Patents

Literature

6074results about How to "Reduce processing steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

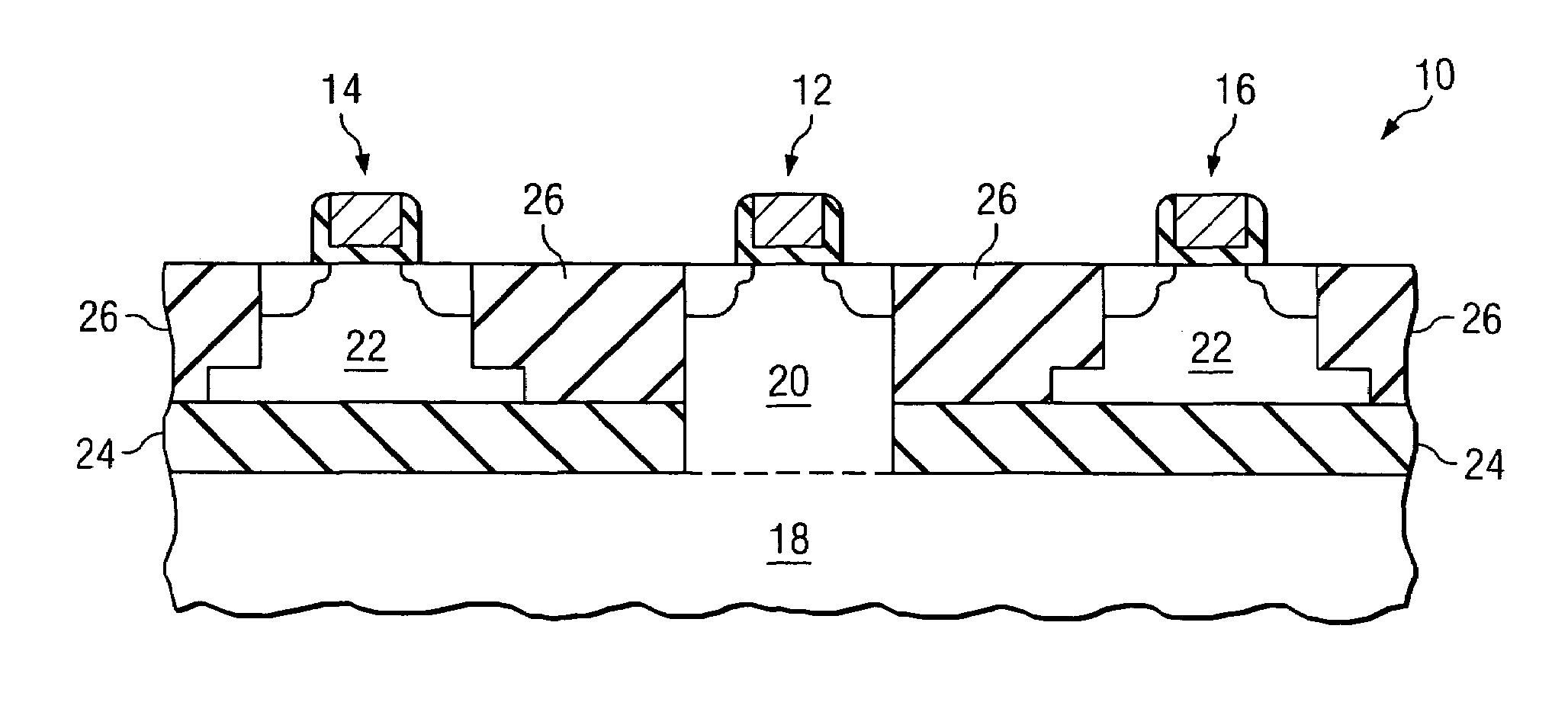

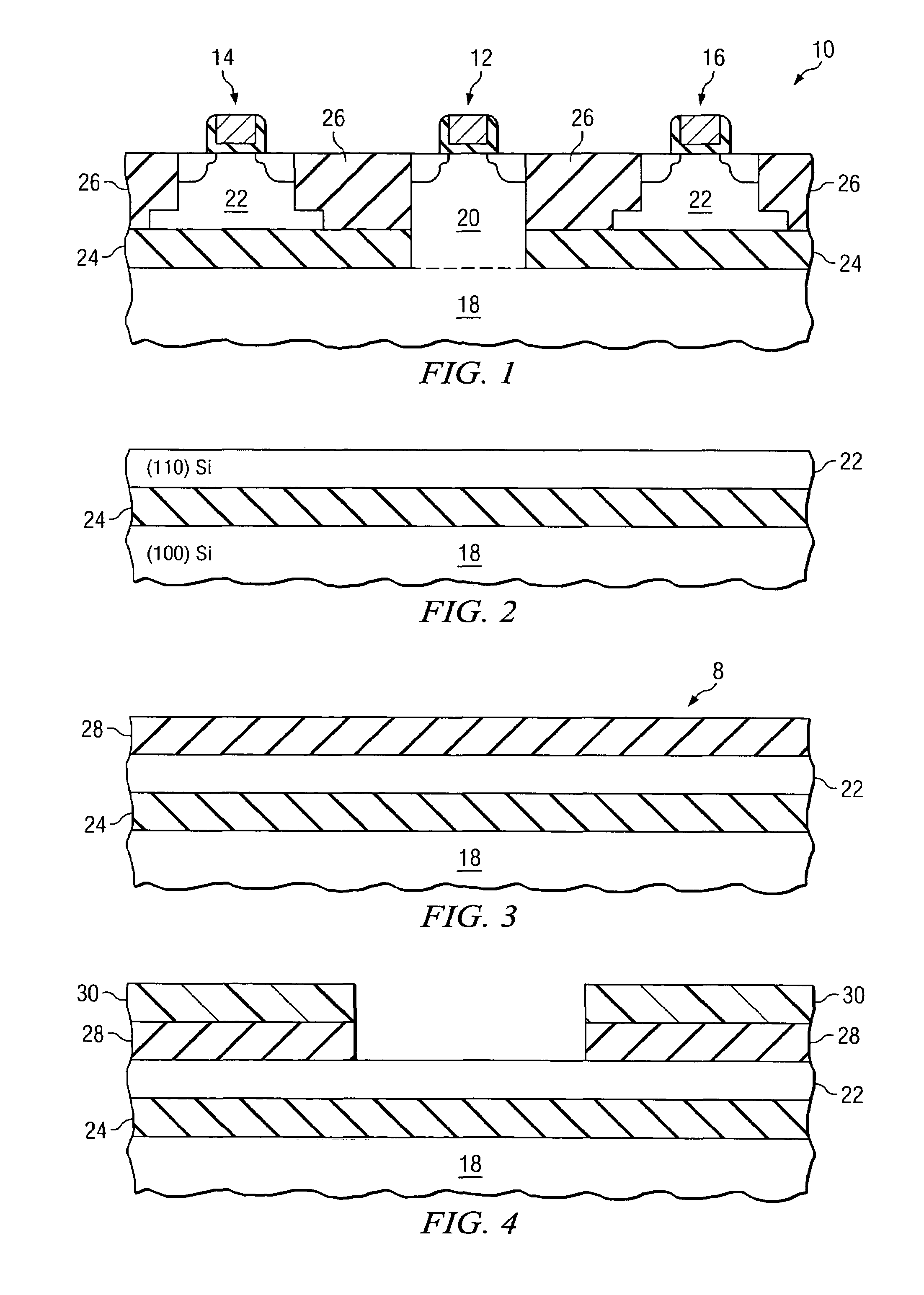

Semiconductor method and device with mixed orientation substrate

InactiveUS7298009B2Critical dimension of this mask is relaxedReduce processing stepsSemiconductor/solid-state device detailsSolid-state devicesSemiconductor materialsCrystal orientation

Owner:INFINEON TECH AG +1

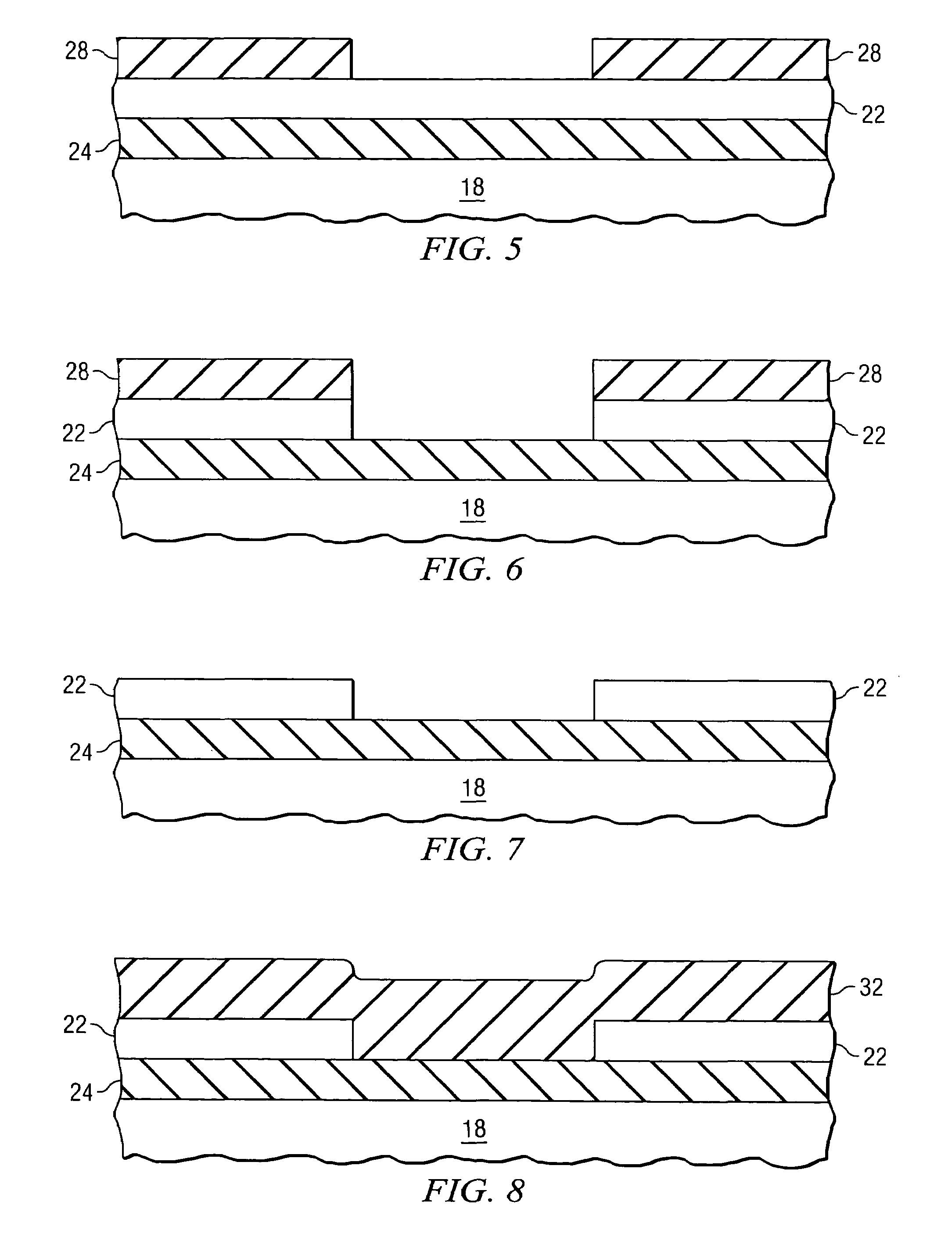

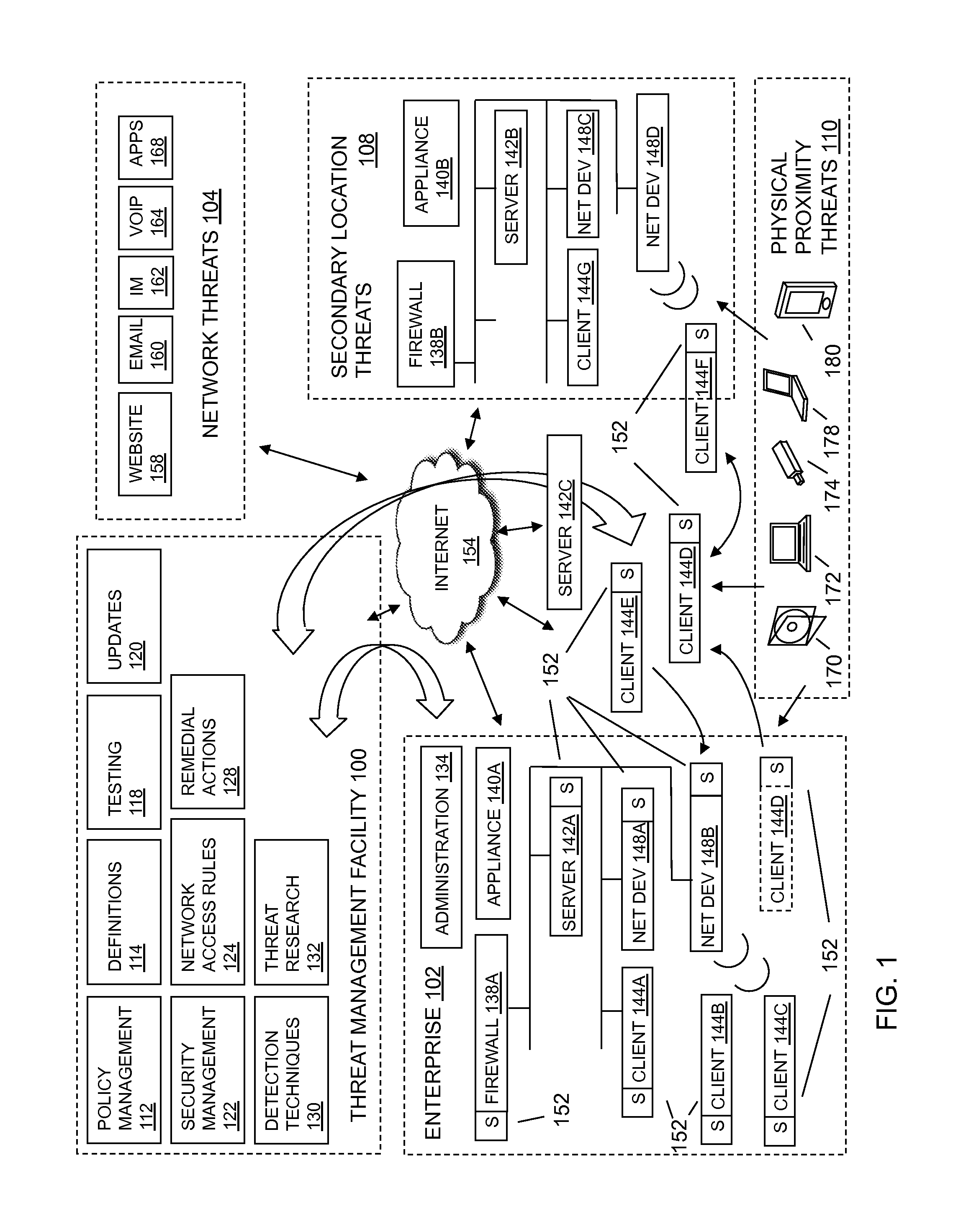

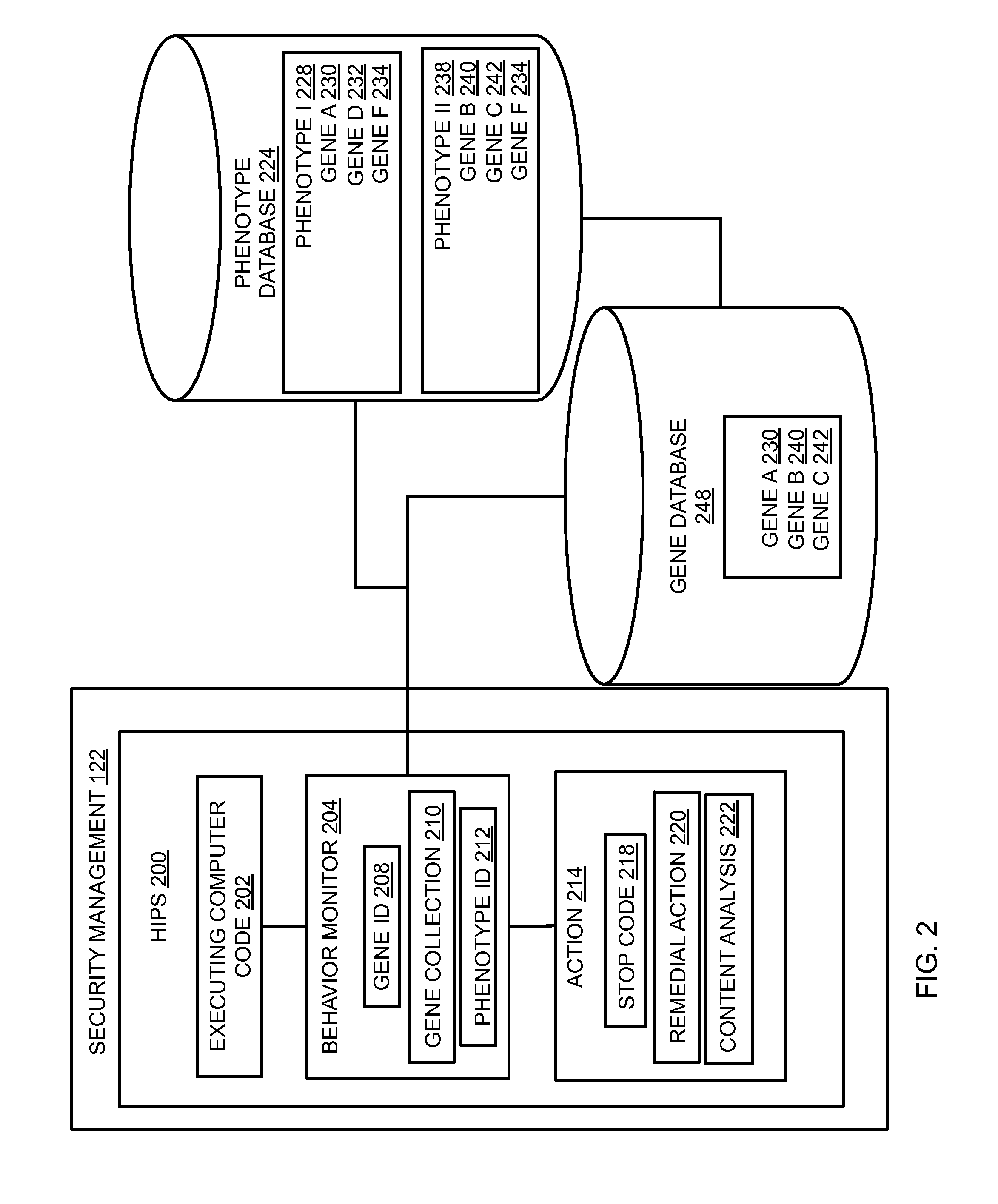

Host intrusion prevention system using software and user behavior analysis

ActiveUS20110023115A1Reduce processing stepsNetwork access restrictionMemory loss protectionError detection/correctionGraphicsGraphical user interface

In embodiments of the present invention improved capabilities are described for threat detection using a behavioral-based host-intrusion prevention method and system for monitoring a user interaction with a computer, software application, operating system, graphic user interface, or some other component or client of a computer network, and performing an action to protect the computer network based at least in part on the user interaction and a computer code process executing during or in association with a computer usage session.

Owner:SOPHOS

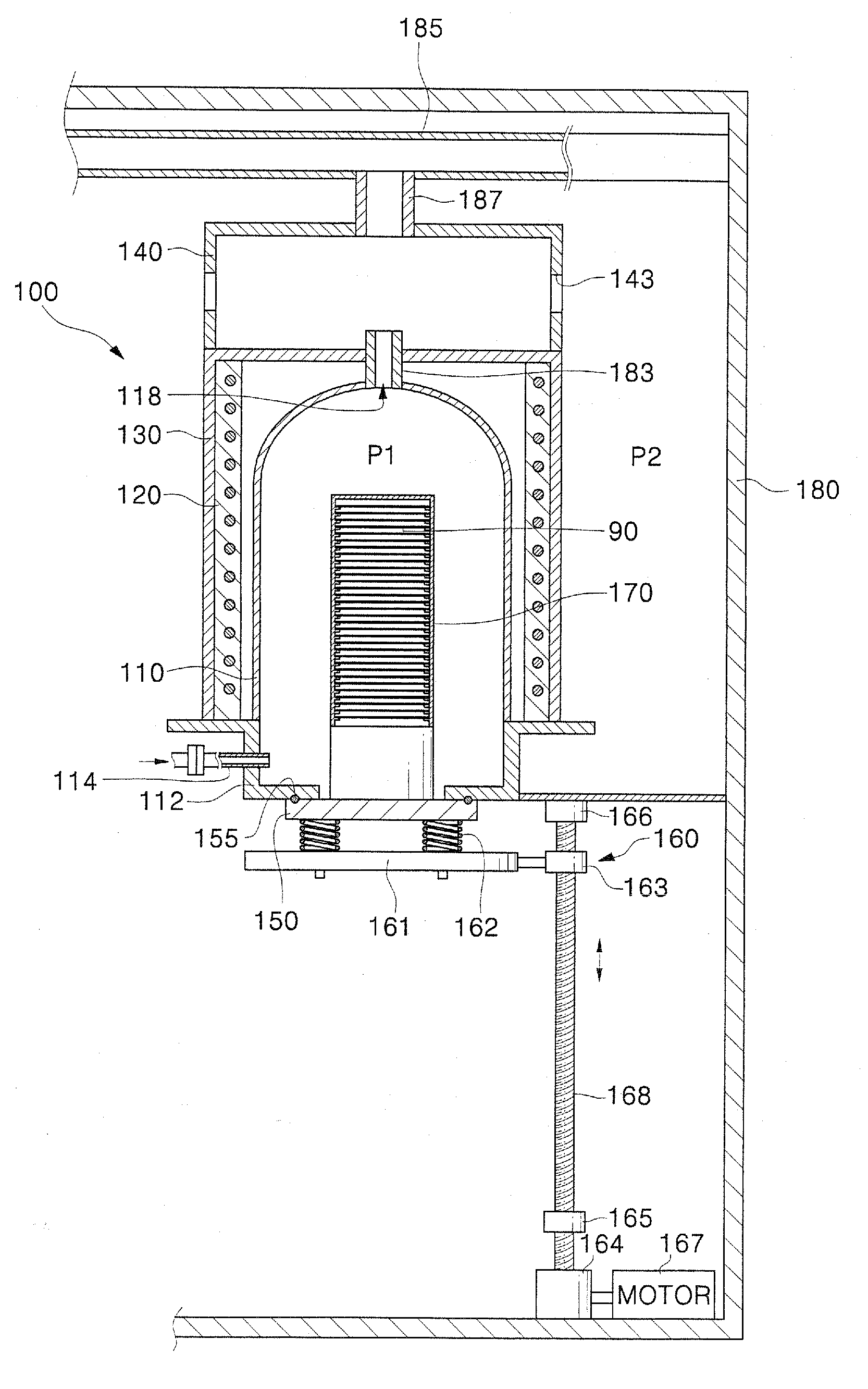

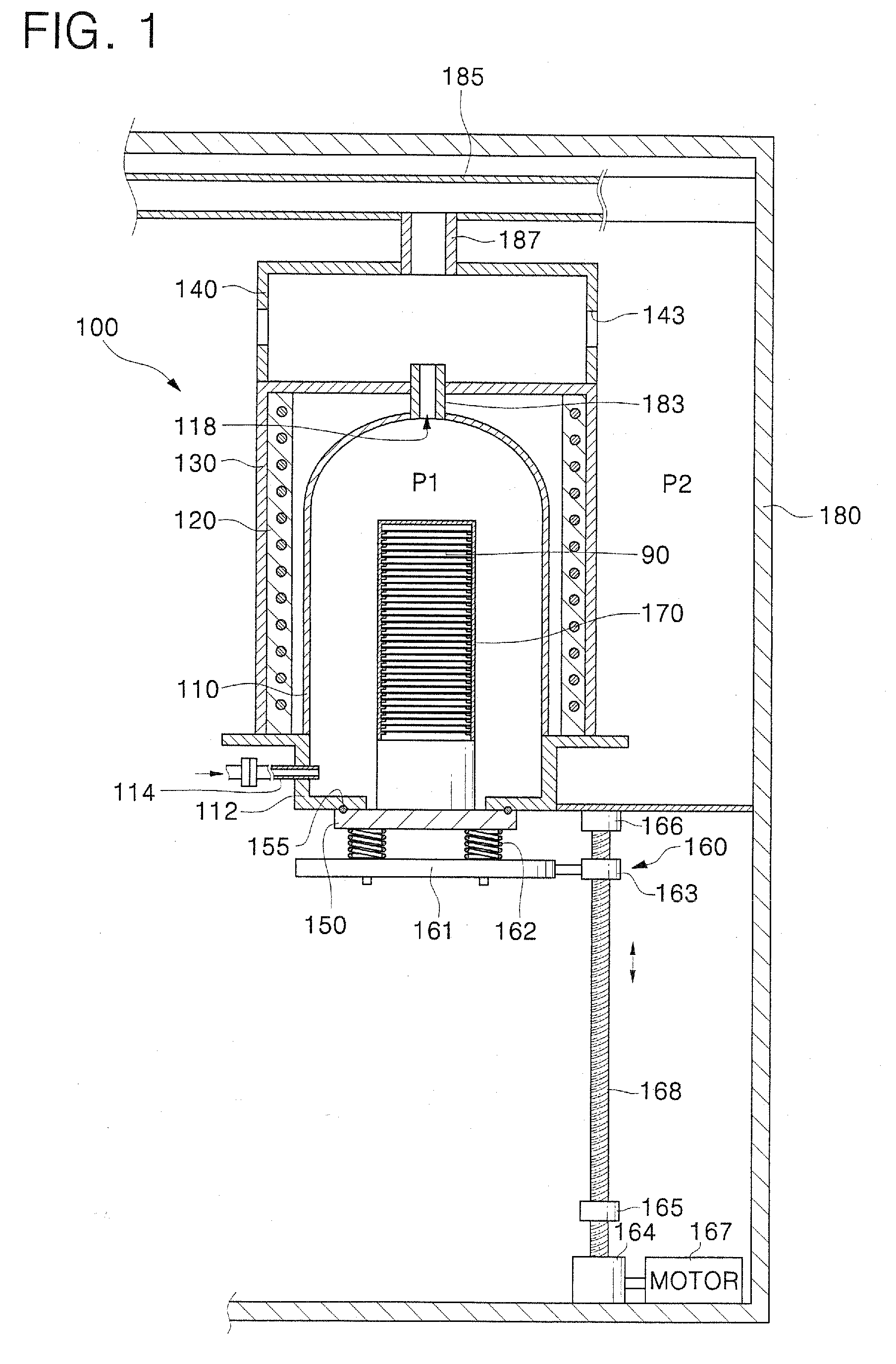

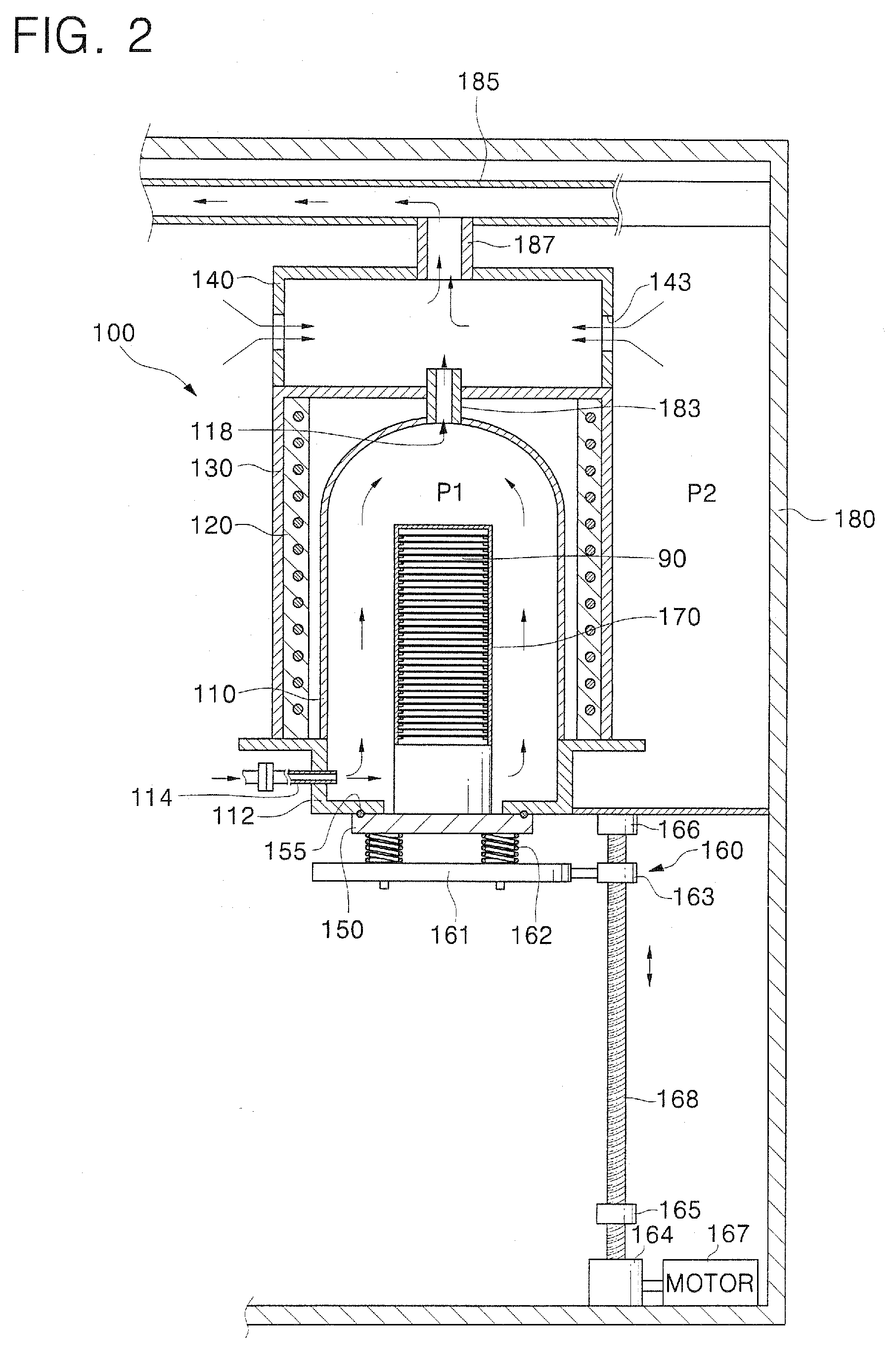

Heat treatment equipment

InactiveUS7850449B2Growth inhibitionReduce processing stepsMuffle furnacesBaking ovenProcess engineeringPressure controlled ventilation

In an embodiment, heat treatment equipment comprises a process tube, an exhaust duct connected to the process tube, and, during operation, exhausting gases present within the process tube. The heat treatment equipment also comprises a hollow pressure control member interposed between the process tube and the exhaust duct, the pressure control member being operatively connected to the process tube and the exhaust duct respectively, and including one or a number of openings. Negative pressure is avoided in the process tube during heat treatment processes so that unwanted gas and impurities cannot enter the process tube from outside.

Owner:SAMSUNG ELECTRONICS CO LTD

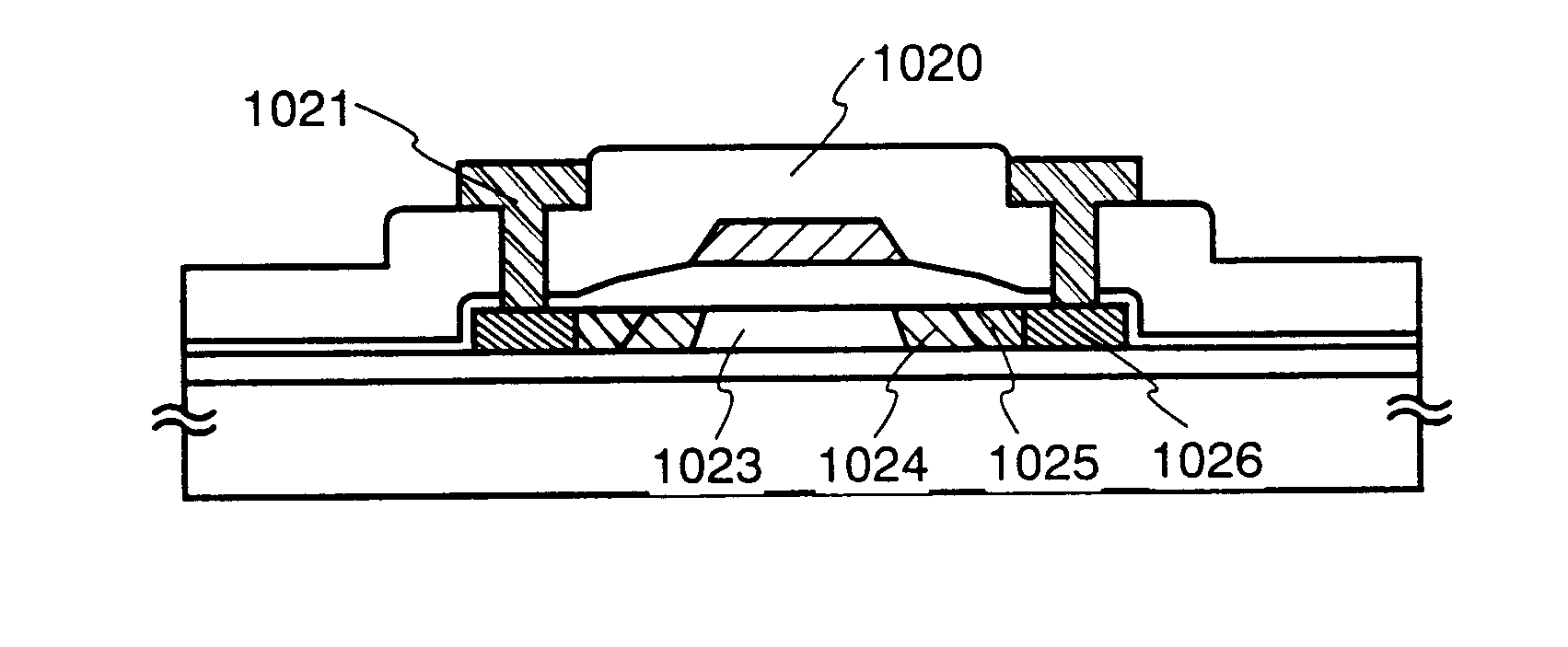

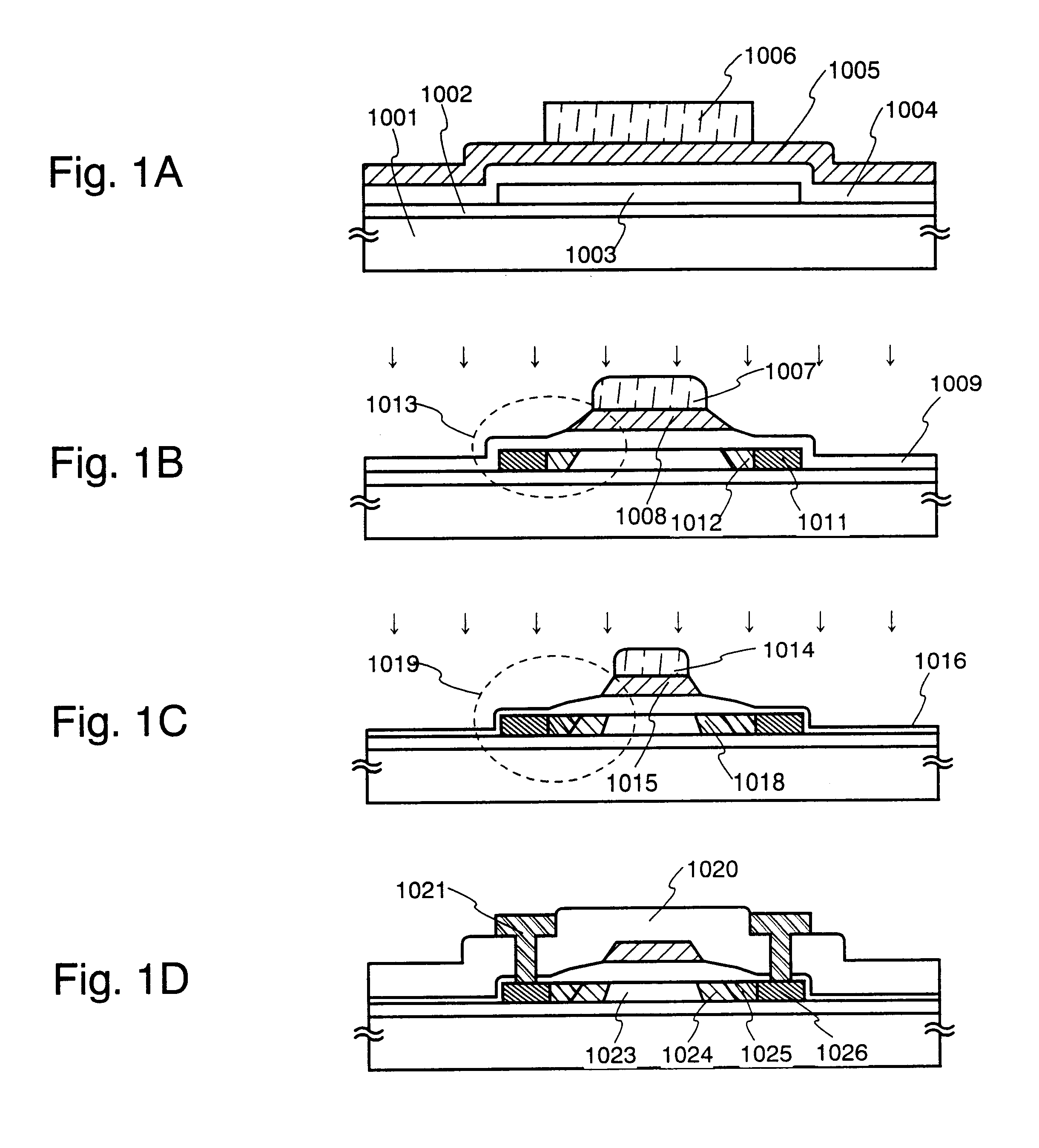

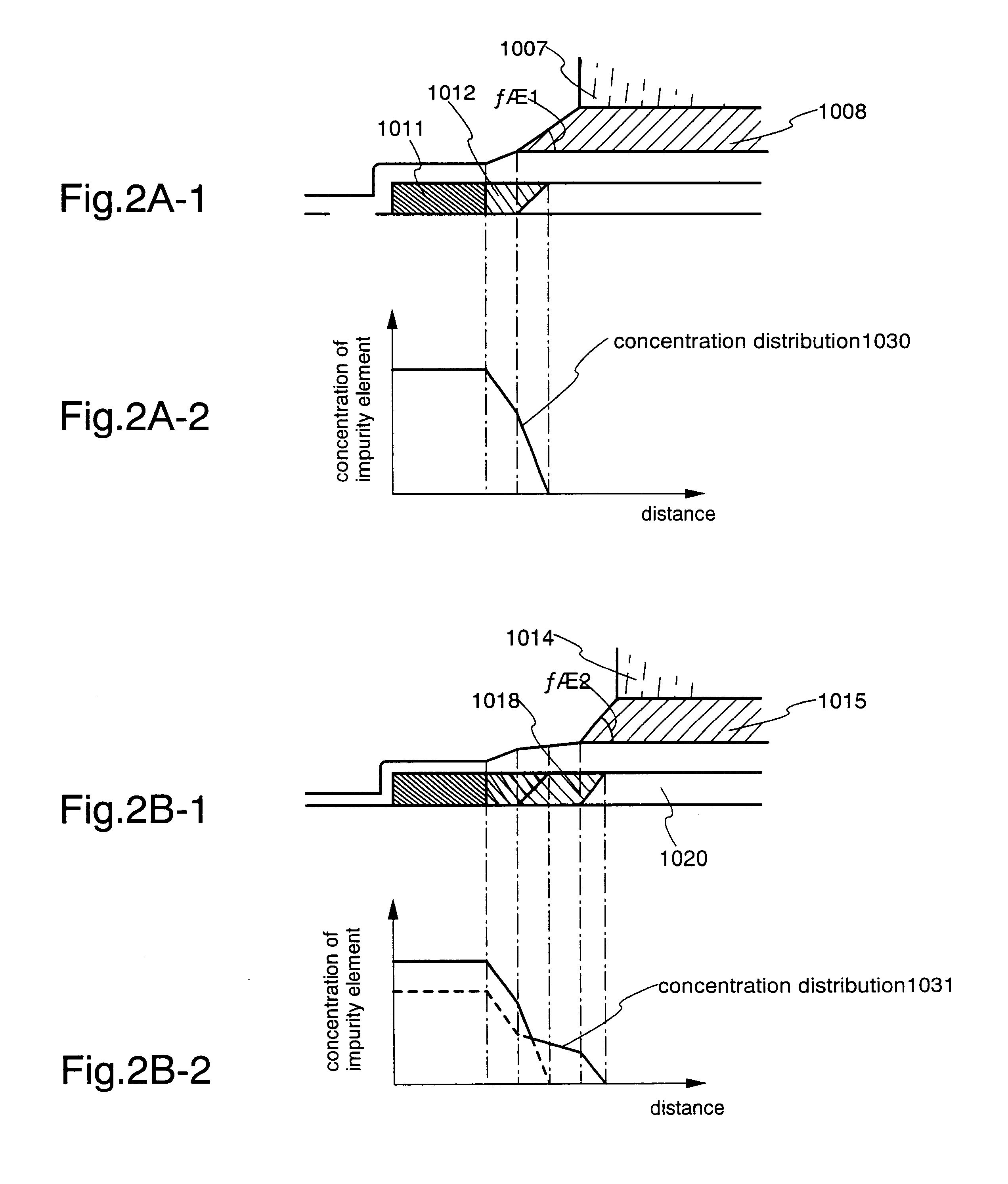

Semiconductor device with tapered gate and insulating film

InactiveUS6646287B1Reduce in quantityReduce manufacturing costTransistorSolid-state devicesContact formationActive matrix

In a semiconductor device, typically an active matrix display device, the structure of TFTs arranged in the respective circuits are made suitable in accordance with the function of the circuit, and along with improving the operating characteristics and the reliability of the semiconductor device, the manufacturing cost is reduced and the yield is increased by reducing the number of process steps. A semiconductor device has a semiconductor layer, an insulating film formed contacting the semiconductor layer, and a gate electrode having a tapered portion on the insulating film, in the semiconductor device, the semiconductor layer has a channel forming region, a first impurity region for forming a source region or a drain region and containing a single conductivity type impurity element, and a second impurity region for forming an LDD region contacting the channel forming region, a portion of the second impurity region is formed overlapping a gate electrode, and the concentration of the single conductivity type impurity element contained in the second impurity region becomes larger with distance from the channel forming region.

