Patents

Literature

45results about How to "Avoid spillover risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

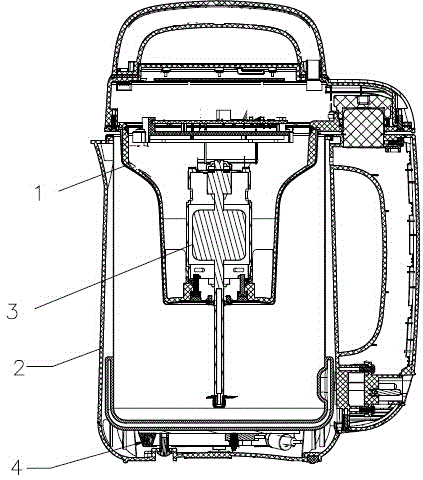

Anti-overflow control method of soybean milk machine

The invention discloses an anti-overflow control method of a soybean milk machine. The soybean milk machine comprises a cup body, a motor, a heating device and a temperature sensor, wherein the motor is used for grinding and mixing materials in the cup body, the heating device is used for heating seriflux in the cup body, and the temperature sensor is used for detecting the temperature of the seriflux in the cup body; the temperature sensor, the heating device and the motor are respectively and electrically connected with a main control chip, the overflow temperature of the seriflux in the cup body is T, and the working state and real-time working efficiency of the motor and the heating device are regulated when the temperature and the overflow temperature T are detected by the temperature sensor; when the main control chip detects that the temperature of the seriflux reaches the overflow temperature, the main control chip controls the heating device to stop heating and controls the motor to stir the seriflux. The problem that the laitance is generated by the seriflux can be solved by carefully controlling the heating device and the motor, so as to cancel an anti-overflow device.

Owner:JOYOUNG CO LTD

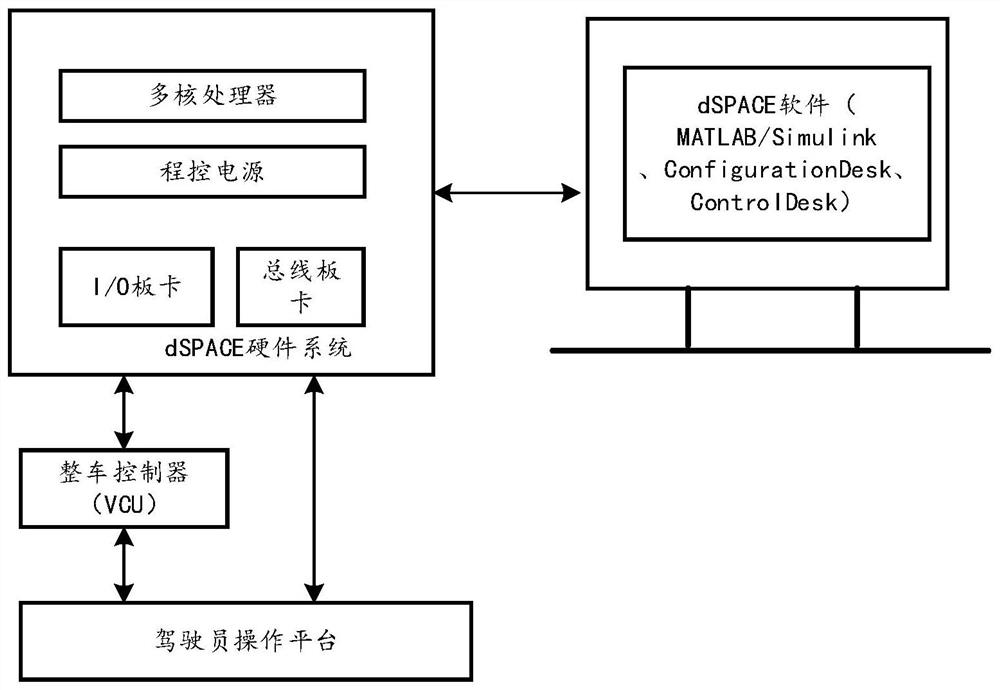

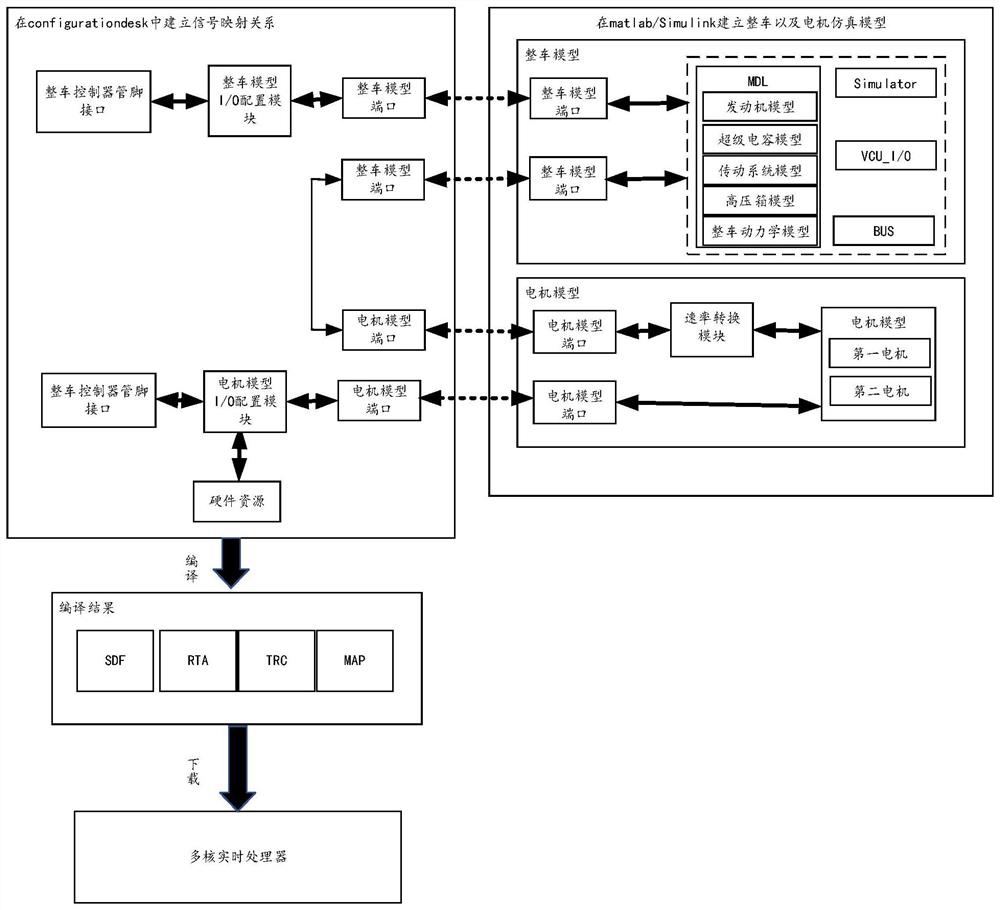

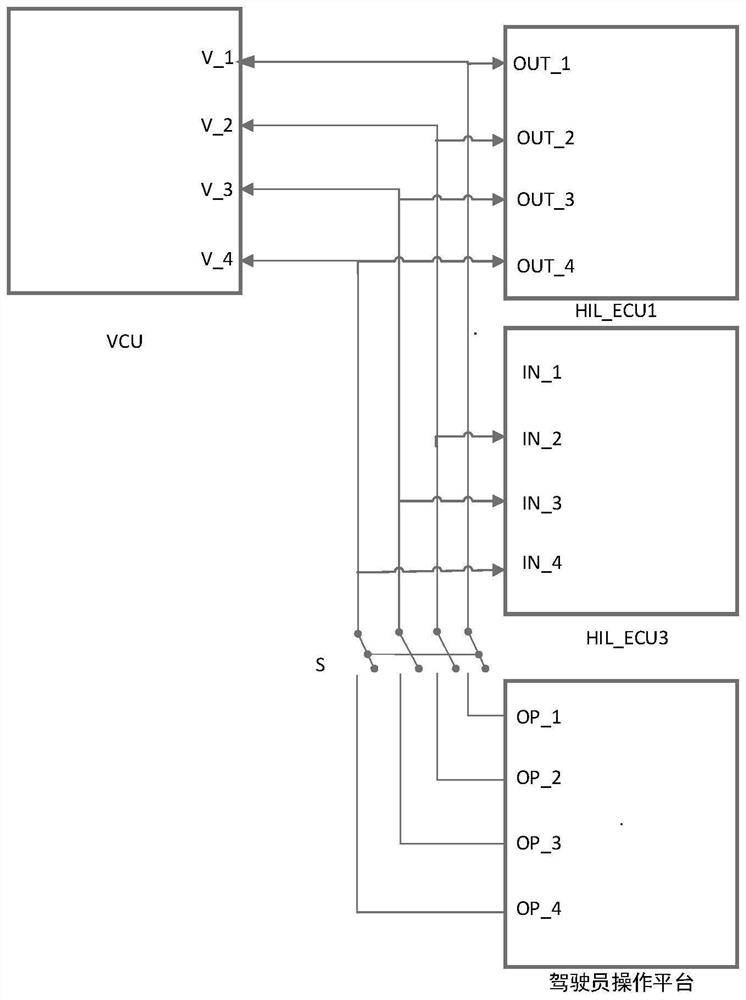

Hybrid electric vehicle hardware-in-loop simulation system construction method based on dSPACE

ActiveCN111650925AMeet the needs of small step size simulationSmall amount of calculationElectric testing/monitoringDriver/operatorReal-time simulation

The invention relates to a hybrid electric vehicle hardware-in-loop simulation system construction method based on dSPACE. A simulation system comprises a driver operation platform, a whole vehicle controller, a dSPACE hardware system and an upper computer. The whole vehicle model and a motor model are established by adopting a separation modeling method; a dSPACE hardware system is configured forthe whole vehicle model and the motor model, the whole vehicle model and the motor model run in parallel in different cores of a processor, and signal connection between thewhole vehicle controller and the whole vehicle model and between the whole vehicle controller and the motor model is established; the established whole vehicle model and the motor model are compiled, and a file generated by compiling is downloaded to a multi-core real-time processor; closed-loop testing of the whole vehicle controller is carried out. The dSPACE real-time simulation technology is adopted, the motor model and the whole vehicle model are constructed respectively and run in different cores, the dSPACE hardware system is connected with the whole vehicle controller and the driver operation platform, semi-physical simulation of the system is achieved, and the accuracy of system simulation is improved.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

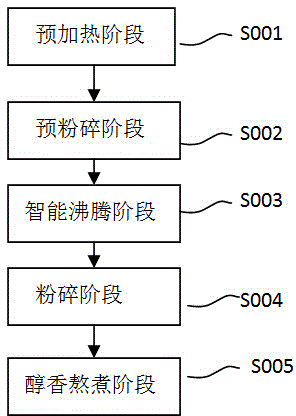

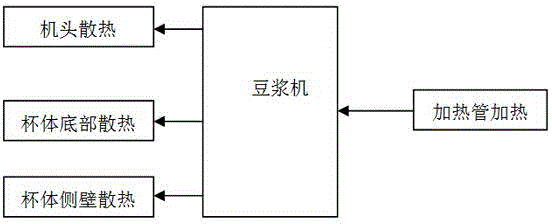

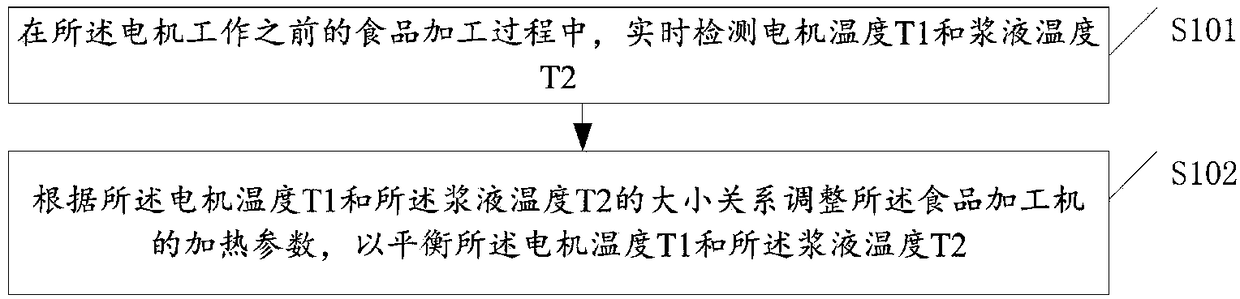

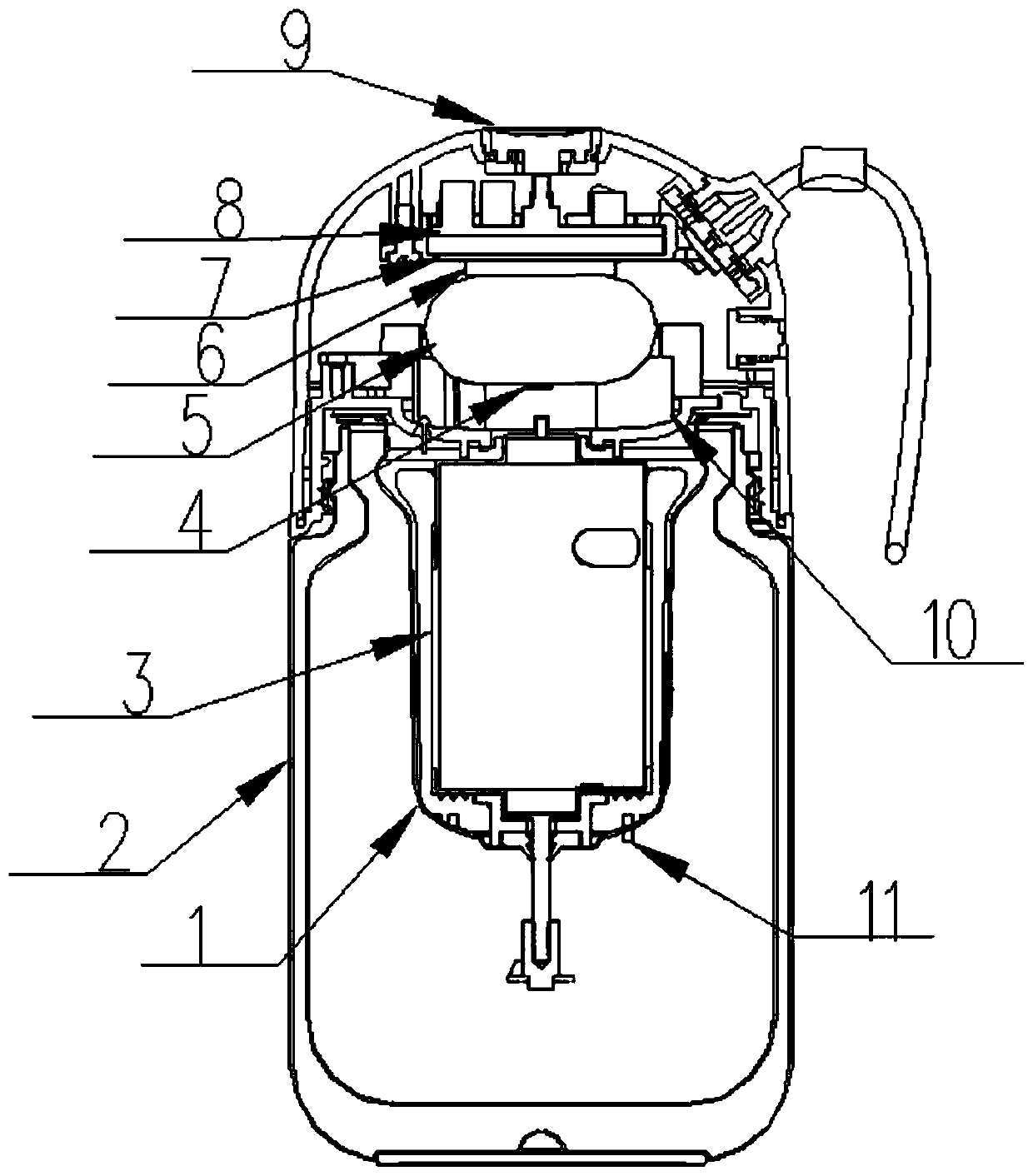

Control method for food processing machine

The embodiment of the invention discloses a control method for a food processing machine. The food processing machine comprises a machine head, and the machine head is provided with a motor; a first temperature sensor and a second temperature sensor are disposed on the machine head, the first temperature sensor is used for detecting the temperature of the motor, and the second temperature sensor is used for detecting the temperature of pulp. The method comprises: in the food processing process before the motor operates, detecting a motor temperature T1 and a pulp temperature T2 in real time; and according to the size relationship between the motor temperature T1 and the pulp temperature T2, adjusting heating parameters of the food processing machine to balance the motor temperature T1 andthe pulp temperature T2. Through the implementation of the scheme, the heating parameters can be adaptively adjusted by detecting the motor temperature and the pulp temperature in the machine head ofthe food processing machine during the food processing stage, thereby avoiding the risk of pulp overflow, improving the pulping effect, and improving the user experience.

Owner:JOYOUNG CO LTD

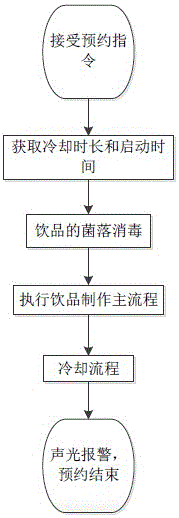

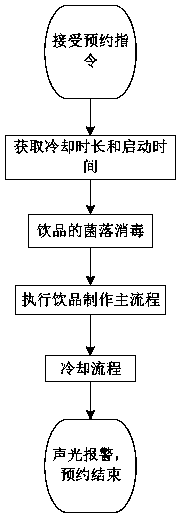

Beverage booking making method for food processing machine

ActiveCN106054981ARealize free customizationAvoid spillover riskAuxillary controllers with auxillary heating devicesTime informationStart time

The present invention relates to a beverage booking making method for food processing machine with the object to solving the problem that the temperature of final beverage cannot be controlled to meet the diversified requirements of users in booked hot drink production. The method includes: a food processing machine receives the booking instruction; acquiring information on the beverage types, booked time and drinking temperature; according to the information on the beverage types and the drinking temperature, completing the preparation of the beverage and cooling the beverage to the drinking temperature over some time; according to the information on the beverage type, obtaining the preset preparation time for the beverage; according to booked time information, presetting a preparation time and a cooling time, acquiring the start time for beverage processing. The invention solves the problem that the drinking temperature of hot beverage can be freely customized to meet the needs of different users while the preparation time for the hot beverage can be booked.

