Patents

Literature

155results about How to "Volume and" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

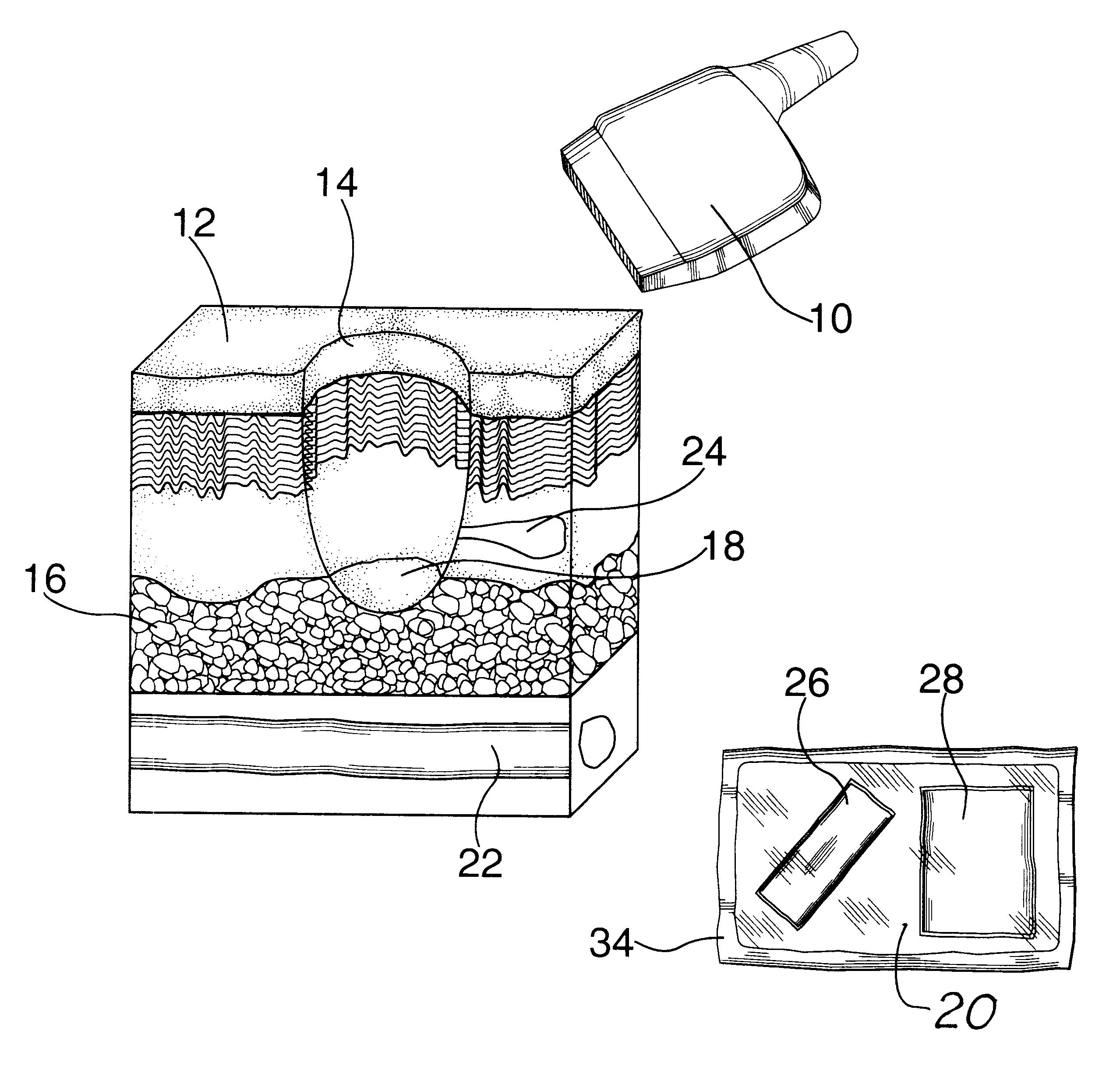

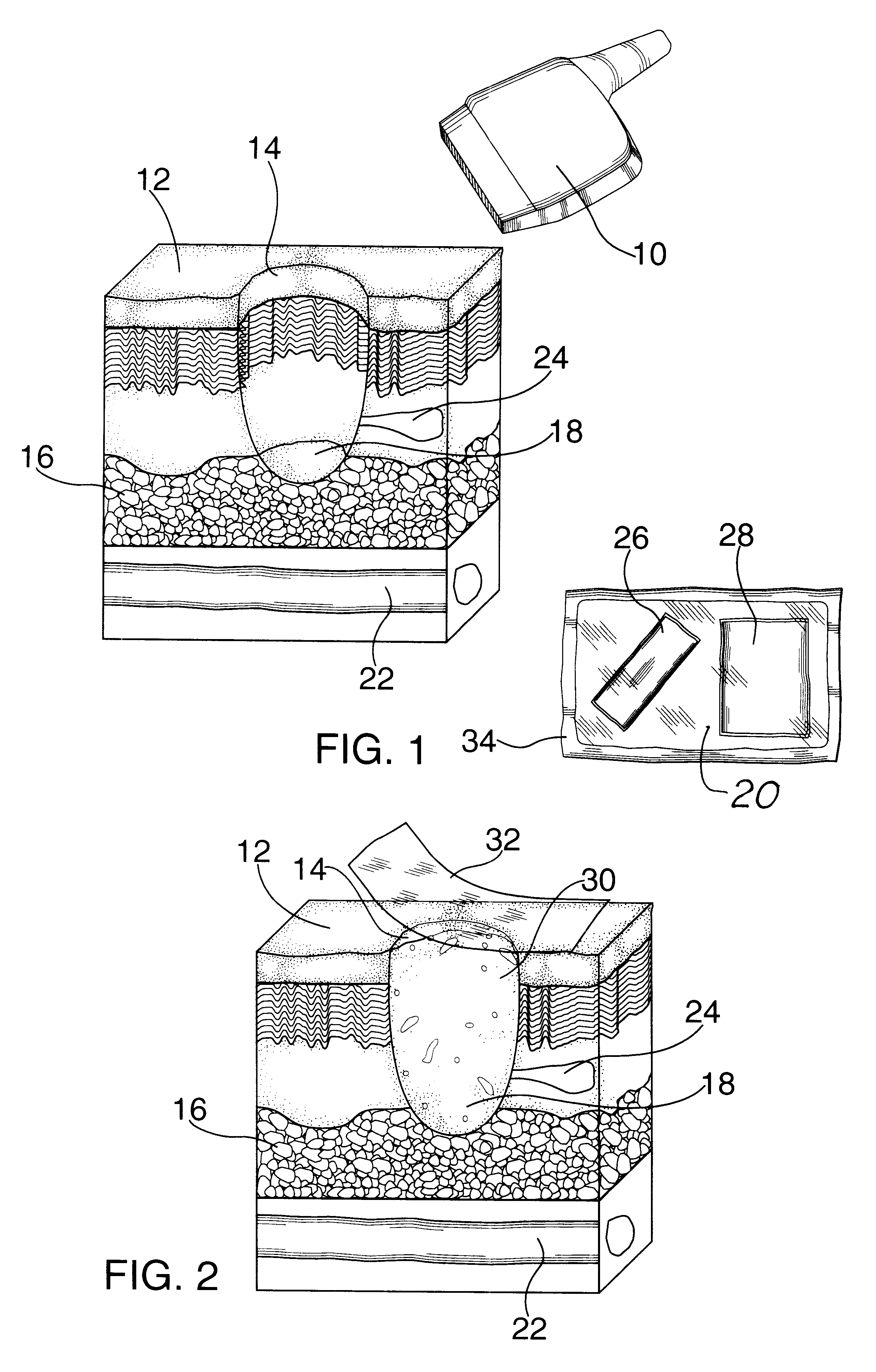

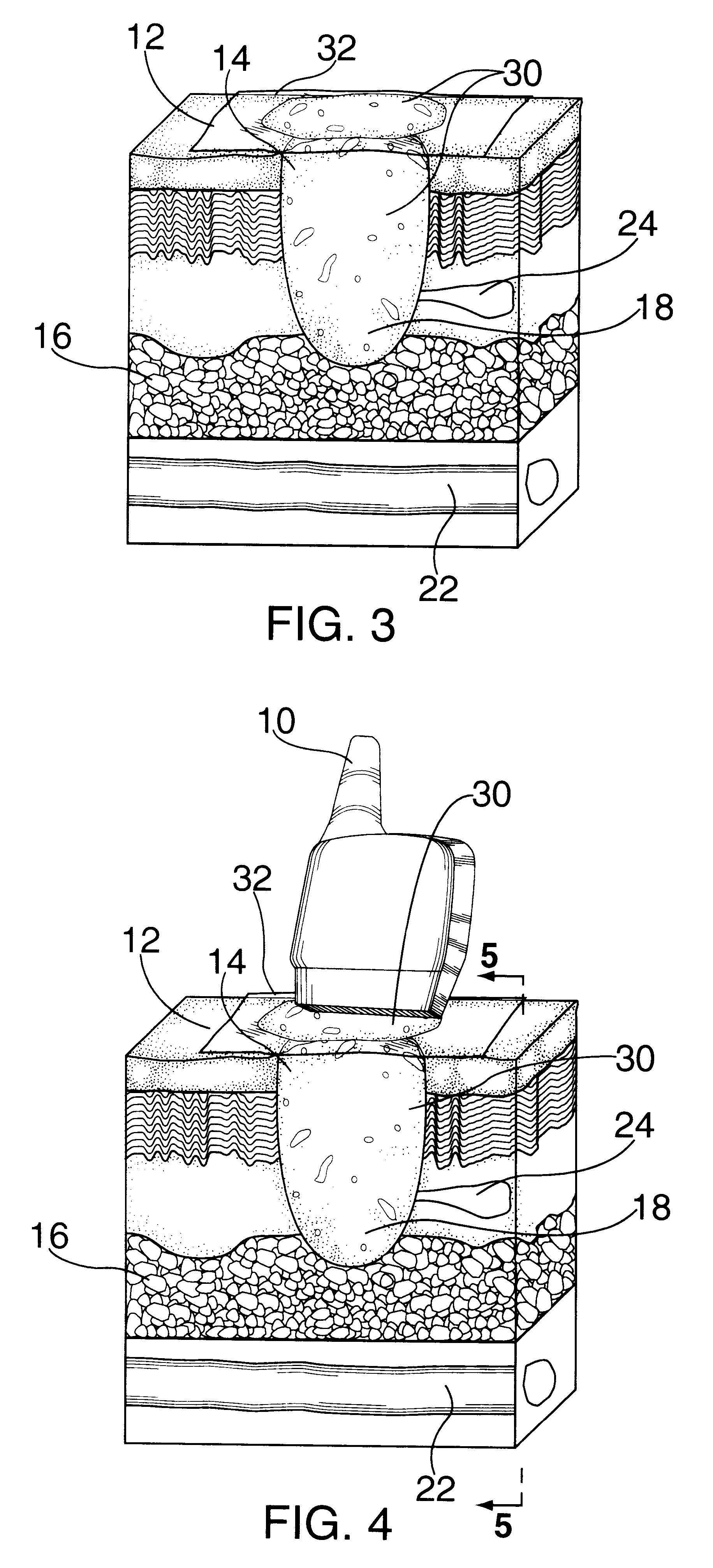

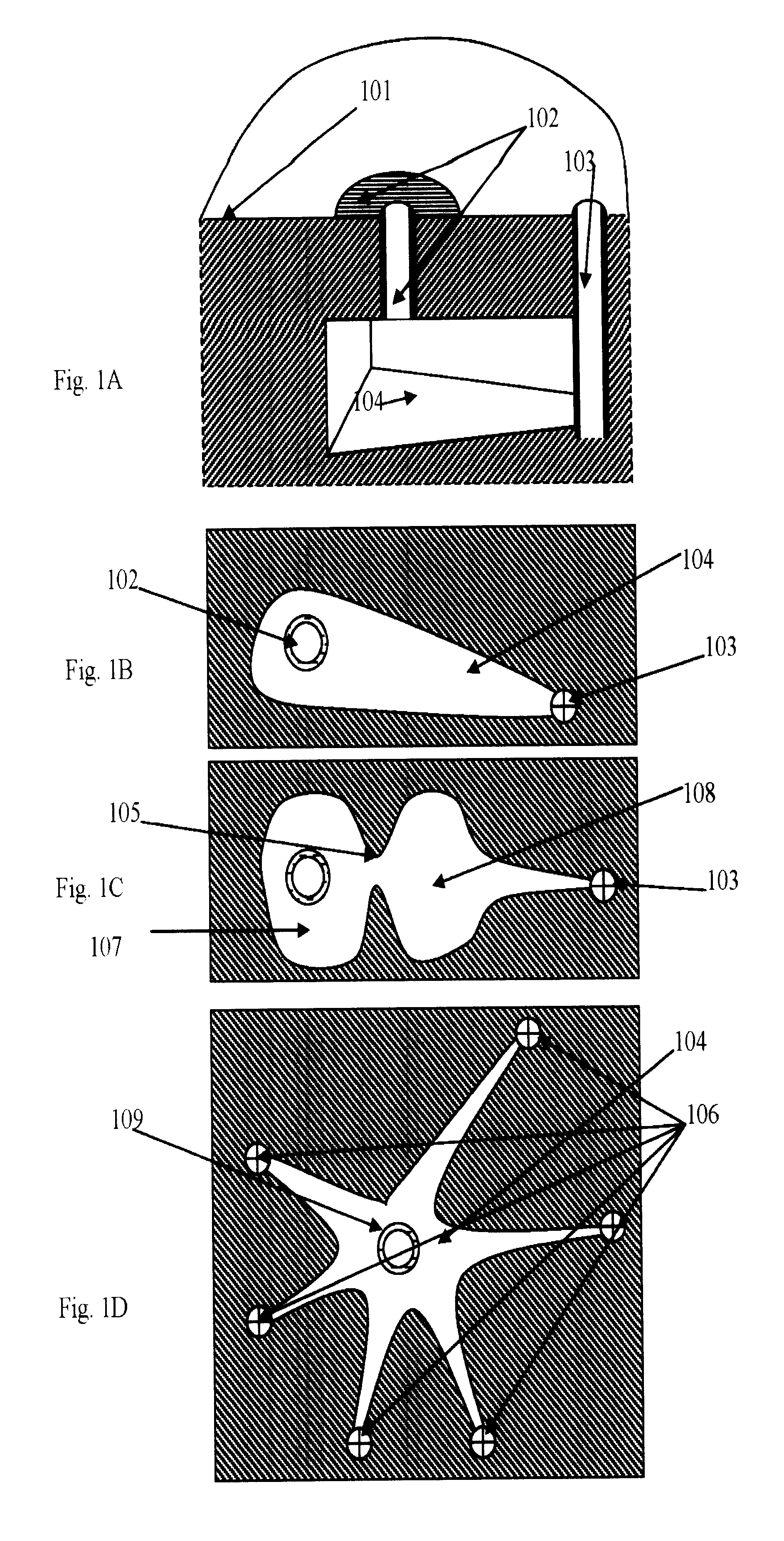

Method and kit for wound evaluation

InactiveUS6193658B1Simple methodHeight canOrgan movement/changes detectionSurgeryWound assessmentMedicine

A method and kit for the evaluation of wounds or ulcers (14) using ultrasound that allows an examiner to measure a wound (14) along with adjacent soft tissue structures (16) and bone (22) including tendon, ligaments, and muscle. This same method and kit contains gel (30) and an adhesive flexible film (32) which has a duo function and serves as a protective barrier preventing cross contamination between transducer (10) and ulcer (14), while allowing unimpeded conduction of ultrasound transmission to tissues (16) and subsequent echoes received from tissues (16) to be evaluated and recorded by a health care practitioner.

Owner:WENDELKEN MARTIN E +1

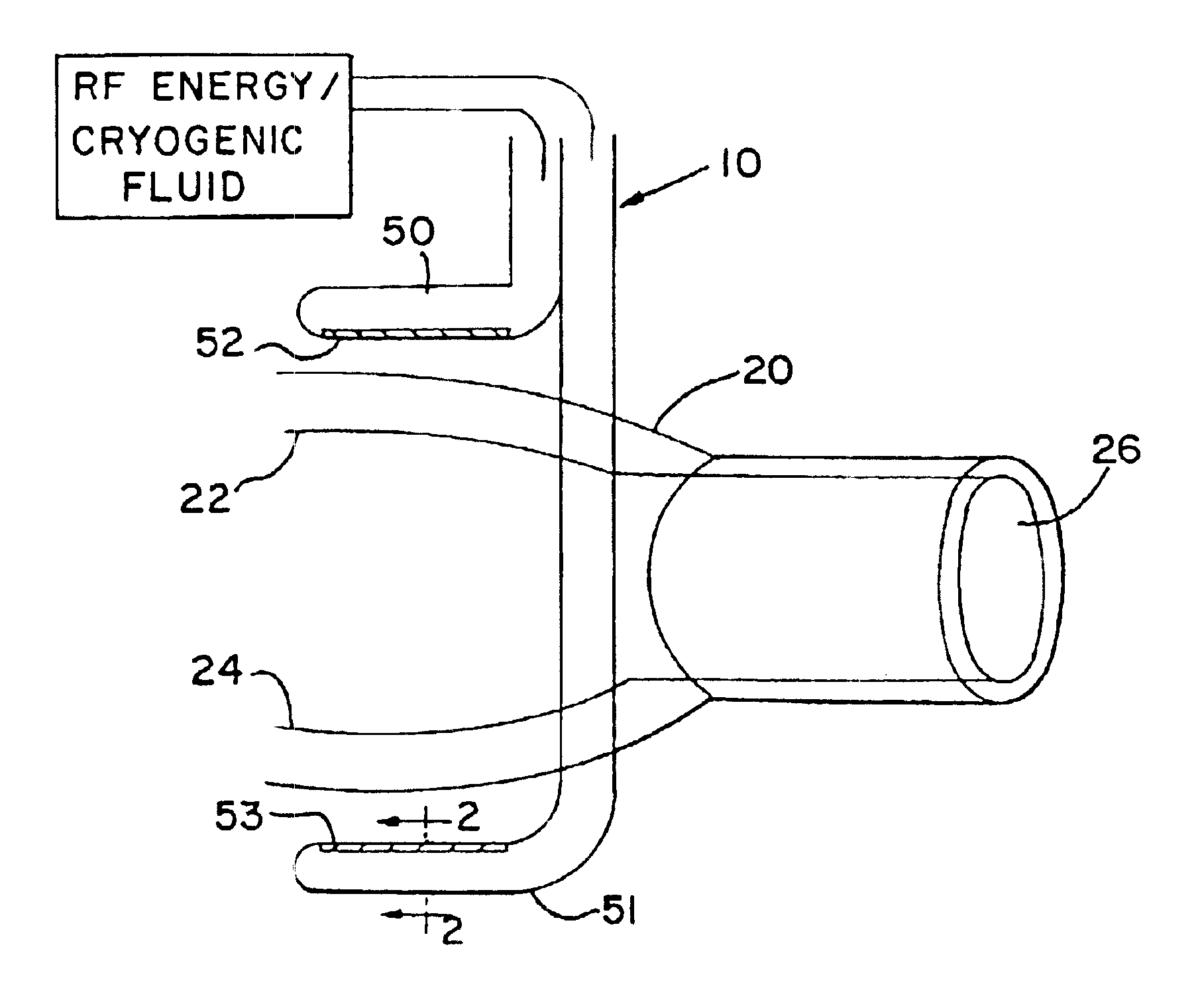

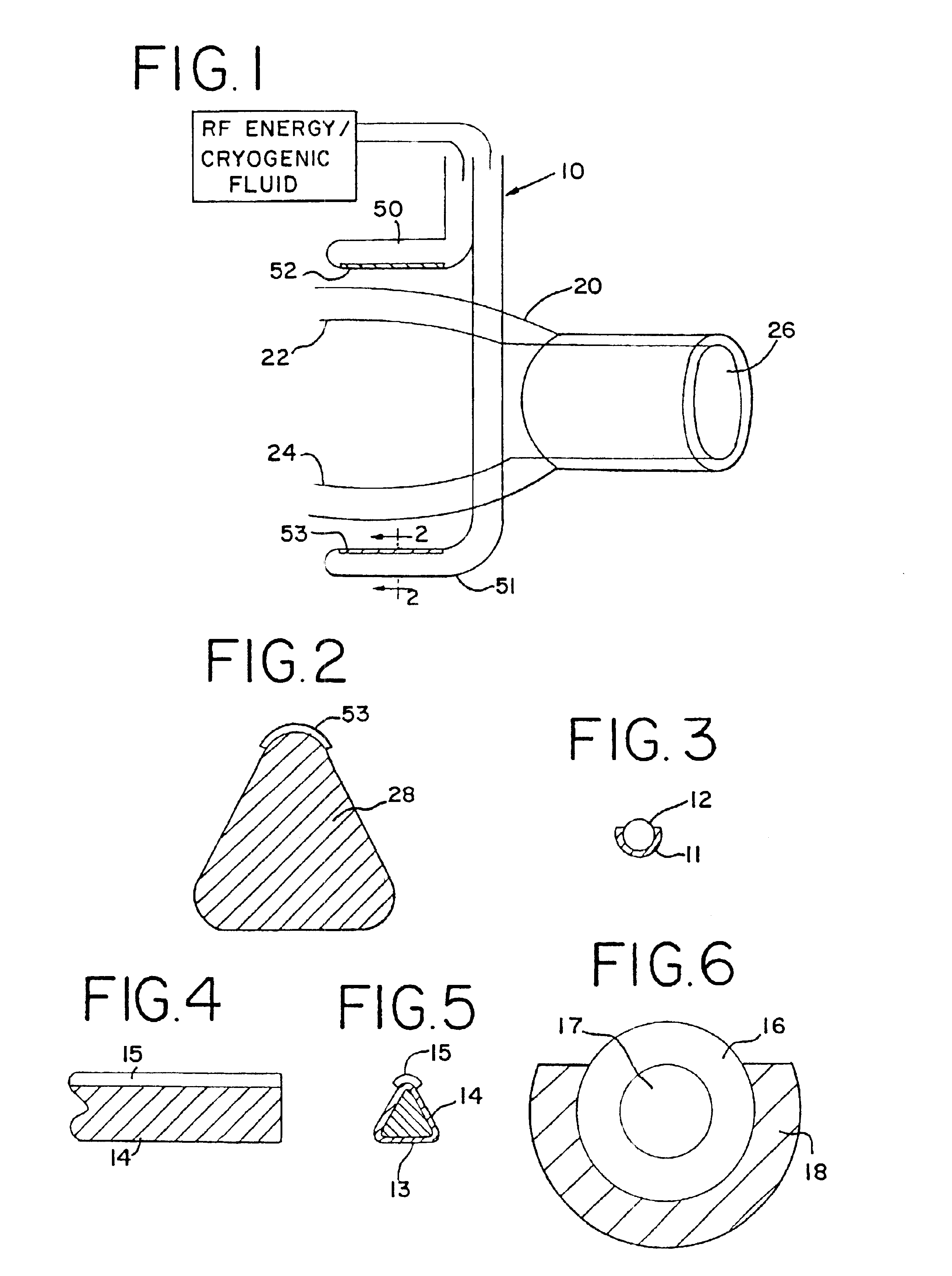

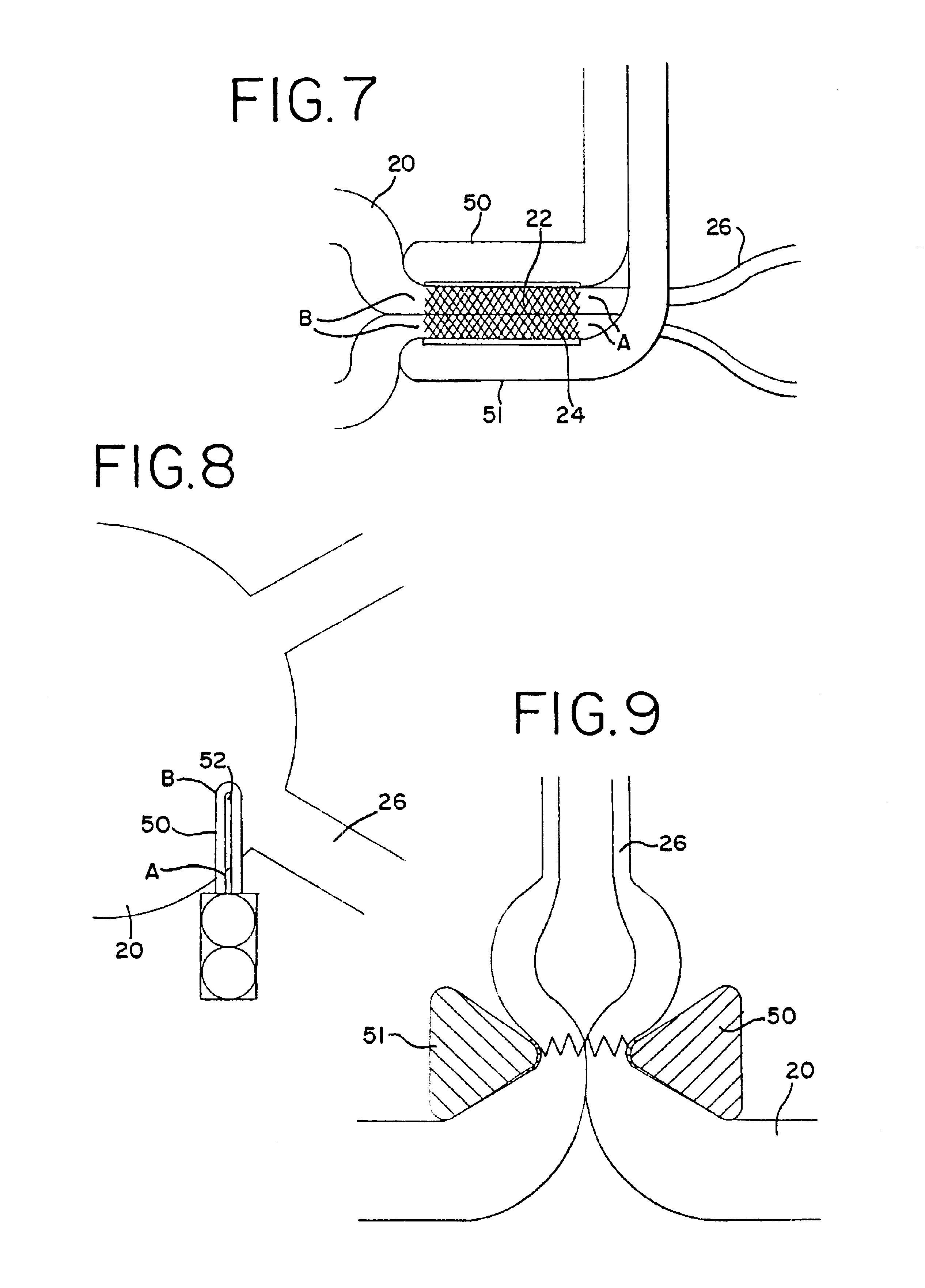

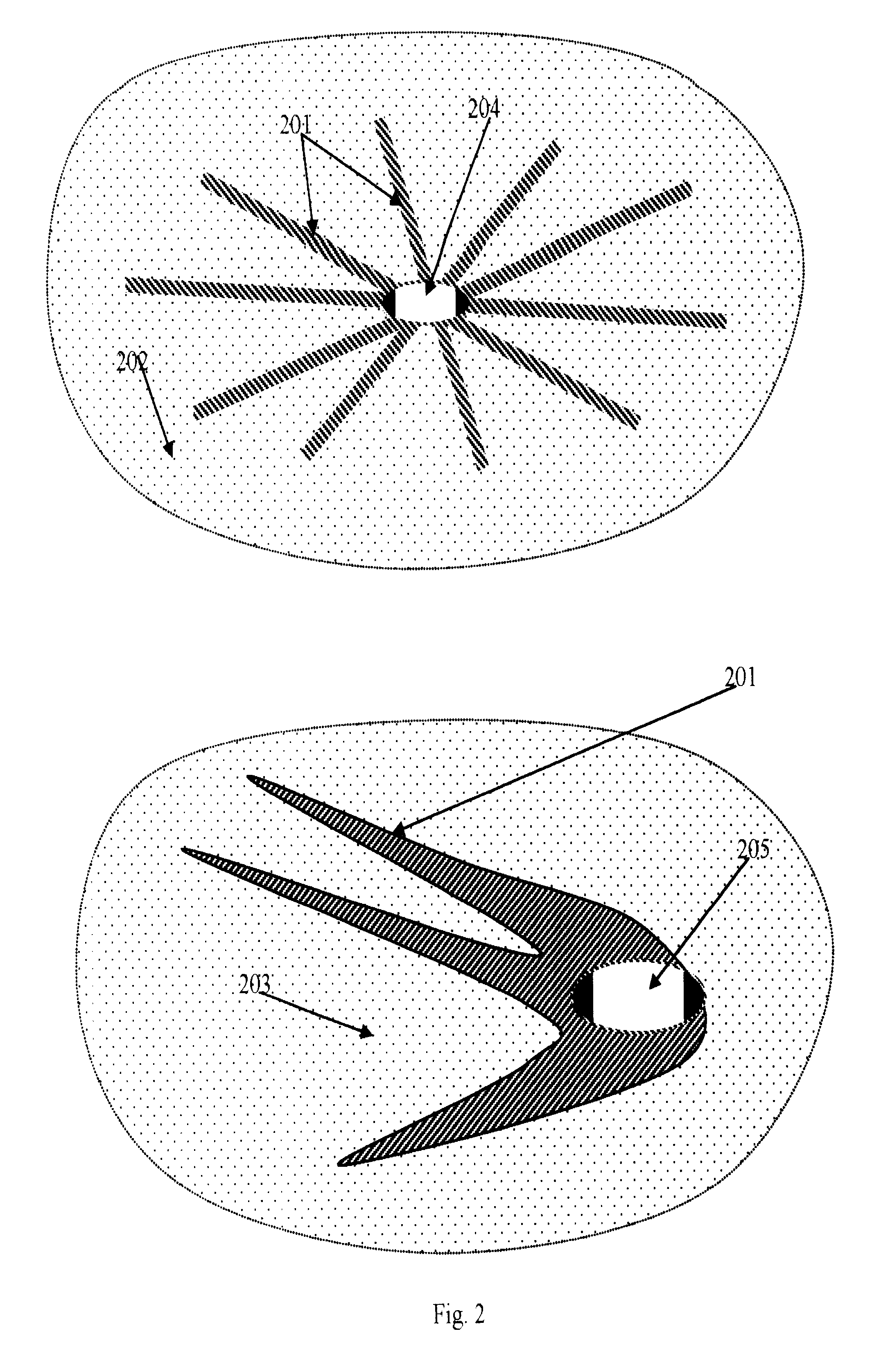

Method for transmural ablation

InactiveUS6896673B2Minimizes the tissue being ablatedVolume andDiagnostic recording/measuringSurgical instruments for heatingBiomedical engineeringOrgan of Corti

A method for transmural ablation using an instrument containing two electrodes or cryogenic probes. A clamping force is exerted on the two electrodes or probes such that the tissue of the hollow organ is clamped therebetween. Bipolar RF energy is then applied between the two electrodes, or the probes are cryogenically cooled, thus ablating the tissue therebetween. A monitoring device measures a suitable parameter, such as impedance or temperature, and indicates when the tissue between the electrodes has been fully ablated.

Owner:ATRICURE

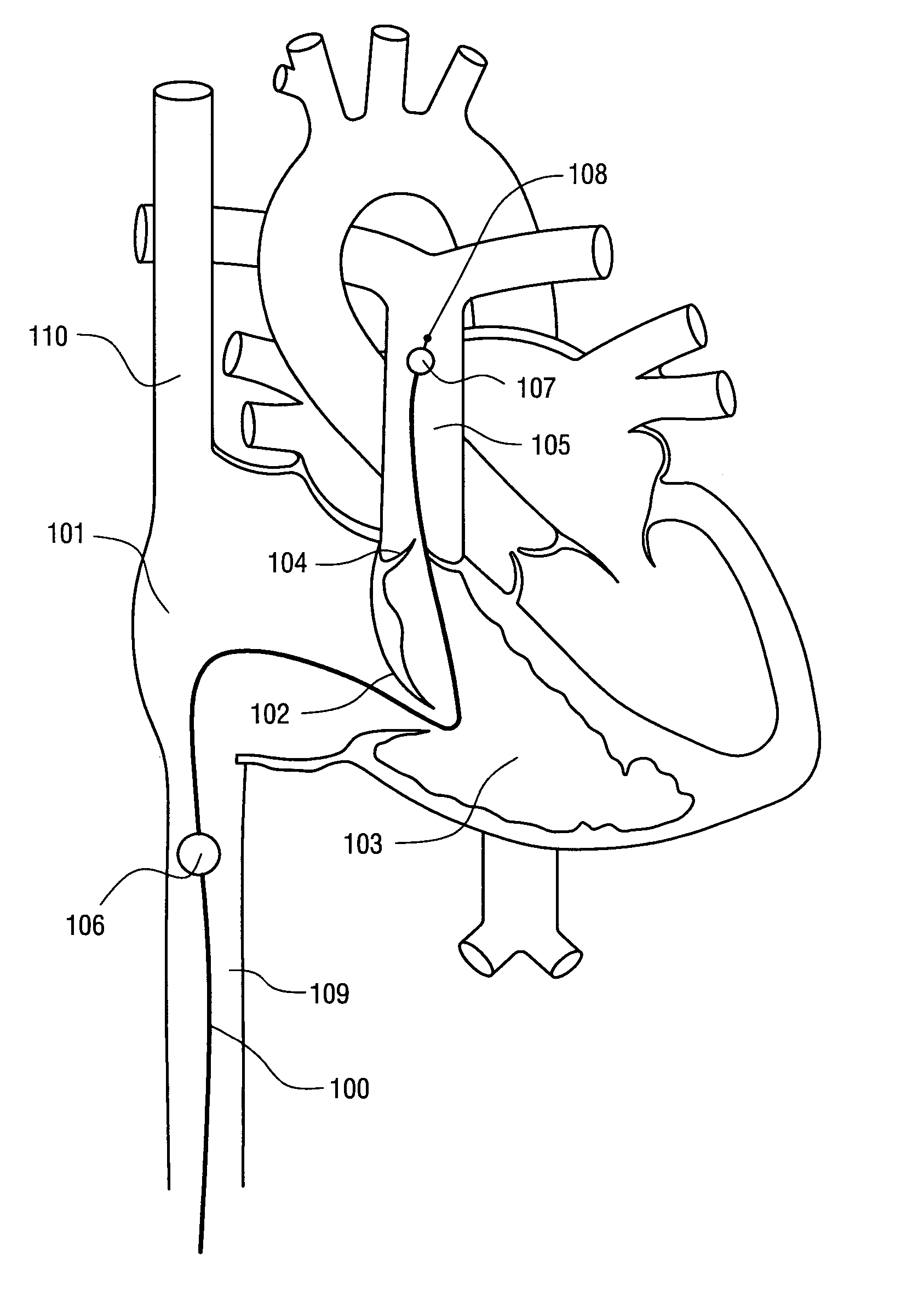

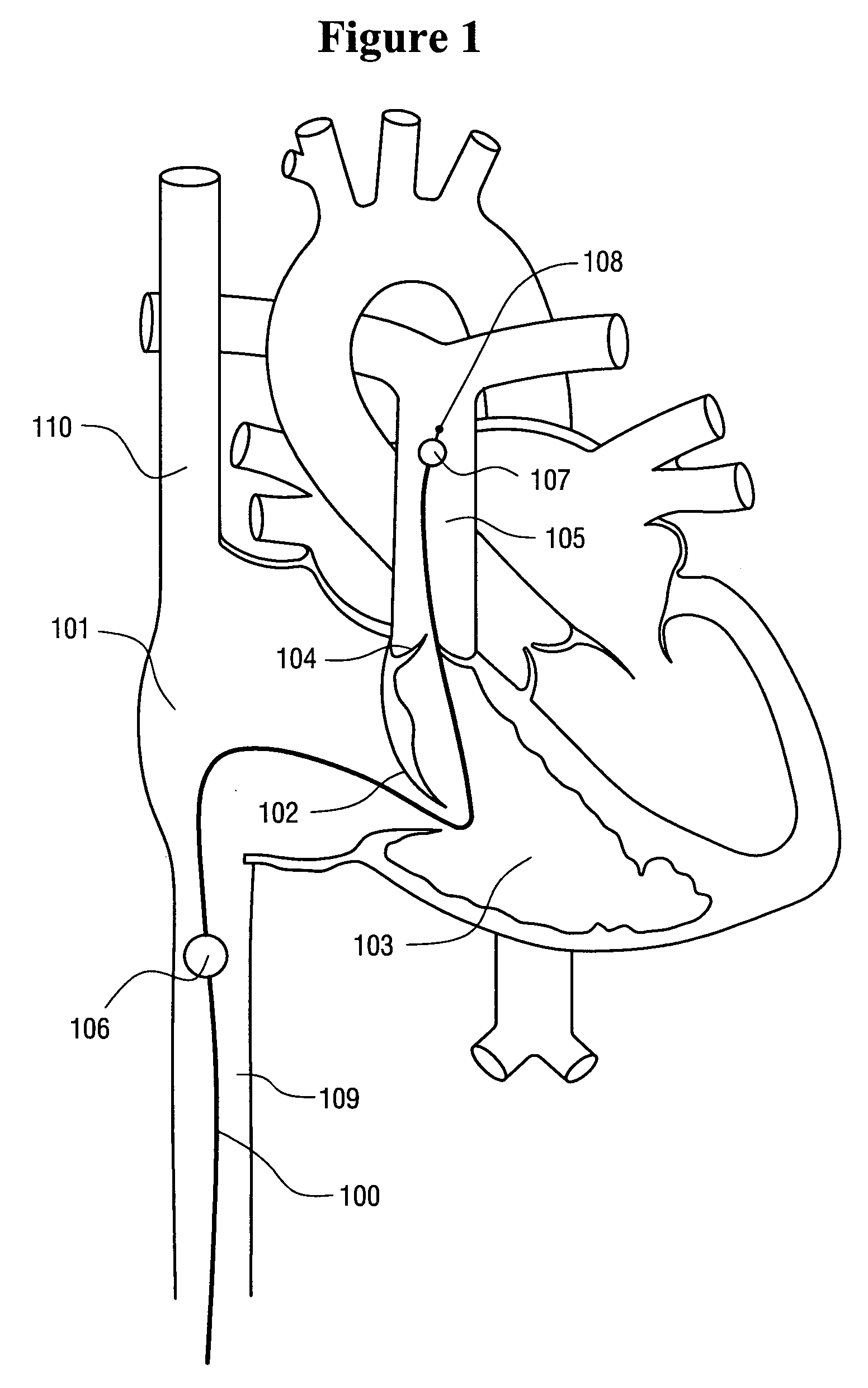

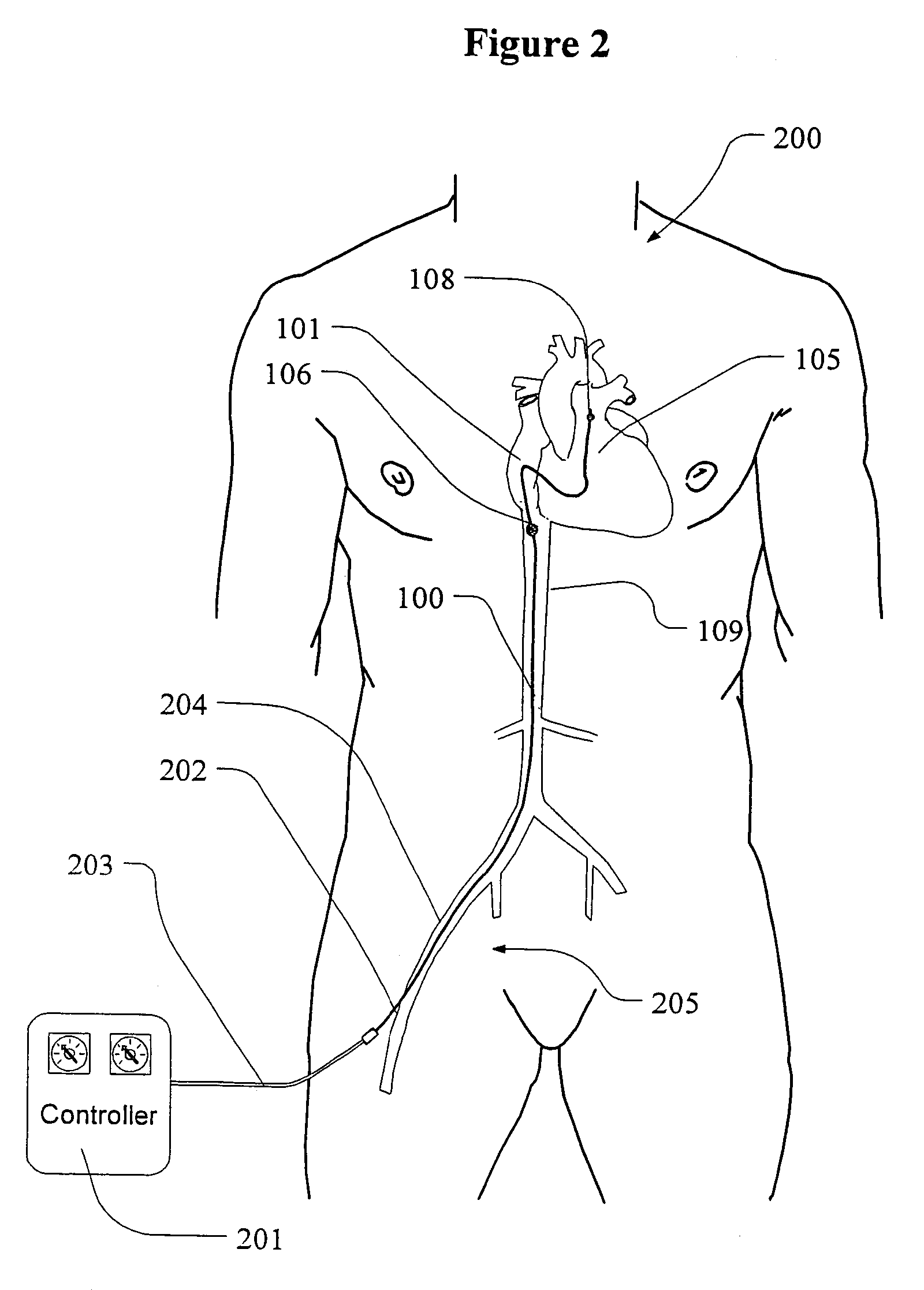

Treatment of infarct expansion by partially occluding vena cava

InactiveUS20060064059A1Reduces severity and complicationReduce expansionBalloon catheterSurgeryVeinVenous blood flow

A method and apparatus for prevention and reduction of myocardial infarct size and / or expansion and heart remodeling by partial, controllable and reversible obstruction of the venous blood flow to the heart. As a result, the ventricular wall stress and dilation are reduced. Blood flow is maintained at a safe level for the duration of treatment. The apparatus consists of a catheter with an occlusion balloon and a control and monitoring system.

