Patents

Literature

33 results about "Pb element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

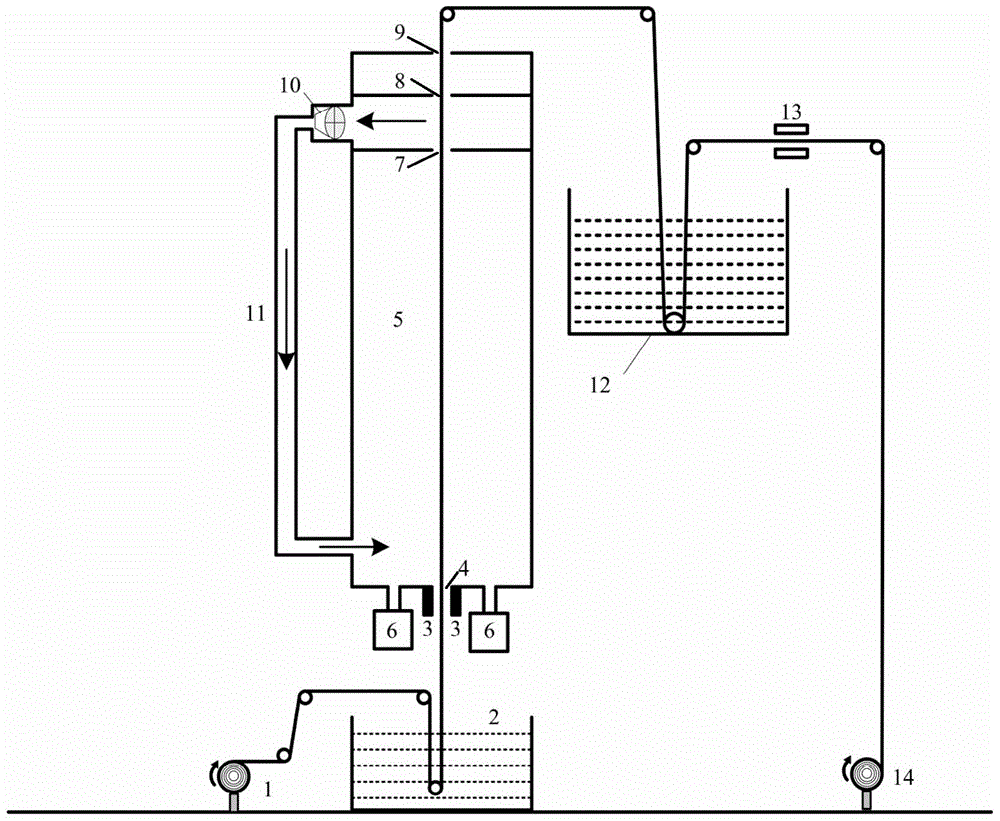

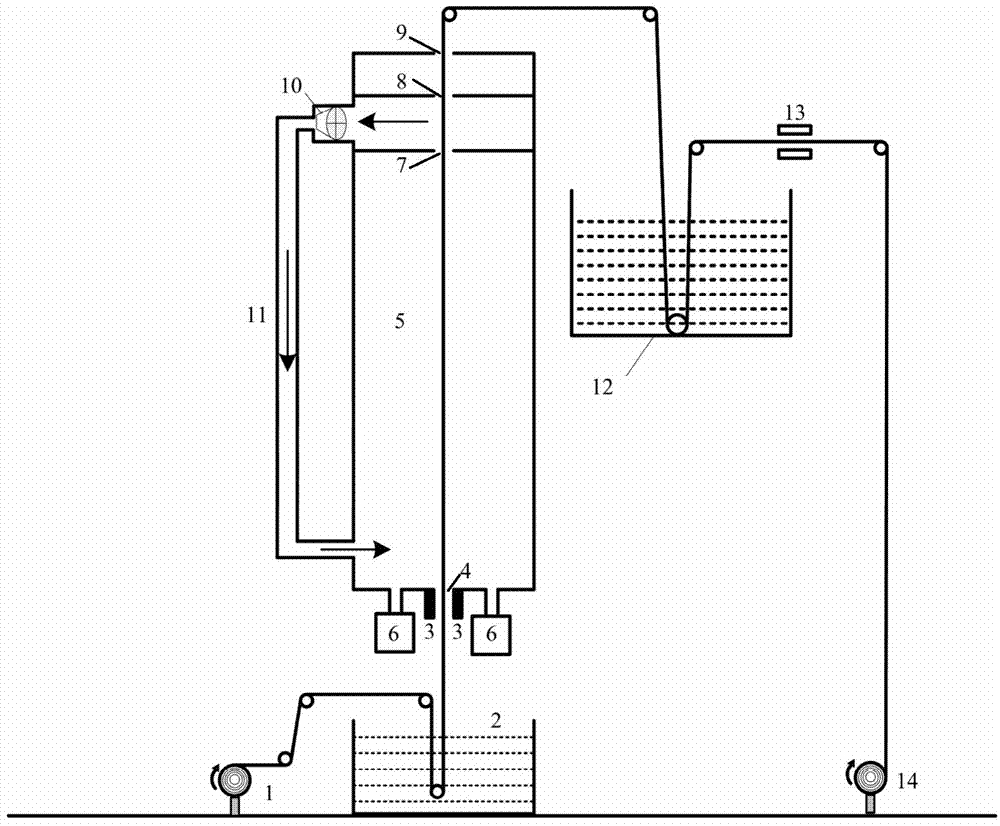

Method and device for depositing disperse tin and zinc crystal nucleuses on surface of highly pure aluminum foil for medium and high voltage anodes in mist spraying mode

ActiveCN104733181AProblems Affecting DepositionLow densityElectrolytic capacitorsCapacitanceElectrolysis

The invention discloses a method and device for depositing disperse tin and zinc crystal nucleuses on the surface of highly pure aluminum foil for medium and high voltage anodes in a mist spraying mode. The method includes the following steps that recrystallization annealing treatment is carried out on the rolled aluminum foil, the highly pure aluminum foil for medium and high voltage anodes is formed, the {100} surface texture occupancy of the highly pure aluminum foil is larger than 95 percent, Mn, Fe, Co, Ni, Cu, Zn, Cd, Ga, Ge, In, Sn and Pb elements of which the electrode levels are higher than that of Al are not rich on the surface of the highly pure aluminum foil, and the purity of Al is more than 99.99 percent; an oxidation film on the surface is removed through an alkali wash pre-treatment method; aluminum foil with the surface covered with a pre-treatment alkali wash film is arranged in a mist box formed by ultrasonic spraying mist to deposit disperse tin and zinc crystal nucleuses. When the highly pure aluminum foil for medium and high voltage anodes with the surface deposited with the tin and zinc crystal nucleuses is adopted, the tin and zinc crystal nucleuses can effectively guide corrosion poring of the aluminum foil in the electrolytic corrosion process, distribution uniformity of channel holes is improved, self-corrosion thinning of the aluminum foil is reduced, and therefore the specific capacitance and bending resistance of the aluminum foil can be obviously improved.

Owner:广西广投正润新材料科技有限公司 +1

Brass strip for button and manufacturing method thereof

The invention discloses a brass strip for a button and a manufacturing method thereof. According to the manufacturing method, the content of Fe and Pb elements in a raw material is strictly controlled, the technology and equipment for annealing treatment are selected according to the thickness of the brass strip, forced fast cooling is conducted on the upper surface and the lower surface of an ingot blank generated after hot rolling is conducted; furthermore, after the upper surface and the lower surface of the ingot blank are quickly cooled, and secondary hot rolling processing is conducted on the ingot blank, so that the produced brass strip has higher environmental protection performance, and no adverse reaction is caused to a human body; little ferromagnetic substance is contained, the button is basically free of magnetism and cannot be detected by a needle detector; meanwhile the content of other elements and the matching among them are adjusted, under the situation that the contents of Pb and the Fe in the brass strip are decreased, the brass strip obtains better structural property and mechanical property, the problems existing in the brass strip for the button are solved, and the brass strip with the structural property and mechanical property more suitable for manufacturing the button is further provided.

Owner:CNMC ALBETTER ALBRONZE

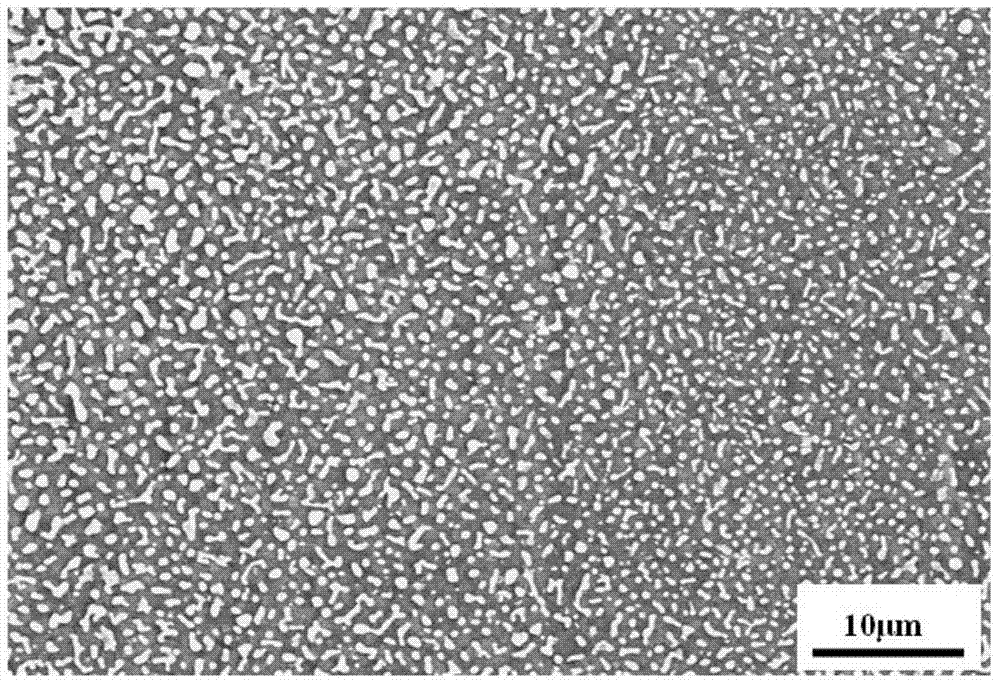

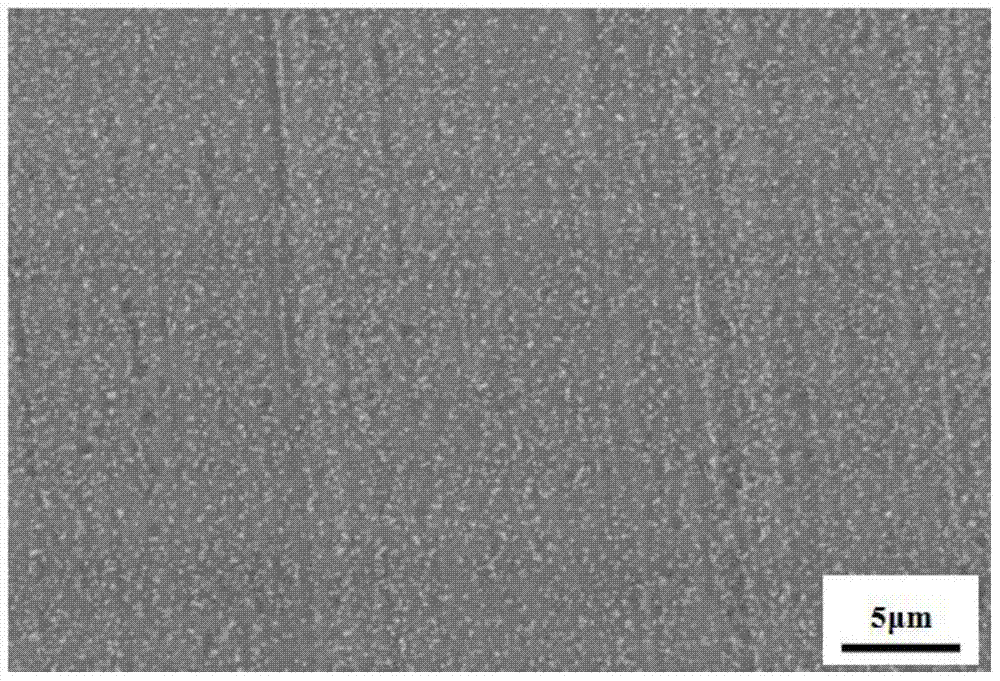

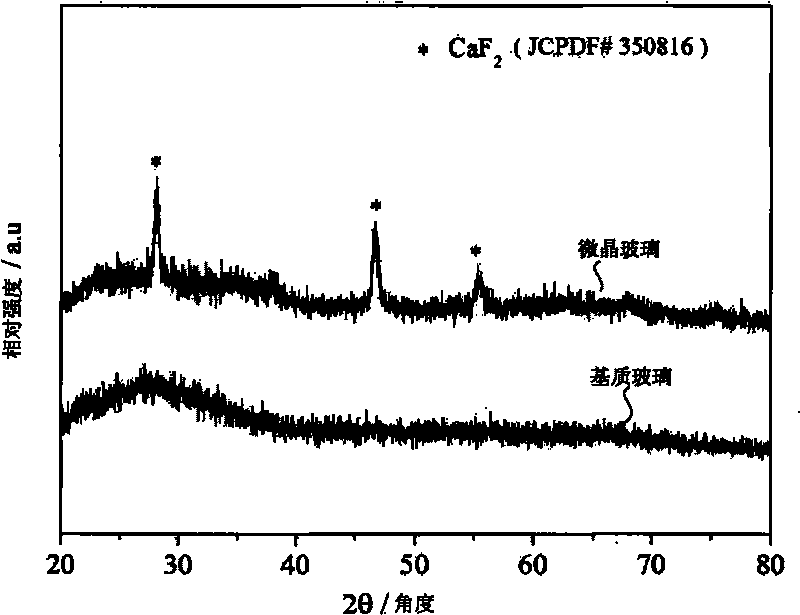

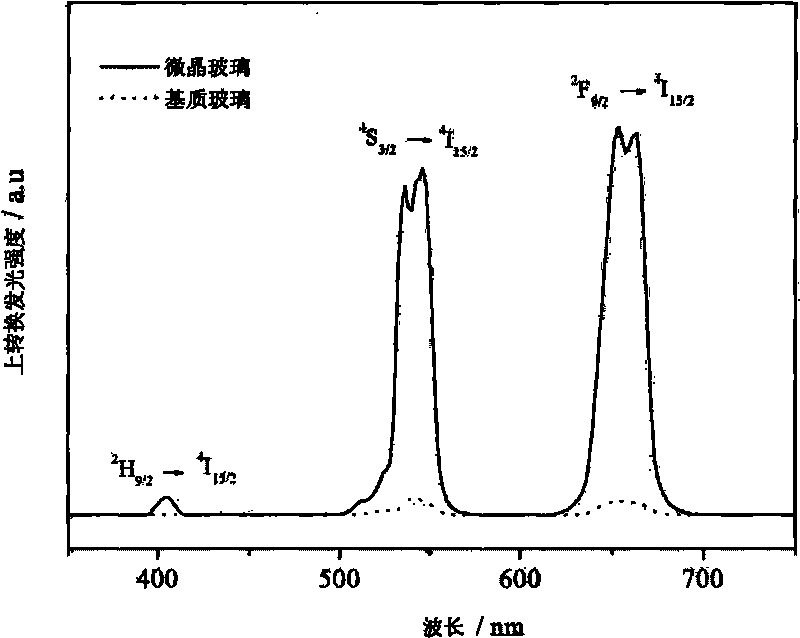

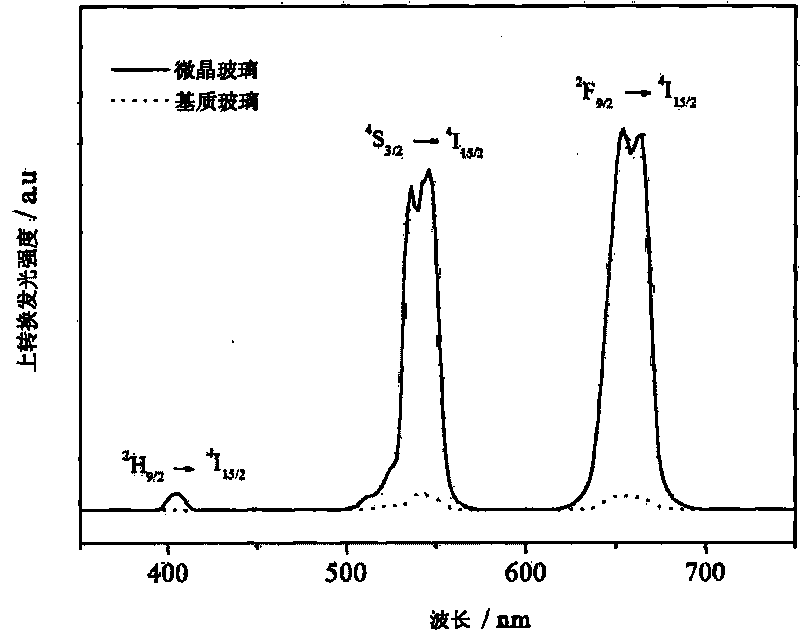

Rare earth iron-doped transparent oxygen fluorine germanate microcrystalline glass and preparation method thereof

The invention discloses a rare earth iron-doped transparent oxygen fluorine germanate microcrystalline glass and a preparation method thereof. The transparent microcrystalline glass comprises the following components by mole percentage: 38-60 percent of GeO2, 4-26 percent of Al2O3, 0-8 percent of Ga2O3, 15-40 percent of CaF2, 0-12 percent of MF, 0-6 percent of ErF3, 0-8 percent of YbF3 and 0-4 percent of PrF3, wherein M is one or more of Li+, Na+ and K+. The preparation method comprises the steps of pouring by melting method to obtain matrix glass and carrying out special thermal treatment on the matrix glass to obtain the microcrystalline glass containing CaF2 crystalline phase in nanometer level. The transparent oxygen fluorine germinate microcrystalline glass is environment-friendly, has stable physicochemical property and does not contain toxic Pb element, and has high transparency from visible area to near-infrared and intermediate infrared areas and excellent active optics property. The invention can be used in the field of optical communication, display, storage, and the like.