Owner:SEMICON ENERGY LAB CO LTD

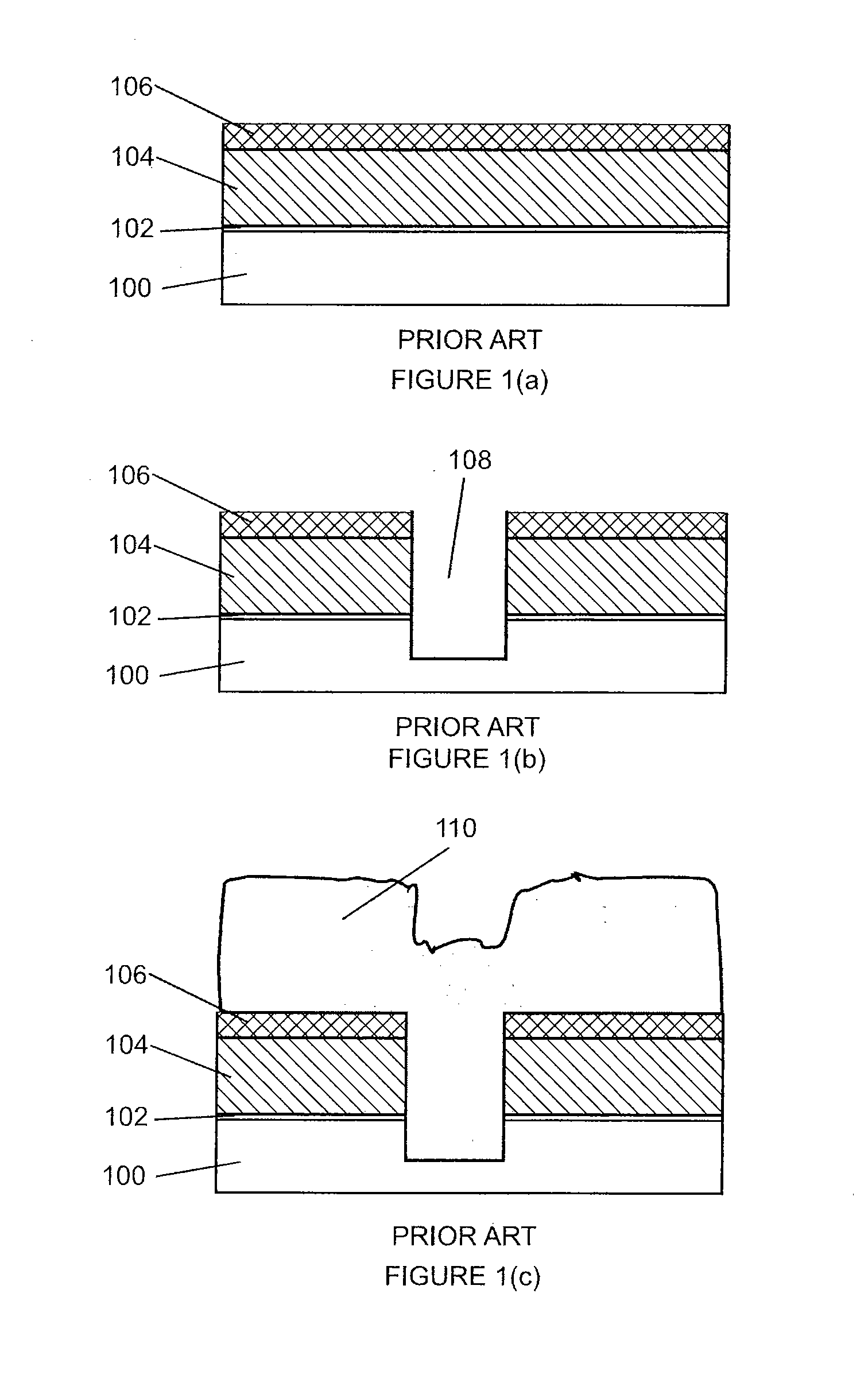

Method and structure for self aligned formation of a gate polysilicon layer

ActiveUS20070243685A1Easy to useReduce processing stepsSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorSemiconductor device

A method for processing semiconductor devices includes providing a semiconductor substrate. The method includes forming a pad oxide layer overlying the substrate and forming a silicon nitride layer overlying the pad oxide layer. The method includes forming a trench region extending through an entirety of a portion of the silicon nitride layer and extends into a depth of the semiconductor substrate. The method also includes filling the trench region with an oxide material. The oxide material extends from a bottom portion of the trench region to an upper surface of the silicon nitride layer. The method includes planarizing the oxide material and selectively removing the silicon nitride layer to form an isolation structure. A polysilicon material is deposited overlying the isolation structure. The polysilicon material is planarized to expose a top portion of the isolation structure and form a first electrode and a second electrode structures separated by a portion of the isolation structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP

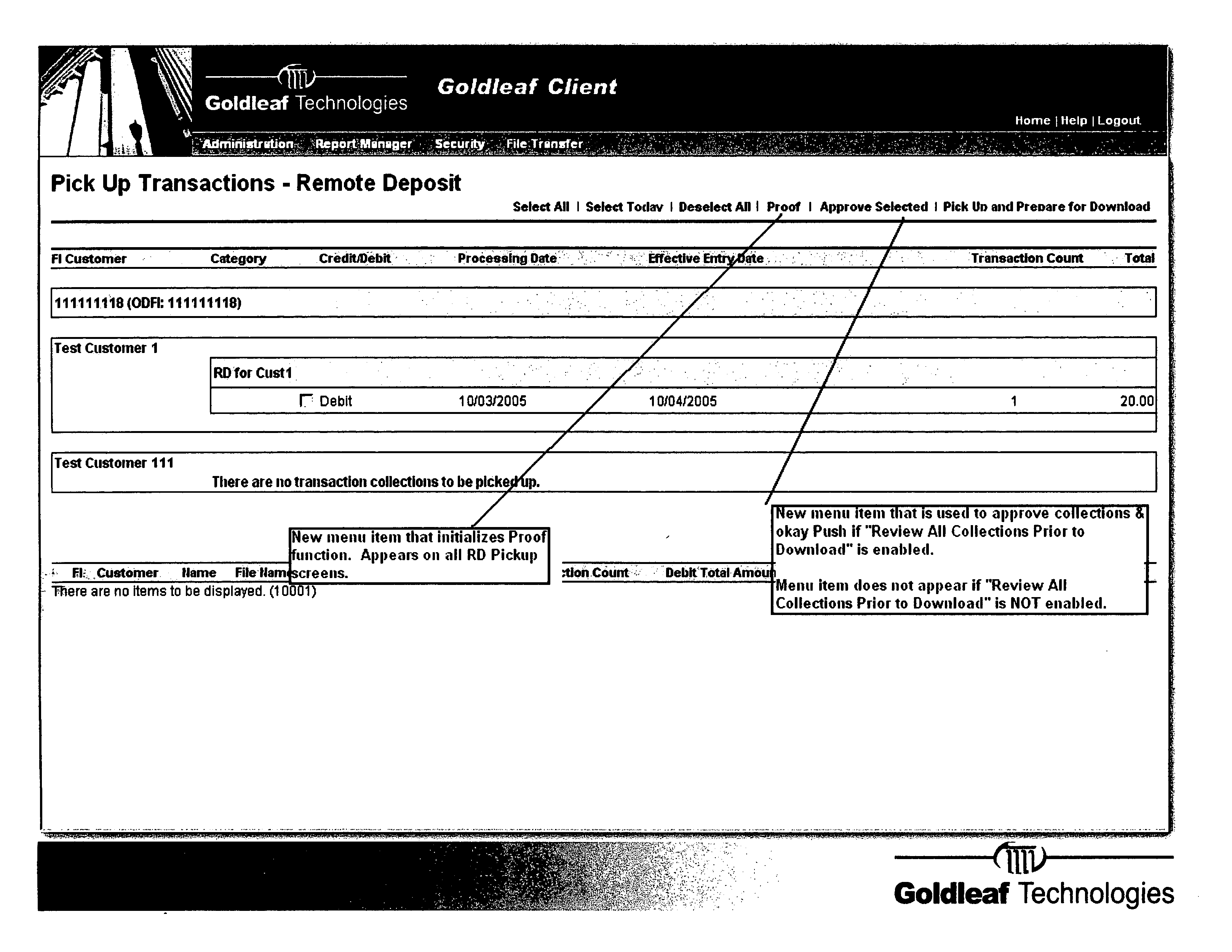

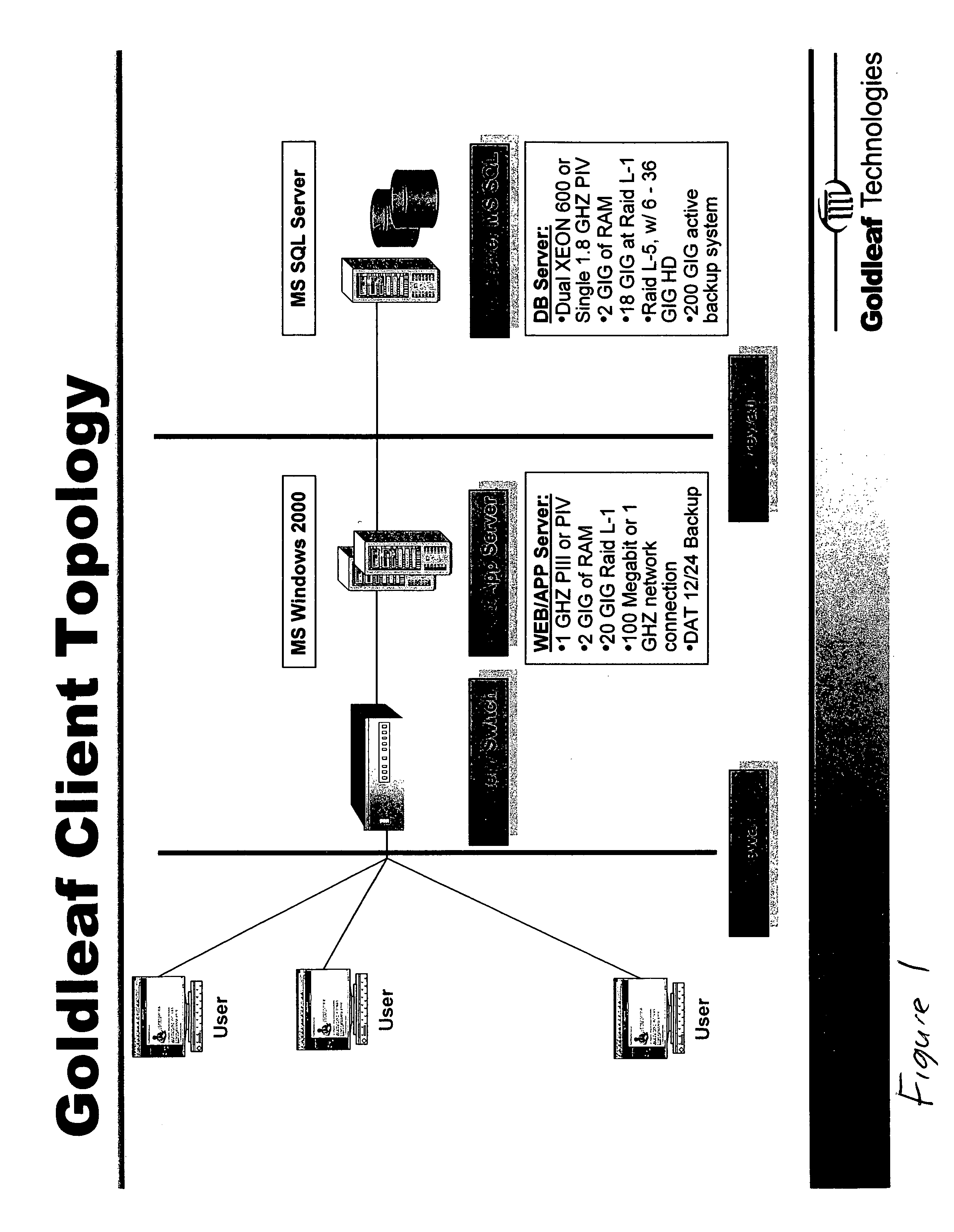

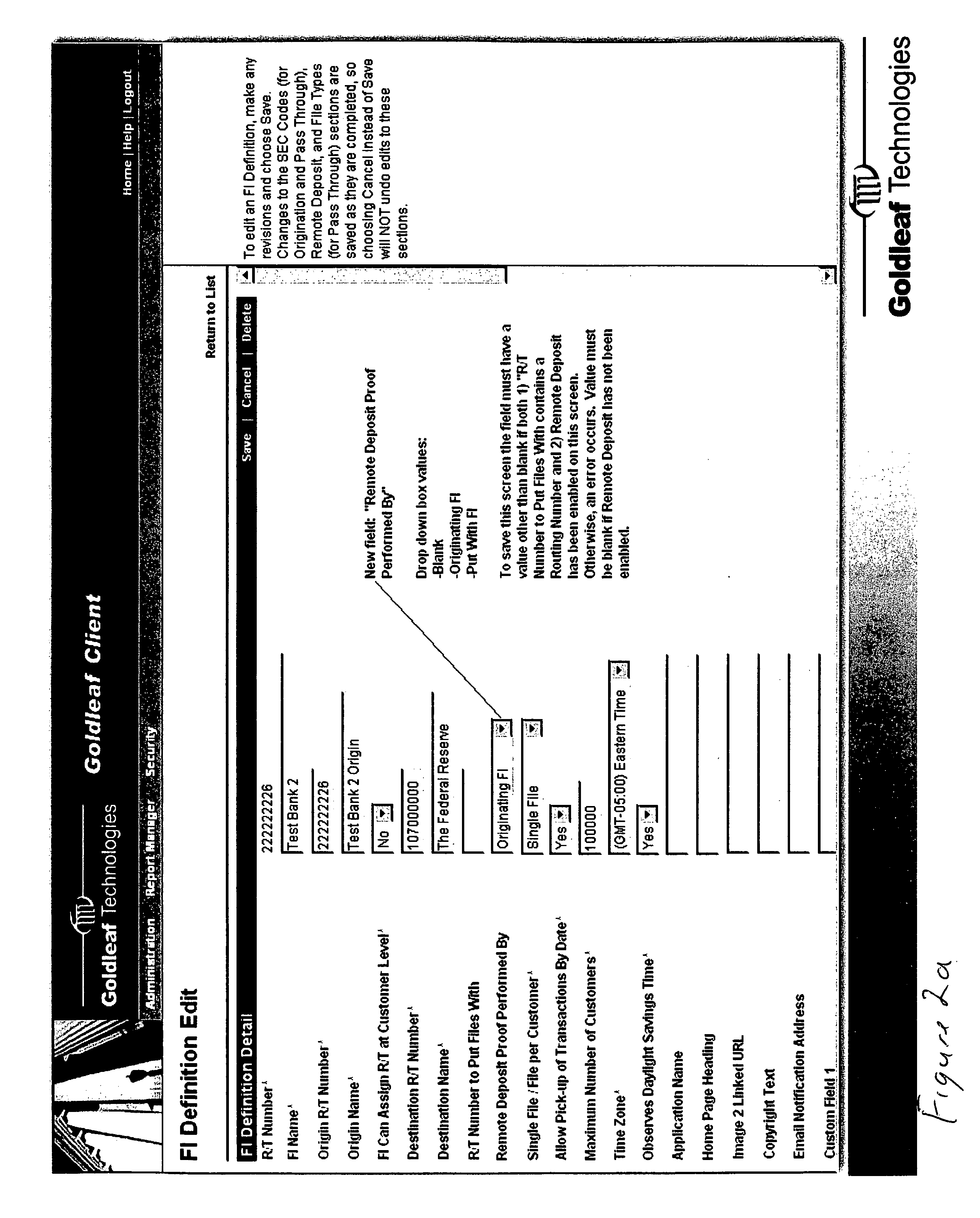

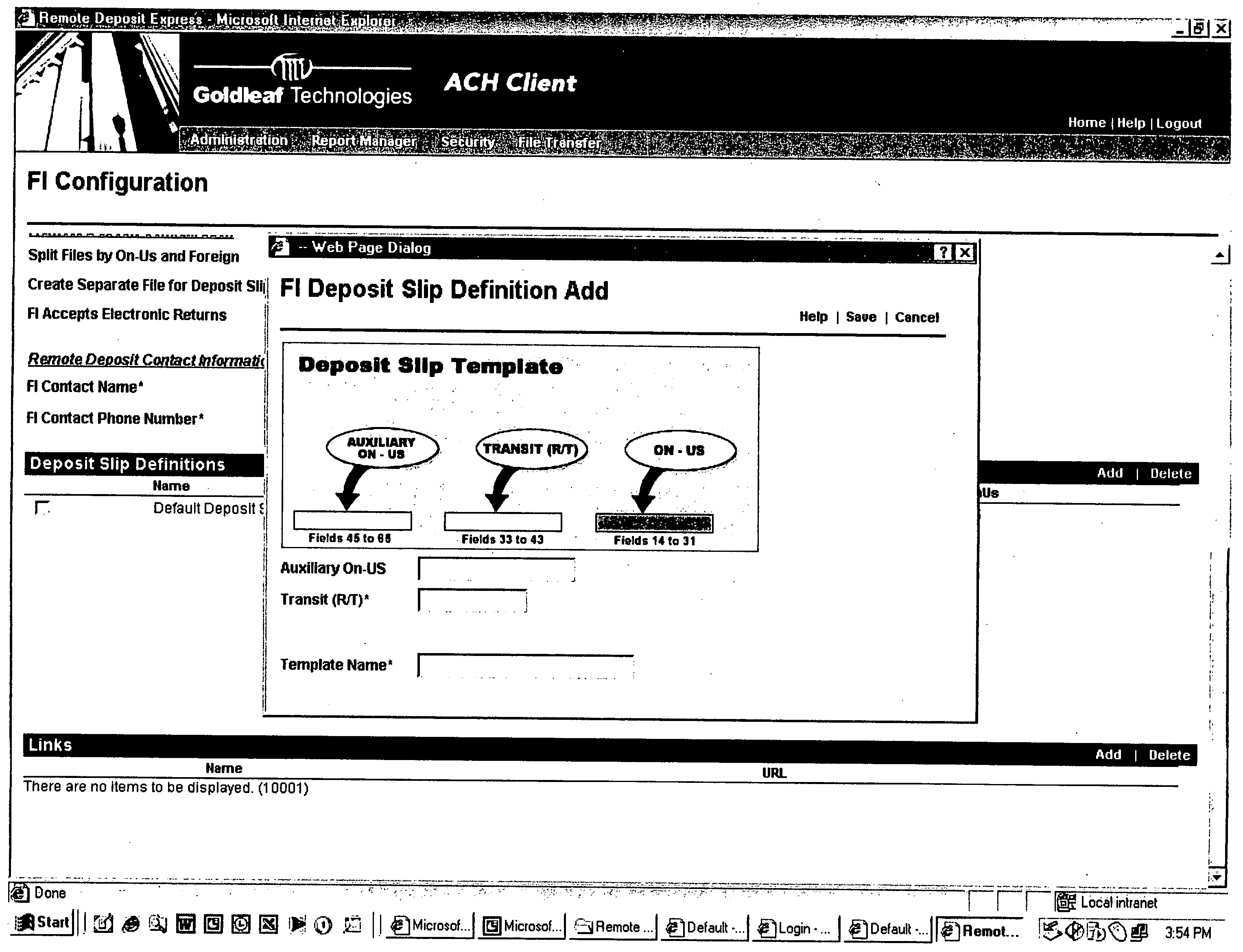

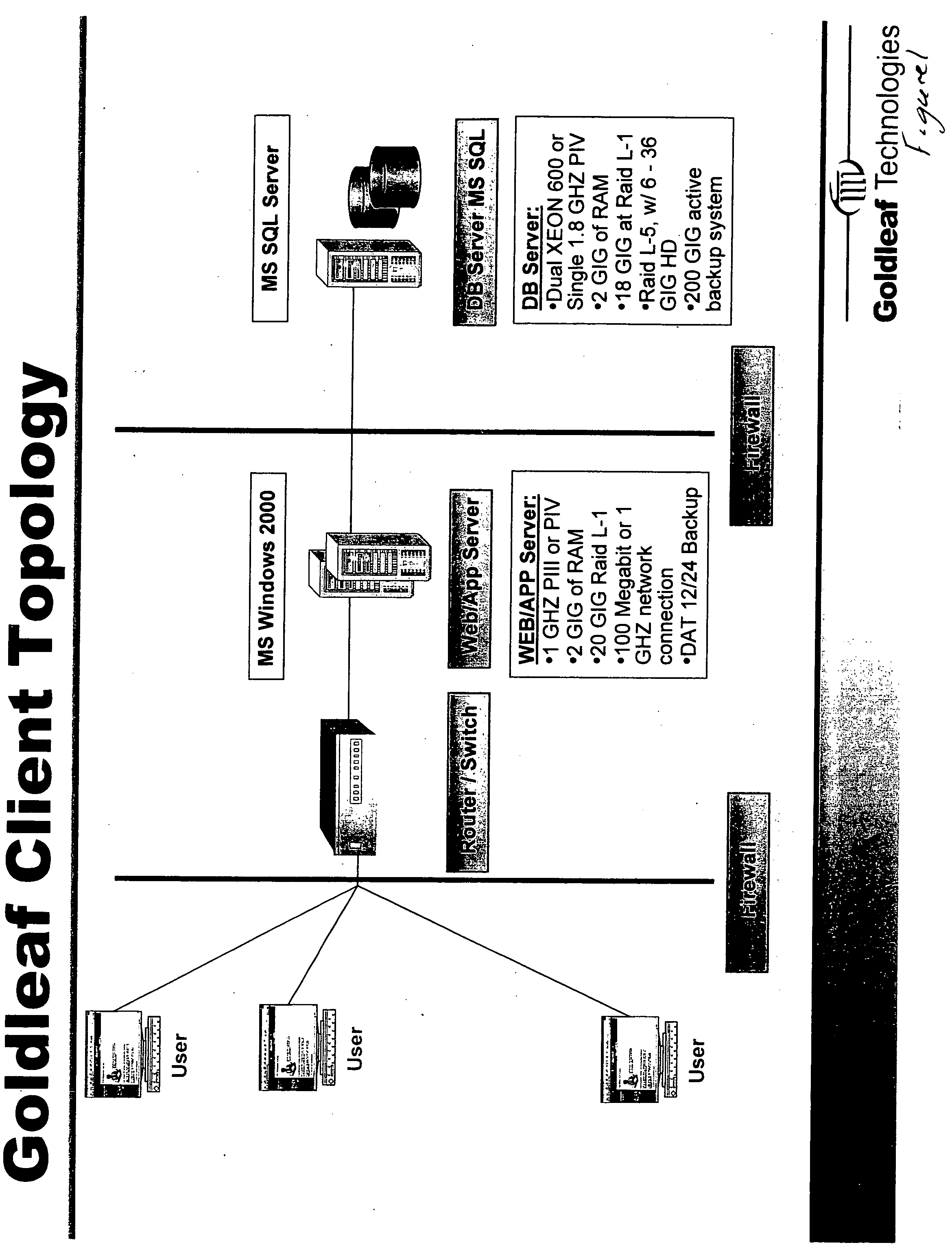

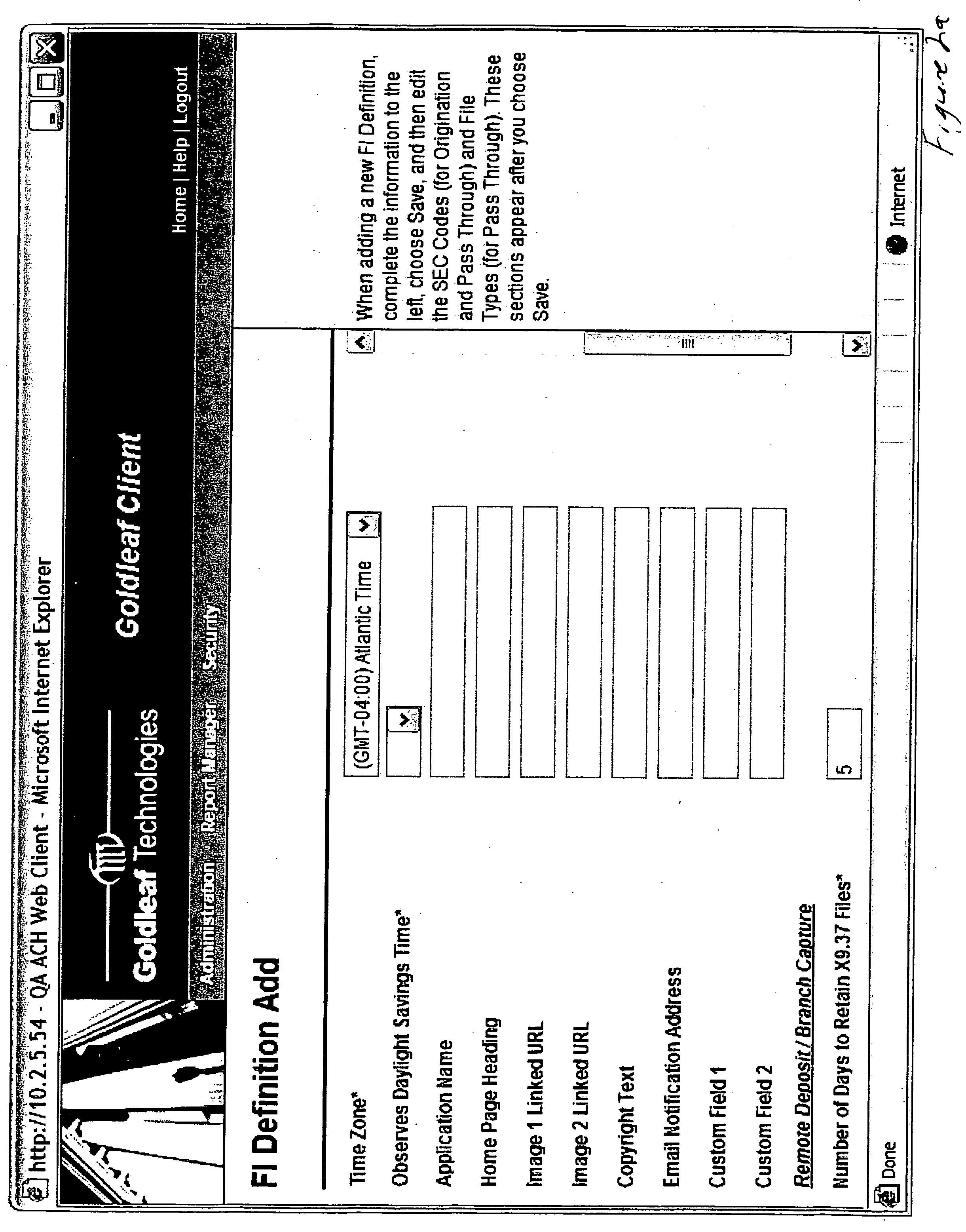

Remote check deposit

In accordance with the principles of the present invention, a system is provided for capturing a customer deposit at their place of business, converting the Magnetic Ink Character Recognition (MICR) data encoded documents into an image with an associated data file, and electronically transmit the data to a financial institution. The system allows the customer to scan each MICR encoded check that is to be deposited with their financial institution, which captures financial institution routing information and customer account information. The associated image the physical check can be franked denoting the check has been electronically processed to avoid further processing. The resulting image and account data can then be edited and processed by the financial institution. There are three options for encoding the amount: 1) the customer enters each amount after scanning the item prior to sending to the financial institution; 2) the financial institution enters the amount of each item after receiving the file from the customer; and 3) the amount field(s) is scanned and the amount is automatically entered. The system allows for both 1) online (Internet) capture of the MICR data and the associated image or 2) offline capture and the subsequent importing of the image and MICR data for transmission to the financial institution via the Internet. The financial institution can review the items captured online, and repair any item that is incorrect. The financial institution can use the system to print substitute checks that confirm to ANSI X9.90 for processing or deliver an electronic file in ANSI X9.37 format to any check processing system. The system includes secure transport over Internet connections for file transfer and dual control security to reduce fraudulent transactions from being initiated by the customer.

Owner:GOLDLEAF TECH

Remote check deposit

InactiveUS20060242062A1Easy to optimizeConvenient truncationFinancePayment circuitsDocumentation procedureSubstitute check

In accordance with the principles of the present invention, a system is provided for capturing a customer deposit at their place of business, converting the Magnetic Ink Character Recognition (MICR) data encoded documents into an image with an associated data file, and electronically transmit the data to a financial institution. The system allows the customer to scan each MICR encoded check that is to deposited with their financial institution, which captures financial institution routing information and customer account information. The associated image the physical check can be franked denoting the check has been electronically processed to avoid further processing. The resulting image and account data can then be processed by the financial institution. There are three options for encoding the amount: 1) the customer enters each amount after scanning the item prior to sending to the financial institution; 2) the financial institution enters the amount of each item after receiving the file from the customer; and 3) the amount field(s) are scanned and the amount is automatically entered. The system allows for both 1) online (Internet) capture of the MICR data and the associated image or 2) offline capture and the subsequent importing of the image and MICR data for transmission to the financial institution via the Internet. The financial institution can review the items captured online, and repair any item that is incorrect. The financial institution can use the system to print substitute checks that confirm to ANSI X9.90 for processing or deliver an electronic file in ANSI X9.37 format to any check processing system. The system includes secure transport over Internet connections for file transfer and dual control security to reduce fraudulent transactions from being initiated by the customer.

Owner:GOLDLEAF TECH

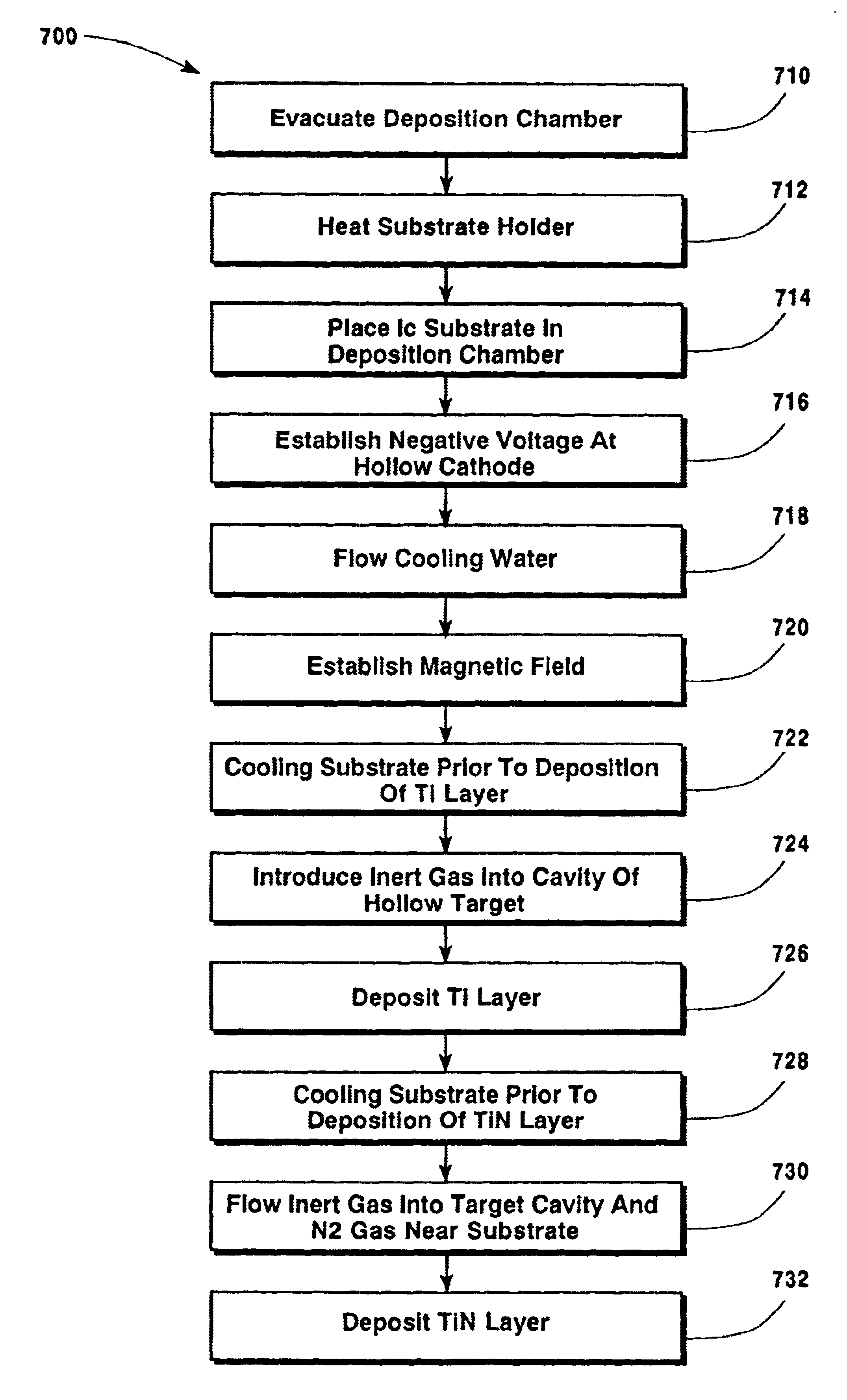

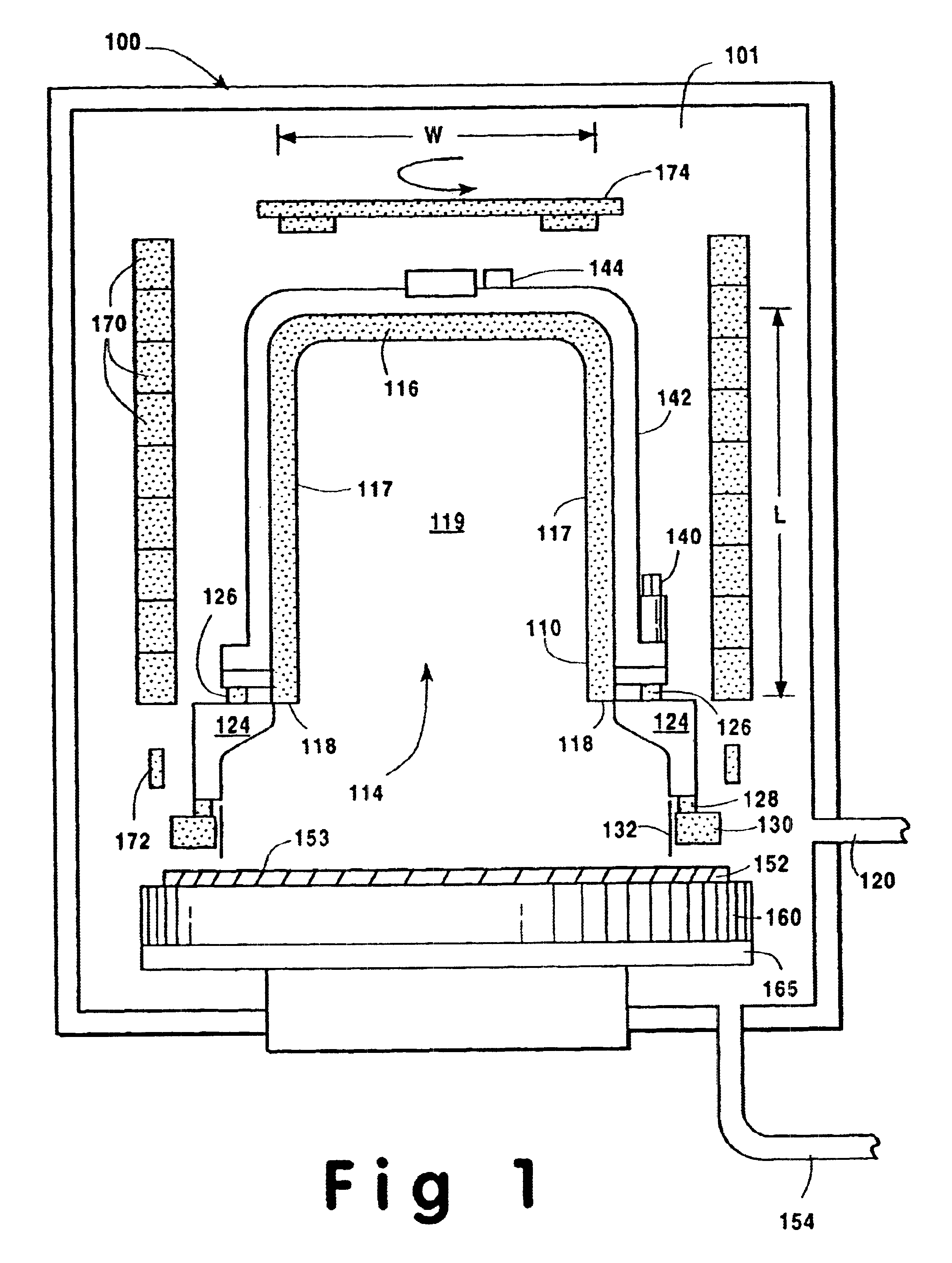

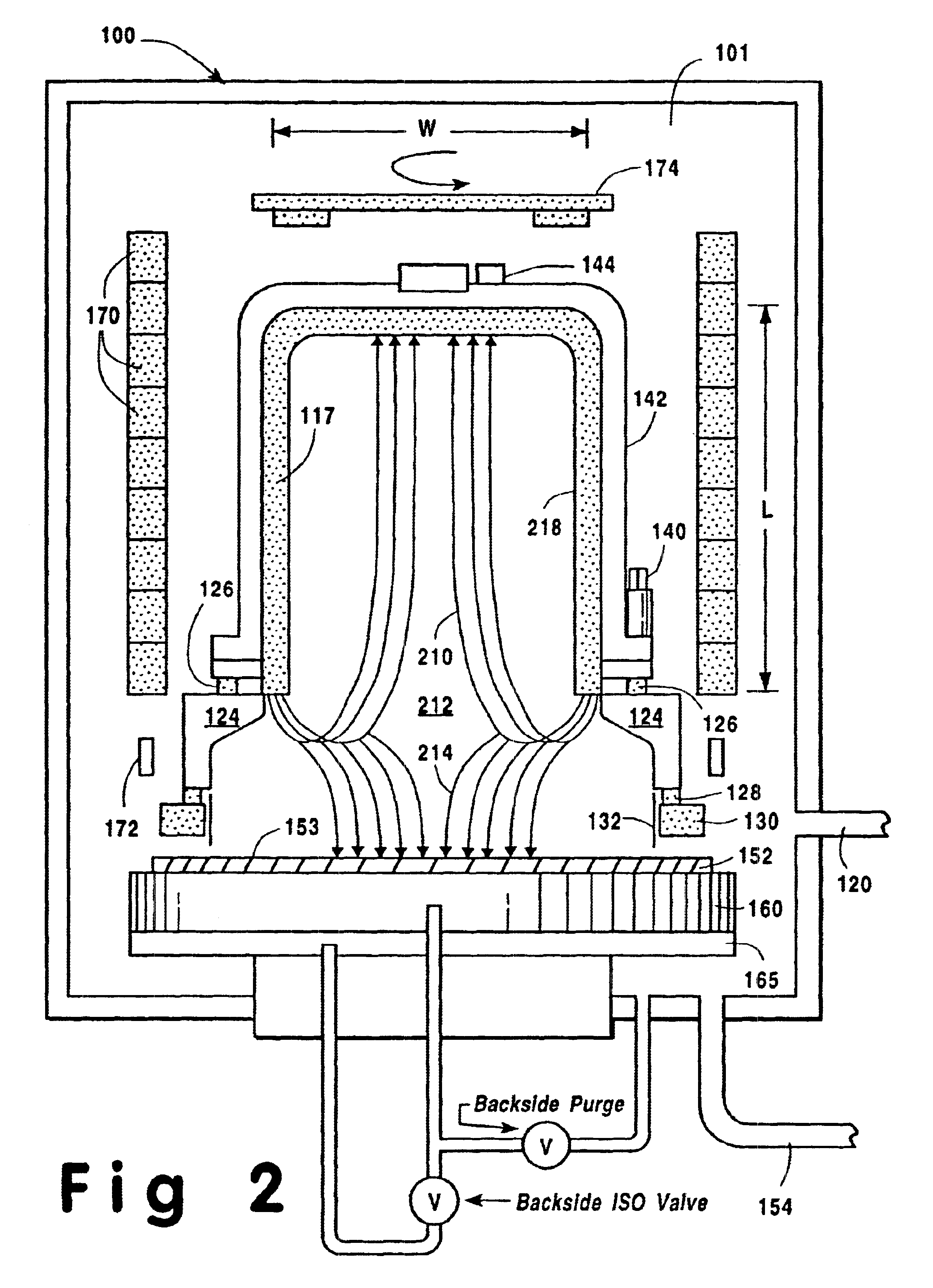

Control of the deposition temperature to reduce the via and contact resistance of Ti and TiN deposited using ionized PVD techniques

InactiveUS6673716B1Reduce processing stepsShorten the timeCellsVacuum evaporation coatingAspect ratioIntegrated circuit

A method of depositing thin films comprising Ti and TiN within vias and trenches having high aspect ratio openings. The Ti and TiN layers are formed on an integrated circuit substrate using a Ti target in a non-nitrided mode in a hollow cathode magnetron apparatus in combination with controlling the deposition temperatures by integrating cooling steps into the Ti / TiN deposition processes to modulate the via and contact resistance. The Ti and TiN layers are deposited within a single deposition chamber, without the use of a collimator or a shutter.

