Patents

Literature

50 results about "Beverage type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

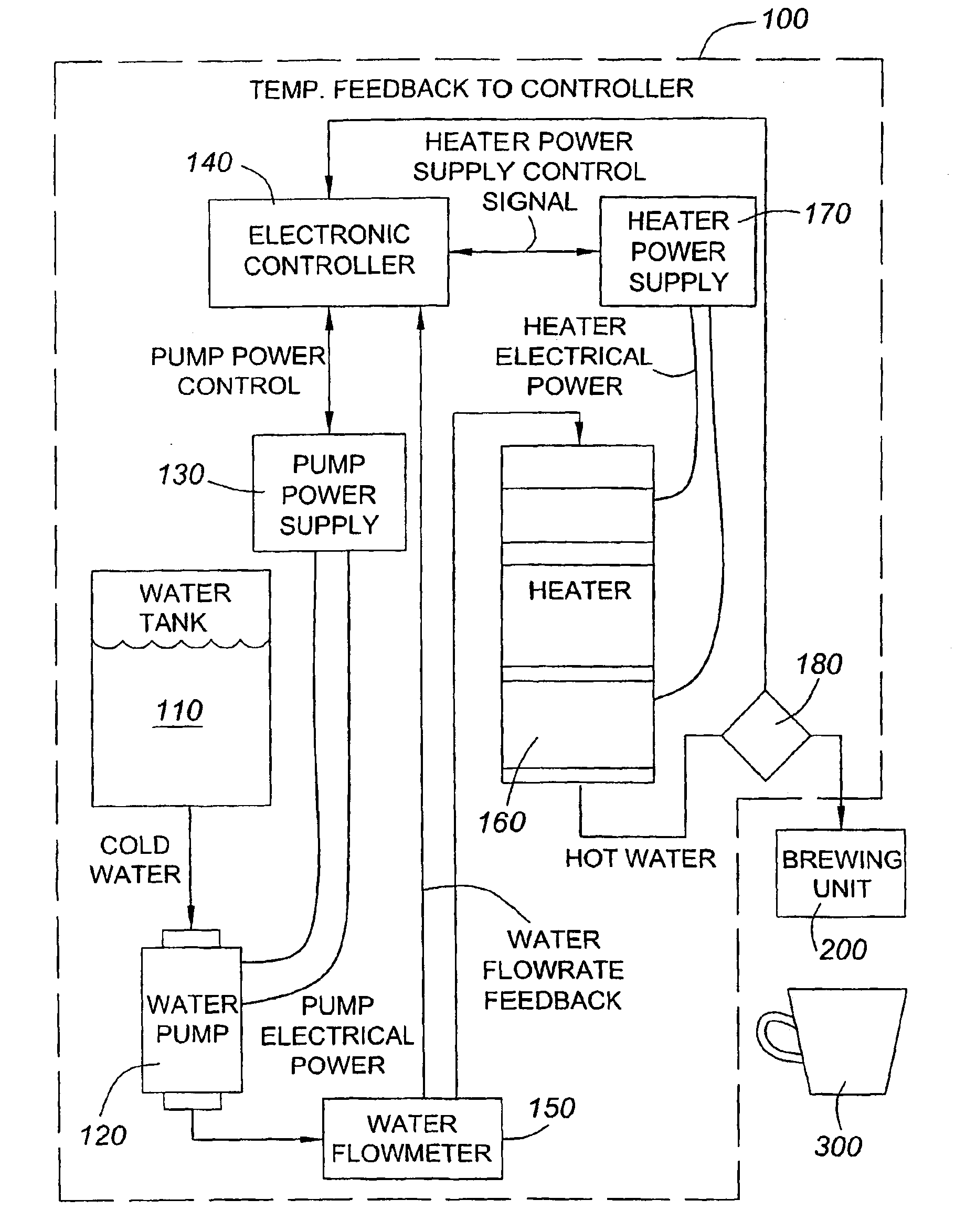

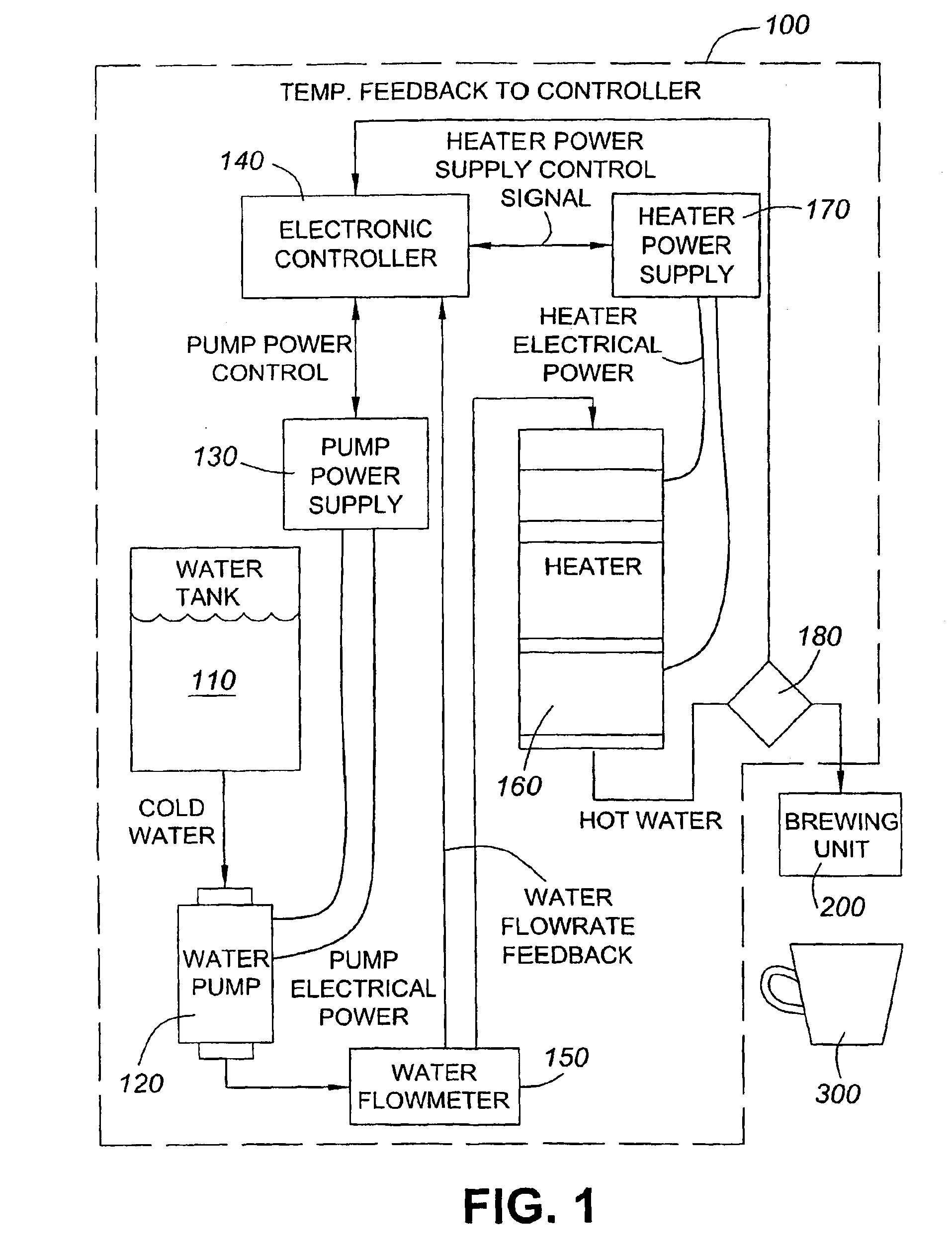

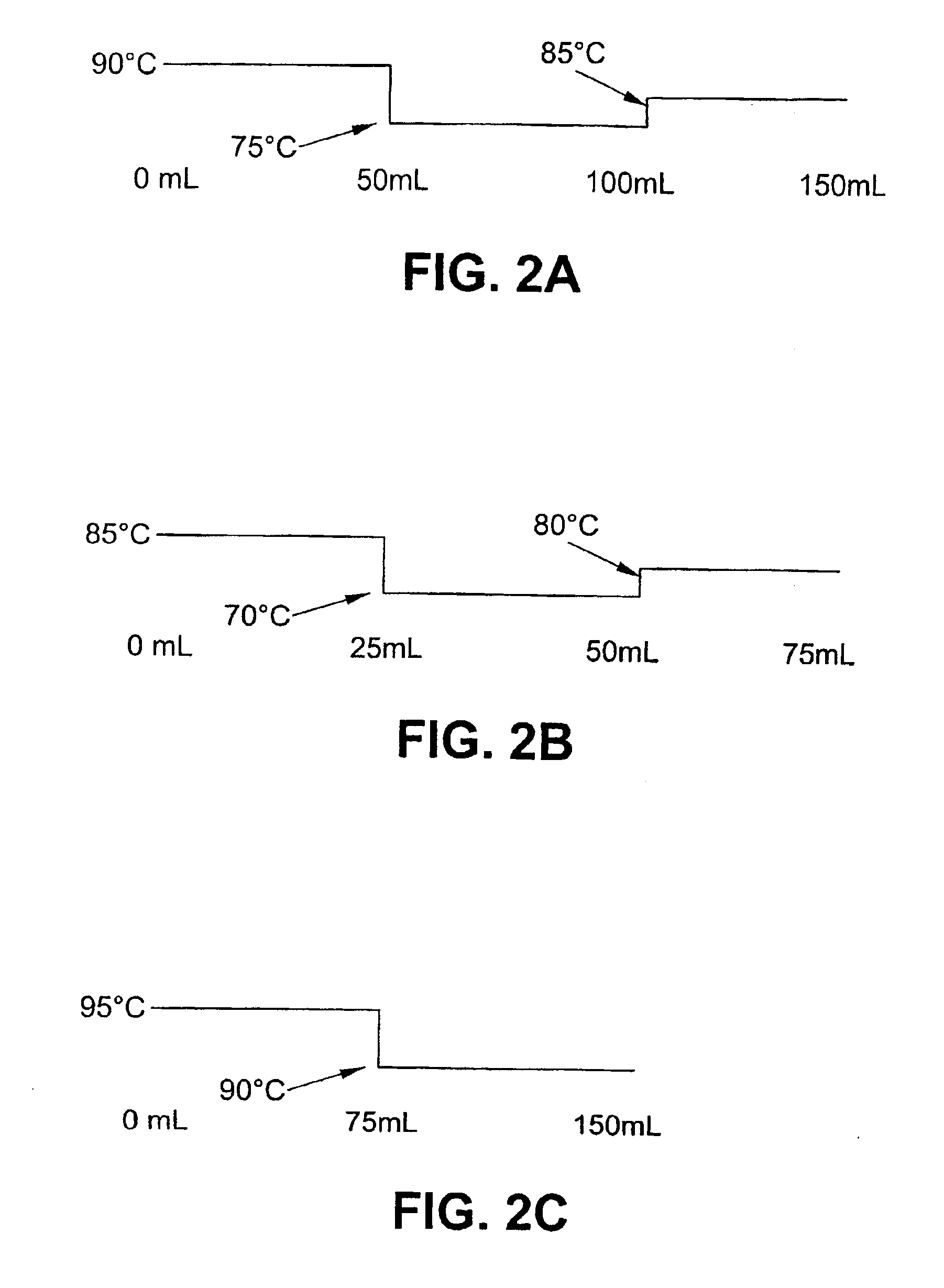

Method and apparatus for optimizing variable liquid temperatures

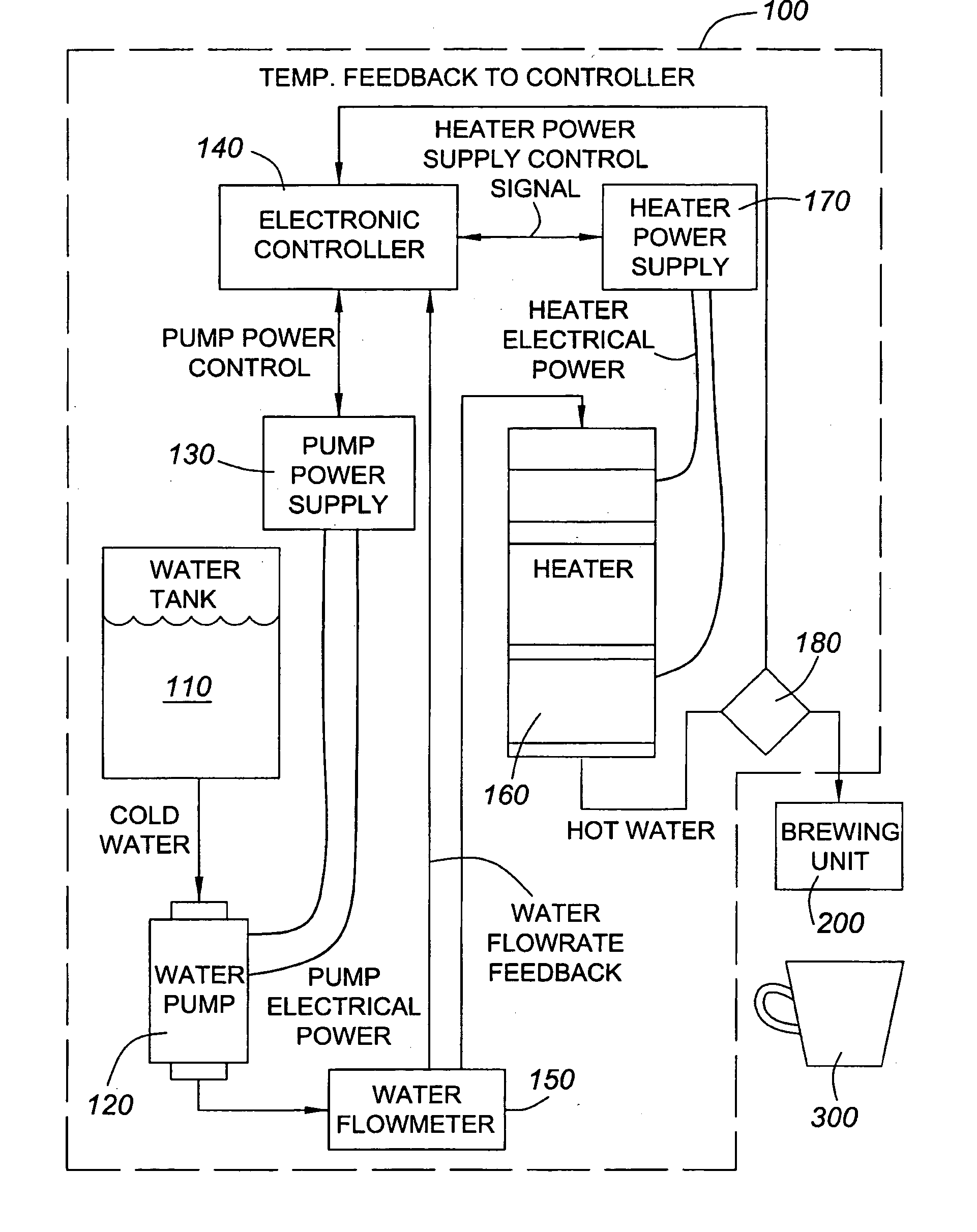

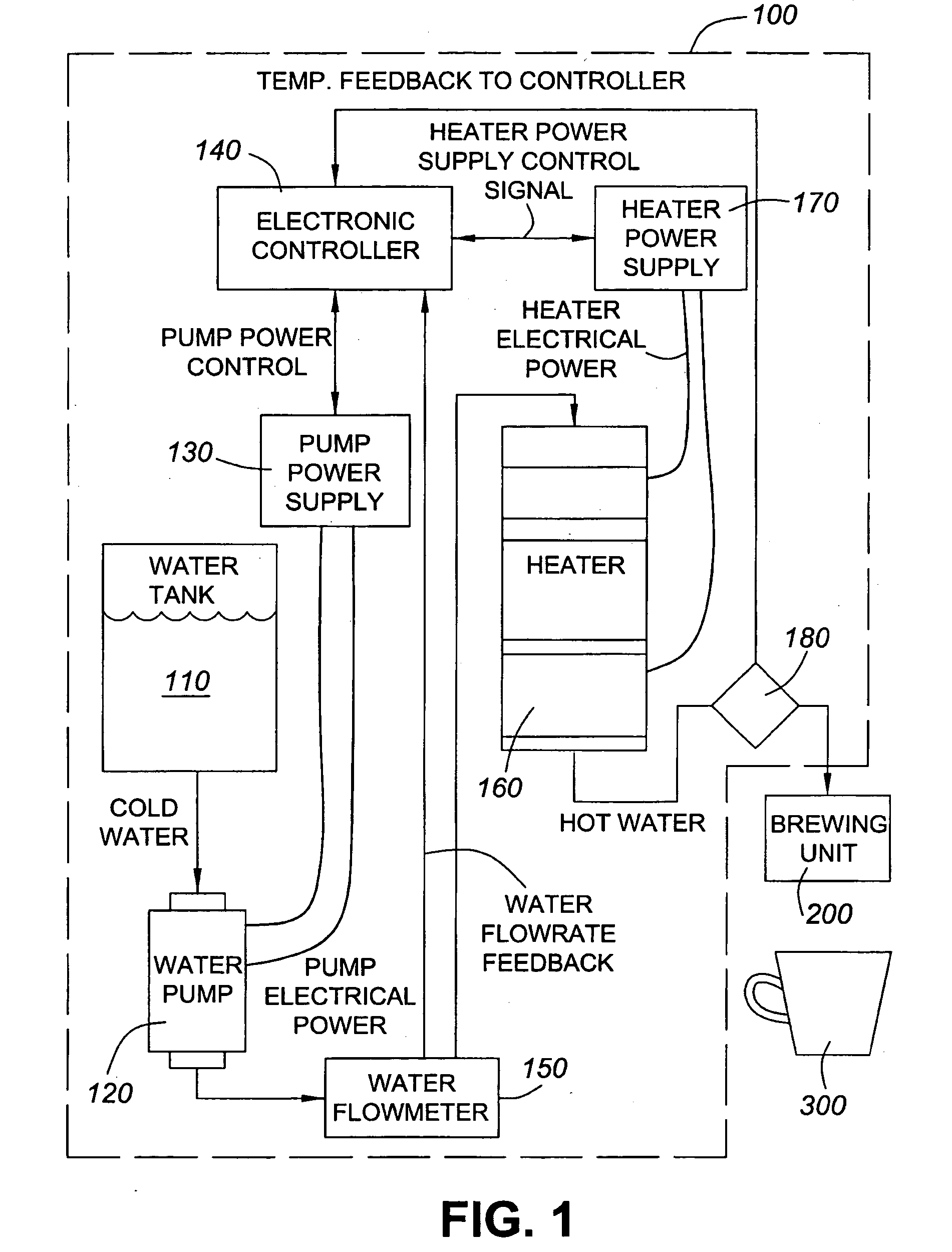

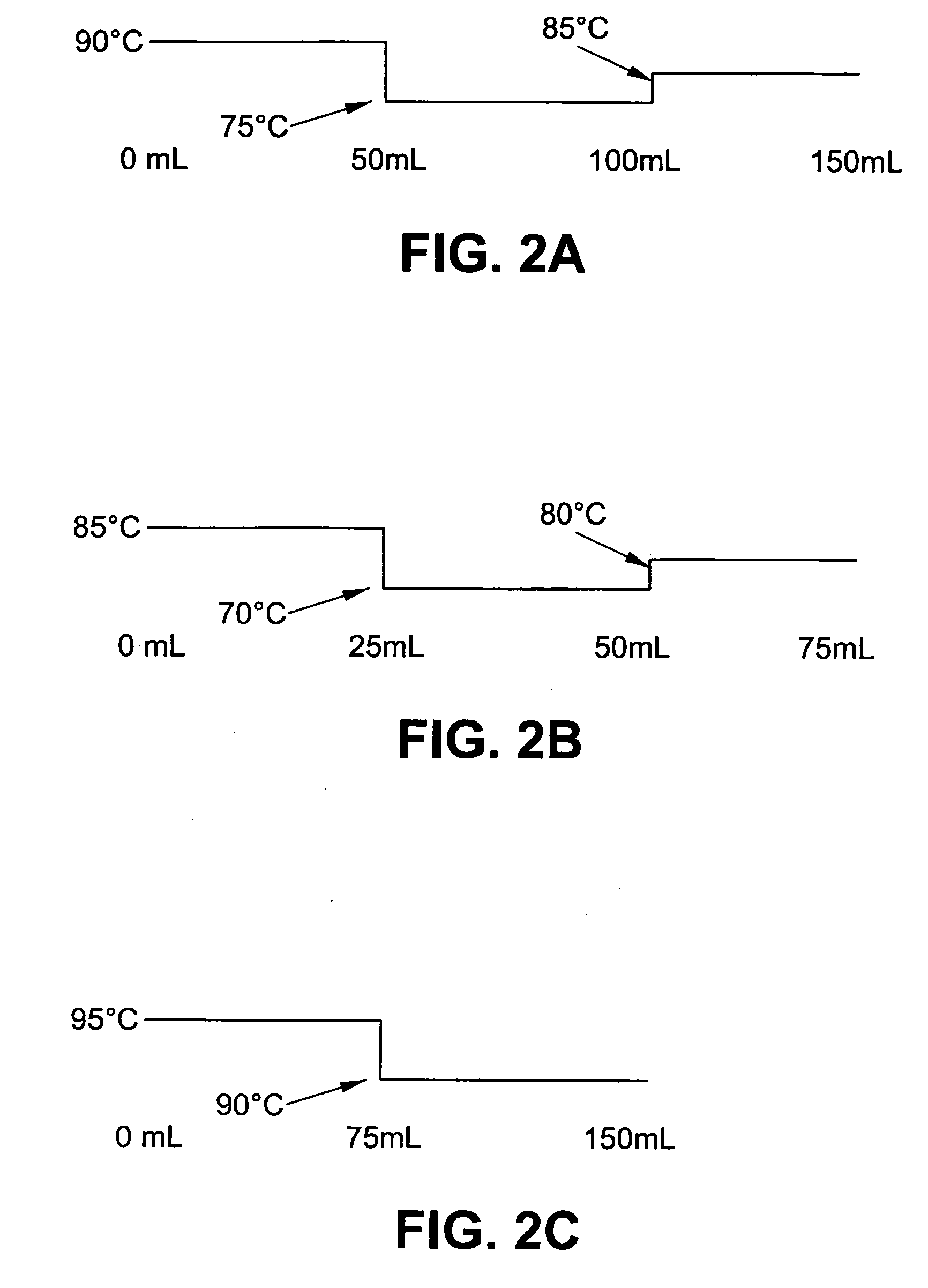

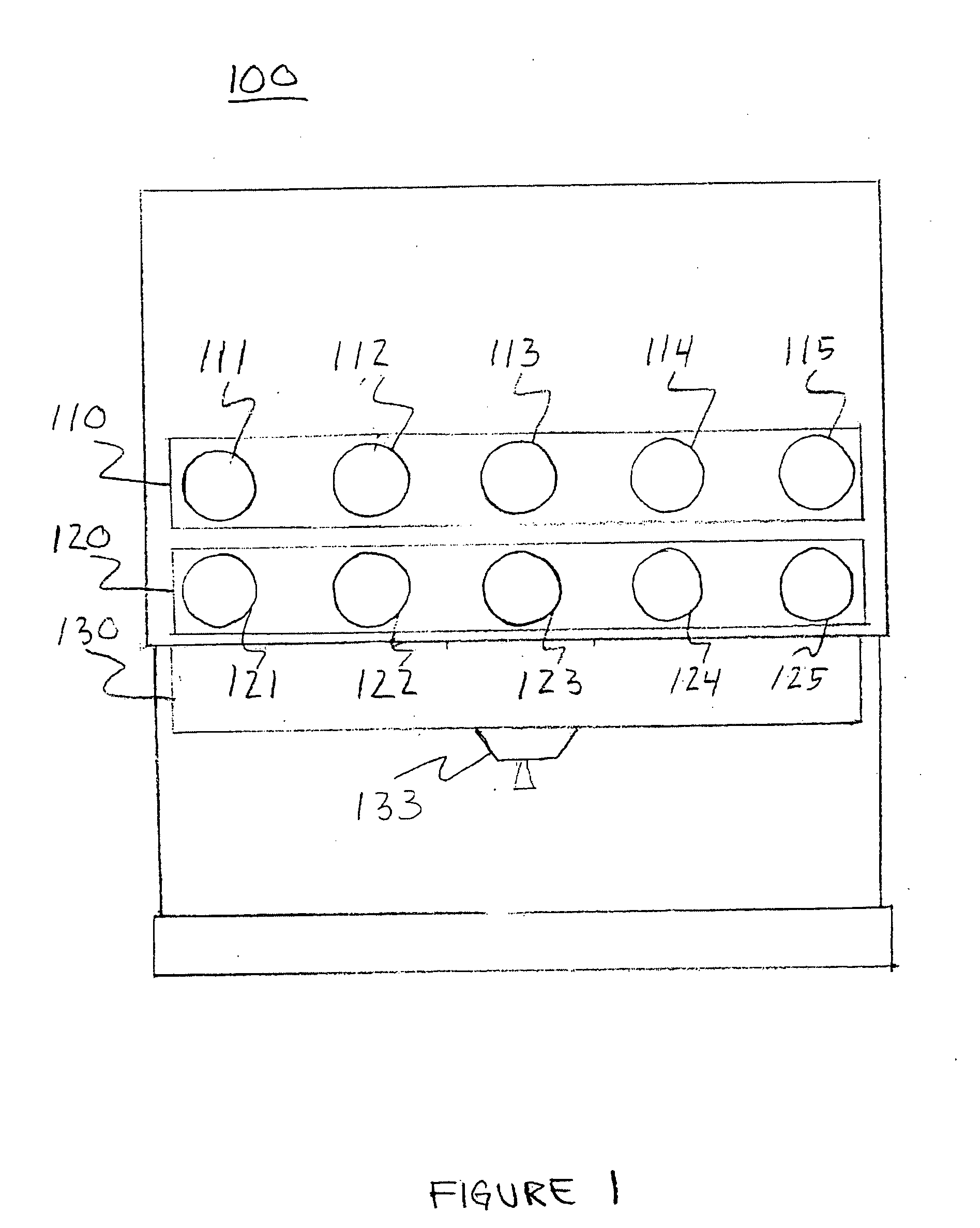

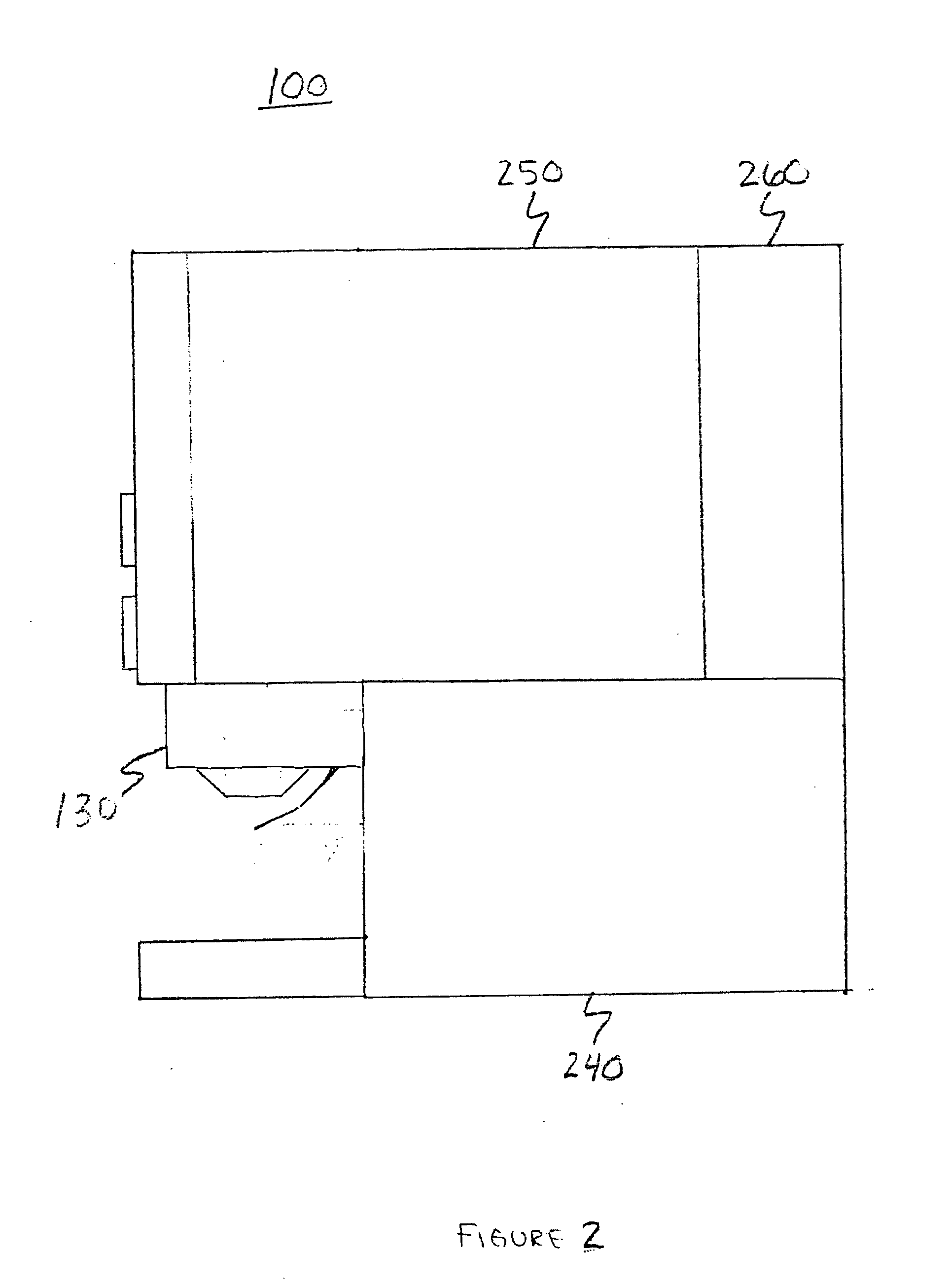

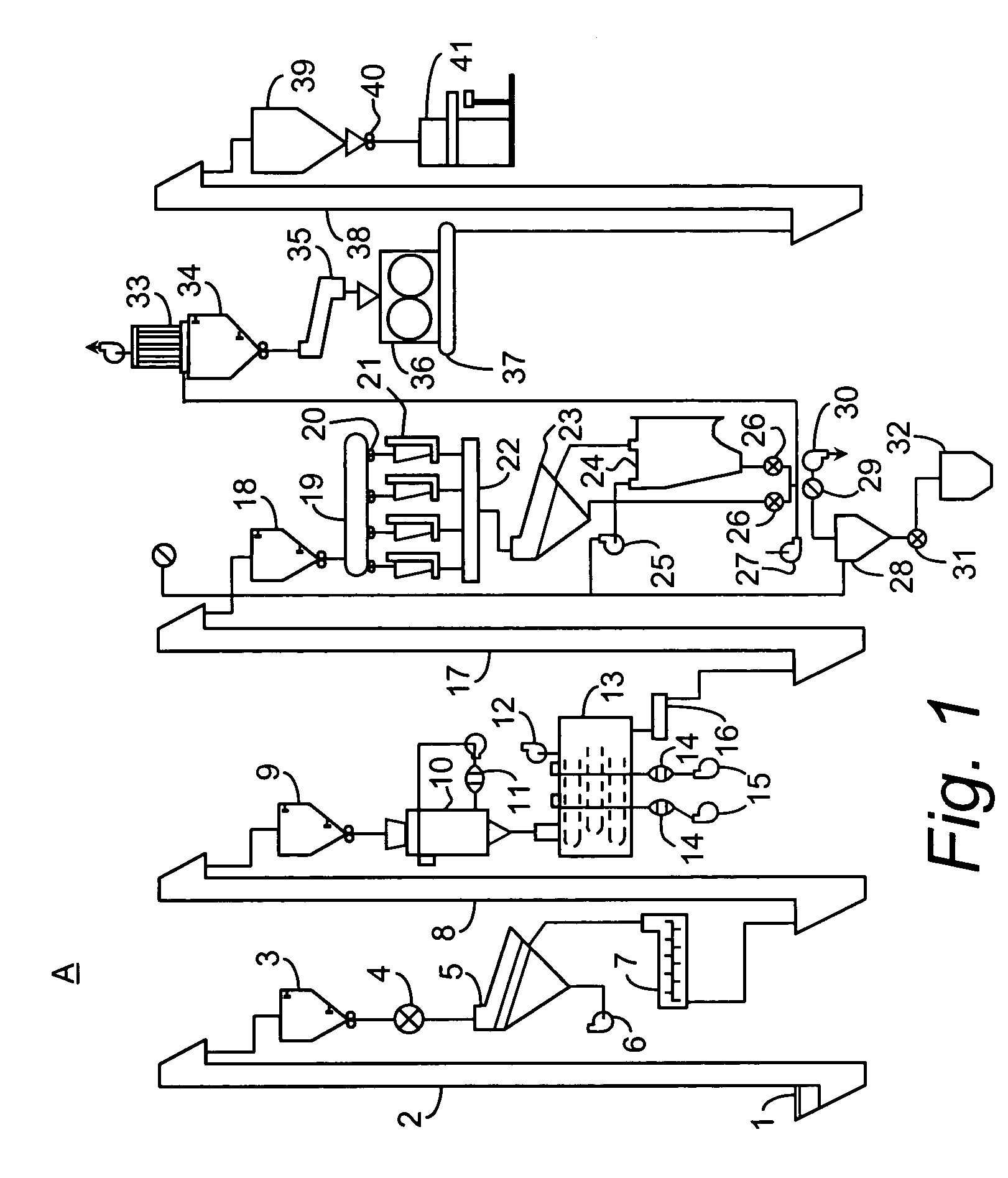

A method, apparatus, and related beverage profiles for on-demand heating of liquid used for beverage dispensing where such heating is dynamically variable according to the applicable profile. The apparatus includes a heating unit, electronic controller, and sensing devices. A water tank supplies the heating unit via a water pump controlled by the controller that also controls the heating unit. Feedback control loops provide control data to the controller to optimize liquid temperatures for a given beverage type in accordance with predetermined profiles.

Owner:NESTEC SA

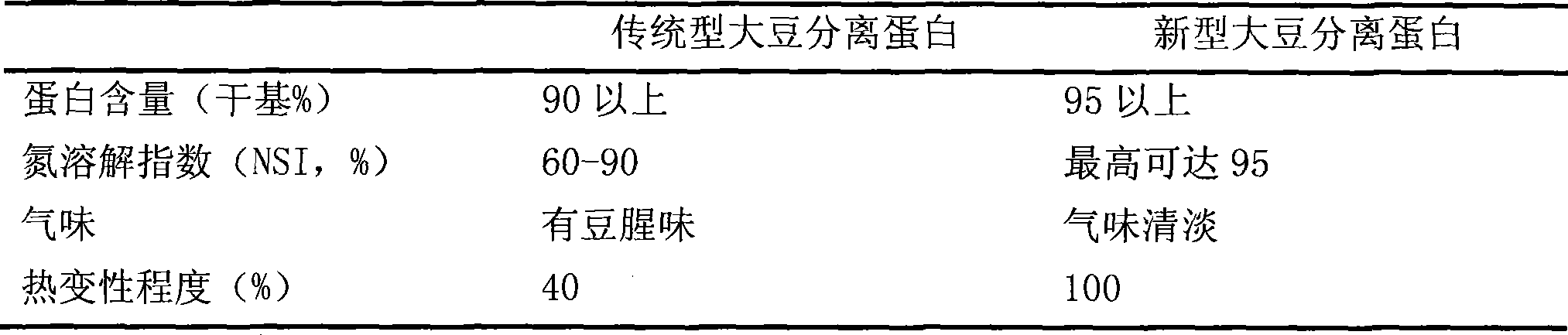

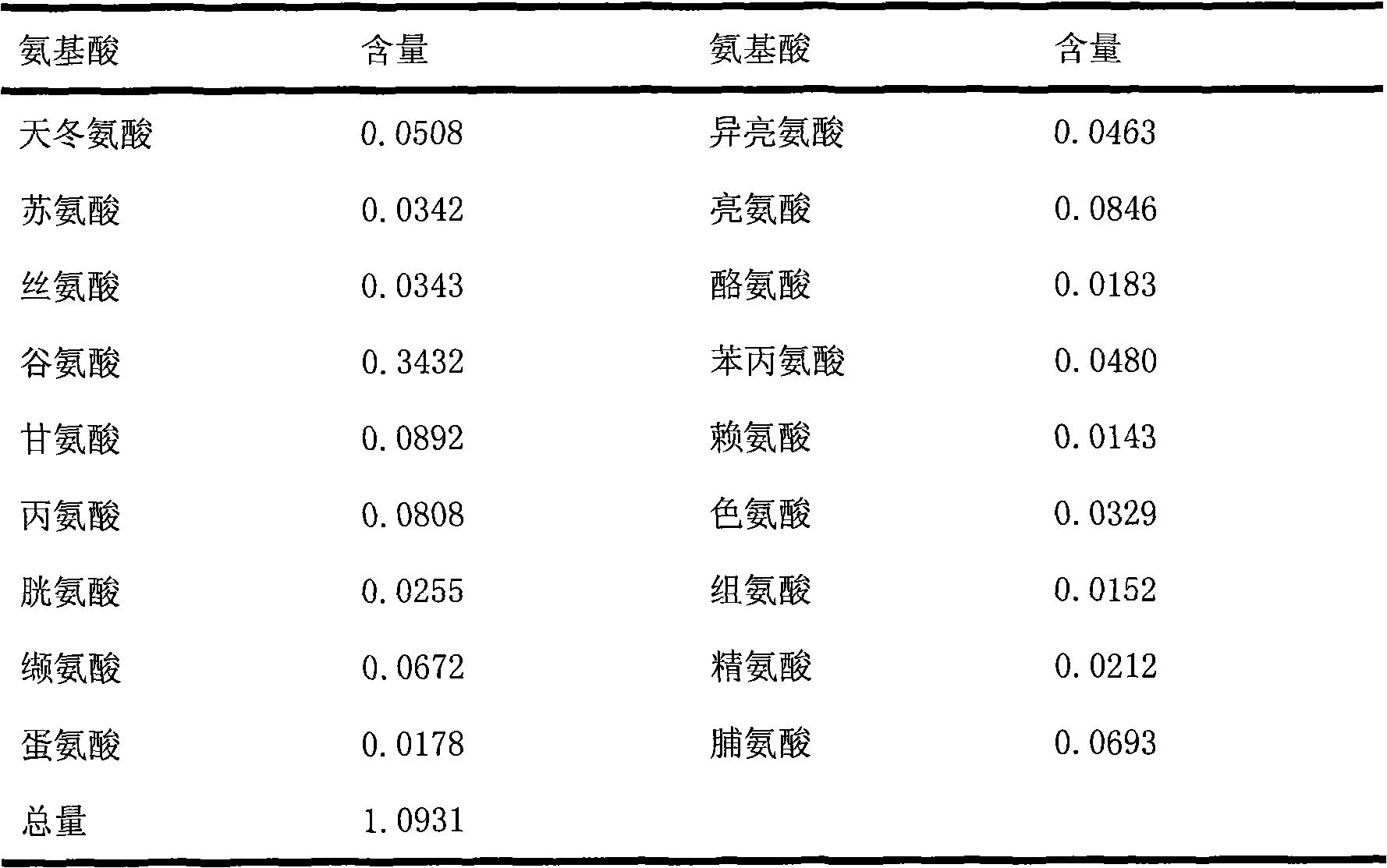

Preparation of soy protein isolate

InactiveCN101372501AAdditional preparation stepsEasy to handlePeptide preparation methodsSolubilityLow activity

The invention provides a method for preparing separated soy protein and comprises the following steps: (1) the preparation of concentrated soybean albumen powder by vacuum drying alcoholic method; (2) solution preparation and heat treatment; (3) acid coprecipitate and neutrality adjustment; (4) instantaneous heating and sterilizing as well as sponging