Rare-earth red light-emitting material for converting purple light LED into white light and preparation process thereof

A technology of red light emission and purple light, which is applied in the field of red light-emitting materials and its preparation, can solve problems such as unstable performance and affecting light-emitting performance, and achieve the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

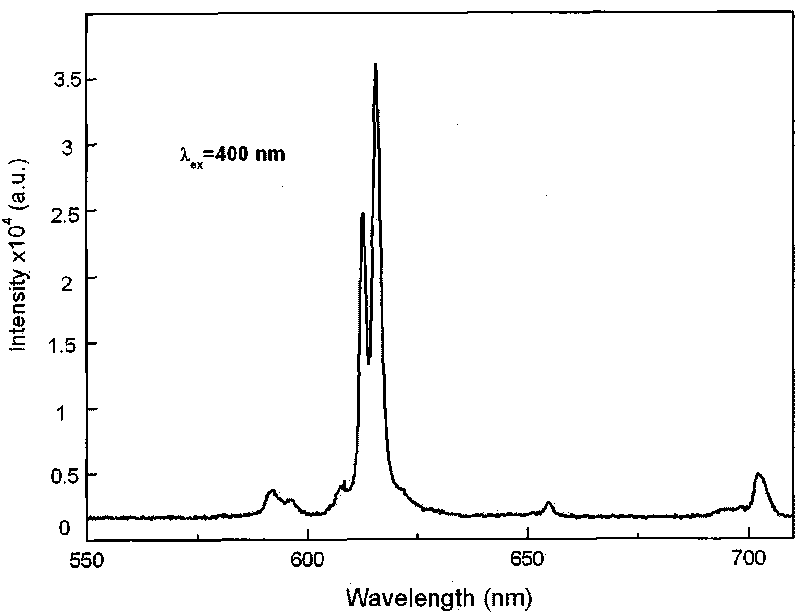

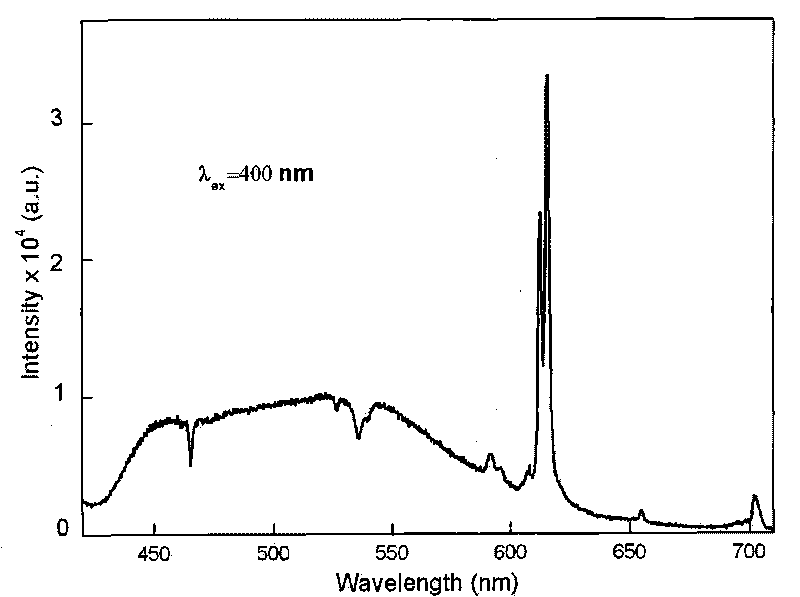

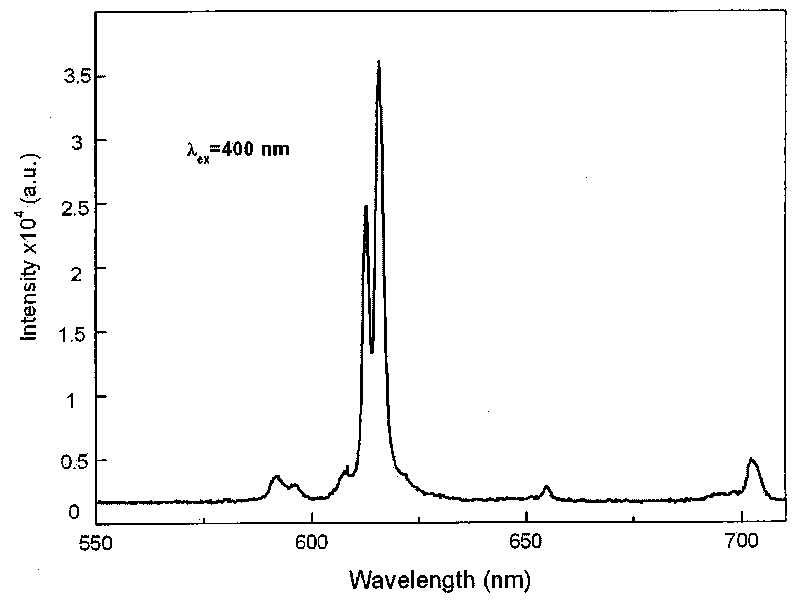

Image

Examples

example 1

[0018] ①According to the chemical structural formula M 4-3a-3b-2c ·(MoO 4 ) 2 :R a · R b ·N c , when M is Li element, R a is Eu element, R b When it is Tb element, N c When it is metal Pb element, take the following high-purity materials by weight percentage:

[0019] Li 2 CO 3 : 11.51% Eu 2 o 3 : 28.70%

[0020] Tb 4 o 7 : 0.76% MoO 3 : 58.75%

[0021] PbO: 0.3%

[0022] ② Grind and mix the above-mentioned weighed materials evenly, put them into an alumina crucible, cover them, put them in a high-temperature furnace, and sinter for the first time in air at 400°C for 1 hour.

[0023] ③ After cooling, take it out and grind it, then put it into an alumina crucible, cover it in a high-temperature furnace, and sinter it in the air for a second time at 700°C for 2 hours. After cooling, take it out and grind it, you can get a product that emits bright red light under the excitation of ultraviolet 365nm and purple LED. Crystal powder.

example 2

[0025] According to the chemical structure M 4-3a-3b-2c ·(MoO 4 ) 2 :R a · R b ·N c , when M is Li element, Ra is Eu element, R b When it is Tb element, N c When it is metal Pb element, take the following high-purity materials by weight percentage:

[0026] Li 2 CO 3 : 8.86% Eu 2 o 3 : 31.8%

[0027] MoO 3 : 57.82% Tb 4 o 7 : 1.12%

[0028] PbO: 0.4%

[0029] The first sintering is at 450°C for 1 hour, and the second sintering is at 750°C for 2 hours. The sintering synthesis steps are the same as in Example 1.

example 3

[0031] According to the chemical structure M 4-3a-3b-2c ·(MoO 4 ) 2 :R a · R b ·N c , when M is Li element, R a is Eu element, R b When it is Tb element, N c When it is metal Pb element, take the following high-purity materials by weight percentage:

[0032] Li 2 CO 3 : 10.95% Eu 2 o 3 : 28.59%

[0033] MoO 3 : 58.49% Tb 4 o 7 : 1.52%

[0034] PbO: 0.45%

[0035] The first sintering temperature is 450°C for 2 hours, the second sintering is 800°C for 2 hours, the sintering synthesis steps are the same as in Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com