Patents

Literature

136results about How to "Increase pulp yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing paper pulp by using biological enzyme

InactiveCN102978986AEasy to handleReduce energy consumptionCellulose material pulpingState of artFermentation

The invention relates to a preparation method of paper pulp, and further relates to a method for preparing the paper pulp through a biological enzyme method. The technical scheme is that the method comprises the following steps of: one, segment cutting; two, puffing; three, heat preservation fermentation; four, shoving; five, pulp washing; six, pulp selecting, wherein screened out coarse residues are put into the step three for fermentation again; seven, pulp grinding; and eight, screening, wherein the screened out pulp residues are put into the step seven for pulp grinding again. Compared with the prior art, the method has the advantages that the pulping and papermaking through the biological enzyme method has the characteristics of 'three highs and three lows' compared with the conventional process technology.

Owner:TIANJIN ZHIZHAN SCI & TECH

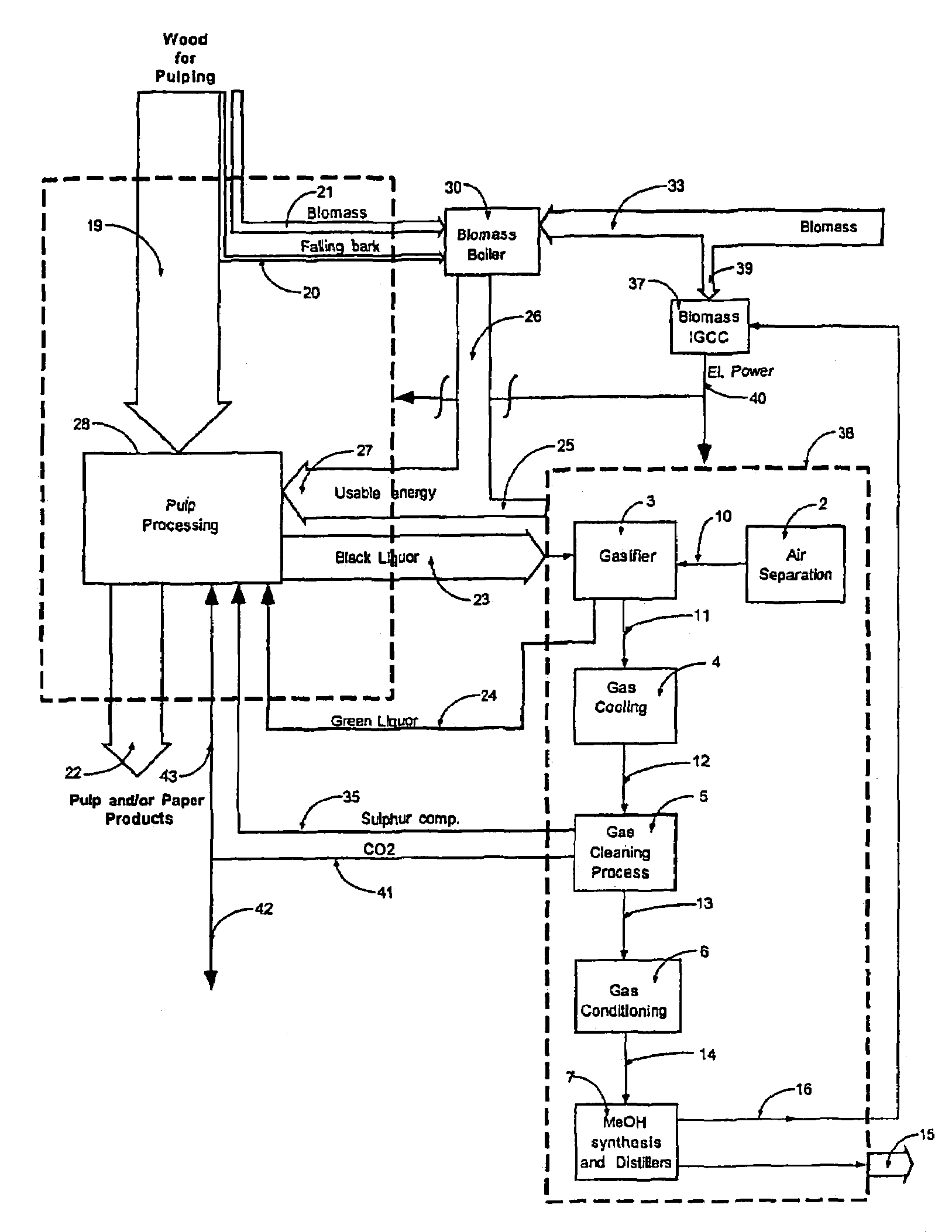

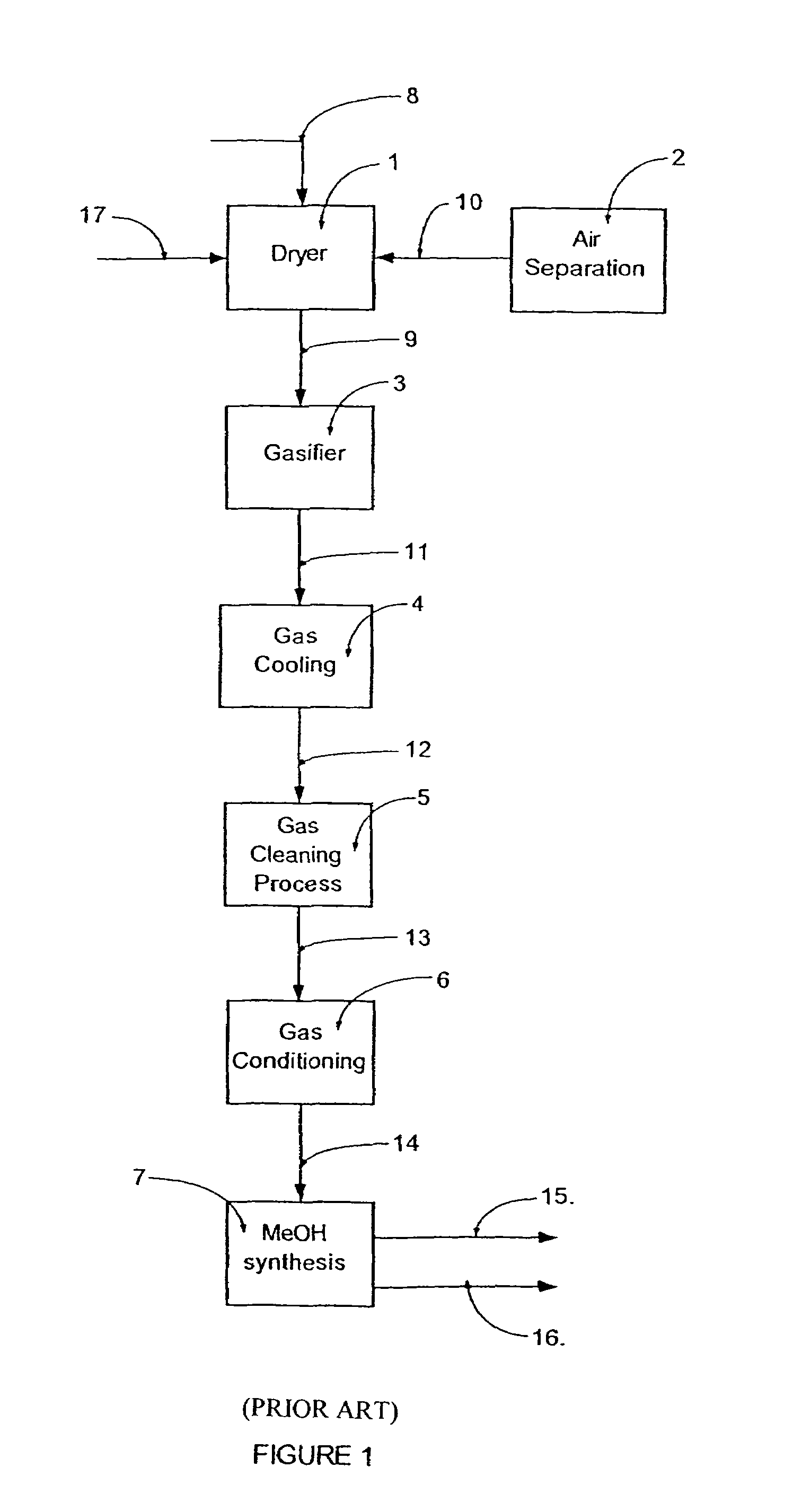

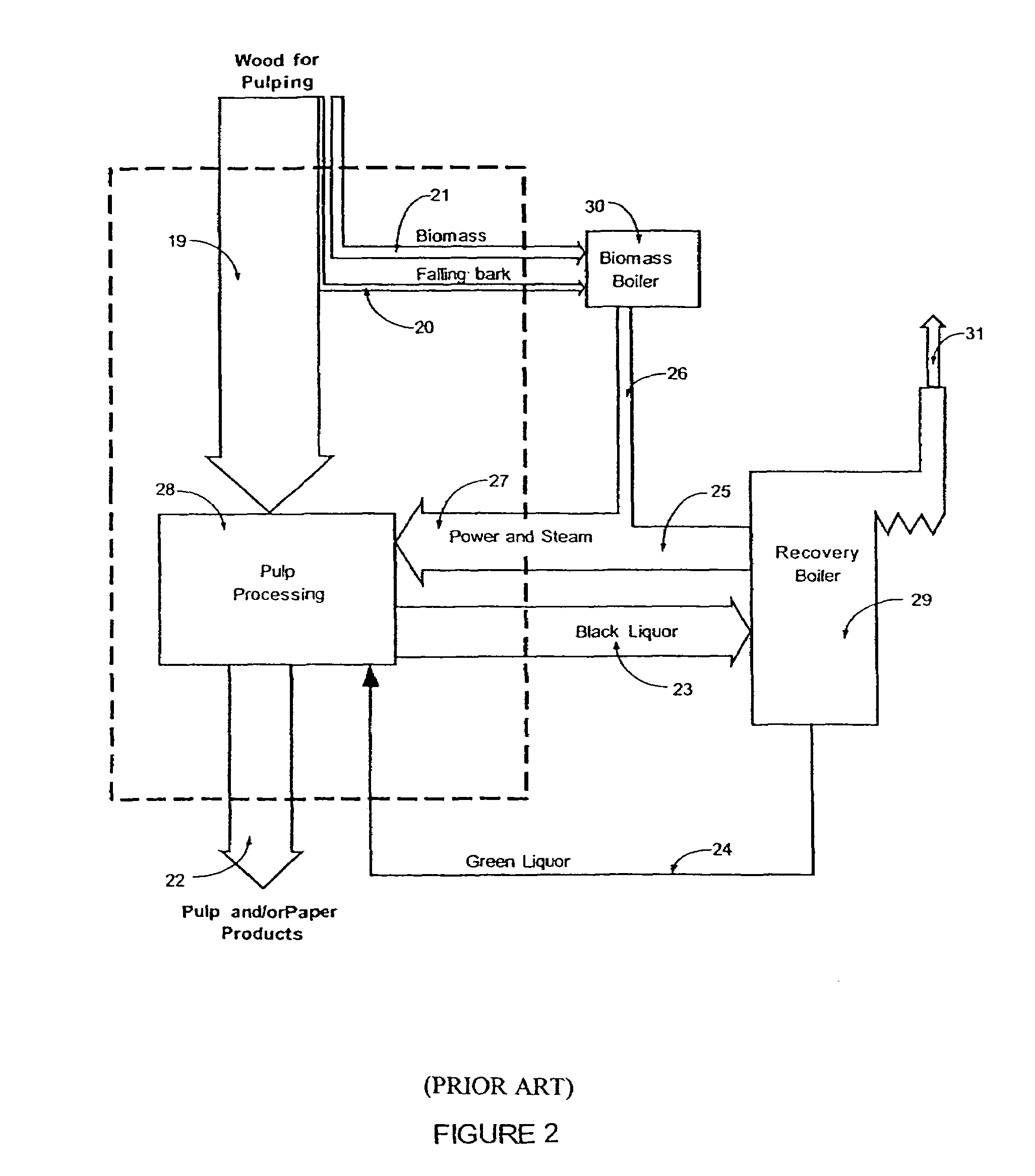

Process for production of synthesis gas in combination with the maintenance of the energy balance for a pulp mill

InactiveUS7294225B2Simpler andImprove energy savingPulp liquors combustionHydrocarbon from carbon oxidesEnergy balancingCombustion

A process (44) for the production of pulp and paper (28), recycling of cooking chemicals (3, 29), combustion of biomass (30, 37) and generation of heat and electric energy (27, 40) comprising a pulp and paper mill (28), in that the part of the process which is recycling cooking chemicals is adjusted from combustion (29) to gasification (3) to generate synthesis gas (14); and that biomass is added (33, 39) in an amount sufficient for compensating of the decrease in heat and electricity generation as a consequence of the generation of synthesis gas (14).

