Patents

Literature

108results about How to "Good pulping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

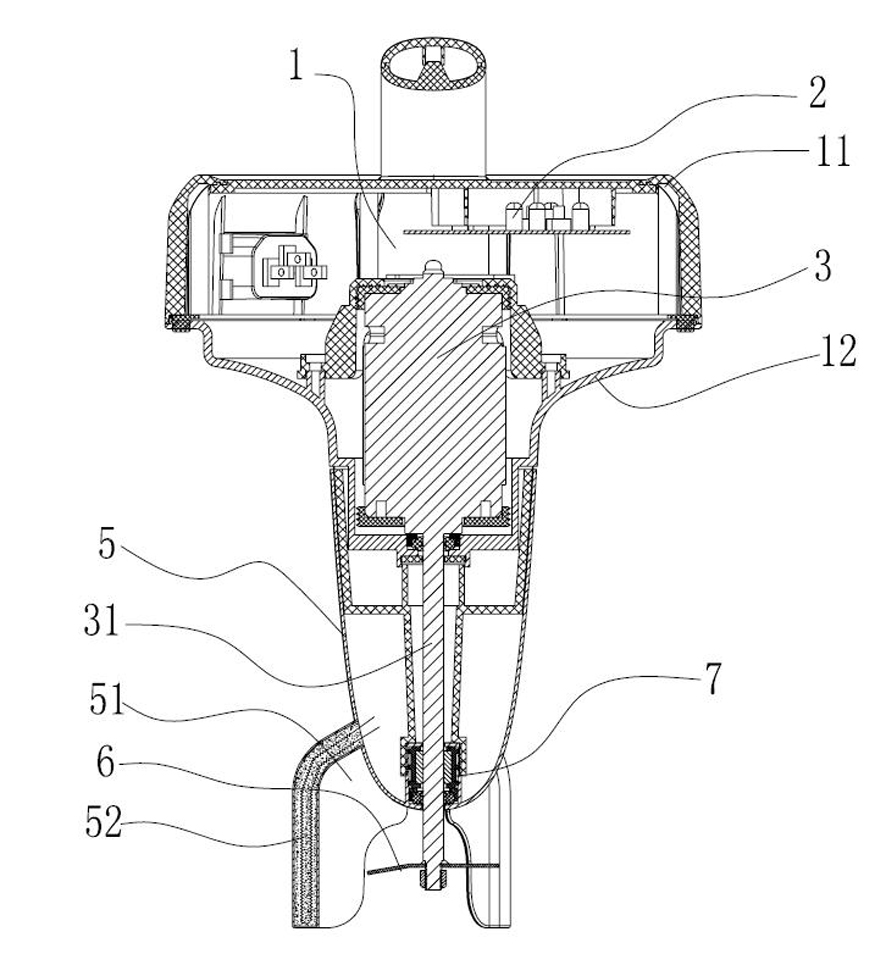

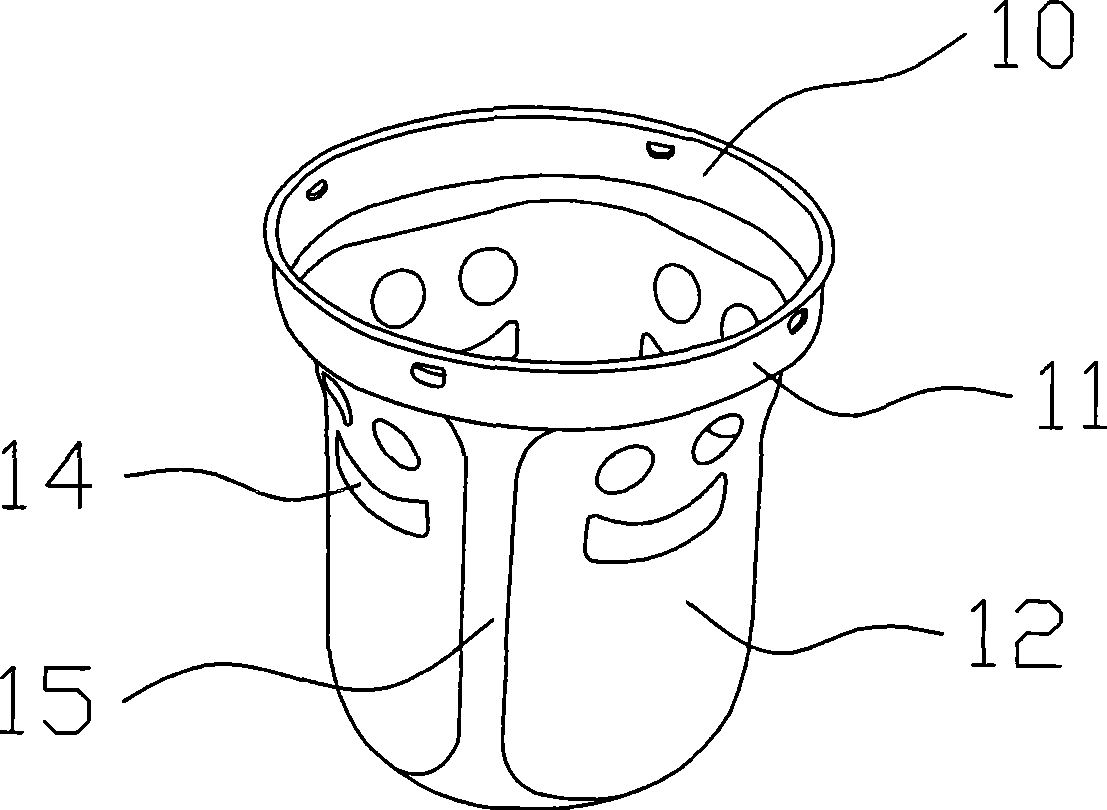

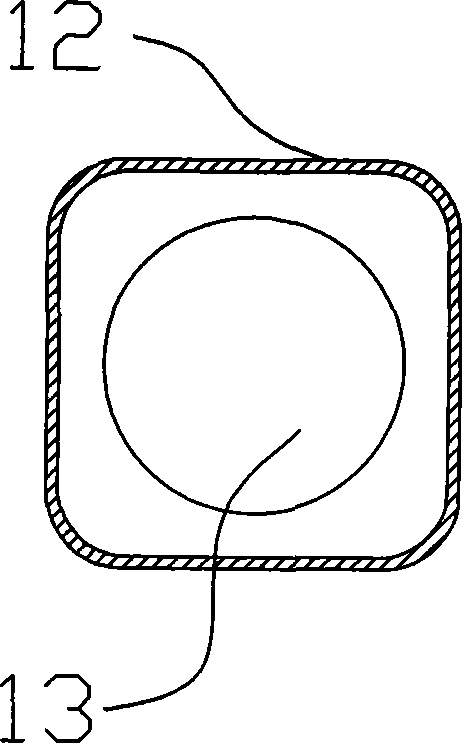

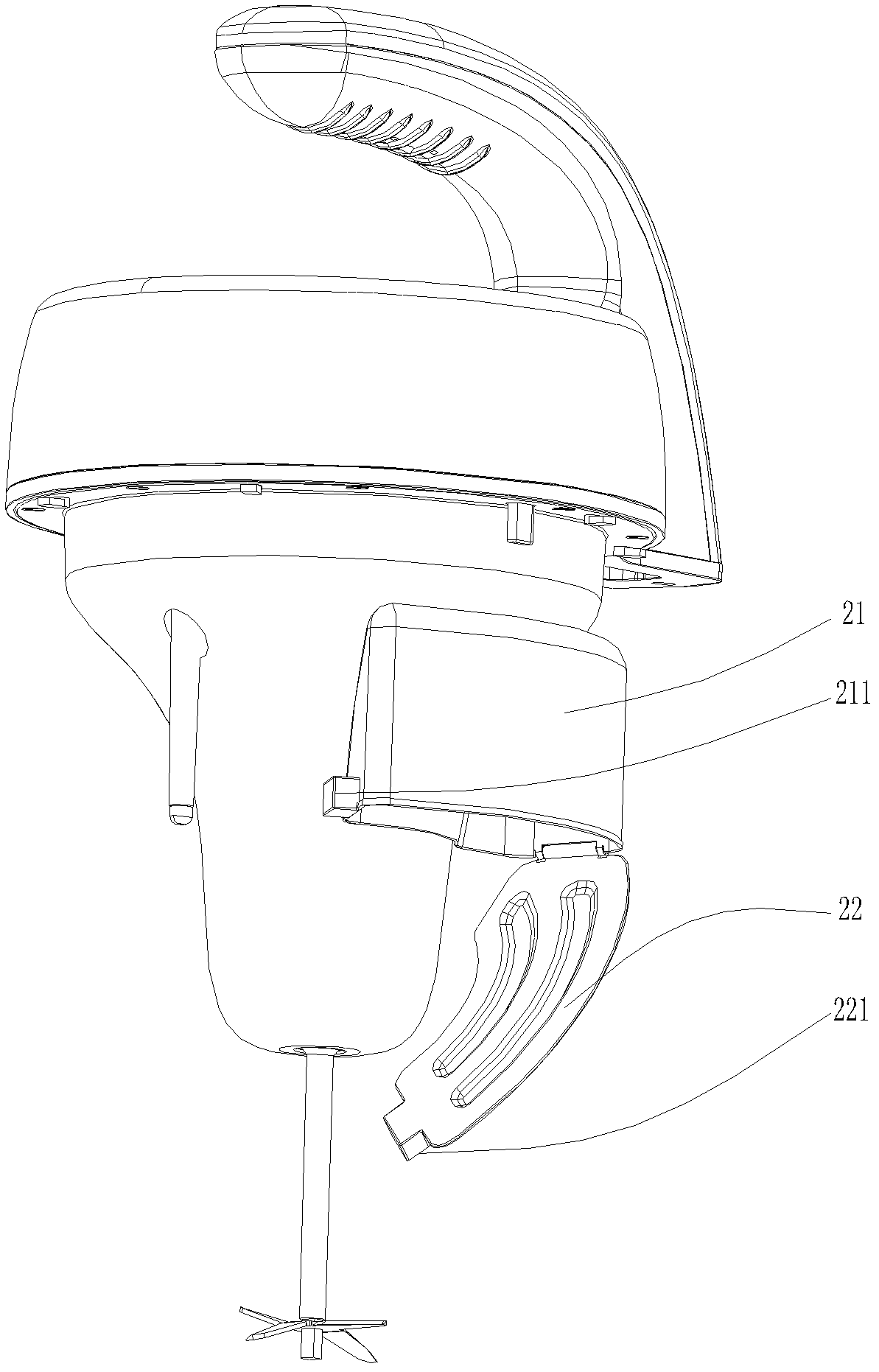

Soymilk grinder

ActiveCN102018053AGood pulping effectSimple structureBeverage vesselsMilk substitutesEngineeringMechanical engineering

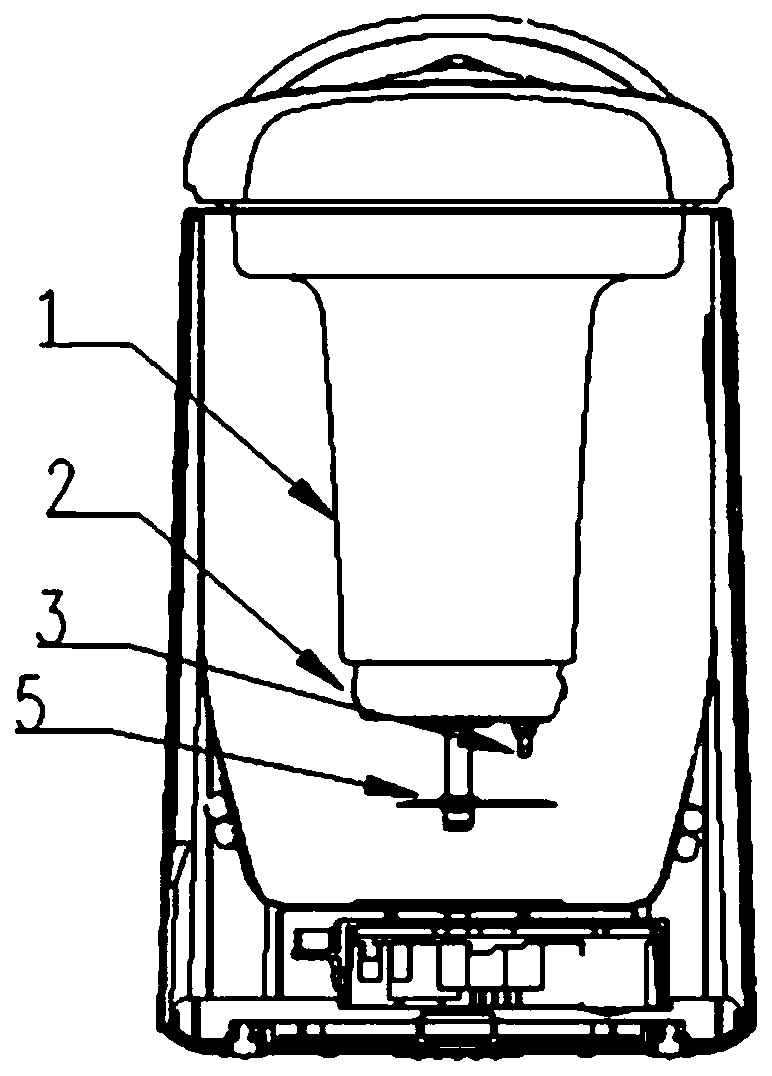

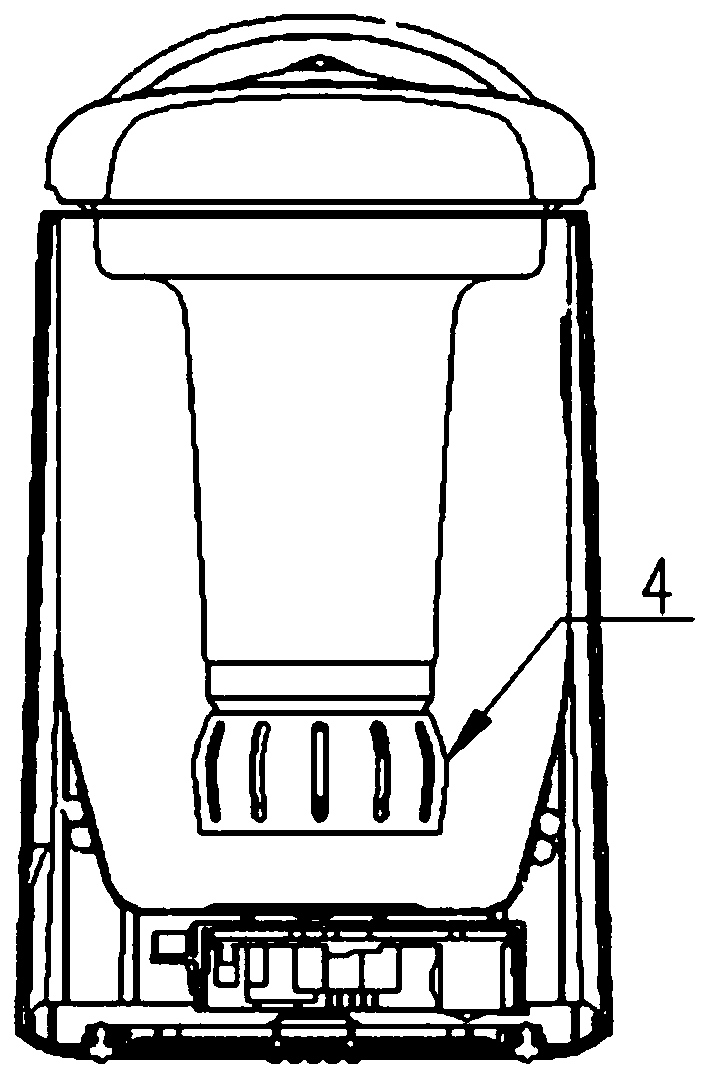

The invention relates to a soymilk grinder. The soymilk grinder comprises a soymilk container with a top opening and a motor serving as a power source, wherein the motor is accommodated in a motor shell; an output shaft passes through the motor shell and extends into the soymilk container; and the tail end of the output shaft of the motor is connected with a crushing blade. The soymilk grinder ischaracterized by also comprising a turbulence frame and a limiting stopper, wherein the turbulence frame is sleeved on a part of the output shaft between the motor shell and the crushing blade; and the limiting stopper is fixedly arranged at a position corresponding to the turbulence frame. Compared with the prior art, the soymilk grinder with the turbulence frame and the related structures in the technical scheme has the advantages that the turbulence frame is distributed around the crushing blade, so that the effect of making soymilk is improved; moreover, the turbulence frame of the soymilk grinder in the technical scheme is convenient to process and manufacture, so that the whole machine has a great advantage in the manufacturing cost.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Additive for anode material of lithium ion battery, preparation method of additive, positive electrode material containing additive and lithium ion battery

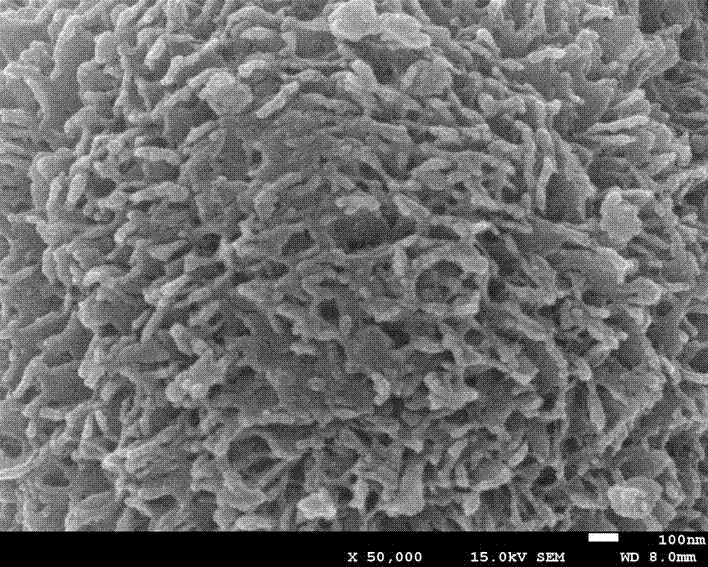

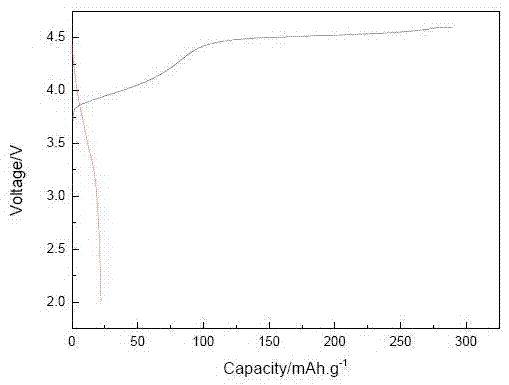

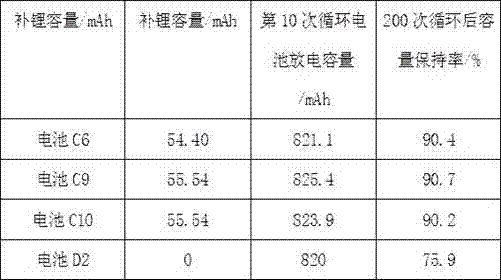

InactiveCN106898737AImprove cycle performanceHelp conductionFinal product manufactureCell electrodesPorosityLithium-ion battery

The invention provides an additive for a positive electrode material of a lithium ion battery, a preparation method of the additive, a positive electrode material containing the additive and the lithium ion battery. The additive has a core-shell structure; a core material contains silane coupling agent modified inorganic lithium salt, and a shell material contains a low-melting-point polymer and a conductive carbon material; and the porosity of a shell is 0.01%-20%. By adding the additive into the positive electrode material of the lithium ion battery, rich lithium at a cathode is realized; and compared with a routine method of supplementing lithium to the positive electrode or the cathode by directly adding active lithium, the safety is relatively high.

Owner:BYD CO LTD

Capacity-self-adaptive pulping method

ActiveCN104872292AAccurate measurementPrecise pulping capacityMilk substitutesThermal energyElectricity

The invention relates to a capacity-self-adaptive pulping method which comprises the following stages: (1), a preheating stage, to be specific, starting a heating device for heating to T1, continuously heating to T2, wherein delta T is equal to T2 minus T1, calculating out electric energy consumed when the temperature is increased to T2 from T1 by a control device, wherein a preset heat efficiency coefficient eta and a specific heat capacity c are stored in the control device, m represents the pulping capacity, and W<electricity> represents electric energy, and calculating out the pulping capacity by the control device according to the law of conservation of energy, namely heating electric energy*eta is equal to thermal energy absorbed during temperature increase and the formula is that (eta)W<electricity> is equal to cm(delta)T; (2), a smashing stage, to be specific, adjusting smashing frequency, smashing time and / or smashing power by the control device according to the pulping capacity; (3), a decocting stage, to be specific, adjusting the heating time and / or heating power by the control device according to the pulping capacity. Therefore, intelligent optimization of pulping parameters is realized and an optimum pulping effect is realized.