Owner:苏州恒仓红外光学材料研发中心有限责任公司

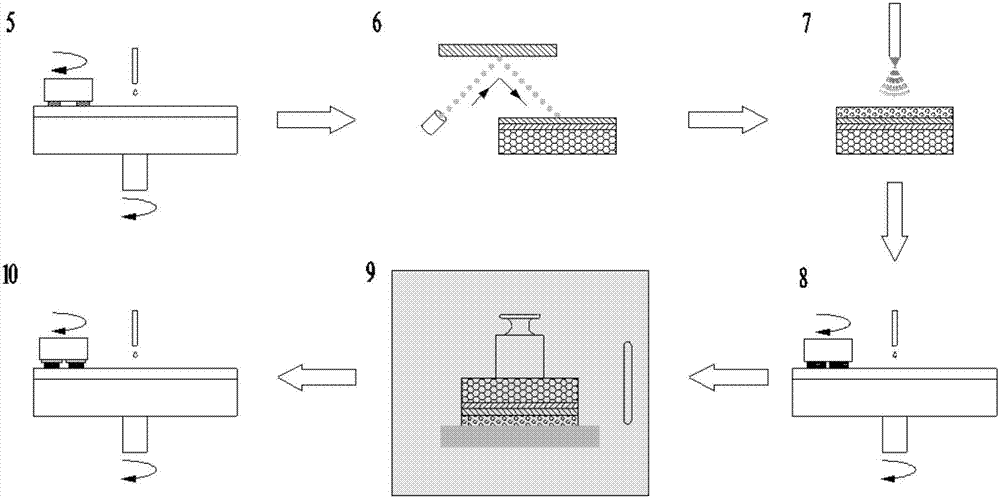

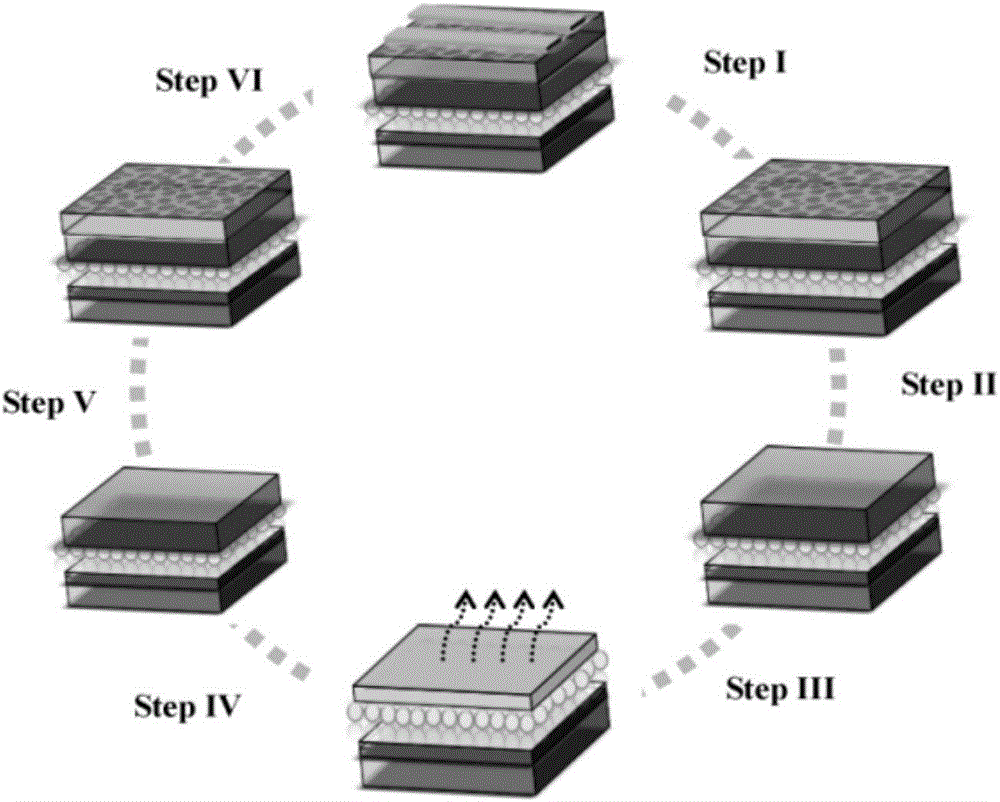

Method for preparing secondary perovskite solar cell

ActiveCN106410048AAchieve recyclingAchieve reuseSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellIodide

The invention relates to a method for preparing a secondary perovskite solar cell. The method comprises the steps of: removing metal electrodes of a perovskite thin-film cell; immersing the perovskite thin-film cell into a chlorobenzene solution for dissolution to remove a hole transport layer; heating a perovskite material to decompose into solid PbA2 and volatile gas methylammonium iodide; growing a perovskite thin film for the second time through immersing or spin-coating a CH3NH3A isopropanol solution; preparing the hole transport layer; and evaporating metal electrodes. The method provided by the invention has the advantages that: 1) the recycling and reuse of various materials in the perovskite cell are realized; 2) the perovskite is decomposed through heating, and a Pb element is recycled in situ in the solid form of the PbA2; 3) the PbA2 recycled in situ can achieve beneficial growth of the perovskite thin film; 4) and the solar cell prepared based on the in-situ grown perovskite thin film CH3NH3PbA3 is simpler in process and lower in cost.

Owner:NINGBO UNIV

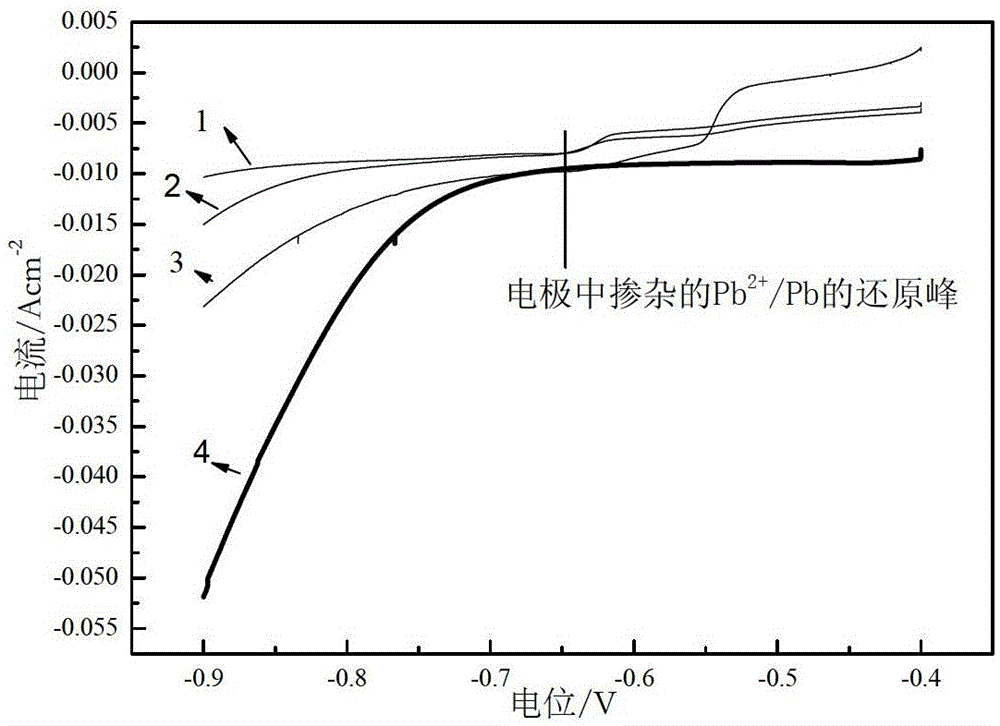

Method for secondary modification of surface of active carbon material for super battery

ActiveCN104659350AImprove buffer current capabilityResolve mismatchHybrid capacitor electrodesLead-acid accumulator electrodesState of artActivated carbon

The invention provides a method for secondary modification of the surface of an active carbon material for a super battery. The method for the secondary modification of the carbon material comprises two steps, including carbon material nanometer Pb modification and carbon material surface Pb coating. According to the method disclosed by the invention, by utilizing microcosmic and macroscopic dual-scale depth, uniformity and great modification of a Pb element in the carbon material, the aims of inhibiting hydrogen evolution of the carbon material in an acidic system, increasing the capacity and regulating an electrochemical window are realized; the problem that only one aspect of defect of the carbon material can be overcome in the prior art is solved, so that an active carbon negative electrode and a Pb electrode of the super battery have the same working potential; the buffer current capability of the C negative electrode is improved, and the problem that the Pb electrode and the C electrode of the super battery are not matched in working potential is solved; compared with the hydrogen evolution current of an unmodified carbon material in the prior art, the hydrogen evolution current of the carbon material modified by the method disclosed by the invention is at least reduced by 52% and is even smaller than the hydrogen evolution current of a pure-lead electrode, so the carbon material can be really applied to the super battery and is suitable for industrial application.

Owner:CENT SOUTH UNIV

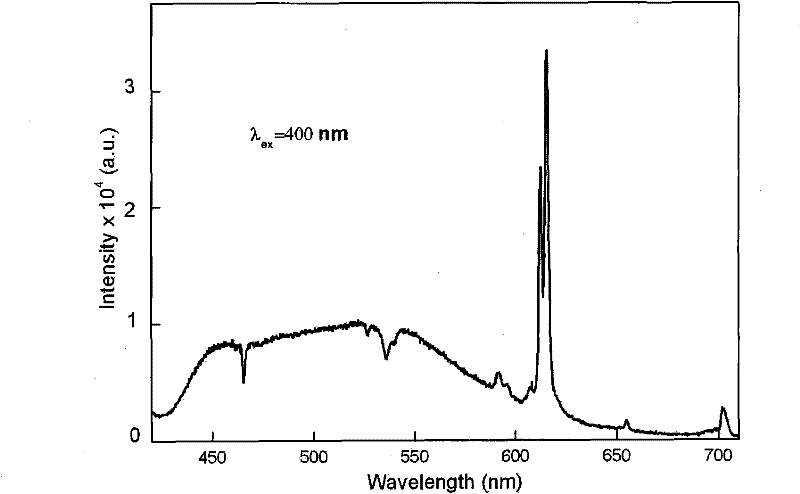

Solar cell of high-efficiency planar heterojunction perovskite structure having interface modification layer formed by [6,6]-phenyl group-C61-butyric acid (PCBA)

InactiveCN105990524ASolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionAbsorption capacity

The present invention relates to a solar cell of a high-efficiency planar heterojunction perovskite structure having an interface modification layer formed by a [6,6]-phenyl group-C61-butyric acid (PCBA). The solar cell is characterized in that iodide perovskite ABI3 is prepared on the FTO / compact TiO2 surface of imporous TiO2, wherein A is the Pb element, and B is organic ammonium iodate CH3NH3I; a perovskite material is made from CH3NH3PbI3, NH2=CHNH3PbI3, CH3NH3SnI3, NH2=CHNH3SnI3 and the like and is good in light absorption capacity, photovoltaic conversion capacity and electron hole transporting capacity. An electron transfer layer which comprises TiO2, ZnO and the like and a hole transporting layer which comprises Spiro-OMe TAD and the like are introduced into the interface of a perovskite active layer and an electrode, so that a perovskite structure-based solar cell device can be constructed. The solar cell is simple in material compounding and low in cost. The device formed is high in stability and long in service life.

Owner:薄志山 +3

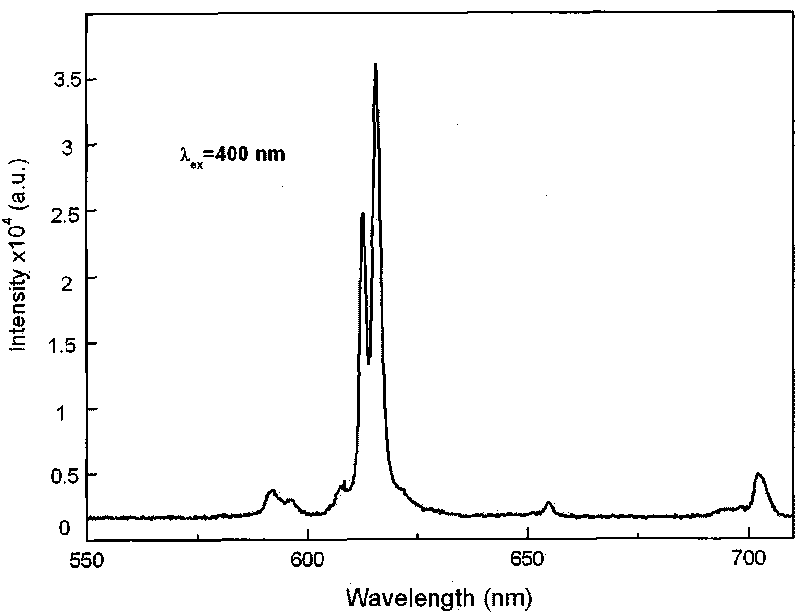

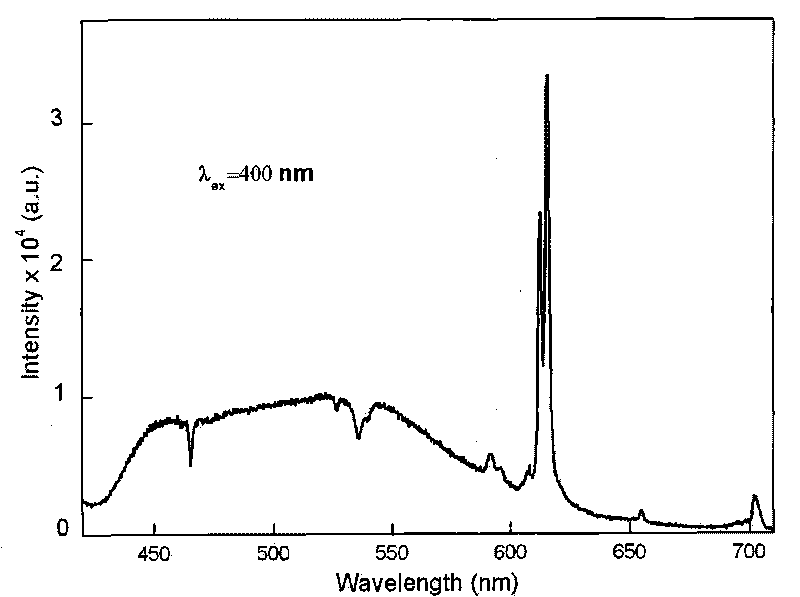

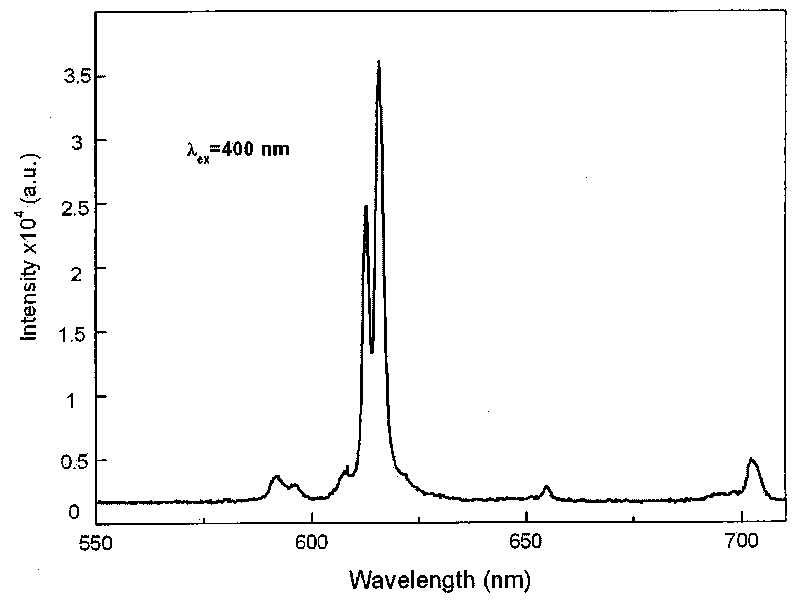

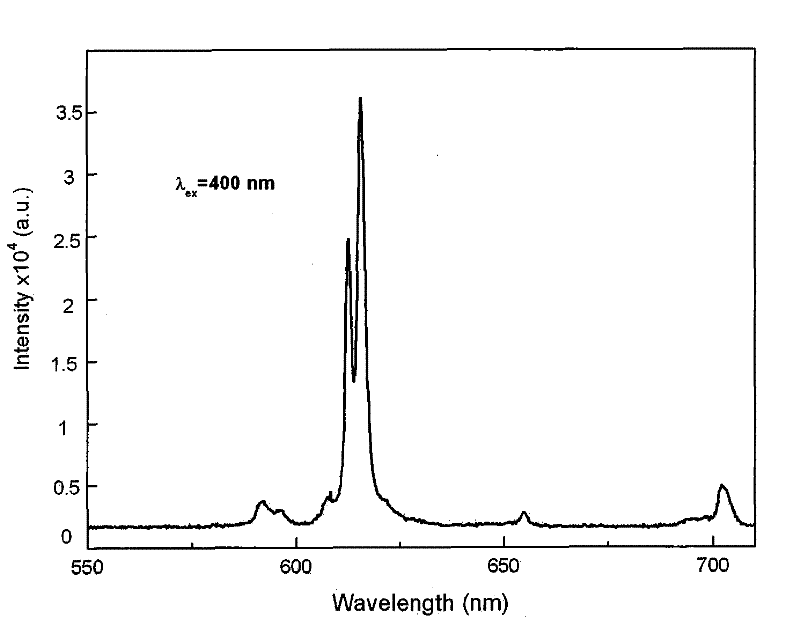

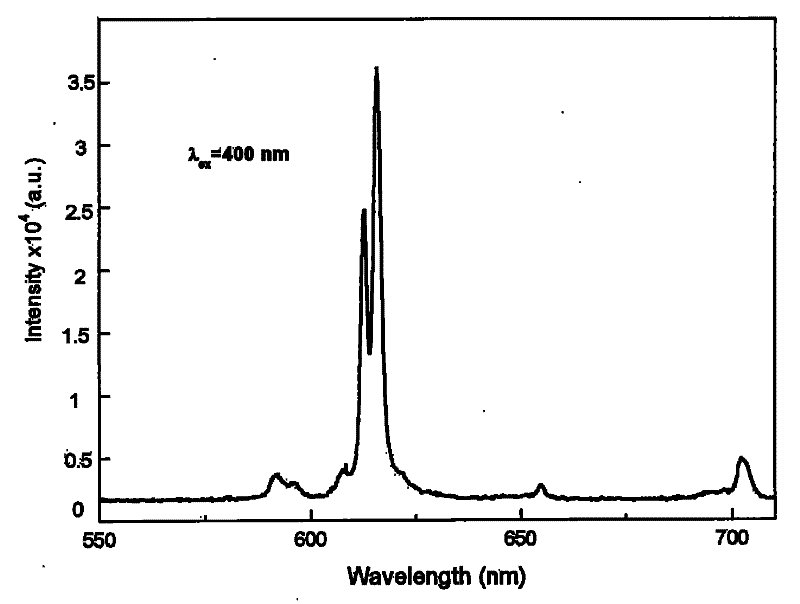

Rare-earth red light-emitting material for converting purple light LED into white light and preparation process thereof

