Patents

Literature

76 results about "Ca element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

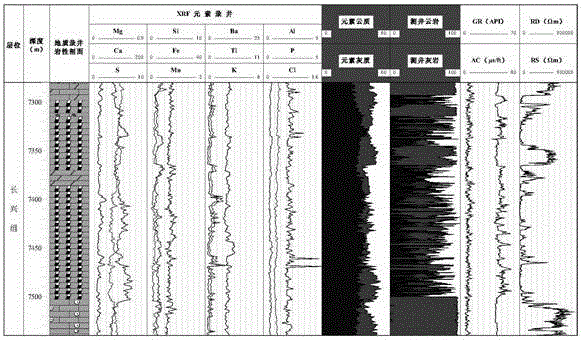

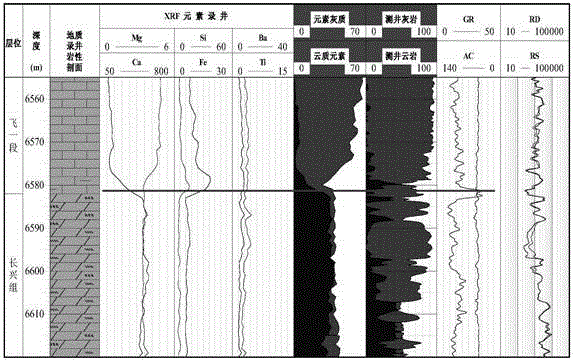

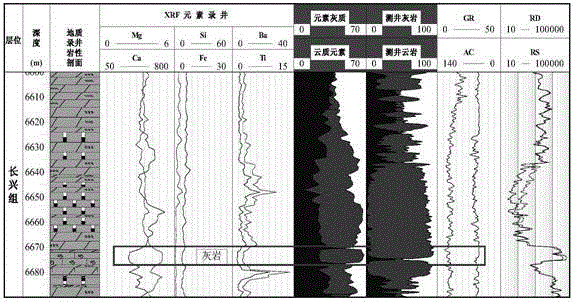

Method for quickly recognizing carbonate formation lithologies while drilling

ActiveCN104612675ASolve the problem of lithology identificationAccurate divisionBorehole/well accessoriesLithologyDolomite

The invention provides a method for quickly recognizing carbonate formation lithologies while drilling. The method includes the first step that the different lithologies are judged; the second step that rock debris of the different lithologies are sampled and are analyzed through the X-ray fluorescence element logging technology, and the Ca element pulse content and the Mg element pulse content are counted; the third step that rock debris of the different lithology centers are sampled, the Mg pulse content and the Ca pulse content of the different lithology centers are counted, and the average interval between the Mg pulse content and the Mg pulse content at the lithology center and the average interval between the Ca pulse content and the Ca pulse content at the lithology center are calculated; the fourth step that the Ca pulse content average value and the Mg pulse content average value of different lithologies are calculated respectively, then logging lithology recognition standards are obtained, and a lithology interpretation chart is established. The method achieves accurate recognition of the lithologies while drilling, judges that whether a horizontal well track passes through dolomite or not in time, and then provides a scientific basis for the necessity of adjustment of a track of an undrilled well segment and for predicament of the track of the undrilled well segment.

