Patents

Literature

1339 results about "Cobalt chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plant nutrient liquid fertilizer

InactiveCN102701861AImprove stress resistanceSolve the problem of lack of nutrientsFertilizer mixturesSucrosePhosphate

The invention relates to a plant nutrient liquid fertilizer. In order to solve the problem of over fertilization, the plant nutrient liquid fertilizer is prepared from the following raw materials in proportion by weight: aqua brassin 12-36, gibberellin 1-4, indoleacetic acid 30-80, abscisic acid 10-20, naphthaleneacetic acid 50-90, salicylic acid 80-180, vitamin C 1-3, cane sugar 40-100, chitin 20-80, 0.05-0.2 percent triacontanol 400-1,000, hydrolyzed protein 2-5, potassium dihydrogen phosphate 300-400, thiourea 40-120, cobalt chloride 5-12, borax 50-100, sodium silicate 30-55, urea 300-500, ammonium molybdate 50-80, copper sulfate 30-65, zinc sulfate 120-200, magnesium sulfate 100-150, calcium chloride 50-120, manganese sulfate 40-80 and water in the amount of 3-8 times the total amount of all the raw materials or water in the amount capable of dissolving all the raw materials, wherein the water is de-ionized water or micro cluster water; and the preparation method is that all the materials are prepared into aqueous solution. The plant nutrient liquid fertilizer has the advantages of favorably solving the problems of over fertilization and shortage of nutrient elements in soil, obviously improving the plant adverse resistance, improving the photosynthesis and the accumulation efficiency of nutritive materials and improving the yield and the quality.

Owner:魏玉芳

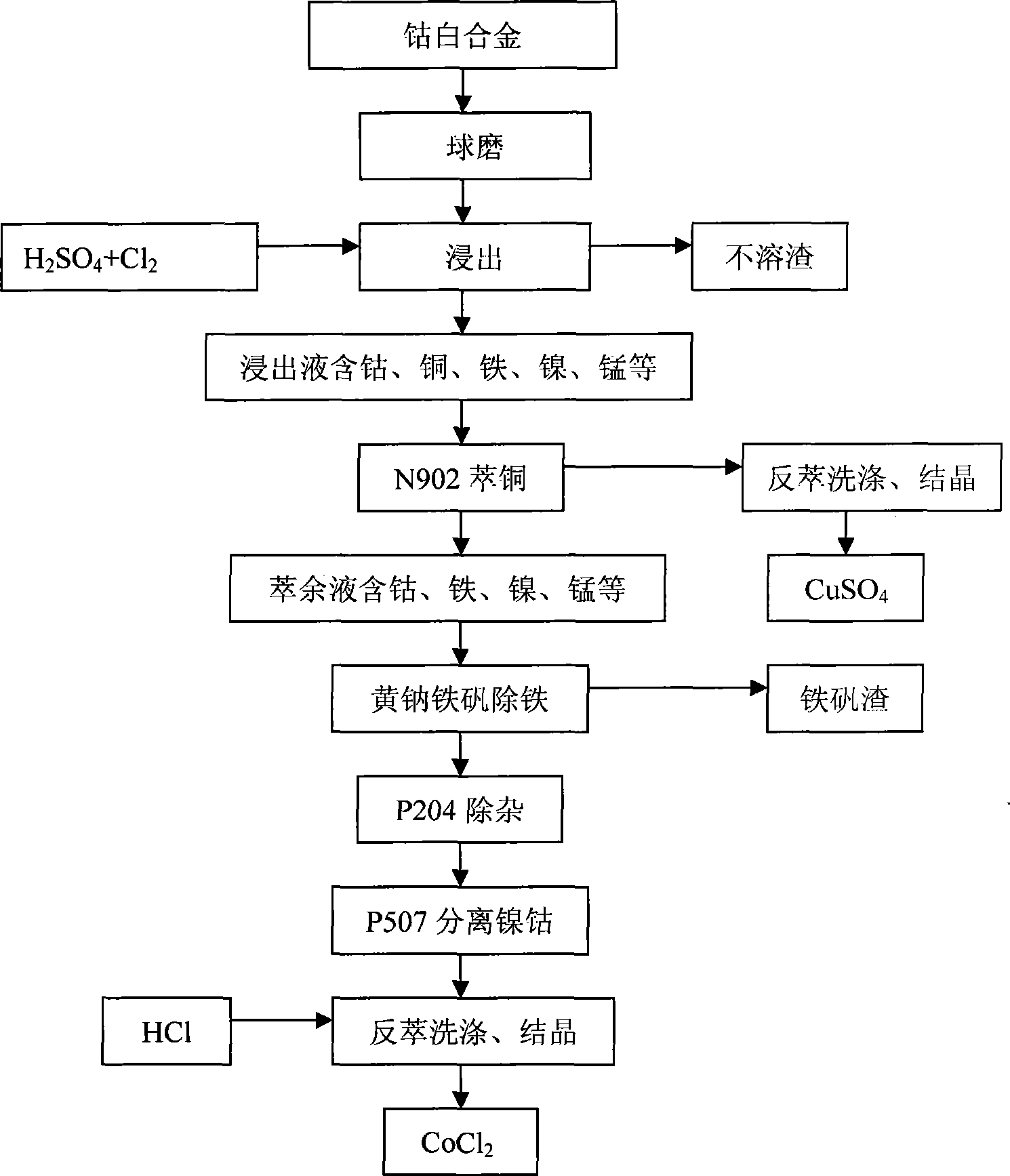

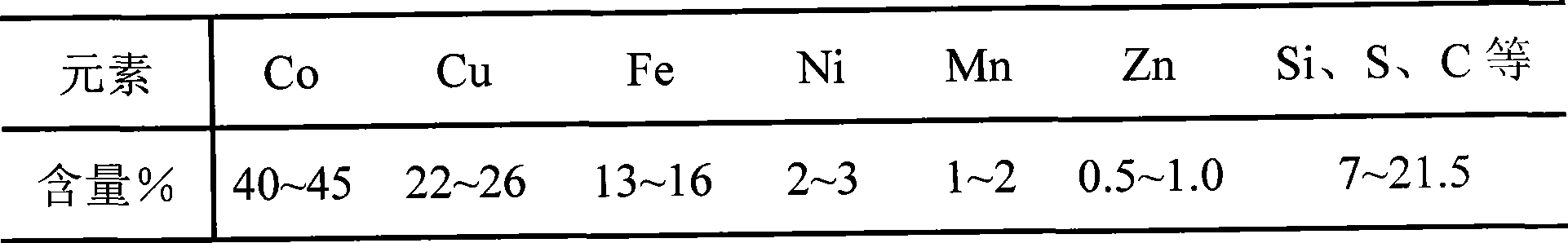

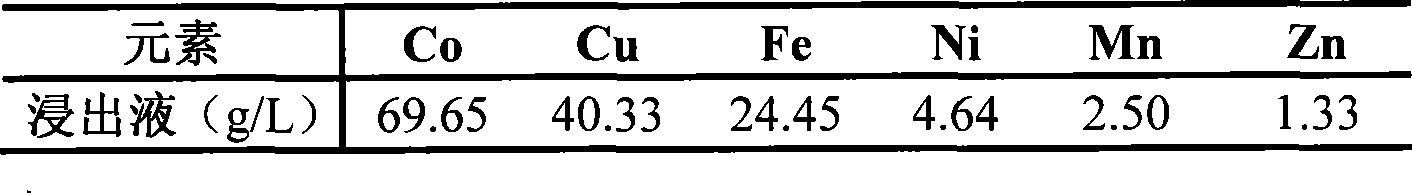

Method for recycling valuable metal from cobalt white alloy

ActiveCN101463427AHigh recovery rateReduce energy consumptionProcess efficiency improvementNational standardAlloy

The invention discloses a method for recovering valuable metals from cobalt white alloy. The method comprises the following main steps: after the cobalt white alloy undergoes ball milling, chlorine and sulphuric acid solution are used for leaching; lixivium adopts N902 to extract copper, and bluestone is prepared after a copper-containing organic phase undergoes back extraction; extraction raffinate undergoes iron elimination by means of using amarillite, extraction and edulcoration by means of using P204, and then the separation of nickel and cobalt by means of using the N902; and cobalt chloride is prepared after a cobalt-containing organic phase undergoes back extraction. The method has simple process and high copper and cobalt recovery rate, the obtained bluestone satisfies quality product requirements of the national standard GB437-93, and the obtained cobalt chloride satisfies feed-grade requirements of the national standard GB437-93.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Gold complex catalyst for hydrochlorinating acetylene

ActiveCN102631947AImprove stabilityHigh activityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsGold contentPotassium

The invention discloses a gold complex catalyst, and particularly relates to a non-mercury catalyst which is applicable to synthesizing vinyl chloride by acetylene hydrochlorination, and a preparation method of the non-mercury catalyst. The non-mercury catalyst comprises potassium aurate tetra-thiocyanate taken as a main active component, one or a combination of more than two of potassium chloride, copper chloride, cobalt chloride and zinc chloride taken as auxiliary active components, and carrier activated carbon, wherein gold complex accounts for 0.1-2.5% of the weight of the catalyst, and the auxiliary active components account for 0.05-15% of the total weight of the catalyst. According to the gold complex catalyst prepared by the invention, the gold content is lower, so that the cost of noble metal catalyst can be remarkably reduced; and the novel non-mercury catalyst is good in activity, high in stability and strong in selectivity. The gold complex catalyst has the advantages of being simple in production technology, short in production cycle and environment-friendly.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD +1