Owner:NOVELLUS SYSTEMS

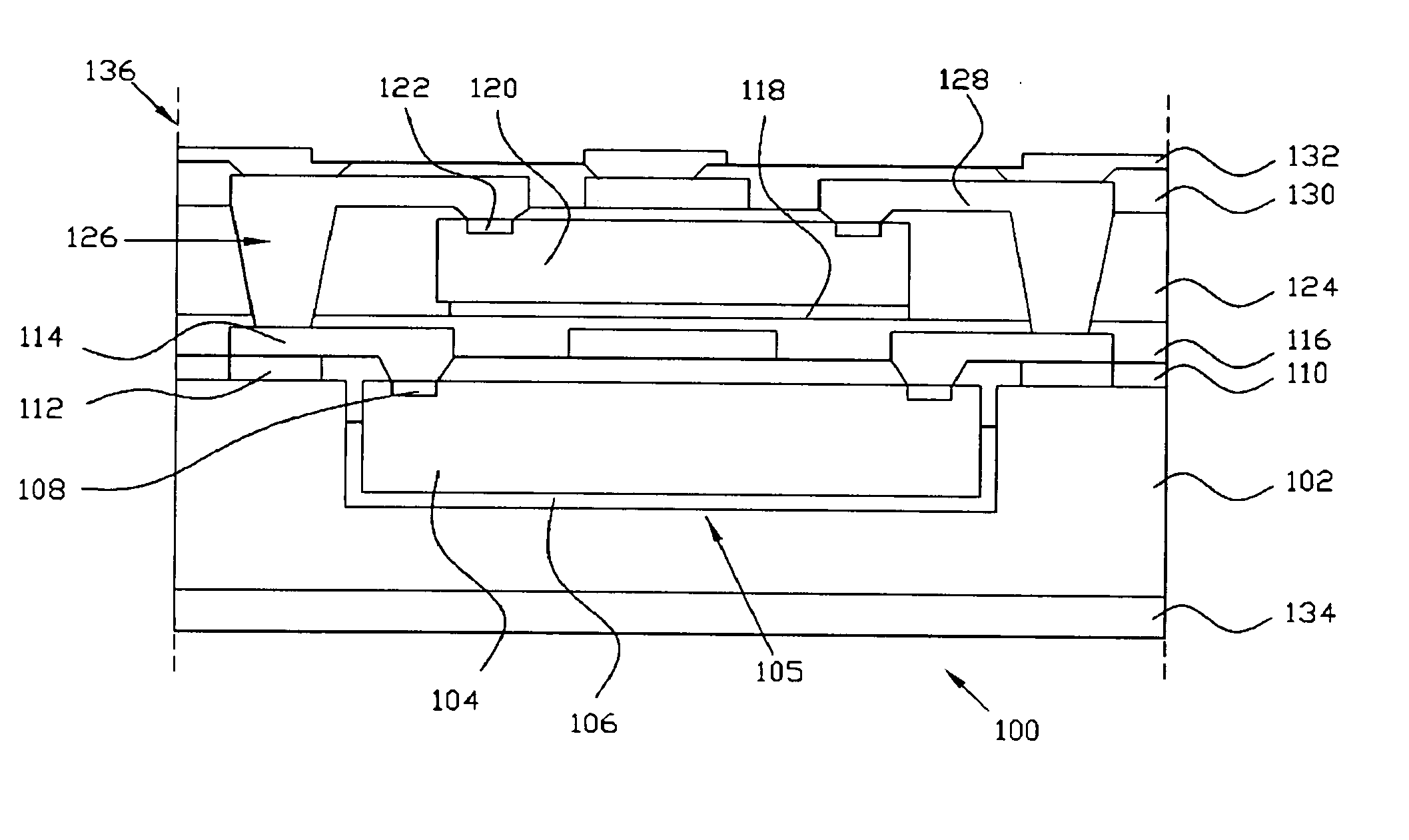

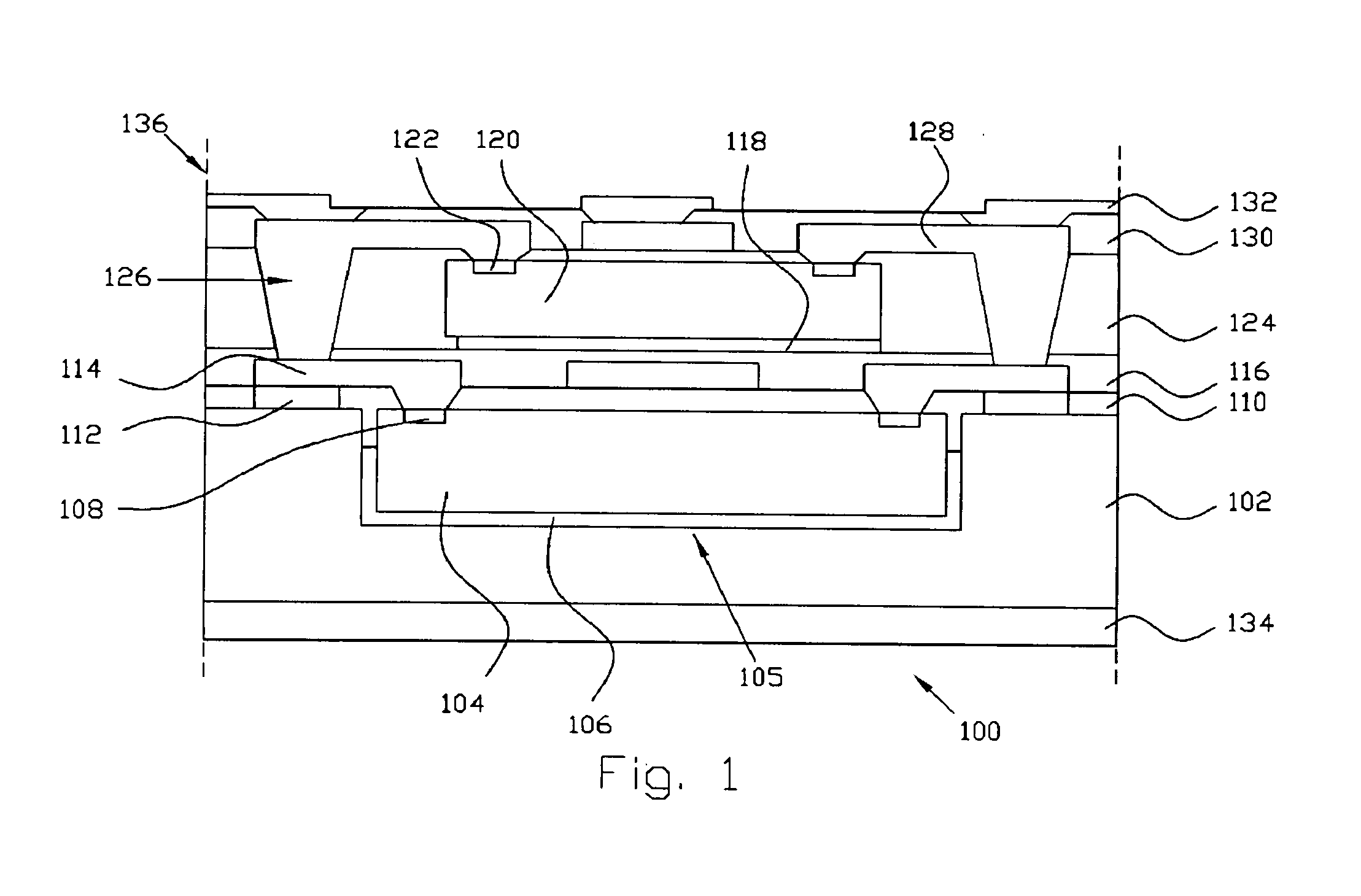

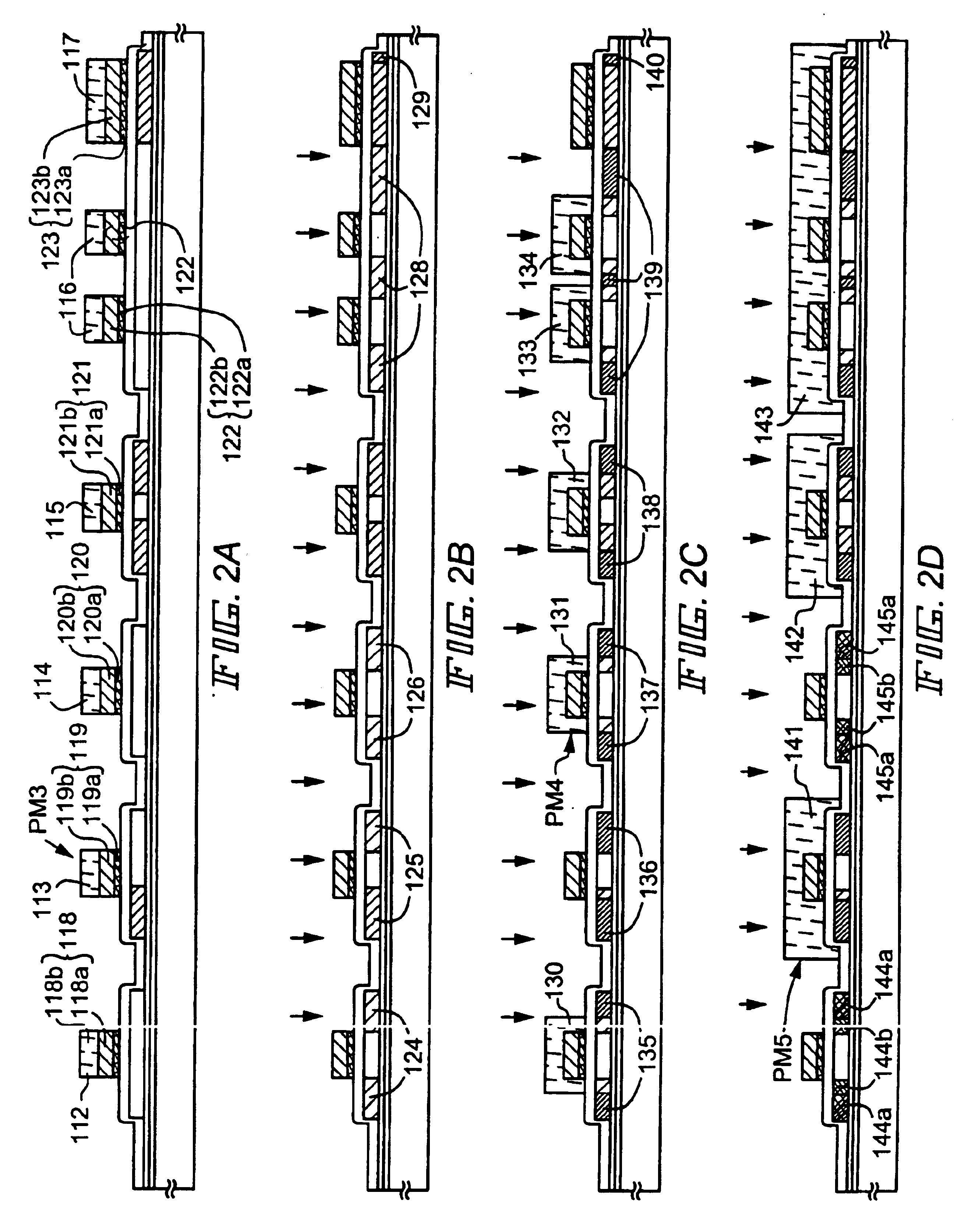

Structure of semiconductor device package and method of the same

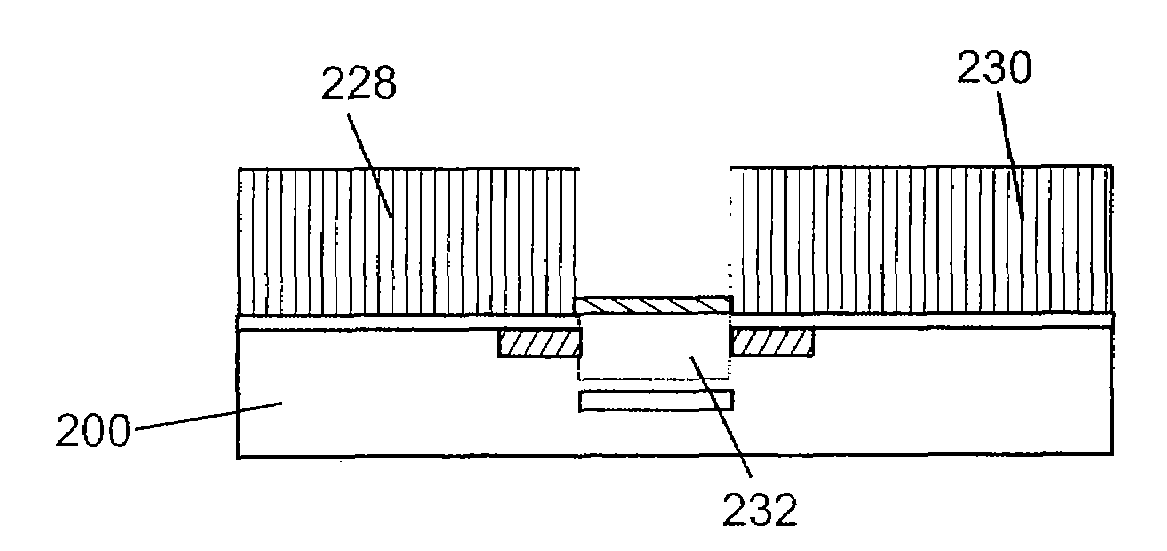

InactiveUS20080217761A1Avoid warpingReduce processing stepsSemiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

The present invention provides a semiconductor device package comprising a substrate with at lease a pre-formed die receiving cavity formed and terminal contact metal pads formed within an upper surface of the substrate. At lease a first die is disposed within the die receiving cavity. A first dielectric layer is formed on the first die and the substrate and refilled into a gap between the first die and the substrate to absorb thermal mechanical stress there between. A first re-distribution layer (RDL) is formed on the first dielectric layer and coupled to the first die. A second dielectric layer is formed on the first RDL, and then a second die is disposed on the second dielectric layer and surrounded by core pastes having through holes thereon. A second re-distribution layer (RDL) is formed on the core pastes to fill the through holes, and then a third dielectric layer formed on the second RDL.

Owner:ADVANCED CHIP ENG TECH

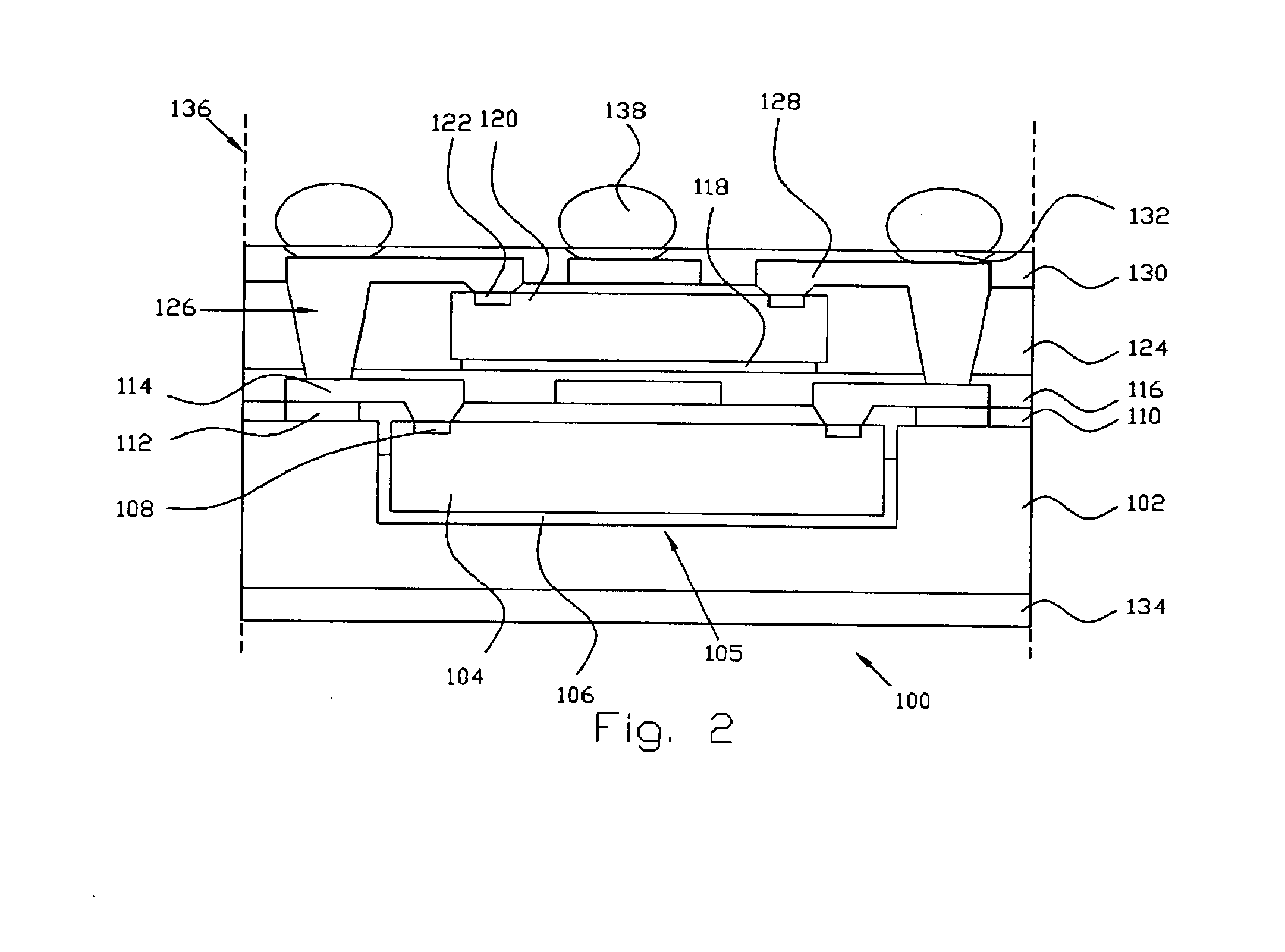

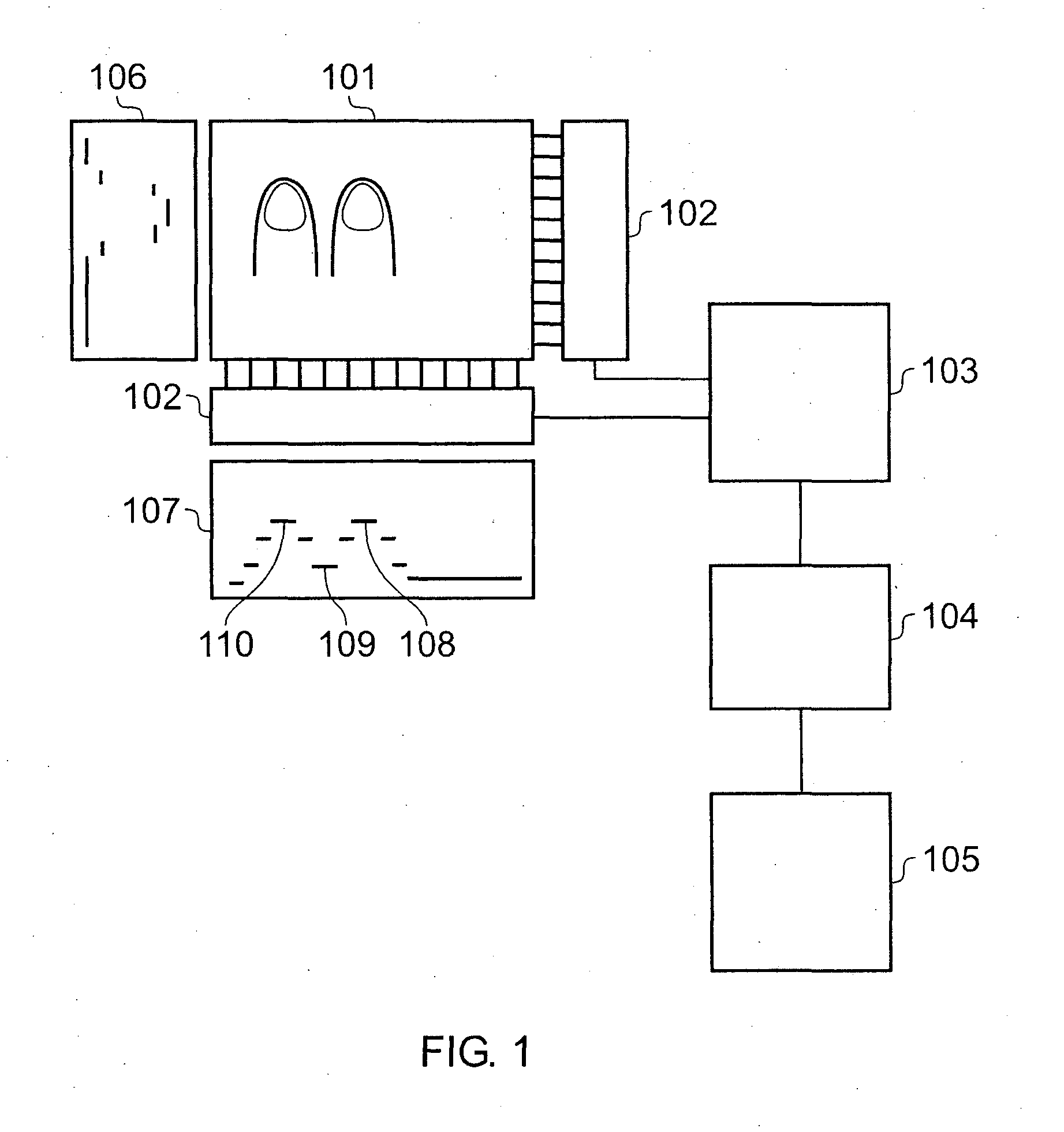

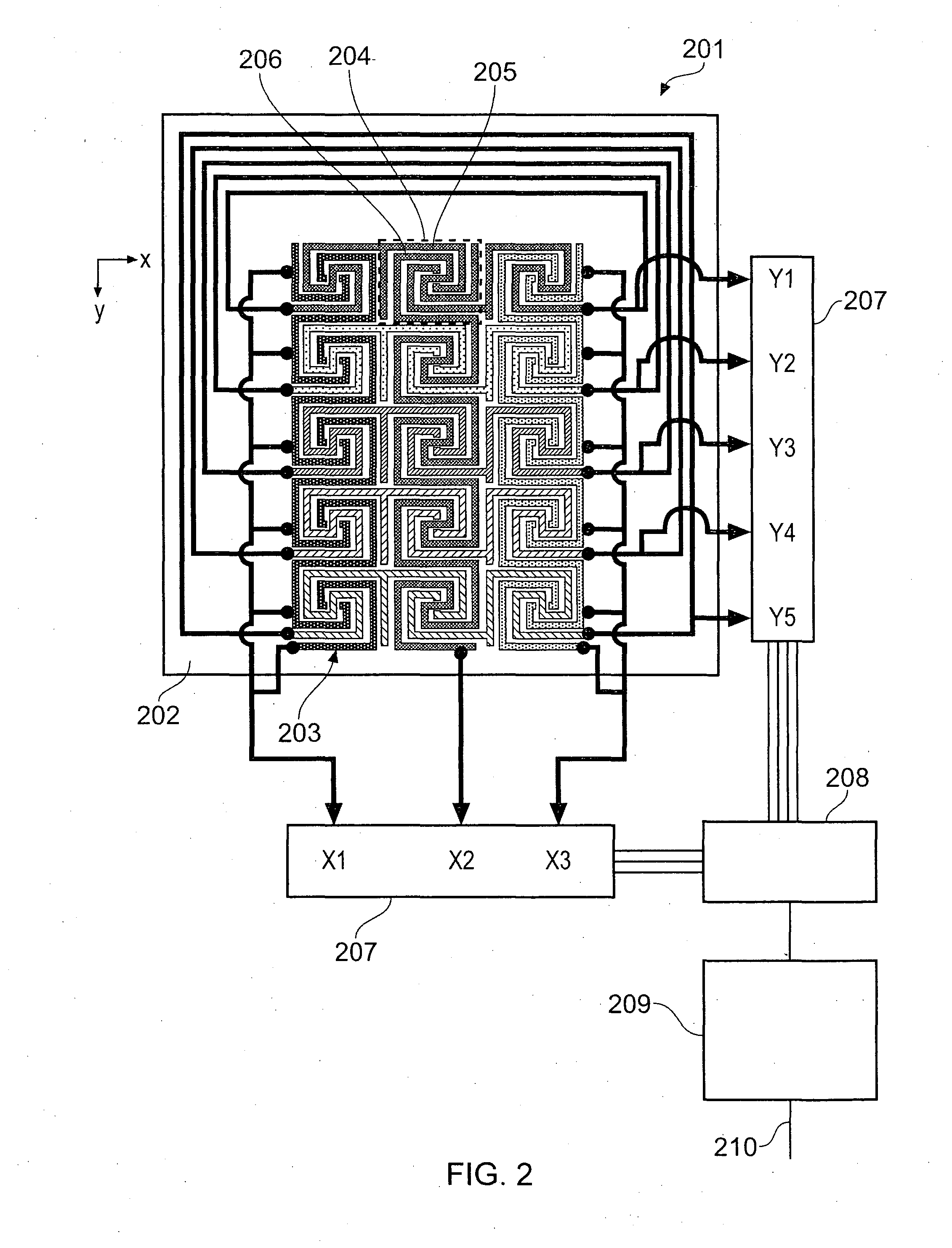

Two-dimensional touch panel

ActiveUS20100193258A1Good position resolutionSimple and reliableTransmission systemsInput/output processes for data processingPosition resolutionTouch panel

A capacitive touch panel is provided capable of detecting multiple simultaneous touches. The touch panel delivers sets of capacitance signal values to a processor which computes the coordinates of single or multiple touch locations on the touch panel. The processing of each set is performed by (i) identifying the sensing element having the largest capacitance signal value; (ii) defining a region around that sensing element; and (iii) repeating the process iteratively, wherein each subsequent identifying step excludes signals that lie in previously defined regions. A multi-touch sensor is thus provided in which the signal processing is based on successive definition of regions or sub-blocks in the touch: panel. The touch location in each region can be determined more accurately by then applying interpolation between the adjacent signal values. This allows for position resolution at a finer scale than that defined by the touch panel's electrode patterning.

Owner:ATMEL CORP

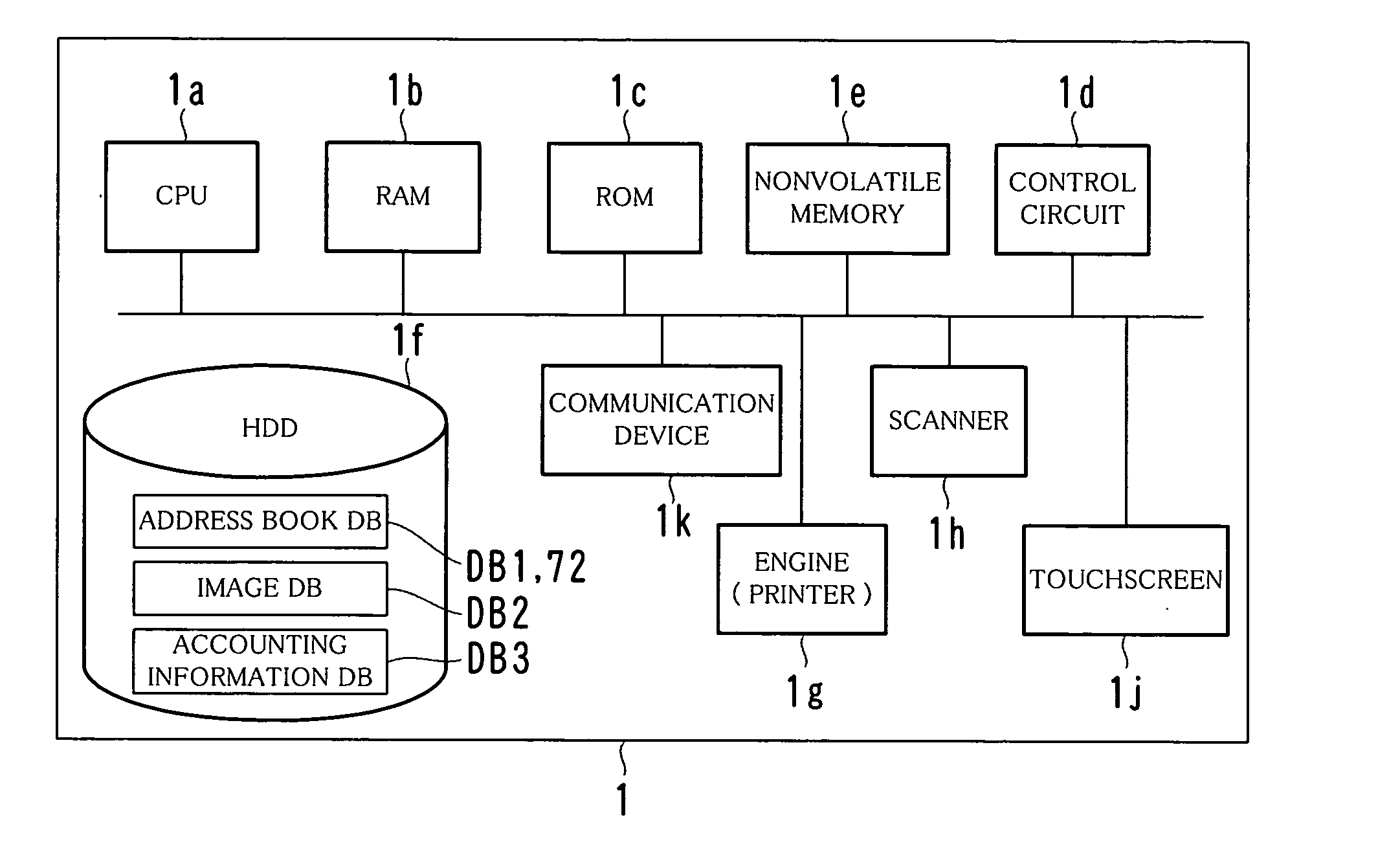

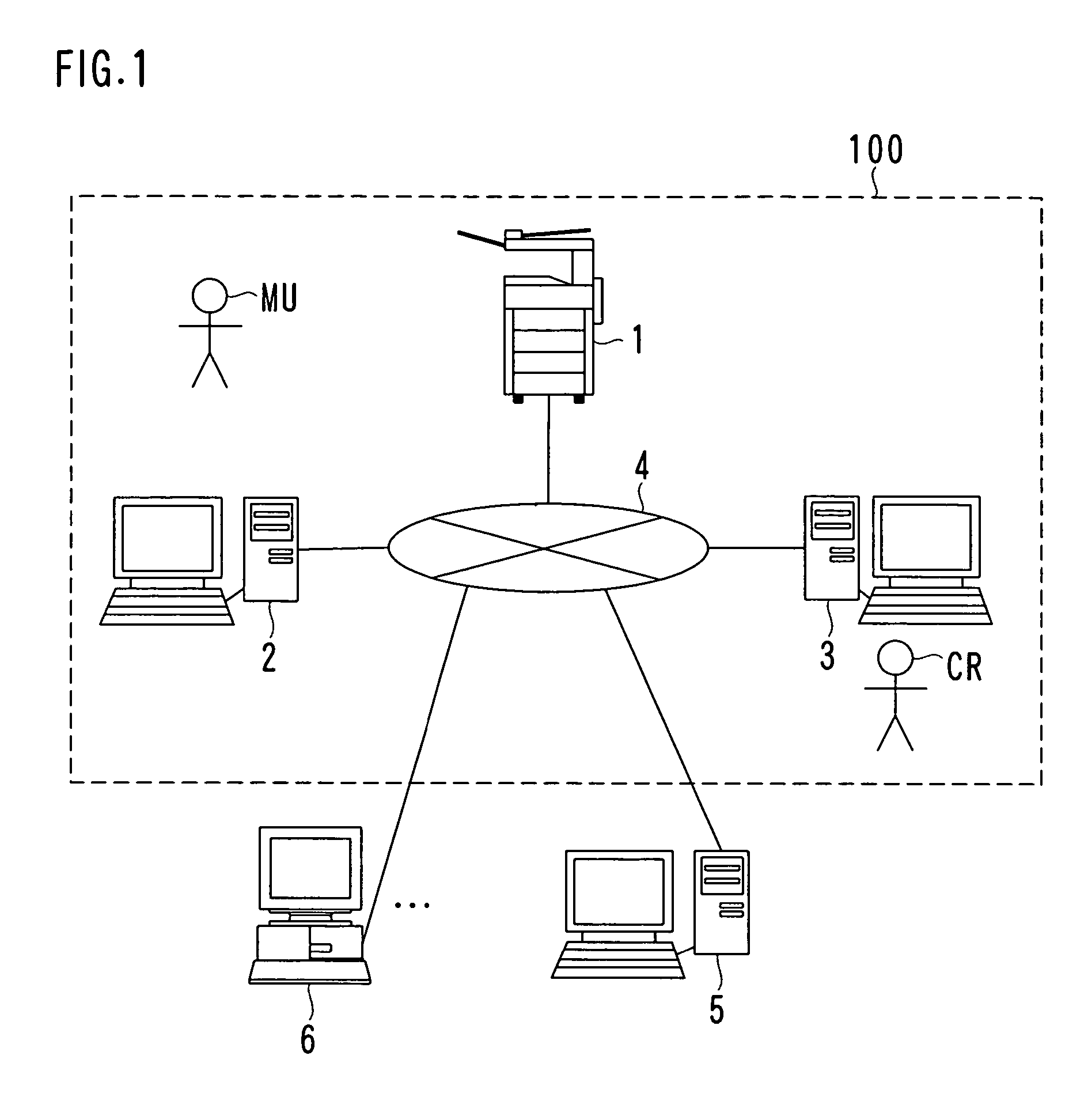

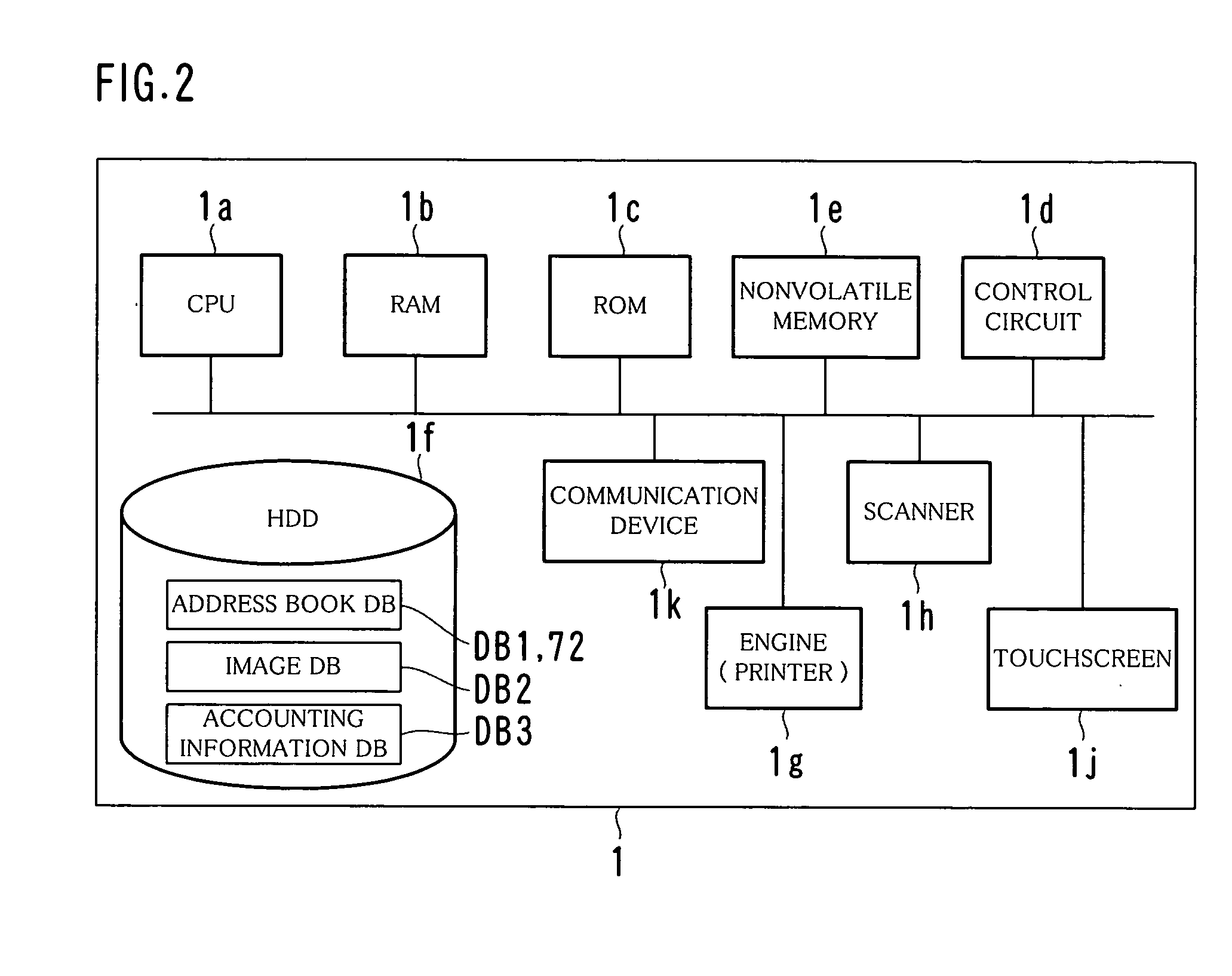

Processing device, multifunction device, network system, control method and computer readable medium

InactiveUS20050060564A1Prevent unauthorized processingReduce processing stepsDigital data processing detailsAnalogue secracy/subscription systemsOperating systemWeb system

A processing device is provided in which unauthorized processing is prevented from being preformed at the time of executing a program or others. The processing device includes a processing portion for executing processing, a program memory portion for memorizing a program that makes the processing portion execute processing, a judge portion for judging whether or not the program is permitted to start, and a control portion for controlling the processing portion so that processing is executed in accordance with the program when the judge portion determines that the program is permitted to start, and for controlling the processing portion so that processing based on the program is not executed when the judge portion determines that the program is not permitted to start.