Owner:GELFAND MARK +1

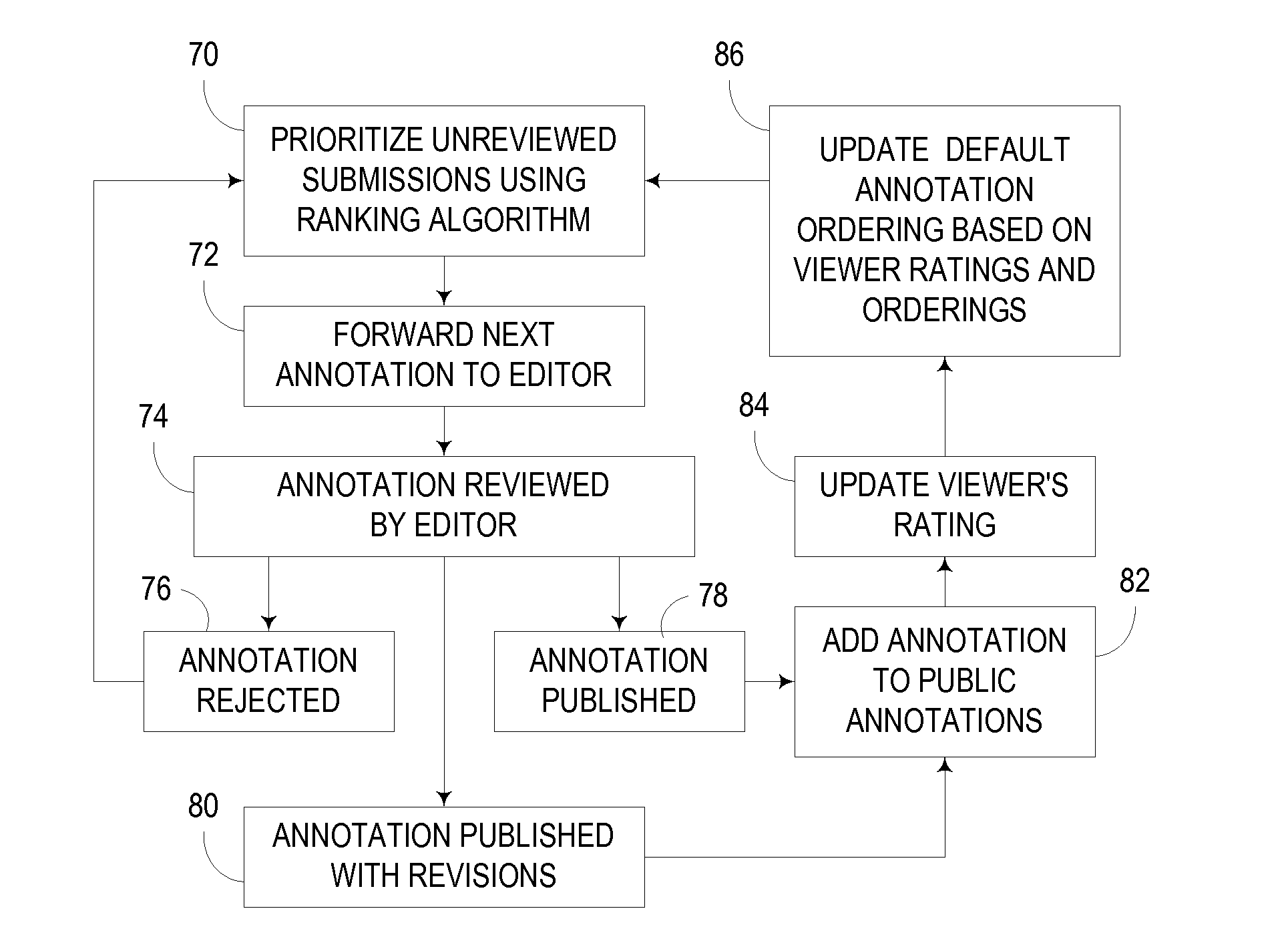

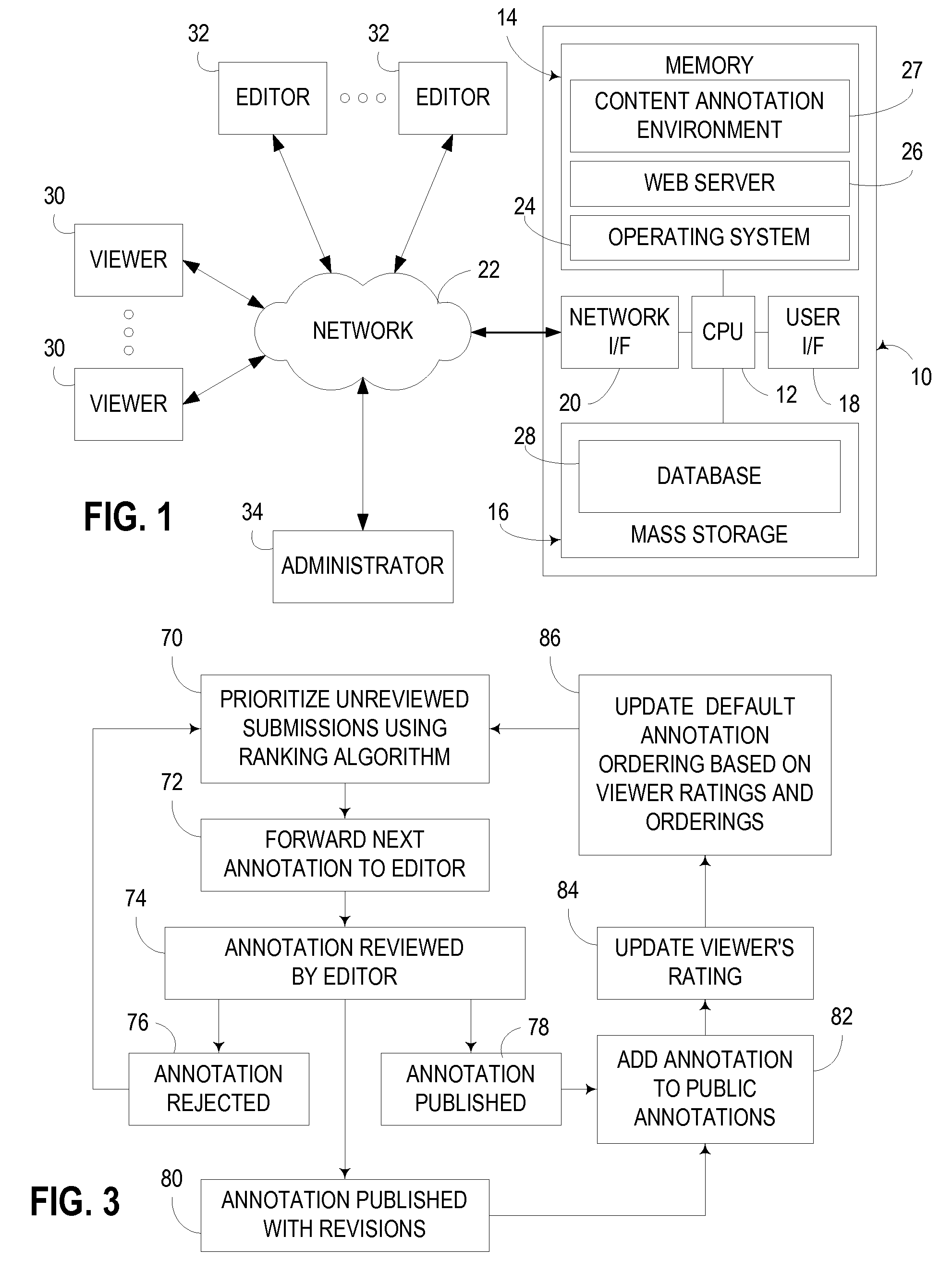

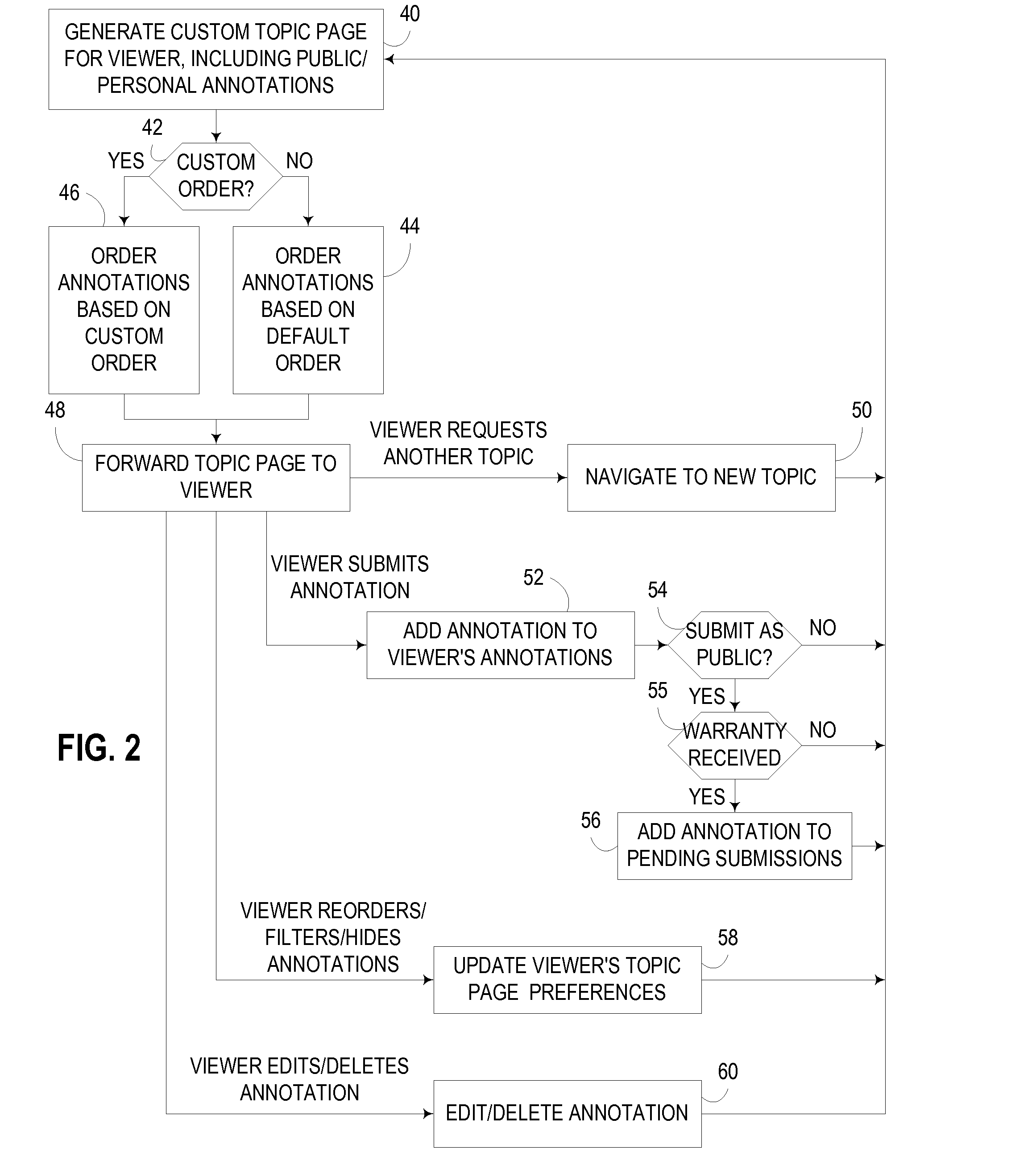

Collaborative annotation of electronic content

InactiveUS20080098294A1Reduce the amount requiredVolume andNatural language data processingSpecial data processing applicationsAnnotationElectronic content

An apparatus, program product and method provide a collaborative annotation environment that permits viewers of electronic content to share their personal annotations with other viewers of the electronic content only after the personal annotations have been reviewed by a party other than the original authors of such annotations. In addition, a default ordering may be generated for a plurality of annotations based upon the manner in which viewers of the annotations reorder the annotations. Furthermore, annotations that are submitted for review by multiple viewers may be scheduled for review according to the relative ratings of those viewers based upon prior submissions of those viewers.

Owner:MEDIQ LEARNING

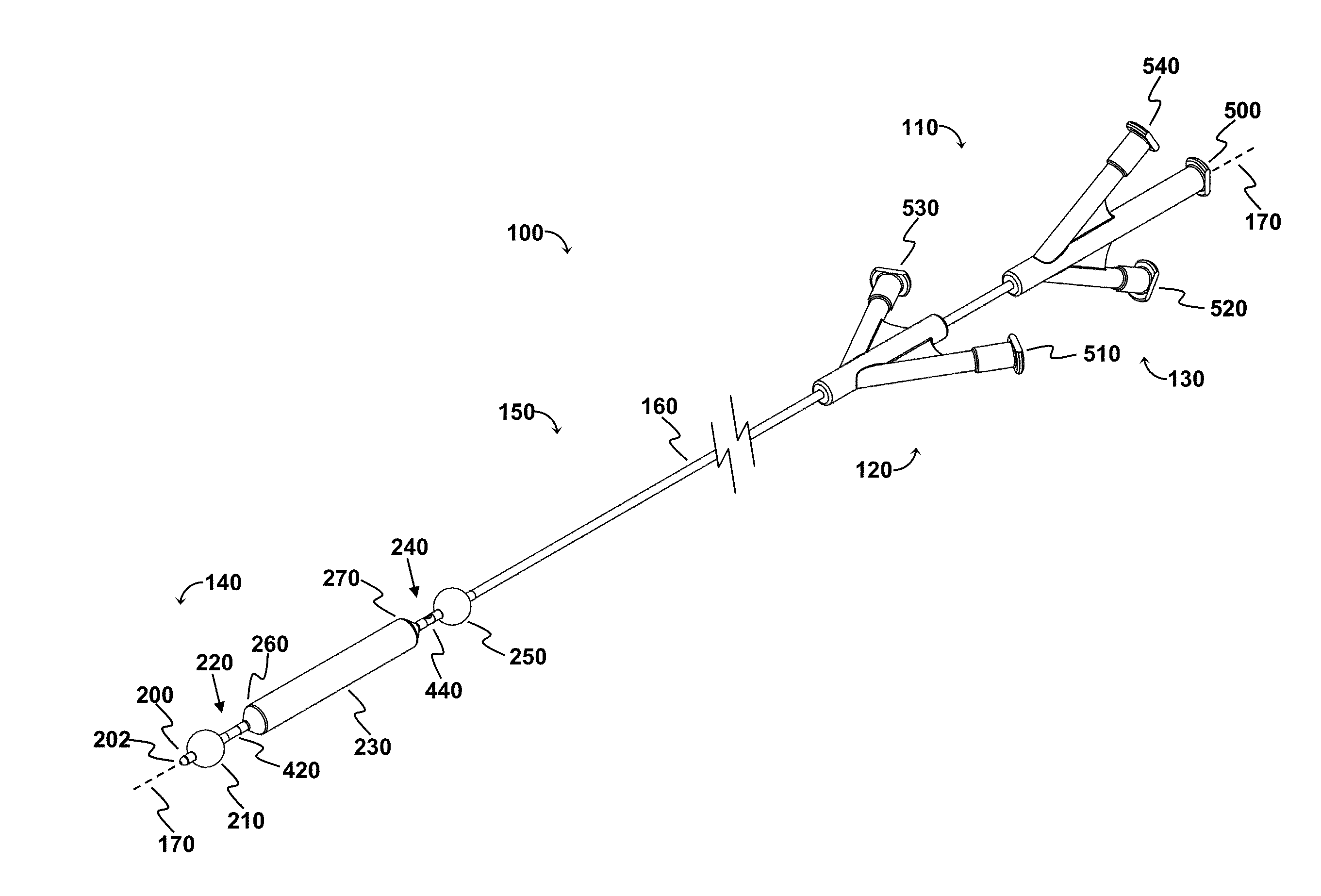

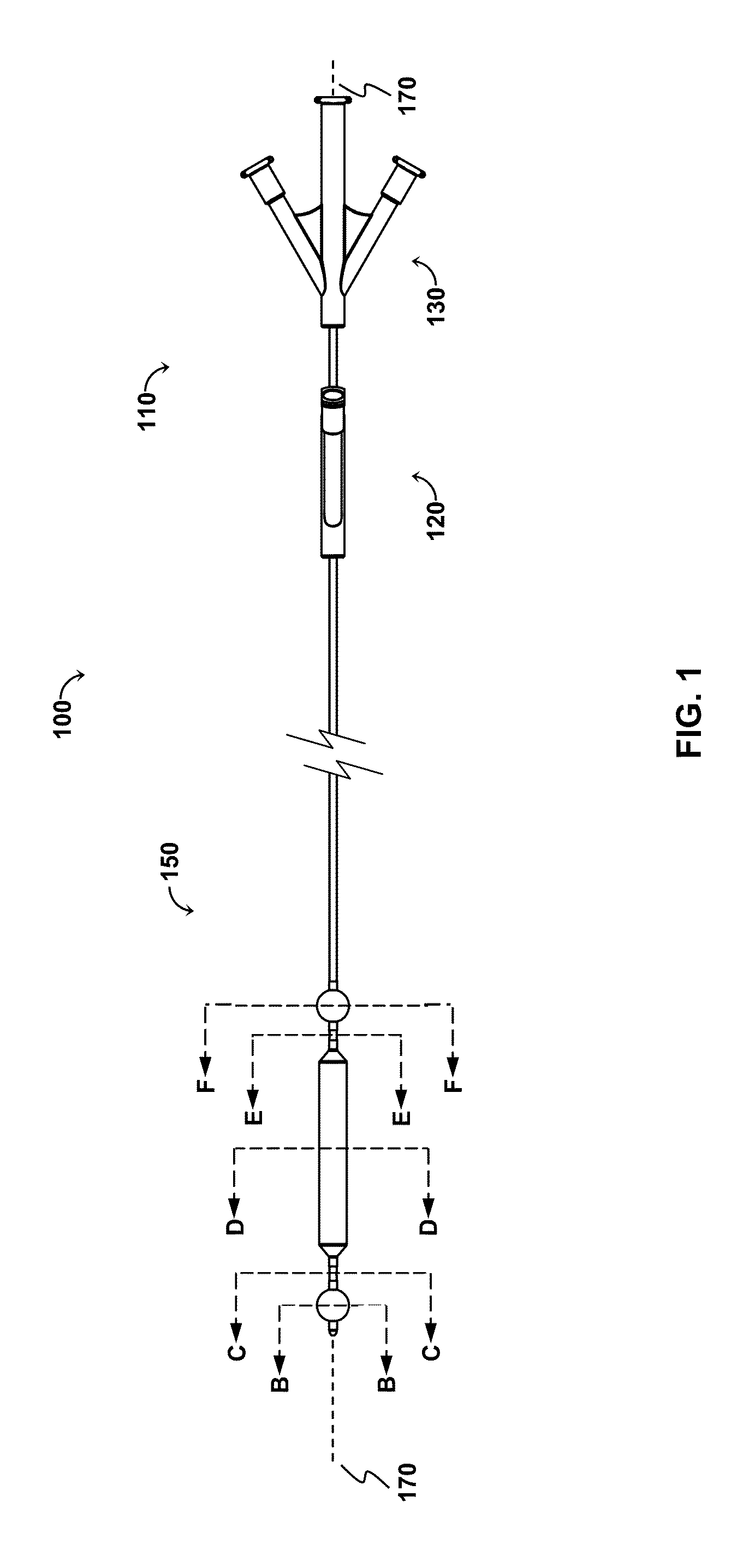

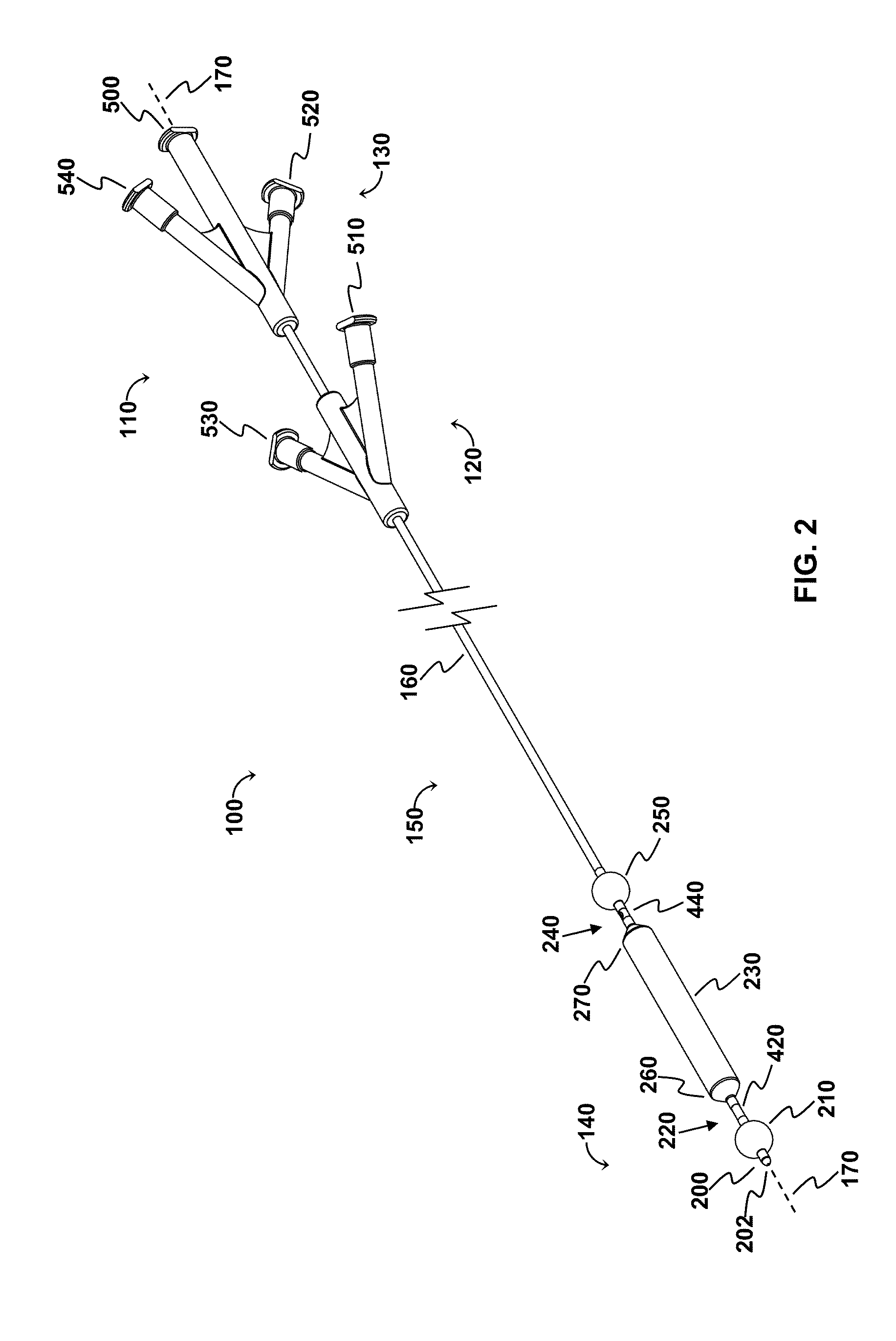

Occlusion Perfusion Catheter

ActiveUS20100280451A1Minimize restenosisImprove visualizationStentsBalloon catheterPerfusionCatheter device

Catheters for occluding, visualizing, irrigating, evacuating, and delivering agents to a treatment area are disclosed. The catheters comprise a catheter body comprising five lumens, first and second occlusion balloons coupled to the catheter body, an optional space-occupying balloon coupled to the catheter body and disposed between the first and second occlusion balloons, and an optional visualization means that enables visualization between the first and second occlusion balloons. Methods for using these catheters are also disclosed. A method comprises inflating the first and second occlusion balloons, inflating the space-occupying balloon, allowing fluid to exit via an evacuation lumen, optionally irrigating or aspirating to facilitate fluid exit via said lumen, and delivering an agent to a treatment area via the agent lumen.

Owner:ADVANCED CATHETER THERAPIES INC

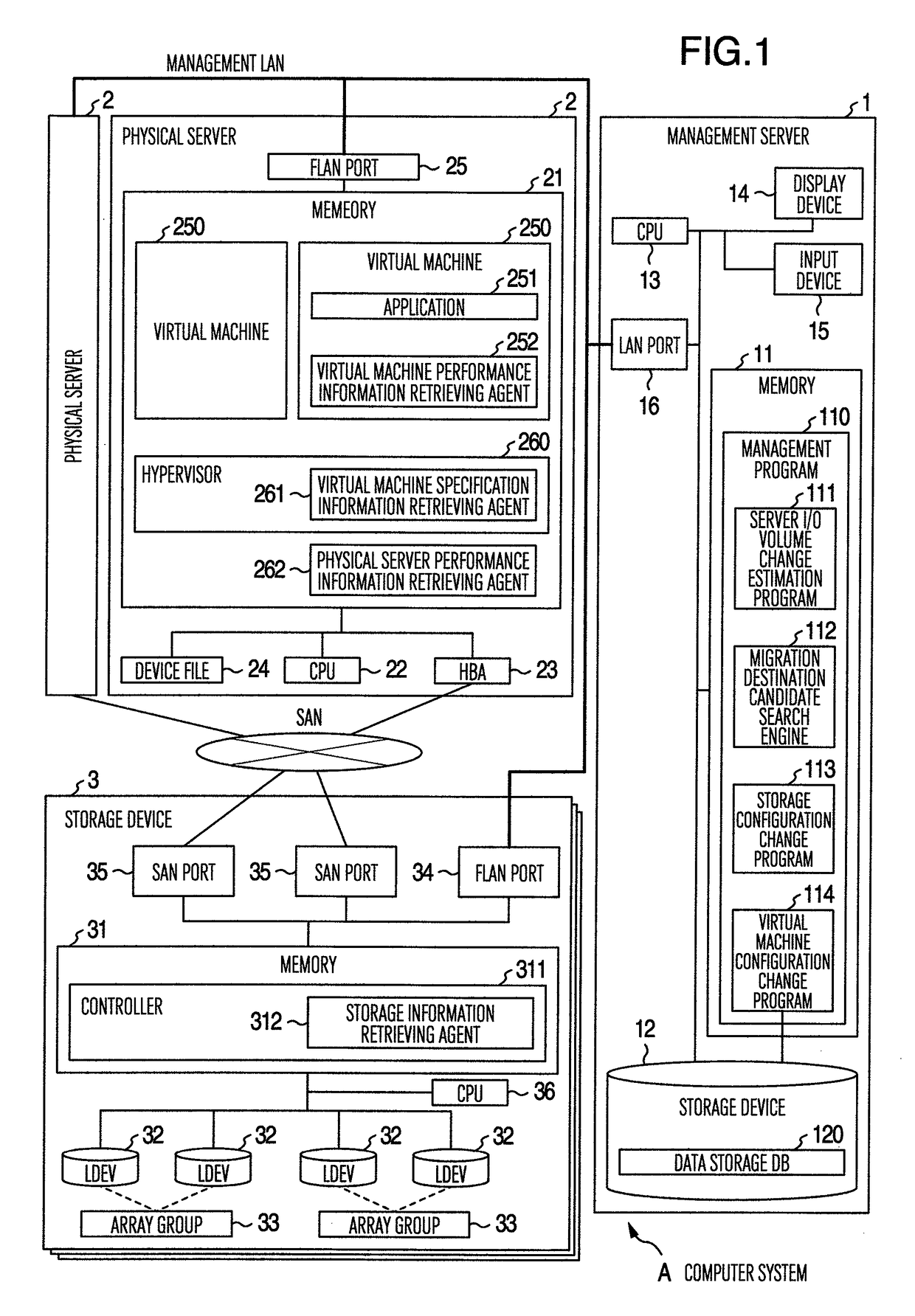

Storage management method and management server

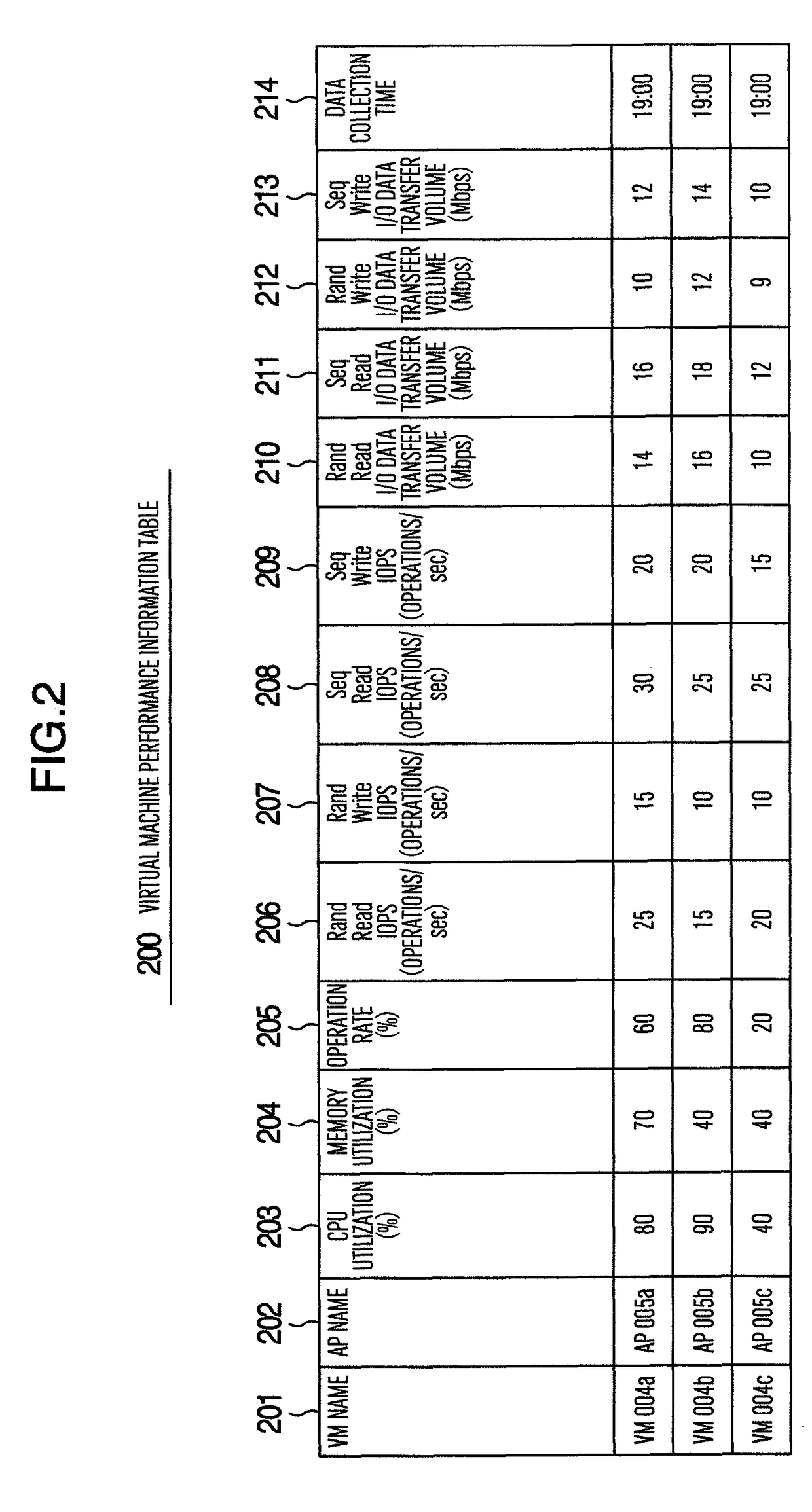

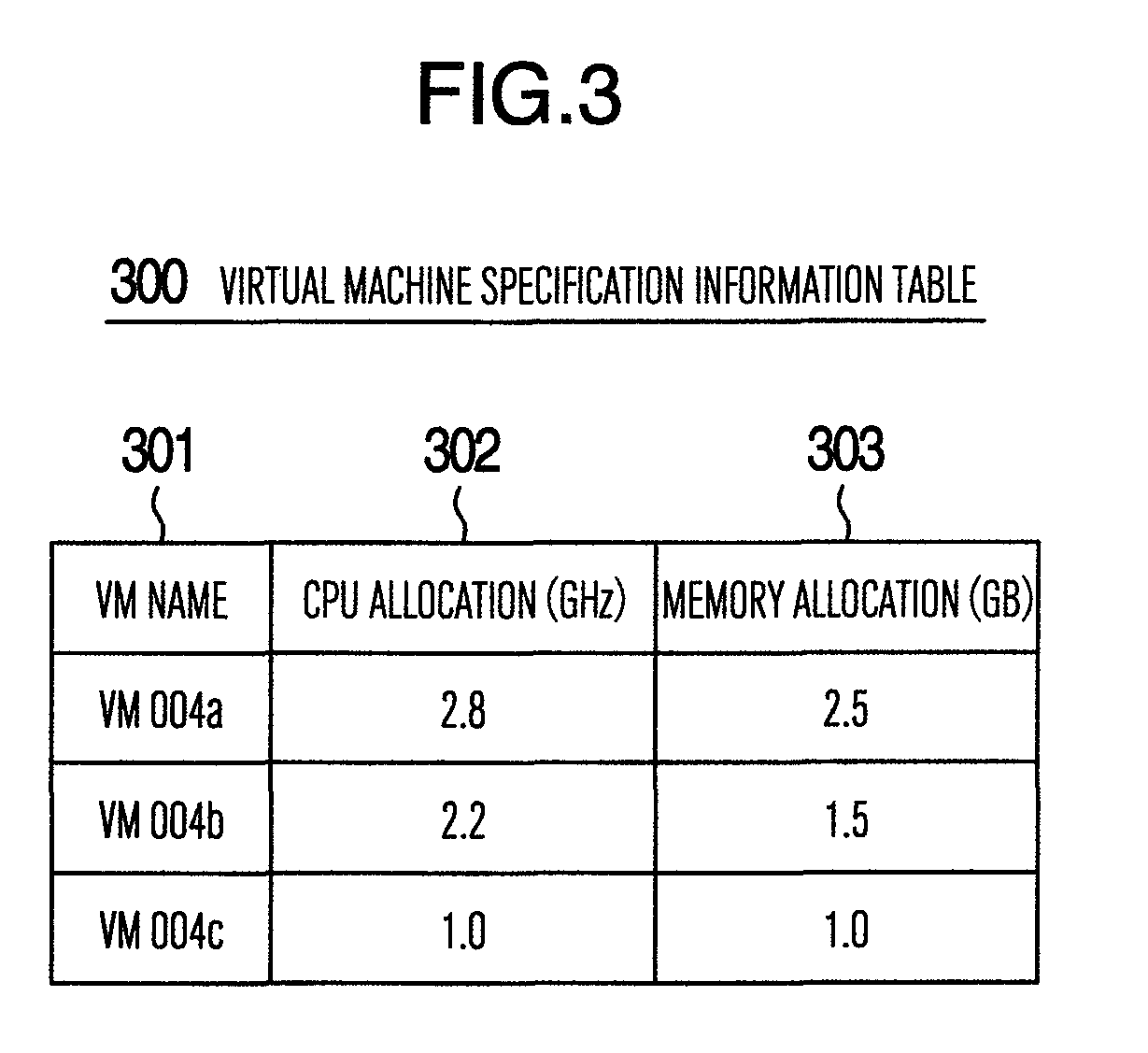

InactiveUS8122116B2More computing resourceLower performance requirementsDigital computer detailsData switching by path configurationComputer architectureComputerized system

A method for moving a virtual machine is provided which considers an input / output between array groups and virtual machines after being moved. The computer system includes a physical server executing the virtual machines, a storage device having array groups, and a management server that manages a link between the virtual machines and the array groups. The computer system is characterized in that an estimated I / O volume of the virtual machine after being moved is calculated and that, if the estimated I / O volume exceeds the maximum I / O volume of the array group connected to the moved virtual machine, a search is made to find an array group whose maximum I / O volume is smaller than the estimated I / O volume.

