Patents

Literature

33results about How to "Good gas response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rare-earth doped modified graphene composite material gas sensitive element for detecting NOx and preparation method of gas sensitive element

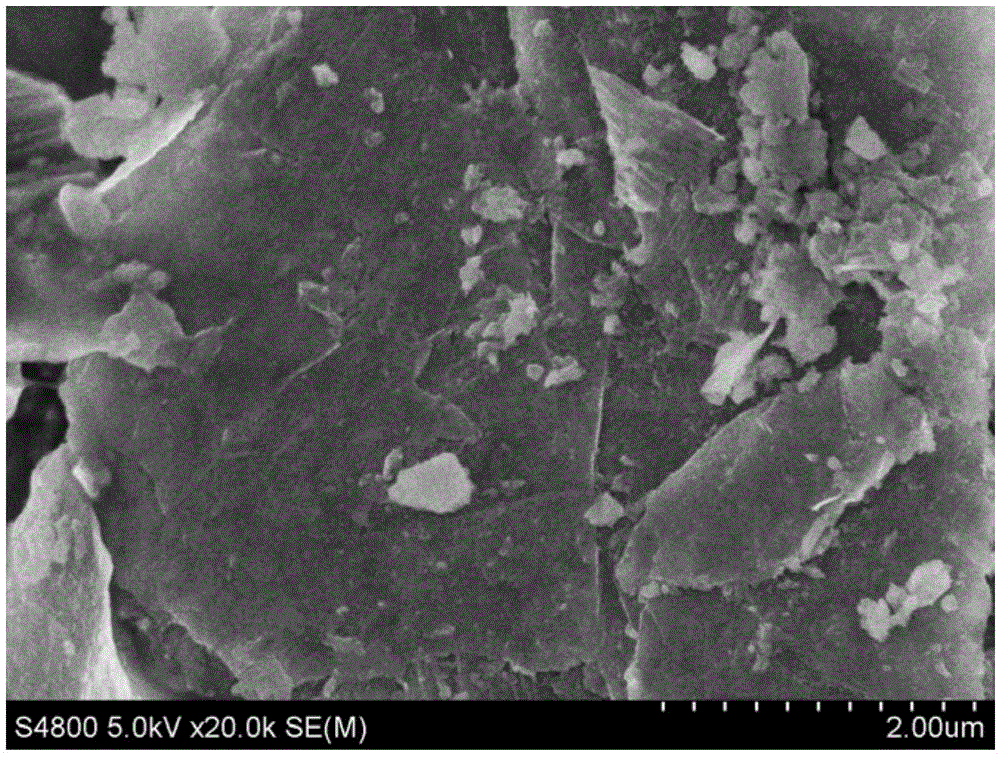

InactiveCN104122305AImprove electrochemical performanceGood gas responseMaterial resistanceRare earthDistilled water

The invention provides a rare-earth doped modified graphene composite material gas sensitive element for detecting NOx and a preparation method of the gas sensitive element, and relates to a gas sensitive element for detecting the NOx and the preparation method of the gas sensitive element, solving the problems that an existing gas sensitive material is low in sensitivity, slow in response, and poor in resistance to factors except gas concentration. The rare-earth doped modified graphene composite material gas sensitive element for detecting the NOx is prepared from graphene, distilled water, a cupric acetate solution, a ceric nitrate solution, a sodium hydroxide solution and a glucose solution; an obtained rare-earth doped modified graphene composite material is mixed with a dispersant and a dispersion solution is dropwise added to the surface of a gold interdigital electrode to prepare the rare-earth doped modified graphene composite material gas sensitive element. The preparation method comprises the following steps: 1, preparation of the rare-earth doped modified graphene composite material; and 2, assembling of the composite material gas sensitive element.