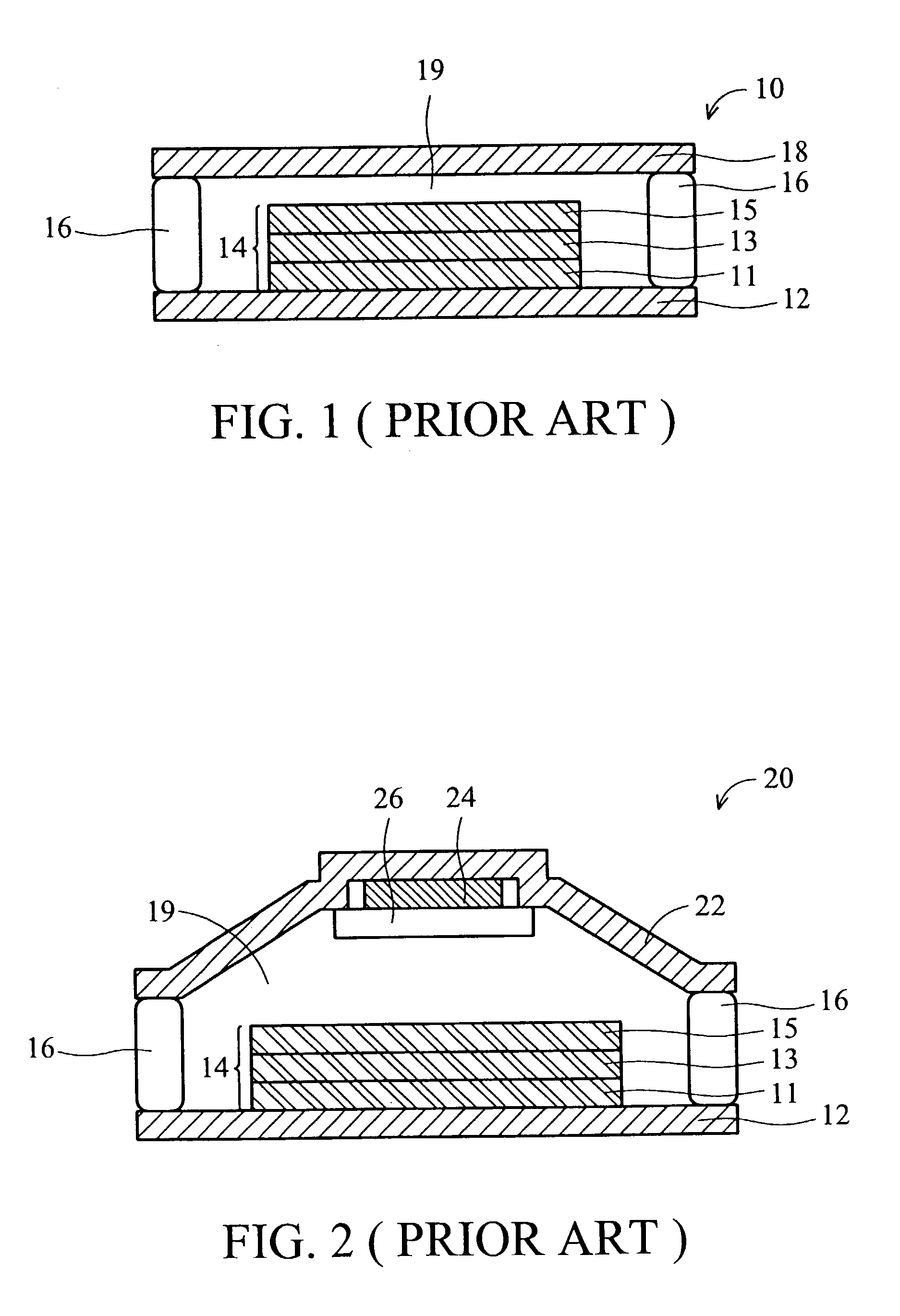

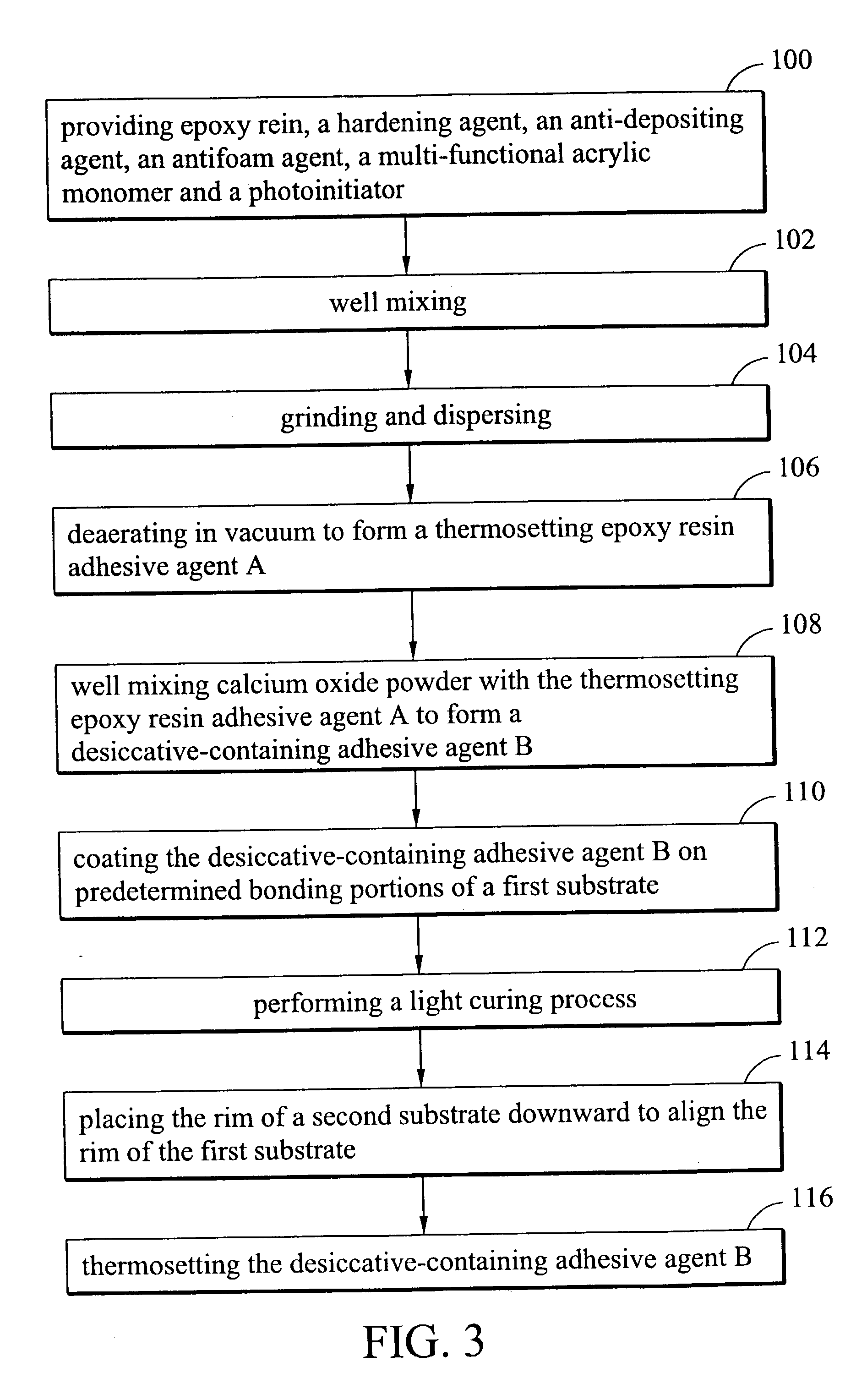

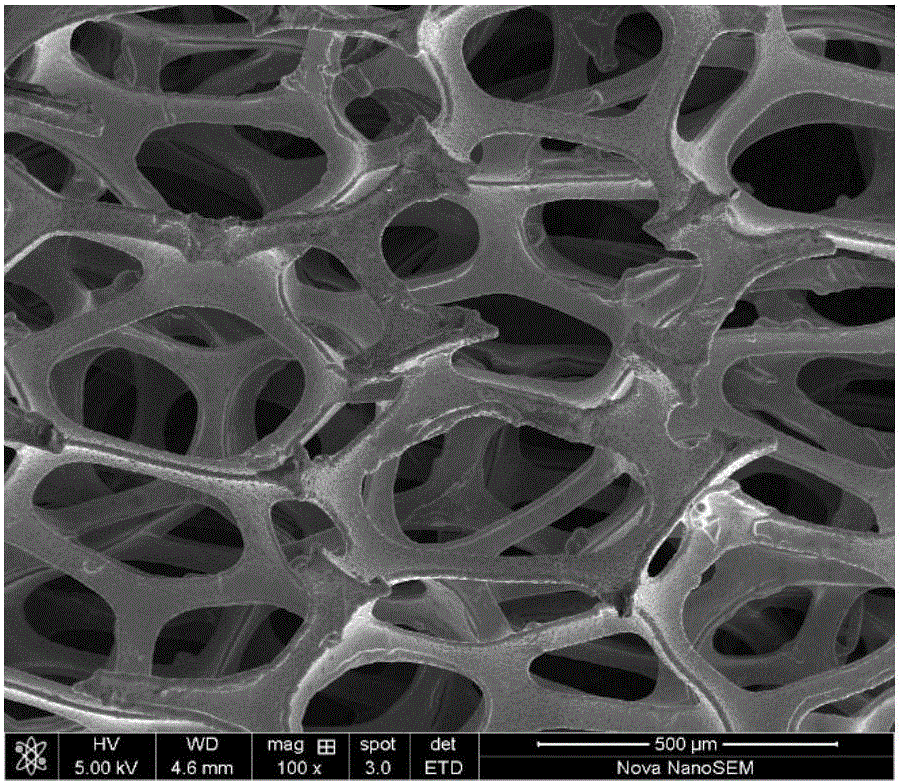

Packaging material used for a display device and method of forming thereof

InactiveUS20040084686A1Non-macromolecular adhesive additivesSemiconductor/solid-state device detailsZinc bromideAlkaline earth metal

A packaging material used for a display device which is a desiccative-containing adhesive agent. The desiccative-containing adhesive agent is composed of a liquid-state organic material selected from a group including epoxy resin, polyurethane, bakelite, polyamide, acrylic resin and polysiloxane, and a solid-state desiccative selected from a group including alkaline metal oxide, alkaline-earth metal oxide, metallic halide, barium oxide, calcium oxide, calcium sulfate, calcium chloride, lithium chloride, calcium bromide, potassium Carbonate, aluminum oxide, magnesium oxide, copper sulfate, zinc chloride, zinc bromide, cobalt chloride, silica gel, zeolite and molecular sieve.

Owner:DELTA OPTOELECTRONICS +1

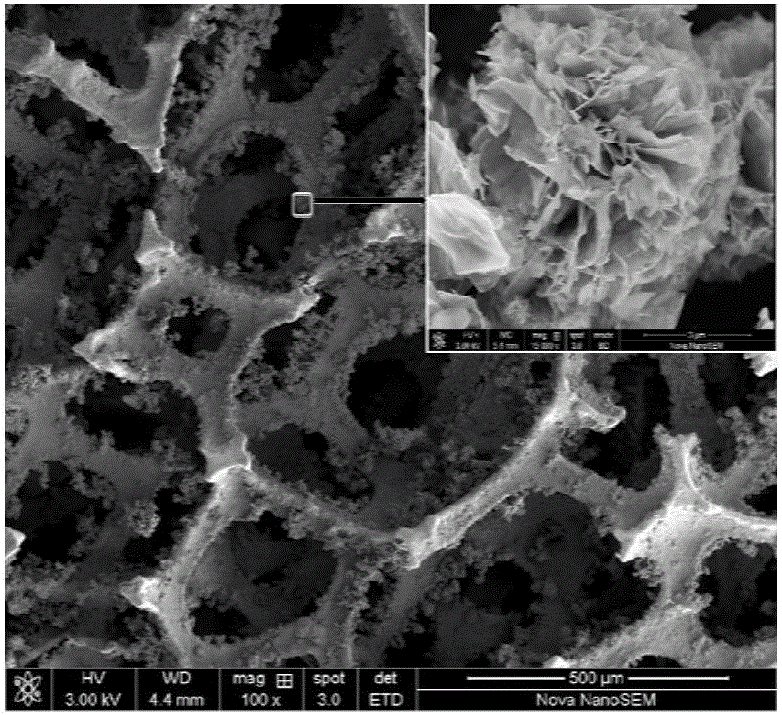

Foamed nickel composite material, and preparation method and application thereof

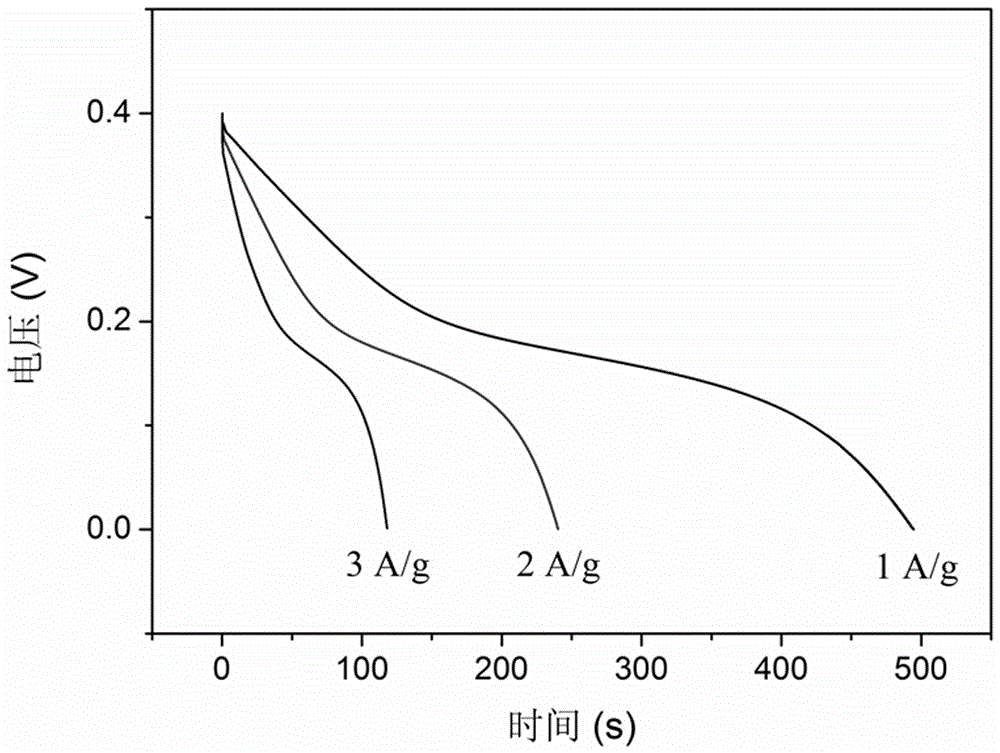

InactiveCN105070515AThe method route is simpleImprove cycle stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceSolvent

The invention relates to a preparation method of a foamed nickel composite material. The method comprises the following steps that oxidized graphene and a surfactant are added to a water and methanol mixed solution, and ultrasonic processing is carried out to obtain a oxidized graphene solution; nickel nitrate and cobalt chloride are added into the oxidized graphene solution and stirred and mixed to form a uniform suspension; and the uniform suspension is poured into a hydro-thermal reactor kettle, foamed nickel is immersed into the suspension, solvothermal reaction is carried out at 100-200 DEG C, the oxidized graphene is changed to graphene by reduction while nickel and cobalt hydroxide is generated at the surface of the foamed nickel in situ, and thus, the foamed nickel composite material whose surface is covered with a graphene and nickel-cobalt hydrotalcite like layer is obtained. The invention also relates to the obtained foamed nickel composite material and application thereof. The preparation method is simple, easy to control and low in cost, and the obtained foamed nickel composite material which serves as electrode material of a super capacitor has higher specific capacitance and high cycle stability.

Owner:EAST CHINA UNIV OF SCI & TECH

Aqueous culture method of anoectochilus

InactiveCN102100171AAbsorb evenlyAdequately meet nutritional needsCultivating equipmentsSoilless cultivationBiotechnologyCalcium nitrate tetrahydrate

The invention relates to an aqueous culture method of anoectochilus. In the method, anoectochilus germchits are cleaned and sterilized, transplanted in a culture dish and cultured in a culture groove filled with an aqueous culture solution; each 10L of aqueous culture solution contains the following components: 650 to 800mg of calcium nitrate tetrahydrate, 50 to 60mg of ammonium nitrate, 280 to 350mg of potassium nitrate, 100 to 130mg of potassium dihydrogen phosphate, 350 to 380mg of magnesium sulfate, 0.5 to 0.8mg of potassium iodide, 2 to 5mg of manganese sulfate, 0.2 to 0.3mg of sodium molybdate, 0.1 to 0.2mg of cobalt chloride, 2 to 4mg of boric acid, 0.5 to 1mg of zinc sulfate, 0.3 to 0.5mg of copper sulfate and 3 to 5ml of iron salt solution, wherein the iron salt solution is prepared by mixing water, green vitriol and ethylenediamine tetraacetic acid disodium. The method has the advantages of lowering production cost, simplifying production process, improving the growth of anoectochilus plants and improving the survival rate of anoectochilus plants.