Owner:HITACHI LTD

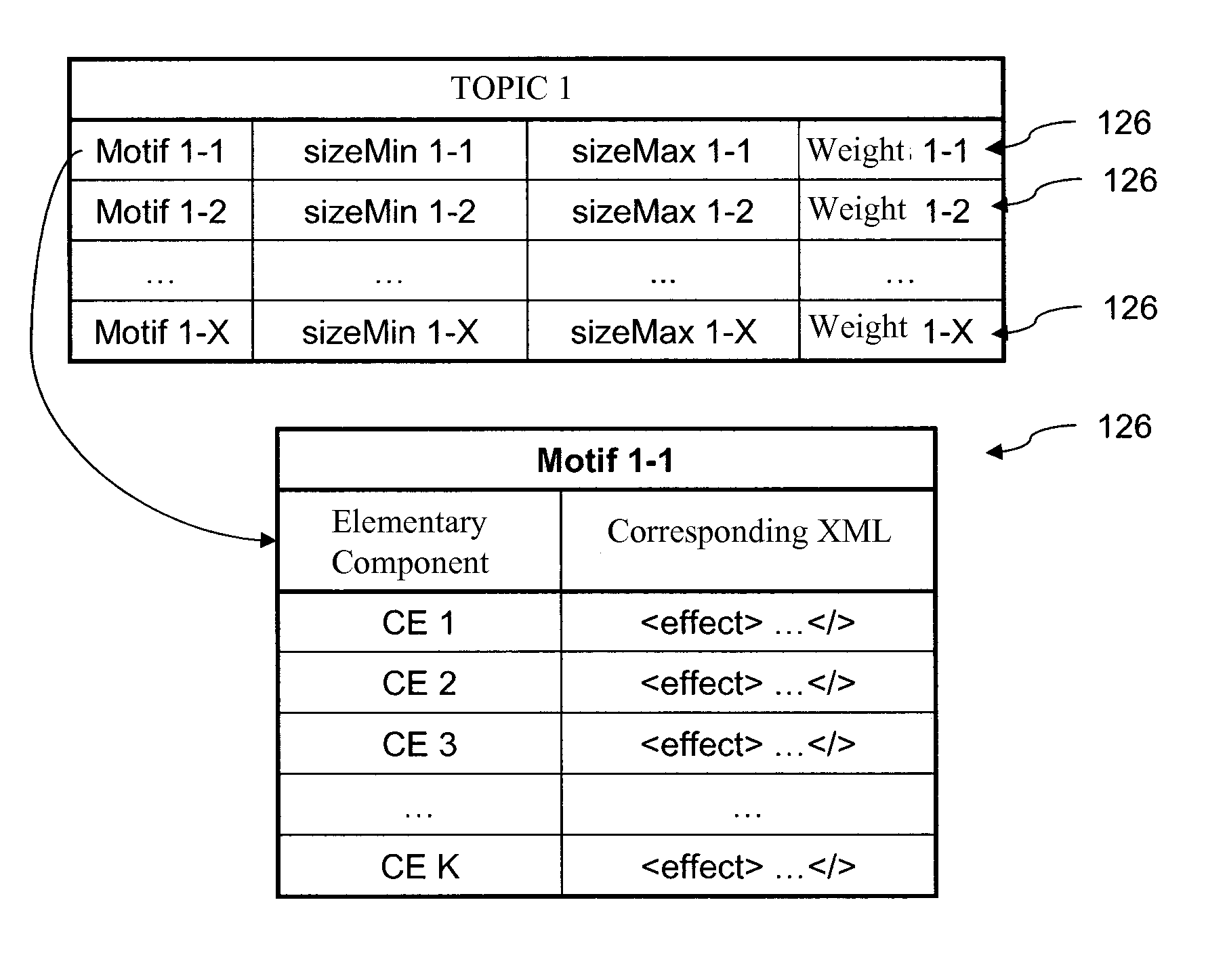

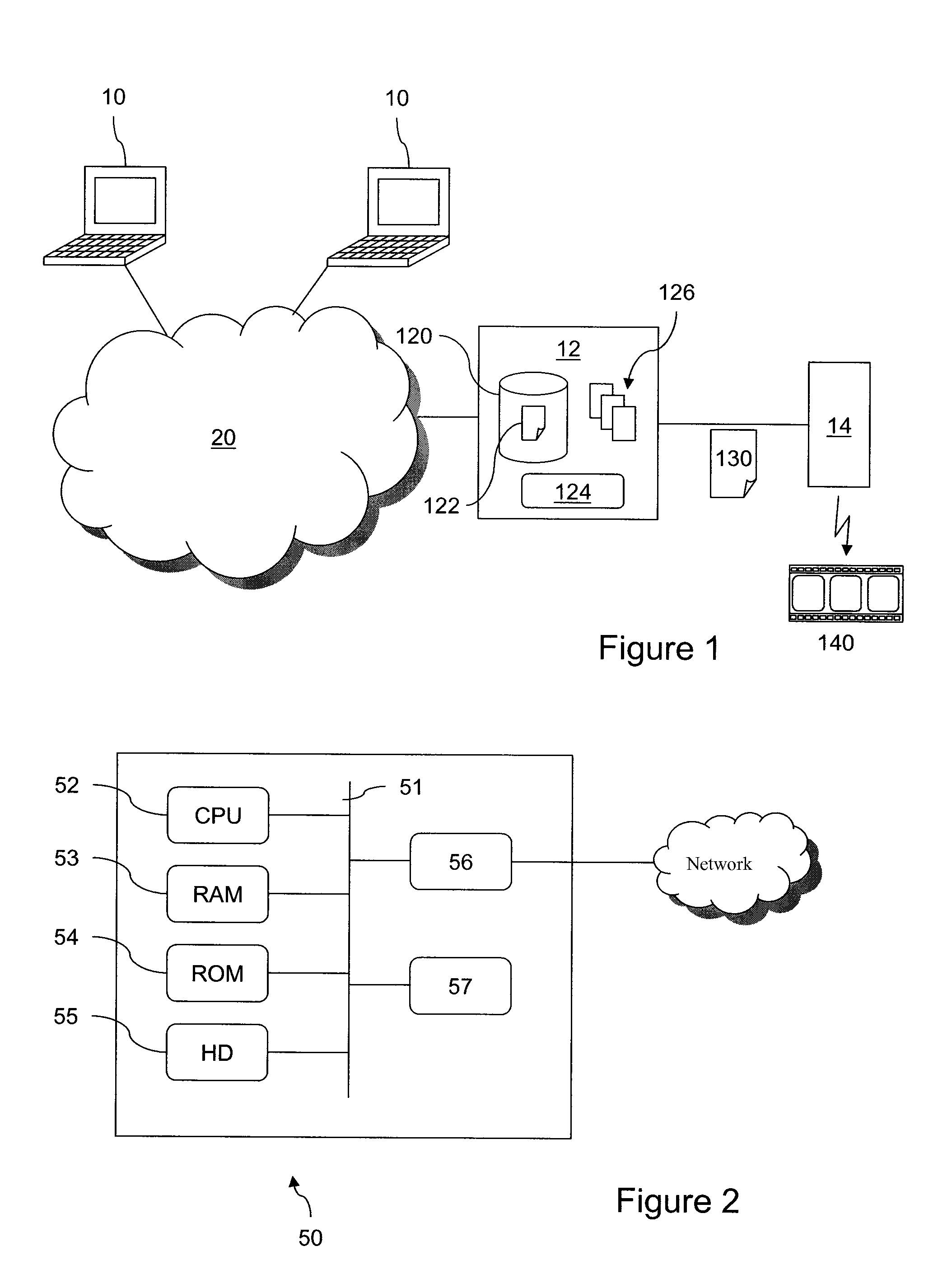

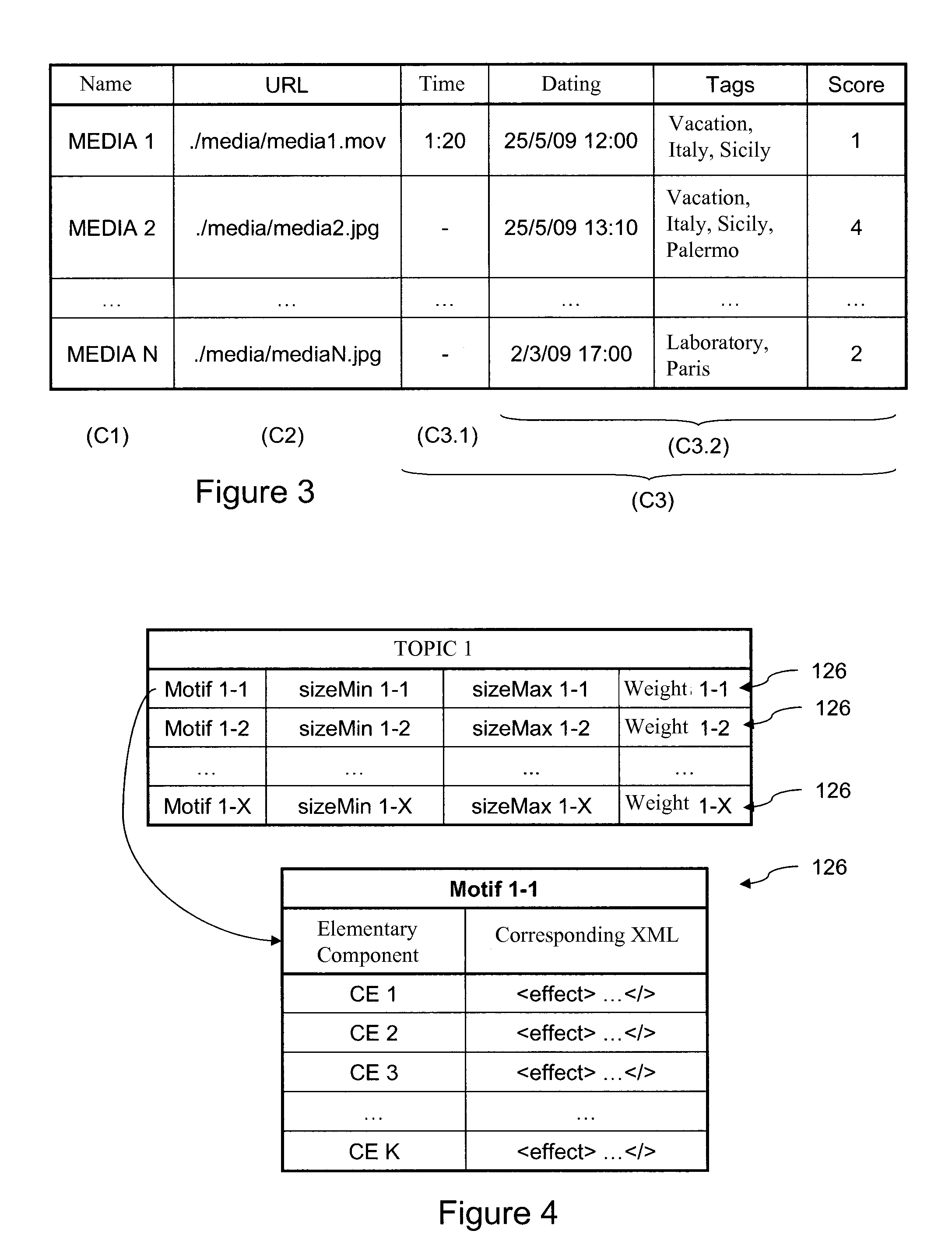

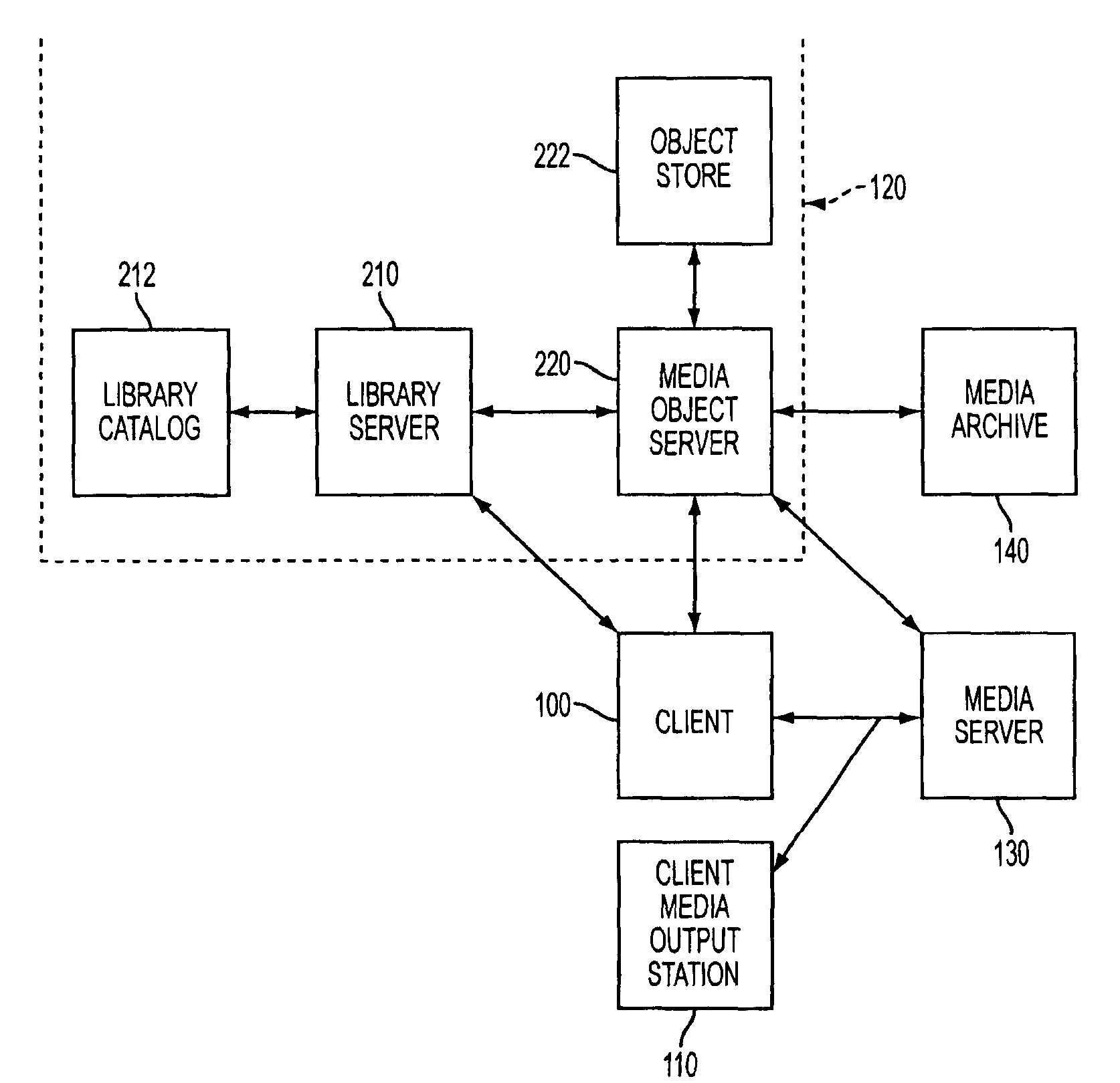

Process for creating a media sequence by coherent groups of media files

InactiveUS20110276864A1Volume andMedia file rendering of the group is reducedMultimedia data indexingMultimedia data queryingWeb serviceVideo editing

A process for creating a media sequence, for example video or audio, and an associated device includes the stages of:obtaining a selection of media files;regrouping the chosen media files into a plurality of groups according to at least one coherence criterion;selecting, for each group of media files assembled in this way, a media motif among a plurality of predefined media motifs, the chosen media motif being able to define a media rendering for the set of media files of the group; andassembling the media motifs selected in this way and their associated media files in such a way as to form at least one definition of the media sequence. The process can relate to automated video editing as implemented on Web servers.

Owner:ORANGE SA (FR)

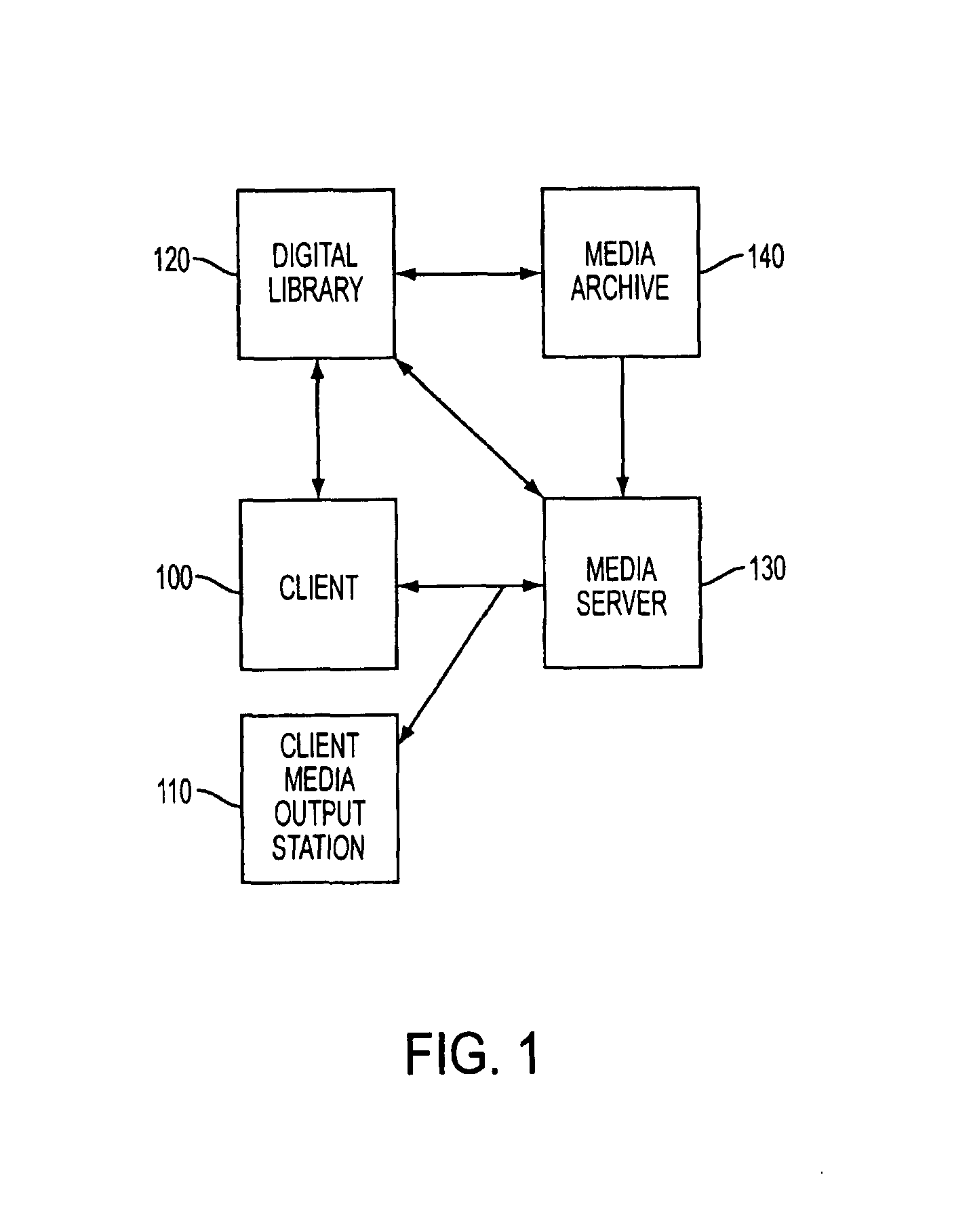

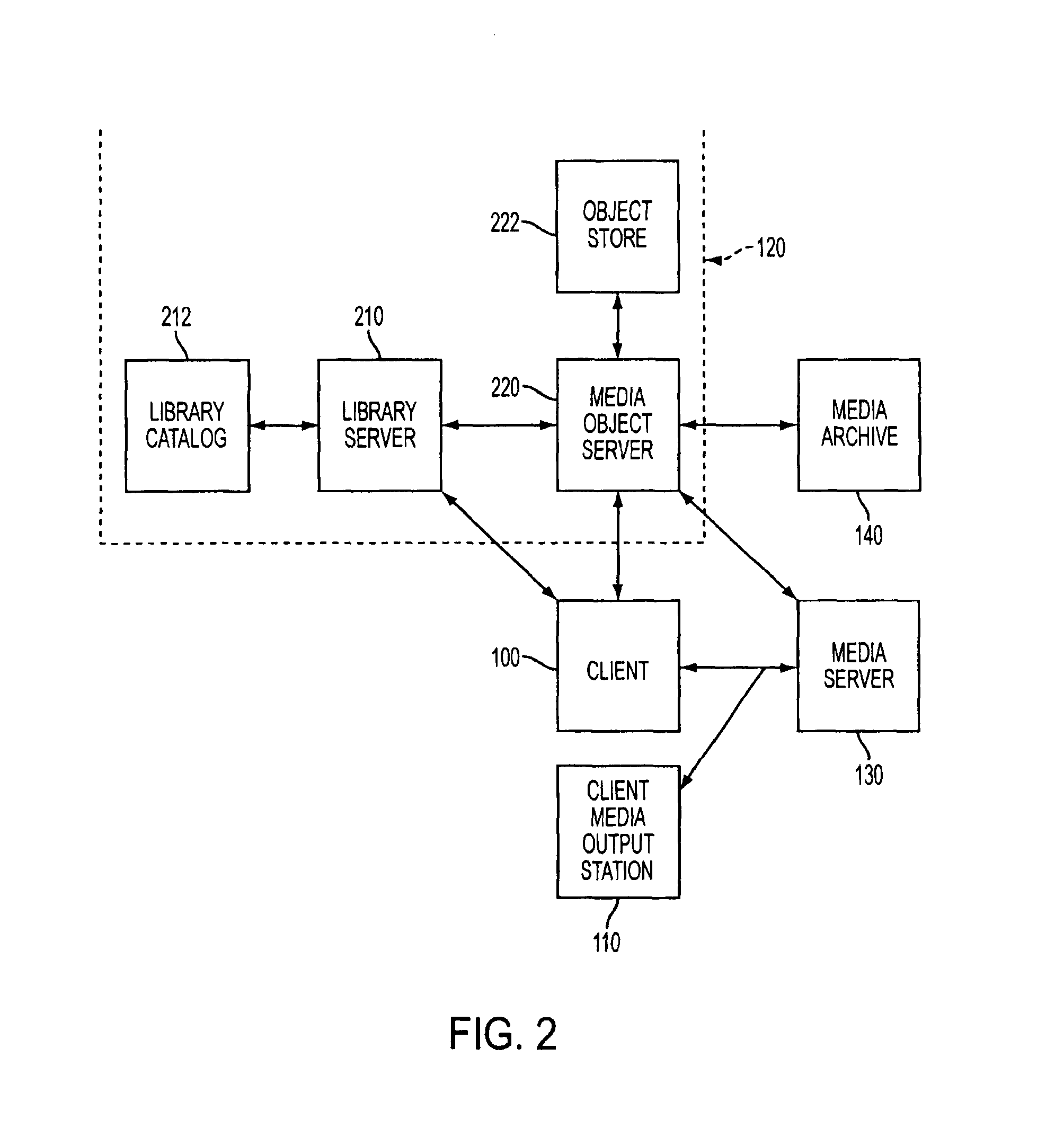

Multimedia data storage system and method for operating a media server as a cache device and controlling a volume of data in the media server based on user-defined parameters

InactiveUS6978348B2Efficient deliveryWithout excessive delayMultimedia data retrievalMemory adressing/allocation/relocationMedia serverShort terms

The present invention is directed to a multimedia data storage system for storing multimedia data including a media server which stores media data on a short-term basis, and a media archive which stores media data on a long-term basis relative to the media server. The media archive is connected to the media server, which operates as a cache device for the media archive, for transmission of media data between the media archive and the media server. According to the present invention, a volume of the media data stored in the media server is controlled based on user-defined parameters. The present invention is also directed to a method of managing a media server as a cache device for a media archive within a multimedia data storage system. The media server stores media data on a short-term basis, whereas the media archive stores media data on a long-term basis relative to the media server. The media archive is connected to the media server for transmission of media data therebetween. According to the present invention, the method of managing includes determining a volume of the media data stored in the media server and controlling the volume of the media data stored in the media server based on user-defined parameters. The present invention is also directed to a computer-readable medium of instructions to be implemented in a multimedia data storage system including a media server and a media archive. The media server stores media data on a short-term basis and the media archive stores media data on a long-term basis relative to the media server. The media archive is connected to the media server for transmission of media data therebetween. The inventive computer-readable medium of instructions includes means for determining a volume of the media data stored in the media server and means for controlling the volume of the media data stored in the media server based on user-defined parameters.

Owner:IBM CORP

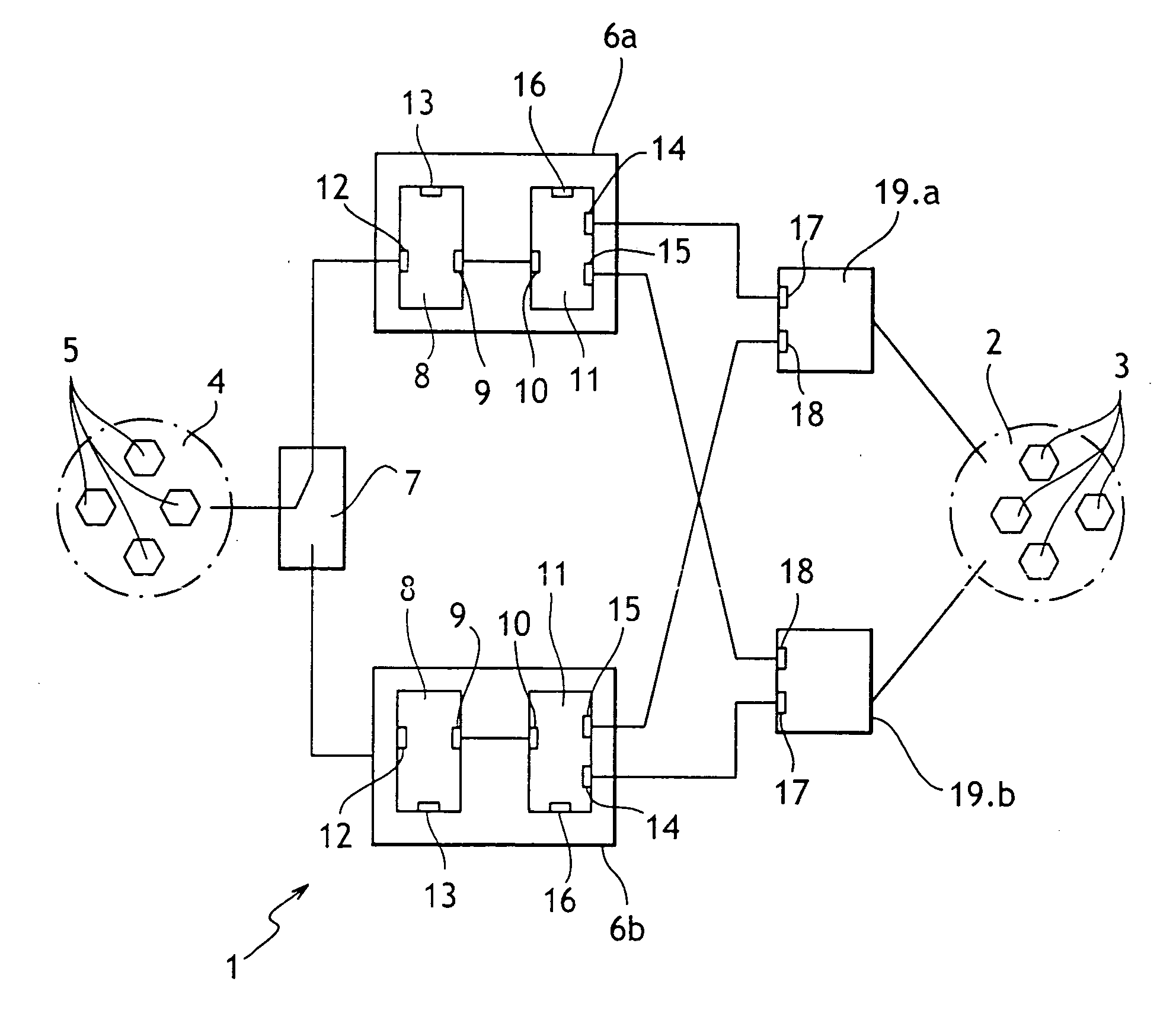

Method of exchanging information between two networks operating under different routing protocols

InactiveUS20100014537A1Reduce workloadSmall loadData switching by path configurationRouting tableAdaptive routing

A method of exchanging information between a first network implementing a routing protocol using static routing tables and a second network implementing a routing protocol using dynamic routing tables and including stages of exchanging identification messages and of exchanging routing table update messages, the method comprising the steps of: a first routing element associated with the first network issuing to a second routing element associated with the second network identification messages containing identifiers of network elements to which the first routing element knows it is connected either directly or indirectly, and in the second routing element updating the routing table from the identification messages coming from the first routing element.

Owner:SAFRAN ELECTRONICS & DEFENSE

Components for nano-scale Reactor

InactiveUS20040115830A1Compensation attenuationAvoid captureMaterial nanotechnologyFlow mixersEvaporationEngineering

Microfluidic devices and methods for operations on micro through nano-meter scales. Methods of processing, handling and analysis of yocto-liter scale volumes. Methods and devices for single-molecule transports in milli-scale dimensions. Methods of laser propulsion of individual cells and droplets. Methods of packaging and manufacturing of micro and nanofluidic devices. Method of improving dispensing accuracy. Methods of uses and manufacturing of micro-optico-fluidic devices. Bottom up processing method. Ionic particle deflector device. Smart package device and methods for high-throughput synthesis and screening. Methods and devices for controlled refills of micro stamps. Methods and devices for insitu concentration and dilution of micro volumes of solids and liquids. Methods and devices for eliminating undesirable dry outs and evaporation of microscale volumes of fluids.

Owner:TOUZOV IGOR

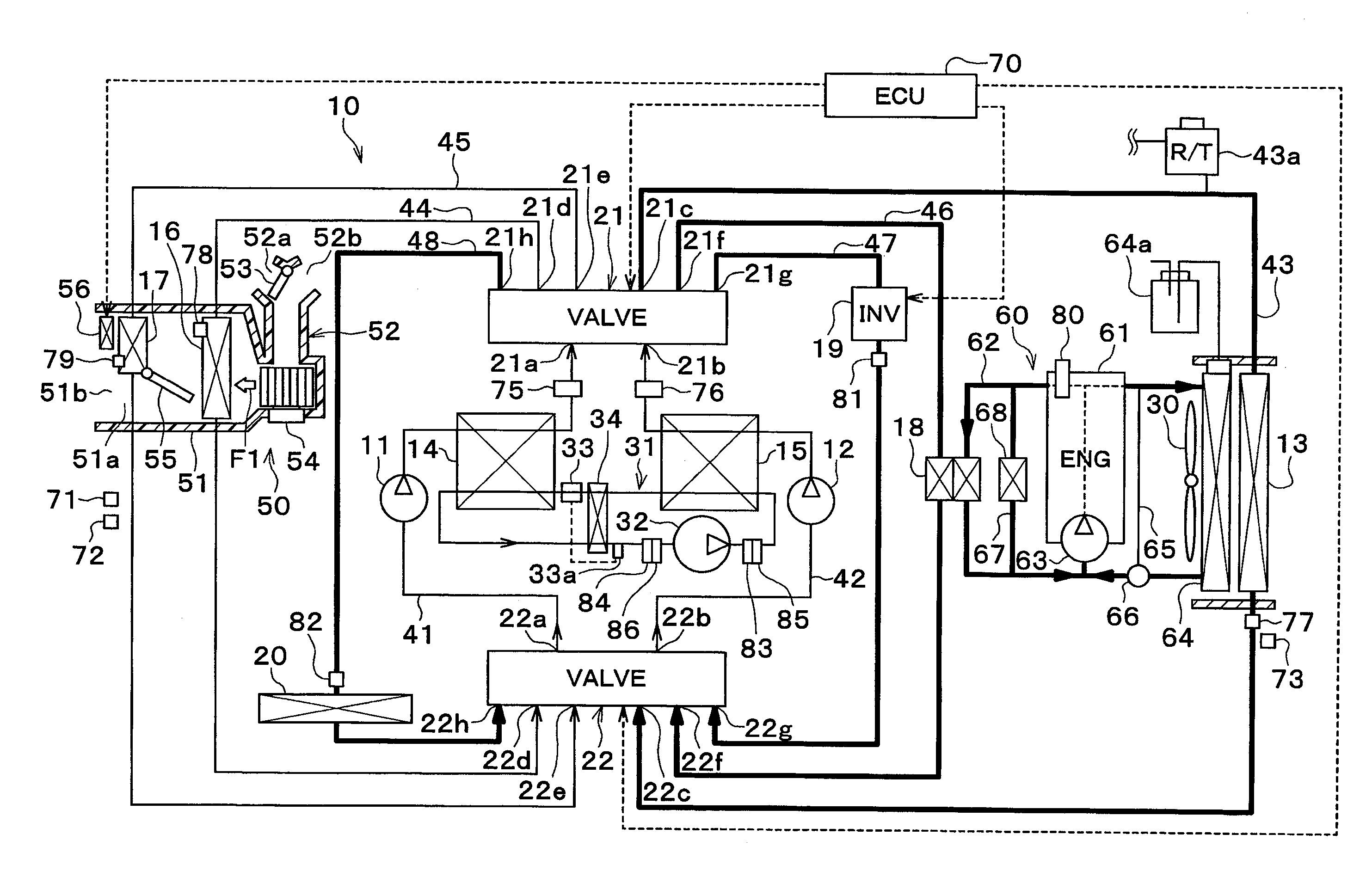

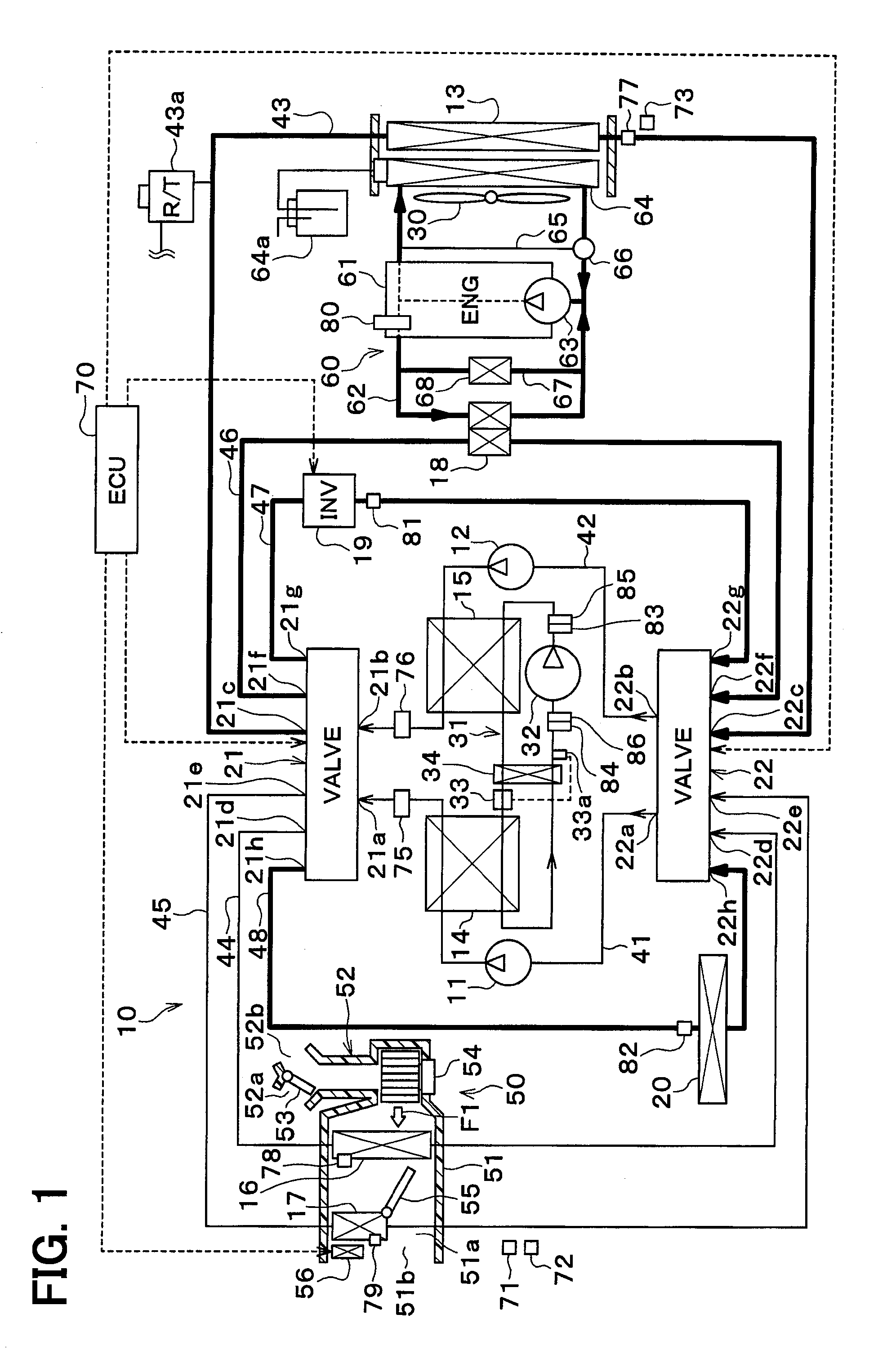

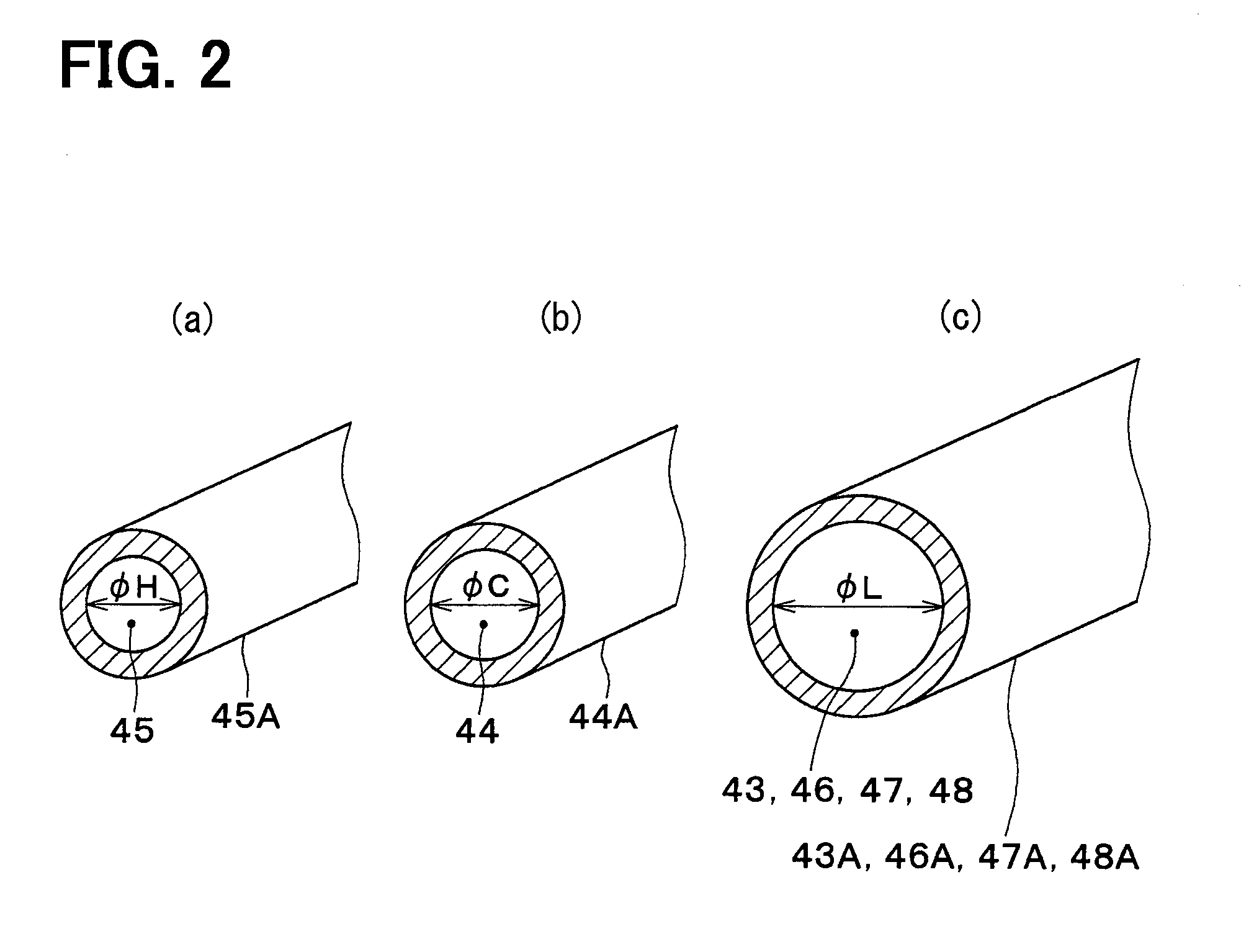

Air conditioner

ActiveUS20160339761A1Thermal capacity is reducedImprove responseAir-treating devicesEvaporators/condensersEngineeringMicro heat exchanger

An air conditioner includes: a heat-medium air heat exchanger that exchanges sensible heat between a heat medium having a temperature adjusted by the heat-medium temperature adjuster and ventilation air blowing to a space to be air-conditioned; a heat transfer portion having a flow path through which the heat medium circulates to transfer heat with the heat medium having the temperature adjusted by the heat-medium temperature adjuster; a large-inner-diameter pipe that forms a heat-medium flow path between the heat-medium temperature adjuster and the heat transfer portion; and a small-inner-diameter pipe that forms a heat-medium flow path between the heat-medium temperature adjuster and the heat-medium air heat exchanger. The small-inner-diameter pipe has small inner diameters φH and φC, compared to the large-inner-diameter pipe.

