Patents

Literature

64results about How to "Increase reaction space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicone polymer insulation film on semiconductor substrate and method for forming the film

InactiveUS6352945B1Low dielectric constantImprove thermal stabilityLiquid surface applicatorsSemiconductor/solid-state device detailsPolymer scienceHigh humidity

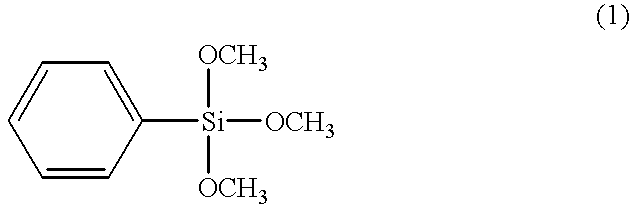

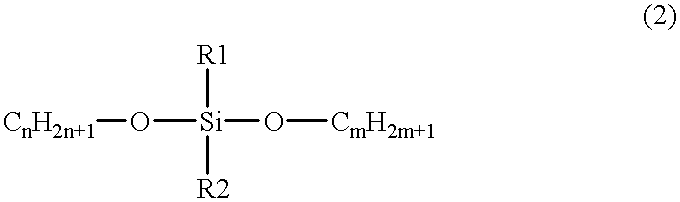

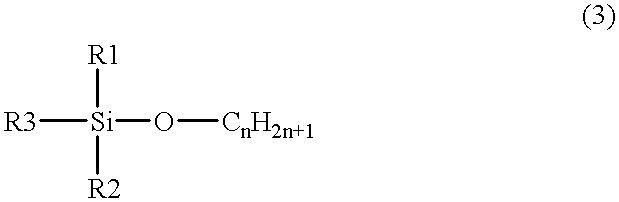

A method for forming a silicone polymer insulation film having a low relative dielectric constant, high thermal stability and high humidity-resistance on a semiconductor substrate is applied to a plasma CVD apparatus. The first step is introducing a silicon-containing hydrocarbon compound expressed by the general formula SialphaObetaCxHy (alpha, beta, x, and y are integers) to the reaction chamber of the plasma CVD apparatus. The silicon-containing hydrocarbon compound has at most two O-CnH2n+1 bonds and at least two hydrocarbon radicals bonded to the silicon. The residence time of the material gas is lengthened by, for example, reducing the total flow of the reaction gas, in such a way as to form a silicone polymer film having a micropore porous structure with a low relative dielectric constant.

Owner:ASM JAPAN

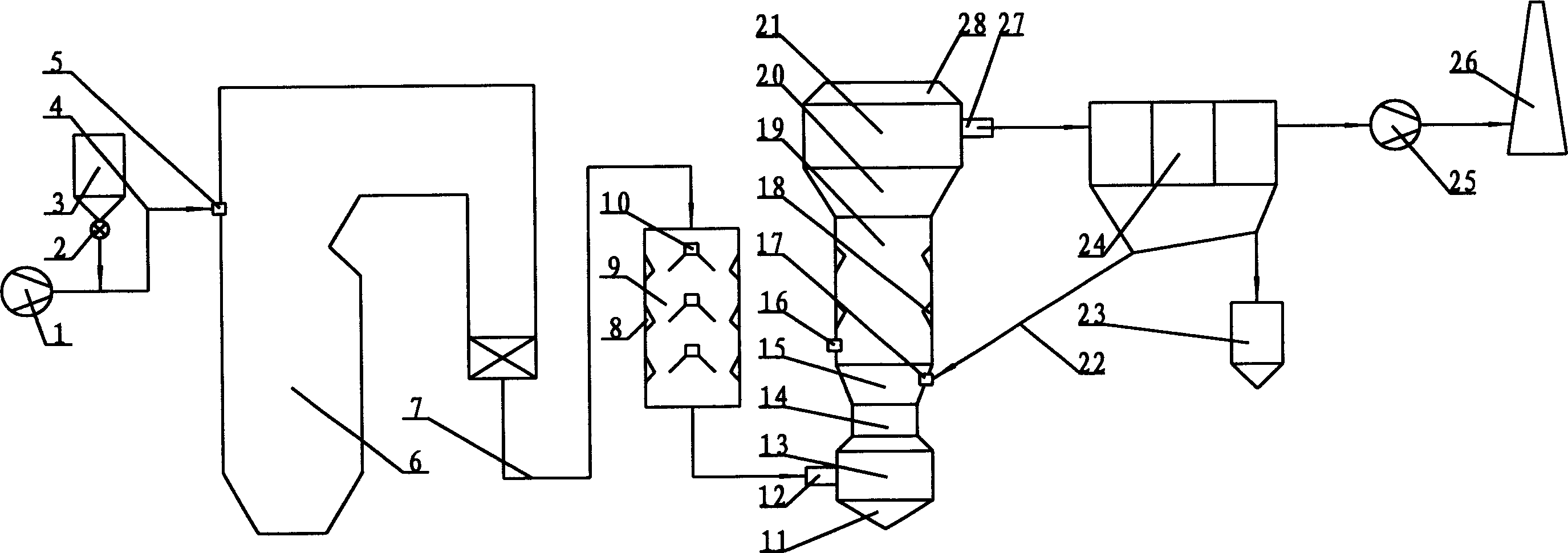

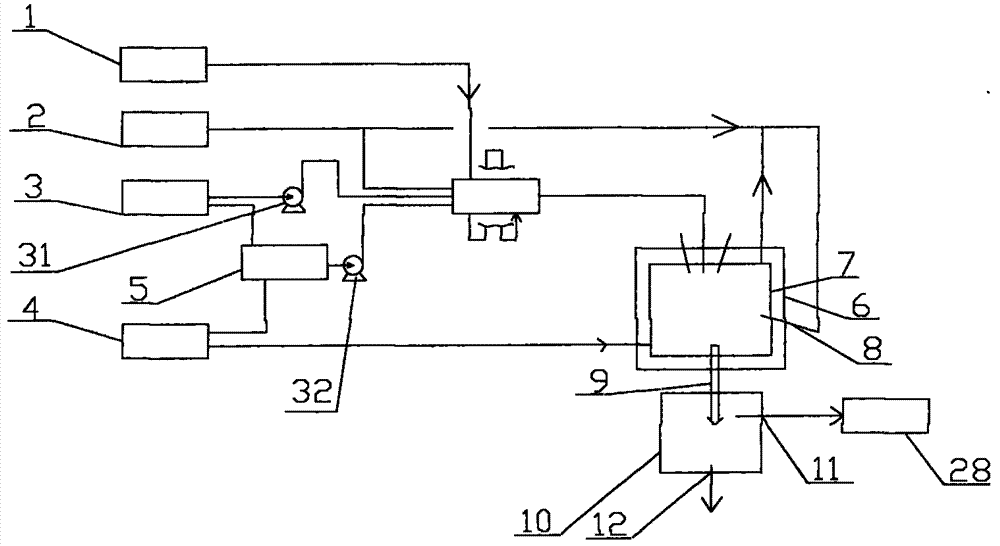

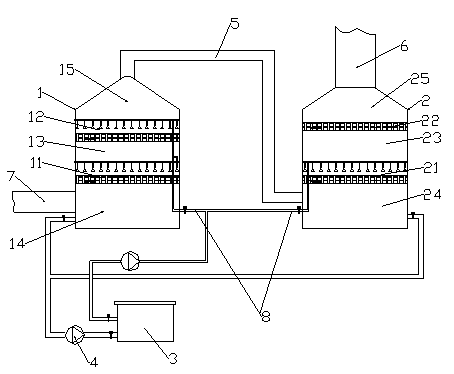

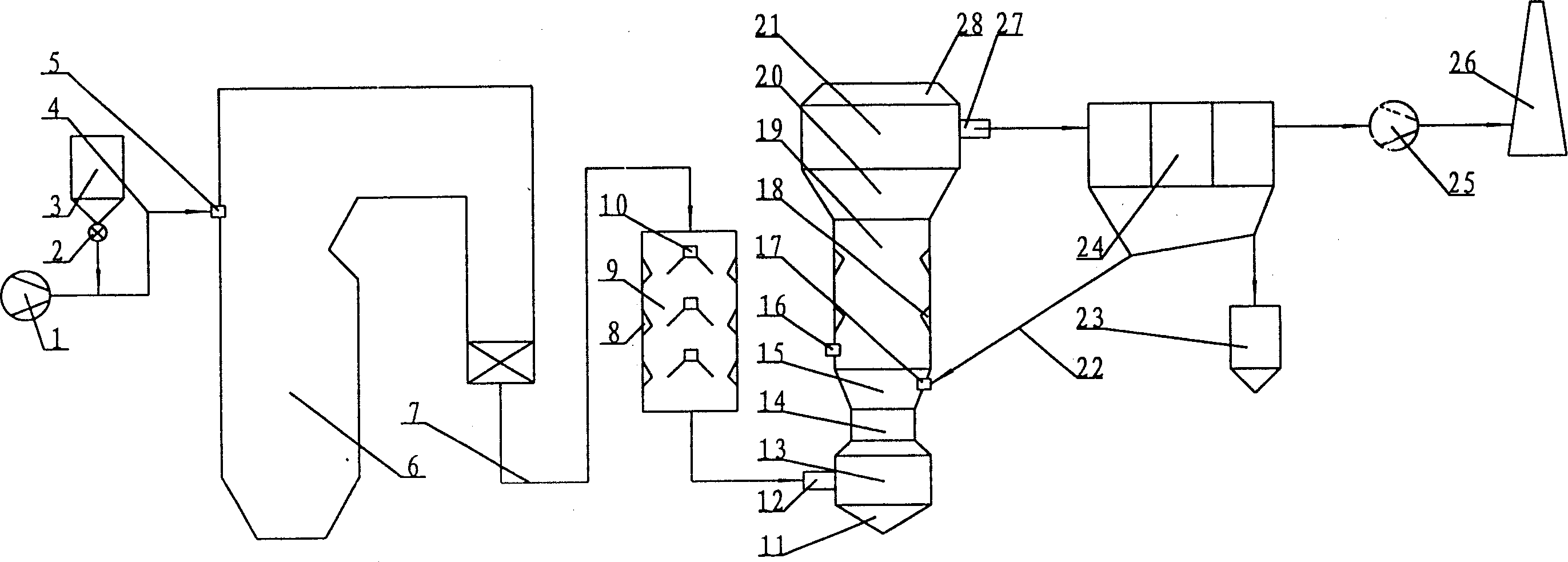

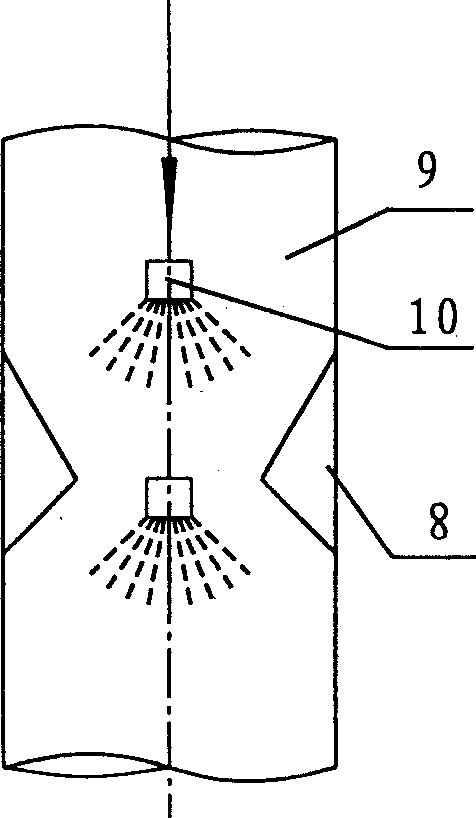

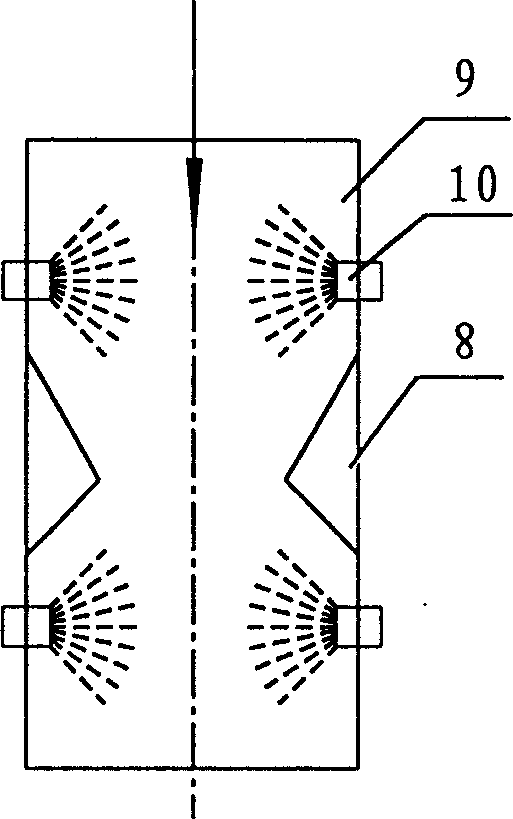

Multiple reaction integrated process for desulfuizing from fume by dry method and its system

ActiveCN1537668AImprove surface activityReduce desulfurization costDispersed particle separationPartial oxidationCalcium sulfite

A multiple reactions integrated process for desulfurizing from the fume by dry method includes such steps as spraying limestone powder in high-temp combustion box from its top to decompose calcium carbonate into calcium oxide and CO2, absorbing SO2 from fume by partial calcium oxide to generate calcium sulfate, spraying water to activate calcium oxide to transform partial calcium oxide to calcium hydroxide and absorb SO2 from fume to generate calcium sulfite, and using the residual calcium hydroxide and calcium oxide to desulfurize the fume in desulfurizing tower. Its system is composed of limestone powder sprayer, moistening flue, desulfurizing tower, external electric duster, draught blower and chimney.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

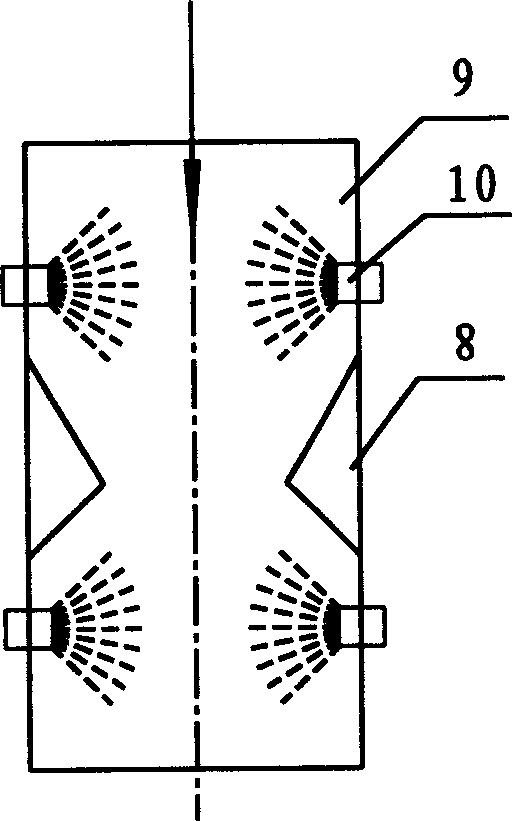

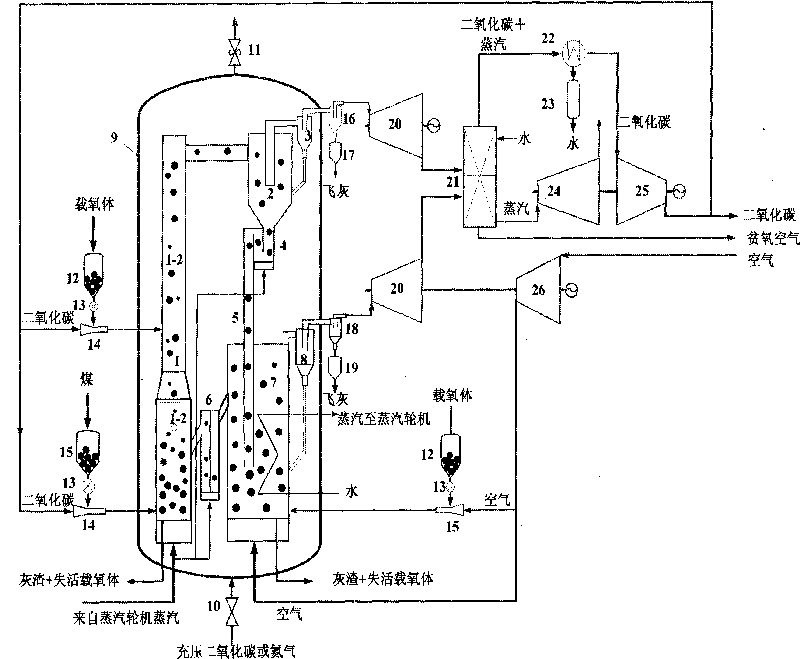

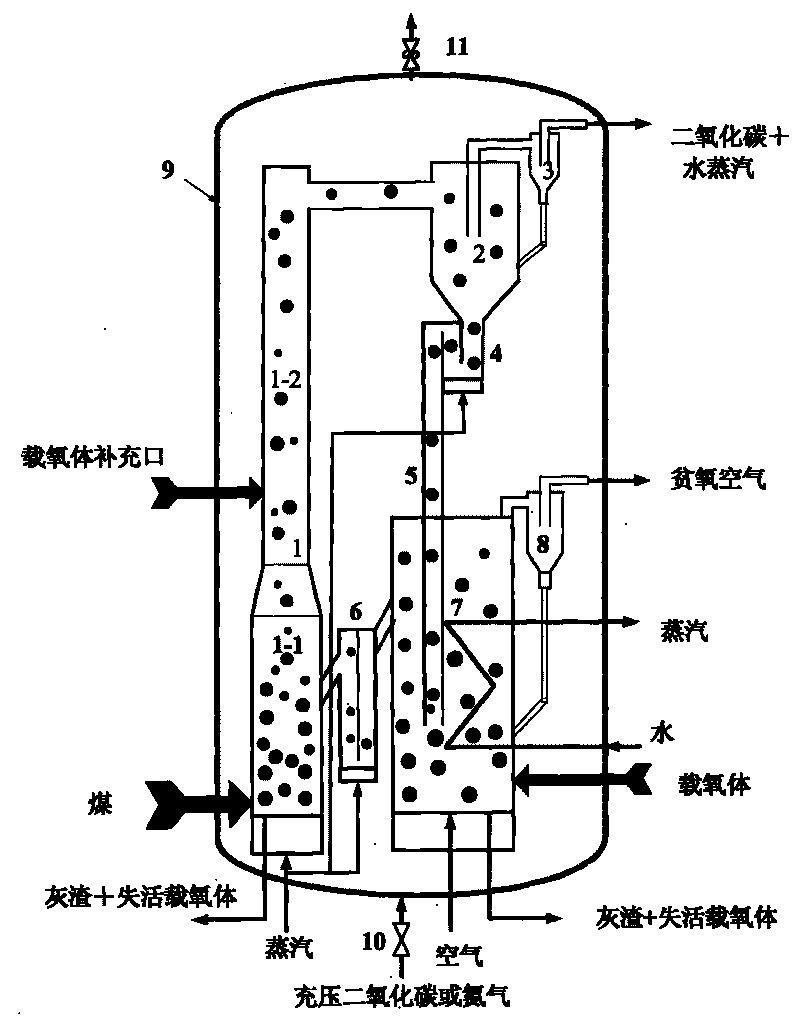

Coal combustion apparatus capable of separating carbon dioxide and separation method thereof

InactiveCN101699187AEasy to handleReduced compression energy consumptionExothermal chemical reaction heat productionCarbon compoundsCycloneEngineering

The invention provides a coal combustion apparatus capable of separating carbon dioxide, which is mainly formed by connecting a fuel reactor, a primary cyclone separator, a dipleg and an air reactor in series; wherein the lower part of the fuel reactor is provided with a mixing chamber with large cross section, and the upper part thereof is provided with a lifting tube with small cross section; and the height of the lifting tube is over three times higher than that of the mixing chamber. The invention also provides a method using the coal combustion apparatus capable of separating the carbon dioxide to separate the carbon dioxide. The fuel reactor adopts the structure of a reactor with long residence time, internal circulation can be formed by granules, and the gas-solid turbulence is improved; the air reactor adopts a moving fluidized bed to ensure the operation to be stable, so that the heat can be evenly released; meanwhile, a heat exchanger is arranged inside the bed, so that coking caused by local overheating since a great deal of heat is released in a centralized way in oxidation reaction can be avoided. Furthermore, the fuel reactor and the air reactor run under the pressure, so that the equipment can be compact, the utilization efficiency of system energy is high, and the subsequent carbon dioxide compression energy consumption is reduced.

