Patents

Literature

651results about How to "Improve manufacturing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

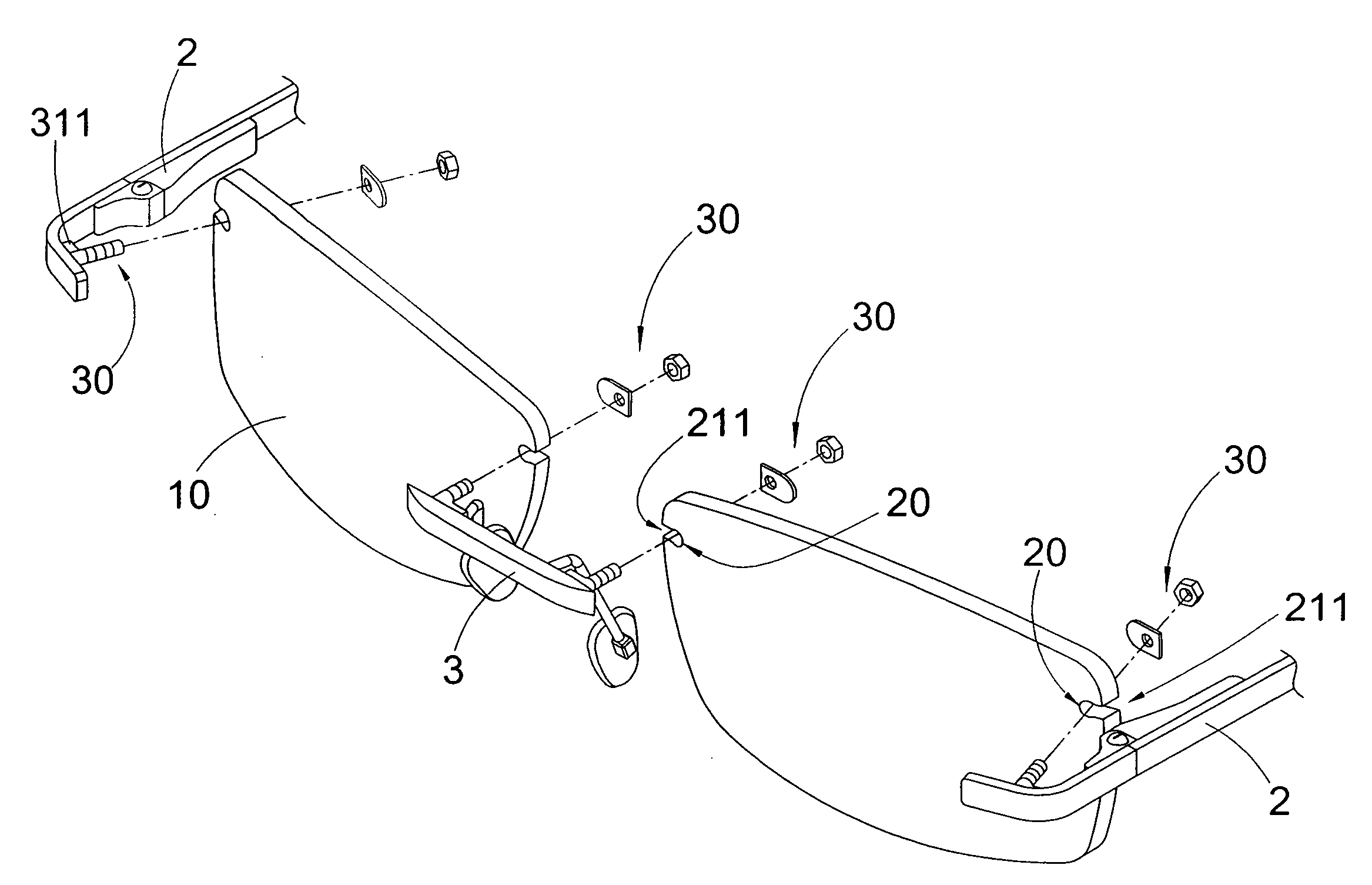

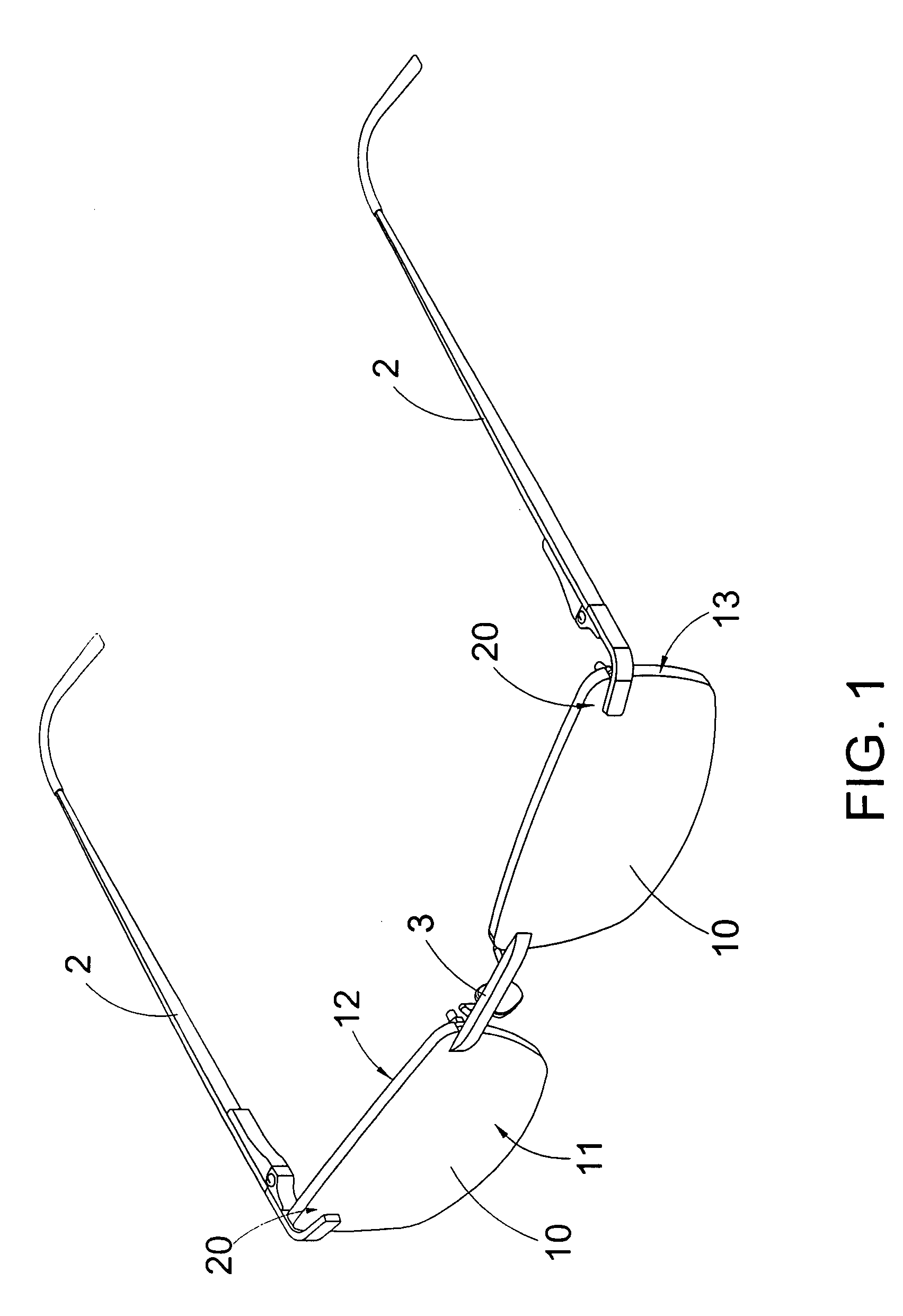

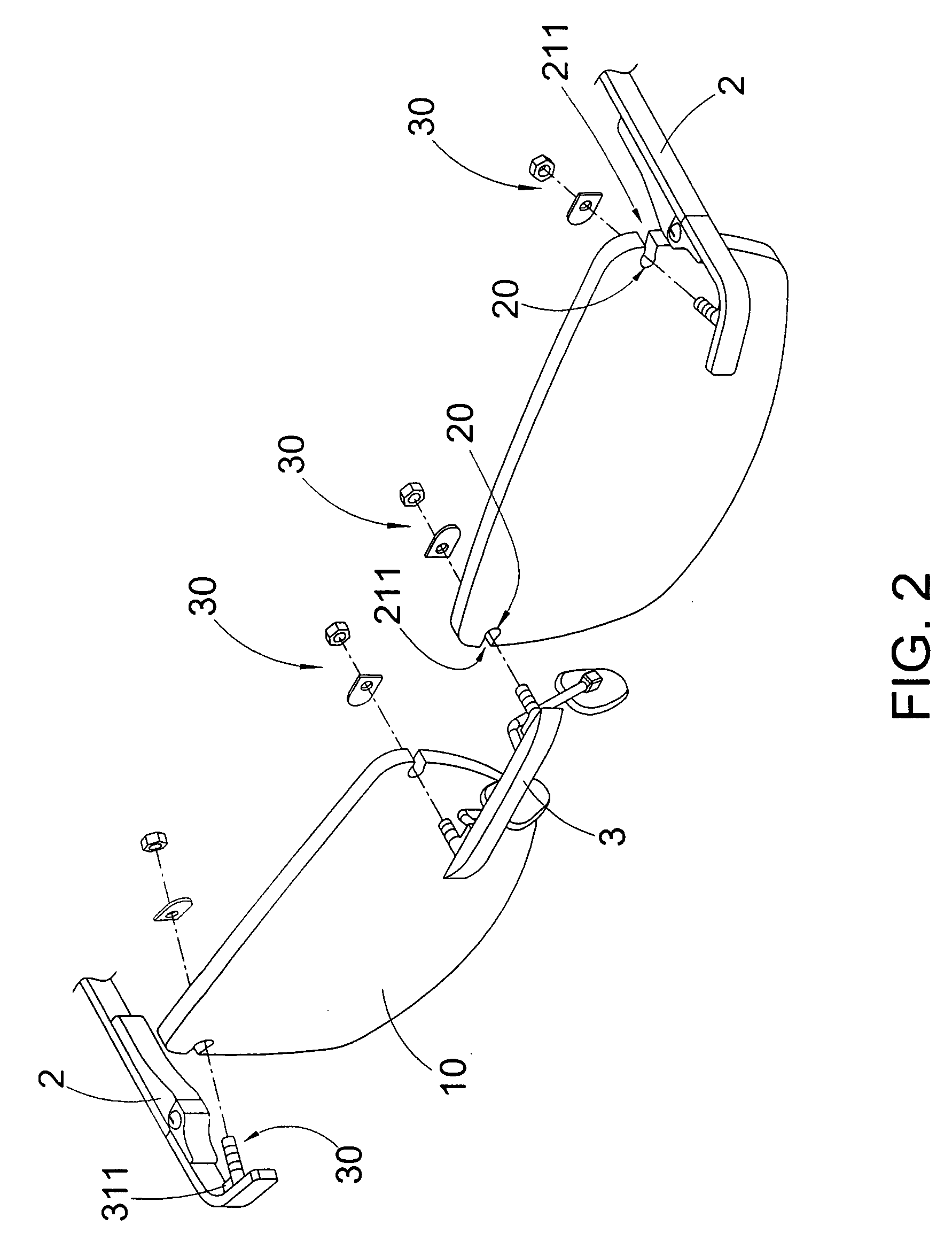

Rimless spectacles

InactiveUS20080198323A1Difficult to manufactureImprove manufacturing efficiencyLens assembliesLens plateElectrical and Electronics engineering

Owner:DONGGUAN JI SHENG OPTICAL

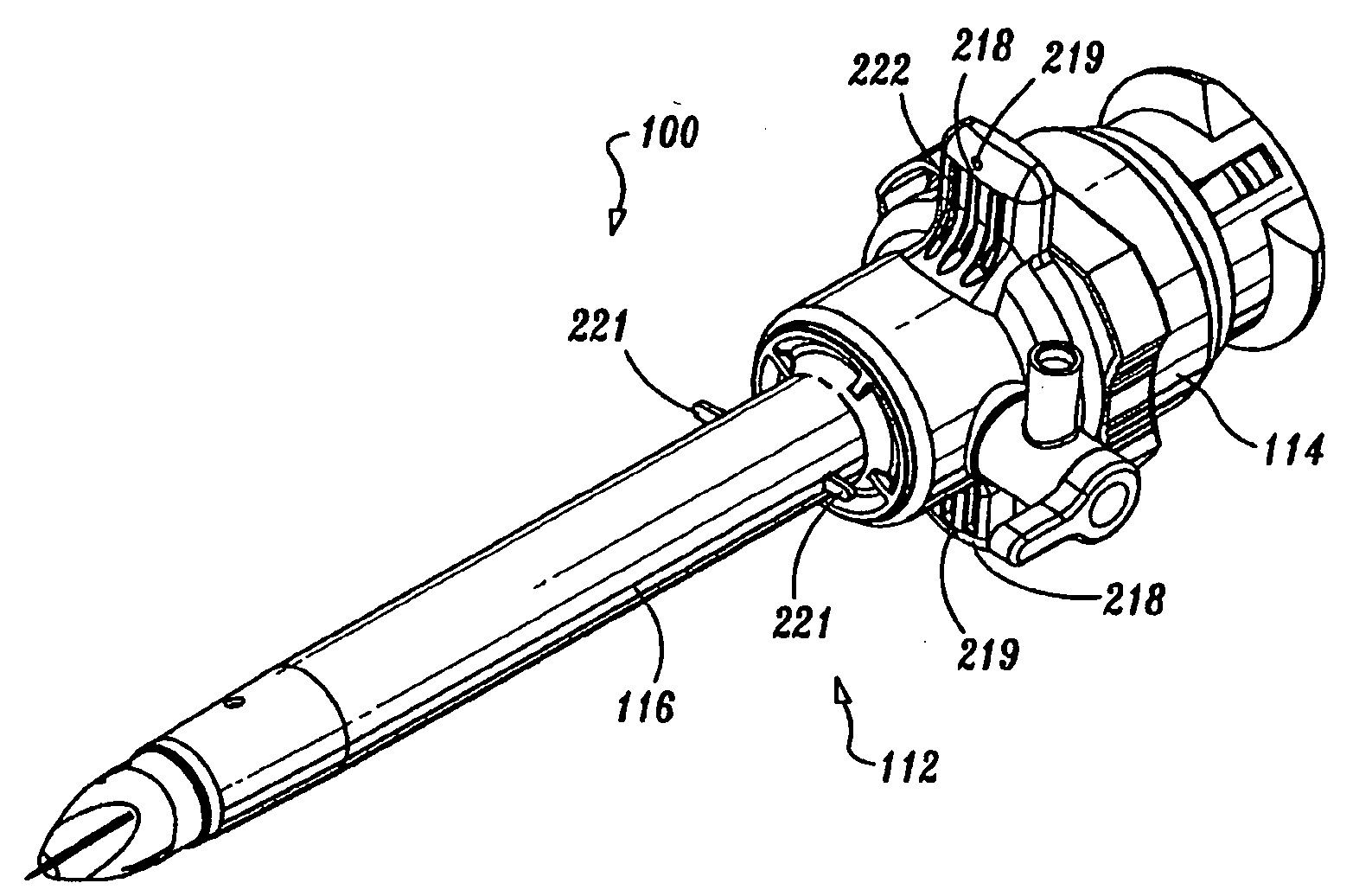

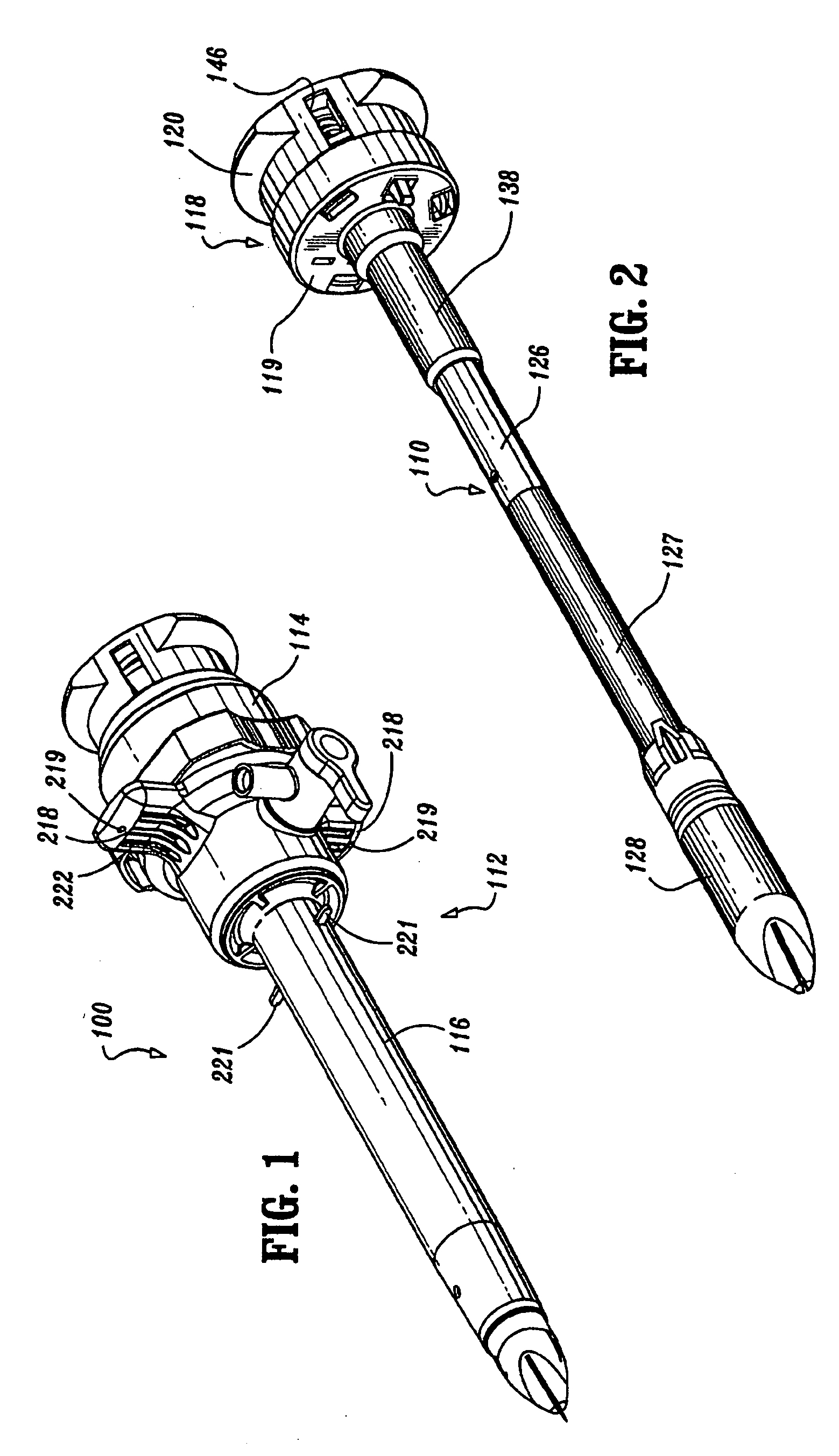

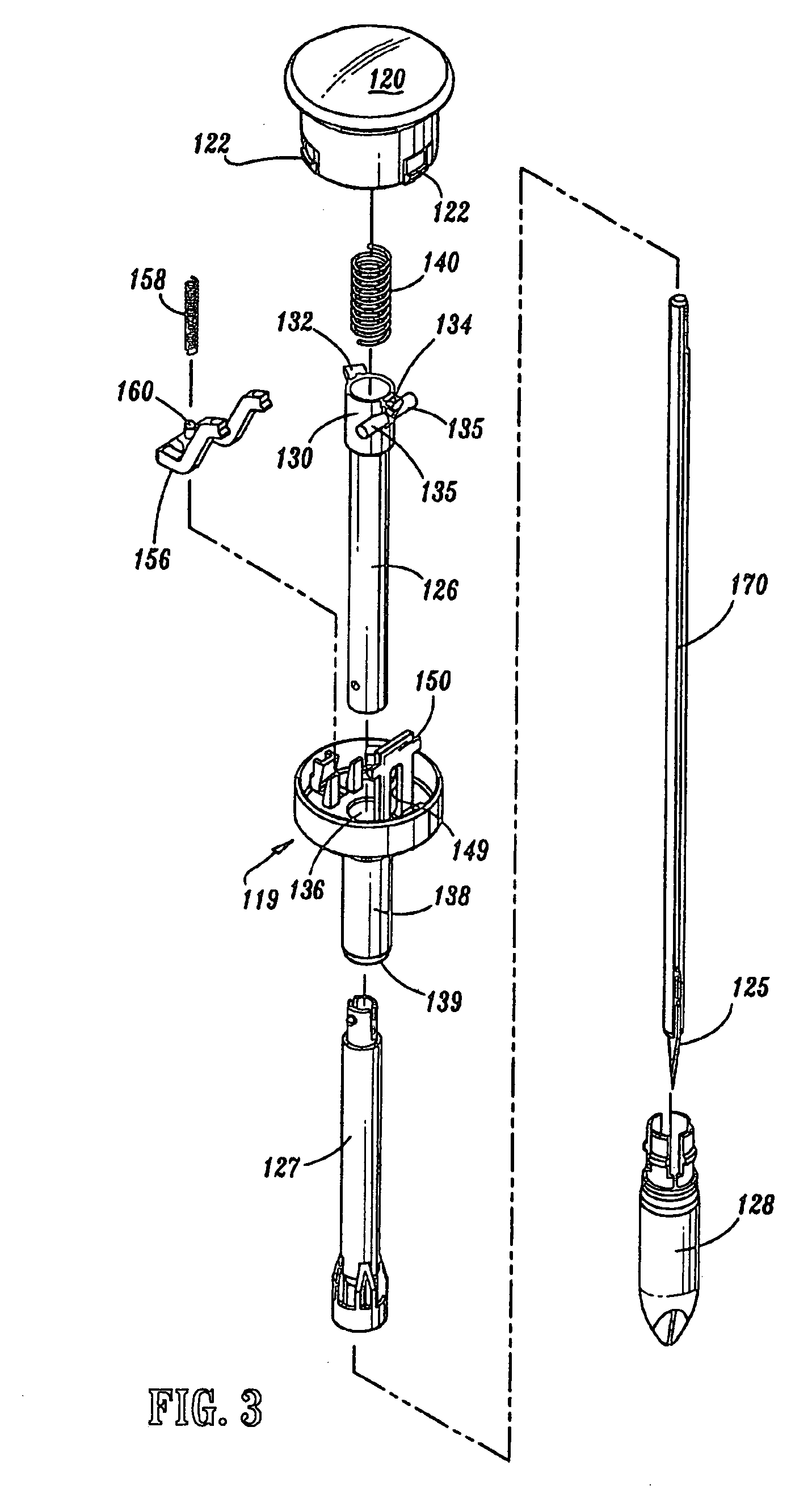

Trocar system and method of use

InactiveUS20080009797A1Improve manufacturing efficiencyFacilitate punctureInfusion syringesSurgical needlesAbdominal trocarEngineering

A trocar system including a cannula and an obturator assembly being at least partially insertable through the cannula. The obturator assembly including a housing, a penetrating tip disposed at a distal end, an elongated shield including a guard extending from a shaft are movable relative to the penetrating tip, and a latch mechanism disposed generally within the housing. The latch mechanism facilitates changing the configuration of the obturator assembly between a fixed-shield orientation, wherein at least a portion of the guard is maintained to extend at least partially distal of the penetrating tip to prevent puncturing of tissue by the penetrating tip, to a non-fixed shield orientation whereby upon application of force to the distal end of the obturator assembly, the guard and penetrating tip are permitted to move relative one another to facilitate puncturing of tissue by the penetrating tip.