Owner:KONICA MINOLTA BUSINESS TECH INC

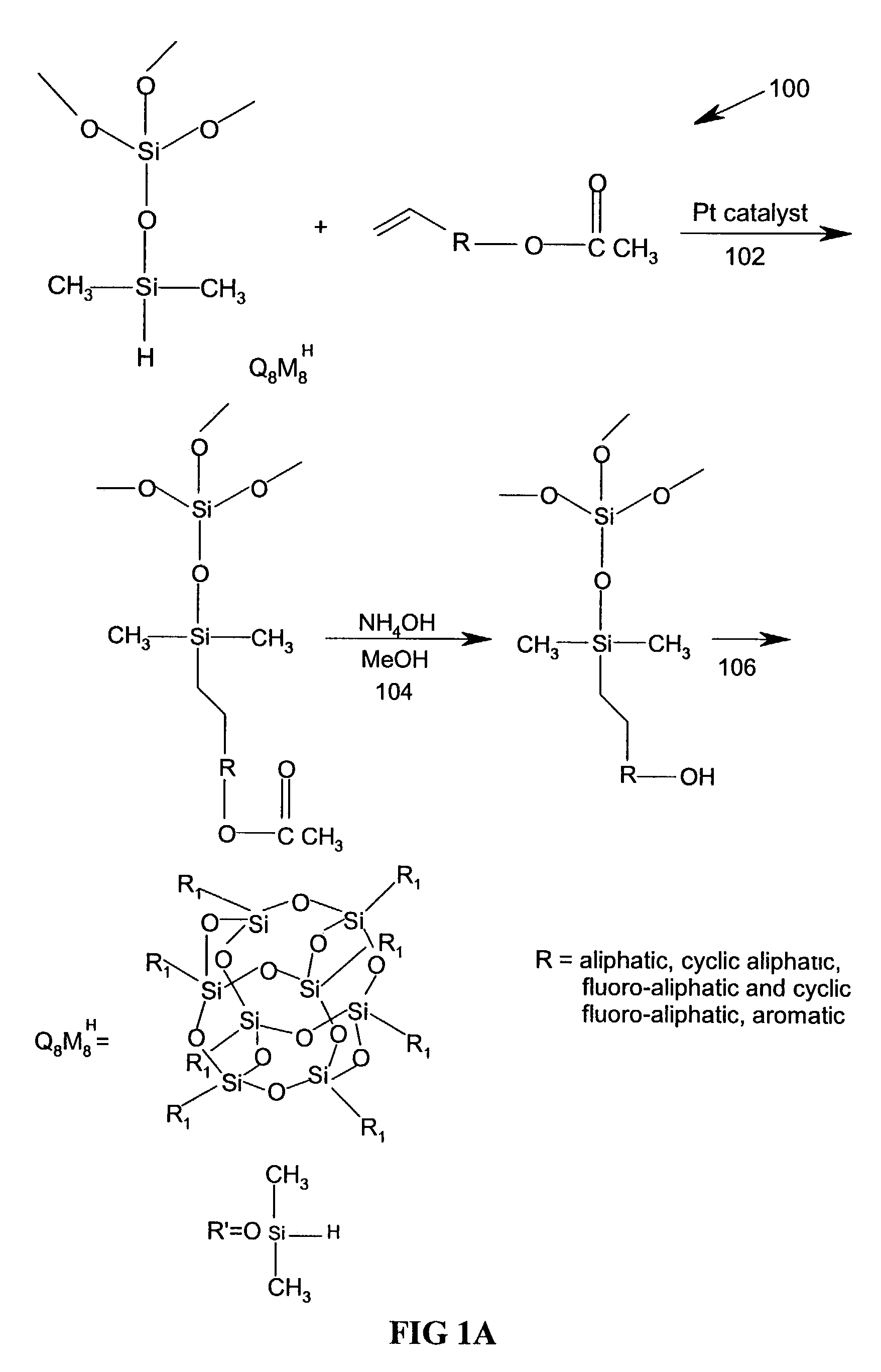

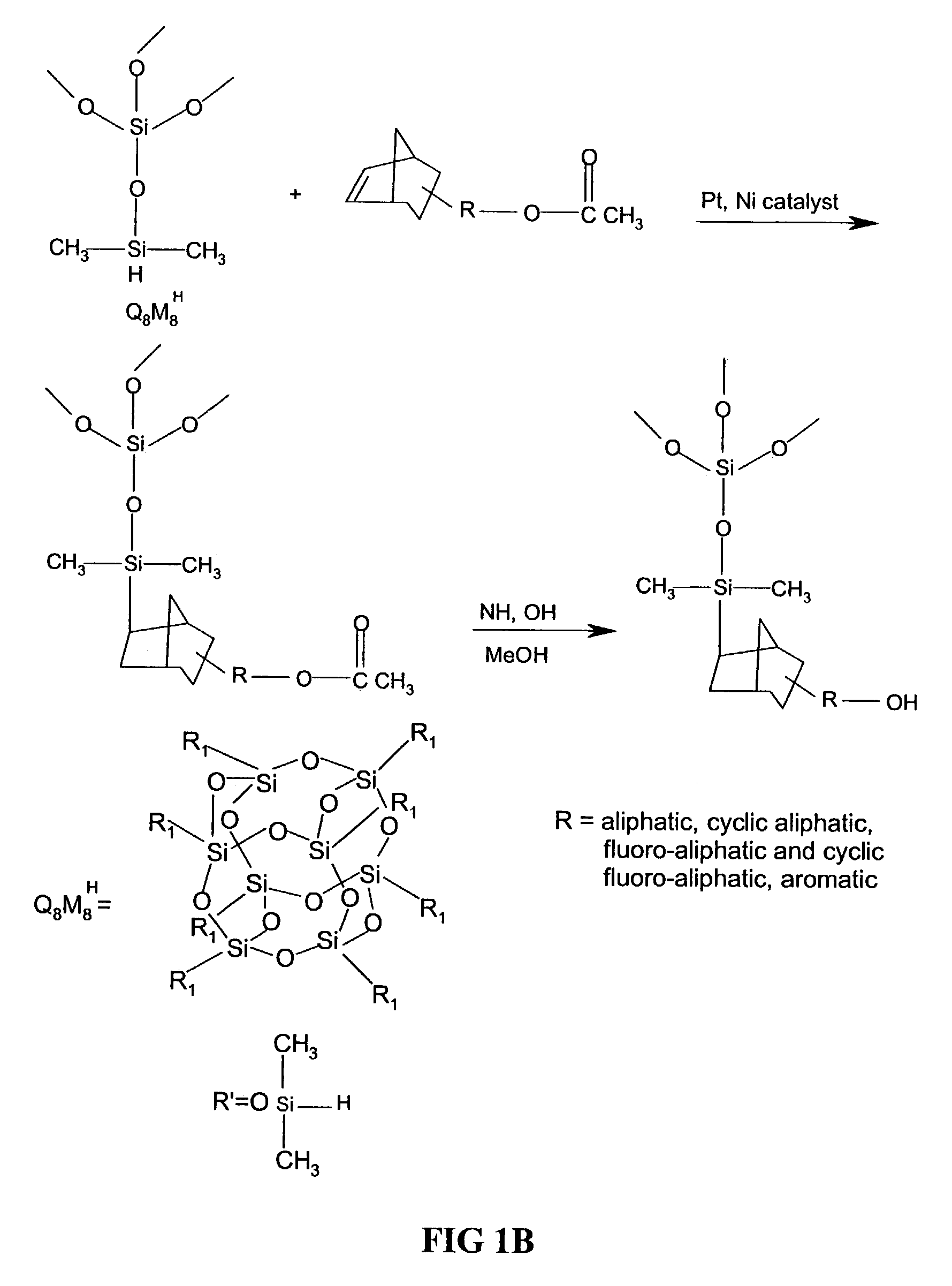

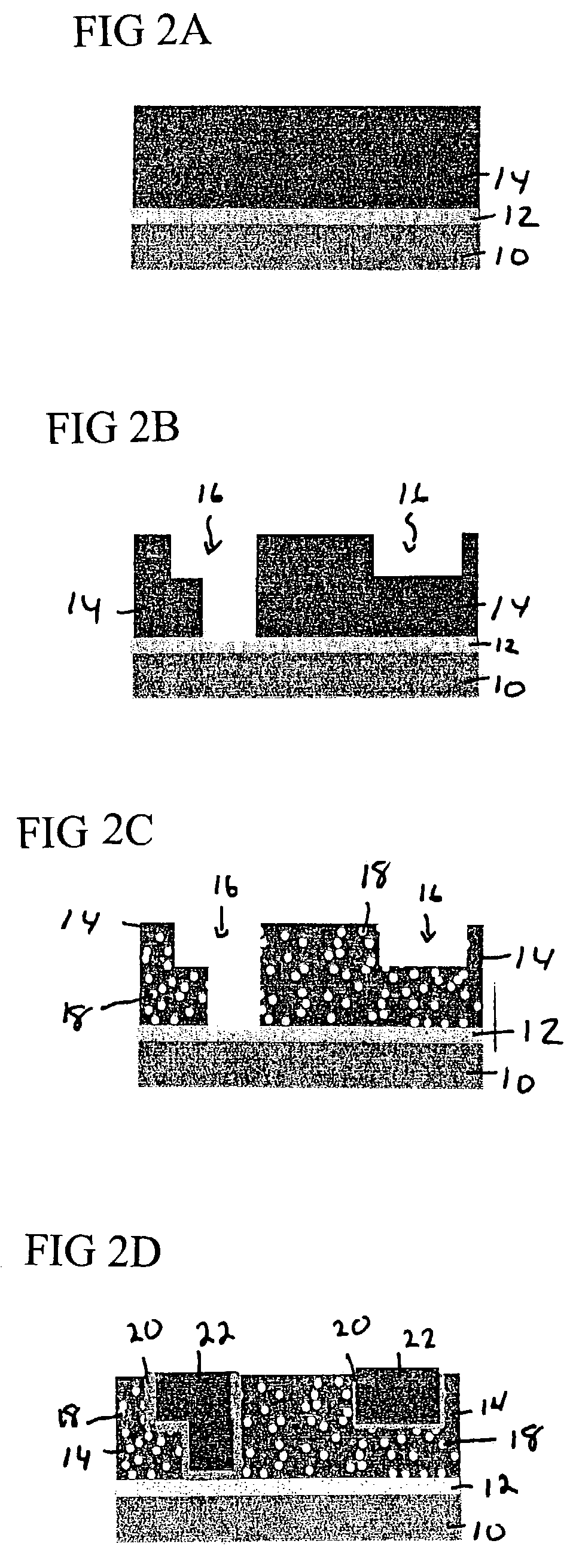

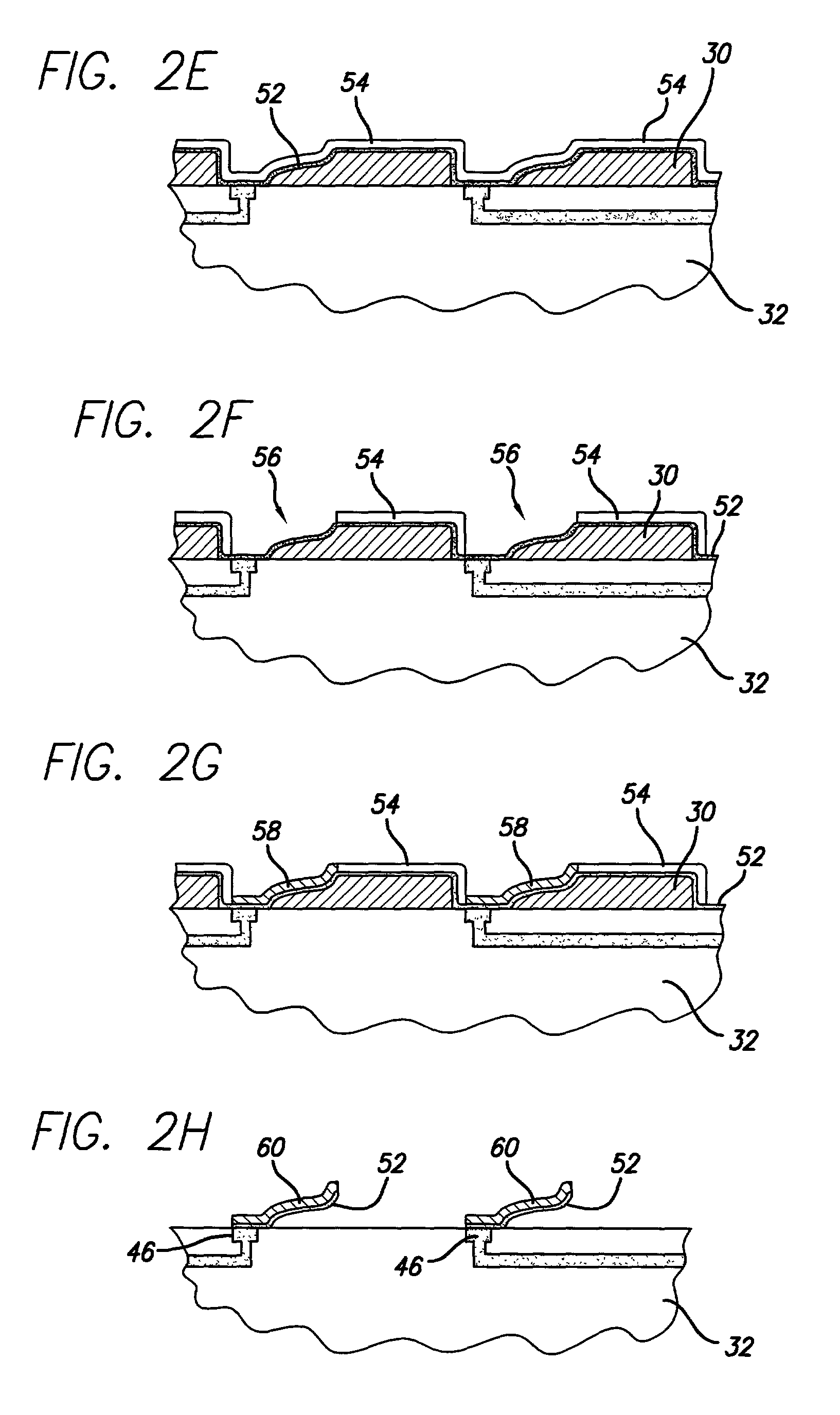

Patternable low dielectric constant materials and their use in ULSI interconnection

ActiveUS7041748B2Process step be reduceLow dielectric constantLayered productsSemiconductor/solid-state device detailsChemistryLow-k dielectric

The present invention relates to ultra-large scale integrated (ULSI) interconnect structures, and more particularly to patternable low dielectric constant (low-k) materials suitable for use in ULSI interconnect structures. The patternable low-k dielectrics disclosed herein are functionalized polymers that having one or more acid-sensitive imageable functional groups.

Owner:AURIGA INNOVATIONS INC

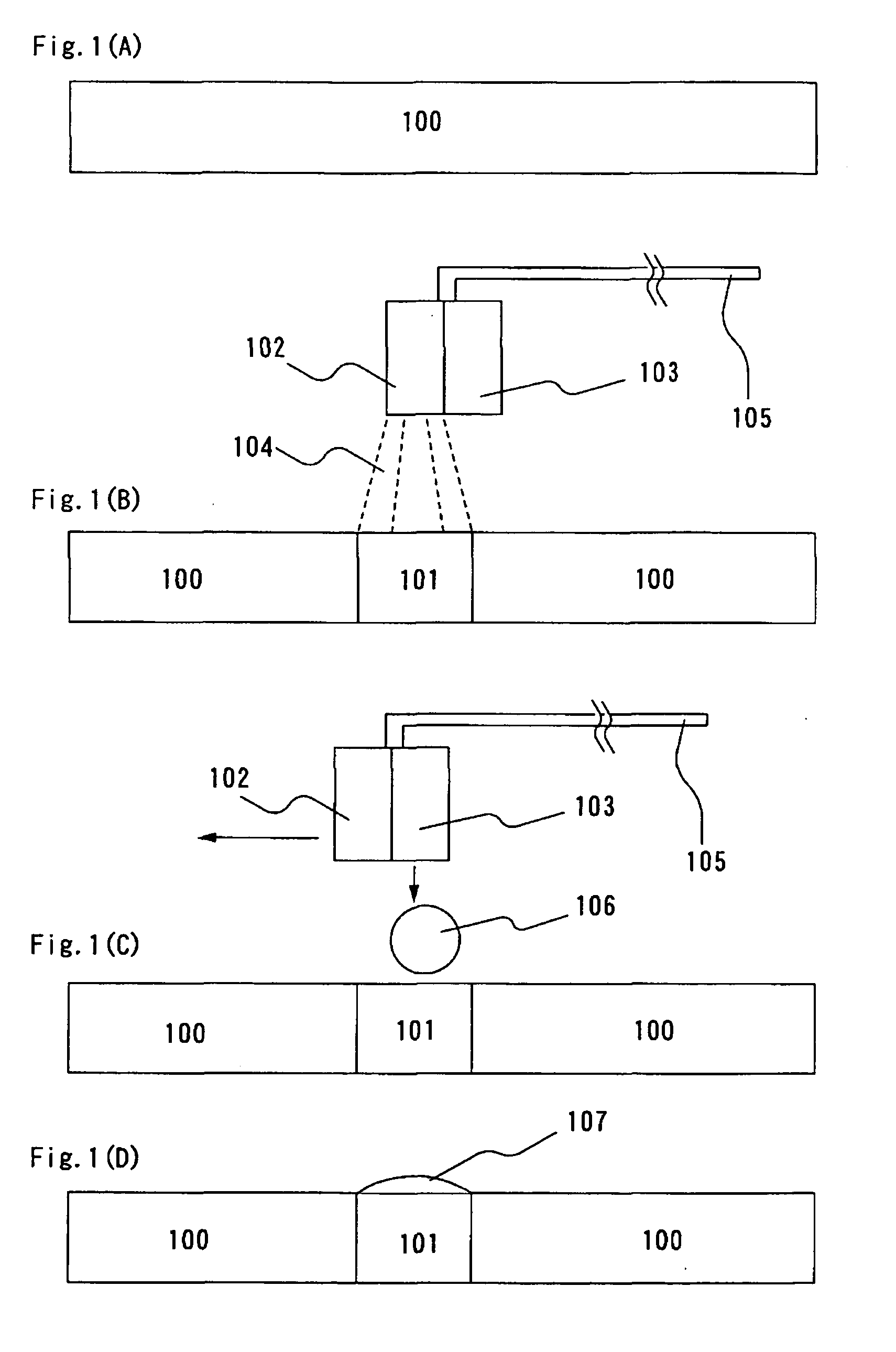

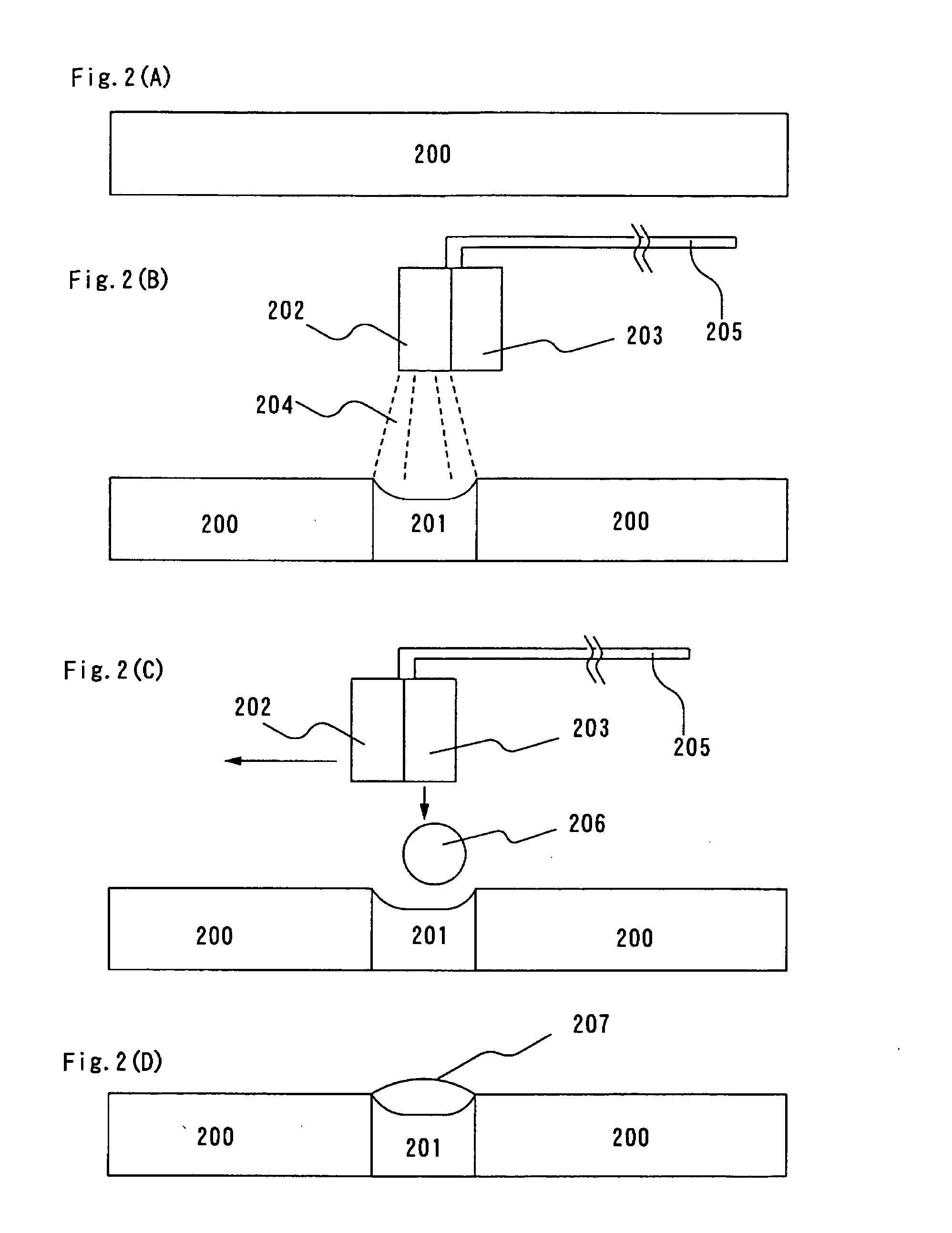

Method for forming pattern and drop discharge apparatus

InactiveUS20050043186A1Process step be reduceImproved yieldSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The present invention is characterized in having a process for forming a pattern by making a substrate having an insulating property, such as a liquid-repellent thin film over a substrate, such as a semiconductor film, selectively have affinity for liquid by plasma generating means 102, and discharging a drop compound to the surface having affinity for liquid by a drop discharging means 103. By putting the region having affinity for liquid, which was selectively formed, between liquid-repellent, a drop after drop landing can be formed without moving the drop landing portion

Owner:SEMICON ENERGY LAB CO LTD

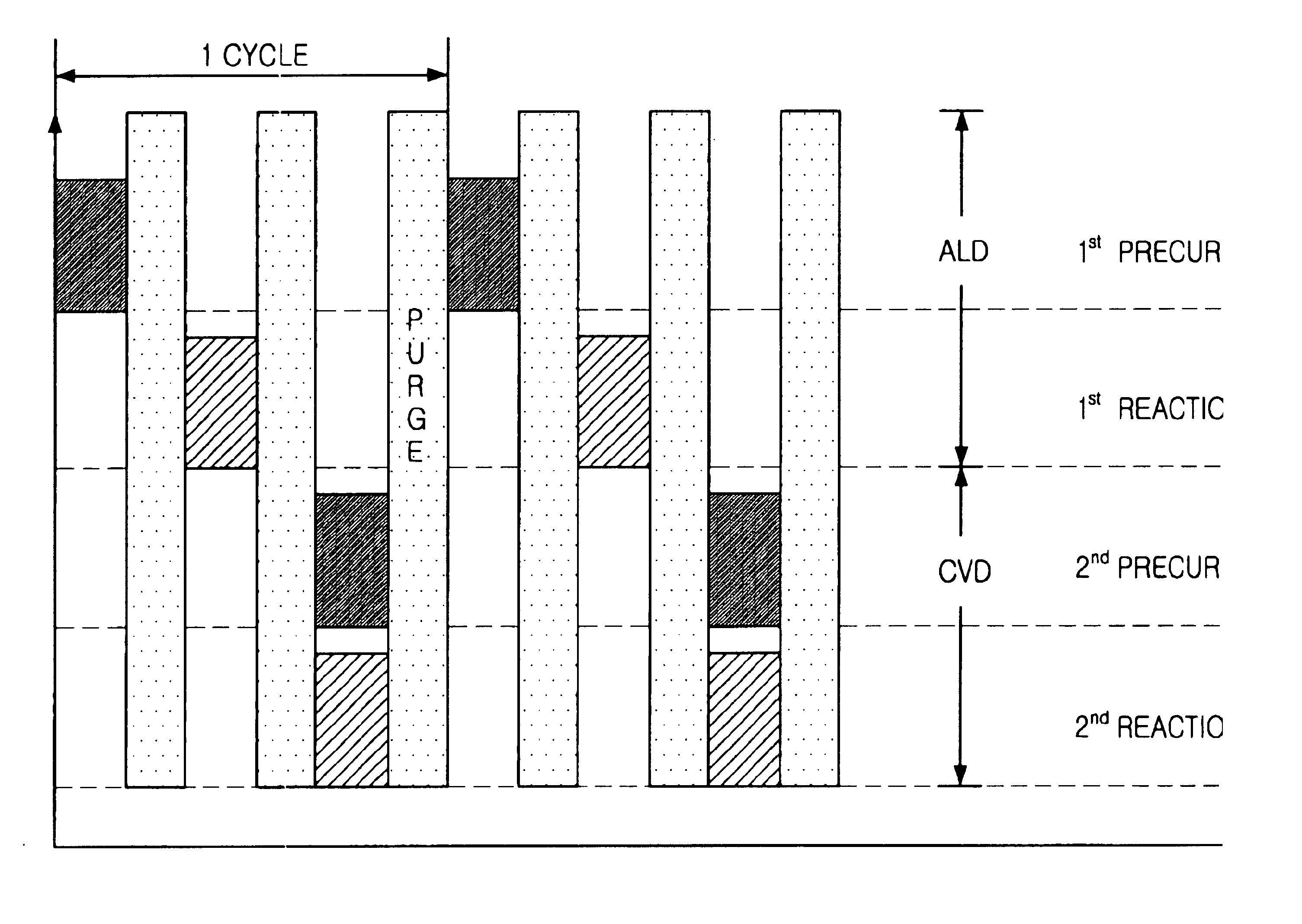

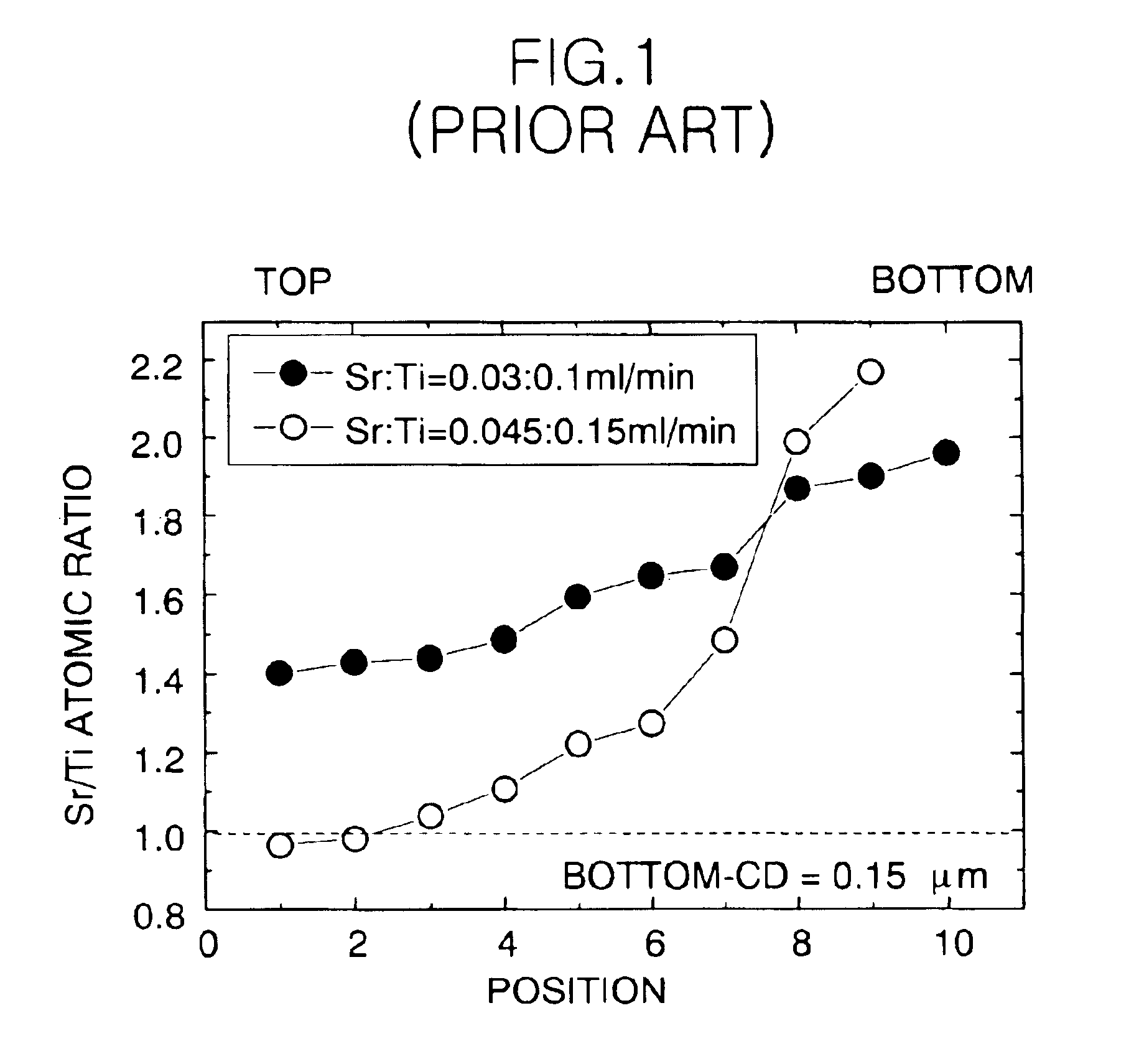

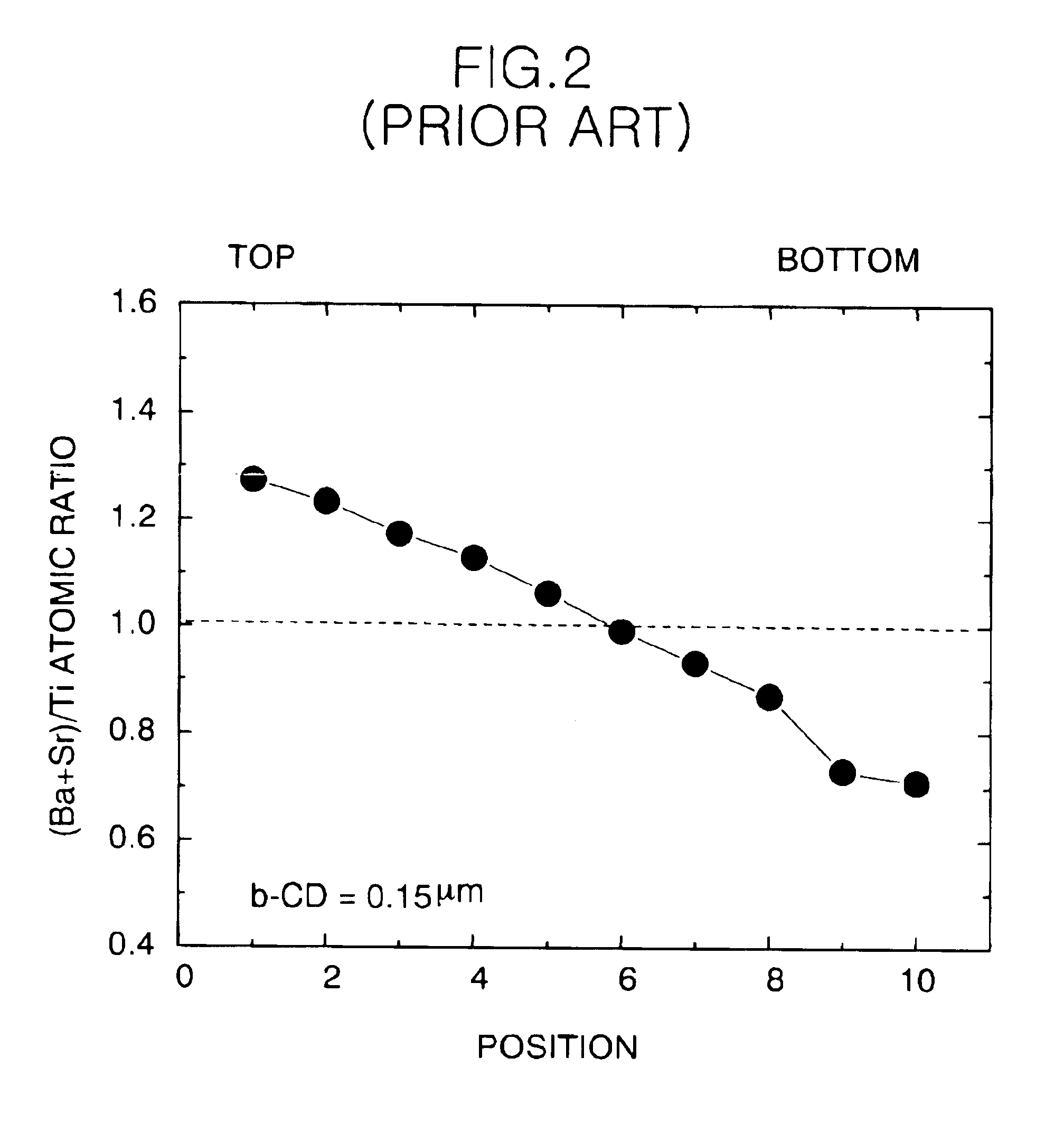

Method for forming polyatomic layers

InactiveUS6800567B2Reduce processing stepsIncrease speedSemiconductor/solid-state device manufacturingGas phaseLow leakage

A method for forming a polyatomic layer with a mixed deposition method consisting of an atomic layer deposition method (ALD) and a chemical vapor deposition method. The mixed deposition method can be adopted to form a polyatomic high dielectric layer, such as BST or STO. Accordingly, it is possible to form a polyatomic high dielectric layer having a uniform composition distribution, and thereby also having a high dielectric characteristic and a low leakage current characteristic.