Owner:JOYOUNG CO LTD

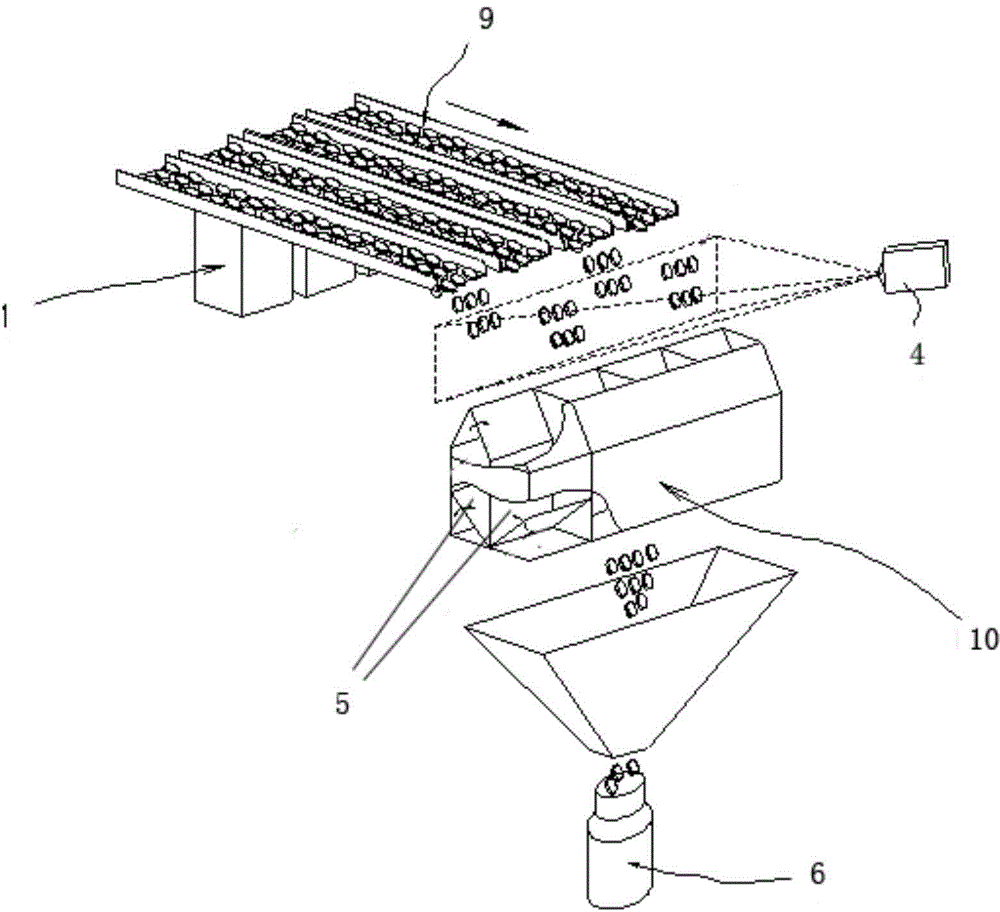

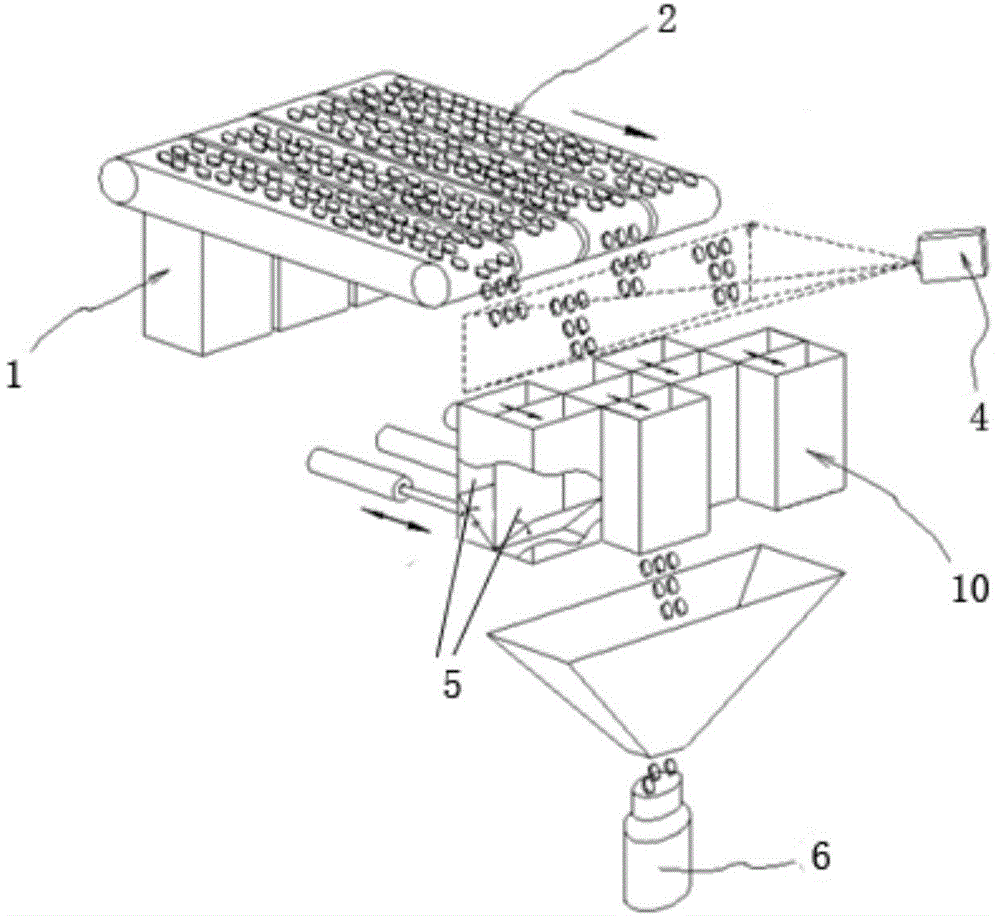

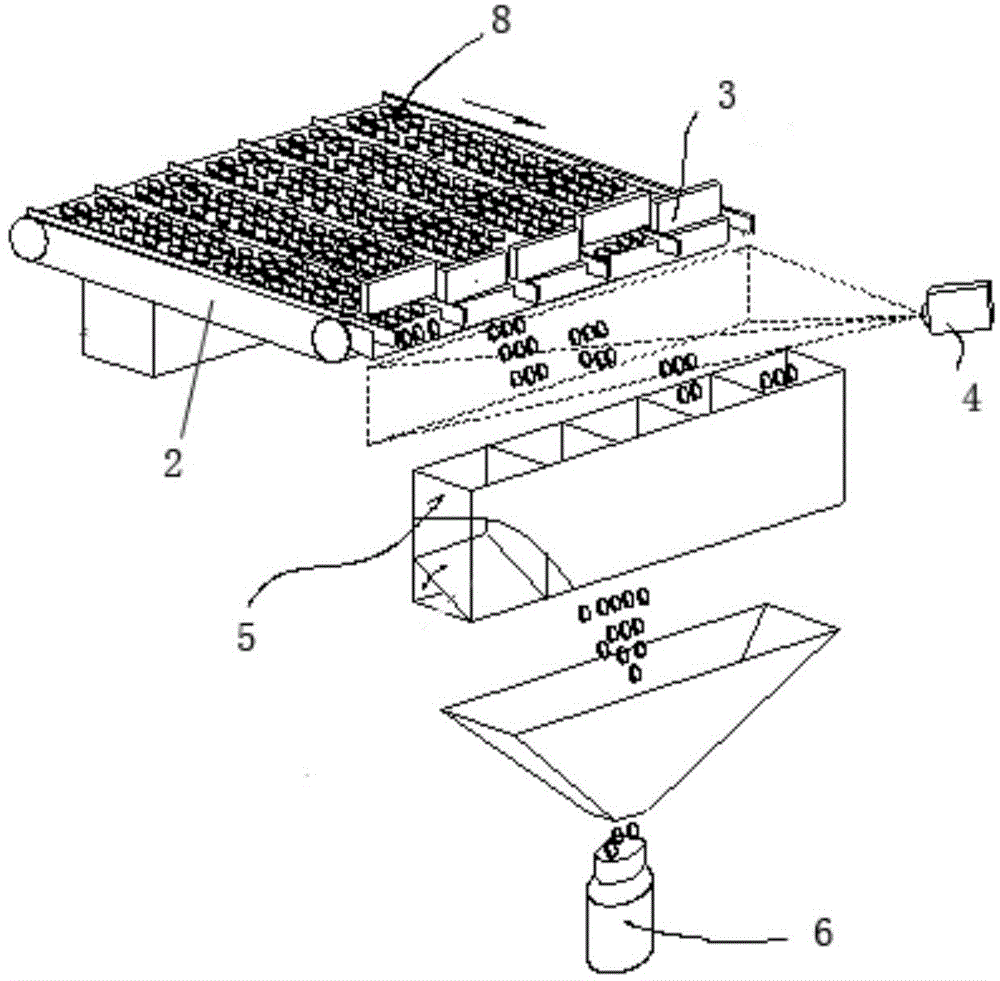

Quantitative piling and counting method and device for independently controlling channel to output articles

ActiveCN104554934AIncrease output capacityReduce the chance of spillagePackaging automatic controlSingle levelControl channel

The invention provides a quantitative piling and counting method for independently controlling a channel to output articles. The method comprises the steps of driving a plurality of articles to be conveyed in a single-layer state through at least two channels, wherein each channel is independently controlled to output the articles or stopping outputting the articles; 2, dividing the articles output by each channel into individual article piles, and accurately counting the quantity of the articles in each article pile by an imaging manner; 3, storing each article pile in a temporary storing bin, conveying all the articles in any temporary storing bin combination to a storage when the total amount of the articles in the temporary storing bin combination meets the target amount, wherein one temporary storing bin combination comprises at least one temporary storing bin, and the total amount of the articles in one temporary storing bin combination is the sum of the quantity of the articles in all temporary storing bins of the combination; the time and time quantum of each channel outputting the articles are individually controlled, so that the probability of obtaining a proper amount can be increased, the distribution efficiency can be obviously raised, and moreover, the quantity of articles difficultly runs over.

Owner:COLAMARK GUANGZHOU LABELING EQUIP

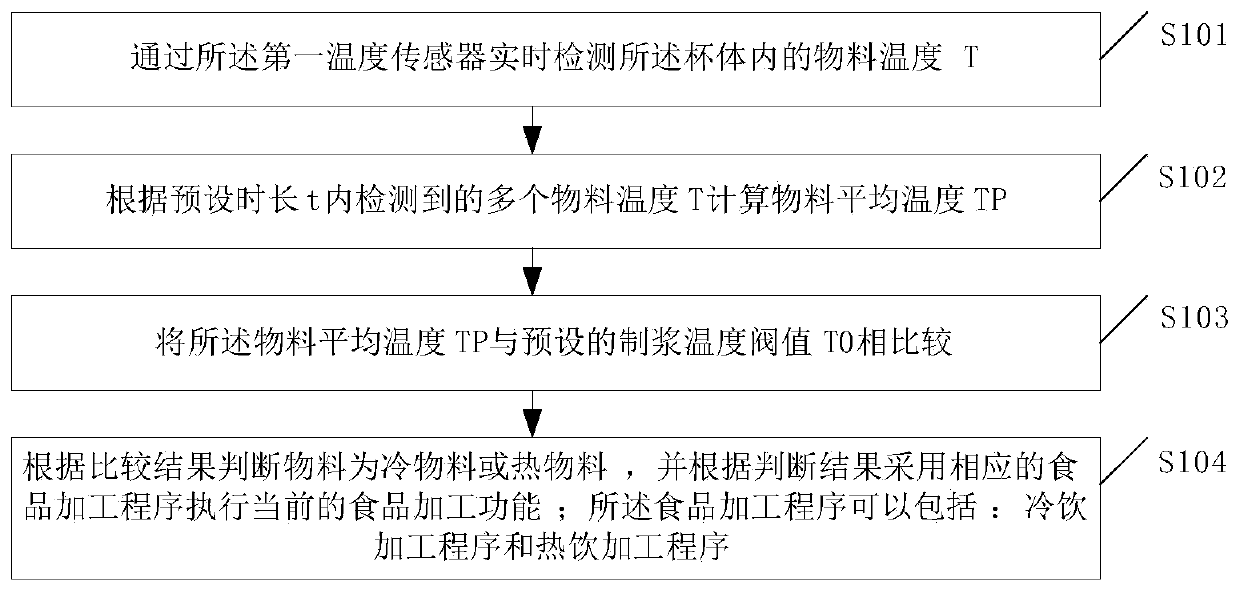

Control method of food processor

ActiveCN111000463AImprove experienceFast pulpingElectric motor controlKitchen equipmentProcess engineeringCold drinks

The embodiment of the invention discloses a control method of a food processor. The food processor comprises an electric power storage device and a first temperature sensor which are arranged on a machine head, and power is supplied to the food processor through the power storage device. The method comprises the steps of detecting the temperature T of materials in a cup body in real time through afirst temperature sensor; calculating a material average temperature TP according to a plurality of material temperatures T detected within a preset time length t; comparing the average temperature TP of the materials with a pulping temperature threshold value T0; judging whether the materials are cold materials or hot materials according to a comparison result, and executing a current food processing function by adopting a corresponding food processing procedure according to a judgment result, wherein the food processing procedure comprises a cold drink processing procedure and a hot drink processing procedure. According to the scheme of the embodiment, the corresponding food processing flow is matched by distinguishing cold drink from hot drink, it is guaranteed that the cold drink function rapidly makes milk, the hot drink function is good in smashing effect, the overflow risk is avoided, and the intelligence of the whole machine is improved.

Owner:JOYOUNG CO LTD

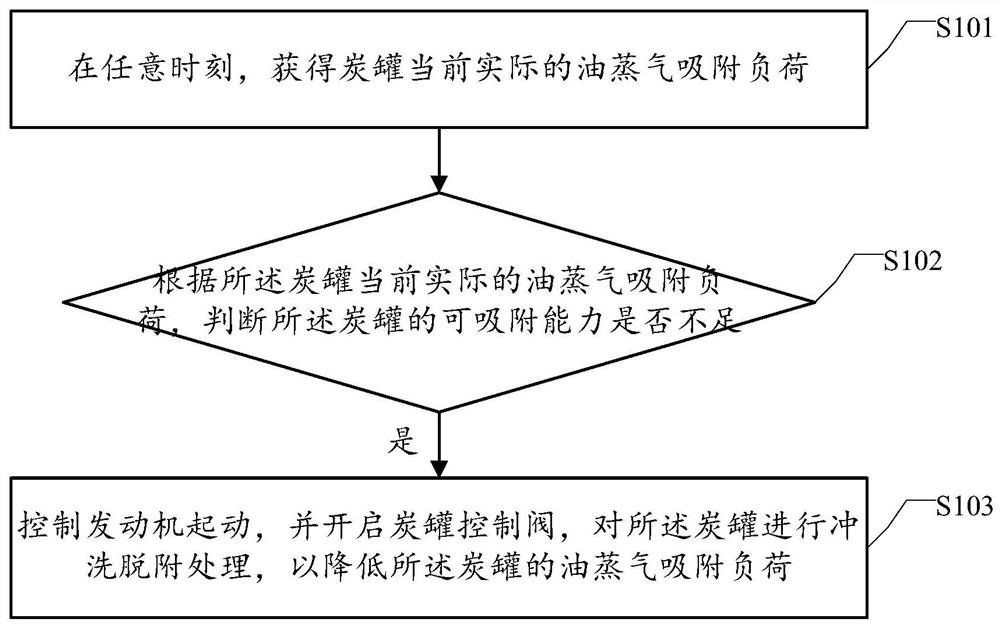

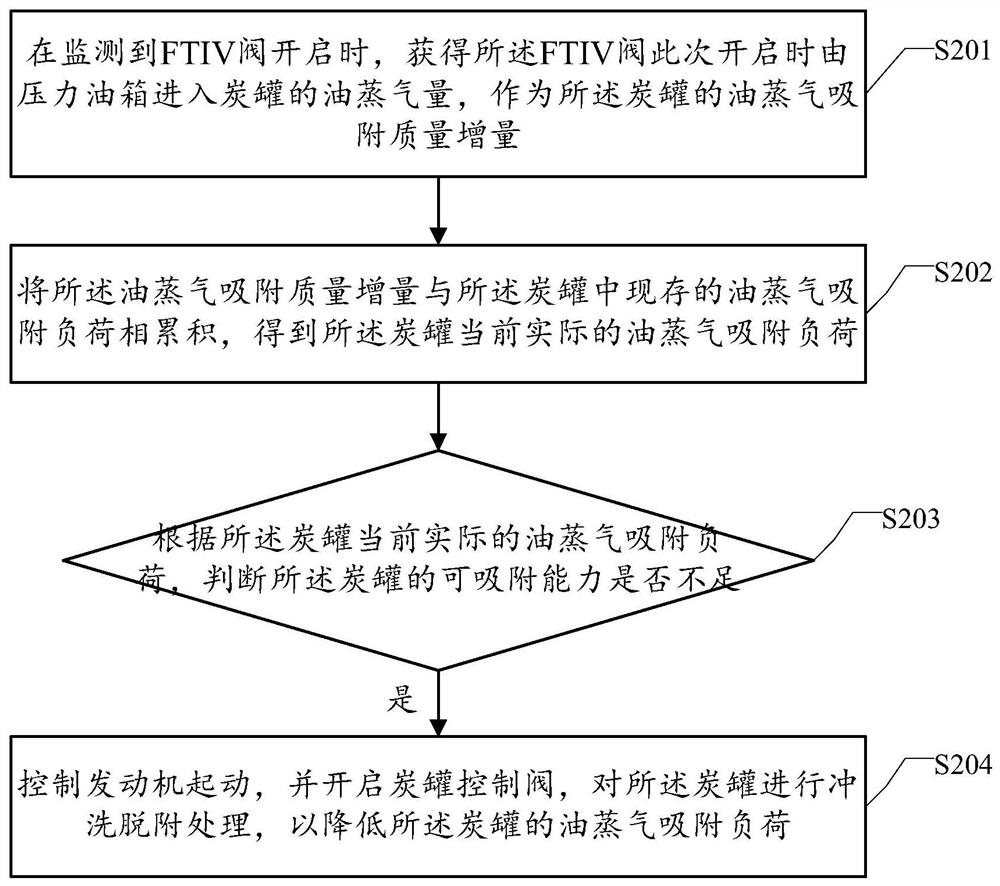

Carbon canister load control method and device and computer readable storage medium

PendingCN112901360AReduce adsorption loadHigh adsorption loadElectrical controlMachines/enginesProcess engineeringControl valves

The invention provides a carbon canister load control method and device and a computer readable storage medium. The carbon canister load control method comprises the steps that a current actual oil vapor adsorption load of a carbon canister is obtained at any moment; whether the adsorbability of the carbon canister is insufficient or not is judged according to the current actual oil vapor adsorption load of the carbon canister; and if the adsorbability of the carbon canister is insufficient, an engine is controlled to start, a carbon canister control valve is opened, and the carbon canister is subjected to washing desorption treatment so as to reduce the oil vapor adsorption load of the carbon canister. According to the carbon canister load control method, the risk that in the prior art, oil vapor overflows due to the fact that too much oil vapor enters the carbon canister and exceeds the adsorption capacity of the carbon canister can be solved.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

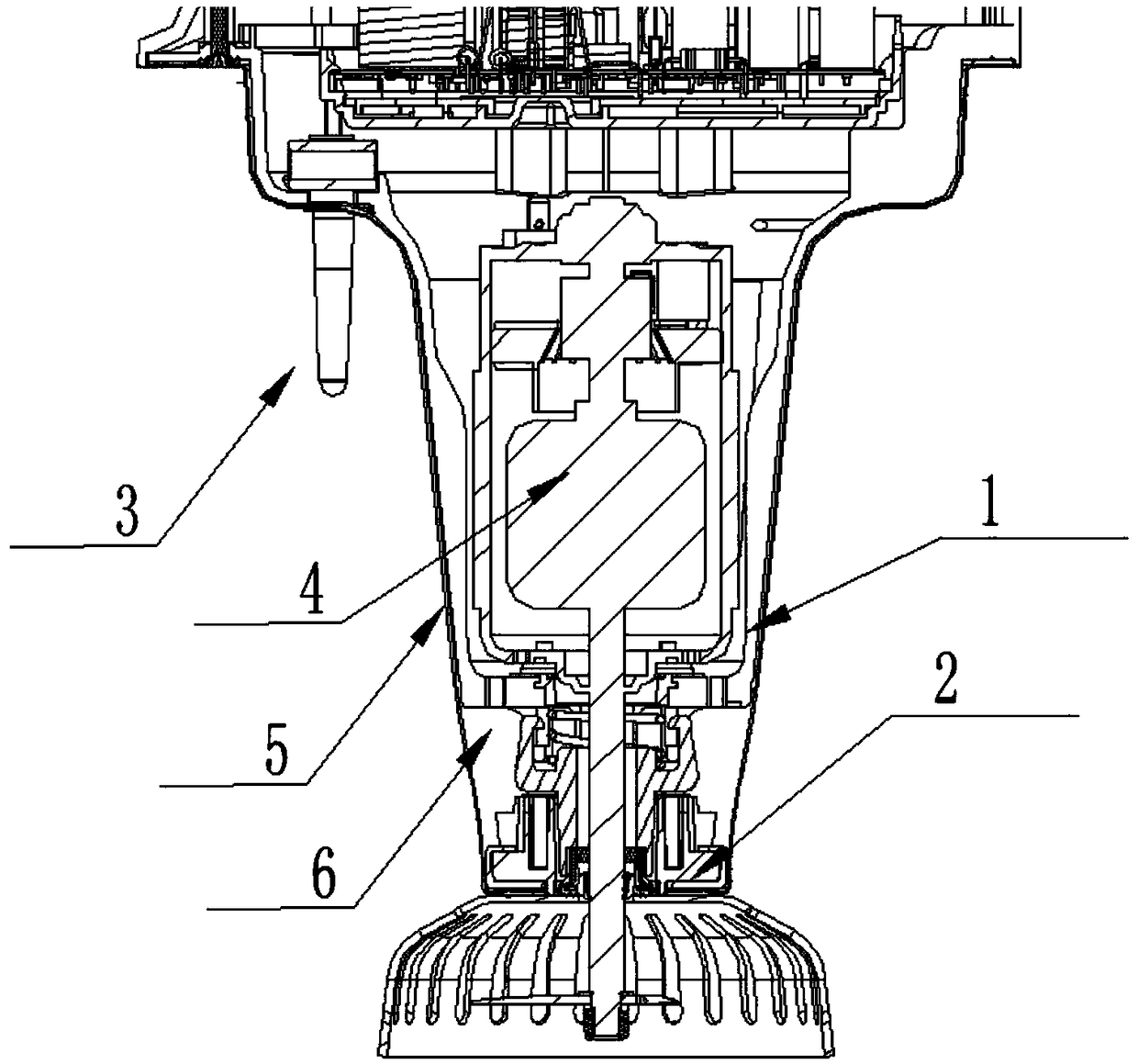

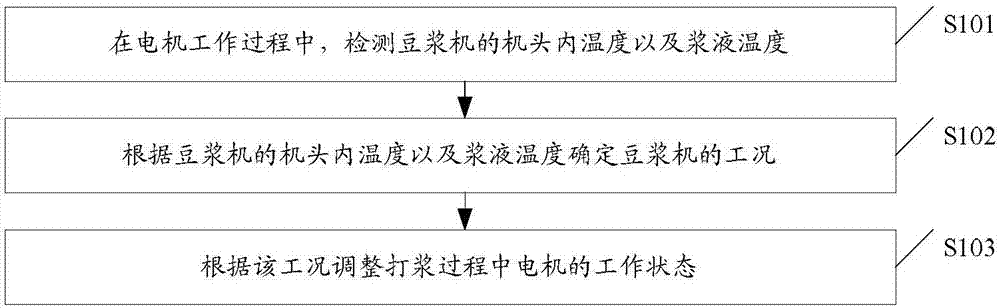

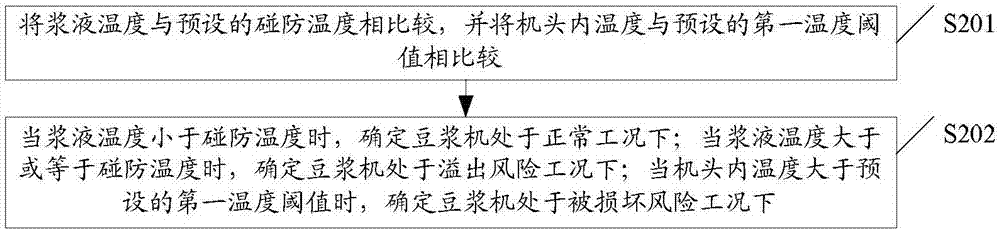

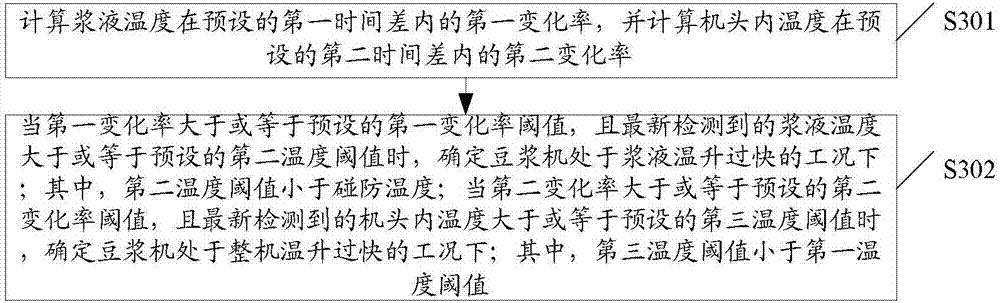

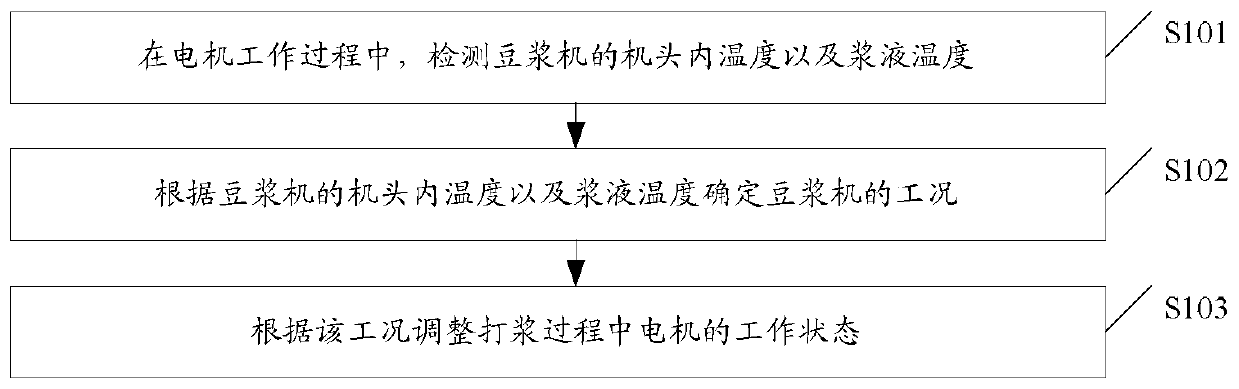

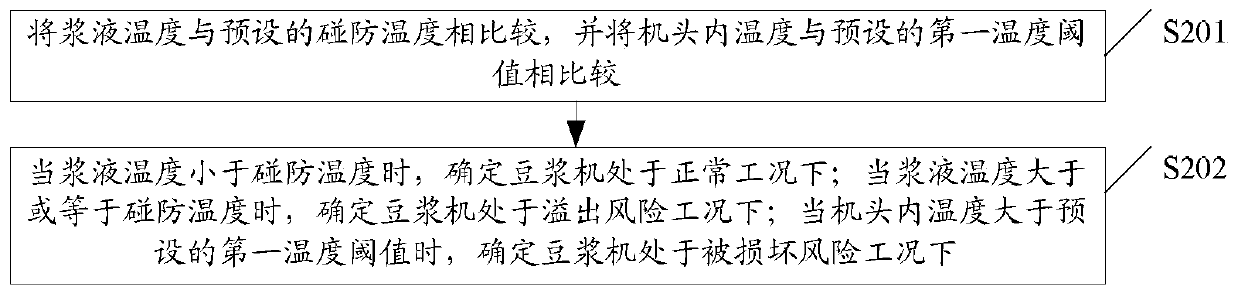

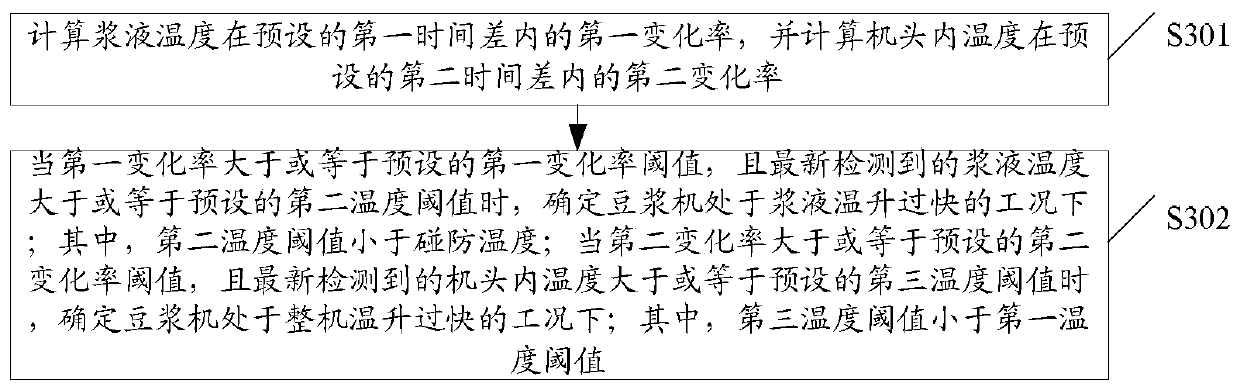

Soybean milk maker control method

ActiveCN107374403ASolve the overflowAvoid security issuesTemperatue controlKitchen equipmentEngineeringSlurry

An embodiment of the invention discloses a soybean milk maker control method. The soybean milk maker control method includes detecting internal temperature of a head of a soybean milk maker and temperature of soybean milk, determining working status of the soybean milk maker according to the internal temperature of the head of the soybean milk maker and the temperature of soybean milk, and regulating motion states of a motor during juicing according to the working status. According to the embodiment, by the soybean milk maker control method, the risk of spilling and potential safety hazard of the soybean milk maker can be detected in time and working performance of the whole soybean milk maker is improved.

