Patents

Literature

4468results about How to "Low dielectric constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicone polymer insulation film on semiconductor substrate and method for forming the film

InactiveUS6352945B1Low dielectric constantImprove thermal stabilityLiquid surface applicatorsSemiconductor/solid-state device detailsPolymer scienceHigh humidity

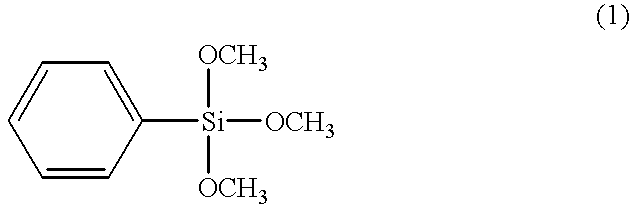

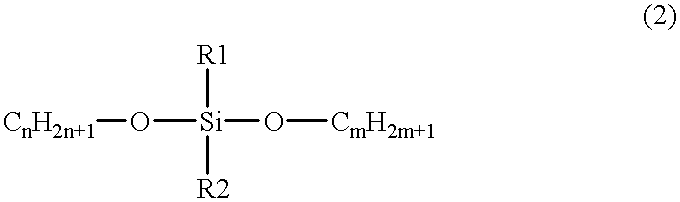

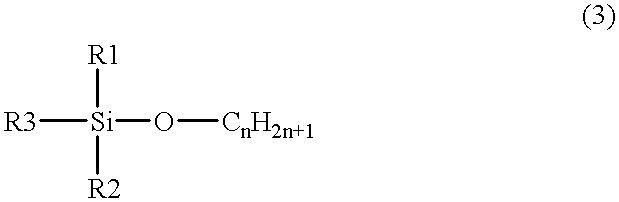

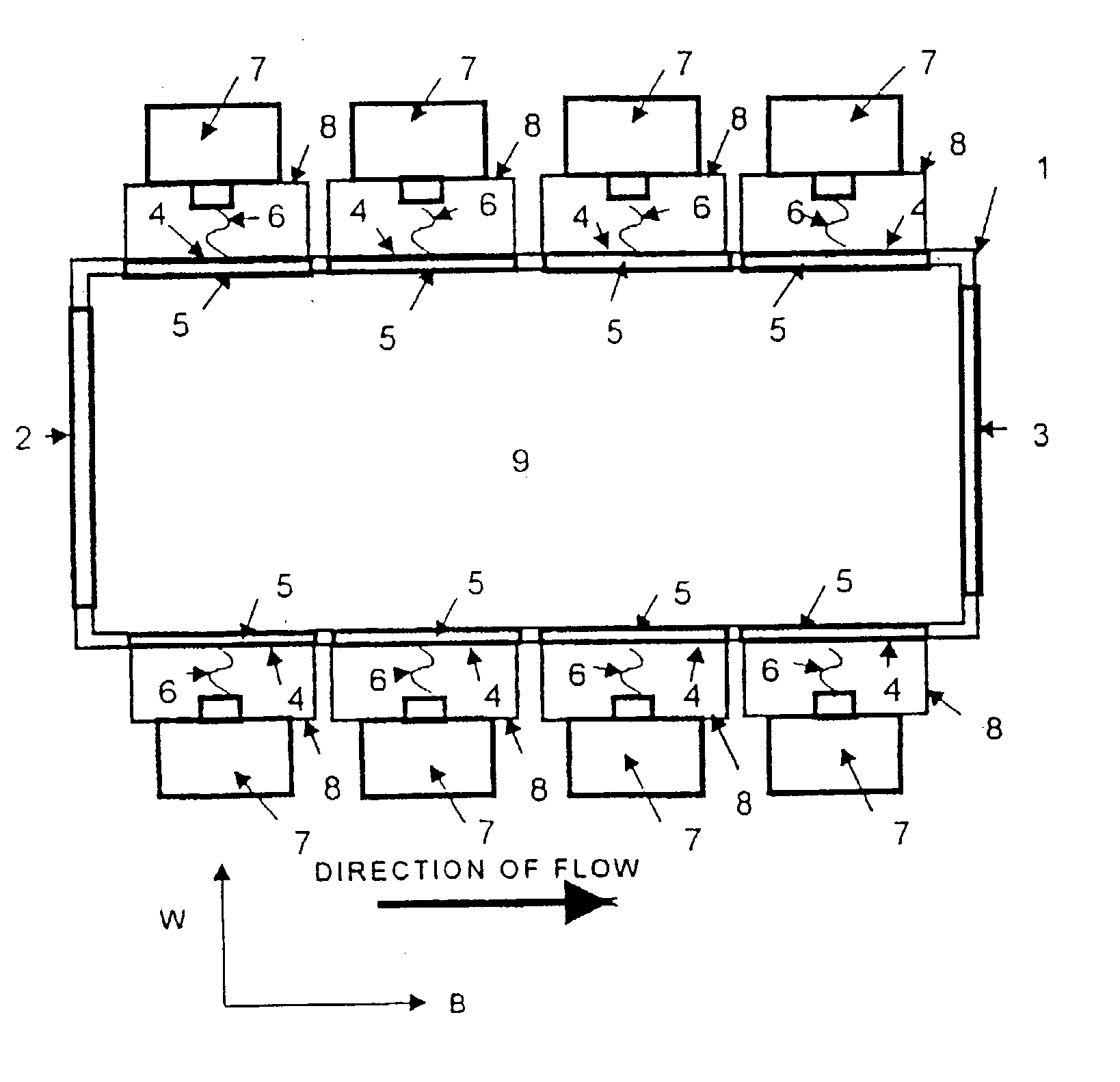

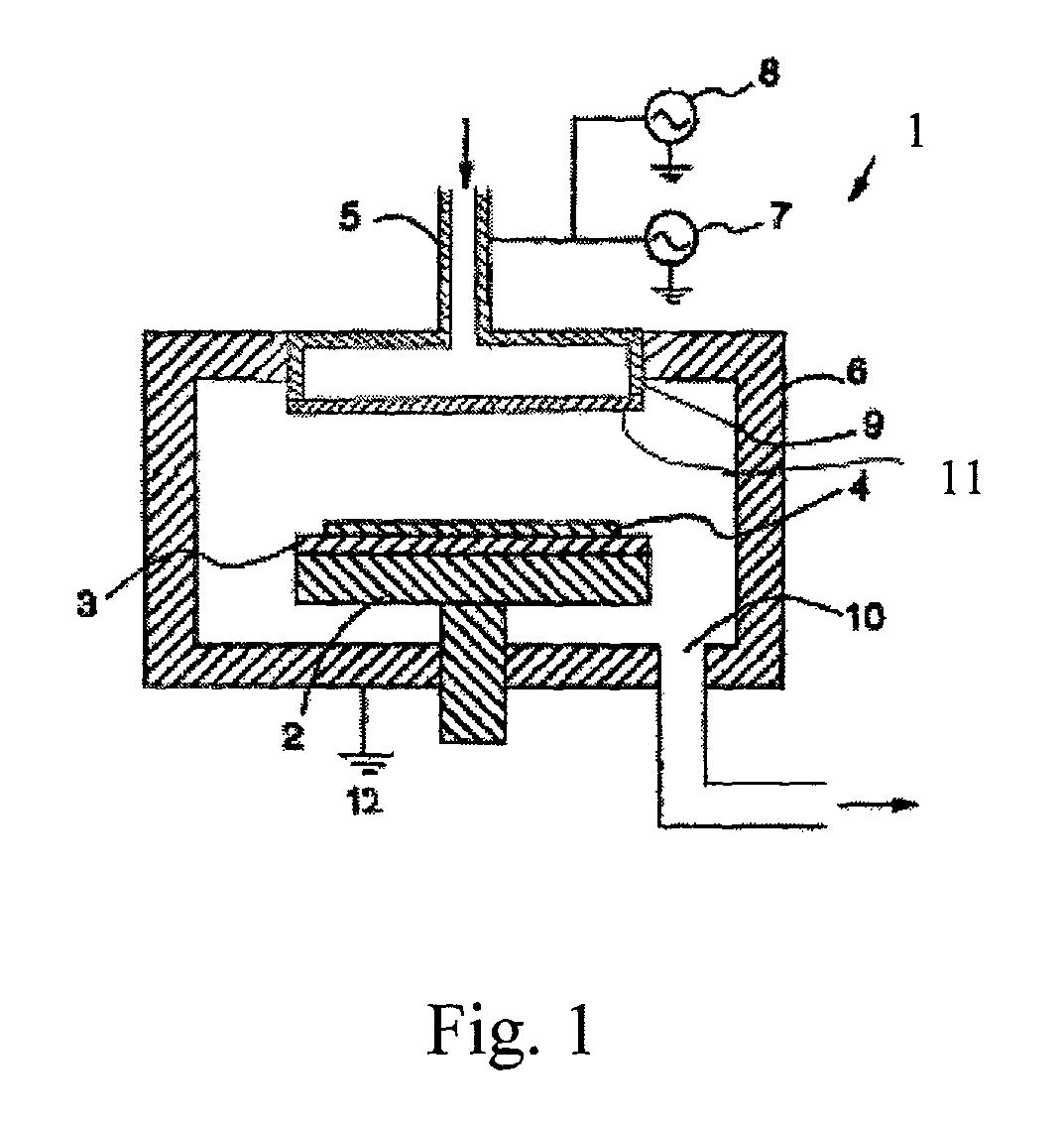

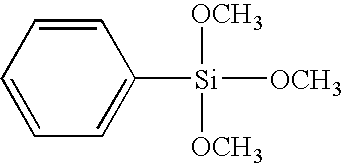

A method for forming a silicone polymer insulation film having a low relative dielectric constant, high thermal stability and high humidity-resistance on a semiconductor substrate is applied to a plasma CVD apparatus. The first step is introducing a silicon-containing hydrocarbon compound expressed by the general formula SialphaObetaCxHy (alpha, beta, x, and y are integers) to the reaction chamber of the plasma CVD apparatus. The silicon-containing hydrocarbon compound has at most two O-CnH2n+1 bonds and at least two hydrocarbon radicals bonded to the silicon. The residence time of the material gas is lengthened by, for example, reducing the total flow of the reaction gas, in such a way as to form a silicone polymer film having a micropore porous structure with a low relative dielectric constant.

Owner:ASM JAPAN

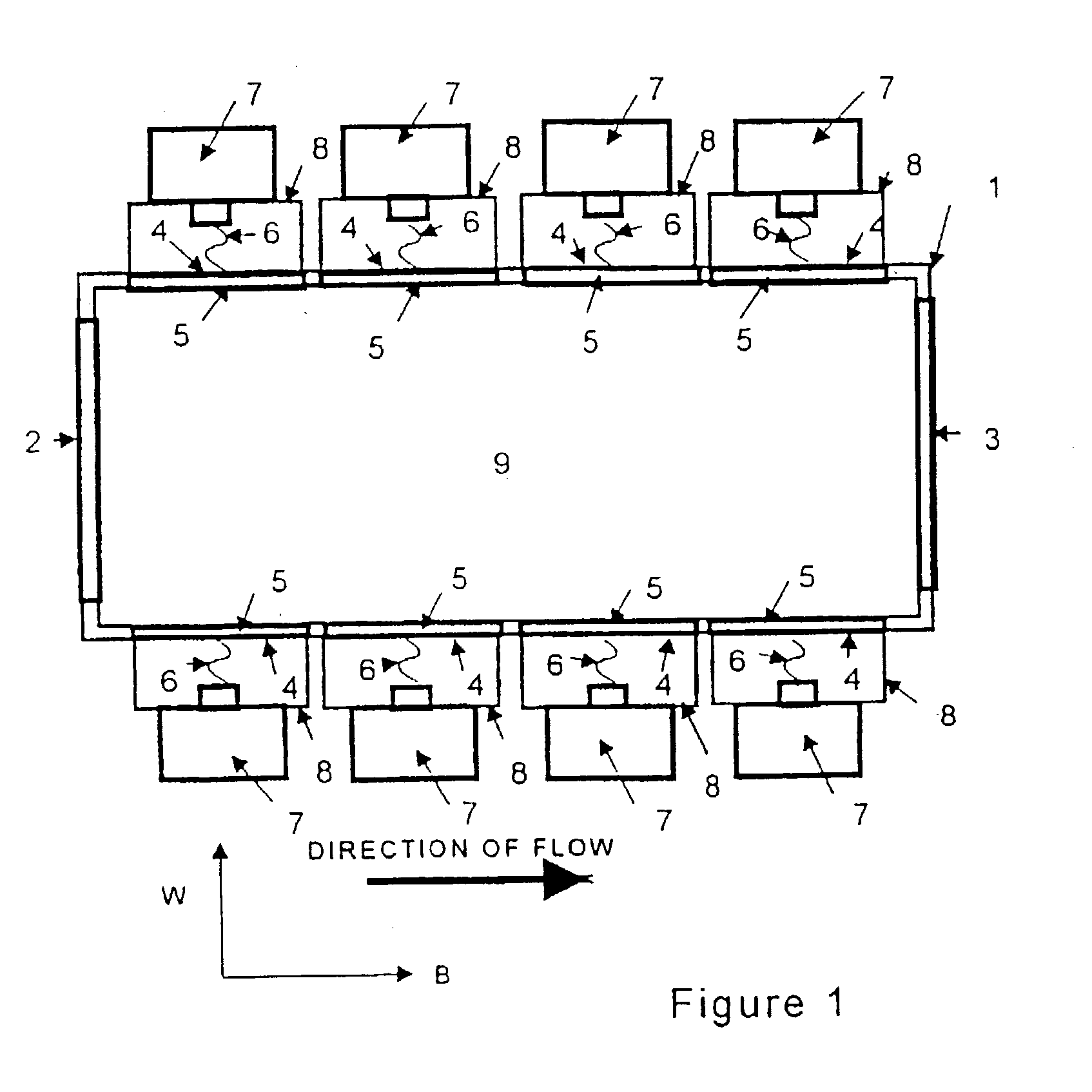

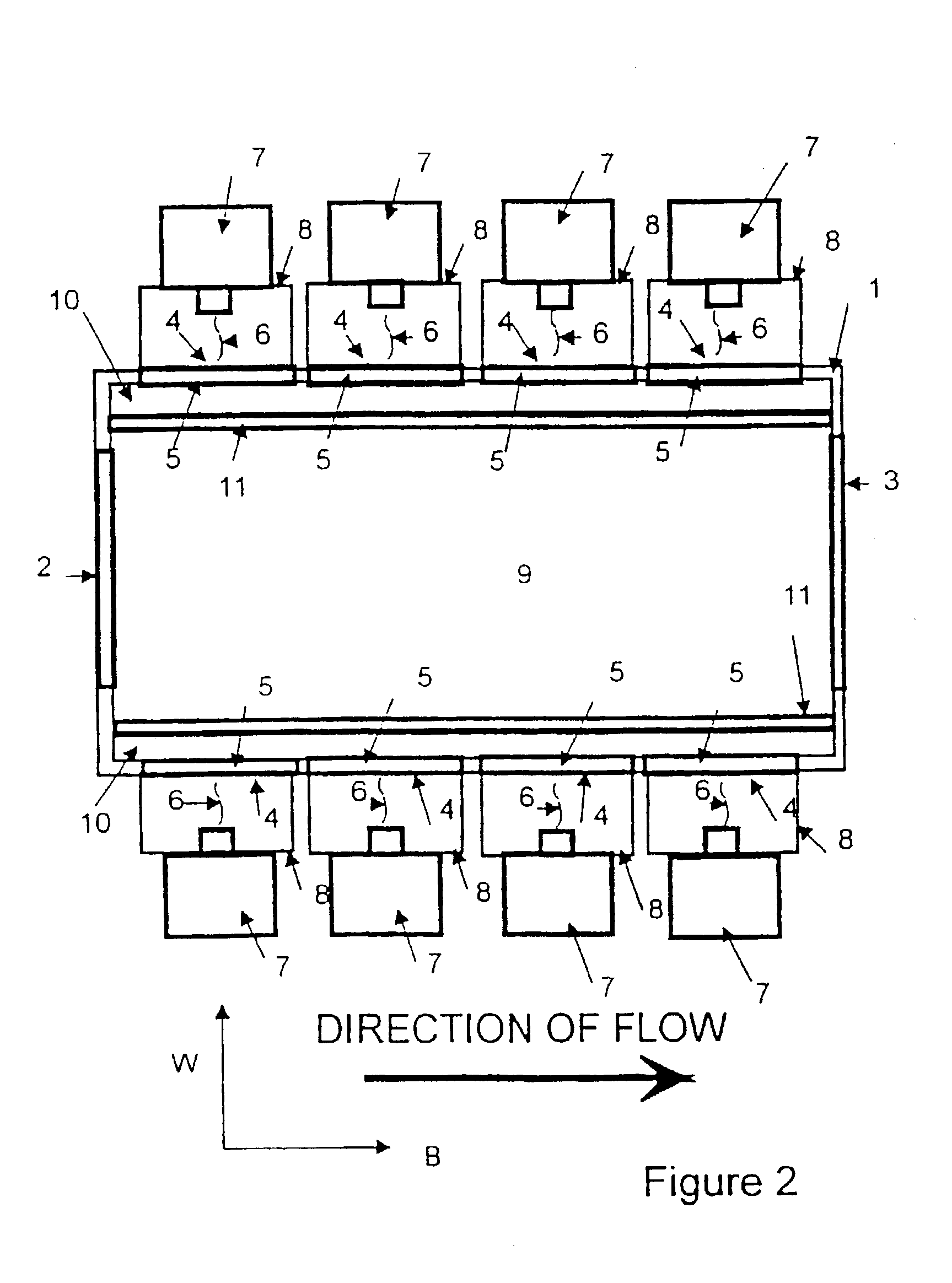

Electromagnetic susceptors with coatings for artificial dielectric systems and devices

InactiveUS20030226840A1Enhanced radiationLow dielectric constantGas treatmentMethane captureChemical treatmentSusceptor

A coated susceptor of electromagnetic energy for chemical processing made of a matrix material that surrounds a non-matrix material that is made from a material that is different from the matrix material, in which the matrix material is constructed of material having lower dielectric losses compared to the non-matrix material, the non-matrix material initially absorbs electromagnetic energy applied to the electromagnetic susceptor to a greater extent than the matrix material, the non-matrix material produces subsequent heat in the matrix material, and the surface of the susceptor is coated with a material that interacts with applied electromagnetic energy of at least one frequency and initially absorbs electromagnetic energy and produces heat.

Owner:DALTON ROBERT C

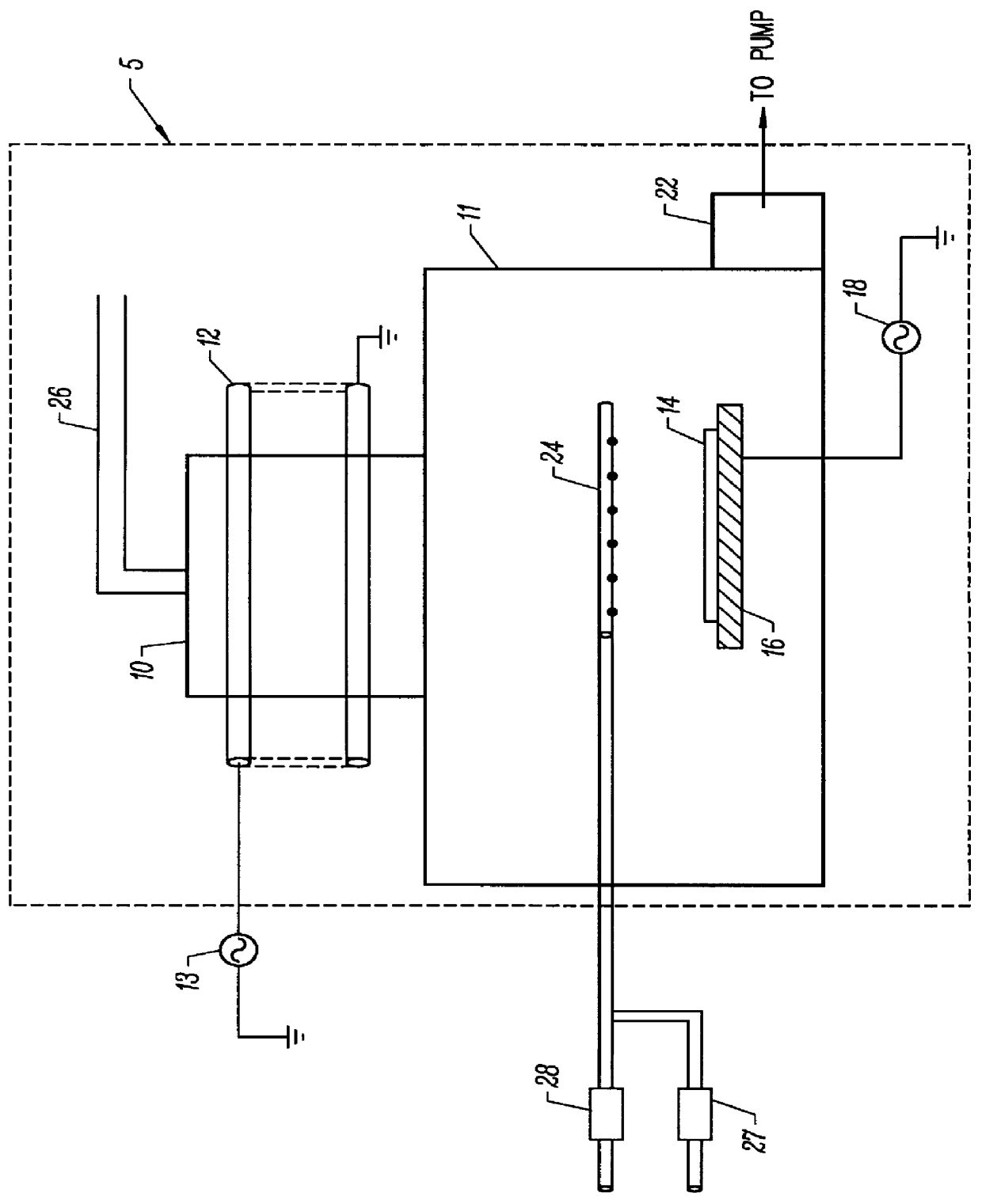

Plasma curing process for porous silica thin film

InactiveUS6558755B2Low dielectric constantHigh elastic modulusSilicaSemiconductor/solid-state device manufacturingSilicon dioxideHeat treated

Low dielectric constant films with improved elastic modulus. The method of making such coatings involves providing a porous network coating produced from a resin containing at least 2 Si-H groups and plasma curing the coating to convert the coating into porous silica. Plasma curing of the network coating yields a coating with improved modulus, but with a higher dielectric constant. The costing is plasma cured for between about 15 and about 120 seconds at a temperature less than or about 350° C. The plasma cured coating can optionally be annealed. Rapid thermal processing (RTP) of the plasma cured coating reduces the dielectric constant of the coating while maintaining an improved elastic modulus as compared to the plasma cured porous network coating. The annealing temperature is typically loss than or about 475° C., and the annealing time is typically no more than or about 180 seconds. The annealed, plasma cured coating has a dielectric constant in the range of from about 1.1 to about 2.4 and an improved elastic modulus.

Owner:AXCELIS TECHNOLOGIES +1

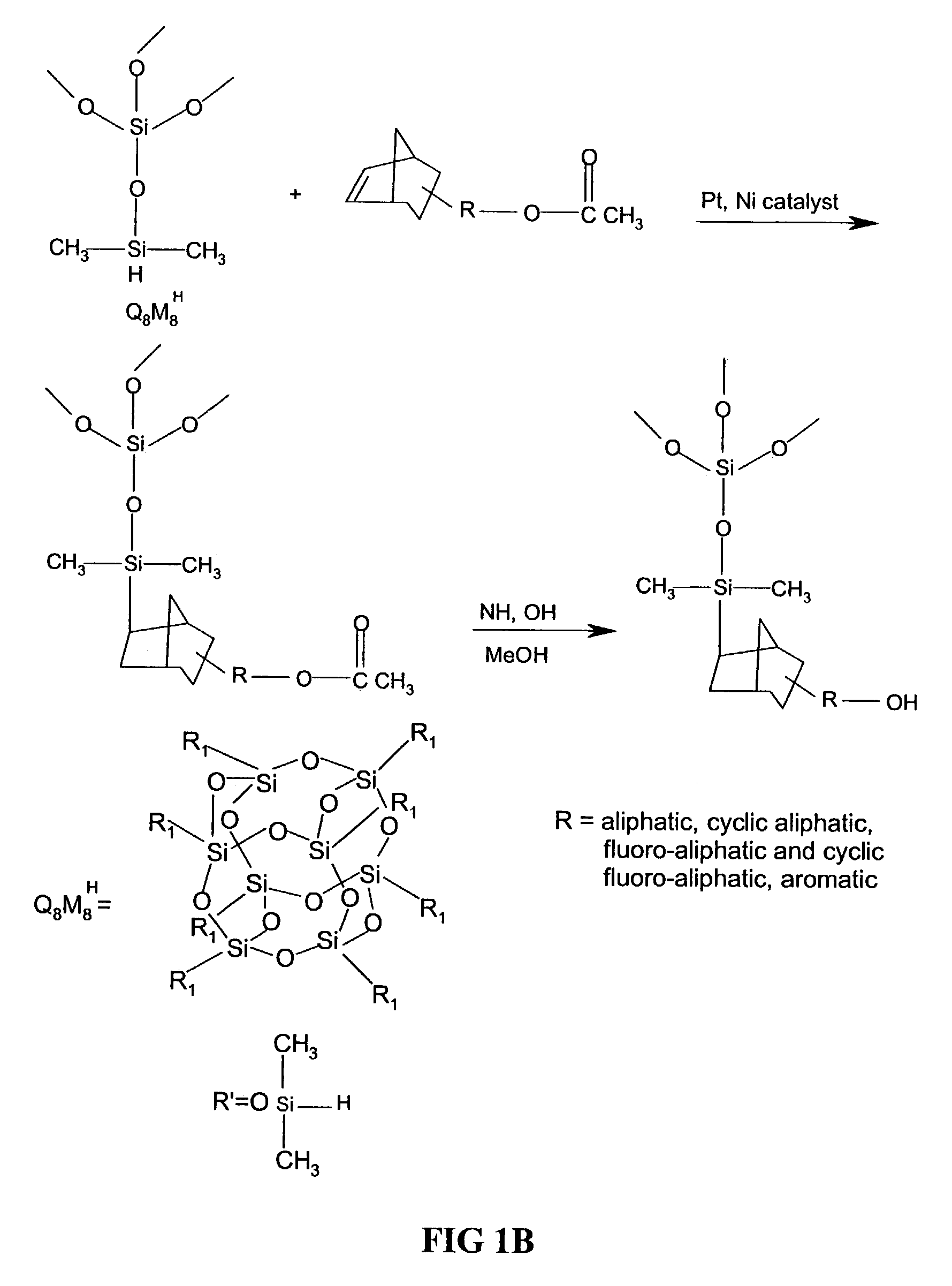

Method of making low kappa dielectric inorganic/organic hybrid films

InactiveUS6068884AImprove thermal stabilityLow dielectric constantLayered productsSemiconductor/solid-state device detailsThermal chemical vapor depositionSemiconductor

A method of depositing a dielectric film exhibiting a low dielectric constant in a semiconductor and / or integrated circuit by chemical vapor deposition (CVD) is provided. The film is deposited using an organosilicon precursor in a manner such that the film is comprised of a backbone made substantially of Si-O-Si or Si-N-Si groups with organic side groups attached to the backbone.

Owner:APPLIED MATERIALS INC

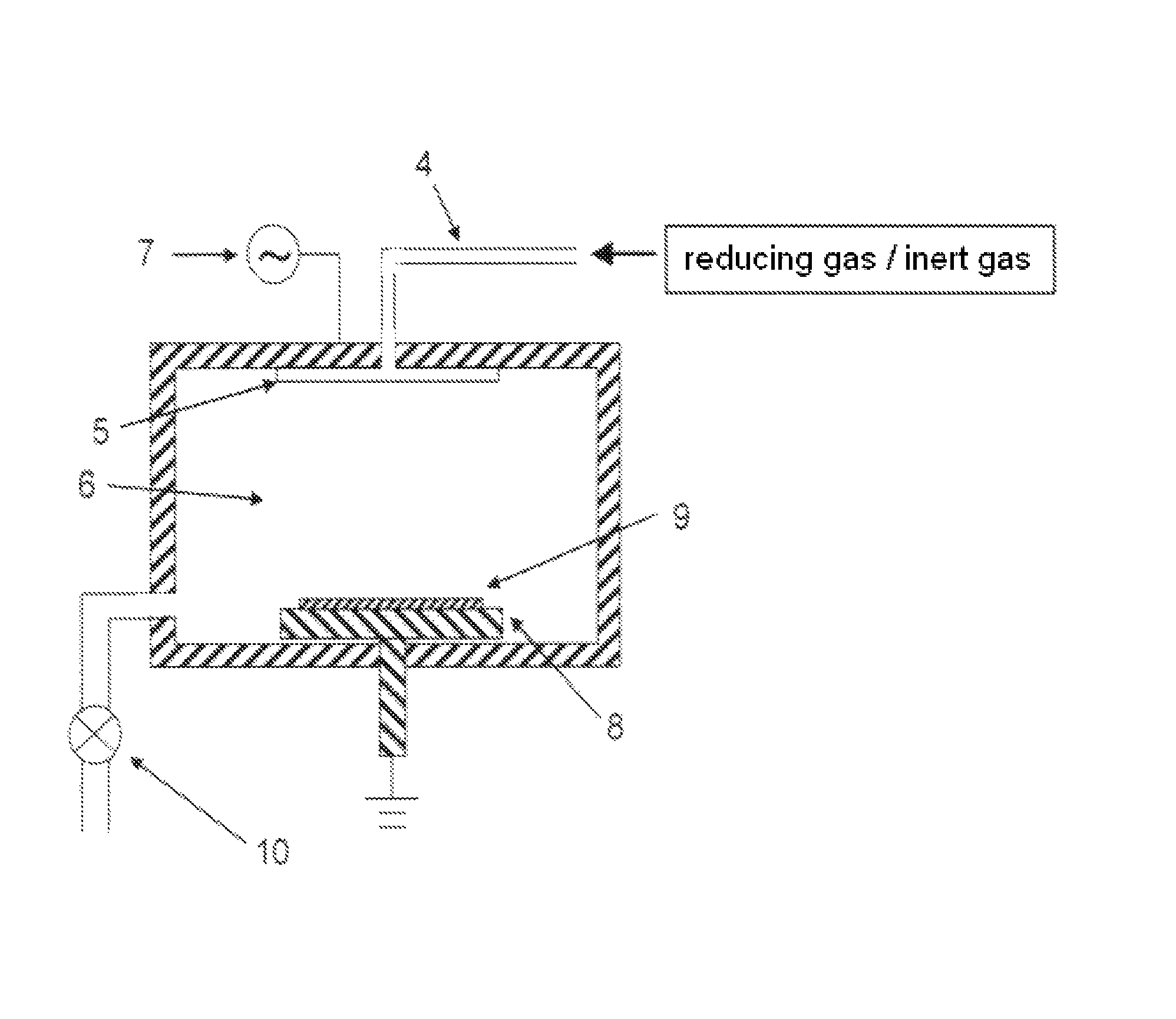

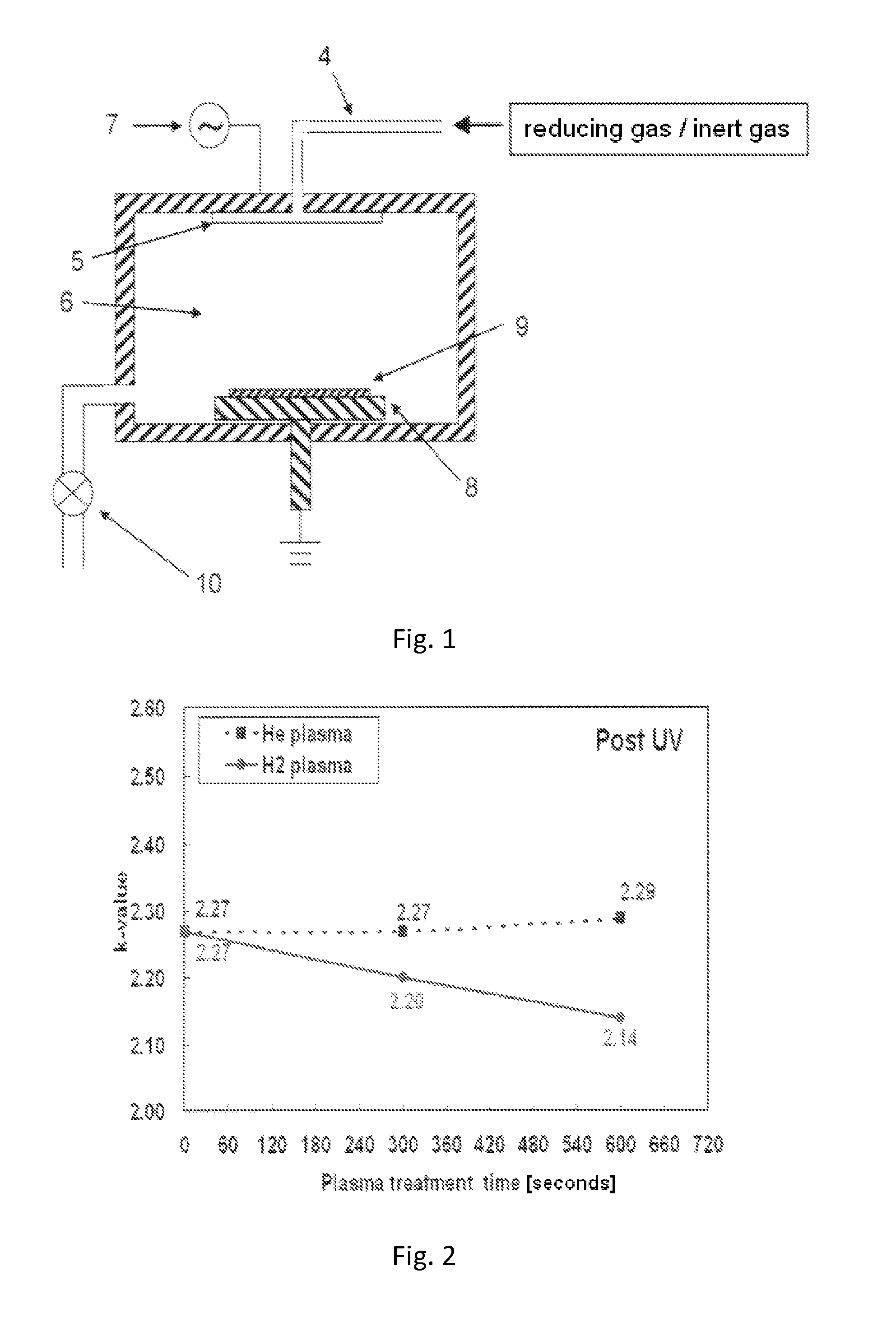

Method for reducing dielectric constant of film using direct plasma of hydrogen

ActiveUS8551892B2Low dielectric constantMaintain mechanical strengthElectric shock equipmentsSemiconductor/solid-state device detailsDielectricCapacitance

A method for reducing a dielectric constant of a film includes (i) forming a dielectric film on a substrate; (ii) treating a surface of the film without film formation, and (III) curing the film. Step (i) includes providing a dielectric film containing a porous matrix and a porogen on a substrate, step (ii) includes, prior to or subsequent to step (iii), treating the dielectric film with charged species of hydrogen generated by capacitively-coupled plasma without film deposition to reduce a dielectric constant of the dielectric film, and step (iii) includes UV-curing the dielectric film to remove at least partially the porogen from the film.

