Control method for food processing machine

A technology of a food processing machine and a control method, which is applied to beverage preparation devices, household appliances, applications, etc., can solve the problems of reducing grinding noise and motor power, existing overflow risks, and adjusting the working state of heating parameters, so as to reduce the overflow of slurry. Probability, ensuring the probability of slurry overflow, and improving the reliability of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

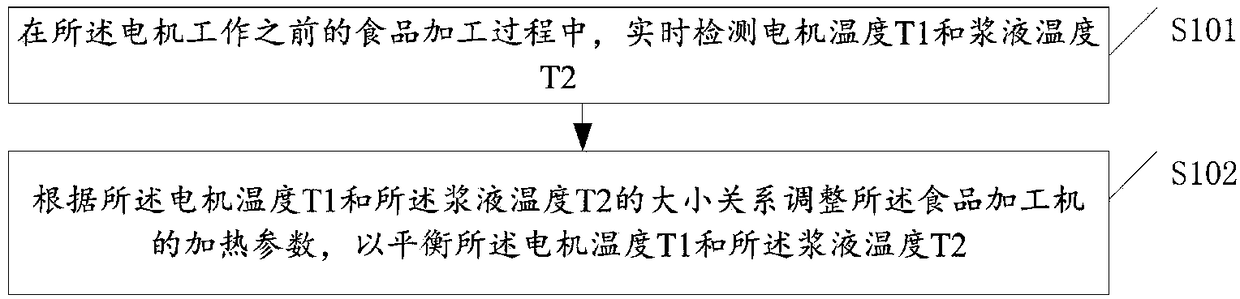

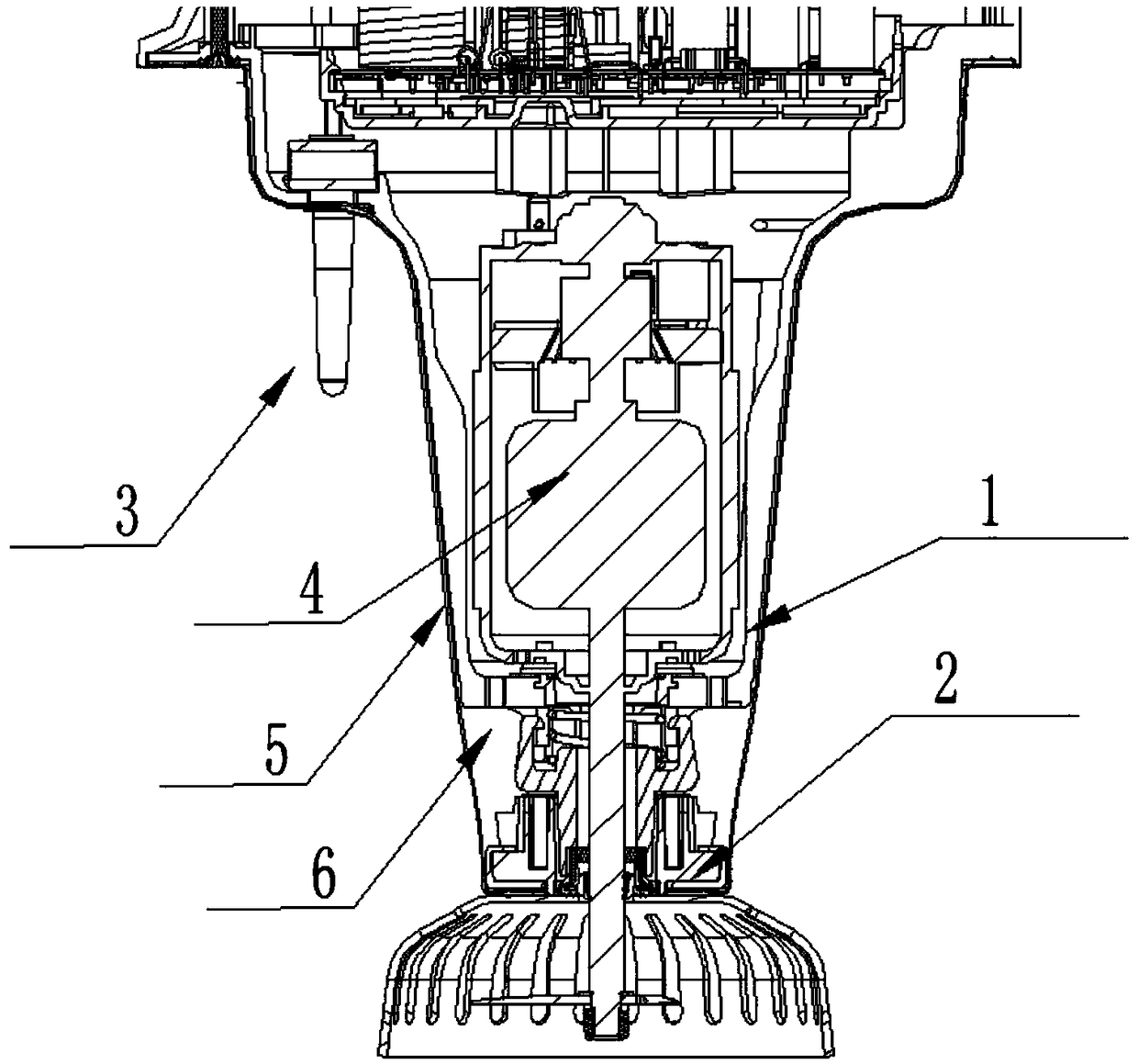

[0043] A control method of a food processing machine, the food processing machine includes a machine head, the machine head is provided with a motor; the machine head is provided with a first temperature sensor and a second temperature sensor, and the first temperature sensor For detecting the temperature of the motor, the second temperature sensor is used for detecting the temperature of the slurry; as figure 1 As shown, the method may include steps S101-S102:

[0044] S101. During the food processing process before the motor works, detect the motor temperature T1 and the slurry temperature T2 in real time;

[0045] S102. Adjust the heating parameters of the food processor according to the magnitude relationship between the motor temperature T1 and the slurry temperature T2, so as to balance the motor temperature T1 and the slurry temperature T2; the heating parameters include: heating power, Heating time and / or waiting time.

[0046] Existing food processors can only judge...

Embodiment 2

[0056] On the basis of the first embodiment, this embodiment provides another embodiment for adjusting the heating parameters according to the motor temperature T1 and the slurry temperature T2.