InactiveCN101693834AImprove luminous efficiencyHigh light efficiencyGas discharge lamp usageLuminescent compositionsAir atmospherePb element

The invention relates to a rare-earth red light-emitting material for converting purple light LED into white light and a preparation process thereof, which belong to the technical field of light emission and display and relate to a red light-emitting material and the preparation process thereof. The structural formula of the red light-emitting material includes M4-3a-3b-2c (MoO4) 2: RaRbNc, wherein the M is an alkali metal Li element, the Ra is a rare-earth activator Eu element, the Rb is a rare-earth sensitizer Tb element, and the Nc is a metal sensitizer Pb element. Materials of the structural formula M4-3a-3b-2c (MoO4) 2: RaRbNc are weighed according to percentage by weight; the weighed materials after being grinded and mixed evenly are placed into an aluminum trioxide crucible and sintered for 1-2 hours in a 400-600 DEG C high-temperature furnace; after being cooled, the materials are fetched out, pulverized, placed into the crucible again and sintered for 2-3 hours in 700-1000 DEG C air atmosphere in the high-temperature furnace; after being cooled, the materials are fetched out and pulverized again, and crystalline powders are obtained and can emit bright red light by stimulation of 365 nanometers and a purple light LED. After the crystalline powders are mixed with rare-earth light-emitting materials emitting green and blue light according to a certain proportion, white light can be emitted by coating the crystalline powders onto a purple light LED tube core.

Owner:NORTHEAST NORMAL UNIVERSITY

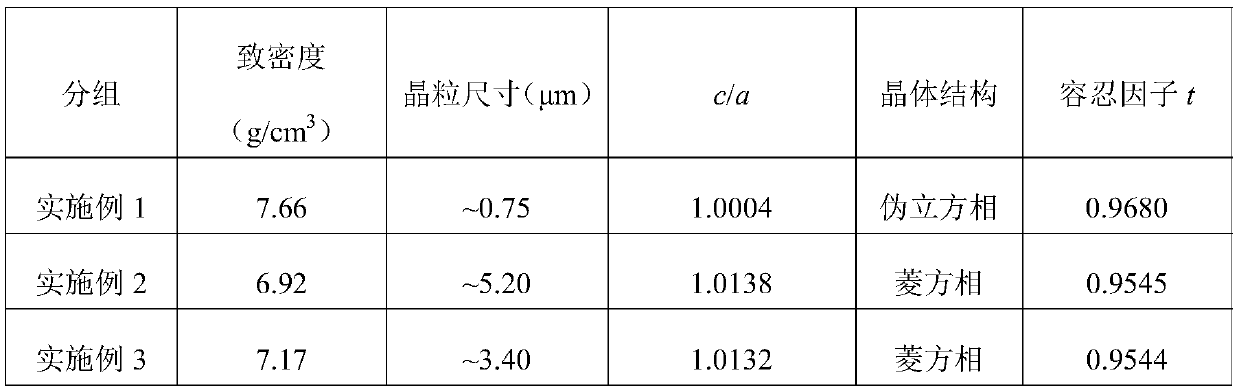

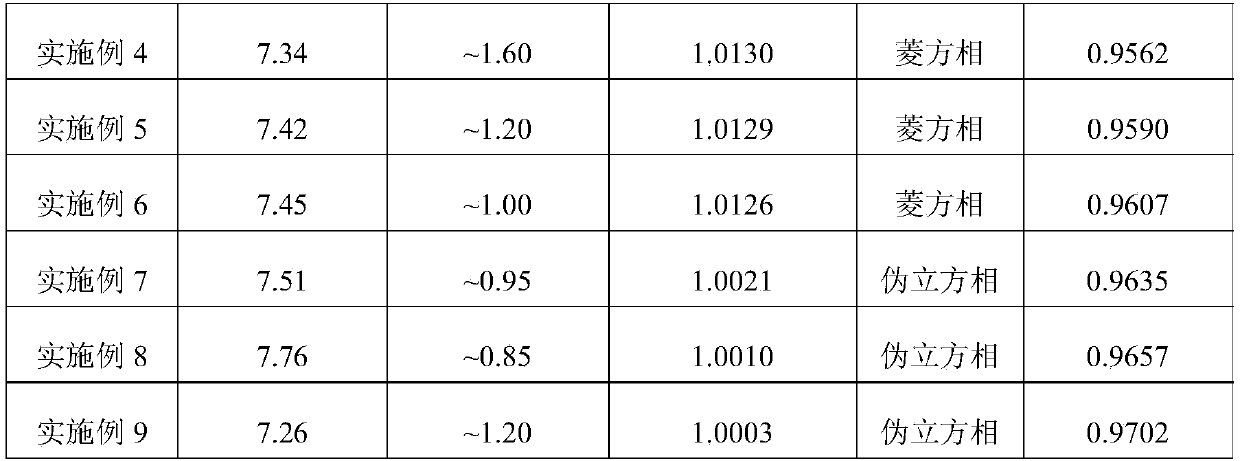

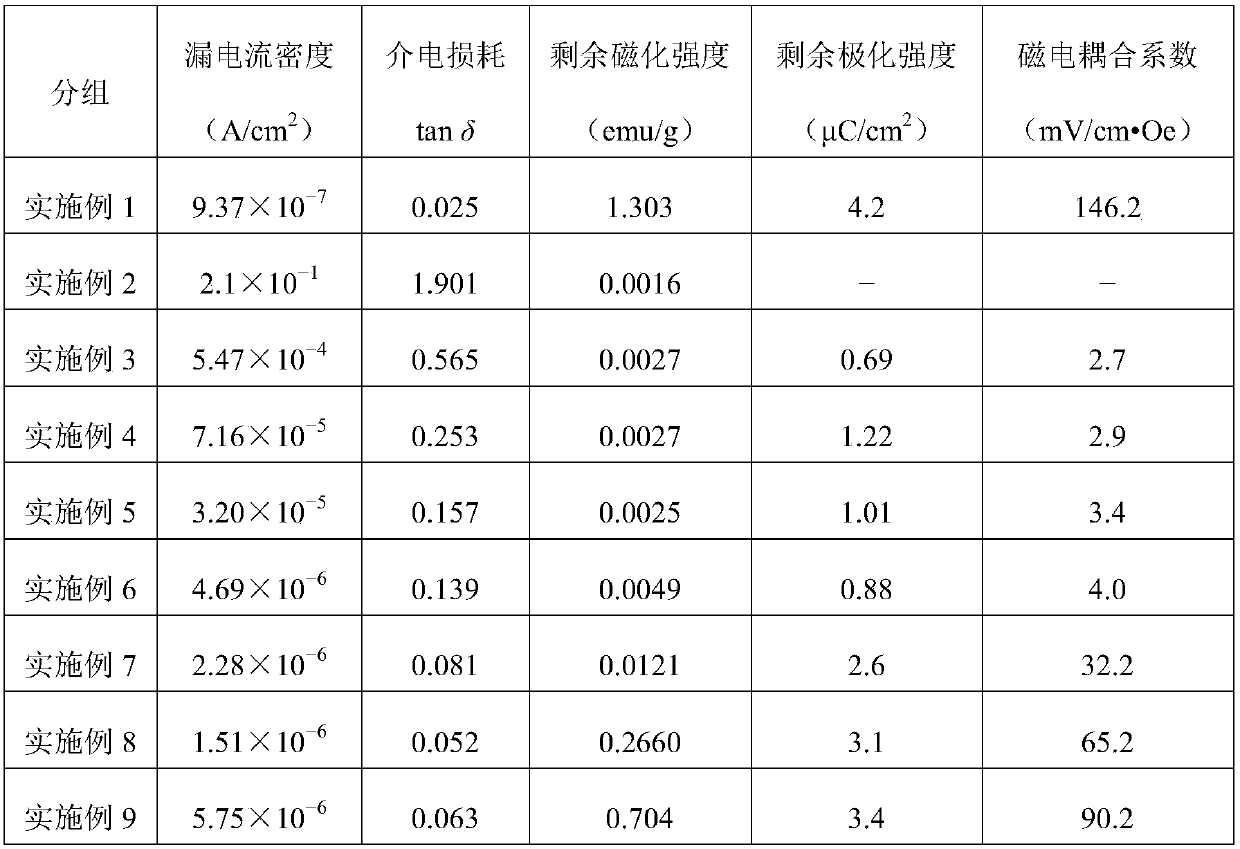

Multiferroic sosoloid ceramic and preparation method thereof

ActiveCN109516796ASolve the problem of large loss and low magnetoelectric coupling effectReduce lossPb elementMultiferroics

The invention provides multiferroic sosoloid ceramic and a preparation method thereof. The chemical constitution of the multiferroic sosoloid ceramic is shown as (1-x-y)BiFeO3-xLaFeO3-yPbFeO2.5, wherein x is the mole percent of LaFeO3; y is the mole percent of PbFeO2.5; x is greater than or equal to 0 but is smaller than or equal to 0.10; y is greater than or equal to 0 but is smaller than or equal to 0.35. The ternary solid solution systems are used and are respectively BiFeO3, LaFeO3 and PbFeO2.5 which respectively have different effects; the BFO has an intrinsic magnetoelectric coupling effect; the LFO can reduce the BFO loss; through the stable BFO structure, PbFeO2.5 can easily realize solid solution and can further reduce the loss; meanwhile, the magnetic and magnetoelectric couplingeffect is improved. BiFeO3 powder, LaFeO3 power and PbFeO2.5 power are respectively prepared, and are then pelleted and sintered together. The preparation method has the advantages that the final sosoloid sintering formation temperature can be effectively reduced; further, the volatilization of Bi and Pb elements at high temperature is reduced.

Owner:JIANGXI UNIV OF TECH

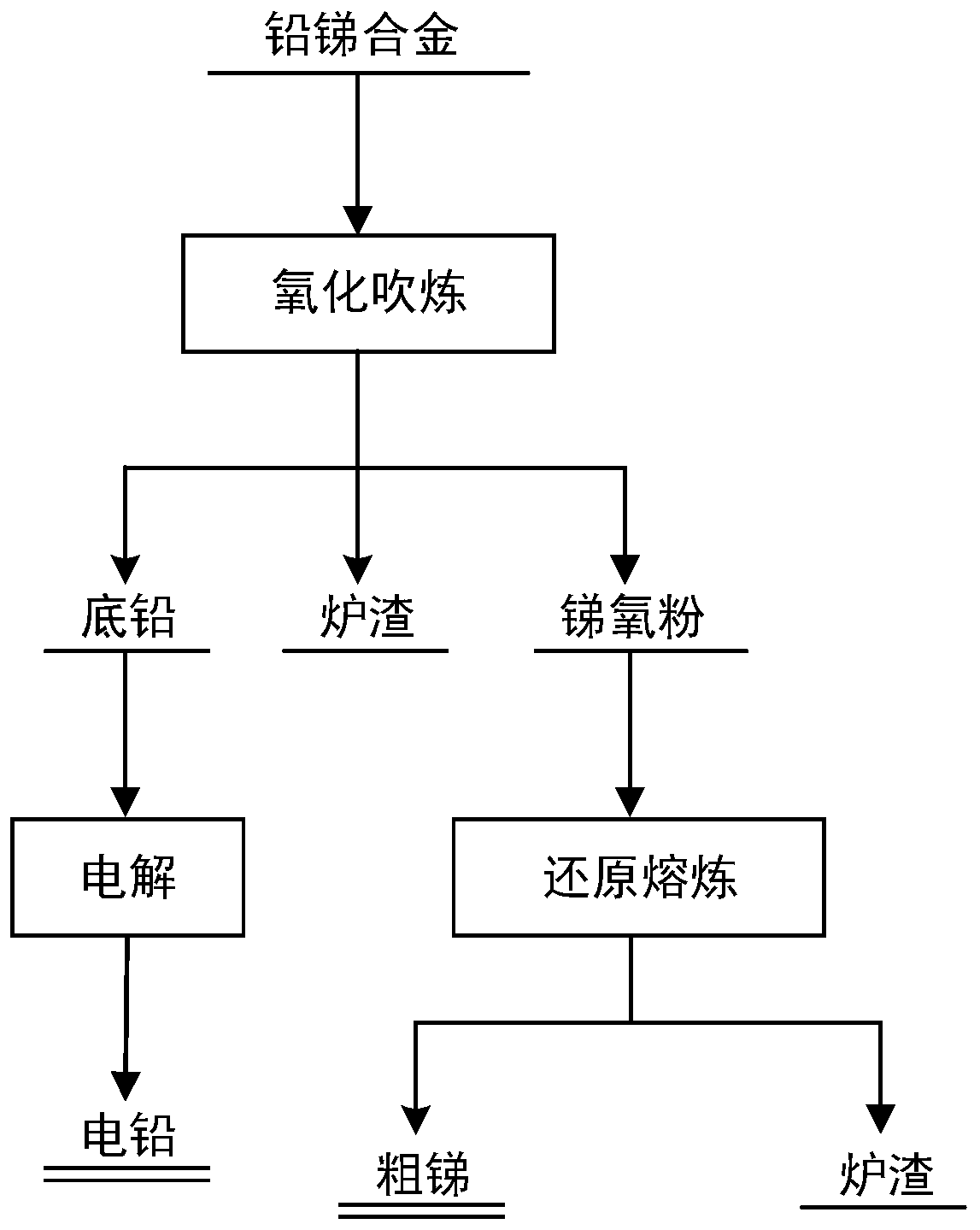

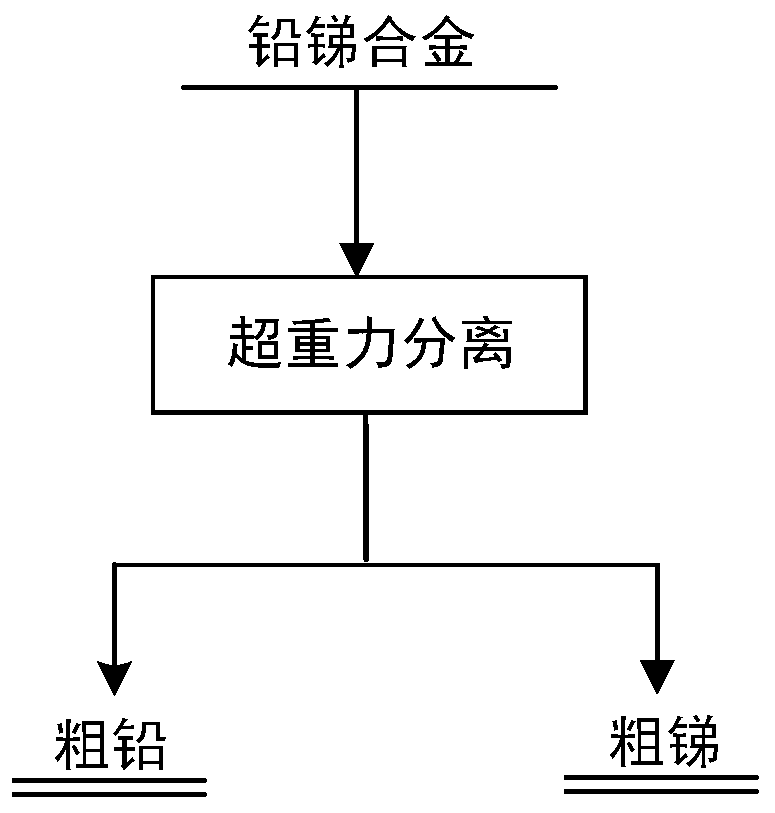

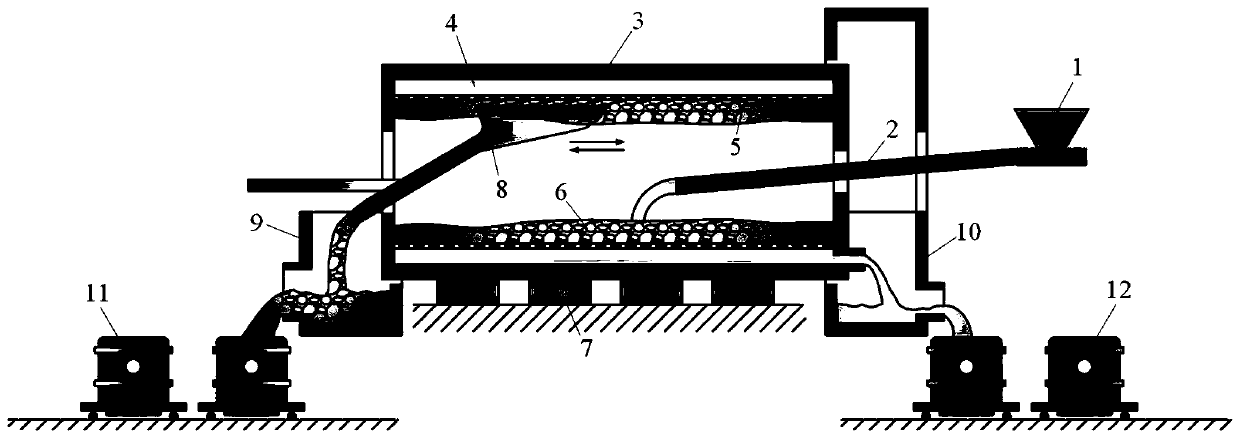

Method and device for separating lead-antimony alloys by supergravity

ActiveCN109825719AHigh recovery rateImprove production efficiencyProcess efficiency improvementPb elementAlloy

The invention discloses a method and a device for separating lead-antimony alloys by supergravity and belongs to the field of nonferrous metallurgy. A large amount of lead-antimony alloys can be produced in the antimony metallurgy or lead metallurgy process, the alloys are continuously input into a rotary supergravity separation reaction cavity through a feeding system, then a rotary supergravityreactor is started, and a stable and adjustable supergravity field is generated by driving a reactor on a rolling shaft by an adjustable-speed motor to rotate. Under the combined action of the supergravity field and a temperature field, the atomic diffusion and mass transfer process of the lead-antimony alloys is greatly accelerated, and continuous separation between a lead-rich liquid and an antimony-rich melt is realized. By adopting the method and the device, rapid separation of the lead-rich liquid and the antimony-rich melt in the lead-antimony alloys can be realized under the supergravity condition, the metal recovery rate is remarkably increased, a lead-rich liquid with the Pb content being larger than 85 percent and an antimony-rich phase with the Sb content being 87-91 percent areobtained, and the total recovery rate of Pb element reaches 90 percent or above. The method and the device have the advantages of simpleness in operation, no production of smoke and smelting slag, continuous production and low cost, are also suitable for separating the alloys in other nonferrous smelting processes and improve the production benefit.