Owner:福建永安天奇健金线莲生态实业有限公司

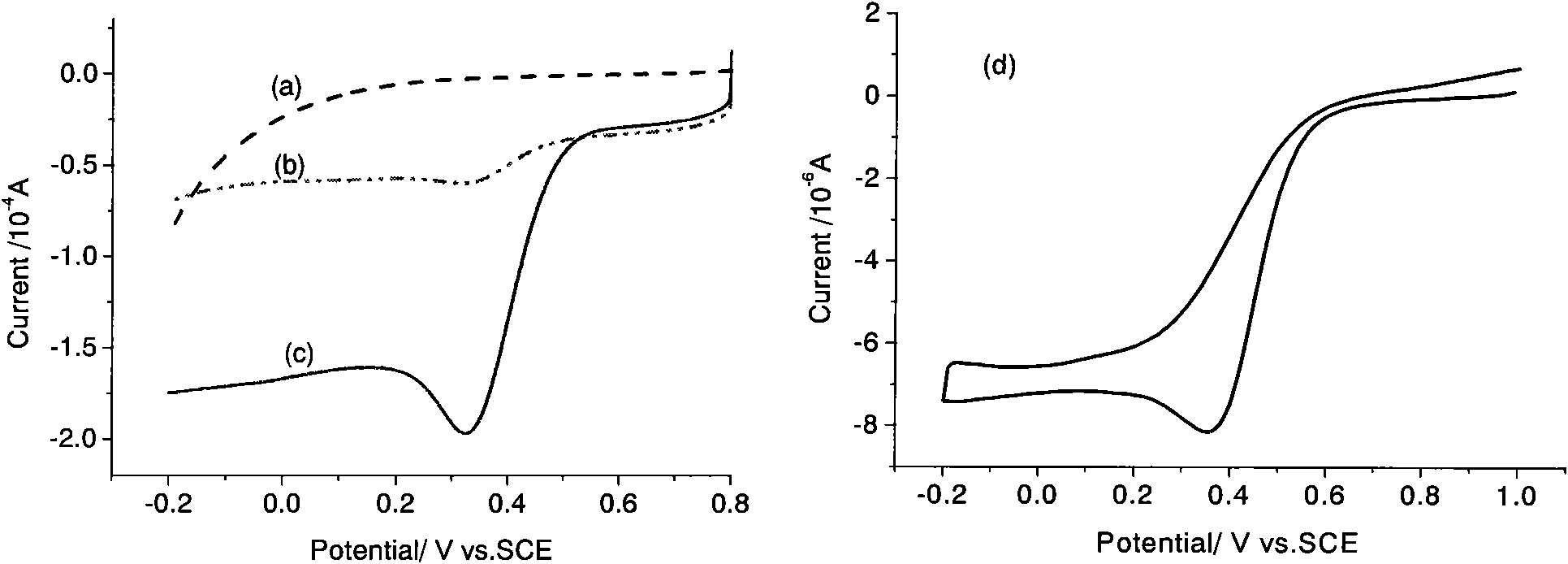

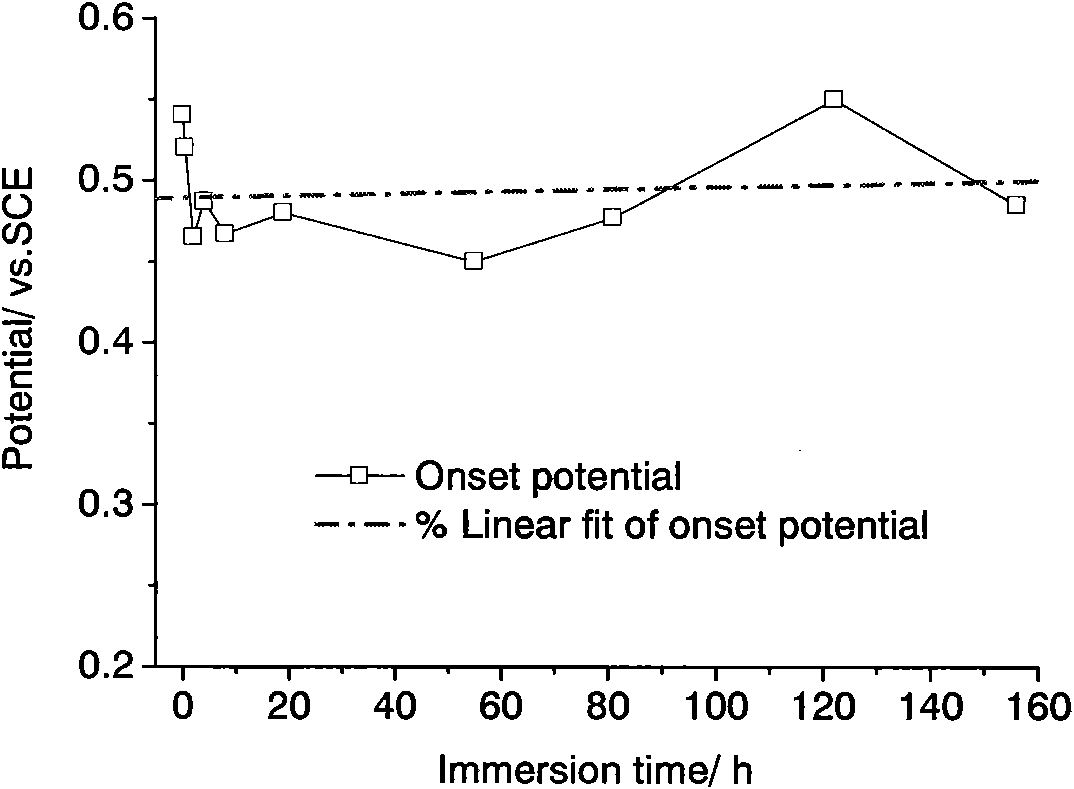

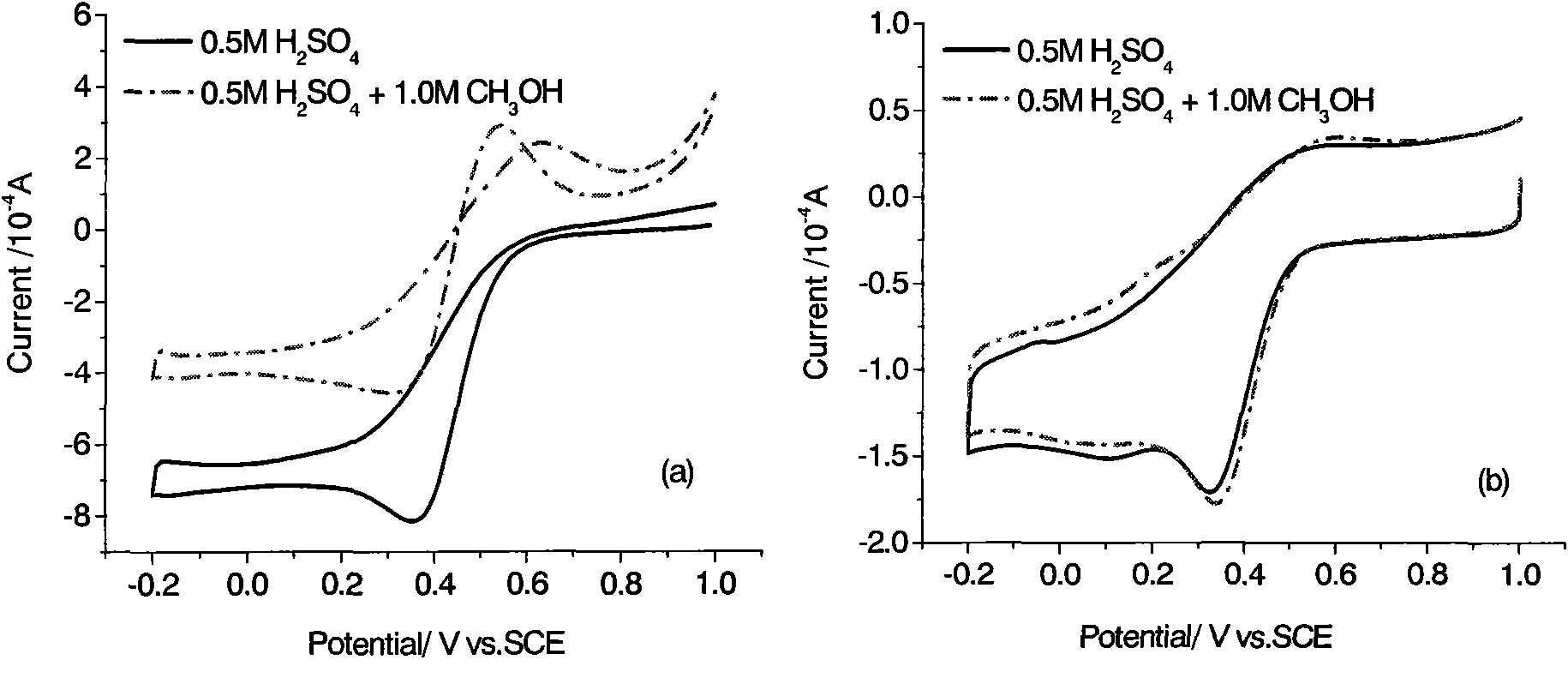

Non-noble metal fuel cell oxygen reduction electrocatalyst

The invention relates to a non-noble metal fuel cell oxygen reduction electrocatalyst which is a product obtained by a method comprising the steps of: (1) pretreatment of acetylene black; (2) mechanical grinding: mixing cobalt chloride (CoC12. 6H2O), nitrogen source (melamine or hexamethylene tetramine) and carbon black (acetylene black or Vulcan XC-72R) which have the mass ratio of 1: 2: 10 into a mortar for mechanical grinding for 30min until even dispersion; and (3) heat treatment: adopting a way of sectional type temperature rise under the nitrogen protection, namely, maintaining for 10min when raising 100 DEG C at every time, then raising the temperature again, and so on; finally, maintaining for 1-5h at the required temperature (500-900 DEG C), and stopping heating; and naturally cooling to the room temperature, and then closing nitrogen. The non-noble metal fuel cell oxygen reduction electrocatalyst is low in the price of raw materials, and greatly reduces the preparation cost of oxygen reduction catalyst. The method is simple, convenient and easy, and is suitable for large-scale production and preparation of the catalyst.

Owner:CHONGQING UNIV

Chinese herbal medicine liquid fertilizer and preparation method and application thereof

The invention discloses a Chinese herbal medicine liquid fertilizer and a preparation method and an application thereof. The method comprises the following steps: (1) a first mixing step, namely mixing ammonium nitrate, potassium dihydrogen phosphate, potassium nitrate and water to obtain a compound liquid A; (2) a second mixing step, namely mixing ferrous sulfate, copper sulfate, manganese sulfate, sodium molybdate, zinc sulfate, boric acid, cobalt chloride and water to obtain a compound liquid B; (3) a Chinese herbal medicine extraction liquid obtaining step, namely decocting immersed Chinese herbal medicines in water and concentrating the decocted mixture to obtain a Chinese herbal medicine extraction liquid; and (4) a third mixing step, namely mixing the Chinese herbal medicine extraction liquid, the compound liquid A, the compound liquid B and water, wherein the Chinese herbal medicines are cortex moutan, folium artemisiae argyi, honeysuckle, pepper, rhizoma atractylodis, mint, sweet-scented osmanthus, lavender, fresh gingers and aloe. The Chinese herbal medicine liquid fertilizer disclosed by the invention integrates the functions of providing nutrition, sterilizing and refreshing air to plant growth.

Owner:罗阳城

Method for preparing high-sphericity-degree and large-particle cobaltosic oxide

InactiveCN105800699AGuarantee quality stabilityPromote productionCell electrodesCobalt oxides/hydroxidesSodium bicarbonateReaction temperature

The invention relates to a method for preparing high-sphericity-degree and large-particle cobaltosic oxide. The method includes the steps that at least one of cobalt chloride, cobaltous sulfate and cobalt nitrate serves as a raw cobalt salt material, and is purified and prepared to obtain a cobalt salt solution; at least one of ammonium carbonate, ammonium bicarbonate, sodium carbonate and sodium bicarbonate serves as a precipitant; a precursor is prepared with the solution direct precipitation method, and added into a reaction vessel with the concurrent adding method, the parameters of the injecting speed, the reaction temperature, the stirring speed, the PH value and the like of the solution are controlled, the batch-type crystallization technology and the kettle dividing technology are adopted, the chemical impurities of the precursor and the crystallinity degree, the granularity, the density and the like of crystals are effectively controlled, a precipitate precursor is synthesized, washing and centrifuging are carried out, then sintering is carried out twice, and the high-sphericity-degree and large-particle cobaltosic oxide is finally obtained. The method is simple in technology and low in cost, and the prepared cobaltosic oxide is high in cut-off voltage, tap density and stability.

