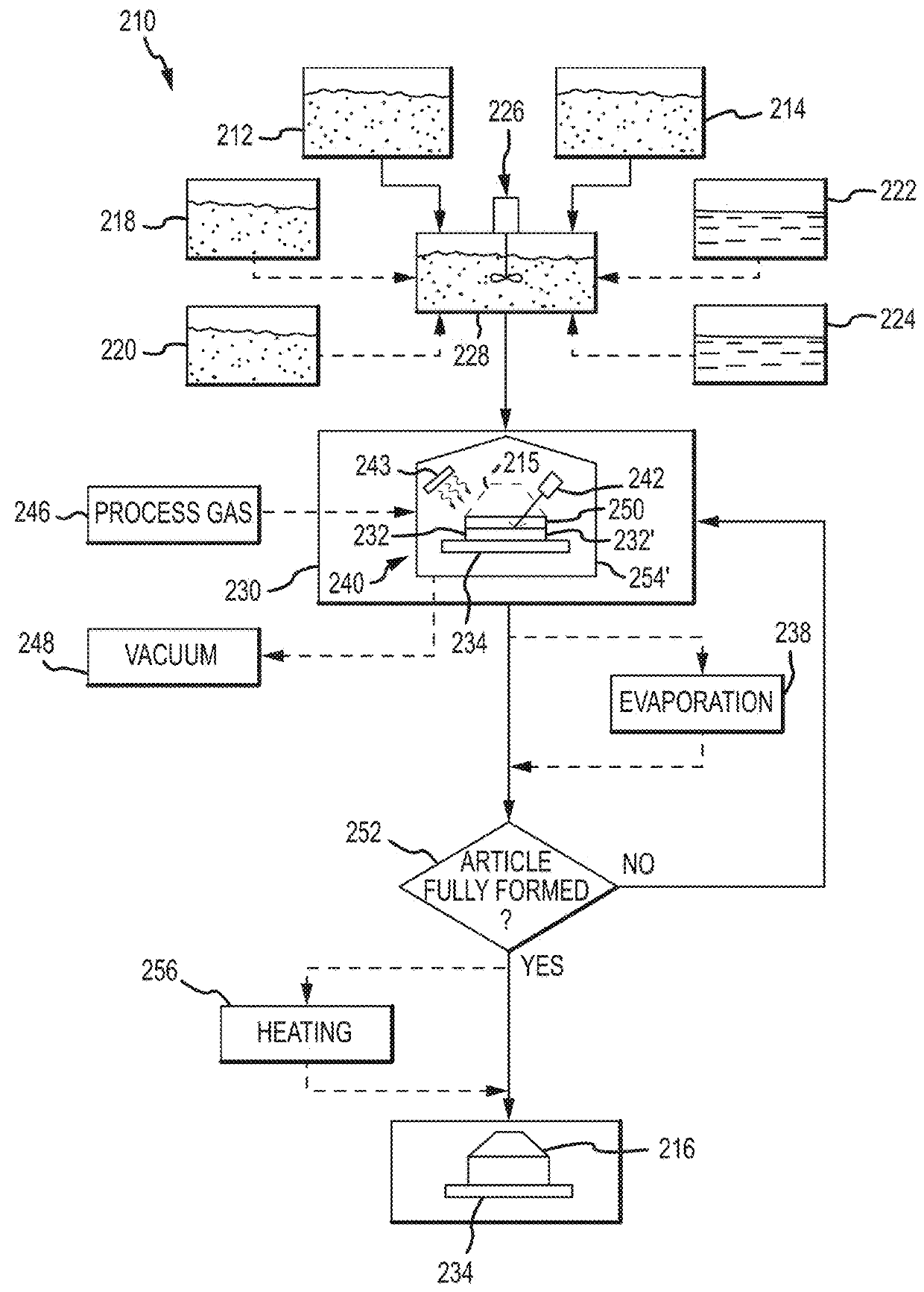

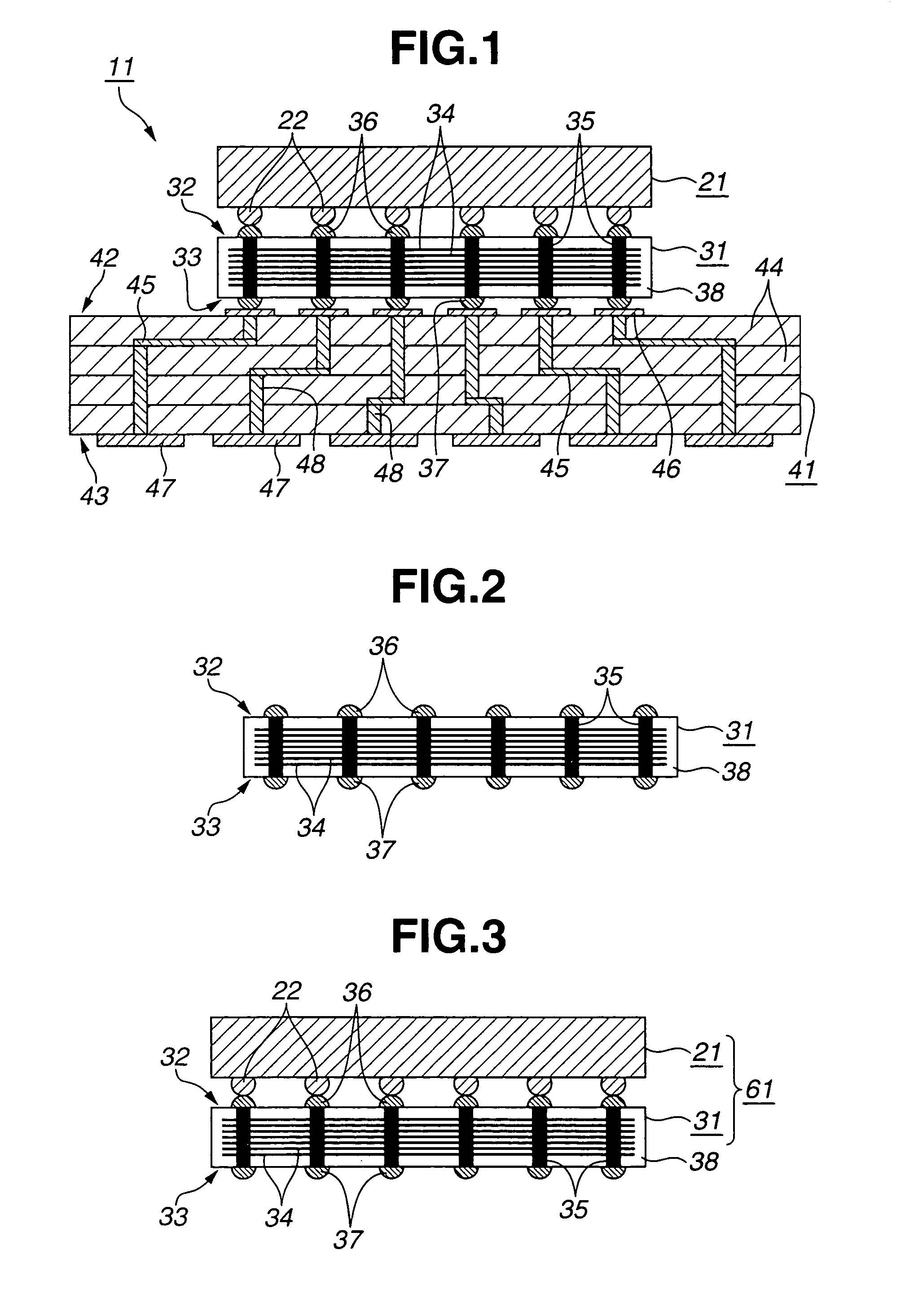

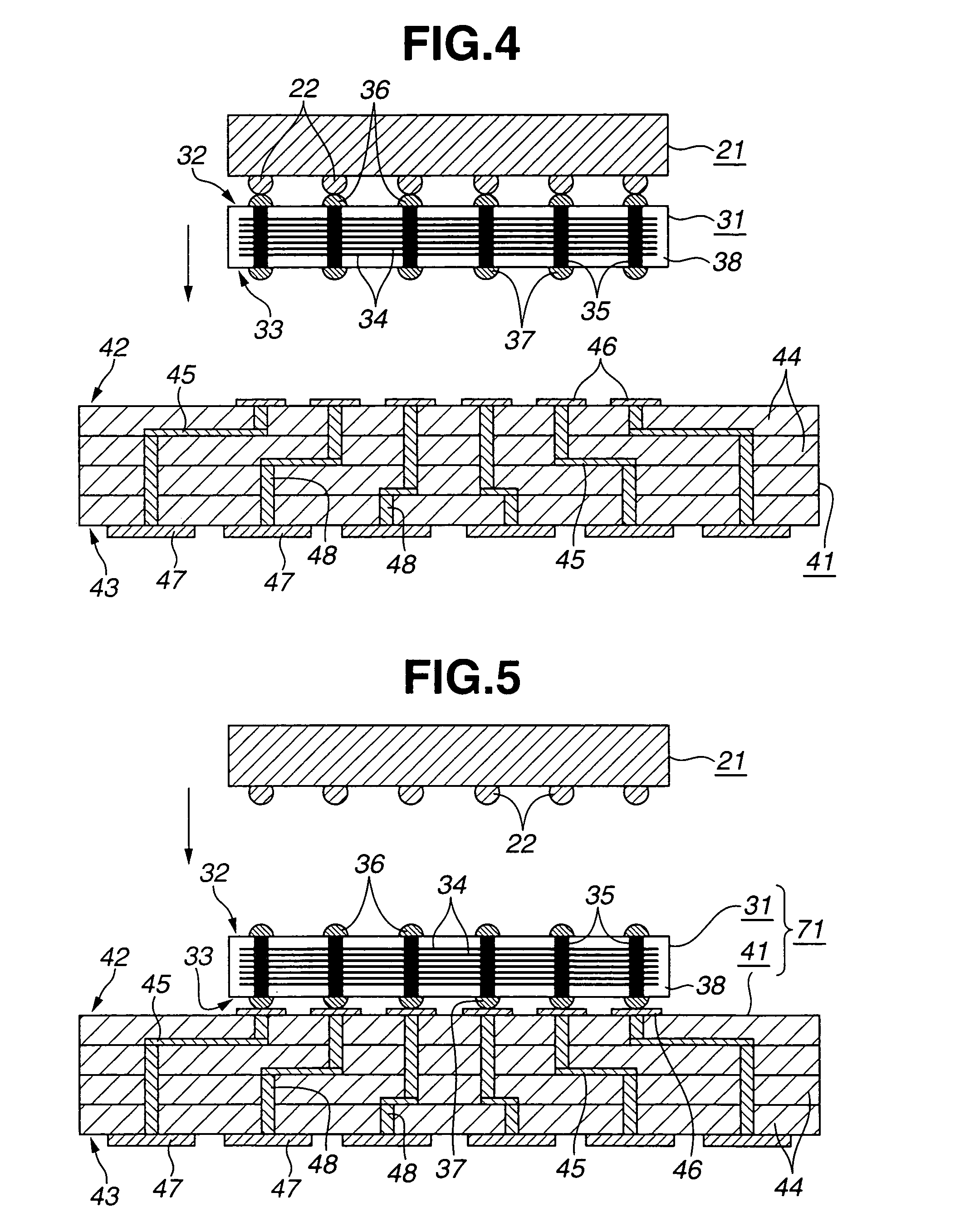

Assembly of semiconductor device, interposer and substrate

InactiveUS7327554B2Improve abilitiesIncrease the lengthSemiconductor/solid-state device detailsFixed capacitor dielectricEngineeringCapacitor

An assembly includes a semiconductor device having surface-connecting terminals, a substrate having surface-connecting pads, and a capacitor having an approximately plate-shaped capacitor main body having a first surface on which the semiconductor device is mounted and a second surface at which the capacitor main body is mounted on the substrate and a plurality of electrically conductive vias penetrating the capacitor main body between the first and second surfaces and connected to the surface-connecting terminals and the surface-connecting pads.

Owner:NGK SPARK PLUG CO LTD

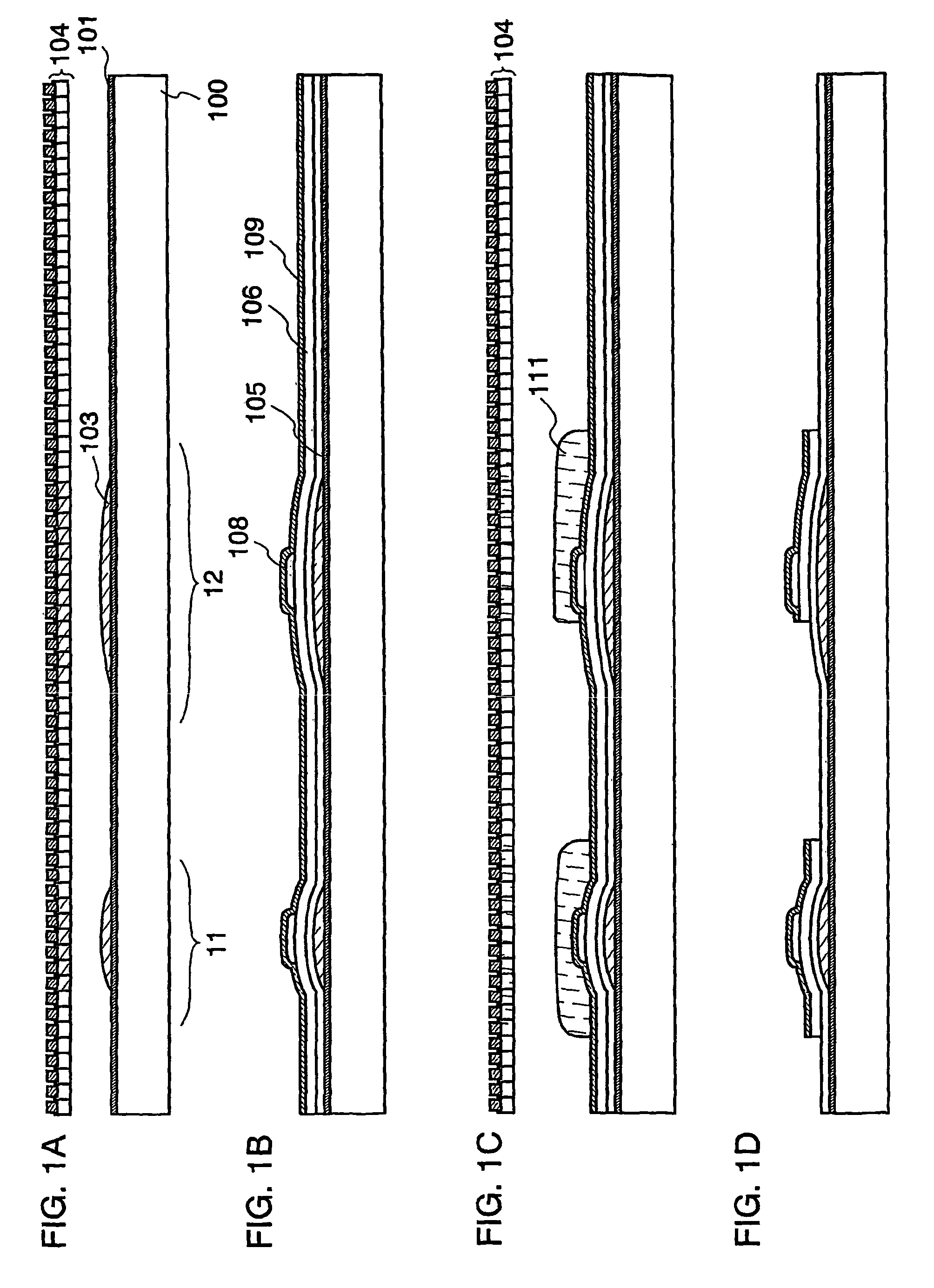

Method for manufacturing liquid crystal display device

InactiveUS20070082443A1Manufacture step be simplifyLow costTransistorSolid-state devicesLiquid-crystal displayEngineering

A conventionally followed technique of manufacturing a liquid crystal display device is a method for forming various types of coatings over an entire surface of a substrate and for removing the coatings with a small region left by etching, which requires wasting a material cost and treating a large quantity of waste. A liquid crystal display device is manufactured by forming at least one or more of patterns necessary for manufacturing a liquid crystal display device by a method capable of selectively forming a pattern. A droplet discharge method capable of forming a predetermined pattern by selectively discharging a droplet of a composition prepared for a specific purpose is employed as the method capable of selectively forming a pattern.

Owner:SEMICON ENERGY LAB CO LTD

Display device and method for fabricating the same

InactiveUS7859187B2Low costBig investmentTransistorLiquid surface applicatorsManufacturing technologyDisplay device

It is an object of the invention to provide a display device which can be manufactured by a simplified manufacturing process by which the efficiency in the use of material is improved. It is a further object of the invention to provide a manufacturing method of the display device. It is another object of the invention to provide a fabrication technology for improving adhesion of a pattern. In view of the above problems, according to the present invention, a pattern is formed by a droplet discharge method. Particularly in the invention, base pretreatment is performed before / after a pattern is formed by a droplet discharge method. As a result of such base pretreatment, adhesion of a pattern can improved, and the pattern may be made finer.