Owner:CHINA PETROCHEMICAL CORP +4

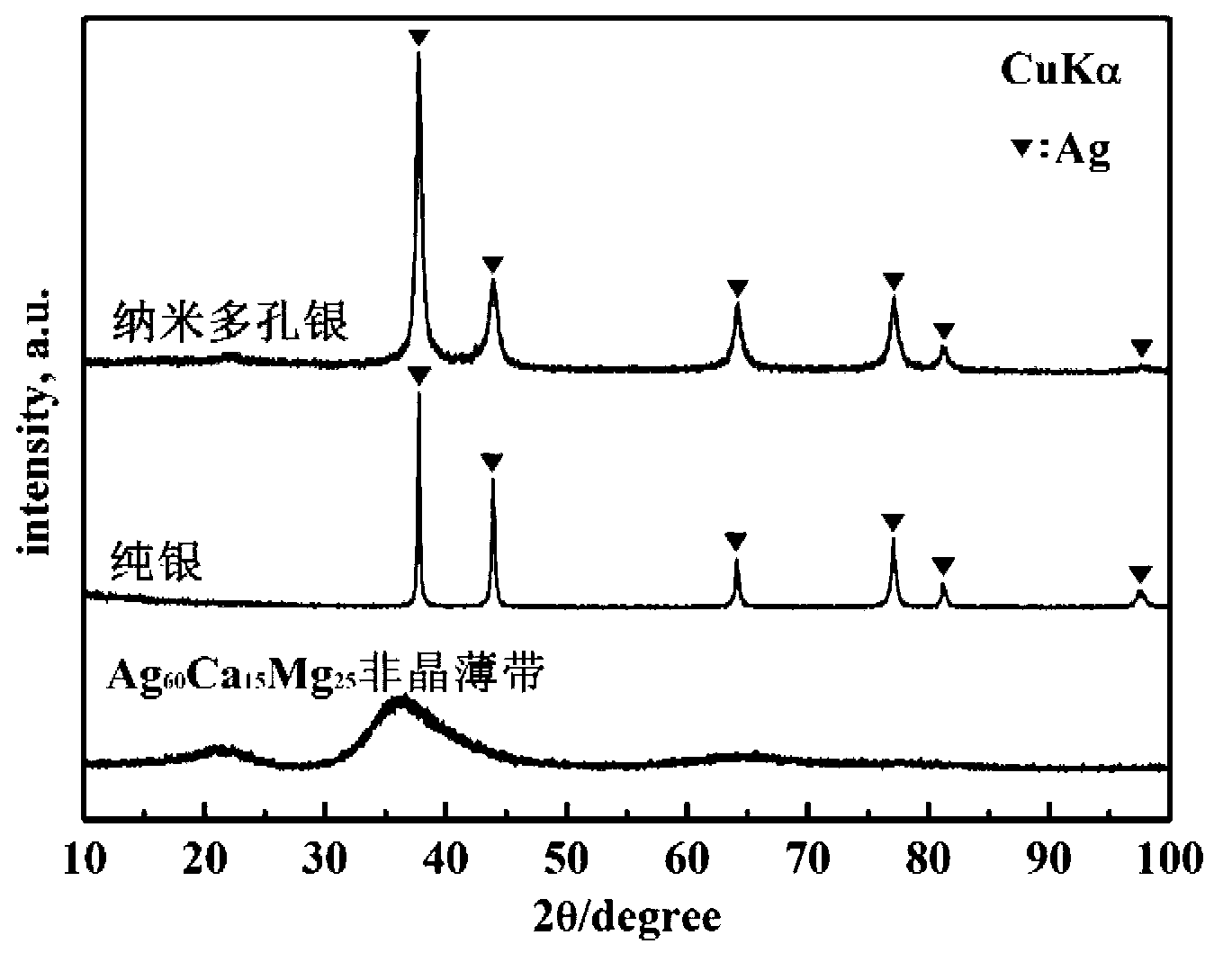

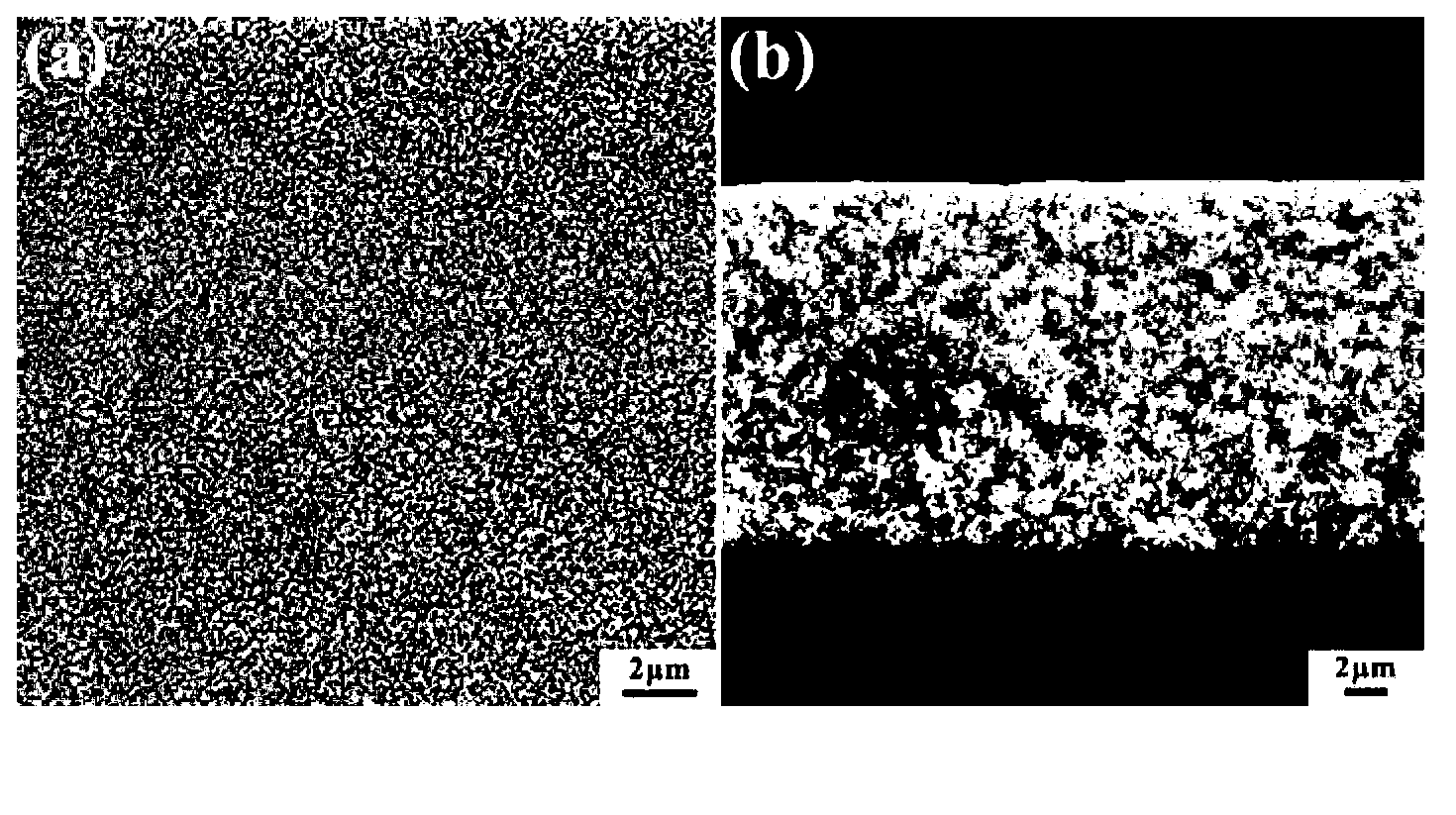

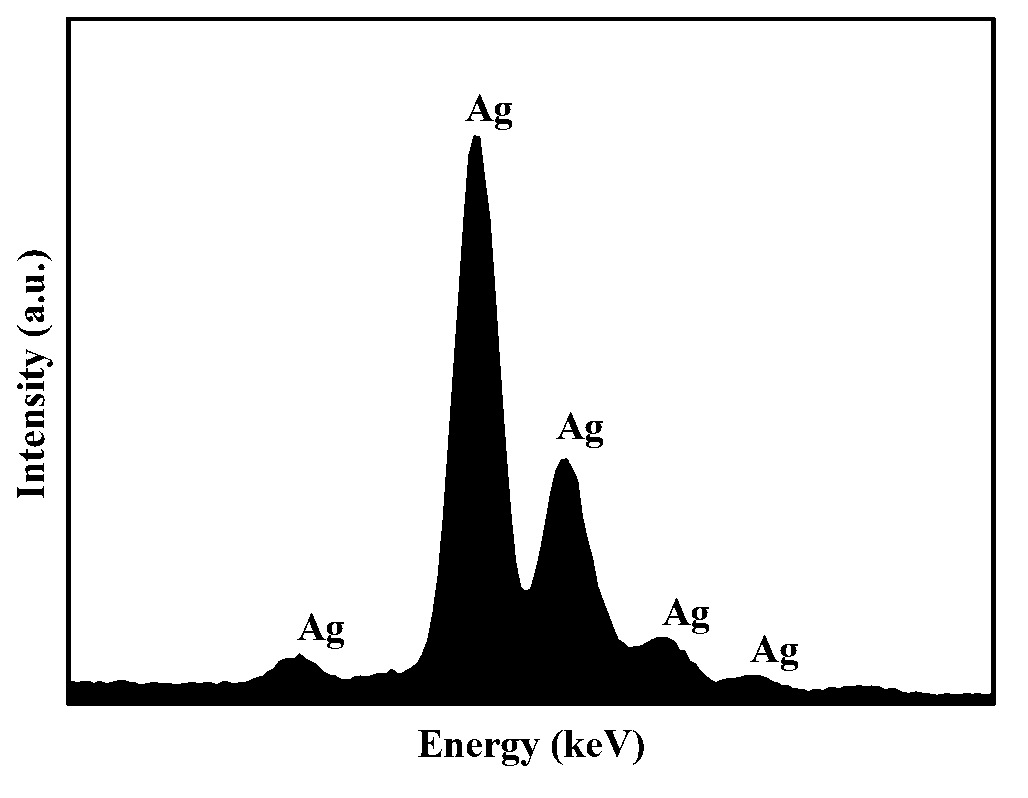

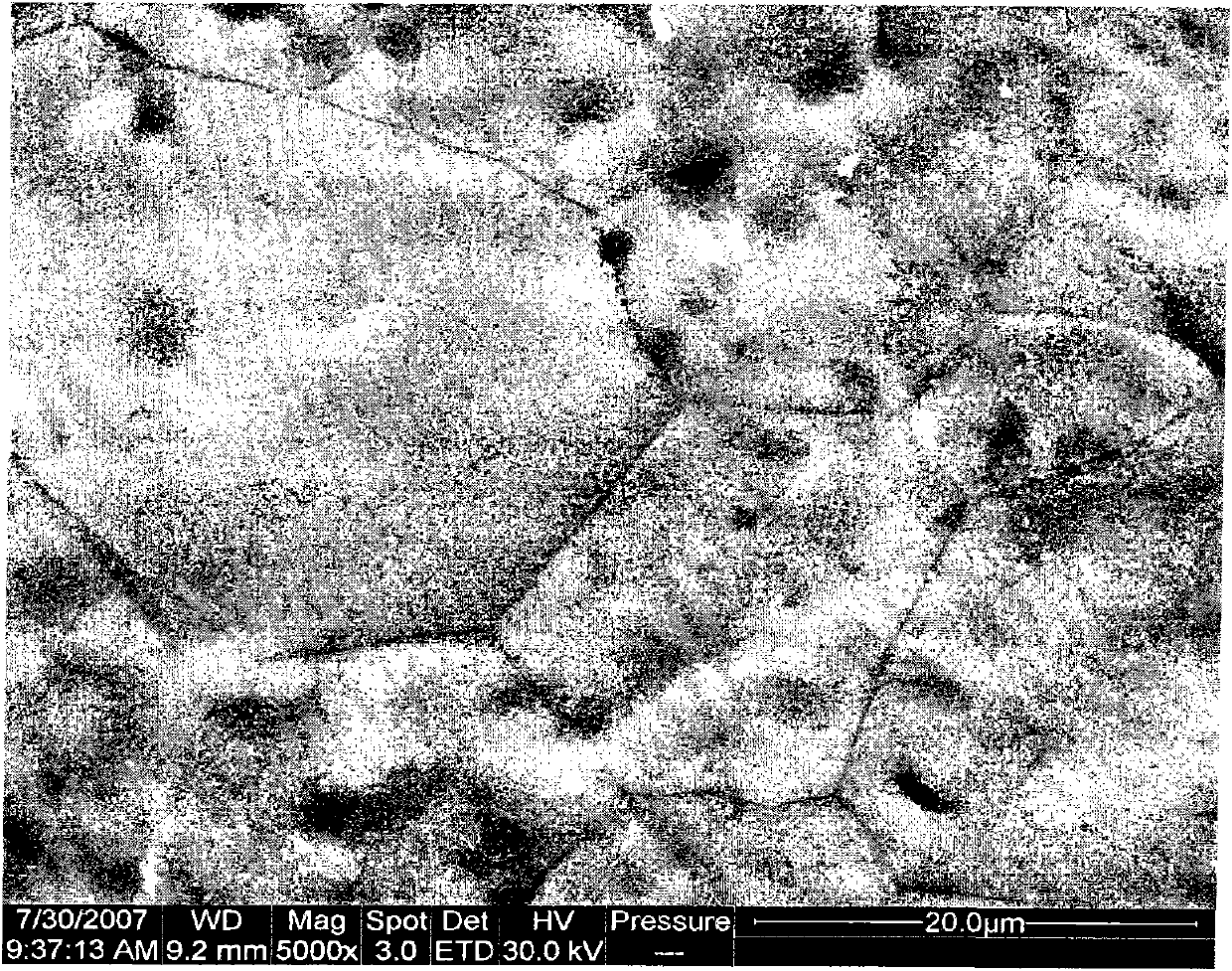

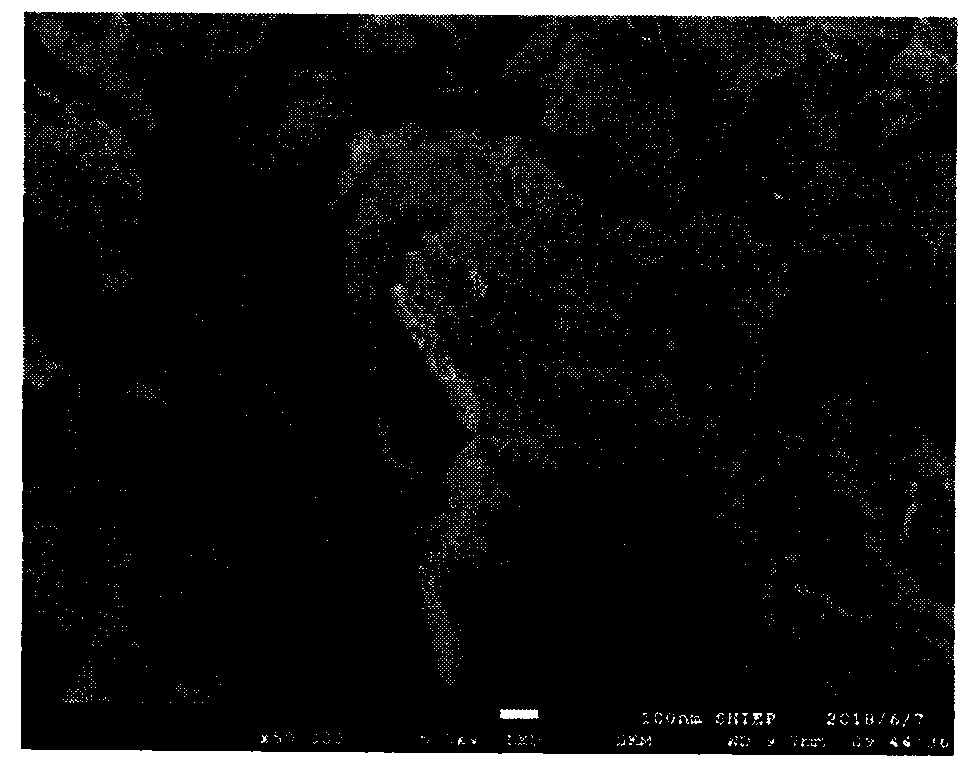

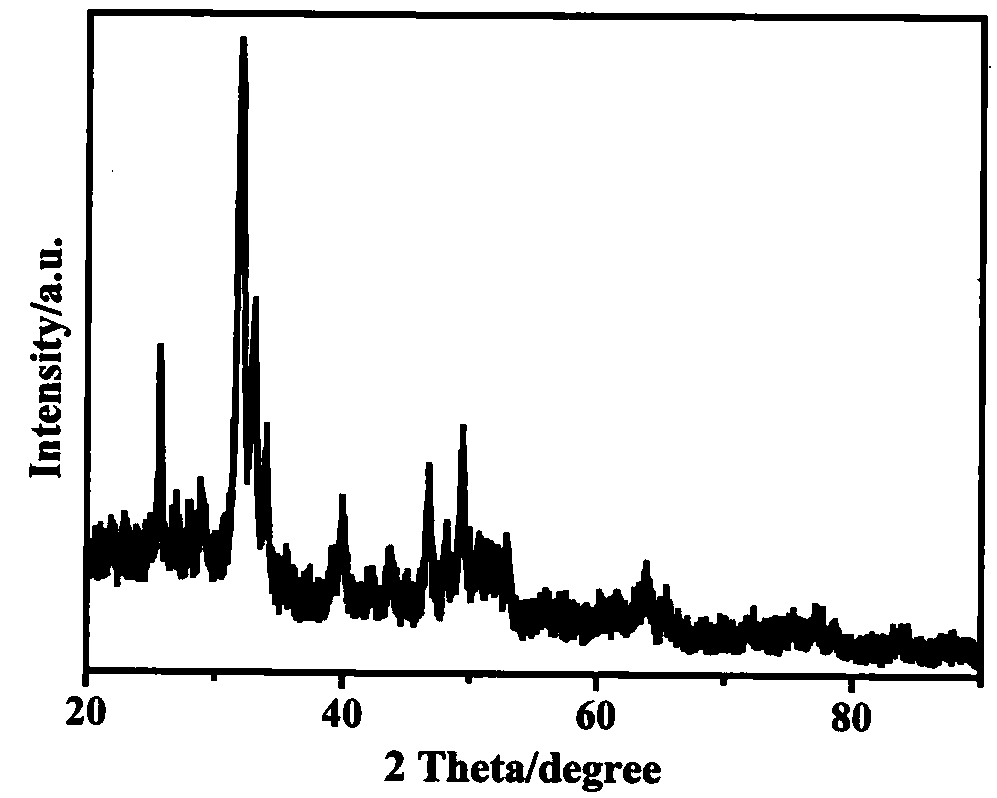

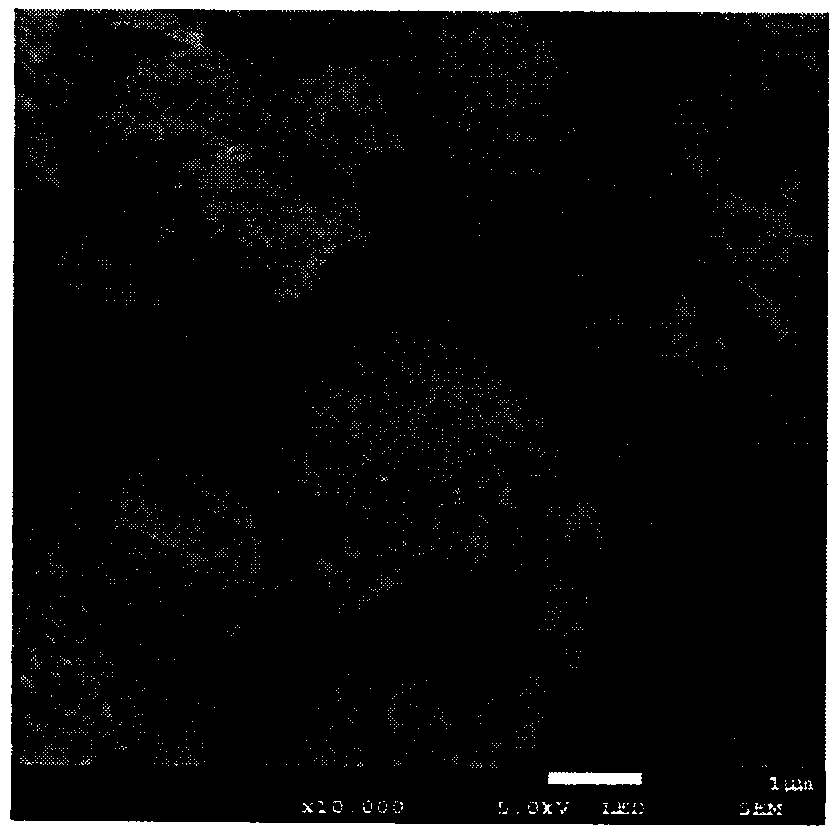

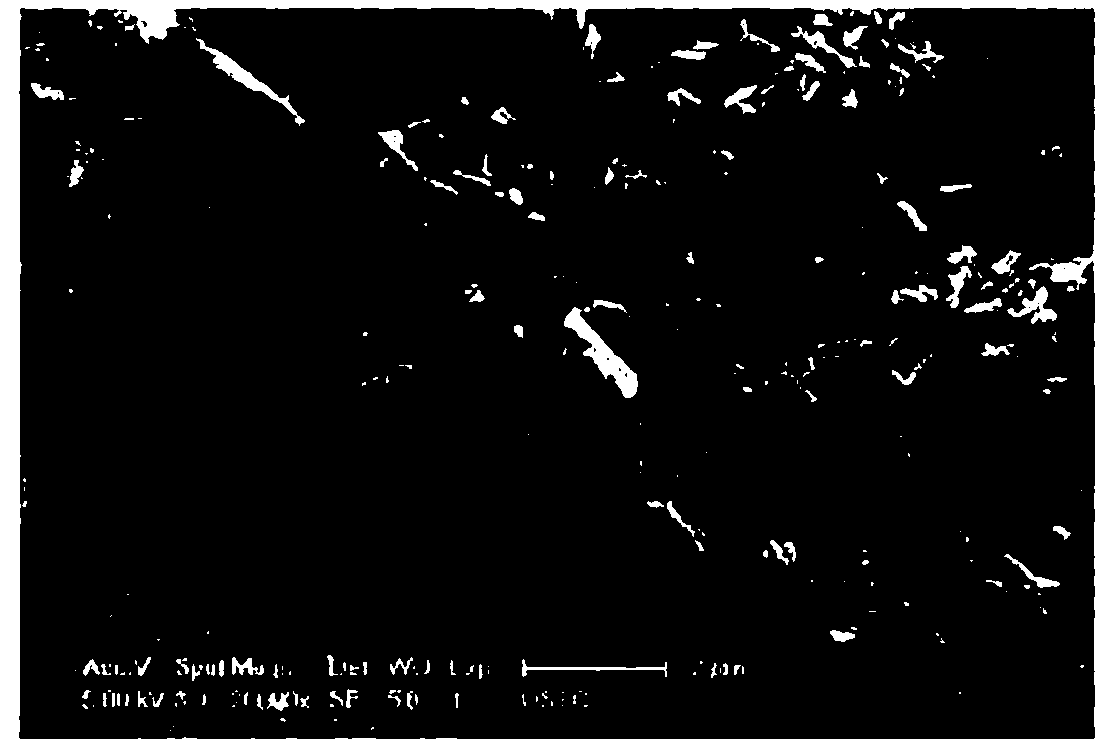

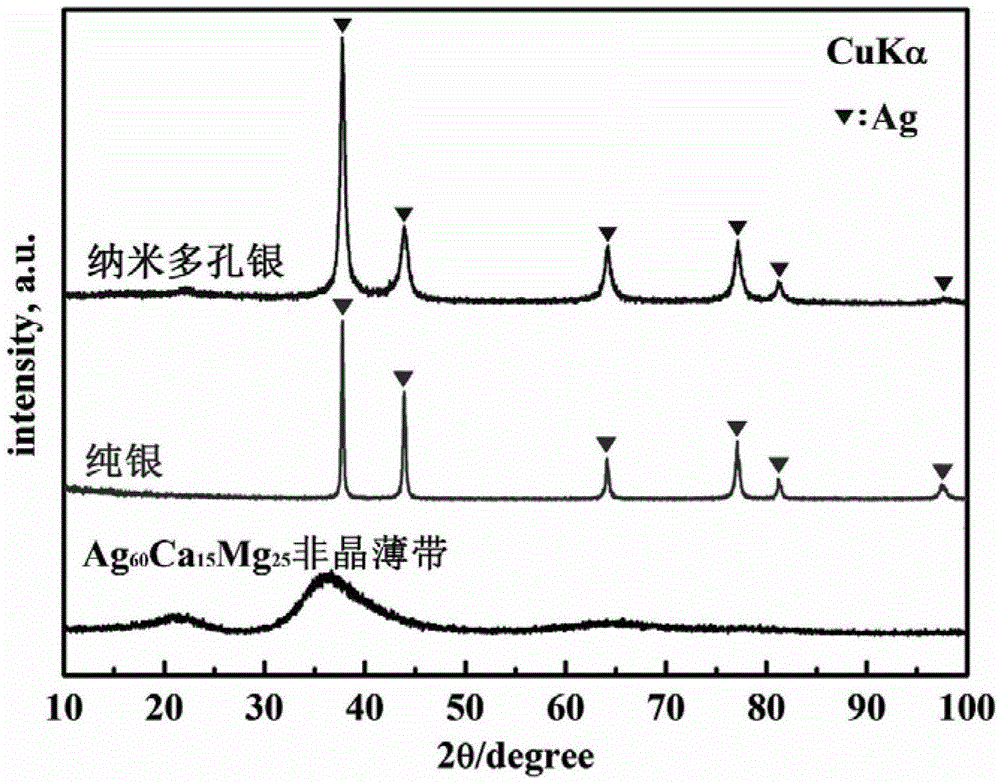

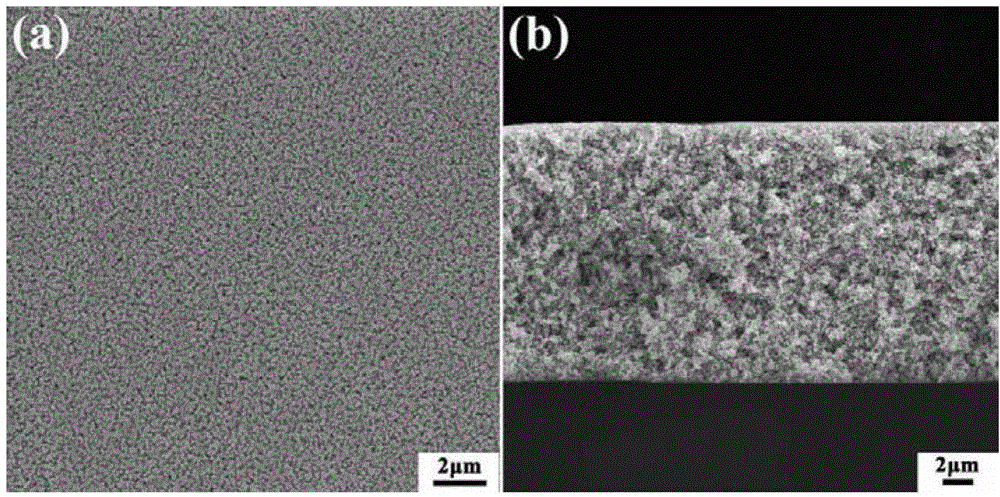

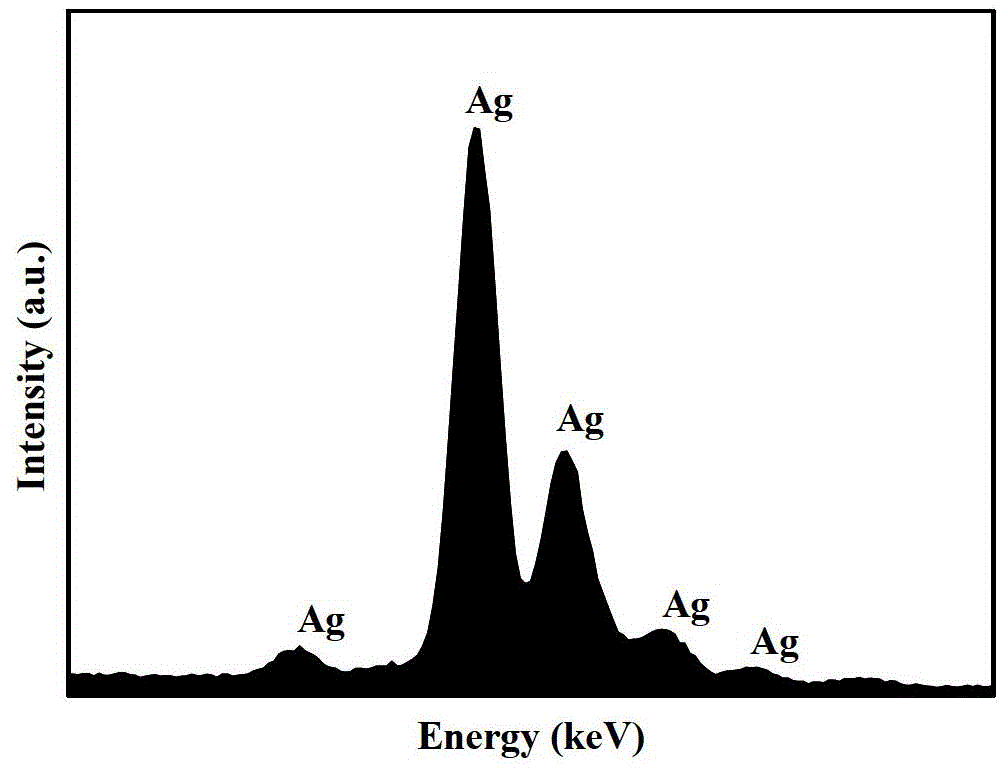

Method for preparing nano porous silver based on Ag-based amorphous alloy

The invention belongs to the field of preparation of nano porous metal materials, and relates to a method for preparing nano porous silver based on an Ag-based amorphous alloy. By the method, the nano porous silver with the aperture of 20-100 nm is finally obtained by preparing a series of Ag-Mg-Ca amorphous alloy thin bands by taking the Ag-based amorphous alloy as a precursor by a solvent quick quenching method and then removing Mg and Ca elements by performing electric chemical alloy component corrosion removal by proper electrolyte. By the method, the structure and the size of the nano porous silver are adjusted and controlled by controlling the amorphous alloy components or electric chemical corrosion temperature; the operation technology is simple; and furthermore, the nano porous silver is extremely high in surface-enhancement raman scattering (SERS) performance and has a wide application prospect in the fields of environment friendliness, catalysis and biological sensors.

Owner:UNIV OF SCI & TECH BEIJING

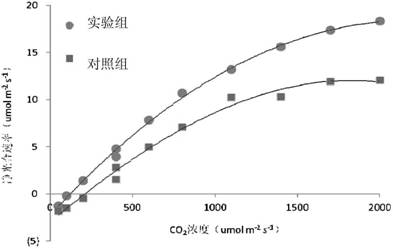

Cultivation method of dendrobium officinale and special nutrient solution thereof

ActiveCN102668956APromote growth and developmentShorten the production cycleCultivating equipmentsSoilless cultivationMass ratioNutrient solution

The invention discloses a cultivation method of dendrobium officinale and a special nutrient solution thereof. The nutrient solution is composed of solutes and a solvent. The solvent is water, and the solutes include an N source, a P source, a K source, a Ca source, a Mg source, a Fe source, a B source, an Mn source, a Zn source, a Cu source and a Mo source, wherein the mass ratio of N element, P element, K element, Ca element and Mg element in the N source, the P source, the K source, the Ca source, the Mg source is (3-5): (1-4): (1-4): (1.5-2.5): 1. According to the cultivation method of the dendrobium officinale, solid culture can be performed under suitable artificial light or natural light, growth and development of the dendrobium officinale can be promoted, production cycle can be shortened, and yield and quality of the dendrobium officinale can be improved finally. Therefore, the cultivation method of the dendrobium officinale and the special nutrient solution thereof have broad application prospects.