Owner:HUNAN HINA NEW MATERIALS

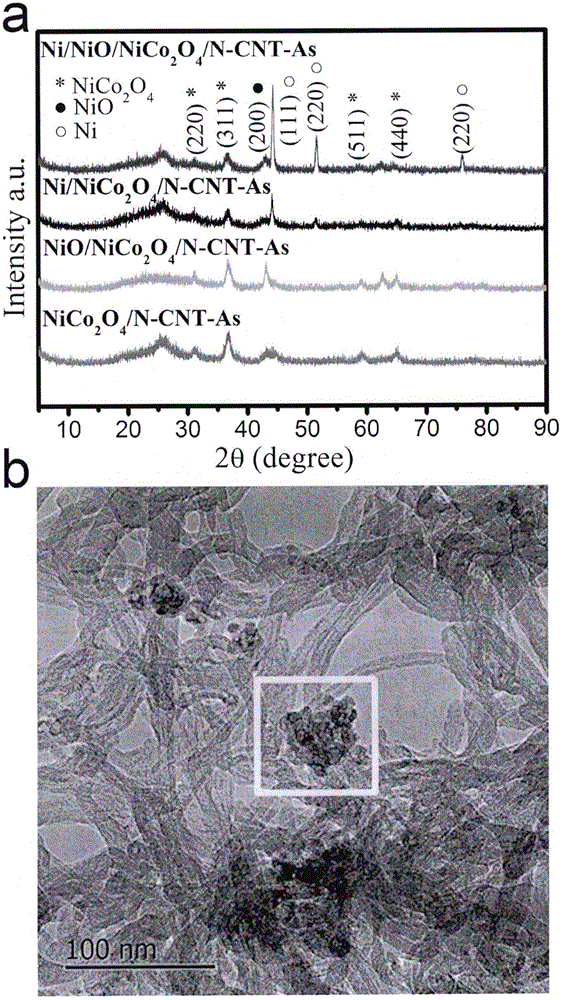

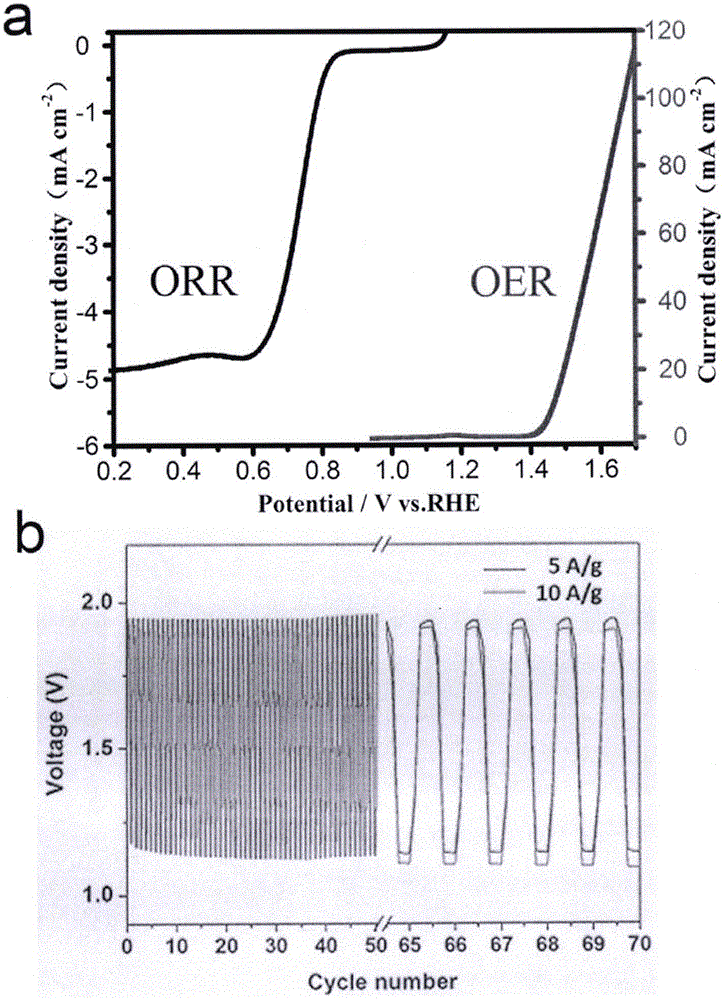

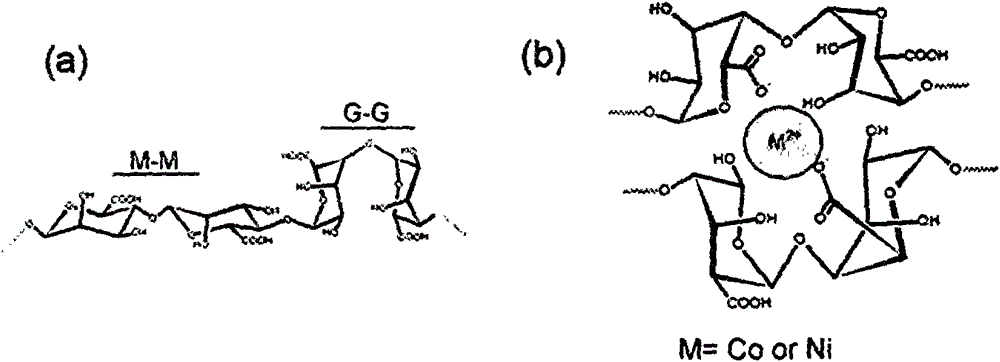

Preparation method for Ni-Co/carbon nanotube aerogel catalyst of zinc-air battery

ActiveCN105609790AWide variety of sourcesImprove securityCell electrodesPtru catalystZinc–air battery

The invention discloses a preparation method for a Ni-Co / carbon nanotube aerogel catalyst of a zinc-air battery, which is used for the field of the zinc-air battery. In the catalyst, the nanometer Ni-Co / carbon nanotube aerogel dual-functional catalyst is successfully prepared by taking sodium alginate, cobalt chloride hexahydrate, nickel chloride hexahydrate and carbon nanotubes as raw materials. The dual-functional catalyst is endowed with excellent oxygen evolution reaction (OER) and oxygen reduction reaction (ORR) catalytic performance, the initial potential of OER is early, the current density of the dual-functional catalyst is large, the initial potential of ORR is early, the limiting current density is large, and the stability is high; and moreover, the charging and discharging voltage difference of the zinc-air battery before and after long circulation test is small, and the energy efficiency after long circulation is high. The preparation method has the advantages of simplicity, rapidness in operation, greenness and environment friendliness, the source of sodium alginate is rich, and the obtained dual-functional catalyst is excellent in performance and is the zinc-air battery catalyst having a very good prospect.

Owner:QINGDAO UNIV

Chelated liquid fertilizer containing multiple types of plant alcohols and medium trace elements and preparation method of liquid fertilizer

The invention relates to a chelated liquid fertilizer containing multiple types of plant alcohols and medium trace elements, which is applied in the field of agriculture and forestry. The liquid fertilizer consists of the following main materials in parts by weight: 80-450 parts of soluble plant alcohols, 1-10 parts of calcium nitrate, 0.5-3.5 parts of zinc sulfate, 0.1-2.5 parts of manganese sulfate, 0.5-5 parts of magnesium sulfate, 0.1-2.5 parts of ferrous sulfate, 0.03-0.08 part of cobalt chloride, 0.01-0.05 part of ammonium molybdate and 0.2-1.0 part of boric acid. The pH value of the liquid fertilizer is adjusted to be neutral with slightly stronger acidity by adding an appropriate amount of water. The liquid fertilizer contains the multiple types of plant alcohols and has the capabilities of activating the biological activity of crops and enhancing the adsorption to the medium trace elements of the crops and the antioxidation of the crops; and the medium trace elements are capable of promoting the healthy growth of the crops and correcting the nutritional deficiency symptom of the crops. The liquid fertilizer has the characteristics of simple processing technology, low production cost, high fertilizer efficiency and the like; the liquid fertilizer is suitable to serving as a toot system and leaf top application for fruit trees, vegetables and field corps, and is particularly suitable to supplying medium trace element nutrition to the leaves or fruits during the late growth period of the fruit trees. The liquid fertilizer with multiple elements is extensive in application.

Owner:GUANGXI NEW ORIENTATION CHEM IND

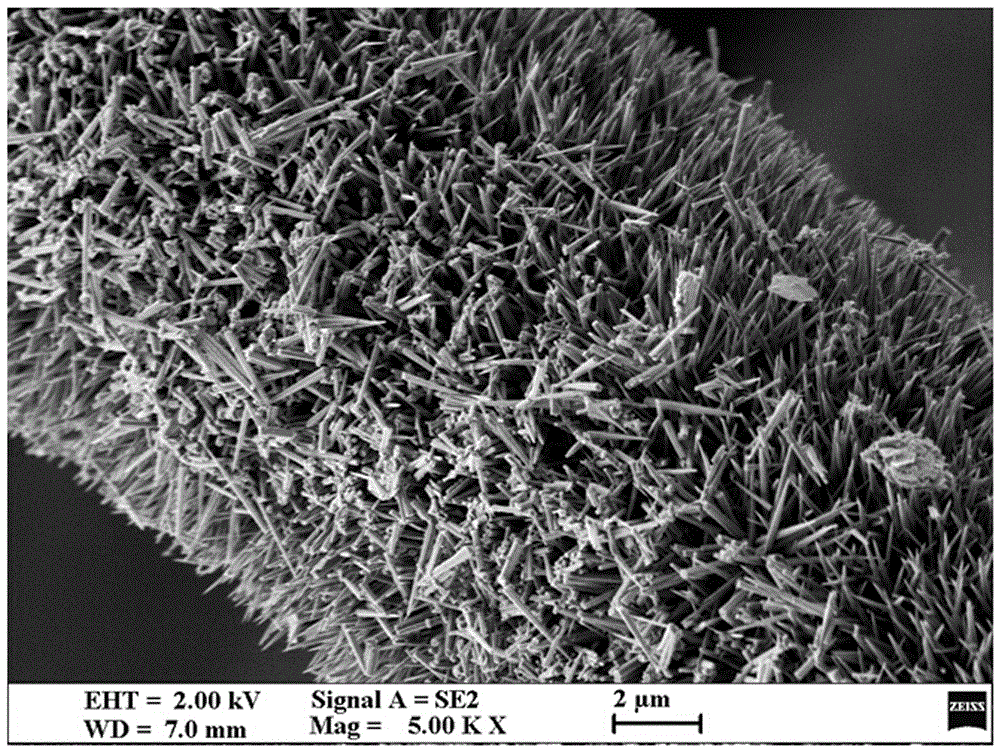

Preparation method and application of NiCo2S4/graphite felt composition electrode material

ActiveCN106206059AStable structureCoated evenlyHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceSolvent

The invention discloses a preparation method and application of a NiCo2S4 / graphite felt composition electrode material. Water and ethyl alcohol serve as solvents, baking soda serves as an alkali source, ammonium fluoride serves as surfactant, cobalt chloride and nickel chloride serve as a cobalt source and a nickel source respectively, and a nickel-cobalt precursor is constructed on pre-oxidized graphite felt through hydrothermal reaction; then thioacetamide serves as a sulfur source, and the needle-shaped NiCo2S4 / graphite felt composition electrode material is prepared through the secondary hydrothermal method. The nickel-cobalt precursor can increase the sulfur loading amount and stabilize appearance of NiCo2S4, ammonium fluoride greatly increases the nucleation rate of NiCo2S4, and accordingly the specific capacitance of the composite material is increased and is as high as 1260-1265 F / g. The prepared NiCo2S4 / graphite felt composition electrode material is good in conductivity and high in specific capacitance, has the mechanical property of softness, and can be used as a supercapacitor electrode material.

