Patents

Literature

230 results about "Viscous resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of viscous resistance. The effect of surface friction between a particle and a liquid when the particle moves through the liquid.

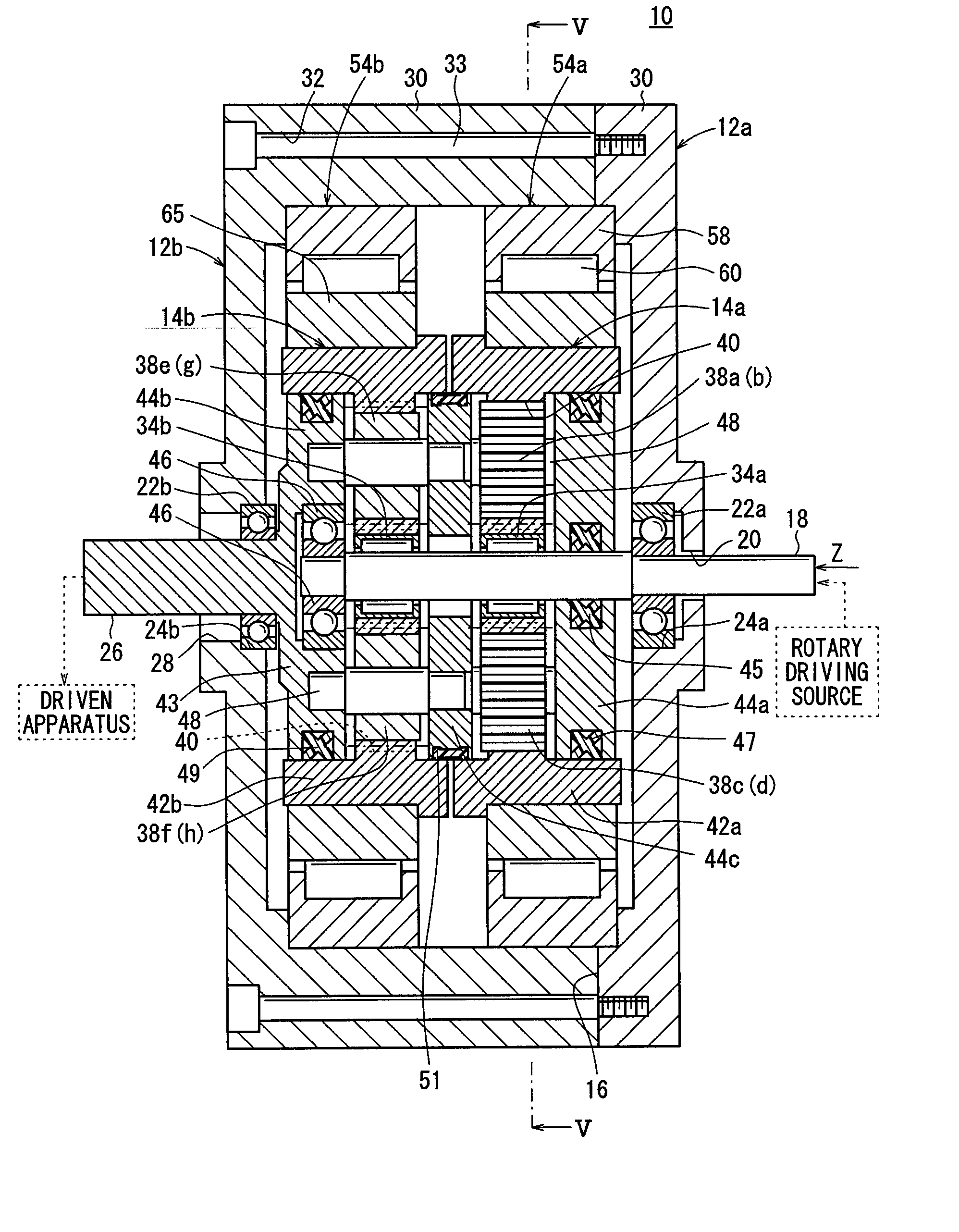

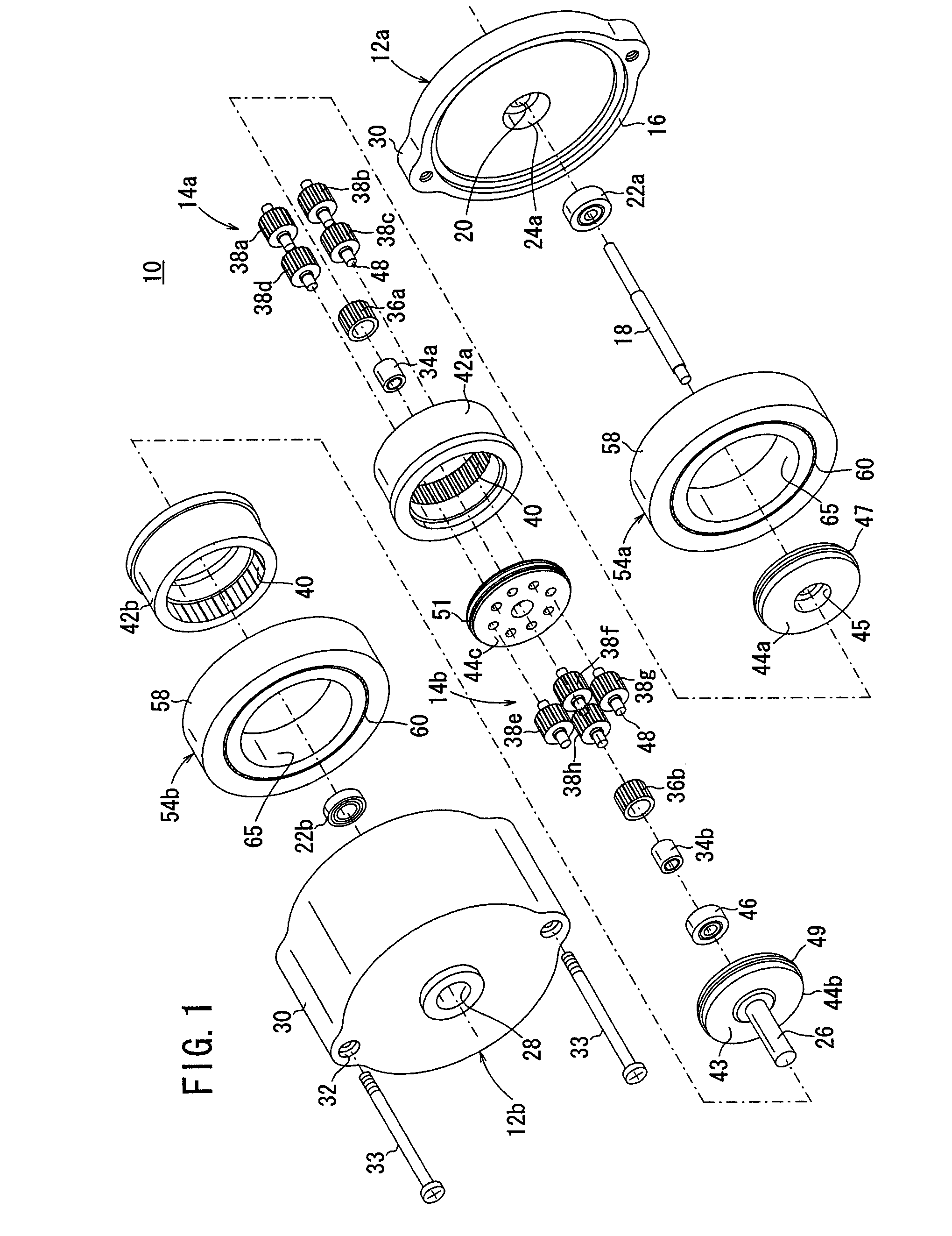

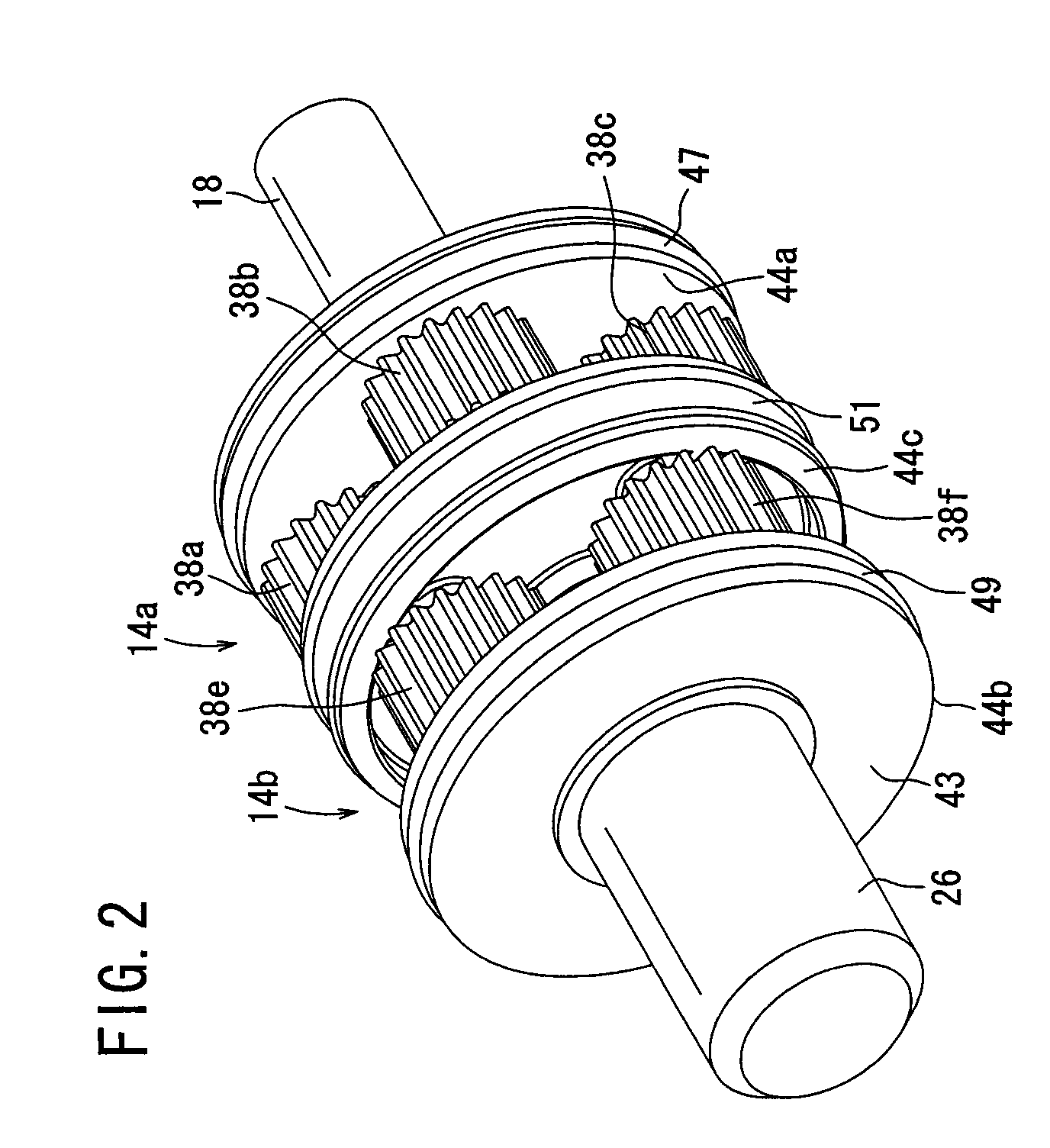

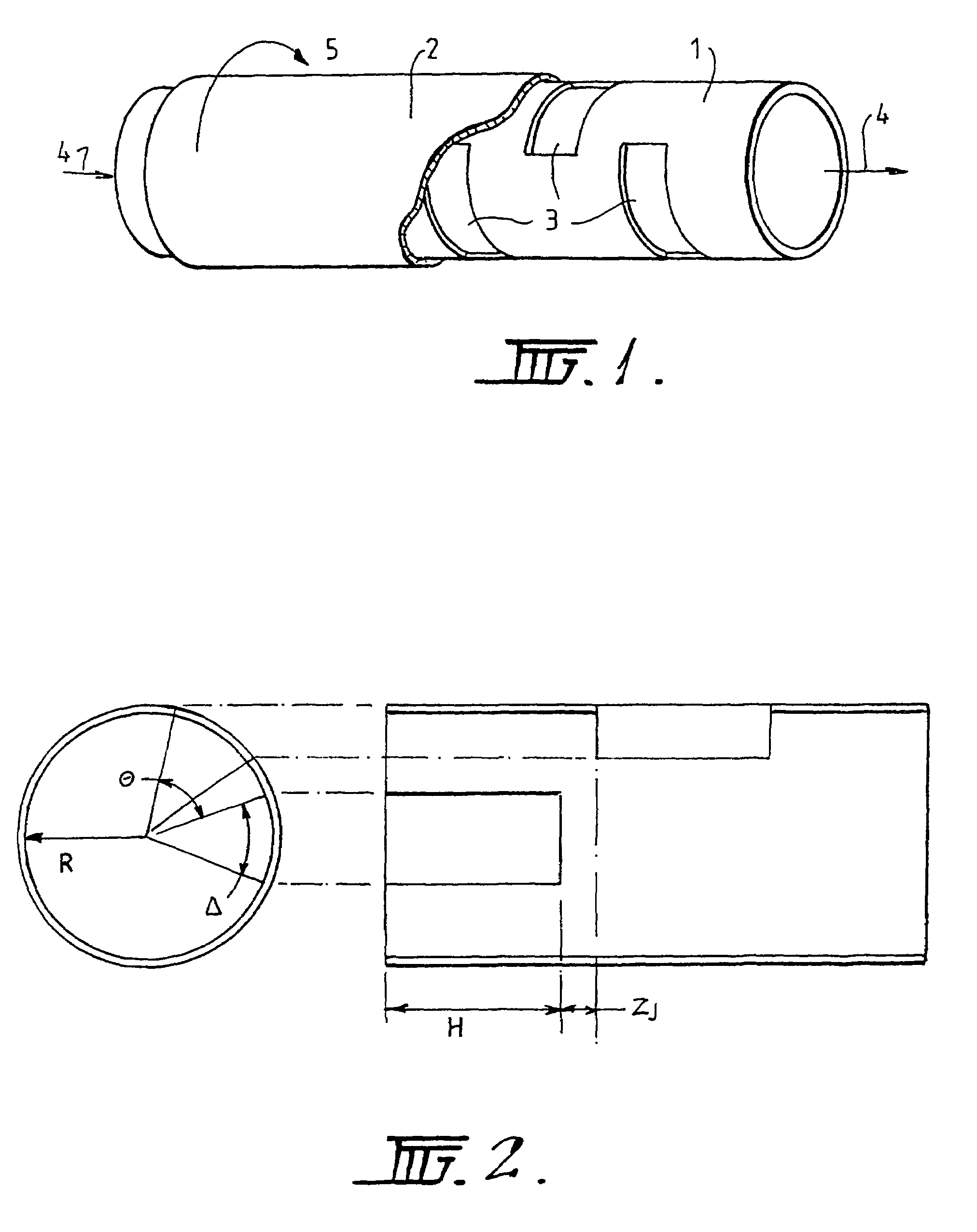

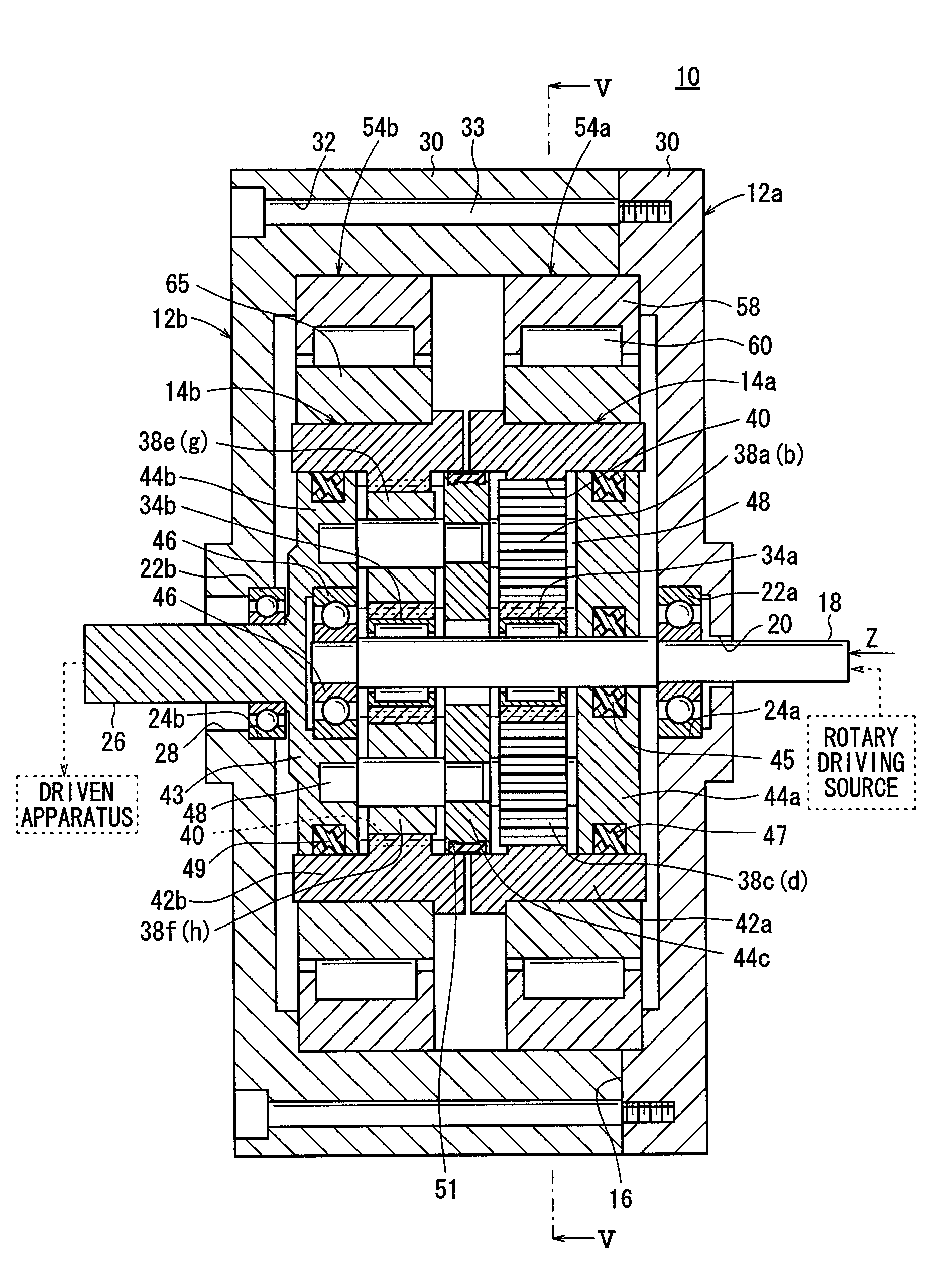

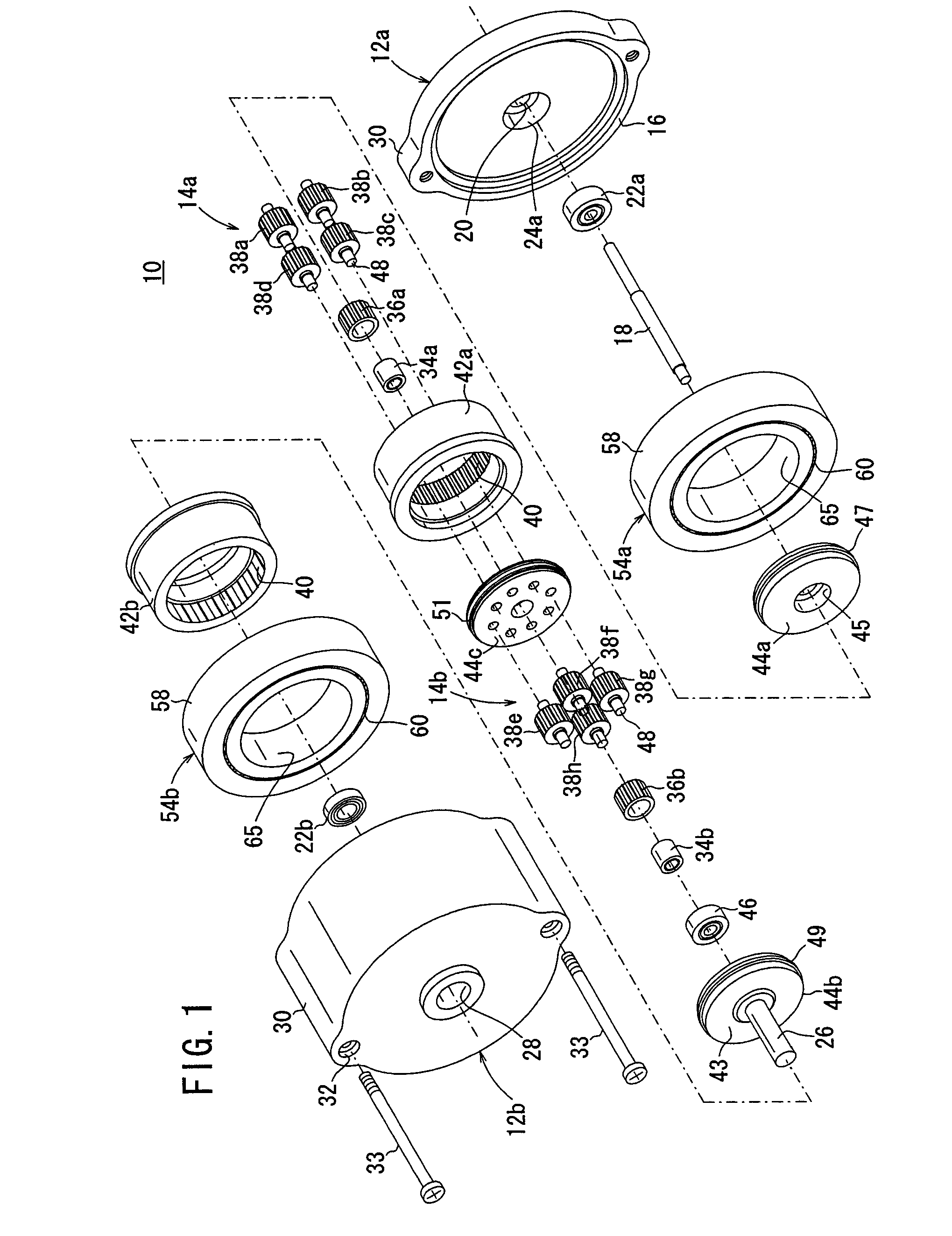

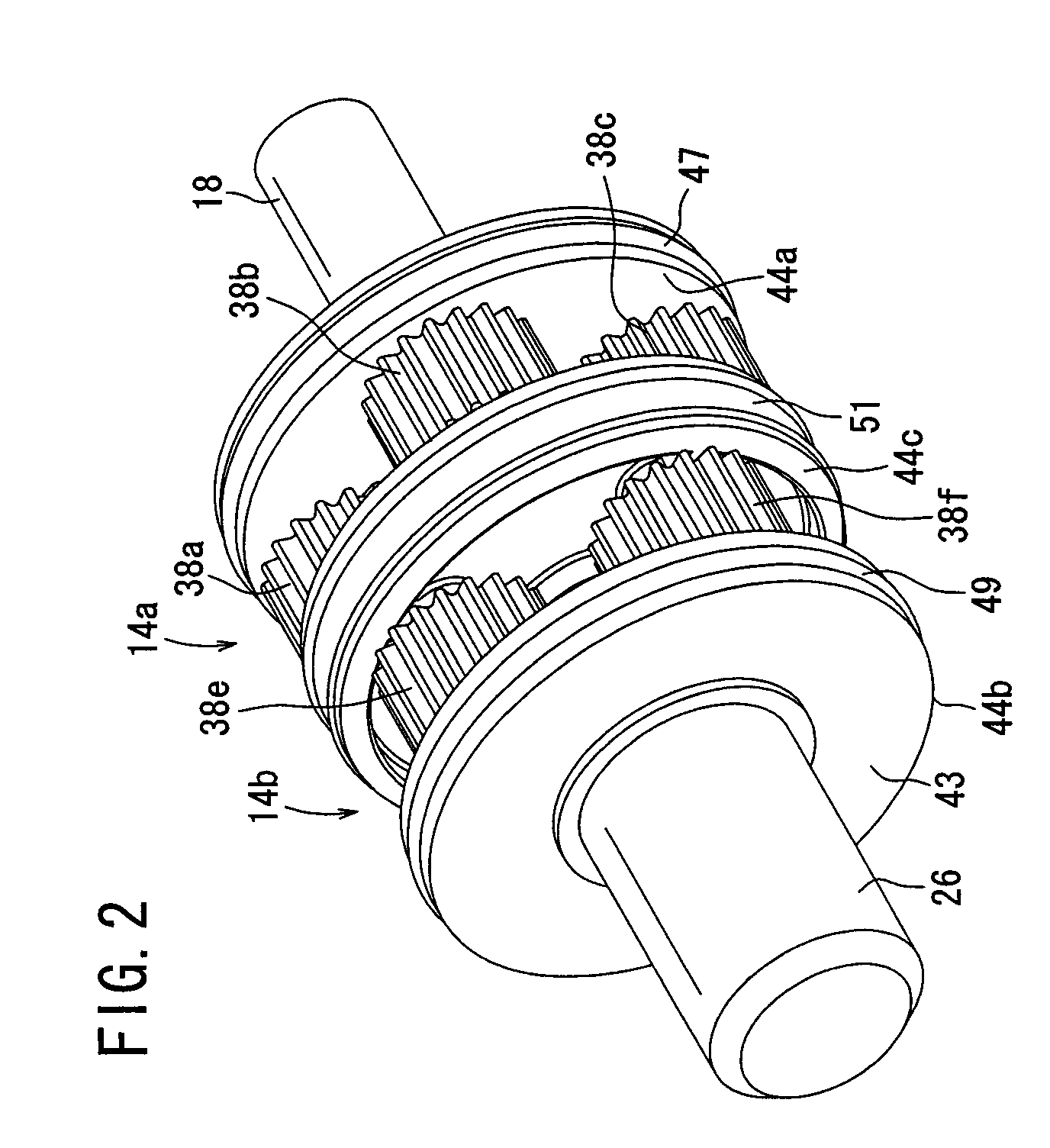

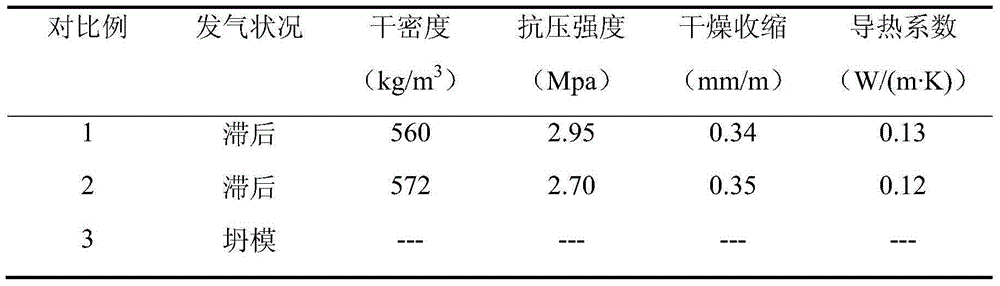

Automatic Speed Reducing Ratio-Switching Apparatus

ActiveUS20070191177A1Smooth transmissionToothed gearingsDifferential gearingsGear wheelStatic friction

An automatic speed reducing ratio-switching apparatus comprising an input side carrier, an output side carrier, and an intermediate carrier includes first and second planetary gear mechanisms juxtaposed in the axial direction of an input shaft, first and second inner clutch members which are rotatable in one direction while locking rotation in the other direction of the input shaft, and have mutually different locking directions, first and second outer clutch members which are rotatable in one direction while locking rotation in the other direction of the input side or output side ring gear, and have mutually different locking directions, and a viscous resistance member functioning under a static frictional force to integrally rotate the input side or output side sun gear, the input side or output side planet gears, and the input side or output side ring gears respectively in an identical direction.