Owner:CHEMREC AB

Zero residual base normal-pressure or low-pressure boiling high-concentration pulp preparing method by using base process

InactiveCN101215794ARapid responseNo residual alkaliDigestersNon-macromolecular organic additionHigh concentrationSodium metasilicate

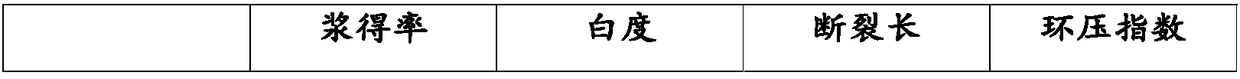

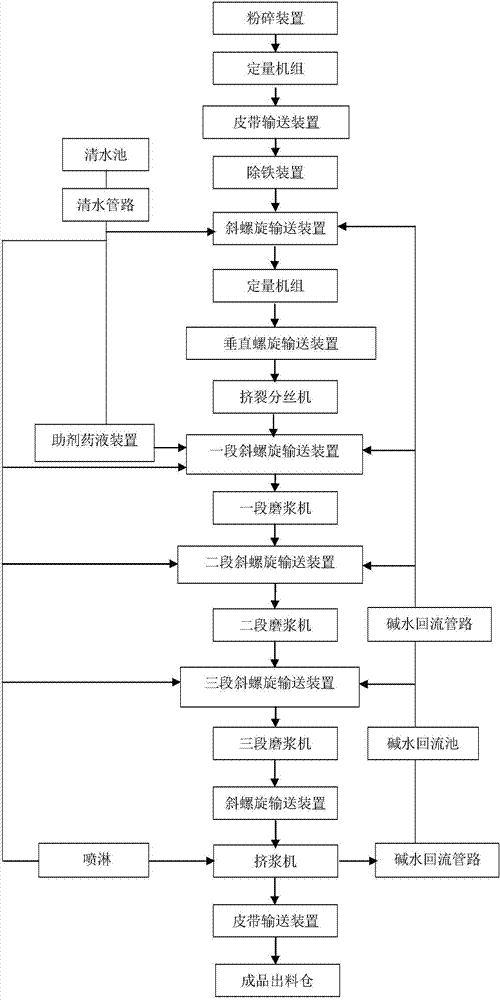

The invention relates to a method for boiling high concentration pulping in normal pressure or low pressure by an alkaline method with zero residual alkaline, and the method comprises adding accelerating agent in the boiling process and utilizing a double screw to rub and squeeze a pulper, leading pulp making and boiling process with an alkaline method to go on in normal pressure or low pressure, and leaving no residual alkaline in black liquor, leading pulp to always keep a higher density in the pulping process of boiling, washing and bleaching, and the pulp which is prepared can meets the requirement of paper making. Accelerating agent chooses one or a plurality of magnesium hydrate, potassium hydrate, sodium metasilicate, sodium sulfide, sodium sulfite, ammonium sulfite and carbamide. Special-purpose pulping boiling equipment and high-pressure boilers are not needed by pulping paper mills through utilizing the invention, in the process of pulping, pulp always keeps higher density, and black liquid has high density, little numbers and low energy consumption, alkaline recovery project with great investment is not needed to be built, and the invention enables black liquid to prepare fertilizer or other chemical products with high quality, and the invention is suitable for popularizing and applying.

Owner:晏永祥

Biocatalytic clean pulping agent and application process thereof

InactiveCN1844572ANo emissionsNo pollutionPulp liquor regenerationWashing/displacing pulp-treating liquorsForeign matterProcess equipment

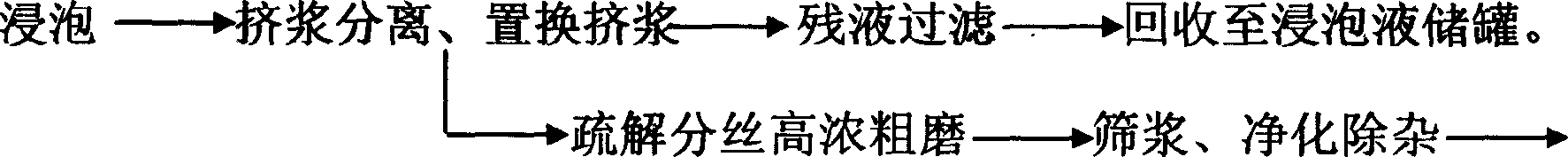

The invention relates to a biochemical catalysis cleaning slurry agent and relative application. Said invention is formed by: amylase, laccase, hydroxybenztriazole, calcii chloridum SL-1 slurry braise agent, sodium carbonate, and water. And the application comprises: 1, cutting raw material to be kneaded and dedusted; 2, preparing material with wet method; 3, dipping to remove lignin colloid; 4, extruding slurry to replaced and separated, dipping to filter the left liquid to be recycled; 5, rough milling and combing wire; 6, screening slurry to remove foreign matters; 7, washing slurry; 8, finish milling slurry; 9, poaching slurry; 10, washing poached slurry; 11, stepped treating and recycling used water. The invention is characterized in dipping said raw material in normal temperature and pressure. The left liquid is not discharged, but be recycled. And the pulp is poached pulp. The invention can support industrial production.

Owner:石建凯

Pulping method with zero discharge of sewage water

InactiveCN101220565AHigh extraction rateLess investmentPulp liquor regenerationWashing/displacing pulp-treating liquorsPolyesterBlack liquor

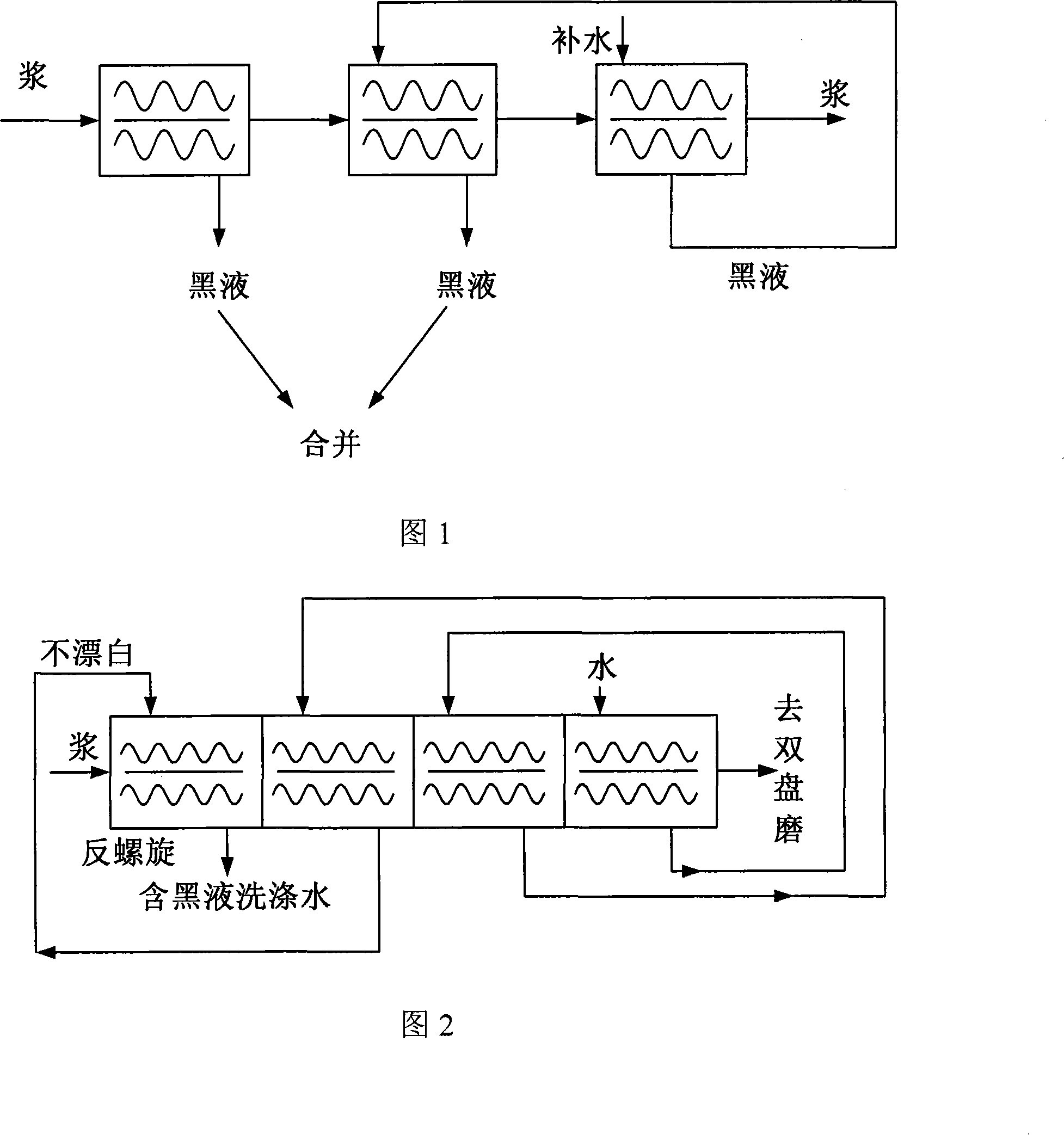

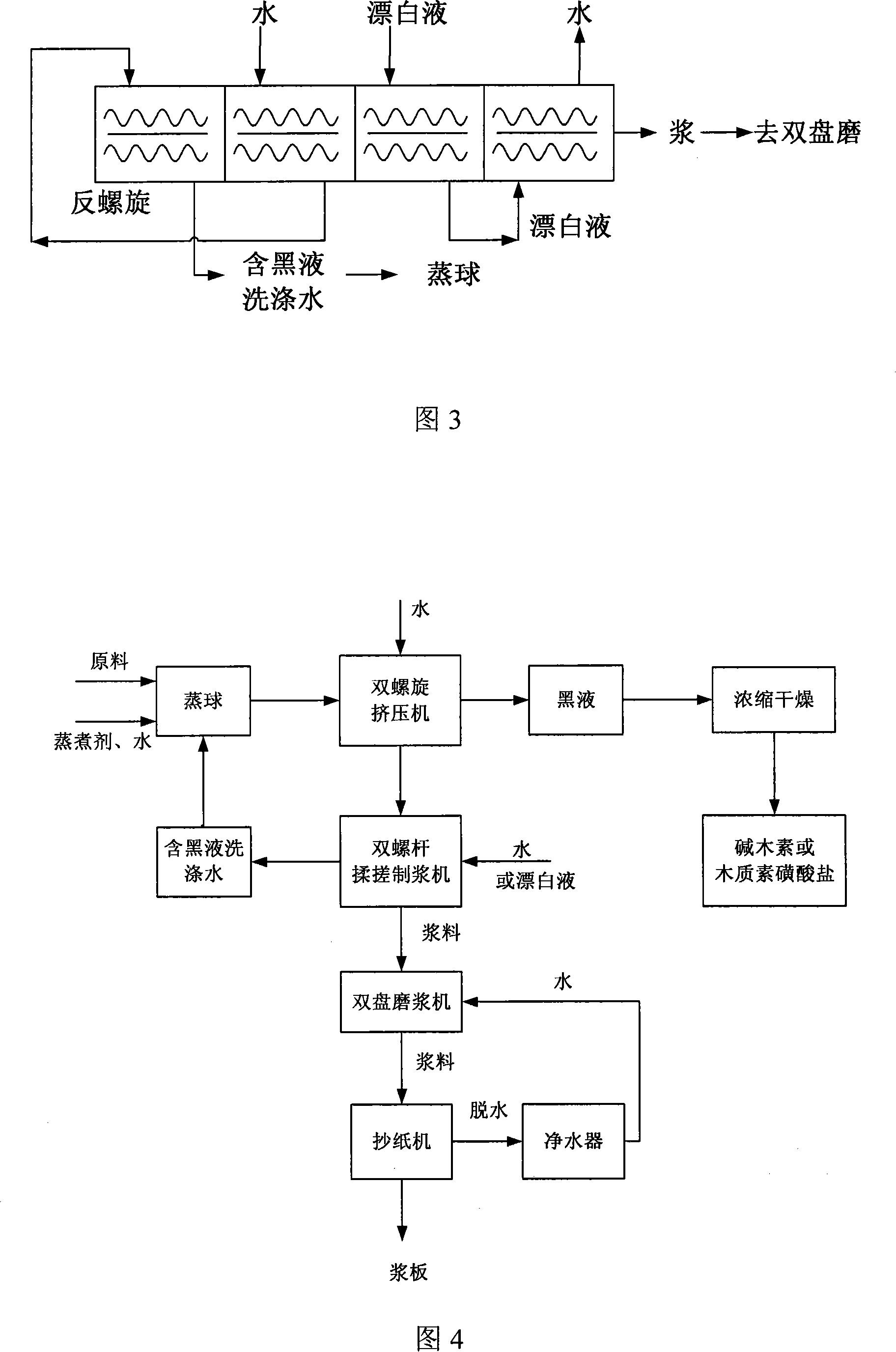

The invention discloses a pulp making method for discharging sewage thoroughly which includes the following steps: pulping material, steam cooking agent and catalyst are mixed evenly and put into a spherical digester and the mixture is cooked by steam; the cooked material is squeezed by passing through a plurality of twin-screw extruders connected in series so as to extract black liquid and obtain the pulp material, and the black liquid obtained from the last twin-screw extruder is squeezed sequentially after returning to the former twin-screw extruder, while the black liquid obtained from a first and a second twin-screw extruders is merged straightly, and the merged black liquid is concentrated and dried to obtain alkali lignin and or lignosulfonate; the pulp material is delivered into a twin-screw rubbing and kneading pulper, the polyester washing is carried out in multiple-section series while the pulp is grinded, or the polyester washing is carried out in multiple-section series and bleached in multiple-section series, the washing water is returned to the washing process in the former section, and finally the residuary black liquid is obtained, that is the washing water coming from the first washing process; then, the residuary black liquid is returned to the pulping material or the spherical digester; the pulp material is refined in a dual-disk refining machine by adding water, then a pulp plate is made after the refined pulp material enters a paper machine. Meanwhile, the removed water circulates to the dual-disk refining machine or other processes needing the water by the pure water treatment.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