Owner:SEMICON ENERGY LAB CO LTD

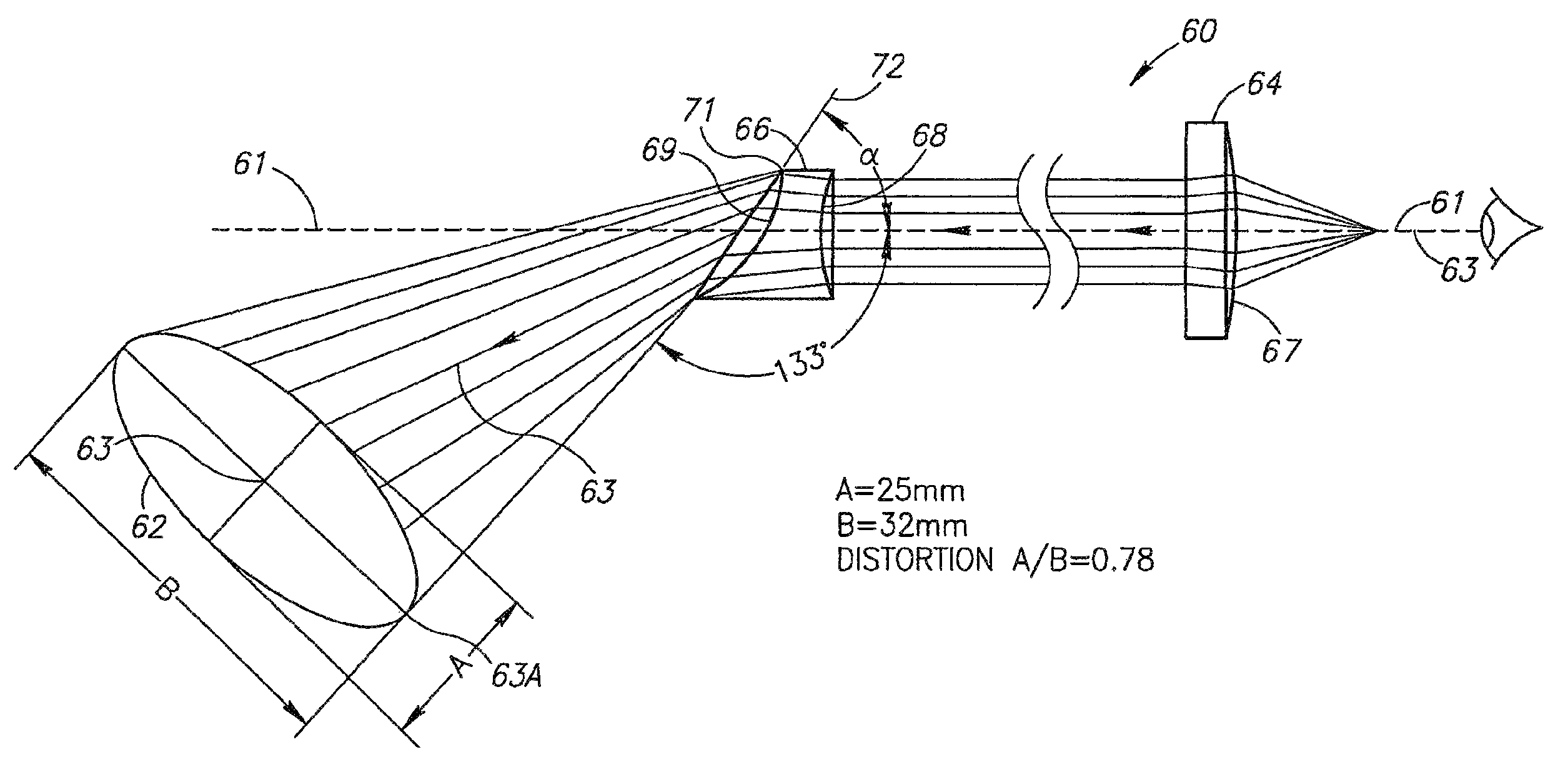

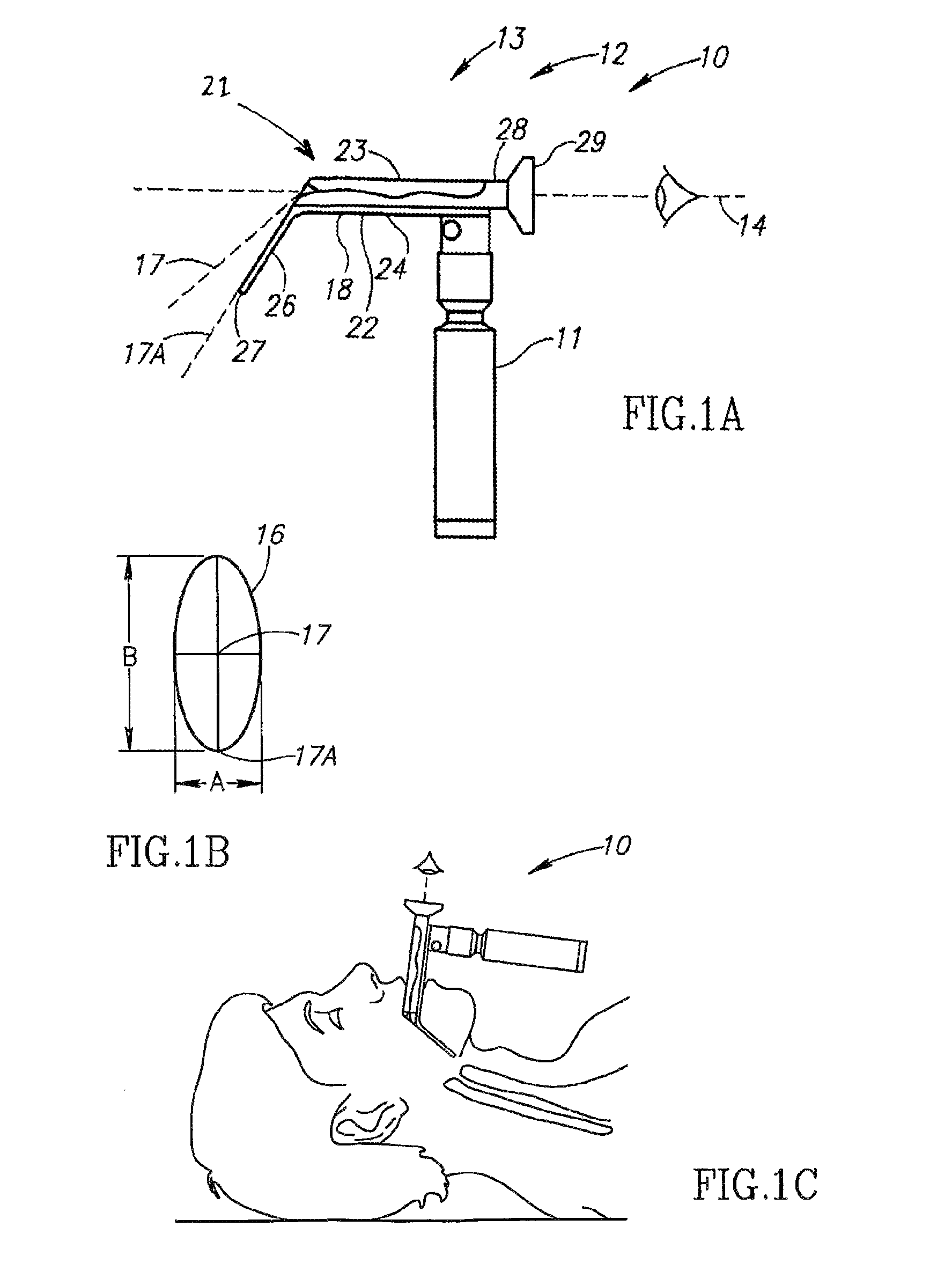

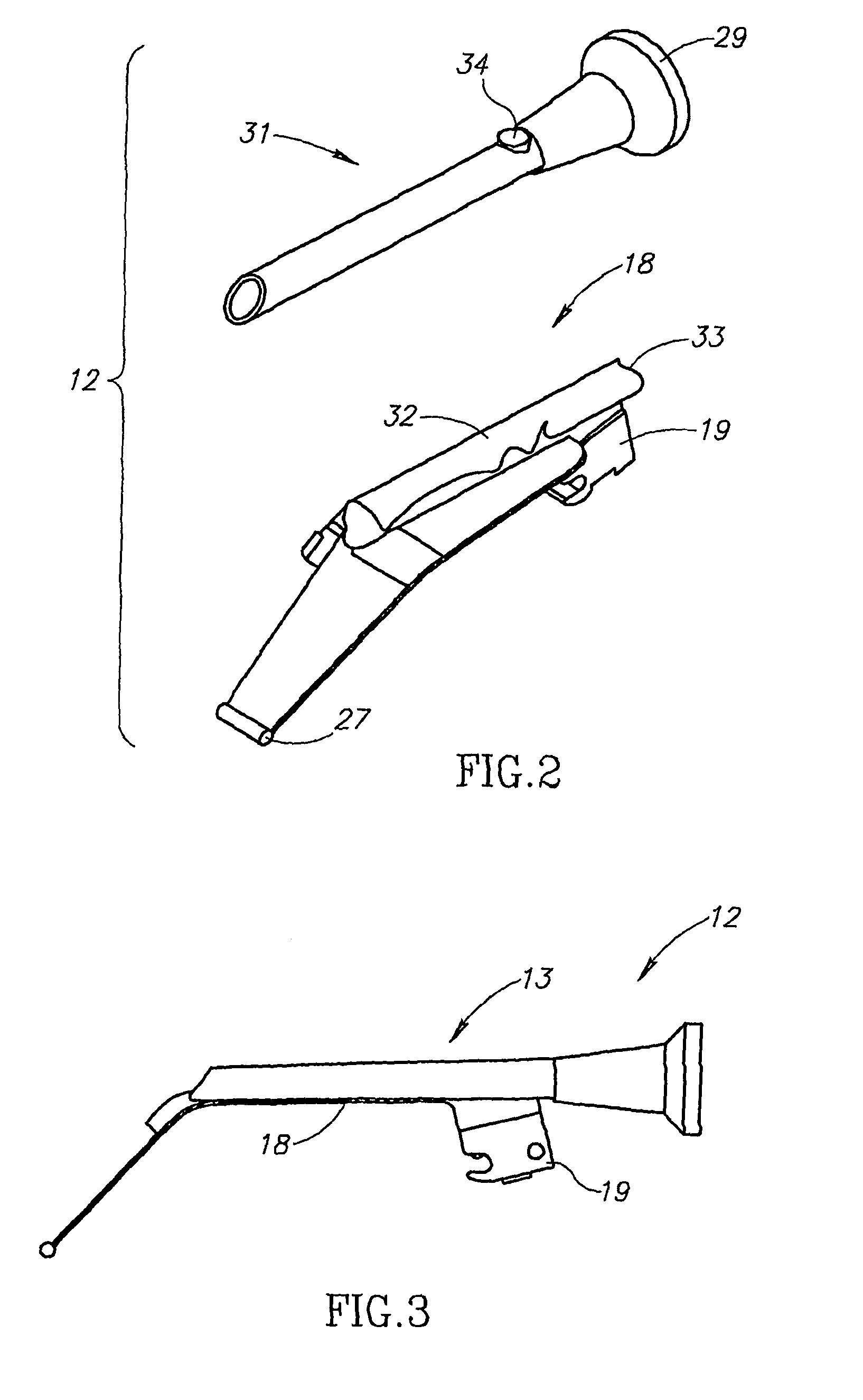

Laryngoscope apparatus with enhanced viewing capability

ActiveUS8251898B2Expand field of viewIncreased FOV magnificationBronchoscopesLaryngoscopesEngineeringCurved laryngoscope blade

Laryngoscope apparatus including a curved laryngoscope blade and an optical system for affording a field of view along a deflected line of sight for reducing patient manipulation and / or the degree of force required to achieve a good glottic view.

Owner:TELEFLEX LIFE SCI PTE LTD

Reactive additive manufacturing

ActiveUS20160271878A1High quality partHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyMaterials scienceReaction product

An additive manufacturing method may involve: Providing a first and a second material, the second material capable of reacting with the first material to form a reaction product; forming at least the first material into a first layer; subjecting at least a portion of the first layer to energy in the presence of the second material, the energy being sufficient to initiate a reaction between at least the first and