Owner:DENSO CORP

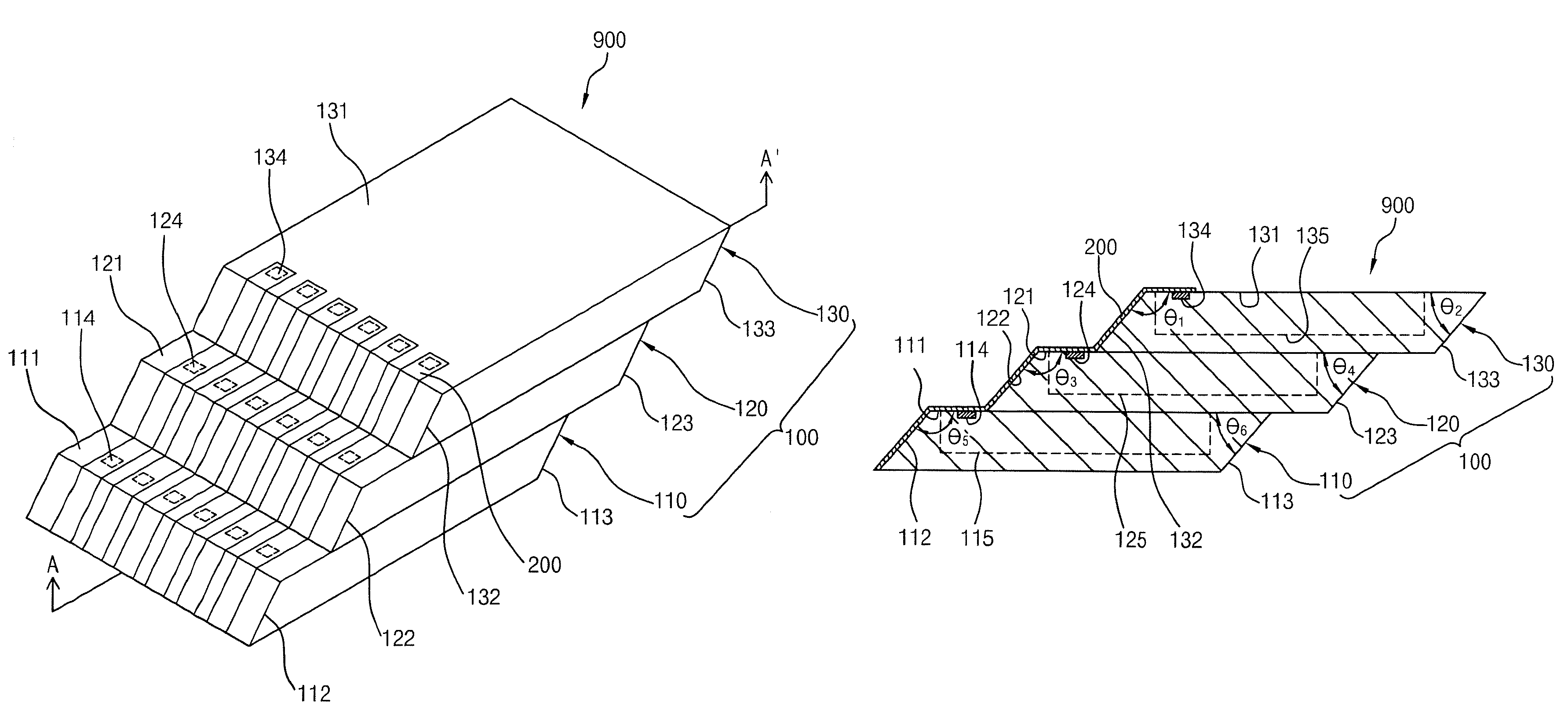

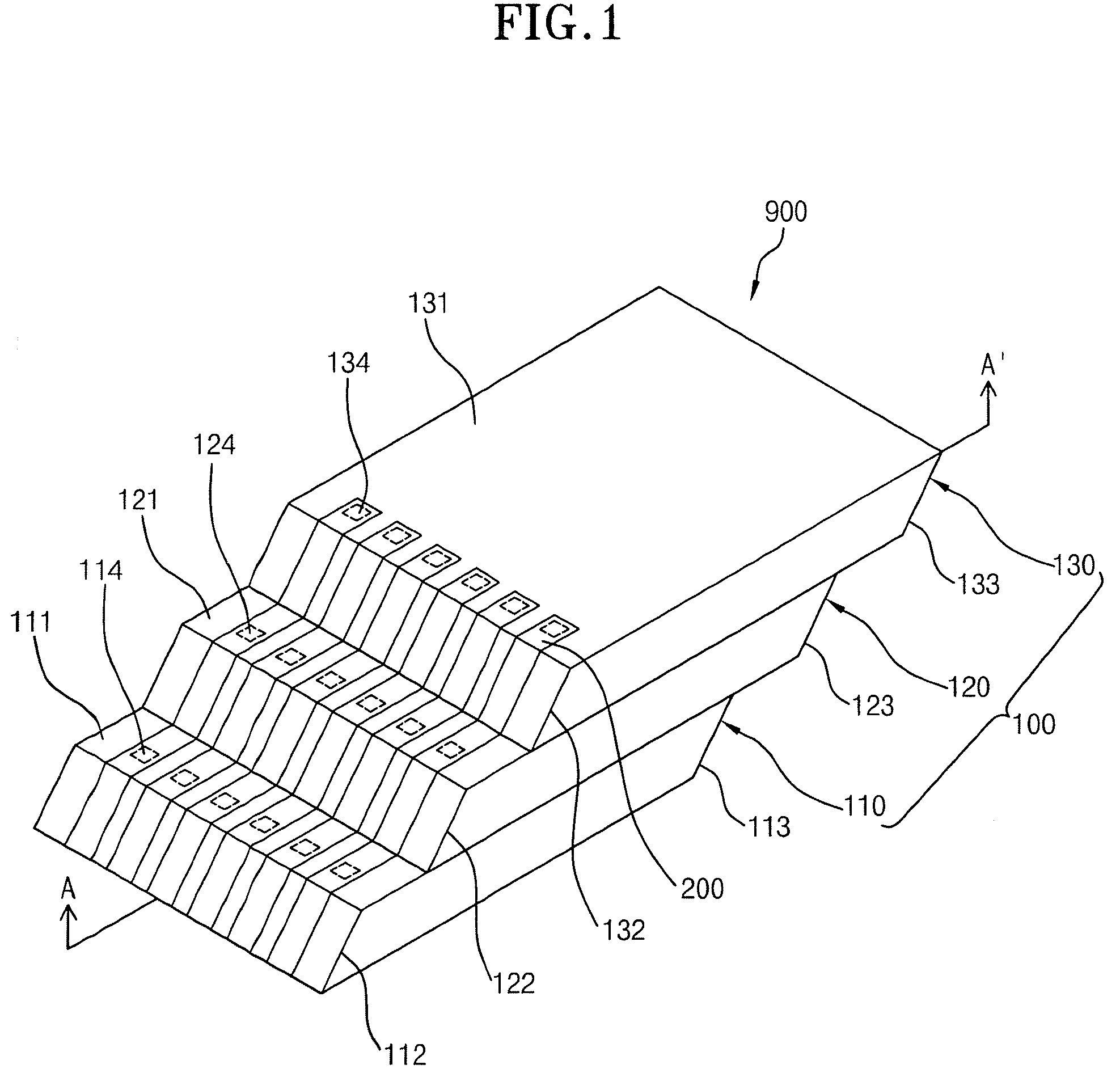

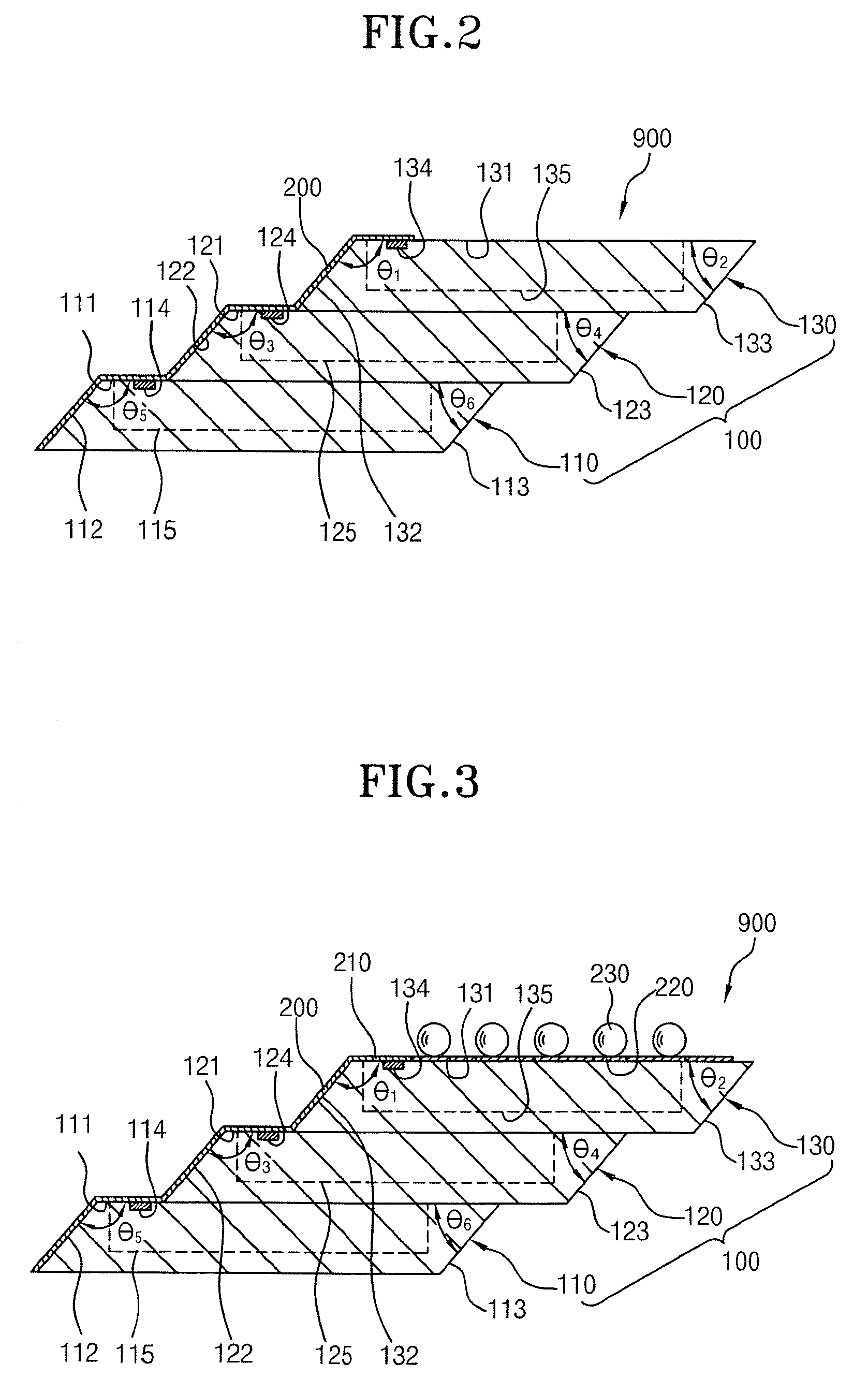

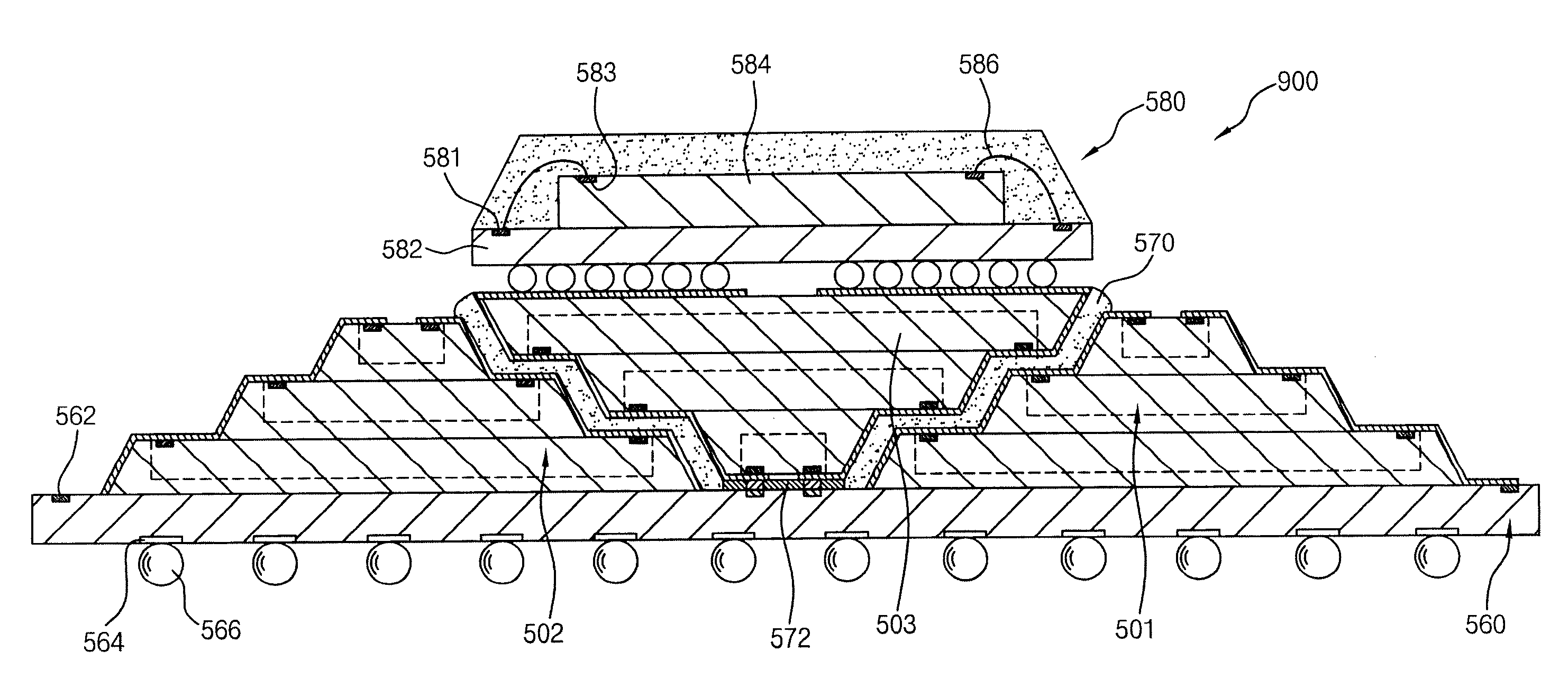

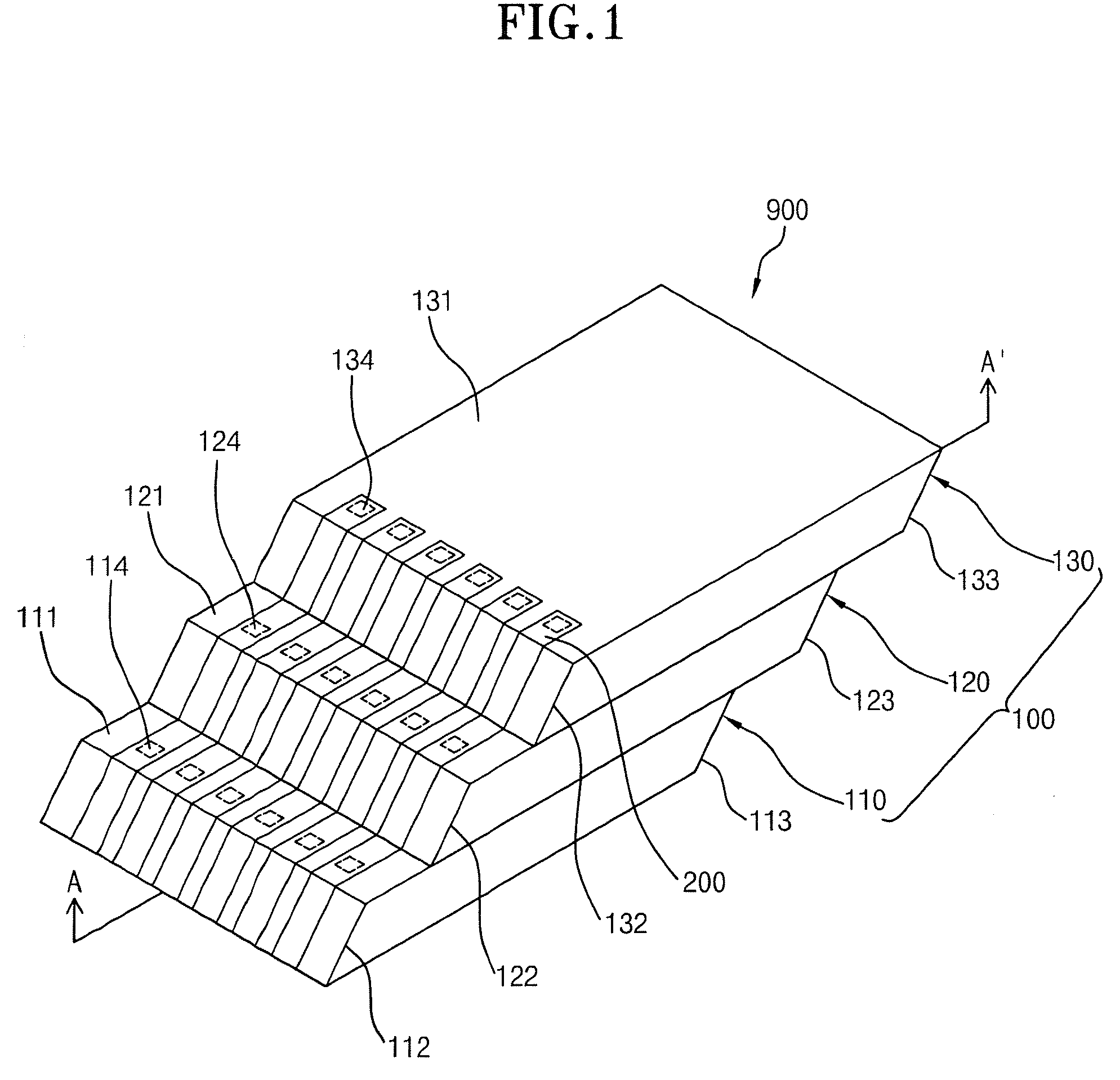

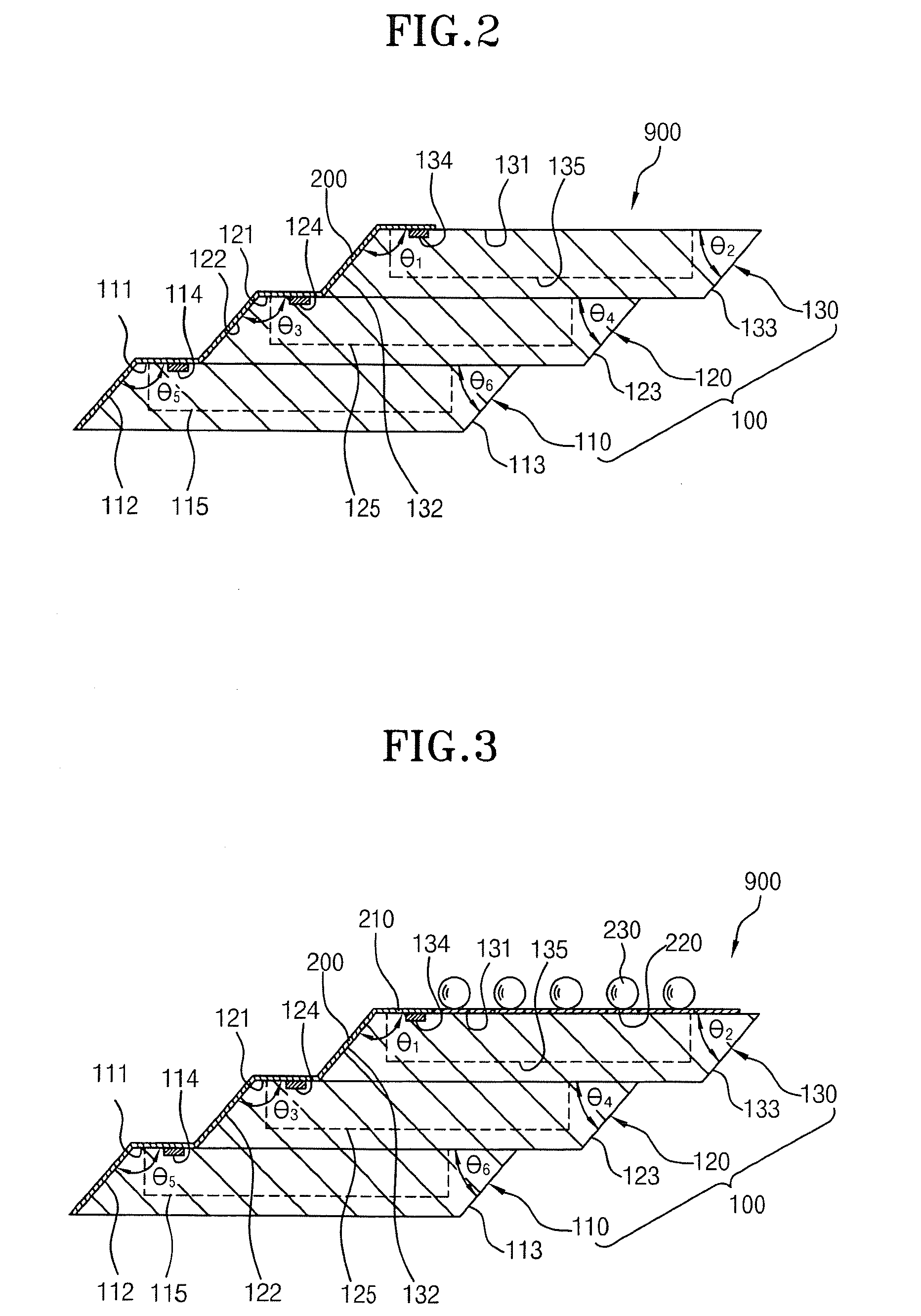

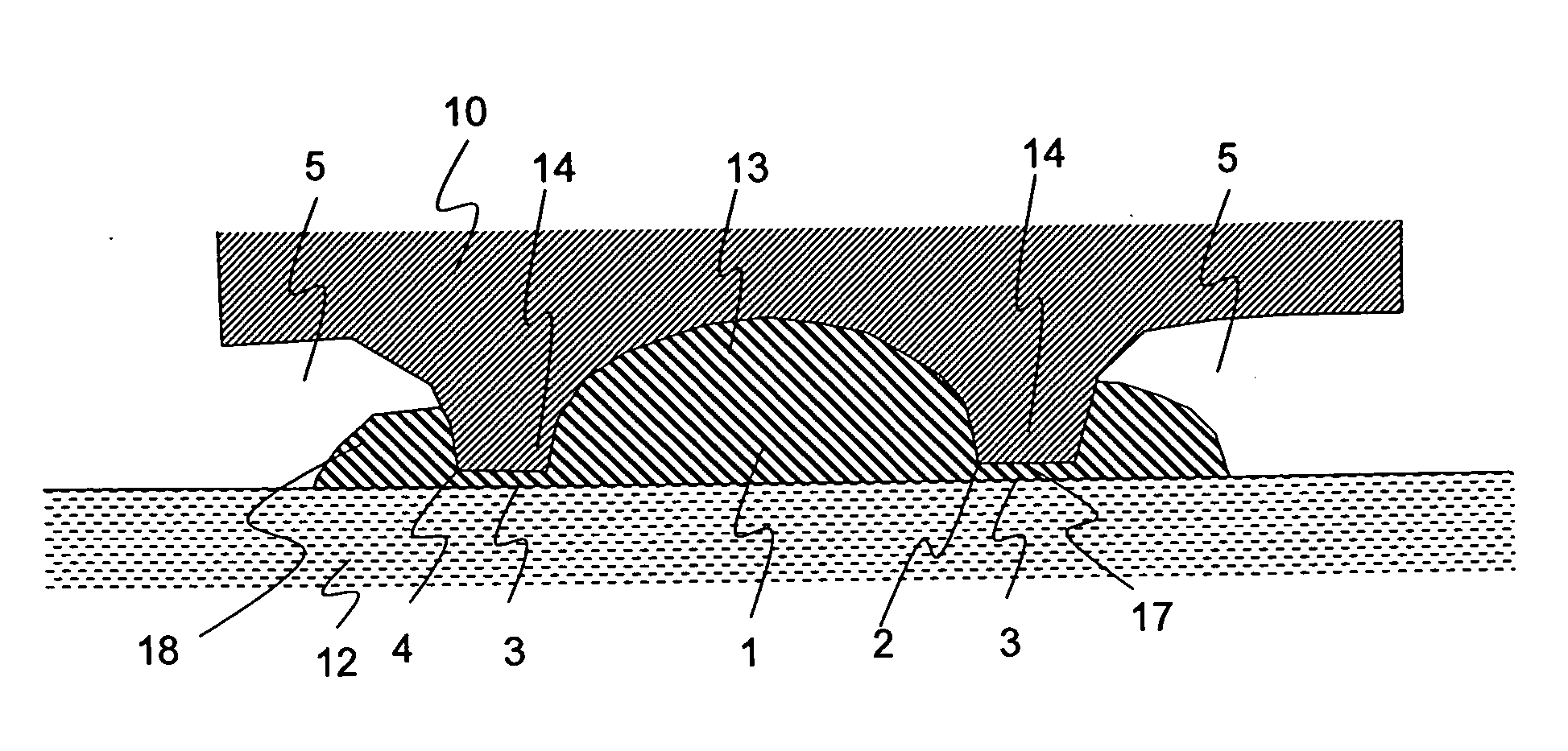

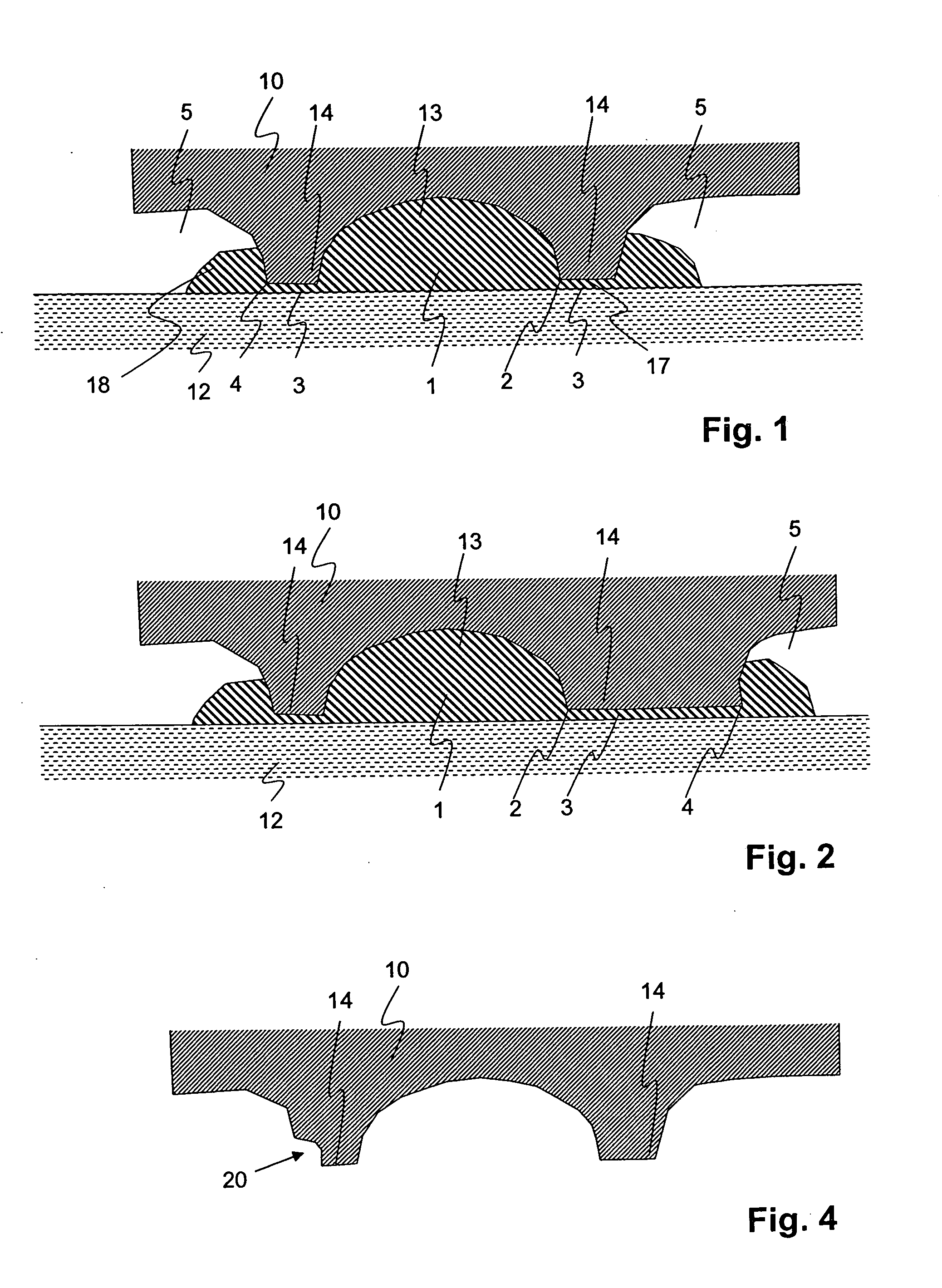

Stacked semiconductor package electrically connecting semiconductor chips using outer surfaces thereof and method for manufacturing the same

ActiveUS7838979B2Volume andReduce in quantitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A stacked semiconductor package and a method for manufacturing the same. The stacked semiconductor package includes a semiconductor chip module having two or more semiconductor chips which are stacked in the shape of steps. Each of the semiconductor chips includes pads located on an upper surface thereof and an inclined side surface connected with the upper surface. Connection patterns are formed in the shape of lines on the inclined side surfaces and the upper surfaces of the semiconductor chips to electrically connect pads of the semiconductor chips.

Owner:SK HYNIX INC

Stacked semiconductor package electrically connecting semiconductor chips using outer surfaces thereof and method for manufacturing the same

ActiveUS20090321954A1Volume andReduce in quantitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A stacked semiconductor package and a method for manufacturing the same. The stacked semiconductor package includes a semiconductor chip module having two or more semiconductor chips which are stacked in the shape of steps. Each of the semiconductor chips includes pads located on an upper surface thereof and an inclined side surface connected with the upper surface. Connection patterns are formed in the shape of lines on the inclined side surfaces and the upper surfaces of the semiconductor chips to electrically connect pads of the semiconductor chips.