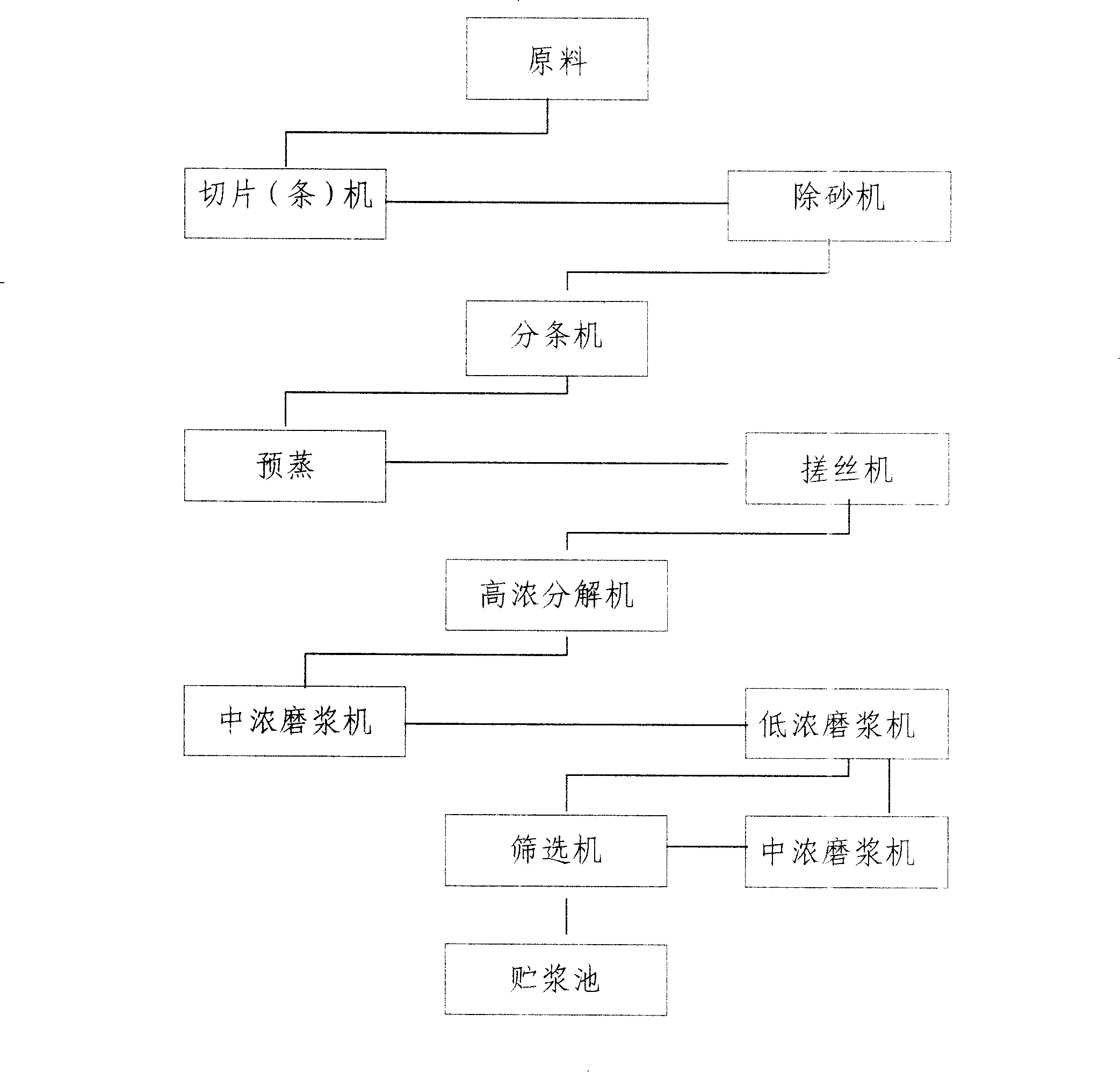

Continuous pulping method for cotton stalk natural color chemomechanical pulp

InactiveCN101177921ASimple processContinuous Cooking and RefiningPretreatment with water/steamWashing/displacing pulp-treating liquorsHigh concentrationDigestion

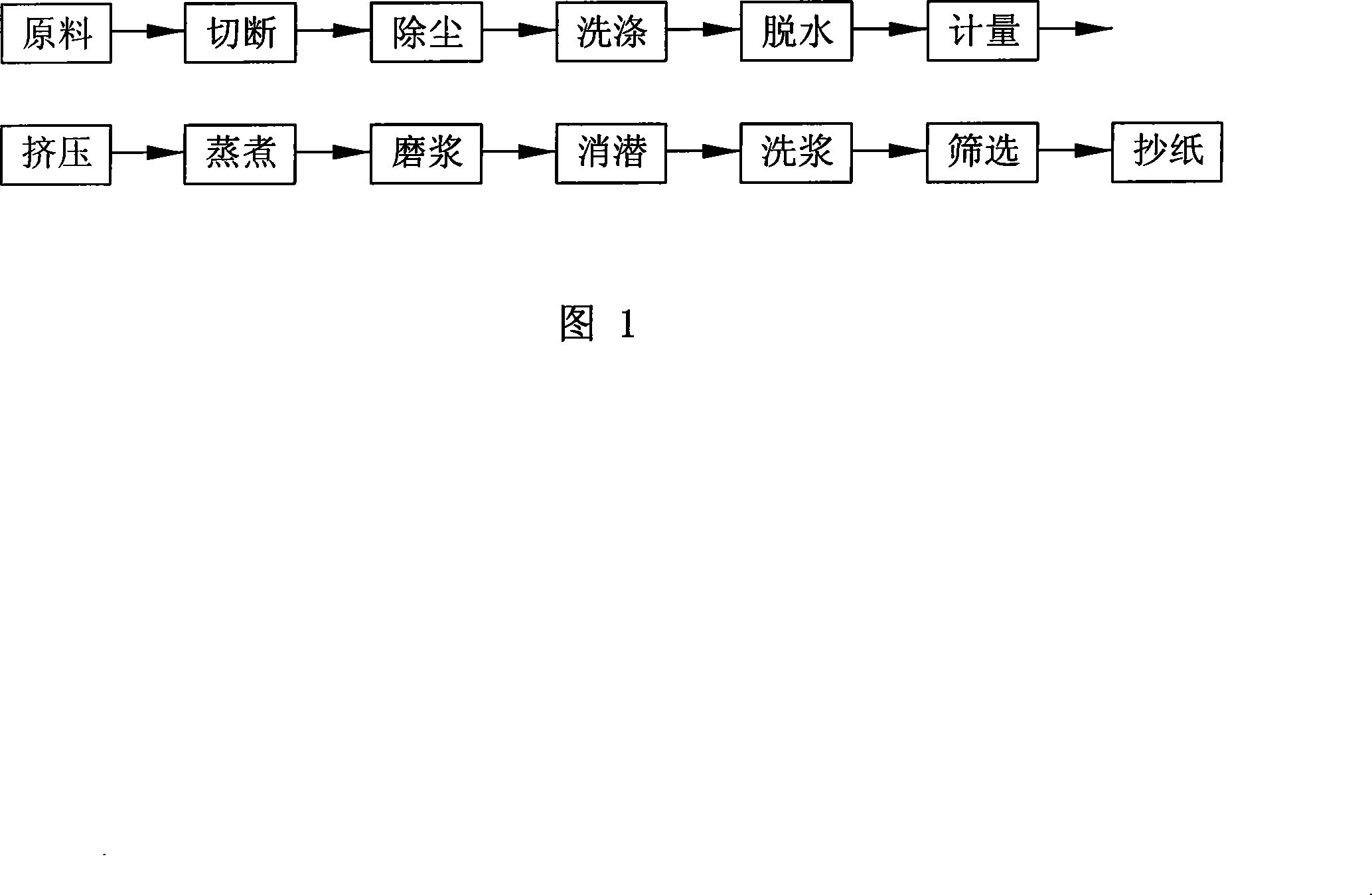

The invention relates to a cotton-stalk true-color chemo-mechanical continuous pulping method. The invention comprises the steps that: (1) the materials are cut into material sheets equal to or smaller than 40mm by machines; (2) the qualified materials are dedusted by a cleaner, sent into a material warehouse to be stored, sent to a washer to be washed, heavy impurities are separated by the function of washing water, and then the materials enter into a dewaterer to be dewatered, to eliminate the sand and dust in the materials; (4) the dewatered materials are sent to a quantifier to be quantified, and the quantified materials are squeezed and dewatered by a helical feeder and form a compact material plunger, which is sent into a digester; (4) digestion liquor is added into the digester to fully soak the material plunger, and steam is introduced for the digestion; (5) after the digestion, the materials drop to a high concentration thermofiner to be defibrinated; (6) the defibrinated pulp is injected to a blow tank to be latented; (7) the latented pulp is washed, sifted, and finally can be sent to a paper machine for papermaking. The invention has the advantages of simple technique process, continuous digestion and defibrination, good pulp quality, and high yielding.

Owner:MCC PAPER YINHE

Biological pulping method adopting crop straw and papermaking pulp

ActiveCN108442162AEmission reductionReduce energy consumptionCellulose treatment using microorganisms/enzymesPectinaseLignin peroxidase

Owner:福建祥业环保科技股份有限公司

Straw cutting-free method for preparing straw pulp by spherical digester alkali digestion

InactiveCN102400404AImprove the environmentImprove qualityPulping with inorganic basesNon-woody plant/crop pulpAnthraquinonesBlack liquor

The invention provides a straw cutting-free method for preparing straw pulp by spherical digester alkali digestion. The method comprises the following steps of: washing a straw raw material; adding a hot alkali solution, adding water, mixing uniformly, and heating; performing digestion by adopting a conventional sulfate method or a caustic soda anthraquinone method; stopping the digestion when the lignin discharged from the straw raw material by the digestion reaches 75 to 90 percent, discharging a black liquor I, and thus obtaining straw pulp; and adding the hot alkali solution into the straw pulp, performing digestion and conventional washing and thus obtaining unbleached pulp, wherein the thin black liquor discharged during washing is a black liquor II, the black liquor II and water are added into the new straw raw material together, and the unbleached pulp is continuously obtained by repeating. The straw cutting process is eliminated in the method, so that the flow for preparing the pulp by using the straw is simplified; and on the premise of ensuring the digestion effect, the concentration of the solid matter of the black liquor can be improved to over 13 percent, the stock loss of the raw material is reduced by about 5 percent, the single-pot digestion capacity is improved by 10 to 15 percent, and the yield and the viscosity of the formed pulp are raised with different degrees.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

Medicament agent for environment friendly pulping and environment friendly pulping process

InactiveCN101302724AReduce consumptionReduce pollutionPulp bleachingPulp beating/refining methodsFiberLignin peroxidase

The invention provides a medicine that is used for environment-friendly pulping, which comprises the following components by weight: each 10 to 20 units of xylanase, hemicellulose, laccase and lignin peroxidase, 15 to 25 units of a strong oxidizing agent, 5 to 15 units of a soaking and softening agent and 3 to 8 units of a stabilizing agent. The invention further provides a pulping technique of a raw material of non-wooden fiber, which comprises the following steps: (1) the raw material is preprocessed; (2) devillicating is implemented; (3) biological and chemical soaking is implemented; (4) dehydrating is implemented; (5) jordaning is implemented; (6) filtering is implemented; (7) multi-section biological bleaching is implemented; wherein, the biological and chemical soaking in the step (3) uses the medicine that is used for the environment-friendly pulping. The medicine and particularly the pulping technique that are provided by the invention and used for the pulping with the raw material of non-wooden fiber can reduce water solubility to the least degree and raise pulp yield greatly, and have strong bleaching property and physical indexes of high-fibrousness papers that are higher than traditional pulping methods, and the medicine can be recycled, thus reducing the consumption of chemical medicines and environmental pollution.

