Patents

Literature

97 results about "Porous spheres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

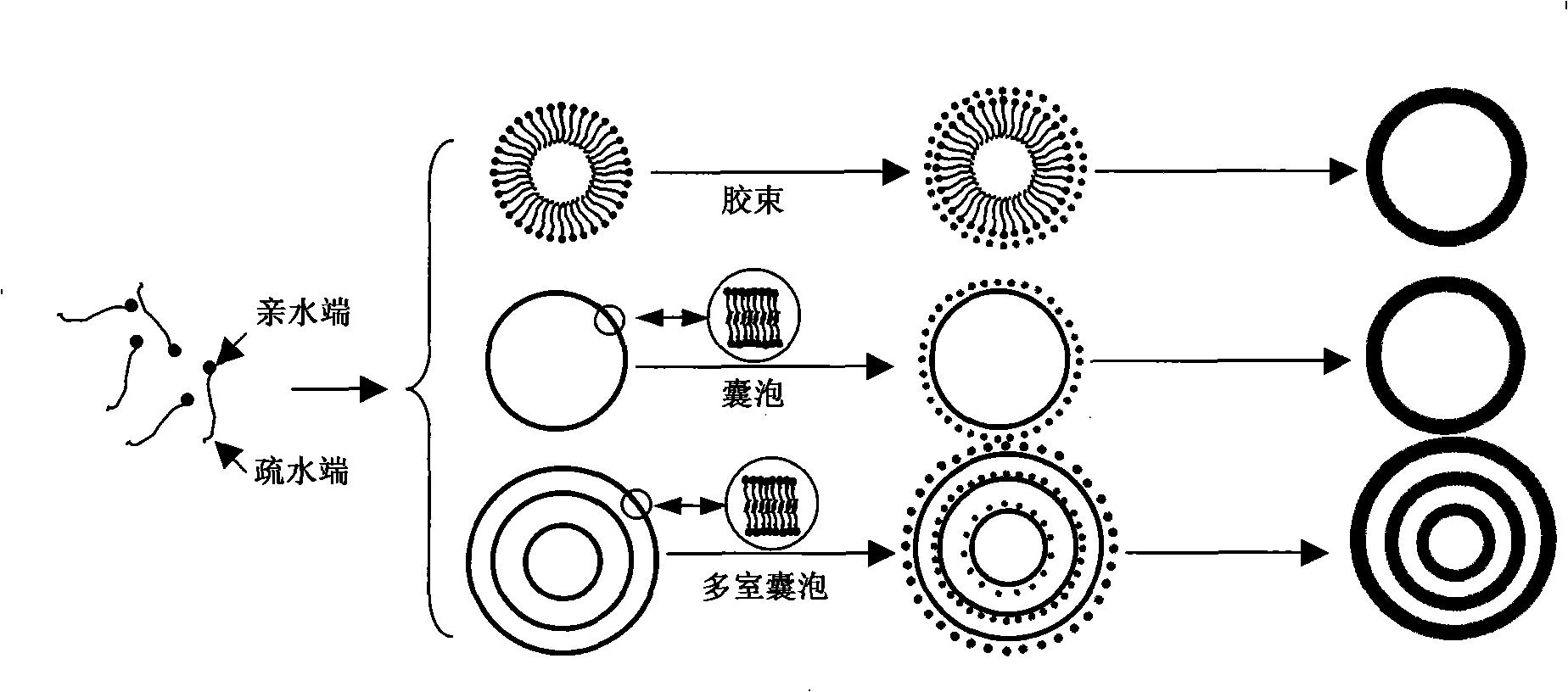

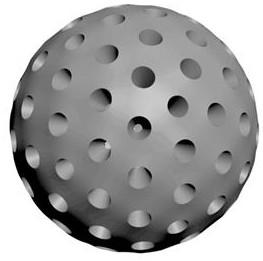

Method for producing multi-layer hollow pellet or stephanoporate pellet with multi-chamber vesicle mould plate method

InactiveCN101293192AEasy to makeControllable structureMicroballoon preparationMicrocapsule preparationActive agentSingle crystal

The present invention relates to a hollow sphere or porous sphere preparation method through vesicle and multi-chamber vesicle template method. The preparation method is characterized in that a surface active agent forms vesicle and multi-chamber as the soft template under certain conditions; inorganic material carries out nucleus growth on the surface of the soft template so as to copy the shape of the vesicle and multi-chamber vesicle and obtain a single-layer hollow sphere and multi-layer hollow sphere structure; due to different growing ways of crystal, the formed hollow sphere can be single crystal, polycrystal or multiaperture. The surface active agent is anion surface active agent, cation active agent or a mixer of the two surface active agents. The deposited inorganic material includes oxide, sulfide, simple metal substance, selenide, hydroxid or inorganic salts, which form core and grow on the surface of the vesicle and multi-chamber vesicle and finally obtain the single-layer and multi-layer hollow sphere structure and the porous sphere structure. Cu2O and ZnS hollow sphere or porous sphere is taken as the embodiment for detailed description.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

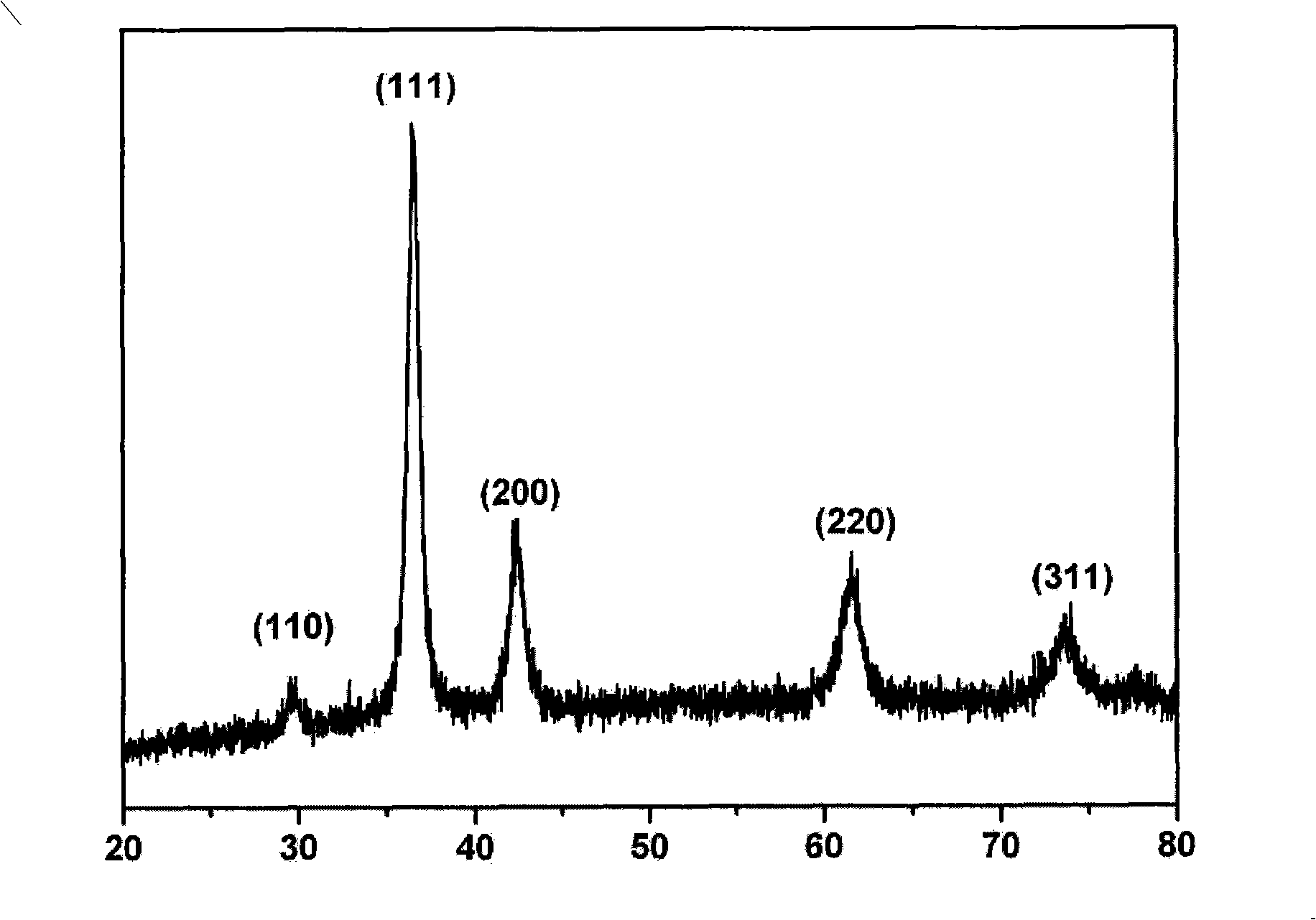

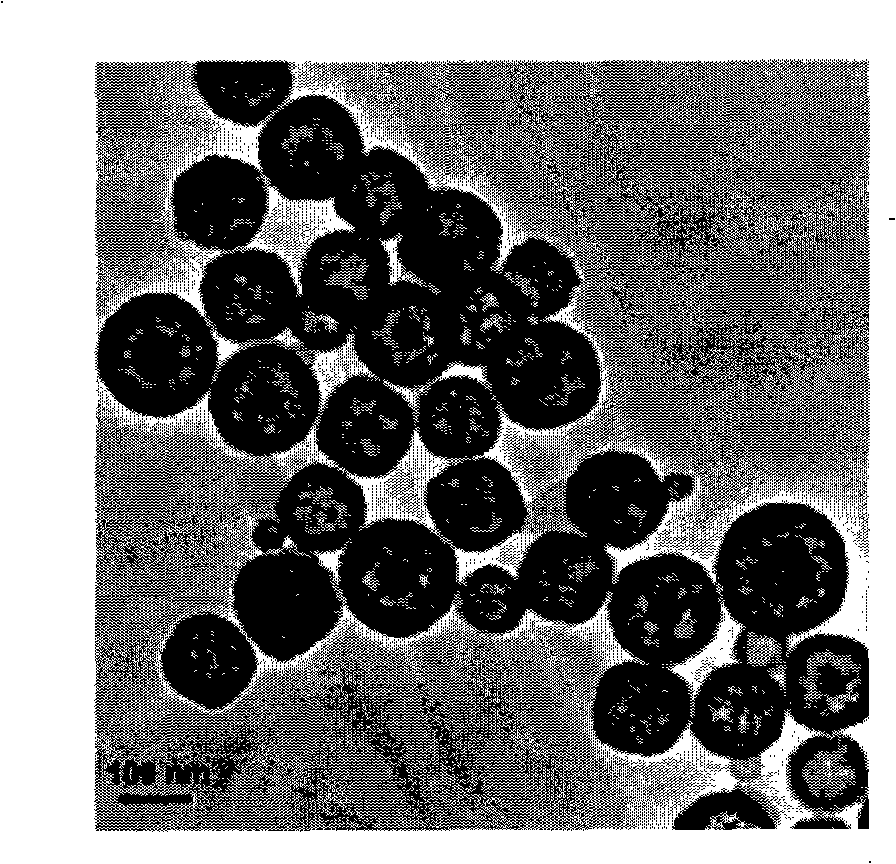

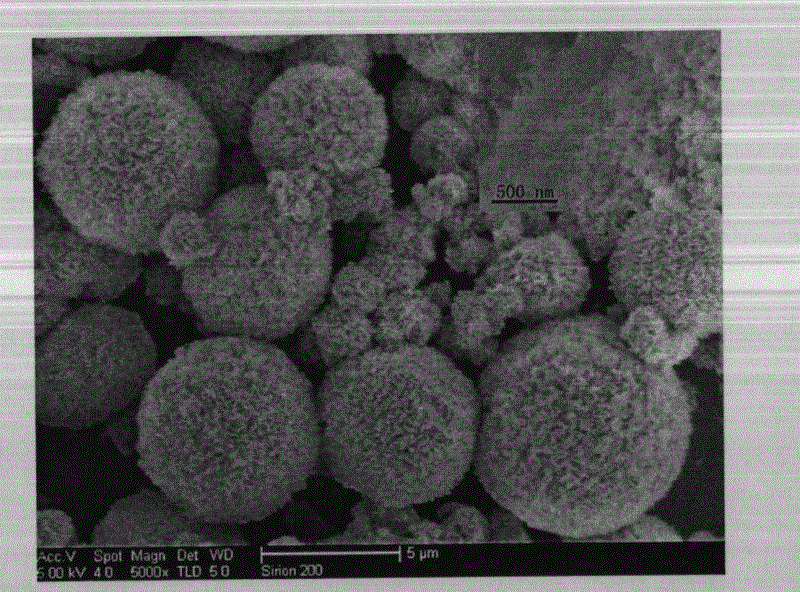

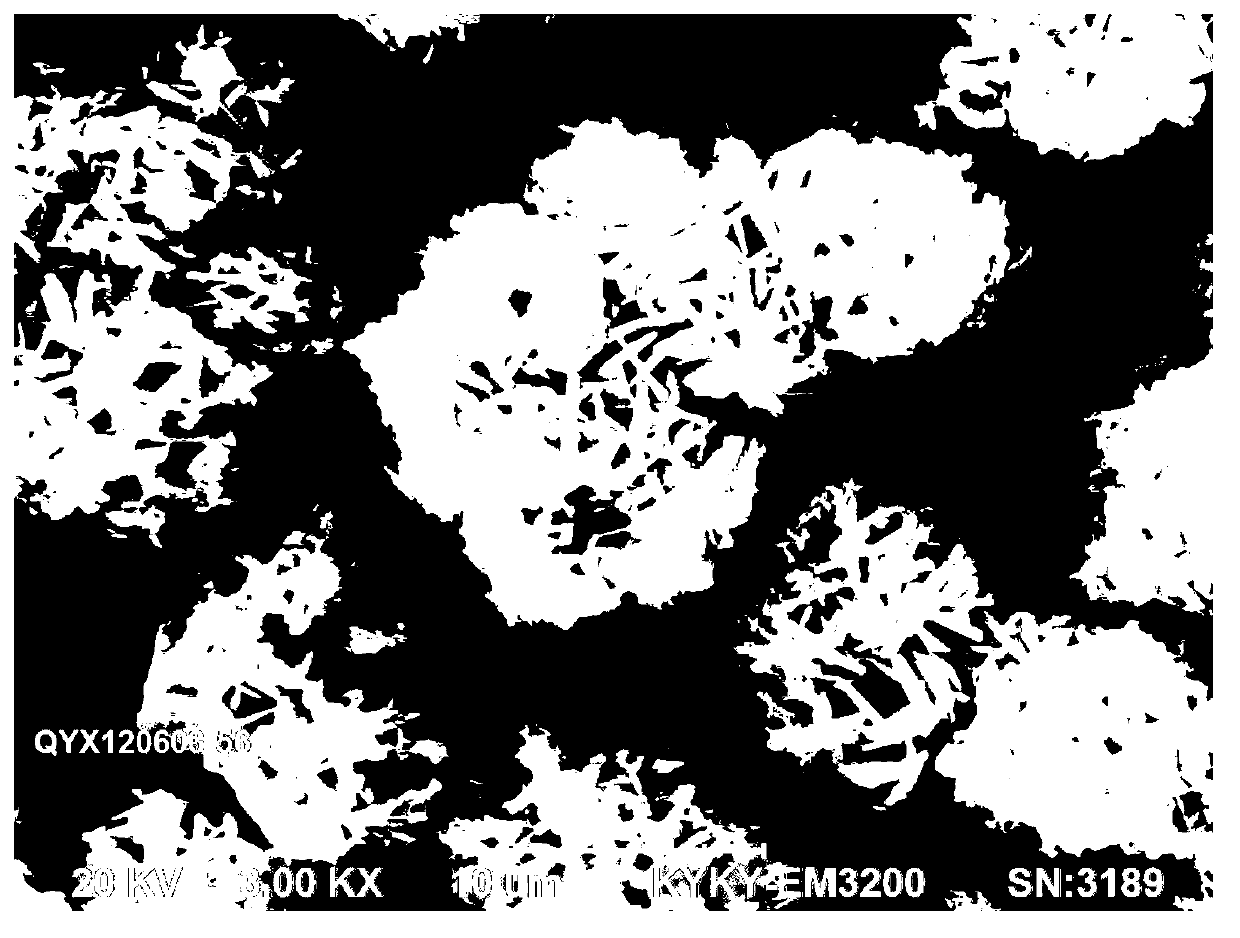

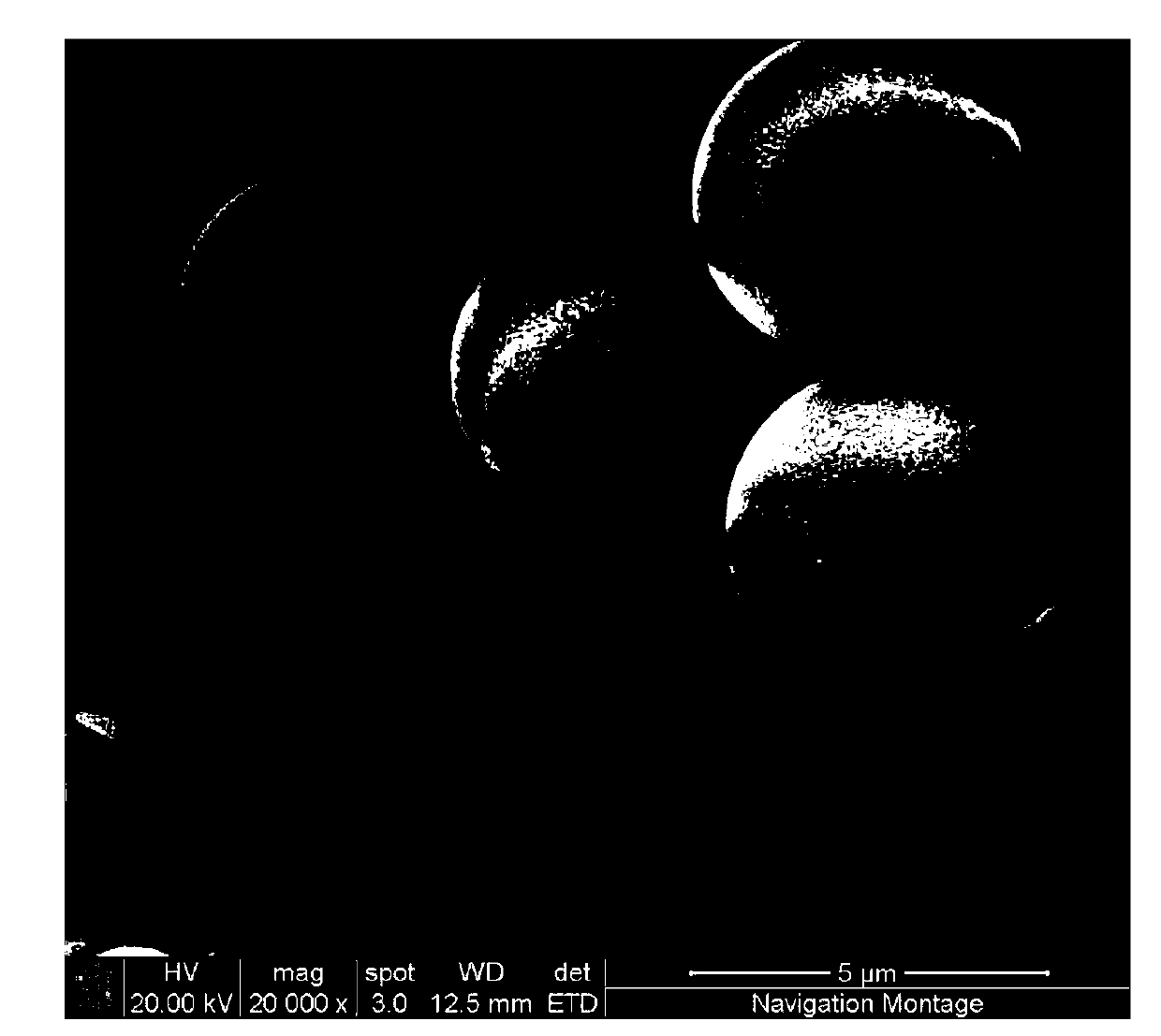

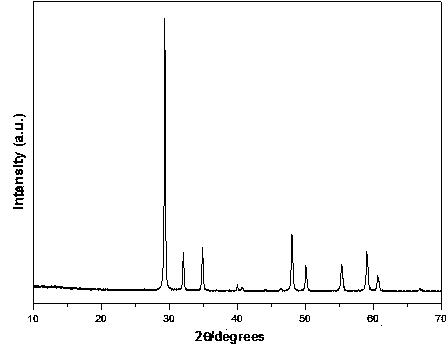

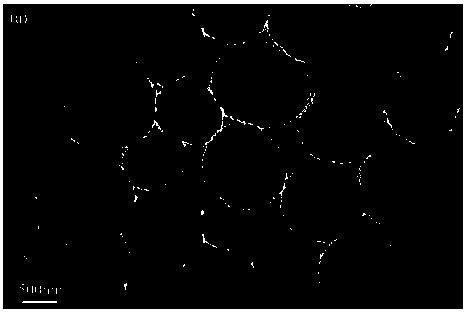

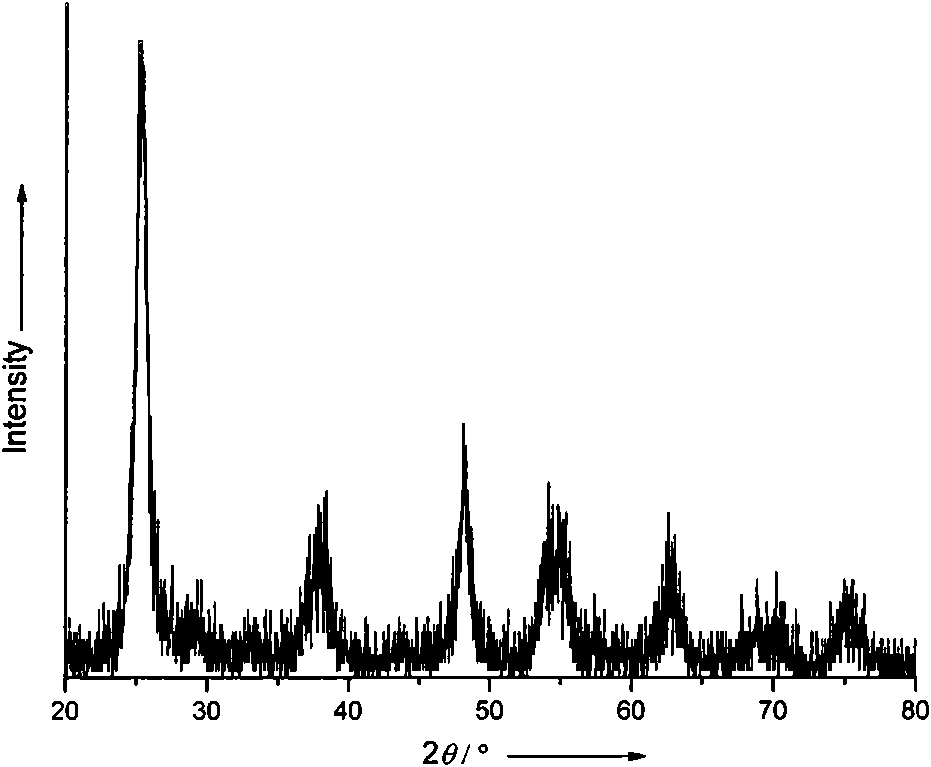

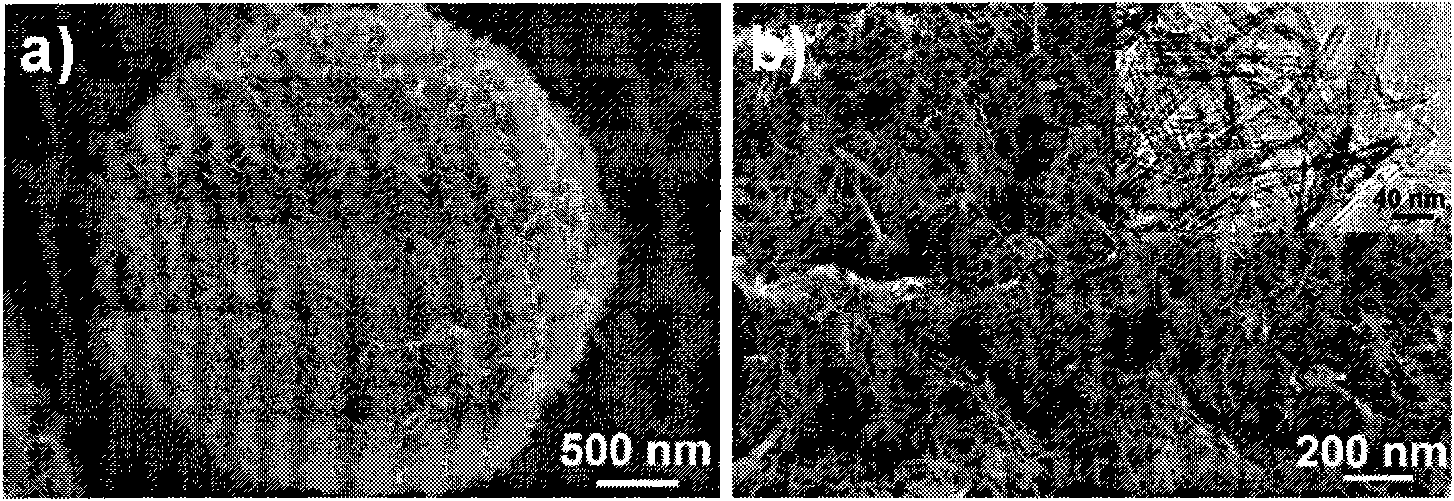

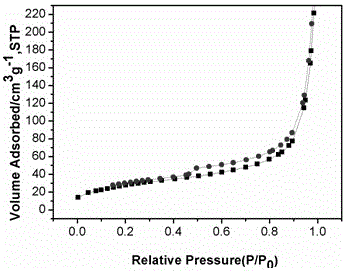

Fe2O3 micro-nano porous sphere, preparation method thereof and uses thereof

InactiveCN102616861ALarge specific surface areaImprove thermal stabilityWater/sewage treatment by irradiationOther chemical processesMicro nanoOrganic dye