drying. The separated soy protein prepared by the method not only has the advantages of high solubility and high protein content of common protein isolate, but also has the advantages of low beanyflavor, light color, low activity of nutrition resistant substance, easy treatment on discharged sewage, and the like which are not possessed by common separated soy protein; therefore, the invention is an ideal preparation method for producing beverage type separated soy protein.

Owner:SOUTH CHINA UNIV OF TECH

Method and system for making and vending ice

ActiveUS20070210105A1Opening closed containersBottle/container closureProcess engineeringBeverage type

A vending machine is disclosed. The vending machine has a selector for a plurality of beverage types and a selector for a plurality of ice types. The vending machine has a first store for storing a supply of the plurality of beverage types and a second store for storing a supply of the plurality of ice types. The vending machine also has a dispenser for dispensing into a container a selected beverage type and a selected ice type.

Owner:MALACHOWSKY MICHAEL WILLIAM +2

Method and system for making and vending ice

InactiveUS7428824B1Domestic cooling apparatusLighting and heating apparatusProcess engineeringBeverage type

A vending machine. The vending machine has a selector for a plurality of beverage types and a selector for a plurality of ice types. The vending machine has a first store for storing a supply of the plurality of beverage types and a second store for storing a supply of the plurality of ice types. The vending machine also has a dispenser for dispensing into a container a selected beverage type and a selected ice type.