Owner:王新军

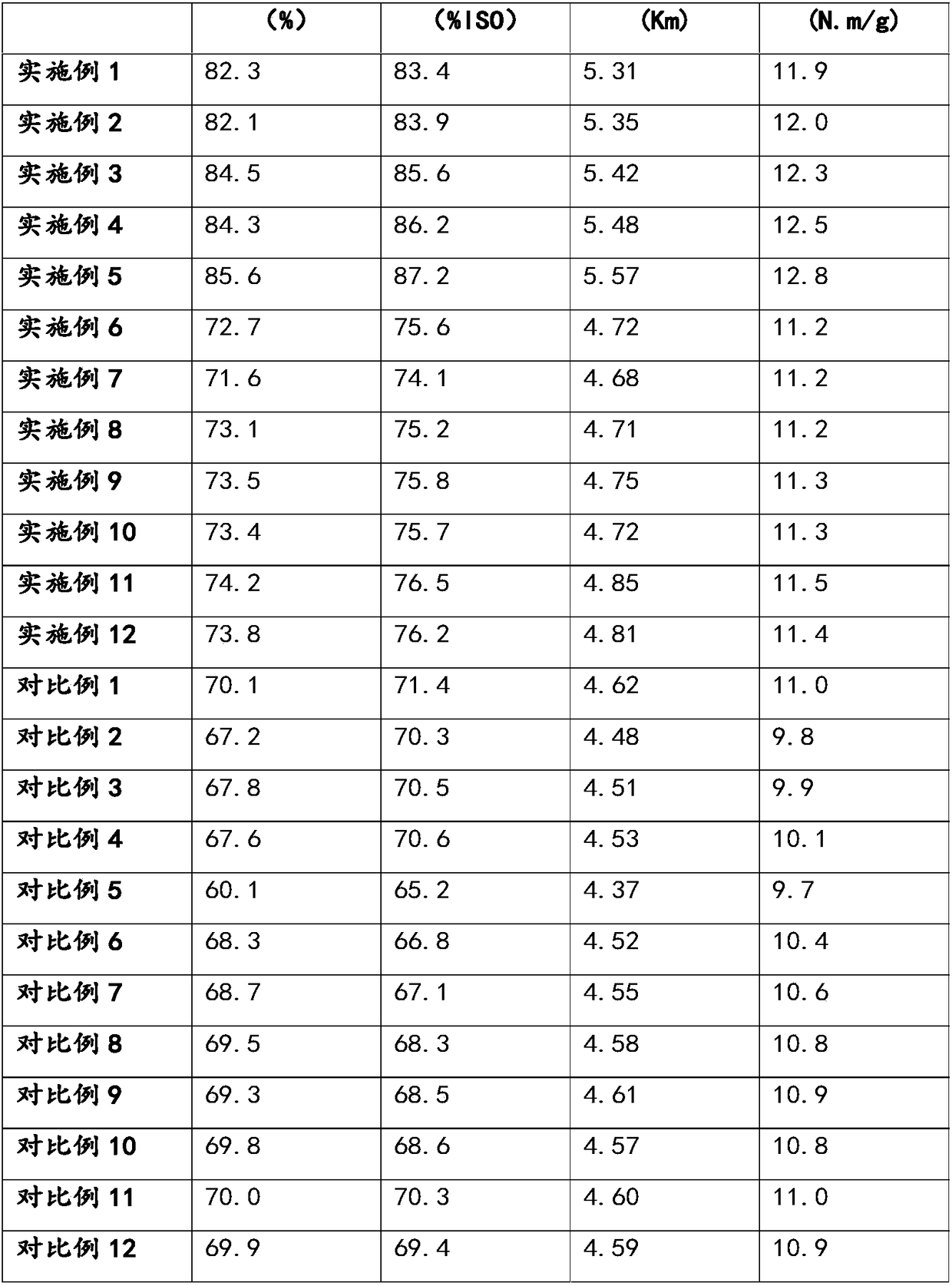

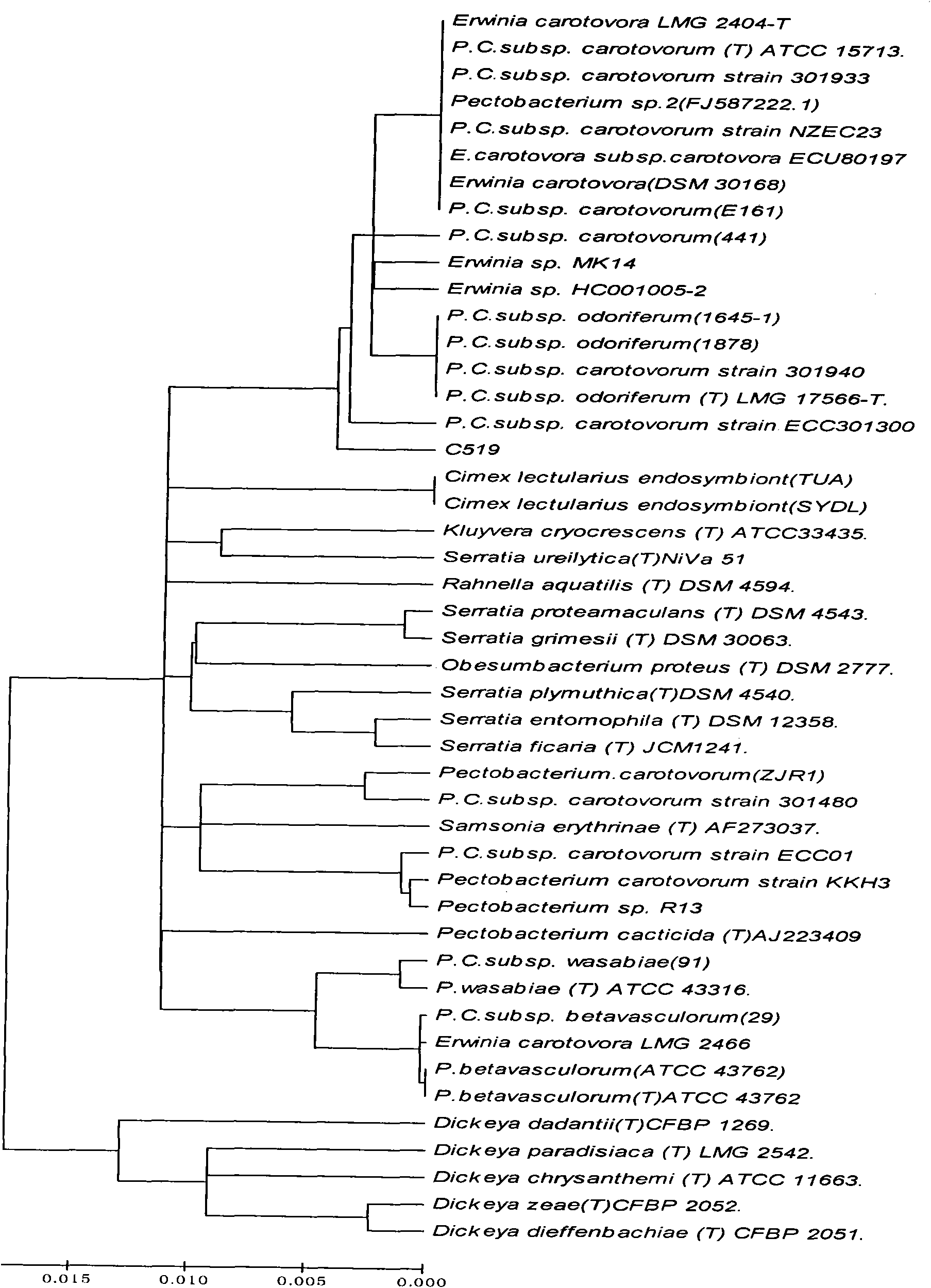

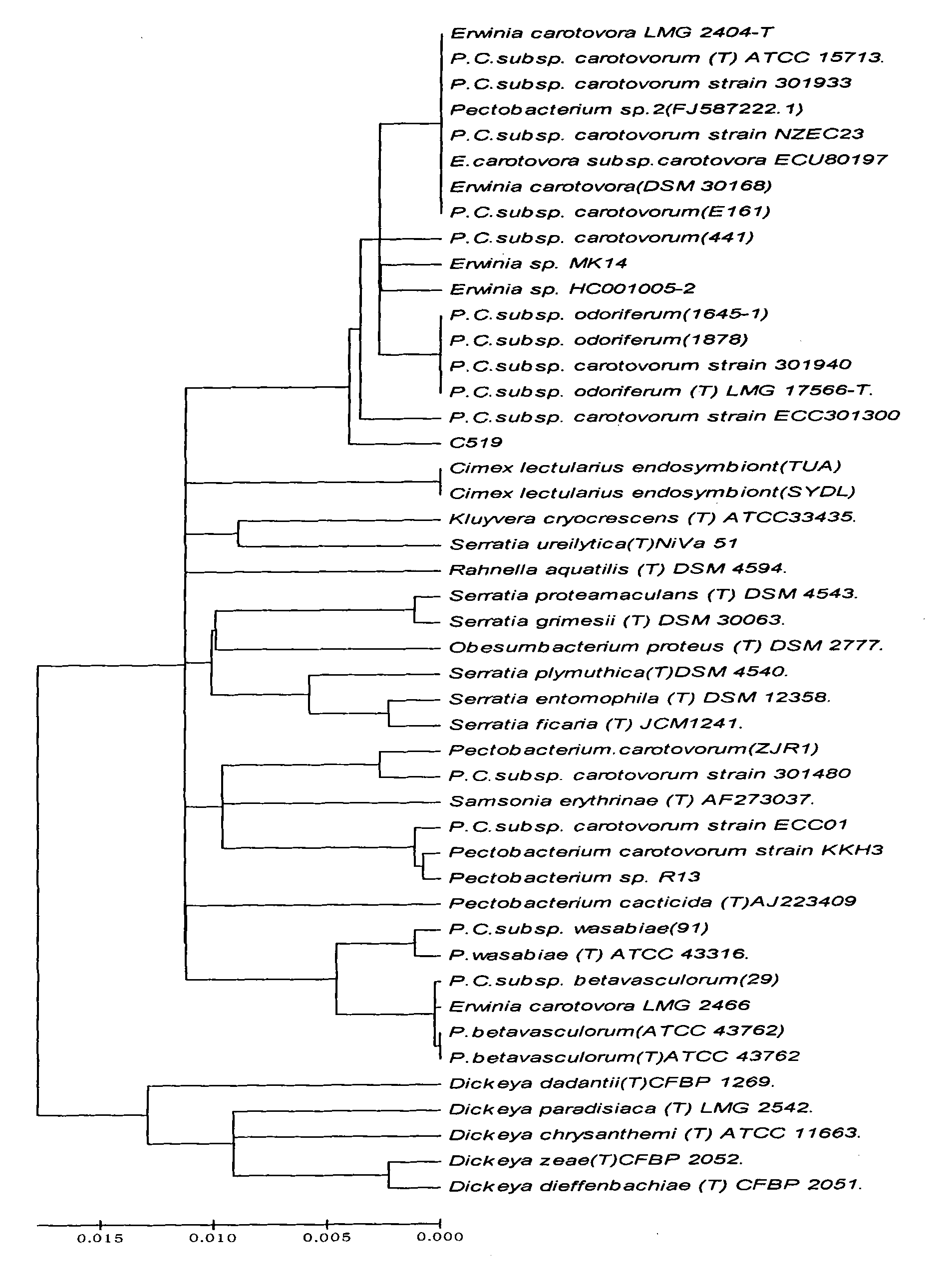

Pectobacterium carotovorum and applications thereof in bio-pulping

InactiveCN101899403APromote rapid proliferationDiffusion fastBacteriaMicroorganism based processesFiberPectobacterium carotovorum

The invention belongs to the field of papermaking and discloses pectobacterium carotovorum and applications thereof in bio-pulping. The pectobacterium carotovorum subsp. carotovorum C519 is preserved in China General Microbiological Culture Collection Center with a preservation number is CGMCC No. 3350. The strain can grow under the condition of high alkalinity (pH11), is suitable for degumming process of plant bast fibers and can be used for biological paper pulp. The C519 (CGMCC No. 3350) can grow under an alkaline condition (pH9 to pH 11), and secretes basophilia pectin with high activities (an appropriate pH value is between 8 and 10). Other general microorganisms are difficult to grow and breed in the range of alkalinity, so that the strain can avoid being polluted by other competitors. Moreover, cellulose has no activities under the alkaline condition, thus the strain greatly keeps the original performance of the bast fibers and improves yield.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

Special size composition for sizing hank yarns

The invention provides a special size composition for sizing hank yarns and application thereof and belongs to a hank yarn fiber spinning finishing agent. The special size composition is prepared from the following raw materials in part by weight: 50 to 60 weight parts of corn starch, 10 to 20 weight parts of polyvinyl alcohol, 10 to 15 weight parts of polyacrylic acid, 8 to 10 weight parts of sized yarn smooth paste, 3 to 6 weight parts of grease EL, 1 to 2 weight parts of DDF catalyst, 0 to 15 weight parts of bone glue, 1 to 2 weight parts of antistatic agent and a proper amount of water. The invention provides an ideal special size composition for sizing hank yarns, which has high yield, excellent yarn separability, low end breakage rate, no strip sticking nor sizing spot, and easy and complete de-sizing. As less polyvinyl alcohol (PVA) in adopted in formula, the ideal special size composition for sizing hank yarns is environment-friendly, diversified and suitable for small-batch production and can be mastered flexibly and operated conveniently. The composition of the invention solves the technical problem that no special size composition for sizing hank yarns exists in the prior art.

Owner:SHANDONG TIANDE IND & TRADE

Food wrapper and manufacturing method thereof

ActiveCN101555672AEmission reductionAvoid damageFlexible coversNatural cellulose pulp/paperFiberBleach

The invention relates to a food wrapper and a manufacturing method thereof. Burst index of the food wrapper is not lower than 3kPa.m / g, longitudinal tensile strength thereof is not lower than 3.0KN / m, lead content thereof is not higher than 5.0mg / kg and arsenic content is not higher than 1.0mg / kg; decoloring testing proves negative; fluorescent matter is not contained; pathogen can not be detected; whiteness of the wrapper ranges from 20% to 30%; the wrapper is brown; the manufacturing method comprises the following steps: DDS displacement cooking, washing screen, oxygen delignification and hydrogen peroxide bleaching are carried out on wood fibrous material to be prepared into micro-bleach pulp with a whiteness of 22% to 36%; beating, desanding, flovoring, fine sizing by a pressurized screen, wiring and moulding, pressing, drying, reeling, rewinding and packaging are carried out on the pulp, thus obtaining the food wrapper.

Owner:YUEYANG FOREST & PAPER CO LTD

Agent for recycling straws by using biologically cold fermentation method and process for producing plant fibers by using straws with biologically cold fermentation method

ActiveCN102321992AImprove performanceMeet production requirementsPulping with inorganic basesAnthraquinonesPlant fibre

The invention relates to an agent for recycling straws by using a biologically cold fermentation method, belonging to the field of recycling and utilization of crop straws. The recycling agent comprises the following components in parts by weight: 2-8 parts of straw rapid corrosion agent, 2-8 parts of sodium dodecyl sulfate, 15-25 parts of dispersed anthraquinone, 60-80 parts of quick lime and 5 parts of fumed silica. The invention also relates to a process for producing plant fibers by using the straws with the biologically cold fermentation method; and the process comprises the following steps of: crushing the straws until the water content reaches 20-50 wt%; adding 40-60% by weight of the agent for recycling the straws by using the biologically cold fermentation method and mixing the mixture uniformly; fermenting and swelling the mixture at a temperature of 20-30 DEG C for 1-3 days to obtain a fermented material; rubbing, devillicating, fibrillating and pulping the fermented material to obtain plant fiber slurry with the beating degree of 37-47 DEG SR (Schopper Riegler). According to the recycling agent and the process provided by the invention, the plant fibers are recycled from the straws by utilizing the biologically cold fermentation method without stewing, so that no waste liquid is discharged in the whole process, the cost is low, the effect is quick, the yield of the prepared slurry is greatly improved, the fibrousness is high, the paper performance is excellent, and the production requirements on various paper products can be met.

Owner:广西梧州伟创植物纤维科技有限公司

Straw fiber and process for separating straw fiber by bio-enzyme method

InactiveCN108286200AImprove fiber qualityQuality improvementCellulose treatment using microorganisms/enzymesNon-woody plant/crop pulpCelluloseBlack liquor