Owner:UNIV OF SCI & TECH BEIJING

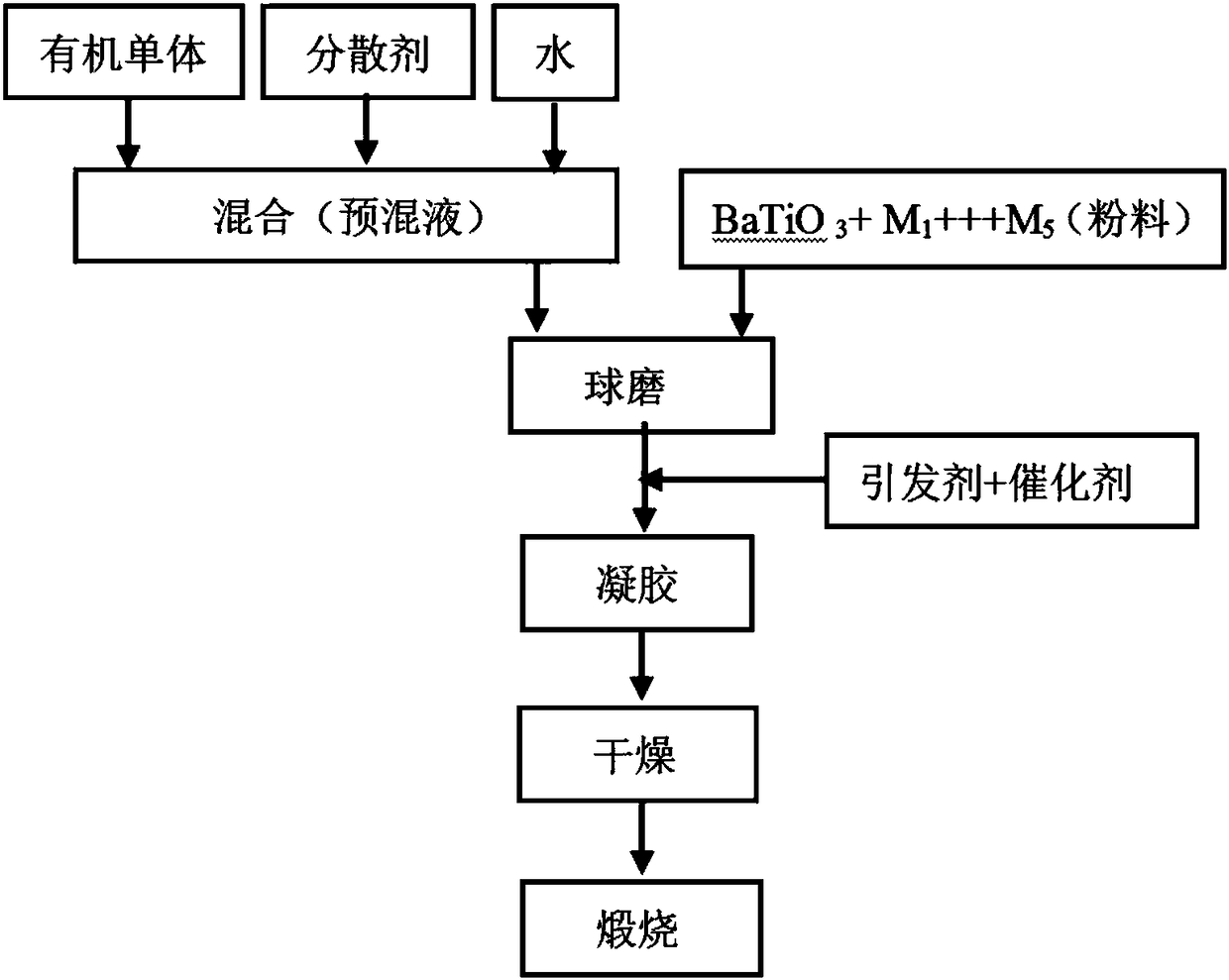

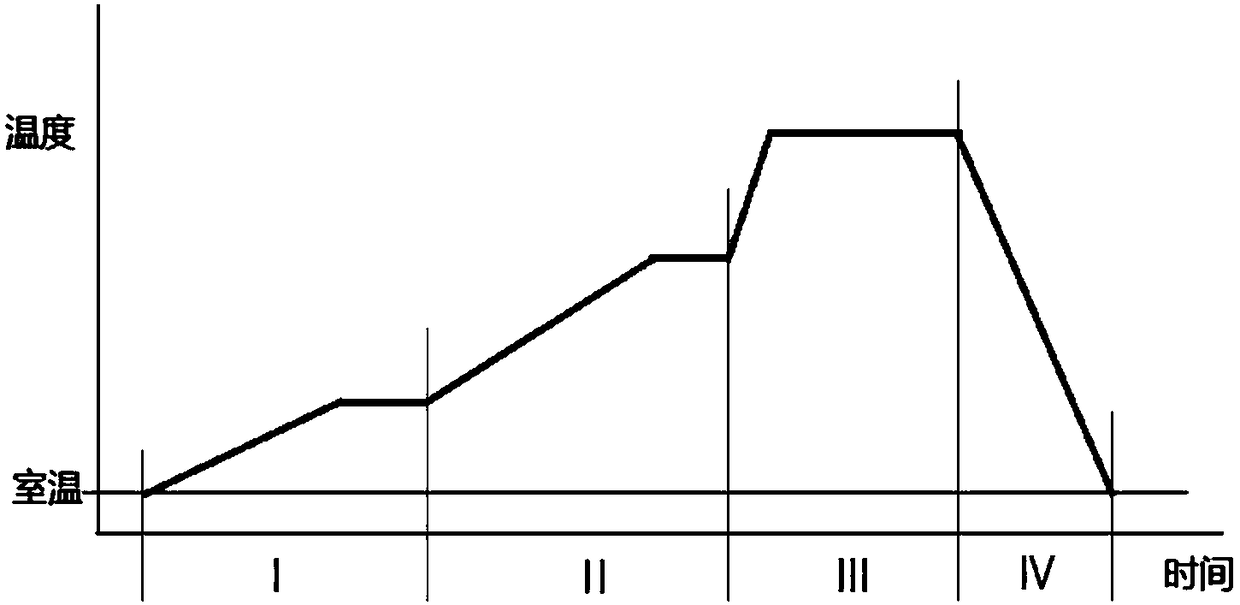

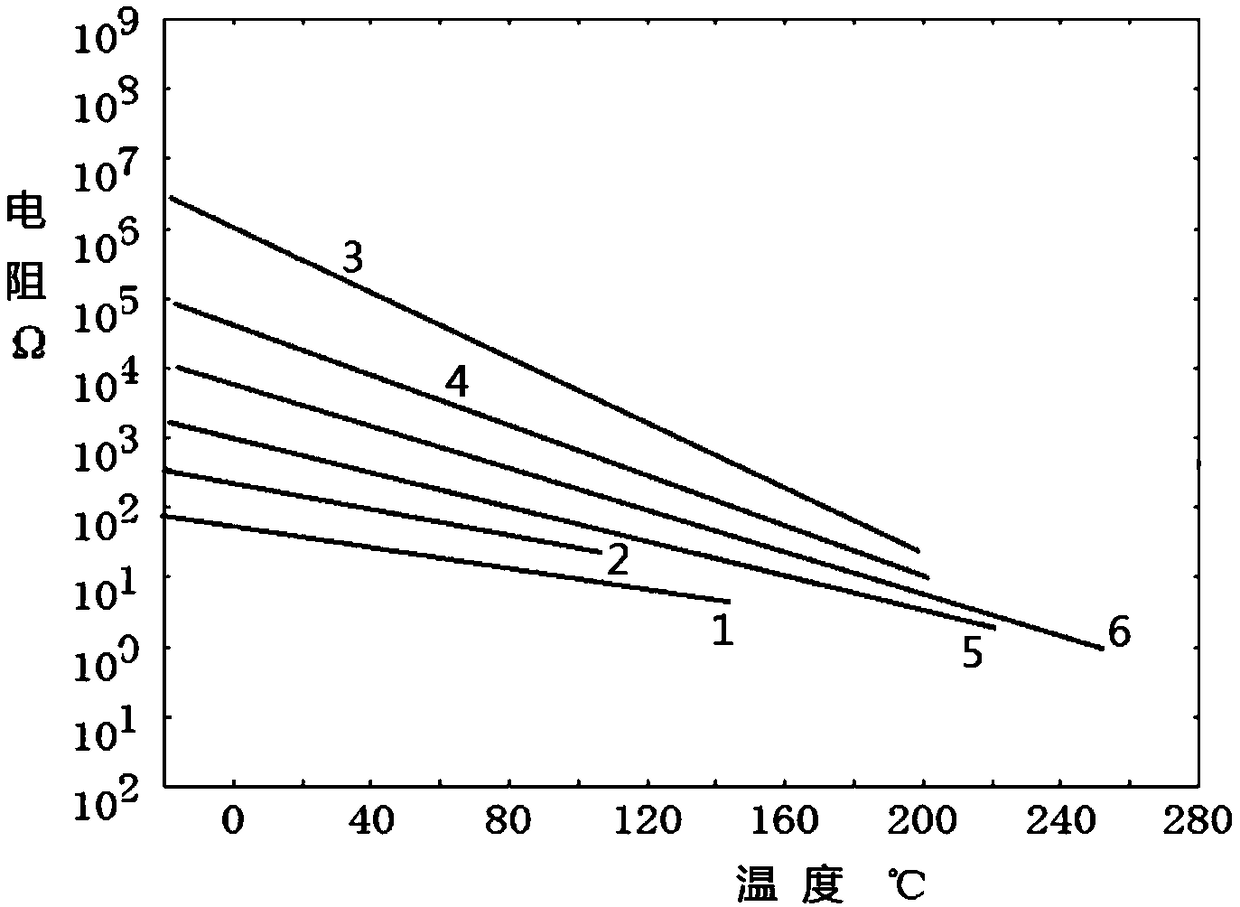

Wide-temperature range negative temperature coefficient heat-sensitive ceramic material and preparation method thereof

ActiveCN108546114AMeasuring temperature range widthAccurate measurementBased wideNegative temperature

The invention discloses a wide-temperature range negative temperature coefficient heat-sensitive ceramic material and a preparation method thereof. Raw materials of the negative temperature coefficient heat-sensitive ceramic material comprise BaTiO3, TiO2, M1O, M2O, M3O, M4O and M5O, wherein M1 is at least one of Sm, Nd, Y, La and Nb elements; M2 is at least two of Si, Al and Ti elements; M3 is acombination of the Ca element and at least one of Sr and Pb elements; M4 is at least one of Sb and Bi elements; and M5 is at least one of Na, K and Li elements. The barium titanate-based wide-temperature range NTC heat-sensitive ceramic material with the measuring temperature range being 300 DEG C or more is obtained through improving and further optimizing the key composition components of the ceramic material and the whole process flow and condition parameters in all reaction steps of the corresponding preparation method and doping and modifying a barium titanate-based semiconductor heat-sensitive ceramic.

Owner:HUAZHONG UNIV OF SCI & TECH

Improved electronic ceramic material and preparation method thereof

The invention discloses an improved electronic ceramic material and a preparation method thereof and relates to the technical field of dielectric ceramic. The electronic ceramic material is prepared from raw materials as follows: modified bauxite, calcined attapulgite clay, barium titanate, carbon fiber, aerated aluminum powder, sodium salicylate, zirconium silicate, zinc stearate, iron oxide red, tungsten oxide, lignosite, polyphenyl ether resin, a plasticizer, a binder, a dispersant and an antistatic agent. The preparation method comprises the steps as follows: raw materials are mixed with water, ground and uniformly mixed, and slurry is obtained; the slurry is injected into a mold, curing and drying are performed, and a biscuit is obtained; finally, the biscuit is subjected to heating sintering treatment in a sintering furnace. The preparation method of the electronic ceramic material is simple and convenient, low-temperature quick sintering is adopted, the energy consumption required for production is low, the price is low, no harmful Pb element is contained, the requirement of environment-friendly materials is met, the capacitance change rate tends to stability with the temperature increasing, and the improved electronic ceramic material has broad market prospects.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

