Patents

Literature

290results about How to "Improve fiber quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

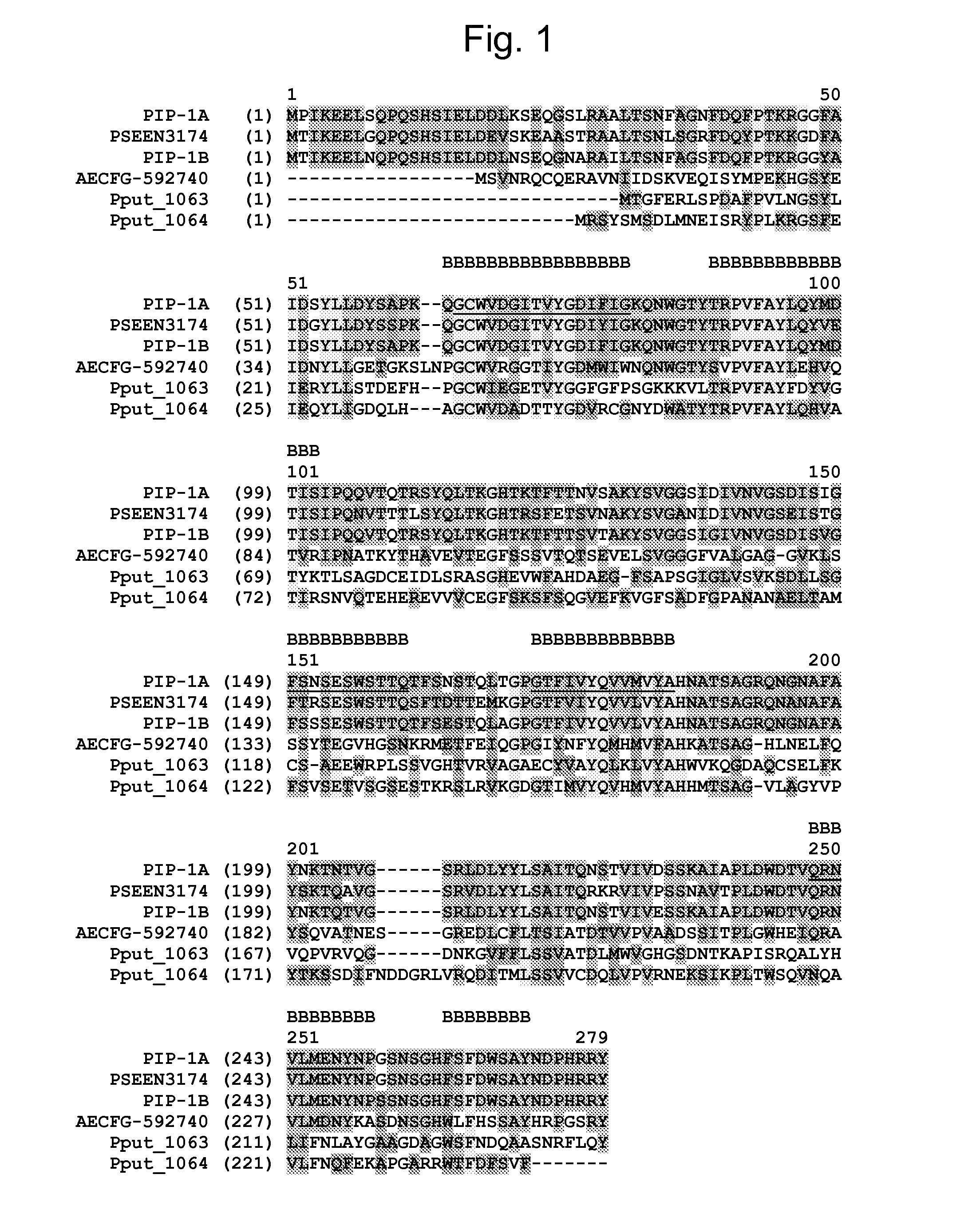

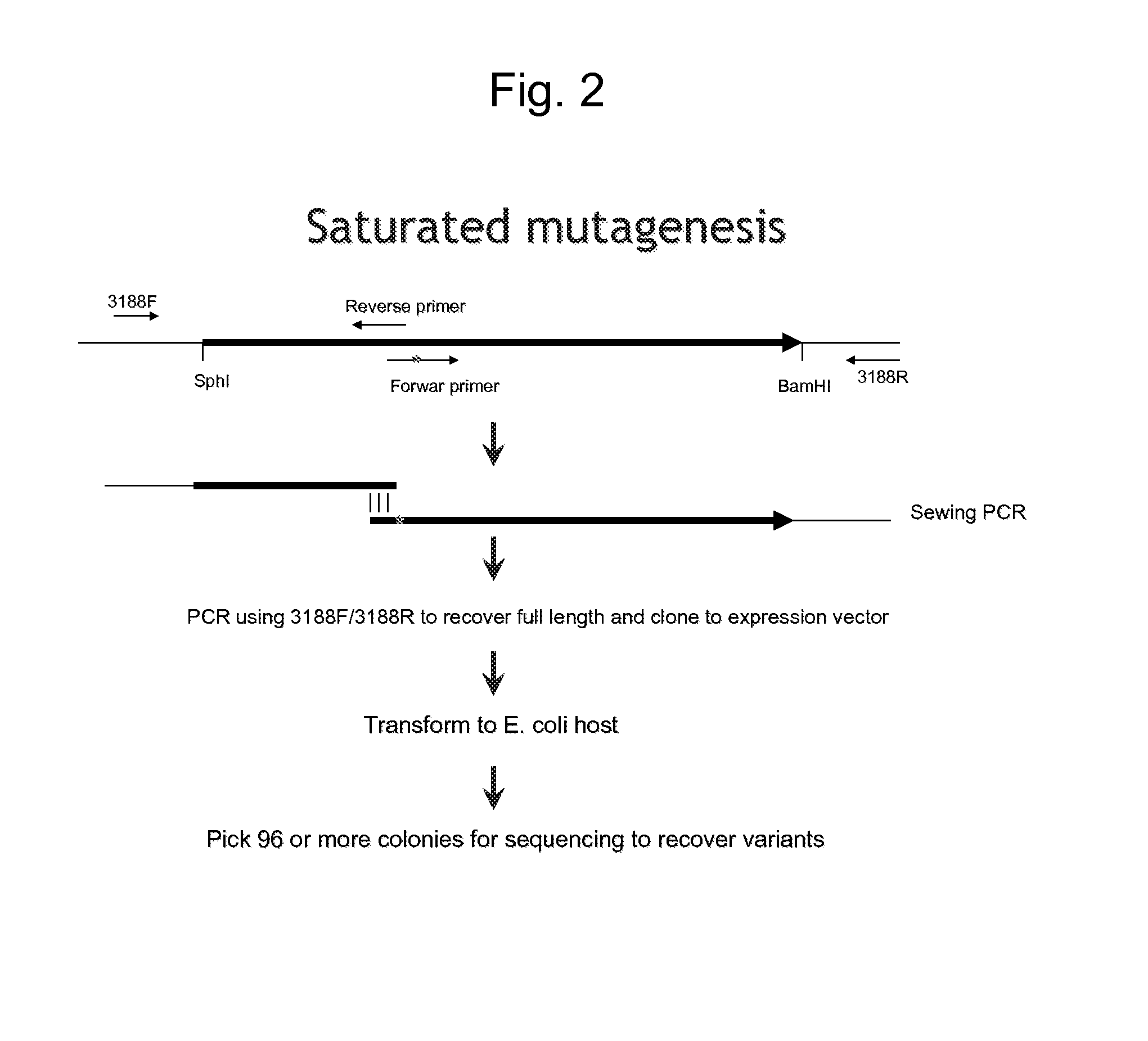

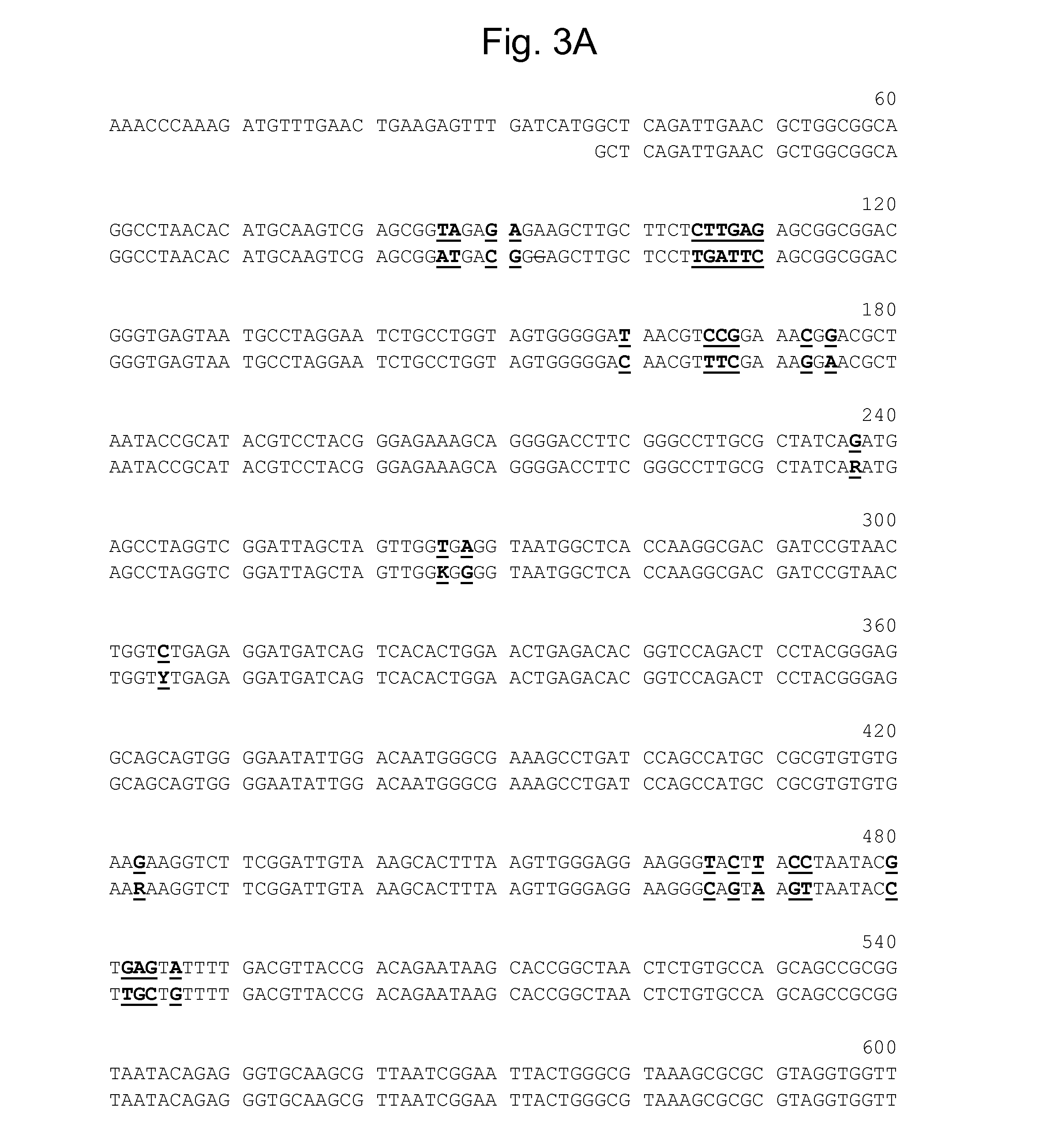

Novel Insecticidal Proteins and Methods for Their Use

Compositions and methods for controlling pests are provided. The methods involve transforming organisms with a nucleic acid sequence encoding an insecticidal protein. In particular, the nucleic acid sequences are useful for preparing plants and microorganisms that possess insecticidal activity. Thus, transformed bacteria, plants, plant cells, plant tissues and seeds are provided. Compositions are insecticidal nucleic acids and proteins of bacterial species. The sequences find use in the construction of expression vectors for subsequent transformation into organisms of interest, as probes for the isolation of other homologous (or partially homologous) genes. The insecticidal proteins find use in controlling, inhibiting growth or killing lepidopteran, coleopteran, dipteran, fungal, hemipteran, and nematode pest populations and for producing compositions with insecticidal activity.

Owner:PIONEER HI BRED INT INC

Cotton cultivar 00S07

ActiveUS7105729B2Enhanced fiber qualityImprove fiber qualityBryophytesOther foreign material introduction processesCultivar

A cotton cultivar, designated 00S07, is disclosed. The invention relates to the seeds of cotton cultivar 00S07, to the plants of cotton 00S07 and to methods for producing a cotton plant produced by crossing the cultivar 00S07 with itself or another cotton variety. The invention further relates to hybrid cotton seeds and plants produced by crossing the cultivar 00S07 with another cotton cultivar.

