Patents

Literature

275results about How to "Low softening temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

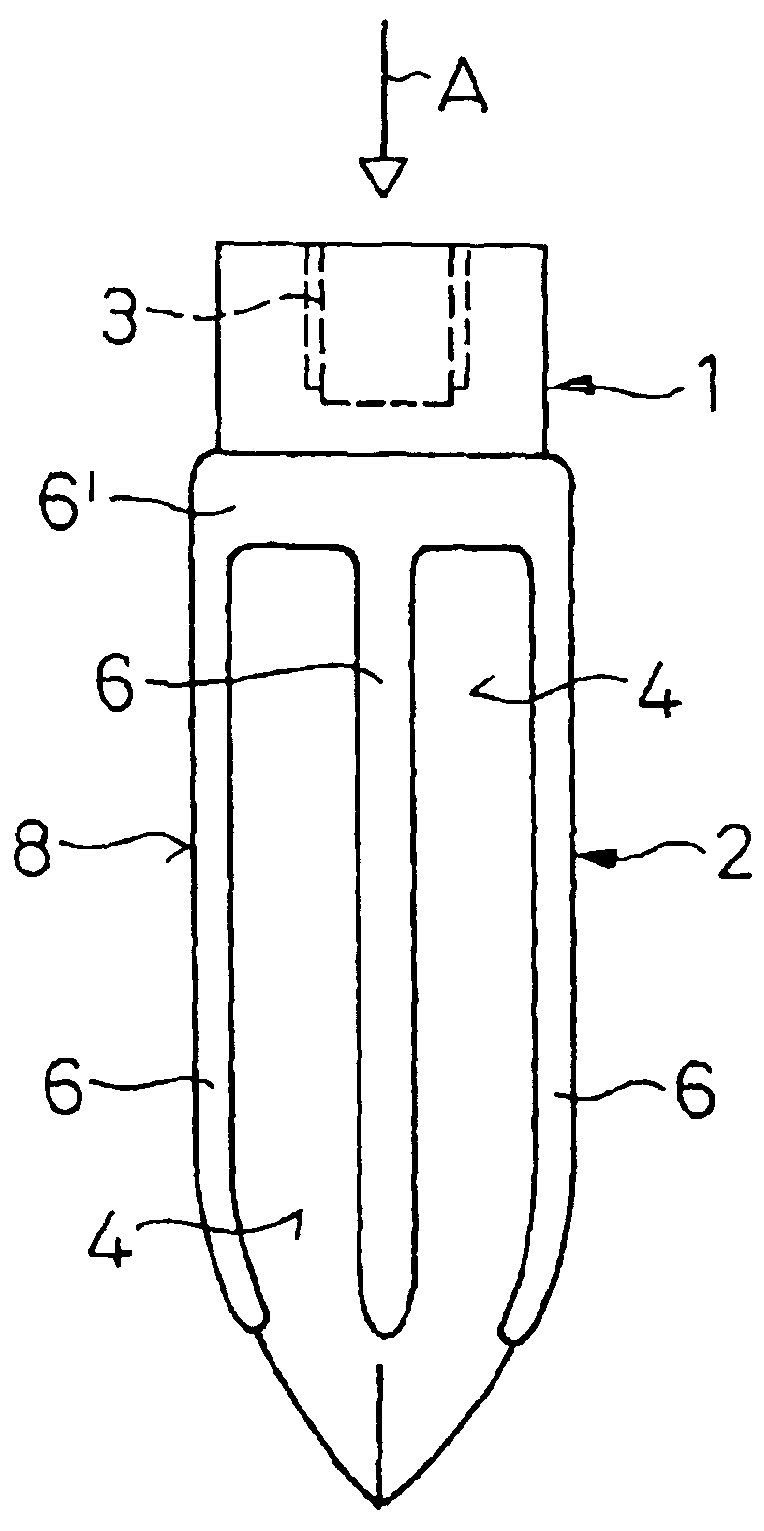

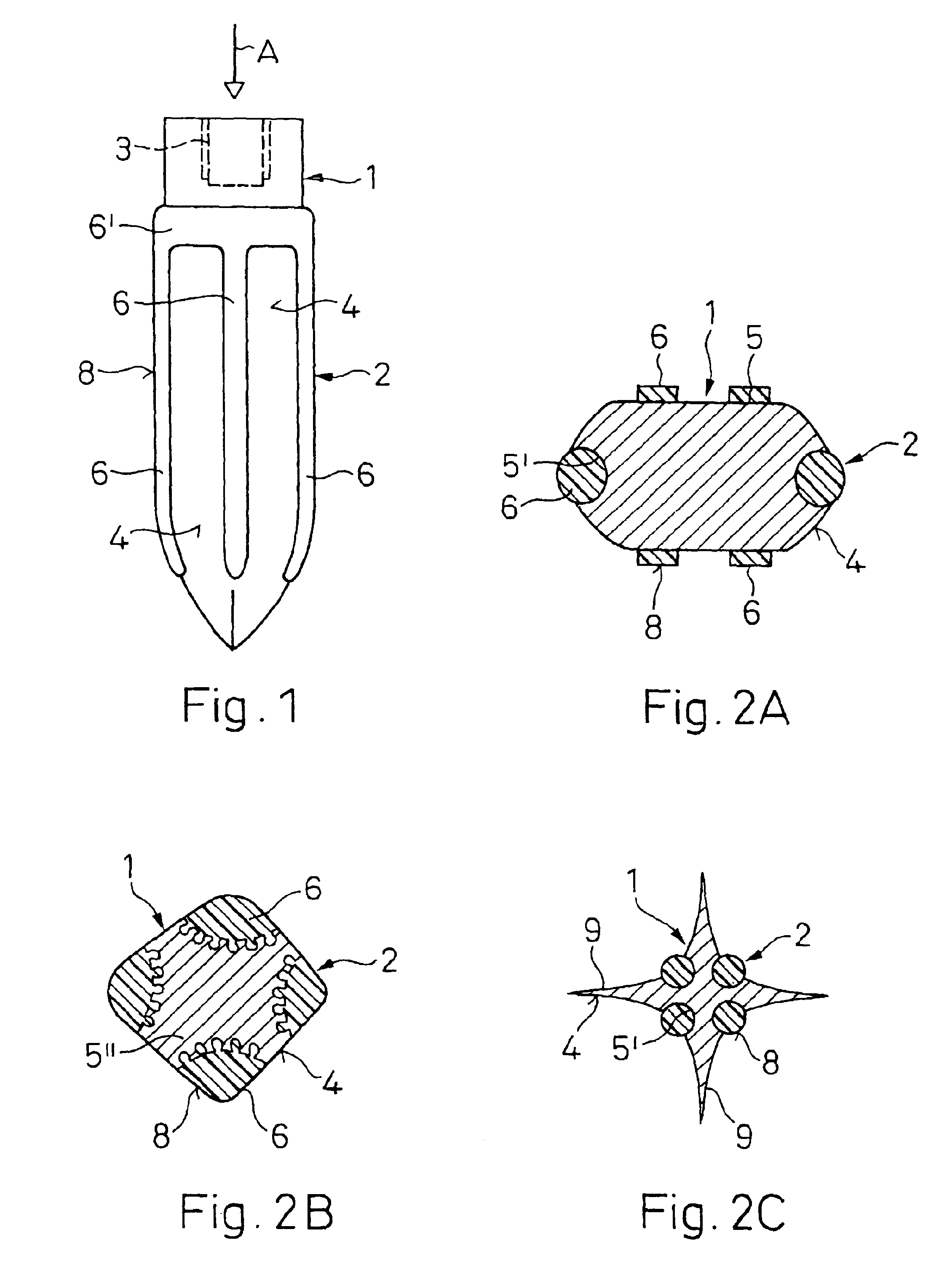

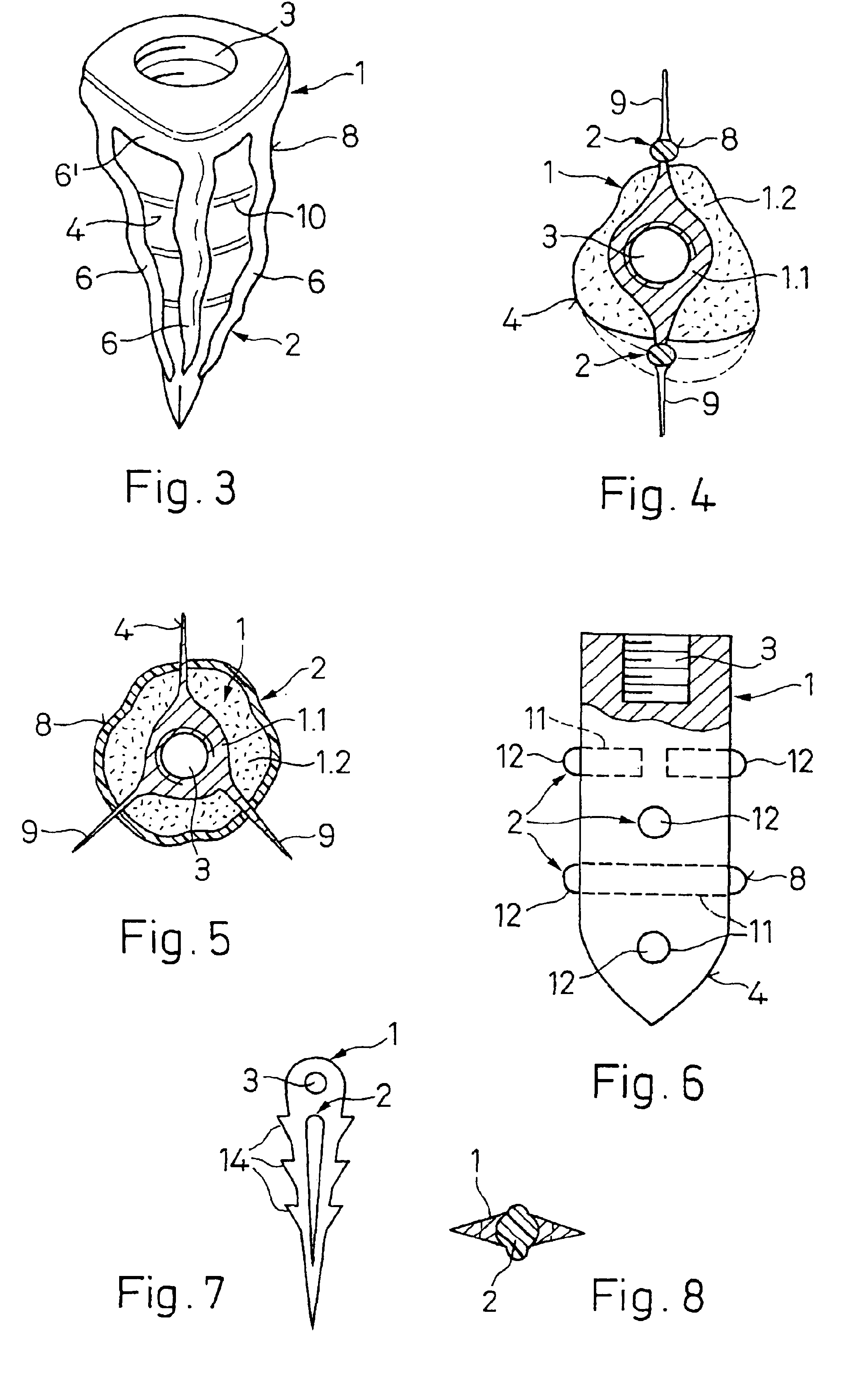

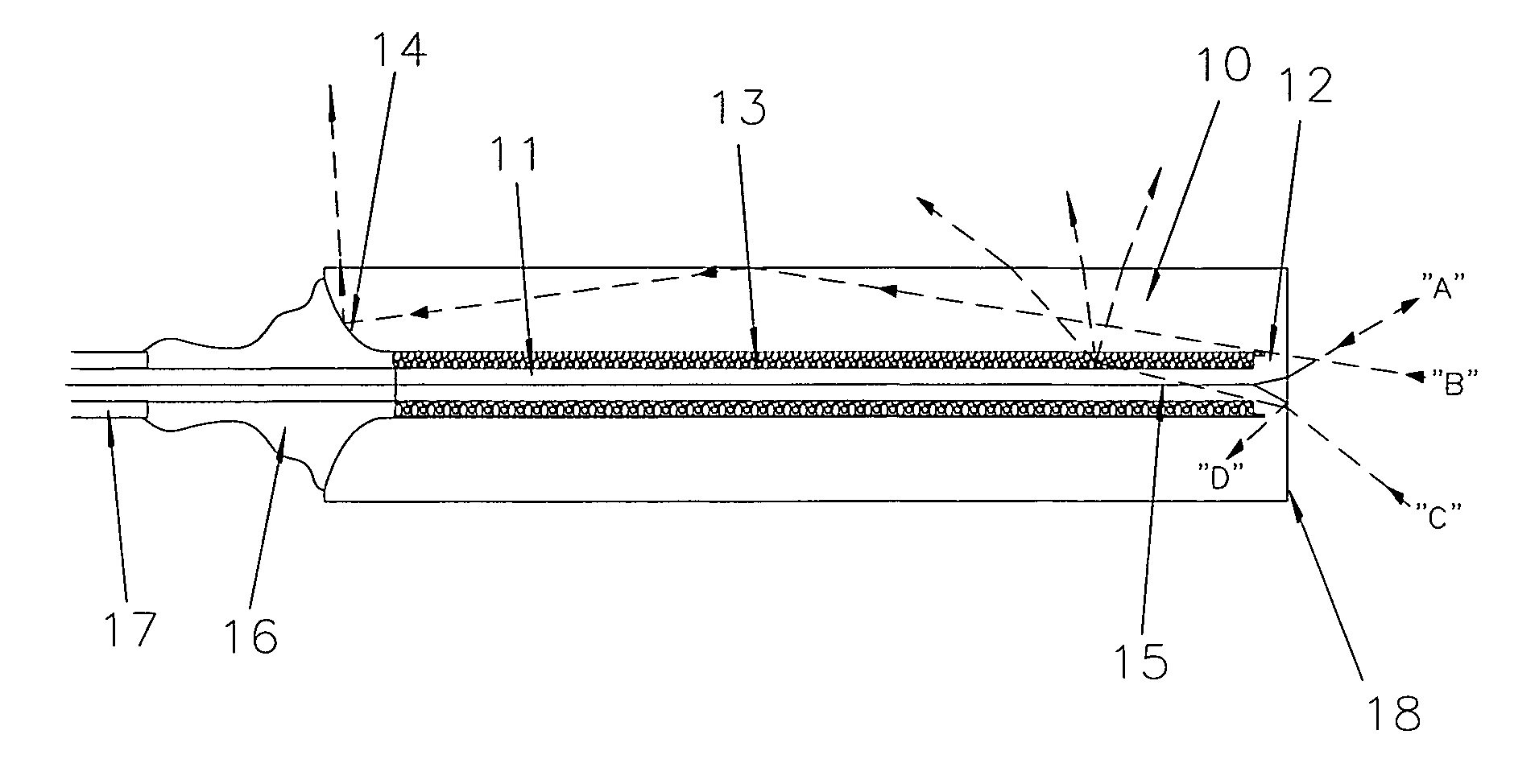

Implant to be implanted in bone tissue or in bone tissue supplemented with bone substitute material

InactiveUS6921264B2High softening temperatureLow softening temperatureDental implantsInternal osteosythesisBone tissueGrowth promoting

