Rotary damper and console box

A technology of rotating dampers and rotating shafts, which is applied in the direction of shock absorbers, shock absorbers, liquid shock absorbers, etc., and can solve problems such as inconvenience, difficulty in adjusting braking force, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

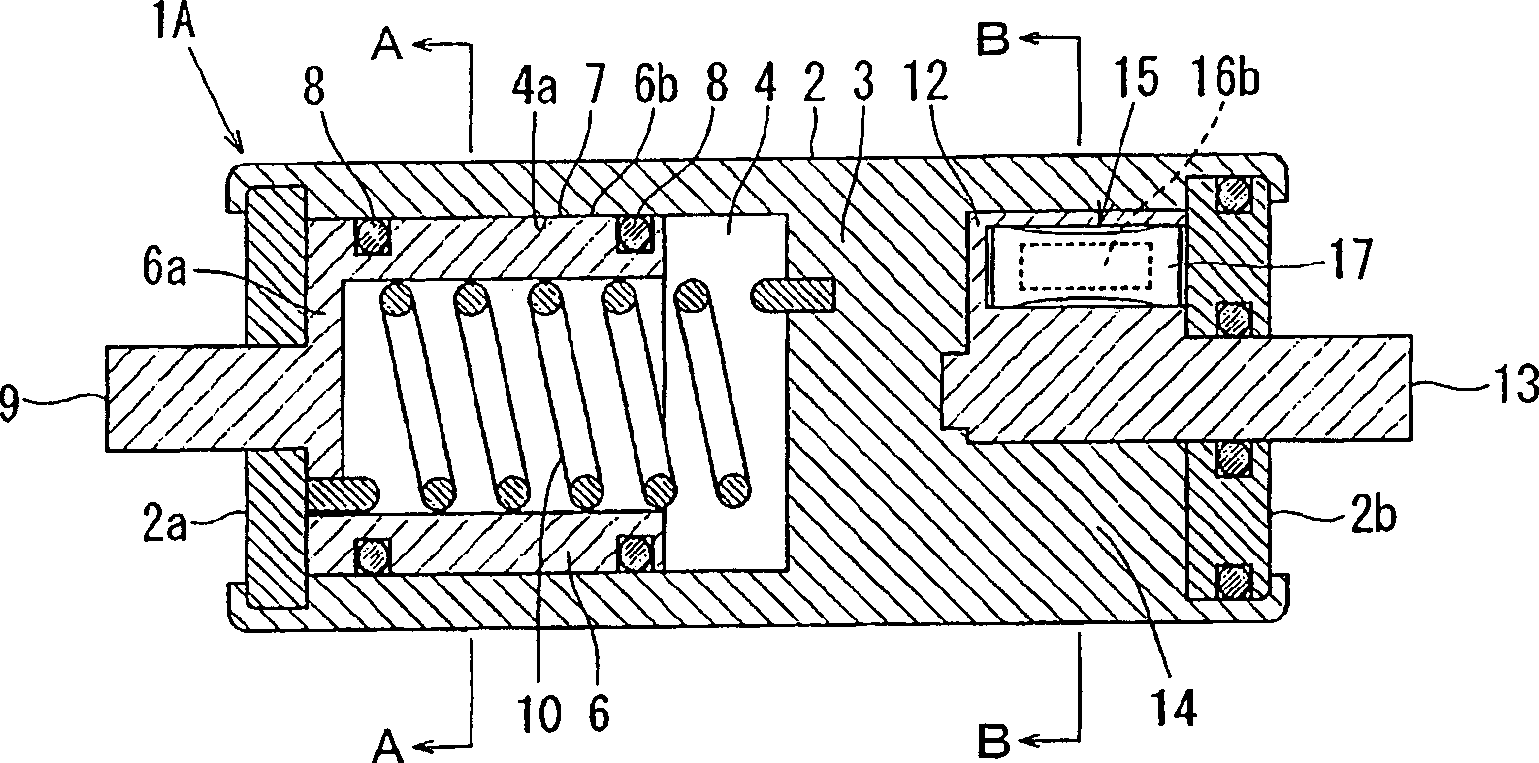

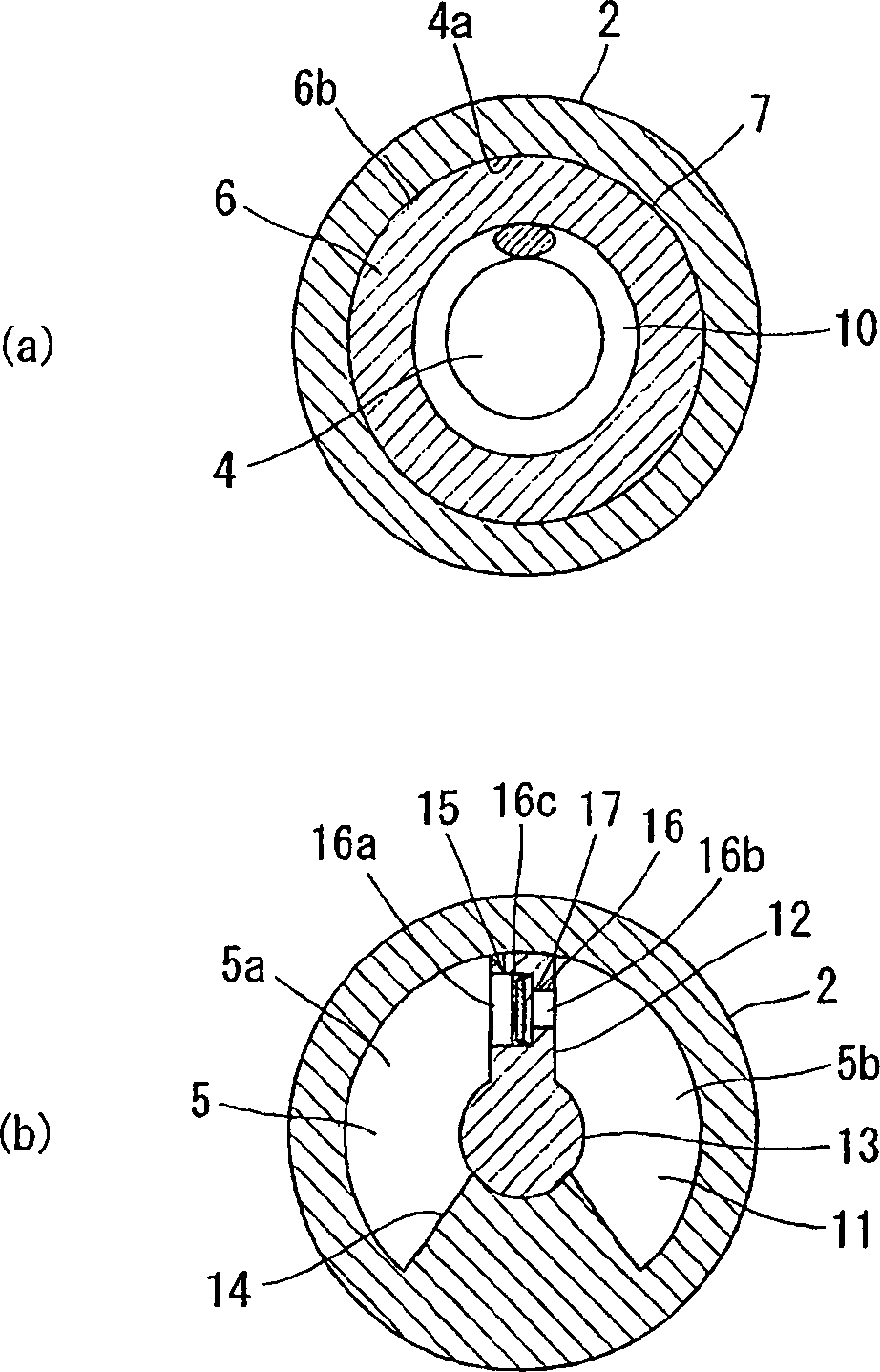

[0050] figure 1 and figure 2 It is a figure which shows the internal structure of the rotary damper related to the 1st Embodiment (hereinafter referred to as "1st Embodiment") of this invention, figure 1 is a sectional view, figure 2 (a) is figure 1 A cross-sectional view of part A-A, figure 2 (b) is figure 1 Sectional view of part B-B of . As shown above, the rotary damper 1A according to the first embodiment has the first chamber 4 and the second chamber 5 separated by the partition wall 3 provided in the main body case 2 . In the main body case 2, openings on both sides in the axial direction are closed by covers 2a and 2b, respectively.

[0051] In the first chamber 4, a rotor 6 is rotatably arranged. The rotor 6 is made into a substantially cylindrical shape with one end closed by an end wall 6a and the other end opened. However, the shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com