Owner:JOYOUNG CO LTD

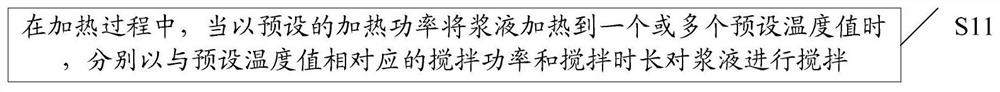

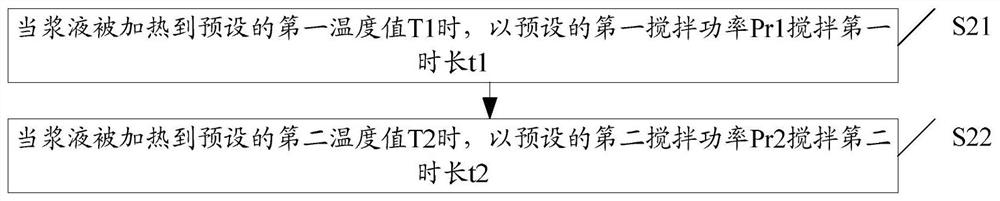

Overheating protecting method of food processing machine

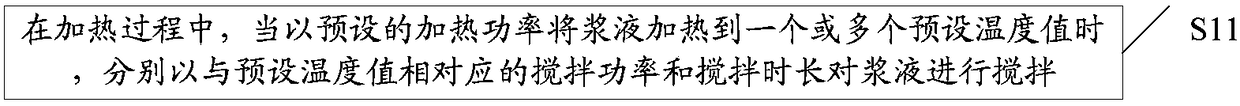

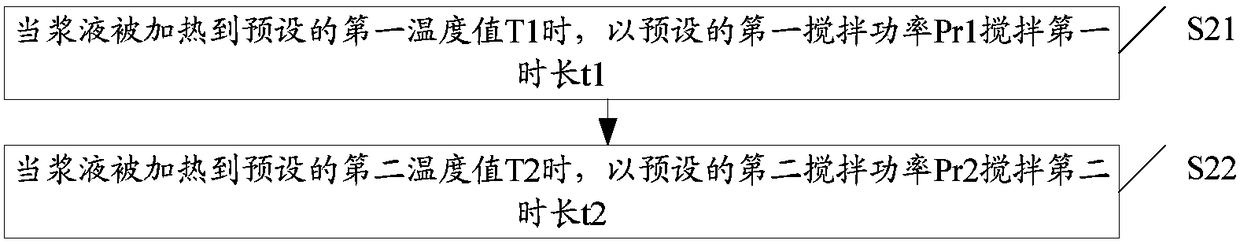

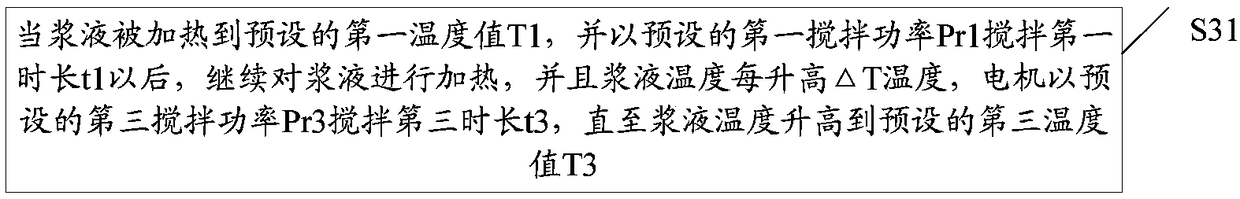

According to the embodiment, the invention discloses an overheating protecting method of a food processing machine. The food processing machine comprises a crushing cup and a motor, wherein a heatingdevice is arranged on the crushing cup; and thermal fuse link protectors, which are serially connected to the heating device, are each arranged at two ends of the heating device. The method comprisesthe following steps: in a heating process, when pulp is heated to one or more preset temperature values by preset heating power, stirring the pulp by stirring power and stirring duration correspondingto the preset temperature values. According to the embodiment, production cost is lowered and potential risks are reduced, and error operations of the thermal fuse link protectors in overheating protection are reduced.

Owner:JOYOUNG CO LTD

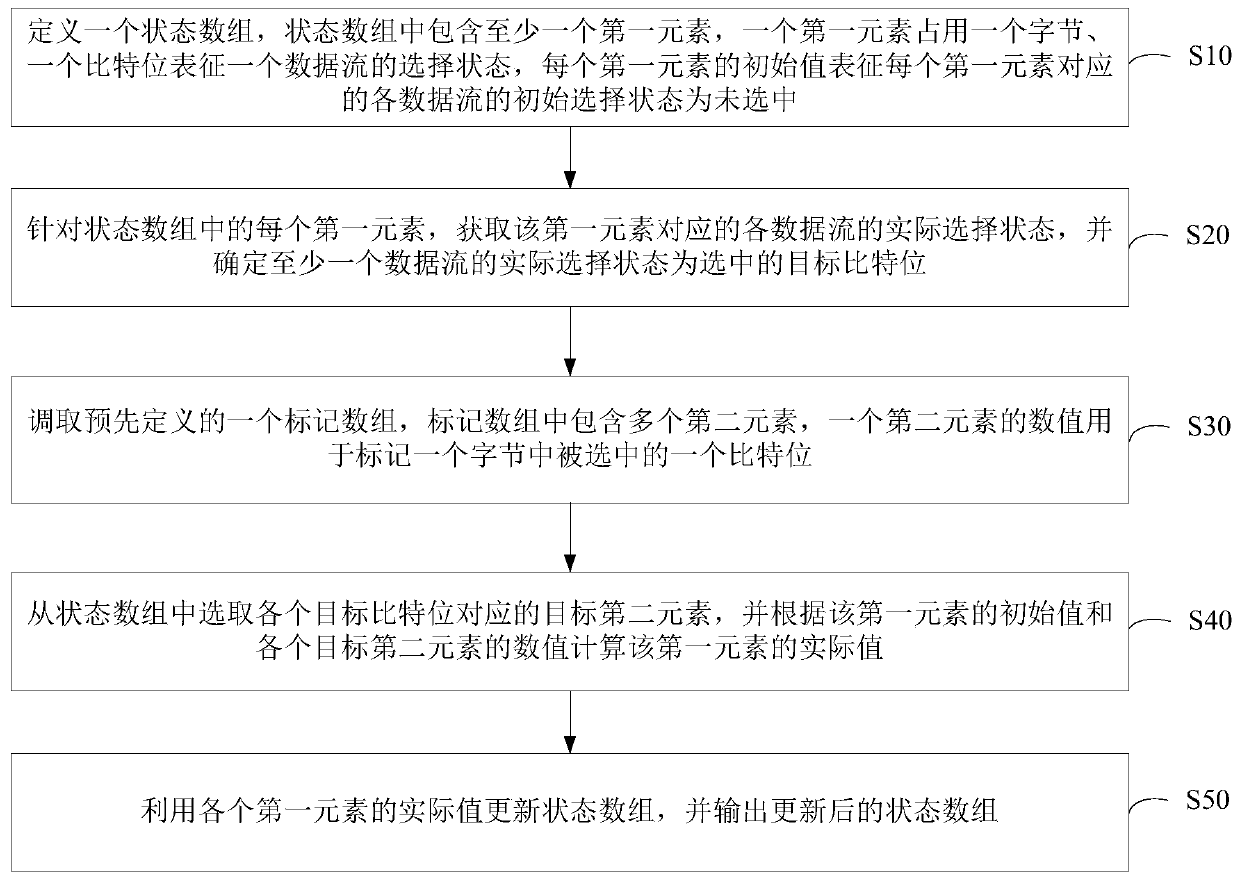

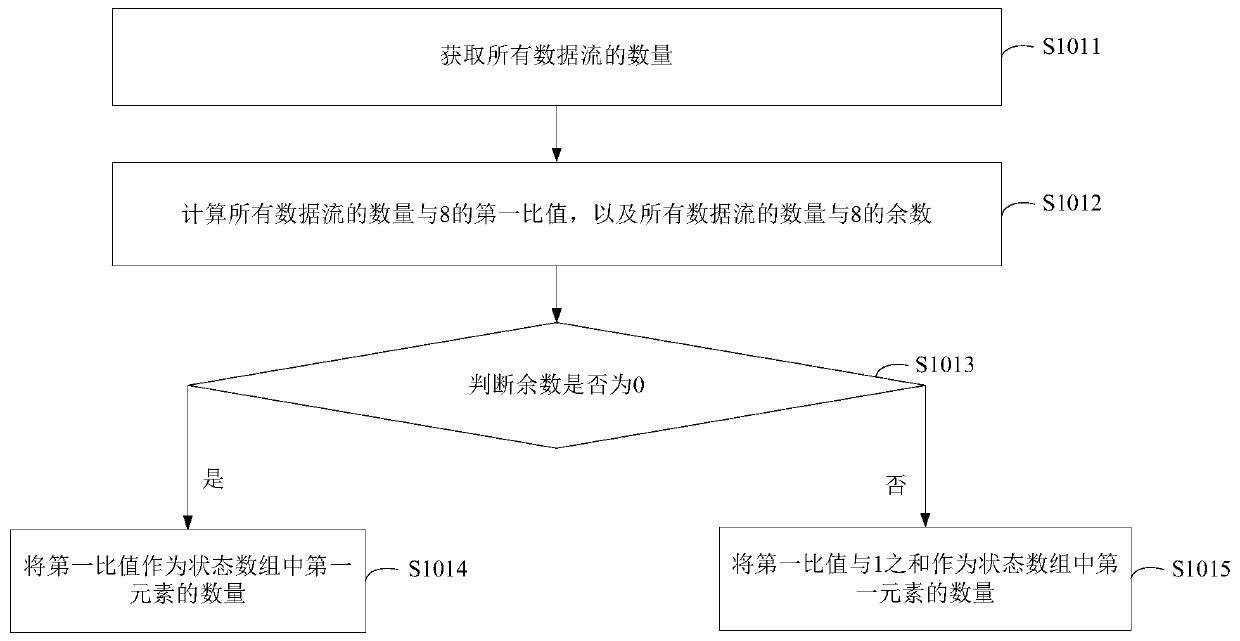

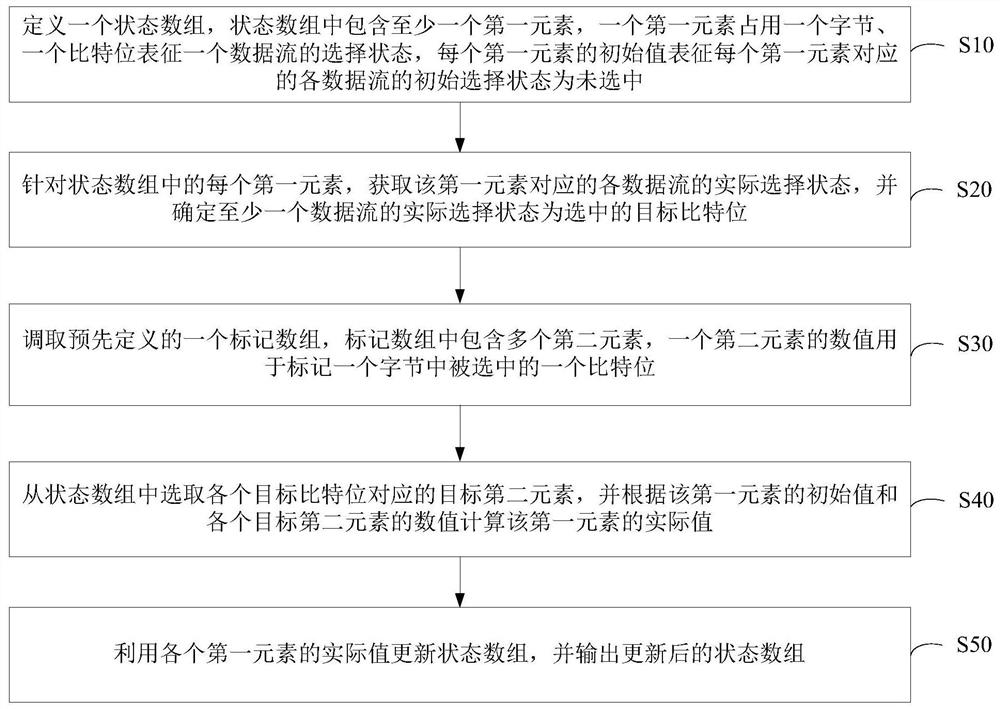

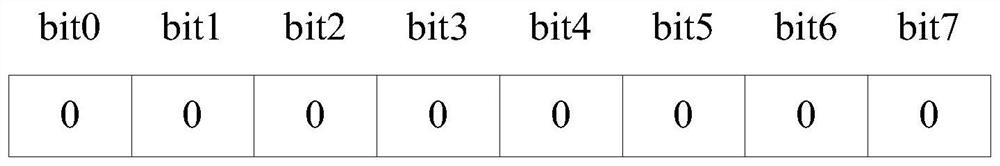

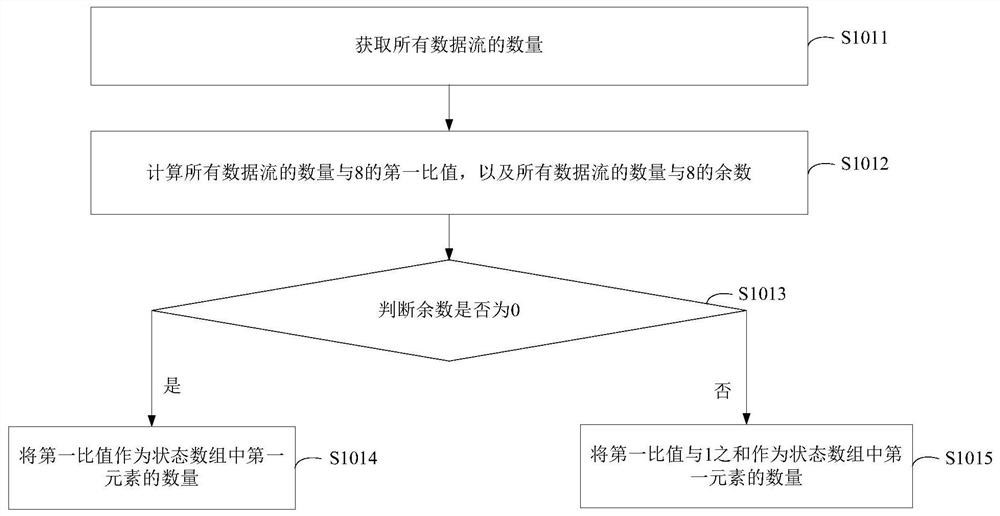

Data stream transmission method, transmission device, electronic equipment and storage medium

ActiveCN110597644AImprove transmission efficiencyReduce the amount of data transferredInterprogram communicationTransmissionData streamArray data structure

The invention provides a data stream interaction method. The method is applied to a display process and comprises: defining a state array containing at least one first element, wherein one first element occupies one byte, one bit represents the selection state of one data stream, and the initial value of each first element represents that the initial selection state of the corresponding data stream is not selected; according to the actual selection state of each data stream corresponding to each first element, selecting a target second element corresponding to each target bit of which the actual selection state is selected from the marked data, and calculating the actual value of each first element; and updating the state array by utilizing the actual value of each first element, and outputting the updated state array. According to the method, the transmission data volume of the data stream can be reduced, the data storage space is greatly compressed, the data transmission efficiency is improved, and the risk of memory overflow caused by excessive data is avoided.

Owner:LAUNCH TECH CO LTD

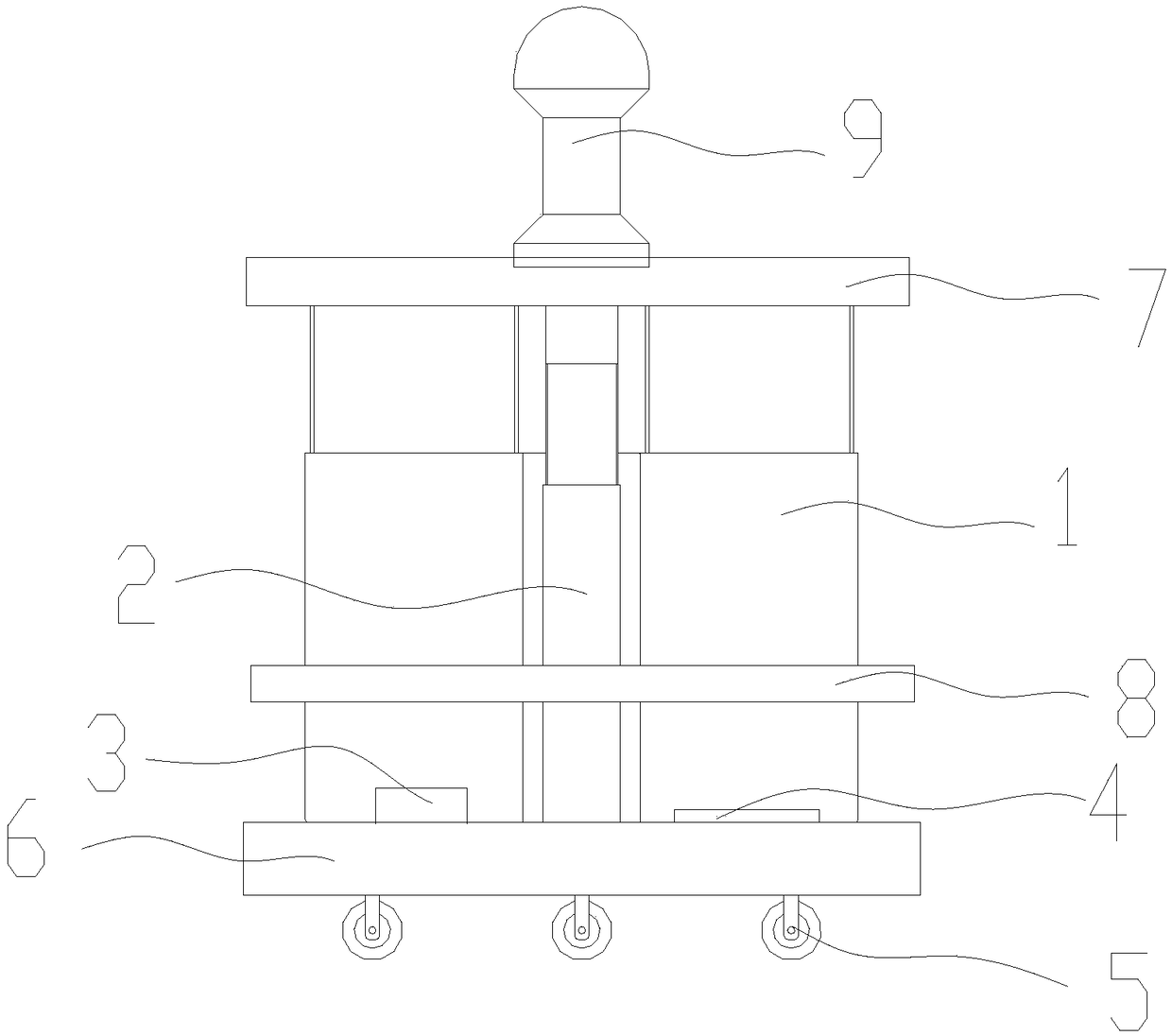

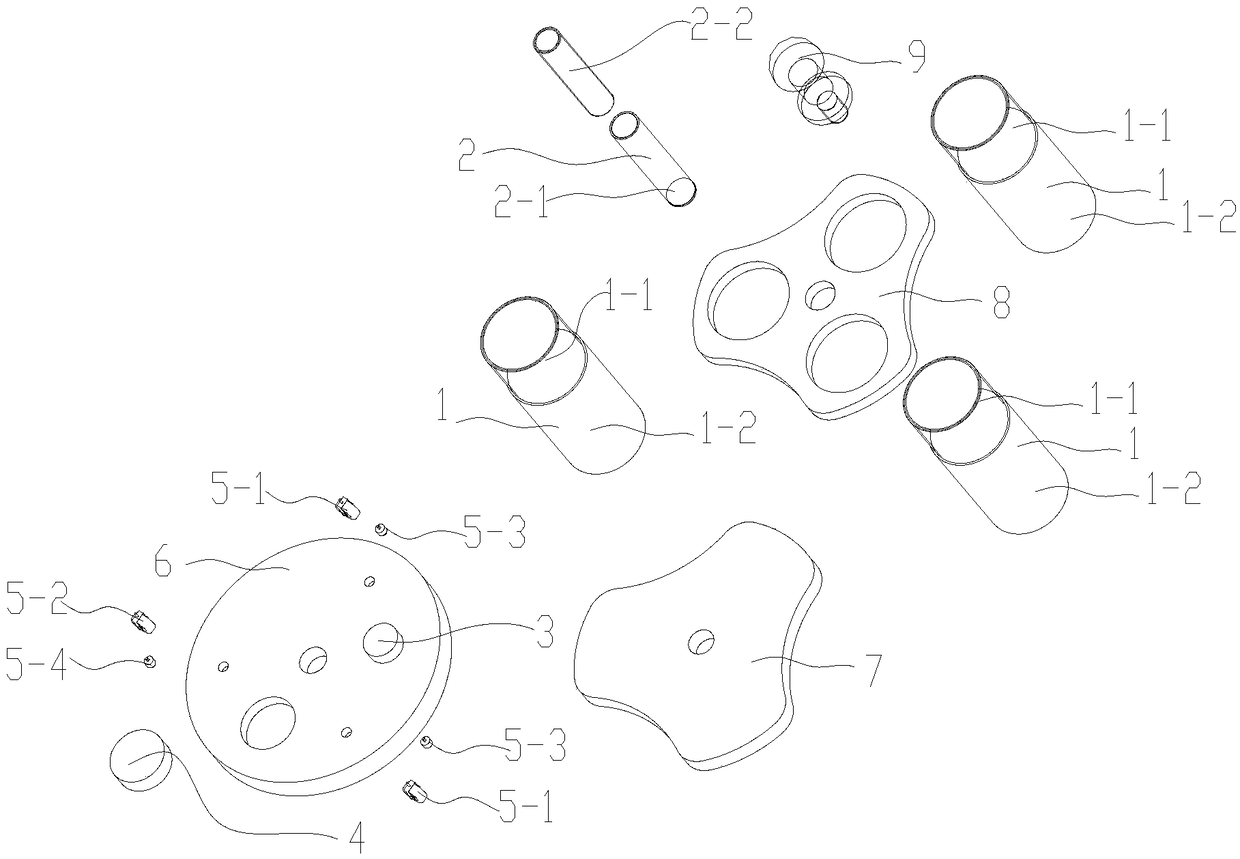

Multifunctional trash can

ActiveCN108974716AIncrease storage spaceEasy to sort garbageRefuse receptaclesPower moduleComputer science