Owner:HEILONGJIANG UNIV

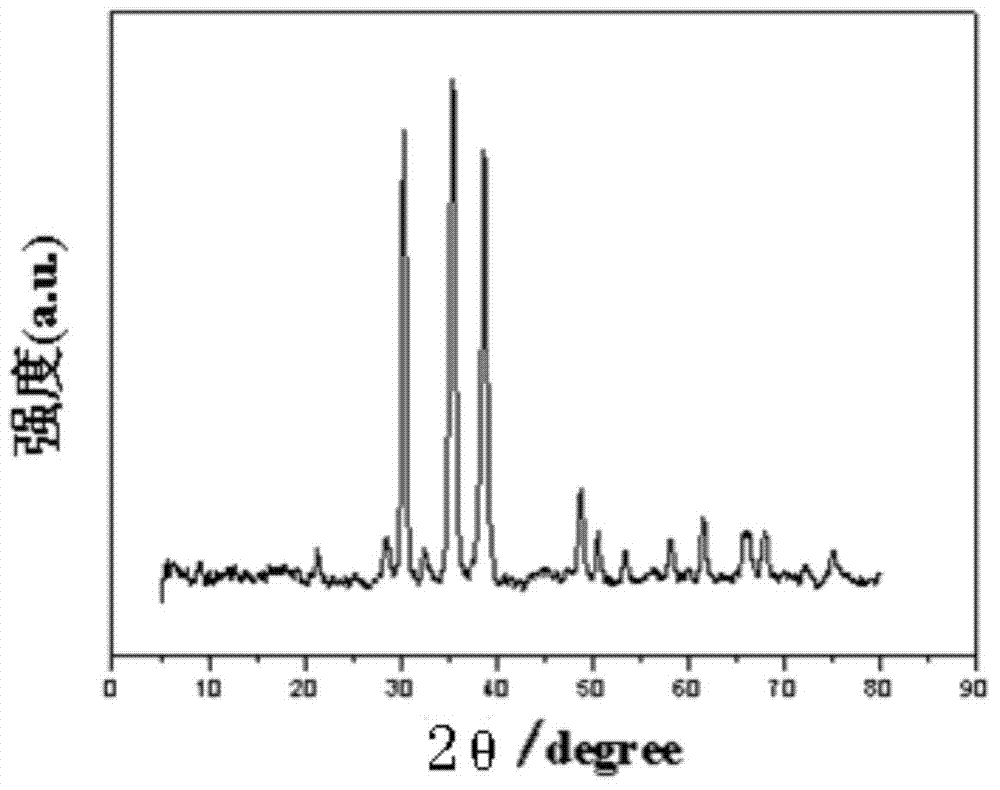

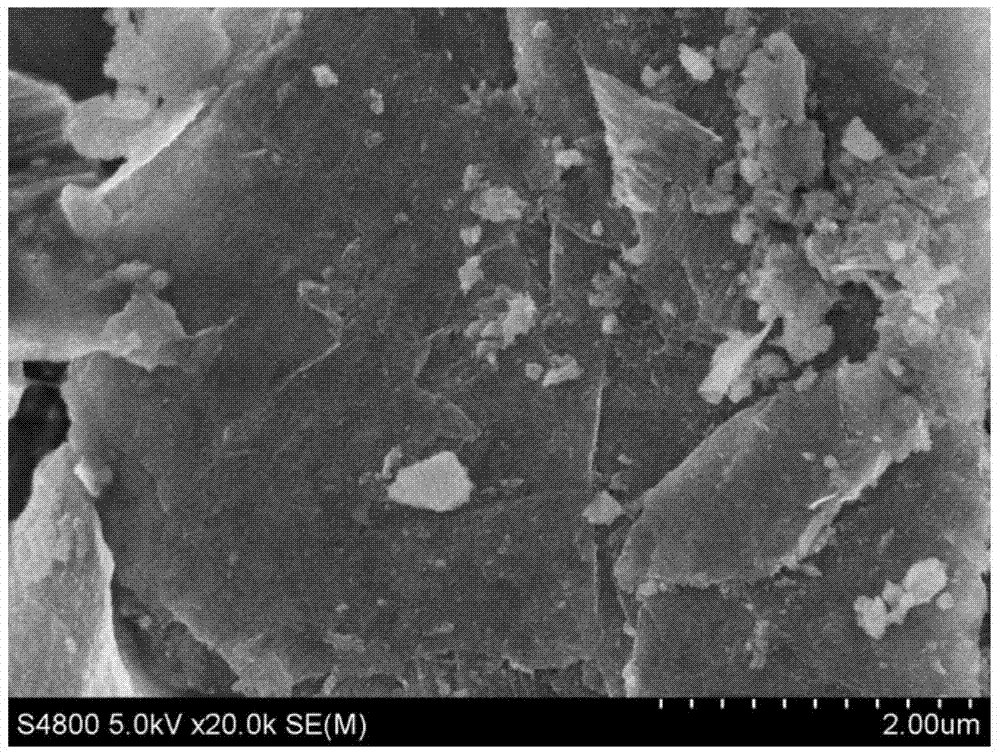

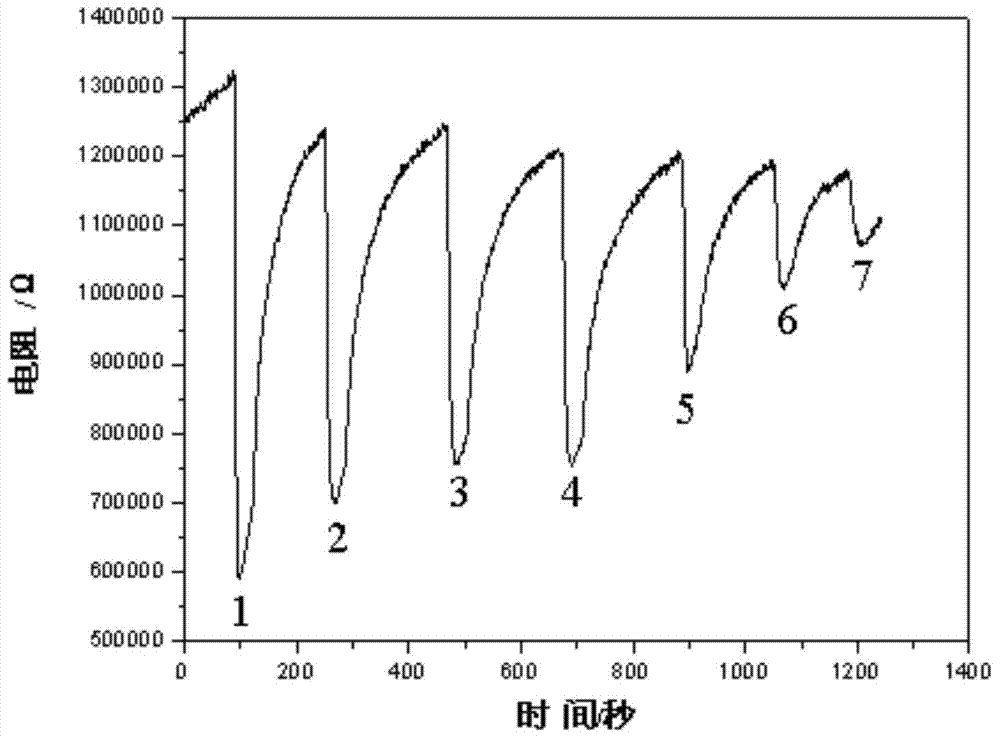

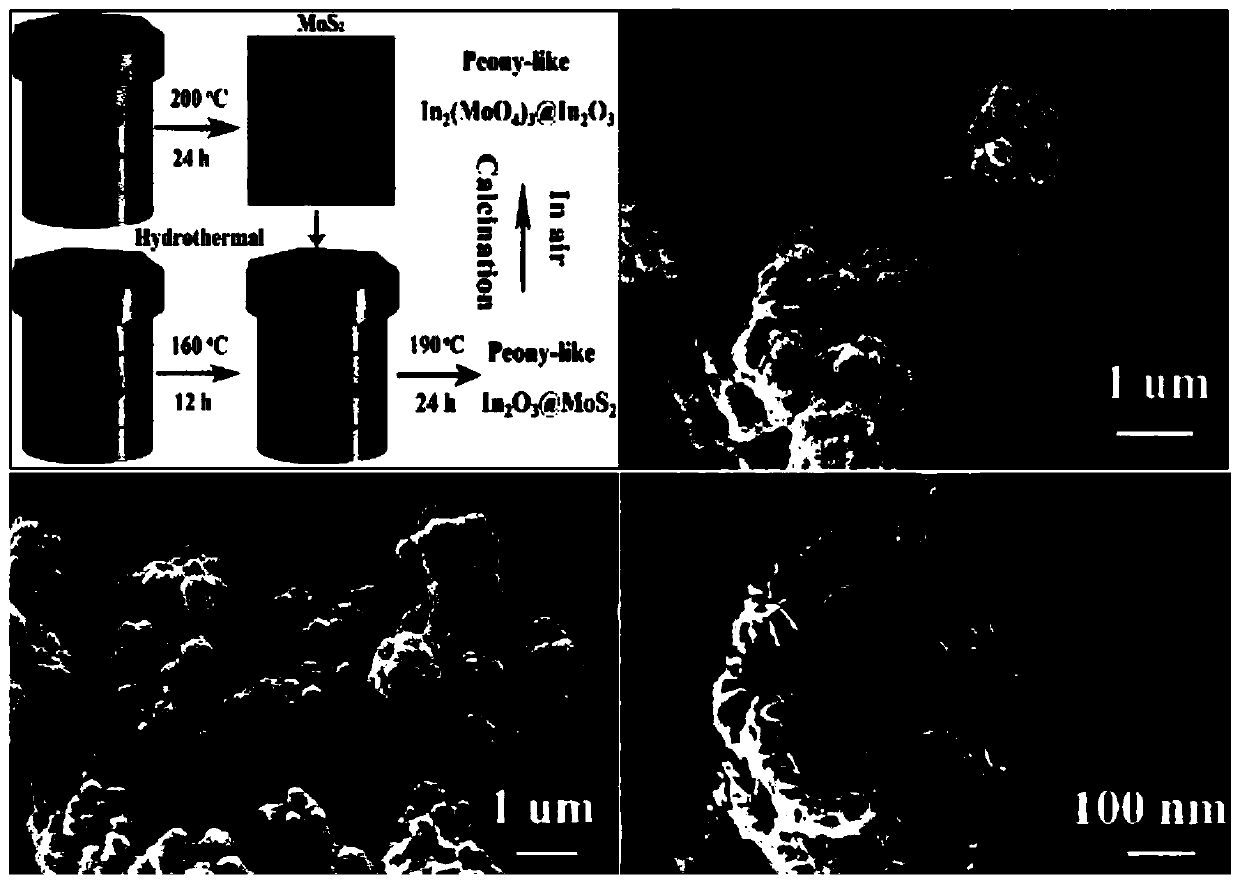

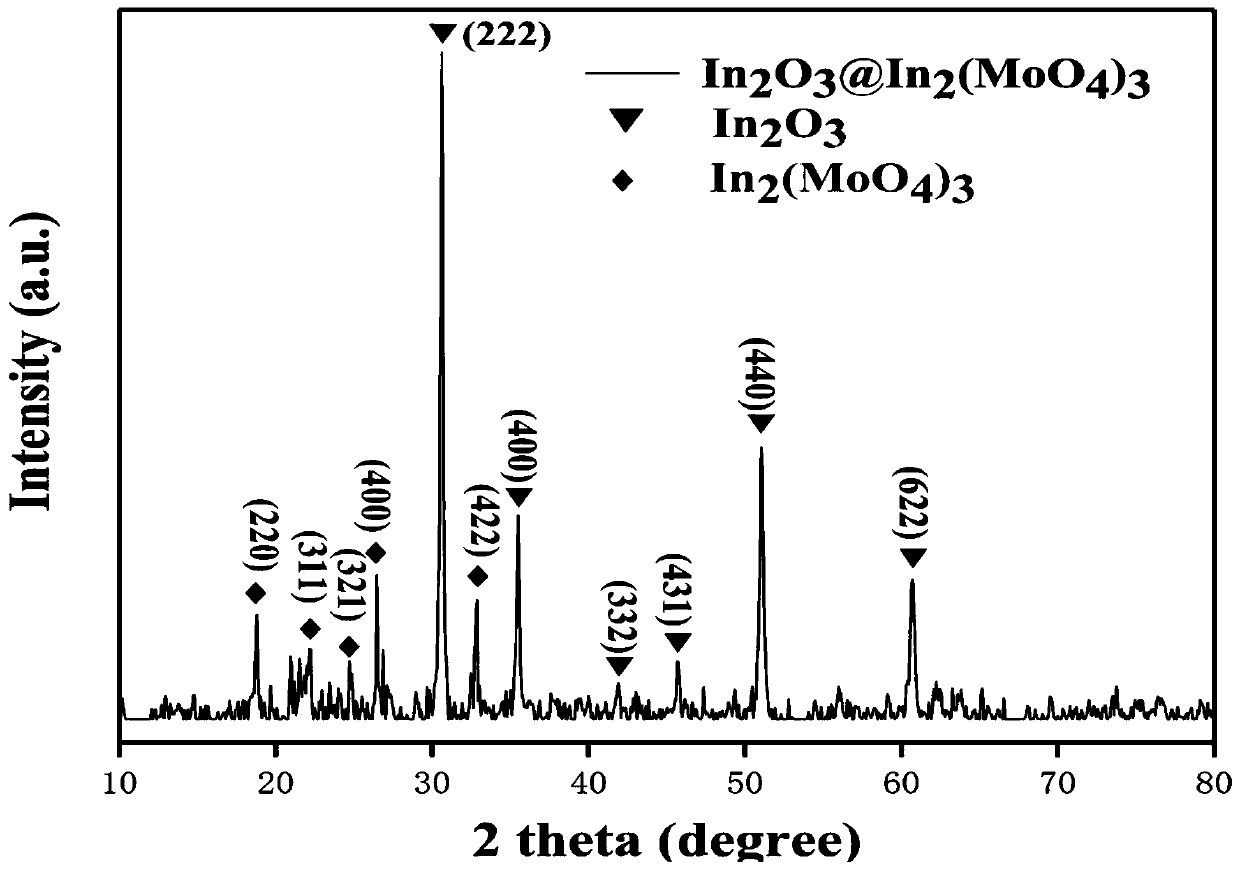

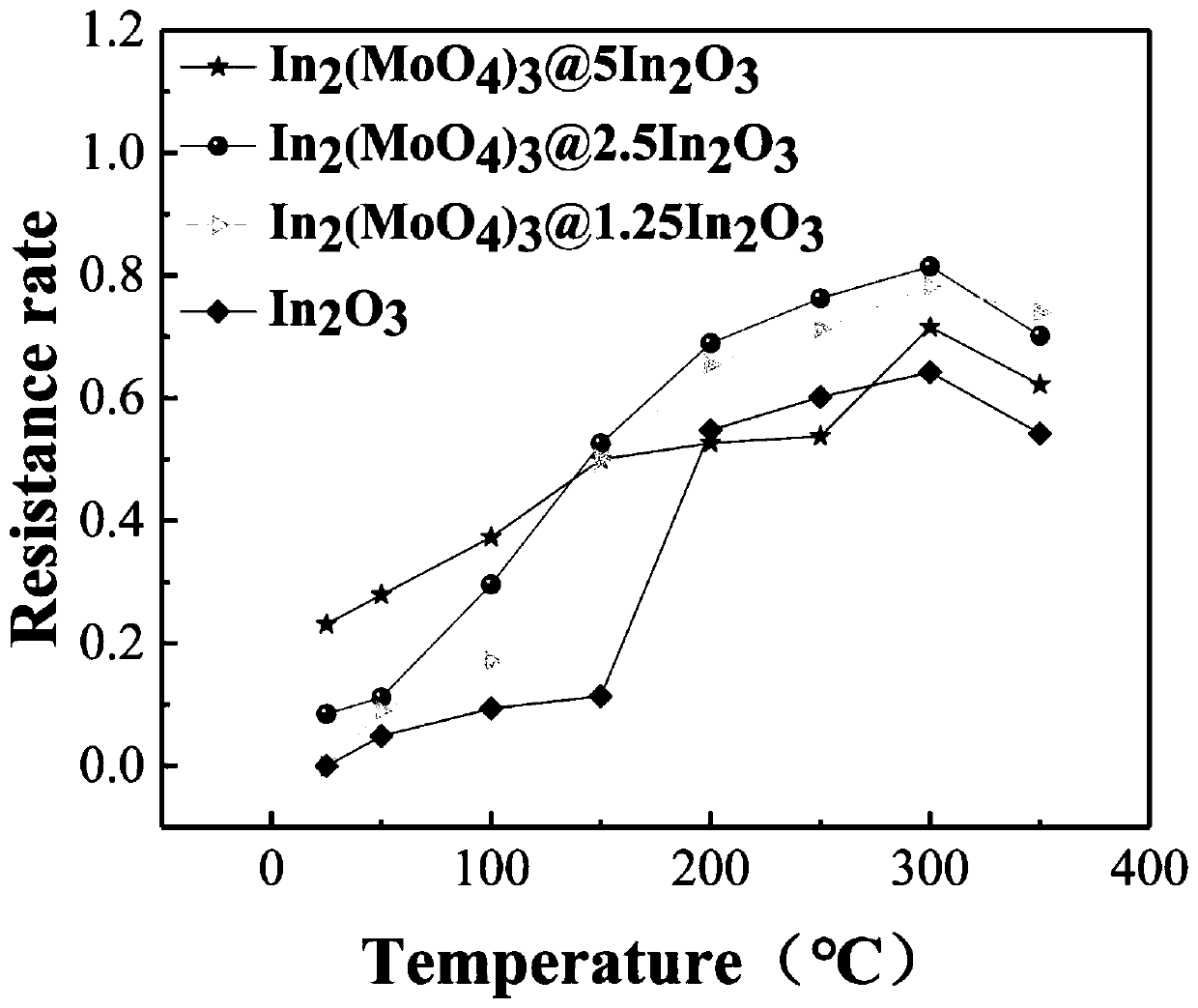

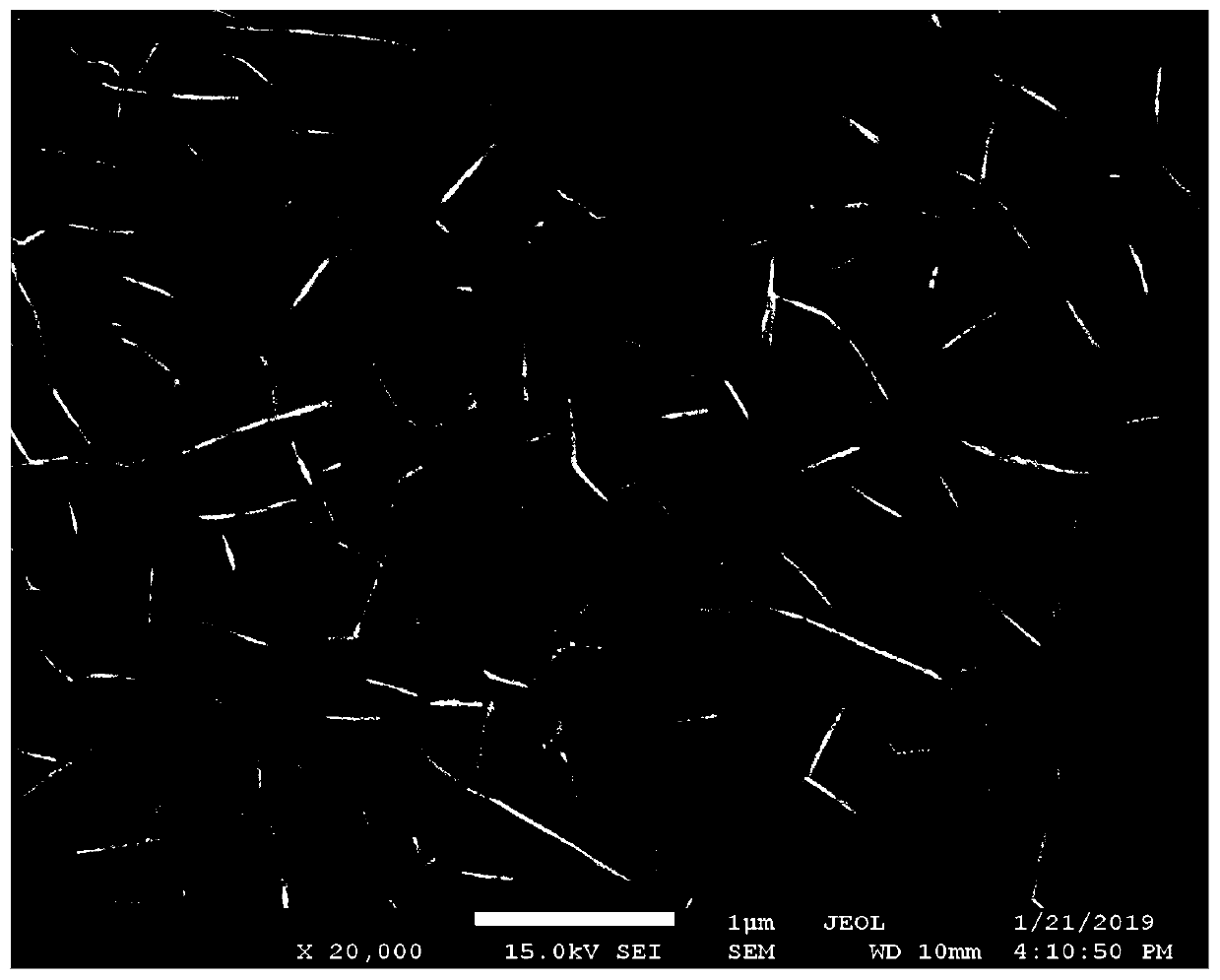

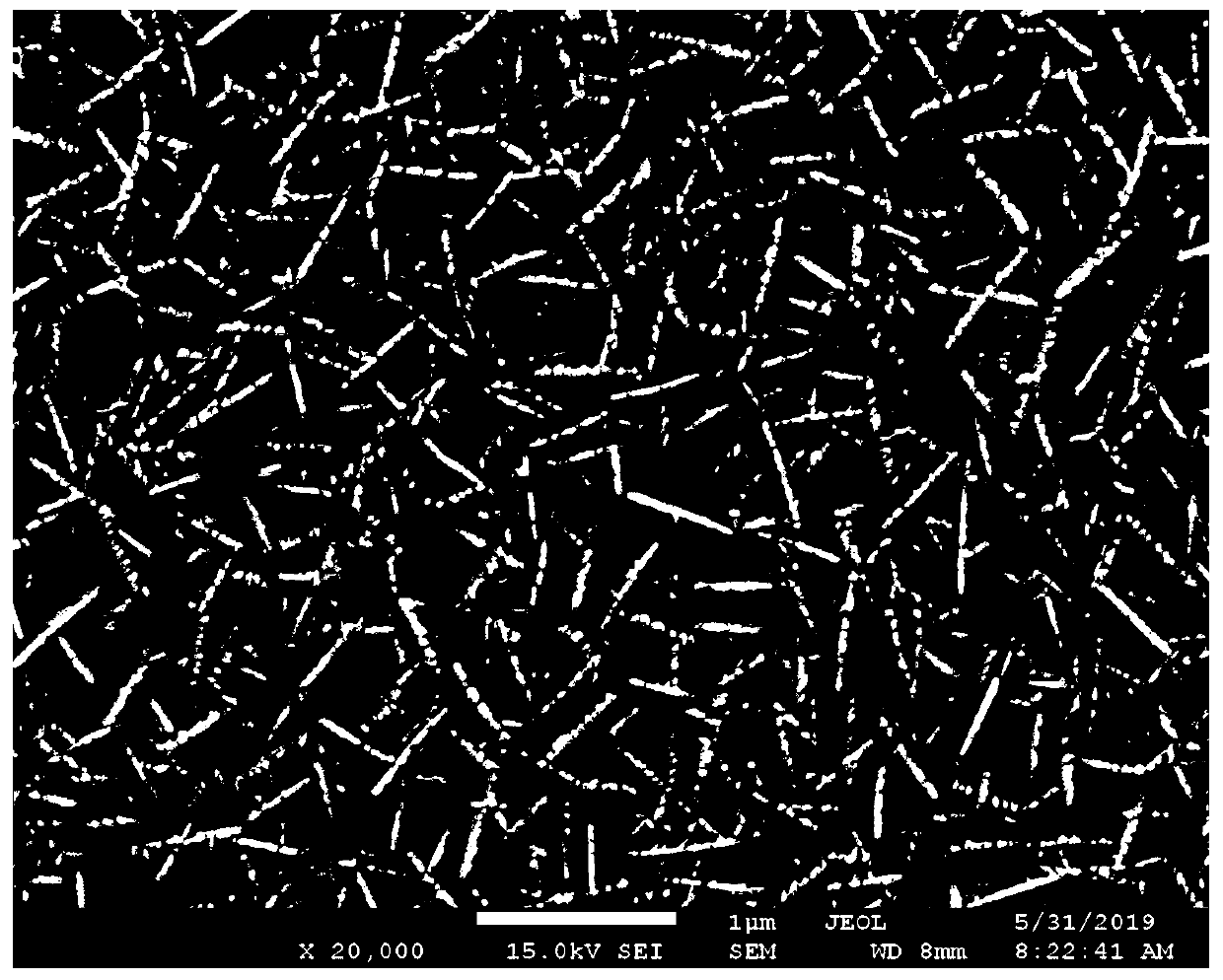

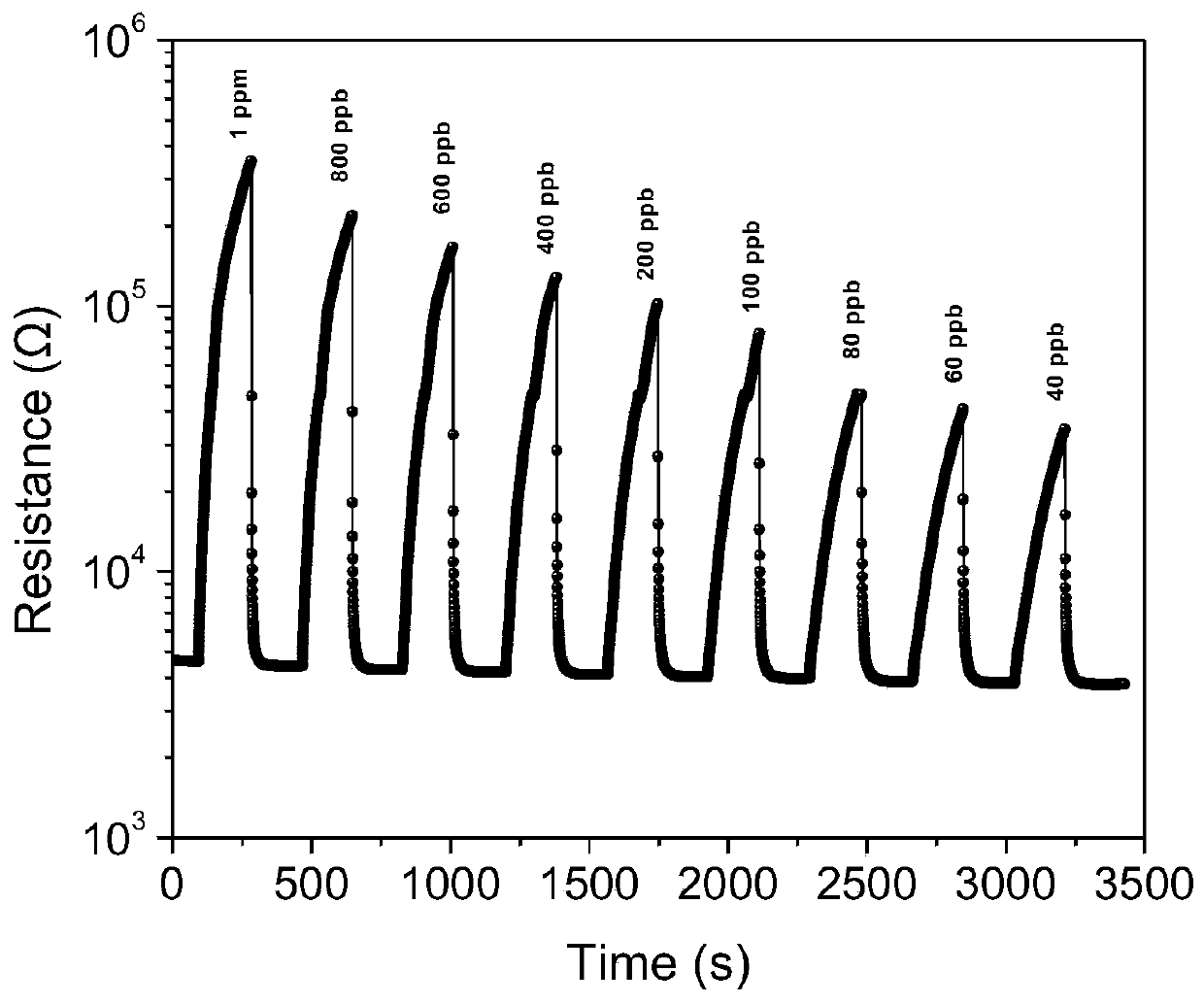

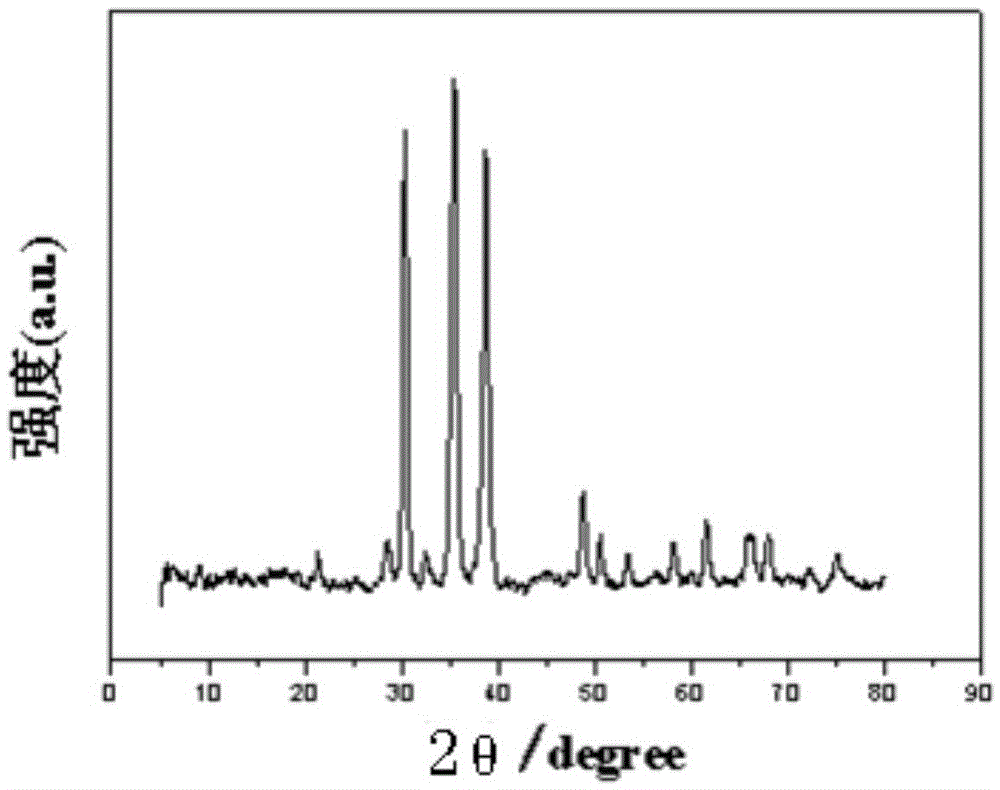

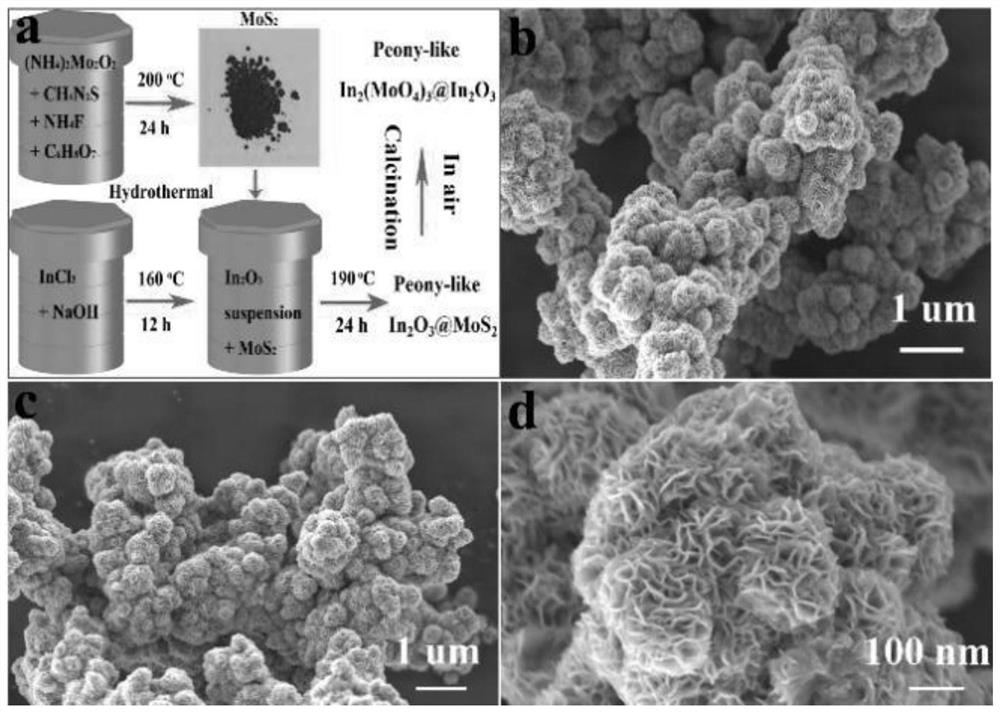

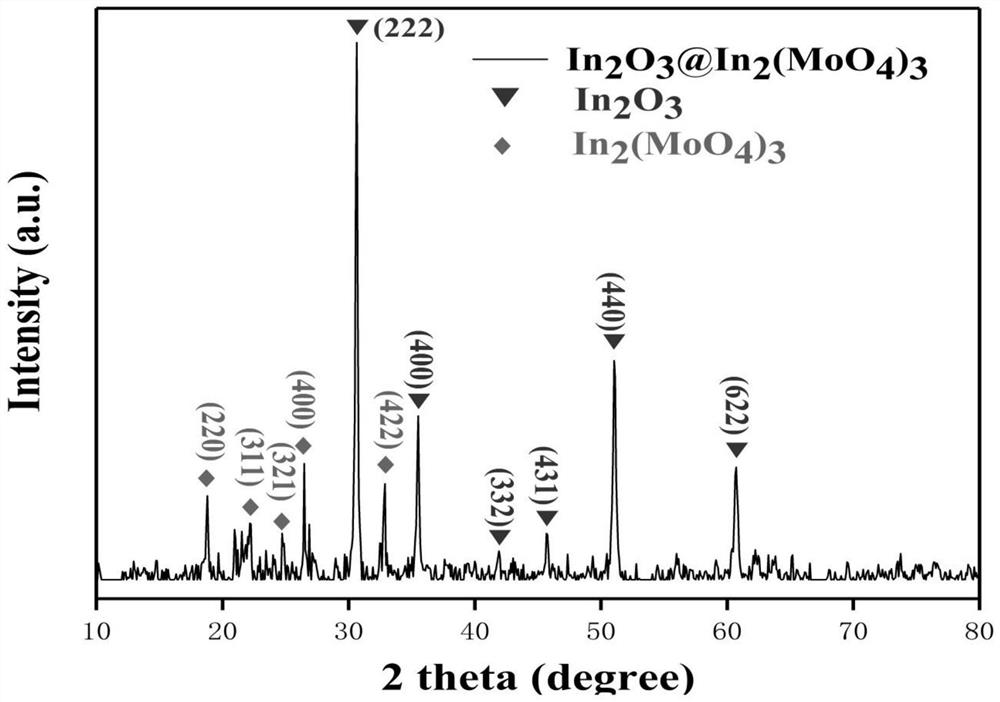

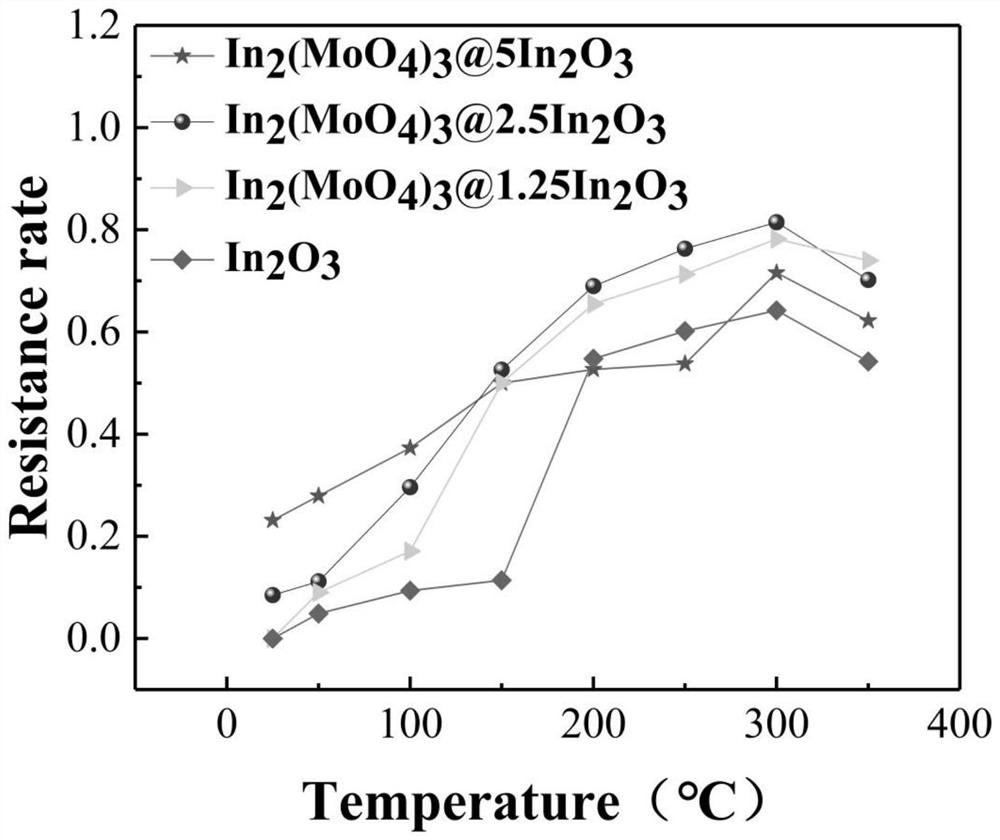

Gas sensor based on metal molybdate nano composite material and preparation method thereof

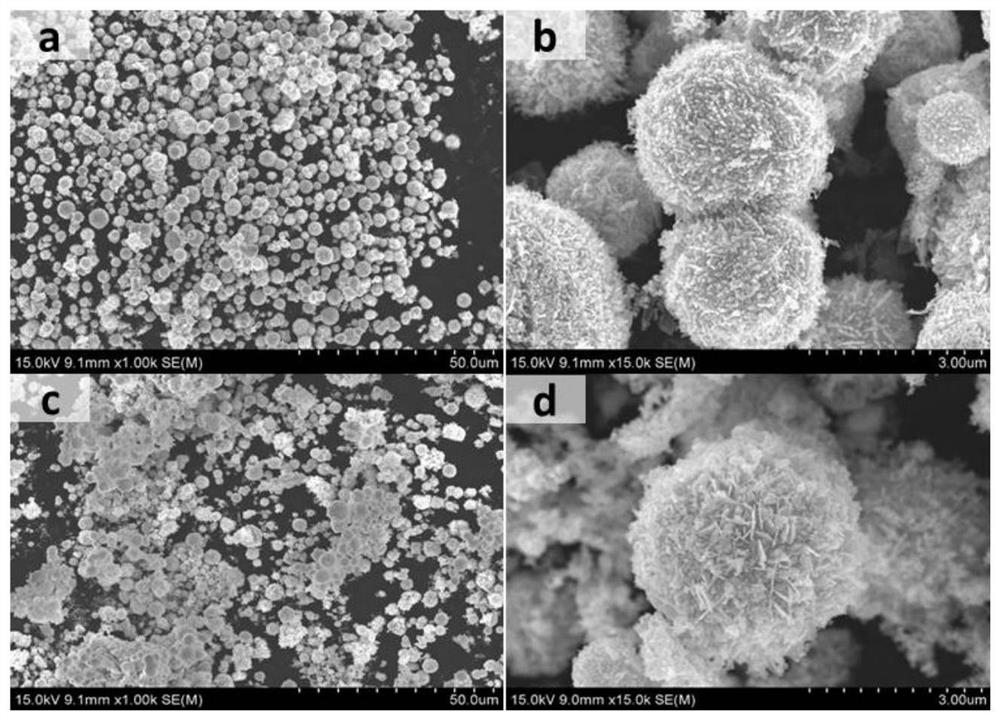

ActiveCN109781800AGood choiceKeep initial response magnitudeMaterial nanotechnologyNanosensorsThioureaNanocomposite

The invention belongs to the technical field of gas sensors, and relates to a gas sensor based on a metal molybdate nanocomposite and a preparation method thereof. An annular gold electrode of the sensor is coated with a metal molybdate nanocomposite film; the specific preparation process of the metal molybdate nano composite material comprises the following steps: firstly, preparing MoS2 powder from ammonium molybdate, thiourea, ammonium fluoride and the like according to a hydrothermal synthesis method, and meanwhile, preparing a semiconductor metal oxide suspension from semiconductor metalsalt through the hydrothermal synthesis method; carrying out hydrothermal synthesis on the molybdenum sulfide powder and the semiconductor metal oxide suspension liquid to obtain a molybdenum sulfidenano composite material precursor, and calcining the prepared molybdenum sulfide nano composite material precursor in an atmosphere to obtain a metal molybdate nano composite material. The ethanol gassensor has the advantages of high selectivity, high sensitivity, good stability, long service life, short response time and recovery time to ethanol gas, excellent performance, and rapid and timely ethanol gas alarm.