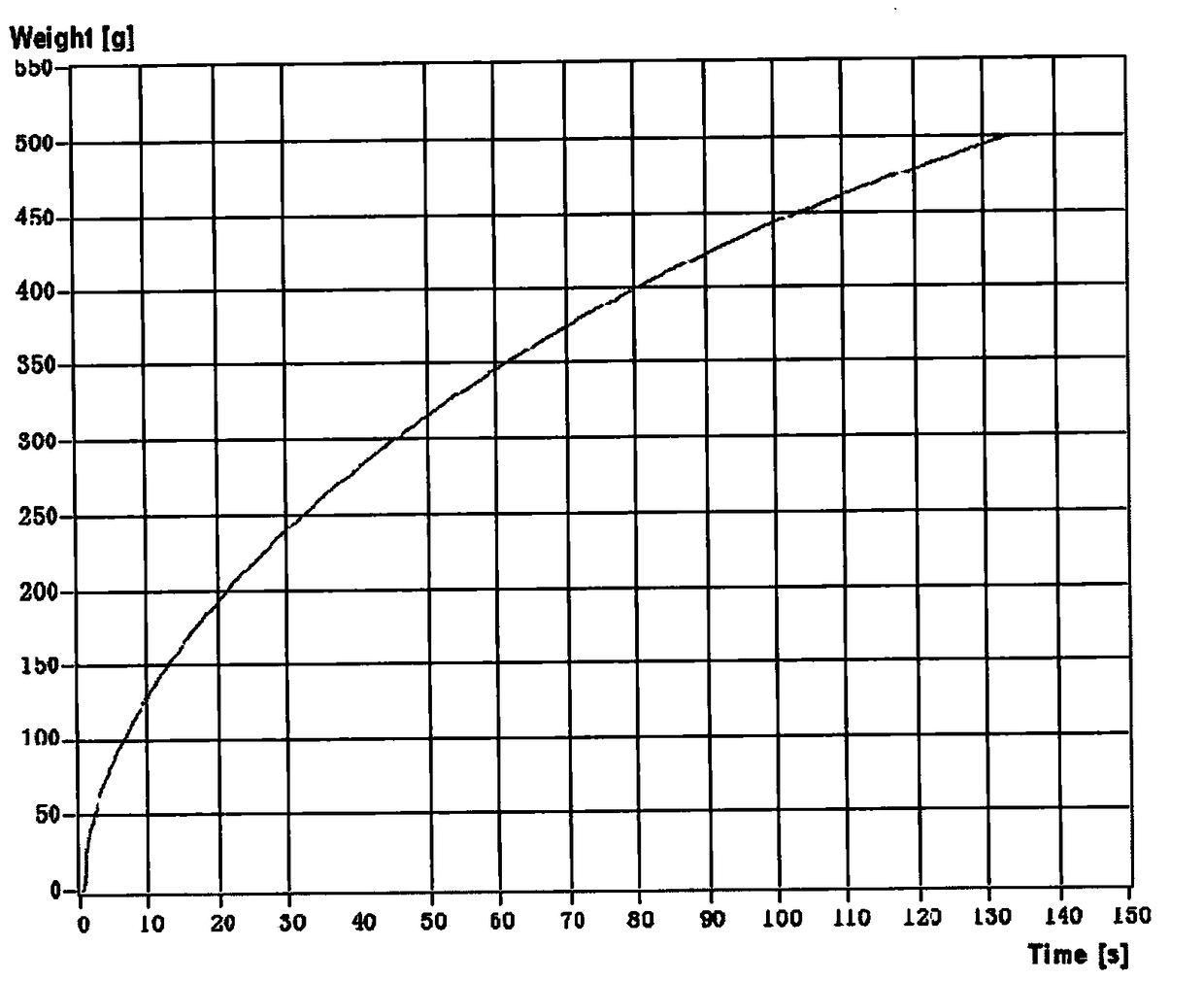

The invention belongs to the field of biological pulping and provides straw cellulose. The straw cellulose is characterized in that straw stalk fiber cut and separated by enzyme molecules directionally is well preserved, the result that fine fiber is damaged in the traditional chemical pulping is overcome, the length-weight average value is 0.70 to 1.10 mm, and the quality-weight average value is1.10 to 1.40 mm. The invention further provides straw fiber. The straw fiber comprises the fiber structure of the straw cellulose; the quality of the straw stalk fiber is as follows: the brightness (whiteness) is 57 to 75 percent, the hardness is 7 to 26 K, the folding resistance is 30 to 78 times, the tearing index is 3.0 to 5.5 mN.m<2> / g, and the tensile index is 41.0 to 62.0 N.m / g. The invention further provides a process for separating fiber from straws and application of the straw fiber. High-temperature chemical cooking black liquid is not generated in the production process, the fiber quality (length, whiteness, short fiber content and the like) is obviously more excellent than the quality of the traditional chemical pulping, the pulp yield is increased by 25 percent or higher whenbeing compared with that of the traditional chemical pulping rate, and water consumption and energy consumption in the production process are reduced by 30 percent or higher when being compared with those of the traditional chemical pulping.

Owner:QILU UNIV OF TECH

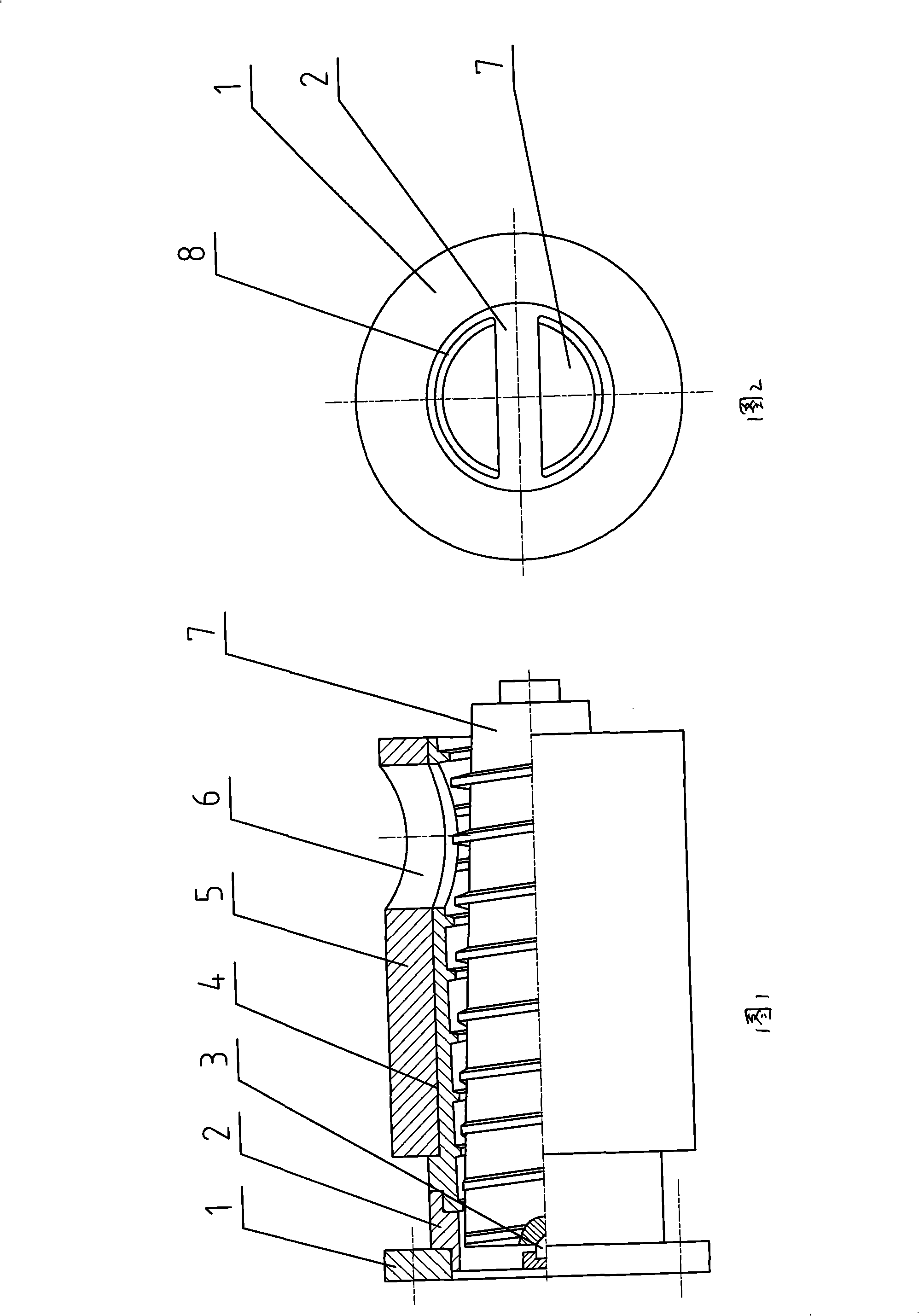

Paper-making pulping method and apparatus

InactiveCN101270555AWill not polluteIncrease pulp yieldRaw material divisionFiberPulp and paper industry

The invention relates to a paper making pulp manufacture method which includes that the fiber material after dipped is arranged into a cylinder; the material rotates at a high speed between a rotary shaft and the inner wall of the cylinder under the action of the rotary shaft; the material generates high temperature high pressure phase transition under kneading and extruding; pressure is released suddenly at the discharge opening of the cylinder to lead the cylinder to blow up, thus finishing fiber dissociation and fibrillating; the pulp is extruded out from the discharge opening. The paper making pulp manufacture device includes a main motor body and a motor. A feed opening is arranged on the main motor body; the cylinder is arranged on the main motor body; a spiral shaft is arranged in the cylinder; one end of the spiral shaft is connected with the motor; the shaft rod of the spiral shaft is a conical structure with a diameter gradually increasing from the feed opening to the discharge opening; a spiral slot is arranged on the inner wall of the cylinder; the depth of the spiral slot is decreased gradually from the feed opening to the discharge opening. The invention finishes the fiber dissociation and fibrillating during the pulp manufacture process and has the advantages of low energy consumption and no pollution.

Owner:李志 +1

Active pulp-making agent for paper making

InactiveCN101070687AConserve waterReduce water consumptionNon-macromolecular organic additionPaper/cardboardChemistryEmulsion

This invention involves a papermaking active pulp making, belongs to the papermaking technology. It is composed by the active ingredient, the host medicinal preparation and the auxiliary medicinal. The active ingredient components is: propyl butyl-carbinol polyethyleneoxide ether, oxidized polyethylene emulsion, ethyl alcohol, lauryl benzene sulfonic acid sodium, sodium monoperoxy, alkalinity proteinase and talcum powder; The main medicinal preparation's components is: calcium hydroxide, anthraquinone, sodium monoperoxy, lauryl benzene sulfonic acid sodium, anhydrous sodium sulfite and talcum powder; The auxiliary medicinal preparation's ingredient is: alkalinity proteinase, sodium monoperoxy and talcum powder; Mix the active ingredient, the host medicinal preparation and the auxiliary medicinal preparation. This invention's papermaking active system paste, may not use the alkali, does not need the massive laundering, has avoided the sewage emissions, greatly economize on water. Its thick liquid rate compares with the strong alkali method, may enhance 20%. The use of industrial chemicals is greatly reduced, and so on.

Owner:WUYUAN DAMINCAI PAPER IND

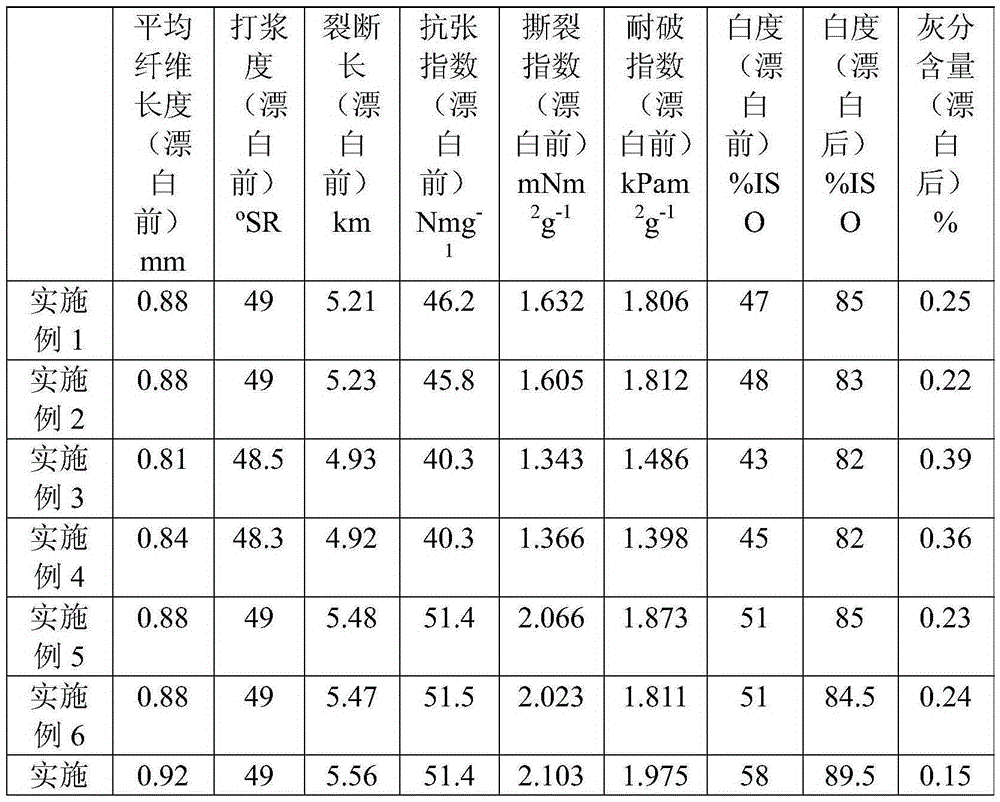

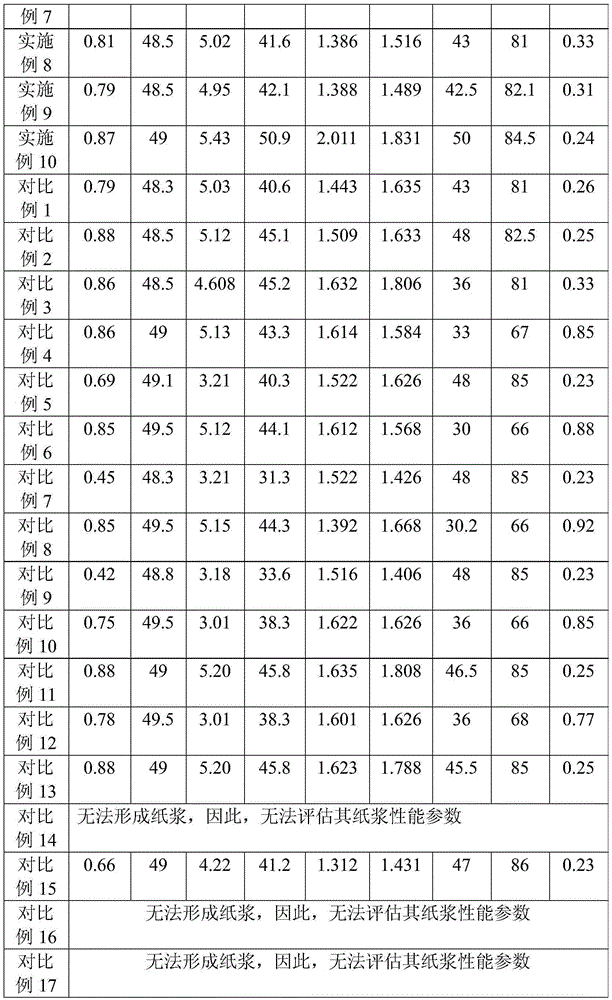

Treatment method of wood fiber raw material

ActiveCN105239435AImprove processing efficiencyIncrease pulp yieldPretreatment with alkaline reacting compoundsPulping with organic solventsOrganic acidFiber

The invention provides a treatment method of wood fiber raw materials, which includes the following steps: (1) pre-impregnation: impregnating the wood fiber raw materials in a Na2CO3 water solution; and (2) steam-boiling: steam-boiling the impregnated wood fiber raw materials with an organic acid water solution as a steam-boiling solvent with addition of an inorganic acid as a catalyst. In the invention, by means of synergistic effect between the pre-impregnation with the Na2CO3 water solution and the steam-boiling of the organic acid water solution and the inorganic acid, yield of paper pulp is increased, ash content is reduced and comprehensive performance of the paper pulp is improved.

