Low-carbon alkane dehydrogenation catalyst and use method thereof

A technology for dehydrogenation catalysts and low-carbon alkanes, which is applied in the direction of hydrocarbons, hydrocarbons, chemical instruments and methods, etc., and can solve the problem of low activity of low-carbon alkane dehydrogenation catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

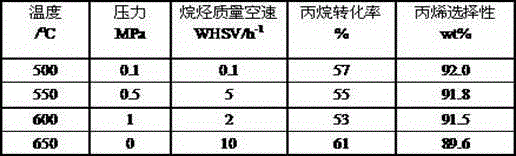

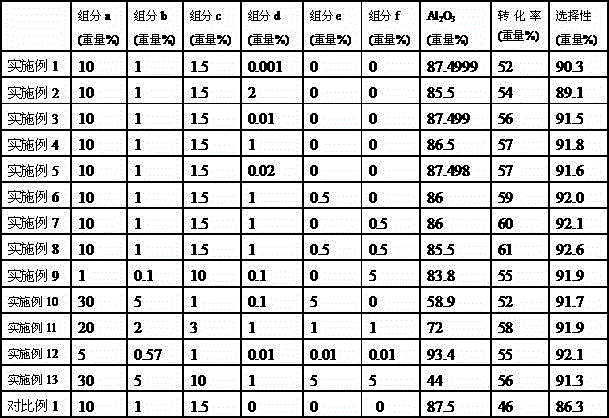

Examples

Embodiment 1

[0031] Weigh 52.65 grams of chromium nitrate, 2.15 grams of potassium nitrate, 4.56 grams of copper nitrate, 0.0014 grams of phosphoric acid, add to 100 ml of deionized water, then add 87.4999 grams of alumina carrier, adjust the pH value of the solution to 3.5 with 2.5% by weight of ammonia water , and then immersed in a water bath at 80°C for 1 hour, the sample was taken out and filtered, dried in an oven at 120°C for 8 hours, and then put into a muffle furnace and calcined at 550°C for 4 hours to obtain the desired catalyst. Adjust the flow rate of propane gas through the mass flow meter, enter the preheating zone for mixing, and then enter the reaction zone. Both the preheating zone and the reaction zone of the reactor are heated by electric heating wires to make them reach the predetermined temperature. The inner diameter of the reactor is Ф9mm— Ф6mm stainless steel casing, about 400mm long. After the reaction gas passes through the condensation tank, it enters the ga...

Embodiment 2

[0035]Weigh 52.65 grams of chromium nitrate, 2.15 grams of potassium nitrate, 4.56 grams of copper nitrate, 1.4 grams of phosphoric acid, add to 100 ml of deionized water, then add 85.5 grams of alumina carrier, adjust the pH value of the solution to 3.5 with 2.5% by weight of ammonia water , and then immersed in a water bath at 80°C for 1 hour, the sample was taken out and filtered, dried in an oven at 120°C for 8 hours, and then put into a muffle furnace and calcined at 550°C for 4 hours to obtain the desired catalyst. Evaluation conditions are the same as in Example 1, and the results are shown in Table 1.

[0036]

Embodiment 3

[0038] Weigh 52.65 grams of chromium nitrate, 2.15 grams of potassium nitrate, 4.56 grams of copper nitrate, 0.014 grams of phosphoric acid, add to 100 milliliters of deionized water, then add 87.499 grams of alumina carrier, adjust the pH value of the solution to 3.5, and then immersed in a water bath at 80°C for 1 hour, take out the sample and filter it, dry it in an oven at 120°C for 8 hours, then put the sample into a muffle furnace and bake it at 550°C for 4 hours to obtain the required catalyst . Evaluation conditions are the same as in Example 1, and the results are shown in Table 1.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com