Owner:SK HYNIX INC

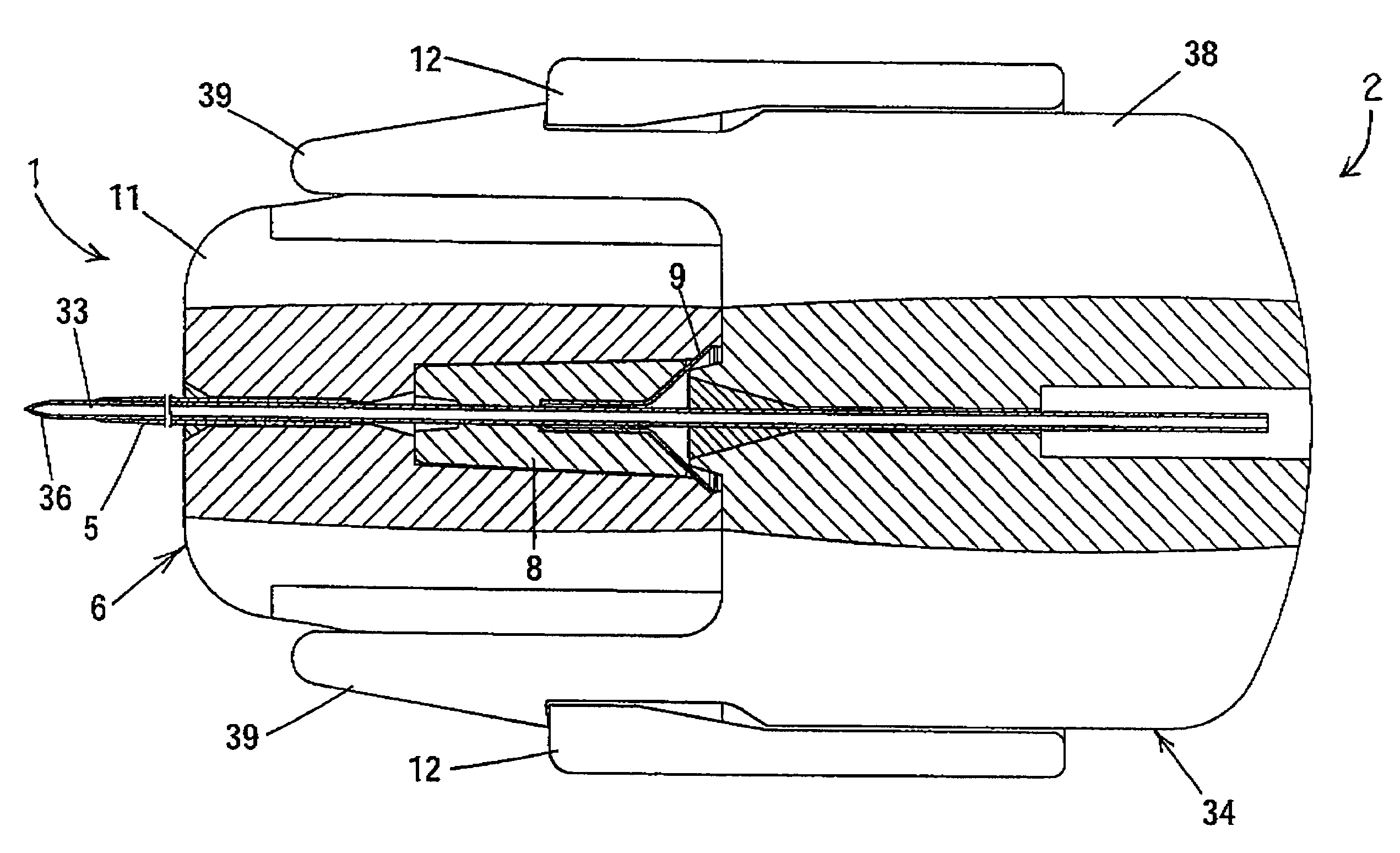

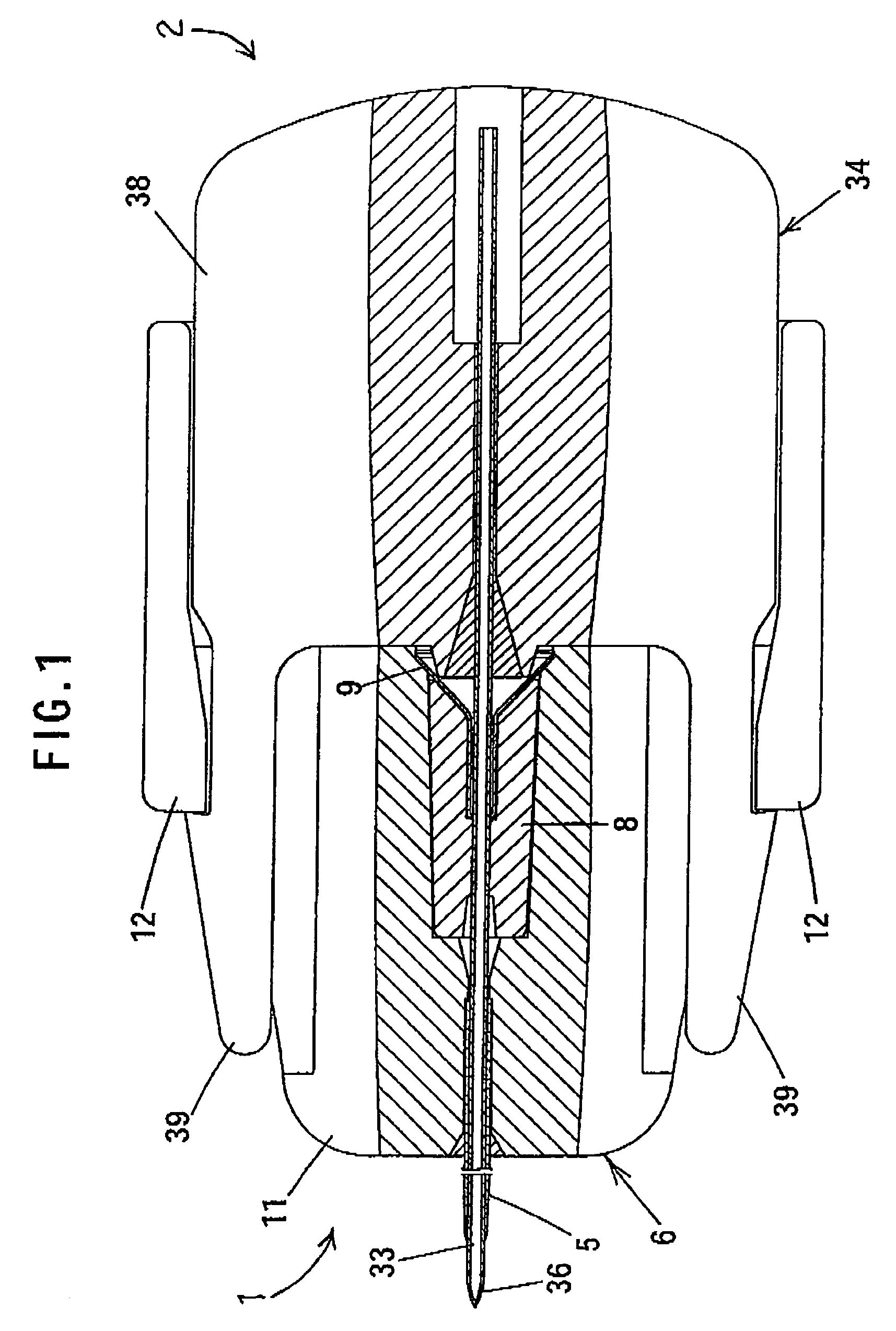

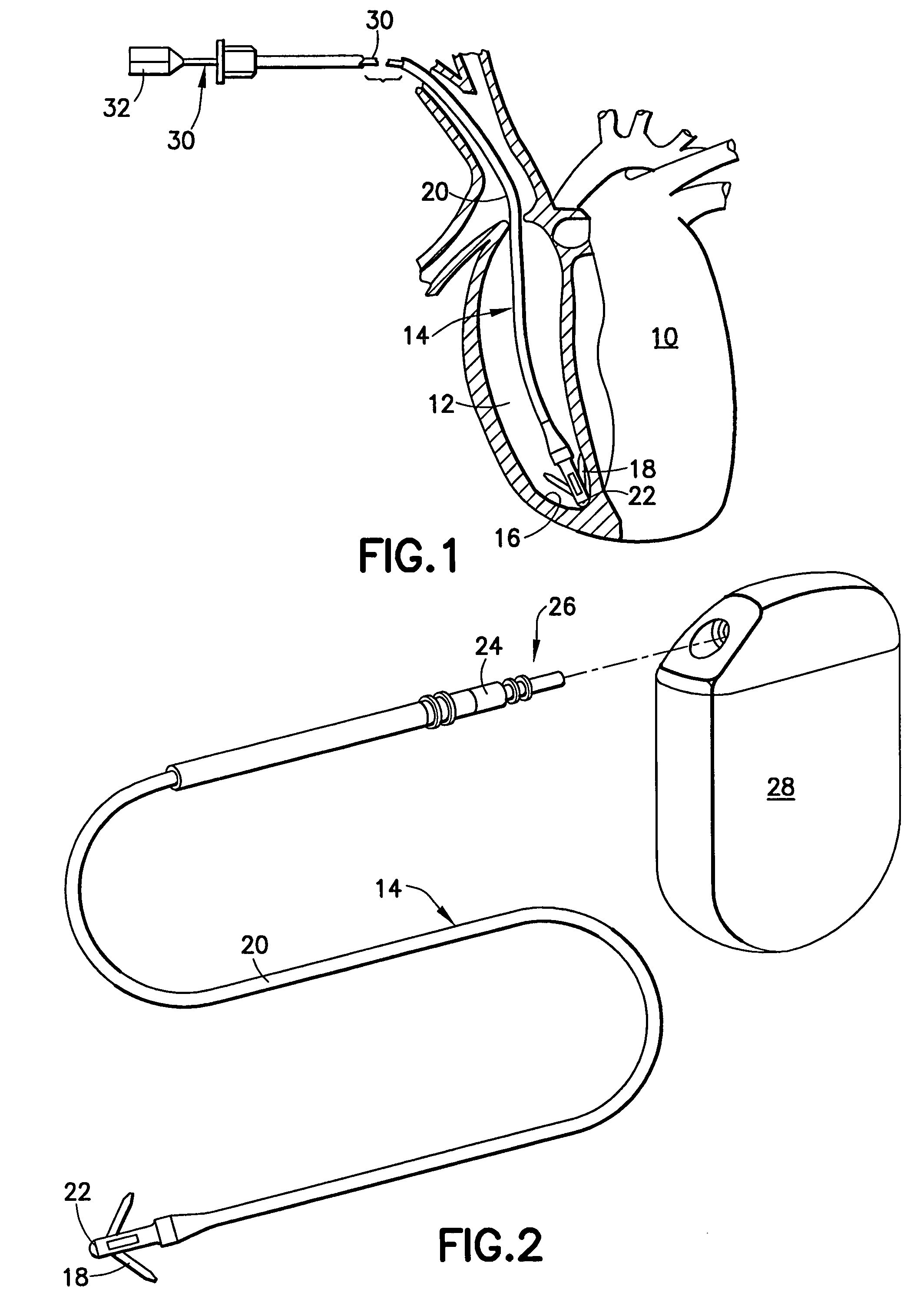

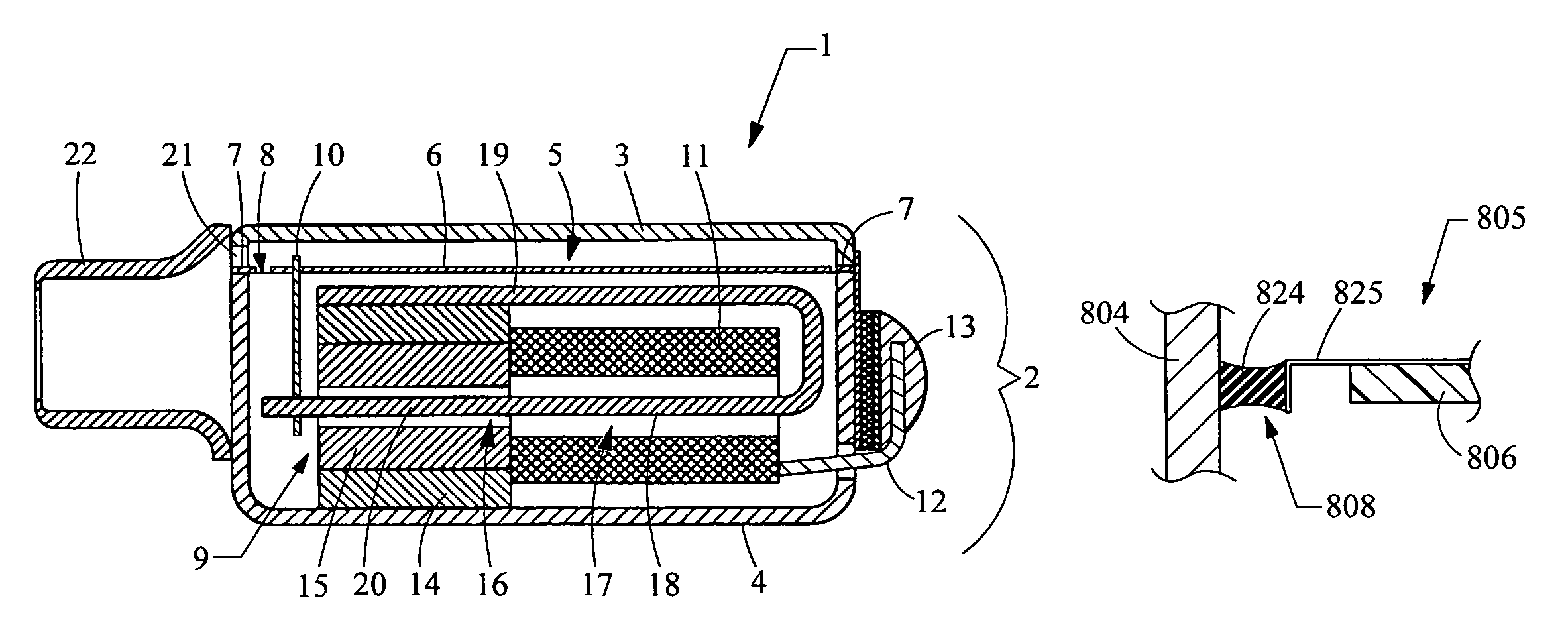

Indwelling catheter set

InactiveUS7318818B2Cost of manufactureReduce settingsGuide needlesInfusion syringesIndwelling catheterCatheter hub

An indwelling catheter set comprises a cannula housing. The cannula housing comprises: (a) a catheter disposed substantially in the axial direction and formed into a hollow body opened at its distal and proximal ends; and (b) a catheter hub comprising a through bore extending substantially in the axial direction for inserting the proximal portion of the catheter therethrough. The catheter is adhered or welded to the catheter hub.

Owner:NIPRO CORP

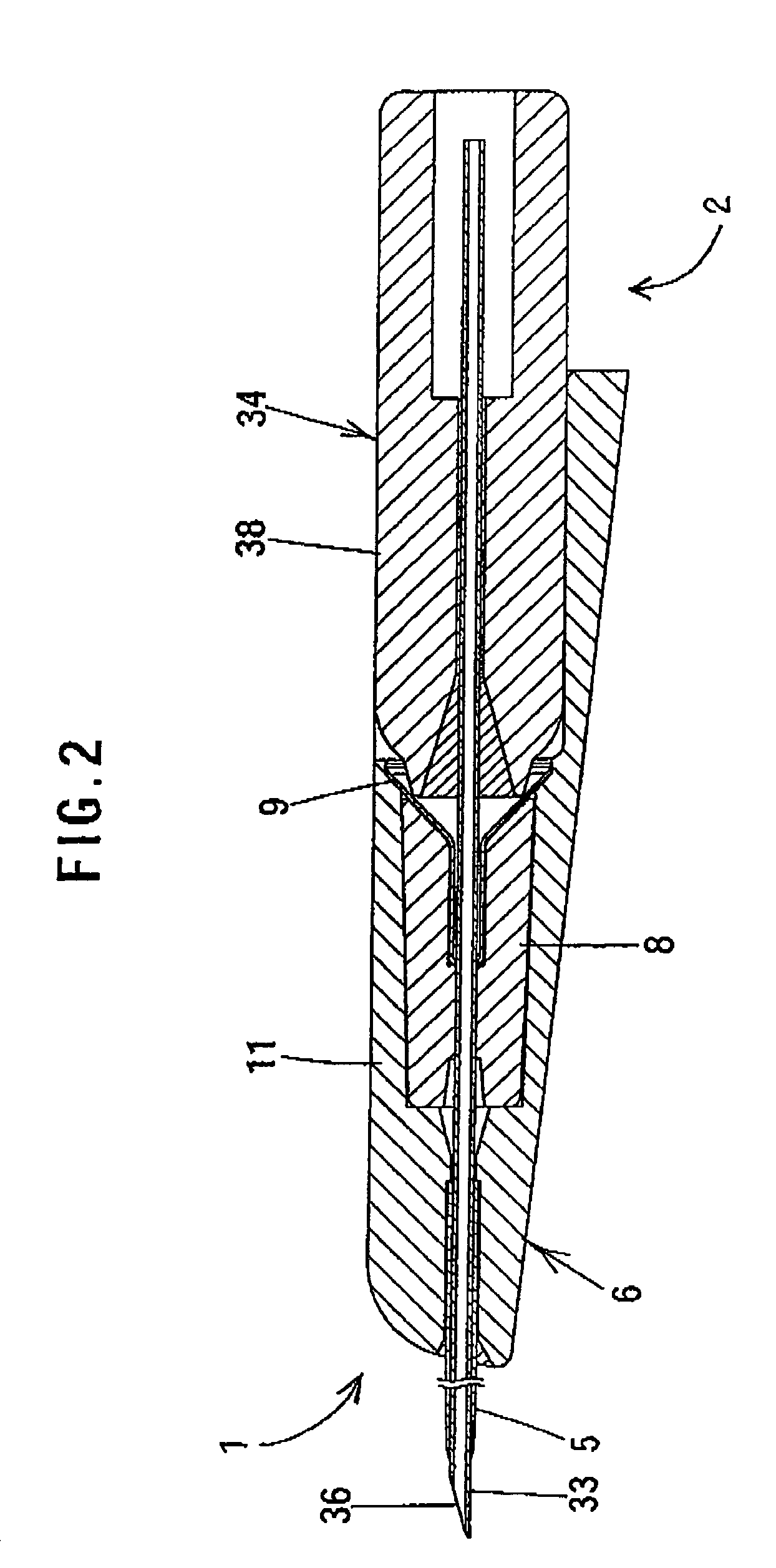

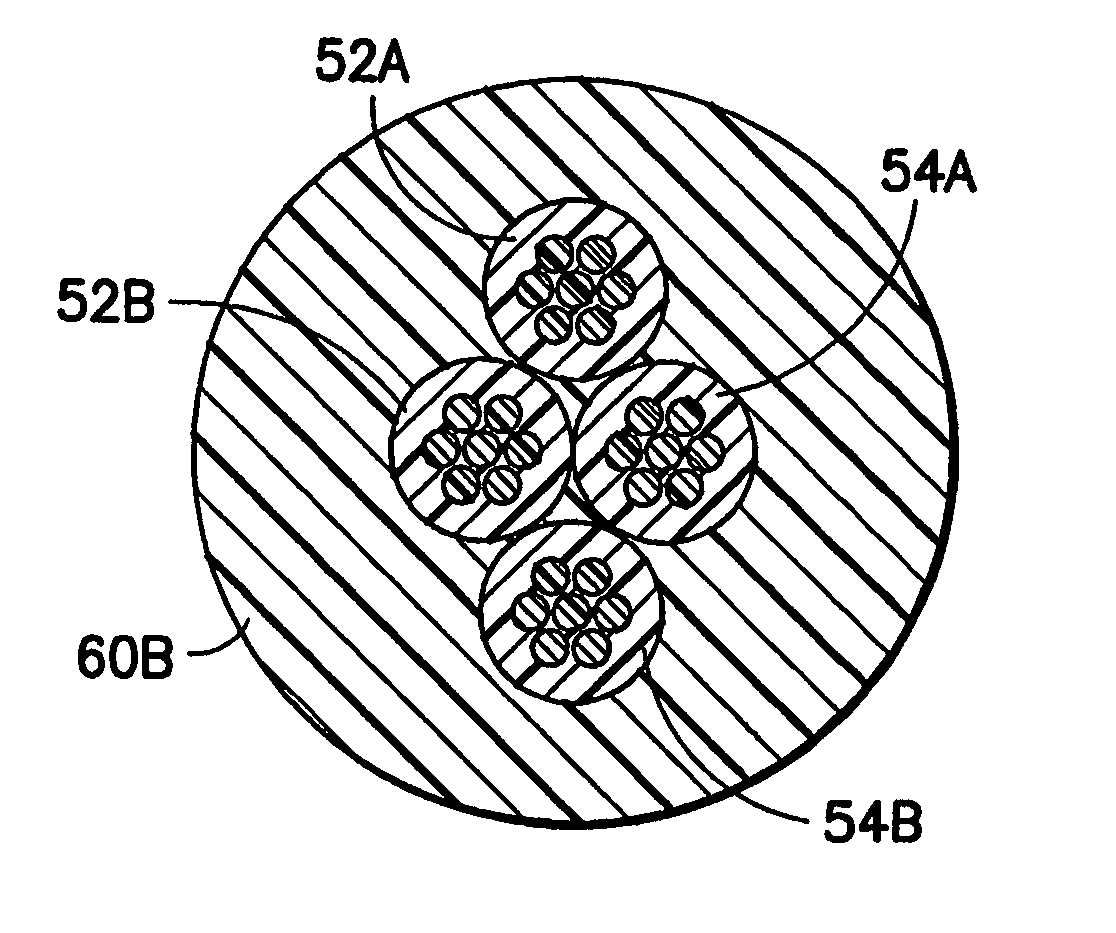

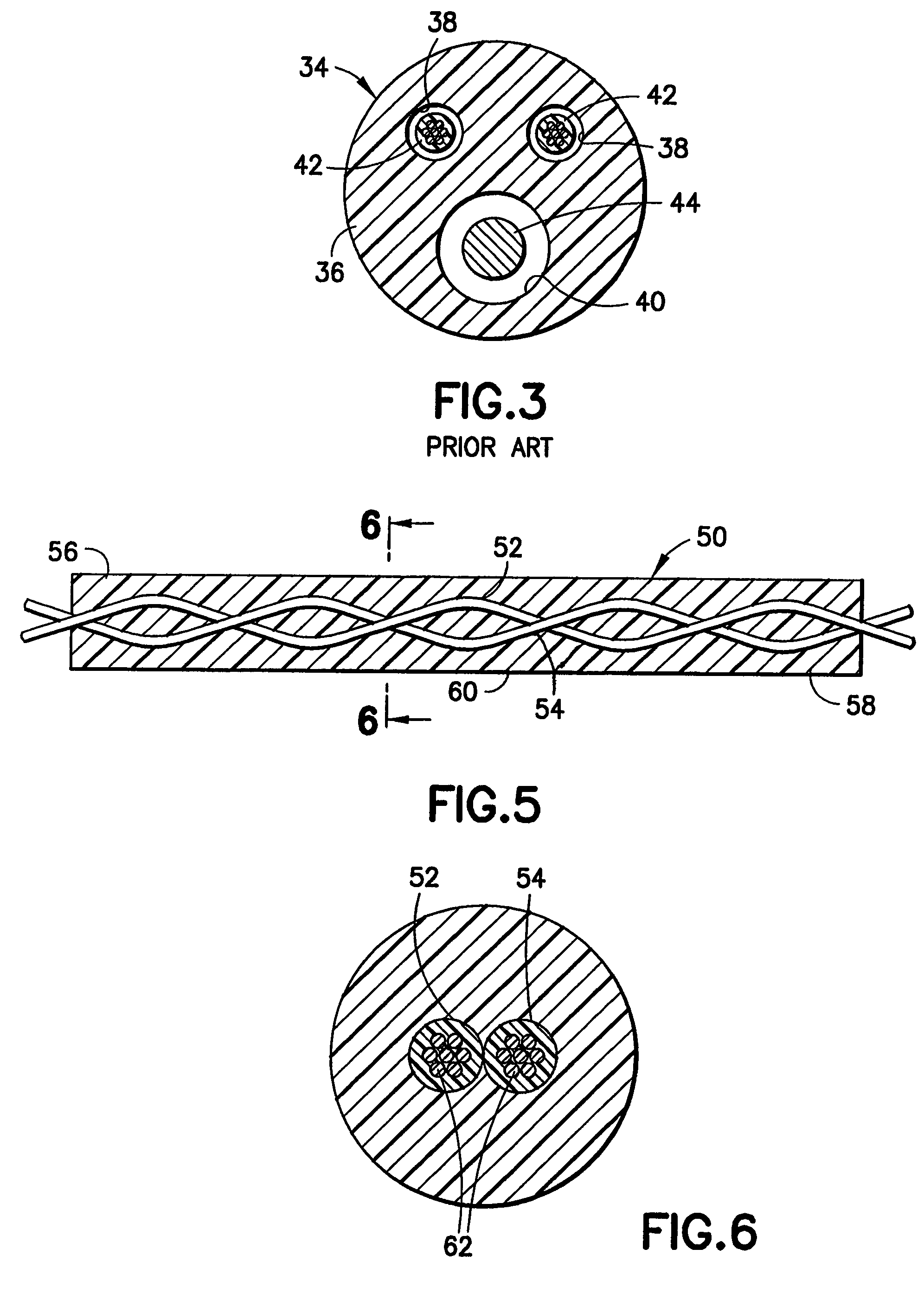

Construction of a medical electrical lead

ActiveUS7174220B1Reduce processing stepsShorten cycle timeTransvascular endocardial electrodesDiagnostic recording/measuringElectricityElectrical conductor

An implantable cardiac stimulation lead system for use with an implantable stimulation device includes at least a pair of conductors, braided together and extending between proximal and distal ends and co-extruded with flexible resilient insulation material. Each conductor may be a multi-strand cable composed of MP35N or DFT and have its outer peripheral surfaces coated with insulative material. An electrical connector is coupled to the proximal end of the lead system for connection with a stimulation device and includes terminals electrically connected to the conductors. The proximal connector is thereby electrically coupled to a distal tip electrode and to at least one electrode proximally spaced from the distal tip electrode. The lead system may include an elongated tubular lead body of flexible resilient insulative material having a longitudinally extending lumen for receiving a stylet for aid in implanting the lead system. Alternatively, an introducer sheath may be employed for implantation.

Owner:PACESETTER INC

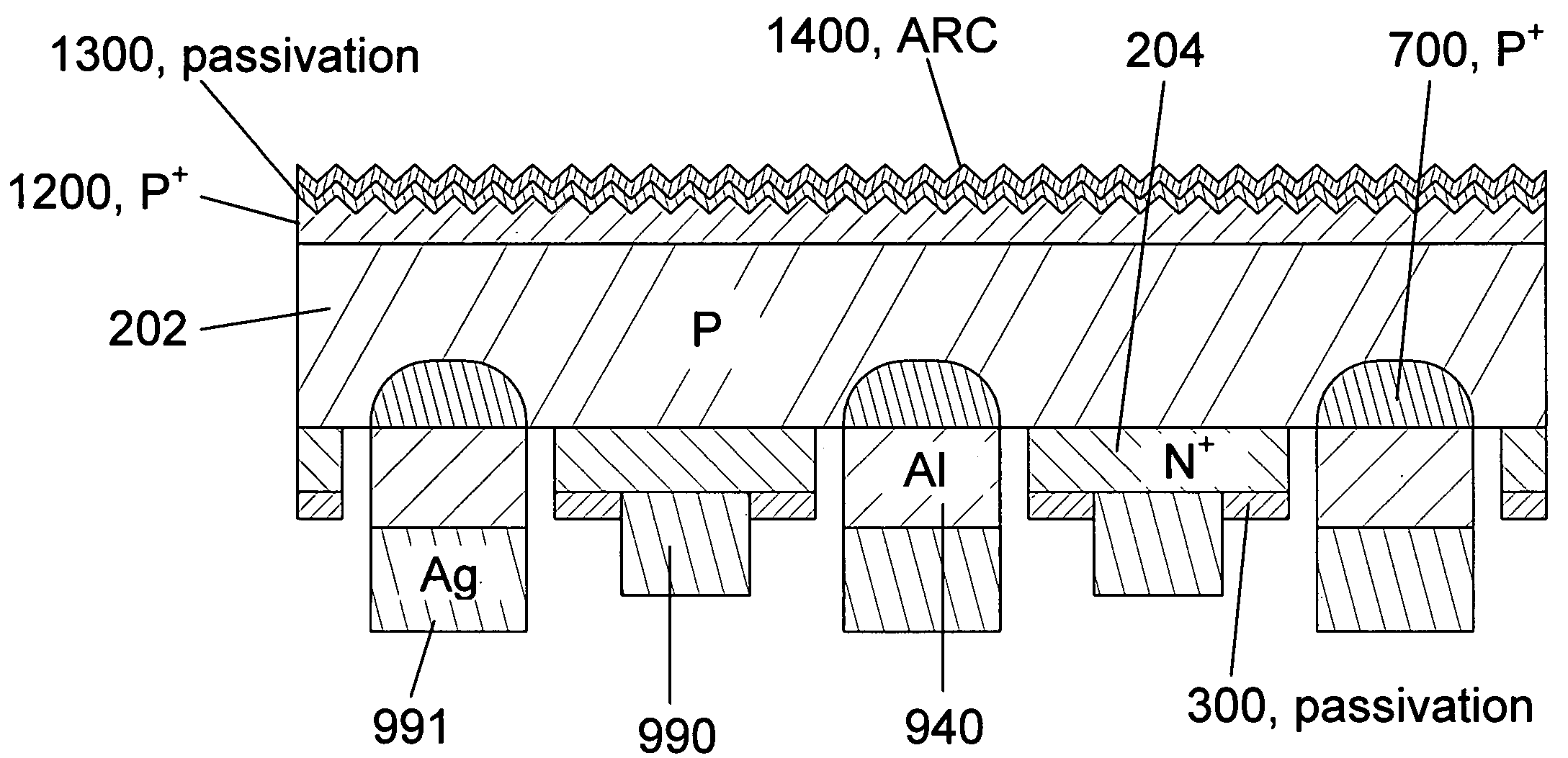

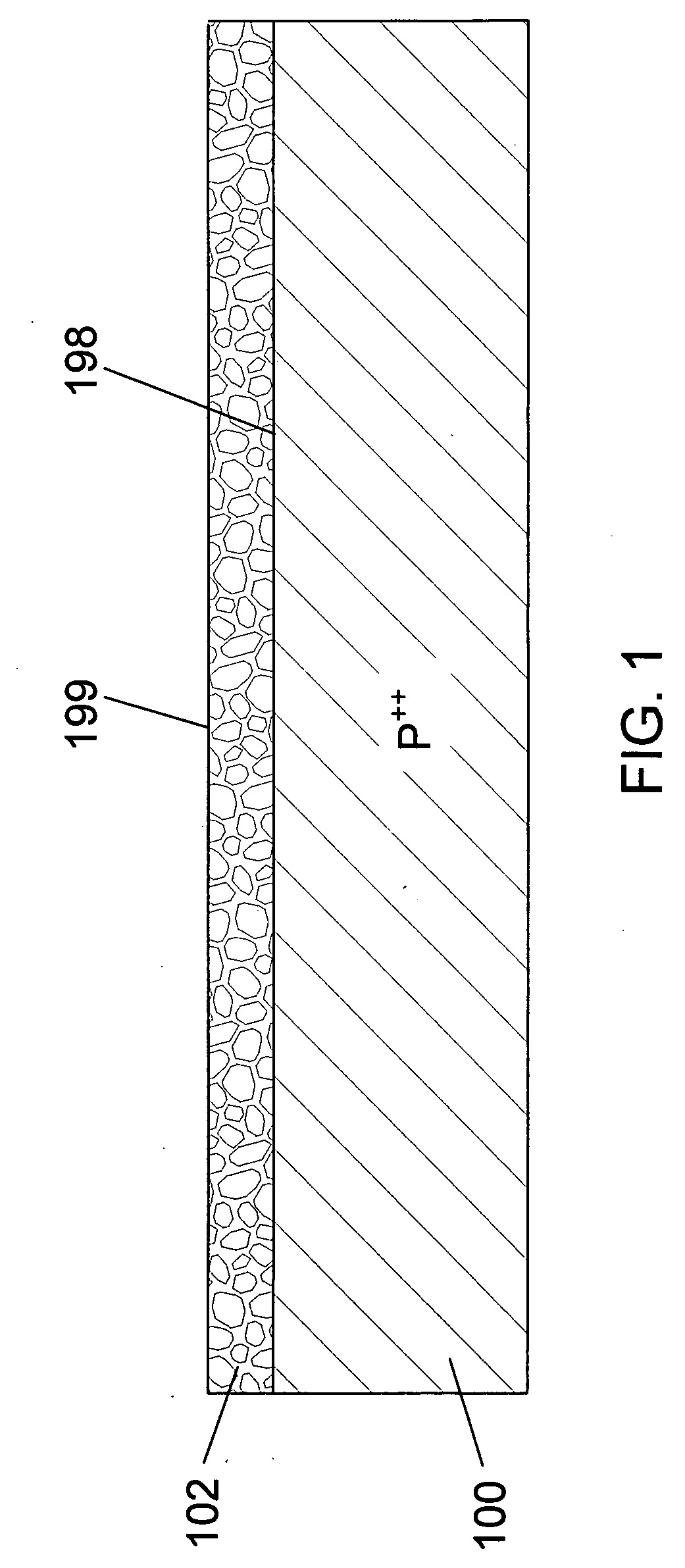

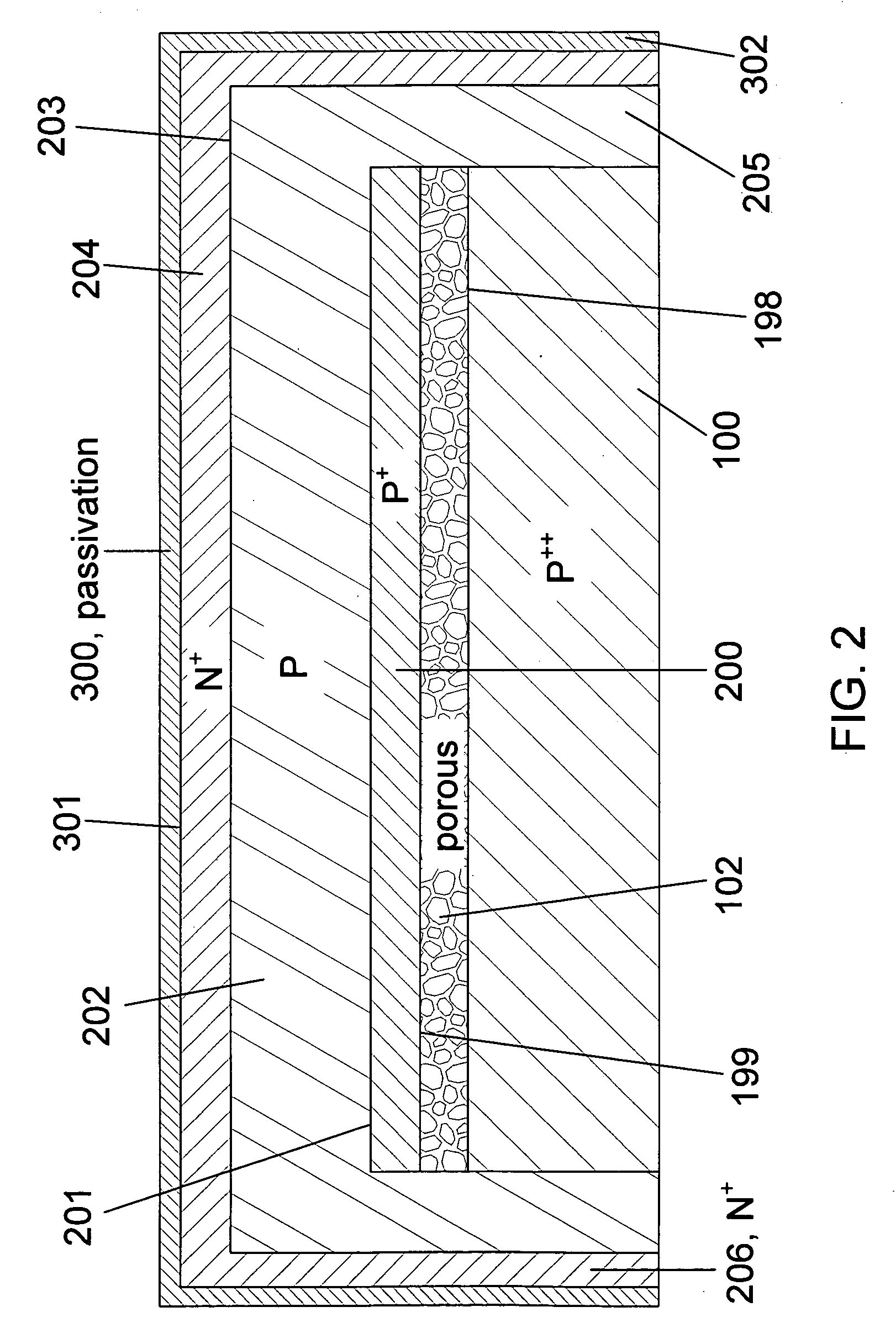

Thin Interdigitated backside contact solar cell and manufacturing process thereof

InactiveUS20100108130A1Material quality is stableControl wellSemiconductor/solid-state device manufacturingPhotovoltaic energy generationPorous layerSolar cell

A design and manufacturing method for an interdigitated backside contact photovoltaic (PV) solar cell less than 100 μm thick are disclosed. A porous silicon layer is formed on a wafer substrate. Portions of the PV cell are then formed using diffusion, epitaxy and autodoping from the substrate. All backside processing of the solar cell (junctions, passivation layer, metal contacts to the N+ and P+ regions) is performed while the thin epitaxial layer is attached to the porous layer and substrate. After backside processing, the wafer is clamped and exfoliated. The front of the PV cell is completed from the region of the wafer near the exfoliation fracture layer, with subsequent removal of the porous layer, texturing, passivation and deposition of an antireflective coating. During manufacturing, the cell is always supported by either the bulk wafer or a wafer chuck, with no processing of bare thin PV cells.

Owner:CRYSTAL SOLAR INC

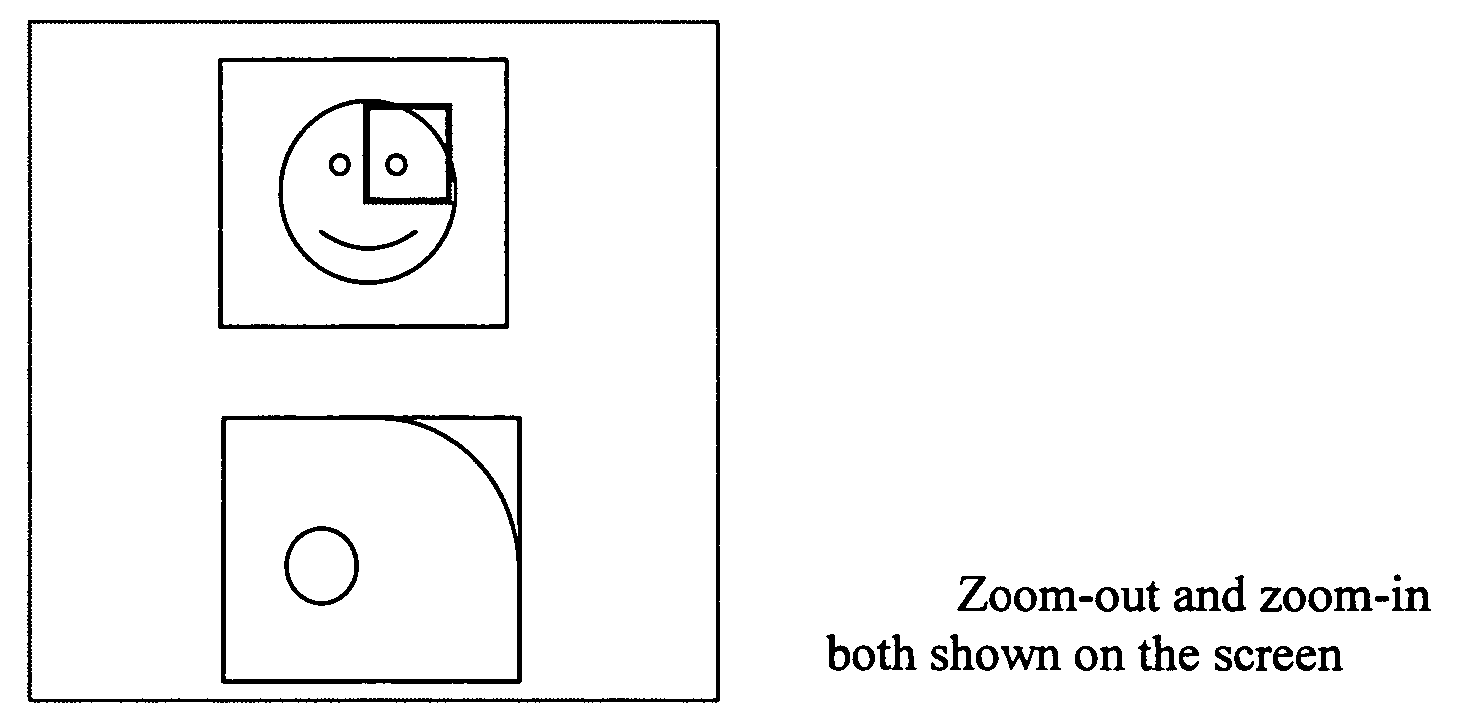

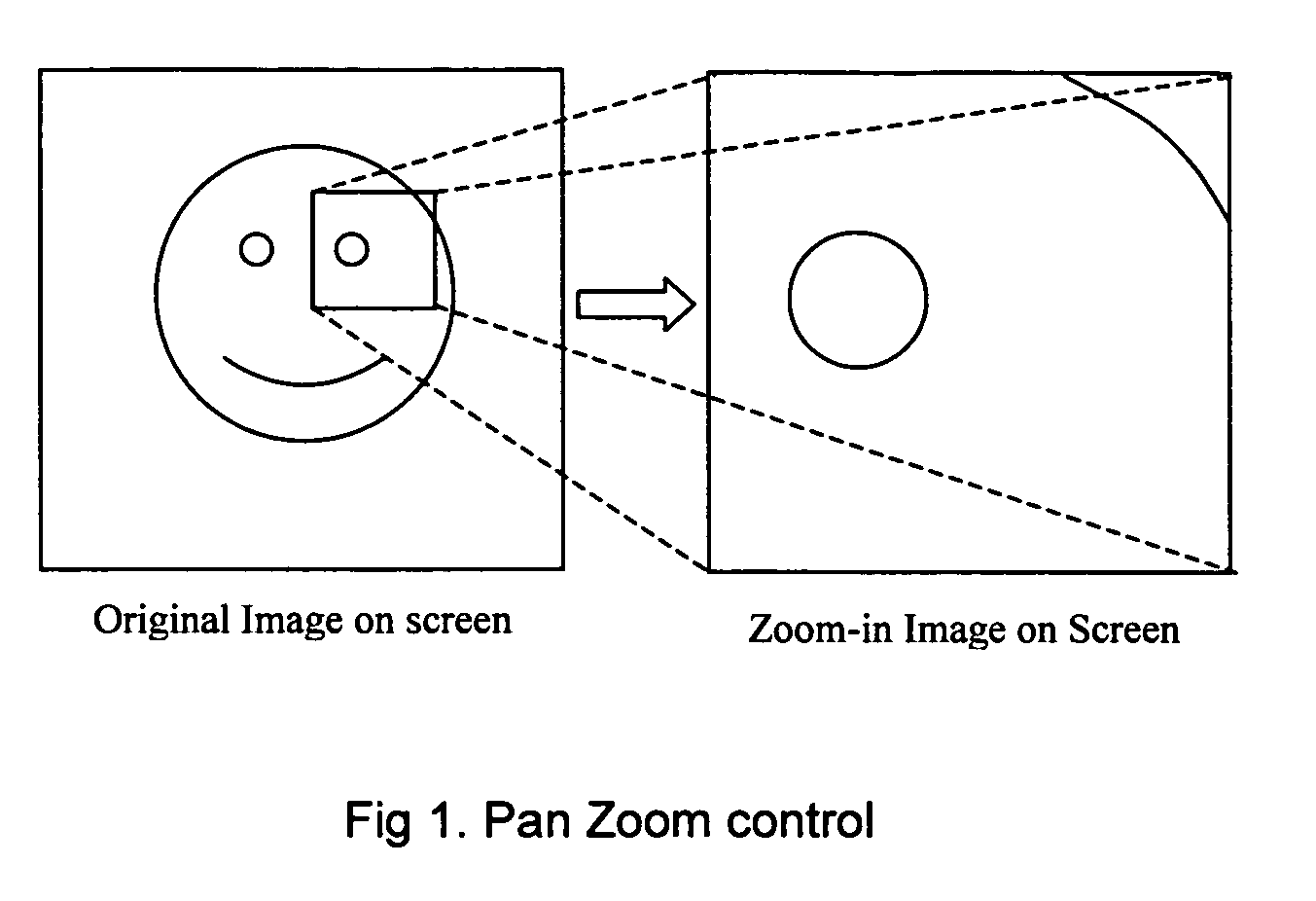

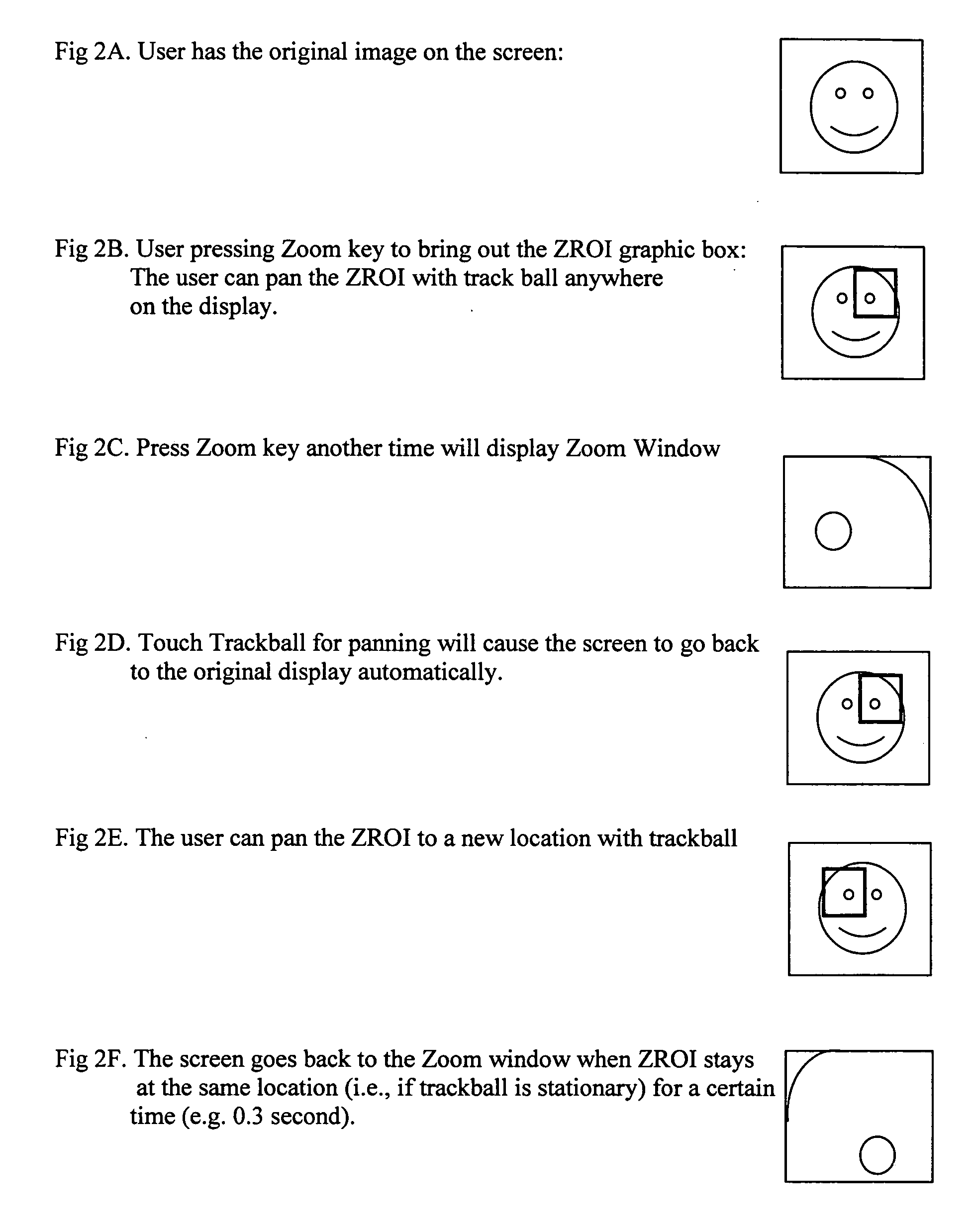

User interface for medical imaging including improved pan-zoom control

ActiveUS20060111634A1Reduce stepsEasy to controlUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsIdle timeUser input

An ultrasonic image scanning system for scanning an organic object that includes a display system for displaying a scanned image of the organic object in a plurality of display modes wherein the display system further includes a user input device sensor for sensing a motion of a user input device in at least one of display modes to automatically switch from one display mode to a different display mode. Furthermore, the display system further counts a length of time the user input device staying idle in at least one of the display modes for switching the display mode back to a last display mode at a predefined idle time limit.