Owner:POLARIS INNOVATIONS +1

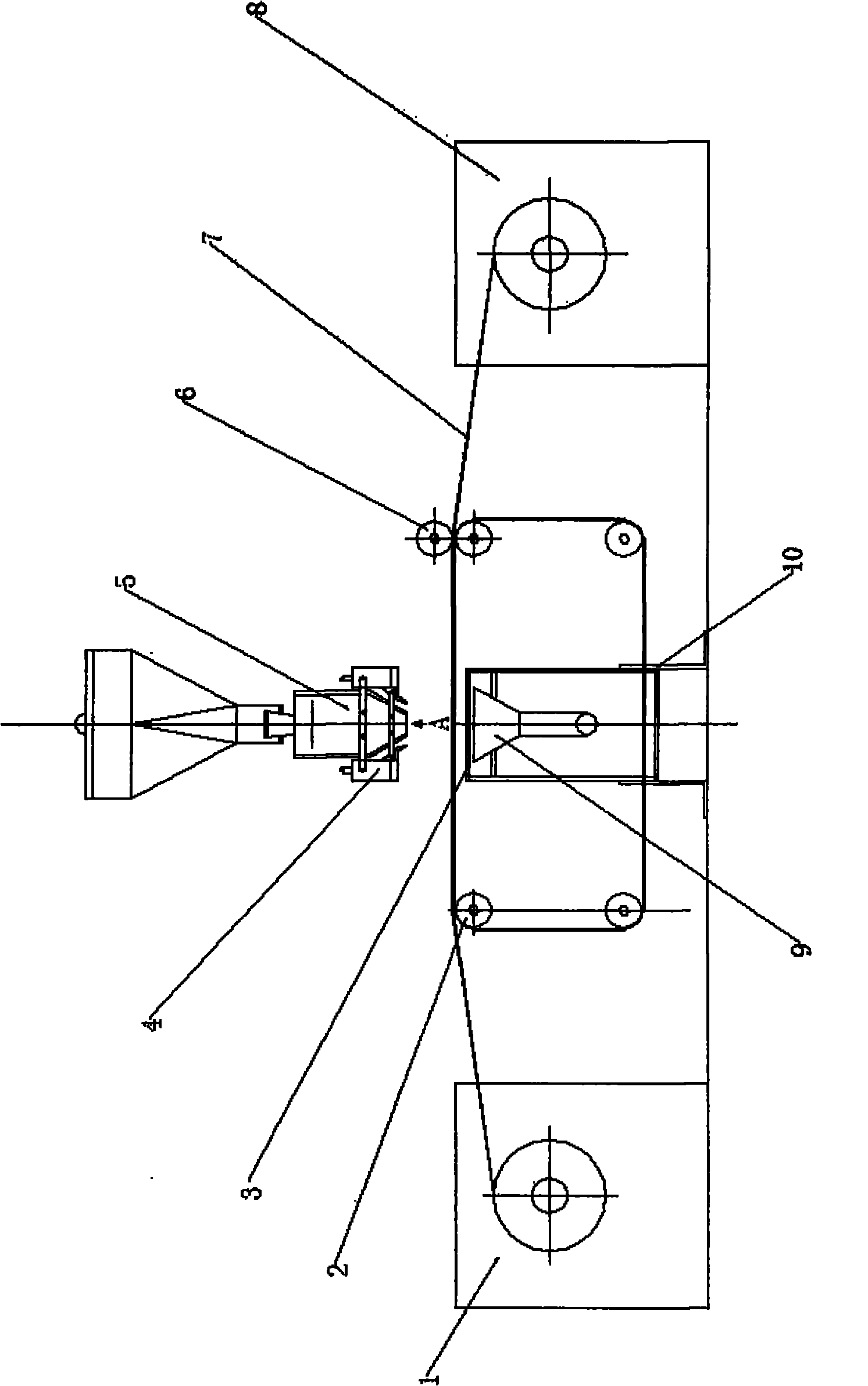

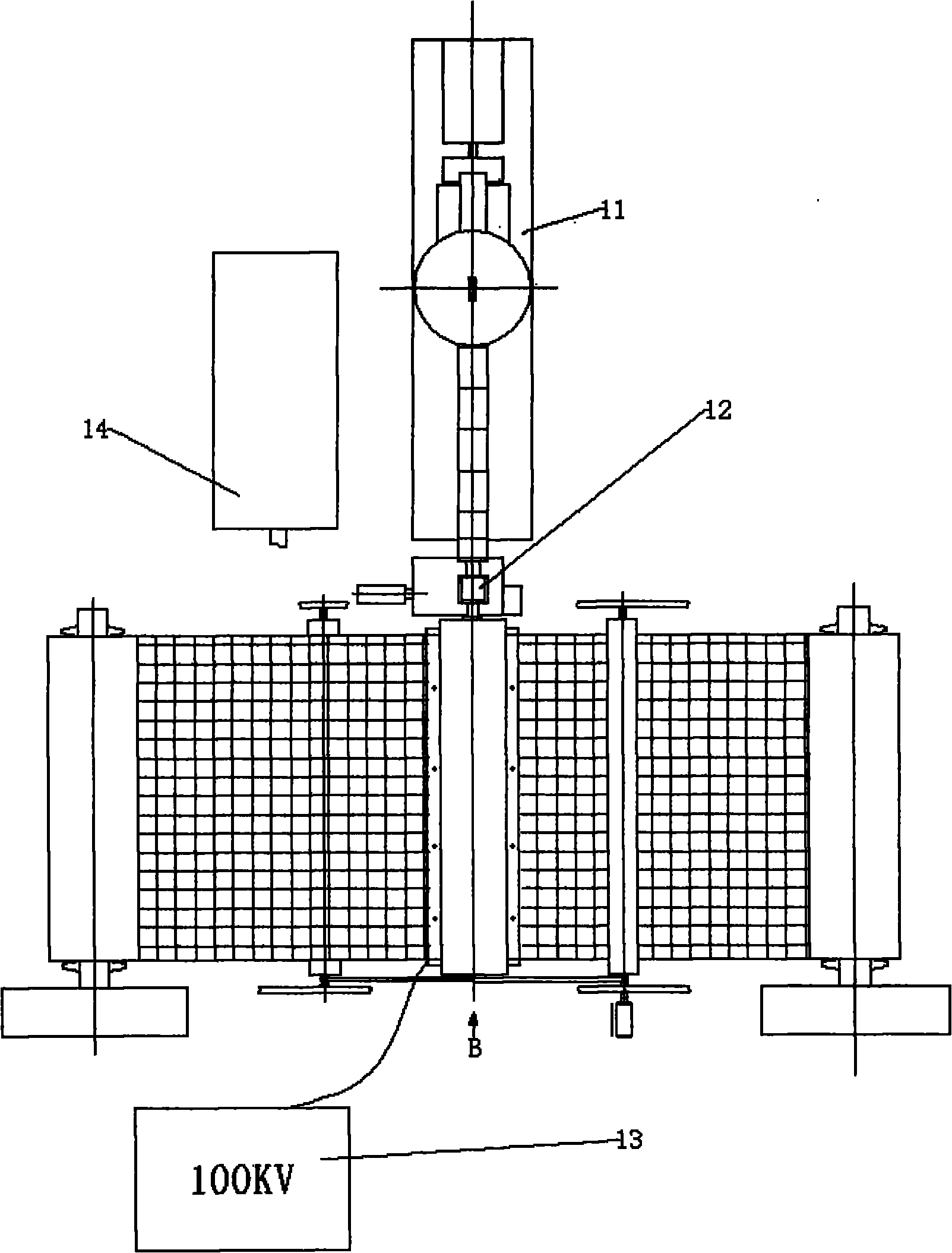

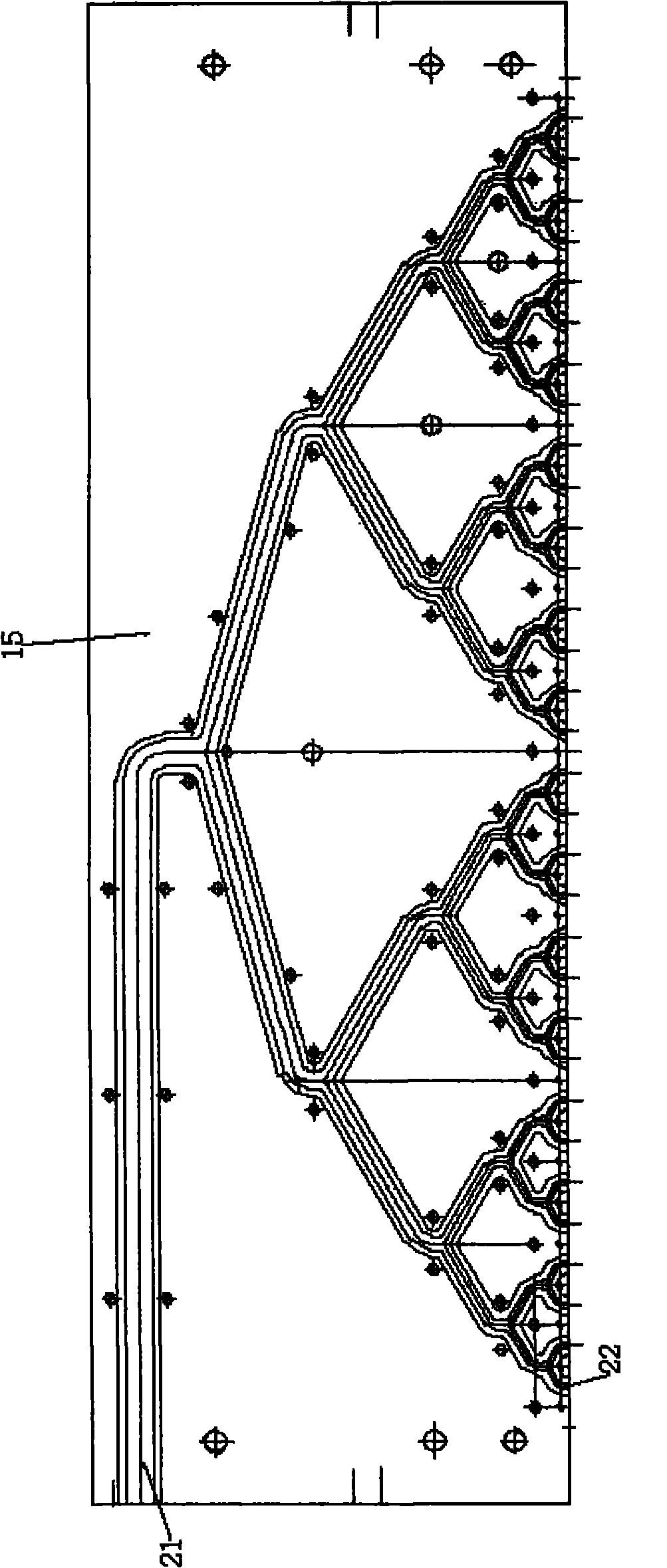

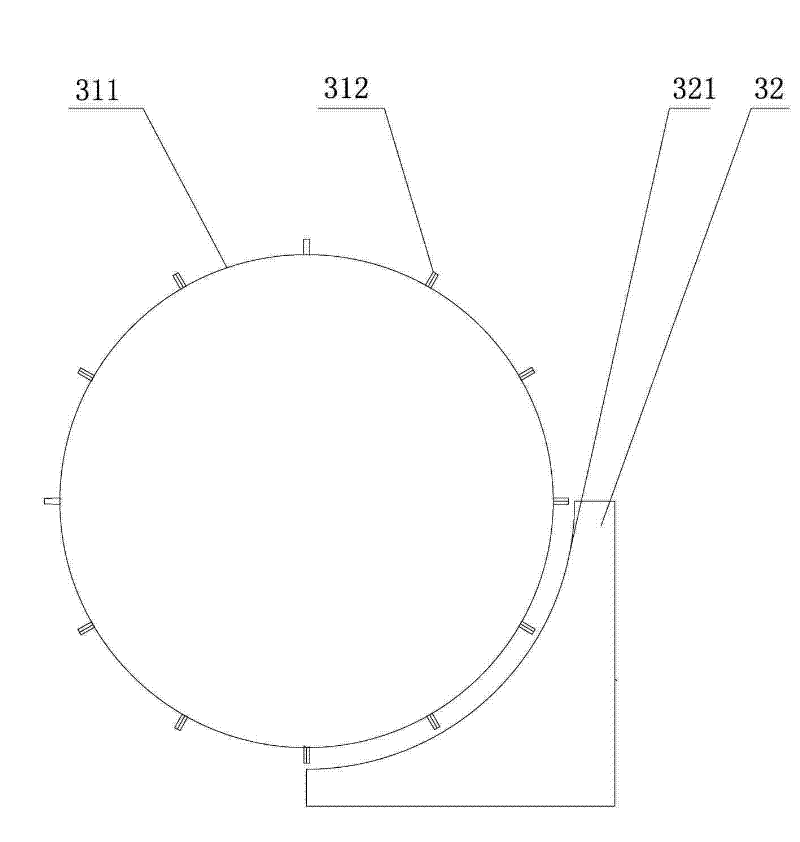

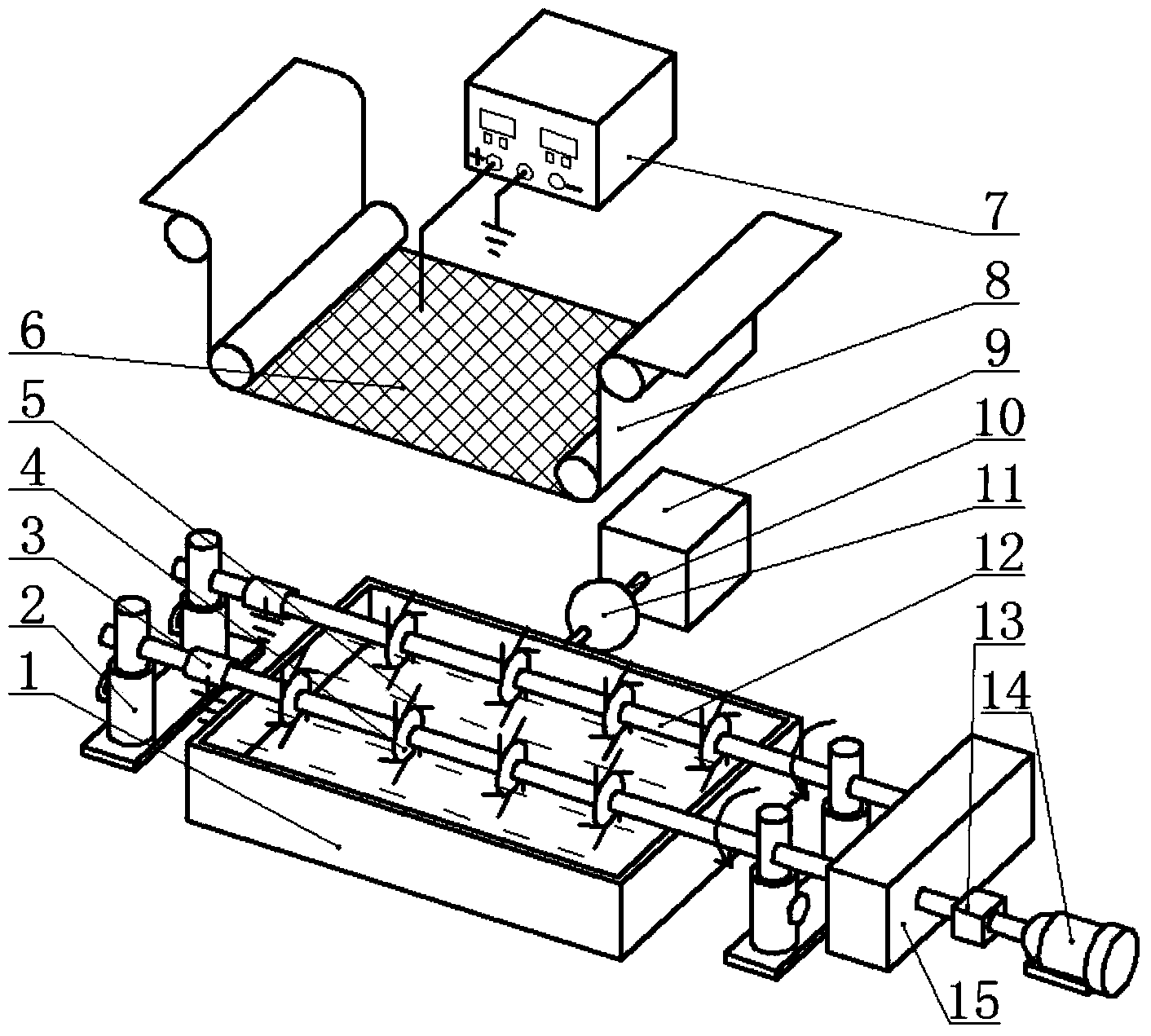

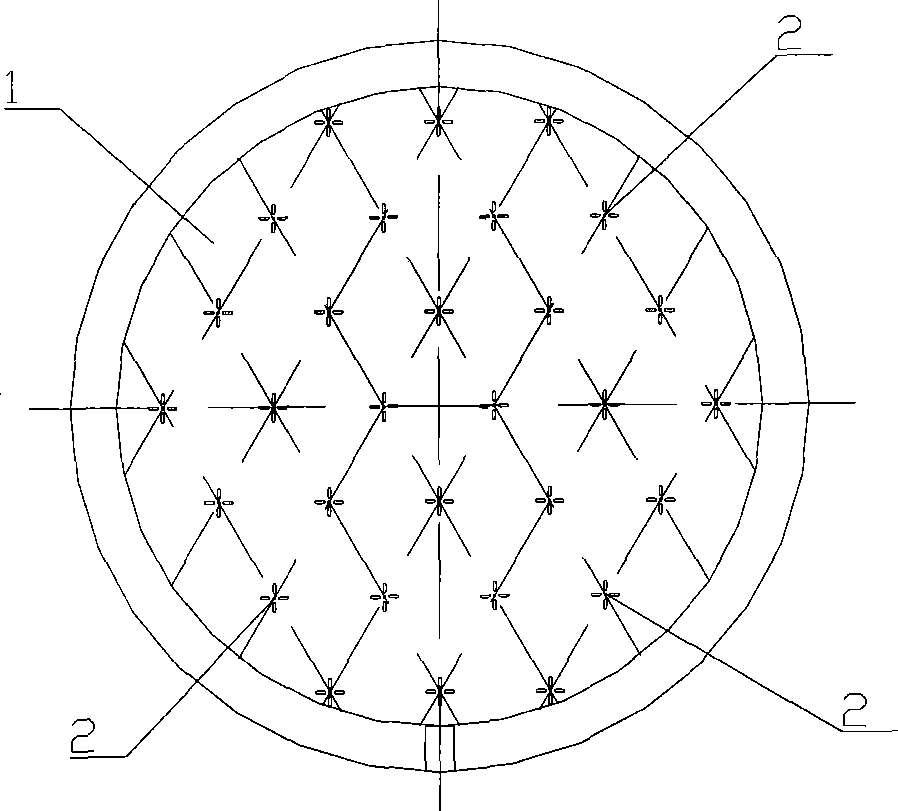

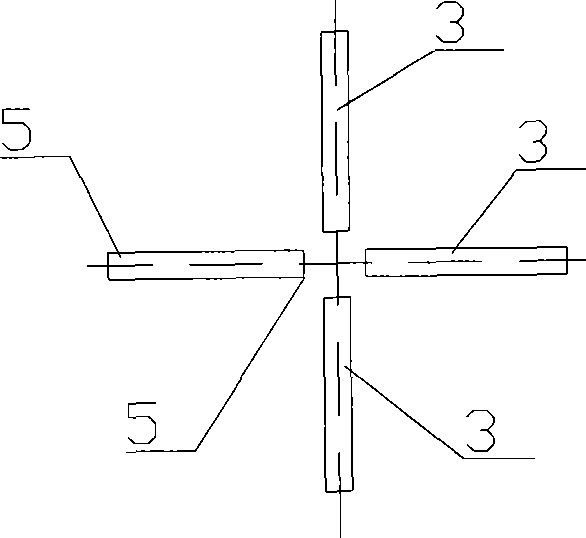

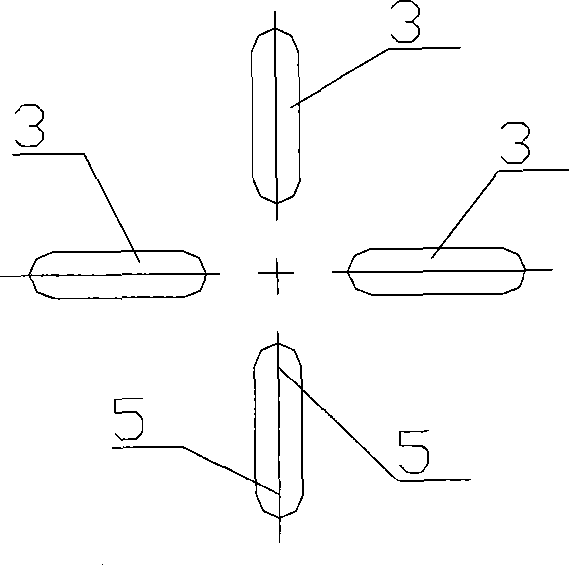

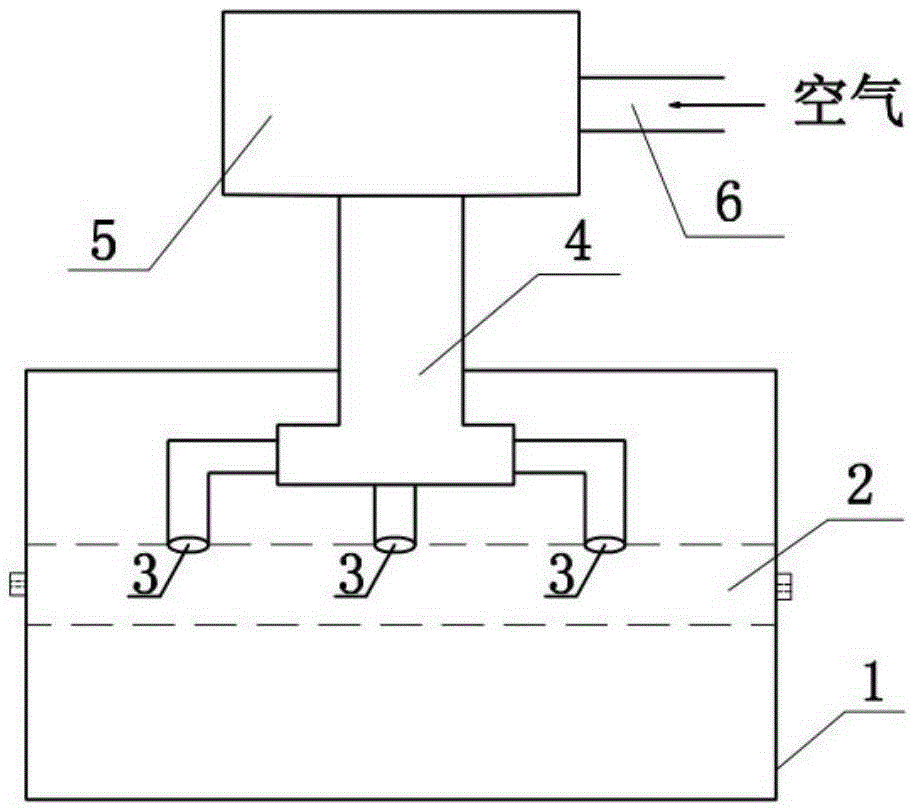

Device for preparing non-woven fabric product continuously with electrostatic spinning method

ActiveCN101985793AEasy to processReduce processing costsSpinnerette packsFilament/thread formingTemperature controlElectrospinning

The invention relates to a device for preparing non-woven fabric products continuously with an electrostatic spinning method, belonging to the field of electrostatic spinning, and mainly comprising a melt body conveying device, a melt body metering pump, an electrostatic spinning die head, a die head temperature control device, a high-voltage static electricity generating device, a collecting device and a bracket, wherein the melt body conveying device is connected with an inlet of the melt body metering pump directly; an outlet of the melt body metering pump is connected with the electrostatic spinning die head; the die head temperature control device is arranged on the electrostatic spinning die head or distributed in the electrostatic spinning die head; the inner part of the electrostatic spinning die head is provided with a distributing passage; the distributing passage distributes a stream of melt body as a plurality of melt bodies uniformly; a spinneret plate of the terminal end of a plurality of the melt bodies is connected with a jet nozzle; the jet nozzle is not a single micro-hole but a hole-slot on a slit; and a passage of hot air is arranged at the outer part of the electrostatic spinning die head. According to the structure of the invention, the manufacturing difficulty of the electrostatic spinning die head is reduced greatly; the fiber diameter is much thinner than that of fiber manufactured by a melt blown method; the fiber quality is better; and modularization production is easy to realize.