Owner:SK HYNIX INC

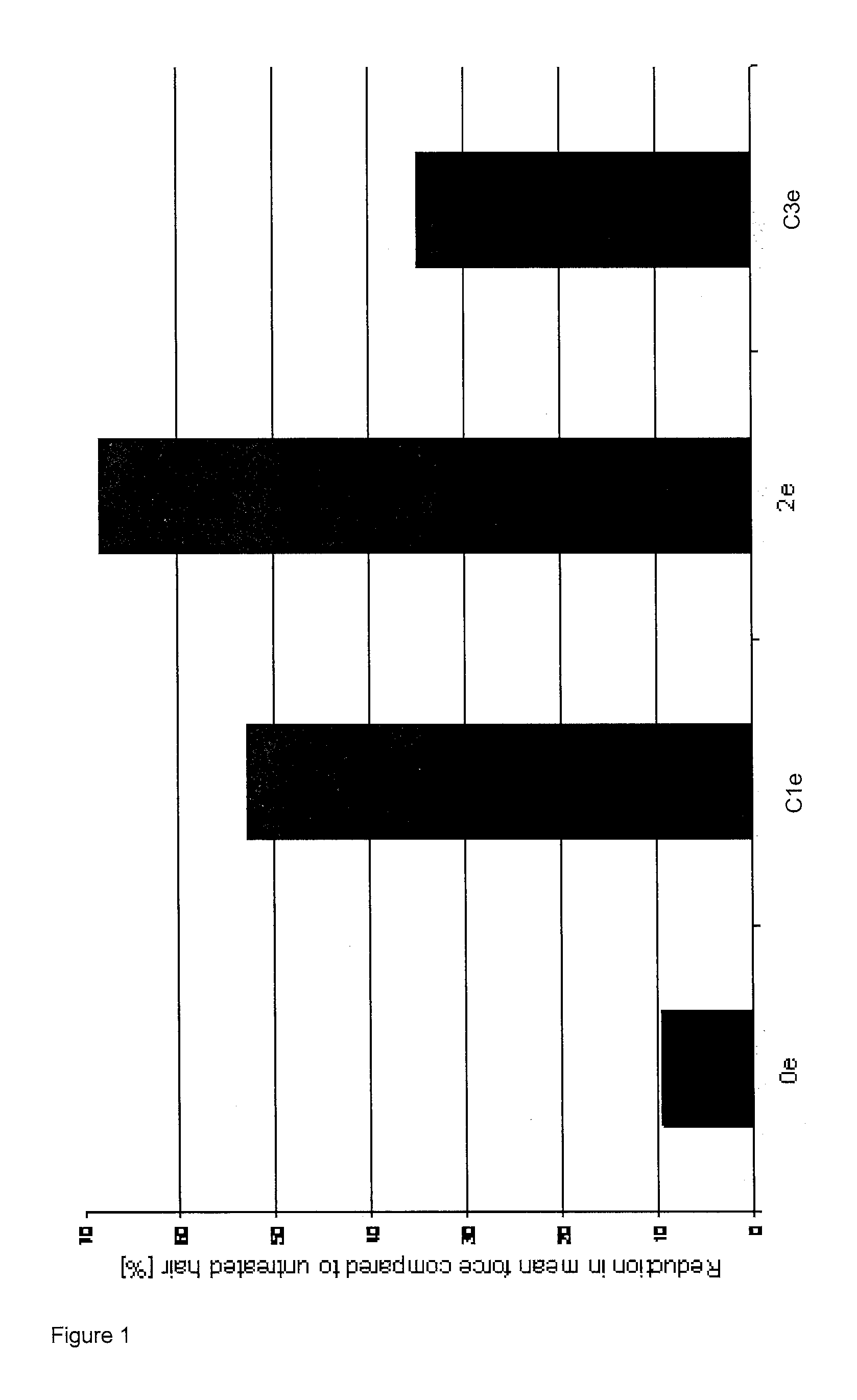

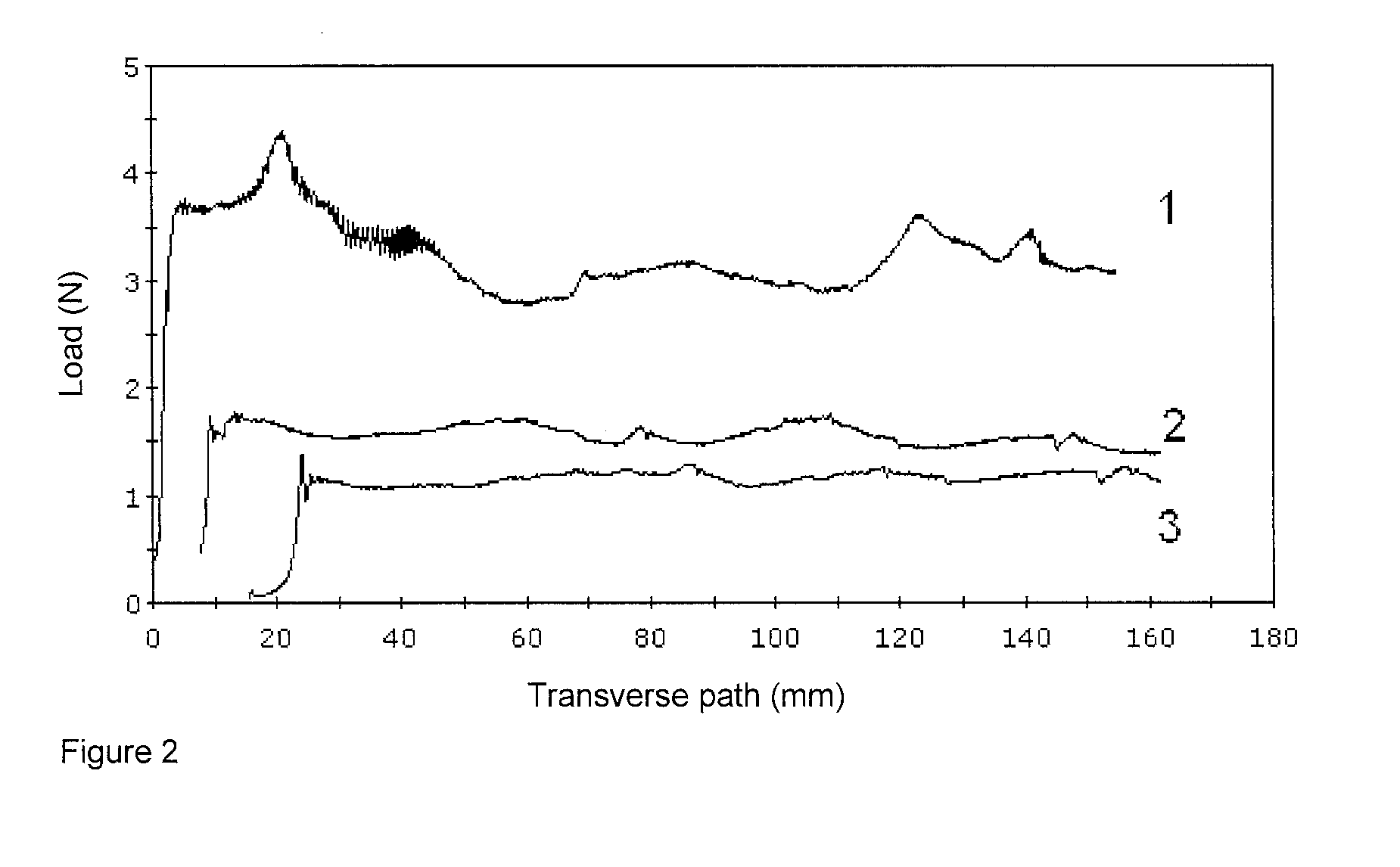

Microemulsion of polysiloxanes containing quaternary ammonium groups, production and use thereof

ActiveUS20140134125A1Improve performanceGood conditioning effectBiocideCosmetic preparationsMicroemulsionOrganic chemistry

The invention relates to microemulsions which comprise, as oil phase, a polysiloxane containing at least one quaternary ammonium group, methods for production thereof and also to the use of such microemulsions.

Owner:EVONIK OPERATIONS GMBH

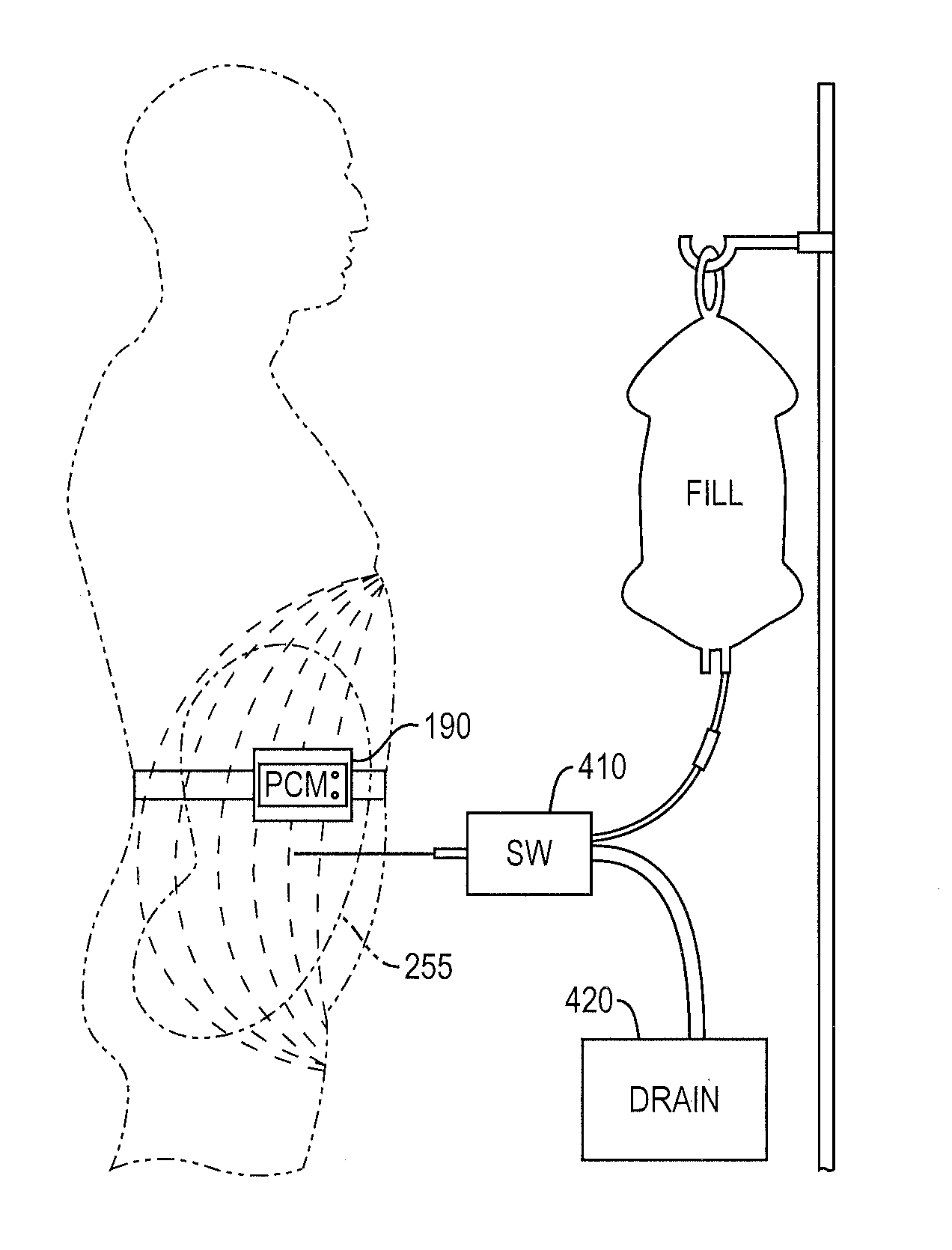

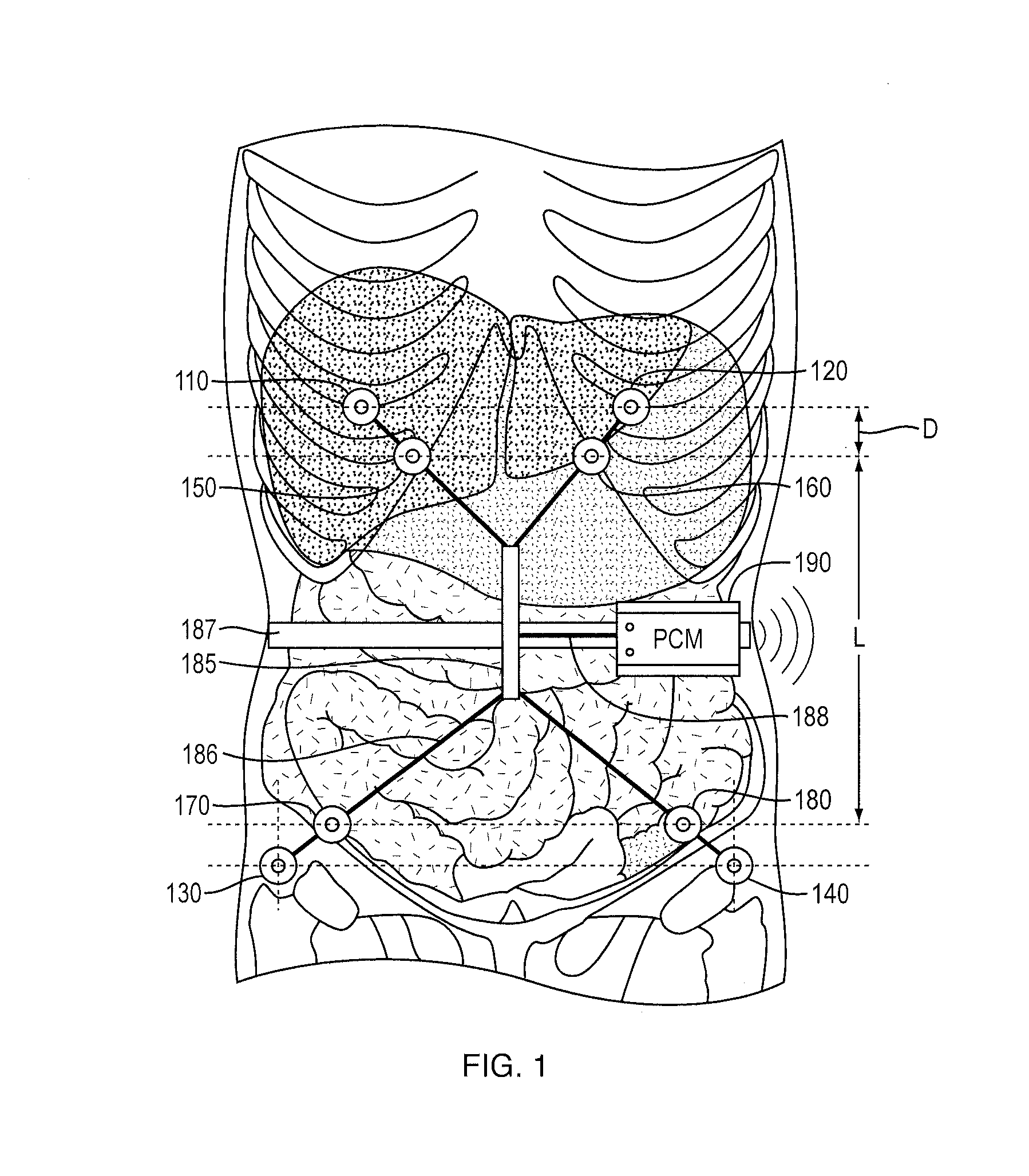

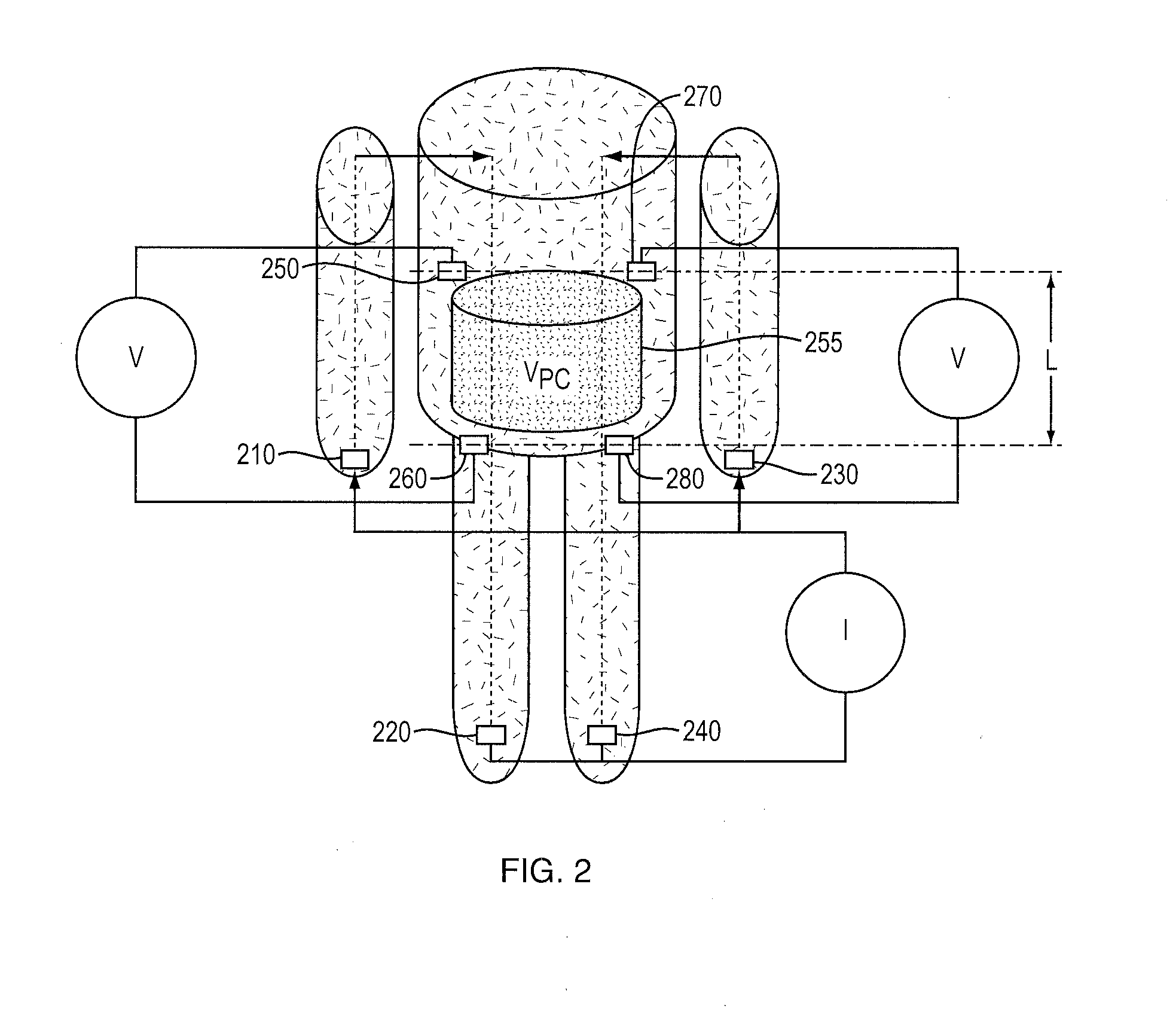

System and method of monitoring and control of ultrafiltration volume during peritoneal dialysis using segmental bioimpedance

ActiveUS20150133854A1Reduction in ultrafiltration volumeMinimize fluid reabsorption backMedical devicesSensorsUltrafiltrationPeritoneal dialysis fluid

A peritoneal dialysis (PD) system for infusing a volume of PD solution into a patient's peritoneal cavity in order to perform peritoneal dialysis on the patient includes a peritoneal cavity monitor (PCM) that measures this volume of fluid in the patient's peritoneal cavity by segmental bioimpedance spectroscopy (SBIS), to thereby determine an ultrafiltration volume of fluid in the patient's peritoneal cavity, and a switch, controlled by the PCM, for filling the patient's peritoneal cavity and draining the patient's peritoneal cavity when the ultrafiltration volume is unchanged over time, significantly decreased, or decreasing at a significant rate.

Owner:FRESENIUS MEDICAL CARE HLDG INC

Ink ejector

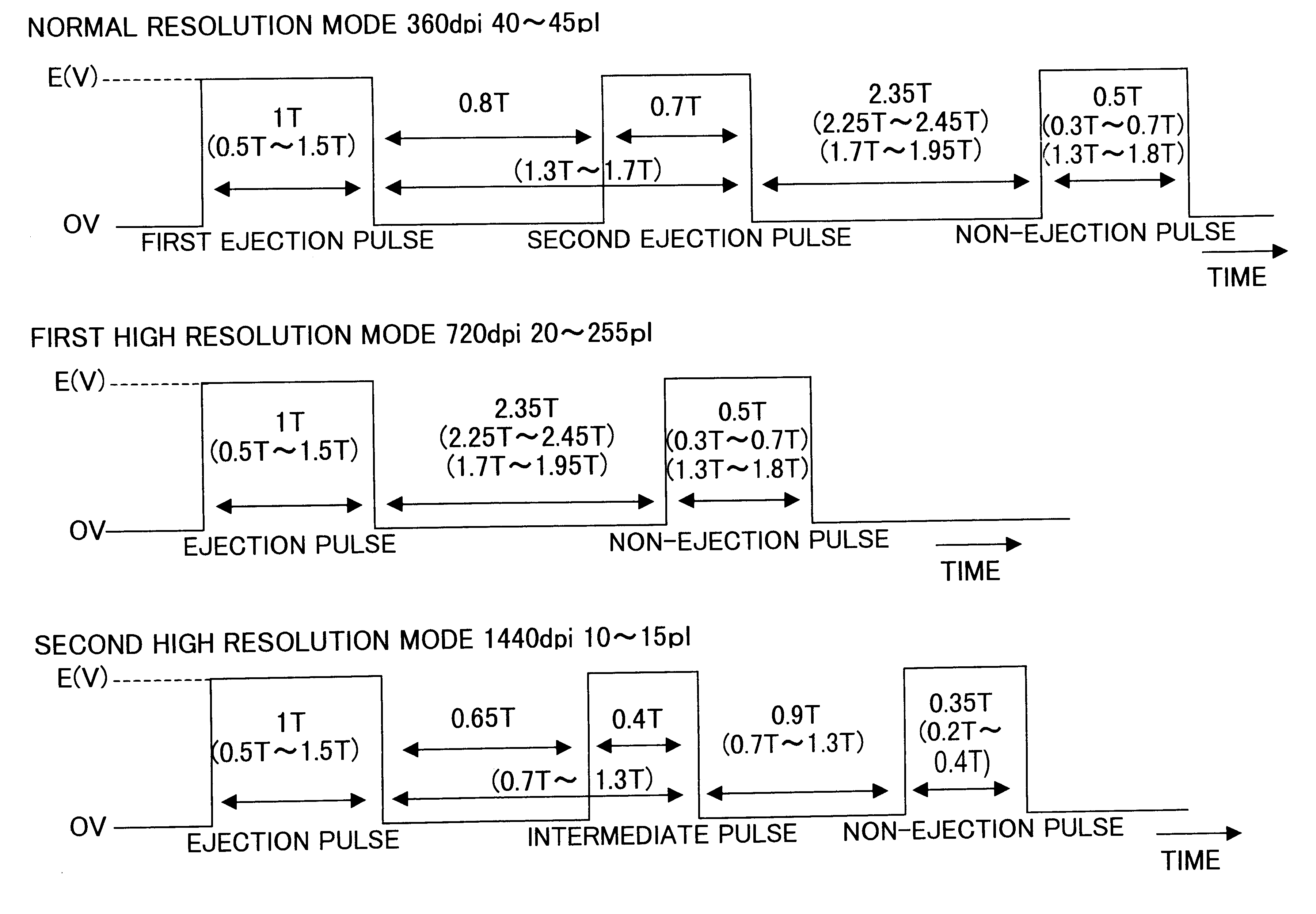

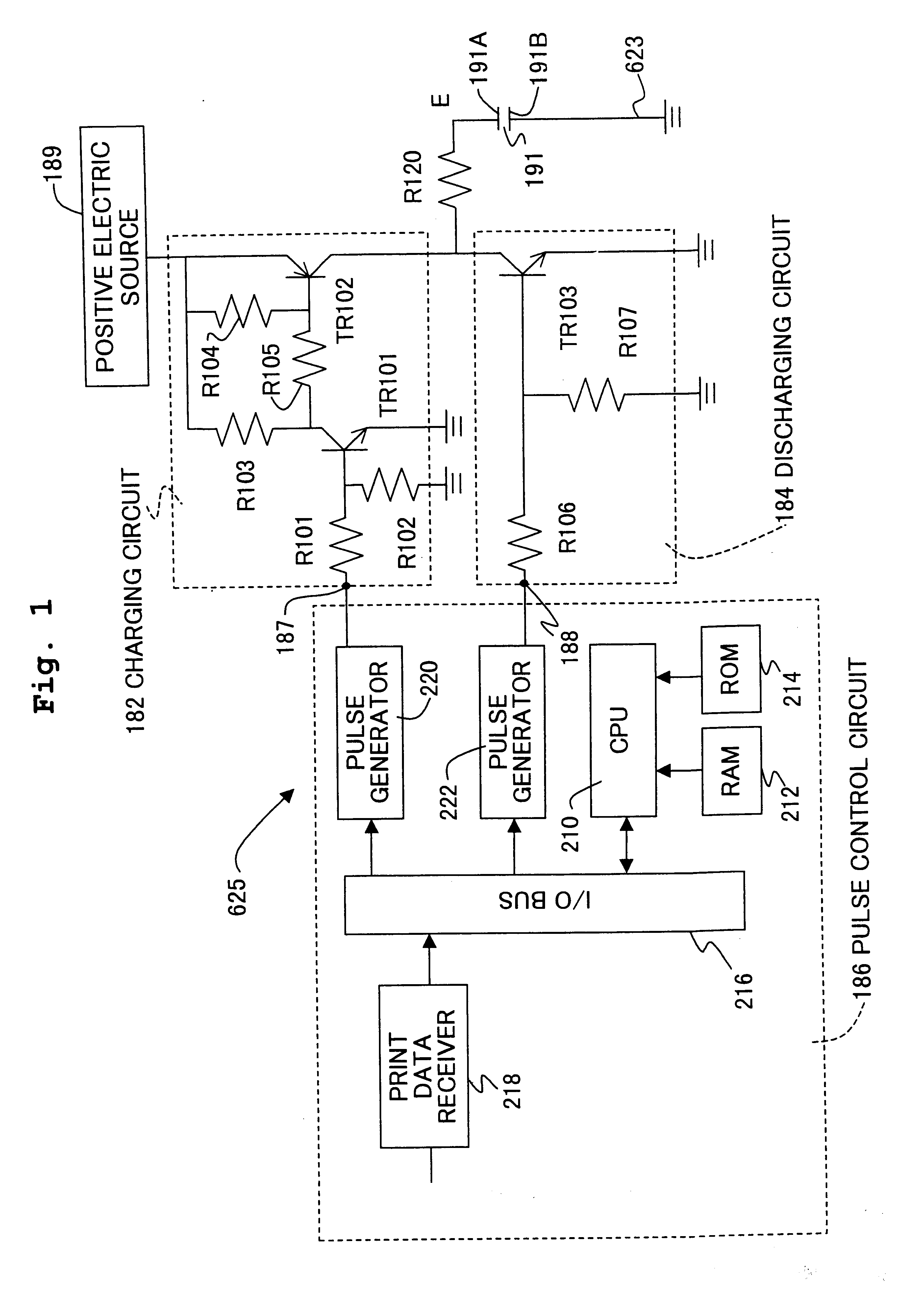

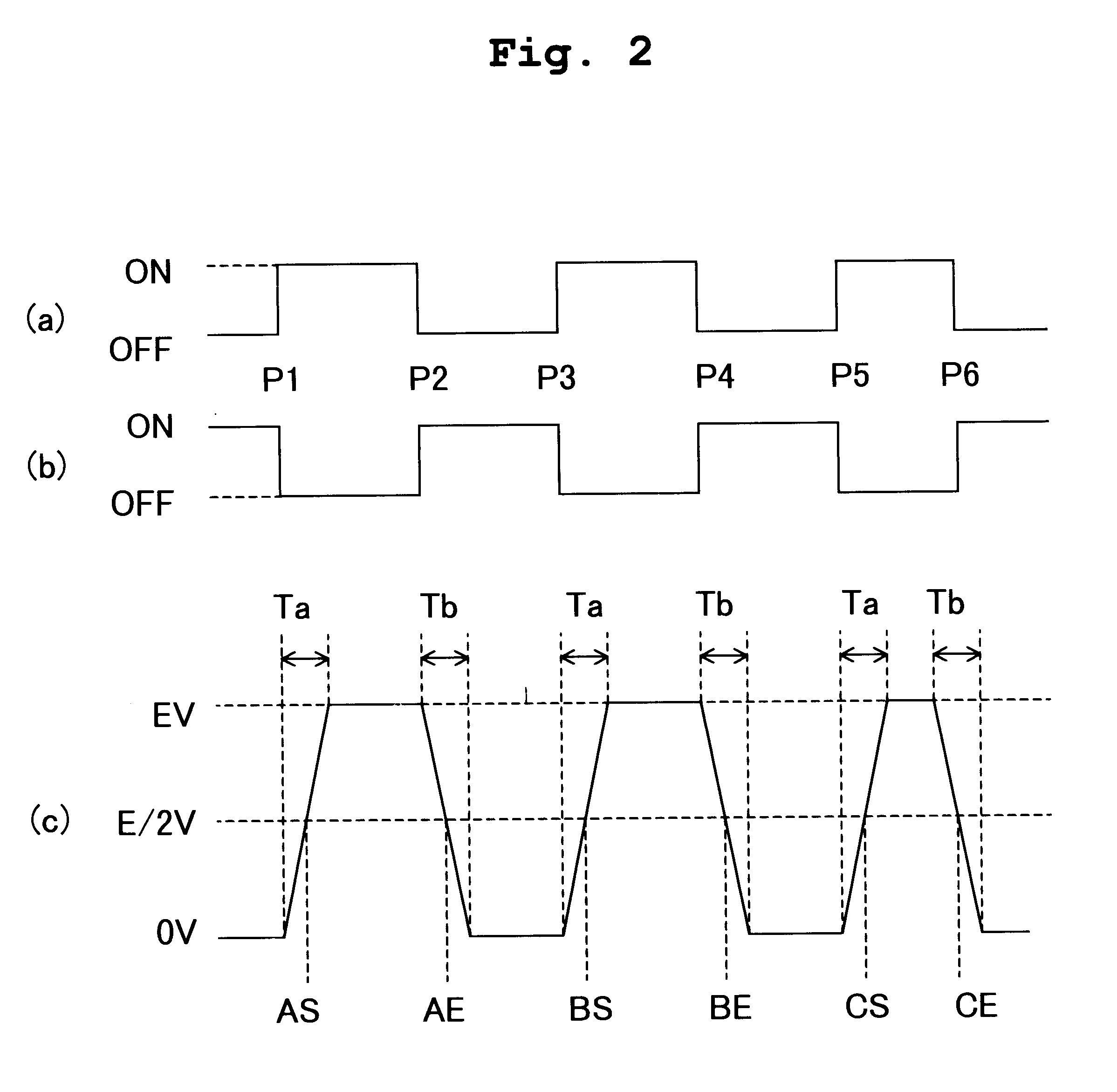

InactiveUS6419336B1Large spot and areaReduce in quantityInking apparatusOther printing apparatusImage resolutionVoltage

An ink ejector includes an ink jet head. The head has ink channels each defined between a pair of actuator walls. The head also has nozzles each communicating with one of the channels. In accordance with a print instruction, a controller applies to the appropriate actuator walls one or two ejection pulses of voltage depending on the resolution specified by the instruction. Each ejection pulse increases the volume of the associated channel once and decreases it subsequently to eject an ink droplet from the channel through the associated nozzle. In a normal resolution mode, two such ejection pulses are applied. In a first high resolution mode, one such ejection pulse is applied. In a second high resolution mode, one such ejection pulse is followed by an auxiliary pulse for making the droplet smaller. The ratio of the total volume of the two droplets in the normal resolution mode to the volume of the droplet in the first high resolution mode is approximately 2 / 1. The ratio of the droplet volume in the first high resolution mode to that in the second high resolution mode is approximately 2 / 1. This enables the difference in dot density between the resolution modes to be distinct for good printing.

Owner:BROTHER KOGYO KK

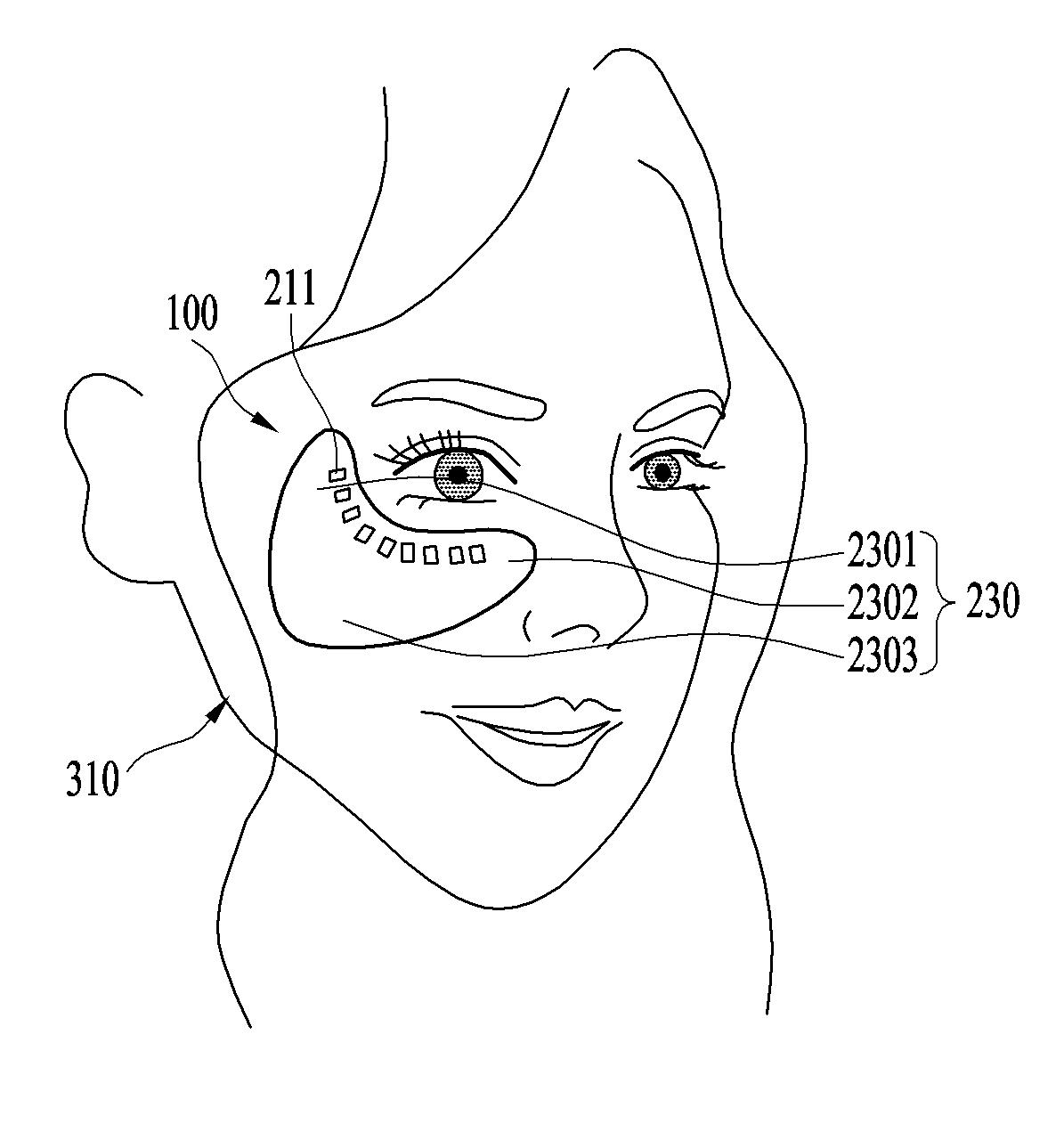

Skin care device

ActiveUS20180099143A1Solve the real problemVolume andPhysical therapyLight therapyCurrent elementMedicine

Disclosed is a skin care device which performs skin care under the condition that it is attached to a user's face, performs both skin care using light and skin care using microcurrent, and prevents electrical interference between light source elements and microcurrent elements. The skin care device includes a non-conductive flexible substrate, at least one light source element provided on the flexible substrate, microcurrent elements provided on the flexible substrate, an insulating layer provided with first holes to expose the at least one light source element and second holes to expose the microcurrent elements, and a conductive layer including a plurality of conductive parts, each conductive parts contacting each microcurrent element through each second hole, and the conductive parts are divided so as to be spaced apart from one another and are provided with third holes to expose the at least one light source element.

Owner:LG ELECTRONICS INC

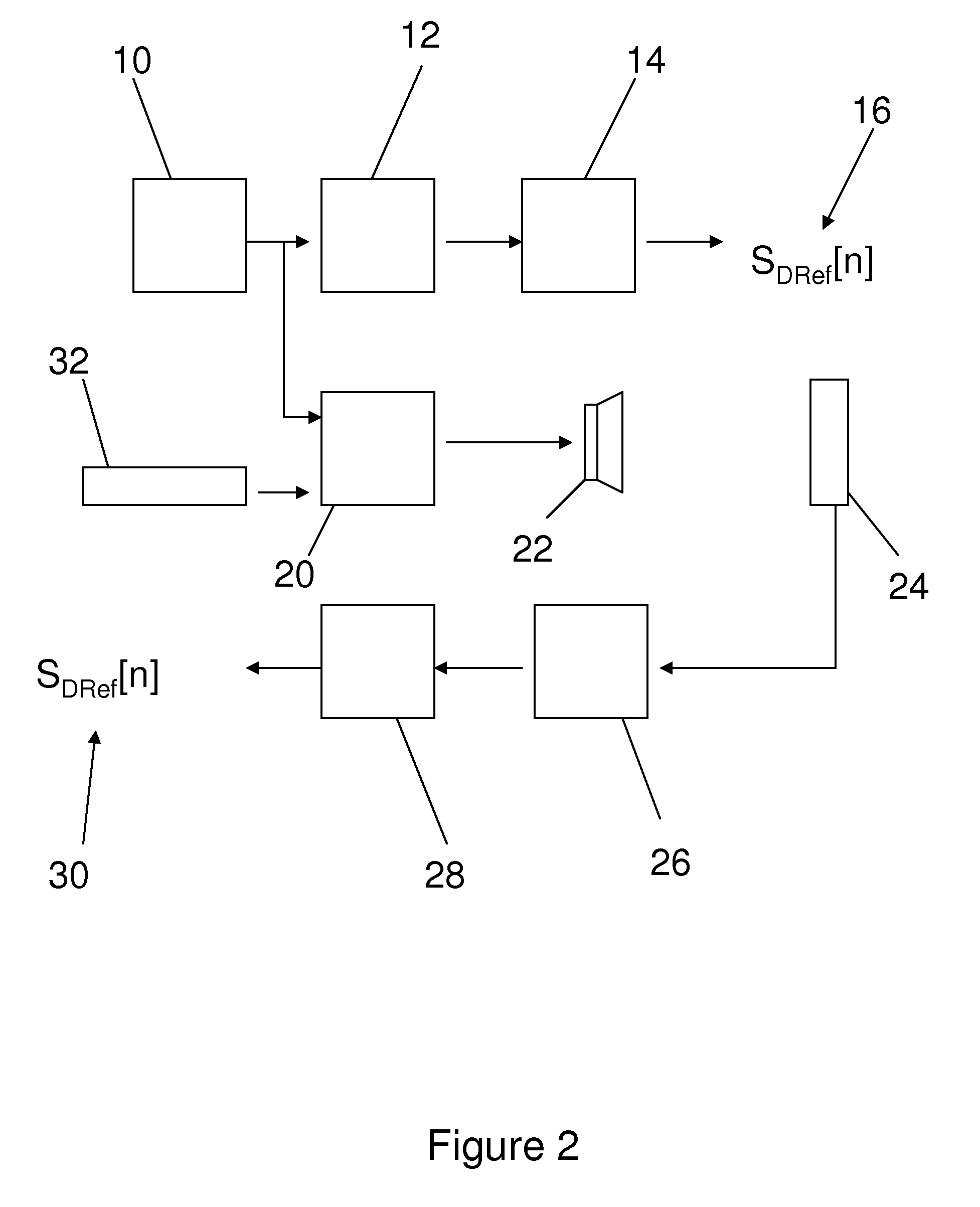

Ambient noise compensation system

InactiveUS20100329471A1Eliminate the problemVolume andGain controlTransducer protection circuitsEnvironmental noiseEngineering

An ambient noise compensation system having an automatic gain control to adjust the volume of a desired sound in a listening area. A sound pick-up may be placed in the listening area to capture the sound level, including both the desired sound and ambient noise. A measured value is then determined based on the sound level received by the sound pick-up. The measured value may then be compared to a predictive value to determine an acceptable range. The gain control automatically adjusts the volume of the desired sound to maintain the measured sound within the acceptable range.