Owner:SONOWISE

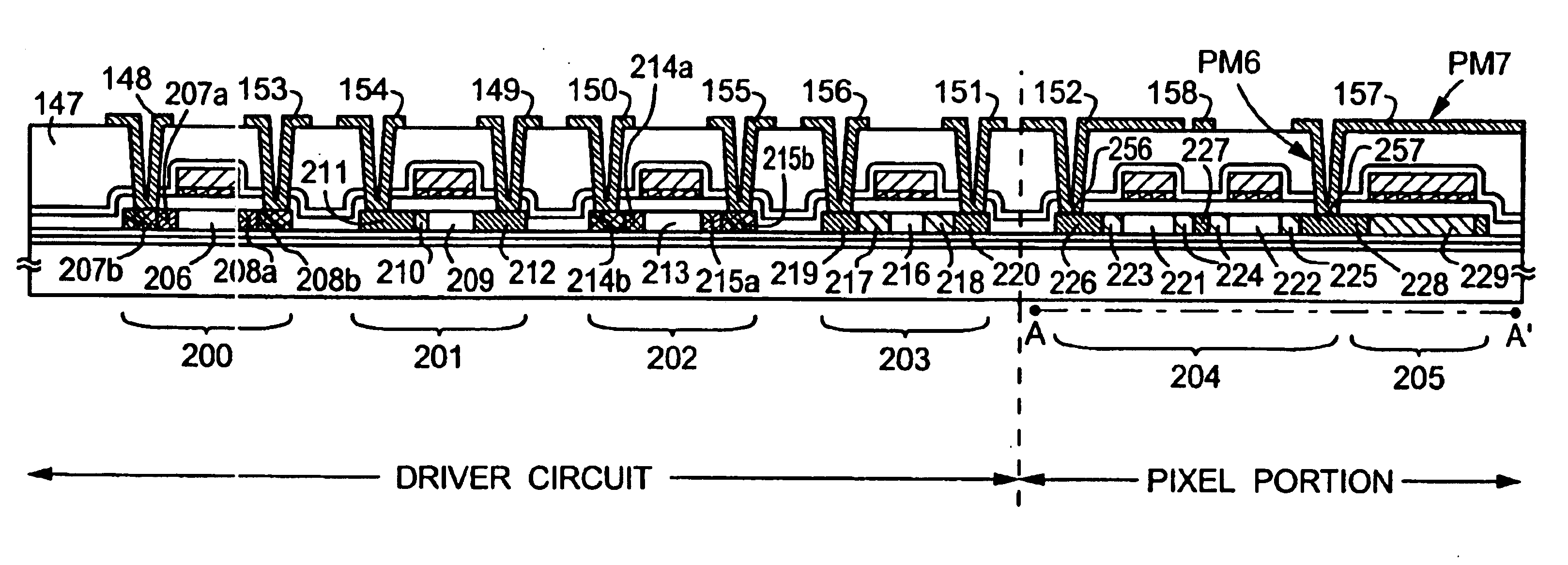

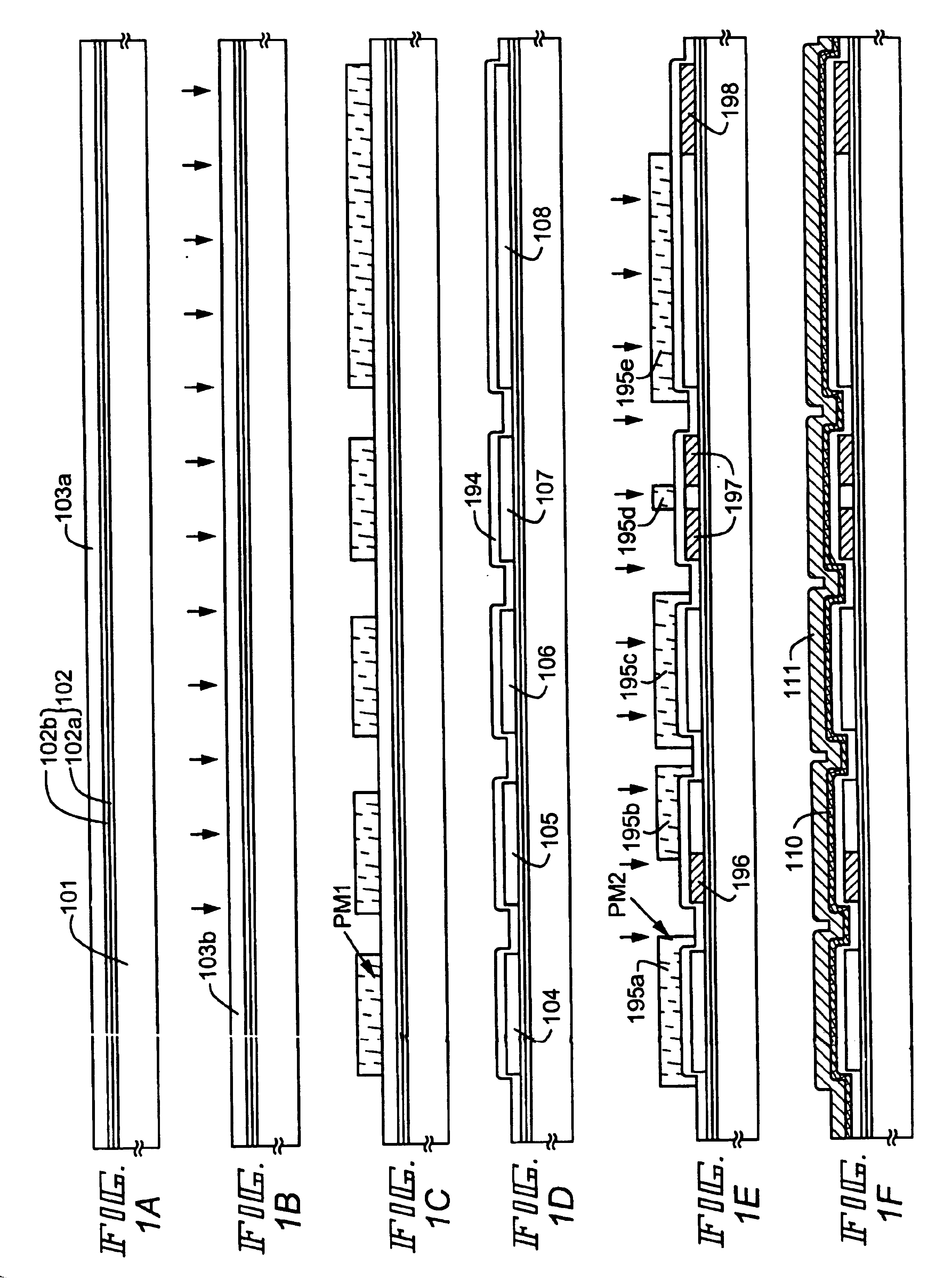

Semiconductor device and manufacturing method thereof

InactiveUS6952020B1Improve operation characteristic and reliabilityLow production costTransistorSemiconductor/solid-state device detailsEngineeringP channel

A p channel TFT of a driving circuit has a single drain structure and its n channel TFT, a GOLD structure or an LDD structure. A pixel TFT has the LDD structure. A pixel electrode disposed in a pixel portion is connected to the pixel TFT through a hole bored in at least a protective insulation film formed of an inorganic insulating material and formed above a gate electrode of the pixel TFT, and in an interlayer insulating film disposed on the insulation film in close contact therewith. These process steps use 6 to 8 photo-masks.

Owner:SEMICON ENERGY LAB CO LTD

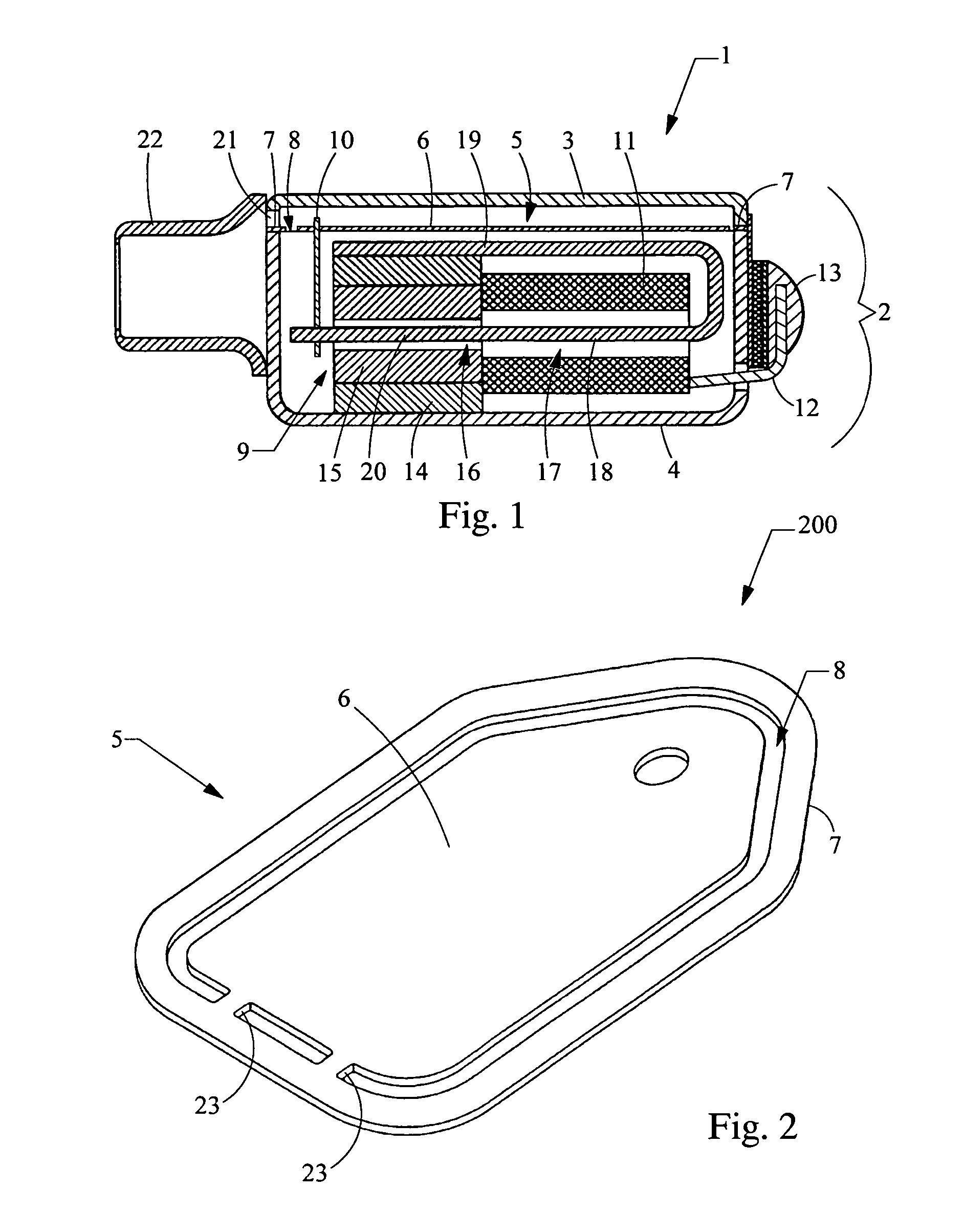

Electroacoustic transducer with a diaphragm and method for fixing a diaphragm in such transducer

InactiveUS7706561B2Improve acoustic propertiesImprove deformationTransducer detailsDeaf-aid setsTransducerEngineering

Apparatus and method for manufacturing an electroacoustic transducer for, for instance, a hearing aid, with a diaphragm arranged in a housing. The diaphragm is attached onto a film or punched from a sheet of material, such that along the circumferential edge of the diaphragm, a free strip of film or a strip of material remains present, in a capillary space between the circumferential edge of the film and the inner wall of the housing, or in a capillary space between the diaphragm and the strip of material, a polymer of a low viscosity is provided to connect to diaphragm with the housing wall. Through the method, the production of the transducer is greatly simplified.

Owner:SONION NEDERLAND

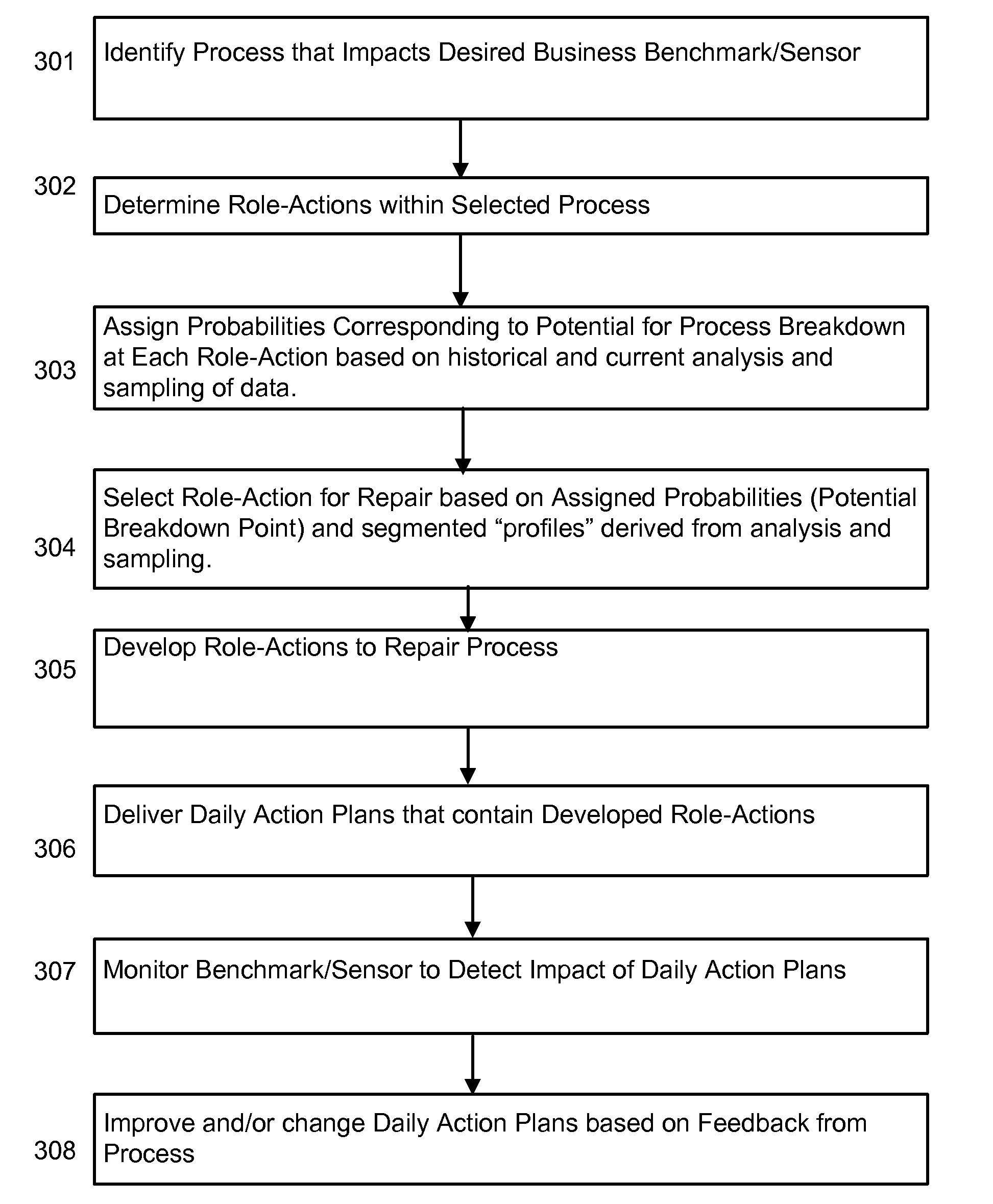

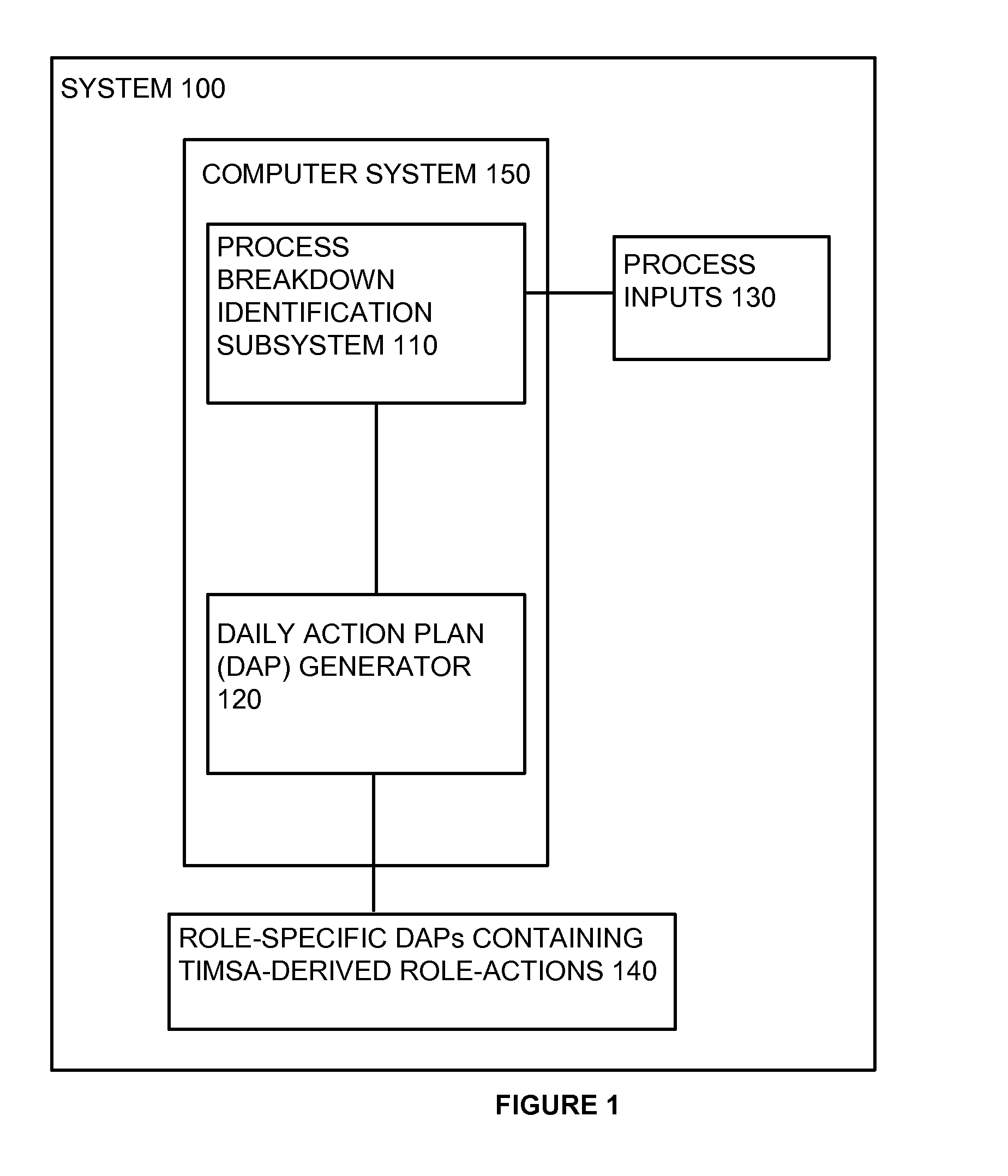

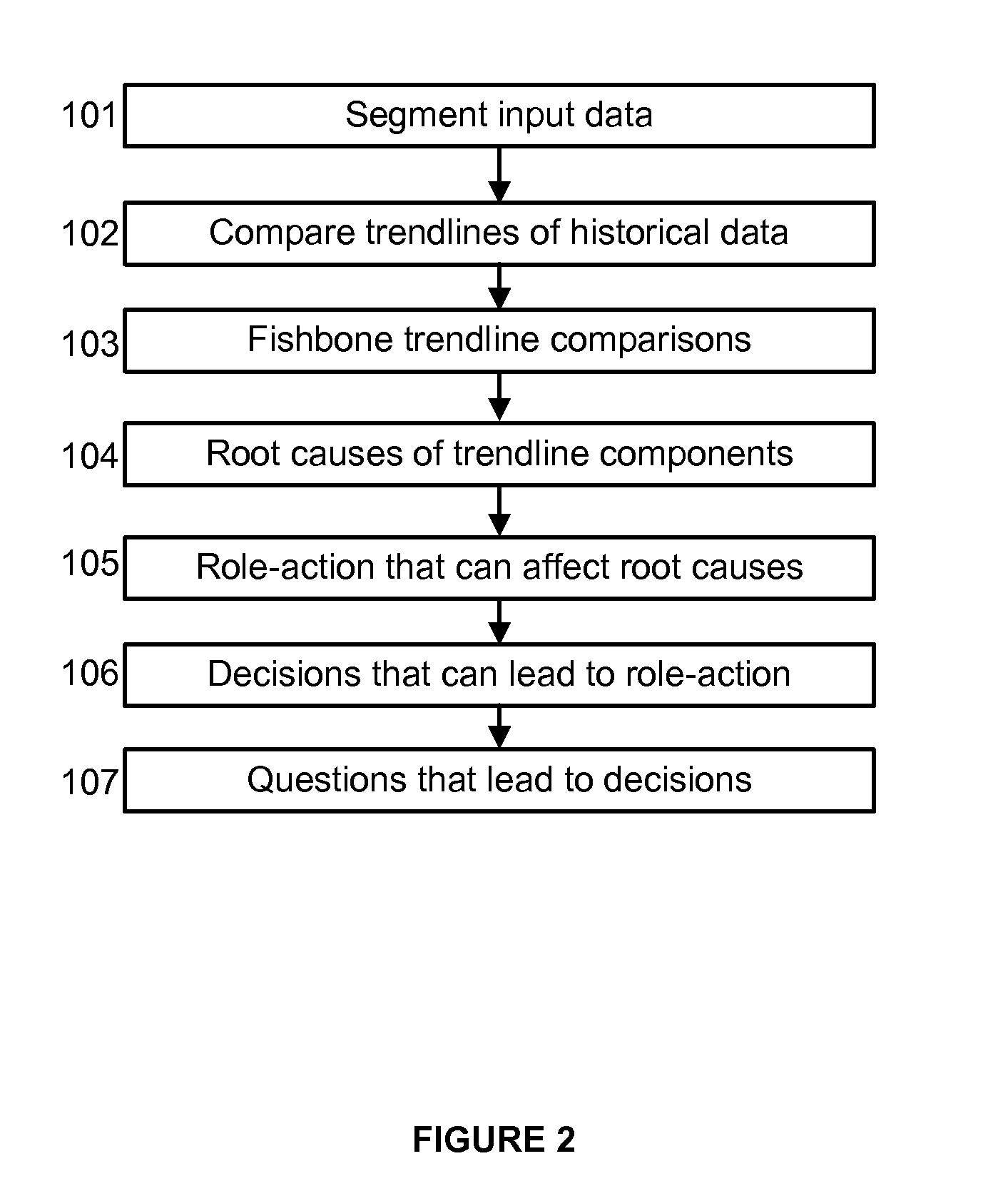

Method and system for improving efficiency in an organization using process mining

ActiveUS8073731B1Lower opportunity costAvoid interruptionInstrumentsOrganizational efficiencyData science

Systems and methods are provided for improving processes in a healthcare organization by mining historical data for information that can be used to more effectively allocate resources and process components. Factors used for the analysis include time, information, motivation, skills, and authority for particular resources. Arbitrage processing is used to minimize opportunity costs and increase efficiency.

Owner:PROCESSPROXY CORP

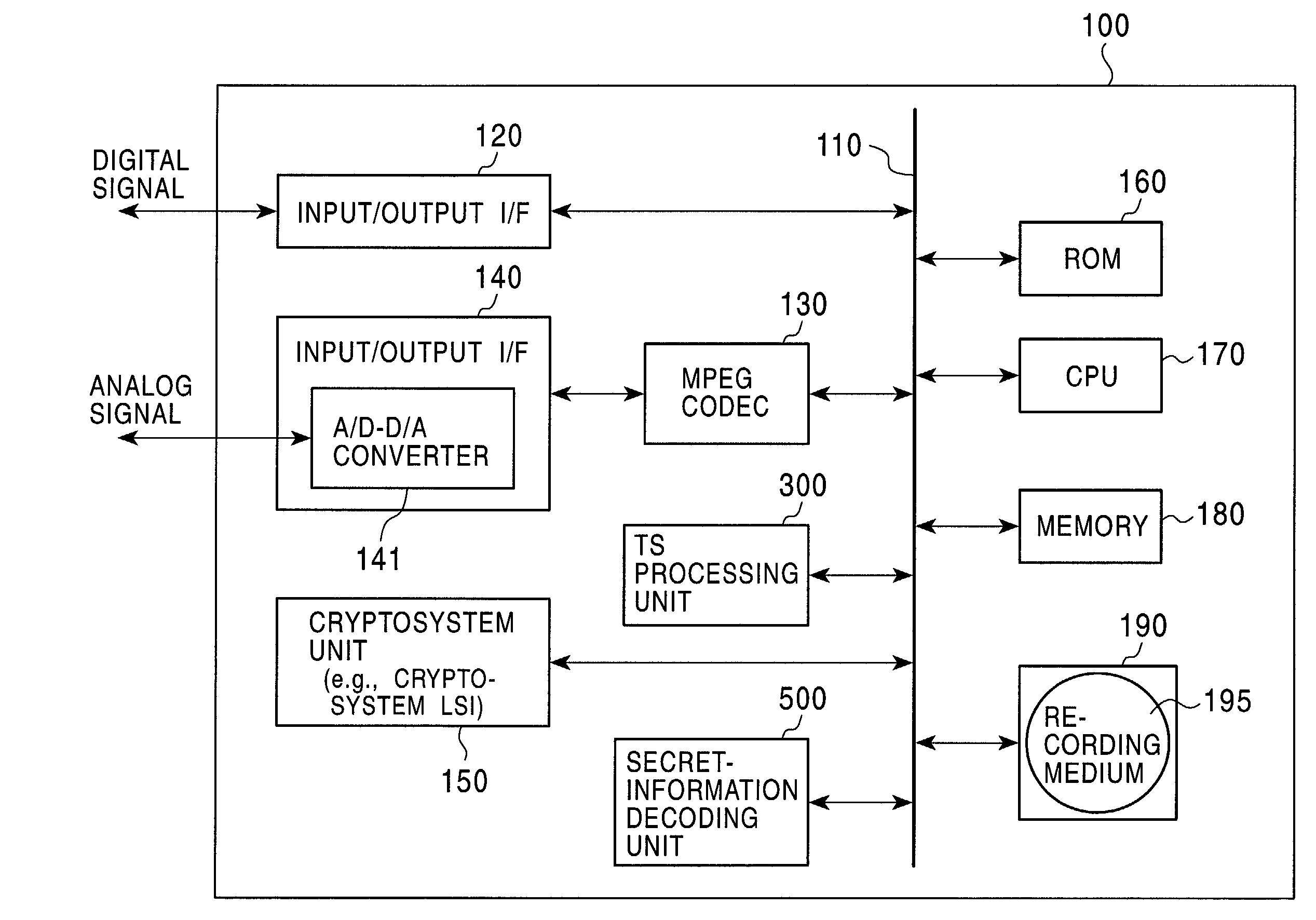

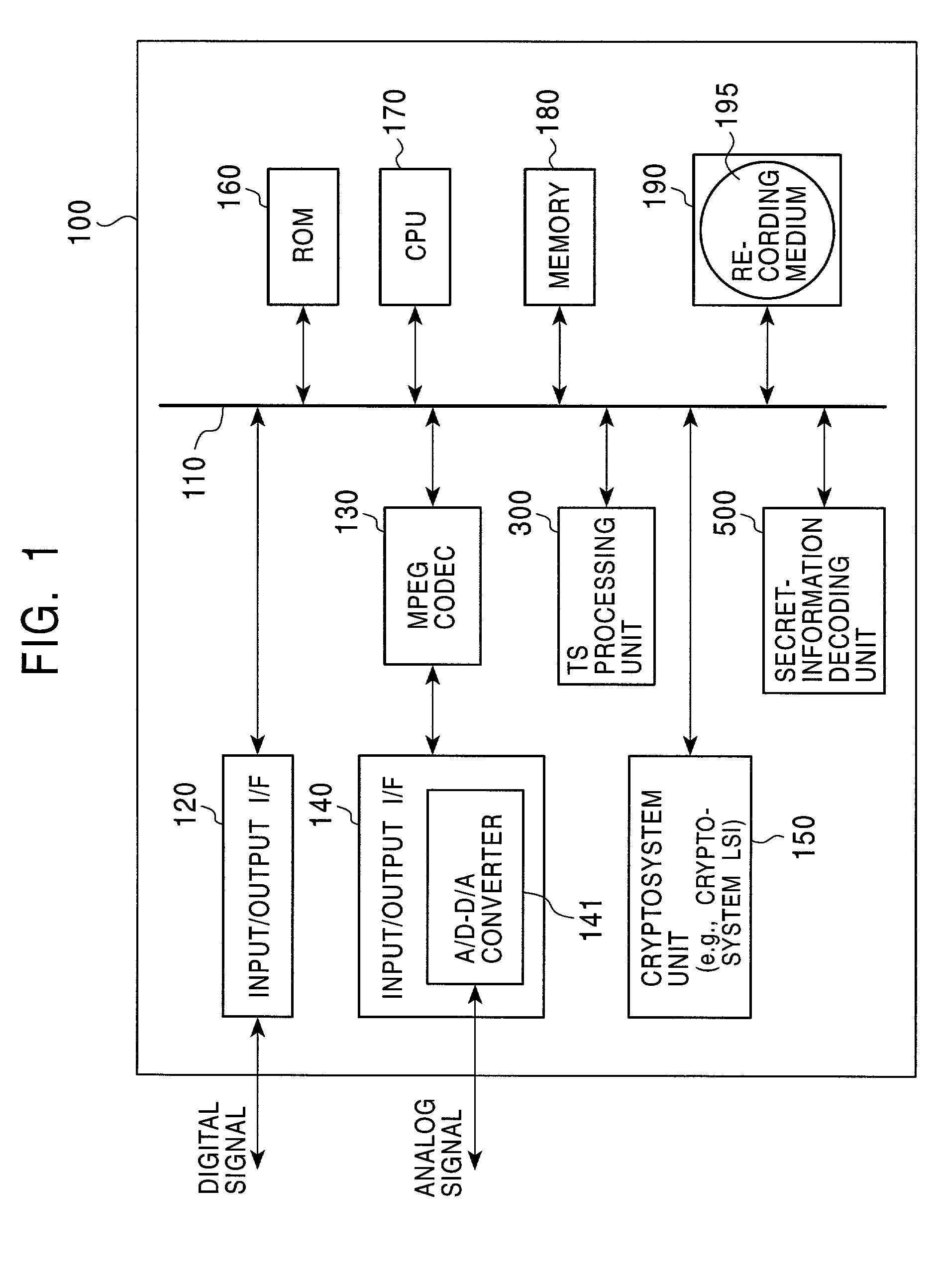

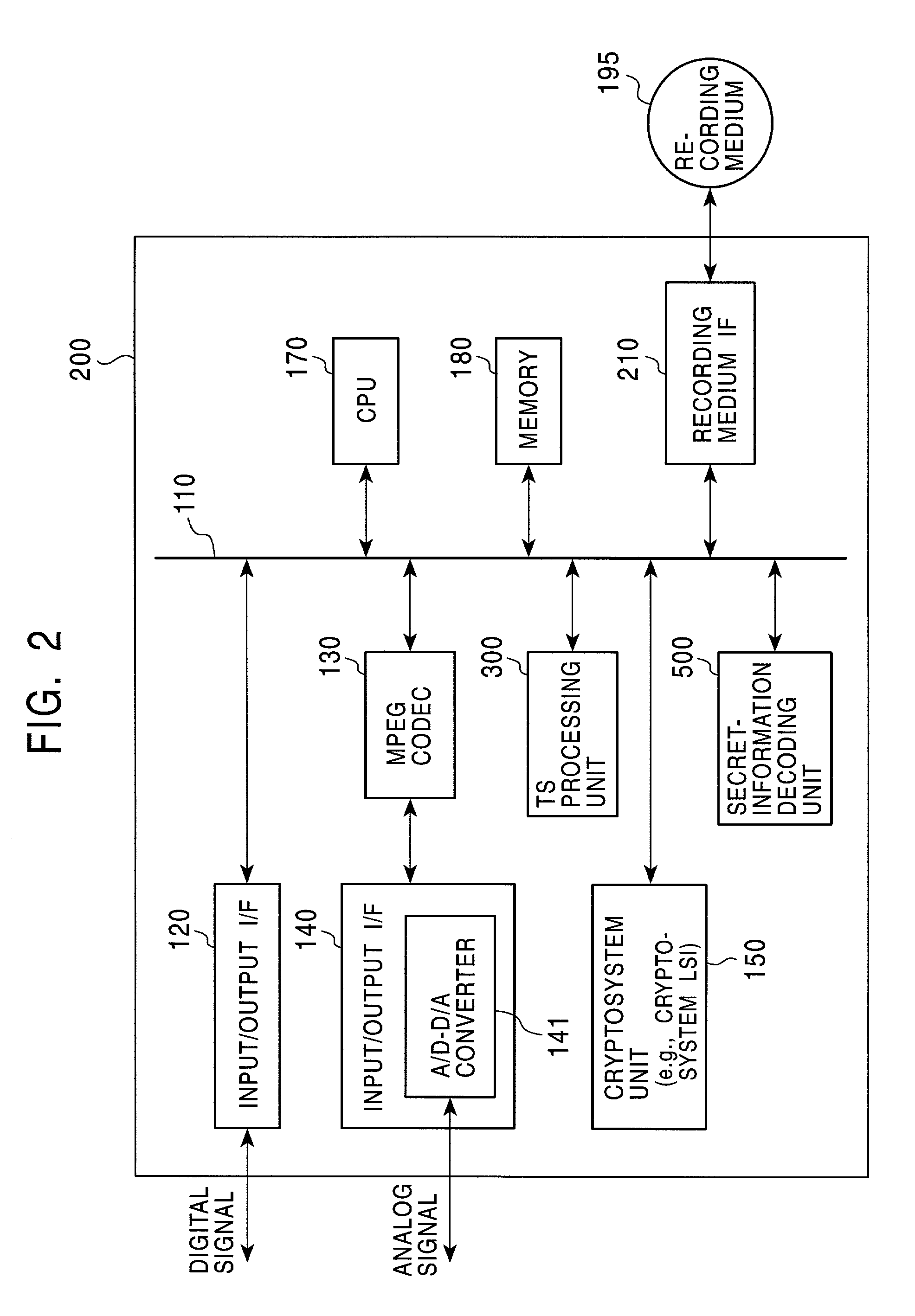

Information recording device, information playback device, information recording method, information playback method, and information recording medium and program providing medium used therewith

InactiveUS7319752B2Raise security concernsUnauthorized useTelevision system detailsKey distribution for secure communicationComputer hardwareCryptosystem

An information recording / playback device stores beforehand, on a recording medium, secret information in which a writing / reading method thereof cannot be analyzed and which can be read only by a special reading method. The secret information is applied to a key for content encryption or decryption when performing recording or playback of contents on the recording medium, such as music data and image data. The secret information is, for example, a stamper ID. By using the stamper ID as secret information, and a master key and a media key which are distributed in a tree-structure key-distribution system, a content-cryptosystem key is generated. Accordingly, each content is allowed to be used in only an appropriate device in which the special reading method for the secret information can be executed and to which the key is distributed by the tree-structure key-distribution system.