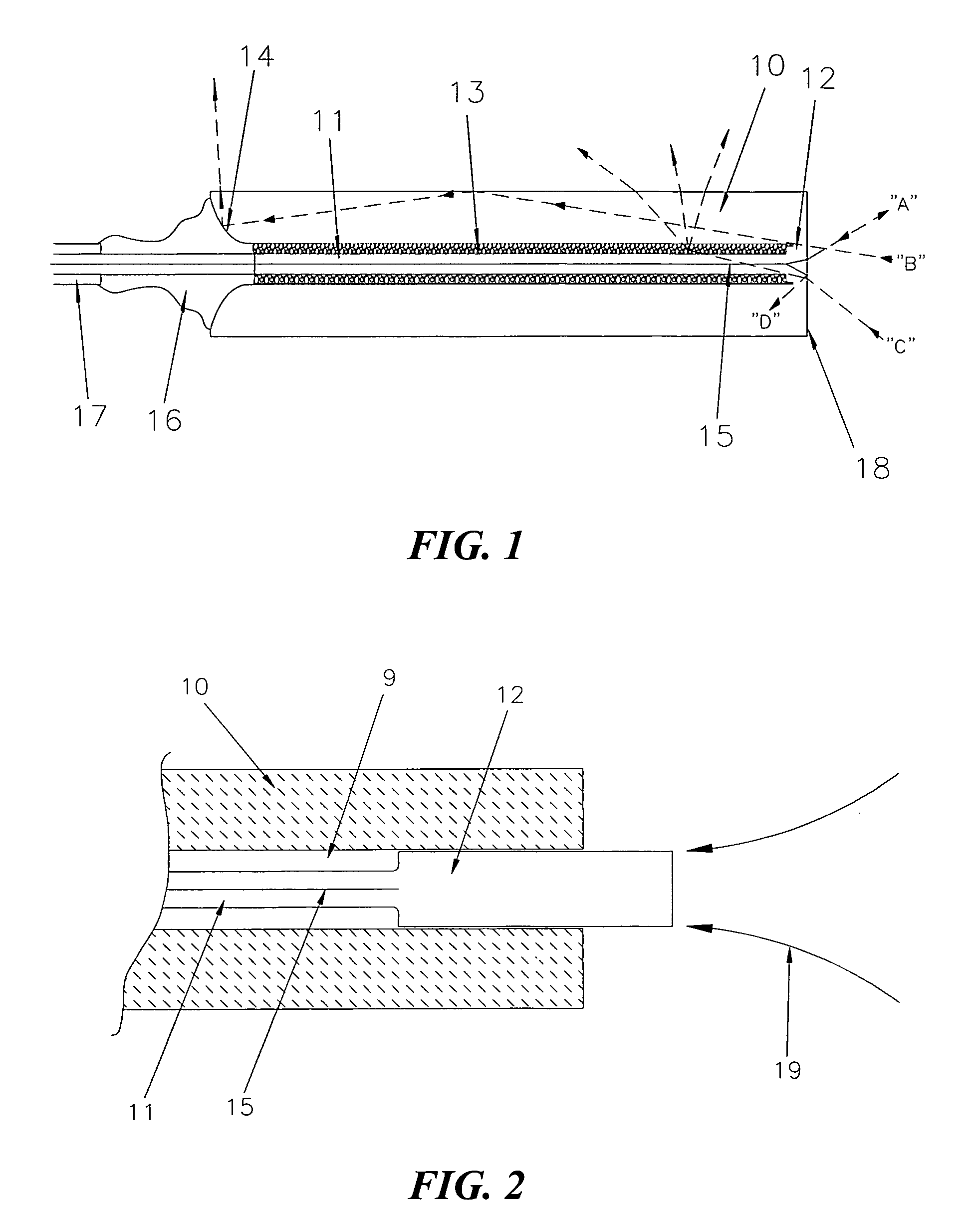

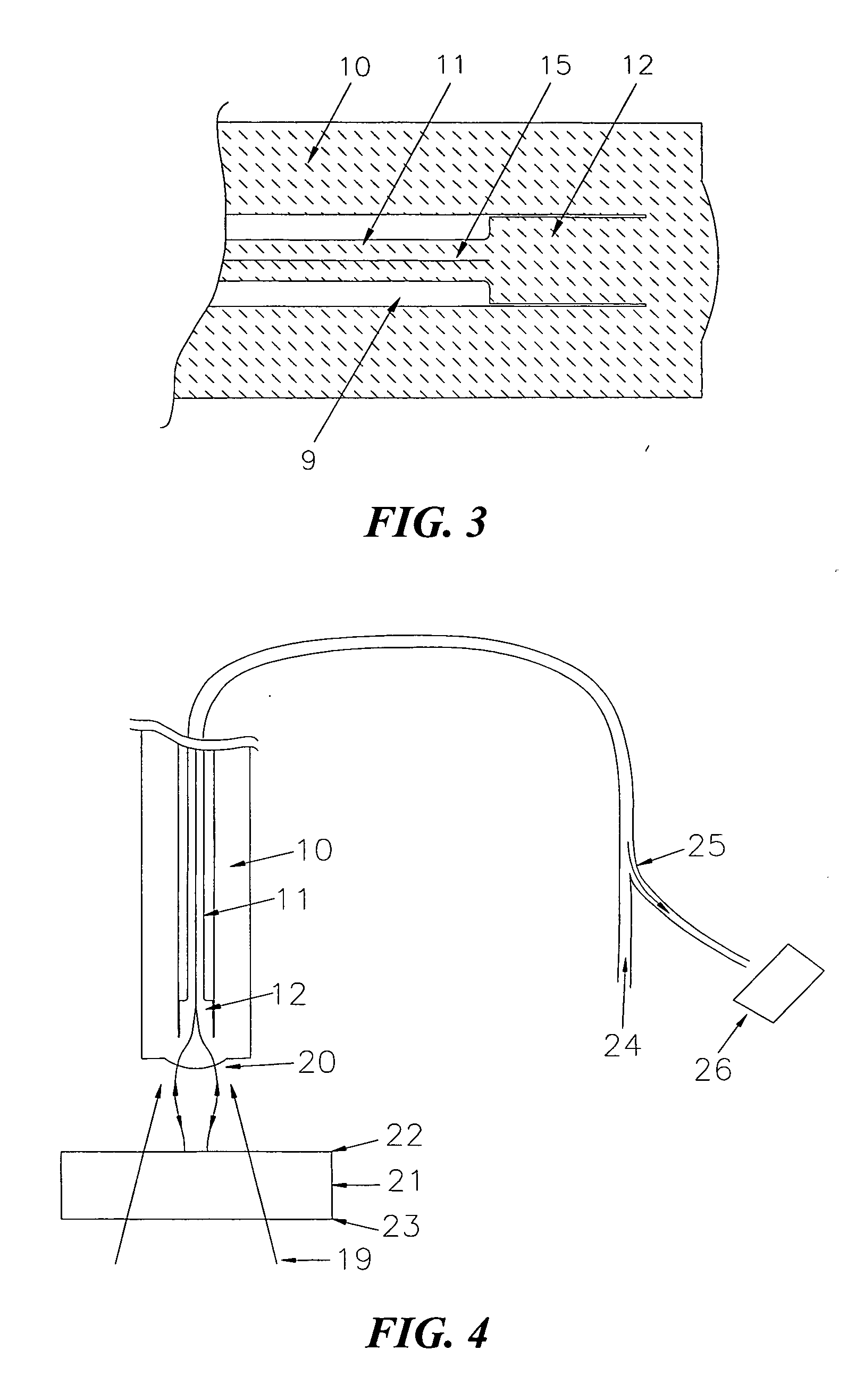

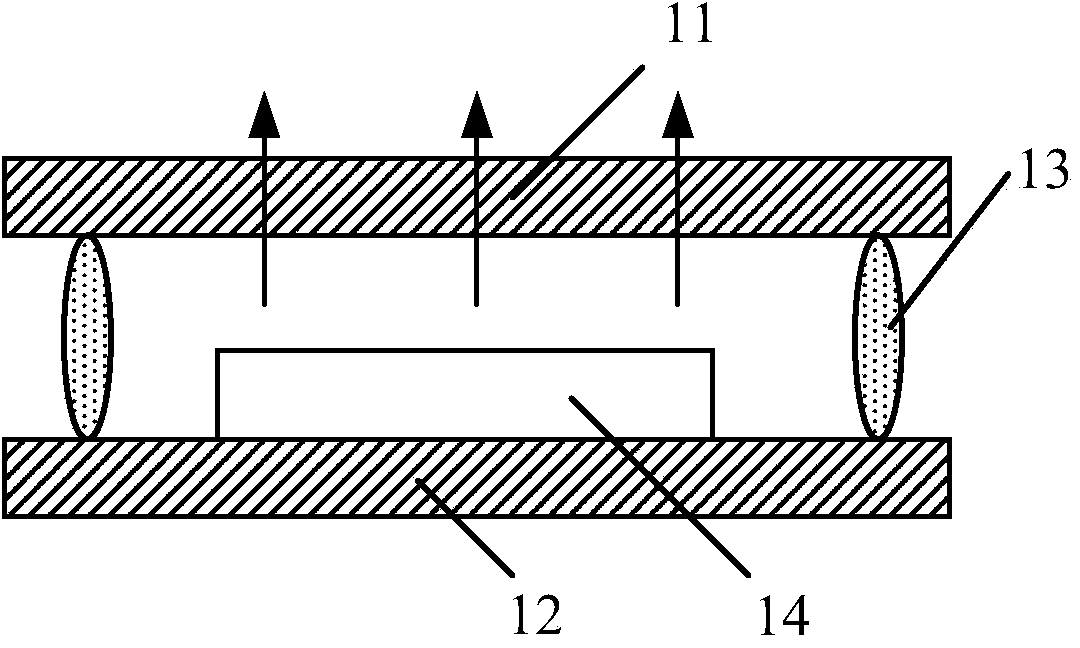

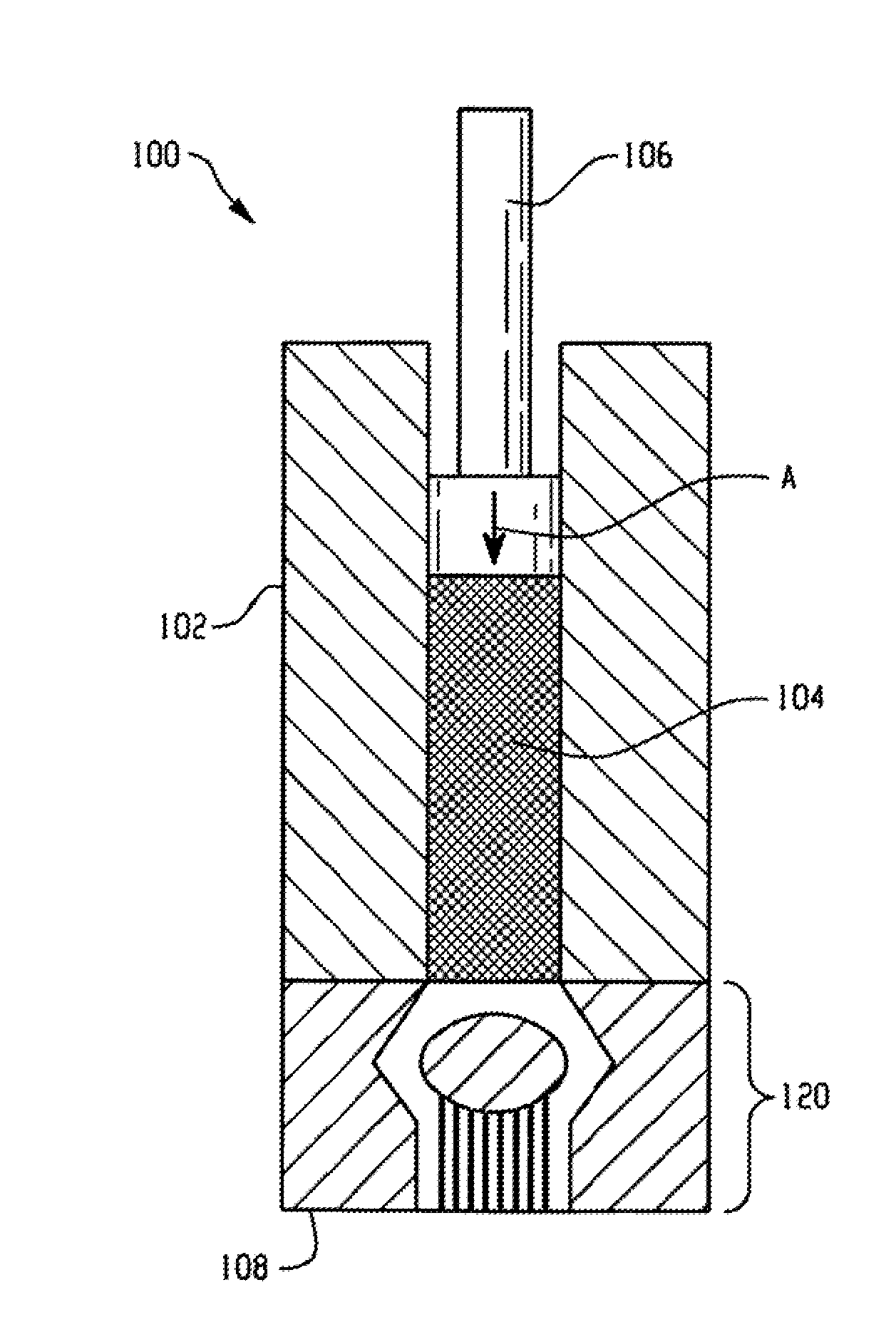

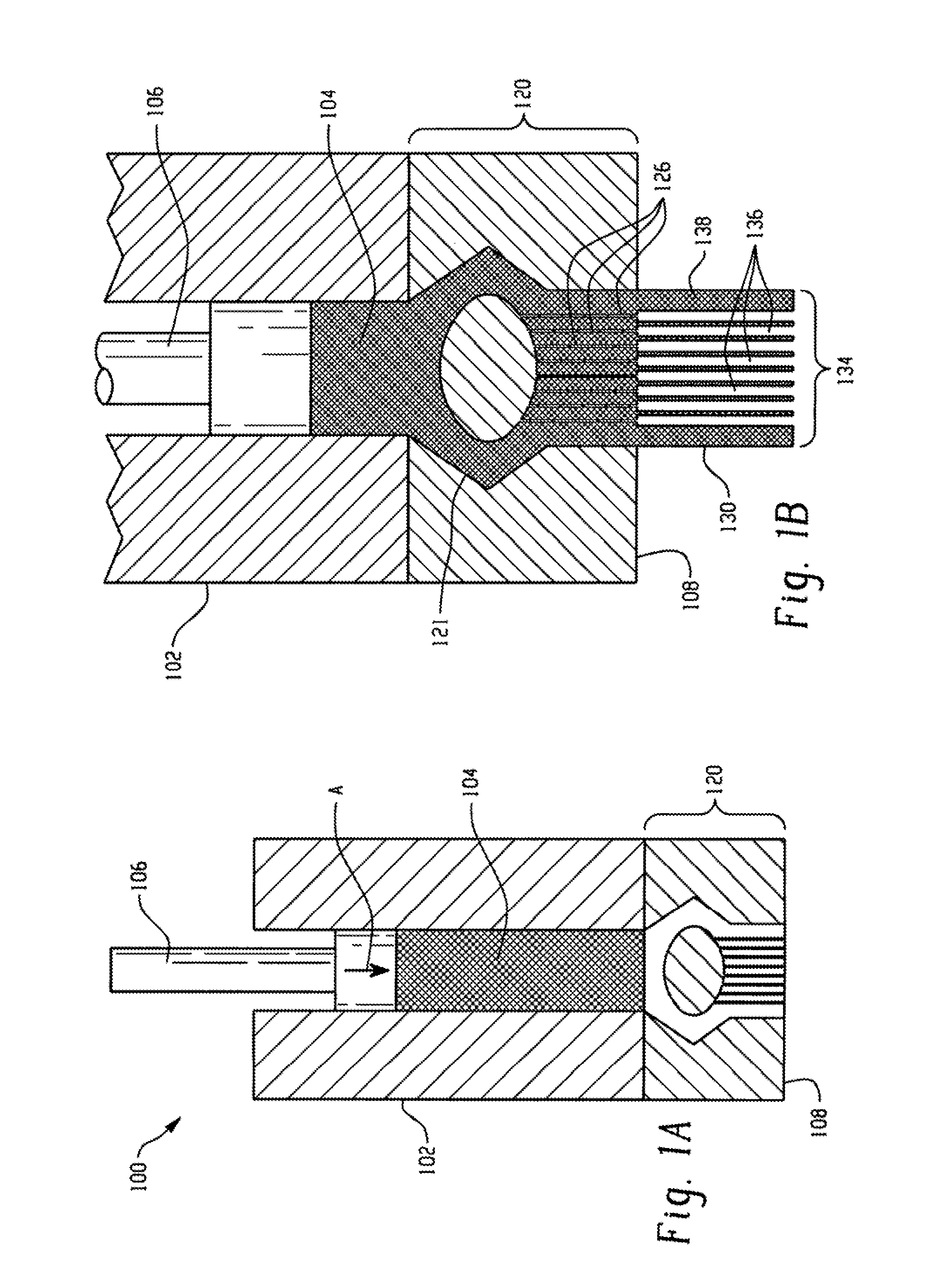

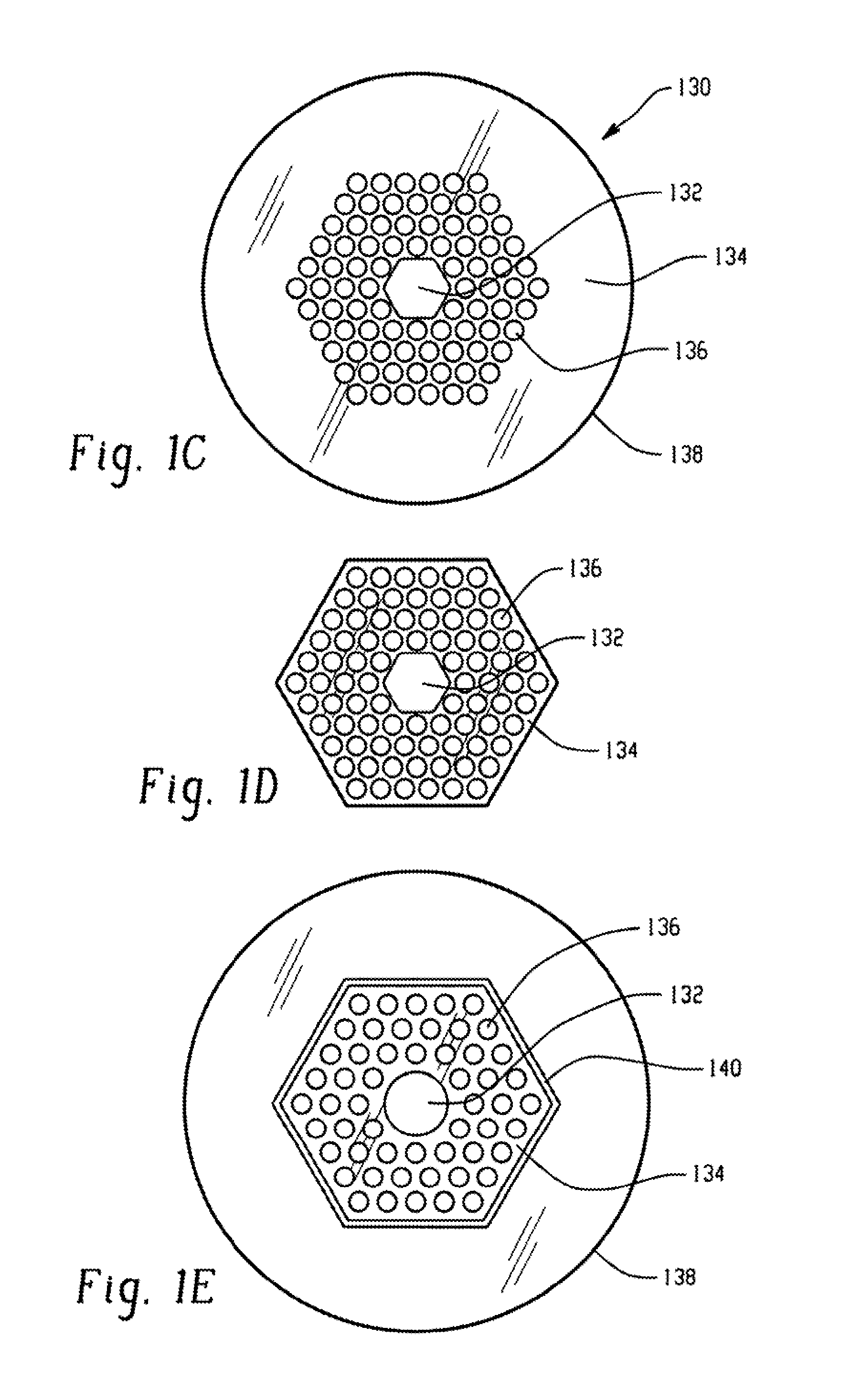

An implant (1) to be implanted in bone tissue, e.g. a dental implant or an implant for an orthopedic application, comprises surface regions (4) of a first type which have e.g. osseo-integrative, inflammation-inhibiting, infection-combating and / or growth-promoting properties, and surface regions (8) of a second type which consist of a material being liquefiable by mechanical oscillation. The implant is positioned in an opening of e.g. a jawbone and then mechanical oscillations, e.g. ultrasound is applied to it while it is pressed against the bone. The liquefiable material is such liquefied at least partly and is pressed into unevennesses and pores of the surrounding bone tissue where after resolidification it forms a positive-fit connection between the implant and the bone tissue. The surface regions of the two types are arranged and dimensioned such that, during implantation, the liquefied material does not flow or flows only to a clinically irrelevant degree over the surface regions of the first type such enabling the biologically integrative properties of these surface regions to start acting directly after implantation. The implant achieves with the help of the named positive fit a very good (primary) stability, i.e. it can be loaded immediately after implantation. By this, negative effects of non-loading are prevented and relative movements between implant and bone tissue are reduced to physiological measures and therefore have an osseo-integration promoting effect.