Owner:HONGYANG HOME APPLIANCES

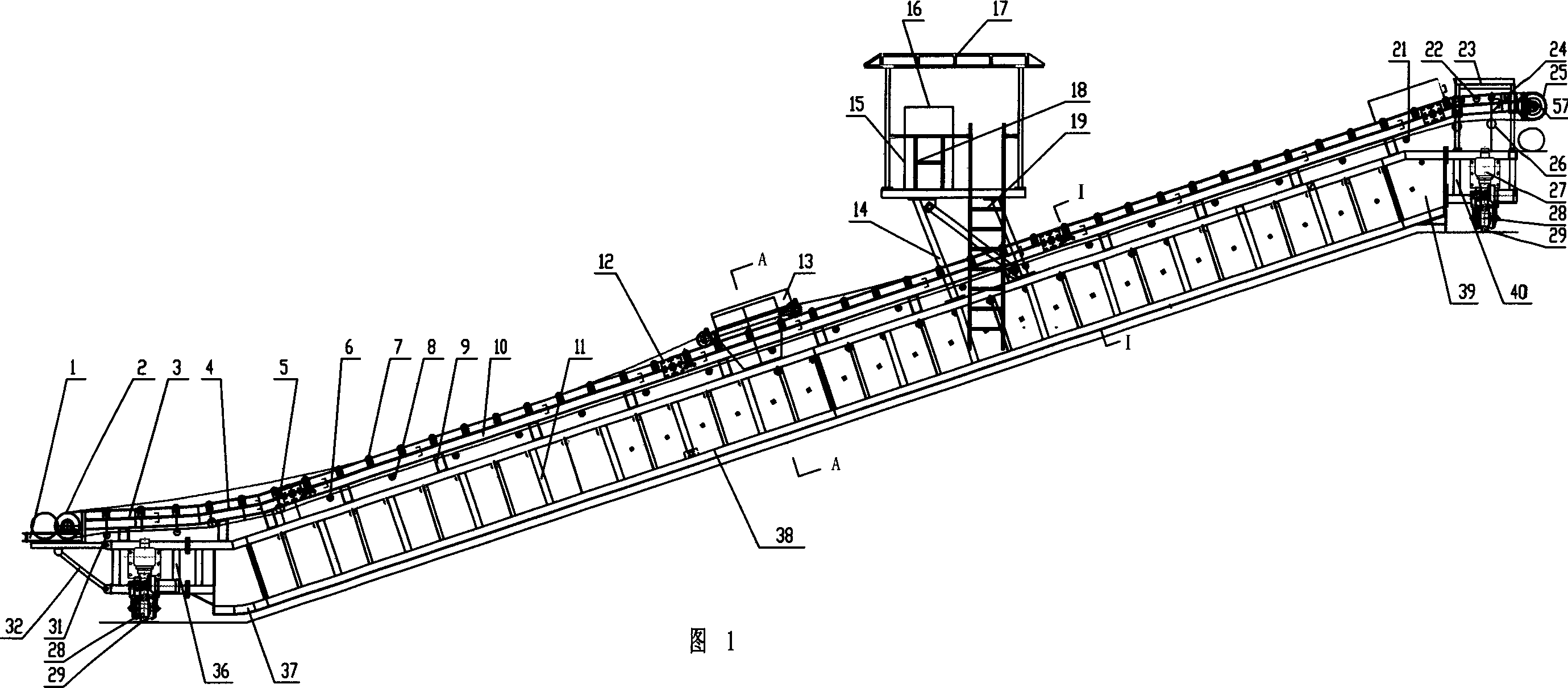

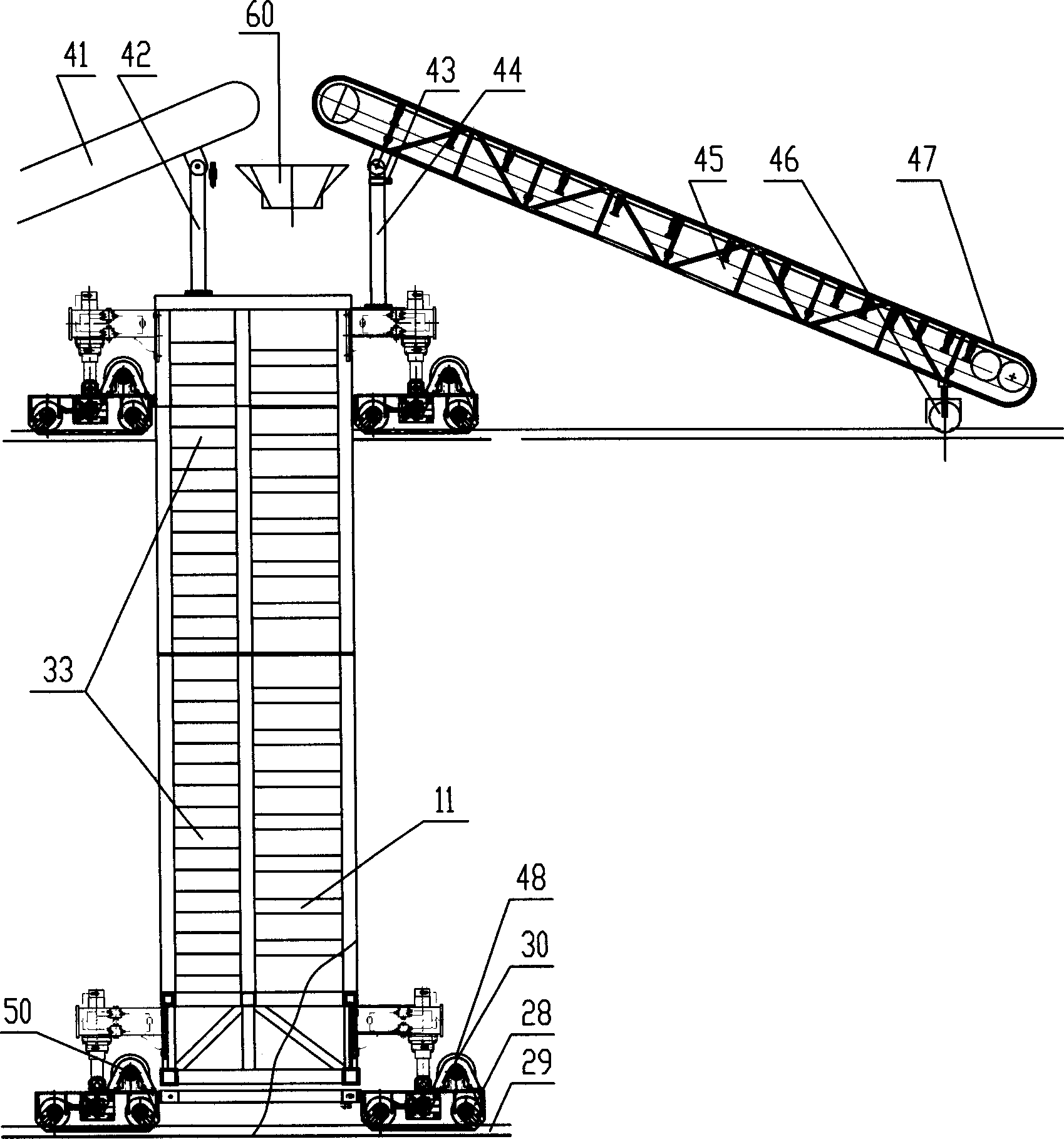

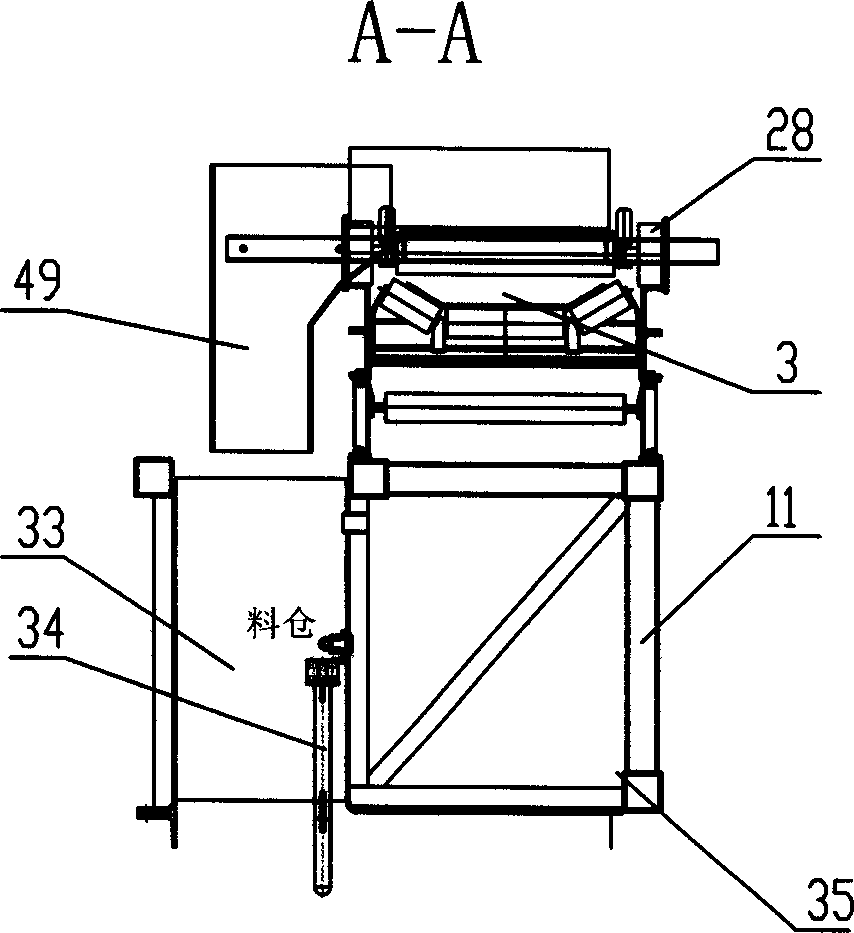

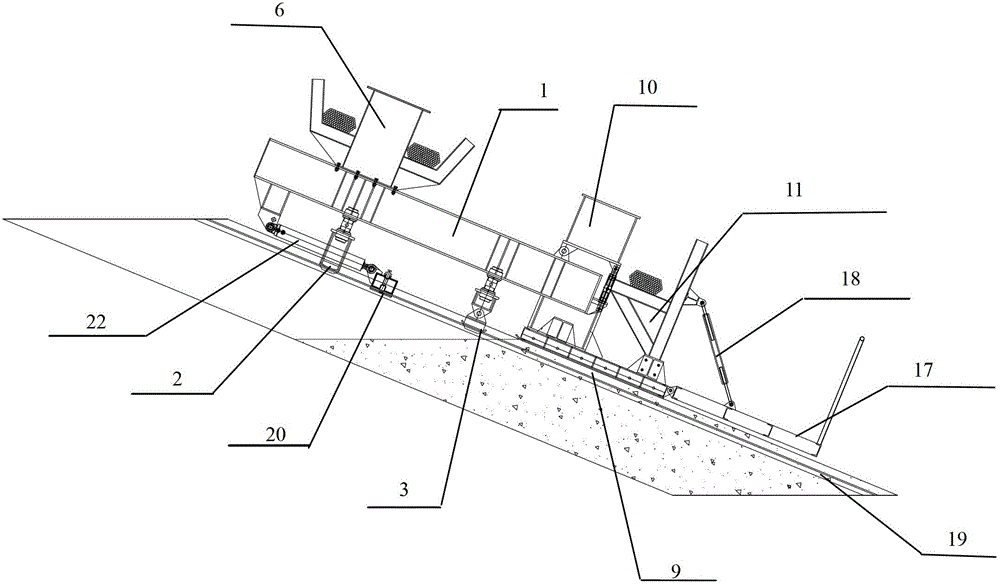

Long slope vibratory slipform shaping mill

InactiveCN1789565AHigh density and uniformFast constructionIrrigation ditchesBuilding material handlingResonanceEngineering

This invention relates to long slope resonance module shaping machine in water mechanic filed, wherein the machine comprises Power source, , control device, distribution device with move structure with feeding device. The device is characterized by the following: the distribution device comprises relative racket with cloth transmission band fixed; the band is set with mobile distribution cargo; the distribution transmission band side is set with materials barrel with electrical resonance heads; the cargo has materials bin relative to the one of transmission band. The invention is of simple structure and easy maintenance and of low cost and simple operation.

Owner:耿福明 +1

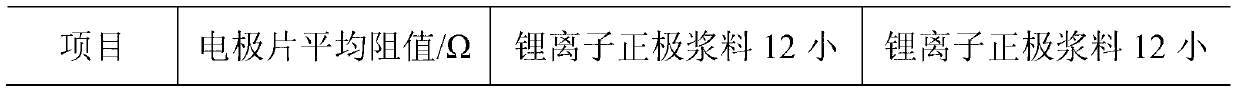

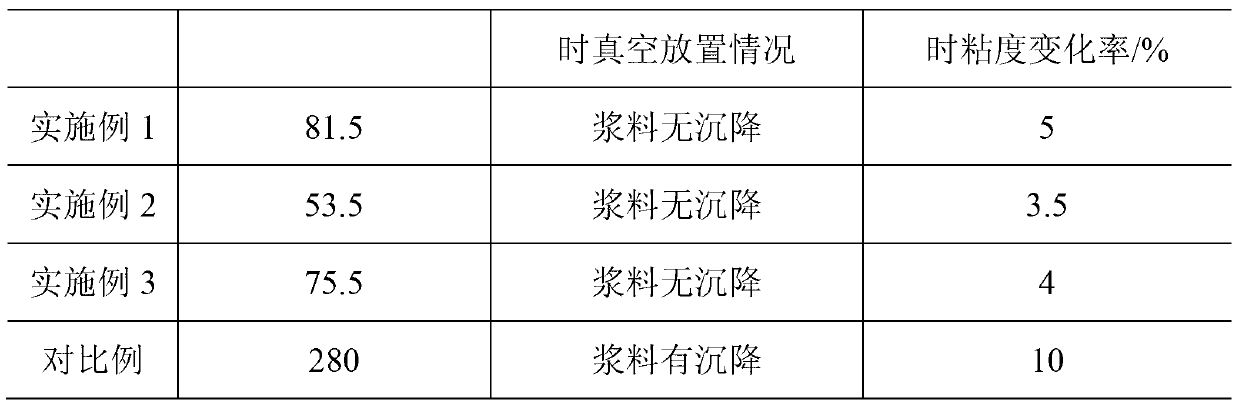

Li-ion positive electrode slurry and preparation method thereof

InactiveCN103346318AEvenly dispersedSolve the defect of easy reunionCell electrodesLithium iron phosphatePyrrolidinones

The invention provides a Li-ion positive electrode slurry and a preparation method thereof. The preparation method comprises the following steps of: mixing lithium iron phosphate and dry inorganic conductive agent powder, wherein uniform mixing is judged by randomly sampling and measuring the resistance value of the powder, and is considered to be achieved when the difference of the resistance value of each sample powder is less than 5%; then adding PVDF (Polyvinylidene Fluoride) colloidal fluid into the mixture step by step; finally regulating the viscosity of the slurry by utilizing 1-Methyl-2-pyrrolidinone, thereby obtaining the Li-ion positive electrode slurry. The viscosity of the Li-ion positive electrode slurry is 3000-5000cps, and the Li-ion positive electrode slurry comprises 1-methyl-2-pyrrolidinone, as well as lithium iron phosphate, polyvinylidene fluoride and the inorganic conductive agent which are at a mass ratio of (85-95):(3-8):(2-10). According to the preparation method, whether the inorganic conductive agent is uniformly dispersed in lithium iron phosphate is determined by a method of randomly sampling dry powder, mixing samples and measuring the resistance values, and meanwhile, the PVDF colloidal fluid is added step by step in a substep slurry preparation process, so that the conventional thought of firstly mixing solid materials and adding the colloidal fluid in one step in a slurry preparation process in the field is broken through, and a favorable slurry preparation effect is achieved.