Owner:SONY CORP

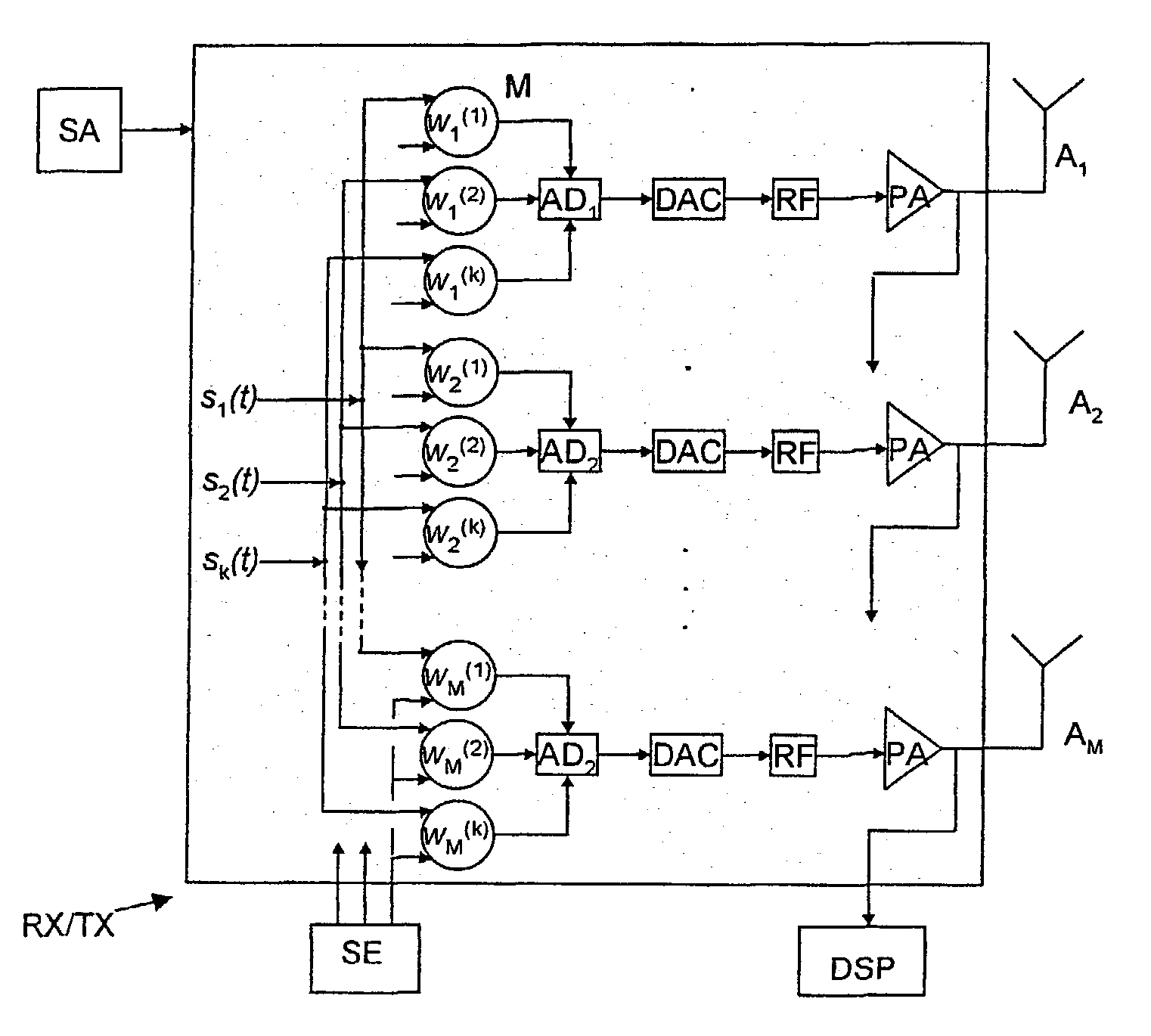

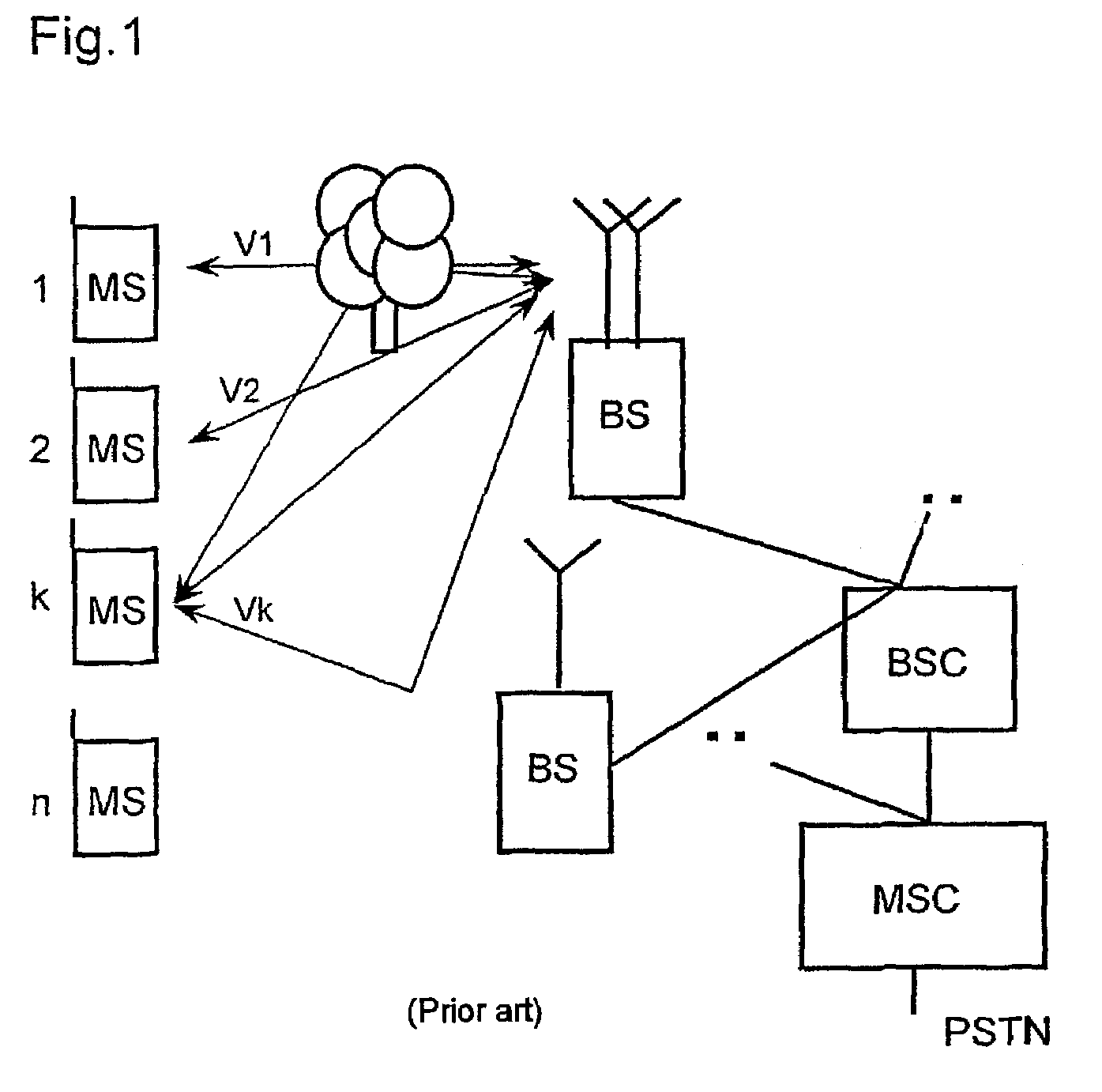

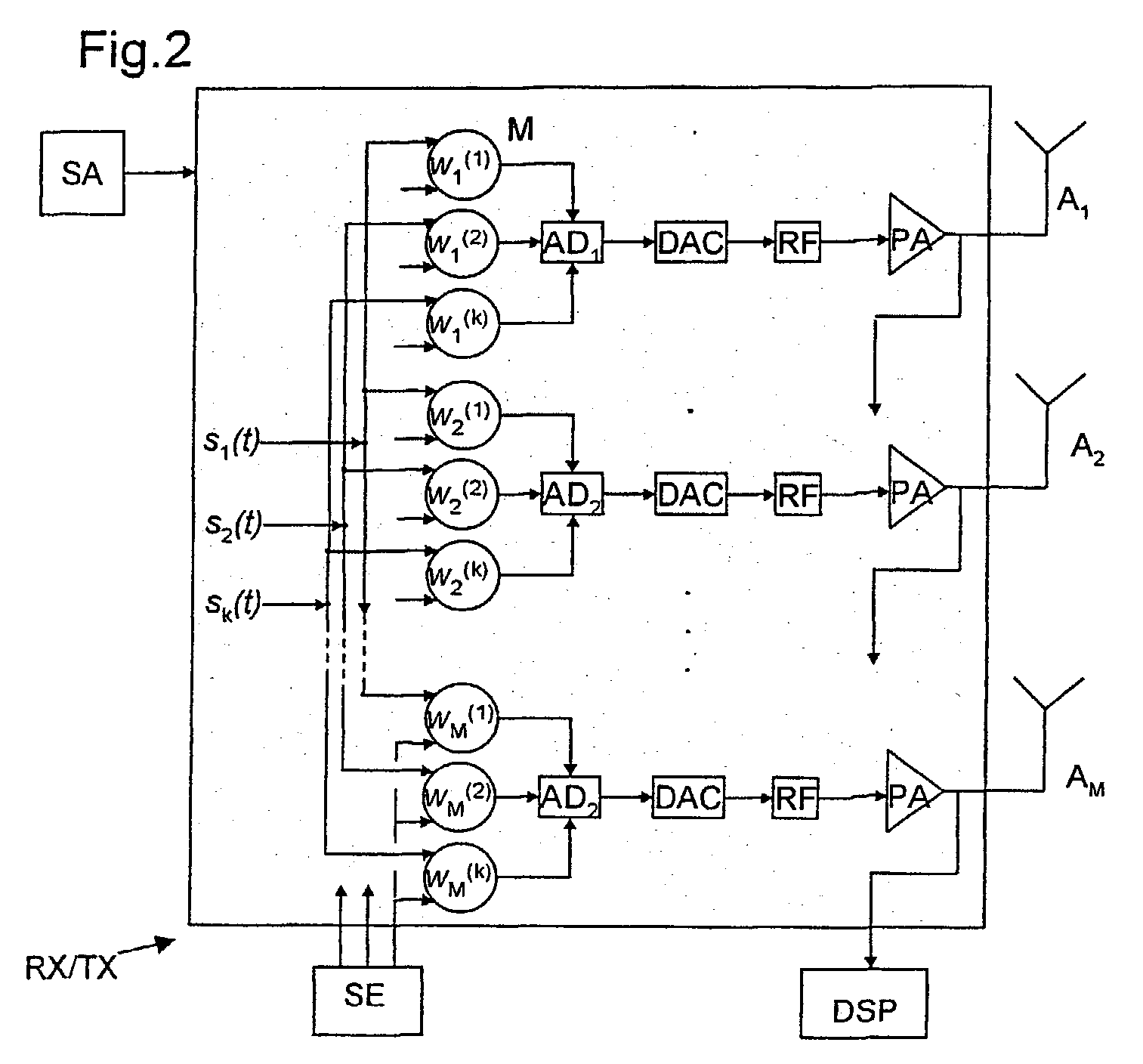

Beam forming method

InactiveUS7099630B2Reliably formReliable formingSpatial transmit diversityPolarisation/directional diversityA-weightingRadio communications

A radio communications system has subscriber stations and a base station that is provided with an antenna system with a plurality of antenna elements that emit a downlink signal in a weighted manner with coefficients of a weighting vector. In order to form a beam, a plurality of weighting vectors is determined at the subscriber station and the determined weighting vectors are transmitted to the base station. In a subsequent working phase, the subscriber station selects a dominant vector among the determined weighting vectors and transmits an indicator of the selected weighting vector to the base station.

Owner:NOKIA SOLUTIONS & NETWORKS GMBH & CO KG

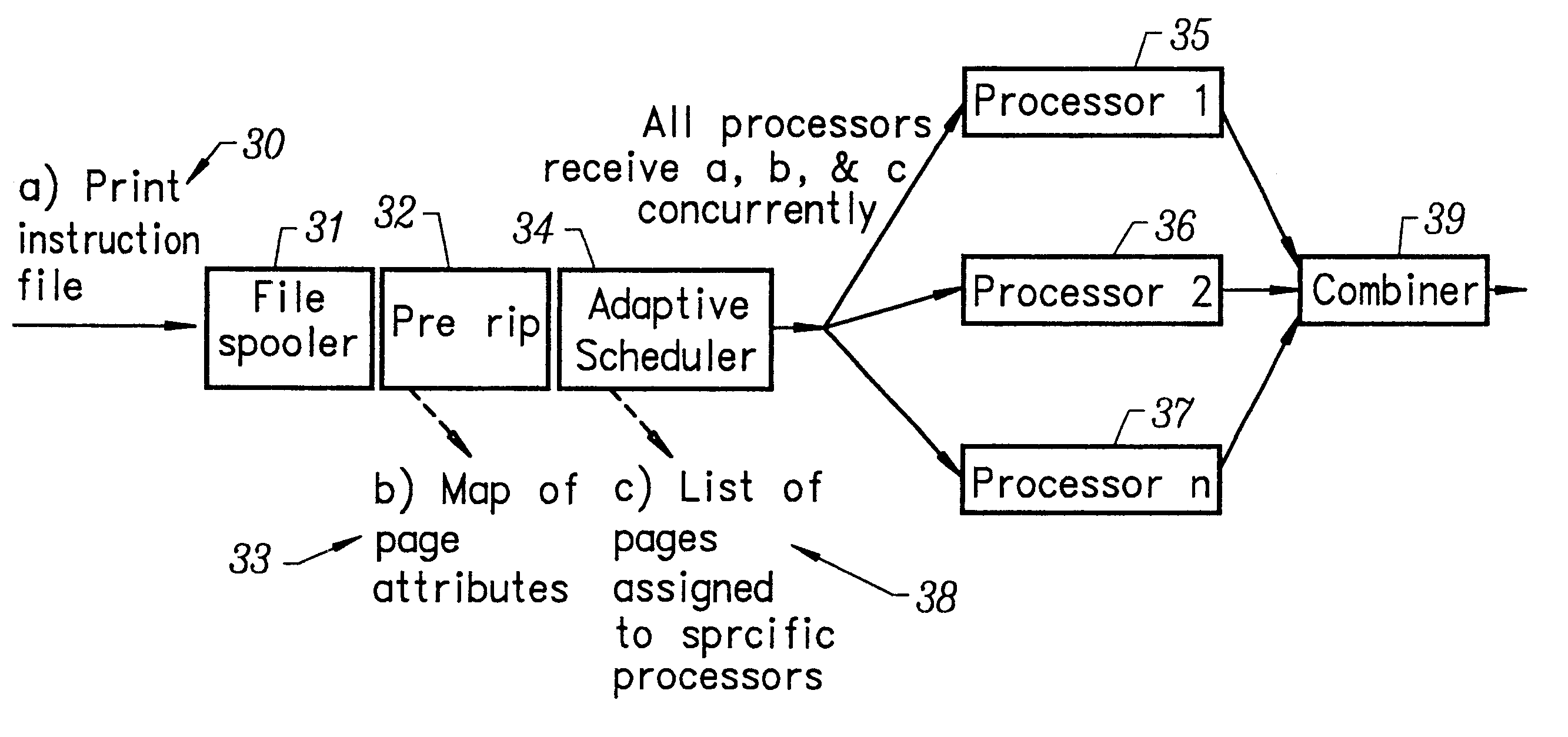

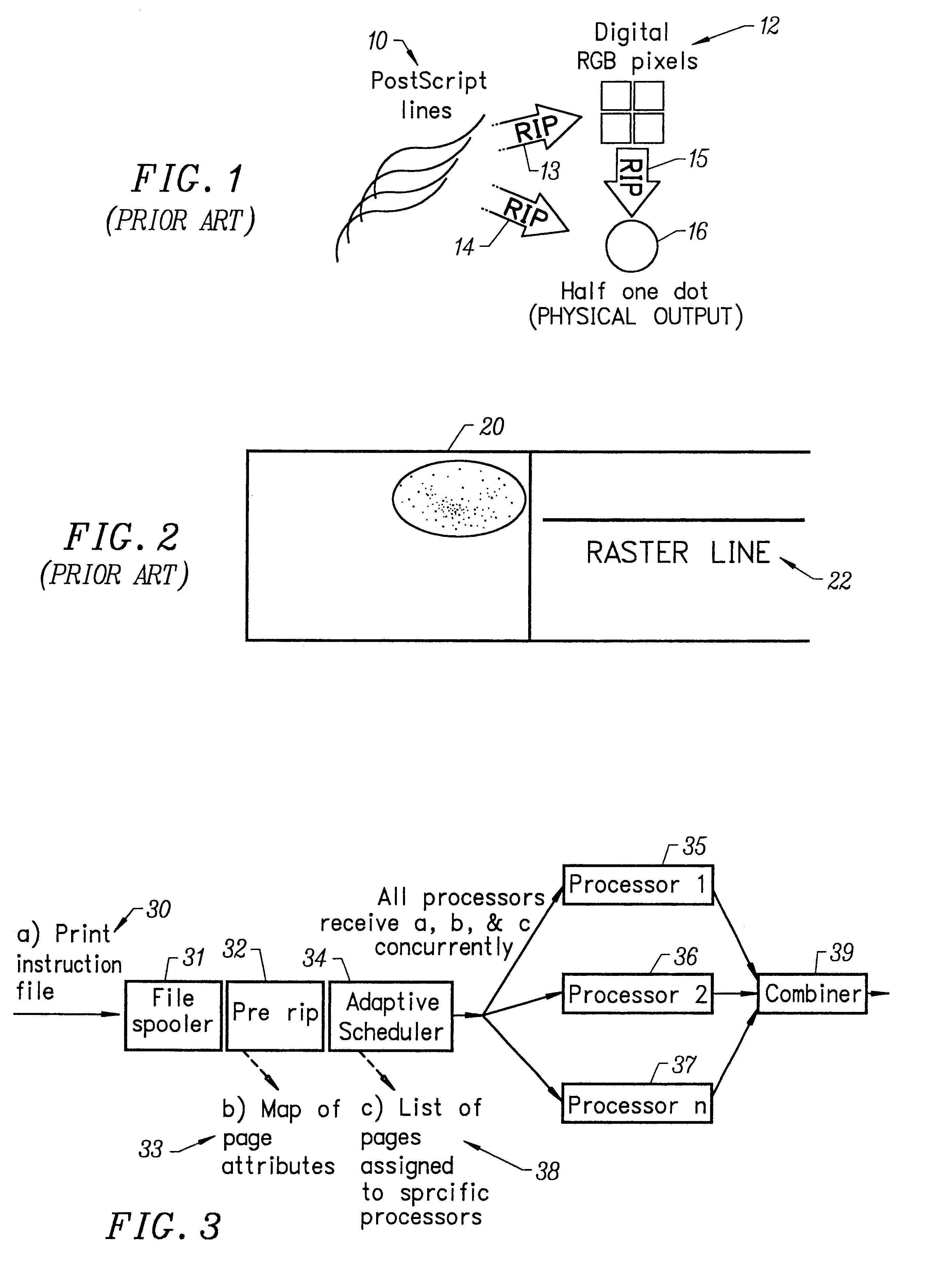

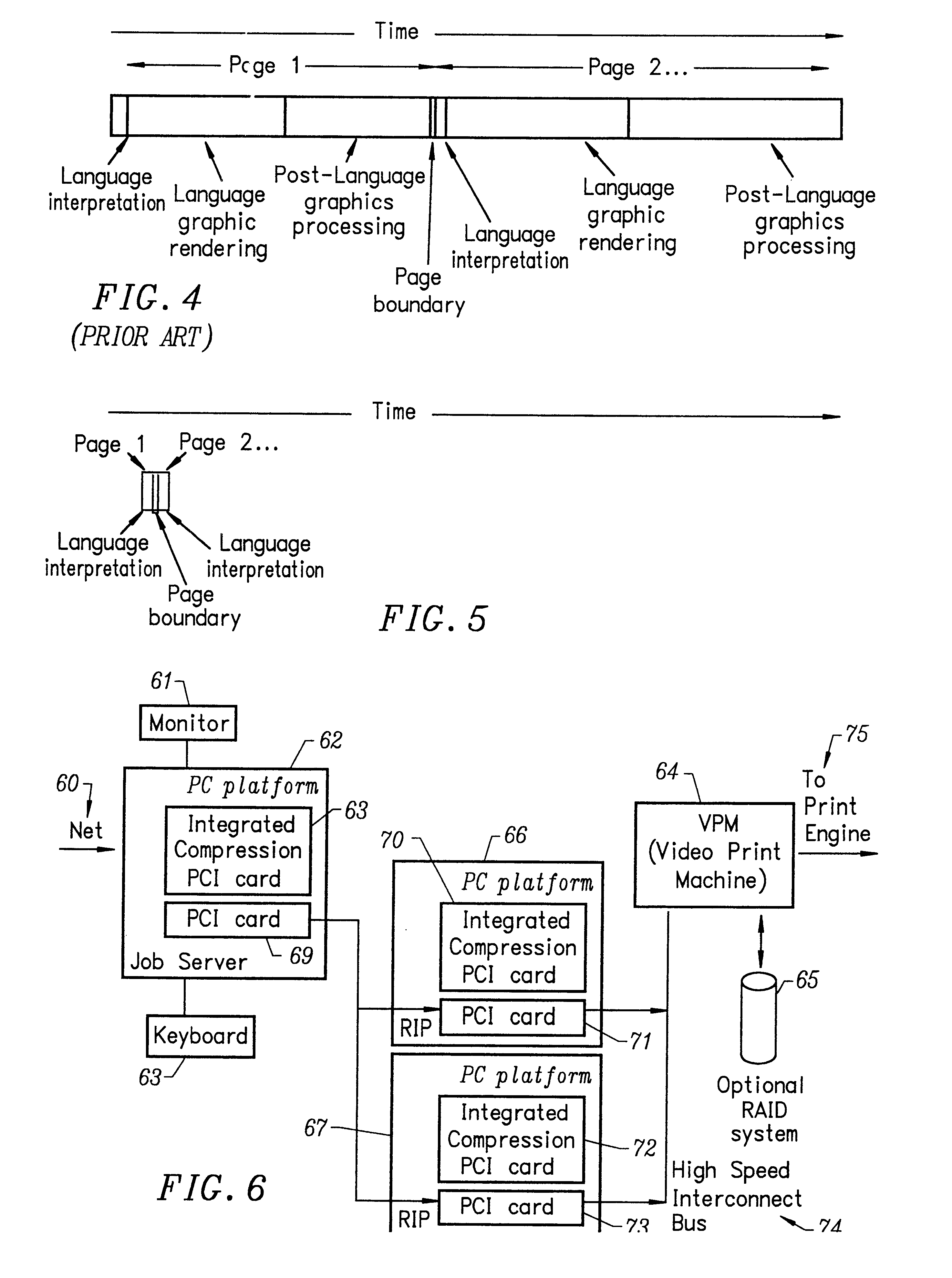

Printing method and apparatus having multiple raster image processors

InactiveUS6559958B2Reduce contentionReduce overheadDigitally marking record carriersDigital computer detailsGraphicsRaster image processor

Owner:ELECTRONICS FOR IMAGING INC

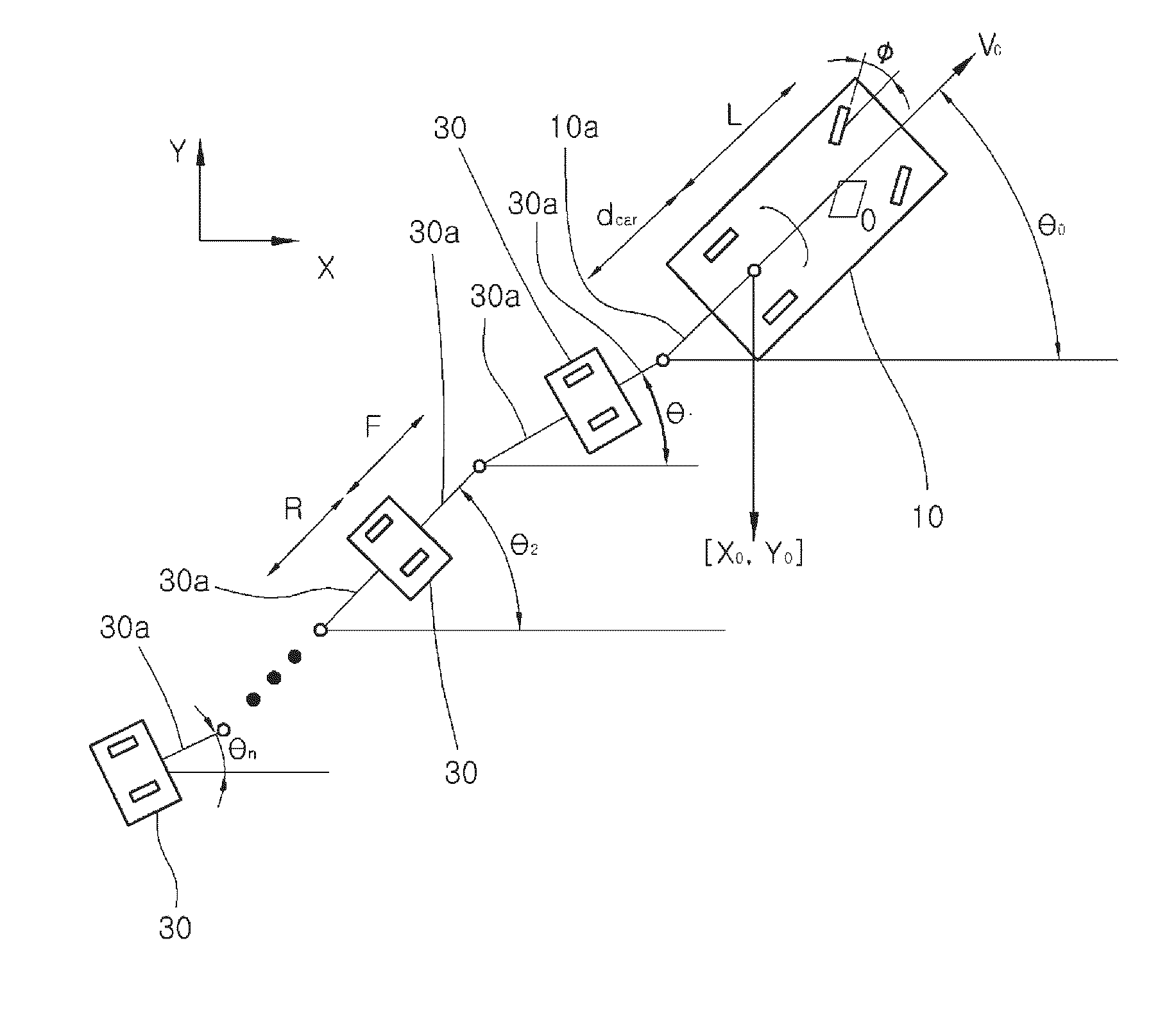

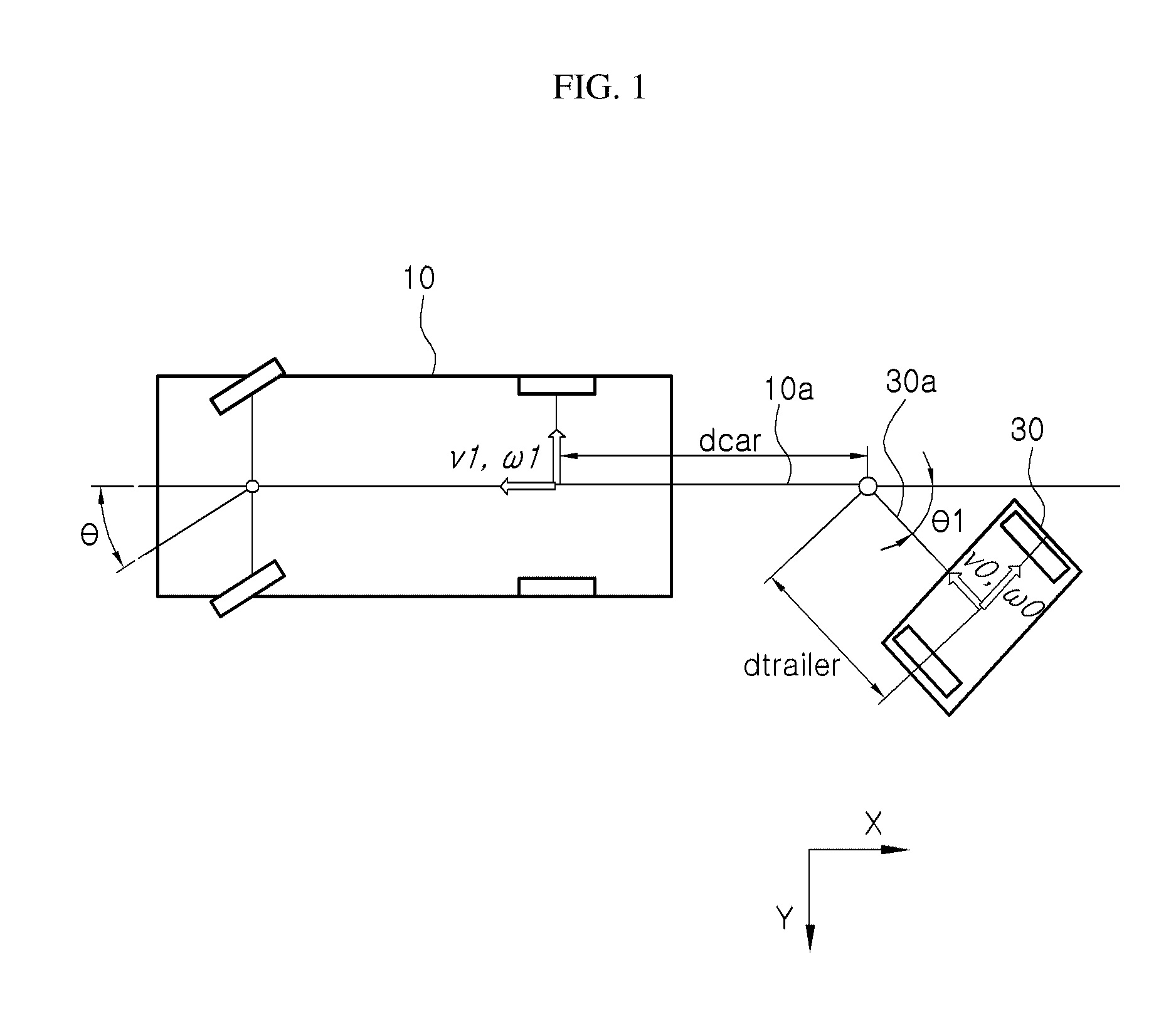

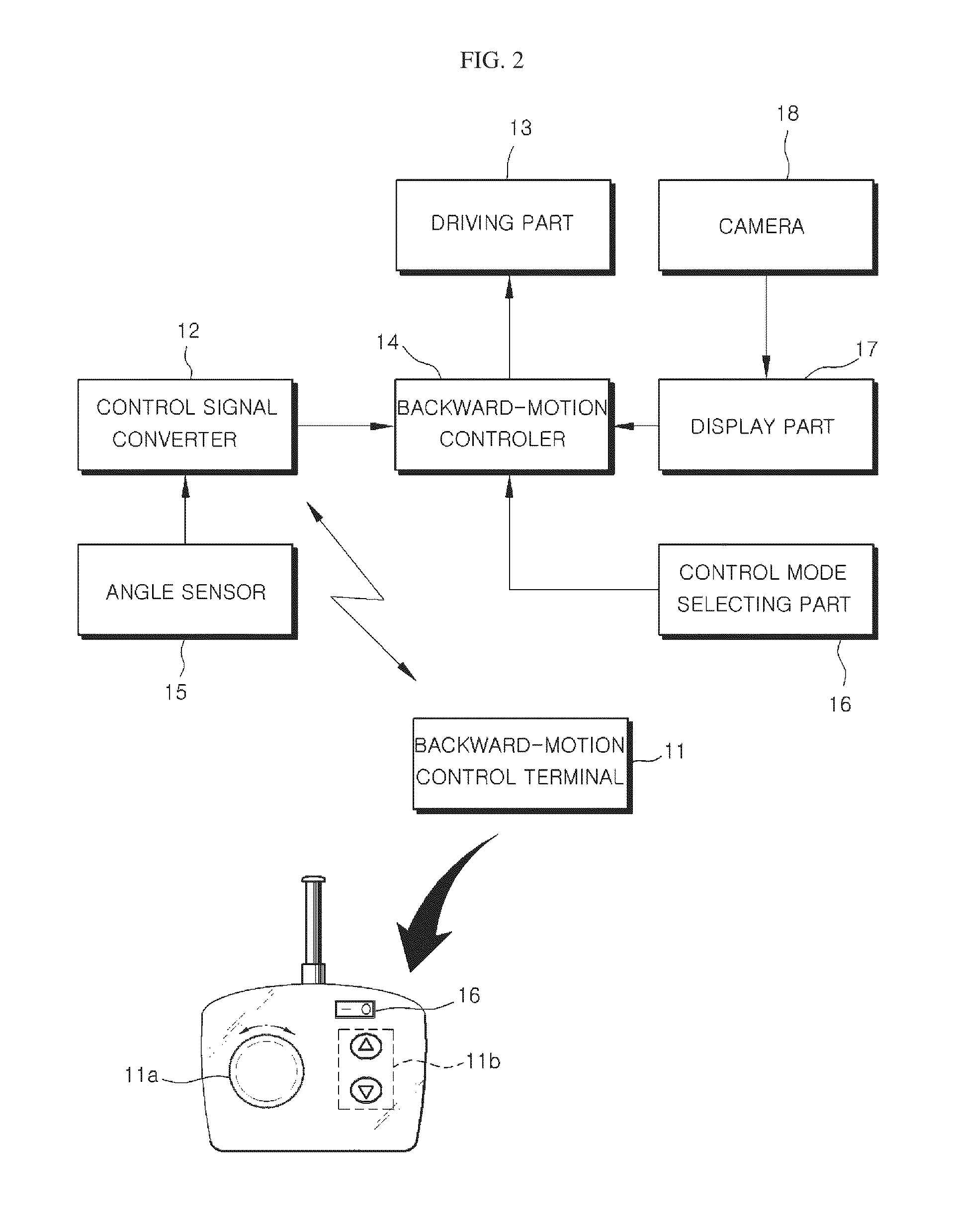

Car connected to at least one trailer and backward motion control method

ActiveUS20110160956A1Easy to controlReduce processing stepsSteering initiationsDigital data processing detailsEngineeringMotion controller

A car connected to at least one trailer and backward motion control method are provided. The car includes a driving part controlling a velocity and a direction of the car, a backward-motion control terminal outputting a first backward-motion control signal corresponding to a backward velocity and a backward direction of the last trailer according to a user's operation, a control signal converter converting the first backward-motion control signal to a second backward-motion control signal which corresponds to a backward velocity and a backward direction of the car and makes the last trailer move backward as the backward velocity and the backward direction corresponding to the first backward-motion control signal, and a backward-motion controller controlling the driving part on the basis of the second backward-motion control signal so that the last trailer moves backward by the backward velocity and the backward direction corresponding to the first backward-motion controlling signal.

Owner:KOREA UNIV RES & BUSINESS FOUND

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

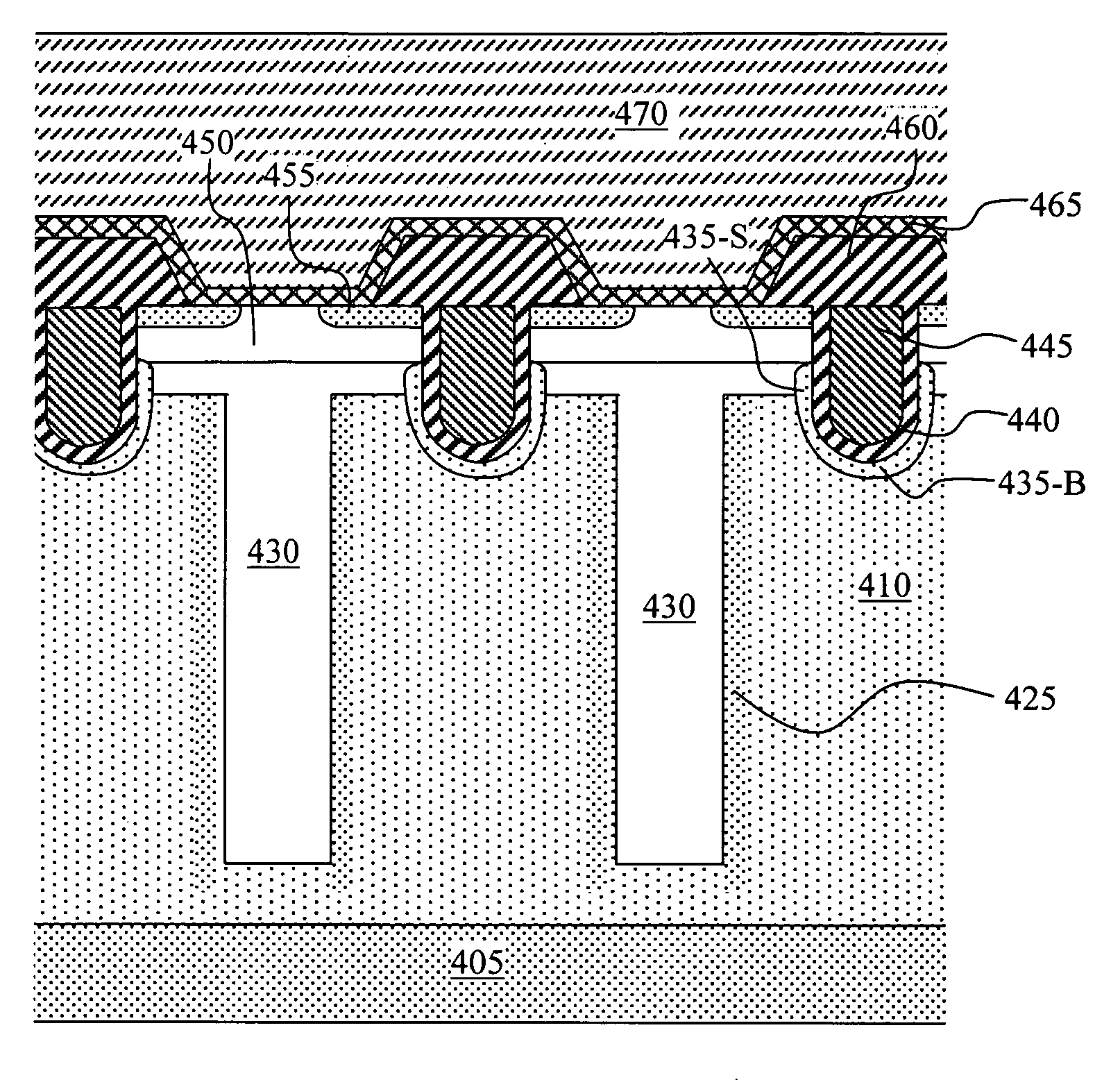

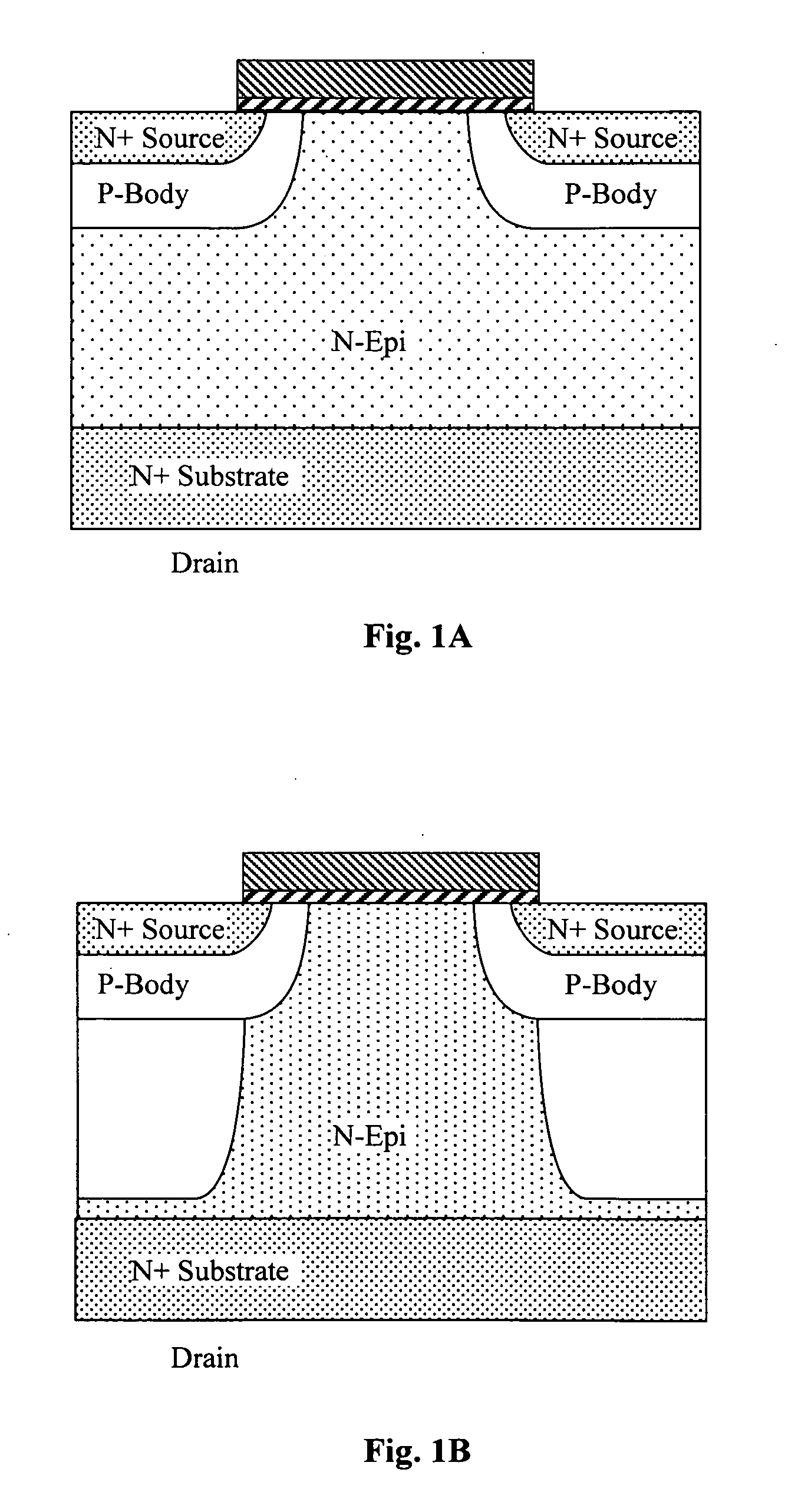

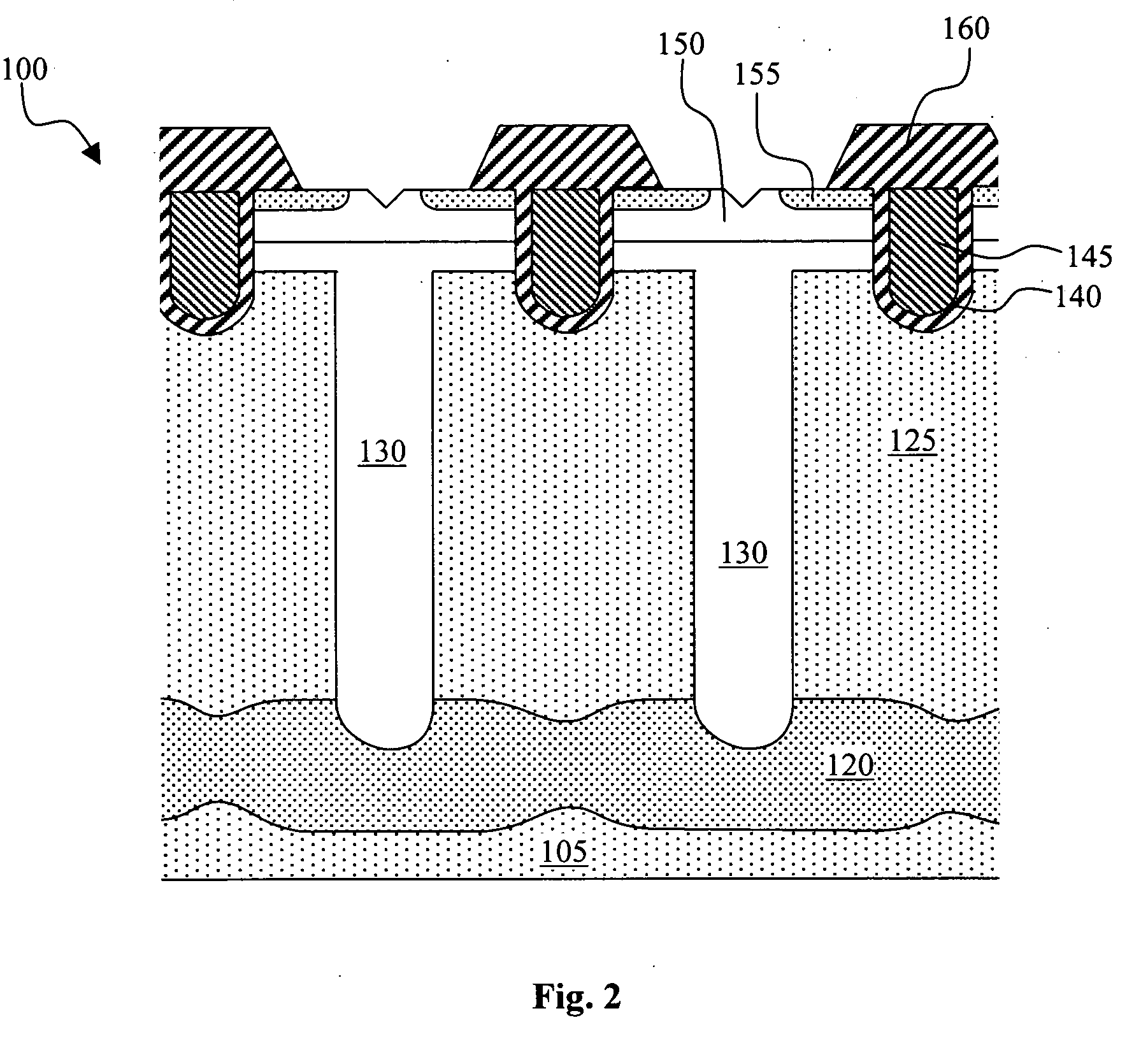

Configurations and methods for manufacturing charge balanced devices

ActiveUS20100044791A1Simple and convenient processing stepReduce processing stepsSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricTrench gate

This invention discloses a semiconductor power device disposed in a semiconductor substrate and the semiconductor substrate has a plurality of deep trenches. The deep trenches are filled with an epitaxial layer thus forming a top epitaxial layer covering areas above a top surface of the deep trenches covering over the semiconductor substrate. The semiconductor power device further includes a plurality of transistor cells disposed in the top epitaxial layer whereby a device performance of the semiconductor power device is dependent on a depth of the deep trenches and not dependent on a thickness of the top epitaxial layer. Each of the plurality of transistor cells includes a trench DMOS transistor cell having a trench gate opened through the top epitaxial layer and filled with a gate dielectric material.