Owner:SOUTHEAST UNIV

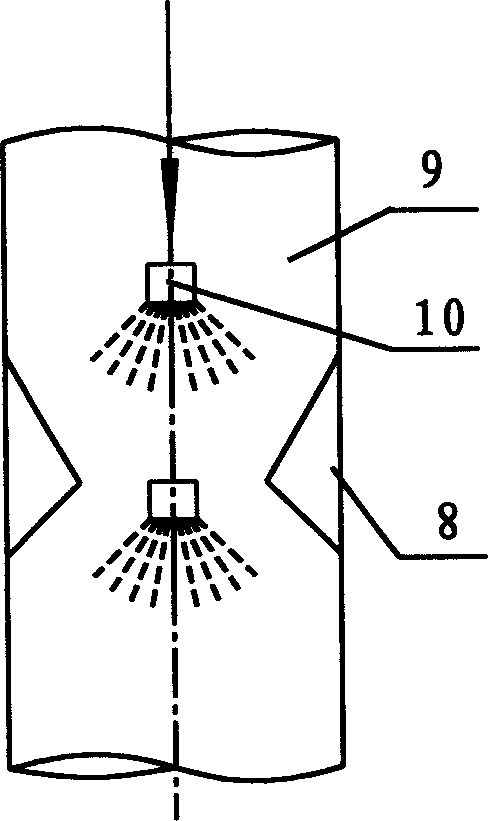

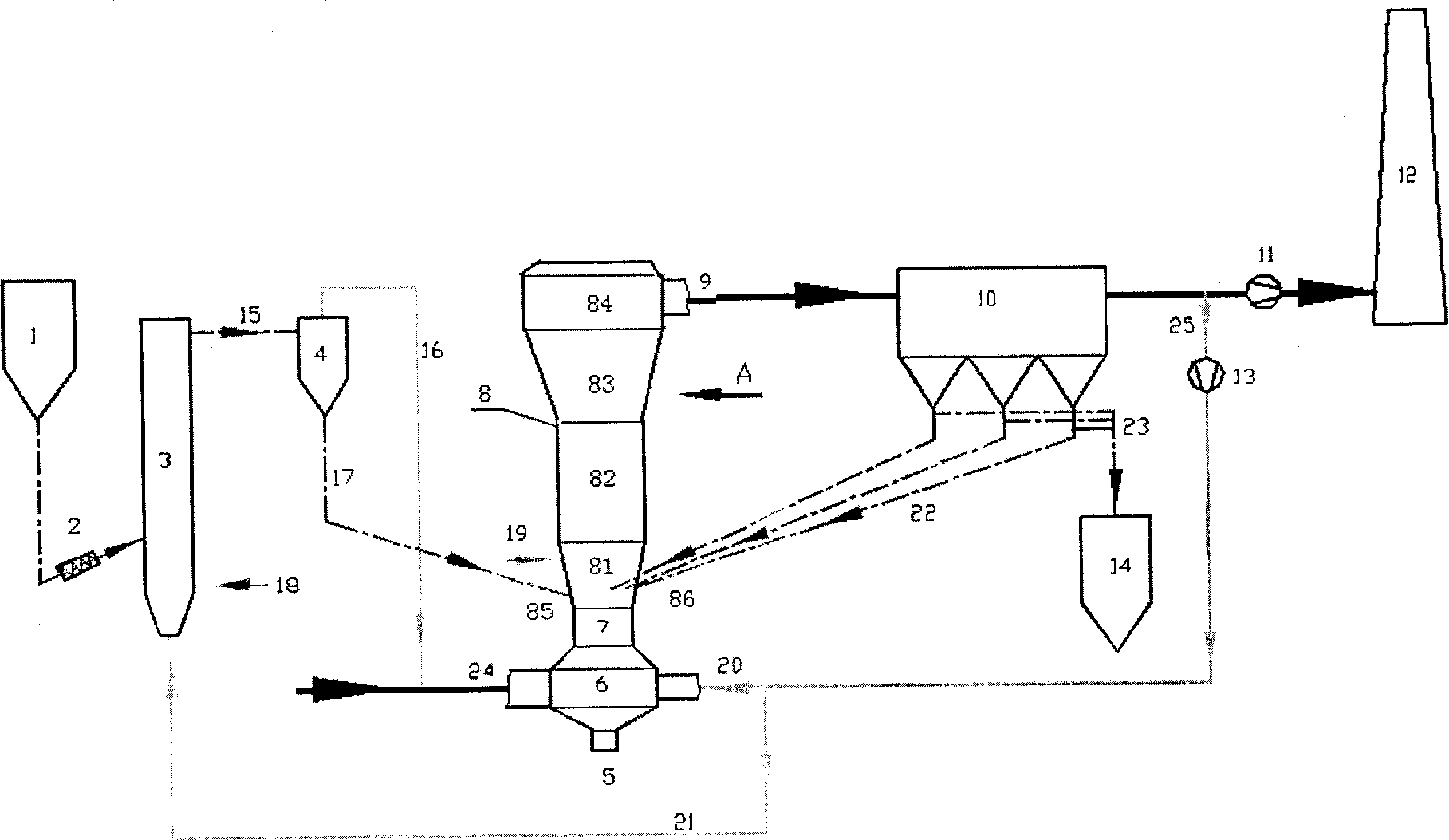

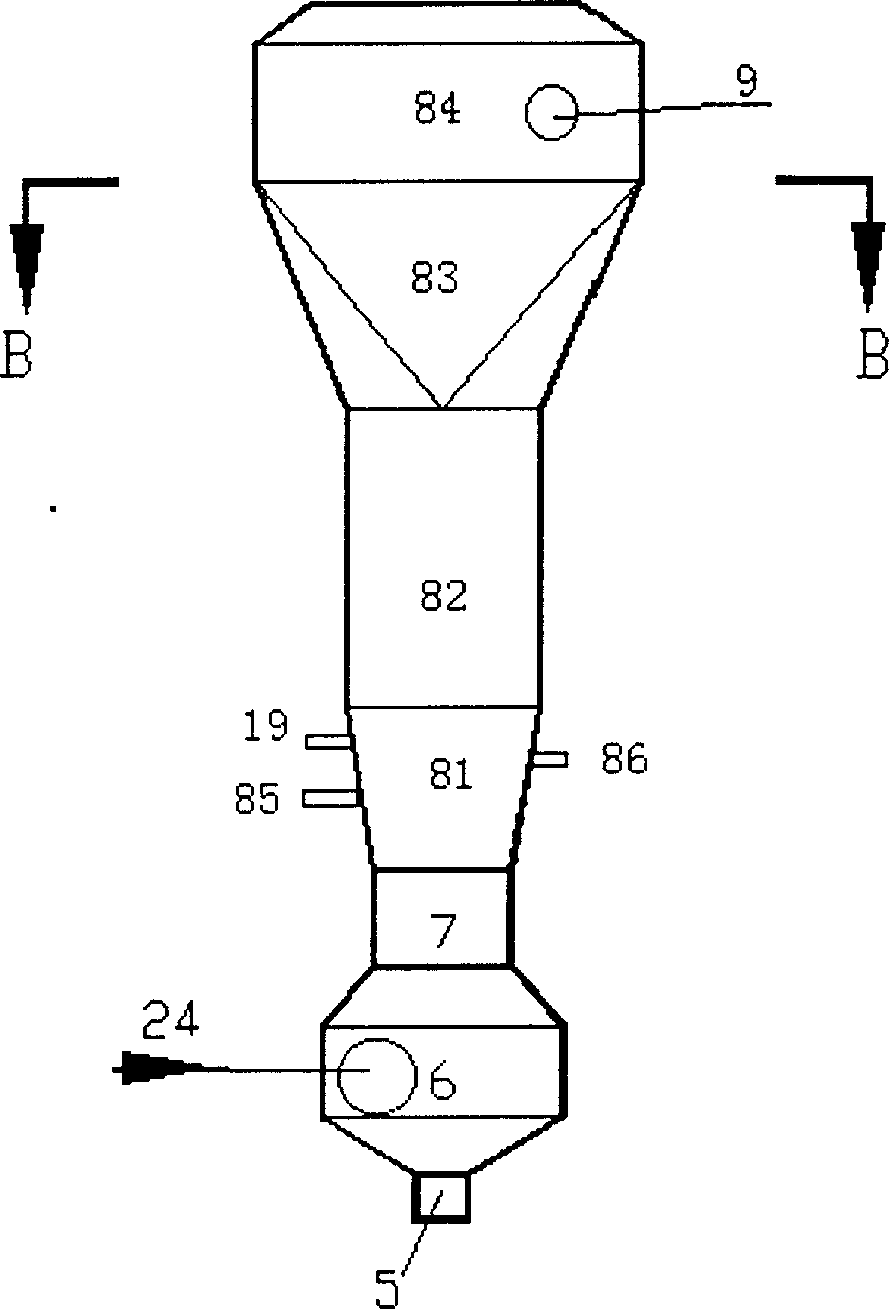

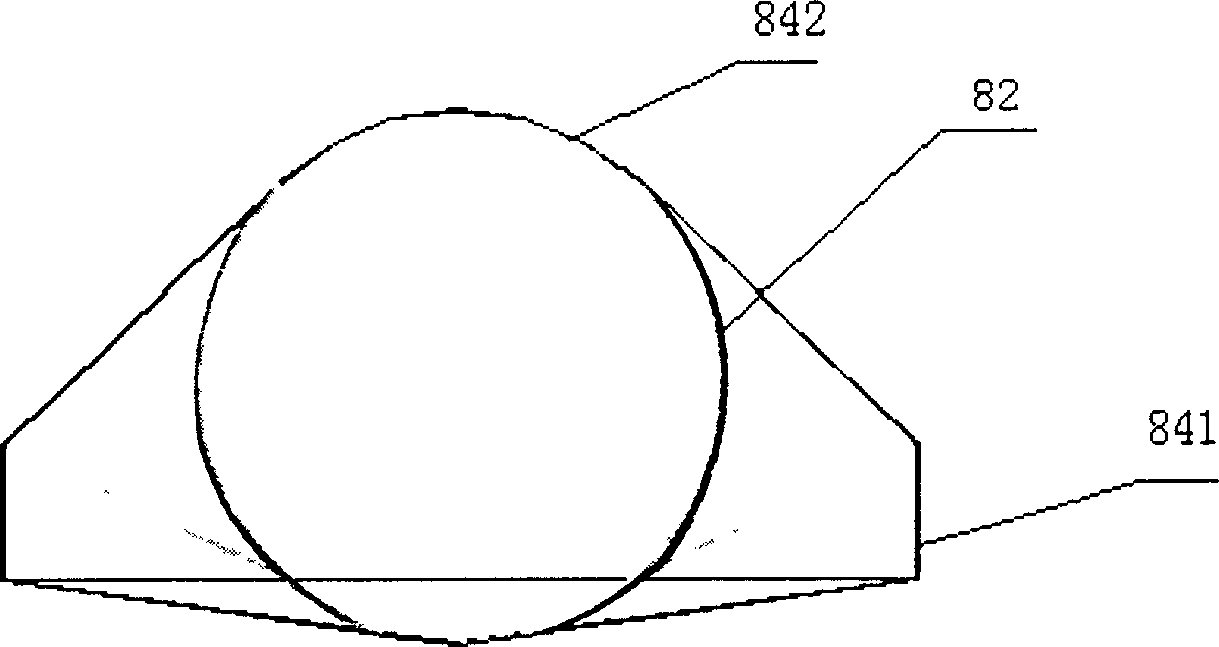

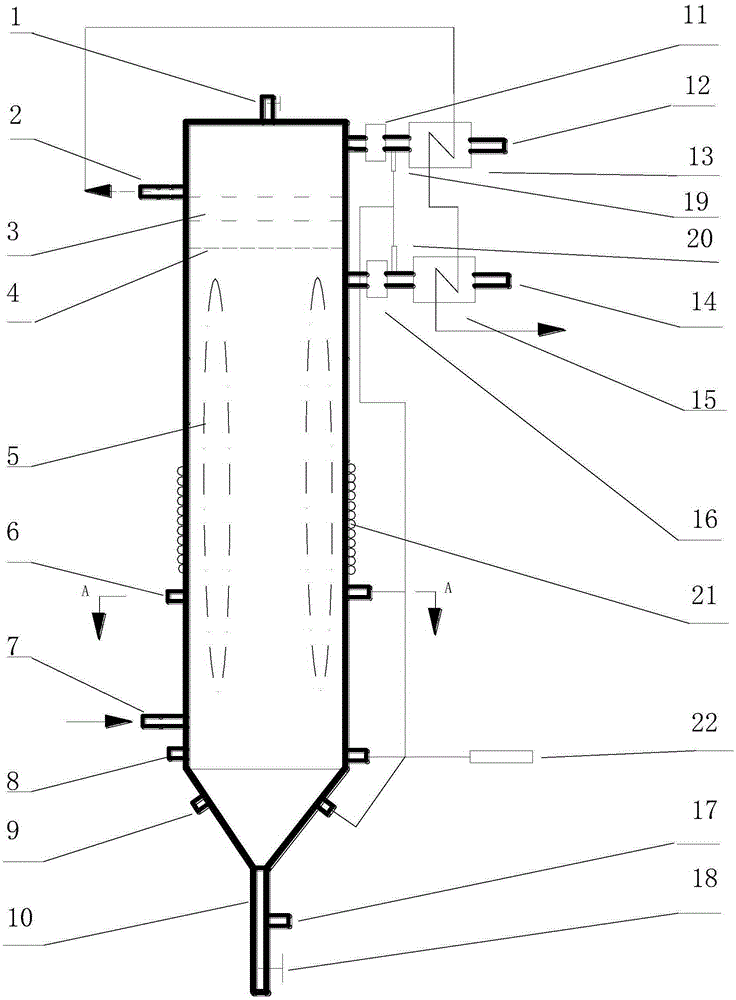

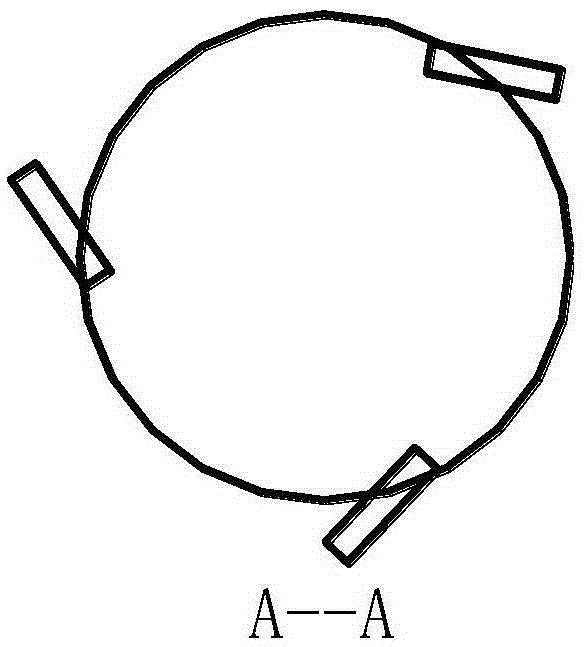

Composite Circulation fluidized dry desulfurization process for flue gas and desalfurizing reaction tower

InactiveCN1425491AImprove space utilizationExtend time and spaceDispersed particle separationFlue gasEngineering

The present invention features that line as desulfurizer material is made to pass through one clean wet fume slaking equipment to form slaked lime desulfurizer with high surface activity. In the system, there are three kinds of circulation modes, including inner circulation of desulfurizer grains; outer circulation and circulation of clean wet fume. The present invention is superior to available technology in that desulfurizing efficiency up to 90-92 % may be reached at relatively low Ca / S ratio, 1.1-1.3; that wide regulation ratio characteristic can meet the high efficiency desulfurizing requirement in load of the combustion equipment from 20% to 110%, and that the present invention has low water consumption and low cost.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

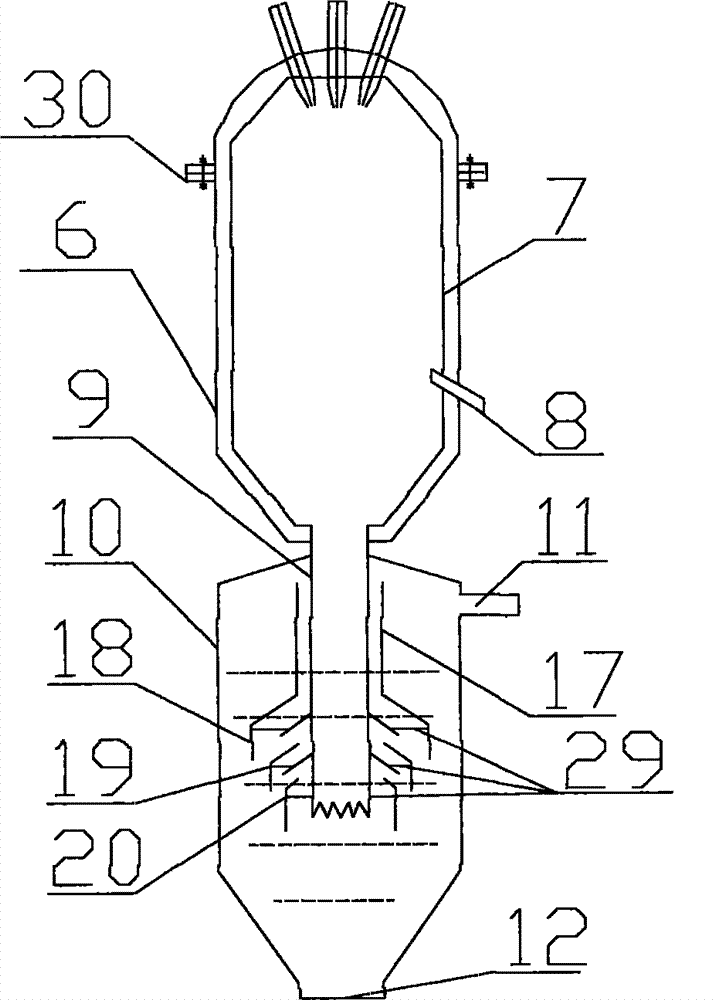

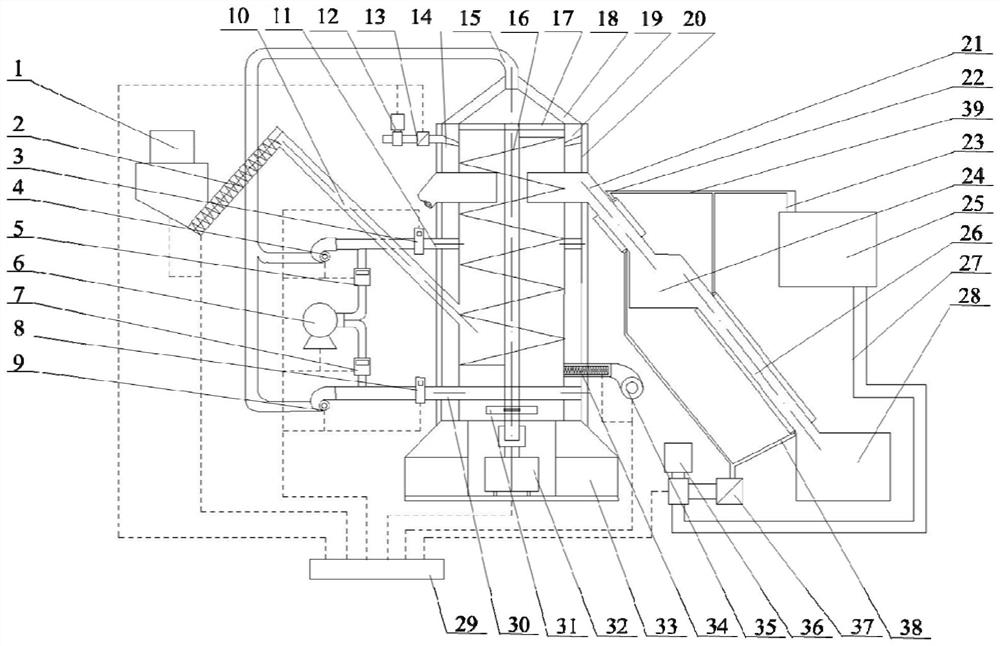

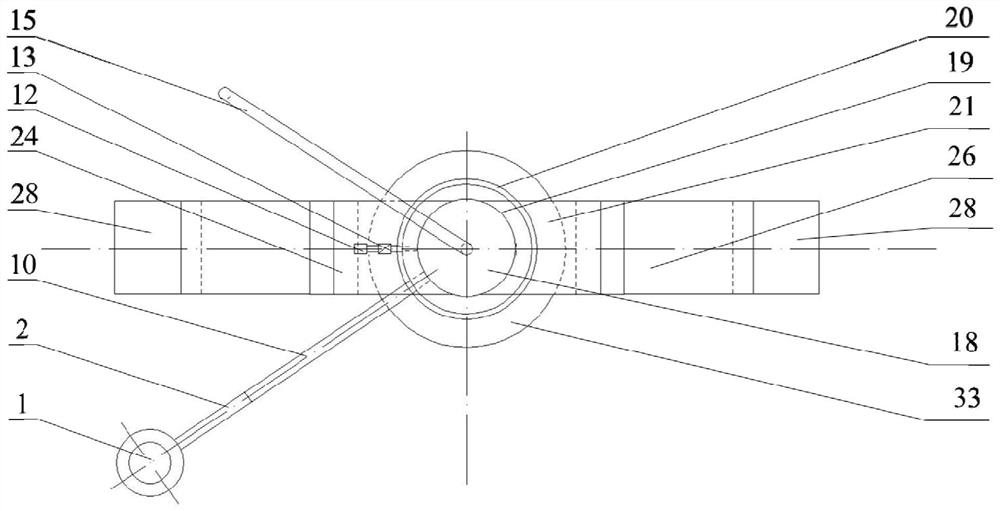

Coal gasification device and process capable of combusting organic effluent sewage

ActiveCN103695039AAvoid parkingIncrease reaction spaceCombined combustion mitigationGranular/pulverulent flues gasificationCoal waterCombustor

The invention belongs to a coal gasification device and process capable of combusting organic effluent sewage. The coal gasification device comprises an organic effluent sewage storage tank, an oxygen storage tank, a dry pulverized coal storage tank and a water storage tank, wherein the dry pulverized coal storage tank and the water storage tank are respectively connected with the inlet of a coal water slurry storage tank, outlets of the organic effluent sewage storage tank, the oxygen storage tank, the dry pulverized coal storage tank and the coal water slurry storage tank are respectively connected with a burner part at the top of a combustor; the burner part is connected with the interior of a membrane type water cooling film, the oxygen storage tank is connected with an oxygen and gas increasing nozzle arranged at the middle of the combustor through a pipeline, the water storage tank is connected with the inlet of the membrane type water cooling wall, a connecting cylinder is arranged at the bottom of the combustor, penetrates through the top of a water cooler and is arranged at the inner-upper part of the water cooler, a synthetic gas outlet is formed in the upper part of one side of the water cooler, a deslagging hole is formed in the lower part of the water cooler, and a multilayer baffling boosting cylinder is arranged at the outer part of the connecting cylinder. The coal gasification device has the advantages of strong coal type adaptability, high coal gasification efficiency, and cleanness and good quality of synthetic gas, and is capable of treating the organic effluent sewage.