Owner:IRICO

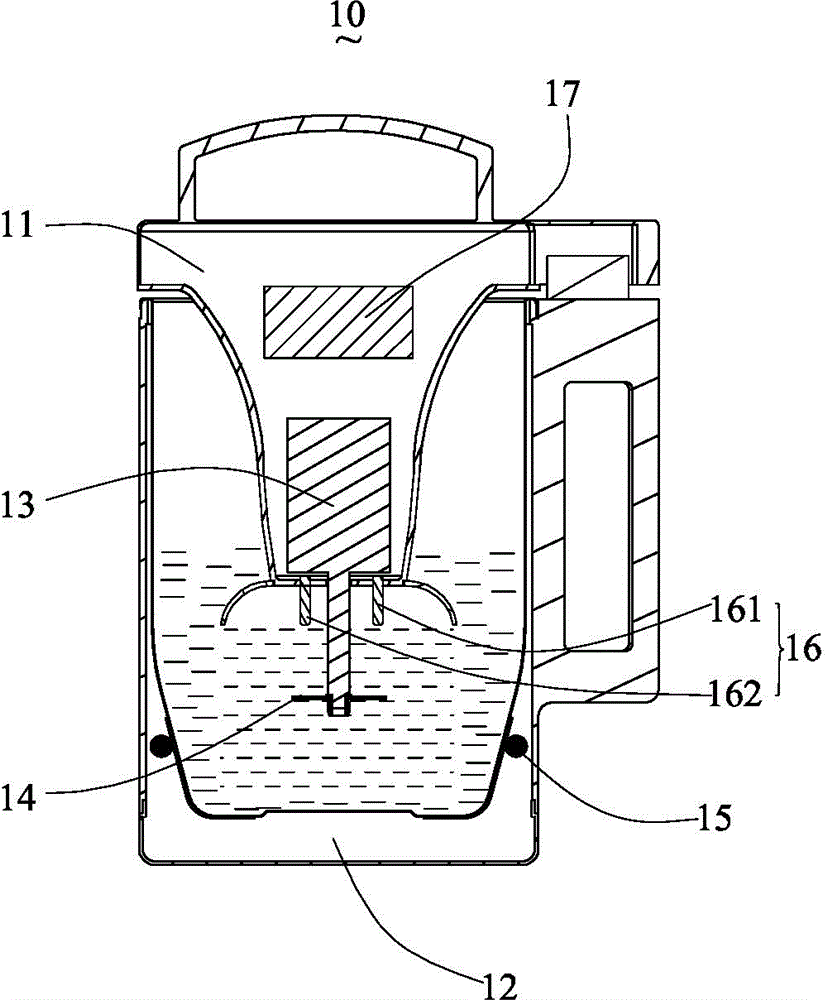

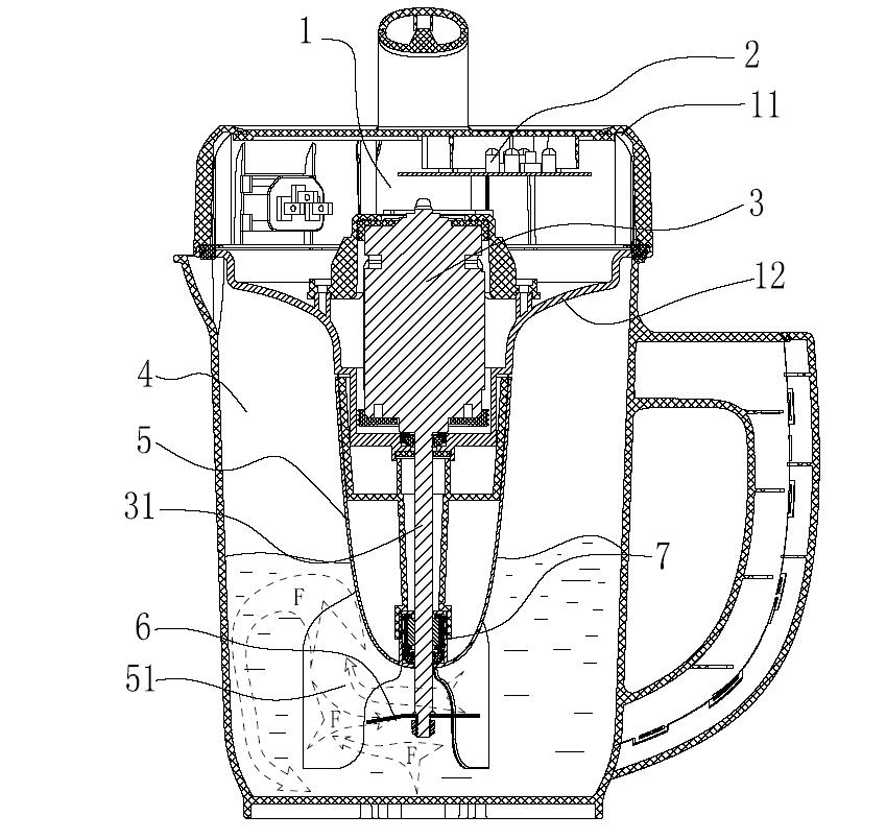

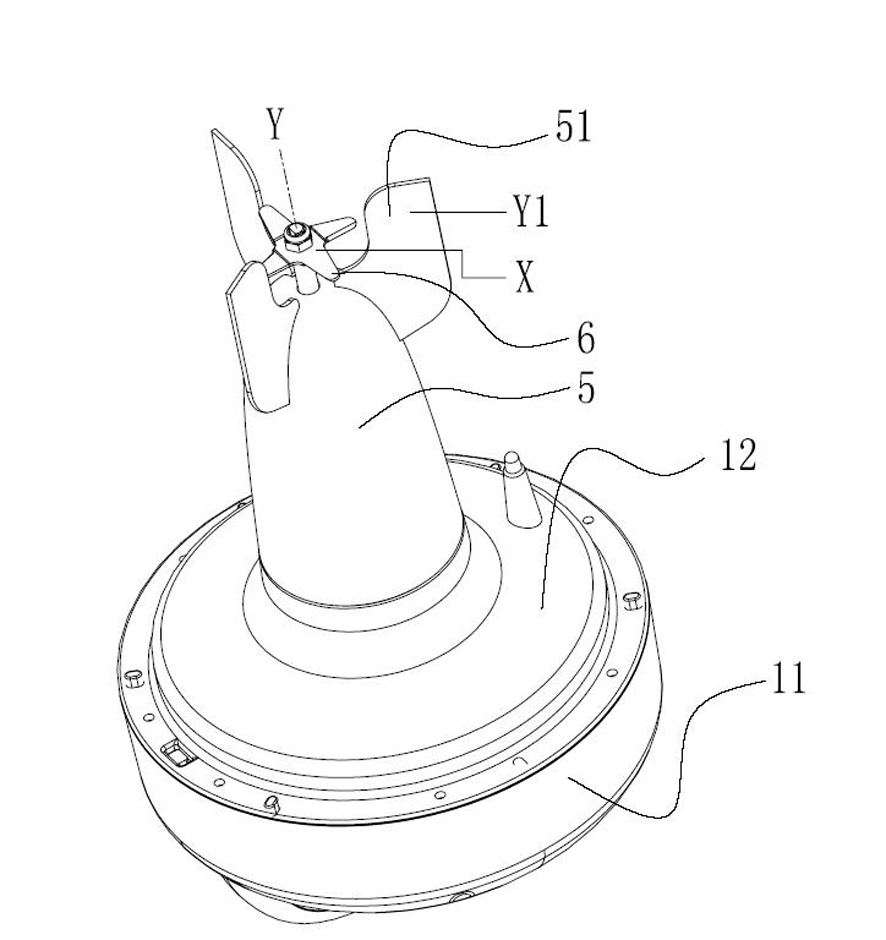

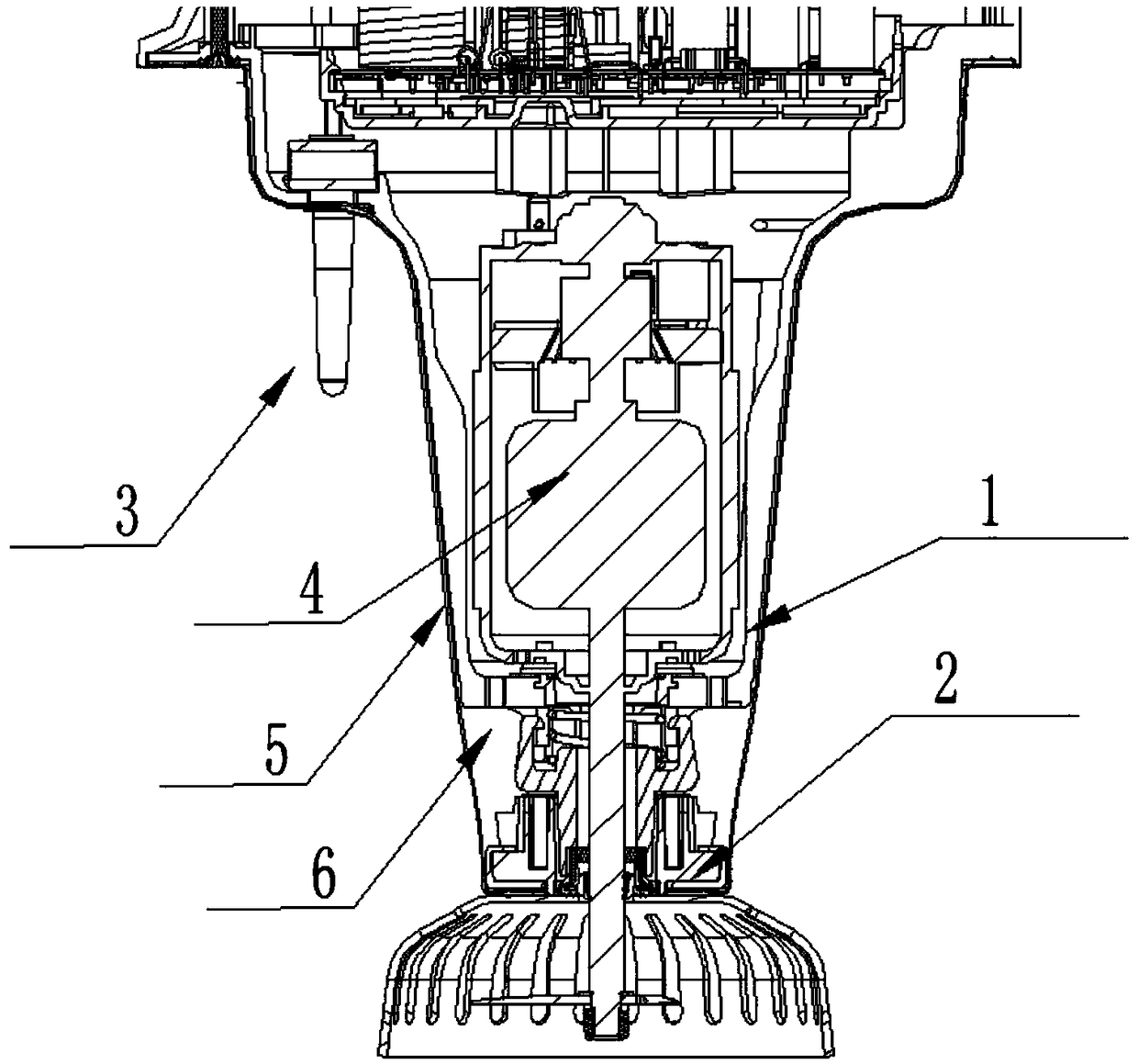

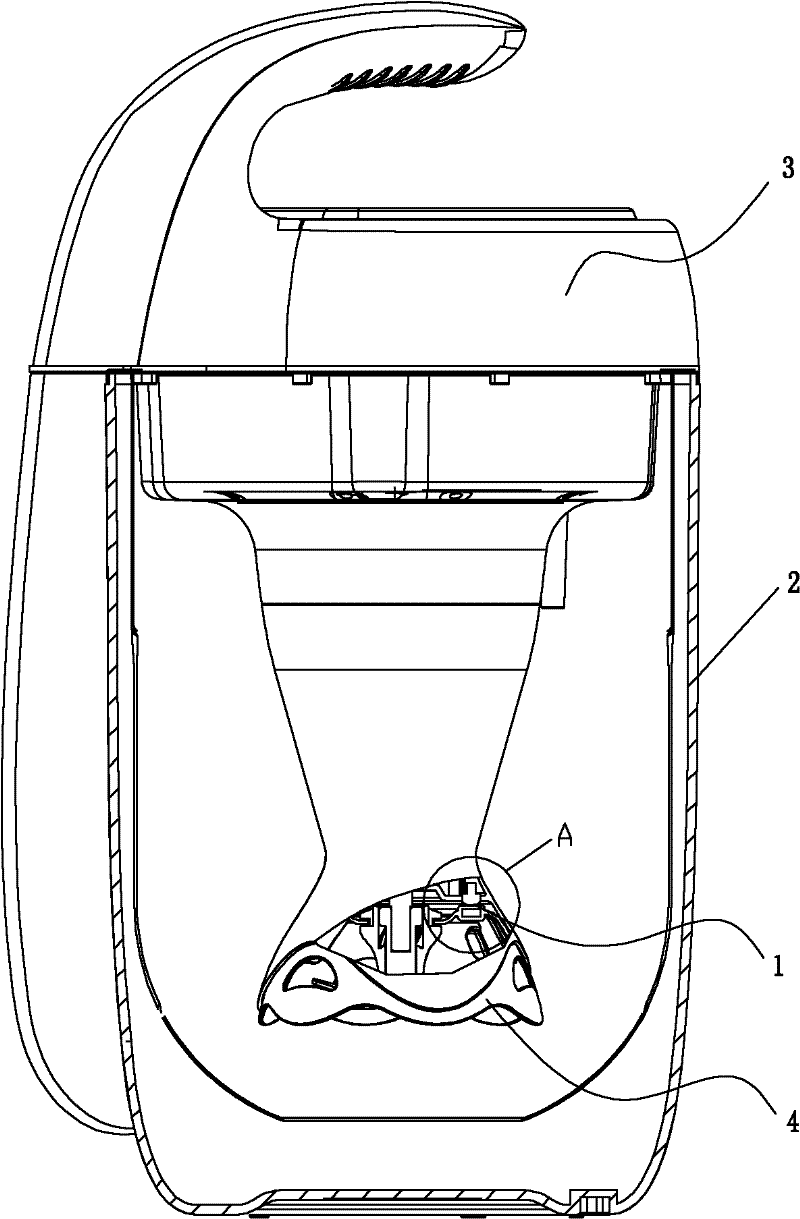

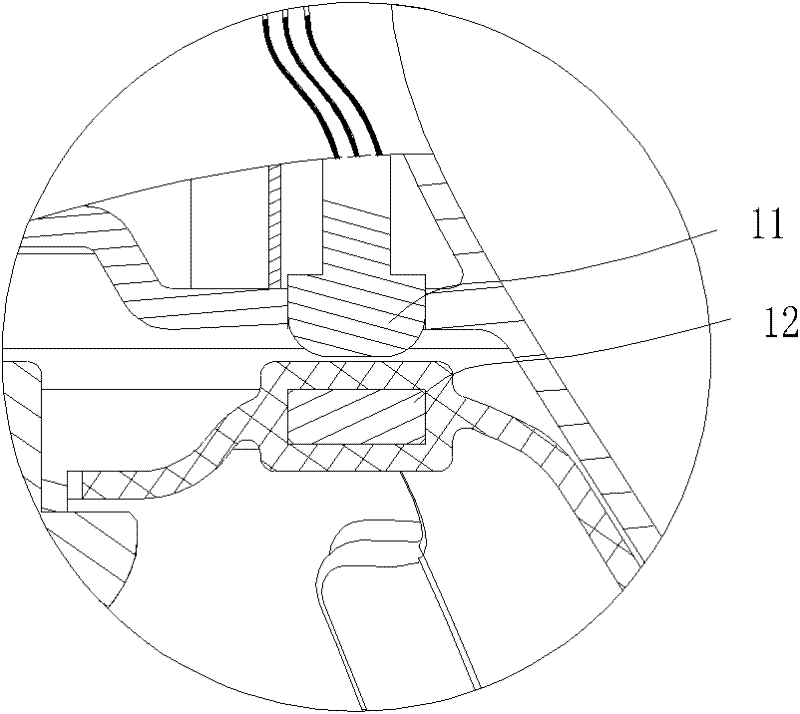

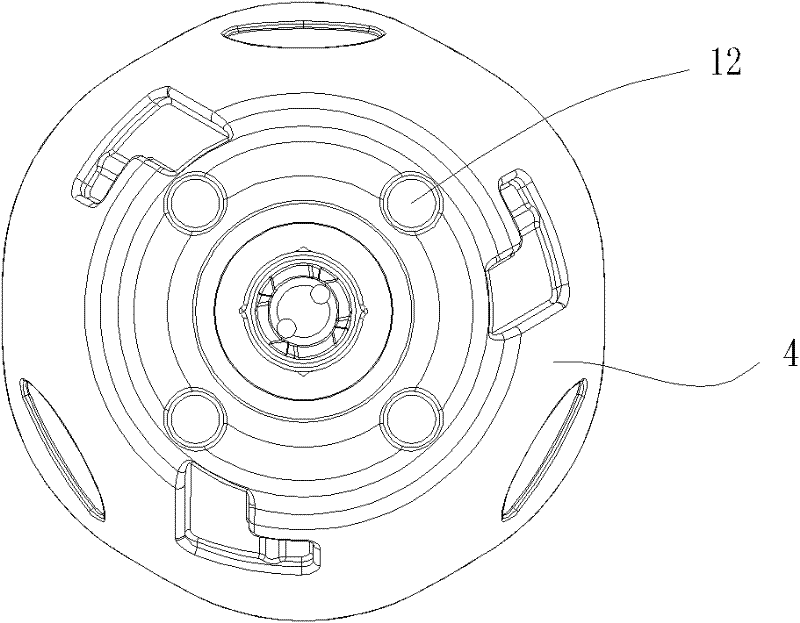

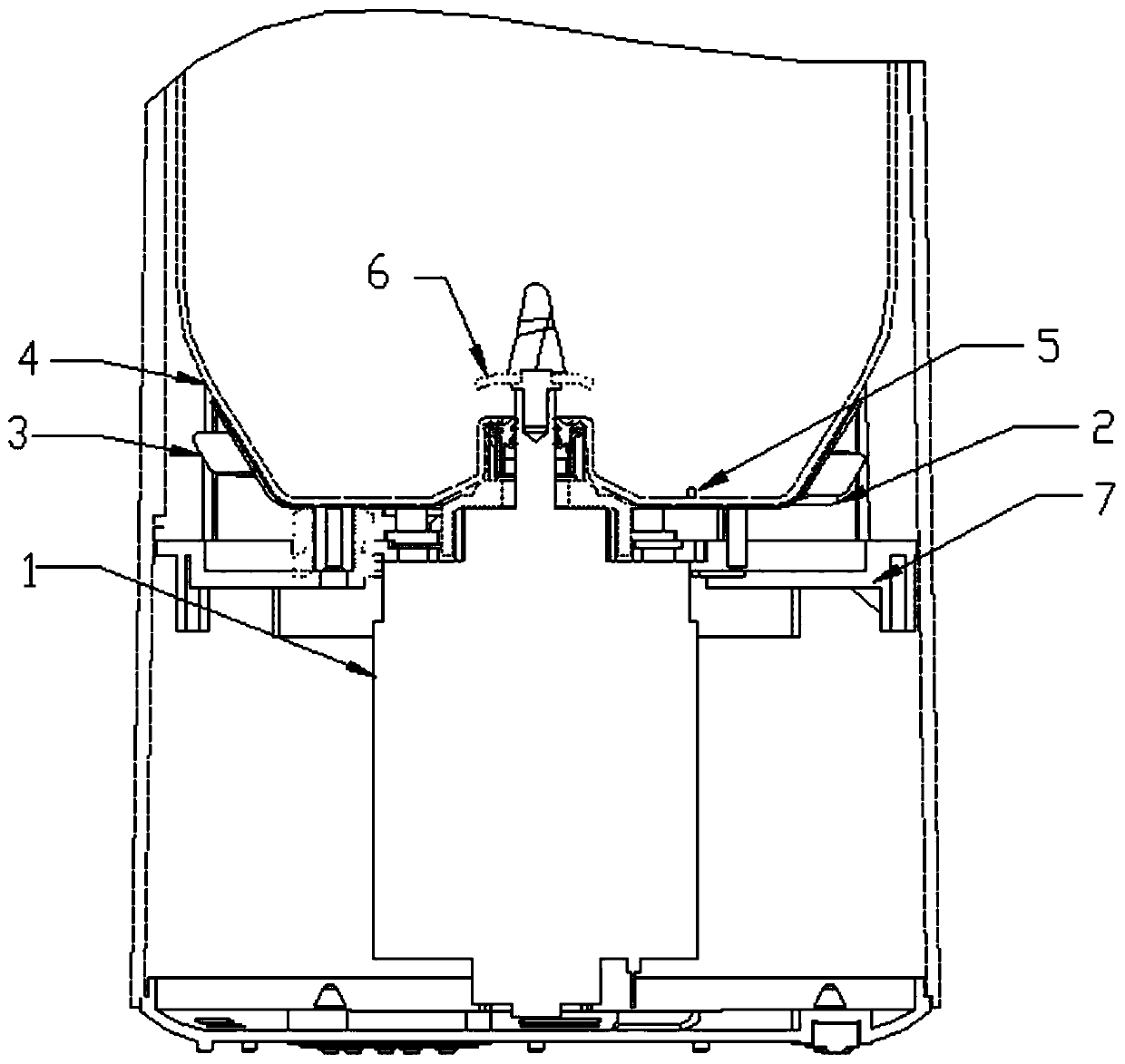

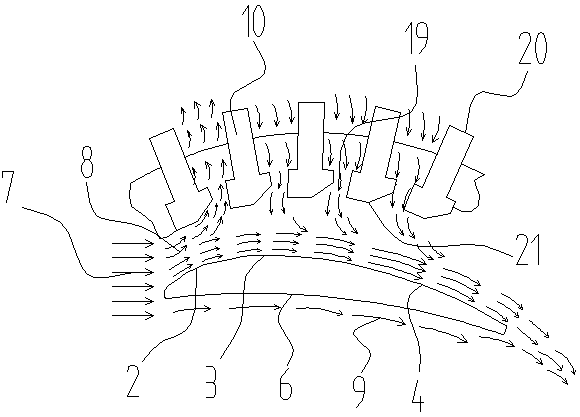

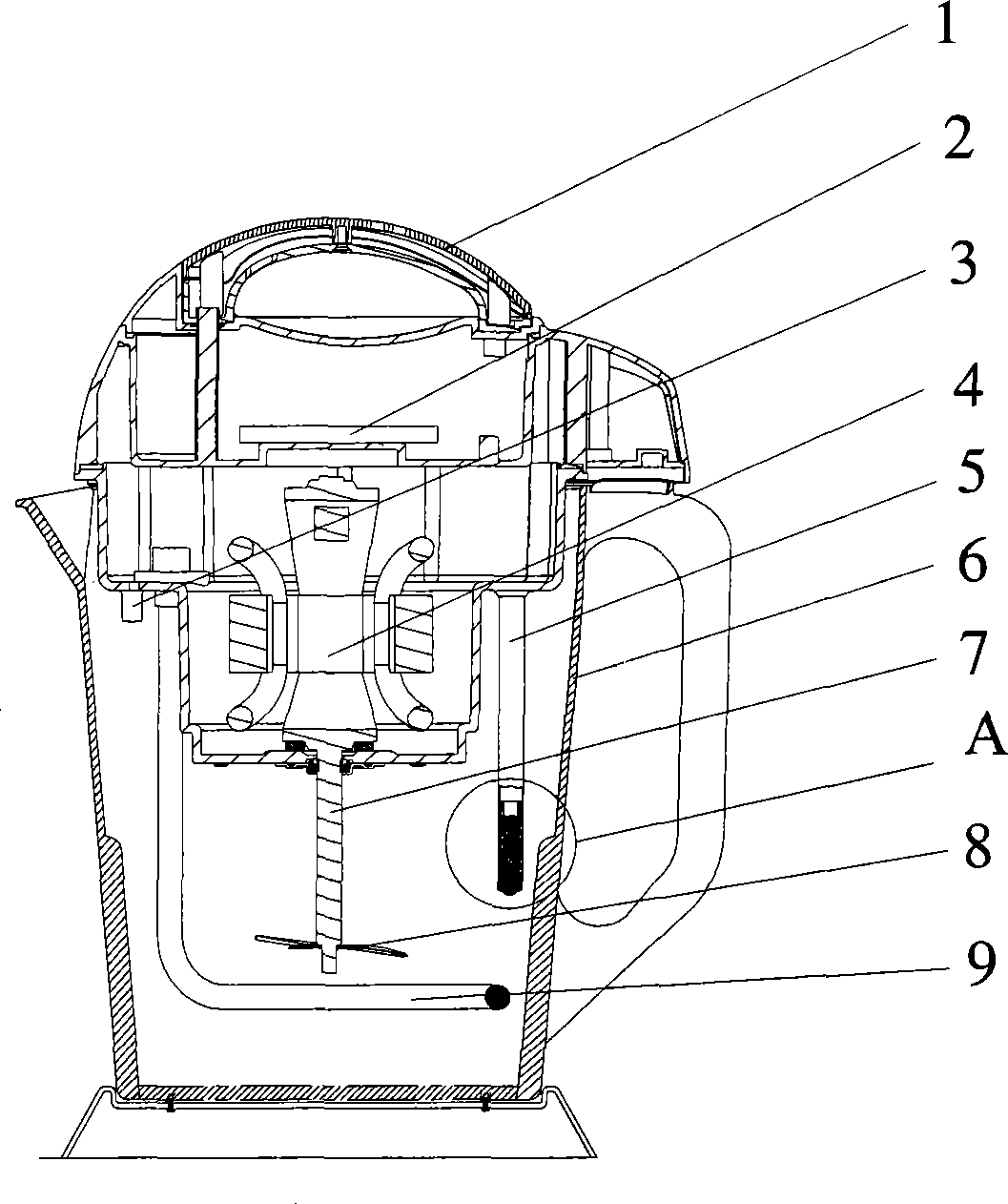

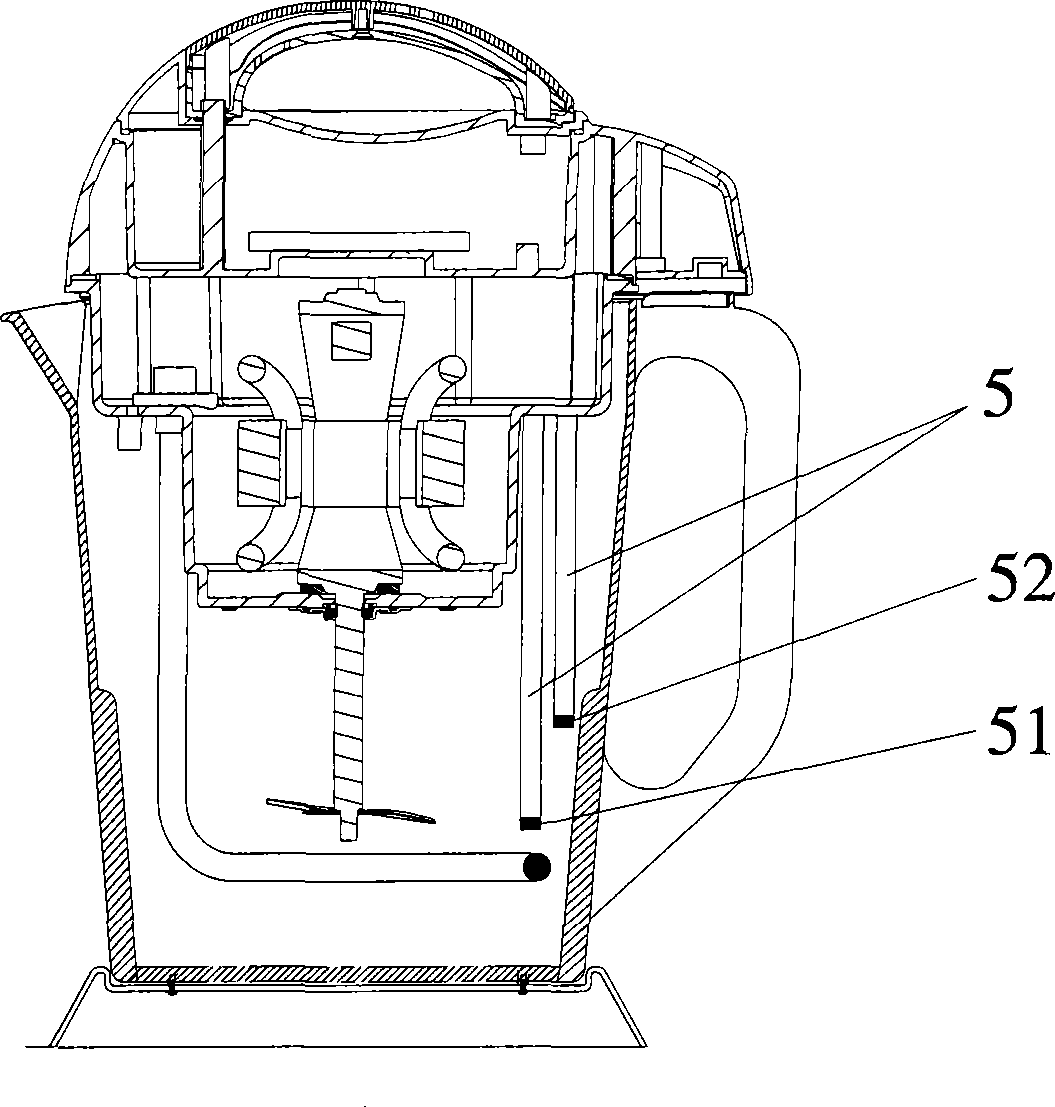

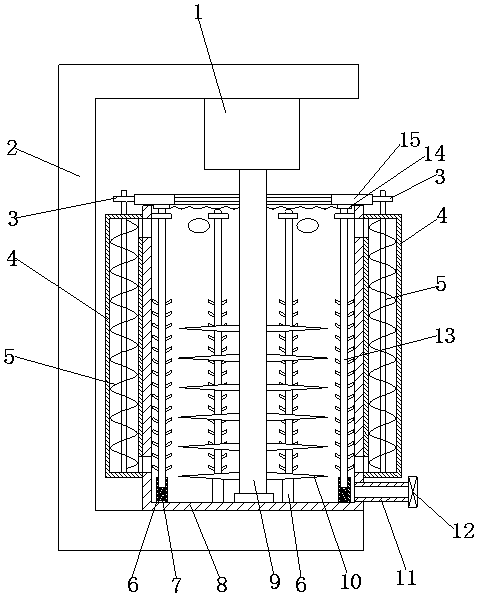

Soybean milk machine

ActiveCN101919447AGood pulping effectBeverage vesselsMilk substitutesEngineeringMechanical engineering

The invention relates to a soybean milk machine, which comprises a soybean milk container (4), a motor (3), a knife shaft (31) and a rotating knife (6), wherein the input end of the knife shaft (31) is connected with the motor (3), the rotating knife (6) is connected at the output end of the knife shaft (31), and the rotating knife (6) is positioned in a space formed by the soybean milk container (4). The soybean milk machine is characterized in that: the periphery of the rotating knife (6) is provided with a static knife (51) which is arranged on a static knife support body (5) positioned in the space formed by the soybean milk container (4). The scheme of the soybean milk machine is favorable for generating longitudinal guide effect during making milk to form circulating material flow F from bottom to top and from inside to outside from the center of the knife shaft to the inner wall of the soybean milk container so as to increase the cutting frequency of the material and the rotating knife; and meanwhile, under the drive of the high-speed rotating knife, the rotating material flow F is collected into a flow bundle by using the knife shaft as a center, the material collides with the surface of the static knife at a high speed, and the crushing modes comprise active cutting and crushing of the movable knife and passive cutting and crushing of the static knife, so the crushing frequency is increased and the crushing effect is promoted.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

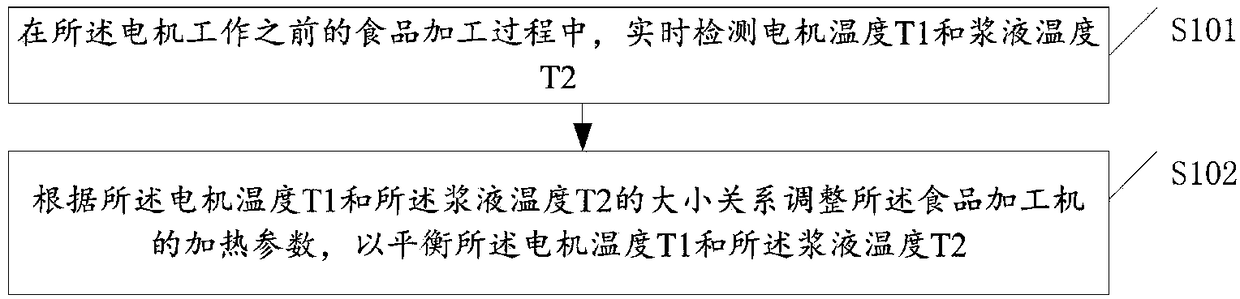

Control method for food processing machine

The embodiment of the invention discloses a control method for a food processing machine. The food processing machine comprises a machine head, and the machine head is provided with a motor; a first temperature sensor and a second temperature sensor are disposed on the machine head, the first temperature sensor is used for detecting the temperature of the motor, and the second temperature sensor is used for detecting the temperature of pulp. The method comprises: in the food processing process before the motor operates, detecting a motor temperature T1 and a pulp temperature T2 in real time; and according to the size relationship between the motor temperature T1 and the pulp temperature T2, adjusting heating parameters of the food processing machine to balance the motor temperature T1 andthe pulp temperature T2. Through the implementation of the scheme, the heating parameters can be adaptively adjusted by detecting the motor temperature and the pulp temperature in the machine head ofthe food processing machine during the food processing stage, thereby avoiding the risk of pulp overflow, improving the pulping effect, and improving the user experience.

Owner:JOYOUNG CO LTD

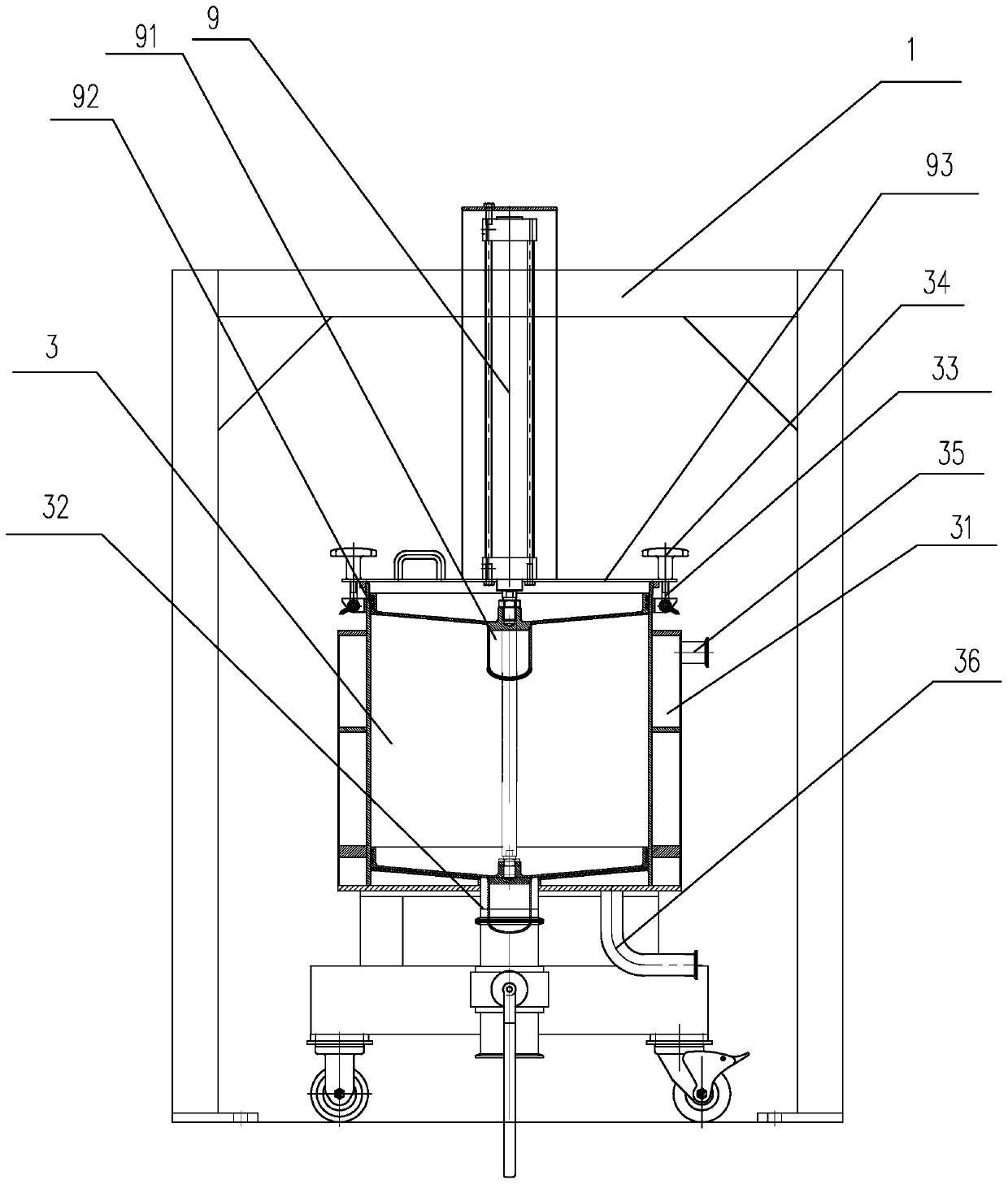

Pulp mixing device

PendingCN110193320AAvoid cloggingAvoid badRotary stirring mixersTransportation and packagingPulp and paper industryMixing effect

The invention discloses a pulp mixing device, which comprises a mounting frame, a pulp mixing tank, a pulp adding tank, a cooling mechanism and a pulp discharging mechanism, wherein a pulp adding tankis movably arranged below the pulp mixing tank, the cooling mechanism and the pulp discharging mechanism; a mass scale is arranged below the pulp adding tank; a stirring cavity is formed in the pulpmixing tank; a stirring valve is arranged in the stirring cavity; a stirring motor is arranged on the pulp mixing tank; a discharge port is arranged at the bottom of the stirring cavity; an oil bath cavity is formed between the pulp mixing tank and the stirring cavity; and the cooling mechanism comprises a lifting cylinder and a lifting seat. The lifting seat is provided with a rotating paddle anda rotating motor, the lifting cylinder is arranged on a mounting frame, the output end of the lifting cylinder is connected with the lifting seat, the pulp discharging mechanism comprises a piston and a driving cylinder, the piston is connected with the output end of the driving cylinder, the piston is provided with an elastic sealing ring along the circumferential direction, and the bottom of the pulp adding tank is provided with a pulp outlet. The pulp mixing device has simple structure, good pulp mixing effect, and simultaneously has the functions of conveying, cooling and extruding pulp,thereby improving the production and processing efficiency.