Owner:GUANGZHOU YINNOVATOR BIOTECH CO LTD

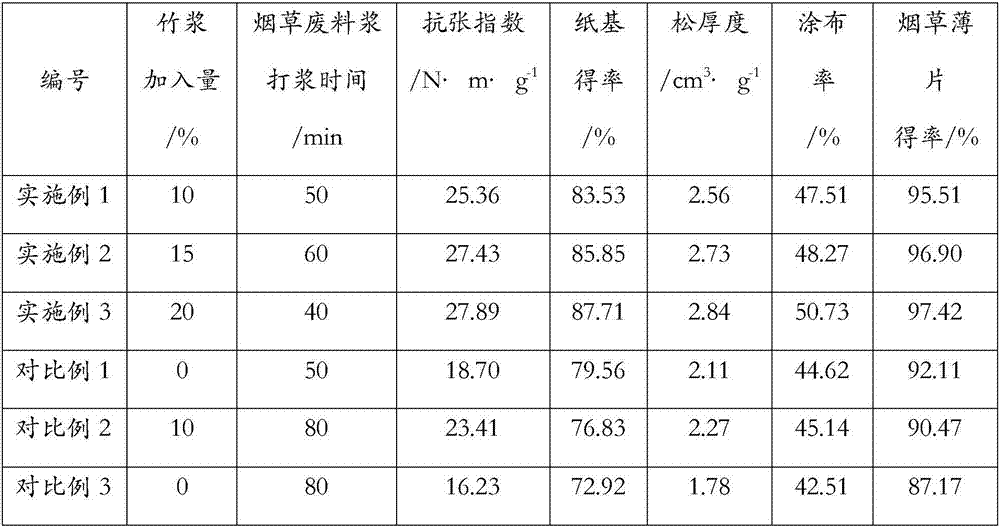

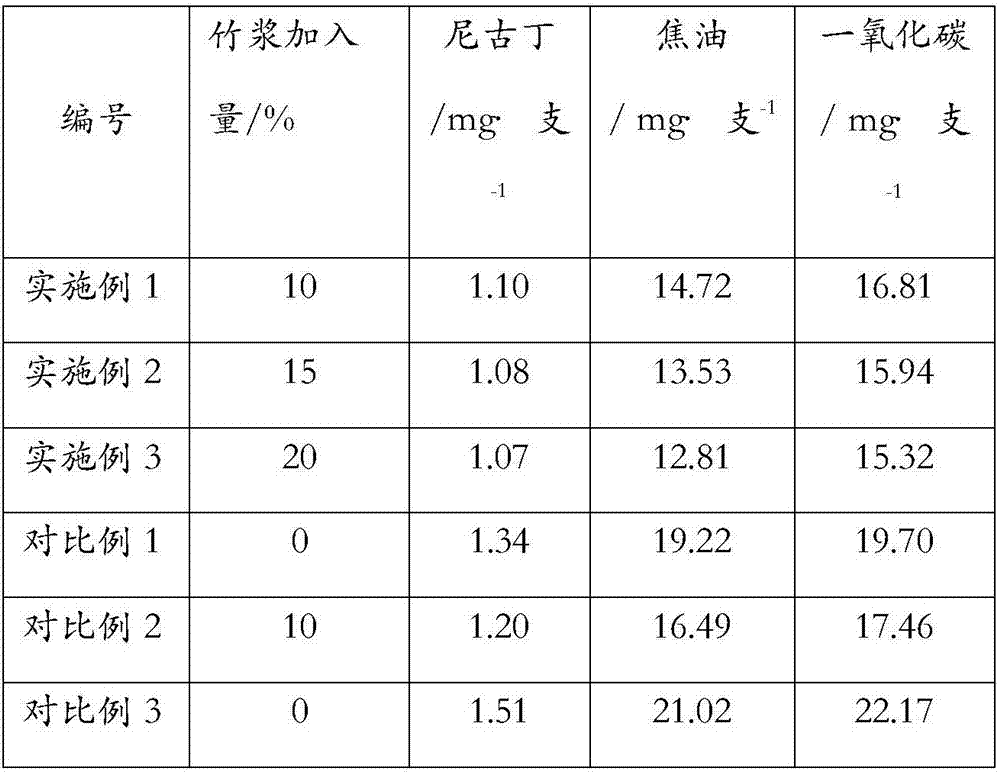

Natural-color bamboo pulp for reconstituted tobacco additive and preparation method thereof

The invention belongs to the technical field of reconstituted tobacco, and specifically relates to natural-color bamboo pulp for a reconstituted tobacco additive and a preparation method thereof. The method is characterized in that bamboo is used as the raw material and subjected to preparing, stewing, squeezing extrusion, dipping, pulping and papermaking to obtain a high-purity product. The physical performance indexes of the natural-color bamboo pulp are that the tensile index is 35-45N-m / g; the burst index is 2.5-3.5kPa-m<2> / g; the tearing index is 6.5-9.5mN-m<2> / g; the intrinsic viscosity is 800-1000mL / g; the whiteness is 30-40% ISO; the pentosane is less than 8%; the ash content is less than 1.0%; the bulk is 5.0-8.5cm<3> / g. The prepared tobacco slices are added to finished cut tobacco based on ratio; the prepared cigarette is capable of supplying more air intake quantity while smoking, so that the cigarette can be promoted to completely burn, and the quantity of pyrolysis products under oxygen-poor condition can be effectively decreased, and as a result, the releasing quantity of harmful components such as tar and nicotine can be decreased.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

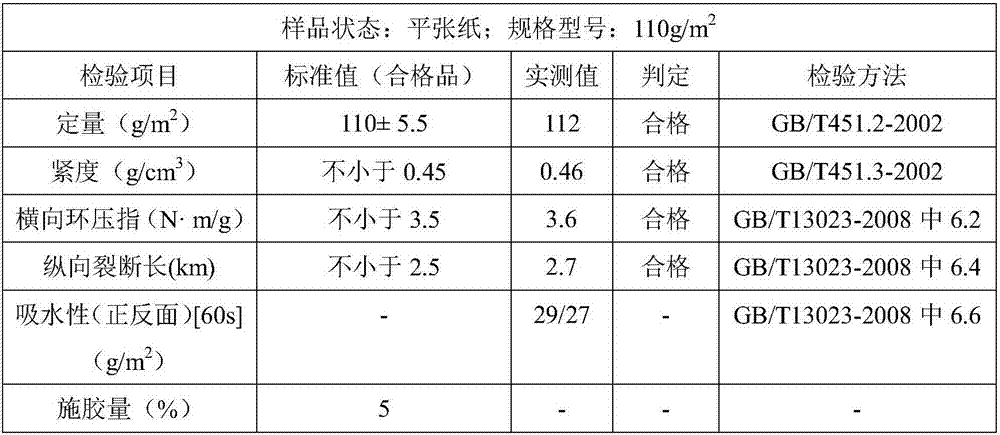

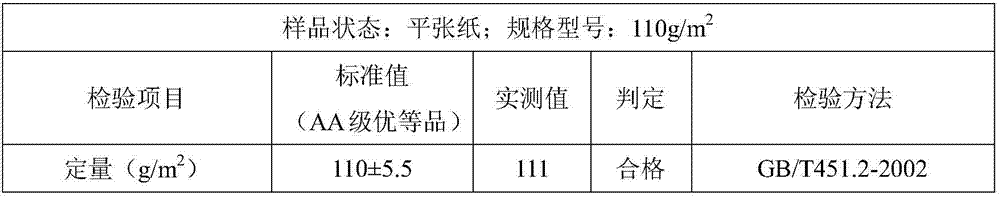

Tape base paper and production method thereof

InactiveCN102041744AReduce energy consumptionReduce emissionsSpecial paperReinforcing agents additionHydrogen peroxideFiber

The invention provides tape base paper and a production method thereof. As for the tap base paper, the fracture length is more than or equal to 6.0km; the tensile strength is more than or equal to 1.5kN / m; the moisture content is within the range of 7-10%; the tightness is more than or equal to 0.62g / cm<3>; the wet strength is more than or equal to 0.33kN / m; and the whiteness is within the range of 17-25%. The production method of the tape base paper comprises the following steps: carrying out low-energy consumption displacement cooking, oxygen-alkali delignification and hydrogen peroxide bleaching processes on a wood fiber raw material to produce micro-bleaching pulp, wherein the whiteness of the bleached pulp is 19-27%, the beating concentration of the bleached pulp is 2.5-4.5%, the beating degree of the bleached pulp is 26-32 degree SR, and the wet weight of the bleached pulp is 10.5-15g; and the pulp is formed by beating, degritting, adding a wet strength agent, carrying out fine screening with a pressurized screen, forming on a mesh, squeezing, drying, reeling, rewinding, and packaging.