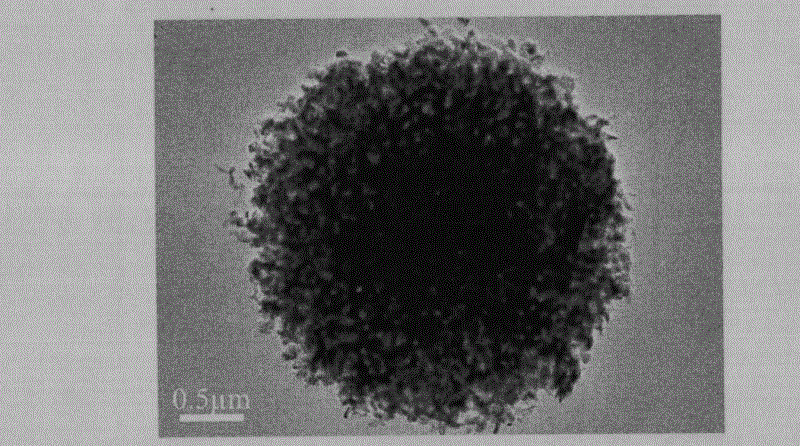

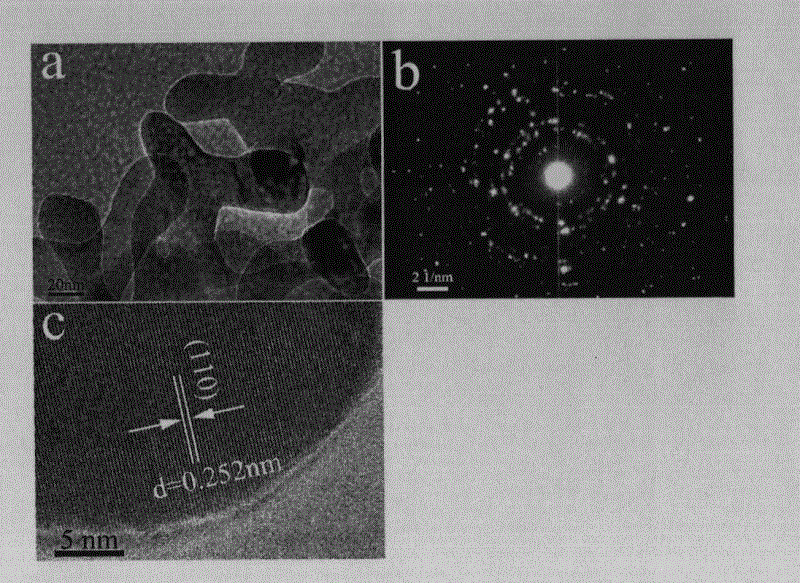

The invention discloses a Fe2O3 micro-nano porous sphere, a preparation method thereof and uses thereof. The porous sphere is formed by Fe2O3 nanoparticles having a nanometer mesoporous alpha-Fe2O3 phase structure therebetween, wherein the diameter of the sphere is 500-5000nm, the specific surface area of the sphere is 15-25m<2> / g, particle sizes of the particles are 20-60nm, and pore diameters of mesopores are 2-50nm. The method comprises the following steps: mixing ferric chloride hexahydrate, ascorbic acid, urea and water, and uniformly stirring them to obtain a mixed liquid; reacting the mixed liquid under conditions that the temperature is 140-180DEG C and the pressure is a self-generated pressure for at least 4h to obtain an intermediate product; separating, washing and drying the intermediate product to obtain porous iron carbonate; and annealing the porous iron carbonate at 450-550DEG C for at least 4h, and naturally cooling the porous iron carbonate to room temperature to prepare the Fe2O3 micro-nano porous sphere. The Fe2O3 micro-nano porous sphere can be placed in water polluted by organic dyes to photocatalytically degrade under visible light, or in water polluted by potassium dichromate to adsorb.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Process for making macro porous ceramic spheres

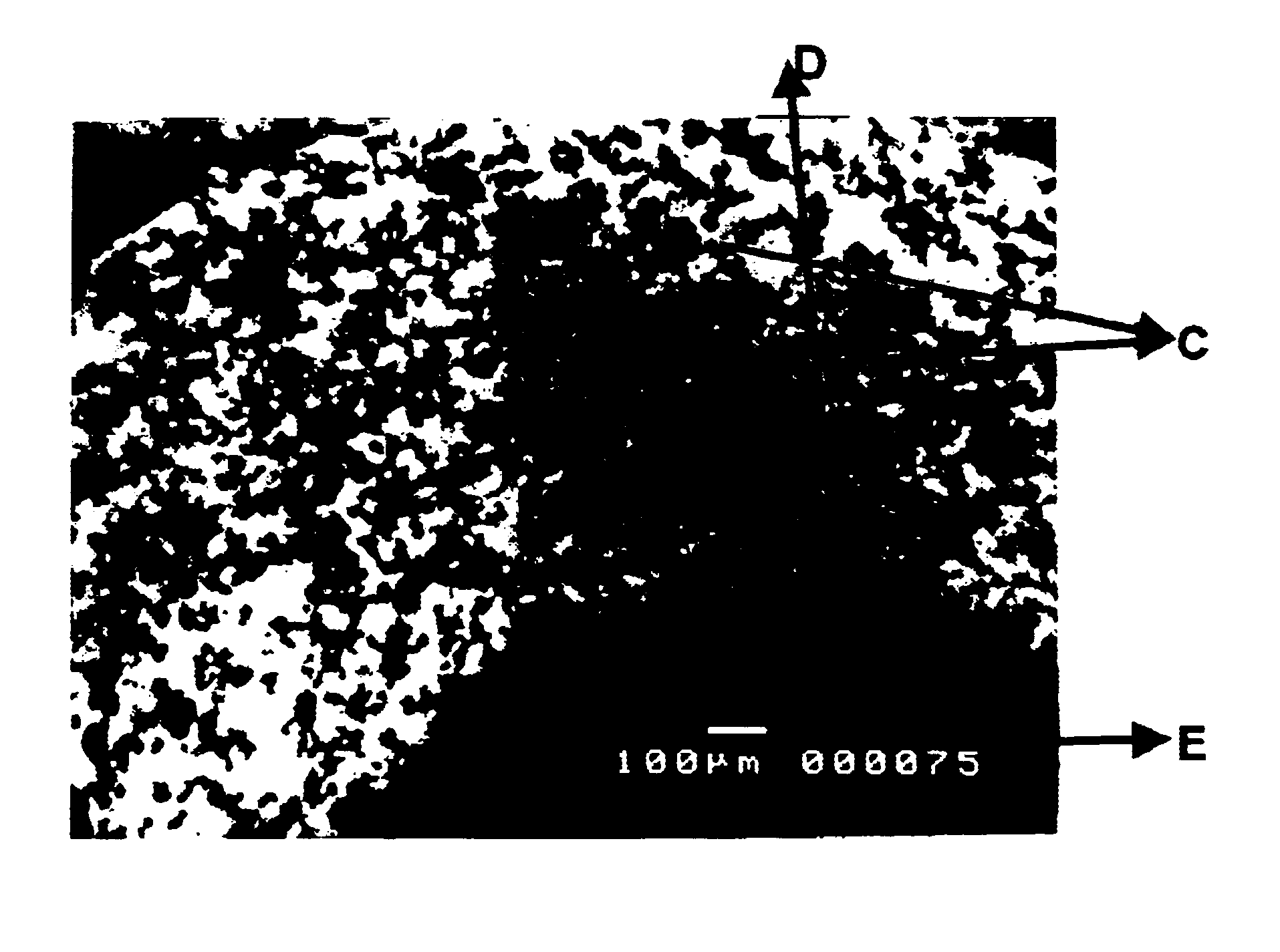

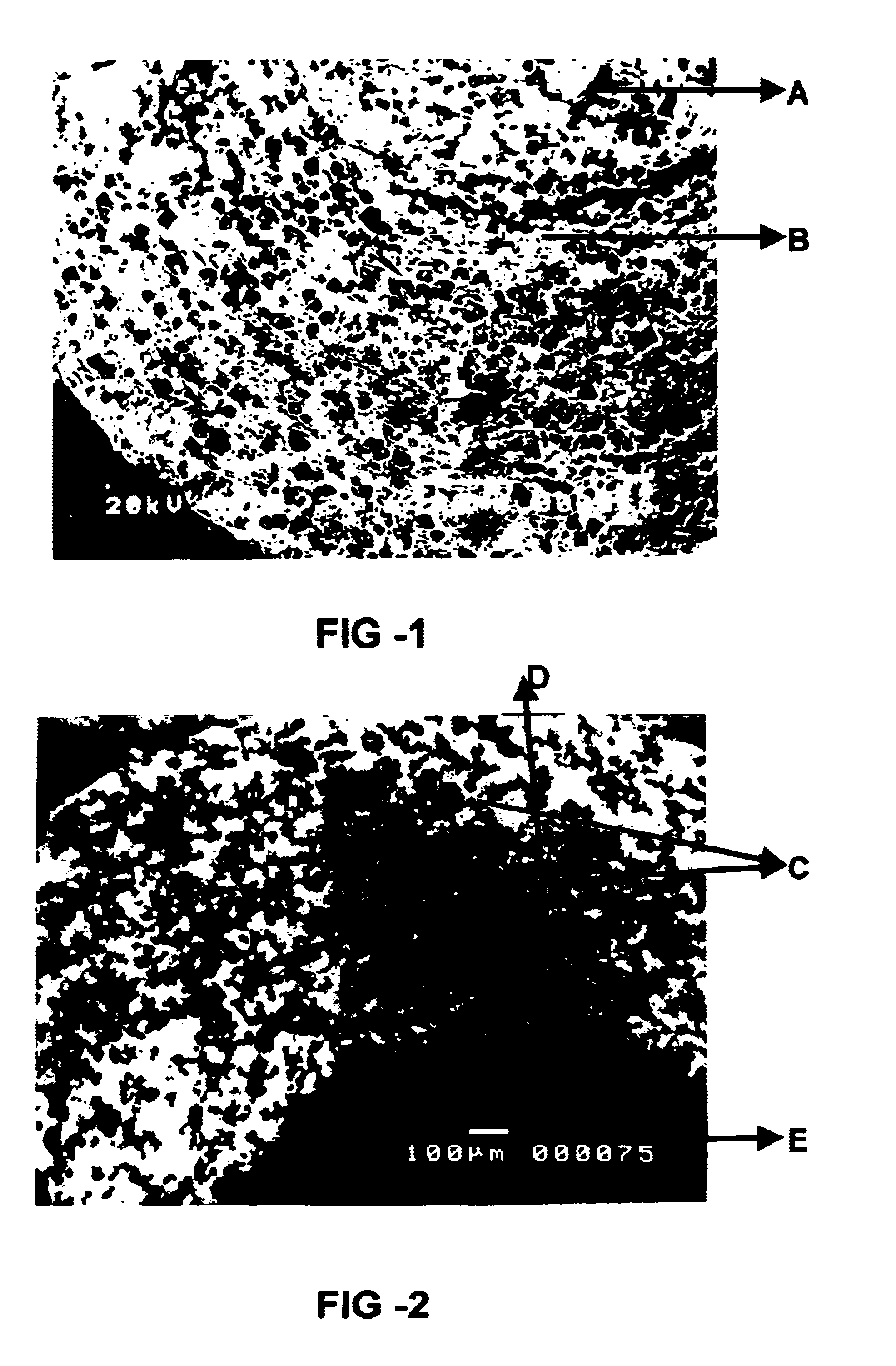

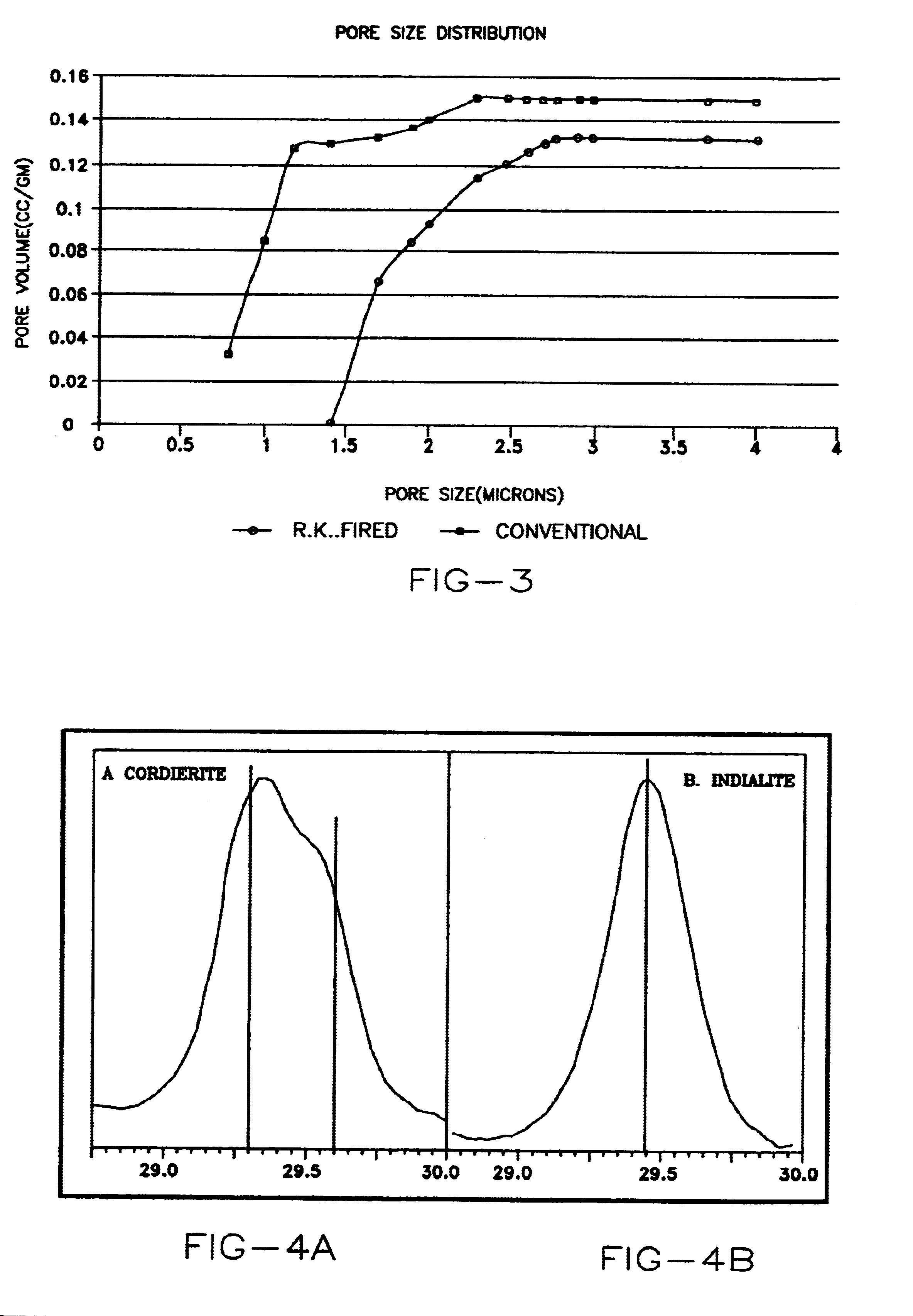

InactiveUS6616873B1High compressive strengthUniform heat treatmentCeramic shaping apparatusCeramicwareBrickCooling down

Process for making thermally stable macro porous spheres with or without central core cavity includes steps of homogenizing dry pulverized selective constituents with or without burnable core particles and with <25% combustibles; sprinkling over pan pelletizer wetted with PVA aqua sol binder and rolling to form spheres having <25% moisture and dry compacting in pelletizer before oven drying at 90-100° C. until moisture and core particles are partially destroyed and sintering under rotary motion of the spheres for 45-60 minutes at 1350-1380° C. before being rapidly cooled down to ambient temperature and sieving and recovering therefrom low-to-high temperatures >90% loose fill macro porous spheres for catalyst and moulded bricks / monoliths forming refractory insulation applications.

Owner:THE ASSOC CEMENT CO LTD

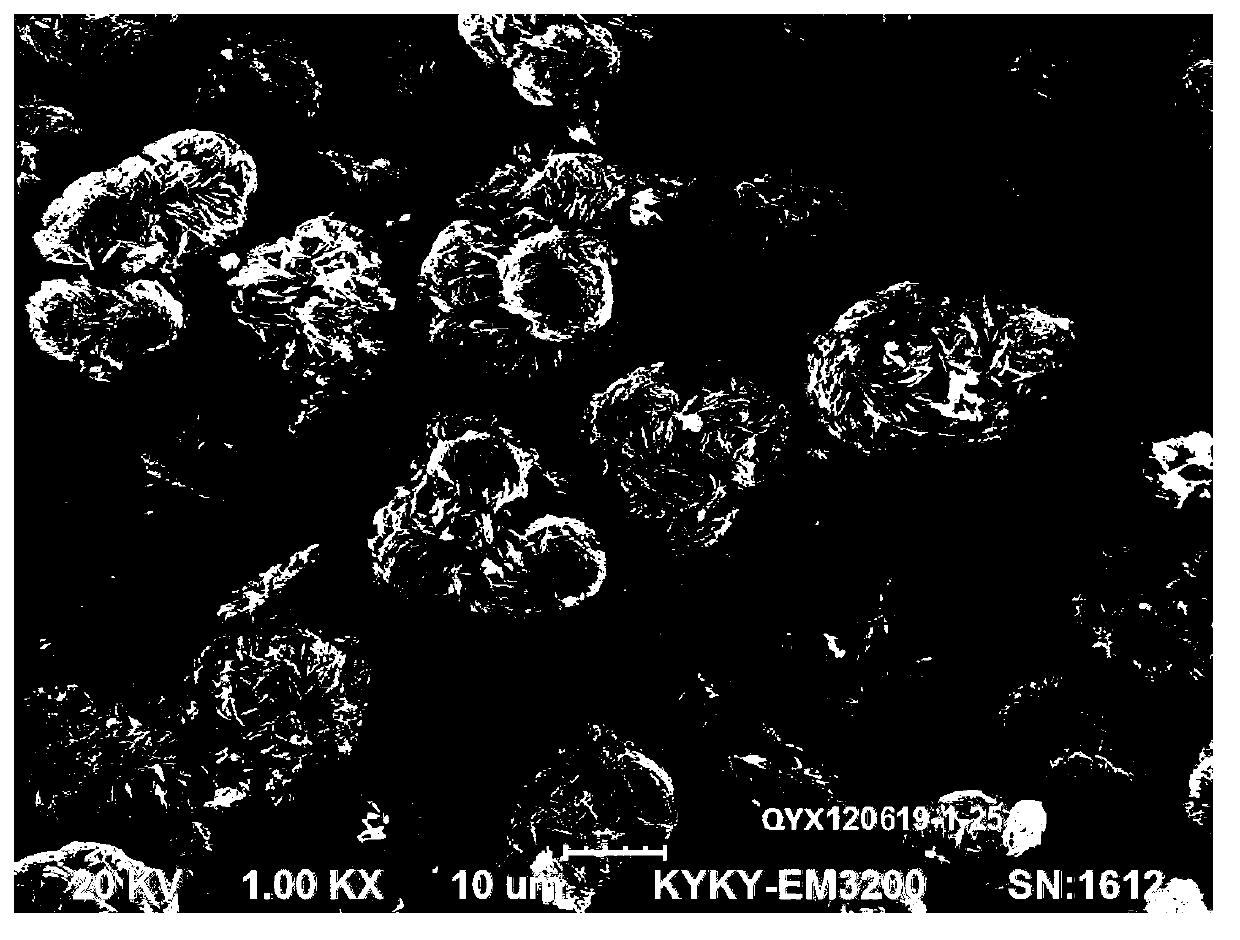

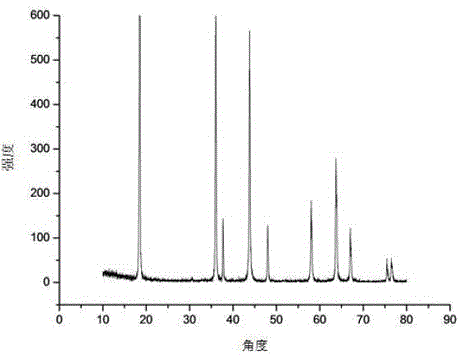

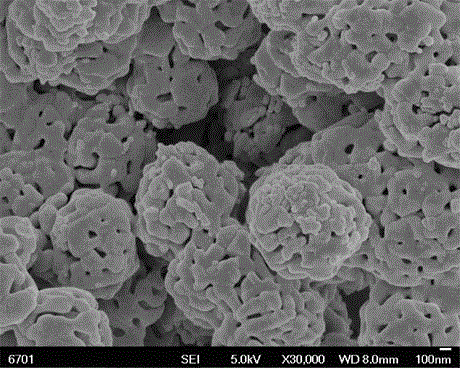

Method for continuously preparing cobalt hydroxide with high bulk density

ActiveCN103342394ASimple processContinuous productionCobalt oxides/hydroxidesPhysical chemistryImpurity

The invention discloses a method for continuously preparing cobalt hydroxide with high bulk density. The current cobalt hydroxide preparation methods include an alkali solution sedimentation method, a sedimentation conversion method and the like which have the following three difficulties: cobalt hydroxide sedimentation particles are smaller, difficult to filter and wash, and the recovery rate of materials is low; the materials are low in quality and high in impurity content; the high energy consumption is caused by intermittent production. The technical scheme is as follows: the method is characterized by comprising the following steps of: with cobalt-contained ore material as the raw material, leaching the cobalt-contained ore material, and then, purifying the cobalt-contained ore material to obtain a cobalt chloride solution; with NaOH as a base solution, merging NaOH, cobalt chloride and a complexing agent solution, adding the mixed solution into a reaction kettle, rapidly controlling the pH value at 8-12, the temperature at 30-90 DEG C and the stirring speed at 200-1000rpm in the flow merging process, and opening an overflow valve of the reaction kettle to begin to carry out continuous production after the reaction is carried out for 6-40h. The method is simple in process, capable of realizing continuous production, convenient in operation and beneficial to the industrial production; a product is excellent and is shaped like a porous sphere, and the particle size of the product is distributed normally.