Owner:ZHEJIANG CANAAN TECH

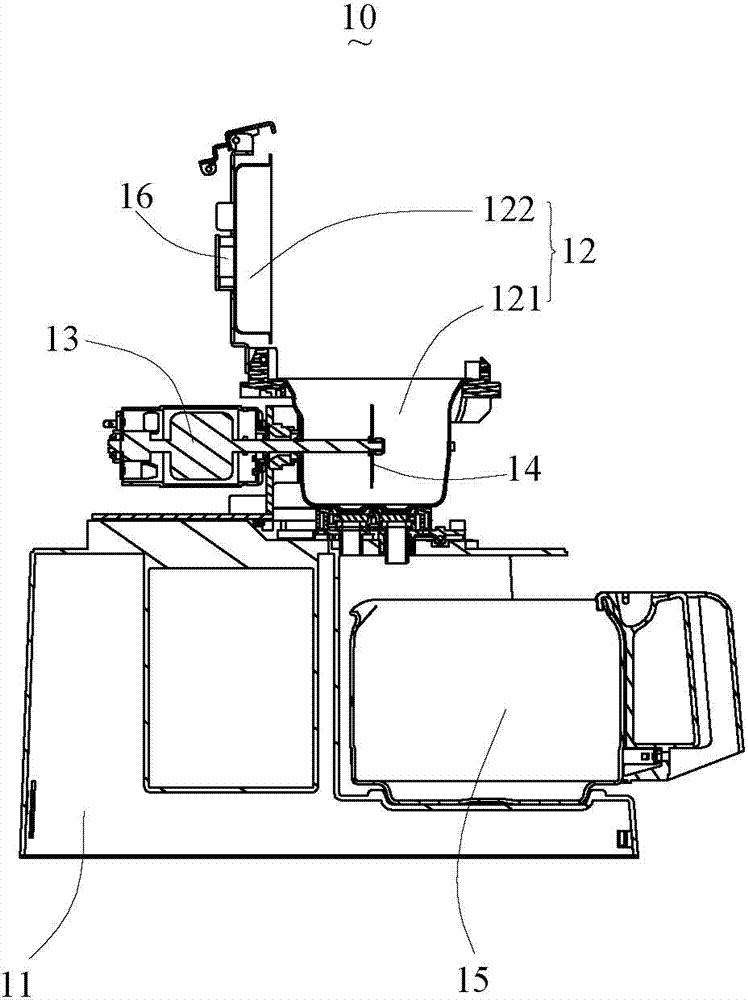

Soybean milk making method of rapid soybean milk maker

ActiveCN102771575AAvoid wastingReduce wasteBeverage vesselsMilk substitutesHigh concentrationWater resources

The invention relates to a soybean milk making method of a rapid soybean milk maker. The soybean milk making method at least comprises the steps: injecting the water of capacity V1 in a small-space smasher at a time, and heating the water in the small-space smasher through a heating device, draining the heated water to a milk receiving cup and mixing the milk in the milk receiving cup. Compared with the prior art, the residue of high-concentration milk / paste in the small-space smasher can be reduced, so that waste is avoided; furthermore, the water resources for cleaning at later stage can be effectively reduced, and the waste of water resources can also be reduced.

Owner:JOYOUNG CO LTD

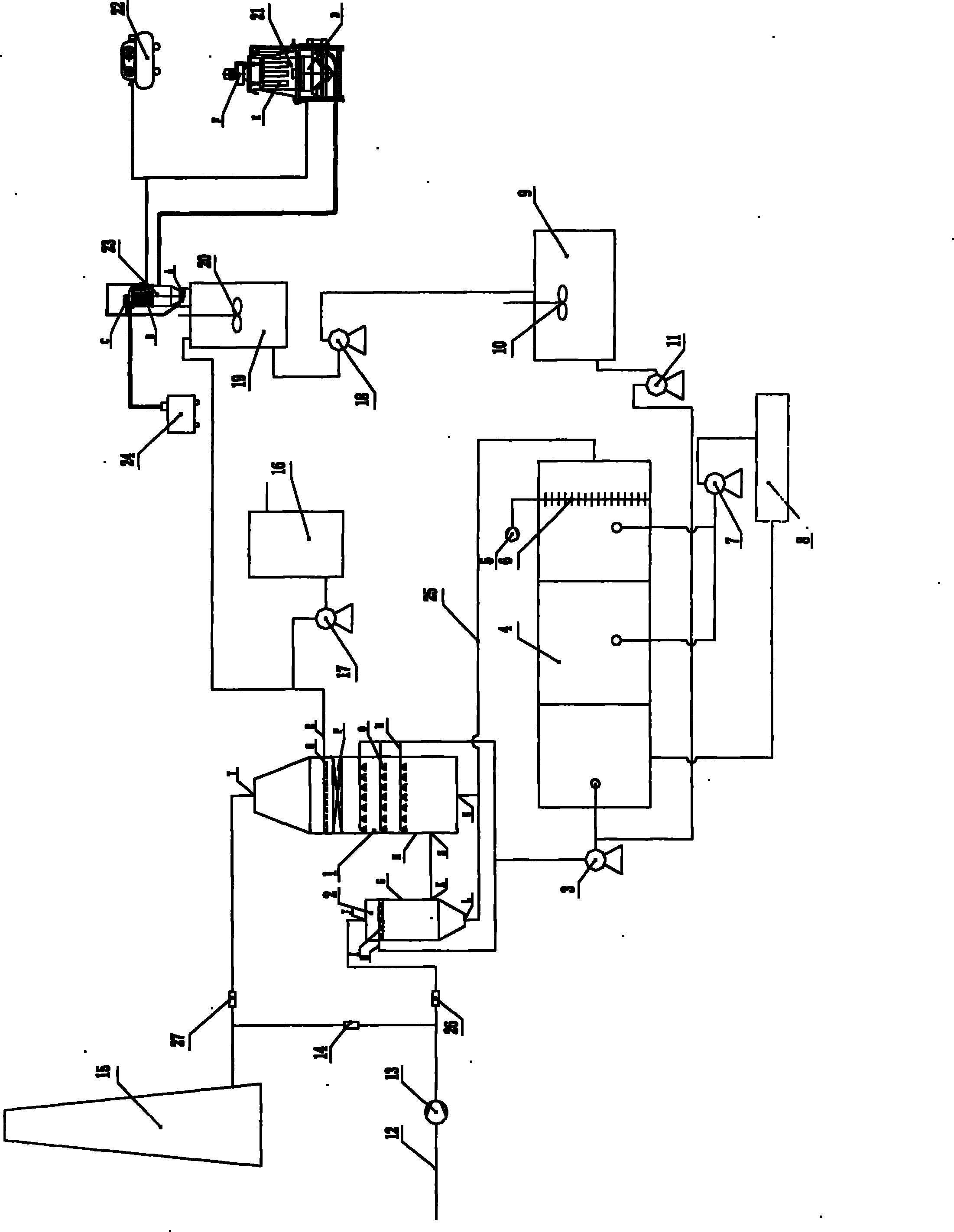

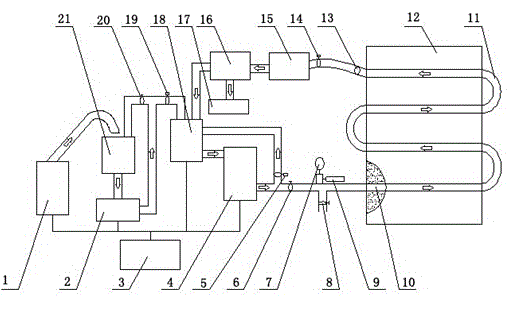

Flue gas desulfurization method of heating boiler and device thereof

InactiveCN101804293AAvoid pollutionCause secondary pollutionLighting and heating apparatusAluminium oxide preparationEngineeringDigestion

The invention relates to a flue gas desulfurization method of a heating boiler and a device thereof, belonging to the technical field of heating boilers. The flue gas desulfurization method of the heating boiler comprises the following steps of: precooling, desulfurizing, magnesium oxide pulping, absorption liquid aeration and crystallizing dehydration. In the precooling step, glue gas enters a precooling tower through a flue gas inlet channel for precooling, and absorption liquid is atomized and sprayed; in the desulfurizing step, the flue gas enters a desulfurizing tower for desulfurizing, and the absorption liquid is atomized and sprayed; the flue gas is discharged through a chimney; in the step of magnesium oxide pulping, magnesium oxide powder is pulped in a digestion tank; in the step of absorption liquid aeration, an air blower carries out aeration on the absorption liquid by a gas distribution pipe; and in the step of crystallizing dehydration, magnesium sulfate crystal size is crystallized and dehydrated. The flue gas desulfurization device of the heating boiler is characterized in that the flue gas inlet channel is communicated with the precooling tower by a draught fan; the precooling tower is communicated with the desulfurizing tower through a flue; the desulfurizing tower is communicated with the chimney; an absorption liquid atomization spray mechanism is respectively arranged in the precooling tower and the desulfurizing tower; the air blower is communicated with an aeration gas distribution pipe; a circulating water pool is communicated with a dehydrator; and a spray circulating pump is communicated with the digestion tank. The invention has the advantages of good desulfurizing effect, high desulfurizing efficiency, little water along with flue gas discharge, convenient operation, environmental protection and the like.

Owner:TIANJIN XIAOWO ENVIRONMENTAL PROTECTION ENG CO LTD

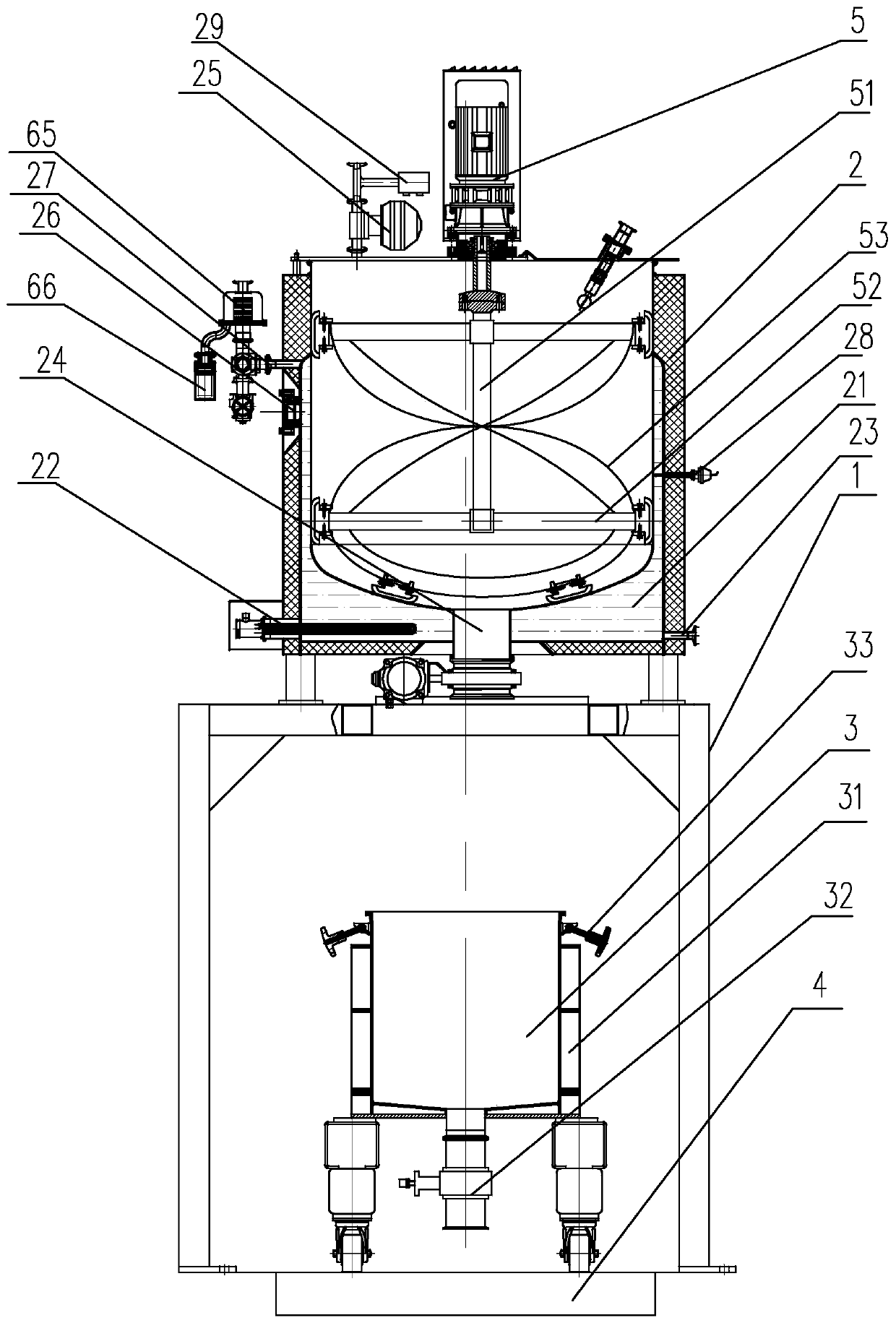

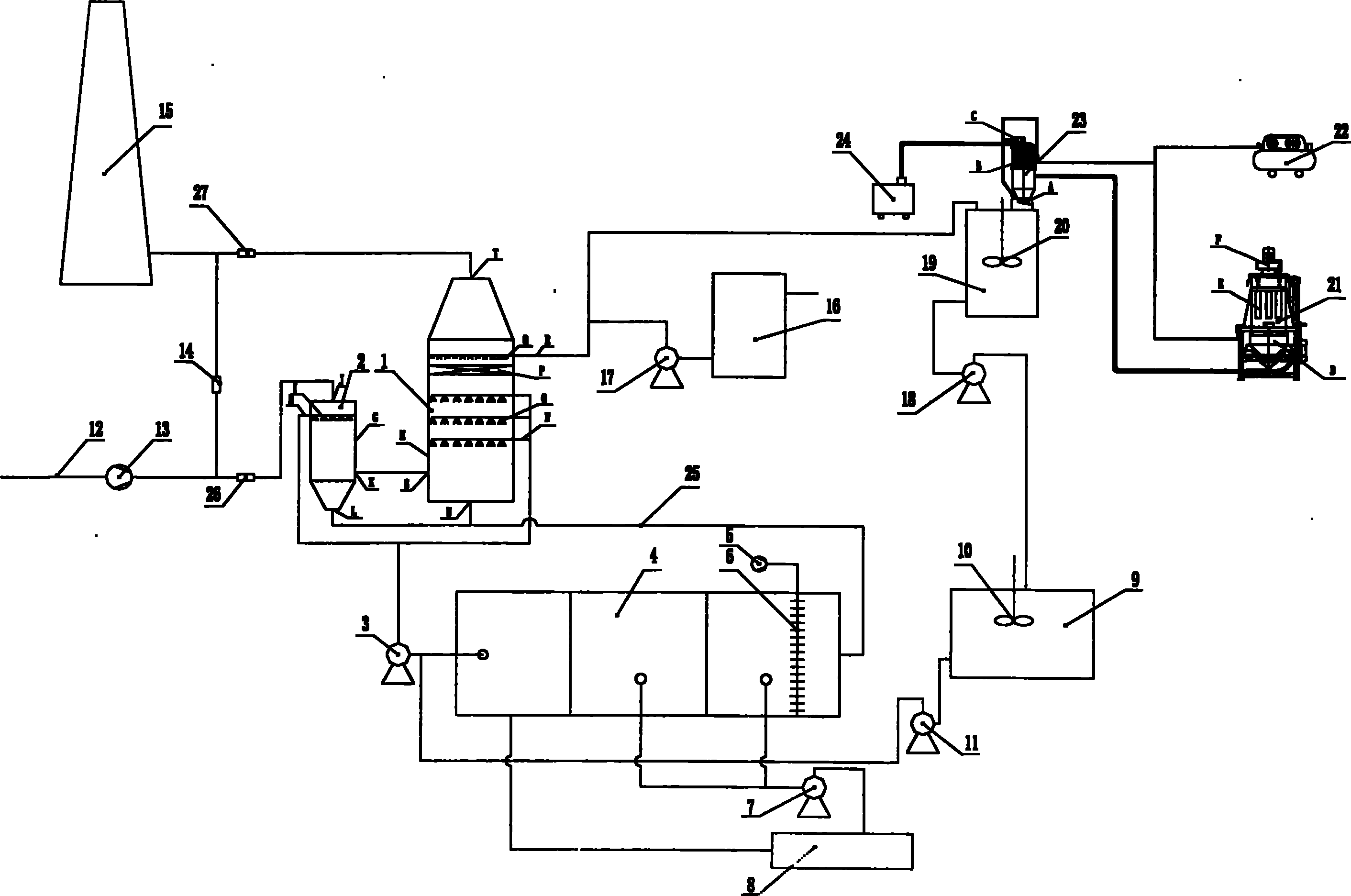

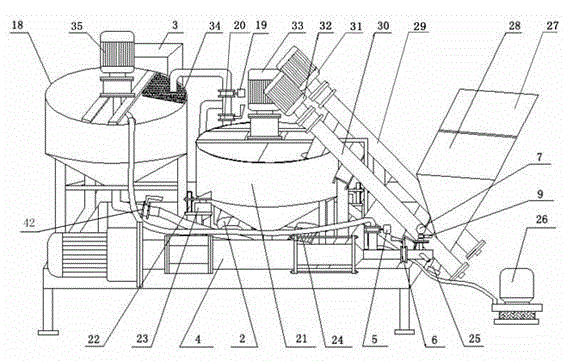

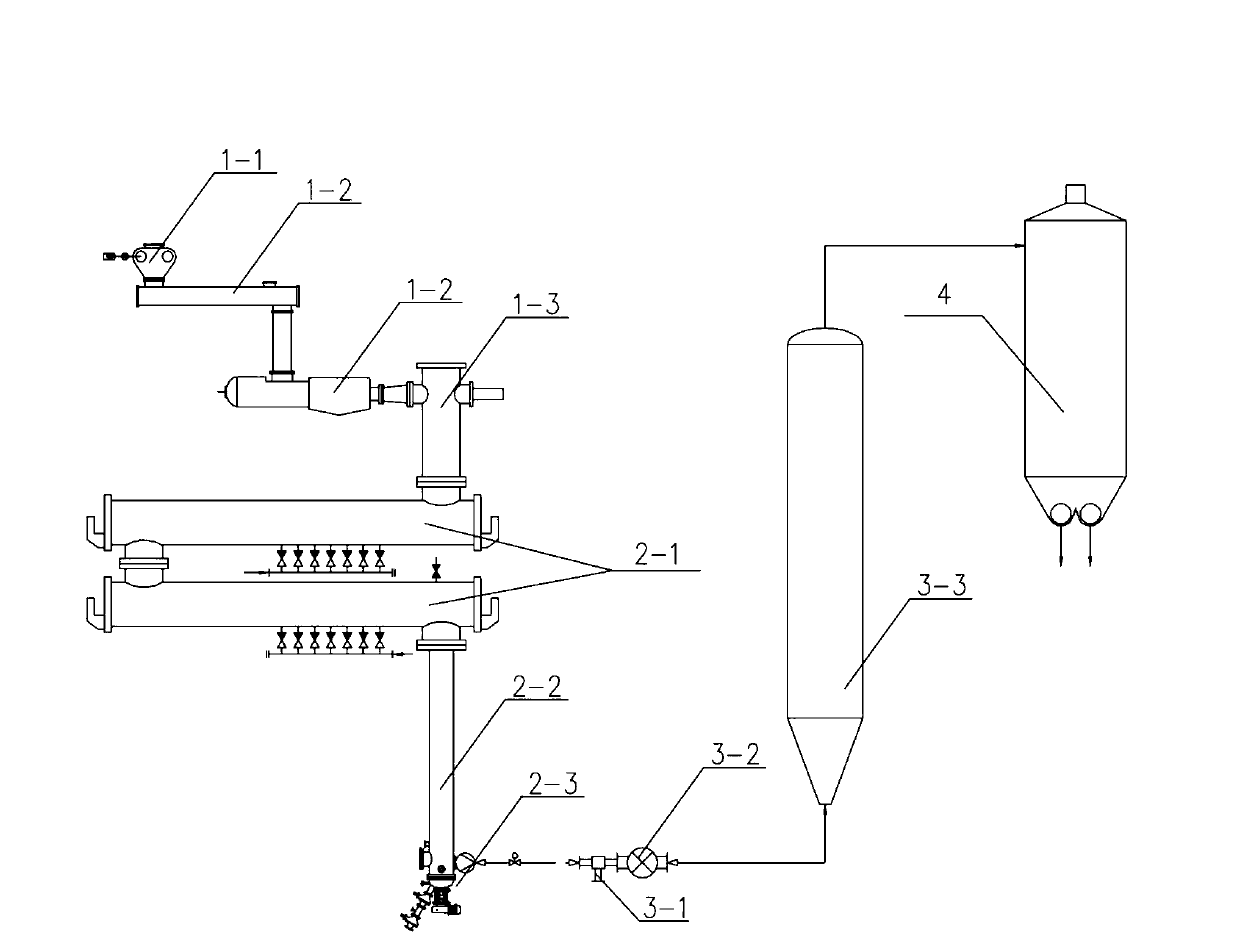

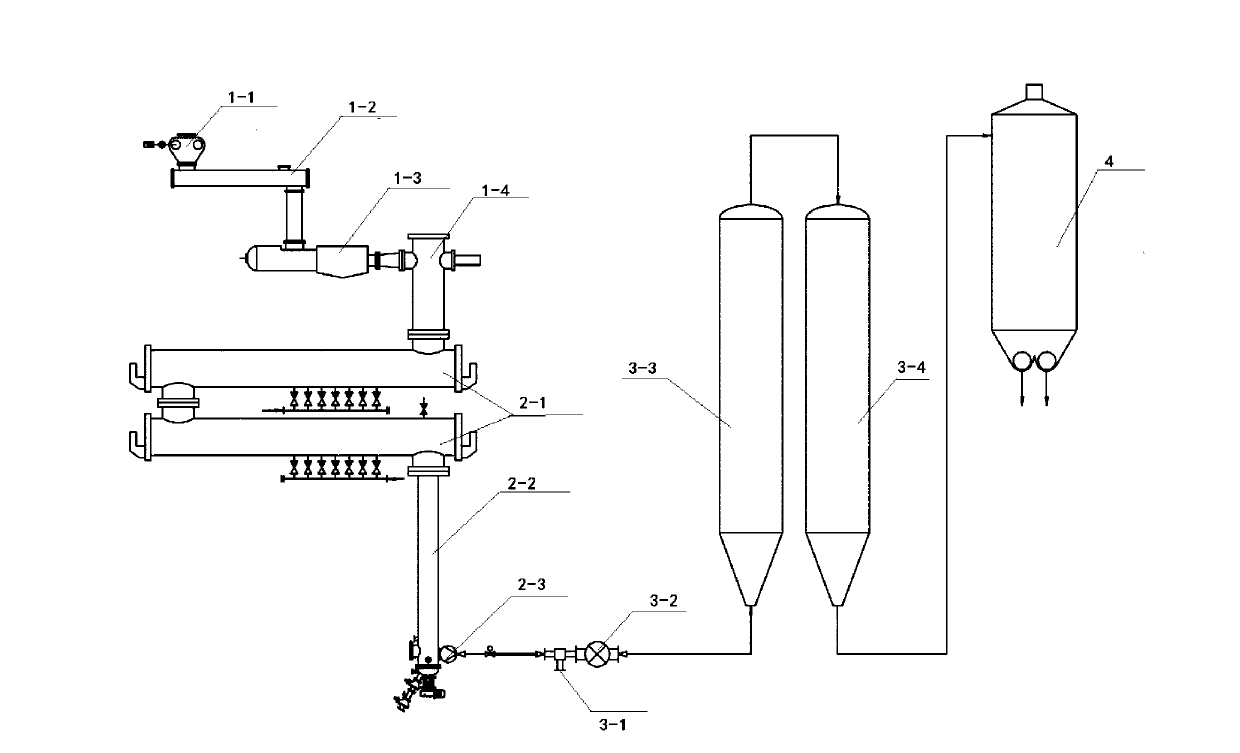

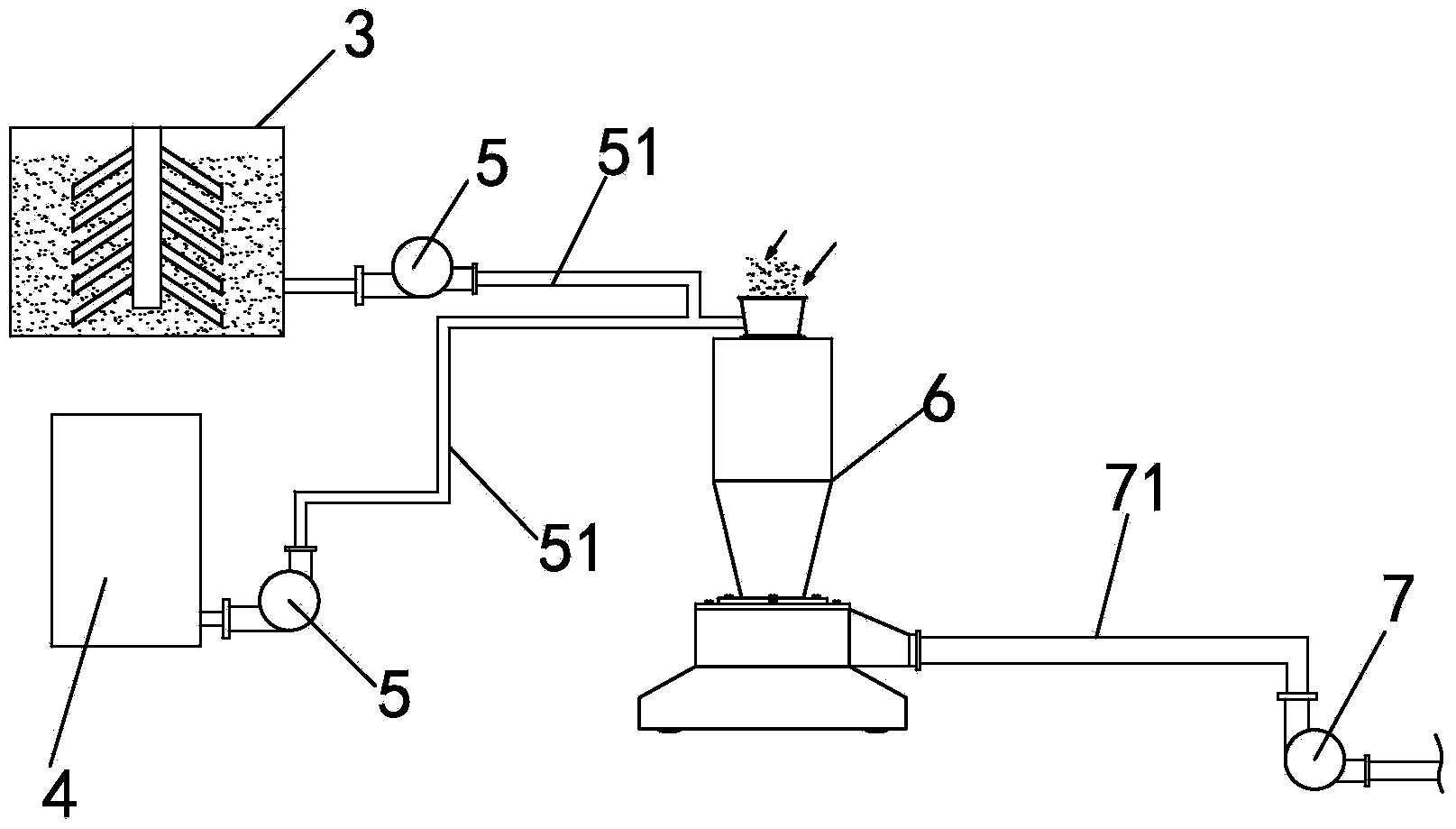

Intelligent multi-circulation mortar production and grouting system

ActiveCN104818850AFast pulping efficiencyGood pulping effectBuilding material handlingCement mixing apparatusHigh pressureProduction effect

Disclosed is an intelligent multi-circulation mortar production and grouting system. A mortar water-binder ratio automatic judgment device is arranged on a conveying pipeline which is communicated with a low-speed stir mortar storage barrel and arranged in a prestressed duct mortar outlet, and is used for judging whether the mortar water-binder ratio meets the standard or not. An electric three-way valve is arranged, and three ports of the electric three-way valve are connected with the mortar water-binder ratio automatic judgment device, a waste mortar barrel and the low-speed stir mortar storage barrel respectively. A circulating pump is arranged, so that a circulating loop of the circulating pump and a high-speed stir mortar production barrel is formed. A circulating loop of a mortar grouting machine and the low-speed stir mortar storage barrel is formed. The intelligent multi-circulation mortar production and grouting system has the advantages that automatic weighing, automatic feeding, automatic mortar production, automatic mortar grouting, automatic mortar grouting data recording and automatic generation of pressure-time curves can be achieved, the mortar production efficiency is higher, and the mortar production effect is better; the damage caused by idling of the mortar grouting machine can be avoided, and the phenomena of pipeline breakage and mortar leakage caused by the over-high pressure can be effectively avoided; whether the mortar water-binder ratio meets the standard or not can be automatically judged, and mortar which does not meet the standard is automatically removed; and mortar accumulation in pipelines is avoided, and cleaning is convenient.