Owner:ASM JAPAN

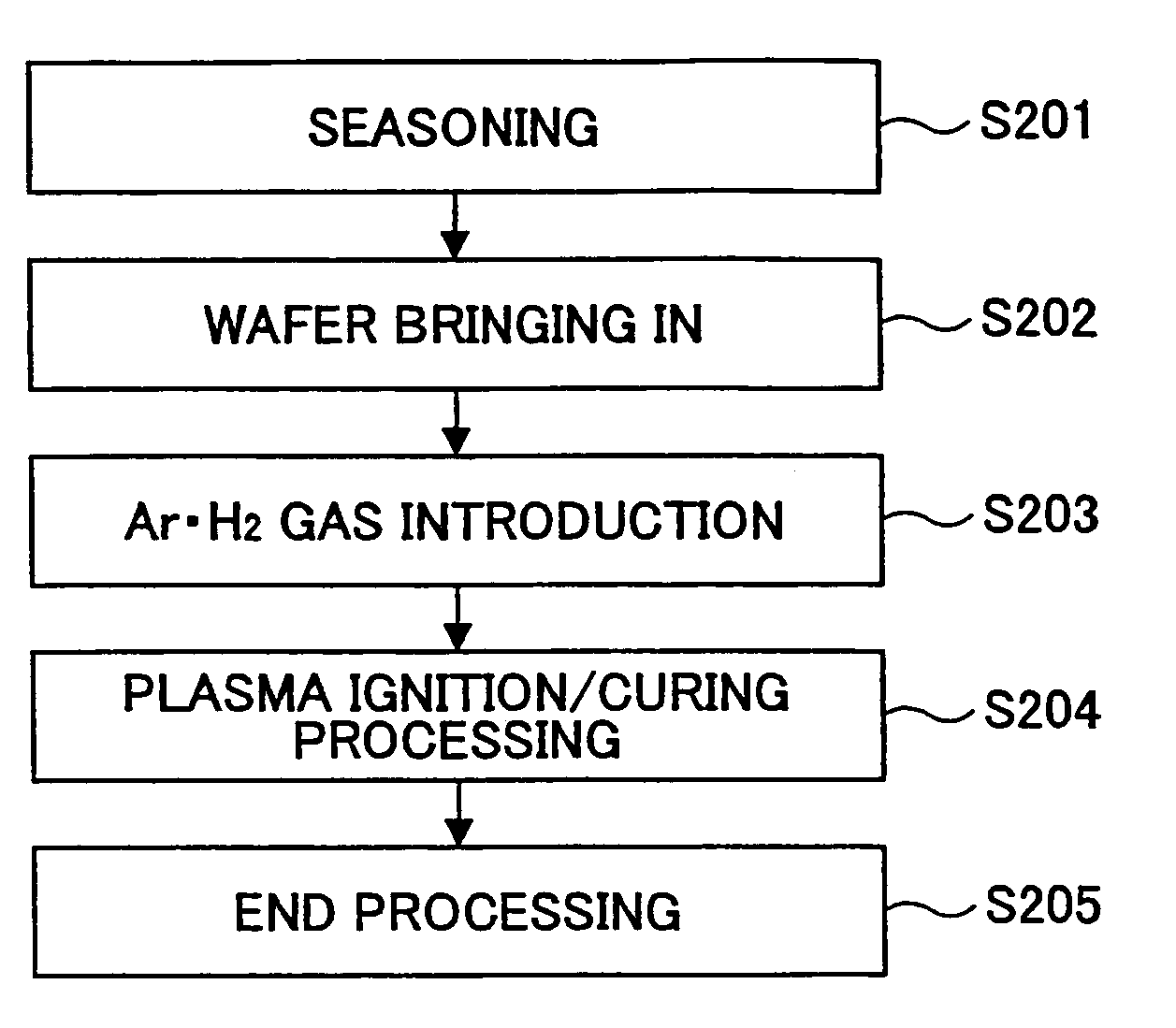

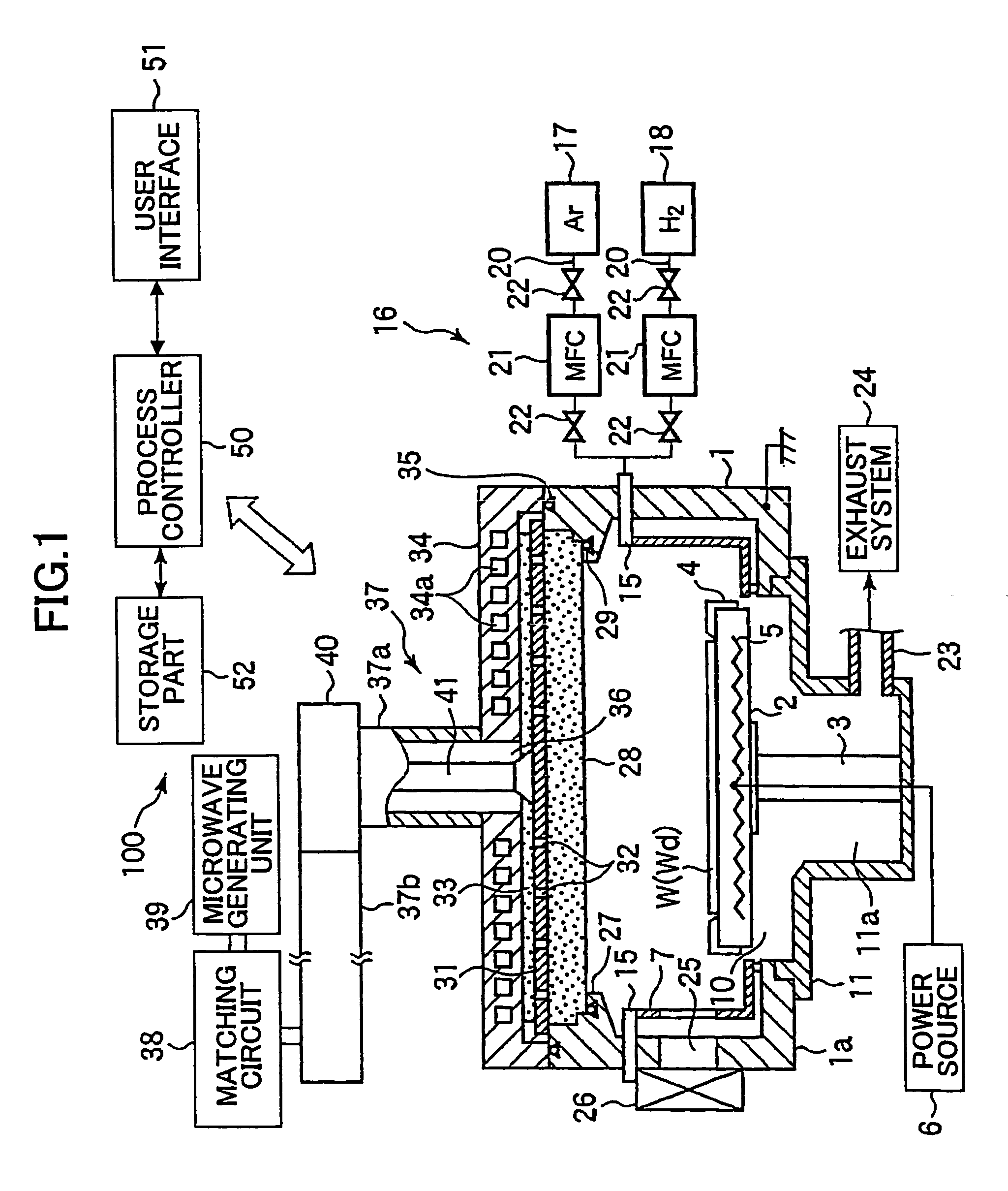

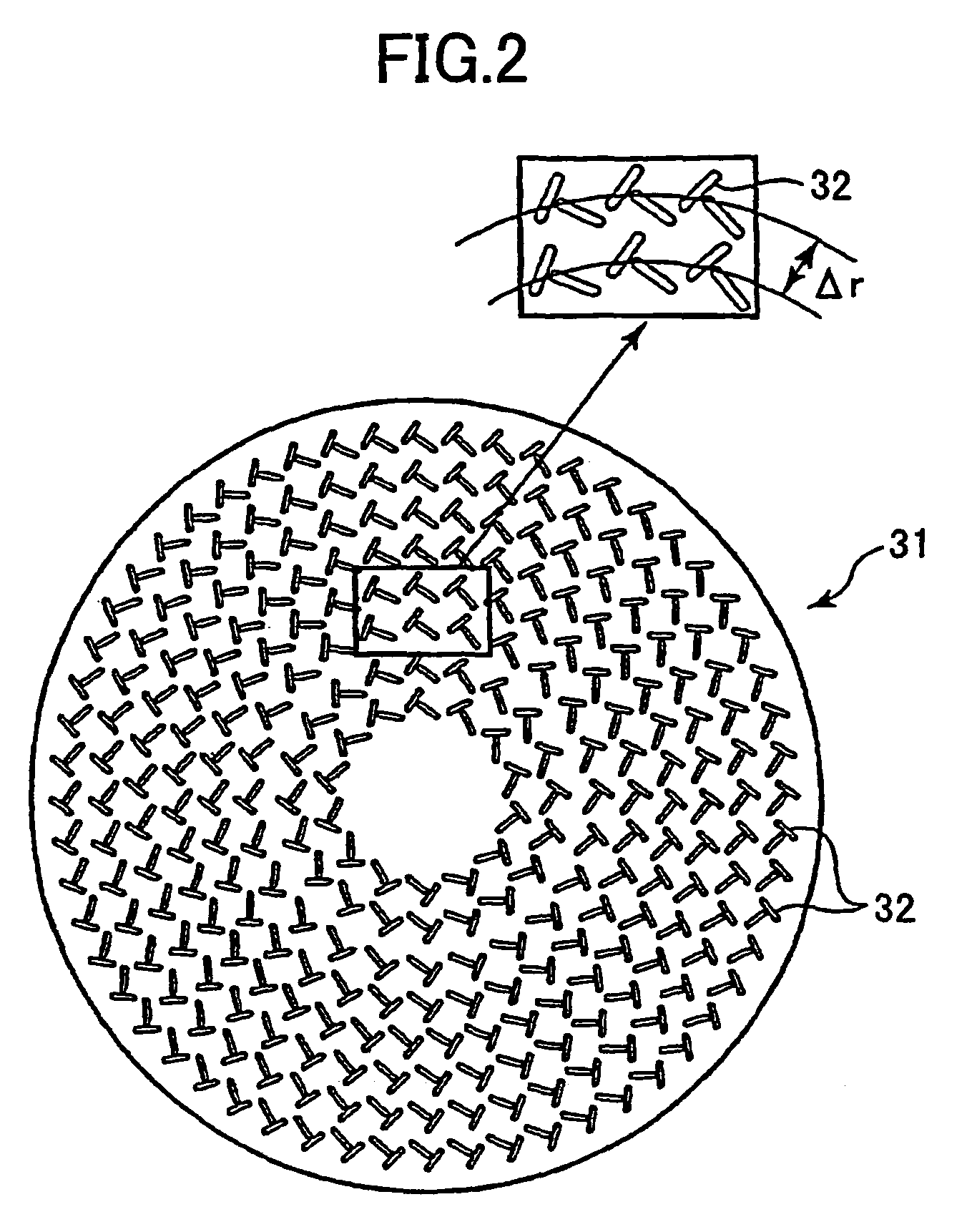

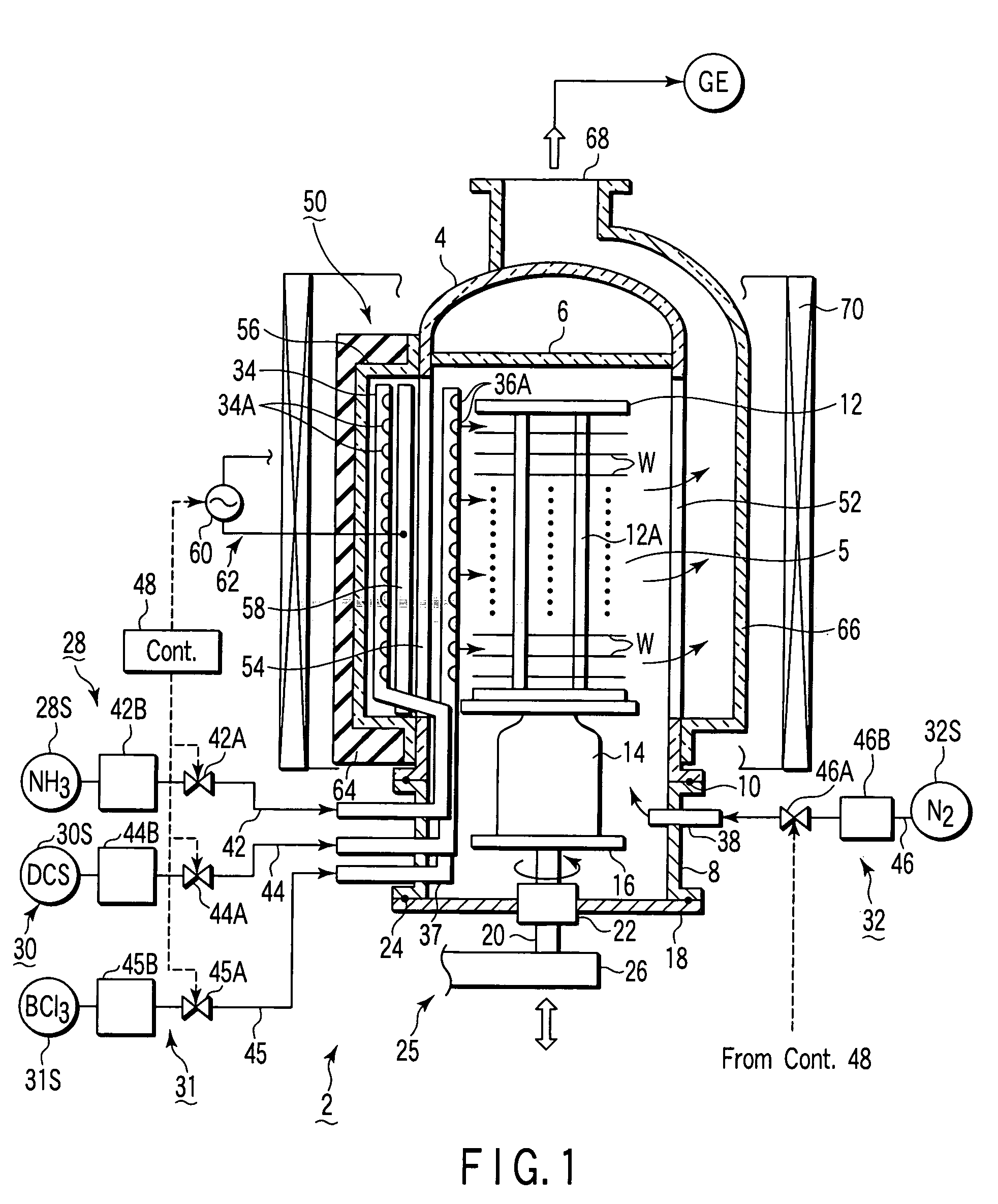

Plasma processing method and film forming method

InactiveUS7771796B2Low dielectric constantImprove adhesionElectric discharge tubesSemiconductor/solid-state device manufacturingHydrogenProduct gas

A plasma processing method of carrying out curing processing on a low dielectric constant film produced on a to-be-processed substrate by applying plasma thereto in a processing chamber of a plasma processing apparatus, includes the steps of: a) introducing, in the plasma processing chamber, a first gas having a function of stabilizing plasma and a second gas generating active hydrogen, and, after that; b) generating plasma, and carrying out curing processing on the low dielectric constant film.

Owner:TOKYO ELECTRON LTD

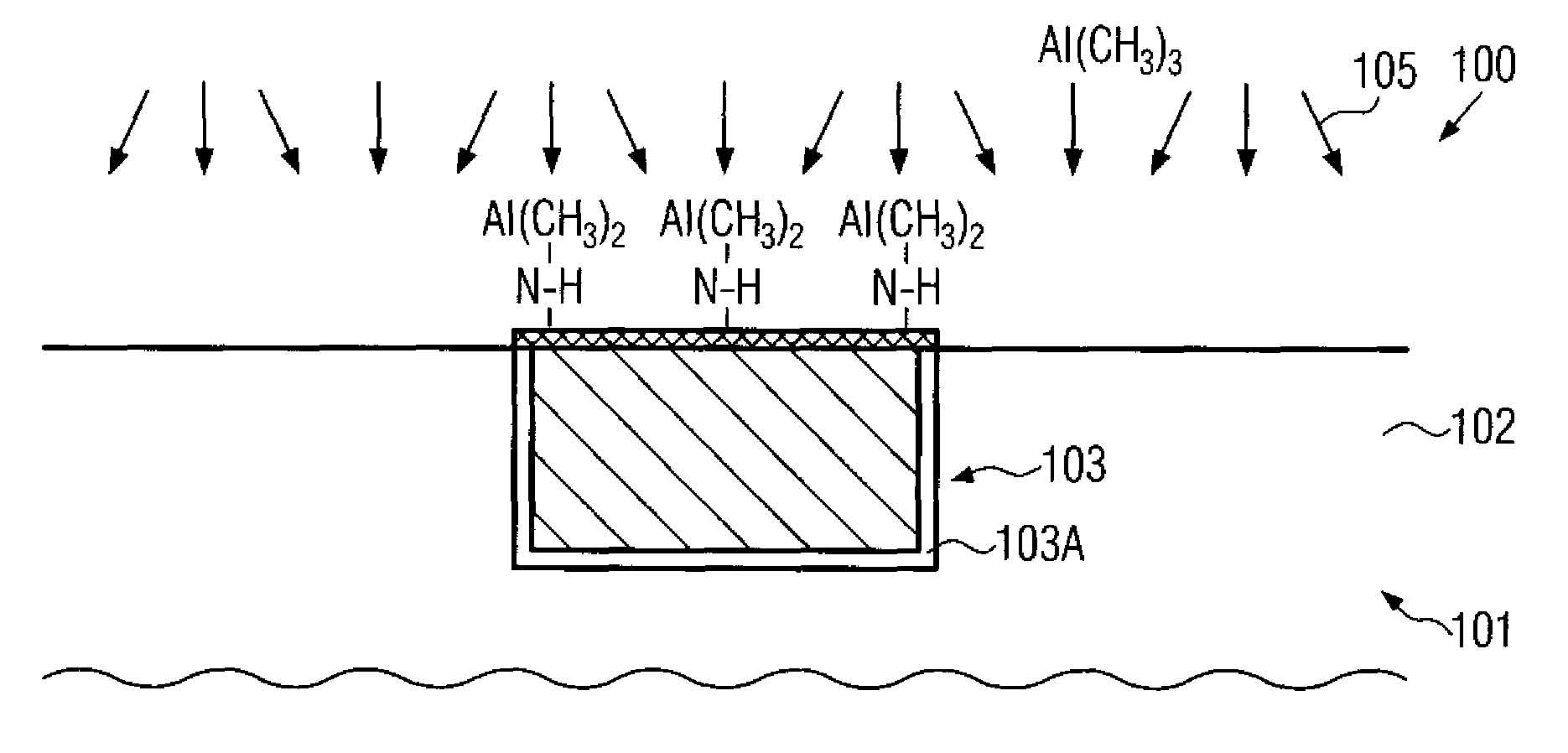

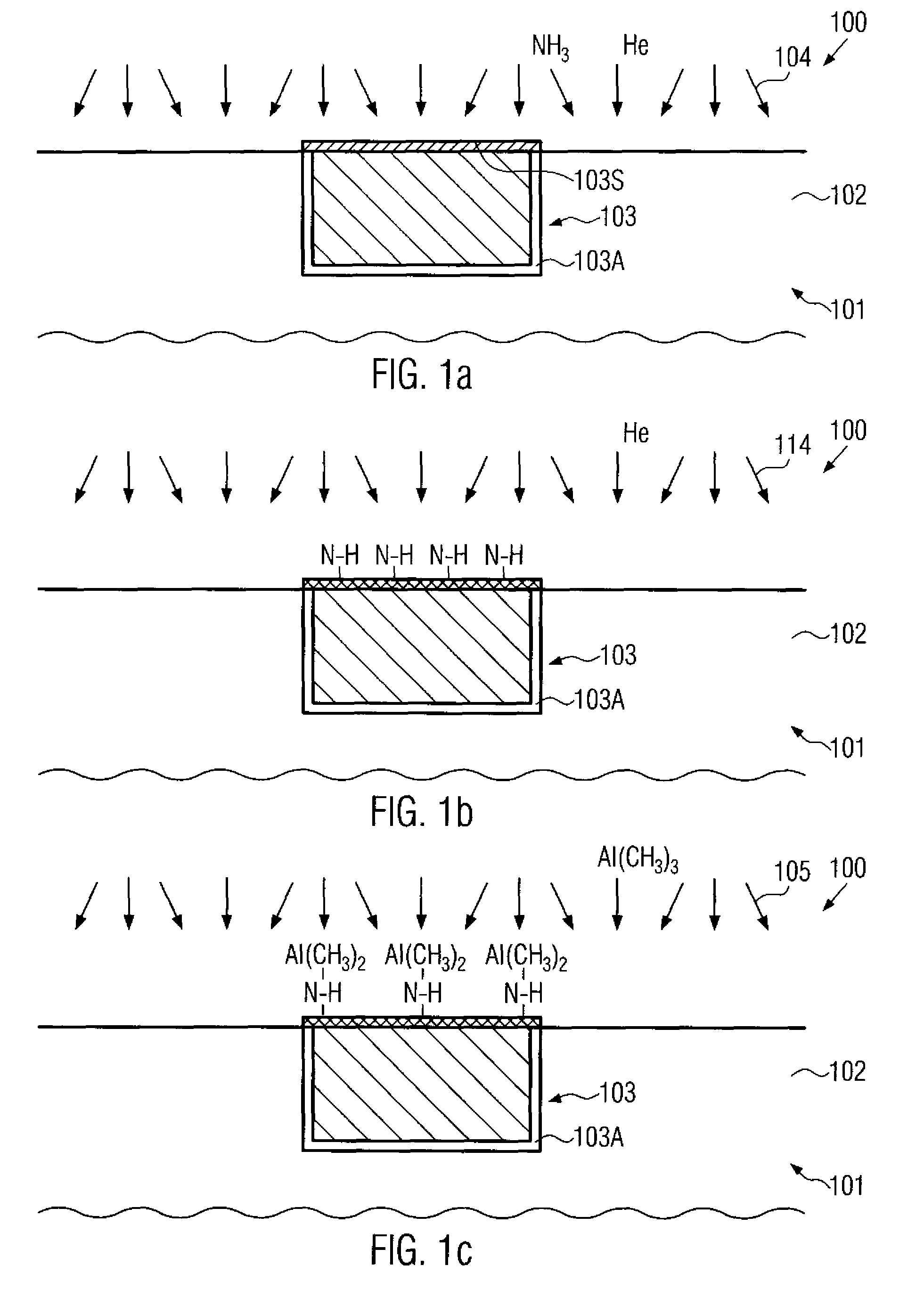

Method of manufracturing increasing reliability of copper-based metallization structures in a microstructure device by using aluminum nitride

ActiveUS7829460B2Reduce parasitic capacitanceEasy to controlSemiconductor/solid-state device detailsSolid-state devicesSelf limitingPermittivity

Owner:GLOBALFOUNDRIES U S INC

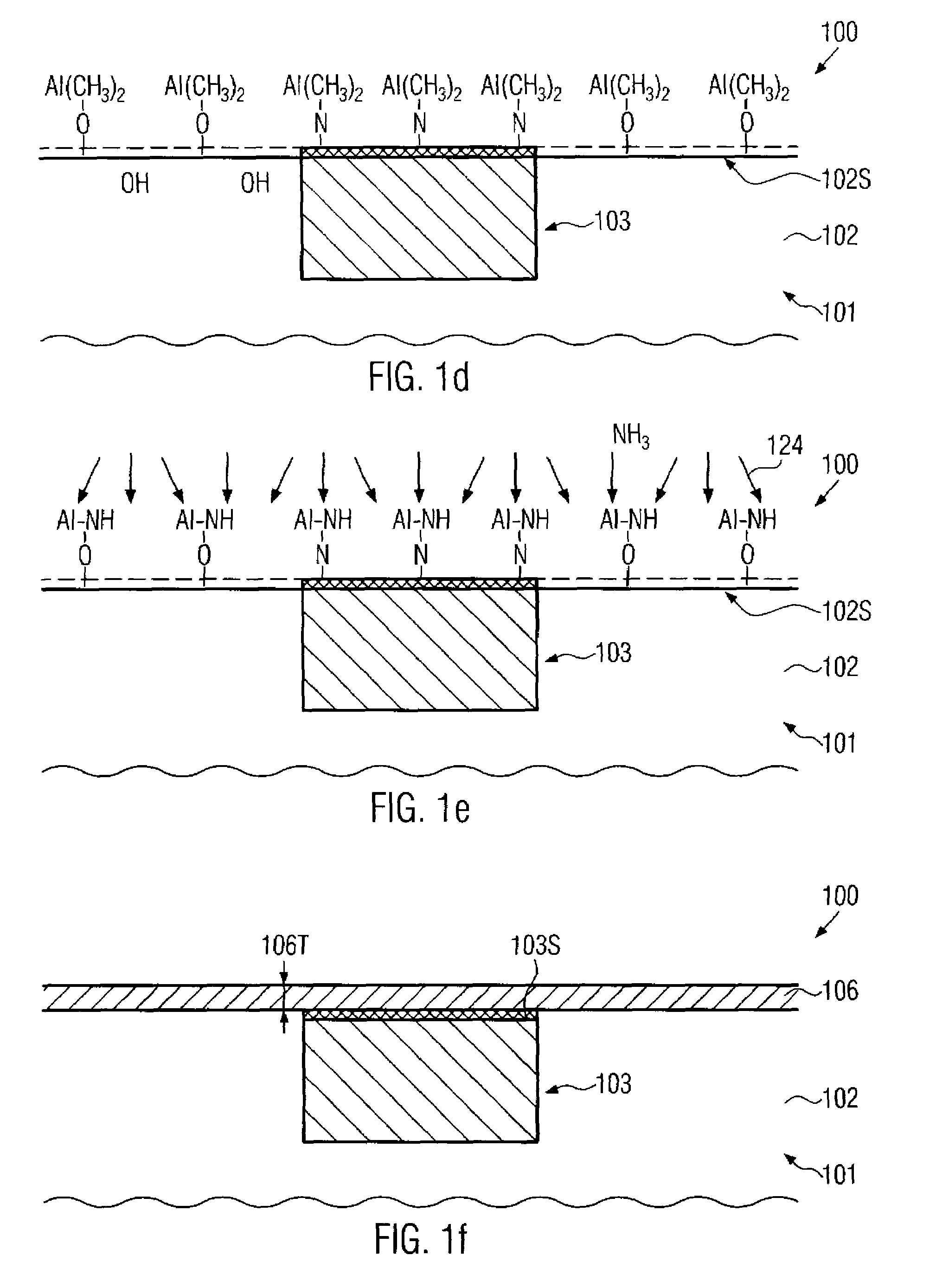

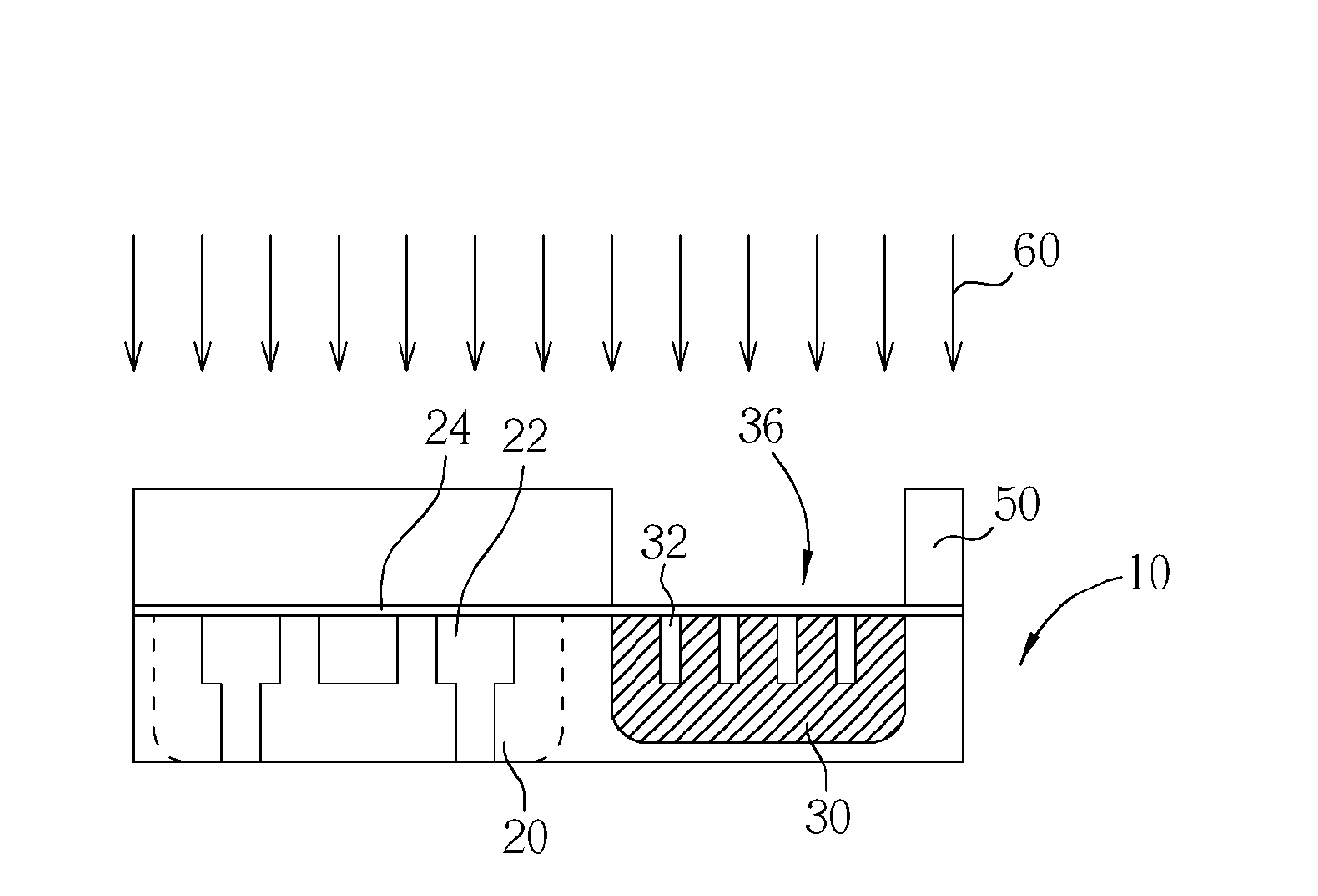

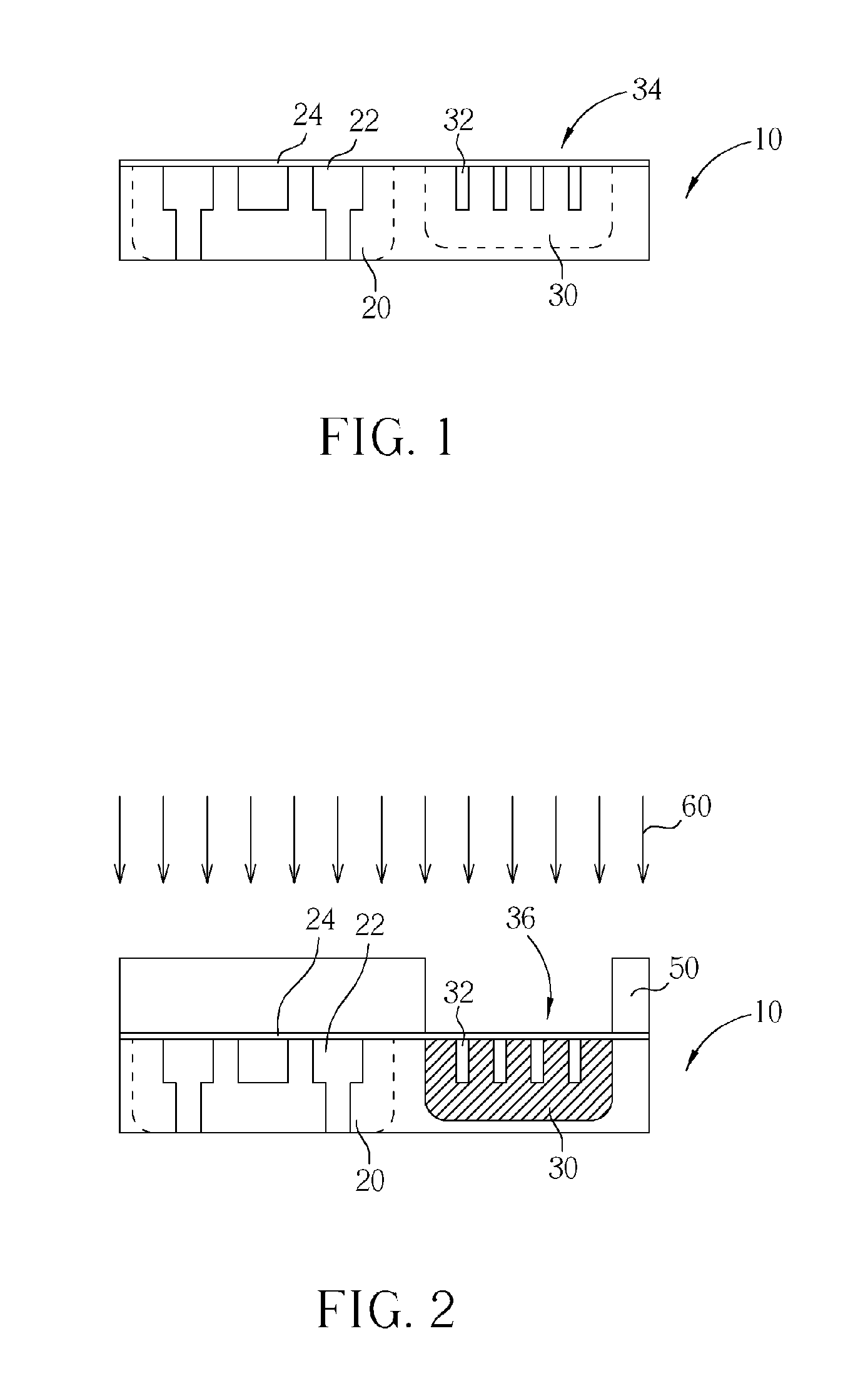

Metal capacitor and method of making the same

ActiveUS8114734B2Increase capacitanceAvoid delaySemiconductor/solid-state device detailsSolid-state devicesCapacitanceInterconnection

A method of making a metal capacitor includes the following steps. A dielectric layer having a metal interconnection and a capacitor electrode is provided. Then, a treatment is performed to increase the dielectric constant of the dielectric layer surrounding the capacitor electrode. The treatment can be UV radiation, a plasma treatment or an ion implantation. Accordingly, the metal capacitor will have a higher capacitance and RC delay between the metal interconnection and the dielectric layer can be prevented.

Owner:MARLIN SEMICON LTD

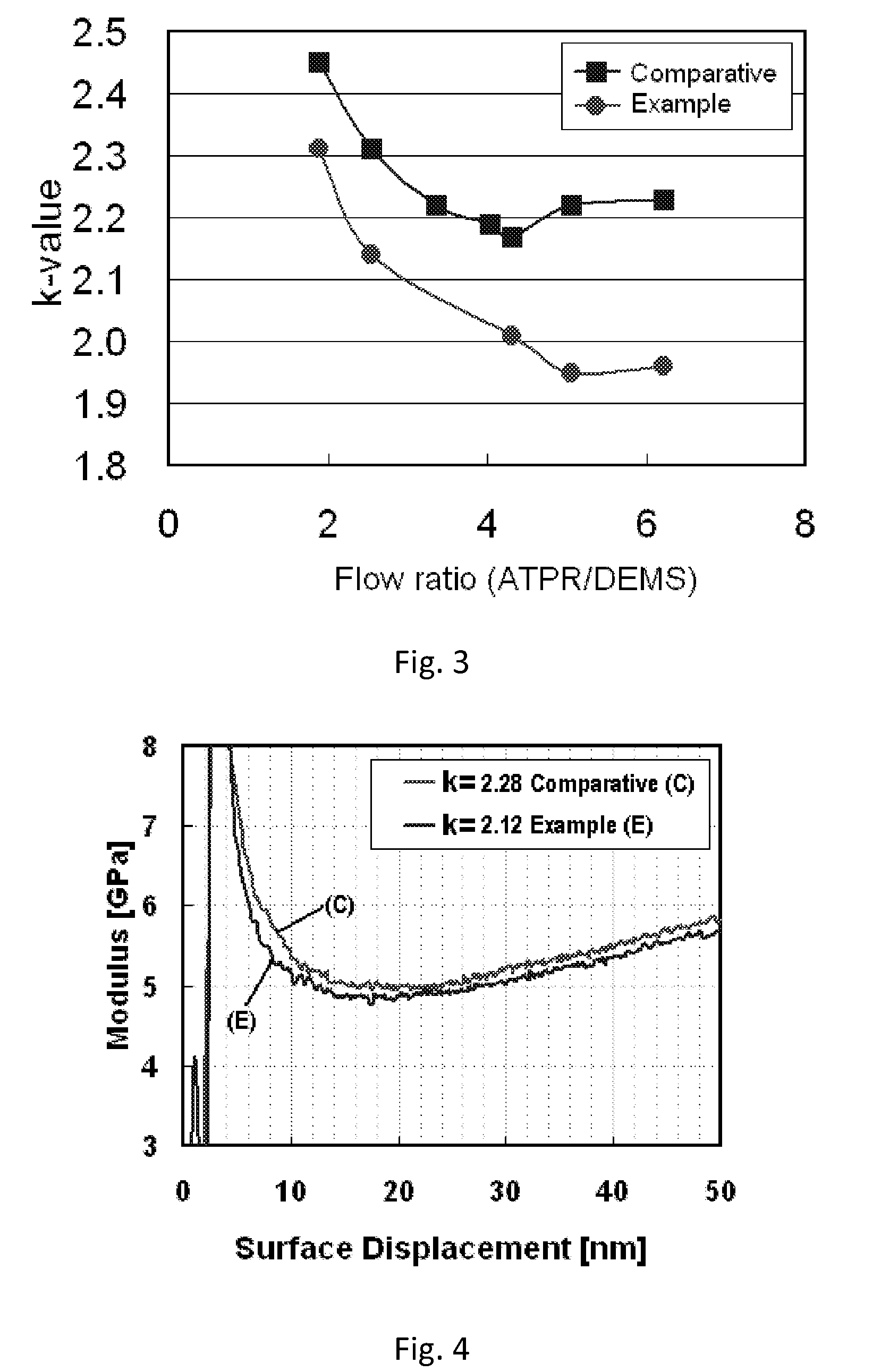

Method for forming dielectric film using porogen gas

ActiveUS7955650B2Low mechanical strengthIncrease equipment costSemiconductor/solid-state device manufacturingSpecial surfacesDielectric permittivityGas formation

Owner:ASM JAPAN

Method of manufacturing semiconductor device

InactiveUS20110171775A1Without deteriorating reliability of deviceHigh bonding strengthSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorPlasma polymerization

A method of manufacturing a semiconductor device includes forming a first insulating film over an underlying film by plasma polymerization of cyclic siloxane, and forming a second insulating film on the first insulating film by plasma polymerization of the cyclic siloxane continuously, after forming the first insulating film. The deposition rate of the first insulating film is slower than the deposition rate of the second insulating film.