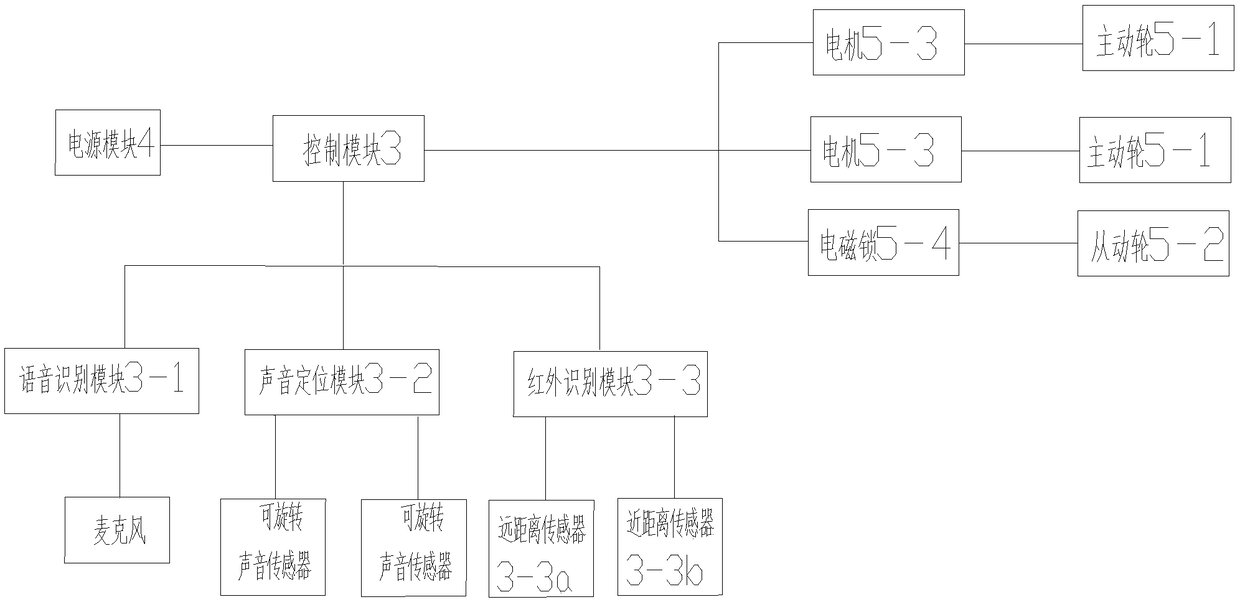

The invention discloses a multifunctional trash can, and relates to the field of household goods, mainly solving the usage defects that existing trash cans cannot move autonomously, the space of the trash cans is limited and the like. The multifunctional trash can comprises a barrel, a telescopic rod component, a control module, a power module, a drive unit, a base, a cover plate, a support plateand a handle. The control module can perform algorithm processing on voice commands to determine positions of sound sources. The control module also detects a human body infrared sensor in real time so as to control the drive unit to achieve moving, steering, braking and the like of the trash can. The multifunctional trash can has the advantages that the trash can is capable of accurately reachingcommanders according to the voice commands, thereby being particularly suitable for households and offices; the barrel with adjustable storage volume has a retractable function, does not occupy space, has a good sealing effect, and can store trash in a classified way.

Owner:XIAOGAN RUICHUANG MACHINERY TECH CO LTD

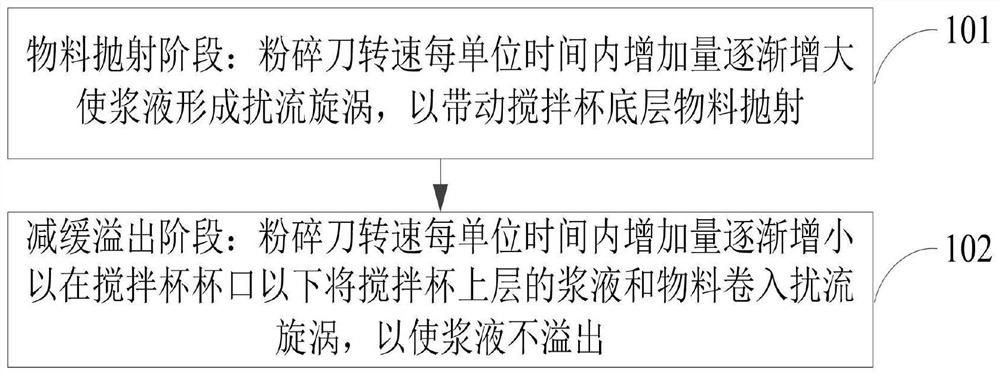

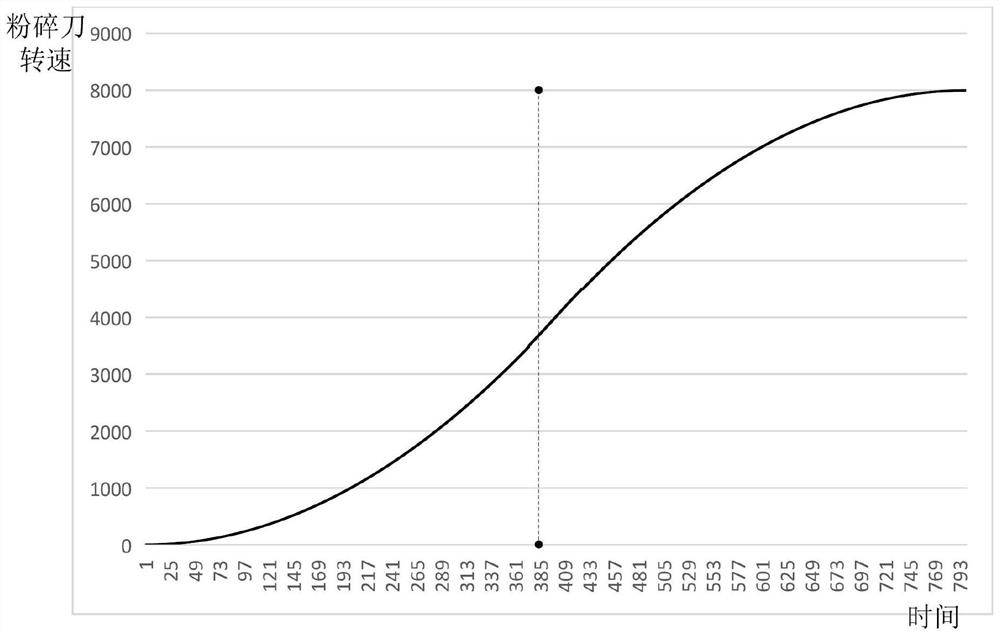

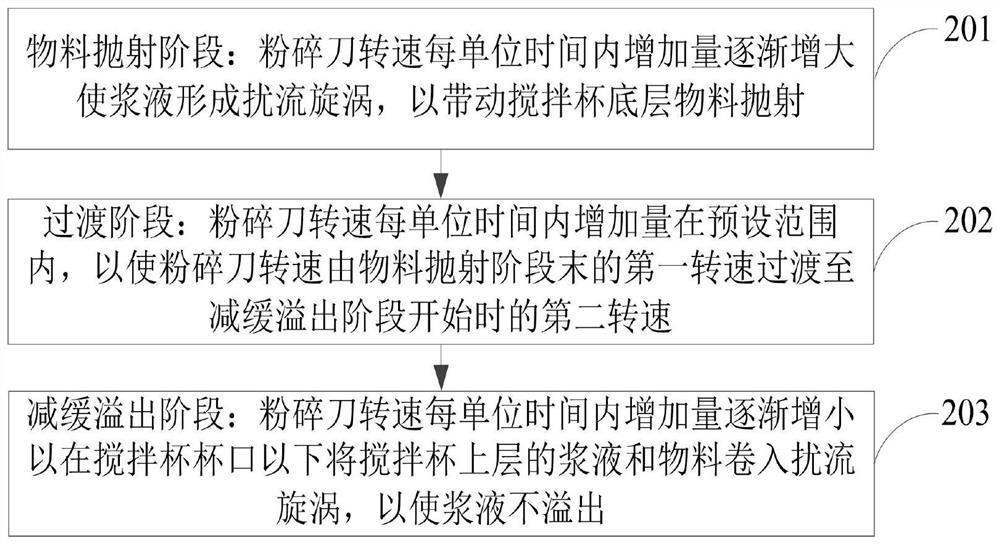

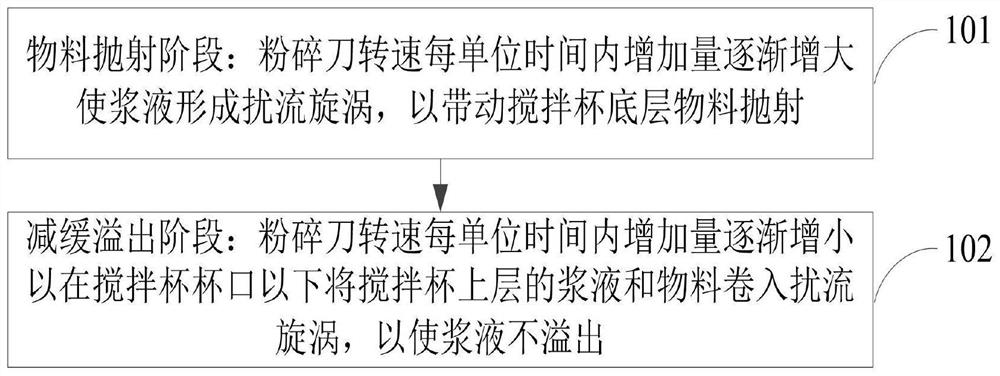

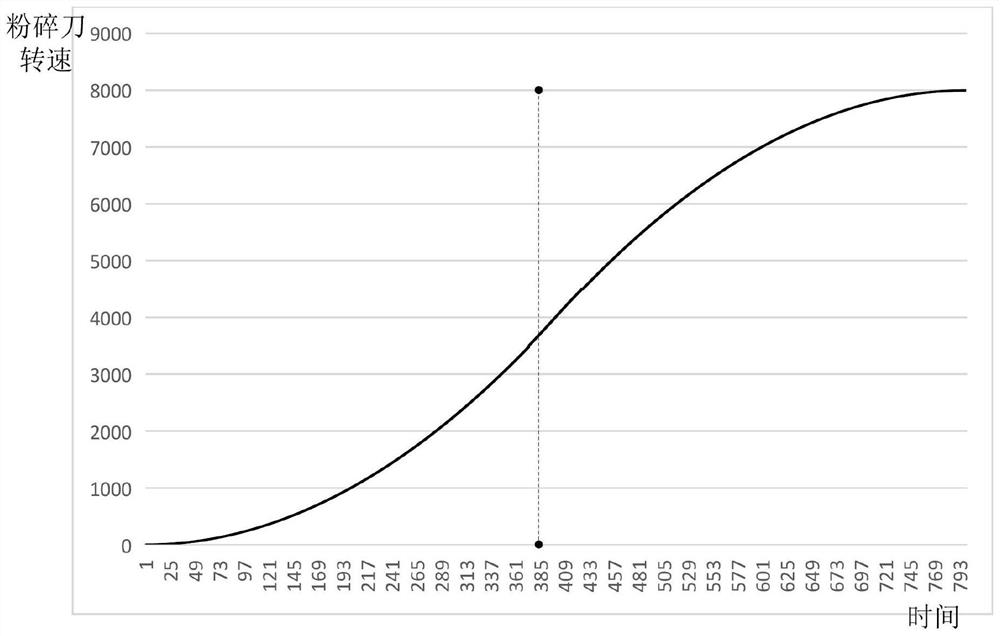

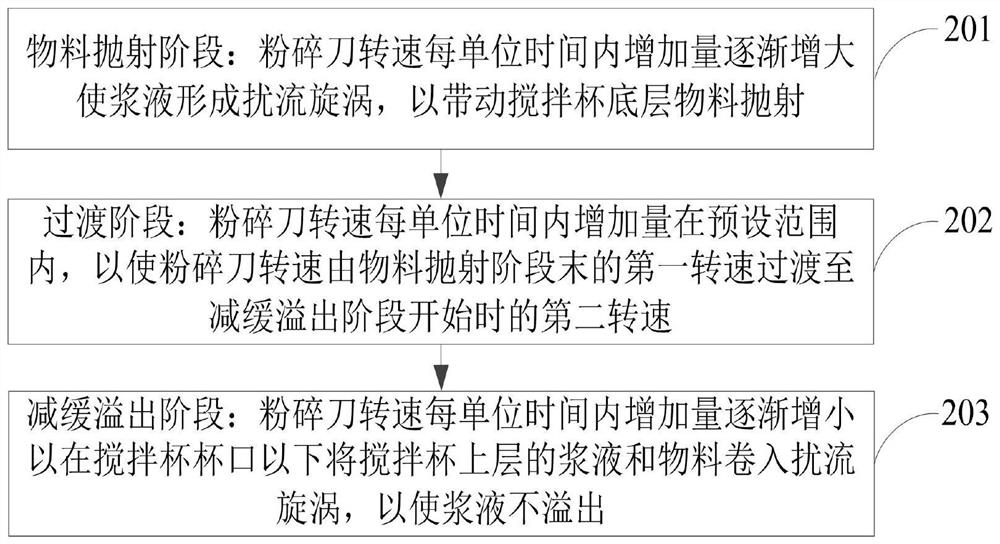

Processing method of food processor and food processor

ActiveCN113520183AAvoid stickingAvoid getting stuck in the seam of the bottom of the cup and avoid sticking the bottomKitchen equipmentElectric machineryProcess engineering

The invention provides a processing method of a food processor and the food processor. The food processor comprises a machine body, a processor, a stirring cup, a motor and a crushing cutter driven by the motor. The processing method comprises the steps of a material throwing stage in which the increment of the rotating speed of the crushing cutter per unit time is gradually increased to enable slurry to form a turbulent flow vortex, thereby driving materials at the bottom layer of the stirring cup to cast; and an overflow slowing stage in which the increment of the rotating speed of the crushing cutter in each unit time is gradually reduced so as to enable the slurry and the materials on the upper layer of the stirring cup to be involved into the turbulent flow vortex below the cup opening of the stirring cup, thereby avoiding overflow of the slurry. In the pulping process of the food processor, the food processor is beneficial to quickly forming turbulent flow vortexes of pulp and driving materials on the bottom layer of the stirring cup to be thrown, the thrown materials can be drawn into the turbulent flow vortexes, and the risk that the pulp overflows due to the fact that the rotating speed fluctuation is too large when the wall breaking machine is in a high rotating speed state is avoided.

Owner:JOYOUNG CO LTD

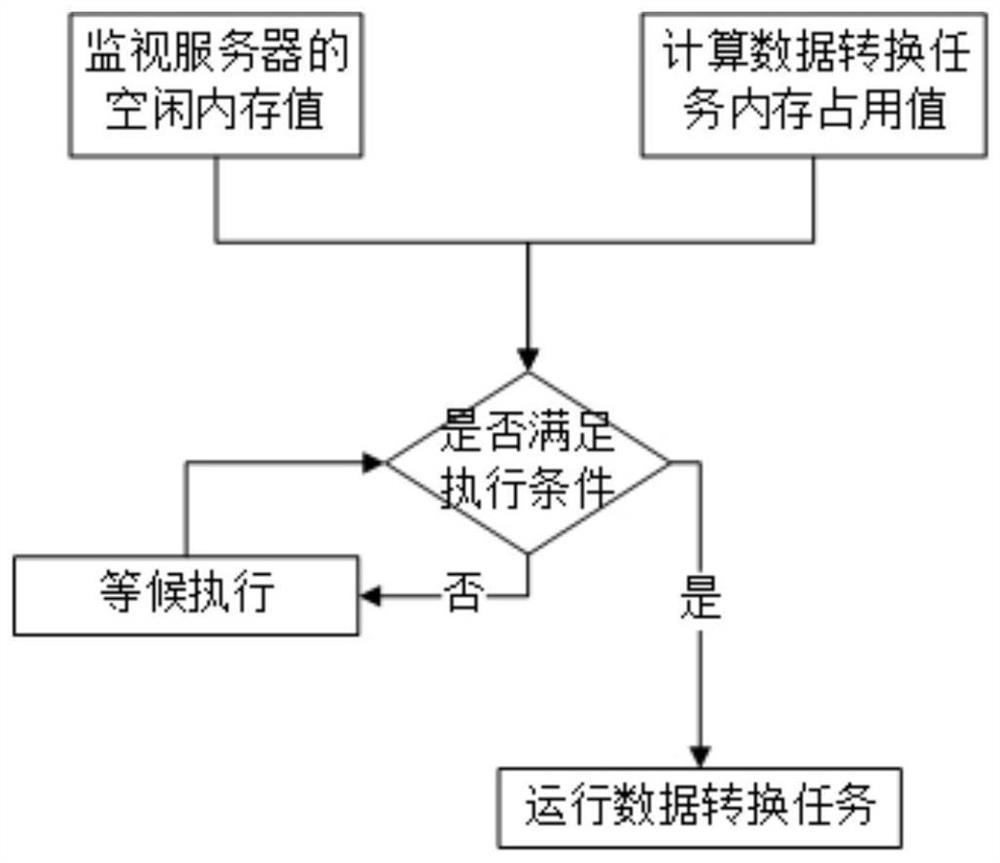

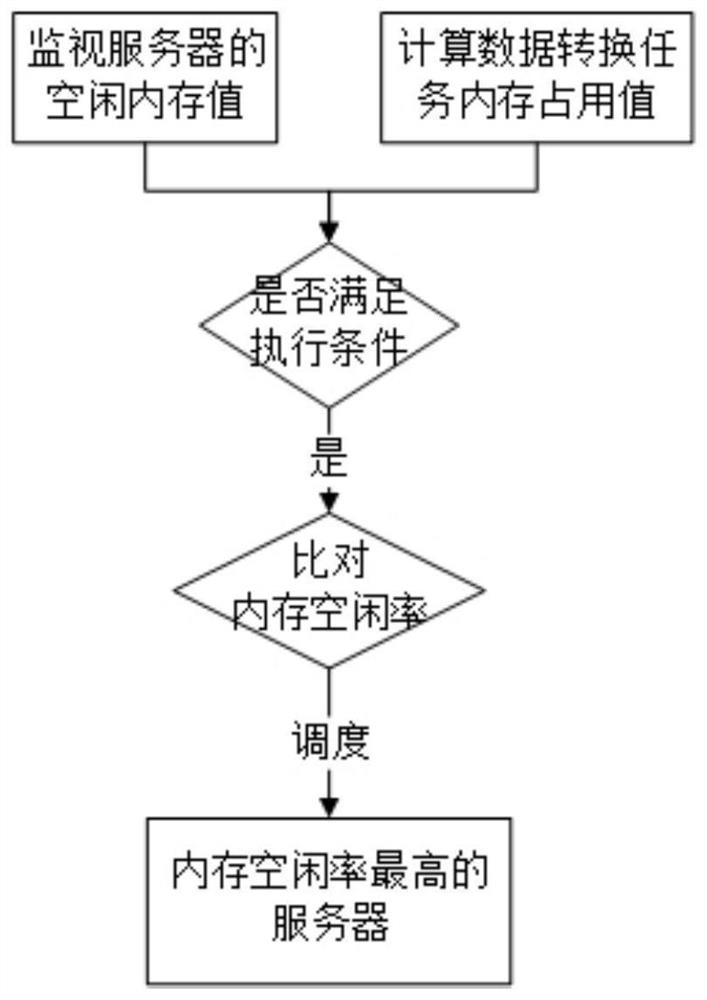

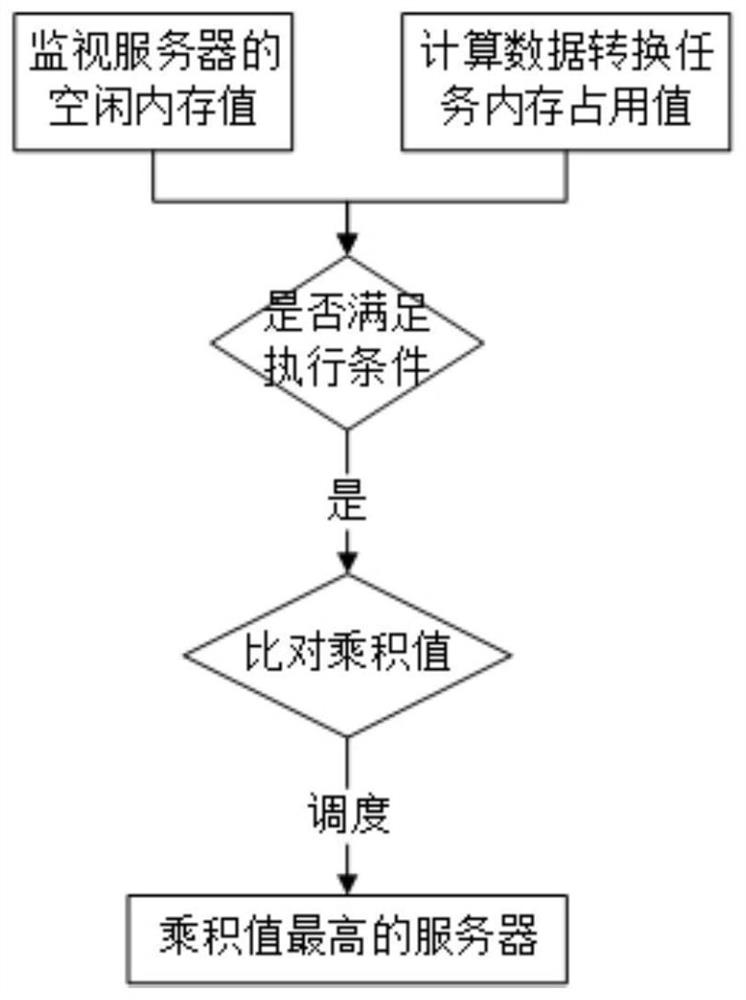

Data conversion task scheduling method

PendingCN114356515AAvoid spillover riskAchieving Overall Execution EfficiencyProgram initiation/switchingResource allocationData transformationMemory footprint

The invention provides a scheduling method for a data conversion task, which comprises the following steps of: monitoring the memory use condition of a server, and calculating to obtain a data extraction memory occupancy value, an incremental extraction memory occupancy value and an incremental data write-in memory occupancy value according to data source information and the data conversion task; according to the calculation result, whether the free memory of the server meets the execution condition of the data conversion task or not is judged, and if yes, the data conversion task is operated. According to the scheme, the risk of memory overflow is avoided, the use efficiency of server memory resources is improved, and the task completion efficiency is improved.