[0057] In an exemplary embodiment of the present invention, the method may further include: according to the magnitude relationship between the motor temperature T1 and the slurry temperature T2, and the relationship between the motor temperature T1 and the slurry temperature T2 and a first preset The temperature T0, the slurry heating target temperature Tx and / or the slurry boiling temperature Td adjust the heating parameters.

[0058] In an exemplary embodiment of the present invention, before the motor works, the main control can combine the slurry temperature T2, the motor temperature T1, the boiling temperature Td, the boiling temperature deviation value ΔTd, the main control set temperature T0, and the heating target temperature Tx Logical relationship, comprehensive adjustment...

Embodiment 3

[0078] On the basis of the first or second example, this example provides an example plan for determining the adjustment range of the heating parameters according to different pulping capacities and / or different food processing stages.

[0079] In an exemplary embodiment of the present invention, the method may further include: determining the adjustment range of the heating parameter according to different pulping capacities and / or different food processing stages.

[0080] In an exemplary embodiment of the present invention, firstly, different heating parameters can be set according to different slurry capacities.

[0081] In an exemplary embodiment of the present invention, the determining the adjustment range of the heating parameter according to different pulping capacities and / or different food processing stages may include: when the current pulping capacity is within a range of different pulping capacities , the adjustment range of the heating parameter is determined ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com