Owner:ZHEJIANG HUAYOU COBALT

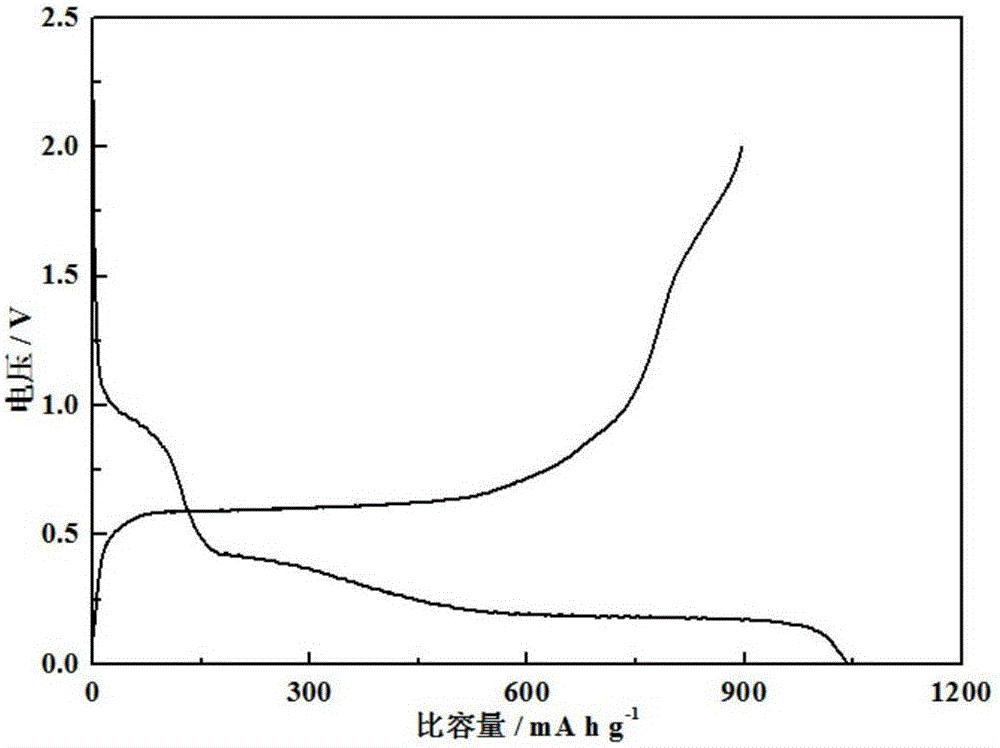

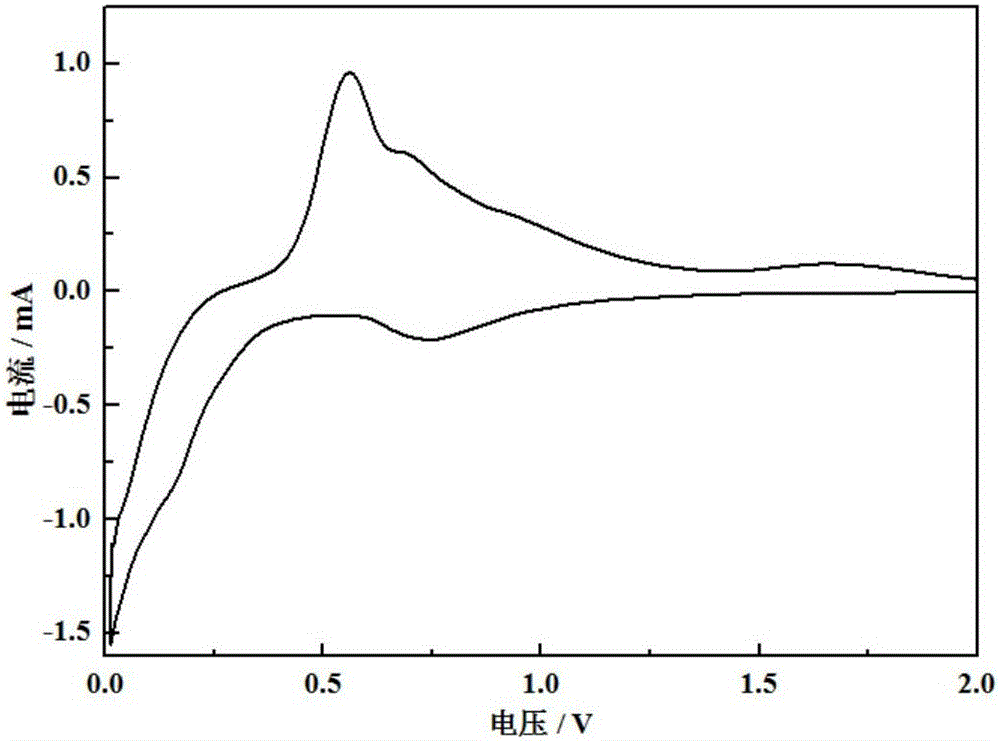

Phosphorus-carbon composite material and preparation method and application thereof

ActiveCN105702939AIncrease contactAvoid chalkingCell electrodesSecondary cellsCarbon compositesSodium-ion battery

The invention provides a phosphorous-carbon composite material and a preparation method and application thereof. The phosphorus-carbon composite material is prepared from red phosphorus, a carbon material and an additive through simple and high-efficiency mass production at a large scale and is of a porous spherical structure, wherein the red phosphorous is uniformly dispersed in the spherical phosphorous-carbon composite material in a form of nanometer phosphorous. The phosphorous-carbon composite material has the advantages of high first-circle coulombic efficiency, high cycle stability and the like when used for a sodium ion battery. The preparation method of the phosphorous-carbon composite material is simple, is cheap and available in raw materials, is easy for commercial production, and has very wide application prospect.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Shape-controlled battery grade iron phosphate and preparation method thereof

The invention discloses shape-controlled battery grade iron phosphate and a preparation method thereof. The method comprises the following steps of: (1) preparing reaction mother liquor; (2) dissolving raw materials in the mother liquor to form reaction liquor; (3) carrying out a hydrothermal reaction; and (4) filtering, washing and drying the product. The preparation method disclosed by the invention is simple in technical process and less in control parameters, and iron phosphate with regular shape can be obtained without any plasticizers and dispersants. The filtrate in the step (4) is recovered as the reaction mother liquor which can be repeatedly used, so that the method is saving and environmental-friendly. The iron phosphate prepared by the method is high in purity, wherein the ratio of phosphorus to iron is 1:1. The iron phosphate is formed by iron phosphate particles with regular shapes. The particles are combined by sheet or columnar primary particles in nanoscale. The shapes of the particles after combination are circular sheets, similar spheres, spheres or porous spheres. The monodispersity of the iron phosphate particles is good, and the diameter size is adjusted in the range of 1-50 mu m.

Owner:NANJING UNIV

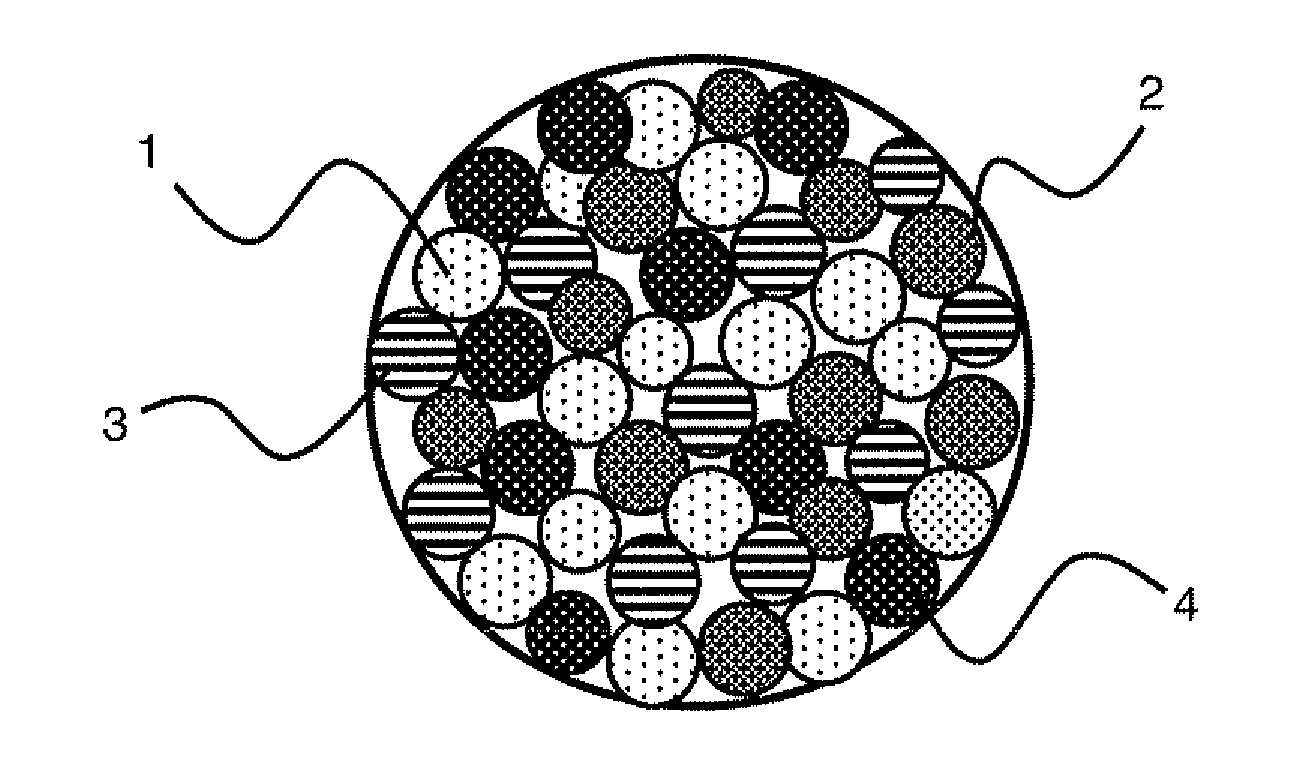

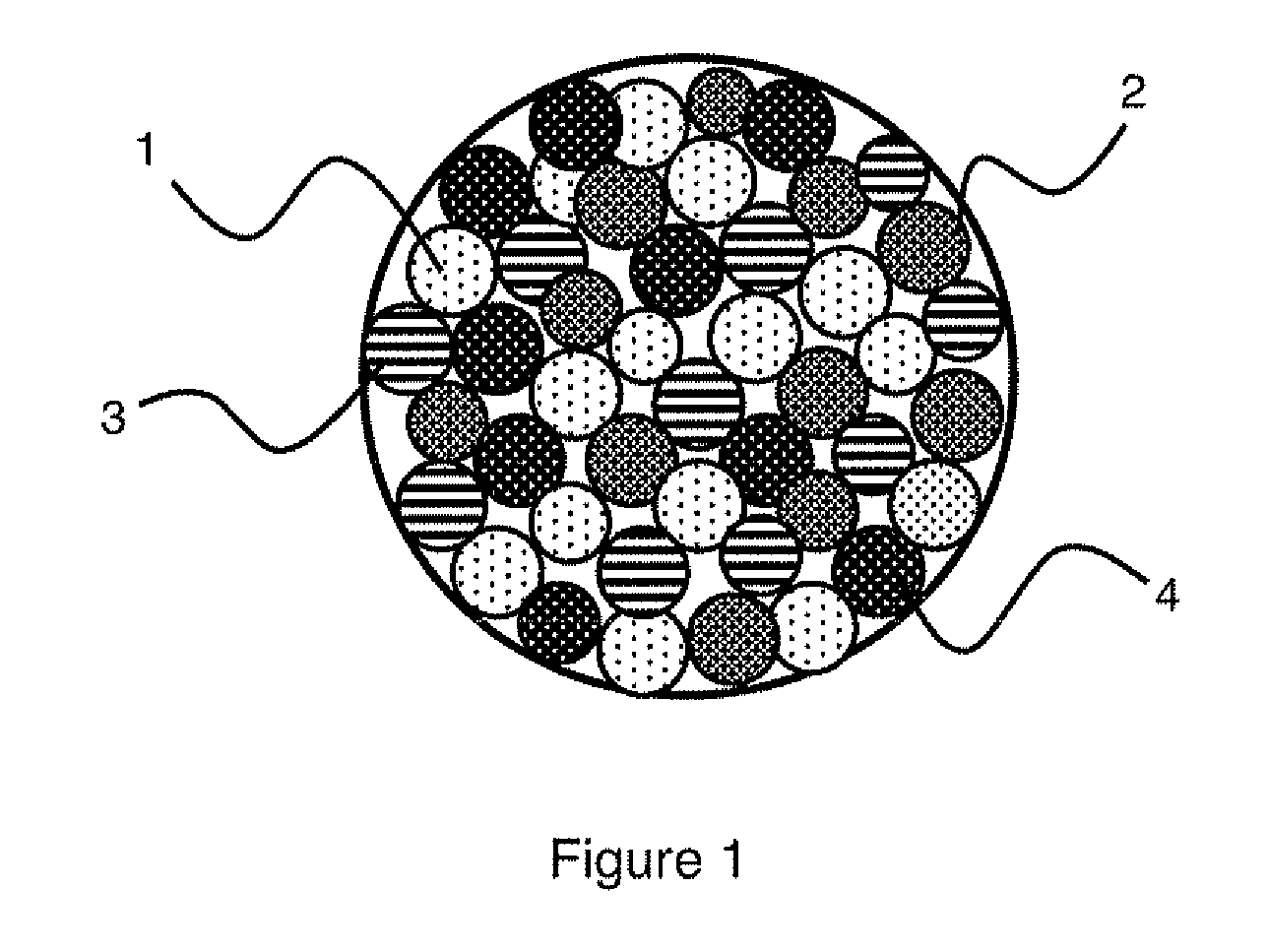

Silicon/carbon composite material, method for the synthesis thereof and use of such a material

InactiveUS20130273433A1Improve conductivityImprove electrochemical performanceConductive materialActive material electrodesCarbon compositesSynthesis methods

The invention relates to a silicon / carbon composite material, to a method for the synthesis thereof and to the use of such a material. The silicon / carbon composite material is formed by an aggregate of silicon particles and of carbon particles, in which the silicon particles and the carbon particles are dispersed. The carbon particles are formed by at least three different carbon types, a first type of carbon being selected from among non-porous spherical graphites, a second type of carbon being selected from among non-spherical graphites and a third type of carbon being selected from among porous electronically-conductive carbons. The first and second carbon types each have a mean particle size ranging between 0.1 μm and 100 μm and the third carbon type has a mean particle size smaller than or equal to 100 nanometers.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

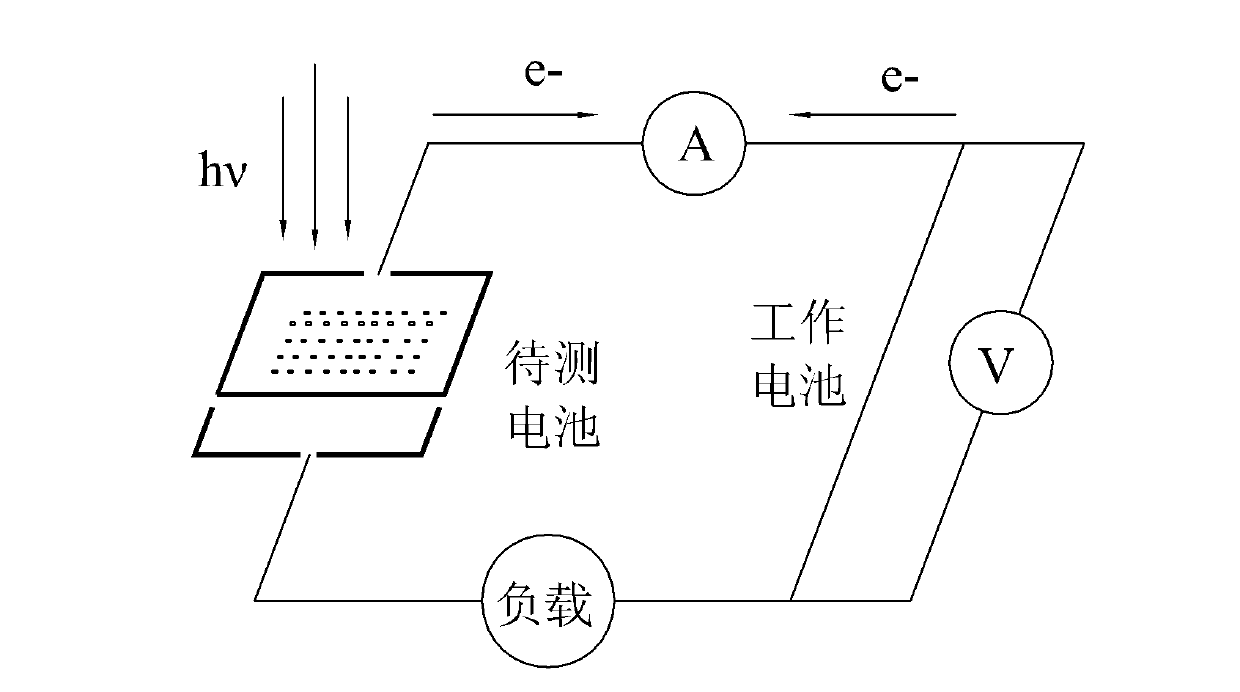

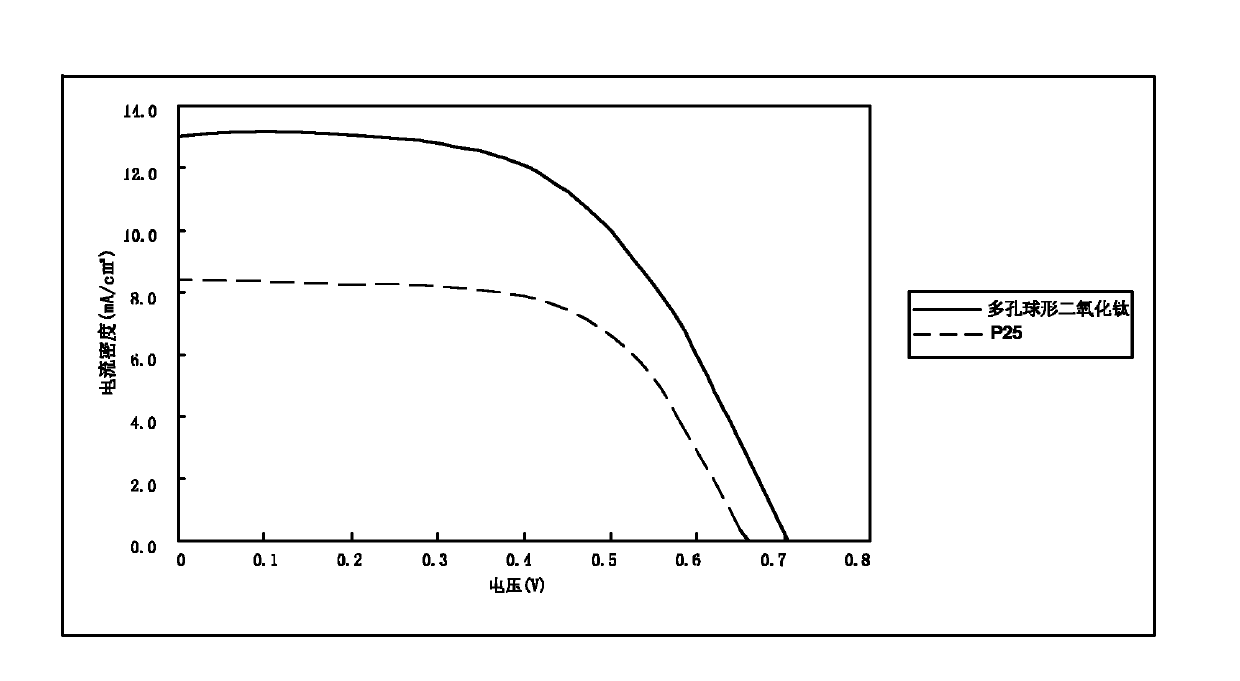

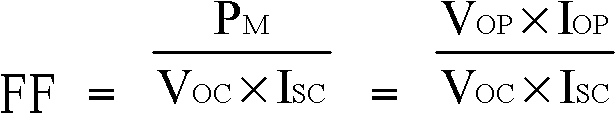

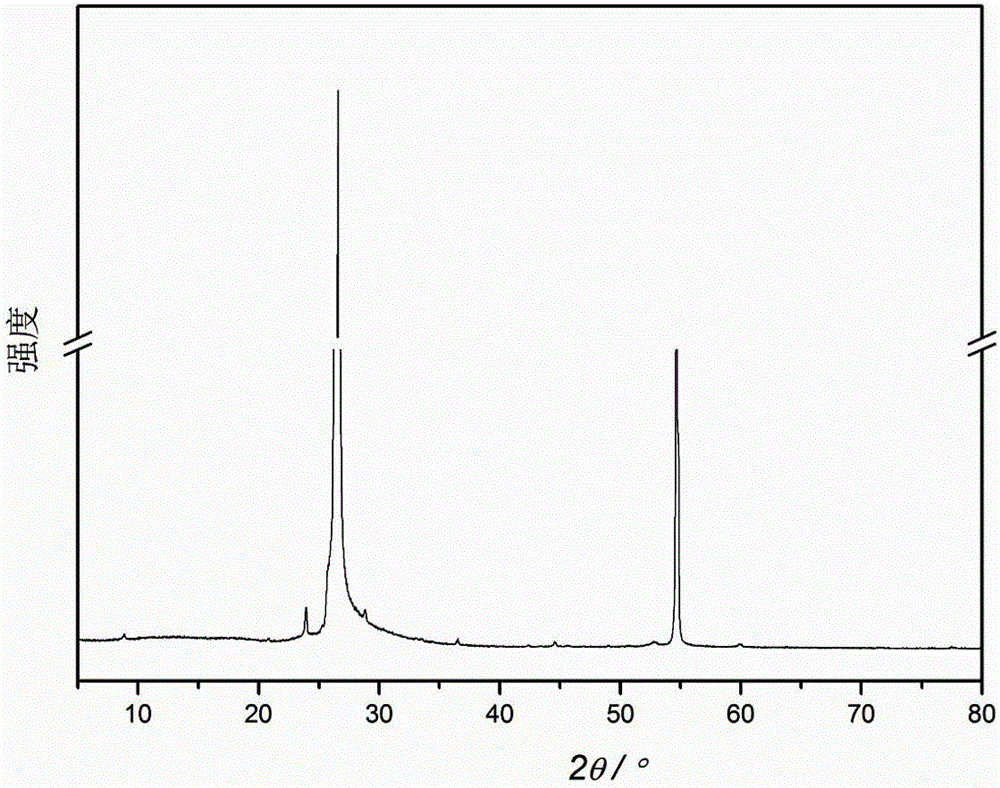

Methods for preparing porous spherical titanium dioxide and light positive pole

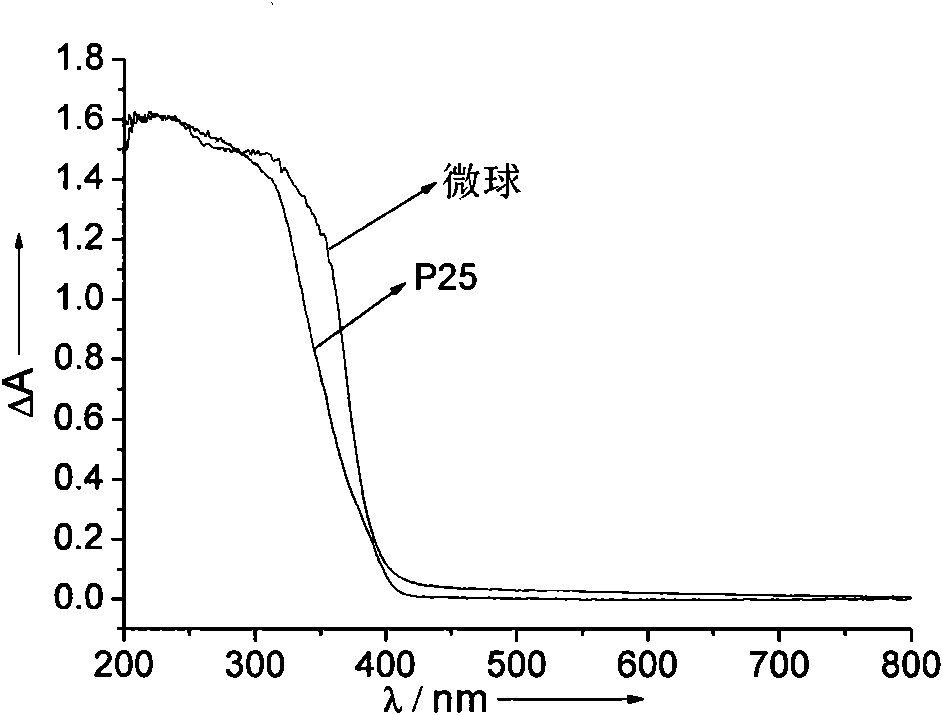

InactiveCN102167397ARaw materials are easy to getEasy to operateLight-sensitive devicesSolid-state devicesSemiconductor electrodeDye absorption

The invention provides a method for preparing porous spherical titanium dioxide and a method for preparing a dye solar cell light positive pole from porous spherical titanium dioxide prepared by the method, and a dye-sensitized solar cell prepared from the dye solar cell light positive pole. The prepared porous spherical titanium dioxide can be used as a dye absorption carrier in the electrode ofa dye-sensitized semiconductor, is large titanium dioxide particles with porous structures, and has the characteristics of P25 and submicron titanium dioxide. In the method, the porous spherical titanium dioxide is prepared by taking cetylamine as a structural guiding agent, and ammonia water as a surface aperture regulator; and the raw materials are easily obtained, the method is easy to operate, the energy consumption is low and the repeatability is high. Compared with a battery prepared from the conventional P25 titanium dioxide, the prepared porous spherical titanium dioxide has a large specific surface area and high photochemical stability, improves the dye absorption efficiency and electron transport efficiency by over 50 percent, and is suitable for the research of high-efficiency dye batteries.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD +1