Owner:UNITED STATES SURGICAL CORP

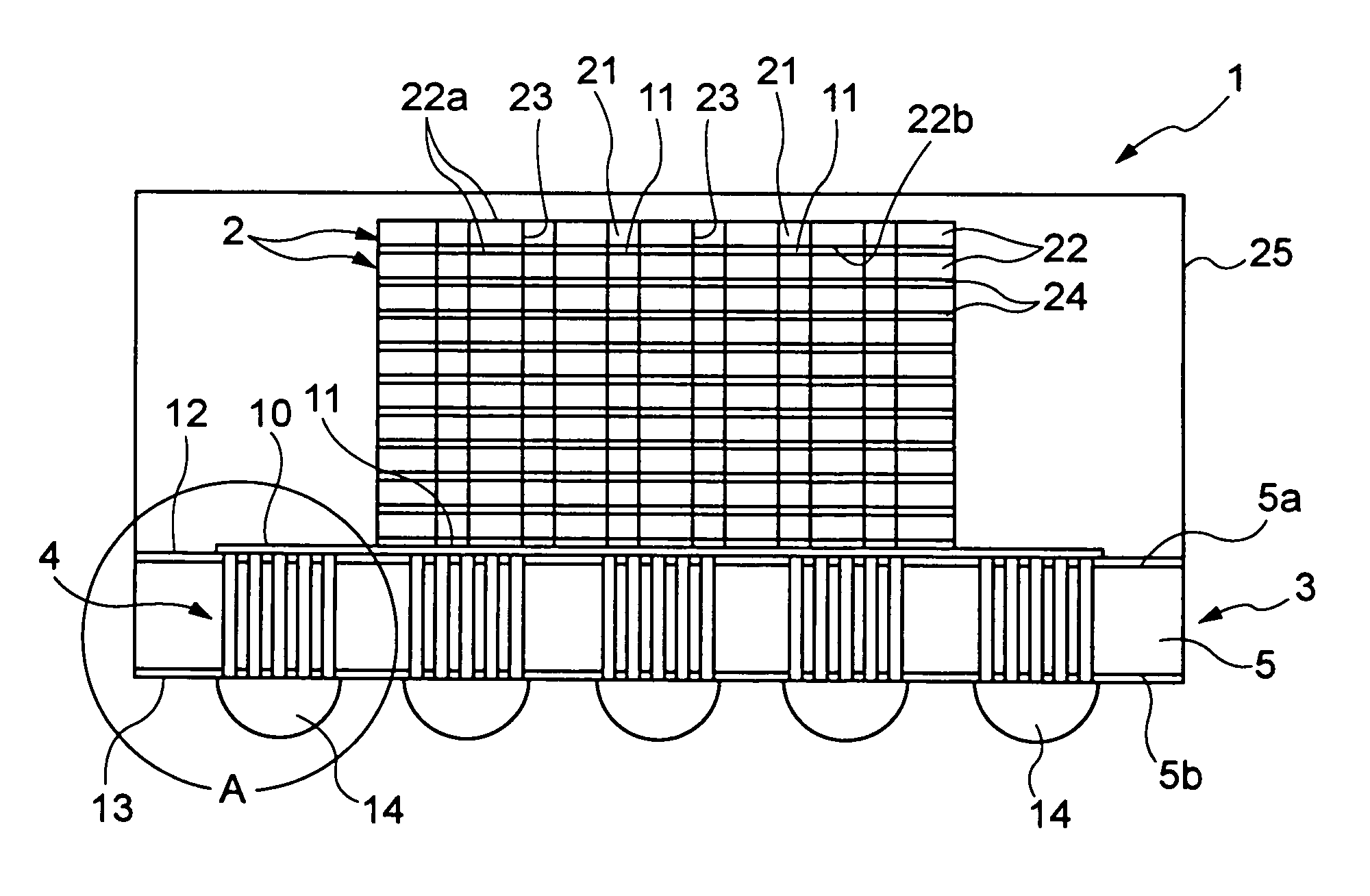

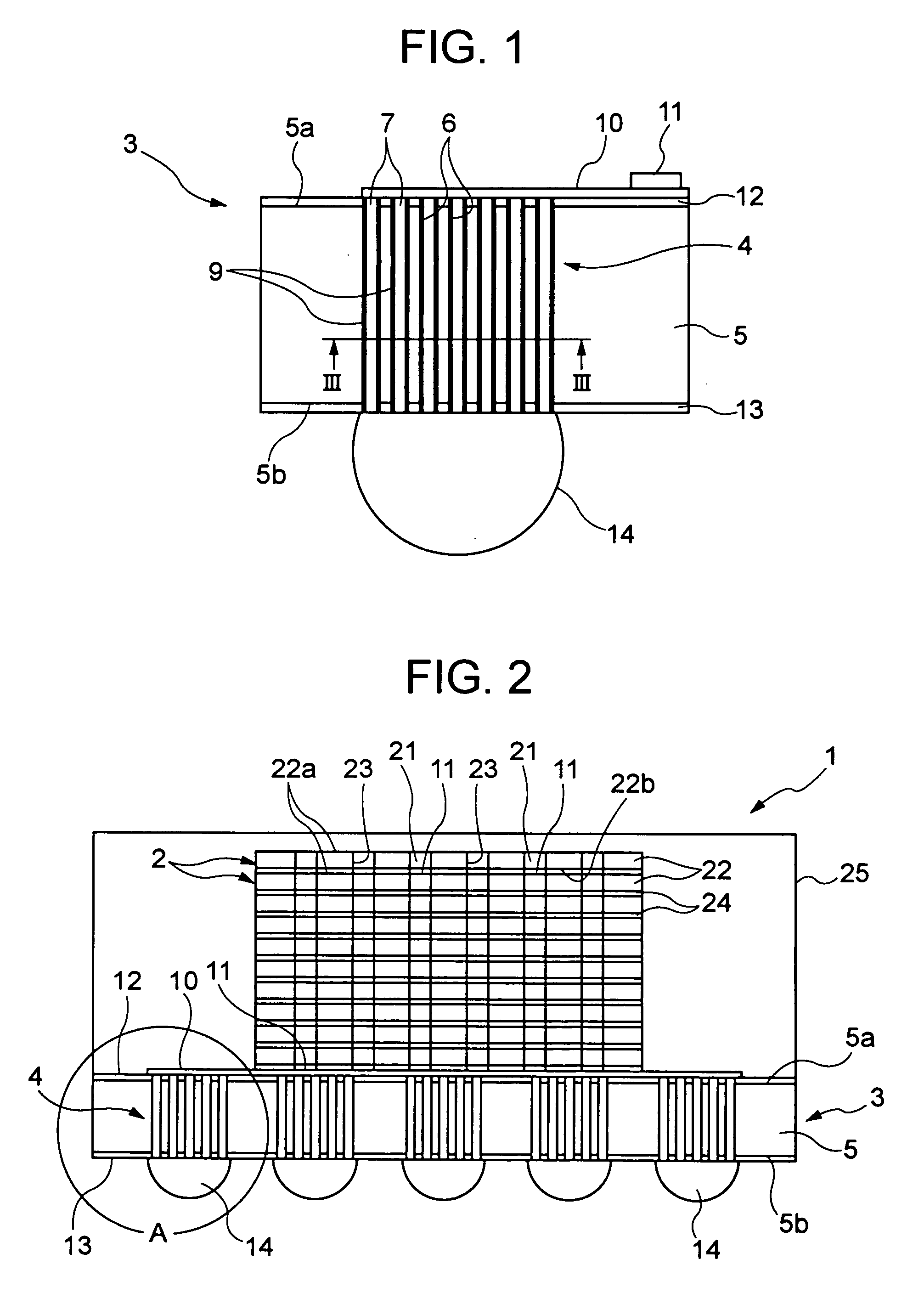

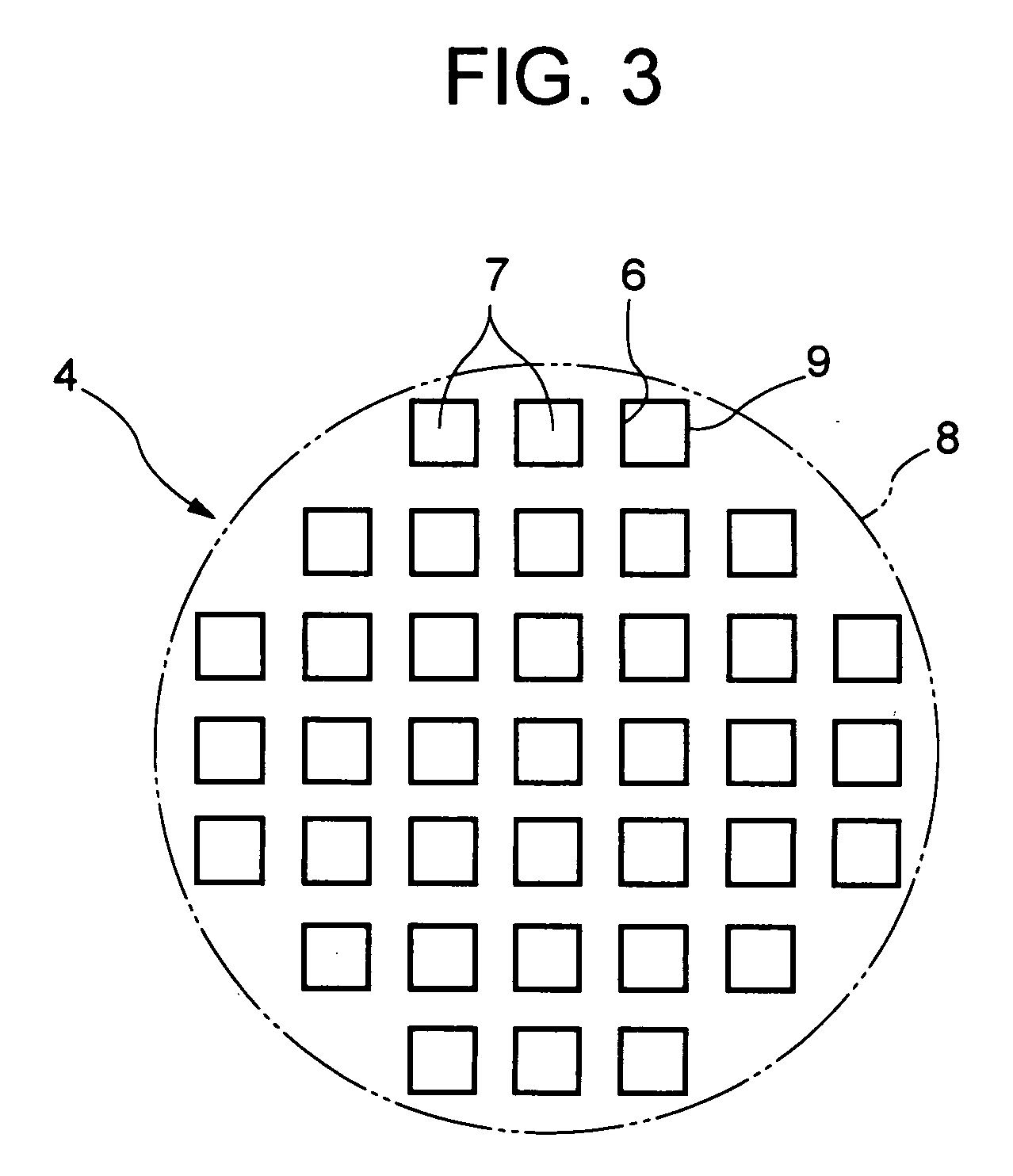

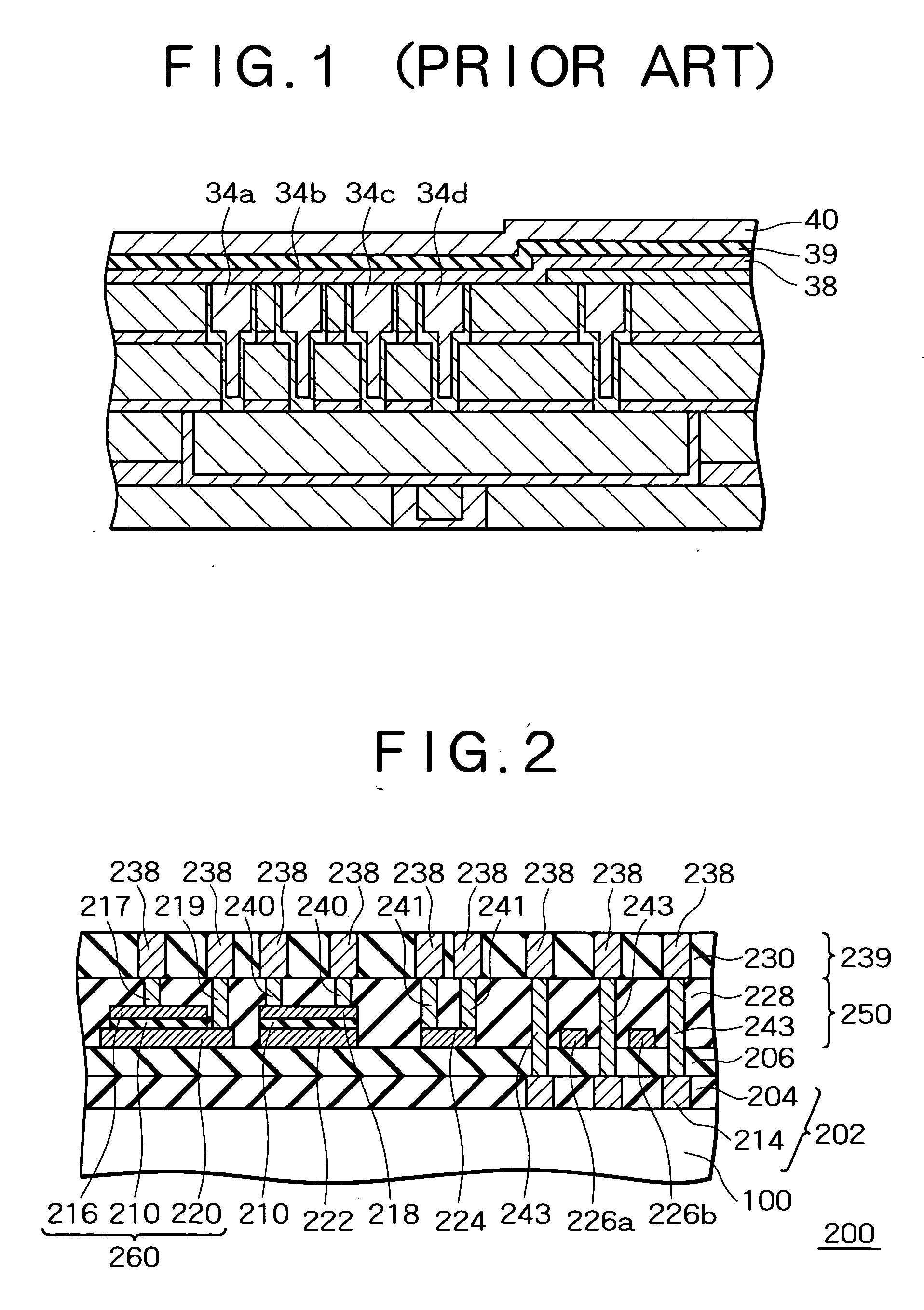

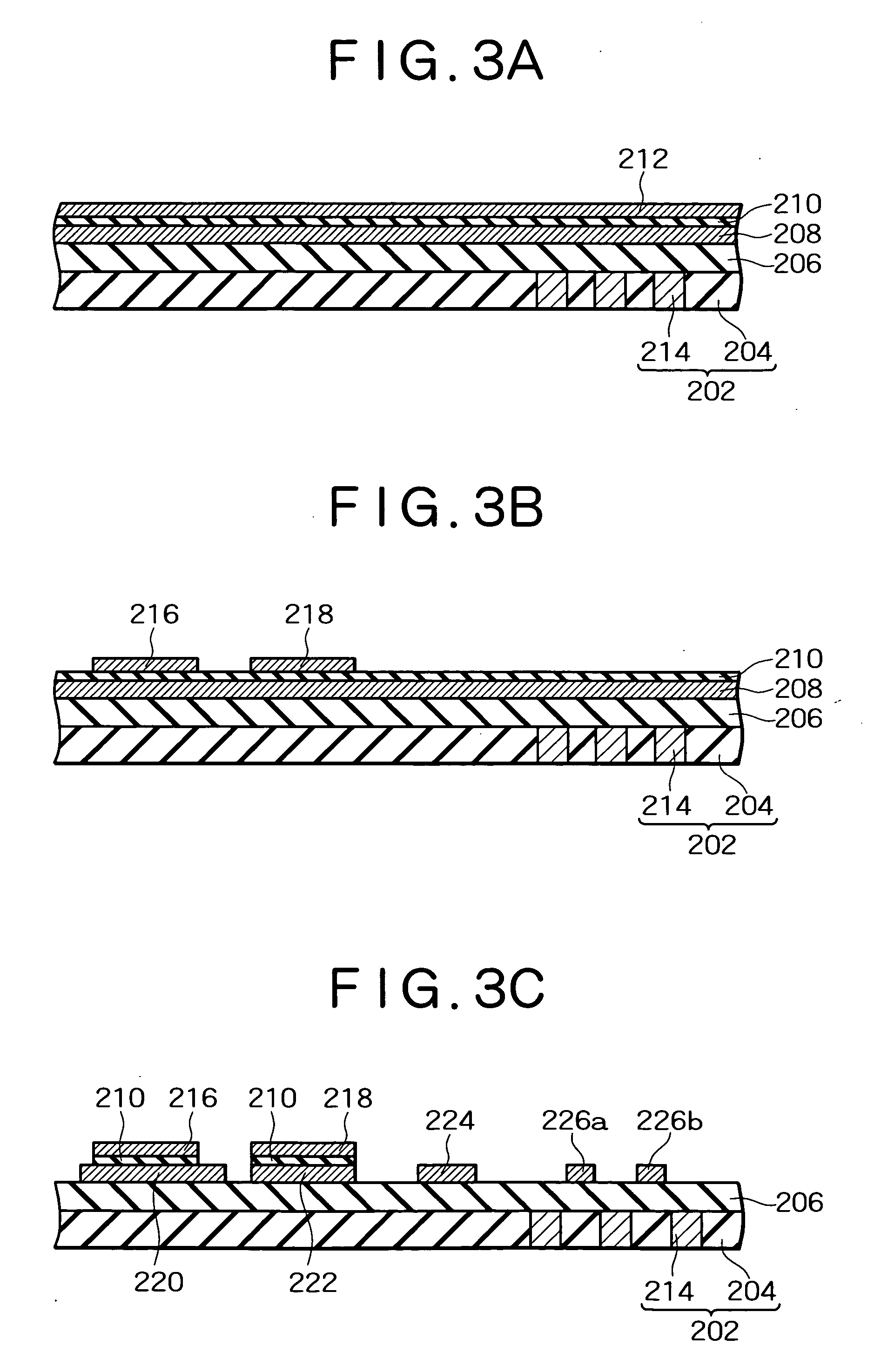

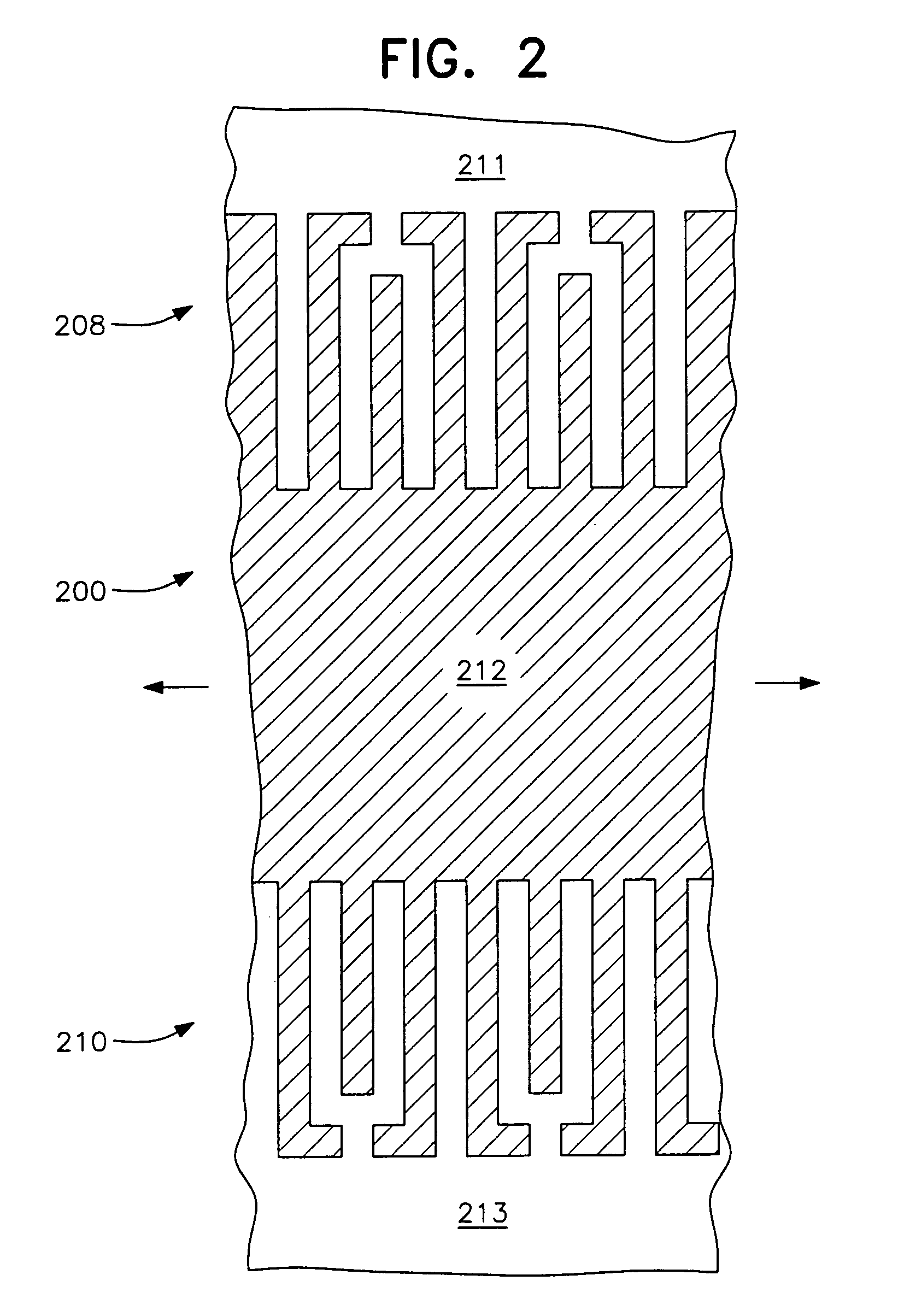

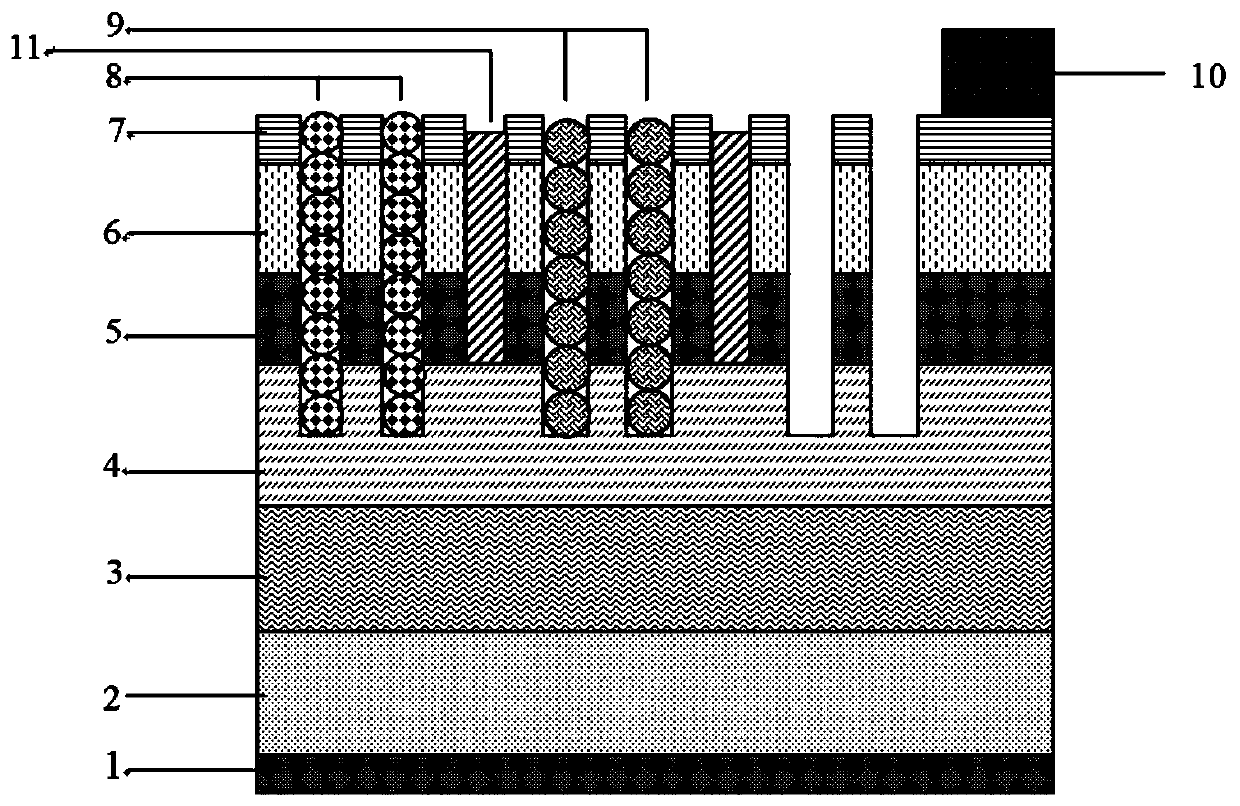

Through electrode, package base having through electrode, and semiconductor chip having through electrode

ActiveUS20060202347A1Reduce timeImprove manufacturing efficiencySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipElectrical conduction

A through electrode extends through a silicon substrate from the upper surface to the lower surface of the substrate to accomplish electrical conduction between the upper and lower surfaces of the substrate. The through electrode includes a plurality of slender through holes formed in a through electrode forming area of the silicon substrate. The slender through holes extend through the silicon substrate from the upper surface to the lower surface of the silicon substrate. The through electrode also includes a plurality of conductive bodies fitted in the slender through holes. The conductive bodies are electrically connected with each other.

Owner:TAIWAN SEMICON MFG CO LTD

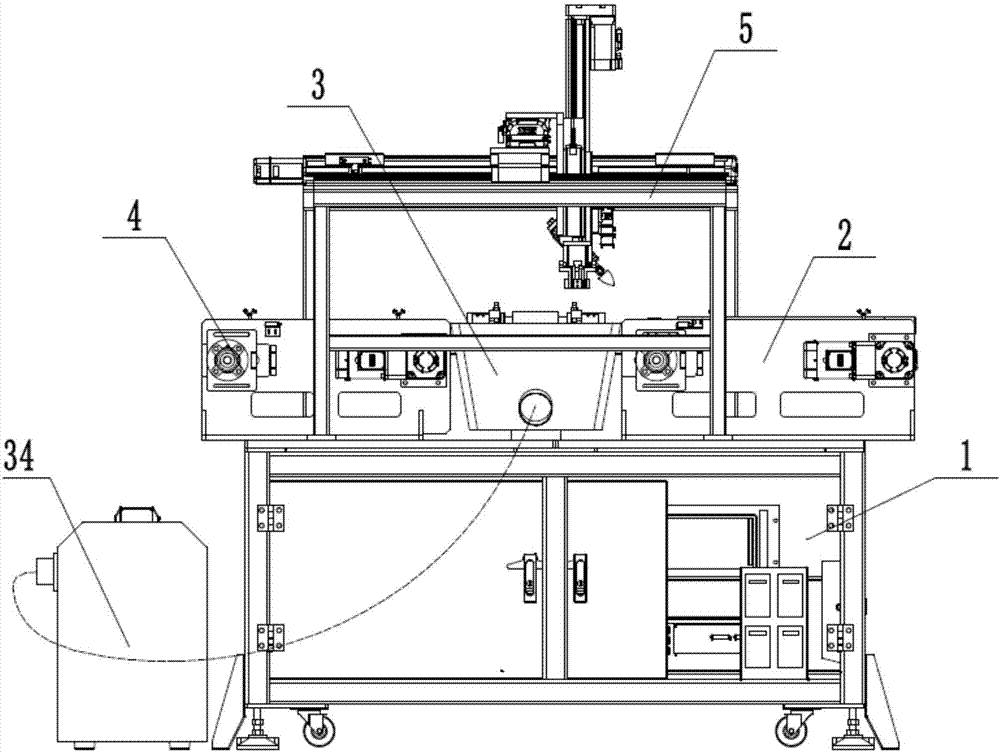

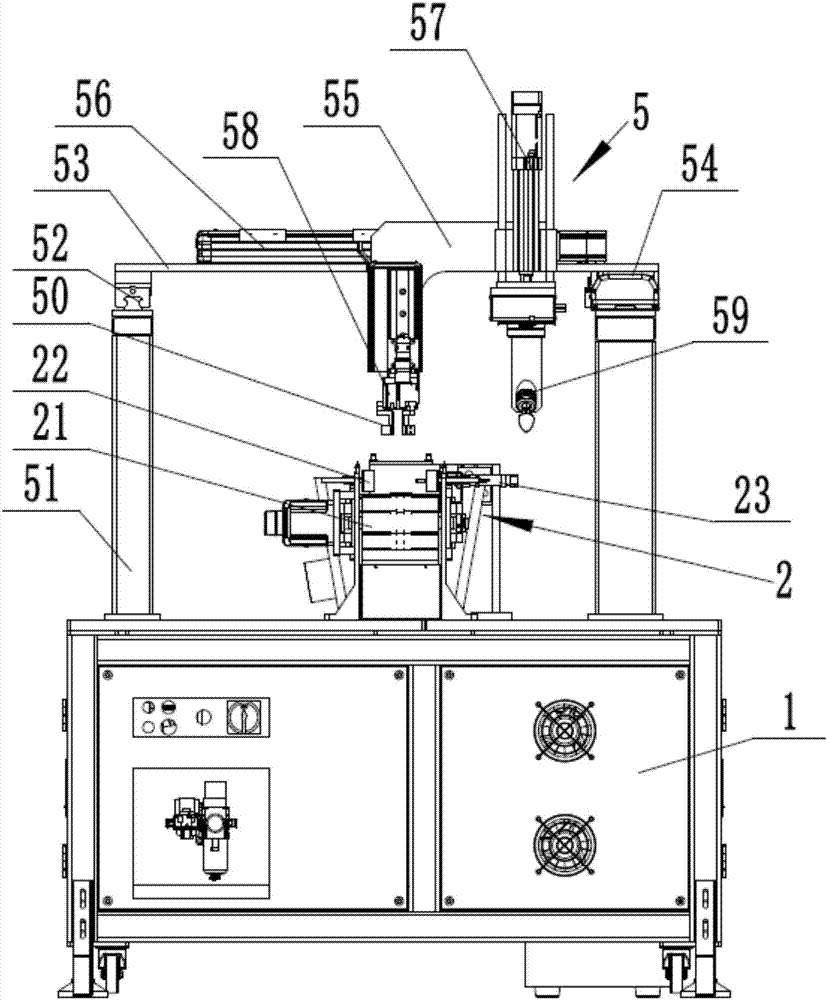

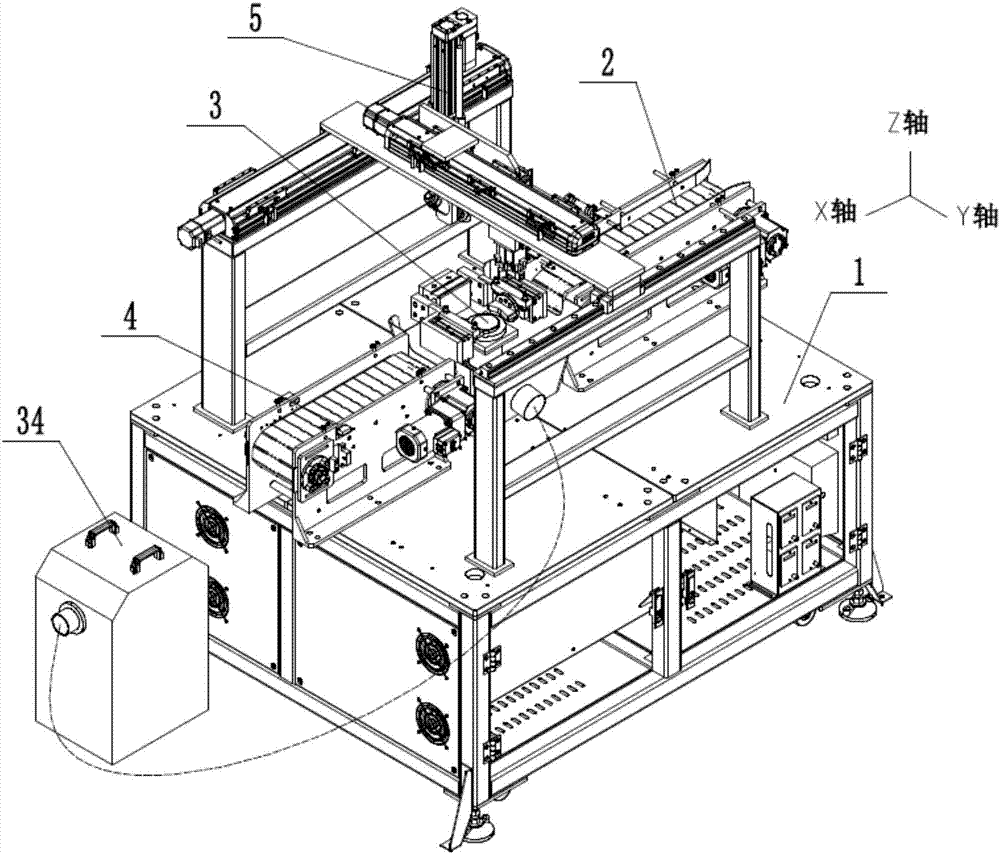

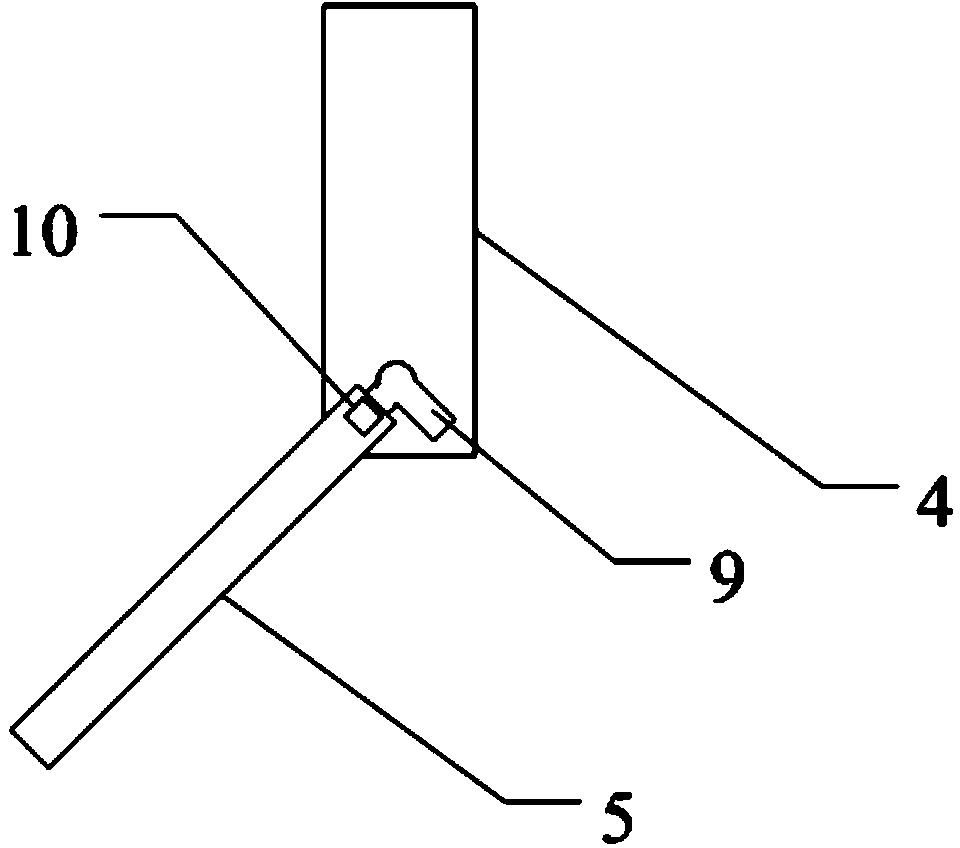

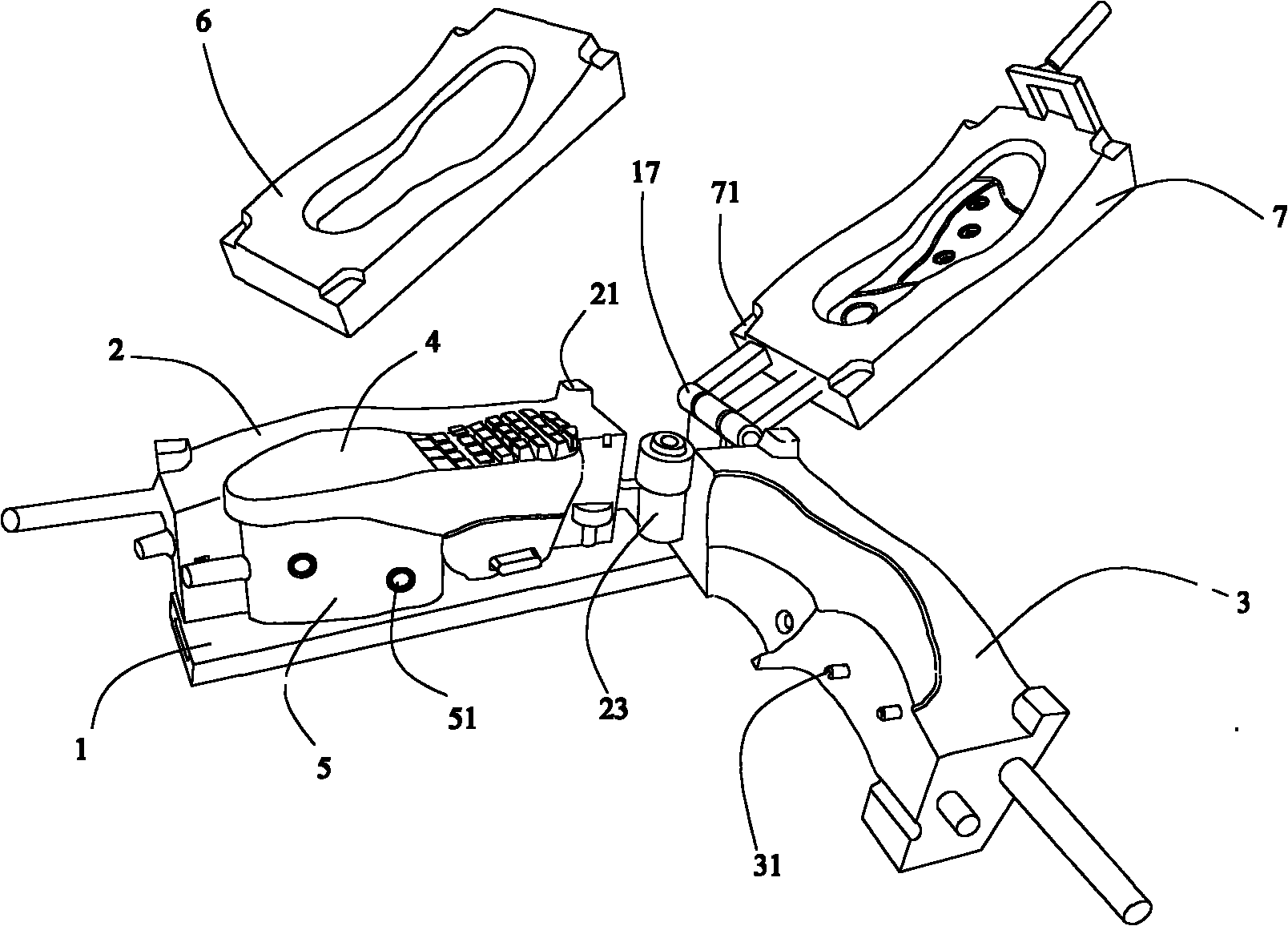

Automobile hub double-face full-automatic polishing production line

InactiveCN108000273AAccurate capturePrecise positioningEdge grinding machinesGrinding carriagesProduction lineManipulator

The invention discloses an automobile hub double-face full-automatic polishing production line which comprises a rack and a polishing mechanism. The rack is sequentially provided with a feeding mechanism, a hub polishing rotary table and a discharging mechanism, the polishing mechanism is located above the polishing mechanism, and the characteristics are that the feeding mechanism comprises a first chain plate conveyor, two guide plates and a stopping air cylinder; the hub polishing rotary table comprises a grinding collecting box, a hub polishing jacking table and an overturning tool; the overturning tool comprises a vertical plate, a wide type gas claw, two clamping connecting plates, two rotary air cylinders and two clamping blocks; the polishing mechanism comprises a support, an X-axisguide rail, an X-axis sliding base, a Y-axis sliding base, an X-axis electric cylinder, a Y-axis electric cylinder, a Z-axis electric cylinder, a Z-axis stretchable cylinder, an electric polishing head and a carrying mechanical arm; and the discharging mechanism at least comprises a second chain plate conveyor. The automobile hub double-face full-automatic polishing production line is used for automobile hub full-automatic polishing production, the front and back faces of a hub can be switched at will, and the reliability and the stability can be improved.

Owner:李茂菊

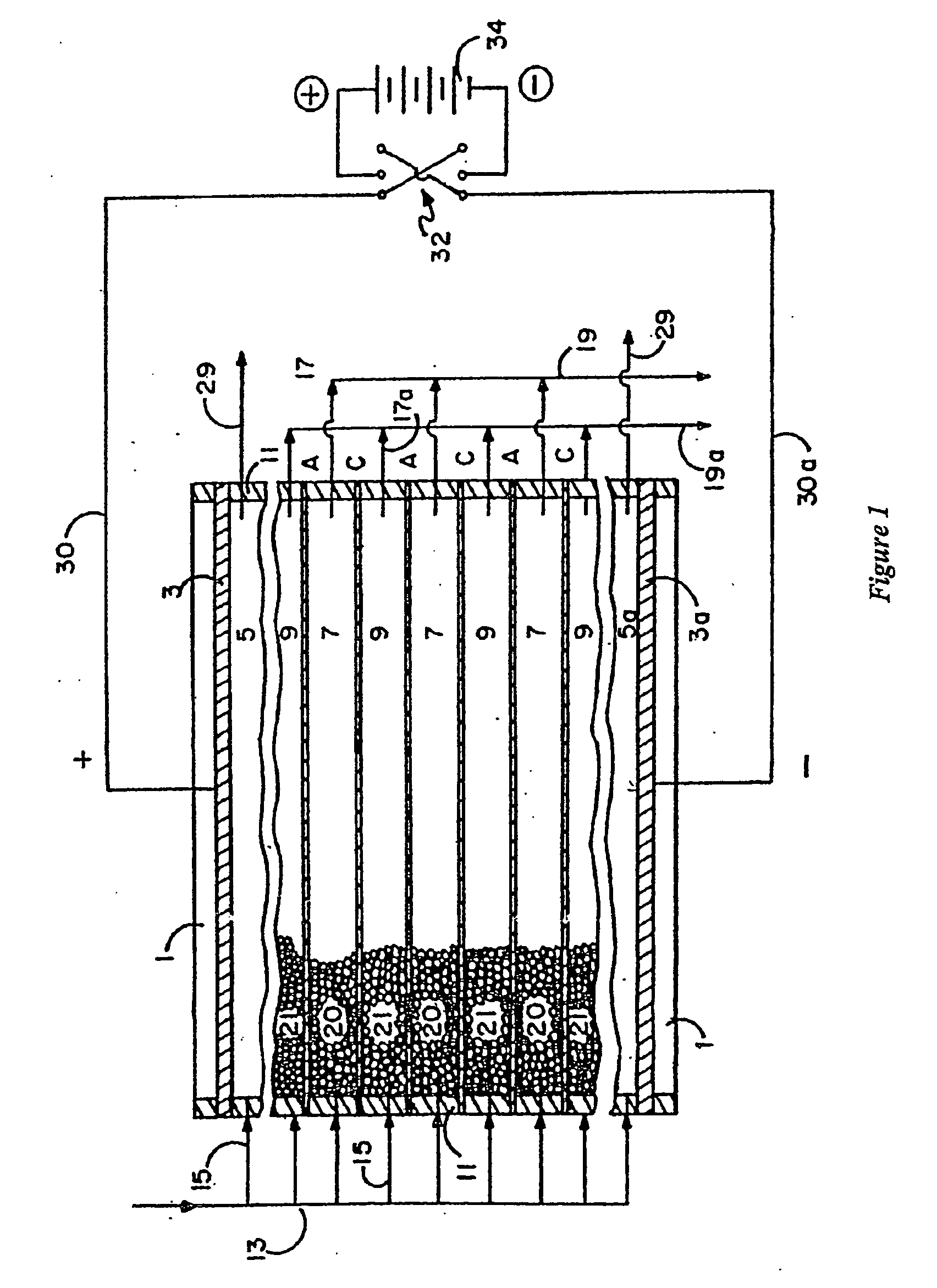

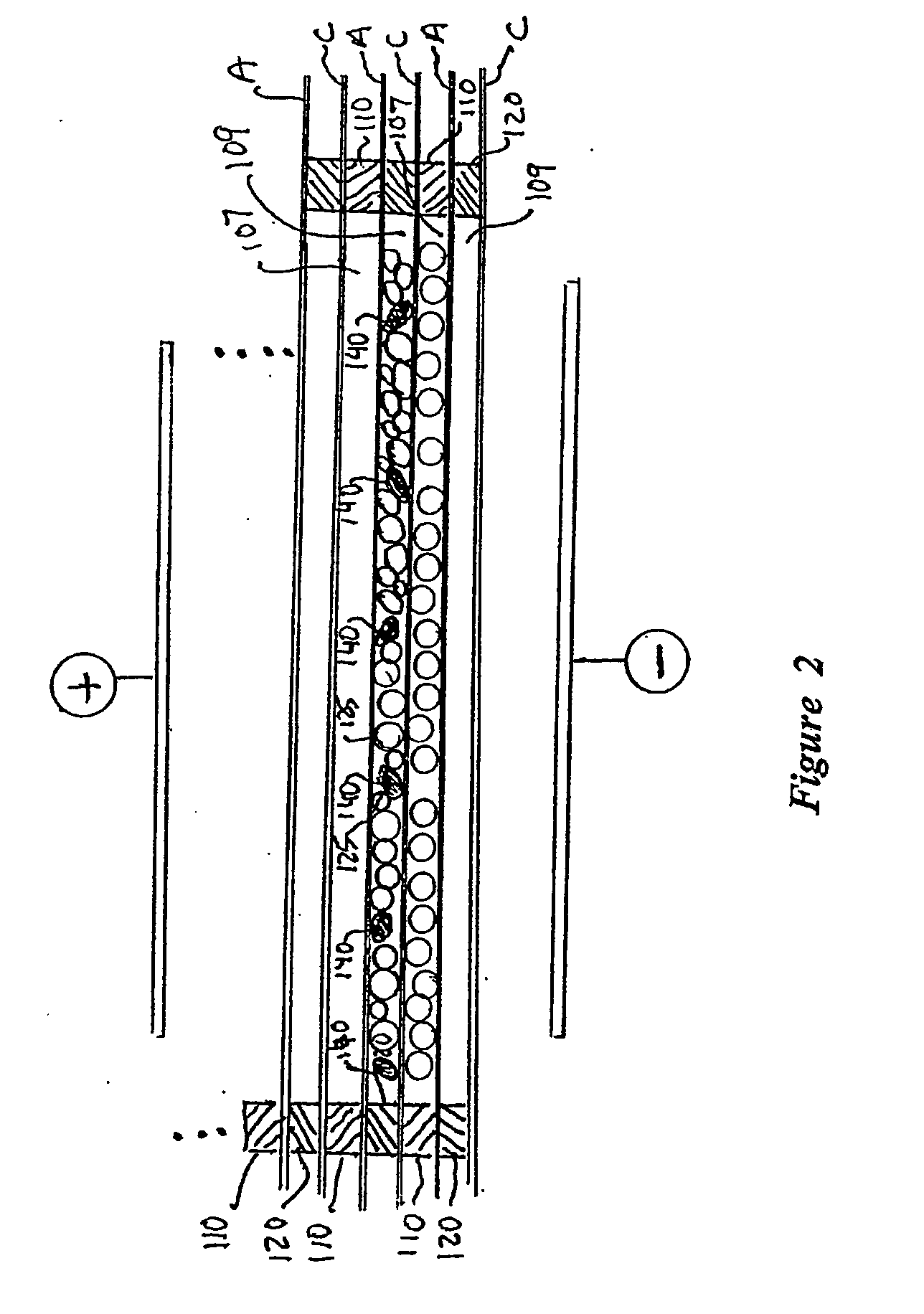

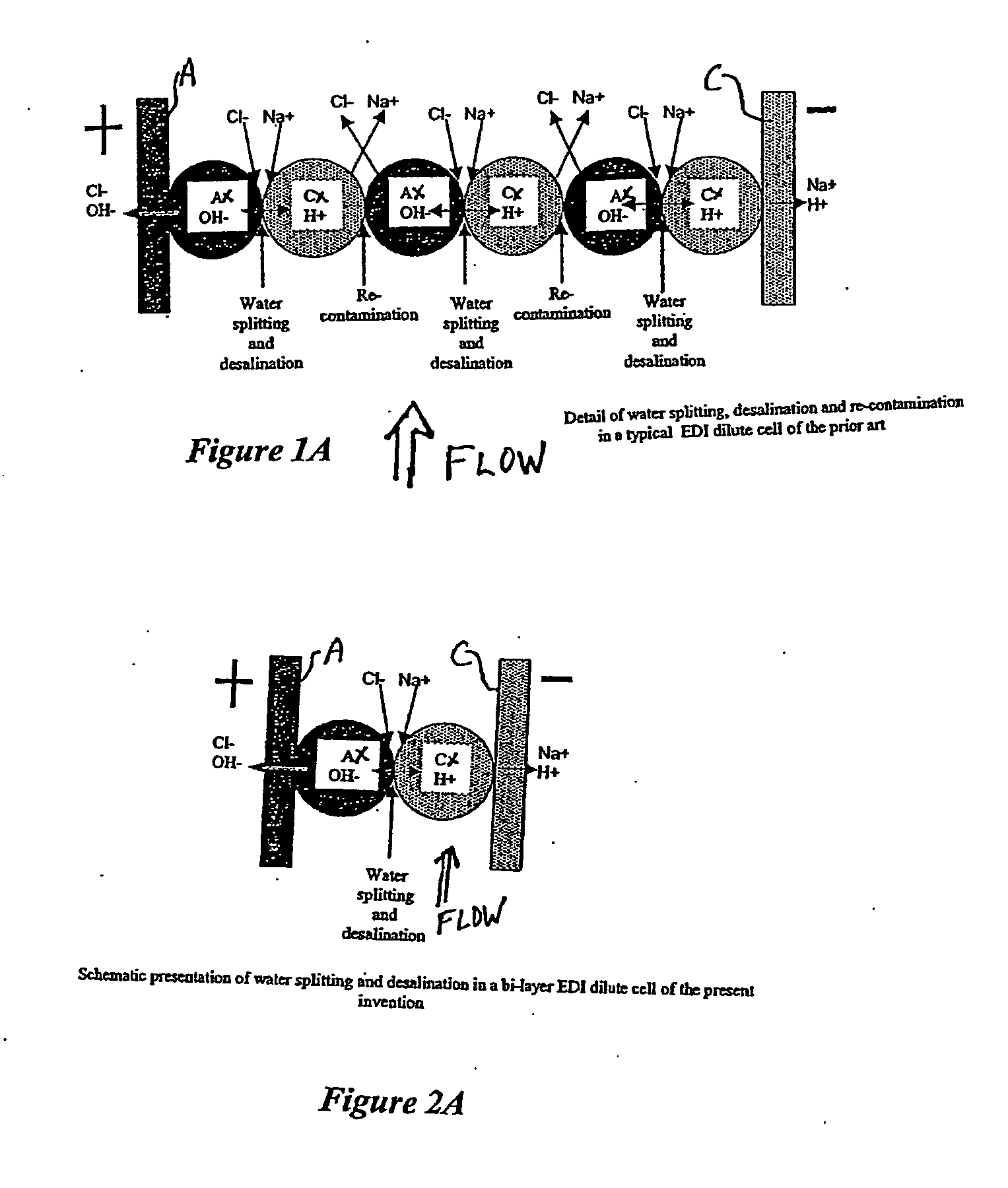

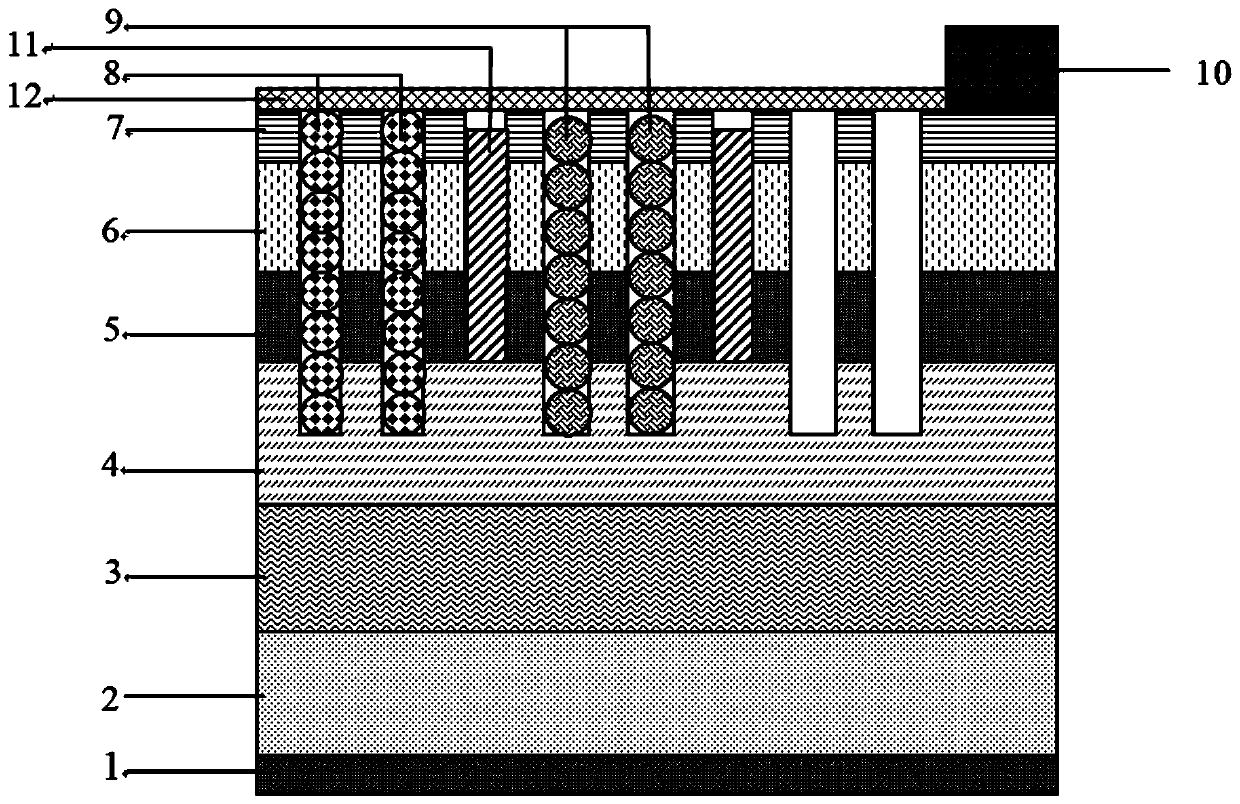

Sparse media edi apparatus and method

An electrodeionization, (EDI) apparatus has flow cells with a sparse distribution of ion exchange (IX) material or beads. The beads extend between membranes defining opposed walls of the cell to separate and support the membranes, and form a layer substantially free of bead-to-bead dead-end reverse junctions. The beads enhance capture of ions from surrounding fluid in dilute cells, and do not throw salt when operating current is increased. In concentrating cells, the sparse bead filling provides a stable low impedance bridge to enhanced power utilization in the stack. A monotype sparse filling may be used in concentrate cells, while mixed, layered, striped, graded or other beads may be employed in dilute cells. Ion conduction paths are no more than a few grains long and the lower packing density permits effective fluid flow. A flow cell thickness may be below one millimeter, and the beads may be discretely spaced, form a mixed or patterned monolayer, or form an ordered bilayer, and a mesh having a lattice spacing comparable to or of the same order of magnitude as resin grain size, may provide a distributed open support that assures a stable distribution of the sparse filling, and over time maintains the initial balance of uniform conductivity and good through-flow. The cells or low thickness and this resin layers relax stack size and power supply constraints, while providing treatment efficiencies and process stability. Reduced ion migration distances enhance the ion removal rate without reducing the product flow rate. The sparse resin bed may be layered, graded along the length of the path, striped or otherwise patterned. Inter-grain ion hopping is reduced or eliminated, thus avoiding the occurrence of salt-throwing which occurs at reverse bead junctions of prior art constructions. Conductivity of concentrate cells is increased, permitting more compact device construction, allowing increases in stack cell number, and providing more efficient electrical operation without ion additions. Finally, ion storage within beads is greatly reduces, eliminating the potential for contamination during reversal operation. Various methods of forming sparse beds and assembling the stacks are disclosed.

