Epoxy resin composition and composite material for wind power generator blade

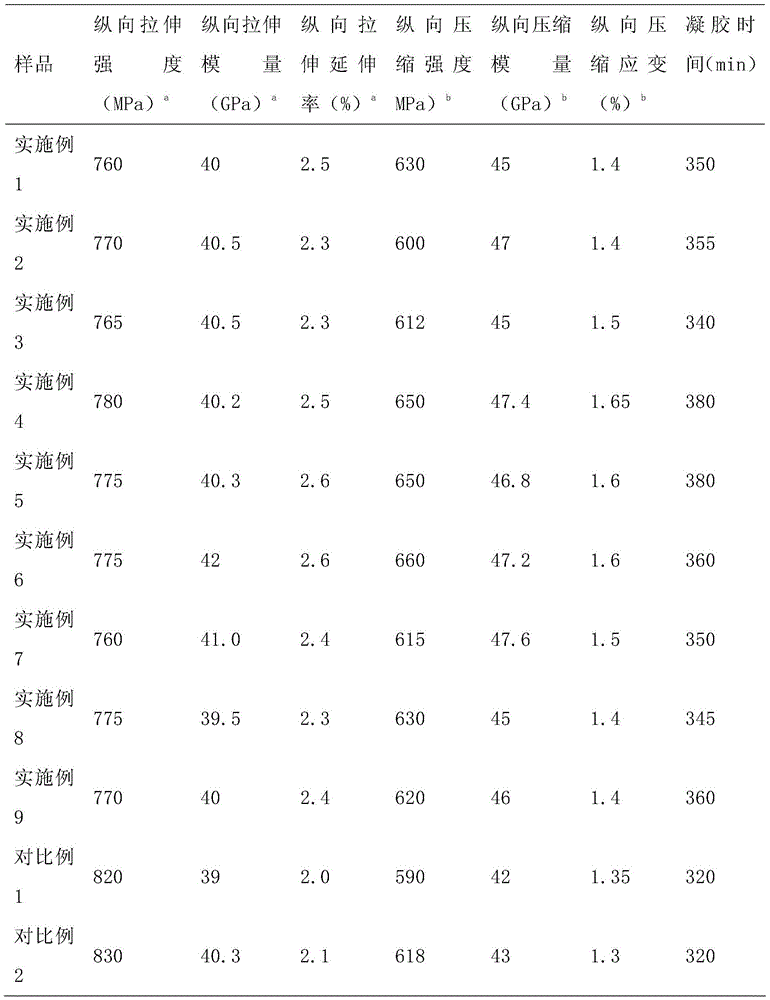

A technology of wind power generation blades and epoxy resin, which is applied in the field of resin-based composite materials, can solve the problems of gelling time, post-curing speed, and elongation at break that are not in an ideal state, achieve less volatiles, improve manufacturing efficiency, The effect of short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

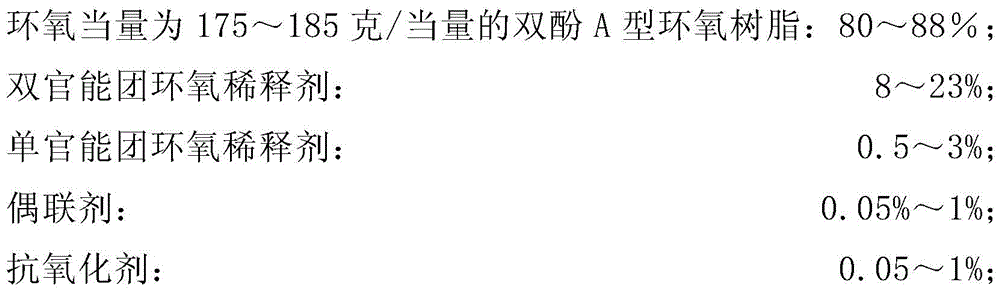

[0035] In terms of percentage by weight, the raw materials of component A of the epoxy resin composition: 80% of bisphenol A epoxy resin (brand: E54) with an epoxy equivalent of 175-190 grams / equivalent, 1,4-butanediol dishrunk Glyceryl ether 19%, C 8 -C 10 Fatty alcohol glycidyl ether 0.8%, propyltrimethoxysilane 0.05% and antioxidant 10100.15%.