Owner:MFG RESOURCES INT INC

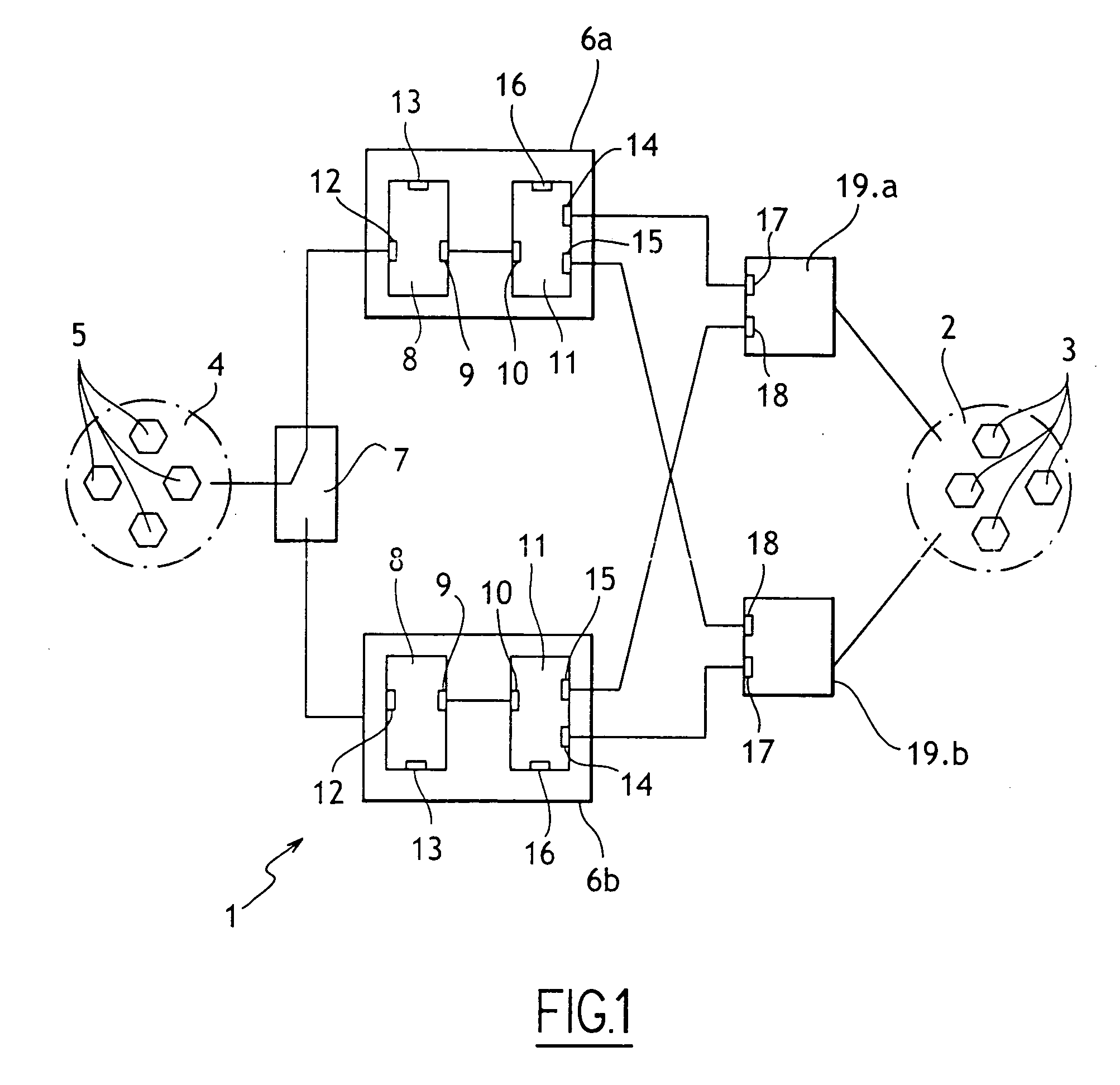

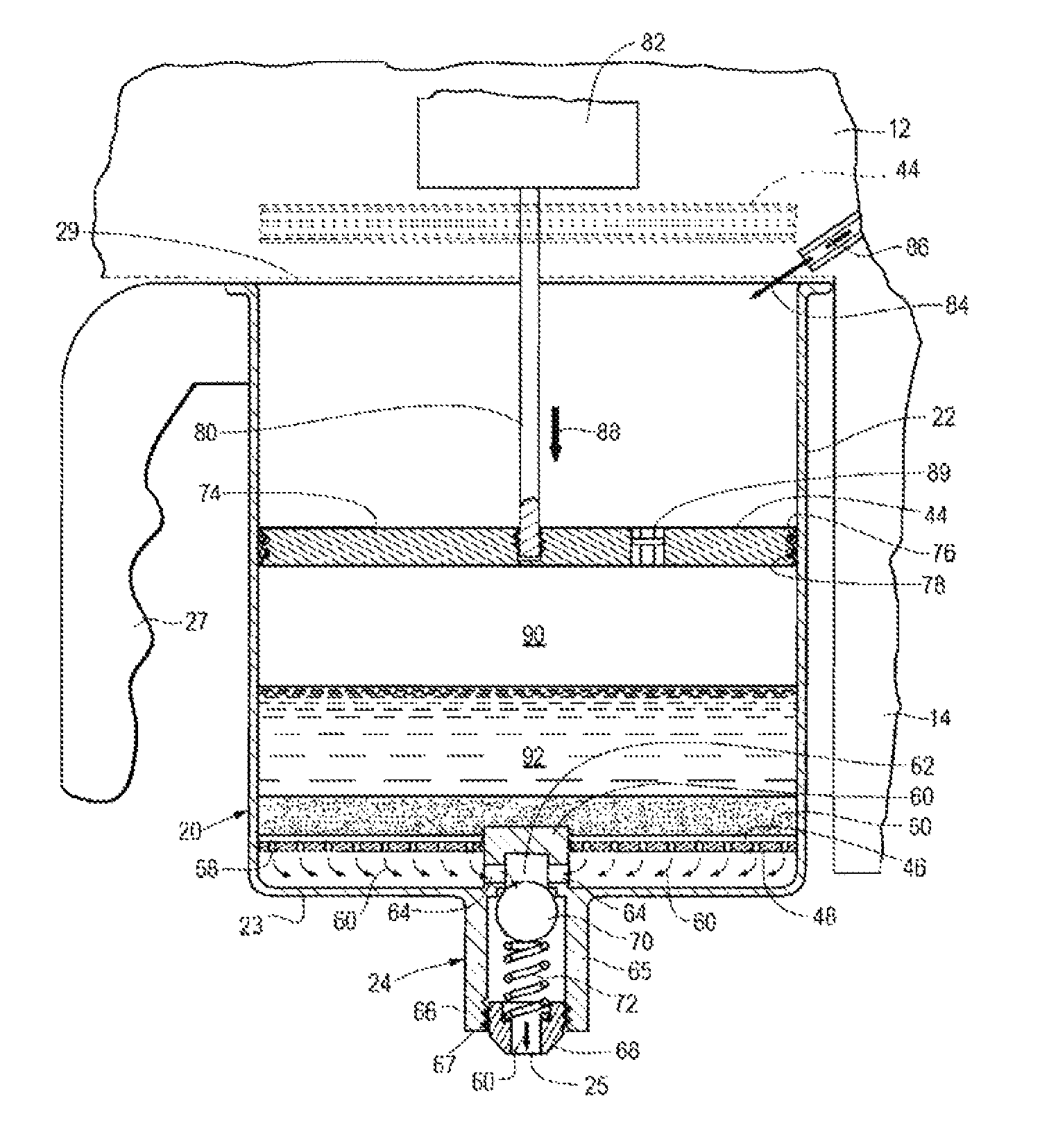

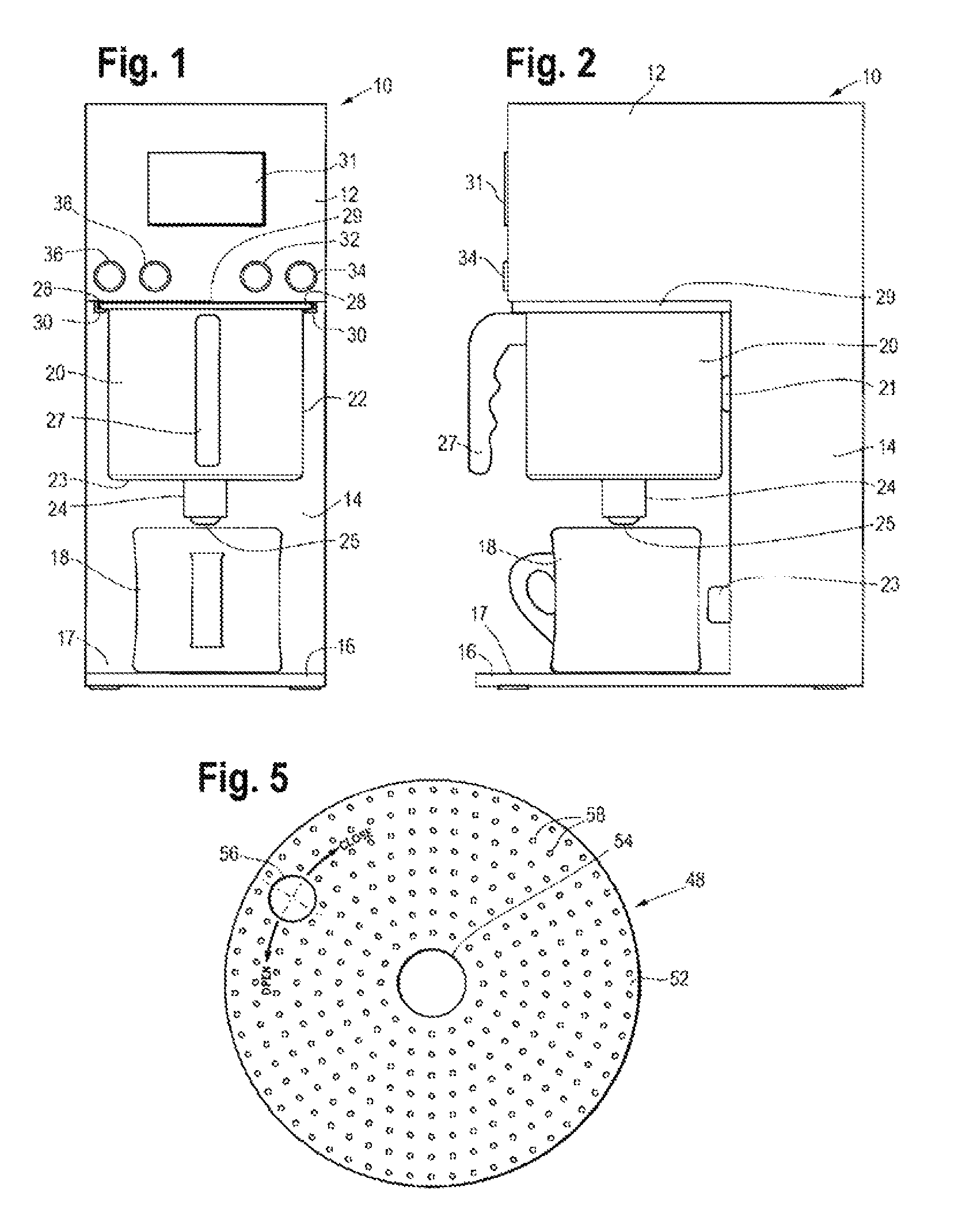

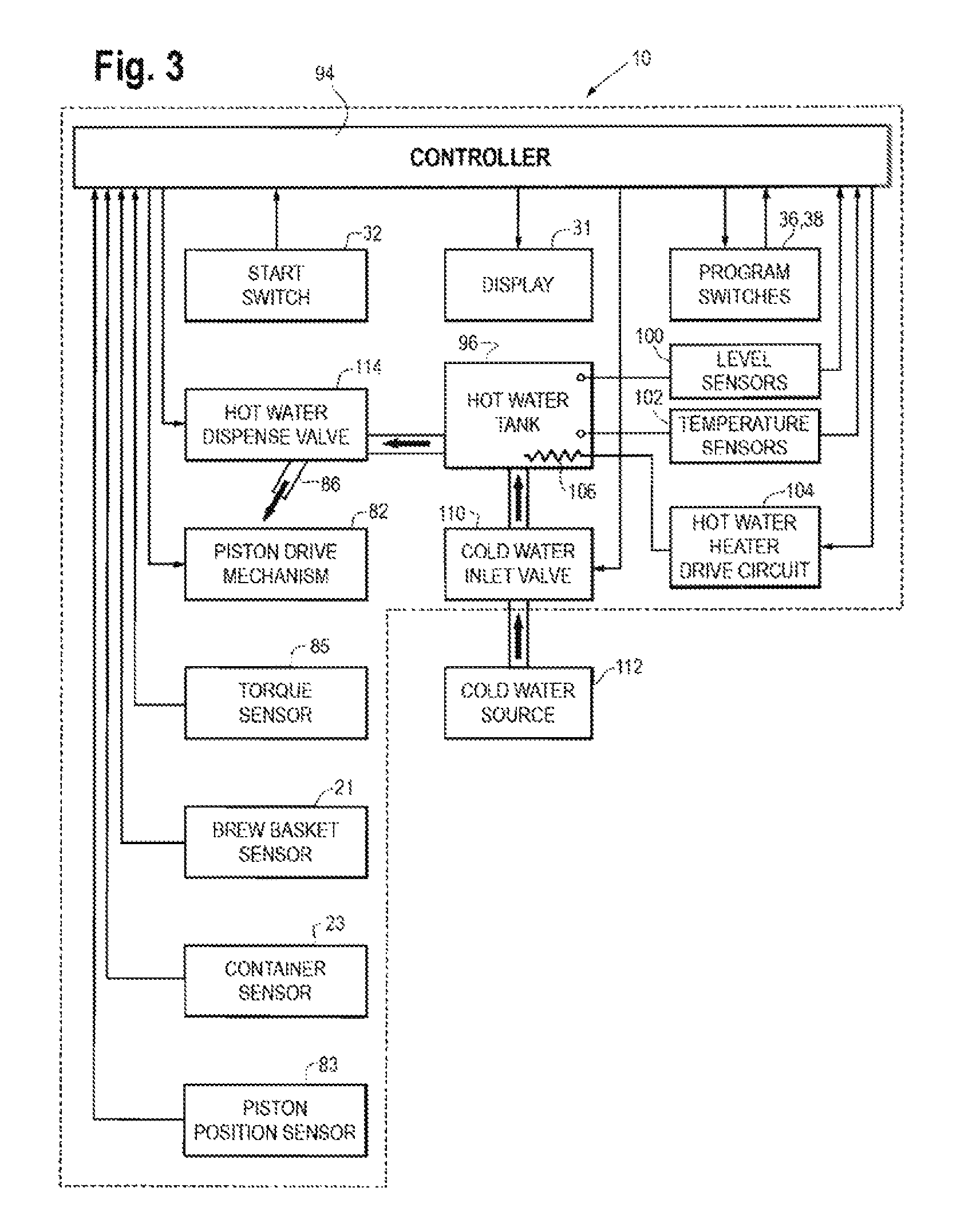

Automated beverage brewing method

ActiveUS8663724B1Facilitate easy upward movement of pistonReduce pressureBeverage vesselsFood preparationEngineeringAtmospheric pressure

An electrical, automatic hot beverage brewer (10) and method of brewing in which a removable brew chamber (20) has a drain hole (25) in the bottom fitted with a normally closed, pressure responsive brew chamber drain valve assembly (24) maintained in a normally closed position except when pressure against the drain valve (24) exceeds a preselected minimum pressure limit that is greater than the fluidic pressure applied by virtue of head pressure of a full load of hot water and a piston (74) is moved within the brew chamber to control the opening and closing of the drain valve (24) When the piston (74) moves downwardly toward the drain hole the air pressure of a pocket of air (90) above the beverage (92) in the brew chamber (20) is increased to open at the end of a seeping period when it is desired to rapidly expel freshly brewed beverage out the brew drain valve at a relatively rapid rate depending upon the total of the hydraulic pressure and the added pressure from the air pressure source to avoid the need to wait for the end of a drip period. The drain valve (24) automatically closes after the piston (74) is removed from the brew chamber (20) to enable removal of the brew chamber (20) from a brewer housing (12) without risks of hot beverage leaking out of the brew chamber (20).

Owner:FOOD EQUIP TECH

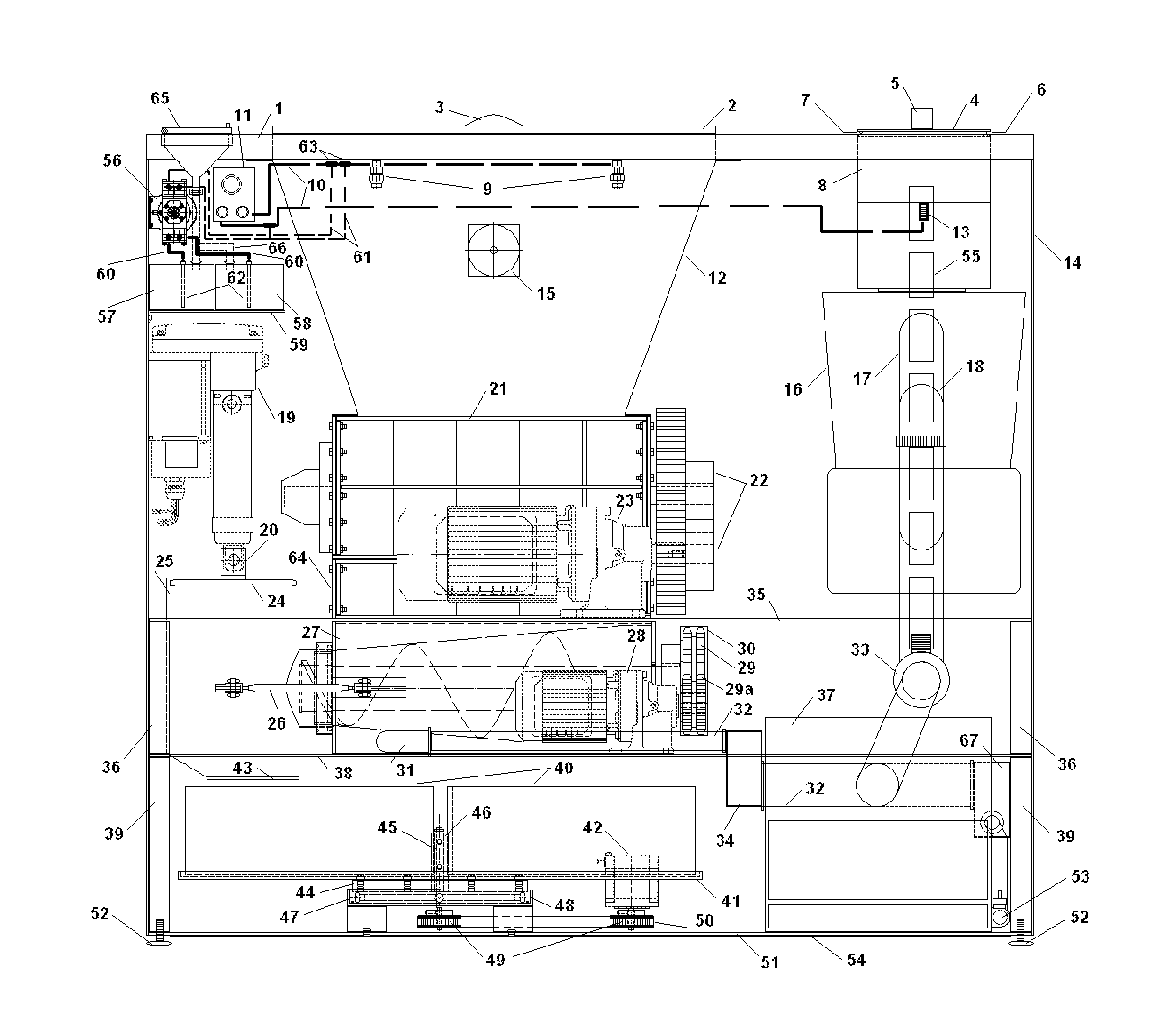

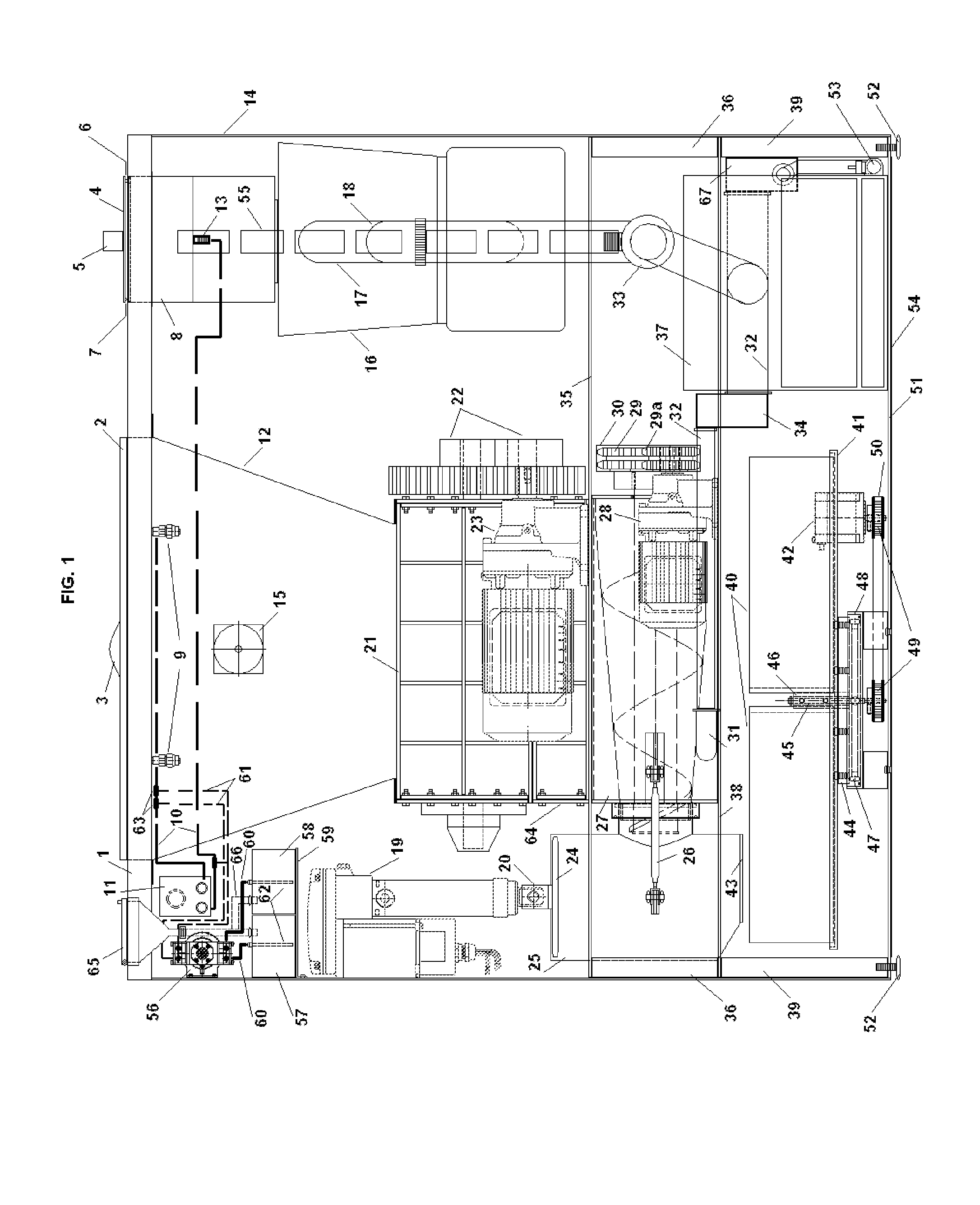

Universal Recycling & Disposal Machine (URDM)

InactiveUS20140060347A1Small sizeReduce volumePlastic recyclingGrain treatmentsPublic placeHome appliance

Universal Recycling Disposal Machine designed to recycle and dispose almost all daily Municipal Solid Wastes (MSW) that generated by homes, offices and public places which refer to trash / rubbish. Machine will maximize the delivery (Direct Delivery) of the clean materials (Recycled Materials) to re-production plants and minimize or eliminate the volume / weight of MSW which should be delivered to landfill. The main concept was to design a machine that can be fixed within every kitchen cabinet or kitchen area and to be used as a home appliance (Dimensions of machine are match with standard kitchen cabinet). Machine designed in a way to minimize the sound & dust pollution during recycling and disposal processes. All items after recycling will be washed and rinsed before storing in plastic bins. During disposal process, big particles of disposed items will be filtered to avoid drainage blockage and all FOG will be removed from water.

Owner:SAHEBKAR YAZDI JAVAD

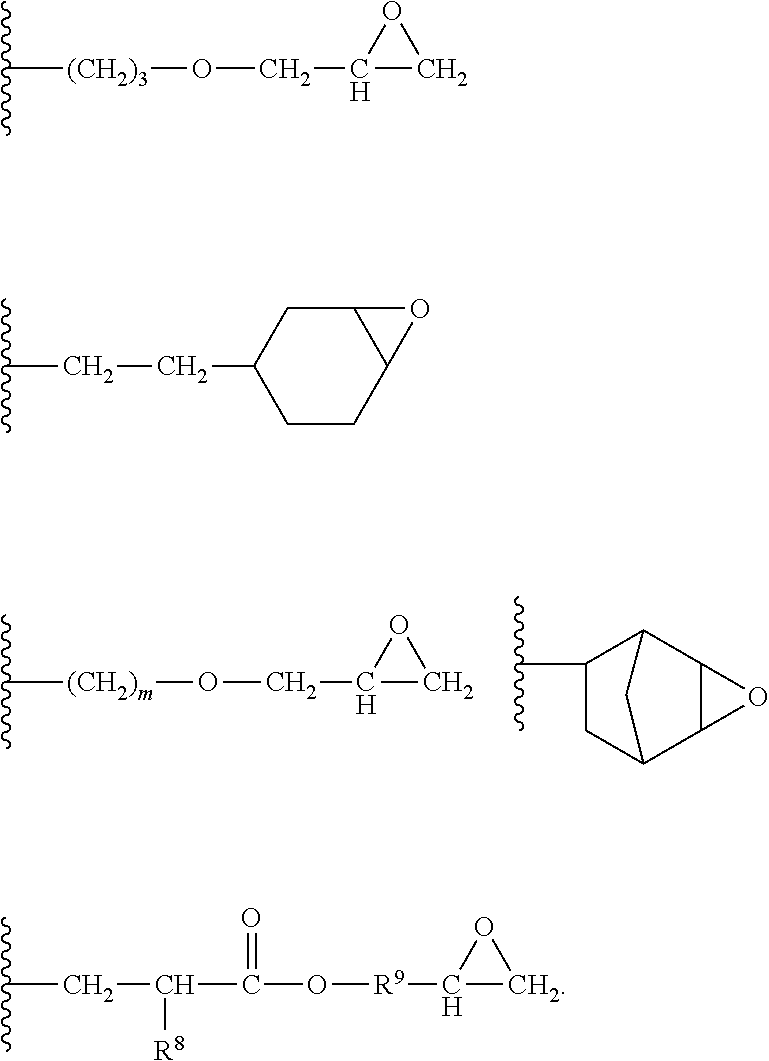

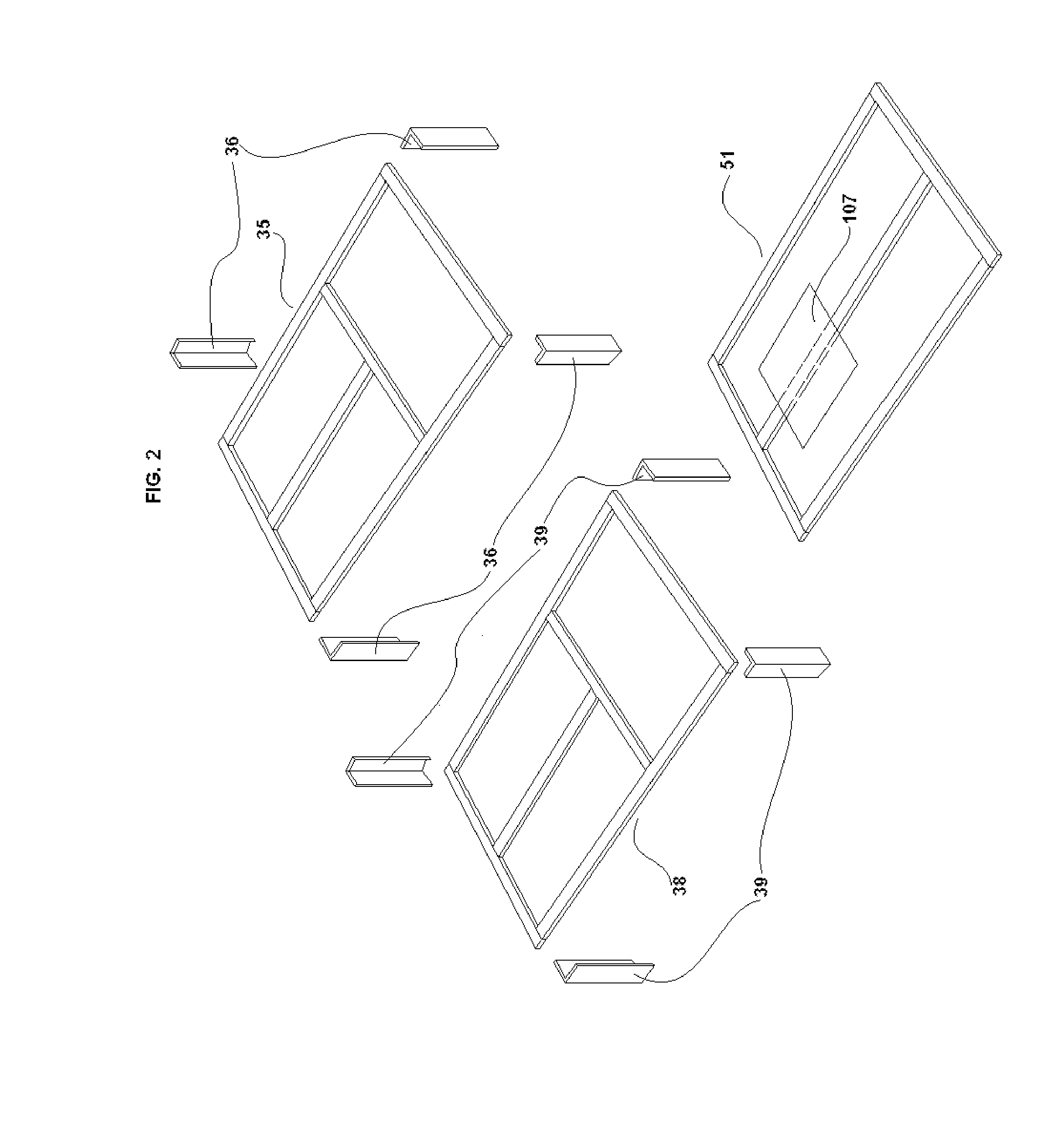

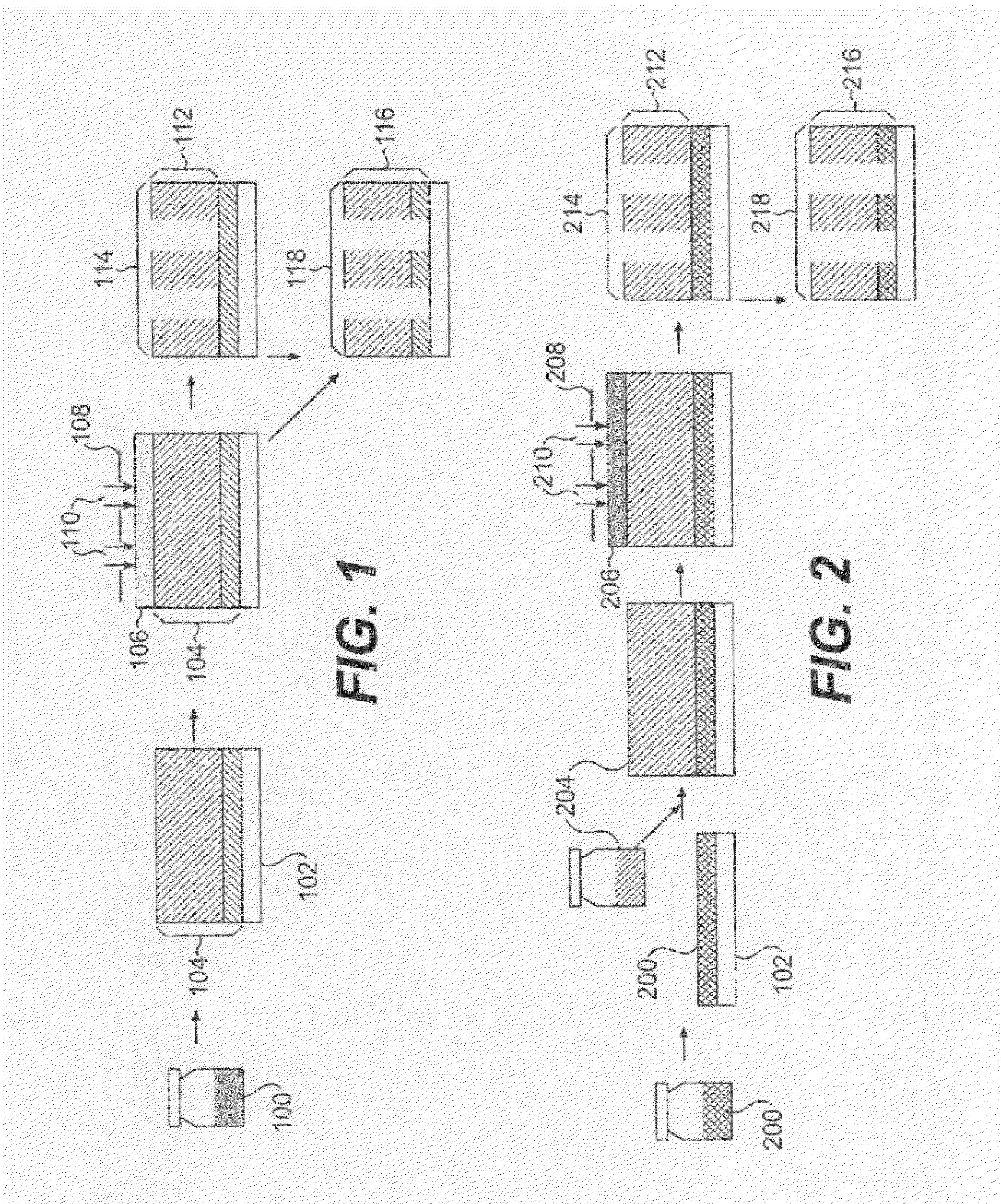

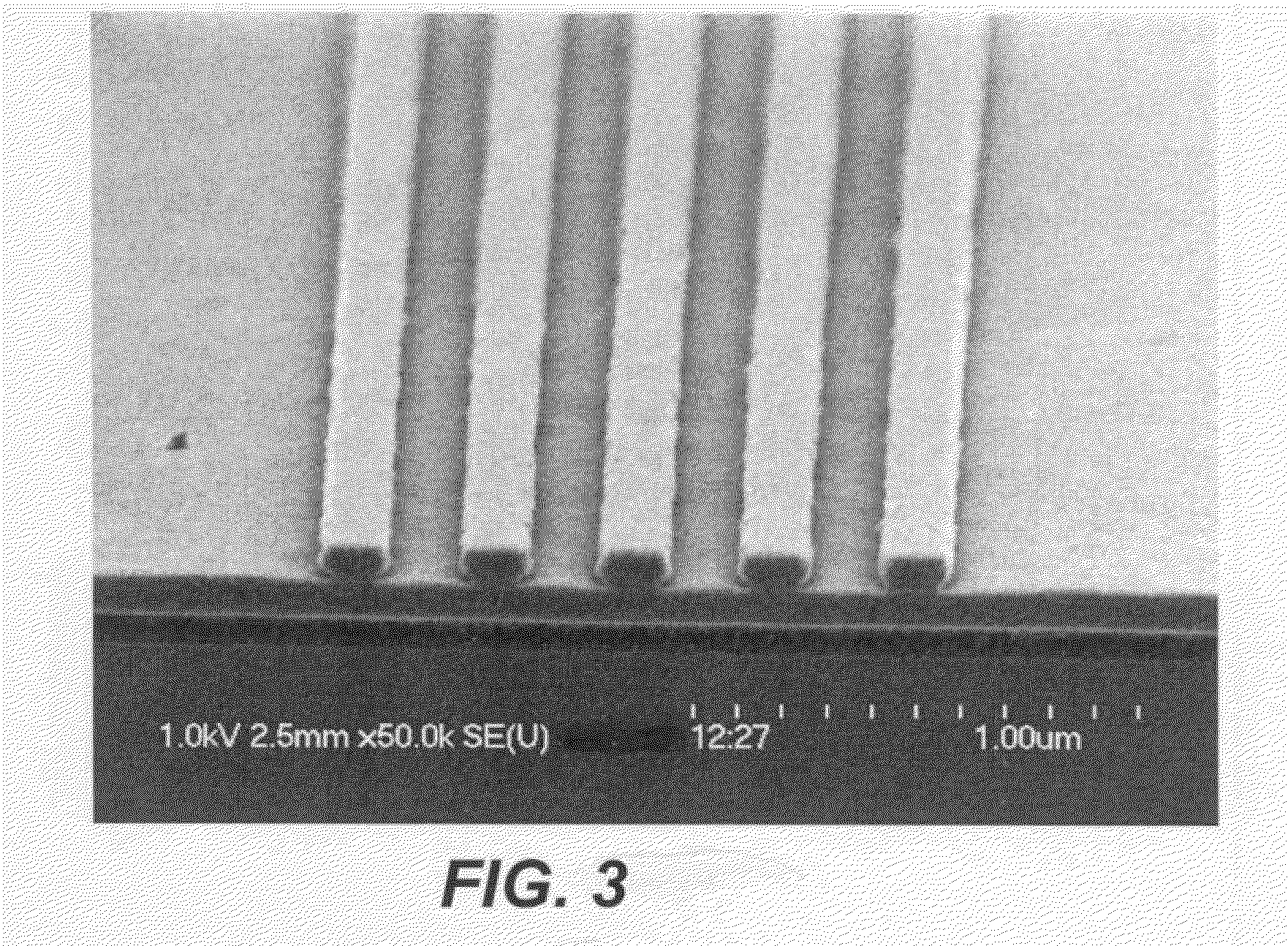

Self-segregating multilayer imaging stack with built-in antireflective properties

InactiveUS20100009132A1Reduce processing stepsVolume andPhotosensitive materialsRadiation applicationsResistAnti-reflective coating

A coating process comprises forming a patterned material layer on a substrate using a self-segregating polymeric composition comprising a polymeric photoresistive material and an antireflective coating material. The polymeric photoresistive material and the antireflective coating material that make up the self segregating composition are contained in a single solution. When depositing this solution on a substrate and removing the solvent, the two materials self-segregate into two layers. The substrate can comprise one of a ceramic, dielectric, metal, or semiconductor material and in some instances a material such as a BARC material that is not from the self segregating composition. The composition may also contain a radiation-sensitive acid generator and a base quencher. This produces a coated substrate having a uniaxial bilayer coating oriented in a direction orthogonal to the substrate with a top photoresistive coating layer and a bottom antireflective coating layer. The process may also include optionally coating a top coat material on the coated substrate. Pattern-wise exposing the coated substrate to imaging radiation and contacting the coated substrate with a developer, produces the patterned material layer wherein the optional top coat material and a portion of the photoresist layer are simultaneously removed from the coated substrate, thereby forming a patterned photoresist layer on the substrate. Alternatively, the optional top coat material, a portion of the photoresist layer and a portion of the bottom antireflective layers are simultaneously removed from the coated substrate by the developer, thereby forming a patterned photoresist layer on the substrate.

