Fiber jetting device

A spraying device and fiber technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve problems such as low spinning efficiency and easy clogging of spinnerets, so as to overcome low spinning output and avoid nozzles Easy clogging, uniform preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

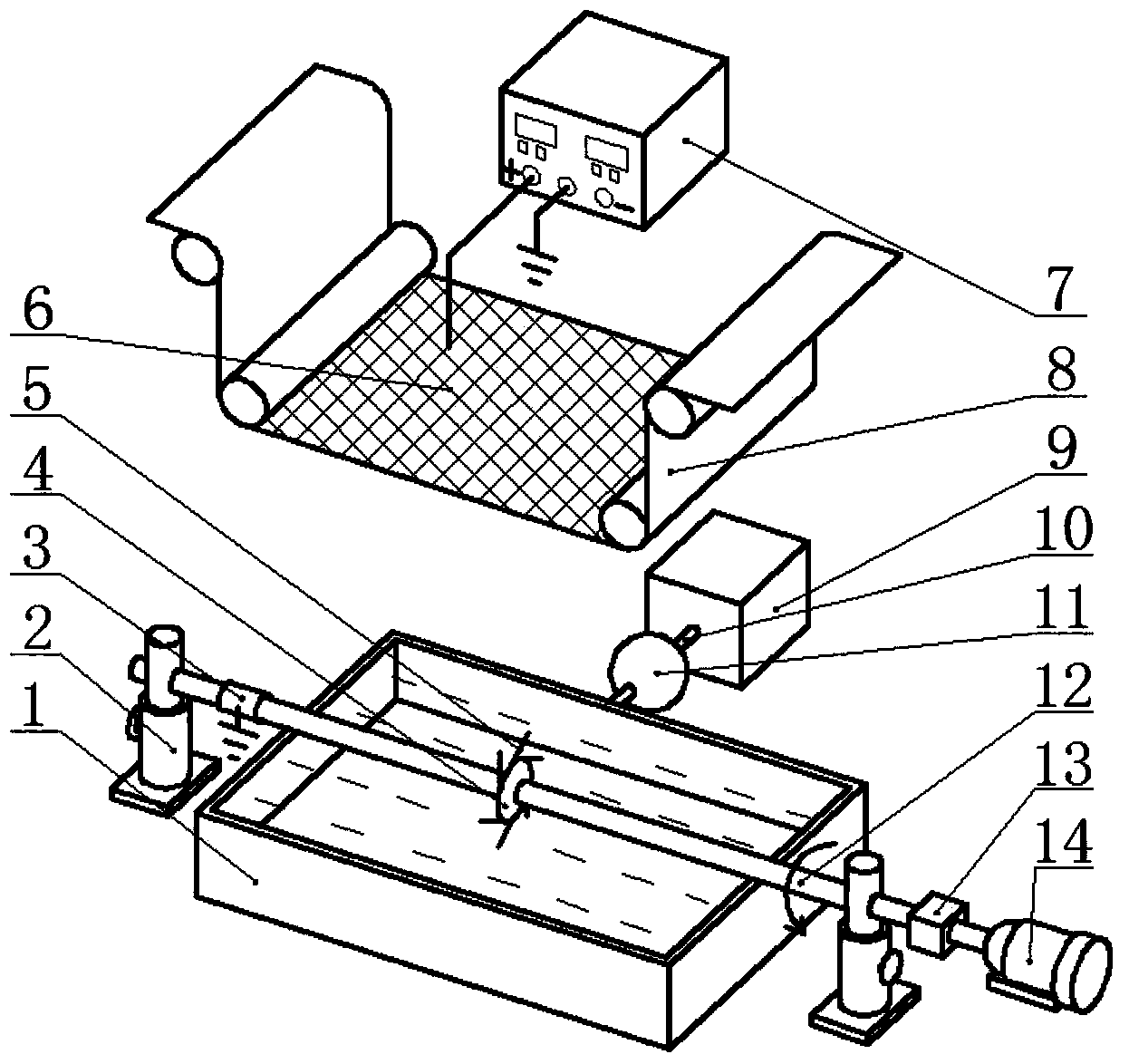

[0026] This embodiment adopts a group of spinnerets, and the assembly relationship is as follows:

[0027] The runner 4 and the rotating shaft 12 are located directly above the solution tank 1, and the plane where the runner 4 is located is perpendicular to the plane where the solution is located; 6 ropes 5 are evenly distributed on the edge of the runner 4, and the distance between adjacent ropes 5 on the circumference The angle is 60°, wherein the runner 4 and the rope 5 form the spinneret; the runner 4 is installed on the rotating shaft 12, and the rotating shaft 12 is the center of rotation; the rotating shaft 12 is connected with the driving motor 14 and the coupling 13 Connected and fixed by the lifting platform 2, the relative position of the runner 4 and the solution tank 1 can be adjusted by using the lifting platform 2, thereby changing the length of the rope 5 immersed in the solution, and fibers with different shapes, orientations and diameters can be obtained; The...