Owner:FUZHOU UNIV

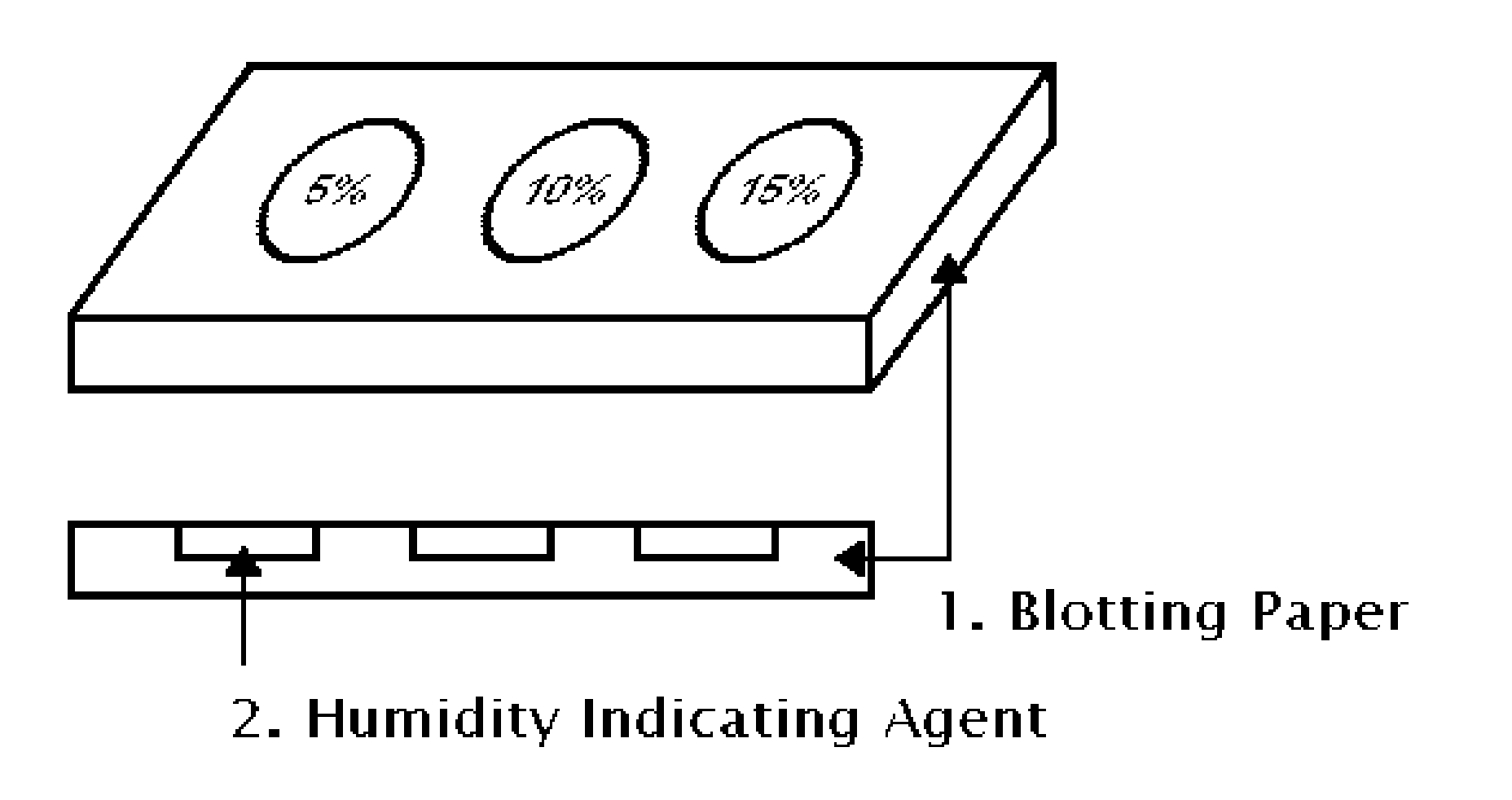

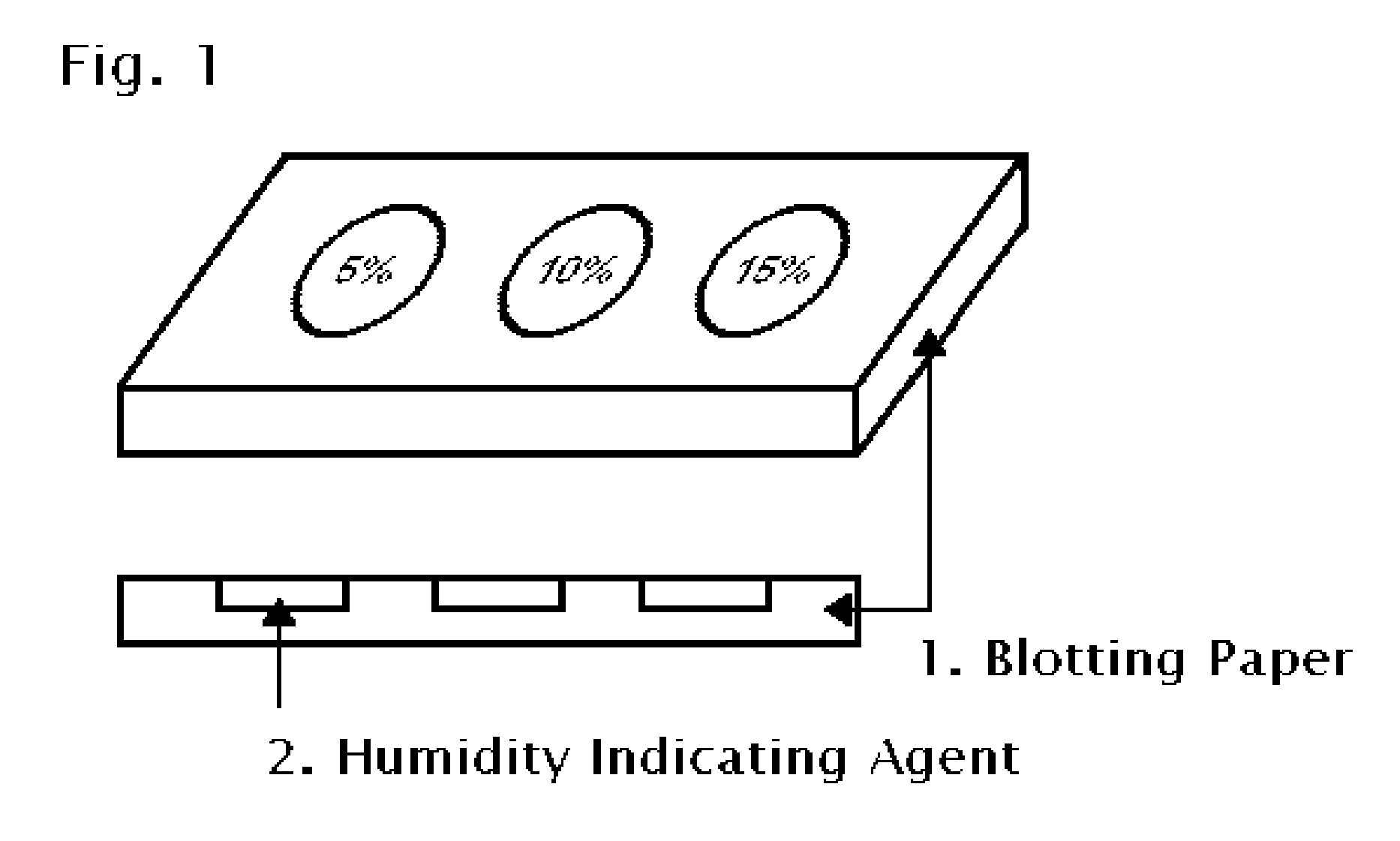

Compositon for non-toxic, non-hazardous, and environmentally friendly humidity-indicating agent and its application

InactiveUS20050106735A1Material analysis by observing effect on chemical indicatorTesting waterCarcinogenAdditive ingredient

Cobalt chloride, copper chloride, and zinc chloride have been used as a humidity-indicating medium. European Union classified cobalt chloride as a category 2 carcinogen while repeated exposure to copper chloride can lead to copper poisoning. Zinc chloride is also known to be very harmful to the environment. These materials are very toxic to aquatic organisms and may cause long-term adverse effects in the aquatic environment. The present invention relates to composition for non-toxic, non-hazardous, and environmentally friendly humidity-indicating agent and its application to humidity indicator, specifically humidity indicator card and humidity-indicating desiccant. The present invention discloses a humidity-indicating agent comprising; pH indicator dye, color-enhancing additive, and natural hygroscopic salt such as magnesium chloride and sodium chloride. All of the ingredients are carefully selected from non-toxic, non-hazardous, and environmentally friendly materials. The humidity-indicating agent changes color reversibly as a function of the relative humidity.

Owner:GP&E AMERICA +1

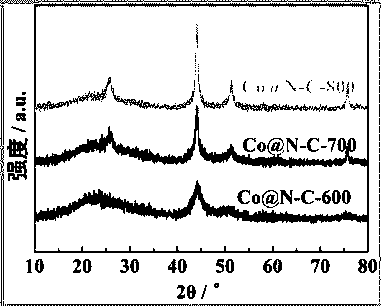

Preparation method and application of nitrogen-doped porous carbon-loaded cobalt catalyst

InactiveCN105498823ASimple methodIncreased Cobalt LoadingPhysical/chemical process catalystsHydrogen productionPorous carbonSynthesis methods

The invention discloses a preparation method of a nitrogen-doped porous carbon-loaded cobalt catalyst. The preparation method includes: adding N, N-bis(salicylidene) ethylene dimino cobalt (II) or bi(3-methoxysalicylaldehyde) ethylenediamine cobalt chloride into a crucible, placing into a tubular furnace, and heating to 400-900 DEG C for calcining for 1-10 h in a hydrogen-argon mixed atmosphere; cooling to room temperature to obtain the nitrogen-doped porous carbon-loaded cobalt catalyst which is used for hydrolytic dehydrogenation of ammonia borane. The preparation method has the advantages that the catalyst is prepared by adopting a one-step pyrolysis synthesis method, the preparation method is simple, cobalt loading quantity is greatly increased, and industrial production is facilitated; the catalyst is used for catalyzing hydrolytic dehydrogenation of ammonia borane, maximum dehydrogenation rate reaches 1383 mL H2min-1gCo-1, and activation energy is 31.0kJ / mol; especially, after cobalt nanoparticles are embedded in nitrogen-doped porous carbon, circulating stability is improved greatly.

Owner:NANKAI UNIV

Composite copper-based catalyst, preparation method and application thereof in the production of vinyl chloride

ActiveCN109821546AHigh activityImprove stabilityPreparation by halogen halide additionCatalyst activation/preparationCeriumPotassium

The invention provides a composite copper-based catalyst, a preparation method and an application thereof in the production of vinyl chloride. The preparation method of the composite copper-based catalyst includes the following steps: soaking acid-treated activated carbon in a solution containing copper salt and an auxiliary agent, and drying and roasting to obtain the composite copper-based catalyst, wherein the auxiliary agent is one or more of ferric chloride, cerium chloride, tin chloride, barium chloride, manganese chloride, zinc chloride, cobalt chloride, lanthanum chloride, nickel chloride, bismuth chloride and potassium chloride; and the mass ratio of the acid-treated activated carbon, the copper salt and the auxiliary agent is 100: 5: 1-100: 10: 5. The catalyst is environment-friendly, low in cost, simple in process and short in production period. The catalyst shows high activity, selectivity and good stability in the reaction of hydrochlorination of acetylene to produce the vinyl chloride, and is expected to be a good substitute for a mercury catalyst.

Owner:鄂尔多斯市瀚博科技有限公司

Method for preparing NiB non-crystalline alloy catalyst with the aid of microwave

InactiveCN1792440ACluster size controllableGood dispersionCatalyst carriersHydrocarbon by hydrogenationChemical platingIron(II) chloride

A microwave aided process for preparing the catalyst of non-crystalline NiB alloy suitable for catalytic hydro-reaction with high catalytic active features that the chemical reduction and chemical plating in microwave field is used, KBH4 is used as reducer, its primary salt is chosen from nickel sulfate, nickel acetate, etc, its secondary salt is chosen from cobalt chloride, iron chloride, etc, its carrier is chosen from oxide, molecular sieve, etc, its solvent is chosen from water, tetrahydrofuran, etc and the complex agent, stabilizer and additive is used.

