Preparation of soy protein isolate

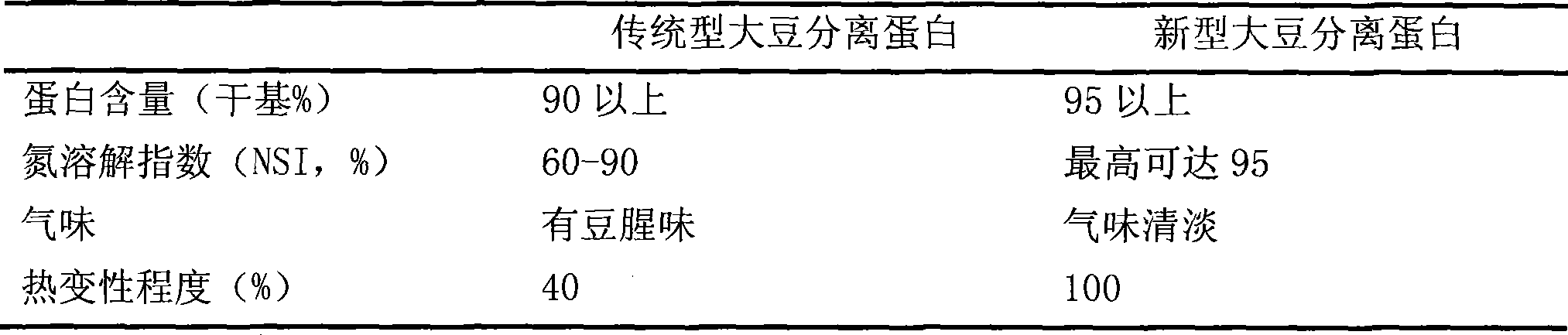

A technology of soybean protein isolate and soybean, which is applied in the field of preparation of soybean protein isolate, and can solve the problems of low beany smell and light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Pass the defatted soybean flakes through a 20-mesh inspection sieve, move the sieved material into a container, soak it with 65% ethanol at a solid-to-liquid ratio of 1:5, extract it in four stages of countercurrent, and filter off the filtrate. The raffinate is placed in a vacuum drying oven and continuously dried at 40°C with a vacuum degree of 0.1 bar or higher for 2 hours, then taken out, and the dried soybean protein concentrate is crushed with a pulverizer, passed through a 200-mesh sieve, and stored in bags to obtain vacuum-dried alcohol French soy protein concentrate powder.

[0025] The obtained concentrated soybean protein powder was dispersed in the aqueous solution with a solid-to-liquid ratio of 1:10, and the pH value was adjusted to 8.0 with 2 mol / L sodium hydroxide. The solution was heated to 60 °C, kept at this temperature for 1 min and then cooled to room temperature.

[0026] The resulting solution was adjusted to pH 4.5 with 2mol / L hydrochloric acid,...

Embodiment 2

[0029] Pass the defatted soybean flakes through a 20-mesh inspection sieve, move the sieved material into a container, soak it with 75% ethanol at a solid-to-liquid ratio of 1:4, extract 8 stages of countercurrent extraction, and filter off the filtrate. The raffinate is placed in a vacuum drying oven and continuously dried at a vacuum degree of 0.1 bar or higher at 55°C for 1 hour, then taken out, and the dried soybean protein concentrate is crushed with a pulverizer, passed through a 100-mesh sieve, and stored in bags to obtain vacuum-dried alcohol French soy protein concentrate powder.

[0030] The obtained concentrated soybean protein powder was dispersed in the aqueous solution with a solid-to-liquid ratio of 1:15, and the pH value was adjusted to 9.0 with 2 mol / L sodium hydroxide. The solution was heated to 90 °C, kept at this temperature for 1 s and then cooled to room temperature.

[0031] Adjust the pH of the resulting solution to 3.0 with 2mol / L hydrochloric acid, a...

Embodiment 3

[0034] Pass the defatted soybean flakes through a 20-mesh inspection sieve, move the sieved material into a container, soak it with 70% ethanol at a solid-to-liquid ratio of 1:3, extract 6 stages of countercurrent extraction, and filter the filtrate. The raffinate is placed in a vacuum drying oven and continuously dried at 80°C with a vacuum degree of 0.1 bar or higher for 1 hour, then taken out, and the dried soybean protein concentrate is crushed with a grinder, passed through a 200-mesh sieve, and stored in bags to obtain vacuum-dried alcohol French soy protein concentrate powder.

[0035] The obtained concentrated soybean protein powder was dispersed in the aqueous solution with a solid-to-liquid ratio of 1:20, and the pH value was adjusted to 10.0 with 2 mol / L sodium hydroxide. The solution was rapidly heated to 141° C. in a pressure reactor, kept at this temperature for 30 minutes, and then cooled to room temperature.

[0036] Adjust the pH of the resulting solution to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com