Owner:HENAN XINLIANXIN FERTILIZER +2

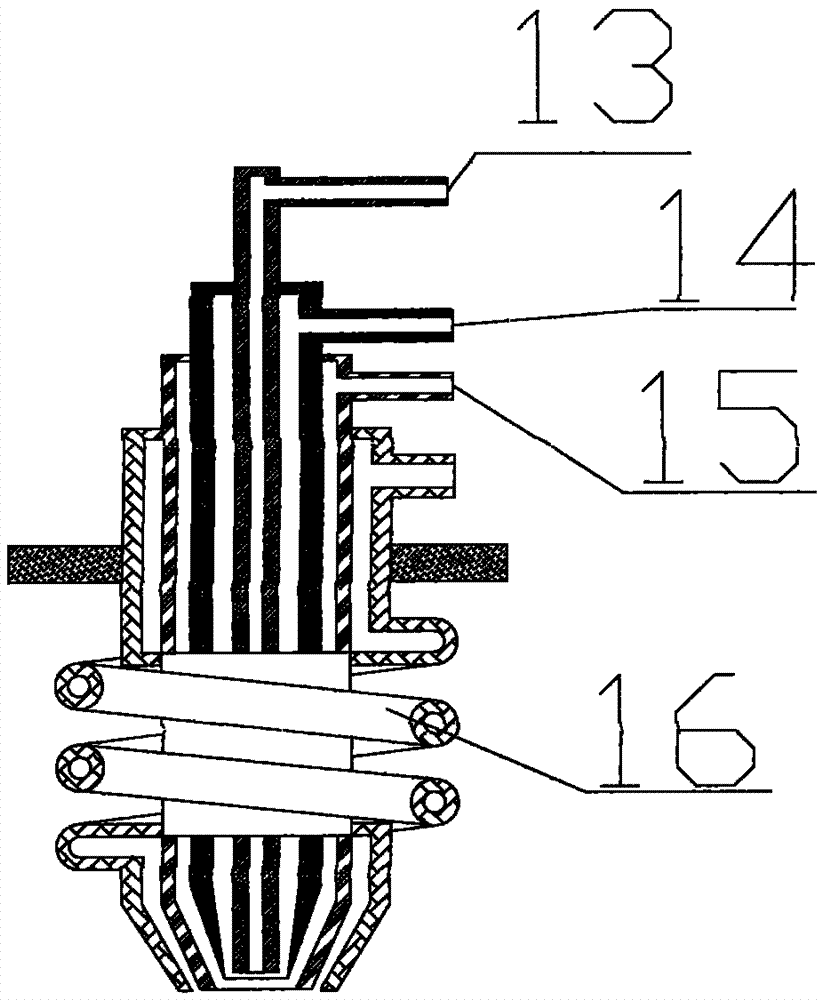

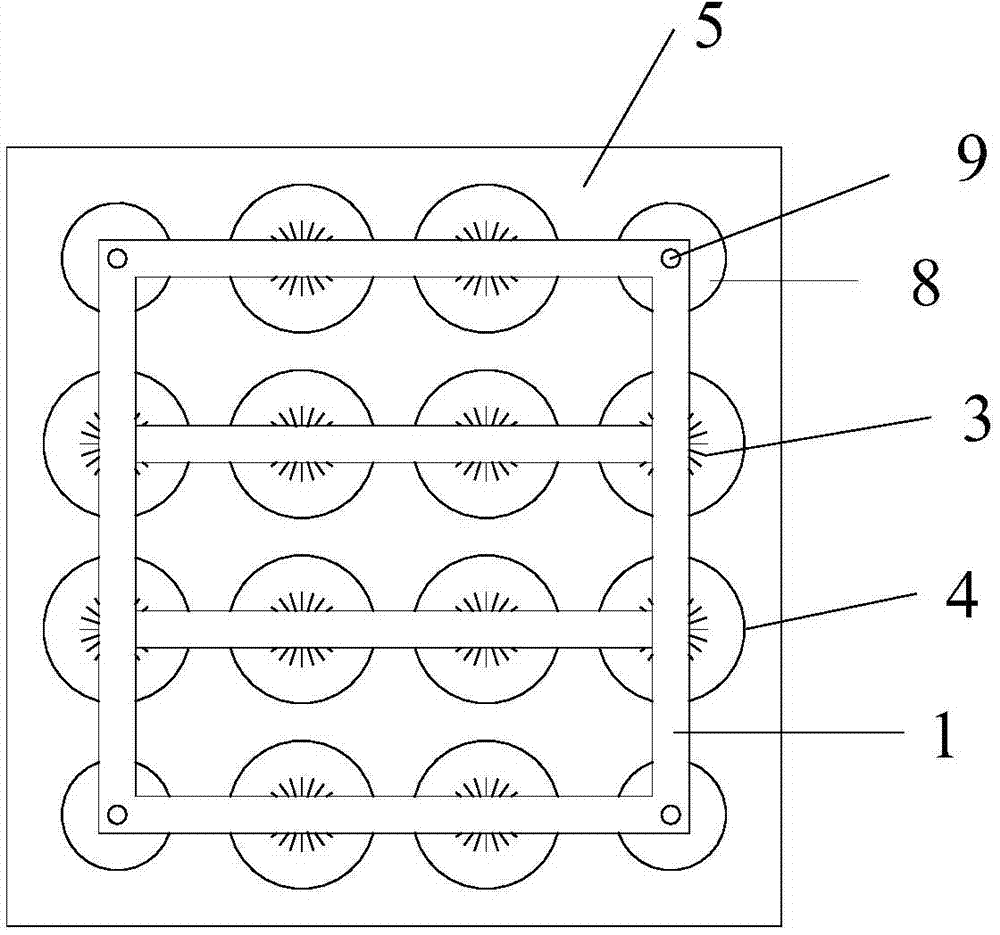

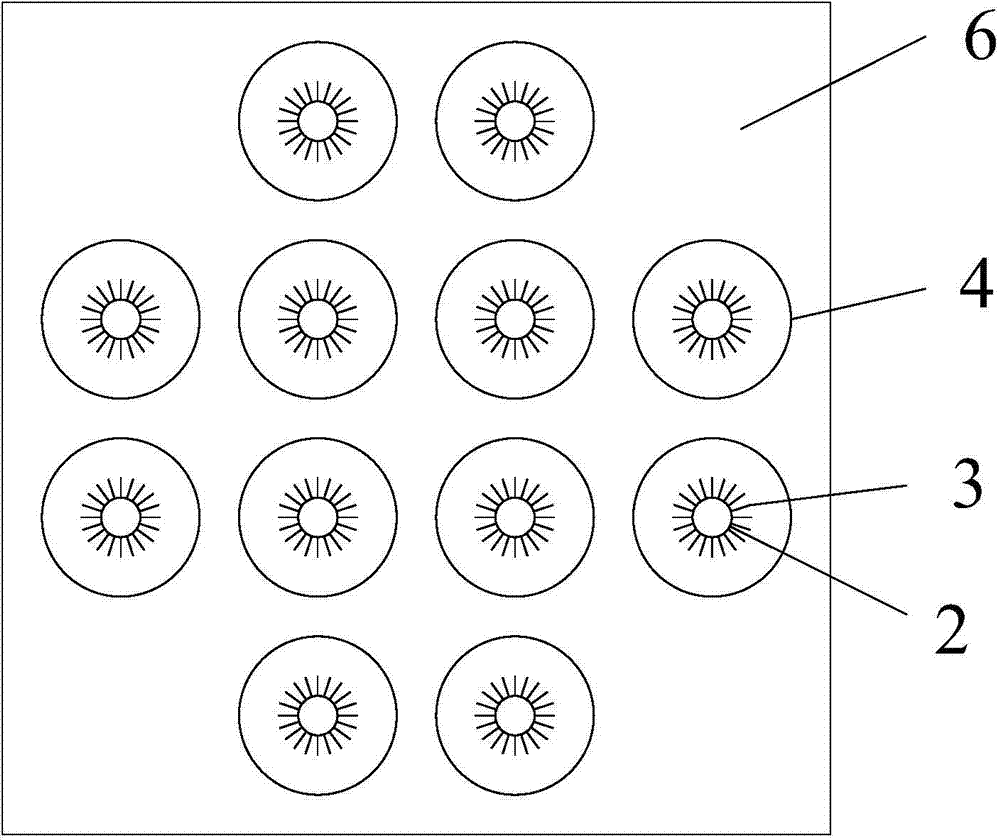

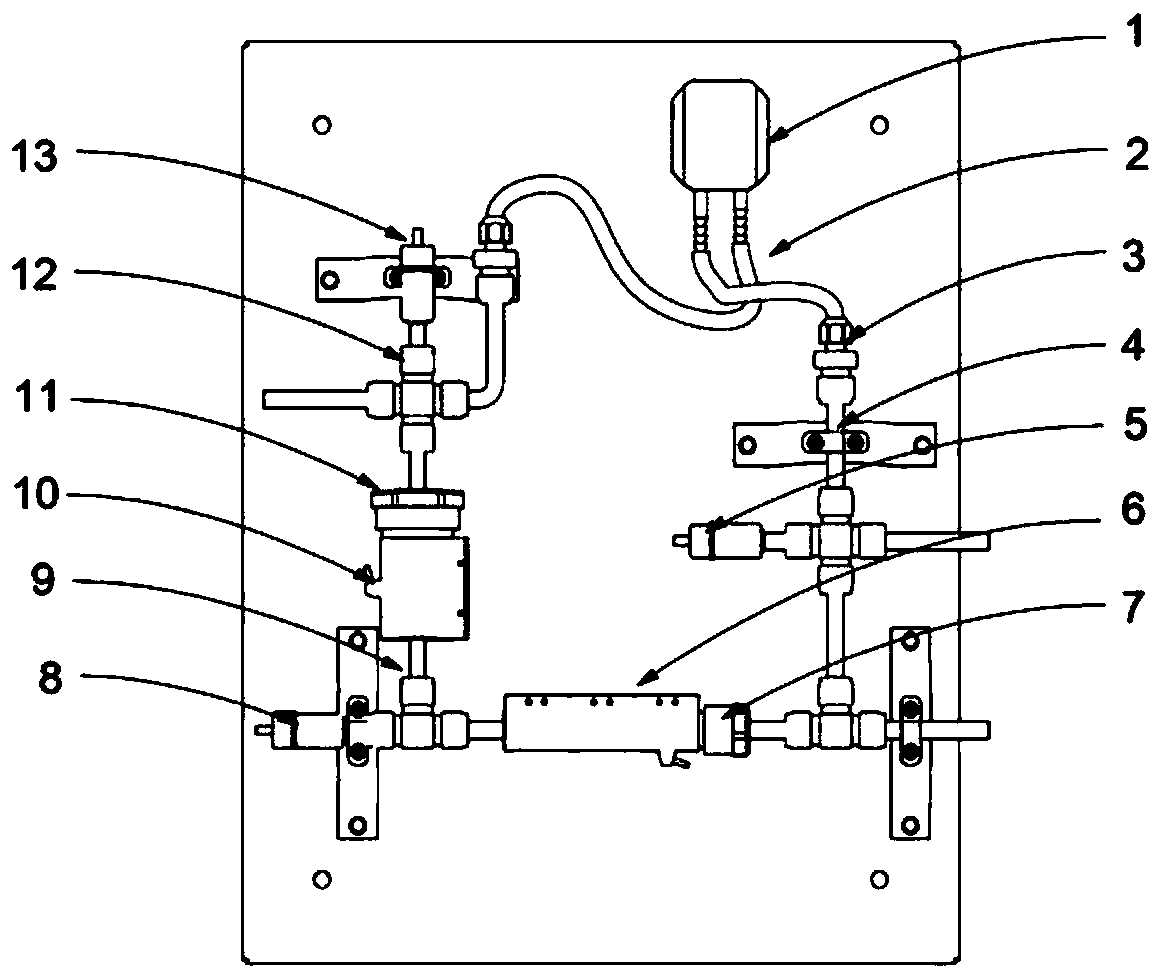

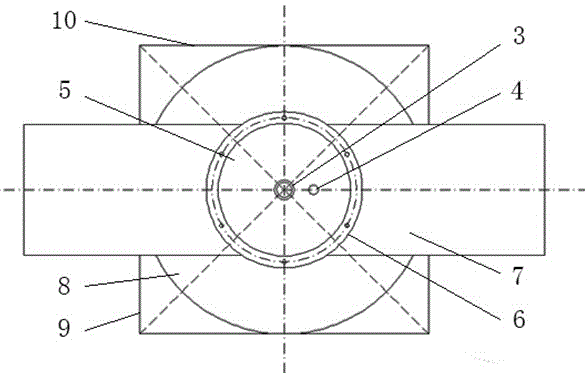

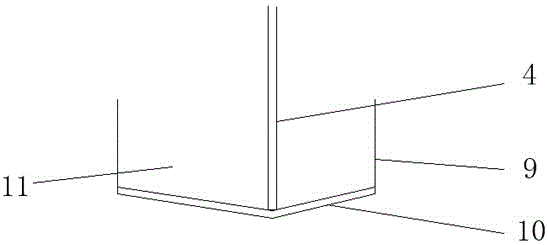

Low-temperature plasma generating device

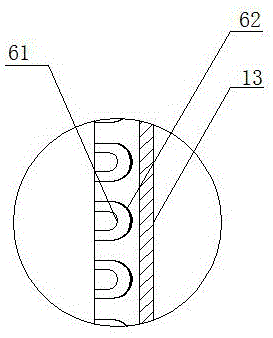

InactiveCN103906334AIncrease reaction spaceReduce the chance of breakdownPlasma techniqueHigh energyEngineering

The invention relates to the technology of purifying organic waste gas in the industry and aims to provide a low-temperature plasma generating device. A reactor of the device comprises an electric corona tube support, insulators, an upper baffle and a lower baffle in a sequential connection mode, and n plasma reacting cavities are formed in parallel. Outer shells of the reacting cavities are in a hollow cylinder shape, and electric corona tubes and the outer shells of the reacting cavities are coaxial. Multiple bars of discharging fluff made of metal material are evenly distributed on the outer walls of the electric corona tubes in a spiral step shape. Inward extending lines of the discharging fluff pass through the axes of the electric corona tubes. The electric corona support is provided with supporting pillars perpendicular downwards, the supporting pillars are sleeved with the electric corona tubes, and rain caps are arranged at the bottoms of the electric corona tubes. High-energy electrons, ions, atoms in an excited state, free radical particles and other high-activity substances generated by the device are improved by 35% on the basis of the same-size reactor, and effective reaction space is enlarged. Because fluff-shaped electrodes are adopted, the probability of breakdown of a positive electrode and a negative electrode is greatly reduced, and energy consumption is greatly reduced.

Owner:浙江菲尔特环保工程有限公司

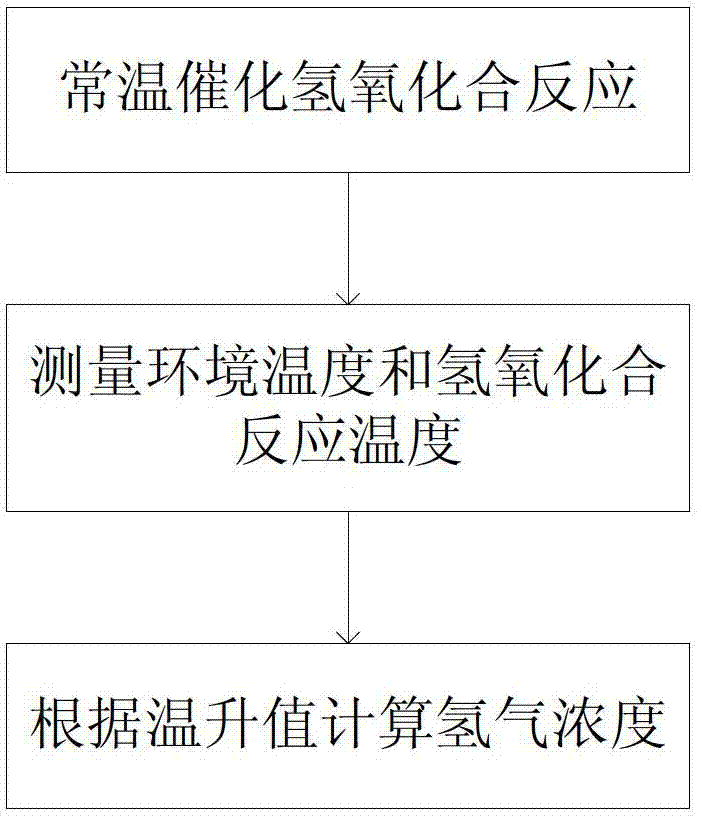

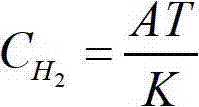

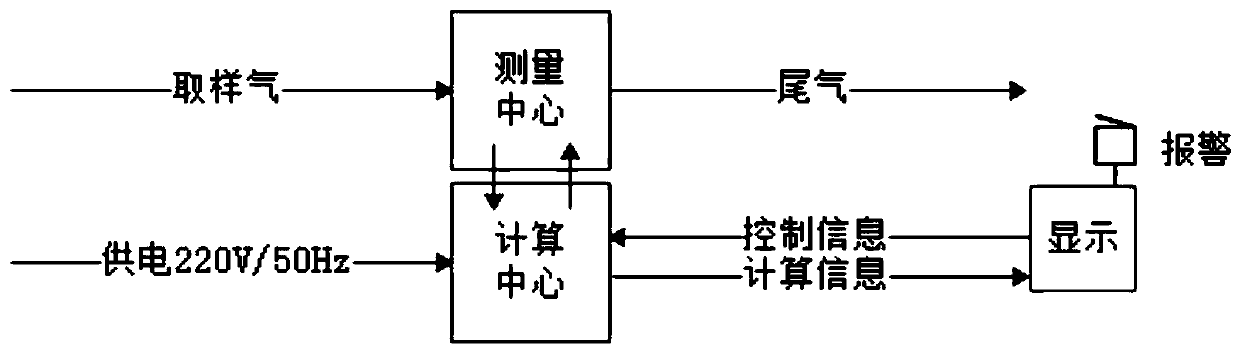

Method for measuring hydrogen concentration in containment vessel of nuclear power plant

ActiveCN102928550ASimple methodLarge measuring rangeChemical analysis using catalysisHydrogen concentrationNuclear power

The invention discloses a method for measuring hydrogen concentration in a containment vessel of a nuclear power plant, belonging to the field of flammable and explosive gas concentration measuring technique. The method comprises the steps as follows: (1) carrying out combination reaction on hydrogen and oxygen in the containment vessel of the nuclear power plant under normal temperature conditions; (2) respectively measuring the ambient temperature T1 and the combination reaction temperature T2 in the containment vessel of THE nuclear power plant; and (3) calculating by adopting a formula to obtain the hydrogen concentration. The method is simple, safe and reliable, and large in measurement range.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

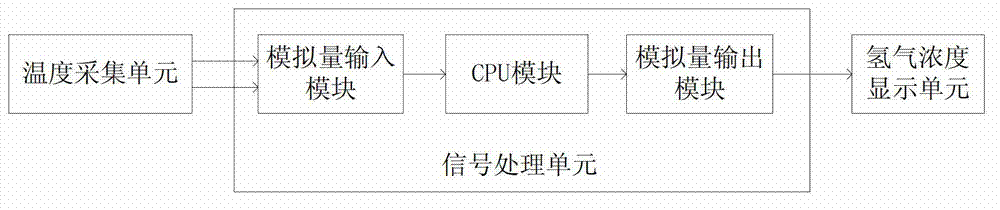

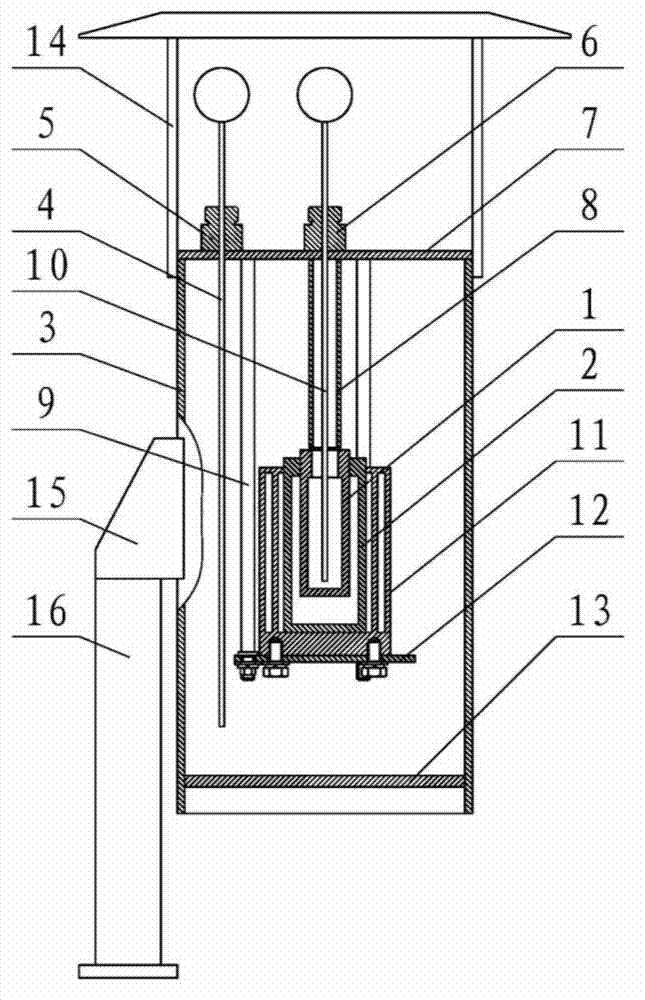

Concentration measuring system of hydrogen in containment vessel

ActiveCN102928463ASafe continuous measurementReduce energy consumptionMaterial heat developmentContinuous measurementHydrogen concentration

The invention discloses a concentration measuring system of hydrogen in a containment vessel, belonging to the technical field of concentration measurement of flammable and explosive gasses. The concentration measuring system comprises a temperature acquisition unit, a signal processing unit and a hydrogen concentration display unit, wherein the signal processing unit comprises an analog value input module, a CPU (Central Processing Unit) module and an analog value output module; and the temperature acquisition unit, the analog value input module, the CPU module, the analog value output module and the hydrogen concentration display unit are connected in sequence. The concentration measuring system is low in energy consumption, simple to assemble and capable of safely and reliably realizing continuous measurement of concentration of hydrogen in the containment vessel under accident conditions of a nuclear power plant.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

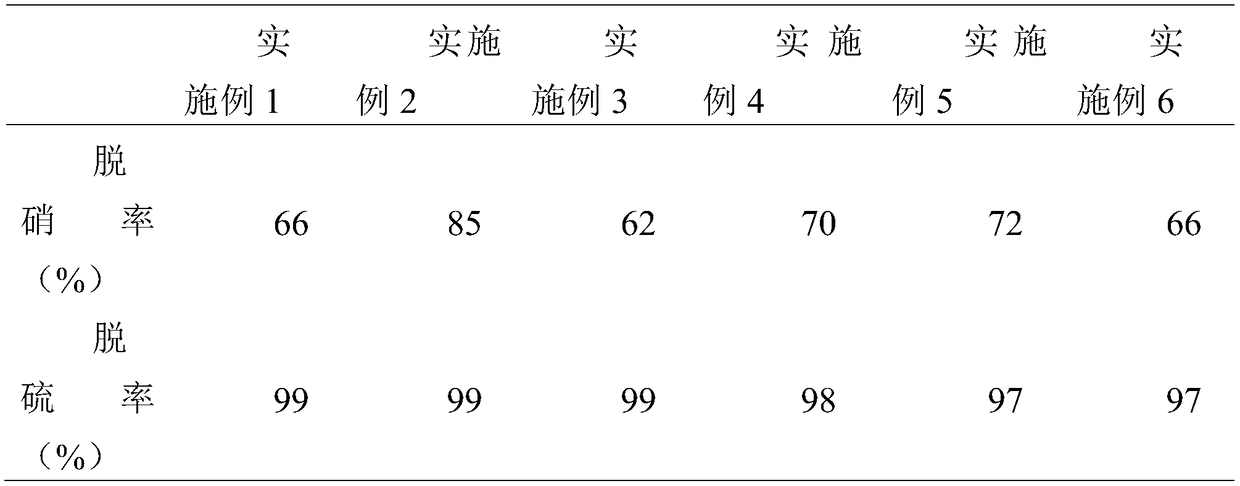

Preparation method of flue gas desulfurization and denitrification absorbent for rice hull ash/carbide slag system

ActiveCN108654315AHigh desulfurization activityLarge specific surface areaGas treatmentDispersed particle separationCalcium silicateHydration reaction

The invention discloses a preparation method of a flue gas desulfurization and denitrification absorbent for a rice hull ash / carbide slag system, and belongs to the technical field of environmental protection. The absorbent is prepared by performing a hydration reaction on rice hull ash and the carbide slag, carrying out suction filtration and dehydration on the obtained slurry and drying at the temperature of 80 to 150 DEG C for 2 to 5 hours. The mass ratio of the rice hull ash to the carbide slag is (1 to 1) to (6 to 1), the solid-liquid mass ratio is (1 to 5) to (1 to 20), the hydration temperature is 70 to 130 DEG C and the hydration time is 5 to 11 hours. The absorbent of the rice hull ash / carbide slag system is mixed with 85 to 95 percent of cement raw material according to the massratio of 5 to 15 percent, and a simultaneous removal experiment of SO2 and NO is carried out under simulated flue gas conditions. A variety of hydrate calcium silicate is formed by hydration of the rice hull ash and the carbide slag; meanwhile, various metal oxides contained in the rice hull ash and the carbide slag can catalyze C-NO reaction and improve denitrification efficiency. The preparationmethod disclosed by the invention has the advantages of simple process, low raw material cost and capability of achieving the simultaneous desulfurization and denitrification effect at lower preheater temperature, wherein the absorbent can preferably reach 85 percent of denitrification rate and 99 percent of desulfurization rate.