Owner:IONICS INC

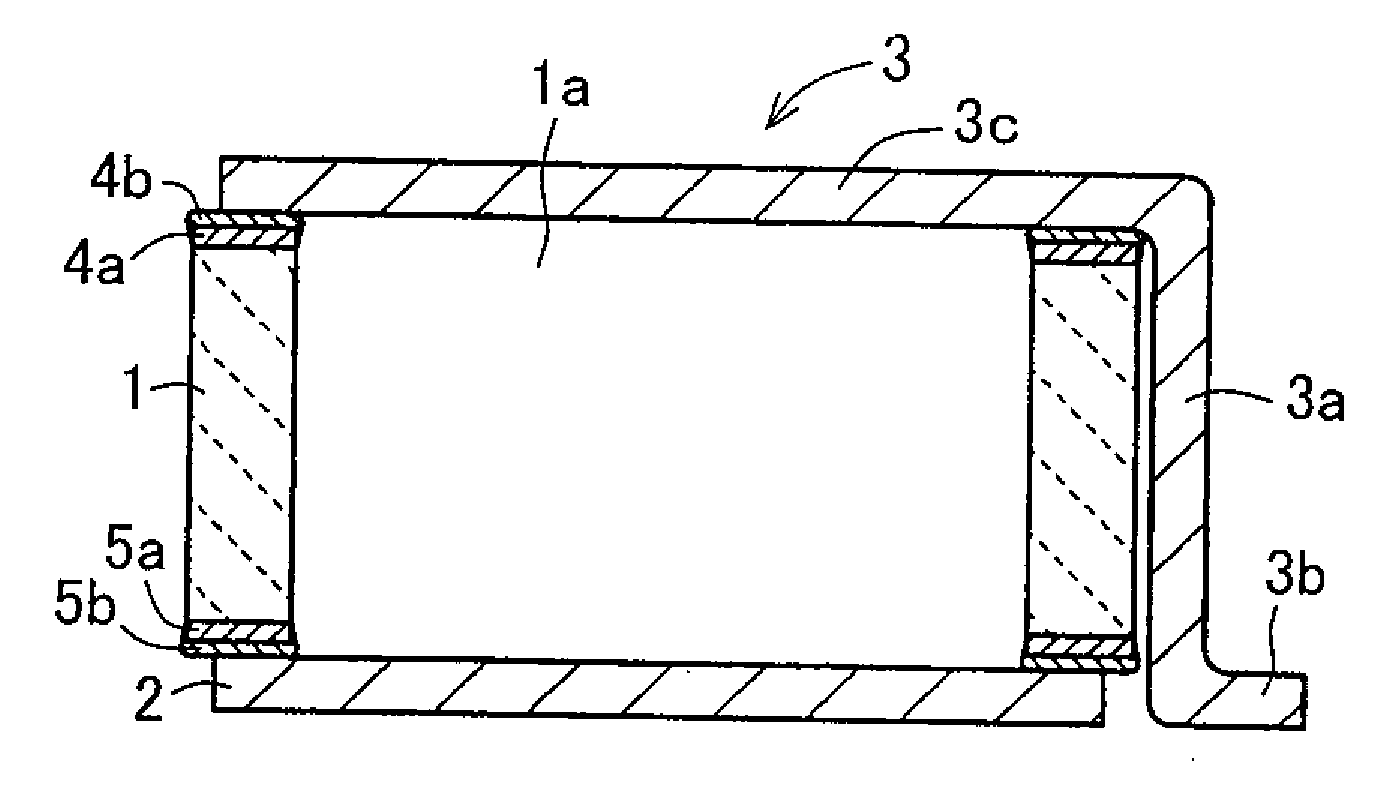

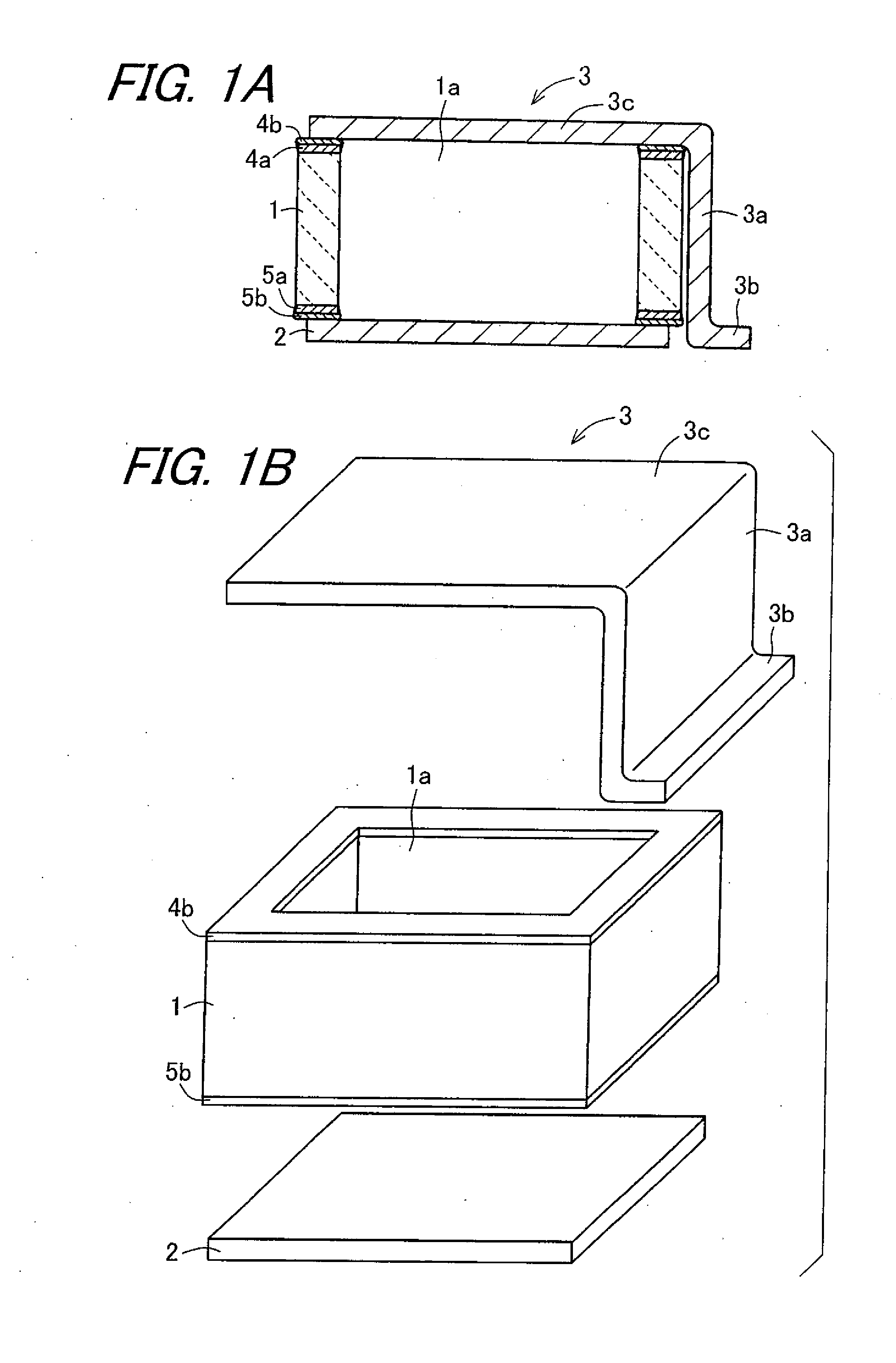

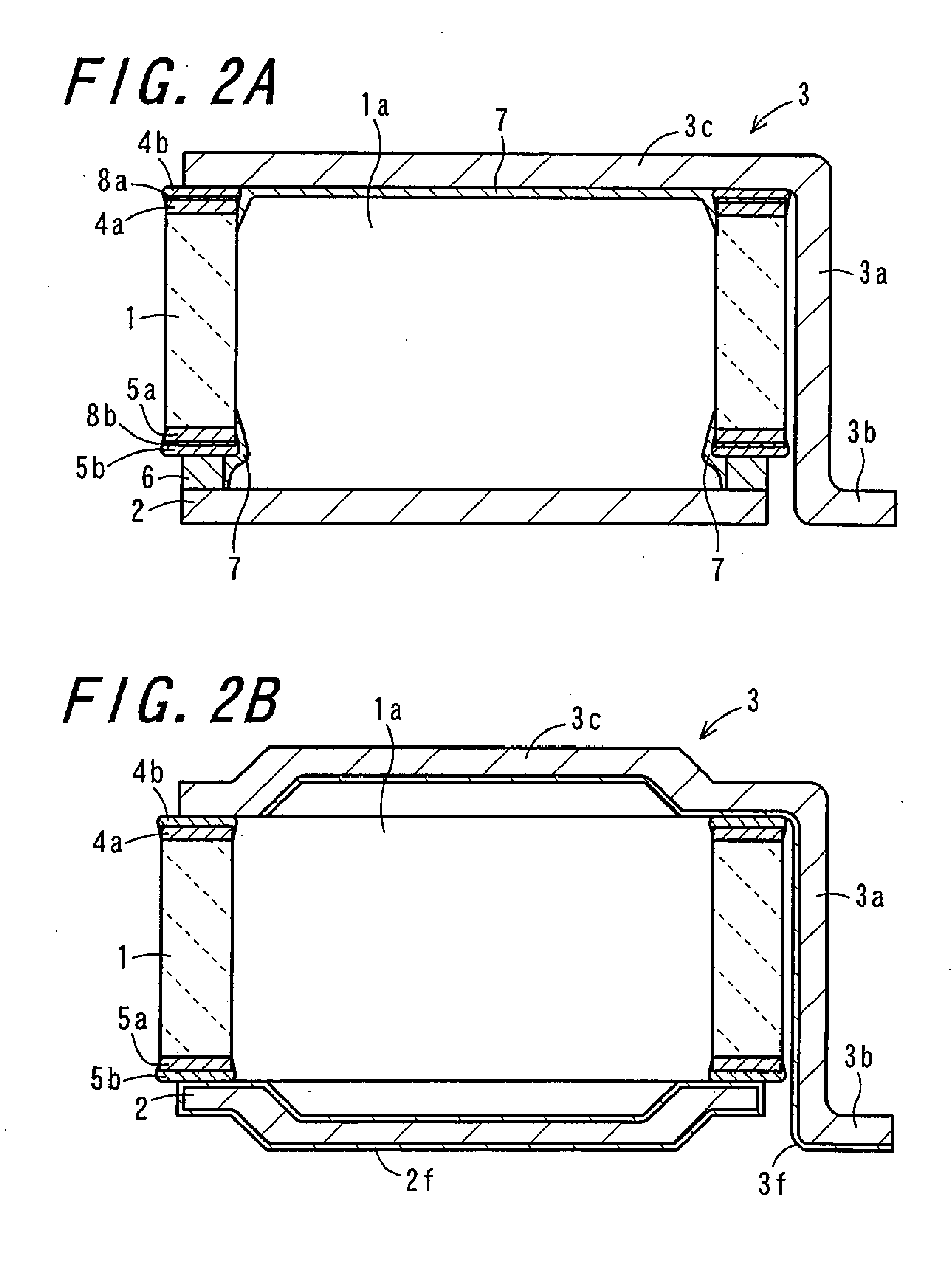

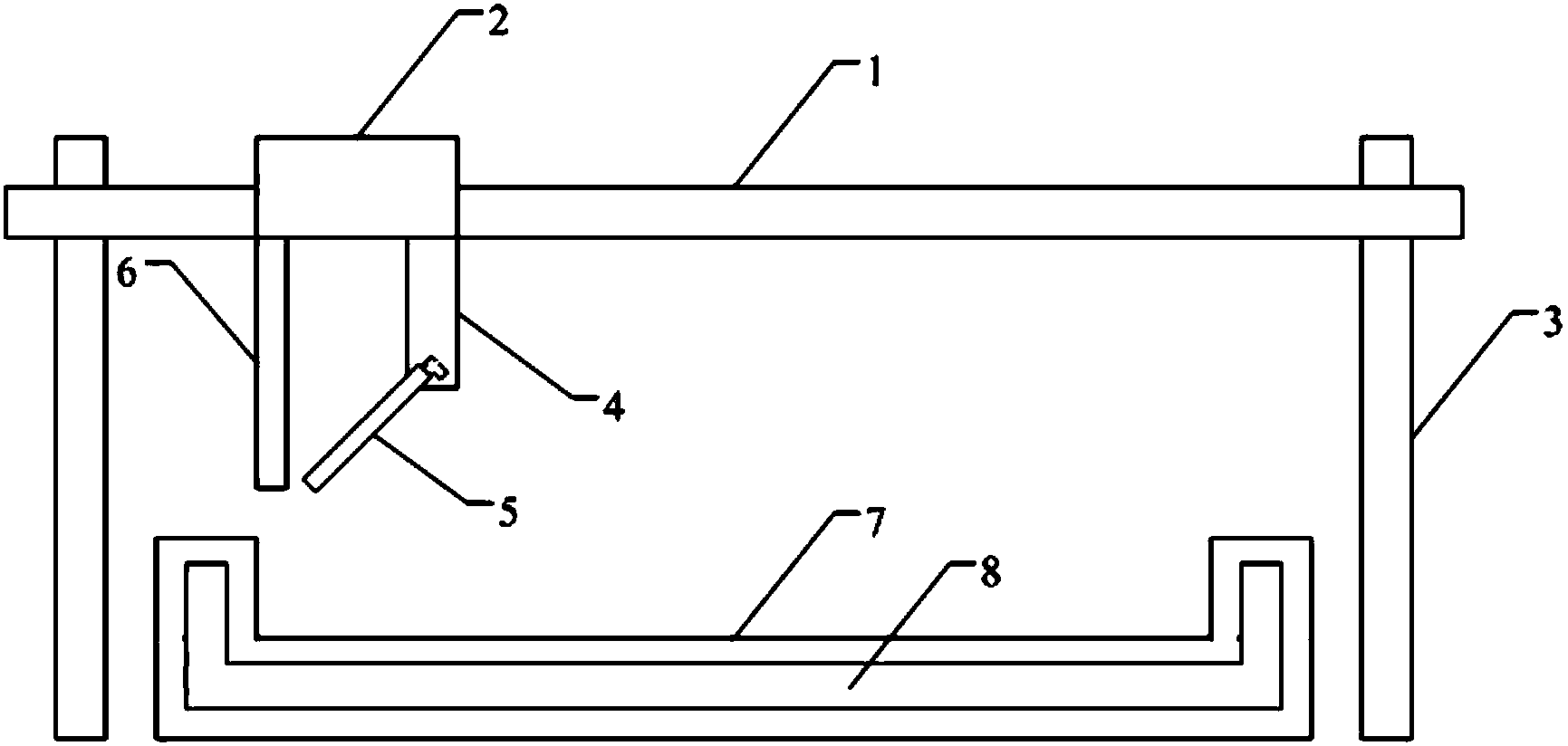

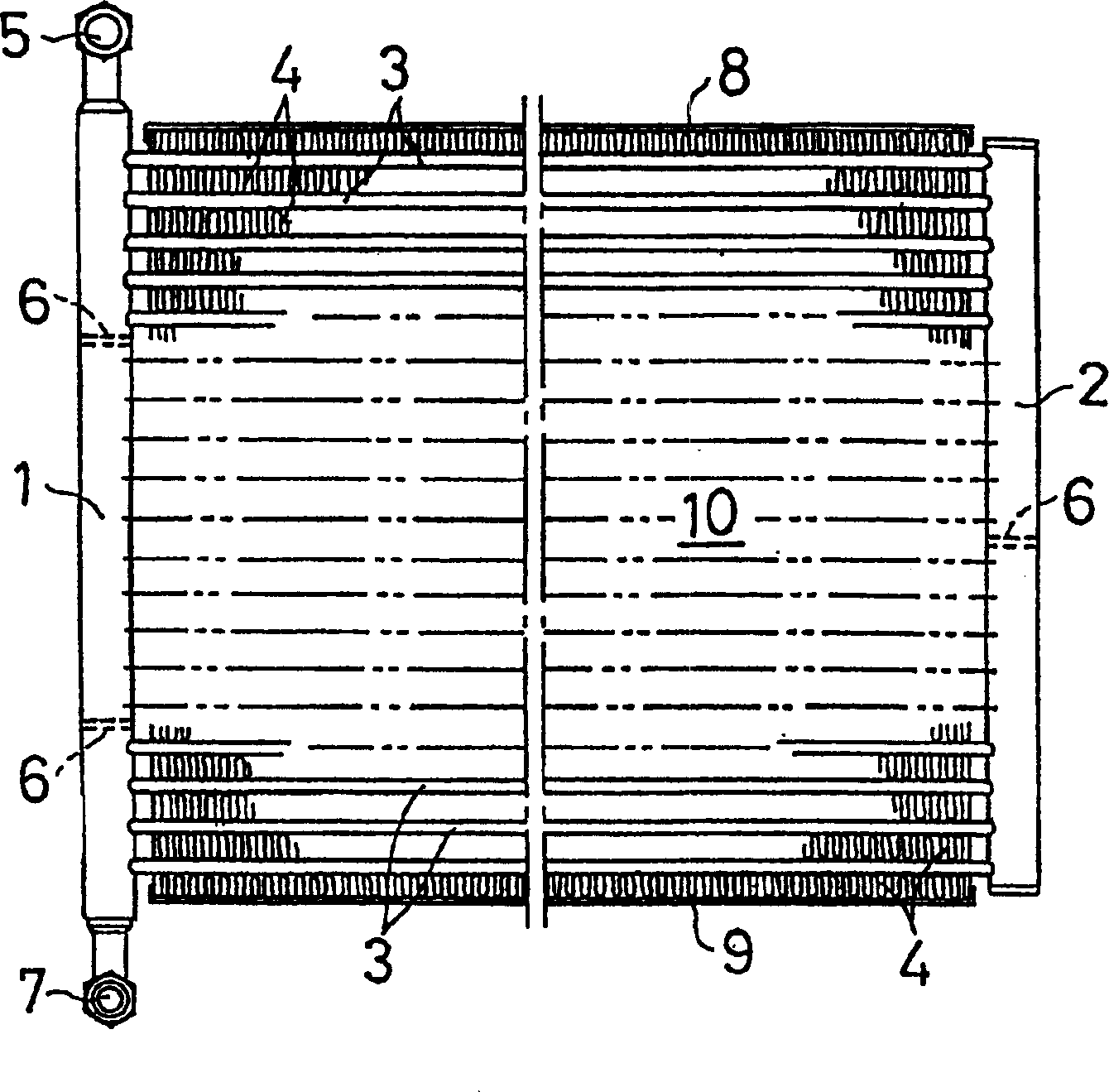

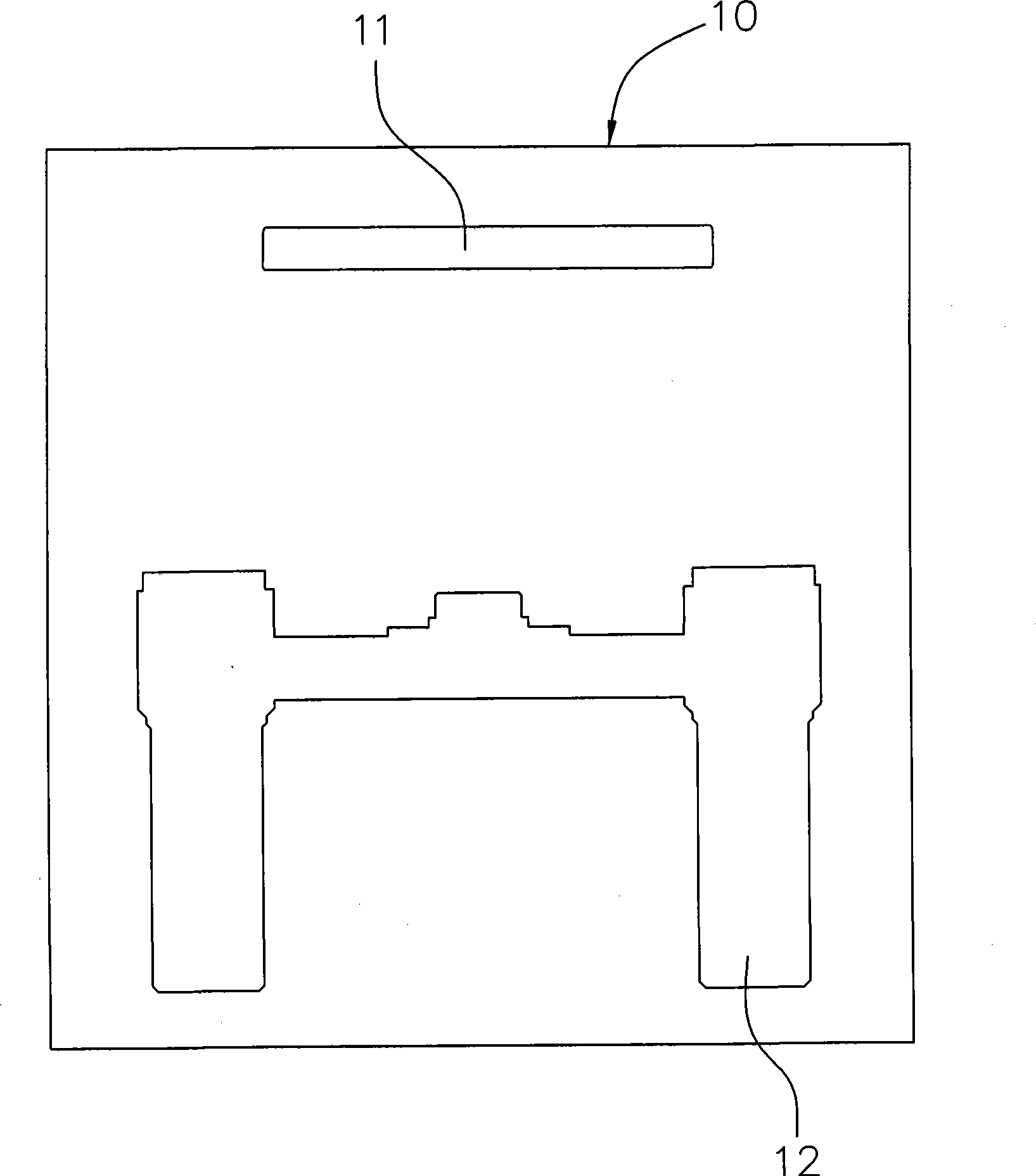

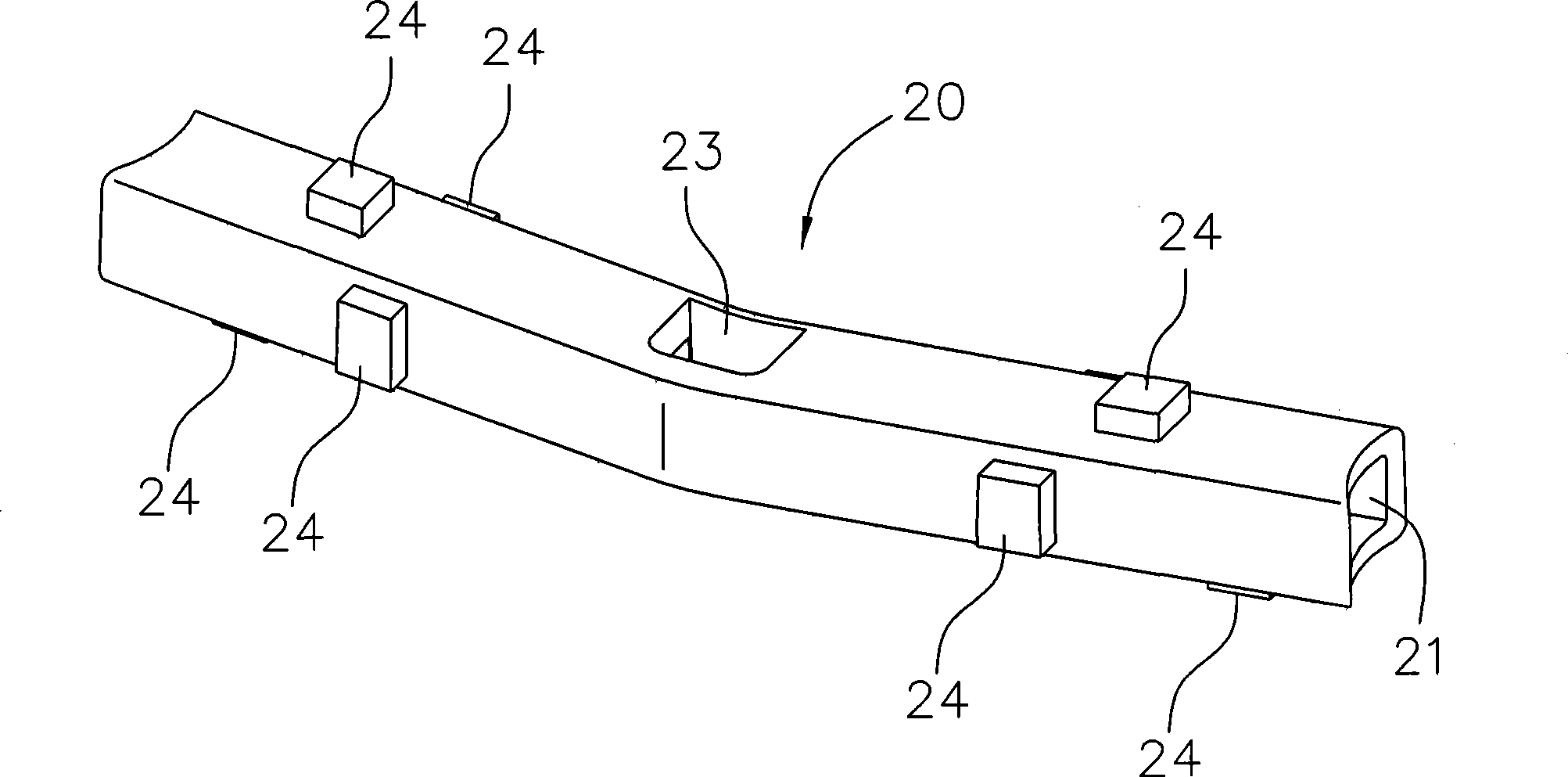

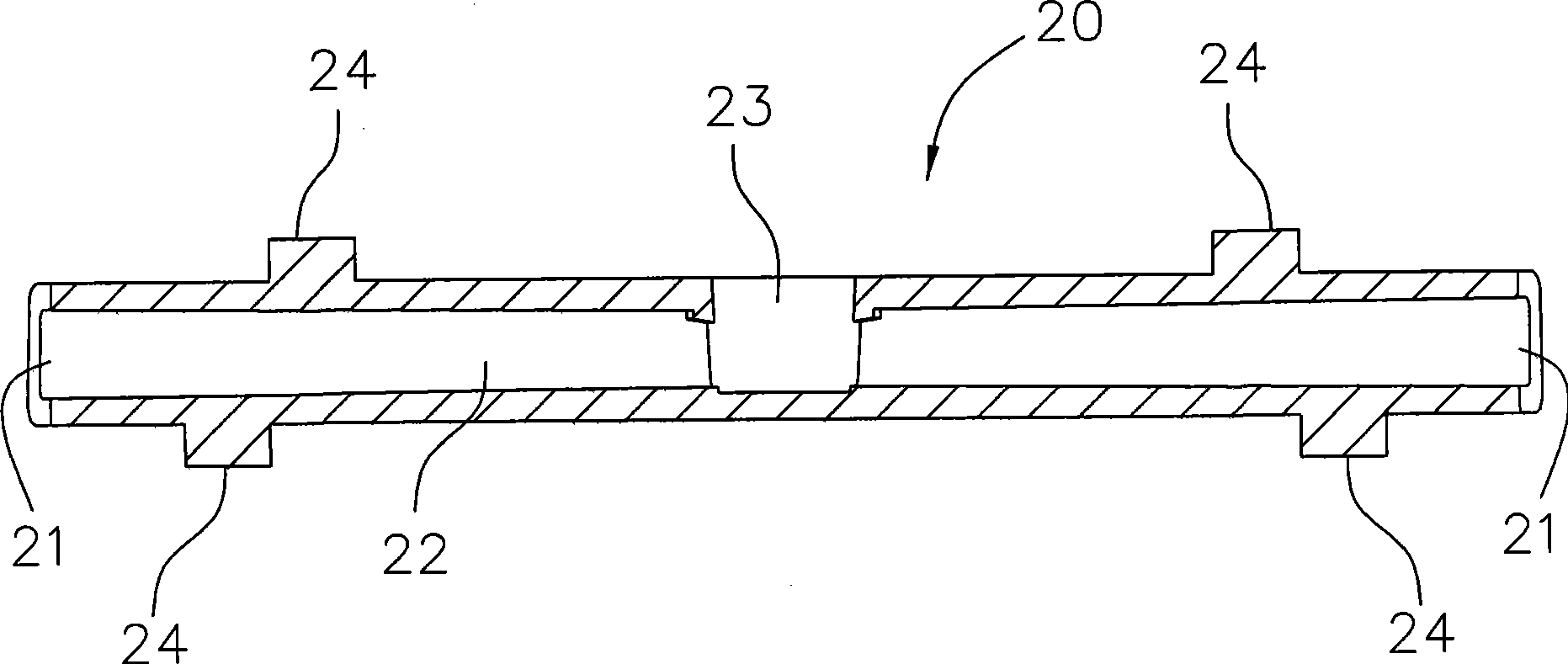

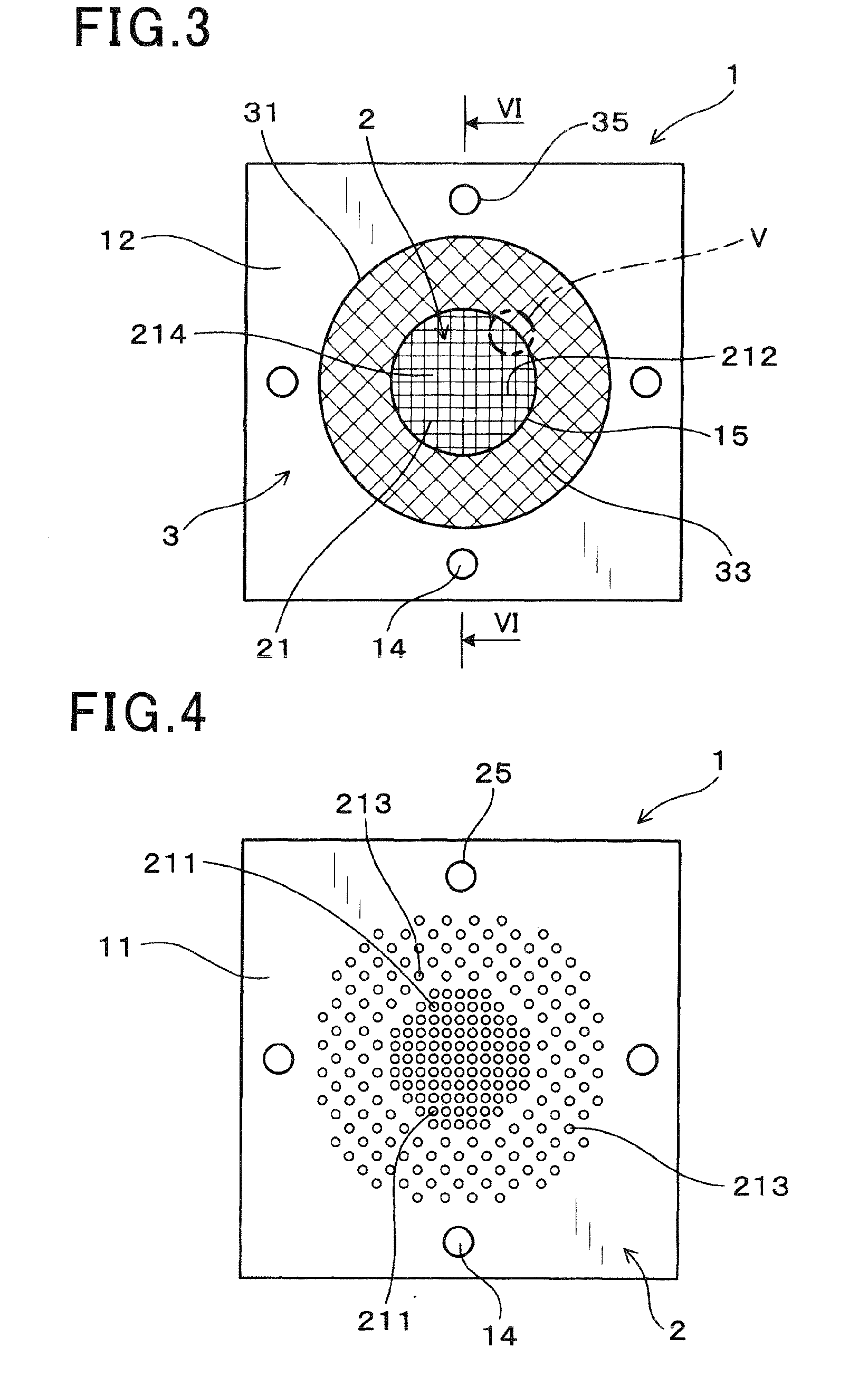

Container for Electric Energy Storage Device, and Battery and Electric Double Layer Capacitor Using the Same

InactiveUS20100119934A1Improve manufacturing efficiencyEasy for surface mountingSmall-sized cells cases/jacketsDouble layer capacitorsSurface mountingExternal circuit

The invention relates to a container for electric energy storage device excellent in the manufacturing efficiency and easy for surface mounting to an external electric circuit board, and a battery and electric double layer capacitor at high performance using the same. A container for electric energy storage device includes a frame (1), a first sealing member (2) bonded to the frame (1) so as to close a first opening of the frame (1), and a second sealing member bonded to the frame (1) so as to close a second opening of the frame (1) and having a connection end portion disposed side by side with the first sealing member (2). The container for electric energy storage device can be manufactured through a simple manufacturing process and can be surface-mounted easily.

