Method for continuously preparing cobalt hydroxide with high bulk density

A technology of cobalt hydroxide and pine ratio, applied in cobalt oxide/cobalt hydroxide and other directions, can solve the problems of long production process, unfavorable industrial production, harsh drying conditions, etc., and achieves convenient operation, is conducive to industrial production, and has excellent products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

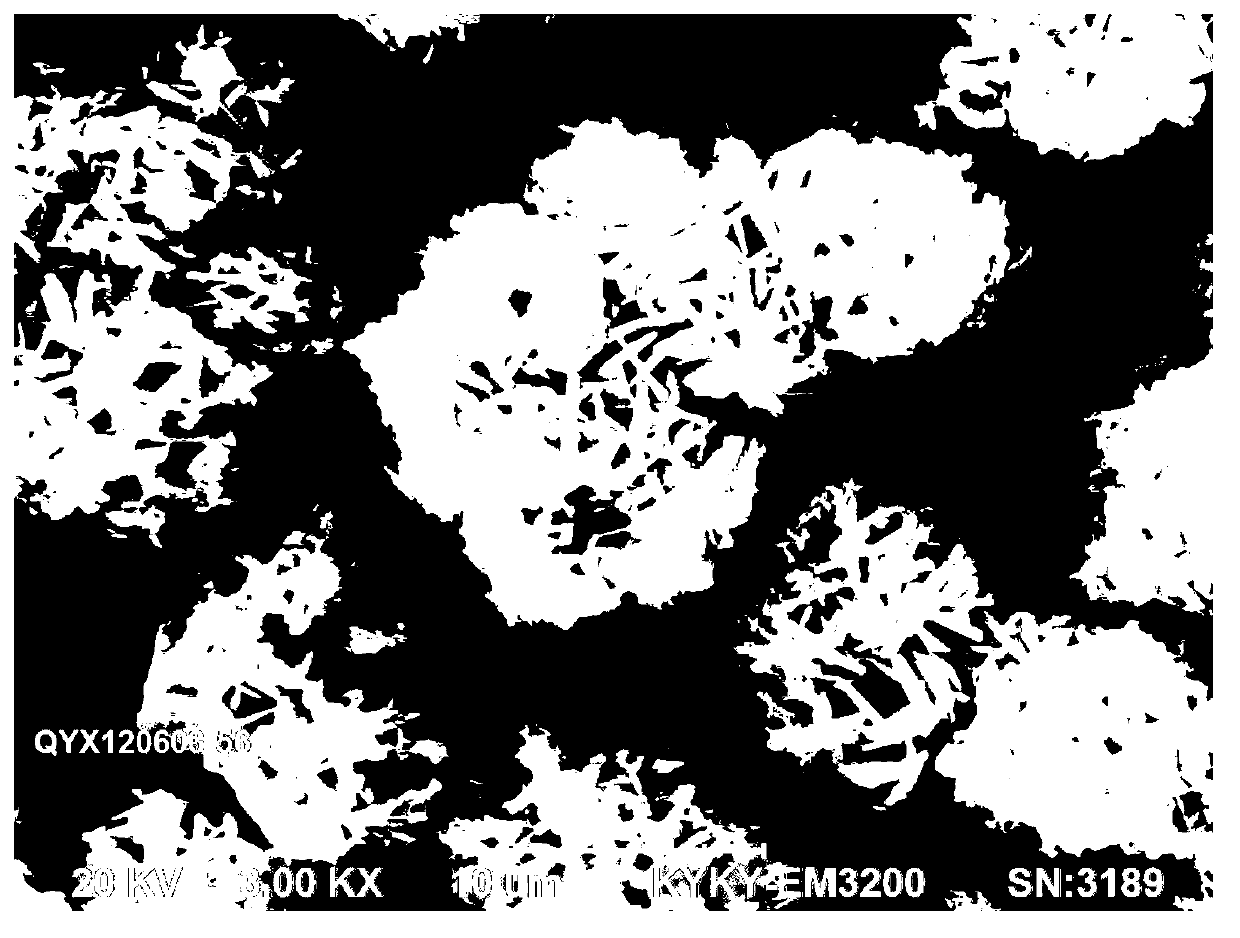

Embodiment 1

[0020] Using NaOH as the bottom liquid, add 60g / L NaOH, 100g / L cobalt chloride, and 12g / L polyvinyl alcohol solution into the reactor in parallel, and quickly control the pH value at 10.0 and the temperature at 30-90°C during the process , stirring speed 200 ~ 1000rpm, after 6 ~ 40h of reaction, open the overflow valve and start continuous production. Add appropriate amount of glucose to the overflowing reaction material, and age for 2-4 hours. Cobalt hydroxide can be obtained after filtering, washing and drying.