Owner:CHINA AGRI UNIV

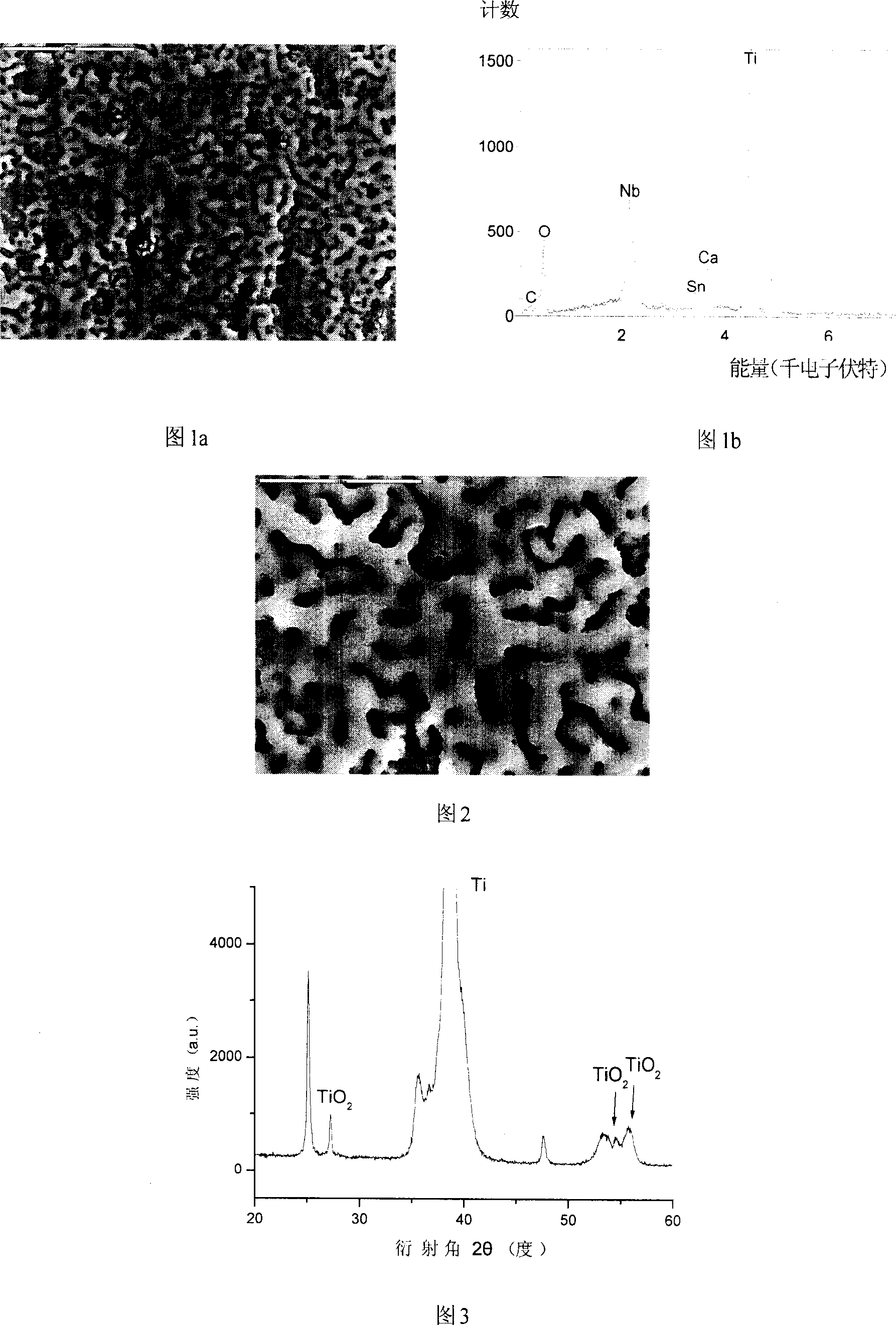

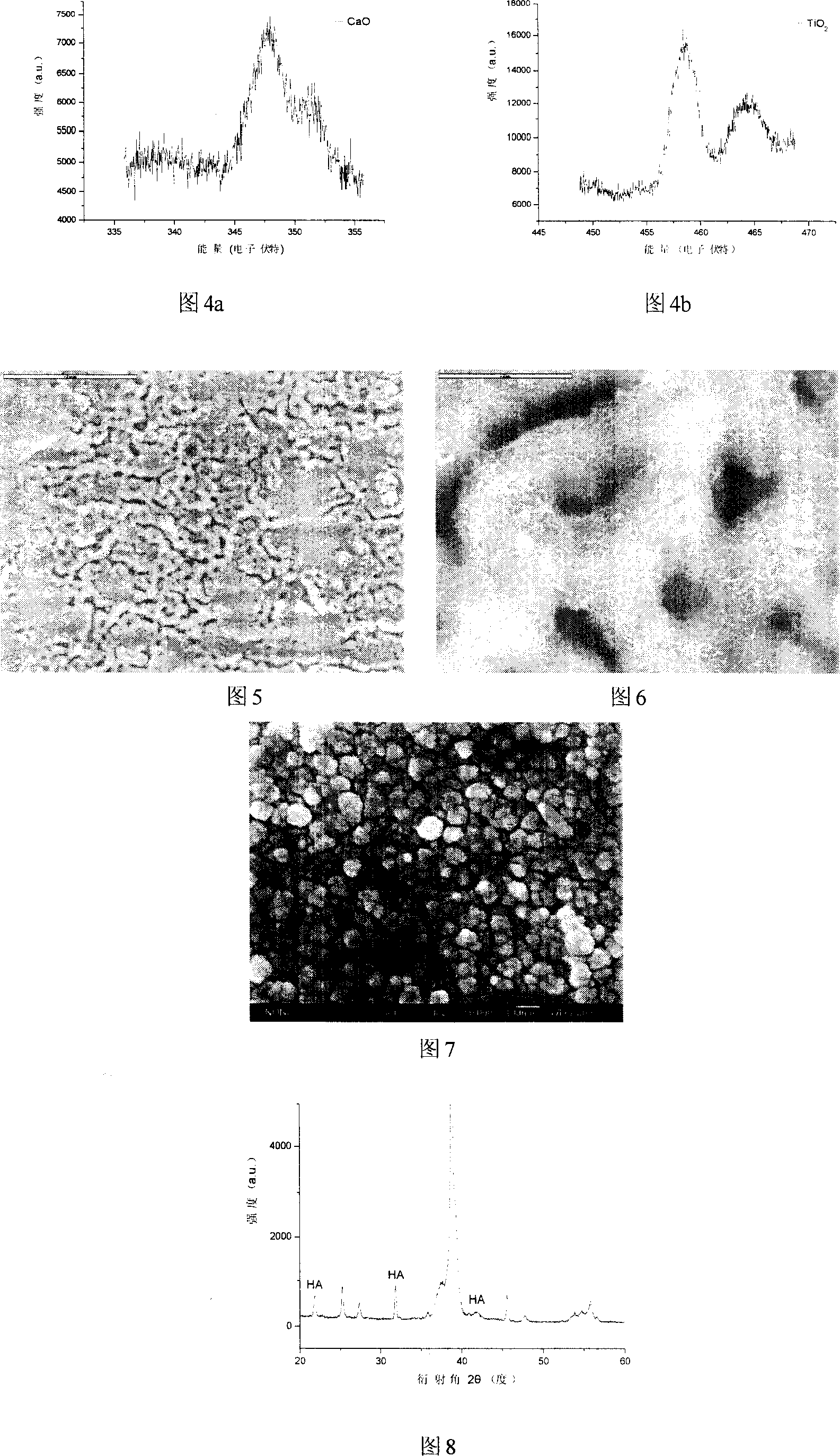

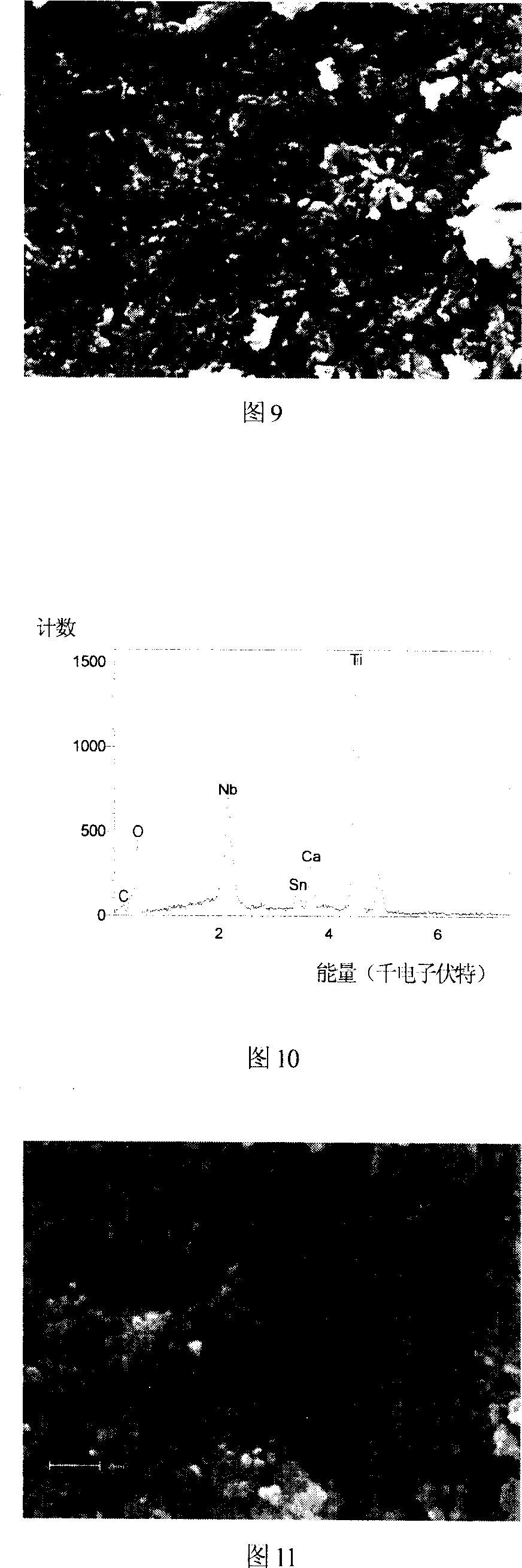

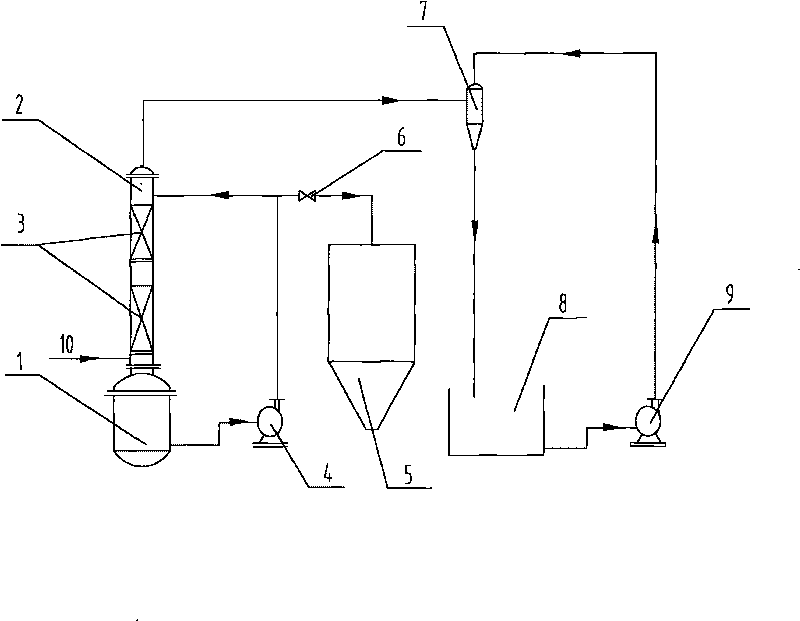

Bioactive coating on surface of Titanium or titanium alloy and its preparing method

InactiveCN1986003AGood biocompatibilityImprove biological activityCoatingsHigh cellBiocompatibility Testing

The present invention relates to bioactive coating on the surface of titanium or titanium alloy and its preparation process. The process includes the following steps: the first anode oxidation, alkali treatment and heat treatment of titanium or titanium alloy to form surface gradient coating in the thickness of 3 micron and comprising one inner thin and compact titania film and one outer porous titania film; introducing Ca element by means of the electrolyte solution into the coating to raise the biocompatibility; boiling in NaOH solution for 1-5 hr to form thin surface sodium titanate and calcium titanate layer; and final depositing a bone-like hydroxyapatite layer. The present invention raises the bioactivity of titanium or titanium alloy surface, and has high binding force of hydroxyapatite layer and high cell adhering capacity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Fruit foliar fertilizer containing Se, Zn and Ca

The invention relates to a fruit foliar fertilizer containing Se, Zn or Ca, which is prepared by the following steps of: weighting 80 parts of biological fermentation amino acid, 20 parts of sodium hydrogensulfite, 6 parts of sodium selenite, or zinc sulfate or calcium nitrate and 0.4 part of abscisic acid in a certain mass ratio, and mixing. Se, Zn and Ca elements are added in the components of the foliar fertilizer, so that functional elements in the harvested fruits are enriched and enhanced and the technical effect of directionally supplementing mineral substance nutrient elements for users are achieved. The invention is suitable for spraying and applying onto the leaves of fruit plants.

Owner:北京禾盛绿源科贸有限公司

Gelatin/calcium phosphate composite porous microsphere for bone repair and preparation method and usage of the porous microsphere

ActiveCN101444646AGood biocompatibilityImprove biological activityProsthesisPhosphatePhosphoric acid

The invention belongs to the field of the preparation of gelatin derivative materials and in particular relates to a composite porous microsphere material formed by compounding gelatin, calcium phosphate and an antler polypeptide bioactive tissue or bone morphogenic protein (BMP). The composite porous microsphere is formed by uniformly dispersing, in a gelatin composite porous microsphere, the calcium phosphate and active-substance antler polypeptide or bone morphogenic protein which is capable of promoting bone growth; wherein, the weight of the active-substance antler polypeptide or the bone morphogenic protein accounts for millesimal to five percent of the weight of the gelatin; soluble calcium salt which forms the calcium phosphate ranges from 0.0003 to 0.03 mol in each gelatin; and the amount of soluble phosphate causes the ratio between Ca element and P element to range from 1:1 to 2:1. The composite porous microsphere material can also contain crosslinking agent. The composite porous microsphere material is a bone repair biological material which has good biocompatibility and good bone induction activity.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

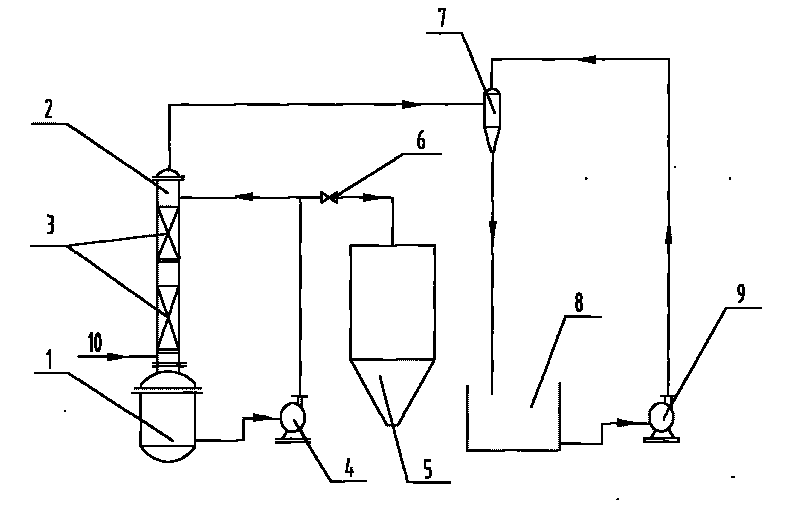

Method for recycling tail gas generated by granulation of compound fertilizer

InactiveCN101698132AHighlight substantiveSignificant progressUsing liquid separation agentGrowth plantWastewater

The invention relates to a method for recycling tail gas generated by the granulation of the compound fertilizer, which belongs to the recycling of carrying materials in industrial exhaust gas. The method comprises the steps of fine dust recovery and tail gas washing, and is characterized in that washing liquor is circulated and recycled completely. The method comprises the following operating steps: a, acidification, namely adding inorganic acid aqueous solution into the circulating washing liquor to enable the pH value of the washing liquor to be less than or equal to 6.5; b, vacuum absorption; c, solid-liquid separation; and d, neutralization. The invention provides a process method which recycles tail gas generated in the process of producing the compound fertilizer completely and really implements the zero release of the waste gas, waste residues and waste water in a compound fertilizer producing device, increases S and Ca elements required in plant growth in the compound fertilizer, saves energy resources, is favorable for environmental protection, reduces the production cost of the compound fertilizer, and is suitable for the processing of the tail gas generated in the process of producing the compound fertilizer and compound or mixed fertilizer.