Owner:QINGDAO UNIV

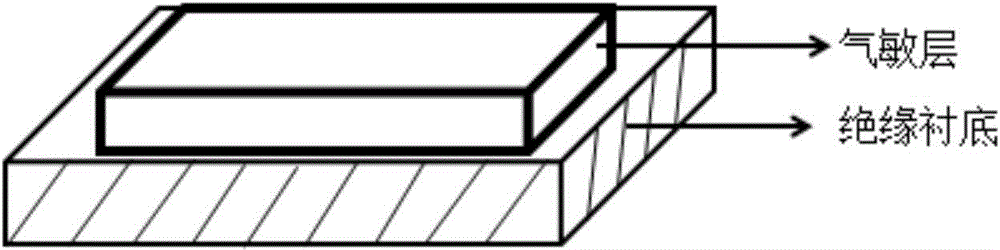

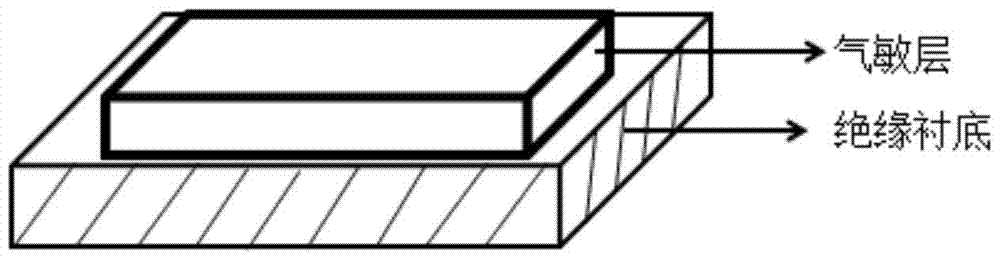

Electrodeless semiconductor gas sensor and preparation method thereof

ActiveCN104614413AGood gas responseImprove conductivityMaterial resistanceWorking temperatureSemiconductor

The invention discloses an electrodeless semiconductor gas sensor and a preparation method thereof. By adopting the electrodeless-type design, a gas sensitive layer is produced from a colloidal-state nano crystal composite material which is high in sensitivity and good in conductivity, the gas sensitive layer is smeared on an insulation substrate to form a device, no additional signal electrode is needed, the device structure and the process procedure are simple, the cost is reduced, and the mass production can be realized; moreover, the method is suitable for producing a flexible gas sensor. The gas sensor has characteristics of light weight, thinness, shortness, small size and good portability; moreover, the working temperature is low, and the application prospect is good.

Owner:HUAZHONG UNIV OF SCI & TECH

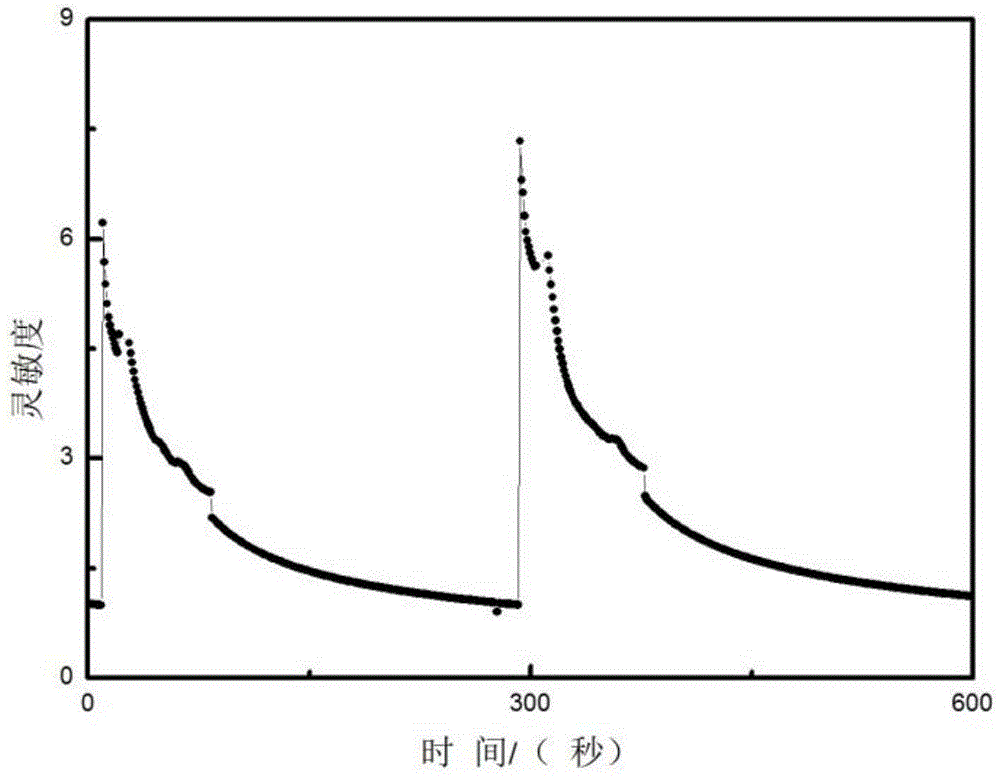

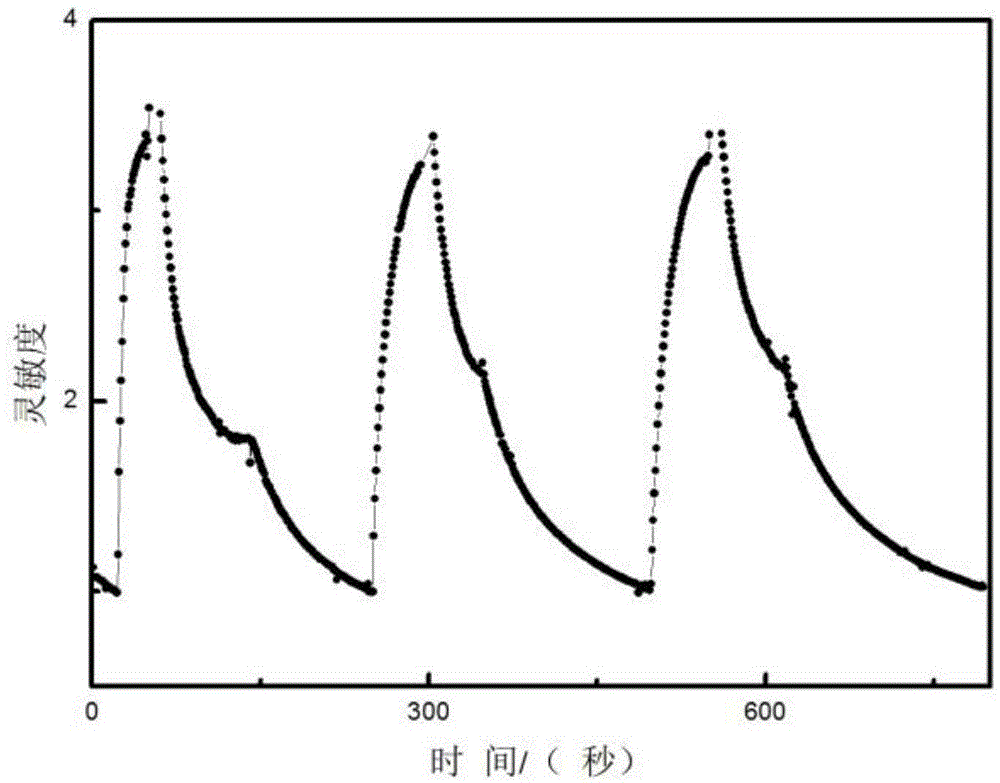

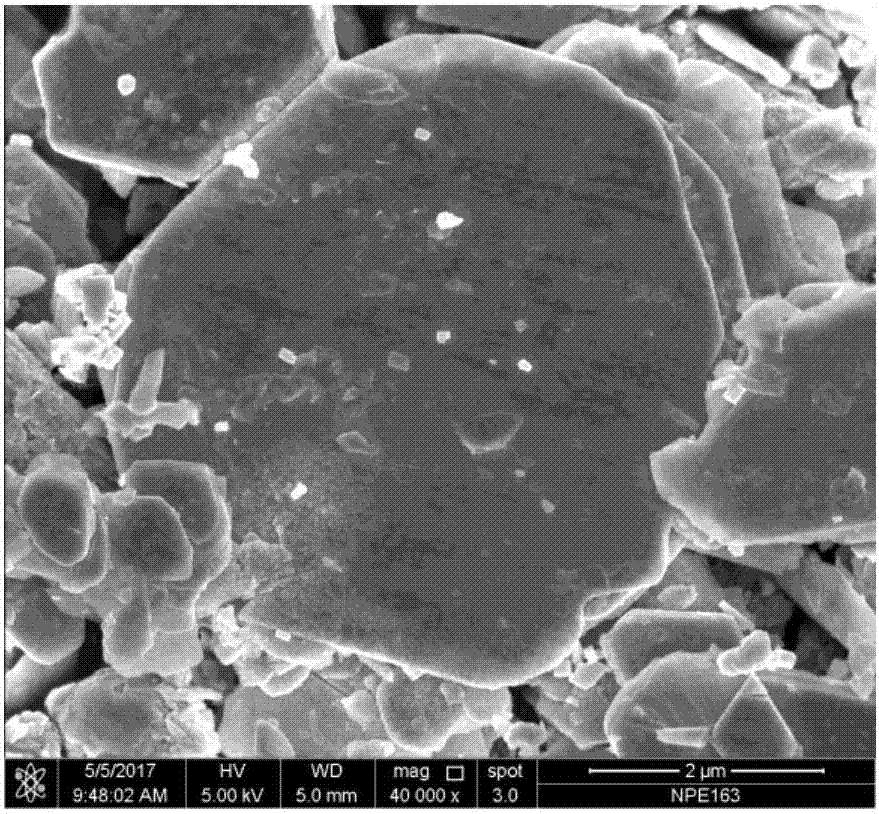

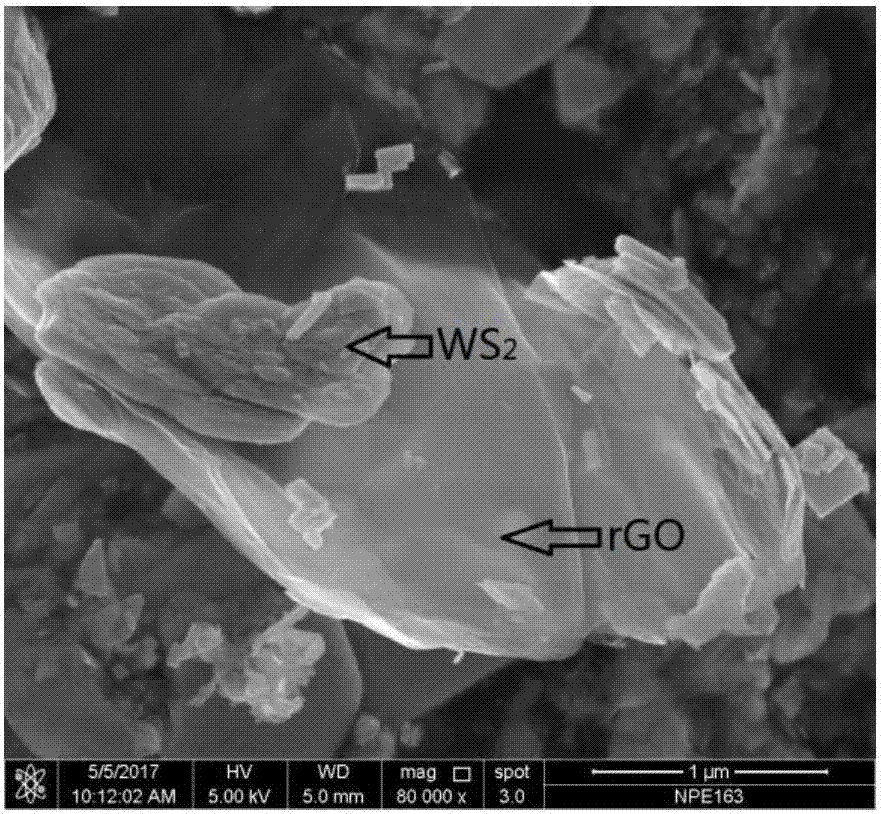

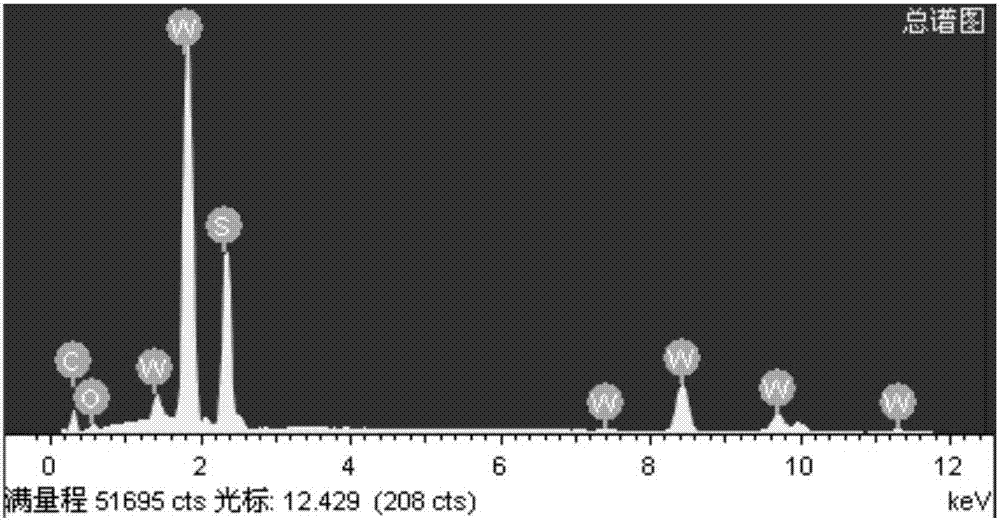

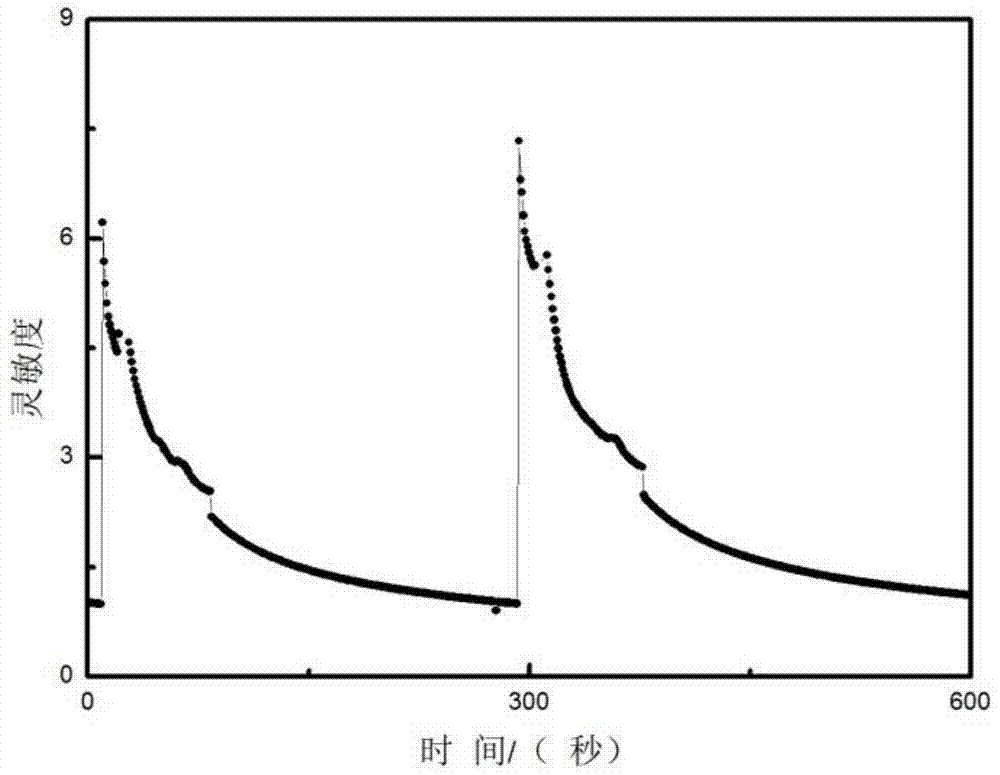

Novel ammonia gas sensor based on reduced graphene oxide-tungsten disulfide composite and preparation technology thereof

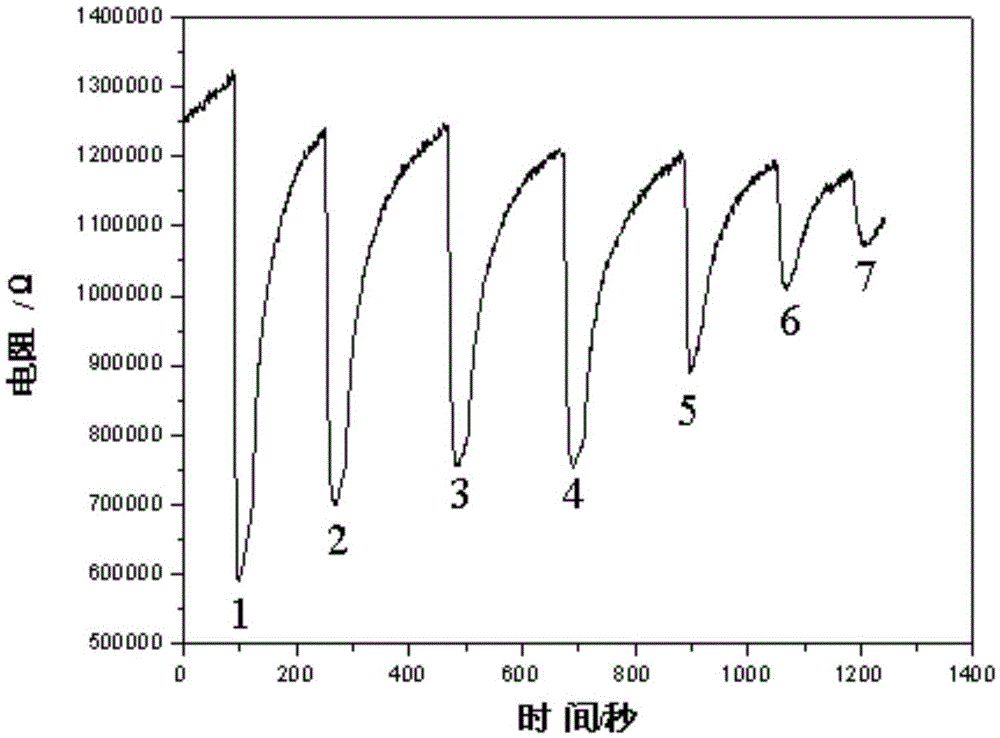

ActiveCN107219270AGood gas responseReduce agingMaterial resistanceHydrothermal synthesisRecovery stage

The invention provides a novel ammonia gas sensor based on a reduced graphene oxide-tungsten disulfide composite and a preparation technology thereof and belongs to the technical field of sensors. The novel ammonia gas sensor comprises a gas-sensitive composite and a sensor substrate, wherein the gas-sensitive composite is a nano material obtained through one-step hydrothermal synthesis, the gas-sensitive composite is uniformly coated on a gold interdigitated electrode on the sensor substrate, transient heating temperature of a heating plate on the back of the sensor substrate is 140 DEG C, and heating recovery time is linearly varied along with concentration of detected gas. The reduced graphene oxide-tungsten disulfide composite disclosed by the invention shows good response performance on ammonia gas in a room temperature environment and has good selectivity, stability and repeatability. In a recovery stage of the gas sensor provided by the invention, transient heating is used, time required for reduction is effectively shortened without influencing performance of a gas-sensitive material, and concrete transient heating time can be set according to the gas concentration obtained through detection.