Owner:MALACHOWSKY MICHAEL WILLIAM +2

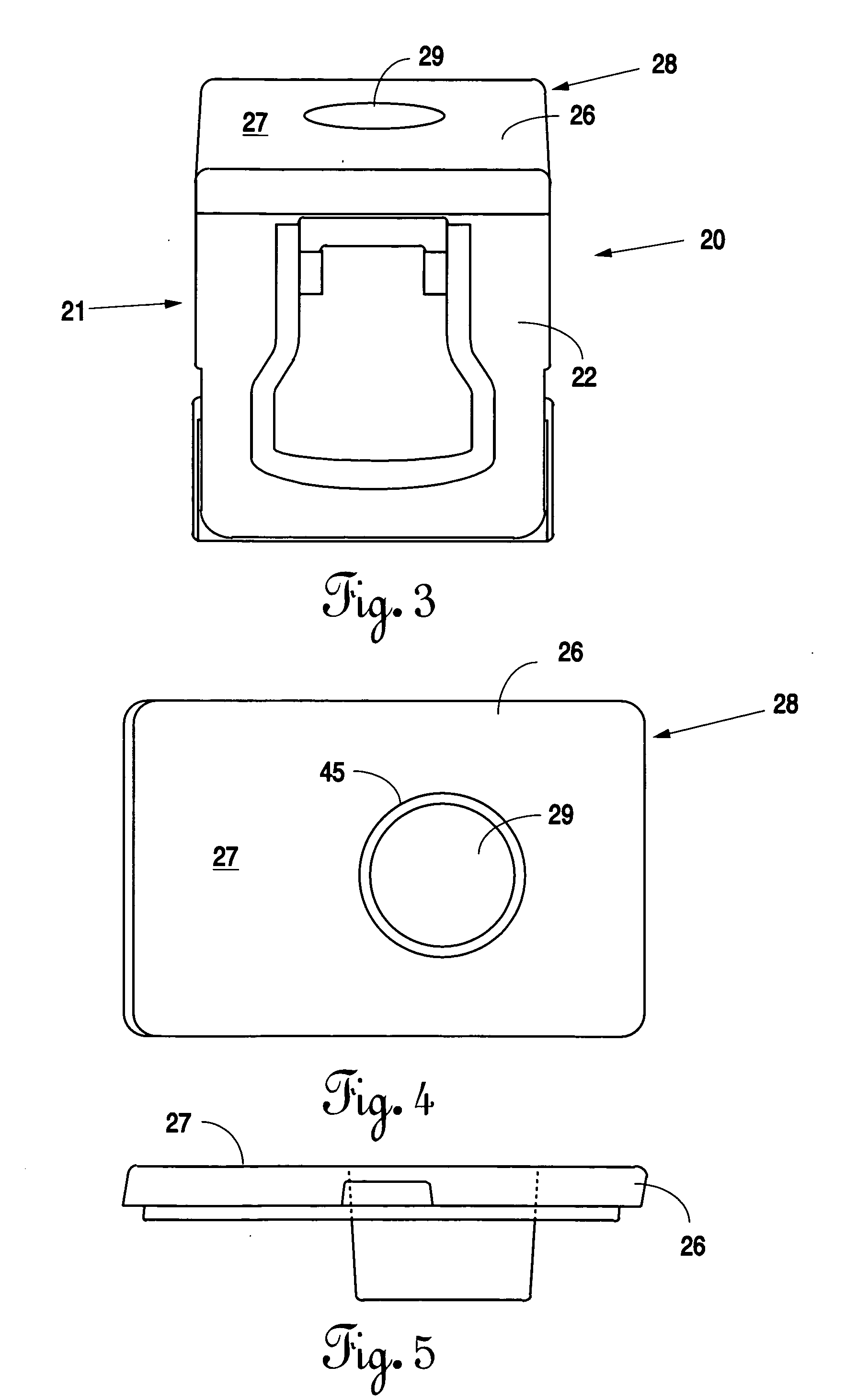

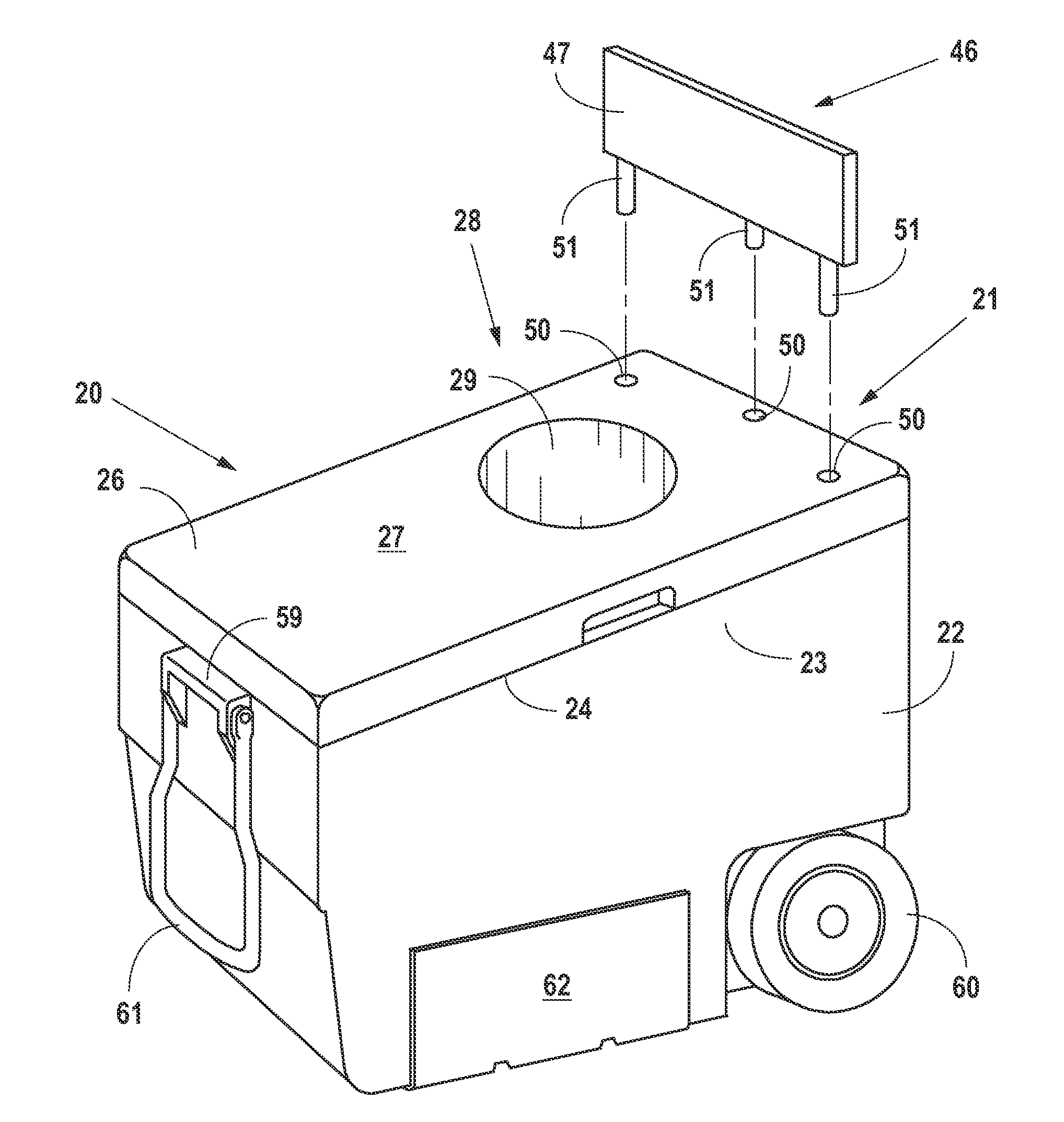

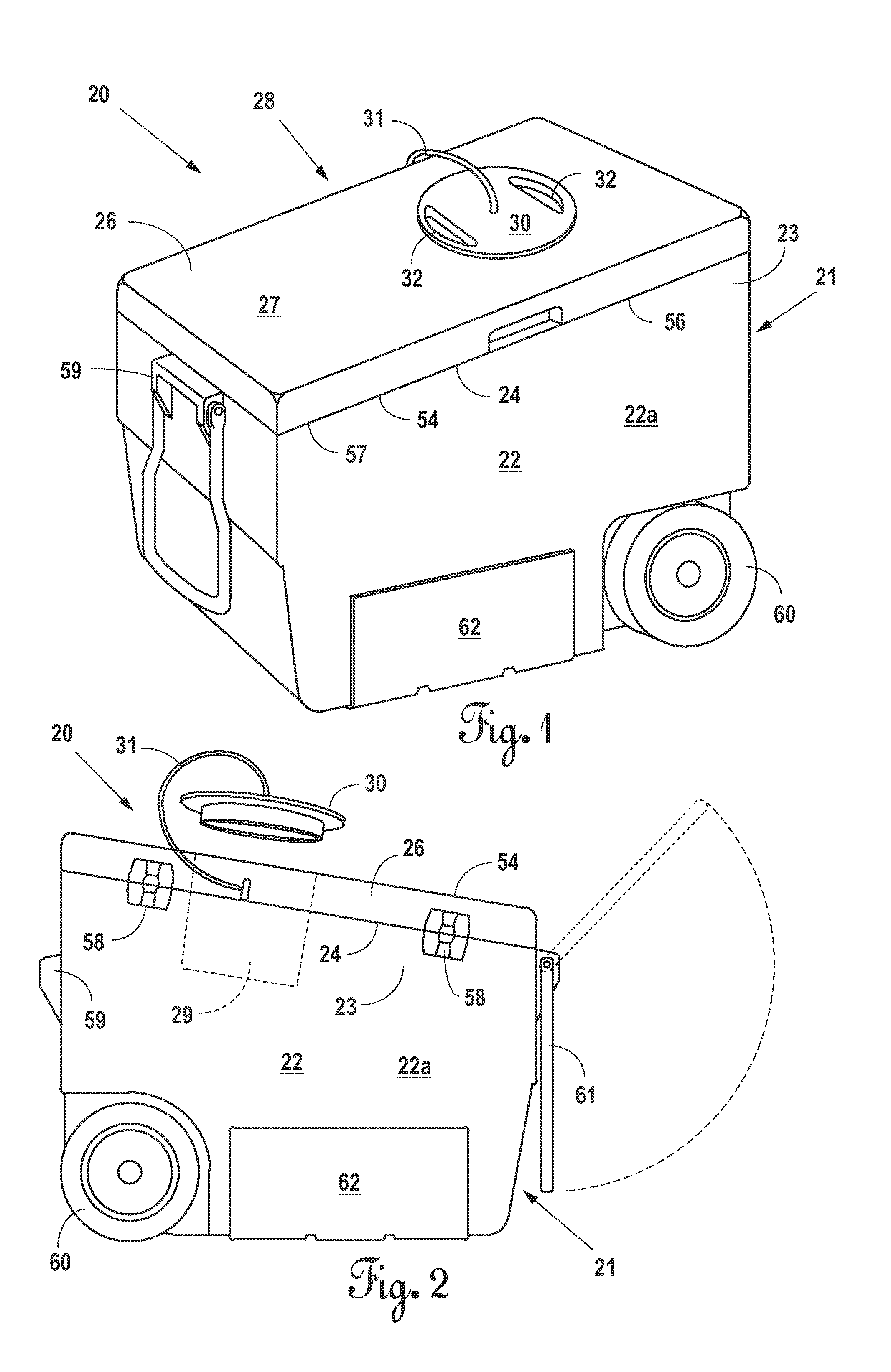

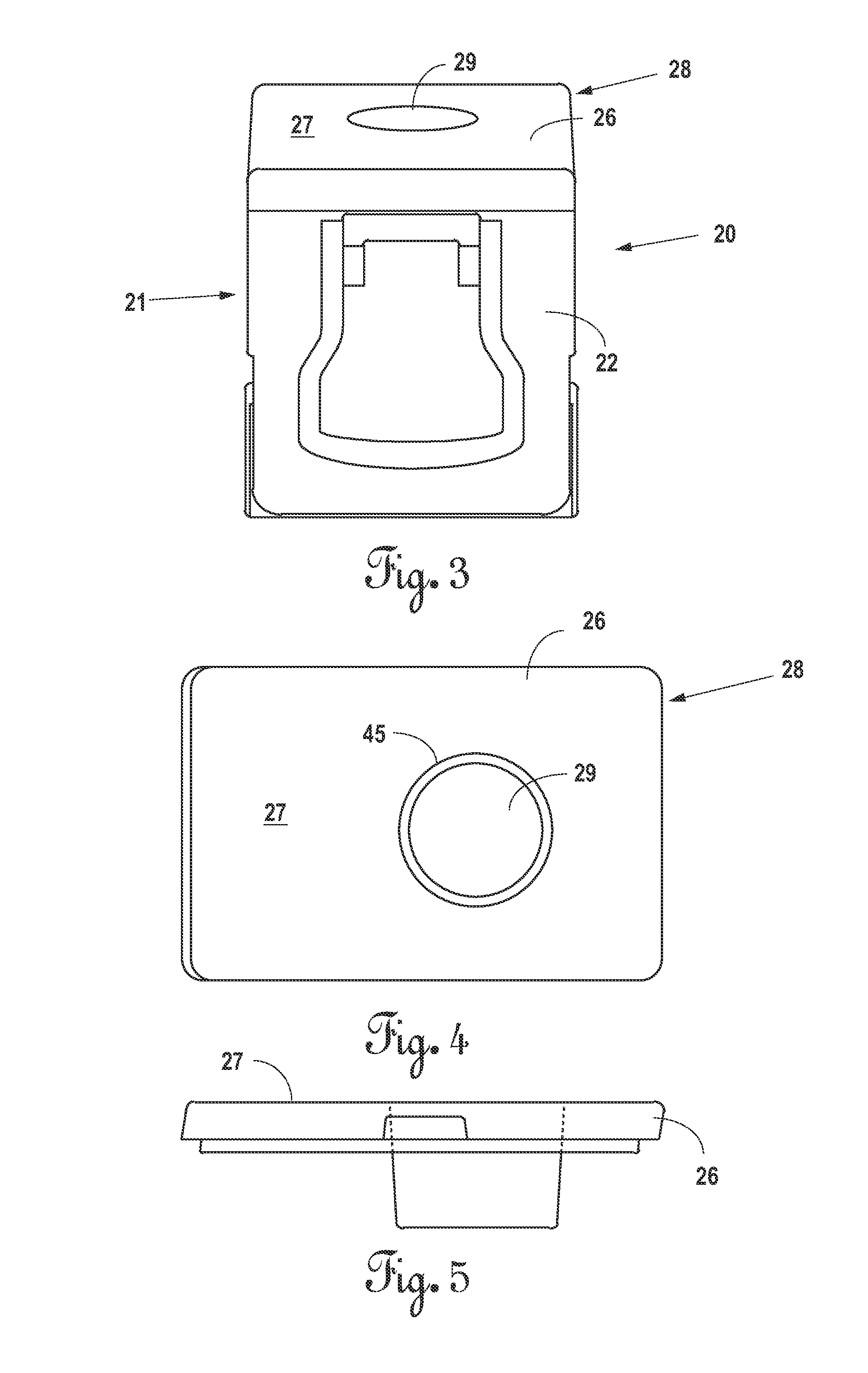

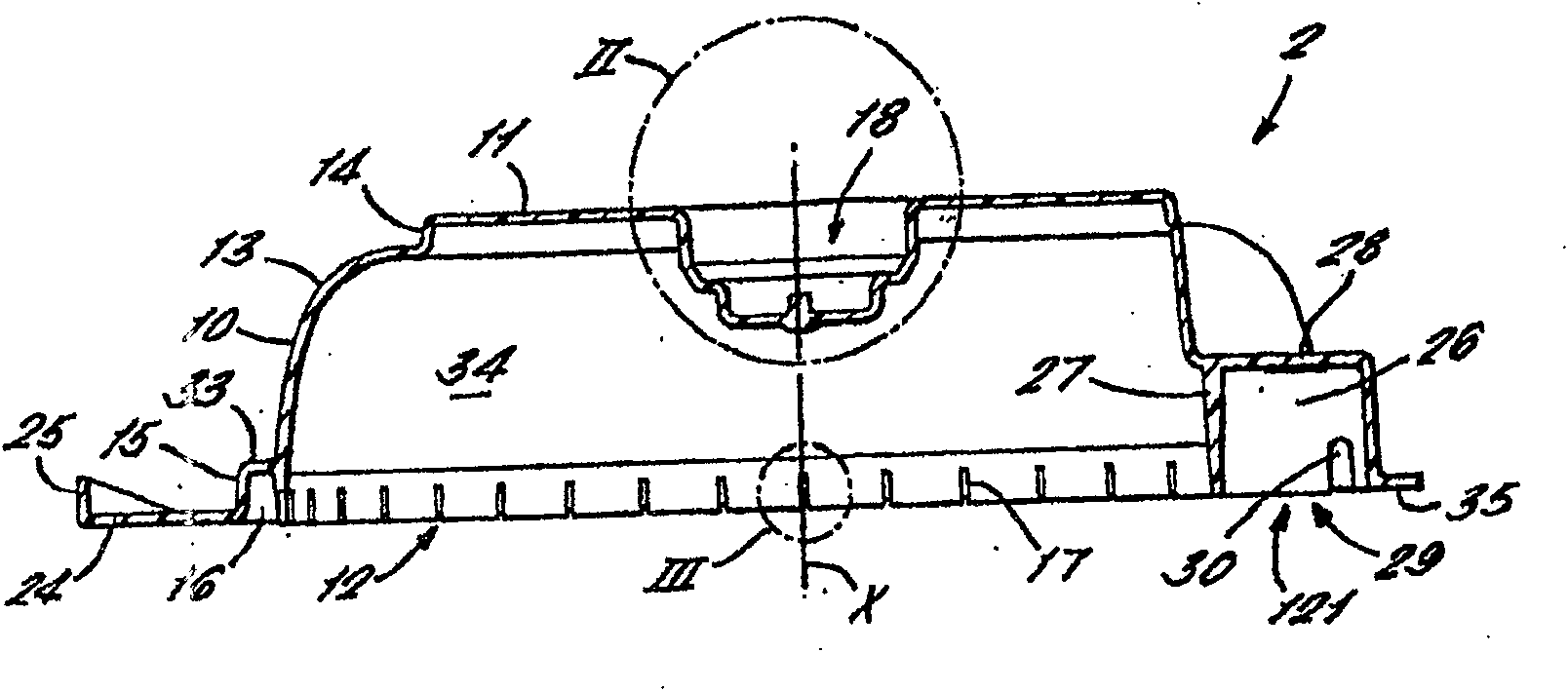

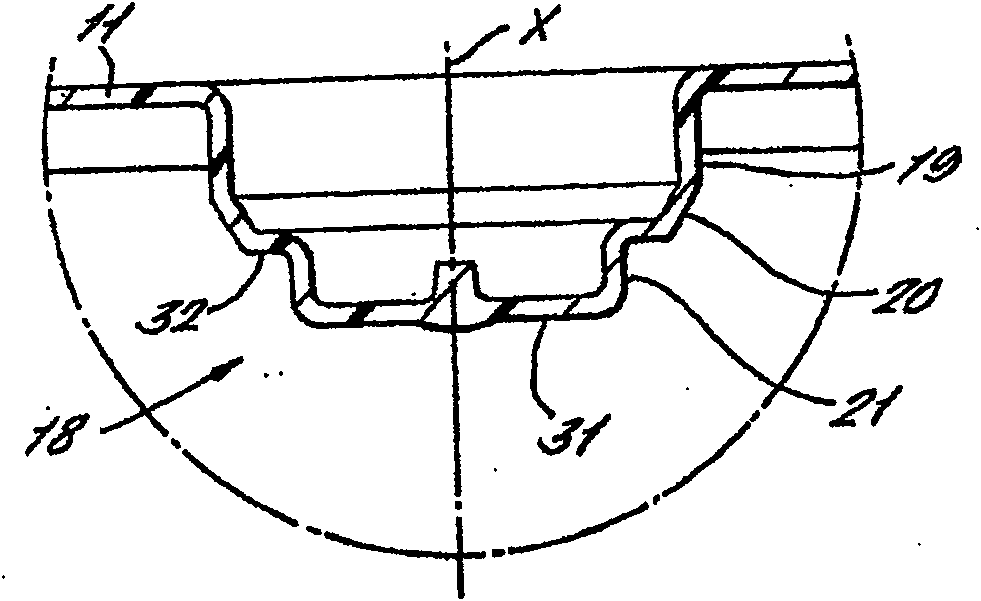

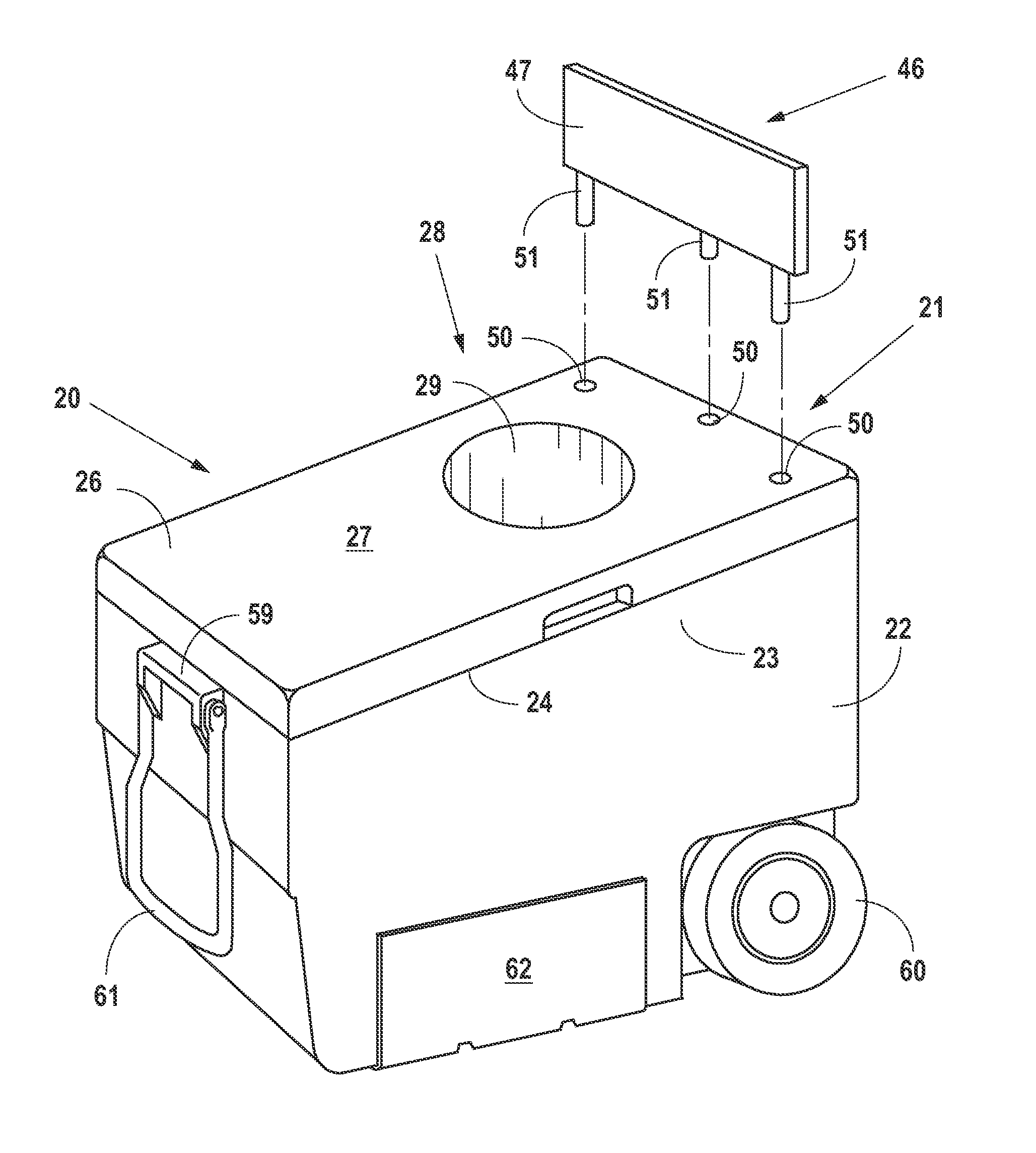

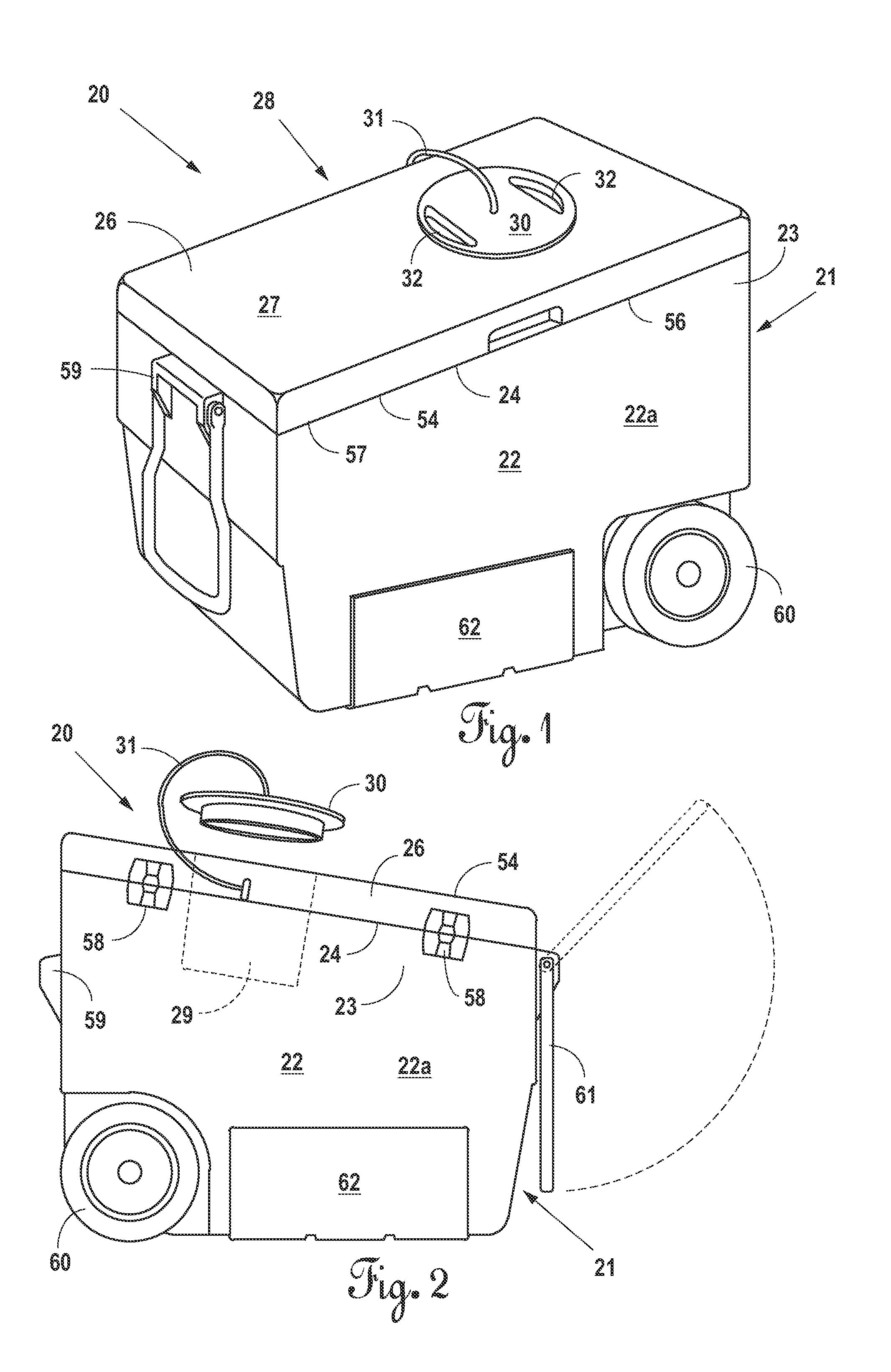

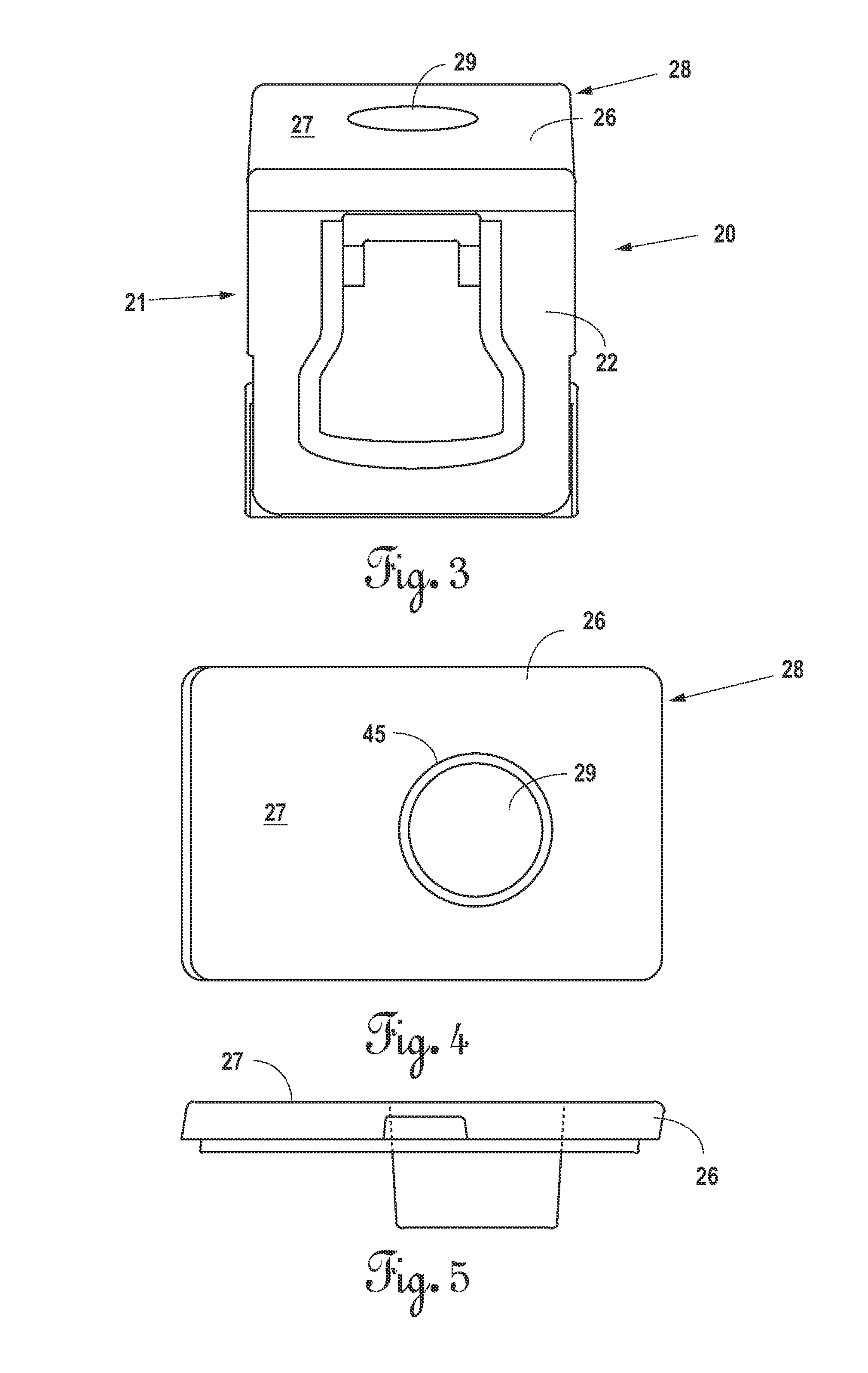

Recreational amusement

InactiveUS20100275641A1Domestic cooling apparatusLighting and heating apparatusRecreational useEngineering