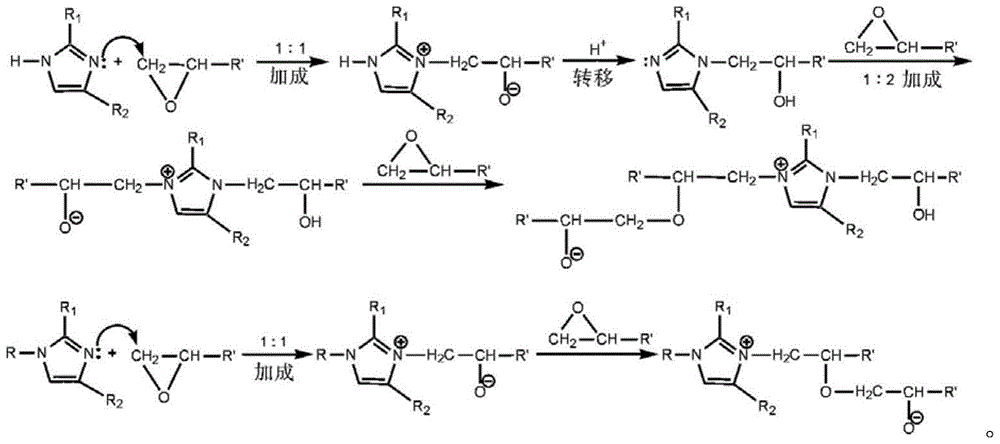

[0036] In terms of weight percentage, the raw materials of component B of the epoxy resin composition: 67% of polyetheramine (D230), 28% of N-aminoethylpiperazine and 5% of 2-phenylimidazole.

[0037] The weight ratio of component A to component B is 100:27.

[0038] The fiber reinforced fabric has a modulus of 100000N / mm 2 glass fiber, accounting for 68% by weight of the epoxy resin composition.

[0039] The viscosity of the epoxy resin composition measured by the DIN53015 method is 208mps.

Embodiment 2

[0041] In terms of percentage by weight, the raw materials of component A of the epoxy resin composition: 85% of bisphenol A epoxy resin (brand E54) with an epoxy equivalent of 175-190 grams / equivalent, 1,4-butanediol diglycidyl Ether 14%, C 12 -C 14 Alcohol glycidyl ether 0.8%, propyltrimethoxysilane 0.1% and antioxidant 10100.1%.

[0042] In terms of weight percentage, the raw materials of component B of the epoxy resin mixture: 69% of polyetheramine (D230), 28% of N-aminoethylpiperazine and 3% of 2-phenylimidazole.

[0043] The weight ratio of component A to component B is 100:29.

[0044] The fiber reinforced fabric has a modulus of 120000N / mm 2 glass fiber, accounting for 70% by weight of the epoxy resin composition.

[0045] The viscosity of the epoxy resin mixture measured by the DIN53015 method is 242mps.

Embodiment 3

[0047] In terms of percentage by weight, the raw materials of component A of the epoxy resin composition: 88% of bisphenol A epoxy resin (brand E54) with an epoxy equivalent of 175-190 grams / equivalent, 1,4-butanediol diglycidyl Ether 11%, C 12 -C 14 Alcohol glycidyl ether 0.8%, propyltrimethoxysilane 0.15% and antioxidant 10100.05%.

[0048] In terms of weight percentage, the raw materials of component B of the epoxy resin mixture: 67% of polyetheramine (D230), 30% of N-aminoethylpiperazine and 3% of 2-phenylimidazole.

[0049] The weight ratio of component A to component B is 100:30.

[0050] The fiber reinforced fabric has a modulus of 120000N / mm 2 glass fiber, accounting for 71% by weight of the epoxy resin composition.

[0051] Adopt DIN53015 method to measure the viscosity of epoxy resin mixture to be 212mps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com