Owner:DALIAN UNIV OF TECH

Tungsten trioxide gas-sensitive film material, tungsten trioxide-based composite gas-sensitive film material, and preparation methods and applications of tungsten trioxide gas-sensitive film material and tungsten trioxide-based composite gas-sensitive film material

InactiveCN110511059AAvoid destructionAvoid problems such as accumulationMaterial resistanceComposite filmNanoparticle

The invention discloses a tungsten trioxide gas-sensitive film material, a tungsten trioxide-based composite gas-sensitive film material, and preparation methods and applications of the tungsten trioxide gas-sensitive film material and the tungsten trioxide-based composite gas-sensitive film material, wherein a tungsten trioxide thin gas-sensitive material with a nanometer structure is directly prepared on an electrode substrate through in-situ solution deposition, and second phase oxide compounding is performed at the prepared tungsten trioxide thin film through a sol-gel method to obtain a tungsten trioxide-based composite gas-sensitive film material. According to the present invention, the tungsten trioxide film with the nanometer structure can be subjected to direct deposition growth on the electrode substrate; the prepared nanometer structure tungsten trioxide thin film and the composite thin film based on the nanometer structure tungsten trioxide have the network-like structure formed by the nano-sheets growing perpendicular to the substrate; the method has advantages of high efficiency, low cost and simple process, and is suitable for industrial production; and the obtainednanometer structure tungsten trioxide film has a large specific surface area, can effectively overcome the agglomeration problem among nanoparticles, has good gas-sensitive response to gases such as NO2, H2S and the like, and has excellent gas-sensitive application prospect.