Owner:LINYI UNIVERSITY

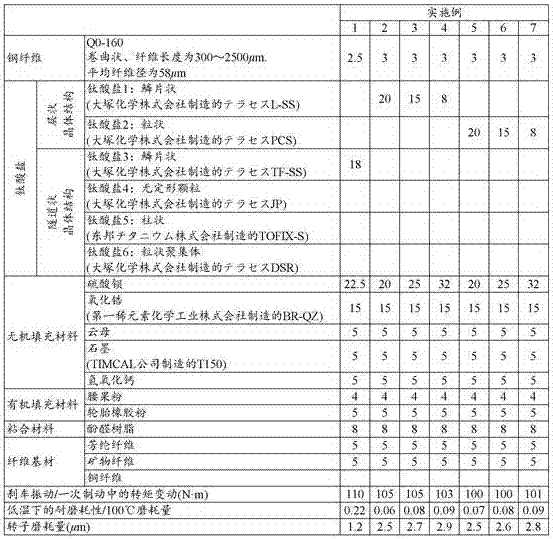

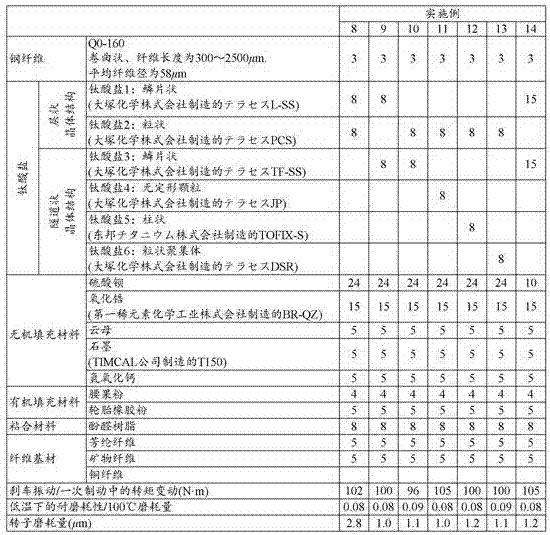

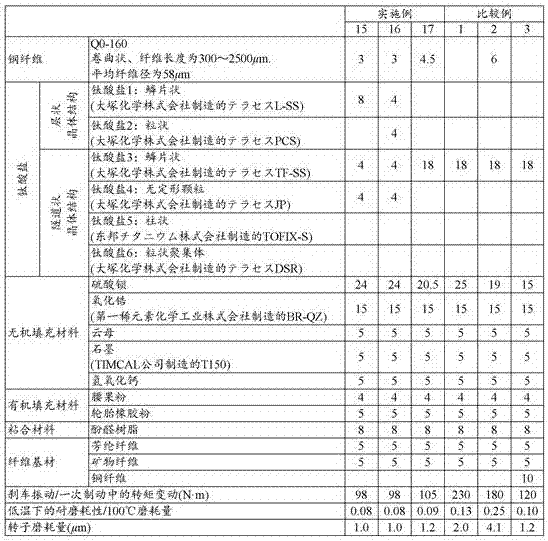

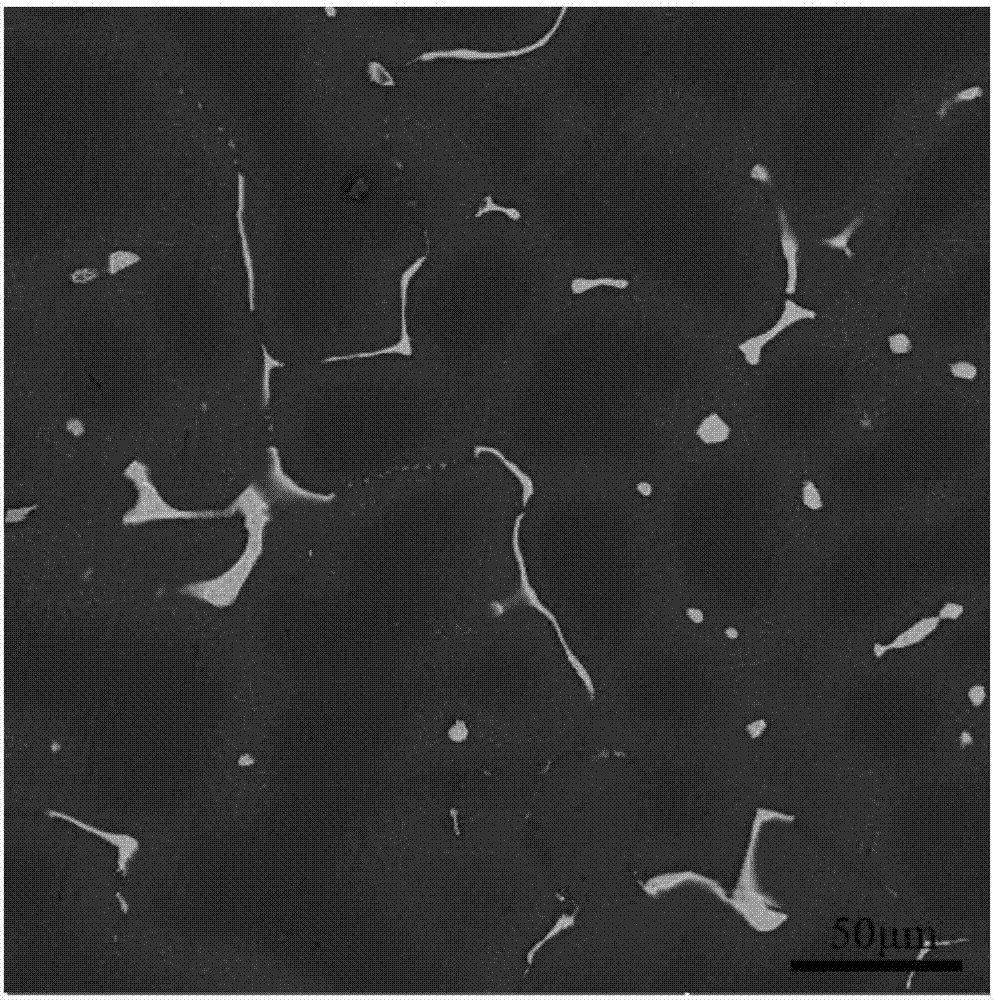

Friction material composition, and friction material and friction member using said friction material composition

Provided are: a friction material composition exhibiting minimal brake vibration in high-temperature braking when used in a friction material such as a vehicular disk brake pad in cases in which the friction material composition does not contain high-environmental-impact copper, or contains copper in a small amount of 0.5 mass% or less; and a friction material obtained by molding this composition. A friction material composition including a binder, an organic filler, an inorganic filler, and a fiber base material, wherein the friction material composition does not contain copper as an element or has a copper content of 0.5 mass% or less, and contains 2-5 mass% of steel fibers having a fiber length of 2,500 um or less.

Owner:JAPAN BRAKE IND CO LTD

High-strength corrosion-resistant wrought magnesium alloy and preparing method thereof

ActiveCN107236884AImprove mechanical propertiesImprove corrosion resistanceSolid solution strengtheningCa element

The invention relates to a high-strength corrosion-resistant wrought magnesium alloy and a preparing method thereof. The magnesium alloy comprises, by mass percentage, 6.0%-9.0% of Sn, 1.5%-4.0% of Zn, 0.1%-1.0% of Mn, 0%-1.0% of Ca, 0.01%-0.1% of Na, less than 0.03% of inevitable impurities in total and the balance Mg. The Sn element serves as a main alloy element, and therefore the solution strengthening effect and the second phase strengthening effect are guaranteed, SnO2 can be formed in the corrosion process, and the protection performance of a Mg(OH)2 film is improved; the Zn element is added into a solution strengthening magnesium base; through adding of the Mn element, the content of impurity elements in the magnesium base can be reduced, the grain size of the extrusion state alloy is reduced, and the mechanical property and the decay resistance of the alloy are improved; through adding of the Ca element, a CaMgSn phase can be formed to participate in formation of an oxidation film, and the density of the oxidation film is increased; and through adding of the Na element, the size of a second phase can be refined. In cooperation with joint effects of several aspects, the alloy has the excellent mechanical property and decay resistance.