Owner:LIANYI TECHNOLOGY CO LTD

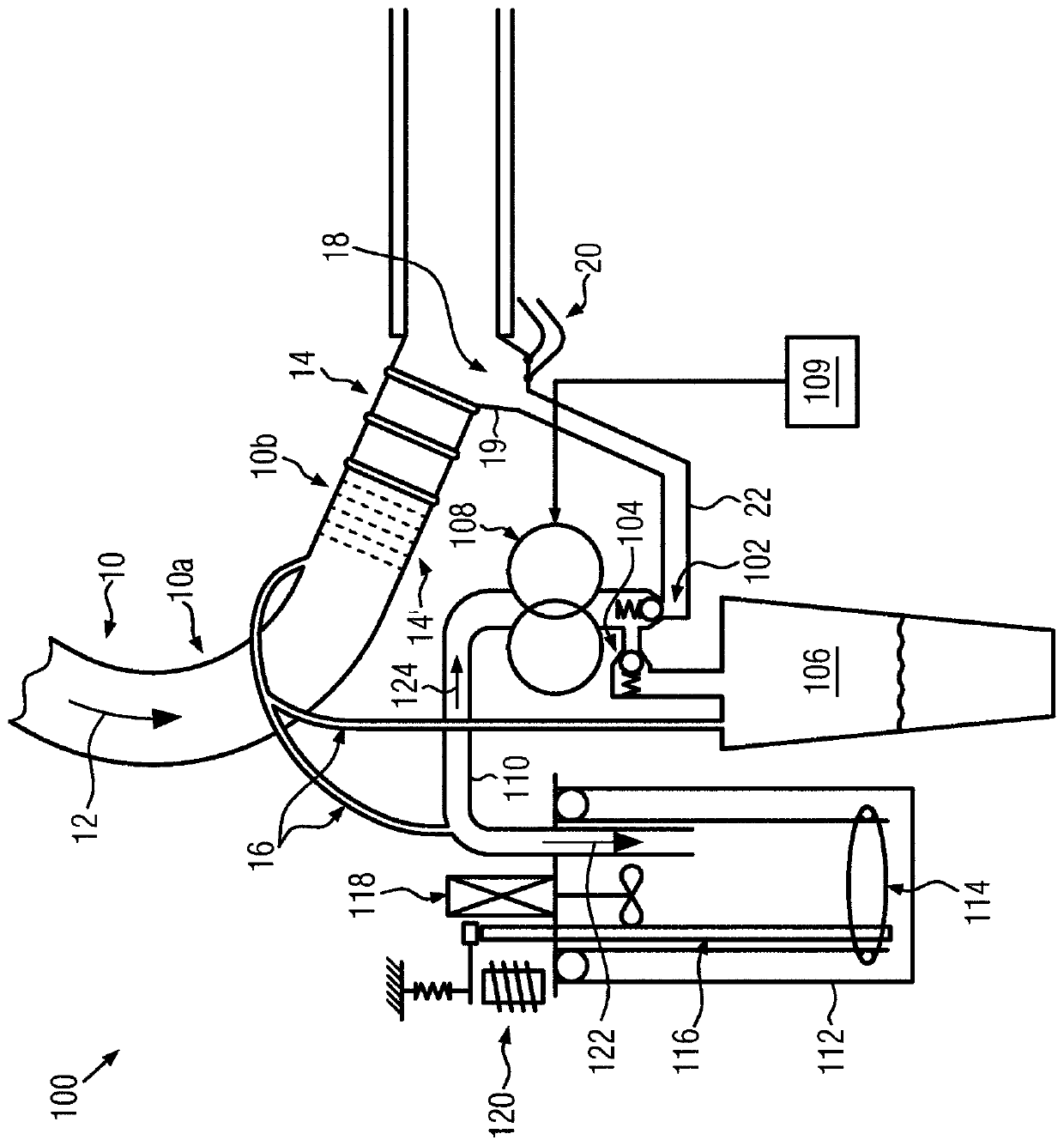

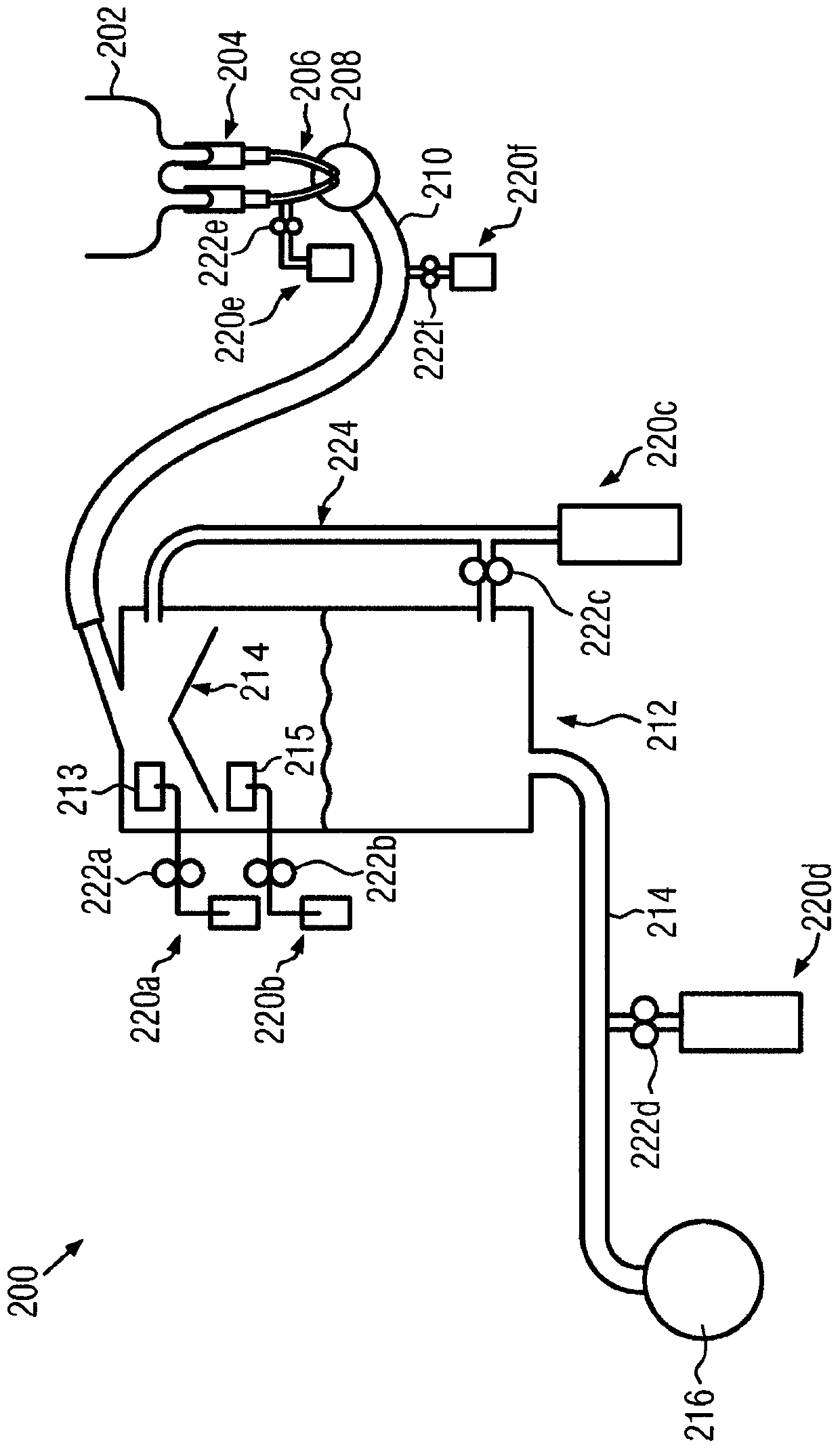

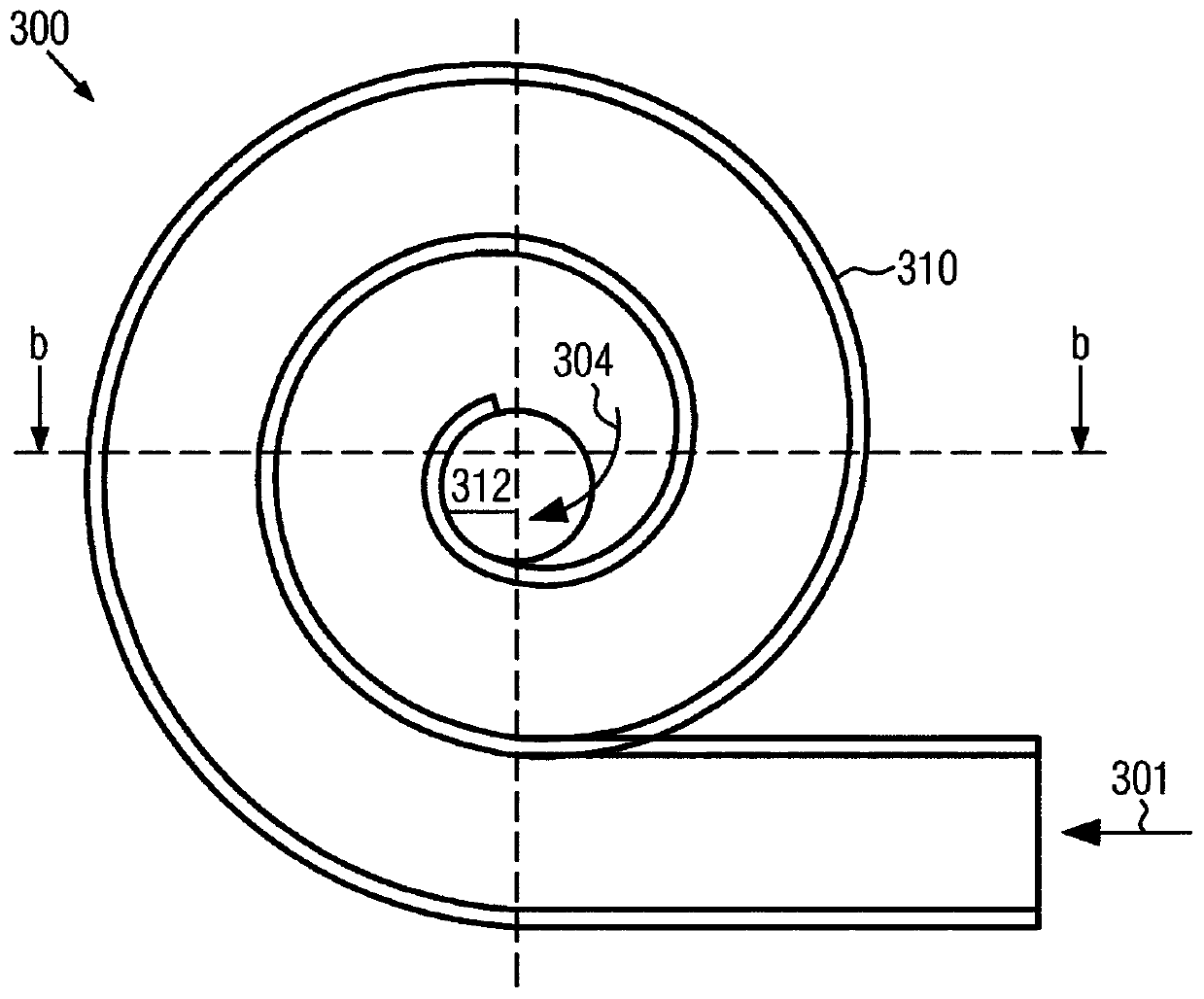

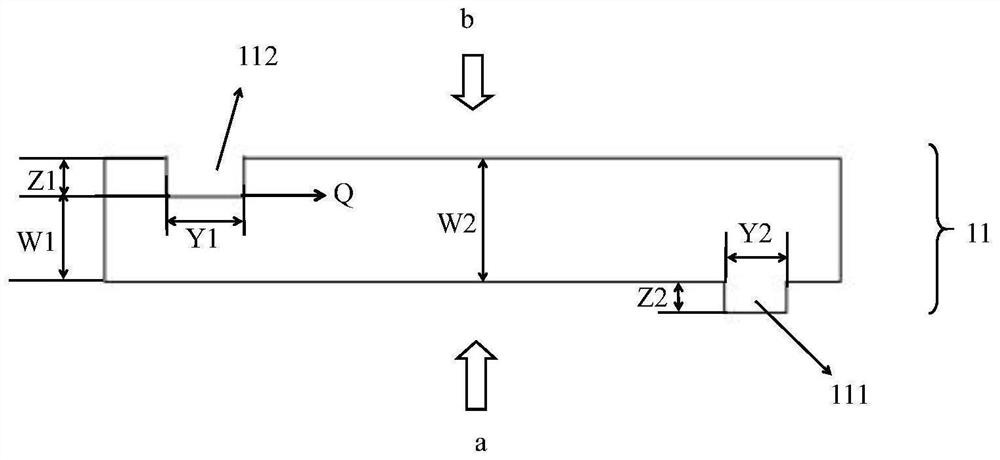

Sampling apparatus for taking a representative milk sample and method for taking representative milk samples

ActiveCN111247414AAvoid pollutionLarge expansion of flow rateWithdrawing sample devicesVolume/mass flow measurementMilk sampleEngineering

Sampling apparatus for taking a representative foodstuff sample and method for taking representative foodstuff samples. In one aspect, the invention provides a sampling apparatus (100) for taking a representative milk sample in a prescribed quantity range from a conveying line (10) in which milk is conveyed in conveying intervals of unknown length. The sampling apparatus (100) comprises a pump (108), a controller (109) of the pump (108) and a sample container connecting element connected to the pump (108), wherein the controller (109) is configured to take the prescribed quantity range and a measured variable denoting a flow rate of the milk conveyed in the conveying line (10) and / or a prescribed variable denoting a total quantity of milk to be conveyed by the conveying line (10) in a conveying interval as a basis for controlling a pulsed mode of the pump (108) in a conveying interval, wherein the pump (108) conveys a discrete sample subquantity along a first conveying direction (122)of the pump (108) in a respective sample pulse interval during the pulsed mode, and wherein the prescribed quantity range is greater than or equal to a total quantity corresponding to a total number of discrete sample subquantities in the conveying interval.

Owner:LACTOCORDER

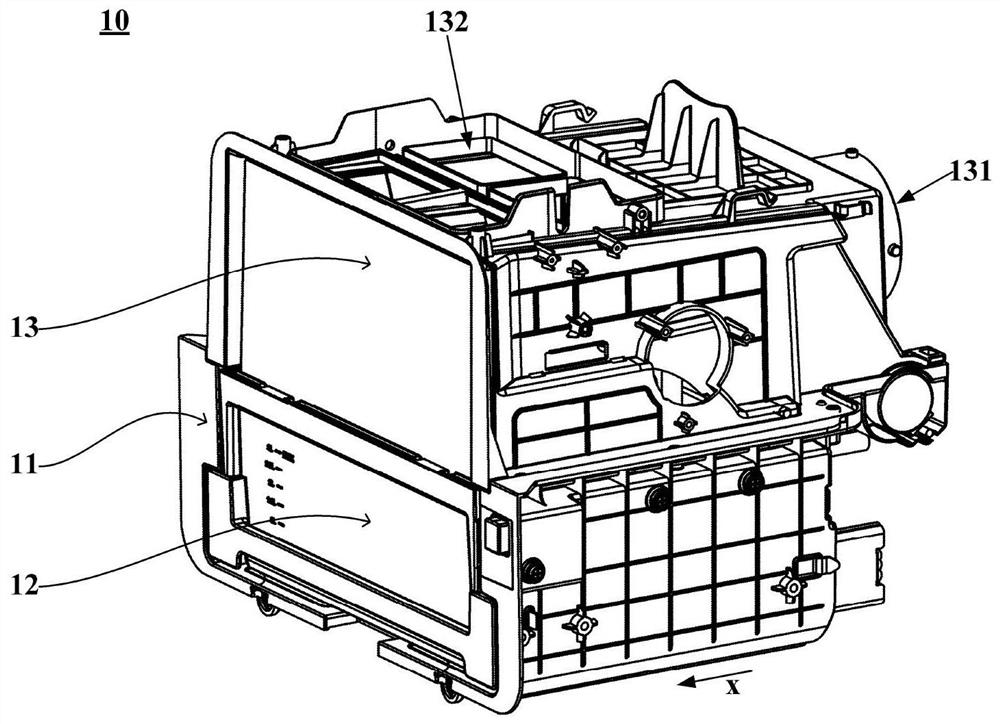

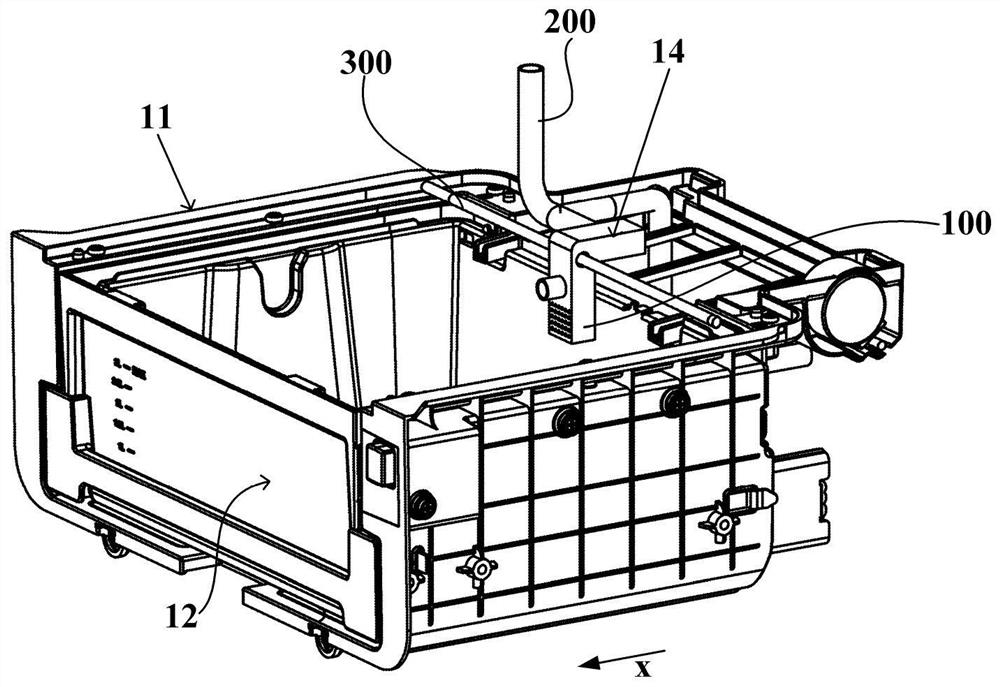

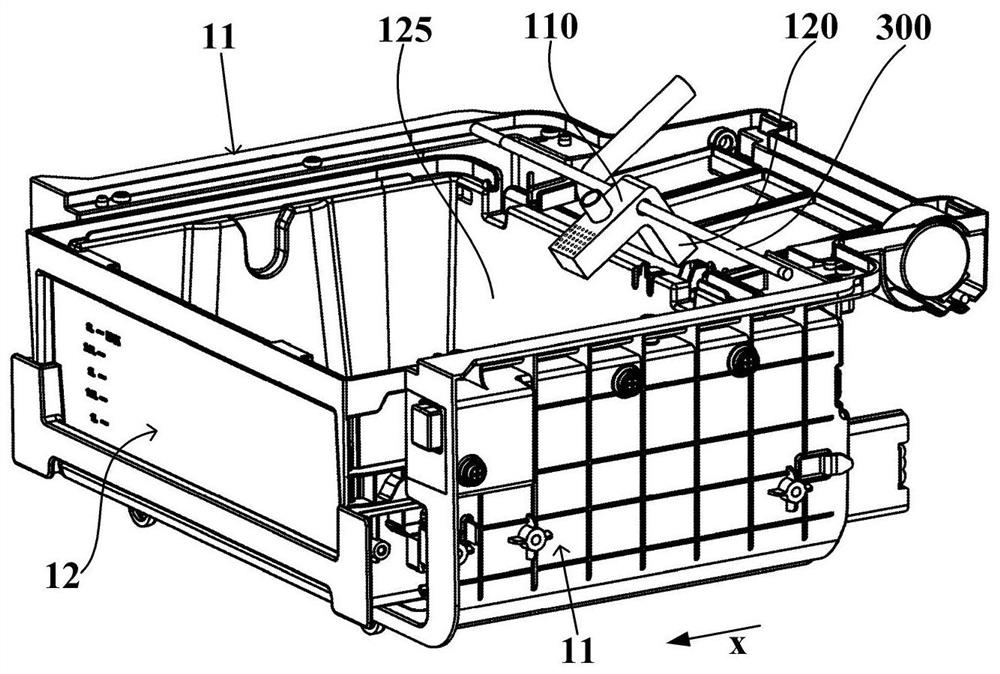

Air purification device and air conditioner

ActiveCN113819562AGood user experienceIntelligent water adding processMechanical apparatusLighting and heating apparatusProcess engineeringEnvironmental engineering

The invention provides an air purification device and an air conditioner. The air purification device comprises a shell, a drawer installed on the shell in a front-back drawing mode and used for containing water used for purifying air, and a water adding mechanism used for adding water into the drawer in a controlled manner. The air purification device is configured to allow the water adding mechanism to add water into the drawer when the drawer is in a closed state; and after the drawer is moved forwards and opened, the water adding mechanism is forbidden to add water into the drawer. According to the air purification device, water can be automatically added, anda the water adding process is more intelligent.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