Owner:RENESAS ELECTRONICS CORP

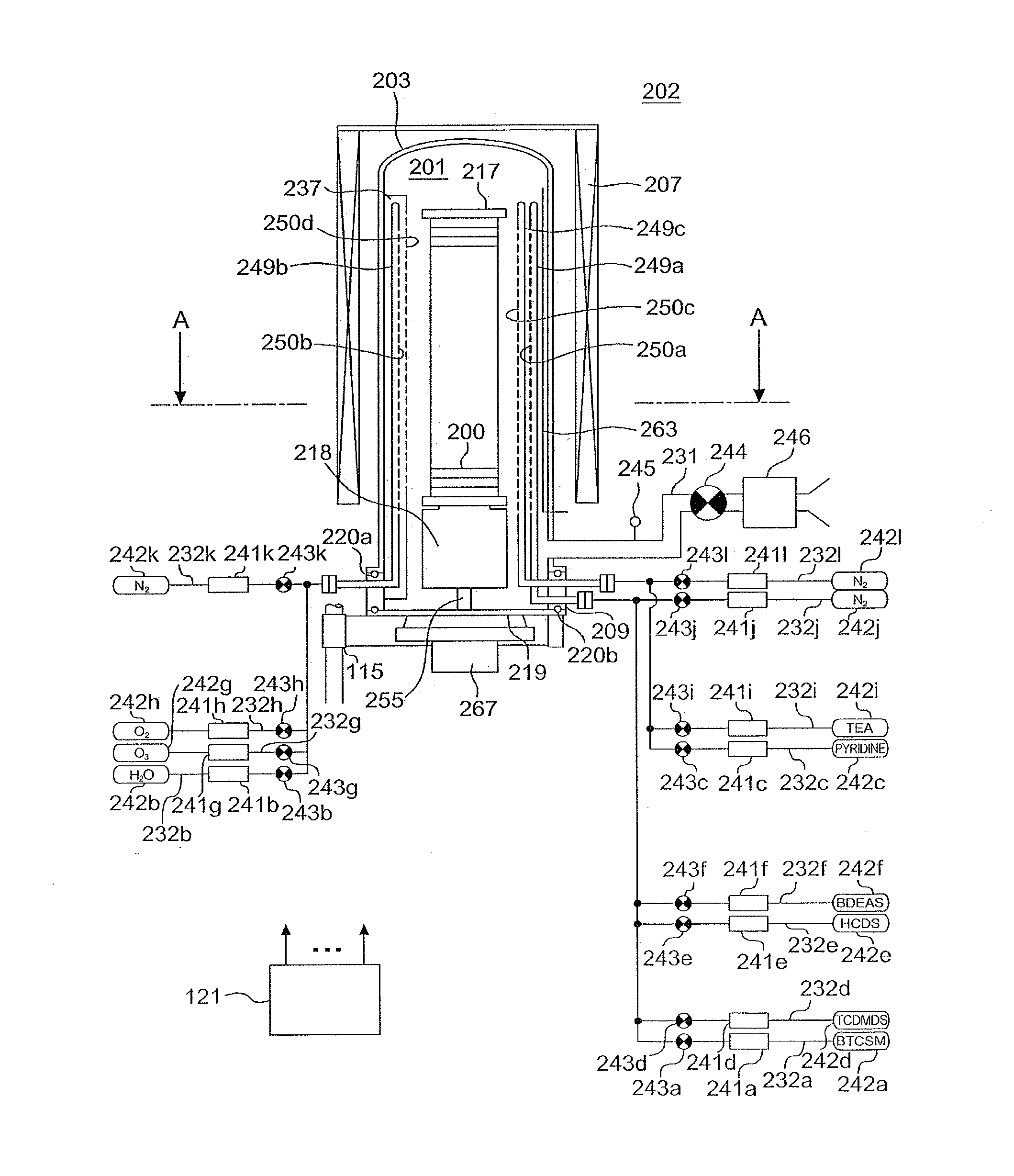

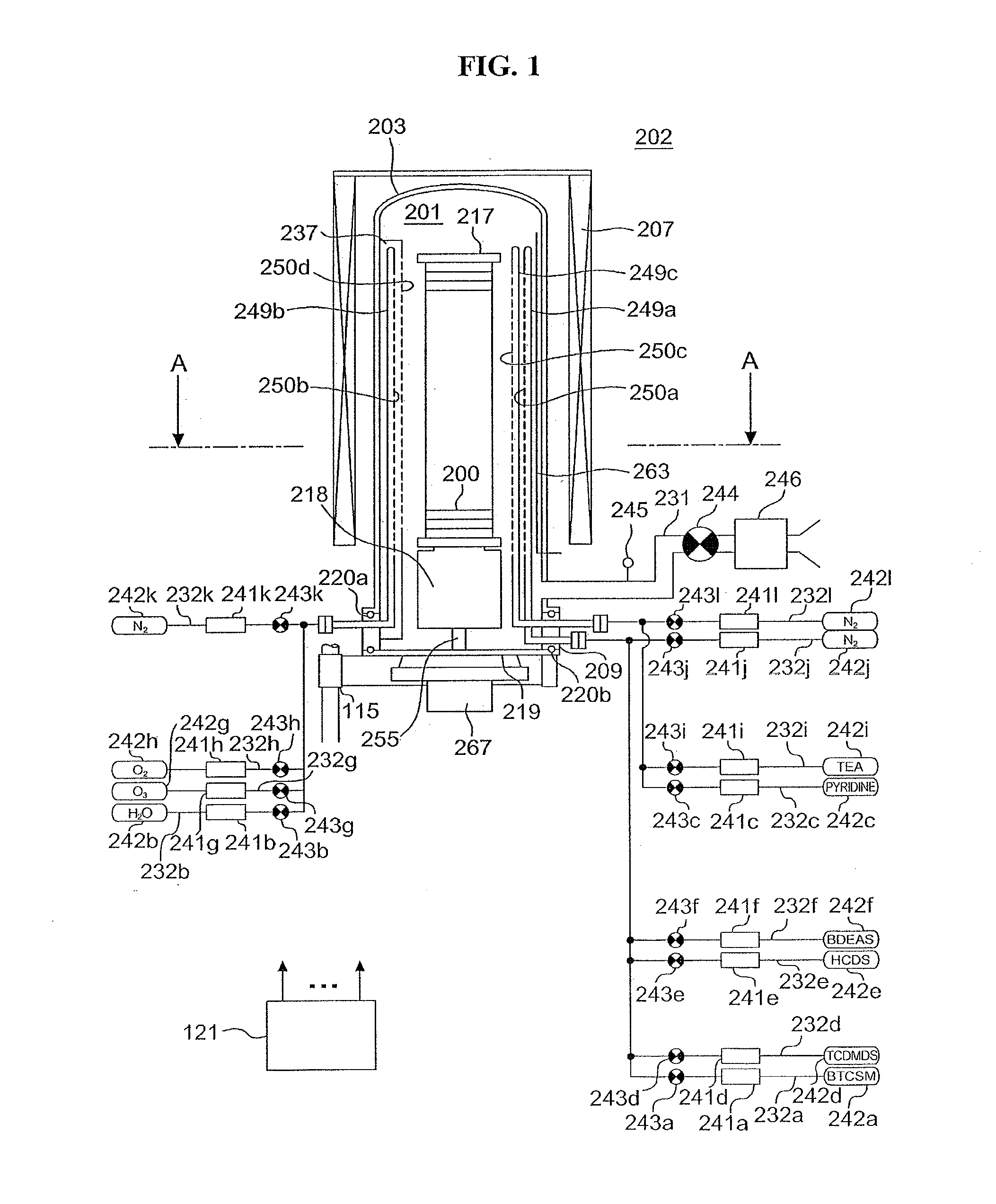

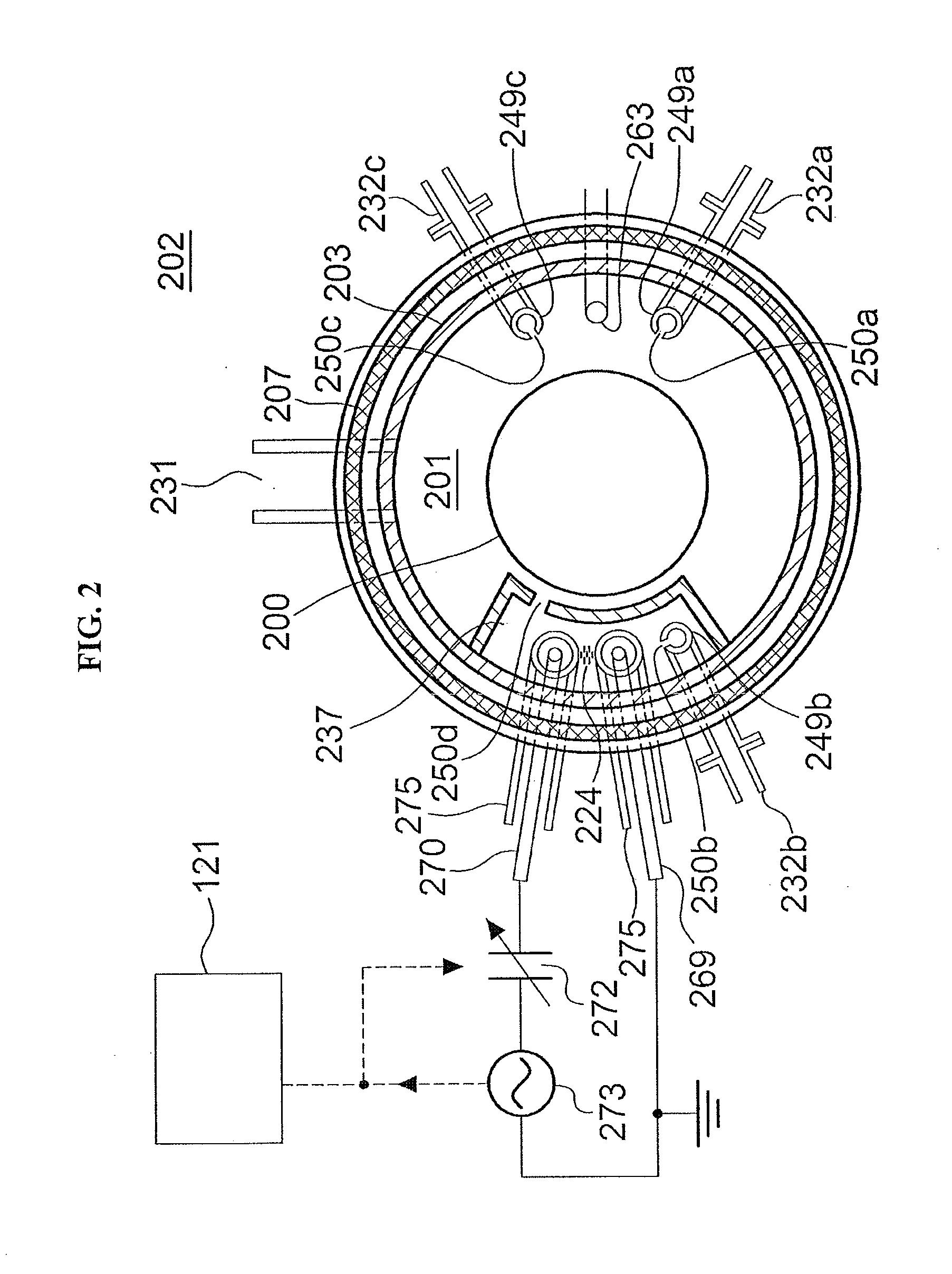

Method of manufacturing semiconductor device, substrate processing apparatus, substrate processing system and recording medium

ActiveUS20160211135A1Quality improvementImprovement of resistance to wet etchingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHalogenDevice material

There is provided a technique including: (a) forming a thin film containing a predetermined element, oxygen and carbon on a substrate by performing a cycle a predetermined number of times, the cycle including: (a-1) supplying a source gas containing the predetermined element, carbon and a halogen element having a chemical bond between the predetermined element and carbon to the substrate; (a-2) supplying an oxidizing gas to the substrate; and (a-3) supplying a catalytic gas to the substrate; (b) removing a first impurity from the thin film by thermally processing the thin film at a first temperature higher than a temperature of the substrate in (a); and (c) removing a second impurity different from the first impurity from the thin film by thermally processing the thin film at a second temperature equal to or higher than the first temperature after performing (b).

Owner:KOKUSA ELECTRIC CO LTD

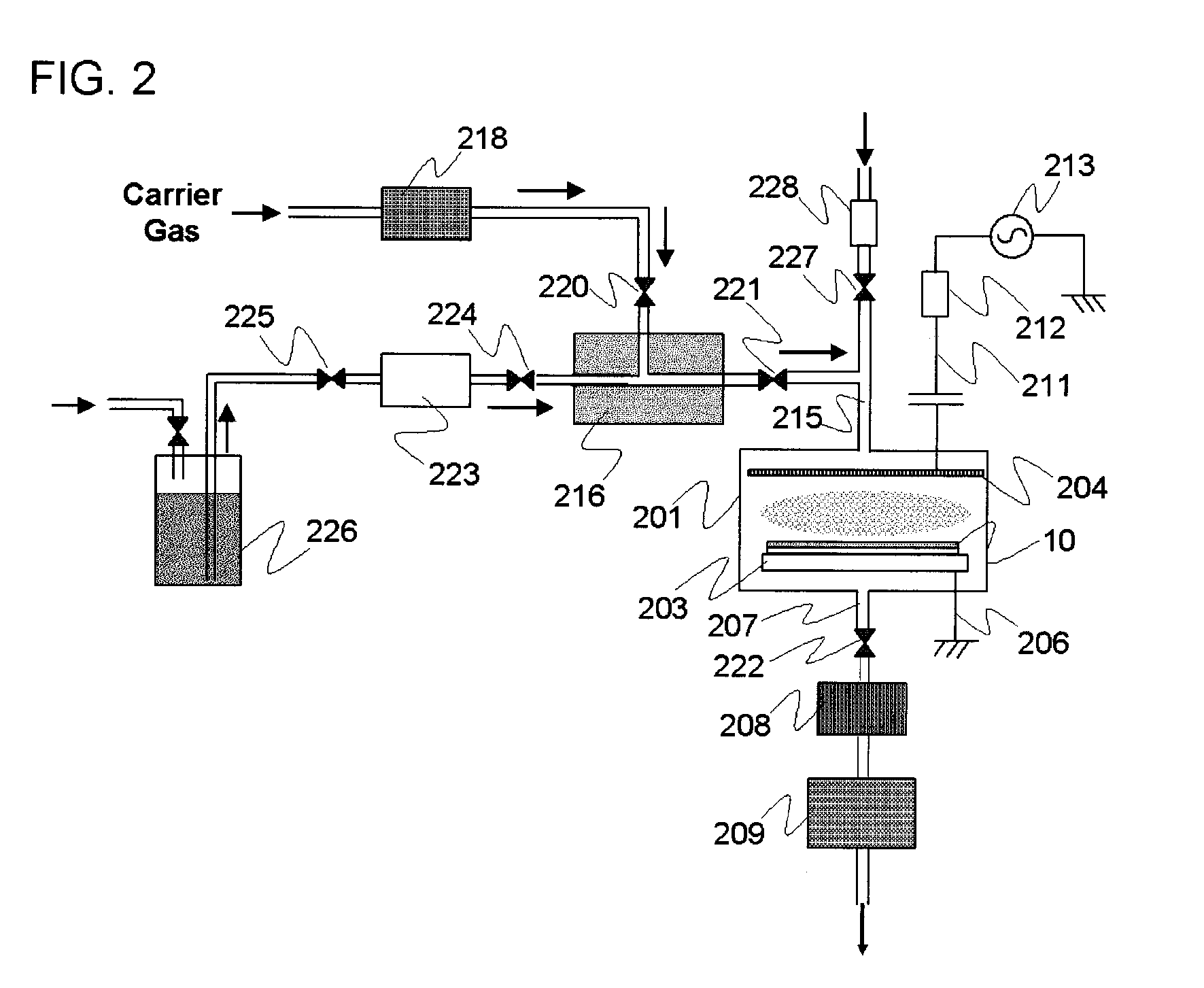

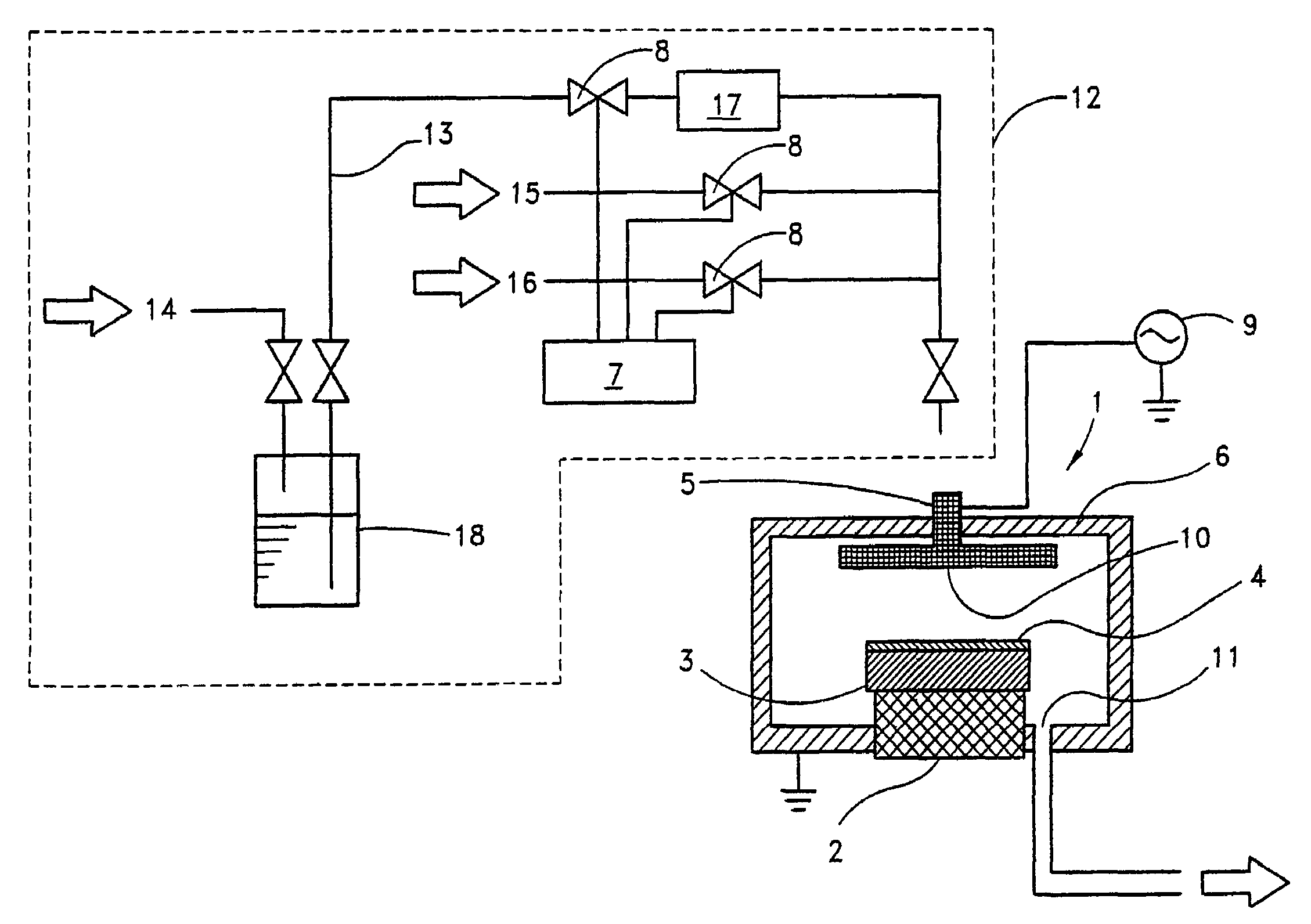

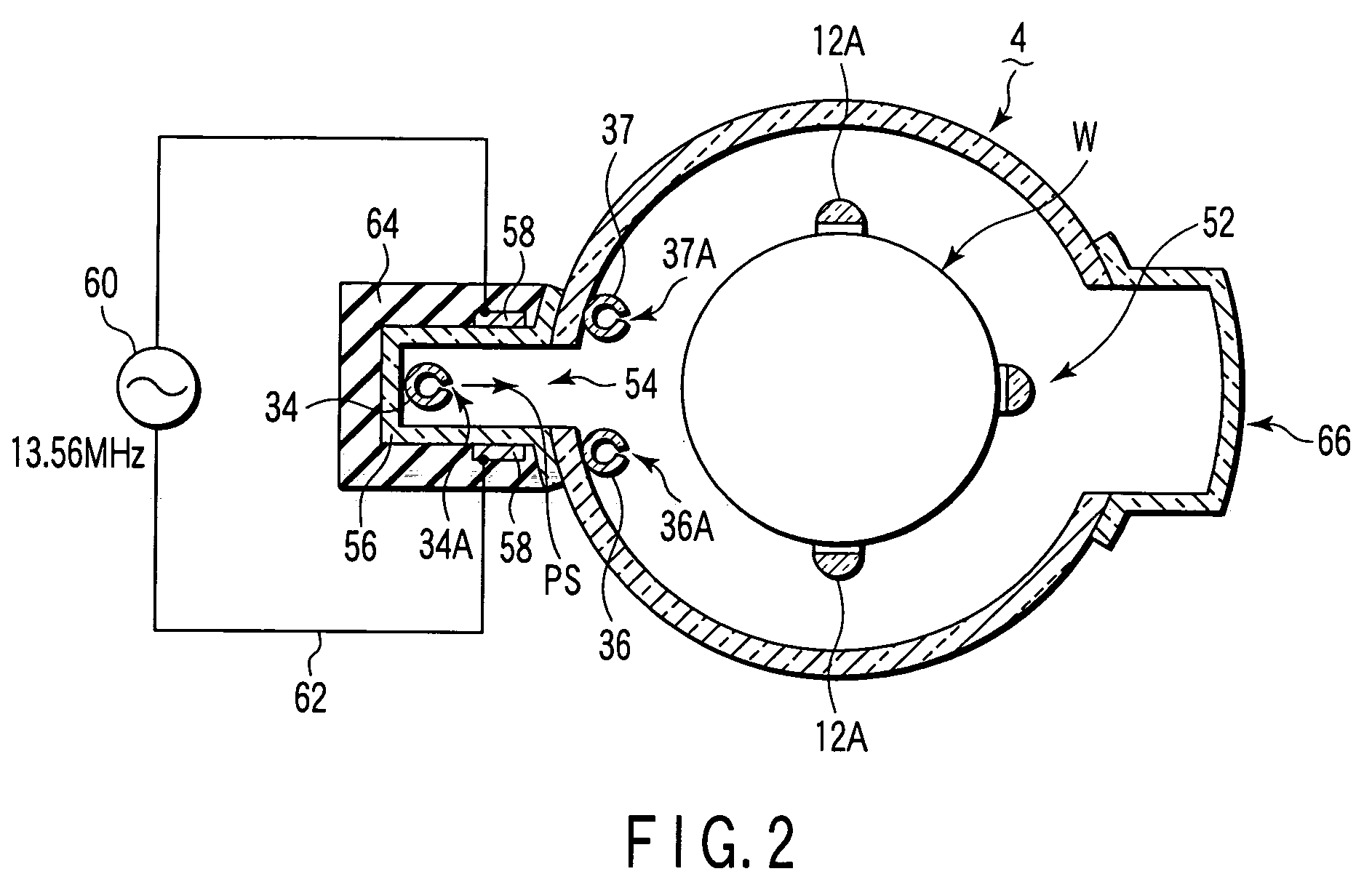

Method for forming insulation film

InactiveUS7582575B2Reduce trafficReduce volumeSolid-state devicesSemiconductor/solid-state device manufacturingPlasma reactionResidence time

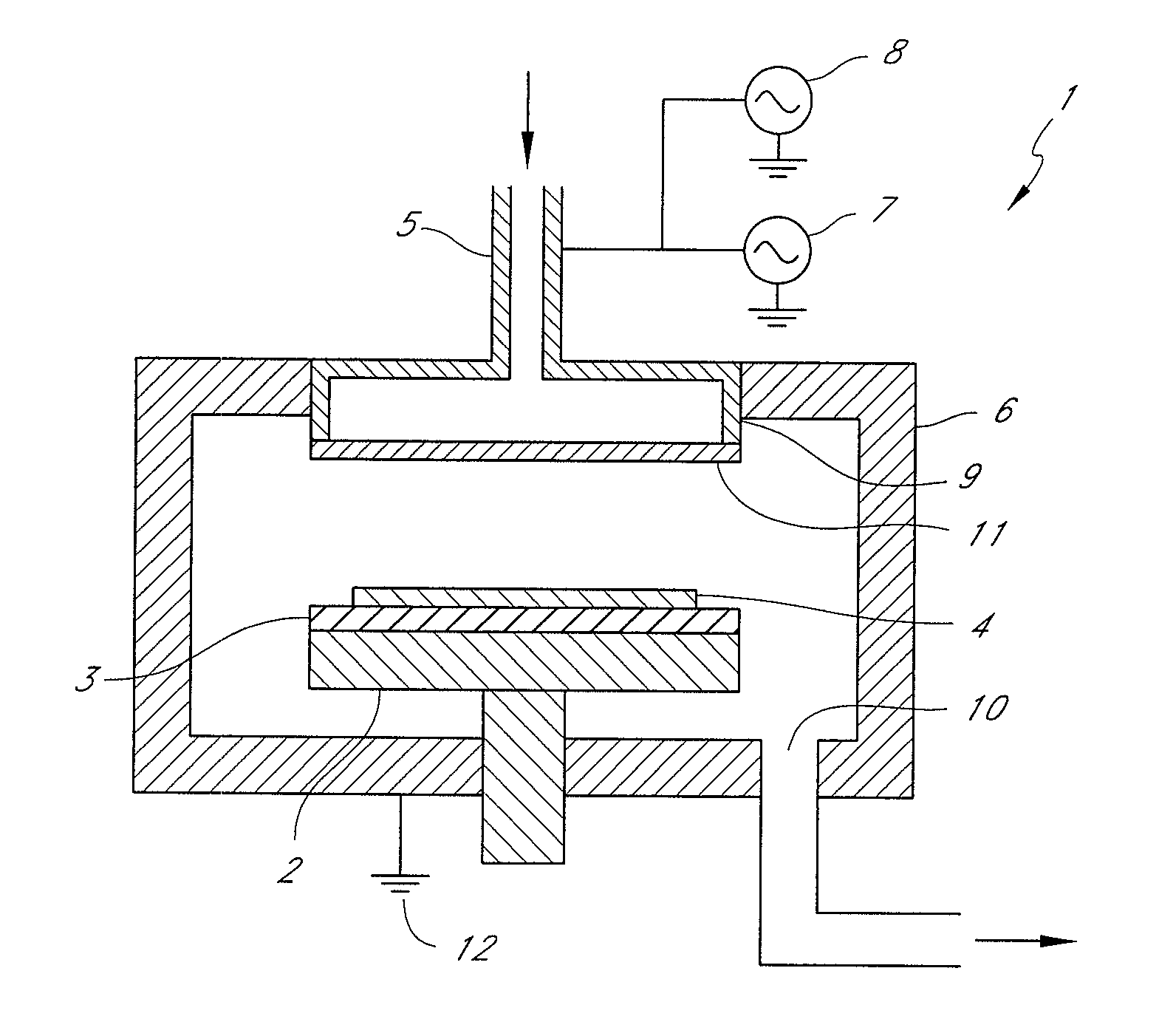

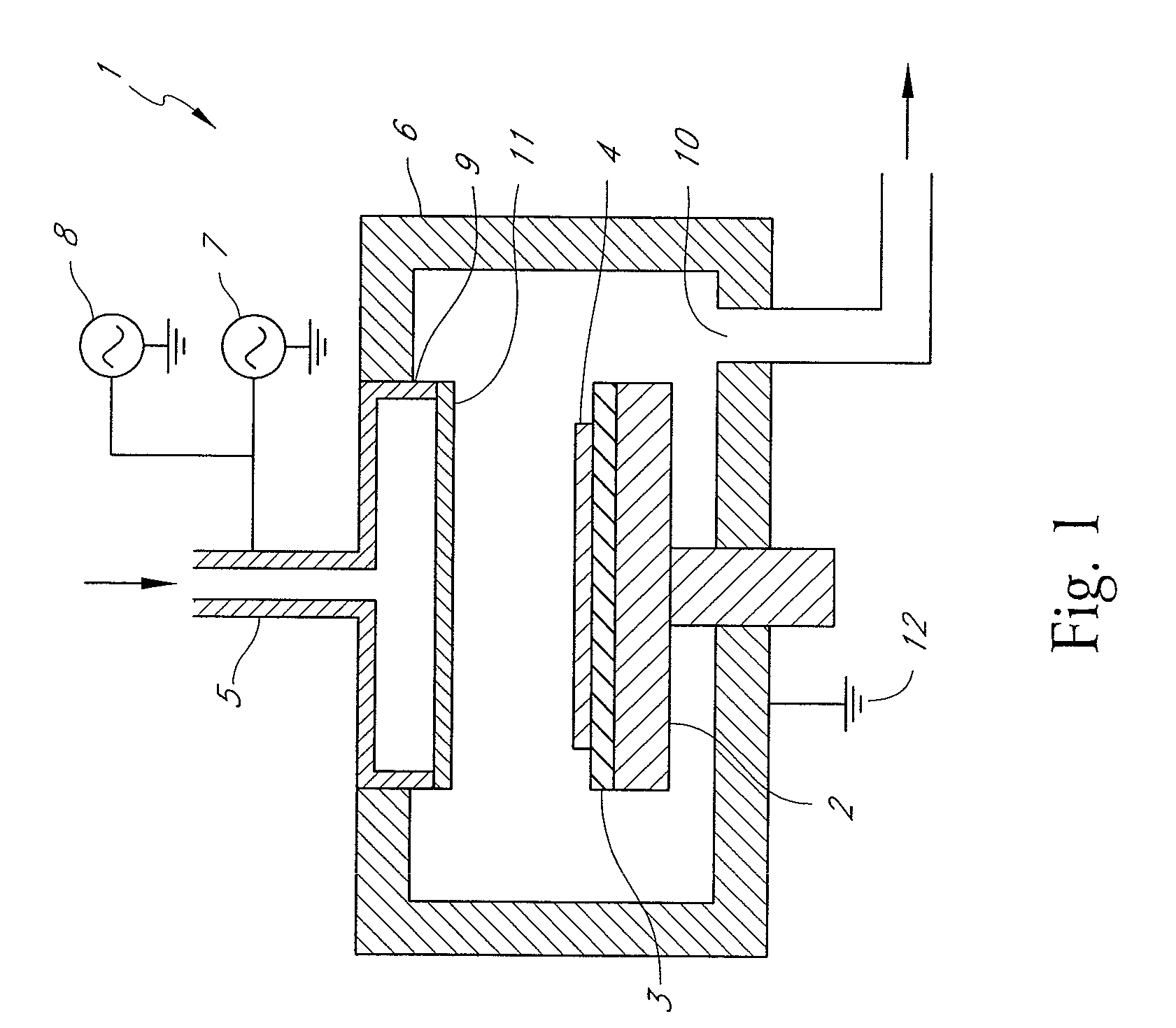

A method for forming an insulation film on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, C, O, and H on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

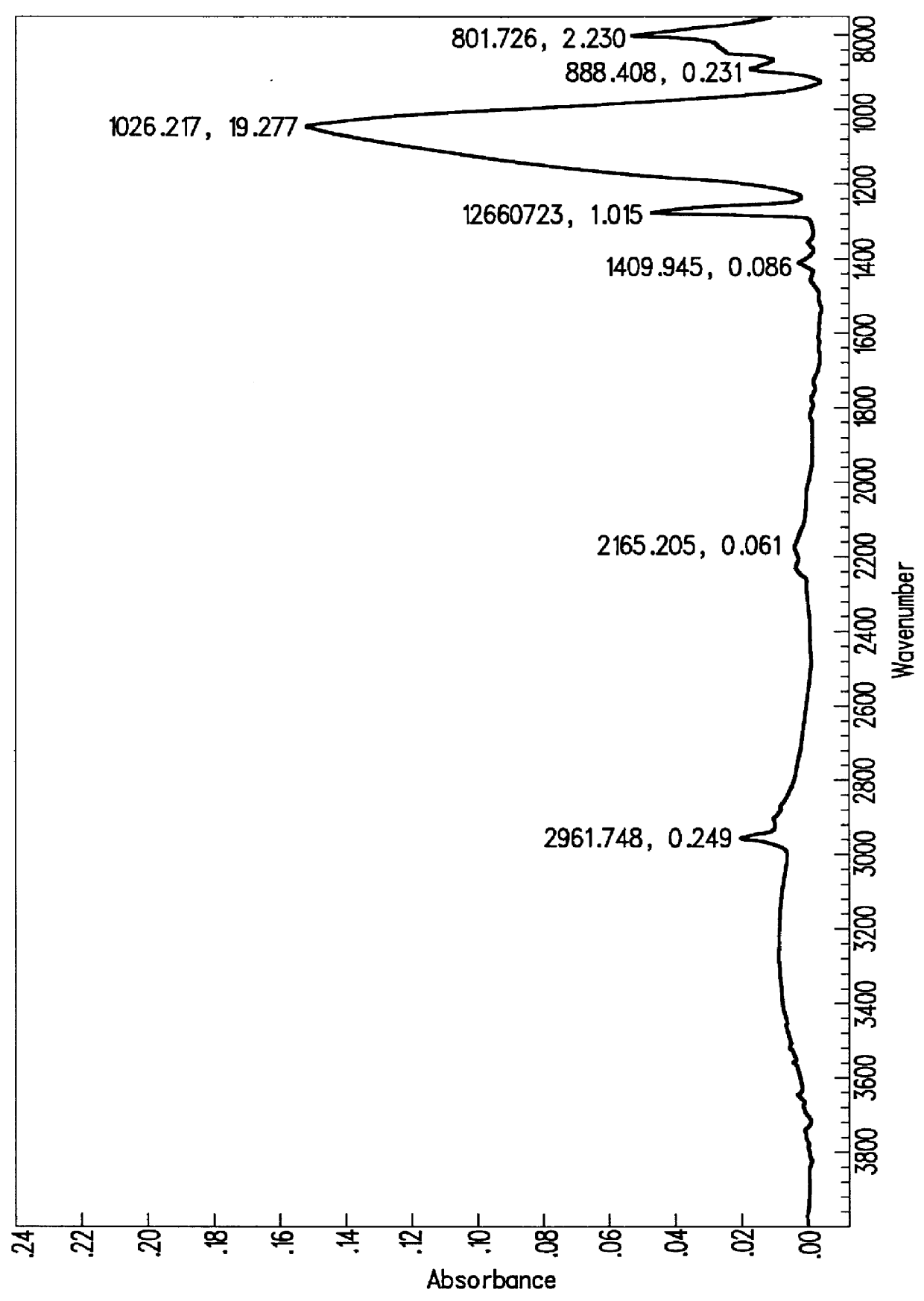

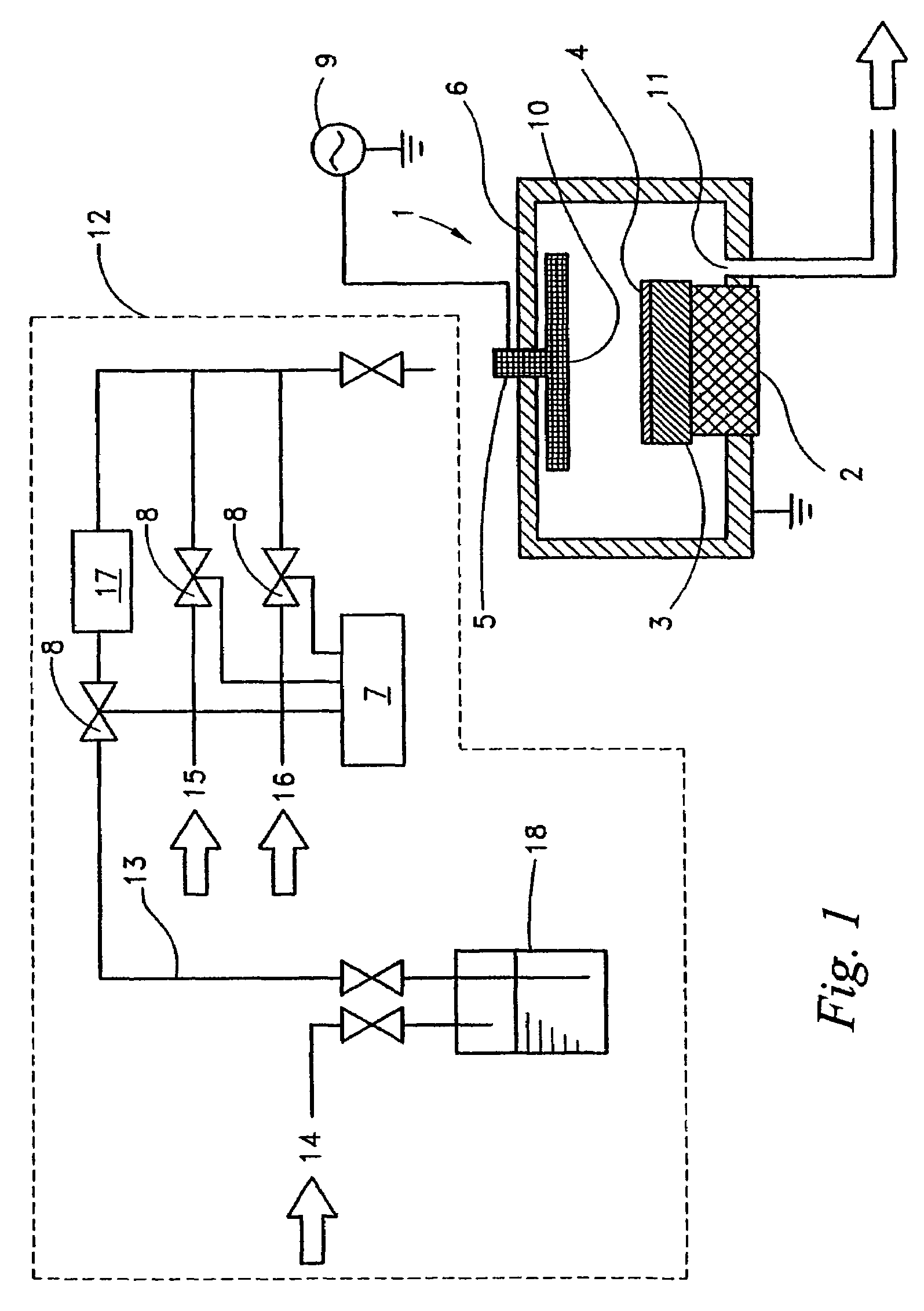

Method for forming dielectric SiOCH film having chemical stability

ActiveUS7807566B2Good chemical stabilityLow dielectric constantSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingDielectricSusceptor

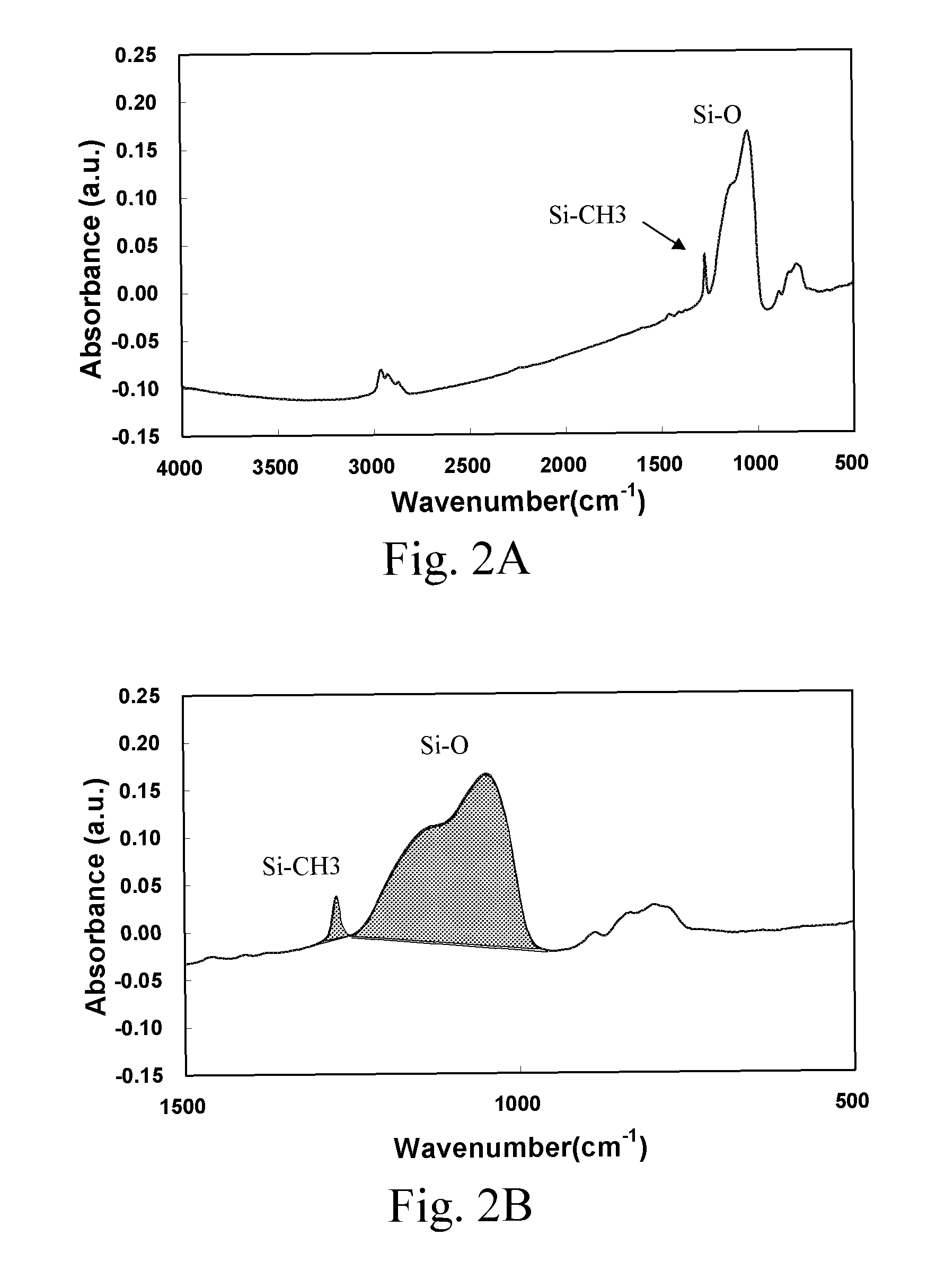

A method for determining conditions for forming a dielectric SiOCH film, includes: (i) forming a dielectric SiOCH film on a substrate under conditions; (ii) evaluating the conditions using a ratio of Si—CH3 bonding strength to Si—O bonding strength of the film as formed in step (i); (iii) if the ratio is 2.50 % or higher, confirming the conditions, and if the ratio is less than 2.50 %, changing the conditions by changing at least one of the susceptor temperature, the distance between upper and lower electrodes, the RF power, and the curing time; and (iv) repeating steps (i) to (iii) until the ratio is 2.50 % or higher.