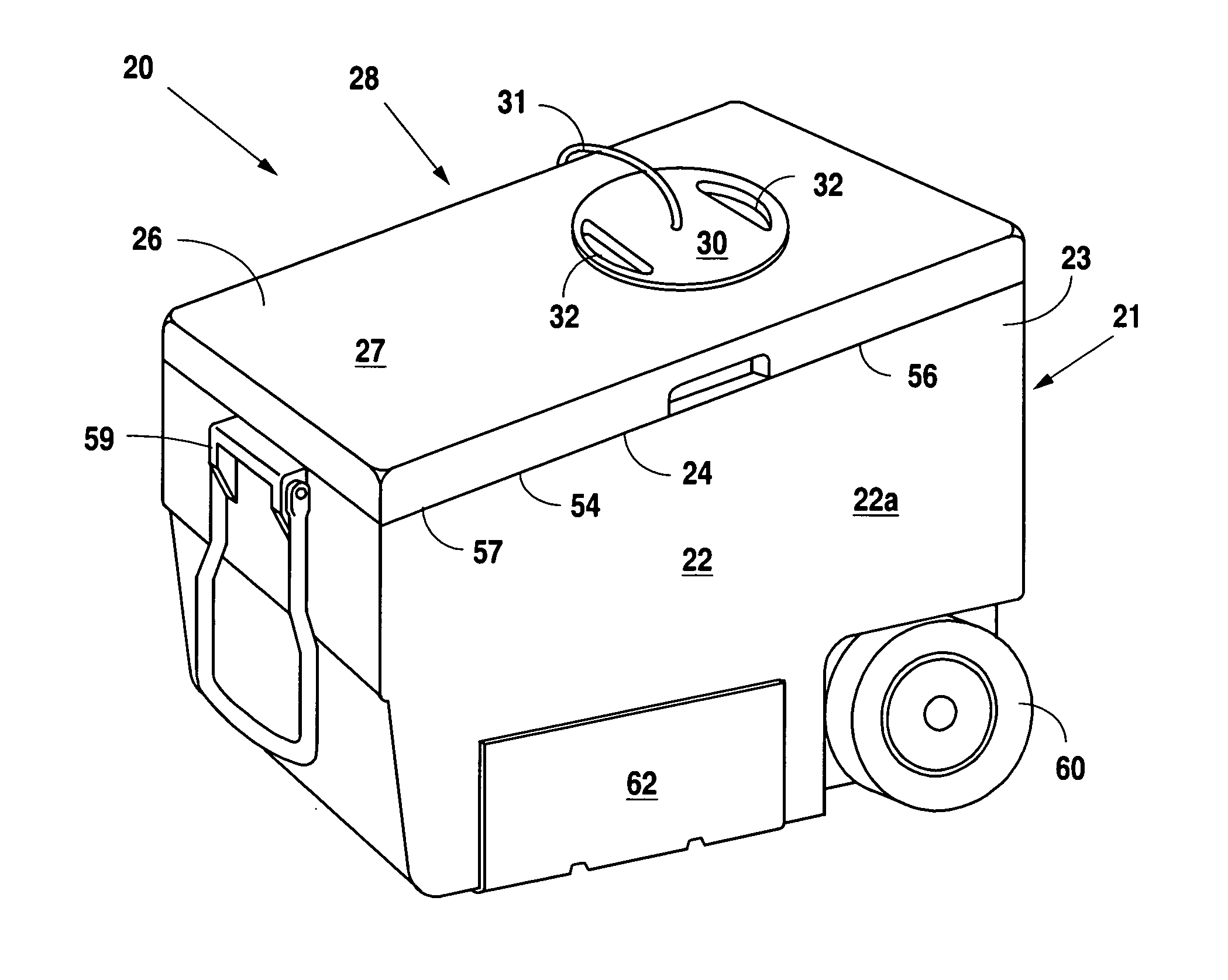

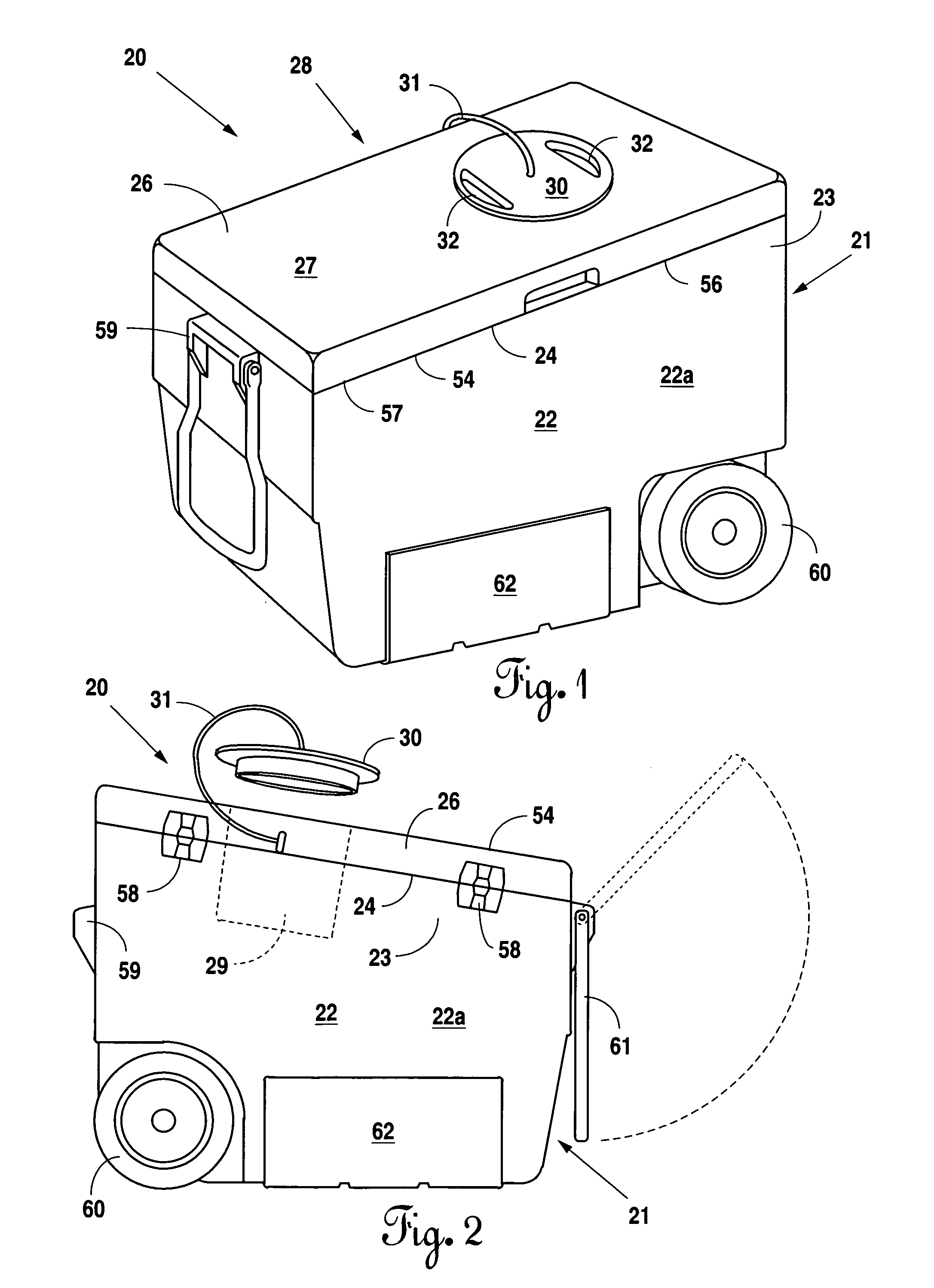

A recreational amusement (20) takes the form a cooler (21) having a toss-type game board (28) integrated with the cooler's lid (26). The toss-type game board (28) includes one or more cavities (29) in the top (27) of the lid (26). Provision is made for orienting the top (27) of the lid (26) in a sloping position for play of the game enabled by the game board (28). The cooler (21) retains all conventional features of a beverage type cooler.

Owner:MANNER KEVIN EDWARD +1

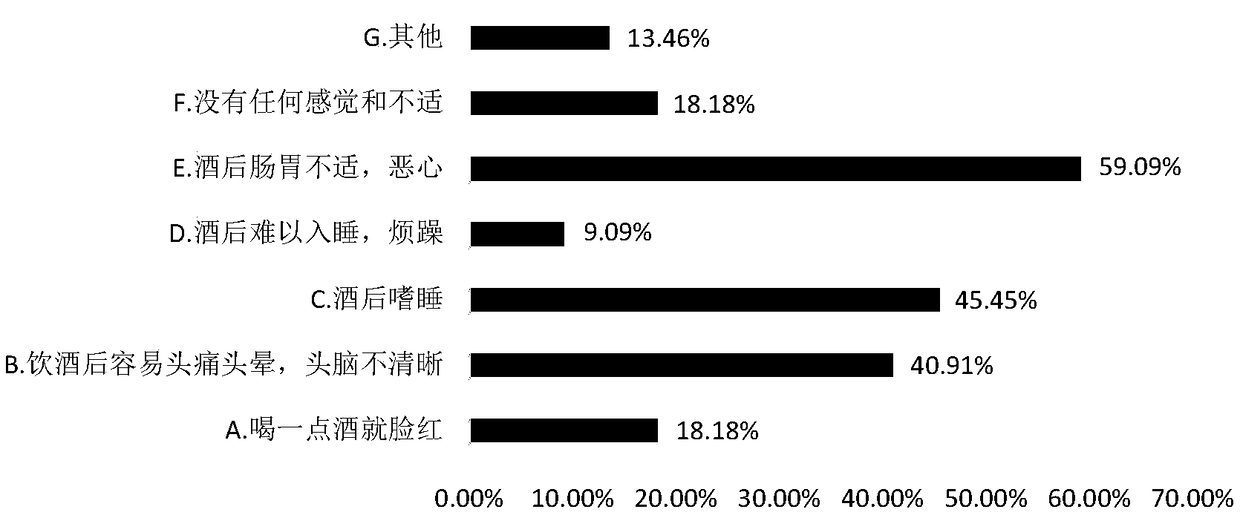

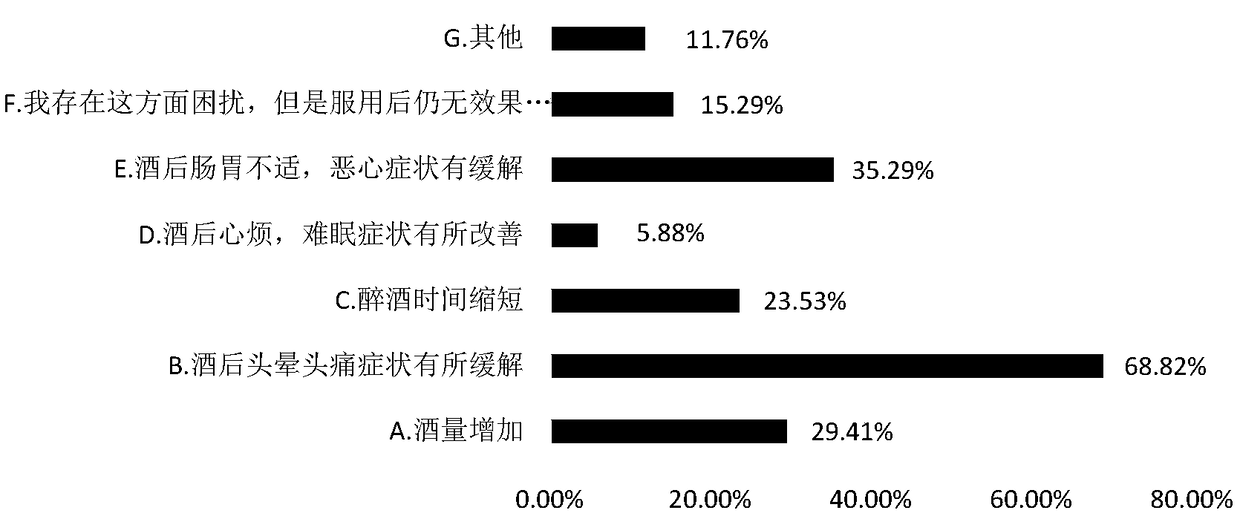

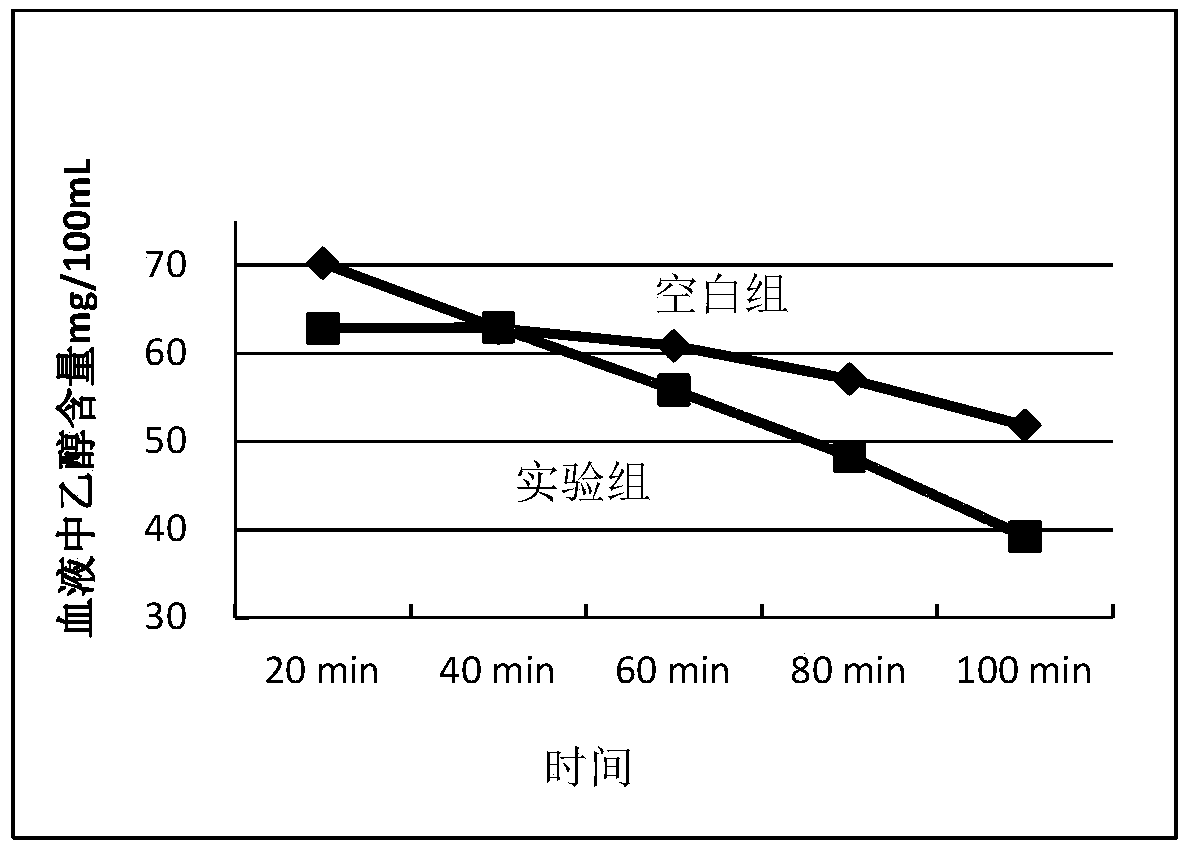

Anti-alcohol liver-protecting composition and anti-alcohol liver-protecting preparations comprising composition

InactiveCN109007808AHas anti-cancer propertiesShort stayHydrolysed protein ingredientsDigestive systemPotential toxicityAlcohol

The invention discloses an anti-alcohol liver-protecting composition and anti-alcohol liver-protecting preparations comprising the composition, and relates to the technical field of food preparations.The anti-alcohol liver-protecting composition comprises 10-55 parts of corn oligopeptide, 2-20 parts of turmeric, 2-20 parts of kudzuvine root extract, 5-20 parts of raisin tree seed extract, and 0.5-23 parts of broccoli seed water extract. The invention also provides a preparation method of tablet-type, solid beverage-type and drink-type anti-alcohol liver-protecting preparations. The anti-alcohol liver-protecting preparations of the invention solve the problems that anti-alcohol liver-protecting products in the prior art have poor anti-alcohol effect, some traditional Chinese medicine ingredients have potential toxicity, and the product stability in actual production is difficult to ensure. The preparation method is simple and convenient.