Owner:BEIJING UNIV OF CHEM TECH

Nanometer polyester fiber FDY spinning oil prepn and its prepn process

The nanometer polyester fiber FDY spinning oil preparation consists of inorganic nanometer additive, smoothing agent, emulsifier, antistatic agent and other additive. Owing to the added nanometer material, the nanometer polyester fiber FDY spinning oil preparation has excellent smoothing performance, capability of raising the quality of spun yarn, high heat stability, no smoke, simple compounding process, certain antibiotic capacity and other advantages, and is suitable for use in the one-step FDY spinning production line.

Owner:杨国栋

Method for producing antibacterial polylactic acid fiber

ActiveCN1891870AImprove qualitySpin wellMonocomponent polyesters artificial filamentArtifical filament manufactureAntibiosisMaterials science

The invention offers antibiosis poly lactic acid fiber producing method. It processes inorganic superfine antibiosis powder contained silver firstly, make antibiosis agglomerate with smashed poly lactic acid slice which are processed cross blend melt spinning in certain proportion. The formed ploy lactic acid antibiosis fiber has the advantages of antibiosis, washable, good fiber forming and quality, and biodegradable.

Owner:SINOPEC YIZHENG CHEM FIBER

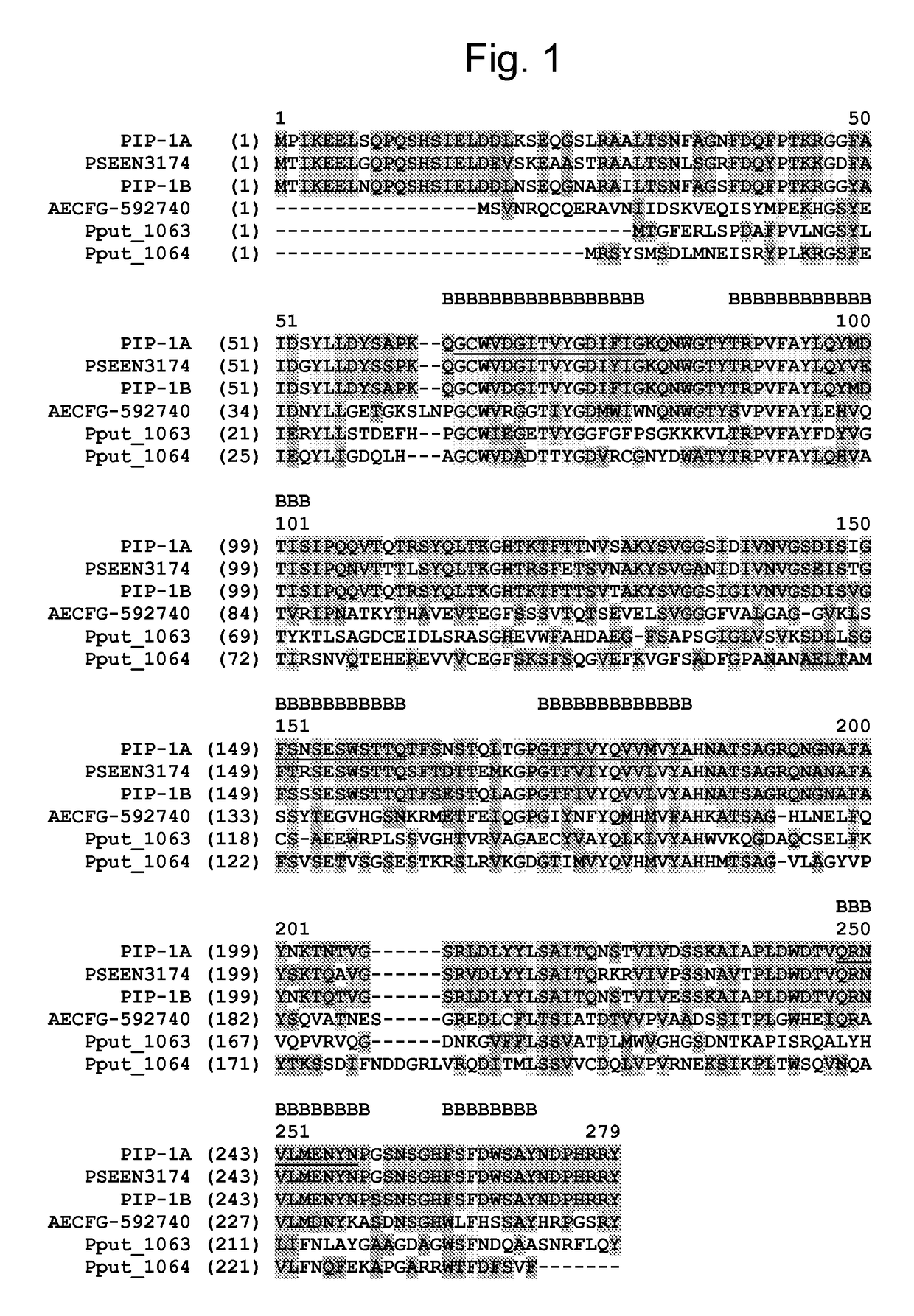

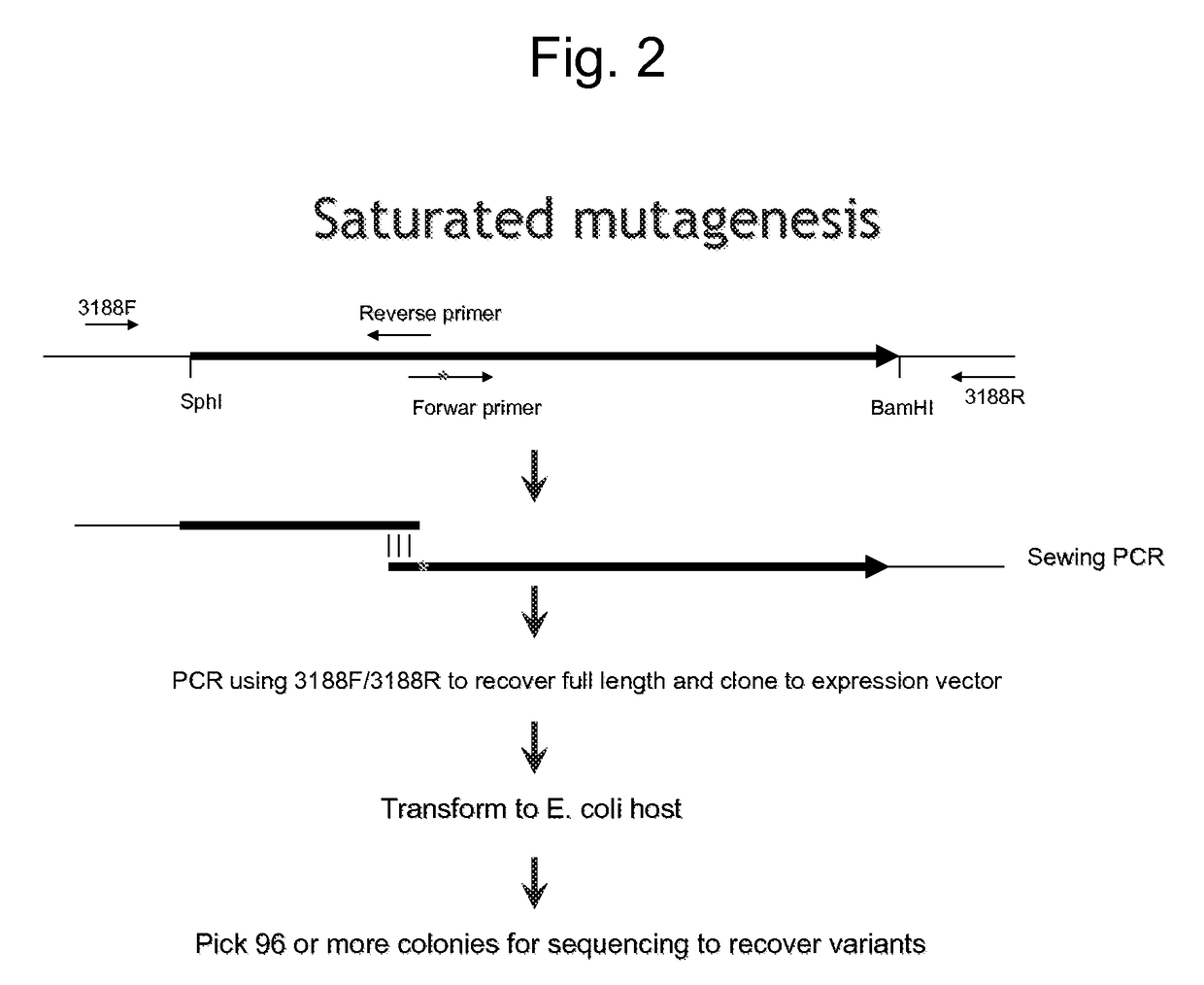

Insecticidal proteins and methods for their use

ActiveUS9688730B2Increase productionEnhance the imageBiocideClimate change adaptationBiotechnologyOrder Lepidoptera

Compositions and methods for controlling pests are provided. The methods involve transforming organisms with a nucleic acid sequence encoding an insecticidal protein. In particular, the nucleic acid sequences are useful for preparing plants and microorganisms that possess insecticidal activity. Thus, transformed bacteria, plants, plant cells, plant tissues and seeds are provided. Compositions are insecticidal nucleic acids and proteins of bacterial species. The sequences find use in the construction of expression vectors for subsequent transformation into organisms of interest, as probes for the isolation of other homologous (or partially homologous) genes. The insecticidal proteins find use in controlling, inhibiting growth or killing lepidopteran, coleopteran, dipteran, fungal, hemipteran, and nematode pest populations and for producing compositions with insecticidal activity.

Owner:PIONEER HI BRED INT INC

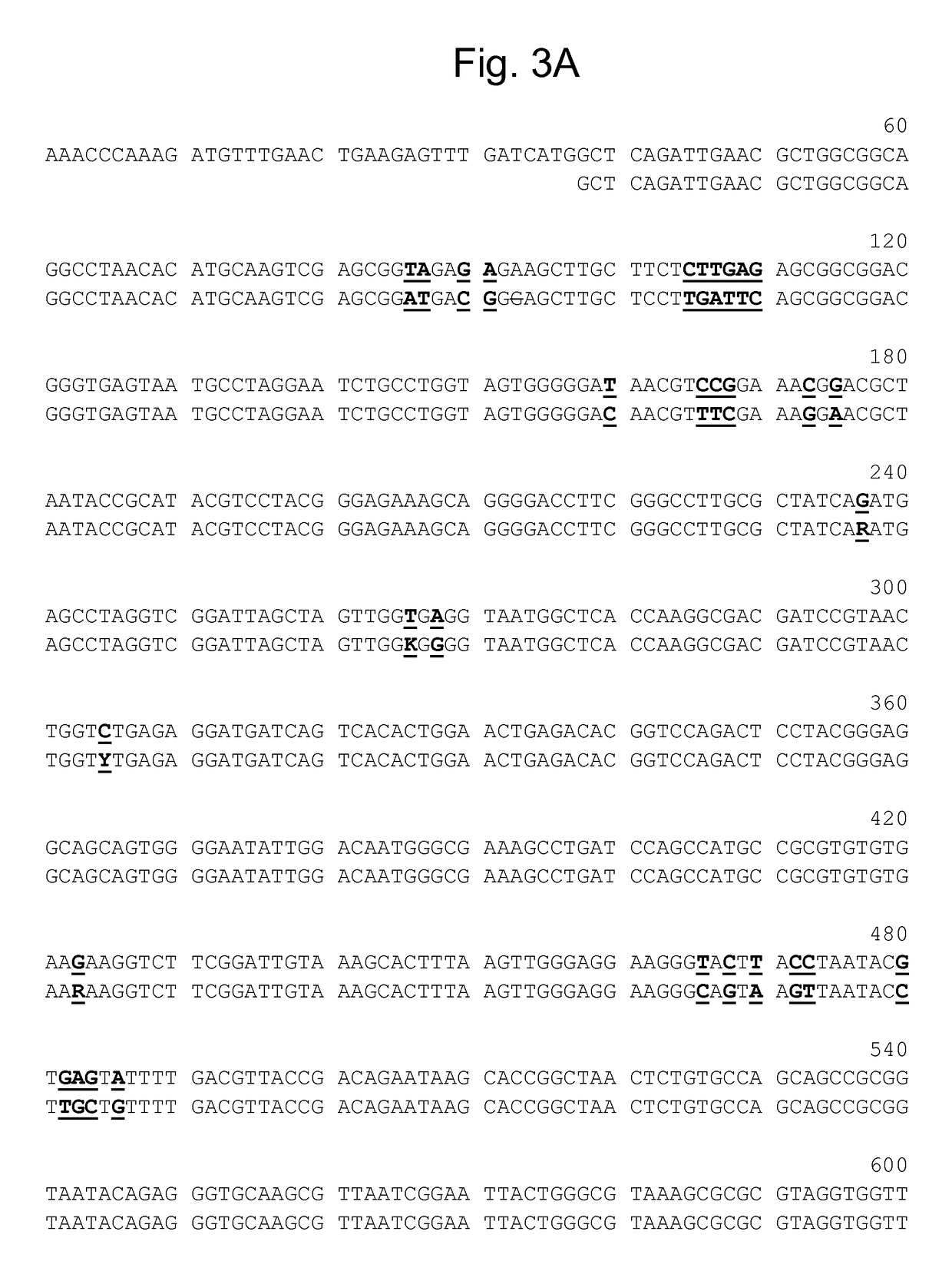

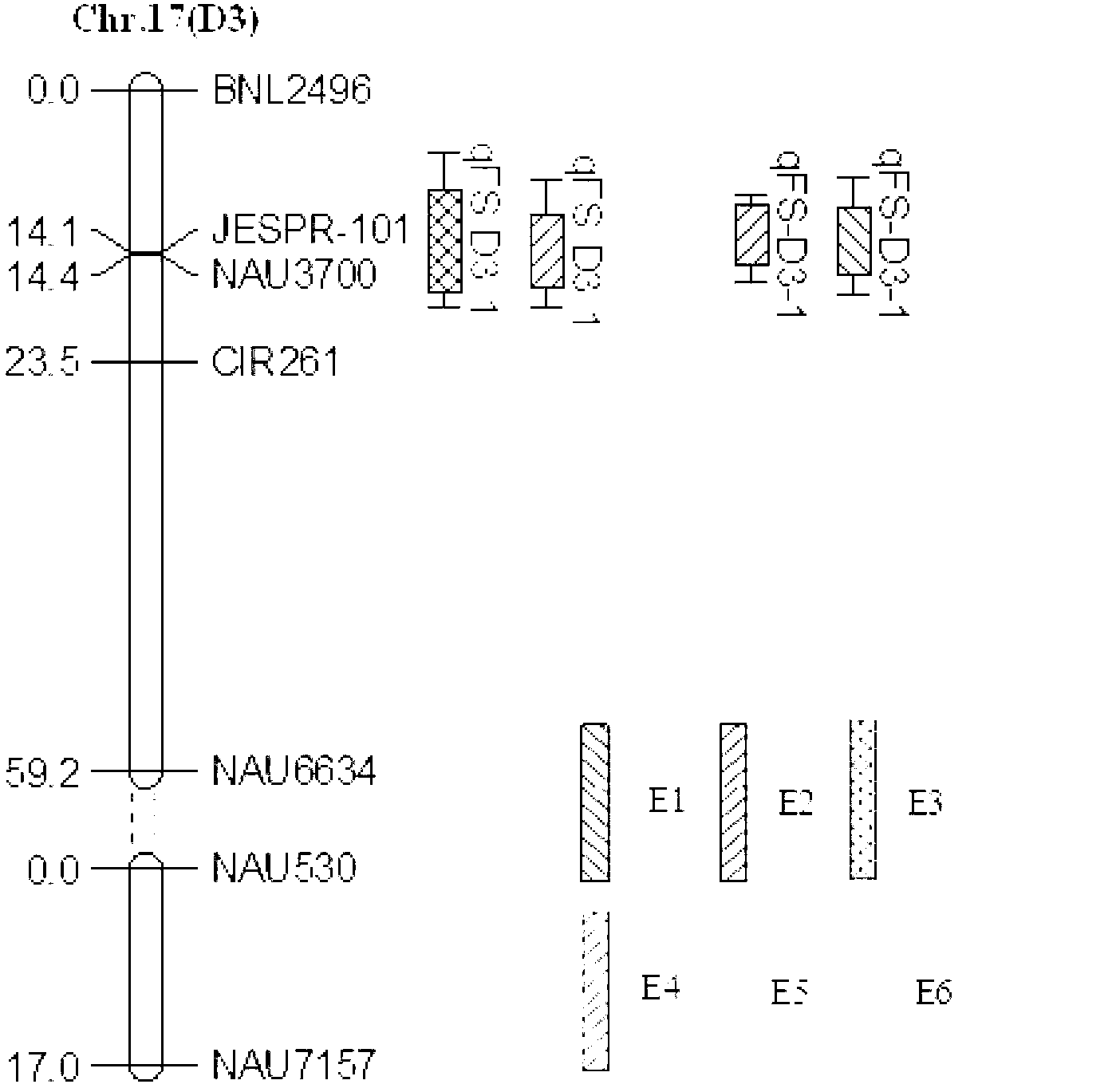

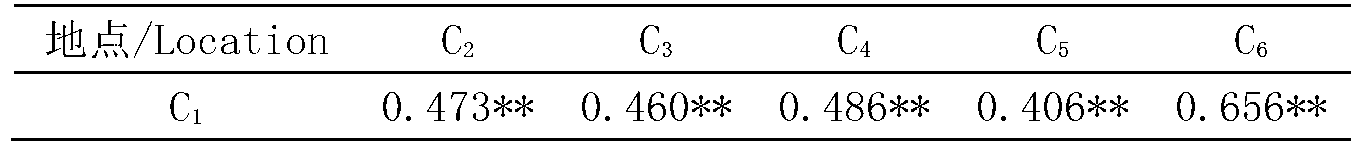

Major QTL (Quantitative Trait Locus) of cotton high-strength fiber and molecular marker and application thereof