Owner:JIANGSU UNIV

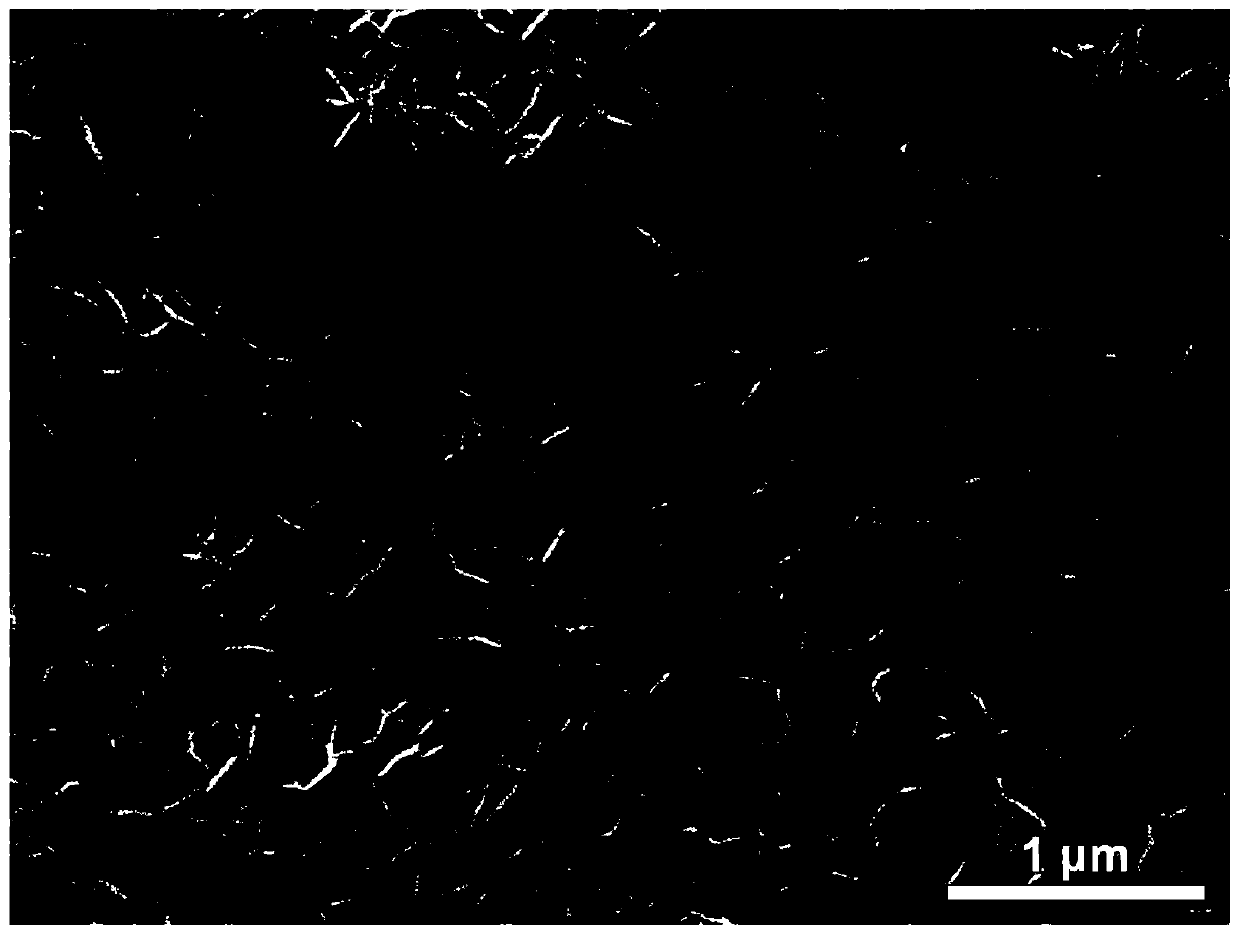

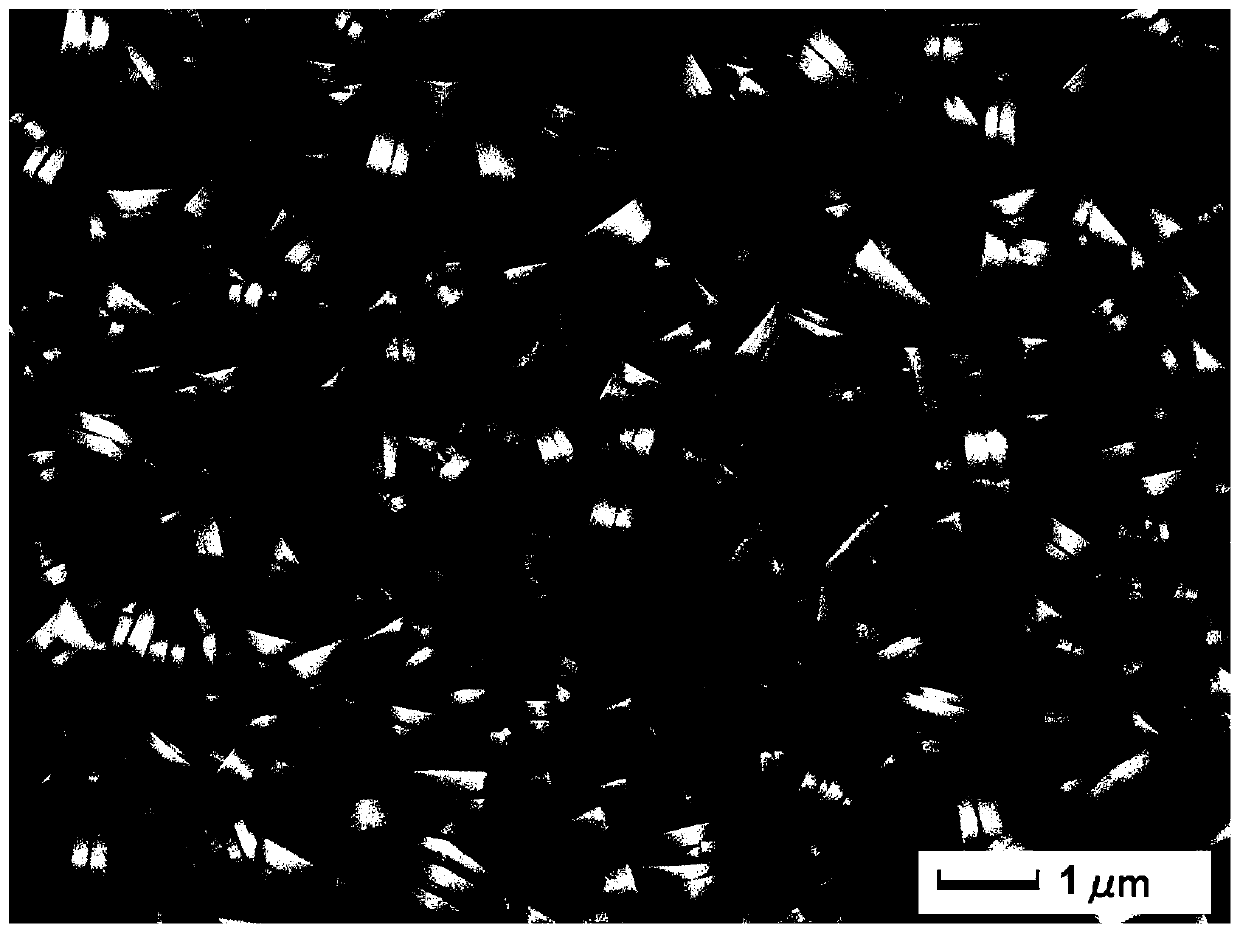

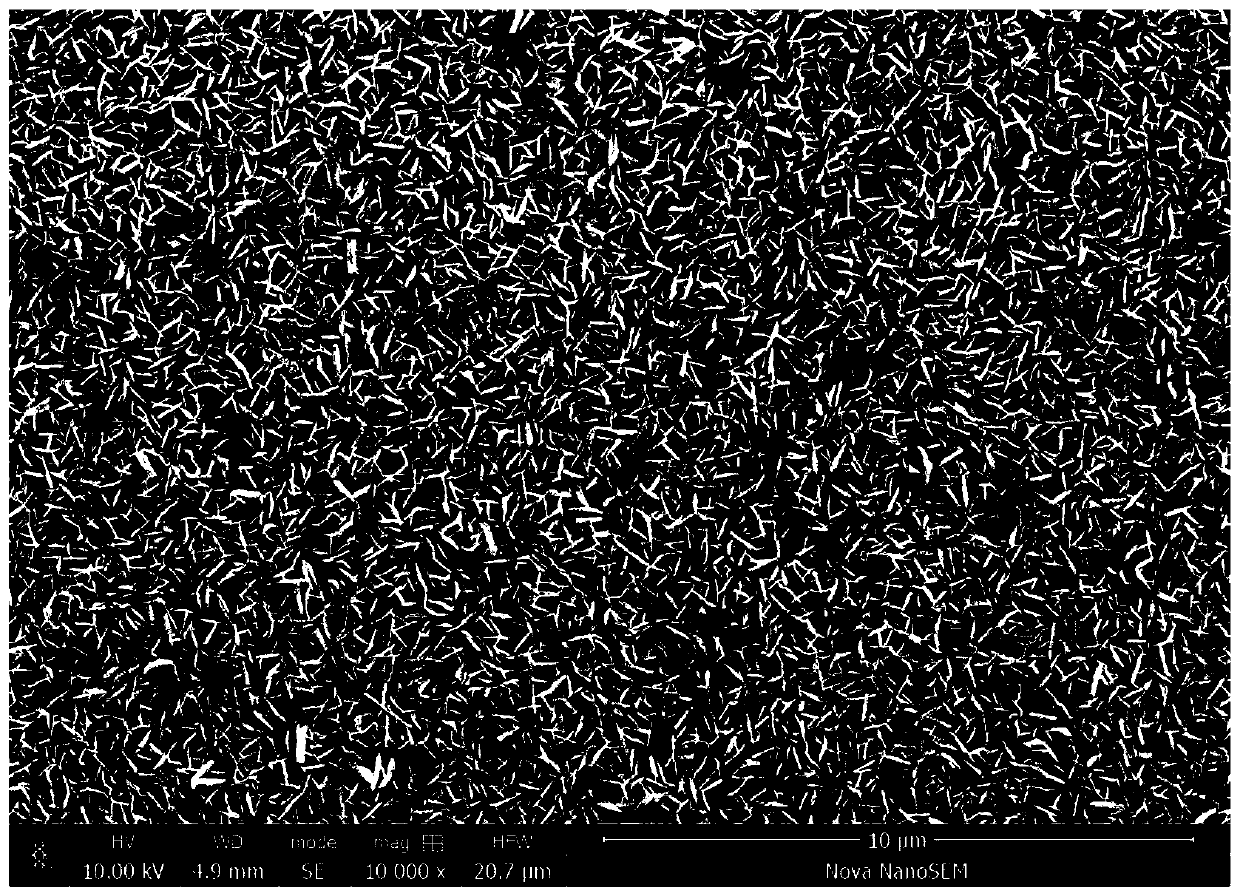

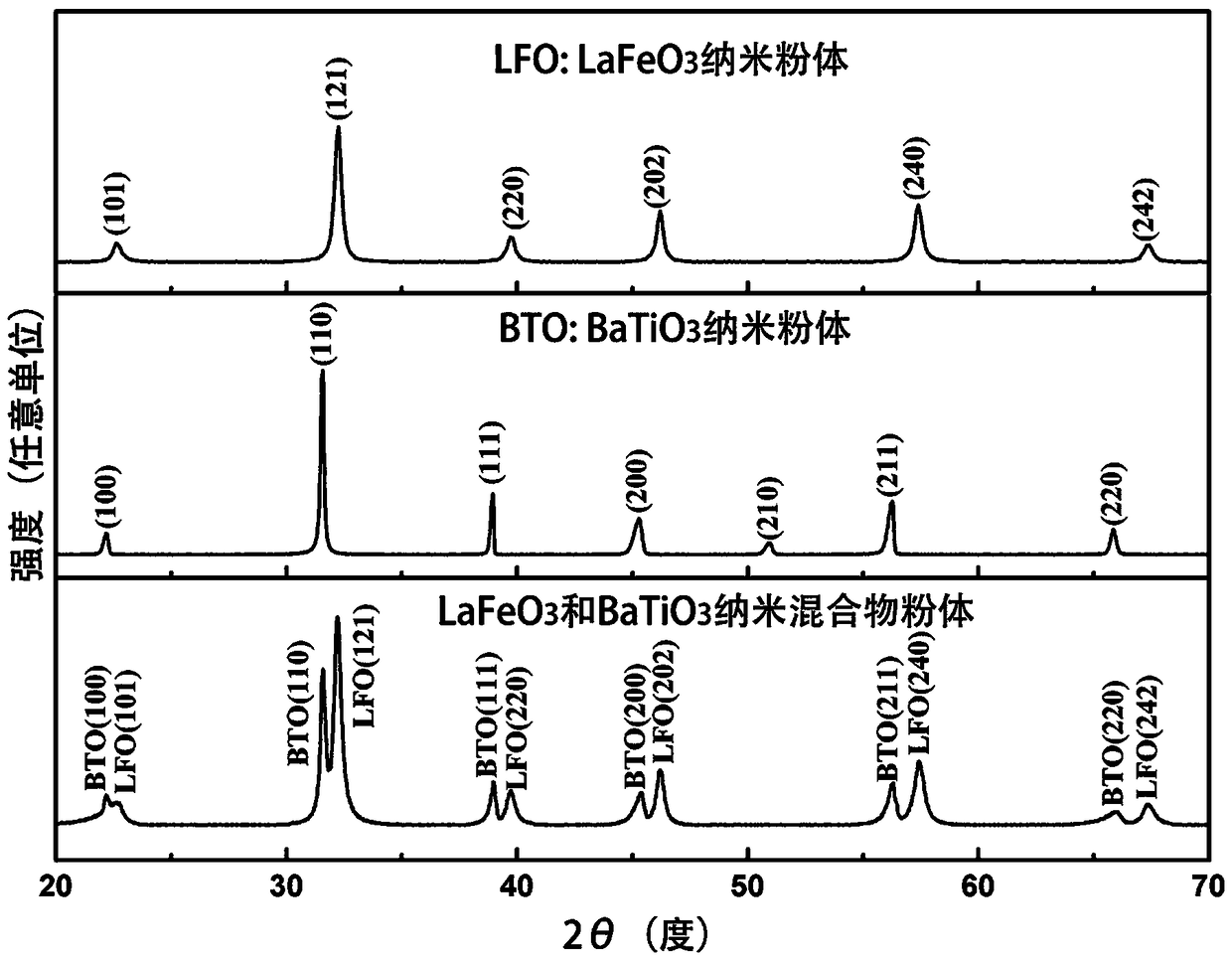

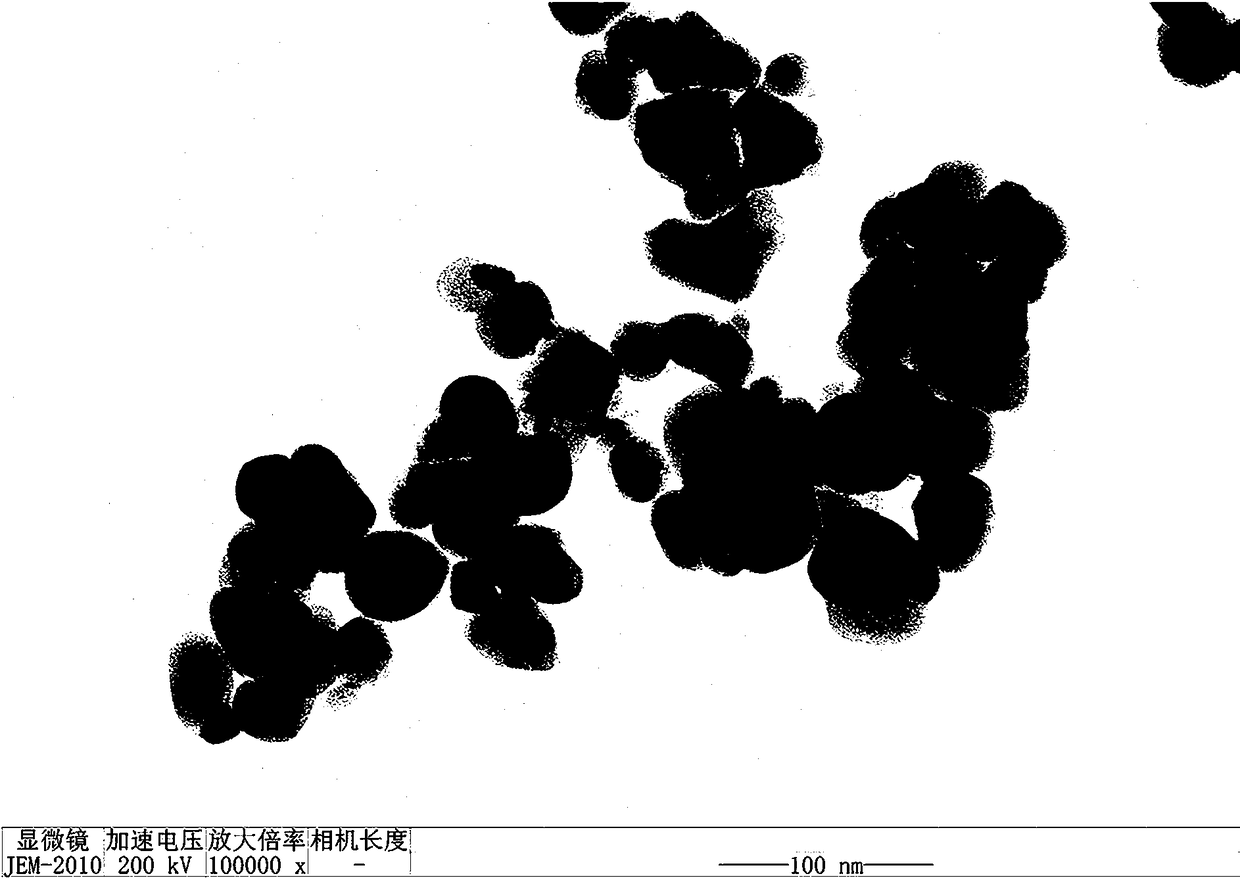

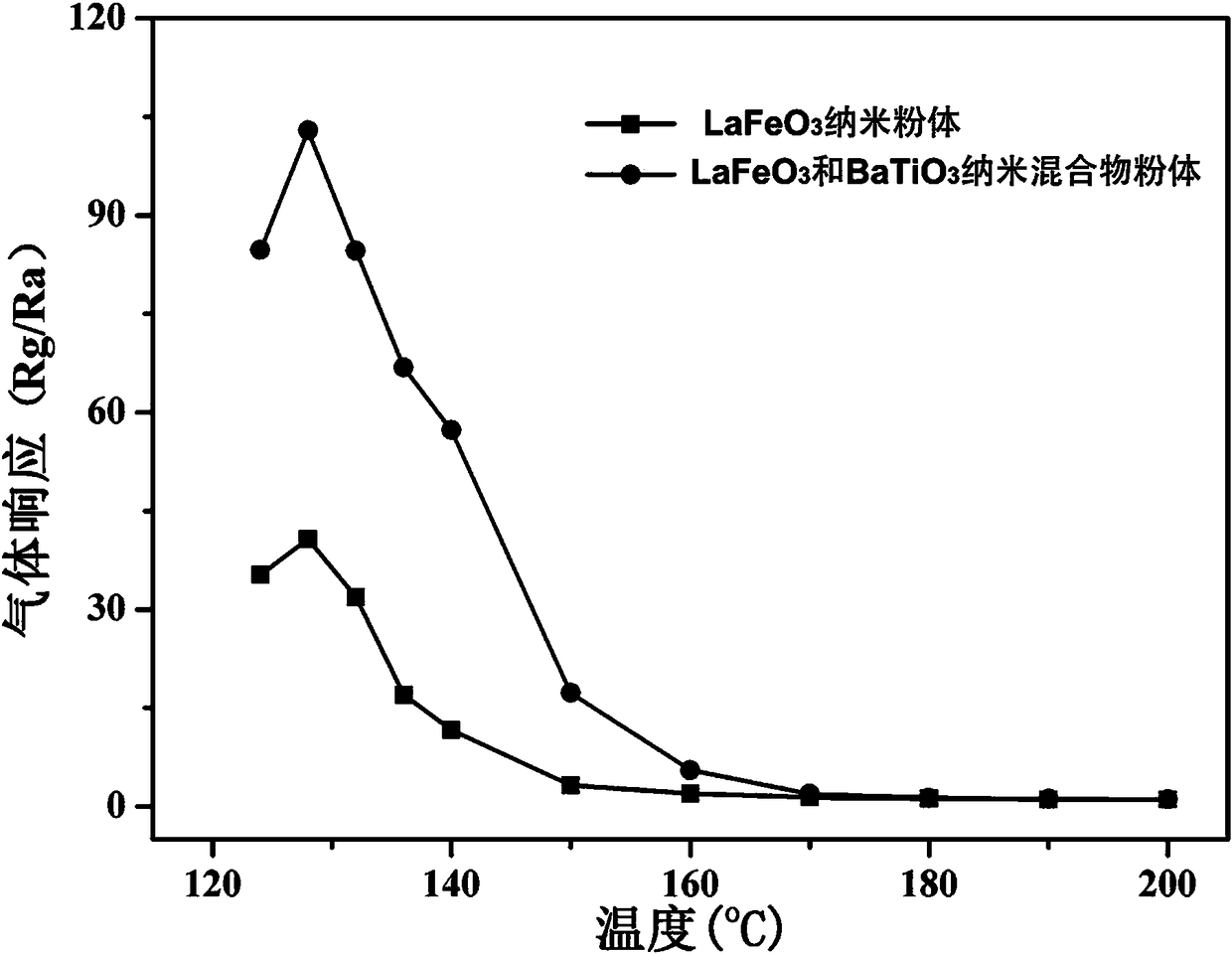

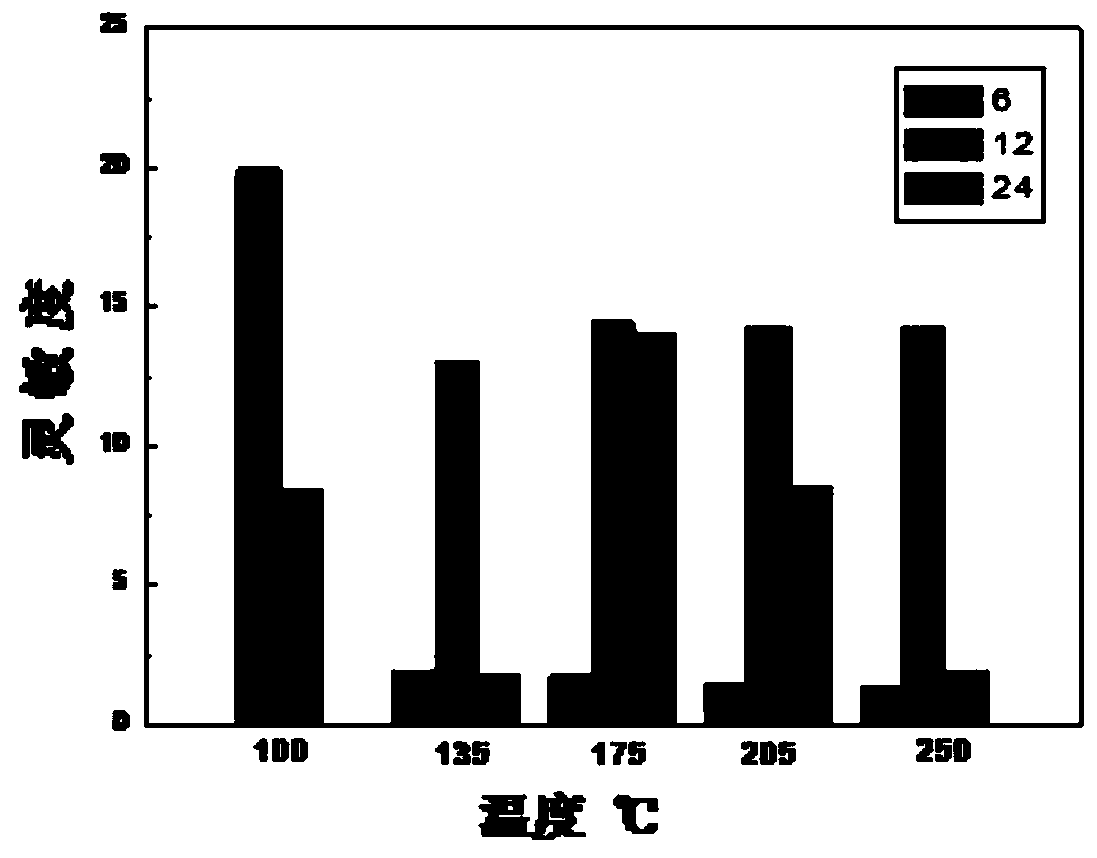

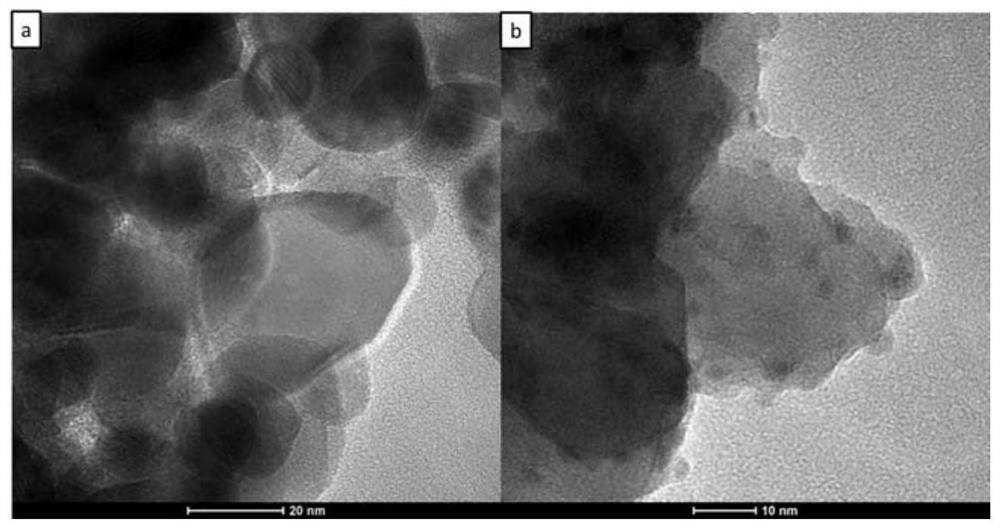

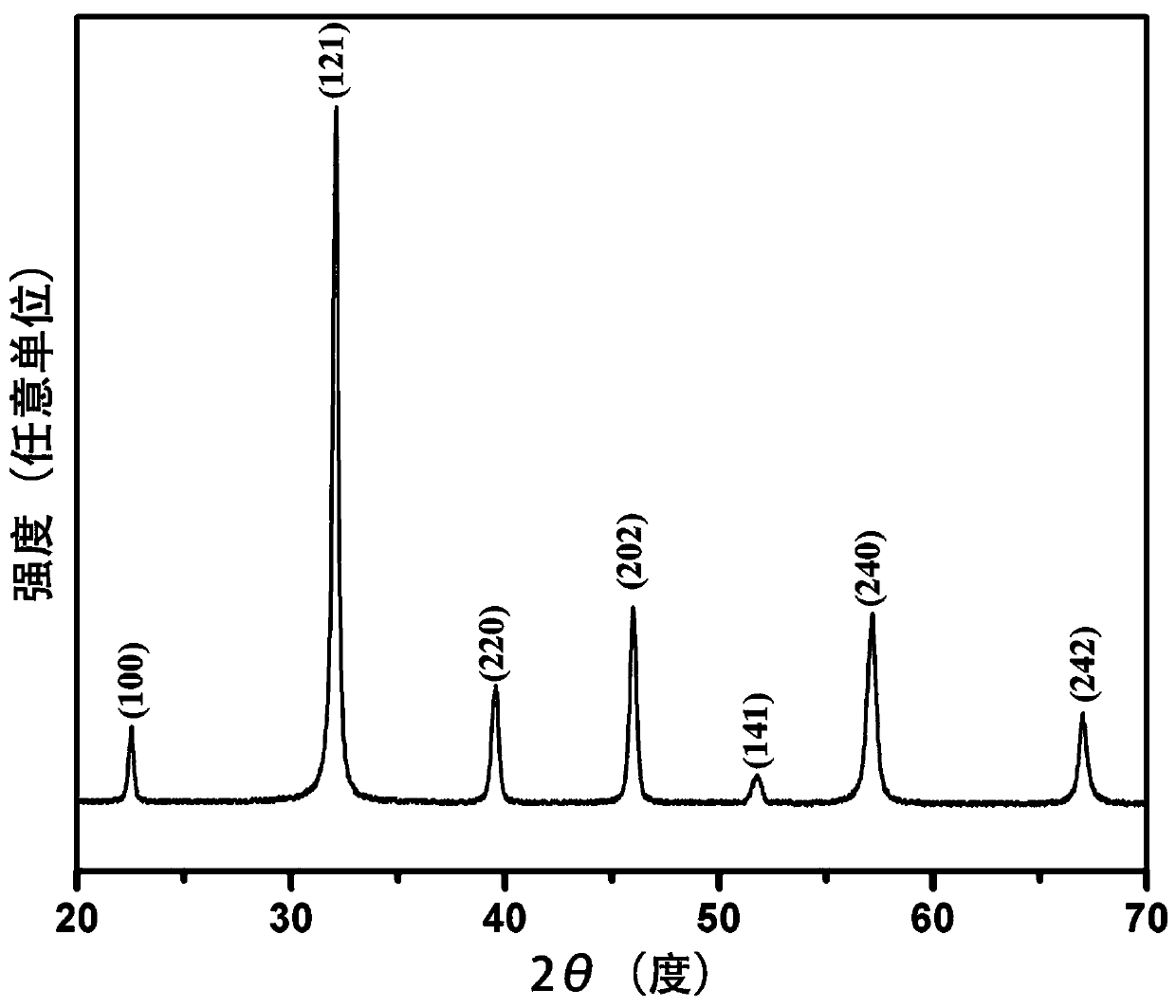

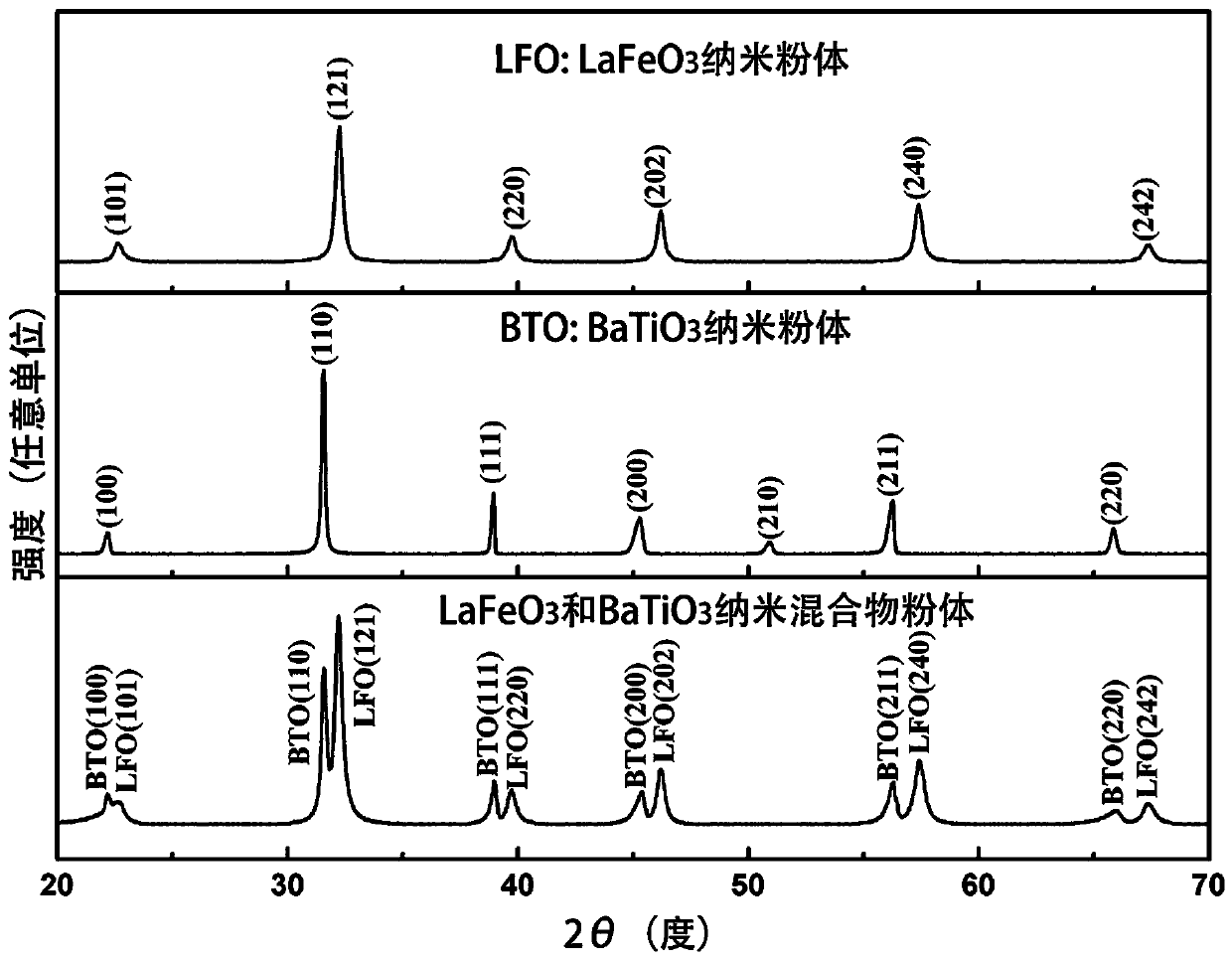

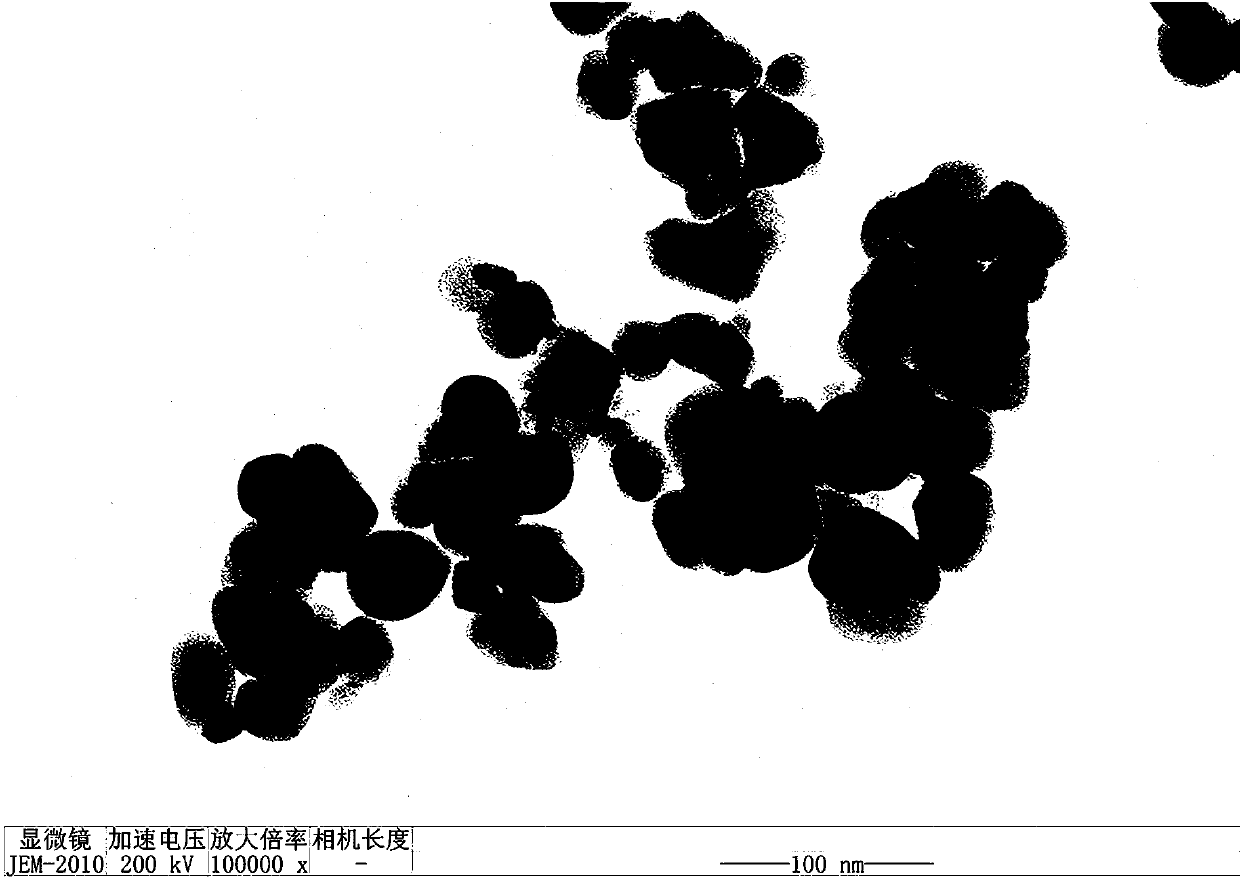

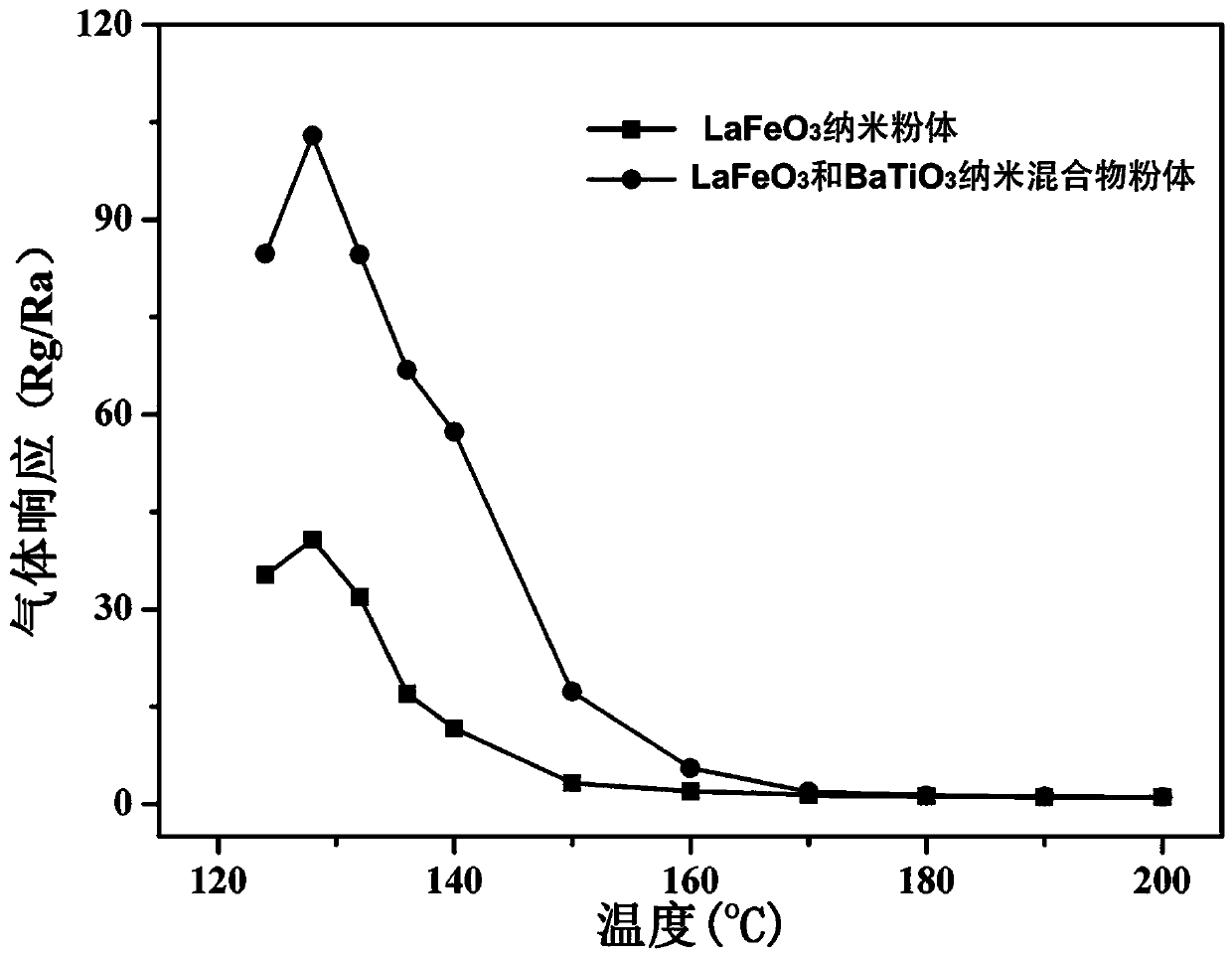

High gas response and selective LaFeO3-based ethanol gas sensor element and preparation method thereof

ActiveCN108205002AHigh originalityLower working temperatureMaterial resistanceHydrogenOperating temperature

The invention belongs to the technical field of gas sensors, and provides a high gas response and selective LaFeO3-based ethanol gas sensor element and a preparation method thereof. LaFeO3 and BaTiO3nano powder are prepared by a sol-gel method and mixed at a molar ratio of 2:1; the mixture is sintered for 2 h at 190-210 DEG C, a nano gas-sensitive material is obtained, and a side-heating ceramictube structure gas sensor element is obtained. The oxygen adsorption capability of the surface of the nano-gas sensitive material is enhanced, and the gas response and selectivity are significant improved at lower operating temperatures. The optimum operating temperature of the gas sensor element for ethanol is 128 DEG C; the gas response to 100 ppm ethanol at the optimum operating temperature is102.9, and good stability is achieved; for 100 ppm acetone, dichloromethane, n-hexane, carbon dioxide and hydrogen and the like, the gas response is 38 or below, and good selectivity is achieved; andthe gas sensor element has a very high gas response to low concentration ethanol gas.

