Optical glass and optical element

A technology of optical glass and optical components, applied in optical components, optics, instruments, etc., can solve the problems of poor chemical stability of glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

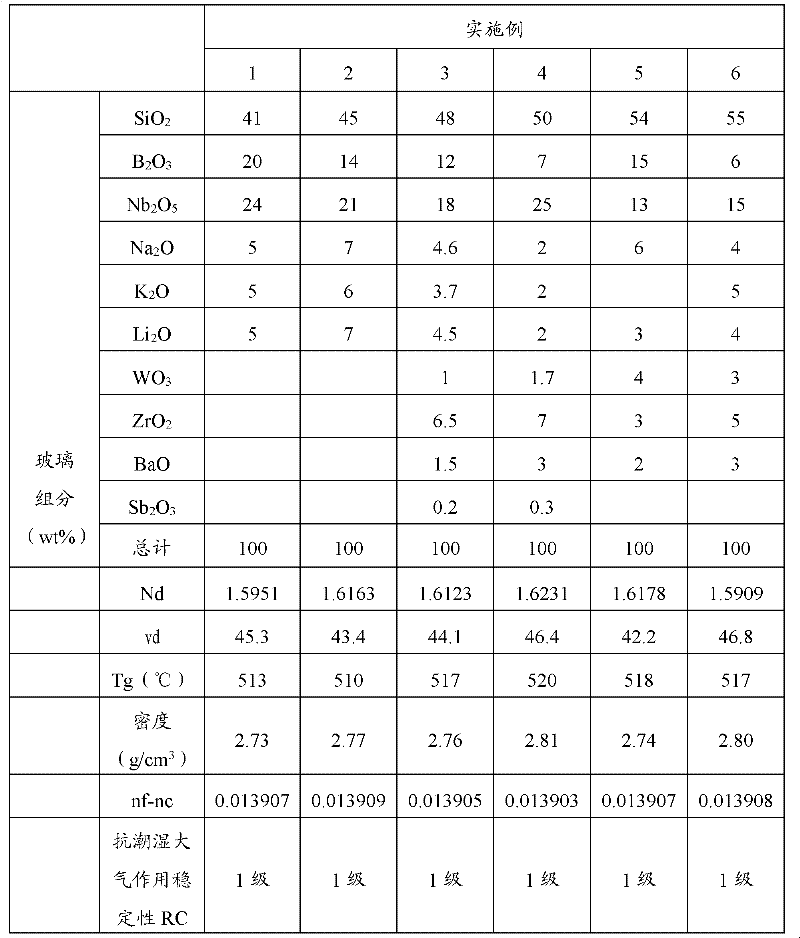

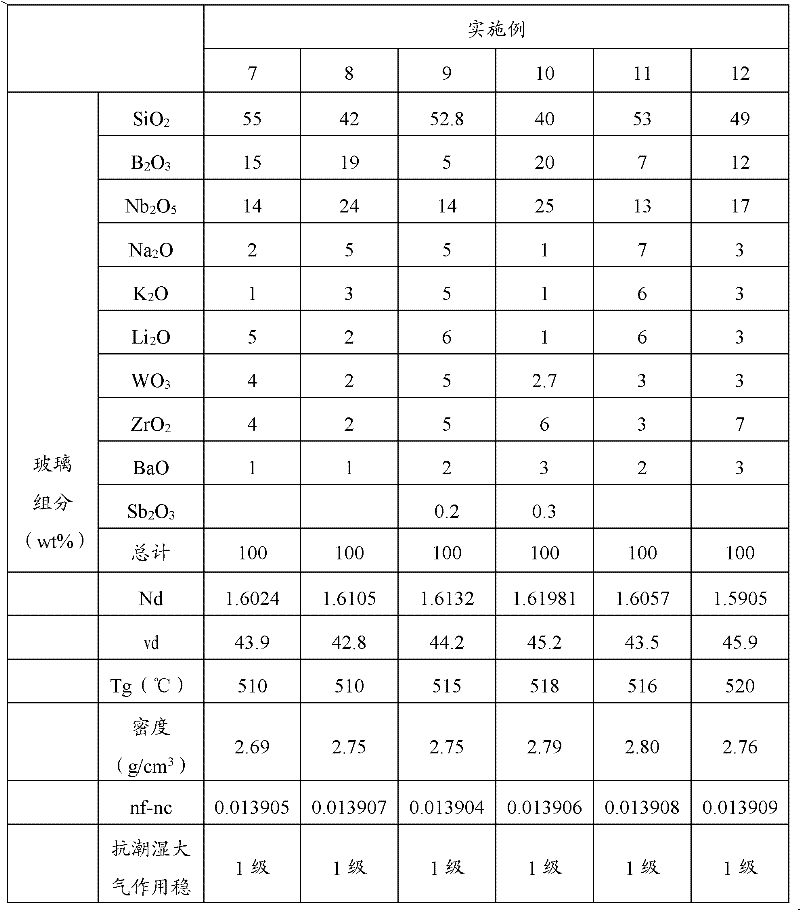

Examples

preparation example Construction

[0054] There is no special limitation on the preparation method of the optical glass provided by the present invention, and it is prepared according to methods well known to those skilled in the art. The raw materials are melted, clarified, homogenized, cooled and molded to obtain optical glass.

[0055] The performance parameters of the optical glass provided by the present invention are tested according to the following methods.

[0056] Among them, the refractive index (nd) value is the annealed value of (-2°C / h)-(-6°C / h), and the refractive index and Abbe number are in accordance with "GB / T 7962.1-1987 Colorless Optical Glass Test Method Refractive Index and Dispersion coefficient" test.

[0057] Transition temperature (Tg) is tested according to "GB / T7962.16-1987 Test Method for Colorless Optical Glass Linear Expansion Coefficient, Transition Temperature and Sag Temperature", that is, when the tested sample is within a certain temperature range, every time the temperatur...

Embodiment 1

[0075] The high temperature viscosity of the optical glass prepared in Example 1 is shown in Table 3.

[0076] The high-temperature viscosity of the optical glass that table 3 embodiment 1 provides

[0077]

[0078] It can be seen from the above embodiments that the optical glass provided by the embodiments of the present invention does not need to add non-environmentally friendly elements. Experimental results show that the optical glass provided by the invention has a refractive index of 1.59-1.63 and an Abbe number of 42-47, meeting the needs of modern imaging equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com