Owner:ASM JAPAN

Two-layer film for next generation damascene barrier application with good oxidation resistance

InactiveUS7749563B2Low dielectric constantLiquid surface applicatorsSemiconductor/solid-state device manufacturingOxygenPhenyl group

A method is provided for processing a substrate including providing a processing gas comprising an organosilicon compound comprising a phenyl group to the processing chamber, and reacting the processing gas to deposit a low k silicon carbide barrier layer useful as a barrier layer in damascene or dual damascene applications with low k dielectric materials. A method is provided for depositing a silicon carbide cap layer that has substantially no phenyl groups attached to silicon atoms from a processing gas comprising an oxygen-free organosilicon compound on a low k silicon carbide barrier layer.

Owner:APPLIED MATERIALS INC

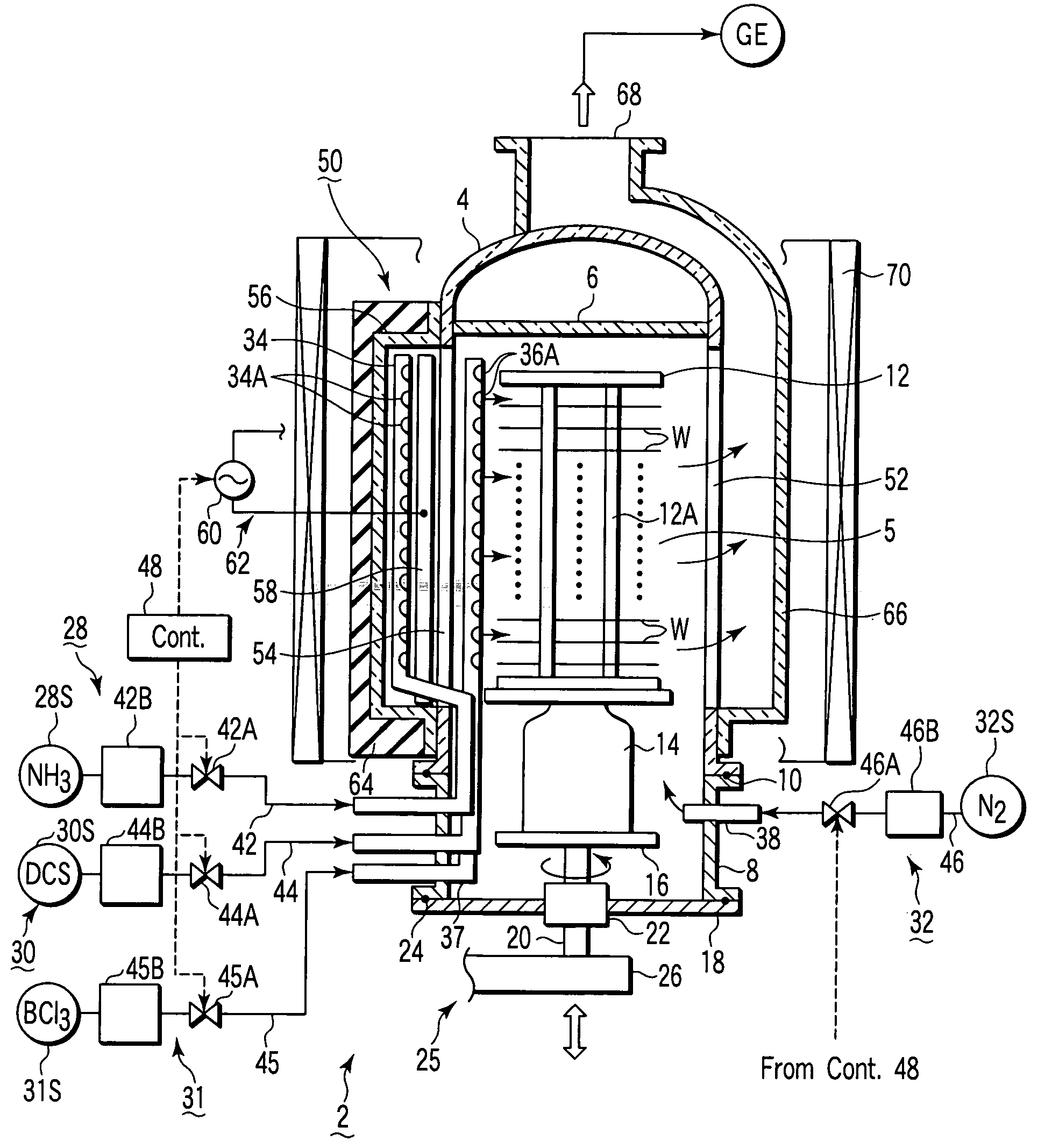

Film formation method and apparatus for semiconductor process

ActiveUS20060032443A1Low dielectric constantImprove corrosion resistanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesProcess engineering

An impurity-doped silicon nitride or oxynitride film is formed on a target substrate by CVD, in a process field to be selectively supplied with a first process gas containing a silane family gas, a second process gas containing a nitriding or oxynitriding gas, and a third process gas containing a doping gas. This method alternately includes first to fourth steps. The first step performs supply of the first and third process gases to the field. The second step stops supply of the first to third process gases to the field. The third step performs supply of the second process gas to the field while stopping supply of the first and third process gases to the field, and includes an excitation period of exciting the second process gas by an exciting mechanism. The fourth step stops supply of the first to third process gases to the field.

Owner:TOKYO ELECTRON LTD

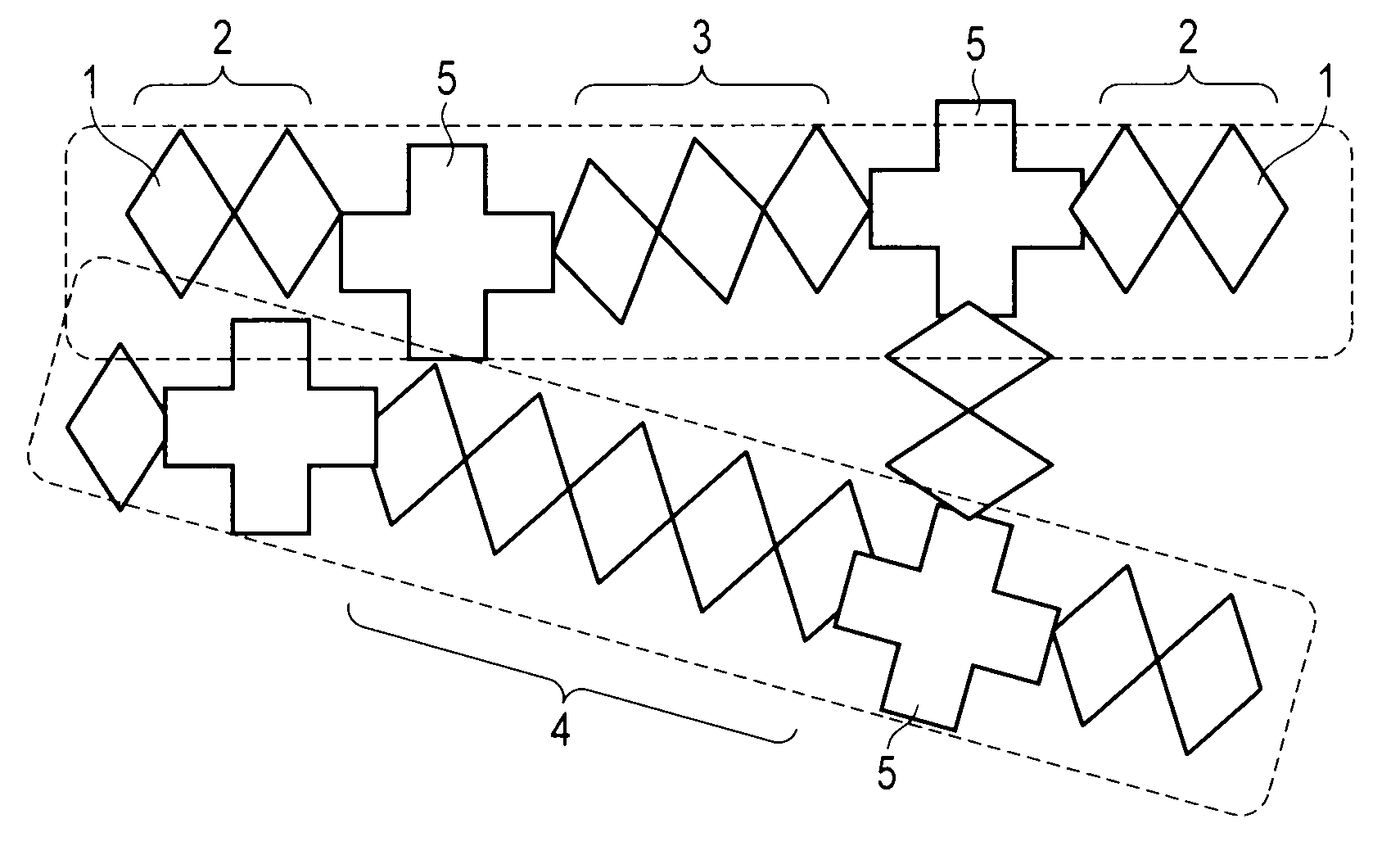

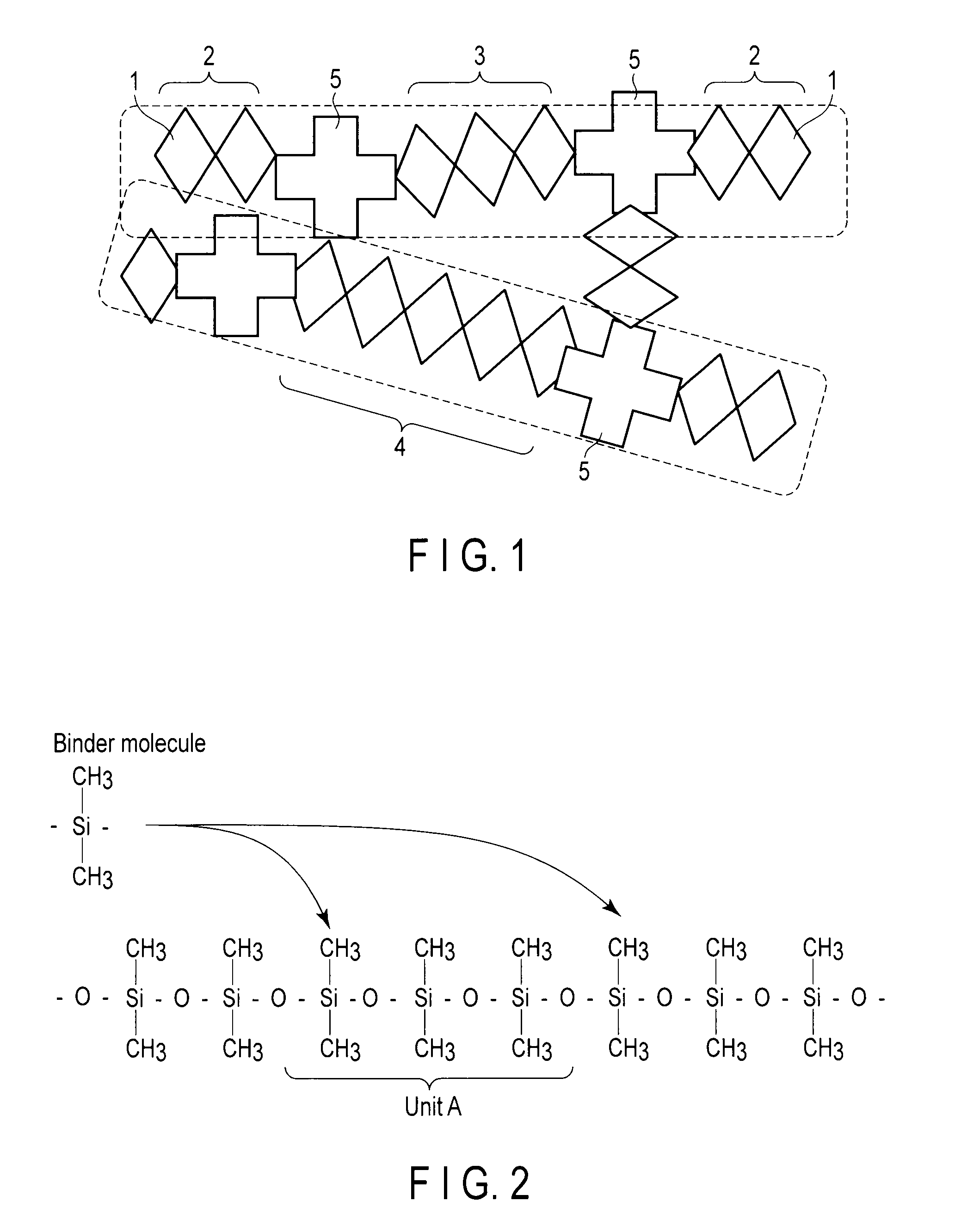

Low dielectric constant insulating film and method for forming the same

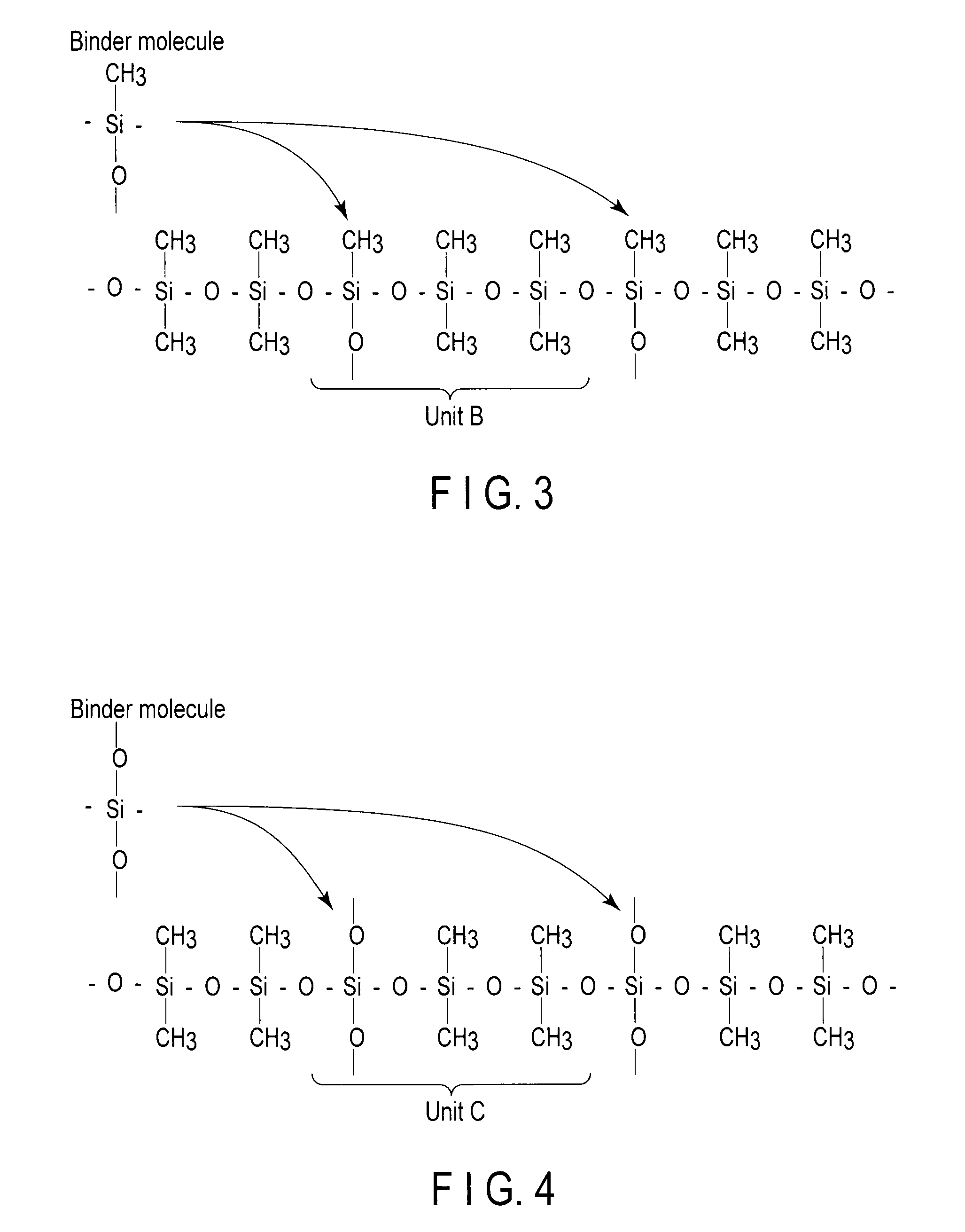

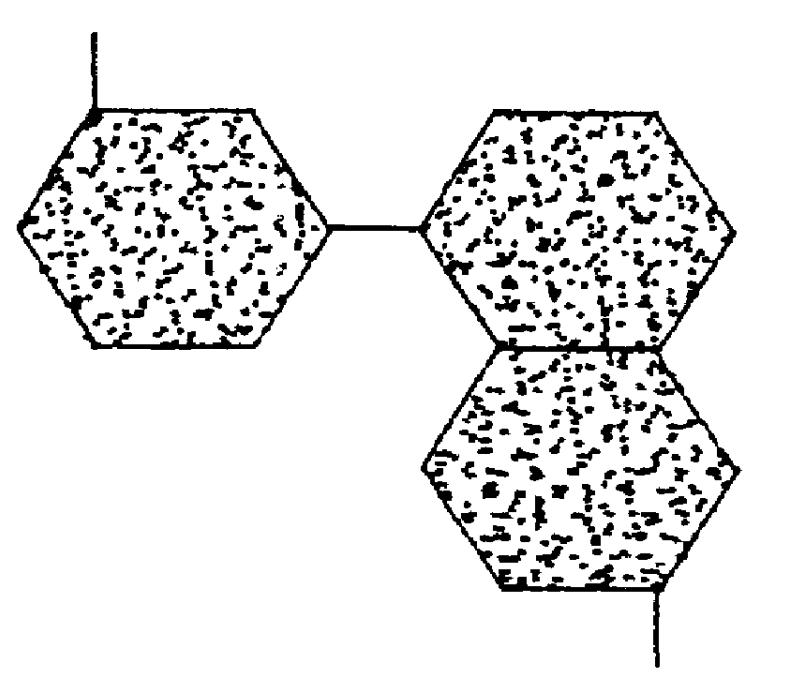

InactiveUS8828886B2Improve resistance to damageLow dielectric constantSemiconductor/solid-state device manufacturingChemical vapor deposition coatingArea ratioPolymer

Disclosed is a low dielectric constant insulating film formed of a polymer containing Si atoms, O atoms, C atoms, and H atoms, which includes straight chain molecules in which a plurality of basic molecules with an SiO structure are linked in a straight chain, binder molecules with an SiO structure linking a plurality of the straight chain molecules. The area ratio of a signal indicating a linear type SiO structure is 49% or more, and the signal amount of the signal indicating Si(CH3) is 66% or more.