Owner:GLOBALFOUNDRIES INC

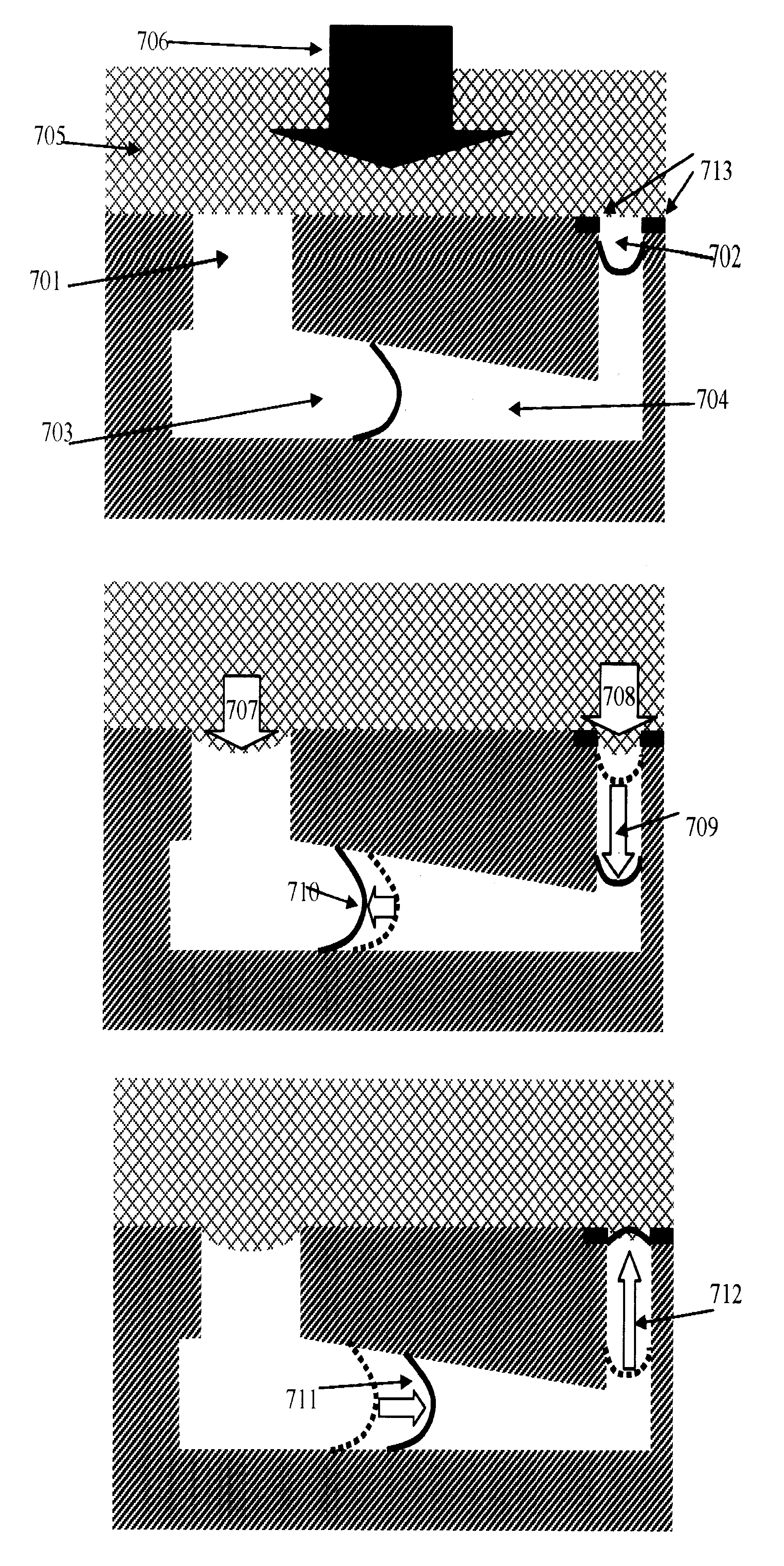

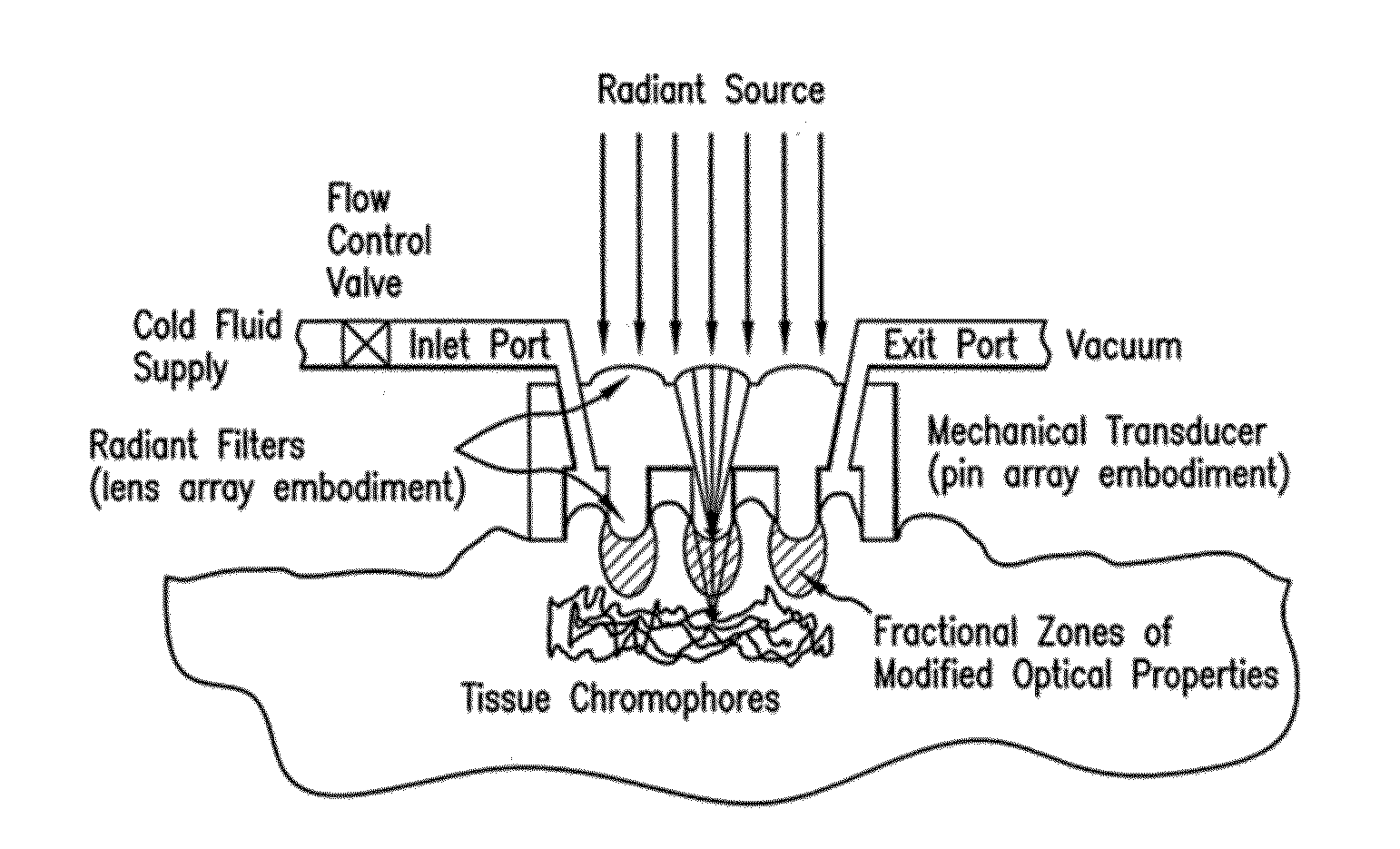

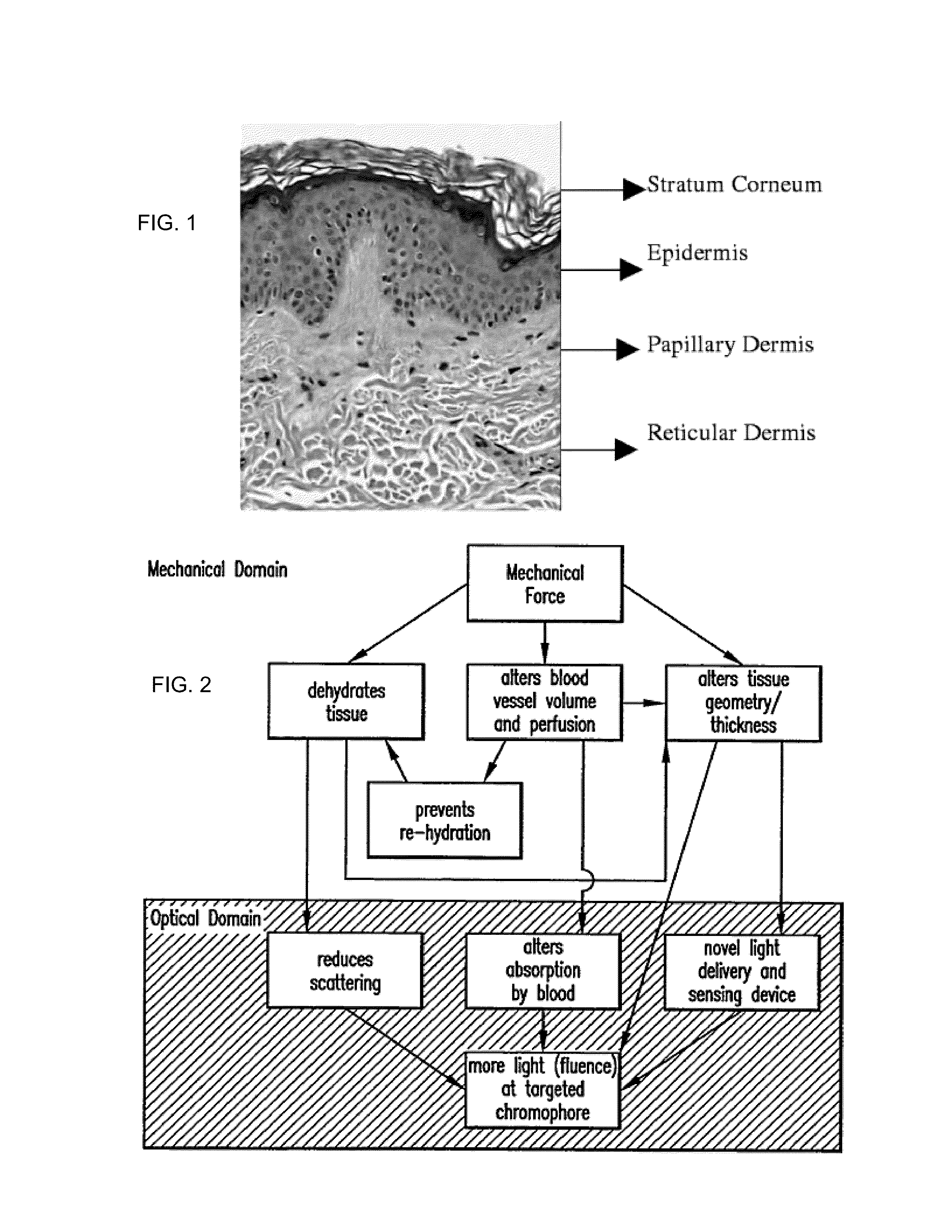

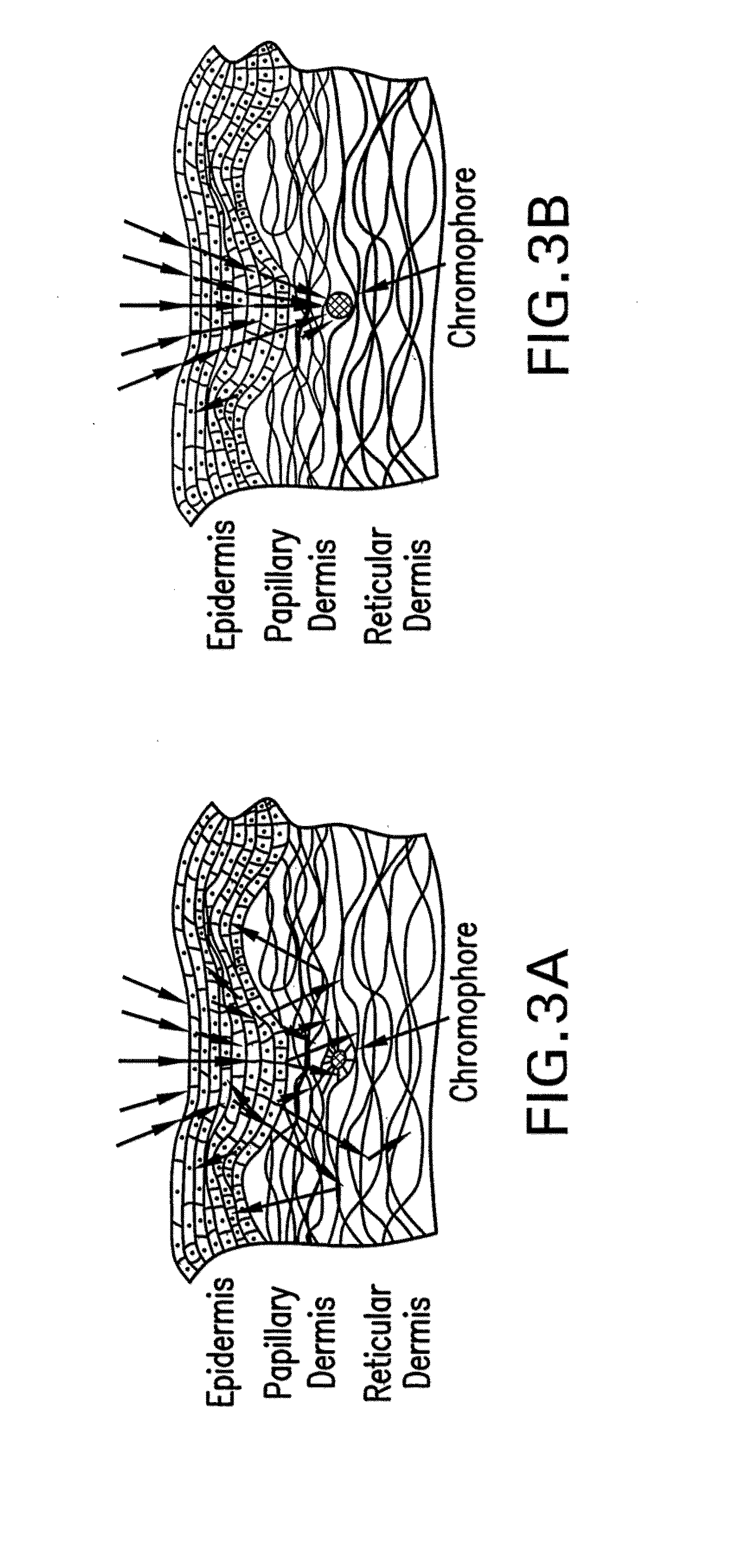

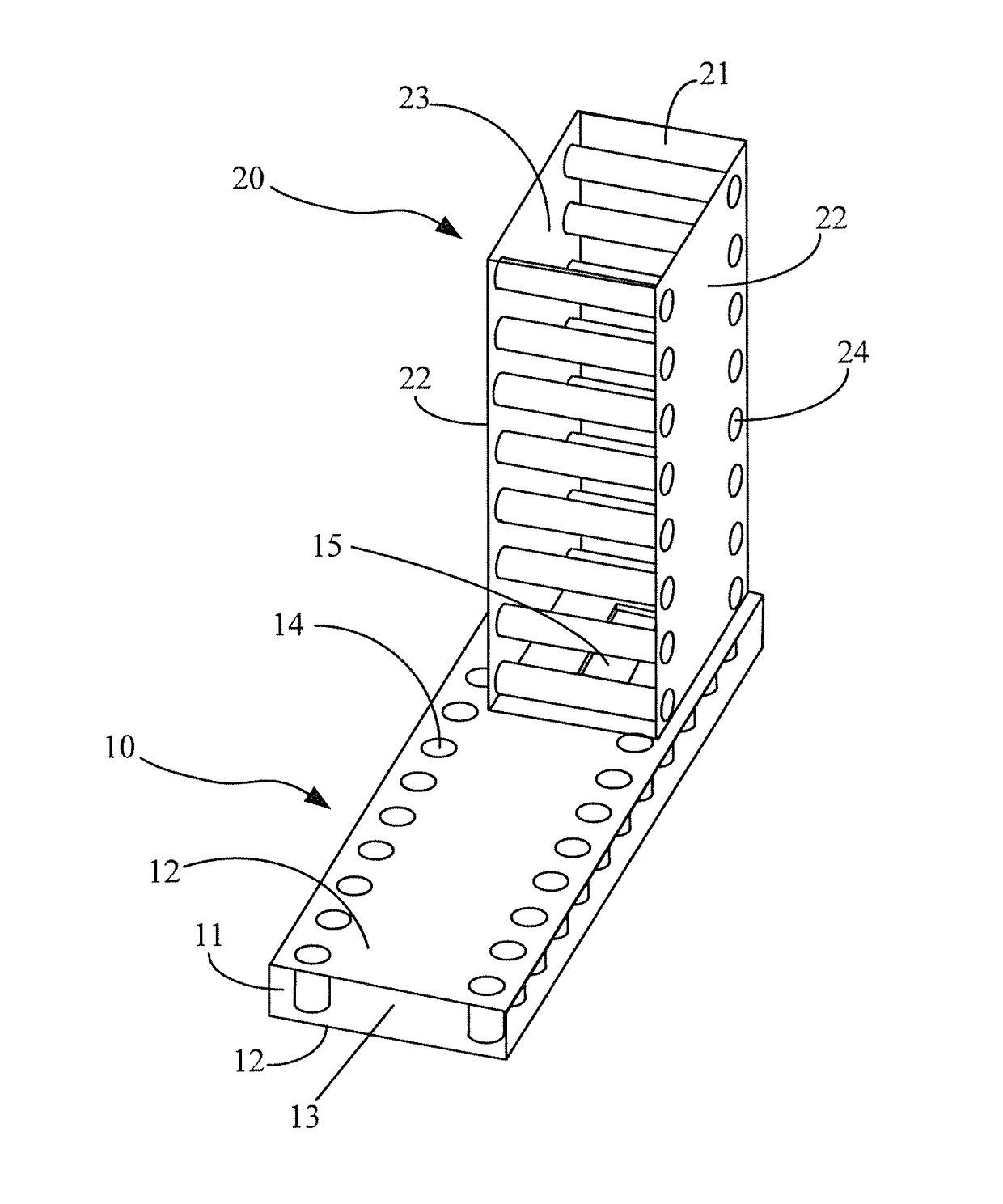

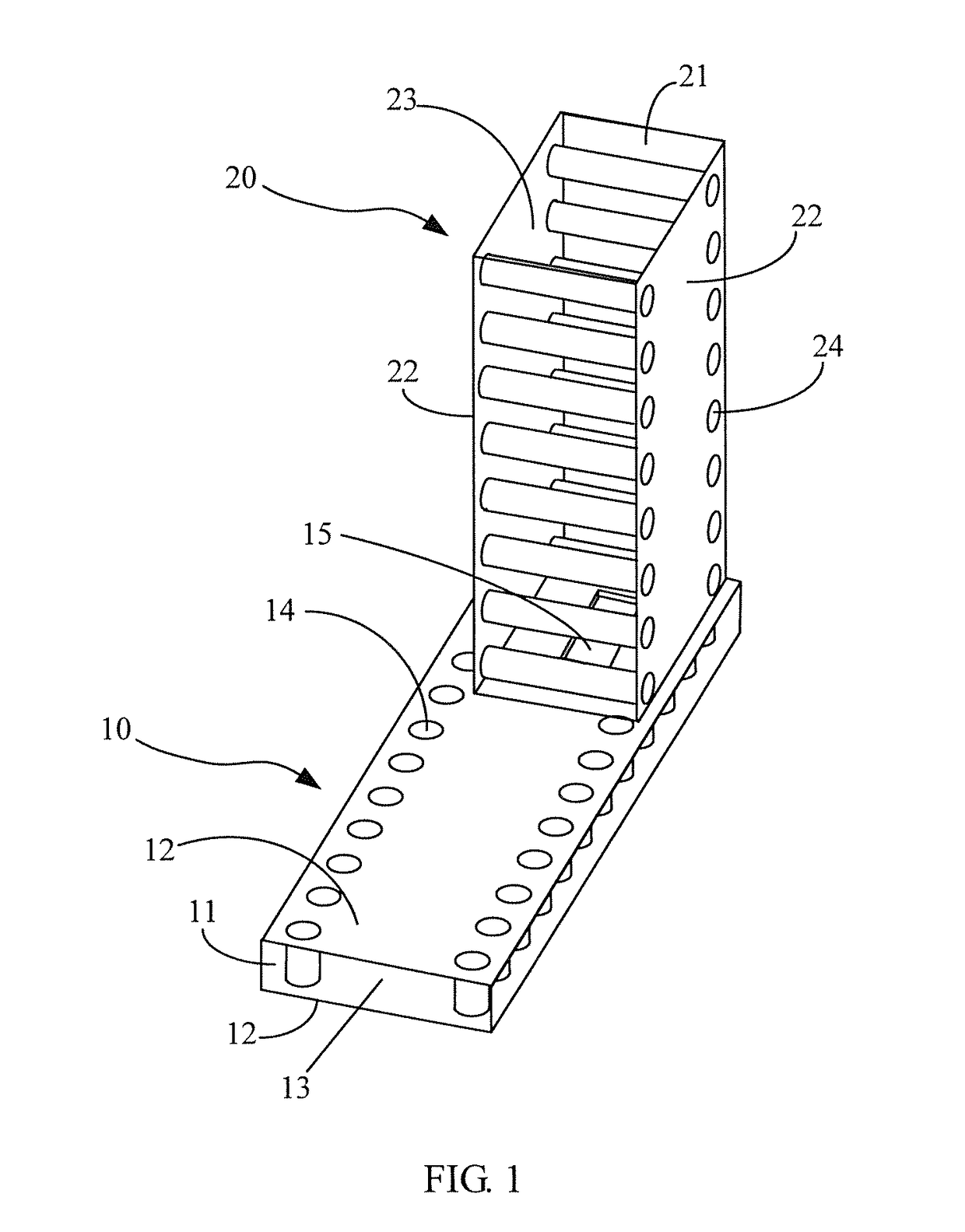

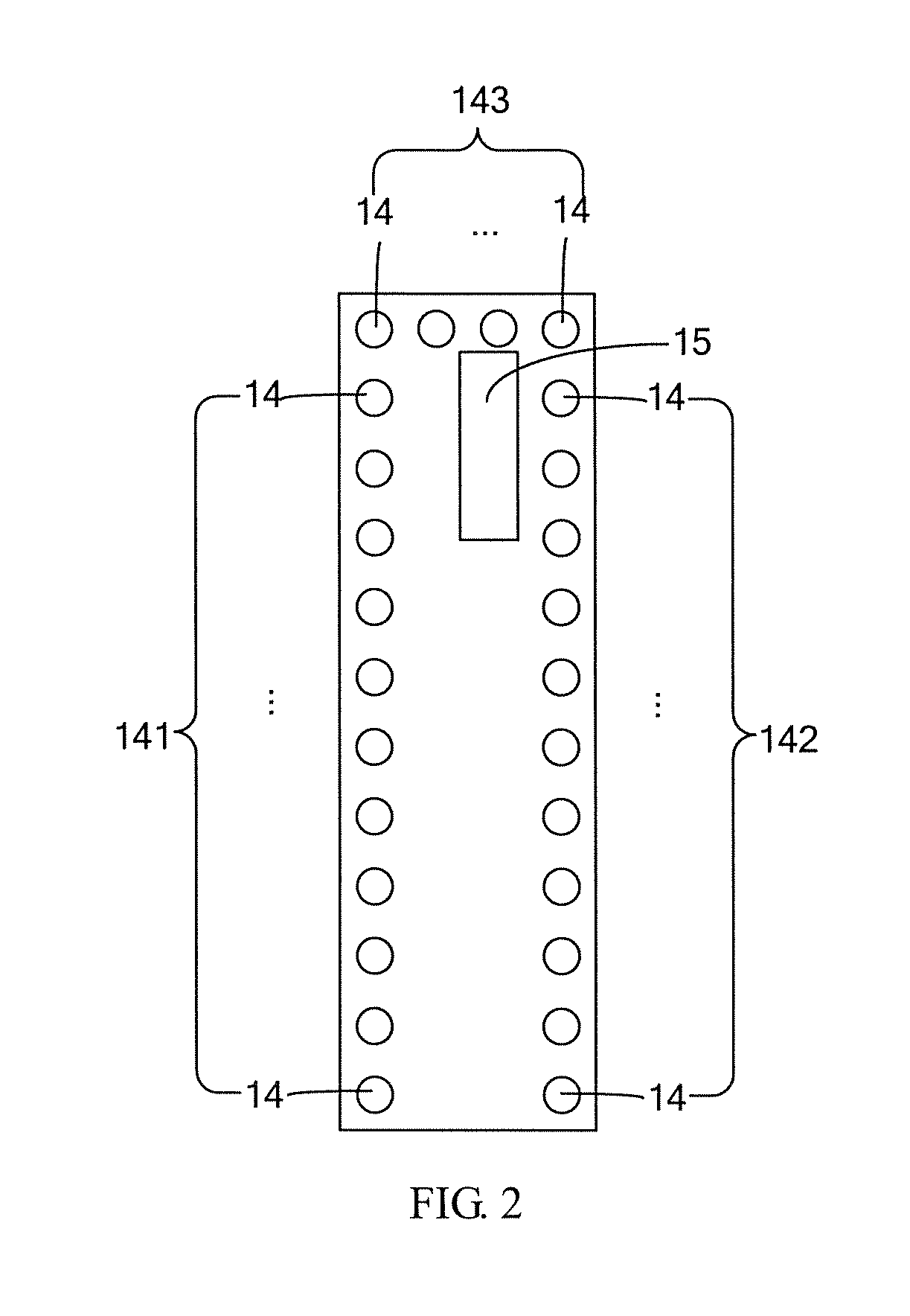

System, devices, and methods for optically clearing tissue

ActiveUS20130178916A1Reduce light scatterReduce the scattering intensityDiagnostics using spectroscopyDiagnostics using fluorescence emissionOptical clearingOptical property

Embodiments of the present disclosure provides systems, devices, and methods for non-invasively modifying, maintaining, or controlling local tissue optical properties. Methods and devices of the disclosure may be used for optically clearing tissue, for example, for diagnostic and / or therapeutic purposes. A method of optically clearing a tissue may comprise contacting the tissue with an optical clearing device having a base, an array of pins fixed to one side of the base, a brim fixed to the base, an inlet port in the base, an exit port in the base, and a handpiece interface tab fixed to the side of the base opposite the array of pins, applying a mechanical force to the tissue, and illuminating said tissue with at least one wavelength of light through the optical clearing device. A method may further comprise controlling the temperature of the tissue illuminated.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

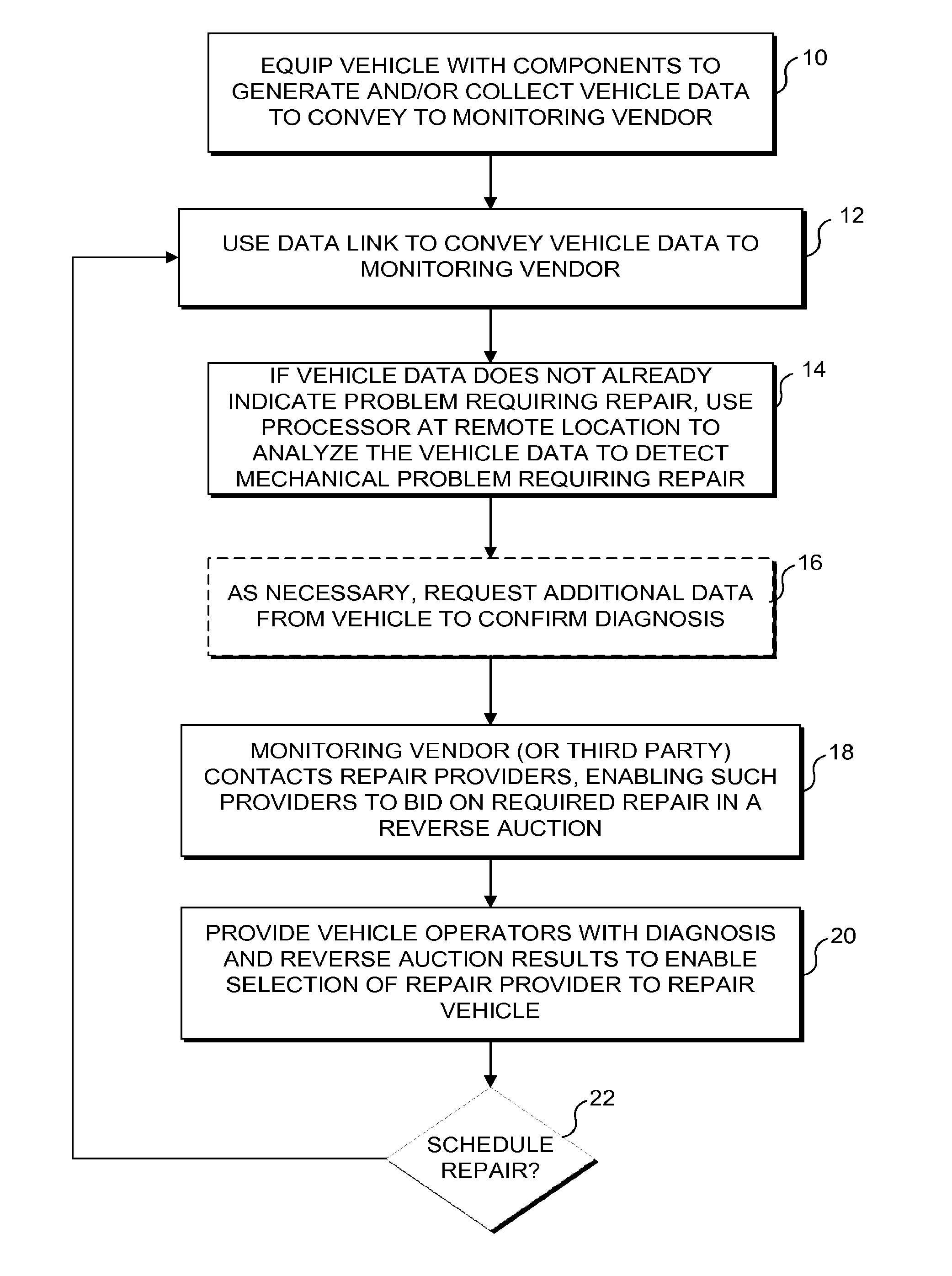

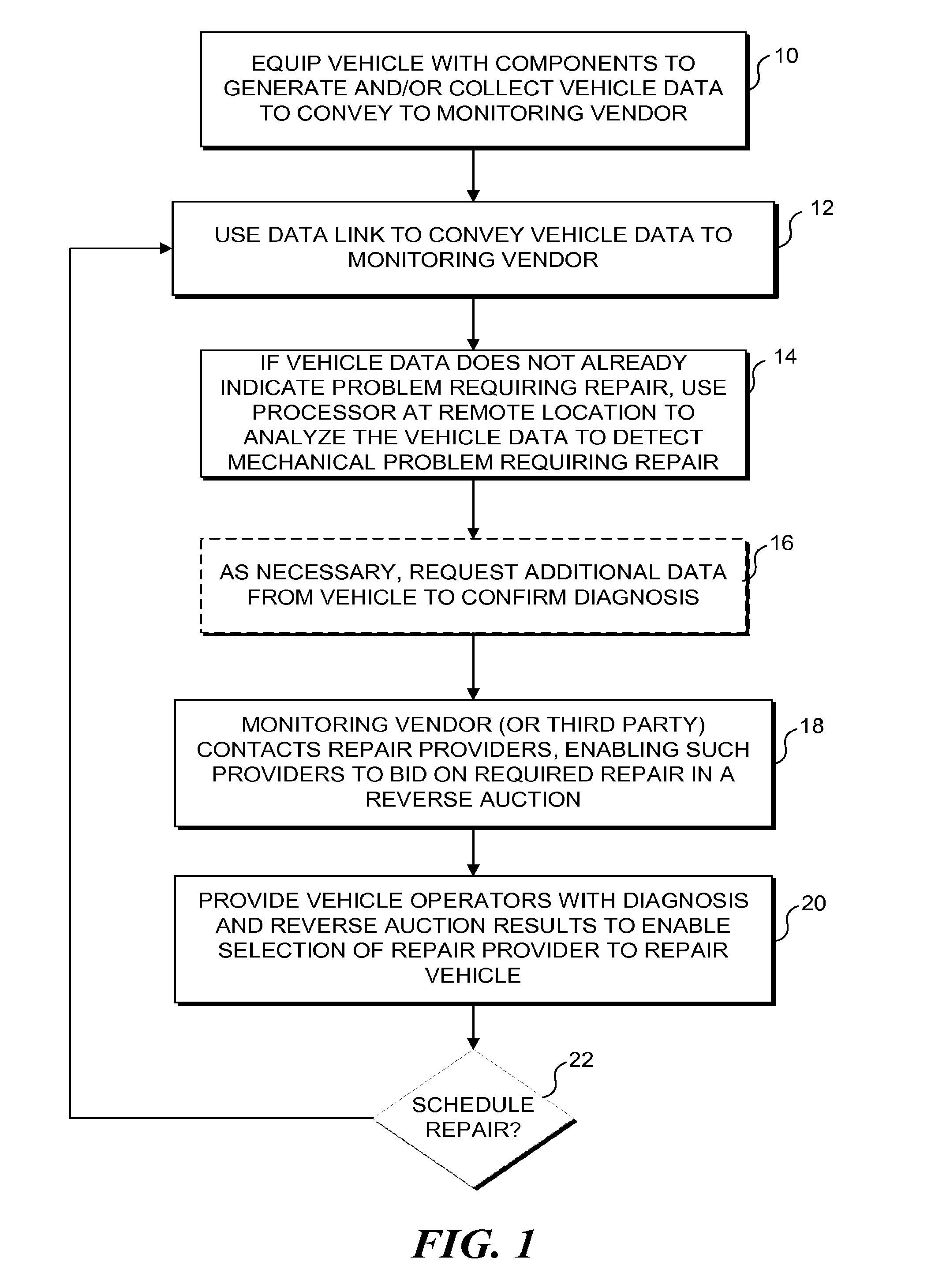

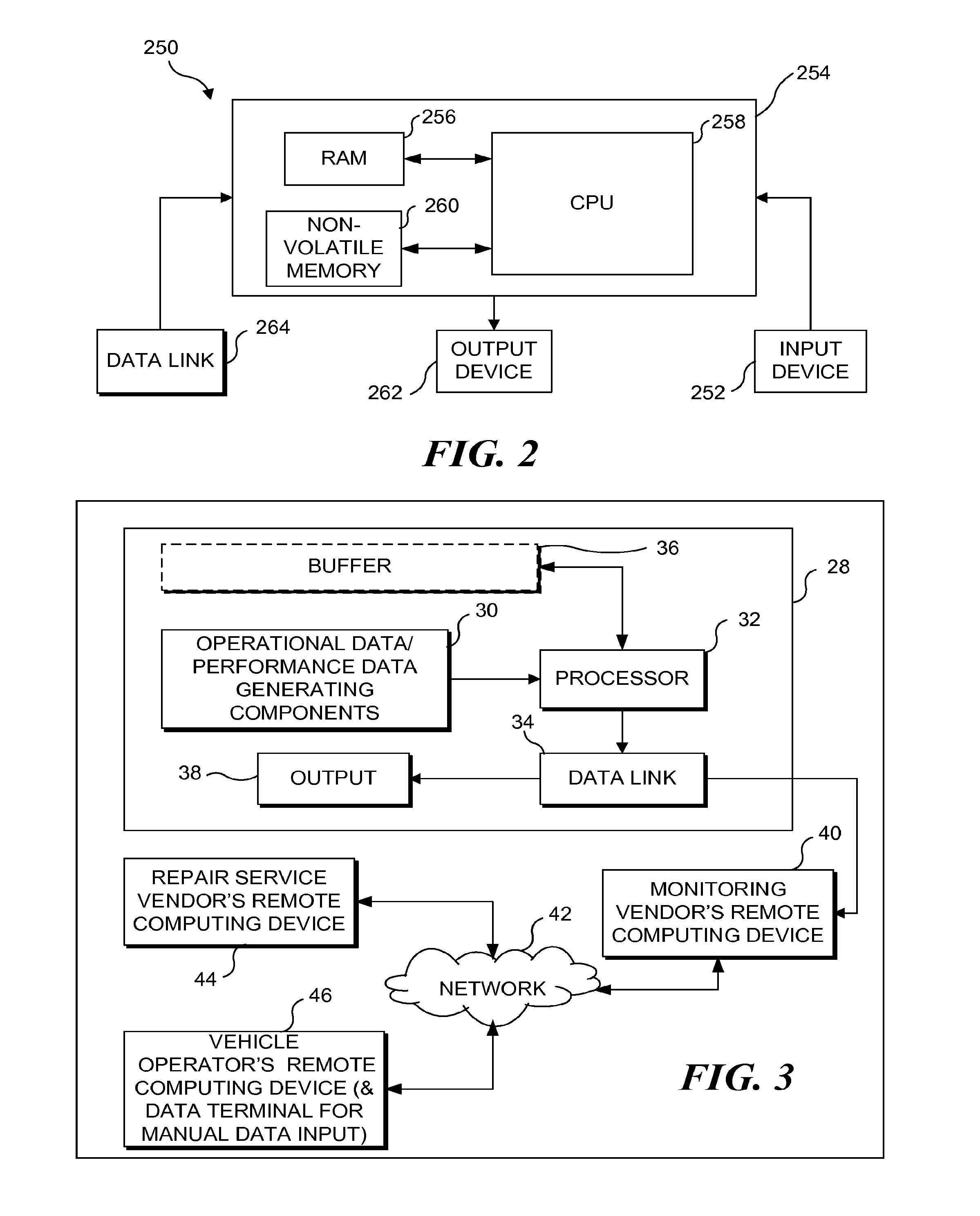

Diagnostic unit and method

InactiveUS20160071338A1Accurate identificationVolume andVehicle testingRegistering/indicating working of vehiclesDiagnostic dataService information

A diagnostic unit is coupled to at least one vehicle control subsystem. The vehicle control subsystem includes one or more of a brake control unit, an engine control unit, and a transmission control unit to provide vehicle data. The diagnostic unit generates diagnostic log information based on the vehicle data and communicates the diagnostic log information to a remote computing device, which hosts a reverse auction to identify at least one vendor that can provide vehicle service based on the diagnostic log information. After identifying the vendor, the diagnostic unit generates and presents service information representing the identified vendor to a vehicle operator via an input / output interface in the vehicle. The input / output interface can accept vehicle data, configuration data, and diagnostic data from the vehicle and the vehicle operator.