Owner:WOODWELDING

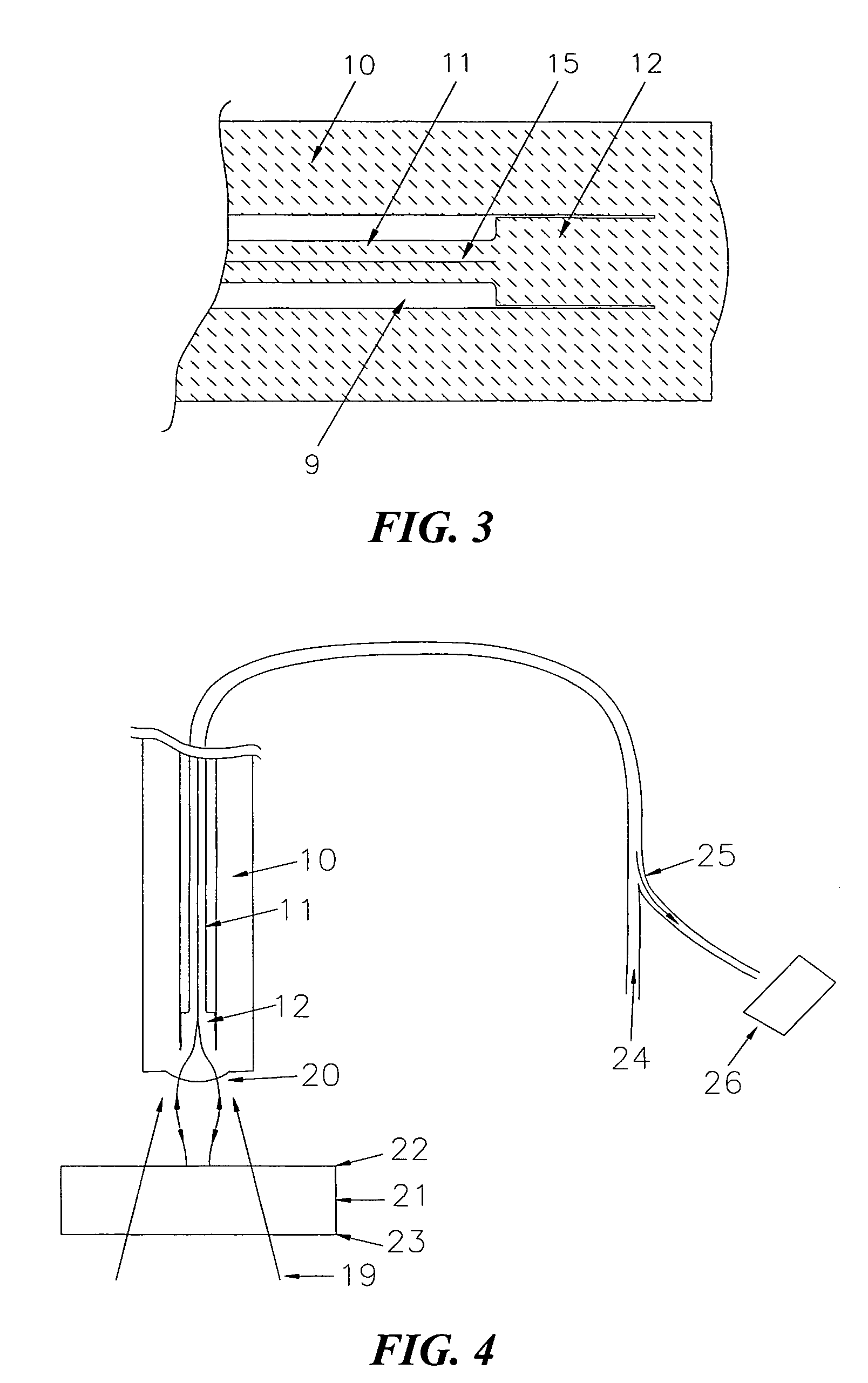

Monolithic mode stripping fiber ferrule/collimator and method of making same

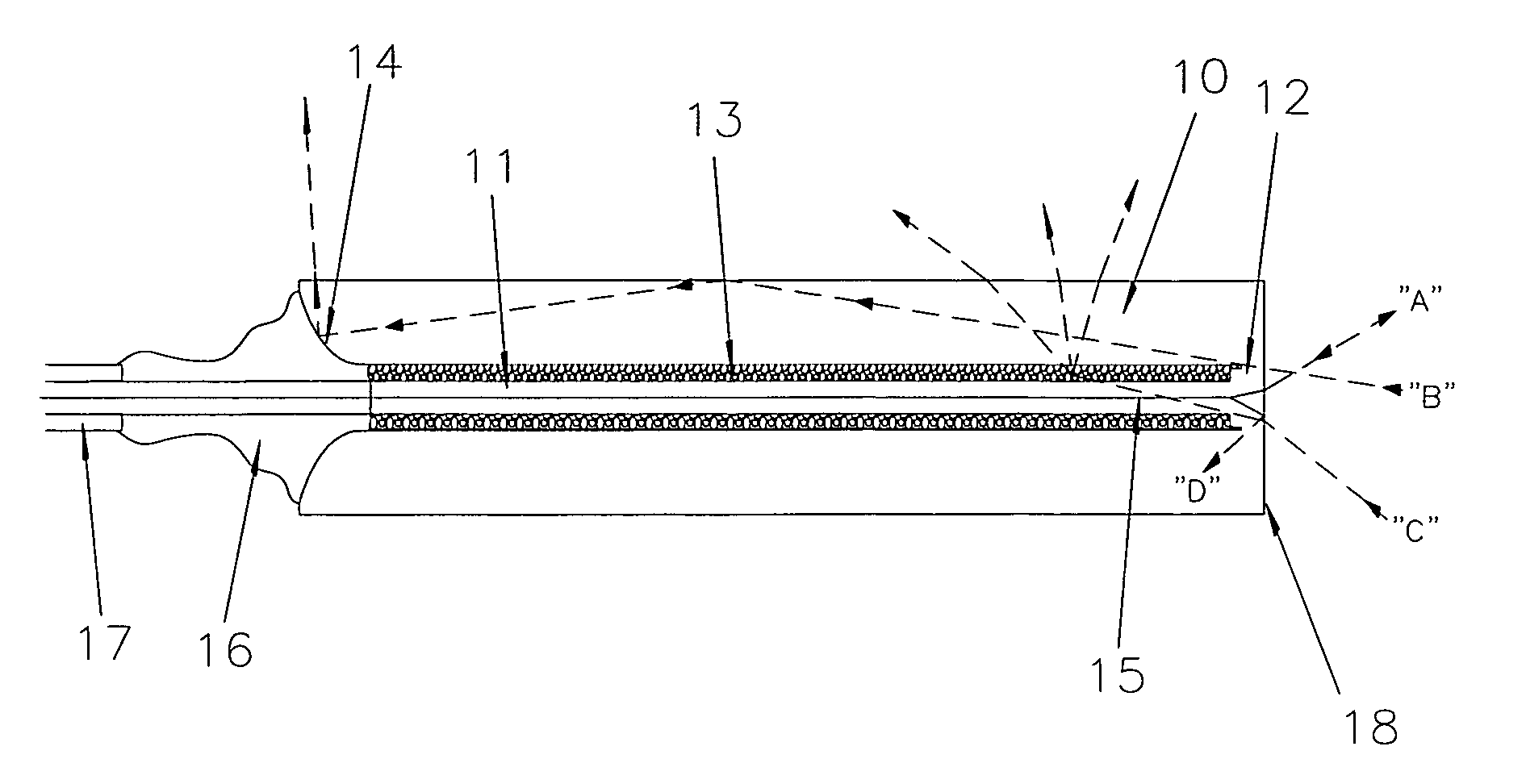

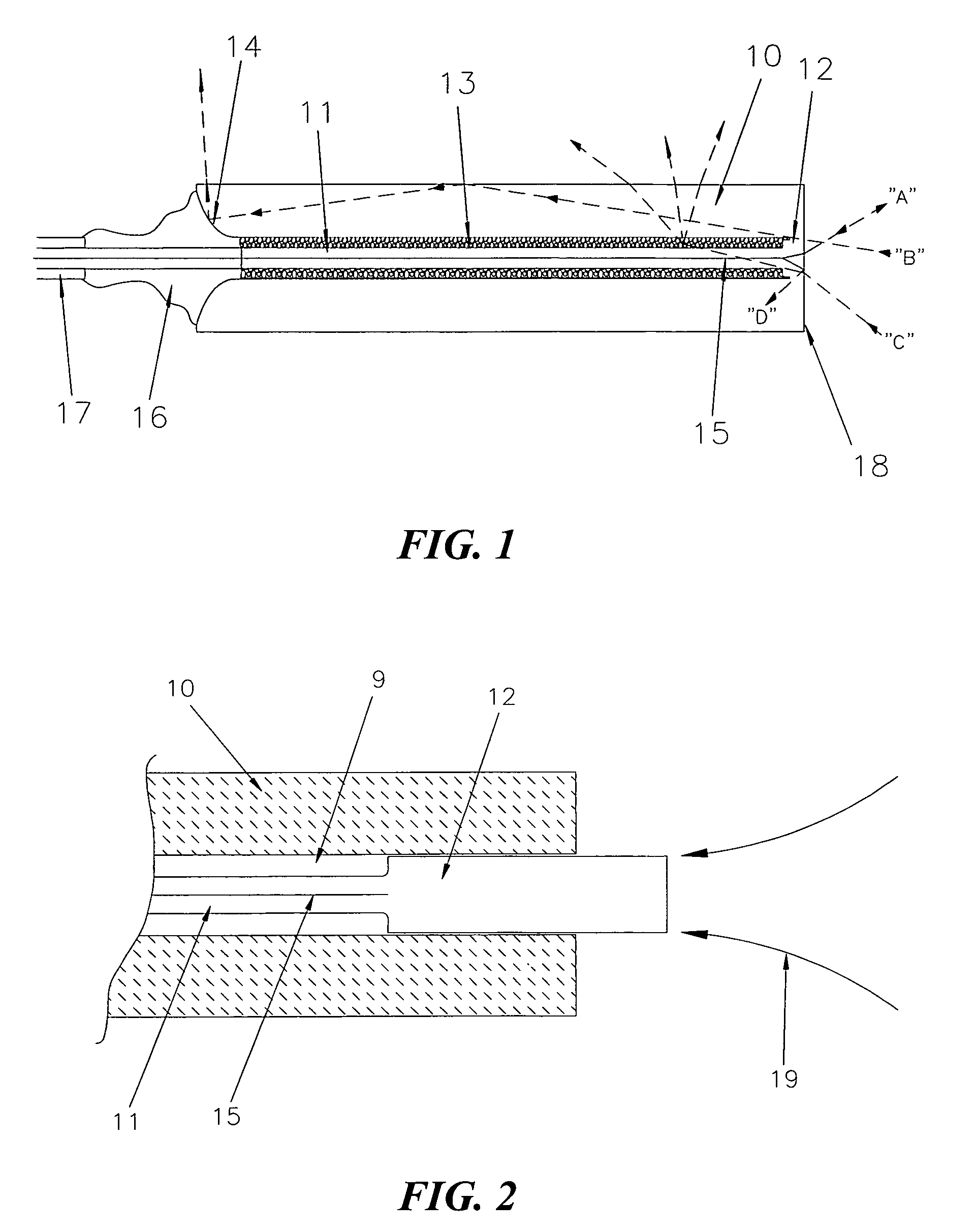

A monolithic ferrule / endcap / optical fiber structure is provided wherein an optical fiber is terminated in a ferrule and bonded by fusion to form a monolithic unit which minimizes optical loss and is typically capable of transmitting high power laser radiation, preferably on the order of 500 W and higher, without damage to the optical fiber and ferrule. Ferrule, endcap, optical fiber and fusible powder are composed of material of substantially the same physical characteristics such that, when all are fused together, the structure so formed is monolithic and the optical path is transparent.

Owner:ELECTRO OPTICS TEVCHNOLOGY

Monolithic mode stripping fiber ferrule/collimator and method of making same

A monolithic ferrule / endcap / optical fiber structure is provided wherein an optical fiber is terminated in a ferrule and bonded by fusion to form a monolithic unit which minimizes optical loss and is typically capable of transmitting high power laser radiation, preferably on the order of 500 W and higher, without damage to the optical fiber and ferrule. Ferrule, endcap, optical fiber and fusible powder are composed of material of substantially the same physical characteristics such that, when all are fused together, the structure so formed is monolithic and the optical path is transparent.

Owner:ELECTRO OPTICS TEVCHNOLOGY

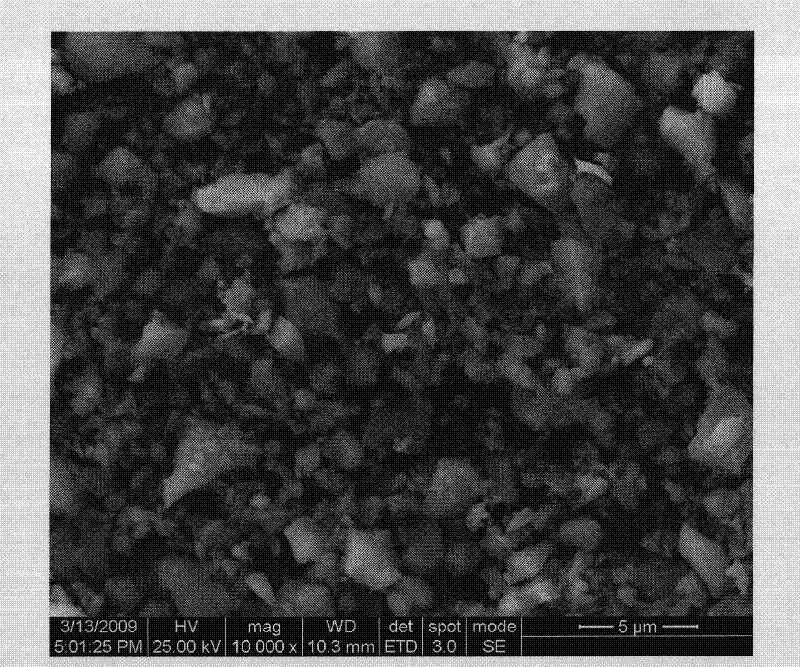

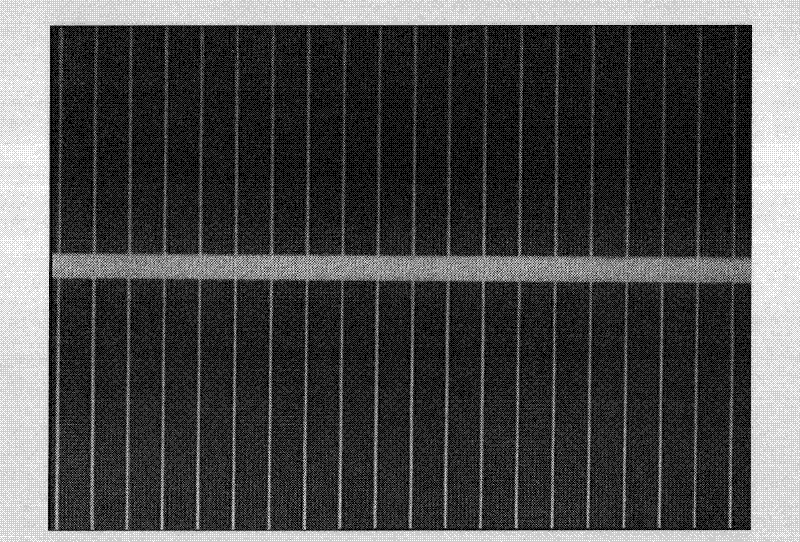

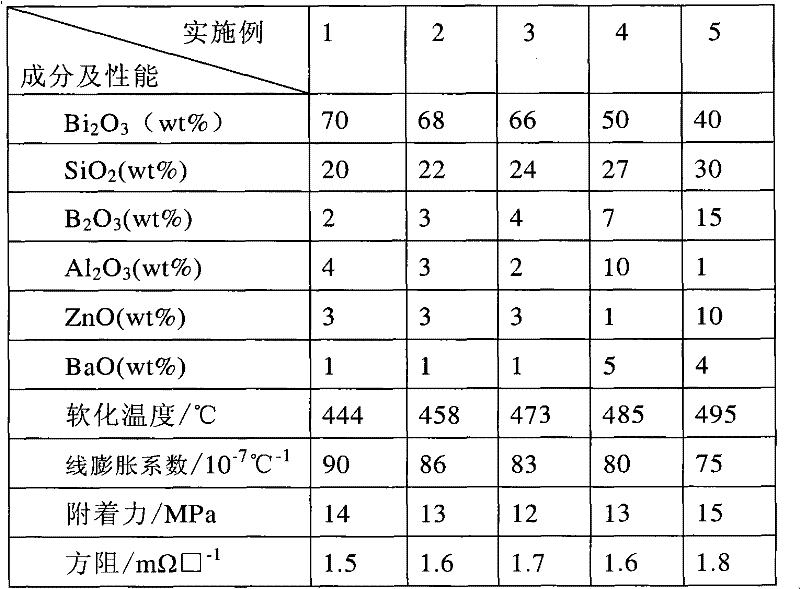

Lead-free glass powder, preparation method thereof, silver paste containing glass powder and crystal silicon solar cell manufactured by using silver paste

InactiveCN102126829AImprove adhesionStrong adhesionNon-conductive material with dispersed conductive materialSemiconductor devicesSilver pasteScreen printing

The invention discloses lead-free glass powder, a preparation method thereof, silver paste containing the glass powder and a crystal silicon solar cell manufactured by using the silver paste. The lead-free glass powder comprises the following components in percentage by weight: 20-30 percent of SiO2, 2-15 percent of B2O3, 40-70 percent of Bi2O3, 1-10 percent of ZnO, 1-10 percent of Al2O3 and 1-5 percent of BaO. The preparation method comprises the following steps of: (1) weighing the components for preparing a mixture; (2) putting the mixture into a crucible for melting; (3) performing water quenching on molten glass; (4) drying; (5) smashing the mixture into powder by planetary ball milling; and (6) screening. The needed silver paste is prepared from the lead-free glass powder, silver powder, an additive and an organic carrier. A solar panel front face electrode and a grid line are manufactured by performing screen printing and sintering on conductive silver paste on a cell substrate, so that the needed solar cell is obtained. The lead-free glass powder has low melting temperature, low softening temperature and low linear expansion factor.

Owner:湖南威能新材料科技有限公司

Method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder

The invention discloses a method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder. The method comprises the following steps: grinding the high titanium blast furnace slag and waste glass powder, uniformly and fully mixing the high titanium blast furnace slag, the waste glass powder, a fluxing agent, a foaming agent and a foam stabilizer, pressing into a block, adding the mixture block into a heating device and preparing the microcrystalline foam glass at a low temperature according to a specific heat treatment process by using a one-step sintering method. According to the characteristic that the high titanium blast furnace slag which is rich in TiO2 can serve as a nucleation agent, the low-melting-point waste glass powder serves as a silicious raw material, a proper amount of corresponding fluxing agent and sintering process are matched, the preparation temperature is greatly reduced, and the preparation can be finished through one-step sintering; and therefore, the energy consumption can be reduced, the process is simplified, the cycle is shortened, the cost is saved, the product which is uniform in cells, moderate in cell diameter, low in volume density, low in water absorption rate, good in thermal insulation effect and high in mechanical strength can be obtained, and the additional value of high titanium blast furnace slag utilization is improved.

Owner:SICHUAN UNIV

Medium temperature sintering type electro-conduction slurry with lead-free glass powder and preparation method of medium temperature sintering type electro-conduction slurry

InactiveCN103903677ALow softening temperatureMeet the requirements of energy saving and environmental protectionNon-conductive material with dispersed conductive materialCable/conductor manufactureMicron scaleAlkali metal oxide

The invention discloses a medium temperature sintering type electro-conduction slurry with lead-free glass powder and a preparation method of the medium temperature sintering type electrocondution slurry. The preparation method is characterized by comprising the steps of preparing an organic carrier, preparing the lead-free glass powder, preparing silver powder and preparing the electro-conduction slurry. The electro-conduction slurry comprises, by mass, 0 to 80% of micron-scale spherical silver powder, 5% to 70% of micron-scale flake silver powder, 2% to 25% of the lead-free glass powder and 0 to 25% of the organic carrier. The lead-free glass powder comprises, by mass, 25% to 75% of Bi2O3, 20% to 60% of B2O3, 0 to 20% of ZnO, 0 to 20% of Sb2O3, 0 to 10% of Al2O3 and 0 to 8% of alkali metal oxide. The organic carrier comprises, by mass, 50% to 80% of terpilenol, 10% to 40% ofbutyl carbitol acetic ester, 0 to 10% of tributyl citrate, 3% to 10% of ethocel, 0 to 2% of hydrogenated castor oil and 0 to 3% of addition agent.

Owner:SHANGHAI INTELLIGENT SENSOR ELECTRONICS TECHCO

Glass powder and silver aluminum paste comprising glass powder and used on positive side of N-type double-sided solar cell

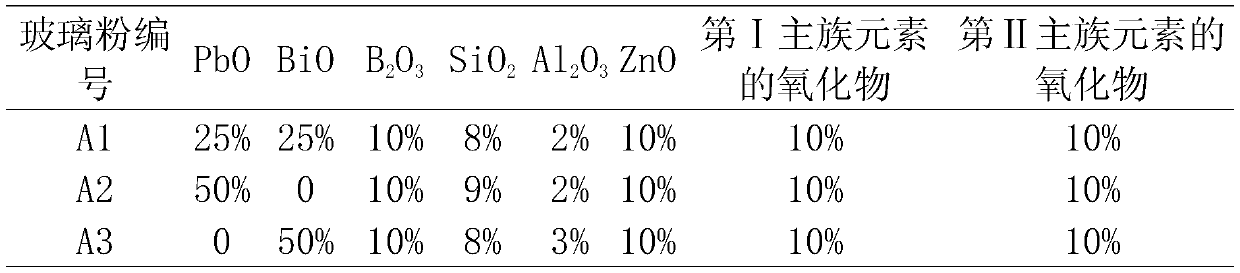

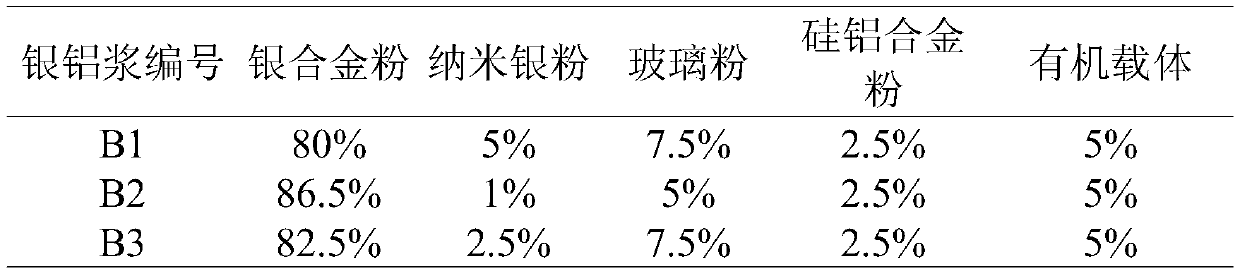

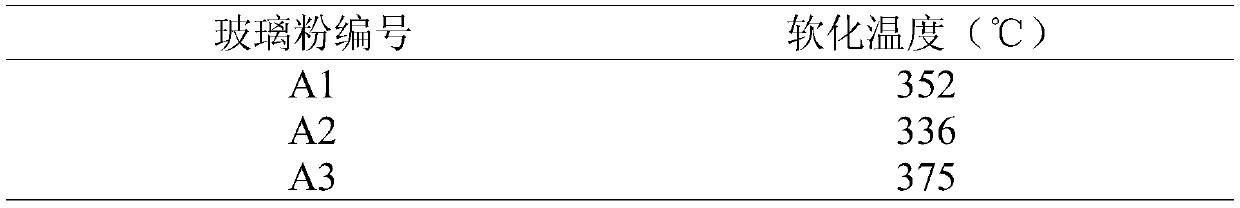

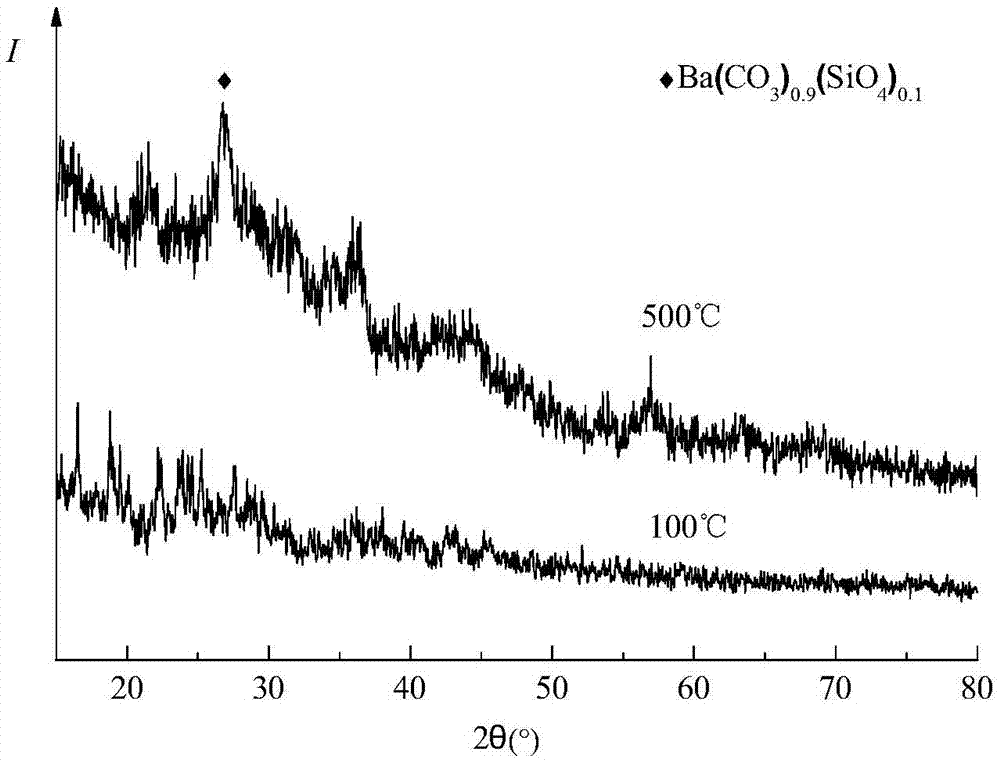

PendingCN110040968ALow softening temperatureIncrease the degree of vitrificationTransportation and packagingMetal-working apparatusMass ratioSilicon solar cell

The invention discloses glass powder and silver aluminum paste which comprises the glass powder and used on the positive side of an N-type double-sided solar cell. The silver aluminum paste comprisesconductive silver powder, silicon aluminum alloy powder, the glass powder and an organic carrier, wherein the glass powder is prepared from the following components in percentage by weight: 0-50% of PbO, 0-50% of BiO, 5-15% B2O3, 8-9% of SiO2, 2-3% of Al2O3 and 5-15% of ZnO; the mass ratio of silicon to aluminum in the glass powder is (4-5) to 1; the content of the conductive silver powder is 80wt% to 90wt%; the conductive silver powder comprises nano silver powder and silver alloy powder in a mass ratio of 1 to (18-90). The glass powder not only guarantees the corrosiveness of SiNx, but alsodoes not cause relatively strong metallized composition. The silver aluminum paste prepared by using the glass powder solves the problem of the contradiction between contact resistance and open circuit voltage when the silver aluminum paste is printed on the positive side of an N-type crystalline silicon solar cell.