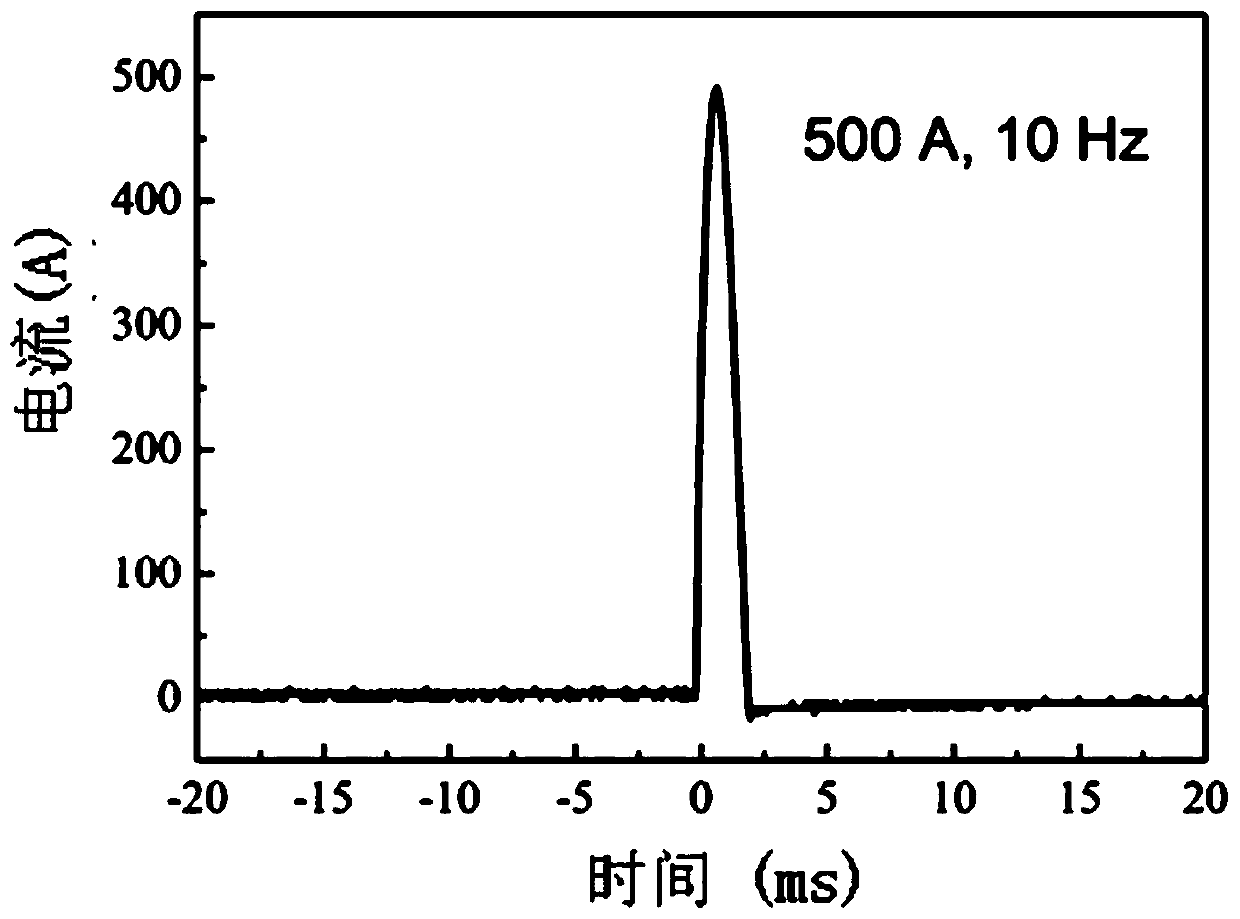

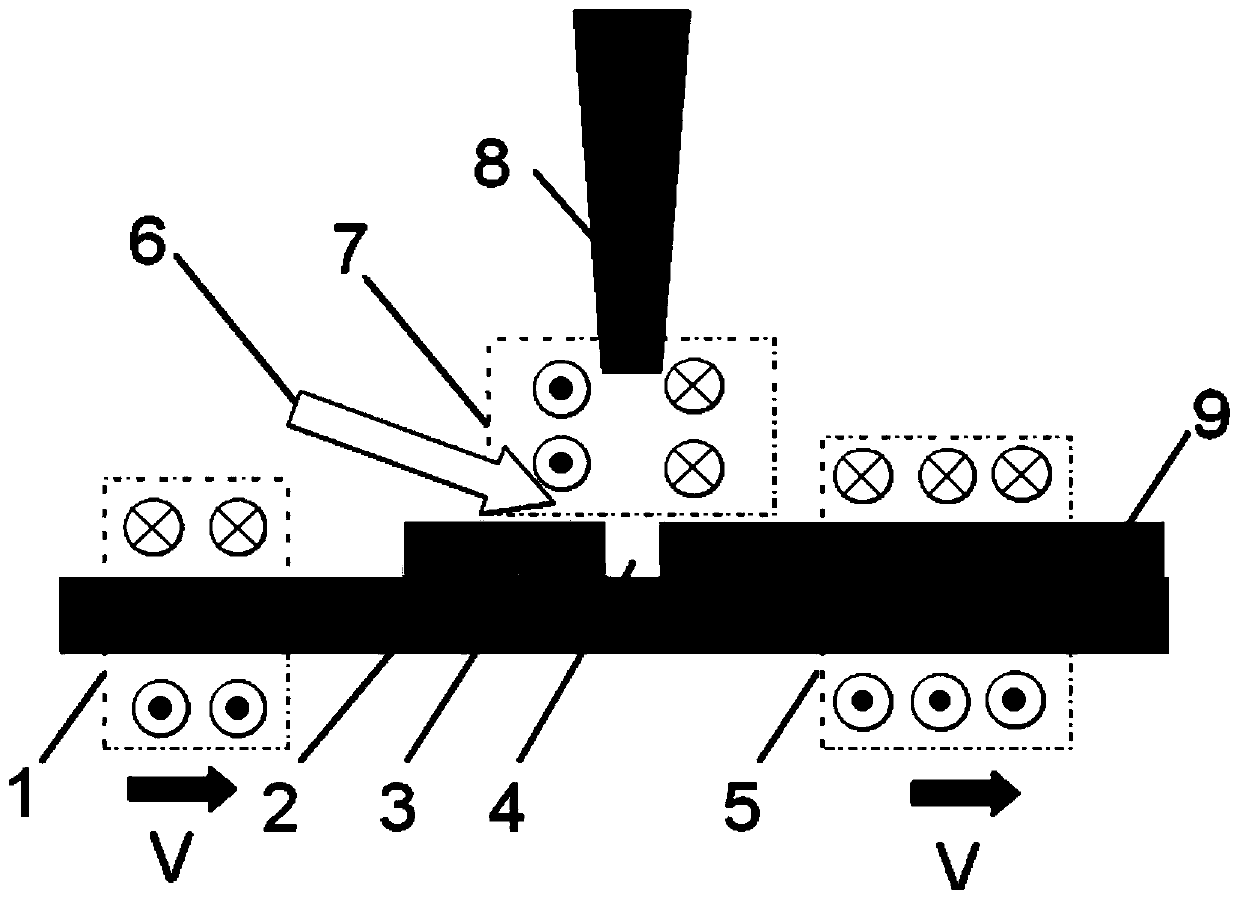

Method of pulsed deposition of nano tin dots on medium and high voltage anodic aluminium foils for aluminium electrolytic capacitors

ActiveCN110085429AEvenly distributedHigh specific capacitanceElectrolytic capacitorsElectrode potentialCapacitance

The invention relates to the field of manufacturing medium and high voltage anode aluminum foils for aluminum electrolytic capacitors. The method is characterized in that the medium and high voltage anode aluminum foils with purity of 99.99% are pre-treated, Mn, Fe, Co, Ni, Cu, Zn, Cd, Ga, Ge, In, Sn and Pb elements with higher electrode potential than aluminum are not enriched on the surface of the medium and high voltage anode aluminum foils, an oxide film on the surface is removed, pulsed deposition is then employed, and the approximately orderly-distributed nano tin dots are deposited on the surface of the aluminum foils. The method is advantaged in that the medium-high voltage anode aluminum foils of which the surface is deposited with the nano tin dots is utilized, uniformity of generated tunnel holes can be significantly improved when the holes are electrolytically etched, tunnel hole merging is reduced, and thereby the specific capacitance of the aluminum foils can be increased.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

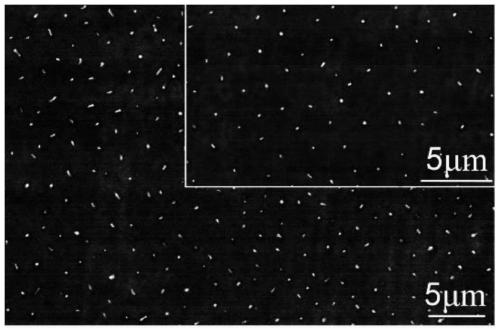

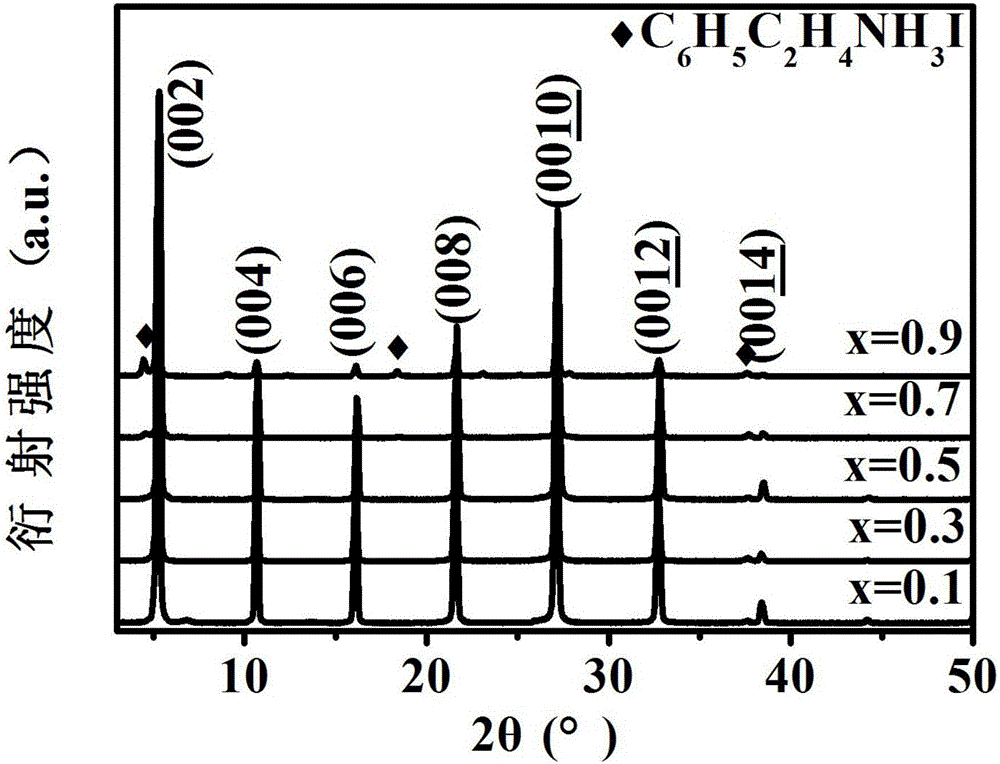

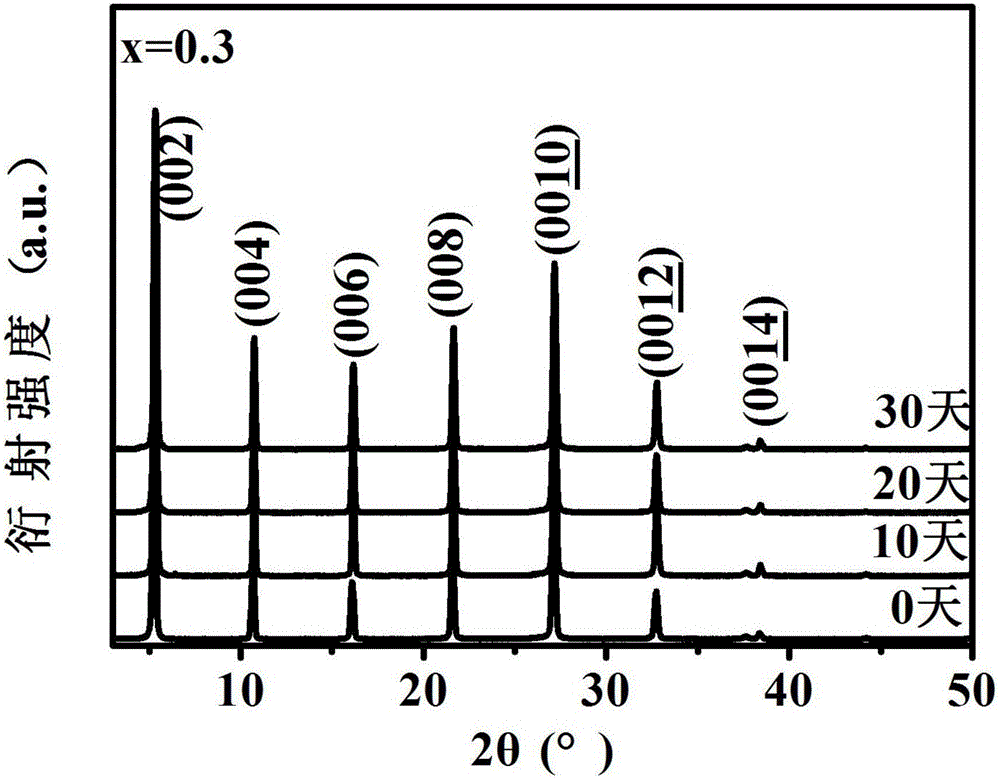

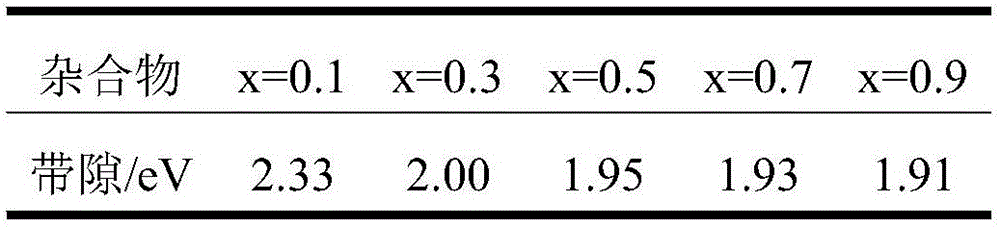

Layered hybrid thin film with adjustable band gap and preparation method of layered hybrid thin film

InactiveCN105742502AImprove stabilityImprove protectionSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solventIodide

The invention discloses a layered hybrid thin film with an adjustable band gap and a preparation method of the layered hybrid thin film. The material of the layered hybrid thin film is a layered hybrid. The layered hybrid thin film is prepared by the following steps: mixing iodobenzeneethanamine, stannous iodide and lead iodide at the stoichiometric ratio that x is smaller than or equal to 0.9 and greater than or equal to 0.1, dissolving the mixture with an organic solvent, and shaking and stirring the solution for 5-60 minutes to obtain a precursor solution; and carrying out spin coating on the precursor solution on a substrate in an inert atmosphere environment and carrying out thermal treatment to obtain the hybrid thin film. The crystal structure of the hybrid thin film is in a layered form; the hybrid thin film has good stability in air when x is smaller than 0.7; and the band gap of the hybrid thin film can be adjusted within a range of 1.91eV to 2.33eV along with the difference of the x. According to the hybrid thin film, a Pb element is replaced with an Sn(II) part, and use of Pb is reduced, so that environmental protection is facilitated; and the layered hybrid thin film also has a potential application prospect in the aspect of a photovoltaic device.

Owner:WUHAN UNIV OF TECH

Remelted low-lead low-bismuth copper alloy with no hot crack

The invention discloses a remelted low-lead low-bismuth copper alloy with no hot crack and relates to the field of metal alloy material manufacturing technology. The remelted low-lead low-bismuth copper alloy with no hot crack comprises the following components of: by weight, 58-61% of Cu, 0.3-0.8% of Al, 0.009-0.35% of Zr, 0.008-0.035% of B, 0.05-0.20% of Pb, 0.1-0.40% of Bi, Mn being less than 0.15%, Si being less than 0.15%, Sn being less than 0.35%, Fe being less than 0.35%, and the balance being zinc and unavoidable impurities, wherein the total amount of the impurities is less than 0.25%. According to the copper alloy, the contents of the lead element and the bismuth element are minimized, thus reducing the harm to the environment and human body and decreasing the cost; The purity of gravity ingot casting melting is excellent, fluidity of the casting process is excellent, and thermal stress crack resistance is strong; the density of the microstructure is high, and crystal grains are fine and uniform; the cutting ability is raised, the polishing degree is excellent, there is no welding stress crack, the corrosion resistance is raised, and old copper materials can be recycled and reused while the cutting ability of the copper alloy is guaranteed.

Owner:苏州撼力合金股份有限公司

A steel-wear-resistant copper alloy layered bearing material, its preparation device and preparation method

The invention provides a steel-abrasion resisting copper alloy laminar bearing bush material and a preparing device and method thereof. The preparing method of the steel-abrasion resisting copper alloy laminar bearing bush material comprises the following steps that abrasion resisting copper alloy powder is prepared; a steel substrate material is cleaned, and oil dirt and oxide are removed; a steel substrate subjected to high-frequency induction heating is covered with the abrasion resisting copper alloy powder with a certain thickness; the abrasion resisting copper alloy powder and the steel substrate with a certain thickness are heated and melted through a laser under the protection atmosphere, meanwhile, a pulse electromagnetic field is applied above an abrasion resisting copper alloy powder and steel substrate molten bath, the abrasion resisting copper alloy powder and the steel substrate are fused together, and metallurgical bonding is achieved; and the inner stress is eliminated in an online high-frequency heating normalizing manner, and the steel-abrasion resisting copper alloy laminar bearing bush material is prepared. The content of the Pb element in the steel-abrasion resisting copper alloy laminar bearing bush material can be accurately controlled, and segregation of the Pb element is reduced.