Owner:ALPHA & OMEGA SEMICON LTD

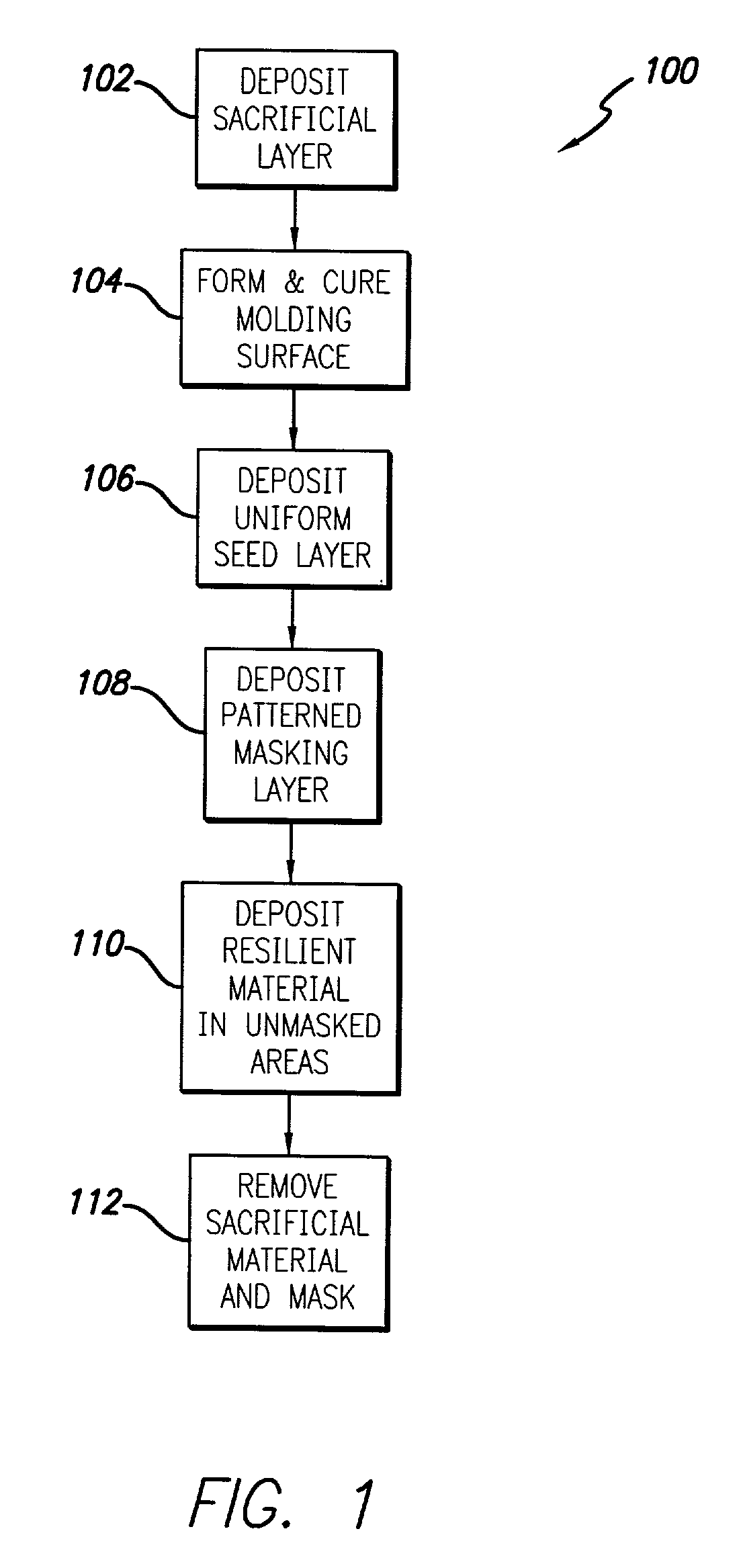

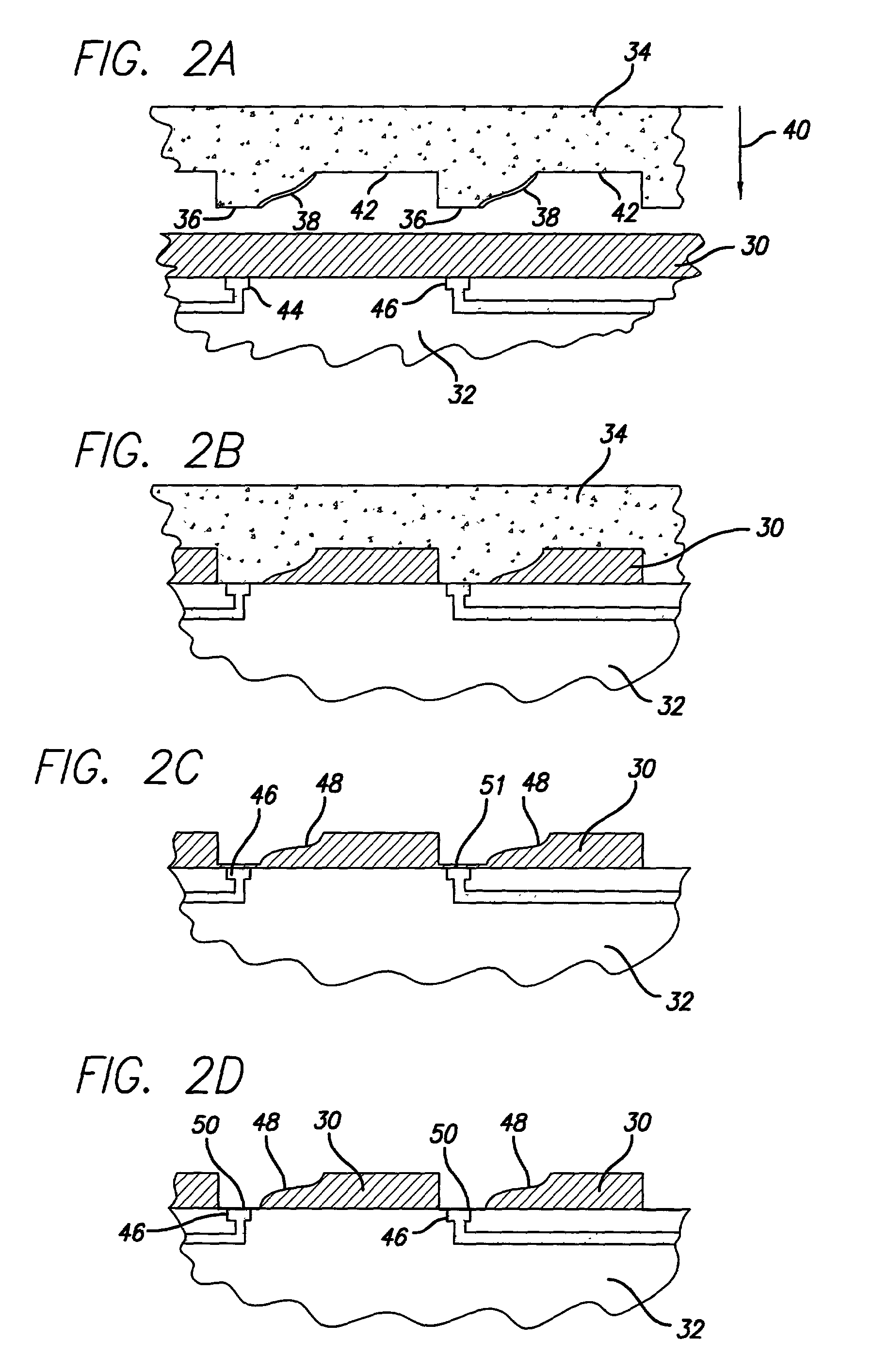

Method for forming microelectronic spring structures on a substrate

InactiveUS20010044225A1Reduce processing stepsEasy to adaptDecorative surface effectsSemiconductor/solid-state device detailsEngineeringSubstitution method

A method for fabricating microelectronic spring structures is disclosed. In an initial step of the method, a layer of sacrificial material is formed over a substrate. Then, a contoured surface is developed in the sacrificial material, such as by molding the sacrificial material using a mold or stamp. The contoured surface provides a mold for at least one spring form, and preferably for an array of spring forms. If necessary, the sacrificial layer is then cured or hardened. A layer of spring material is deposited over the contoured surface of the sacrificial material, in a pattern to define at least one spring form, and preferably an array of spring forms. The sacrificial material is then at least partially removed from beneath the spring form to reveal at least one freestanding spring structure. A separate conducting tip is optionally attached to each resulting spring structure, and each structure is optionally plated or covered with an additional layer or layers of material, as desired. An alternative method for making a resilient contact structure using the properties of a fluid meniscus is additionally disclosed. In an initial step of the alternative method, a layer of material is provided over a substrate. Then, a recess is developed in the material, and fluid is provided in the recess to form a meniscus. The fluid is cured or hardened to stabilize the contoured shape of the meniscus. The stabilized meniscus is then used to define a spring form in the same manner as the molded surface in the sacrificial material.

Owner:FORMFACTOR INC

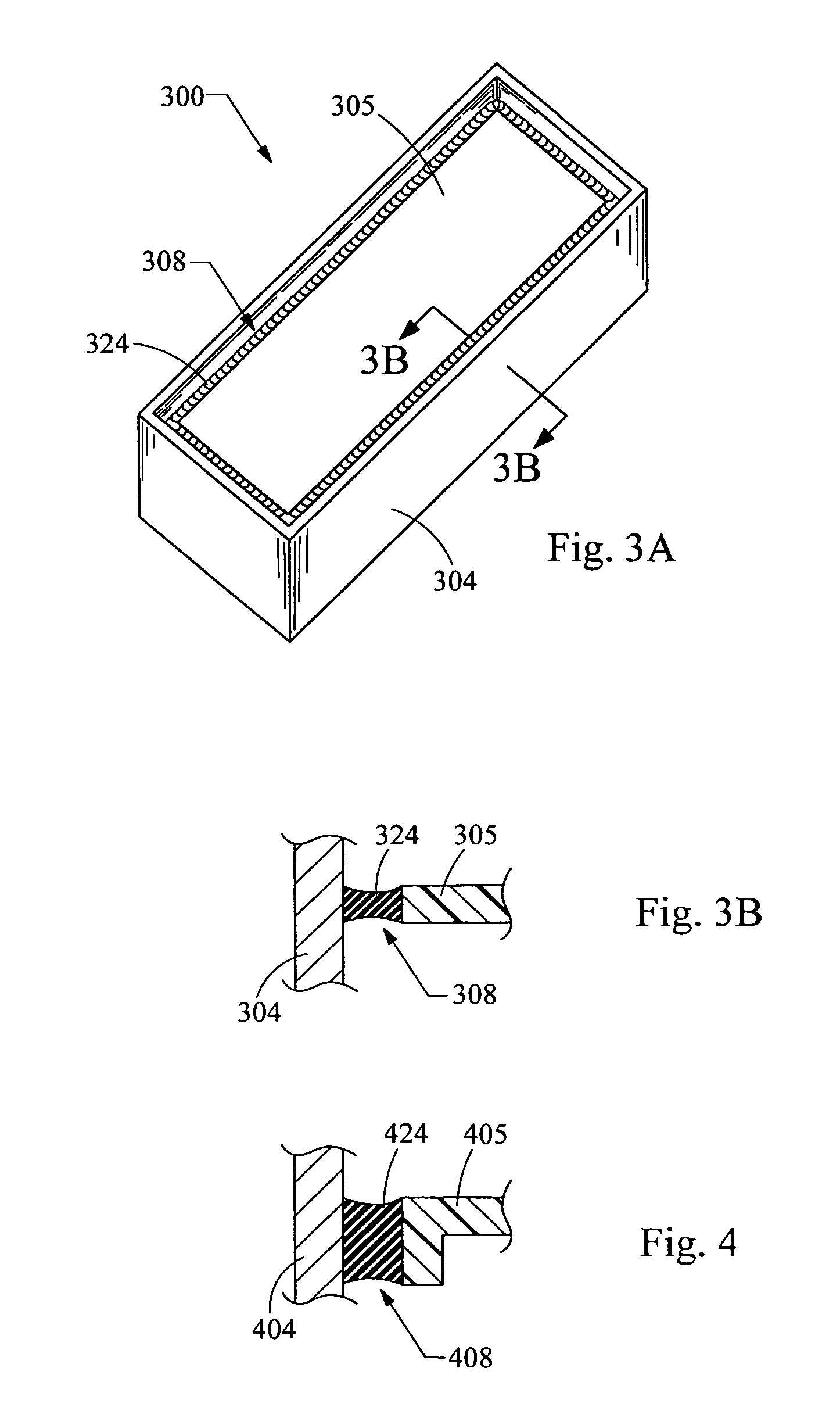

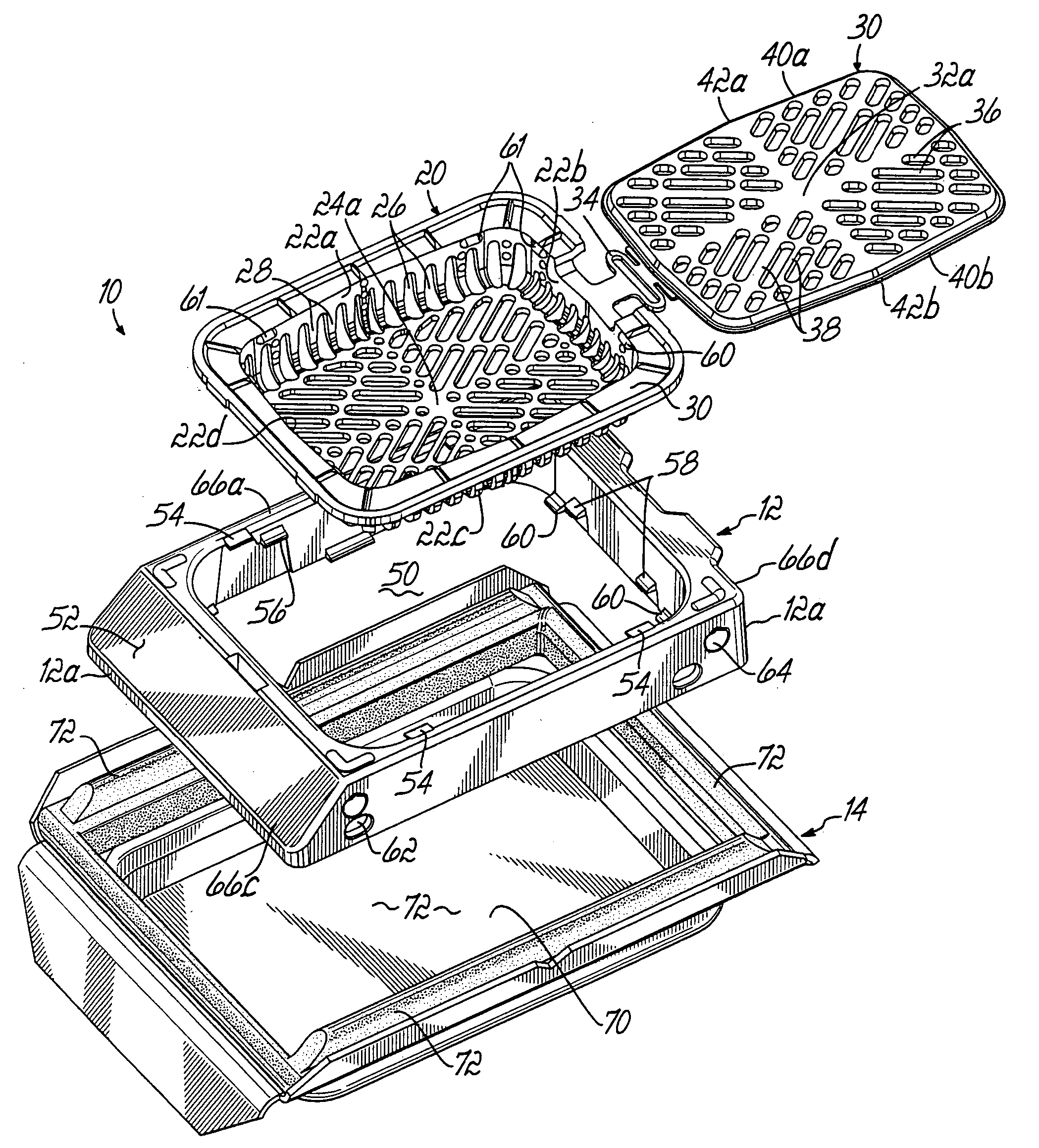

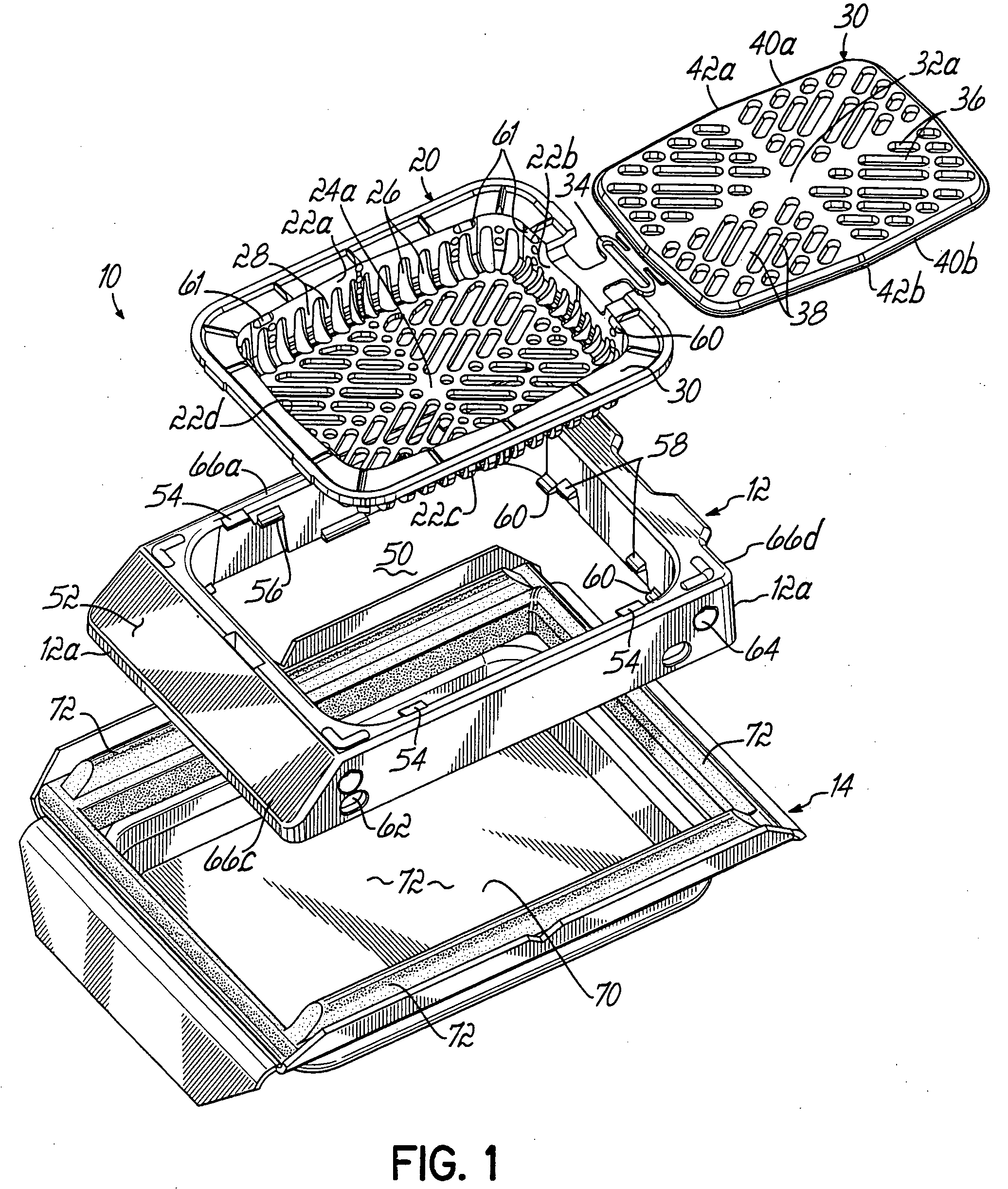

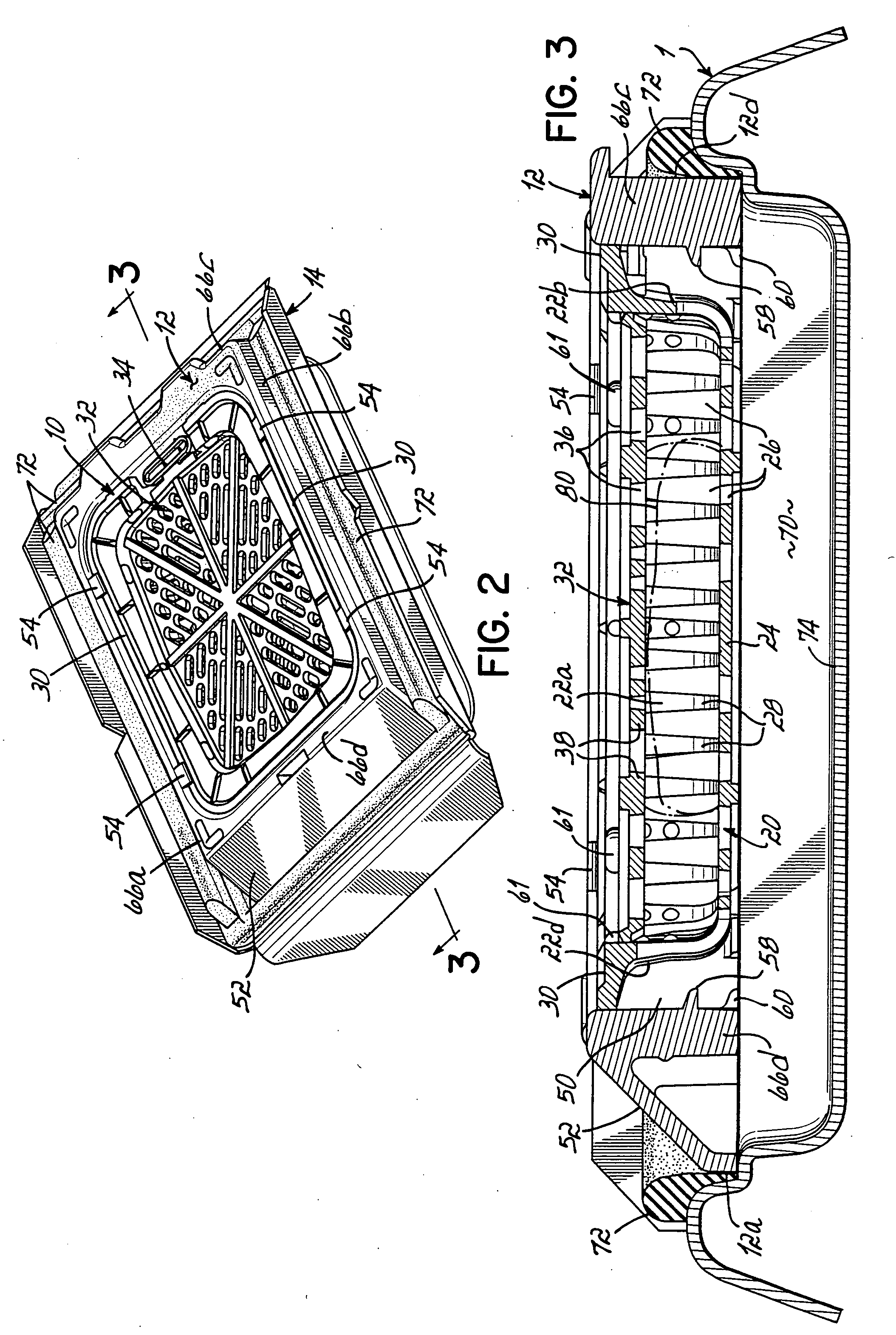

Cassette and embedding assembly for handling and holding tissue samples during processing, embedding and microtome procedures, staging devices therefore, and methods therefor

ActiveUS20050147538A1Reduce processing stepsSave amountBioreactor/fermenter combinationsBiological substance pretreatmentsDetentTissue sample

The disclosure relates to a cassette, frame and mold for holding a tissue sample during an embedding and mircotoming process, and related methods. The cassette is sectionable in a microtome and includes a body with a bottom wall and a plurality of side walls. First and second side walls are generally V-shaped to present an apex of the “V” to the microtome blade. A lid of the cassette is stiffer than the bottom wall of the cassette to assist with positioning the tissue sample. The side walls of the cassette are perforated so as to significantly reduce the amount of cassette material that must be cut by the microtome blade. In one embodiment, to additionally reduce blade wear the ribs on one side wall are offset lengthwise relative to the ribs on an opposite side wall. An upper flange of the cassette includes depressions configured to register with detents in the frame.

Owner:BIOPATH AUTOMATION

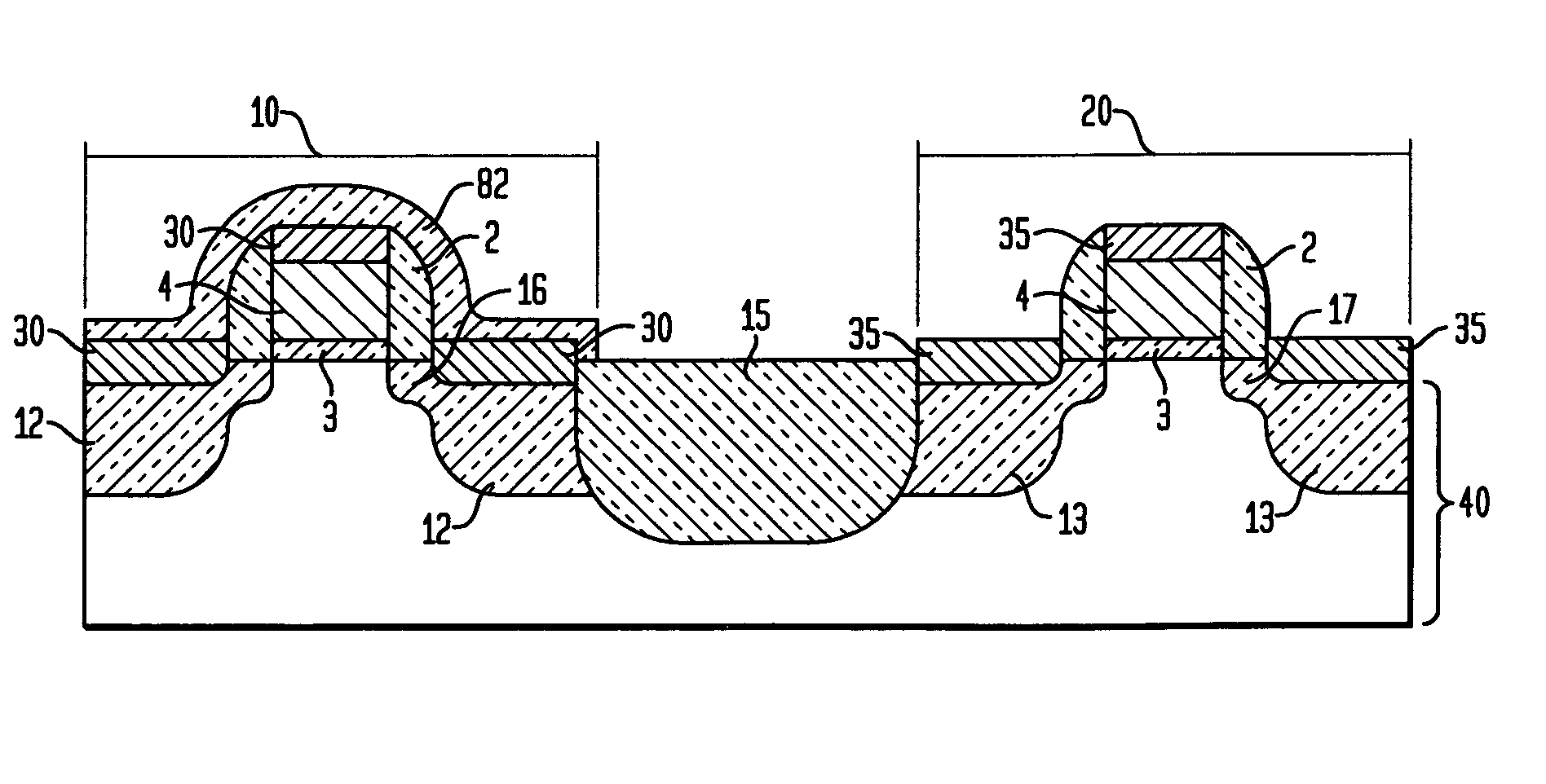

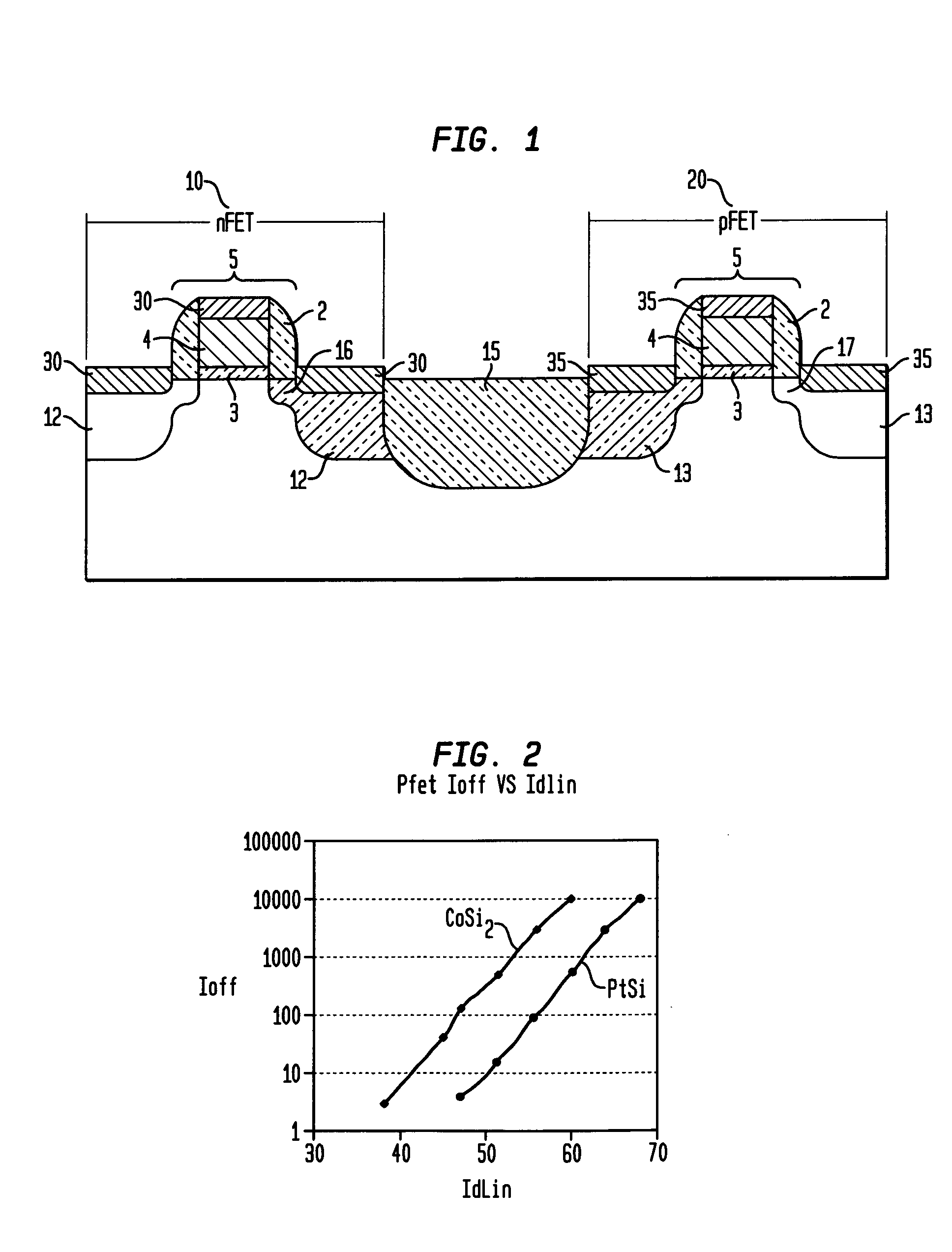

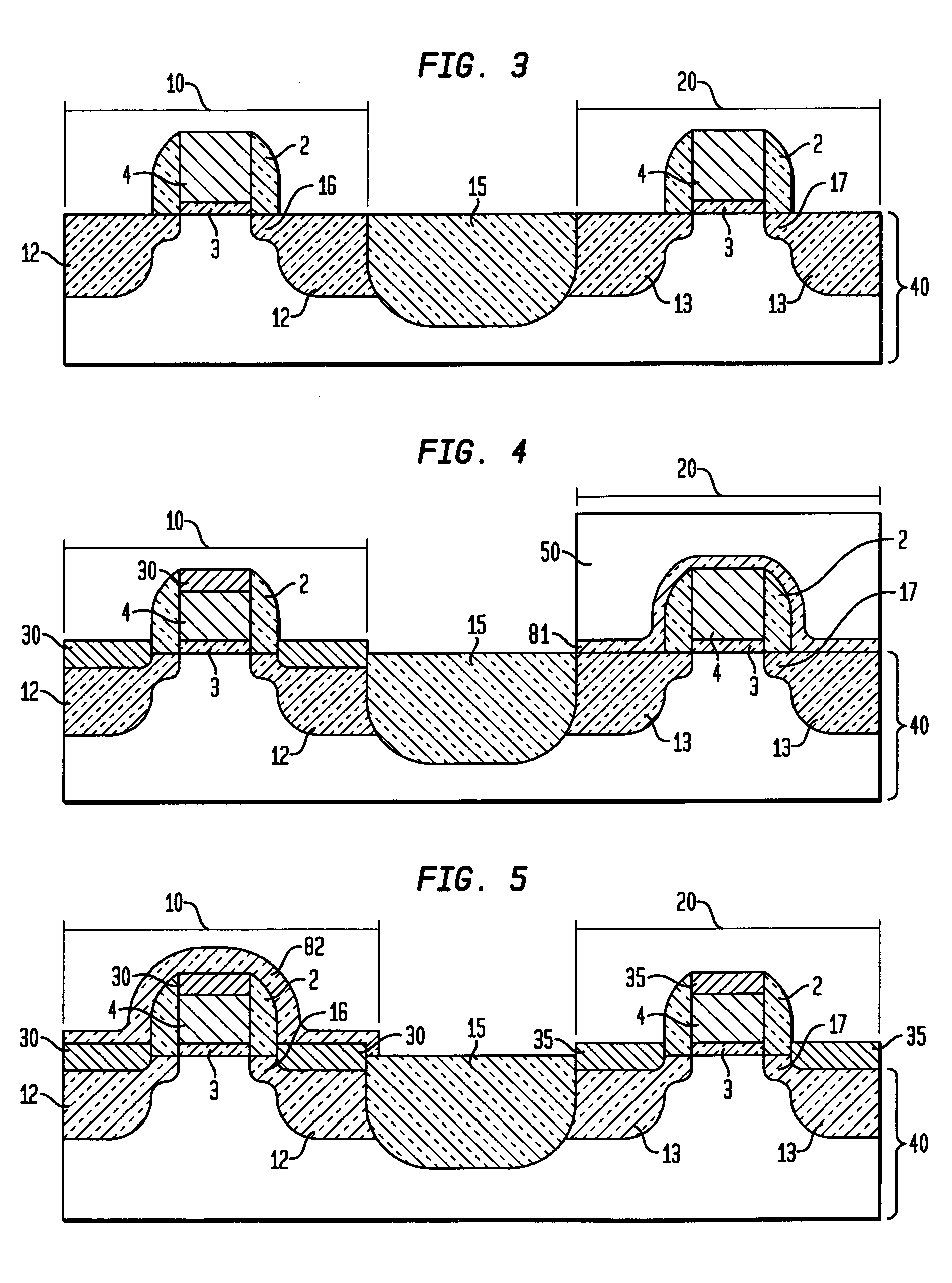

Dual silicide process to improve device performance

InactiveUS20060163670A1Reduced resistivity for contactingReduce contactTransistorSemiconductor/solid-state device manufacturingValence bandSalicide

A semiconducting structure and a method of forming thereof, includes a substrate having a p-type device region and an n-type device region; a first-type suicide contact to the n-type device region; the first-type suicide having a work function that is substantially aligned to the n-type device region conduction band; and a second-type silicide contact to the p-type device region; the second-type silicide having a work function that is substantially aligned to the p-type device region valence band. The present invention also provides a semiconducting structure and a method of forming therefore, in which the silicide contact material and silicide contact processing conditions are selected to provide strain based device improvements in pFET and nFET devices.

Owner:IBM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com