Owner:SMC CORP

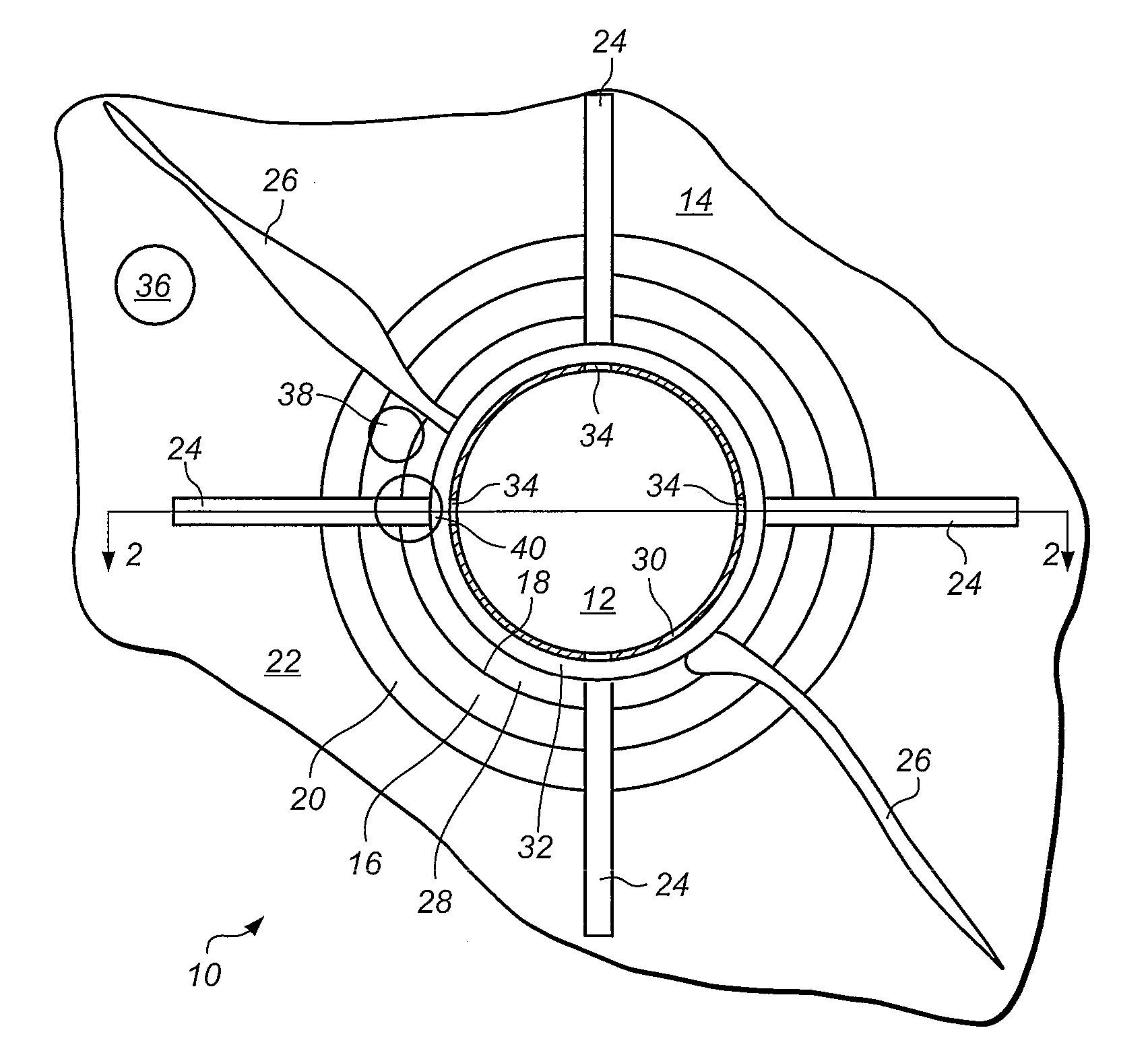

Fluid mixer utilizing viscous drag

Owner:COMMONWEALTH SCI & IND RES ORG

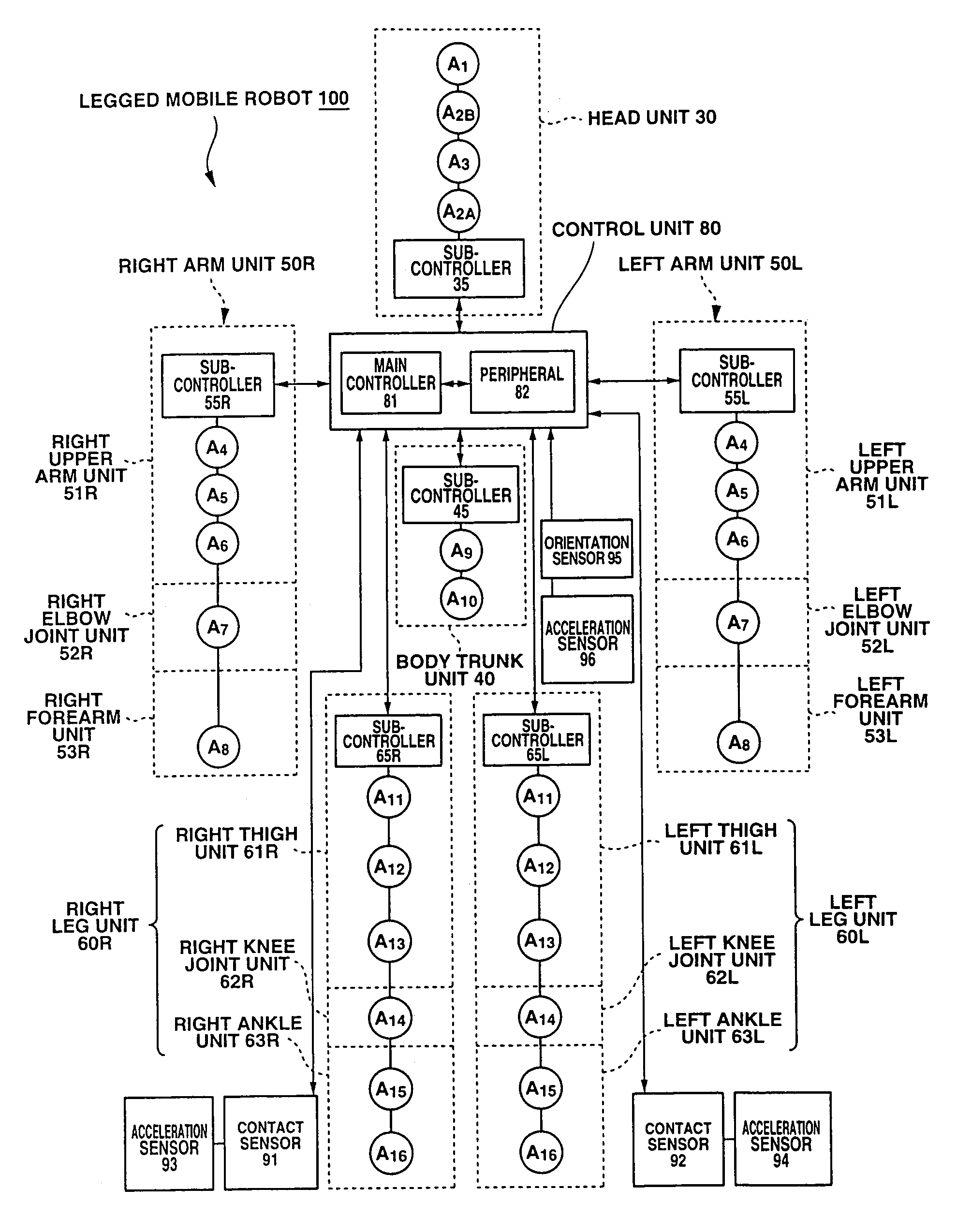

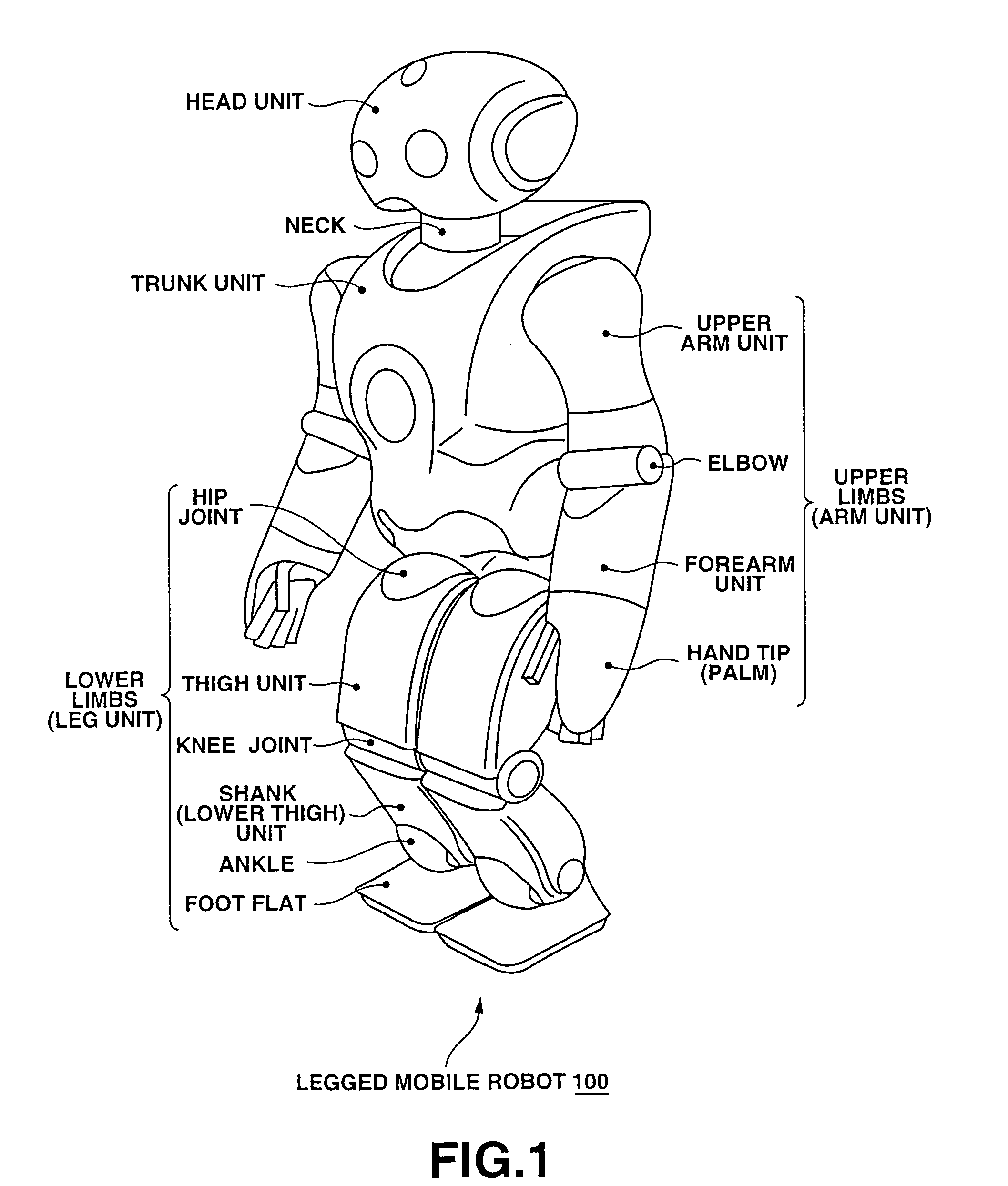

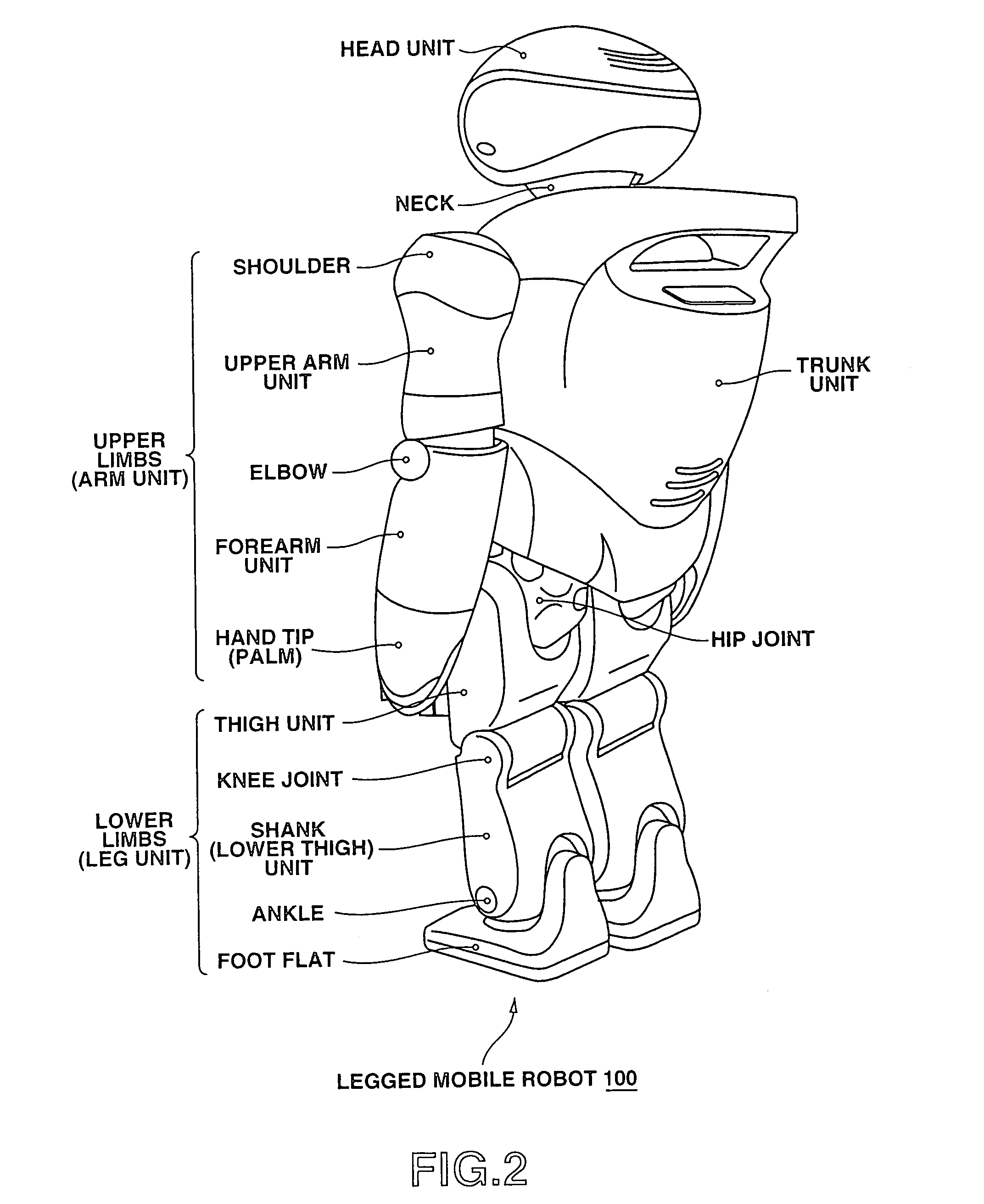

Legged mobile robot

ActiveUS7072740B2Reduce harmStable and highly motionProgramme-controlled manipulatorComputer controlEngineeringViscous resistance

In a mobile robot, the actuator characteristics are dynamically or statically controlled, during motions of an entire robot body in the course of falldown or descent, to realize stable highly efficient motions. In each stage of the falldown motions, the characteristics of each joint site taking part in controlling the stable area are set so that the low range gain is low, the quantity of phase lead is large and the viscous resistance of the motor is large, in such a manner that these joint sites may be positioned to high accuracy in a controller manner to increase orientation stability. This assures the positioning accuracy of the joints as main component for controlling the quantity ΔS / Δt as a reference in controlling the falldown motions of the robot body to increase the motion stability.

Owner:SONY CORP +1

Strong gas-wetting nanosilicon dioxide water block removal agent, preparation method thereof and method for wetting transition of rock surface

ActiveCN104449631AReduce viscous resistanceImprove mobilityDrilling compositionPorous mediumWater block

The invention relates to a strong gas-wetting nanosilicon dioxide water block removal agent, a preparation method thereof and a method for wetting transition of rock surface. The modified nanosilicon dioxide water block removal agent comprises the following raw materials: 0.1-0.5% of modified nanosilicon dioxide, 0.5-1% of an emulsifying agent OP-10, 0.5-1% of lauryl sodium sulfate, 25-50% of ethyl alcohol and the balance of water; the nanosilicon dioxide modified treating fluid is 0.05-0.3% of a non-ionic fluorocarbon surfactant water solution. The invention further provides a preparation method and application of the modified nanosilicon dioxide water block removal agent. The modified nanosilicon dioxide material has a super-hydrophobic and super-oleophobic property, can be used for changing the liquid-wetting property of the rock surface into strong gas-wetting property, so as to reduce the viscous resistance of fluid flowing on the rock surface, improve the flowing status of fluid in a porous medium, remove water blocking damage, is used for low-permeability oil and gas field exploitation and increasing of the oil and gas recovery ratio.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

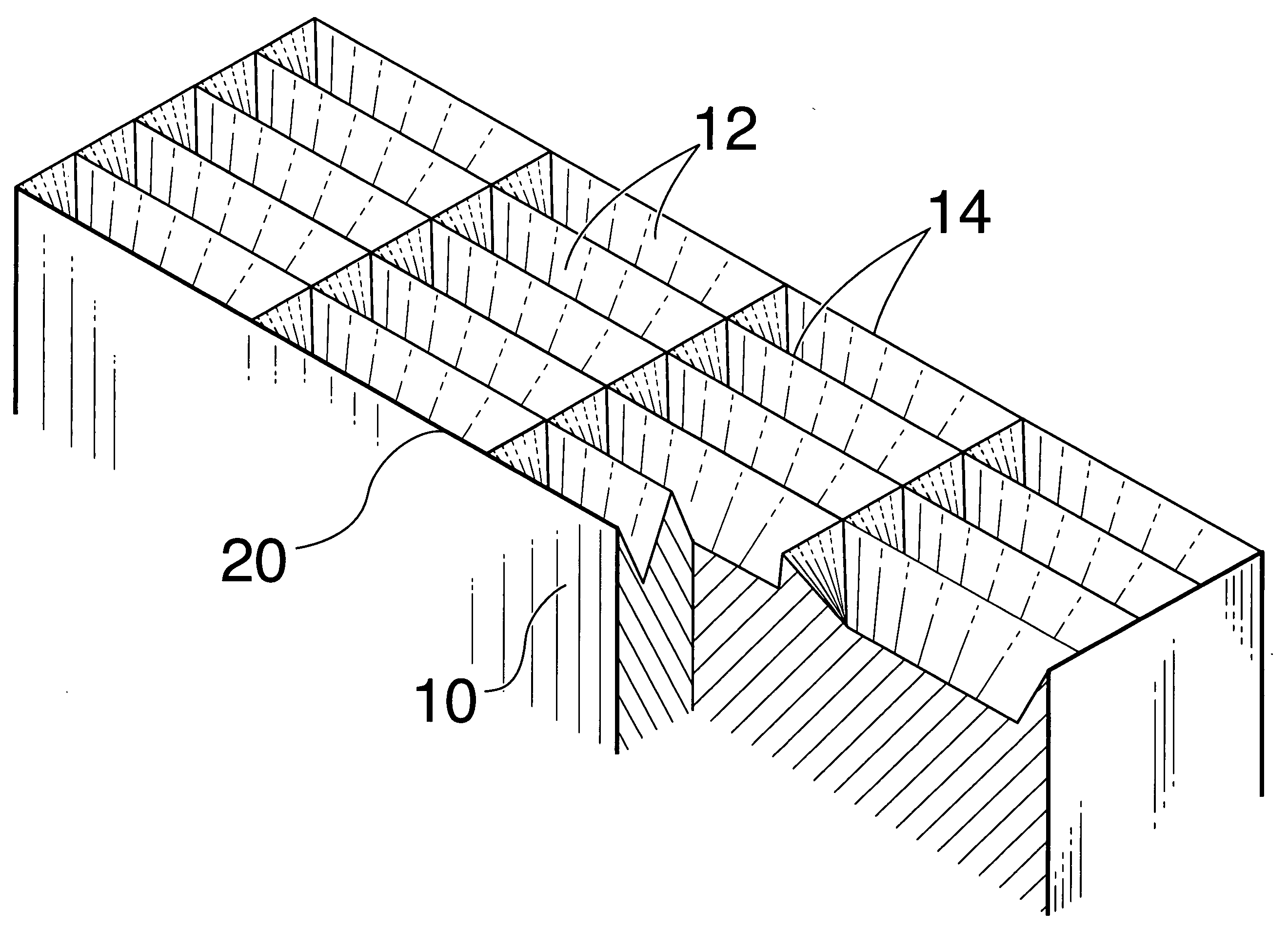

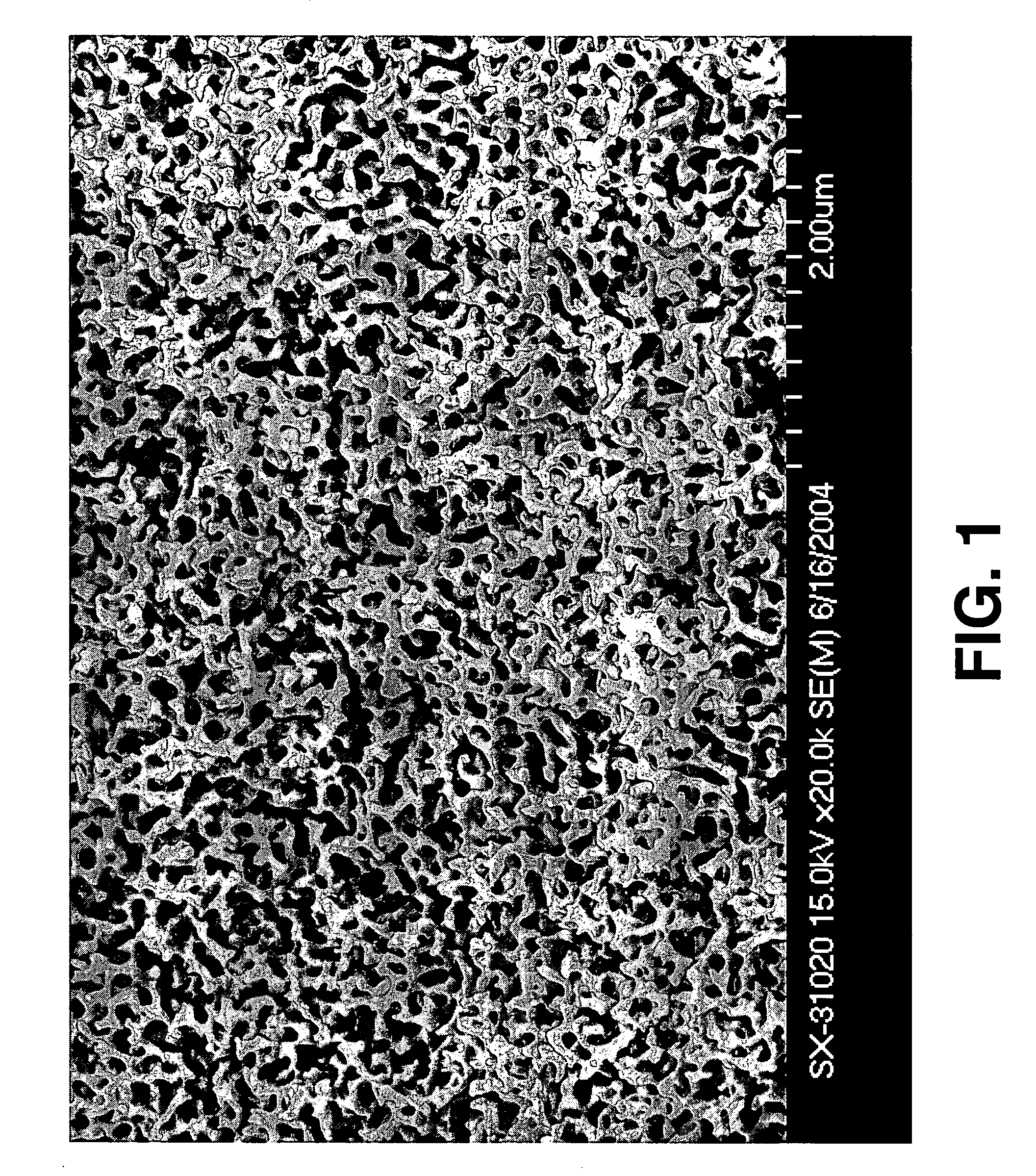

Friction drag-reducing surface

InactiveUS20060251859A1Reduce viscous dragMaterial nanotechnologyLayered productsViscous resistanceMechanical engineering

An article includes a body having at least one viscous drag-reducing surface defining a multiplicity of macro-scale depressions separated and enframed by ridges, at least a portion of the surface being phobic to a preselected liquid so that gas bubbles may be trapped in the macro-scale depressions in order to reduce viscous drag between the article and the liquid.

Owner:UT BATTELLE LLC

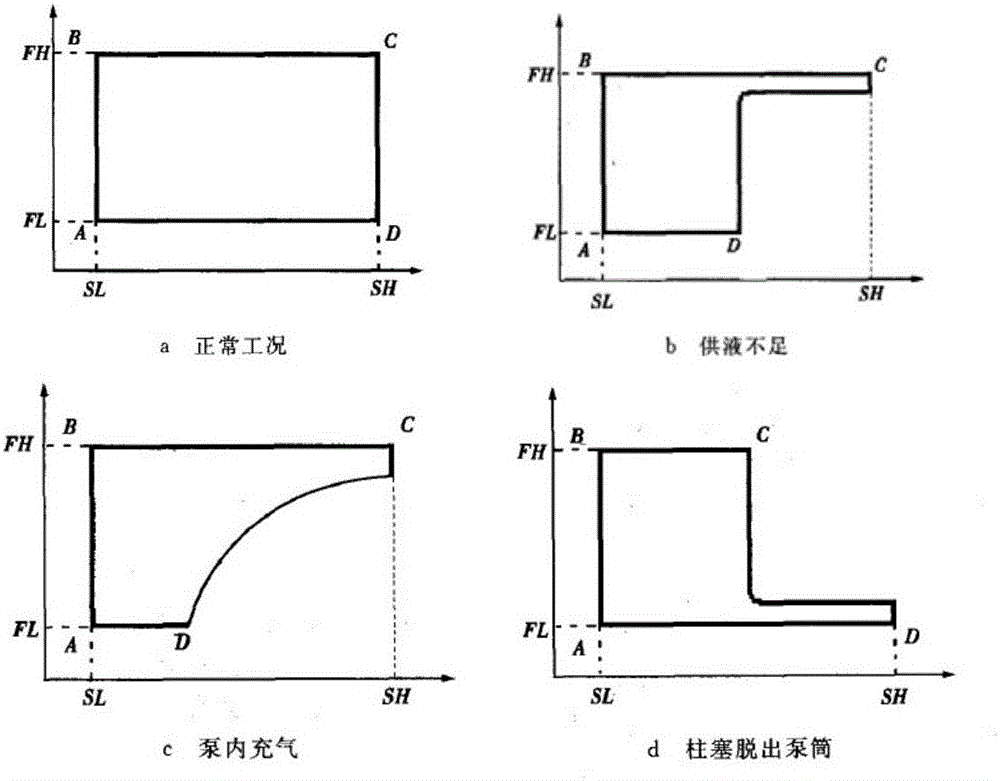

Method for online calculation of working fluid level of oil well by using pumping unit pump indicator diagram

The invention discloses a method for online calculation of a working fluid level of an oil well by using a pumping unit pump indicator diagram. The method for online calculation of the working fluid level of the oil well by using the pumping unit pump indicator diagram is characterized by comprising the following steps: a ground indicator diagram is obtained; a computer is used for mathematically processing to eliminate such influences as deformation of a pumping rod column, viscous resistance of the rod column, vibration and inertia to obtain an underground pump indicator diagram simple in shape and capable of truly reflecting pump working conditions; an underground pump indicator diagram model is built to calculate a fu's series solution and a viscous resistance coefficient v of the underground pump indicator diagram; and then, a curvature model is built according to the relationship between the obtained underground pump indicator diagram and a valve opening / closing point and the viscous resistance coefficient v to determine the valve opening / closing point.

Owner:SINOPEC SHENGLI OILFIELD

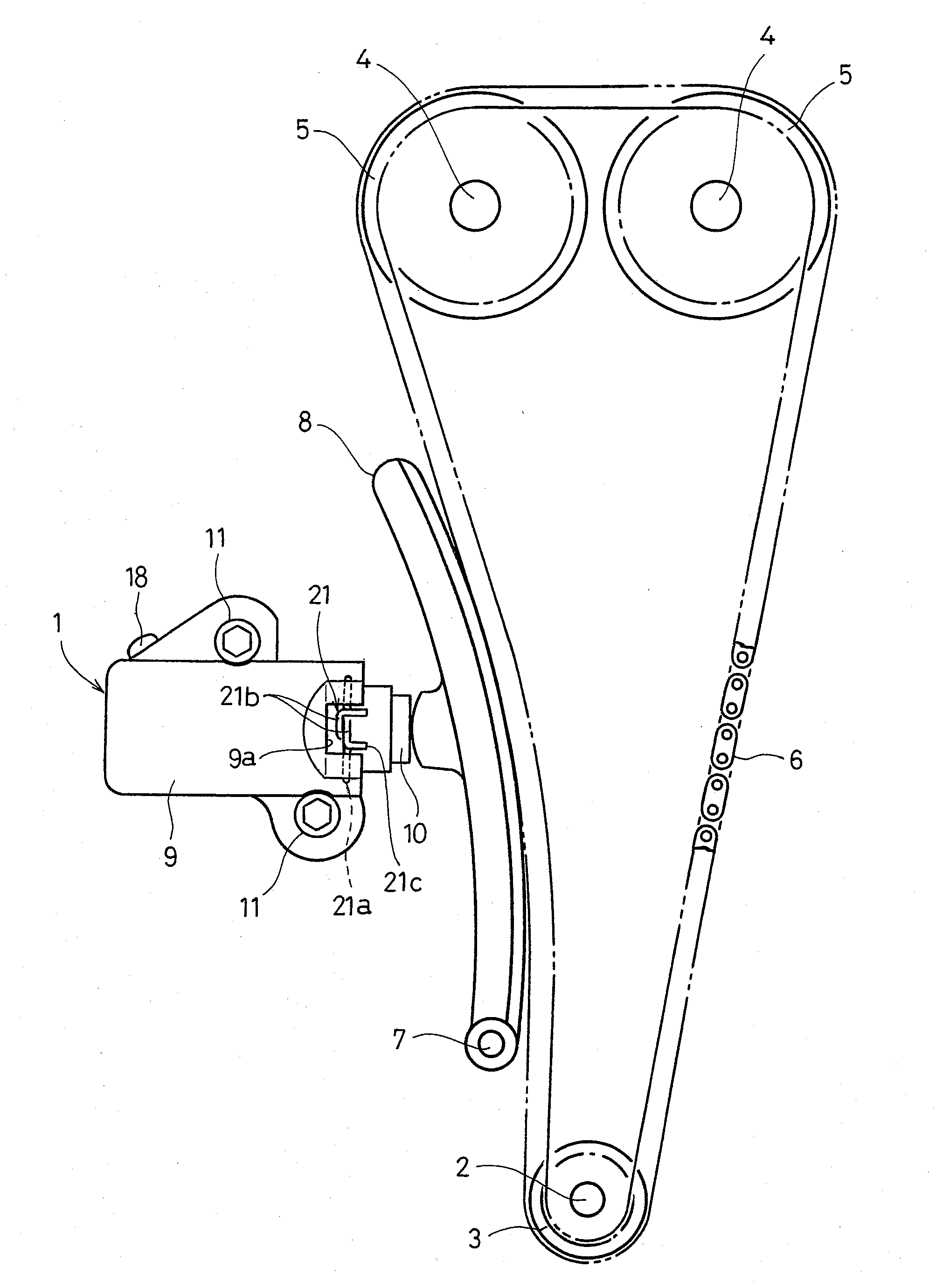

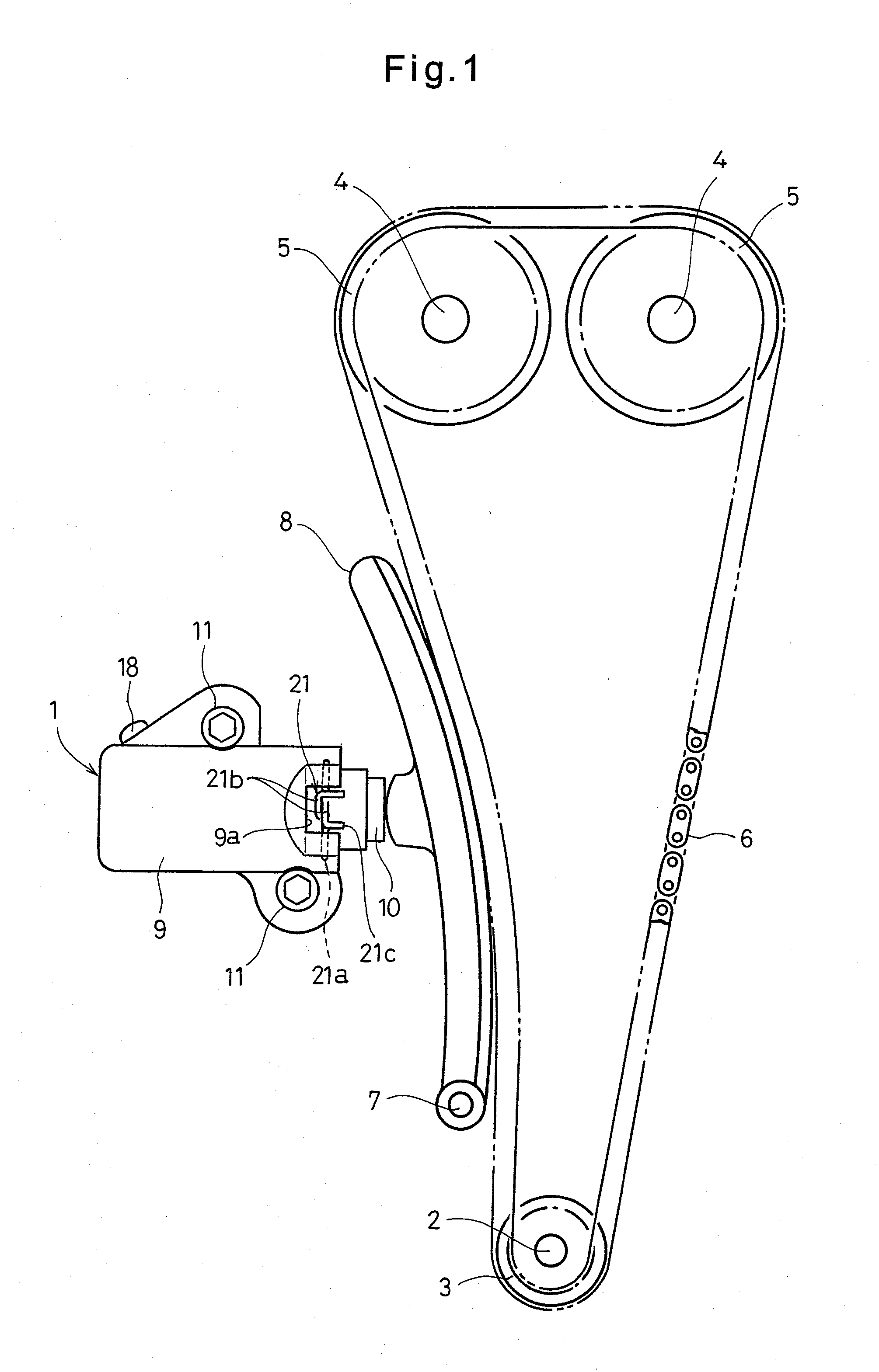

Automatic speed reducing ratio-switching apparatus

ActiveUS7628727B2Smooth transmissionToothed gearingsDifferential gearingsStatic frictionViscous resistance

An automatic speed reducing ratio-switching apparatus comprising an input side carrier, an output side carrier, and an intermediate carrier includes first and second planetary gear mechanisms juxtaposed in the axial direction of an input shaft, first and second inner clutch members which are rotatable in one direction while locking rotation in the other direction of the input shaft, and have mutually different locking directions, first and second outer clutch members which are rotatable in one direction while locking rotation in the other direction of the input side or output side ring gear, and have mutually different locking directions, and a viscous resistance member functioning under a static frictional force to integrally rotate the input side or output side sun gear, the input side or output side planet gears, and the input side or output side ring gears respectively in an identical direction.

Owner:SMC CORP

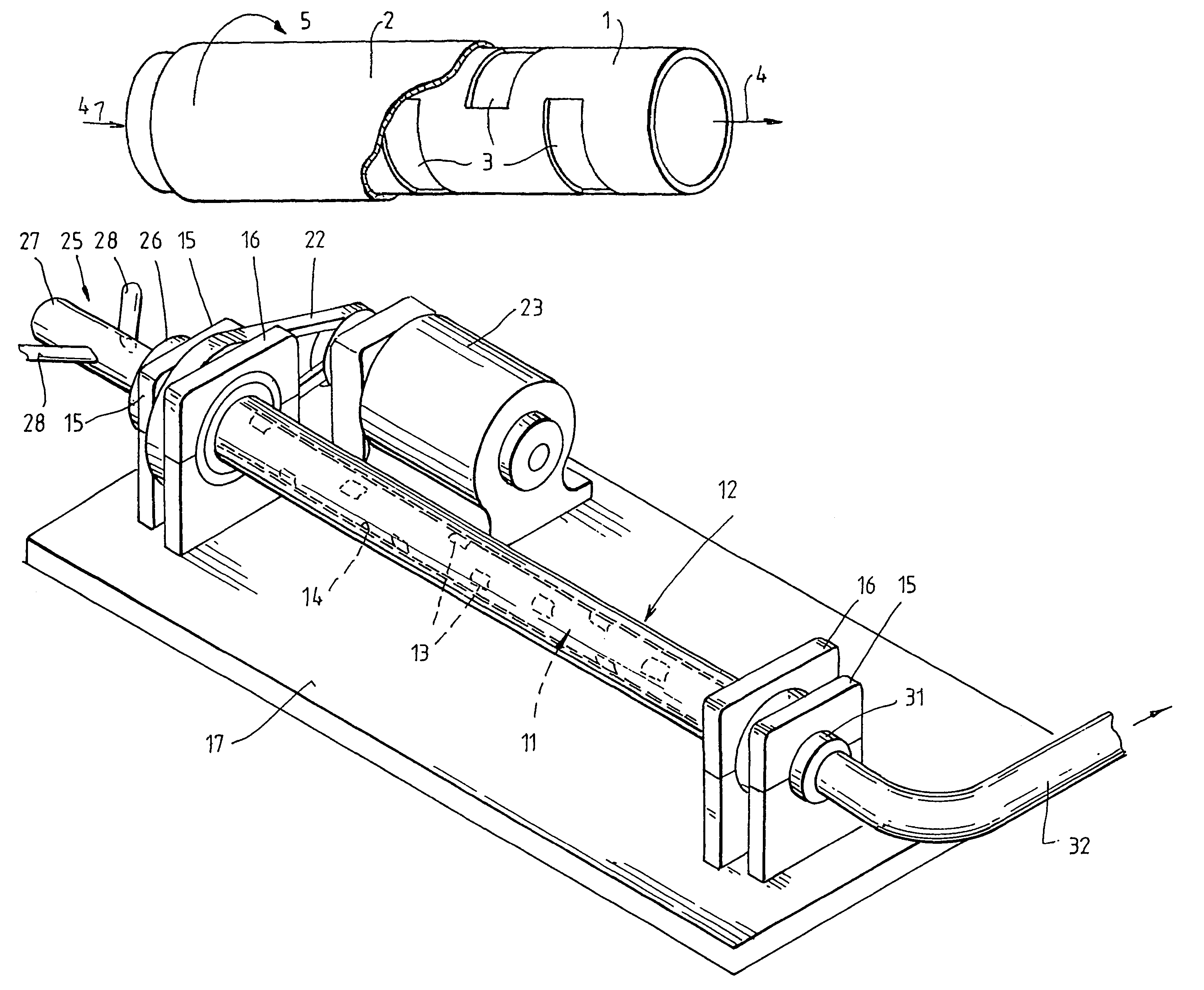

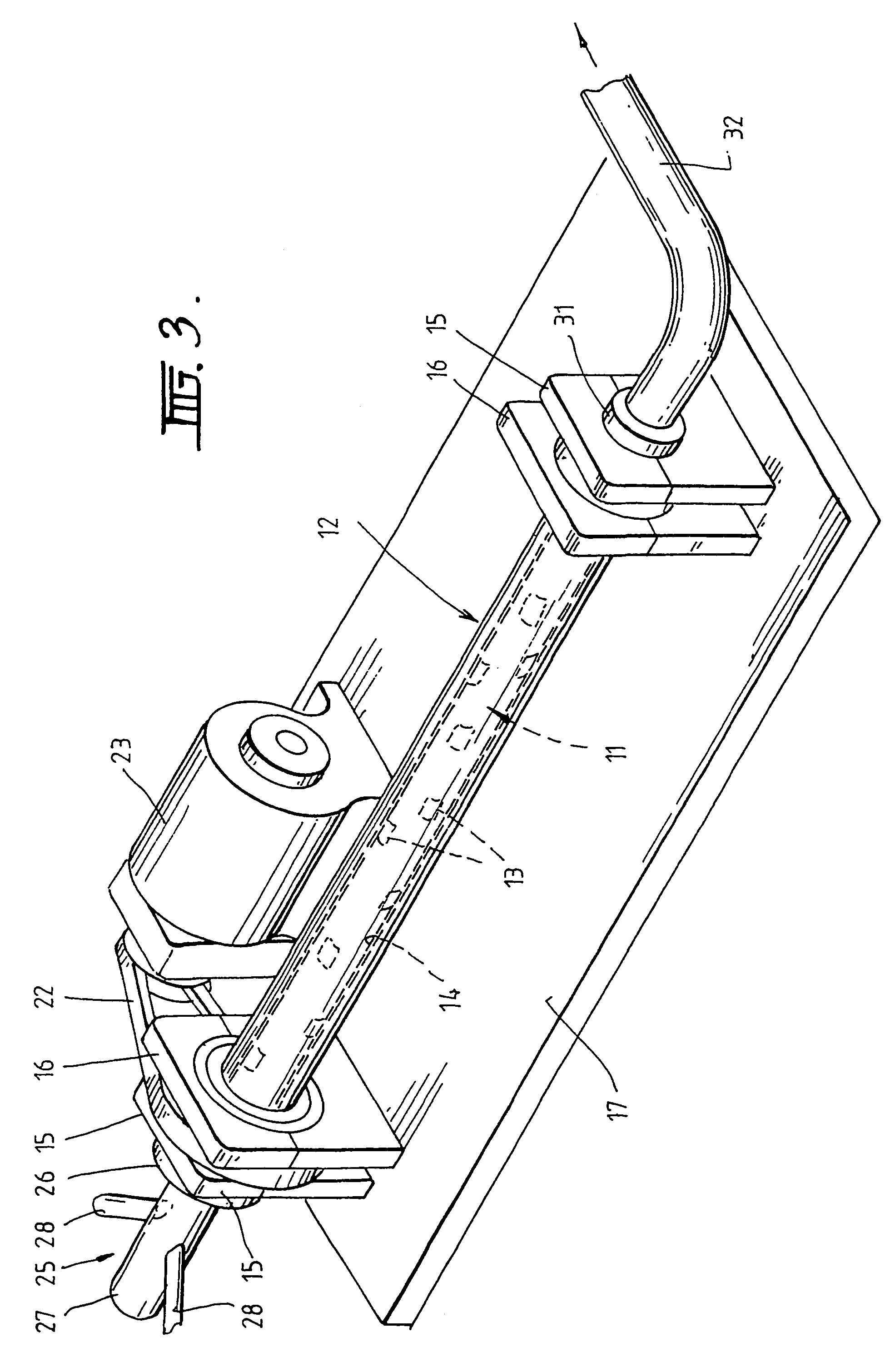

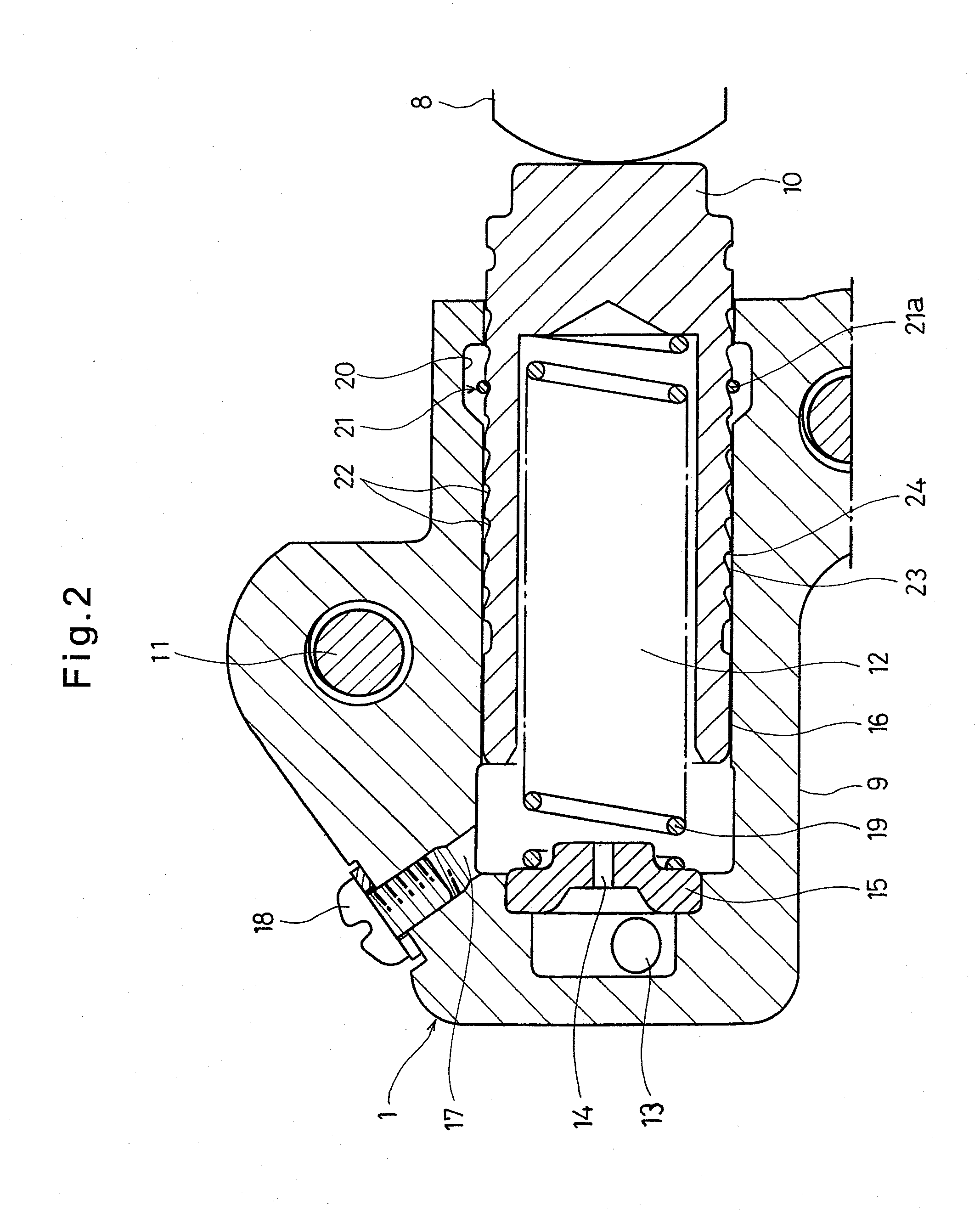

Chain tensioner

InactiveUS20100130320A1Reduce tensionDamper force can be reducedGearingViscous resistanceEngineering

A chain tensioner includes a cylindrical cylinder having a closed end, a plunger slidably mounted in the cylinder, and a return spring biasing the plunger. The cylinder is formed with an oil supply passage through which hydraulic oil is introduced into a pressure chamber defined by the plunger and the cylinder. The oil supply passage has an orifice at its end portion facing the pressure chamber. A leak gap is defined between sliding surfaces of the plunger and the cylinder. A damper force is produced by viscous resistance of hydraulic oil flowing from the pressure chamber through the leak gap, and by viscous resistance of hydraulic oil flowing from the pressure chamber into the oil supply passage through the orifice.