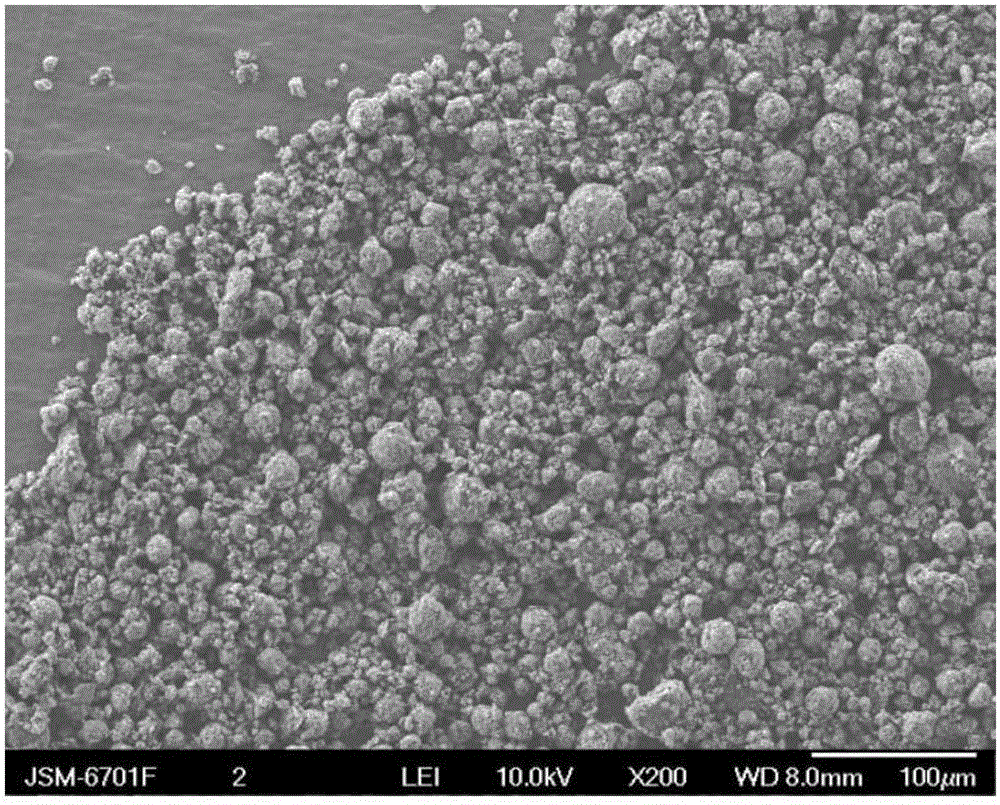

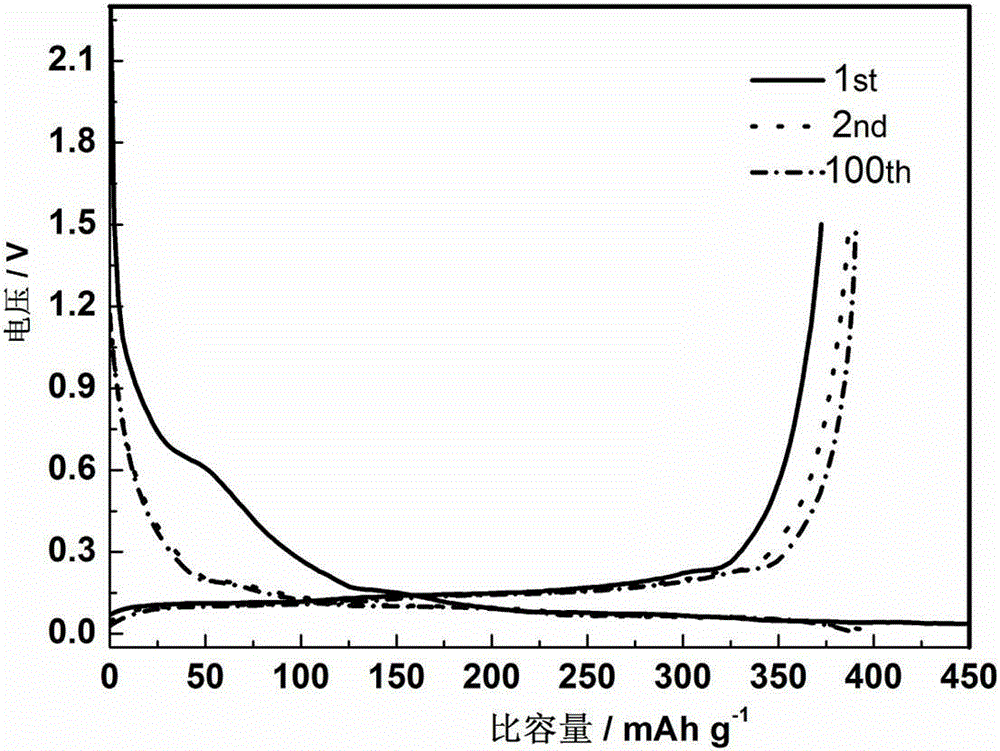

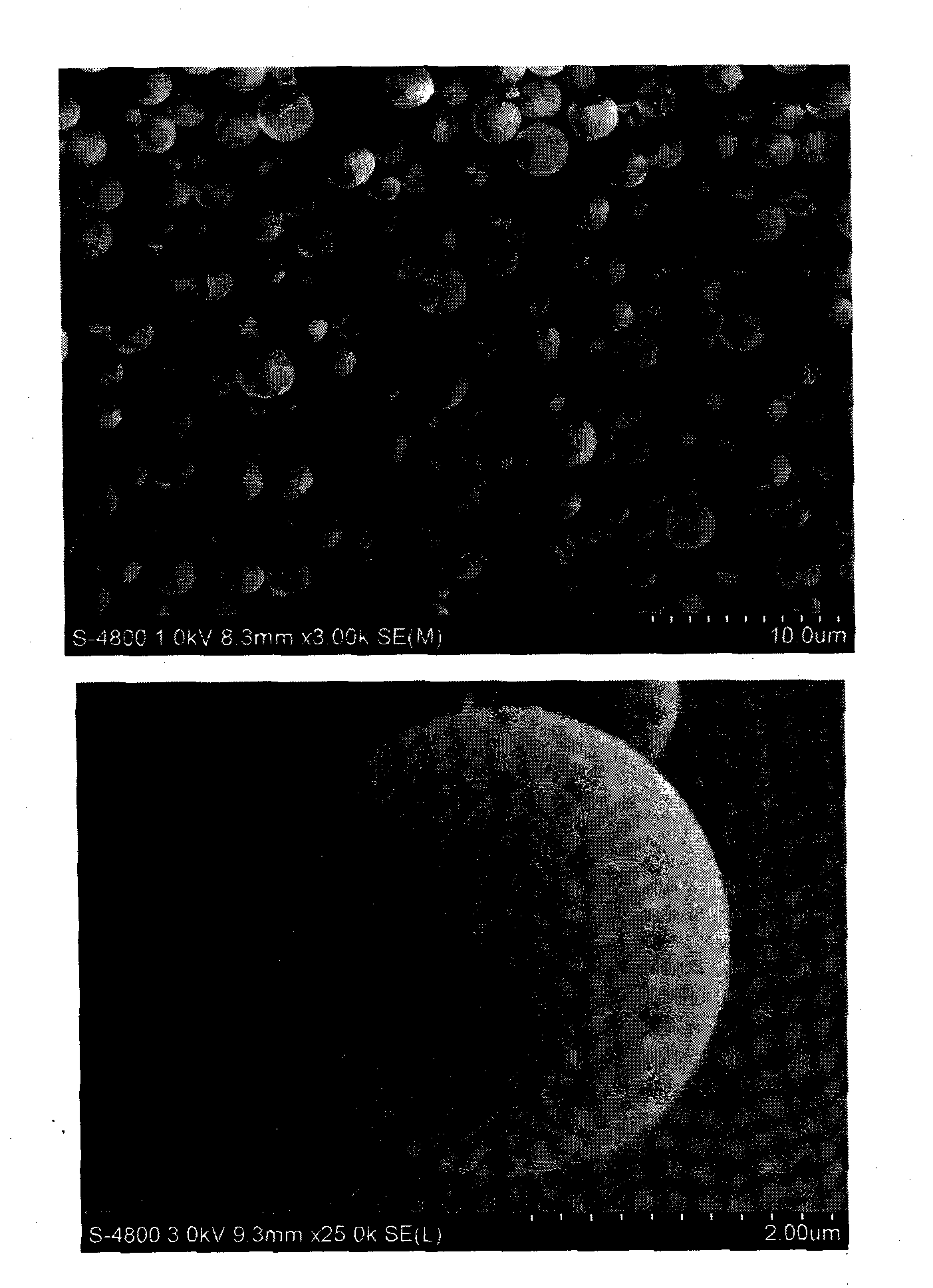

Spherical porous artificial graphite anode material and preparation method of same

ActiveCN105236393AHigh purityStrong penetrating powerCell electrodesSecondary cellsElectrolytic agentPhysical chemistry

The invention provides a spherical porous artificial graphite anode material, which is in the form of spherical particles formed by graphite nano crystals being less in 0.5 [mu]m in size in a binding manner. The spherical particles is 5-15 [mu]m in diameter and has large quantity of pores distributed therein. A preparation method of the artificial graphite includes the steps of ball-milling anthracite ore, removing impurities, performing dispersion and coating and performing high-temperature thermal treatment. The artificial graphite can reach 99.99% in purity and can reach 390 mAh / g in 0.5C reversible capacity by means of regulation of graphitization degree and introduction of coating carbon having a special structure. The porous spherical structure is formed by large quantity of the graphite nano crystals, so that the porous artificial graphite has a large specific surface area and is beneficial to permeation of electrolytes into the spherical particles. The anode material can be commercially popularized.

Owner:CHINA THREE GORGES UNIV +1

Porous spherical titanium dioxide with controllable diameter and preparation and application thereof

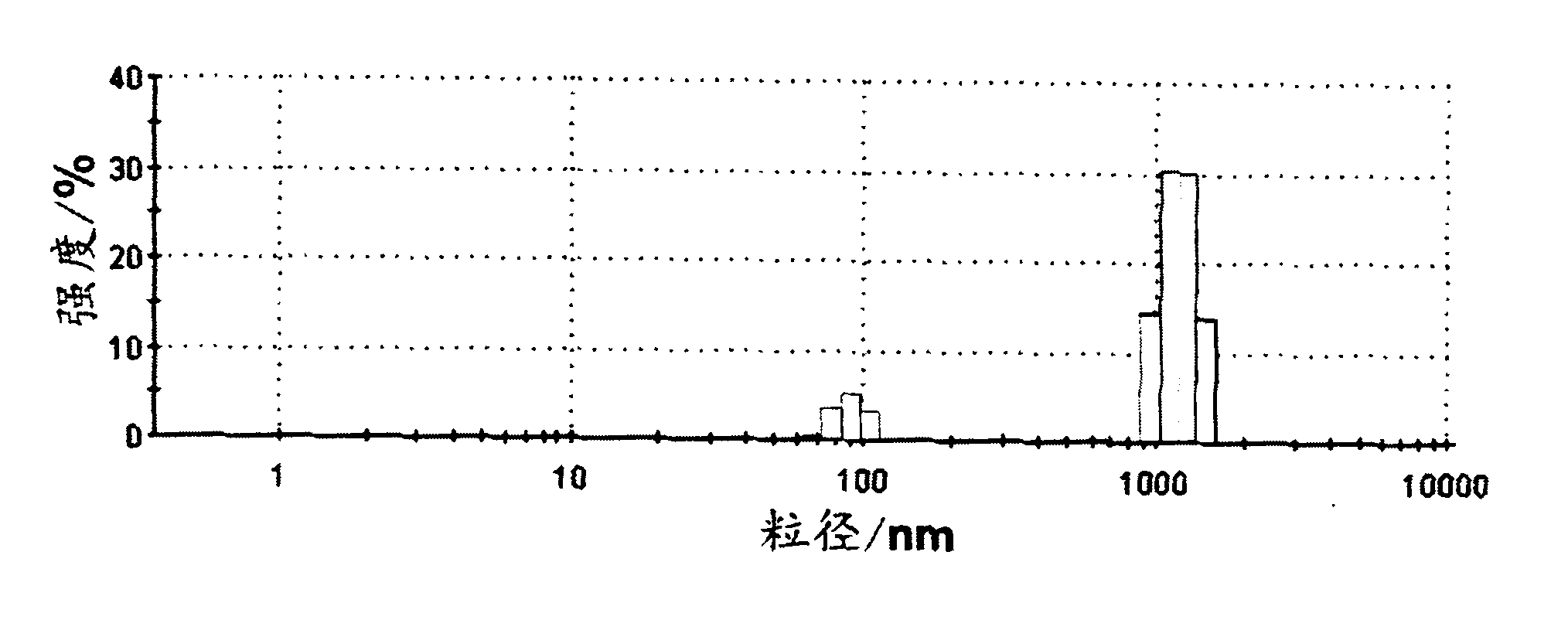

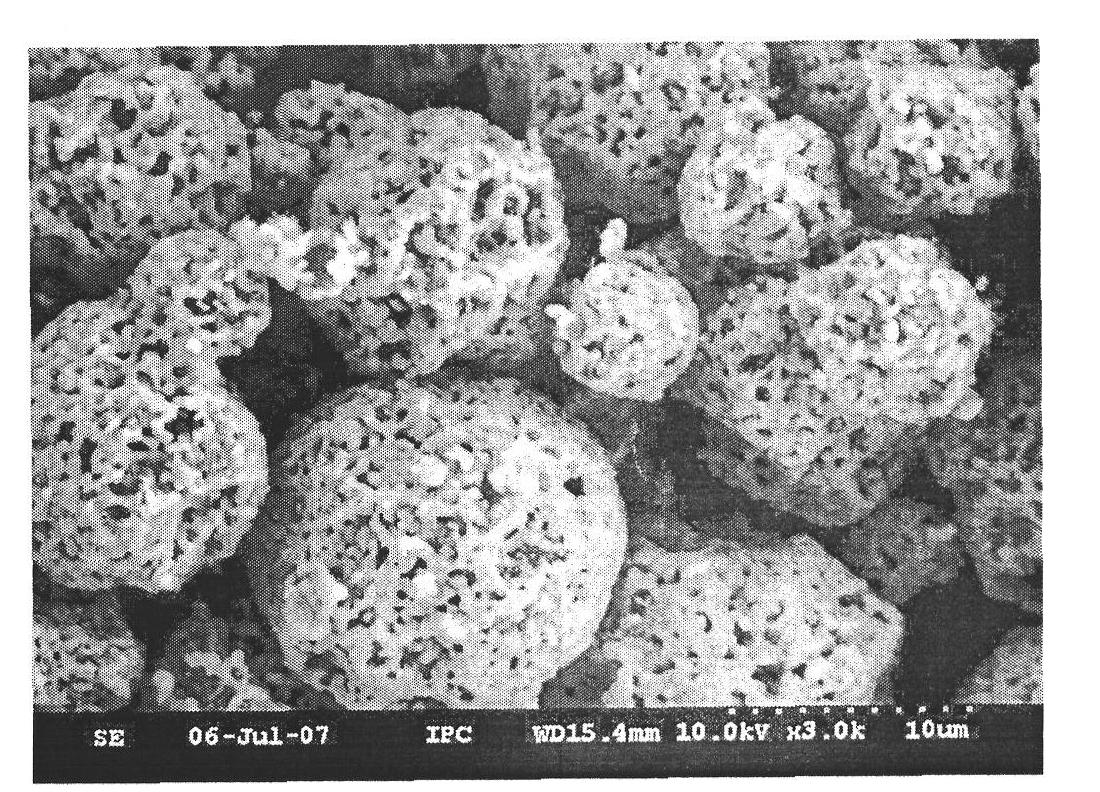

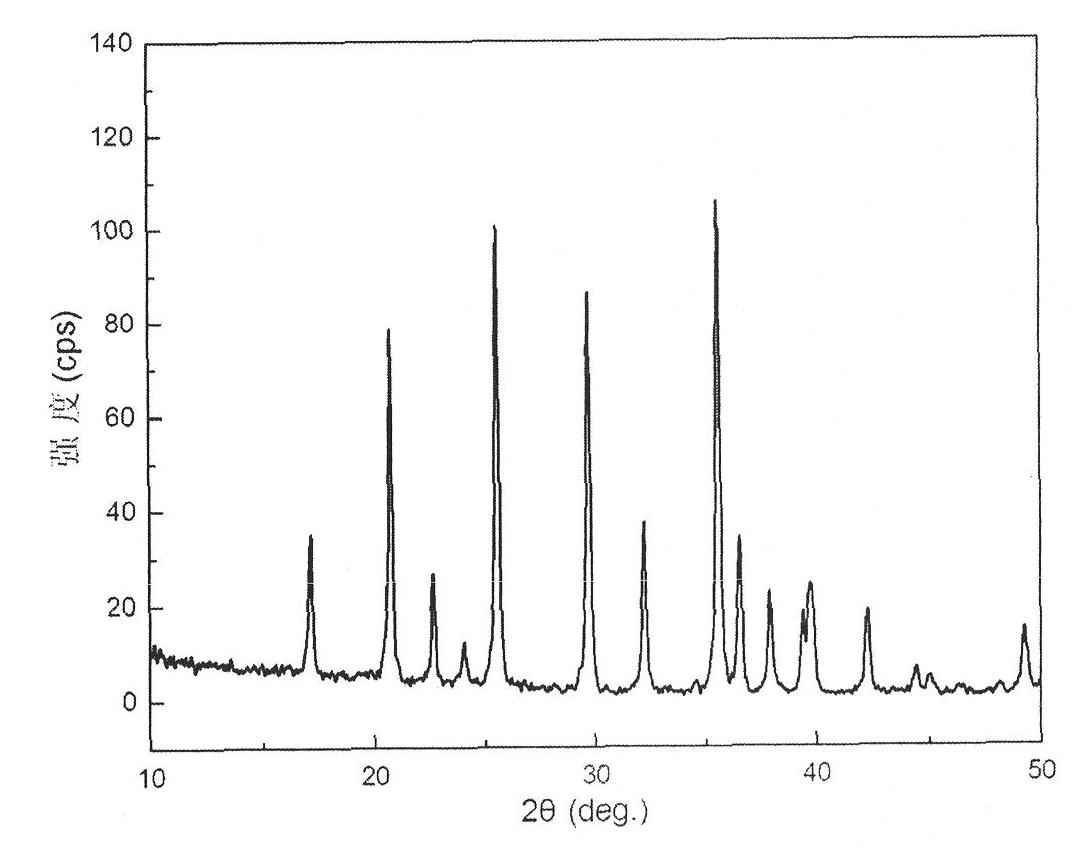

InactiveCN103739013ALarge specific surface areaImprove permeabilityMaterial nanotechnologyElectrolytic capacitorsPyrrolidinonesSolar battery

The invention discloses porous spherical titanium dioxide with controllable diameter and preparation and application thereof, belonging to the technical field of titanium dioxide and application thereof. The porous spherical titanium dioxide with controllable diameter is a sphere with diameter of 150nm-4mu m, which is gathered by granule titanium dioxide. The preparation process comprises steps of carrying out reaction on titanium tetrachloride water solution and reaction liquid prepared by urea, polyvinylpyrrolidone and ethyl alcohol, washing, drying and calcining the precipitate so as to obtain the porous spherical titanium dioxide with controllable diameter. The preparation has the advantages of having simple processes, being applicable to industrial production, and realizing control on diameter size of the spherical titanium dioxide by controlling the proportion of raw material amount. The prepared spherical titanium dioxide has large specific surface area, has multiple pores inside, is used for preparing dye sensitization solar energy batteries and endows the dye sensitization solar energy batteries with good photoelectric property.

Owner:TIANJIN UNIV

Flavone-metal complex microsphere and preparation method and application thereof

InactiveCN101891783AEasy to shapeSimple structureSugar derivativesCopper organic compoundsSolid sphereFluorescence

The invention relates to a flavone-metal complex microsphere which is in a spherical shape and in the structure of a solid sphere or a hollow sphere or a porous sphere, and the particle size of the sphere is 50nm-5000nm. The flavone-metal complex microsphere is formed by complexing flavonoid substances such as flavanol, anthocyanidin, tea polyphenol and the like with metal, and the preparation process comprises the following sequential steps: (1) preparing a flavone solution, (2) reacting and synthesizing, and (3) collecting and drying the product. In the reaction for synthesis, glycerin or glycol is used as an assistant, and the reaction temperature is 60 DEG C-70 DEG C for obtaining the solid microsphere. In the reaction for synthesis, ethyl acetate or vinyl alcohol is used as an assistant, and the reaction temperature is 90 DEG C-150 DEG C for obtaining the hollow microsphere. In the reaction for synthesis, ethanol is used as an assistant, and the reaction temperature is 70 DEG C-90 DEG C for obtaining the porous microsphere. The flavone-metal complex hollow microsphere can be used as a drug carrier or fluorescence molecular carrier for application.

Owner:SICHUAN UNIV

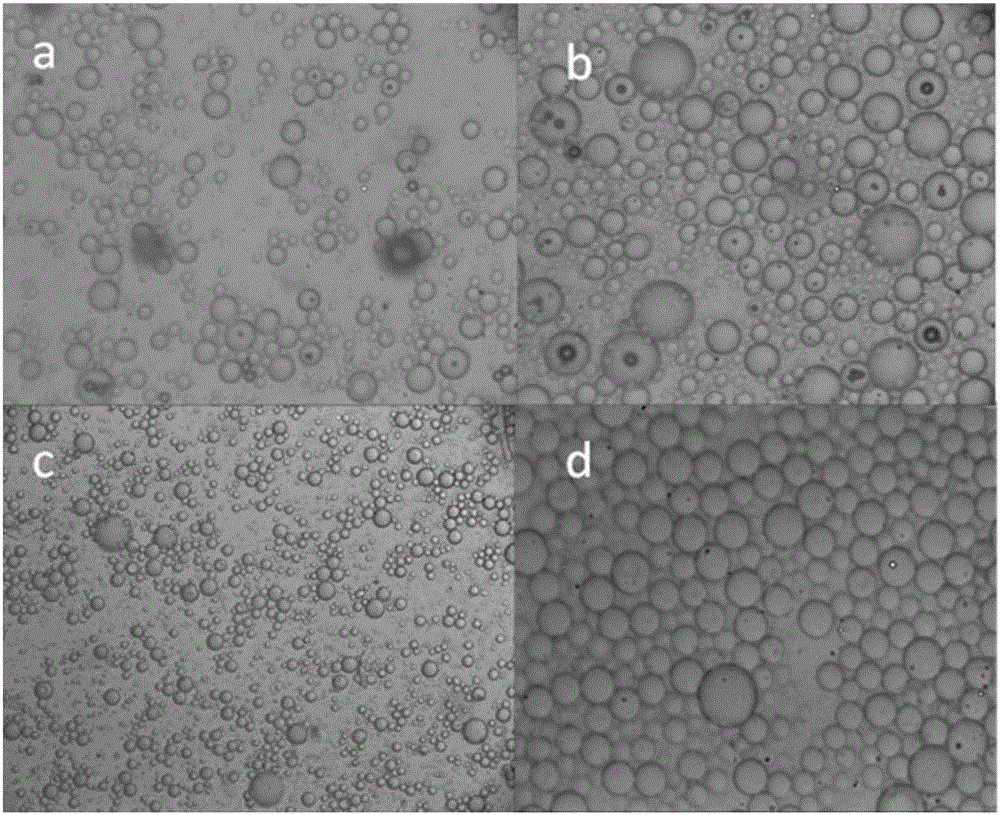

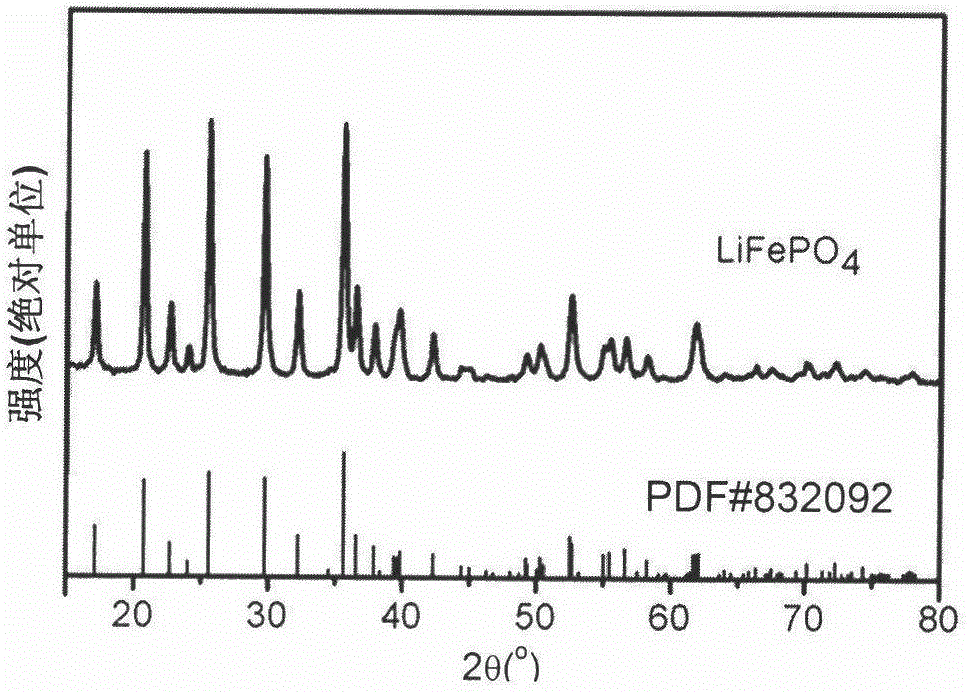

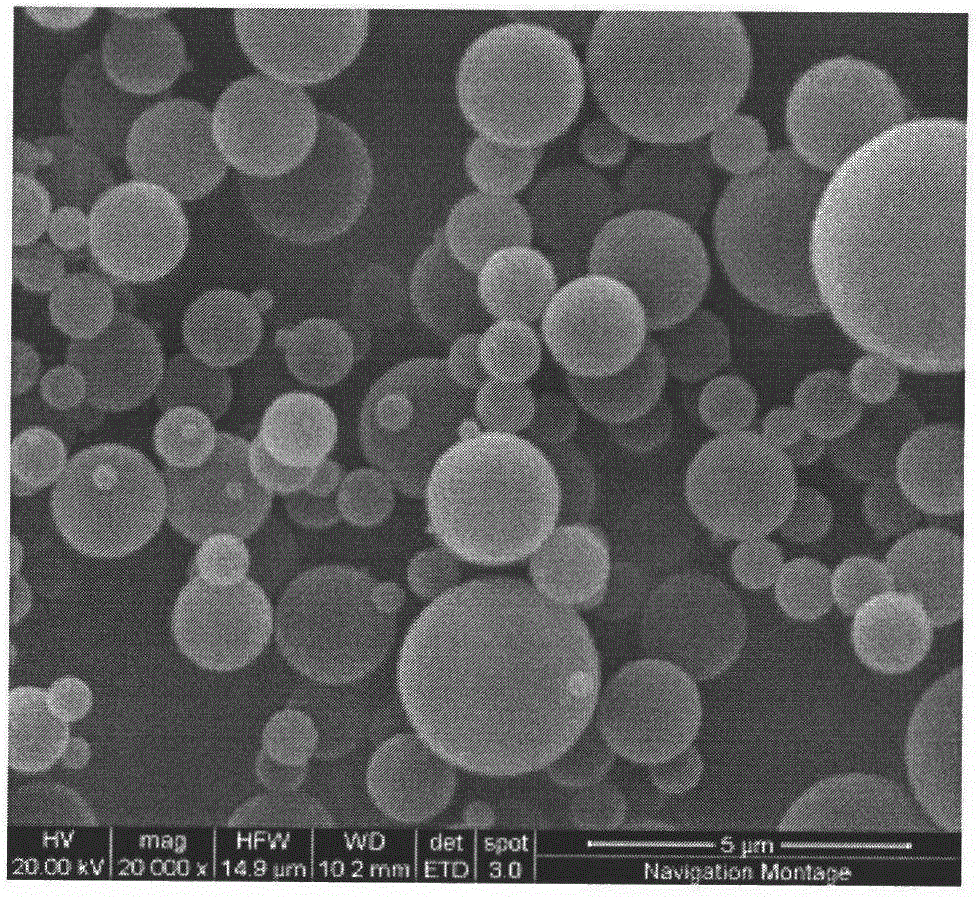

Preparation method of positive-electrode cellular material used by lithium ion battery