Owner:DONGHAO MECHANICAL & ELECTRONICS

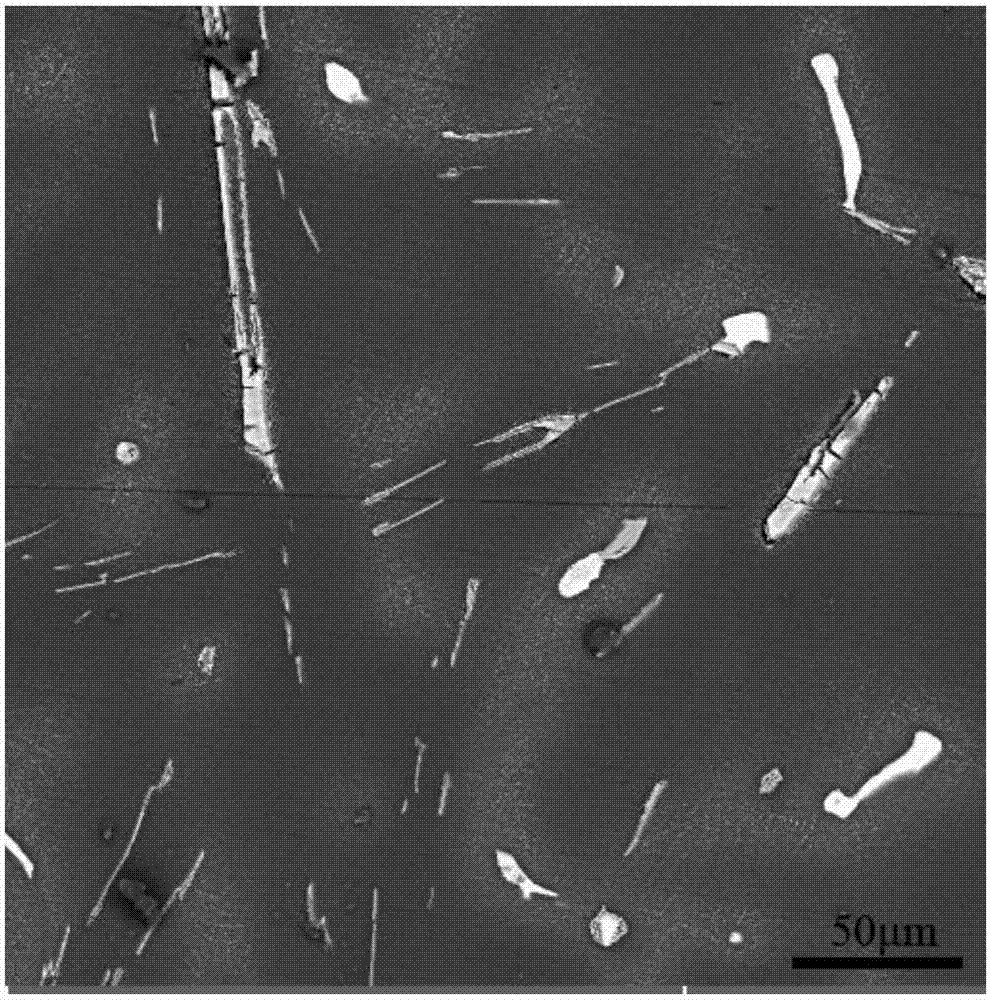

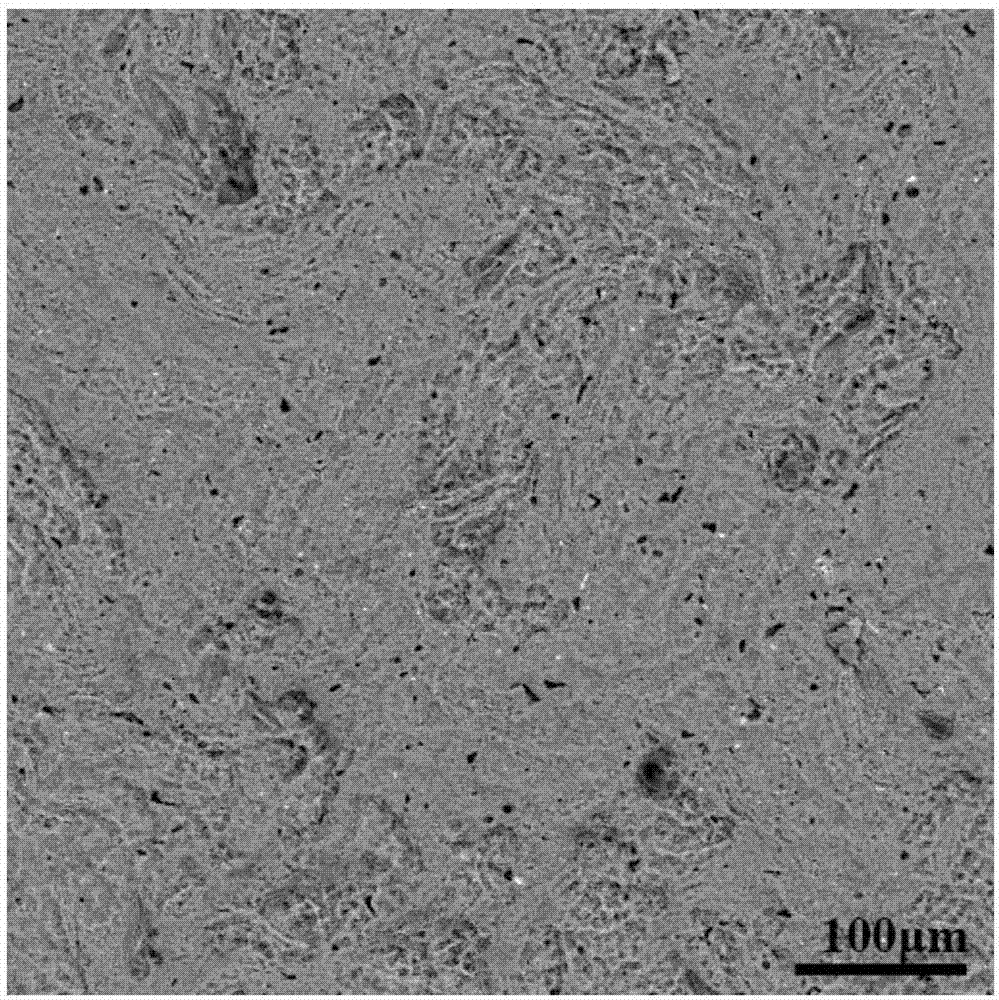

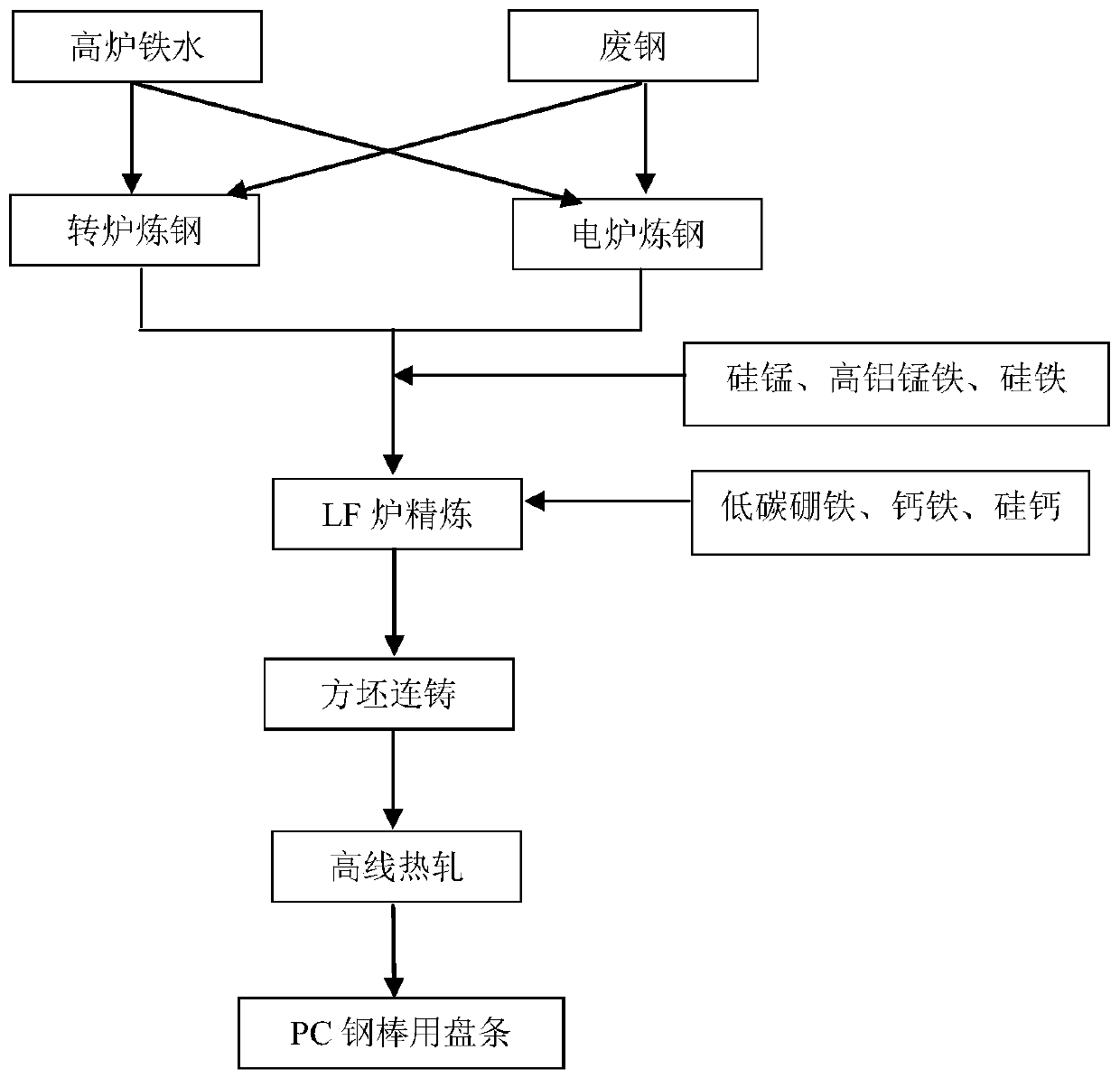

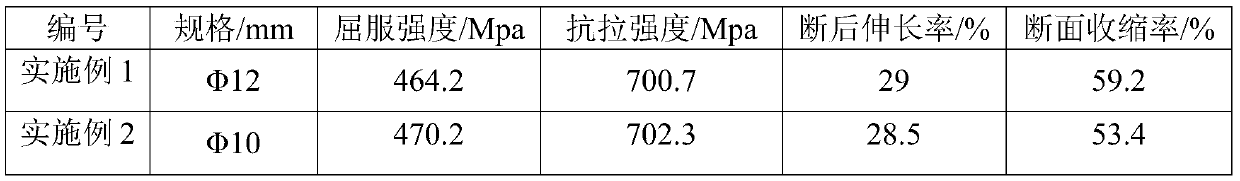

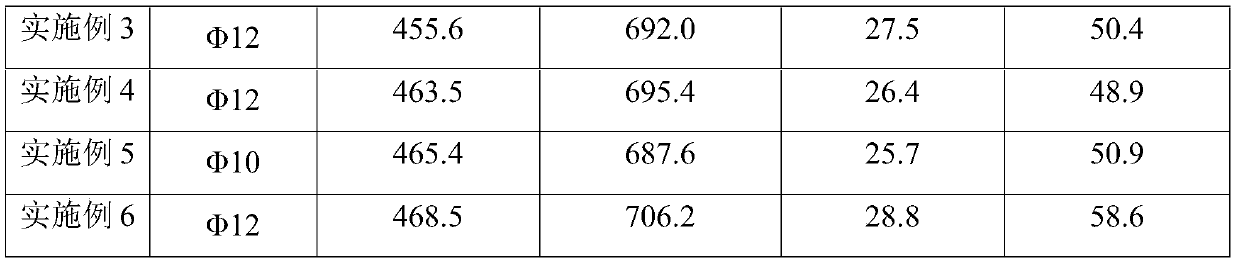

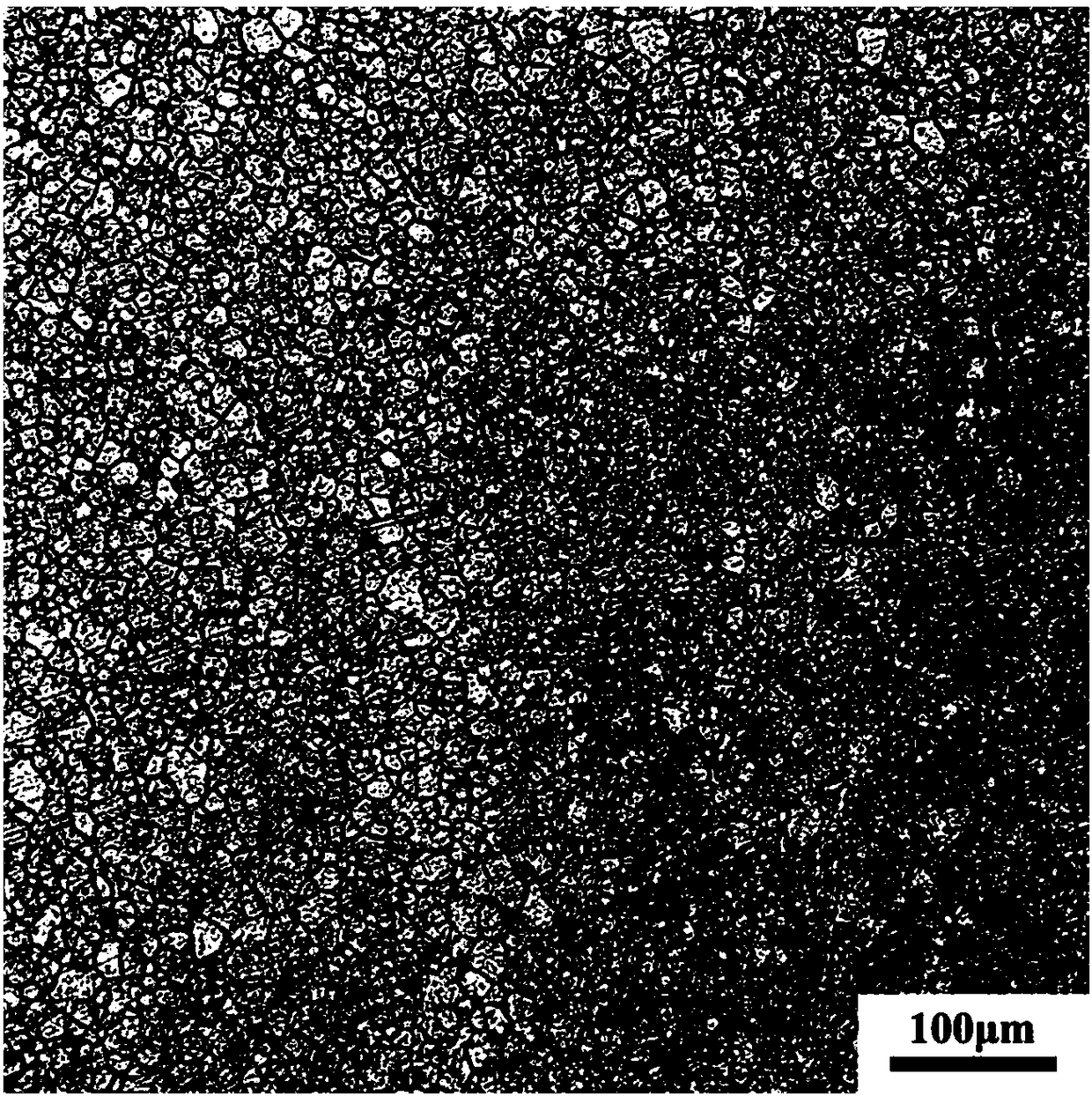

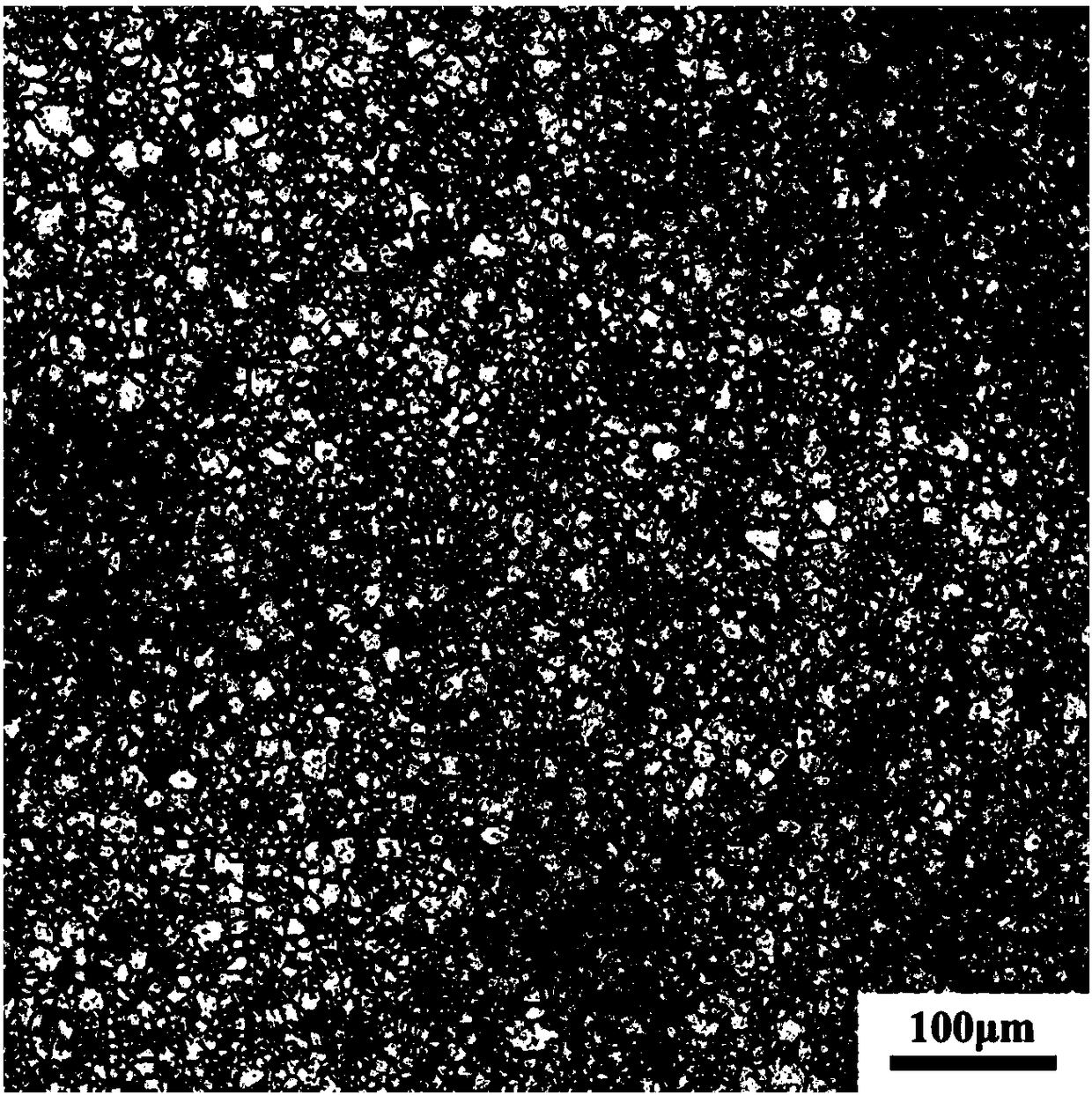

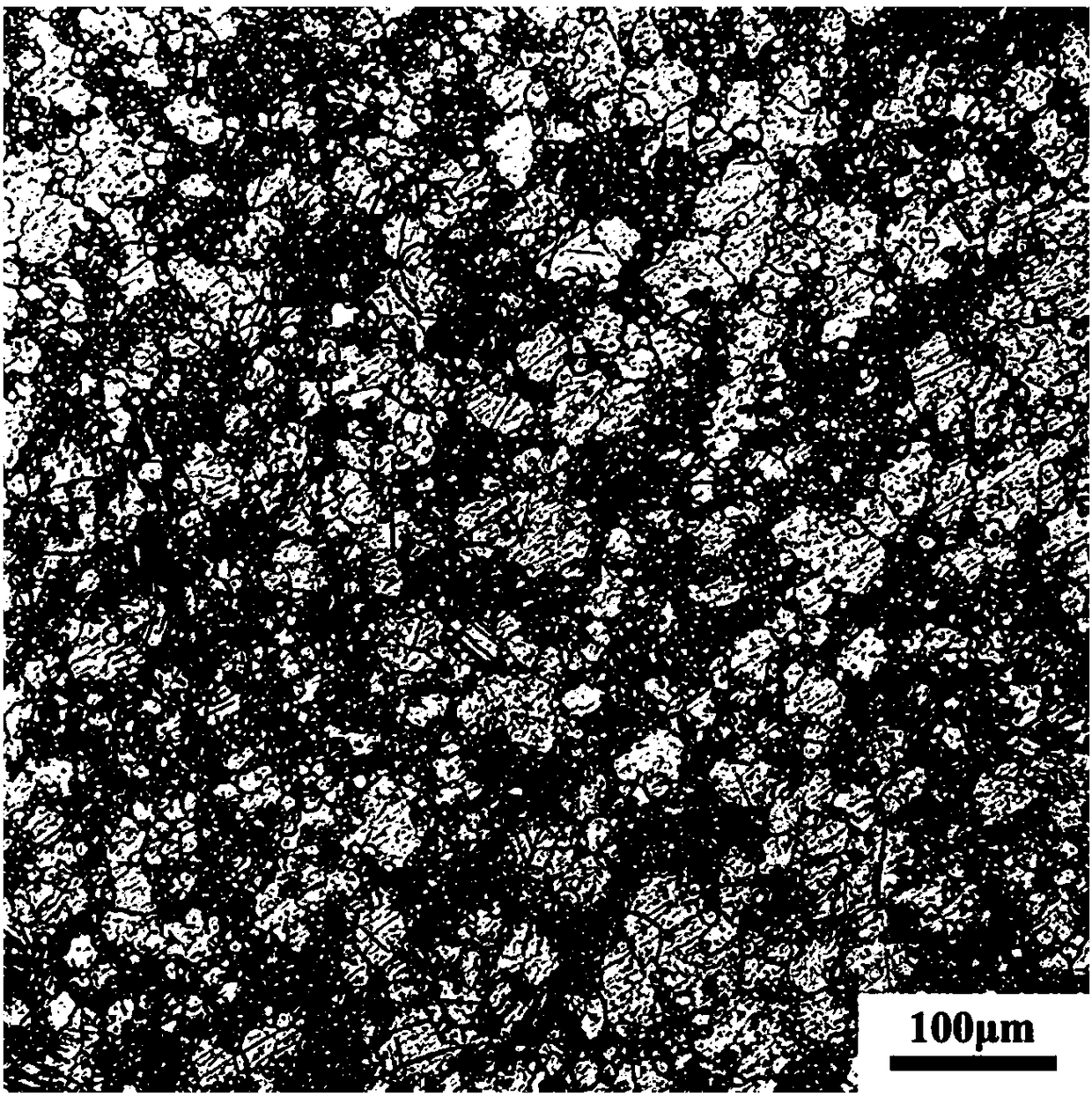

30MnSiBCa hot-rolled wire rod for PC steel bar and preparation method of 30MnSiBCa hot-rolled wire rod

ActiveCN110527917AImprove hardenabilityIncrease elasticityProcess efficiency improvementWire rodSteel bar

The invention relates to a 30MnSiBCa hot-rolled wire rod for a PC steel bar and a preparation method of the 30MnSiBCa hot-rolled wire rod; B and Ca elements are added into the 30MnSiBCa hot-rolled wire rod, and the hardenability and delayed fracture resistance of the wire rod are improved by controlling the ratio of B to Cr, Mn and Si and the content of Ca and B; meanwhile, an existing preparationprocess of the hot-rolled wire rod is optimized, molten steel is smelted by a converter / electric furnace; lF refining is carried out, and the 30MnSiBCa hot-rolled wire rod is prepared through the process route of continuous casting of steel billets and hot rolling and controlled cooling, so that the same batch of head and tail and different batches of hot-rolled wire rods are stable in performance and small in component fluctuation, the purity of steel is greatly improved, and the technical effects of avoiding frequent adjustment of the subsequent PC steel bar production process and being high in cost are achieved.

Owner:YANGCHUN NEW STEEL CO LTD +1

Medicament for preventing and controlling jujube witches broom

Owner:TAISHAN RES INST OF FORESTRY

Low-cost high-compression-strength wrought magnesium alloy and preparation method thereof

InactiveCN108118225ANo significant increase in preparation costsRich varietyElemental compositionCu element

The invention relates to a low-cost high-compression-strength wrought magnesium alloy and a preparation method thereof. The magnesium alloy material is composed of six elements, namely Mg, Zn, Mn, Sn,Ca and Cu, wherein the content of the Zn element is 4.0%-8.5%, the content of the Mn element is 0.1%-0.4%, the content of the Sn element is 0.1%-0.4%, the content of the Ca element is 0.1%-0.4%, thecontent of the Cu element is 0.1%-0.4%, the content of inevitable impurities is less than or equal to 0.15%, and the balance is the Mg; and compared with a traditional commercial grade magnesium alloymaterial, high compressive yield strength can be obtained after the magnesium alloy material is subjected to a conventional extrusion treatment, and the compressive yield strength of the alloy is obviously higher than tensile yield strength. The magnesium alloy material does not contain precious alloy elements, and is simple in preparation process and low in cost, has very important practical value for manufacturing a pressed magnesium alloy component.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