Owner:BEIJING UNIV OF TECH

Combustor implementing ultra-low oxidized burning loss during heating steel billet

InactiveCN101131235AImprove organizationAchieve low oxygen combustionGaseous fuel burnerProduct gasEngineering

The present invention relates to burning equipment technology, and is especially one kind of gas burner for heating billet in very low burning loss. The burner has one mounting plate, burner blocks before the mounting plate, one burner shell following mounting plate, and one gas passage and one air passage. All the burner blocks have their corners cut off, so that the air passage may be communicated to the hearth through the holes the burner blocks form. During operation, the high speed airflow forms negative pressure and great amount of fume is sucked into air to reduce oxygen concentration, so as to realize stable burning and reduce burning loss of heated billet. The burner has completely separated air and gas, simple structure, long service life and well organized gas flow inside the hearth, and is suitable for burning various kinds of gas fuel with high heat value.

Owner:UNIV OF SCI & TECH BEIJING

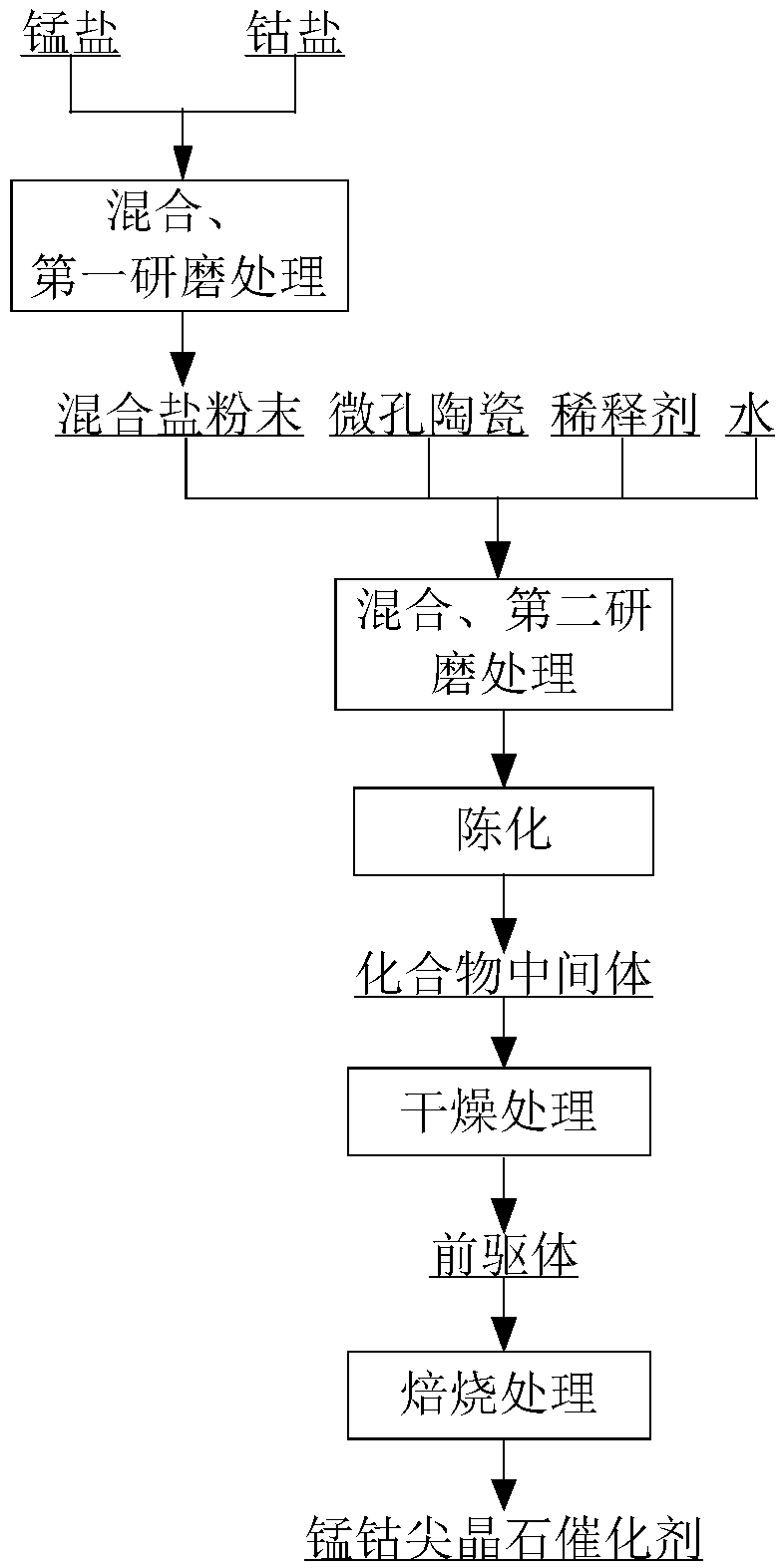

Manganese-cobalt spinel catalyst and preparation method thereof

InactiveCN108636422ALarge specific surface areaHigh mechanical strengthMetal/metal-oxides/metal-hydroxide catalystsActive componentSpinel

The invention discloses a manganese-cobalt spinel catalyst and a preparation method thereof. The manganese-cobalt spinel catalyst adopts manganese-cobalt spinel as an active component and microporousceramic as a carrier. The manganese-cobalt spinel catalyst not only has excellent mechanical strength, high-temperature resistance, alkali corrosion resistance and good storage stability, but also hasgood catalytic activity in oxygen reduction catalysis.

Owner:YUNNAN ALUMINUM

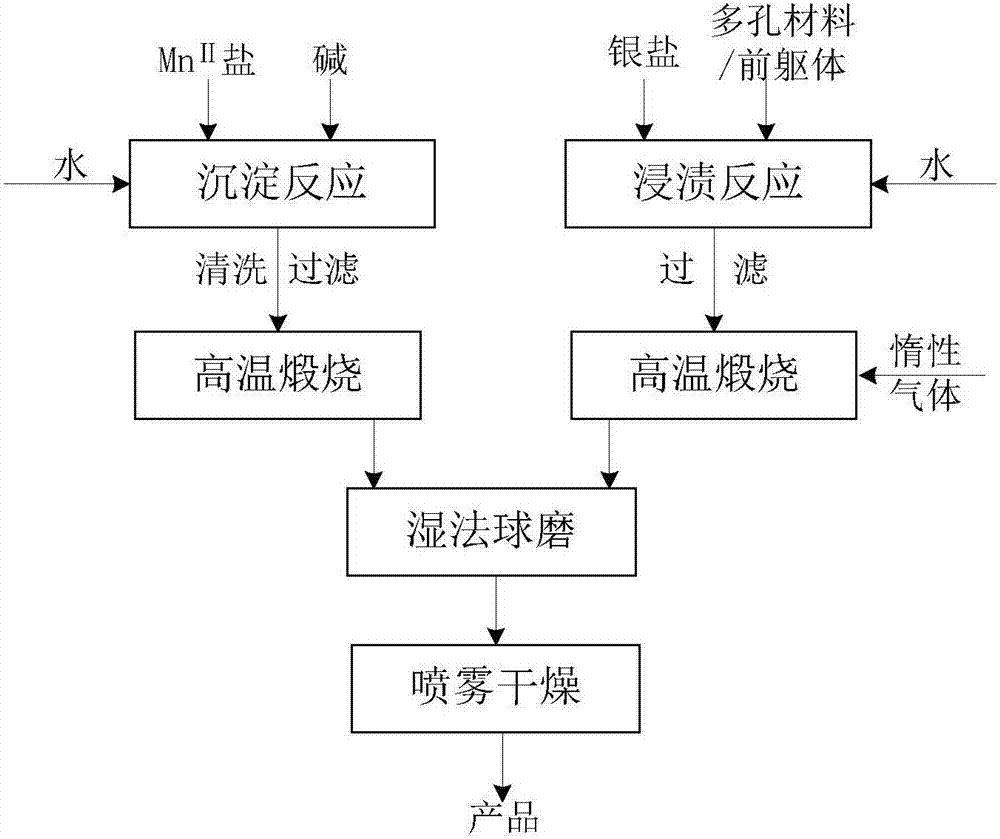

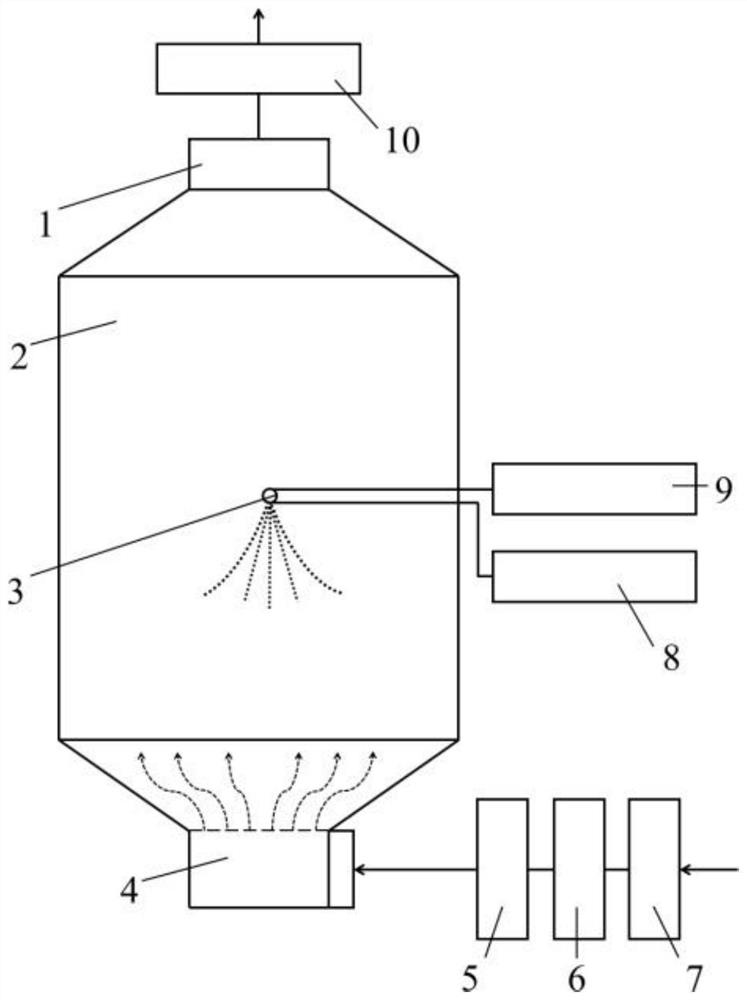

Air purification composite catalyst material and preparation method thereof

InactiveCN107243343AImprove catalytic performanceEffective and durable degradationDispersed particle separationCatalyst activation/preparationNitrogen gasHigh pressure

The present invention discloses an air purification composite catalyst material and a preparation method thereof. The preparation method comprises: adding an oxidizing agent and a MnII salt in water, stirring until completely dissolving, and carrying out a precipitation reaction to obtain a mixed solution containing a precursor; adding the mixed liquid to a reaction kettle, carrying out a high temperature and high pressure reaction, washing after the reaction, and filtering to obtain manganese dioxide filter residue so as to be spare; soaking an inorganic porous material in a silver salt solution, carrying out an adsorption reaction, filtering, and calcining under the protection of nitrogen or inert gas to obtain a silver supported inorganic porous material; and carrying out liquid phase ball mill mixing on the manganese dioxide filter residue and the silver supported inorganic porous material to obtain a suspension, and carrying out spray drying to obtain the spherical air purification composite catalyst material.

Owner:NINGBO TAIAN NEW MATERIAL TECH CO LTD

Method of degrading glyphosate in water body

InactiveCN109592773AImprove adsorption capacityImprove catalytic performanceWater contaminantsCatalyst activation/preparationNitrogen gasMuffle furnace

The invention relates to a method of degrading glyphosate in a water body. The method comprises the following steps: adding honeycomb ceramic packing into a 30-70% by mass of oxalic acid solution, boiling, condensing and refluxing the solution, washing the cooled solution with deionized water till the pH is 4-10 and putting the solution in an oven to be dried; weighing Co(NO3)2.6H2O, Ce(NO3)2.6H2Oand Al(OH)3 in deionized water, stirring the mixture and dropwise adding an aluminum sol to be fully mixed to form a mixed solution; impregnating the honeycomb ceramic packing in the mixed solution for 1-3 hours and taking out the same, blowing a residual liquid in ducts by nitrogen, putting the filler into the oven to be dried, and impregnating and drying the filler repeatedly for 3-5 times; putting the filler into a muffle furnace to combust to prepare a Co3O4-CeO2 / CH catalyst, wherein the molar ratio of Co to Ce is (1-5): 1 and the loading amount is 0.3-0.7; and activating persulfate by the catalyst to degrade glyphosate in the water body, wherein the removal rate of glyphosate reaches 95-100%.

Owner:TIANJIN UNIV

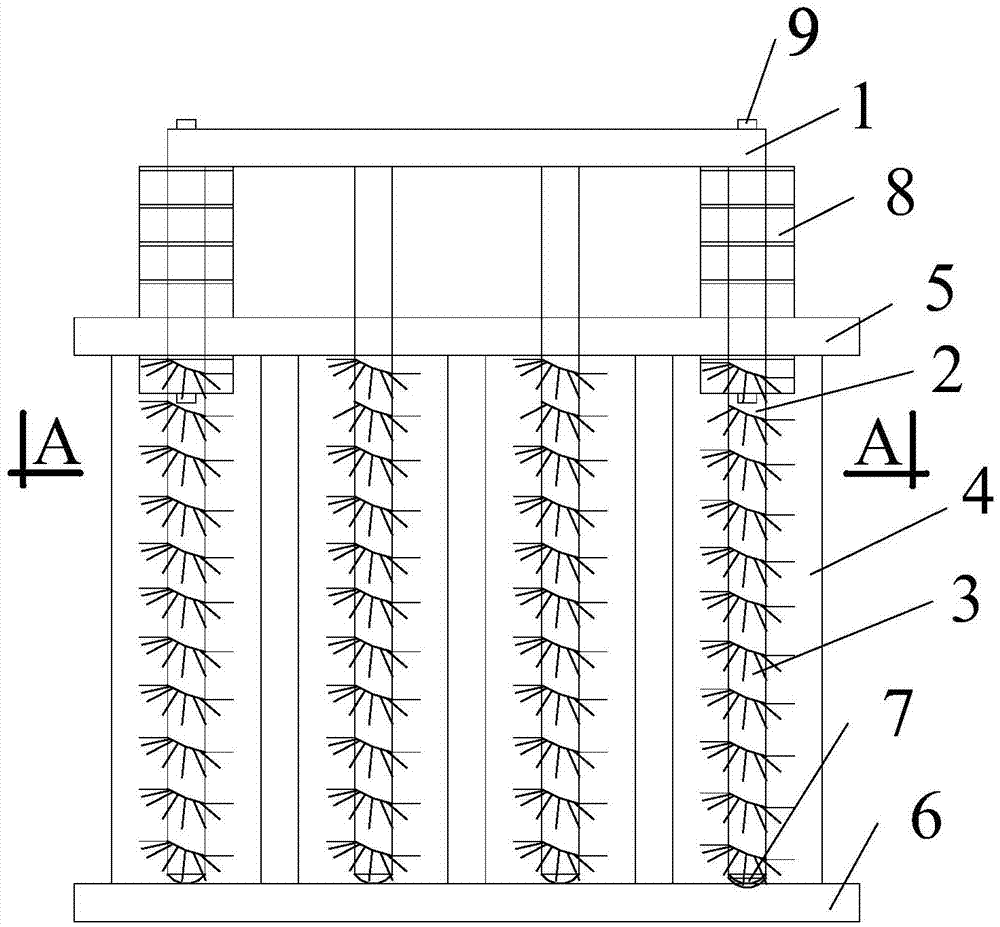

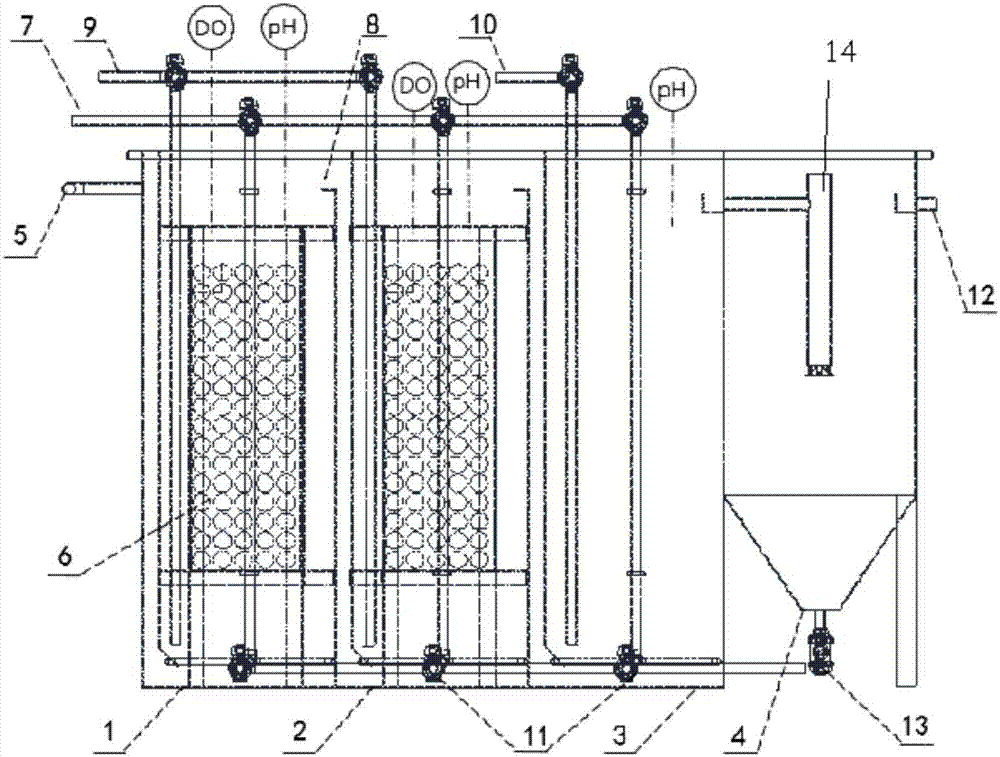

Micro-electrolysis pretreatment device of printing and dyeing wastewater, and device thereof

PendingCN107010699AFast removal rateFast electrochemical reactionWater treatment parameter controlWater contaminantsElectrolysisWater flow

A micro-electrolysis pretreatment device of printing and dyeing wastewater comprises a primary baffled micro-electrolysis cell, a secondary baffled micro-electrolysis cell, a neutralization tank and a sedimentation tank which are serially arranged, and wastewater enters a reaction tank from the bottom end through flow guiding channels arranged in the primary baffled micro-electrolysis cell, the secondary baffled micro-electrolysis cell, the neutralization tank and the sedimentation tank. The serially arranged primary and secondary baffled micro-electrolysis cells prolong the reaction time, increase the reaction space, and avoid the press hardening and channeling phenomena of a packing layer, caused by the gravity effect, under the action of the water flow and aeration; and the device can effectively remove the chroma and improve the biodegradability of printing and dyeing wastewater with high CODs, difficult degradation and poor biodegradability, greatly improves the treatment effect of the micro-electrolysis reaction, and provides good conditions for subsequent biochemical treatment.