Owner:KYOCERA CORP

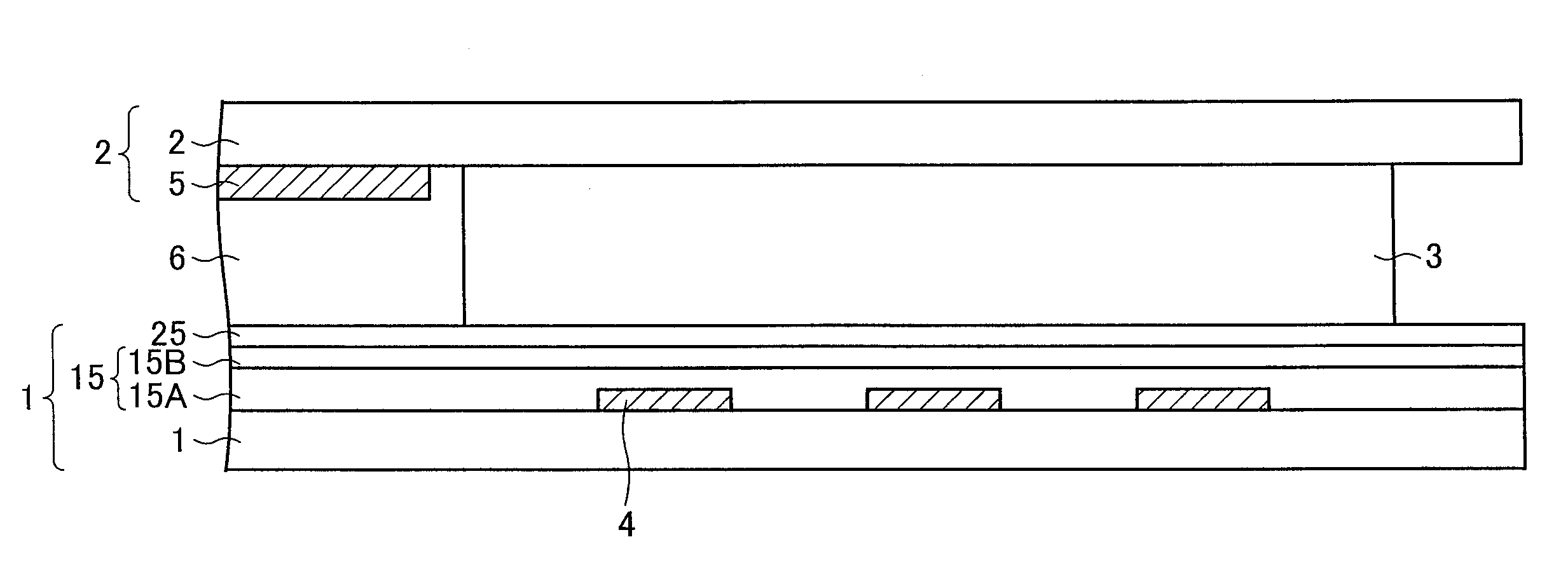

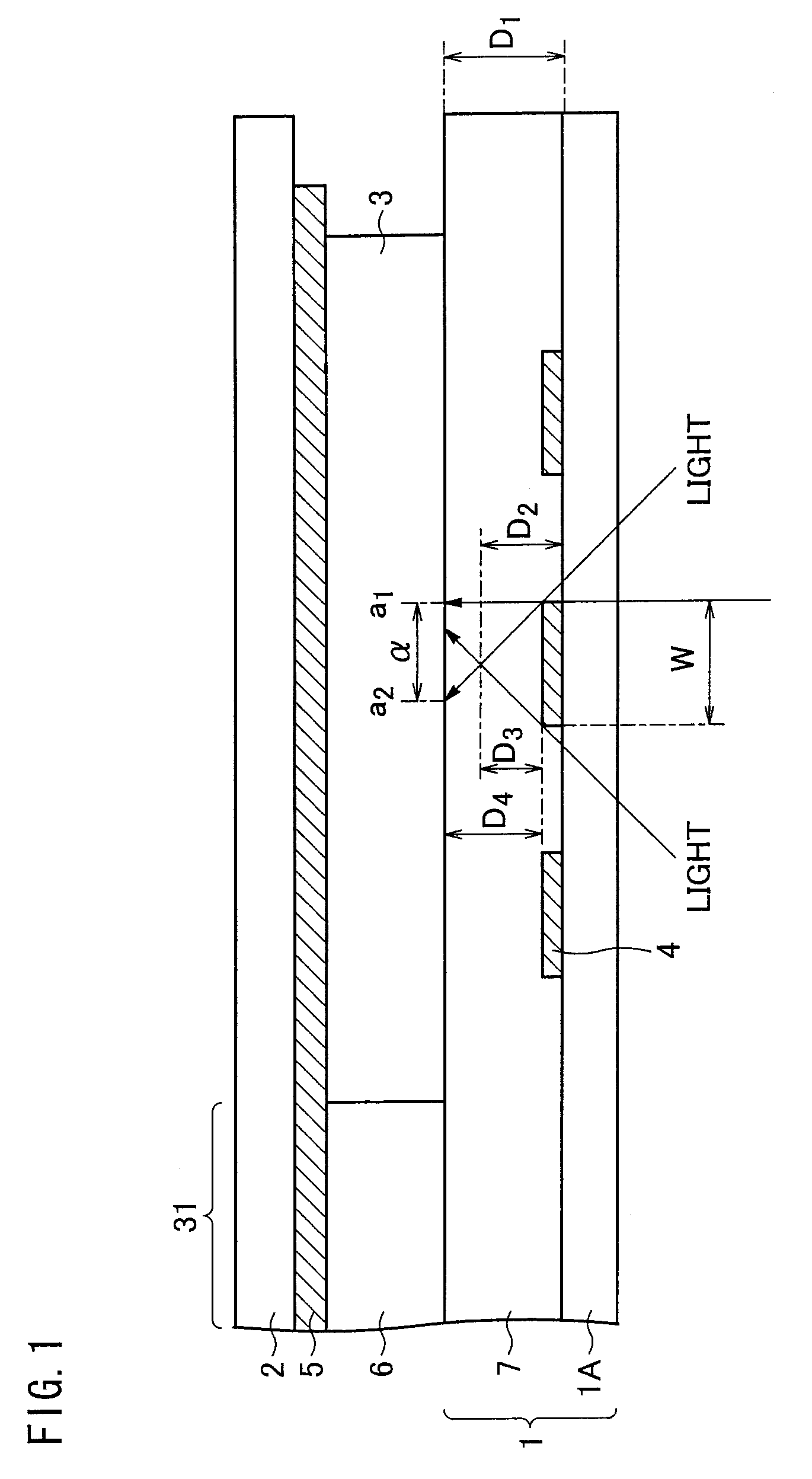

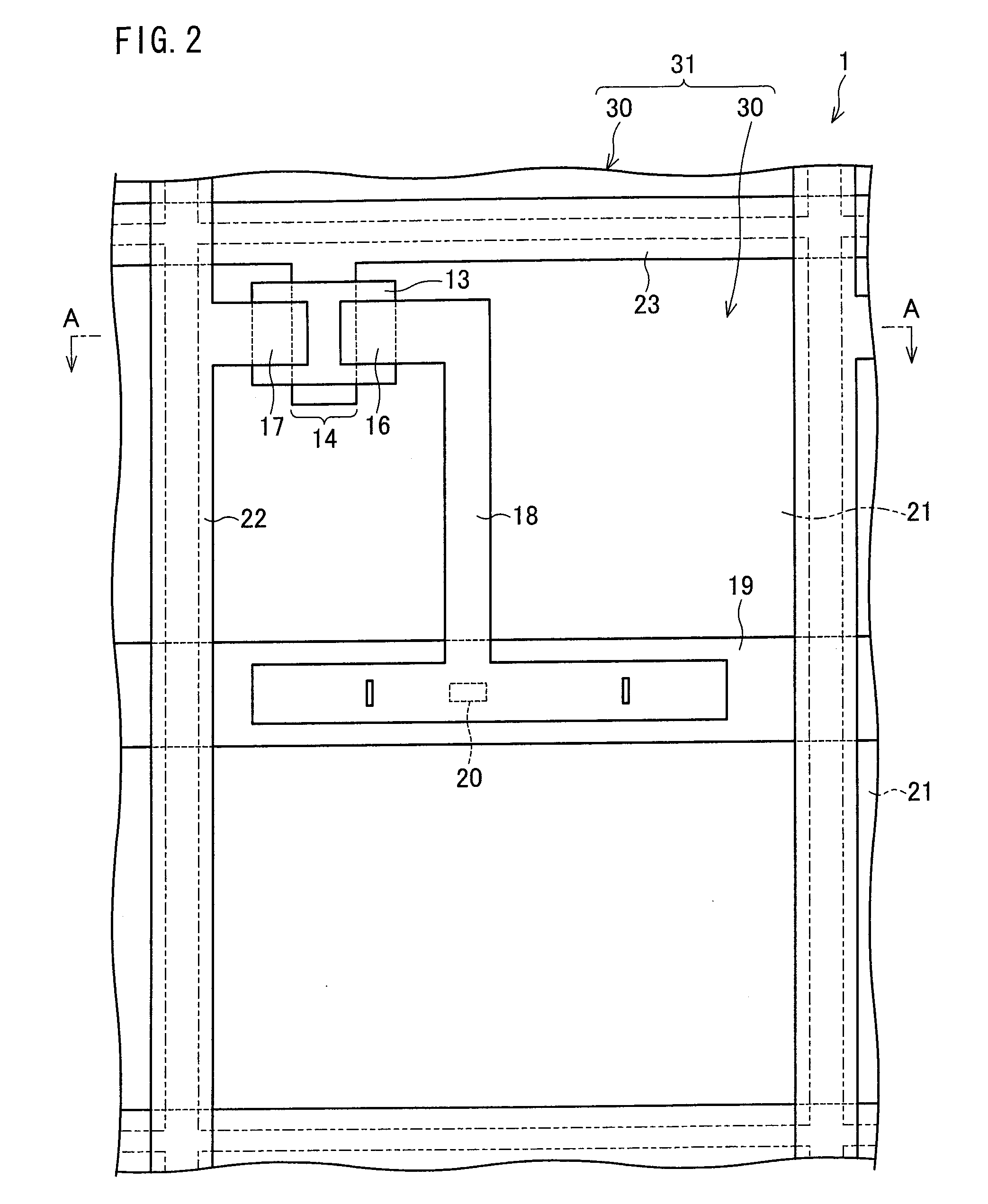

Liquid crystal display device and manufacturing method thereof

InactiveUS20090033846A1Easy curingReduces light irradiation energyNon-linear opticsLiquid-crystal displayMaterials science

In a liquid crystal display device, an array substrate and a CF substrate arranged face to face with each other. A liquid crystal layer is provided between the array substrate and the CF substrate. The array substrate and the CF substrate are bonded together by a sealing member containing a photo curing material. The array substrate has a surface opposed to the CF substrate. Metal wires are provided in the circumferential portion of the opposed surface. A transparent film is disposed between the metal wires and the sealing member.

Owner:SHARP KK

3D printing method for building beam component

ActiveCN103707387AImprove manufacturing efficiencyReduce production cost and labor costCeramic shaping apparatusManufacturing efficiencyManufacturing engineering

The invention discloses a 3D printing method for a building beam component. The method comprises the steps of manufacturing a forming mold frame, wherein the forming mold frame is provided with a square groove with an opening in one side and a cavity, and the square groove is wrapped by the cavity; manufacturing a supporting frame body, wherein a printing mechanism and a heat steam jetting mechanism are mounted on a walking mechanism; adding heat exchange media to the cavity in advance, wherein the inner surface temperature of the forming mold frame reaches 35-40 DEG C; generating a 3D CAD model of the beam component on a computer, wherein the thickness of a concrete layer corresponding to each cross section layer is 5-10cm; sending a control command to the walking mechanism by the computer, and enabling the walking mechanism to do reciprocating movement on a beam, wherein the hot steam jetting mechanism jets hot steam to the surface of the formed concrete layer, and the temperature of the hot steam is 40-45 DEG C. According to the method, the manufacturing efficiency of the building beam component can be improved, labor cost and production cost are lowered, and due to the more precise control over the production process, the product with the higher quality can be obtained.

Owner:无锡华工大光电智能科技有限公司

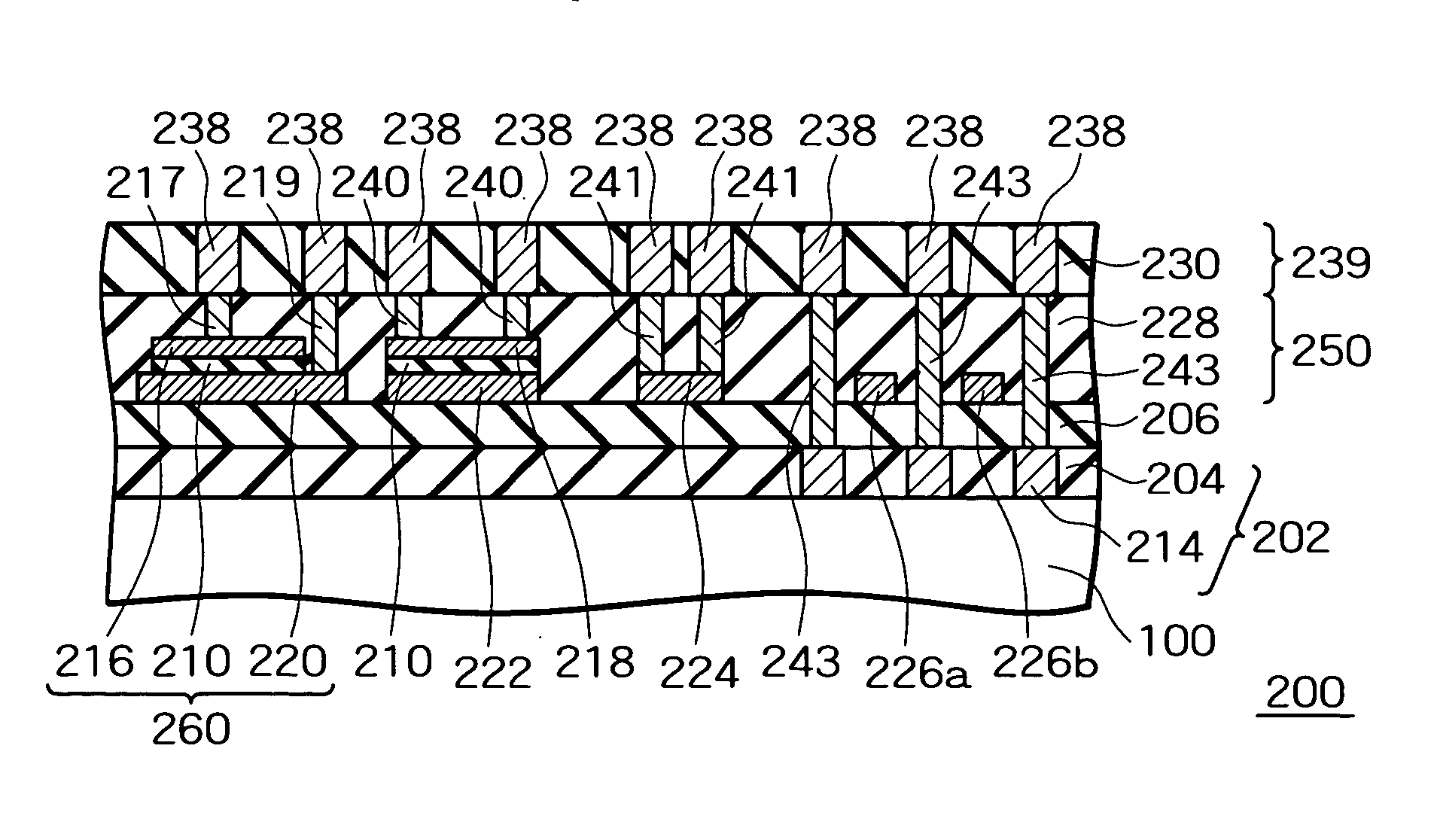

Semiconductor device and manufacturing method for the same

ActiveUS20050218520A1Highly reliable MIM structureReduce resistanceTransistorSemiconductor/solid-state device detailsCapacitanceElectrical resistance and conductance

A lower interconnection is provided on a semiconductor substrate. A MIM capacitive element is provided on a first interlayer insulation film in which the lower interconnection is buried, and includes a lower electrode, an upper electrode, and a dielectric film sandwiched therebetween. An upper interconnection is provided on a second interlayer insulation film in which the MIM capacitive element is buried. A contact electrically connects the lower electrode and the upper interconnection. The lower electrode is mainly formed of Al, so that they are lower in electrical resistance than barrier metal, and also low in stress value. Therefore, it becomes possible to widen the area of the lower electrode for electrically connecting the contact while restraining their influences on charge accumulation and close contact between the lower electrode and the insulation film. In addition, since the electrical resistance is lowered, the thickness of the lower electrode can be increased. Accordingly, the MIM capacitive element with a large capacitance can be manufactured with a high yield.

Owner:RENESAS ELECTRONICS CORP

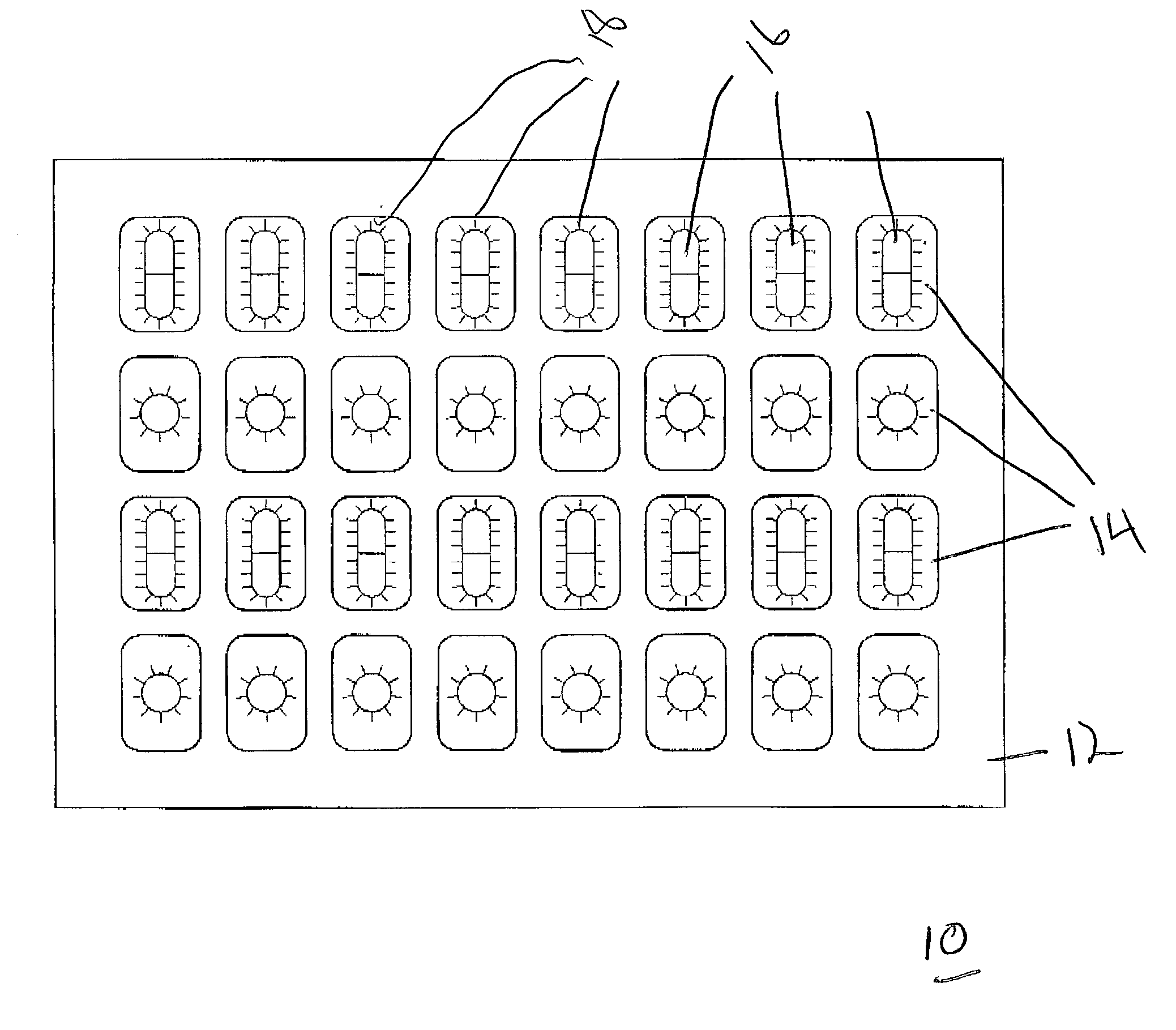

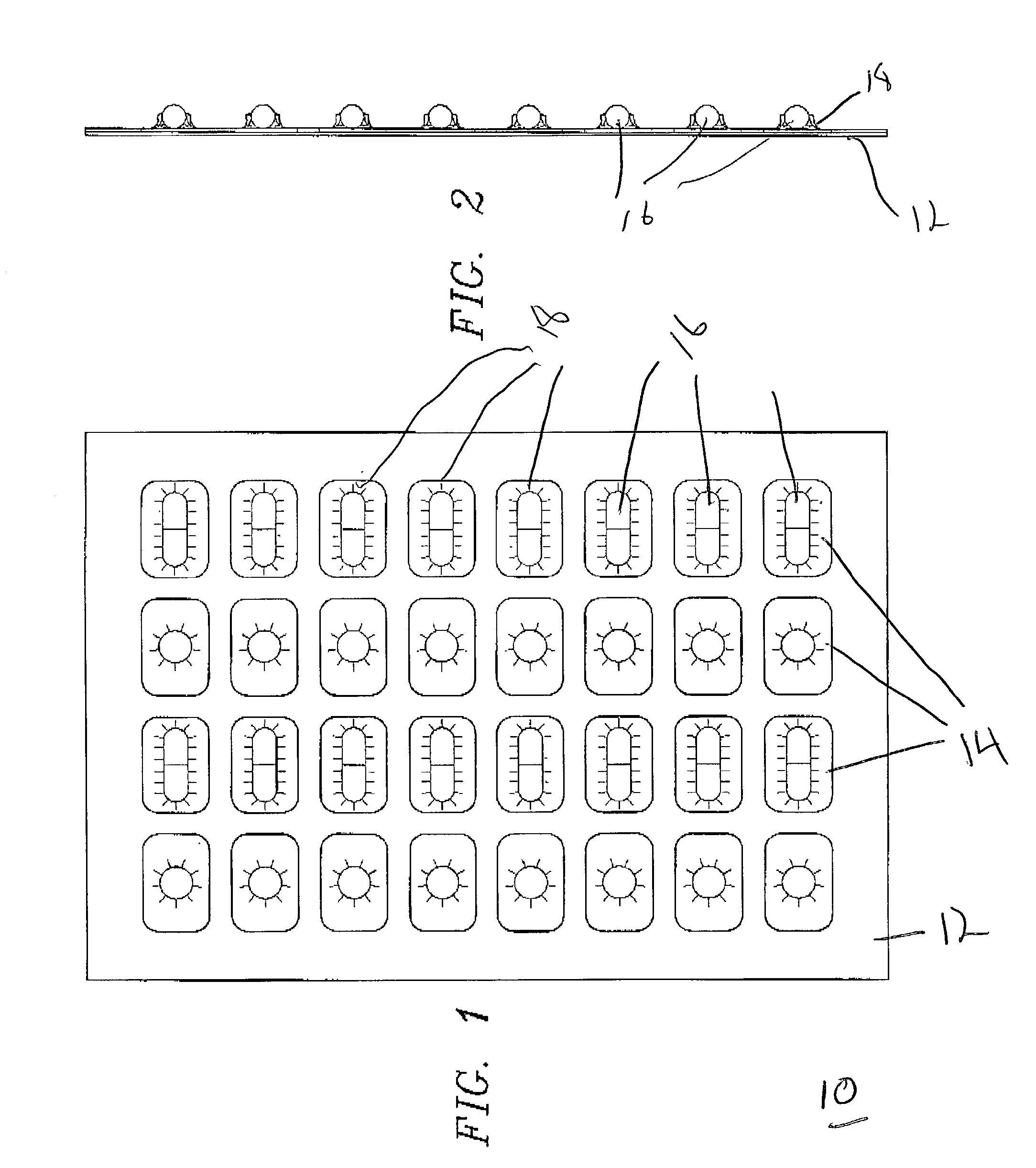

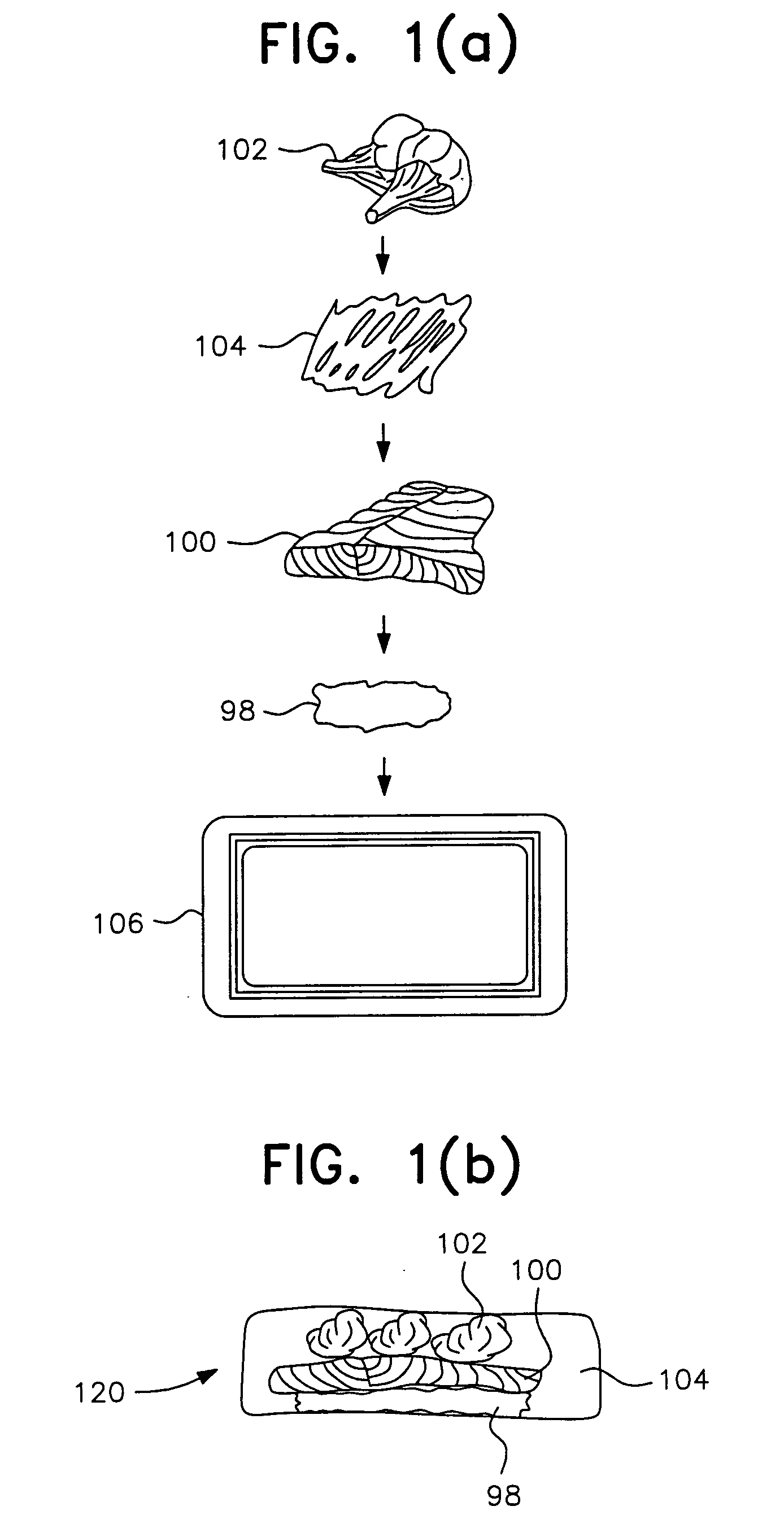

Systems and methods for forming blister packages with support members for pharmaceutical product packaging

InactiveUS20040093835A1Few machine and processing stepEfficiently formedWrappingSolid materialBlistersBlister pack

Systems and methods are provided for forming both backing and support members of a solid pharmaceutical product package as well as the blister portions for the packages. The disclosed solid pharmaceutical product packaging solutions utilize fewer machines and processing steps in order to form an overall solid pharmaceutical product package. In accordance with the preferred exemplary embodiments of the present invention, the manufacturing processing steps associated with the formation of the blister members in the clear plastic sheets is integrated in line with manufacturing of the backing material.

Owner:MTS MEDICATION TECH

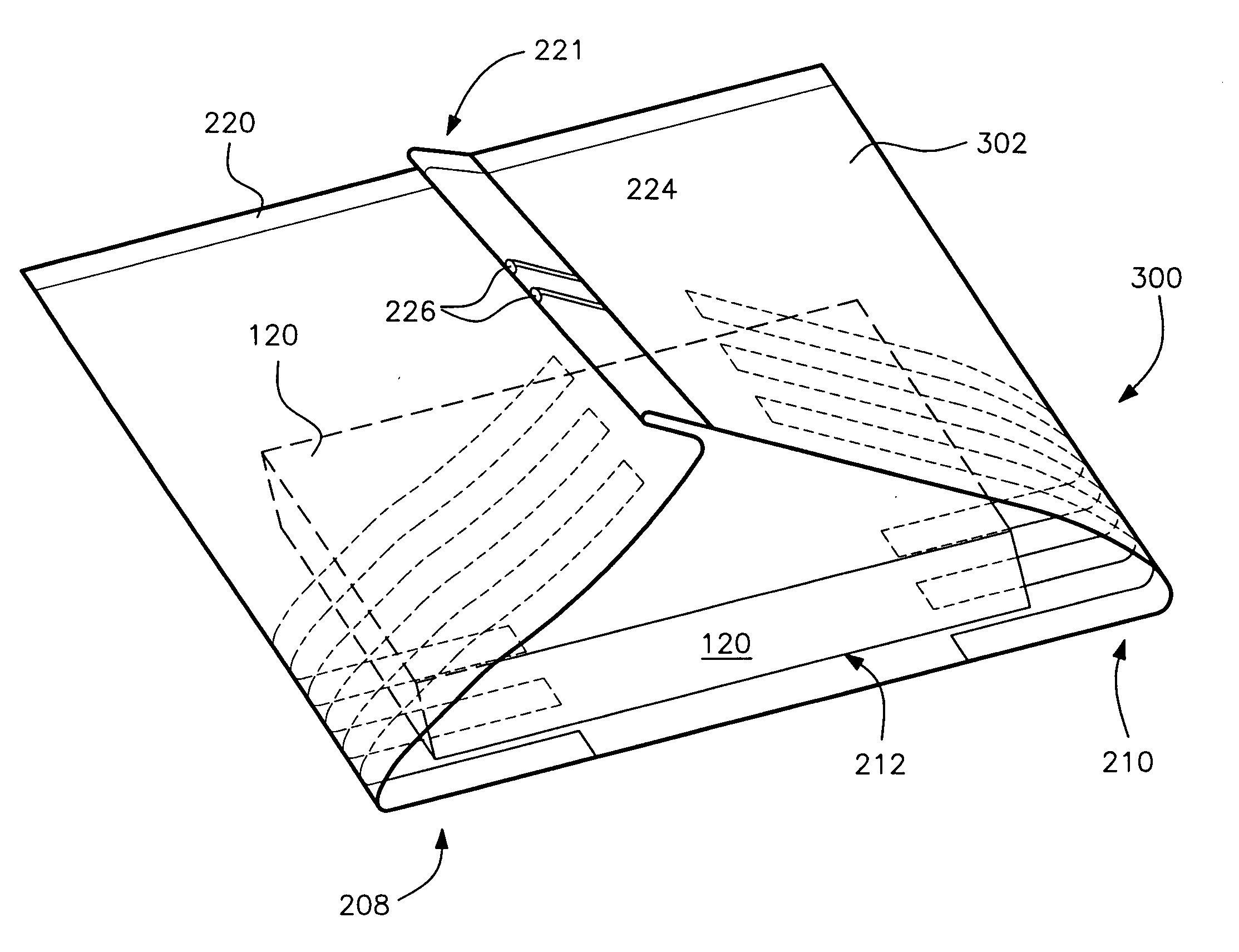

Flexible microwave cooking pouch containing a raw frozen protein portion and method of making

ActiveUS20050184065A1Improve manufacturing efficiencyEnhance perceive valueBio-packagingClimate change adaptationWaxChemistry

A sealed cooking pouch specifically designed for microwave cooking raw frozen protein entrees containing a raw meat protein portion, preferably beef, poultry, fish, pork or veal, along with starch, sauce and vegetable portions. The packaging material is manipulated into a pouch shape, meant to receive the protein entree ingredients before sealing, during the manufacturing process. The packaging material is composed of a heat-sealable polyester layer with a thin layer of aluminum deposited on one side and a layer of water-repellant 20 lb-25 lb. structural paper stock, laminated together through the use of a water-based adhesive. The aluminum can be uniformly deposited centrally where maximum temperature concentration is desired, and deposited in patterns that allow for temperature attenuation in parts of the package where this is desirable. The structural paper outer layer is treated with a wax emulsion to repel water that forms from condensation on the outside of the cooking pouch.

Owner:SMART POUCH

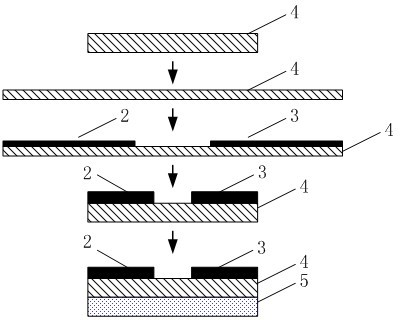

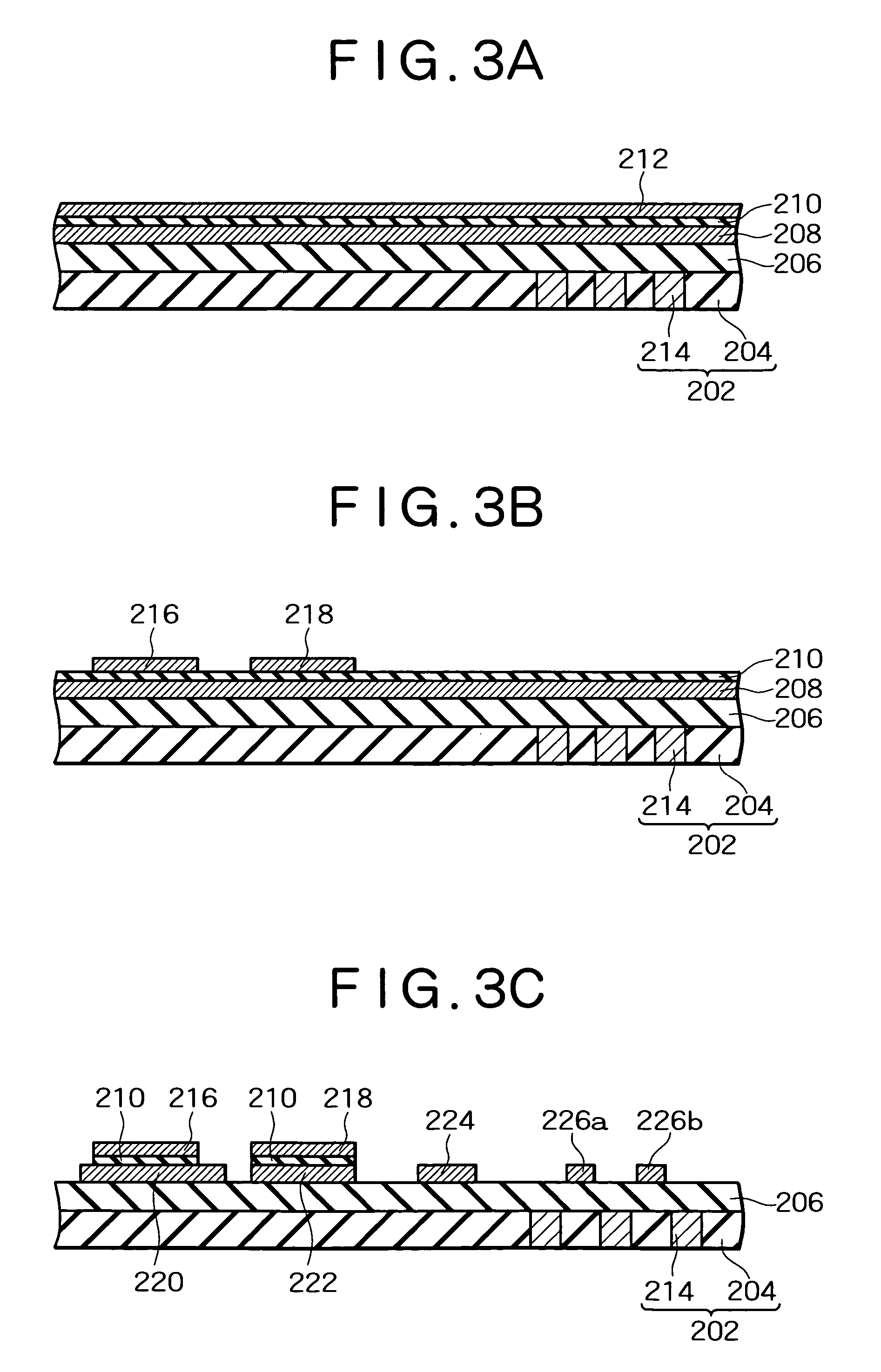

Preparation method of thin film transistor of flexible electronic device

ActiveCN102169960AImprove manufacturing efficiencyReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingFlexible electronicsChannel width

The invention provides a preparation method of a thin film transistor of a flexible electronic device. The method comprises the following steps of: (1) preparing a bendable and stretchable substrate; (2) stretching the substrate, and coating an adhesive on a surface of a stretched rubber substrate; (3) depositing a gate on the substrate; (4) depositing an organic dielectric layer unit on the device which is processed in the step (3); (5) respectively depositing a source unit layer and a drain unit layer on the organic dielectric layer unit; (6) loosening the substrate, releasing loads which are acted on the substrate, and carrying out heat treatment to eliminate an interface stress and a pressure stress of the device; and (7) depositing the organic dielectric layer unit. The invention provides the method for mechanically stretching the substrate, so the channel width of the device is reduced, manufacturing accuracy is improved effectively, and the resolution ratio of the flexible electronic device is improved.