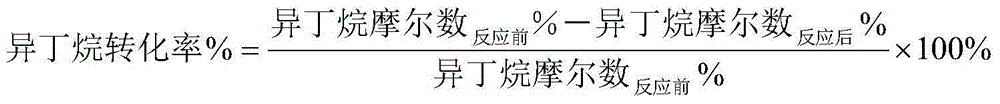

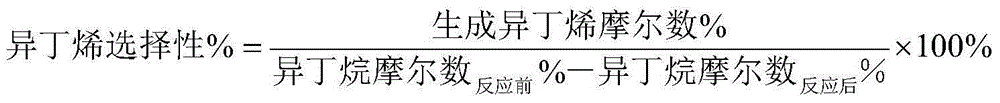

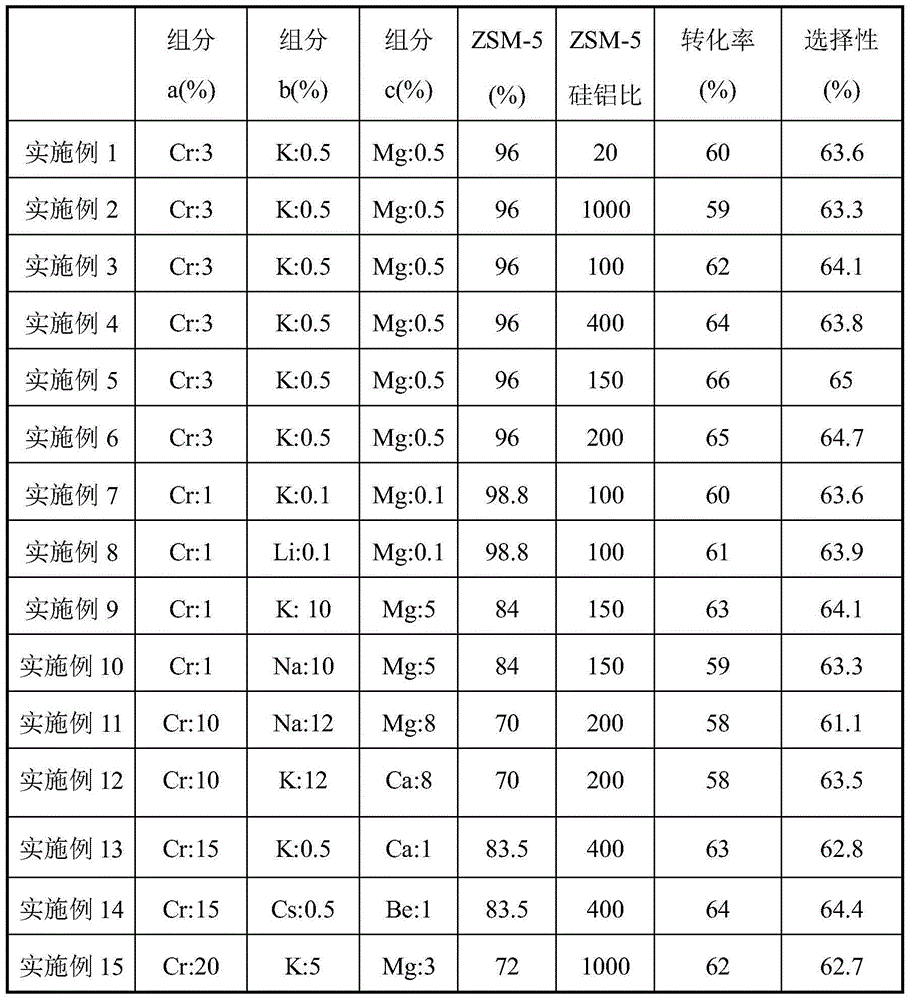

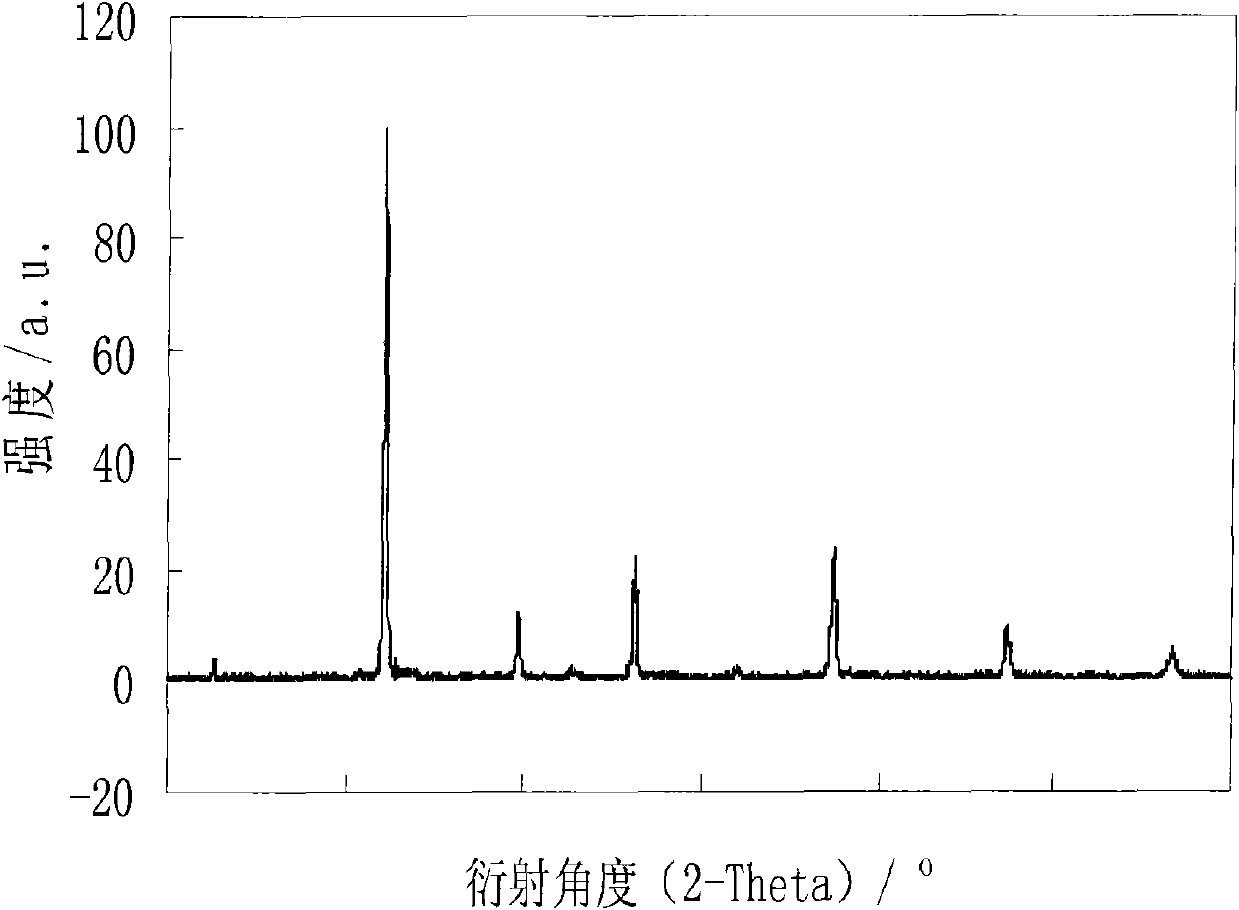

Isobutane oxidation dehydrogenation catalyst and preparation method and application method thereof

The invention relates to an isobutane oxidation dehydrogenation catalyst and a preparation method thereof, and mainly solves the problems of low activity and rapid inactivation of catalysts in the prior art in isobutane oxidation dehydrogenation. The isobutane oxidation dehydrogenation catalyst includes the following components by weight: a) 1-20% of Cr element or an oxide thereof; b) 0.1-12% of Li, Na, K, Rb, Cs elements or oxides thereof; c) 0.1-8% of Be, Mg, Ca element or oxides thereof; and d) ZSM-5 zeolite with the silica alumina ratio of 20-1000, and by the technical scheme, the problem is better solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

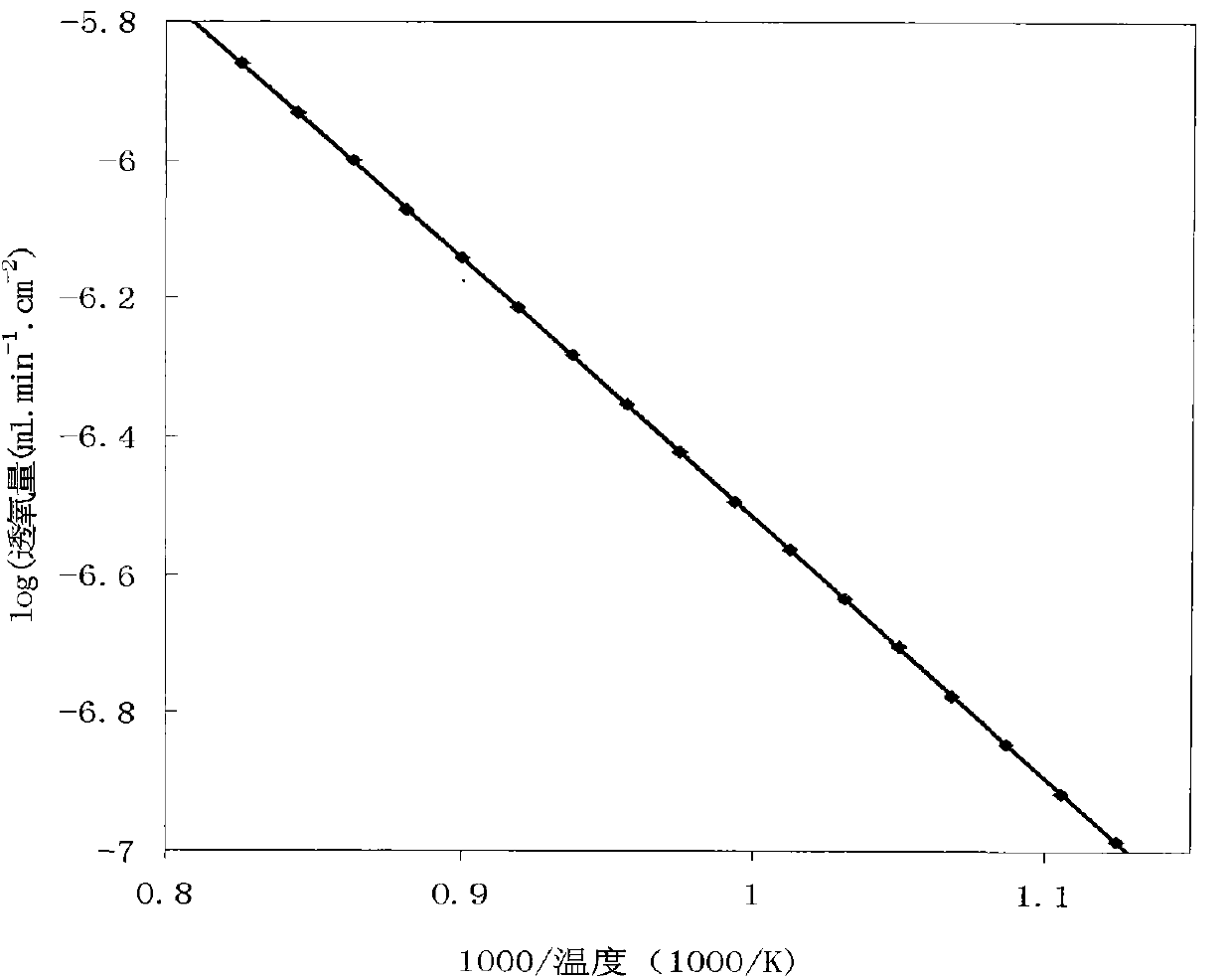

A-site Ba, Sr, Ca ions-doped SrCo0.8Fe0.2O3-delta-base perovskite oxygen permeable membrane material and application thereof

The invention provides an A-site Ba, Sr, Ca ions-doped SrCo0.8Fe0.2O3-delta-base perovskite oxygen permeable membrane material and application thereof, and relates to inorganic oxygen permeable membrane material, wherein, Ba, Sr and Ca elements are doped to the A-site of SrCo0.8Fe0.2O3-delta at the same time. The general formula of the material is BaxSr1-x-yCayCo0.8Fe0.2O3-delta, wherein, x is 0.1-0.9, and y is 0.1-0.9. In the invention, by adjusting the doping ratio of the three metal ions, the material forms a cubic perovskite structure; and studies show that the melting point of the material is lower than that of an A-site single-ion or dual-ion-doped perovskite material, and the material has stable structure and higher oxygen permeation quantity, thus being applicable to the fields such as oxygen permeable membrane sealing, pure oxygen separation, partial oxidation of methane, a solid oxide fuel cell cathode material and the like.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

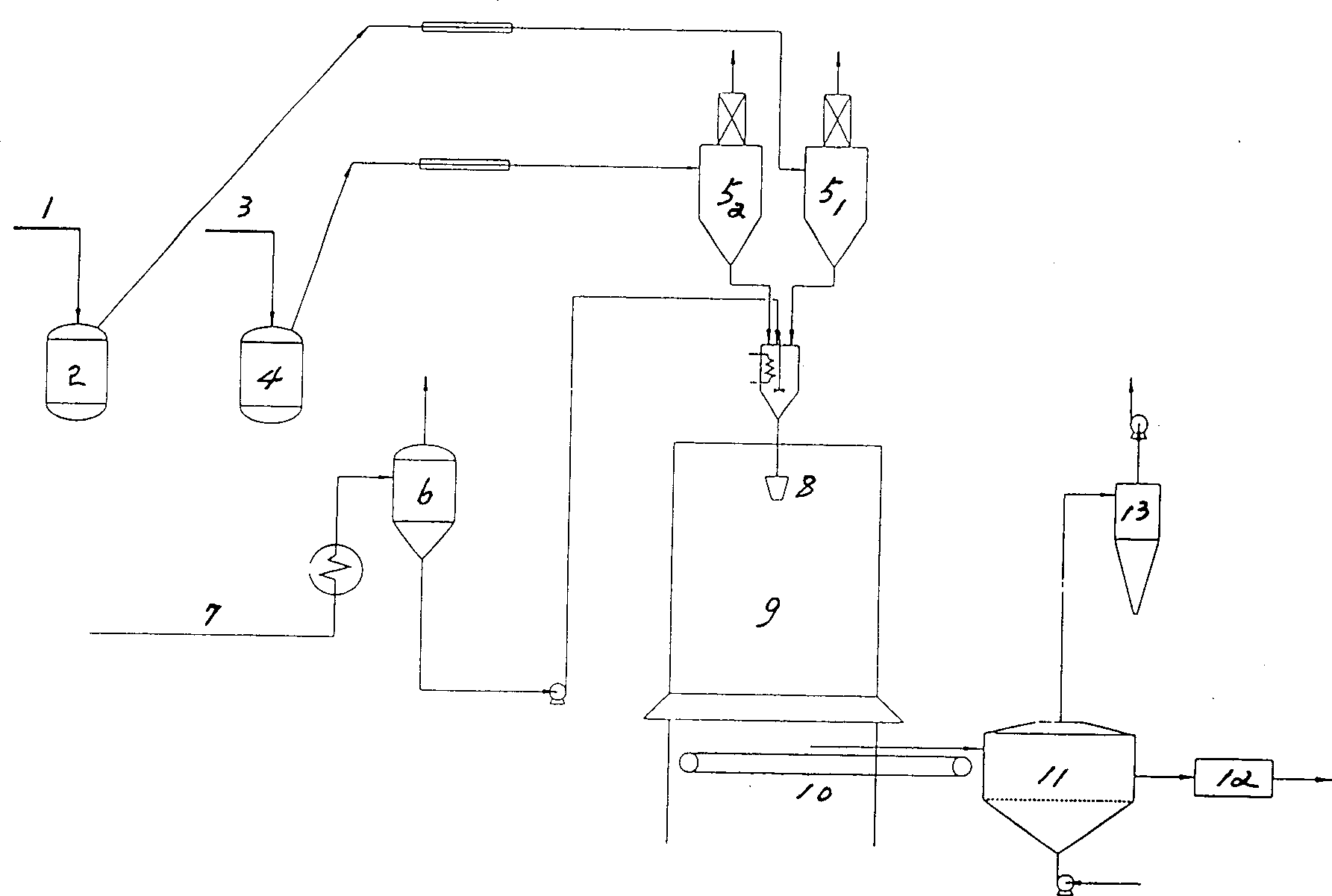

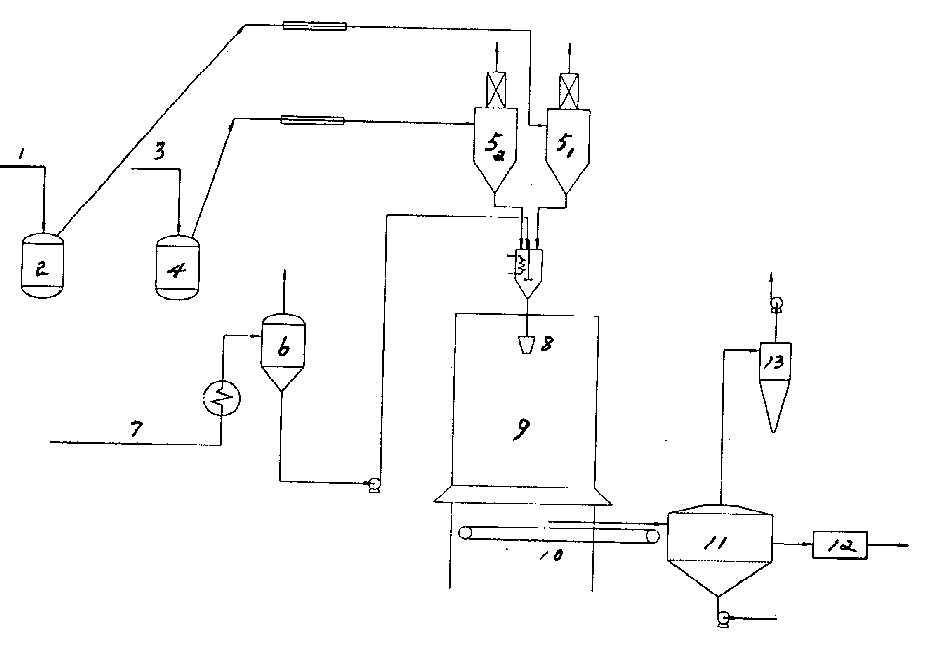

Multicompentnt granular urea and its production process

InactiveCN1357513ASuitable for growth needsOvercome the defect of single ingredientFertiliser formsUrea compound fertilisersEvaporationCa element

The multicomponent granular urea contains urea 60-80 wt%, ammonium sulfate 10-20 wt% and dolomite 10-20 wt% and has grain size of 2-4 mm. The production process includes evaporation of urea solution, preheating of ammonium sulfate and dolomite, mixing, granulation, cooling and packing. the multicomponnet granular urea can introduce S, Mg and Ca elements for the growth of crop while providing urea component, regulate soil nutrients and raise crop yield. It has delayed release function and high fertilizer effect.