Owner:LIUZHOU QIAN BRIDGE ENG MATERIALS

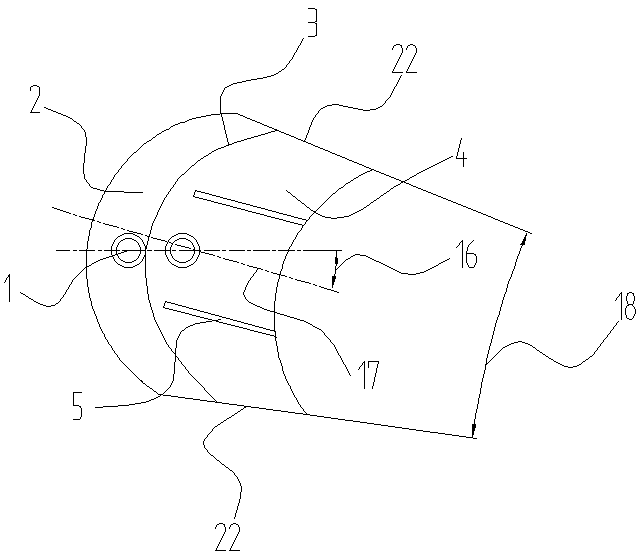

Choked flow cover for food processing machine

InactiveCN101433436AIncrease speedIncrease the relative speed differenceBeverage vesselsFood preparationChoked flowEngineering

Owner:田莉

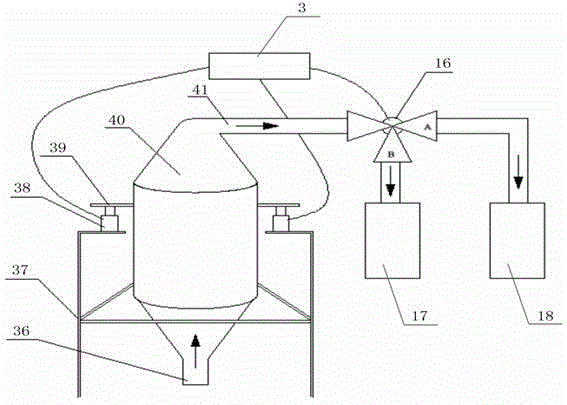

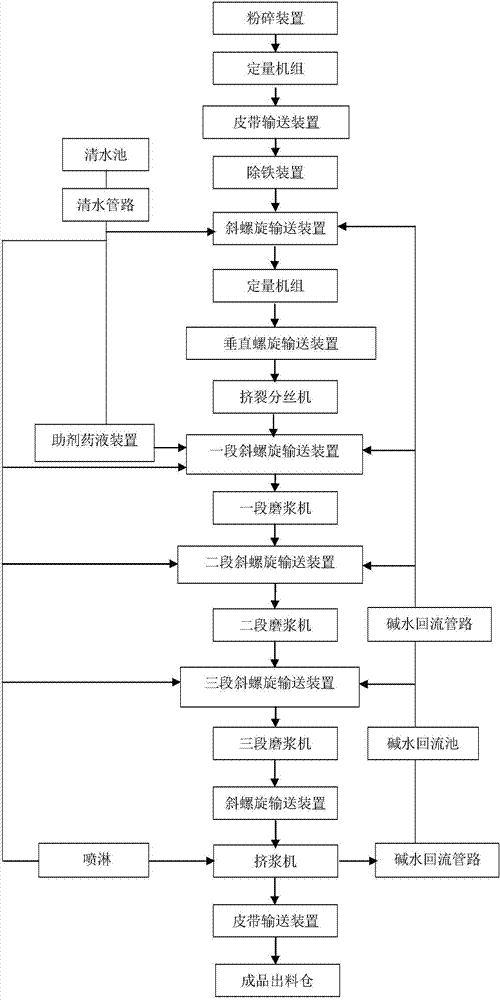

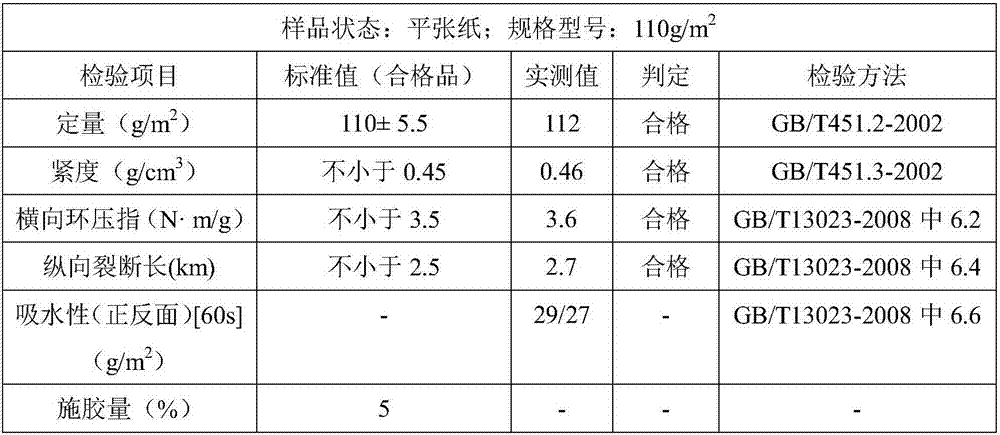

Unbleached pulp, and preparation process, application and preparation device of unbleached pulp

InactiveCN107268327AImprove insulation effectEfficient power savingPretreatment with alkaline reacting compoundsMultistage pulping processElectricityBlack liquor

The invention provides an unbleached pulp, and a preparation process, an application and a preparation device of the unbleached pulp, and relates to the technical field of pulping by utilizing a straw. The choices for the raw material of the unbleached pulp are wide, a wheat straw, a rice straw, a reed straw or a waste wood chip are used efficiently as the pulping raw material, so that the pulping cost is obviously lowered. The preparation process of the unbleached pulp uses the new technique to replace steam heating to soften the raw material, the problem of a pulp black liquor existing in the pulping process is solved while the heating cost is obviously reduced. The flow of the production process is simplified, the electricity and the water are efficiently saved, the resource utilization rate is effectively increased, and the production of no wastewater or waste materials is guaranteed in the production process. The special production process is used to pulp, the beating degree is high, the quality is better, the performance of a pulp product is stable, the pulp product is widely applied to the functional degradable material, and the functional applicability and the material quality are obviously strengthened in the application fields of preparation of corrugated paper, industrial packaging materials, preparation of plates, and preparation of tableware.

Owner:北京泽鑫荣创秸秆科技开发有限公司

Soymilk machine cutter detection method

ActiveCN102353555APreventing the use of dropped knivesImprove securityStructural/machines measurementBeverage vesselsSoftware bugProduction effect

The invention belongs to the kitchen small household appliances field, concretely relating to a soymilk machine and soymilk machine cutter detection method. The method comprises the following steps: a. starting a soymilk preparation program; b. reloading a cutter; c. selecting a corresponding soymilk preparation program and starting the program; d. carrying out detection; e. finishing cutter detection. The cutter is installed at a lower part of a machine head, the machine head is placed to match a soymilk preparation container, and a needed program is selected and started. An MCU starts to detect whether the cutter matches the program, if the cutter is wrong or the program is wrong, an alarm is given, a prompt of changing the cutter is given, and the program returns to cutter selection. If the cutter matches the program rightly, a machine enters into a next step, and water level detection crushing and soymilk boiling are carried out until the end. According to different cutters, different programs are determined and started. In assembling, an assembling position of the cutter can be determined, a problem of falling cutter is avoided, and safety performance is raised; each kind of cutter is corresponding to a proper program to carry out crushing, and a crushing effect and a soymilk production effect are raised.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

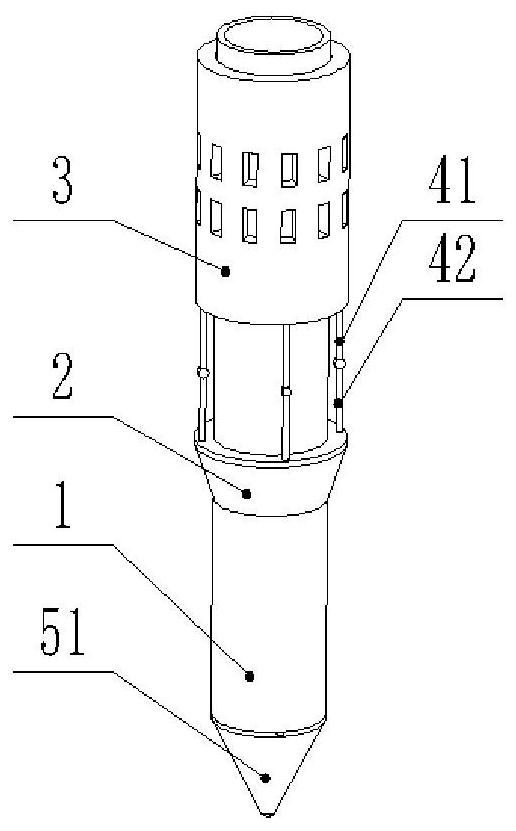

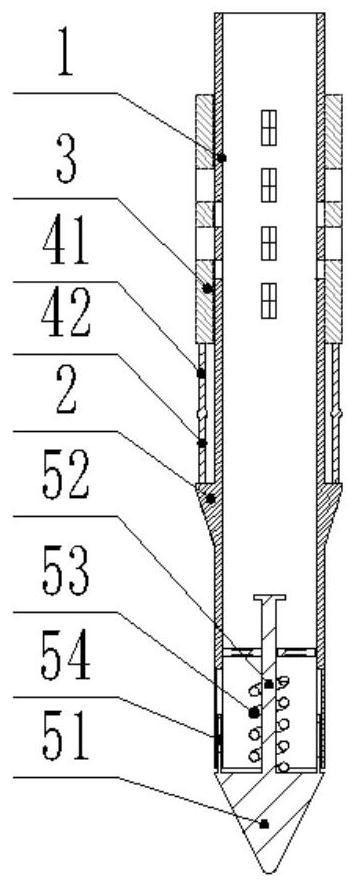

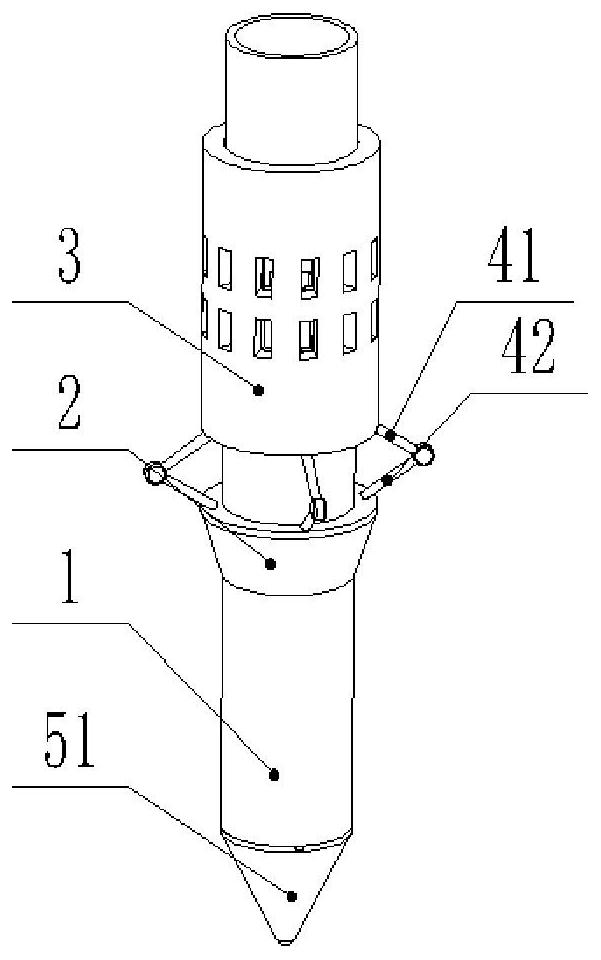

Grouting pipe reinforcing and grouting structure and construction method thereof

ActiveCN111827259AAvoid shakingImprove installation stabilitySoil preservationSoil scienceGeotechnical engineering

The invention particularly relates to a grouting pipe reinforcing and grouting structure and a construction method thereof. The grouting structure comprises a grouting pipe, and a soil breaking mechanism arranged on the grouting pipe. The soil breaking mechanism comprises a fixed part fixedly sleeving the grouting pipe, a sliding pipe part and a soil breaking assembly, the sliding pipe part sleeves the position, above the fixed part, of the grouting pipe and is in sliding fit with the grouting pipe, and the soil breaking assembly is arranged between the fixed part and the sliding pipe part. When the sliding pipe part slides in the fixed direction, the soil breaking assembly can expand out in the axis direction away from the grouting pipe. Slurry output grooves corresponding to the positions of slurry output holes formed in the grouting pipe are formed in the outer surface of the sliding pipe part. The invention correspondingly discloses the construction method of the grouting structure. According to the grouting pipe reinforcing and grouting structure and the construction method thereof, the slurry output size of the grouting pipe can be increased, and therefore slurry output by the grouting pipe can permeate into the soil layer around the pipe, and the slurry output effect of the grouting pipe and the connecting stability of the grouting pipe and the soil layer around the pipecan be improved.

Owner:CHONGQING JIAOTONG UNIVERSITY

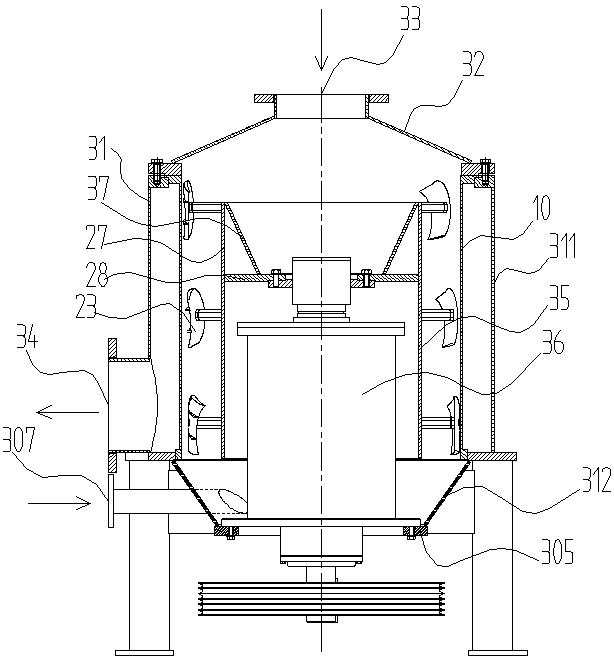

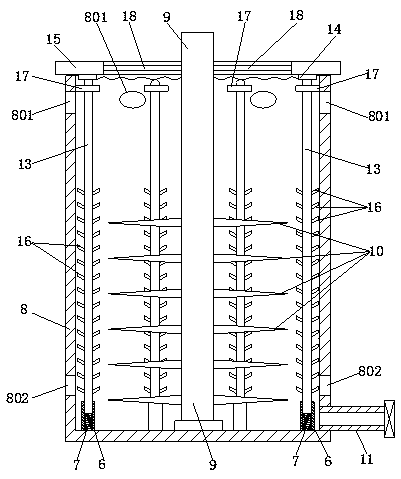

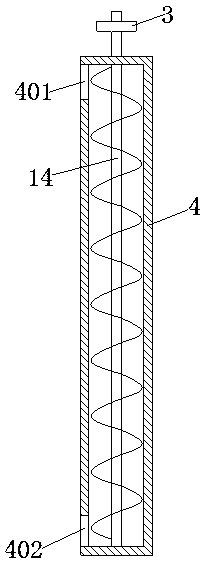

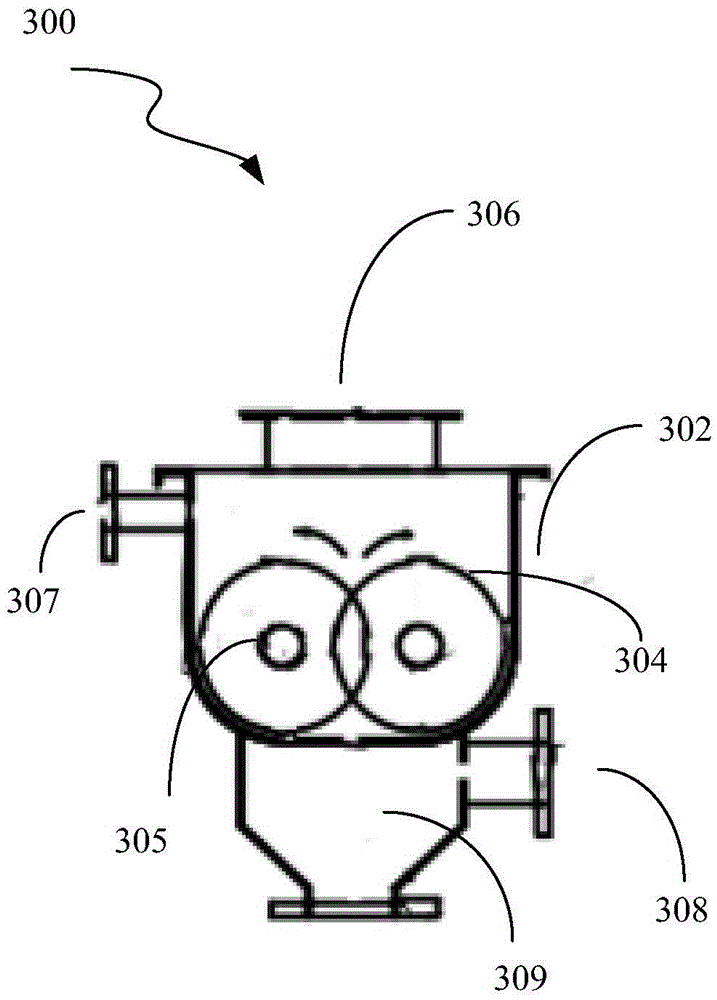

Oxygen alkaline pulping cooking device

InactiveCN103276617AReduce foulingGood clarificationPulping with inorganic basesWhite liquorBlack liquor

The invention discloses an oxygen alkaline pulping cooking device which comprises a feeding device, a pre-cooking device, a cooking device and a spraying device, wherein the feeding device is connected with the first end of the pre-cooking device and is used for conveying the pulping raw material into the pre-cooking device for pre-cooking; the second end of the pre-cooking device is connected with the first end of the cooking device, and the pre-cooking device is used for conveying the pre-cooked pulping raw material into the cooking device for cooking; and the second end of the cooking device is connected with the spraying device, and the cooking device is used for conveying the cooked pulp into the spraying device for spraying. The oxygen alkaline pulping cooking device can be used for carrying out oxygen-alkaline cooking pulping on straw pulp and wood pulp, the prepared straw pulp contains more than 10% of silicon dioxide, the yield of a cooking work section reaches up to be more than 50%, and the whiteness reaches 50-60%, so that the device is easy to bleach, reduces the scaling phenomenon of a black liquor concentration evaporator pipeline, is beneficial to clarifying the white liquor in the subsequent causticization process, and improves the alkali recovery rate.

Owner:JIAMUSI AMUR PULP & PAPER

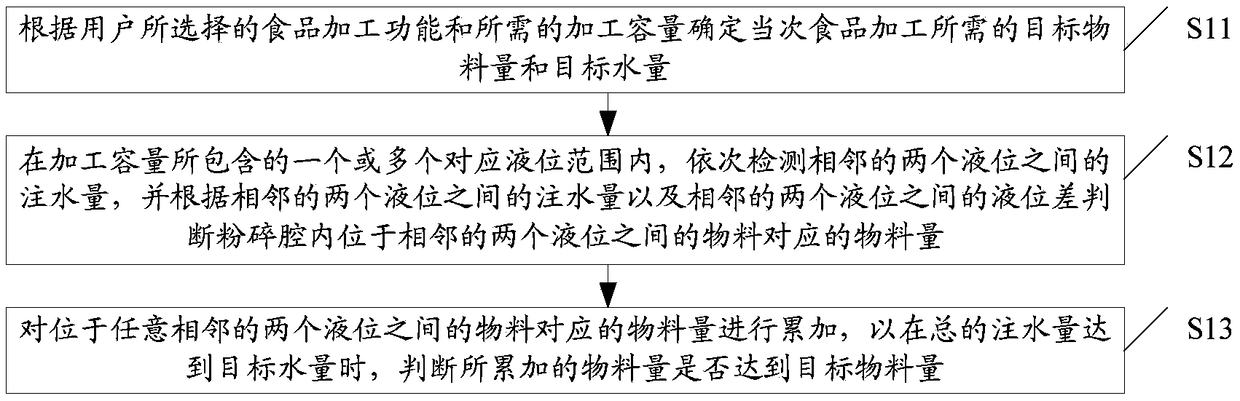

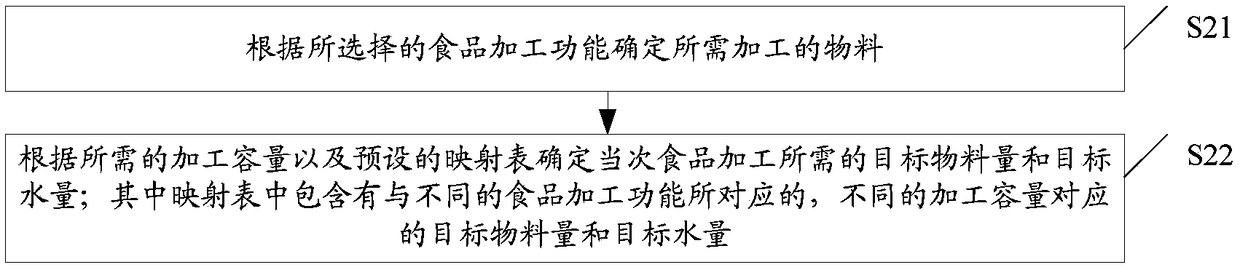

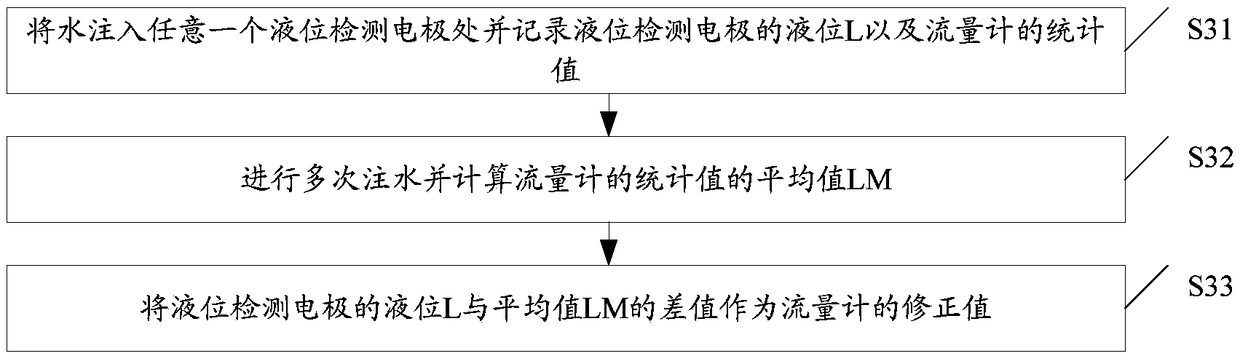

Material detecting method for food processor

ActiveCN108645474AGood pulping effectImprove processing efficiencyVolume measurement apparatus/methodsTesting/calibration apparatusProcess engineeringFood processing

An embodiment of the invention discloses a material detecting method for a food processor. The method includes determining a target material quantity and a target water quantity according to a food processing function and a processing capacity selected by a user; detecting an water injecting quantity between every two adjacent liquid levels sequentially within one or more corresponding liquid level ranges contained in the processing capacity and judging the material quantity of materials in a crushing cavity between the two adjacent liquid levels according to the water injecting quantity between the two adjacent liquid levels and the liquid level difference between the two adjacent liquid levels; accumulating the material quantity of the materials between every two adjacent liquid levels and judging whether the accumulated material quantity reaches the target material quantity when the total water injecting quantity reaches the target water quantity. The method solves the safety problems of unsatisfactory pulping effect and overflowing paste caused by over-proof feeding of the materials into the existing food processor.