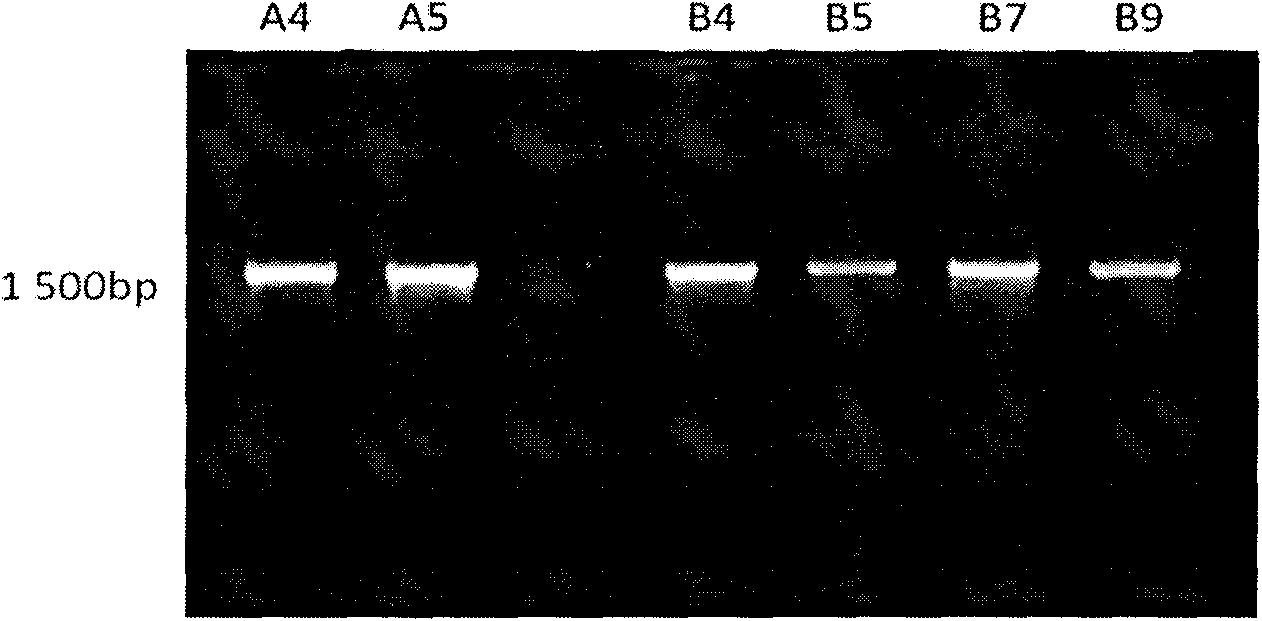

ActiveCN103255139AHigh strengthImprove fiber quality levelsMicrobiological testing/measurementVector-based foreign material introductionFiberAgricultural science

The invention discloses a major QTL (Quantitative Trait Locus) of a cotton high-strength fiber and a molecular marker and application thereof. The major QTL of the cotton high-strength fiber is linked with two SSR (Simple Sequence Repeat) markers, is positioned through markers NAU / SSR / FS1195 and JESPR / SSR / FS2127 and is 0.01-2.39 centimeters away from a marker NAU3700; and the major QTL locus can explain 4.51%-17.55% of phenotype variation and achieves the LOD (Limit Of Detection) value between 3.23 and 7.09. The major QTL disclosed by the invention overcomes the defects of high cost, high difficulty and slow progress of quality breeding in the prior art, greatly increases the selection efficiency of the high-strength fiber by utilizing the major QTL locus of a cotton high-strength fiber gene and the molecular marker thereof, can be used for exploring high-quality fiber gene resources, provides the gene resources and a marker auxiliary selection technology for the quality breeding of cotton and can be applied to the production and quality detection of high-strength fiber cotton varieties.