Owner:TOHOKU UNIV

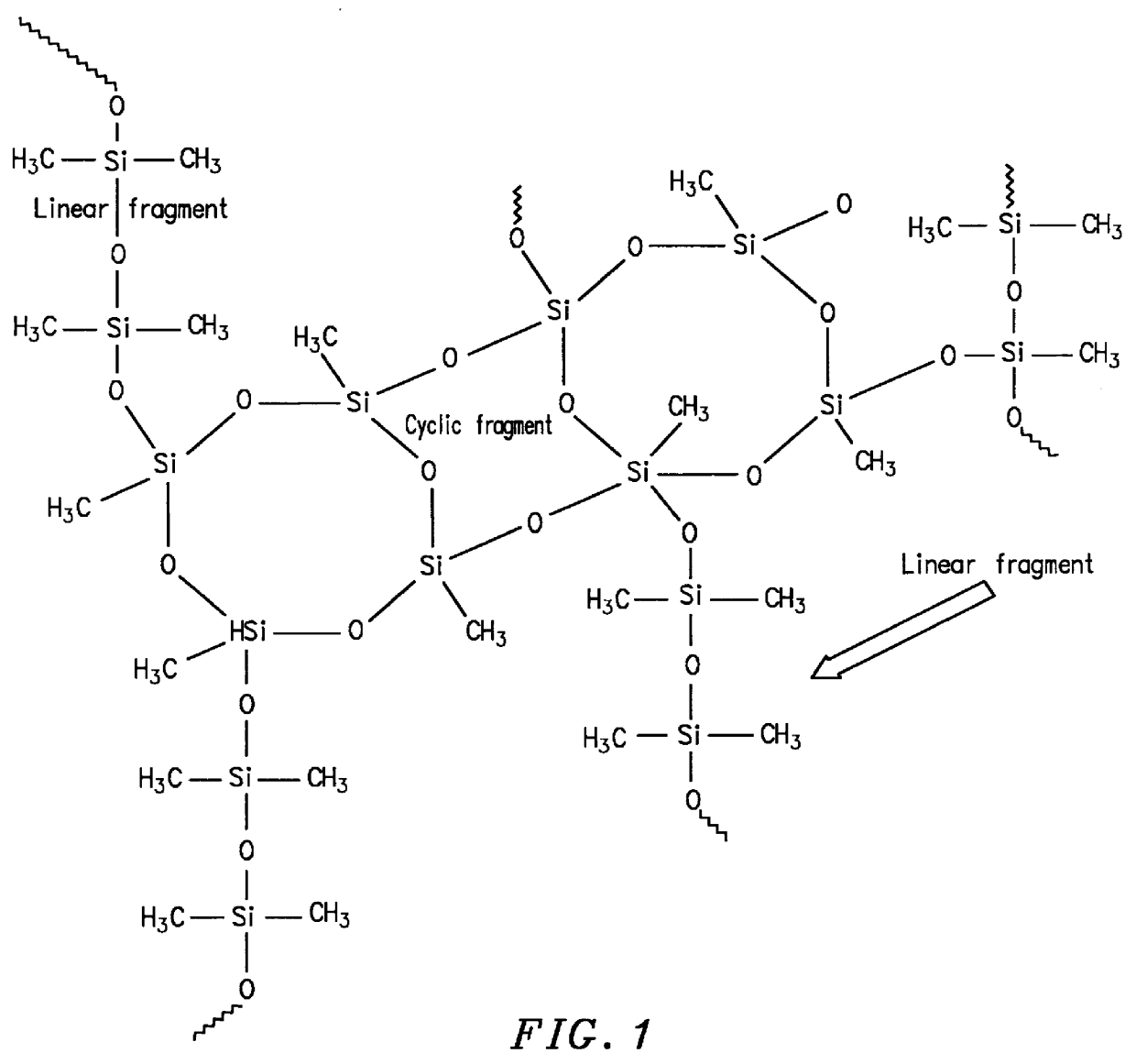

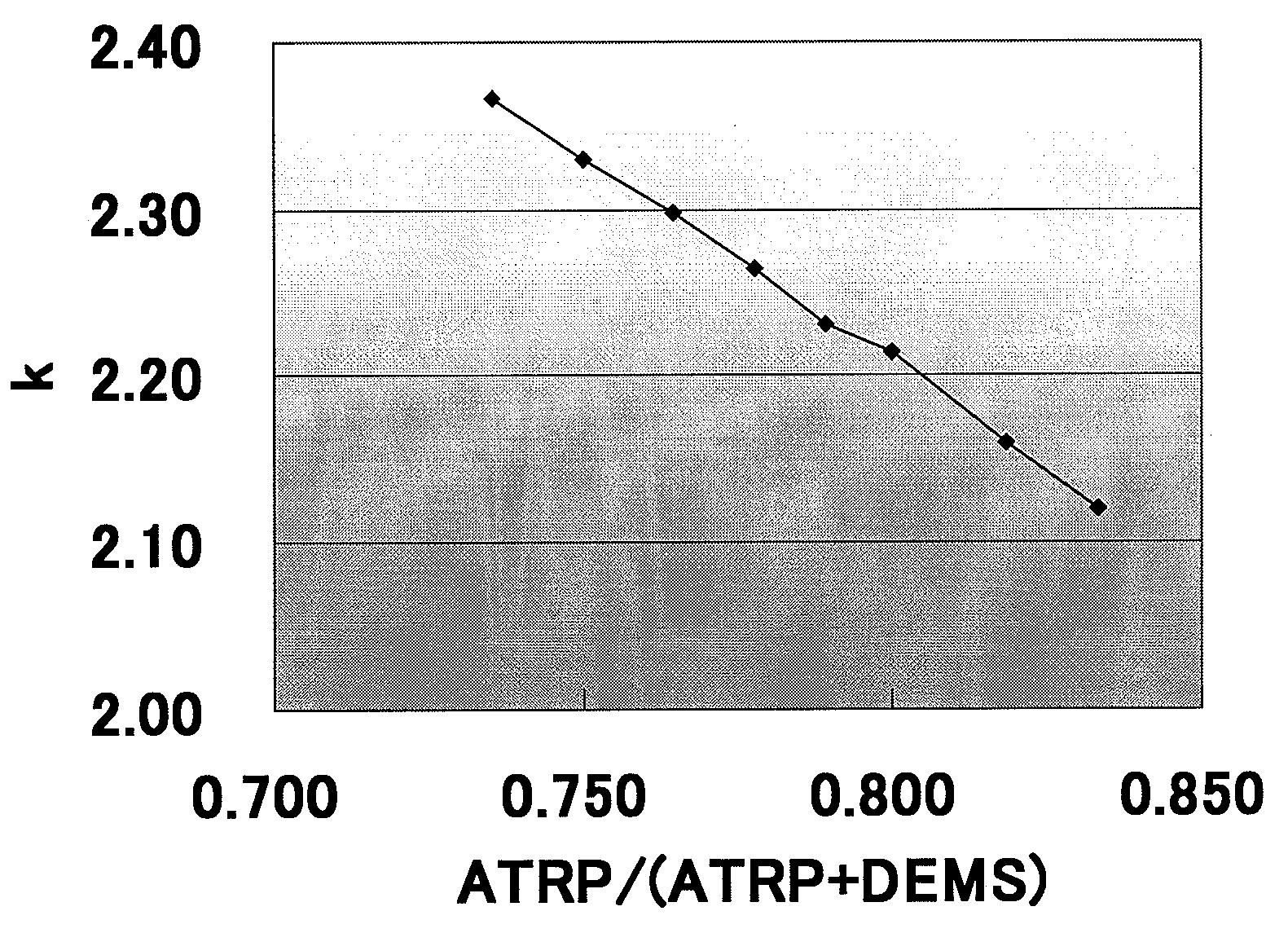

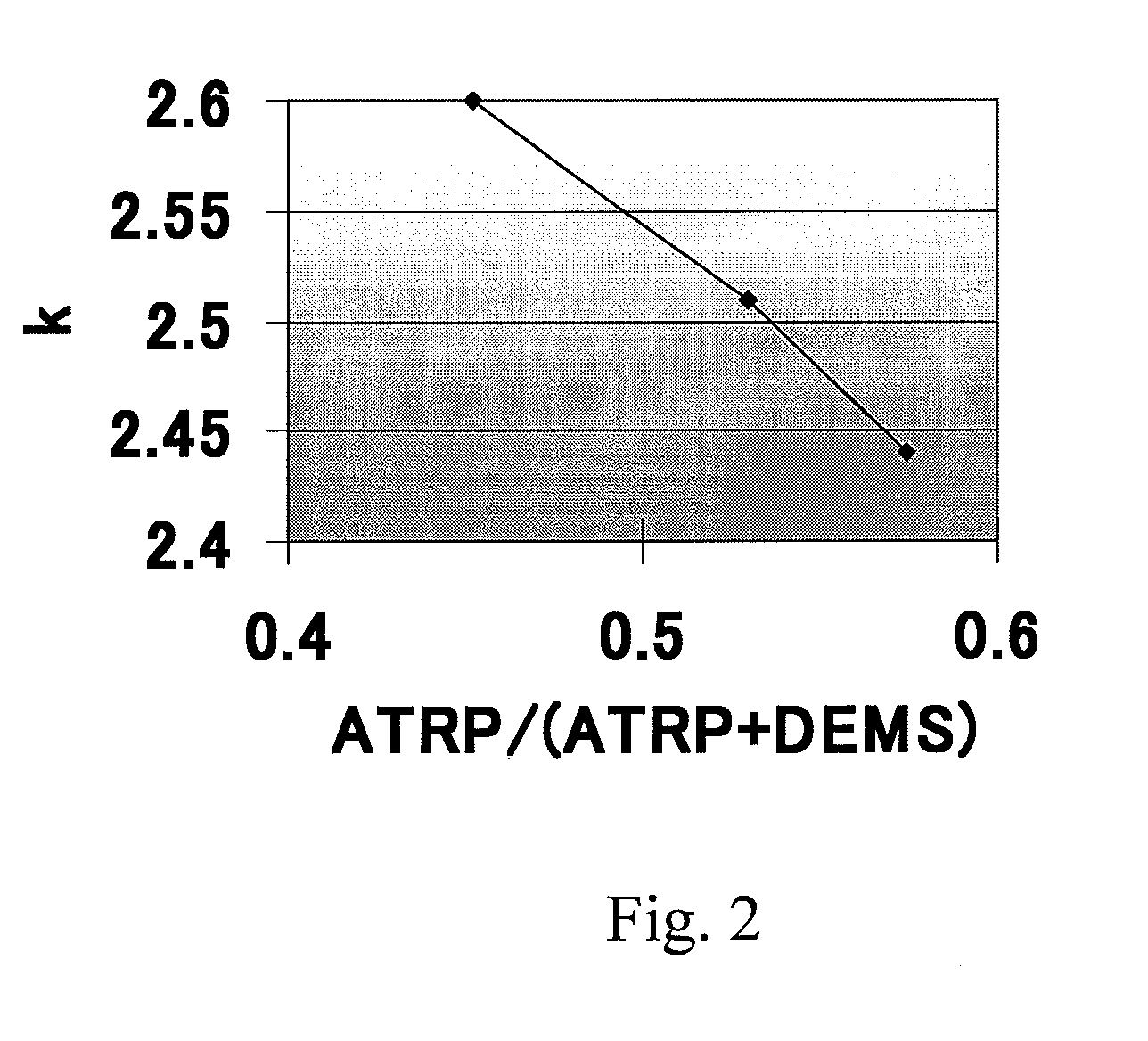

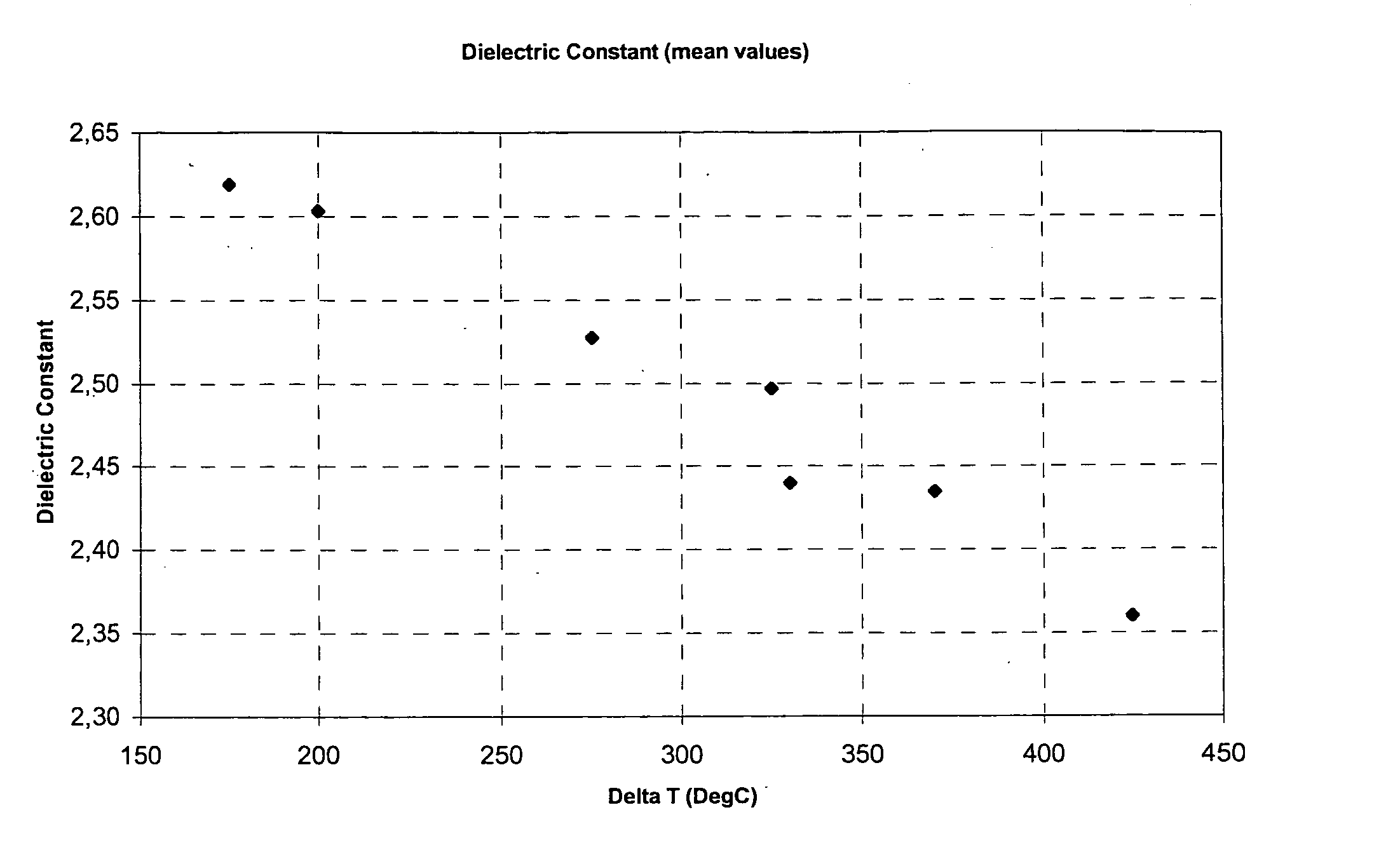

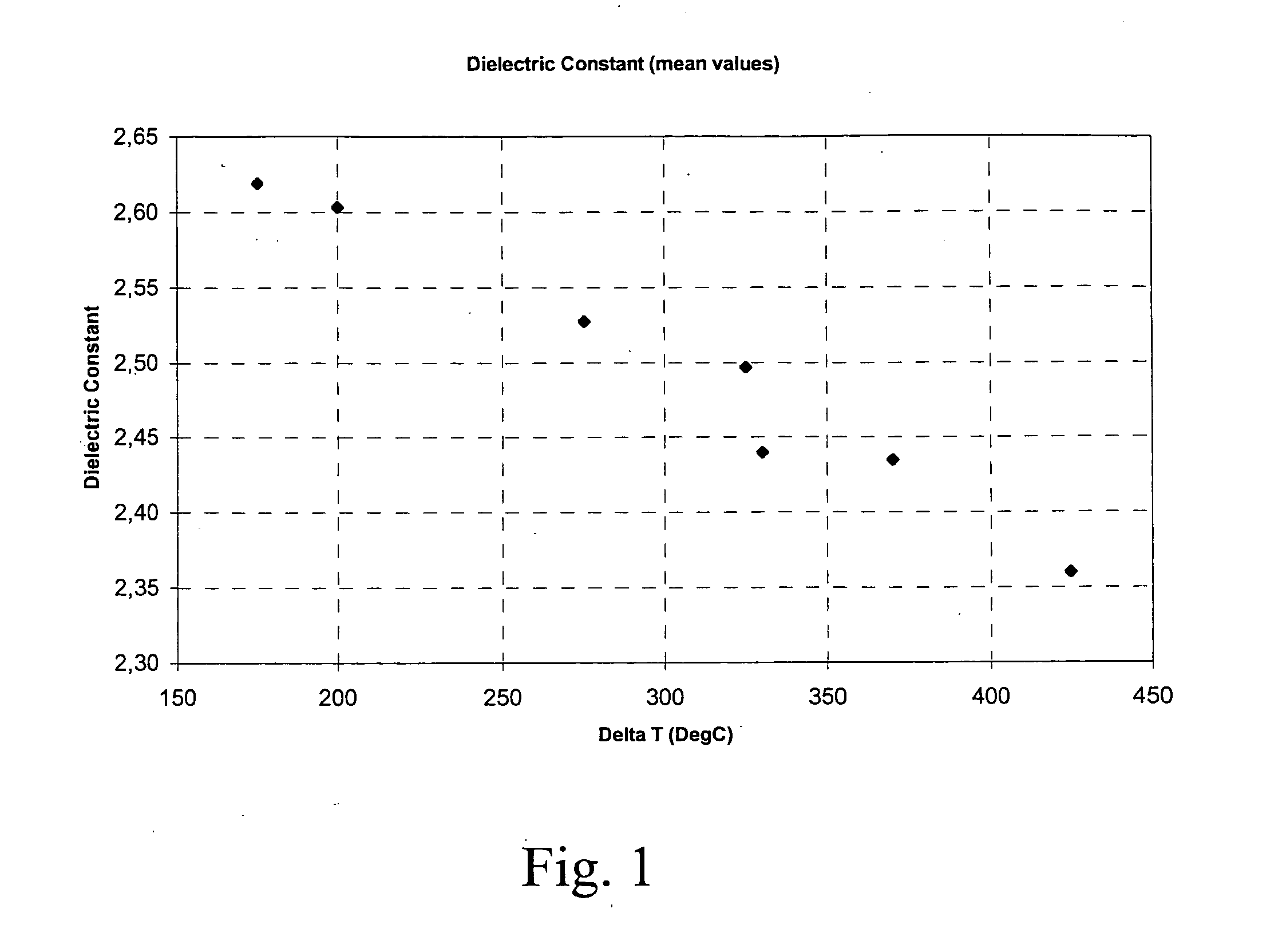

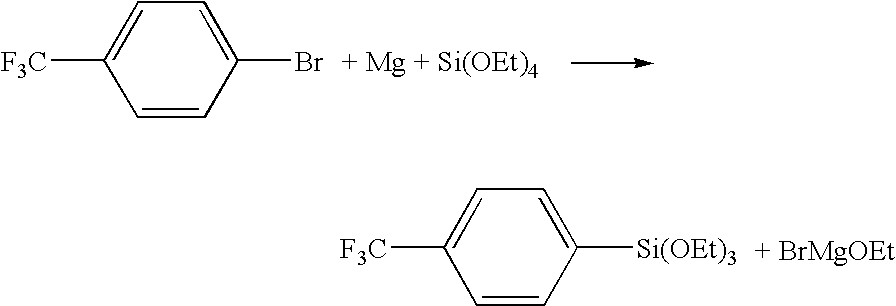

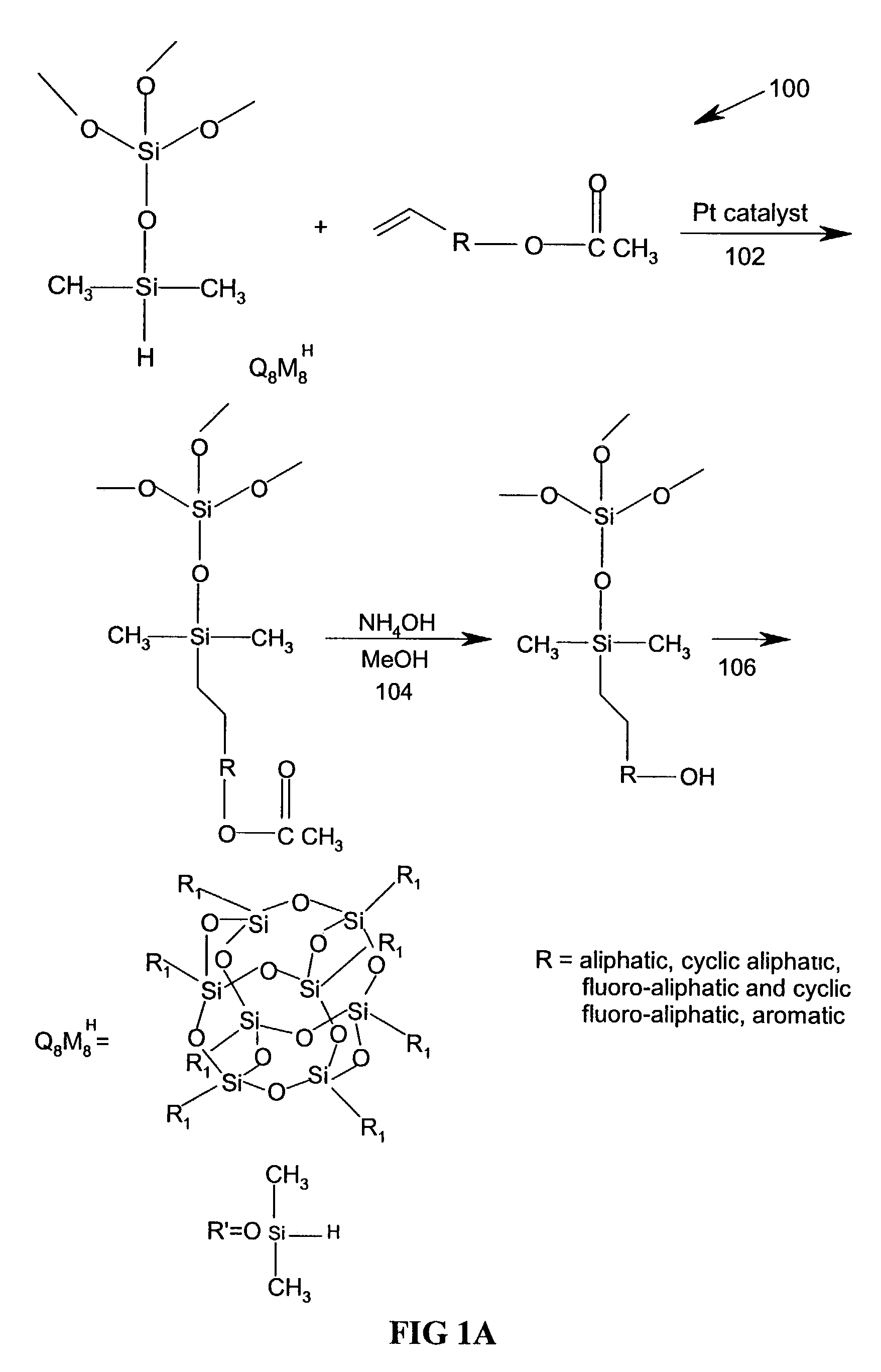

Low dielectric constant materials and method

InactiveUS6051321AImprove rotational flexibilityTightly boundSemiconductor/solid-state device detailsSynthetic resin layered productsElectrical conductorCopper

Intermetal dielectric (IMD) and interlevel dielectric (ILD) that have dielectric constants (K) ranging from 2.0 to 2.6 are prepared from plasma or photon assisted CVD (PACVD) or transport polymerization (TP). The low K dielectric (LKD) materials are prepared from PACVD or TP of some selected siloxanes and F-containing aromatic compounds. The thin films combine barrier and adhesion layer functions with low dielectric constant functions, thus eliminating the necessity for separate adhesion and barrier layers, and layers of low dielectric constant. The LKD materials disclosed in this invention are particularly useful for <0.18 .mu.m ICs, or when copper is used as conductor in future ICs.

Owner:CANON USA

Film forming method and film forming device

InactiveUS6958175B2Increase resistanceImprove thermal conductivitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenOptoelectronics

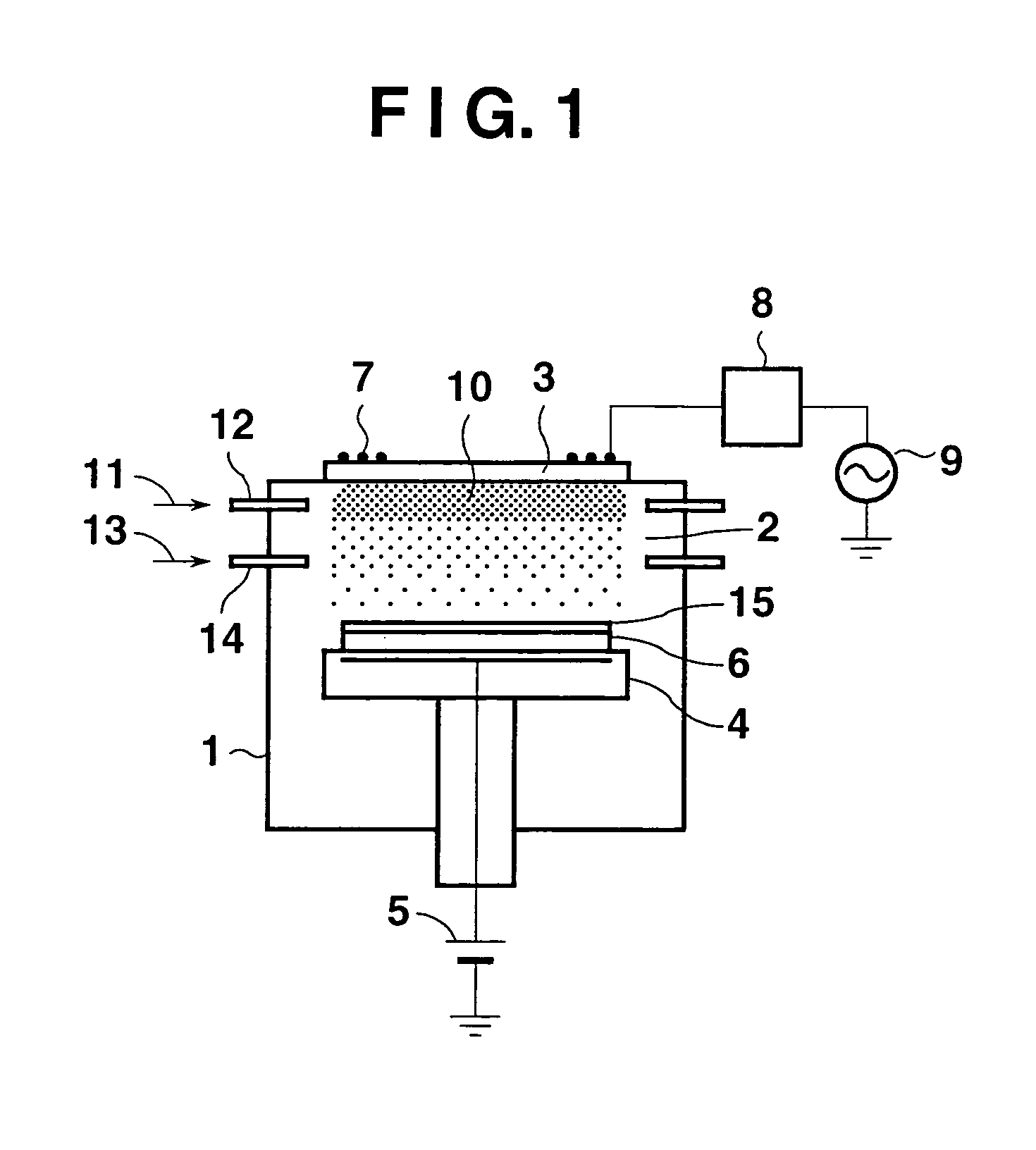

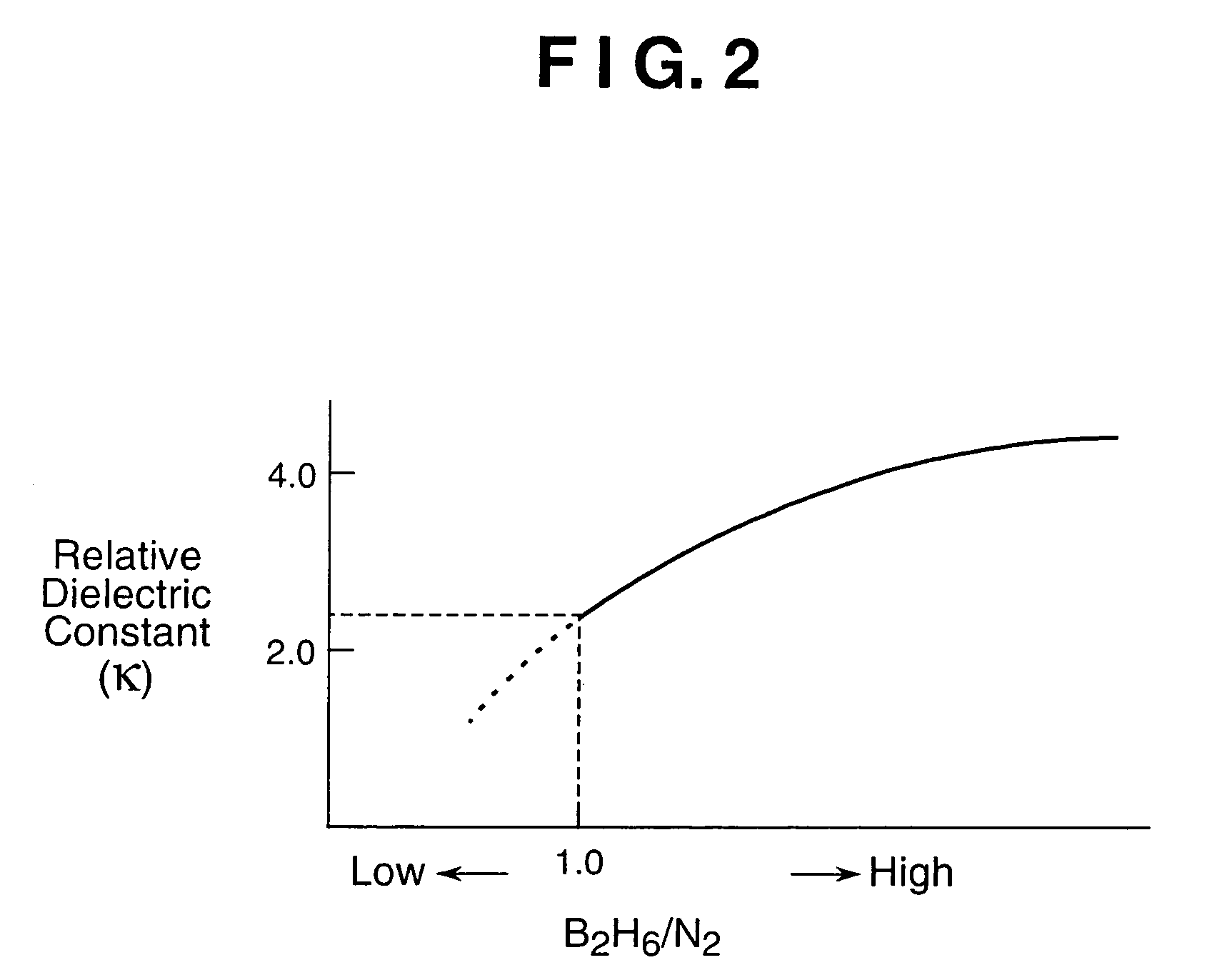

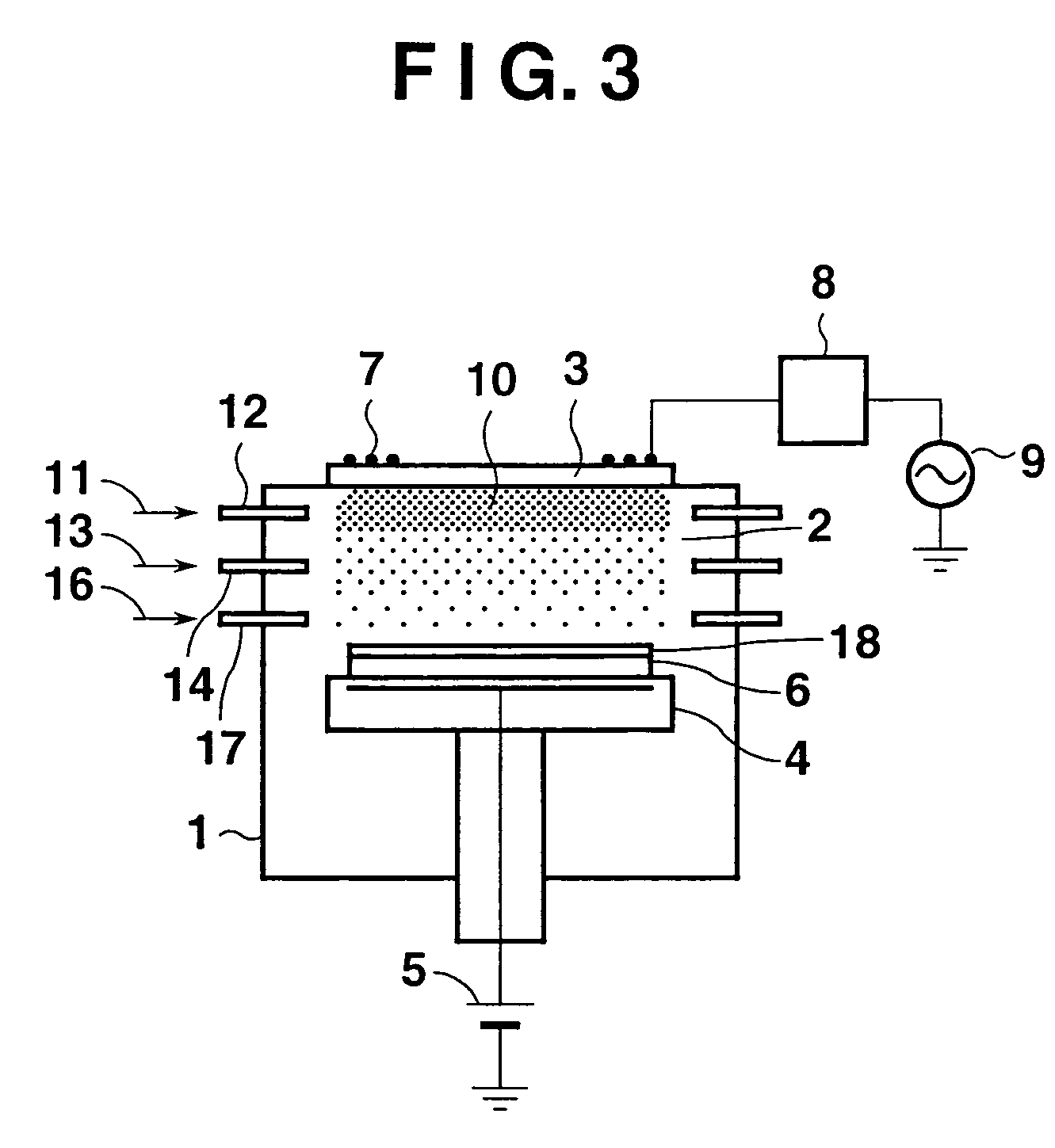

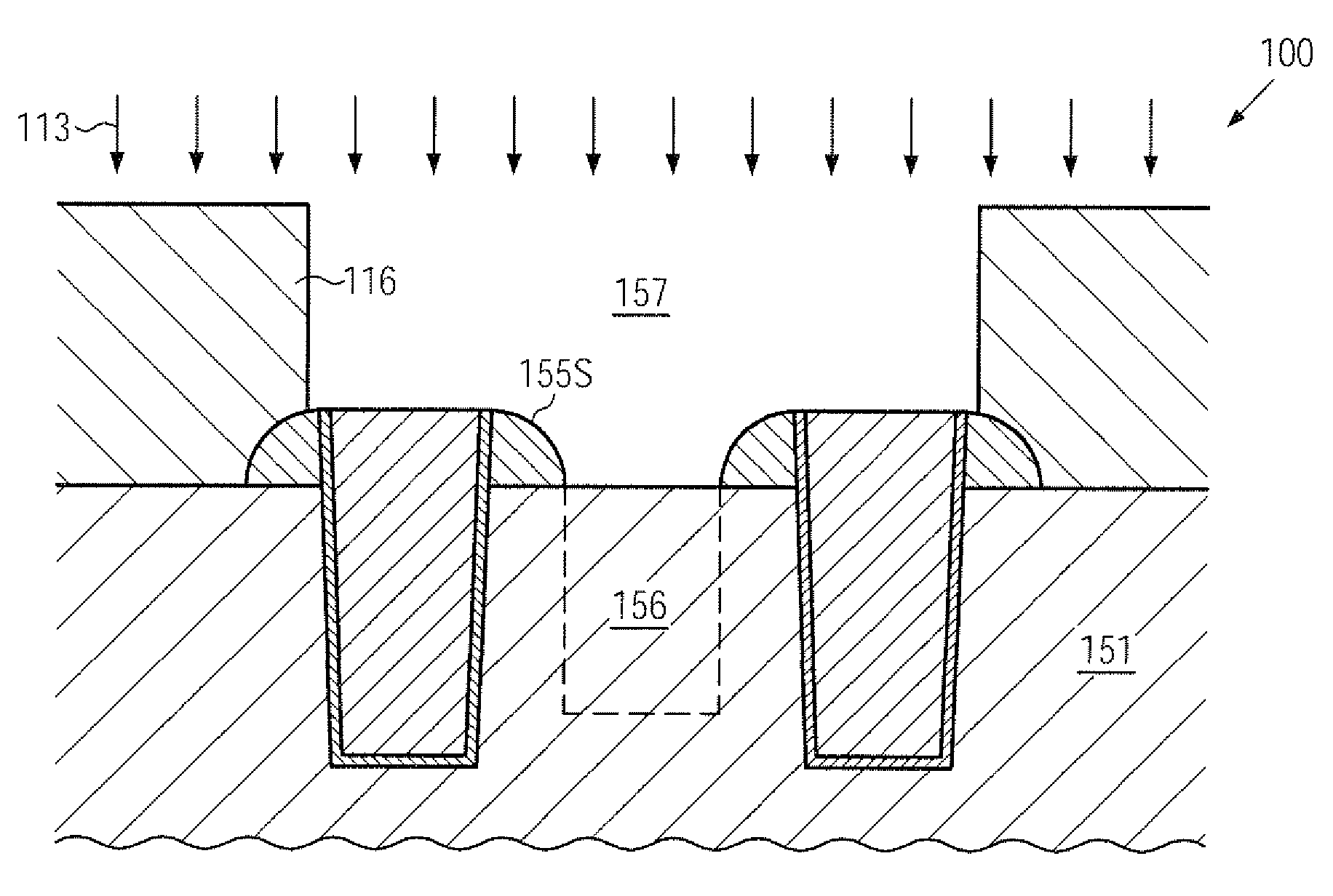

A plasma 10 is generated within a film formation chamber 2, and mainly a nitrogen gas 11 is excited within the film formation chamber 2. Then, the excited nitrogen gas 11 is reacted with a diborane gas 13 diluted with a hydrogen gas, thereby forming a boron nitride film 15 on a substrate 4. Thus, the boron nitride film 15 excellent in mechanical and chemical resistance, high in thermal conductivity, and having a low relative dielectric constant κ can be formed speedily.

Owner:M WATANABE CO LTD

Microstructure device including a metallization structure with self-aligned air gaps between closely spaced metal lines

InactiveUS20090294898A1Low dielectric constantAvoiding cost-intensive sophisticated lithography processSemiconductor/solid-state device detailsSolid-state devicesLithographic artistImage resolution

Owner:ADVANCED MICRO DEVICES INC

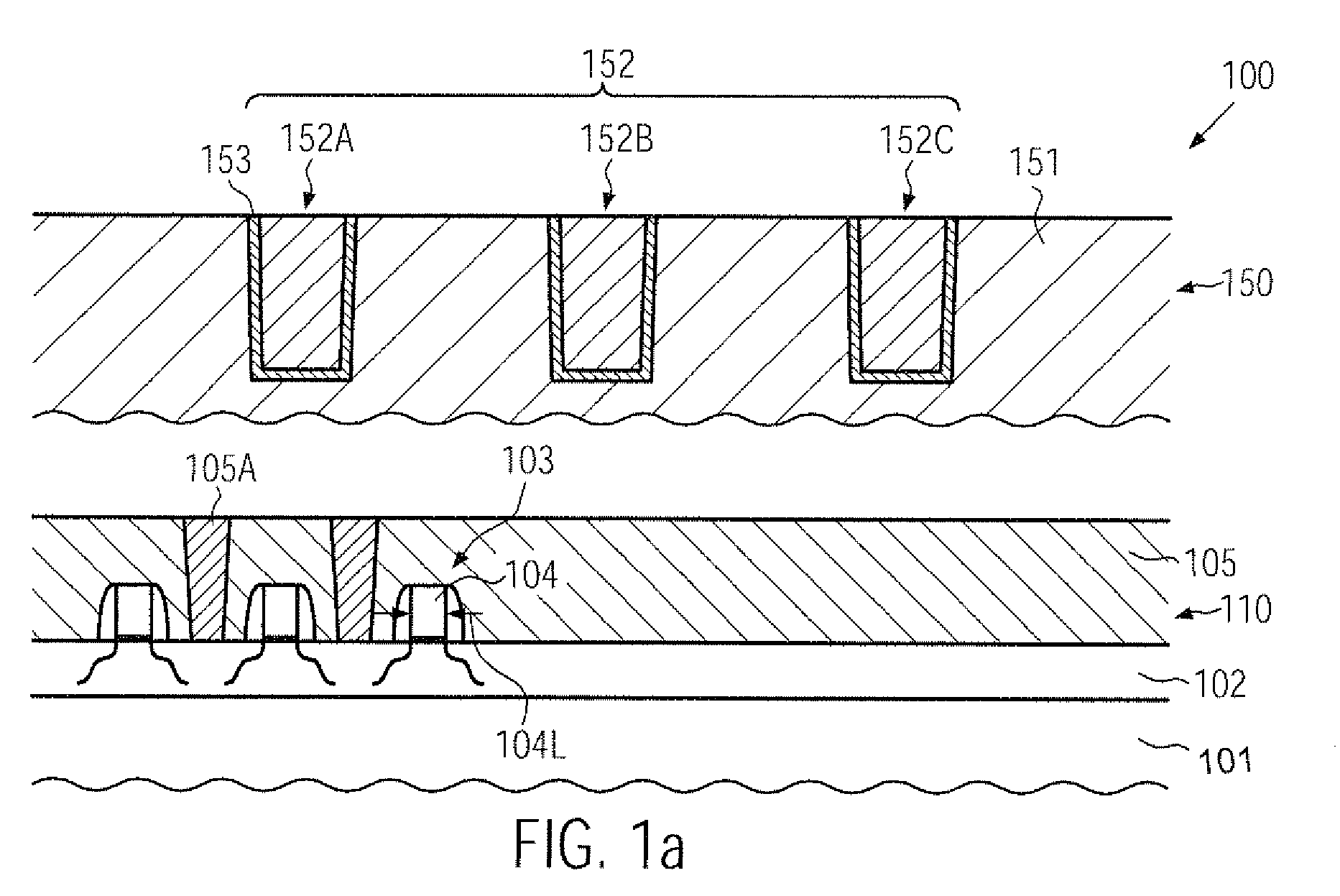

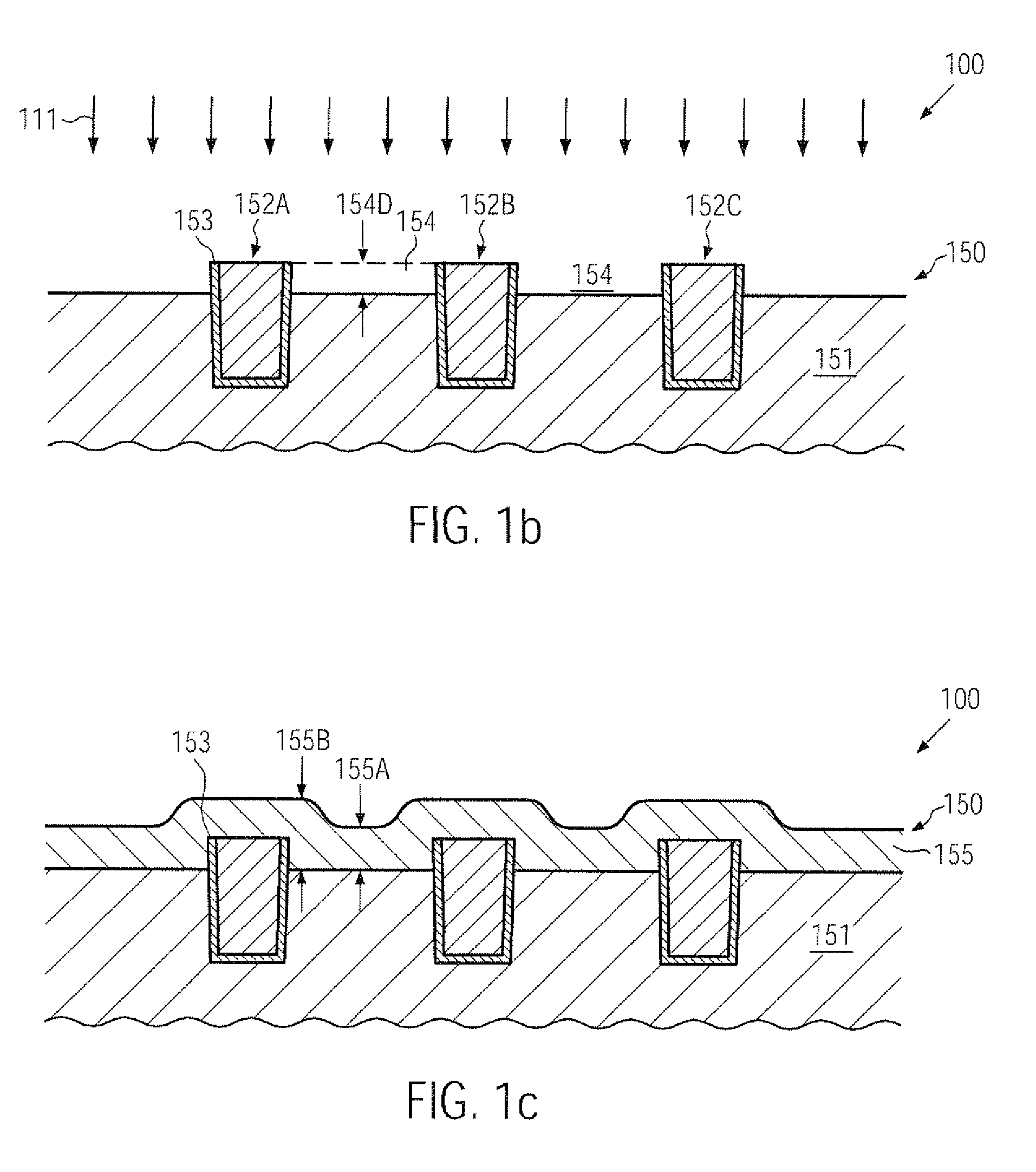

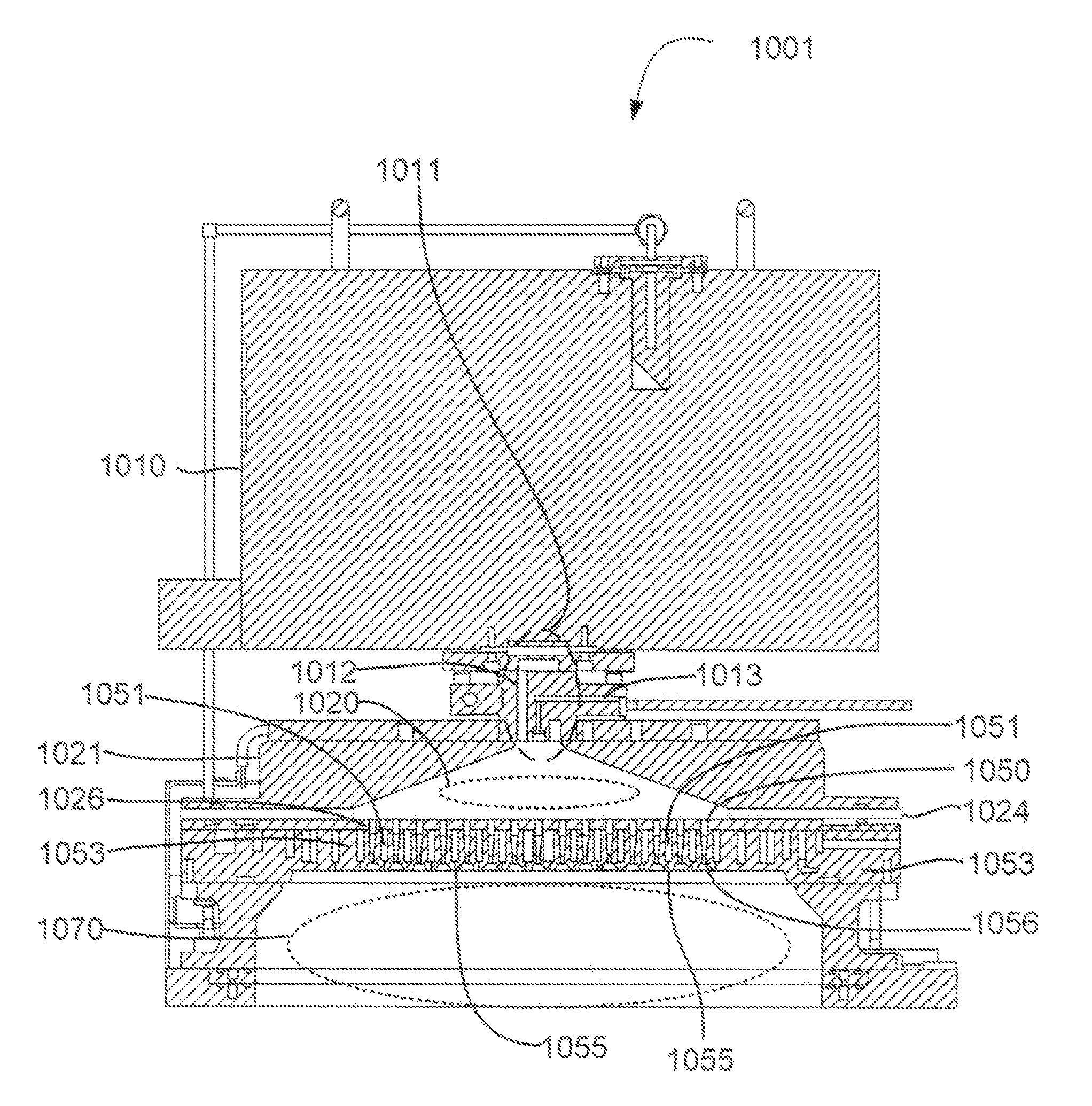

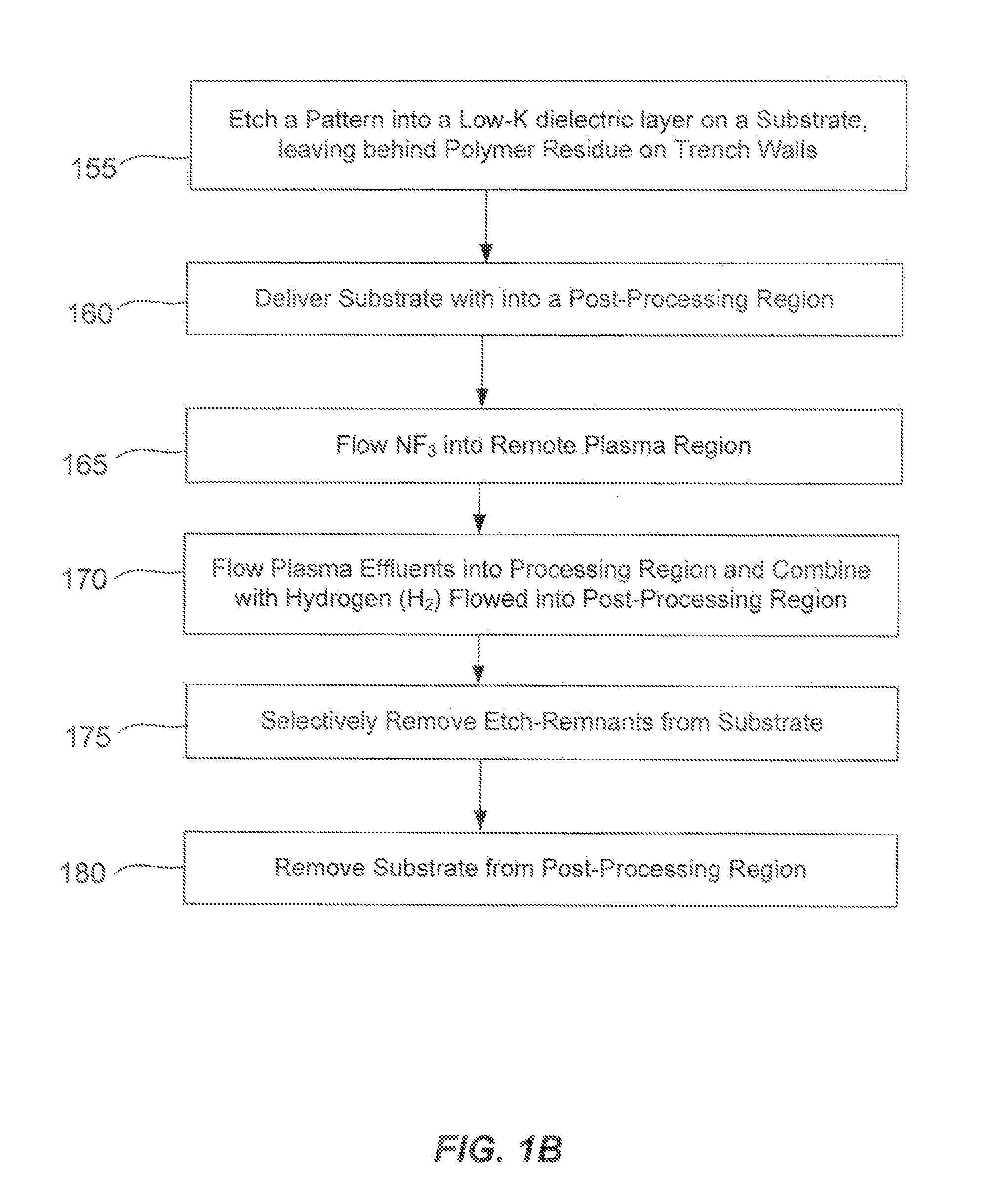

Etch remnant removal

InactiveUS20130298942A1Delicate featureLow dielectric constantElectric discharge tubesElectrostatic cleaningGas phaseDielectric layer

Methods of removing residual polymer from vertical walls of a patterned dielectric layer are described. The methods involve the use of a gas phase etch to remove the residual polymer without substantially disturbing the patterned dielectric layer. The gas phase etch may be used on a patterned low-k dielectric layer and may maintain the low dielectric constant of the patterned dielectric layer. The gas phase etch may further avoid stressing the patterned low-k dielectric layer by avoiding the use of liquid etchants whose surface tension can upset delicate low-K features. The gas phase etch may further avoid the formation of solid etch by-products which cars also deform the delicate features.