second materials to form a portion of the article, the portion of the article comprising the reaction product; forming a second layer of at least the first material on the first layer; and subjecting at least a portion of the second layer to energy in the presence of the second material, the energy being sufficient to initiate a reaction between the first and second materials to form an additional portion of the article.

Owner:ELEMENTUM 3D INC

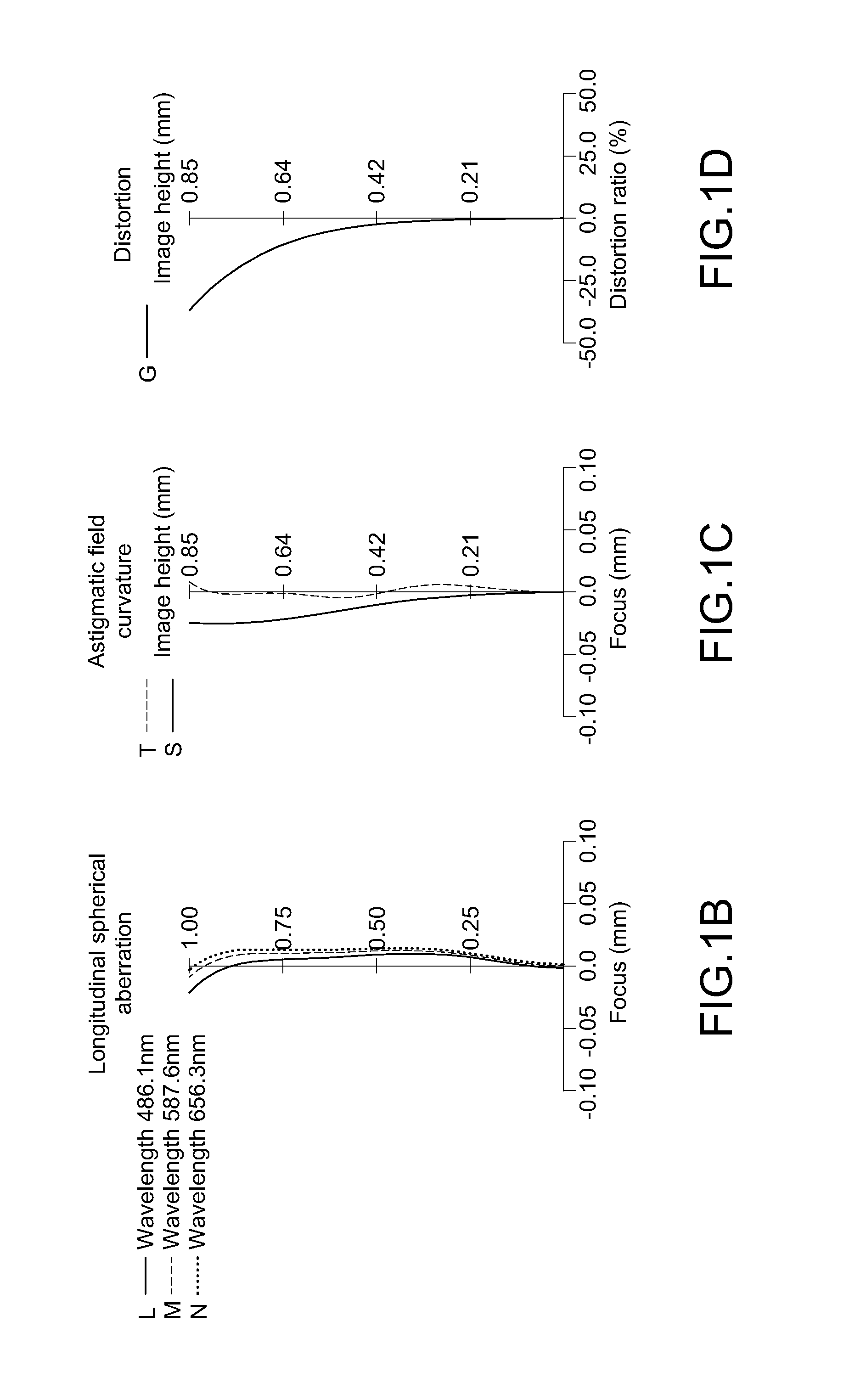

Optical lens system for image taking

An optical lens system for image taking includes, in order from an object side to an image side, a first lens element with negative refractive power having a concave object-side surface and a concave image-side surface, a second lens element with positive refractive power having a convex image-side surface, and a third lens element with negative refractive power having a concave image-side surface of the third lens element near an optical axis and a convex image-side surface of the third lens element away from the optical axis. Both the object-side surface and the image-side surface of the third lens element are aspheric. The third lens element is made of plastic.