Owner:NANJING AGRICULTURAL UNIVERSITY

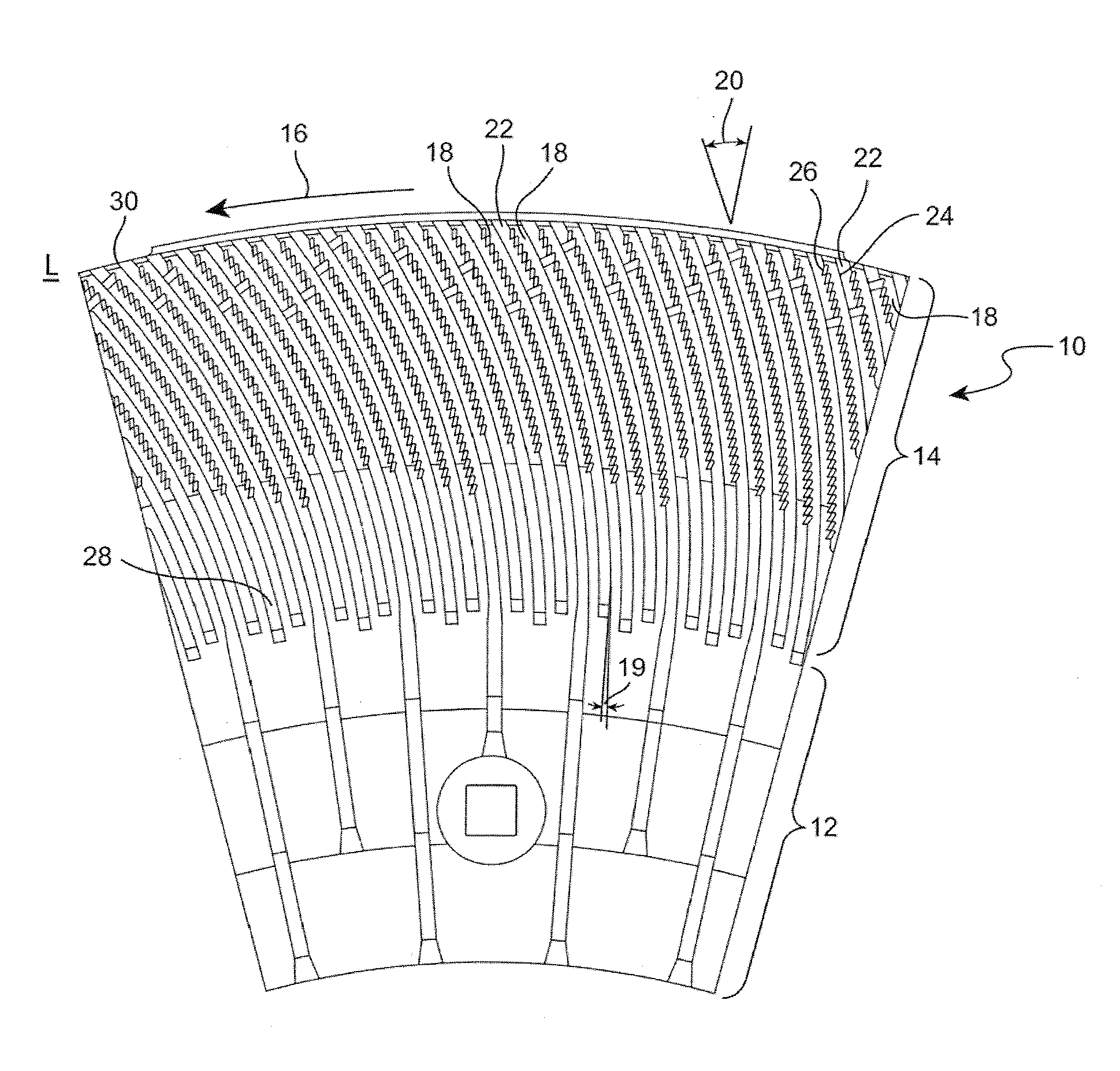

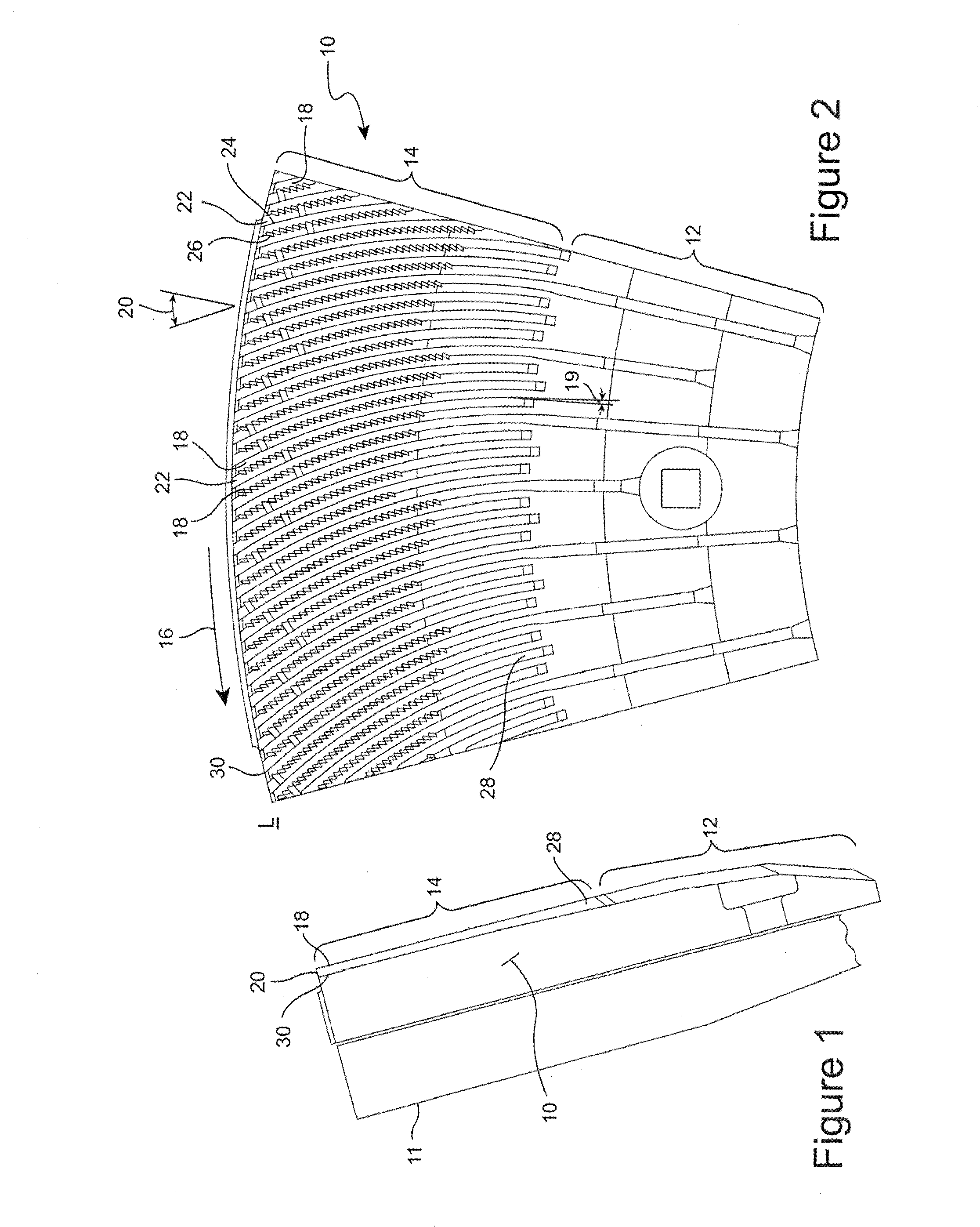

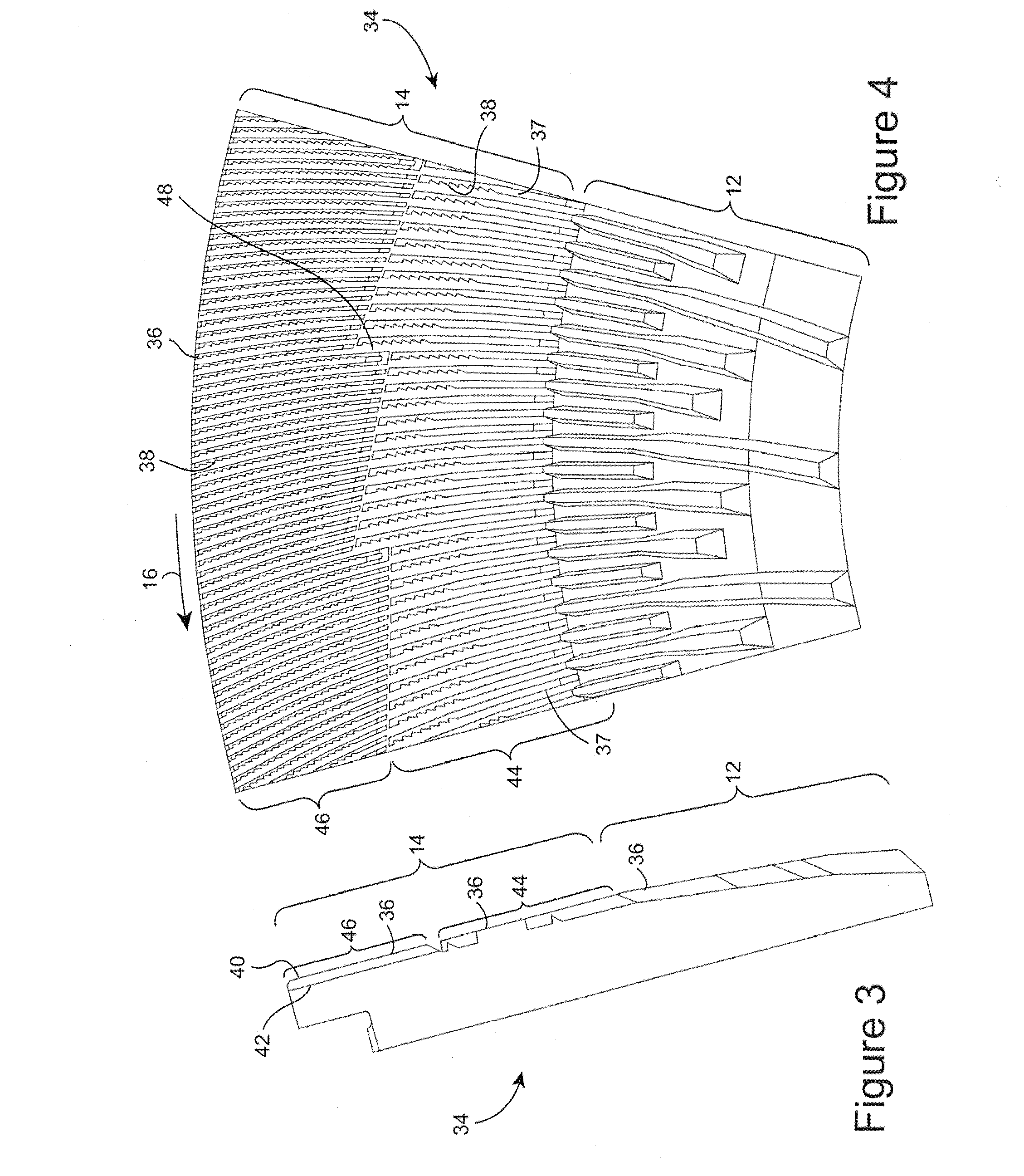

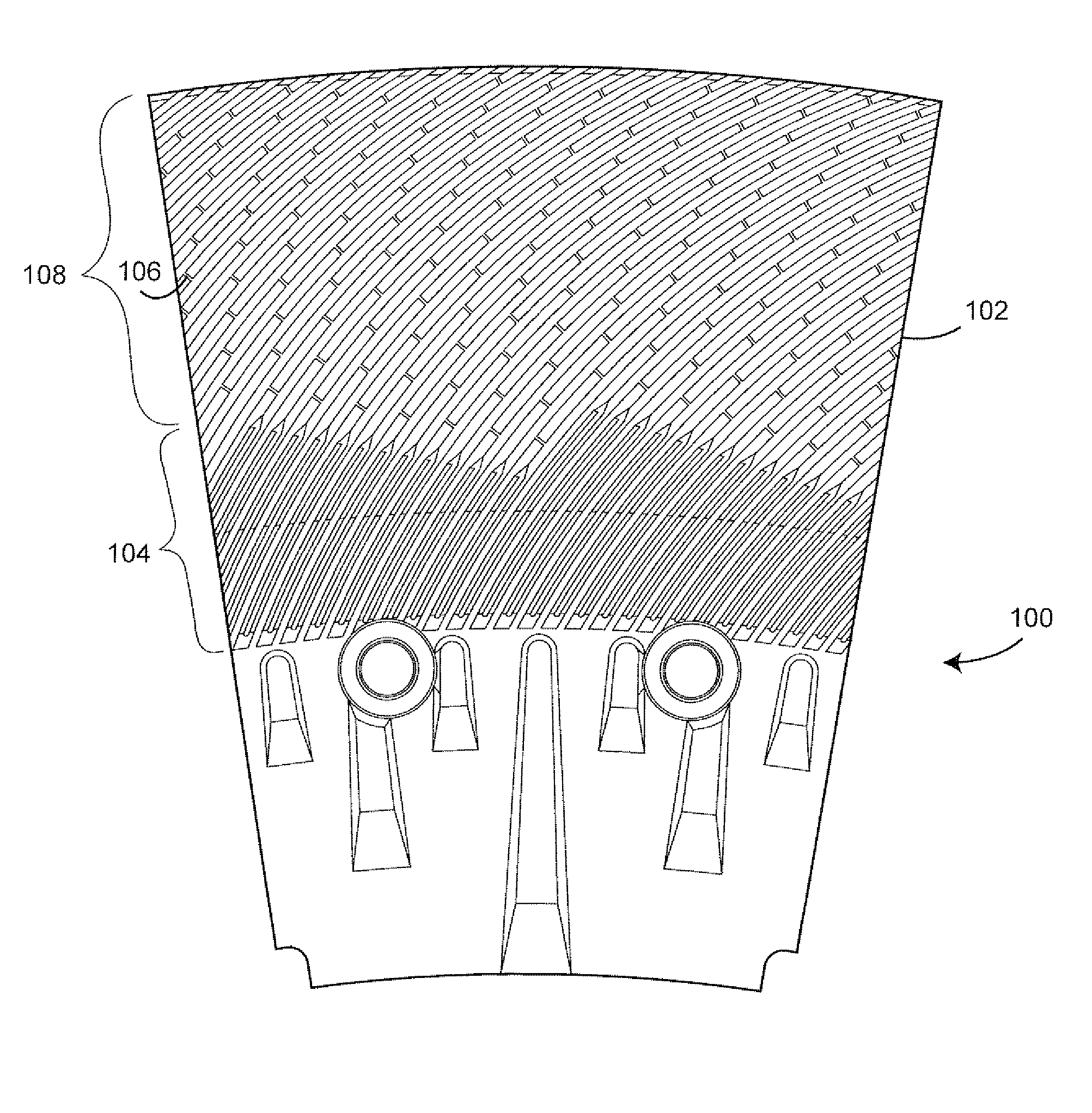

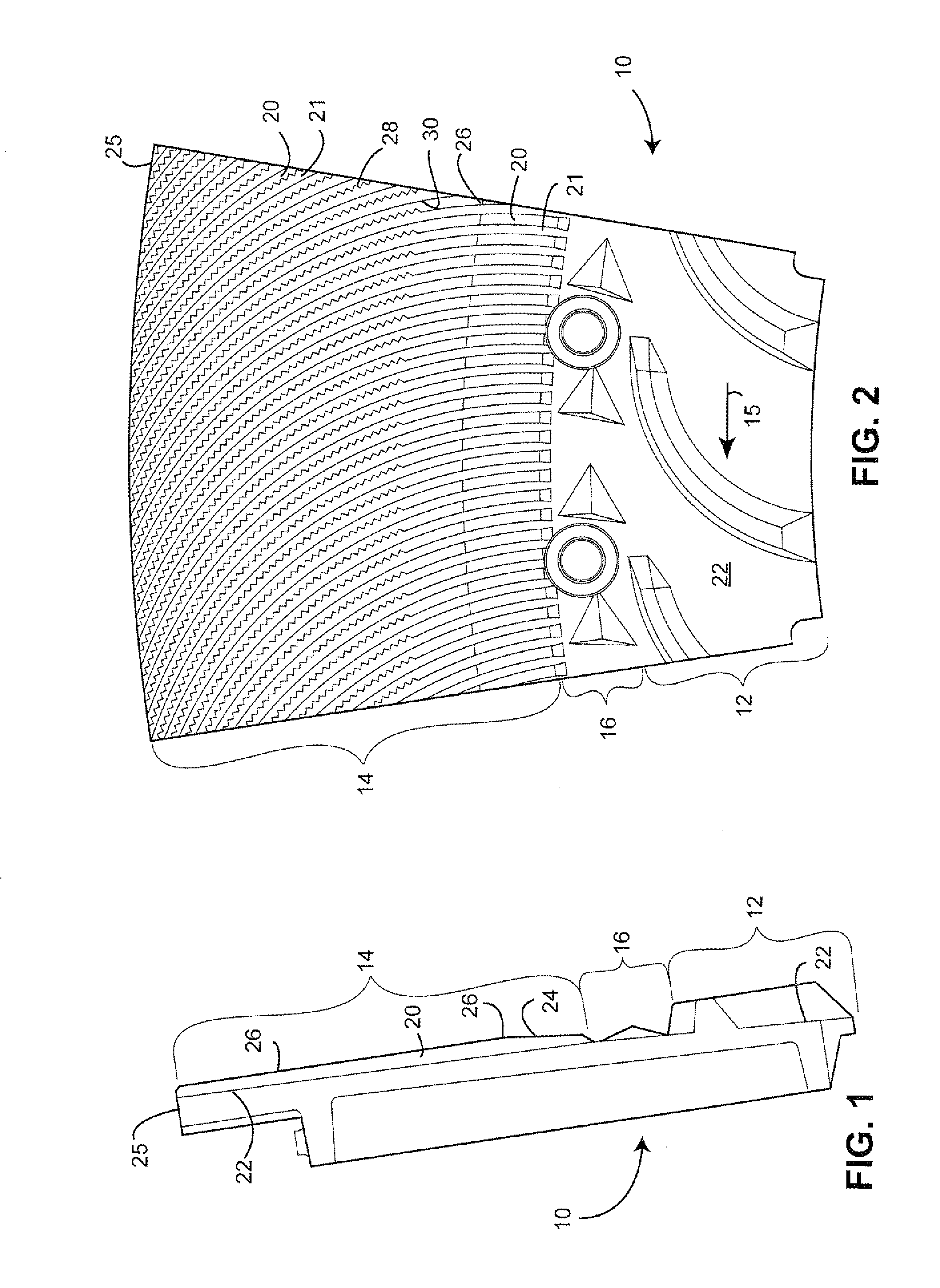

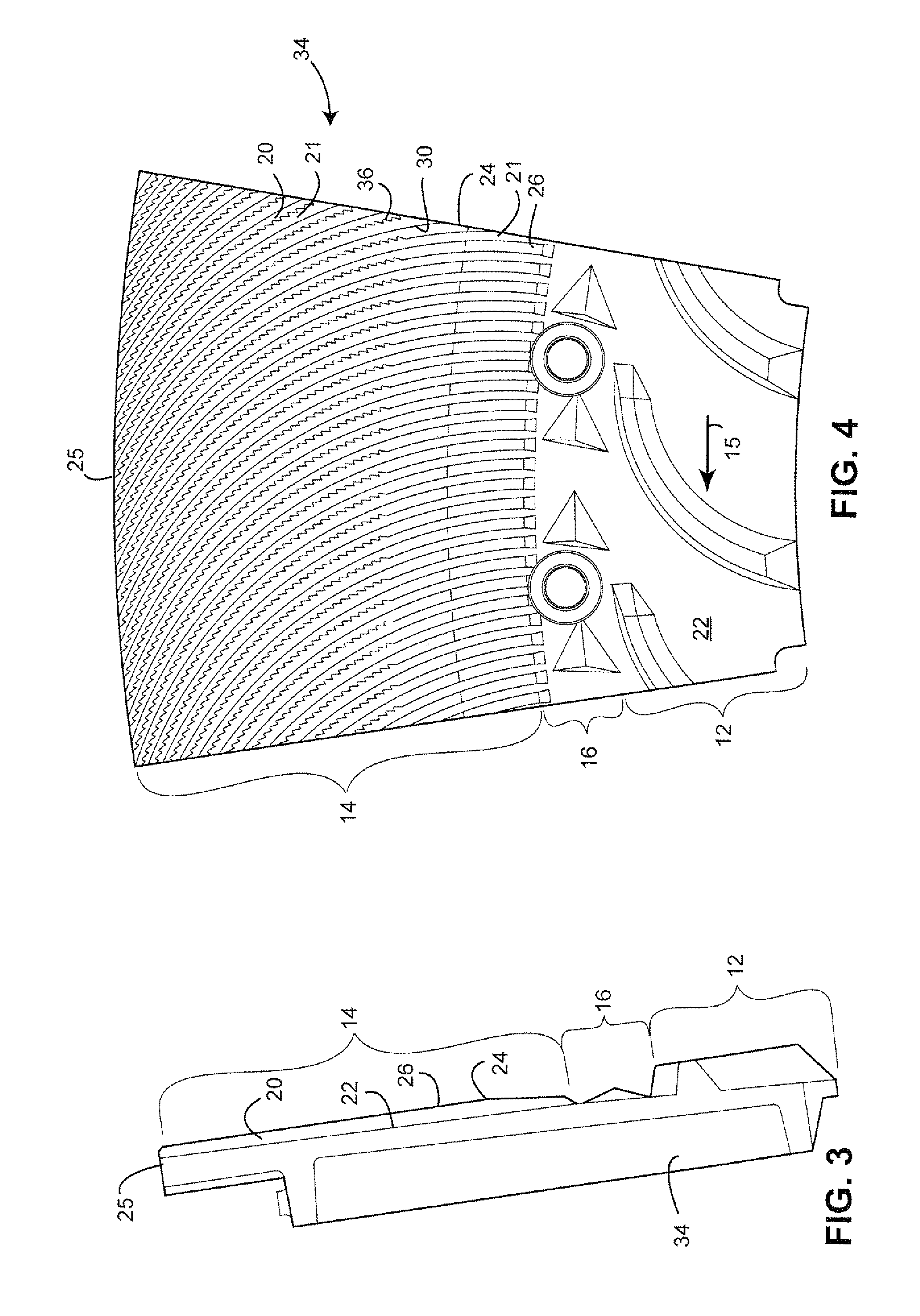

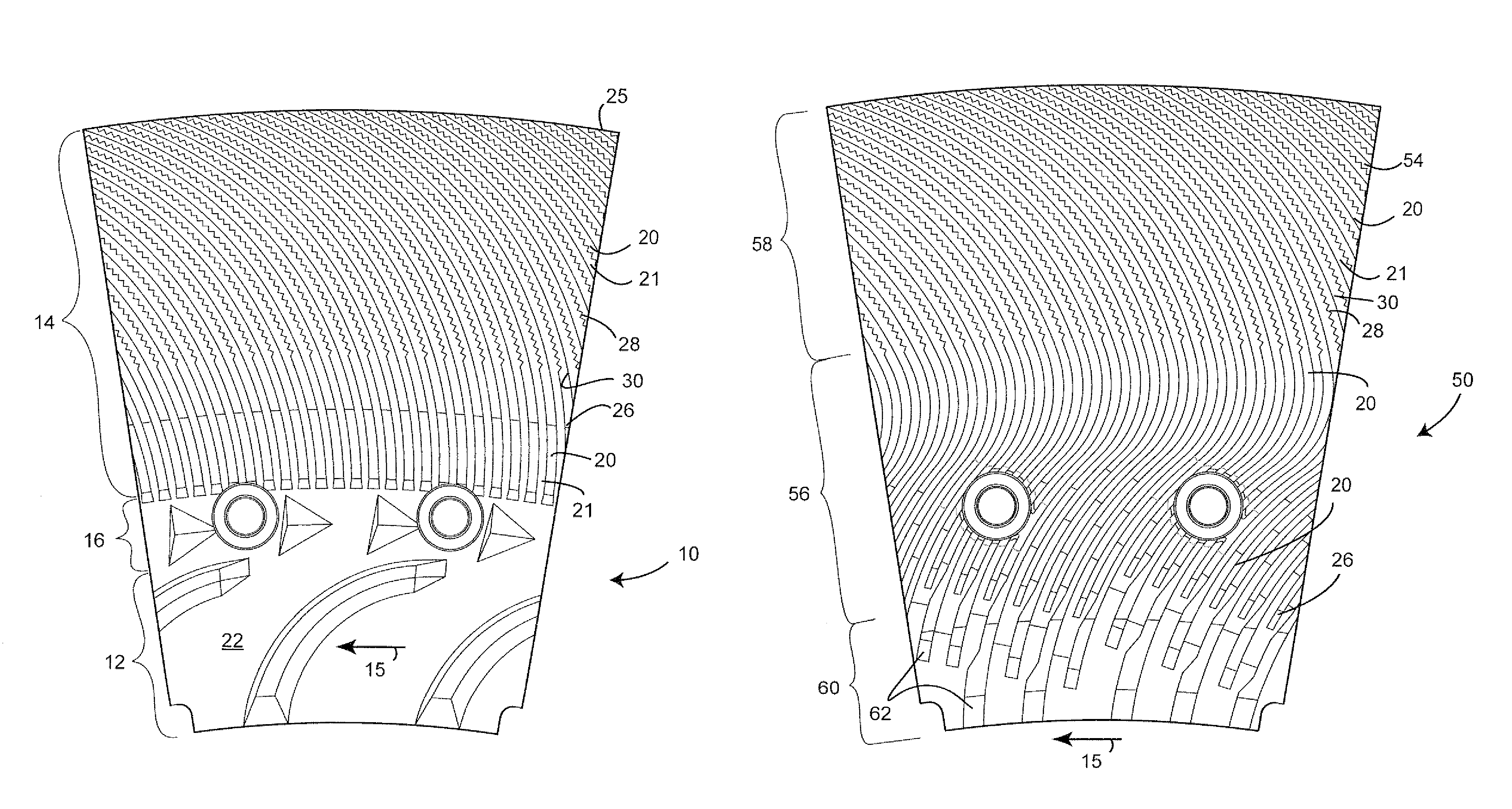

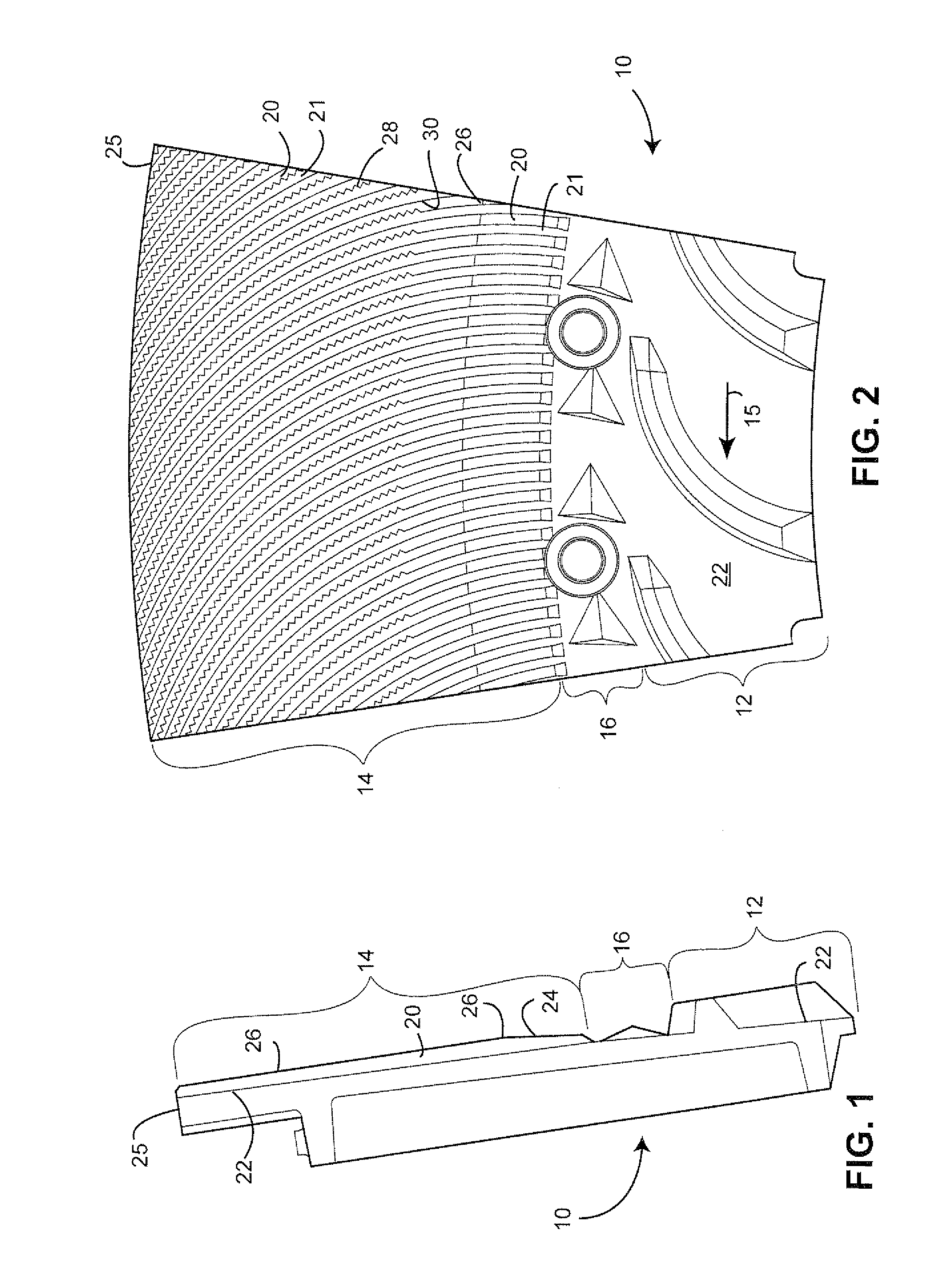

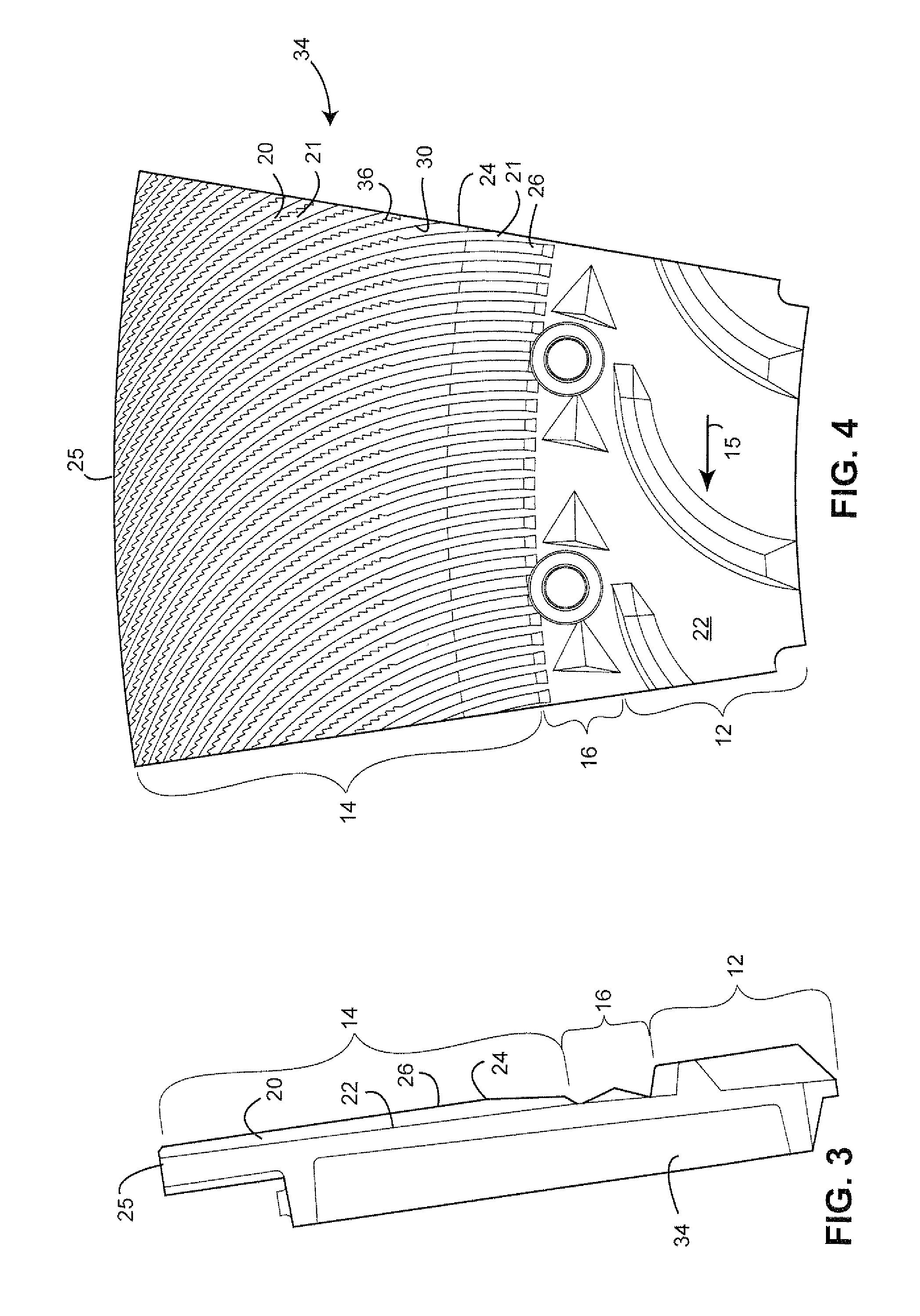

Rotor refiner plate element for counter-rotating refiner having curved bars and serrated leading edges

ActiveUS20130015281A1Improve refining efficiencyReduce decreaseCocoaPulp beating/refining methodsLeading edgeEngineering

A refining plate segment for a mechanical refiner of lignocellulosic material including: a refining surface on a substrate, wherein the refining surface faces a refining surface of an opposing refiner plate, the refining surface including bars and grooves between the bars, wherein an angle of each bar with respect to a radial line corresponding to the bar increases at least 15 degrees along a radially outward direction, and the angle is a holdback angle in a range of 10 to 45 degrees at the periphery of the refining surface, and wherein the bars each include a leading sidewall having an irregular surface, wherein the irregular surface includes protrusions extending outwardly from the sidewall towards a sidewall on an adjacent bar and the irregular surface extends from at or near the outer periphery of the refining surface extends radially inwardly along the bars without reaching an inlet of the refining surface.

Owner:ANDRITZ INC

Mechanical pulping refiner plate having curved refining bars with jagged leading sidewalls and method for designing plates

ActiveUS20080191078A1Increased operating lifeImprove energy efficiencyCocoaPulp beating/refining methodsEngineeringMechanical engineering

Owner:ANDRITZ INC

Mechanical pulping refiner plate having curved refining bars with jagged leading sidewalls and method for designing plates

ActiveUS7900862B2Increased operating lifeImprove energy efficiencyCocoaGrain treatmentsEngineeringMechanical engineering

Owner:ANDRITZ INC

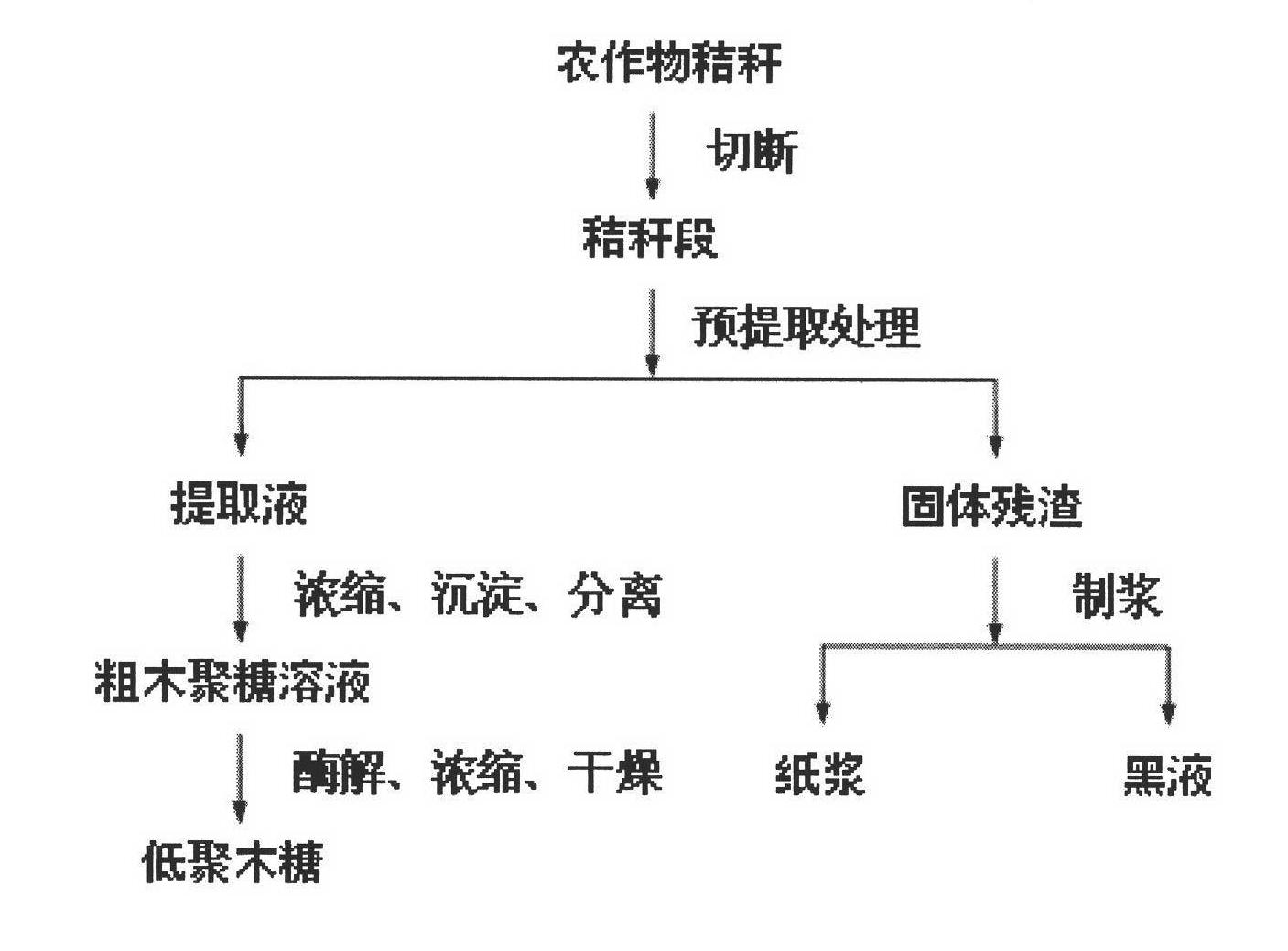

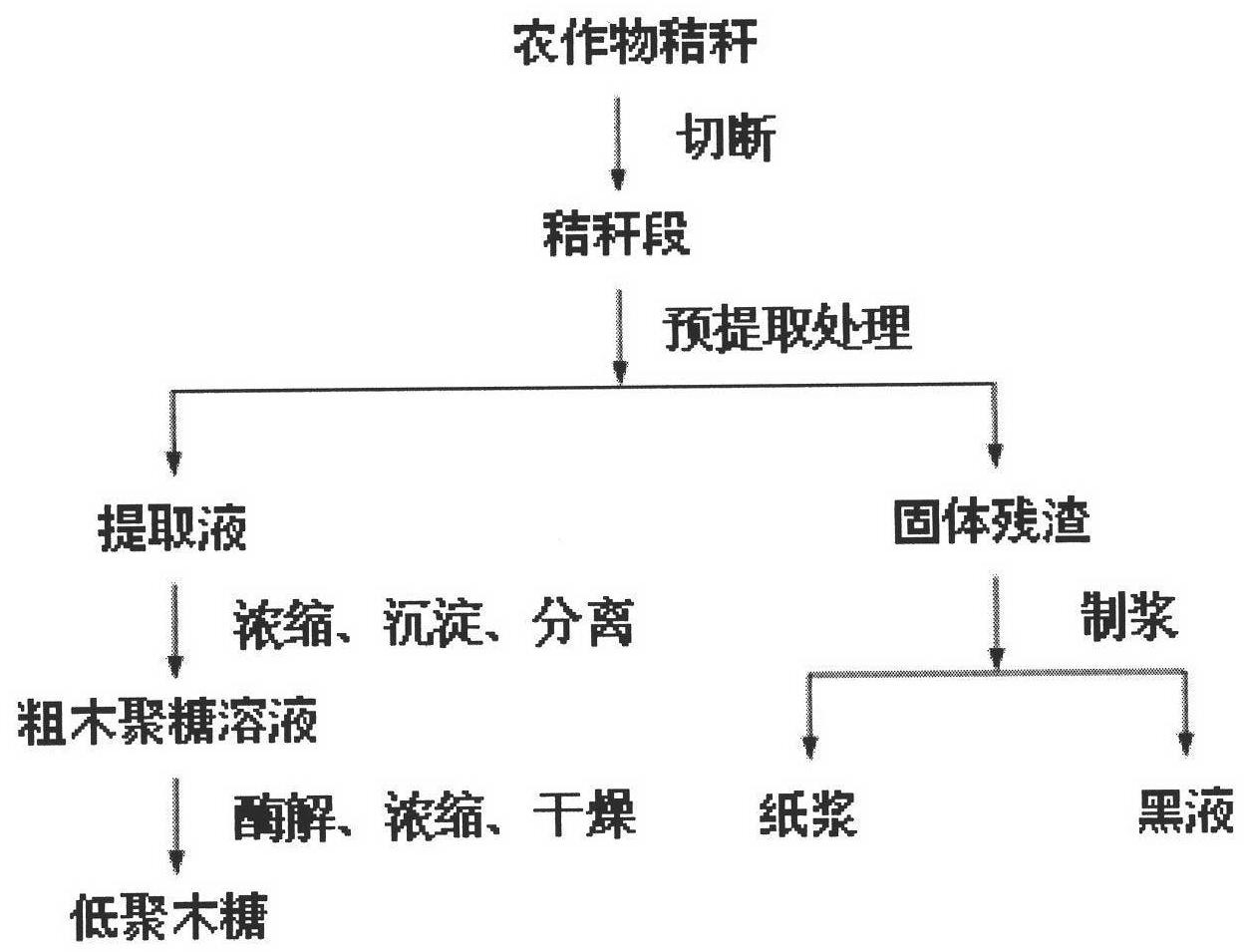