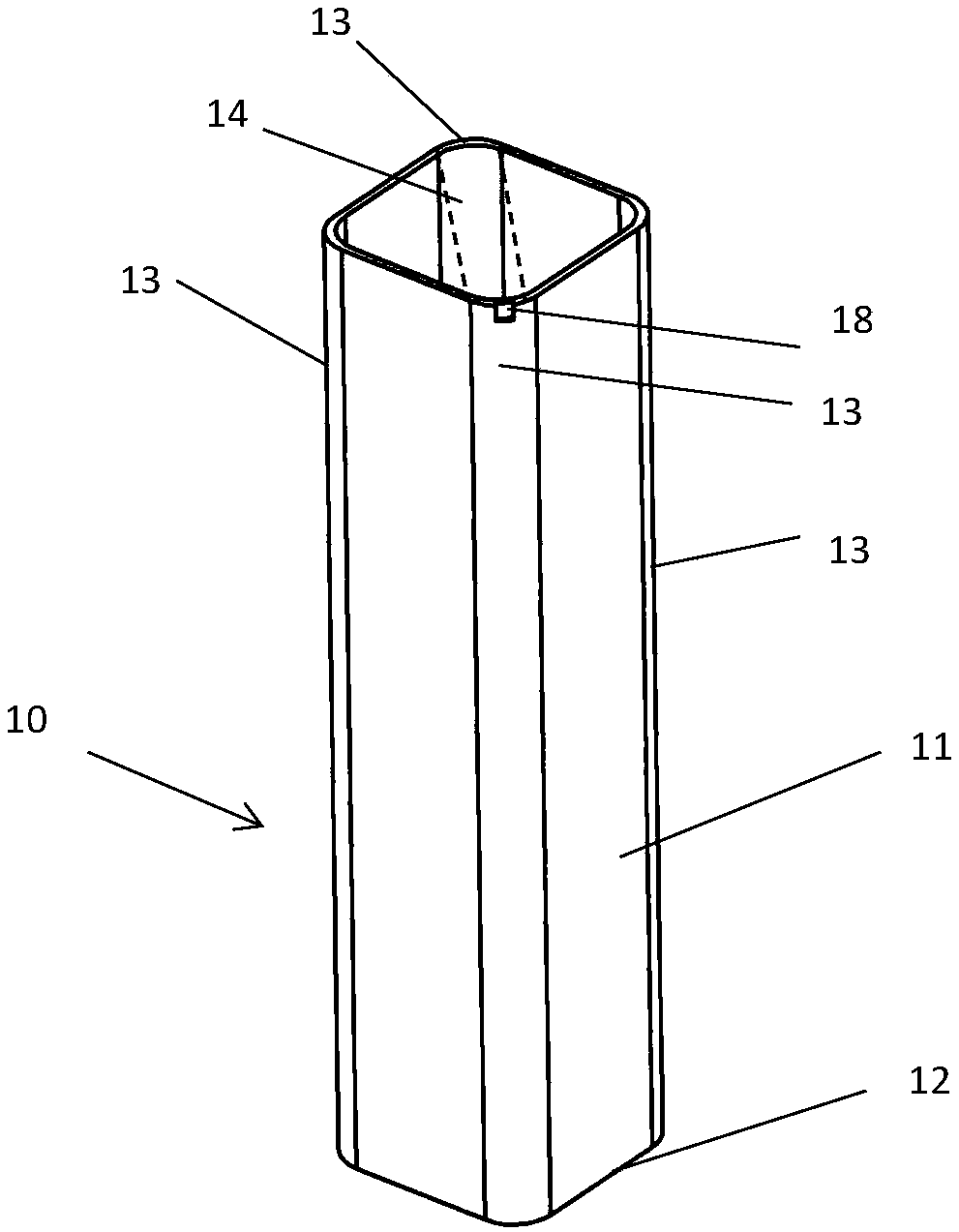

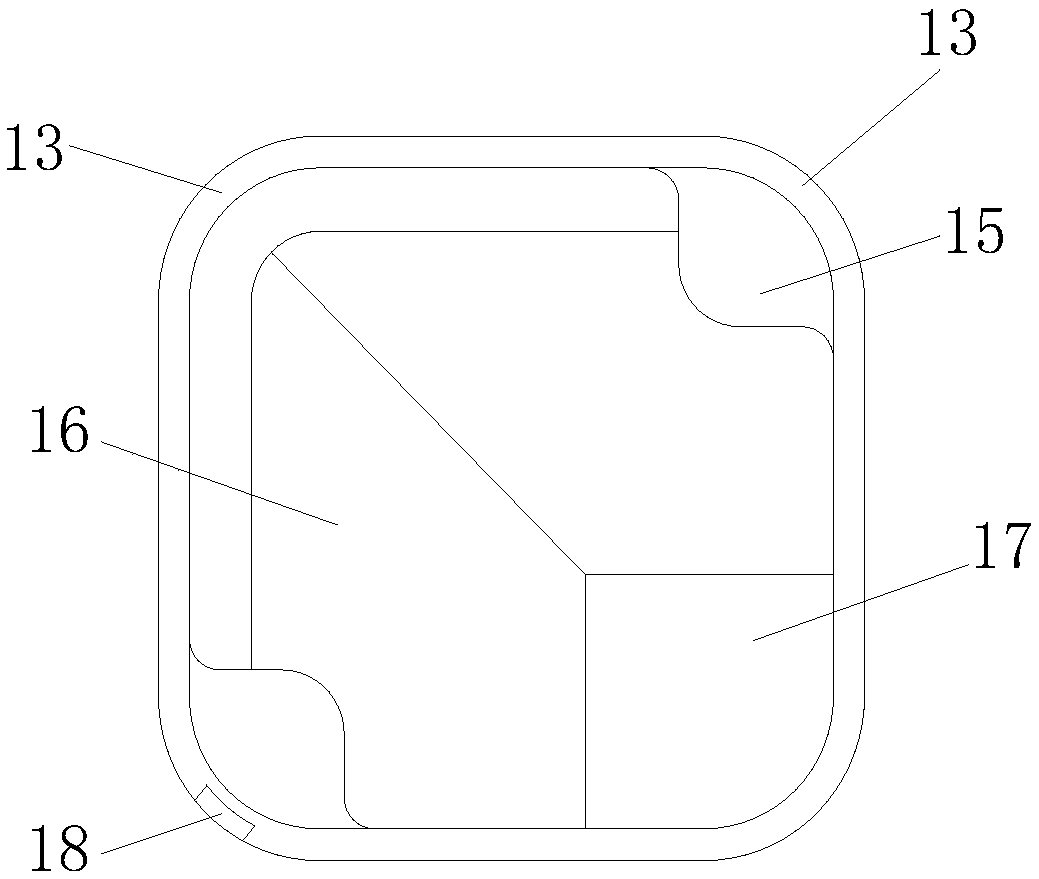

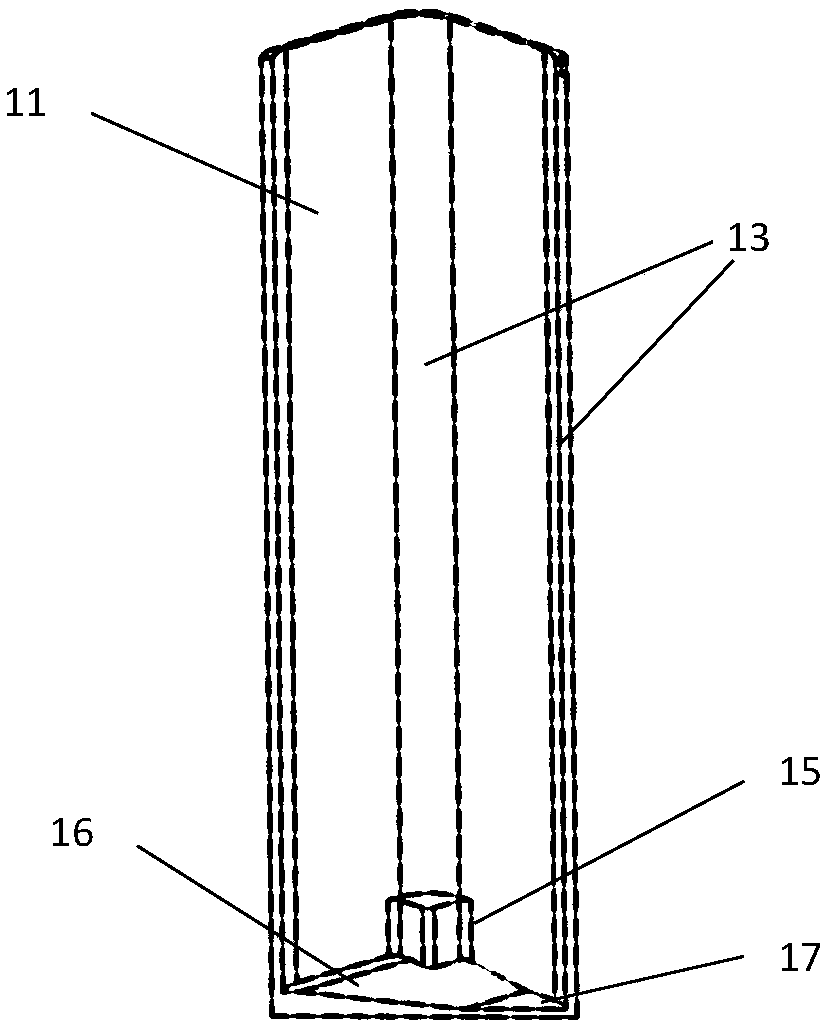

Reaction cup, molecular hybridization instrument, application of reaction cup and detection method

PendingCN111254044AFully cleanedAvoid destructionBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteDot blot

The invention provides a reaction cup. The reaction cup comprises a cup wall and a cup bottom; the cup wall is further provided with retaining parts; the retaining parts can make dot blot membranes stand upright in the reaction cup, and a dot blot membrane upright placement position is formed in a region of connecting lines of two opposite retaining parts. The invention further provides a nucleicacid molecular hybridization instrument comprising the reaction cup, and a detection method for detecting an analyte. The new reaction cup provided by the invention can vertically hold the dot blot membranes, and can be operated in an open state, so that the area of the reaction cup on the molecular hybridization instrument is reduced; and more reaction cups can be placed on the molecular hybridization instrument once, so that the working efficiency of the molecular hybridization instrument to detect the analyte is improved.

Owner:ACON BIOTECH (HANGZHOU) CO LTD

Data stream transmission method, transmission device, electronic equipment and storage medium

ActiveCN110597644BImprove transmission efficiencyReduce the amount of data transferredInterprogram communicationTransmissionData streamTerm memory

The present application provides a data flow interaction method, which is applied to the display process, including: defining a state array containing at least one first element, one first element occupies one byte, and one bit represents the selection state of a data flow , the initial value of each first element indicates that the initial selection state of each corresponding data stream is unselected; according to the actual selection state of each data stream corresponding to each first element, the actual selection state is selected from the tag data. The target second element corresponding to the target bit, and calculate the actual value of each first element; use the actual value of each first element to update the state array, and output the updated state array. The application can reduce the amount of data transmitted by the data stream, greatly compress the space for data storage, improve the efficiency of data transmission, and avoid the risk of memory overflow caused by too many data streams.

Owner:LAUNCH TECH CO LTD

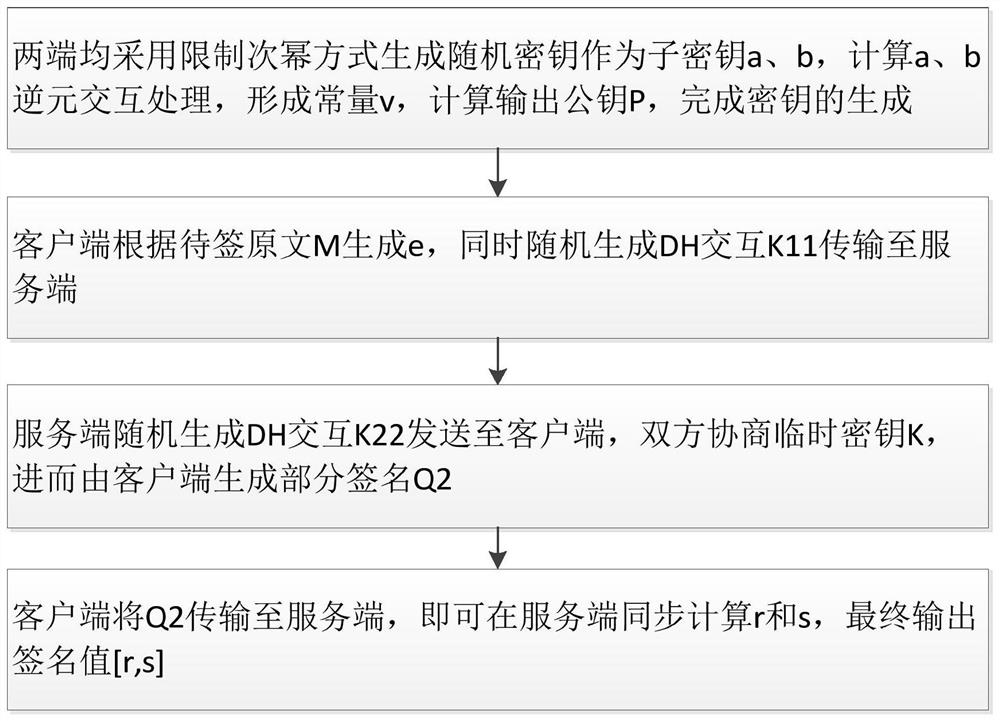

Signature method based on sm2 algorithm

ActiveCN107342855BAvoid spillover riskConvenient for Subsequent Synthesis SubstitutionKey distribution for secure communicationPublic key for secure communicationTheoretical computer scienceEphemeral key

Owner:同智伟业软件股份有限公司

A kind of control method of soymilk machine

ActiveCN107374403BSolve the overflowAvoid security issuesTemperatue controlKitchen equipmentProcess engineeringIndustrial engineering

Owner:JOYOUNG CO LTD

Processing method of a food processing machine and food processing machine

ActiveCN113520183BAvoid stickingAvoid sticky bottomKitchen equipmentElectric machineryProcess engineering

Owner:JOYOUNG CO LTD

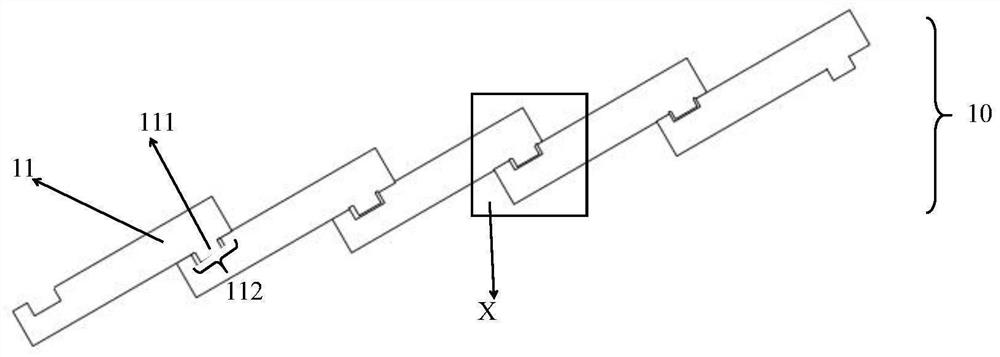

Solar cell piece group and preparation method thereof

PendingCN112951931AHigh mechanical strengthStrong pullFinal product manufacturePhotovoltaic energy generationConvex structureEngineering

The embodiment of the invention provides a solar cell piece group and a preparation method thereof. Thesolar cell piece group comprises at least two cell pieces; the cell piece is provided with a lower surface and an upper surface, and comprises a convex structure and a concave structure; the convex structures are convex structures which are formed on the lower surfaces of the cell pieces and are convex outwards; the concave structure is formed on the upper surface of the cell piece and is concave inwards, and the lowest point of the concave structure is lower than the plane where the upper surface is located; the convex structure and the concave structure are respectively arranged at two ends of the cell piece; and the convex structures of the cell pieces are matched with the concave structures of the adjacent cell pieces, so that the connection of the adjacent cell pieces is realized. According to the embodiment of the invention, the mutual connection of the plurality of cell pieces is realized through the convex structures and the concave structures, so that the hidden crack risk of the overlapped parts of the cell pieces is avoided, the connection between the cell pieces is firm, and the cell pieces are not loosened to generate relative sliding in the conveying process of the solar cell piece group.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

A beverage reservation production method of a food processor

ActiveCN106054981BRealize free customizationAvoid spillover riskAuxillary controllers with auxillary heating devicesTime informationStart time

Owner:JOYOUNG CO LTD

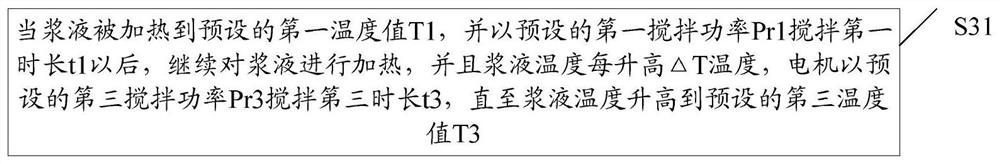

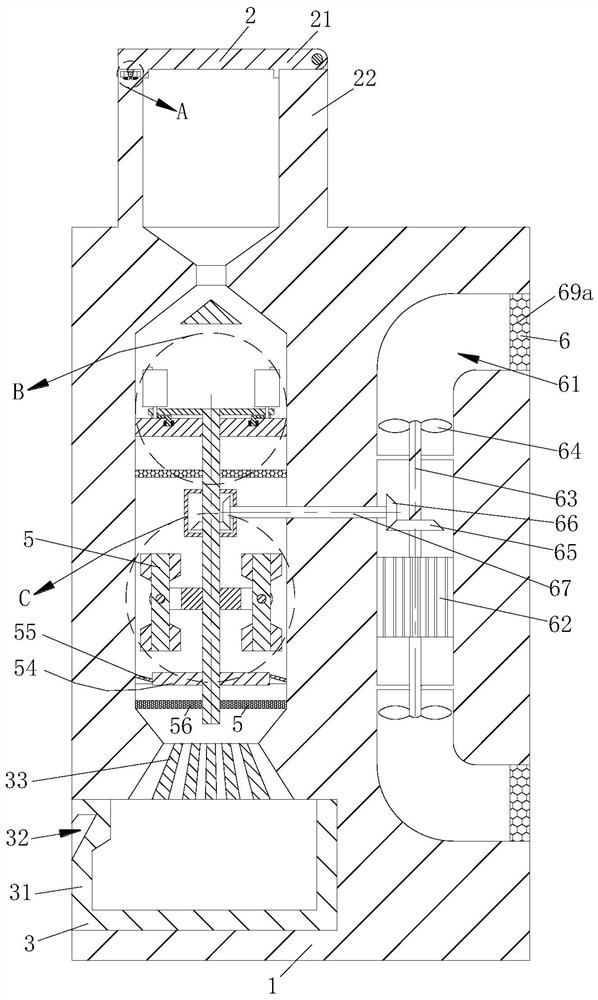

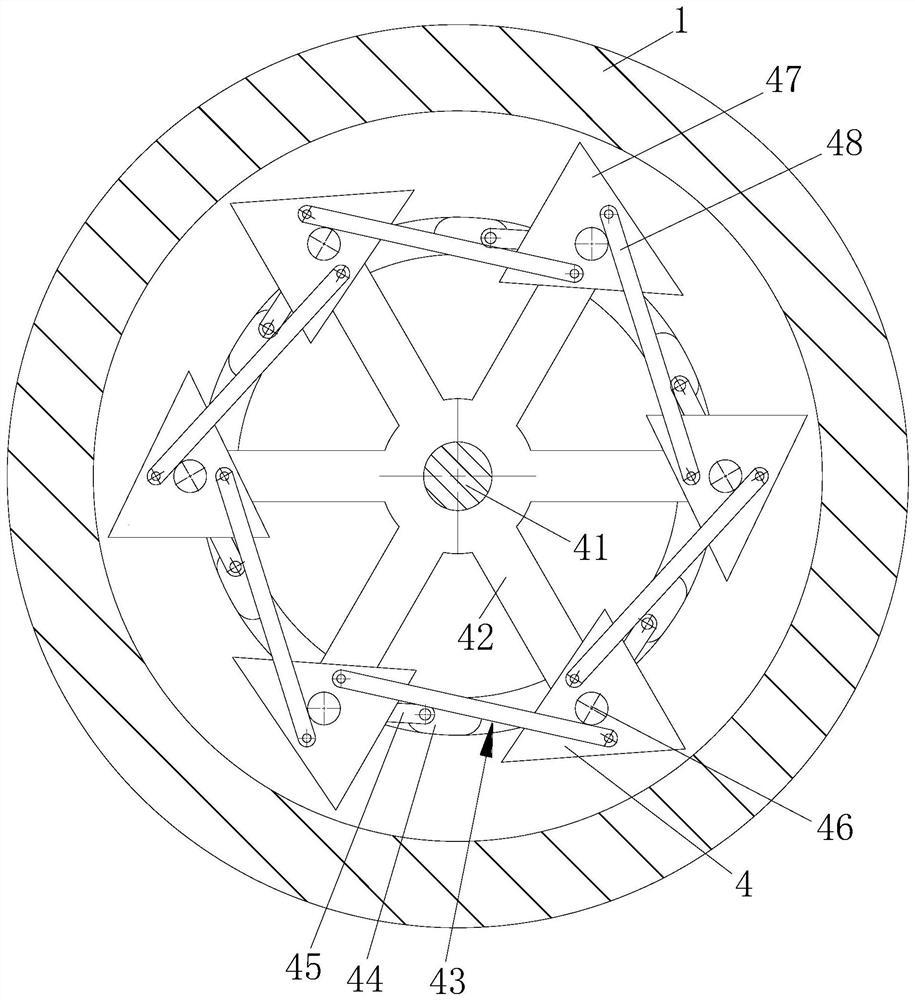

A kind of overheat protection method of food processing machine

ActiveCN108185848BReduce misuseReduce manufacturing costKitchen equipmentElectric machineryProcess engineering

The embodiment of the present invention discloses an overheat protection method for a food processor. The food processor includes: a crushing cup and a motor. A heating device is arranged on the crushing cup. A thermal fuse connected in series with the heating device is respectively arranged at both ends of the heating device. A body protector, the method includes: during the heating process, when the slurry is heated to one or more preset temperature values with a preset heating power, respectively using the stirring power and the stirring time corresponding to the preset temperature value The slurry is stirred. Through the solution of this embodiment, the production cost is reduced, potential safety hazards are reduced, and misoperation of the thermal fuse protector in overheating protection is reduced.