Owner:YONGZHOU XIANGJIANG PAPER CO LTD

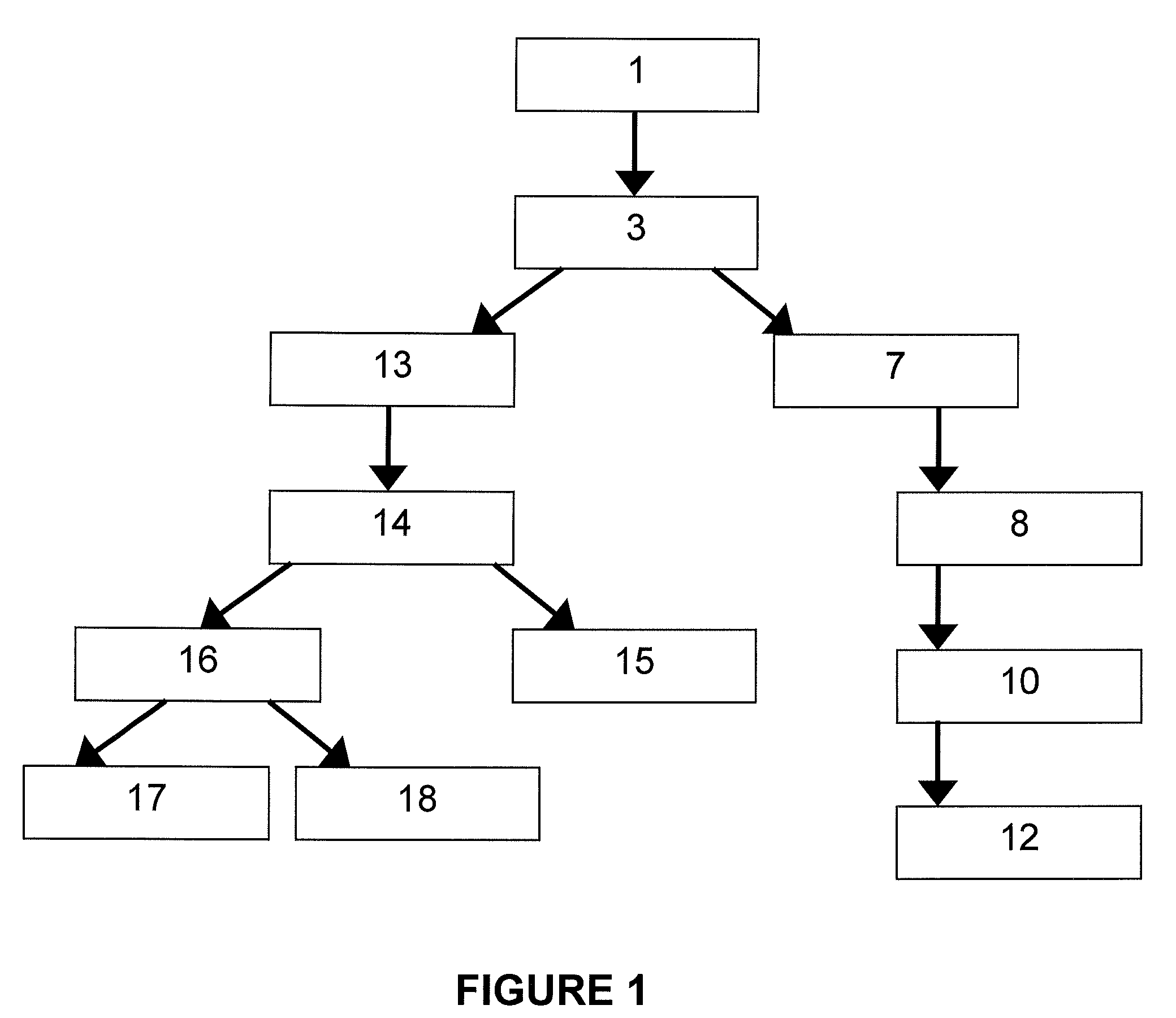

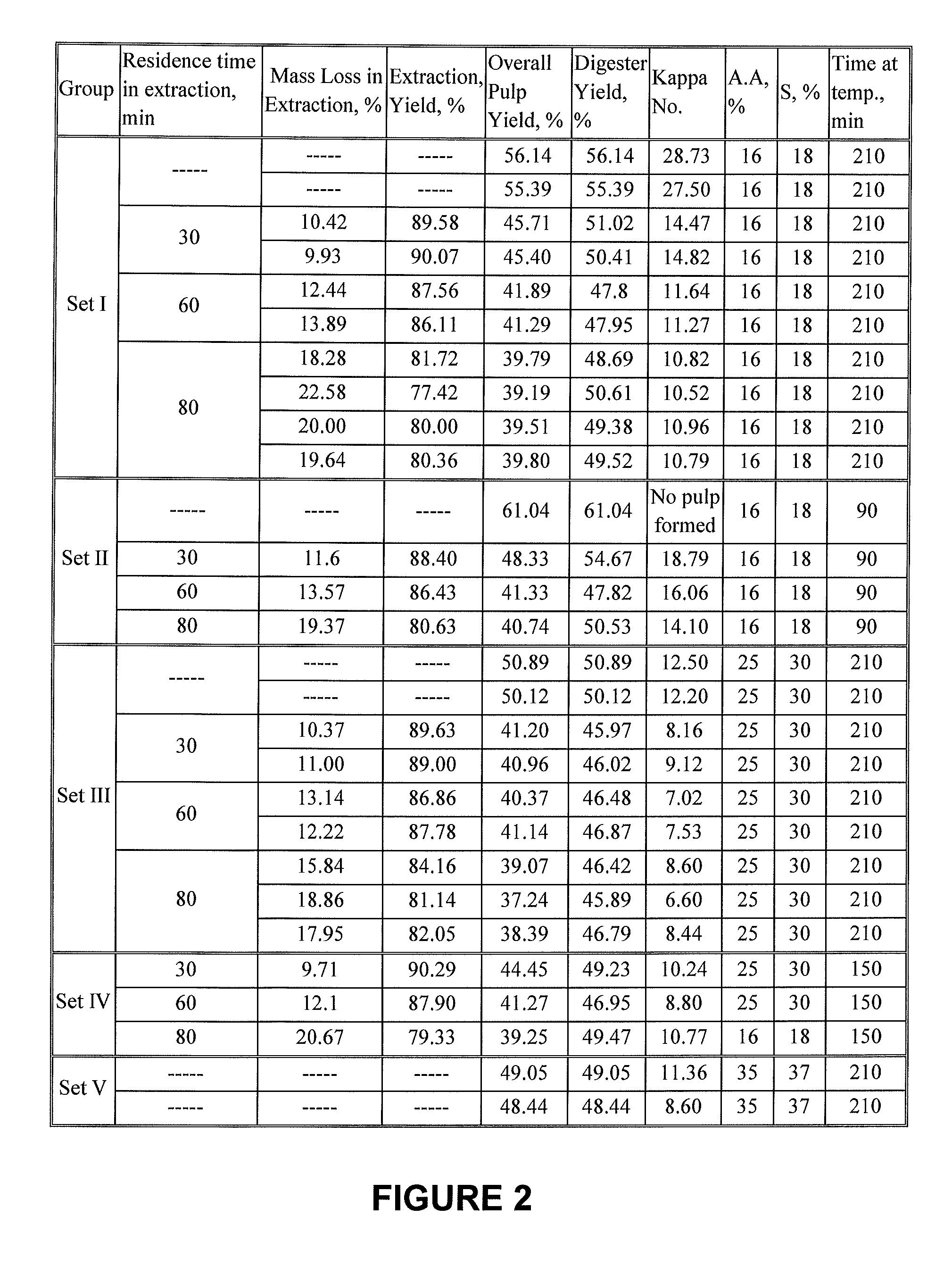

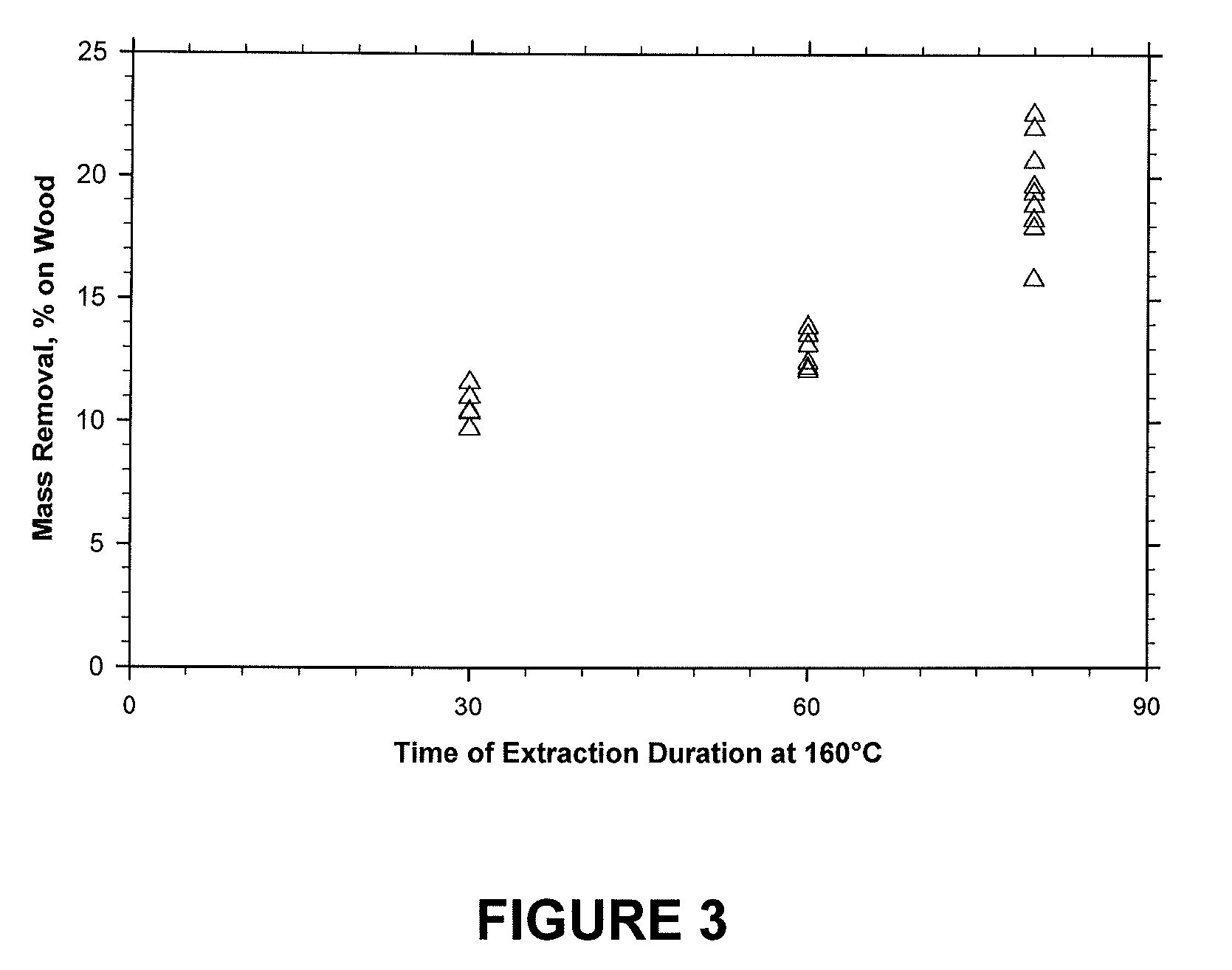

Kraft-Pulping of Hot Water Extracted Woodchips

InactiveUS20110073264A1Reduce weightIncrease in sizePretreatment with water/steamPulping with inorganic basesKappa numberWhitening Agents

The method of the present invention is directed towards a method to increase the pulp yield of a lignocellulosic material, or increasing pulp bulk and / or pulp viscosity. This method comprises the following steps; preparing a lignocellulosic material, contacting the lignocellulosic material in a vessel with hot water or steam for a predetermined time, producing acetic acid from the reaction of the hot water or steam and the lignocellulosic material, lowering the pH to less than about 4, removing lignocellulosic material extracts including a large percentage of hemicellulose, acetic acid and metal ions, exposing contacted lignocellulosic material to pulping chemicals in a pulping reactor, forming a contacted lignocellulosic material pulp with a kappa number below about 19 after about 90 minutes of contact with the pulping chemicals, exposing the contacted lignocellulosic material pulp to whitening agents, and producing a whitened hot water contacted lignocellulosic material pulp.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

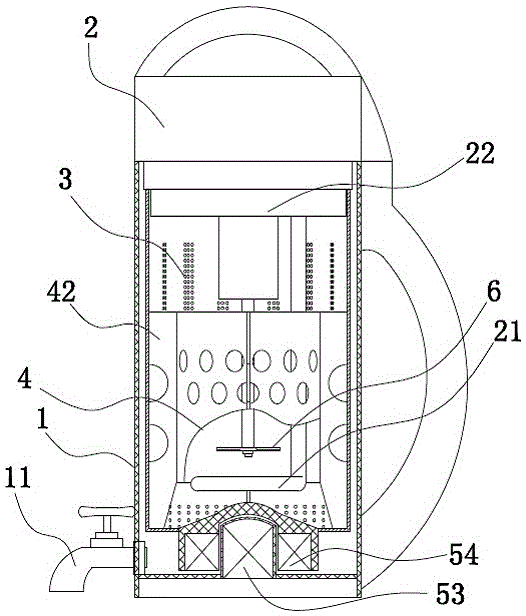

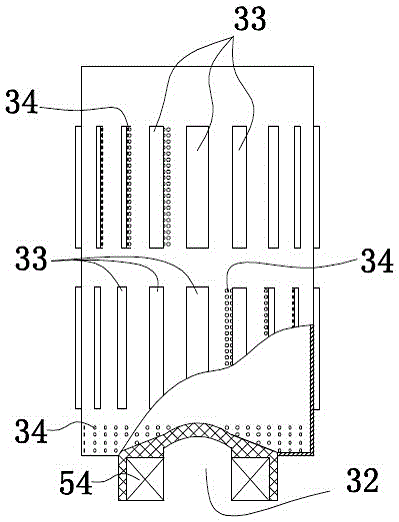

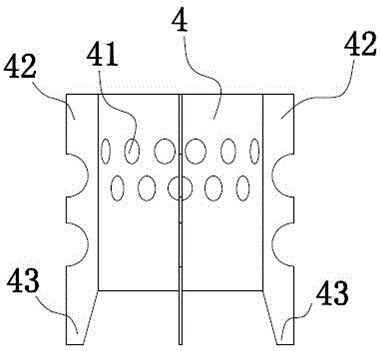

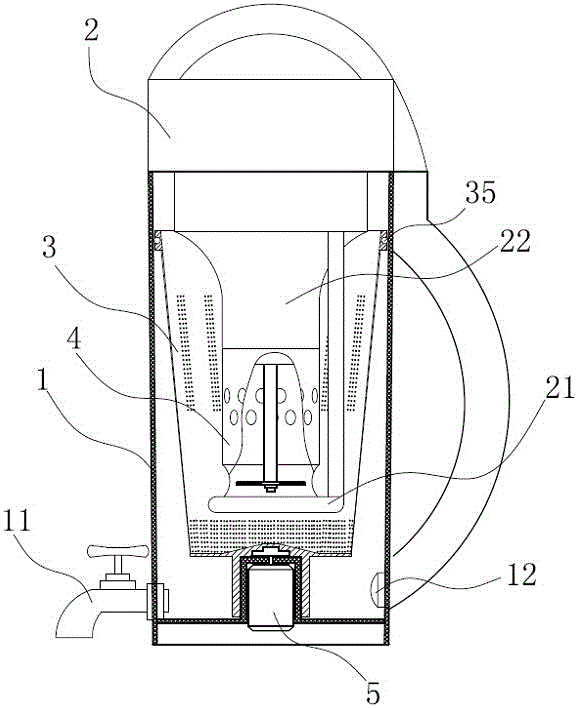

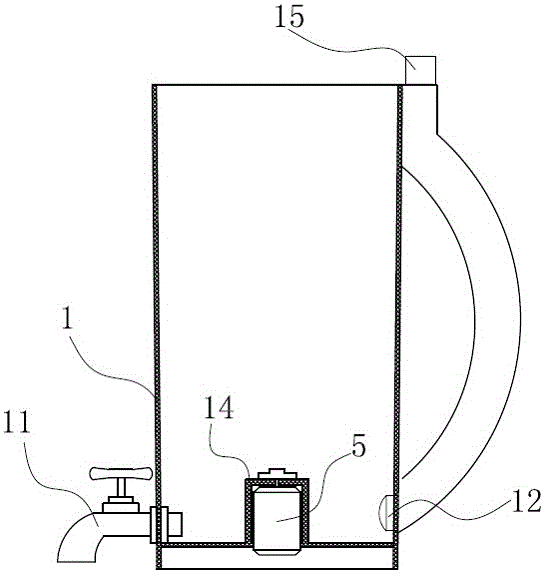

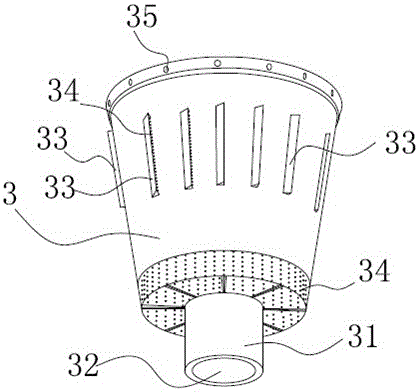

Soybean milk machine

InactiveCN105054783AResidue reductionAchieve separationBeverage vesselsMilk substitutesInterference fitEngineering

The invention relates to a soybean milk machine, aiming at overcoming the shortcomings of an existing soybean milk machine which is low in milk and dreg separation efficiency, high in personnel participation and high in soybean milk residue in separated bean dregs during making milk. The soybean milk machine comprises a cup body, a milling motor arranged in a cavity formed by an upper cover and a lower cover on a machine head, and a circuit controller, wherein a cutter shaft extends into the machine head from the lower cover and is connected to the milling motor, and the lower end is fixedly connected to a blade; a filter cup and a filter cup driving motor are arranged inside the cup body, and the blade is arranged inside the filter cup; the mouth of the filter cup is sleeved on the lower cover, and the mouth of the filter cup is in interference fit to the lower cover; a rotating pivot is arranged at the bottom of the filter cup; and a milk discharging valve communicated to inside and outside of the cup body is arranged at the bottom of the cup body. The soybean milk machine disclosed by the invention can be used for carrying out and achieving milk and dreg separation after boiling the milk, so that soybean milk residue in the separated bean dregs is low and milk yield is high; and during milling and extracting the milk, soybean milk producing materials are limited in the filter cup in a relatively concentrated mode, so that milk grinding and extracting speed is improved.

Owner:陈伟群

Corncob bark pulp for chemical fiber and preparation method thereof

ActiveCN102220719AGood quality indexIncrease pulp yieldPulp bleachingArtificial filaments from viscosePaper manufacturingMaterials science

The invention relates to corncob bark pulp for chemical fiber, which is prepared and formed from corncob bark by the working procedures of pretreatment, stewing, washing, pulping, pre-selection desanding, concentration, chlorine alkalization, bleaching, acid treatment, scouring, post-selection desanding, concentration and paper manufacturing with pulp; in the corncob bark pulp, the content of alpha-cellulose is larger than or equal to 90%, the content of ash content is smaller than or equal to 0.10%, and the content of iron content is smaller than or equal to 25 mg / kg; the stewing is performed by using sulfate process, and the stewing condition manner and bleaching conditions are improved; and the quality indicator of the corncob bark pulp obtained through the method is more prior to thatof the pulp for the conventional viscose staple fiber, and the pulp yield is high. The invention achieves the purpose of producing the pulp for viscose fiber by using agricultural waste of the corncob bark pulp, and eases the problem of the shortage of materials of the viscose fiber.