Owner:江苏艾特克环境工程设计研究院有限公司

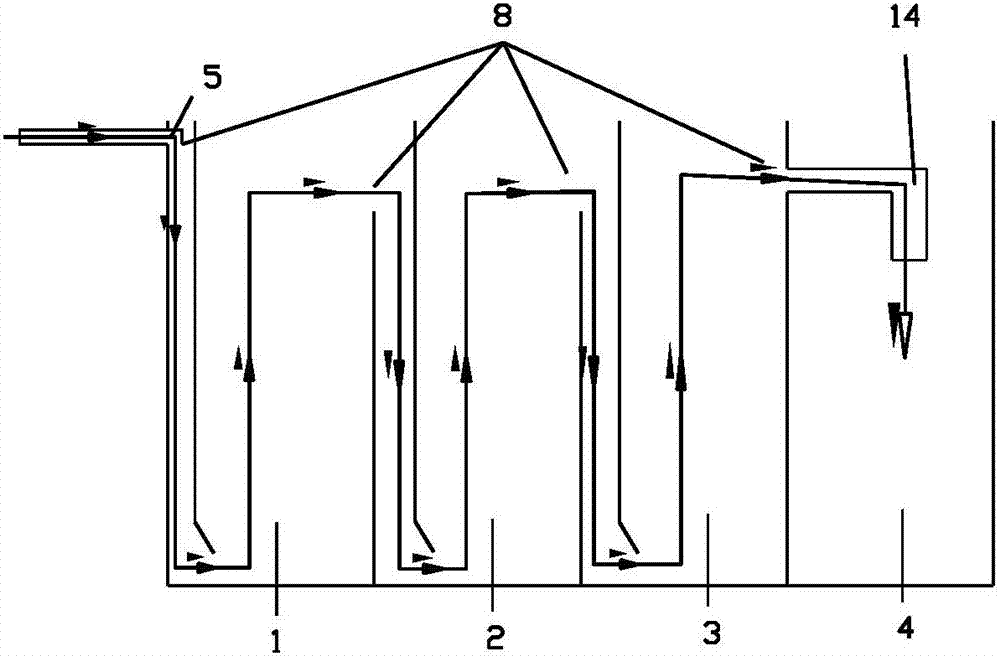

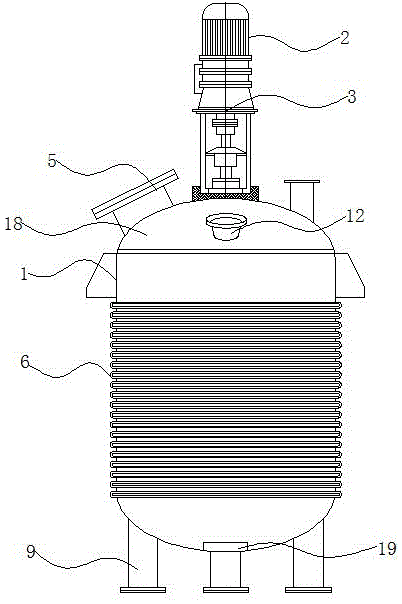

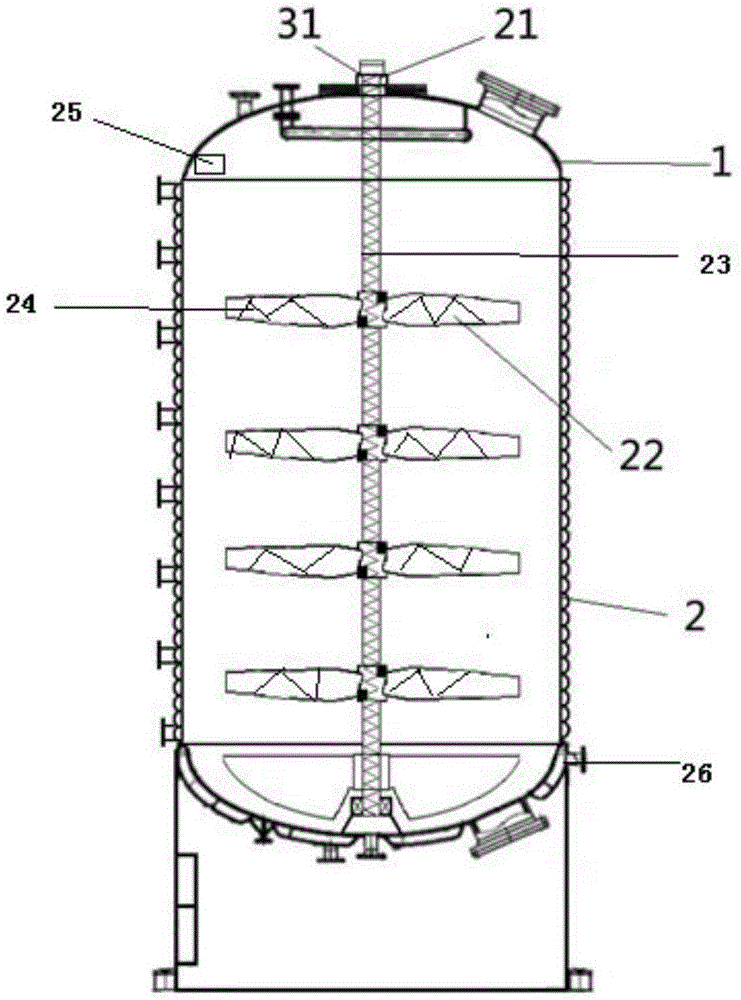

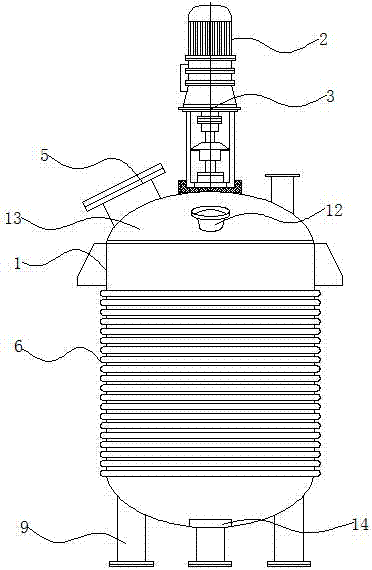

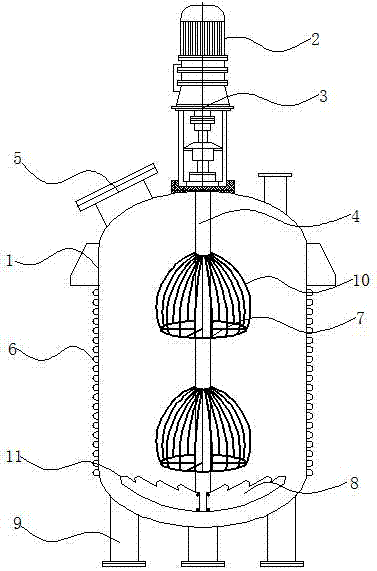

Scraping apparatus containing reactor for resin production

ActiveCN105056863AIncrease reaction spaceReduce lossRotary stirring mixersMixer accessoriesThermal insulationThermal energy

The invention discloses a scraping apparatus containing reactor for resin production. The reactor is characterized in that an external coil pipe is arranged around the external periphery of the reactor body, the external coil pipe is prepared by sleeving a steam outer sleeve on a thermal conductive inner pipe, the external of the external coil pipe is covered by a thermal insulation layer; a stirring shaft is provided with a cage-type stirrer, horizontal shafts are horizontally and fixedly arranged on two opposite side surfaces of the stirring shaft, the end part of each horizontal shaft is vertically provided with a vertical plate, a scarping device (a) is fixed on the external side surface of each vertical plate, the top part and bottom part of the stirring shaft are both provided with an arc plate, and a scraping device (b) is arranged on the projected surface of each arc plate. The discloses reactor has the advantages of good stirring effect, improved reaction efficiency, good heating effect, rapid heating speed, good thermal insulation effect, little thermal energy loss, and complete reactions, moreover, the heating device is arranged out of the reactor, the inner reaction space is saved, the maintenance becomes easier, the scales can be removed easily and conveniently, the normal operation of equipment can last for a long time, and the cleaning difficulty is reduced.

Owner:JIANGSU JIANYA ENVIRONMENTAL PROTECTION TECH CO LTD

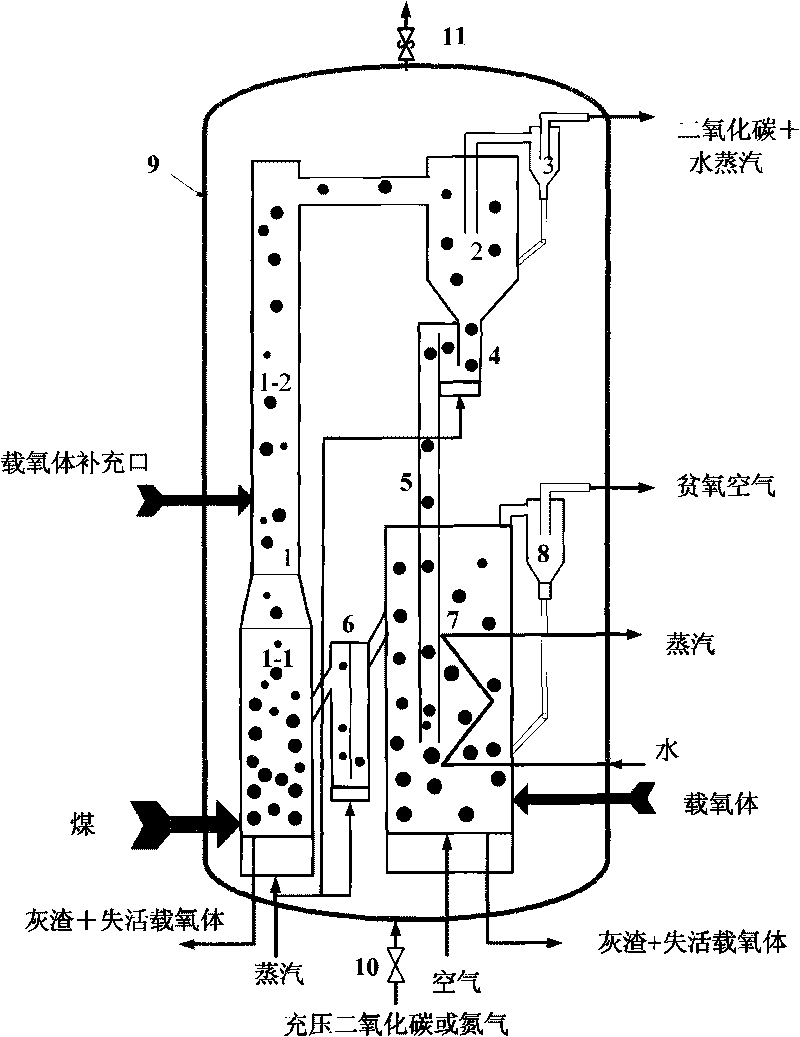

Method for preparing oxygenous fuel by coal synthesis gas slurry bed

InactiveCN105289423AIncrease reaction spaceAdded stirring functionLiquid carbonaceous fuelsChemical/physical processesSlurryCoal

The invention relates to a method for preparing oxygenous fuel by a coal synthesis gas slurry bed. According to the method, a solid catalyst and inert liquid molten paraffin are placed in a slurry bed reactor from the bottom to the liquid level of the reactor, synthesis gas tangentially and swirlingly enter the slurry bed reactor and reacts in a bubble form to form a gas, liquid and solid fluidized form, then the obtained product is processed by a gas-liquid separator and a heat exchanger and the processed product is discharged from an outlet; cold water enters the reactor from the lower part, a natural convection recirculation zone is formed on the inner surface of a membrane water cooled wall, heat is absorbed by the membrane water cooled wall, and then the obtained product is discharged by the heat exchanger through a high-temperature hot water outlet of the reactor. The method adopts a plurality of spray nozzles to enable slurry to take the swirling motion so as to enable bubbles to spirally ascend, thereby reinforcing a stirring function and increasing contact time with slurry by 1.2 to 1.8 times; moreover, temperature difference of the slurry is between 4 DEG C and 8 DEG C, so that reaction efficiency of the reactor is greatly improved.

Owner:TAIYUAN UNIV OF TECH

Processing method of waste nitric acid fume and device thereof

The invention discloses a processing method of waste nitric acid fume, comprising the following steps: 1) introducing waste nitric acid fume into a main absorbing tower so as to perform first integrated reaction between the waste nitric acid fume and an introduced medicine, wherein the medicine is sprayed in the motion direction of the waste nitric acid fume through spray equipment when the integrated reaction is performed, and during the first integrated reaction, a filter pack is used for deceleration of the waste gas, uniform distribution of the sprayed medicine and complete reaction; 2) arranging a hollow layer in the main absorbing tower, allowing the waste gas to pass through the hollow layer, and performing a second integrated reaction between the waste gas and the medicine introduced in the main absorbing tower; and 3) introducing the waste gas from the main absorbing tower into an auxiliary absorbing tower so as to perform reaction and absorption again in the auxiliary absorbing tower, and discharging into the atmosphere through a chimney. The invention also discloses a treatment device. By the adoption of the treatment device provided by the invention, acid fog and acid gas in the waste gas can be rapidly and thoroughly absorbed through reactions. The device has a simple structure, and is energy saving and environmentally friendly.

Owner:台澳铝业(台山)有限公司

Temperature control and stirring integrated device

InactiveCN105688782AGuaranteed uniformityMaterial composition and temperature uniformityChemical/physical/physico-chemical stationary reactorsInert gas productionEngineeringHeating power

The invention relates to a temperature control and stirring integrated device. The volume of a tank can be huge; an external heating device is used for adjusting temperature for the liquid phase from the exterior of the tank; a stirring device is used for mechanically stirring the liquid phase; an internal heating device is used for internally heating; a ventilating space between a first rotating shaft and a second rotating shaft is utilized to introduce air into the tank, for performing air stirring. The temperature of the liquid phase in a liquid phase reaction vessel can be kept constant by reasonably controlling the heating power of the external heating device and the internal heating device. The liquid phase reaction vessel is fit for mass production and is capable of causing the components and temperature of the inner liquid phase matters be uniform.

Owner:山东瀚华工程设计有限公司

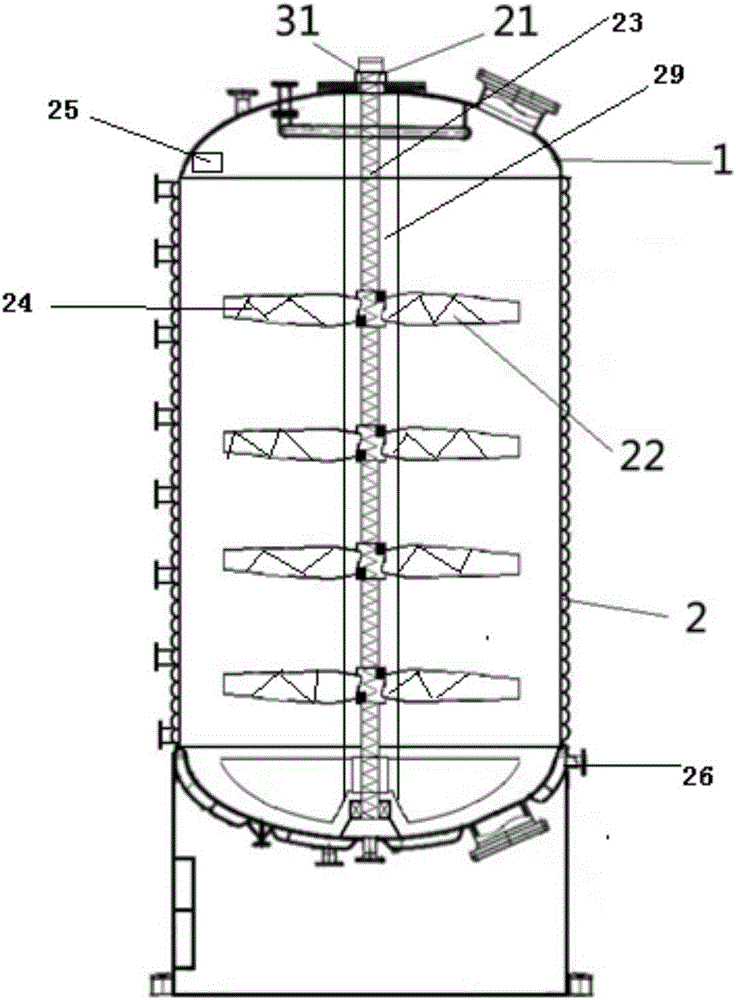

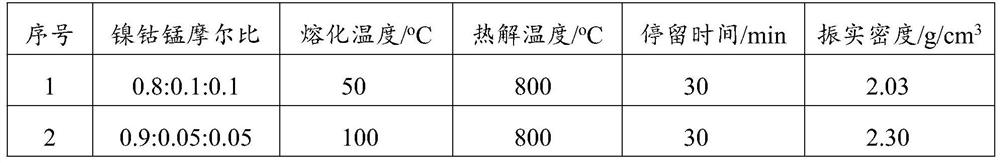

High-tap-density multi-element oxide precursor and preparation method and preparation system thereof

ActiveCN112919552ASolve the problem of low tap densityHigh tap densityCell electrodesSecondary cellsFluidized bedPhysical chemistry

The invention relates to the technical field of powder material preparation methods, in particular to a high-tap-density multi-element oxide precursor and a preparation method and a preparation system thereof. The preparation method comprises the steps that S1, metal salt containing crystal water is added into a liquid feeding device according to the stoichiometric ratio of all metal elements in the multi-element oxide to be stirred, heated and melted, and sub-molten salt liquid is obtained; S2, the sub-molten salt liquid is atomized through a two-fluid atomizer to form atomized liquid drops, and the atomized liquid drops are brought into a fluidized bed pyrolyzing furnace through compressed gas for pyrolysis; and S3, a pyrolysis product is collected in the step S2 through a dust collector to obtain the high-tap-density multi-element oxide precursor. According to the method, sub-molten salt liquid, double-fluid atomization and fluidized bed pyrolysis are combined, efficient preparation of the high-tap-density multi-element oxide precursor is achieved, and the precursor is uniform in element distribution, uniform in particle size, high in purity and good in spherical morphology.