InactiveCN101794880ALarge specific surface areaImprove liquidityCell electrodesPhosphateSodium-ion battery

The invention relates to a preparation method of positive-electrode cellular material used by a lithium ion battery, and belongs to the technical field of battery materials. The invention provides a preparation method of used positive-electrode cellular material of ferrous phosphate lithium used by the lithium ion battery, the obtained material has large specific surface area and high porosity, large contact area with electrolyte, improves the deintercalation and intercalation rate of Li+, and is favor of improving the volume and the power density; and the method overcomes the defects that the raw materials can not be fully contacted of methods such as a solid phase method, can obtain the material with controllable grain size, even grain size distribution, with a regular porous sphere or sphere-like shape. The method has simple process, can be continually operated and is easy for industrialization production.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

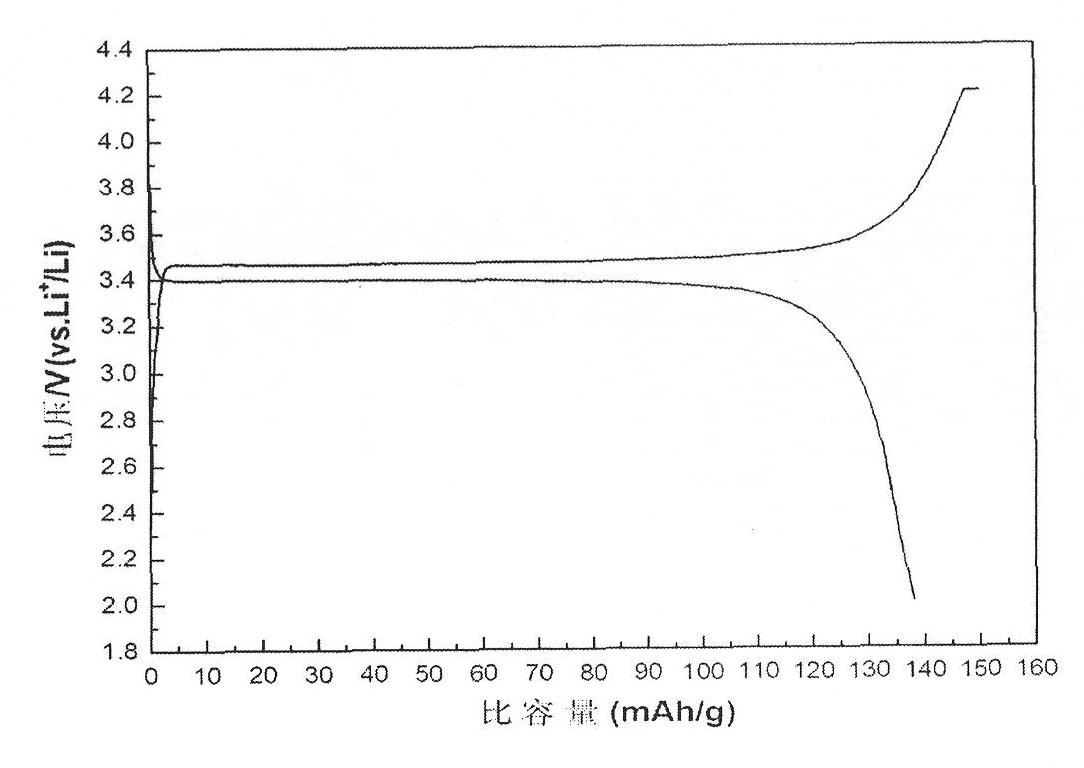

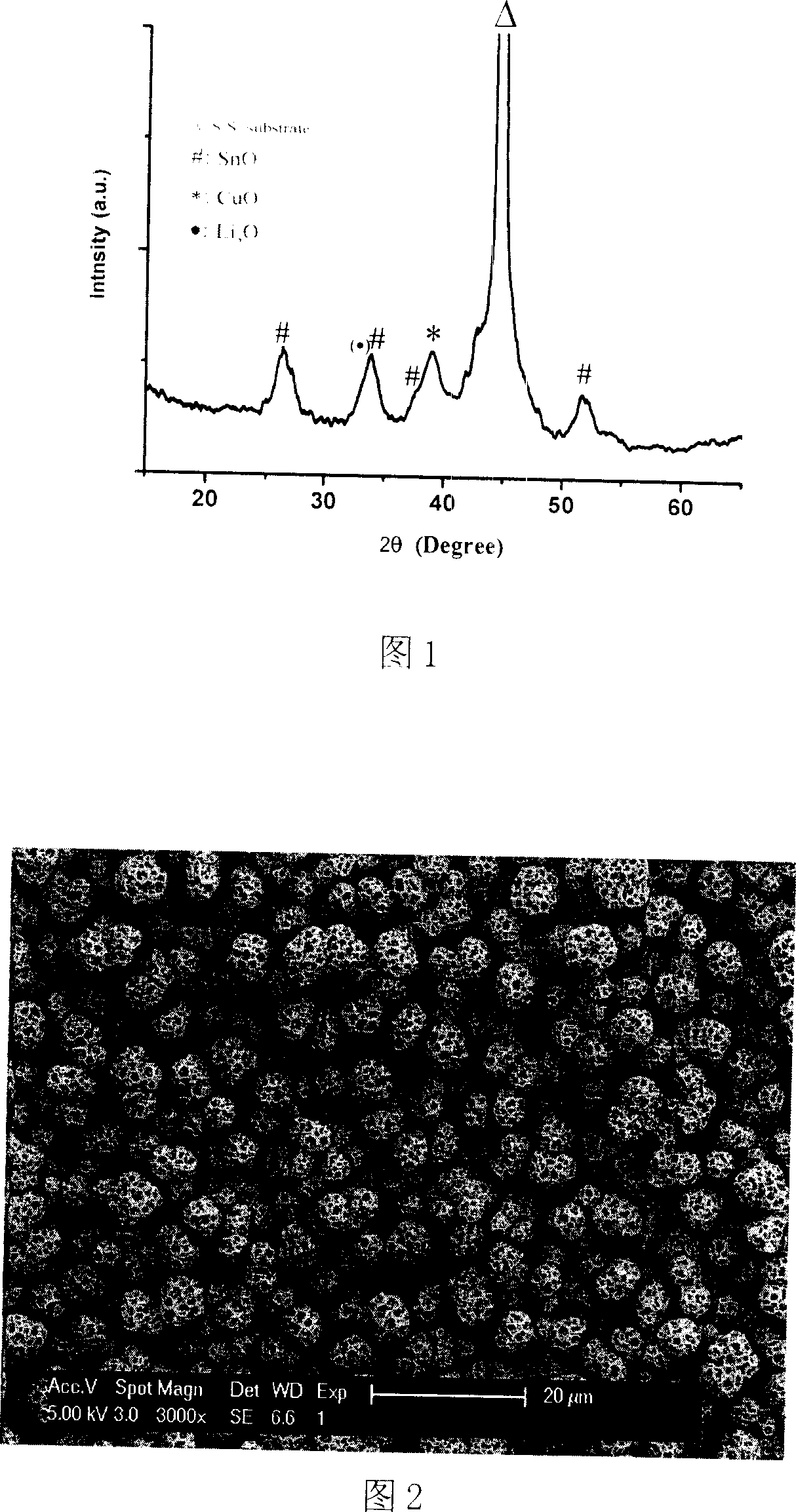

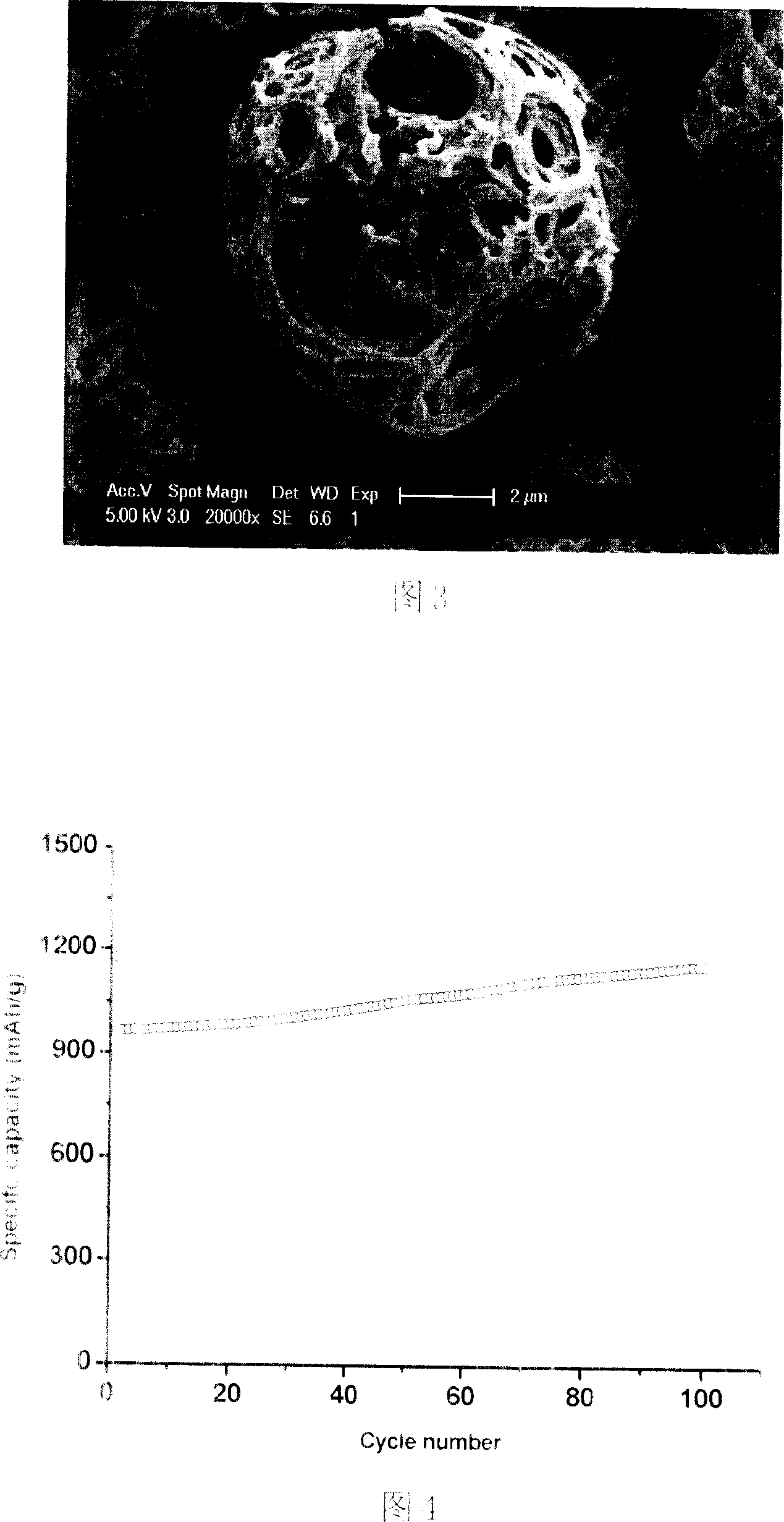

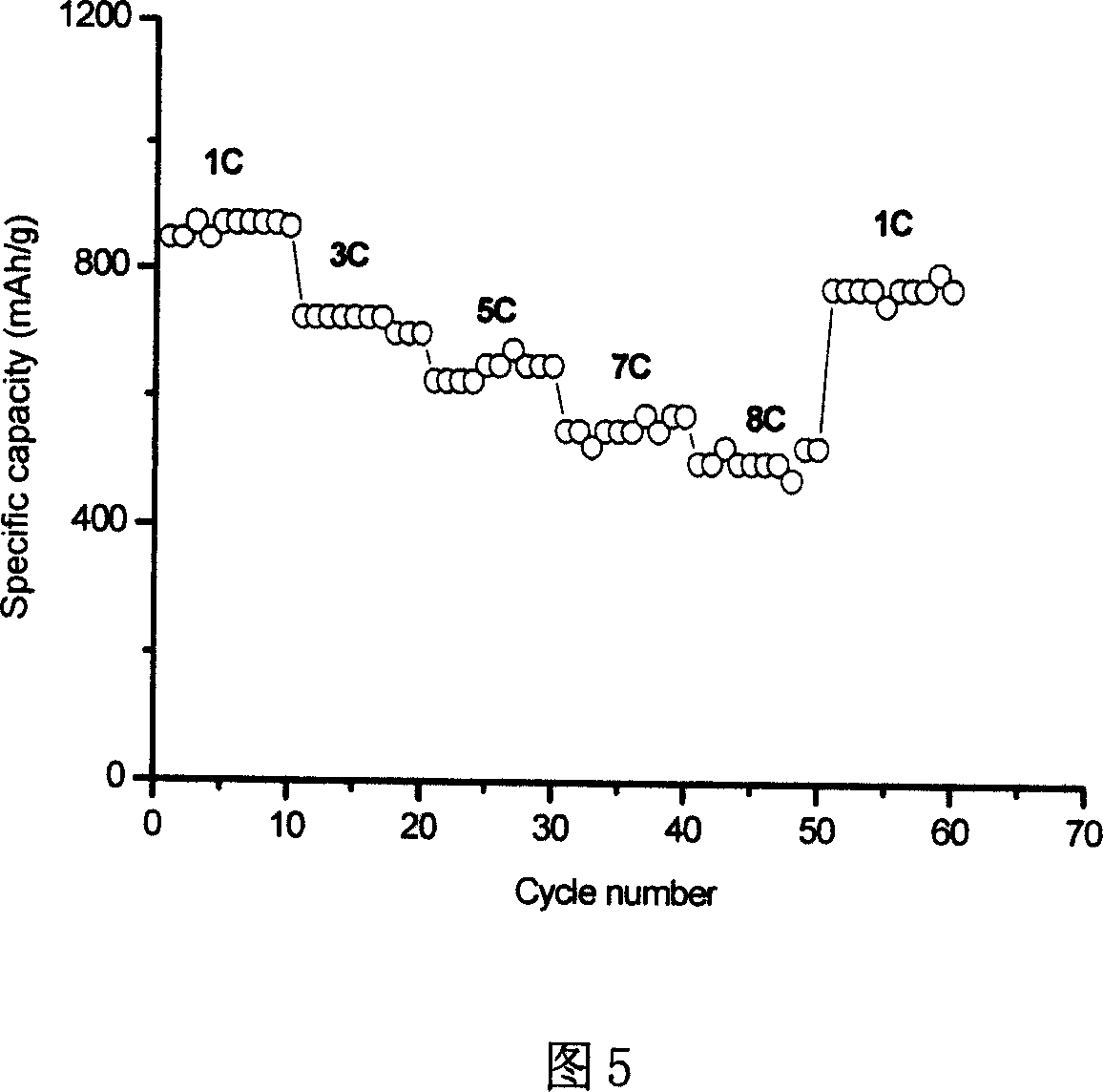

A lithium ion film battery cathode and its preparing method

InactiveCN101017895AGood repeatabilityImprove permeabilityLiquid surface applicatorsElectrode manufacturing processesSolventDc voltage

The disclosed preparation method for negative electrode of a Li-ion thin film cell comprises: mixing the LiNO3, Sn(NO3)4 and Cu(NO3)2 with mole ratio as 0.25-4:1:0.25-4, dissolving into mixed solution of glycol, 1,2-propylene glycol, and ethanol; uniform flowing the obtained predecessor with 2-4ml / h velocity to a fog head with a distance to the substrate as 1-4cm; forcing dc voltage between the head and substrate for 60-240min, while controlling substrate temperature as 200-500 deg. Wherein, the porous ball-shaped thin film chemical formula is XLi2OíñYSnO2íñZCuO with X: Y: Z = 0.1-2: 1:2-0.1 (1:1:1 for better), of 1-200um height, of 5-10um ball diameter, well first discharge capacity, low first capacity loss, and super cycle performance.

Owner:UNIV OF SCI & TECH OF CHINA +1

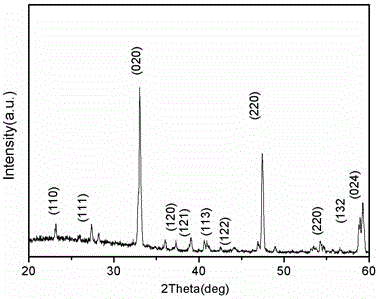

Preparation method for cadmium molybdate porous spheres

The invention discloses a preparation method for cadmium molybdate porous spheres. The preparation method comprises the following steps of mixing a cadmium chloride solution and a sodium acetate solution to prepare a cadmium acetate precipitate solution, mixing the cadmium acetate precipitate solution and a sodium molybdate solution, loading the mixed solution in a reaction kettle, preserving heat for 2 to 12 hours at 110 to 200 DEG C, performing hydrothermal treatment, repeatedly washing a reaction product by using distilled water after the reaction product is unloaded from the reaction kettle, and filtering and drying the reaction product to obtain the cadmium molybdate porous spheres. The preparation method has the advantages of simple process, no organic surfactants, no pollution, easiness in industrial production, high crystallinity, high purity, capability of effectively controlling the morphology of cadmium molybdate crystals, and the like.

Owner:LUOYANG INST OF SCI & TECH

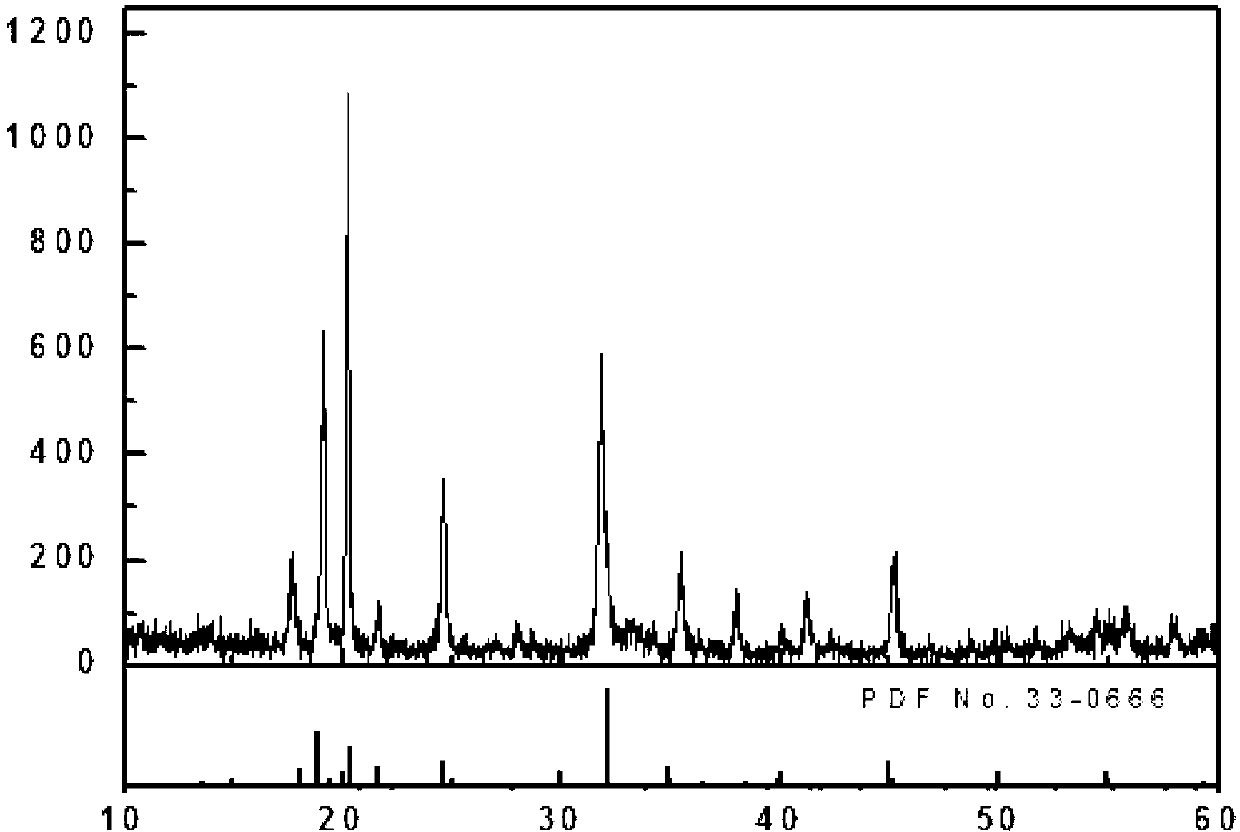

Porous spherical lithium manganate cathode material and preparation method thereof

ActiveCN104409719AWide variety of sourcesReduce energy consumptionMaterial nanotechnologyPositive electrodesLithium carbonateSodium carbonate

The invention relates to a porous spherical lithium manganate cathode material and a preparation method thereof. The porous spherical lithium manganate cathode material is prepared by accumulating nanoscale particles of 30-400nm, wherein the diameters of sphere are 500nm -2Mum, and the average pore diameters of pores are 10-100nm. The preparation method comprises the following steps: (1) dissolving manganese salt in an aqueous solution, and adding hydrogen peroxide with a certain molecular weight; (2) under the condition of stirring, adding a sodium carbonate and sodium hydroxide aqueous solution into the solution, and centrifugally separating, washing and drying the obtained precipitates; (3) uniformly mixing the dried precipitates with lithium carbonate, then roasting for 3-10 hours at the temperature of 700 DEG C, and thus obtaining the porous lithium manganate material.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

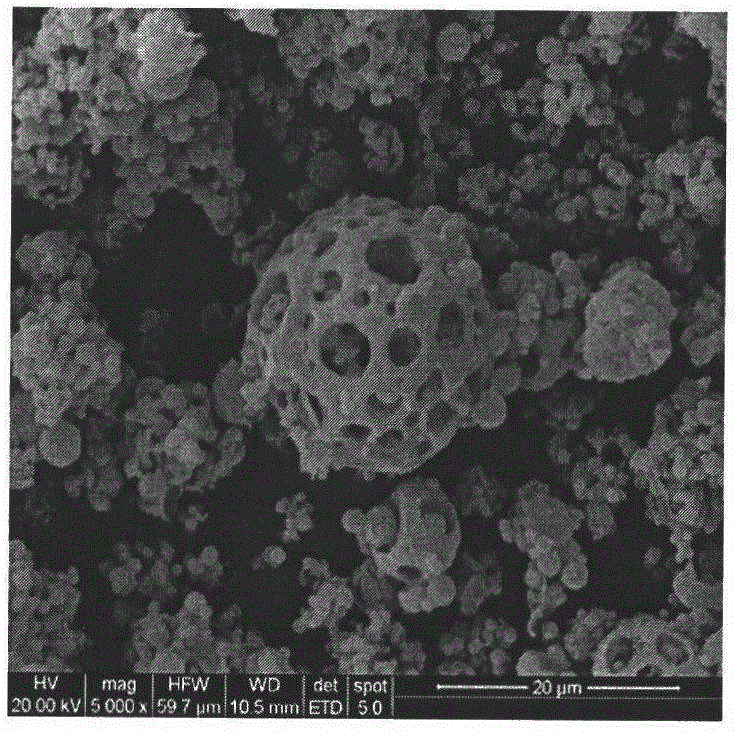

Preparation method for iron phosphate used for lithium battery

ActiveCN111362243AGood ability to deintercalate lithiumShorten the diffusion pathSecondary cellsPositive electrodesIonic diffusionLithium iron phosphate