Owner:LARGAN PRECISION

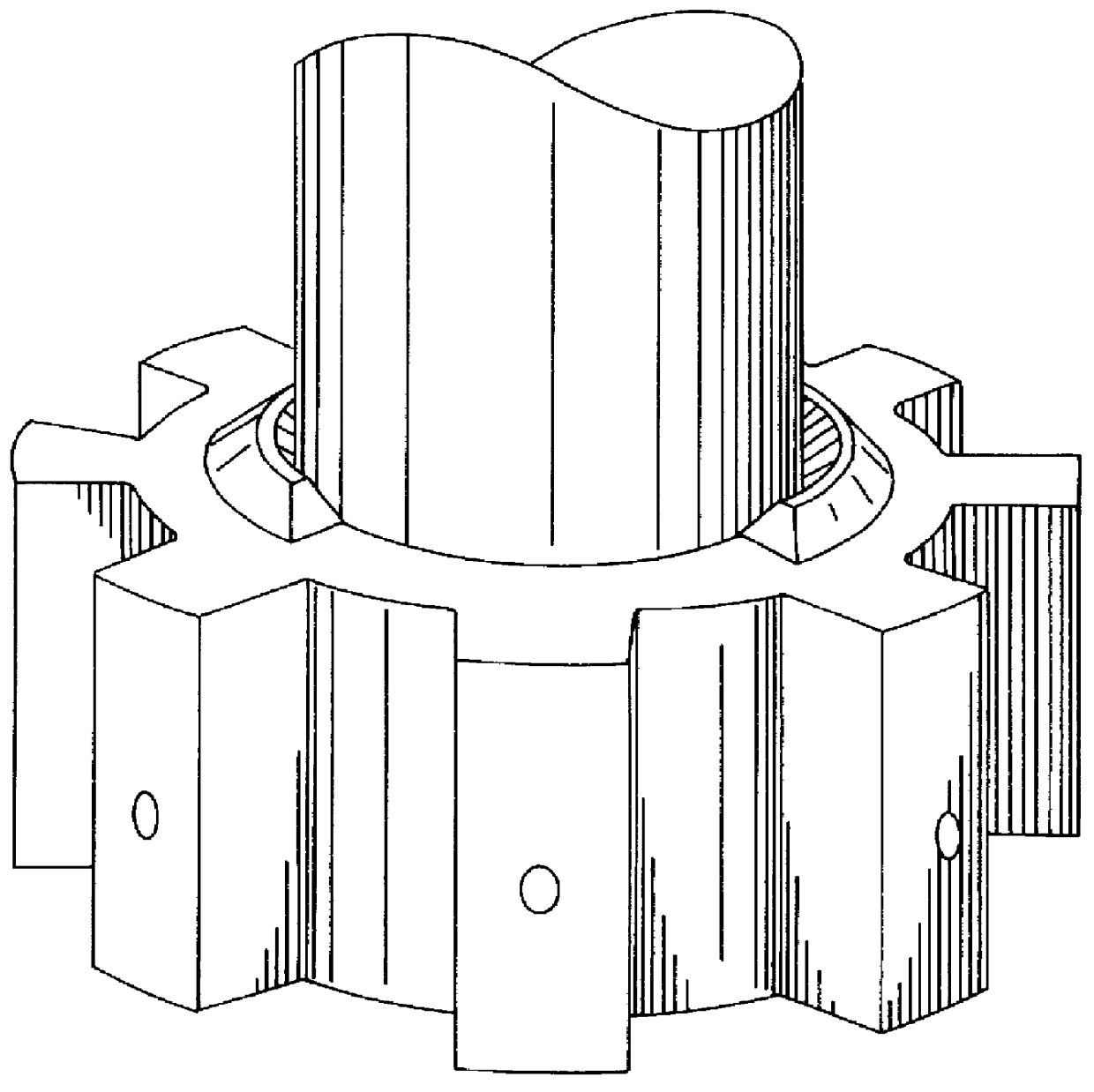

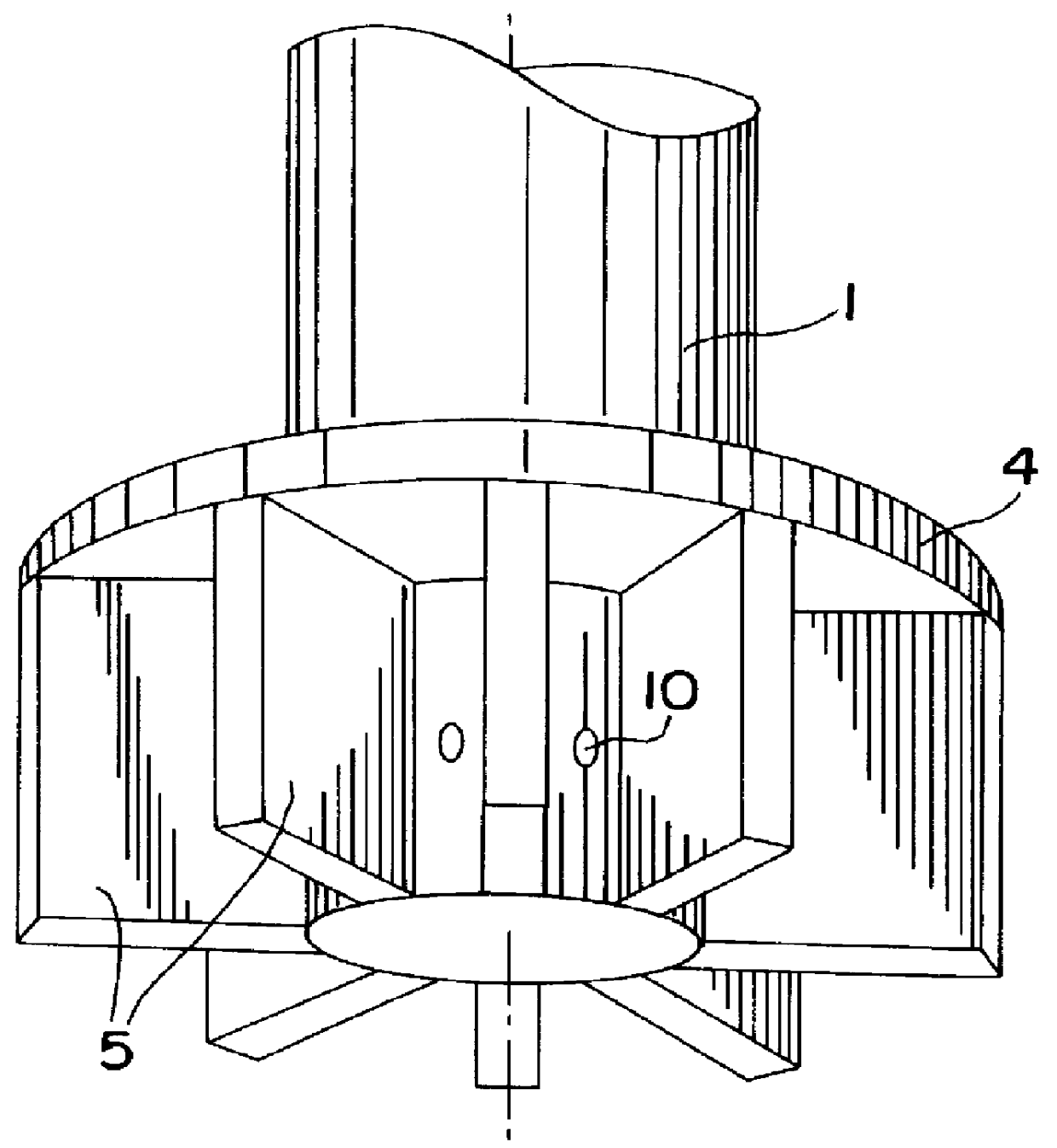

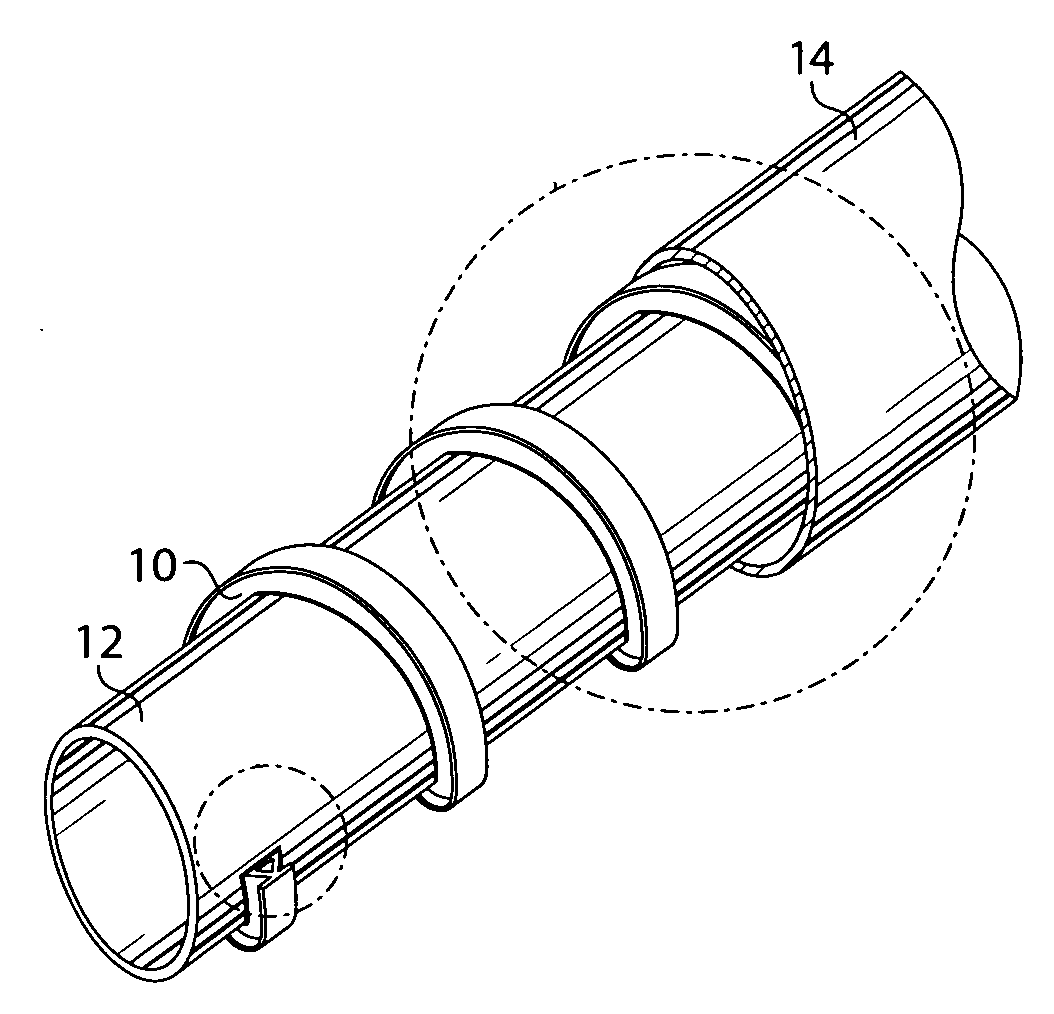

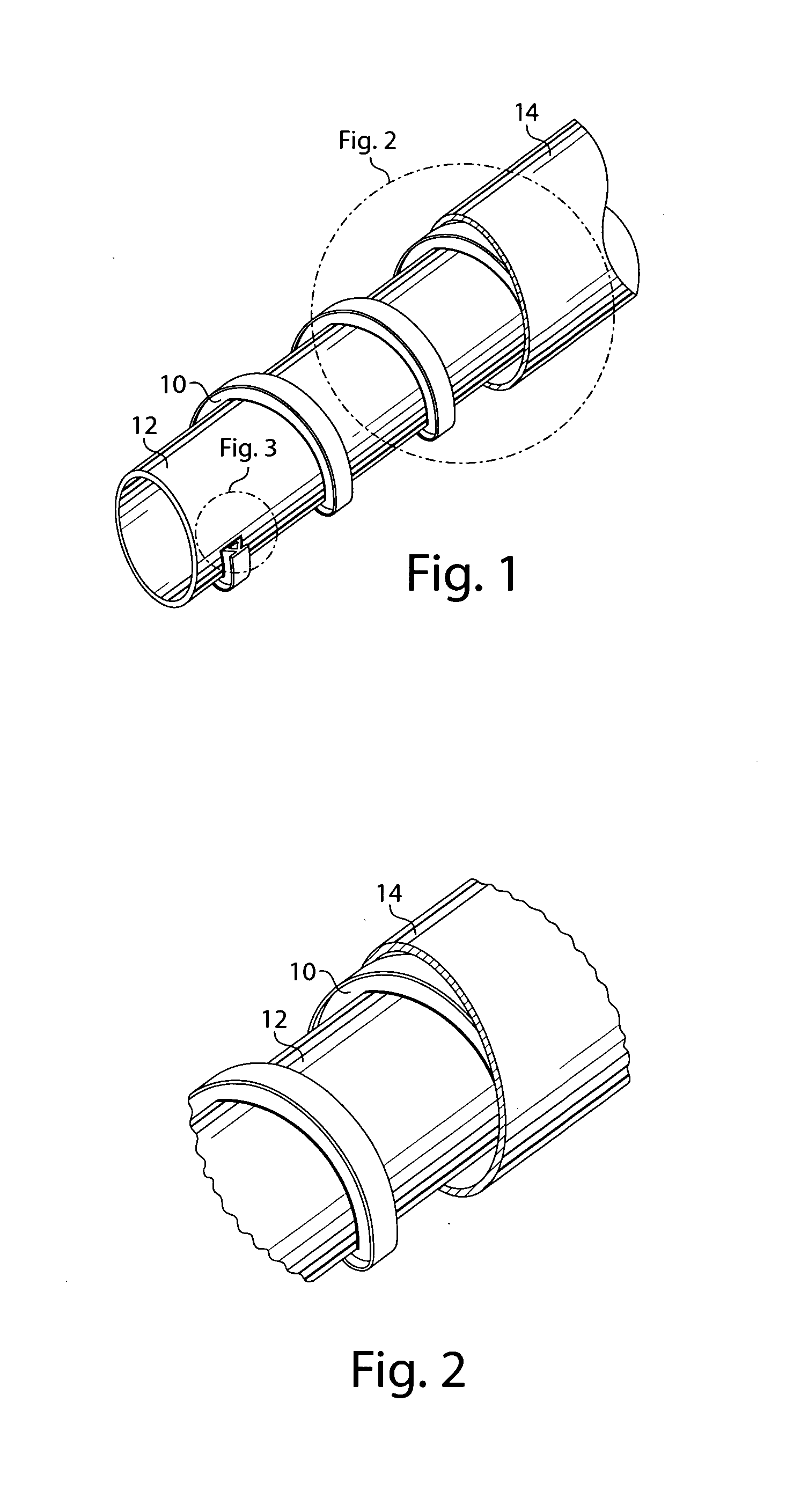

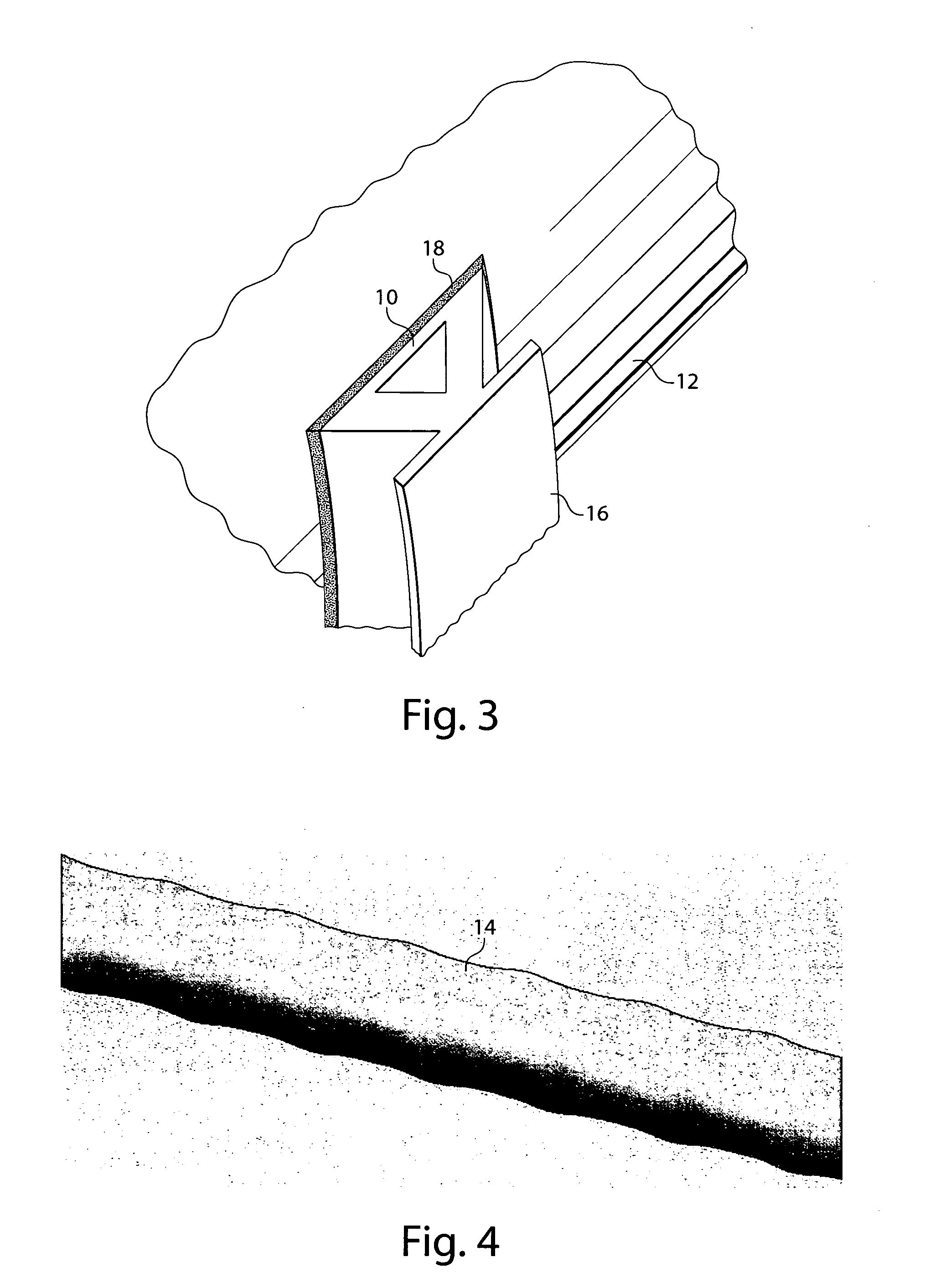

Rotary gas dispersion device for treating a liquid aluminium bath

InactiveUS6060013AHigh blade lift ratioDifficult to manufactureMechanical apparatusStirring devicesEngineeringLiquid aluminium

PCT No. PCT / FR97 / 01367 Sec. 371 Date Mar. 8, 1999 Sec. 102(e) Date Mar. 8, 1999 PCT Filed Jul. 23, 1997 PCT Pub. No. WO98 / 05915 PCT Pub. Date Feb. 12, 1998A rotary gas dispersion device for use in a liquid aluminium treatment vessel is disclosed. The device is useful for reducing surface disturbance, splashing and vortices while maintaining the effectiveness of the treatment. Said device includes a rotor (1) consisting of a set of blades (5) and a substantially flat disc (4) thereabove. Gas is injected through the central hub and side ports (10) between the blades. The ratio of the outer diameter of the rotor to the diameter of the central hub thereof is of 1.5-4.

Owner:NOVELIS INC

Load-bearing, lightweight, and compact super-insulation system

ActiveUS20050047871A1Easy to installEasy maintenanceDrilling rodsService pipe systemsEngineeringInsulation system

A lightweight and compact super-insulation system that is also capable of supporting a high level of compressive load is described. The system utilizes spacers to provide structural support and utilize controlled buckling of a thin protective outer skin supported by spacers to form strong catenary surfaces to protect insulation material underneath. The spacers may comprise an aerogel, or an aerogel may provide insulation separate from the spacer yet contained within the thin outer skin. The system will be useful for thermal management of variety of deep underwater structures such as pipe-in-pipe apparatus, risers or subsea trees for ultra-deep water oil-and-gas exploration.