Owner:宝健(北京)生物技术有限公司

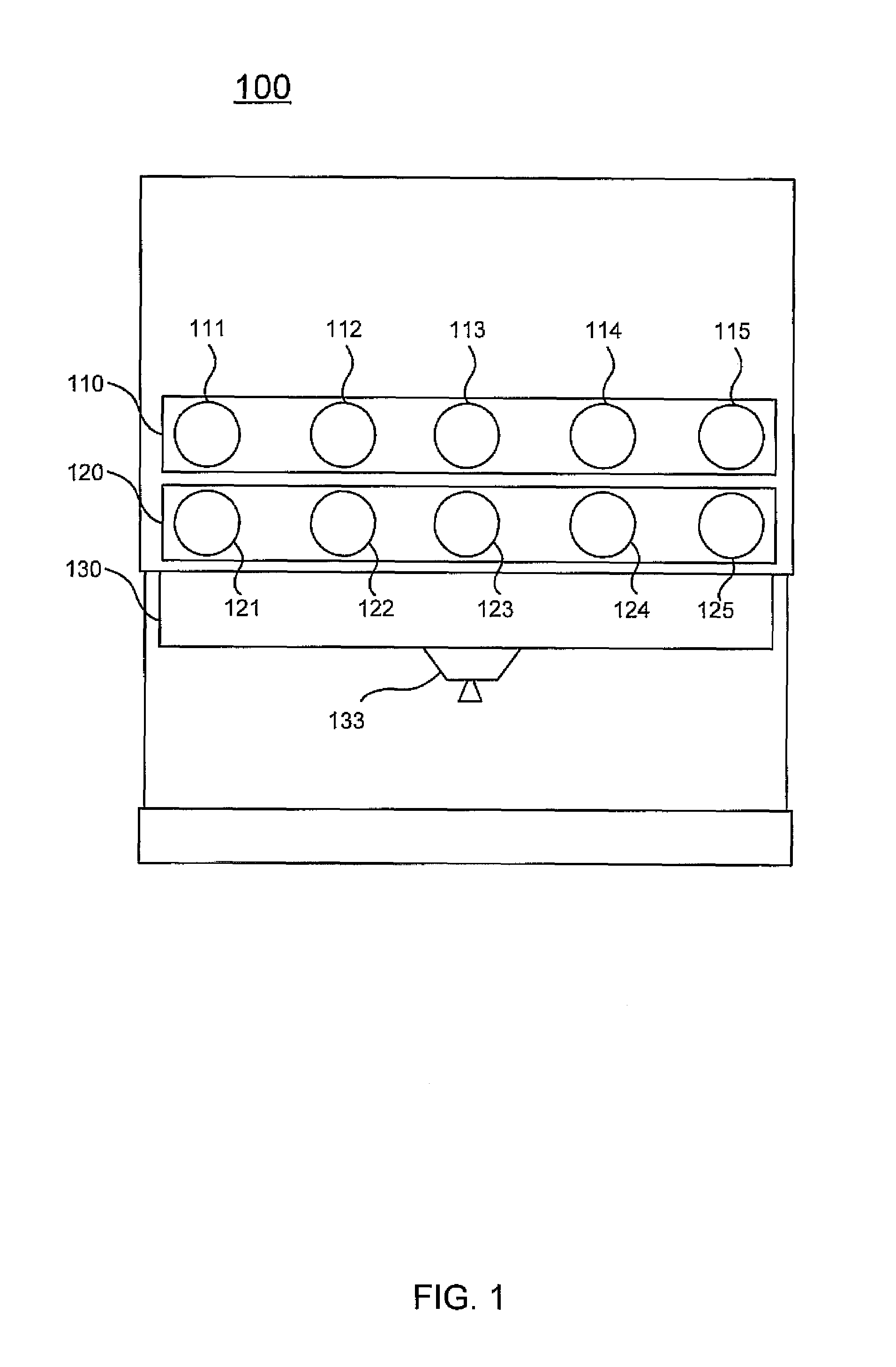

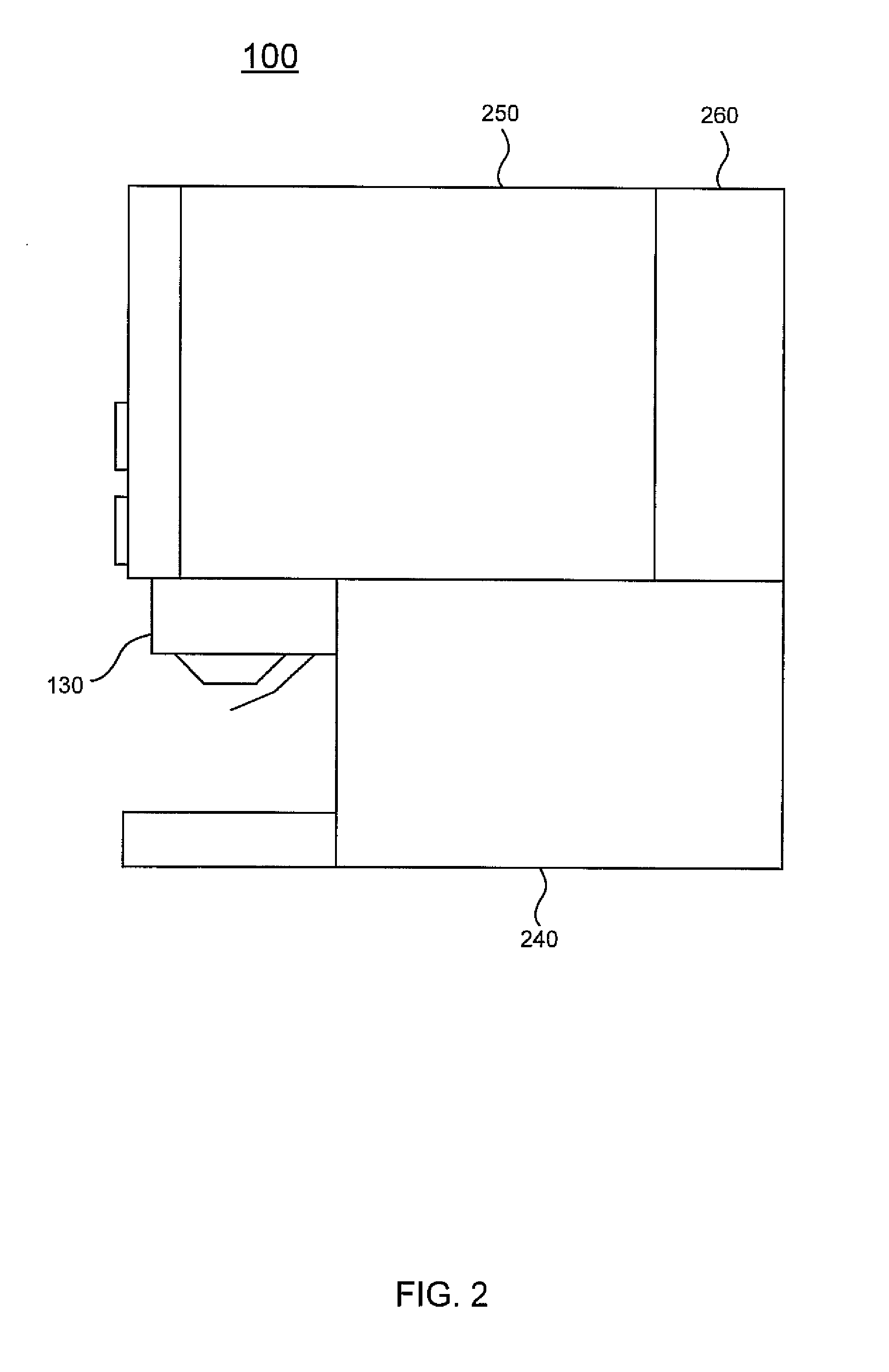

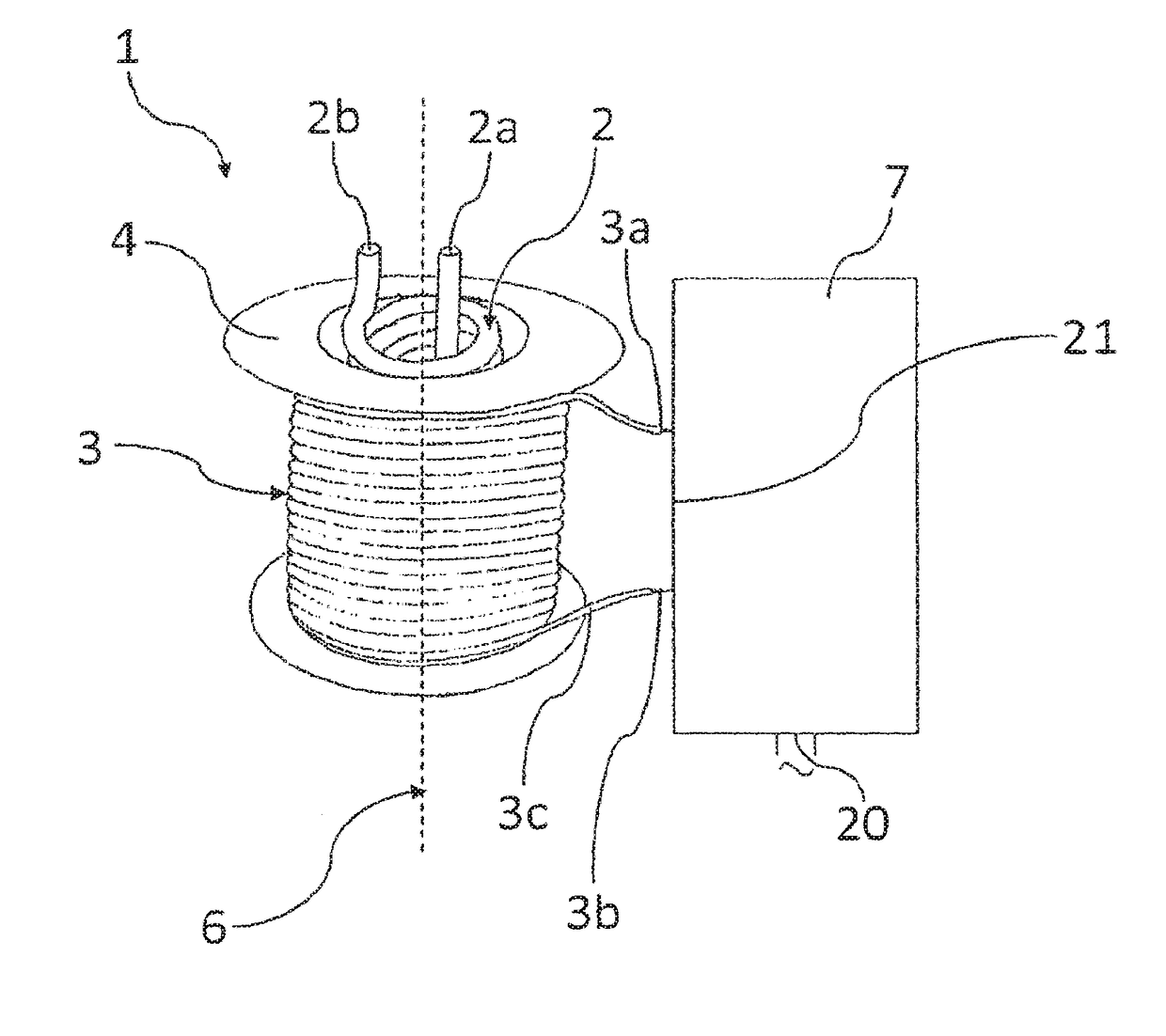

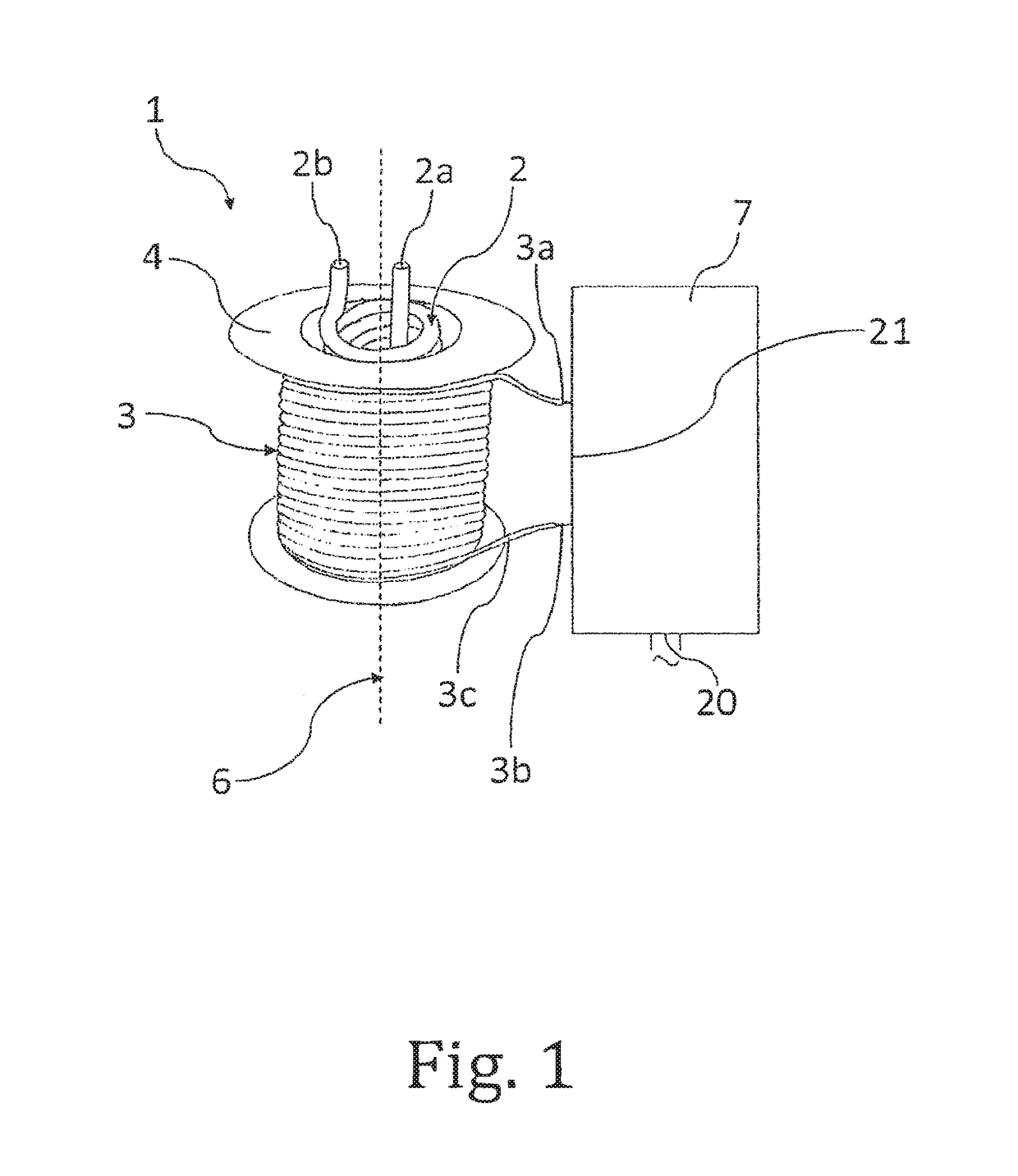

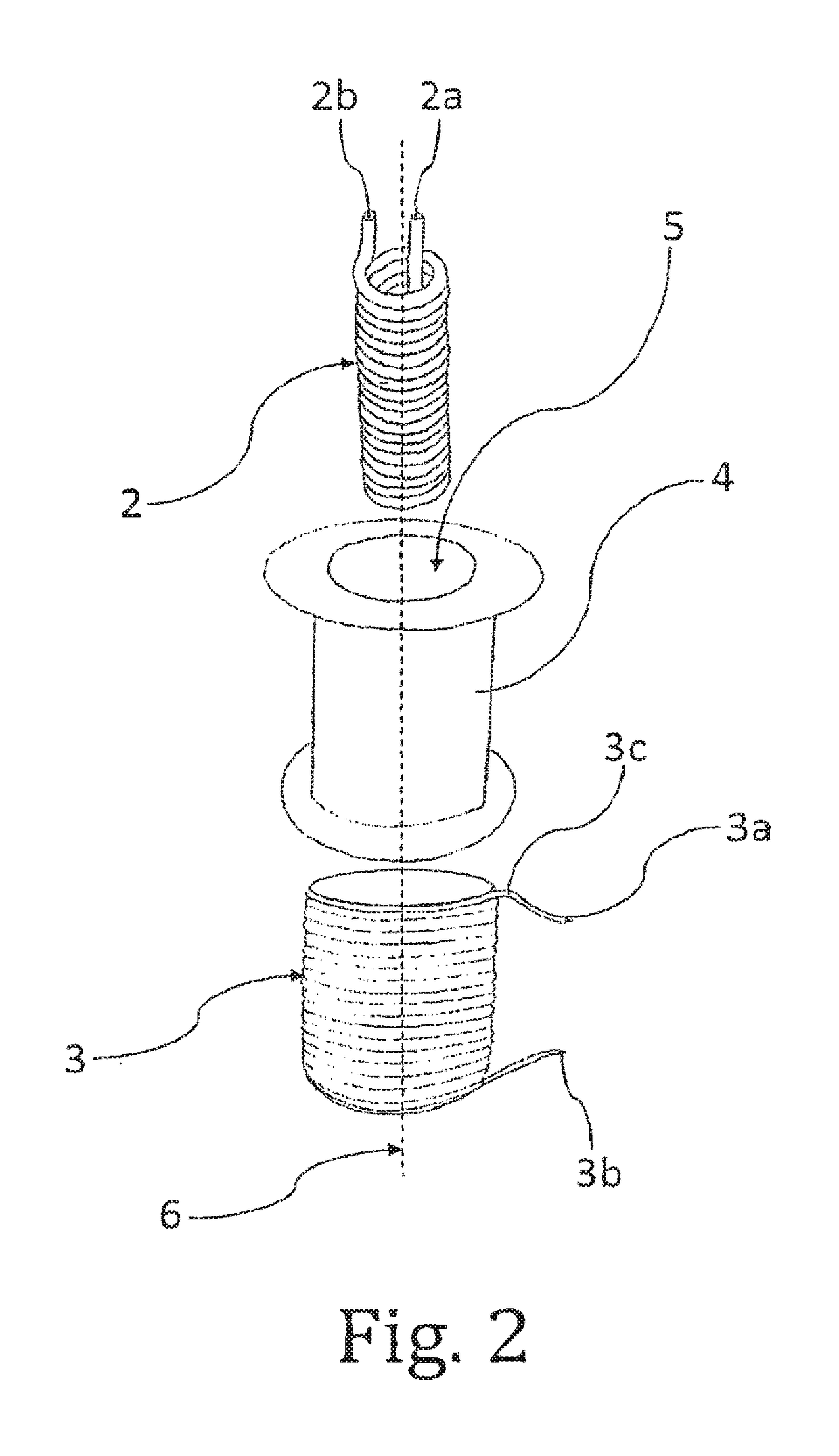

Method and Apparatus for Optimizing Variable Liquid Temperatures

A method apparatus (100), and related beverage profiles for on-demand heating of liquid used for beverage dispensing where such heating is dynamically variable according to the applicable profile. The apparatus (100) includes a heating unit (160), electronic controller (140), and sensing devices (150, 180). A water tank (110) supplies the heating unit (160) via a water pump (120) controlled by the controller (140) that also controls the heating unit. Feedback control loops provide control data to the controller (140) to optimize liquid temperatures for a given beverage type in accordance with predetermined profiles.

Owner:NESTEC SA

Recreational amusement

InactiveUS8764017B2Domestic cooling apparatusLighting and heating apparatusInterior spaceEngineering

A recreational amusement takes the form a cooler having a toss-type game board integrated with the cooler's lid. The toss-type game board includes one or more cavities in the top of the lid. Provision is made for orienting the top of the lid in a sloping position for play of the game enabled by the game board. The cooler retains all conventional features of a beverage type cooler and, in particular, the characteristic of the interior space of the cooler being substantially sealed off from the environment about the cooler by placement atop the body of the cooler of the lid.

Owner:THE TAILGATE CREW

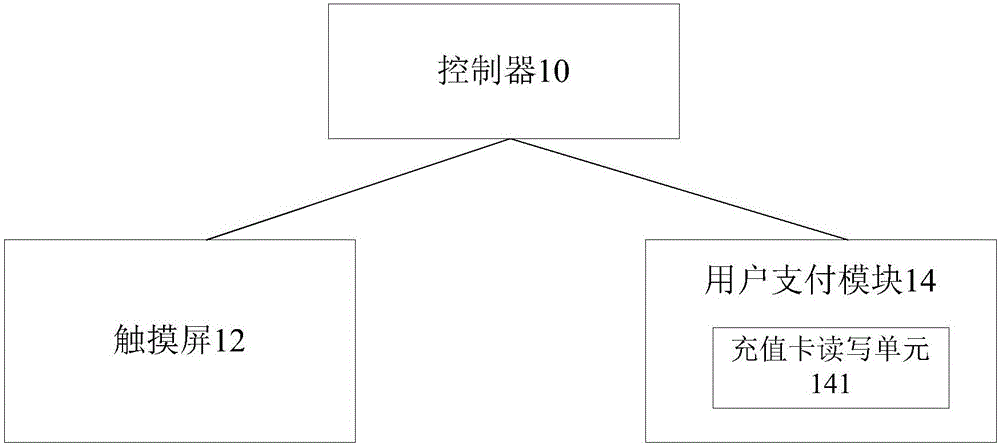

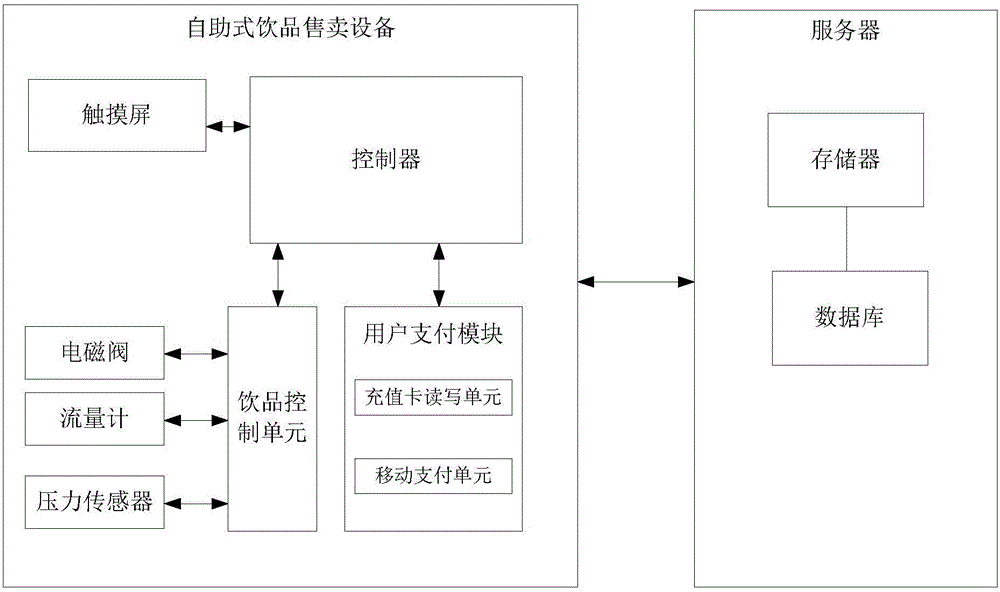

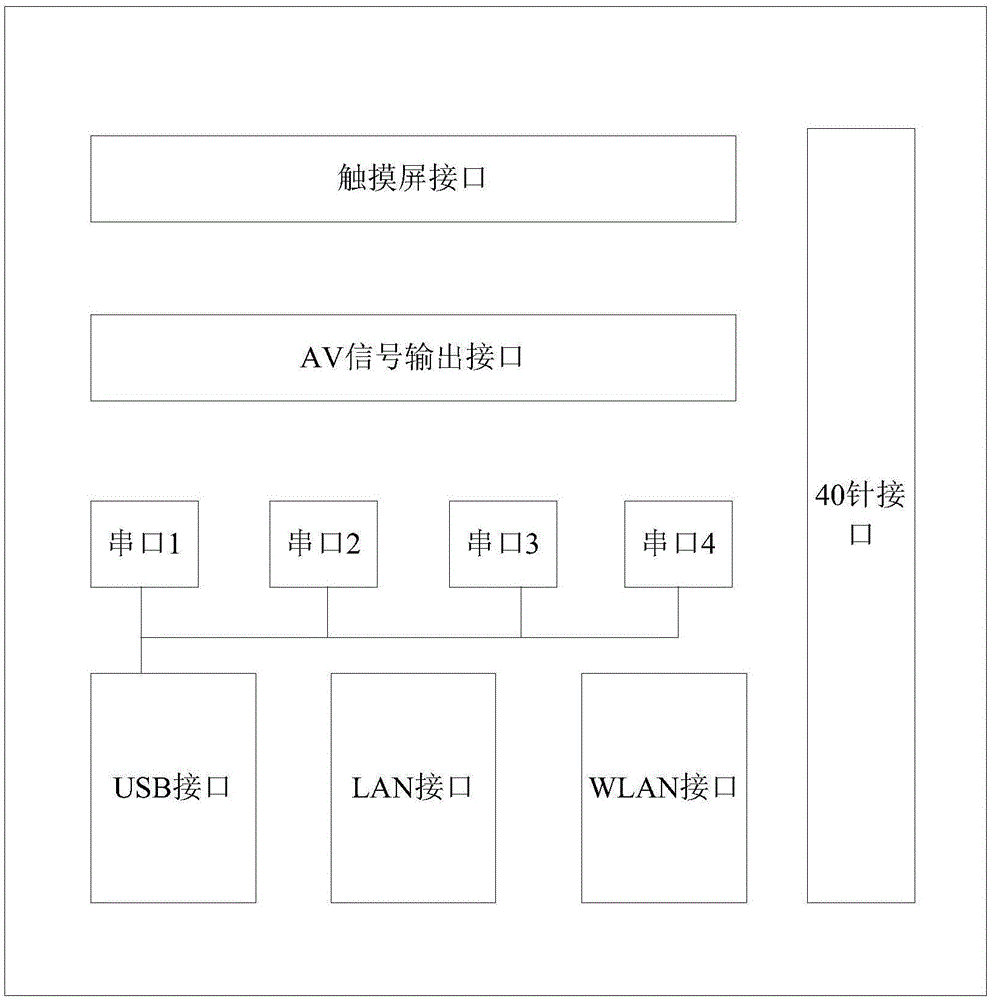

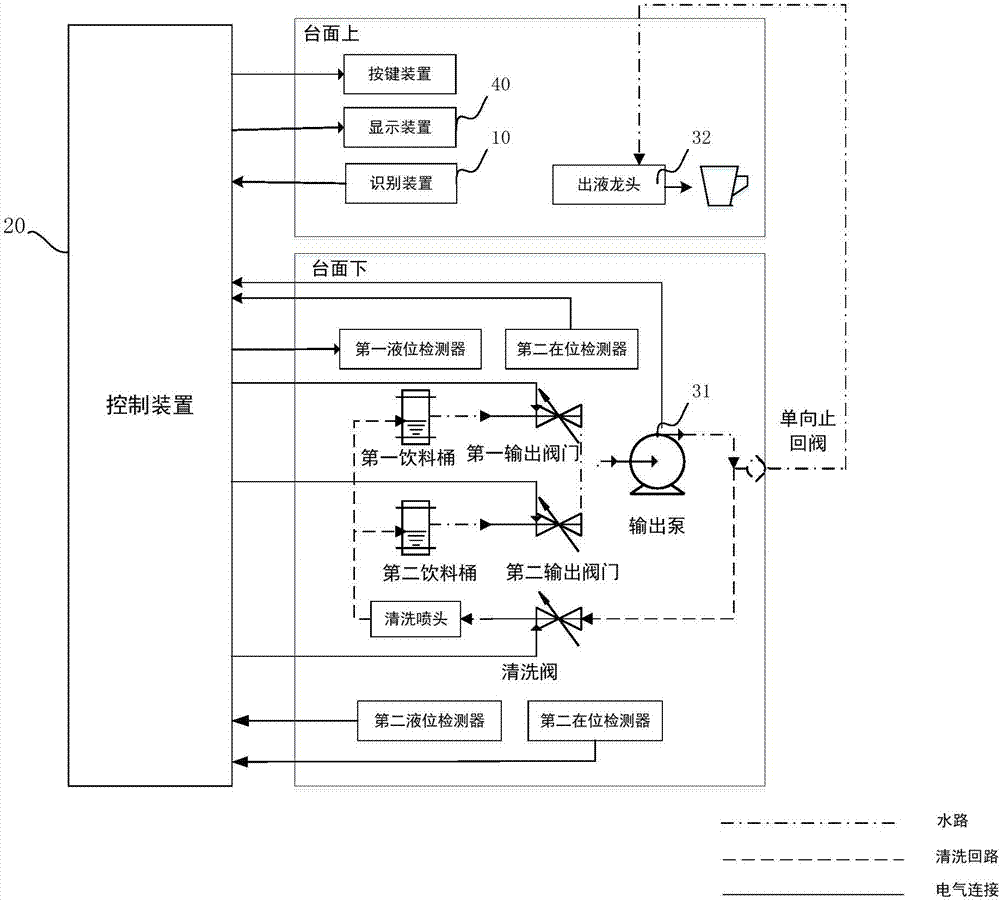

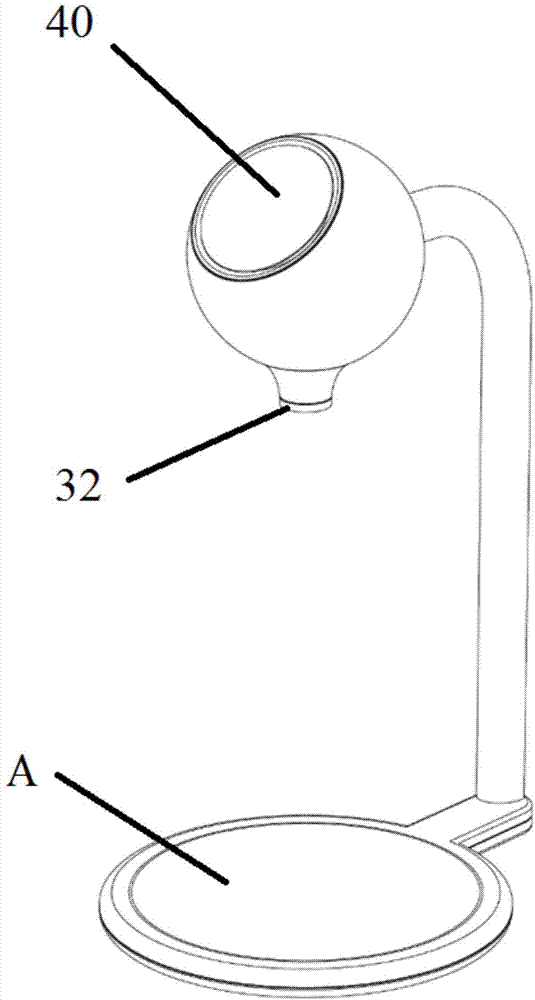

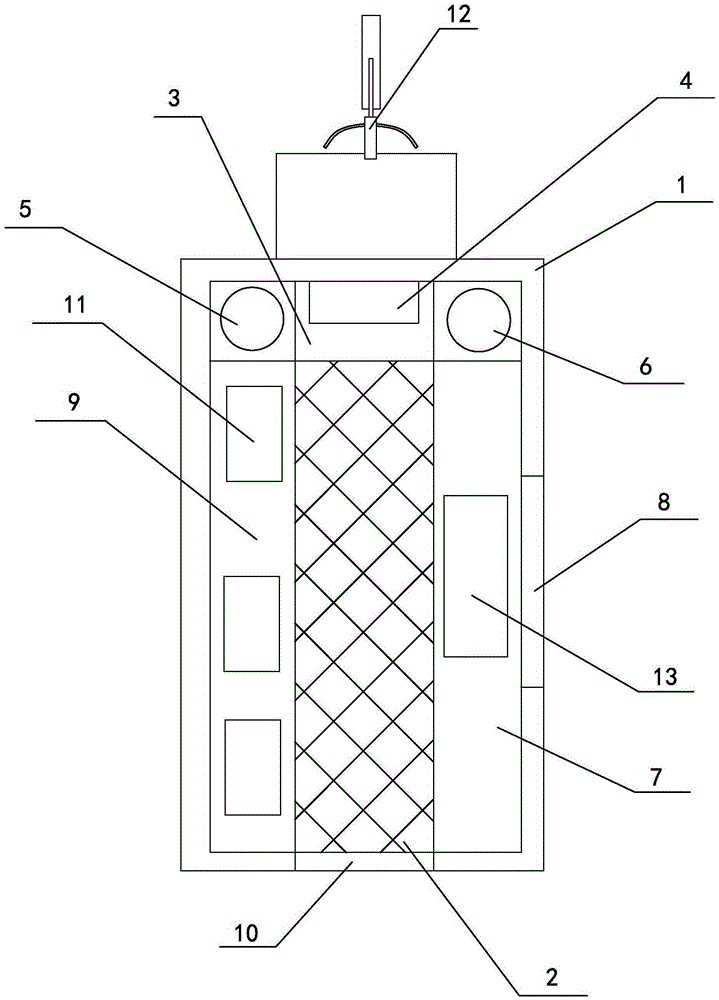

Self-service beverage vending equipment and self-service beverage vending system

InactiveCN106327694AImprove efficiencyImprove experienceApparatus for dispensing fluids/granular materialsPaymentValue set