A kind of method for preparing xylo-oligosaccharide and paper pulp

ActiveCN102277761AImprove fiber qualityImprove physical performance indicatorsPretreatment with alkaline reacting compoundsPulping with inorganic basesFiberOligosaccharide

The invention discloses a method for preparing oligosaccharide and paper pulp, belonging to the technical fields of pulping and the comprehensive utilization of pulping. The method comprises the steps of: using crop straws as raw materials, pre-treating the raw materials to obtain a pre-extracting solution, concentrating the pre-extracting solution by a membrane separation method, then obtaining a crude xylan solution via precipitation and centrifugal separation, and then preparing oligosaccharide via enzymolysis, vacuum concentration and frozen-drying. The pre-treated solid residues are stewed via an alkaline process so as to prepare unbleached paper pulps of which the indexes such as fiber length, whiteness, fracture length, tear resistance, folding strength and the like are all improved. The generated black liquid has the characters of low viscosity and high heat productivity. The method for preparing oligosaccharide and paper pulp integrates the comprehensive utilization method with the biomass transformation method on the premise of optimizing the traditional alkaline chemical pulping technique to prepare products with high additional values, namely oligosaccharide, thereby increasing the quality of the paper pulp and the extraction, vaporization and combustion performances of the black liquid.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Cotton cultivar DP 143 B2RF

ActiveUS7635802B2Improve fiber qualityOther foreign material introduction processesFermentationCultivar

A cotton cultivar, designated DP 143 B2RF, is disclosed. The invention relates to the seeds of cotton cultivar DP 143 B2RF, to the plants of cotton DP 143 B2RF and to methods for producing a cotton plant produced by crossing the cultivar DP 143 B2RF with itself or another cotton variety. The invention further relates to hybrid cotton seeds and plants produced by crossing the cultivar DP 143 B2RF with another cotton cultivar.

Owner:MONSANTO CO (MONSANTO CY)