Owner:JOYOUNG CO LTD

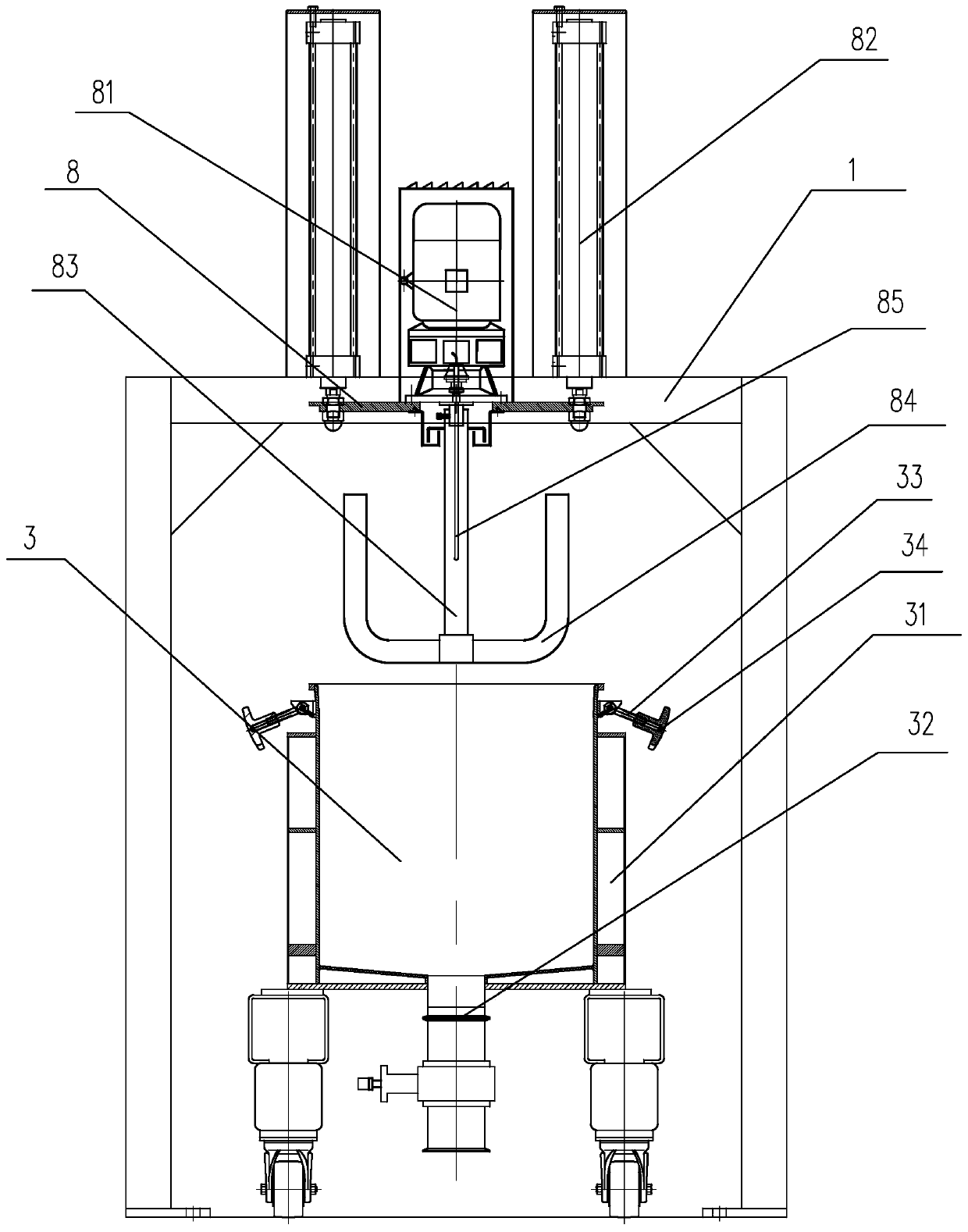

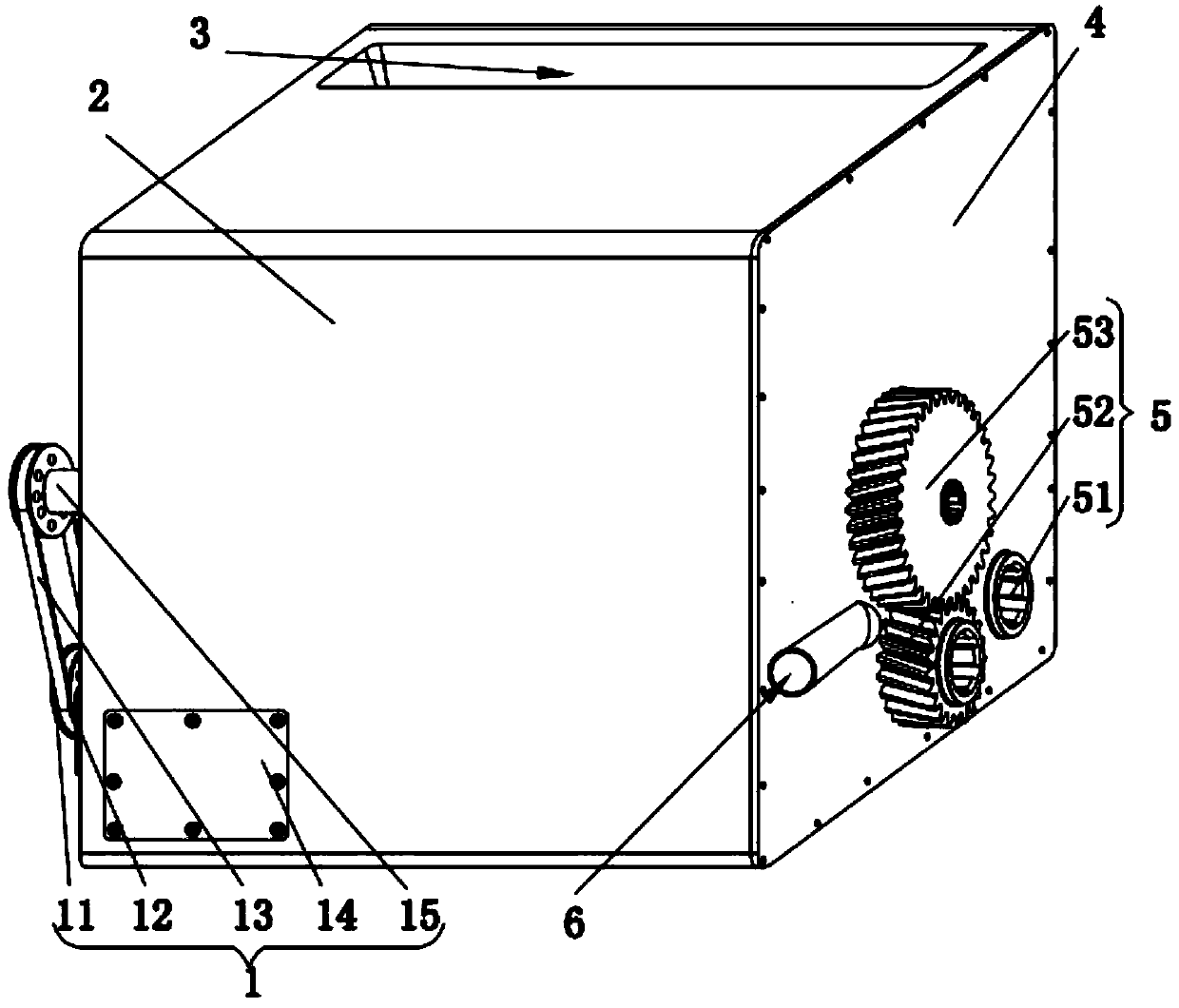

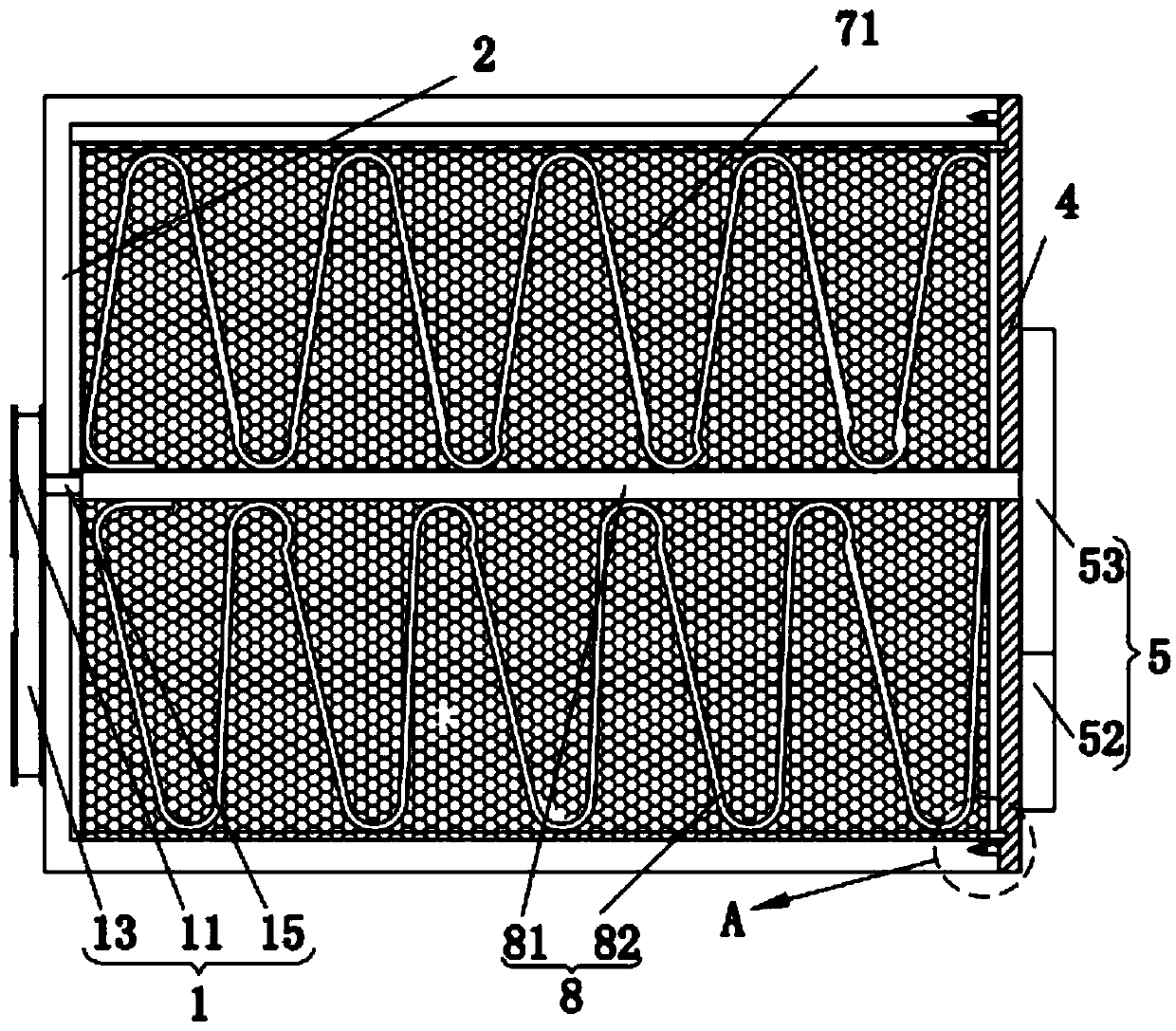

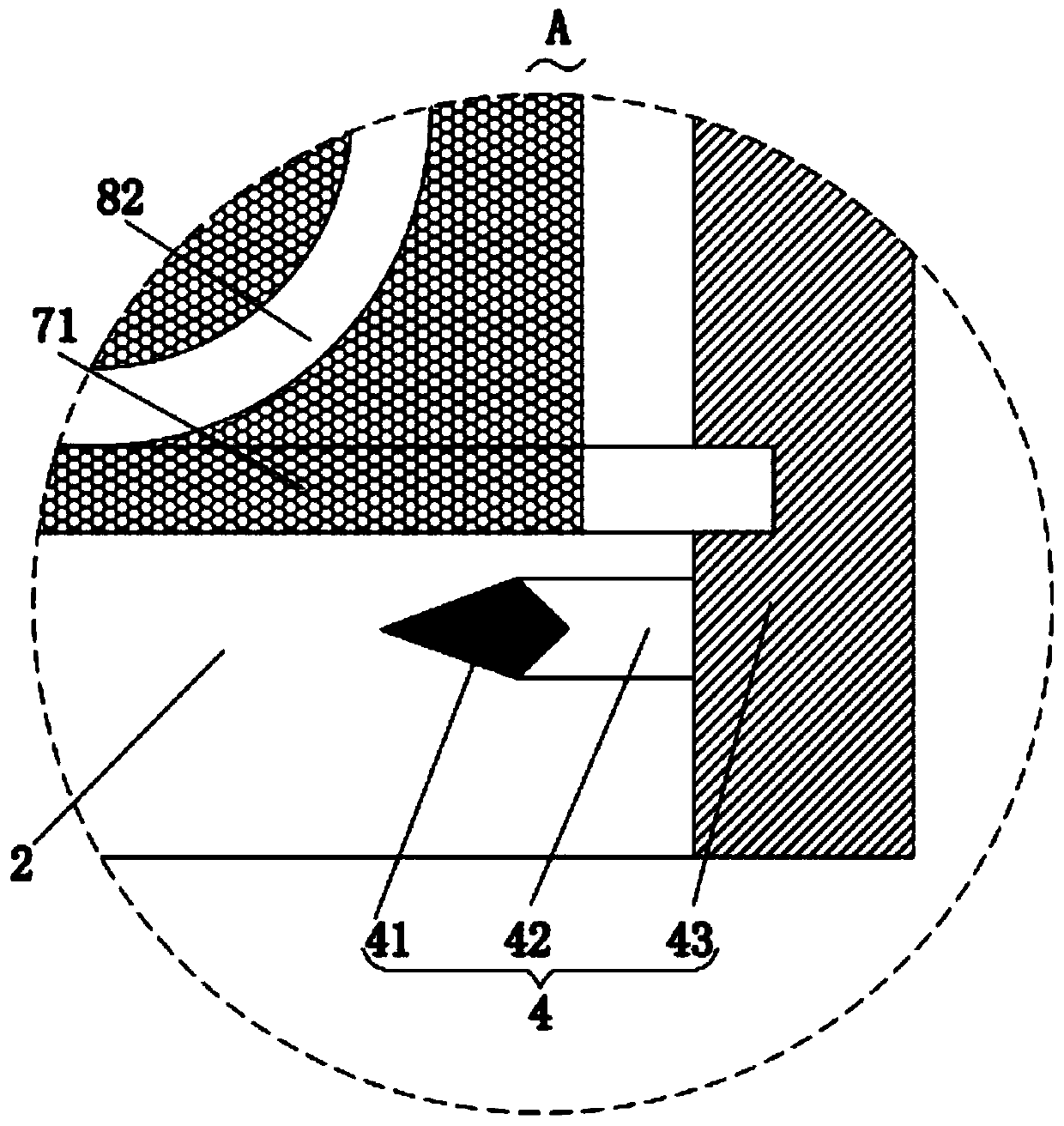

Papermaking pulping equipment

ActiveCN109629291AAvoid cloggingImprove stabilityRaw material divisionFiltrationPulp and paper industry

The invention relates to the field of papermaking pulping equipment, in particular to papermaking pulping equipment. The papermaking pulping equipment includes a drive structure, a storage box, a feeding hopper, an overhaul structure, a transmission structure, a liquid discharging pipe, a filtration structure, a support structure and a pulping structure; the drive structure is connected with the filtration structure which is used for filtering pulp and arranged inside the storage box, and the transmission structure connected with the drive structure is arranged on the end portion of the filtration structure; the pulping structure which is connected with the transmission structure and is used for conducting secondary pulping on the pulp is arranged inside the storage box. According to the papermaking pulping equipment, the drive structure cooperates with the filtration structure during usage, paper which is incompletely pulped is conveniently filtered out and then is conveyed to the pulping structure, the quality of the pulp after pulping is improved, and therefore the pulping effect is better; due to cooperation of the drive structure and the transmission structure, it is convenient to drive the pulping structure to pulp the incompletely pulped paper again, meanwhile, the pulping contact area of the pulp is increased, and therefore the pulping quality and efficiency are greatlyimproved.

Owner:戴玲玲

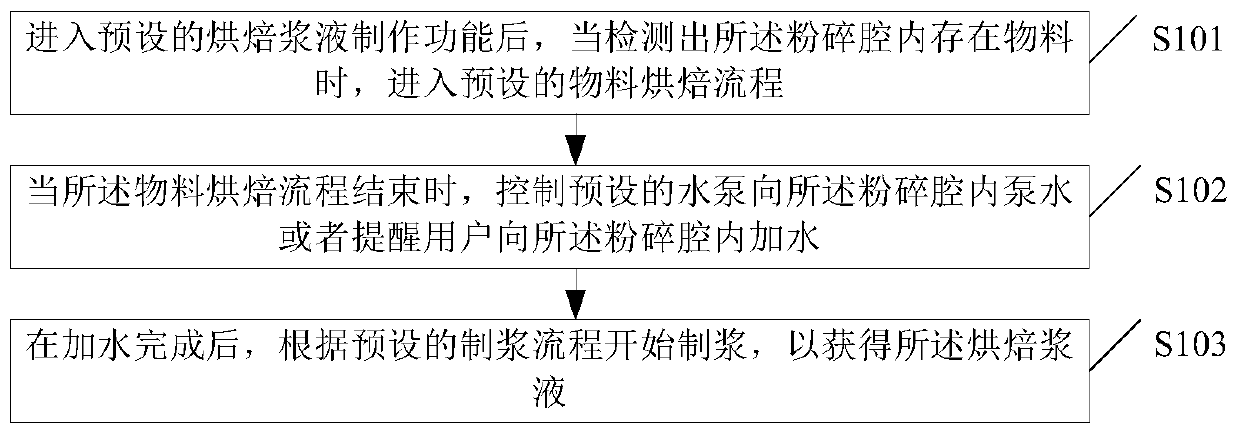

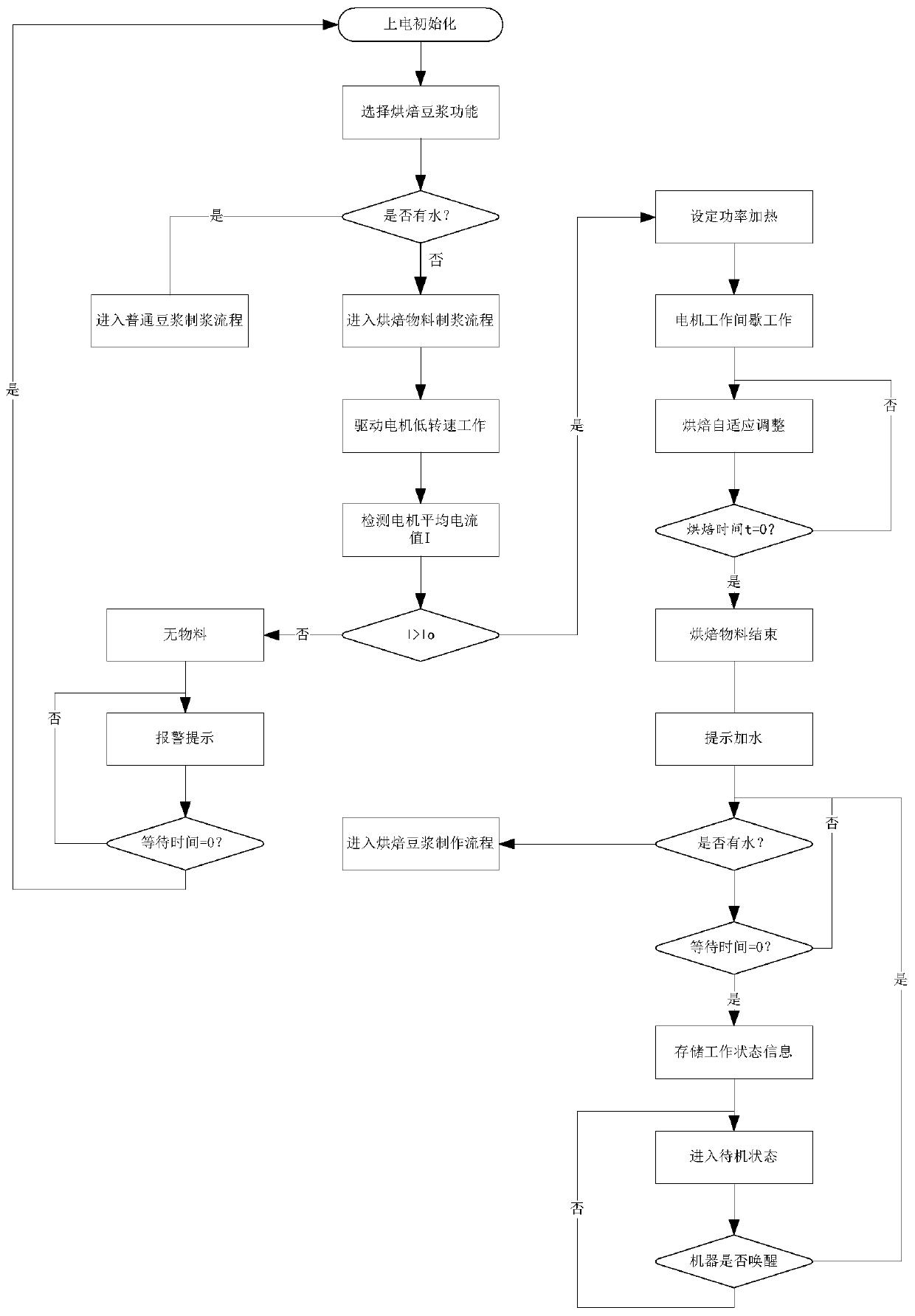

Method for making baked pulp

ActiveCN109965739AGuaranteed baking effectImprove baking efficiencyWarming devicesCooking & bakingSlurry

The embodiment of the invention discloses a method for making baked pulp. A food processor for making the baked pulp comprises a motor, a crushing blade, a crushing cavity, a heating device and a temperature sensor; the temperature sensor is used for detecting the temperature of the heating device in real time; the motor is located below the bottom of the crushing cavity, a motor shaft of the motor penetrates upwards into the crushing cavity, and the crushing blade is installed on the motor shaft and is close to the bottom of the crushing cavity. The method includes the steps that after a preset baked pulping making function is started, when it is detected that materials exist in the crushing cavity, a preset material baking process is started; when the material baking process is finished,a prearranged water pump is controlled to pump water into the crushing cavity or a user is reminded to add water into the crushing cavity; after water adding is finished, pulp making is begun according to a preset pulp making process to obtain the baked pulp. By manes of the scheme, adaptive baking of the materials is realized, problems existing when a user bakes materials by other devices are solved, and a good baked pulp making effect is achieved.