The invention discloses a preparation method for iron phosphate used for a lithium battery. The iron phosphate comprises a secondary particles aggregated by a plurality of primary particles, wherein each primary particle is of a hollow porous spherical structure; and the secondary particle is of a hollow porous sphere-like structure. According to a scheme of the invention, the iron phosphate is ofa unique hollow porous sphere-like structure; lithium iron phosphate prepared by taking the iron phosphate as a precursor has a porous structure; the contact area of an electrolyte and a positive electrode material is increased; good wettability is achieved; meanwhile, the porous structure also has the advantages of reducing ion diffusion resistance and the like; through the hollow structure, thediffusion path of lithium ions is shortened; meanwhile, a plurality of paths are provided for diffusion of the lithium ions; the problems of low diffusion speed, polarization and the like of a lithium iron phosphate material in the prior art are solved; and thus, the lithium iron phosphate with good performance, specifically good low-temperature performance, can be prepared by using the lithium iron phosphate as the precursor.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

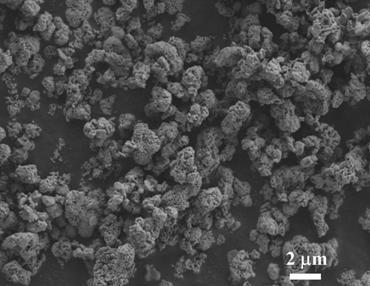

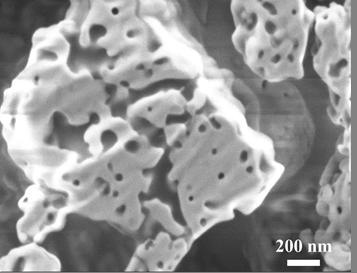

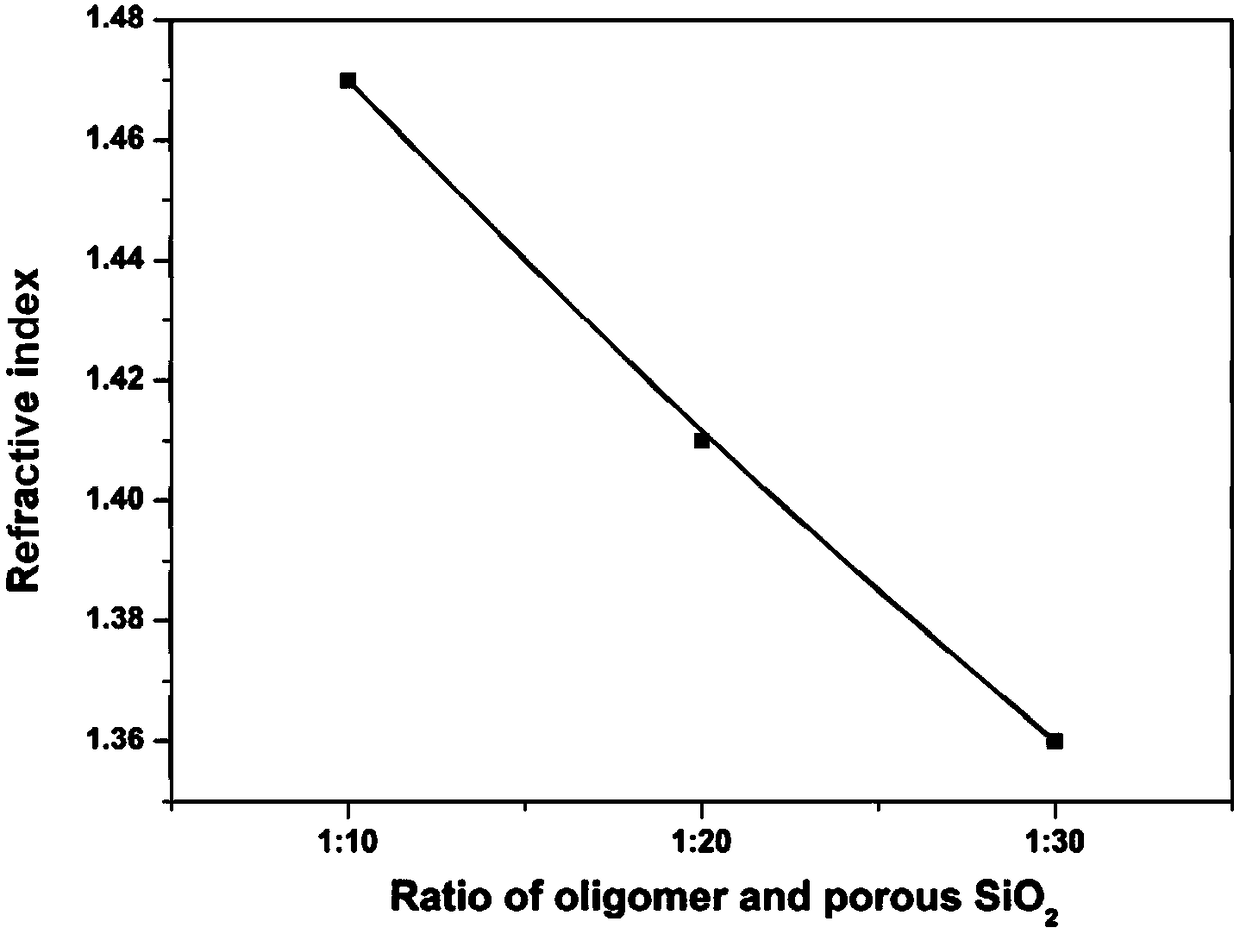

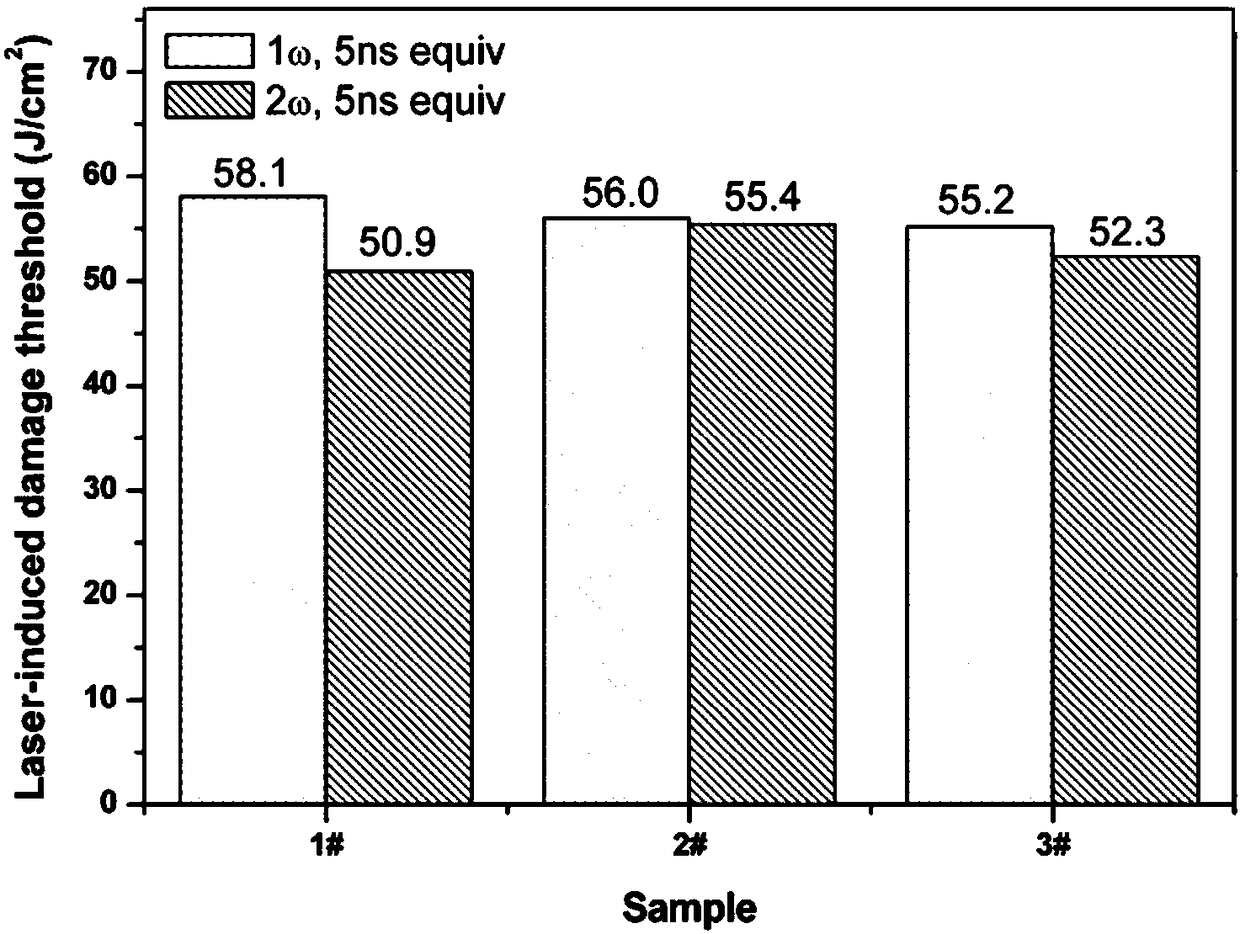

Ultraviolet-cured thin film with adjustable refractive index and preparation method of ultraviolet-cured thin film

ActiveCN108424537AAdjustable refractive indexWide range of refractive index controlCoatingsHigh resistanceMethacrylate

The invention provides an ultraviolet-cured thin film with an adjustable refractive index and a preparation method of the ultraviolet-cured thin film. The preparation method comprises steps as follows: ethyl orthosilicate, deionized water and an organic solvent are mixed and subjected to a reaction for 12-24 h at 8-12 DEG C, an oligomer is prepared and then is aged for 48-72 h at 45-55 DEG C, andSiO2 porous spheres are prepared by self-assembly clustering of the oligomer; (2), silane methacrylate, deionized water and the organic solvent are mixed and subjected to a reaction for 6-8 h at 110-130 DEG C, an oligomer is prepared, a photoinitiator is added, and UV-curable sol is prepared; (3), the SiO2 porous spheres and the UV-curable sol are mixed, and a to-be-cured thin film is prepared; (4), the to-be-cured thin film is irradiated under ultraviolet light, and the ultraviolet-cured thin film with the adjustable refractive index is prepared. The prepared thin film has wider refractive index regulating range and high resistance to laser damage, and high-energy laser output of an intense laser device can be realized.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

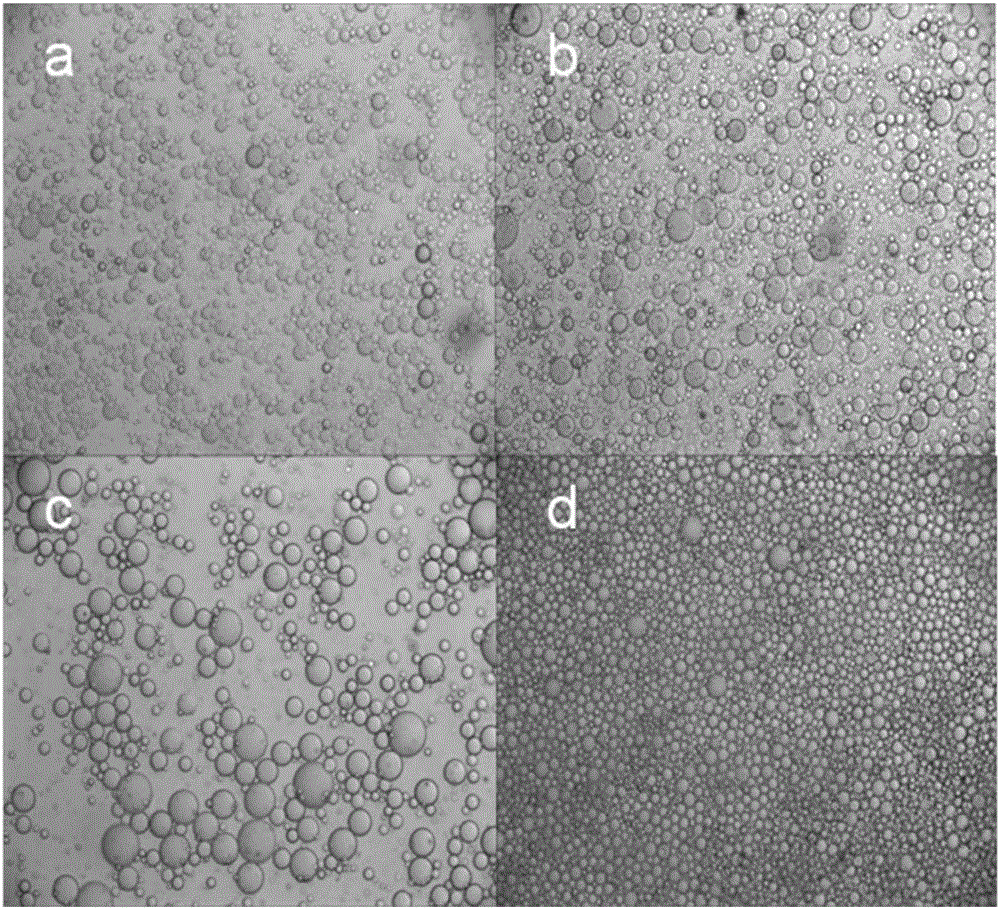

Porous spherical silica chromatography filler and preparing method thereof

ActiveCN106215908ANarrow particle size distributionEasy to makeOther chemical processesMicrosphereSilica gel

The invention discloses porous spherical silica chromatography filler and a preparing method thereof. The method includes the steps that 1, absolute ethyl alcohol and a first component are mixed to obtain a mixed solution; 2, a hydrochloric acid water solution is added into the mixed solution and stirred, solvent is removed to obtain a polysiloxane prepolymer; 3, absolute ethyl alcohol and viscosity modifier are prepared into a continuous phase, the polysiloxane prepolymer is dispersed into the continuous phase to obtain an emulsion dispersing system; 4, strong ammonia water is added into the emulsion dispersing system and stirred for reaction, the mixture stands for ageing and is filtered to collect microspheres, and the microspheres are washed and dried to obtain spherical silica microspheres; 5, the spherical silica microspheres are dispersed in deionized water; 6, strong ammonia water is added into the spherical silica microsphere dispersion liquid and stirred, solid is collected, washed, dried and calcined to obtain the porous spherical silica chromatography filler. The filler is in a regular sphere shape and narrow in particle size distribution and can be used in normal-phase chromatography and other separating modes. The preparing method is simple and high in yield, and conditions are easy to control.

Owner:TIANJIN UNIV

Spherical cathode material for lithium-ion secondary battery and preparation method of spherical cathode material

ActiveCN105552370AImprove electrochemical performanceShorten the diffusion pathCell electrodesSecondary cellsChemical compositionFreeze-drying

The invention relates to a spherical cathode material for a lithium-ion secondary battery and a preparation method of the spherical cathode material. The chemical composition of the spherical cathode material for the lithium-ion secondary battery is LiFe<x>Mn<1-x>PO<4>, x=0-1; the spherical structure is one of a solid sphere, a hollow sphere or a porous sphere; and the diameter is 5nm to 50 microns. The cathode material with a controllable spherical structure for the lithium-ion secondary battery is prepared by carrying out atomizing freeze-drying or atomizing heat-drying on a solution prepared from a lithium compound, an iron compound, a manganese compound, a phosphorus compound, a complexing agent and a carbon source and then carrying out high-temperature pyrolysis reaction. The preparation method provided by the invention can greatly shorten the sintering time of the cathode material for the lithium-ion secondary battery and avoids rapid growth of cathode material crystal for the lithium-ion secondary battery, so that the rapid charge-discharge performance of the cathode material for the lithium-ion secondary battery is improved. The cathode material for the lithium-ion secondary battery with the spherical structure is beneficial to subsequent preparation of a lithium-ion secondary all-battery, is also beneficial to full contact of the cathode material for the lithium-ion secondary battery and an electrolyte, shortens a diffusion path of lithium ions, and can improve the electrochemical properties of the cathode material for the lithium-ion secondary battery.

Owner:SUZHOU SUN SOURCE NANO TECH CO LTD

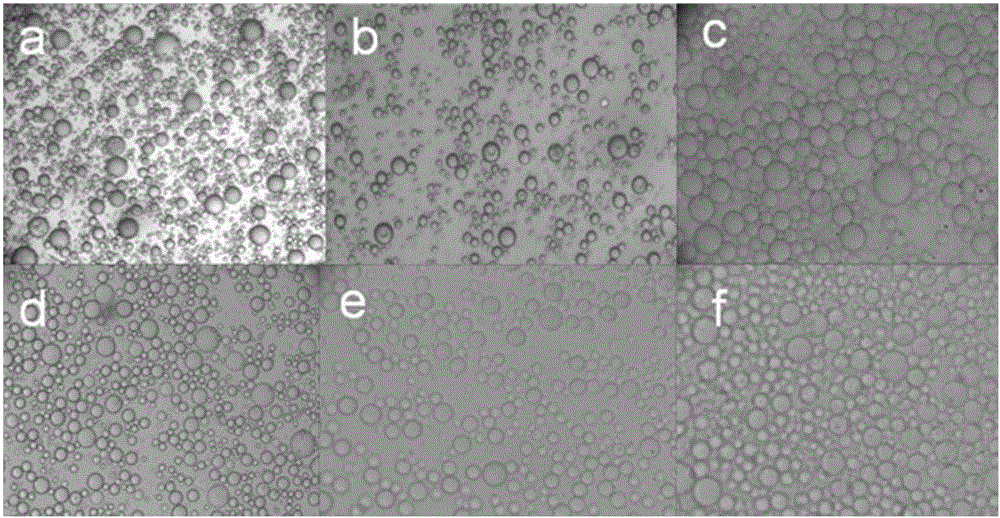

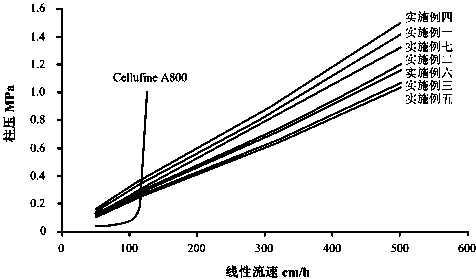

Anion exchange chromatographic filler for purification of low molecular weight heparin, preparation method, chromatographic column filled thereby and purification method

ActiveCN104275166ACation exchanger materialsComponent separationGlycidyl methacrylateEthylene glycol dimethacrylate

The invention provides an anion exchange chromatographic filler for purification of low molecular weight heparin. The matrix of the anion exchange chromatographic filler is porous spherical particles of crosslinked poly(glycidyl methacrylate)-ethylene glycol dimethacrylate, the particle size range is 30-150 micrometers, the average particle size is 50-80 micrometers, and the aperture range is 30-180nm. The filled chromatographic column has high dynamic adsorption capacity and good pressure resistant performance, is suitable for use under a high flow rate, and can adapt to the requirements of efficient production. The invention also provides a preparation method of the anion exchange chromatographic filler, the anion exchange chromatographic column filled by the filler, and a method for purifying low molecular weight heparin by the anion exchange chromatographic column.

Owner:WUXI GALAK CHROMATOGRAPHIC TECH

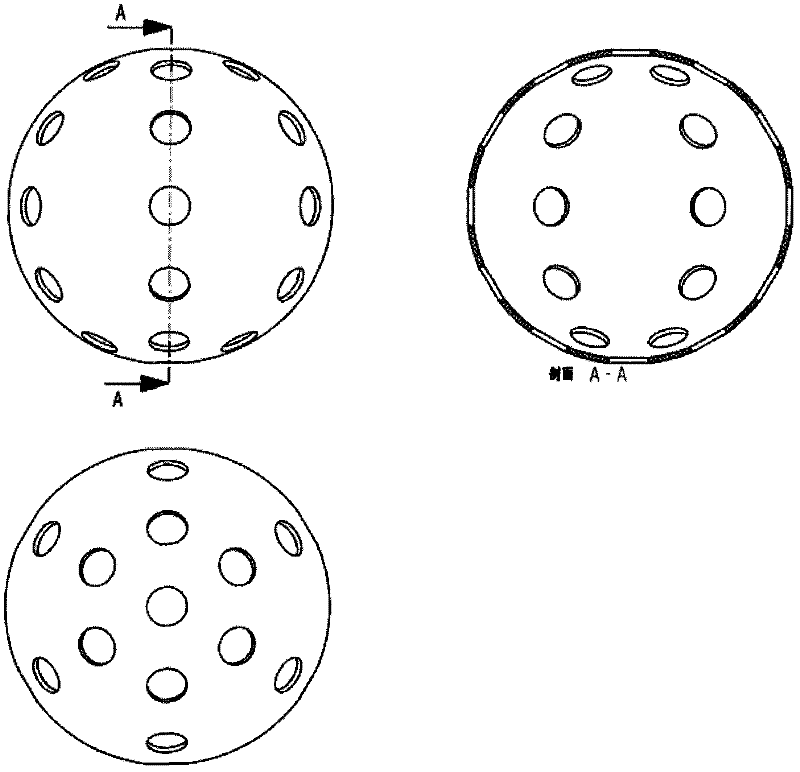

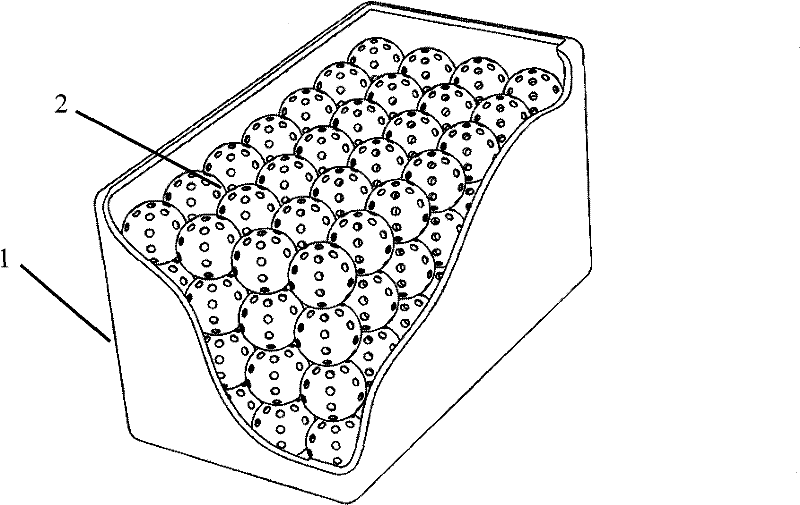

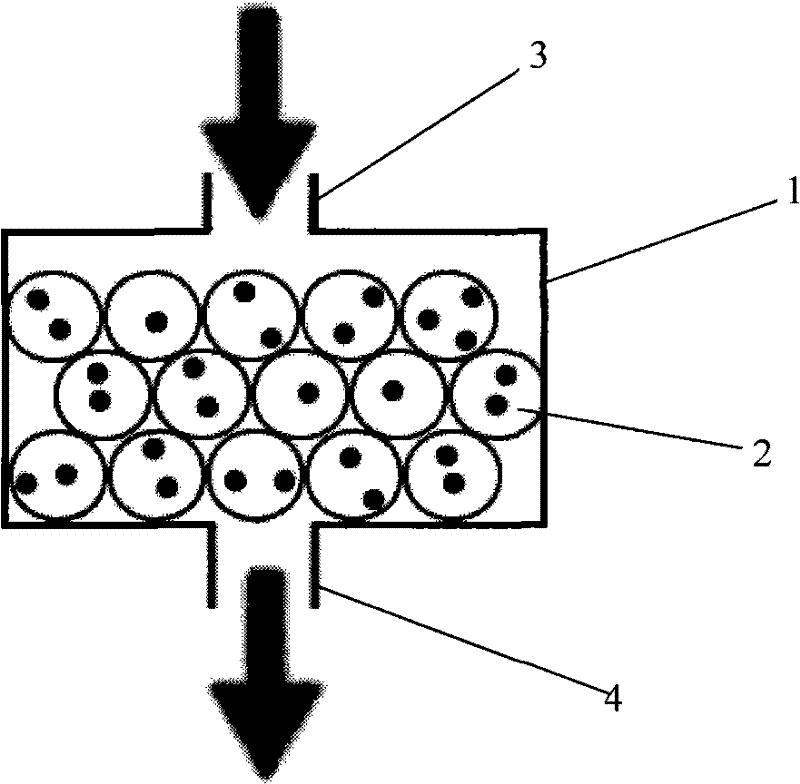

Damping method for liquid delivery

InactiveCN102514828AReduce weightImprove volumetric efficiencyLarge containersEngineeringKinetic energy

The invention provides a damping method for liquid delivery, which belongs to the field of technology. Porous spherical fillers are filled in a container containing liquid, pores on the surfaces of the fillers function in damping, the inside of the container is divided into innumerable small spaces through small spheres, and the spaces are communicated with one another through the spherical pores. When the container vibrates, the liquid in the container flows through the pores in vibration, and kinetic energy is consumed by means of damping of seams and the pores, so that damping is achieved.