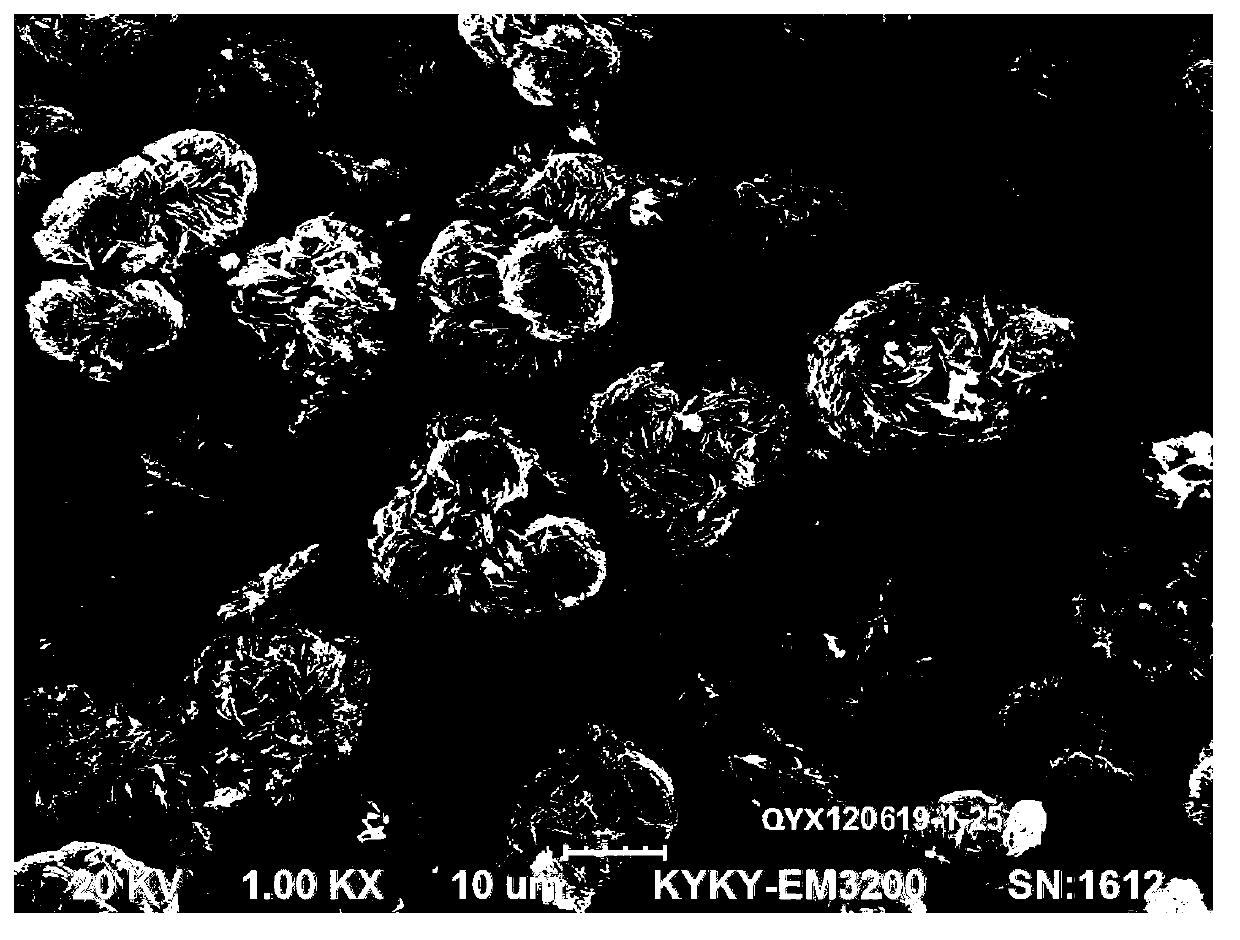

Embodiment 2

[0022] Using NaOH as the bottom liquid, mix 250g / L NaOH with 25g / L disodium ethylenediaminetetraacetic acid solution, and add 150g / L cobalt chloride into the reactor in parallel flow, and quickly control the pH value at 10.5 during the process. The temperature is controlled at 30-90° C., the stirring speed is 200-1000 rpm, and after 6-40 hours of reaction, the overflow valve is opened to start continuous production. Add an appropriate amount of ascorbic acid to the overflowing reaction material, and age for 2 to 4 hours. Cobalt hydroxide can be obtained after filtering, washing and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com