Manganese-cobalt spinel catalyst and preparation method thereof

A spinel and catalyst technology, applied in the field of manganese-cobalt spinel catalyst and its preparation, can solve the problems of difficult reaction mechanism of manganese oxide, limit the application of manganese oxide, unstable catalytic performance, etc., and achieve good industrial value, Improve the oxygen reduction catalytic performance and conductivity, and realize the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

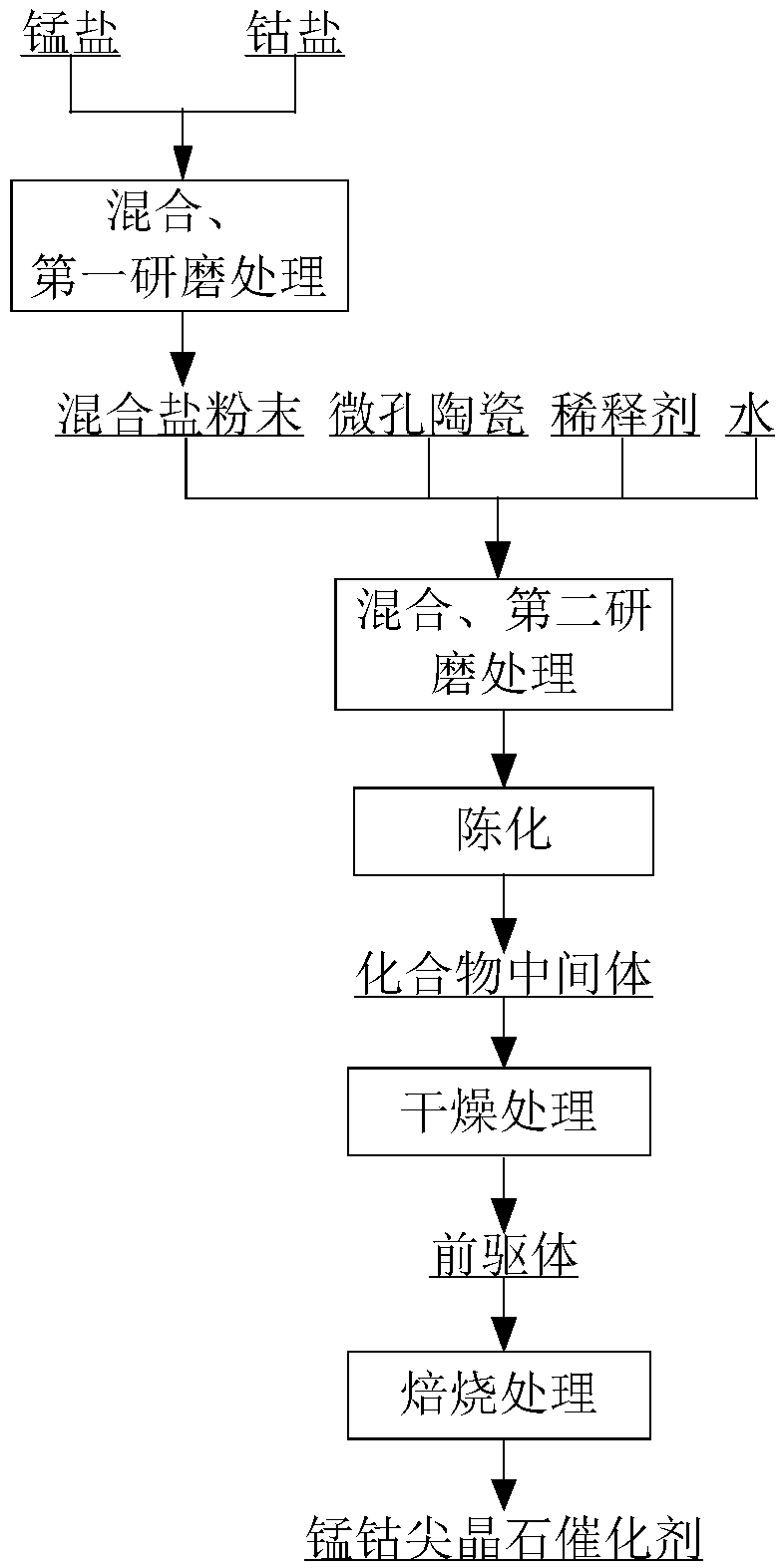

[0053] (1) At room temperature, manganese salt and cobalt salt are mixed and subjected to the first grinding treatment to obtain mixed salt powder. Wherein, the manganese salt is manganese sulfate, the cobalt salt is cobalt sulfate, and the molar ratio of manganese ions in the manganese salt to cobalt ions in the cobalt salt is 2:1.

[0054] (2) The mixed salt powder and microporous ceramics (ZrO 2 -Al 2 o 3 -SiO 2 ), the diluent (glucose) and water are mixed for the second grinding treatment, and when the mixed solution changes from thin to thick, it is aged to obtain a compound intermediate. Among them, the molar ratio of the microporous ceramics to the sum of manganese ions and cobalt ions in the mixed salt powder is 2:1, the diluent is 10% of the mass sum of manganese ions and cobalt ions in the mixed salt powder, and the aging is carried out at 60°C for 12h Finish.

[0055] (3) Perform drying treatment on the compound intermediate to obtain a precursor, and the dryin...

Embodiment 2

[0058] (1) At room temperature, manganese salt and cobalt salt are mixed and subjected to the first grinding treatment to obtain mixed salt powder. Wherein, the manganese salt is manganese chloride, the cobalt salt is cobalt chloride, and the molar ratio of manganese ions in the manganese salt to cobalt ions in the cobalt salt is 2:1.

[0059] (2) The mixed salt powder and microporous ceramics (ZrO 2 -ZnO-SiO 2 ), the diluent (polyvinyl alcohol) and water are mixed for the second grinding treatment, and when the mixed solution changes from thin to thick, it is aged to obtain a compound intermediate. Among them, the molar ratio of the microporous ceramics to the sum of manganese ions and cobalt ions in the mixed salt powder is 2:1, the diluent is 12% of the mass sum of manganese ions and cobalt ions in the mixed salt powder, and the aging is carried out at 70°C for 10h Finish.

[0060](3) Perform drying treatment on the compound intermediate to obtain a precursor, and the dr...

Embodiment 3

[0063] (1) At room temperature, manganese salt and cobalt salt are mixed and subjected to the first grinding treatment to obtain mixed salt powder. Wherein, the manganese salt is manganese oxalate, the cobalt salt is cobalt oxalate, and the molar ratio of manganese ions in the manganese salt to cobalt ions in the cobalt salt is 2:1.

[0064] (2) The mixed salt powder and microporous ceramics (ZrO 2 -Al 2 o 3 -TiO 2 ), the diluent (citric acid) and water are mixed for the second grinding treatment, and when the mixed solution changes from thin to thick, it is aged to obtain the compound intermediate. Among them, the molar ratio of the microporous ceramics to the sum of manganese ions and cobalt ions in the mixed salt powder is 2:1, the diluent is 18% of the mass sum of manganese ions and cobalt ions in the mixed salt powder, and the aging is carried out at 50°C for 12h Finish.

[0065] (3) Perform drying treatment on the compound intermediate to obtain a precursor, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com