Owner:NANKAI UNIV

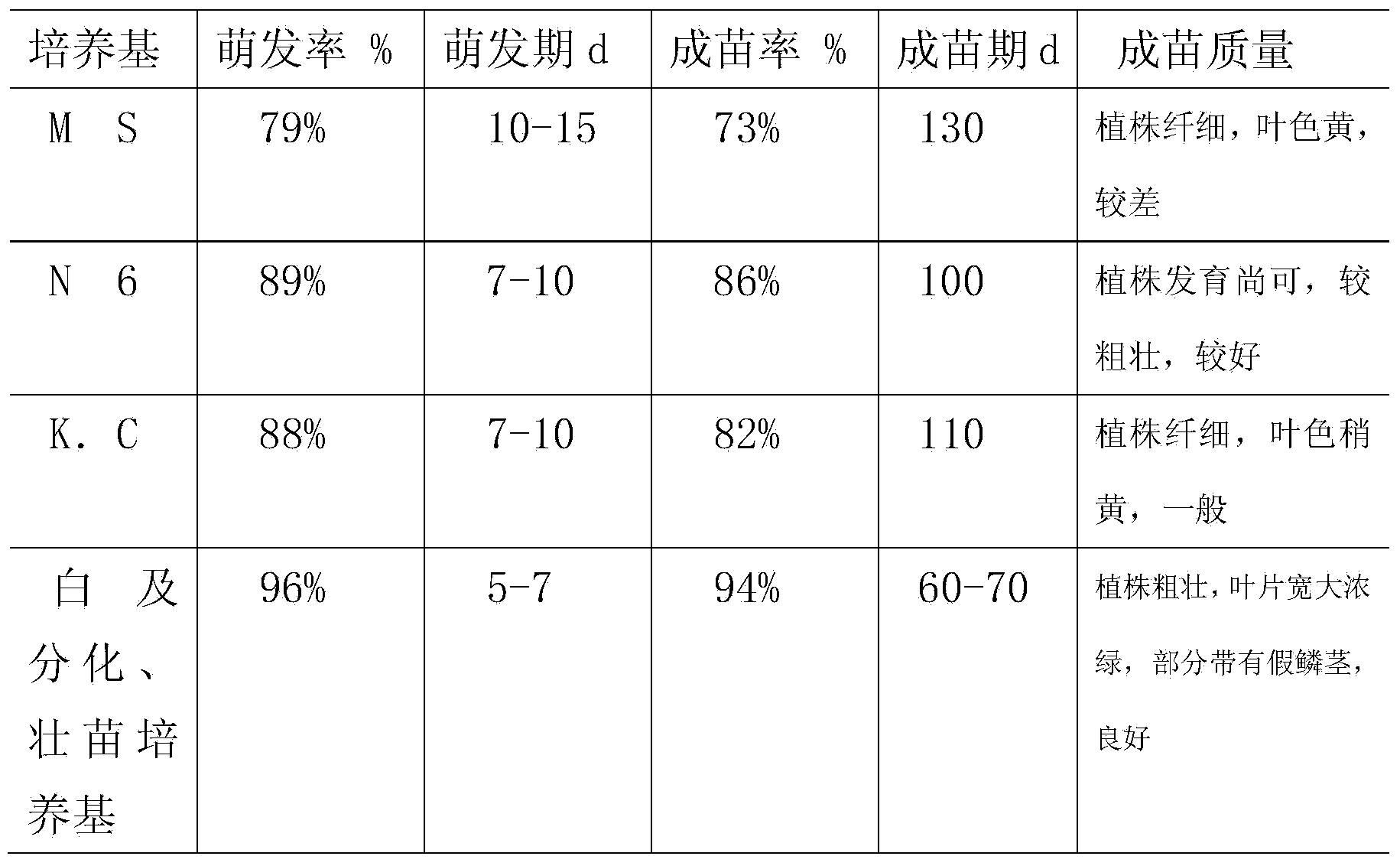

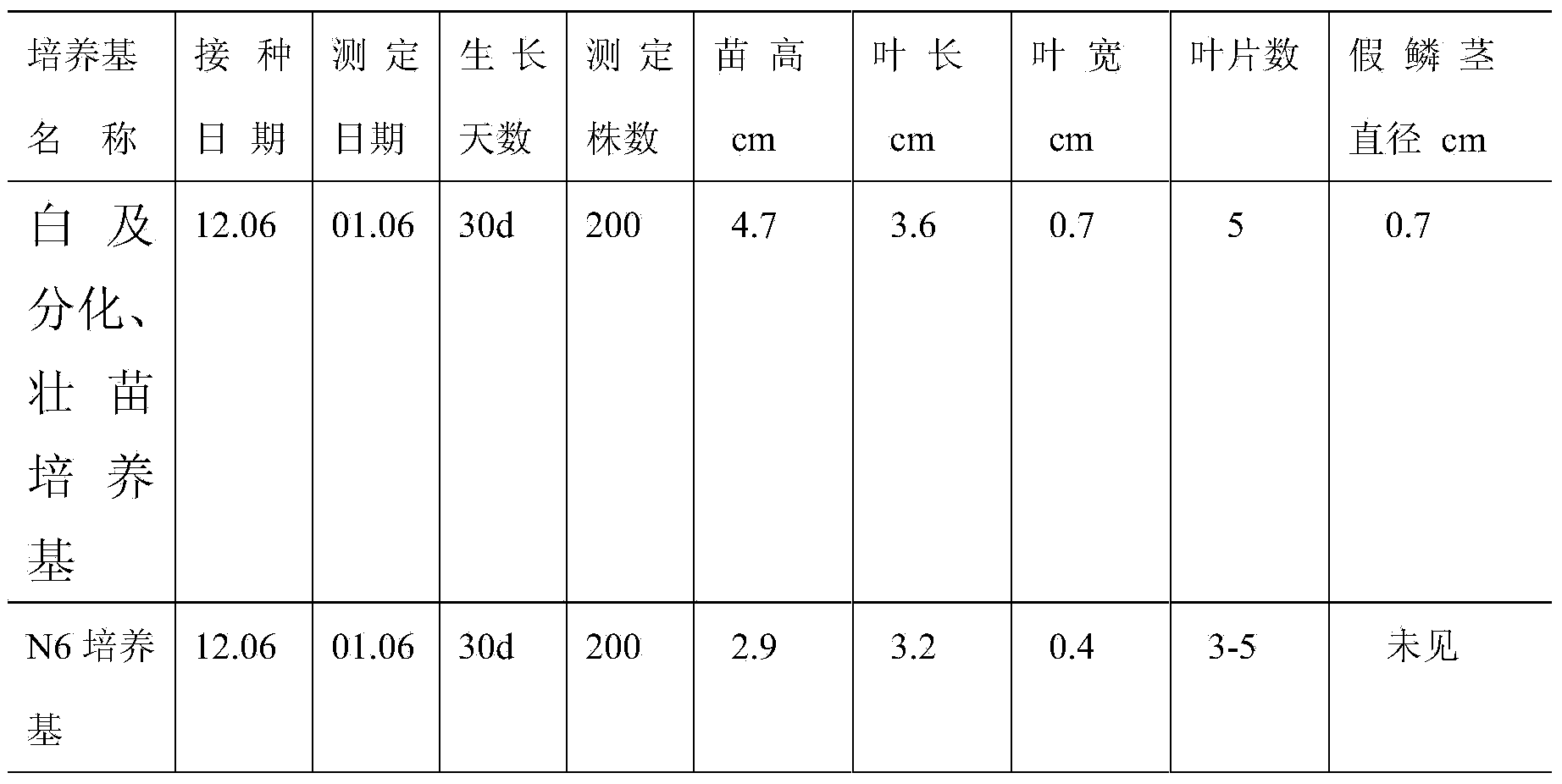

Bletilla striata differentiation and seedling strengthening medium

InactiveCN103651121AStrong differentiation abilityImprove germination ratePlant tissue cultureHorticulture methodsMonopotassium phosphatePotassium iodine

The invention a bletilla striata differentiation and seedling strengthening medium and relates to the technical field of bletilla striata planting and cultivation. The bletilla striata differentiation and seedling strengthening medium is prepared from the following raw materials including potassium nitrate, 440-490mg of ammonium sulfate, monopotassium phosphate, magnesium sulfate, calcium chloride, manganese sulfate, zinc sulfate, boric acid, potassium iodide, sodium molybdate, copper sulfate, cobalt chloride, ferrous sulfate, EDTA (Ethylene Diamine Tetraacetic Acid), phaseomannite, thiamine sulfate, pyridoxine sulfate, nicotinic acid, glycine, DMPT, sodium para-nitrophenolate, sodium ortho-nitrophenol, 5-nitroguaiacol sodium salt, 6-BA, NAA, PP-333, CPPU, citric acid, and cane sugar under a proper pH value condition. The bletilla striata differentiation and seedling strengthening medium can improve the differentiation effects of bletilla striata seeds, and promotes the growth of seedlings and the fast formation of pseudobulb, so that the germination rate of the seeds can be effectively increased, and the growth speed of an embryoid can be increased.

Owner:ANHUI ZHENYANG AGRI & FORESTRY ECOLOGY DEV

Soil water content colorimetric-determination method

InactiveCN103592248AImprove detection accuracyImprove efficiencyColor/spectral properties measurementsSoil typeLength wave

The invention relates to a soil water content colorimetric-determination method. The soil water content colorimetric-determination method comprises the following steps of 1, carrying out extraction on a soil sample to be detected by a cobalt chloride hexahydrate organic solution having a concentration of 0.1-30g / L as a color developing agent to remove solids and to obtain a solution to be detected, and determining the absorbance of the solution to be detected at the wavelength of 380-680nm, and 2, searching the corresponding soil water content in a built absorbance-soil water content standard curve according to the absorbance obtained by the step 1, or substituting the absorbance obtained by the step 1 into the built absorbance-soil water content standard curve equation and calculating the corresponding soil water content. The soil water content colorimetric-determination method is not influenced by soil types, components, unit weight and disturbance, has an error ratio below 2% is a pervasive soil moisture content detection method, is suitable for fast determination in the field and is suitable for soil water fast-determination in the laboratory.

Owner:河南农大迅捷测试技术有限公司

Process for rapidly producing basic nickel carbonate or basic cobaltous carbonate

InactiveCN101708868AReduce pollutionRapid productionNickel carbonatesCobalt carbonatesChlorideUltimate tensile strength

The invention discloses a process for rapidly producing basic nickel carbonate or basic cobaltous carbonate, comprising the following steps of: dissolving, synthetizing, filtering, water scrubbing and drying. The dissolving proportion by weight of nickel chloride or cobalt chloride in the dissolving process is NiCl2:H2O=1:4-8, CoCl2:H2O=1:4-8, and the dissolving proportion by weight of sodium carbonate is Na2CO3:H2O=1:4-8. Aqueous alkali and a nickel chloride or cobalt chloride solution are added by adopting a spray mode in the synthetic process. The synthetic reaction time is 2-4 hours. The invention not only has simple process, short production cycle, low labor intensity and arbitrary enlargement of production scale but also has simple and practicable operation, low cost, stable quality and high efficiency. The process has the characteristics of fast production, high quality of products and high efficiency; products can be turned out after water scrubbing at one time, and therefore, electricity, water, labor and time are saved. The products have even and superfine granules without crushing and sieving, thereby being beneficial to application.

Owner:江西核工业兴中科技有限公司

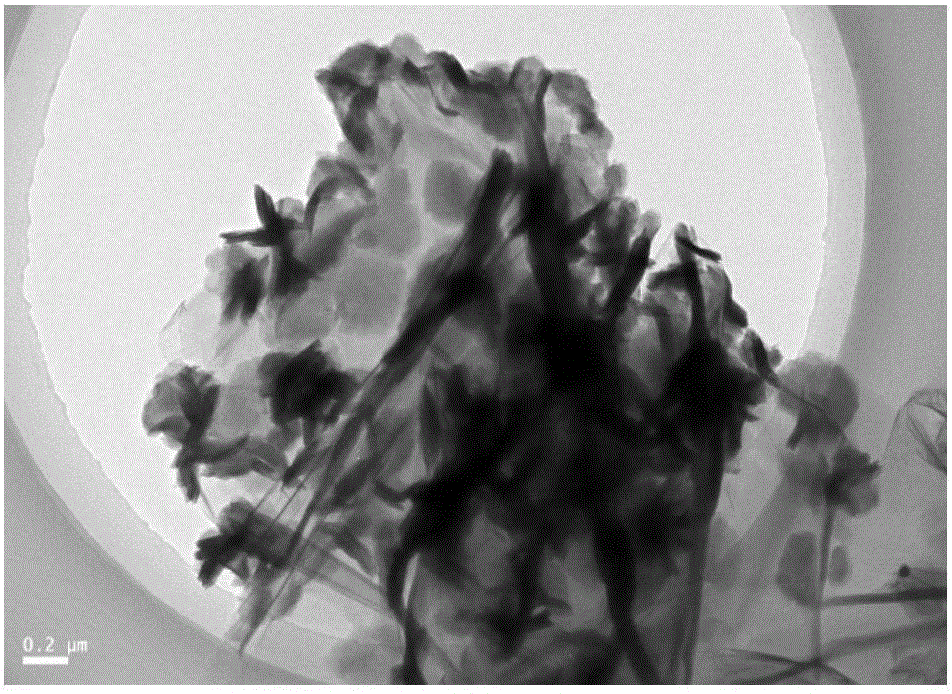

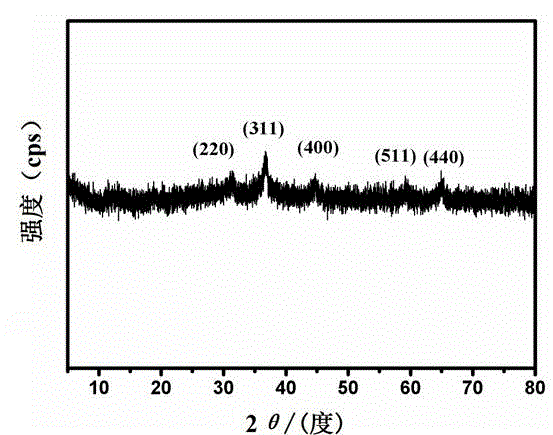

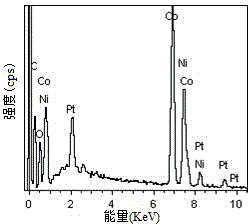

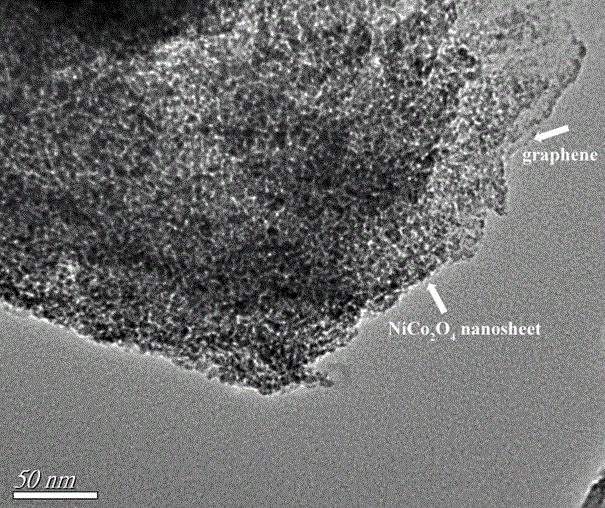

Method for preparing NiCo2O4/graphene supercapacitor material with microwave method

InactiveCN104882298AImprove electrochemical performanceSimple processHybrid/EDL manufactureAir atmosphereMicrowave method

The invention belongs to the field of preparation of nano composite materials, and relates to a method for preparing a NiCo2O4 / graphene supercapacitor material with a microwave method. The main steps includes: using natural graphite as a raw material, oxidizing with a Hummers method to obtain graphite oxide, ultrasonically dispersing the graphite oxide in water, then adding cobalt chloride and nickel chloride, stirring and then adding urea, continuing to stir, then heating the mixed solution in a microwave reactor to 100 DEG C and carrying out a reflux reaction for 5 to 25 min, thereby obtaining a precursor, and calcining the precursor in an air atmosphere at 300 DEG C for 2h, thereby obtaining a porous flaky NiCo2O4 / graphene supercapacitor material. The prepared composite supercapacitor material is synthesized through the microwave method, the preparation method is simple in technology, convenient to operate, high in feasibility, and rapid and efficient, and is easy to realize industrial implementation. The synthesized NiCo2O4 is tightly attached to the graphene, and excellent electrochemical performance is represented.