Owner:WUHAN INTELLIGENT EQUIP IND INST CO LTD

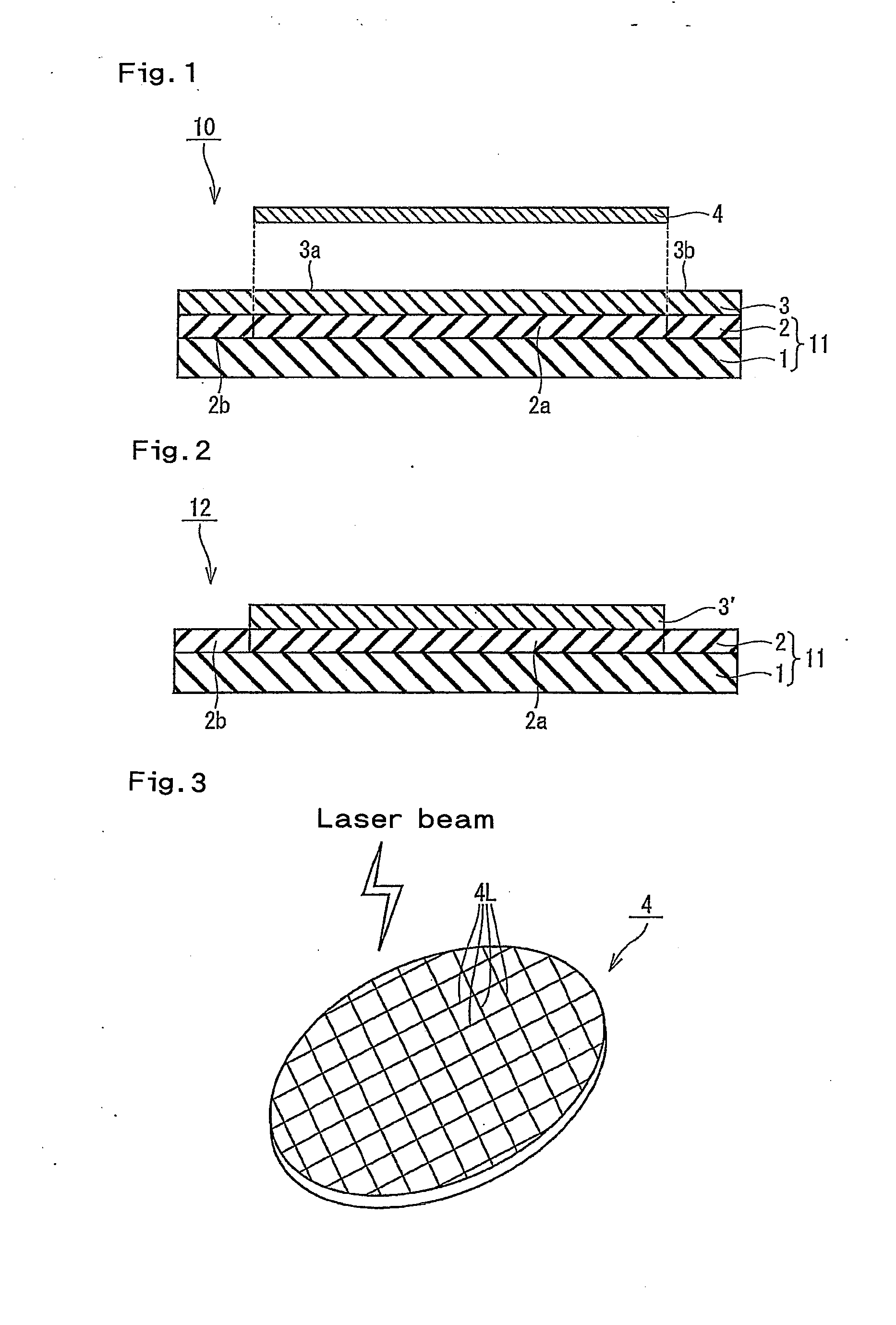

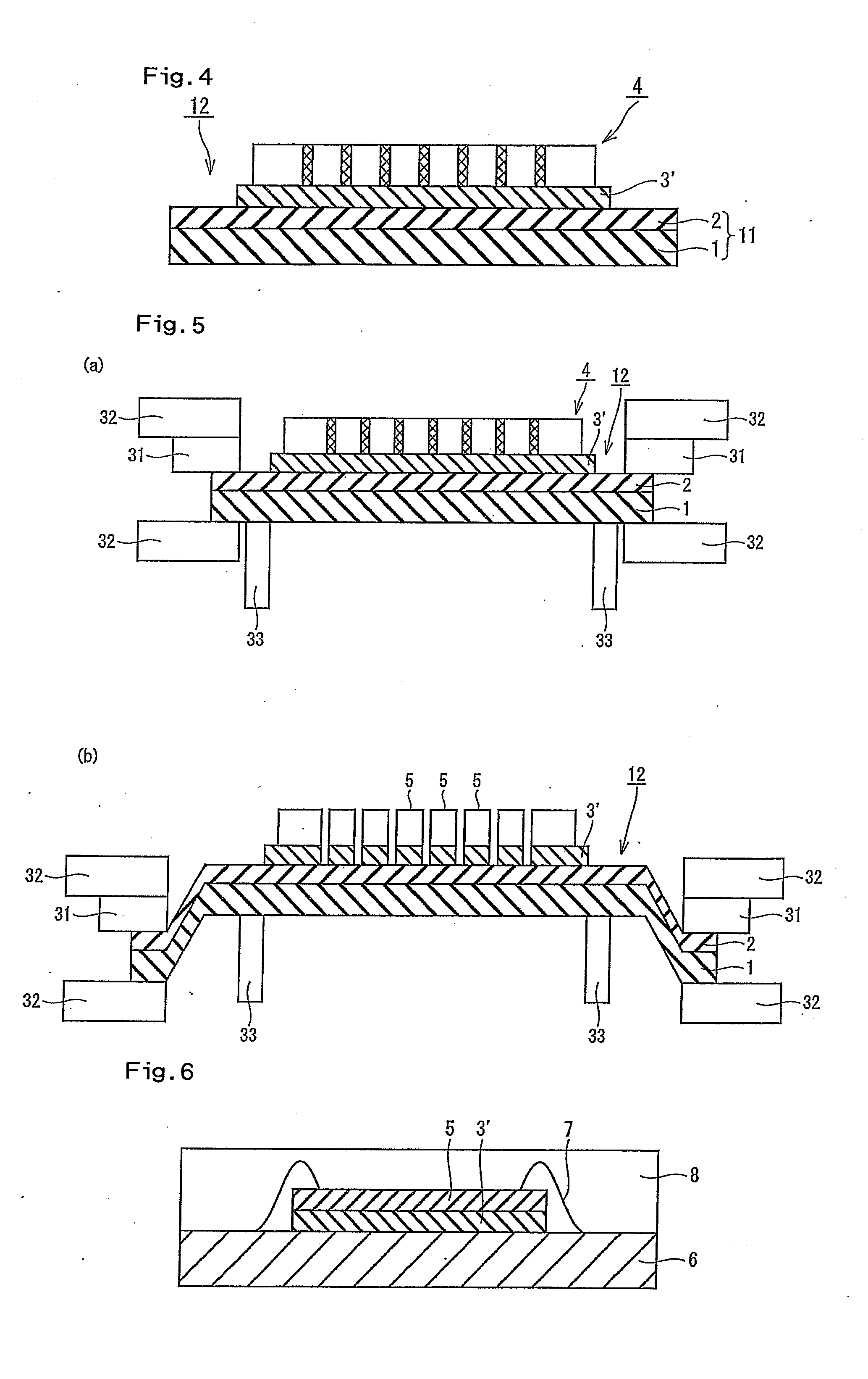

Thermosetting die bond film, dicing die bond film and semiconductor device

InactiveUS20110256666A1Improve manufacturing efficiencyImproved yieldSolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceEngineering

The present invention provides a thermosetting type die bond film that can be preferably broken by tensile force. It is a thermosetting type die bond film used for a method of obtaining a semiconductor element from a semiconductor wafer by forming a reforming region by irradiating the semiconductor wafer with a laser beam and then breaking the semiconductor wafer in the reforming region or a method of obtaining a semiconductor element from a semiconductor wafer by forming grooves that do not reach the backside of the semiconductor wafer on a surface thereof and then exposing the grooves from the backside by grinding the backside of the semiconductor wafer, wherein the elongation rate at break at 25° C. before thermal curing is larger than 40% and 500% or less.

Owner:NITTO DENKO CORP

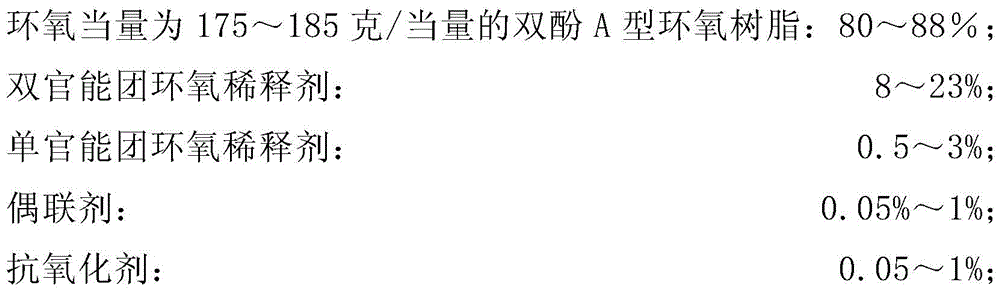

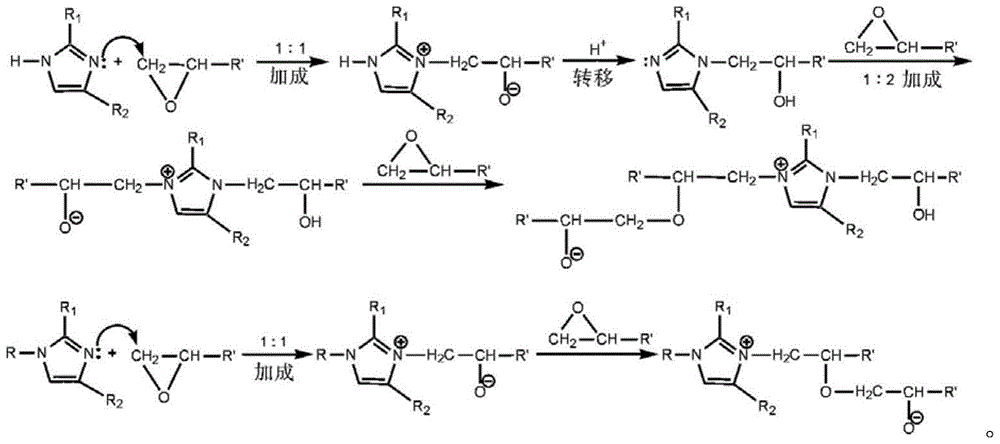

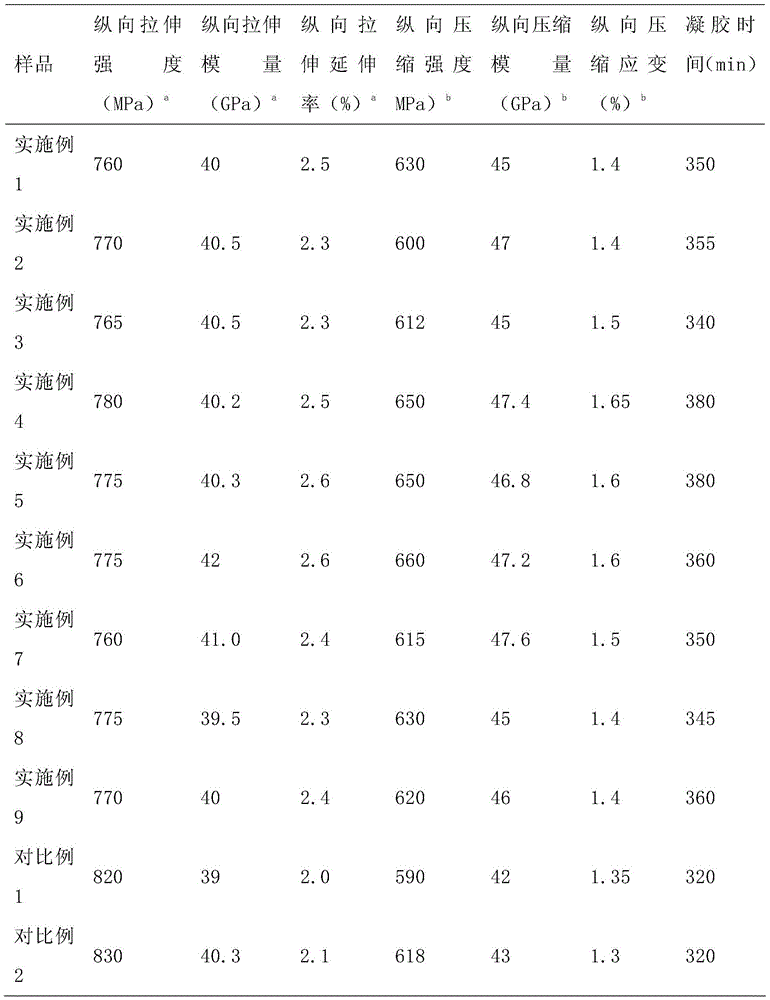

Epoxy resin composition and composite material for wind power generator blade

The invention relates to a composite material for wind power generator blades, wherein the composite material is composed of an epoxy resin composition and a fiber-reinforced fabric accounting for 68-73% by weight of the epoxy resin composition. The epoxy resin composition includes a component A and a component B according to the weight ratio of 100:28-33, wherein the component A is composed of bisphenol-A epoxy resin being 175-185 g / equivalent in epoxy equivalent, a bi-functional-group epoxy diluent, a mono-functional-group epoxy diluent, an epoxy coupling agent and an antioxidant, and the component B is composed of aliphatic polyamine, cycloaliphatic amine and imidazole. The fiber-reinforced fabric is described as the specification. The invention discloses the weight ratio of the raw materials. The composite material, which is prepared through a liquid moulding method, can reach the demand on strength and anti-wind-impact performance of the wind power generator blades.

Owner:上海康达新材料科技有限公司

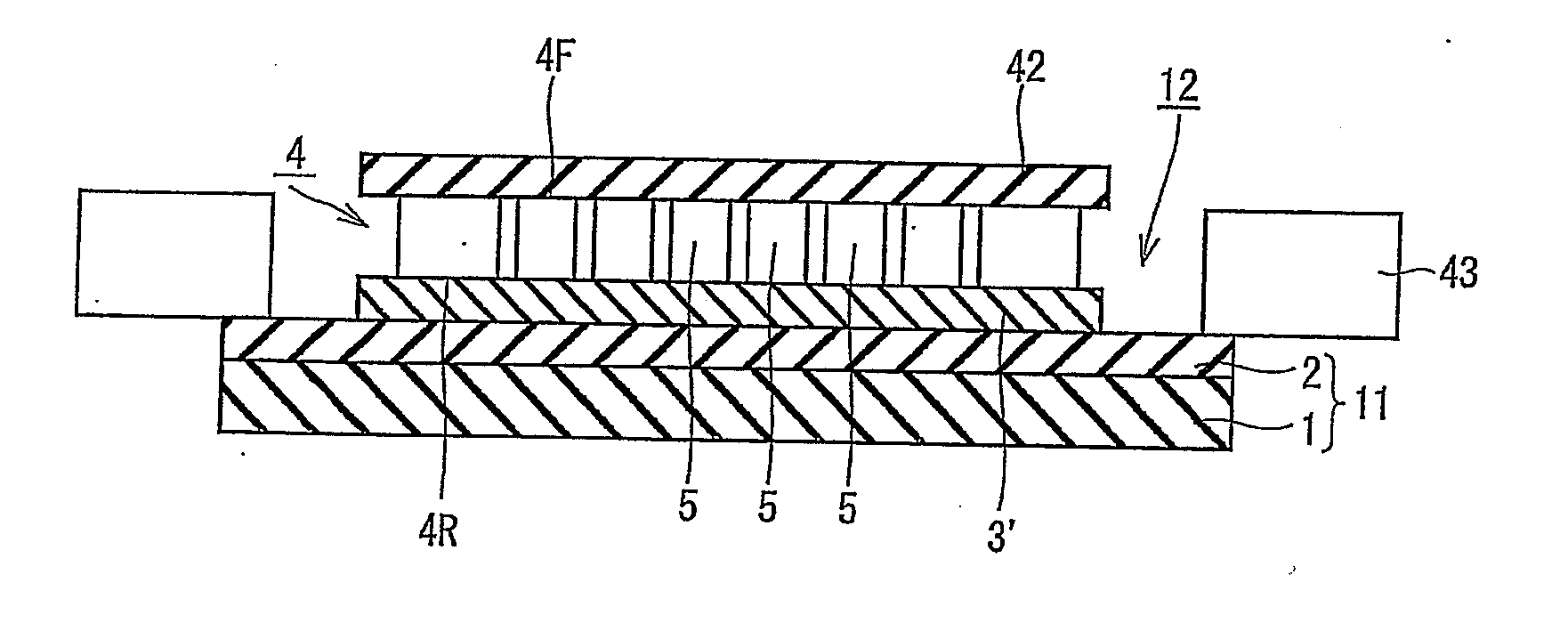

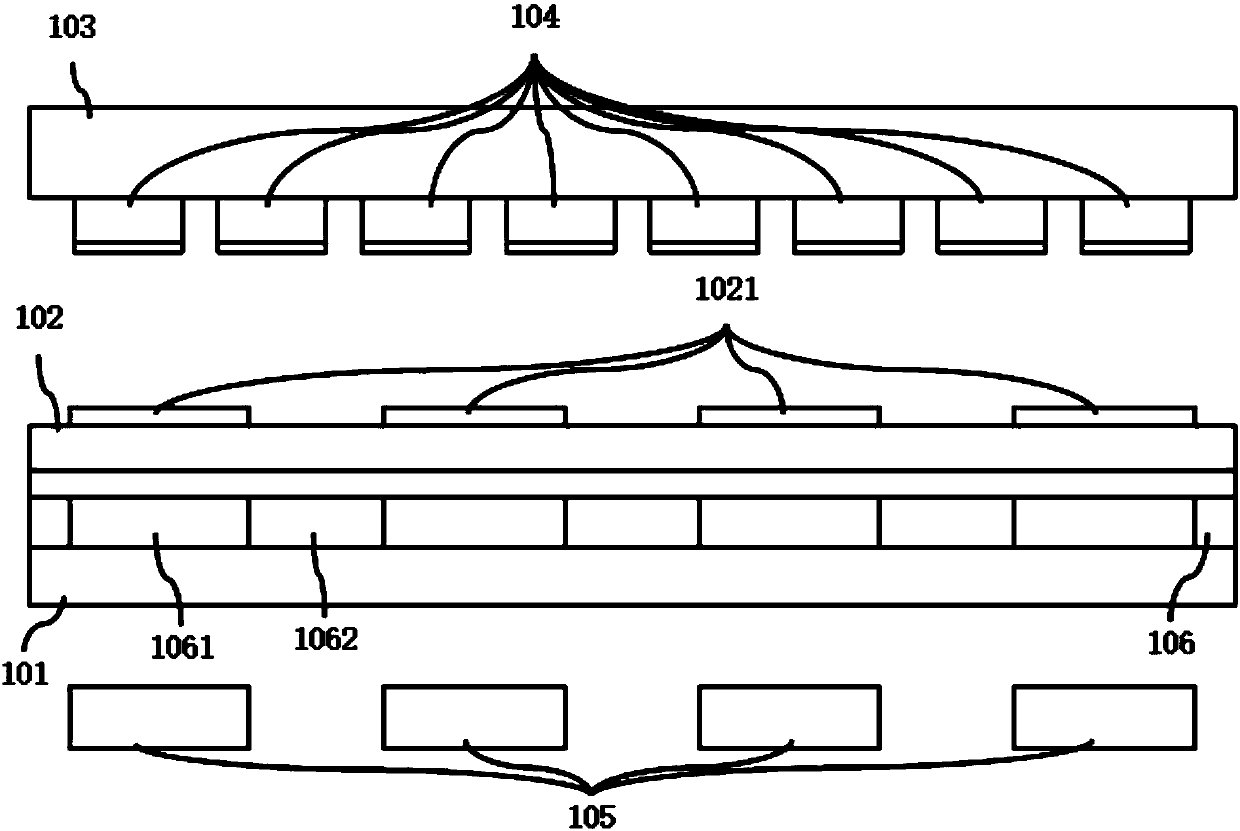

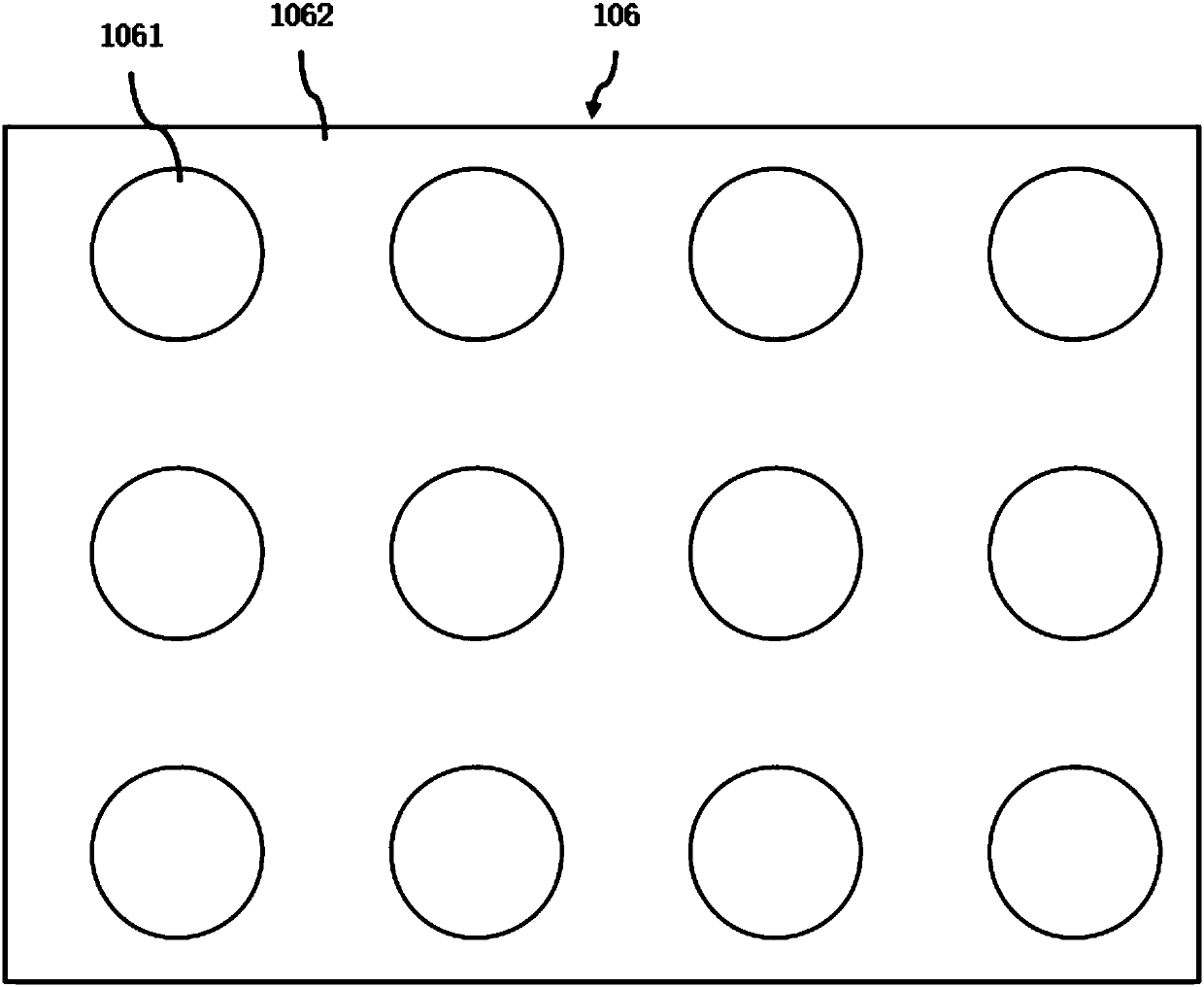

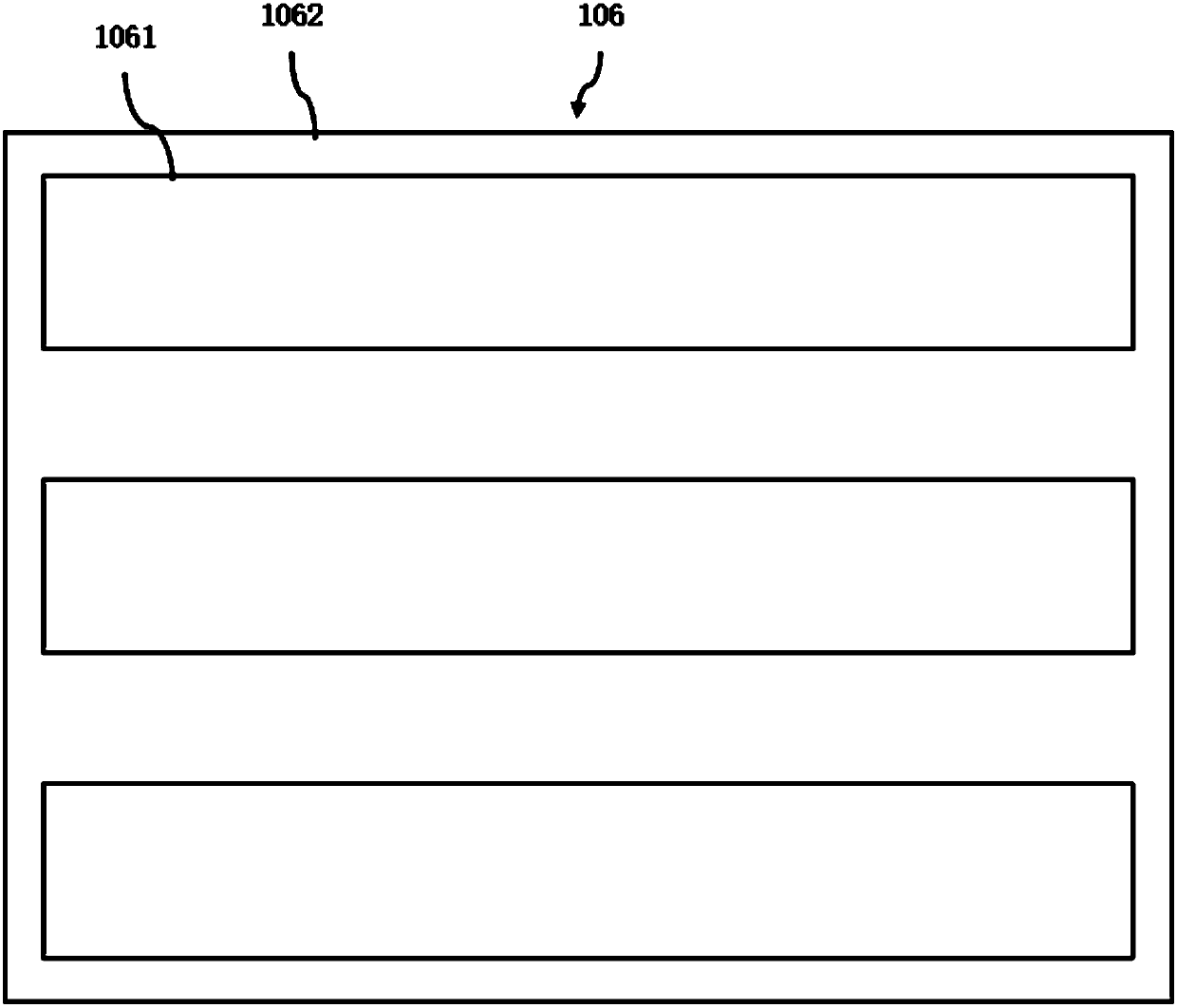

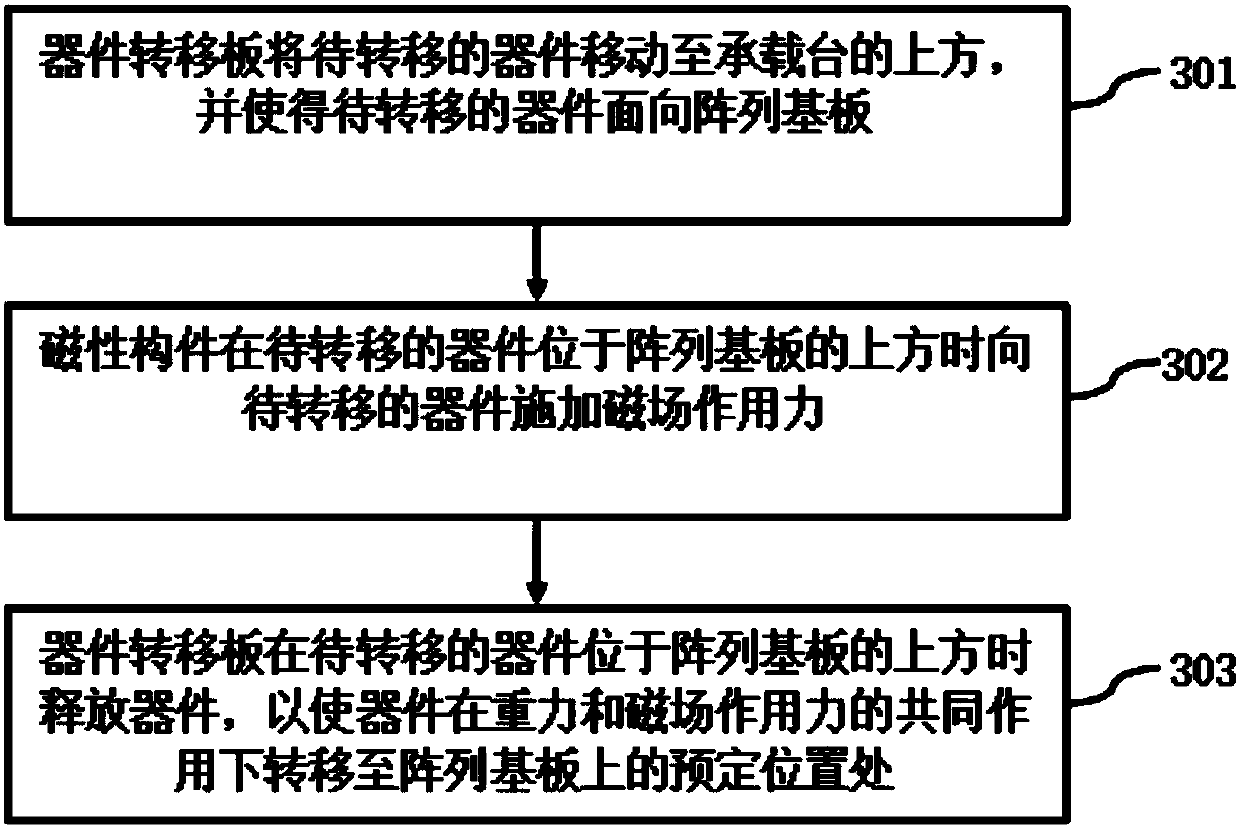

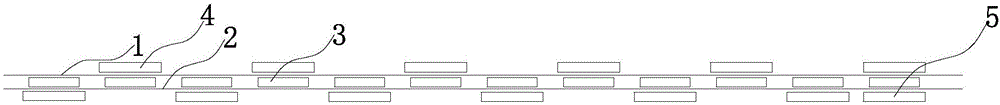

Concentrating flux plate and device transfer equipment

ActiveCN107808835AImprove manufacturing efficiencyFast transferSemiconductor/solid-state device manufacturingPhysicsManufacturing efficiency

The invention discloses a concentrating flux plate and device transfer equipment. The concentrating flux plate comprises a first preset area and a second preset area. The concentrating flux plate is used for enabling the magnetic field generated by the magnetic components in the corresponding device transfer equipment to be concentrated in the first preset area and shielding the magnetic field inthe second preset area adjacent to the first preset area so that the corresponding magnetic field acting force of the magnetic field is enabled to be concentrated in the first preset area, and the device to be transferred by the device transfer equipment is enabled to be transferred to the preset position of the array substrate arranged on the bearing table of the device transfer equipment withinthe preset path range corresponding to the first preset area. A lot of devices can be rapidly arranged on the array substrate so that the manufacturing efficiency of the device array substrate including the devices and the array substrate can be enhanced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

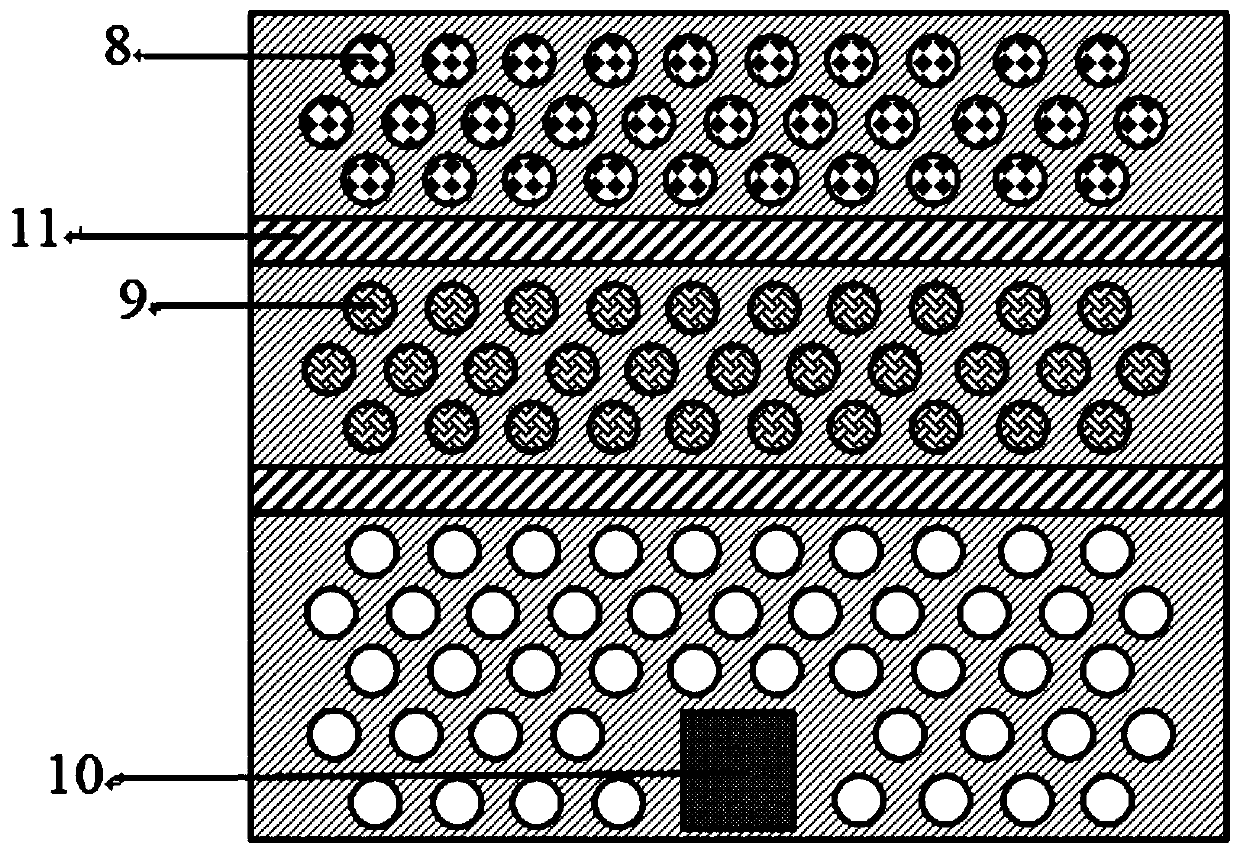

Panchromatic micrometer LED display chip based ona gallium nitride nanopore array/quantum dot composite structure and preparation method thereof

ActiveCN110112172AShorten manufacturing timeImprove manufacturing efficiencyMaterial nanotechnologySolid-state devicesHigh contrastNanopore

The invention discloses a panchromatic micrometer LED display chip based on a gallium nitride nanopore array / quantum dot composite structure. On the GaN blue-light LED epitaxial layer of a silicon substrate, an array rectangular mesa structure penetrating through a p-type GaN layer and a quantum well active layer to a n-type GaN layer is disposed. Each rectangular mesa structure constitutes one RGB pixel unit. In each rectangular pixel unit, a red-light rectangular sub-pixel region, a green-light rectangular sub-pixel region and a blue-light rectangular sub-pixel region are included. The adjacent sub-pixel regions are isolated by an isolation trench. Each sub-pixel region is provided with a nanopore array structure and is filled with red and green quantum dots. Panchromatic display is realized by quantum dot color conversion. A preparation method of the panchromatic micrometer LED display chip is also disclosed. The panchromatic micrometer LED display chip utilizes a nanopore structureto improve the stability and lifetime of the quantum dots, and utilizes the energy resonance transfer between quantum dots to improve the internal quantum efficiency and color conversion efficiency,and achieve panchromatic display with high resolution, high color gamut, and high contrast.

Owner:NANJING UNIV

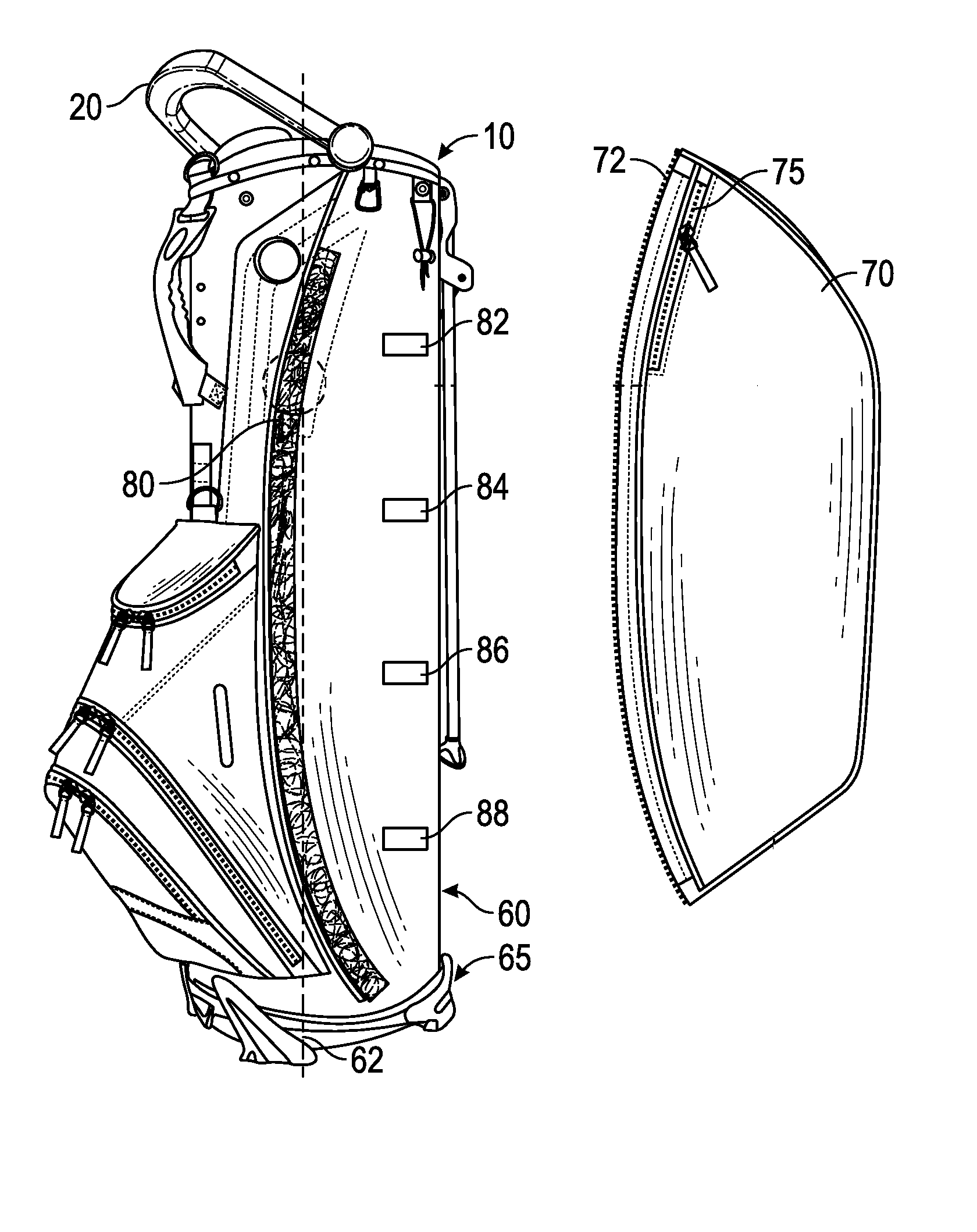

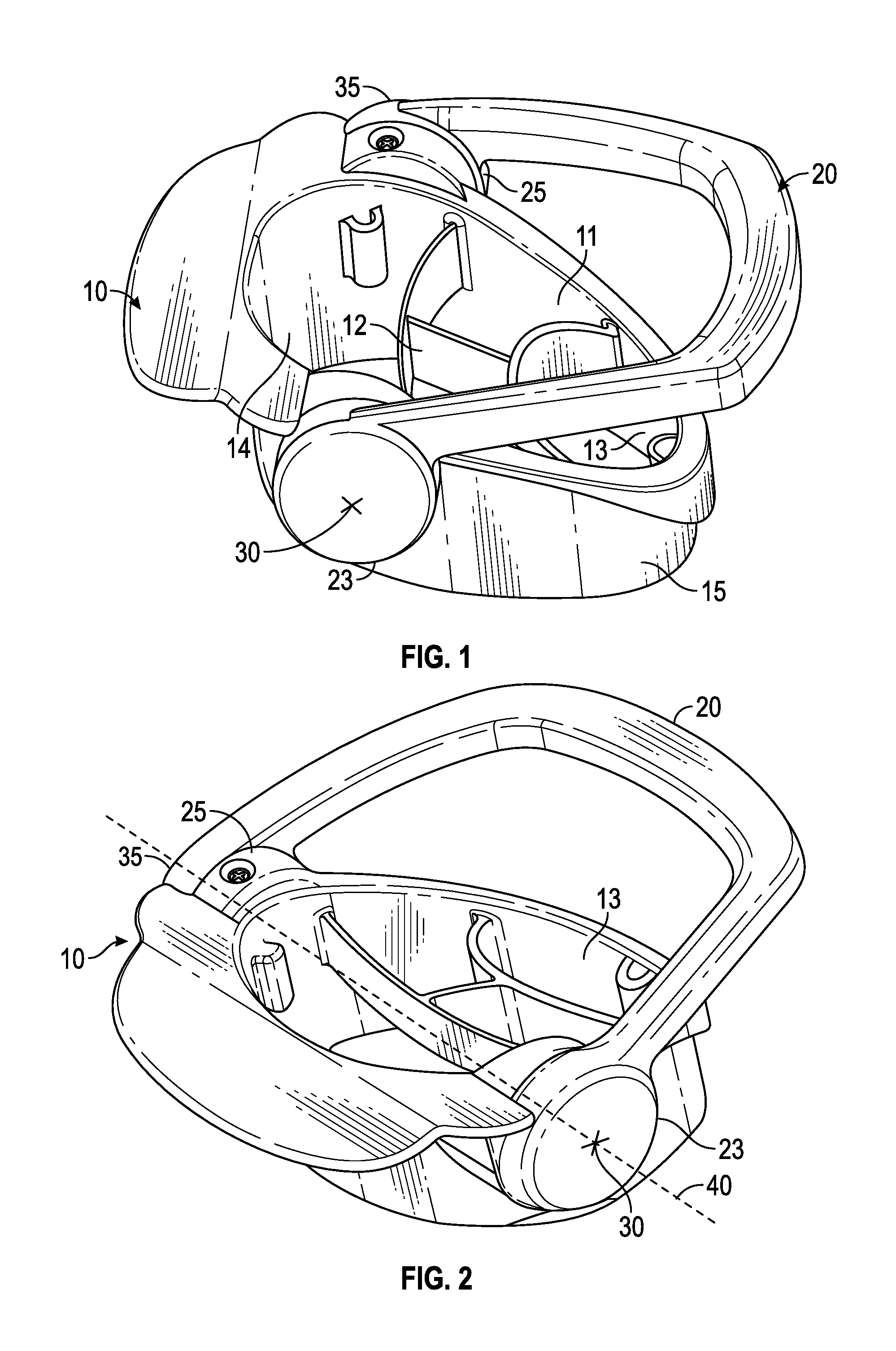

Golf bag having adjustable characteristics

InactiveUS20140061075A1Improve usabilityGreat custom embroidery manufacturing efficiencyOther accessoriesContainer/bottle contructionLocking mechanismEngineering

A golf bag having one or more adjustable features is disclosed herein. In particular, the golf bag comprises a handle rotatable around an axis perpendicular to a vertical axis extending through the body of the golf bag, and may be fixed in place via a locking mechanism so that the handle maintains a desired angle with respect to the vertical axis. The handle of the present invention preferably is rotatably affixed to a collar or upper portion of the golf bag. The golf bag also comprises an external pocket that is removably affixed to an exterior surface of the golf bag with hook and loop fasteners and other attachment mechanisms.