Owner:NANTONG T SUN NEW ENERGY CO LTD

Method for preparing copper/ceramic composite substrate on basis of low-melting-point glass powder

InactiveCN105439643ALow softening temperatureImprove adhesionGlass shaping apparatusSol-gelGel method

The invention provides a method for preparing a copper / ceramic composite substrate on the basis of low-melting-point glass powder. The method comprises the following steps: (1) preparing low-melting-point glass powder; (2) preparing an organic carrier; (3) preparing copper electronic paste; and (4) preparing a copper / ceramic composite substrate. According to the method, the BZBS glass powder which is prepared by employing a sol-gel method is used as a glass binder, and the copper powder is used as a functional phase, so that a copper thick film with good properties is obtained. The glass binder is good in wettability and relatively low in beginning wetting temperature, so that the thick film is sintered to be compacted, and good properties can be obtained. Meanwhile, the sintering temperature is kept for a period of time to melt the glass powder and to sufficiently wet the functional phase and the substrate, so that the increment of copper powder particles is facilitated, and the sintering is promoted.

Owner:SINOTENG SILICA MATERIALS TECH (JIANGSU) CO LTD

Crystalline silicon solar cell front silver paste and preparation method thereof

InactiveCN108766618AGood ink permeabilityEasy to fillNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteSilver electrode

The invention discloses a crystalline silicon solar cell front silver paste and a preparation method thereof. The front silver paste comprises the following components in percentage by weight: 85-90%of silver powder, 5-10% of an organic carrier, 5-10% of an organic carrier, 1.5-5% of composite glass powder, and 0.05-1% of a silver paste additive. The silver powder in different particle size distribution is cooperatively used, the slurry is good in ink permeability, and the silver powder particles in the grid line are more uniformly and tightly filled, so that the sintering density of the gridline is facilitated, the resistance of the grid lines is reduced, and the photoelectric conversion efficiency is improved. The preparation process of the glass powder is simple, the control is facilitated; the glass powder with different components is compounded and used, so that a series of particles are uniform, the softening temperature is low, and the composite glass powder has good wettability to the silver powder and the silicon substrate, a front silver paste prepared from the composite glass powder is sintered on the front surface of the cell, the silver electrode and the silicon havegood ohmic contact and welding performance, and the adhesion strength of the electrode is high.

Owner:湖南省国银新材料有限公司

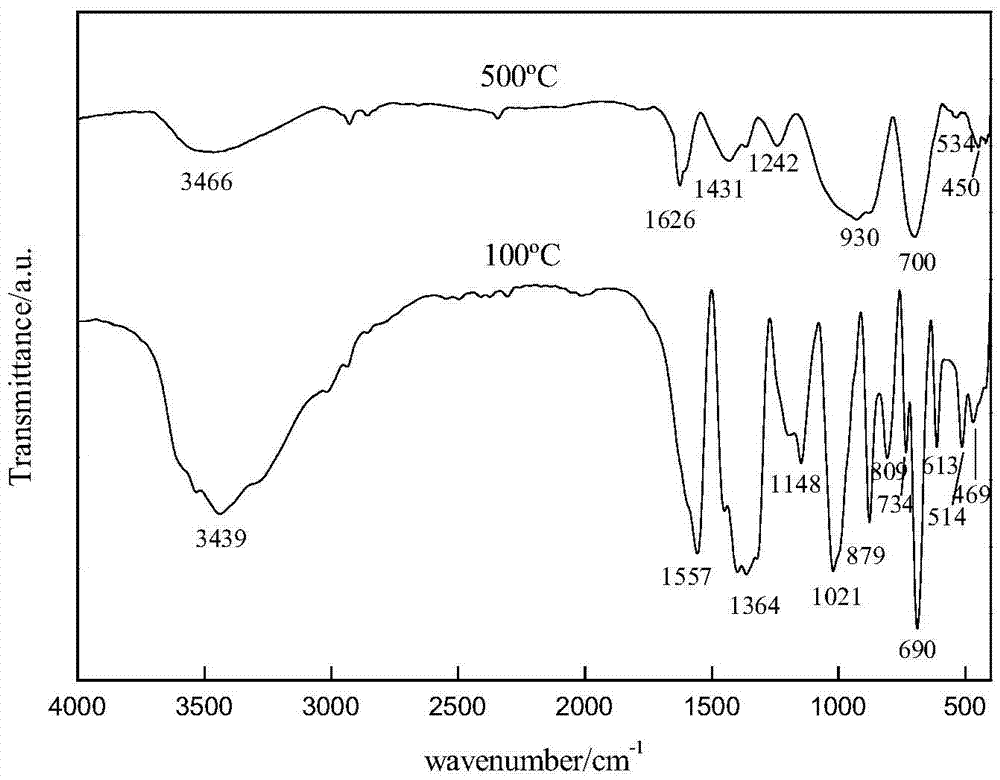

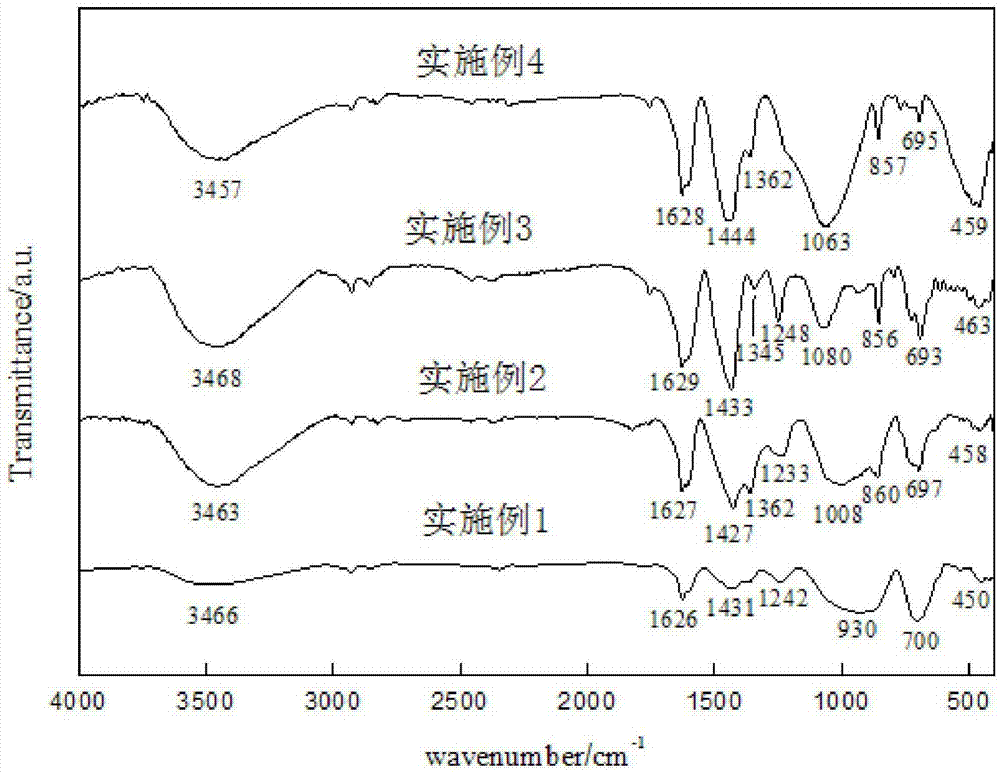

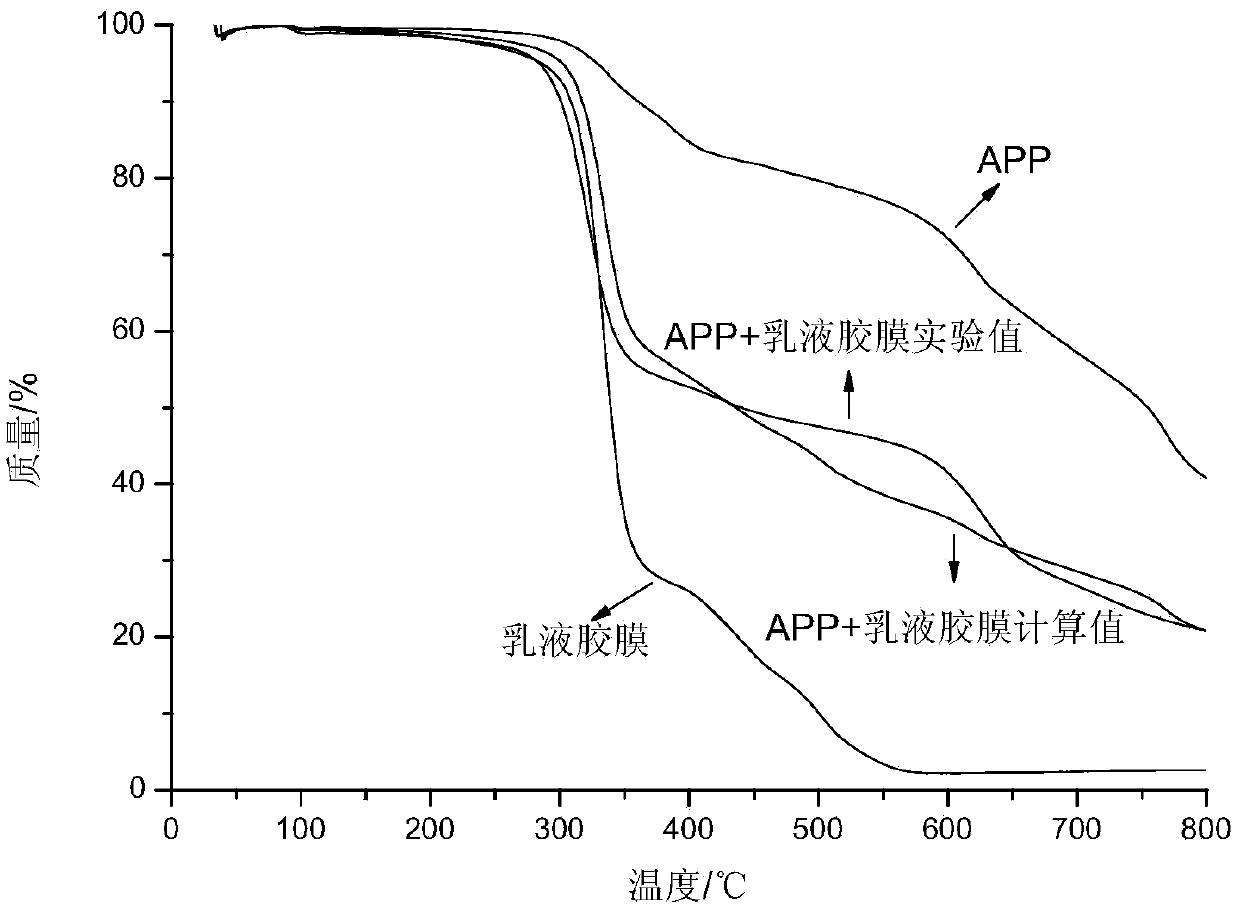

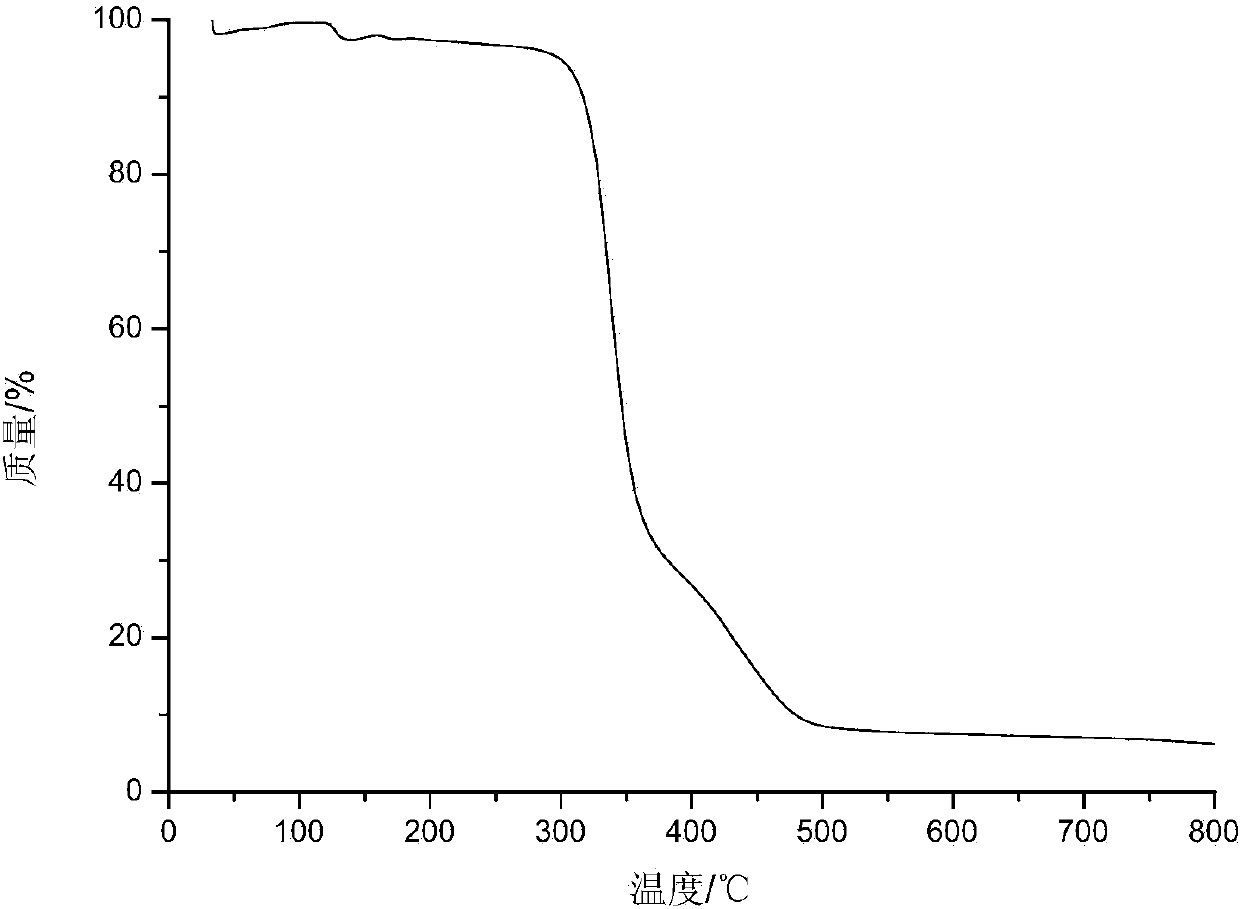

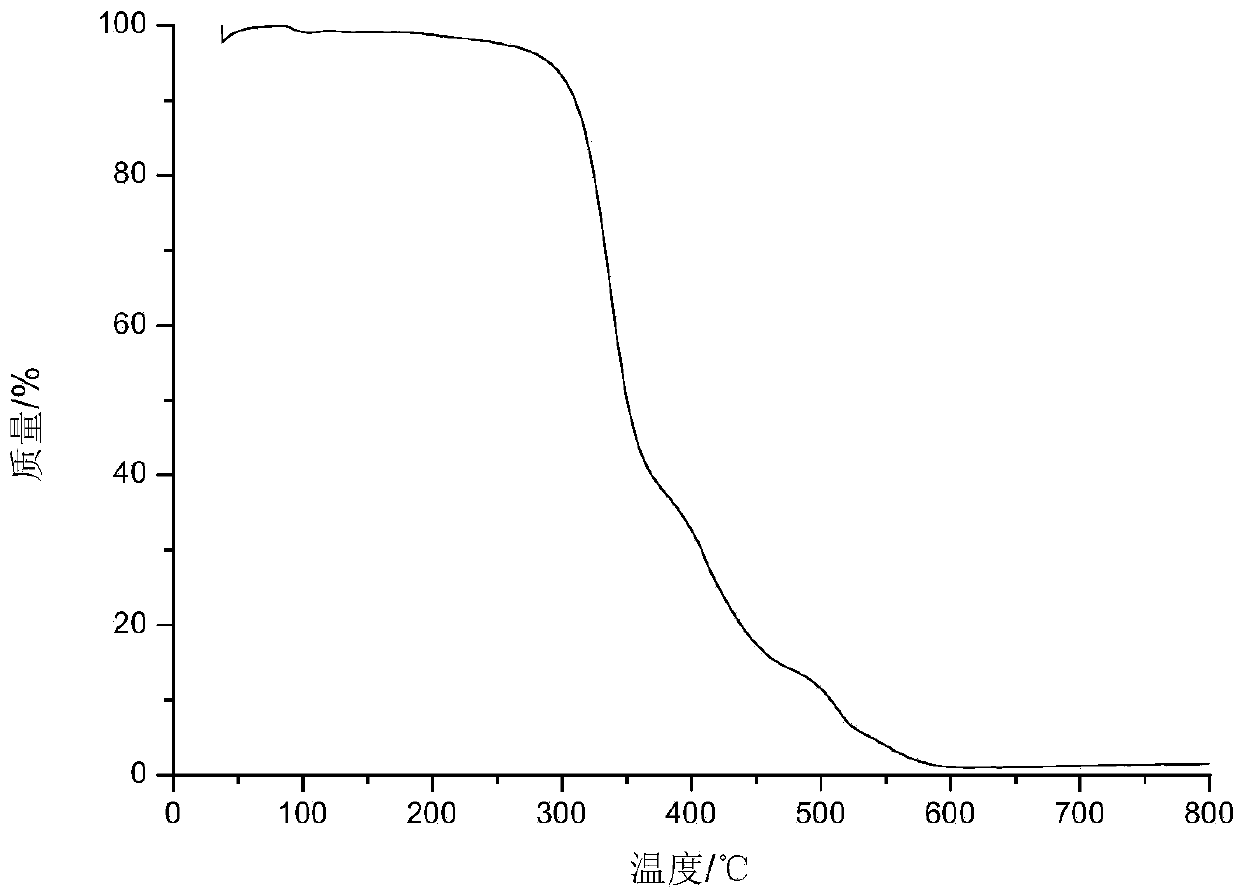

Emulsion for water-based intumescent fire-retardant coating and preparation method thereof

InactiveCN103435736AThe preparation process is stableThe preparation process is simple and easyFireproof paintsDecompositionChemistry