Owner:TAIYUAN UNIV OF TECH

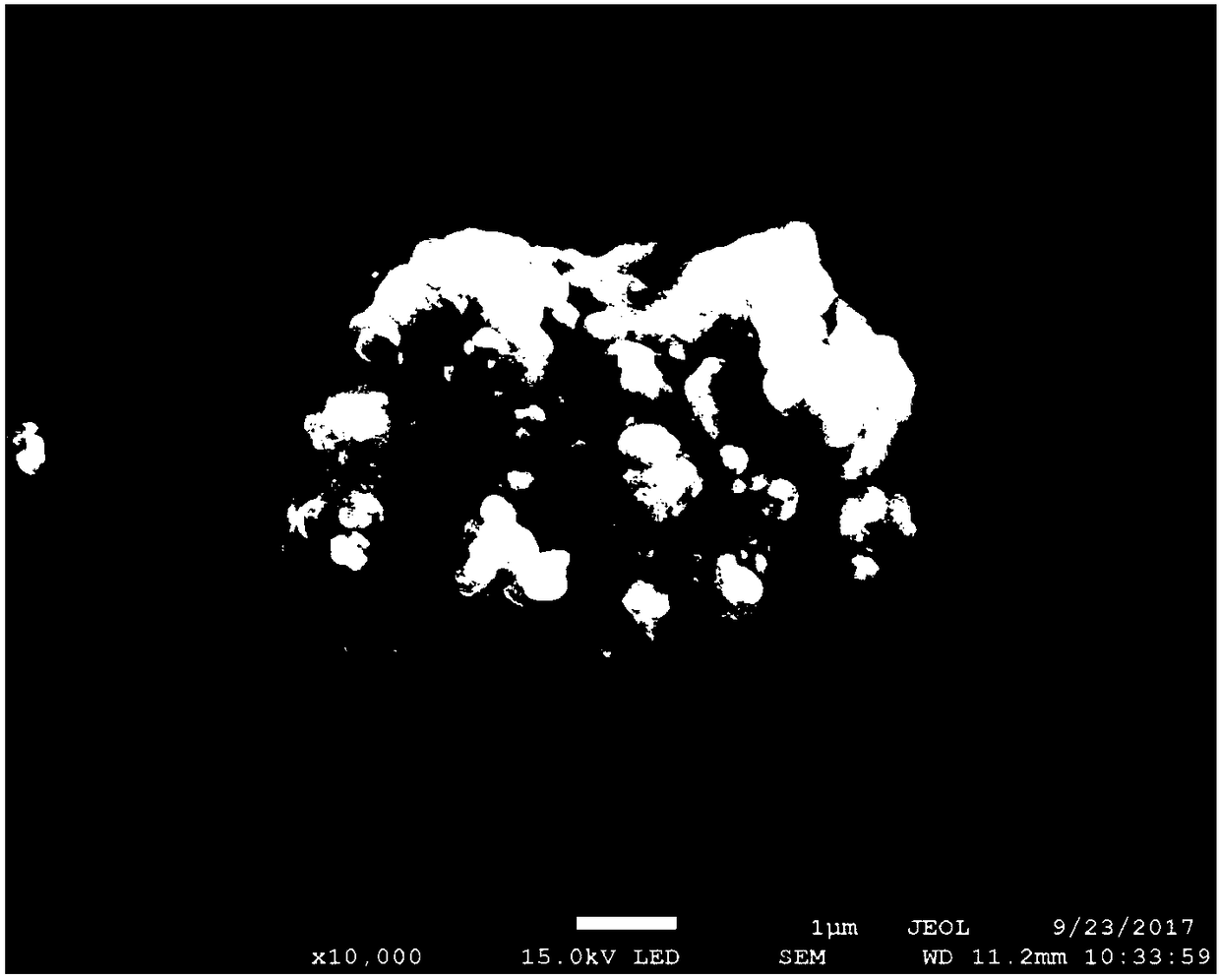

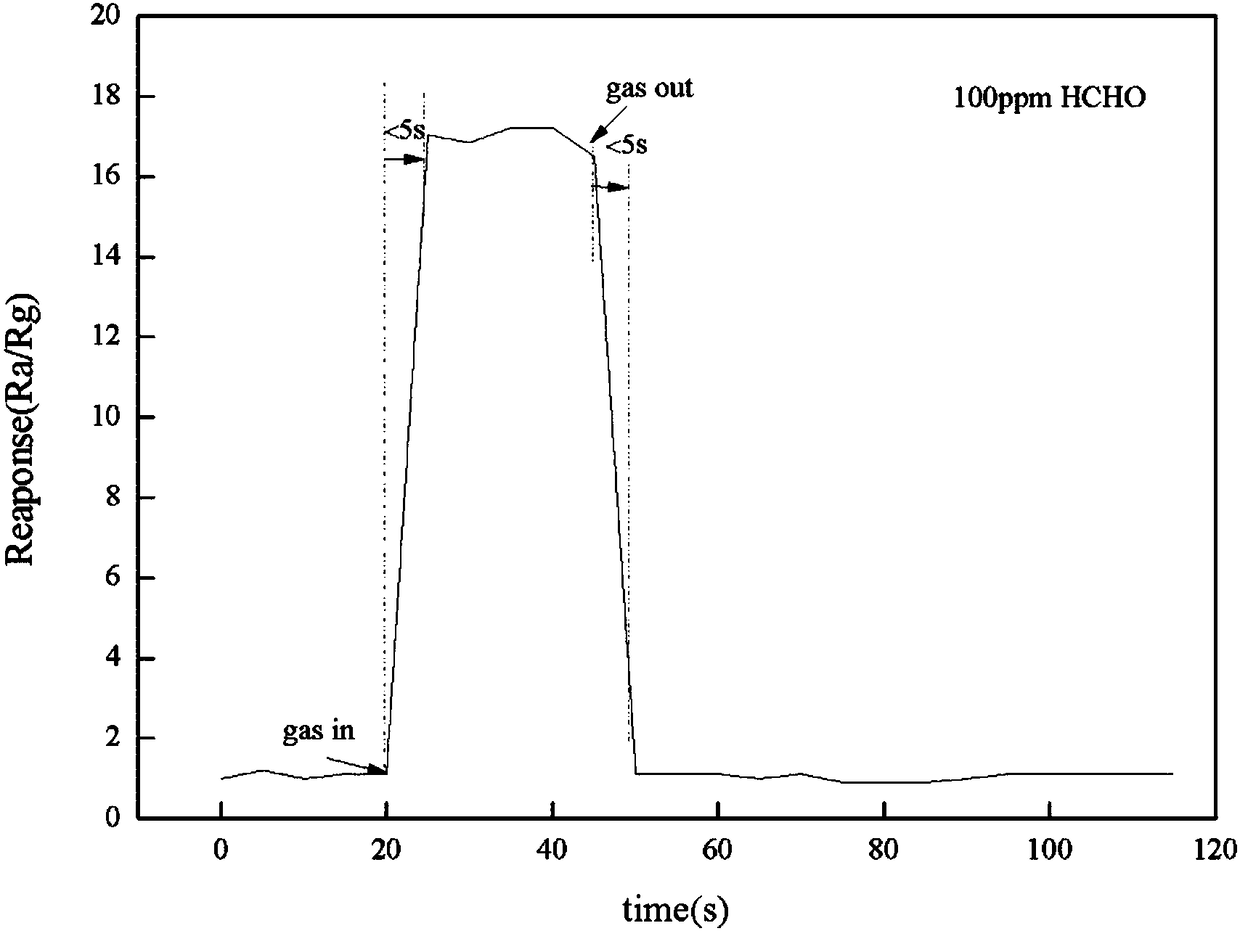

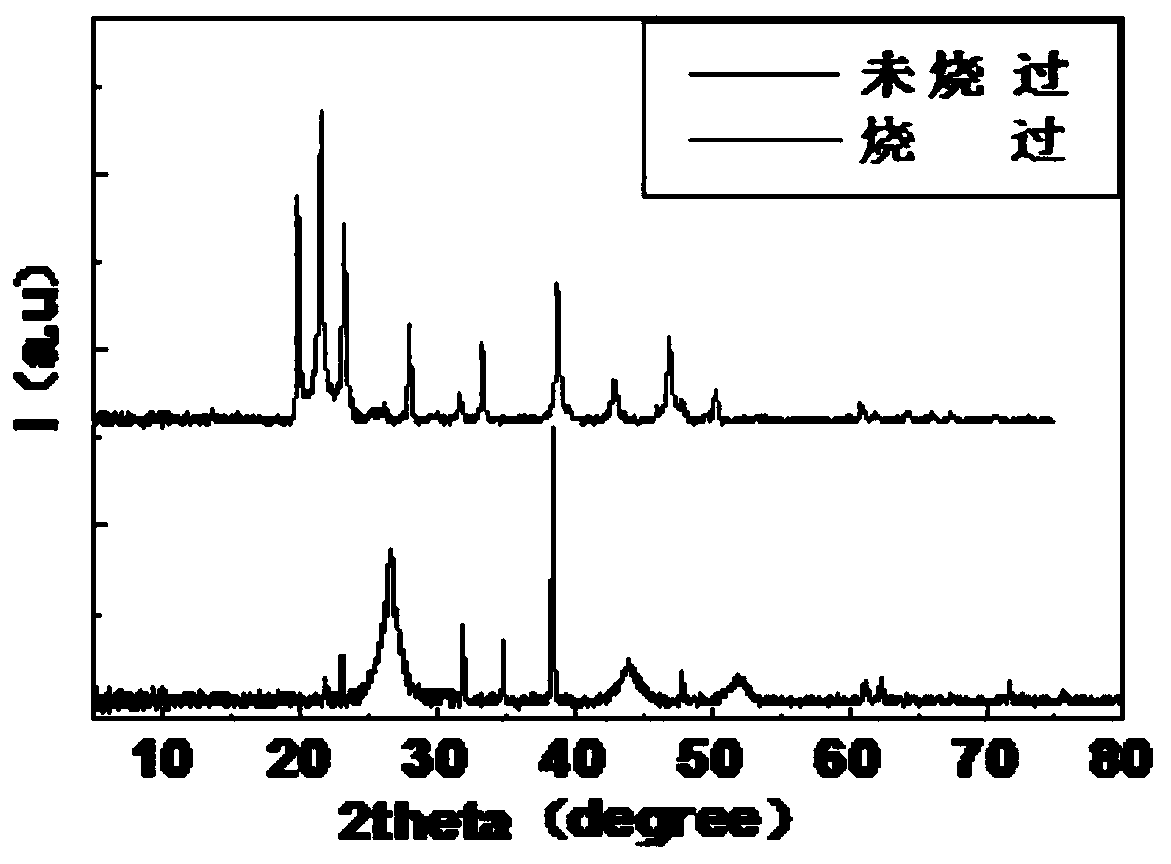

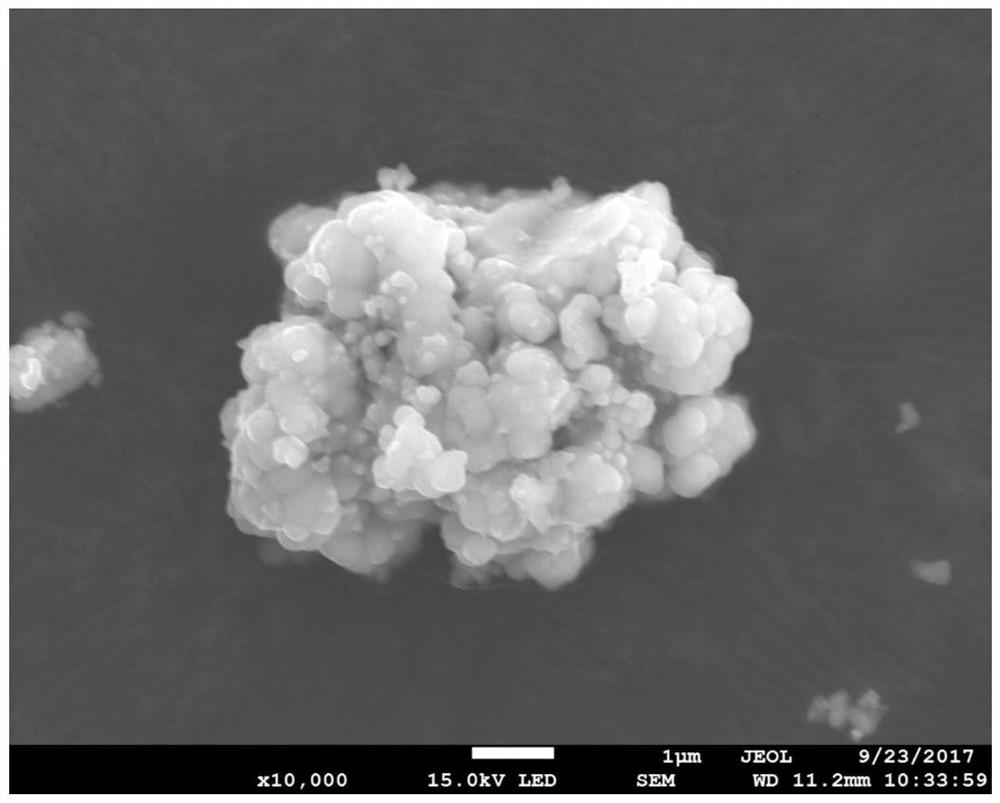

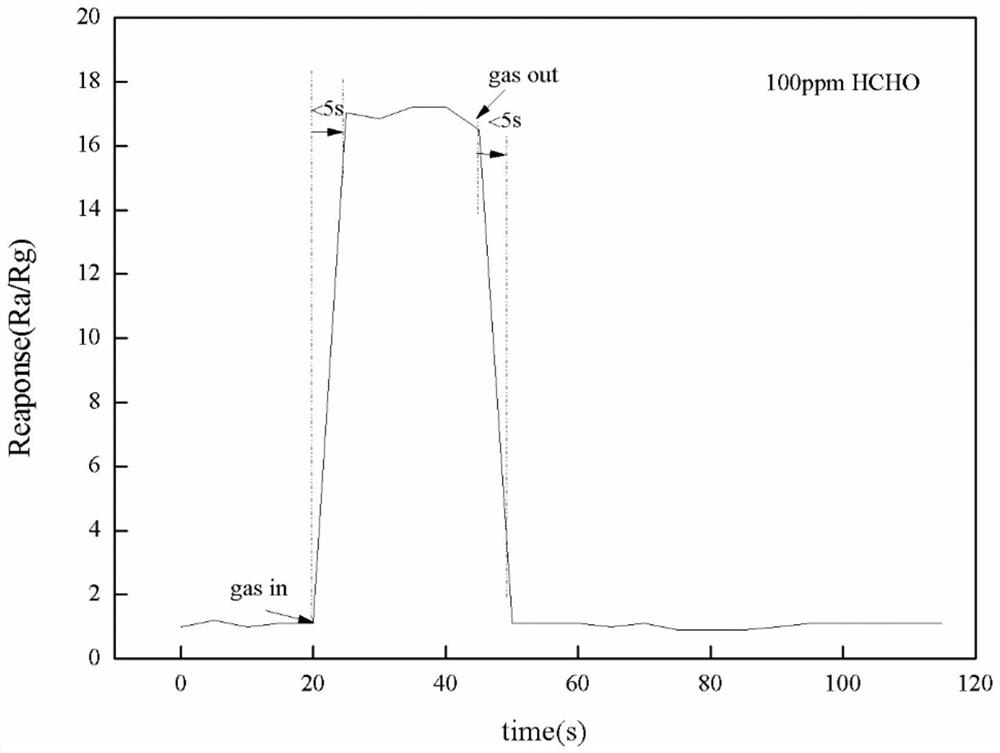

Preparation method of formaldehyde gas sensitive materials based on tin mud modification in tin plating process and application

ActiveCN108426923ASolve processingSolve pollutionMaterial resistanceTin platingBiological activation

The invention belongs to the field of comprehensive recycling of industrial waste tin, environmental protection and semiconductor oxide formaldehyde gas sensors, and relates to a preparation method offormaldehyde gas sensitive materials based on tin mud modification in a tin plating process and an application. The formaldehyde gas-sensitive materials are prepared from waste tin mud existing at the bottom of a plating bath on a tin plating production line by acidification activation, washing, drying, noble metal doping and subsequent heat treatment. The prepared gas sensor has excellent gas-sensitive performance such as high sensitivity, fast response, high recovery speed and the like for formaldehyde. Effective and reasonable utilization of tin resources is realized, the economic cost isreduced, environmental pollution caused by waste is reduced, and the preparation method is environmentally friendly.

Owner:NORTHEASTERN UNIV +1

A novel ammonia gas sensor based on reduced graphene oxide-tungsten disulfide composite material and its preparation process

ActiveCN107219270BImprove responsivenessNo performance impactMaterial resistanceHydrothermal synthesisInterdigitated electrode