Owner:APPLIED MATERIALS INC

Tunable dielectric compositions including low loss glass

InactiveUS6905989B2Lower sintering temperatureIncrease varietyFixed capacitor dielectricCeramic layered productsBreakdown strengthStrontium titanate

Tunable dielectric materials including an electronically tunable dielectric ceramic and a low loss glass additive are disclosed. The tunable dielectric may comprise a ferroelectric perskovite material such as barium strontium titanate. The glass additive may comprise boron, barium, calcium, lithium, manganese, silicon, zinc and / or aluminum-containing glasses having dielectric losses of less than 0.003 at 2 GHz. The materials may further include other additives such as non-tunable metal oxides and silicates. The low loss glass additive enables the materials to be sintered at relatively low temperatures while providing improved properties such as low microwave losses and high breakdown strengths.

Owner:NXP USA INC

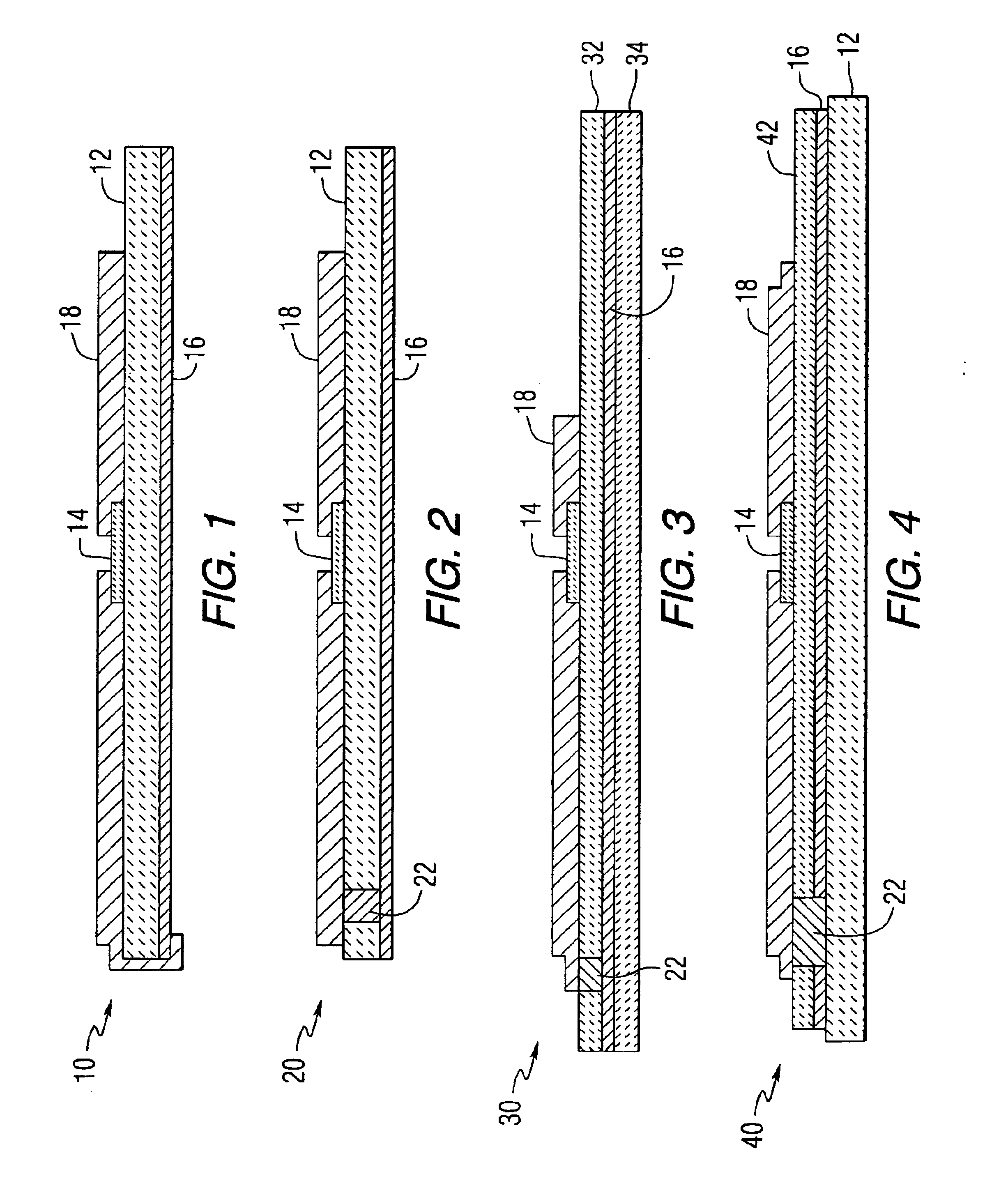

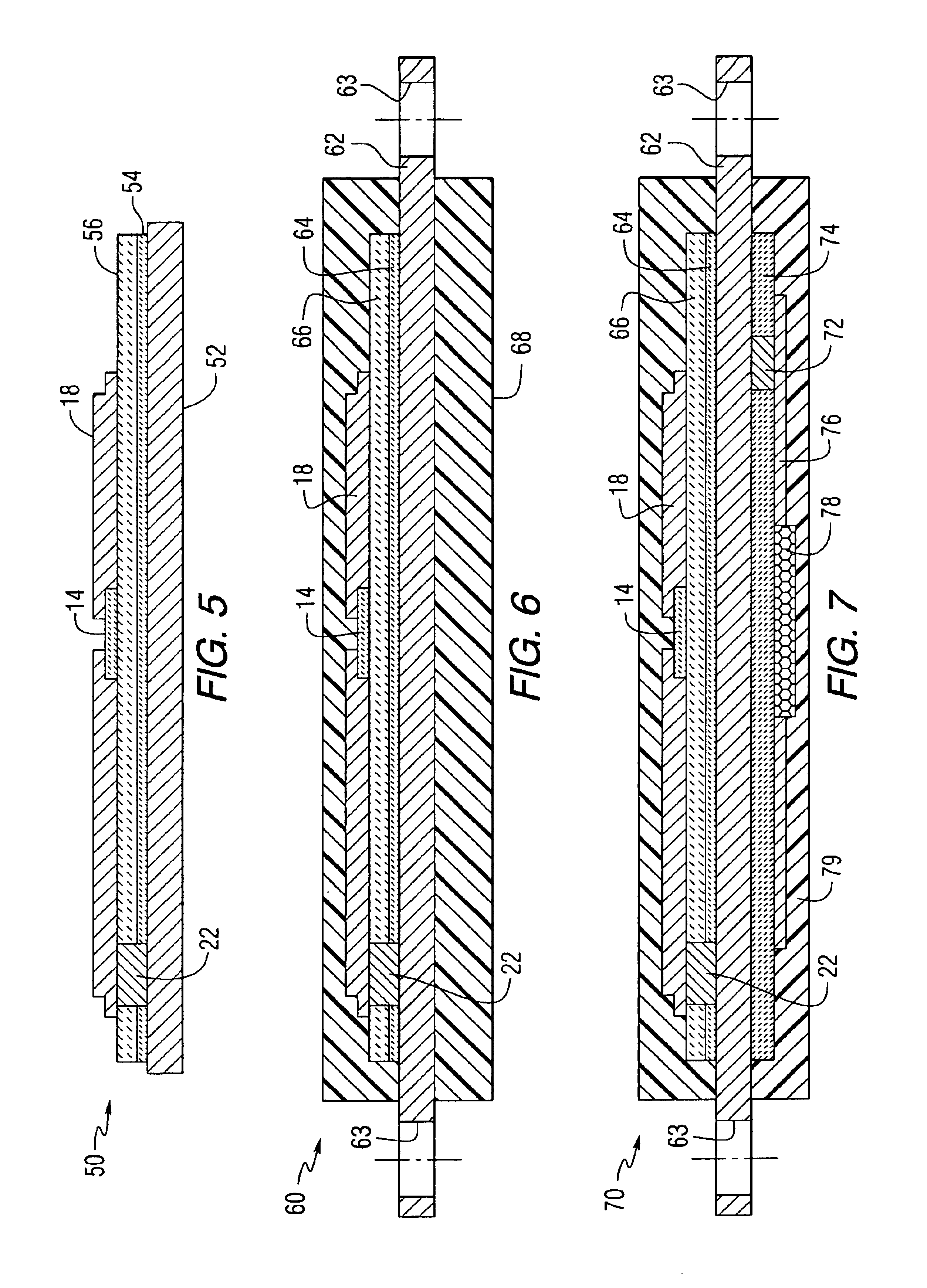

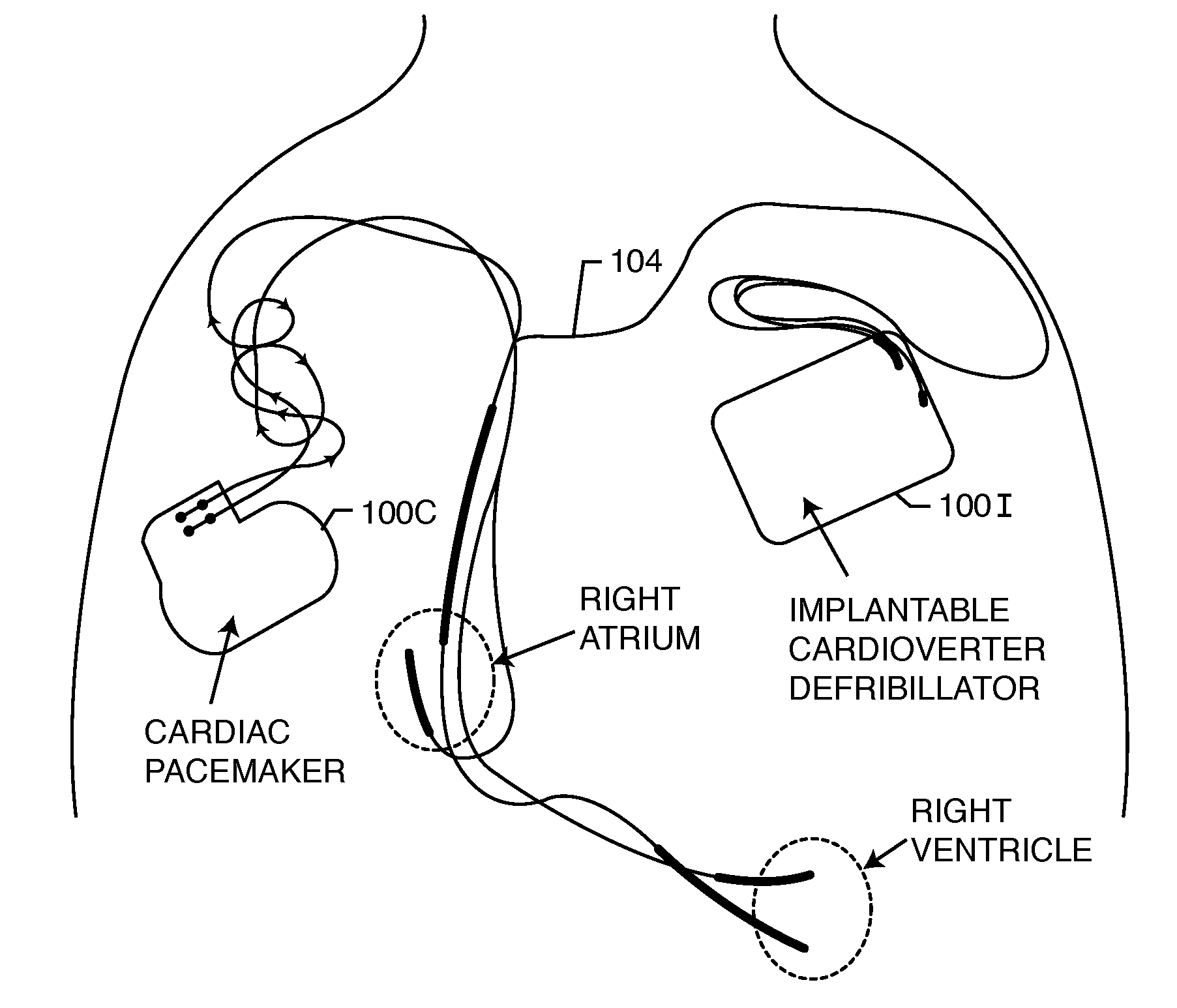

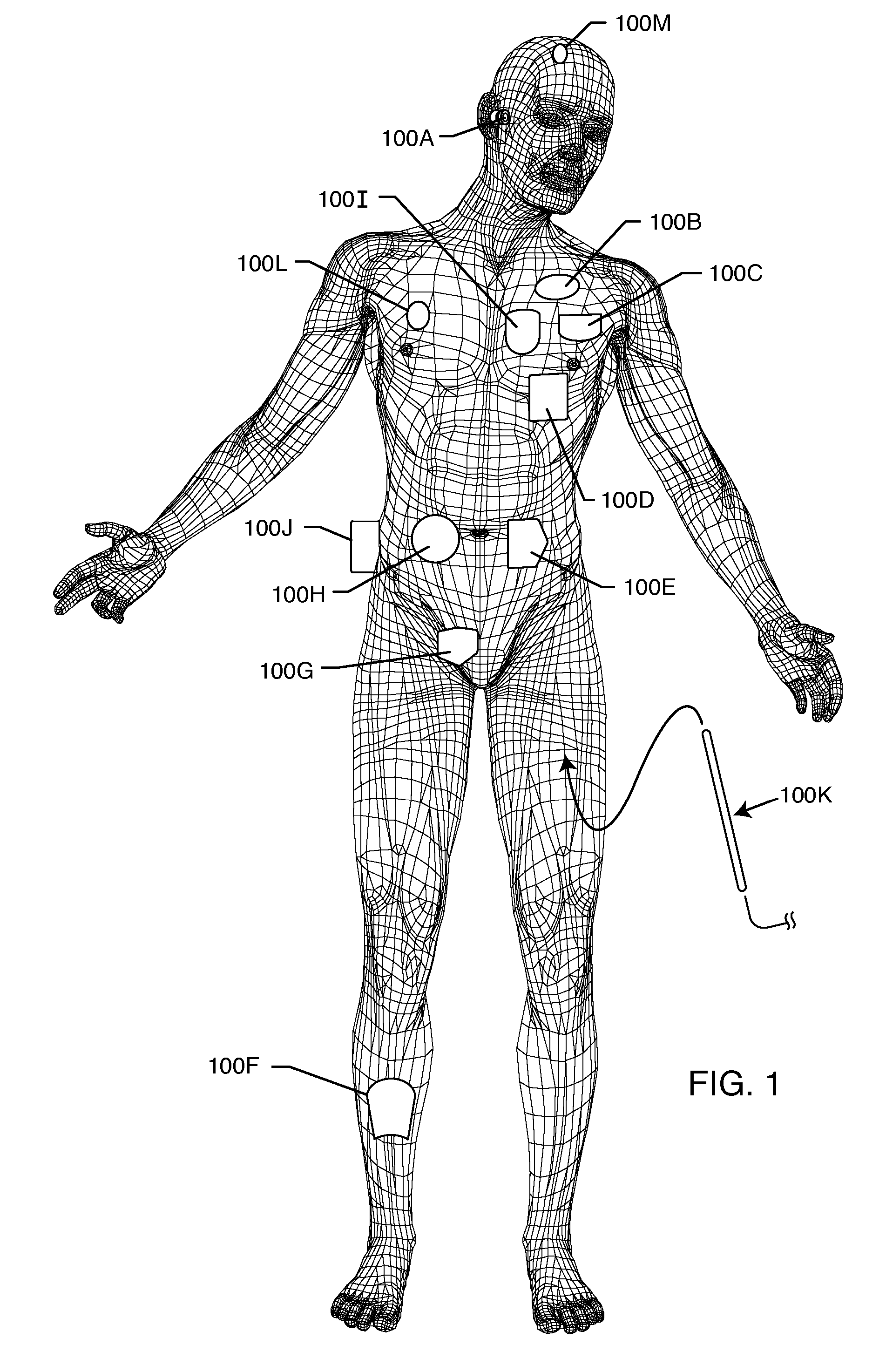

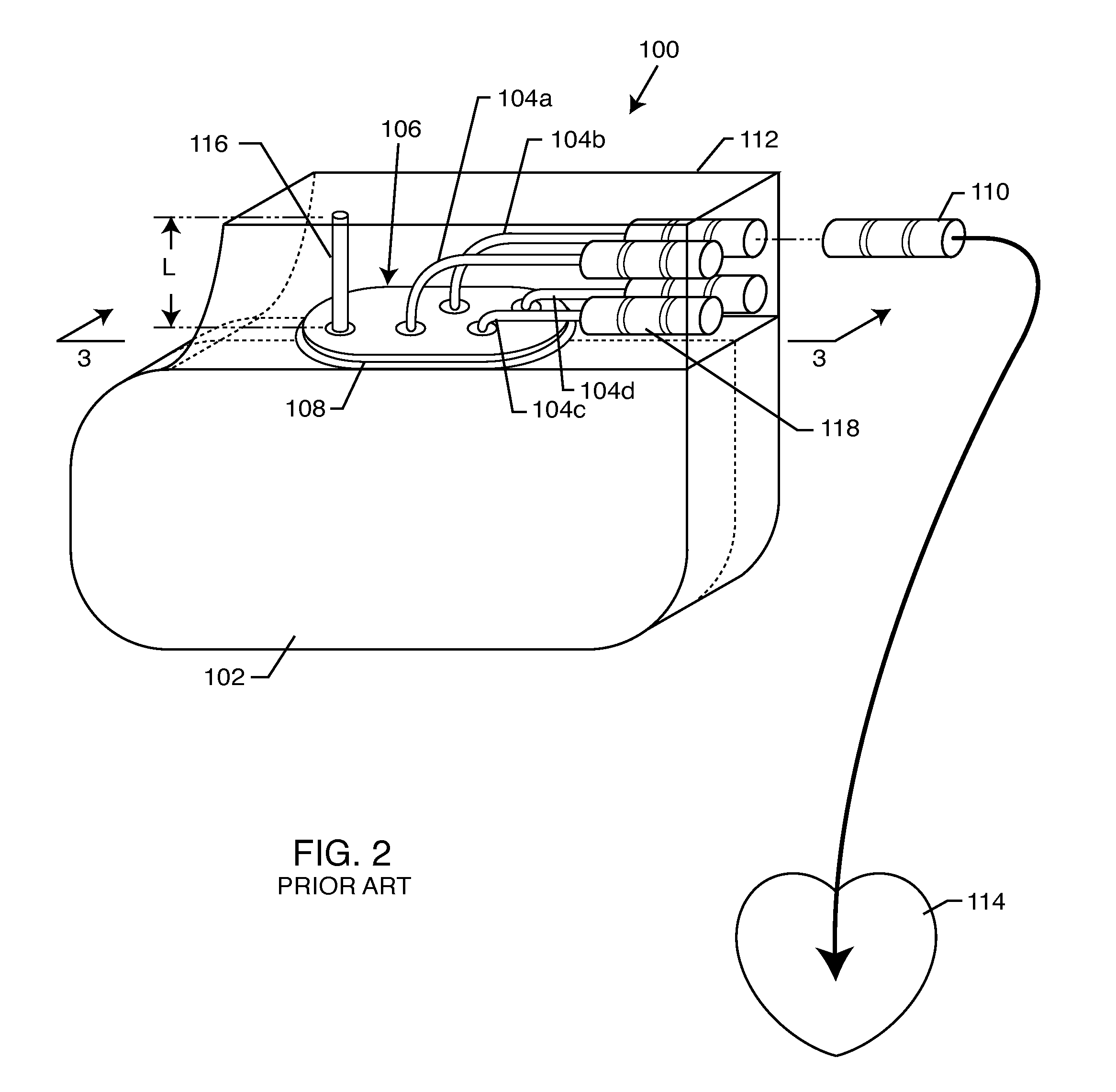

Tank filters utilizing very low k materials, in series with lead wires or circuits of active medical devices to enhance MRI compatibility

ActiveUS20080071313A1Low dielectric constantHigh strengthMultiple-port networksAnti-noise capacitorsCapacitanceEngineering

A TANK filter is provided for a lead wire of an active medical device (AMD). In a preferred form, the TANK filter is integrated into a TIP and / or RING electrode for an active implantable medical device. The TANK filter includes a capacitor in parallel with an inductor. The parallel capacitor and inductor are placed in series with the lead wire of the AMD, wherein values of capacitance and inductance are selected such that the TANK filter is resonant at a selected frequency to attenuate current flow through the lead wire along a range of selected frequencies. In a particularly preferred form, the TANK filter is manufactured using very low k materials of sufficient strength to handle forces applied thereto during installation and use.

Owner:WILSON GREATBATCH LTD

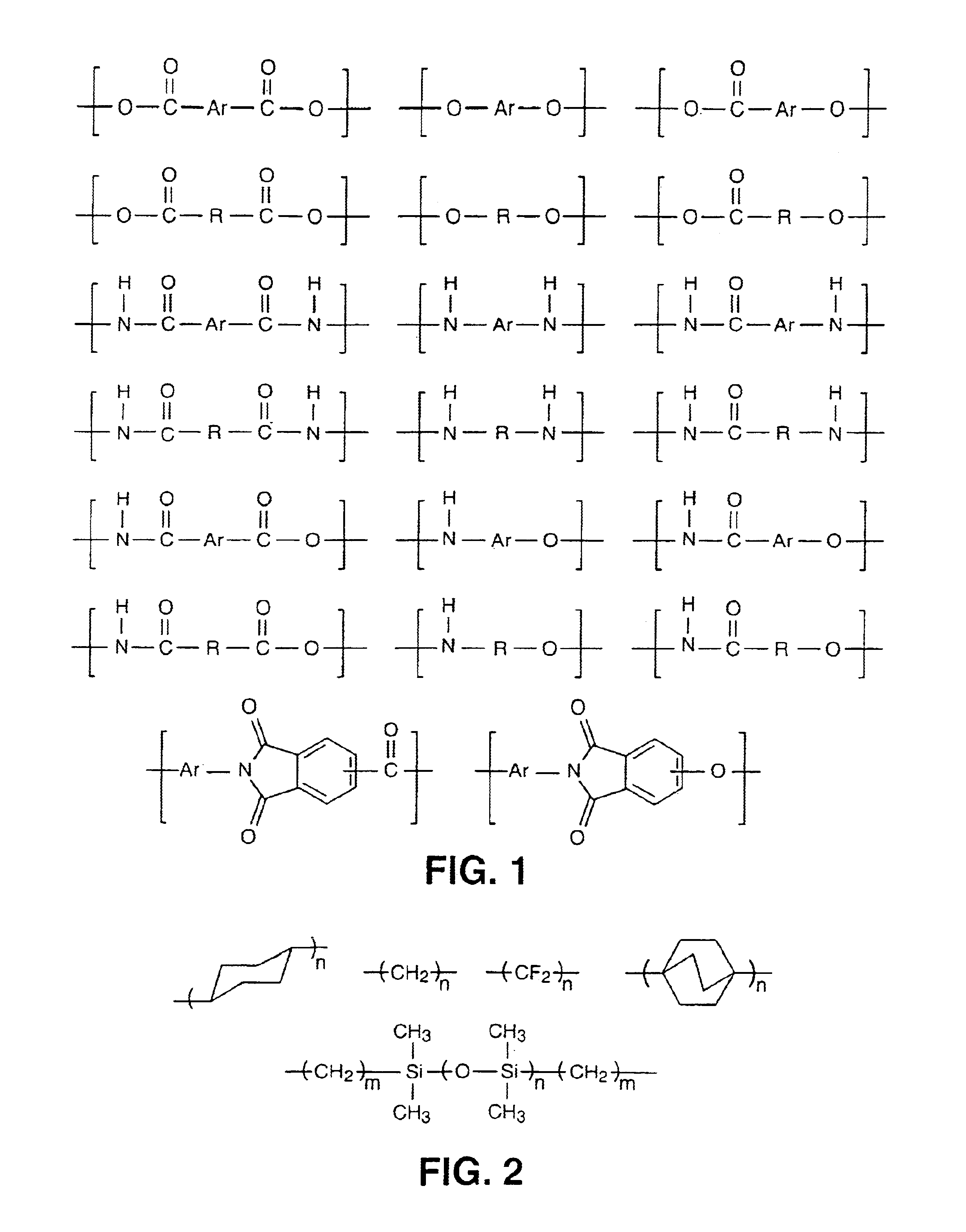

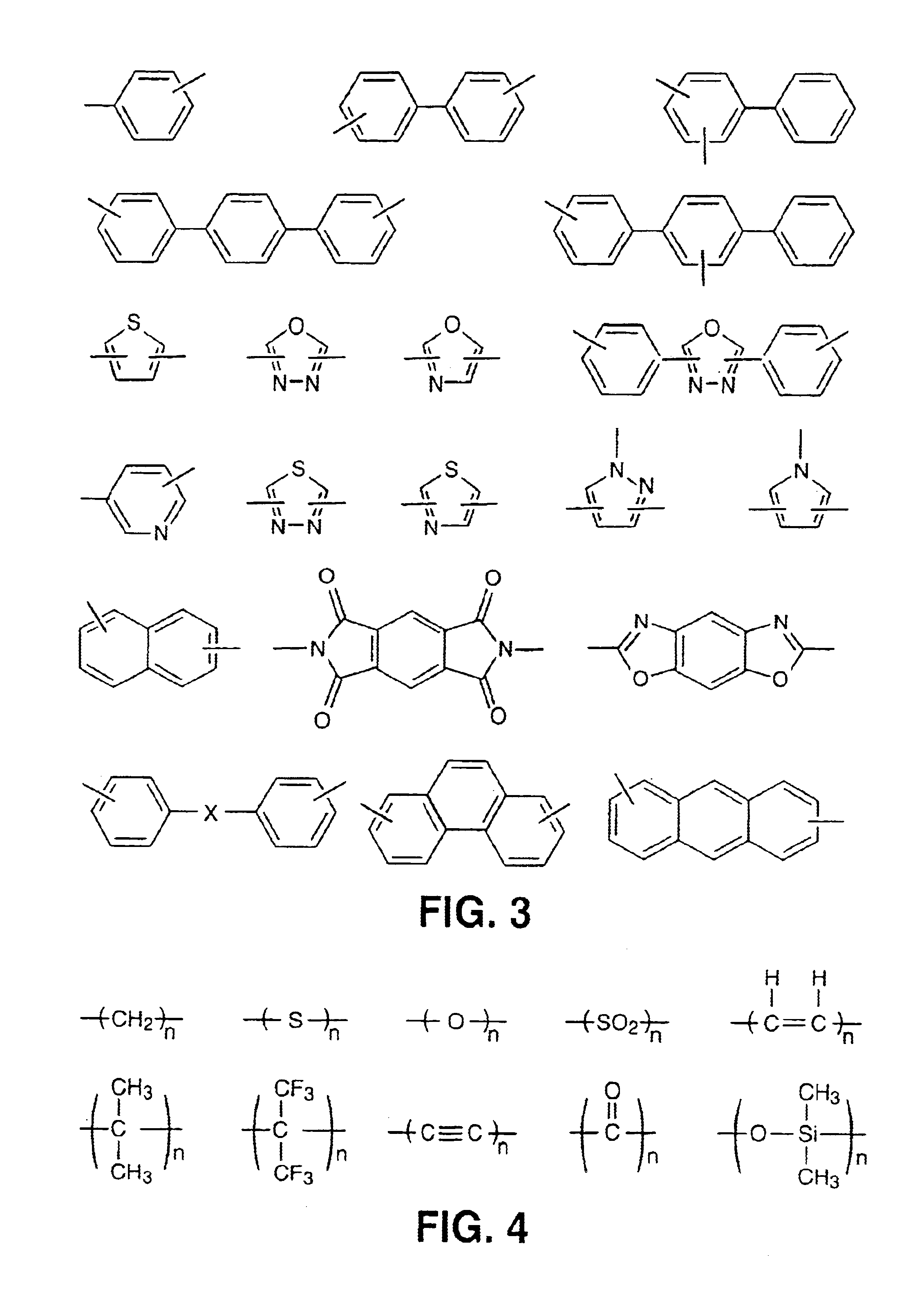

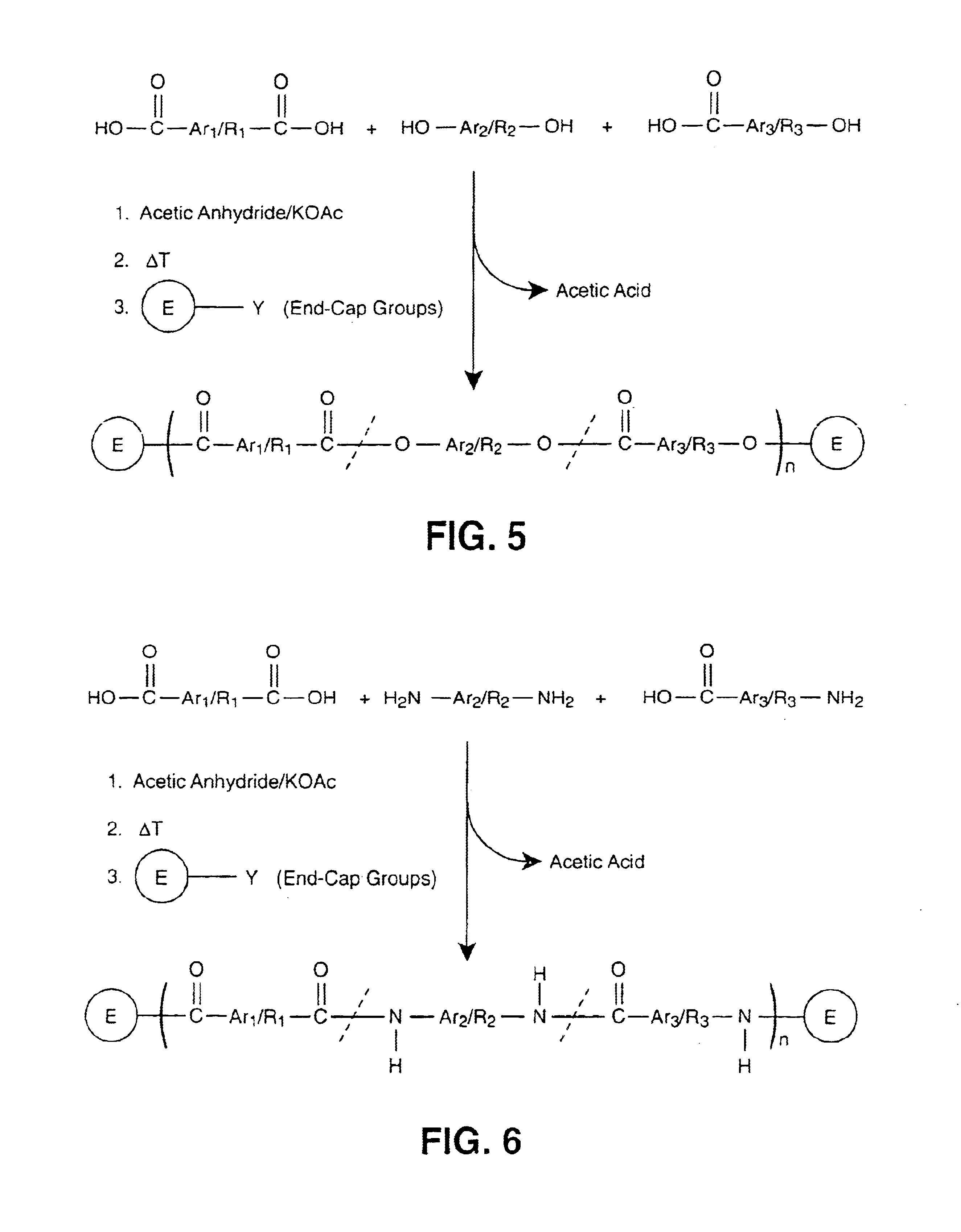

Liquid crystalline thermosets from ester, ester-imide, and ester-amide oligomers

InactiveUS6939940B2Low viscosityLow dielectric constantLiquid crystal compositionsLiquid crystallineEnd-group

Main chain thermotropic liquid crystal esters, ester-imides, and ester-amides were prepared from AA, BB, and AB type monomeric materials and were end-capped with phenylacetylene, phenylmaleimide, or nadimide reactive end-groups. The resulting reactive end-capped liquid crystal oligomers exhibit a variety of improved and preferred physical properties. The end-capped liquid crystal oligomers are thermotropic and have, preferably, molecular weights in the range of approximately 1000-15,000 grams per mole. The end-capped liquid crystal oligomers have broad liquid crystalline melting ranges and exhibit high melt stability and very low melt viscosities at accessible temperatures. The end-capped liquid crystal oligomers are stable for up to an hour in the melt phase. These properties make the end-capped liquid crystal oligomers highly processable by a variety of melt process shape forming and blending techniques including film extrusion, fiber spinning, reactive injection molding (RIM), resin transfer molding (RTM), resin film injection (RFI), powder molding, pultrusion, injection molding, blow molding, plasma spraying and thermo-forming. Once processed and shaped, the end-capped liquid crystal oligomers were heated to further polymerize and form liquid crystalline thermosets (LCT). The fully cured products are rubbers above their glass transition temperatures. The resulting thermosets display many properties that are superior to their non-end-capped high molecular weight analogs.