Owner:SOUTH CHINA UNIV OF TECH

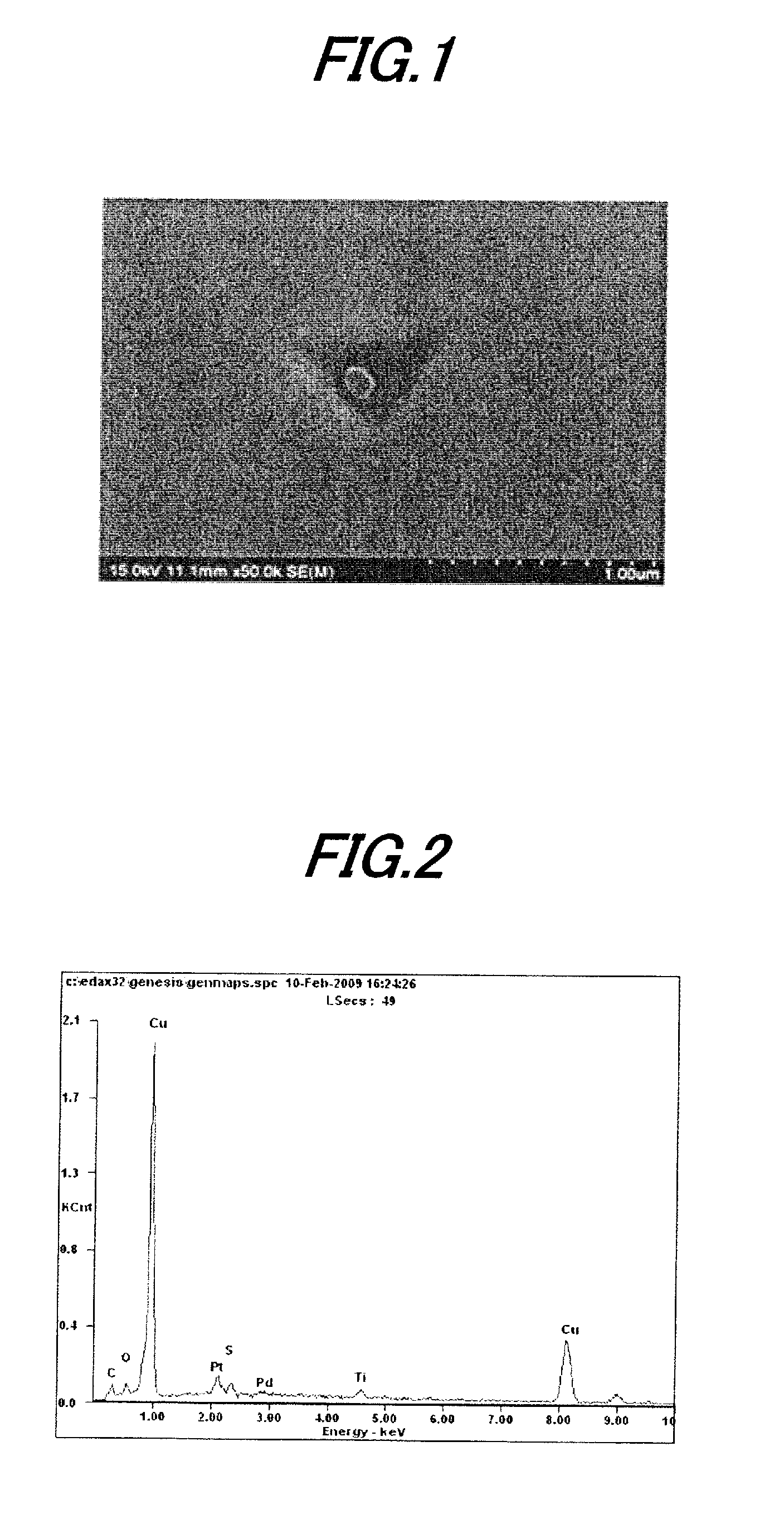

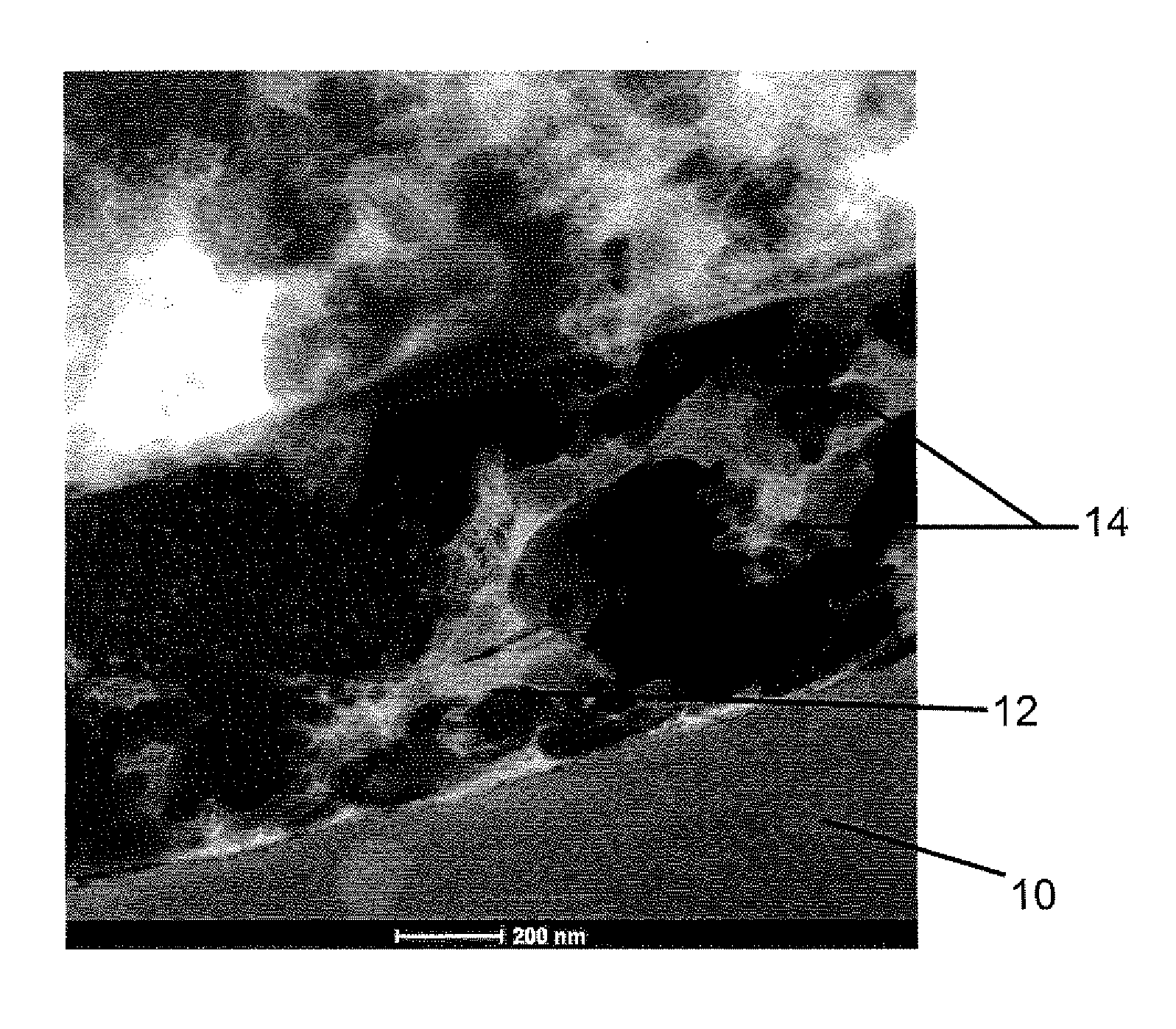

Dilute copper alloy material, dilute copper alloy wire, dilute copper alloy twisted wire and cable using the same, coaxial cable and composite cable, and method of manufacturing dilute copper alloy material and dilute copper alloy wire

ActiveUS20100263905A1Improve productivityImprove conductivityNon-insulated conductorsConductive materialCoaxial cableSulfur

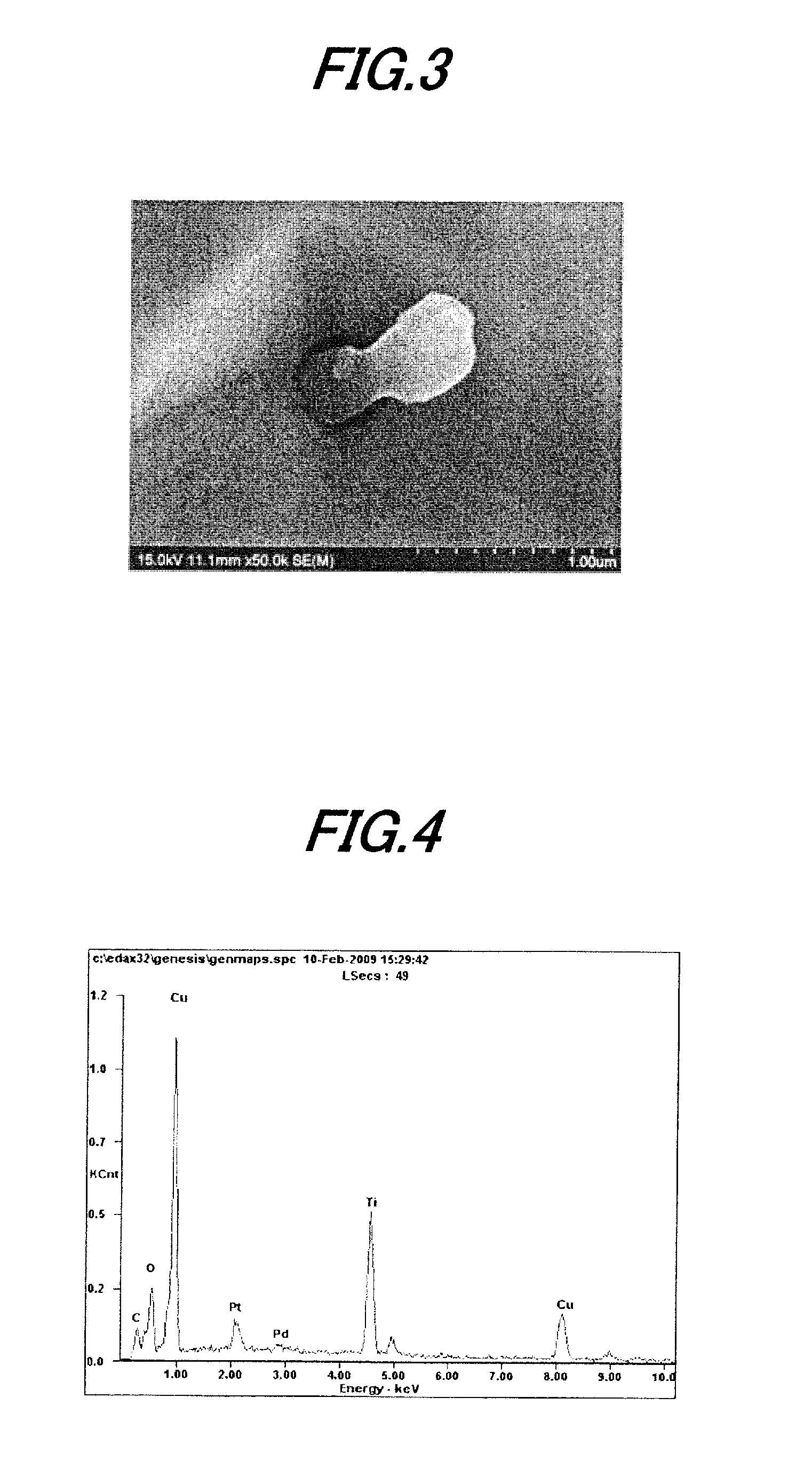

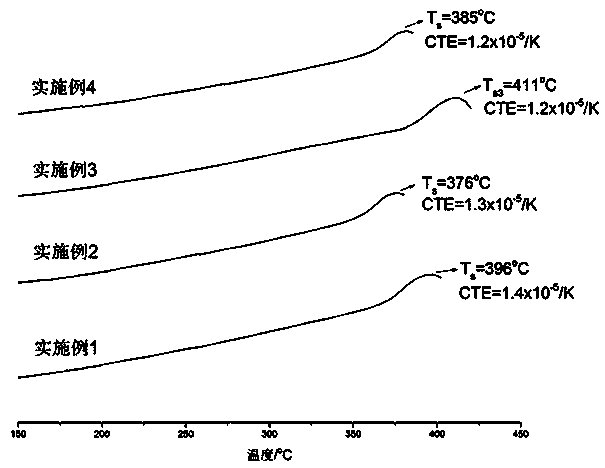

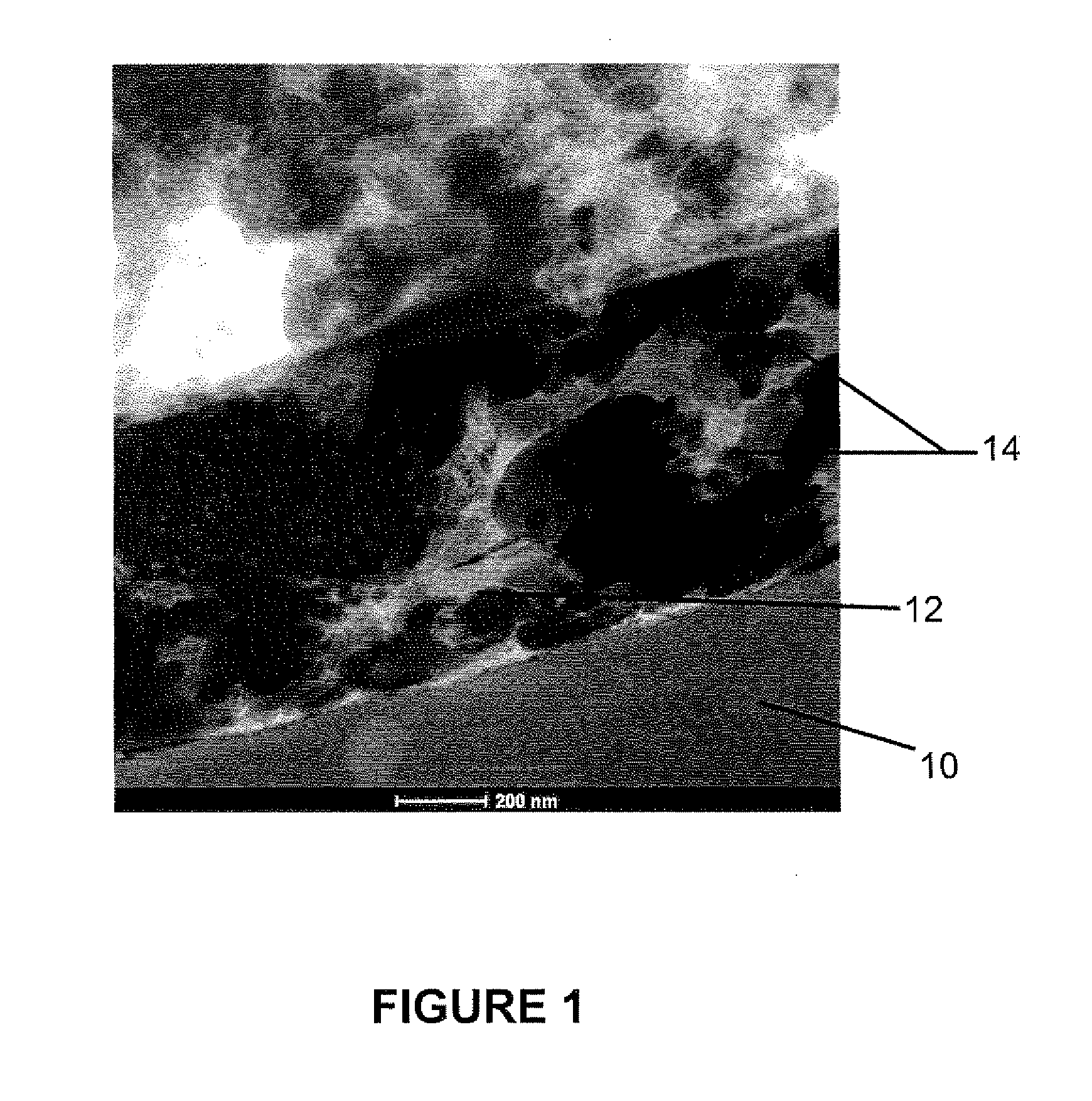

A dilute copper alloy material includes, based on a total mass of the dilute copper alloy material, 2 to 12 mass ppm of sulfur, 2 to 30 mass ppm of oxygen, 4 to 55 mass ppm of titanium, and a balance consisting of pure copper and an inevitable impurity. A part of the sulfur and the titanium forms a compound or an aggregate of TiO, TiO2, TiS or Ti—O—S, and an other part of the sulfur and the titanium forms a solid solution. TiO, TiO2, TiS and Ti—O—S distributed in a crystal grain of the dilute copper alloy material are not more than 200 nm, not more than 1000 nm, not more than 200 nm and not more than 300 nm, respectively, in particle size thereof, and not less than 90% of particles distributed in a crystal grain of the dilute copper alloy material are not more than 500 nm or less in particle size.

Owner:HITACHI METALS LTD

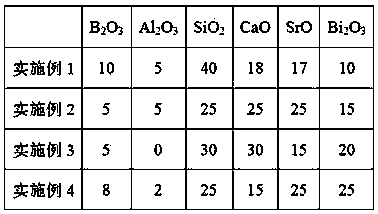

Devitrification type lead-free low-temperature sealing glass as well as preparation method and application method thereof

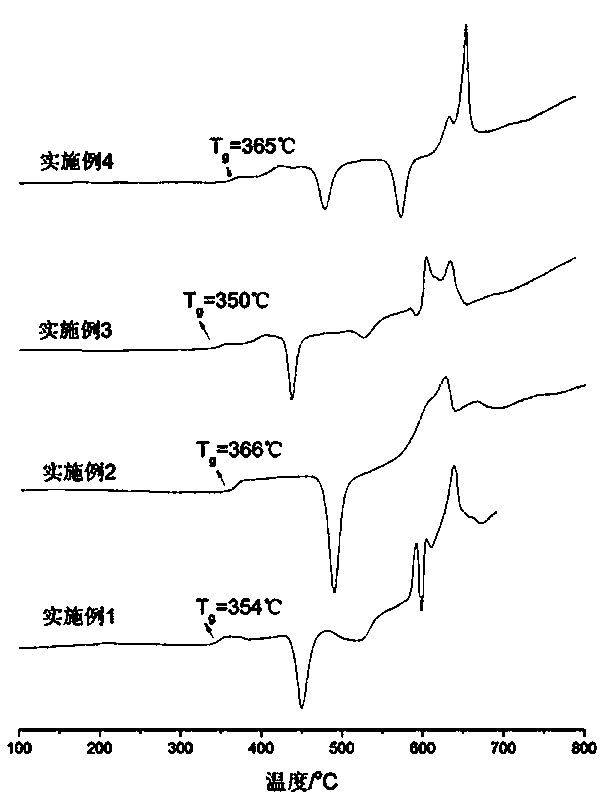

The invention discloses devitrification type lead-free low-temperature sealing glass as well as a preparation method and application method thereof. The devitrification type lead-free low-temperature sealing glass includes the following raw materials with the molar ratio of (0-10):(0-5):(20-40):(30-60):(5-30): B2O3, Al2O3, SiO2, MO (one or a mixture of MgO, CaO, SrO and BaO), and Bi2O3. Through the synergy between the Bi2O3 and the B2O3, the softening temperature range of the glass is reduced to 370-420 DEG C, and the coefficient of thermal expansion within the range of 150-300 DEG C reaches 1.2 minus 1.4*10<-5> / K, so that the sealing performance of the glass is remarkably improved; meanwhile, the sealing glass has good stability while being placed in hot water with the temperature of 80 DEG C for 1,000 hours, so that the sealing glass is applicable to electronic material and other low-temperature sealing fields. The raw materials for preparation of the sealing glass are simple and easy to get, the process is stable, simple and feasible, the cost is low, and the requirements for practicality and industrialization are met.