Owner:CENT SOUTH UNIV

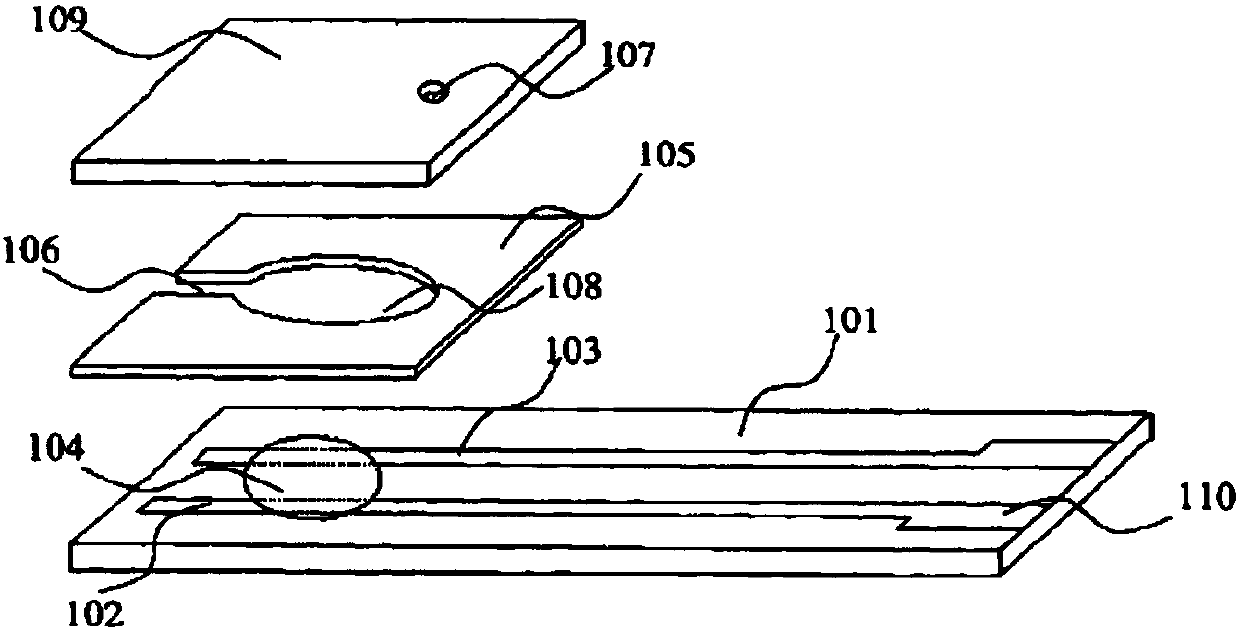

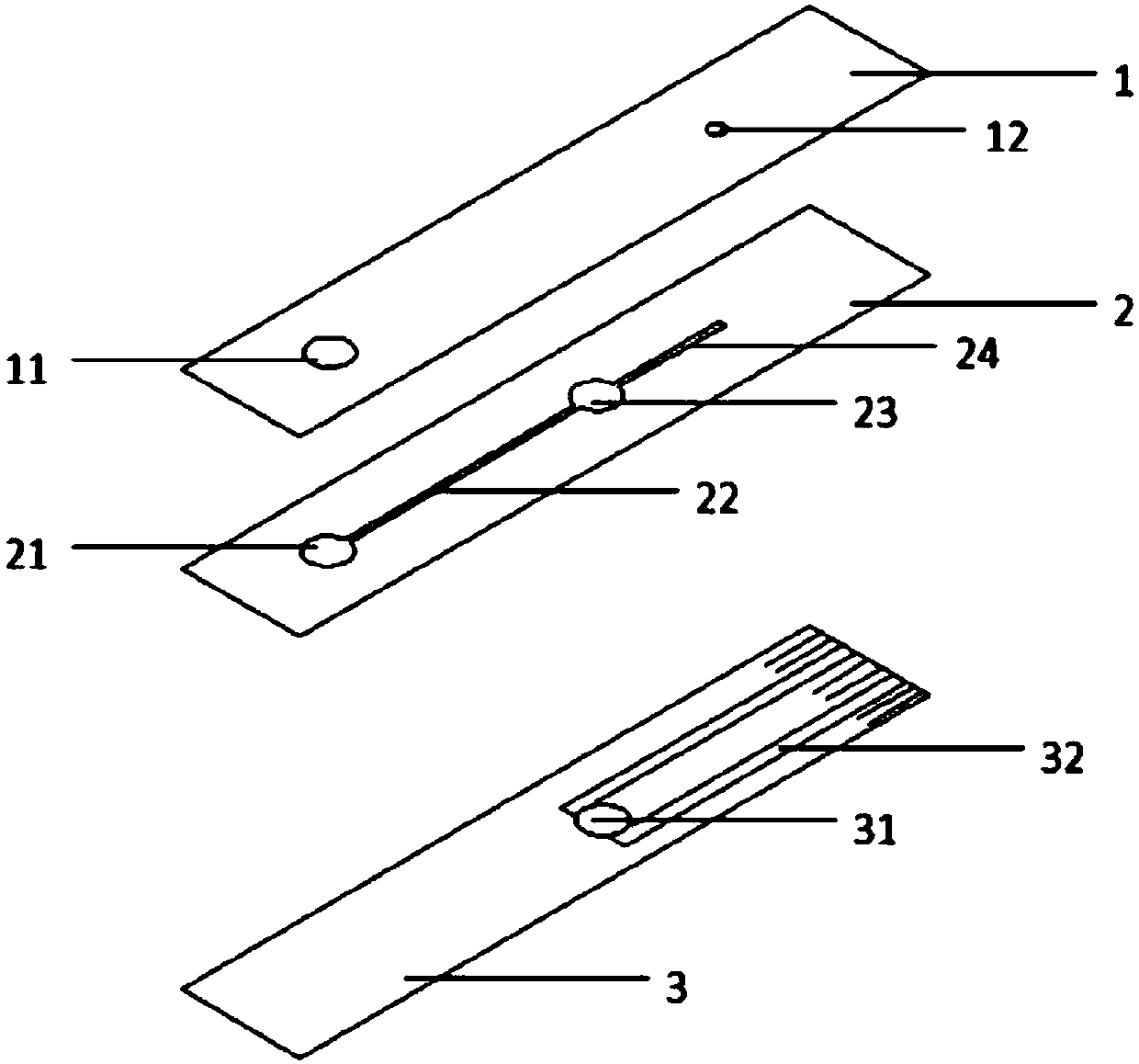

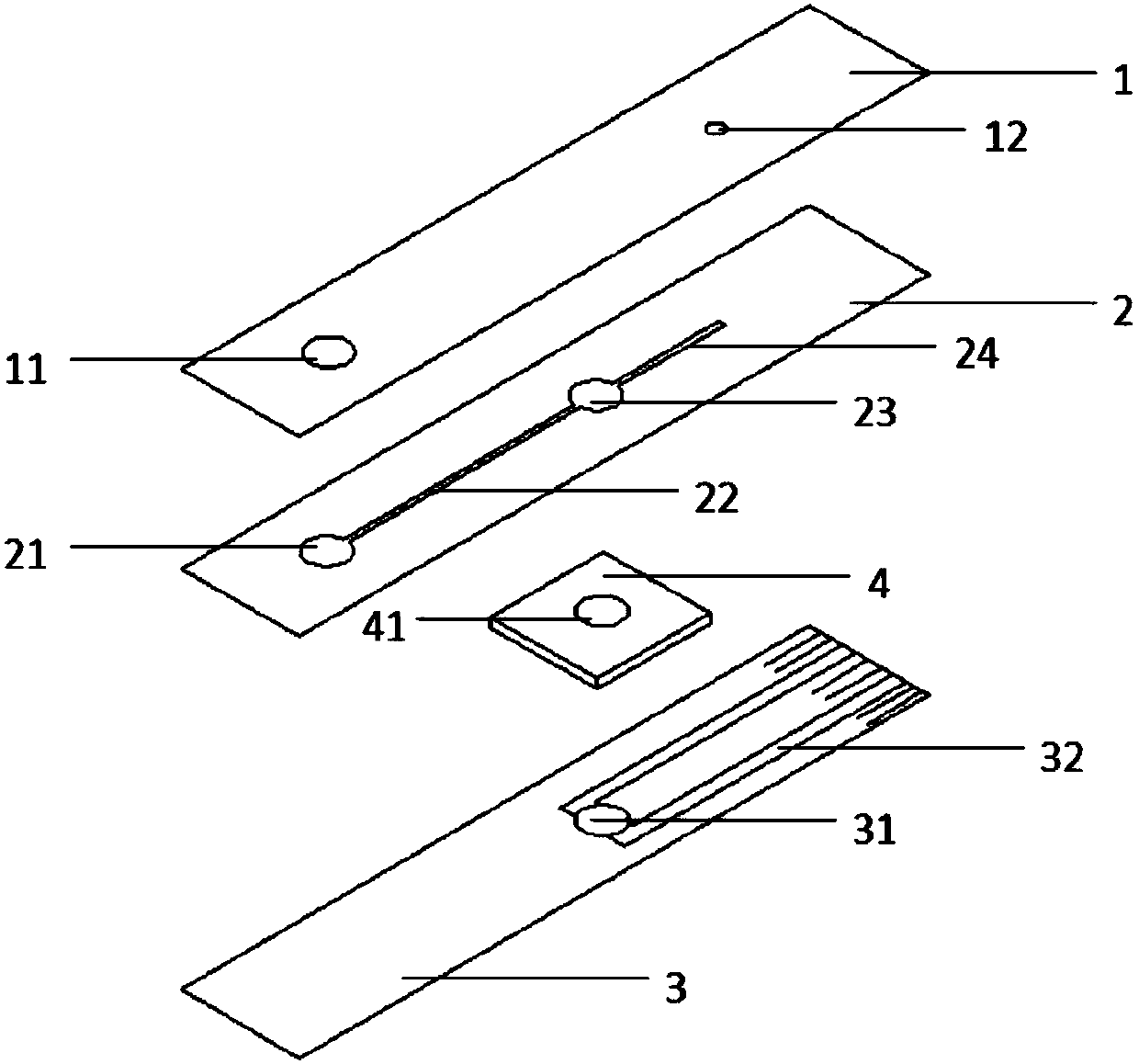

Liquid sample guiding device and detection equipment comprising same

InactiveCN107918031AImprove repeatability and reliabilityGood repeatabilityBiological testingTesting equipmentEngineering

The invention discloses a liquid sample guiding device and detection equipment comprising the same. The guiding device comprises a cover plate and a channel plate, wherein a sampling hole is formed inone end of the cover plate and an air outlet is formed in the other end; a sampling cavity, a liquid circulating channel and a circulating hole are formed in the channel plate, the sampling cavity islocated below the sampling hole and connected with the circulating hole through the liquid circulating channel, an extension pipeline extends out of the far end, relative to the sampling cavity, of the circulating hole in the channel plate, when the cover plate is stacked on the channel plate, the channel plate defines a vent port communicated with the outside through the air outlet, and the ventport is located at any pint of the extension pipeline or located at the further end, relative to the sampling cavity, of the tail end of the extension pipeline. The detection equipment also comprisesa base plate stacked with the cover plate and the channel plate to form a detection test strip. Besides, the detection equipment also comprises a detector comprising the detection test strip.

Owner:HELIXGEN GUANGZHOU

Multiple reaction integrated process for desulfuizing from fume by dry method and its system

InactiveCN1239232CImprove surface activityReduce desulfurization costDispersed particle separationPartial oxidationCalcium sulfite

A multiple reactions integrated process for desulfurizing from the fume by dry method includes such steps as spraying limestone powder in high-temp combustion box from its top to decompose calcium carbonate into calcium oxide and CO2, absorbing SO2 from fume by partial calcium oxide to generate calcium sulfate, spraying water to activate calcium oxide to transform partial calcium oxide to calcium hydroxide and absorb SO2 from fume to generate calcium sulfite, and using the residual calcium hydroxide and calcium oxide to desulfurize the fume in desulfurizing tower. Its system is composed of limestone powder sprayer, moistening flue, desulfurizing tower, external electric duster, draught blower and chimney.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

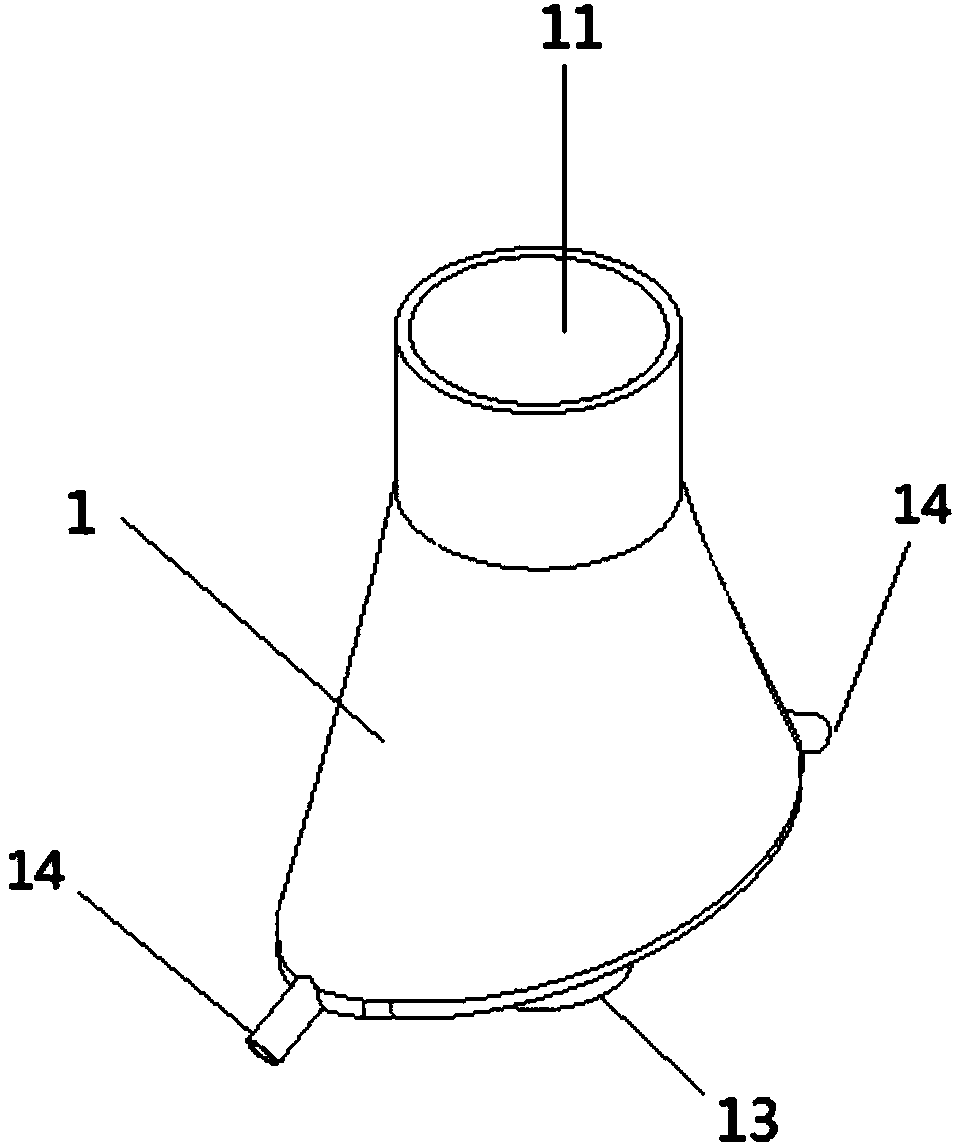

Stem cell separating device

PendingCN109988700AAvoid pollutionAchieve safe aseptic separationBioreactor/fermenter combinationsBiological substance pretreatmentsFully automaticStem cell

The invention provides a stem cell separating device, which comprises a tank and a a driving device, wherein a conical reaction cavity is formed in the tank; an injection conduit and an suction conduit, which are hermetically communicated with the conical reaction cavity, are arranged at the top of the tank; stem cell collecting parts, which are communicated with the conical reaction cavity, are arranged at the lower part of the tank; the stem cell collecting parts and the tank perform exchanging with external substances through the injection conduit and the suction conduit; and the driving device is arranged outside the bottom wall of the tank in a detachable manner, and is used for driving the tank to rotate for vibration or centrifugal separation. The device has the advantages of simplestructure, low cost, fully automatic operation and capability of accurately controlling the efficient separation and extraction of stem cells.

Owner:肖锷

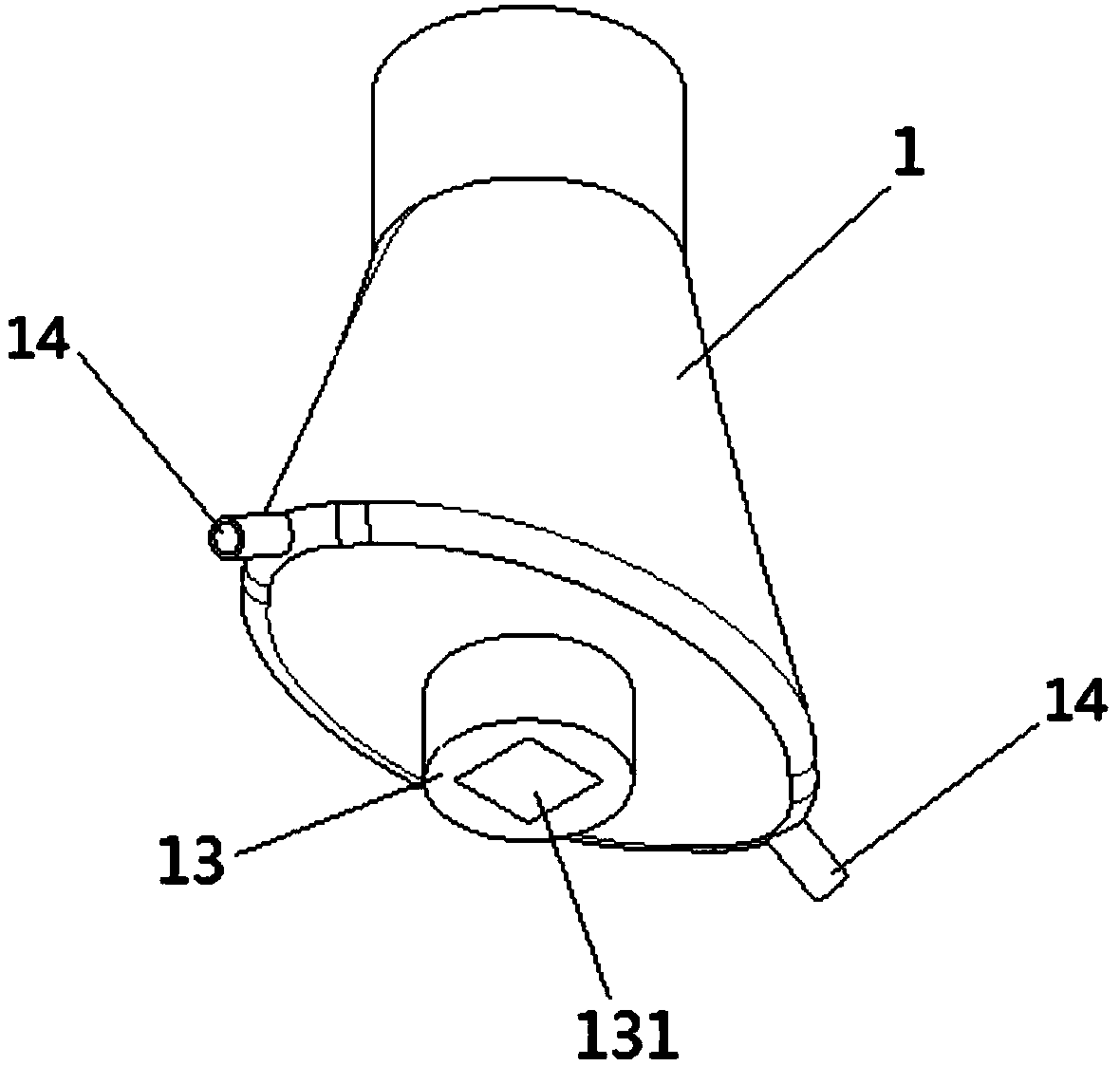

Online measurement device for VOCs (Volatile Organic Compounds) concentration

PendingCN110297066AImprove accuracySimple structureChemical analysis using catalysisPreparing sample for investigationChemical reactionMeasurement device

The invention provides an online measurement device for VOCs (Volatile Organic Compounds) concentration. The device mainly consists of a measurement unit, a calculation unit, and a display and alarming unit, wherein the measurement unit is used for measuring the temperature of sample gas and the pressure of sampling gas before and after chemical reaction; the calculation unit is used for calculating the concentration of the sample gas according to data measured by a measurement center; and the display and alarming unit is used for displaying the concentration of the sample gas, and giving an alarm when the concentration of the sample gas exceeds a set threshold value. The online measurement device for VOCs concentration has the advantages of simple structure and large measurement range andis safe and reliable.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Control system and method for flue dynamic air distribution cooperating with SNCR denitration