Owner:保利国防科技研究中心有限公司

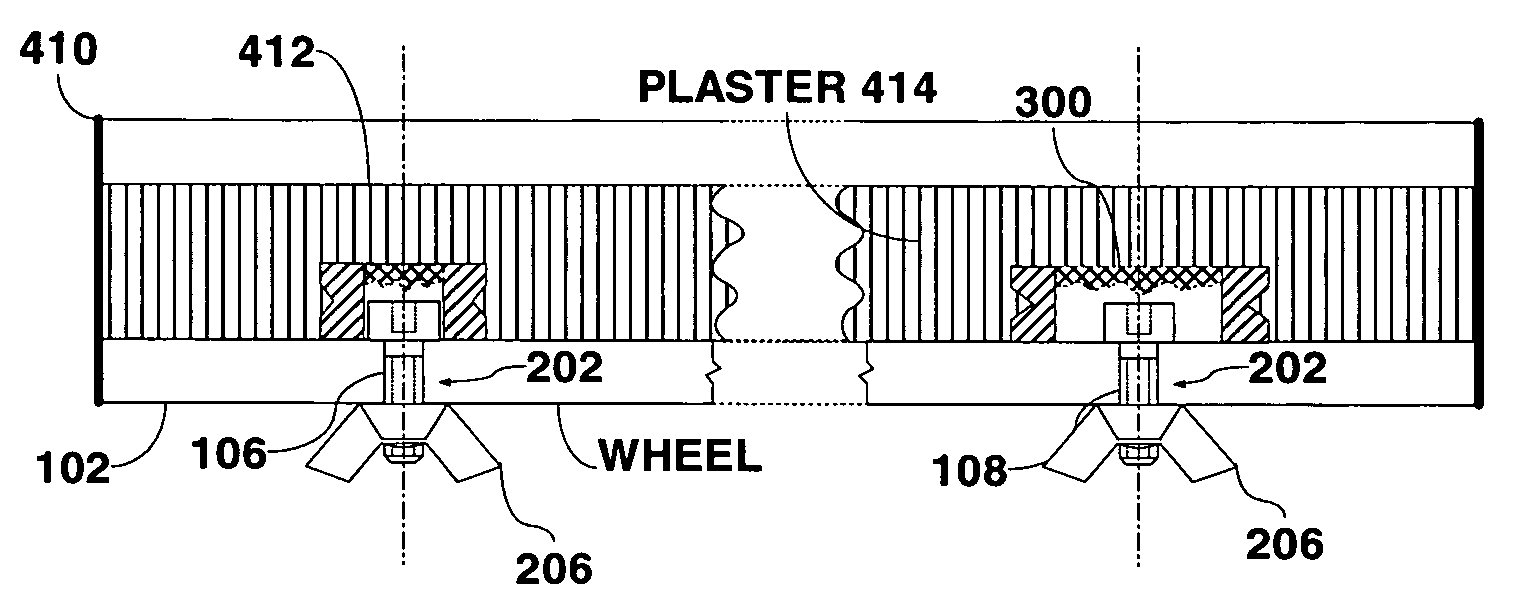

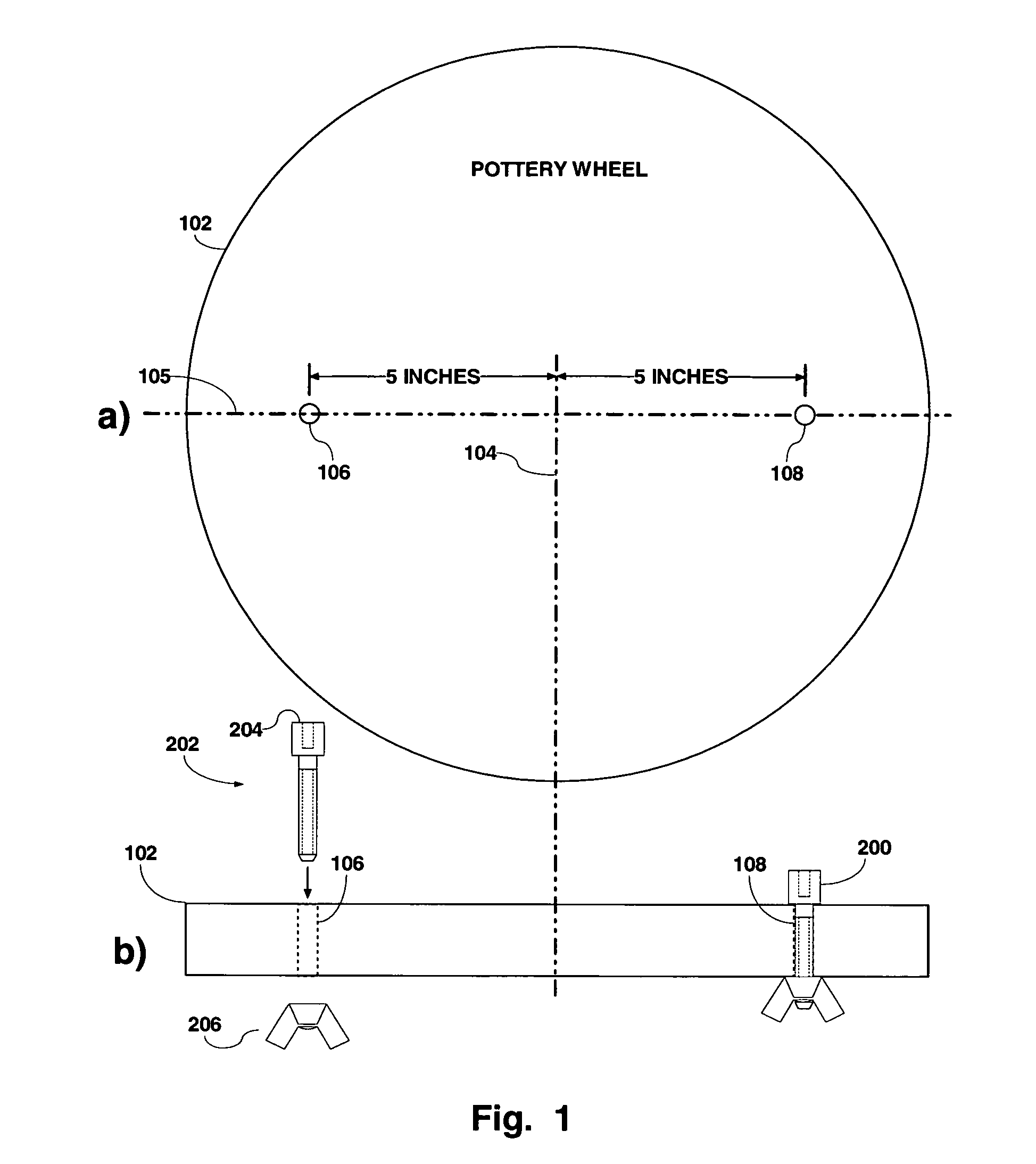

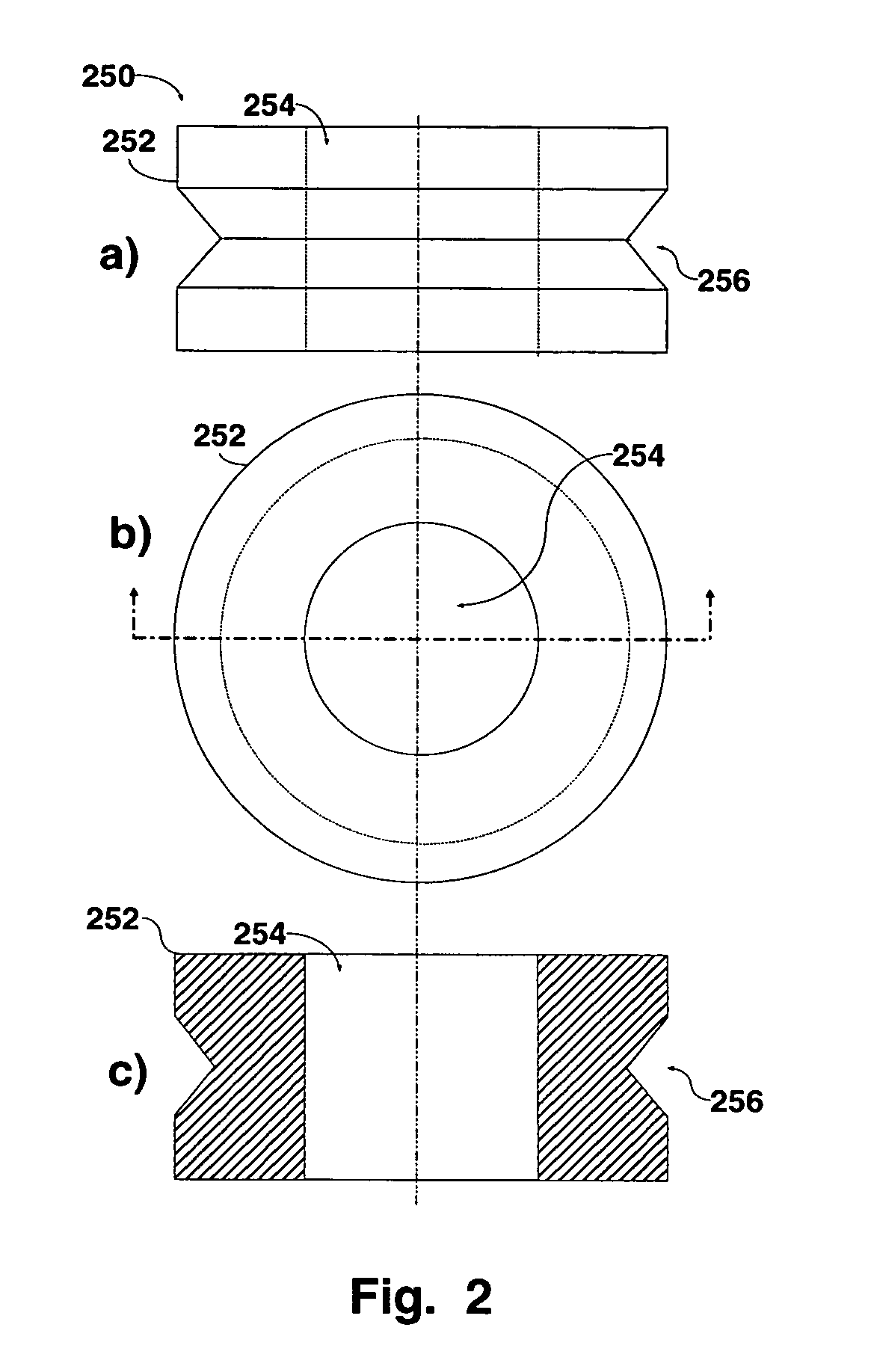

Apparatus for mounting accessories to pottery wheels

Owner:LESTER SAM

Titania nanotube/nanorod microspheres with hierarchical structure and preparation method thereof

InactiveCN101891248AUnique three-dimensional hierarchical structureLarge specific surface areaNanostructure manufacturePhysical/chemical process catalystsMicrosphereUltraviolet lights

The invention discloses titania nanotube / nanorod microspheres with a hierarchical structure and a preparation method thereof. The microspheres are porous spheres formed by intertwining titania nanotubes or nanorods, and are obtained by reacting a titania microsphere precursor in alkali solution, dispersing and washing in diluted acid, and annealing at the temperature of between 400 and 500 DEG C. The microspheres have a three-dimensional hierarchical structure and high specific surface area; and the microspheres have higher ultraviolet absorption capability and high catalytic activity under ultraviolet light because of a hierarchical tubular structure.

Owner:SHANDONG UNIV

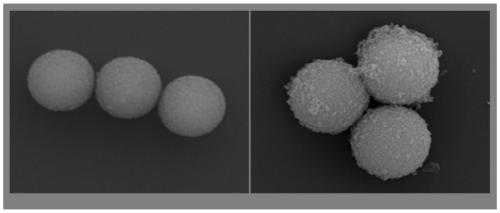

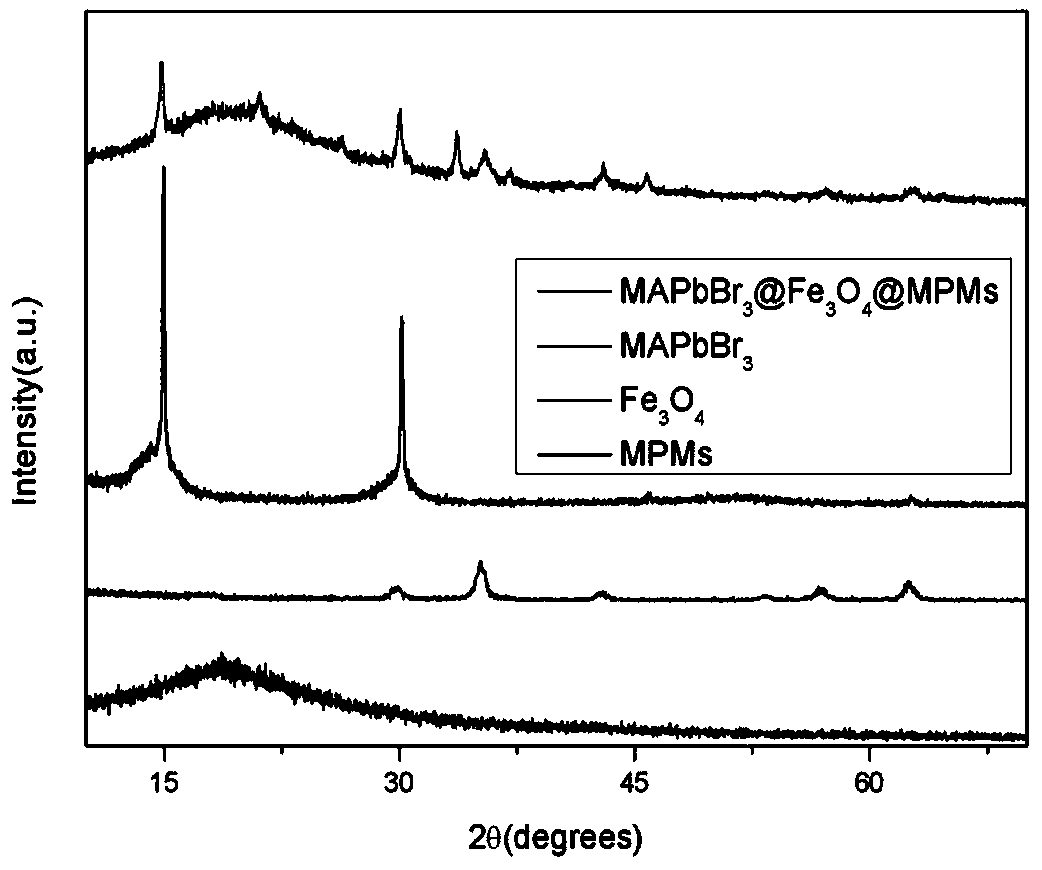

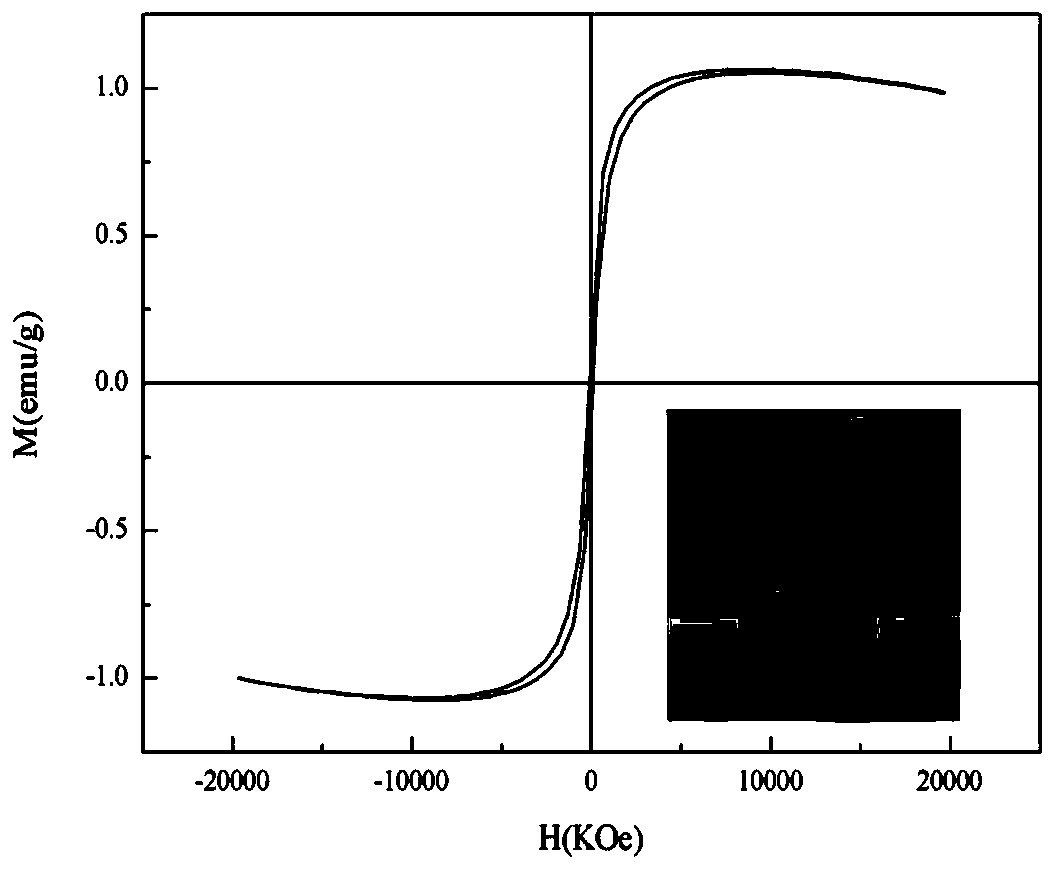

High-brightness stable perovskite magneto-optical microsphere for CTC capture

ActiveCN111100628AHigh fluorescence stabilityAvoid direct contactMaterial nanotechnologyNanomagnetismQuantum yieldMicrosphere

The invention discloses a high-brightness stable perovskite magneto-optical microsphere for CTC capture. The preparation method comprises the following steps: by taking polystyrene porous spheres as shells, uniformly encapsulating Fe3O4 magnetic particles and MAPbBr3 quantum dots in the shells by utilizing a self-assembly method, and coating SiO2 shell layers on the surfaces of the shells to successfully construct (MAPbBr3 / Fe3O4)-coated MPSs-coated SiO2 magneto-optical microspheres; through surface modification, connecting a biological specific antibody SA and anti-EpCAM, and specifically capturing and identifying circulating tumor cells (CTCs), wherein perovskite quantum dots selected by the magneto-optical microspheres have high green fluorescence emission and high fluorescence quantum yield; and packaging the porous polystyrene microspheres and coating a silicon shell layer with the porous polystyrene microspheres. Compared with the prior art, the fluorescence stability of the magneto-optical microspheres is remarkably improved, direct contact between the MAPbBr3 quantum dot and a monitoring target object is avoided, the toxicity problem of heavy metal Pb in the biological monitoring process is solved, safety and no toxicity are achieved, and application in biomedicine is well developed. The preparation method disclosed by the invention has the advantages of mild reaction conditions, simple preparation process, short consumed time and relatively low cost.

Owner:JILIN NORMAL UNIV

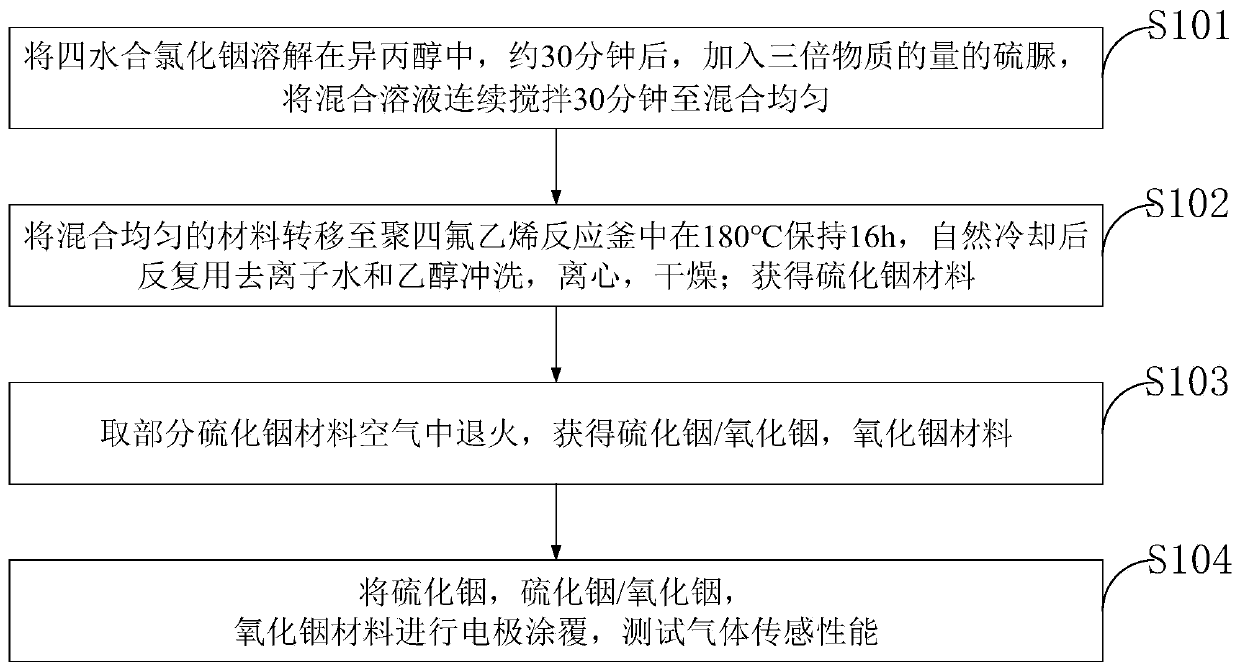

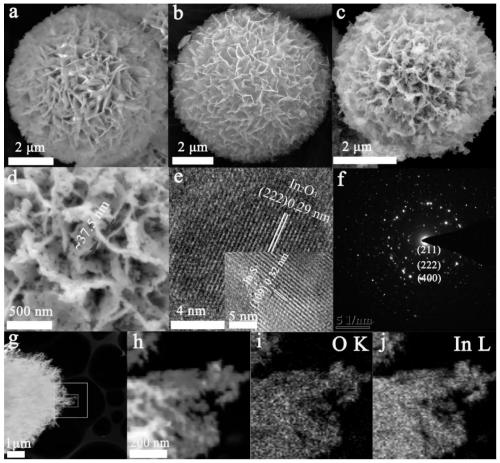

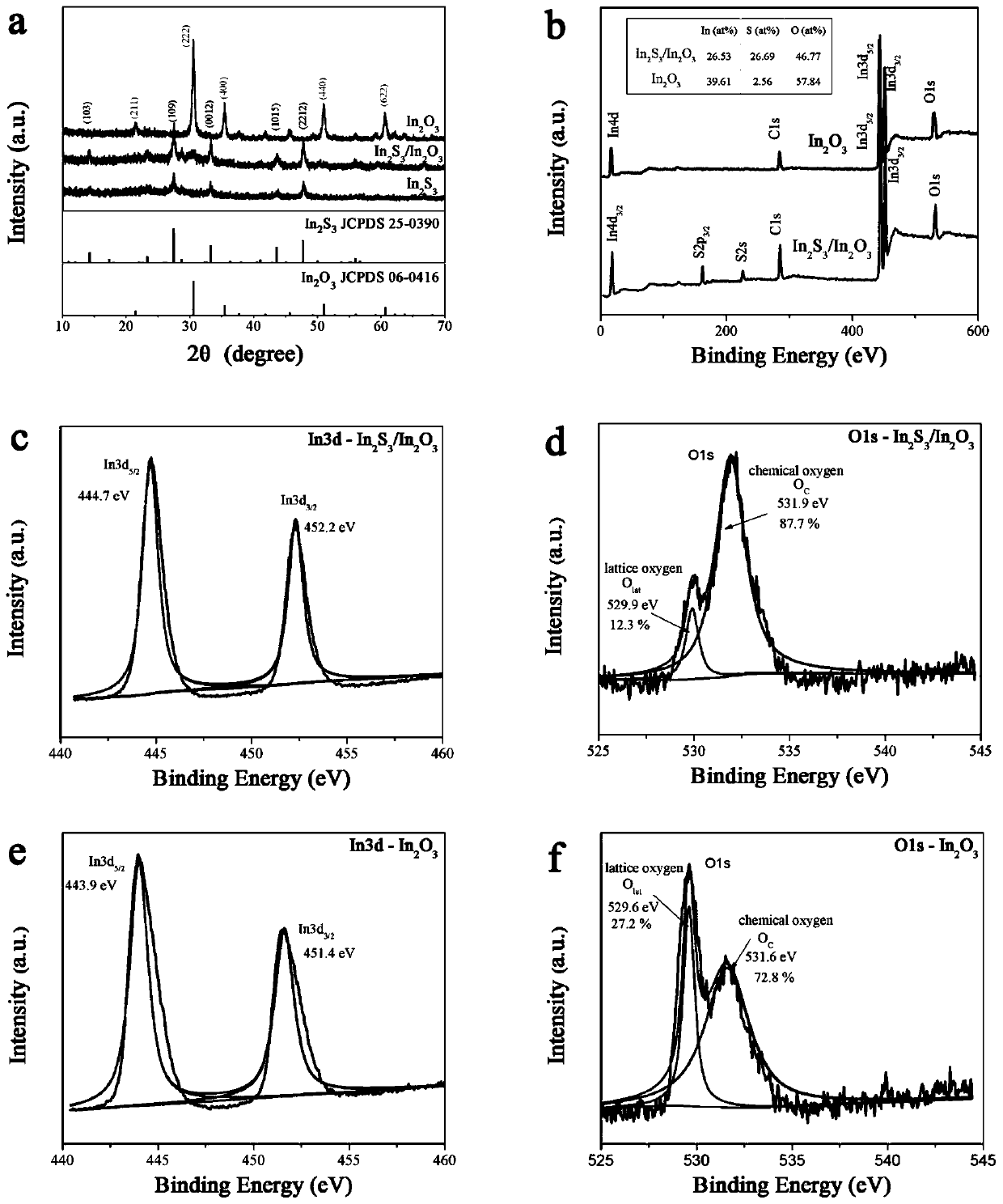

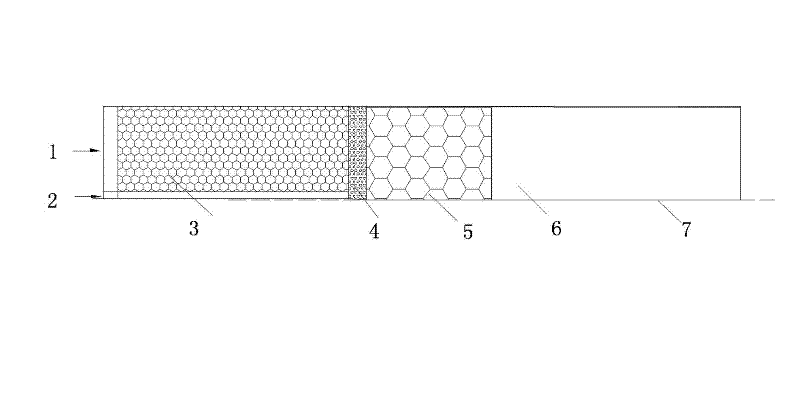

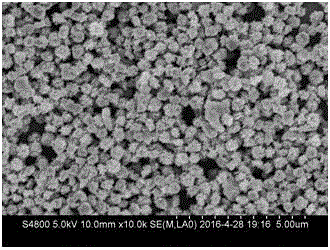

Indium oxide material for gas detection and preparation method thereof

InactiveCN110282653AGood gas responseMeeting the Needs for Rapid Response RecoveryMaterial nanotechnologyGallium/indium/thallium compoundsOxygen vacancyThiourea

The invention belongs to the technical field of gas detection, and discloses an indium oxide material for gas detection and a preparation method thereof. The preparation method is characterized in that thiourea and indium chloride tetrahydrate are taken as raw materials, first uniform mixing is performed by magnetic stirring, and a reaction is performed in a teflon reaction kettle for 16 h at 180 DEG C to obtain an indium sulfide material. Compared with indium sulfide and indium sulfide / indium oxide intermediate products, indium oxide has better ethanol sensing performance at 260 DEG C, the linear range is 2 ppm to 100 ppm, and the limit of detection (LOD) is as low as 0.4 ppm. Meanwhile, an indium oxide sensor also has good repeatability and selectivity mainly due to more chemical oxygen and oxygen vacancies on the surface of the indium oxide material. The preparation strategy of a flower-shaped porous sphere sensing material assembled by simple two-dimensional nanosheets can provide convenience for the preparation of other ethanol gas sensors and the preparation of other sensors based on two-dimensional metal oxide semiconductor materials.