Owner:JOYOUNG CO LTD

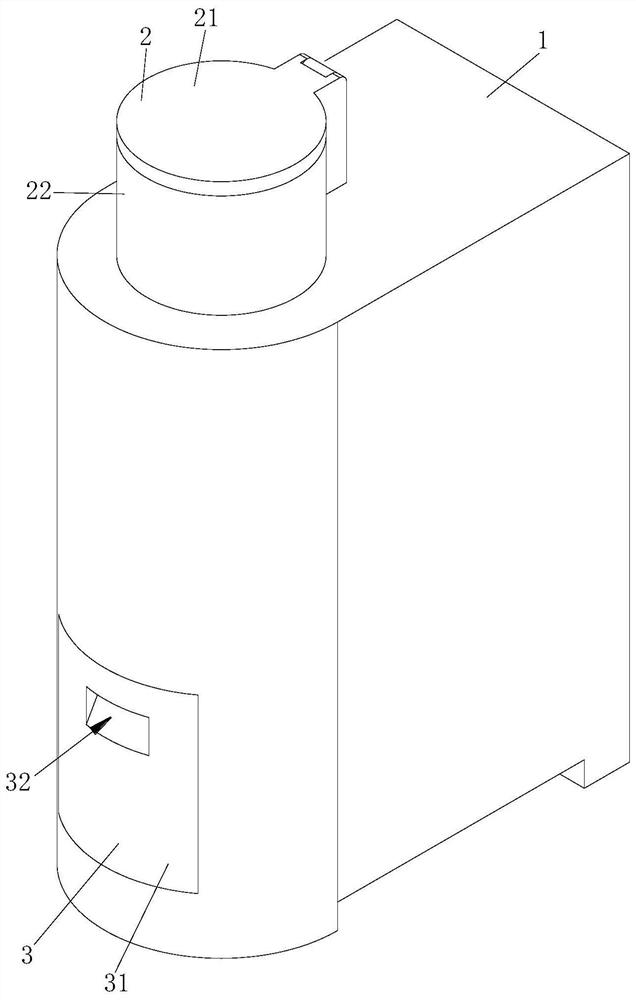

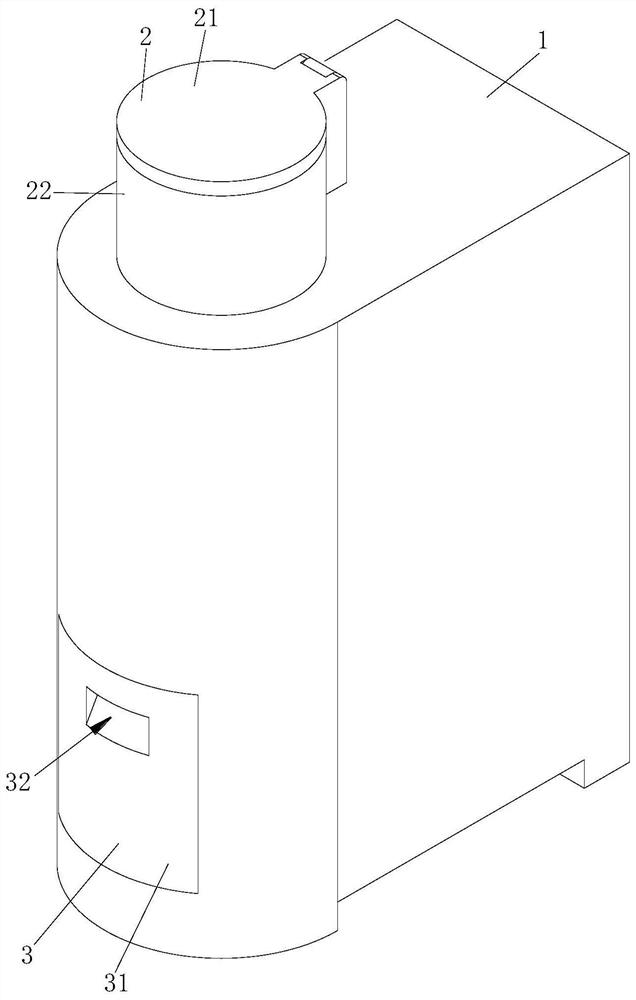

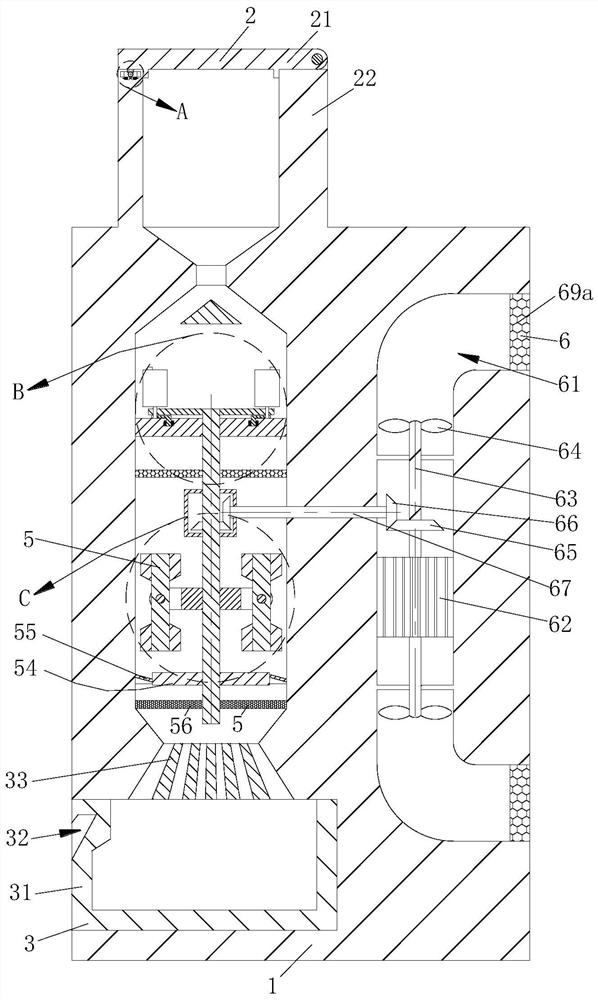

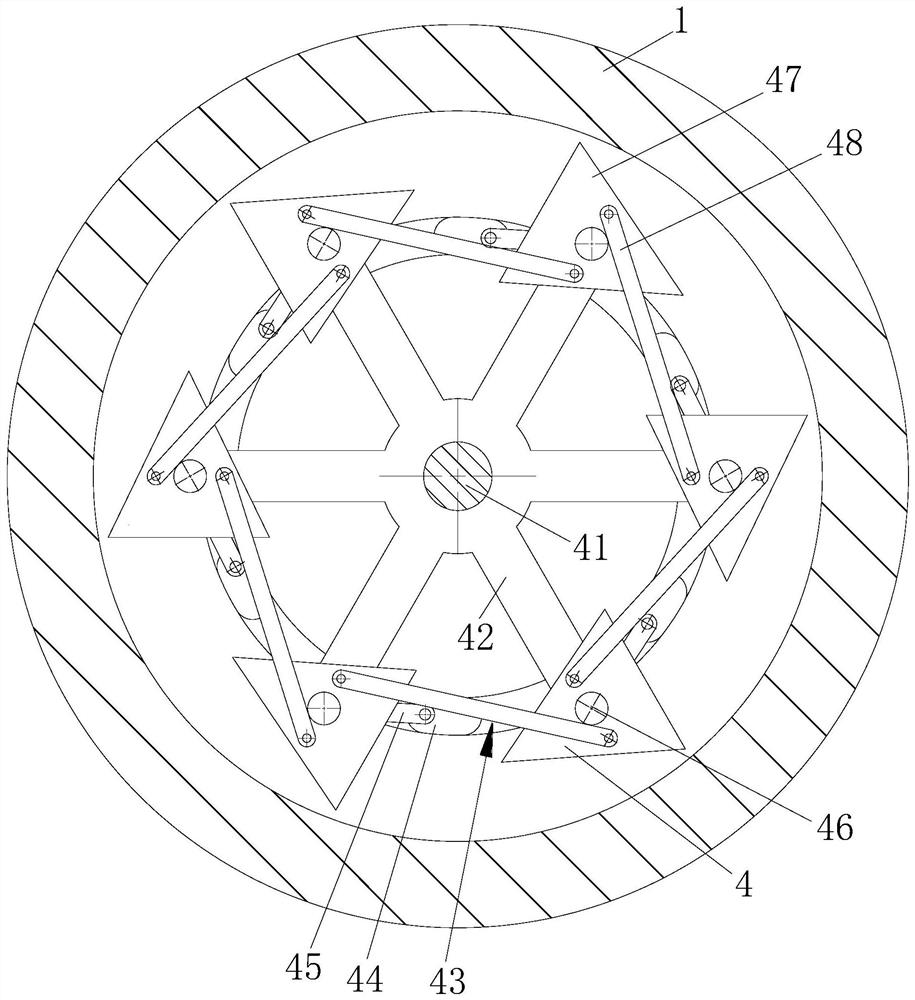

Coffee beverage raw material grinding device

The invention relates to the field of coffee grinding devices, in particular to a coffee beverage raw material grinding device which comprises a main body, a containing mechanism, a storage mechanism,a coarse grinding mechanism, a fine grinding mechanism and a power mechanism. Coffee beans can be conveniently placed in a containing container through the arrangement of the containing mechanism, and the fixed containing capacity corresponds to the storage capacity of the storage mechanism, so that the overflow risk caused by too many manufactured finished products is avoided; large-particle coffee beans can be conveniently smashed through the arrangement of the coarse grinding mechanism, so that conditions are provided for follow-up fine grinding of the fine grinding mechanism; through thearrangement of the fine grinding mechanism, semi-finished coffee bean particles can be conveniently ground, so that the powder making effect is further improved; through the arrangement of the storagemechanism, powder can be conveniently and evenly stored in the storage unit, so that the phenomenon that the storage space is insufficient due to the fact that the middle is stacked too high is avoided; and through the arrangement of the power mechanism, power can be conveniently provided for the rough grinding mechanism and the fine grinding mechanism, and heat dissipation can be conducted on the power component of the mechanism at the same time.

Owner:正大(海南)兴隆咖啡产业开发有限公司

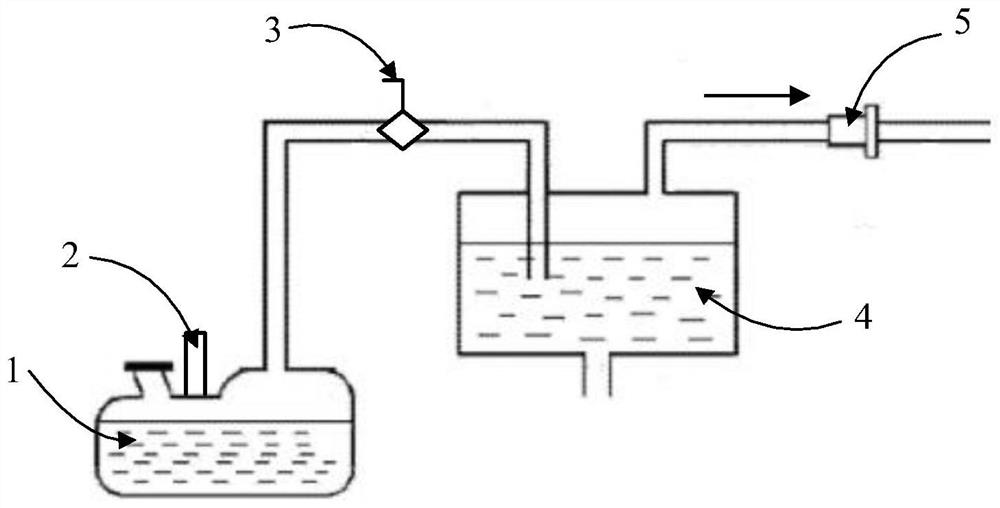

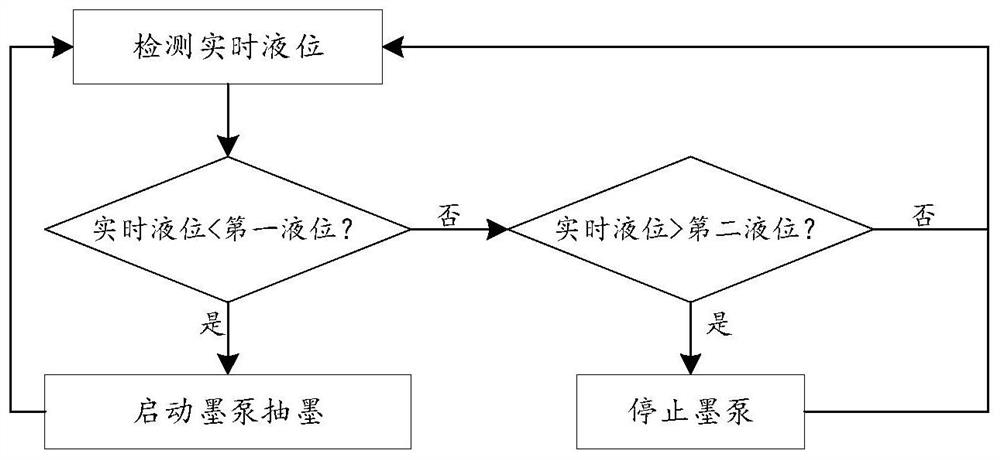

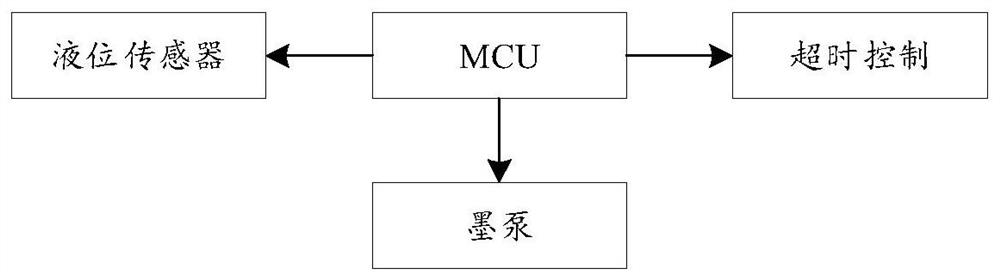

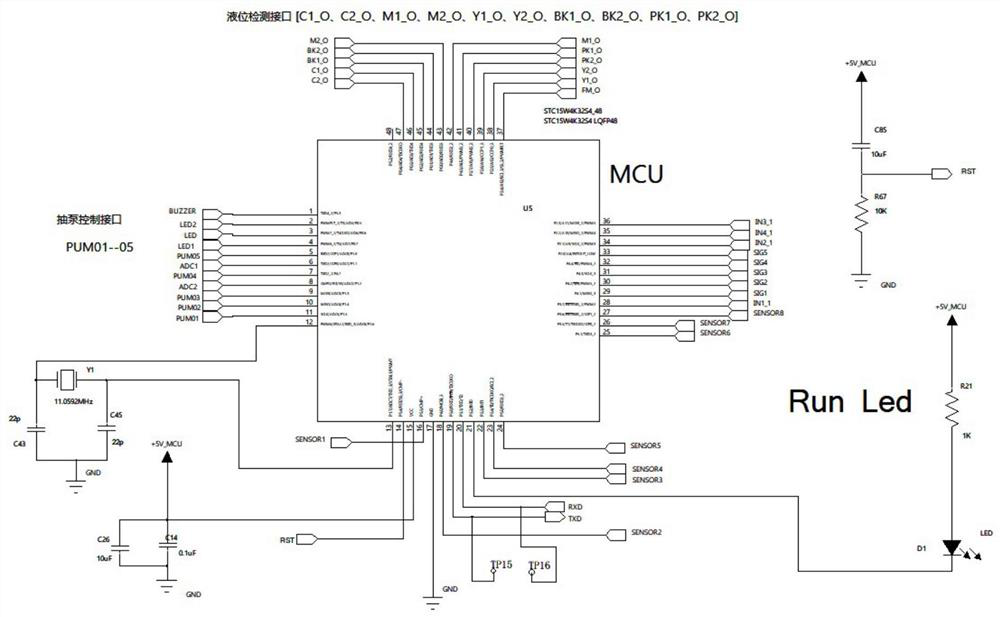

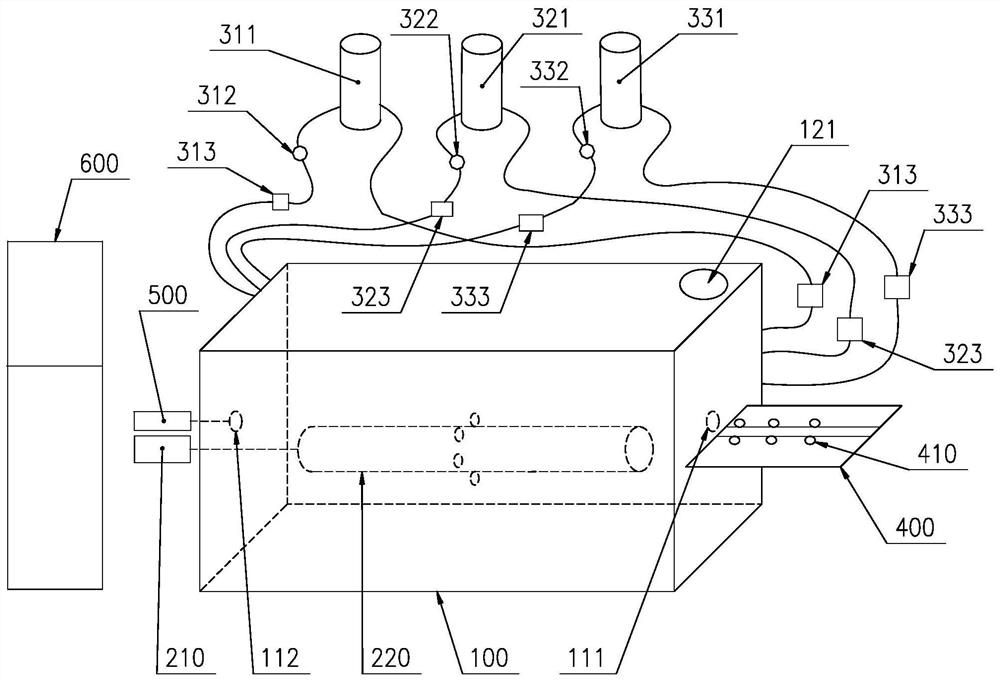

Ink supply control method and device

PendingCN111605319AGuaranteed continuitySolve the problem of small capacity requiring multiple shutdowns for replacementPrintingProcess engineeringIndustrial engineering

The invention discloses an ink supply control method and device. The ink supply control method is characterized in that ink supply is controlled in real time by detecting the real-time liquid level ofan ink transfer bin, an ink pump is started to pump ink when the ink amount is lower than the low-level threshold value, ink pumping is stopped when the ink amount is higher than the high-level threshold value, the risk of excessive ink overflow is avoided while the ink supply continuity of the ink transfer bin to an ink box is guaranteed. The cascading structure of a large-capacity main ink barrel and the ink transfer bin is adopted, the problem that the ink box needs to be stopped and replaced many times due to the small capacity can be effectively solved, the printing efficiency is greatlyimproved, and manpower and material resources are saved.