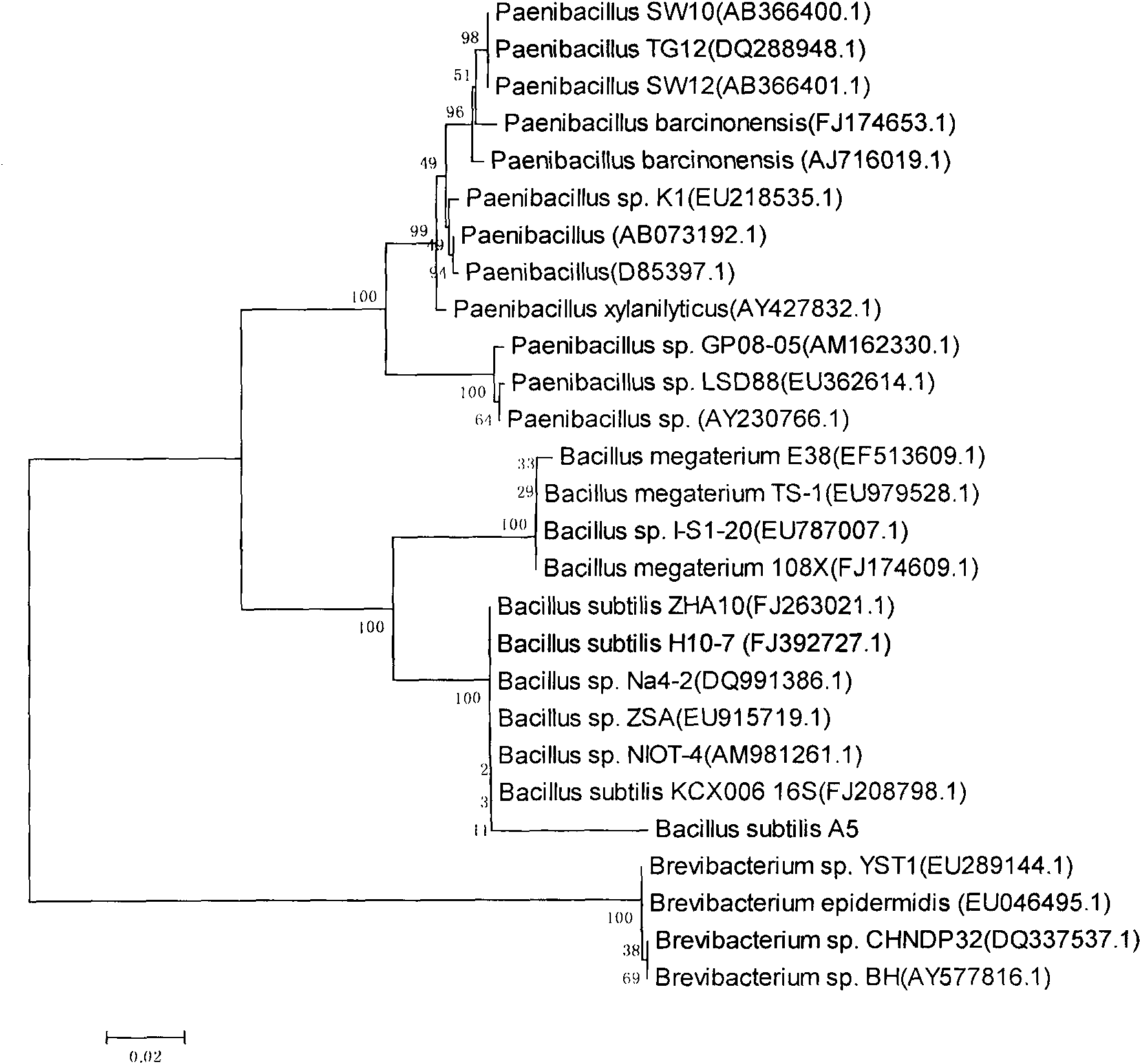

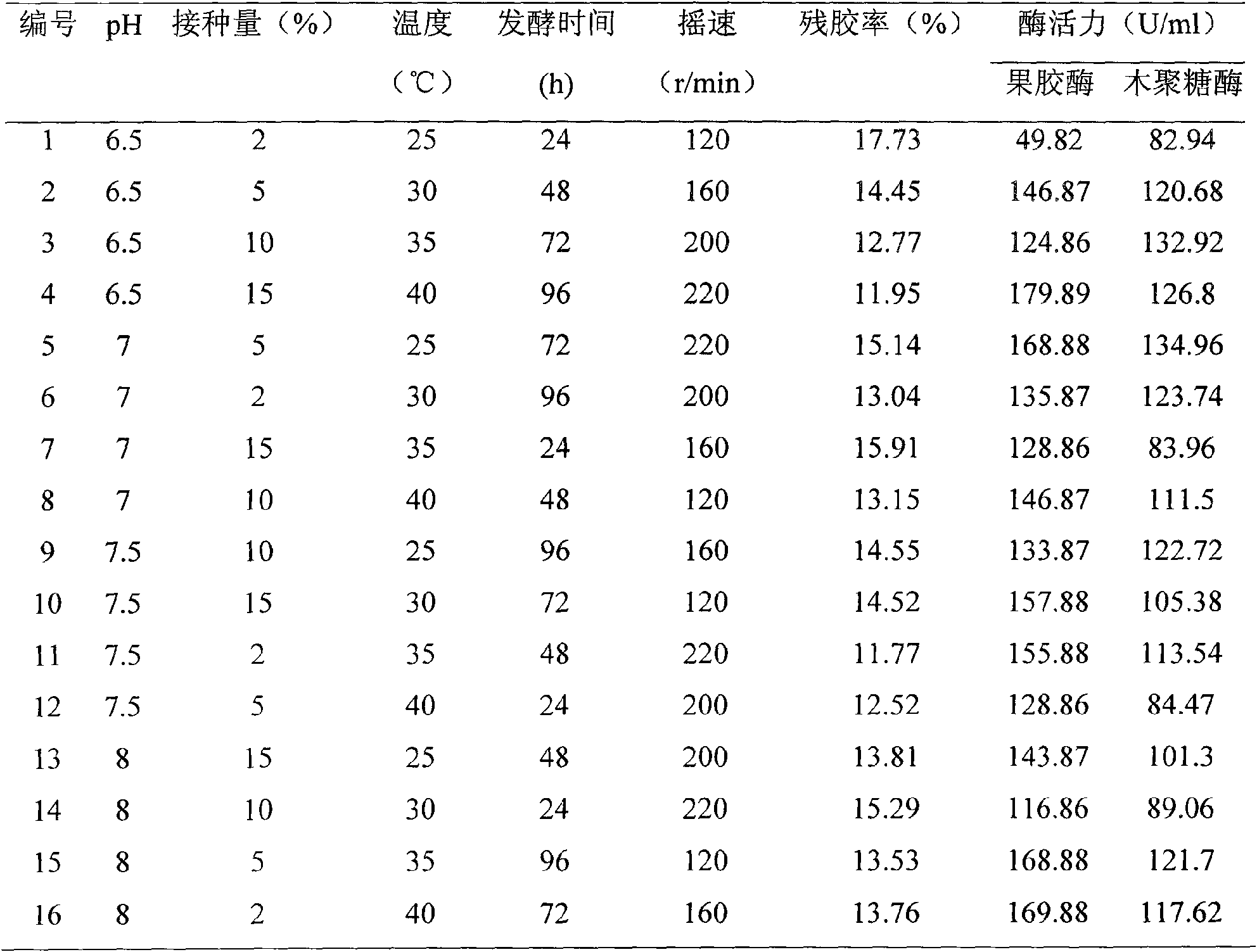

Bacillus subtillis strain containing ramie degumming activity, preparation and application thereof

InactiveCN101654660ANot easy to polluteNo pollution in the processBacteriaMicrobiological testing/measurementPectinaseBiotechnology

The invention relates to a bacillus subtillis strain containing ramie degumming activity, preparation and application thereof, which uses a system taking the strain as the core for ramie degumming. The strain of the system has high reproductive rate, high yield of pectase and xylanase, short production period, strong contamination resistance and favorable heat-resistant quality. The system and thecultivating process are safe to operate, have no toxicity and pollution no environment. Compared with the prior art, the invention has simple technology, is suitable for large-scale industrial production and the like. When the system is used for ramie degumming, degumming time is short, the dispersion coefficient of ramie fiber can reach 100%, degumming ratio can reach above 90%, and the qualityof refined dry ramie can reach the standard of chemical degumming.

Owner:DONGHUA UNIV

Cotton cultivar DP 515 BG/RR

ActiveUS7247775B2Improve fiber qualityTissue cultureOther foreign material introduction processesCultivar

Owner:MONSANTO CO (MONSANTO CY)

Preparation method of elastic polylactic acid fiber

ActiveCN103255503AGood spinning formabilityImprove fiber qualityMelt spinning methodsConjugated synthetic polymer artificial filamentsFiberToughening

The invention relates to a preparation method of elastic polylactic acid fiber. The method comprises the following steps of: (1) uniformly mixing a polylactic acid section, a compatibilizer, and an initiator, and then carrying out reactive melt blending to obtain a grafted polylactic acid master batch; (2) uniformly mixing the grafted polylactic acid master batch and the polylactic acid section, and carrying out melt blending and cooling granulating to obtain a modified polylactic acid master batch; (3) uniformly mixing the modified polylactic acid master batch and a toughening agent, and carrying out melt blending and cooling granulating to obtain a toughened polylactic acid master batch; and (4) spinning the toughened polylactic acid master batch to obtain as-spun fiber, and at last drawing the as-spun fiber and processing the drawn fiber to obtain the elastic polylactic acid fiber. The elastic polylactic acid fiber material prepared by the preparation method provided by the invention is good in spinning molding performance, excellent in fiber quality, environment-friendly and wide in market prospect, and can be applied to the fields having quite high requirements for resilience performance, such as garment, interior trim, and medical application.

Owner:DONGHUA UNIV

Cotton cultivar DP 543 BGII/RR

ActiveUS7109400B2Improve fiber qualityHigh yieldOther foreign material introduction processesTissue cultureCultivar

A cotton cultivar, designated DP 543 BGII / RR, is disclosed. The invention relates to the seeds of cotton cultivar DP 543 BGII / RR, to the plants of cotton DP 543 BGII / RR and to methods for producing a cotton plant produced by crossing the cultivar DP 543 BGII / RR with itself or another cotton variety. The invention further relates to hybrid cotton seeds and plants produced by crossing the cultivar DP 543 BGII / RR with another cotton cultivar.

Owner:MONSANTO CO (MONSANTO CY)

Cotton cultivar DP 449 BG/RR

InactiveUS6953879B2Improve fiber qualityOther foreign material introduction processesFermentationCultivarBiology

A novel cotton cultivar, designated DP 449 BG / RR, is disclosed. The invention relates to the seeds of cotton cultivar DP 449 BG / RR, to the plants of cotton DP 449 BG / RR and to methods for producing a cotton plant produced by crossing the cultivar DP 449 BG / RR with itself or another cotton variety. The invention further relates to hybrid cotton seeds and plants produced by crossing the cultivar DP 449 BG / RR with another cotton cultivar.

Owner:D&DL TECH HLDG

Cotton cultivar DP 611 BGII/RR

ActiveUS7166775B2Improve fiber qualityTissue cultureOther foreign material introduction processesCultivar

A cotton cultivar, designated DP 611 BGII / RR, is disclosed. The invention relates to the seeds of cotton cultivar DP 611 BGII / RR, to the plants of cotton DP 611 BGII / RR and to methods for producing a cotton plant produced by crossing the cultivar DP 611 BGII / RR with itself or another cotton variety. The invention further relates to hybrid cotton seeds and plants produced by crossing the cultivar DP 611 BGII / RR with another cotton cultivar.

Owner:MONSANTO CO

Preparation method of lignin-based carbon fiber

ActiveCN104593906AImprove spinnabilityImprove fiber qualityArtificial filament chemical after-treatmentUltimate tensile strengthCeramic membrane

The invention provides a preparation method of a lignin-based carbon fiber. The preparation method of the lignin-based carbon fiber comprises the following steps: dissolving lignin in an alkaline solution, filtering by using a ceramic membrane filtration device, adjusting pH value of a filtrate until the filtrate is acidic to obtain a lignin precipitate, washing and drying the lignin precipitate to obtain purified lignin; extruding the dried and purified lignin at 100-260 DEG C by a twin-screw extruder, removing volatile components and prilling; taking a thermoplastics polymer as a skin layer, taking lignin slices as a core layer to melt and spin by a melting and spinning device, wherein the spinning temperature of the thermoplastics polymer is 160-350 DEG C; the spinning temperature of the lignin is 160-260 DEG C; the mass ratio of the thermoplastics polymer adopted by the skin layer to the lignin slices adopted by the core layer is (1 to 9)-(9 to 1); oiling, curing, pre-oxidizing and carbonizing the fiber with a skin-core structure to obtain the lignin-based carbon fiber. The lignin-based carbon fiber has the advantages of being high in spinning property, small in diameter, high in strength, low in production cost and applicable to continuous production.

Owner:DONGHUA UNIV

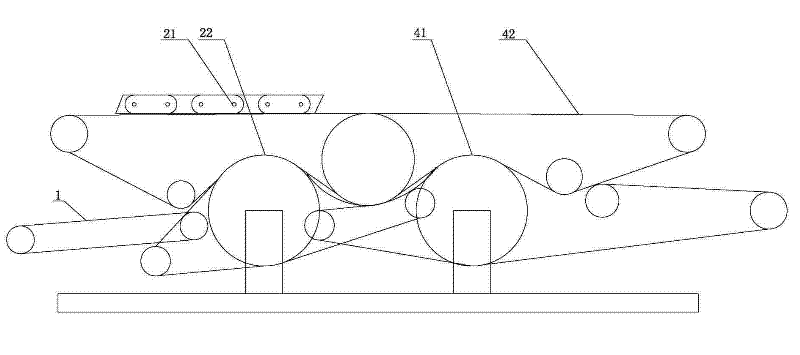

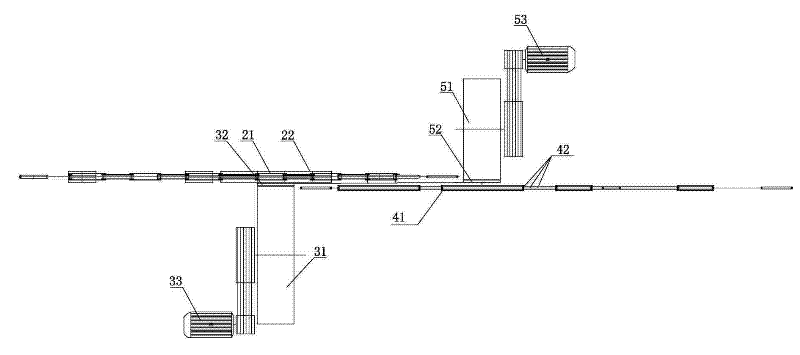

Sisal processing method and sisal scraping device thereof

InactiveCN102230229AHigh extraction rateThe draw rate does not affectMechanical fibre separationEngineeringSISAL

The invention discloses a sisal processing method and a sisal scraping device thereof. The sisal processing method comprises the steps of: 1) arranging sisals and quantitatively feeding; 2) neatly spacing blades of the sisals; 3) stretching and conveying; 4) scraping the sisals: firstly clamping the base parts of the blades of the sisals; then scraping the tip parts of the blades of the sisals; clamping scraped tip fibre parts; and completely scraping the base parts of the remainder blades of the sisals; 5)squeezing water of straight fibres; 6) drying the straight fibres; and 7) packing and warehousing. The sisal scraping device comprises a sisal arranging and conveying mechanism, a first sisal clamping mechanism, a first knife ball mechanism, a second sisal clamping mechanism and a second knife ball mechanism; the base parts of the blades of the sisals are clamped by the first sisal clamping mechanism and are conveyed forwards; the tip parts of the blades of the sisals are scraped by the first knife ball mechanism; the scraped edge fibre parts are clamped by the second sisal clamping mechanism and are conveyed forwards; and the base parts of the blades of the sisals are scraped by the second knife ball mechanism. According to the invention, the extraction rate of the straight fibres and the comprehensive quality of the fibres are improved; and the production cost is reduced.

Owner:湛江农垦第二机械有限公司

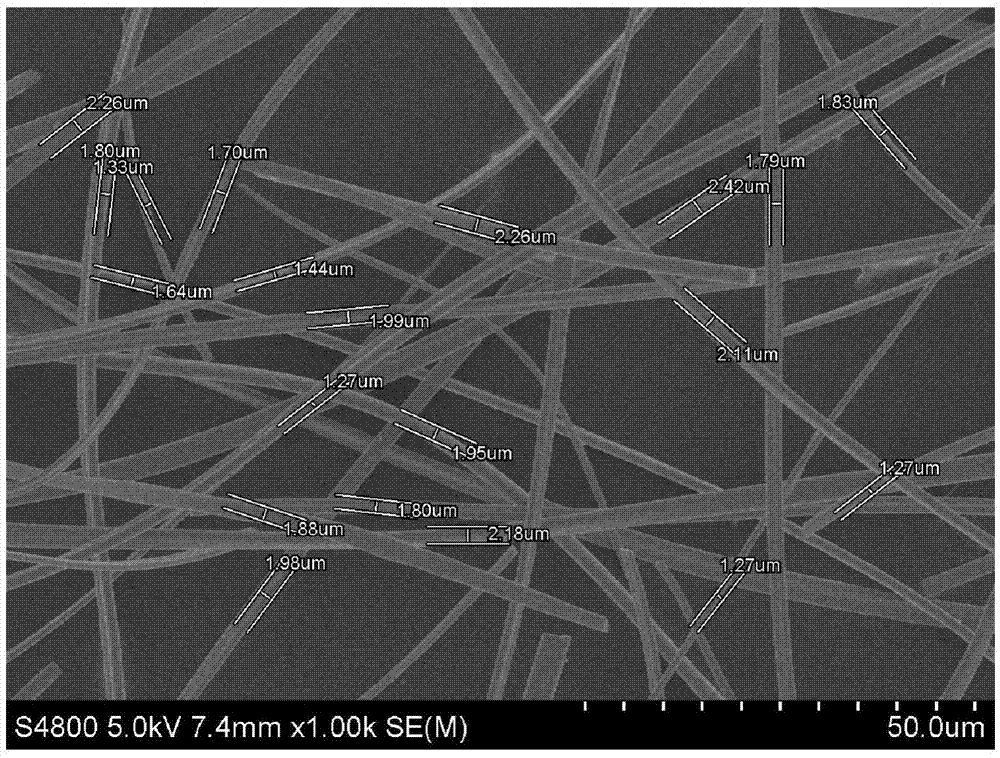

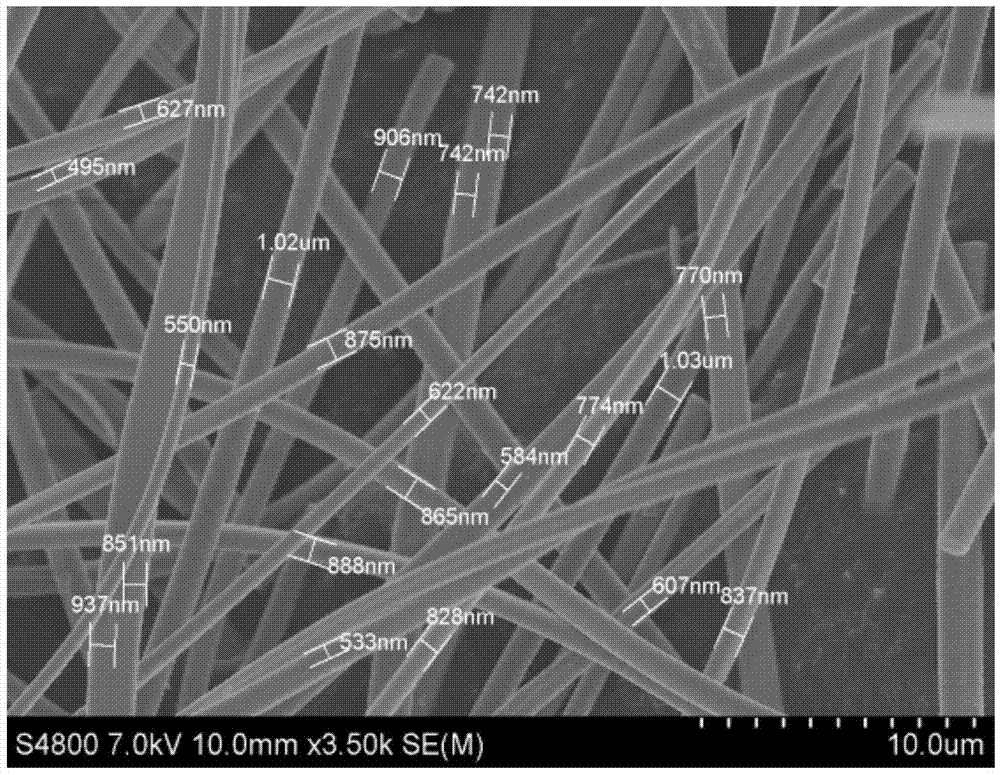

Method for preparing polyvinyl acetate zirconyl precursor sol spinning solution and sub-micron zirconium oxide crystal fibers

InactiveCN106929947AGood flexibilityGood heat insulationInorganic material artificial filamentsFilament/thread formingFiberMechanical property

The invention relates to a method for preparing polyvinyl acetate zirconyl precursor sol spinning solution and sub-micron zirconium oxide crystal fibers. The method mainly includes dissolving basic zirconium carbonate, glacial acetic acid, yttrium nitrate hexahydrate and spinning auxiliaries in absolute methanol according to certain proportions to obtain mixed solution and concentrating the mixed solution under reduced pressures at the temperatures of 30-40 DEG C to obtain the colorless, transparent and homogenous polyvinyl acetate zirconyl precursor sol spinning solution; acquiring polyvinyl acetate zirconyl precursor fibers by the aid of electrostatic spinning processes; carrying out pressure resolution on the precursor fibers to remove a ligand which is acetic acid, and then carrying out high-temperature treatment on the precursor fibers in a program-control sintering furnace. The method has the advantages that the diameters of the sub-micron zirconium oxide crystal fibers obtained byte ha id of the method range from 100 nanometers to 2.5 micrometers, and the sub-micron zirconium oxide crystal fibers are excellent in continuity, flexibility and heat-insulation and mechanical properties; the polyvinyl acetate zirconyl precursor sol spinning solution and the sub-micron zirconium oxide crystal fibers can be used at ultrahigh temperatures higher than or equal to 1800 DEG C for a long term.