Owner:DALIAN UNIV OF TECH

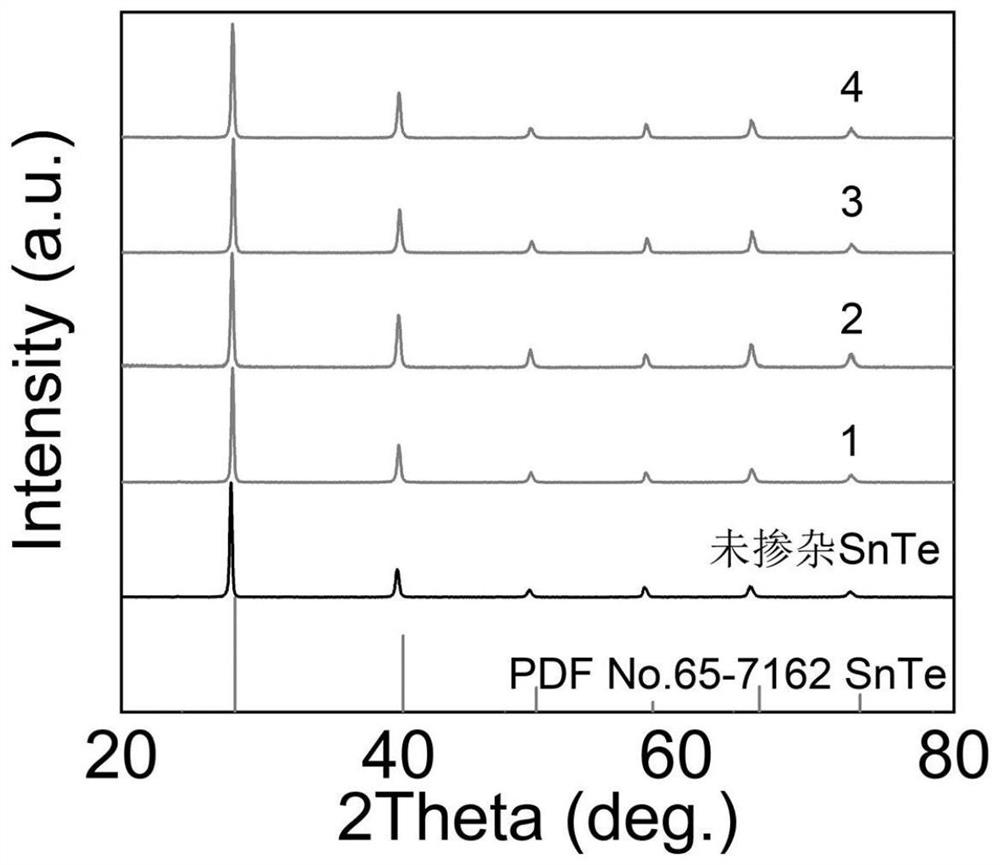

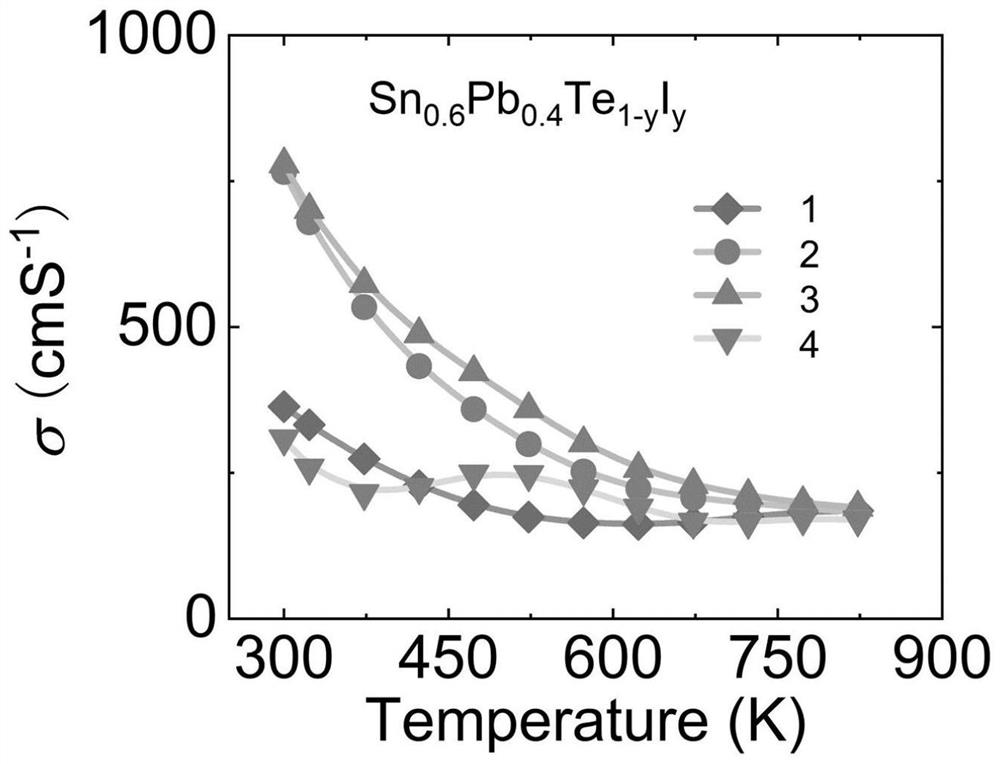

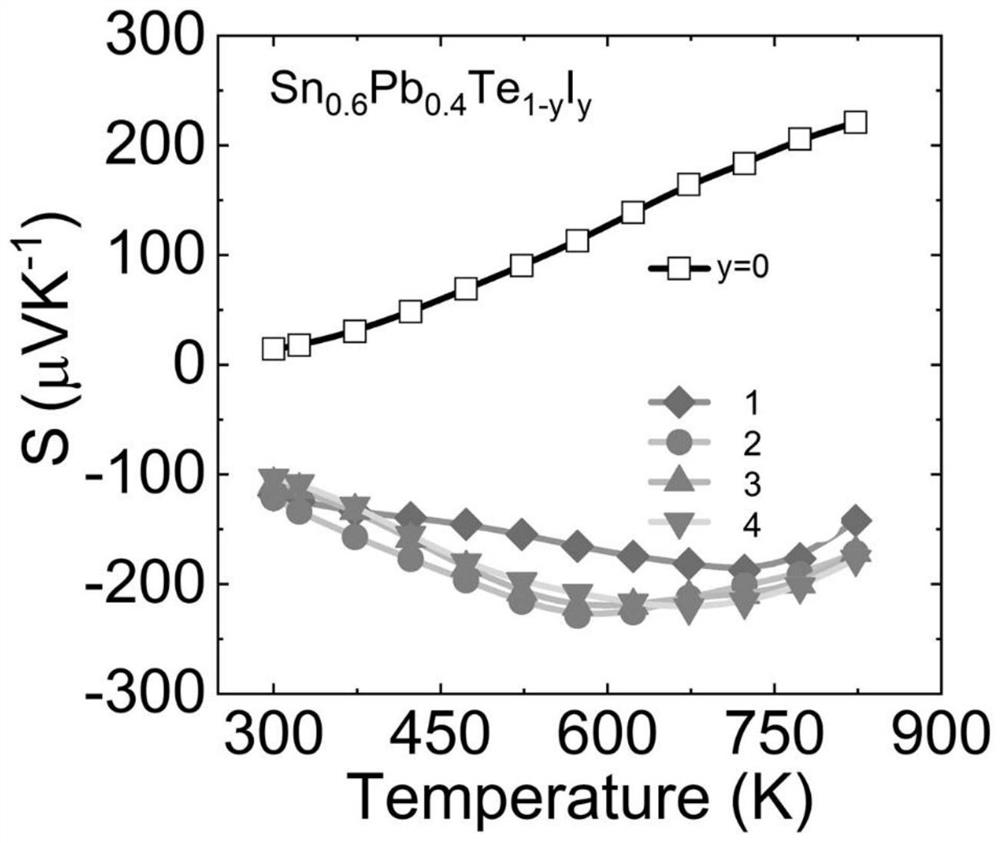

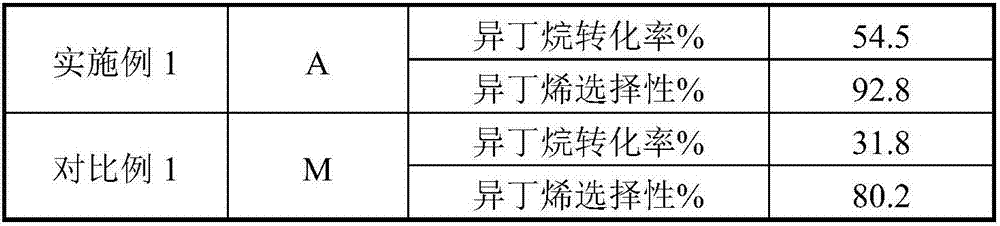

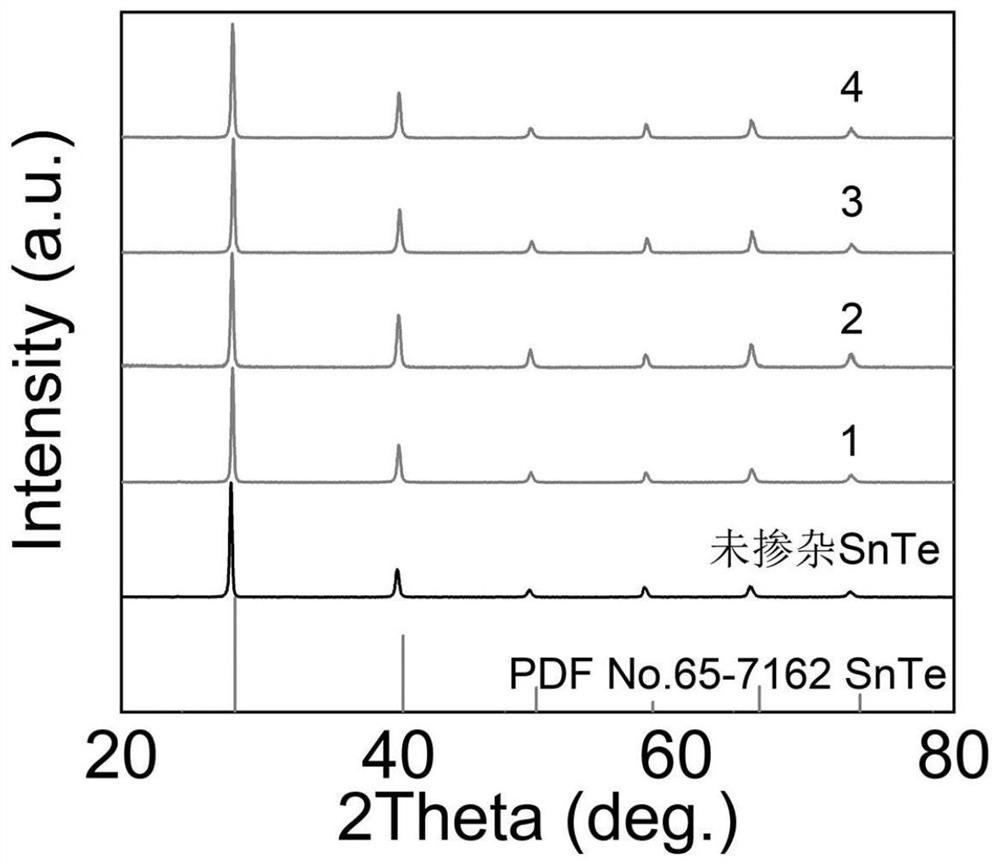

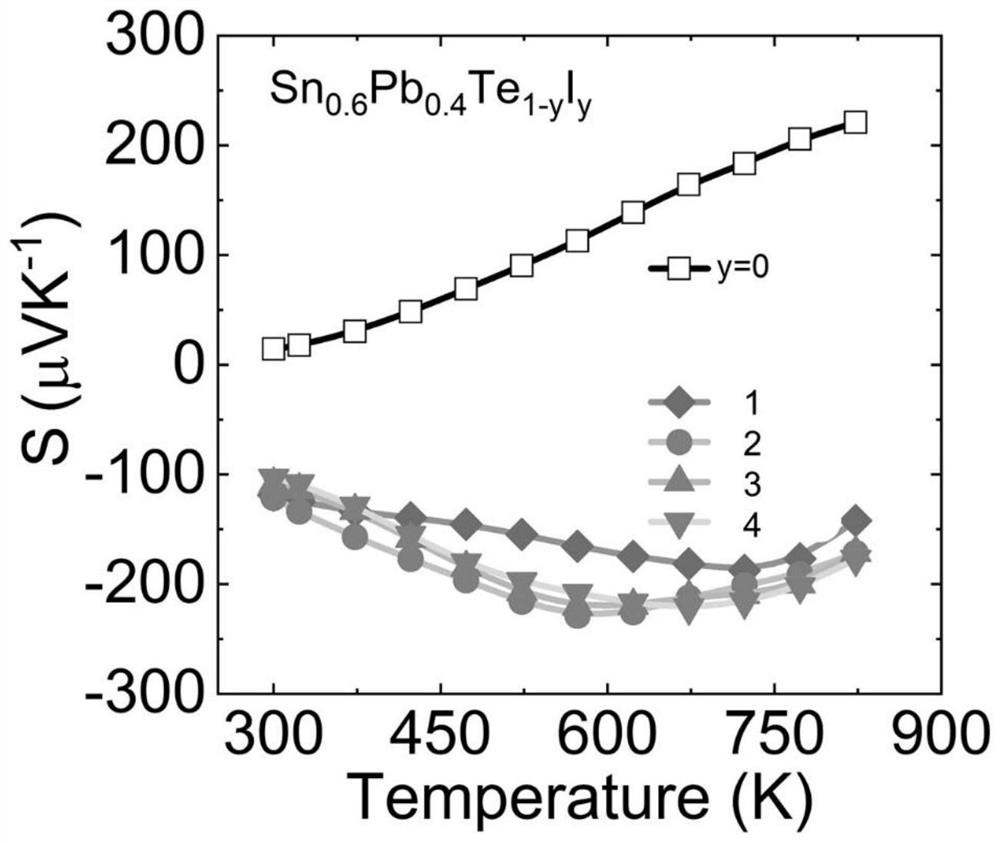

N-type tin telluride thermoelectric material and preparation method thereof

ActiveCN113066922AReduce hole concentrationExcellent thermoelectric performanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsSemiconductor materials

The invention belongs to the technical field of semiconductor materials, and provides an n-type tin telluride thermoelectric material and a preparation method thereof. The preparation method comprises the steps: mixing Sn, Te, Pb and SnI2 according to the molar ratio of (1-x-y), (1-2y), x and y, and obtaining a mixed material; putting the mixed material into a quartz tube, and carrying out vacuumizing treatment; placing the quartz tube filled with the mixed material in a heat treatment furnace for synthesis reaction to obtain an n-type SnTe cast ingot; and grinding the n-type SnTe cast ingot into powder, filling the powder into a graphite mold, and sintering the graphite mold filled with the n-type SnTe cast ingot powder in a sintering furnace to obtain an n-type SnTe sample. According to the invention, the Pb element is introduced and is completely dissolved in the SnTe matrix, so that the intrinsic Sn vacancy is made up, the hole concentration of SnTe is reduced, a precondition is provided for realizing the purpose of conversion from p type to n type of SnTe, and meanwhile, the Te element is replaced by I and electron doping is carried out, so that the n-type SnTe thermoelectric material is successfully synthesized.