Owner:FUZHOU UNIV

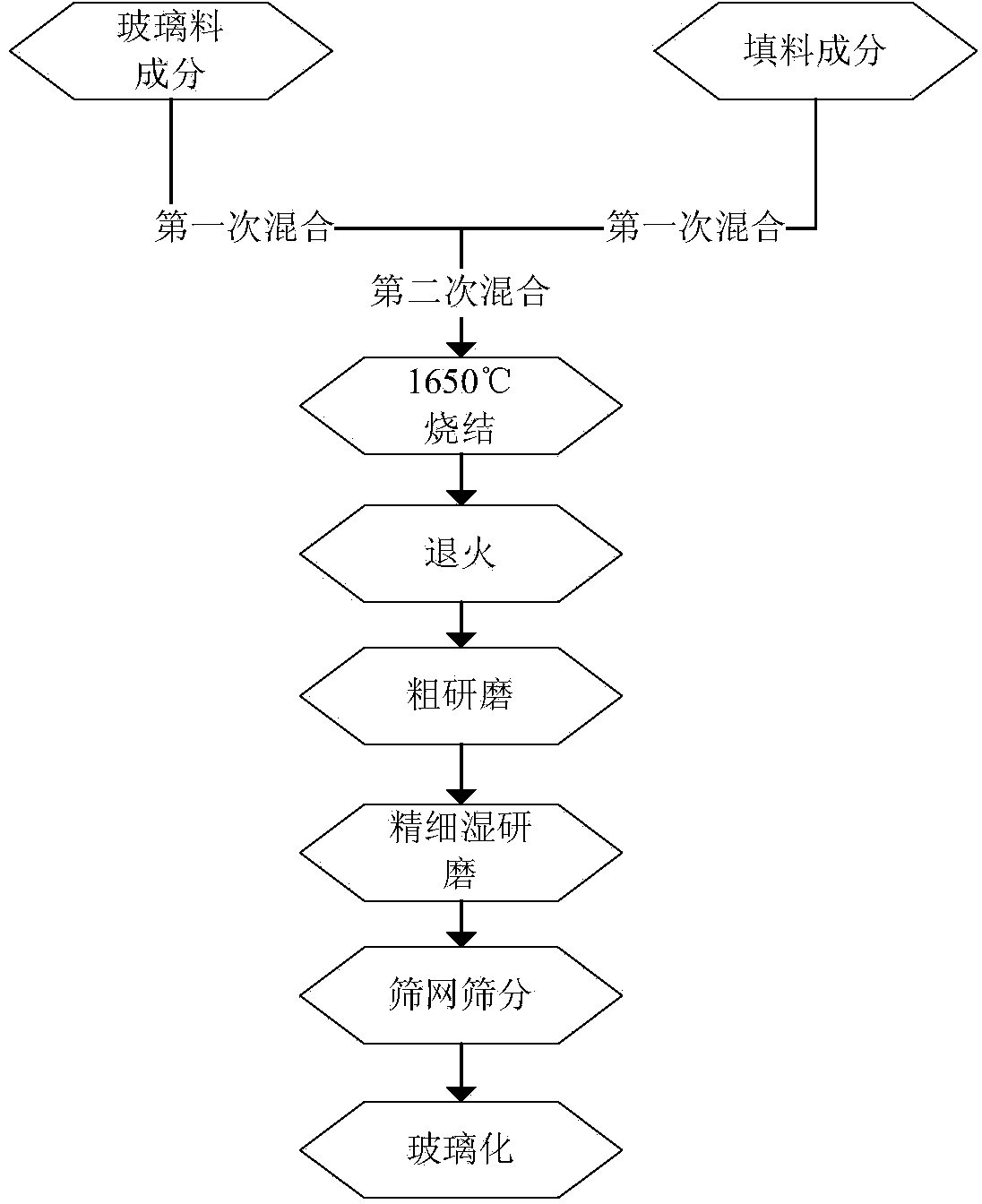

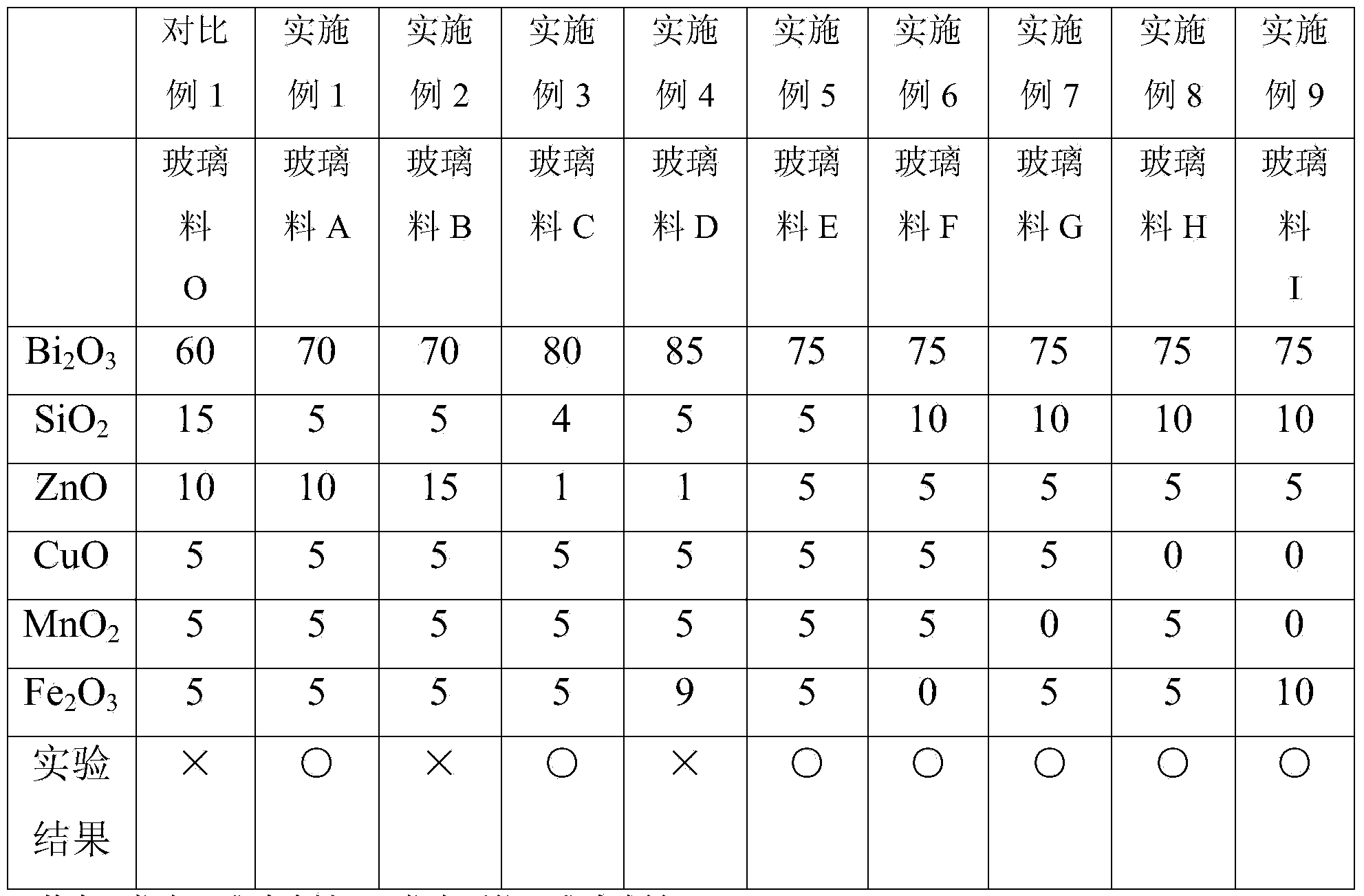

Frit mixture as well as application and preparation method thereof

The invention provides a frit mixture which comprises glass powder, wherein the glass powder comprises low-melting-point frit and a filler, and the low-melting-point frit comprises 60-80 wt% of Bi2O3, 1-10 wt% of SiO2 and 1-10 wt% of ZnO. The frit composition can be applied to airtight type sealing of an electrical element, the glass transition temperature and the softening temperature are reduced, excellent low-temperature firing stability is shown, electrical devices are protected, and energy is saved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

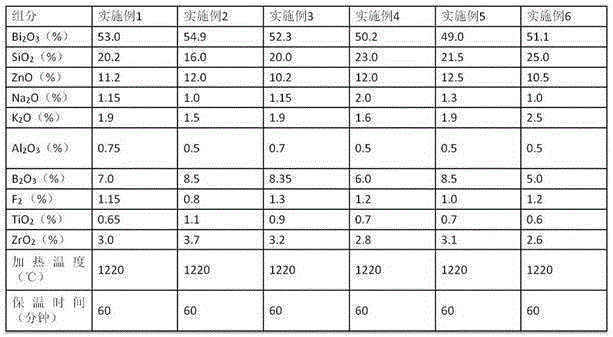

Low-temperature lead-free glass powder for vehicle front windscreen laminated glass ink, and preparation method thereof

InactiveCN106430988ASimple componentsGood adhesion and chemical stabilityAcid resistanceLaminated glass

The invention discloses low-temperature lead-free glass powder for a vehicle front windscreen laminated glass ink, and a preparation method thereof, wherein the low-temperature lead-free glass powder contains, by mass, 15-25% of SiO2, 45-60% of Bi2O3, 4-12% of ZnO, 1.5-4.0% of Na2O, 0.5-2.5% of K2O, 0.3-1.0% of Al2O3, 5-10% of B2O3, 0.4-1.3% of F2, 0.5-1.0% of TiO2, and 2.5-3.8% of ZrO2. The low-temperature lead-free glass powder of the present invention has characteristics of low softening temperature, wide softening temperature range, suitable expansion coefficient, high acid resistance, high alkali resistance, high adhesion, and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

Direct extrusion method for the fabrication of photonic band gap (PBG) fibers and fiber preforms

ActiveUS20120321263A1Low softening temperatureHigh processing temperatureGlass making apparatusCladded optical fibrePhotonic bandgapCore (optical fiber)

A method and apparatus for making a substantially void-free preform for a microstructured optical fiber using a one-step process is provided. A preform is prepared from specialty glasses using a direct extrusion method. A die for use with the direct extrusion method is also provided, and a method for drawing the preform into a HC-PBG fiber for use in transmitting infra-red wavelength light is also provided. The preform comprises an outer jacket made of solid glass, a cladding having a plurality of air holes arranged in a desired pattern within the jacket, and a core which is hollow.

Owner:NAVY U S A AS REPRESENTED BY THE SEC OF THE THE

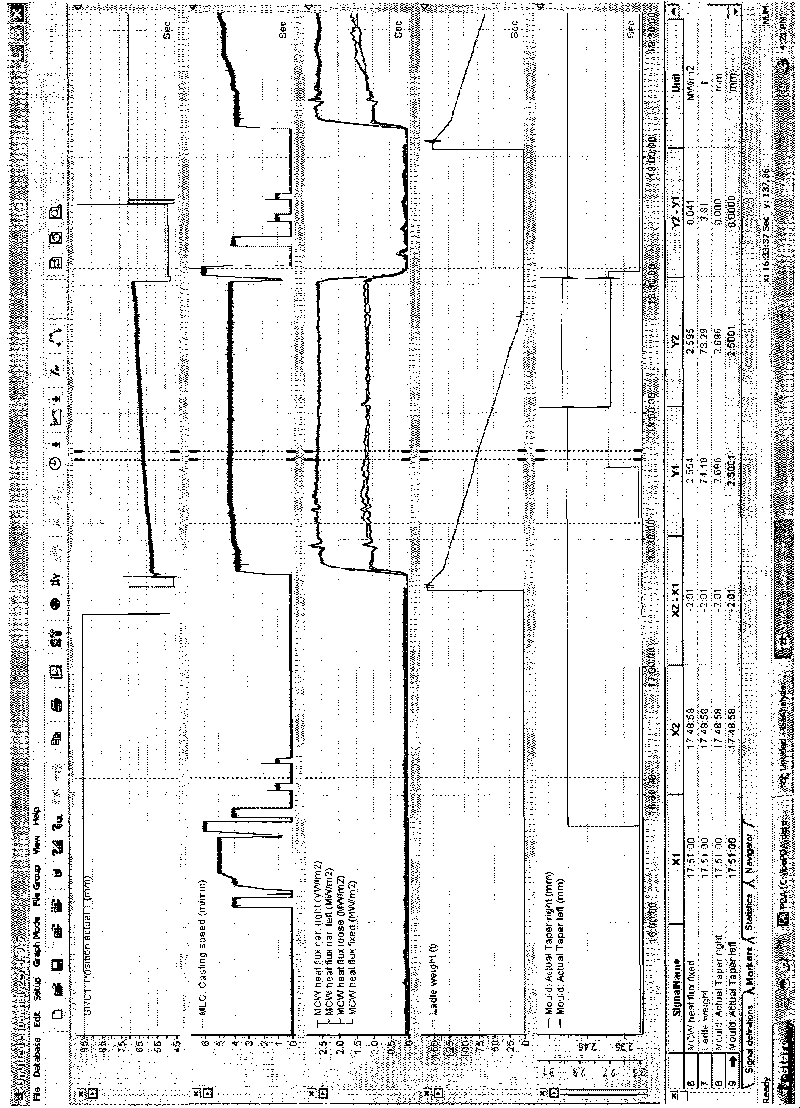

Continuous casting mold fluxes for medium-high carbon steel and alloy steel

The invention provides continuous casting mold fluxes specific for production of medium-high carbon steel and alloy steel. The mold fluxes are applicable to the production of the medium-high carbon steel and the alloy steel with a carbon content ranging from 0.26 to 1.0 weight percent by a thin slab continuous casting machine. The mold fluxes mainly comprise the following components in weight percentage: 23.0 to 31.0 percent of SiO2, 22.0 to 29.0 percent of CaO, 4.0 to 6.0 percent of MgO, 2.5 to 4.5 percent of Al2O3, less than or equal to 1.3 percent of Fe2O3, less than or equal to 1.0 percent of MnO2, 10.0 to 13.0 percent of Na2O, 8.7 to 12.0 percent of F and 7.0 to 10.0 percent of C. The mold fluxes of the invention have relatively low crystallization and softening temperatures, so when the medium-high carbon steel and the alloy steel with a relatively low liquidus temperature are poured, the lubrication of a non-Newtonian fluid and the probability of surface cracking caused by the inhomogeneous heat dissipation of a casting slab due to the crystallization are greatly reduced in a relatively low crystallization and softening temperature range.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

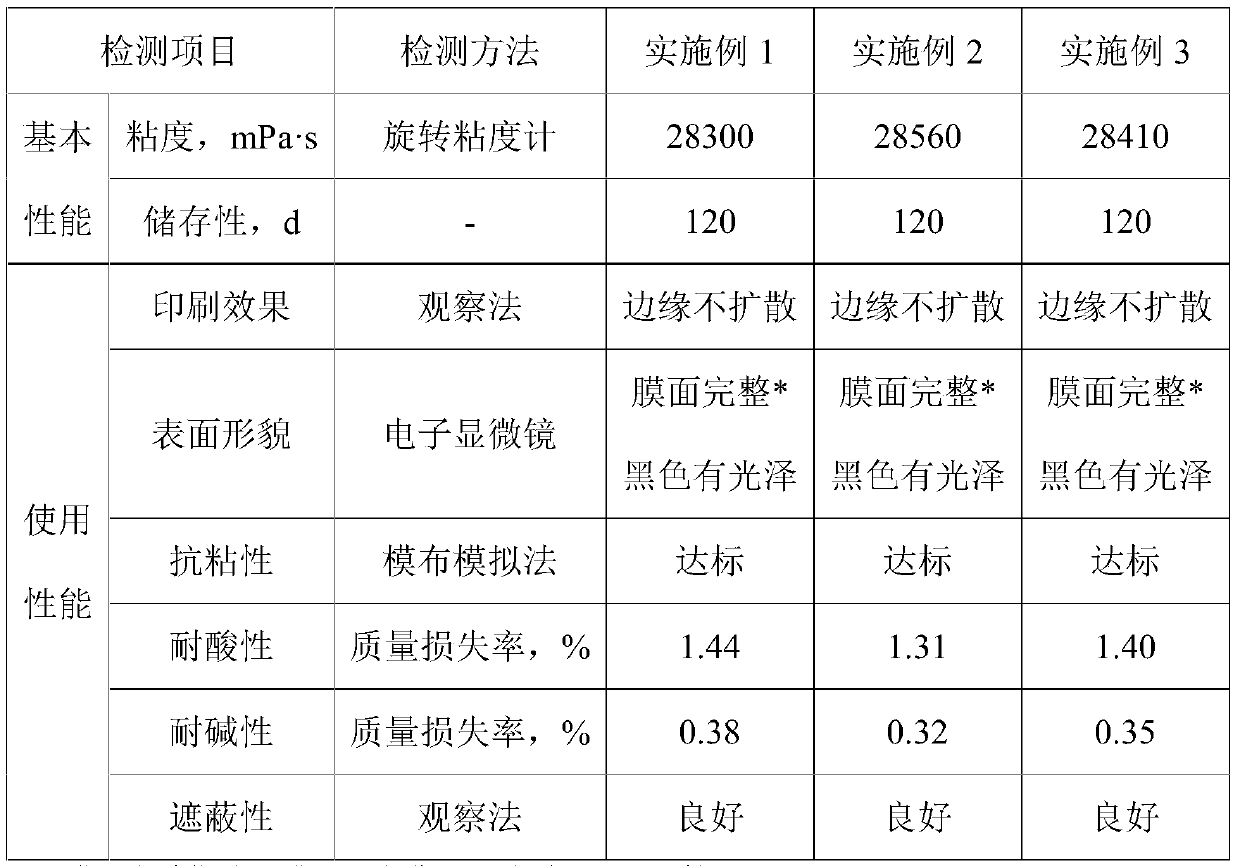

Lead-free glass printing ink for automobile toughened glass and preparation method of printing ink

The invention relates to lead-free glass printing ink for automobile toughened glass and a preparation method of the lead-free glass printing ink. The glass printing ink is prepared from lead-free low-melting-point glass powder, an inorganic pigment, varnish and auxiliaries, and the lead-free low-melting-point glass powder is prepared from the following components in percentage by mole: SiO2 32.0%-32.6%, B2O3 15.1%-15.7%, Bi2O3 12.2%-12.8%, ZnO 22.8%-23.4%, TiO2 4.0%-4.6%, Al2O3 2.6%-3.2%, Li2O 2.2%-2.8%, Na2O 2.2%-2.4%, CaO 2.0%-2.6%, ZrO2 1.8%-2.0%, and Y2O3 0.45%-0.50%. The lead-free glassprinting ink has good storage property, printability, viscosity resistance, acid and alkali resistance and shielding property, and is suitable for being used as automobile toughened glass.

Owner:郑州知淘信息科技有限责任公司

Water-based adhesive for lamination of polymers to metal substrates

ActiveUS20110076486A1Thin thicknessSignificant costManual label dispensersAdhesive articlesWater basedPolymer science

What is disclosed is a water-based adhesive composition that is an aqueous dispersion or emulsion of a polymer component having functional groups that are inactive in a reversible manner in the adhesive composition as prepared; and a water-soluble, or water emulsion, or dispersion of a cross linker component having functional groups wherein the functional groups are inactive in a reversible manner in the adhesive composition as prepared. Preferably the adhesive composition has a pH of from 7 to 11 and a volatile stabilizing base component is used to inactivate the functional groups and to provide the pH. The functional groups in the polymer component and the cross linker component are activated when the volatile base is removed during lamination heat treatment. The adhesive composition can be used to adhere a variety of plastic films to metal substrates without reliance on non-water-based adhesives.

Owner:HENKEL KGAA

Method for preparing ceramic tiles from calcium silicate slag

InactiveCN103641446ARealize mass utilizationReduce consumptionCeramic materials productionClaywaresCalcium silicatePyrophyllite

The invention relates to a method for preparing ceramic tiles from calcium silicate slag, belonging to the field of comprehensive utilization of resources and novel technologies for ceramic preparation. The ceramic tiles contain the following raw materials in percentage by weight: 30-60% of calcium silicate slag, 10-30% of clay, 2-25% of quartz, 0-20% of feldspar, 0-10% of pyrophyllite, 0-10% of green coke and 0-10% of talc. According to the method, ceramics are produced from calcium silicate slag, so that the stacked discharge of calcium silicate slag is reduced, the aim of resource recycling is achieved, and a new way for the high-added-value utilization of calcium silicate slag is added; the utilization ratio of calcium silicate slag in calcium silicate slag ceramics can reach 60%; by using the characteristic that a great deal of alkali metal ions are contained, a feldspar raw material can be replaced partially or totally, and the ceramic tiles are produced under the low-temperature condition of 1,130-1,180 DEG C; all properties of the ceramic tiles prepared by the method disclosed by the invention are better than the national ceramic standards.