Owner:黑龙江黑化集团有限公司

Wear resistant member, wear resistant device and method for manufacturing the wear resistant member

ActiveUS20110039068A1Improve compactnessEfficient removalLayered productsRecord information storageRare-earth elementLongest Diameter

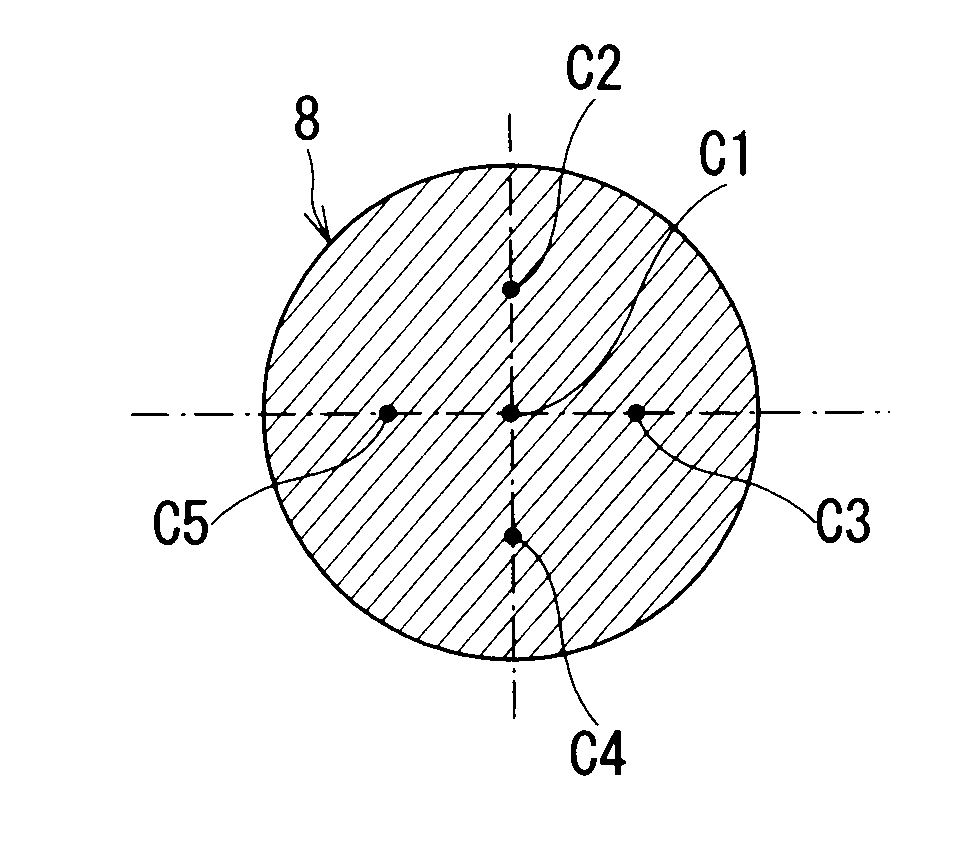

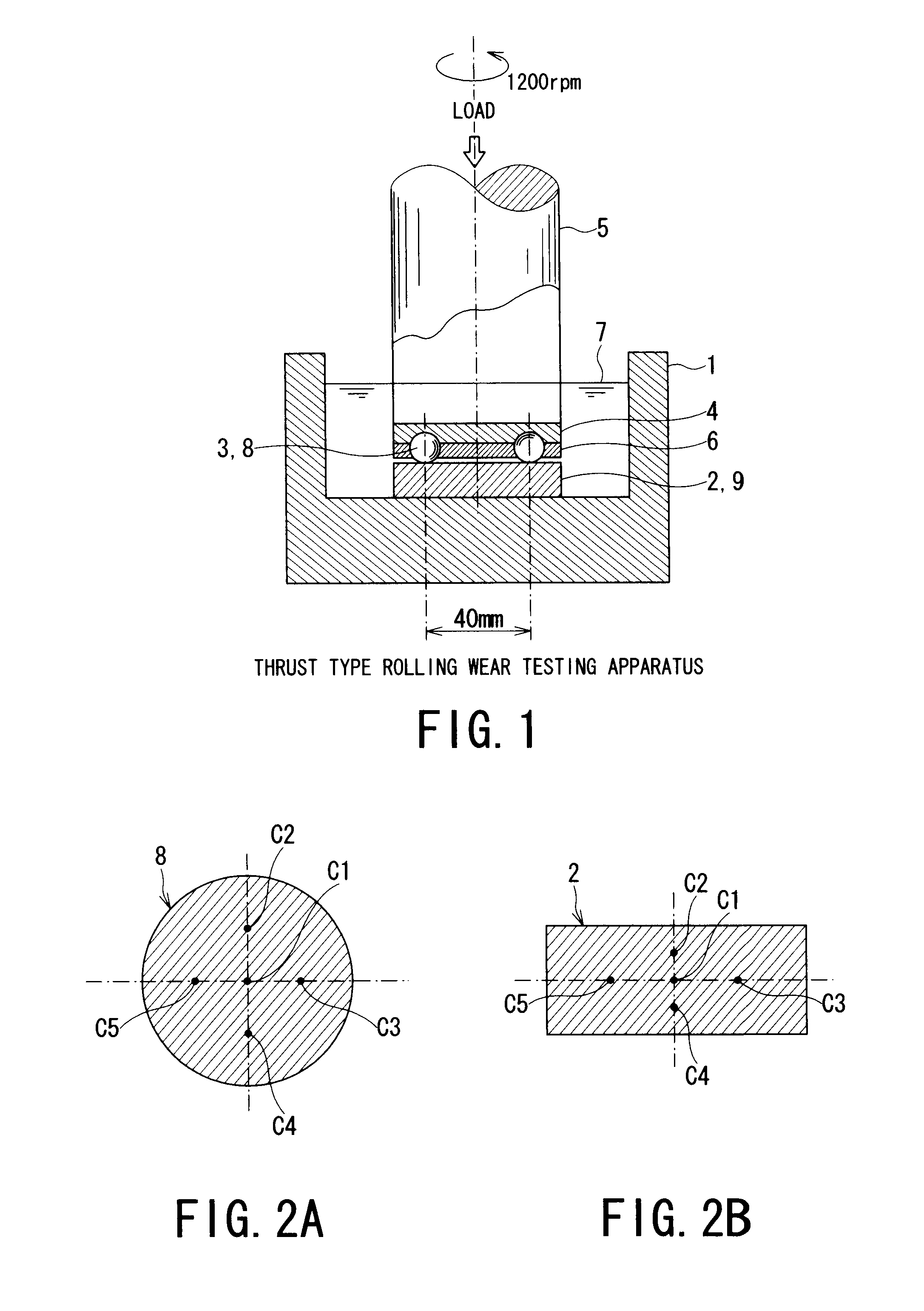

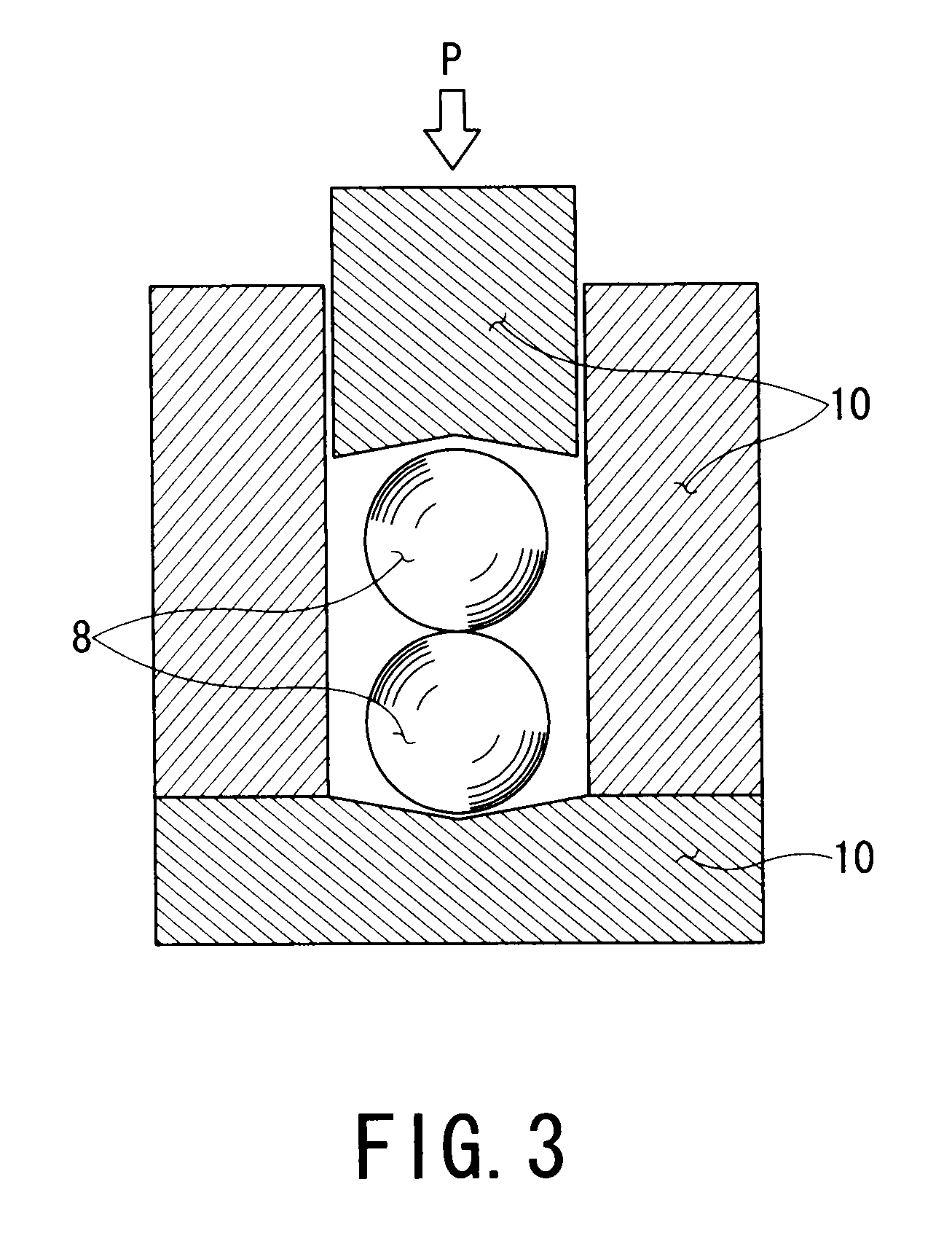

A wear resistant member formed of silicon nitride sintered body having a volume of 4000 mm3 or more, the silicon nitride sintered body containing 1 to 5 mass % of a rare earth component in terms of rare earth element, 1 to 6 mass % of an Al component in terms of Al element, 10 to 3500 ppm of an Fe component in terms of Fe element, and 10 to 1000 ppm of a Ca component in terms of Ca element, wherein a β-phase ratio of silicon nitride crystal grains is 95% or more, a maximum longer diameter of the silicon nitride crystal grains is 40 μm or less, and each of dispersions in Vickers hardness and fracture toughness of an inner portion of the wear resistant member is within a range of ±10%. According to this structure, the wear resistant member can be manufactured with a low cost, and there can be provided a wear resistant member comprising a silicon nitride sintered body excellent in reliability and the dispersion in characteristics is effectively suppressed.

Owner:KK TOSHIBA +1

Large-scale ceramic plate

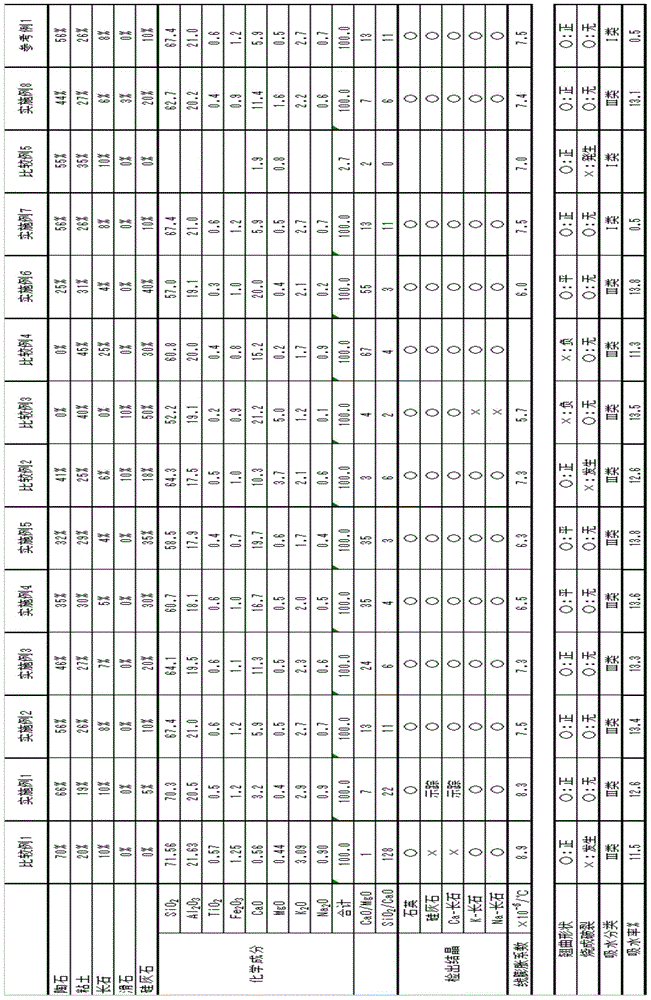

The invention provides a thin and large scale ceramic plate capable of preventing damages and deformation in dryness and burning state, and mass change caused by temperature change can be prevented; specifically, the large scale ceramic plate comprises the following elements: Ca element converted by CaO with above 2mass% and under 20mass%; Mg element converted by MgO between 0.1mass% and 4mass%; ALelement converted by Al2o3 under 30mass%; Si element, and CaO / MgO mass ratio is between 5-60mass%. More preferably, the large scale ceramic plate has SiO2 / CaO mass ratio between 3-30mass%.

Owner:TOTO LTD

Smilax china L. tuberous root yield and quality improvement method

InactiveCN104719016AIncrease productionQuality improvementFertilising methodsPlant cultivationMonopotassium phosphateBiology

The invention discloses a Smilax china L. tuberous root yield and quality improvement method. The method comprises the steps that 1, available nitrogen fertilizer is additionally applied to the ground during the period from April to June, 0.25% of urea and leaf fertilizer are sprayed on leaves once a week, and rattan is trimmed to be maintained in the length of 1.5m - 2m; 0.3% of monopotassium phosphate solution and the leaf fertilizer including B, Zn, Mg and Ca elements are sprayed once every fifteen days during the period from August to October; 2, an aqueous solution with the mass fraction of 0.05% - 0.1% is prepared by coumarin, leaf spraying is conducted on Smilax china L. from May to September, the spraying is conducted before sunrise or after sunset once every three to five days, and a spraying dosage for each time is judged by the fact that the leaves are evenly stained with the solution. By the implementation of the smilax china L. tuberous root yield and quality improvement method, Smilax china L. tuberous roots can be harvested just after two years; besides, the yield is improved by 15%-25%, and the diosgenin content is improved by 7%-15%. The method is simple, the industrialization, large-scale and standardization embodiment is facilitated, and the prospects are wide.

Owner:JISHOU UNIVERSITY

Preparation method of composite material capable of realizing high efficiency adsorption-photocatalysis degradation of antibiotics

InactiveCN108786889AGood removal effectImprove adsorption capacityPhysical/chemical process catalystsWater/sewage treatment by irradiationCentrifugationRoom temperature

The invention provides a preparation method of a composite material capable of realizing high efficiency adsorption-photocatalysis degradation of antibiotics. The preparation method comprises following steps: a CaCl2 solution is added into a sodium polystyrenesulfonate solution; Na2CO3 solution is added into an obtained mixed solution drop by drop, stirring is carried out at room temperature, centrifugation and drying are carried out so as to obtain white powdery CaCO3; the CaCO3 and Na2HPO4 are dissolved in deionized water, wherein the molar ratio of Ca element to P element is controlled to be 1.67; a certain amount of g-C3N4 is added, the pH value is adjusted to 11, and an obtained mixture is introduced into a high pressure reaction vessel for 0.5 to 2h of hydro-thermal reaction at 100 to 140 DEG C, and centrifugation drying is carried out so as to obtain a g-C3N4 / HAp composite material. The g-C3N4 / HAp composite material is capable of improving pollutant eliminating effect through cooperative effect of adsorption and photocatalysis.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

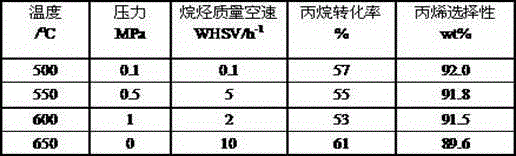

Propane oxidation dehydrogenation catalyst and preparation method and application thereof

ActiveCN104043456AImprove conversion rateHigh selectivityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsDehydrogenationCa element

The invention relates to a propane oxidation dehydrogenation catalyst and preparation method and application thereof, and mainly solves the problems of low conversion rate and poor stability of dehydrogenation catalysts in the prior art. The propane oxidation dehydrogenation catalyst comprises the following components: a) 1-30% of Cr element or its oxide; b) 0.2-10% of K, Na, Ca element or its oxide; c) 0.2-10% of Cu, Fe element or its oxide; and d) 40-98.5% of SiO2 with the silicon aluminum ratio of 20-300, and by use of the technical scheme of the propane oxidation dehydrogenation catalyst, the problems of low conversion rate and poor stability of the dehydrogenation catalysts in the prior art can be well solved, and the a propane oxidation dehydrogenation catalyst can be used for industrial production of propane oxidation dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aluminum nitride sintered body and substrate for electronic devices

ActiveUS6953761B2Small sizeSemiconductor/solid-state device detailsSolid-state devicesSurface roughnessCa element

An aluminum nitride sintered body produced by sintering under pressure of a powder composition comprising aluminum nitride and 5 to 30% by weight of at least one sintering aid selected from the group consisting of Nd, Sm, Eu, Er, Dy, Gd, Pr and Yb, per 100% by weight of the powders of aluminum nitride and the sintering aid, wherein the amount of the sintering aid is a conversion value as oxides of the elements, the sintering body that has been subjected to mirror-polishing having a surface roughness R max of 0.2 μm or less and a thermal conductivity of 200 (W / mK) or more.