Owner:山东德艾普节能材料有限公司

Epicoccum nigrum DB3 bacterial strain as well as preparation and application thereof

InactiveCN102329738AExtensive culture conditionsGood heat resistanceFungiMicroorganism based processesSea grassEpicoccum nigrum

The invention relates to an epicoccum nigrum DB3 bacterial strain as well as a preparation and an application thereof. The preparation method comprises the steps of: 1, placing rotten sea grass in an enrichment culture medium, standing and culturing at room temperature, then coating the enrichment culture medium in a separation culture medium, standing and culturing at a temperature of 30 DEG C for 1-4 days to obtain a wild type flax biological treatment bacterial strain; 2, inoculating the bacterial strain obtained from the step 1 into a flax lignin nutrition culture medium, culturing at a temperature of 28 DEG C for 72 hours; and 3, selecting the bacterial strain with the capacity of degrading the lignin from the flax lignin nutrition culture medium to obtain the epicoccum nigrum DB3 bacterial strain. The epicoccum nigrum DB3 bacterial strain can be applied to a process for preparing spinning flax, hemp, jute or red ramie fibers through peroxide degumming. The epicoccum nigrum DB3 bacterial strain has the characteristics of short growth period, low possibility of being polluted, low treatment cost, mild reaction conditions, strong pollution resistance capacity, good heat-resistant performance, no environment pollution and good quality of the treated fibers. The preparation method has a simple process and is suitable for large-scale industrial production.

Owner:DONGHUA UNIV

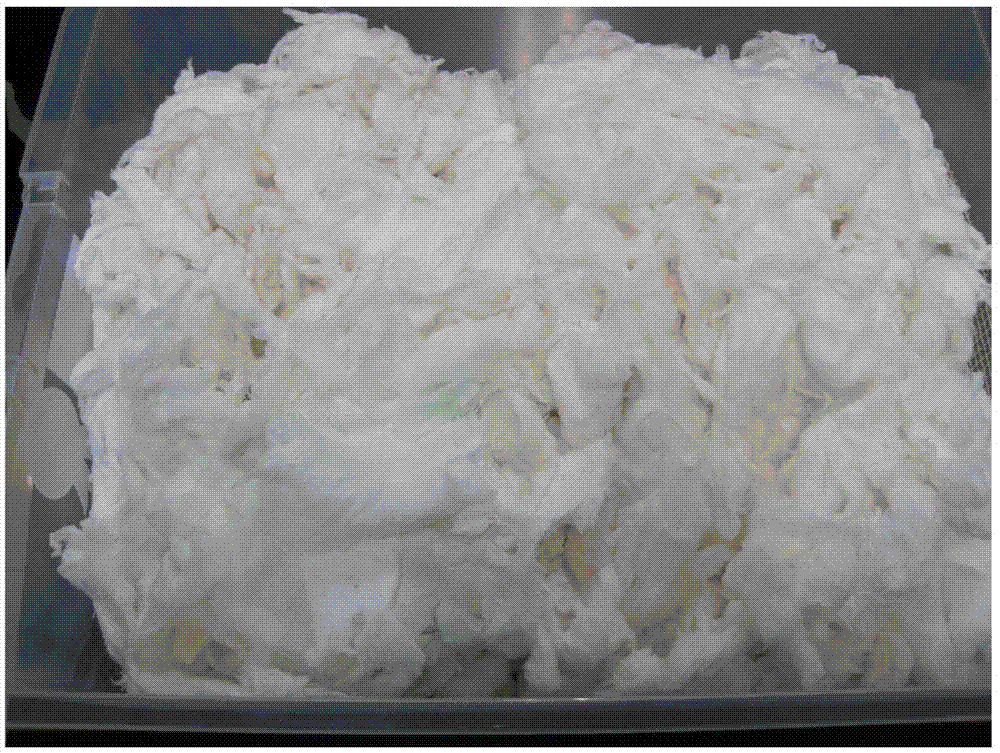

Fiber jetting device

The invention discloses a fiber jetting device, and relates to a fiber manufacturing device. The device is provided with a rotary wheel, a throwing rope, a rotary shaft, a solution tank, a driving motor, a lifting platform, an electric brush, a liquid storage box, a liquid supplying pipe, a metering pump, a coupler, a fiber collecting and conveying device, a high-voltage electrode net, a high-voltage power source and a control circuit. Electrostatic spinning liquid feeding is performed through the throwing rope, the defects that in a needle head type electrostatic spinning technology, a sprayer is blocked easily, the device is difficult to clean, the spinning efficiency is low and the spinning quality is poor are avoided, and meanwhile electric field interference phenomena such as the fringe effect happening in the multi-sprayer electrostatic spinning process are avoided. By changing the material, the diameter, the length and the shape of the cross section of the throwing rope, the shape, the arrangement and the output of fibers can be controlled. Further, by controlling the immersion length of the throwing rope, the rotation speed of the rotary wheel, the distance between the rotary wheel and the fiber collecting and conveying device, the electric field intensity and other electric spinning technological parameters, the electrostatic spinning efficiency and the quality of the fibers are improved, the nanometer fibers can be manufactured fast and evenly, and large-scale industrial production of the nanometer fibers is facilitated.

Owner:XIAMEN UNIV

Prepn process of spinning dope for producing cellulose fibre through solvent process

InactiveCN1336451AImprove uniformityWell mixedMonocomponent cellulose artificial filamentMorpholineDiameter ratio

The present invention relates to preparation of spinning liquid for producing cellulose fiber by solvent method, it is characterized in that: the powdered fiber paste from crusher is dried under -9X1,000 to -5X1,000 Pa and 30-50 deg.c for 6-12 hr. to make the water content is 2-4%; distill and concentrate N-methyl morpholine oxide (NMMO) aqueous solution under reduced pressure to water content lower than 15%; mix above mentioned powder and NMMO with certain proportion at 70-90 deg.C in mixer and stir for 10-30 min, to form light yellow coloured paste which is extruded by twin screw extruder with length-diameter ratio 1:42-1:52, after dissolve and defoam for 3-15 min., the obtained light brown transparent solution can be used for spinning. Advantages: energy saving, high efficiency etc.

Owner:DONGHUA UNIV

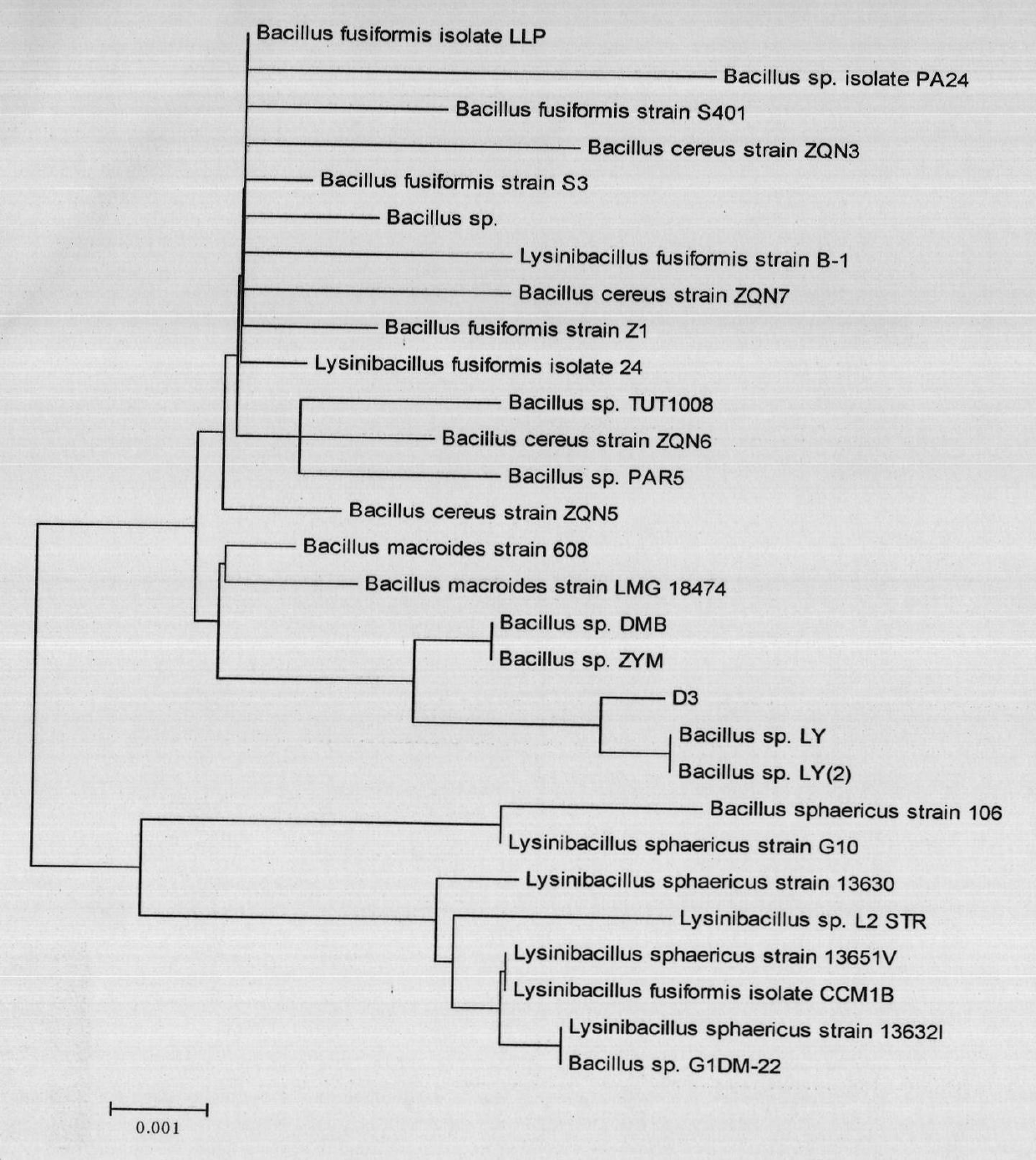

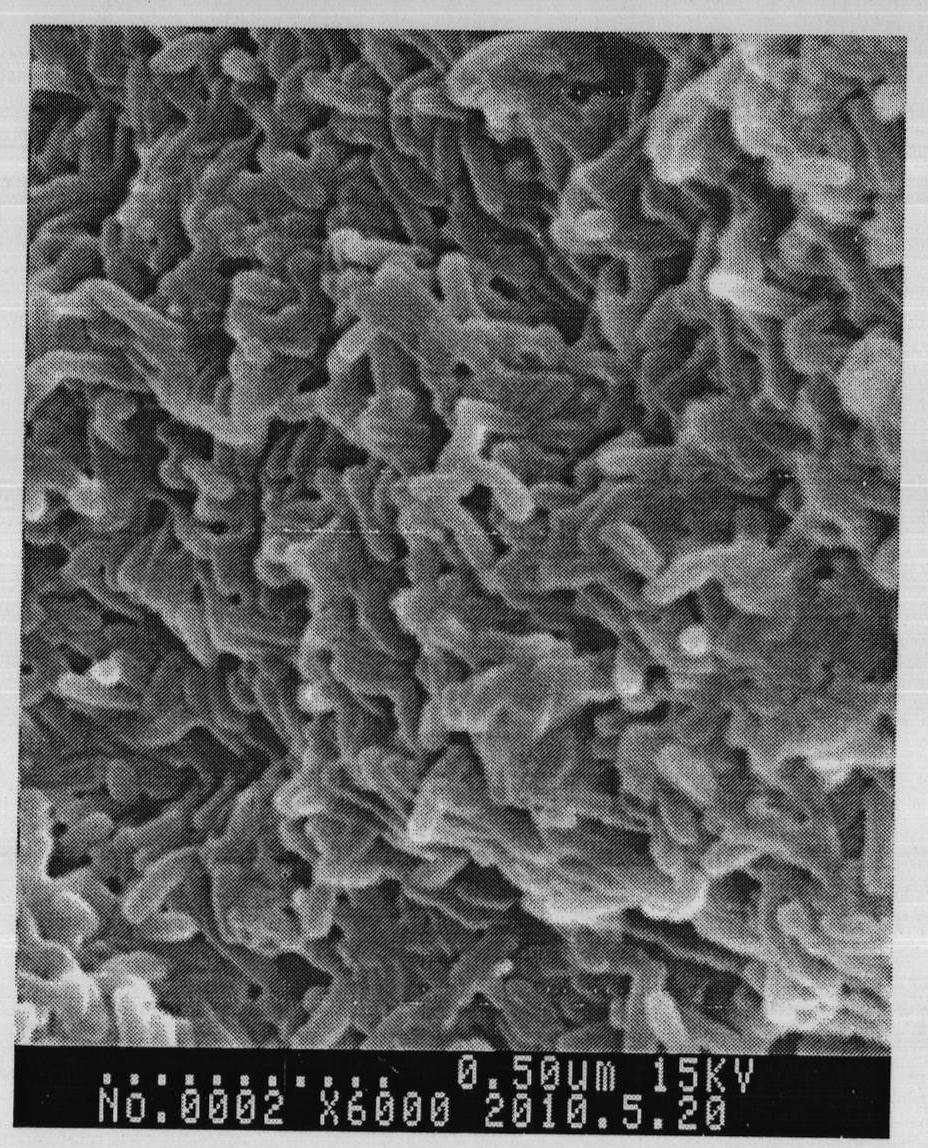

Bacillus cereus DA3 strain and preparation method and application thereof

InactiveCN102002467AShort degumming cycleNot easy to be pollutedBacteriaBiochemical fibre treatmentPectinaseBiology

The invention relates to a bacillus cereus DA3 strain and a preparation method and application thereof. The strain has the capacity of producing pectinase and hemicellulase and has flax retting activity. The provided strain and a culture system can be directly used for flax retting and have the advantages that: the retting period is short, the fiber dispersion rate is 100 percent, the retting efficiency is 95 percent, and the strain is not easily polluted, and is low in treatment cost, high in fiber quality, mild in retting condition, high in pollution resistance, good in heat resistance, free of environmental pollution and the like. Compared with the prior art, the invention has the characteristics of simple technology, suitability for large-scale industrial production and the like, and has potential theoretical and practical significance for exploring flax retting of the bacillus cereus under the alkaline condition.

Owner:DONGHUA UNIV

Strange-shaped fibre processing technique and spinning jet used in the technique

InactiveCN101429685AHigh degree of abnormalityImprove fiber qualityArtificial filament physical treatmentFibre typesFiberPolymer science

The invention belongs to the field of chemical fiber shaping, and discloses a technology for processing a profiled fiber and a spinneret plate used by the technology. The processing technology comprises the following steps: a. high polymer melts are spouted from spray slits of each spinneret orifice on the spinneret plate via heating and pressurizing; b. the high polymer melts spouted from the spray slits of each spinneret orifice expand because of Barus effect, and are spliced one another to form the profiled fiber; and c. the processed profiled fiber is oiled. The structure of the spinneret plate is as follows: a plurality of spinneret orifices are distributed on the plate body to form a spinneret orifice array, wherein each spinneret orifice comprises at least two immediate spray slits. The profiled fiber has excellent degree of profile, good performances such as silkiness, hydroscopic property.

Owner:GUANGDONG XINHUI MEIDA NYLON

Gel preparation method for polytetrafluoroethylene fibre

InactiveCN1970857ASimple processLow costConjugated synthetic polymer artificial filamentsSpinning solutions preparationFiberEmulsion

The invention relates to a manufacturing method for polytetrafluoroethylene fiber. The method is that ptfe concentration dispersion emulsion and polyvinyl alcohol are mixed; gelling and spinning fluid is produced as the gel is formed by polyvinyl alcohol and borate or borax under the alkaline condition; the mixed fiber of polytetrafluoroethylene and polyvinyl alcohol is obtained by the dried spinning method, and the polytetrafluoroethylene fiber is produced by sintering and drawing so on. The polytetrafluoroethylene fiber produced by said method is provided with good quality and is applied in filtering material widely. Compared with prior technology it is provided with easy technology, low manufacturing method and no-pollution so on.

Owner:ZHEJIANG SCI-TECH UNIV +2

Method for preparing high-modulus carbon fiber by adopting precursor drawing technology

InactiveCN105200566AReduce microstructural defectsImprove mechanical propertiesArtificial filament chemical after-treatmentVitrificationCarbon fibers

The invention relates to a method for producing a high-modulus carbon fiber by adopting a precursor drawing technology. The method comprises the following steps: preparing a spinning solution, carrying out the wet-method spinning, solidifying a nascent fiber, drawing in steam, stretching a precursor to precursor fiber, pre-oxidizing the fiber, and carbonizing the fiber. By adopting the method, the defect of a micro structure in the fiber precursor preparation process can be effectively reduced, compared with the process which does not utilize the process, the orientation degree of the pre-oxidized fiber is further improved, and the mechanical performance of the carbonized fiber is remarkably improved; since the fiber is re-stretched at a temperature above a vitrification temperature, the fiber fineness is reduced, the specific surface area is increased in the high-temperature treatment process, and the thermal treatment efficiency is effectively improved; by virtue of the process, the fiber quality is obviously improved.

Owner:THE NORTHWEST RES INST OF CHEM IND

Method of preparing rayon staple by benne stalk

PendingCN101016653AAbundant resourcesReduce manufacturing costWet spinning methodsMechanical fibre separationFiberPolymer science

The invention relates to a method for using pedaliin stem to prepare adhesive staple fiber, comprising that preparing pedaliin stam adhesive slurry and using said slurry to prepare adhesive staple fiber. The first step comprises that preparing material, degelatinizing, beating, refining, dechlorinating, acid treating, and softening. And the second step comprises that feeding slurry, immerging, compressing, aging, cooling, sulfidising, dissolving, filtering, ripening, defoaming, filtering, spinning, beaming drawing, following treating, circling and drying. The invention has the advantages that the resources are abundant, with low cost, while the prepared fiber has high quality, high mechanism strength, soft face, or the like.

Owner:马立峰

Cotton cultivar DP 444 BG/RR

InactiveUS6838600B2Improve fiber qualityOther foreign material introduction processesFermentationCultivar

A novel cotton cultivar, designated DP 444 BG / RR, is disclosed. The invention relates to the seeds of cotton cultivar DP 444 BG / RR, to the plants of cotton DP 444 BG / RR and to methods for producing a cotton plant produced by crossing the cultivar DP 444 BG / RR with itself or another cotton variety. The invention further relates to hybrid cotton seeds and plants produced by crossing the cultivar DP 444 BG / RR with another cotton cultivar.

Owner:D&PL TECH HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com