Owner:筱马科技(北京)有限责任公司

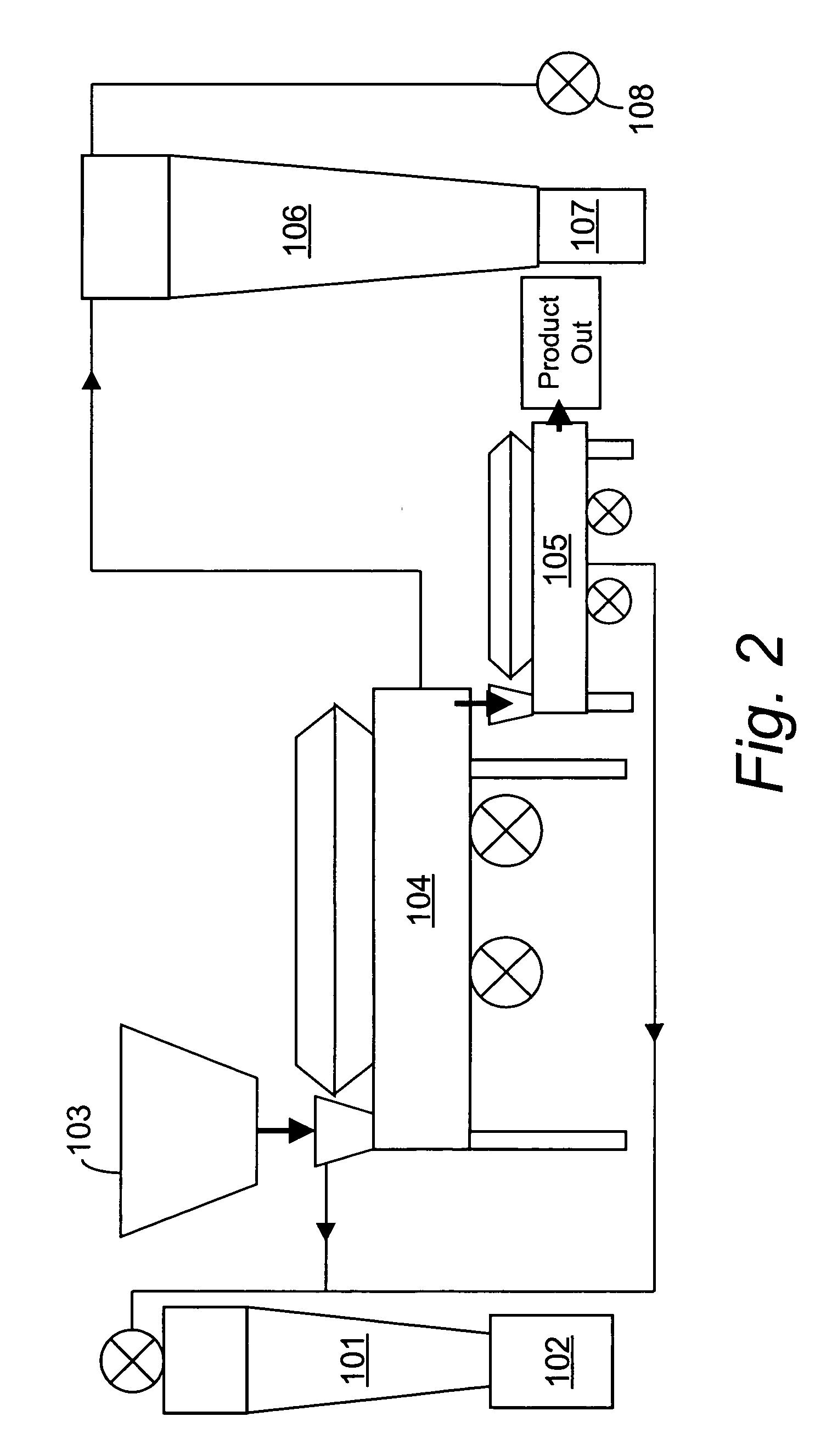

Machine for the preparation of beverages

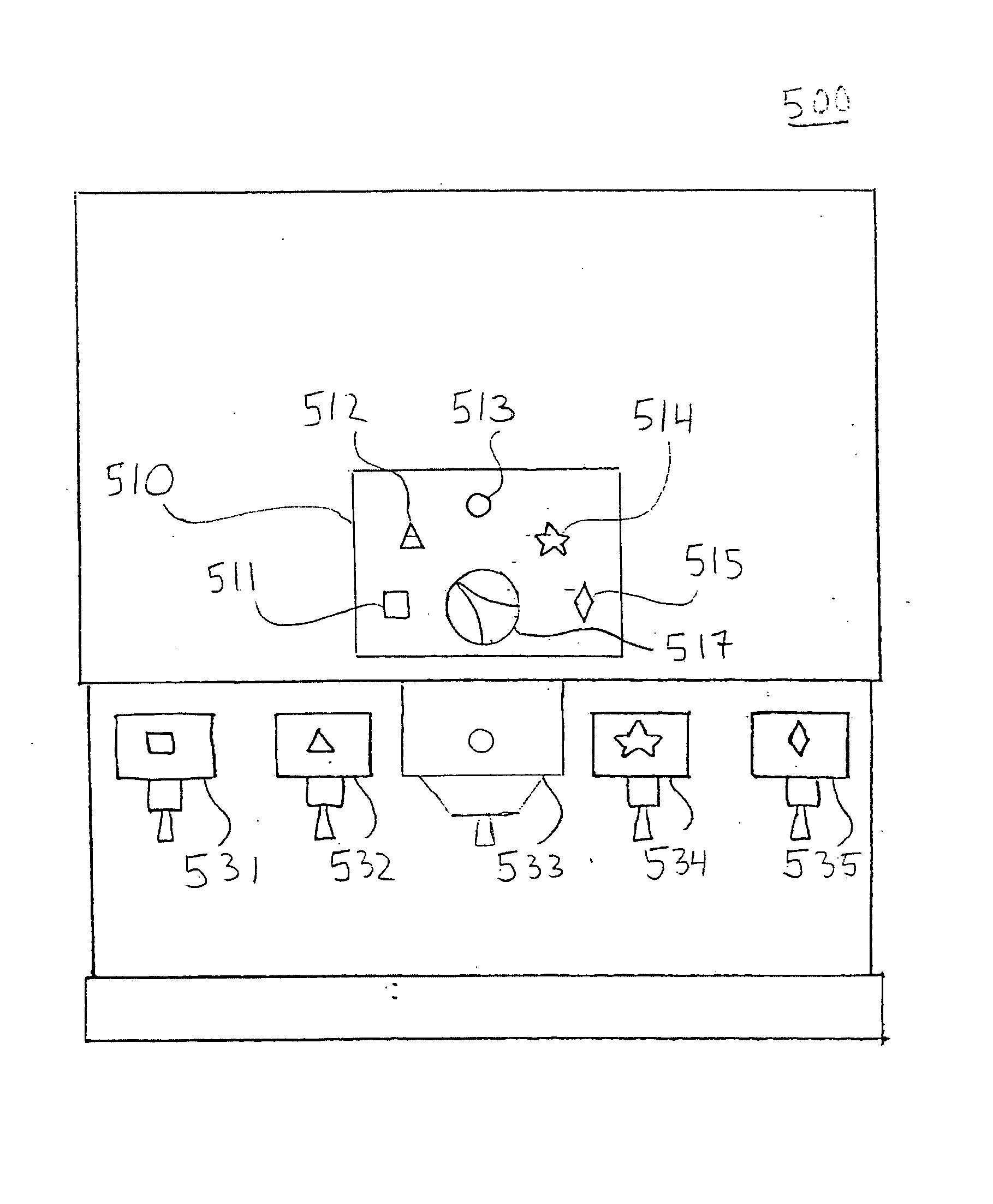

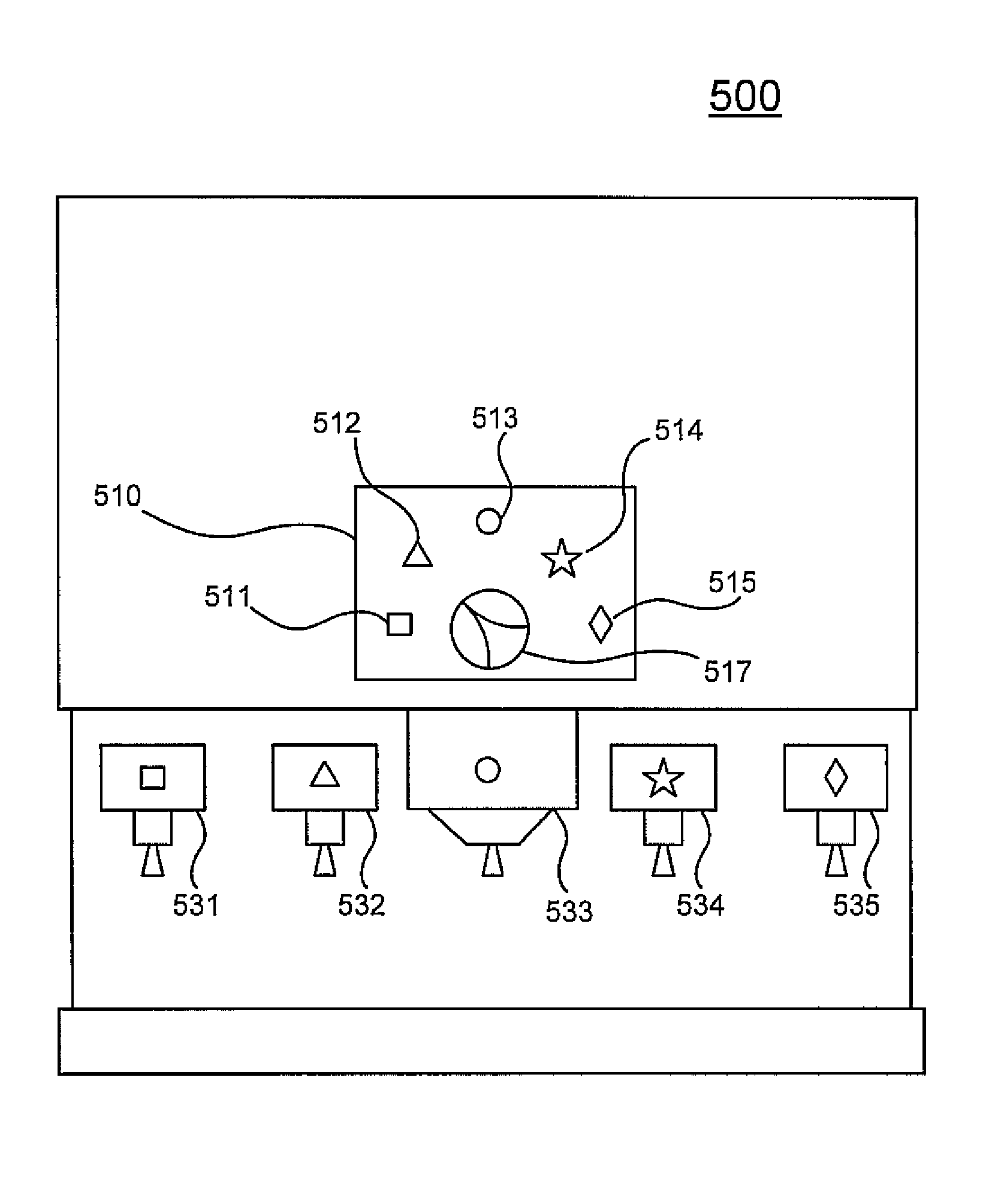

A low pressure beverage preparation system for automatically preparing a range of beverage types from a range of beverage cartridges, the system comprising: a beverage preparation machine (201); and aplurality of beverage cartridges (1), each beverage cartridge containing one or more beverage ingredients (200) associated with a specific beverage type, wherein the beverage preparation system comprises: a reader (252) for automatically interpreting a code (320) written on said beverage cartridge; processing means for creating a specific brewing cycle based on said code.

Owner:KONINK DOUWE EGBERTS BV

Recreational amusement

A recreational amusement takes the form a cooler having a toss-type game board integrated with the cooler's lid. The toss-type game board includes one or more cavities in the top of the lid. Provision is made for orienting the top of the lid in a sloping position for play of the game enabled by the game board. The cooler retains all conventional features of a beverage type cooler and, in particular, the characteristic of the interior space of the cooler being substantially sealed off from the environment about the cooler by placement atop the body of the cooler of the lid.

Owner:THE TAILGATE CREW

Noni fruit vinegar and production method thereof

InactiveCN101514319AImprove physical fitnessEnhance immune functionMicroorganism based processesVinegar preparationLactic acid fermentationMORINDA CITRIFOLIA FRUIT JUICE

The invention discloses noni fruit vinegar and a production method thereof, filtrate obtained by hot leaching of mixture of edible vinegar, noni fruit lactic acid fermentation undecanted wine, honey, arillus longan and matrimony vine is the noni fruit vinegar, the noni fruit lactic acid fermentation undecanted wine is prepared by steps of crushing selected noni fruit, and adding sugar, Lactobacillus bulgaricus and thermophilic streptococcus to ferment. The nonifruit vinegar provided by the present invention can maintain function and character of noni fruit, can improve body diathesis and immunization function, has efficacy of antioxidation and liver protection, and characteristic of mild sour flavour and non-stimulation, can be used as edible vinegar for cooking and being eaten together with rice or bread, can be drunk as beverage type and health care type edible vinegar, caters to human diet health care, diseases prevention and body-building trend, and has great exploitation potential. The invention has advantages of simple production method, and easily available raw material.

Owner:张海德 +1

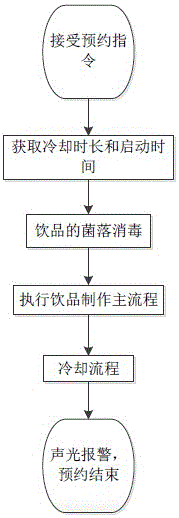

Beverage booking making method for food processing machine

ActiveCN106054981ARealize free customizationAvoid spillover riskAuxillary controllers with auxillary heating devicesTime informationStart time

The present invention relates to a beverage booking making method for food processing machine with the object to solving the problem that the temperature of final beverage cannot be controlled to meet the diversified requirements of users in booked hot drink production. The method includes: a food processing machine receives the booking instruction; acquiring information on the beverage types, booked time and drinking temperature; according to the information on the beverage types and the drinking temperature, completing the preparation of the beverage and cooling the beverage to the drinking temperature over some time; according to the information on the beverage type, obtaining the preset preparation time for the beverage; according to booked time information, presetting a preparation time and a cooling time, acquiring the start time for beverage processing. The invention solves the problem that the drinking temperature of hot beverage can be freely customized to meet the needs of different users while the preparation time for the hot beverage can be booked.

Owner:JOYOUNG CO LTD

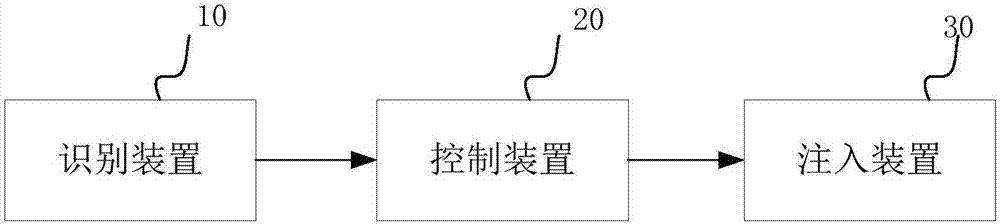

Beverage machine and beverage separate injection system

The invention discloses a beverage machine and a beverage separate injection system. The beverage machine is used for injecting beverage into beverage cups and comprises a recognition device, a control device and an injection device, wherein the recognition device is used for reading recognition information of the beverage cups and sending the recognition information, the control device receives the recognition information, obtains beverage type information and / or beverage quantity information corresponding to the recognition information and outputs injection control information according to the beverage type information and / or the beverage quantity information, and the injection device receives the injection control information and injects the corresponding beverage types and / or the beverage quantities into the beverage cups according to the injection control information. According to the beverage machine and the beverage separate injection system, the recognition device reads the recognition information of the beverage cups, and the control device obtains the beverage type information and / or the beverage quantity information corresponding to the recognition information and controls the injection device to inject the corresponding beverage types and / or the beverage quantities into the beverage cups, so that the beverage machine is easier to operate and capable of effectively lowering the requirement for an operator.

Owner:BUBBLE LAB CO LTD

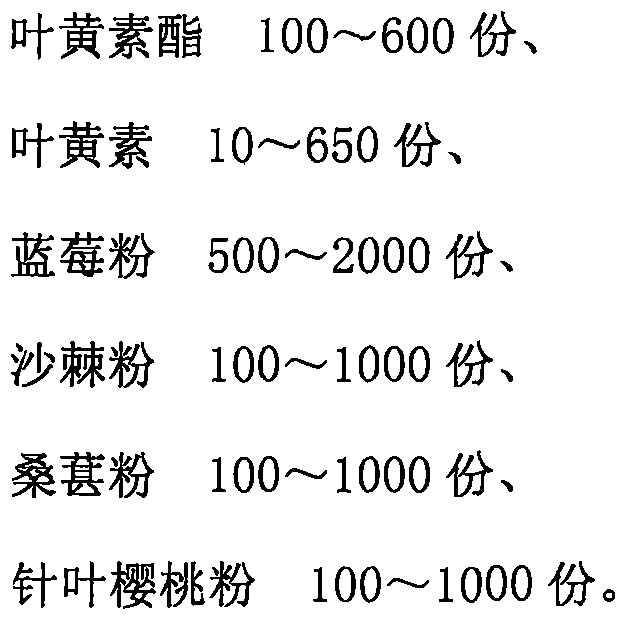

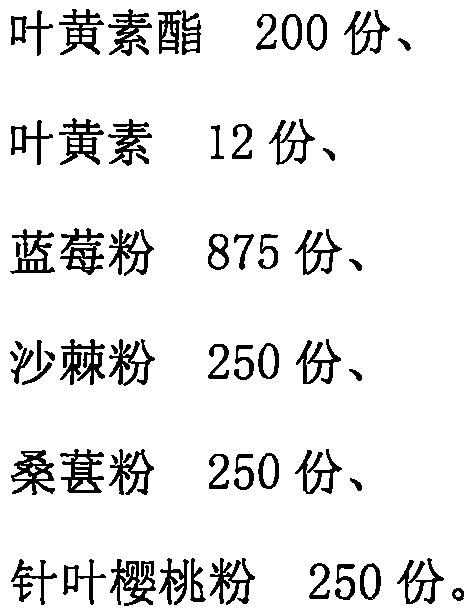

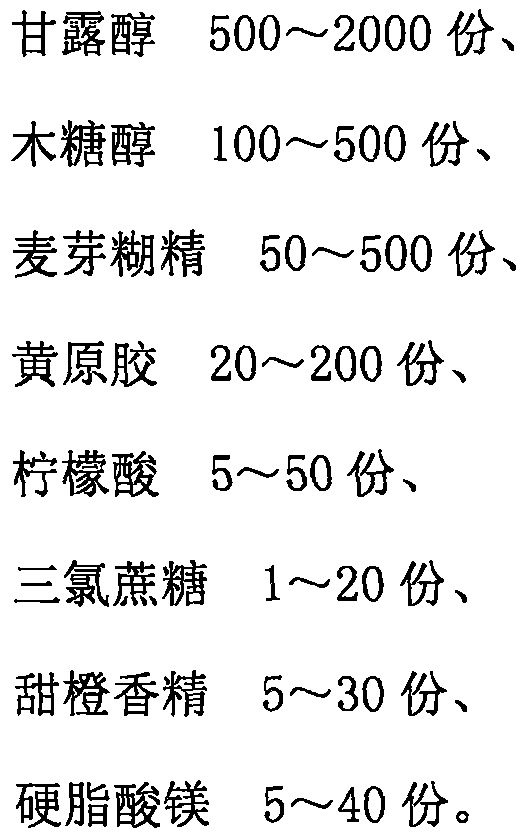

Nutritious visual cell, composition capable of improving regulating ability and resisting blue light damage and preparation method of composition

InactiveCN105795474AImprove stabilityGuaranteed content of active ingredientsConfectionerySweetmeatsProduct typeBeta-Carotene

The invention discloses a nutritious visual cell, a composition capable of improving regulating ability and resisting blue light damage and a preparation method of the composition. The composition is used for providing nutrients, vitamins and minerals, such as xanthophyll, zeaxanthin, anthocyan, linolenic acid, linoleic acid, amino acids, beta carotene (vitamin A precursors ), vitamin P, vitamin C, zinc, calcium, iron and selenium, is prepared through a certain compounding ratio, can be made into varied food categories, and is preferably a beverage type, a dairy type, a biscuit type, a confectionery product type, and a special meal type. According to the composition disclosed by the invention, the components are scientific in compatibility, the raw materials are preferably selected, and a technology is optimized, so that the content of effective components is guaranteed to the maximum extent, the daily needs for eye nutrient elements of teenagers and children are met, the regulating ability of eyes and the blue light damage resistance to the eyes are improved, and the effect of relieving visual fatigue is achieved.

Owner:BEIJING YUANLAI HEALTH MANAGEMENT CO LTD

Honey and tomato juice and preparation method thereof

ActiveCN103859519AFit for consumptionFull of nutritionFood ingredient functionsFood preparationFruit juiceThree stage

The invention discloses honey and tomato juice which is characterized by being formed by performing vacuum back pressure mixing on 1-3 parts of honey, 10-15 parts of xylitol, 40-50 parts of tomato paste, 30-40 parts of water, 3-8 parts of mixed juice and 0.6-1.2 parts of edible salt, performing pre-sterilization, sealing and filling and performing three-stage gradient cooling. According to the materials, the tomatoes and the honey which have unique combination effects and the juice which is rich in nutrition and tastes good are selected; the rich nutrition of the honey and tomato juice, the unique flavor and the mellow taste are guaranteed, and the effects of a beverage type product for helping produce saliva, slaking thirst, clearing heat and relieving summer-heat are particularly outstanding; furthermore, edible essence, an emulsifier and a stabilizing agent are not added, so that the safety of the honey and tomato juice is greatly improved.

Owner:BEIJING YUANXIANJI FOOD SCI & TECH

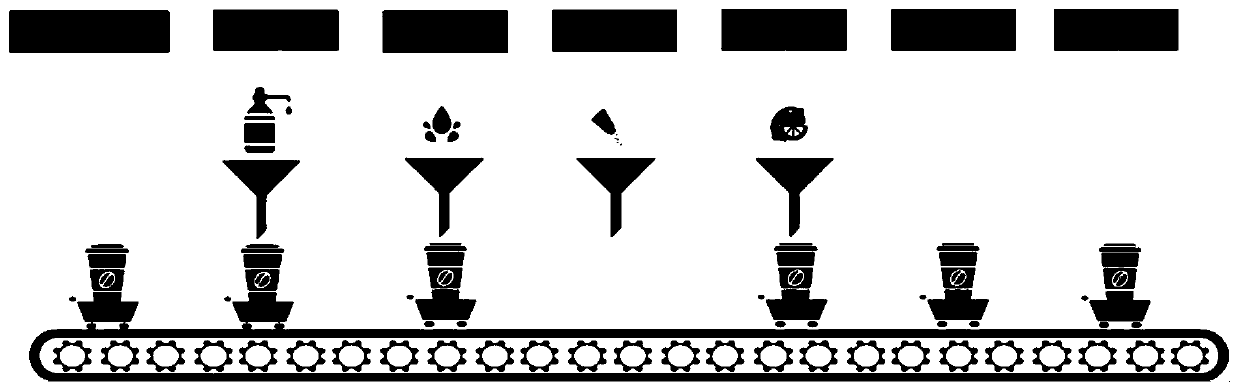

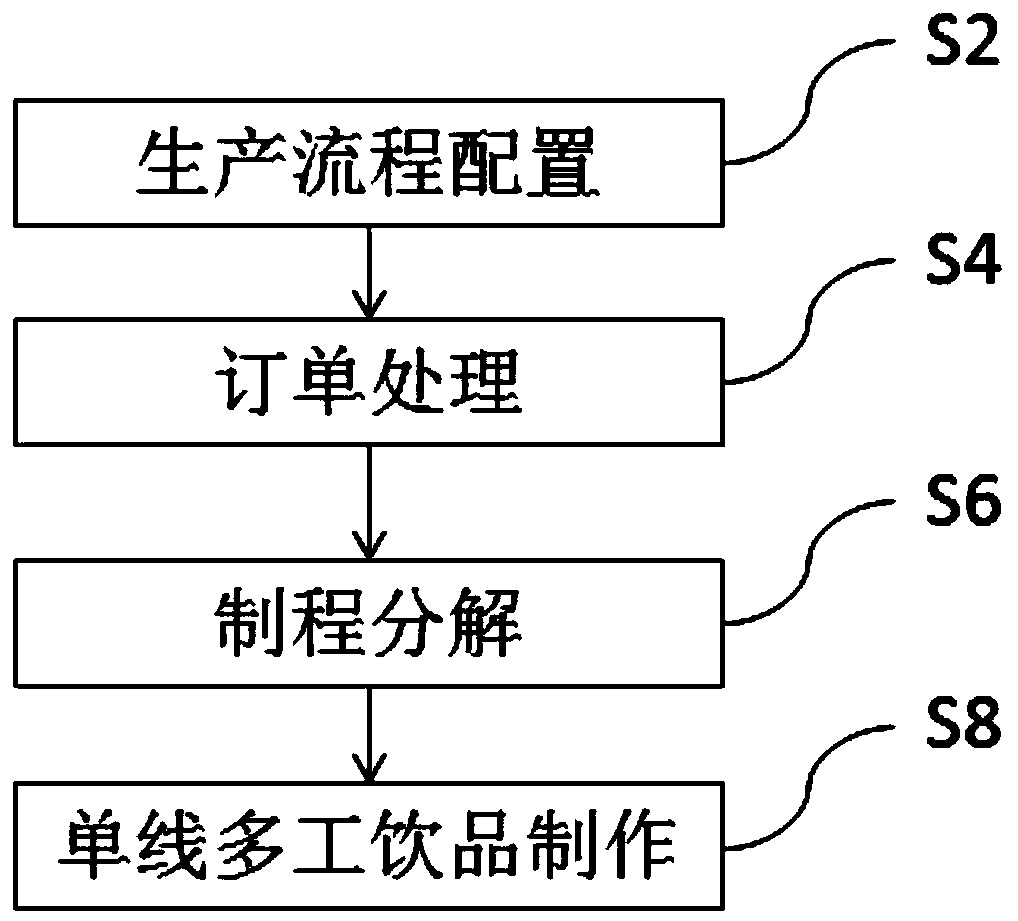

Single-line multi-station beverage making method and single-line multi-station beverage making system

PendingCN110458381AMeet the needs of different product categoriesDiversity guaranteedCo-operative working arrangementsBeverage vesselsProcess moduleMode control

The invention provides a single-line multi-station beverage making method. The single-line multi-station beverage making method comprises the steps of production process configuration, order processing, process decomposition and single-line multiplex beverage making. The single-line multi-station beverage making system comprises a production process configuration module, an order processing module, a process decomposition module, a multi-station process station control module and a multi-path multi-station communication module; in the beverage production process, the bar code is read at each station, the manufacturing procedure corresponding to the product is inquired, whether materials are added at the current station or not, what kind of materials are added and how many materials are added are determined, and the diversity of beverage types selectable for users is guaranteed; meanwhile, different from a traditional beverage making mode controlled by a mechanical arm, the single-linemulti-station making mode greatly improves the beverage making efficiency.

Owner:苏州提点信息科技有限公司

Method for heating water in a machine for making and dispensing drinks

ActiveUS20180249860A1Avoid disadvantagesEasy to useBeverage vesselsOhmic-resistance heatingEngineeringBeverage type

Owner:RHEAVENDORS SERVI CES SPA

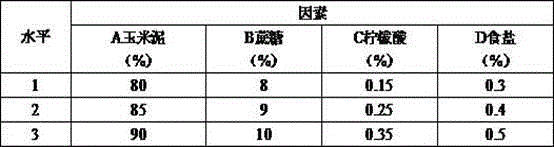

Healthy beverage type corn paste and preparation method thereof

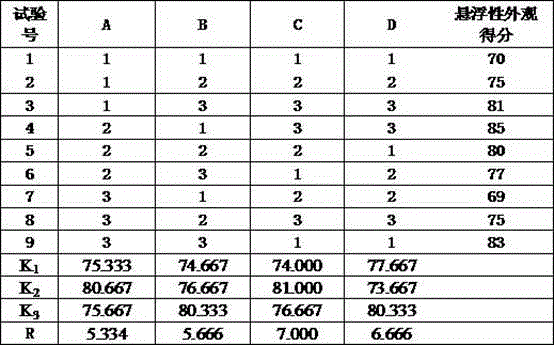

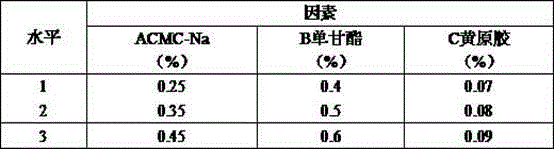

The invention discloses a preparation method for healthy beverage type corn paste. By taking sweet corn as a raw material, the beverage type corn paste is prepared by refining after cleaning, threshing and blanching, gelatinizing, passivating, carrying out enzymolysis, mixing, adding a compound stabilizer, homogenizing and carrying out vacuum packaging after sterilizing. In the mixing step, the materials are as follows in percentage by weight: 80-90% of corn, 8-10% of saccharose, 0.15-0.35% of citric acid and 0.3-0.5% of table salt. The compound stabilizer is prepared from the following components in percentage by concentration: 0.25-0.45% of CMC-Na, 0.04-0.06% of monoglyceride and 0.07-0.09% of xanthan gum. By taking the sweet corn as the raw material and adding saccharose, citric acid and salt, the healthy beverage type corn paste is moderate in sweetness and sourness and has obvious special flavor and aroma of corn. The corn paste which is continuously processed is free of sediments and good in solubleness and flowability. The corn paste is good in stability if being mixed to a corn juice beverage.

Owner:FUJIAN BISHAN FOOD CO LTD

Prepn. method for mineral water contg. real natural plant color and pure water

InactiveCN1947599AHas the function of strengthening the body and health careCardiovascular protectionFood sciencePlant ingredientsBeverage typePurified water

A beverage-type mineral water or purified water with natural vegetative color is prepared from the mineral water or purified water and the flower, fruit, leaf, or stem of natural plant. It has health-care function. Its preparing process is also disclosed.