Owner:南阳柯丽尔科技有限公司

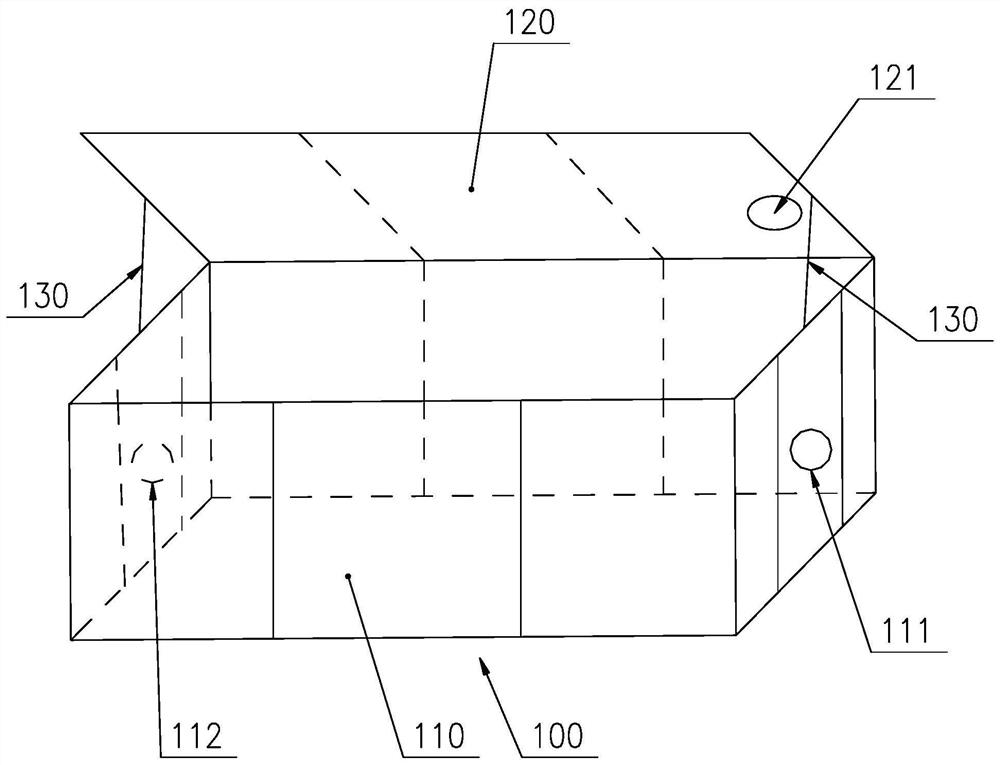

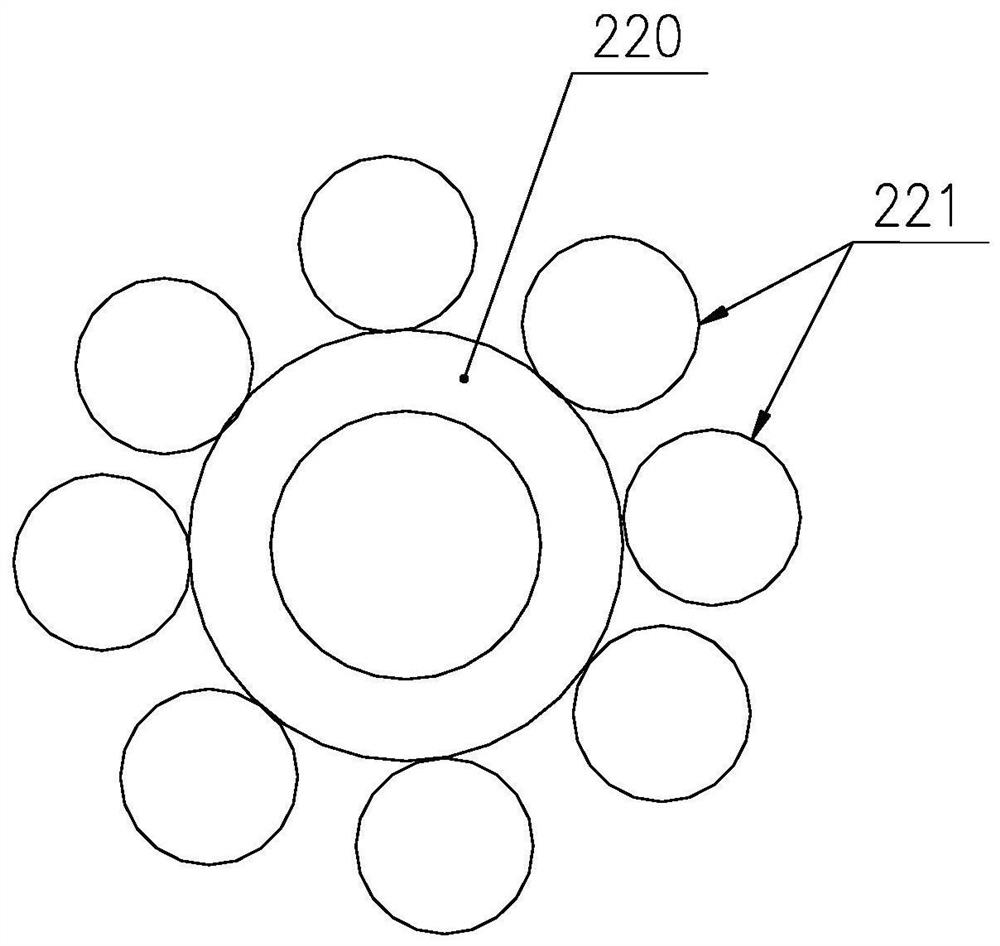

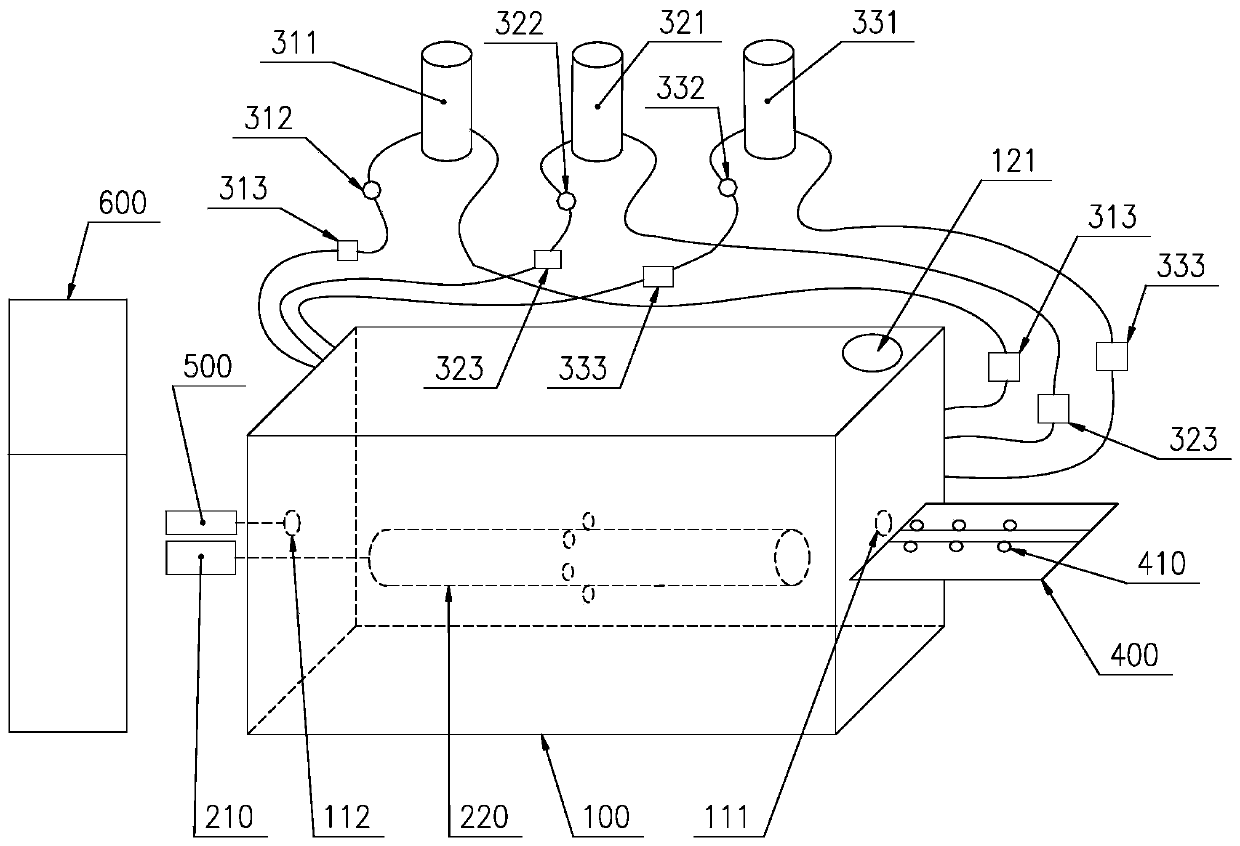

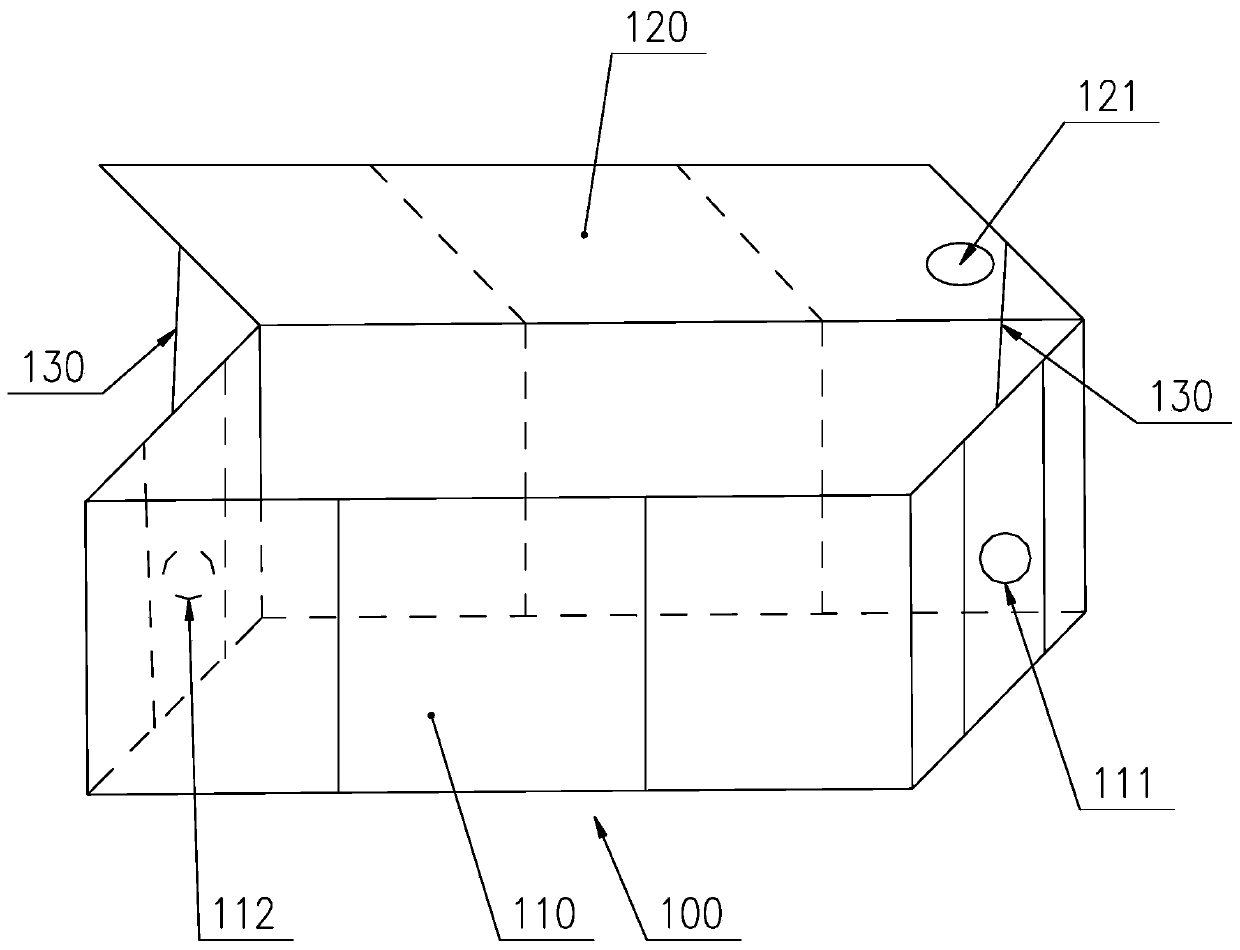

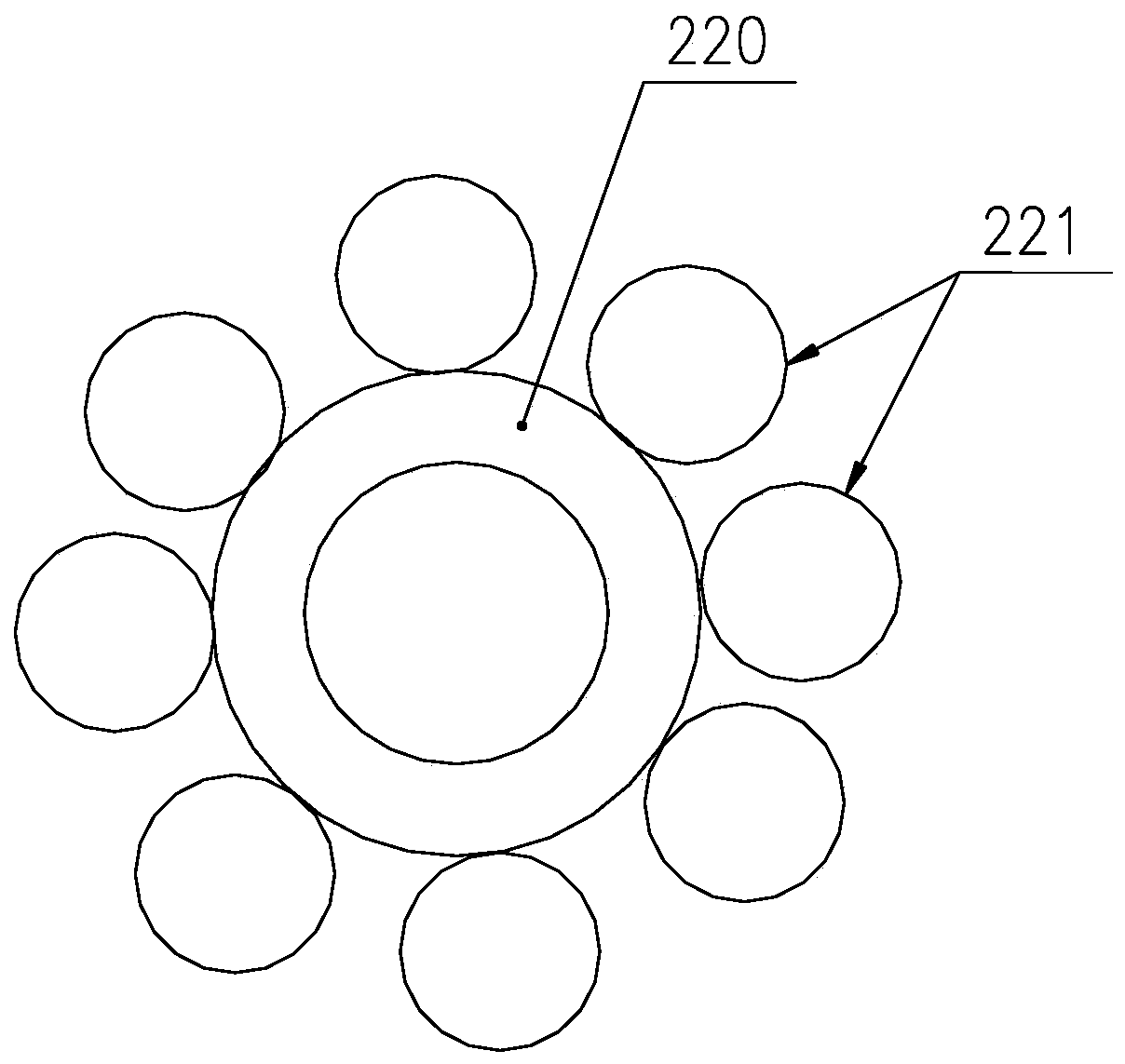

Equipment and method for continuous pickling of titanium and titanium alloy oil pipes

ActiveCN111501054BSimple structureLow costDirt cleaningCleaning using gasesProcess engineeringTitanium

The invention belongs to the field of manufacturing technology, and specifically discloses a device and method for continuous pickling of titanium and titanium alloy oil pipes, which have low safety risks and are beneficial to control the surface quality and size uniformity of oil pipe pickling. The equipment for continuous pickling of titanium and titanium alloy oil pipes includes an equipment box, an actuator, a circulation mechanism and an acid mist collection device. The equipment for continuous pickling of titanium and titanium alloy tubing can fix the tubing on the rotary shaft and drive it to rotate in the equipment box to complete the pickling, neutralization and cleaning steps, which is beneficial to ensure the surface quality and size of the tubing pickling Uniformity; at the same time, the acid liquid, neutralizing liquid and cleaning liquid are pumped separately, which can not only improve the pickling efficiency, but also reduce the labor intensity of workers and reduce the risk of corrosion damage; in addition, during the pickling process, the acid produced The mist can be pumped into the lye tank by the fan through the acid mist discharge hole for neutralization treatment, which avoids the risk of acid mist overflow and meets the environmental protection requirements.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Raw material grinding device for coffee beverage

ActiveCN112386128BEasy to placeEasily brokenCoffee millsSpice millsProcess engineeringIndustrial engineering

The invention relates to the field of coffee grinding devices, in particular to a raw material grinding device for coffee beverages, which includes a main body, a holding mechanism, a storage mechanism, a rough grinding mechanism, a fine grinding mechanism and a power mechanism; The coffee beans are placed in the holding container, and the fixed holding capacity corresponds to the storage capacity of the storage mechanism, so as to avoid the risk of overflow caused by too many finished products, and it is convenient to crush the large-grained coffee beans through the setting of the coarse grinding mechanism , to provide conditions for the follow-up fine grinding mechanism, through the setting of the fine grinding mechanism, it is convenient to grind the semi-finished coffee bean particles, and further improve the milling effect, through the setting of the storage mechanism, it is convenient to store the powder evenly in the storage unit The interior of the machine avoids the phenomenon of insufficient storage space caused by excessive accumulation in the middle. The setting of the power mechanism is convenient for providing power for the rough grinding mechanism and the fine grinding mechanism, and can simultaneously dissipate heat for its own power components.

Owner:正大(海南)兴隆咖啡产业开发有限公司

Plant and method used for continuous acid washing of titanium and titanium alloy oil pipe

ActiveCN111501054ASimple structureLow costDirt cleaningCleaning using gasesProcess engineeringTitanium

The invention belongs to the manufacturing technical field and specifically discloses a plant and method used for continuous acid washing of a titanium and titanium alloy oil pipe, and the plant and method are low in safety risk and beneficial to control over the oil pipe acid washing surface quality and size uniformity. The plant used for continuous acid washing of the titanium and titanium alloyoil pipe comprises a plant box, an executive mechanism, a circulating mechanism and an acid mist collecting device. By the adoption of the plant used for continuous acid washing of the titanium and titanium alloy oil pipe, the oil pipe can be fixed to a rotation pipe shaft so as to be driven by a drive device to rotationally finish an acid washing step, a neutralizing step and a washing step in the plant box, and the oil pipe acid washing surface quality and size uniformity can be guaranteed; meanwhile, acid liquid, neutralizing liquid and washing liquid are pumped through pumps, acid washingefficiency can be improved, the labor intensity of workers is reduced, and corrosion harm risks are reduced; and in addition, in the acid washing process, generated acid mist can be exhausted by a draught fan through an acid mist exhausting hole into an alkali liquor barrel to be neutralized, the risk that the acid mist overflows is avoided, and the requirement for environment friendliness is met.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

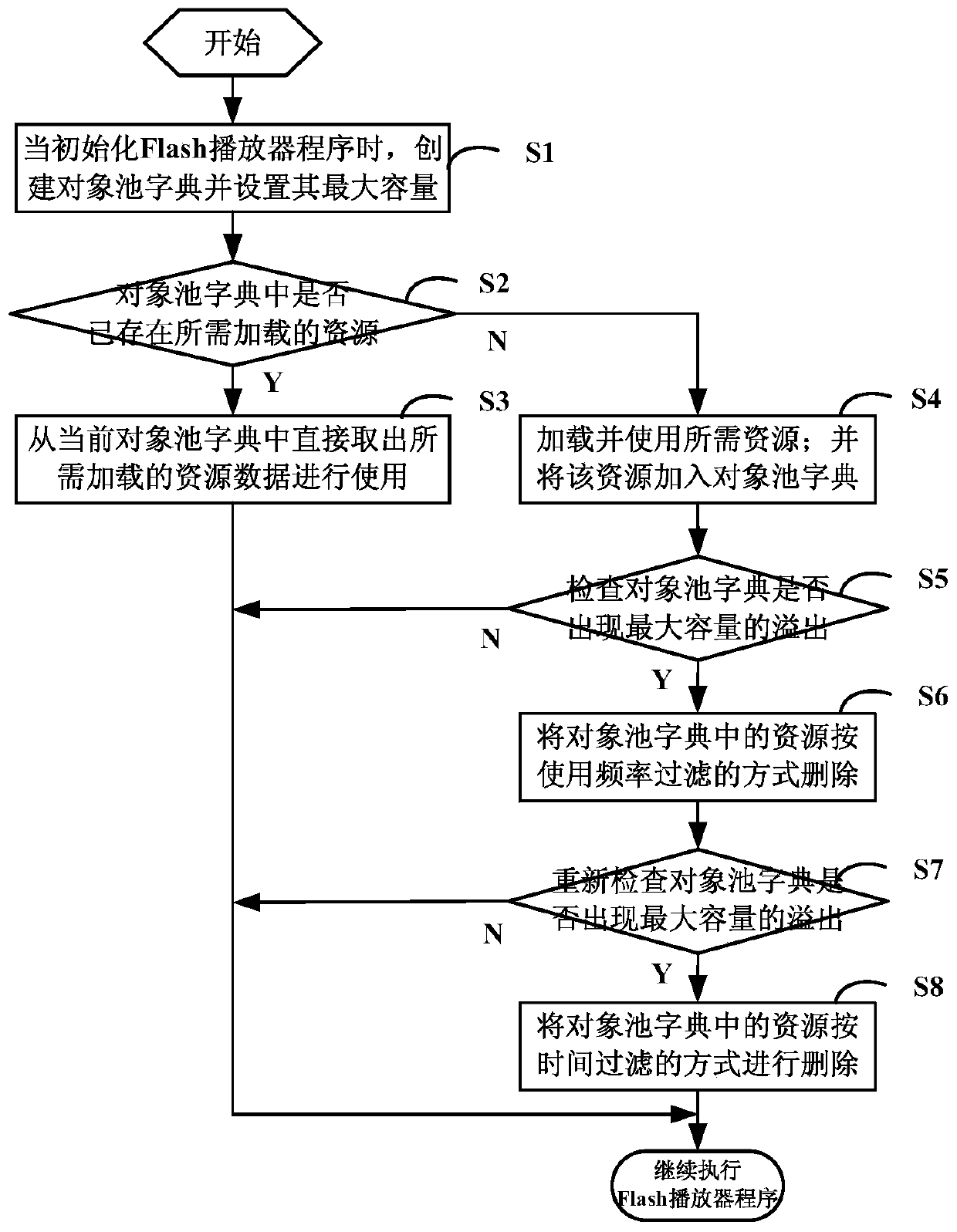

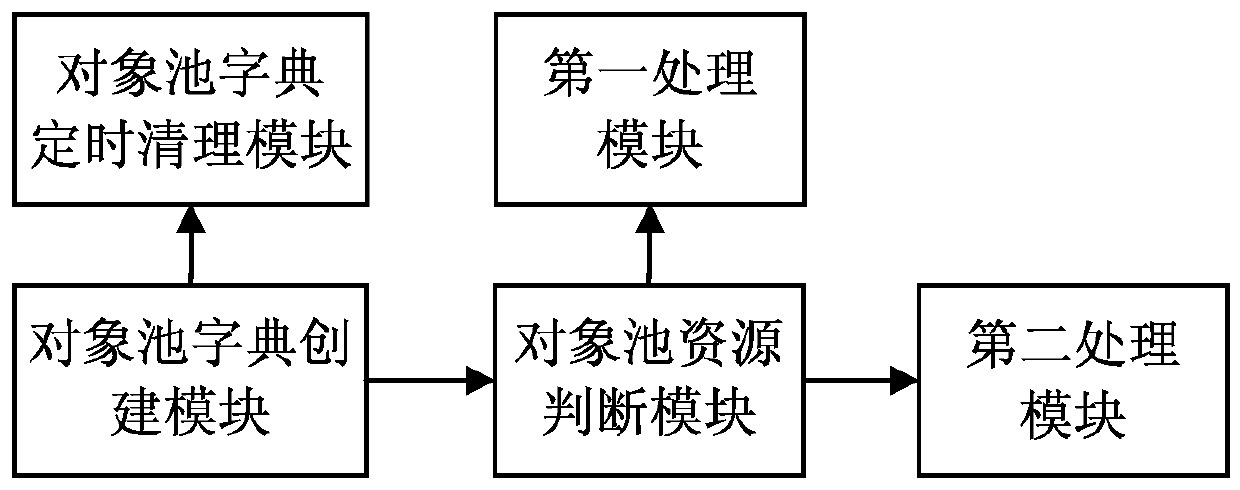

Method and system for realizing flash player resource loading by using object pool

ActiveCN106775889BAvoid double loadingImprove loading speedResource allocationProgram loading/initiatingTerm memoryPool

Owner:WUHAN DOUYU NETWORK TECH CO LTD

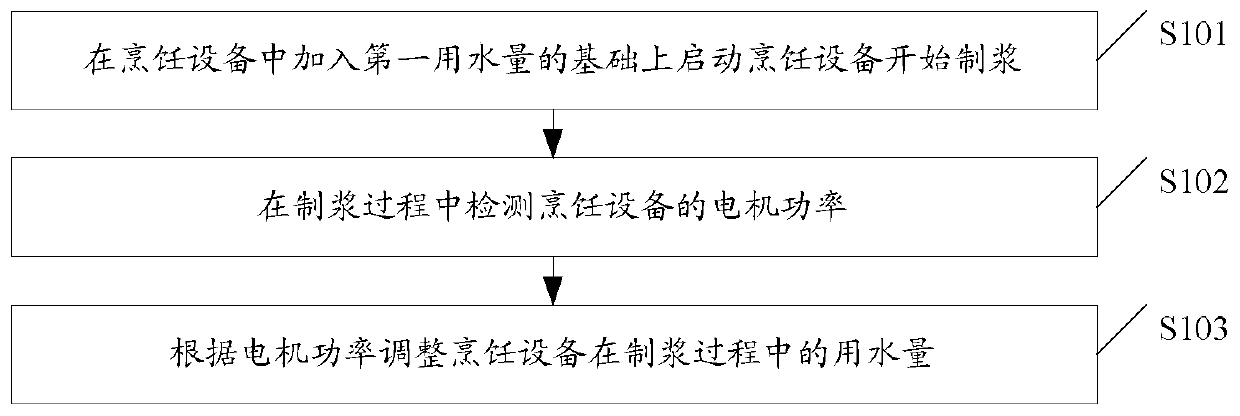

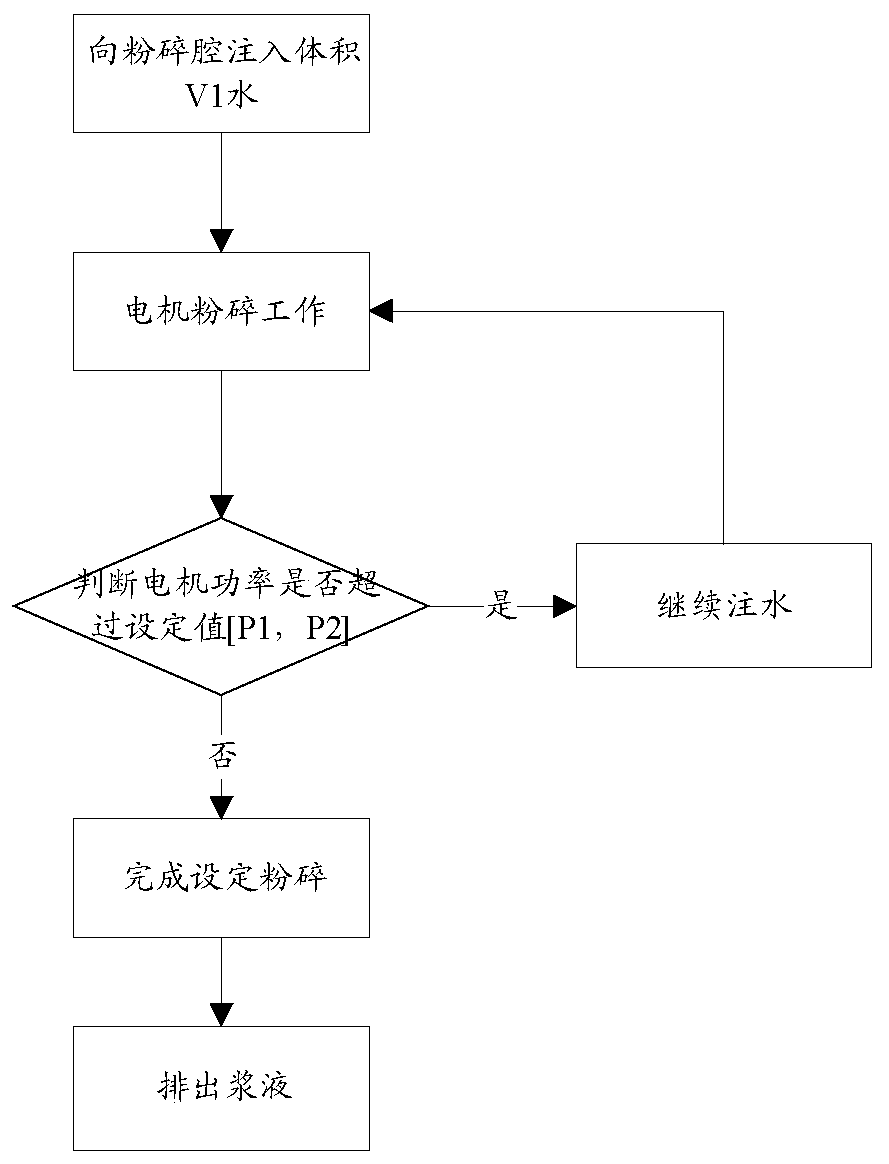

A kind of pulping control method

ActiveCN107198470BMeet factory requirementsMeet delivery habitsKitchen equipmentElectric machineryProcess engineering

An embodiment of the invention discloses a thick-liquid-making control method. The method includes: adding water into cooking equipment according to first water consumption, and starting the cooking equipment to start make thick liquid; detecting the motor power of the cooking equipment during the thick liquid making; regulating the water consumption during the thick liquid making according to the motor power. By the method, a reasonable material-water proportion range can be achieved.

Owner:JOYOUNG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com