Owner:NTN CORP

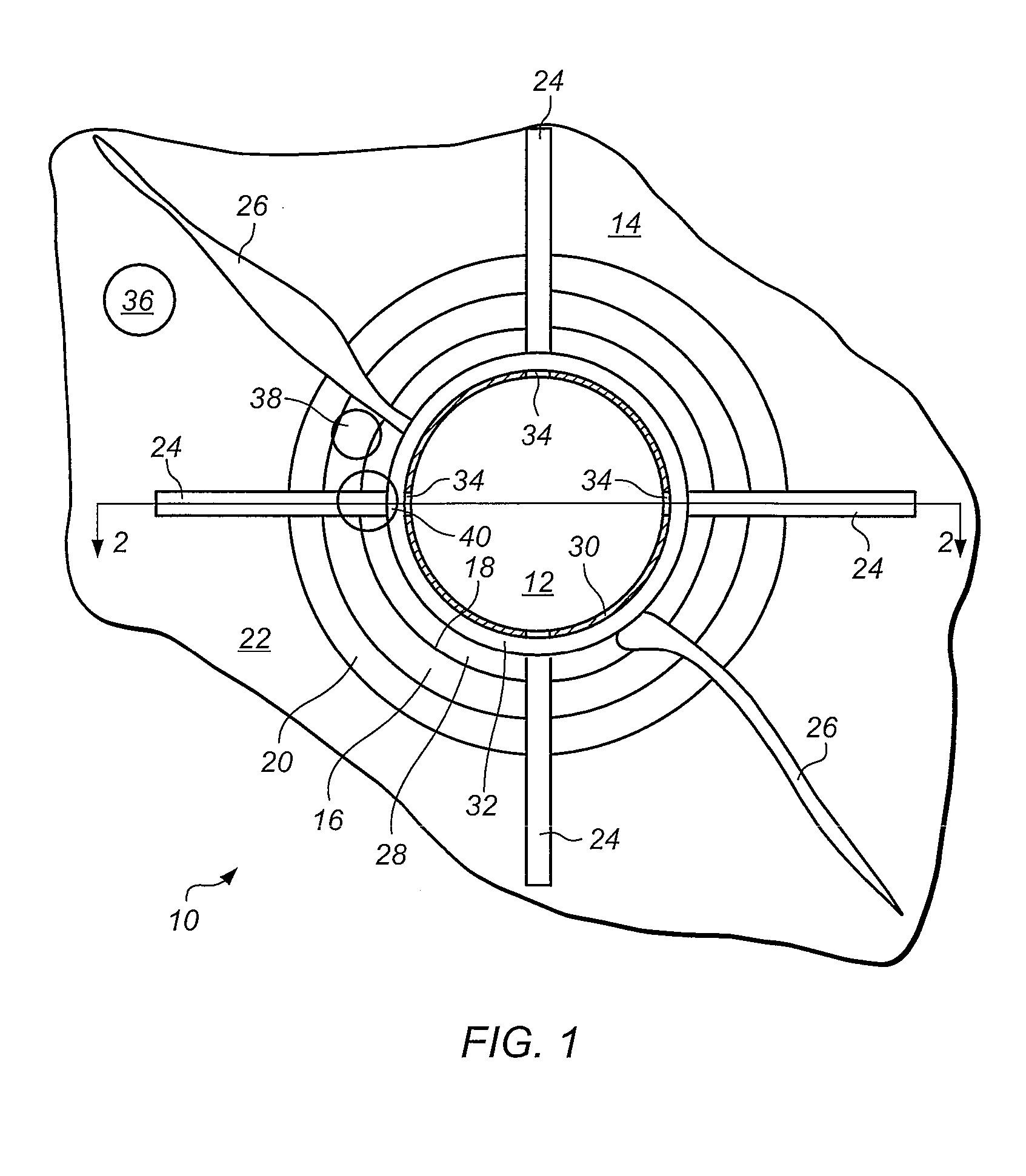

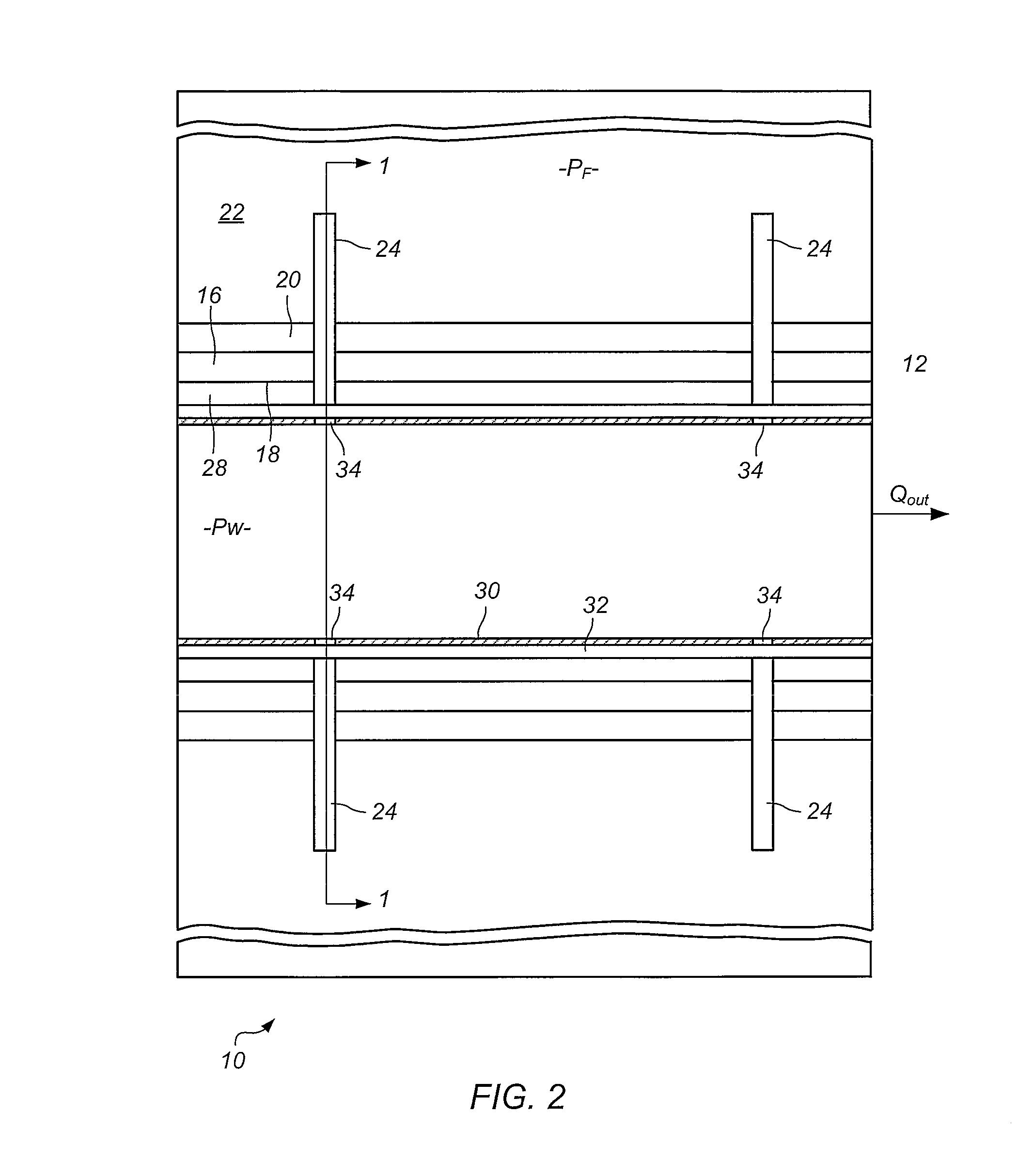

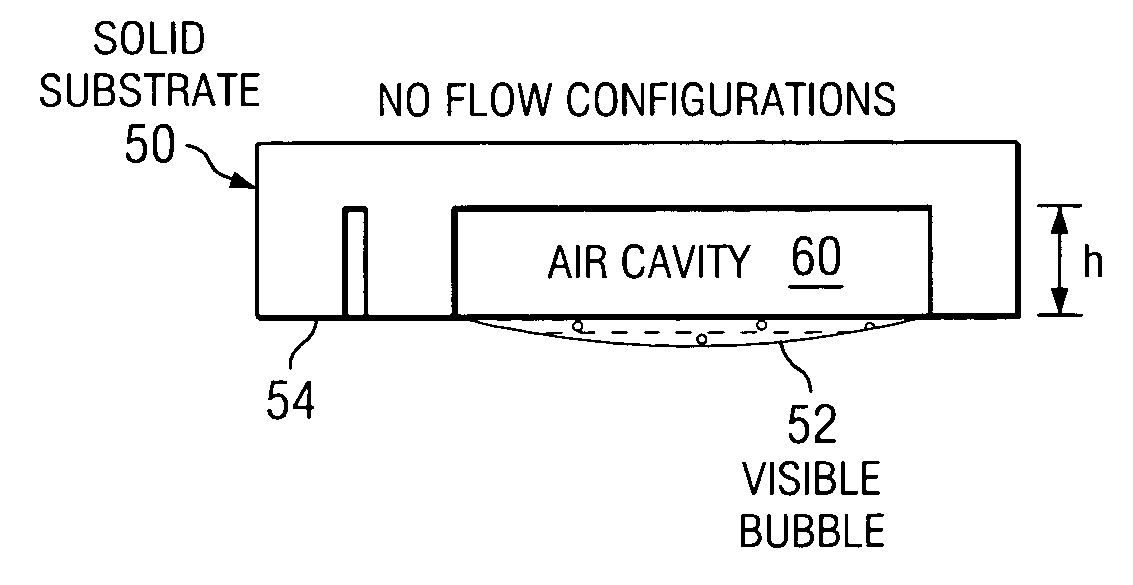

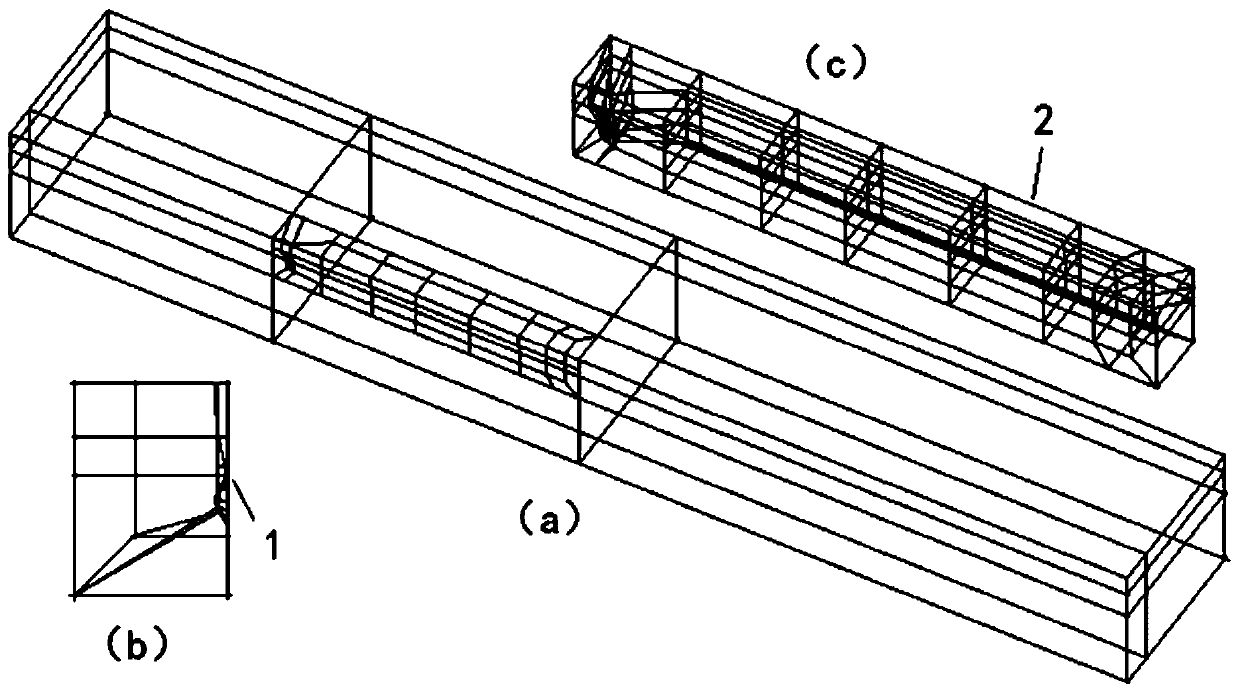

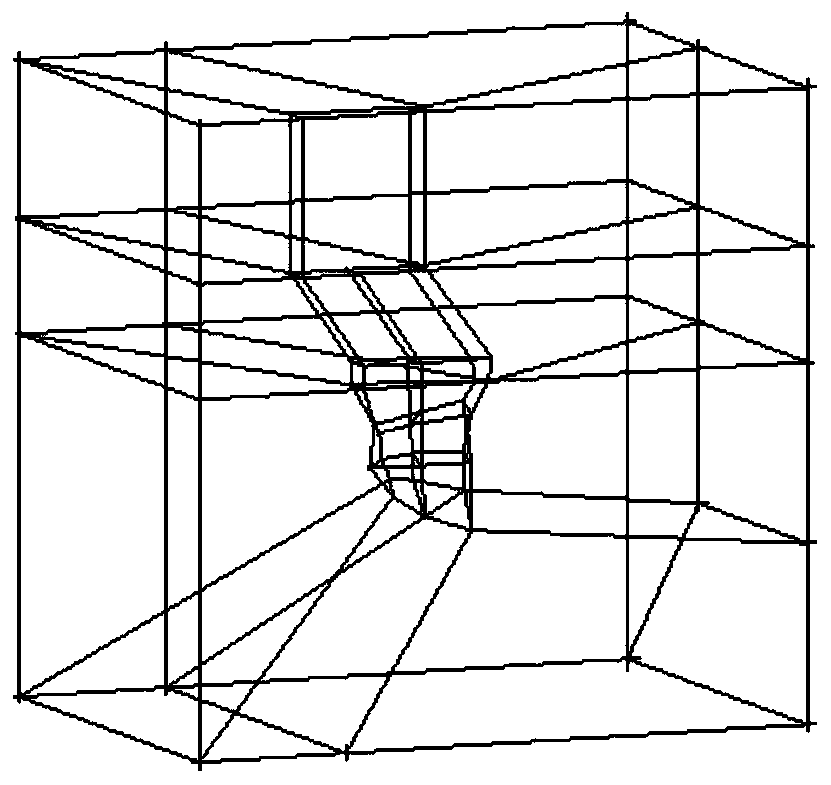

Well simulation

A method of computational fluid dynamic modelling of a subterranean region comprises: defining a computational domain by generating a geometrical model of a subterranean region comprising a wellbore and a surrounding formation; associating knowledge of a physical property of the subterranean region with a computational parameter; and inputting the computational parameter into the computational domain. In one embodiment knowledge of permeability within the subterranean region is defined as a viscous resistance within the computational domain.

Owner:LLOYDS REGISTER DIGITAL PROD LTD

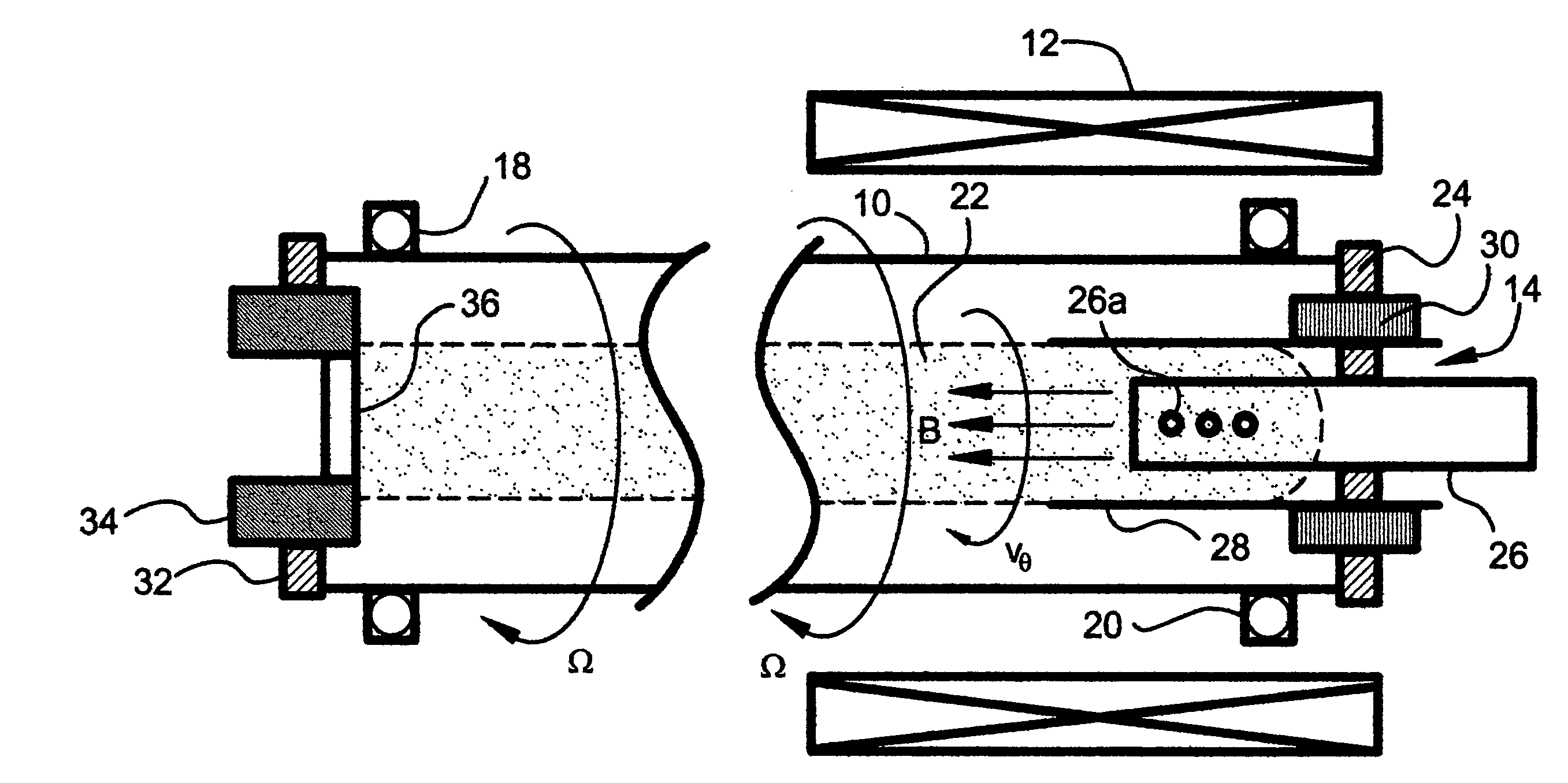

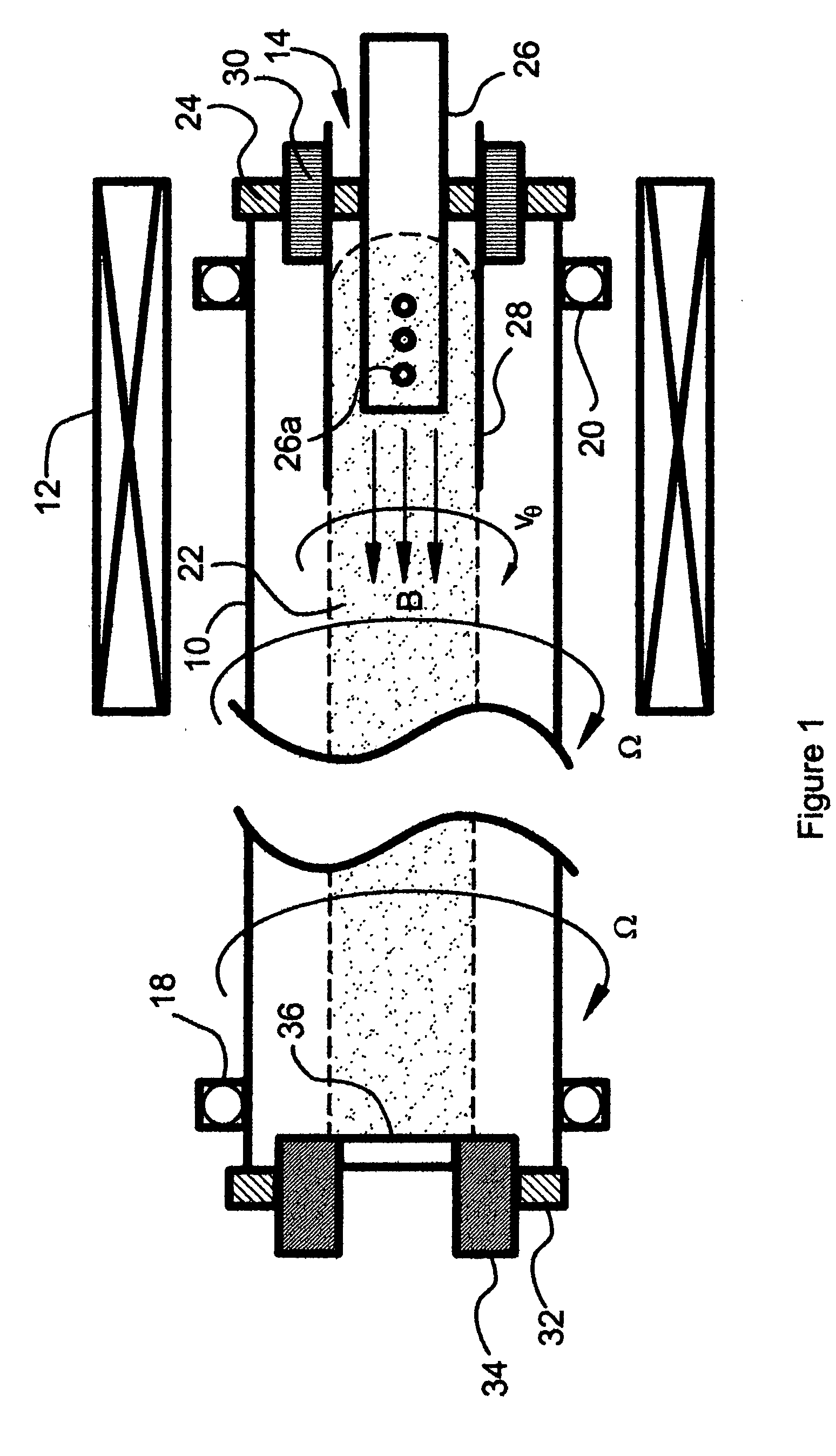

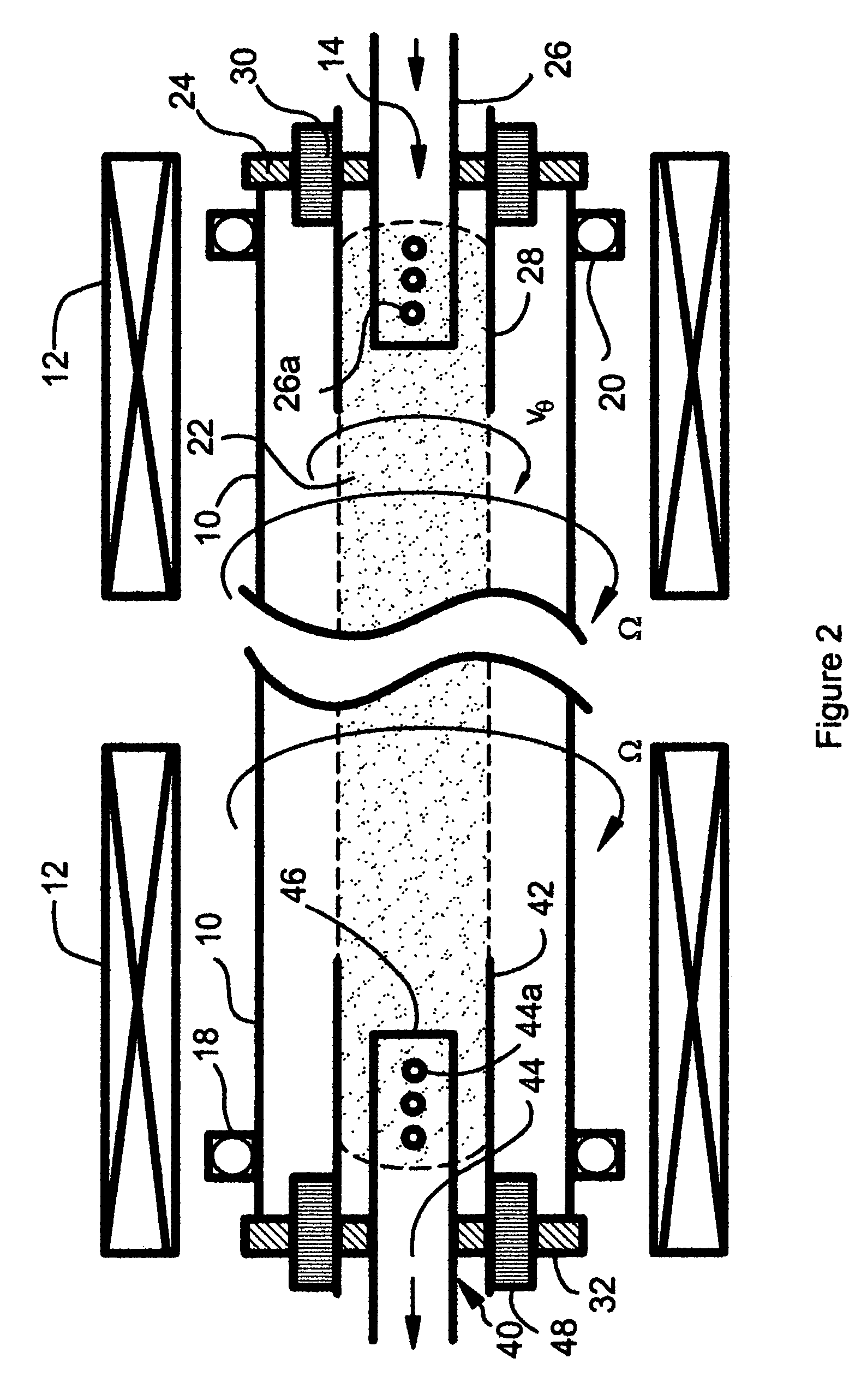

Soft x-ray laser based on Z-pinch compression of rotating plasma

InactiveUS20060232215A1Reduce light lossIncrease currentBeam/ray focussing/reflecting arrangementsBeam/ray deflecting arrangementsMagnetic tension forceVolumetric Mass Density

A method and apparatus for producing soft x-ray laser radiation based on z-pinch compression of a rotating low pressure plasma column are disclosed. A rotating, low pressure plasma column is created by electric discharge or by laser excitation inside a containment tube. Rotation of the plasma may be induced by viscous drag caused by rotation of the tube, or by magnetically driven rotation of the plasma as it is created in a plasma gun in the presence of an axial magnetic field, or both. A high power electrical discharge is then passed axially through the rotating plasma column to produce a rapidly rising axial current, resulting in z-pinch compression of the rotating plasma column radially inwardly with resultant stimulated emission of soft x-ray radiation in the axial direction. A rotating containment tube used in combination with magnetically driven rotation of the plasma column results in a concave electron density profile that in turn results in reduced wall ablation and also reduced refraction losses of the resultant soft x-rays.