Owner:ASPEN AEROGELS INC

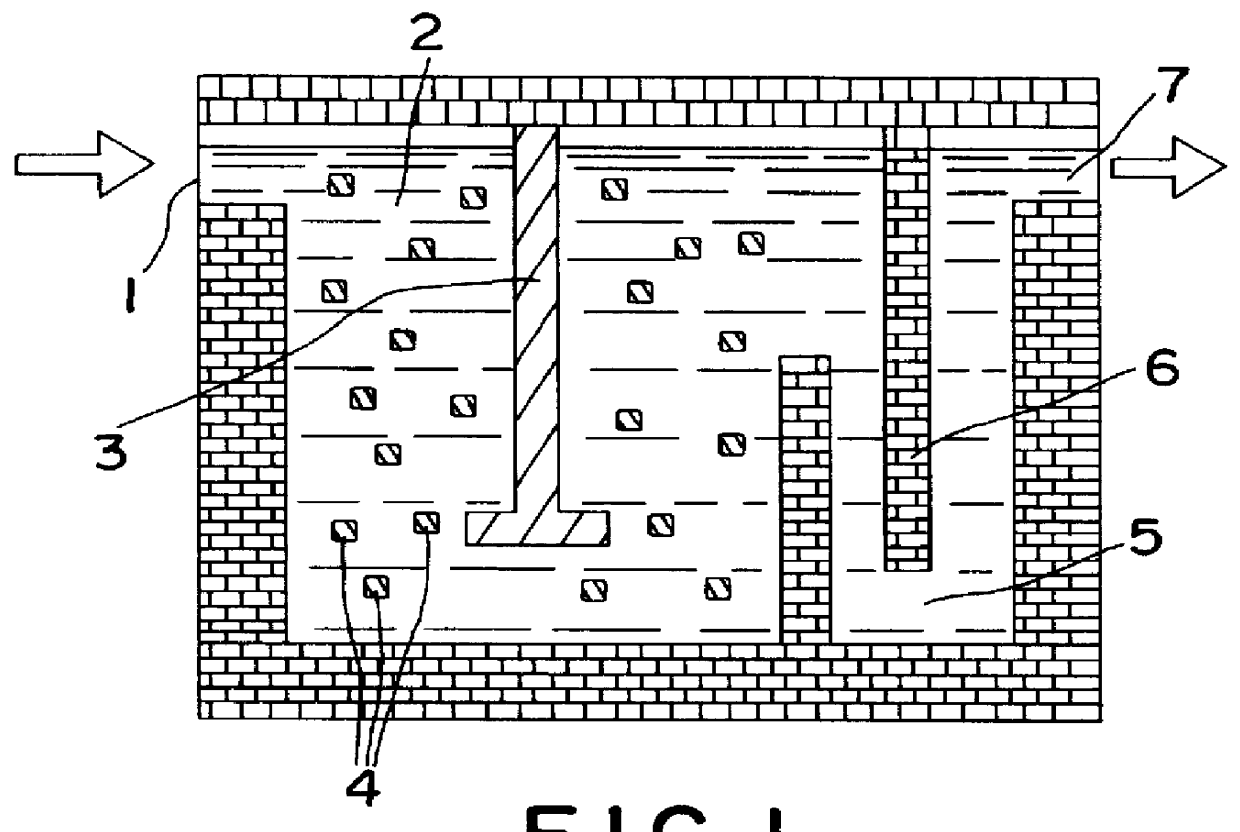

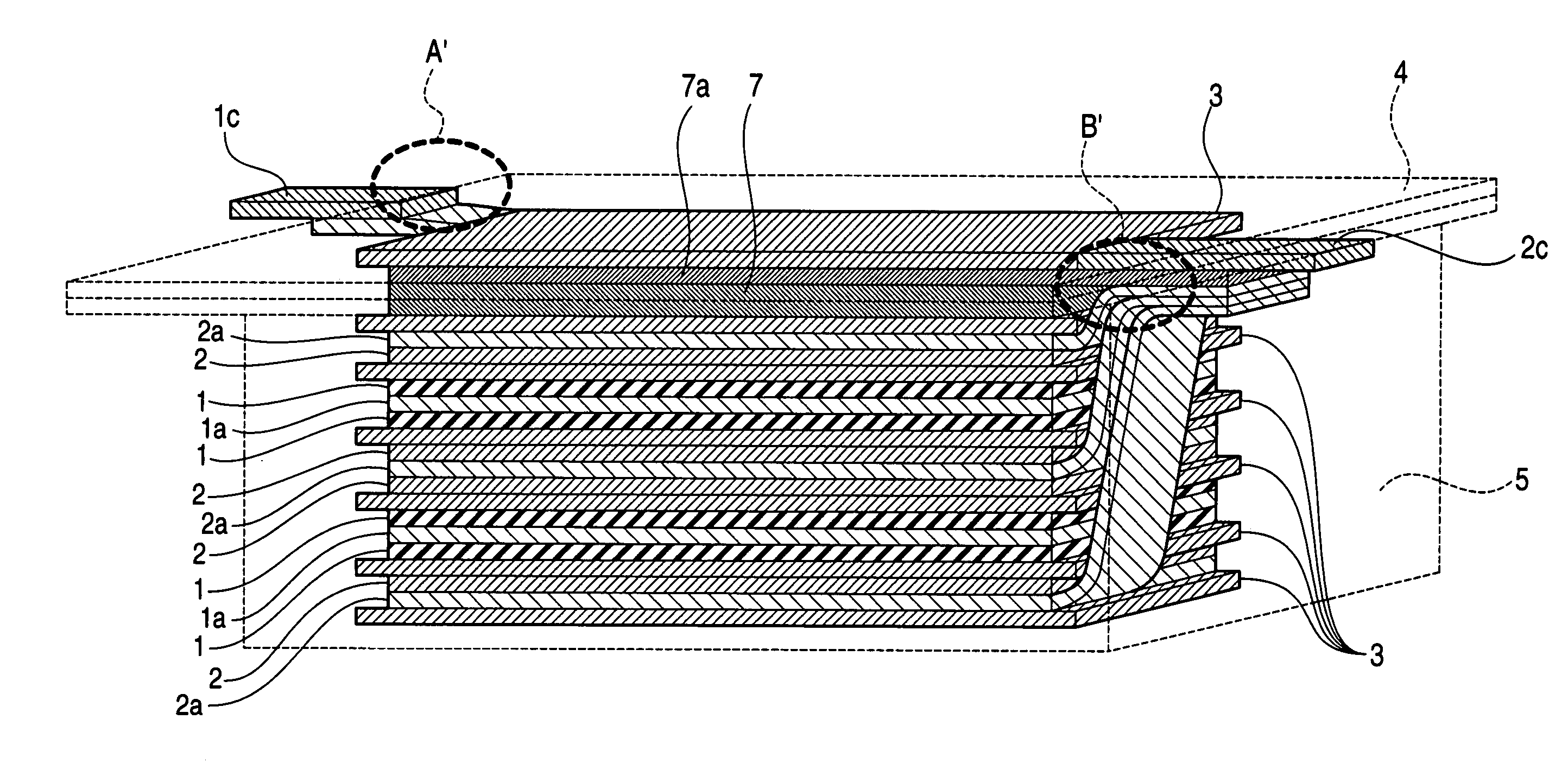

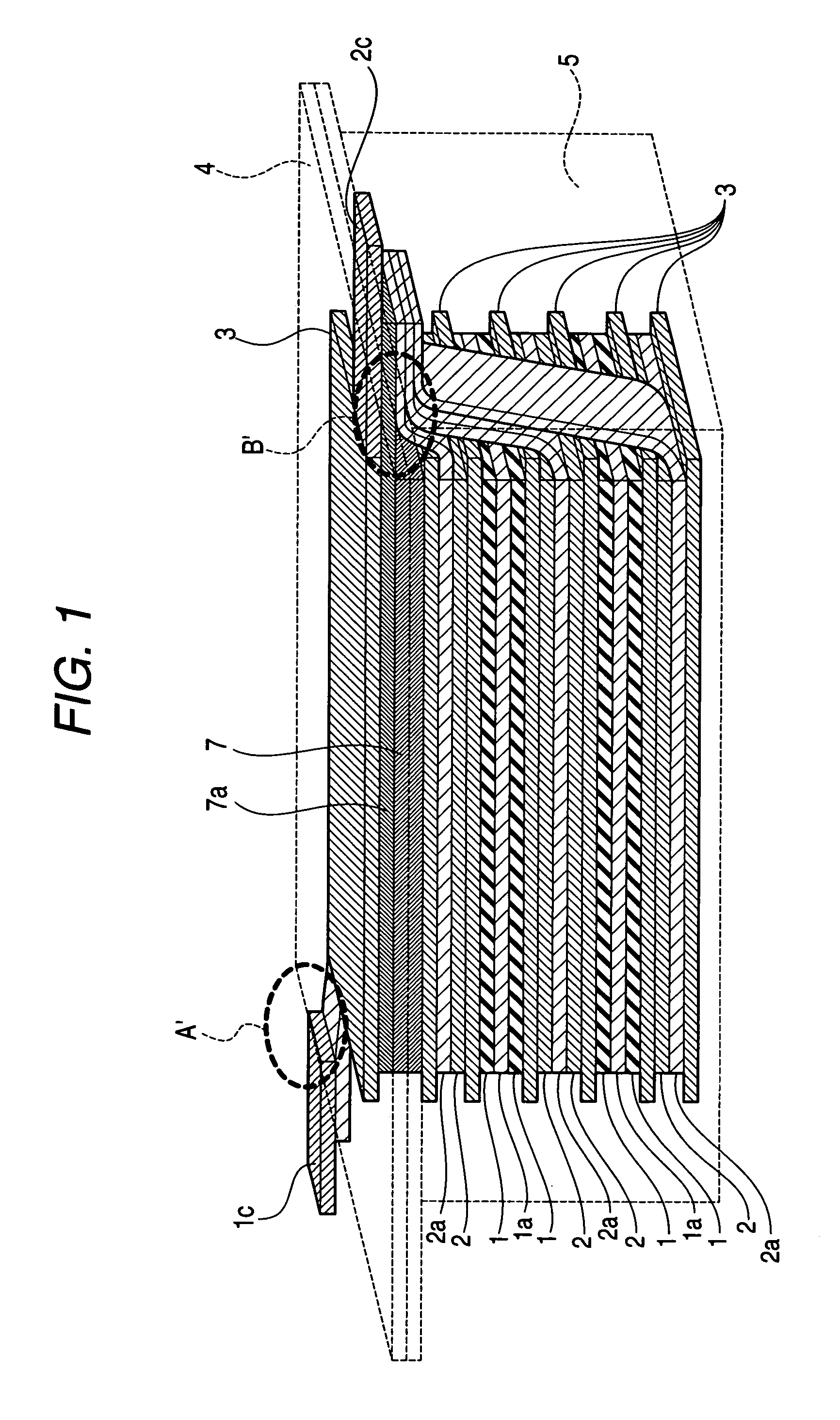

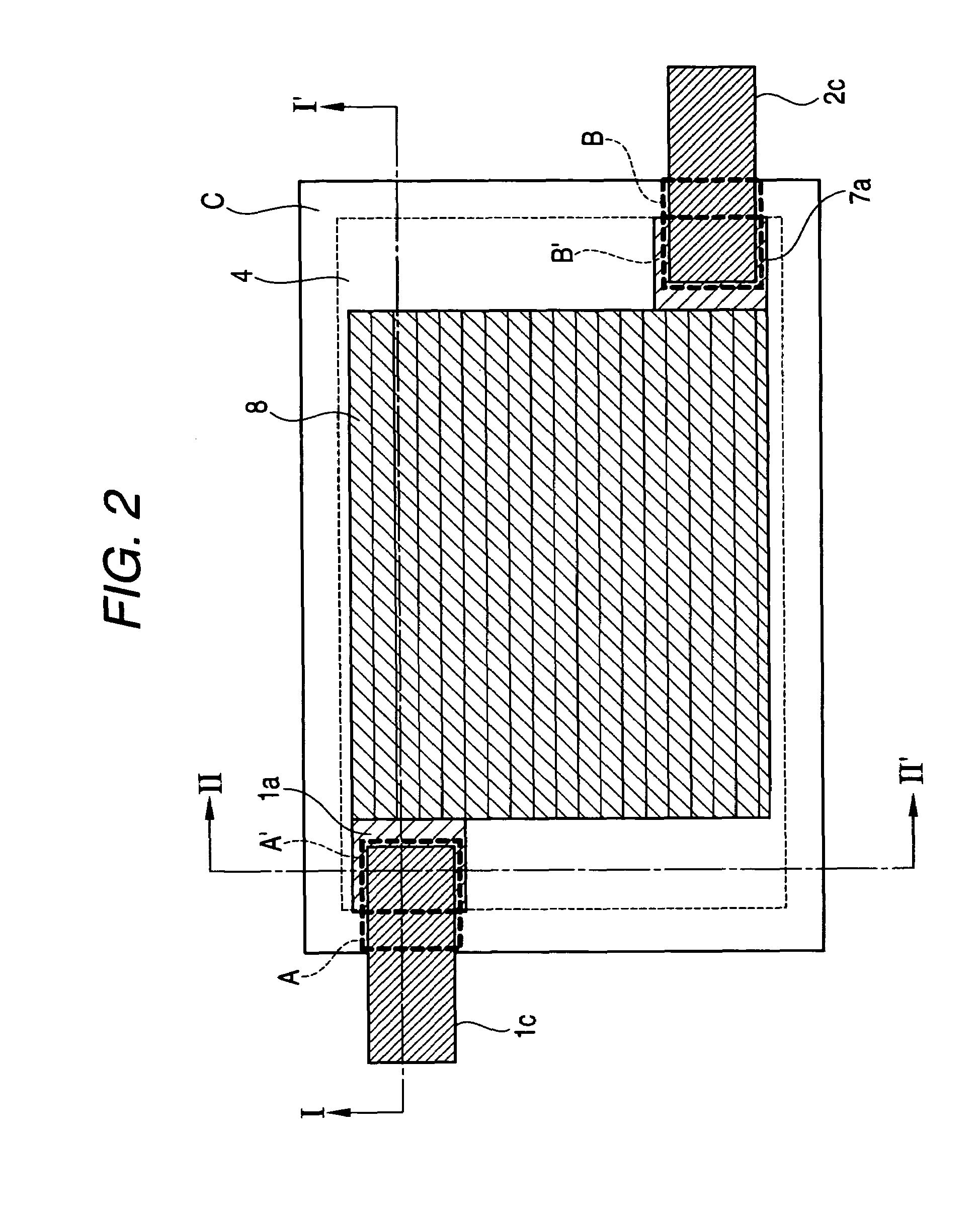

Organic electrolyte capacitor

ActiveUS7385801B2High voltageLarge capacityLiquid electrolytic capacitorsFinal product manufactureLithiumElectrolysis

There is provided an organic electrolyte capacitor having electrodes on current collectors that have holes penetrating the front and rear surfaces, in which electrode materials formed on the through-holes of the current collectors seldom fall off and high energy density and high power density can be obtained. The organic electrolyte capacitor includes positive electrodes, negative electrodes and an electrolyte capable of transferring lithium ions, in which the positive electrodes contain a substance capable of carrying lithium ions and / or anions reversibly as a positive electrode active material, the negative electrodes contain a substance capable of carrying lithium ions as a negative electrode active material, the positive and negative electrodes possess the positive or negative electrode active material layers on an electrode substrate that has conductive layers made of conductive materials on current collectors, which have through-holes, and the negative electrodes carry lithium electrochemically.

Owner:SUBARU CORP

Self-aligned last-metal C4 interconnection layer for Cu technologies

InactiveUS6426557B1Reduce resistanceReduce mechanical stressSemiconductor/solid-state device detailsSolid-state devicesShunt DeviceCopper conductor

A controlled collapse chip connection (C4) structure having stronger resistance to failure is constructed for use with integrated circuit devices having copper wiring. Failure resistance is obtained by replacing the mechanically weak final passivation to copper interface. The weak interface is eliminated by use of a specific peg on peg structure together with a layer of shunt metal having excellent adhesion and barrier characteristics. A shunt metal, e.g., Ta or TaN, is placed between both the copper and final passivation and the copper and C4 metals such that it overlaps the edge of the peg defined wiring mesh to encase the copper. Overlap is obtained by the peg on peg structure where a SiO2 peg defines the copper wire mesh and a smaller Si3N4 peg placed on the SiO2 peg defines the overlap above the mesh wire and provides the ability to pattern the overlayer shunt without exposure of the copper conductor.

Owner:IBM CORP

Method for manufacturing liquid crystal display device