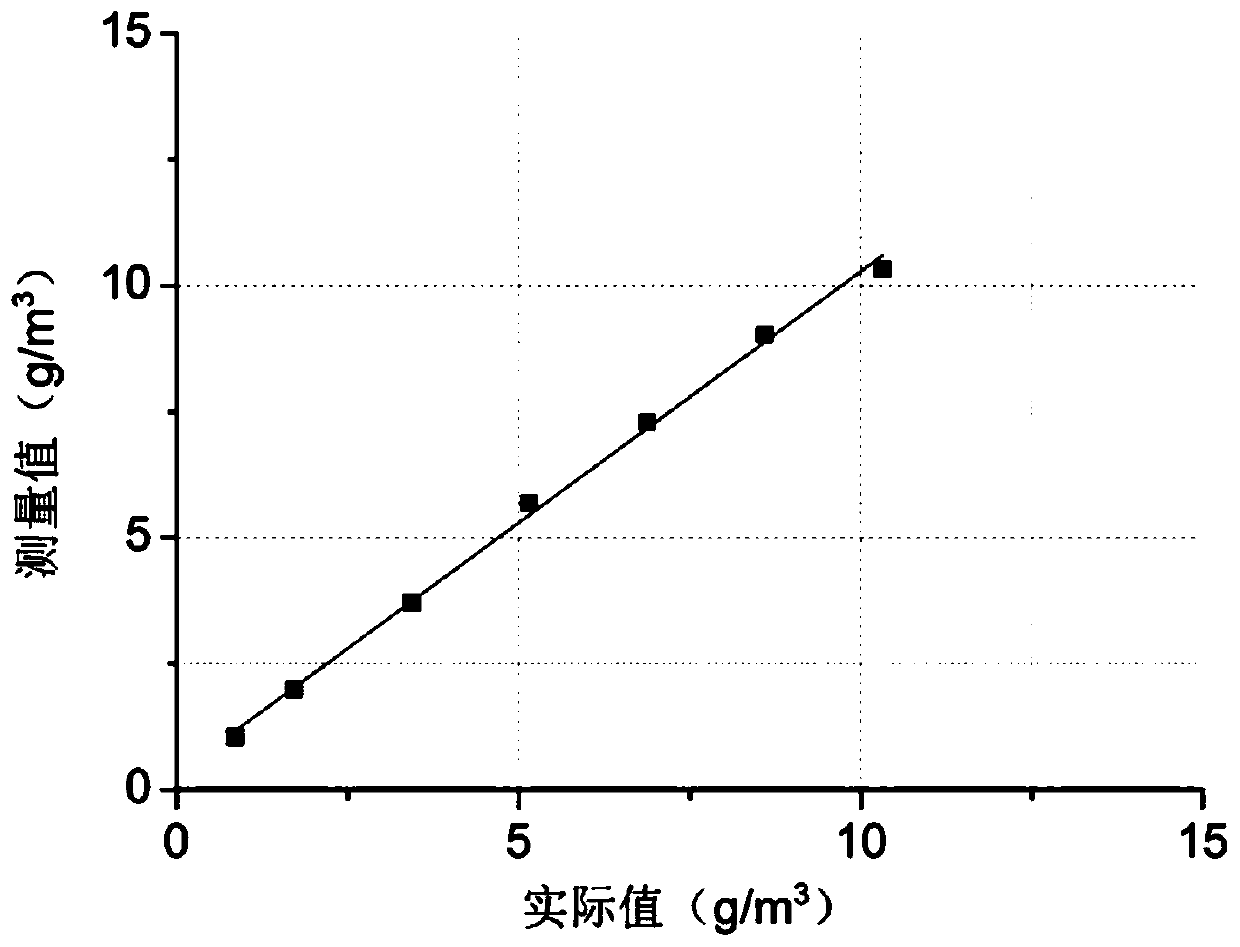

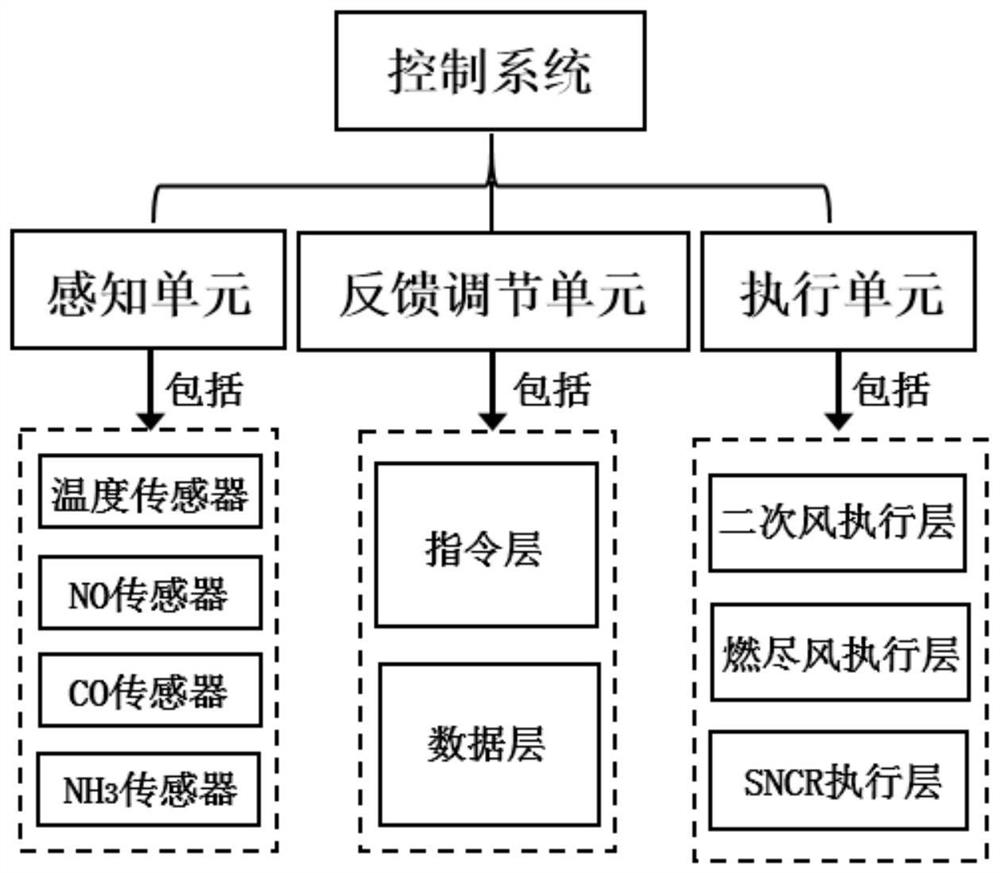

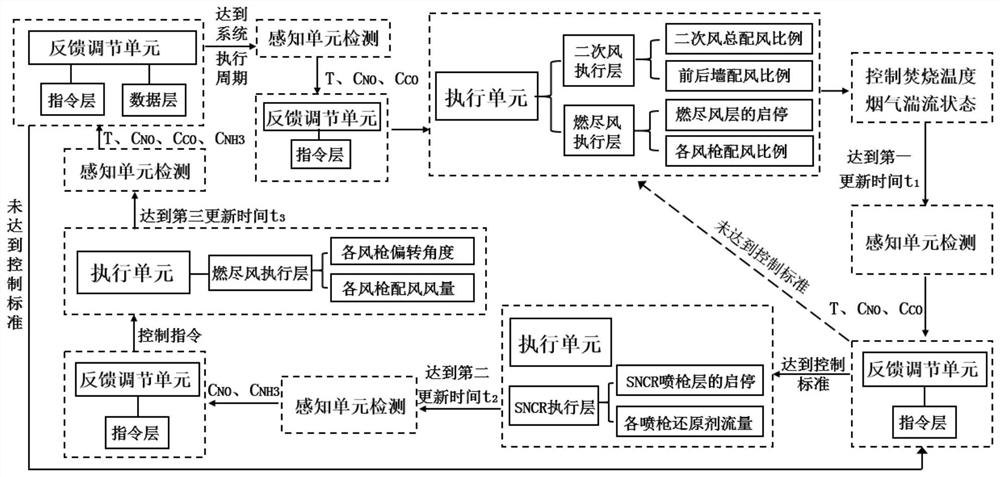

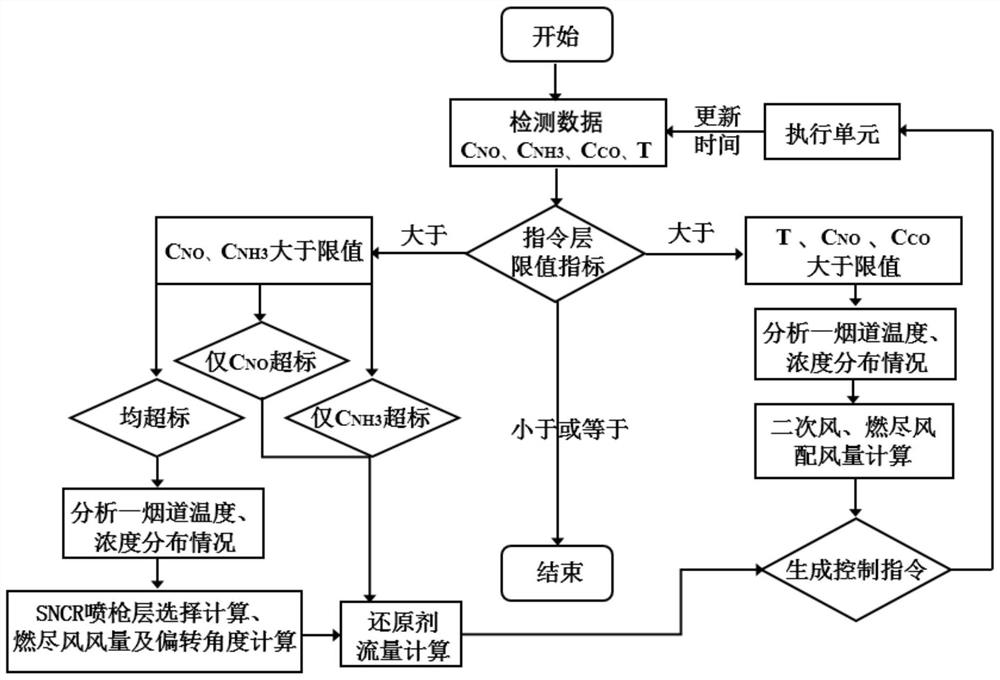

PendingCN112728544AReduce generationImprove denitrification efficiencyGas treatmentDispersed particle separationThermodynamicsControl system

The invention provides a control system and method for flue dynamic air distribution cooperating with SNCR denitration. The control system is composed of a sensing unit, an executing unit and a feedback adjusting unit, wherein the sensing unit comprises a temperature, NO concentration, CO concentration and NH3 concentration detection module, the execution unit comprises a secondary air execution layer, an over fire air execution layer and an SNCR execution layer, and the feedback adjustment unit comprises an instruction layer and a data layer. The control method comprises: detecting the parameters by the sensing unit; analyzing the data and generating a control instruction through the feedback adjustment unit, and storing detection parameters and the control instruction; and dynamically regulating and controlling the air distribution state and the reducing agent injection state through the execution unit. The control system and the control method have a feedback regulation function to realize dynamic regulation and control of combustion and denitration and self-correction of the system, and can be widely applied to the technical field of low-nitrogen combustion and SNCR denitration.

Owner:SOUTH CHINA UNIV OF TECH

Liquid phase reaction vessel with uniform reaction function

InactiveCN105617967AUniform temperatureGuaranteed uniformityTransportation and packagingRotary stirring mixersChemistryLiquid phase

The invention relates to a liquid phase reaction vessel with a uniform reaction function. The volume of a tank body can be very large, the temperature of a liquid phase is adjusted by an external heating device outside the tank body, the liquid phase is mechanically stirred through a stirring device, an internal heating device is used for internal heating, inert gas is introduced to enhance stirring, and the temperature of the liquid phase is reduced when too high. The temperature of the liquid phase in the liquid phase reaction vessel can be kept constant by reasonably controlling heating power of the external heating device and the internal heating device and the introducing amount of the inert gas. The liquid phase reaction vessel is suitable for large-scale production, and enables substance components and temperature of the internal liquid phase to be uniform.

Owner:周跃

External coil heating reactor for resin production

ActiveCN104984716BIncrease reaction spaceStrong stirringChemical/physical/physico-chemical stationary reactorsEngineeringOuter coil

The invention discloses an external coil type heating reaction kettle for resin production, comprising a kettle body, a kettle cover and a power mechanism, the power mechanism is located on the kettle cover, and the power mechanism includes a motor, a speed reducer from top to bottom machine, a frame and a stirring shaft located inside the kettle body, an outer coil is arranged around the periphery of the kettle body, at least one cage stirrer is arranged on the stirring shaft, and at the lowest end of the stirring shaft At least one tooth-type agitator is provided; the reaction kettle disclosed by the invention has good stirring effect, high reaction efficiency, complete reaction, and heating peripheral equipment, which saves internal reaction space and is convenient for maintenance.

Owner:JIANGSU JIANYA ENVIRONMENTAL PROTECTION TECH CO LTD

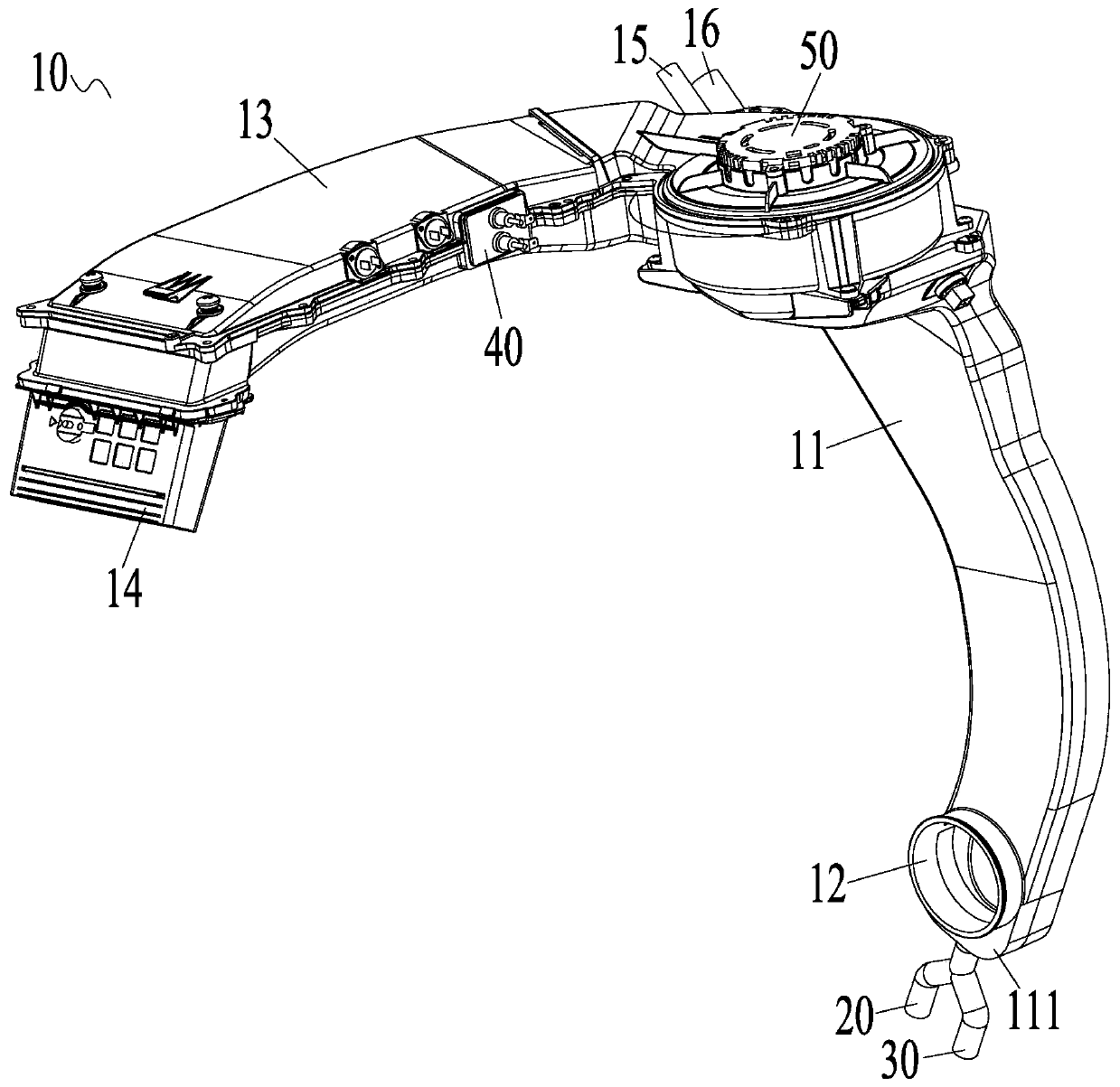

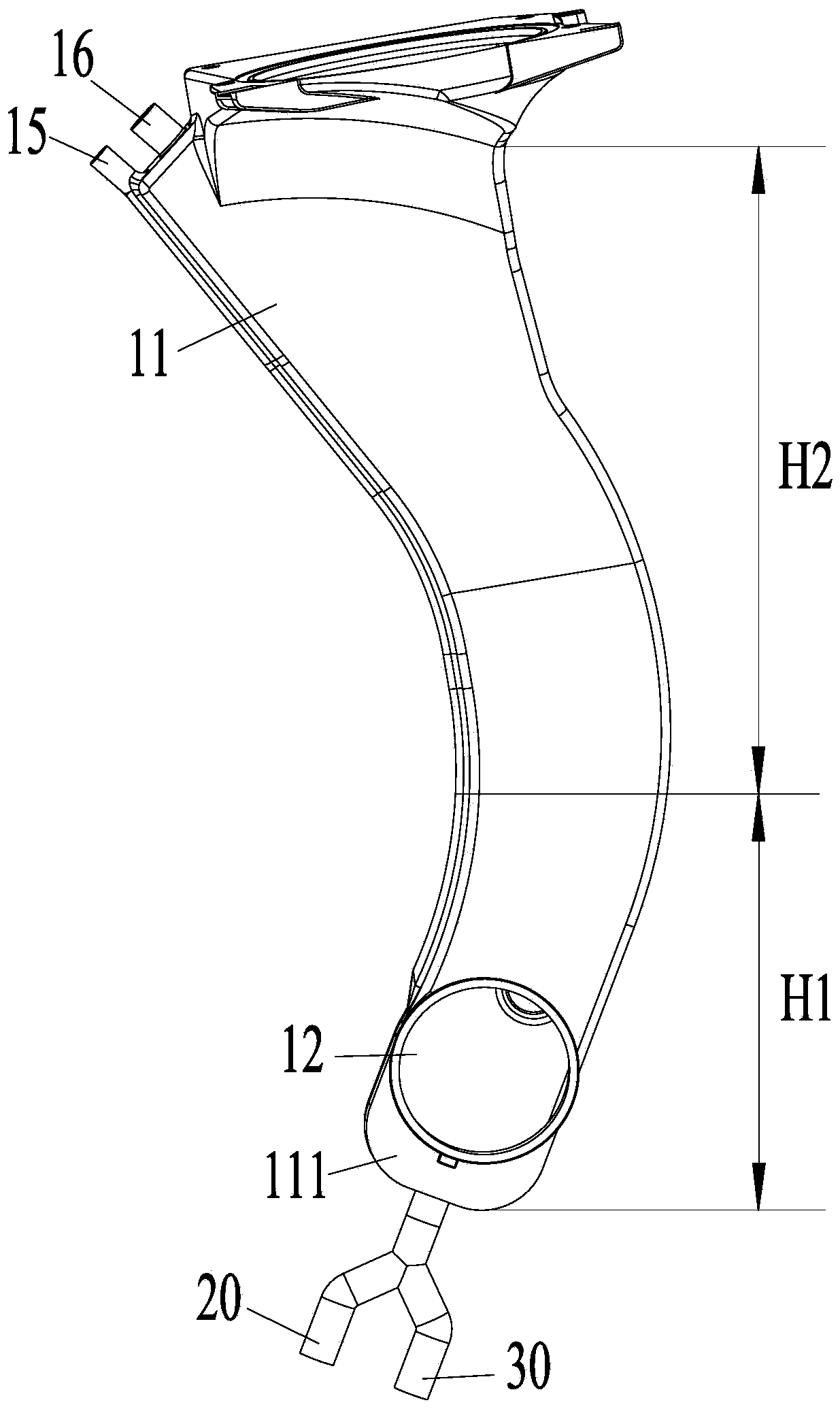

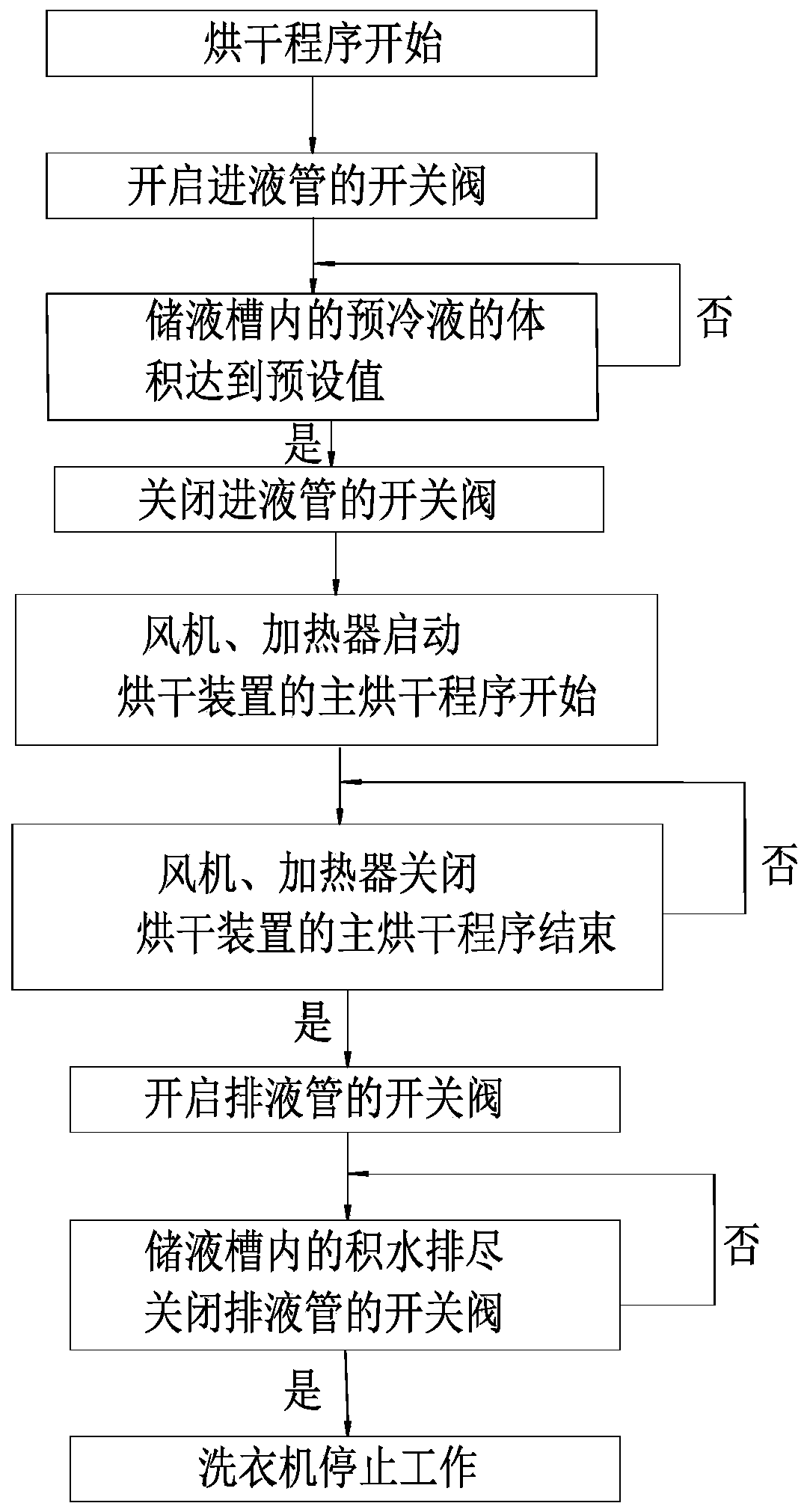

Drying device and washing machine with same

PendingCN110747597AImprove performanceGuaranteed practicalityWashing machine with receptaclesTextiles and paperThermodynamicsLaundry washing machine

The invention provides a drying device and a washing machine with the same, wherein the drying device comprises an air duct structure, and the air duct structure is provided with a condensation chamber and a humid hot air inlet communicated with the condensation chamber; a liquid storage cavity is also formed in the condensation chamber of the air duct structure, is positioned at the position of the humid hot air inlet, and is used for storing a pre-cooling liquid to be preliminarily mixed with humid hot air entering the condensation chamber from the humid hot air inlet. The invention solves the problems that the structure of the drying device in the prior art is unreasonable, drying effect of a drum of the washing machine for clothes is poor, and the performance of the washing machine isdecreased.