Owner:BEIHANG UNIV

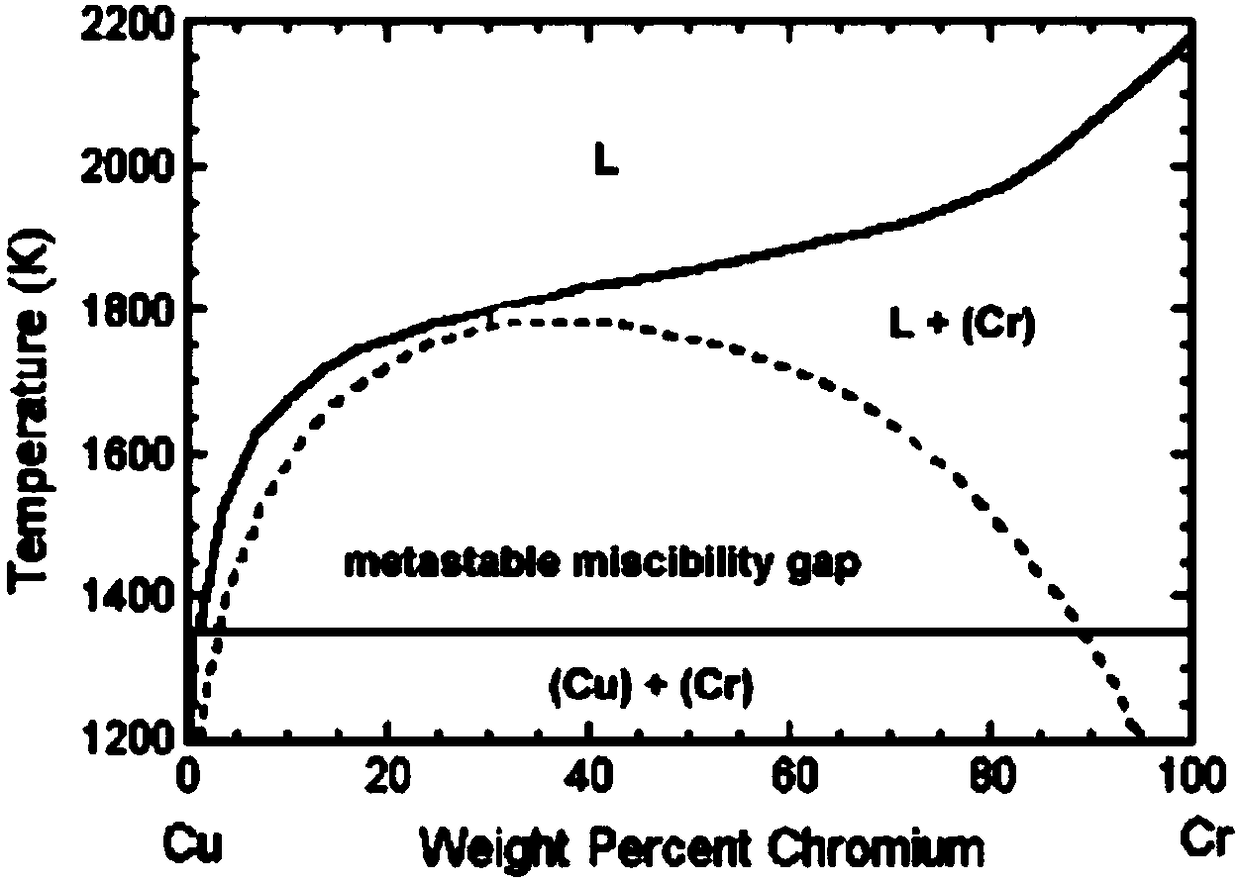

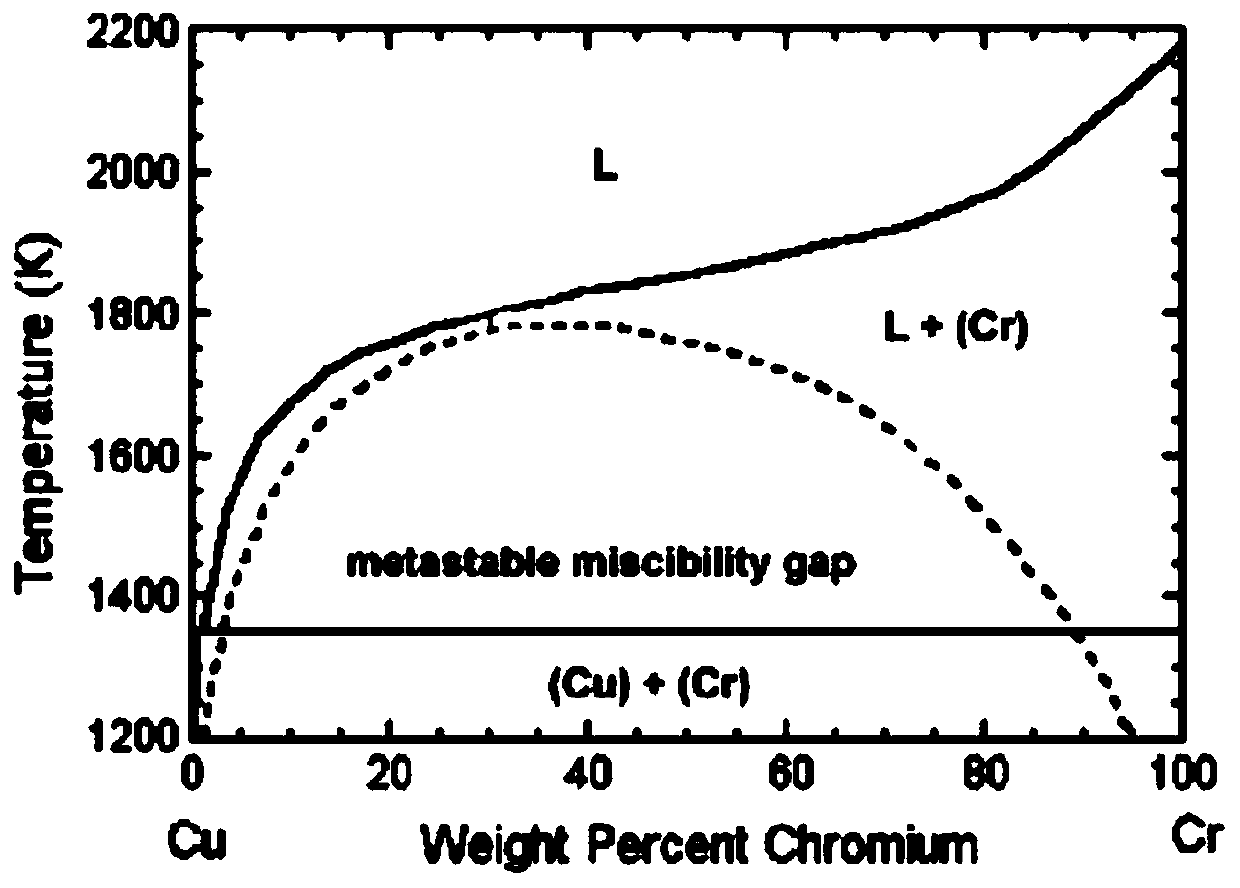

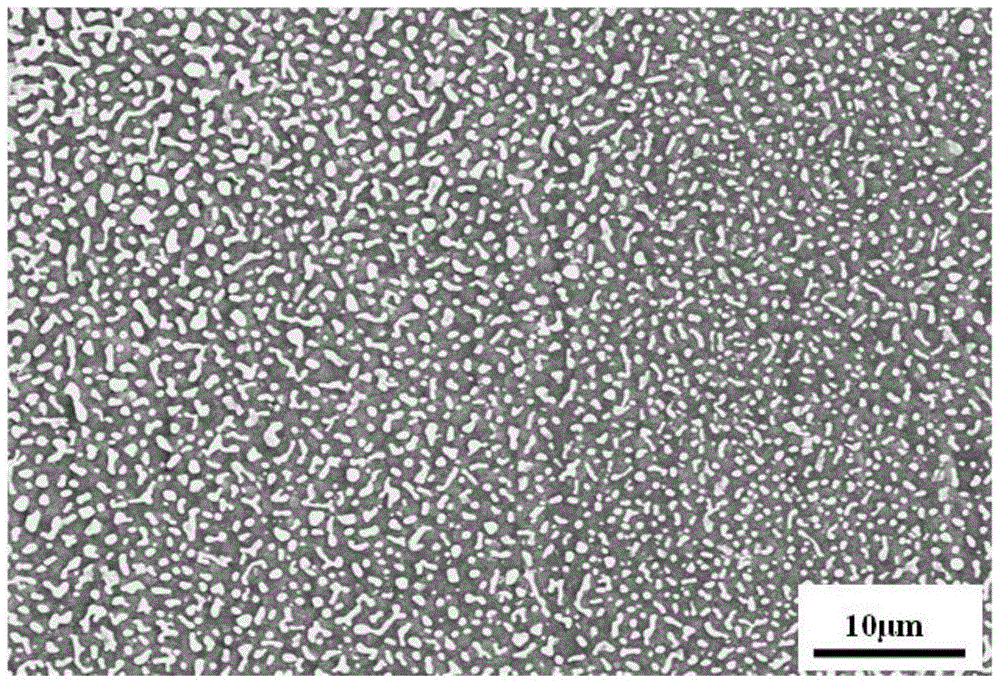

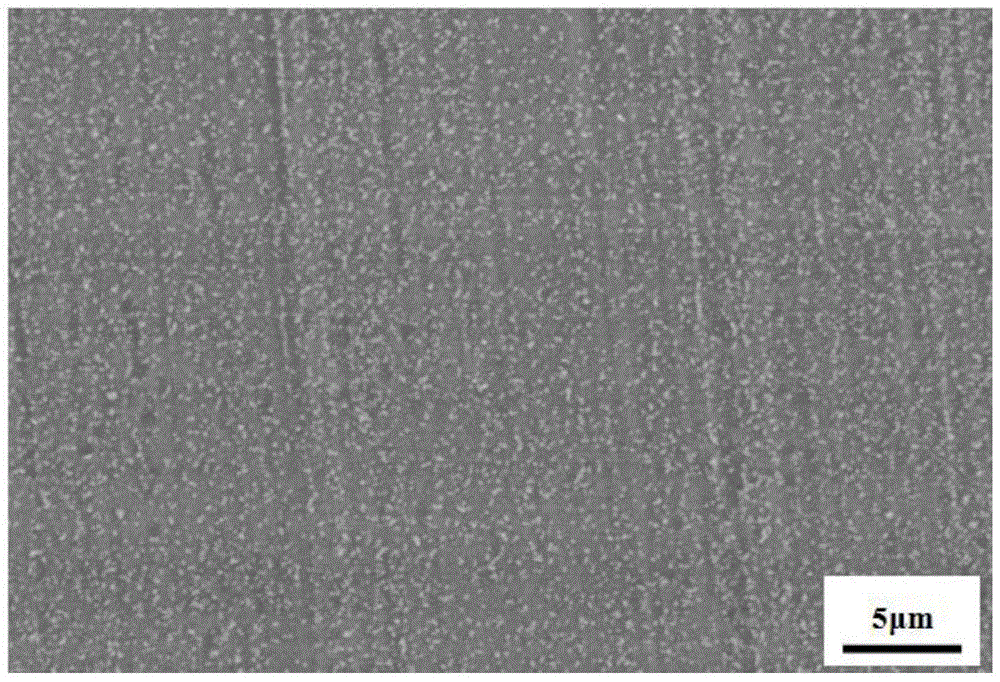

Cu-Cr alloy containing trace Pb elements and solidification preparation method thereof

The invention discloses a Cu-Cr alloy containing trace Pb elements and a solidification preparation method thereof, and belongs to the technical field of the Cu-Cr alloy preparation. The trace elements Pb are added into the Cu-Cr alloy, a nucleation rate of Cr-enriched rich phase liquid drops during a liquid-liquid phase change in a cooling process of Cu-Cr alloy melt is improved, and the formation of a diffuse-type Cu-Cr alloy compound solidification structure is promoted. The method can be used for preparing a Cu-Cr alloy material of a Cu-enriched matrix in which rich Cr particles are diffused and distributed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

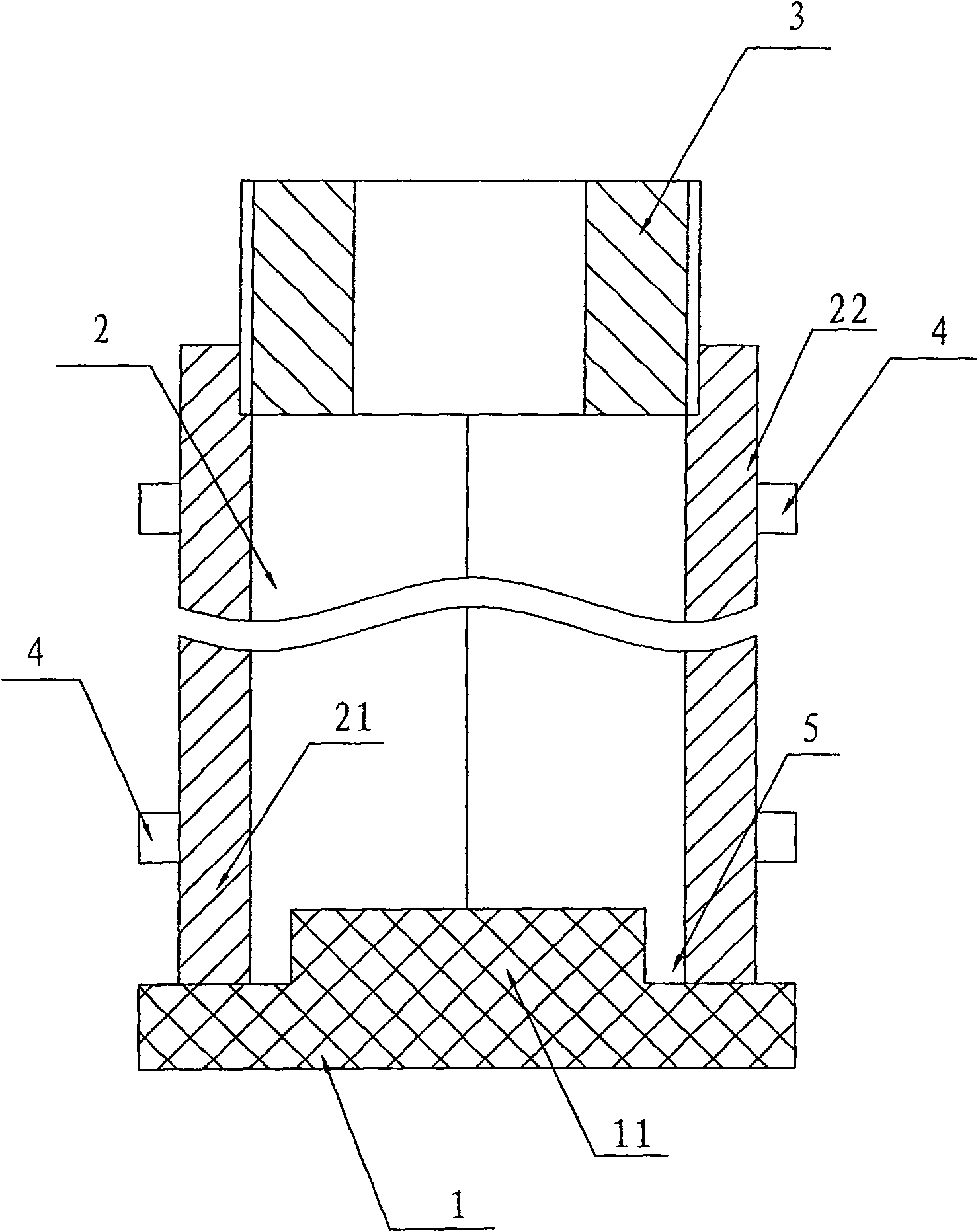

Fast cooling shaping casting mold of copper base catalyst alloy

A rapid chilling shaping casting mold for a copper based catalyst alloy comprises a chill seat, a forming die casing graphite insulating cover opening and a fastening buckle. The forming die casing is combined mold composed of the left die casing and a right die casing. The combined mold is fixed by the fastening buckle. The cross-sectional shape of the forming die is a circular shape. The chill seat is disposed at the lower end of the forming die casing. A location pole corresponding to the inner cavity of the forming die casing is disposed at the upper end of the chill seat. Expansion clearance with a height of 1 / 10-1 / 5 of that of the forming die casing is disposed between the location pole outer circle and the forming die casing inner cavity. The graphite insulating cover opening is disposed at the upper end of the forming die cashing. By using the invented mold to cast the copper based catalyst alloy, a cooling rate of 150 DEG C / min and an up-down temperature gradient can be formed, thereby the melt metal can form columnar crystal growing directionally along the S100 crystallographic axis, so that micro region concentration gradient of Zn, Pb elements in the alloy is formed.

Owner:JINTAN HENGXU TECH

A kind of environment-friendly high-strength free-cutting aluminum alloy and preparation method thereof

The invention discloses an environment-friendly high-strength and easy-to-cut aluminum alloy. The environment-friendly high-strength and easy-to-cut aluminum alloy is prepared from the following components in parts by weight: 0.6 to 1.4 parts of Si, less than or equal to 0.7 part of Fe, 0.2 to 0.5 part of Cu, 0.2 to 1.0 part of Mn, 0.6 to 1.2 parts of Mg, less than or equal to 0.3 part of Cr, 0.5to 1.5 parts of Bi, a single impurity with the content of less than or equal to 0.05 part, less than or equal to 0.15 part of total impurities and the balance of Al. According to the environment-friendly high-strength and easy-to-cut aluminum alloy, Si and Mg elements and Cu element have a strengthening effect in the alloy to improve the mechanical strength of the alloy and refine grain structuresof a material; the Bi element is added to replace a common Pb element (the Pb element belongs to a banned substance control element in environment protection) and has the effect of optimizing alloy cutting performance, so that the material is easily subjected to chip breaking in a machining process and is not wound on a knife. The final tensile strength of the material can reach 400Mpa or more and the material rigidity can reach HB 110 or more.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

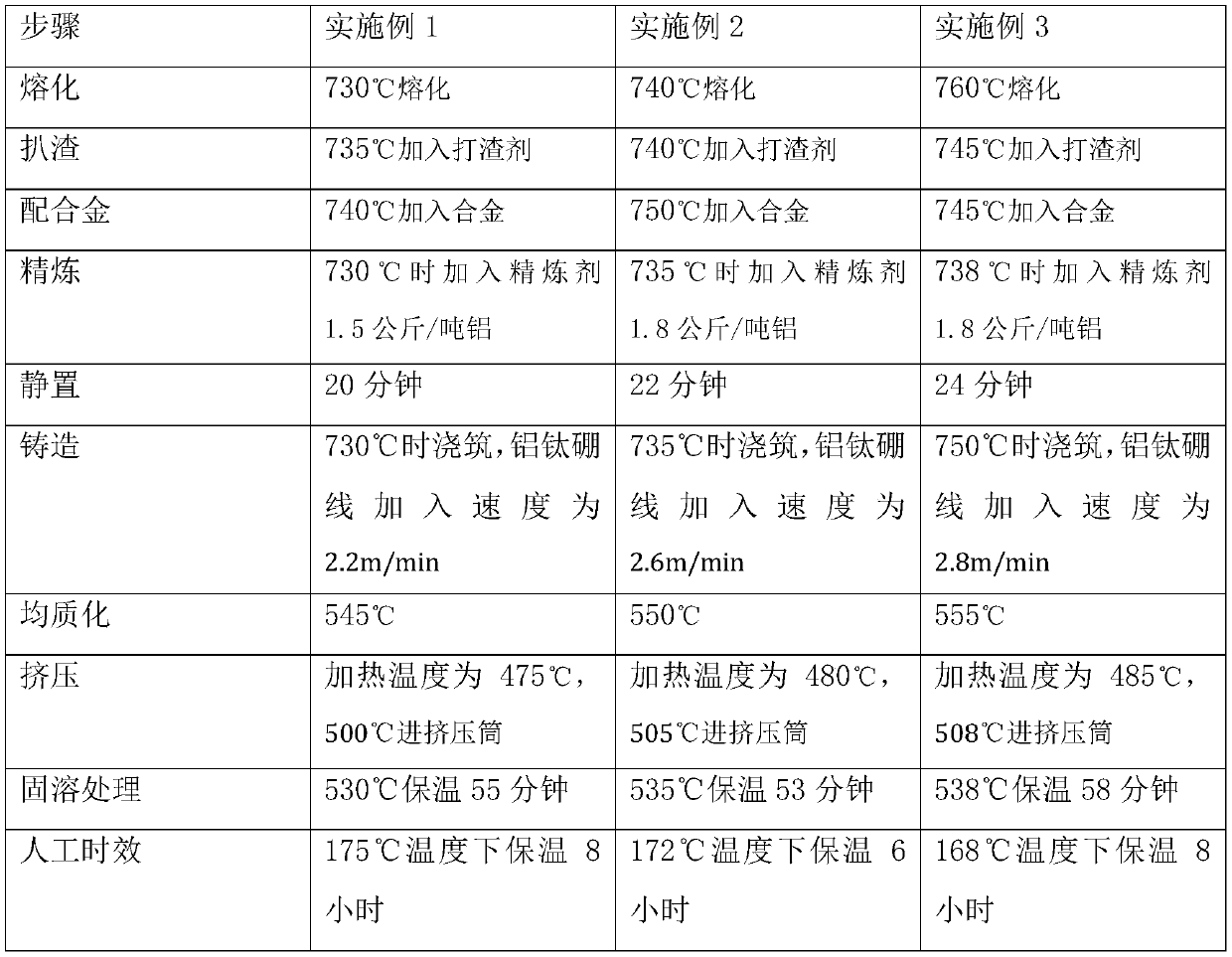

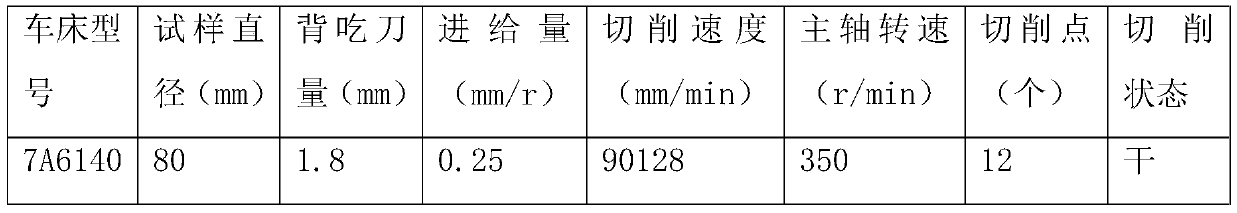

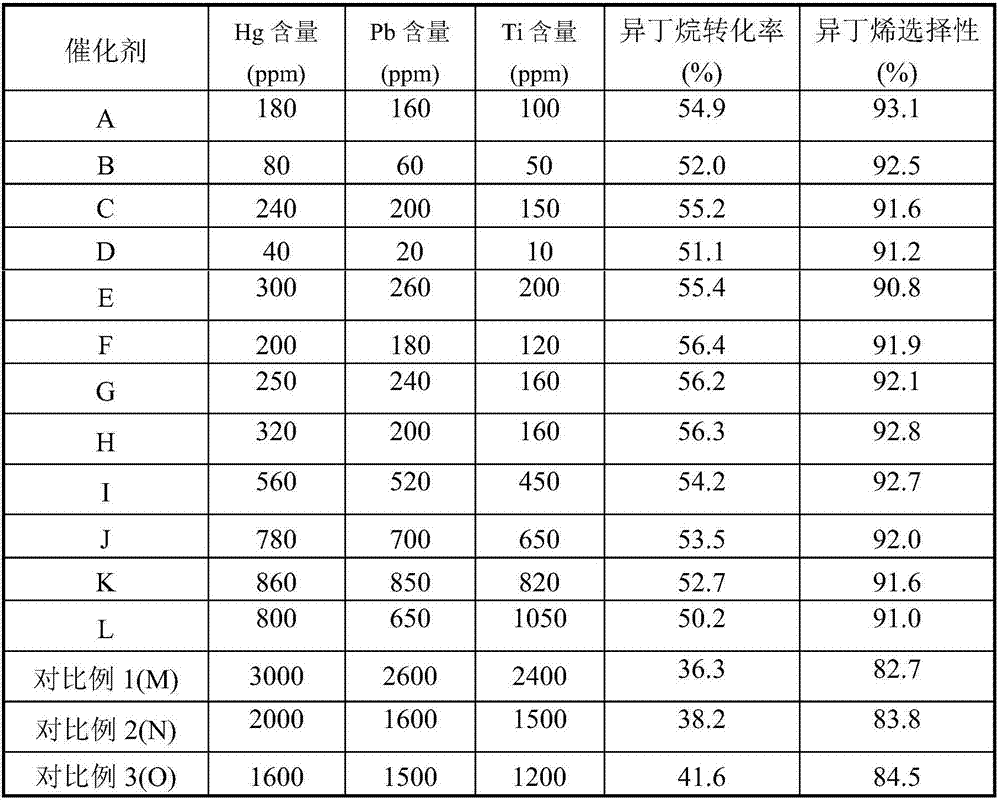

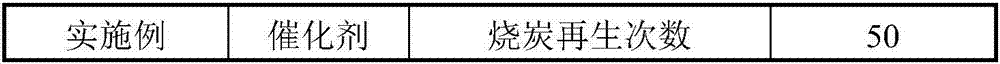

Catalyst used for preparing low-carbon alkene by dehydrogenation of low-carbon alkane and process method of catalyst