InactiveUS7439086B2Low costBig investmentTransistorSolid-state devicesLiquid-crystal displayEngineering

A conventionally followed technique of manufacturing a liquid crystal display device is a method for forming various types of coatings over an entire surface of a substrate and for removing the coatings with a small region left by etching, which requires wasting a material cost and treating a large quantity of waste. A liquid crystal display device is manufactured by forming at least one or more of patterns necessary for manufacturing a liquid crystal display device by a method capable of selectively forming a pattern. A droplet discharge method capable of forming a predetermined pattern by selectively discharging a droplet of a composition prepared for a specific purpose is employed as the method capable of selectively forming a pattern.

Owner:SEMICON ENERGY LAB CO LTD

Stabilized pharmaceutical solid compositions of low-solubility drugs and poloxamers, and stabilizing polymers

InactiveUS20070148232A1Improve concentrationHigh dissolution rateBiocidePowder deliverySolubilityPhysical stability

Solid compositions with improved physical stability comprise an amorphous, low-solubility drug, a poloxamer, and a stabilizing polymer. The compositions provide good physical stability during storage and concentration enhancement of dissolved drug when administered to an aqueous environment of use.

Owner:BEND RES

Solid catalyst for olefin polymerization, olefin polymerization method, and olefin polymer particle produced by the method

InactiveUS20100029877A1Particles in good shapeImprove efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsParticulatesHydrogen atom

An object of the present invention is to provide solid catalyst component for manufacturing an olefin polymer having an excellent particulate morphology without the concern of causing fouling, and a polymerization of olefin in the presence of said solid catalyst component.A solid catalyst (K) for olefin polymerization of the invention is characterized by meeting the following requirements [1] and [2]:[1] a loss of ignition is 30 wt % or less as measured on a differential thermogravimeter; and[2] after treating the catalyst with water vapor of room temperature and then contacting it with acetonitrile, a component eluted into the acetonitrile comprises a compound having a molecular skeleton represented by the following general formula [I].(R in the above formula [I] is a hydrogen atom or an alkyl group having 1 to 12 carbon atoms.)

Owner:MITSUI CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com