Owner:FARTECH

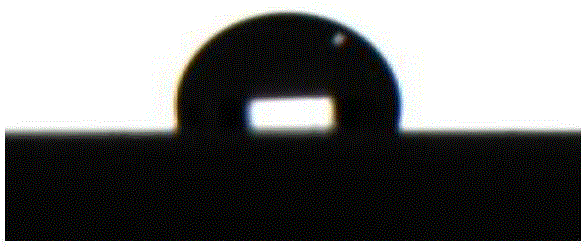

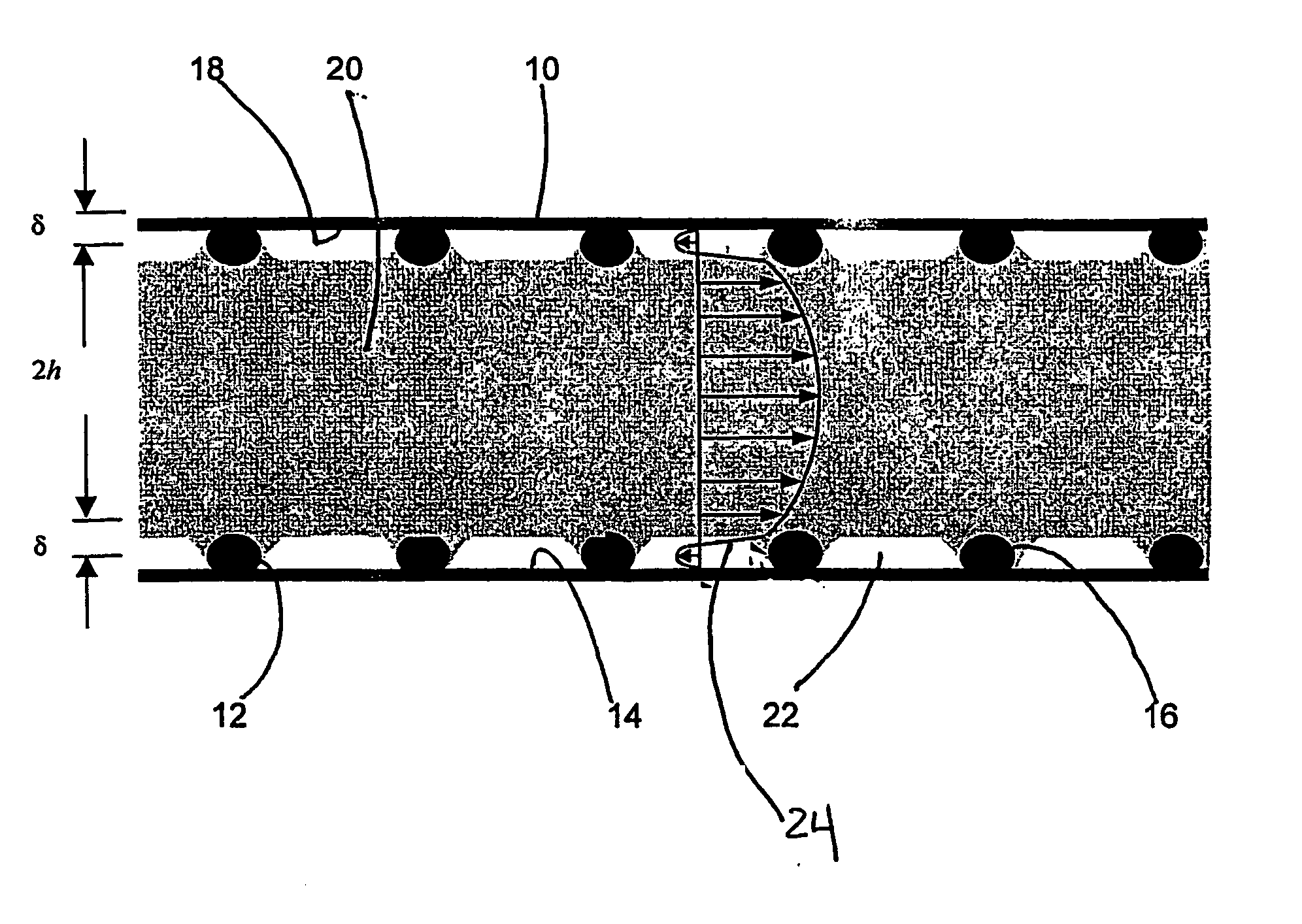

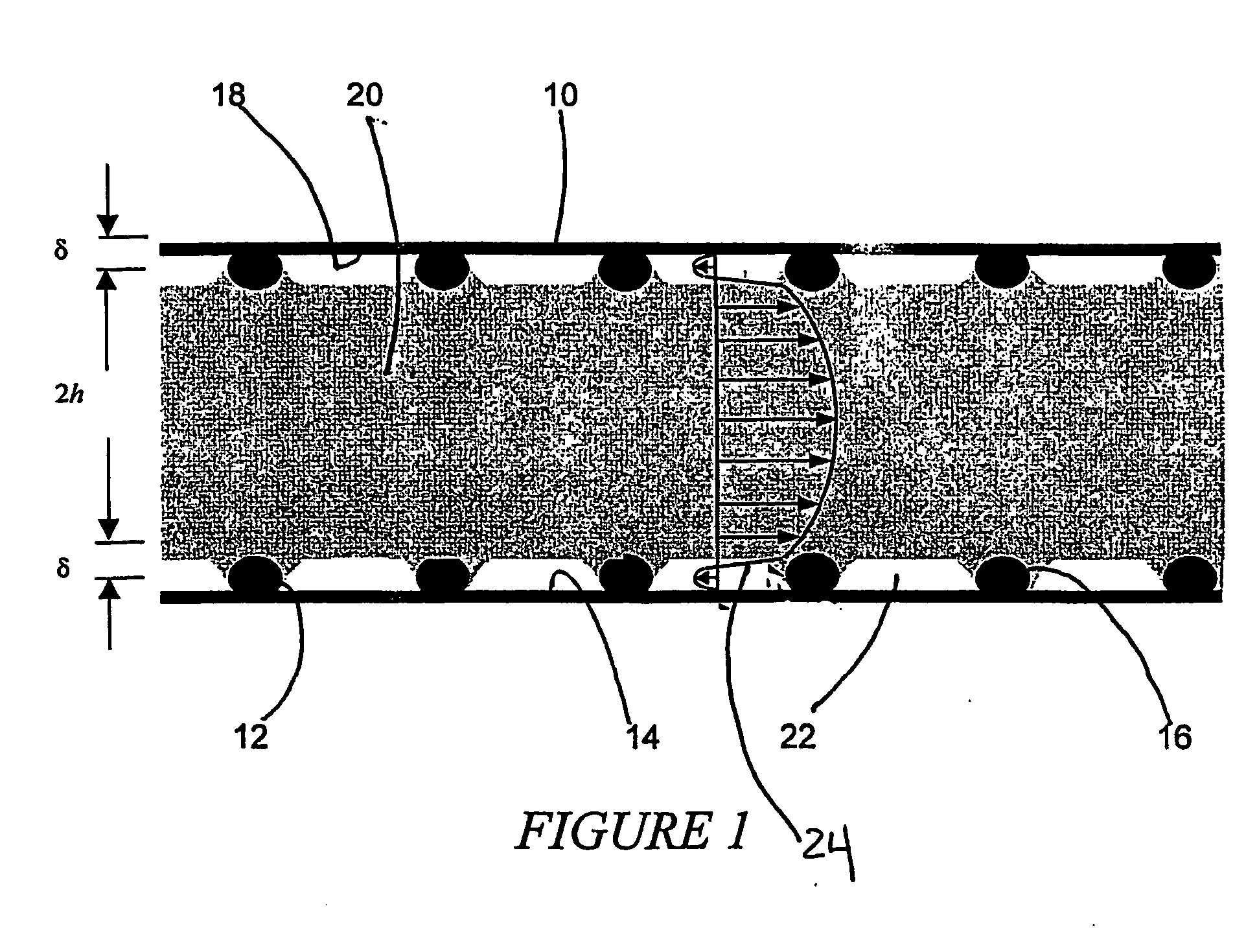

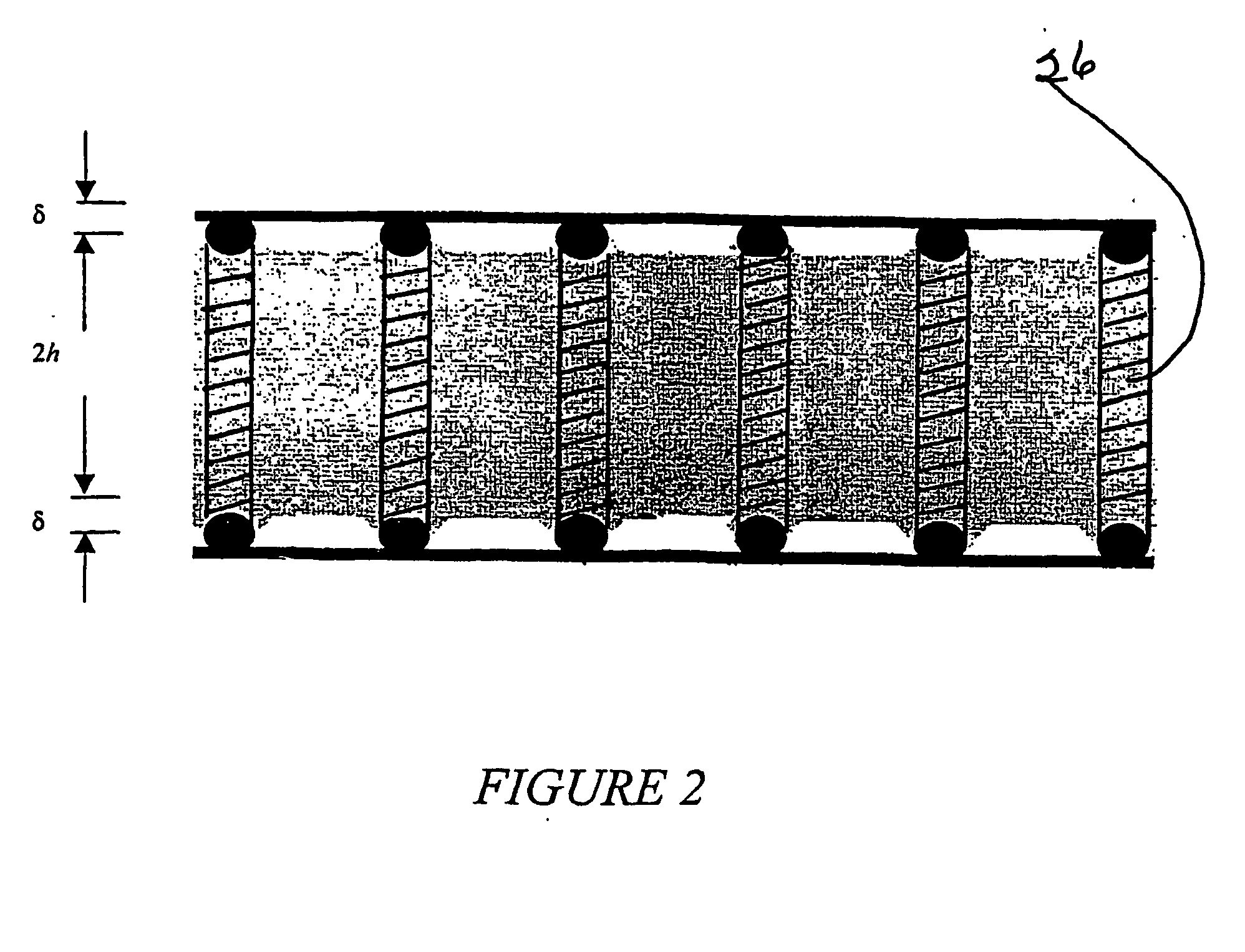

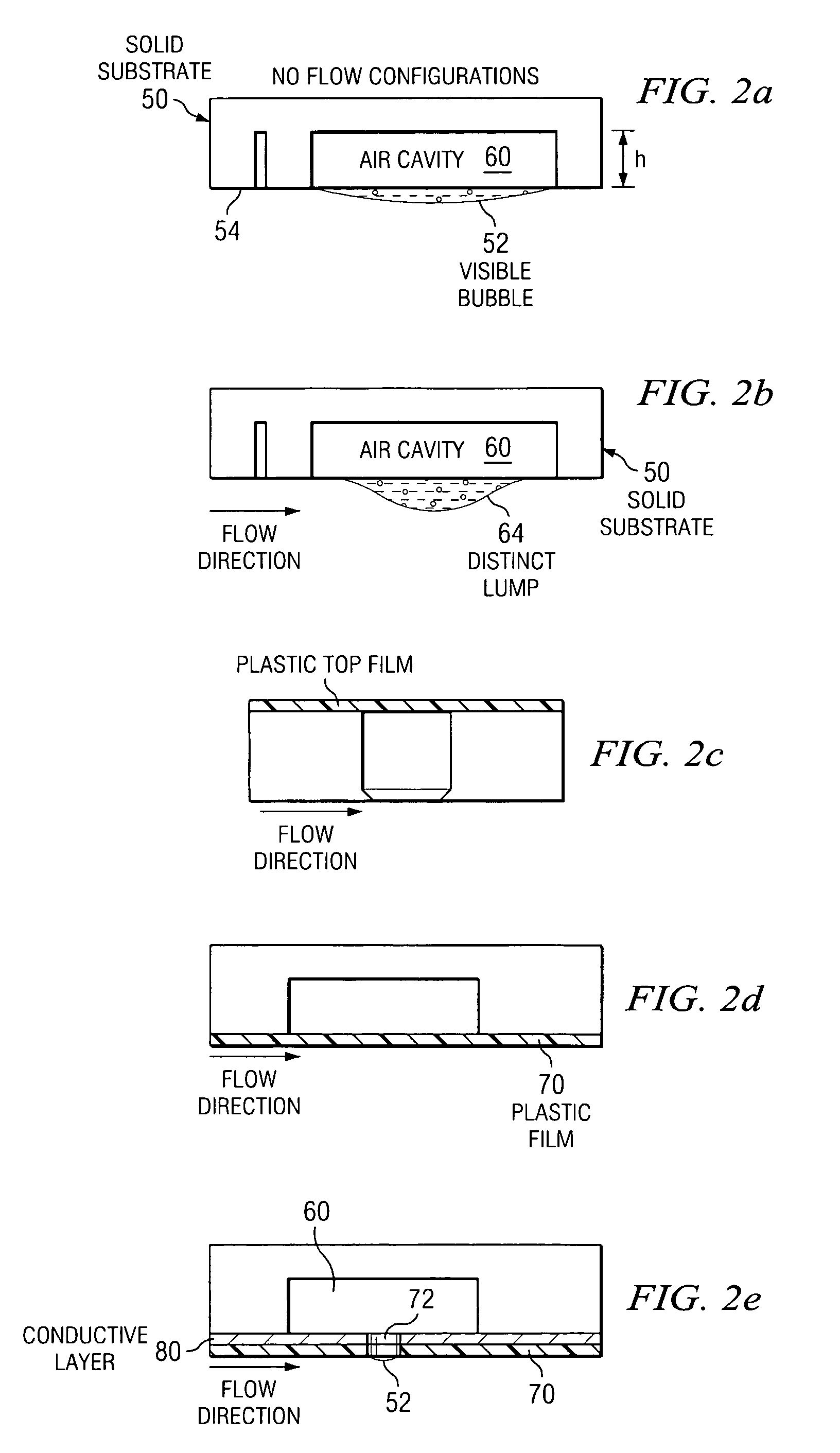

Microchannels for efficient fluid transport

InactiveUS20050036918A1Enhanced fluid transportReduce viscous resistanceSemi-permeable membranesAnalysis using chemical indicatorsFluid transportEngineering

A structure having one or more micruchannels capable of forming air gaps between the inner surface of the microchannel and a fluid in the microchannel. As a result, the viscous resistance can be decreased by a factor of 5 or more. A microchannel according to this invention can have a textured inner surface which provides for air gap formation. The hydrophobicity of the microchannel can provide enhanced fluid transport by adjusting surface tension.

Owner:RGT UNIV OF CALIFORNIA +1

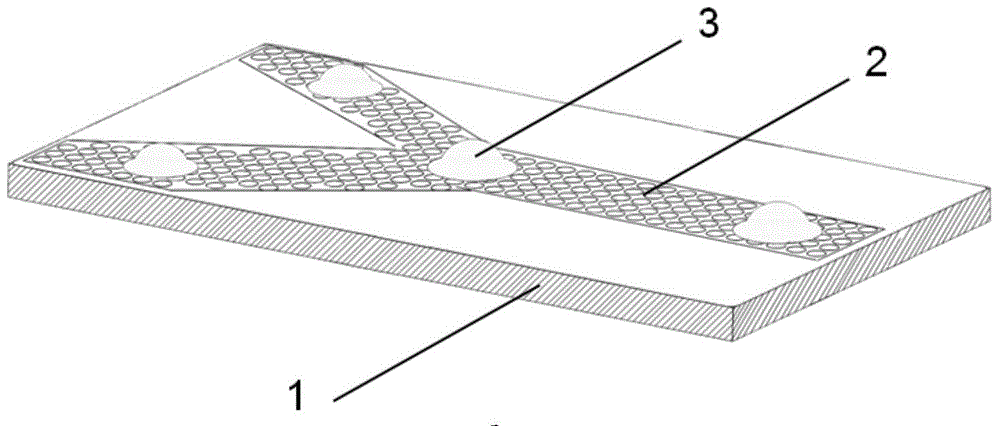

Opening type micro-fluidic chip, as well as manufacture method and operation method of micro-fluidic chip

ActiveCN104307582AReduce viscous resistanceExpand driveLaboratory glasswaresMicro structureViscous resistance

The invention discloses an opening type micro-fluidic chip, as well as a manufacture method and an operation method of the micro-fluidic chip. The opening type micro-fluidic chip comprises a chip substrate, wherein a super-smooth surface is formed on the chip substrate; the super-smooth surface is a liquid coating layer which is filled with a lubricant and formed by a surface with a sunk micro-structure. According to the opening type micro-fluidic chip, the super-smooth surface is adopted, the viscous resistance of exogenous substances moving on the surface of the micro-fluidic chip can be greatly reduced, and thus the driving mode of the exogenous substances, especially fluid, can be expanded, the operation flexibility can be improved, and a sensitive system can be operated and controlled.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Printhead nozzle with reduced ink inertia and viscous drag

Owner:MEMJET TECH LTD +1

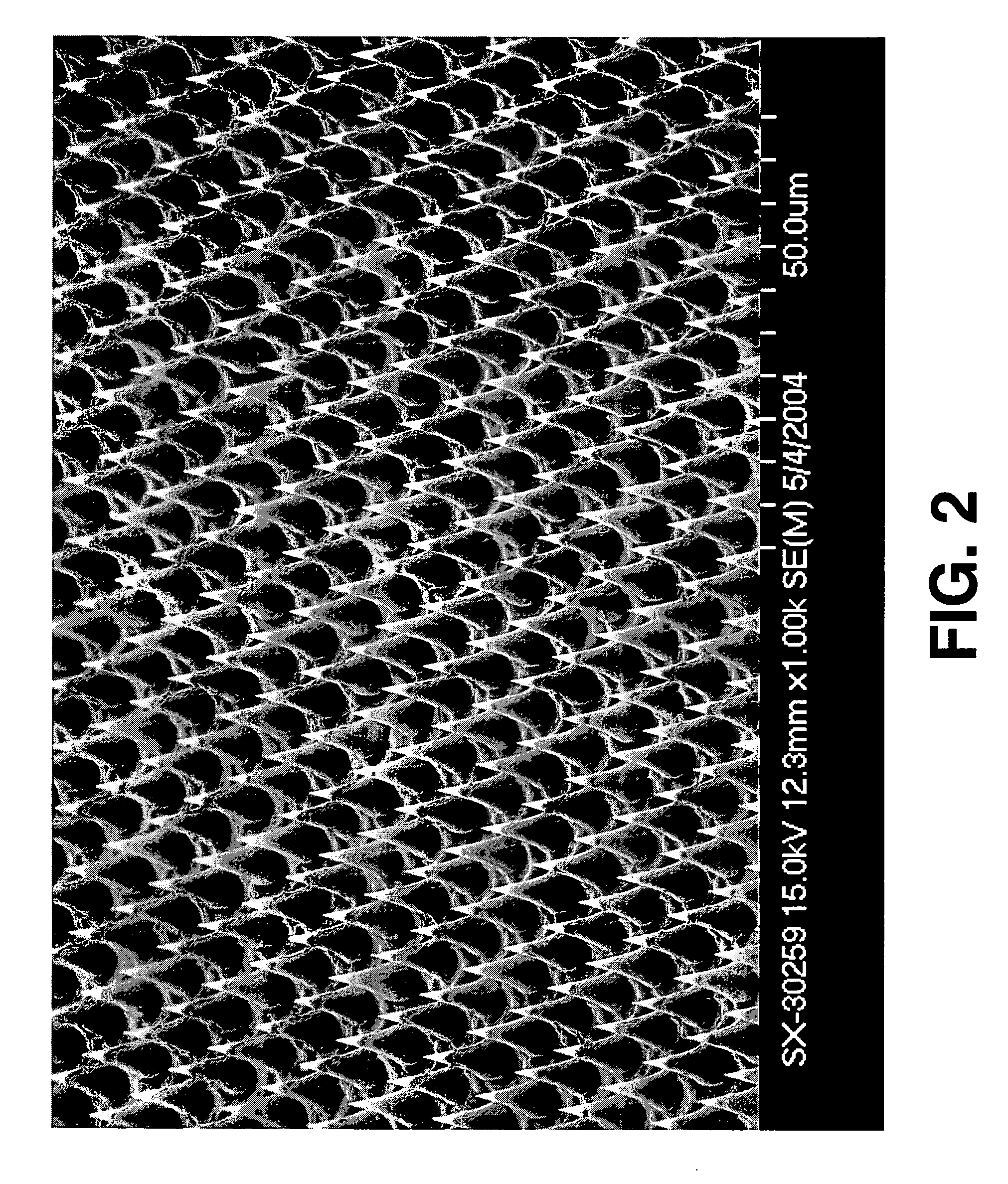

Methods for reducing the viscous drag on a surface and drag reducing device

InactiveUS7044073B2Large drag reductionsLarge power inputWatercraft hull designFloating buildingsMarine engineeringViscous resistance

A submerged surface is created, either as an add-on application or as an integral part of the submerged structure, having an array of closely spaced small bubble-filled holes which cover a large fraction of the wetted surface area. The viscous drag on the bubbles is much smaller than that on the surrounding solid surface and the net drag on the entire submerged surface is less than that on an equivalent solid surface.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

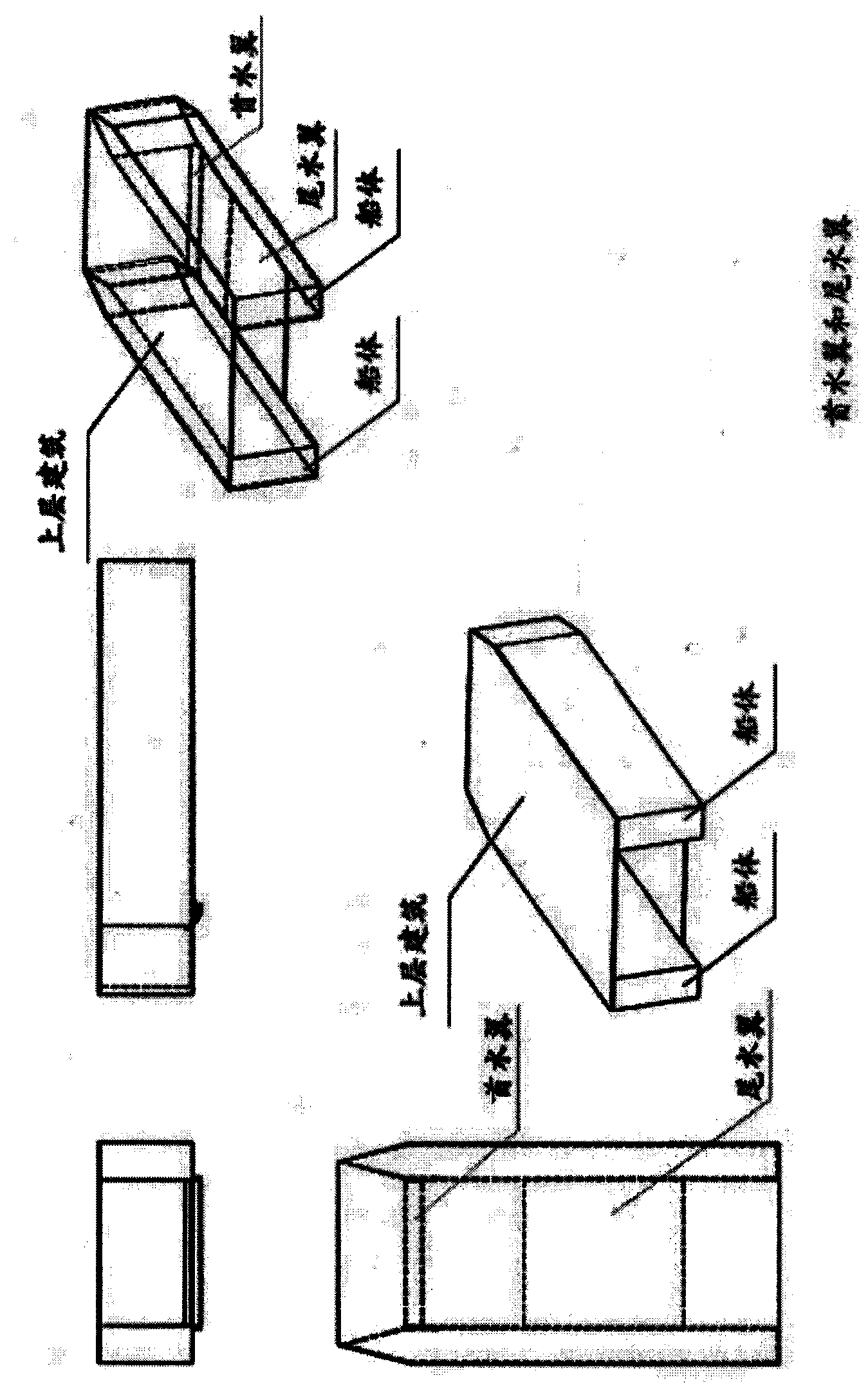

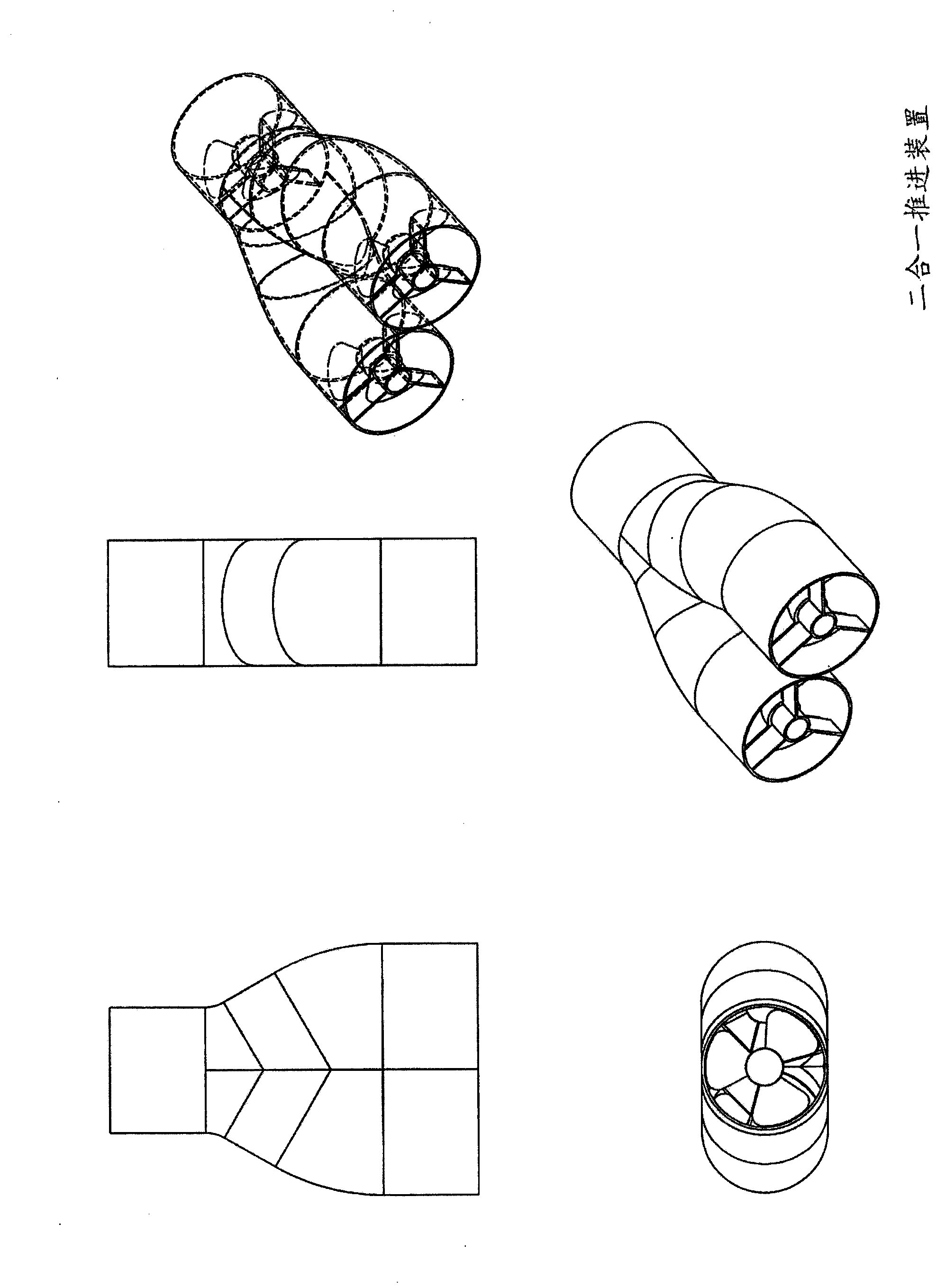

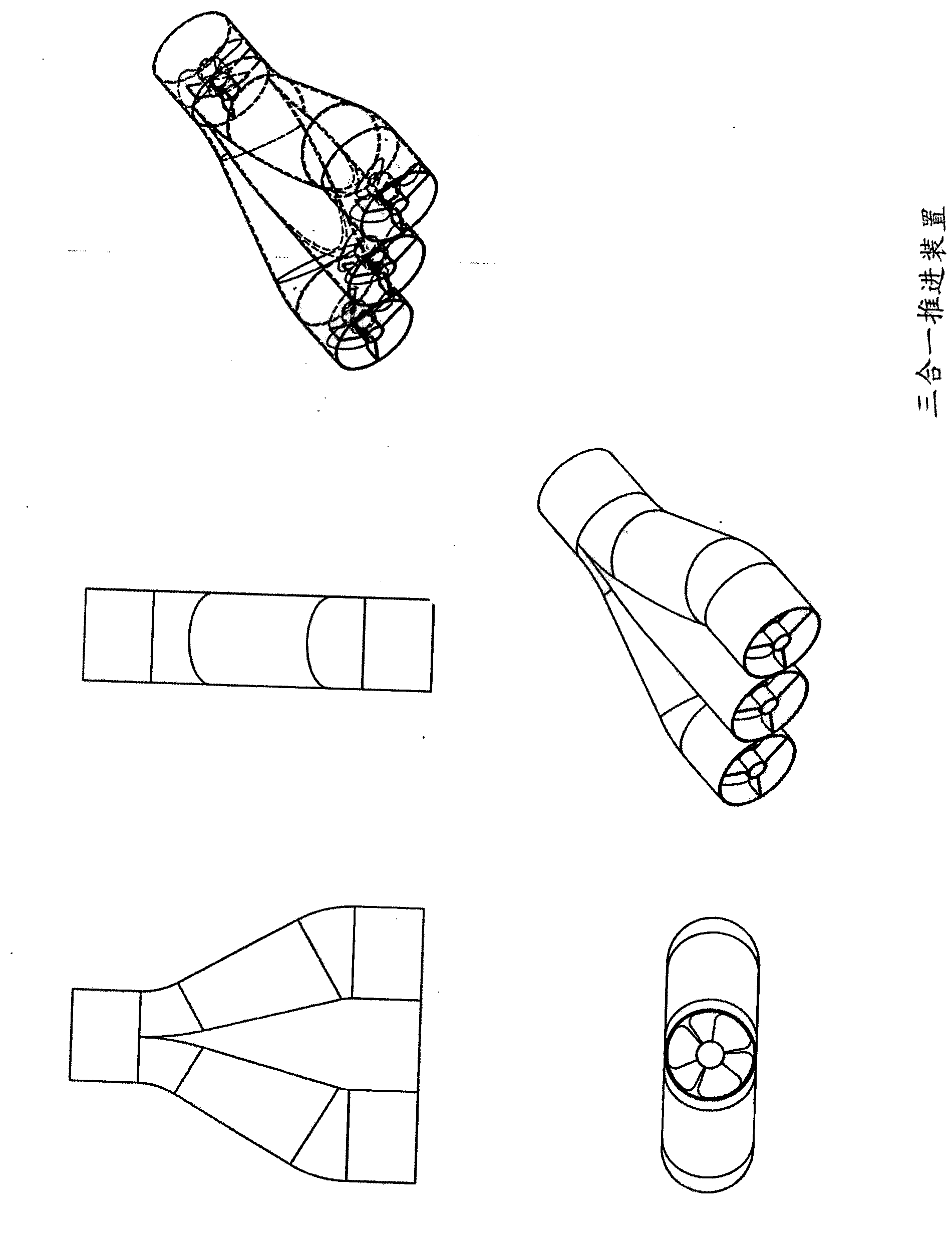

Ultra-high-speed and super-cavitation catamaran with hydrofoils

The invention relates to an ultra-high-speed and super-cavitation catamaran with hydrofoils. The head hydrofoil and the tail hydrofoil are arranged between two ship bodies of the catamaran, the head hydrofoil is an adjustable rising hydrofoil, the tail hydrofoil is a fixed main hydrofoil which extends from the lateral gravity center of the catamaran to the head and the tail of the catamaran by equal distances, the head hydrofoil supplies rising force to the catamaran in the sailing process, the tail hydrofoil is the main hydrofoil and supports the ship bodies to sail on the water, and the tonnage of the catamaran can be increased from current hundreds of tons to tens of thousands of tons or more due to the hydrofoils. Due to the rising force surfaces of the hydrofoils and the two ship bodies of the catamaran, super-cavitation is achieved, and therefore viscous resistance between the catamaran bottom and water and viscous resistance between the hydrofoils and water can be reduced by more than 90%. A plurality of water inlet pipes are combined in the middle, a propelling device of a shrouded combined type propeller of a water outlet pipe is arranged at the rear portion of the catamaran, negative pressure is reduced on the water inlet opening in front of the catamaran so that no cavitation phenomenon can happen to the propeller, and the propelling speed is multiplied due to the water outlet opening in the rear portion of the catamaran.

Owner:缪德贵

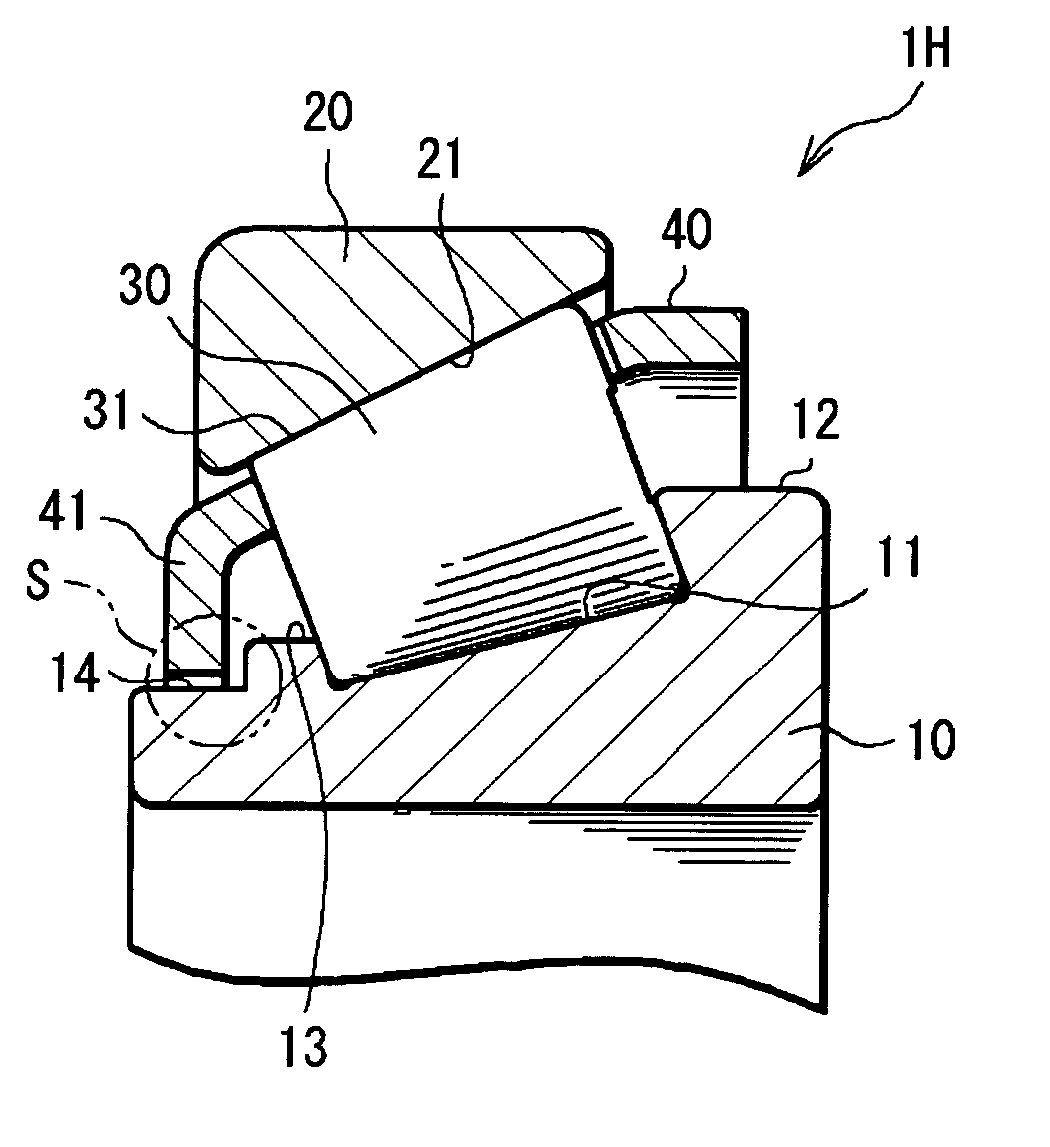

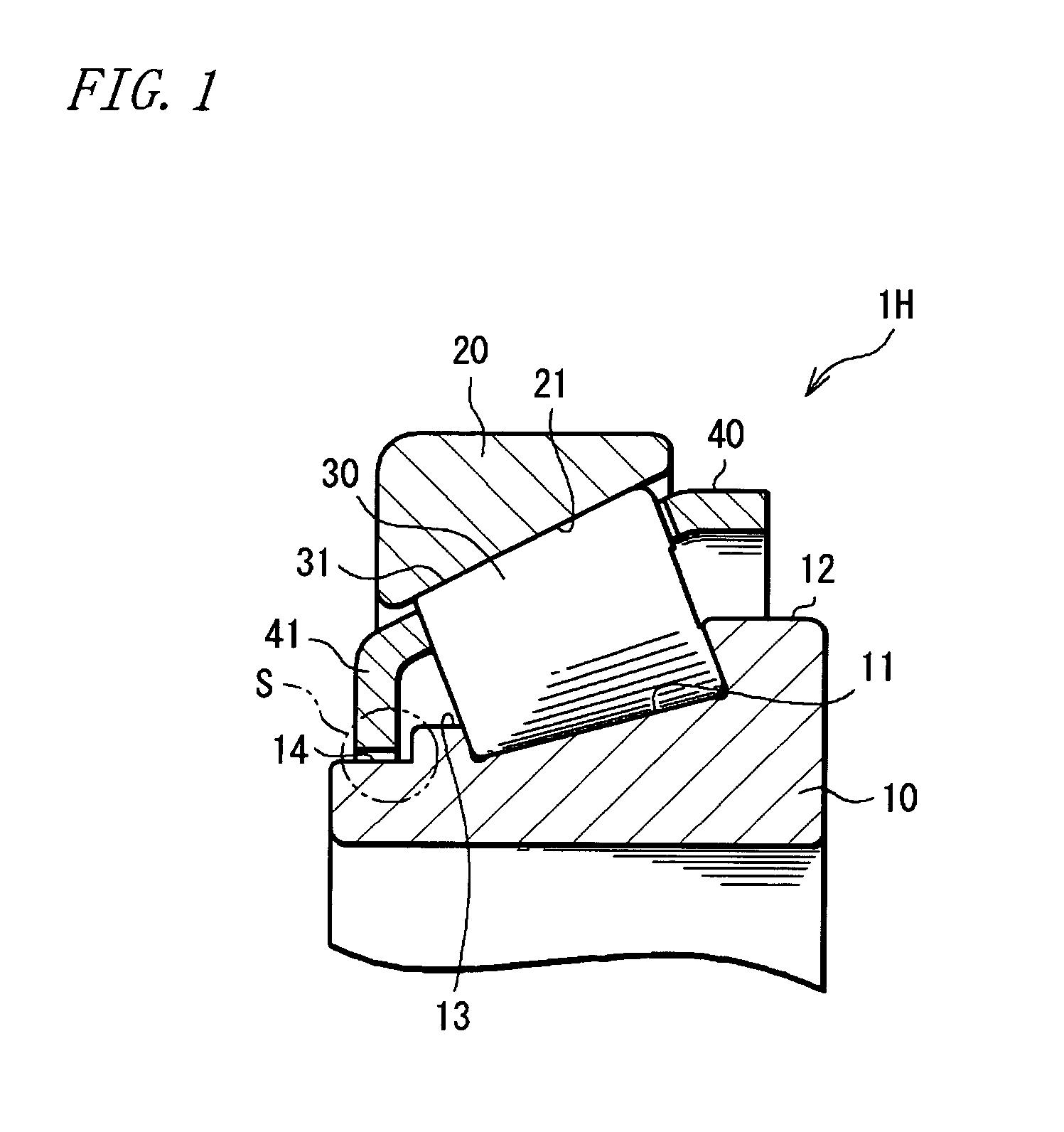

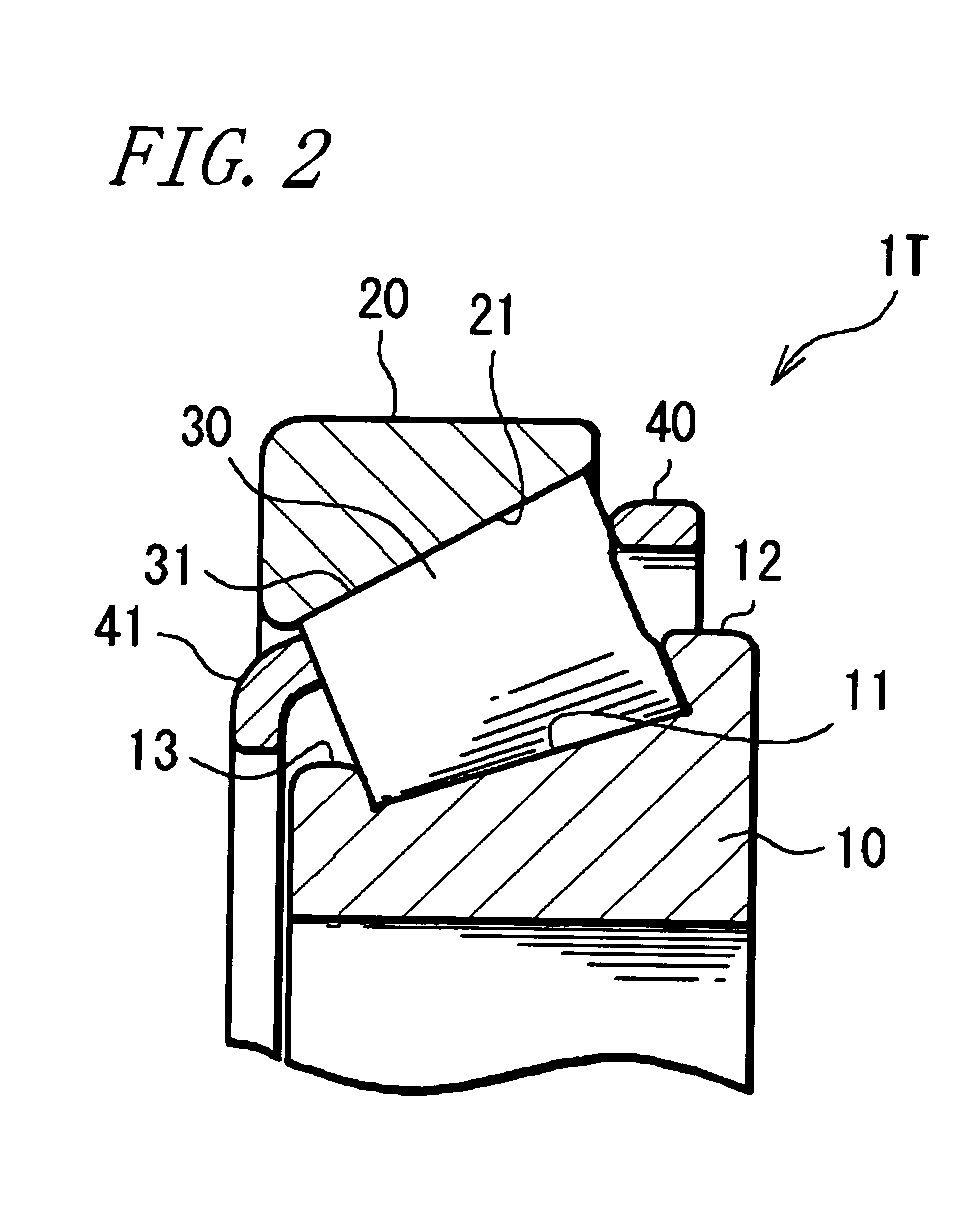

Tapered Roller Bearing, a Tapered Roller Bearing Assembly and a Pinion-Shaft Supporting Assembly Using the Same