Owner:DALIAN UNIV OF TECH

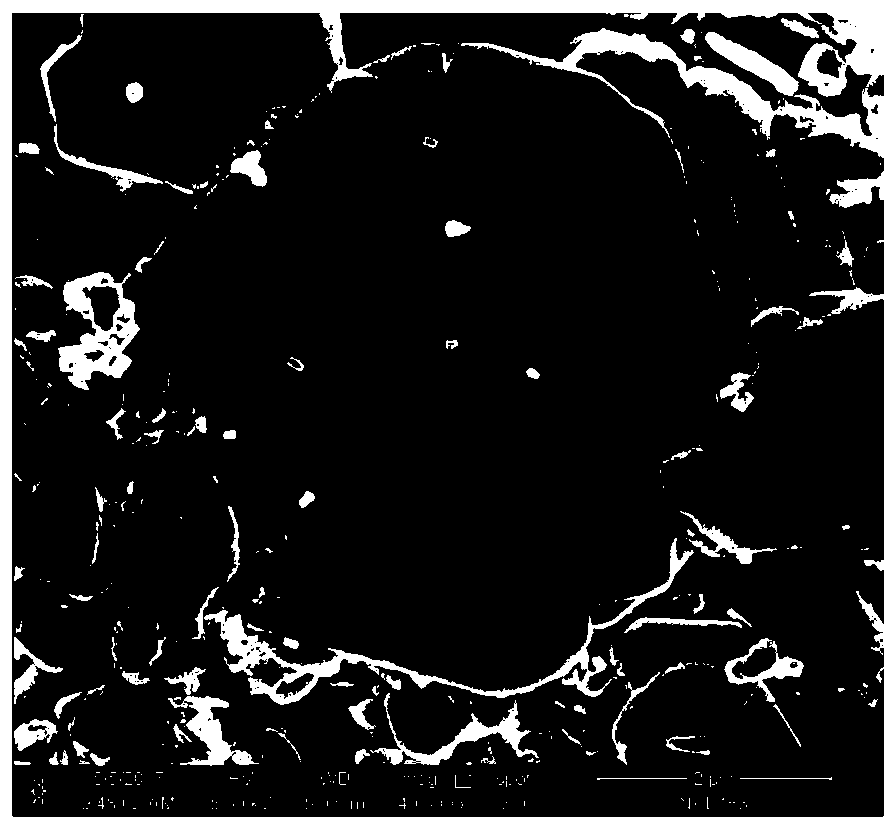

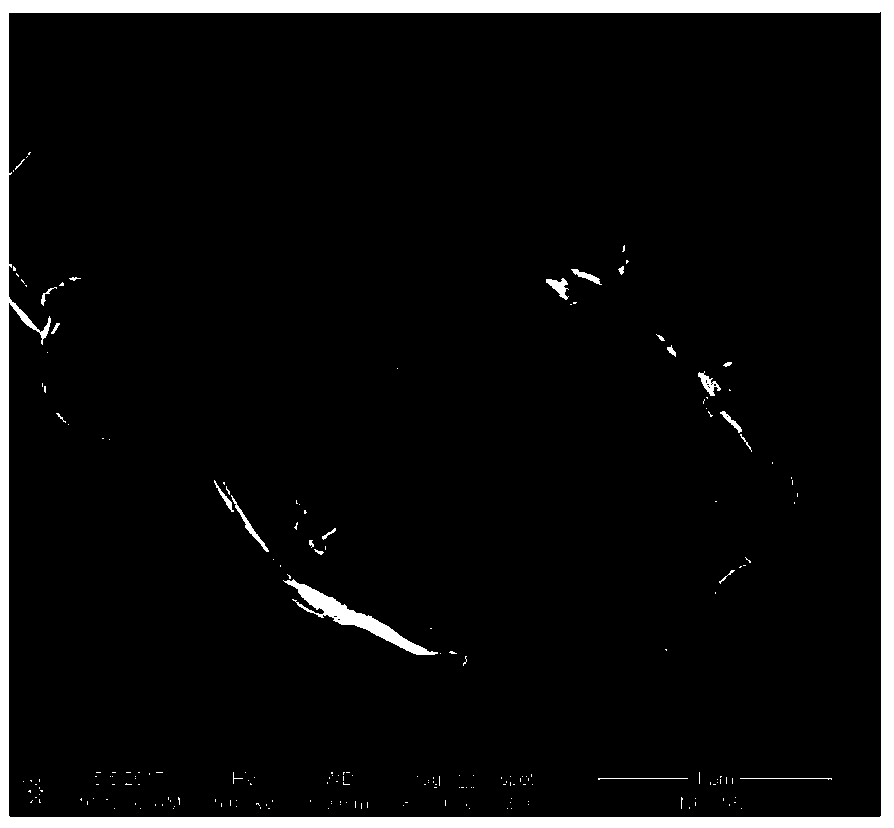

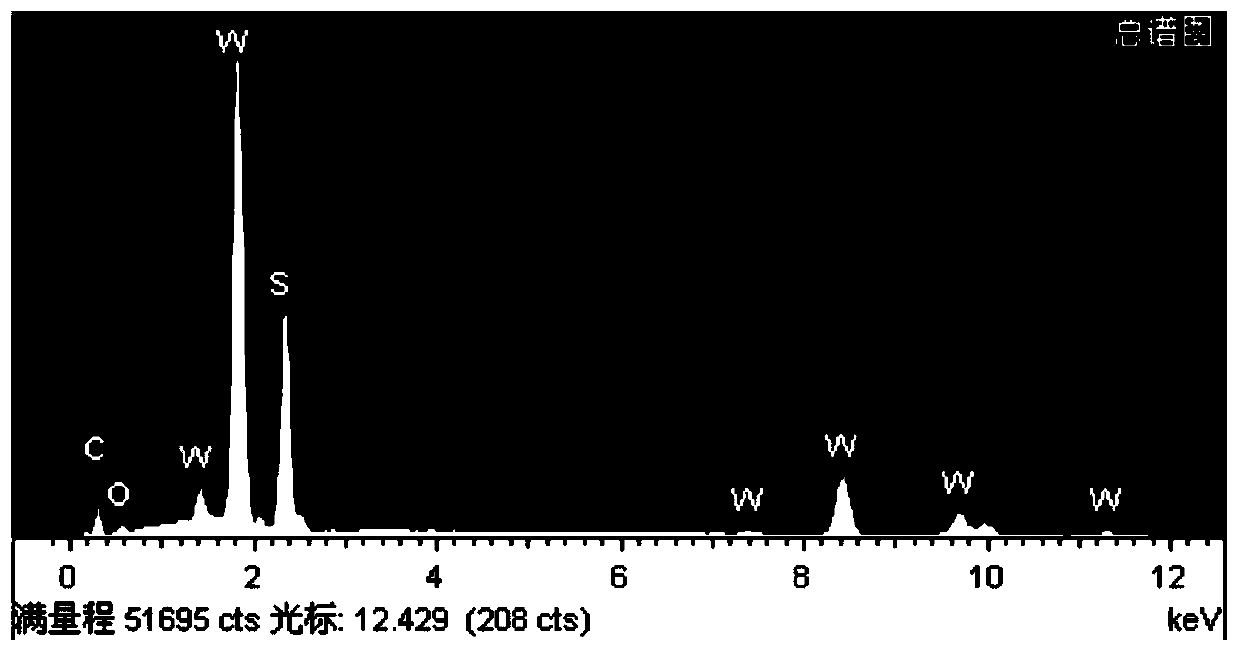

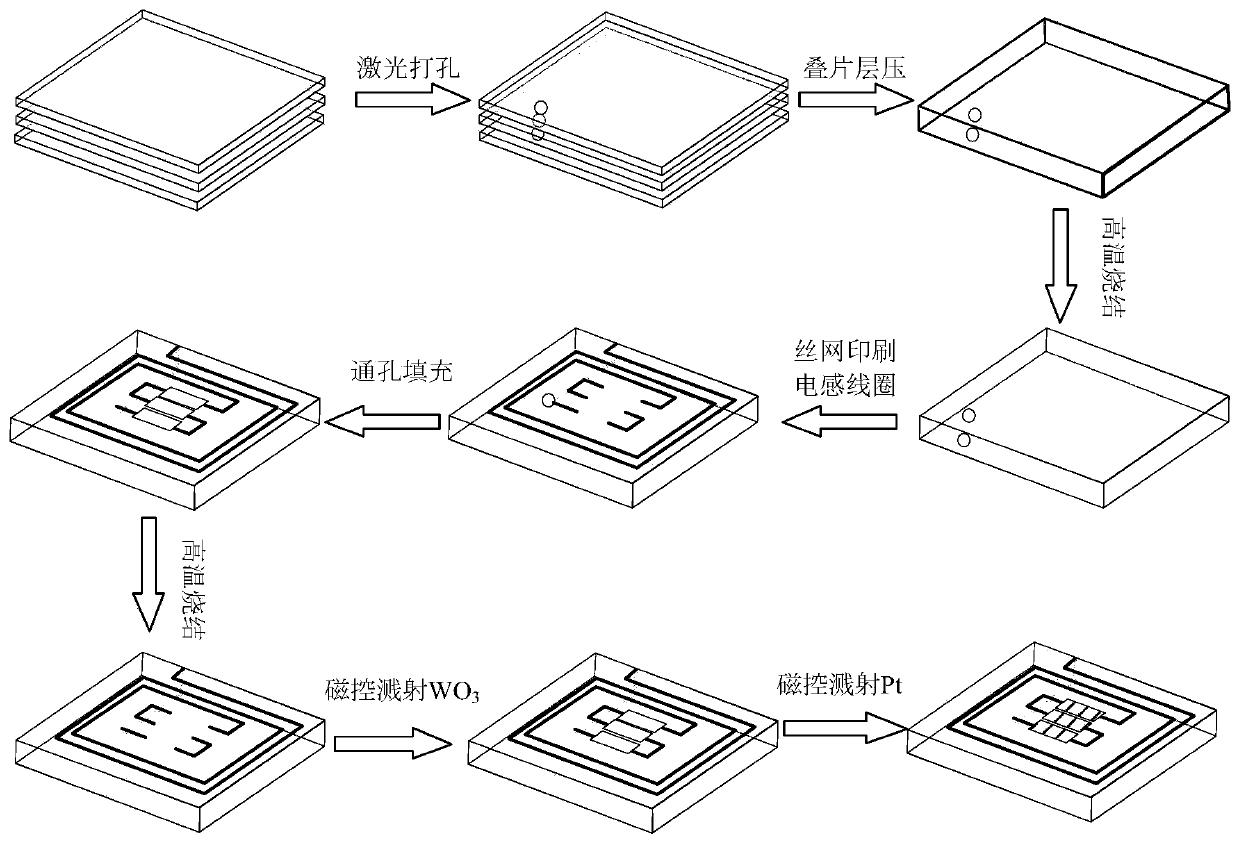

Wireless passive H2 gas sensor based on WO3 and preparation method thereof

PendingCN110646474AHigh sensitivityIncrease reaction rateMaterial resistanceCoils manufactureSilver pasteScreen printing

The invention discloses a wireless passive H2 gas sensor based on WO3 and a preparation method thereof. The gas sensor comprises a ceramic substrate, and an inductance coil and a composite gas sensitive resistor, which are printed on the ceramic substrate, wherein an outer end of the inductance coil is connected with one end of the composite gas sensitive resistor through silver paste filled in athrough hole in the ceramic substrate, and an inner end of the inductance coil is connected with the other end of the composite gas sensitive resistor to form an LR sensitive circuit; the ceramic substrate is made of an aluminium oxide raw ceramic tape and is prepared by an HTC process, the inductance coil is prepared by silk-screen printing process with Ag as paste, and the composite gas sensitive resistor is prepared from a Pt-WO3 composite material by a magnetron sputtering process. The gas sensor disclosed by the invention uses a wireless non-contact measurement method, can accurately realize the detection of a gas H2 to be measured under low temperature conditions by analyzing the threshold that changes with resistance, adopts the mature silk-screen printing process and the magnetronsputtering preparation process, and has the advantages of simple and convenient processing, low cost, etc.