Owner:UNIV OF SCI & TECH BEIJING

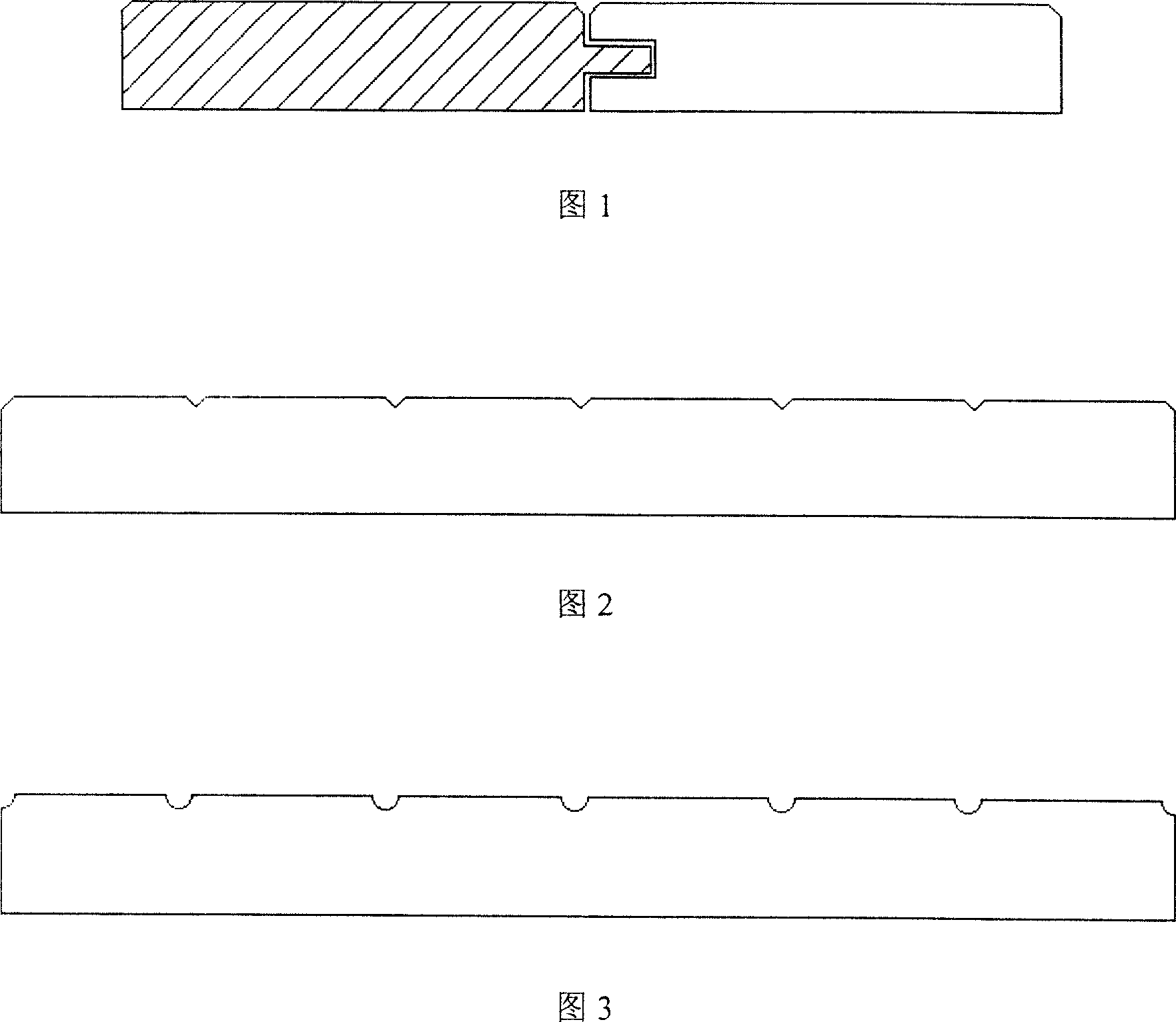

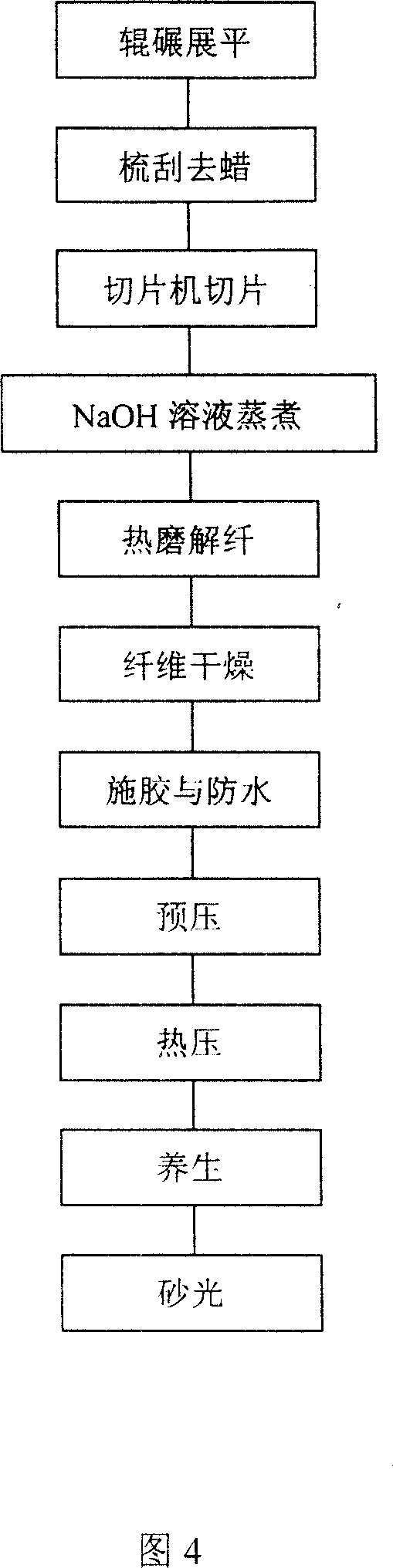

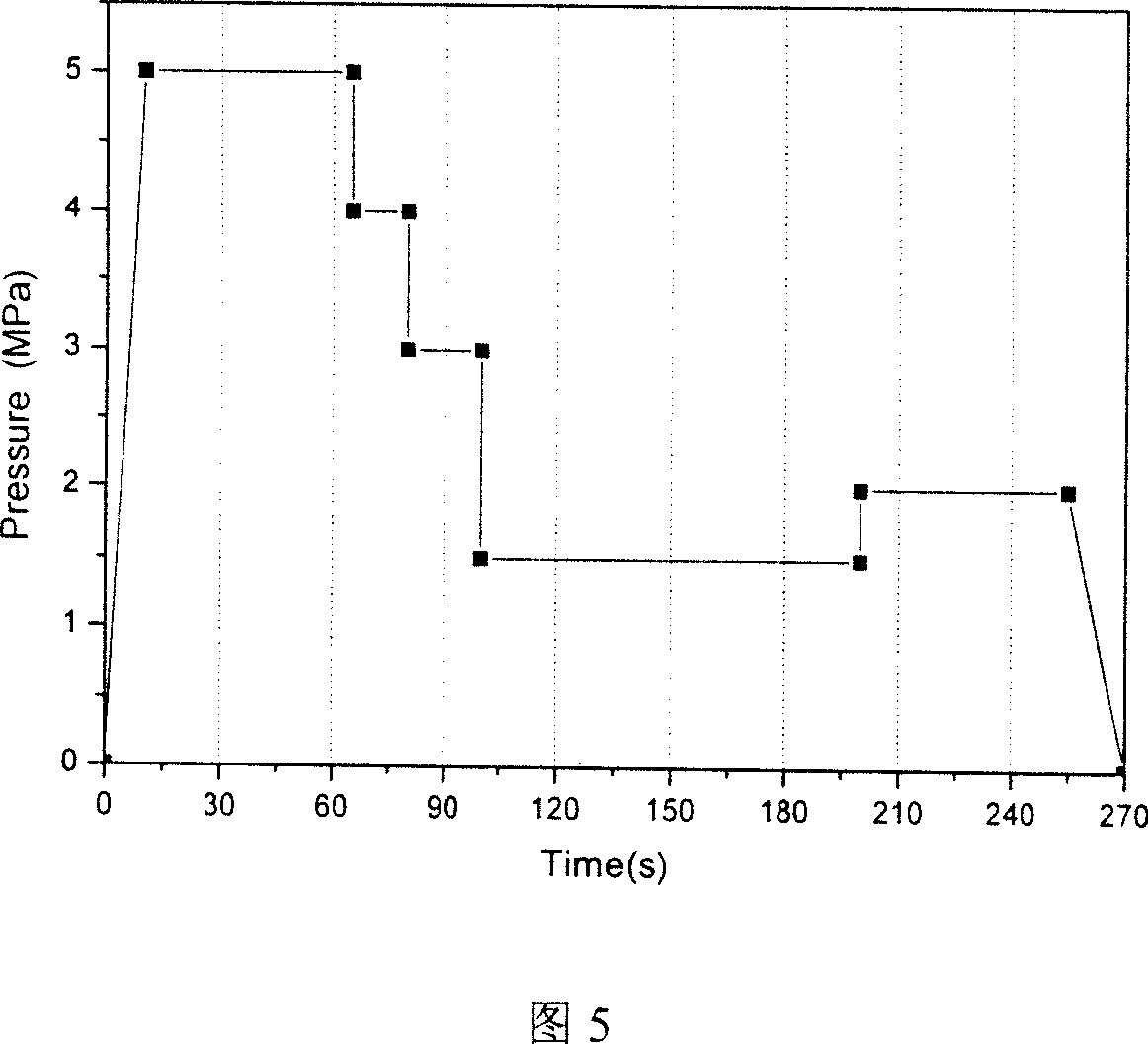

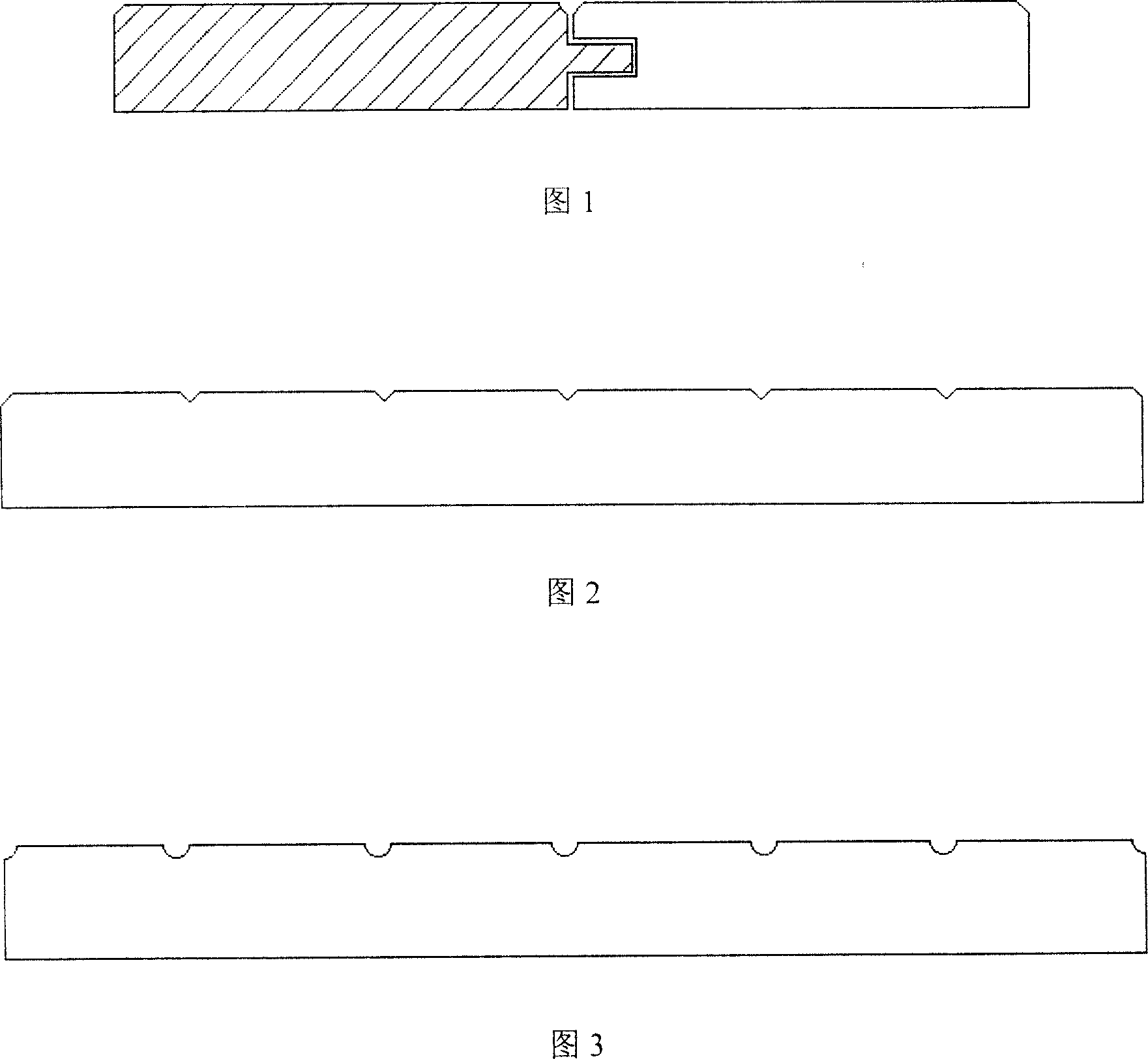

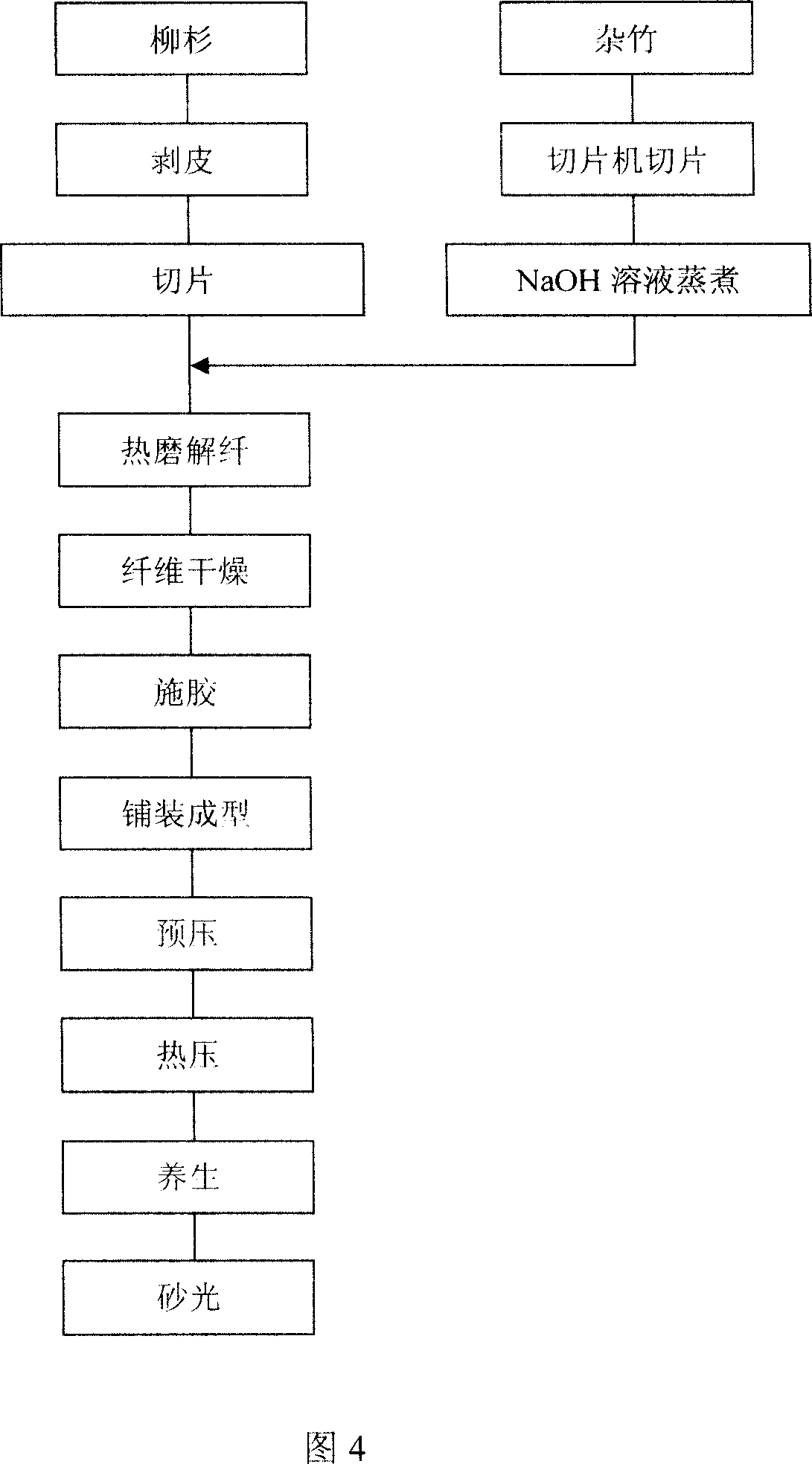

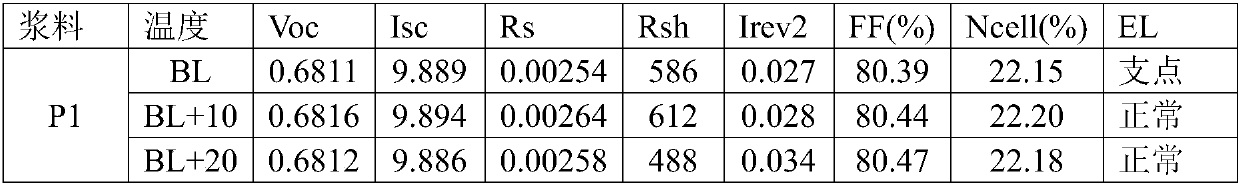

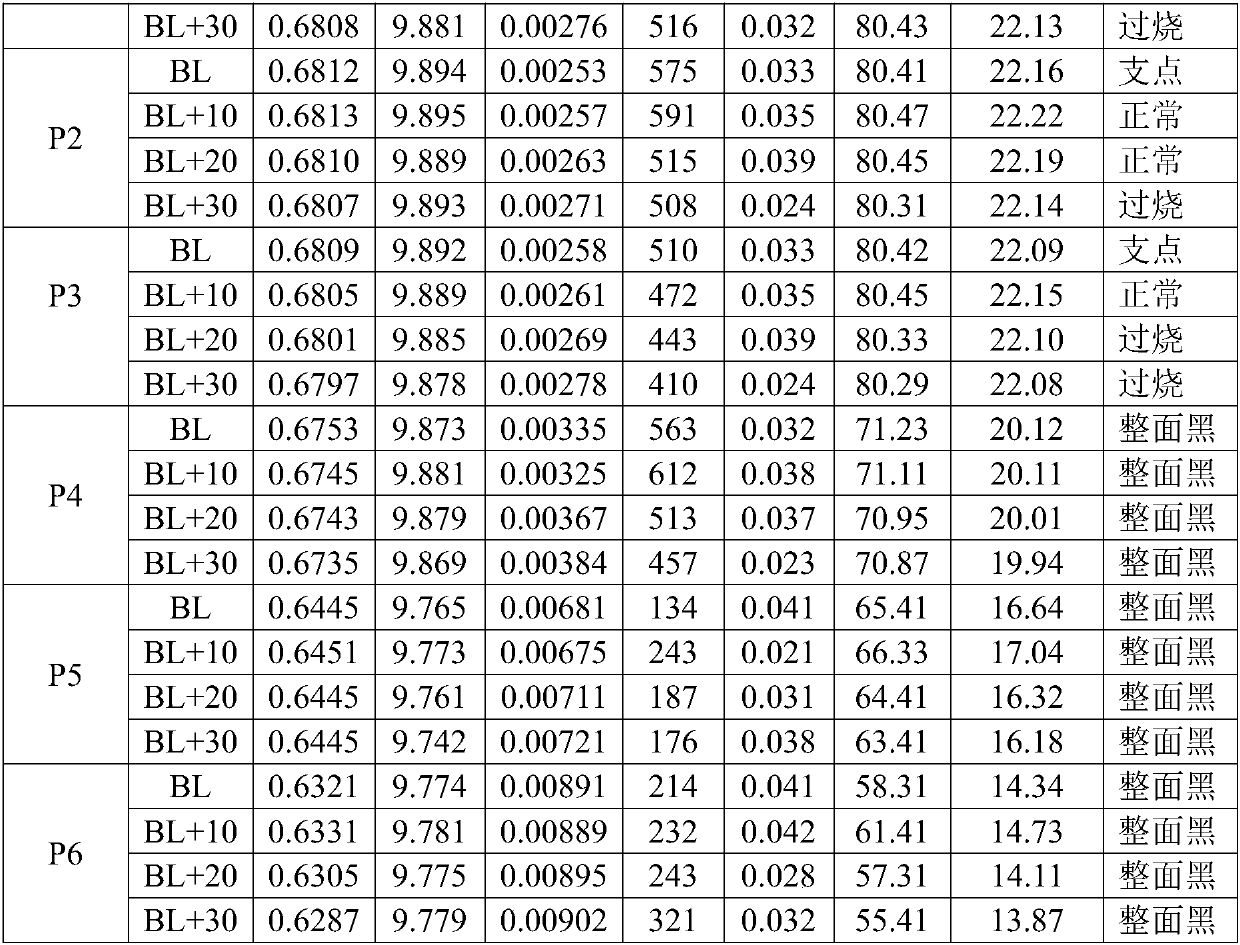

Medium density fiber board made from bamboo

InactiveCN1994702AIncrease profitImprove appearance qualityFibrous raw materialsDomestic articlesParaffin waxFiber

The invention relates to a bamboo middle-density fiber plate, made from bamboo and Japanese cedar, wherein it is formed by 50-95 Japanese cedar sheets, 1-100 bamboo sheets, 8-15 urea-formaldehyde glue, 0.5-5 anti-fungus agent, 0.2-3 solidifier, and 1-3 ceresin wax. And its preparation comprises that: putting bamboo sheets into solution while NaOH is 1-5% of bamboo weight; at 80-130Deg. C and 0.5MPa pressure, boiling it for 10-15min, to be mixed with Japanese cedar sheets, to be grinded and dried; plating urea-formaldehyde glue added with anti-fungus agent, solidifier and wax emulsion on the fiber to be thermally compressed.

Owner:SICHUAN SHENGDA FOREST PROD IND GRP CO LTD

Preparation method of aluminum conductive paste of high-performance environment protection solar cell

InactiveCN101752459AImprove photoelectric conversion rateReduce stressFinal product manufactureNon-conductive material with dispersed conductive materialSilicon chipLinear expansion coefficient

The invention discloses a preparation method of aluminum conductive paste of a high-performance environment protection solar cell. The aluminum conductive paste produced by the method is free of lead and solves the problem of environment pollution. The linear expansion coefficient of lead-free glass powder obtained in the preparation process is close to that of a silicon chip, and the success rate after burning is improved. The preparation method of the paste comprises the following steps: (1) preparing glass powder; (2) preparing inorganic adhesive glass metal powder; (3) manufacturing organic carriers; (4) adopting carbon powder of 2-5 mu m for later use; and (5) preparing the aluminum conductive paste: taking the following components by mass percent: 75-85% of aluminum powder coated by aluminum nitride, 9-20% of organic carrier, 3-4% of inorganic adhesive glass metal powder and 1-3% of C powder, wherein the total amount is 100%, and after mixing, grinding with a three-roller mill to particle size of 15-30 mu m to obtain the product with the viscosity of 25000-35000 mpa.s.

Owner:广东鑫皇冠新材料有限公司

Medium density fiber board made from bamboo and wood

InactiveCN1994700AHigh yieldImprove mechanical propertiesFibrous raw materialsFlat articlesFiberParaffin wax

The invention relates to a bamboo middle-density fiber plate, made from bamboo and Japanese cedar, wherein it is formed by 50-95 Japanese cedar sheets, 5-50 bamboo sheets, 8-15 urea-formaldehyde glue, 0.5-5 anti-fungus agent, 0.2-3 solidifier, and 1-3 ceresin wax. And its preparation comprises that: putting bamboo sheets into solution while NaOH is 1-5% of bamboo weight; at 80-130Deg. C and 0.5MPa pressure, boiling it for 10-15min, to be mixed with Japanese cedar sheets, to be grinded and dried; plating urea-formaldehyde glue added with anti-fungus agent, solidifier and wax emulsion on the fiber to be thermally compressed.

Owner:SICHUAN SHENGDA FOREST PROD IND GRP CO LTD

Frit for front silver paste of monocrystalline silicon solar cell and preparation method and application of frit

ActiveCN111499208AEnhanced solder resistanceReduce the temperatureNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteFrit

The invention discloses frit for front silver paste of a monocrystalline silicon solar cell as well as a preparation method and application of the frit. The glass frit comprises a main glass frit andan auxiliary glass frit, wherein the main glass frit comprises 55-90 mol% of TeO2, 1-30 mol% of Li2O, 5-20 mol% of ZnO and 1-10 mol% of X; and the auxiliary glass frit comprises 1-50 mol% of PbO, 1-40mol% of Bi2O3, 1-30 mol% of Li2O and 1-30 mol% of Y. The main glass frit and the auxiliary glass frit for the front silver paste of the monocrystalline silicon solar cell are compounded for use, so that the silver paste has excellent properties of the main glass frit and the auxiliary glass frit, and has the characteristics of low series resistance, high open-circuit voltage and high tension. After the main glass frit and the auxiliary glass frit are compounded, the glass is not sensitive to temperature change, so that the glass has a wide sintering window. The front silver paste can be applied to a single crystal PERC silicon wafer and can also be applied to a double-sided aluminum oxide monocrystalline silicon wafer.

Owner:CHANGZHOU JUHE NEW MATERIAL CO LTD

Special glass fiber reinforced plastic panel material of electric cabinet

The invention discloses a special glass fiber reinforced plastic panel material of an electric cabinet. The panel material is manufactured by using the following raw materials in parts by weight: 30-35 parts of epoxy acrylic resin, 30-40 parts of glass fiber, 3-5 parts of furane resin adhesive, 2-4 parts of polytetrafluoroethylene, 0.1-0.3 part of graphite powder, 1-2 parts of curing agent and 2-4 parts of titanium dioxide powder. The special glass fiber reinforced plastic panel material has the technical effects that the manufactured panel material is small in density, light in weight, high in hardness, good in toughness, good in electric insulation, good in fire resistance, corrosion resistance, abrasive resistance and antistatic capability, time-saving and labor-saving to mount, safe and reliable; the service life of the electric cabinet is prolonged.