Owner:JIANGSU UNIV

Complex nutrient additive block special for yaks

ActiveCN101978856AReduce adverse effectsEnhance immune functionFood processingAnimal feeding stuffDiseaseAntibiotic Y

The invention discloses a block for the nutrient balance and health of special livestock yaks under the low-oxygen condition of the Tibet plateau, which consists of the components of molasses, urea, salt, corn flour, calcium hydrogen phosphate, bentonite, oligosaccharide, zinc sulfate, ferrous sulphate, potassium iodide, sodium selenite and cobalt chloride. The block provides mineral elements andcrude proteins of which the yaks are lack due to unbalanced ingestion, improves the constitution of the yaks, enhances disease resistance, reduces the using amount of antibiotics, and also can increase the hemoglobin content of the blood of the yaks to further improve the adaptability of the yaks to a low-oxygen environment.

Owner:LANZHOU UNIVERSITY

A compound premix for pigs that can improve immune function

ActiveCN102293340AImprove survival rateGain weight fastFood processingAnimal feeding stuffQuinolinePantothenic acid

Belonging to the premix field, the invention provides a compound premix able to improve the immune function for pigs. The premix mainly comprises: ferrous sulfate, copper sulfate, zinc sulfate, manganese sulfate, potassium iodide, cobalt chloride, sodium selenite, organic trace elements, multiple vitamins, pantothenic acid, nicotinic acid, folic acid, biotin, lysine, a compound microecological preparation, ethoxy quinoline, 50% of choline chloride, zeolite powder and wheat bran. Without any antibiotic, the premix of the invention has a rational formula, contains a variety of probiotics and isof high live bacteria content. Animal feeding experiments prove that the premix has ideal feeding effects of high pig survival rate, fast weight gain and improved feed conversion efficiency. Being conducive to improve the intestinal microenvironment of pigs, maintain intestinal health, improve the immune function of pigs, reduce the occurrence of diseases and promote pig growth, the premix provided in the invention can satisfy the demands of vast raising households, and is suitable for developing green and healthy breeding as well as producing pollution-free livestock products.

Owner:BEIJING DABEINONG TECH GRP CO LTD +2

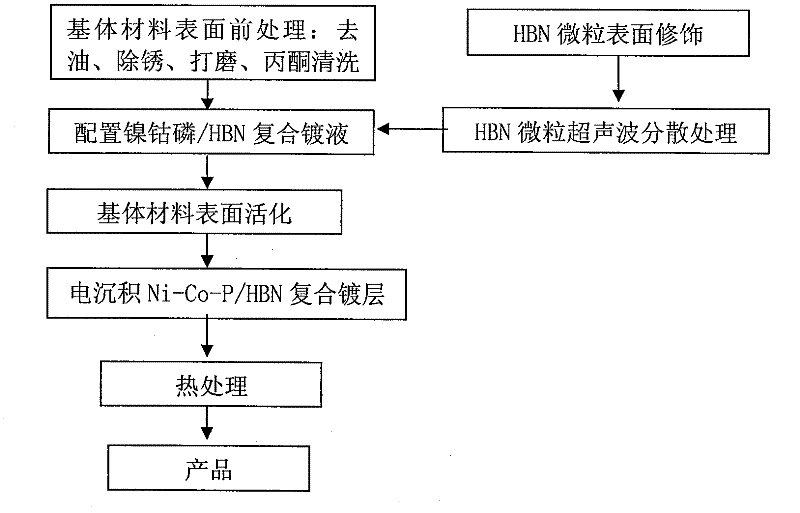

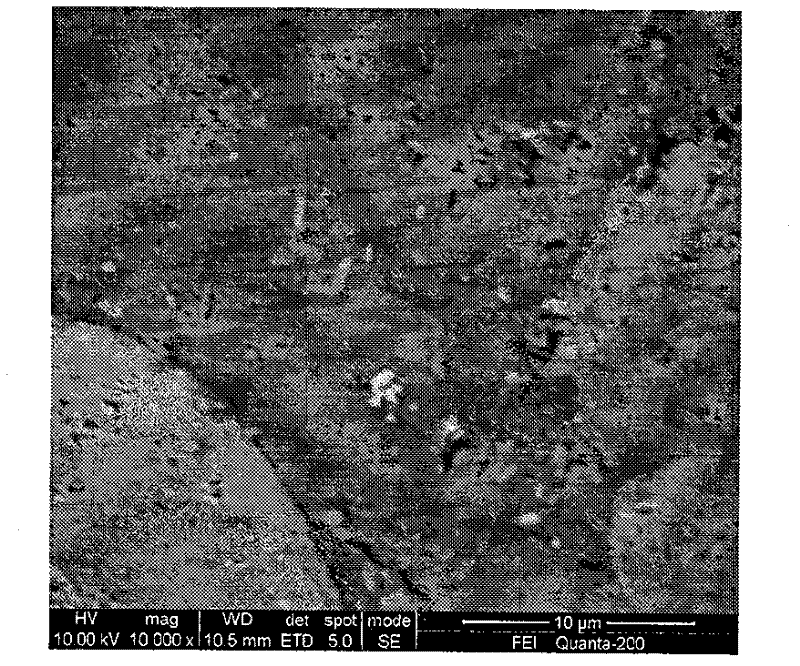

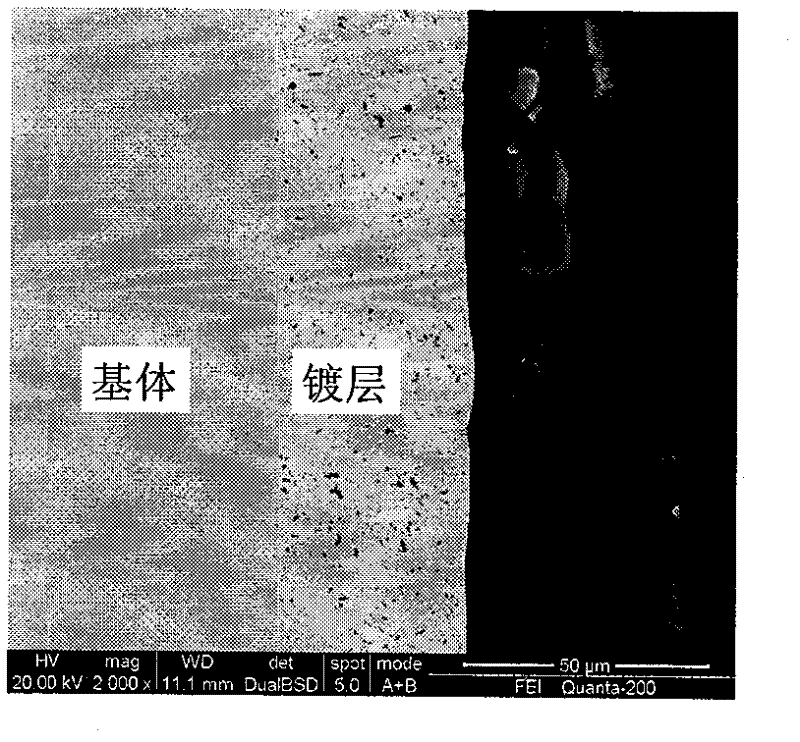

Pulse-electrodeposited Ni-Co-P/HBN composite plating and preparation method thereof

InactiveCN102534732AImprove electrodeposition efficiencyEasy to useElectrolytic coatingsPolyvinyl alcoholHexagonal boron nitride

A pulse-electrodeposited Ni-Co-P / HBN composite plating and a preparation method thereof. The preparation method adopts a metal material as a substrate, and comprises the following steps: firstly pretreating the substrate surface, preparing a composite plating solution with nickel sulfate, cobalt chloride, sodium hypophosphite, citric acid, trisodium citrate, boric acid, and polyvinyl alcohol as main components and hexagonal boron nitride HBN powder as a dispersed phase, performing surface modification and dispersion treatment of the HBN particles by using a surfactant through ultrasonic vibration, allowing the HBN particles to disperse uniformly in the plating solution through reasonable setting of pulse electrodeposition parameters and full stirring, performing codeposition and heat treatment of the HBN particles and the substrate metal nickel cobalt phosphor in a state of applying pulsed current so as to obtain a corrosion-resistant, wear-resistant and antifriction pulse-electrodeposited Ni-Co-P / HBN composite plating. The invention overcomes defects of single component of current composite plating, coarse plating crystal grain, low interface bonding strength with the substrate, non-ideal comprehensive properties of corrosion resistance, wear resistance, and antifriction, and the like; the pulse-electrodeposited Ni-Co-P / HBN composite plating of the invention is applicable to wear-resistant, antifriction and corrosion-resistant surface plating of friction kinematic pair parts in industries of machinery, metallurgy, chemical engineering, and the like.