Embodiment 2

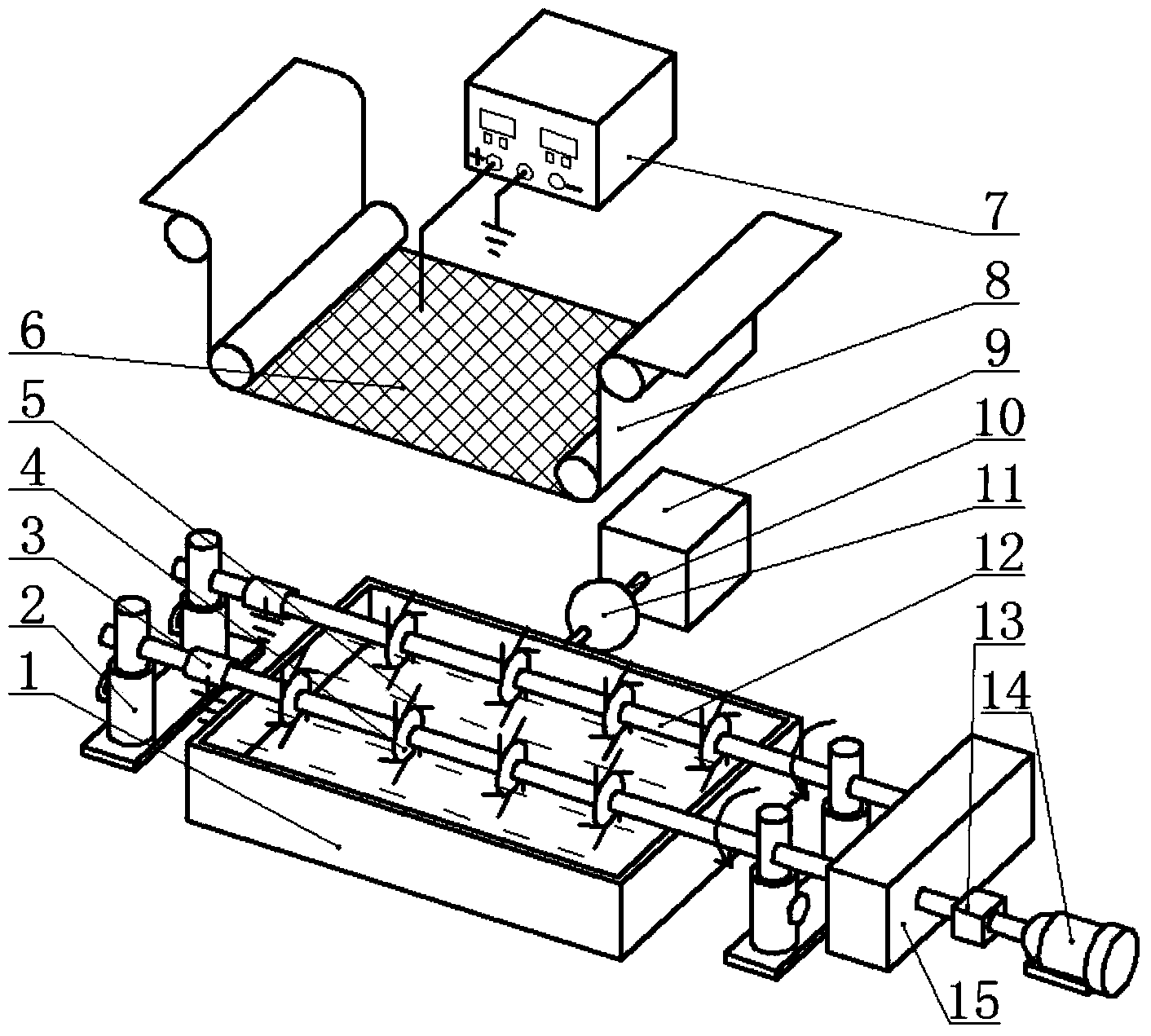

[0038] This example figure 2 As shown, multiple groups of spinnerets arranged in parallel arrays along the rotating shafts 12 are provided with a plurality of rotating shafts 12 arranged side by side, which can realize batch production of nanofibers with multiple rotating shafts 12 . A multi-axis output box 15 is provided between the drive motor 14 and the multiple rotating shafts 12 to meet the requirement that the same power drives multiple rotating shafts 12 to work simultaneously.

[0039] The remaining mechanical structures and connections are the same as in Embodiment 1.

[0040] This embodiment can further improve the efficiency of electrospinning and realize the large-scale production of nanofibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com