Owner:STATE GRID CORP OF CHINA +2

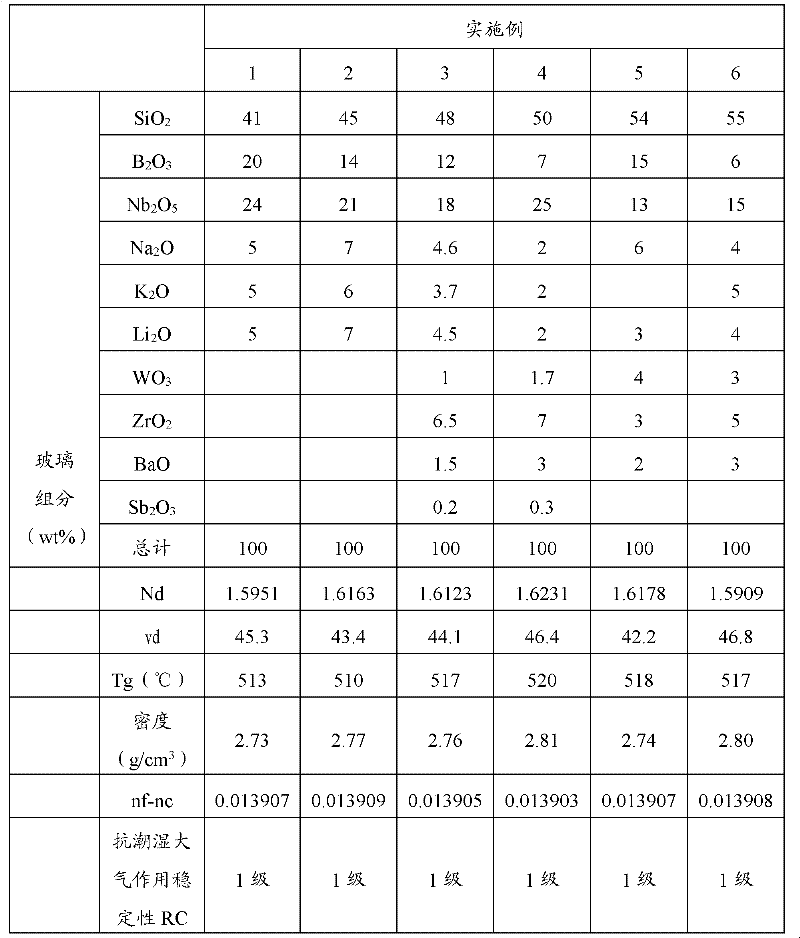

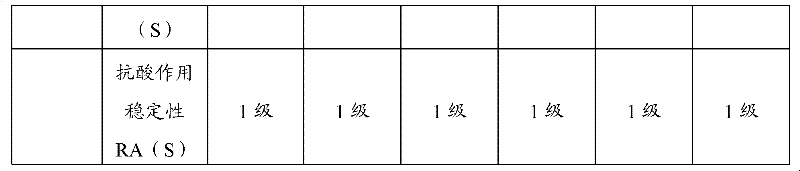

Optical glass and optical element

InactiveCN102199001AMaintain devitrification resistanceImprove thermal stabilityOptical elementsRefractive indexImaging equipment

The invention discloses an optical glass, comprising the following components: 40wt%-55wt% of SiO2, 5wt%-20wt% of B2O3, 13wt%-25wt% of Nb2O5, 3wt%-20wt% of R2O, 0-5wt% of WO3, 0-10wt% of ZrO2, 0-5wt% of BaO, and 0-0.5wt% of Sb2O3, wherein the R2O includes one or a plurality of components selected from a group of Na2O, K2O and Li2O. The optical glass provided by the invention does not need to be added with non-green elements. Experiment results show that the optical glass provided by the invention has a refractive index of 1.59-1.63, an abbe number of 42-47, which satisfies requirements of modern imaging equipment.

Owner:CDGM OPTICAL GLASS

Precision press-molding glass preform, optical element and processes for the production thereof

ActiveCN1590329ALow dispersion propertiesLower glass transition temperatureGlass pressing apparatusLensRefractive indexOptical glass

Provided is a precision press-molding glass preform, which is formed of a high-refractivity low-dispersion optical glass containing no PbO and which requires none of cutting and polishing of an optical-function surface after the precision press-molding is carried out, the optical glass containing, by mol%, 40 to 60 % of B2O3 exclusive of 40 %, 5 to 25 % of La2O3, 2 to 22 % of Gd2O3, 5 to 45 % of ZnO and 0 to 10 % of SiO2 exclusive of 10 % as glass components but containing no PbO, wherein the ratio of the content of B2O3 to the total content of B2O3 and SiO2 (B2O3 / (B2O3+SiO2)) is over 0.84 but not more than 1.00, and the ratio of the content of Gd2O3 to the total content of Gd2O3 and Nb2O5 as an optional component (Gd2O3 / (Gd2O3+Nb2O5)) is over 0.91 but not more than 1.00, the optical glass having a refractive index (nd) of over 1.80 but not more than 2.00 and an Abbe's number ( nu d) of 40 to 45 exclusive of 45.

Owner:HOYA CORP

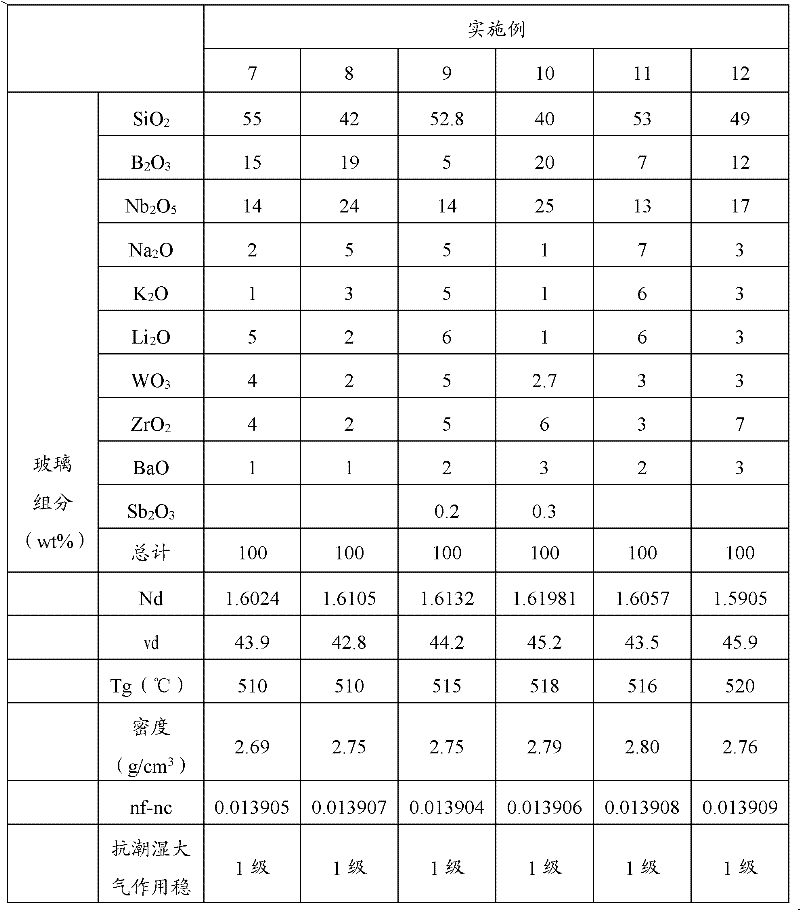

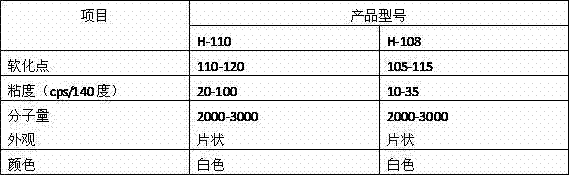

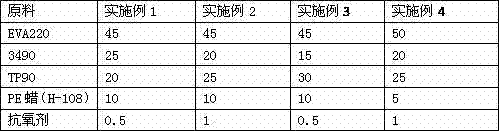

Hot melt adhesive for bonding cable heat shrinkage bush

ActiveCN103709963AImprove heat resistanceSmall molecular weightMineral oil hydrocarbon copolymer adhesivesPolymer scienceHot melt

The invention relates to a hot melt adhesive for bonding a cable heat shrinkage bush. The hot melt adhesive comprises, by weight, 40-60 parts of ethylene-vinyl acetate, 10-20 parts of PE hot melt adhesive, 10-30 parts of a tackifying resin, 1-10 parts of wax and 0-5 parts of an assistant, and the modified PE hot melt adhesive is extrusion-grade linear PE. The hot melt adhesive for bonding a cable heat shrinkage bush has the advantages of required bonding strength, low-temperature use, good adhesion resistance, and satisfying of transport requirements after use.

Owner:江阴伟韬塑料新材料有限公司

High energy graphene battery

ActiveCN107369828AImprove internal conductivityImprove conductivityCell electrodesLi-accumulatorsSolid state electrolyteHigh energy

The invention discloses a high energy graphene battery which comprises a battery anode prepared from graphene wrapped Li0.89Ti0.11FePO4, a solid electrolyte membrane prepared from a Li11Si2PS12 material and a battery cathode prepared from a graphene wrapped silica-based material; the solid electrolyte membrane is arranged between the battery anode and the battery cathode, and the Li11Si2PS12 solid electrolyte membrane is prepared by taking Li2S particles, SiS2 particles and P2S5 particles at a mole mass ratio of 11:4:1 as raw materials, performing grinding and mixing by a high energy ball milling method, preparing sheets by taking molten polyphenyl ether, and performing roll squeezing, hot press molding and chloroform soaking. The prepared graphene battery has the advantages of safety, stability, and high weight energy density, the high pressure is not required in a preparation process, and the preparation cost is low.

Owner:深圳市荣利伟业科技有限公司

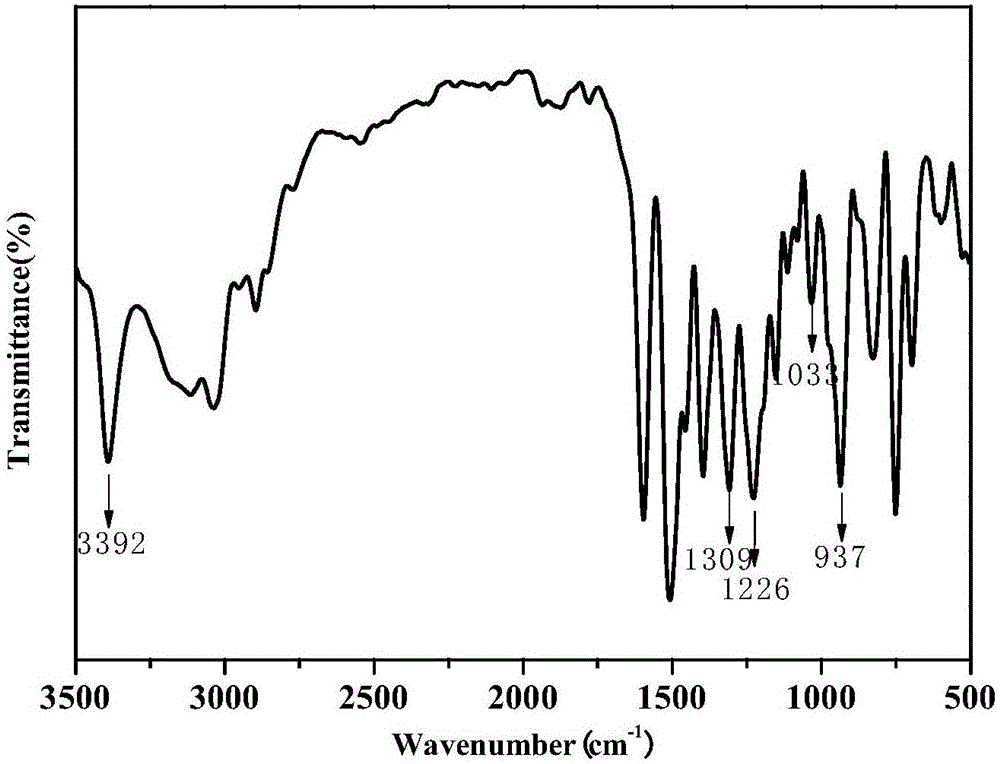

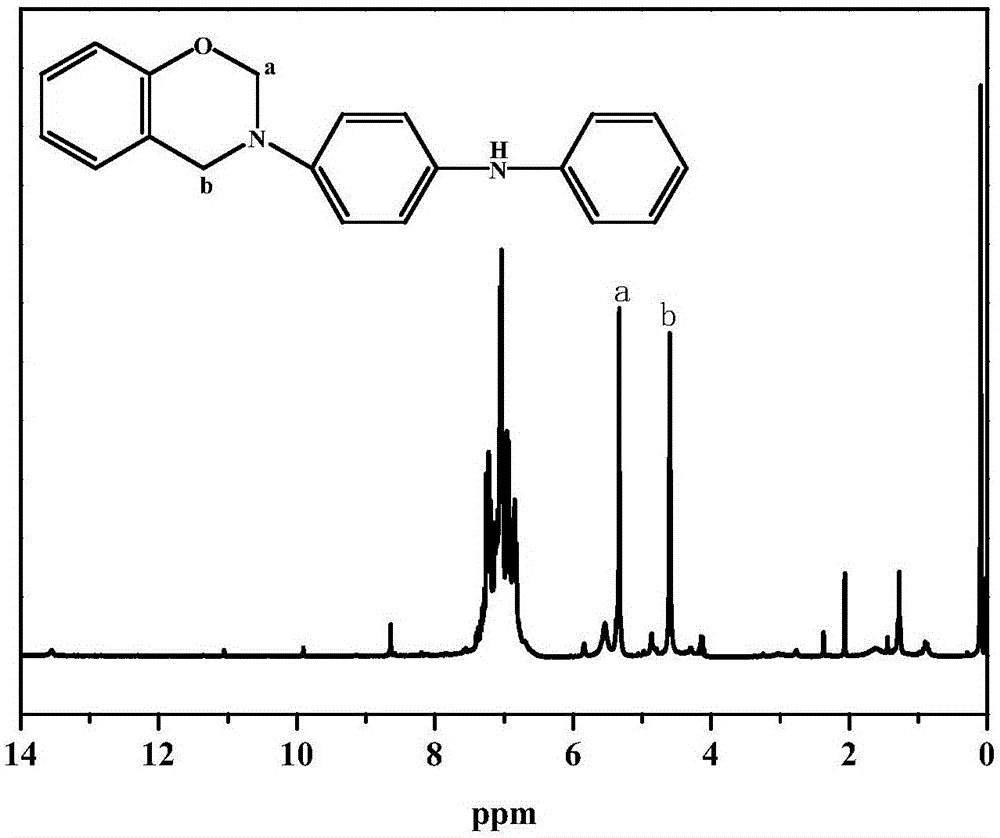

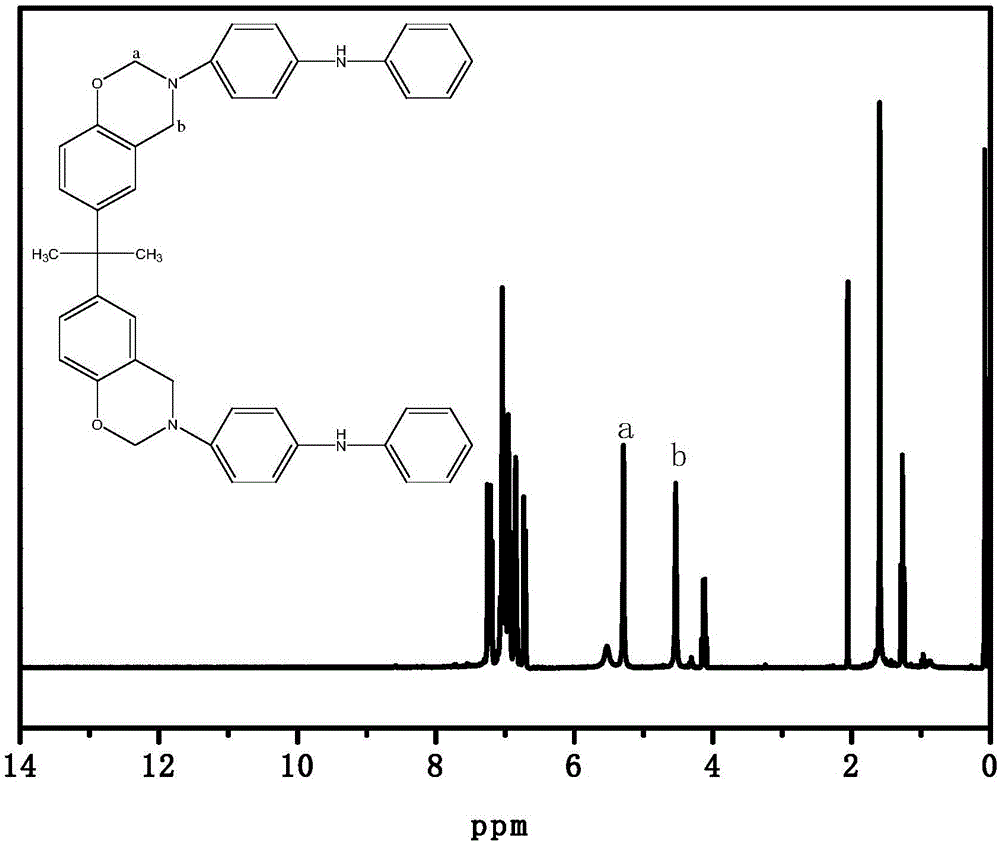

Benzoxazine resin with electroactivity and preparation method thereof

The invention discloses a benzoxazine resin with electroactivity and a preparation method thereof. The benzoxazine resin with electroactivity is prepared through thermal ring-opening, curing and crosslinking of benzoxazine monomer with electroactivity. The benzoxazine monomer with electroactivity is prepared from paraformaldehyde, phenol and primary amine intermediate with electroactivity, wherein phenol is any one selected from a group consisting of phenol, cardanol, bisphenol A, hydroquinone and biphenol. The benzoxazine resin with electroactivity provided by the invention has good electrical performance and excellent mechanical properties and thermal behavior and is widely applicable to fields like electrochromic devices, chemical sensors, anticorrosion coatings and medical biomaterials; the benzoxazine resin with electroactivity is free of release of small molecules in the process of curing, and a curing process is simple and can easily realize industrial production; the benzoxazine monomer with electroactivity has the advantages of flexible molecular designing, low melting temperature, low viscosity in a molten condition, etc.; meanwhile, the benzoxazine monomer with electroactivity is soluble in a plurality of low-boiling-point solvents like acetone and chloroform, and has excellent processability.

Owner:四川天策聚材科技有限公司

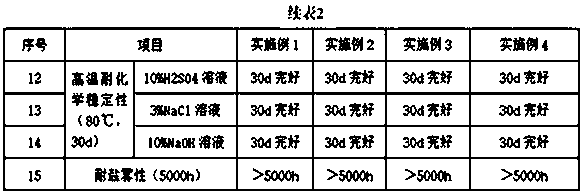

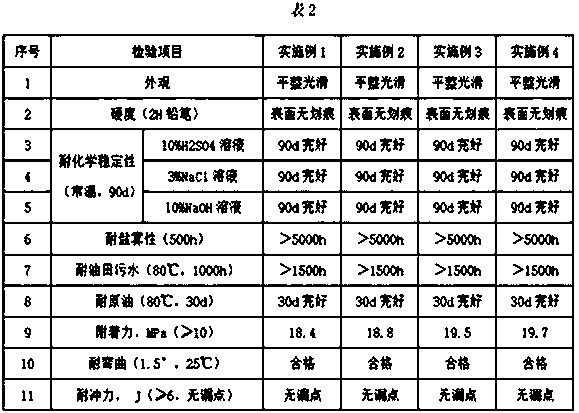

Solvent-free oil pipeline anti-corrosion and anti-drag special coating and preparation method thereof

ActiveCN111205746AImprove thixotropyEvenly dispersedAnti-corrosive paintsEpoxy resin coatingsFatty amineSolvent free

The invention discloses a solvent-free oil pipeline anti-corrosion and anti-drag special coating and a preparation method thereof, belongs to the field of anti-corrosion coatings, and solves the problems that an existing solvent-free anti-corrosion coating is high in construction difficulty, a coating is prone to scale formation and the like. The coating is prepared from two components, wherein the component I is prepared from bisphenol A epoxy resin, polyethersulfone modified epoxy resin, aromatic hydrocarbon resin, glass fiber powder, polytetrafluoroethylene wax powder, potassium hexatitanate whiskers, silica powder, a dispersing agent, a leveling agent, an epoxy active diluent, polyethylene wax powder, talcum powder, phthalocyanine blue, lemon yellow and an antifoaming agent, and the component II consists of a cashew nut shell oil modified phenolic aldehyde amine curing agent and a resin type modified fatty amine curing agent. The preparation method comprises the following steps: mixing the component I and the component II according to a mass ratio of (4-12): 1, and uniformly stirring. The coating has the advantages of favorable long-acting property, favorable flexibility, favorable temperature resistance, favorable chemical resistance, favorable drag reduction effect, environment friendliness and easiness in construction. The preparation method is simple, and the productionefficiency can be obviously improved.

Owner:西北永新涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com