PendingCN107537483AHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsDehydrogenationPb element

The invention relates to a catalyst used for preparing low-carbon alkene by dehydrogenation of low-carbon alkane and a process method of the catalyst, and mainly solves problems that in a current catalyst which is used for preparing the low-carbon alkene by dehydrogenation of the low-carbon alkane, alkene selectivity is low, carbon deposit is serious, and single-way stability is poor under a high-temperature condition. According to the invention, the catalyst used for preparing the low-carbon alkene by dehydrogenation of the low-carbon alkane and the process method of the catalyst are adopted,wherein the catalyst uses Pt, Sn and I B group elements as active ingredients and auxiliary agents, a Hg element mass content in the catalyst is less than 900ppm, the Pb element mass content is lessthan 900ppm, and the Ti element mass content is less than 900ppm, through the above technical scheme, the problems are better solved, the low-carbon alkene is prepared in a high-efficiency and stablemanner, and the catalyst can be used in industrial production of preparing the low-carbon alkene by dehydrogenation of the low-carbon alkane.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of n-type tin telluride thermoelectric material and preparation method thereof

ActiveCN113066922BReduce hole concentrationImprove thermoelectric performanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsSemiconductor materials

Owner:BEIHANG UNIV

Niobium-boron binary alloy brazing material

ActiveCN102284807BLow costLow steam pressureWelding/cutting media/materialsSoldering mediaSteam pressureNiobium

The invention discloses a niobium-boron binary alloy brazing material, and the brazing material comprises the following raw materials by weight percent: 1.5%-5.5% of boron and the balance of niobium and inevitable impurities, wherein the content by weight percent of each of Zn, Cd and Pb elements in the impurities is not greater than 0.001%. The niobium-boron binary alloy brazing material is low in cost and low in steam pressure and can be used in a high-reliability cathode environment of a vacuum electronic device, the melting temperature of the brazing material is 1600 DEG C-1800 DEG C, thebrazing temperature is 1650 DEG C-1900 DEG C, and the niobium-boron binary alloy brazing material is suitable for brazing refractory metals, namely W and Mo and alloys thereof, under an Ar atmosphereor vacuum state; after the brazing material is in brazing connection with the refractory metals, namely the W and the Mo, the wettability and the spreadability are good, the brazing material is good in flowability, strong in gap filling capability and good in high-temperature strength of welding lines; and the steam pressure of the brazing material is lower than 1*10<-5>Pa under the vacuum working condition of a cathode weld assembly at the temperature of 1000 DEG C-1200 DEG C.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A method for chemically doping Pb on the surface of negative electrode carbon material for super battery

Owner:CENT SOUTH UNIV

Cu-cr alloy containing trace pb element and solidification preparation method thereof

The invention discloses a Cu-Cr alloy containing trace Pb elements and a solidification preparation method thereof, and belongs to the technical field of the Cu-Cr alloy preparation. The trace elements Pb are added into the Cu-Cr alloy, a nucleation rate of Cr-enriched rich phase liquid drops during a liquid-liquid phase change in a cooling process of Cu-Cr alloy melt is improved, and the formation of a diffuse-type Cu-Cr alloy compound solidification structure is promoted. The method can be used for preparing a Cu-Cr alloy material of a Cu-enriched matrix in which rich Cr particles are diffused and distributed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Formula of core-free soft welding wire product for TC power device

InactiveCN111085799ASmall range of variationProne to stratificationWelding/cutting media/materialsSoldering mediaPb elementMaterials science

The invention discloses a formula of a core-free soft welding wire product for a TC power device, and relates to the field of chip bonding material manufacturing industry. According to the formula, the product is formed through mixing and melting of 1 to 5.5% of Sn, 1 to 3% of Ag and 2000 ppm of microelements of Ga, Ge, P and the like and remaining Pb. The formula has the beneficial effects that the formula has the wide adaptation and high innovation, through adding of the microelements, the change range of BLT is reduced, control undesirability of the BIT can be solved, wettability is improved, the potential layering phenomenon easily appearing in the chip bottom and a welding material can be solved, tin waves are not generated, through innovation of the production process, oxide is reduced, alloy component uniform distribution and welding wire forming consistency can be ensured, and the problems that the product is easily oxidized and is only applied in a discrete device, and qualityneeds of high-end power devices cannot be met are solved.

Owner:上海锡喜材料科技有限公司

A kind of niobium-boron binary alloy brazing material

ActiveCN102284807ALow costLow steam pressureWelding/cutting media/materialsSoldering mediaSteam pressureNiobium

The invention discloses a niobium-boron binary alloy brazing material, and the brazing material comprises the following raw materials by weight percent: 1.5%-5.5% of boron and the balance of niobium and inevitable impurities, wherein the content by weight percent of each of Zn, Cd and Pb elements in the impurities is not greater than 0.001%. The niobium-boron binary alloy brazing material is low in cost and low in steam pressure and can be used in a high-reliability cathode environment of a vacuum electronic device, the melting temperature of the brazing material is 1600 DEG C-1800 DEG C, thebrazing temperature is 1650 DEG C-1900 DEG C, and the niobium-boron binary alloy brazing material is suitable for brazing refractory metals, namely W and Mo and alloys thereof, under an Ar atmosphereor vacuum state; after the brazing material is in brazing connection with the refractory metals, namely the W and the Mo, the wettability and the spreadability are good, the brazing material is good in flowability, strong in gap filling capability and good in high-temperature strength of welding lines; and the steam pressure of the brazing material is lower than 1*10<-5>Pa under the vacuum working condition of a cathode weld assembly at the temperature of 1000 DEG C-1200 DEG C.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method and device for spraying and depositing dispersed tin and zinc nuclei on the surface of high-purity aluminum foil for medium and high voltage anodes

The invention discloses a method and device for depositing disperse tin and zinc crystal nucleuses on the surface of highly pure aluminum foil for medium and high voltage anodes in a mist spraying mode. The method includes the following steps that recrystallization annealing treatment is carried out on the rolled aluminum foil, the highly pure aluminum foil for medium and high voltage anodes is formed, the {100} surface texture occupancy of the highly pure aluminum foil is larger than 95 percent, Mn, Fe, Co, Ni, Cu, Zn, Cd, Ga, Ge, In, Sn and Pb elements of which the electrode levels are higher than that of Al are not rich on the surface of the highly pure aluminum foil, and the purity of Al is more than 99.99 percent; an oxidation film on the surface is removed through an alkali wash pre-treatment method; aluminum foil with the surface covered with a pre-treatment alkali wash film is arranged in a mist box formed by ultrasonic spraying mist to deposit disperse tin and zinc crystal nucleuses. When the highly pure aluminum foil for medium and high voltage anodes with the surface deposited with the tin and zinc crystal nucleuses is adopted, the tin and zinc crystal nucleuses can effectively guide corrosion poring of the aluminum foil in the electrolytic corrosion process, distribution uniformity of channel holes is improved, self-corrosion thinning of the aluminum foil is reduced, and therefore the specific capacitance and bending resistance of the aluminum foil can be obviously improved.

Owner:广西广投正润新材料科技有限公司 +1

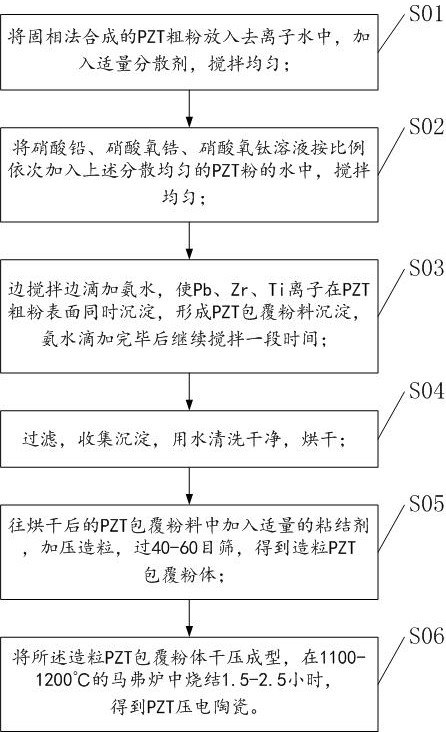

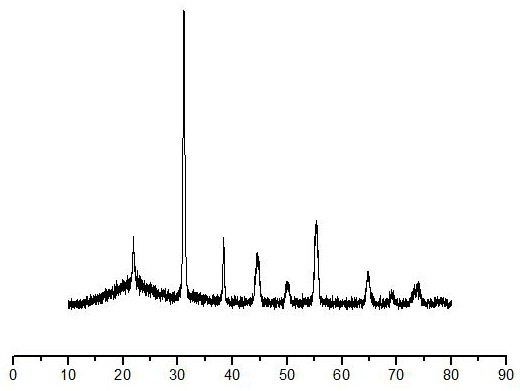

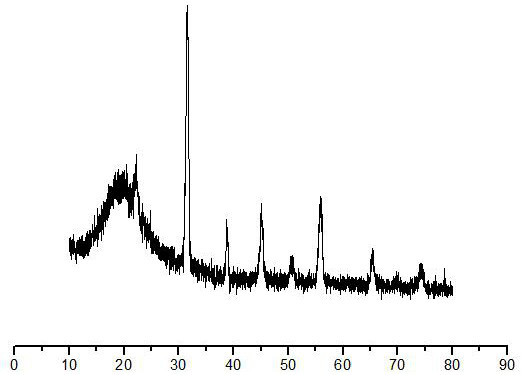

Method for sintering pzt piezoelectric ceramics at low temperature and piezoelectric ceramics

The invention discloses a method for sintering PZT piezoelectric ceramics at low temperature and piezoelectric ceramics. The method comprises the following steps: putting PZT coarse powder synthesized by a solid phase method into deionized water, adding an appropriate amount of dispersant, and stirring evenly; Add lead nitrate, zirconium oxynitrate, and titanyl nitrate solutions in proportion to the water of the above-mentioned uniformly dispersed PZT powder, and stir evenly; while stirring, add ammonia water dropwise, so that Pb, Zr, and Ti ions are simultaneously precipitated on the surface of the PZT coarse powder, Form the PZT coating powder precipitation, continue to stir for a period of time after the ammonia water is added dropwise; filter, collect the sediment, wash it with water, and dry it; add an appropriate amount of binder to the dried PZT coating powder, pressurize Granulating and passing through a 40-60 mesh sieve to obtain a granulated PZT-coated powder; dry pressing the granulated PZT-coated powder, and sintering in a muffle furnace at 1100-1200°C for 1.5-2.5 hours to obtain PZT piezoelectric ceramics; the sintering temperature of the method is low, the volatilization of lead element is less during the sintering process, and the composition ratio of the finished product is close to the original designed formula.

Owner:FOSHAN YIQIANG ELECTRONICS

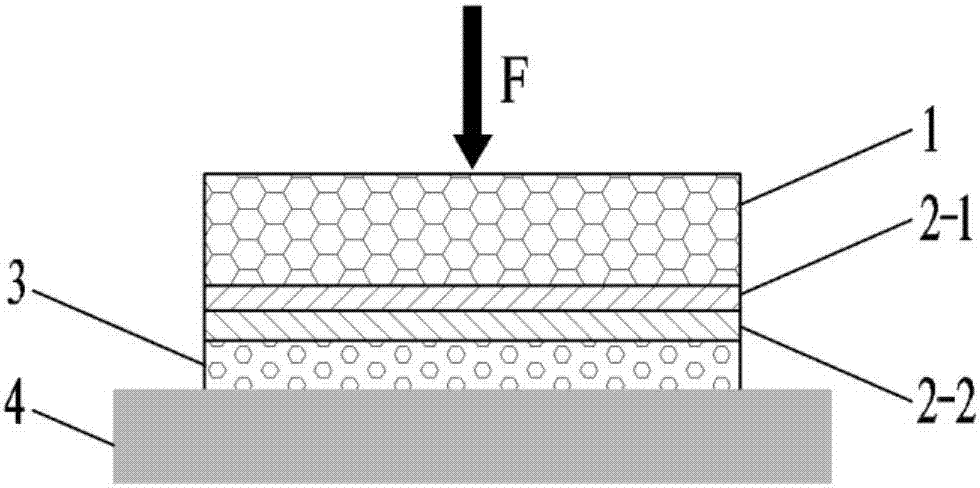

PZT/Si diffusion bonding method

ActiveCN107482114ASimple processHigh bonding strengthPiezoelectric/electrostrictive/magnetostrictive devicesDiffusion reactionSilicon

The present invention belongs to the field of advanced manufacturing technology and provides a PZT / Si diffusion bonding method. First, an electrode layer is prepared on the surface of a PZT bulk material, and a PZT film is deposited on the surface of the electrode layer to form a PZT device. Then, under certain temperature conditions, through the exertion of pressure on the PZT device and the silicon substrate, the lead and the silicon elements in the PZT film are subjected to a diffusion reaction to form a diffusion bonding layer with a certain depth and a high bonding force. In this way, the stable and solid combination of the PZT device with the silicon is realized. Finally, a PZT piezoelectric layer with required thickness is obtained by the subsequent mechanical grinding and polishing process. The PZT / Si bonding mode achieves a high bonding strength, is simple to process, and convenient to implement. Low in cost, the method is favorable for commercial popularization and application.

Owner:DALIAN UNIV OF TECH

Rare-earth red light-emitting material for converting purple light LED into white light and preparation process thereof

InactiveCN101693834BImprove luminous efficiencyHigh light efficiencyGas discharge lamp usageLuminescent compositionsAir atmospherePb element

The invention relates to a rare-earth red light-emitting material for converting purple light LED into white light and a preparation process thereof, which belong to the technical field of light emission and display and relate to a red light-emitting material and the preparation process thereof. The structural formula of the red light-emitting material includes M4-3a-3b-2c (MoO4) 2: RaRbNc, wherein the M is an alkali metal Li element, the Ra is a rare-earth activator Eu element, the Rb is a rare-earth sensitizer Tb element, and the Nc is a metal sensitizer Pb element. Materials of the structural formula M4-3a-3b-2c (MoO4) 2: RaRbNc are weighed according to percentage by weight; the weighed materials after being grinded and mixed evenly are placed into an aluminum trioxide crucible and sintered for 1-2 hours in a 400-600 DEG C high-temperature furnace; after being cooled, the materials are fetched out, pulverized, placed into the crucible again and sintered for 2-3 hours in 700-1000 DEG C air atmosphere in the high-temperature furnace; after being cooled, the materials are fetched out and pulverized again, and crystalline powders are obtained and can emit bright red light by stimulation of 365 nanometers and a purple light LED. After the crystalline powders are mixed with rare-earth light-emitting materials emitting green and blue light according to a certain proportion, white light can be emitted by coating the crystalline powders onto a purple light LED tube core.

Owner:NORTHEAST NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Solar cell of high-efficiency planar heterojunction perovskite structure having interface modification layer formed by [6,6]-phenyl group-C61-butyric acid (PCBA) Solar cell of high-efficiency planar heterojunction perovskite structure having interface modification layer formed by [6,6]-phenyl group-C61-butyric acid (PCBA)](https://images-eureka.patsnap.com/patent_img/acefd54d-edc6-4ed6-859a-5008fea2935a/180401DEST_PATH_HSB0000142053520000011.PNG)

![Solar cell of high-efficiency planar heterojunction perovskite structure having interface modification layer formed by [6,6]-phenyl group-C61-butyric acid (PCBA) Solar cell of high-efficiency planar heterojunction perovskite structure having interface modification layer formed by [6,6]-phenyl group-C61-butyric acid (PCBA)](https://images-eureka.patsnap.com/patent_img/acefd54d-edc6-4ed6-859a-5008fea2935a/HSA0000113771020000012.PNG)

![Solar cell of high-efficiency planar heterojunction perovskite structure having interface modification layer formed by [6,6]-phenyl group-C61-butyric acid (PCBA) Solar cell of high-efficiency planar heterojunction perovskite structure having interface modification layer formed by [6,6]-phenyl group-C61-butyric acid (PCBA)](https://images-eureka.patsnap.com/patent_img/acefd54d-edc6-4ed6-859a-5008fea2935a/HSA0000113771020000013.PNG)