Owner:HUNAN UNIV OF SCI & TECH

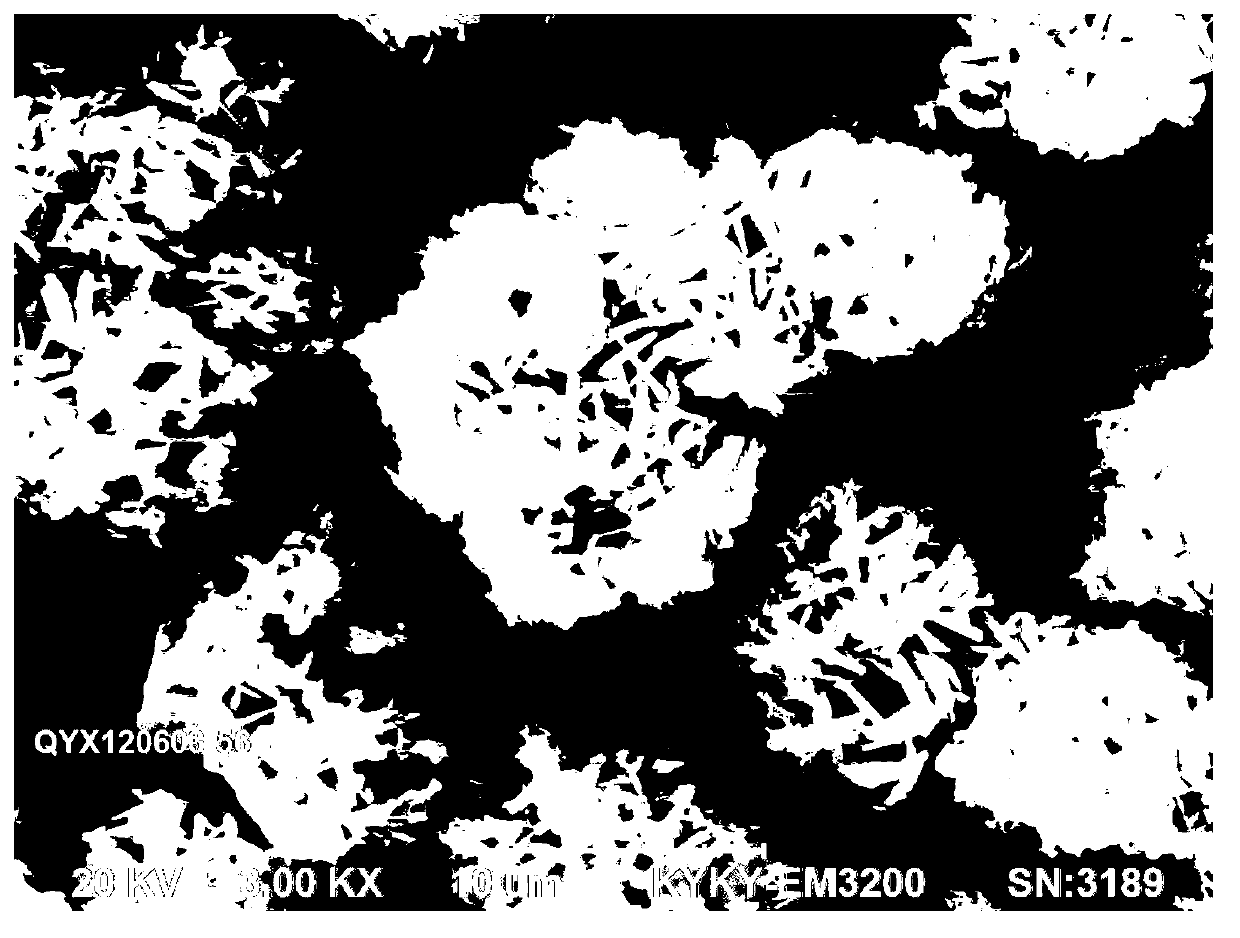

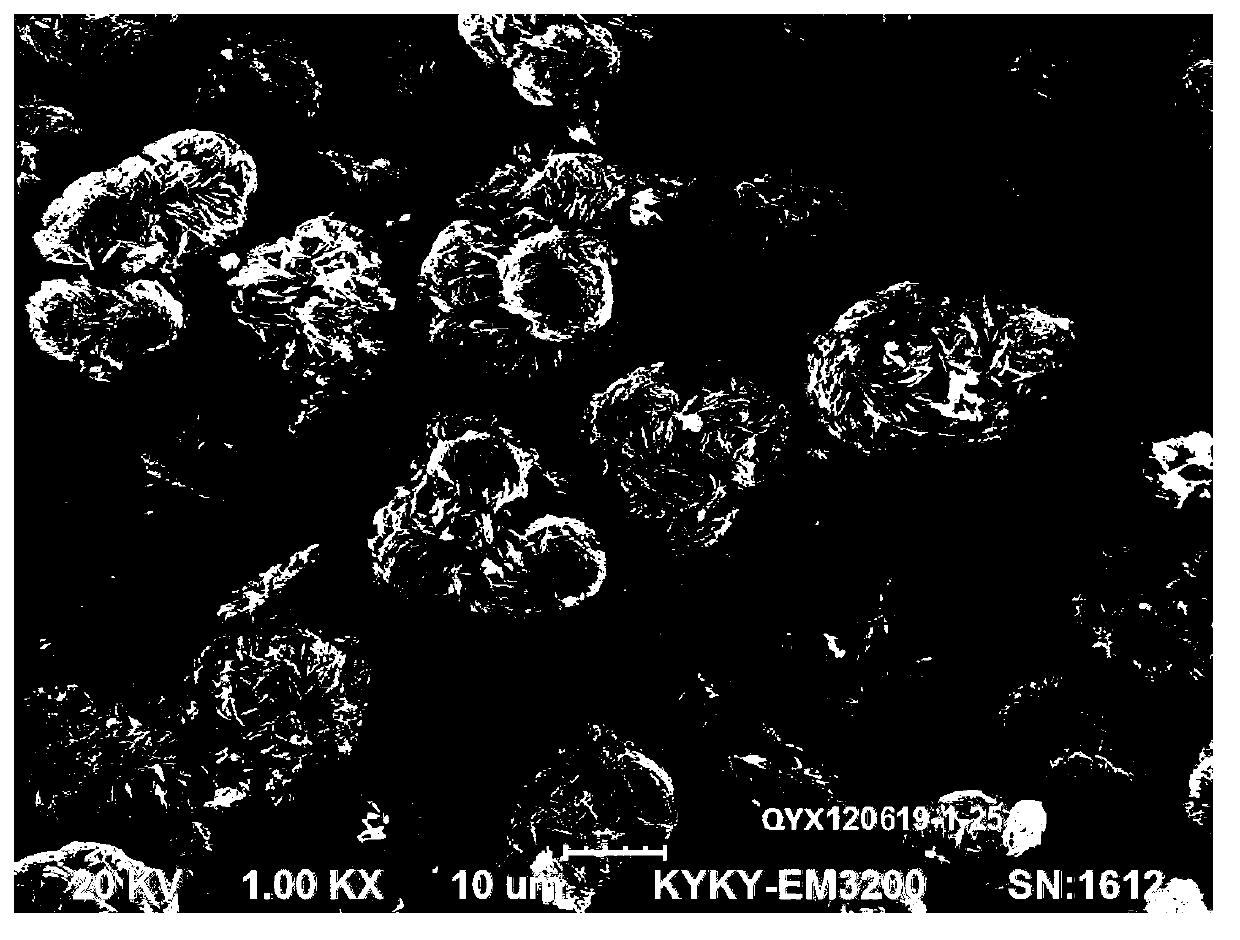

Method for continuously preparing cobalt hydroxide with high bulk density

ActiveCN103342394ASimple processContinuous productionCobalt oxides/hydroxidesPhysical chemistryImpurity

The invention discloses a method for continuously preparing cobalt hydroxide with high bulk density. The current cobalt hydroxide preparation methods include an alkali solution sedimentation method, a sedimentation conversion method and the like which have the following three difficulties: cobalt hydroxide sedimentation particles are smaller, difficult to filter and wash, and the recovery rate of materials is low; the materials are low in quality and high in impurity content; the high energy consumption is caused by intermittent production. The technical scheme is as follows: the method is characterized by comprising the following steps of: with cobalt-contained ore material as the raw material, leaching the cobalt-contained ore material, and then, purifying the cobalt-contained ore material to obtain a cobalt chloride solution; with NaOH as a base solution, merging NaOH, cobalt chloride and a complexing agent solution, adding the mixed solution into a reaction kettle, rapidly controlling the pH value at 8-12, the temperature at 30-90 DEG C and the stirring speed at 200-1000rpm in the flow merging process, and opening an overflow valve of the reaction kettle to begin to carry out continuous production after the reaction is carried out for 6-40h. The method is simple in process, capable of realizing continuous production, convenient in operation and beneficial to the industrial production; a product is excellent and is shaped like a porous sphere, and the particle size of the product is distributed normally.

Owner:ZHEJIANG HUAYOU COBALT

Process for recovering cobalt, copper, zinc and manganese in manganese chloride residual liquid

The invention relates to a process for recovering cobalt, copper, zinc and manganese in a manganese chloride residual liquid. By using the process, the recovery rates of cobalt, copper, zinc and manganese are above 90%, the contents of impurities in recovered cobalt, copper, zinc and manganese products are below 1g / L, and the contents of the impurities in the manganese product are below 2%. The process mainly comprises the following steps: regulating the concentration of chlorine ions in the manganese chloride residual liquid to 250-350g / L; extracting cobalt, copper and zinc in the manganese chloride residual liquid with N235, and reserving manganese in raffinate; then stripping cobalt, copper and zinc in an organic phase with a stripping agent so as to obtain pure cobalt chloride, a copper chloride solution and a zinc precipitate, washing, drying and calculating the zinc precipitate so as to obtain a zinc oxide product; extracting manganese in the raffinate with P204, stripping with an acid so as to obtain a manganese salt solution; and carrying out evaporation, crystallization and drying on the manganese salt solution so as to obtain the manganese salt product. The process has the advantages of short process flow, high valuable metal recovery, high recovered product purity and low recover cost.

Owner:JINCHUAN GROUP LIMITED

Cold season nutrition-balanced compound yak block and technology for producing same

InactiveCN102657291ASuitable for supplementary purposesWide variety of sourcesFood processingAnimal feeding stuffCold seasonSodium Bentonite

The invention provides a cold season nutrition-balanced compound yak block, each kg of the block consists of the following raw materials of: 0.3-0.6g of zinc sulfate, 0.2-0.4g of copper sulfate, 0.01-0.02g of sodium selenite, 0.02-0.25g of potassium iodide, 0.02-0.04g of cobalt chloride, 10-20g of magnesium oxide, 70-100g of calcium hydrophosphate, 80-120g of puffing corn seed powder, 50-80g of bran, 20-40g of rapeseed meal, 50-100g of high-energy fat powder, 20-40g of urea, 150-250g of salt, 200-300g of bentonite, 30-60g of portland cement, 80-150g of molasses and 20-40g of vitamin premix. In addition, a technology for producing the block is provided, and better combines a chemical solidification technology and a mechanical pressing technology; and according to the seasonal variation characteristics of forage grass feed and nutritional statuses during yak raising, through taking the compositions and quantities of earth mineral elements which are ingested by the yak into consideration, the technology optimizes and adjusts the formula of the yak nutrition block, and balances the yak nutrient element supply. A curing agent has wide select sources and is low in price, and the compound yak block has balanced nutrition and larger density, is reasonable in feed intake, and is suitable to the purpose of nutrient element supplement for grazing yaks of different production levels in cold seasons.

Owner:NINGXIA UNIVERSITY

Metal alloy electroplating liquid

The invention discloses a metal alloy electroplating liquid. The metal alloy electroplating liquid is composed of the following raw material components in parts: 30-40 parts of copper sulphate, 30-50 parts of aluminium sulphate, 50-60 parts of copper chloride, 50-60 parts of nickel hydroxide, 20-30 parts of cobalt sulphate, 30-40 parts of cobalt chloride, 10-15 parts of iron sulphate, 30-35 parts of ferrous chloride, 50-58 parts of cuprous oxide, 16-18 parts of hydrochloric acid, 15-20 parts of acetic acid, 3-4 parts of Tween-60, 4-5 parts of sodium hydroxyethyl sulfonate, 5-6 parts of allyl polyethenoxy ether, 6-7 parts of polyethylene glycol, 3-4 parts of ammonium lauryl sulphate, 5-8 parts of sodium lauryl sulphate and 200-300 parts of deionized water. The metal alloy electroplating liquid is good in stability, the surface of a plated film is high in brightness and smoothness, the flexibility of a plated layer is obviously improved, and the defects of burrs, roughness and the like on the outer surface of a plated part are basically eliminated.

Owner:梁胜光

Preparation method of iron-cobalt-nickel oxide/carbon cloth composite flexible electrode

InactiveCN109243856AImprove flexibilityImprove electrochemical performanceHybrid capacitor electrodesHybrid/EDL manufactureCotton clothOxygen

This patent uses cotton cloth as raw material, carbonizes it into carbon cloth, and obtains flexible supercapacitor electrode base material with high specific surface area, oxyge functional groups andgood mechanical properties then through mixed acidification treatment. The obtained treated carbon is added into ferric trichloride hexahydrate, Cobalt chloride hexahydrate, nickel chloride hexahydrate and ethanol solution after a period of time, ammonium bicarbonate is added and continuously stirred, after that reaction is completed, the mixture is washed with deionize water several times, dried, calcined in a high-temperature tubular furnace for a period of time, and taken out after the mixture is cooled to room temperature, so as to prepare an iron cobalt nickel oxide / carbon cloth composite flexible electrode material. By adjusting the reaction time and the amount of iron, cobalt and nickel sources to control the loading amount and morphology of multicomponent transition metal oxides,the flexible supercapacitor electrode materials with good flexibility and excellent electrochemical performance were prepared.

Owner:TIANJIN POLYTECHNIC UNIV

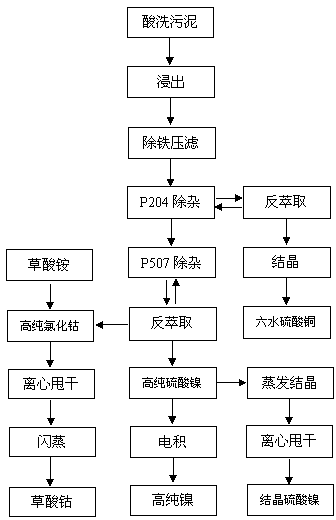

Method for recycling precious metals from stainless steel acid pickling sludge

InactiveCN103695655AIncrease added valueRealize economic valueProcess efficiency improvementCopper sulfateMaterials science

The invention provides a method for recycling precious metals from stainless steel acid pickling sludge, belonging to the field of non-ferrous metallurgy and waste utilization. The method mainly comprises the following steps: 1) thickening and filter pressing; 2) leaching; 3) iron removal and filter pressing; 4) P204 extraction: filtering and clarifying the mother liquid and feeding into a P204 extraction box; performing continuous saponification and counter-current extraction, and separating out an organic phase A and a filtrate A; extracting to remove impurity elements such as Zn, Cu, Mn, Ca and the like; 5) P507 extraction: feeding the filtrate A separated by the step 4) into a P507 extraction box, performing continuous saponification and counter-current extraction in the extraction box at room temperature, and separating out an organic phase B and a filtrate B; performing reverse extraction of the organic phase B by use of dilute hydrochloric acid to obtain a high-purity cobalt chloride solution, and enriching nickel in the filtrate B by use of dilute sulphuric acid to obtain a high-purity high-concentration nickel sulfate solution. The method provided by the invention finally obtains products such as copper sulfate, nickel sulfate, high-purity nickel, cobalt oxalate and the like, realizes resource recycling of precious metals in sludge, and has the comprehensive benefits of economic benefits, environmental benefits and social benefits.

Owner:王洪

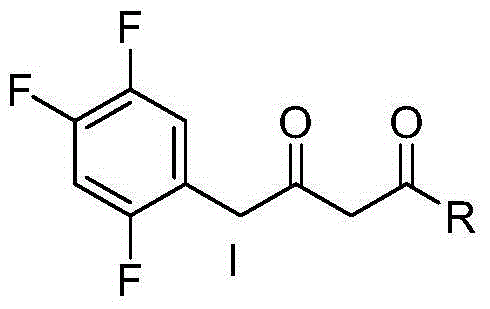

Immobilized transaminase and application of immobilized transaminase in synthesis of sitagliptin intermediate

The invention provides immobilized transaminase. The immobilized transaminase is obtained by fixing transaminase, with histidine tag, derived from Mycobacterium vanbaalenii PYR-1 onto an enzyme immobilization carrier; the enzyme immobilization carrier is obtained by derivatization of epoxy resin through IDA (imino diethyl acetic acid) and cobalt chloride or derivatization of ionic chelate resin through cobalt chloride. The immobilized transaminase has the advantages of firmness in combination, low enzyme activity loss, simplicity in separation and high reusability; low cost of an asymmetric conversion process, mild reaction conditions, environment friendliness, simplicity and convenience in operation, easiness in industrial expanding and promising industrial application prospect are realized.

Owner:ABIOCHEM BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com