Unbleached pulp, and preparation process, application and preparation device of unbleached pulp

A preparation process, a technology for uncolored pulp, applied in multi-stage pulping process, non-woody plant/crop pulp, textiles and papermaking, etc., can solve the problems of high cost, comprehensive utilization rate of less than 40%, complex auxiliary ingredients, etc. Achieve high pulp yield, significant pulping effect, and save heating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

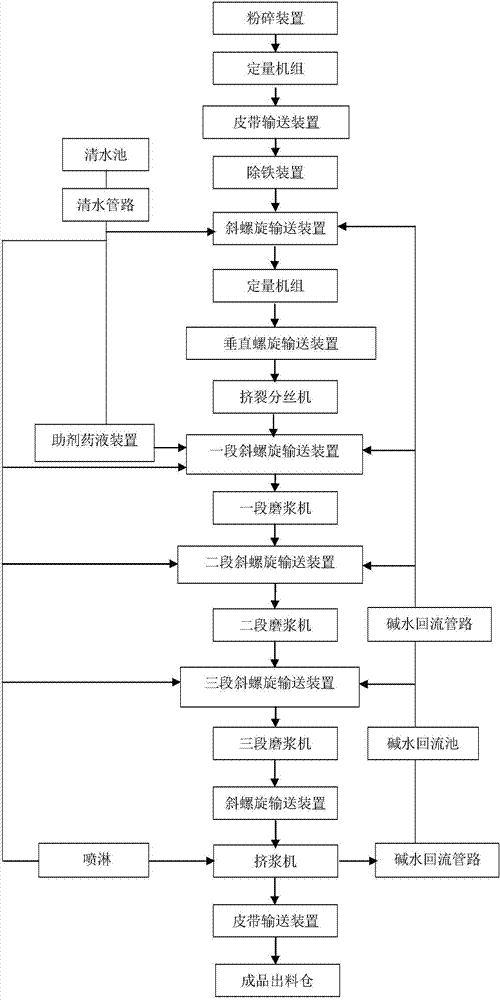

Method used

Image

Examples

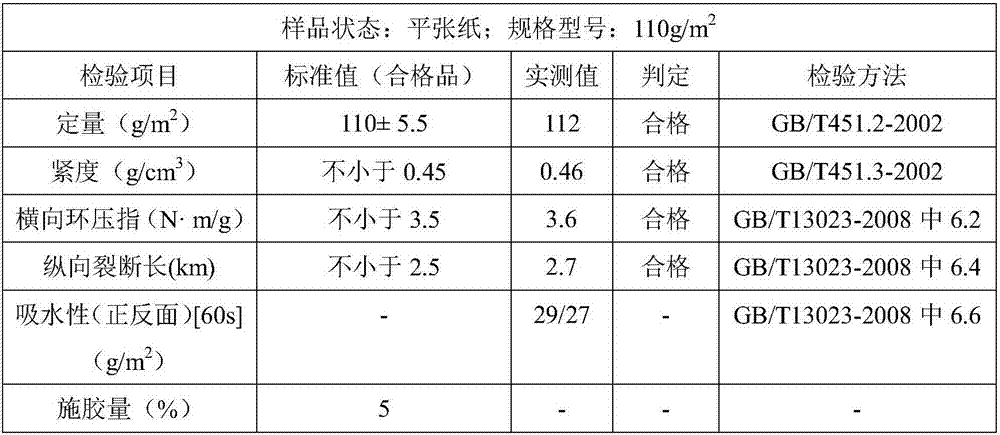

Embodiment 1

[0090] Example 1 A natural color paste and its pulping process

[0091] A kind of natural color paste is made by wheat straw, and the production scale is 10,000 tons of annual output slurry, and the beating degree of gained natural color paste is the beating of 55-70 ° SR, and the preparation process is as follows:

[0092] (1) Raw material crushing: the wheat straw is preliminarily crushed, the crushing rate is 3t / h, and the length after the primary crushing is 2cm.

[0093] (2) Iron removal treatment: the pulverized raw material in step (1) is subjected to iron removal treatment;

[0094] The iron removal treatment is two-stage. The crushed raw materials are firstly subjected to one-stage iron removal to remove iron-containing impurities close to the surface of the belt in the raw materials, and then undergo a second-stage iron removal to remove iron-containing impurities inside the raw materials; iron removal treatment steps and raw materials The raw material processing ra...

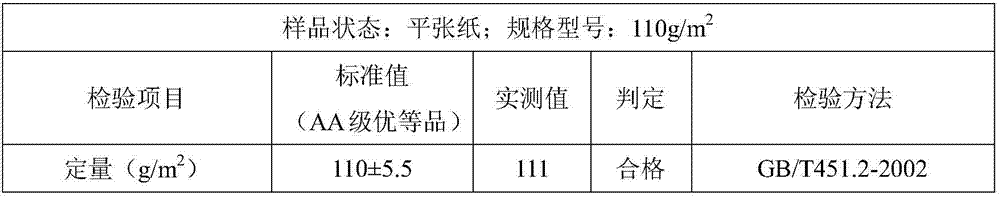

Embodiment 2

[0102] Example 2 A natural color paste and its pulping process

[0103] A kind of natural color paste, made of straw, the production scale is 10,000 tons of annual output of slurry, the beating degree of gained natural color paste is the beating of 55-70 ° SR, and the preparation process is as follows:

[0104] (1) Raw material crushing: the rice straw is preliminarily crushed, the crushing rate is 2t / h, and the length after the primary crushing is 1cm.

[0105] (2) Iron removal treatment: the pulverized raw material in step (1) is subjected to iron removal treatment;

[0106] The iron removal treatment is two-stage. The crushed raw materials are firstly subjected to one-stage iron removal to remove iron-containing impurities close to the surface of the belt in the raw materials, and then undergo a second-stage iron removal to remove iron-containing impurities inside the raw materials; iron removal treatment steps and raw materials The raw material processing rate ratio for t...

Embodiment 3

[0114] Example 3 A natural color paste and its pulping process

[0115] A kind of natural color pulp is made by waste wood chips, and the production scale is 10,000 tons of annual output of slurry, and the beating degree of gained natural color pulp is the beating of 60°SR, and the preparation process is as follows:

[0116] (1) Raw material crushing: Preliminary crushing of waste wood chips, the crushing rate is 4t / h, and the length after primary crushing is 3cm.

[0117] (2) Iron removal treatment: the pulverized raw material in step (1) is subjected to iron removal treatment;

[0118] The iron removal treatment is two-stage. The crushed raw materials are firstly subjected to one-stage iron removal to remove iron-containing impurities close to the surface of the belt in the raw materials, and then undergo a second-stage iron removal to remove iron-containing impurities inside the raw materials; iron removal treatment steps and raw materials The raw material processing rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com