A tapered roller bearing is designed to have a roller loading ratio in the range of 0.7 to 0.92 and a ratio of roller length to roller diameter in the range of 1.1 to 1.7 whereby oil agitation loss and rolling viscous resistance are reduced for achieving the reduction of running torque. Crownings are provided which are designed to have an outer-ring crowning parameter (=RCO / LRO) in the range of 30 to 150 and an inner-ring crowning parameter (=RCI / LRI) in the range of 50 to 260, provided that RCO denotes the radius of an outer ring crowning, LRO denotes the raceway length of an outer ring, RCI denotes the radius of an inner ring crowning and LRI denotes the raceway length of an inner ring. Thus, the rolling viscous resistance is reduced for achieving the reduction of running torque.

Owner:JTEKT CORP

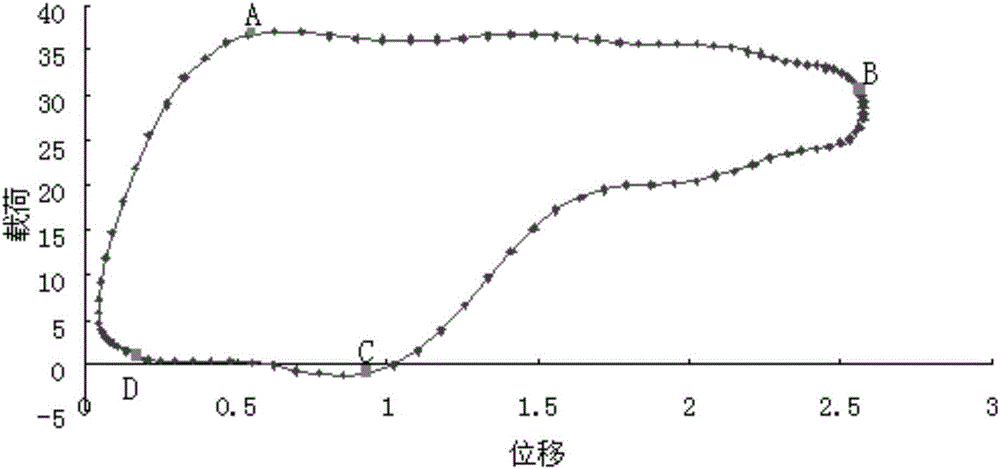

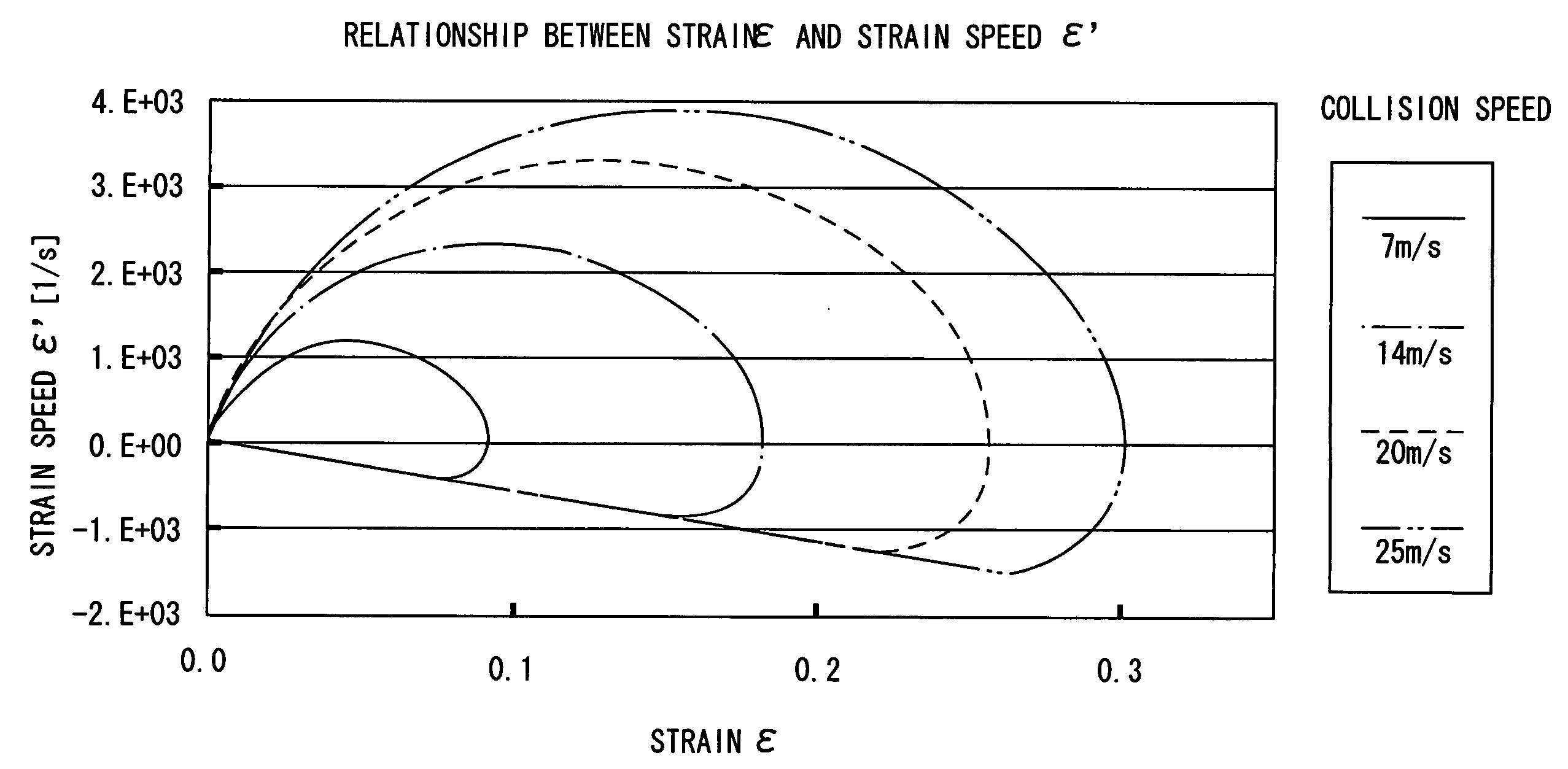

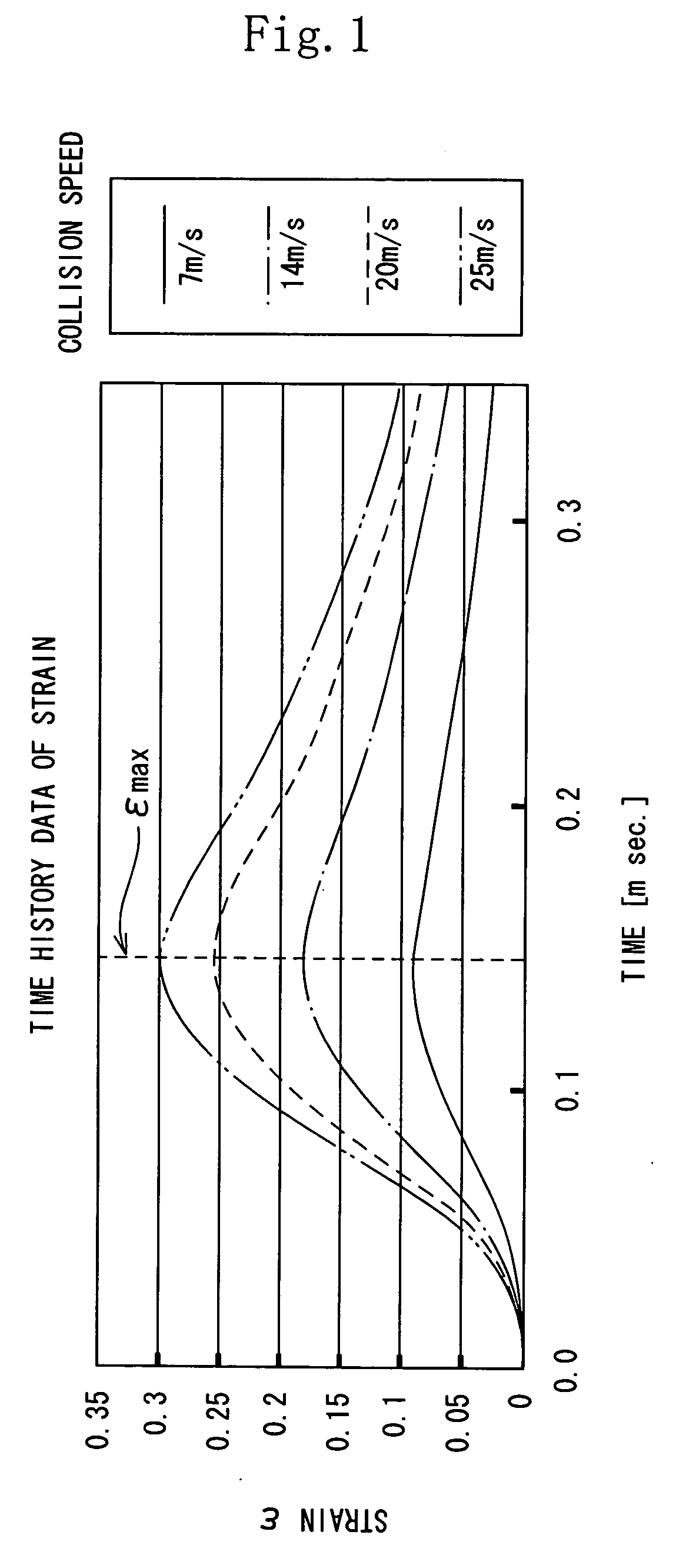

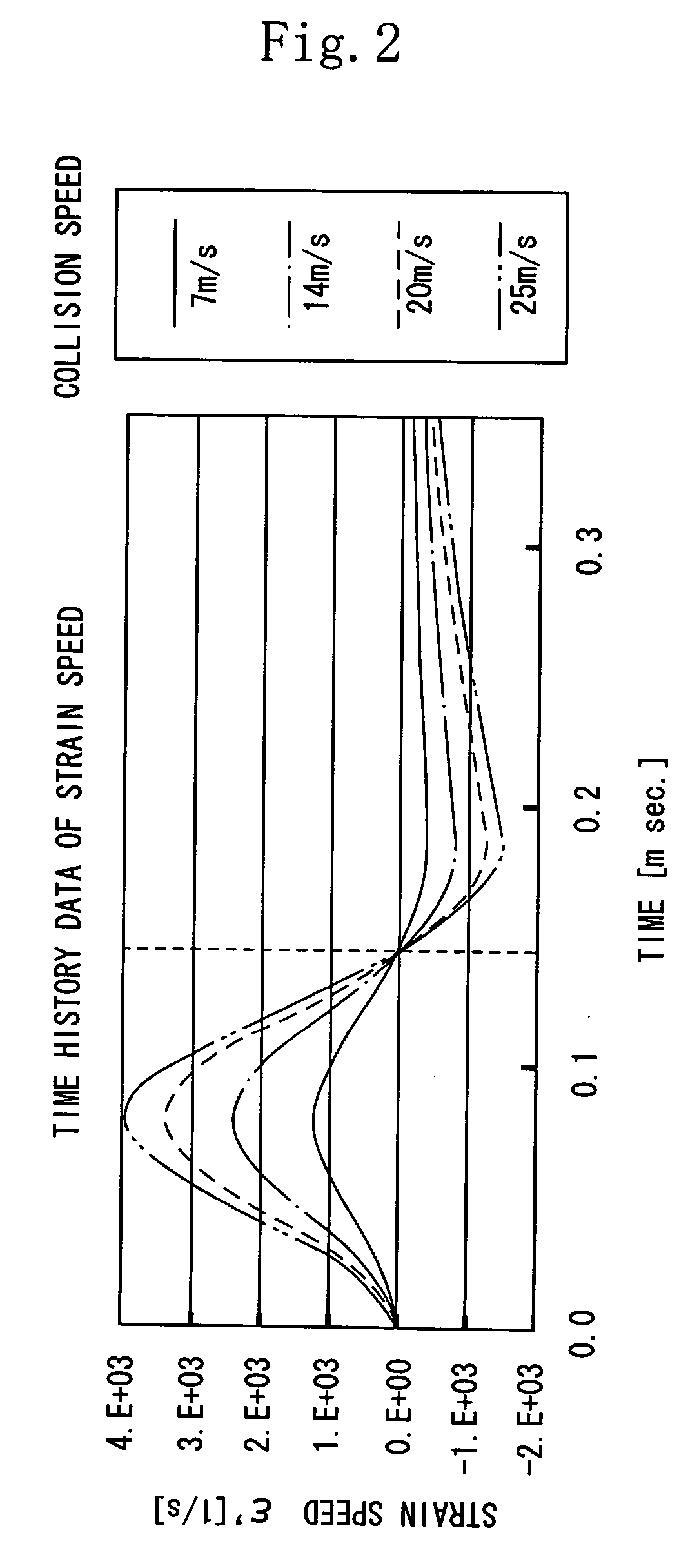

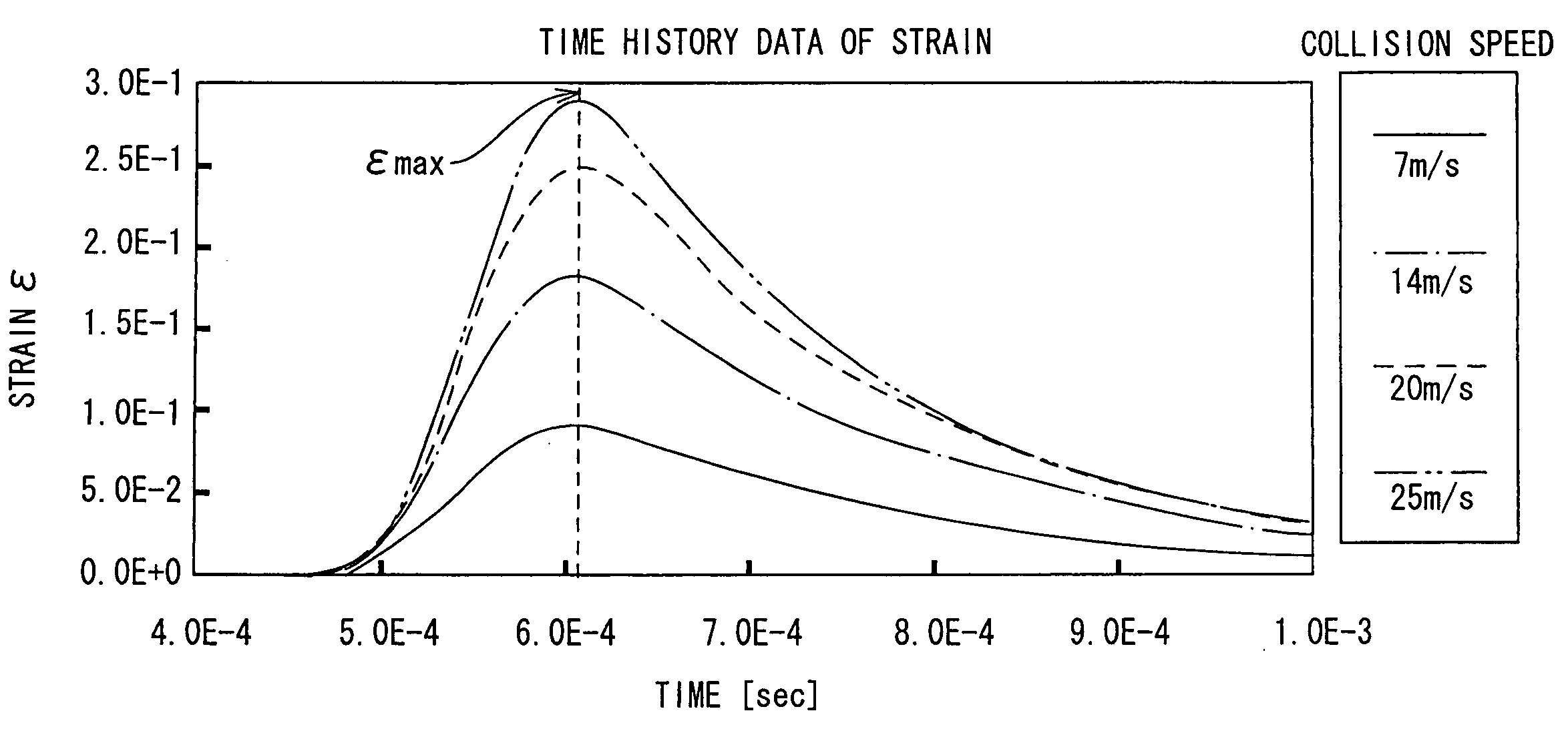

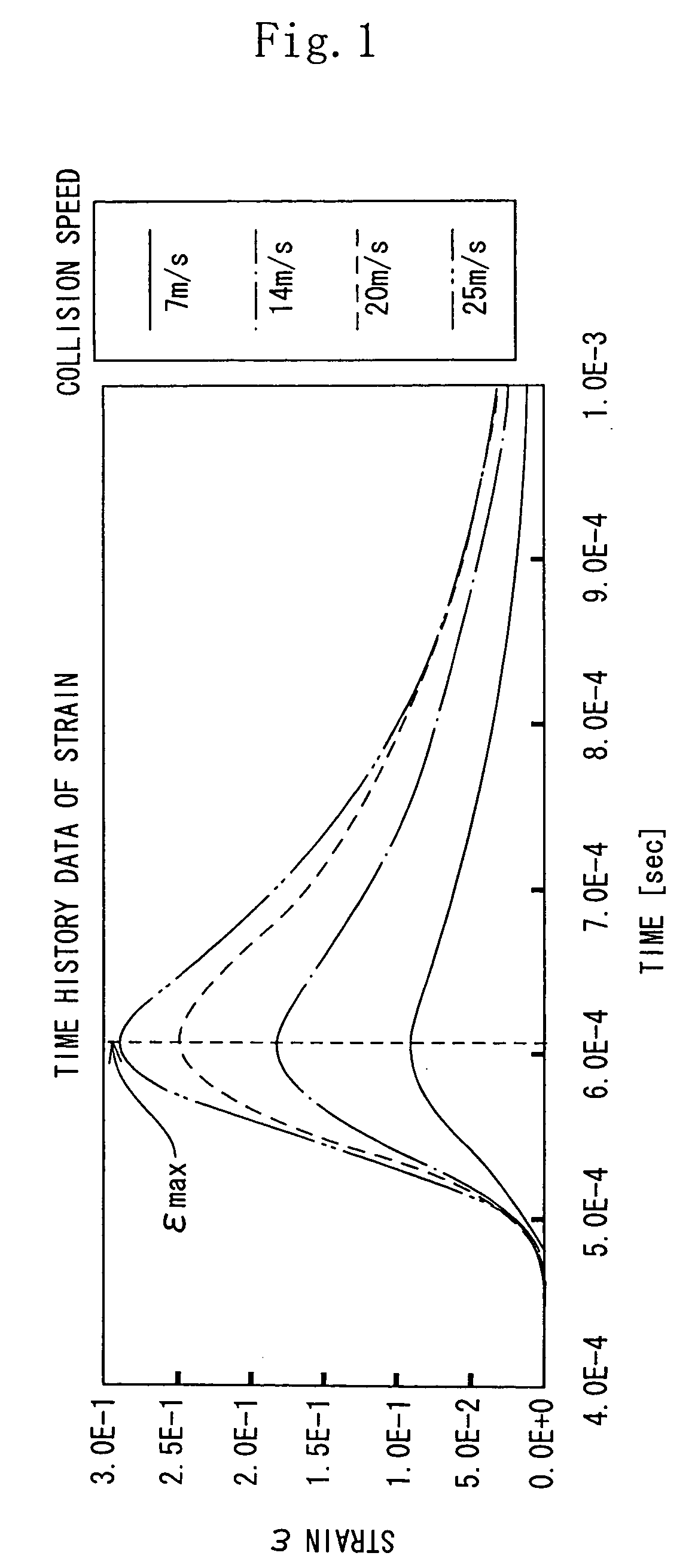

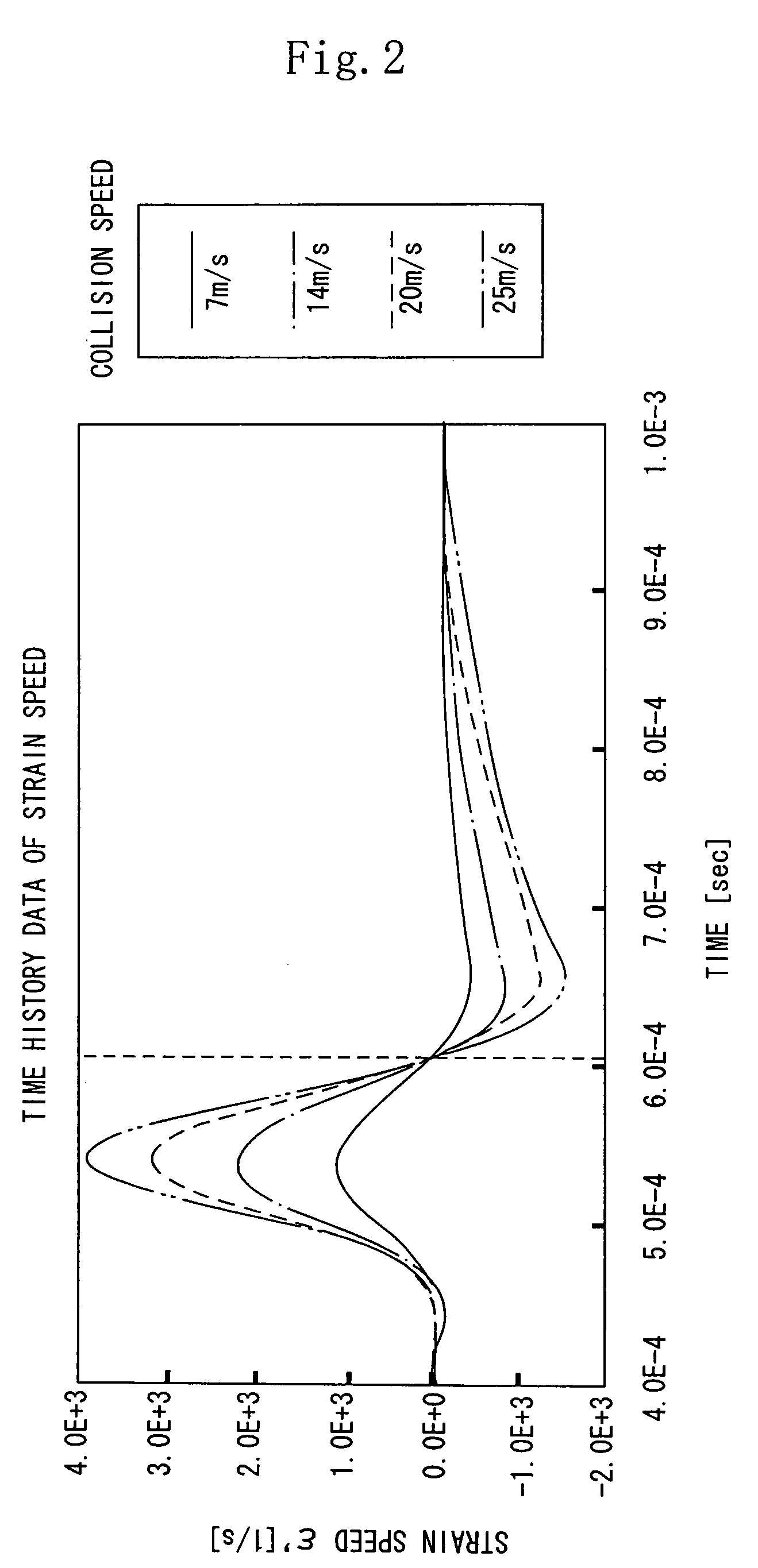

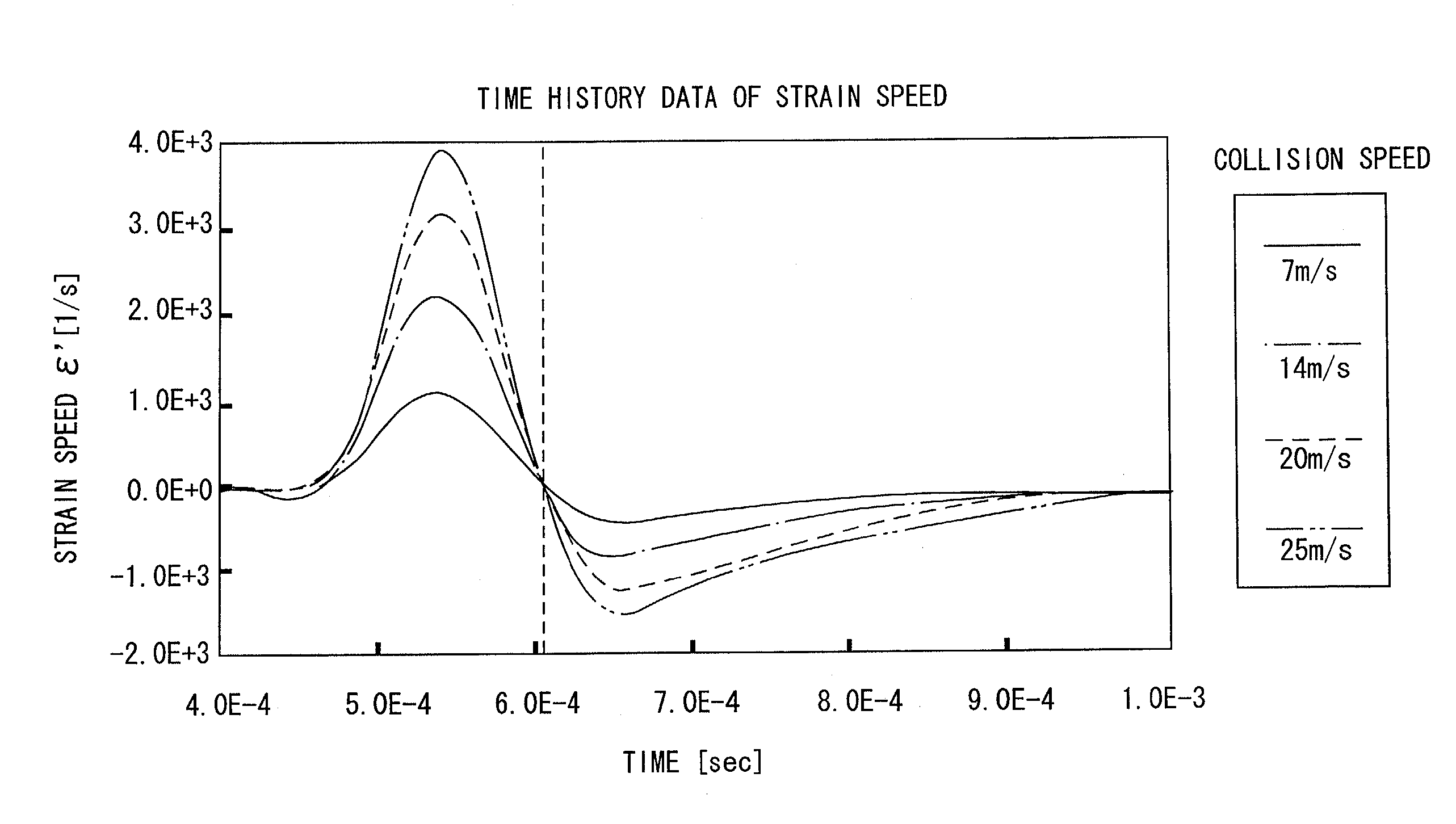

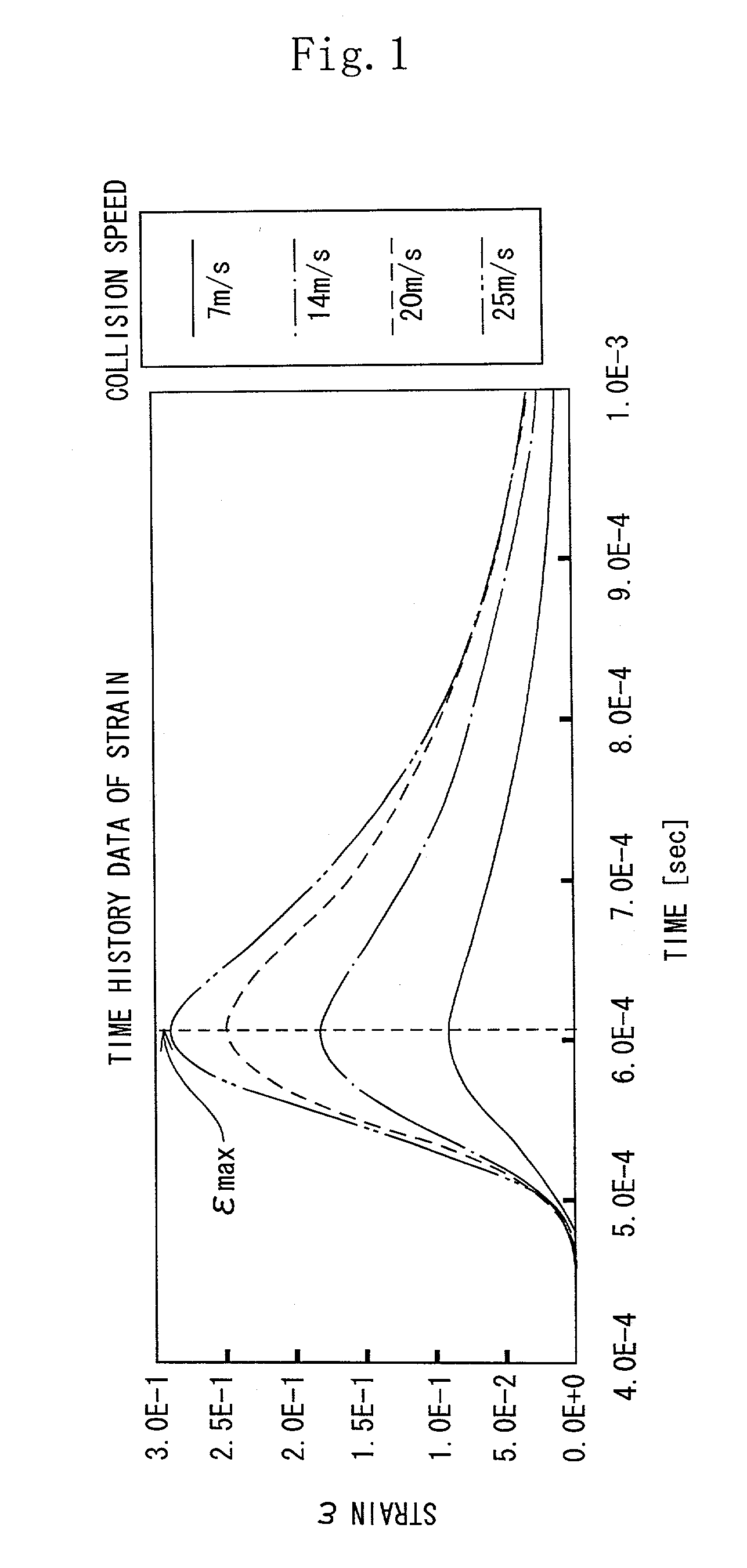

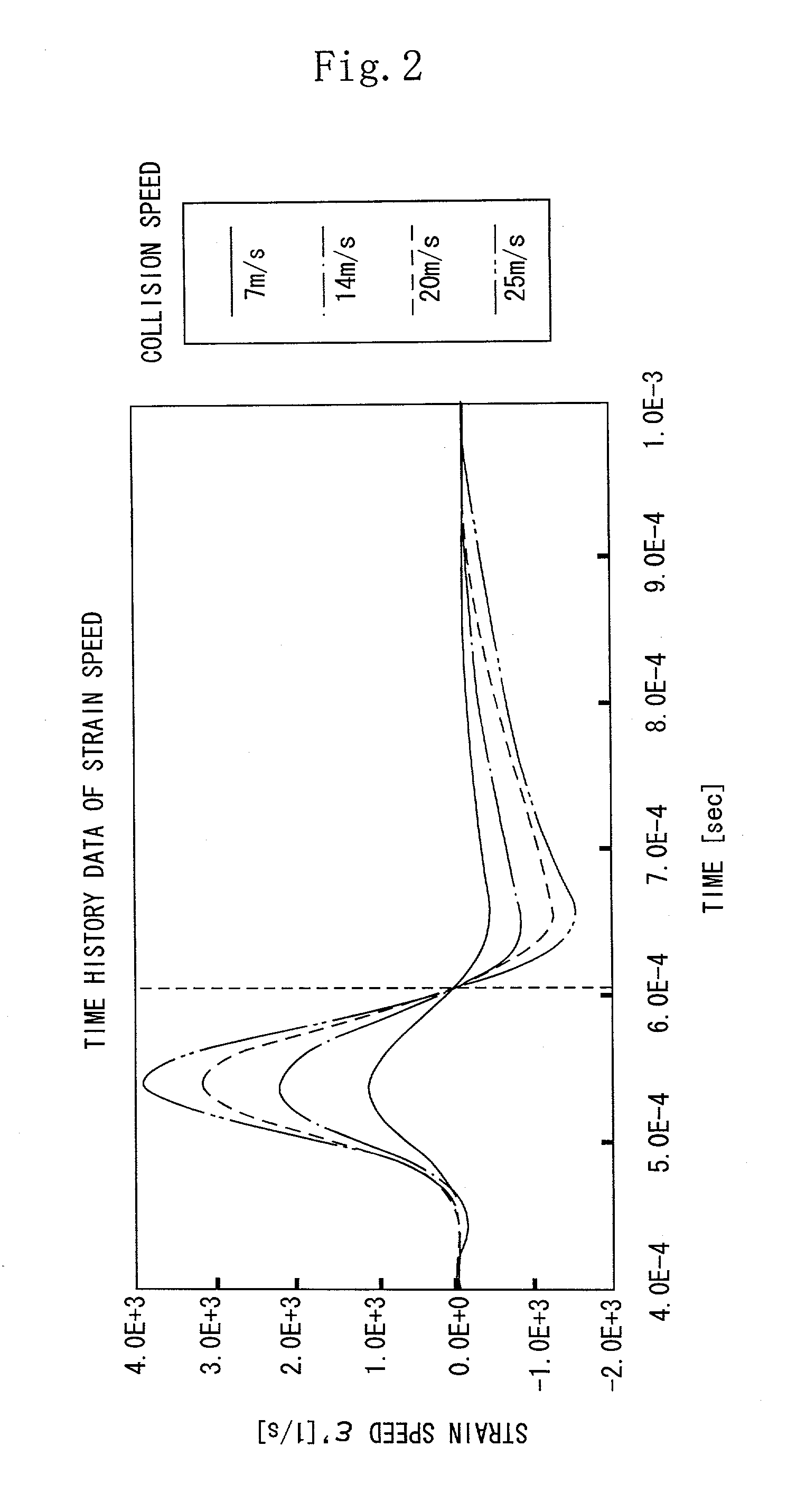

Simulation method for estimating performance of product made of viscoelastic material

InactiveUS20050004779A1Estimation precision can be improvedAccurate analysisForce measurementNuclear monitoringClassical mechanicsViscous resistance

A simulation method includes the step of momently measuring a value of each of a strain, a strain speed, and a stress generated in the viscoelastic material, deriving time history data of a viscous drag, the strain speed and the stress, thereby deriving a relationship among the strain, the strain speed, and the viscous drag and setting the product as a product model whose performance is analyzed; inputting the relationship to the product model; and computing a stress and strain of a deviation component by using a deviation main strain and a deviation main strain speed converted from an entire coordinate system into a main strain coordinate system and a main strain speed coordinate system respectively to thereby conduct a simulation in consideration of a change of the viscous drag which occurs in dependence of a variation of the strain and the strain speed.