Owner:HIATACHI POWER SOLUTIONS CO LTD

Wide-temperature range negative temperature coefficient heat-sensitive ceramic material and preparation method thereof

ActiveCN108546114AMeasuring temperature range widthAccurate measurementBased wideNegative temperature

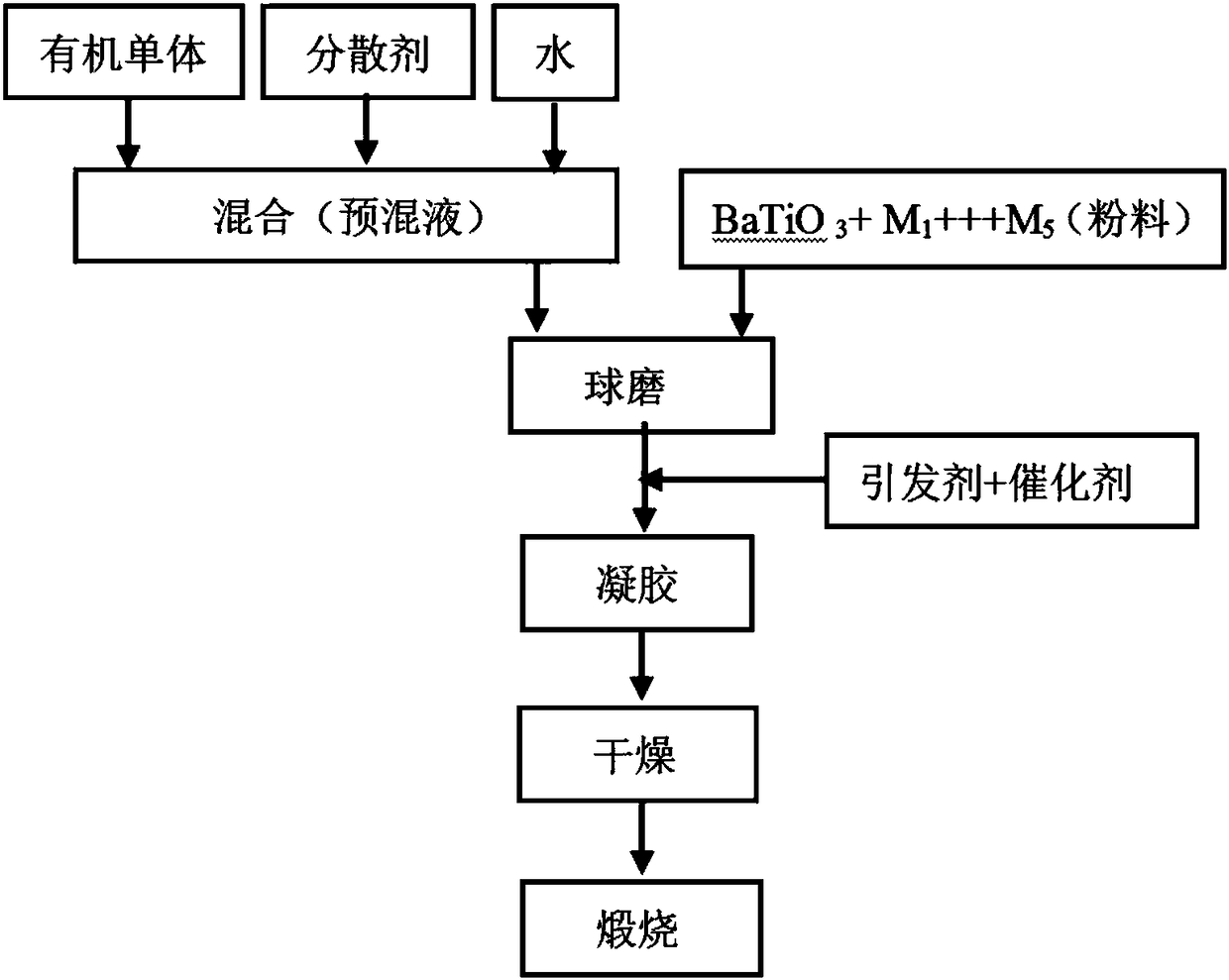

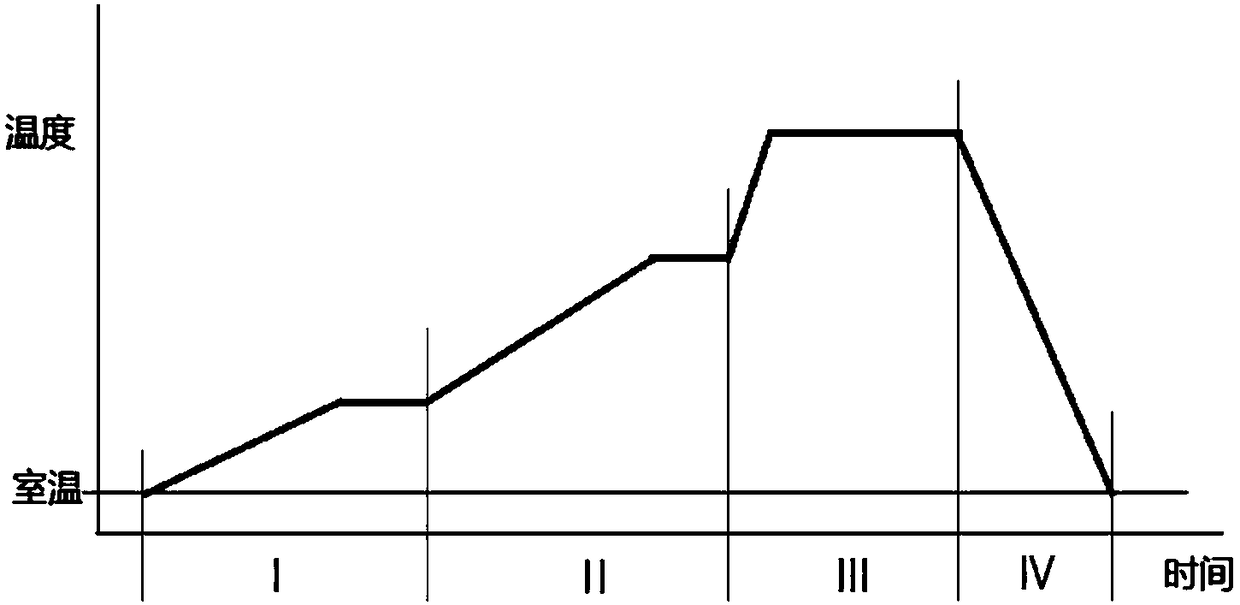

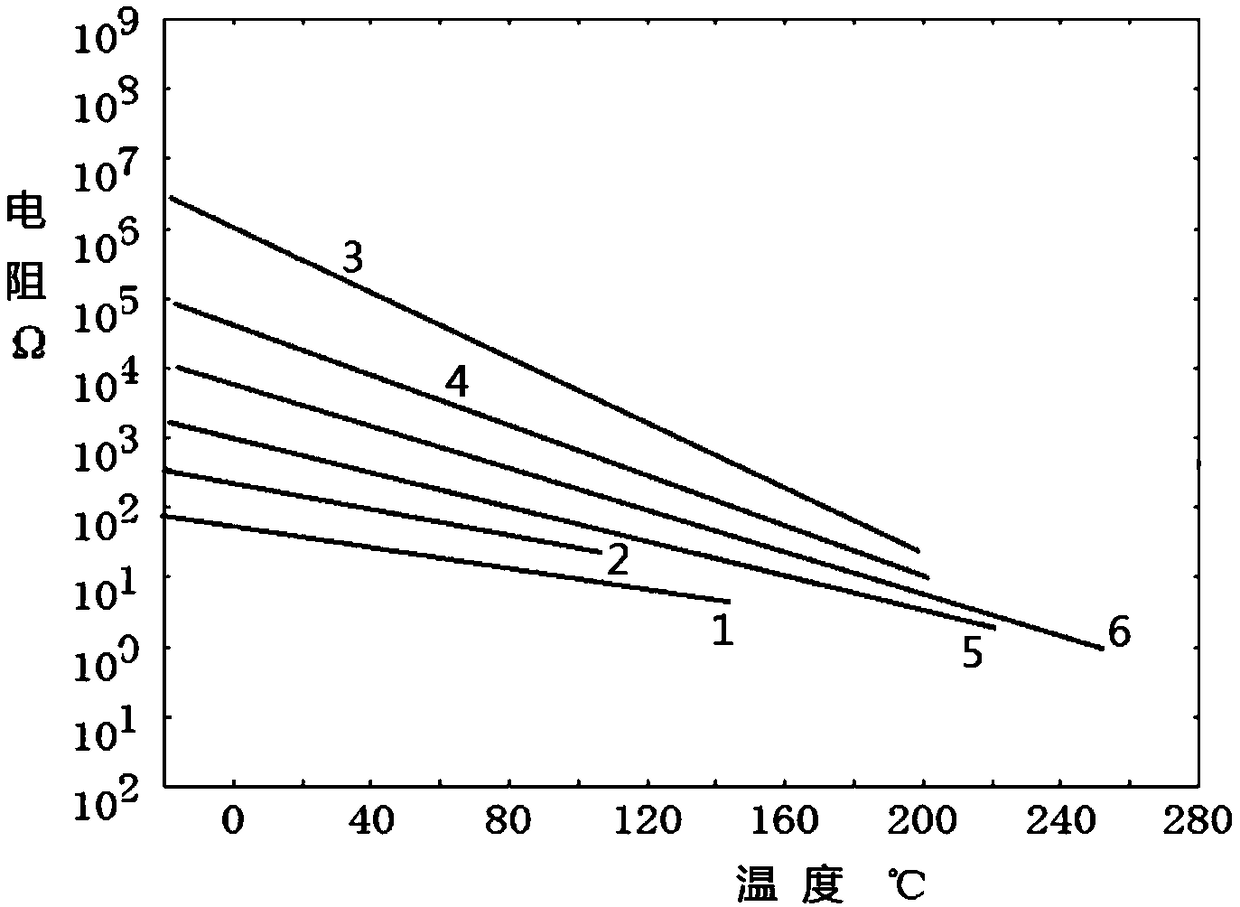

The invention discloses a wide-temperature range negative temperature coefficient heat-sensitive ceramic material and a preparation method thereof. Raw materials of the negative temperature coefficient heat-sensitive ceramic material comprise BaTiO3, TiO2, M1O, M2O, M3O, M4O and M5O, wherein M1 is at least one of Sm, Nd, Y, La and Nb elements; M2 is at least two of Si, Al and Ti elements; M3 is acombination of the Ca element and at least one of Sr and Pb elements; M4 is at least one of Sb and Bi elements; and M5 is at least one of Na, K and Li elements. The barium titanate-based wide-temperature range NTC heat-sensitive ceramic material with the measuring temperature range being 300 DEG C or more is obtained through improving and further optimizing the key composition components of the ceramic material and the whole process flow and condition parameters in all reaction steps of the corresponding preparation method and doping and modifying a barium titanate-based semiconductor heat-sensitive ceramic.

Owner:HUAZHONG UNIV OF SCI & TECH

Silicon and strontium nucleating agent and preparation method thereof

InactiveCN110791607AResistant to recession for a long timeStrong speaking abilityMetallic aluminumAlloy

The invention discloses a silicon and strontium nucleating agent and a preparation method thereof, and relates to the field of nucleating agents. The silicon and strontium nucleating agent includes the following components including, by weight, 68% to 72% of silicon, 0.6% to 1.0% of strontium, 0.8% to 1.5% of barium, 1.0% to 2.0% of calcium, not larger than 2% of aluminum and the balance iron; andthe silicon element comes from non-metallic silicon, the strontium element comes from metal strontium, the barium element comes from metal barium, the calcium element comes from metal calcium, the aluminum element comes from metal aluminum, and the iron is selected from scrap steel. By means of the silicon and strontium nucleating agent and the preparation method, approximate general international standard production of strontium serial alloys with the silicon as the basis is achieved, when the nucleating agent is used as a high-grade grey cast iron nucleating agent, the anti-decay time is long, the white mouth reducing ability is high, under-skin cast pores are reduced, and a unique effect on the aspect of improving the machining performance is improved.

Owner:安徽九华富康冶金材料有限公司

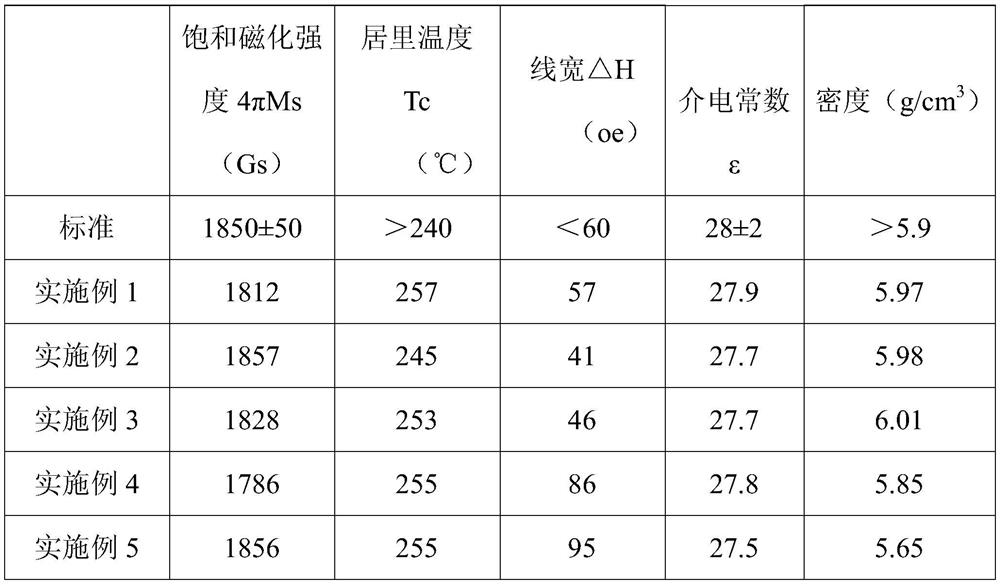

Ferrite material and preparation method and application thereof

ActiveCN112358290AHigh dielectric constantHigh curie temperatureInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementHigh volume manufacturing

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Cranberry collagen polypeptide Ca yoghurt

Owner:GUANGXI PROVINCE NANNING CITY ZHIJIANZHIFAN TECH CONSULTING

Composite inorganic polymeric sludge dehydration conditioner prepared from blast-furnace metallurgical slag

The invention belongs to the field of resource utilization of solid waste, namely blast-furnace metallurgical slag, and particularly relates to a composite inorganic polymeric sludge dehydration conditioner which is mainly prepared from the blast-furnace metallurgical slag discharged after steel enterprises smelt iron. The solid waste, namely the blast-furnace metallurgical slag is taken as a main raw material of the prepared composite inorganic polymeric sludge dehydration conditioner; and by fully utilizing elements such as Si, Al, Ca, Mg and Fe in the blast-furnace metallurgical slag, particularly the Ca element, the disadvantage that the blast-furnace metallurgical slag cannot be fully utilized because the Ca element is required to be removed when a flocculant is prepared from the blast-furnace metallurgical slag in some methods is overcome. The Ca element can achieve a framework effect in sludge conditioning to ensure that flocs cannot be crushed easily and the sludge is convenient to dehydrate, so the Ca element is an effective element in the prepared composite inorganic polymeric sludge dehydration conditioner.

Owner:UNIV OF JINAN

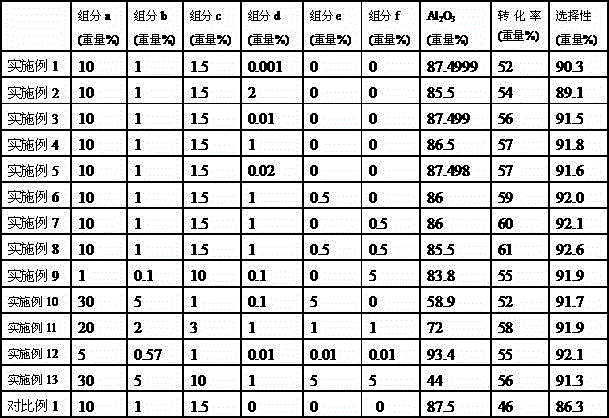

Low-carbon alkane dehydrogenation catalyst and use method thereof

The invention relates to a low-carbon alkane dehydrogenation catalyst and a use method thereof, and the low-carbon alkane dehydrogenation catalyst is mainly used for solving the problem of low activity of a dehydrogenation catalyst prepared in the prior art. In order to better solve the problem, the technical scheme adopted by the invention is as follows: the low-carbon alkane dehydrogenation catalyst provided by the invention comprises the following components in parts by weight: a) 1-30 parts of Cr element or an oxide thereof; b) 0.1-5 parts of K element or an oxide thereof; c) 0.1-10 parts of Cu element or an oxide thereof; d) 0.001-1 part of P element or an oxide thereof; e) 0-5 parts of Ca element or an oxide thereof; f) 0-5 parts of Fe element or an oxide thereof; g) 44-99 parts of Al2O3. The low-carbon alkane dehydrogenation catalyst can be used in the industrial production of low-carbon alkane dehydrogenation for preparing low-carbon olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Thermoplastic resin composition, preparation method and one application thereof

The invention discloses a thermoplastic resin composition, which comprises, by weight, 30-98 parts of a styrene-based anti-impact toughening agent, 10-80 parts of a copolymer of a vinyl aromatic monomer and an alkene-based unsaturated nitrile monomer, and 0.5-20 parts of boehmite, wherein the average particle size of the boehmite is 0.01-10 [mu]m, the specific surface area of the boehmite is 3.0-150 m<2> / g, and the Ca element content of the boehmite does not exceed 1000 ppm. By controlling the Ca element content of boehmite, a large number of micropores are formed in the surface of boehmite, so that boehmite has good compatibility with rubber particles in a matrix, and by controlling the particle size and the specific surface area of boehmite, boehmite easily achieves light extinction so as to bring light extinction effect.

Owner:WUHAN JINFA TECH CO LTD +1

Phosphor, method for producing same, and use of same

ActiveUS20150042222A1Increase brightnessGood chemical stabilityDischarge tube luminescnet screensLamp detailsPhosphorCrystal structure

Provided are: a phosphor that has a crystal structure identical to a CaAlSiN3 crystal phase, which absorbs light of a light emitting element such as an LED and emits red light, as a host crystal and exhibits luminous efficiency more excellent than those of conventional phosphors; and a light emitting device which has high luminance and long service life by the use of this phosphor. A powder phosphor, which is represented by general formula Cax(Si,Al)2(N,O)3+y (wherein 0.75≦x≦0.92 and −0.2≦y≦0.2), and wherein some of Ca element is substituted by Eu element. This powder phosphor has an Si / Al ratio (molar ratio) of from 0.9 to 1.55 (inclusive), an Eu content of from 0.01 at % to 0.3 at % (inclusive), and an amount of intragranular solid-solved oxygen of from 0.4% by mass to 0.7% by mass (inclusive).

Owner:DENKA CO LTD

Method for preparing nano porous silver based on Ag-based amorphous alloy

The invention belongs to the field of preparation of nano porous metal materials, and relates to a method for preparing nano porous silver based on an Ag-based amorphous alloy. By the method, the nano porous silver with the aperture of 20-100 nm is finally obtained by preparing a series of Ag-Mg-Ca amorphous alloy thin bands by taking the Ag-based amorphous alloy as a precursor by a solvent quick quenching method and then removing Mg and Ca elements by performing electric chemical alloy component corrosion removal by proper electrolyte. By the method, the structure and the size of the nano porous silver are adjusted and controlled by controlling the amorphous alloy components or electric chemical corrosion temperature; the operation technology is simple; and furthermore, the nano porous silver is extremely high in surface-enhancement raman scattering (SERS) performance and has a wide application prospect in the fields of environment friendliness, catalysis and biological sensors.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com