Owner:潍坊欣龙生物材料有限公司

Sea-buckthorn pulping method and sea-buckthorn pulp thereof

InactiveCN101205690AWide variety of sourcesIncrease pulp yieldPaper recyclingRaw material divisionPulp and paper industryPollution

The invention provides a sea buckthorn pulping method which adopts mechanical pulping technique; with the method, raw material has wide sources, and a mechanical environment-friendly pulping mode without adding alkali and other chemical substances is adopted; the pulp yield rate reaches 76.5 to 82.5 percent and no pollution produces in the production process.

Owner:廉书平 +1

Method for cultivating hybrid reed

InactiveCN1806522AHigh densityIncrease pulp yieldHorticulture methodsPlant genotype modificationHigh densityPollination

The invention relates to a method for cultivating hybrid reed, which is characterized in that it comprises following steps: constructing two pools for female parent and male parent, choosing yellow reed as female parent, sand reed as male parent during August and September in current year, replanting reed with soil, watering, water discharging and fertilizing at proper time, when male parent is in the middle day of June of second year, cutting sprout, leaving sprout and making sprout growing out again, intercepting reed flower at first ten-day period of September, embedding reed flower in pond for 5-10 days after airing at sunlight and taking out for drying, immersing in seawater, taking out to suspend in female parent pool and flowering with female parent reed at the same time, intercepting female parent flower 10-30 days after artificial pollination, laying in its root area. The hybrid reed is characterized by alkali resistant, water logging-tolerant and drought resistant, straight and rigid reed pole, higher density which is two times as high as current reed production, higher grout rate than that of normal by 8% and higher market price than that of normal reed by about 15%.

Owner:陈必俊

Wheat straw fibers and technology for separating films by biological enzyme method thereof

InactiveCN108286201AImprove fiber qualityQuality improvementCellulose treatment using microorganisms/enzymesNon-woody plant/crop pulpCelluloseBiotechnology

The invention belongs to the field of bio-pulping, provides wheat straw cellulose, and aims at storing straw fibers which are subjected to directional cutting and separating by enzyme molecules and overcoming the result of damage to fine fibers in traditional chemical pulping. The wheat straw cellulose is 0.80-1.10mm in average length based on length-weight ratio and is 1.20-1.50mm in average length based on mass-weight. The invention also provides wheat straw fibers comprising the fiber structure of the abovementioned wheat straw cellulose. The quality of the wheat straw fibers meets that thebrightness (whiteness) is 53-75%; the hardness is 8-26K; the folding strength is 30-75 times; the tearing index is 3.3-5.5mN.m<2> / g; and the tensile index is 45.0-62.0N.m / g. The invention also provides a wheat straw fiber separating technology and application of the wheat straw fibers. According to the technology, high-temperature chemical boiling black liquid is not produced in the production process; the fiber quality (length, whiteness, short fiber content, etc.) is obviously superior to that of traditional chemical pulping fibers; the pulp yield is increased by more than 25% by being compared with traditional chemical pulping yield; the water consumption and the energy consumption in production are decreased by more than 30% by being compared with those in traditional chemical pulping.

Owner:QILU UNIV OF TECH

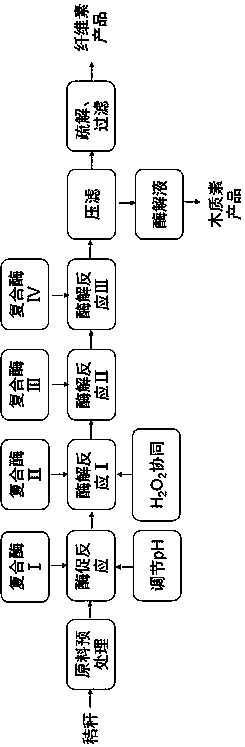

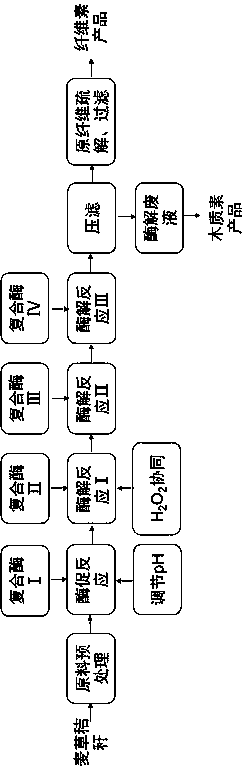

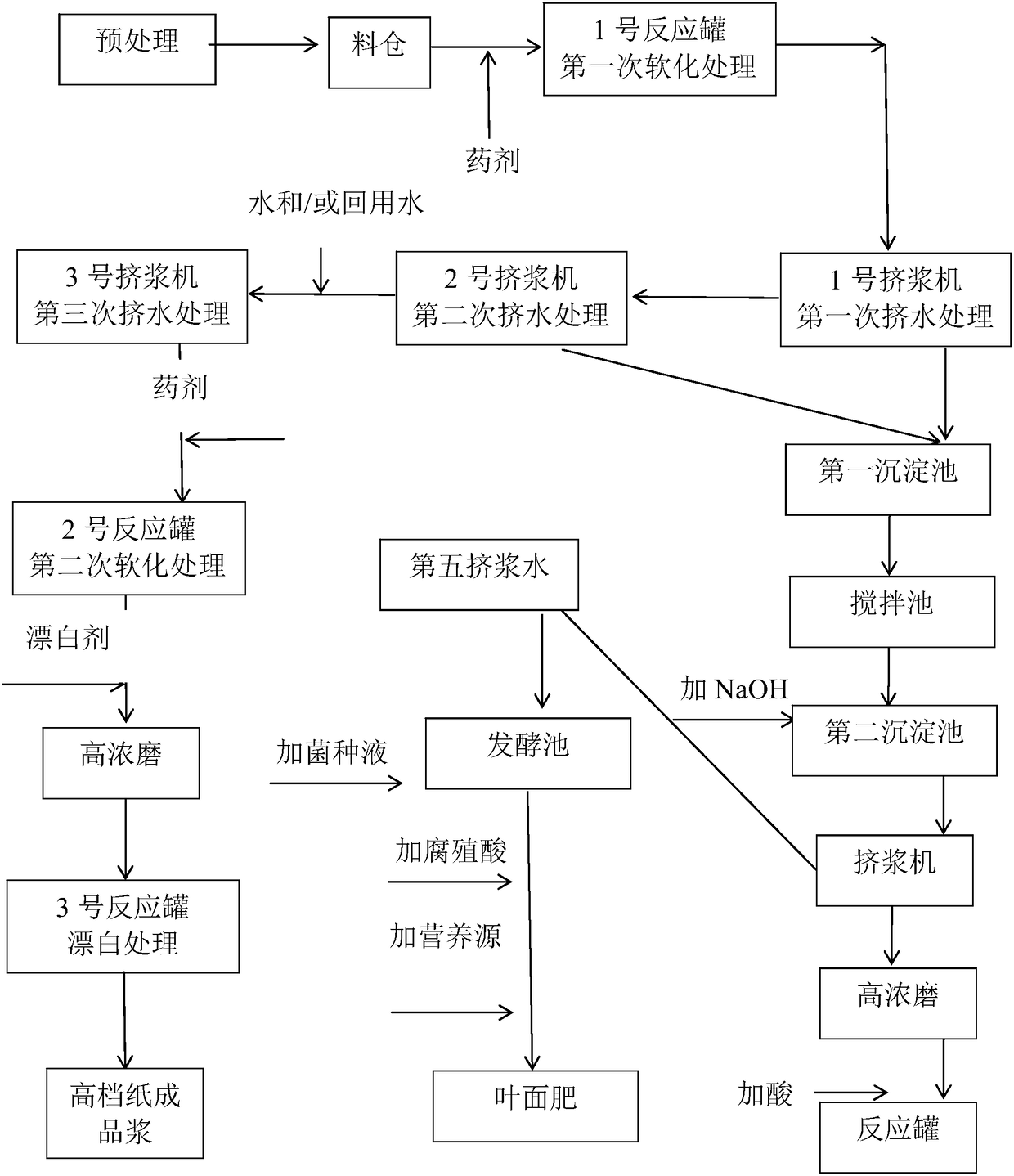

Combined process using grasses as raw materials

The invention discloses a combined process using grasses as raw materials. The combined process is a whole-process reaction process comprising a preparation process of a high-grade paper slurry, a preparation process of a pulp for packaging paper, and a preparation process of a foliar fertilizer. The preparation process of the high-grade paper slurry mainly includes the process steps of: three reactions in three reaction tanks, four times of extrusion and pulping by a high concentration pulping machine; and the slurry with high yield is prepared. Pulp squeezing water obtained by first alkali addition softening, first pulp squeezing and / or first two times of pulp squeezing in the preparation process of the high-grade paper slurry is used as a raw material for the preparation process of thepulp for packaging paper; the pulp squeezing water containing a part of cellulose and unreacted agents is subjected to softening and grinding treatment to obtain the slurry for packaging paper. Squeezing water produced in the preparation process of the pulp for packaging paper is recovered and treated as a raw material for preparation of the foliar fertilizer. The combined process has the advantages of no black liquor discharge, water recycling, and energy conservation; therefore, the combined process is a green pulping process.

Owner:黑龙江如柏科技有限公司

Technology for improving strength and performance of regenerated cardboard paper by recycling OCC (Old Corrugated Containers) waste paper in energy-saving way

InactiveCN101935956AImprove papermaking performanceIncrease productivityPretreatment with alkaline reacting compoundsPaper recyclingFiberCardboard

The invention discloses a method for improving the strength and performance of regenerated cardboard paper by pretreating and disintegrating OCC (Old Corrugated Containers) waste paper, which is characterized in that an OCC waste and old carton which is pretreated by clear water and alkali liquor or not treated is disintegrated into slurry under the alkaline condition. The novel method improves the papermaking performance of regenerated fibers and has the advantages of low treatment cost, disintegrating energy consumption reduction, production efficiency improvement of a disintegrator, flexible and various treatment ways, easy combination with the traditional papermaking process, and the like. The alkali liquor soaking treatment is also beneficial to removing adhesive in the waste paper by filtering during screening. The invention is suitable for the production line for producing the regenerated paper, such as cardboard paper, box paperboard, corrugated paper, white paperboard, and the like by using the waste and old OCC carton as raw materials and is also suitable for a factory for producing the regenerated fibers by using the OCC as the raw material.

Owner:TIANJIN UNIV OF SCI & TECH

Pulping method with zero discharge of sewage

InactiveCN105178083AHigh extraction rateLess investmentCellulose material pulpingBlack liquorSteam cooking

A pulping method with zero discharge of sewage comprises the steps: 1) mixing evenly a pulping raw material with a steam cooking agent and a catalyst, then adding into a spherical digester, then introducing steam, and carrying out steam cooking; 2) allowing the steam-cooked raw materials to pass through a plurality of series-connection twin-screw extruders successively, extruding and extracting black liquids, to obtain a pulp, allowing the black liquid obtained from the final twin-screw extruder to return to the former twin-screw extruder, stirring and mixing, then continuing to extrude, directly merging the black liquids obtained from the first twin-screw extruder and the second twin-screw extruder, concentrating and drying the merged black liquid to obtain alkali lignin or lignosulfonate, wherein the pulp concentration of pulp washing and pulp bleaching is 25-40%; 3) then sending the pulp into a twin-screw rubbing and kneading pulping machine, carrying out multi-section series washing while rubbing kneading and grinding, or carrying out multi-section series washing and multi-section series bleaching, allowing the washing water to return to the former-section washing process, finally obtaining washing water namely residuary washing water containing the black liquid coming from the first-section washing process, and allowing the washing water to return to the pulping raw material or the spherical digester; and 4) finally, allowing the pulp to enter a dual-disk pulp grinding machine, adding water and carrying out fine grinding.

Owner:蒋寿悟

Unbleached pulp, and preparation process, application and preparation device of unbleached pulp

InactiveCN107268327AImprove insulation effectEfficient power savingPretreatment with alkaline reacting compoundsMultistage pulping processElectricityBlack liquor

The invention provides an unbleached pulp, and a preparation process, an application and a preparation device of the unbleached pulp, and relates to the technical field of pulping by utilizing a straw. The choices for the raw material of the unbleached pulp are wide, a wheat straw, a rice straw, a reed straw or a waste wood chip are used efficiently as the pulping raw material, so that the pulping cost is obviously lowered. The preparation process of the unbleached pulp uses the new technique to replace steam heating to soften the raw material, the problem of a pulp black liquor existing in the pulping process is solved while the heating cost is obviously reduced. The flow of the production process is simplified, the electricity and the water are efficiently saved, the resource utilization rate is effectively increased, and the production of no wastewater or waste materials is guaranteed in the production process. The special production process is used to pulp, the beating degree is high, the quality is better, the performance of a pulp product is stable, the pulp product is widely applied to the functional degradable material, and the functional applicability and the material quality are obviously strengthened in the application fields of preparation of corrugated paper, industrial packaging materials, preparation of plates, and preparation of tableware.

Owner:北京泽鑫荣创秸秆科技开发有限公司

Soybean milk making machine

The invention relates to soybean milk making machines, aims to solve the problems of low milk-residue separating efficiency, high personnel participating degree and large quantity of soybean milk residue in soybean residue after separation when existing soybean milk making machines are used for making soybean milk. The soybean milk making machine comprises a cup, a machine head, a blade component and an electric heating pipe, wherein a milling motor and a circuit controller are arranged in a cavity of the machine head composed of an upper cover and a lower cover, and one end of a knife shaft of the blade component extends into the machine head from the lower cover and is connected with an output shaft of the milling motor while the other end of the knife shaft extends into the cup and is fixedly connected with blades at the tail end of the cup; the soybean milk making machine further comprises a filtering cup and a filtering cup driving motor, the filtering cup driving motor is detachably connected with the bottom of the filtering cup and used for driving the filtering cup to rotate, and a milk discharging valve is arranged at the bottom of the cup. The soybean milk making machine can perform milk-residue separation operation to realize milk-residue separation after milk making is completed, soybean milk left in soybean residue after separation is little, and milk yield is high; in the process of milling for milk making, a material for making soybean milk is limited in the filtering cup and centralized relatively, so that milling milk-making speed is increased.

Owner:陈伟群

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com