Owner:NASA

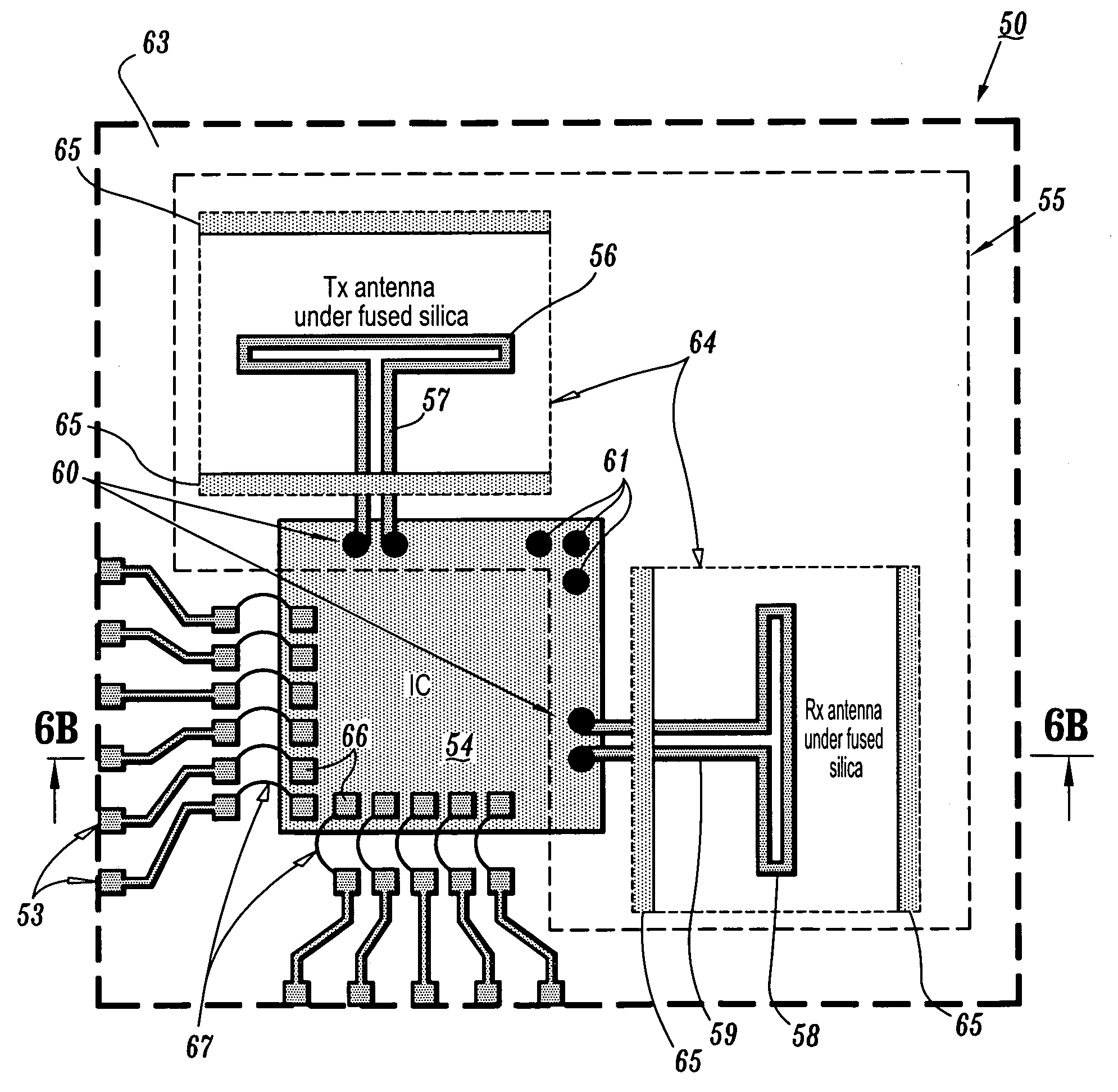

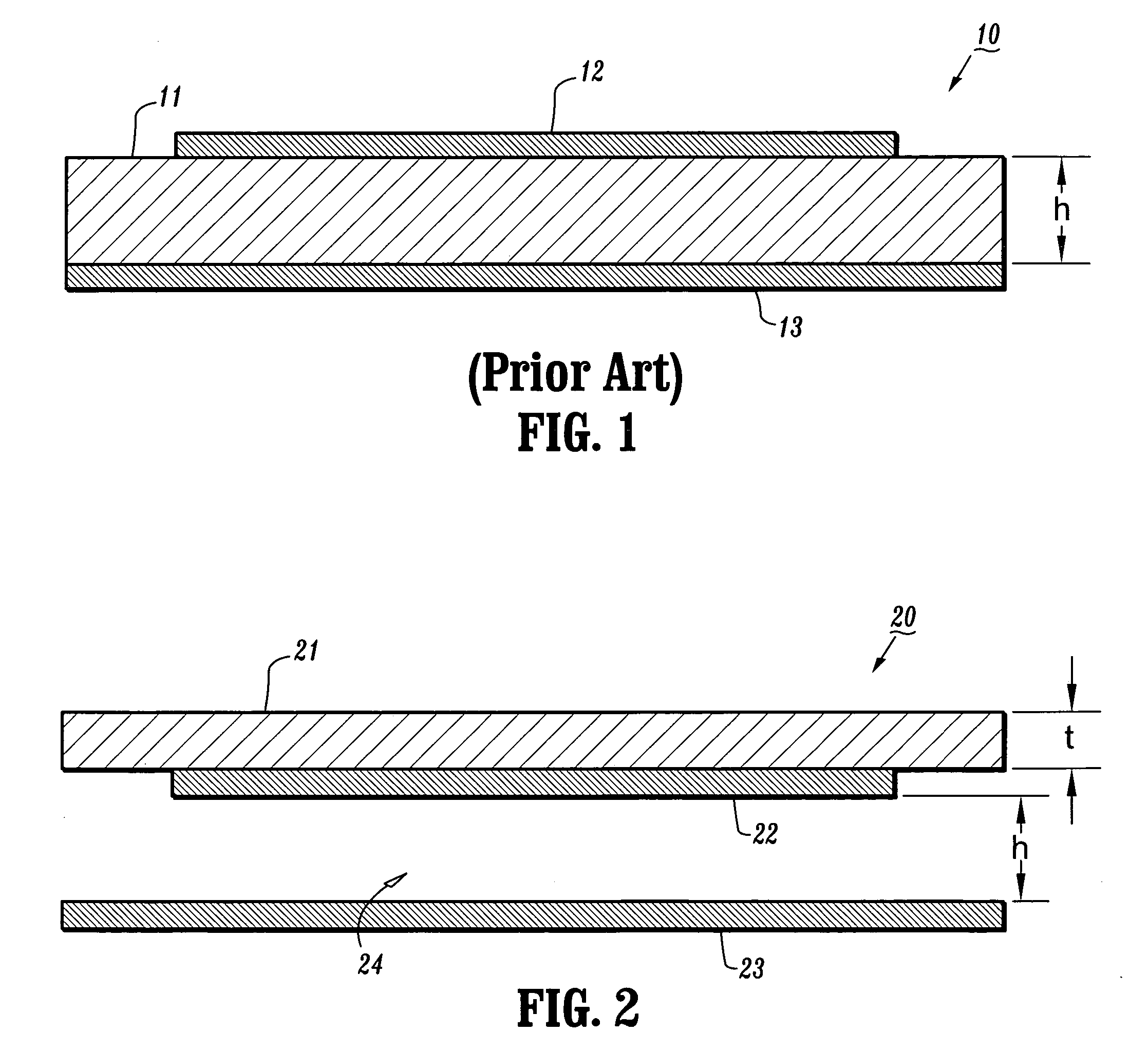

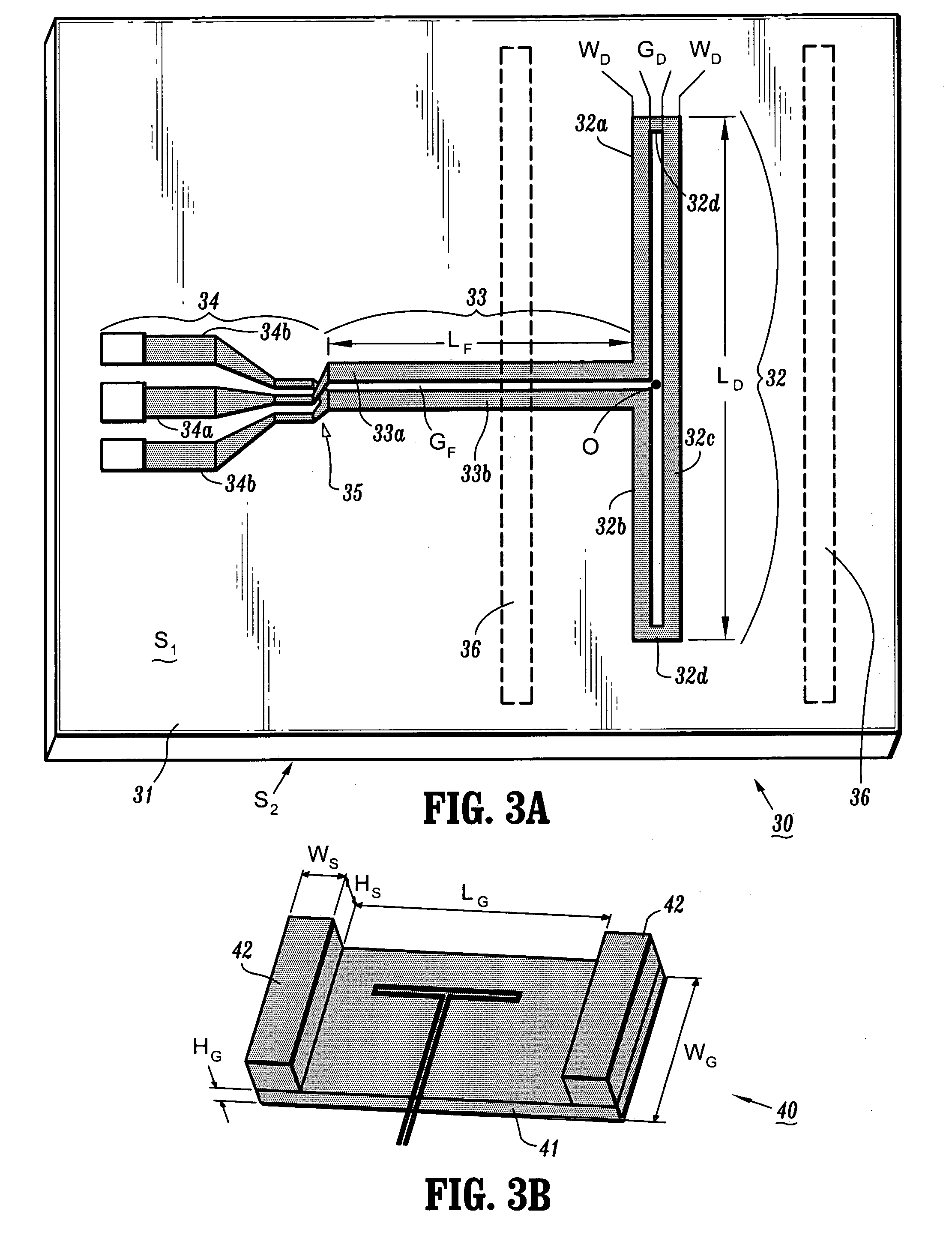

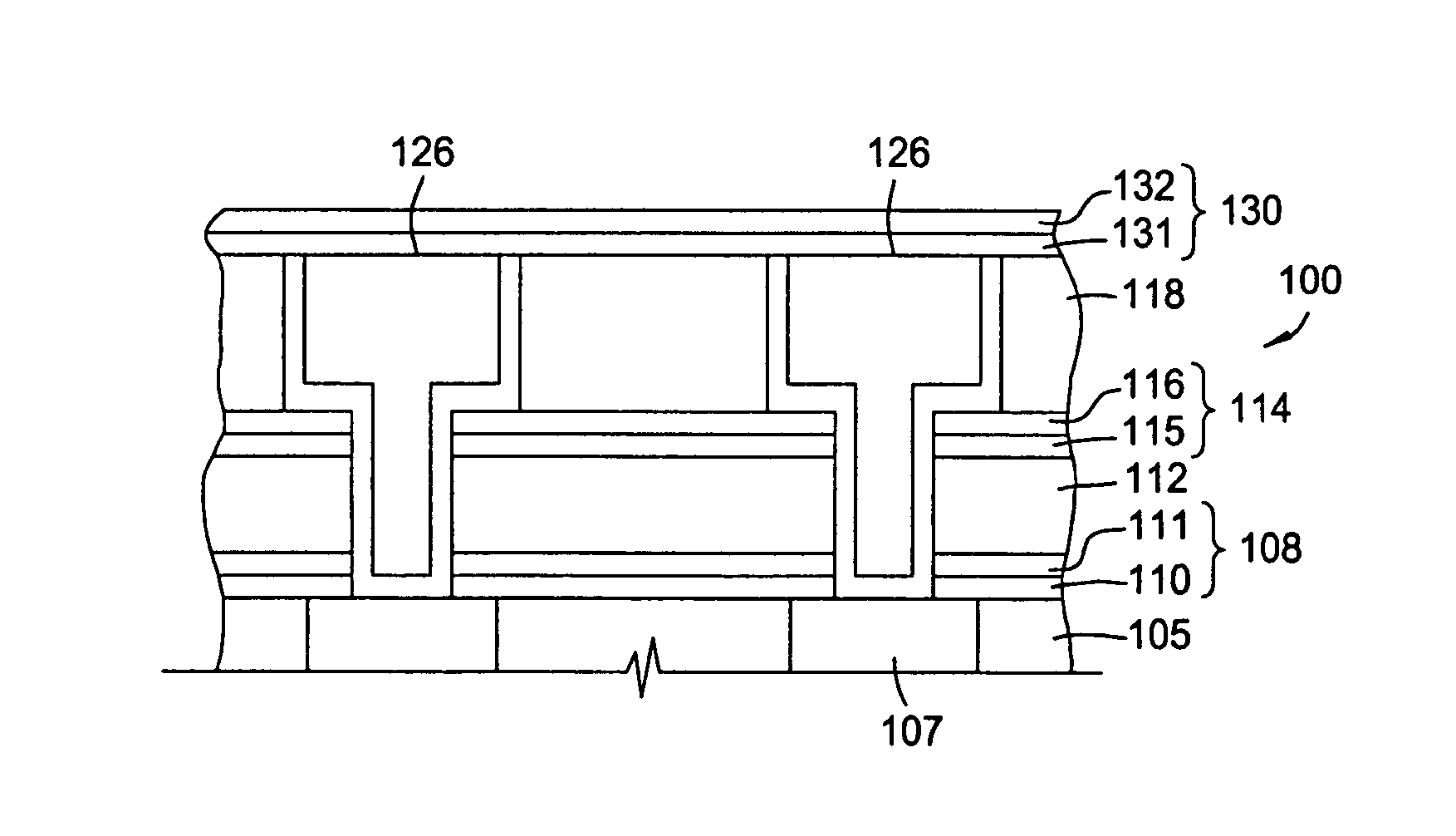

Apparatus and method for constructing and packaging printed antenna devices

ActiveUS7119745B2Improve bandwidth efficiencySimple designSimultaneous aerial operationsAntenna supports/mountingsTransceiverHigh bandwidth

Printed antenna devices are provided, which can operate at RF and microwave frequencies, for example, while simultaneously providing antenna performance characteristics such as high gain / directivity / radiation efficiency, high bandwidth, hemispherical radiation patterns, impedance, etc., that render the antennas suitable for voice communication, data communication or radar applications, for example. Further, apparatus are provided for integrally packaging such printed antenna devices with IC (integrated circuit) chips (e.g., transceiver) to construct IC packages for, e.g., wireless communications applications.