Owner:DUNLOP SPORTS CO LTD

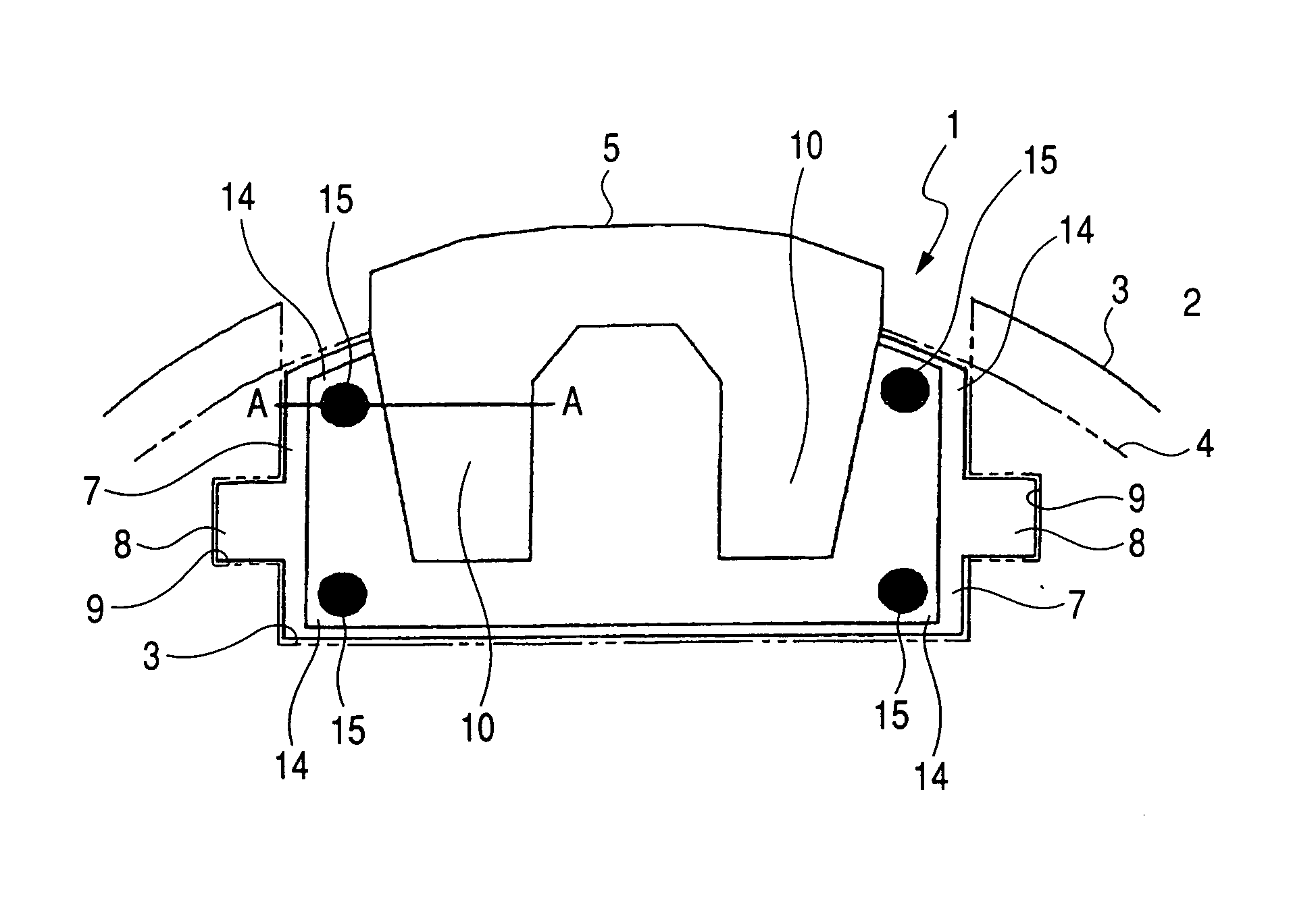

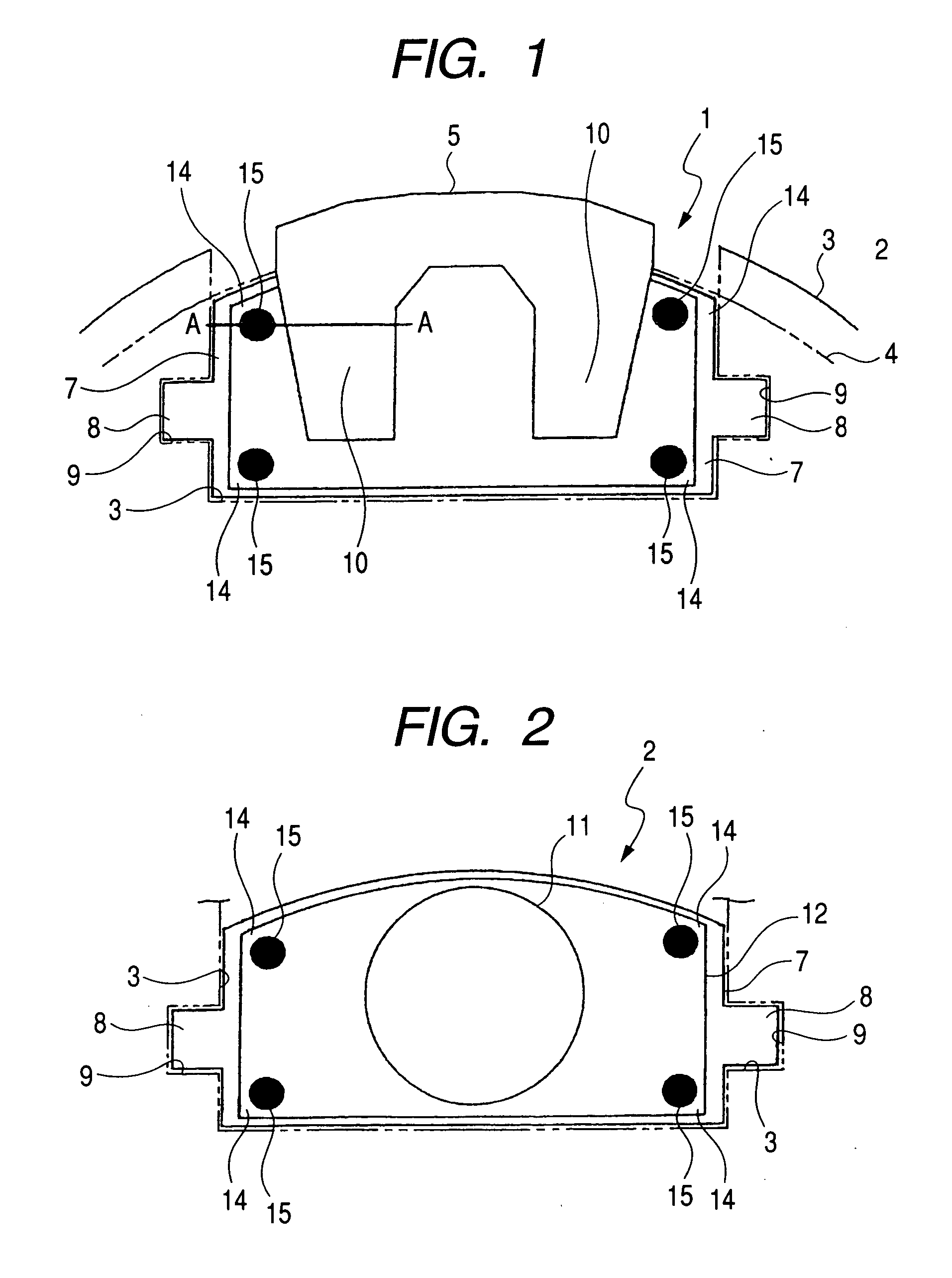

Disc brake pad

InactiveUS20070045063A1Effective preventionSimple and inexpensive structureNoise/vibration controlBraking membersEngineeringViscous resistance

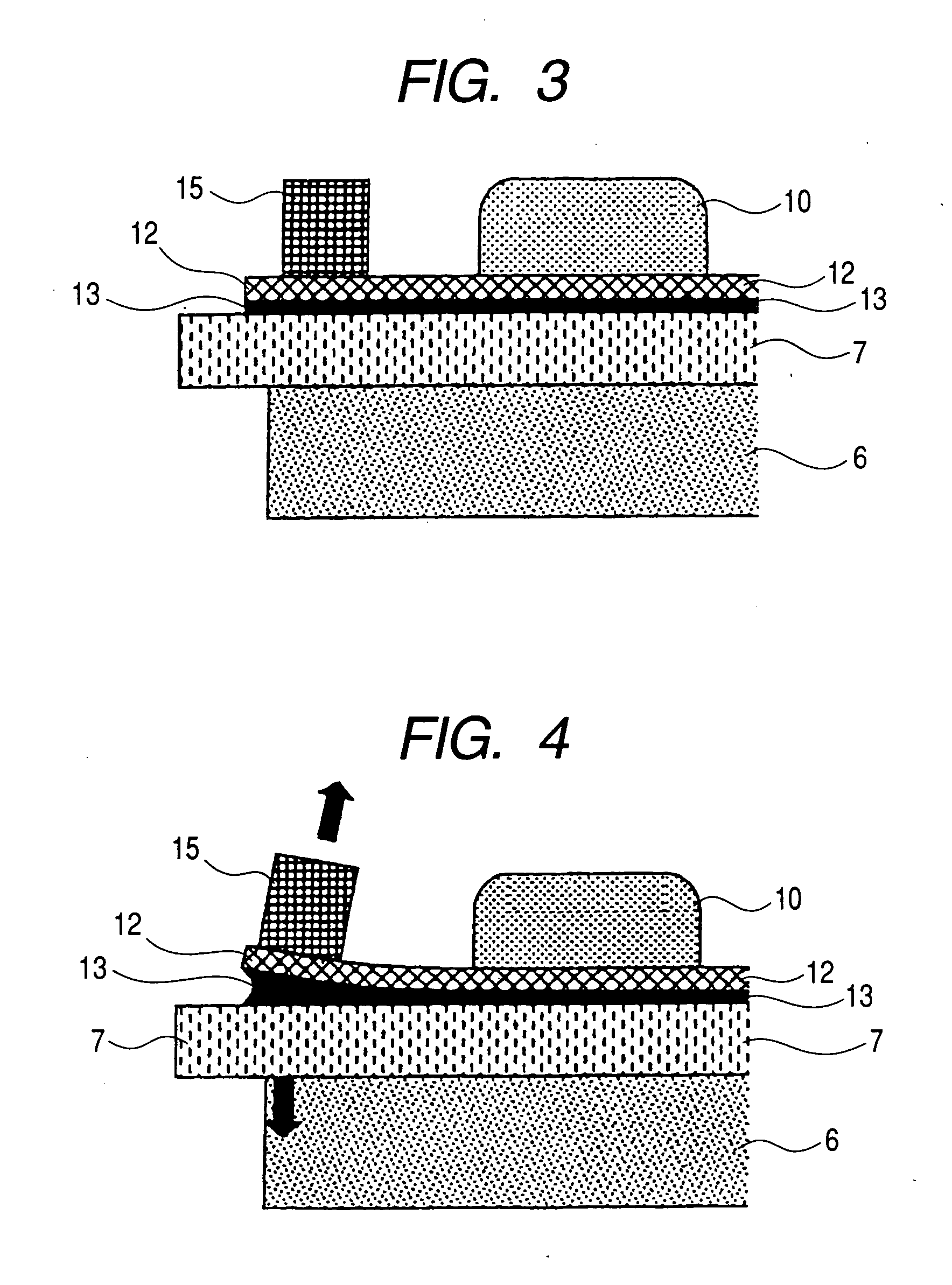

At four corners of a pressure plate 7, weights 15 are adhered an adhesive agent for high temperature use. When a frictional vibration is generated by frictionally engaging with a rotor in operating a brake, a shim 12 is displaced relative to a pressure plate 7 by inertia of the weight 14. Grease 13 between the shim 12 and the pressure plate 7 flows so as to produce a viscous resistance to a vibration of the shim 12 relative to the pressure plate 7. By the viscous resistance, the vibration of the pressure plate 7 is attenuated, as a result, brake squeal can be restrained from being brought about.

Owner:AKEBONO BRAKE IND CO LTD

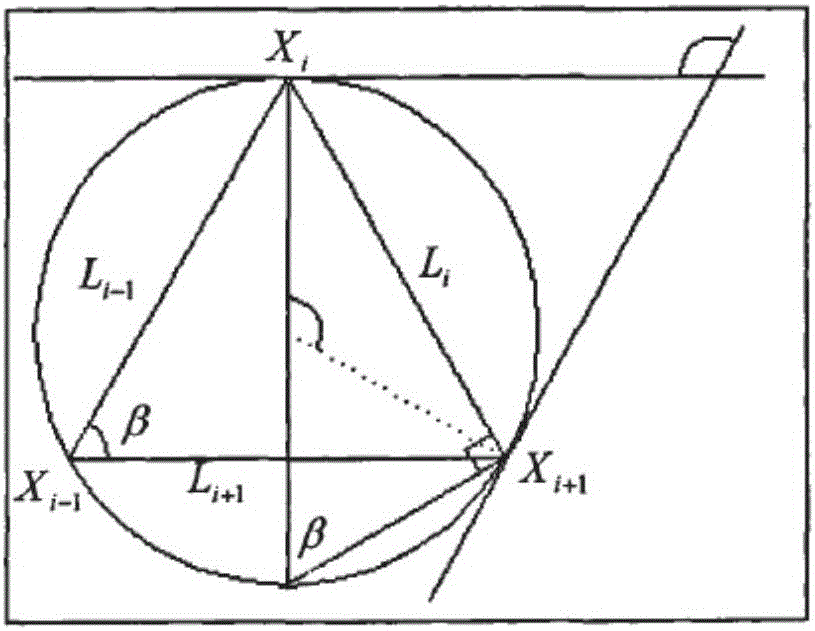

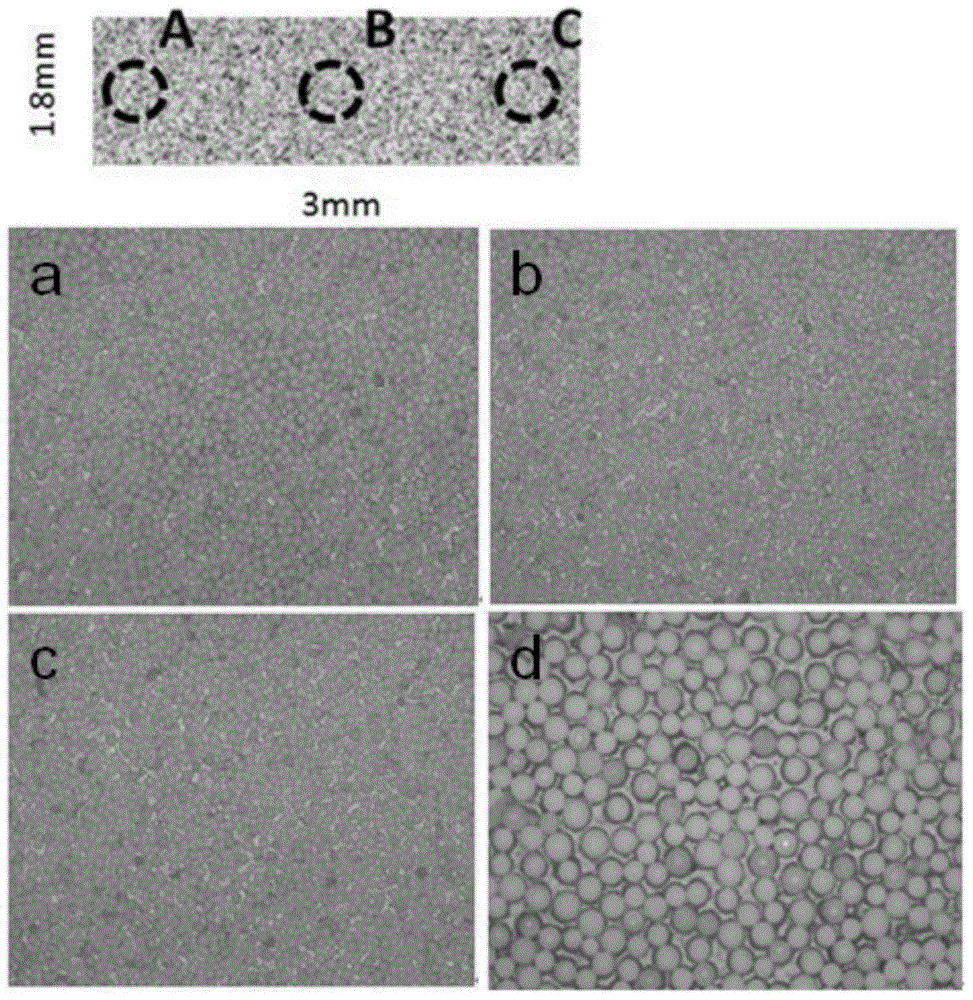

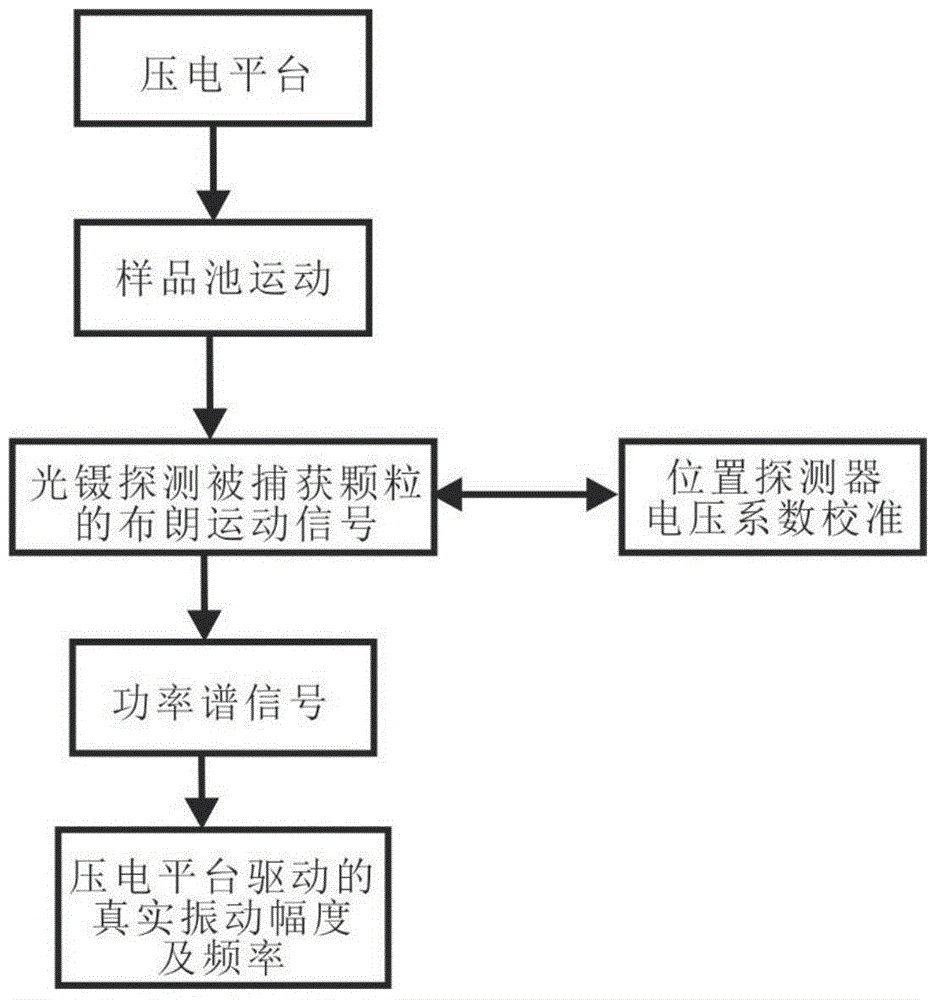

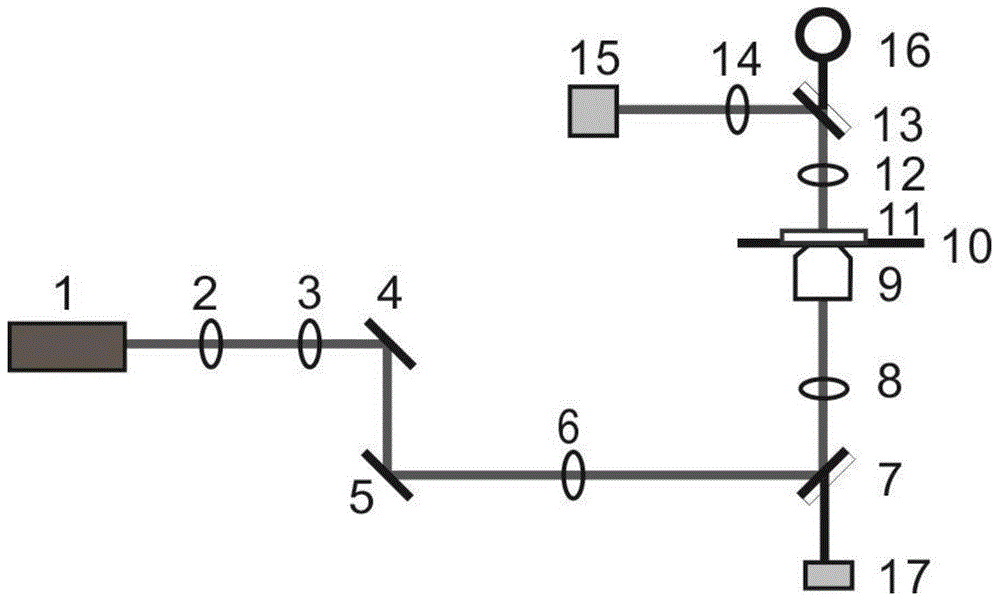

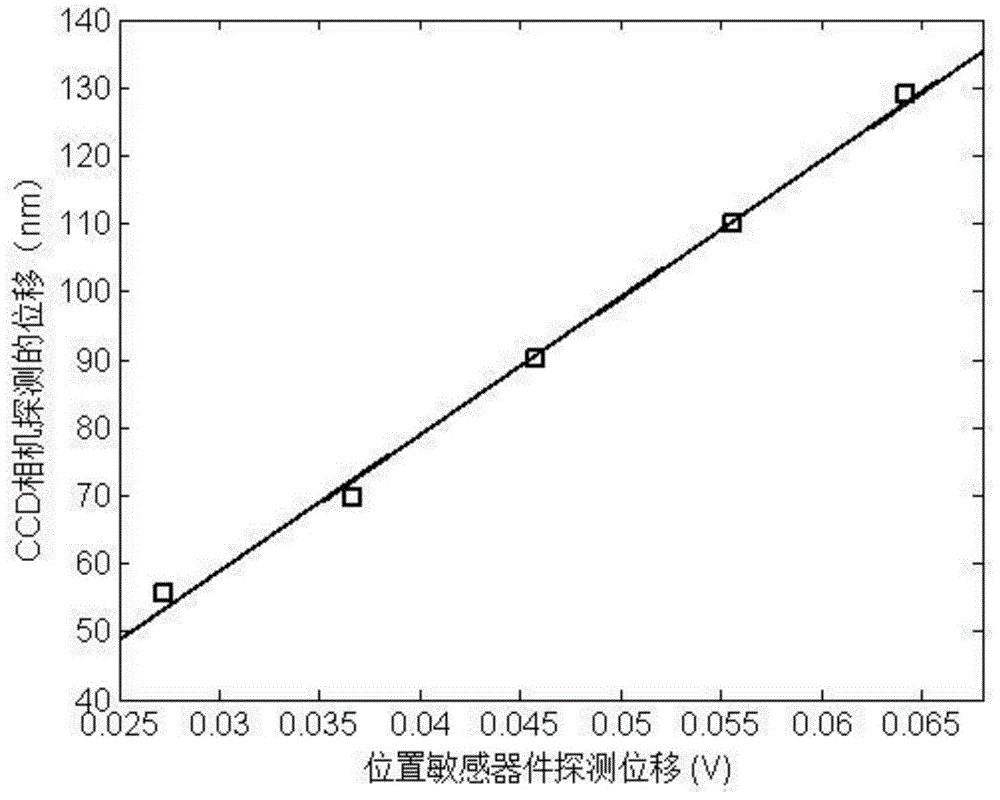

Optical trapping based method for in-situ calibration of displacement of piezoelectric platform

The invention provides an optical trapping based method for in-situ calibration of displacement of a piezoelectric platform. High-precision detection of motion displacement amplitude and frequency of the piezoelectric platform can be realized by analysis of position signals of Brownian motion of standard-size globules trapped in an optical trap system. Besides detection of the piezoelectric platform, standard particles are trapped by laser under microscopic imaging, and position motion signals of the particles are quickly detected by a detector. The piezoelectric platform sends low-frequency fixed-amplitude motion signals to drive a sample chamber to move, the particles trapped in a light trap is subjected to actions of fluid periodic viscous resistance, and voltage proportionality coefficient of a position sensitive detector can be calibrated by detecting the motion signals of the particles. The piezoelectric platform sends signals to drive the sampling chamber to move again, a power spectrum of the trapped particles is analyzed, a peak of the power spectrum is compared with background thermal noise to invert real motion displacement amplitude of the piezoelectric platform, and frequency of the peak stands for motion frequency of the piezoelectric platform.

Owner:UNIV OF SCI & TECH OF CHINA

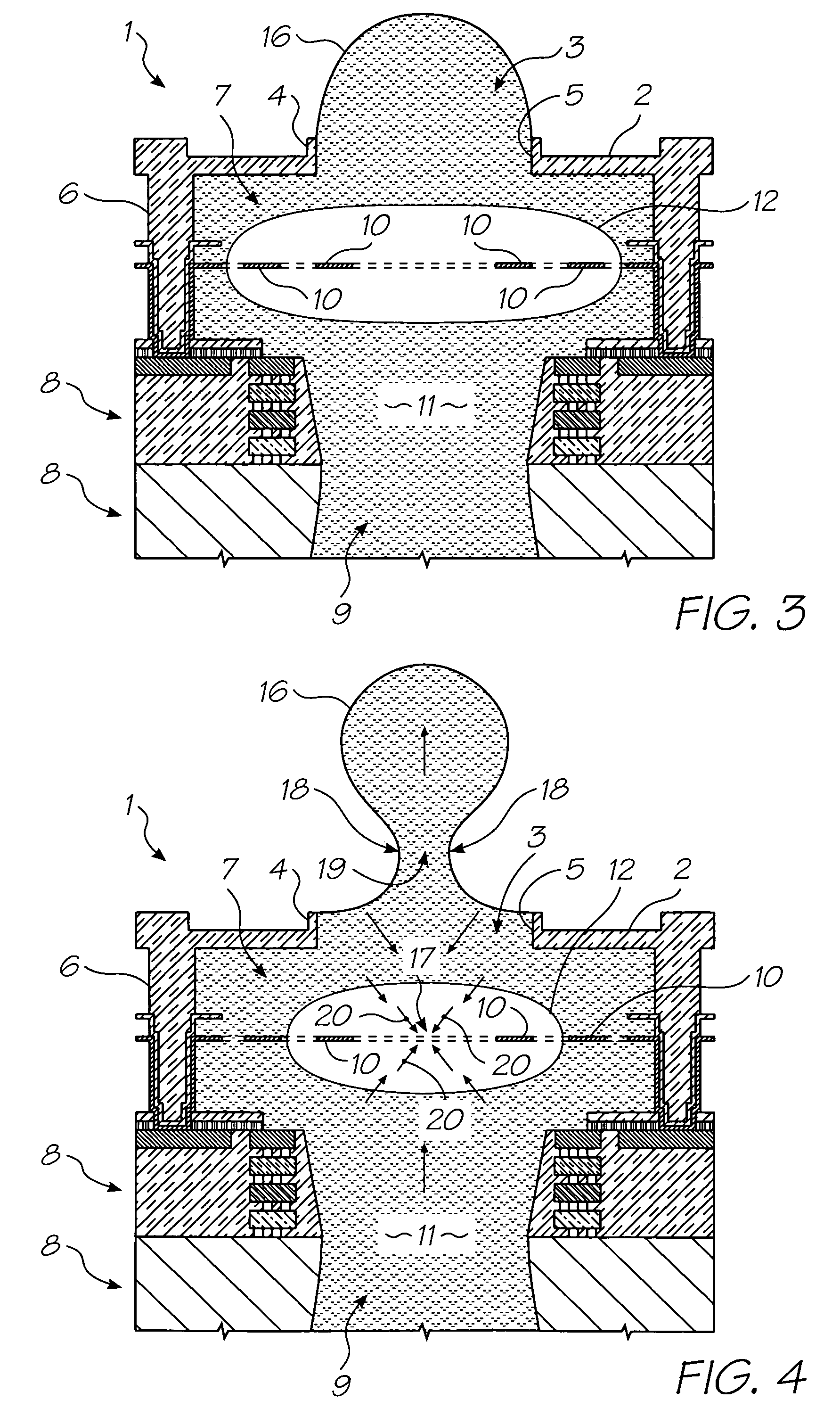

Printhead nozzle with reduced ink inertia and viscous drag

A thermal inkjet printhead with heater elements disposed in respective bubble forming chambers for heating part of the ejectable liquid above its boiling point to form a gas bubble that causes the ejection of a drop of the ejectable liquid from the nozzle, wherein, the heater is separated from the nozzle by less than 5 μm at their closest points; the nozzle length is less than 5 μm; and the ejectable liquid has a viscosity less than 5 cP. The volume of liquid between the heater and the nozzle determines the inertia of the liquid and its acceleration in response to bubble formation. Moving the heater closer to the nozzle reduces the inertia of the liquid and increases its acceleration, so a lower bubble impulse is needed to eject a drop. This allows the printhead to use smaller heater elements with lower power requirements. Viscous drag in the nozzle reduces the momentum of fluid flowing through the nozzle. The viscous drag increases as the nozzle length (in the direction of fluid flow) increases. By reducing the nozzle length, a lower bubble impulse is needed to eject a drop. This also allows the printhead to use smaller heater elements with lower power requirements.