Owner:CALLAWAY GOLF CO

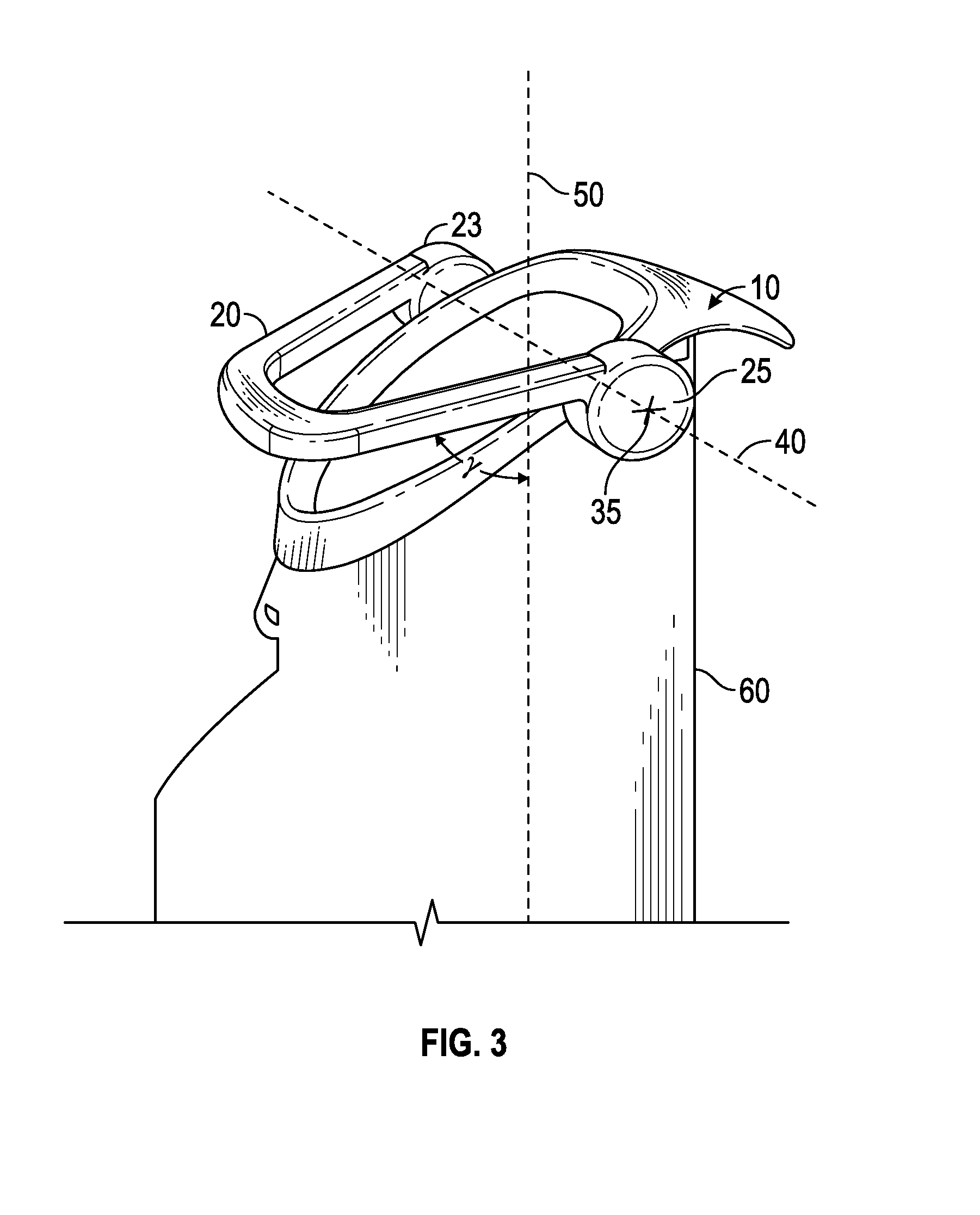

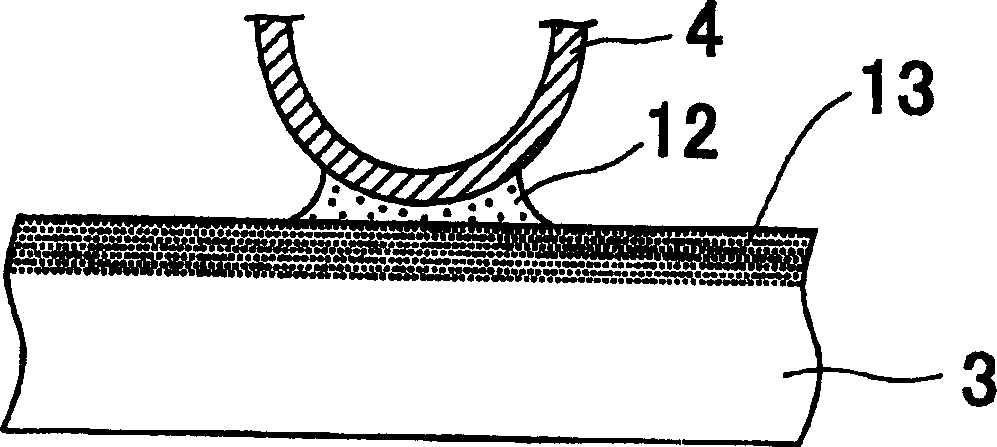

Aluminum alloy brazing material, brazing member, brazed article and brazinh method therefor using said material, brazing heat exchanging tube, heat exchanger and manufacturing method thereof using sai

InactiveCN1726114AAvoid excessive corrosionReduce the predetermined thicknessWelding/cutting media/materialsHeat exchange apparatusPlate heat exchangerImpurity

A heat exchanger 10 includes a brazing heat exchanging tube S and a fin 4. The heat exchanging tube S and the fin 4 are brazed with each other via the brazing layer 11 of the heat exchanging tube S. The brazing layer 11 is formed by spraying of a brazing material consisting of Si: 6 to 15 mass%, Zn :1 to 20 mass%, at least one of Cu: 0.3 to 0.6 mass% and Mn: 0.3 to 1. 5 mass, and the balance being aluminum and inevitable impurities.

Owner:SHOWA DENKO KK

Manufacturing method for integral plastic tap body component and plastic tap body component

ActiveCN101664980BEasy to prepareImprove manufacturing efficiencyValve housingsManufactured suppliesProcess engineering

The invention is suitable for a manufacturing method for an integral plastic tap body component and a product thereof. The manufacturing method mainly adopts the technical scheme of molding a tap by twice injection molding, wherein the primary injection molding is used for molding a first component on a middle connection part of the tap body component; the first component is placed into a mold toundergo secondary injection molding so as to mold a second component on both sides of the tap body component; the second component properly coats and connects the first component; and required holes are reserved as a water inlet, a water outlet and a valve seat. The technical scheme can simplify the complicated and lengthy manufacturing method of the conventional copper casting, improves production efficiency and product quality, reduces cost, reject ratio and product weight, and greatly reduces transportation cost. Compared with the conventional manufacturing method for forming the componentby individual injection molding and then sticking, the method can effectively reduce manual assembly cost, improves production efficiency and product quality, and ensures that the component has better structural strength.

Owner:东莞成霖安博制造有限公司

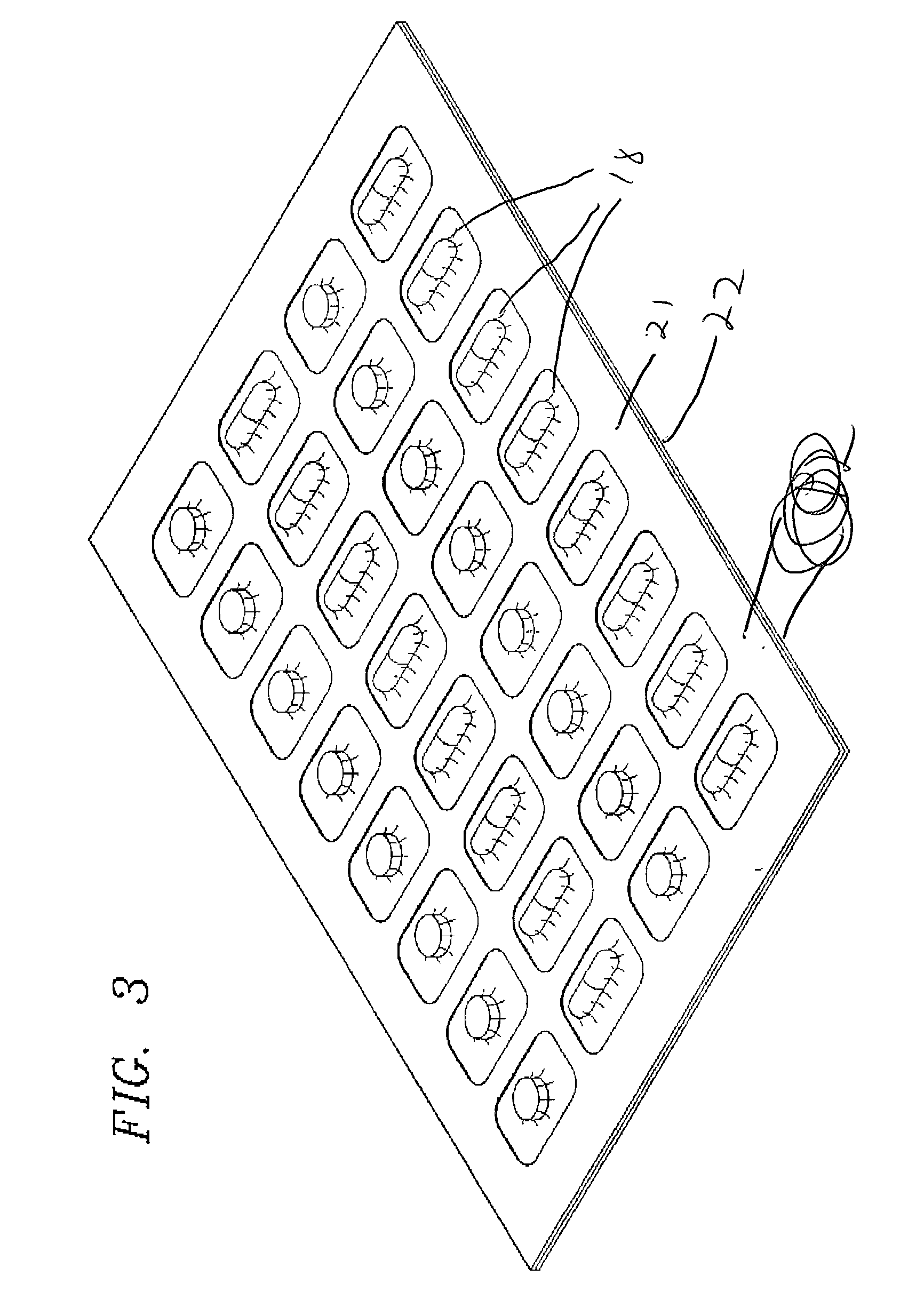

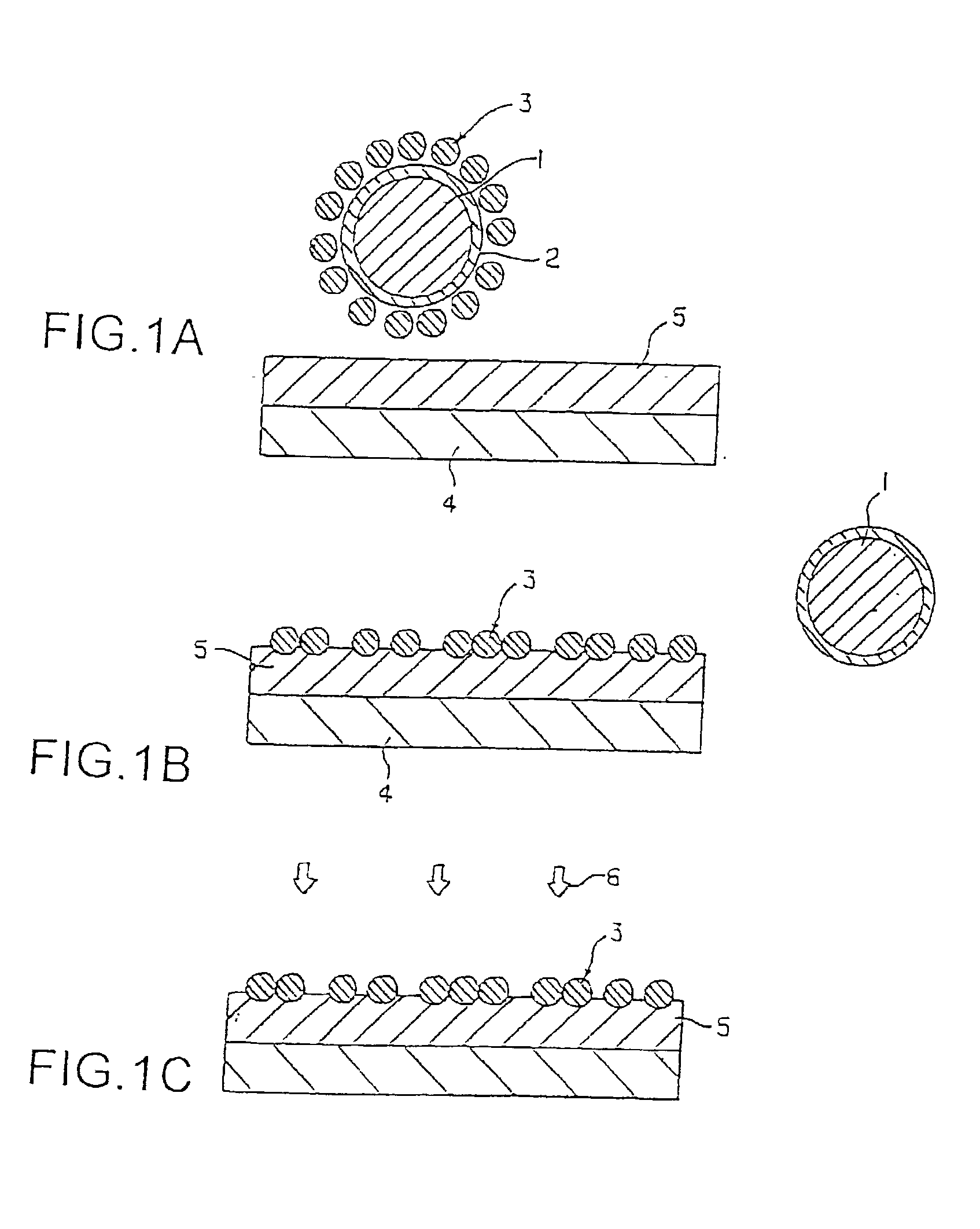

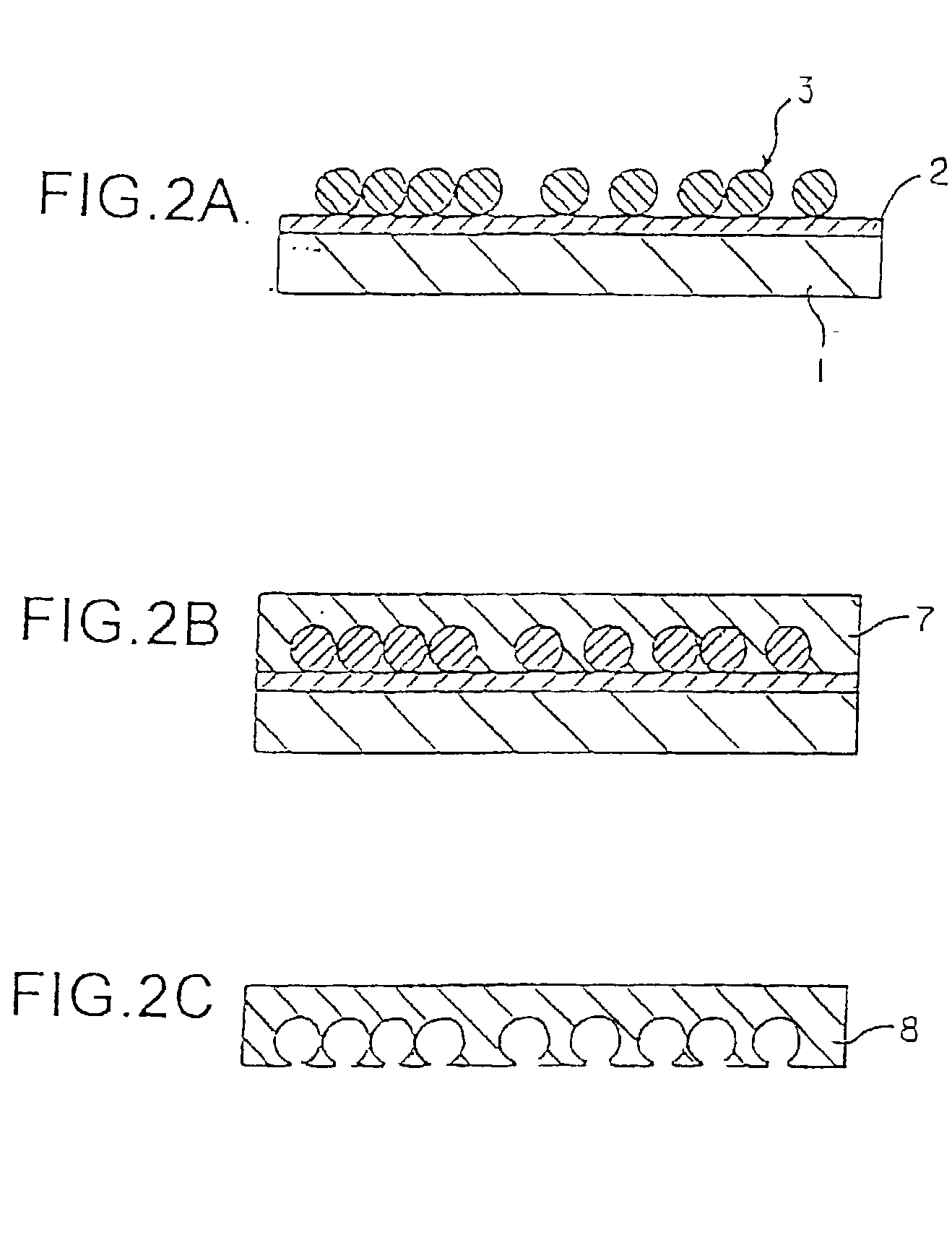

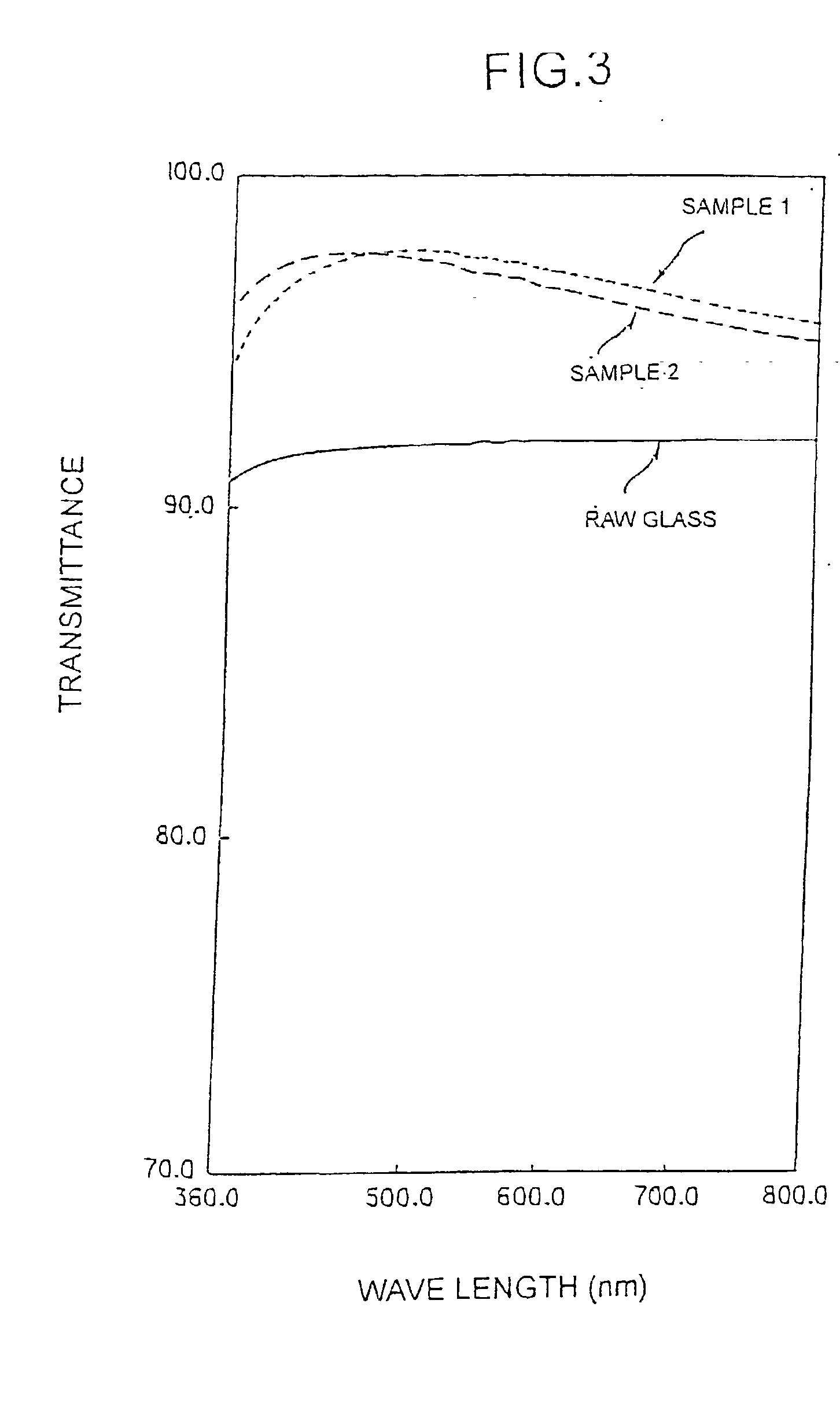

Antireflection film and method for manufacturing the same

InactiveUS20020160166A1Improve firm-forming rateImprove manufacturing efficiencyDecorative surface effectsDiffusing elementsVisibilityRefractive index

An objective of the present invention is to provide an antireflection film having a fine particle layer that is formed on a transparent substrate without allowing particles to aggregate as irregular lumps, while the region having no particles is being reduced to an area that is sufficiently small so as not to impair the visibility. In order to achieve the above-mentioned objective, the present invention provides an antireflection film that is characterized by having: a transparent substrate and a fine particle layer that is placed on the surface of the transparent substrate and made from at least a single layer of fine particles, wherein the surface of the transparent substrate and fine particles are allowed to adhere to each other by at least an electrostatic interaction, while the bulk of the above-mentioned fine particle layer is set to have a refractive index lower than the refractive index of the above-mentioned transparent substrate.

Owner:DAI NIPPON PRINTING CO LTD

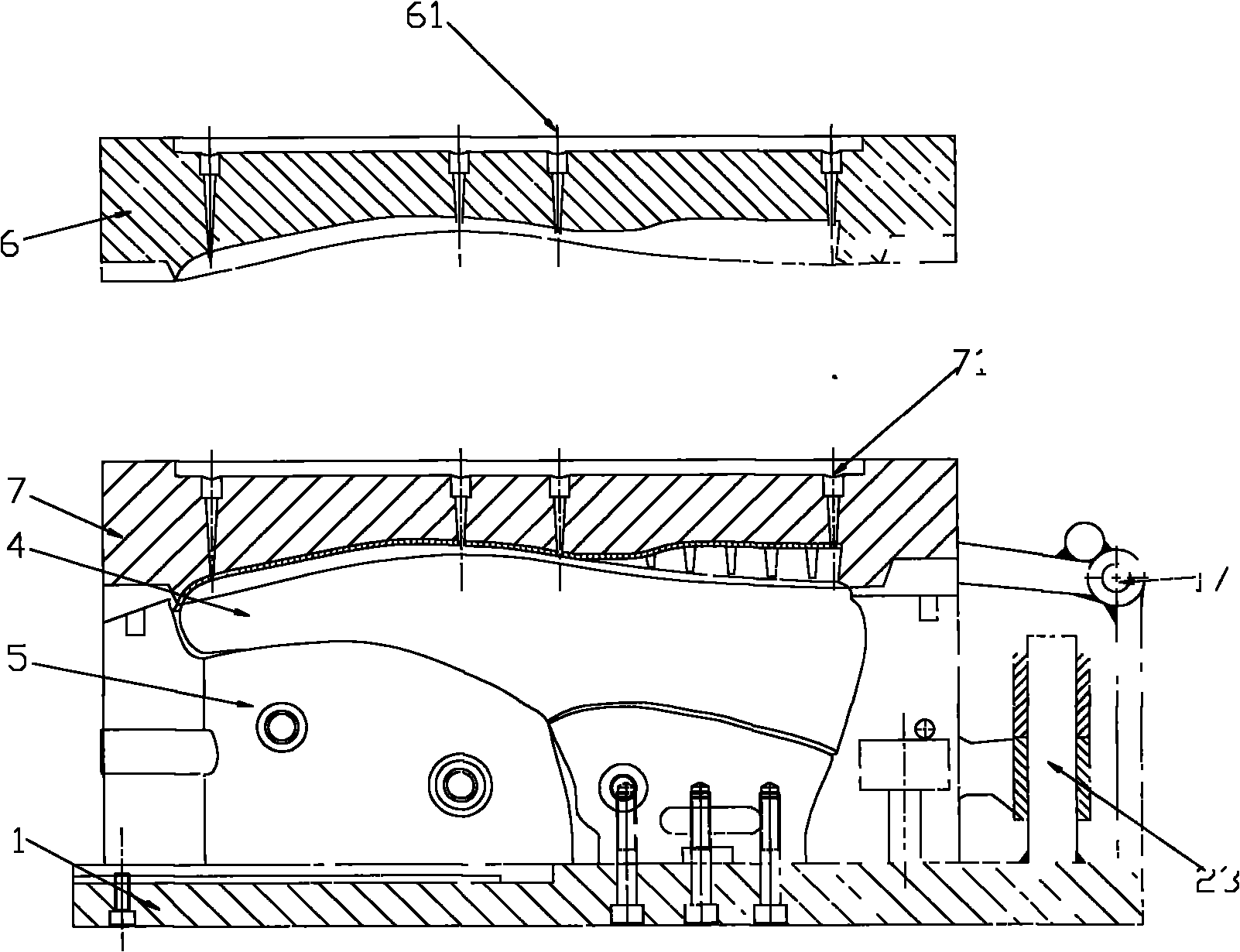

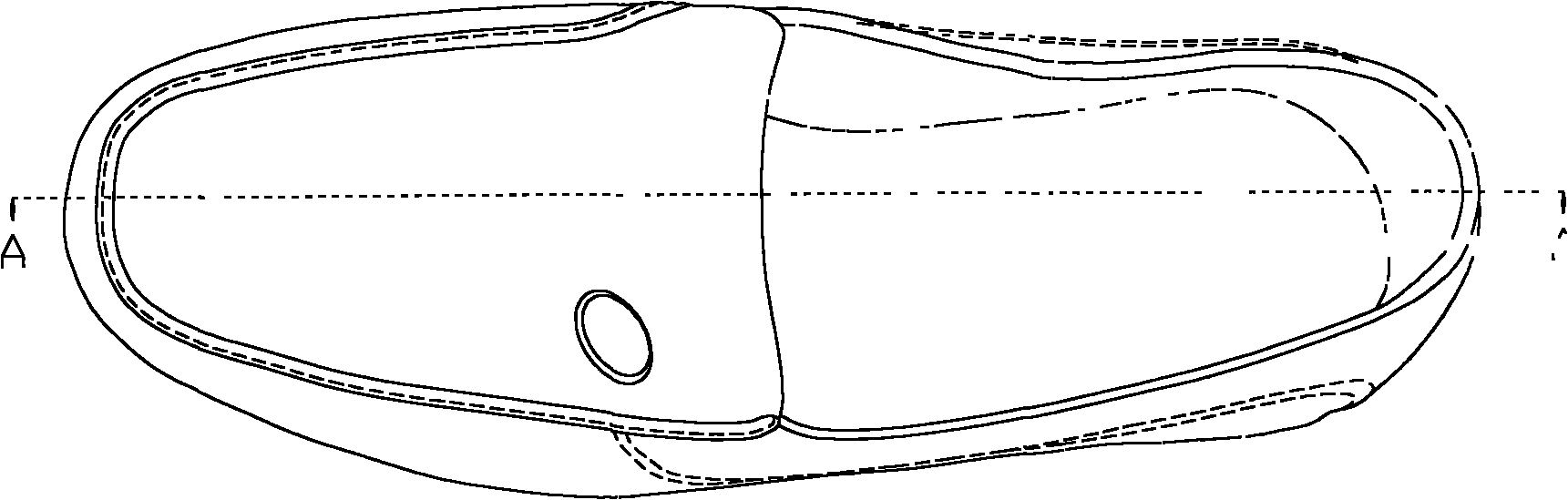

Secondary integrally-forming shoe, shoe-making die and producing method

The invention relates to a secondary integrally-forming shoe, a shoe-making die and a producing method. The shoe-making die comprises a left-side baffle plate, a right-side baffle plate, a shoe last, a toe front baffle plate, an intermediate cover baffle plate, a sole cover plate and a die base plate; the left-side baffle plate, the right-side baffle plate, the shoe blast, the toe front baffle plate and the intermediate-cover baffle plate form a vamp die cavity; the left-side baffle plate, the right-side baffle plate, the shoe last, the toe front baffle plate and the sole cover plate form a shoe vamp and a sole die cavity; and the intermediate cover baffle plate and the sole cover plate are provided with feeding holes. The intermediate cover baffle plate and the sole cover plate can be used by stages, so that the vamp and the sole can be separated and injected into forming, or can be connected with the vamp while injecting the sole into forming in the same die, the vamp and the sole are formed from different flexible same injection material by injection and can be completely combined; in addition, the falling and the water seepage of the vamp and the sole can be completely avoided.

Owner:陈达金

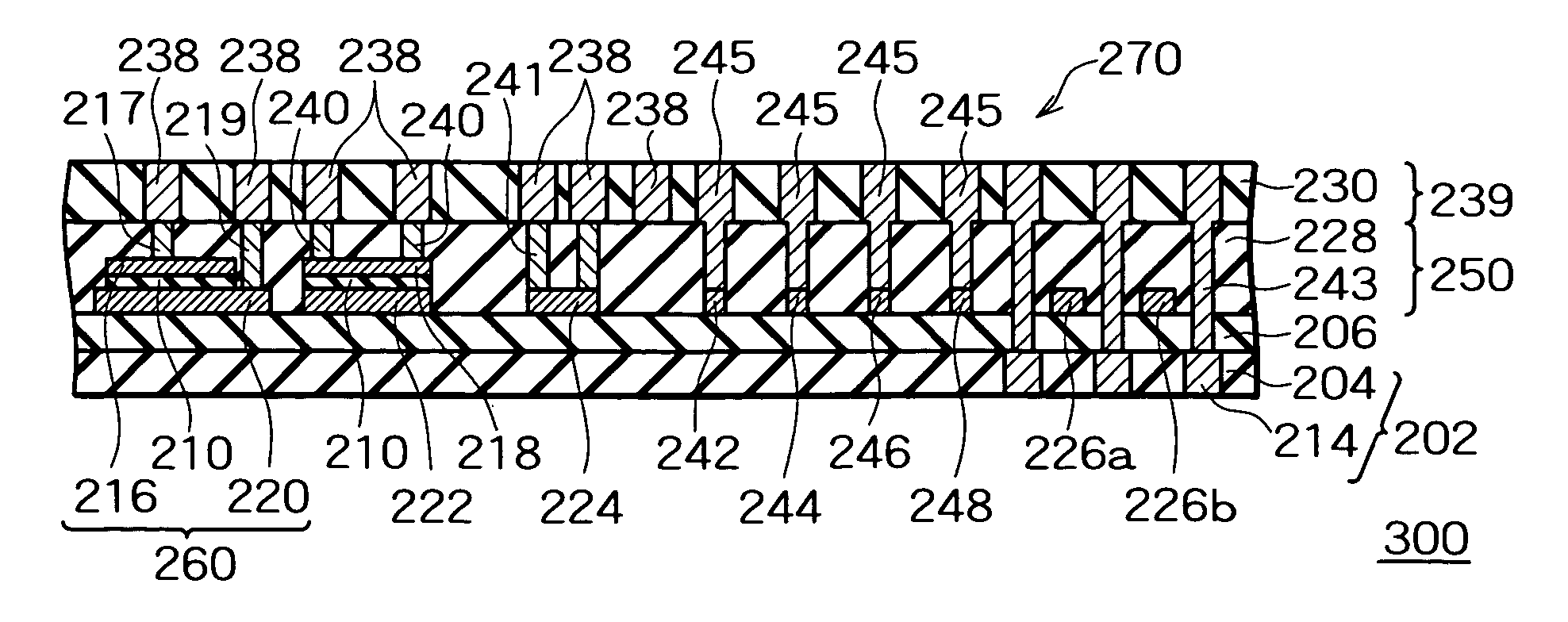

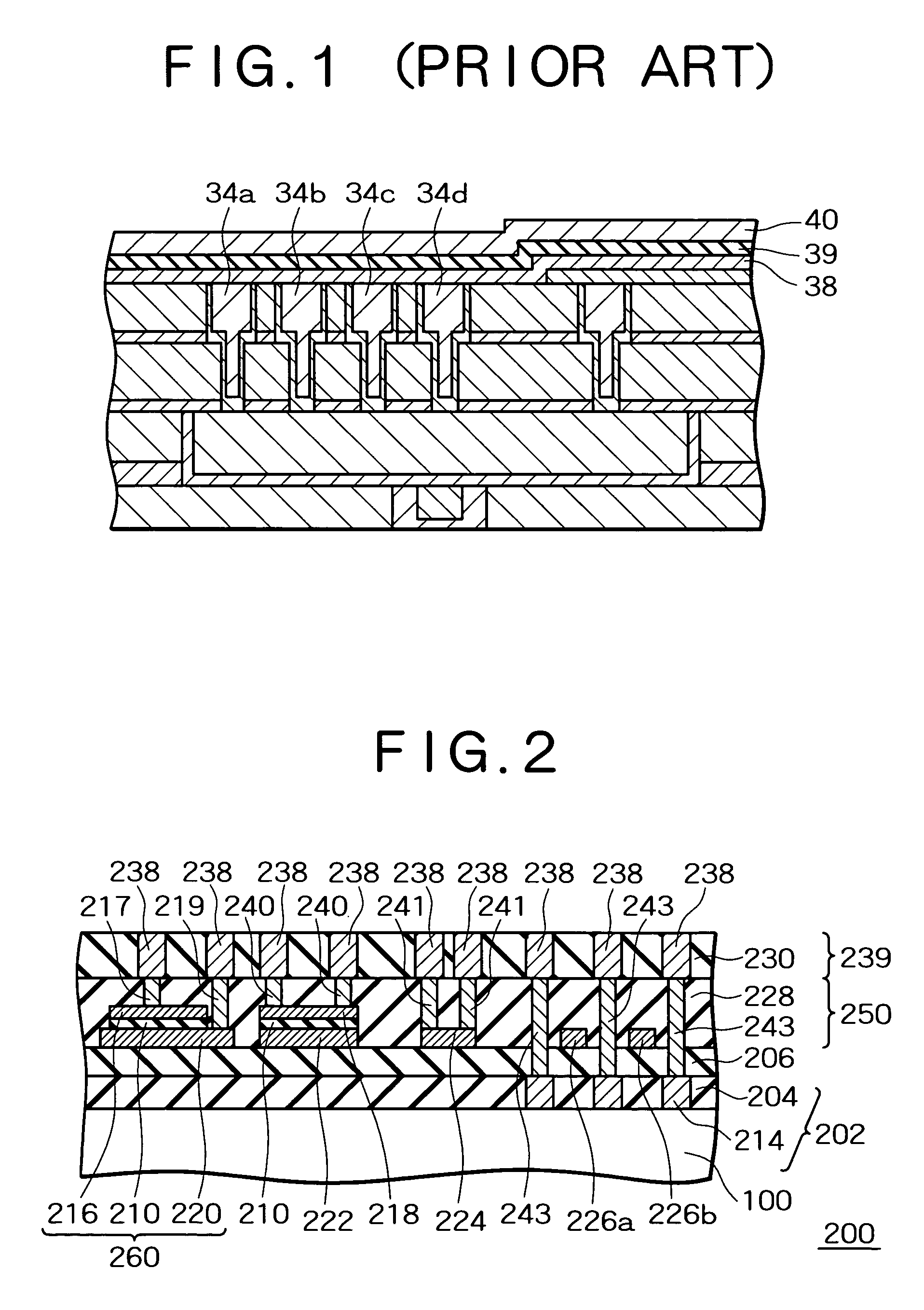

Semiconductor device and manufacturing method for the same

ActiveUS7202567B2Highly reliable MIM structureReduce resistanceTransistorSemiconductor/solid-state device detailsCapacitanceElectrical resistance and conductance

A lower interconnection is provided on a semiconductor substrate. A MIM capacitive element is provided on a first interlayer insulation film in which the lower interconnection is buried, and includes a lower electrode, an upper electrode, and a dielectric film sandwiched therebetween. An upper interconnection is provided on a second interlayer insulation film in which the MIM capacitive element is buried. A contact electrically connects the lower electrode and the upper interconnection. The lower electrode is mainly formed of Al, so that they are lower in electrical resistance than barrier metal, and also low in stress value. Therefore, it becomes possible to widen the area of the lower electrode for electrically connecting the contact while restraining their influences on charge accumulation and close contact between the lower electrode and the insulation film. In addition, since the electrical resistance is lowered, the thickness of the lower electrode can be increased. Accordingly, the MIM capacitive element with a large capacitance can be manufactured with a high yield.