Owner:陈义

Method for preparing beverage type fruit vinegar by using tangerine orange

InactiveCN103948124APrevent spoilageUnique tasteVinegar preparationFood scienceAcetic acidFood grade

The invention discloses a method for preparing beverage type fruit vinegar by using tangerine orange. The method is characterized by comprising the following steps: cutting open pulp of peeled tangerine orange to obtain juice and filter residues; heating the juice to be in a boiling state, and adding a preservative into the cooled juice for later use; removing kernels from the filter residues, and smashing the filter residues into particles being 1.2-0.8 millimeter; heating and boiling; adding food grade glacial acetic acid into filter residue boiling liquid in the ratio of 1:(0.05-0.055) for curing for 9-11 days; adding 5-7 times of cold boiled water or sterilized water, stirring and filtering; mixing cured substance filtrate with standby juice to obtain the beverage type fruit vinegar. Compared with the prior art, the method has the advantages that a large amount of tangerine orange can be consumed within a short time to prevent the tangerine orange from deteriorating due to long-time storage, and a beverage with a unique flavor can be produced.

Owner:叶贤忠

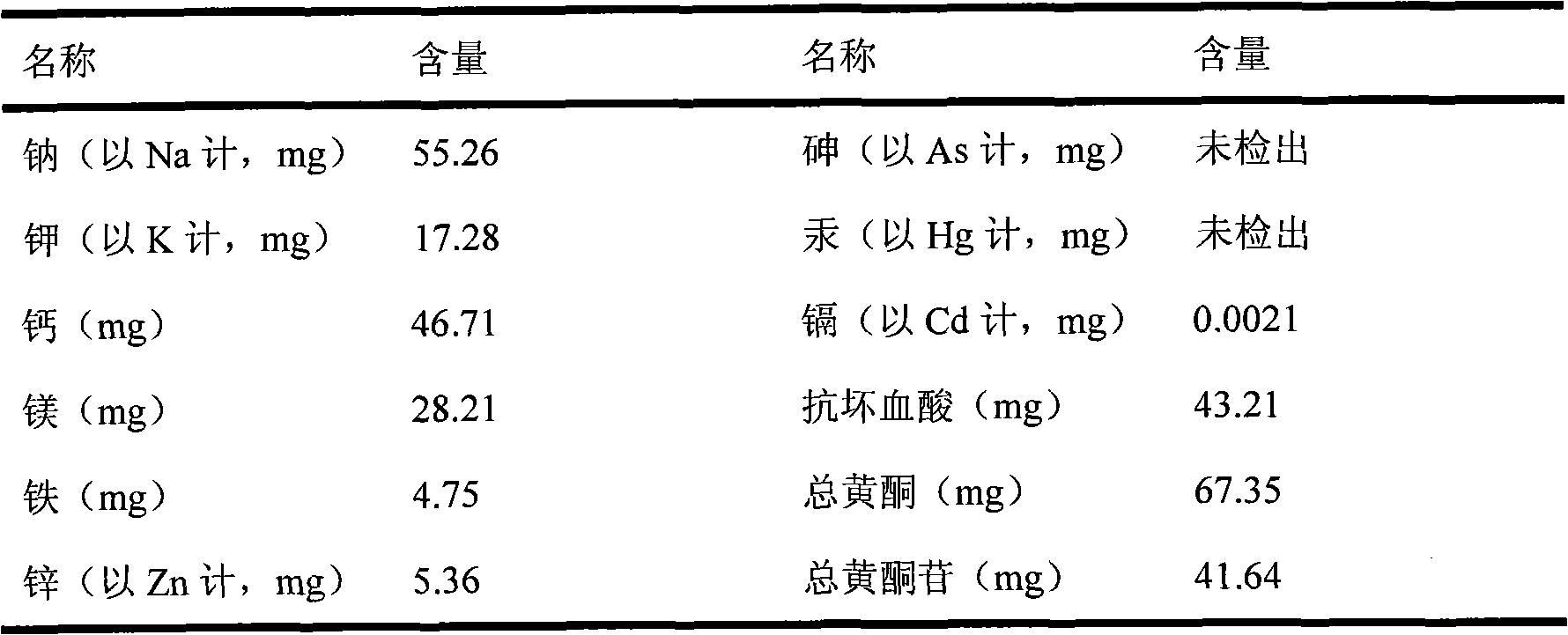

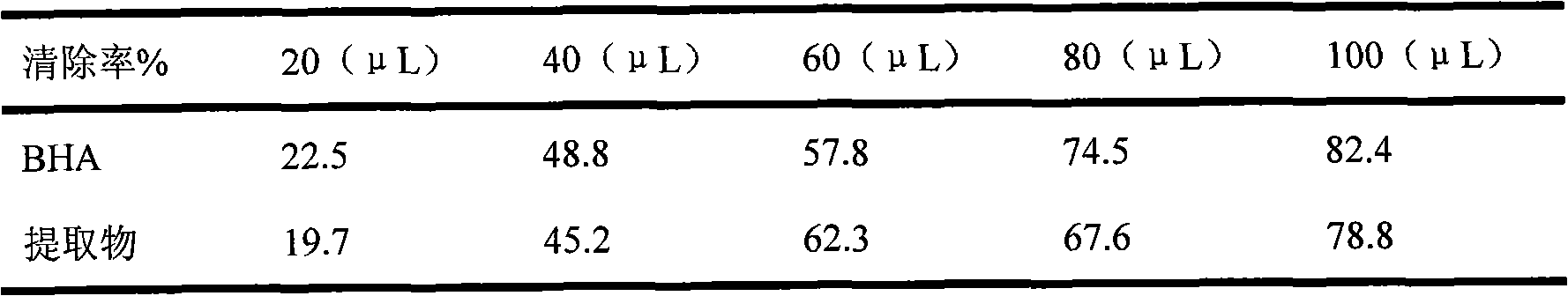

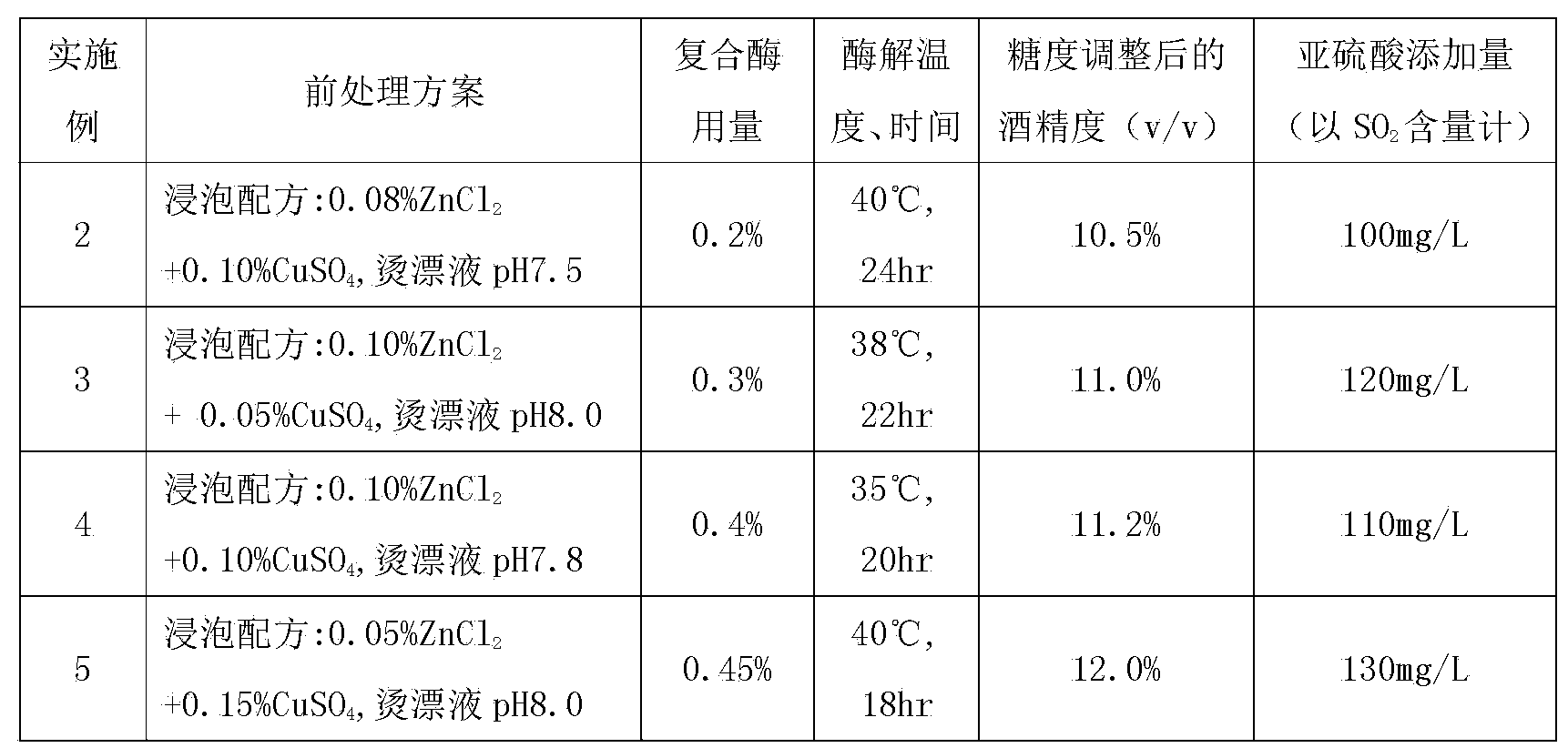

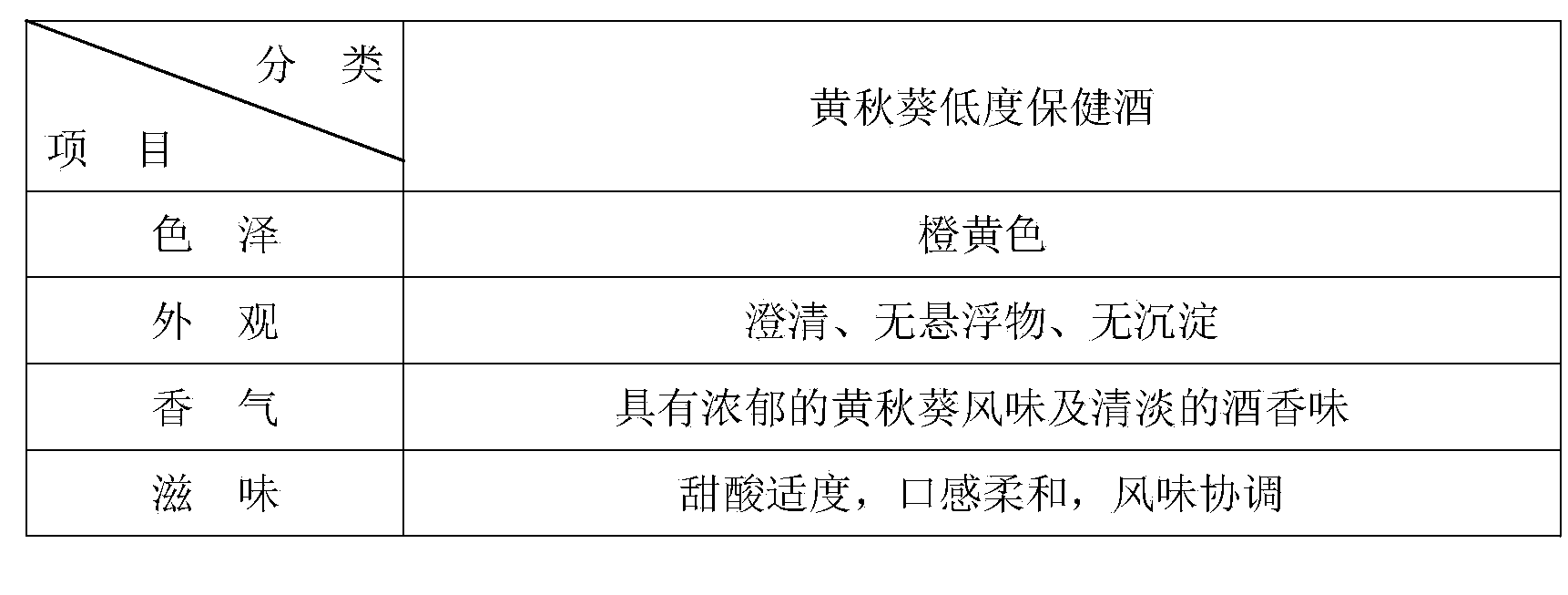

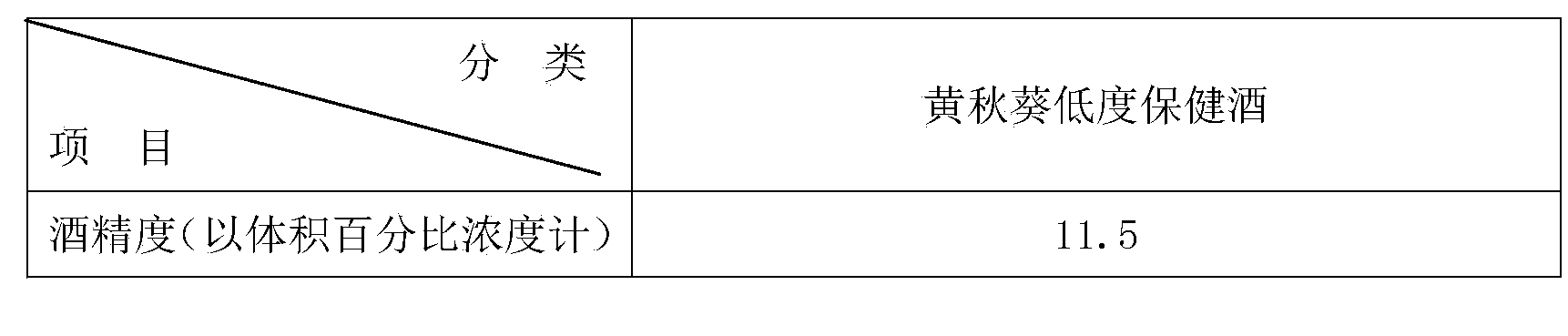

A kind of preparation method of okra wine

InactiveCN103045429BIncrease productionIncrease added valueMicroorganism based processesAlcoholic beverage preparationBULK ACTIVE INGREDIENTTon

The invention provides a preparation method of an okra wine, comprising the steps of slurrying, sugar degree adjustment, alcoholic fermentation and filtering. The preparation method is characterized in that after the slurrying step and before the sugar degree adjustment step, an enzymolysis step is included. The preparation method provided by the invention is low in production cost and high in conversion rate, and about 2 tons of beverage-type okra low-alcohol healthcare wine can be produced from 1 ton of raw materials, and has an alcoholic strength of 10.0-12.0%; the physiological activities of the multiple active ingredients of abundant vitamins, mineral substances, flavone, polysaccharides and the like in okra tender pods are kept; and the okra wine is a novel low-alcohol healthcare wine integrating the functions of nutrition, healthcare, dietary therapy and the like, and has a quality guarantee period of 18 months at normal temperature.

Owner:CHONGQING UNIV OF ARTS & SCI +1

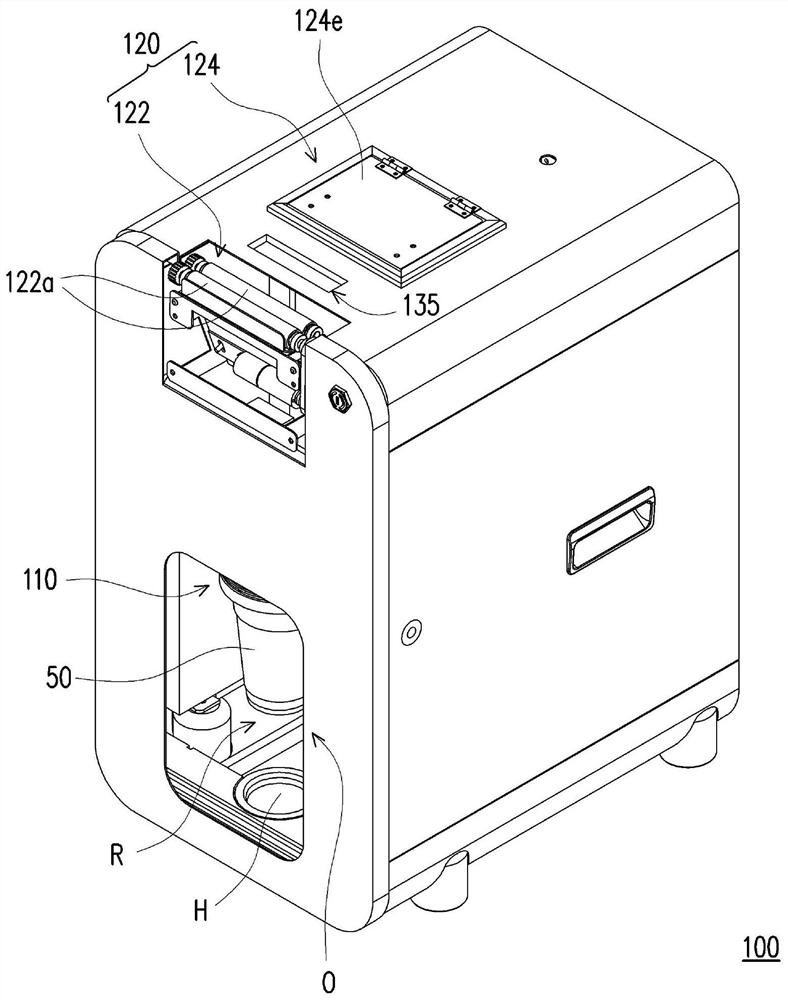

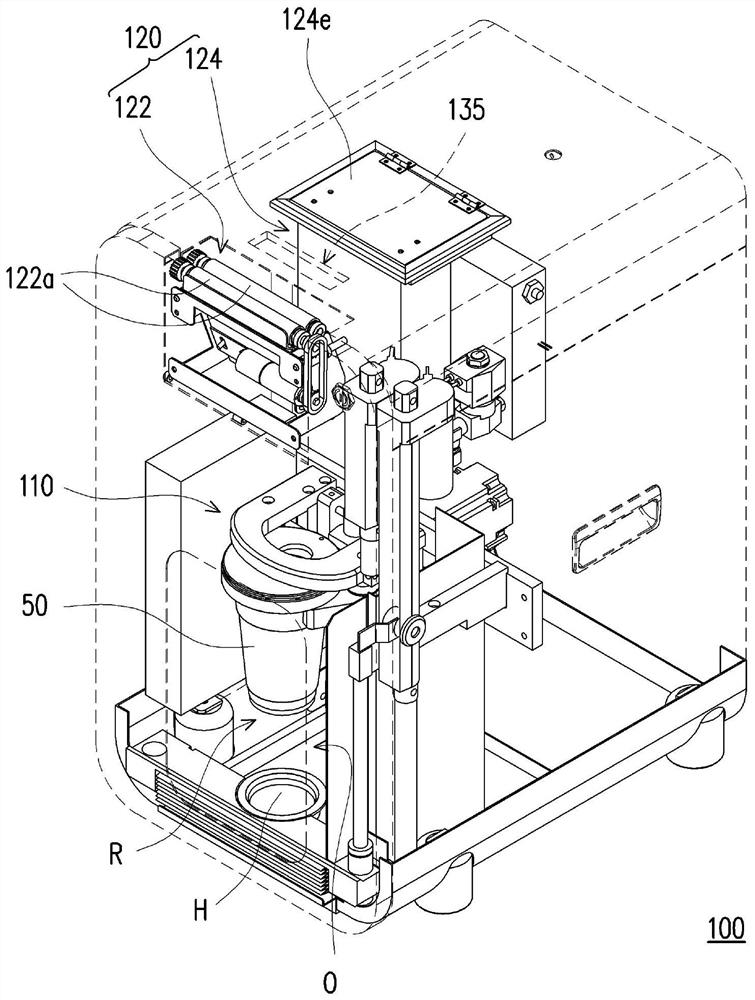

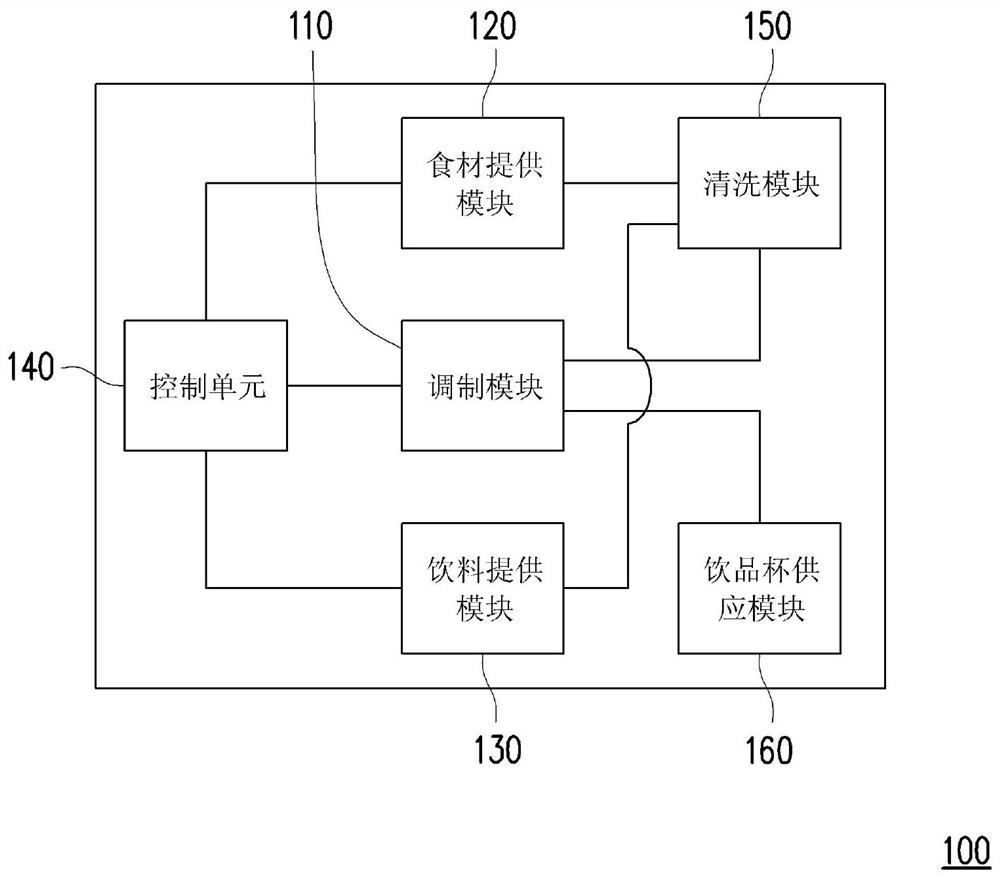

Beverage brewing apparatus

ActiveCN113273894AReduce exposureReduce volumeContainer decorationsLevel indicationsControl cellProcess engineering

A beverage brewing apparatus including a brewing module, an ingredient providing module, a drink providing module and a control unit is provided. The brewing module is adapted to brew at least one drink and at least one ingredient in a beverage cup. The ingredient providing module is adapted to provide the at least one ingredient into the beverage cup. The drink providing module is adapted to provide the at least one drink into the beverage cup. The control unit is adapted to control the brewing module, the ingredient providing module and the drink providing module according to a brewing procedure corresponding to the at least one drink and the at least one ingredient. The beverage brewing apparatus can be used for automatically preparing beverages, and has the advantages of space saving, sanitation, beverage flavor and high selectivity of beverage types.

Owner:CENZ AUTOMATION

Production method of suspended ferric pyrophosphate

ActiveCN107518235AGood suspensionEvenly distributedFood dryingFood ingredient as emulsifierMicro-encapsulationFerric Pyrophosphate

The invention discloses a production method of suspended ferric pyrophosphate, and relates to the technical field of ferric pyrophosphate production. According to the production method of the suspended ferric pyrophosphate, emulsifying-modifying treatments are performed on common ferric pyrophosphate by adopting a micro-encapsulation technology. The production method of the suspended ferric pyrophosphate specifically comprises the following steps: (1), blending superfine ground common ferric pyrophosphate or an undried wet common ferric pyrophosphate material with sodium alginate, glycerol monostearate and enzymatically hydrolyzed soybean lecithin so as to obtain a suspension of which the temperature is 80 DEG C or higher, and carrying out high-speed shearing and homogenization so as to obtain a mixed emulsion by performing emulsification; and (2), performing spray-drying on the emulsion, wherein the air inlet temperature is 160-190 DEG C and the air outlet temperature is 80-95 DEG C, and then, sieving the spray-dried powder so as to obtain a target product. According to the production method of the suspended ferric pyrophosphate, the emulsifying-modifying treatments are performed on the common ferric pyrophosphate by adopting a micro-encapsulation method comprising emulsifying, homogenizing and spray-drying so that the prepared suspended ferric pyrophosphate can be used as an iron element fortifier for beverages which produces no precipitates; moreover, the suspended ferric pyrophosphate is convenient for storage and transportation so that processing performances of the suspended ferric pyrophosphate in beverage-type foods are greatly improved.