Owner:NORTHEAST NORMAL UNIVERSITY

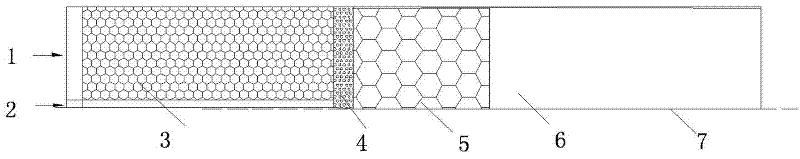

Gas fuel porous medium surface combustor

InactiveCN102444893AWith warm-up effectEmission reductionIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorPorous medium

The invention relates to a gas fuel porous medium surface combustor suitable for gas fuels. The combustor is of an extension-type structure, and a gas nozzle and an air nozzle are coaxially arranged; a combustor body comprises a porous region I and a porous region II; and the porous region I and the porous region II are respectively provided with a sphere I and a sphere II. According to the invention, gas and air are diffused and mixed in a porous medium, thus the combustor has the advantage of adjustable diffusion degree; combustion is stable, and simultaneously the defects of high tempering possibility in premixed combustion as well as long flames and low combustion intensity in diffusion combustion are overcome; and furthermore, partial flames are stayed in the porous spheres, thus the combustor has an effect of preheating the air and gas, is high in combustion temperature and low in CO emission and simultaneously can be used for combusting gases with lower heat value.

Owner:SHENYANG INST OF ENG

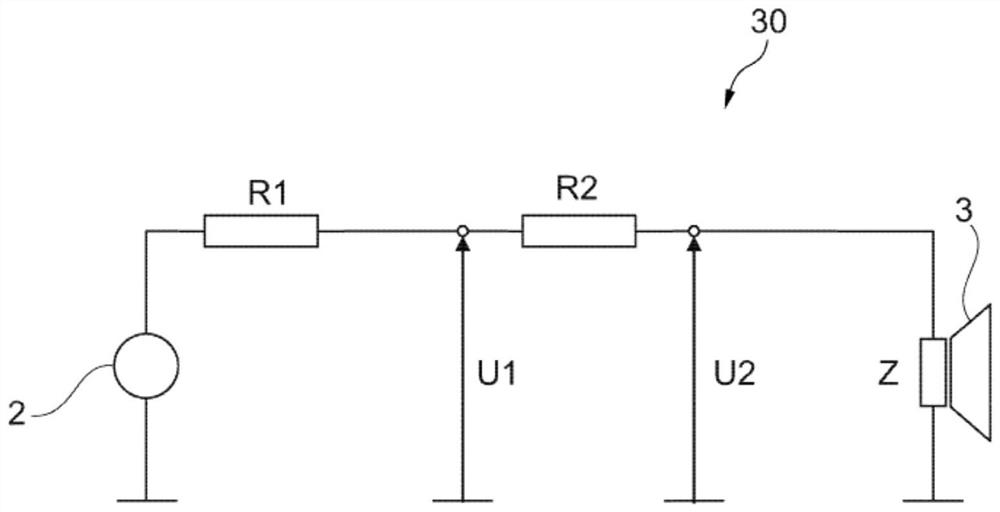

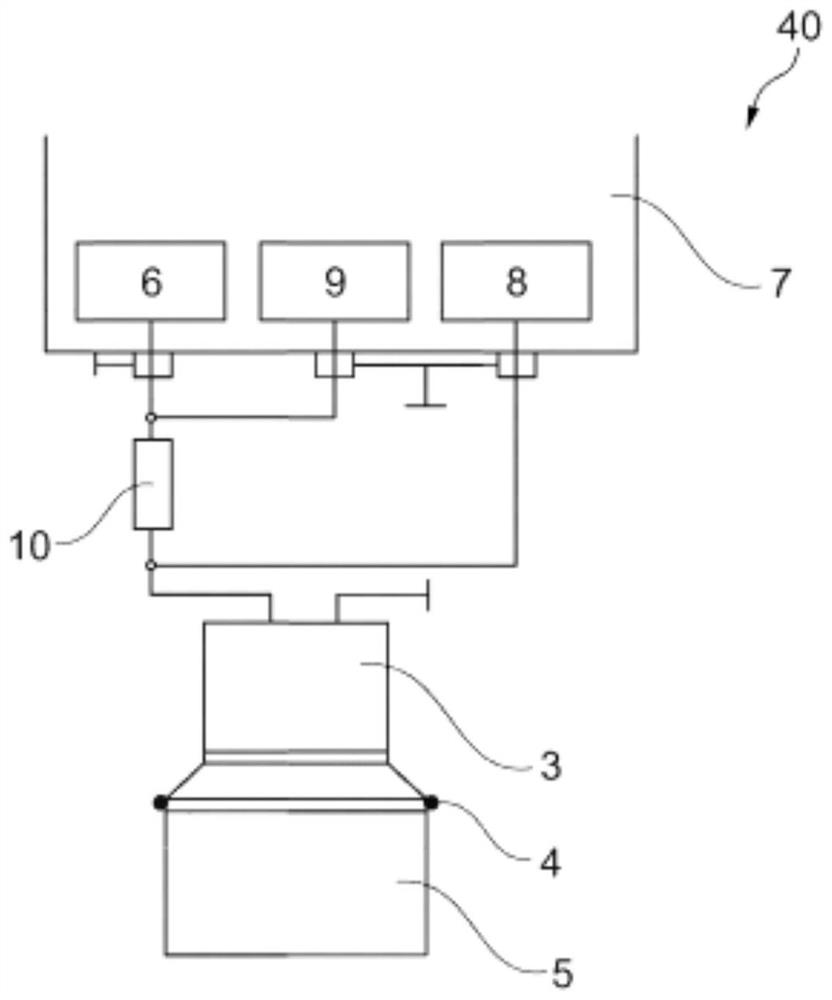

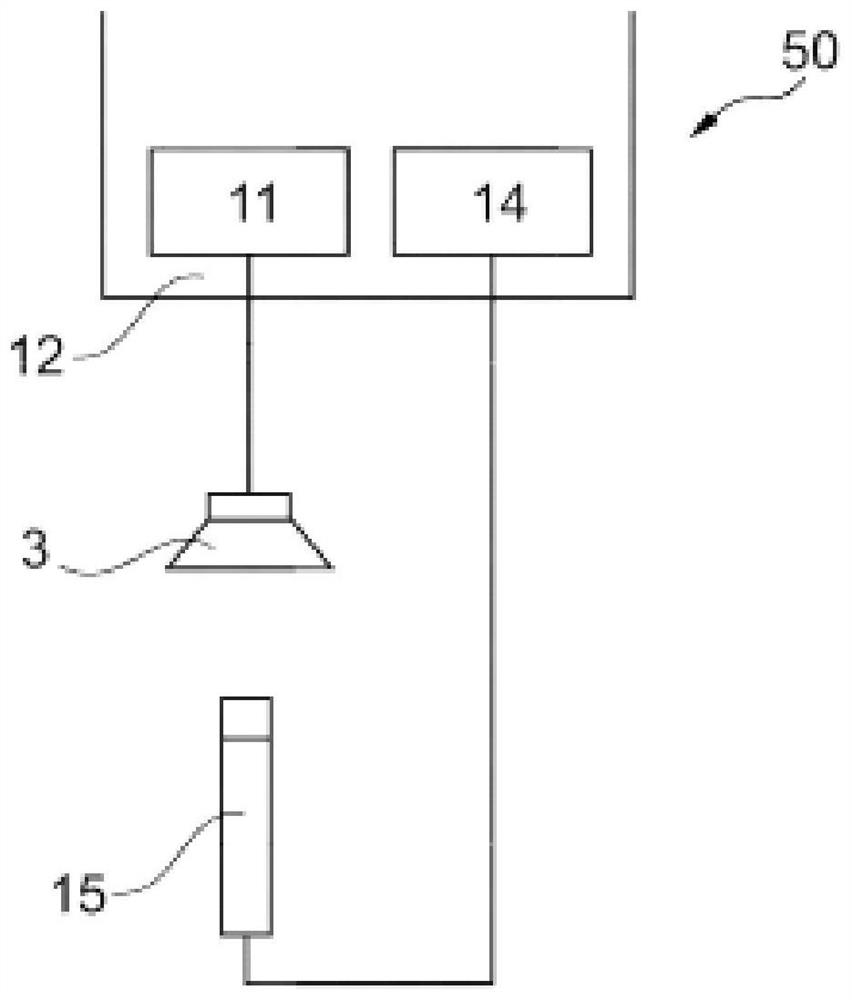

Zeolite spherical porous sound absorption particle, and application thereof in mobile phone loudspeaker system

PendingCN113041993ARaise the resonant frequencyLower resonant frequencyOther chemical processesSound producing devicesBass (sound)Loudspeaker

The invention provides a zeolite spherical porous sound absorption particle, and application thereof in a mobile phone loudspeaker system. The zeolite spherical porous sound absorption particle comprises zeolite porous particles and an adhesive; the zeolite porous particles are bonded together by the adhesive to form the porous spherical particle with abundant macroporous channels; and the main elements of the zeolite porous particles are silicon, oxygen and aluminum, and the mass ratio of silicon to aluminum is at least 150. As a sound absorption material, the zeolite spherical porous sound absorption particle can effectively solve the powder falling problem and the irreversible aging problem caused by high-temperature and high-humidity conditions, the reduction amplitude of the resonant frequency of the mobile phone loudspeaker is increased towards the lower frequency, and the bass effect is obviously improved; and the resonant space is virtually increased, and the resonant frequency of the loudspeaker can be reduced by 100 Hz or above.

Owner:SSI NEW MATERIAL (ZHENJIANG) CO LTD

Solid phase preparation method of porous calcium titanate micro-nano particle spheres

ActiveCN106241859AUniform shapeThe production process is simple and reliableAlkaline earth titanatesNanotechnologyDispersityMicro nano

The invention discloses a solid phase preparation method of porous calcium titanate micro-nano particle spheres. The preparation method comprises the following steps: adding tetrabutyl titanate and organic mixed solution into a high pressure reactor, so as to be subjected to thermal reaction; performing suction filtration, sedimentation and washing on obtained products, so as to obtain porous dititanate submicron particle sphere precursors; stirring and mixing porous dititanate submicron particle spheres and calcium carbonate, heating mixture to preset temperature, keeping a preset time quantum at the preset temperature, and performing natural cooling, so as to obtain the porous calcium titanate micro-nano particle spheres with good dispersity. The method is environmental-friendly for production technology, simple in production method, safe, low in cost, and high in yield, and the prepared products have fractional porous sphere shapes, and are good in dispersity and uniform in particle sizes and shapes.

Owner:淮安新能源材料技术研究院

Aerobic biological membrane material, preparation method and application of aerobic biological membrane material in sewage treatment technology

ActiveCN112960766AImprove hydrophilicityGood biocompatibilityWater contaminantsSustainable biological treatmentActivated sludgeMicrobial agent

The invention provides an aerobic biological membrane material, a preparation method and application of the aerobic biological membrane material in a sewage treatment technology, and relates to the technical field of sewage treatment. The biological membrane material comprises a biological carrier material and a microbial agent or activated sludge fixed inside or on the surface of the carrier material; the biological carrier material comprises a polyurethane foam filler and porous spheres; and microorganisms fixed on the biological carrier material are aerobic bacteria. The biological membrane material provided by the invention has the advantages of high membrane forming speed, high efficiency, short time consumption, large microorganism loading capacity and adsorption capacity, good microorganism adhesive force, short starting time of a biological membrane reactor, high sewage biochemical treatment efficiency and good decontamination and decontamination effects, and can be applied to biochemical treatment technologies of garbage treatment sewage, high-ammonia-nitrogen sewage, high-phosphorus sewage and breeding sewage; and the preparation method can accelerate the biofilm formation speed of the biofilm, prolong the service life of the biofilm, realize sewage reduction and reduce the operation cost of a biological reaction system.

Owner:HANGZHOU NAXI ECOLOGICAL TECH CO LTD

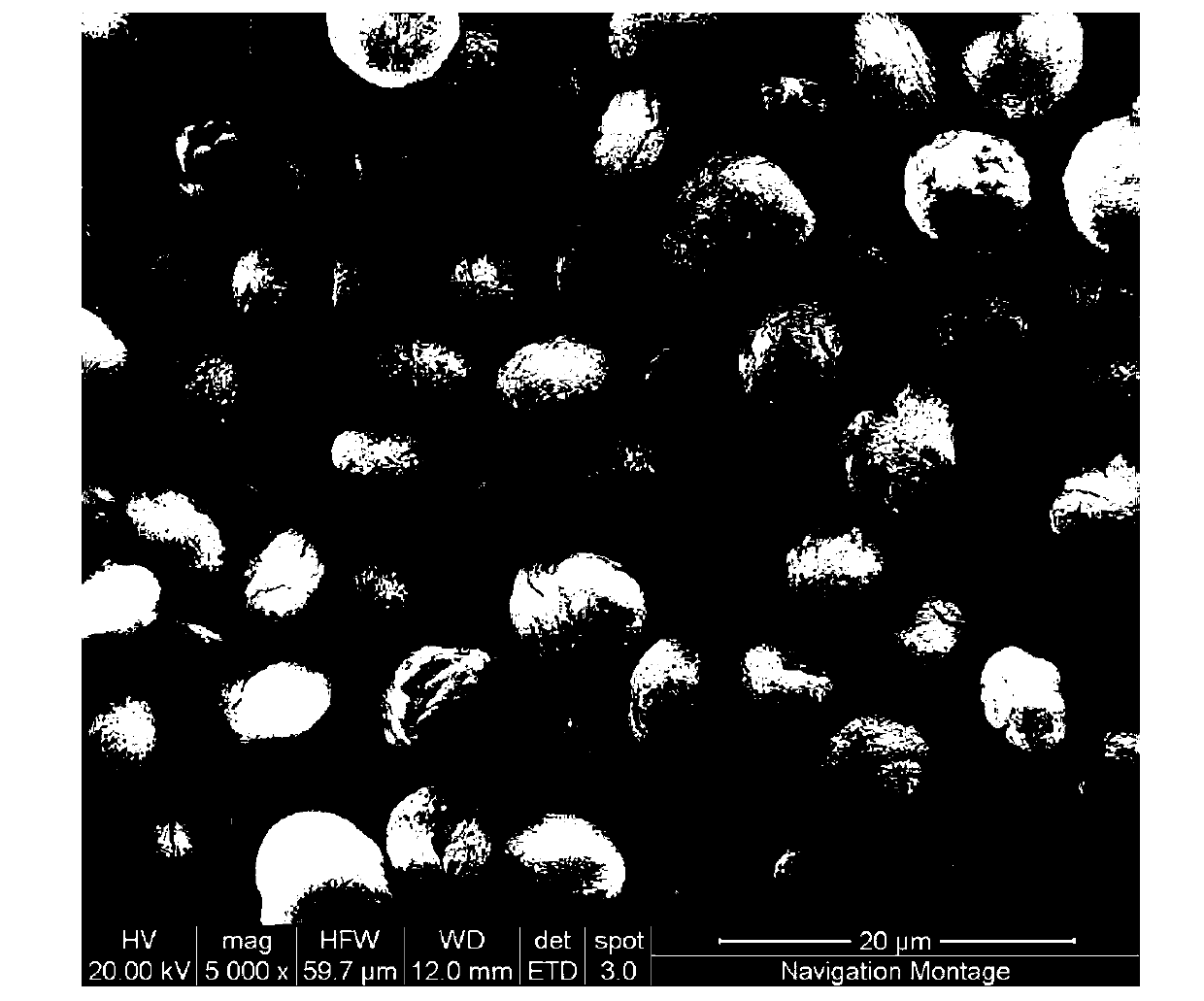

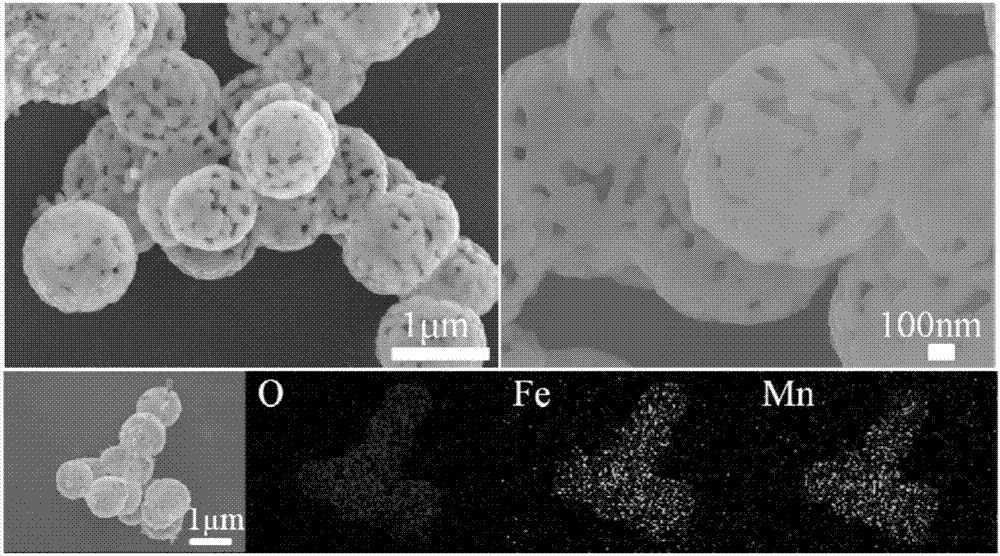

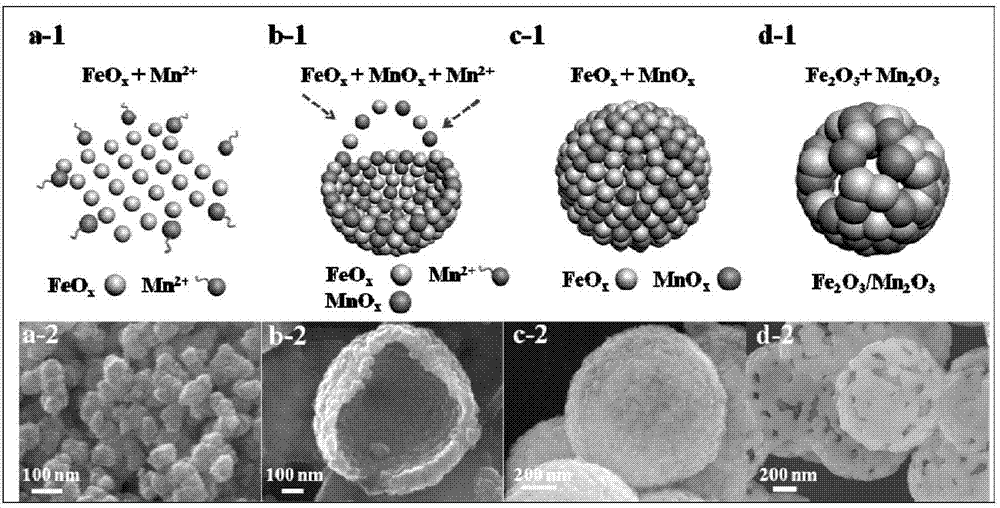

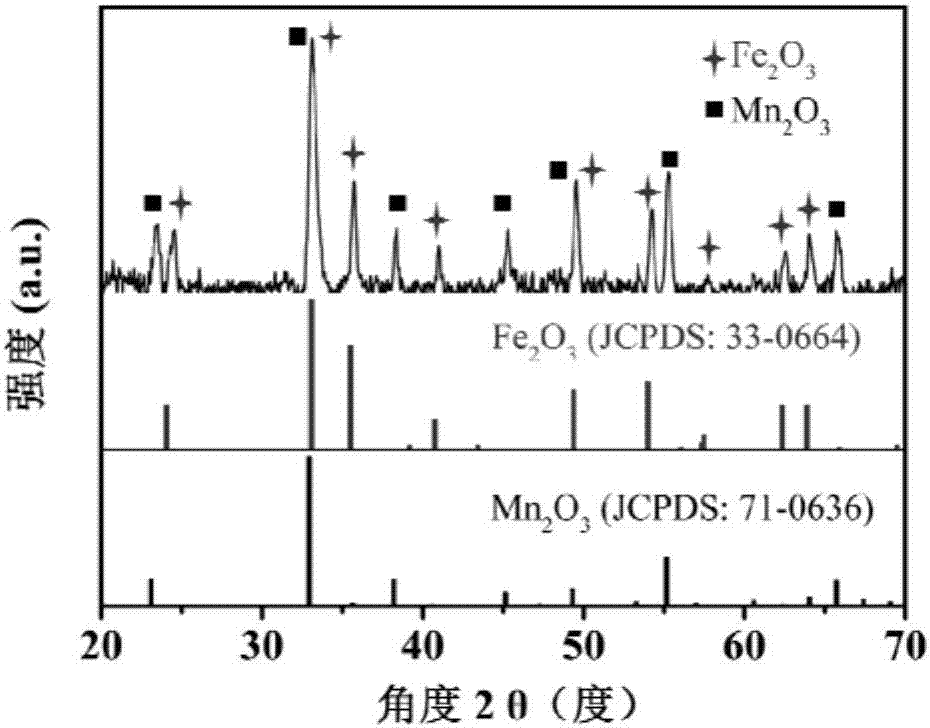

Ferric oxide/manganic oxide hollow porous sphere material, preparation and application thereof

InactiveCN106935837AImprove cycle stabilityGive full play to electrochemical performanceCell electrodesSecondary cellsMANGANESE ACETATEAir atmosphere

The invention relates to an Fe2O3 / Mn2O3 hollow porous sphere electrode material, preparation and application thereof. The preparation method includes the steps of: 1) dissolving ferric nitrate, manganese acetate and oxalic acid in DMF, and stirring the substances evenly to obtain a mixed solution; 2) subjecting the mixed solution to hydrothermal reaction and then taking it out; 3) performing cooling to room temperature, washing the obtained precipitate several times, and then conducting drying to obtain precursor powder; and 4) finally sintering the precursor powder in air atmosphere, thus obtaining the hollow porous sphere electrode material. According to the invention, one-step hydrothermal method is employed to produce the electrode material with 20-100nm holes, the contact area of the electrode material and an electrolyte solution is increased, the diffusion distance of ions and electrons is shortened, the material can have enough free space to adapt to the volume change of electrode material, thus improving the cyclic stability of the material. As a lithium ion battery negative active material, the hollow porous sphere electrode material provided by the invention shows the characteristics of high capacity, good rate capability and good cycle stability.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com