Owner:RENESAS ELECTRONICS CORP

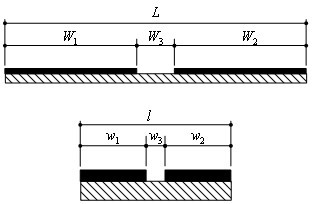

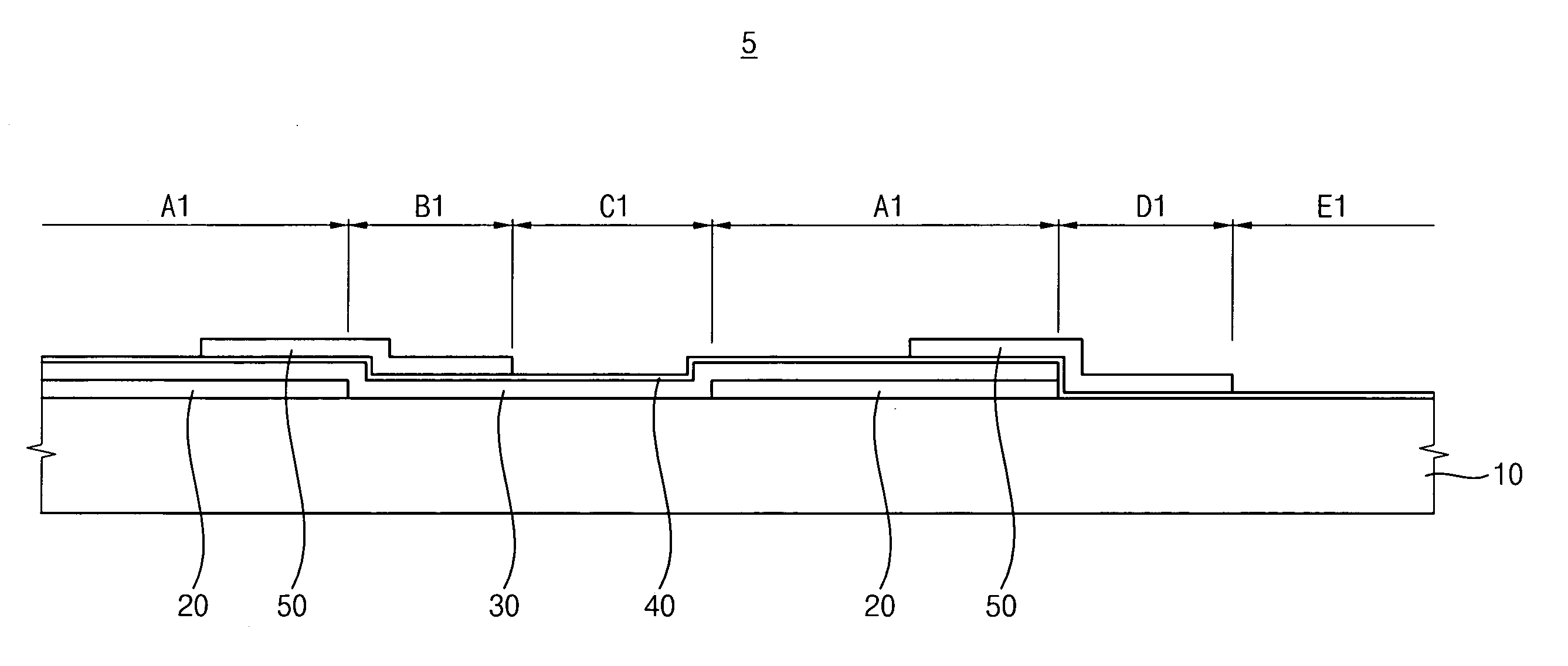

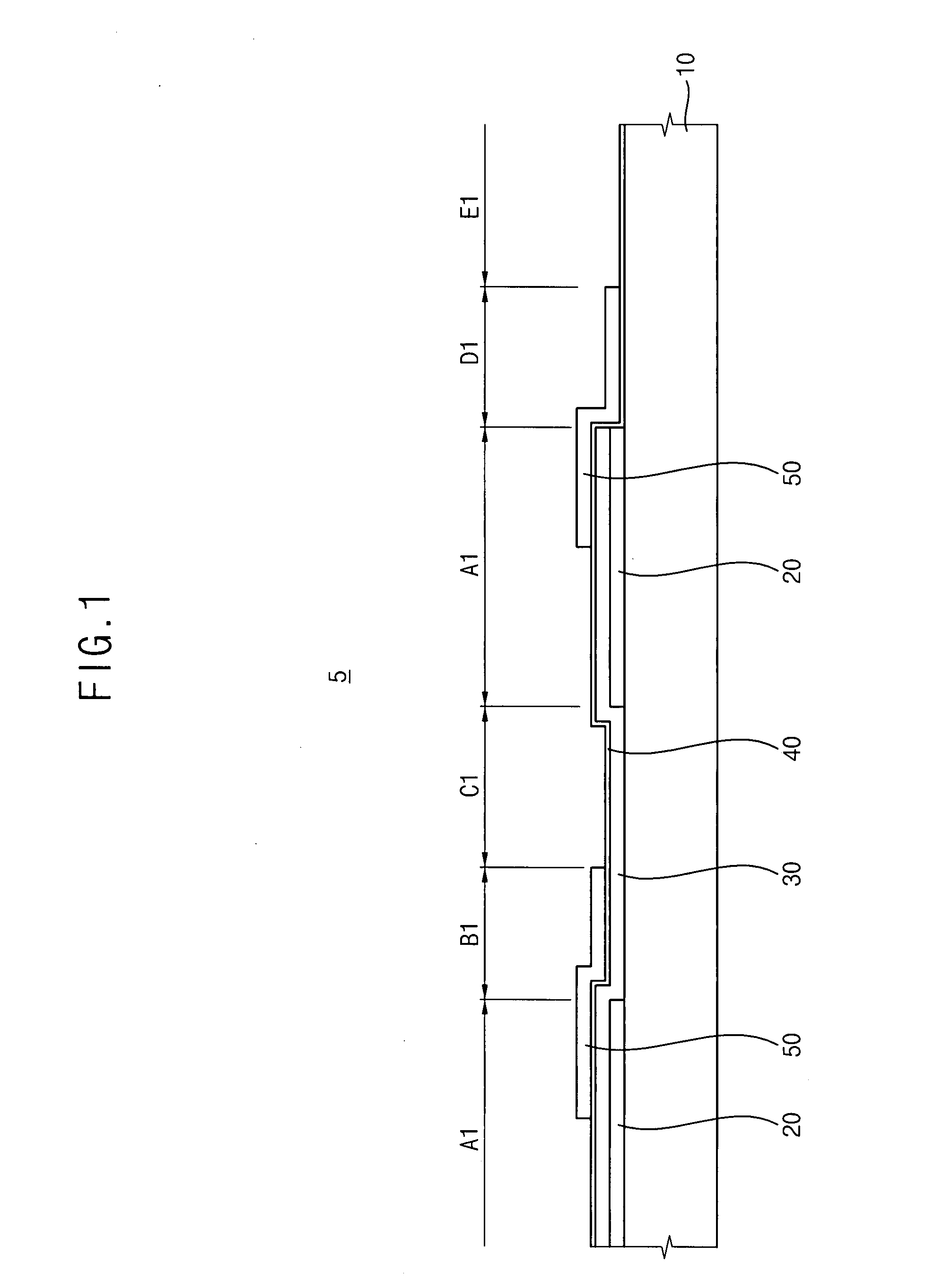

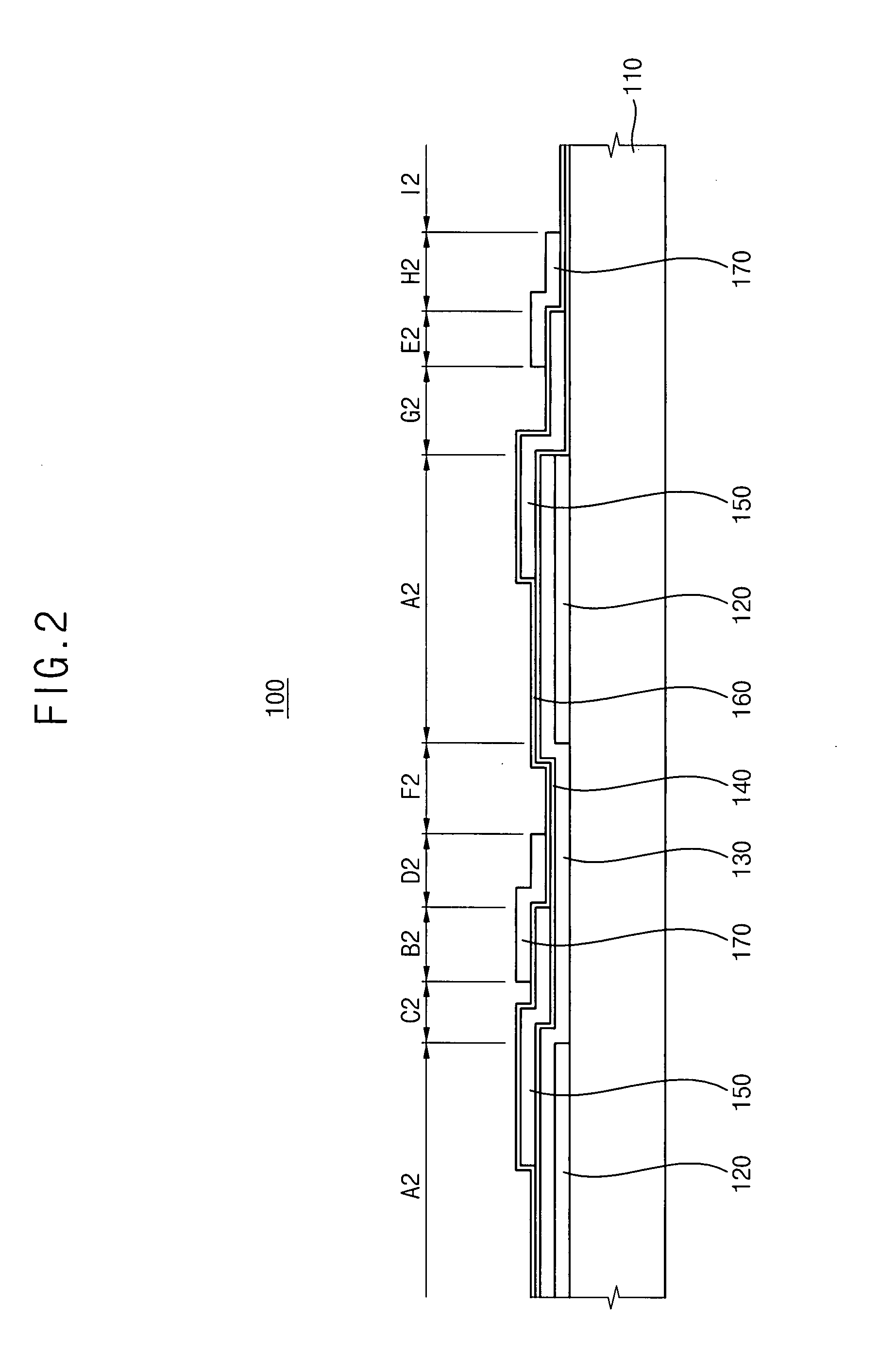

Multi-tone optical mask, method of manufacturing the same and method of manufacturing thin-film transistor substrate by using the same

ActiveUS20080026299A1Improve manufacturing efficiencyIncrease manufacturing yieldTransistorPhotomechanical apparatusTransmittanceTransistor

A multi-tone optical mask includes a substrate, a light-blocking pattern, a first semi-transmitting pattern and a second semi-transmitting pattern. The light-blocking pattern is formed on the substrate. The first semi-transmitting pattern is formed on the substrate. The second semi-transmitting pattern partially overlaps the first semi-transmitting pattern. The multi-tone optical mask has at least five different light-transmittances corresponding to a plurality of areas divided on the substrate.

Owner:SAMSUNG DISPLAY CO LTD

Method of producing honeycomb structural body

ActiveUS20150137431A1Suppress generation of localIncrease production capacityDispersed particle filtrationTransportation and packagingHoneycomb structureMetal

A method feeds raw material into a metal die and extrudes the raw material to produce a honeycomb molded body. The method fires the honeycomb molded body to make a honeycomb structural body. The metal die has a first metal die and a second metal die arranged at an upstream side of an extrusion direction of the raw material and a second metal die arranged at a downstream side of the extrusion direction of the raw material. The first metal die has a projection section and the second metal die has a penetration hole. The projection section is fitted to the penetration hole to assemble the first metal die and the second metal die. Communication holes formed in the second metal die communicate with raw material second feeding holes formed in the first metal die.

Owner:DENSO CORP

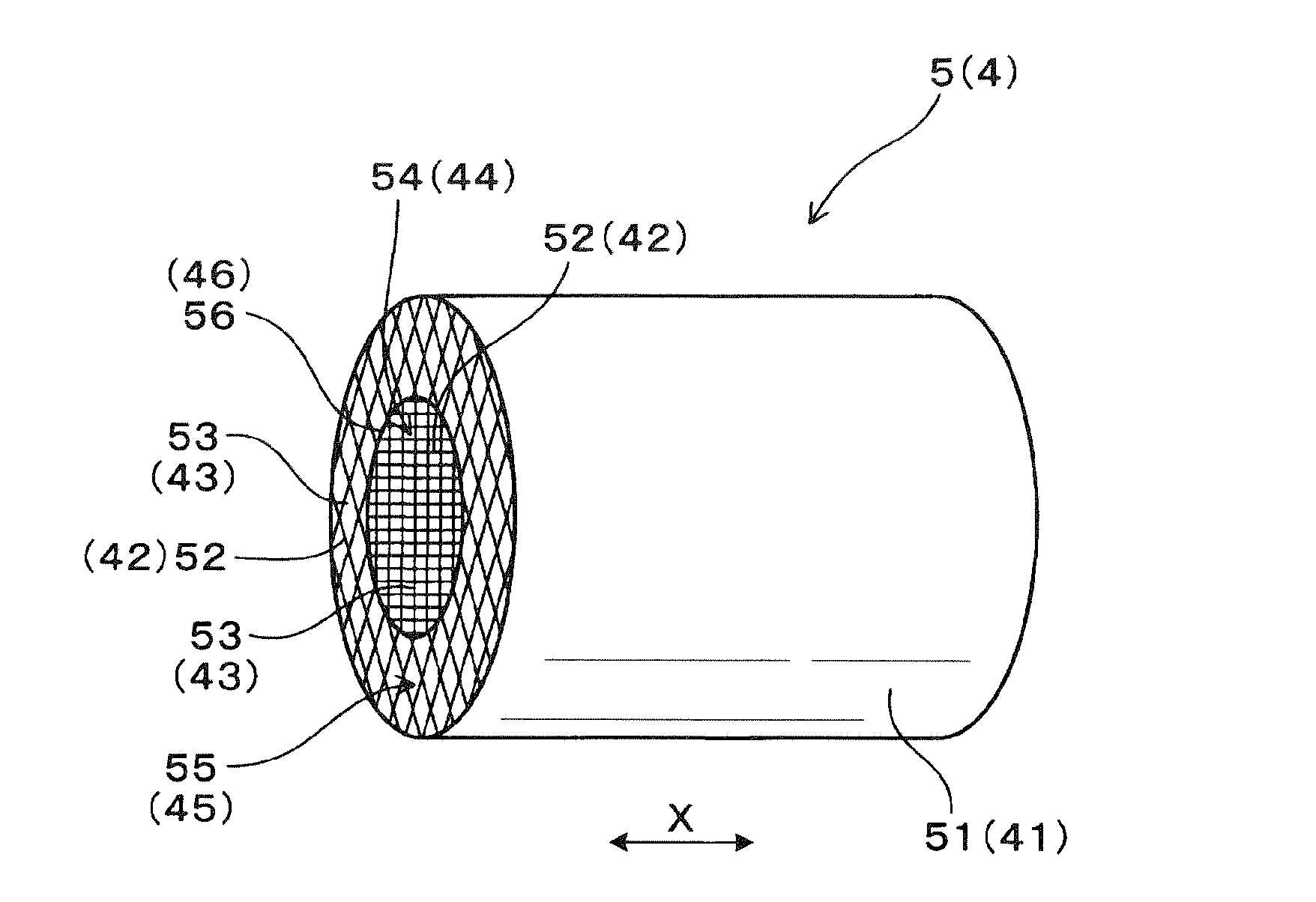

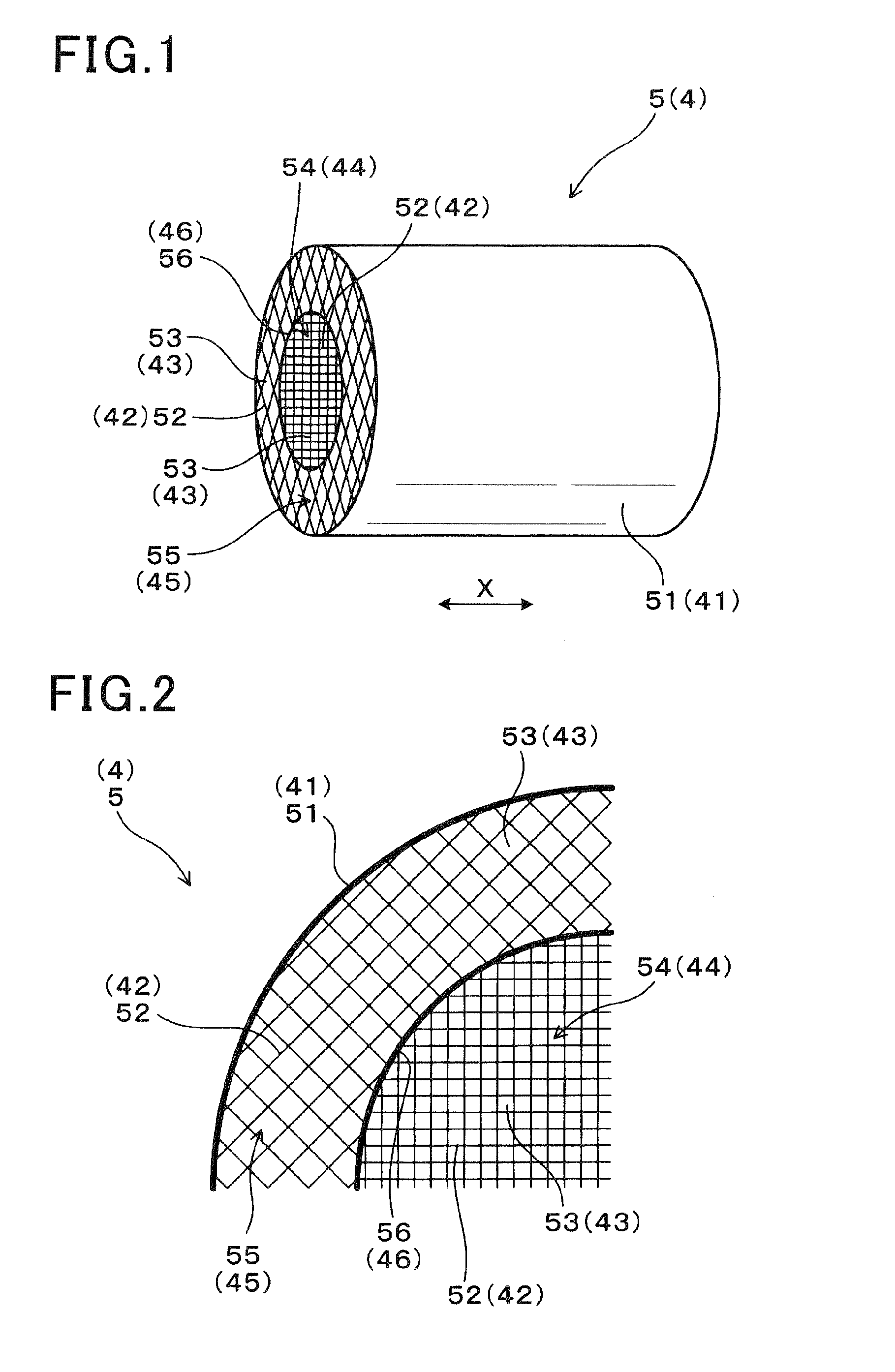

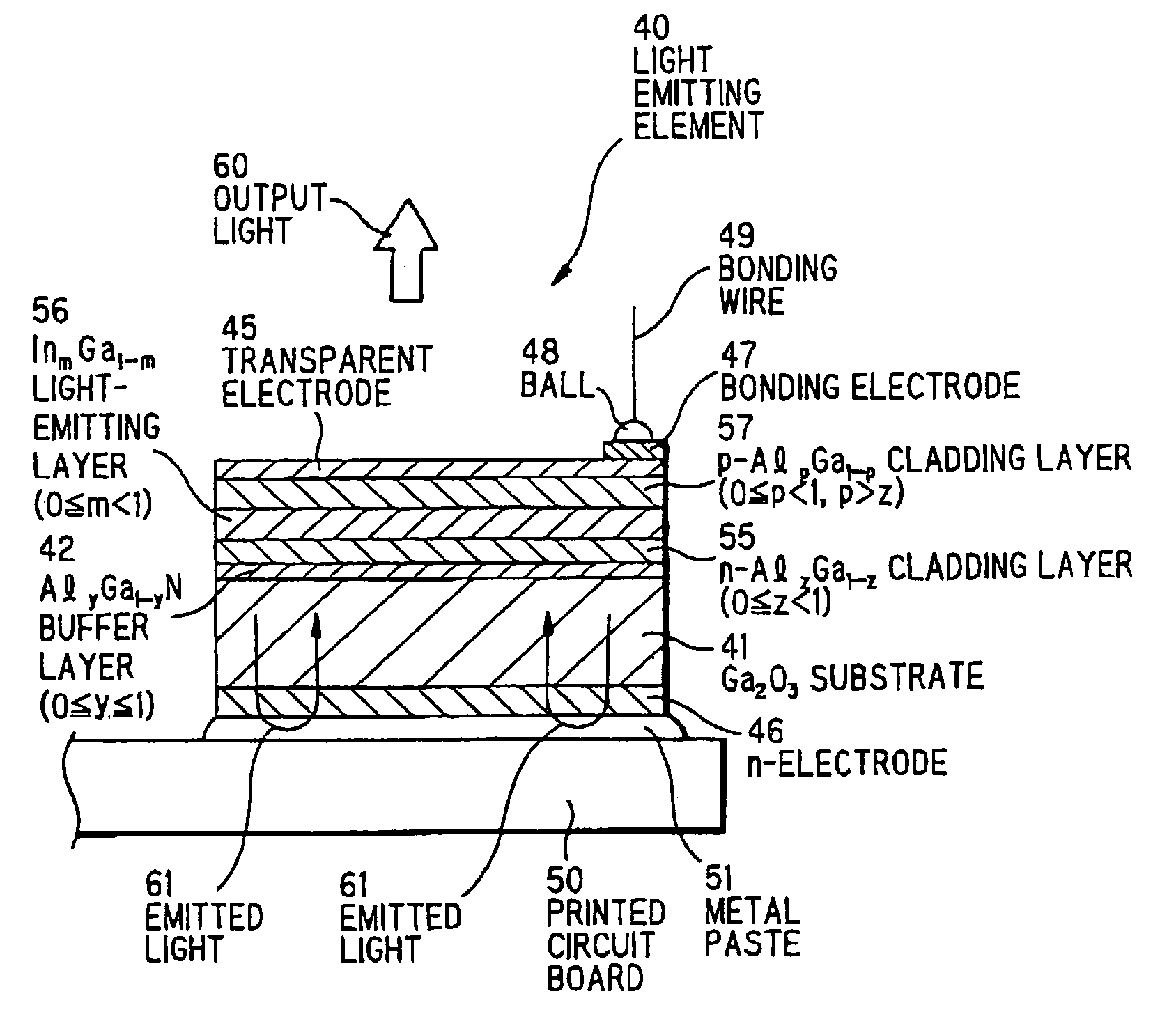

Light emitting element and method of making same

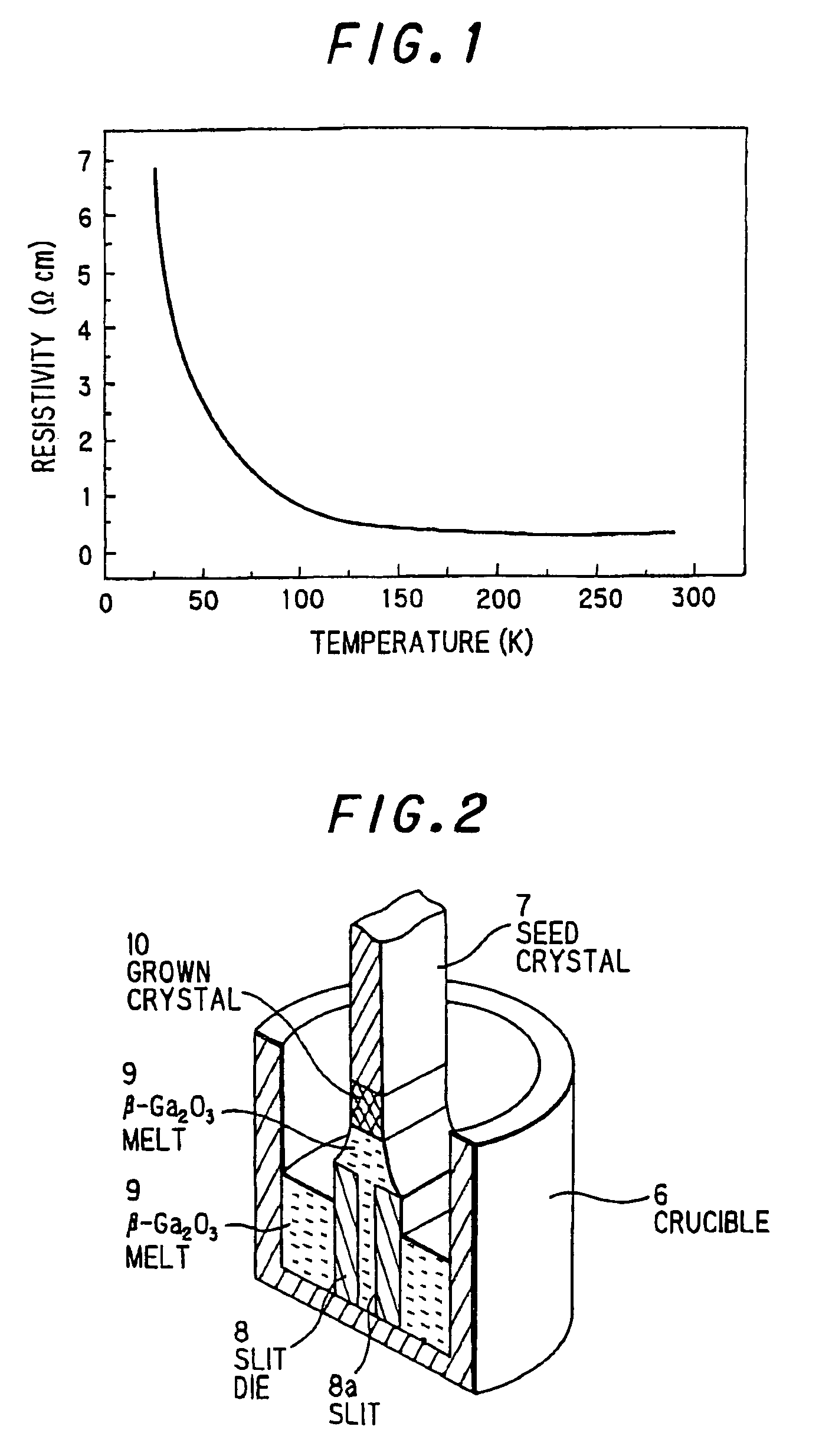

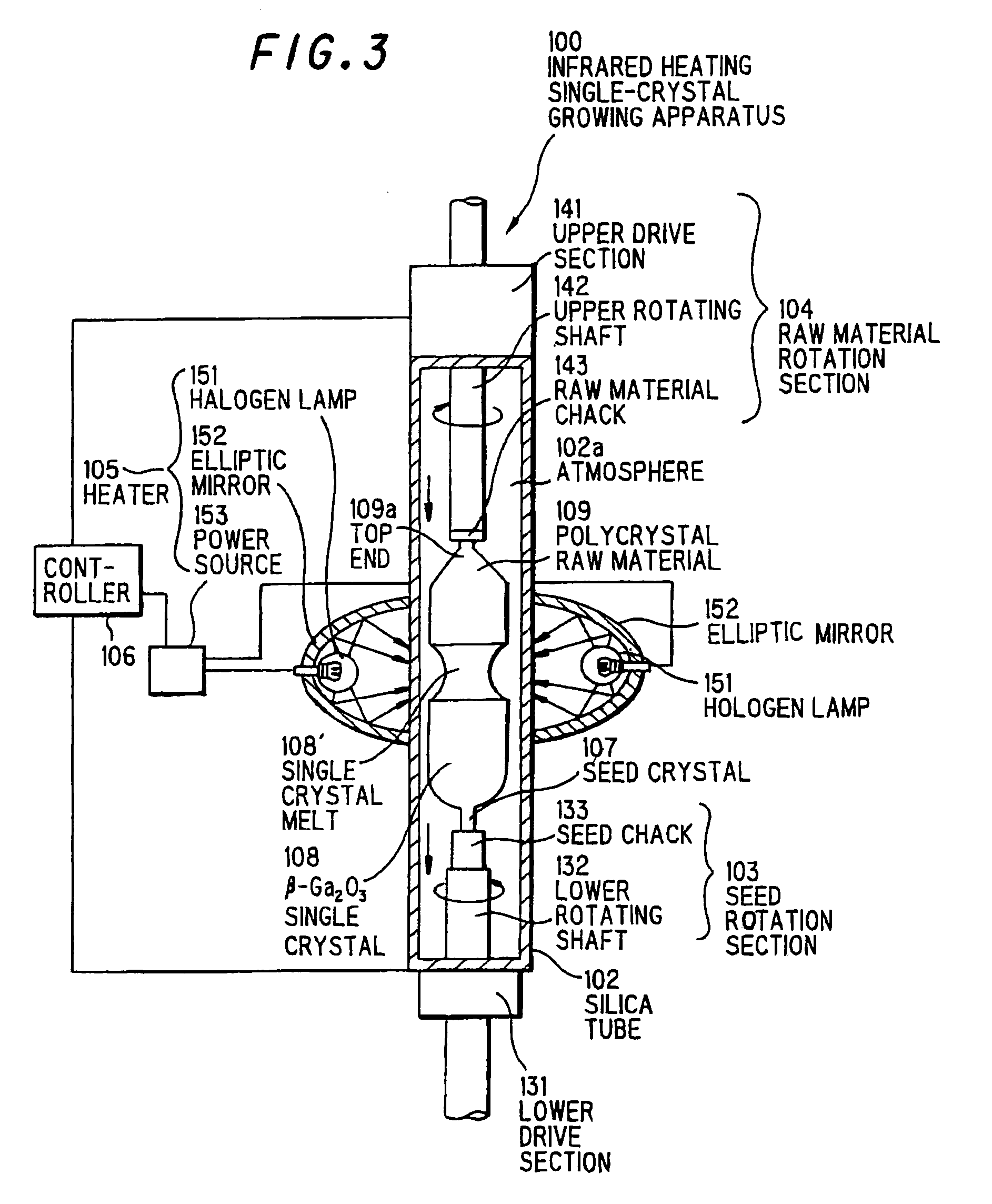

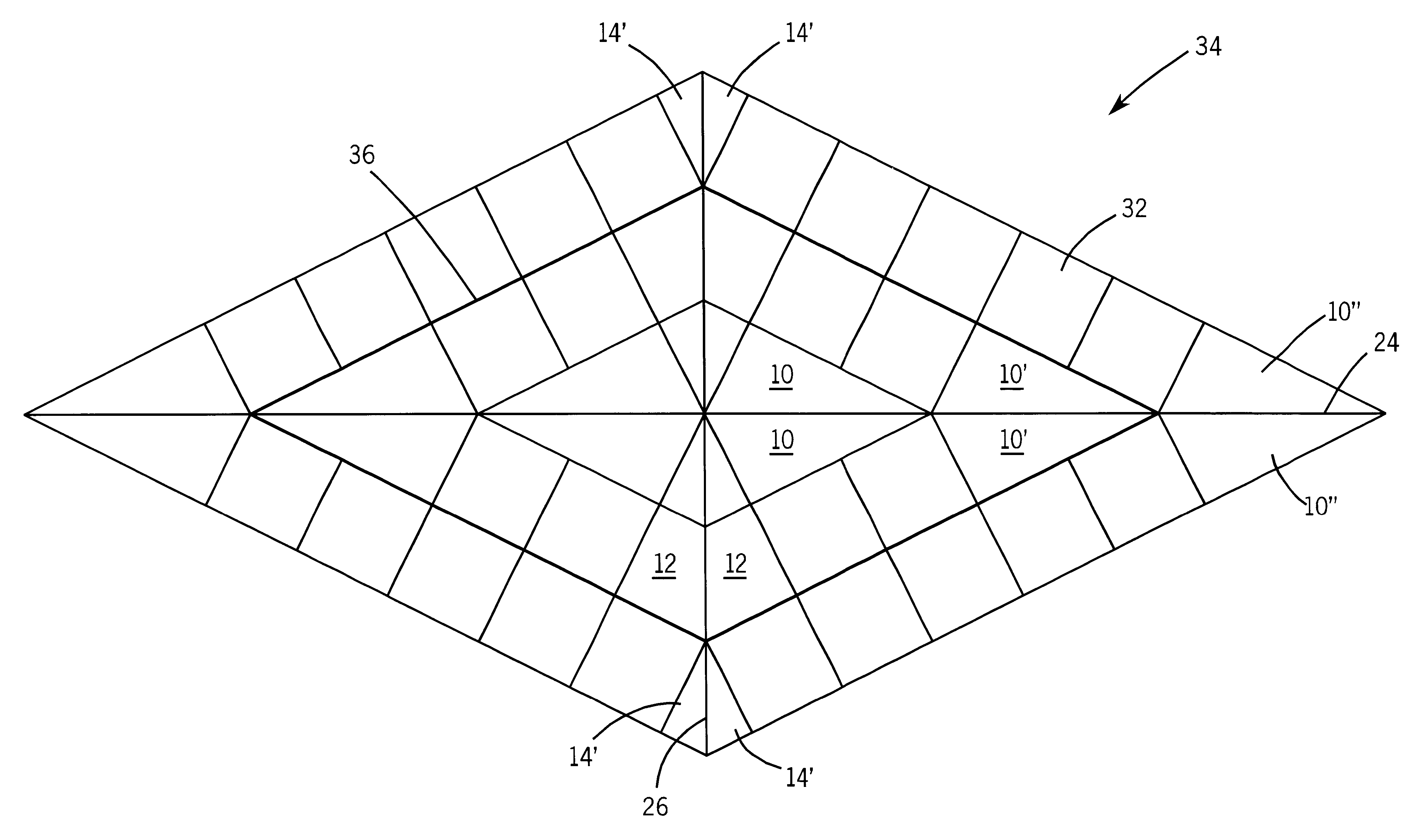

InactiveUS7319249B2Improve manufacturing efficiencyPolycrystalline material growthSolid-state devicesGallium alloyGallium oxide

A light emitting element has a substrate of gallium oxides and a pn-junction formed on the substrate. The substrate is of gallium oxides represented by: (AlXInYGa(1−X−Y))2O3 where 0≦x≦1, 0≦y≦1 and 0≦x+y≦1. The pn-junction has first conductivity type substrate, and GaN system compound semiconductor thin film of second conductivity type opposite to the first conductivity type.