Owner:INT BUSINESS MASCH CORP

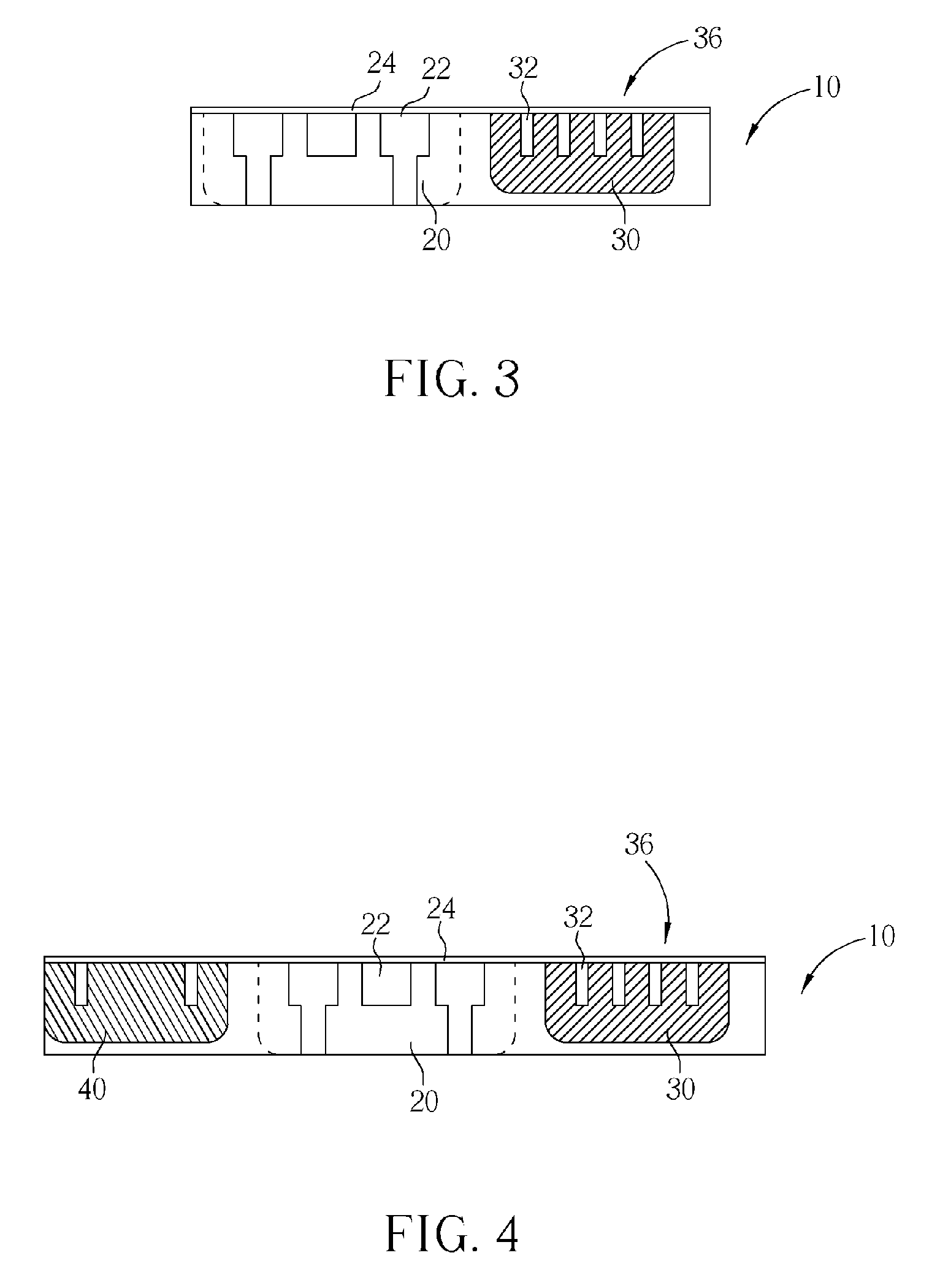

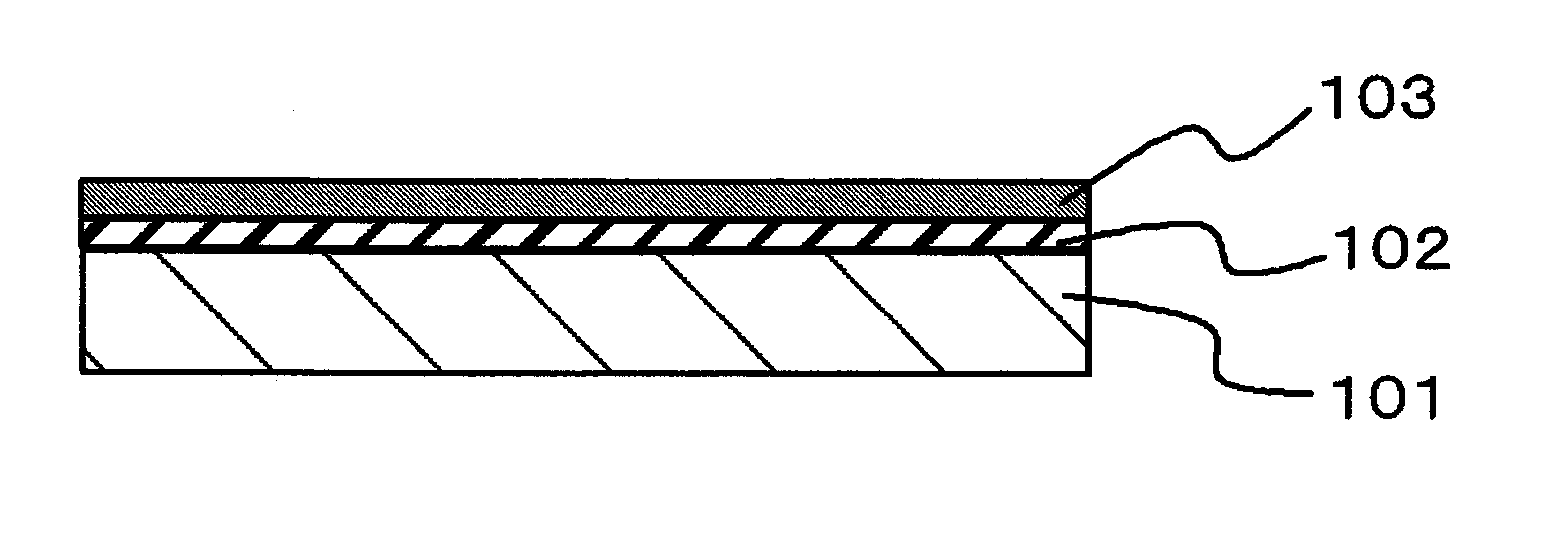

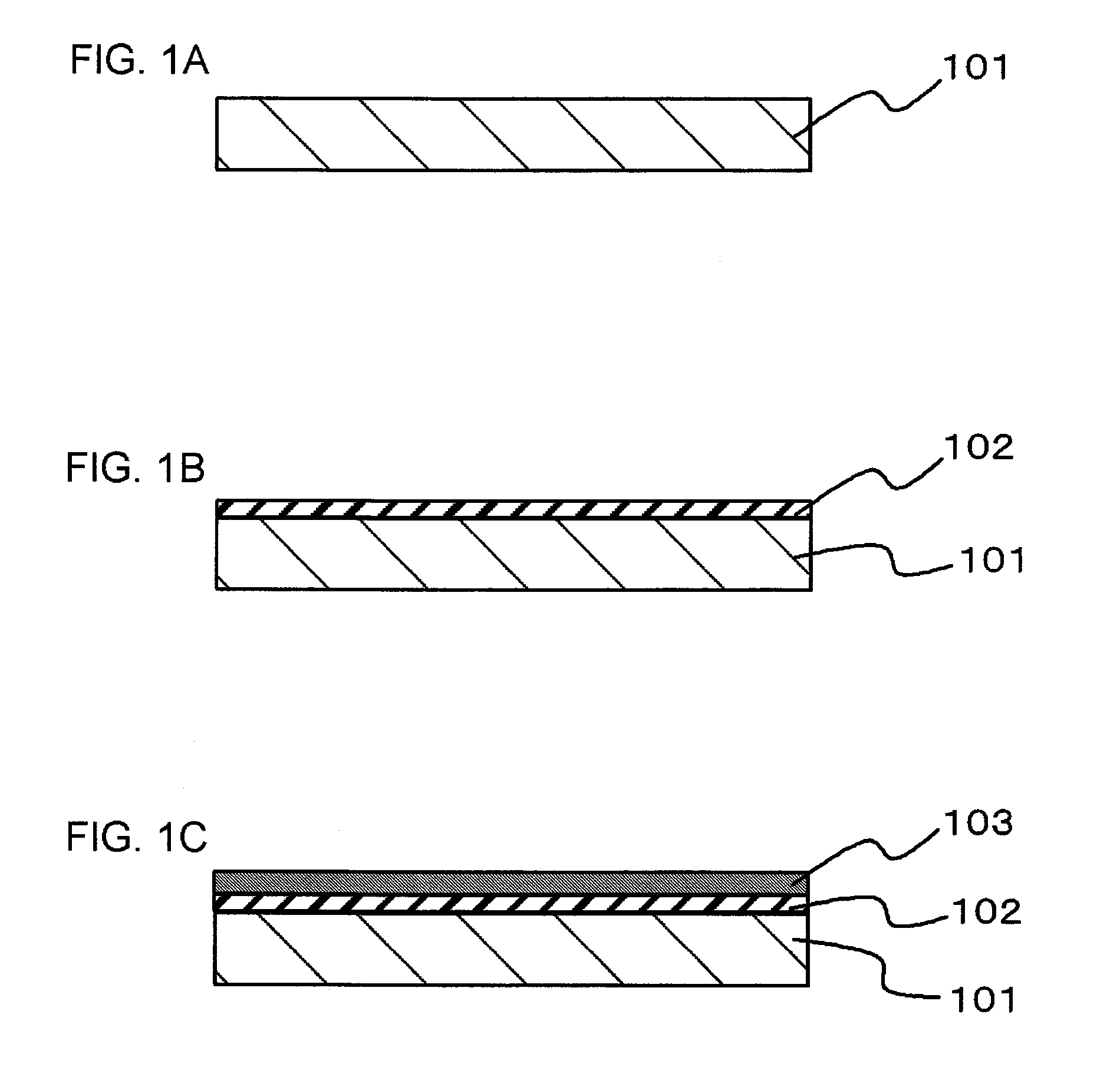

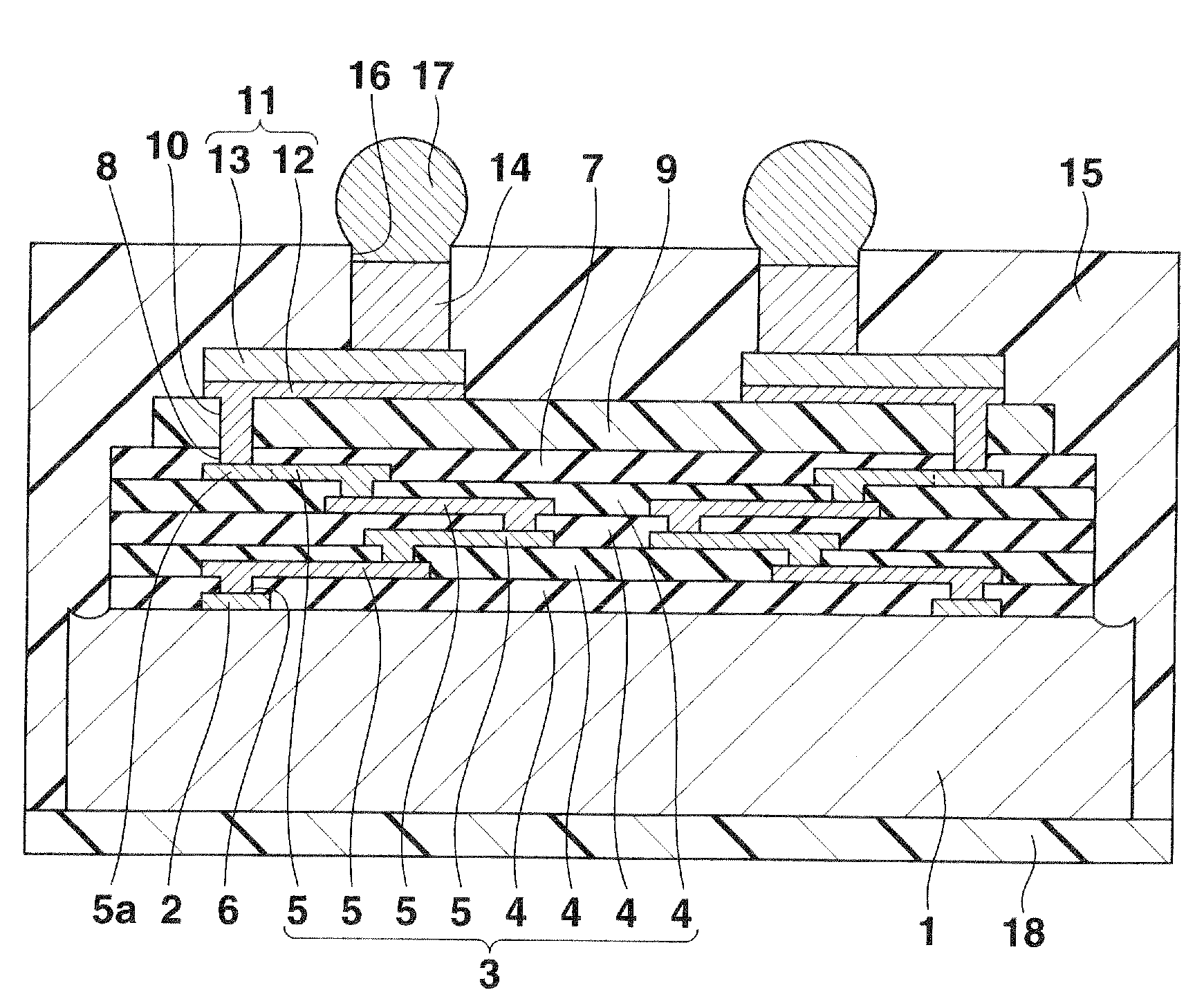

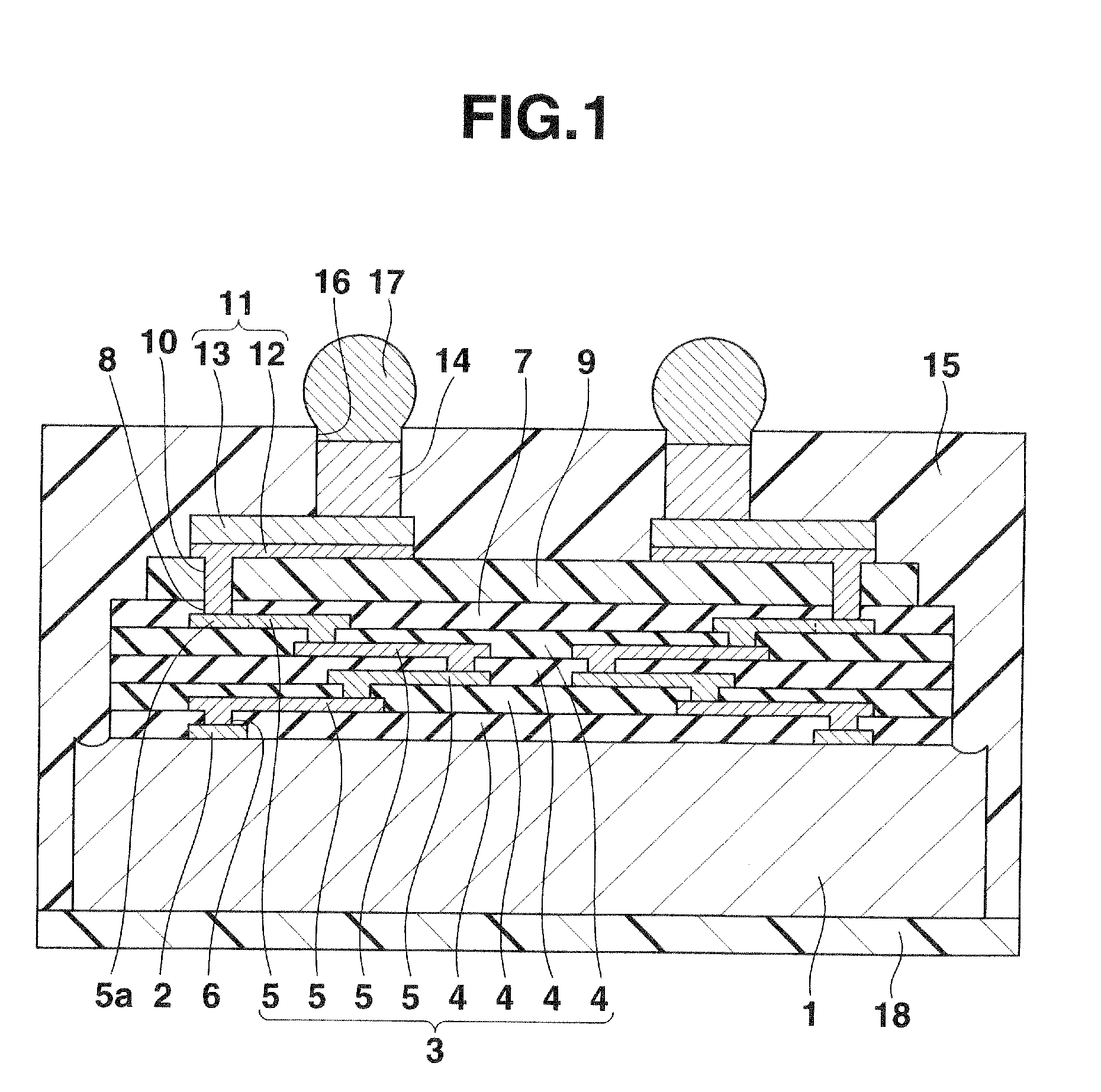

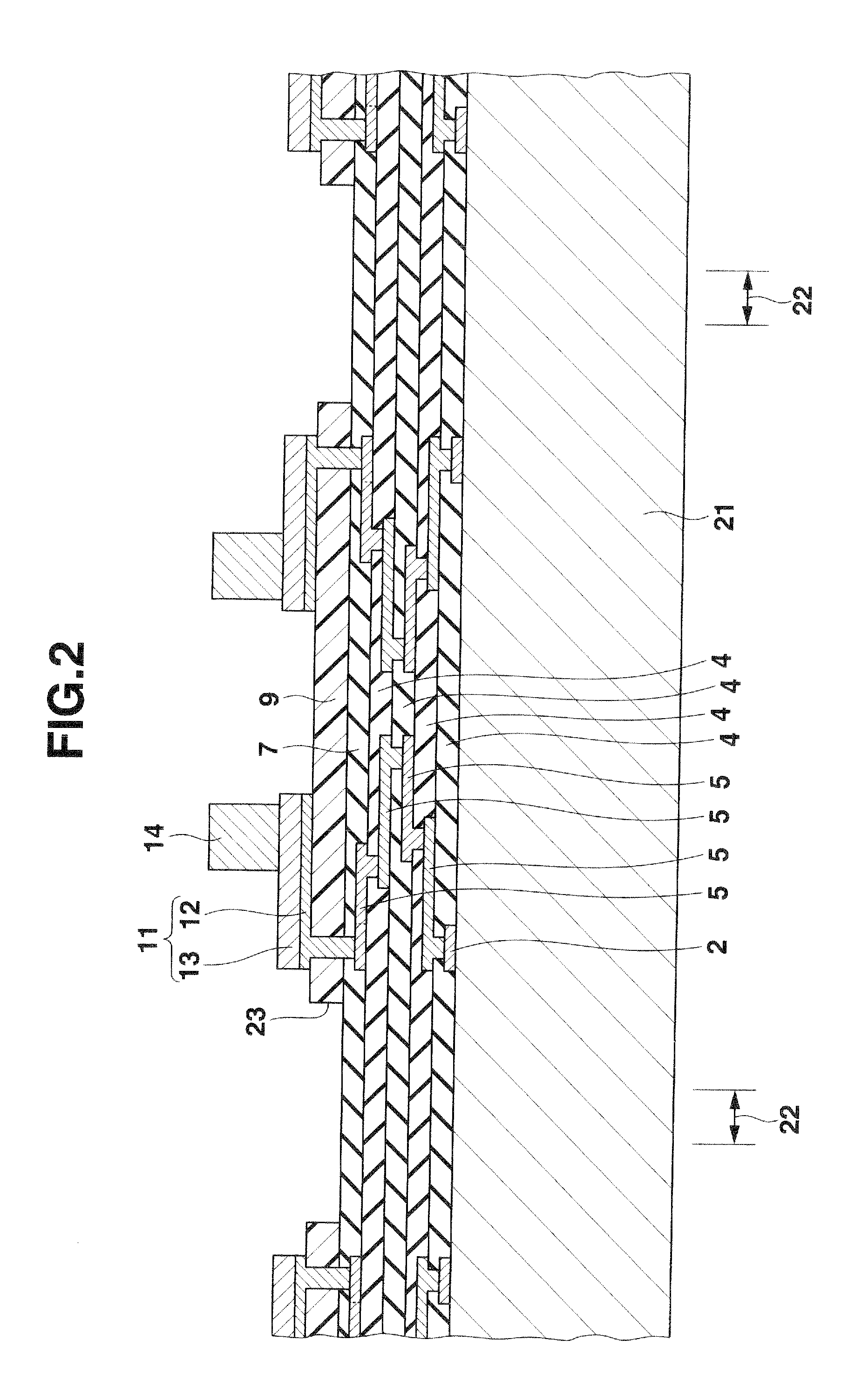

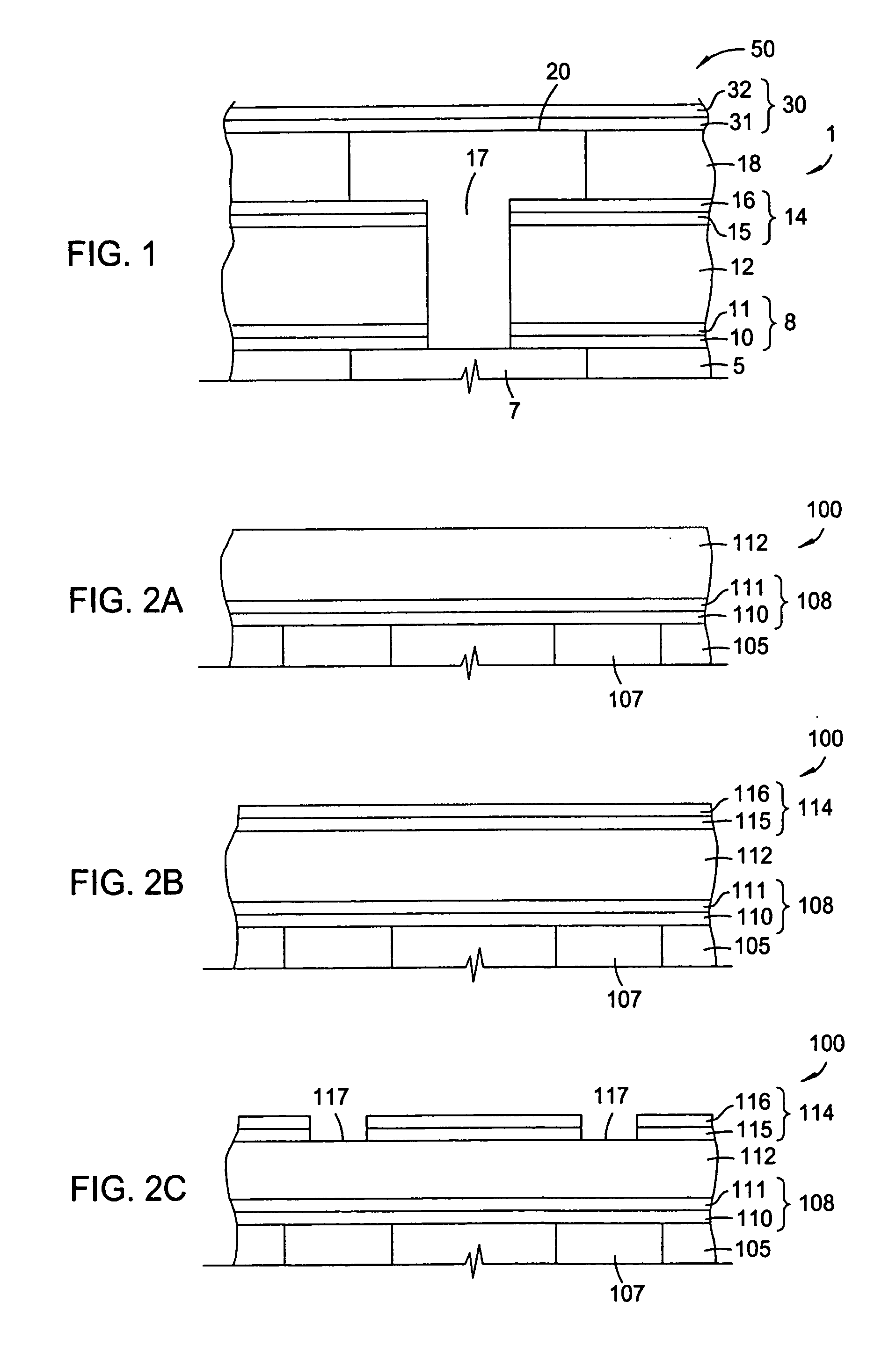

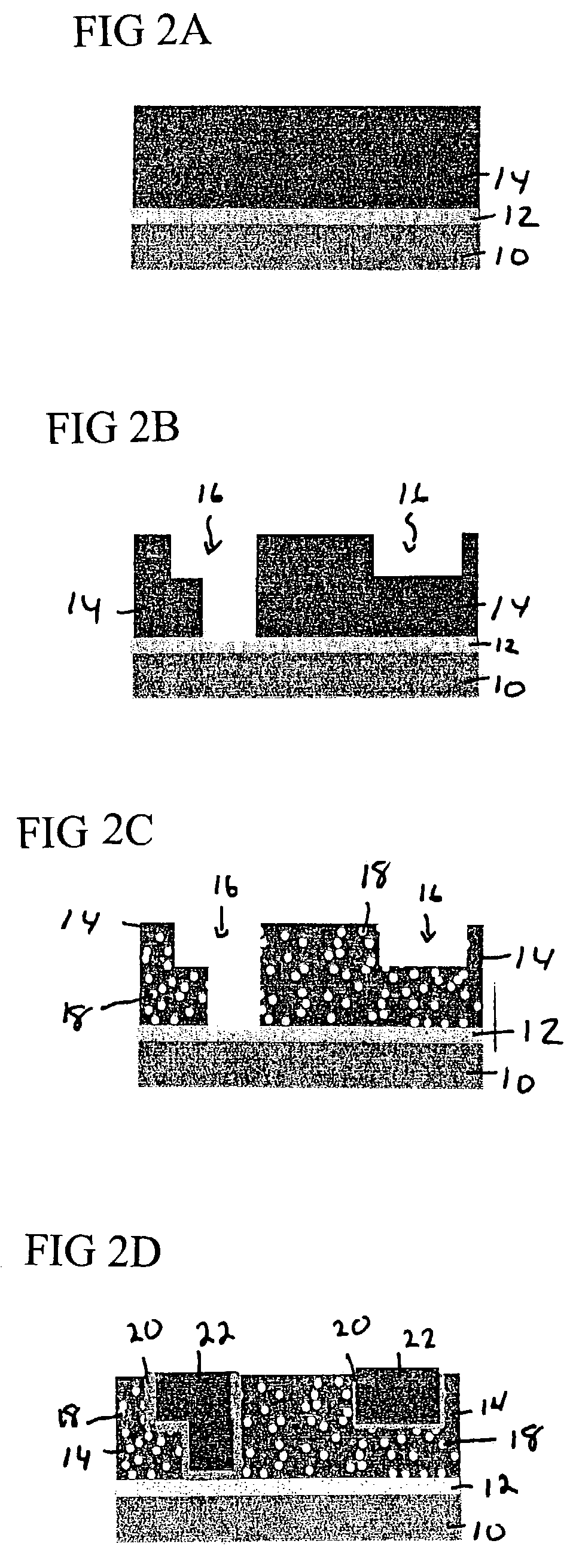

Semiconductor device having low dielectric constant film and manufacturing method thereof

InactiveUS20090243097A1Low dielectric constantSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSilicon

A low dielectric constant film / wiring line stack structure made up of a stack of low dielectric constant films and wiring lines is provided in a region on the upper surface of the semiconductor substrate except for the peripheral part of this surface. The peripheral side surface of the low dielectric constant film / wiring line stack structure is covered with a sealing film. This provides a structure in which the low dielectric constant films do not easily come off. In this case, a lower protective film is provided on the lower surface of a silicon substrate to protect this lower surface against cracks.

Owner:TERAMIKROS INC

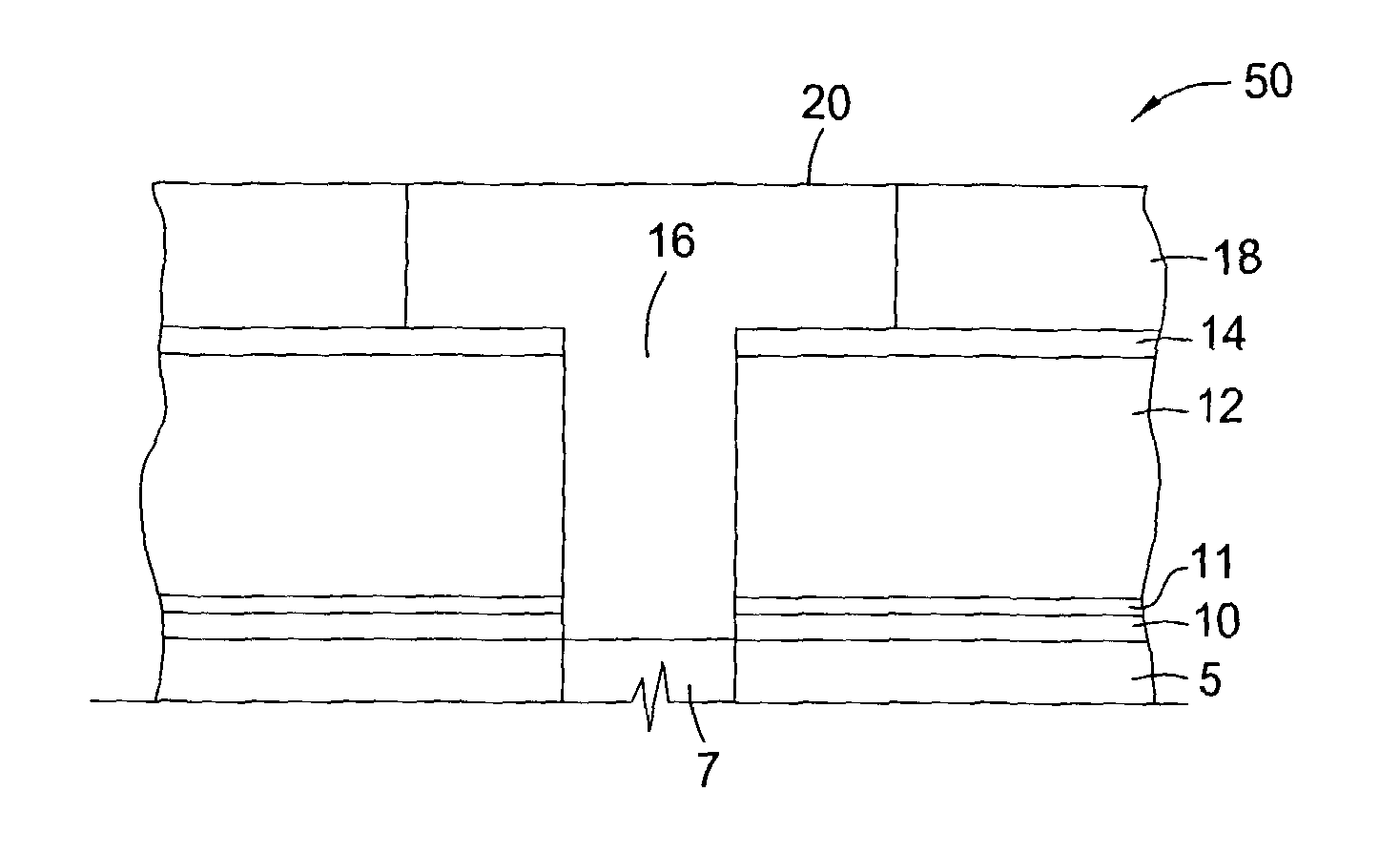

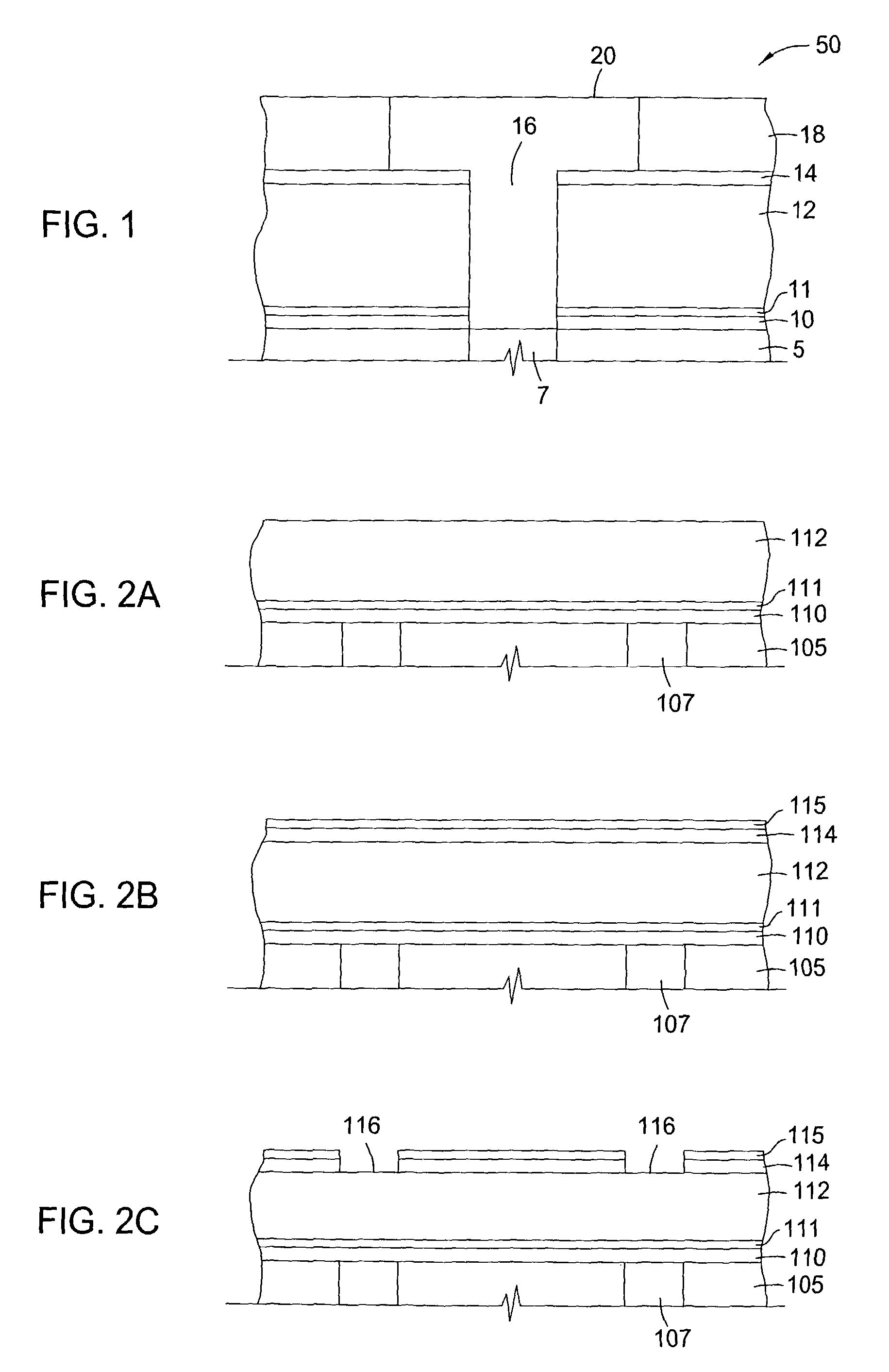

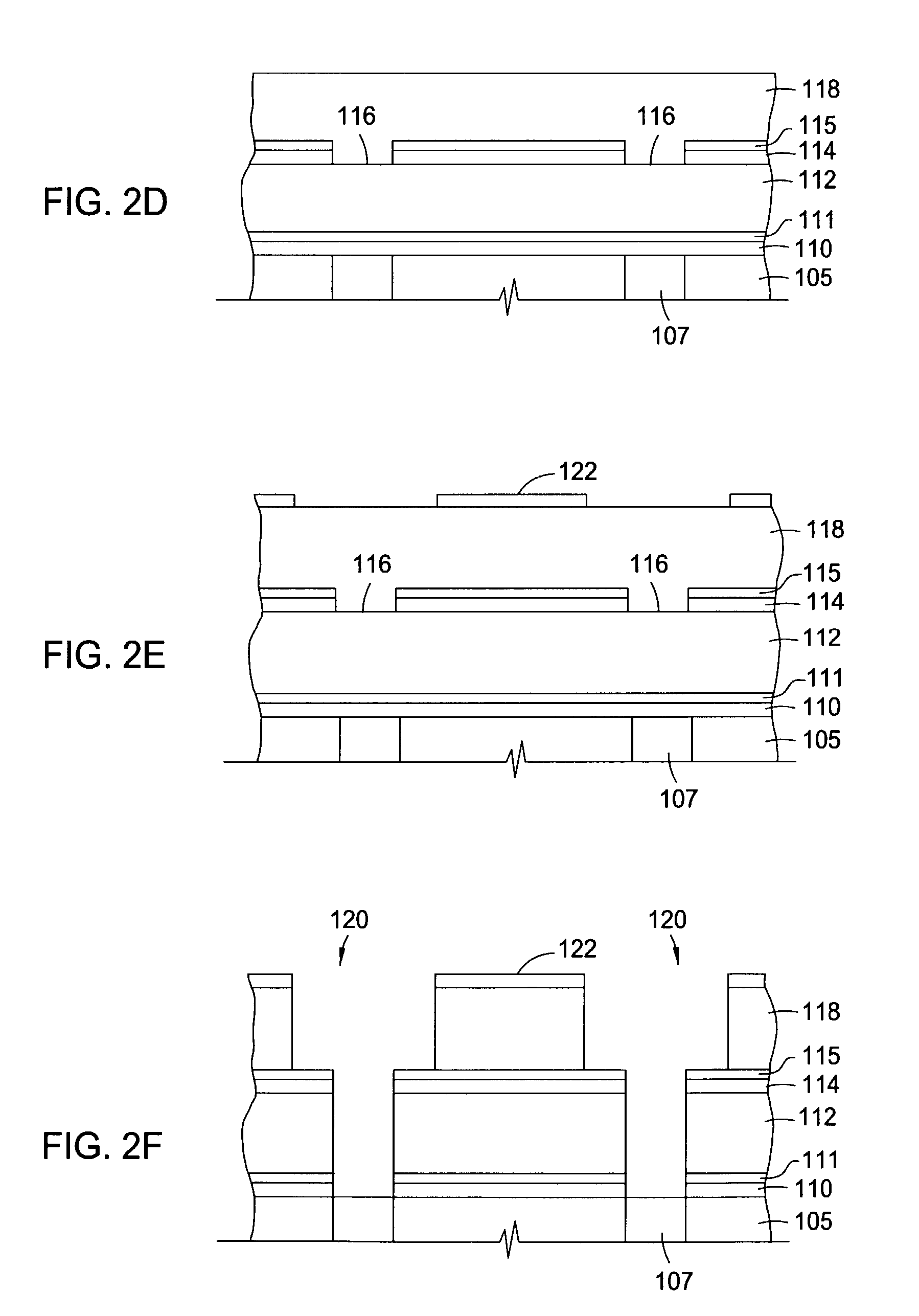

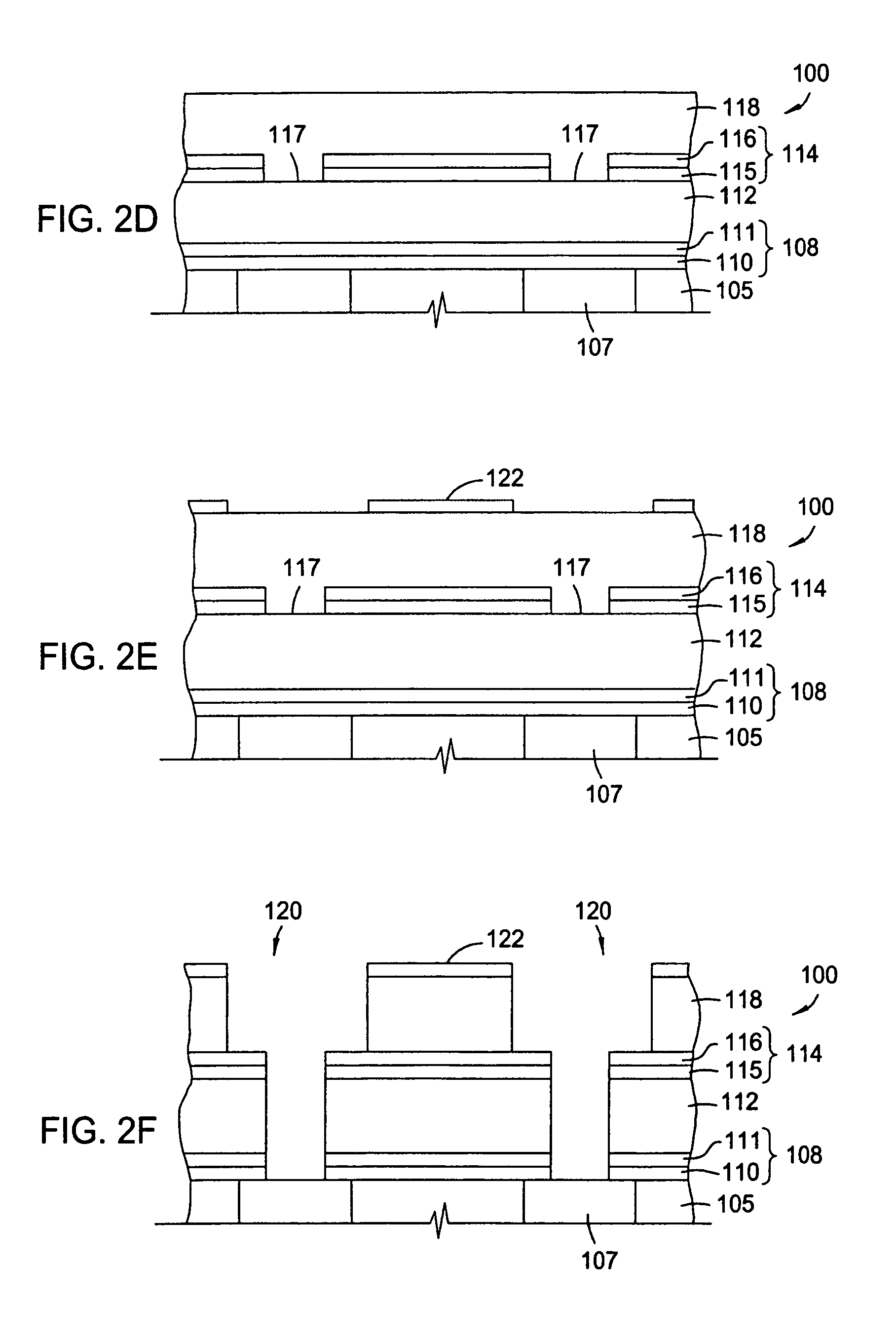

Bi-layer approach for a hermetic low dielectric constant layer for barrier applications

InactiveUS20050042889A1Low dielectric constantSemiconductor/solid-state device manufacturingChemical vapor deposition coatingLow-k dielectricOptoelectronics

Methods and apparatus are provided for processing a substrate with a bilayer barrier layer. In one aspect, the invention provides a method for processing a substrate including depositing a nitrogen containing barrier layer on a substrate surface and then depositing a nitrogen free barrier layer thereon. The barrier layer may be deposited over dielectric materials, conductive materials, or both. The bilayer barrier layer may also be used as an etch stop, an anti-reflective coating, or a passivation layer.

Owner:APPLIED MATERIALS INC

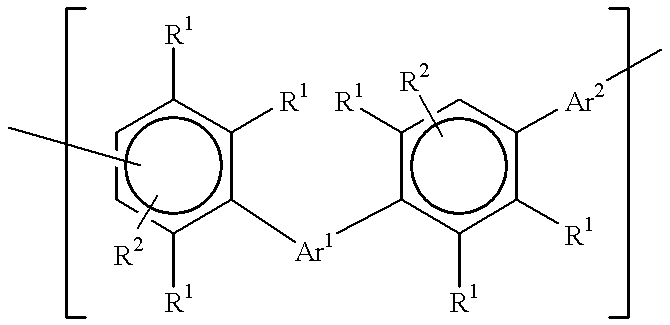

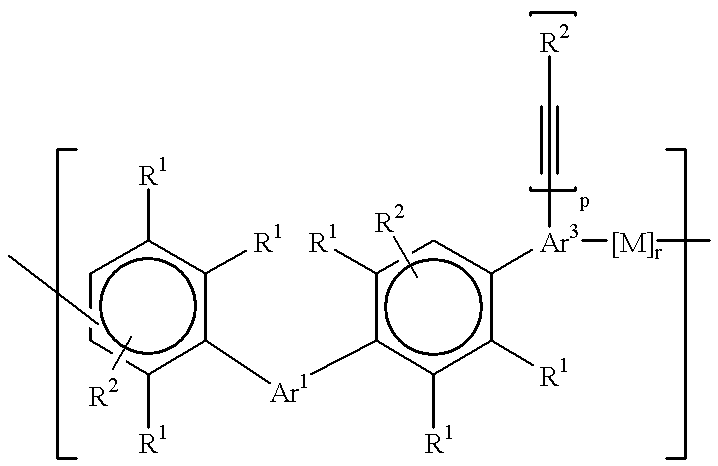

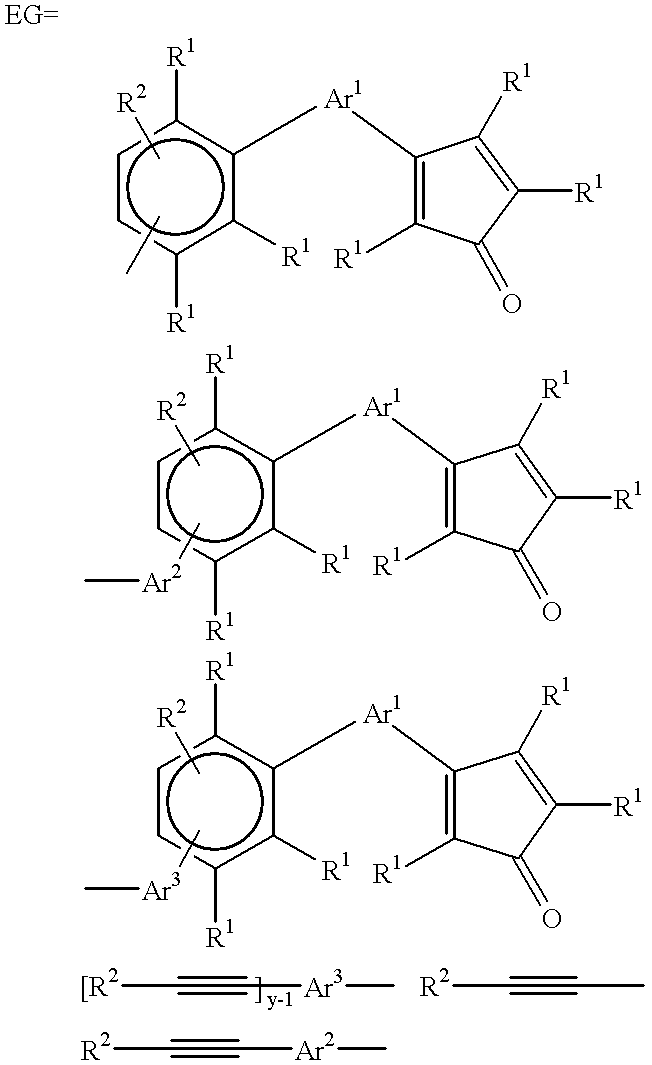

Polyphenylene oligomers and polymers

An oligomer, uncured polymer or cured polymer comprising the reaction product of one or more polyfunctional compounds containing two or more cyclopentadienone groups and at least one polyfunctional compound containing two or more aromatic acetylene groups wherein at least some of the polyfunctional compounds contain three or more reactive groups. Such oligomers and uncured polymers may be cured to form cured polymers which are useful as dielectrics in the microelectronics industry, especially for dielectrics in integrated circuits.

Owner:THE DOW CHEM CO

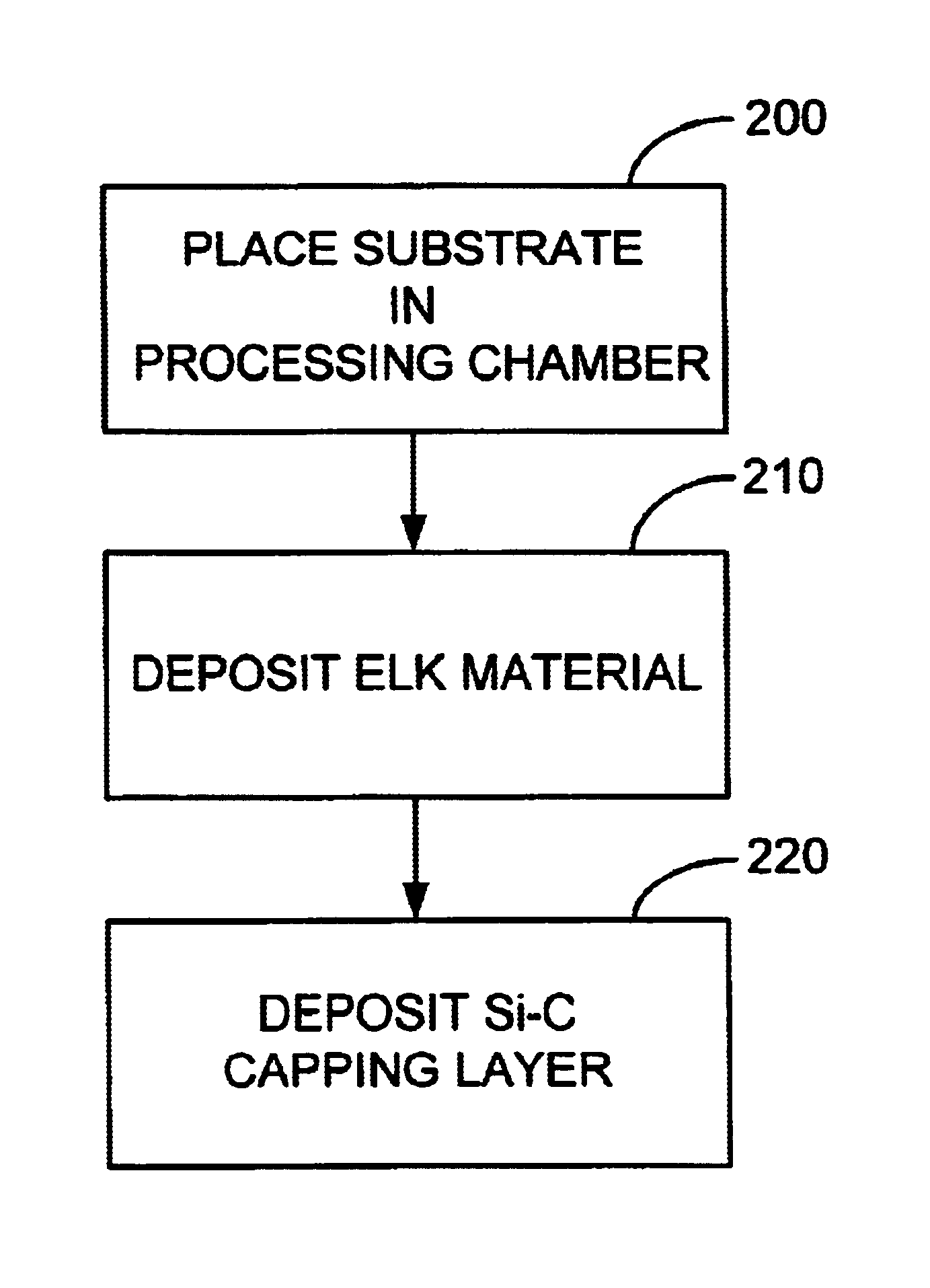

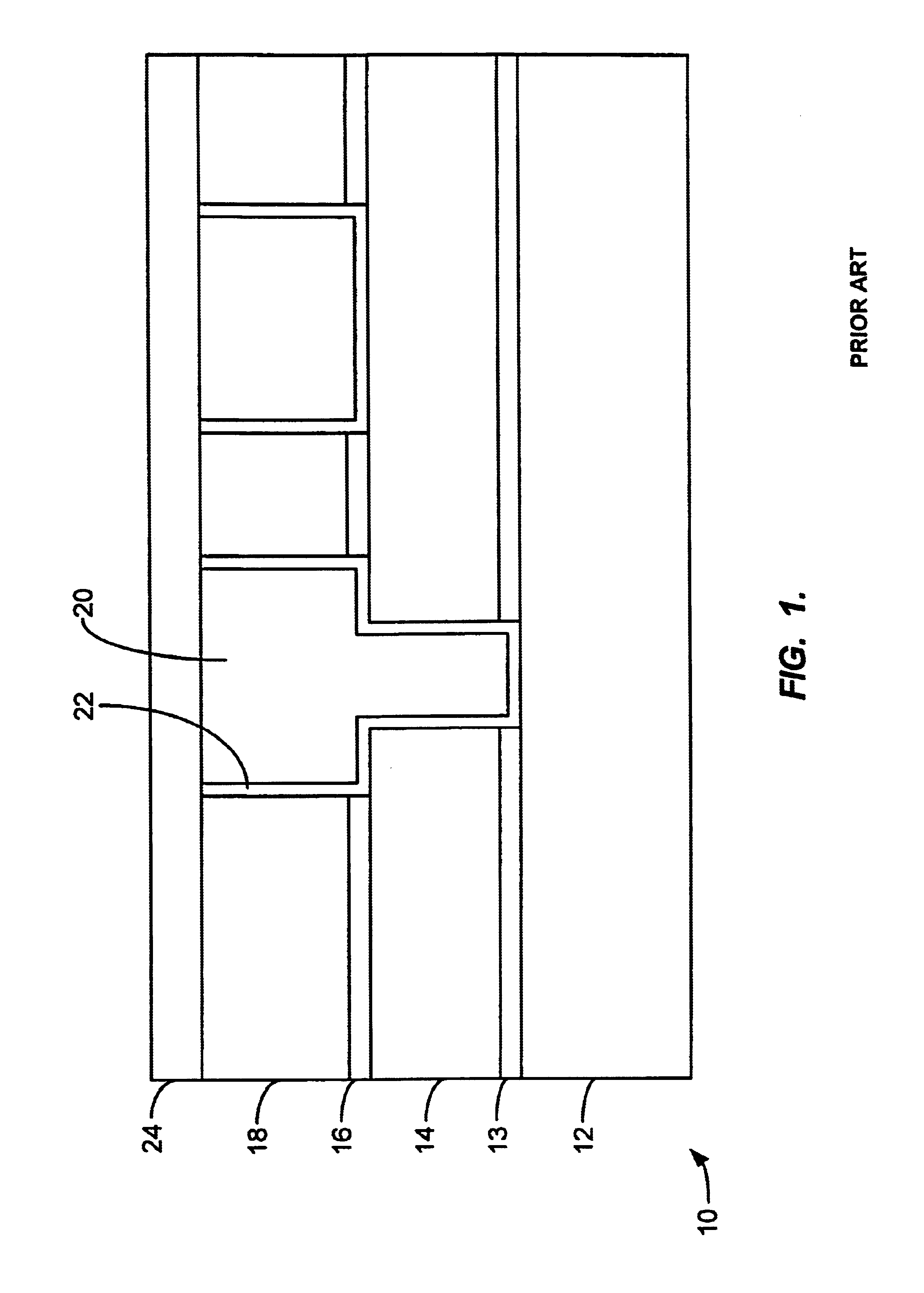

Capping layer for extreme low dielectric constant films

InactiveUS6875687B1Superior adhesion characteristicGood stabilitySemiconductor/solid-state device detailsSolid-state devicesCarbon dopedLow-k dielectric

Specific embodiments of the invention provide a silicon-carbide-type or silicon oxycarbide (also often called carbon-doped-oxide [CDO] or organosilicate glass) capping material and method for depositing this capping material on ELK films which are used as a dielectric material in integrated circuits. The ELK film may include any ELK film including but not limited to inorganic, organic and hybrid dielectric materials and their respective porous versions. The silicon-carbide-type material may be an amorphous silicon carbide type material such as the commercially available BLOk™ material, or a carbon-doped oxide material such as the commercially available Black Diamond™ both of which are developed by Applied Materials of Santa Clara, Calif. The amorphous silicon carbide (a-SiC) material is deposited using a plasma process in a non-oxidizing environment and the CDO-type material is deposited using an oxygen-starved plasma process. The non-oxidative or oxygen-starved plasma processes do not significantly degrade the underlying film's chemical and electrical properties. The CDO material offers the advantageous property of having a lower dielectric constant value of less than 3.5 as opposed to the a-SiC material which has a dielectric constant of approximately 4.5. The CDO material besides, having a lower dielectric constant also has a superior adhesion characteristics to the underlying ELK material. However, experiments have indicated that despite its higher dielectric constant, the a-SiC-type material (e.g. BLOk™) may be used to generate capped ELK films with similar or even reduced dielectric constants relative to lower k capped films, and may provide composite (i.e. ELK+cap) structures exhibiting superior k stability.

Owner:APPLIED MATERIALS INC

Method of forming low-k dielectrics

InactiveUS20050064726A1Improve performanceFast curingPretreated surfacesSemiconductor/solid-state device manufacturingDielectric permittivityMaterials science

A method of forming a low dielectric constant structure. The method comprises providing at a first temperature a dielectric material having a first dielectric constant and a first elastic modulus, and curing the dielectric material by a thermal curing process, in which the material is heated to a second temperature by increasing the temperature at an average rate of at least 1° C. per second. As a result a densified, dielectric material is obtained which has a low dielectric constant.

Owner:SILECS OY

Patternable low dielectric constant materials and their use in ULSI interconnection

ActiveUS7041748B2Process step be reduceLow dielectric constantLayered productsSemiconductor/solid-state device detailsChemistryLow-k dielectric

The present invention relates to ultra-large scale integrated (ULSI) interconnect structures, and more particularly to patternable low dielectric constant (low-k) materials suitable for use in ULSI interconnect structures. The patternable low-k dielectrics disclosed herein are functionalized polymers that having one or more acid-sensitive imageable functional groups.

Owner:AURIGA INNOVATIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com