Owner:MEMJET TECH LTD +1

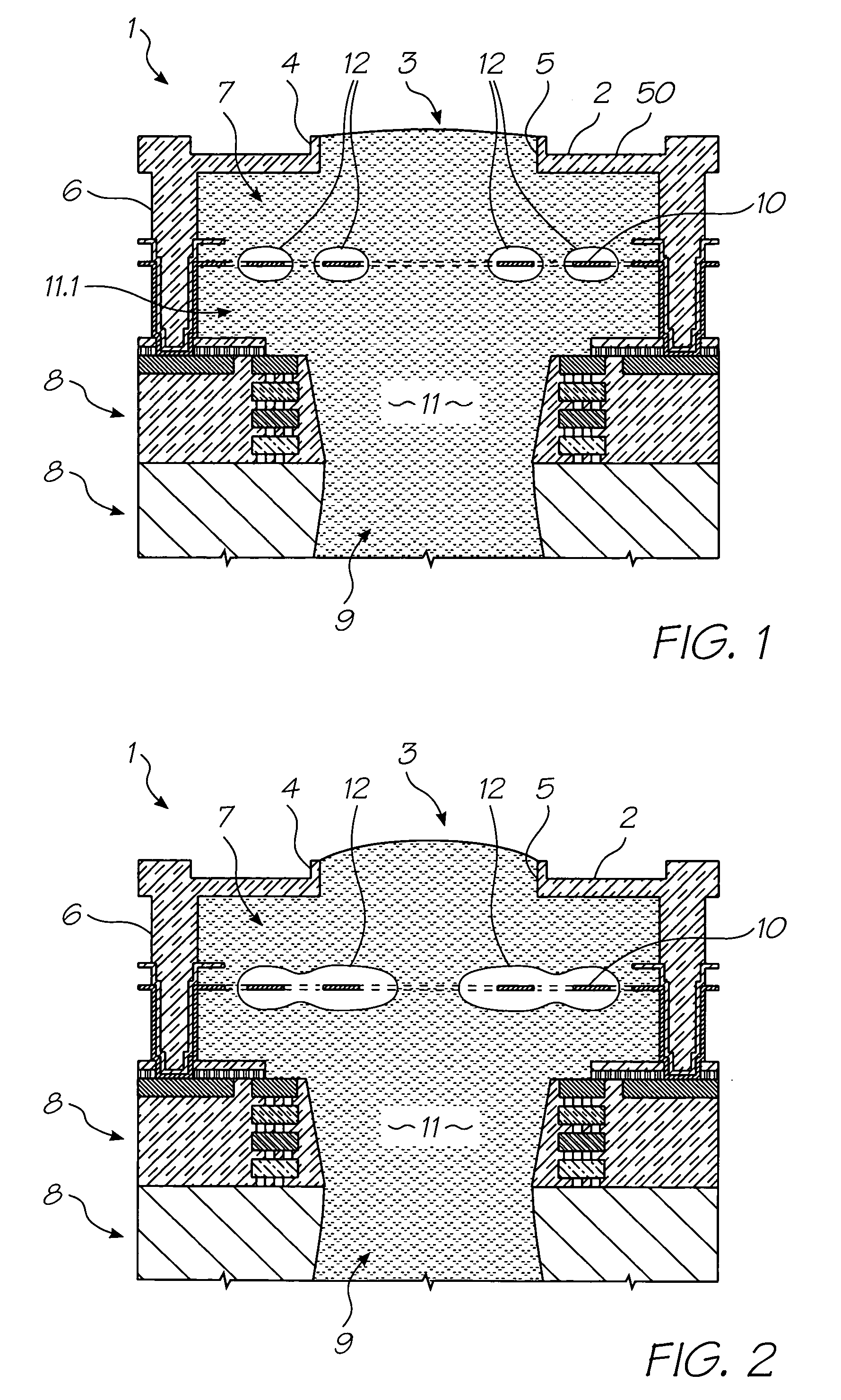

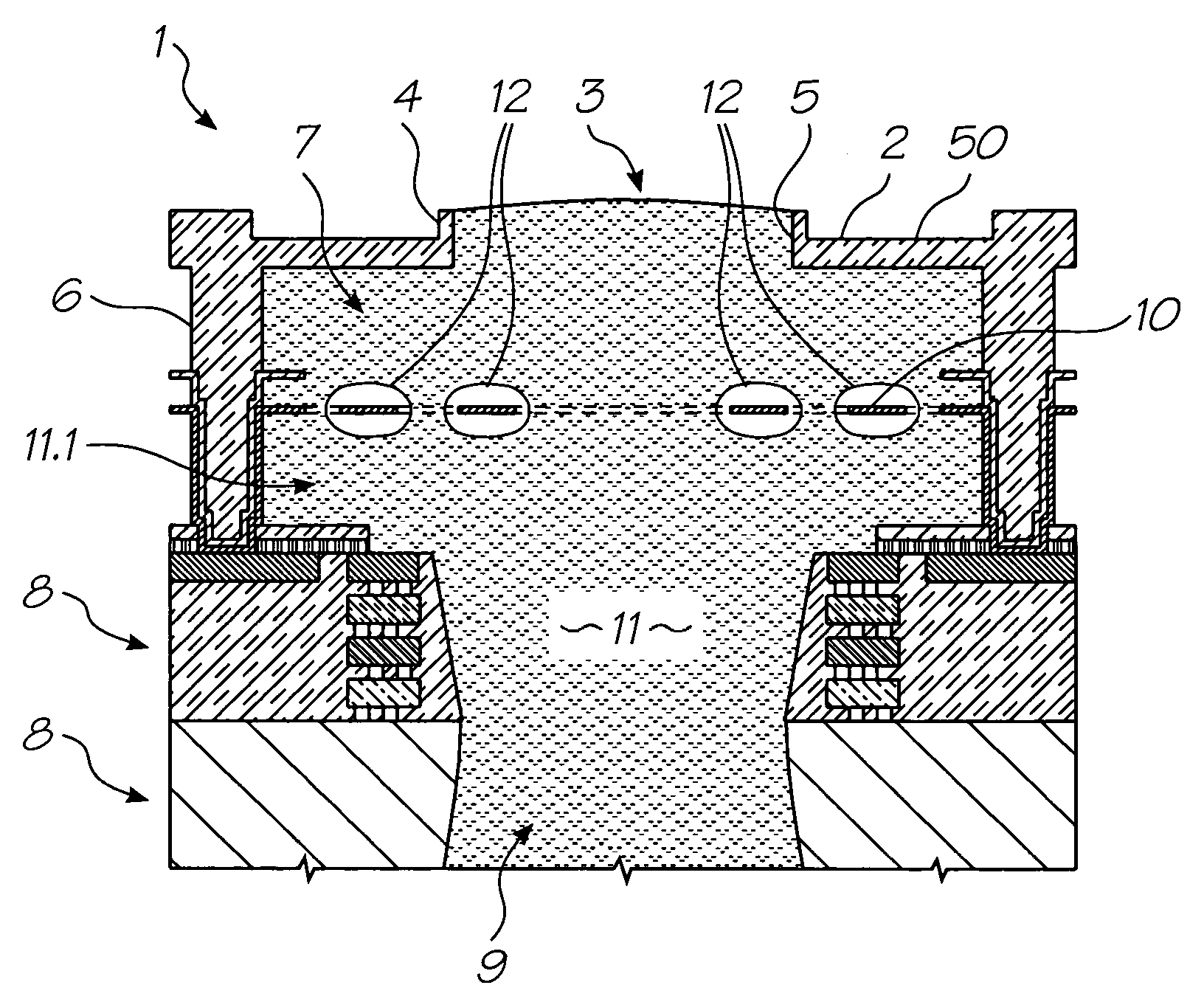

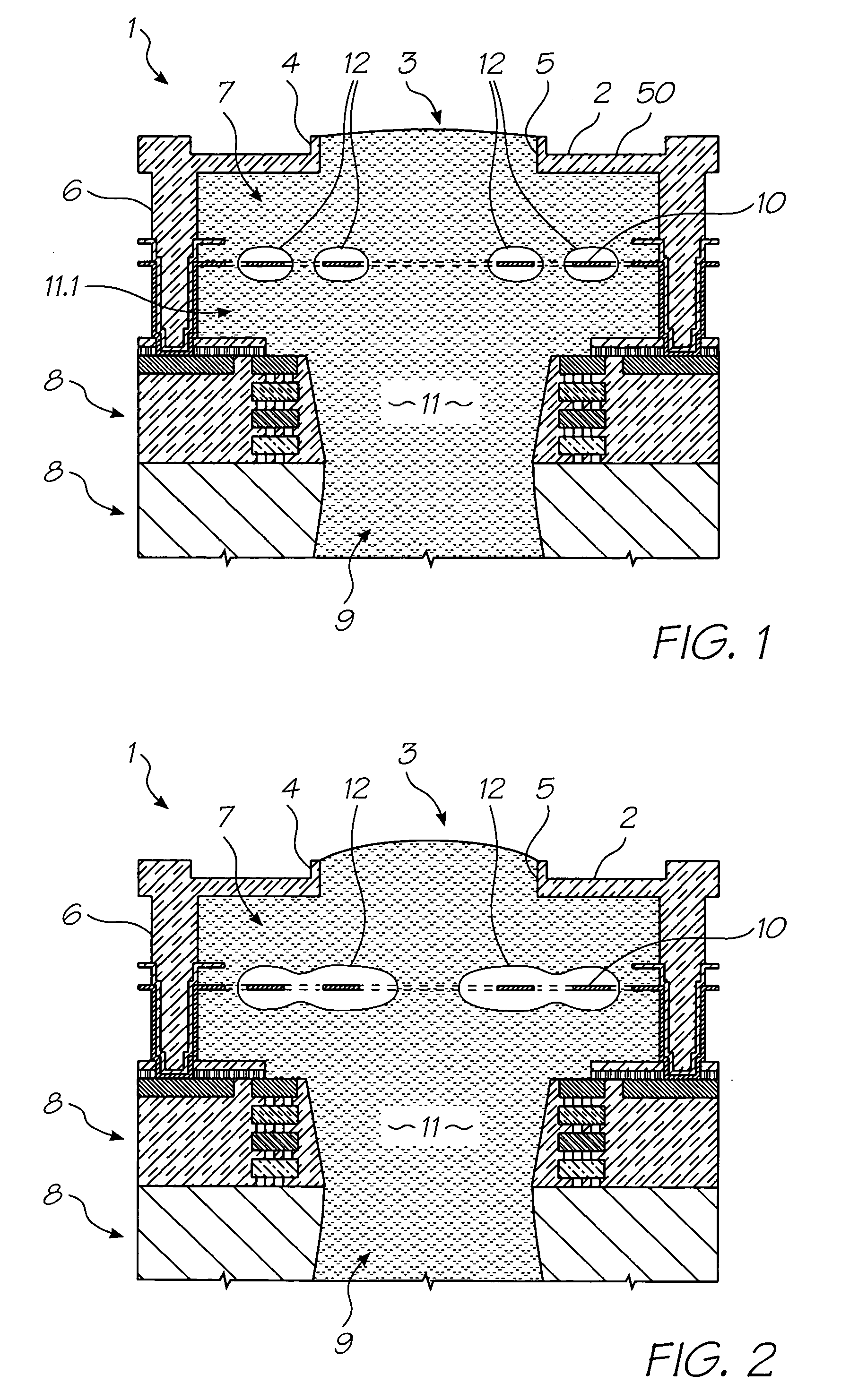

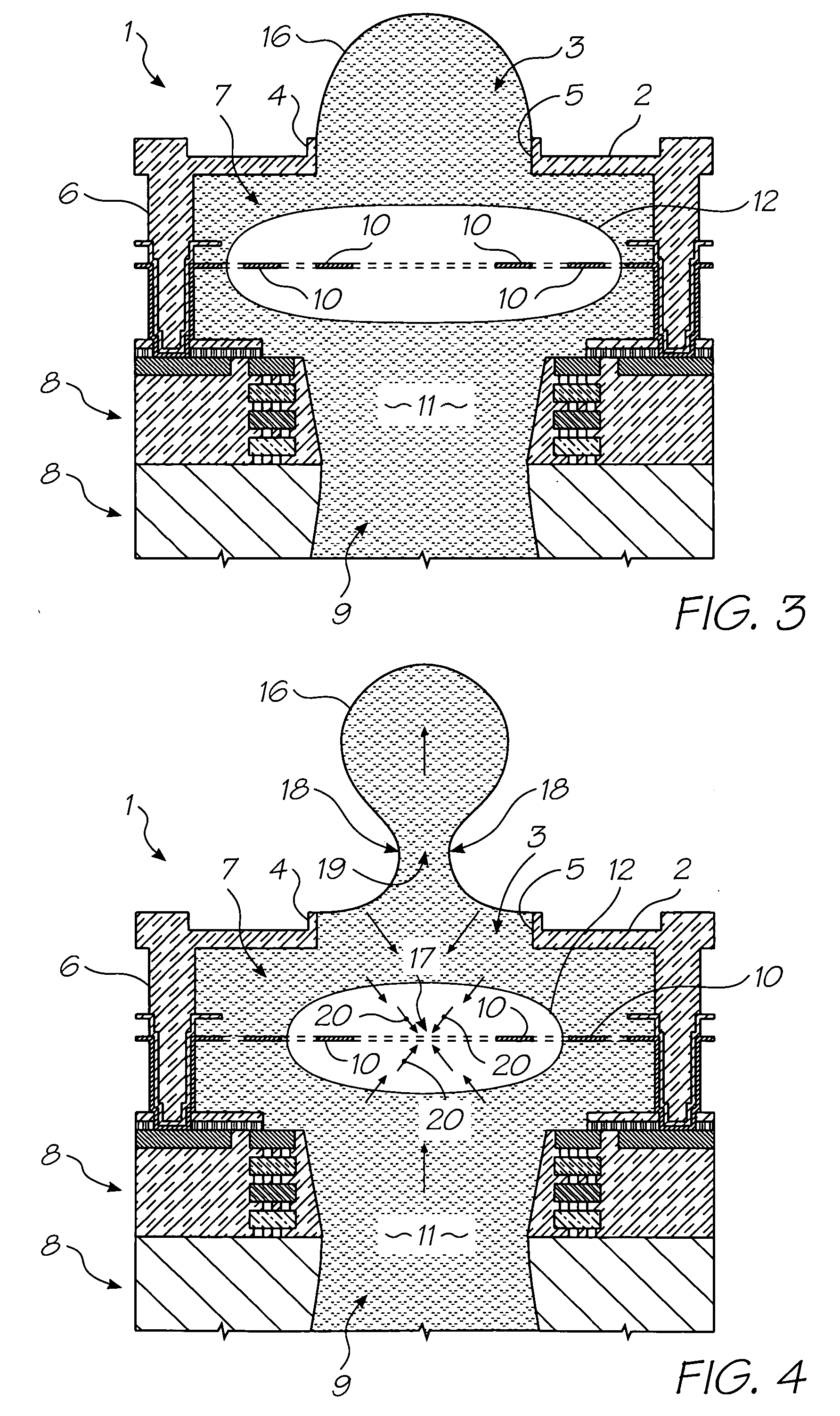

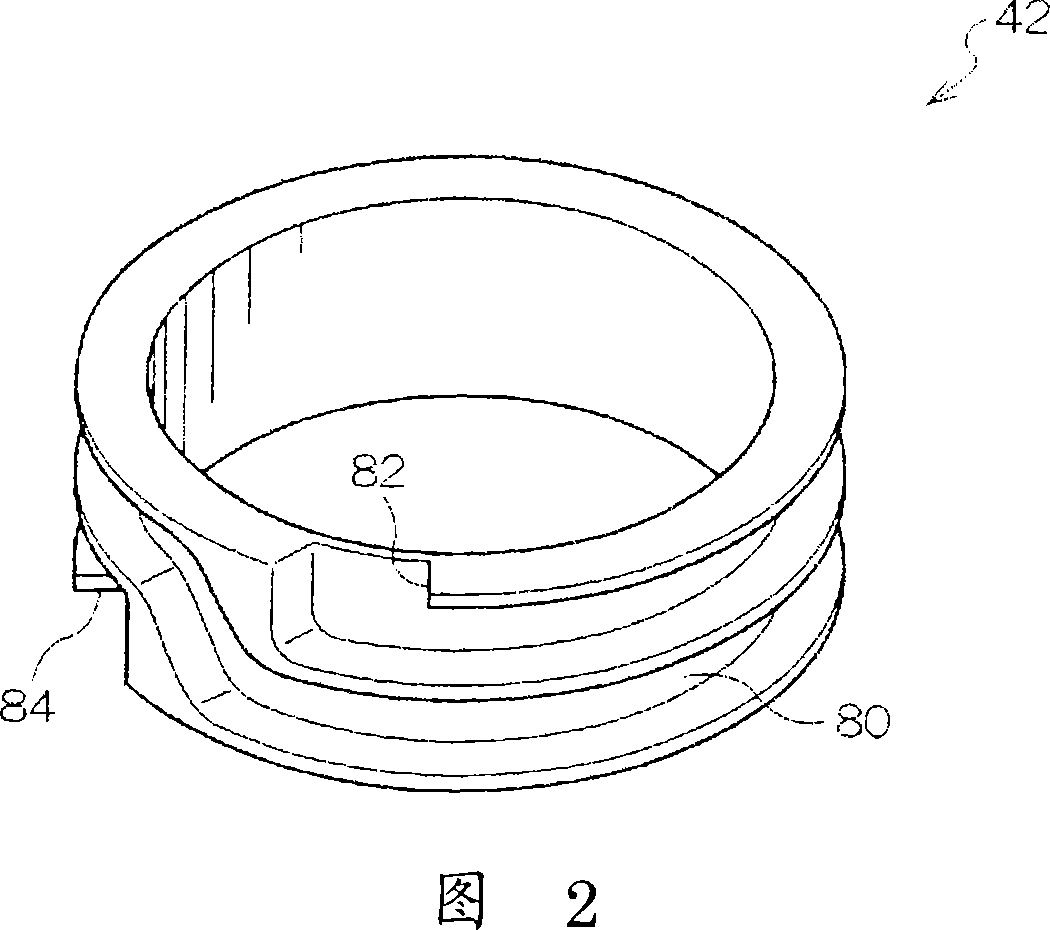

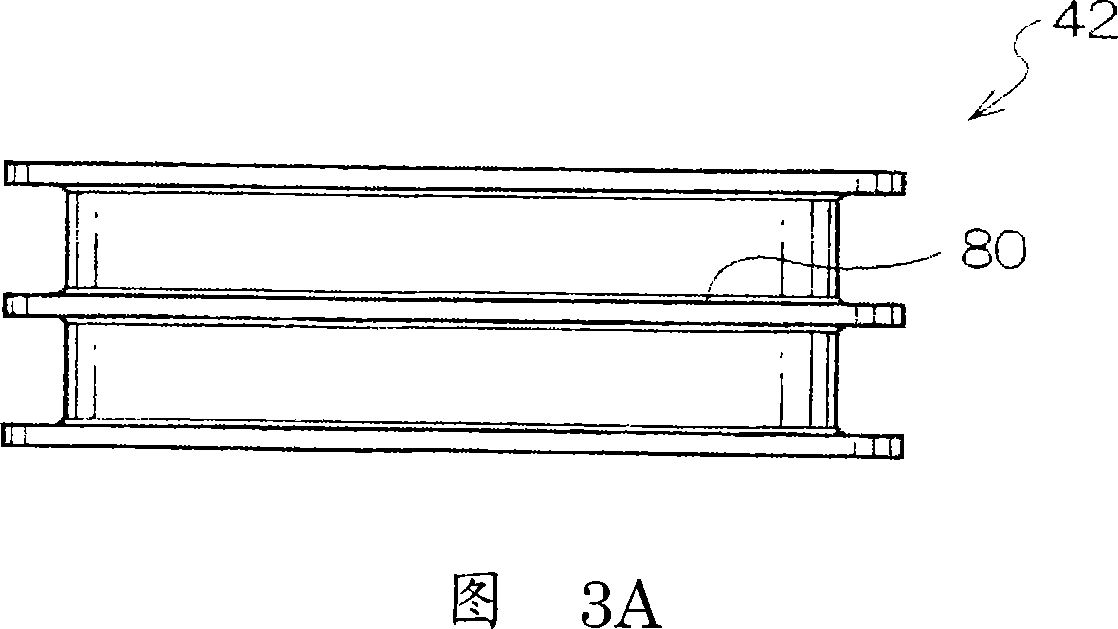

Vibration damper

ActiveCN101031734AInternal volume expands or shrinksIncrease intervalSpringsJet propulsion mountingElastomerResonance

The present invention can effectively attenuate and absorb an auxiliary vibration even in the case that the auxiliary vibration input along a direction approximately orthogonal to a main vibration input along an axial direction of the apparatus, in addition that it is possible to effectively attenuate and absorb the main vibration while suppressing an engagement of a size of the apparatus. In a vibration proofing apparatus (210), two second pressure receiving liquid chambers (302A, 302B) are arranged between an outer tube (224) and a mounting attachment (226), and two second pressure receiving liquid chambers (302A, 302B) are communicated with an auxiliary liquid chamber (272) through two second orifices (308A, 308B). Accordingly, if an auxiliary vibration along an auxiliary amplitude direction orthogonal to an axial direction is input to the mounting attachment (226) from an engine side, a rubber elastic body (222) is elastically deformed along an auxiliary amplitude direction, and expands and contracts an internal volume of the second pressure receiving liquid chambers (302A, 302B), and the liquid circulates in the second pressure receiving liquid chambers (302A, 302B) and the auxiliary liquid chamber (72) with each other through the second orifices (308A, 308B). At this time, since a resonance phenomenon is generated in the liquid circulating between the second pressure receiving liquid chambers (302A, 302B) and the auxiliary liquid chamber (272) through the second orifices (308A, 308B) in synchronization with the input auxiliary vibration, it is possible to particularly effectively absorb a low-frequency vibration input along the auxiliary amplitude direction due to a pressure change, a viscous resistance and the like generated together with the resonance phenomenon of the liquid.

Owner:BRIDGESTONE CORP +1

Simulation method for estimating performance of product made of viscoelastic material

InactiveUS20040254745A1Accurate expressionEstimate performance of product madeForce measurementDigital computer detailsViscous resistanceEngineering

A simulation method of estimating performance of a product made of a viscoelastic material, comprising the steps of measuring a value of a strain, a strain speed, and a stress generated in viscoelastic material momently in a measuring condition equivalent to a state in which the product is actually used; deriving time history data of a viscosity resistance of the viscoelastic material separately in each of a strain increase state and a strain decrease state from time history data of the strain, the strain speed, and the stress and a viscoelastic model set in consideration of a viscosity of the viscoelastic material; setting the product as a product model whose performance is analyzed and inputting a relationship among the strain, the strain speed, and the viscosity resistance to the product model to conduct a simulation in consideration of a phenomenon that the viscosity resistance changes in dependence on a variation of the strain and the strain speed and in consideration of a difference in the viscosity resistance between a strain increase state and a strain decrease state.

Owner:DUNLOP SPORTS CO LTD

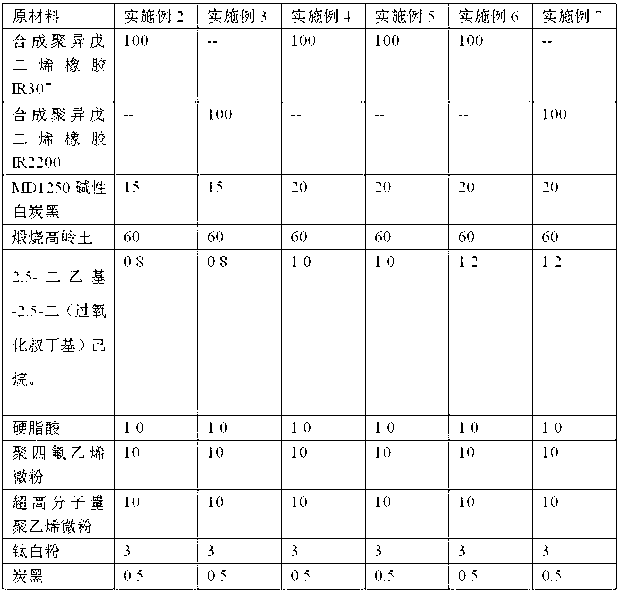

Rubber syringe needle protective cap for pre-encapsulation injection syringe and production method thereof

ActiveCN103232623AIncreased degree of vulcanizationSpeed up vulcanizationPolymer scienceSmell problems

The invention discloses a rubber syringe needle protective cap for a pre-encapsulation injection syringe. The protective cap is prepared from the following raw materials in parts by weight: 100 parts of synthesized polyisoprene rubber, 5-30 parts of alkaline white carbon black, 20-70 parts of calcined kaolin, 0.3-1.2 parts of peroxide, 0.5-1.0 part of stearic acid, 5-20 parts of polytetrafluoroethylene micro powder, 5-20 parts of ultra-high molecular weight polyethylene micro powder, 1-5 parts of titanium dioxide and 1-3 parts of carbon black. The rubber syringe needle protective cap has the obvious characteristics that a clean and simple peroxide sulfuration system is adopted, and a conventional complicated sulfur and zinc oxide promotion system is avoided. Special alkaline fillers are adopted, the sulfuration degree and speed of rubber are improved, and a smell problem caused by adopting the peroxide to sulfurate the polyisoprene rubber is reduced. The polytetrafluoroethylene micro powder and the ultra-high molecular weight polyethylene micro powder with good inertness and dispersibility are added into a formula, the lubricity and chemical inertness of the rubber are improved, and the viscous resistance of a rubber syringe needle protective cap product is improved.

Owner:郑州翱翔医药科技股份有限公司

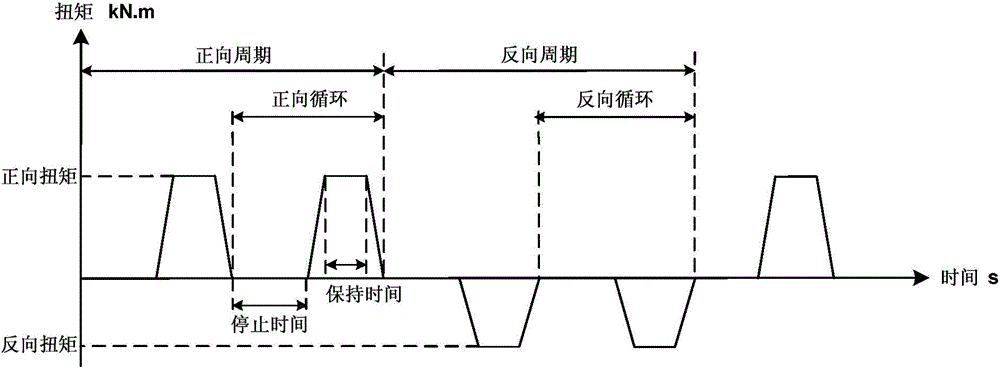

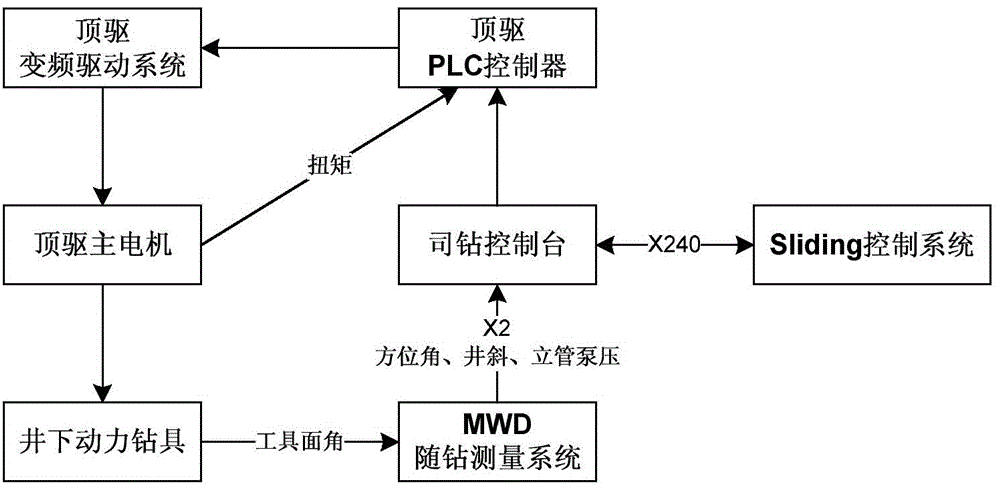

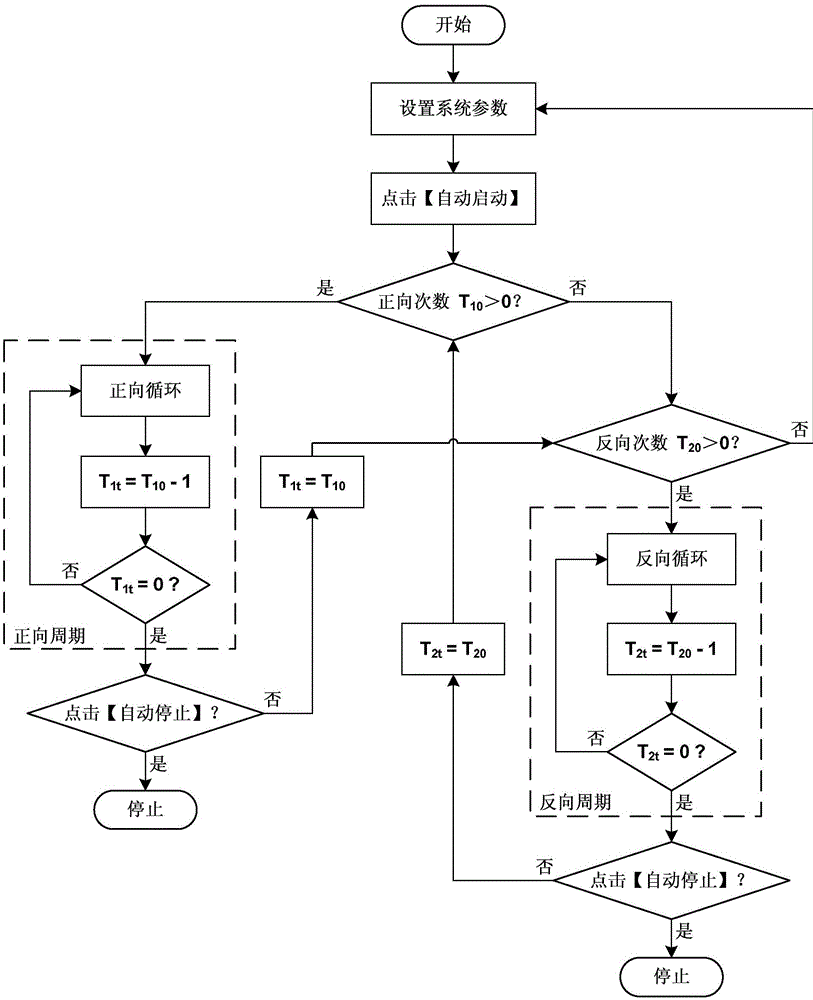

Method for controlling oil and gas well drilling to reduce drill string viscous resistance

ActiveCN104420861AReduce the impactGuaranteed to remain unchangedConstructionsRotary drillingWell drillingViscous resistance

The invention discloses a method for controlling oil and gas well drilling to reduce drill string viscous resistance, and belongs to the field of the oil and gas well drilling technology. A top drive device (or rotating disc) is adopted to drive a drill string to rotate forwardly and reversely according to the set rotating manner; through mud-pulse signals, a tool face angle of a power motor, an azimuth angle and well deviation which are monitored by a directional sensor in an MWD and vertical pipe pump pressure are fed to a ground controller through the digital quantity signal mode and are matched with upper portion drill string torque monitored by the top drive (or rotating disc), and through the method that a top drive main shaft (or rotating disc square drill rod) is controlled to forwardly rotate or reversely rotate, the drill string is rotated forwardly or reversely, so that the tool angle face of the well drilling motor is changed, the azimuth angle and the well deviation are adjusted or corrected, and the drill string viscous resistance is reduced; the top drive main shaft is controlled to forwardly rotate by the set angle and the set number of turns, and after being in place, the top drive main shaft rotates reversely to the initial position, and forward cycling is formed. According to the method, influence of manual factors on well drilling work is reduced, and the drilling efficiency and the production safety are improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Simulation method for estimating performance of product made of viscoelastic material

InactiveUS20030055601A1Accurate expressionEstimate performance of product madeNuclear monitoringDigital computer detailsViscous resistanceEngineering

A simulation method of estimating performance of a product made of a viscoelastic material, comprising the steps of measuring a value of a strain, a strain speed, and a stress generated in viscoelastic material momently in a measuring condition equivalent to a state in which the product is actually used; deriving time history data of a viscosity resistance of the viscoelastic material separately in each of a strain increase state and a strain decrease state from time history data of the strain, the strain speed, and the stress and a viscoelastic model set in consideration of a viscosity of the viscoelastic material; setting the product as a product model whose performance is analyzed and inputting a relationship among the strain, the strain speed, and the viscosity resistance to the product model to conduct a simulation in consideration of a phenomenon that the viscosity resistance changes in dependence on a variation of the strain and the strain speed and in consideration of a difference in the viscosity resistance between a strain increase state and a strain decrease state.