Owner:JOYOUNG CO LTD

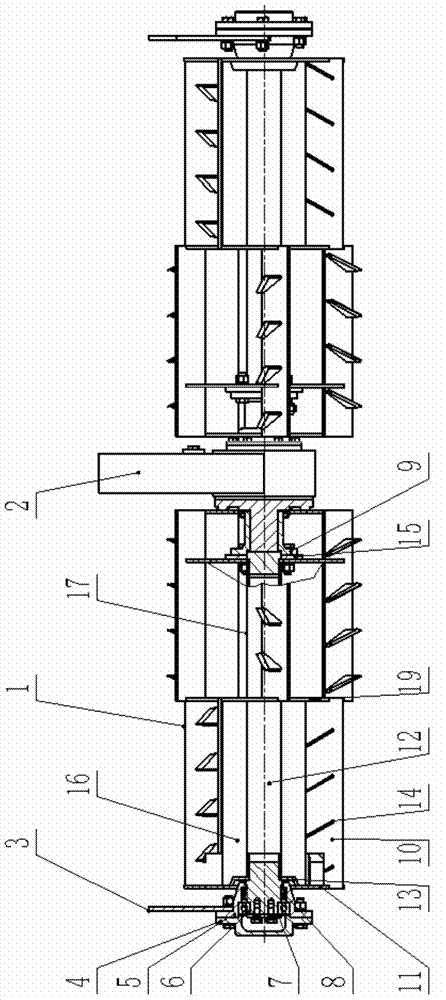

Novel pressure screen

ActiveCN111364274AAvoid destructionImprove slagging abilityPaper material treatmentEngineeringMechanical engineering

The invention discloses a novel pressure screen. The novel pressure screen comprises a pressure screen shell, wherein a screen drum is fixedly arranged in the pressure screen shell; a rotor is arranged at the inner side of the screen drum and comprises a rotor barrel body; a plurality of fin fixing rods are uniformly arranged on the periphery of the rotor barrel body in a layered mode and are divided into a plurality of layers; each layer of the fin fixing rods is uniformly distributed in a circumferential direction; a rotor fin is arranged at the end part of each fin fixing rod and is of a flying wing structure; and every two adjacent layers of rotor fins are overlapped for a distance. According to the invention, through a more streamlined rotor blade structure and arrangement, the powerconsumed by the rotor in the working process is greatly reduced; meanwhile, a good screening effect is achieved.

Owner:ZHENGZHOU LEIZHAN TECH PAPER MACHINERY

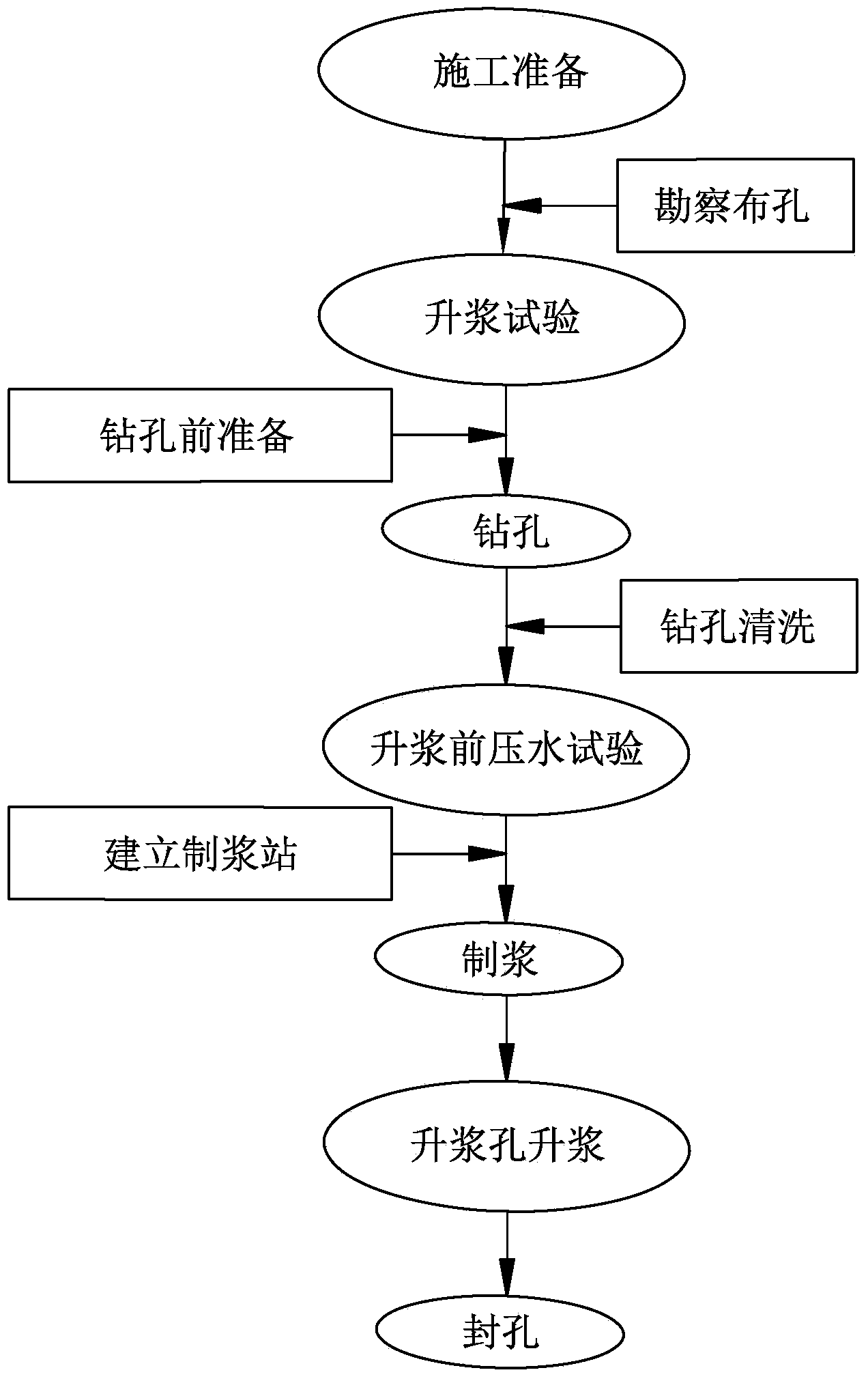

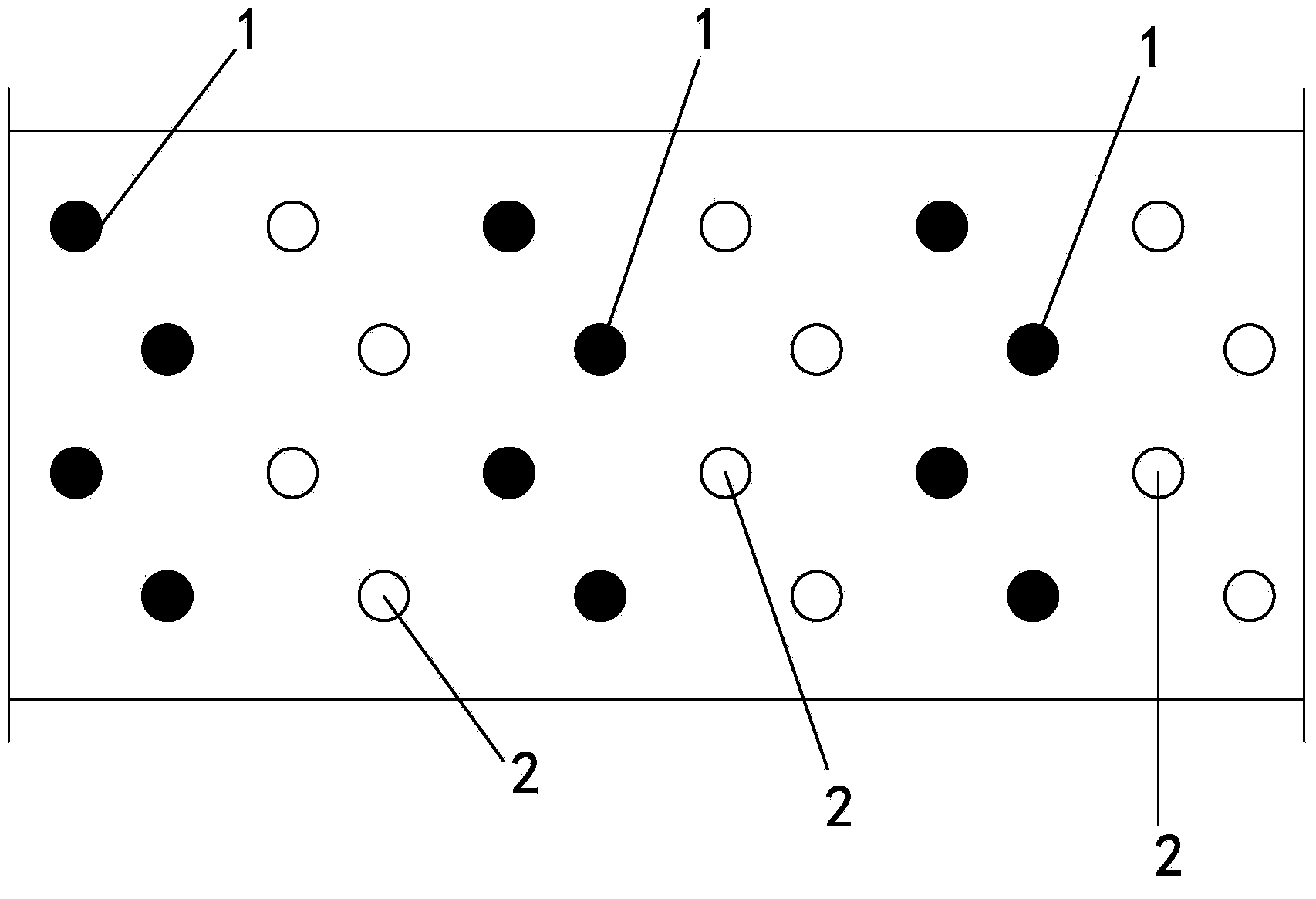

Drill hole prepacked aggregate concrete construction method

The invention discloses a drill hole prepacked aggregate concrete construction method. The method comprises the steps of (a) construction preparation, (b) reconnaissance and hole forming, (c) prepacked aggregate concrete testing, (d) preparation conducted before hole drilling, (e) hole drilling, (f) hole drilling cleaning, (g) pressurized-water testing conducted before prepacked aggregate concrete construction, (h) mortar production station building, (i) mortar production, (j) prepacked aggregate concrete hole prepacked aggregate concrete construction and (k) hole sealing. A reserved prepacked aggregate concrete hole is preformed, a prepacked aggregate concrete pipe is inserted into the prepacked aggregate concrete hole and connected with a mortar injection pipe, the mortar injection pipe enables prepacked aggregate concrete liquid to be directly injected into the prepacked aggregate concrete hole, and then pressure grouting construction is carried out continuously and uninterruptedly. Stone blocks do not need to be crushed to stir concrete. The prepacked aggregate concrete liquid slowly rises from the prepacked aggregate concrete hole in a template, so that water in coarse aggregate gaps can be completely changed into the prepacked aggregate concrete liquid during underwater construction, and concrete with high quality can be easily made. No stirring machines are needed for aggregate stirring, and the construction progress can be easily accelerated. Only cement mortar needs to be pumped during pumping, and the pumping technology is improved compared with common concrete.

Owner:HANGZHOU HUANENG SAFETY ENG POLYTRON TECH CO LTD

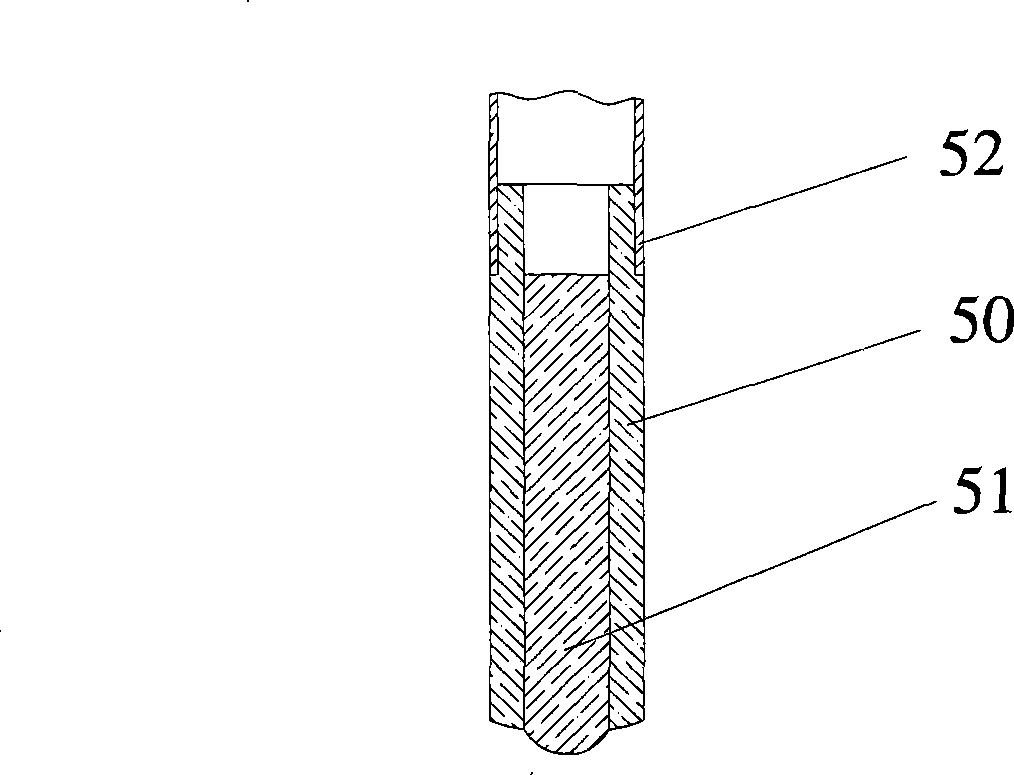

Soybean milk machine capable of automatically selecting pulping program according to water level

InactiveCN101474043ASolve the influence of pulping effectSimple structureBeverage vesselsFood preparationAgricultural engineeringWater level

The invention discloses a soybean milk machine which can choose a pulping program according to a water level. The soybean milk machine comprises a head consisting of a motor, a control circuit, a grinding device, a heating device and an anti-overflow device, a water level detection device connected with the control circuit and a pulping container, the machine head is buckled on the pulping machine, the water level detection device is provided with two or more water level detection points with different heights, and the control circuit is pre-stored with different pulping programs for pulping according to detection results of the water level detection points. Compared with the prior art, the beneficial effects of the soybean milk machine are as follows: the control circuit can automatically choose a pulping program corresponding to water level according to the water level detection results of the water level detection points, thus the influence of overhigh water level on the pulping effect can be effectively avoided. The soybean milk machine is characterized by simple structure, convenience and practicality and good pulping effect.

Owner:MIDEA GRP CO LTD

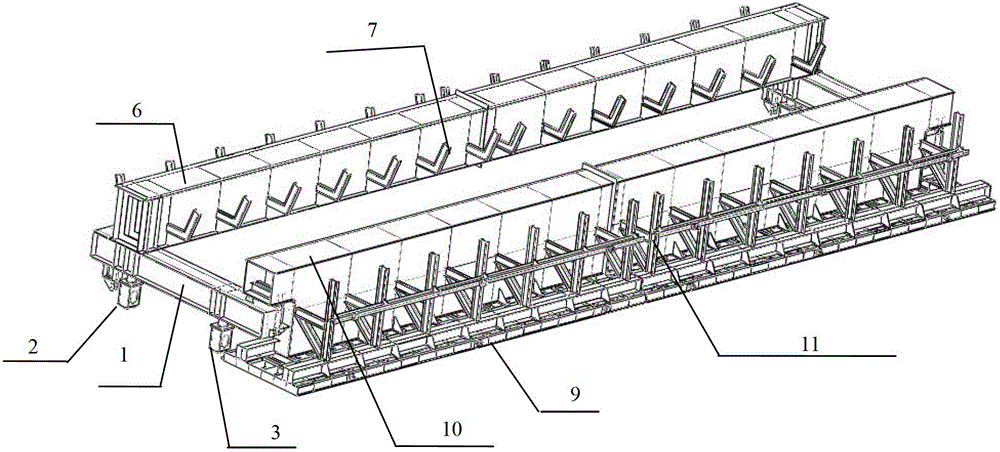

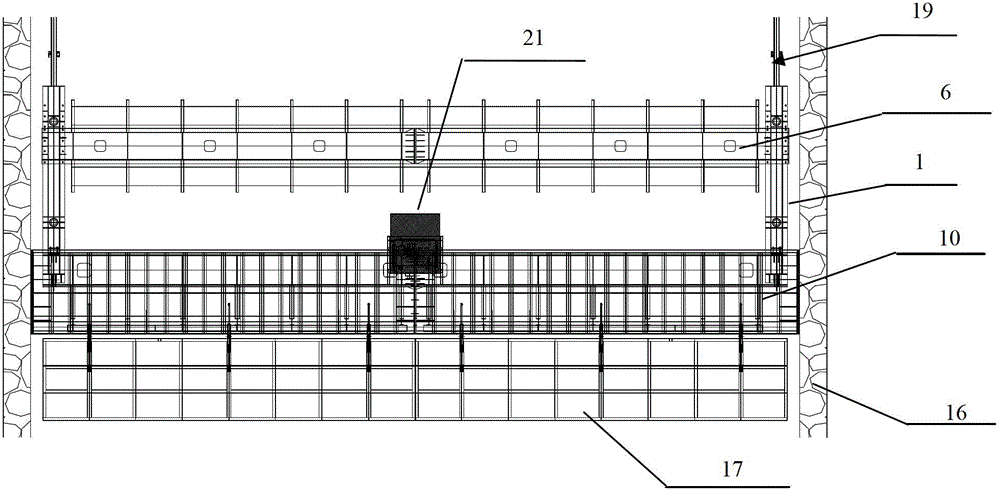

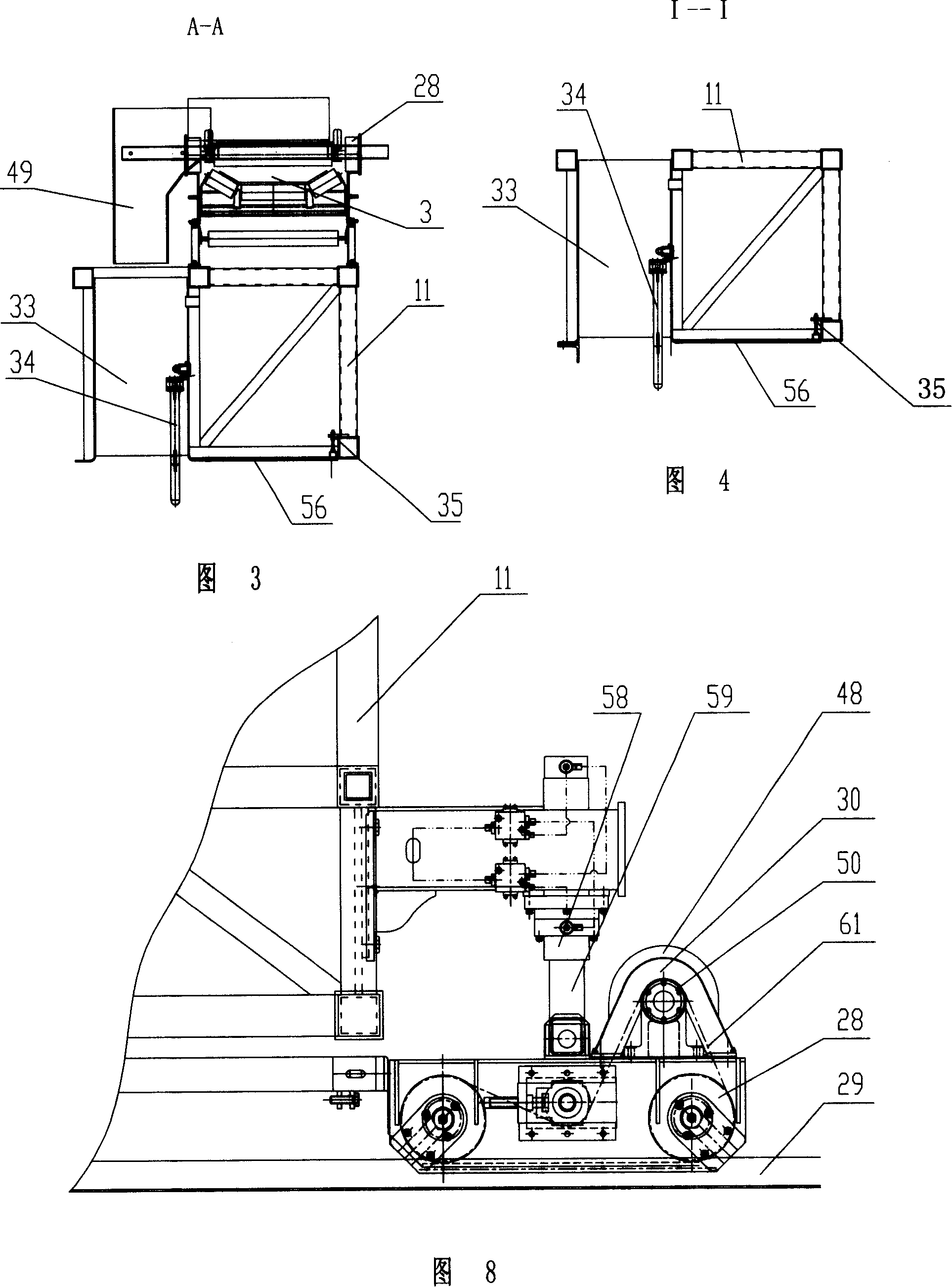

Slope hydraulic self-propelled concealed-rail drag mold

ActiveCN102720162ASolve problems limited by slope slopeFast constructionCoastlines protectionHydraulic pumpEngineering

The invention provides a slope hydraulic self-propelled concealed-rail drag mold, which comprises travel beams, a balance beam, a template system, a working platform, a hydraulic system and the like, wherein each travel beam consists of a crossbeam, a front sliding seat, a back sliding seat, adjusting screws and a cylinder block; the front sliding seat is in rigid connection with the crossbeam, and the back sliding seat is hinged with the crossbeam; the template system consists of a template, a bearing beam and a template system support frame; the bearing beam is parallel to the balance beam; two ends below the bearing beam and the balance beam are respectively provided with a travel beam in the vertical direction; the rear end of the template is provided with the template system support frame; the working platform is parallel to a rail, and is obliquely tensioned on the template system support frame through a spiral lock button; the hydraulic system mainly comprises a hydraulic pump station, advancing cylinders, a hydraulic pipeline and the like; the hydraulic pump station is arranged in the middle of the bearing beam; and an advancing cylinder is arranged below each of two travel beams. The drag mold is not limited to the slope gradient, can ensure that concrete can be continuously poured in large cube amount and large area, and ensures high pouring speed and good quality.

Owner:SINOHYDRO BUREAU 7 CO LTD

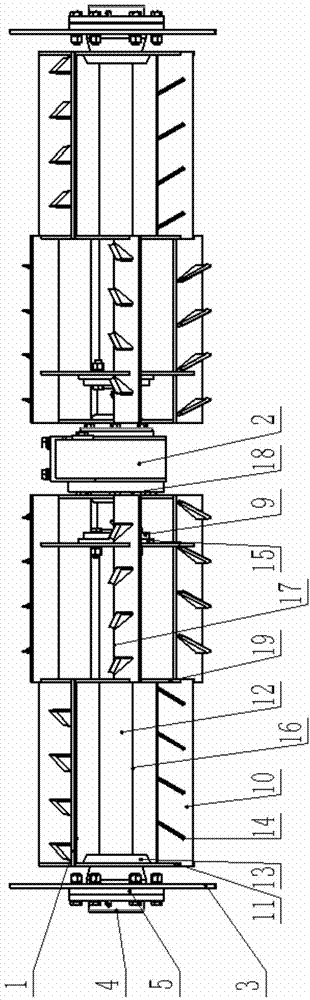

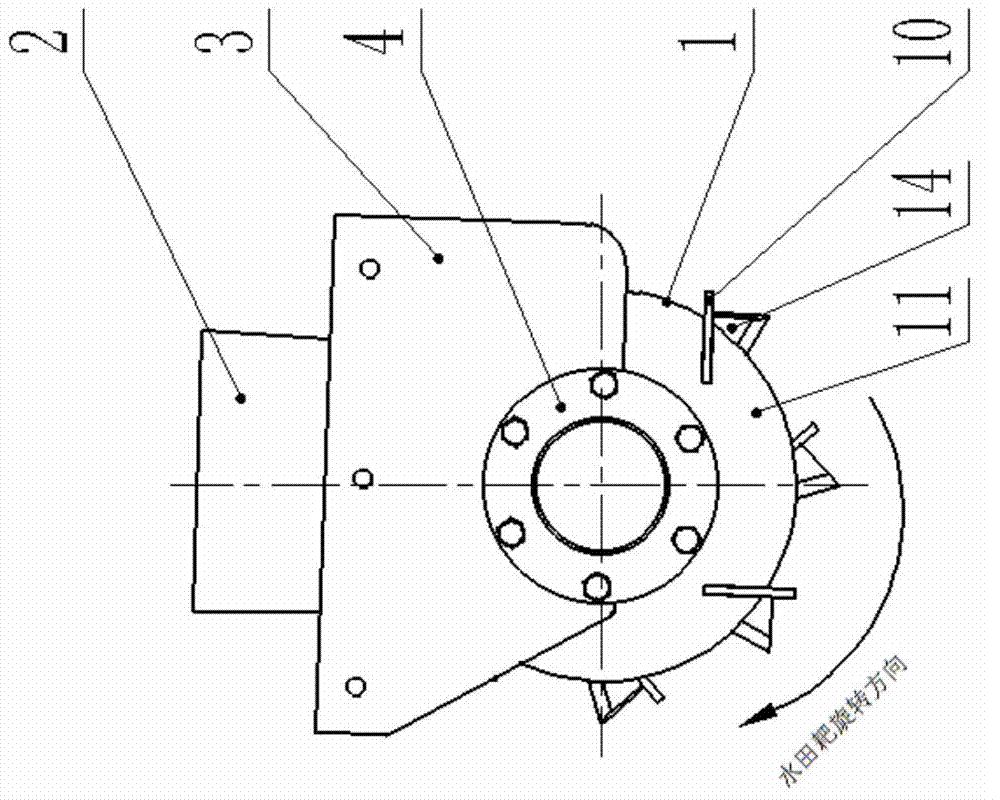

Paddy field harrow with cutting toothed plates

The invention discloses a paddy field harrow with cutting toothed plates. The paddy field harrow comprises two groups of rolling harrows, a power transmission box and main framework suspension plates. The two groups of rolling harrows are symmetrically arranged on two sides of the power transmission box, each group of rolling harrows comprises support-side circular plates, a support shaft, the corresponding cutting toothed plates and cutters, one end of the support shaft of each group of rolling harrows is connected with an output shaft of the power transmission box, the other end of the support shaft of each group of rolling harrows is mounted on a bearing block, the bearing blocks are mounted on the main framework suspension plates, the corresponding support-side circular plates are mounted at two ends of each support shaft, the corresponding cutting toothed plates which are uniformly arranged are arranged between the support-side circular plates of each group of rolling harrows in a fixedly connected manner, and the cutters are transversely uniformly distributed on the cutting toothed plates. The paddy field harrow has the advantages that the paddy field harrow can be divided into a front-rake paddy field harrow and a rear-rake paddy field harrow according to difference of relative welded positions and directions of cutting edges of the cutters on the cutting toothed plates, and the front-rake paddy field harrow and the rear-rake paddy field harrow can be selectively utilized according to difference of paddy field operation environments; the paddy field harrow is simple in structure, excellent soil crushing, pulping and green manure returning effects can be realized, agricultural requirements can be met by operation effects to a great extent, and accordingly the paddy field harrow has certain economical efficiency and practicality.