Owner:ZONAR SYST

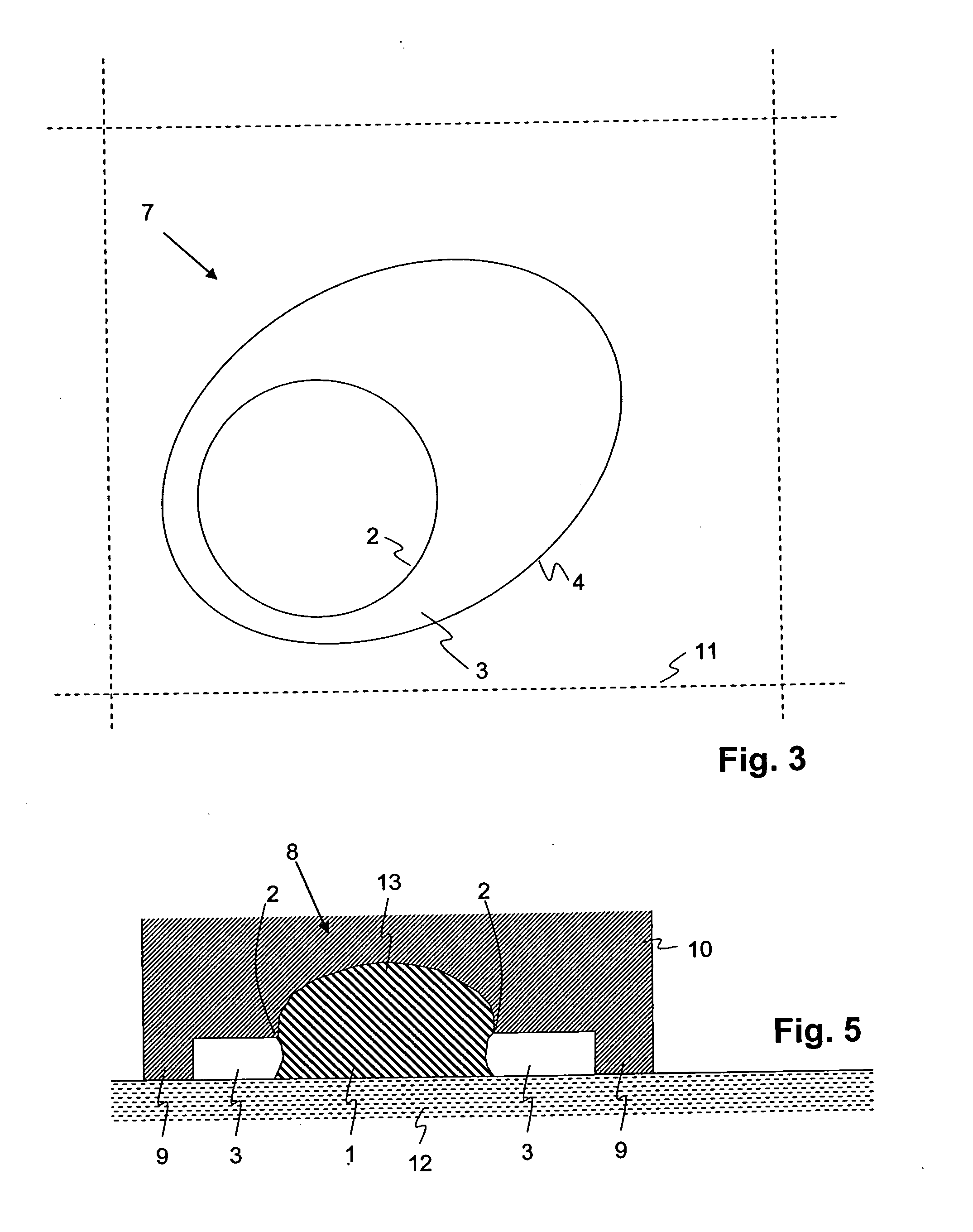

Manufacturing optical elements

Owner:HEPTAGON

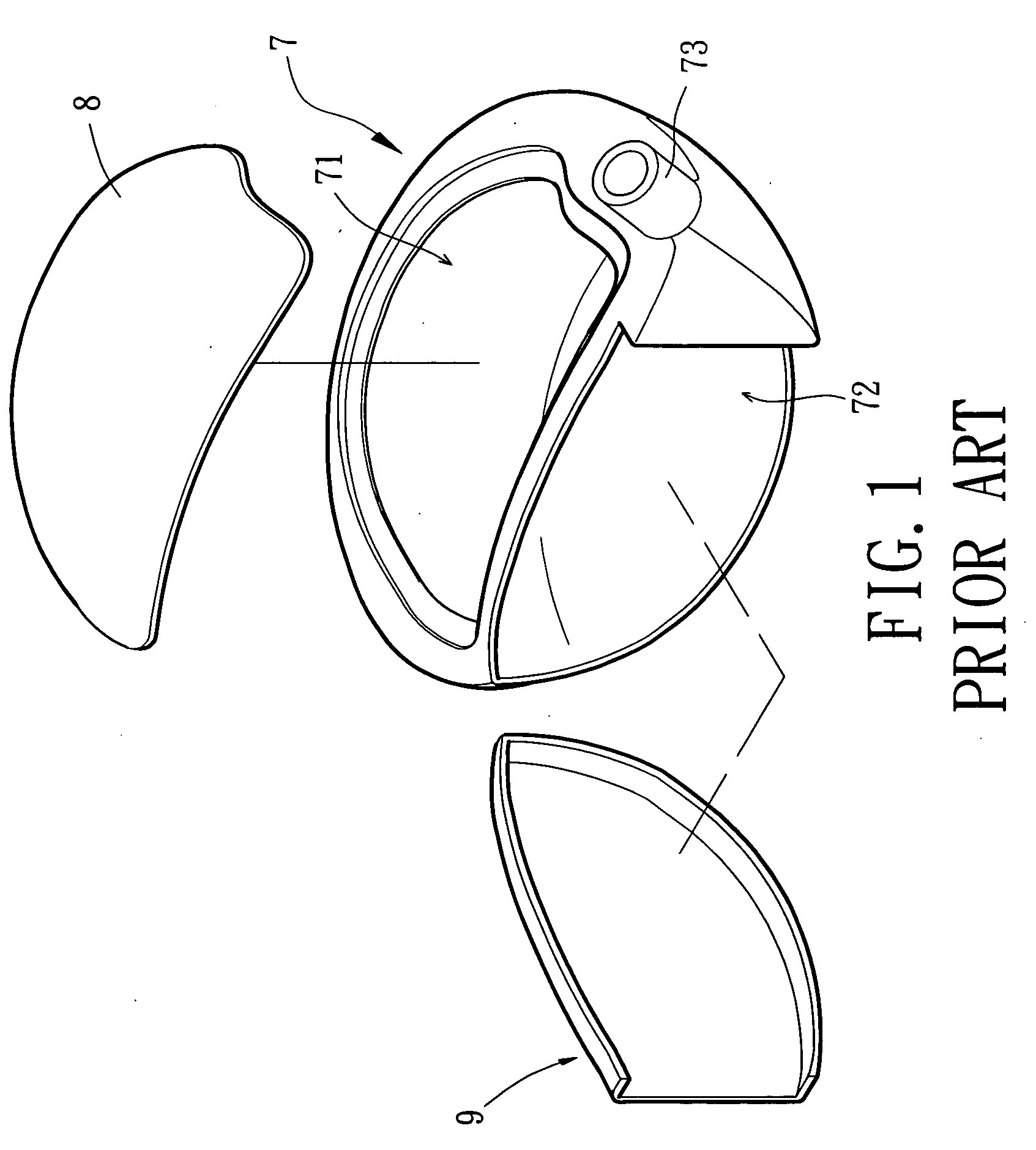

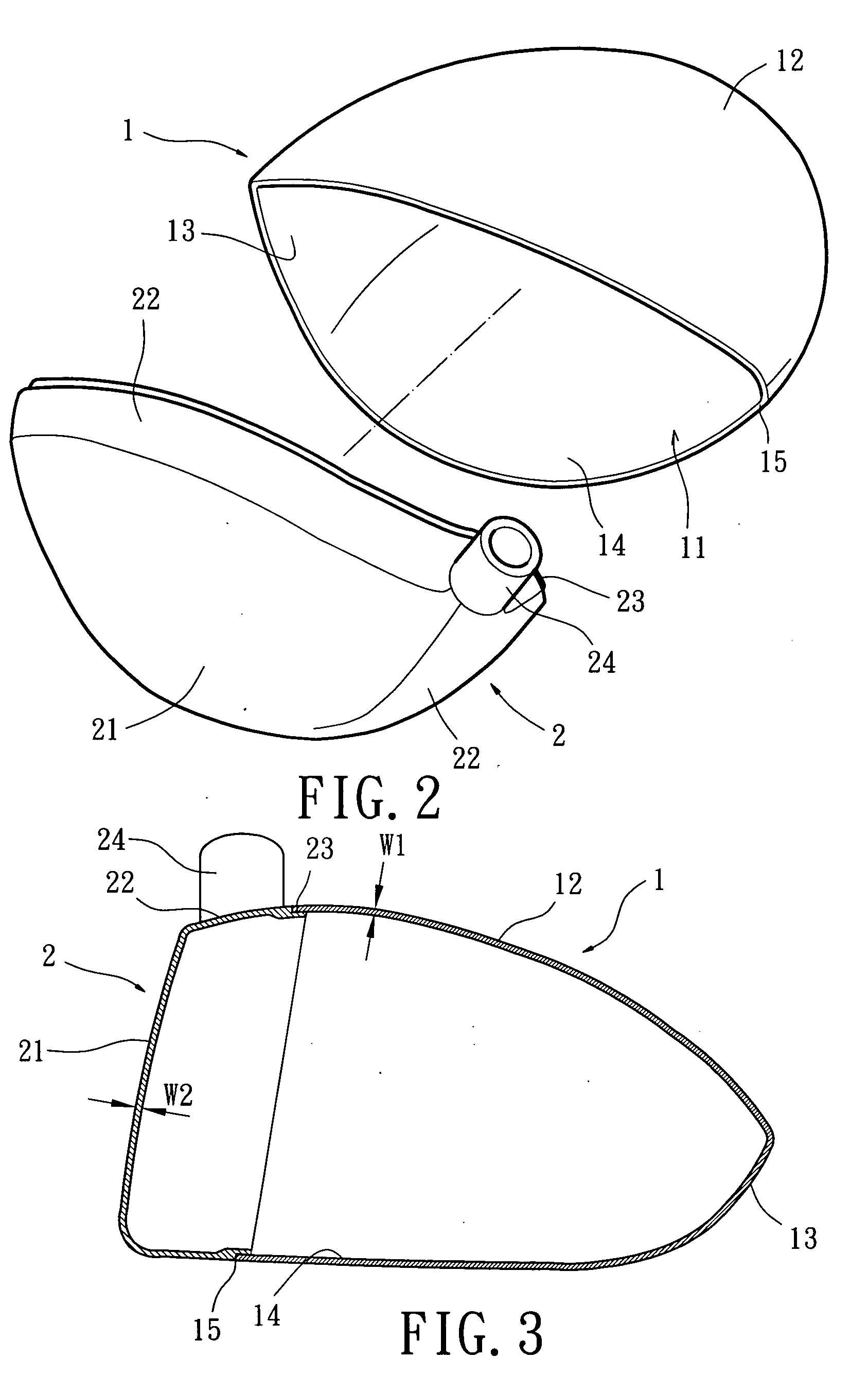

Wooden club head

A wooden club head includes a thin body component and a thin faceplate component. The thin body component has a front engaging opening, a crown, a sidewall, and a sole. The thin faceplate component is coupled with the front engaging opening of the thin body component to form the wooden club head. The thin body component and the thin faceplate component are made of steel alloy having a specific gravity between 6.0 g / cm3 and 10.0 g / cm3. The thin body component has a thickness between 0.25 mm and 0.8 mm, and the thin faceplate component has a thickness between 1.5 mm and 3.0 mm. The wooden club head has an overall volume between 380 cc and 500 cc and an overall weight between 180 g and 220 g.

Owner:FUSHENG IND CO LTD

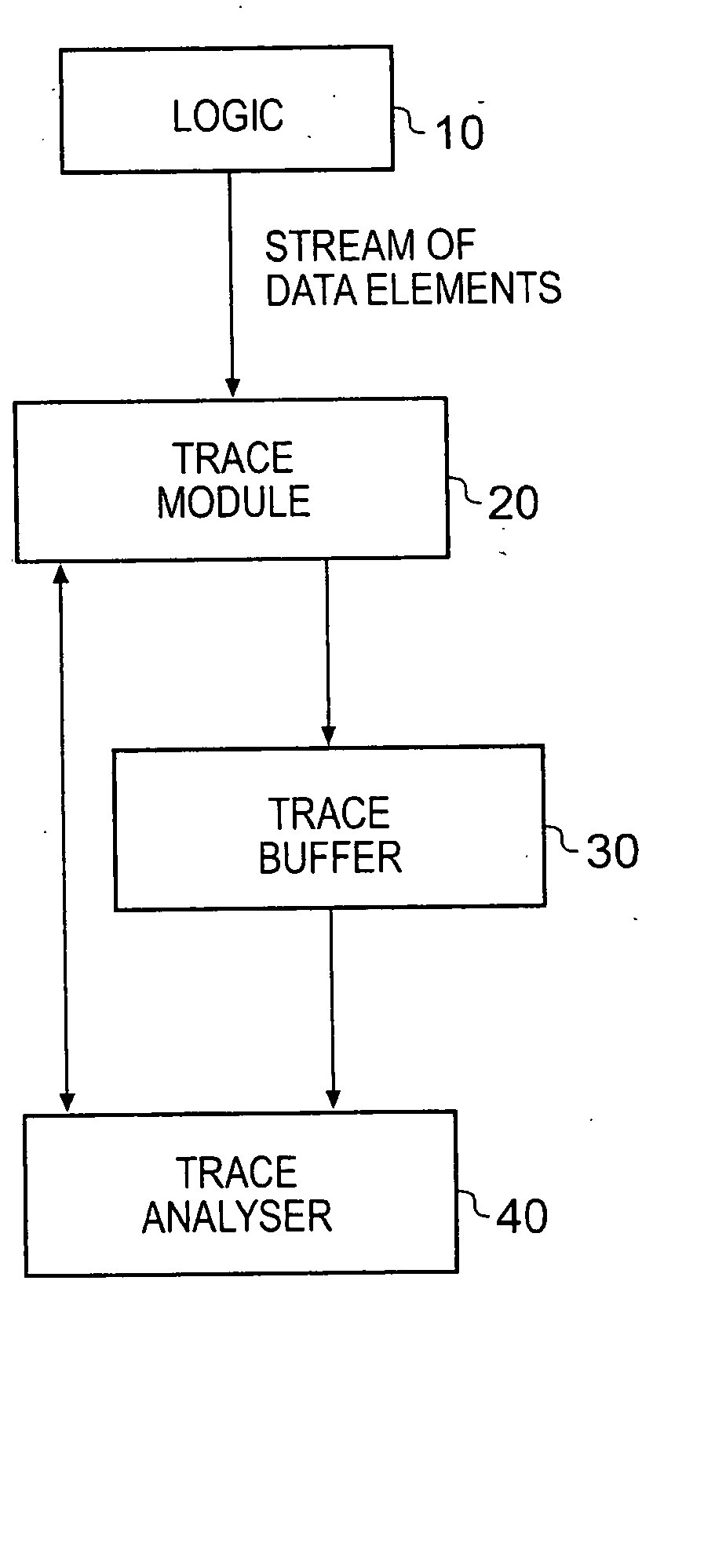

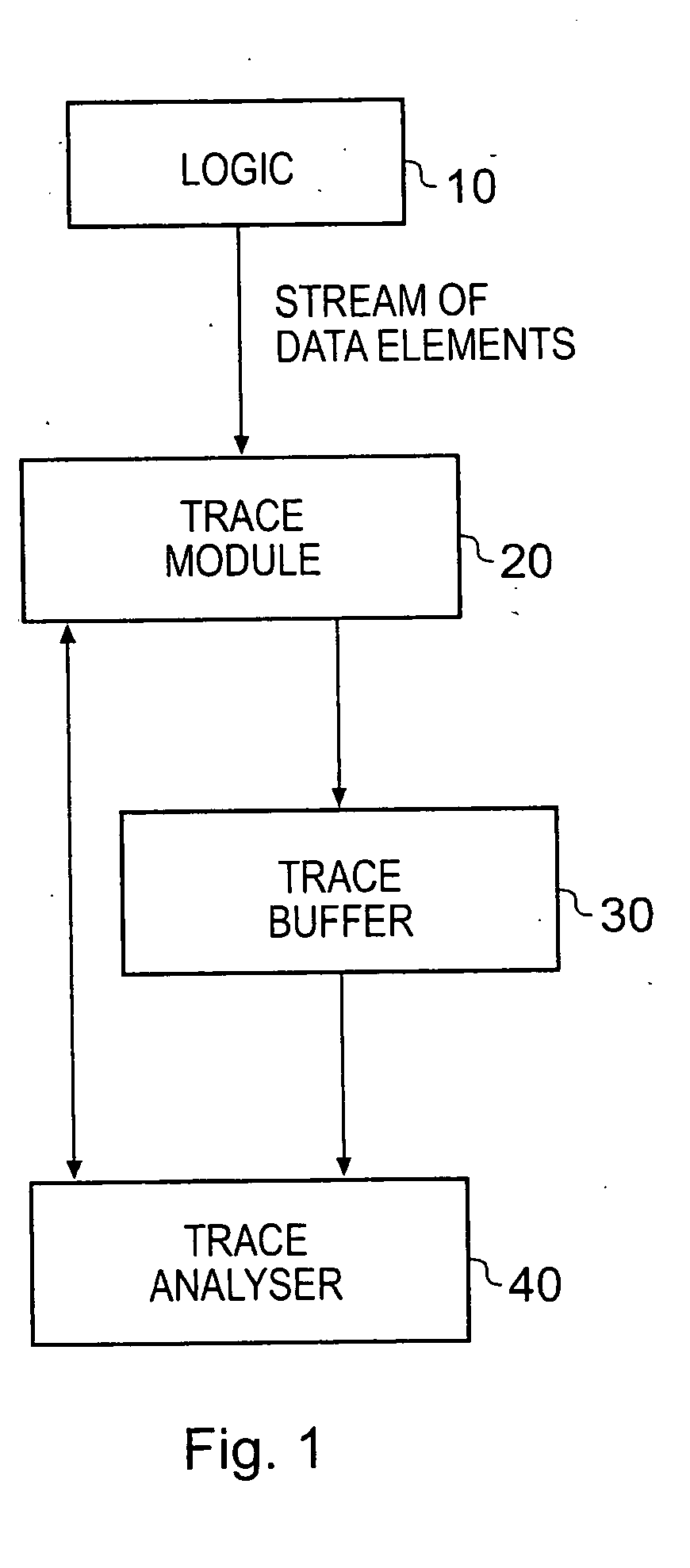

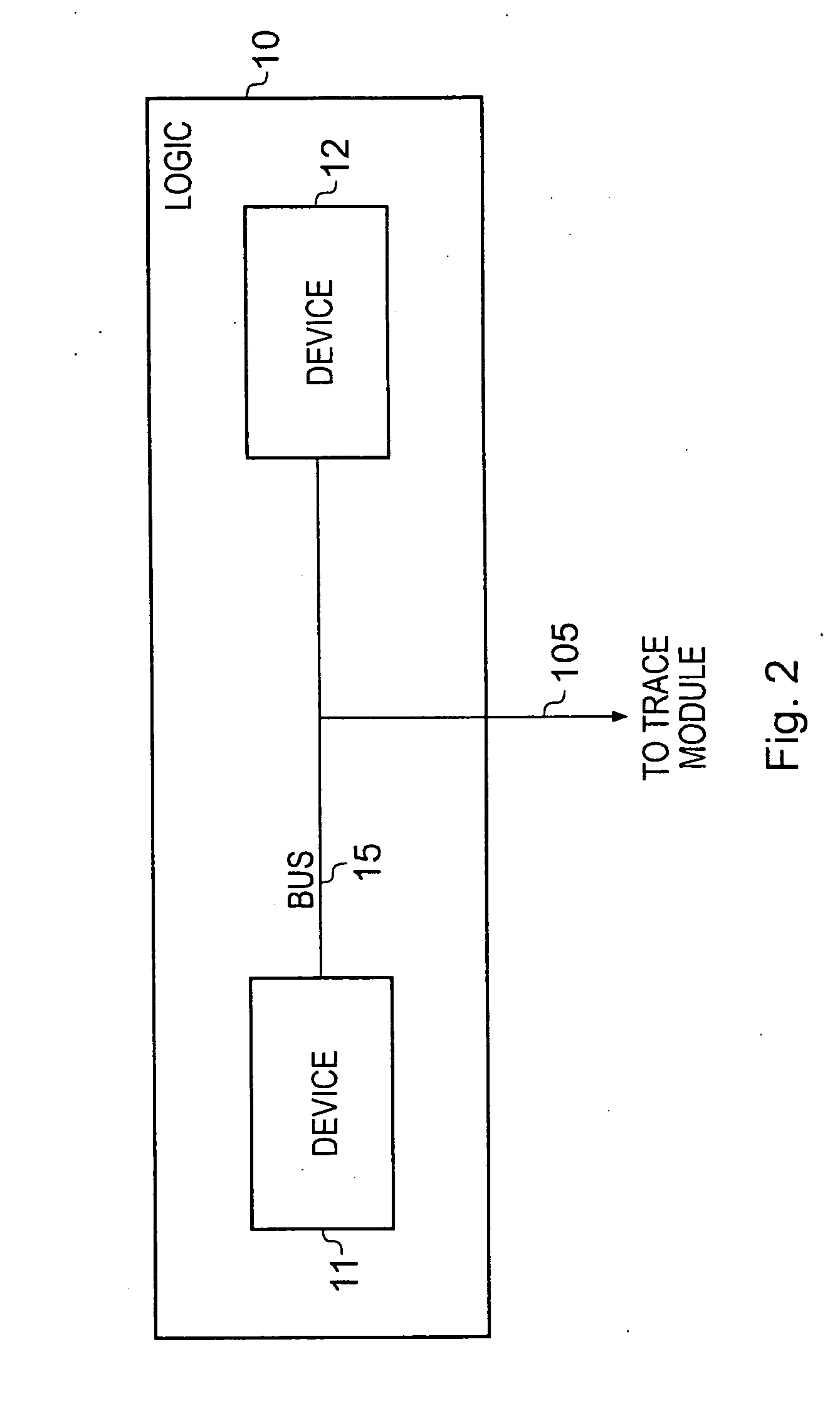

Generation of trace elements within a data processing apparatus

ActiveUS20070226544A1Save bandwidthSave storage spaceError detection/correctionTrace elementParallel computing

A data processing apparatus and method for generating trace elements is provided. The data processing apparatus comprises logic producing a series of data elements, indicative of the operation or state of all or part of the logic. Trace logic is provided for receiving indications of these data elements, and for generating from the indications a stream of trace elements. When for a given data element, at least part of the data element is derivable from a reference to a control value stored in a storage element, the trace logic is operable, dependent on that data element, to omit that part of the associated data element indication from the corresponding trace element generated in respect of the data element, instead including a reference to the corresponding storage element. A trace analysing apparatus can then be used to reconstruct such omitted information based on a copy of the relevant storage element.

Owner:ARM LTD

Rapid multiple panel of biomarkers in laboratory blood tests for TIA/stroke

InactiveUS20060024749A1Volume andPeptide/protein ingredientsMicrobiological testing/measurementNR1 NMDA receptorNMDA receptor

Owner:CIS BIOTECH

Rapid multiple panel of biomarkers in laboratory blood tests for TIA/stroke

InactiveUS20030096331A1Volume andDiagnosing the progression of TIA orPeptide preparation methodsDepsipeptidesNR1 NMDA receptorNMDA receptor

A methods, kits and compositions for diagnosing a central nervous system disorder, particularly transient ischemic attack or stroke, comprising measuring the level of NR2A and / or NR2B NMDA receptor or fragment thereof, in a biological sample from a human subject, and optionally measuring other biomarkers such as homocysteine and glutamate. The method is particularly useful for identifying individuals that are at risk for stroke, and for diagnosing stroke in an emergency room setting.

Owner:CIS BIOTECH

Antenna

ActiveUS9673532B2Increased operating bandwidthLower the volumeWaveguide mouthsRadiating elements structural formsDielectric substrateWaveguide

The present invention relates to an antenna, which includes a feeding part and a radiating part. By using the feeding part and the radiating part that are perpendicular to each other and use dielectric substrates, not only a volume of a normal radiation antenna is reduced, but also a substrate integrated waveguide directly radiates energy outwards, thereby improving operating bandwidth of the antenna.

Owner:HUAWEI TECH CO LTD

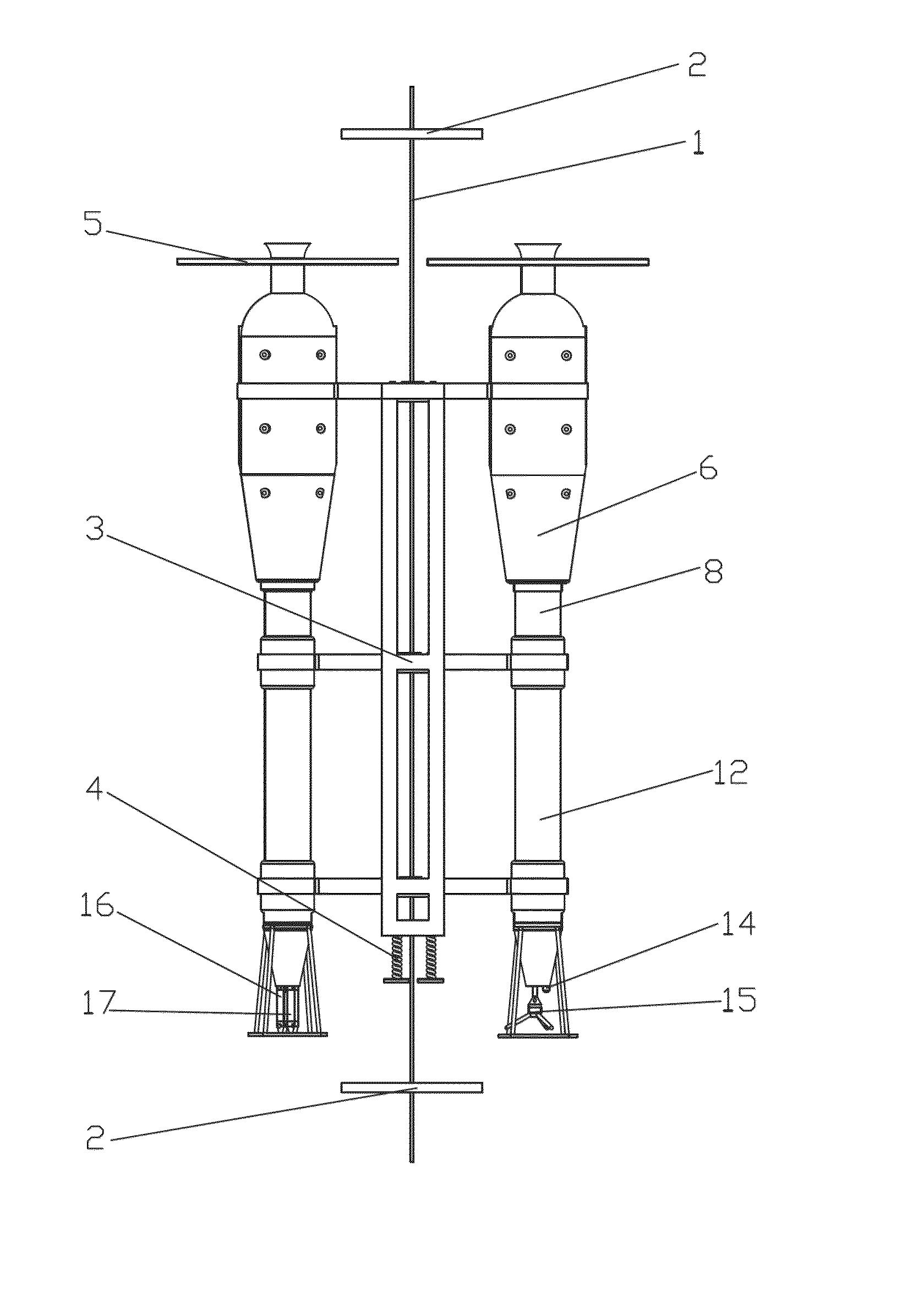

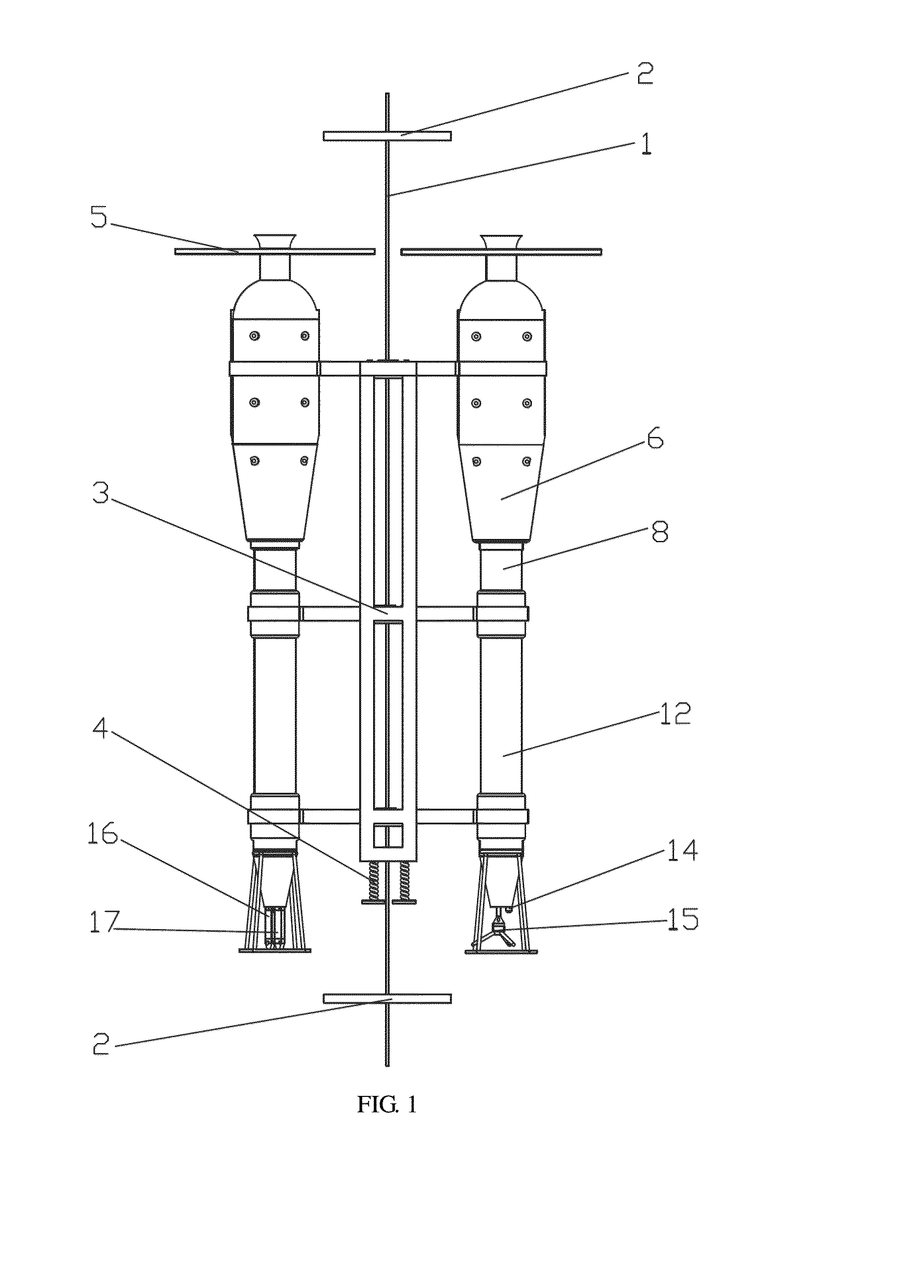

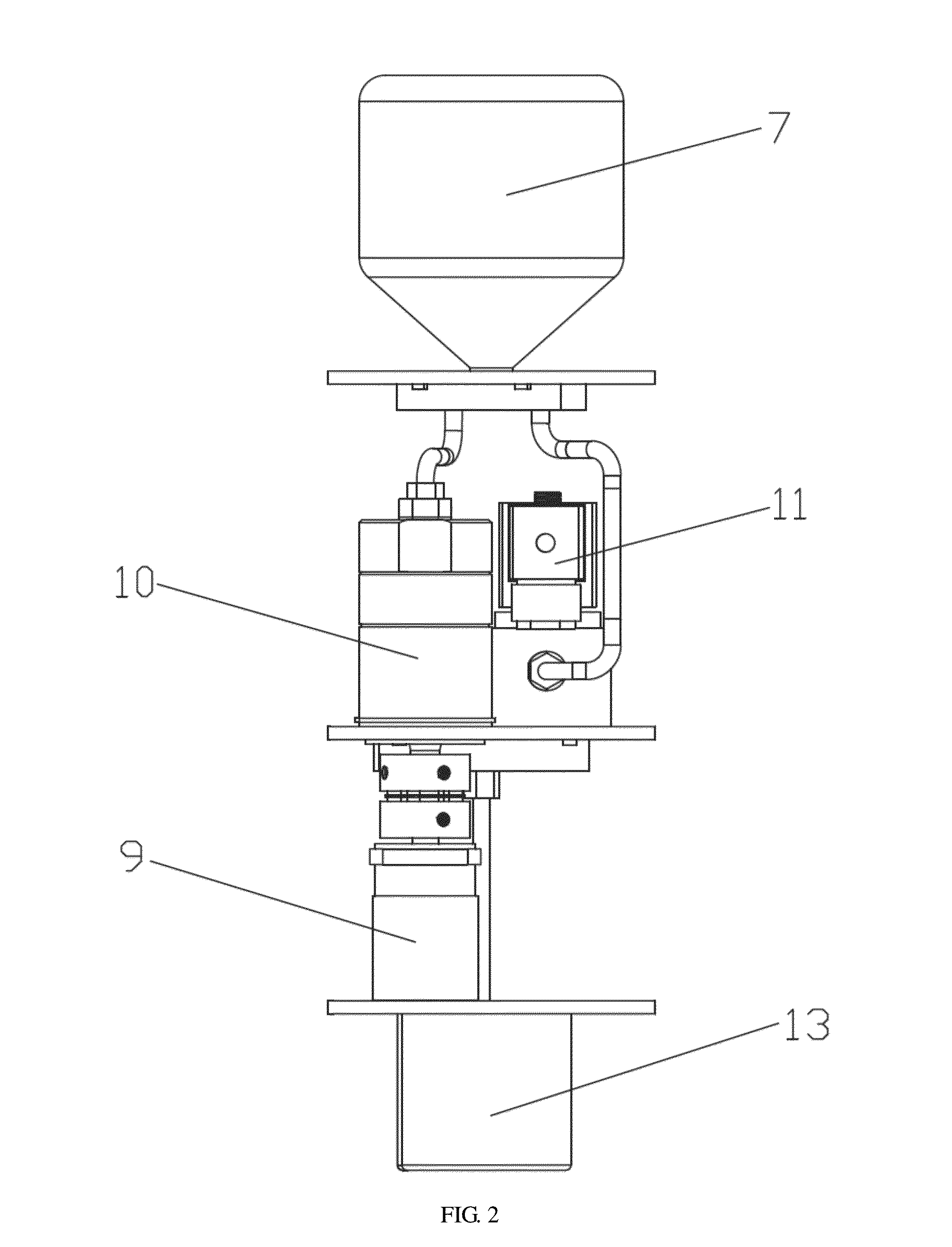

Reciprocating ocean microstructure profiler

ActiveUS20150354957A1Increase volumeLow densitySamplingVolume/mass flow measurementStructure analysisMarine engineering

A reciprocating ocean microstructure profiler includes a first profiler subunit, a second profiler subunit and a central stand. The first profiler subunit is provided with the first buoyancy drive part and the first observation part; and the second profiler subunit is provided with the second buoyancy drive part and the second observation part. Both the first and second buoyancy drive parts are installed with a floating compartment, a drive compartment and a pressure housing each. A top oil bladder is provided in the floating compartment and a bottom oil bladder in the pressure housing. A drive pump assembly and a solenoid valve are installed in the drive compartment. The first and second observation parts are electrically connected to a controller each and each controller is electrically connected to a drive pump assembly and a solenoid valve.

Owner:OCEAN UNIV OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com