Owner:GREE ELECTRIC APPLIANCES INC

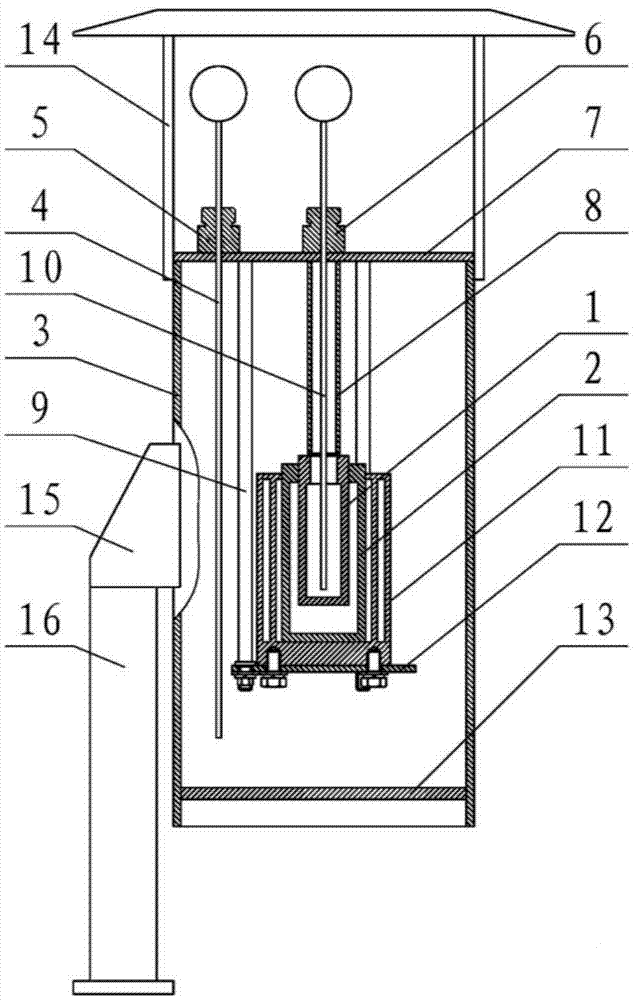

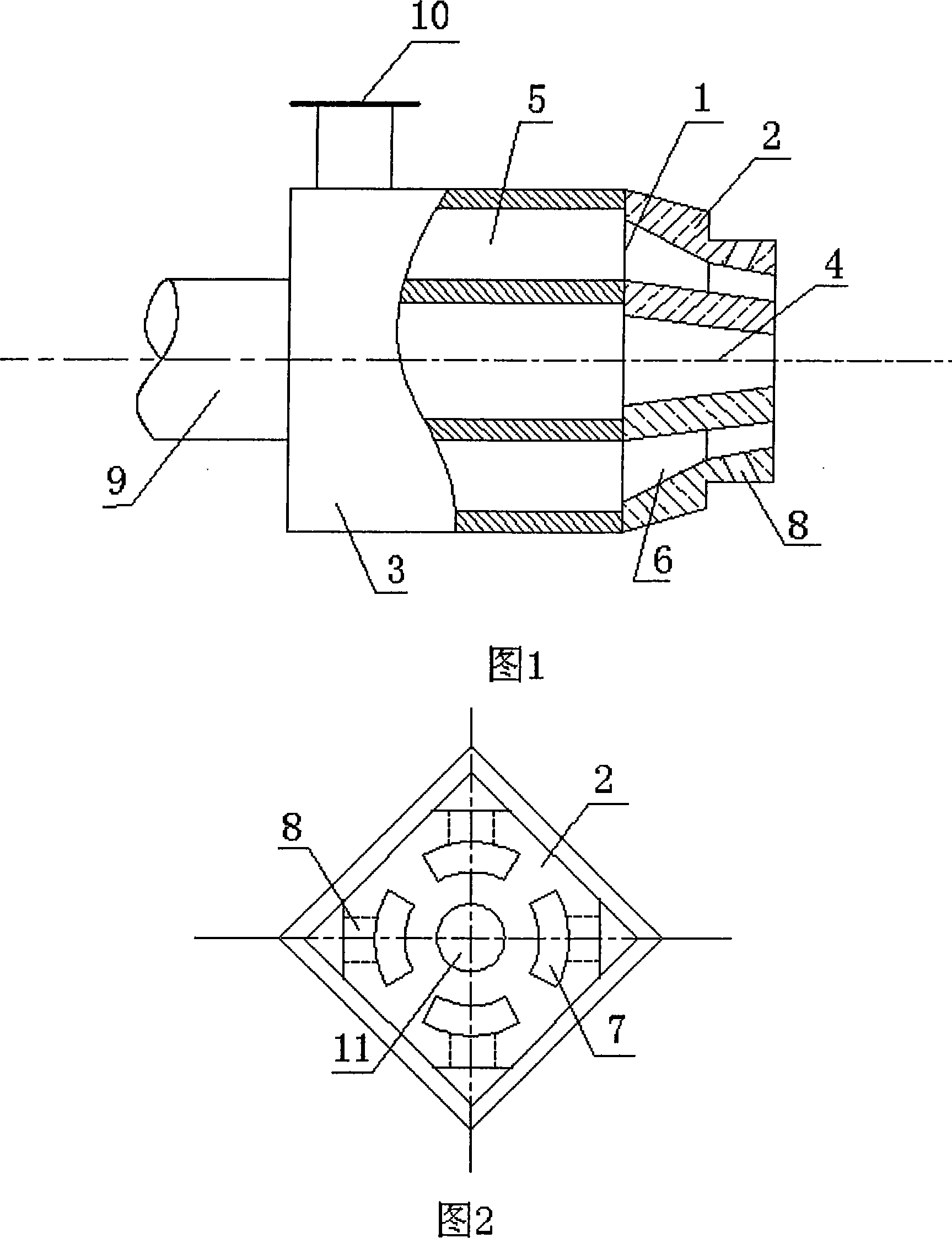

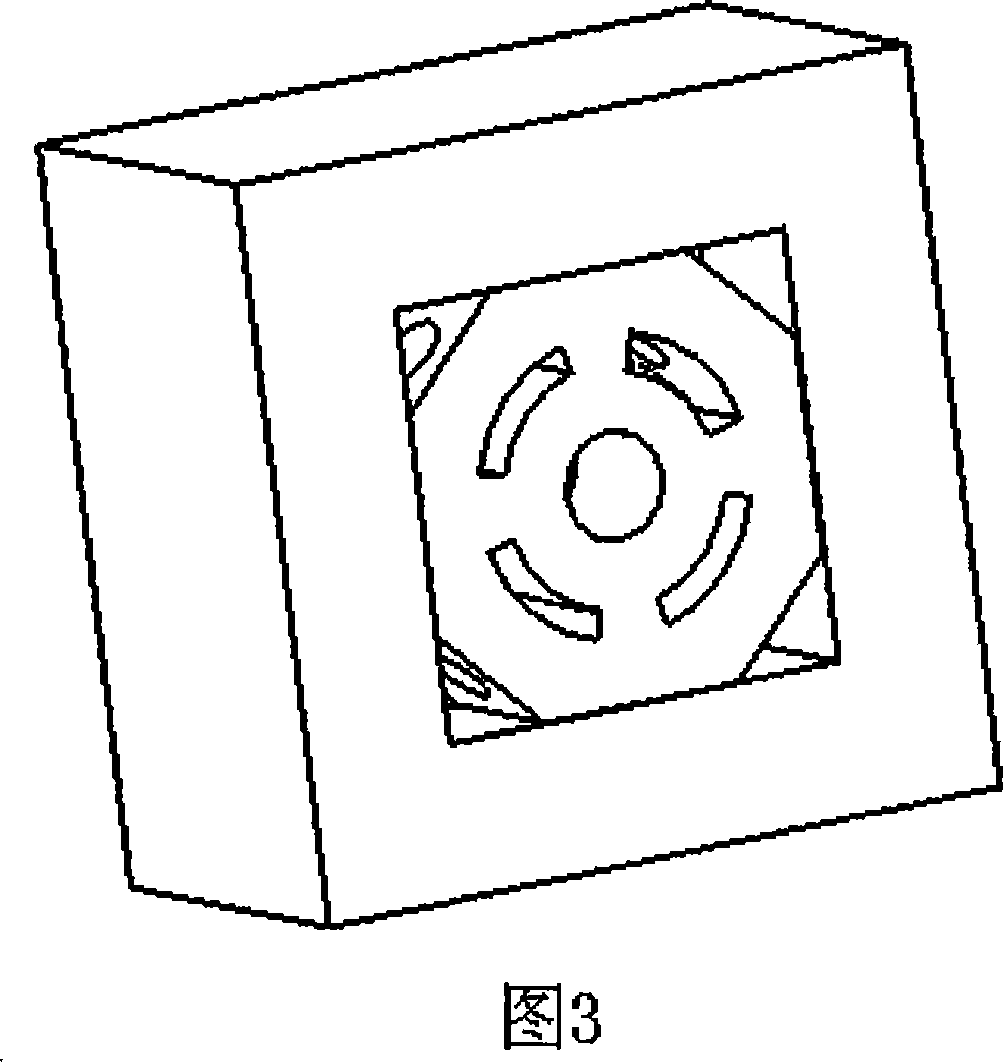

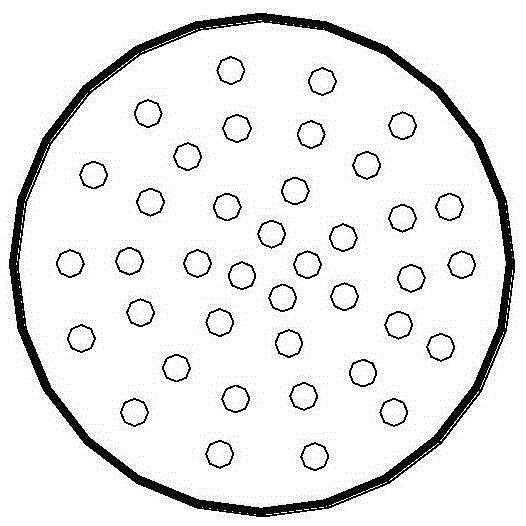

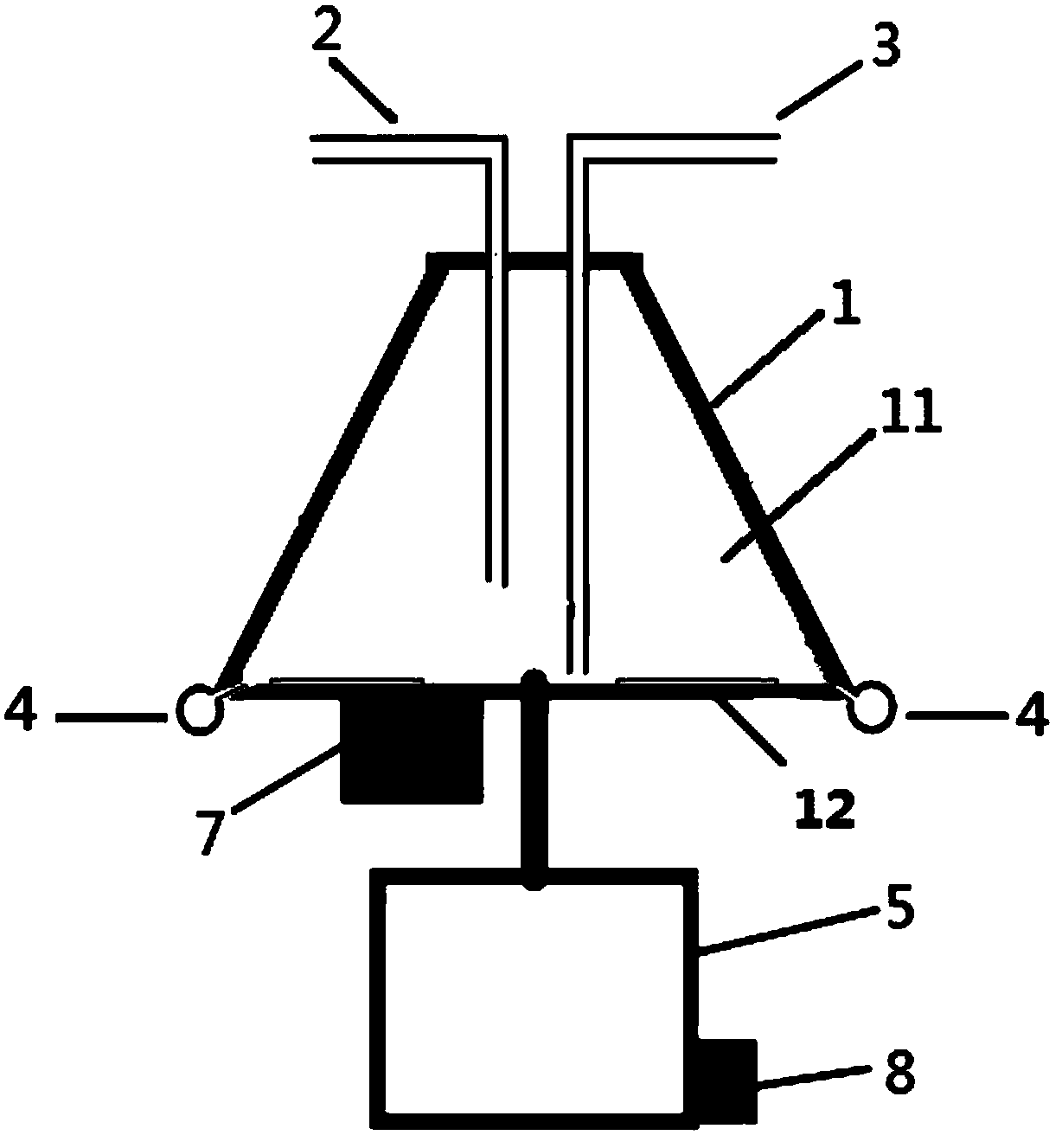

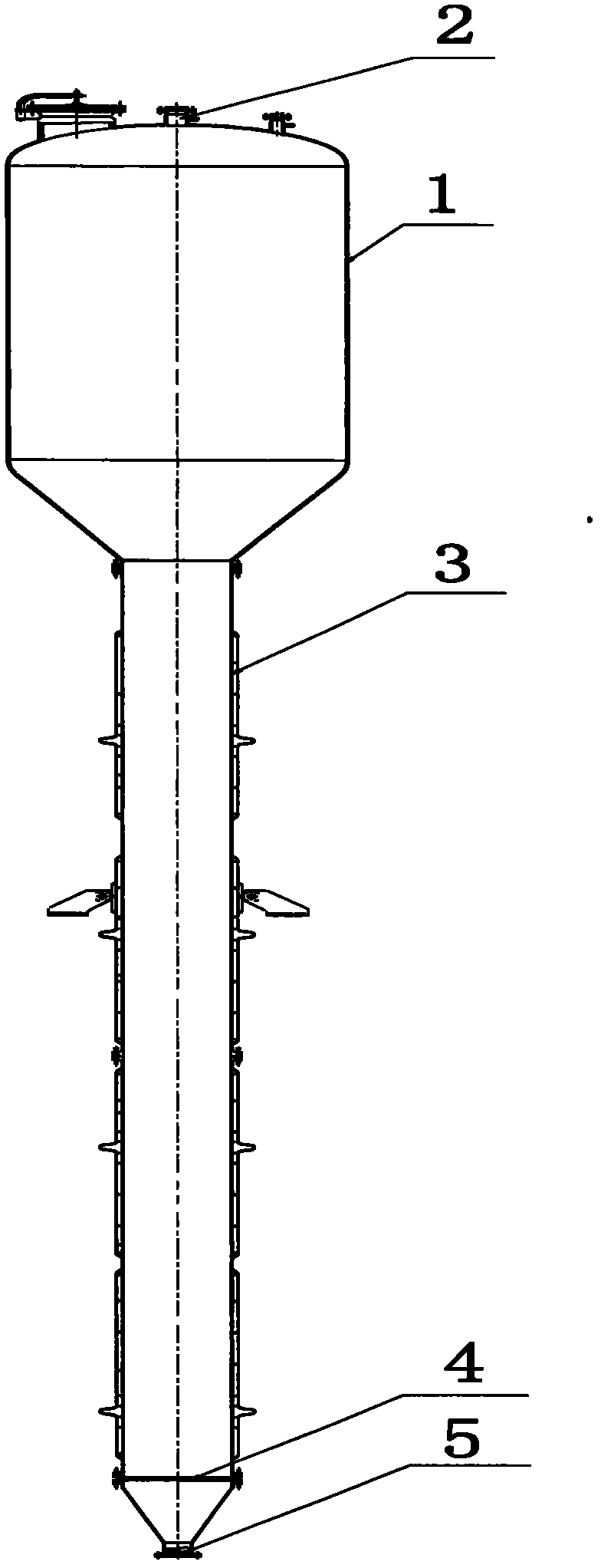

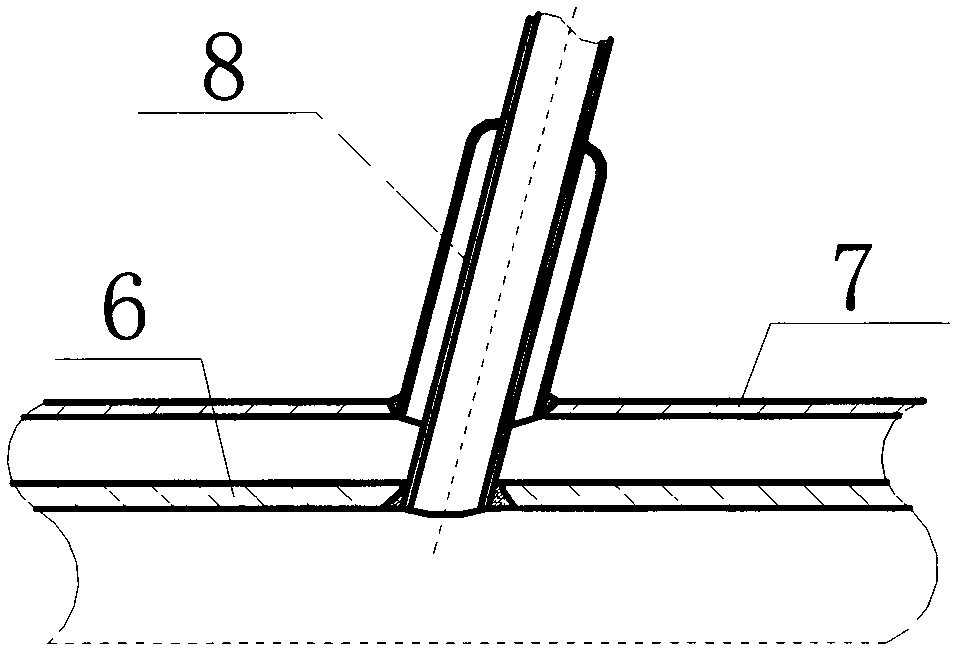

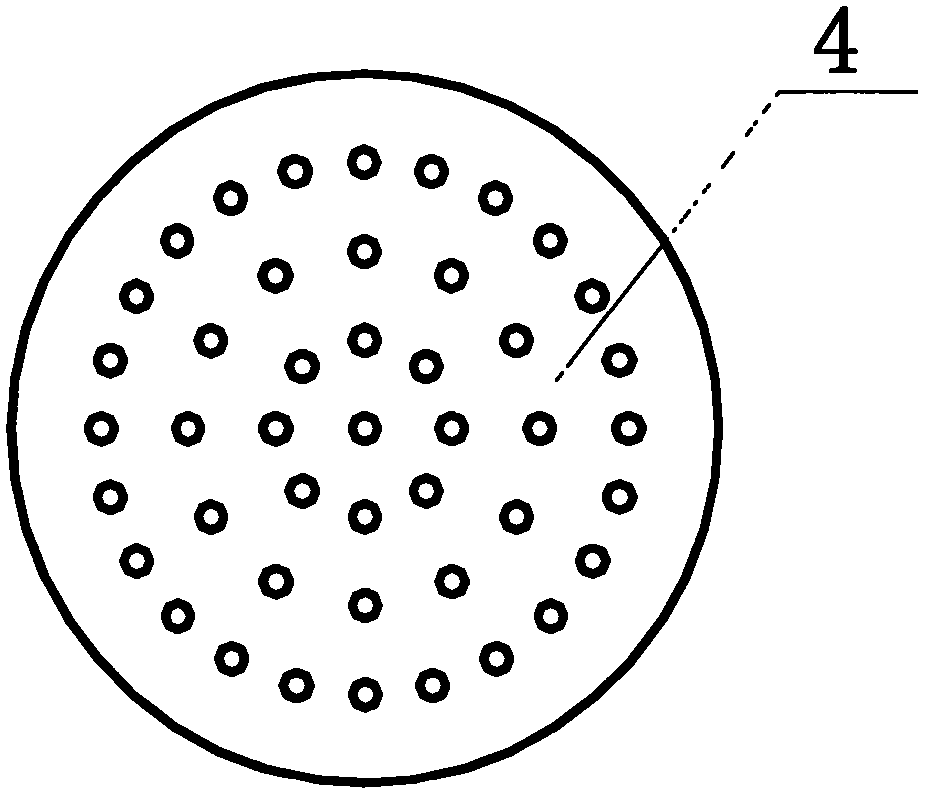

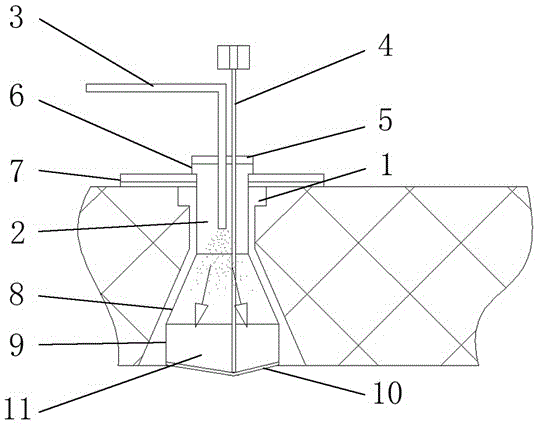

Trichlorosilane reactor

The invention provides a trichlorosilane reactor, overcoming the disadvantages that in the prior art, cost is over high, burning loss failure is easy to occur, and production efficiency is low. The trichlorosilane reactor comprises a main shell 1, a silicon powder inlet 2 and an air inlet 5, wherein the main shell 1 is made of a 15CrMoR carbon steel material; the silicon powder inlet 2 is located on the top of the main shell 1; a water jacket structure 3 is additionally arranged on the outer surface of the main shell 1; an air distributor 4 is added and located above the air inlet 5; and the water jacket structure 3 is formed by welding and sealing of a jacket cylinder body 7, an inner cylinder body 6 and a nozzle 8. Through arrangement of the structure, equipment cost is greatly reduced, production efficiency is improved, the use safety of the equipment is ensured, and the service life of the equipment is prolonged.

Owner:兰州兰石四方容器设备有限责任公司

Biomass granular fuel gasification carbon-making device

PendingCN111978968ARealize real-time monitoringIncrease reaction spaceSpecial form destructive distillationCombustion chamberCarbon storage

The invention provides a biomass granular fuel gasification carbon-making device. The biomass granular fuel gasification carbon-making device comprises a feeding system, a combustion system, an air supply system, an ignition system, a spraying system, a carbon storage system, a cooling system and a control system. The combustion system comprises a combustion chamber communicating with the feedingsystem, a combustion auger, a limiting flow guide cover plate and a motor; the air supply system comprises air blowers communicating with the bottom and the middle of the combustion chamber through air pipes respectively and an air compressor communicating with two stages of air pipes, the two stages of air pipes are connected in parallel and then communicate with an air collecting hood fixed to the top of the combustion chamber, and a primary air loop and a secondary air loop are formed by the two stages of air pipes and the combustion chamber. The carbon storage system comprises an upper coke channel, a middle coke channel, a lower coke channel and a bottom carbon storage chamber which sequentially communicate with one another. The water flow direction of cooling water in the cooling system is opposite to the sliding direction of coke. A structure of feeding from bottom and carbon discharging from top is adopted, the strong reducibility of a high-temperature carbon layer is used forreducing the emission of nitrogen oxides, and diversified gas distribution and control measures can adapt to different types of biomass granular fuels.

Owner:TSINGHUA UNIV

Desulfurization waste liquid pyrolyzer with protective device

InactiveCN106675585AImprove conversion rateAffect qualityEnergy inputWaste water treatment from gaseous effluentsLiquid wasteCoal gas

The invention discloses a desulfurization waste liquid pyrolyzer with a protective device. The desulfurization waste liquid pyrolyzer comprises a coking chamber coal charging hole, the protective device, a desulfurization waste liquid injector and a desulfurization waste liquid pyrolysis channel. The desulfurization waste liquid injector is fixed in the coking chamber coal charging hole through the protective device. Through the desulfurization waste liquid pyrolysis channel, the desulfurization waste liquid is pyrolyzed in a coking chamber. According to the device, the desulfurization waste liquid is fully pyrolyzed by waste heat of raw coke oven gas at the top of the coking chamber, and the desulfurization waste injector is protected so that damage caused by the desulfurization waste liquid dropped in coke in the coking chamber or sprayed to the wall of the coking chamber is avoided.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com