Owner:DUNLOP SPORTS CO LTD

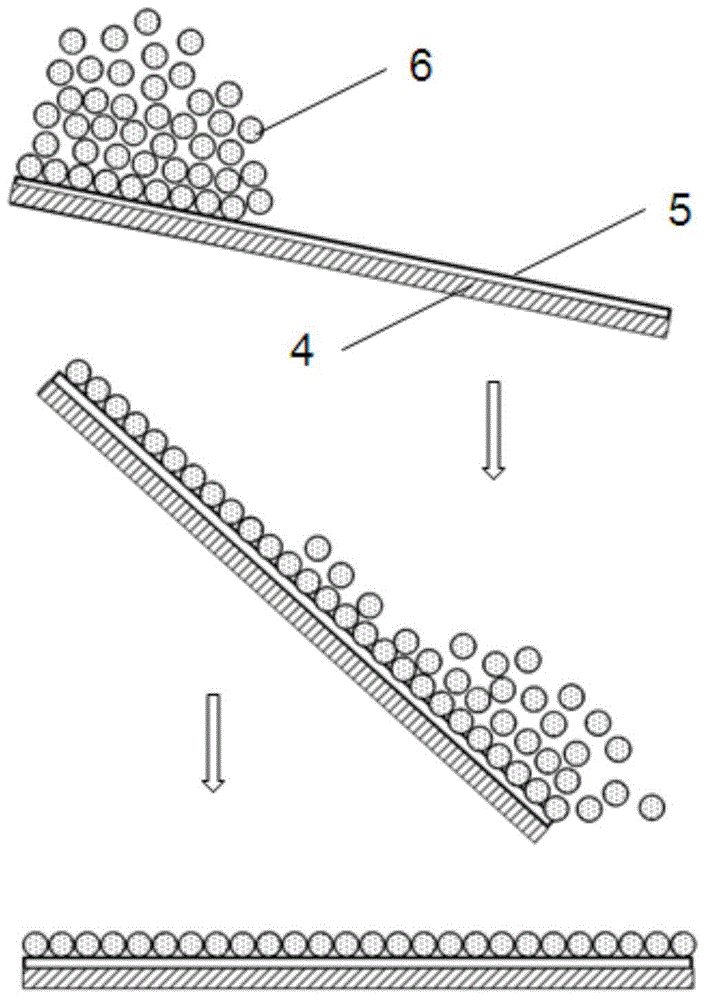

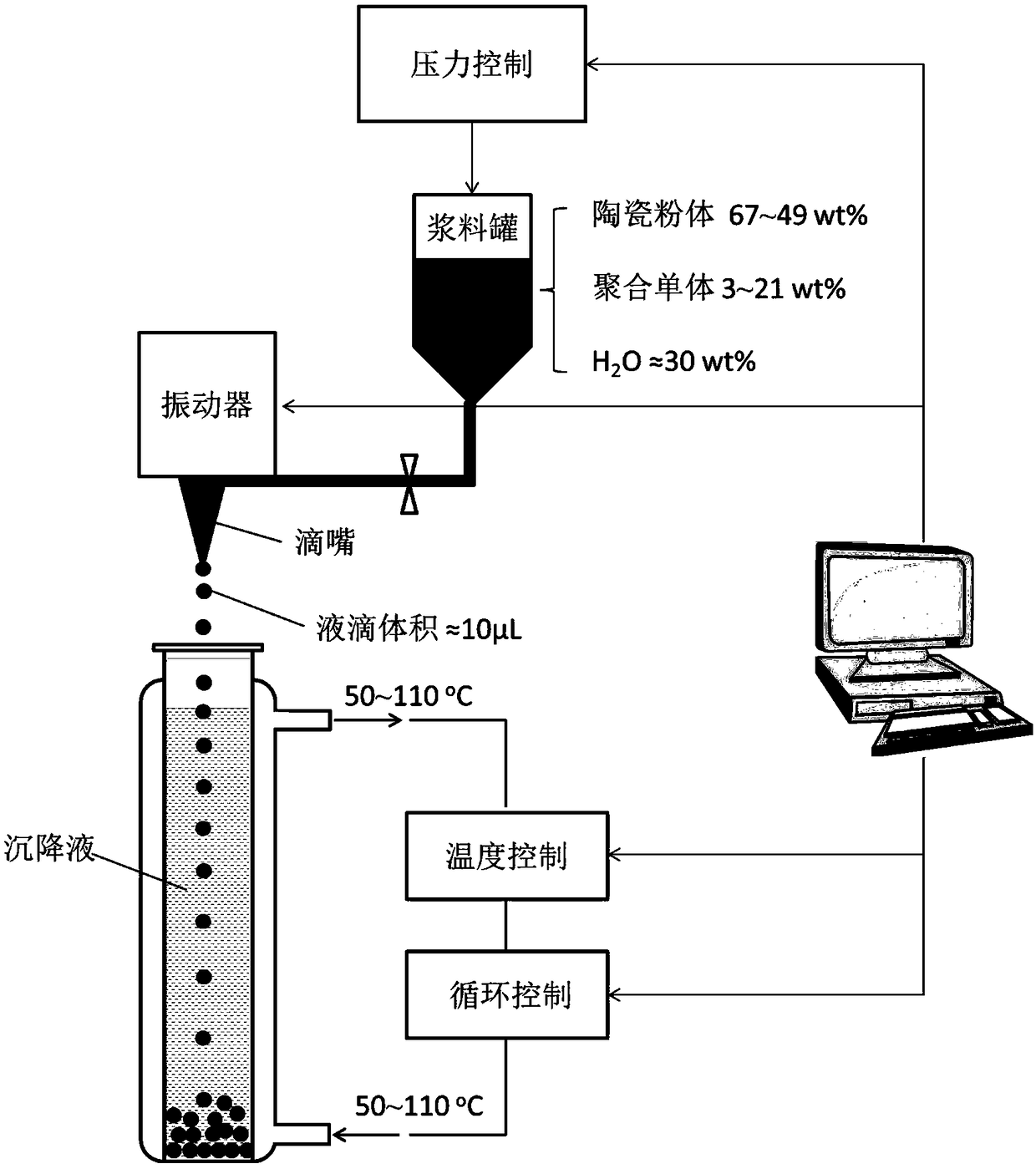

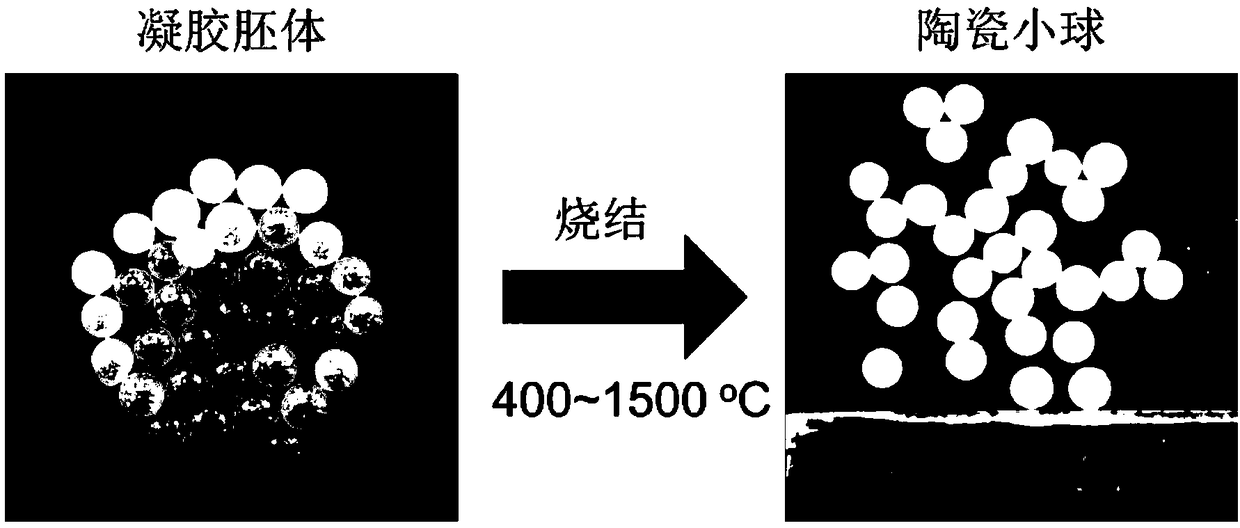

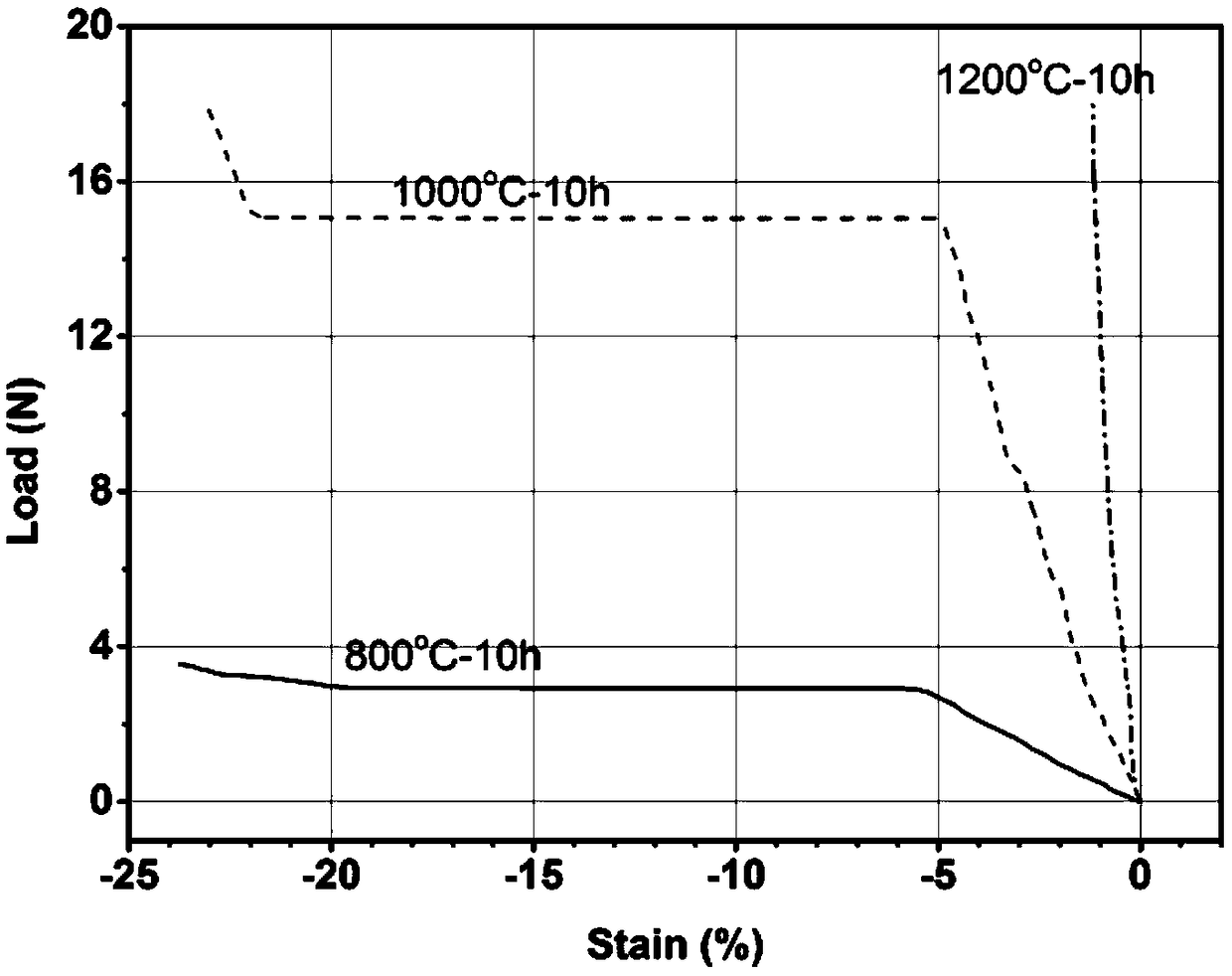

Preparation method of tritium multiplication ceramic pellet in fusion reactor solid blanket

InactiveCN108751975ASimple processHigh sphericityNuclear energy generationThermonuclear fusion reactorLithium oxideViscous liquid

The invention discloses a preparation method of a tritium multiplication ceramic pellet in a fusion reactor solid blanket. A polymer auxiliary settling method is used; a micron order lithium oxide tritium multiplication ceramic powder is used as raw materials; during the ceramic slurry preparation, polymerizable organic monomers are added. When slurry liquid is dropped in viscous liquid and falls,the gravity, the liquid buoyancy and the viscous resistance are balanced, so that slurry liquid drops with high sphericity degree are obtained. Meanwhile, in the falling process, the spherical liquiddrops are polymerized to be cured into a pellet blank. In the sintering process, the pellet blank is subjected to ceramic treatment; the ceramic pellet with high sphericity degree is obtained. By optimizing the technological process and sintering schedule, the mechanical strength, the sphericility degree and the porosity of the pellet can be further improved. The preparation conditions of the pellet blank are mild; in the settling process, the two processes of palletization and curing are simultaneously completed; the purification and transfer processes of the ceramic pellet are simplified; the obtained product has high sphericility degree, particle diameter uniformity, high porosity and high mechanical strength; the industrial production is convenient.

Owner:ANHUI UNIVERSITY

Three-dimensional digital ship model virtual resistance experiment method and system

ActiveCN110118639ARealize measurementAvoid the influence of scale effectHydrodynamic testingMarine engineeringWave-making resistance

The invention discloses a three-dimensional digital ship model virtual resistance test method and system, and belongs to the field of surface ship resistance performance experiments. The method comprises the following steps of (1) establishing digital ship models and flow field calculation domains where the digital ship models are located; (2) arranging full-structured hexahedral grids in the flowfield calculation domains around the digital ship models, and discretizing the flow field calculation domains; (3) setting boundary conditions, dividing the hexahedral grids to simulate the free surface movement and the non-free surface movement of the digital ship models, and respectively measuring a wave-making resistance coefficient and a viscous resistance coefficient of the digital ship models; (4) obtaining a total resistance coefficient of the ship and flow field information in the flow field calculation domains through the wave-making resistance coefficient and the viscous resistancecoefficient; and (5) carrying out fluid power analysis on the flow field information to obtain a ship free surface wave height distribution curve and a ship free surface wave-making distribution clouddiagram. The method and the system provided by the invention can provide reliable water power data and flow field information for the design and optimization of the ship.

Owner:HUAZHONG UNIV OF SCI & TECH

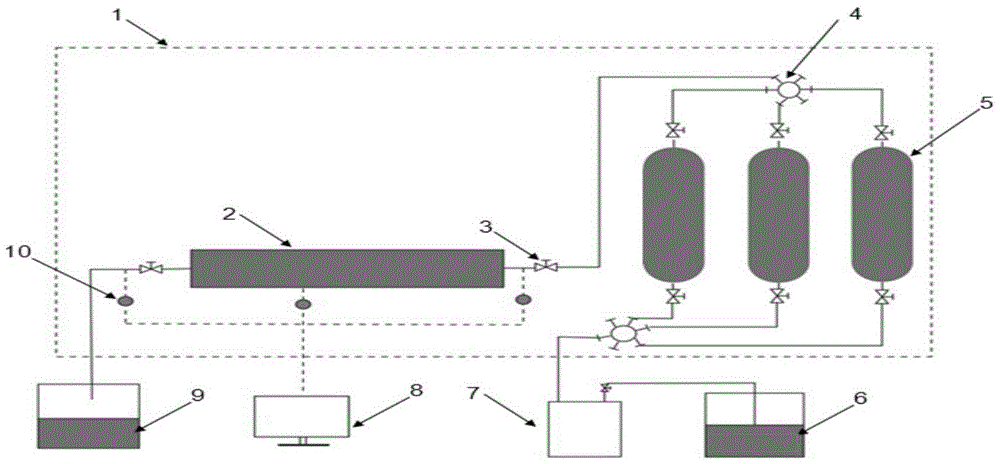

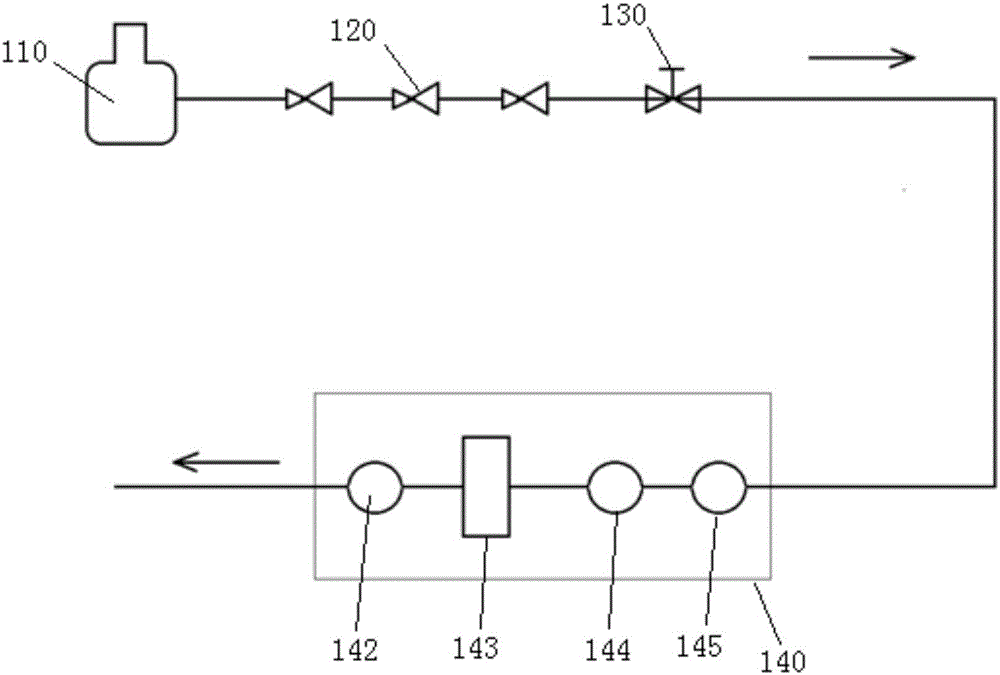

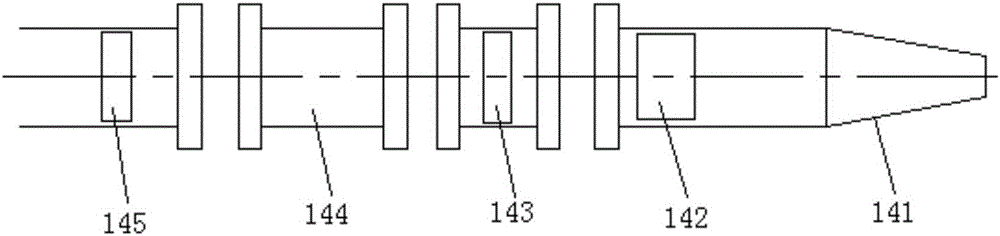

Method and device for measuring viscous resistance coefficient and inertial resistance coefficient of porous medium

PendingCN106706268ACalculation method is simpleHigh precisionHydrodynamic testingMeasurement devicePorous medium

The invention discloses a method and device for measuring the viscous resistance coefficient and the inertial resistance coefficient of a porous medium. The method comprises the following steps: 1, obtaining the pressure drop delta p of fluid before and after the fluid flows through the porous medium, and the flowing speed v of the fluid through the sensor; 2, carrying out the fitting of delta p and v in a quadratic polynomial: delta p=a<1>*v*v+a<2>*v, and obtaining the values of parameters a<1> and a<2>; 3, calculating the viscous resistance coefficient 1 / alpha and the inertial resistance coefficient C2, wherein the viscous resistance coefficient 1 / alpha and the inertial resistance coefficient C2 meets the formulas (shown in the description), delta n is the thickness of the material of the porous medium, mu is the dynamic viscosity of the fluid and Rho is the density of the fluid. The invention also provided a device for measuring the viscous resistance coefficient and the inertial resistance coefficient of the porous medium. The method can calculate the viscous resistance coefficient and the inertial resistance coefficient through measuring the flowing speed of the fluid and the pressure difference before and after the fluid flows through the porous medium, is simple, and is high in precision. The device for measuring the parameters is compact in structure, is low in cost, and is very convenient to use.

Owner:JILIN UNIV

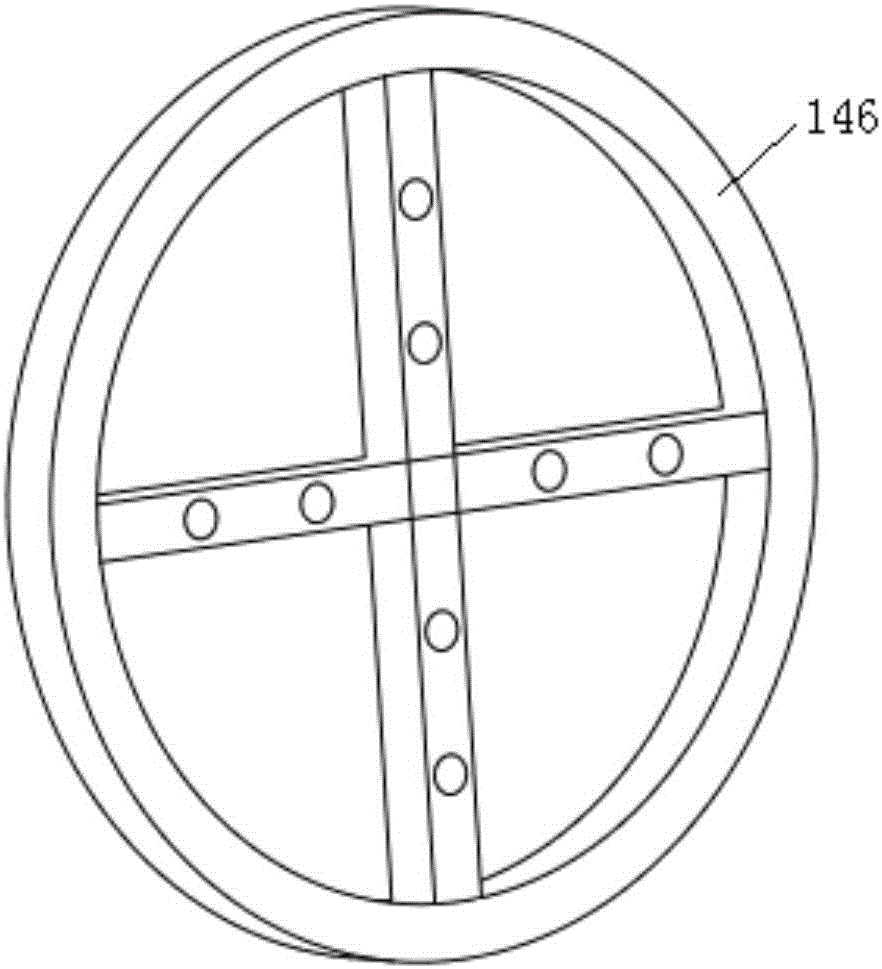

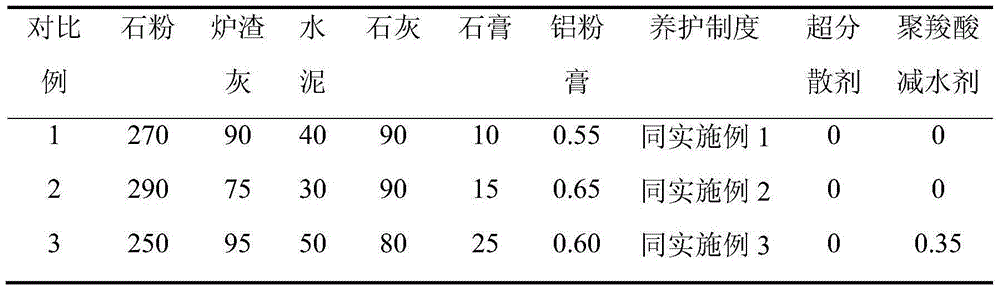

Aerated concrete manufactured by stone material waste and manufacturing method thereof

InactiveCN105110811ASolve the use problemSave natural resourcesSolid waste managementCeramicwareThermal insulationSlag

The invention discloses aerated concrete manufactured by stone material waste. The aerated concrete is manufactured by a pretreated stone powder material, slag ash, cement, unslaked lime, desulfurized gypsum, powdered aluminum paste and a hyper-dispersant, wherein the pretreated stone powder material is produced by crushing, mixing and grinding stone material machining waste and waste aerated concrete building blocks. The stone material machining waste and industrial wet furnace slag ash are machined and re-treated, the utilization problem of a stone material and other waste is effectively solved, energy is saved, and environment is protected. A related manufacturing process is simple and low in cost. The hyper-dispersant can effectively improve the dispersing performance of concrete slurry, the viscous resistance of stone powder granules is reduced, and early-stage coordination between aeration and densification of the slurry is ensured, so that the aerated concrete has the advantages of being low in drying shrinkage value, good in thermal insulation property, high in compressive strength and the like. In addition, natural stone material waste, waste aerated concrete and furnace slag ash are recycled to slow down soil degradation, underground water pollution, dust pollution and other environmental problems, and the aerated concrete is suitable for popularization and application.

Owner:HUBEI UNIV +1

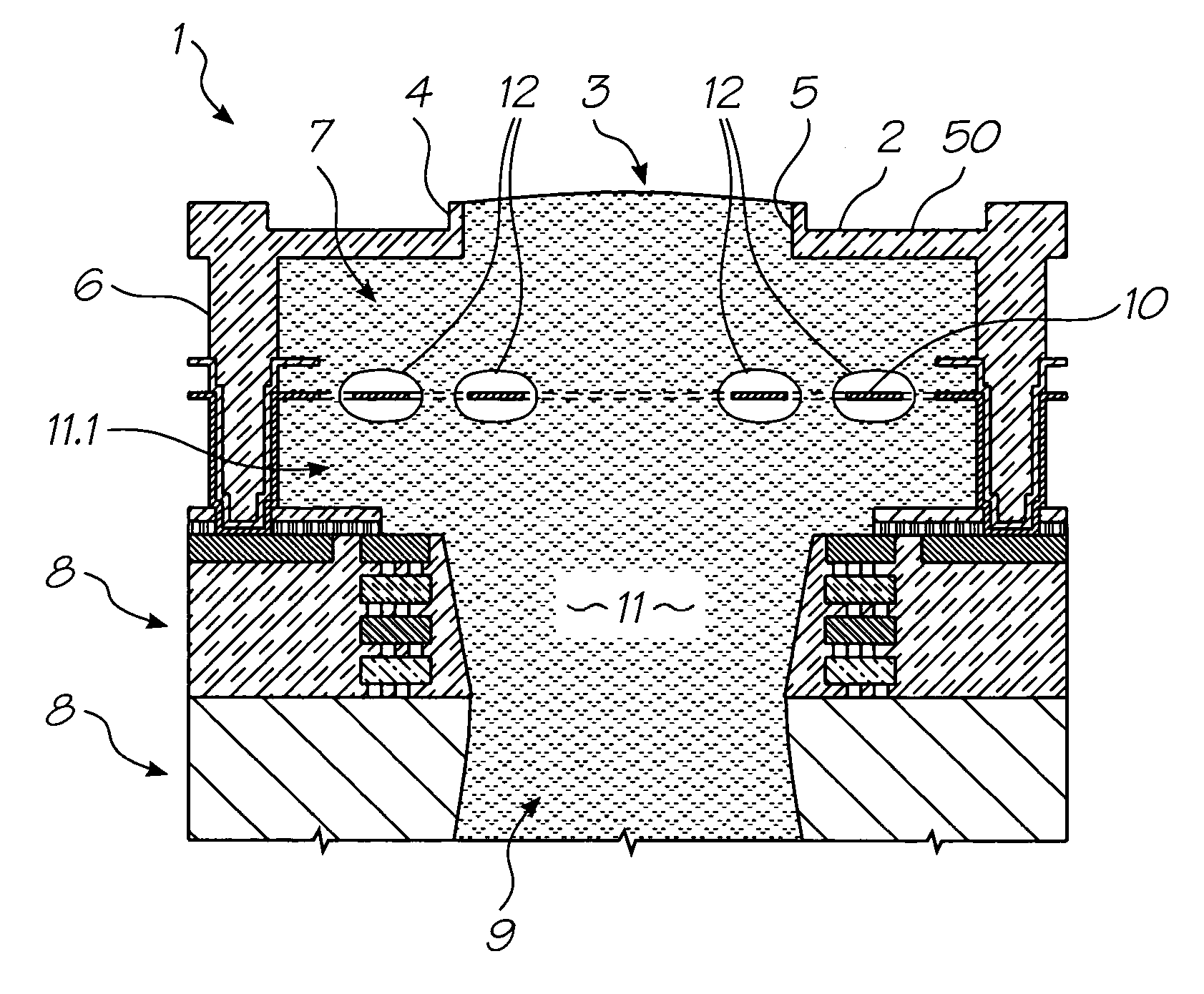

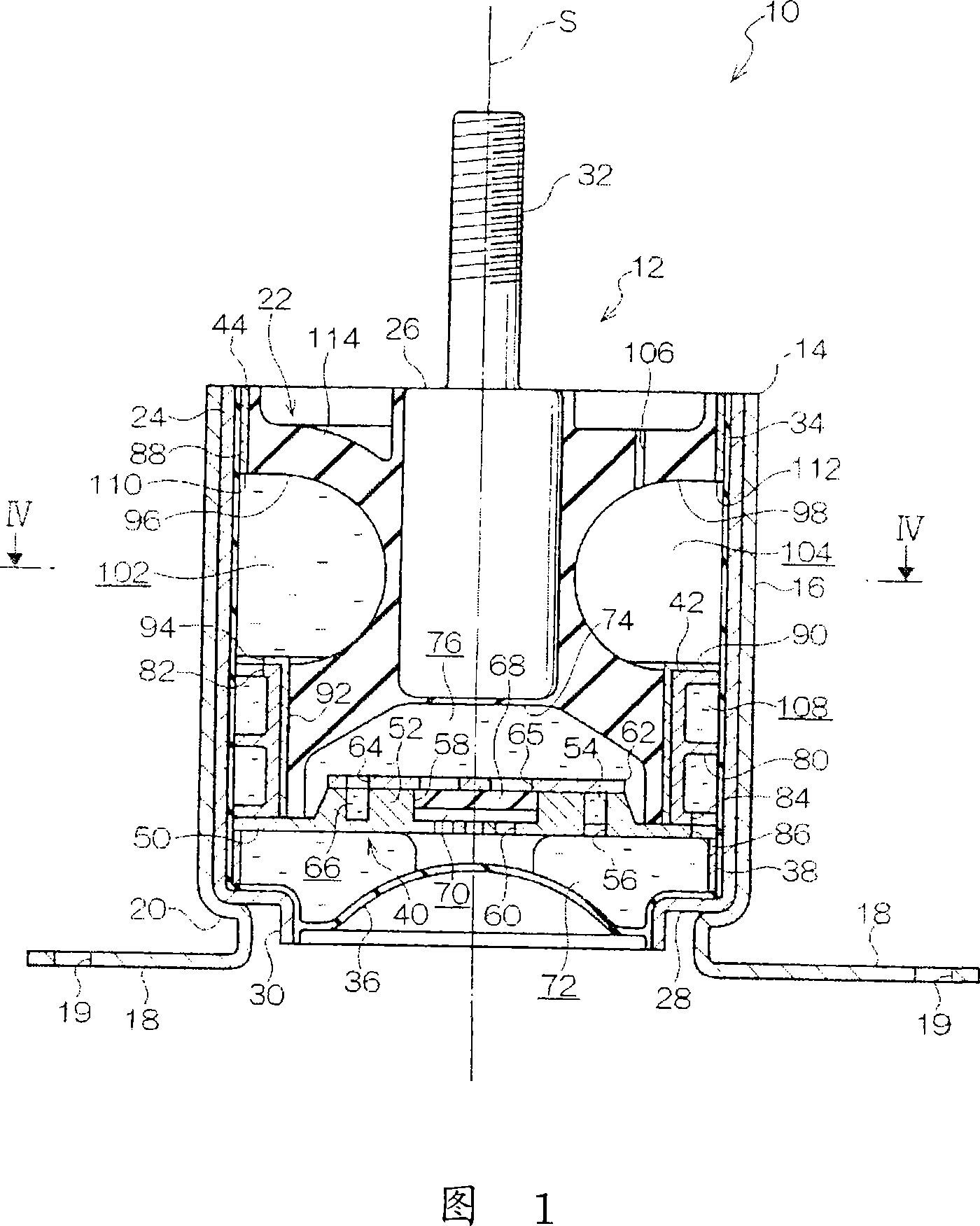

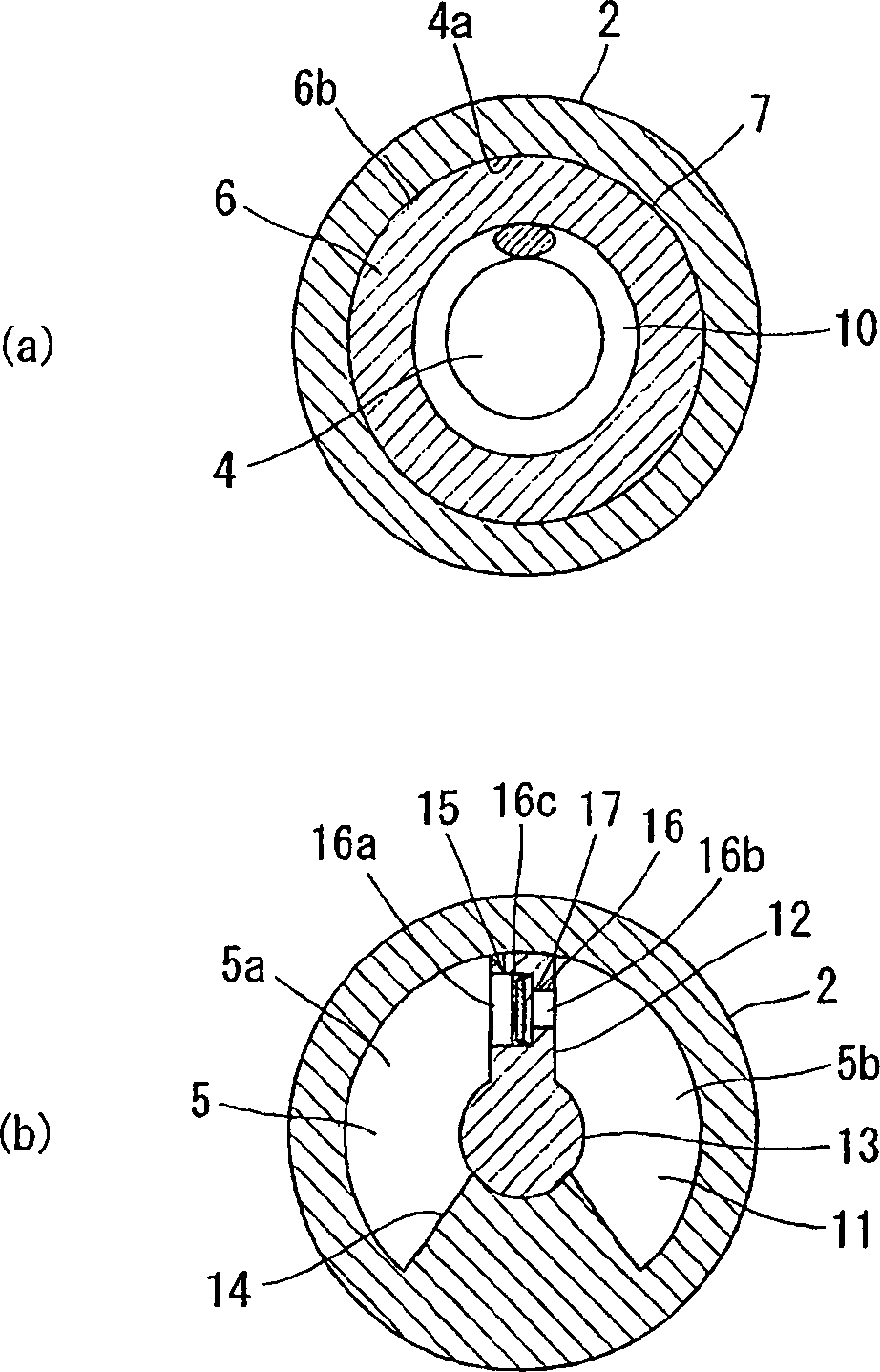

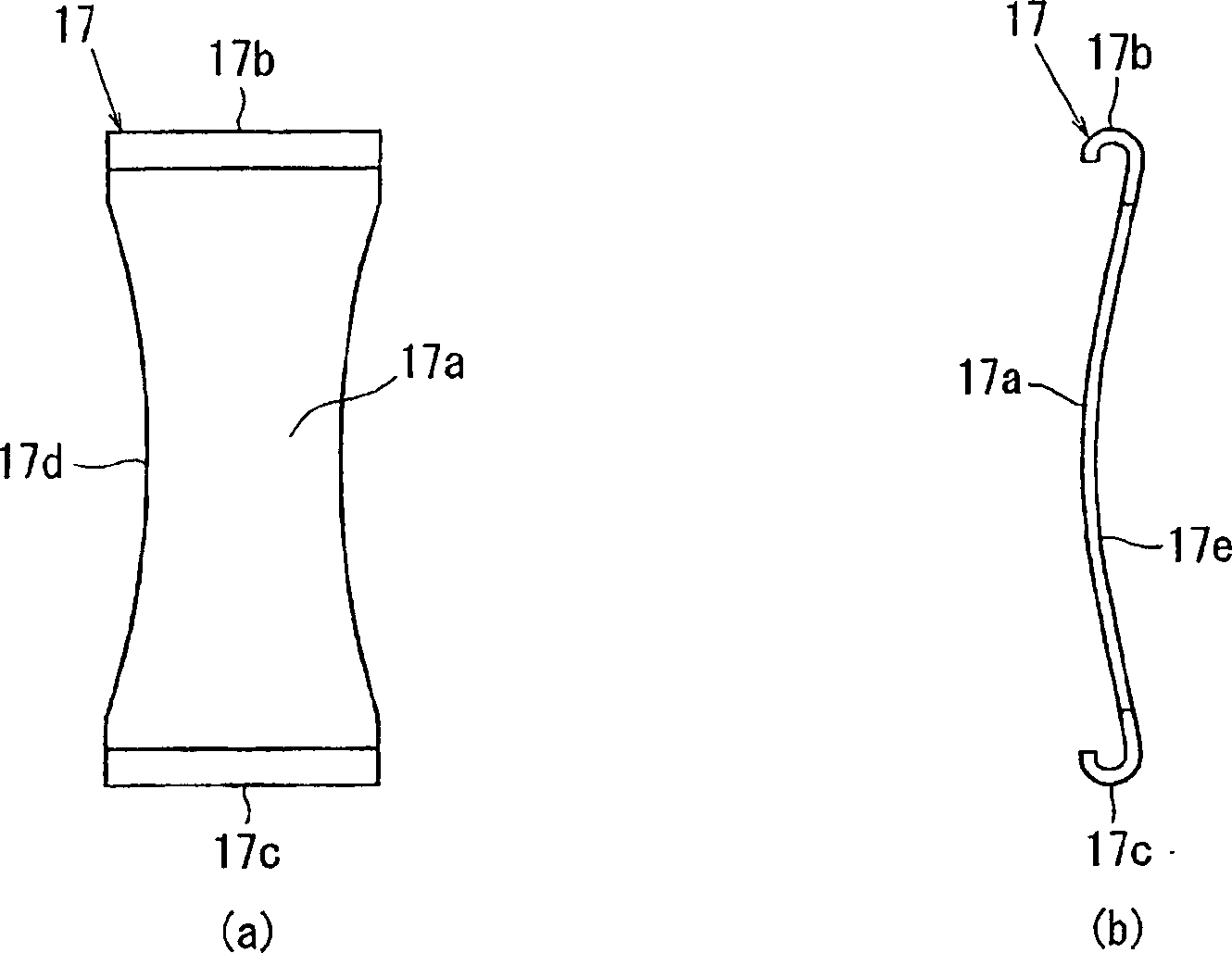

Rotary damper and console box

An object of the invention is to provide a rotary damper which can individually control two controlled subjects independently rotatable with each other by utilizing both a viscous resistance by a viscous material and a resistance by a viscous fluid and putting properties thereof to good use. A rotary damper ( 1 A) is provided with first and second chambers ( 4, 5 ) which are separated by a partition wall ( 3 ), a rotor ( 6 ) which is rotatably arranged within the first chamber ( 4 ), a viscous material ( 7 ) which is filled in a slight gap between the rotor ( 6 ) and a slidable contact surface slidably contacted with the rotor ( 6 ), a viscous fluid ( 11 ) which is filled in the second chamber ( 5 ), and a vane ( 12 ) which is swingably arranged within the second chamber ( 5 ) filled with the viscous fluid ( 11 ).

Owner:SOMIC ISHIKAWA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com