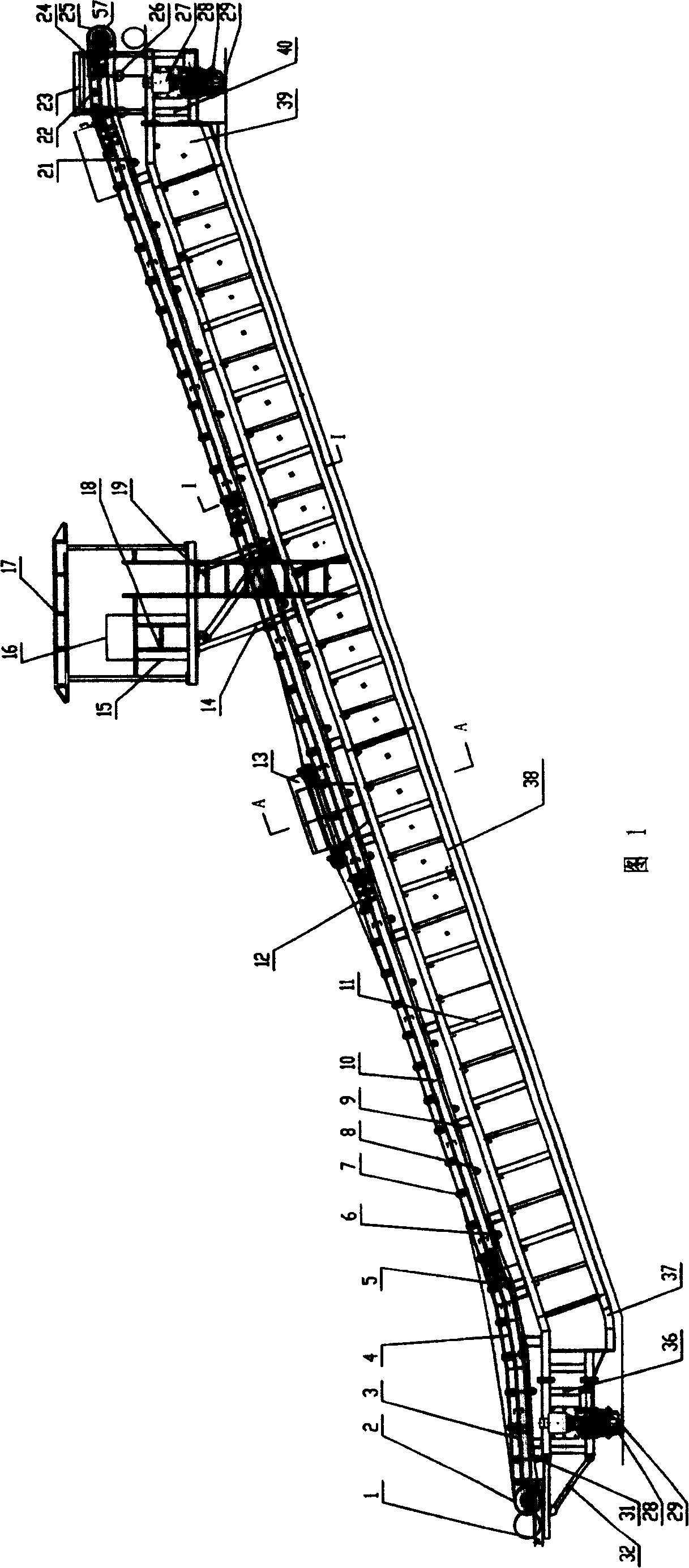

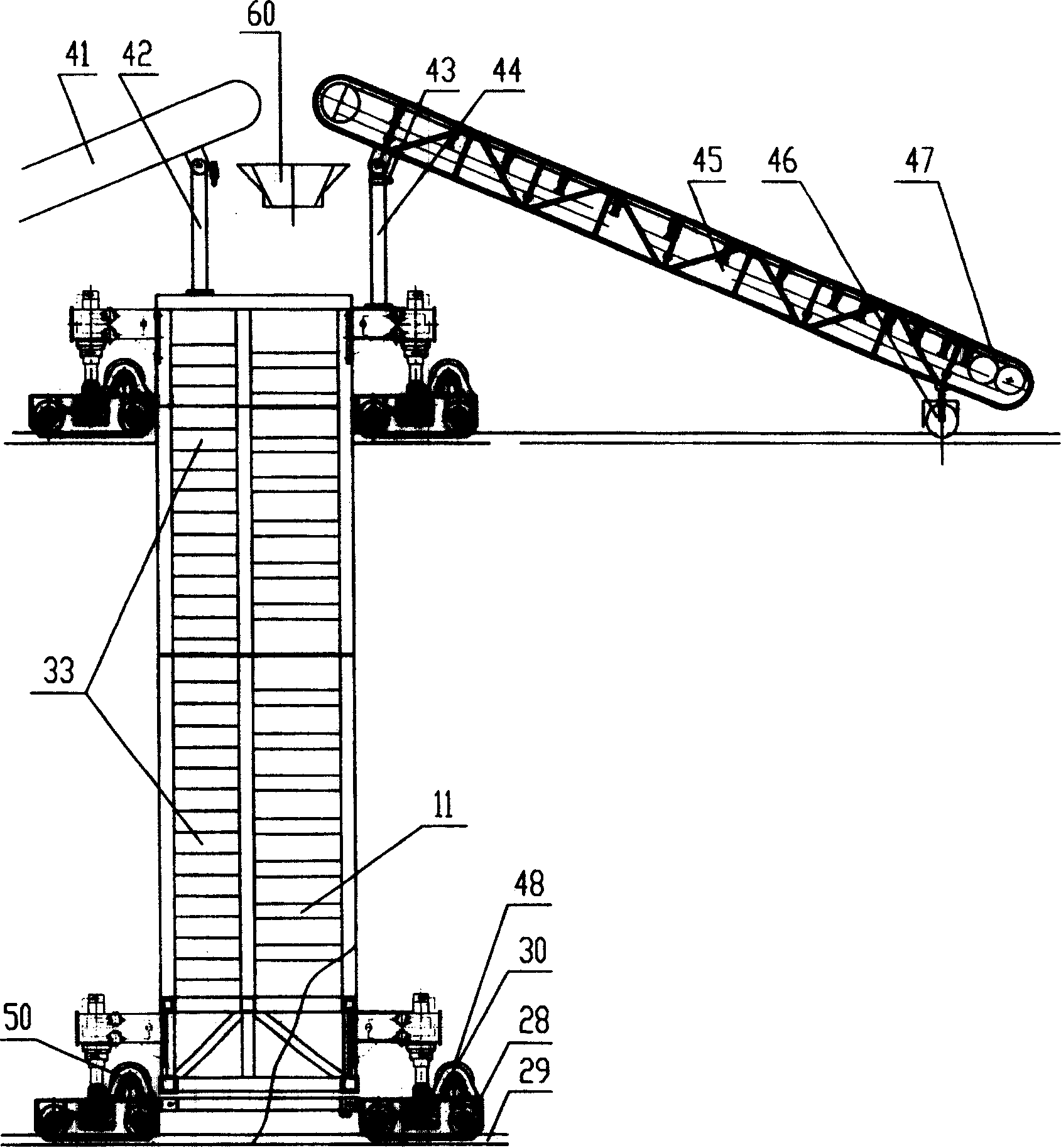

Long slope vibratory slipform shaping mill

InactiveCN100381643CHigh density and uniformFast constructionIrrigation ditchesBuilding material handlingResonanceConstruction aggregate

This invention relates to long slope resonance module shaping machine in water mechanic filed, wherein the machine comprises Power source, , control device, distribution device with move structure with feeding device. The device is characterized by the following: the distribution device comprises relative racket with cloth transmission band fixed; the band is set with mobile distribution cargo; the distribution transmission band side is set with materials barrel with electrical resonance heads; the cargo has materials bin relative to the one of transmission band. The invention is of simple structure and easy maintenance and of low cost and simple operation.

Owner:耿福明 +1

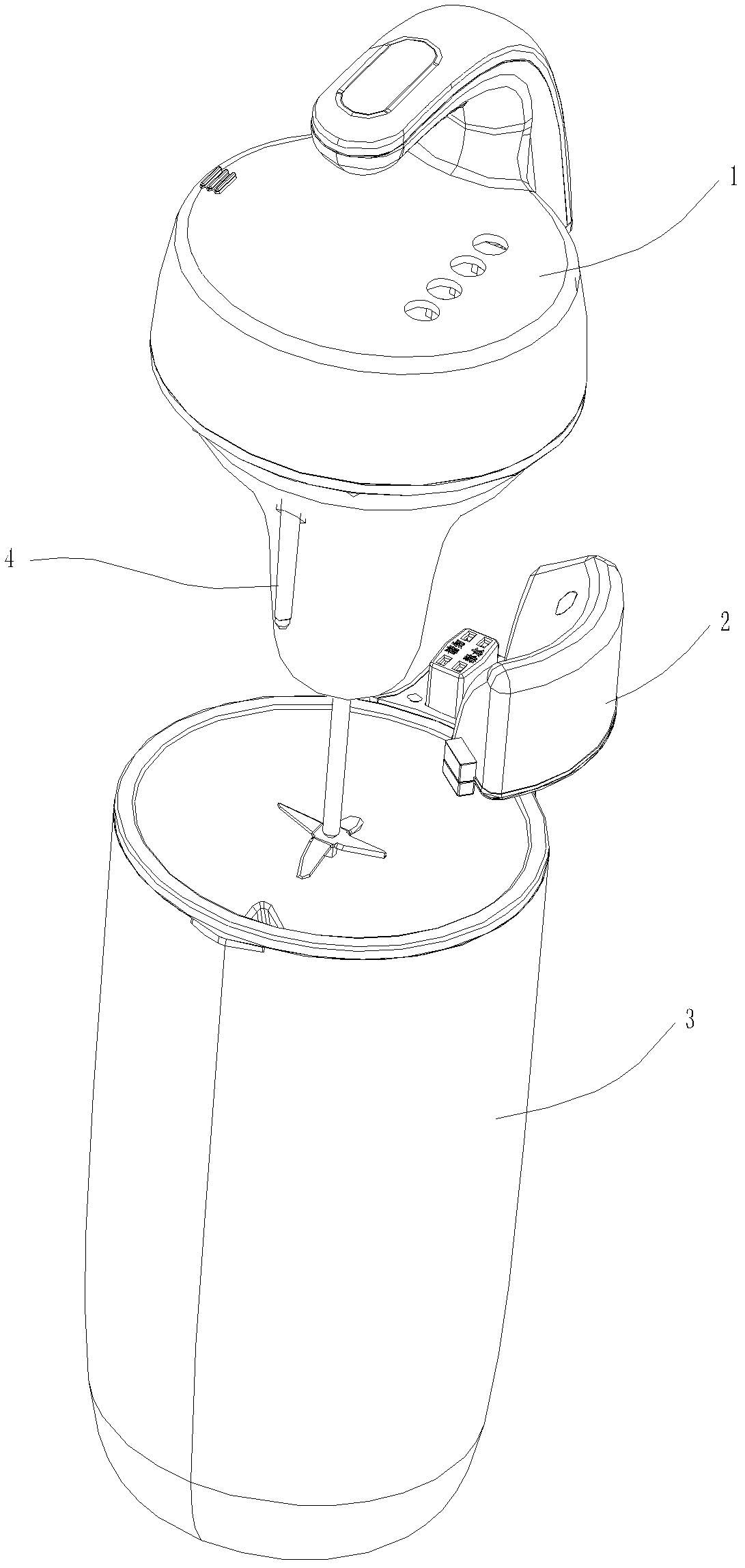

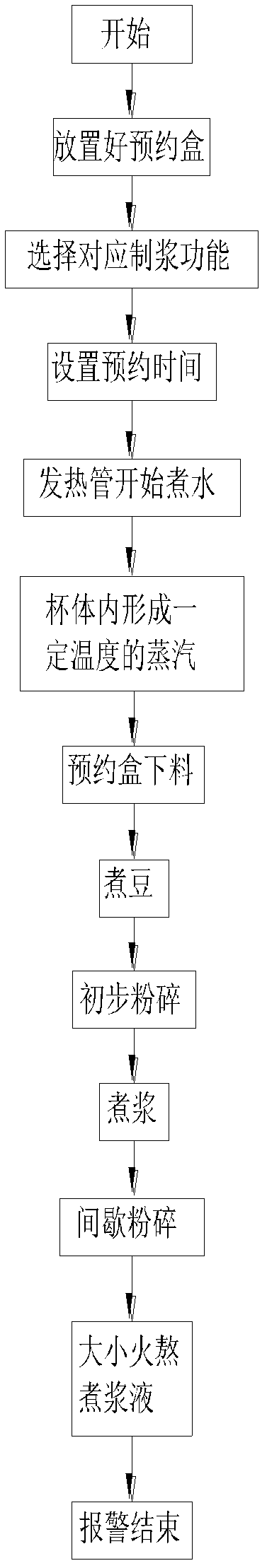

Soybean milk making method of soybean milk making machine with ordering function

ActiveCN102613900ARealize the appointment functionGood pulping effectBeverage vesselsMilk substitutesEngineeringSlurry

A soybean milk making method of a soybean milk making machine with an ordering function comprises the steps: (1) performing soybean milk making procedures; (2) placing an ordering box; (3) selecting a corresponding soybean milk making function; (4) setting the ordering time; (5) starting a heating pipe of the soybean milk making machine to boil water when the ordering time is up; (6) forming steam with certain temperature in a soybean milk making machine body and opening the ordering box to perform blanking; (7) performing a soybean boiling procedure of the soybean milk making machine; (8) starting a motor of the soybean milk making machine and primarily smashing materials by a cutter; (9) performing a soybean milk boiling procedure of the soybean milk making machine; (10) intermittently operating the motor of the soybean milk making machine and smashing materials by the cutter; (11) performing a high-and-low flame boiling procedure of the soybean milk making machine; (12) the soybean milk making machine gives an alarm after boiling soybean milk. The soybean milk making method of the soybean milk making machine with the ordering function has the advantages of achieving the ordering function and being good in soybean milk making effect.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Method for reducing damage of waste-paper fibers in high-concentration pulping process

ActiveCN108824050AReduce the binding forceFor subsequent usePretreatment with water/steamPaper recyclingHigh concentrationPulp and paper industry

The invention discloses a method for reducing damage of waste-paper fibers in the high-concentration pulping process. According to the method disclosed by the invention, through a waste-paper slurry adding step, a first high-pressure puffing step, a first puffing slurry swelling step, a second high-pressure puffing step and a pulping step, a fiber structure in waste-paper slurry is swelled and separated more completely from the pulping process; and the method is more suitable for reutilization of secondary fibers in the waste paper slurry, and at the same time, the method improves efficiency of the pulping process and quality of the secondary fibers obtained after pulping is performed.

Owner:DONGGUAN TAICHANG PAPER CO LTD

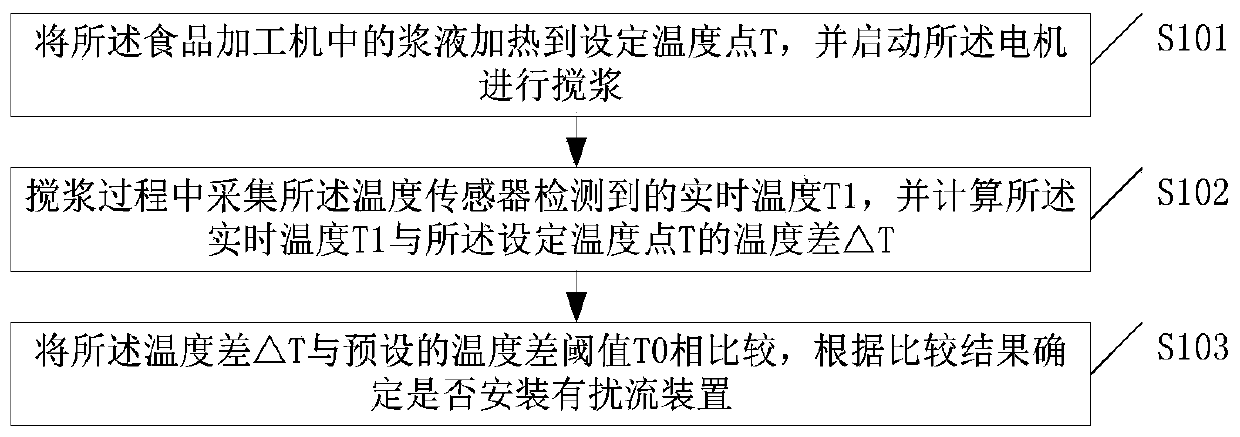

Turbulent flow identification method of food processor

ActiveCN110522321AImprove recognition accuracyAvoid misjudgmentKitchen equipmentTemperature differenceSlurry

The embodiment of the invention discloses a turbulent flow recognition method for a food processor, wherein the food processor comprises a motor and a machine head, and a temperature sensor is arranged at the fixed position of a spoiler on the machine head. The method comprises the following steps: heating slurry in the food processor to a set temperature point T, and starting a motor to stir theslurry; sampling a real-time temperature T1 detected by a temperature sensor in a slurry stirring process, and calculating a temperature difference [delta]T between the real-time temperature T1 and aset temperature point T; and comparing the temperature difference [delta]T with a preset temperature difference threshold T0, and determining whether a turbulence flow device is installed or not according to a comparison result. Through the scheme of the embodiment, whether the turbulent flow device is installed or not is accurately and effectively detected, a technical basis is provided for guaranteeing a good pulping effect, and high-temperature pulp can be prevented from splashing out to scald a user.

Owner:JOYOUNG CO LTD

Pulper structure for tissue production

ActiveCN110644268AAchieve flowCut evenlyPaper recyclingRaw material divisionPaper towelProcess engineering

The invention relates to the technical field of tissue production, in particular to a pulper structure for tissue production. The bottom of a pulping barrel communicates with a discharge pipe; the bottom end of a main shaft is rotatably connected with the inner bottom wall of the pulping barrel; a plurality of pulp lifting components are arranged on the outer side wall of the pulping barrel; a special-shaped surface is of a continuous concave-convex shape along the circumferential direction of a press ring; one end of each lifting column is inserted into a guide cylinder from top to bottom andthen is pressed on a spring; the other end of each lifting column is pressed through the corresponding guide ring and abuts against the special-shaped surface of the press ring; a plurality of fixingplates are uniformly distributed on the column body of each lifting column; and one end, abutting against the press ring, of each lifting column is of a hemispherical surface shape. When the pulper structure is used, flowing capacity of pulp in the pulping barrel can be improved, and the pulping effect is improved; moreover, the pulp can flow and be stirred in multiple directions in the pulping barrel through only one power mechanism, and overall cost of the pulper is reduced.

Owner:中顺洁柔(云浮)纸业有限公司

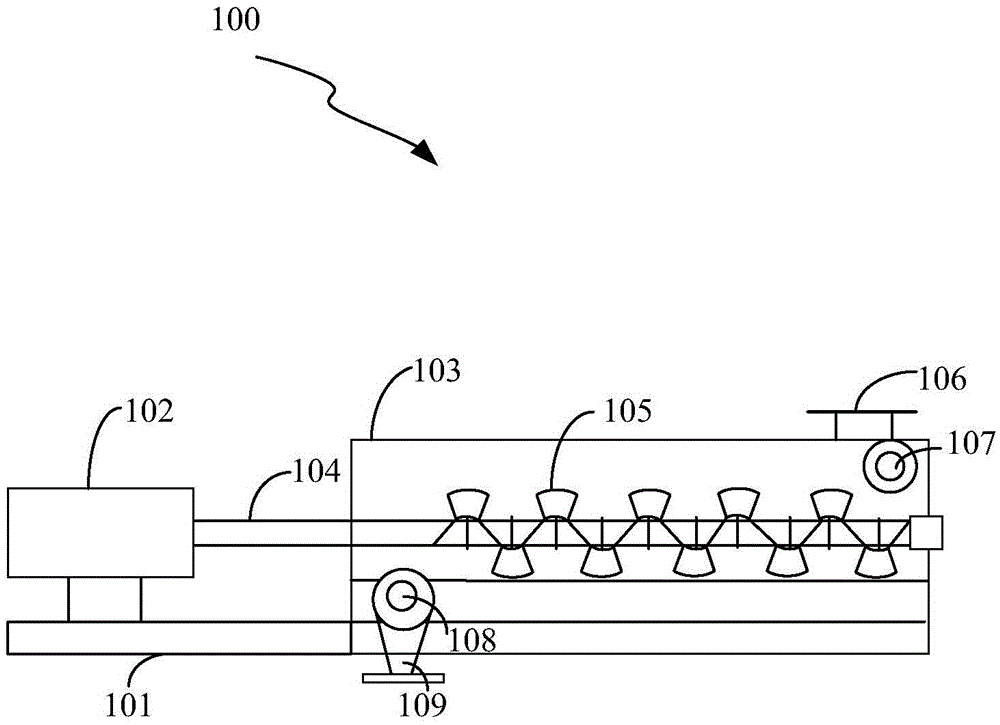

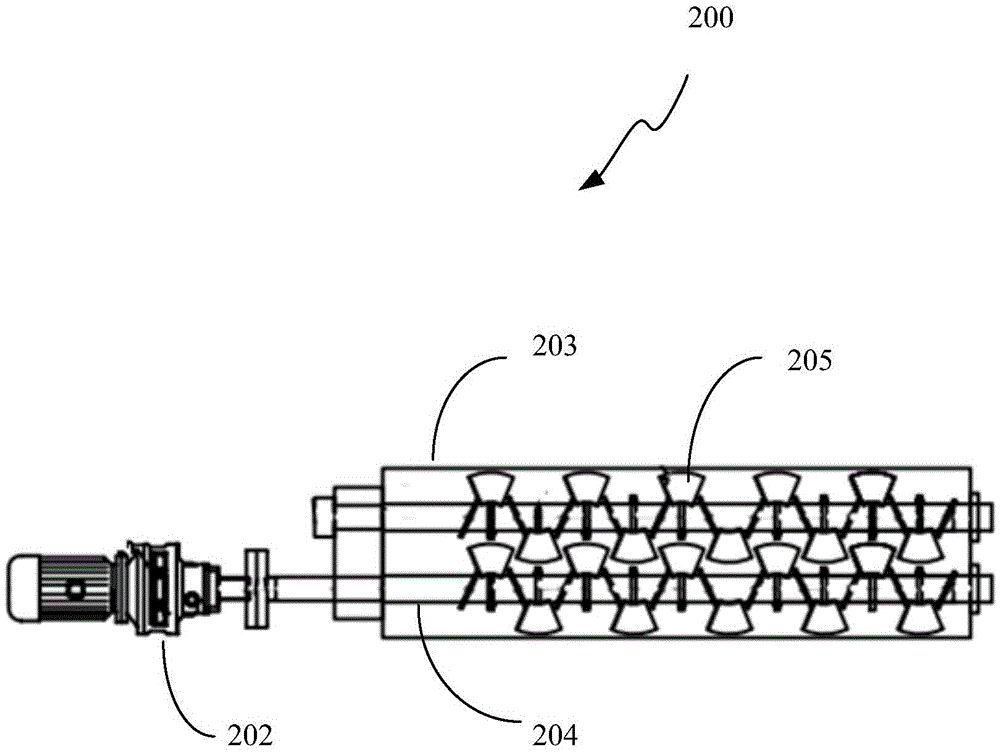

Sludge slurrying machine

InactiveCN105536596AAchieve stirring effectRealize the conveying effectSludge treatmentRotary stirring mixersDrive shaftEngineering

The invention provides a sludge slurrying machine. The sludge slurrying machine comprises a transmission device, a transmission shaft, paddles, a casing and a base, wherein the transmission device and the casing are mounted on the base; the transmission device is connected with the transmission shaft and used for driving the transmission shaft to rotate; one end of the transmission shaft is connected with the transmission device, and the other end extends into the casing and is provided with the paddles; the paddles and the transmission shaft are set to form angles and are used for stirring and conveying sludge; a sludge addition port is formed in the upper end of the casing and used for addition of dewatered sludge to the casing; a discharging end is arranged at the bottom end of the casing and used for outputting a mixed and slurried material out of the sludge slurrying machine; the base is connected with the casing and used for supporting the sludge slurrying machine.

Owner:CSD BEIJING E P DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com