Owner:郑州瑞普生物工程有限公司

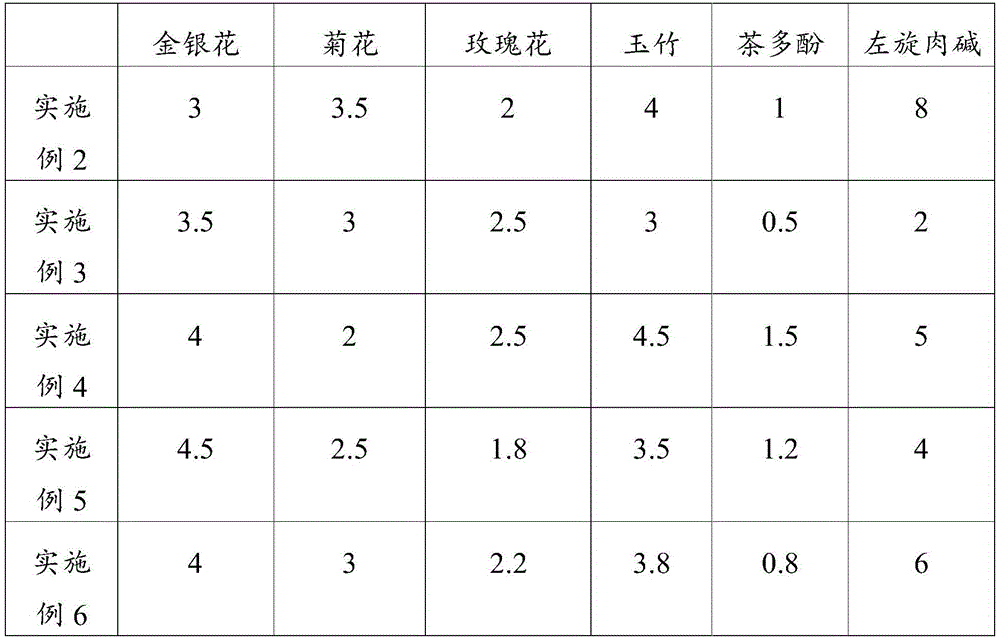

Beverage with weight-reducing effect and application thereof

InactiveCN105533385AProve securityHas weight loss effectTea extractionNatural extract food ingredientsOfficinalisPolyphenol

The present invention relates to a beverage composition with a weight-reducing effect. Raw materials of the beverage composition include the following components: honeysuckles, chrysanthemum, roses, radix polygonati officinalis, polyphenols and L-carnitine. The beverage with the weight-reducing effect is characterized in that the beverage composition can be used to prepare various beverage types with the weight-reducing effect including tea bag, instant solid beverage, beverage or combination thereof. The beverage of the present invention has an assisted weight-reducing health effect.

Owner:COFCO GROUP +1

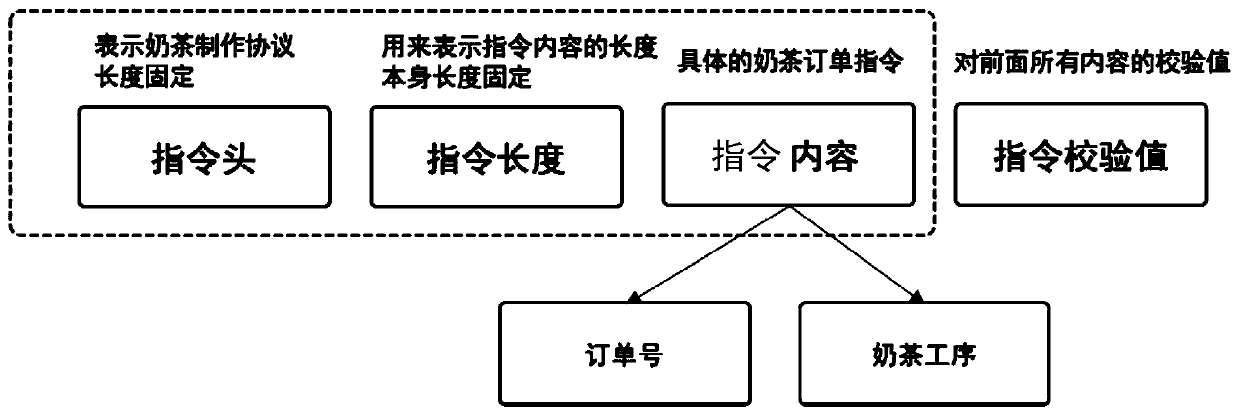

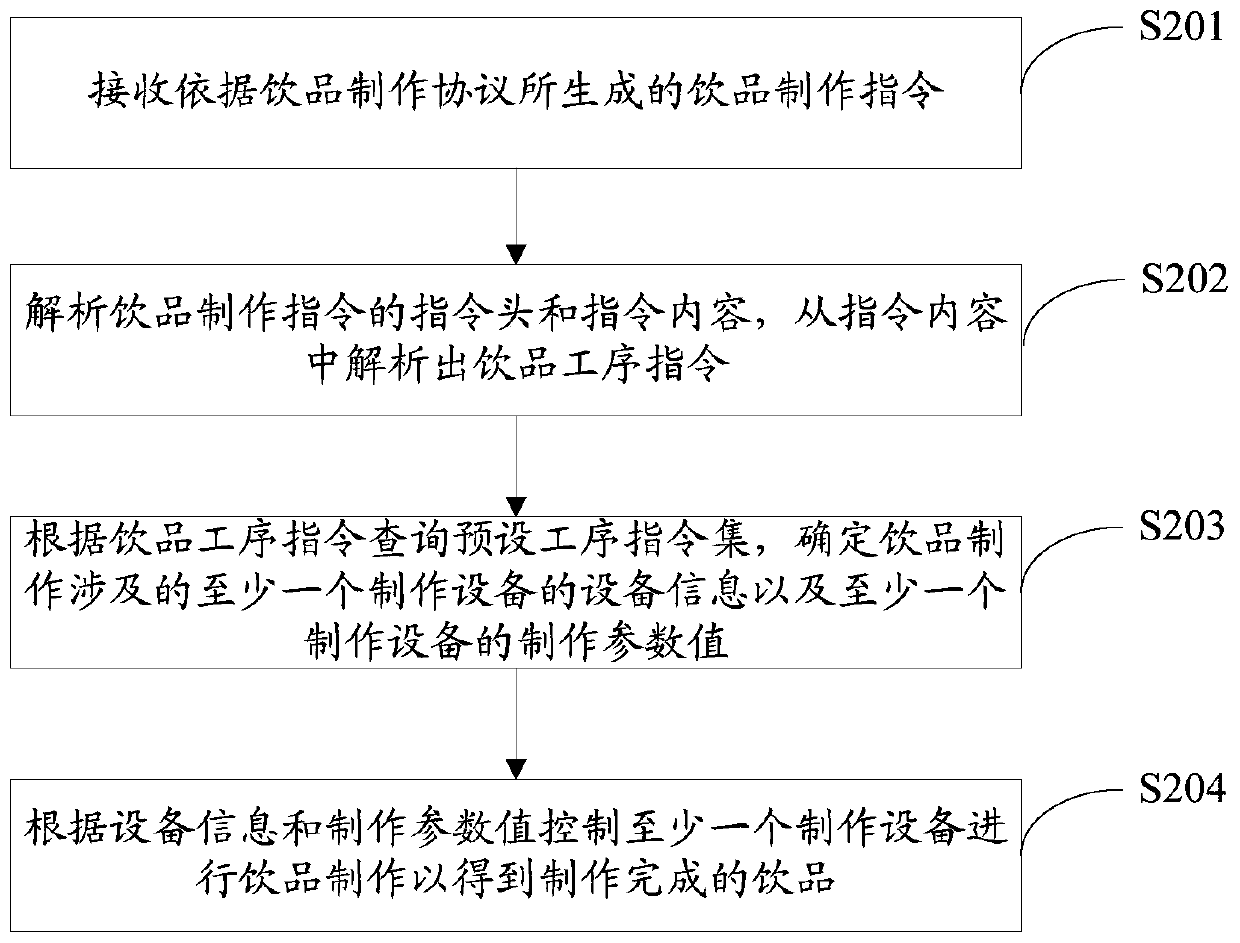

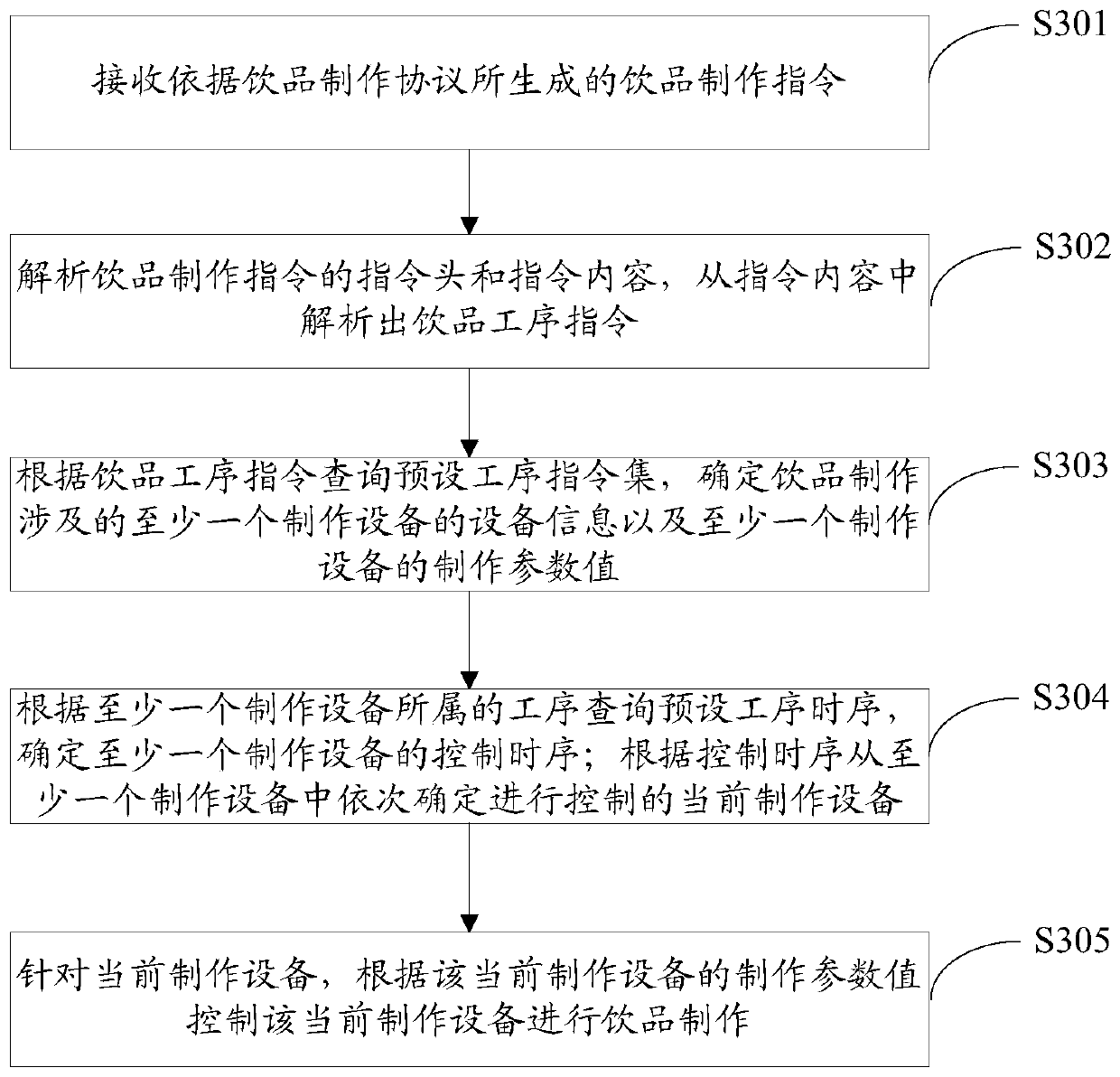

Digital processing method and device for beverage making process

PendingCN110692720AIncrease flexibilityWide applicabilityProgramme controlMilk preparationPersonalizationProcess engineering

The invention discloses a digital processing method and a digital processing device for beverage making process, wherein the method comprises the following steps: receiving a beverage making instruction generated according to a beverage making protocol; analyzing an instruction head and instruction contents of the beverage making instruction, and analyzing a beverage process instruction from the instruction contents; inquiring a preset process instruction set according to the beverage process instruction, and determining device information of at least one making device and making parameter values of at least one making device related to beverage making; and controlling at least one making device to make the beverage according to the device information and the making parameter values, thereby obtaining the finished beverage. According to a scheme of the invention, processes and parameters related to the beverage making process are digitalized, and all the making processes can be accurately controlled after analyzing and inquiring, so that beverages meeting various personalized requirements can be produced, no longer restricted to a regular and single beverage type, thus the flexibility of beverage making is improved, and the method has wider applicability.

Owner:KOUBEI SHANGHAI INFORMATION TECH CO LTD

Toasted soybean flakes and method of making same

InactiveUS20050196516A1Improve flavor profileReduces undesirable beany and off-flavorsVegetable proteins working-upFood preparationChipped potatoesSolanum tuberosum

The invention relates to toasted full fat, enzyme active soybean flakes, and method of making same. The inventive flakes are excellent for use in hot and cold cereal compositions including with rolled oats, in soybean flakes-potato flakes compositions for making soy protein enriched mashed potato products, in granola and power bar type compositions, in shake-and-bake type compositions, and in meat analogue veggie-burger type compositions. The inventive toasted full fat, enzyme active soybean flakes are prepared by subjecting full fat, enzyme active soybean flakes made from dehulled soybeans to relatively high heat from dry heated air for a relatively short time while moving on and / or above a moving or vibrating surface. The invention further relates to use of the inventive toasted soybean flakes in soybean flakes-potato flakes compositions, and said compositions per se. The invention also relates to use of the inventive toasted soybean flakes in cereal compositions containing toasted flakes and rolled oats, shake and bake type compositions, granola and power bar type compositions, hot beverage type compositions similar to malted milk type mixes, and meat analogue veggie-burger type compositions. The invention also includes these compositions, per se.

Owner:DEDHAM COOP ASSOC

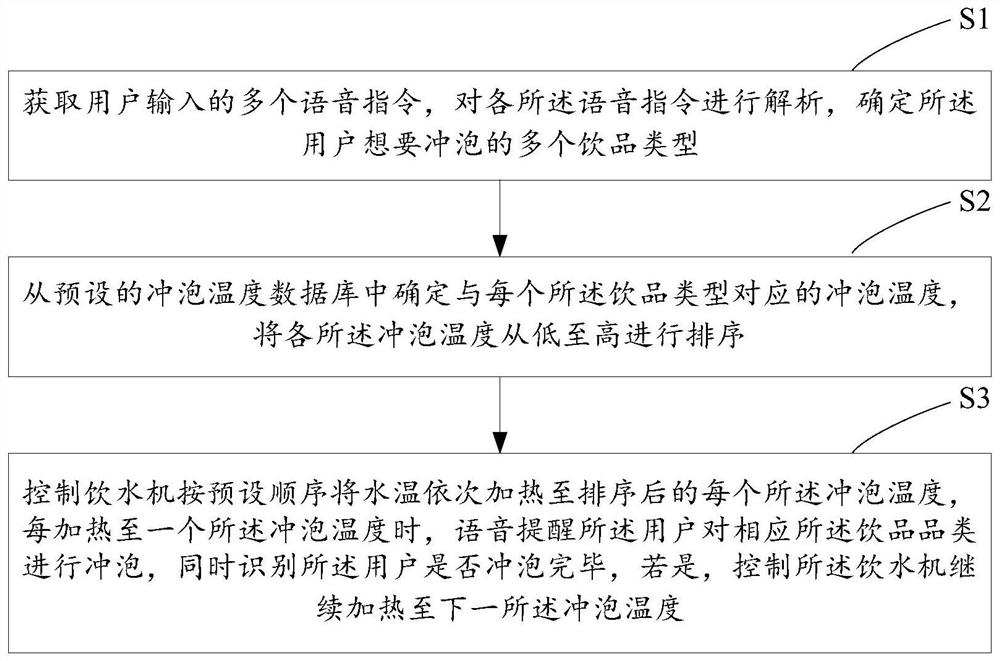

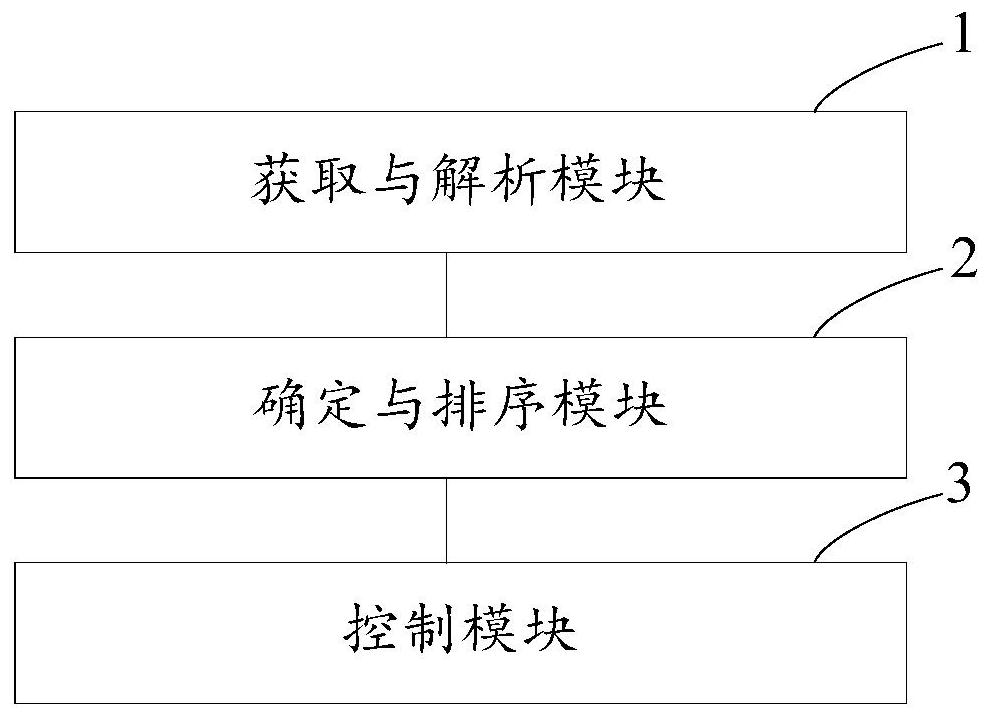

Intelligent water dispenser voice control method and system under multiple instructions

The invention provides an intelligent water dispenser voice control method and system under multiple instructions. The method comprises the steps of obtaining multiple voice instructions inputted by a user, carrying out the analysis of each voice instruction, and determining multiple types of drinks which the user wants to brew; determining the brewing temperature corresponding to each beverage type from a preset brewing temperature database, and ranking the brewing temperatures from low to high; and controlling the water dispenser to sequentially heat the water to each sorted brewing temperature according to a preset sequence, when the water is heated to each brewing temperature, reminding the user to brew the corresponding type of beverage through voice, and recognizing whether the user finishes brewing or not at the same time, and if so, controlling the water dispenser to continue heating to the next brewing temperature. According to the intelligent water dispenser voice control method and system under multiple commands, the user experience is improved to a great extent, and the application range is expanded.

Owner:SHENZHEN LIGHT LIFE TECH CO LTD

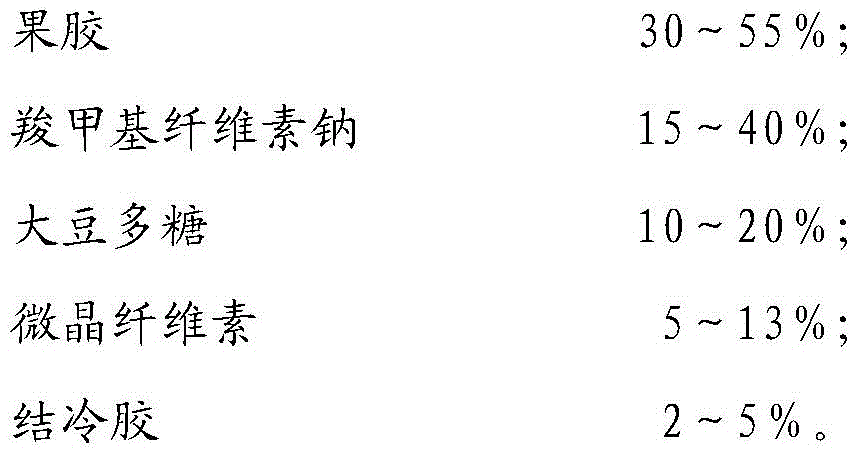

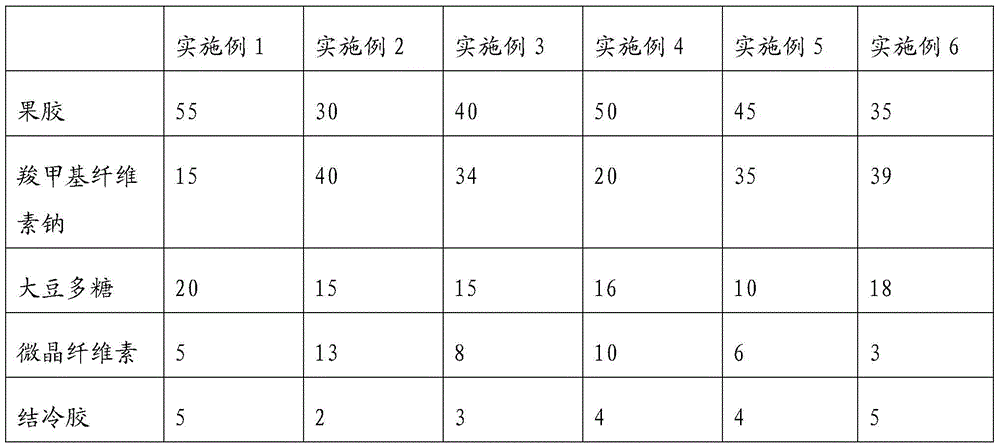

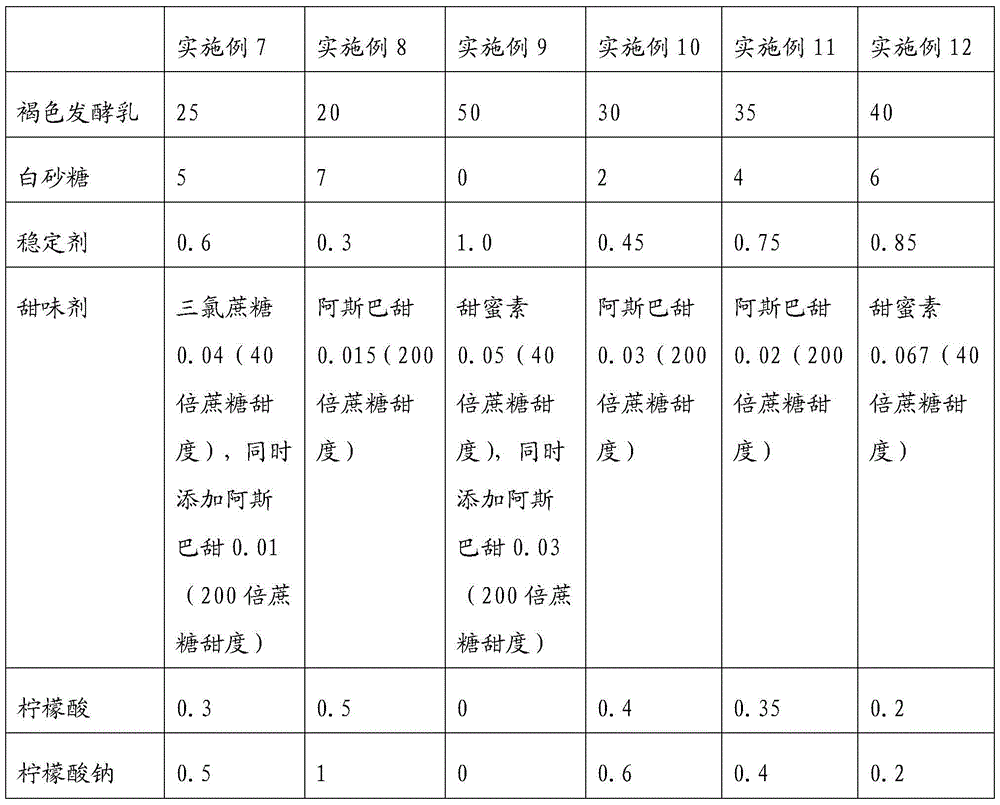

A brown lactic acid bacteria beverage stabilizer, sterilized brown lactic acid bacteria beverage and preparation method thereof

The present invention discloses a brownish lactobacillus beverage stabilizer and a preparation method thereof, and a sterilization-type brown lactobacillus beverage and a preparation method thereof. The stabilizer for the sterilization-type brown lactobacillus beverage includes the following components (weight percentages): 30 to 55% pectin, 15 to 40% sodium carboxymethylcellulose, 10 to 20% soybean polysaccharide, 5 to 13% microcrystalline cellulose, and 2-5% gellan gum. The stabilizer can be used in the preparation of the sterilization-type brown lactobacillus beverage. The stabilizer can effectively prevent certain negative phenomena such as water separating, precipitation, flocculation and stratification appeared in the beverage. During the six-month shelf life, the sterilization-type brown lactobacillus beverage is in uniform and stable state without precipitation and flocculation as well as significant stratification and with water bleeding less than 2.0 mm, and tastes fresh and full.

Owner:厦门欧凯科技有限公司

Electric catering truck

InactiveCN106828259ASimple structureReduce manufacturing costWorkshop/display transportationItem transportation vehiclesTruckBeverage type

The invention relates to an electric catering cart, which is used for selling beverages, and includes a carriage and an electric head installed at the front end of the carriage. A pedestrian passage is provided in the middle of the carriage, a cleaning platform is provided at the head of the carriage, and a water tank is installed above the cleaning platform. There is a garbage bin on one side, a waste water collection bucket on the other side, a sales counter on one side of the pedestrian passage, a sales window on the side of the carriage corresponding to the sales desk, and a beverage production station on the other side of the pedestrian passage. A door is arranged at the rear of the compartment, and a plurality of installation slots are arranged on the beverage making table. The electric catering cart is equipped with pedestrian passages, cleaning stations, sales stations and beverage production stations in the compartment, and the beverage cart can be driven to an appropriate position for production and sales. Cleaning operations can be performed on the cleaning station. Beverages can be made on the stage, and sold through the sales window after the production is completed. Different beverage making equipment can be installed in the installation tank according to the different types of sales. The structure is simple and the manufacturing cost is low.

Owner:卞先南

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com