Owner:KOHA CO LTD

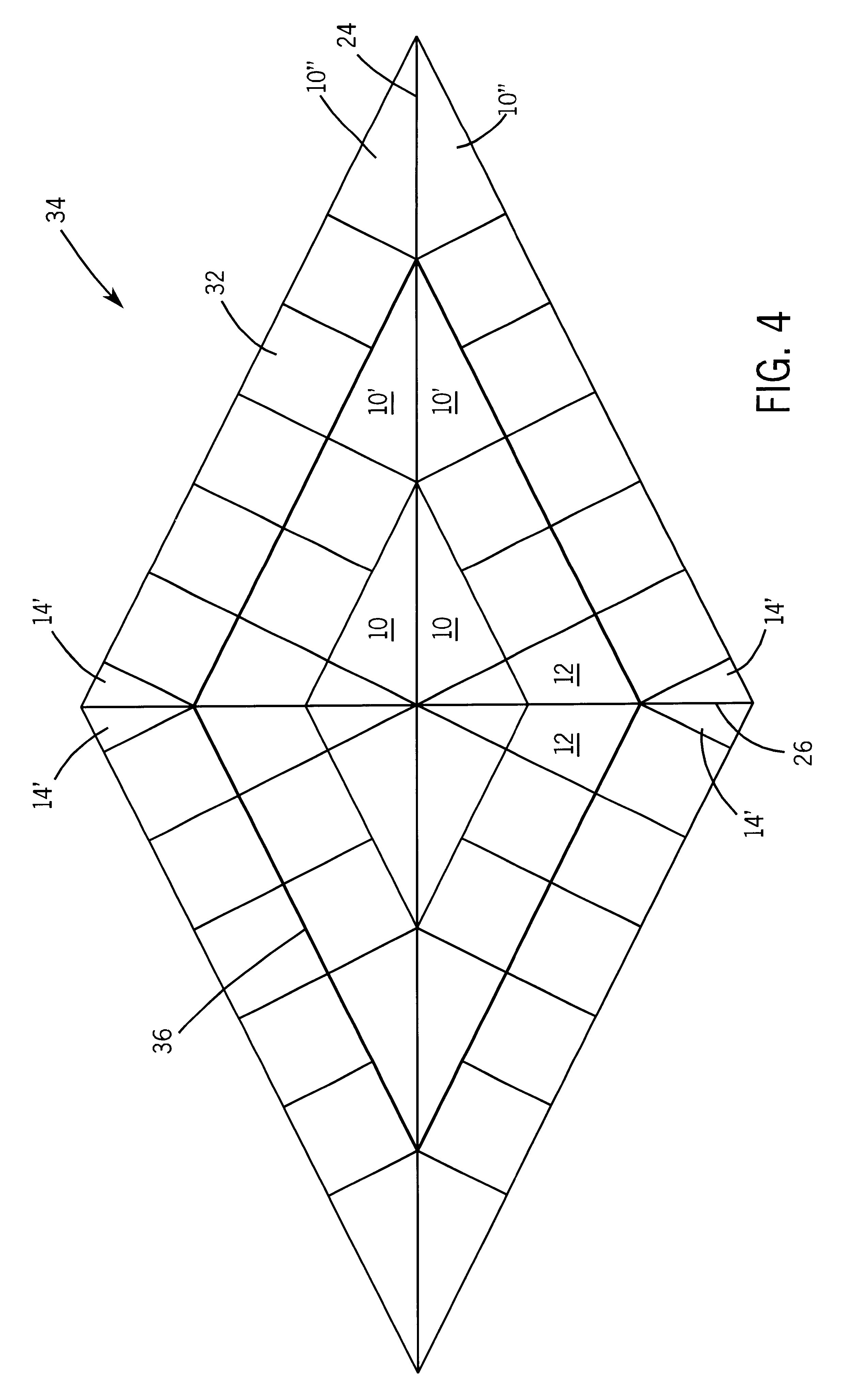

Modular roofing system and assembly

InactiveUS6415570B1Optimize manufacturing efficiencyMinimize wasteBuilding roofsRoof drainageModularityEngineering

Owner:FRANCIS STEPHEN R

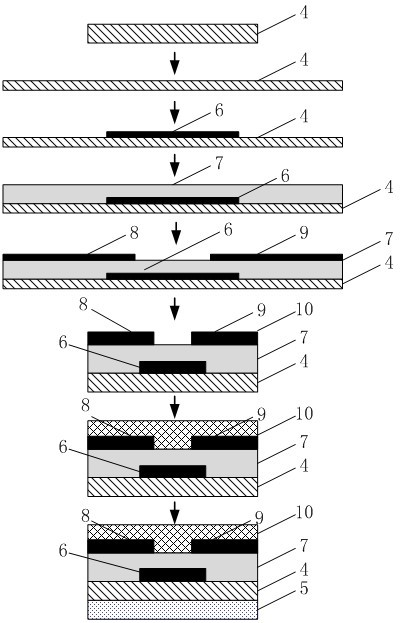

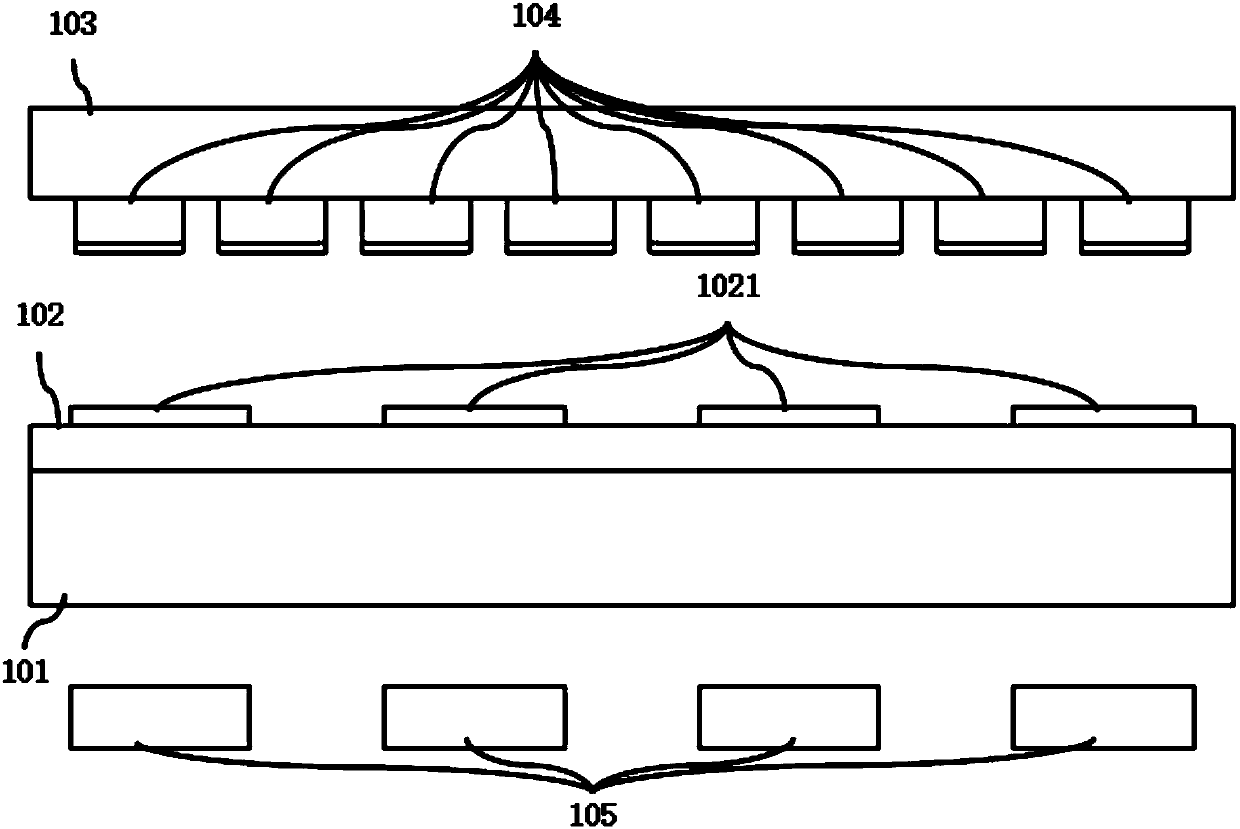

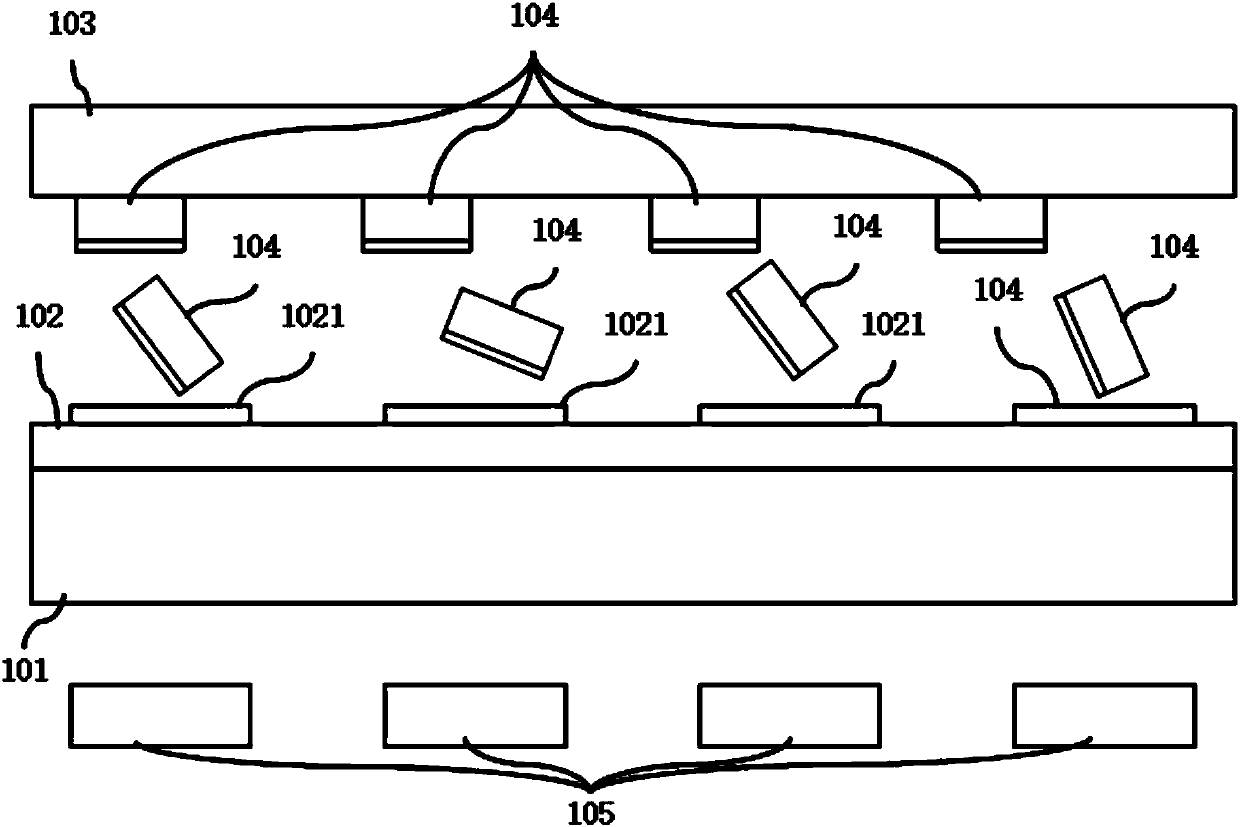

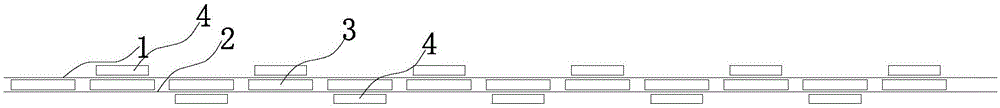

Micro device transfer equipment, method for transferring micro devices by adopting same and micro device transfer board

ActiveCN107783331AImprove manufacturing efficiencyFast transferNon-linear opticsBearing surfaceElectrical and Electronics engineering

The invention discloses micro device transfer equipment, a method for transferring micro devices by adopting the same and a micro device transfer board. The equipment comprises a bearing platform, themicro device transfer board and magnetic components, wherein the bearing platform comprises a bearing surface which is used for bearing an array substrate of to-be-received micro devices; the micro device transfer board comprises an attachment surface which is used for allowing to-be-transferred micro devices to be attached to, and the micro device transfer board is used for moving the to-be-transferred micro devices to the position above the bearing platform and enabling the to-be-transferred micro devices to face the array substrate; the magnetic components are arranged in the bearing platform or arranged on the surface, back to the bearing surface, of the bearing platform, and are used for generating magnetic fields and applying magnetic field acting force to the to-be-transferred micro devices when the to-be-transferred micro devices are located above the array substrate; the micro device transfer board is further used for releasing the micro devices when the to-be-transferred micro devices are located above the array substrate, so that the micro devices are transferred to the preset positions of the array substrate under the joint action of the gravity and the magnetic fieldacting force. A large number of micro devices can be rapidly arranged on the array substrate.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

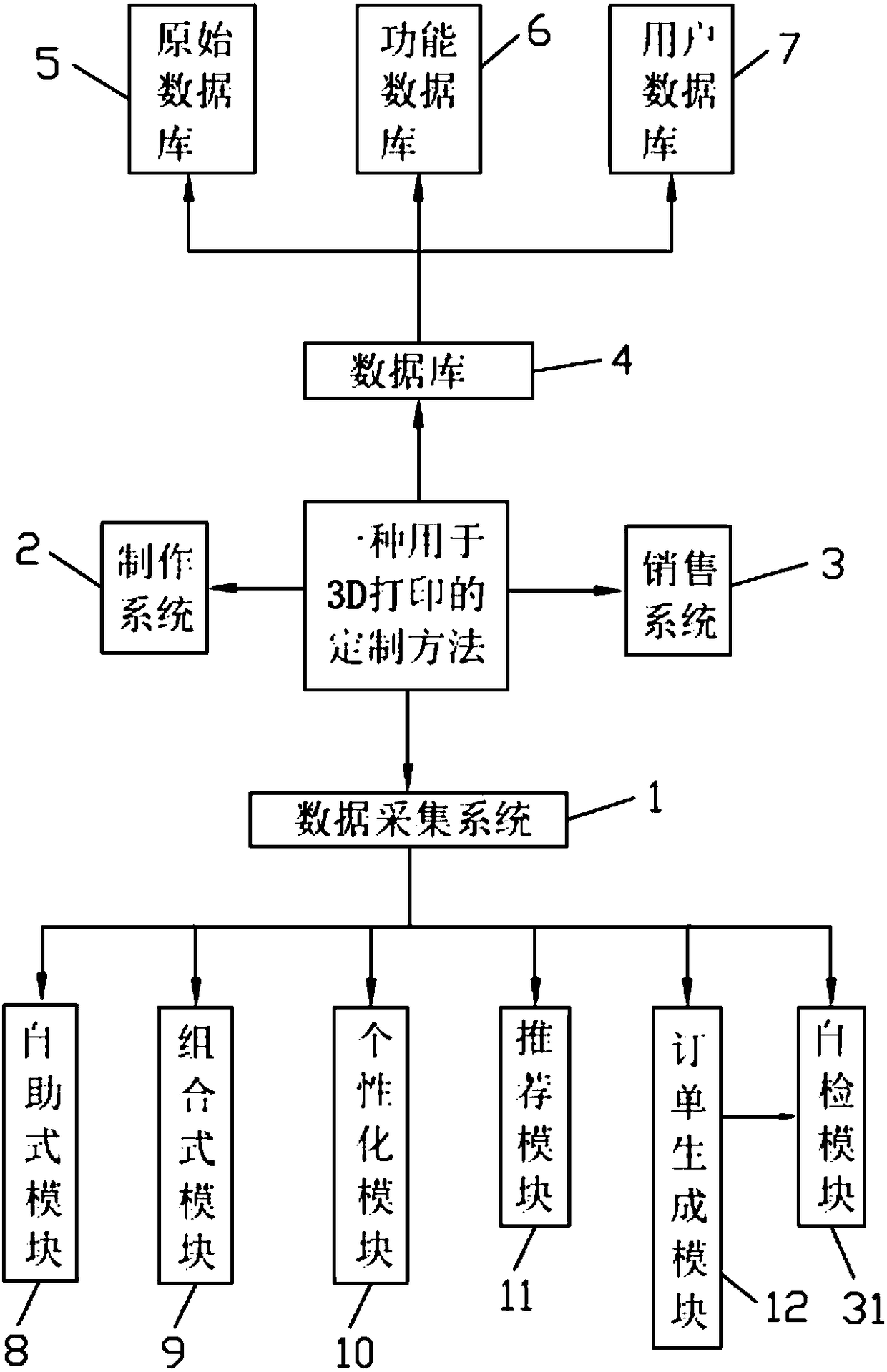

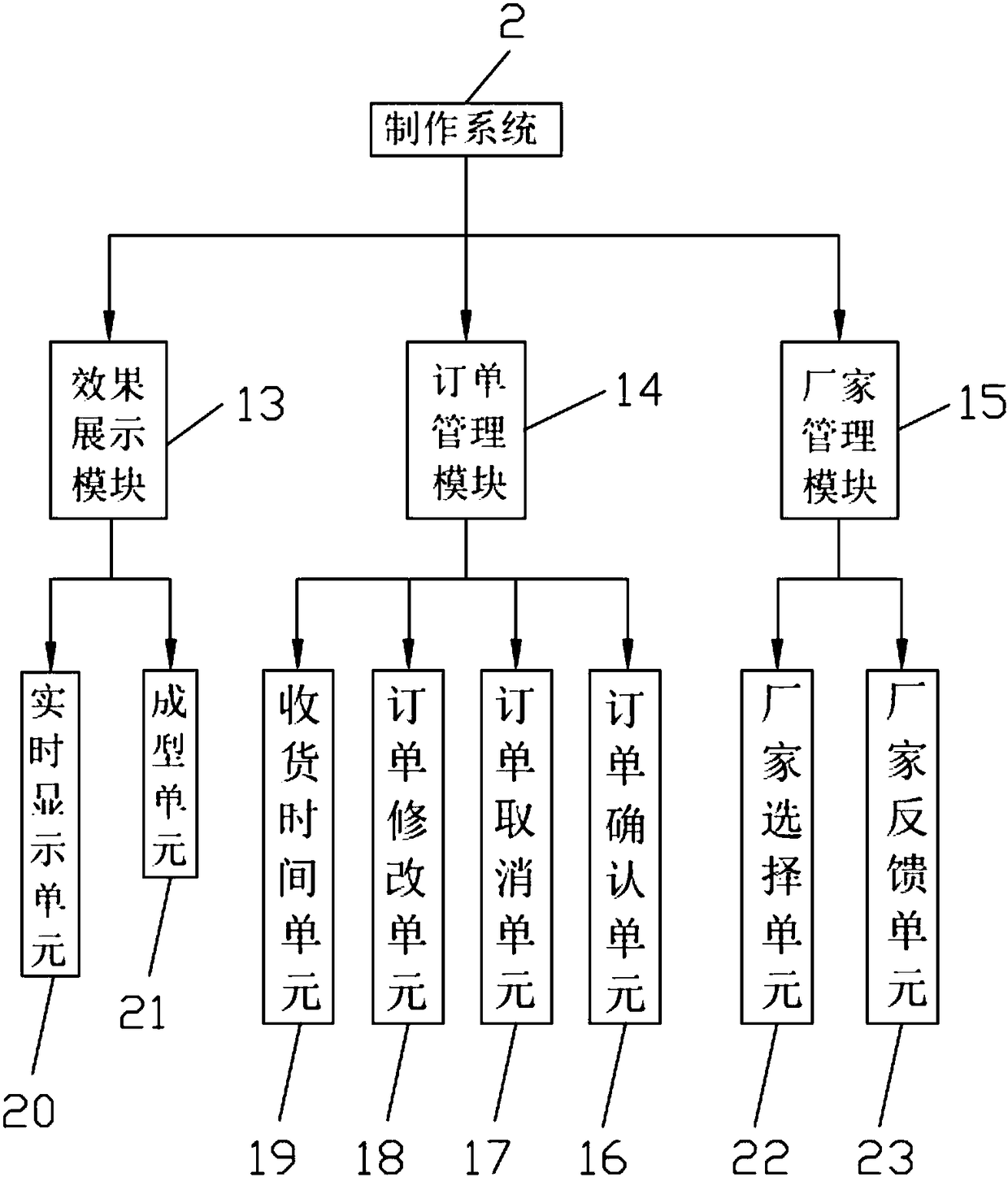

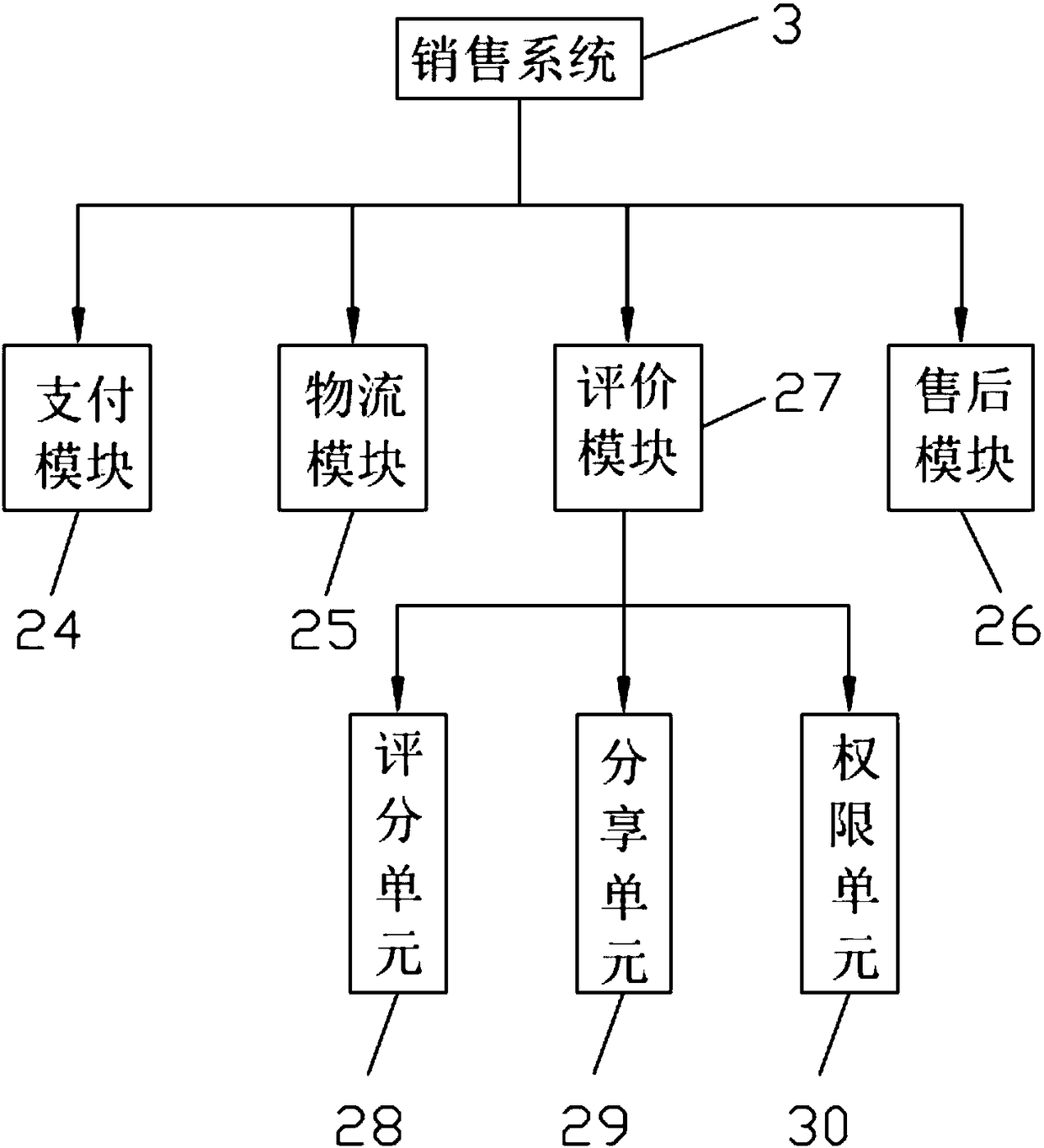

Customized platform for 3D printing, and customization method thereof

InactiveCN108454114AShorten the timeSolve technical problems that are difficult to popularizeAdditive manufacturing apparatusManufacturing data aquisition/processingPersonalizationOriginal data

The invention mainly discloses a customized platform for 3D printing, and a customization method thereof. The customized platform comprises a data collection system, a production system, a sale systemand a database, wherein the database comprises an original database, a function database and a user database, and the data collection system comprises a self-help module, a combined module, a personalization module, a recommendation module and an order generation module. The customization method comprises: collecting 3D printing data, generating an order, confirming the order, producing products,trading the products, and evaluating the products. According to the present invention, with the customized platform and the customization method, the personalized design is achieved, the customized service is improved, the customized platform and the customization method are suitable for various people, the requirements of customers can be achieved to the greatest extent, the user experience is good, the social resource utilization rate is improved, the production cycle is shortened, the operation is convenient, the professional-grade quality 3D product can be printed by the common user, the3D printing data file can be effectively protected, and the information security of the 3D printing platform can be improved.

Owner:ZHEJIANG SCI-TECH UNIV

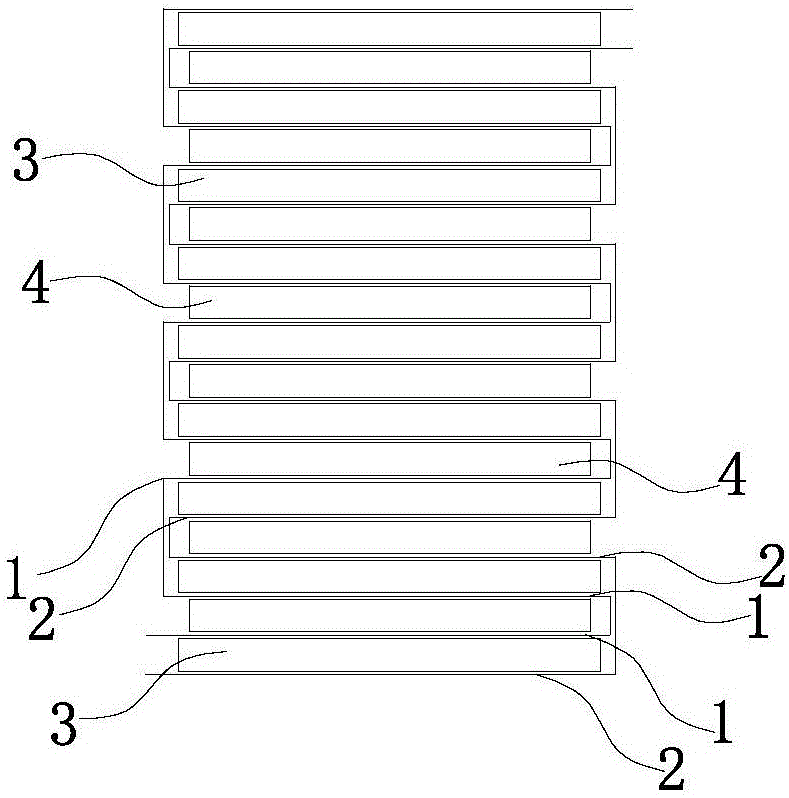

Laminated battery structure, secondary battery pack comprising same and battery pack module

InactiveCN106129478AImprove cycle performanceImprove manufacturing efficiencyFinal product manufactureSecondary cellsElectrical batteryPole piece

The invention discloses a laminated battery structure, a secondary battery pack comprising the same and a battery pack module. The laminated battery structure comprises a battery cell, wherein the battery cell comprises two layers of continuous diaphragms which are oppositely arranged; a plurality of first battery units arranged at intervals are clamped between the two layers of continuous diaphragms; the two layers of continuous diaphragms and the first battery units clamped between the continuous diaphragms are folded in a zigzag form to form the laminated battery cell; second battery units are clamped between the outer sides of the continuous diaphragms; and two pole pieces, which are close to each other, of each second battery unit and the corresponding first battery unit form one electrode pair. By the structure with the two layers of continuous diaphragms, on one hand, the stability of the battery structure is higher and the cycle performance of batteries is improved; and on the other hand, the production and preparation efficiency of the batteries can be improved.

Owner:HIGHPOWER TECH HUIZHOU

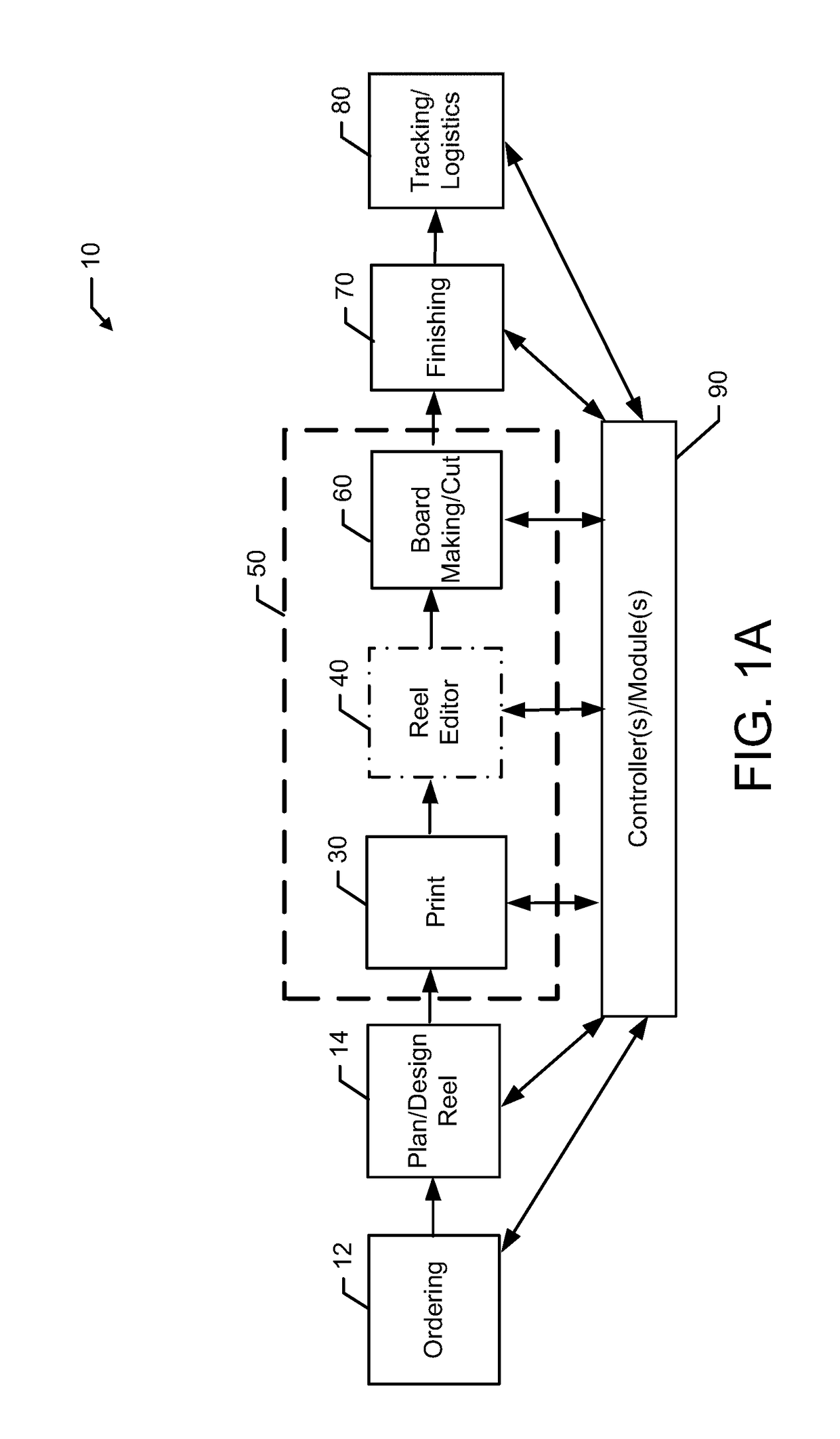

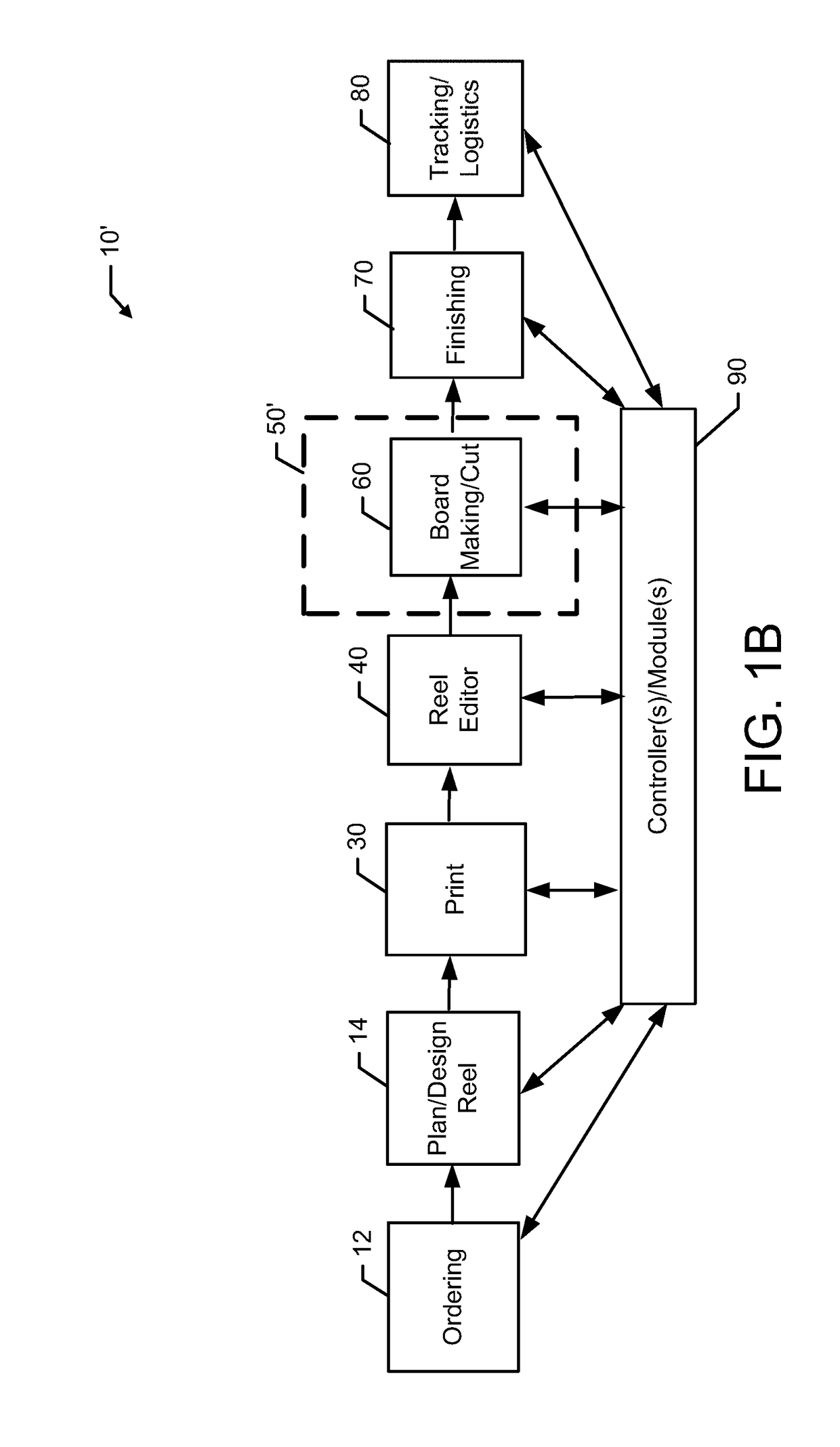

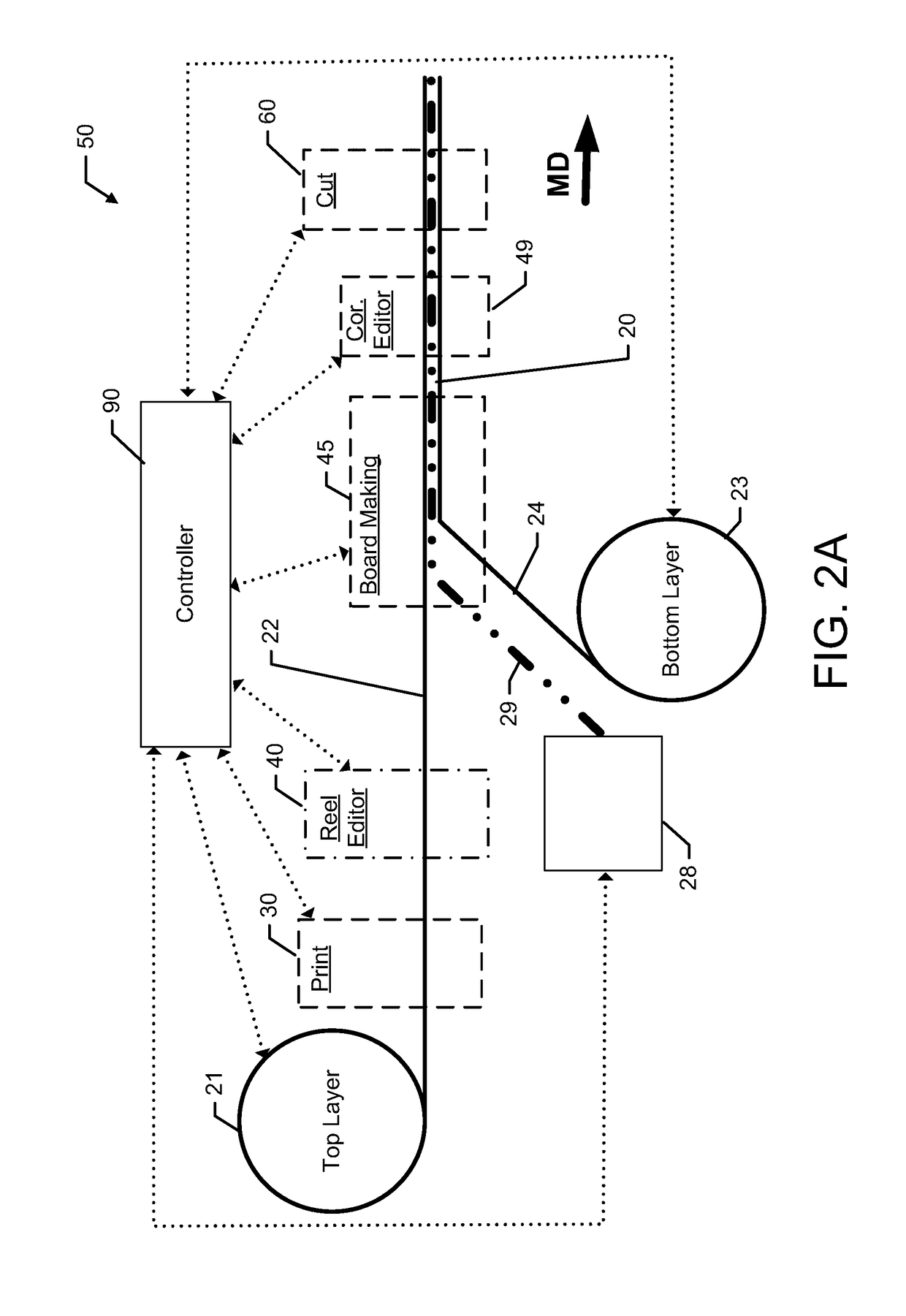

Controls for paper, sheet, and box manufacturing systems

ActiveUS20190016081A1Efficient preparationImprove image qualityMechanical working/deformationBox making operationsAutomatic controlComputer module

Systems for providing efficient manufacturing of sheet or box structures, corrugate sheets, or other products of varying size and structure often with pre-applied print (“pre-print”) are provided herein. The systems include various features and modules that enable automated control of the corrugator, including the knives, slitters, scorers and cut-to-mark detection system(s), are contemplated. Colored markings may be used to indicate an order change section between two order sections of a roll plan for the manufacturing process. The colored markings are detected as the corrugator runs and, once detected, a controller determines a next set of order instructions—e.g., to match the upcoming order. Thus, an order change may occur, thereby enabling automated control of the corrugator based on the new order instructions. Computer readable markings may enable checking of the actual position in the roll plan to an intended position, enabling stopping or changing of the corrugator operation if needed.

Owner:GEORGIA PACIFIC CORRUGATED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com