Owner:ZHONGBEI UNIV

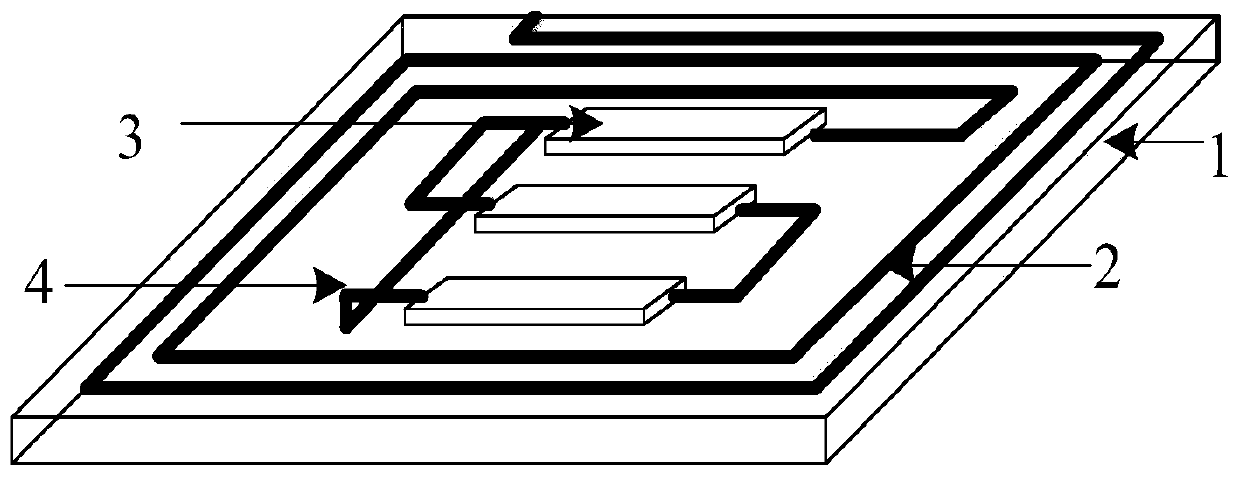

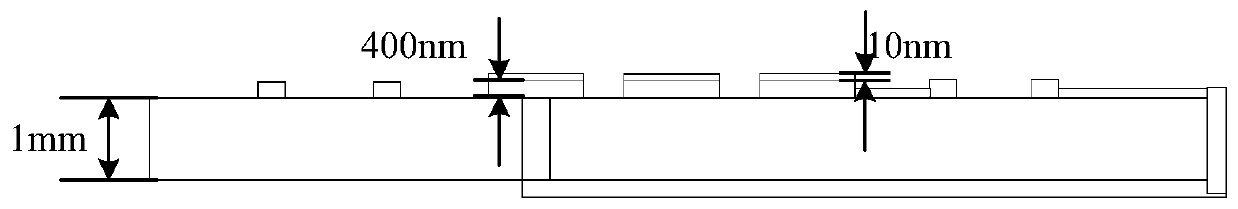

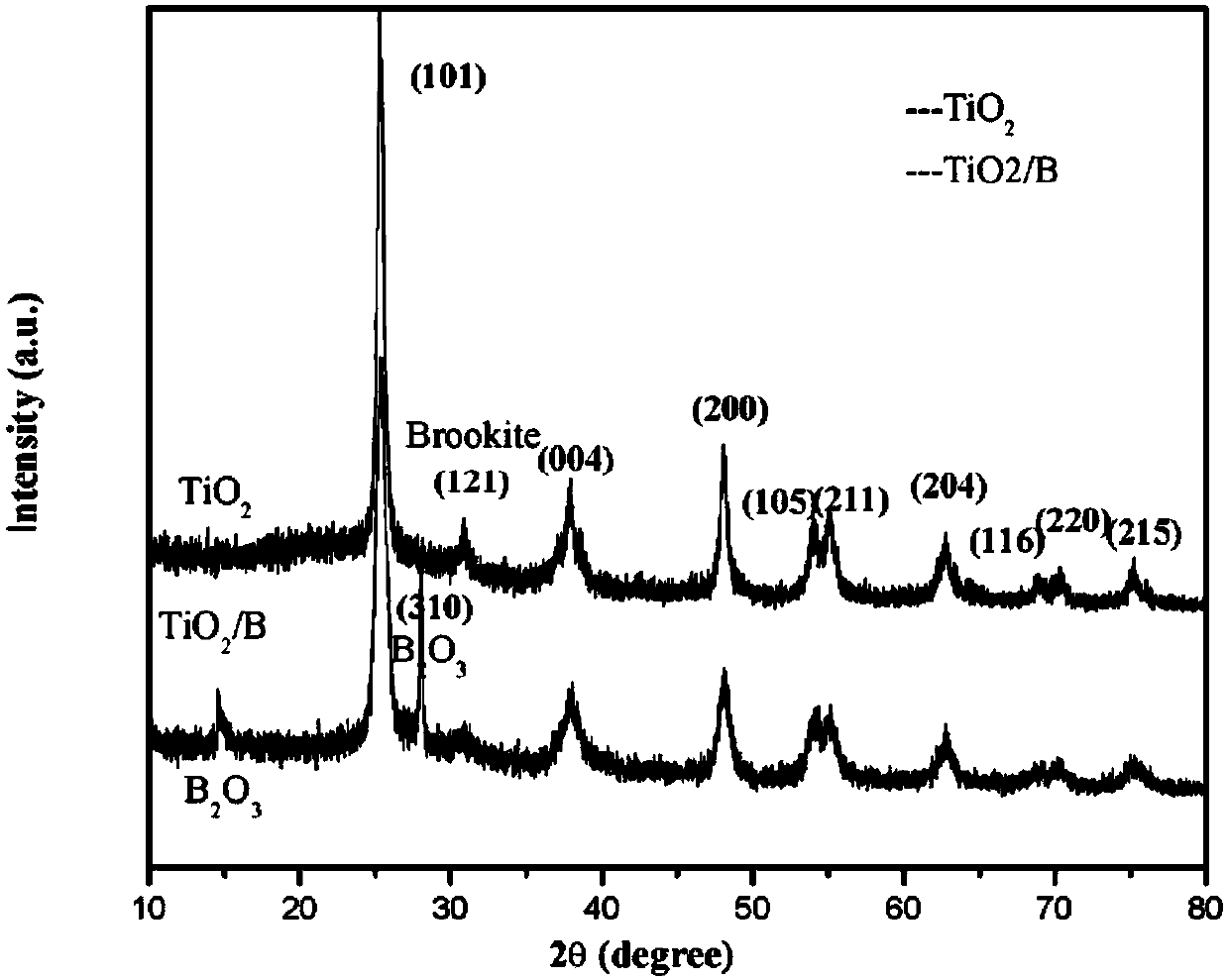

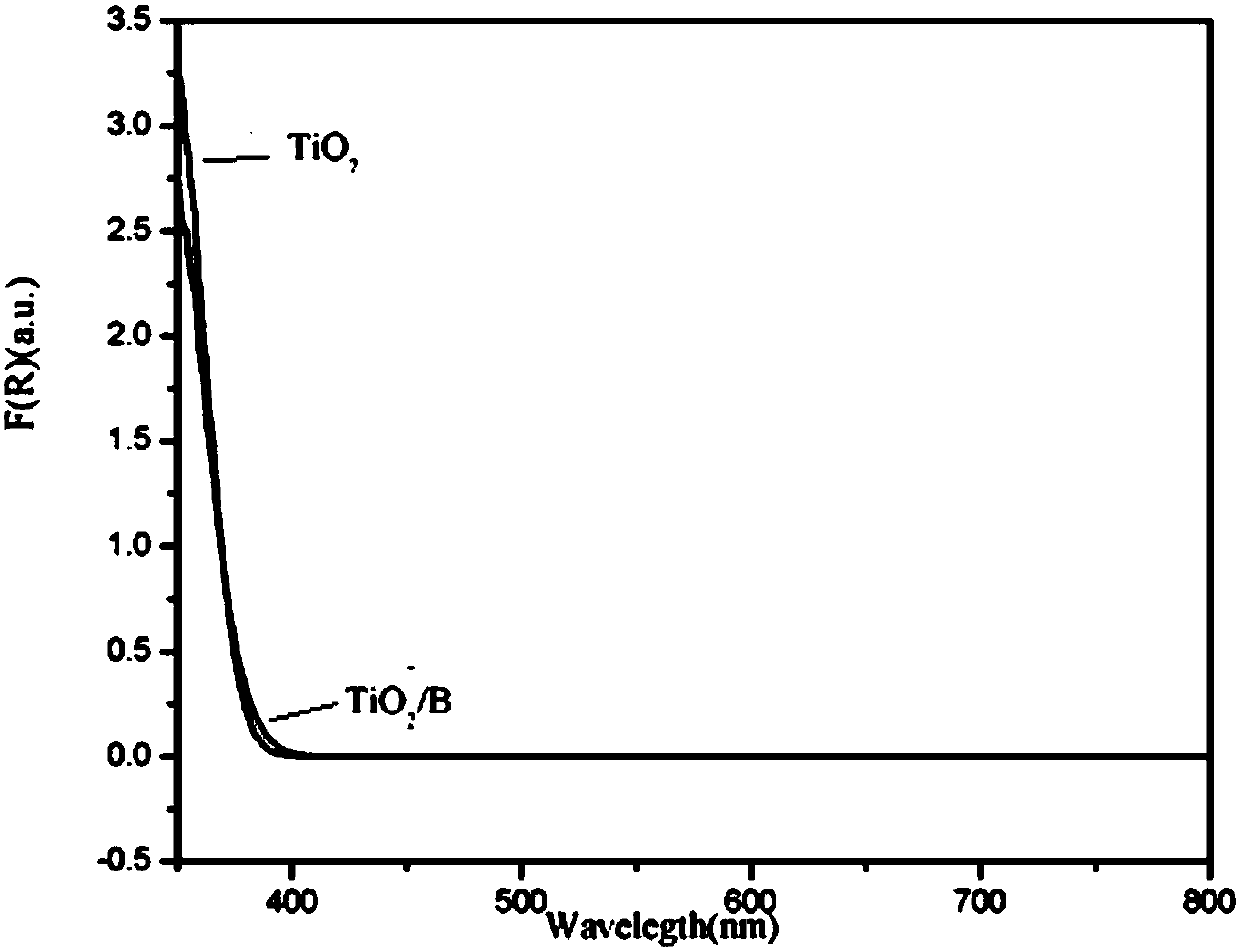

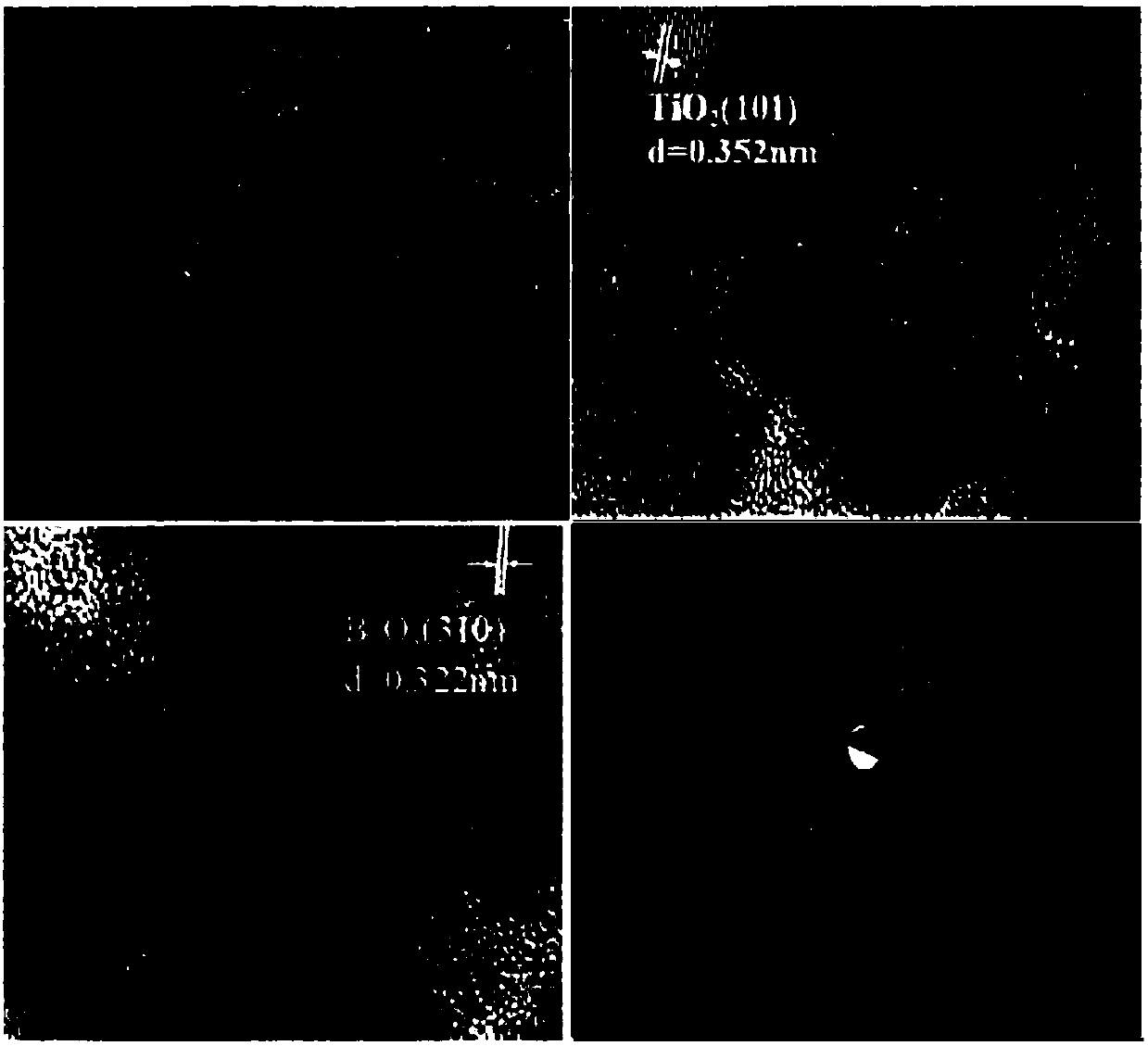

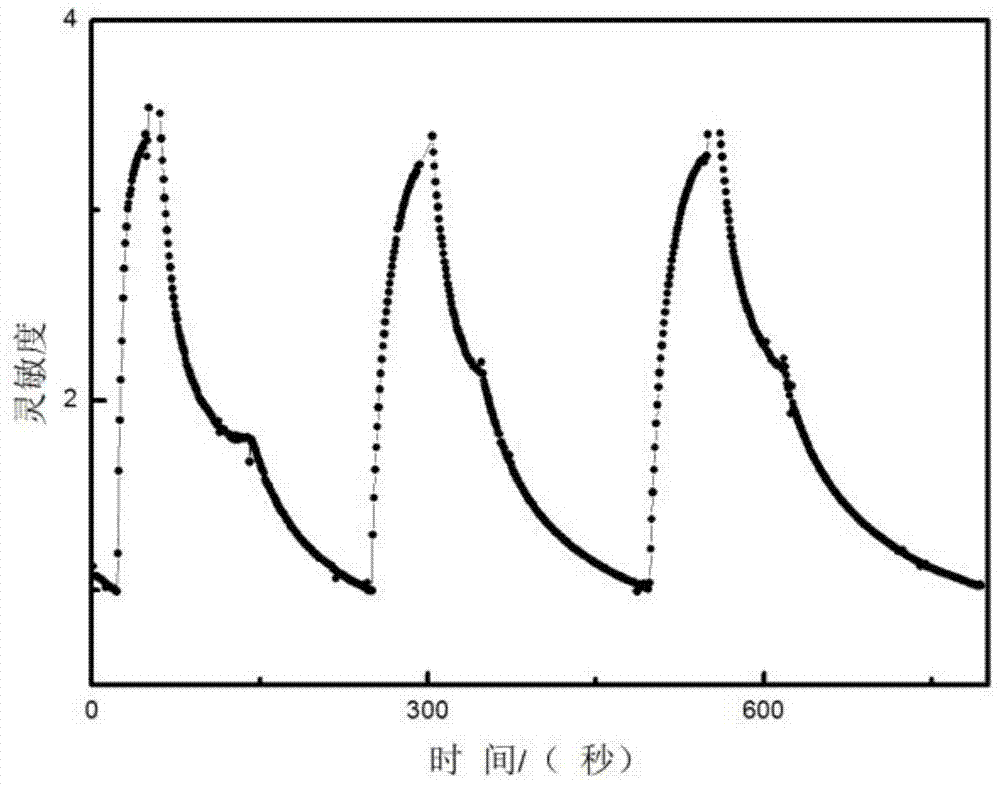

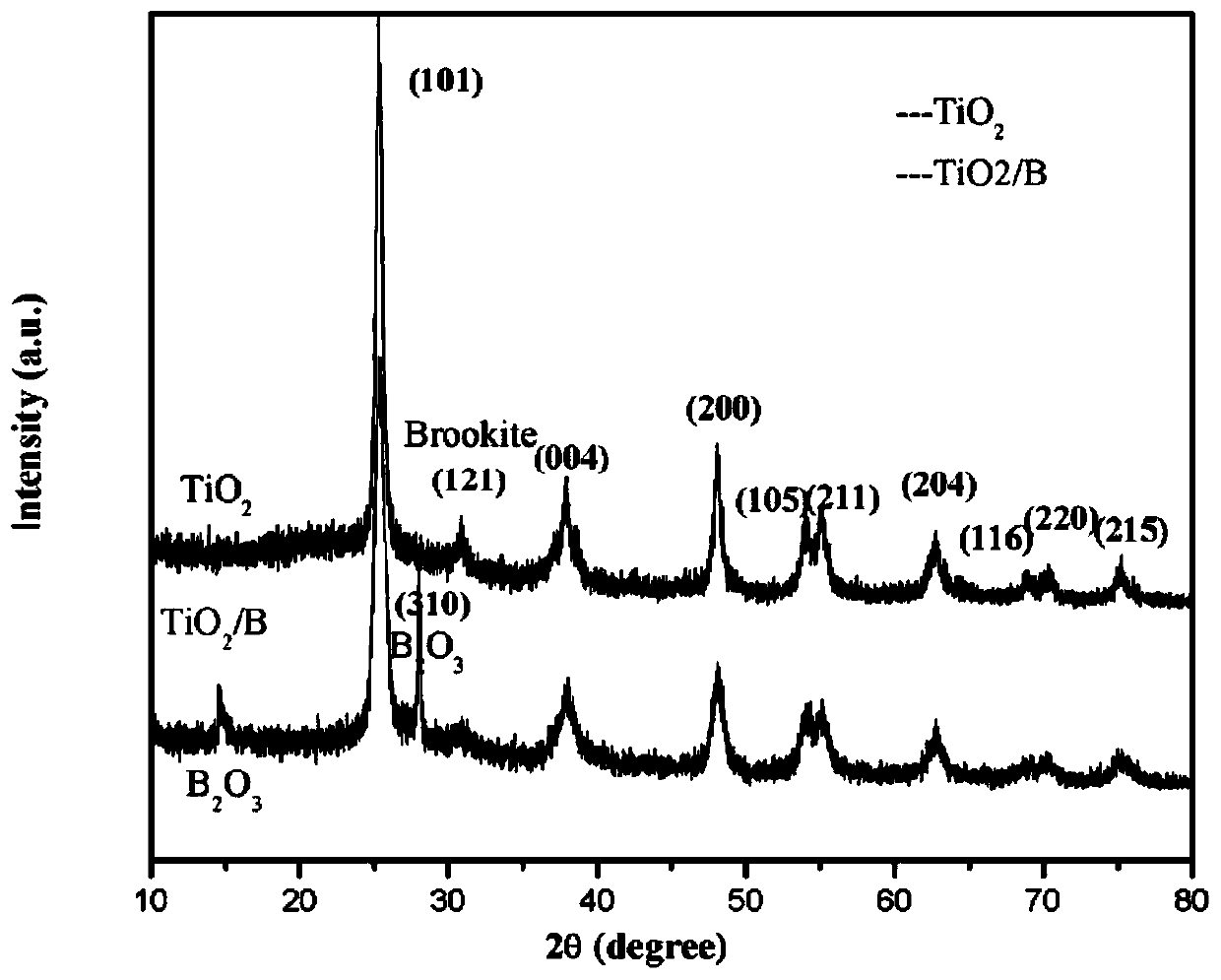

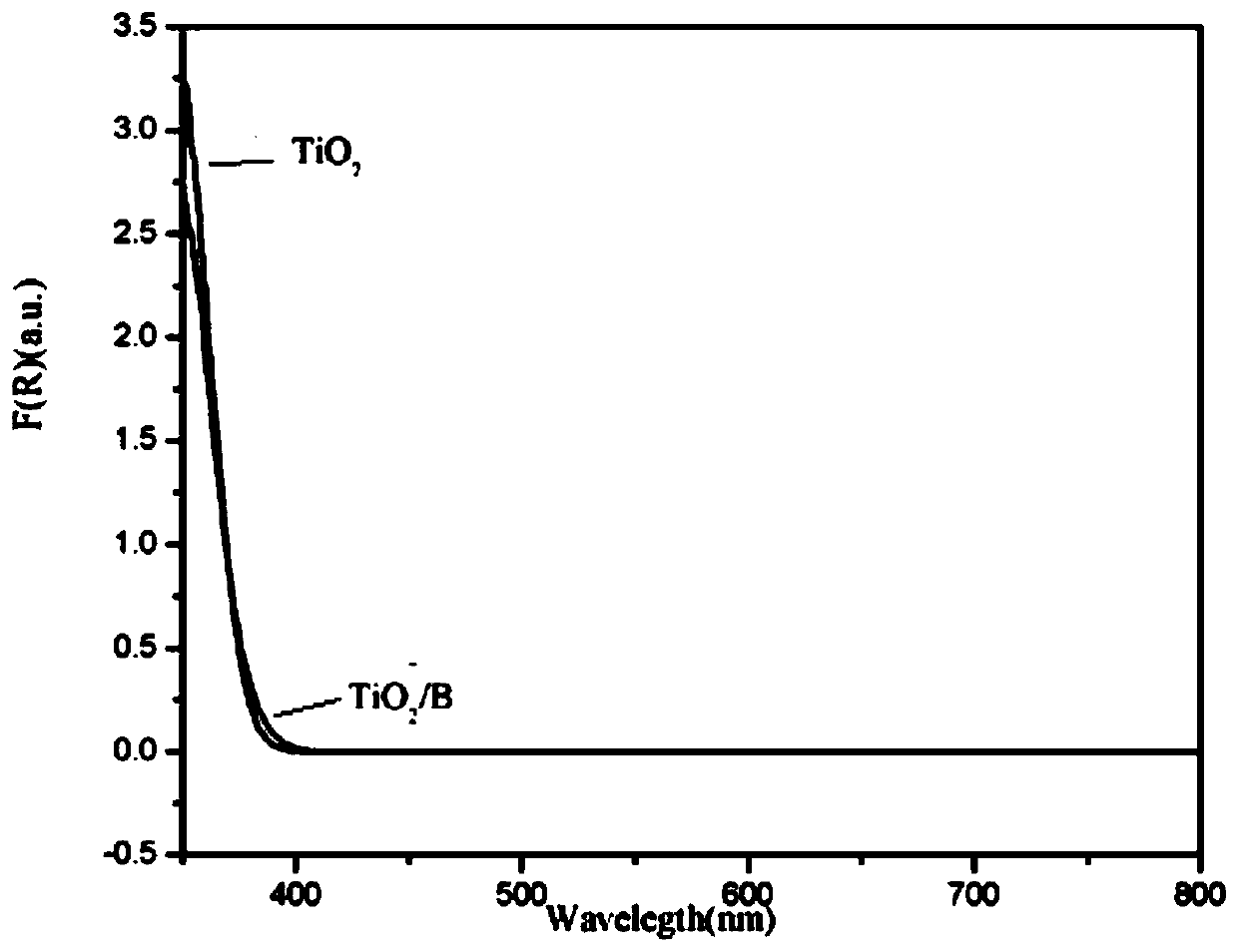

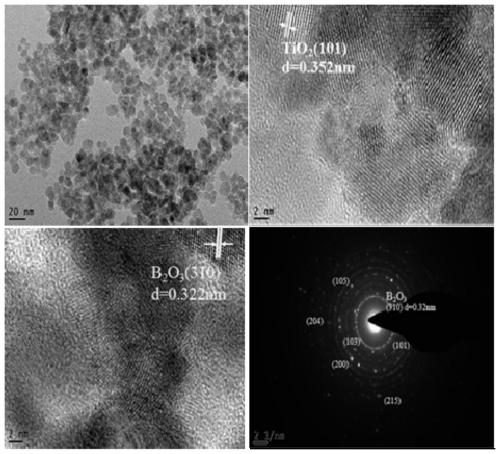

Boron-doped titanium dioxide photo-assisted gas-sensitive element, preparation method and application

ActiveCN107894448AGood gas responseConducive to preparation and applicationMaterial resistancePhysical chemistryUltraviolet lights

The invention discloses a boron-doped titanium dioxide photo-assisted gas-sensitive element, a preparation method and application. According to the method, a boron doping mode is adopted for modifyingTiO2 and used for preparing the photo-assisted gas-sensitive element, the method is mild in condition and easy to operate, and the prepared B / TiO2 gas-sensitive element shows excellent H2 and CO response performance under the action of ultraviolet light, shows high stability and repeatability, and helps to provide convenience for practical application of semiconductor photo-assisted gas-sensitivesensors.

Owner:FUZHOU UNIV

Zinc oxide gas-sensitive film material, preparation method therefor and application of zinc oxide gas-sensitive film material

InactiveCN110498440AFast growthLow costZinc oxides/hydroxidesMaterial resistanceNanoparticleNanostructure

The invention discloses a zinc oxide gas-sensitive film material, a preparation method therefor and an application of the zinc oxide gas-sensitive film material. A nanostructure zinc oxide film is directly prepared on an electrode substrate by using solution low-temperature in-situ deposition. The prepared nanostructure zinc oxide film has a network-shaped structure formed by nanosheets growing vertical to the substrate. The zinc oxide gas-sensitive film material has the advantages of high efficiency, low cost and simple process and is suitable for being industrially produced. The obtained nanostructure zinc oxide film has a relatively large specific surface area, the problem of agglomeration among nanoparticles can be effectively overcome, and the zinc oxide gas-sensitive film material has good gas-sensitive response to gases such as NO2 and H2S and has an excellent gas-sensitive application prospect.

Owner:JIANGSU UNIV

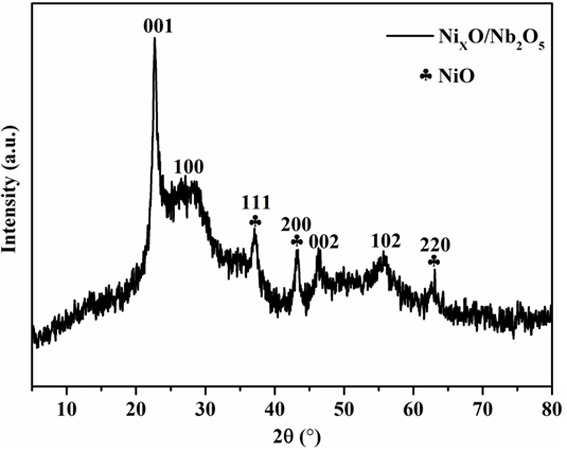

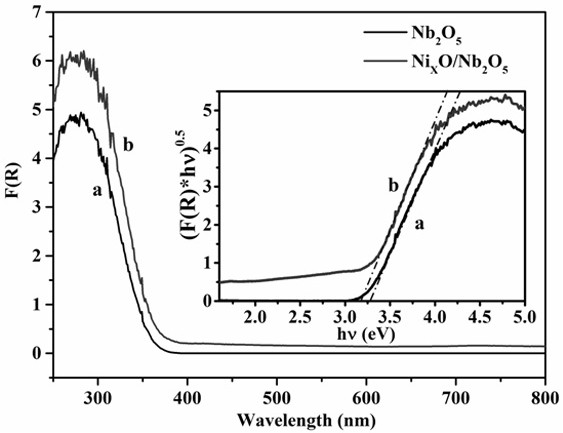

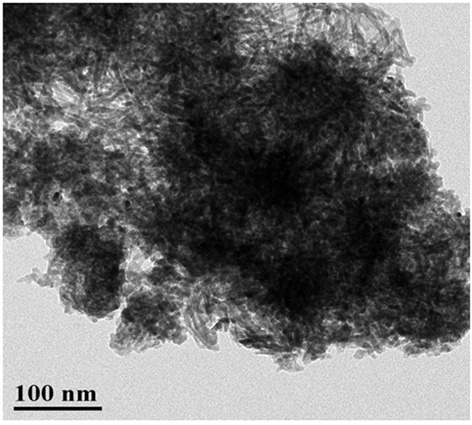

Ni-modified Nb2O5 gas sensitive element and preparation method and application thereof

The invention discloses a Ni-modified Nb2O5 gas sensitive element and a preparation method and application thereof. The preparation method includes the steps that after a washed FTO interdigital electrode slice is subjected to a hydrothermal reaction in a mixed solution containing Ni(NO3)2.6H2O and ammonium niobate oxalate hydrate, the FTO interdigital electrode slice with powdery NiO / Nb2O5 growing on the surface is taken out, washed with deionized water, dried, calcined at high temperature and reduced; and the NixO / Nb2O5 gas sensitive element generated by the in-situ hydrothermal method is prepared. The NixO / Nb2O5 gas sensitive element obtained by the invention shows better response performance to CO2 and H2 under the conditions of room temperature and ultraviolet light, and has good stability and repeatability, the preparation process of the gas sensitive element is simplified, and the NixO / Nb2O5 gas sensitive element has a better application prospect in the aspect of preparation of semiconductor photo-assisted gas sensitive sensors.

Owner:FUZHOU UNIVERSITY

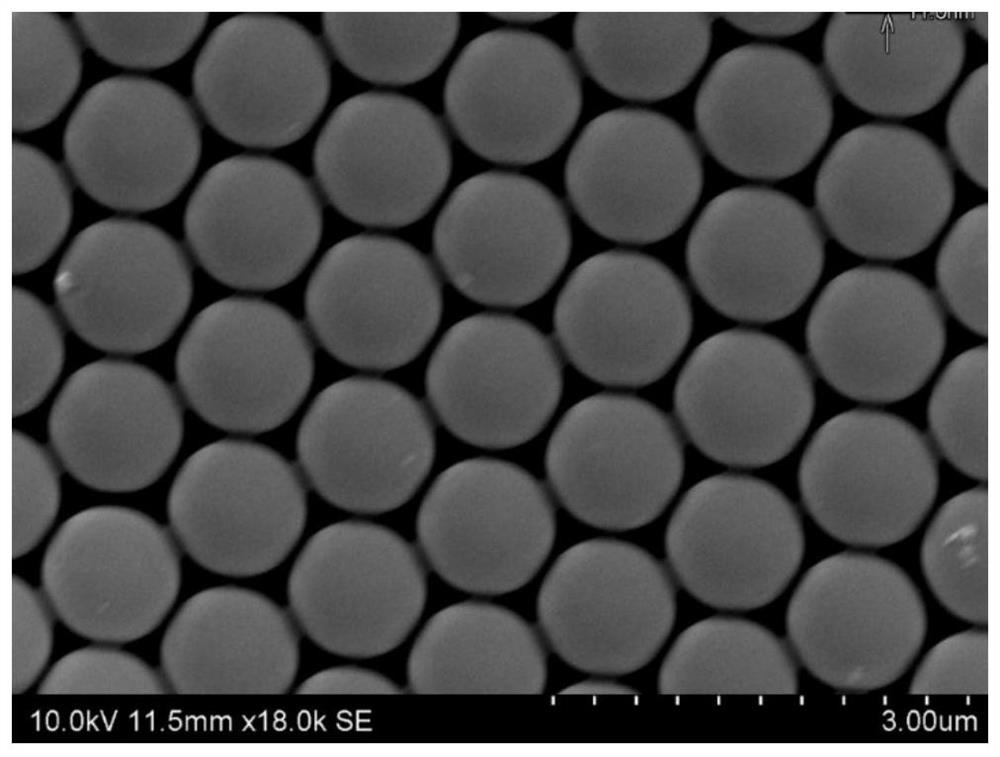

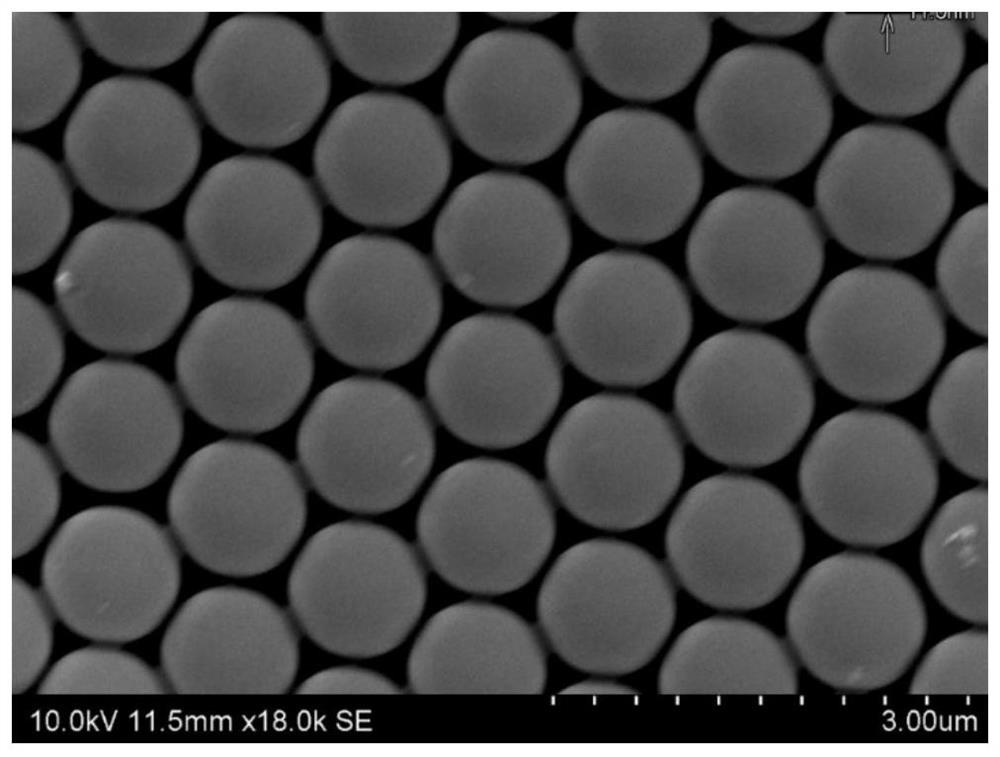

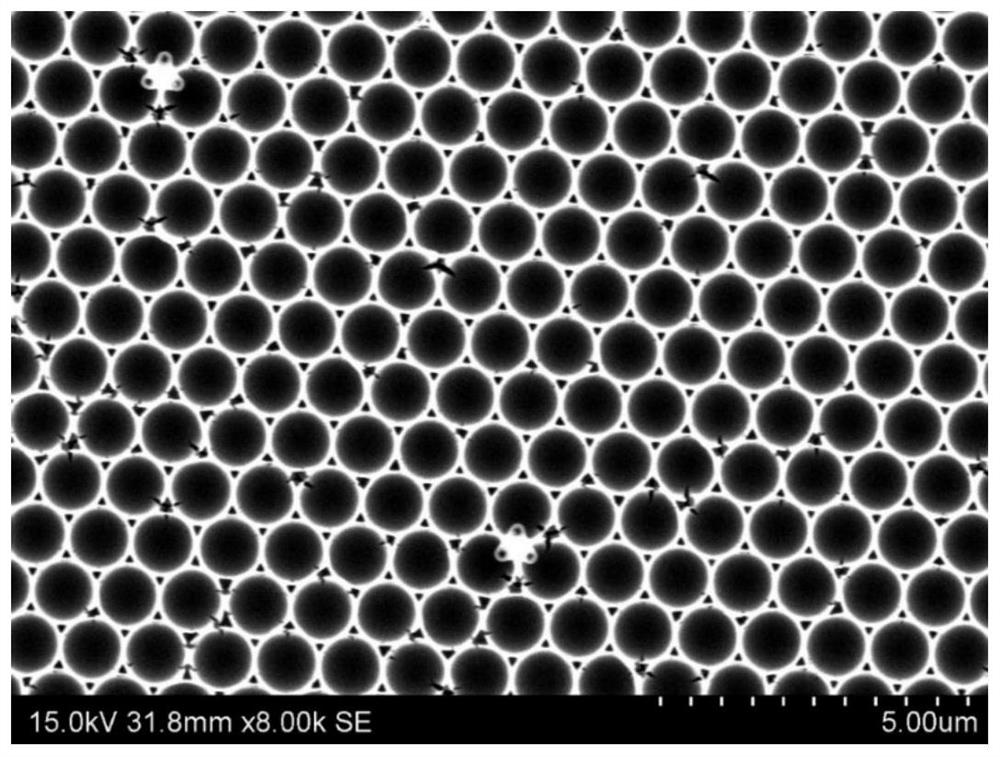

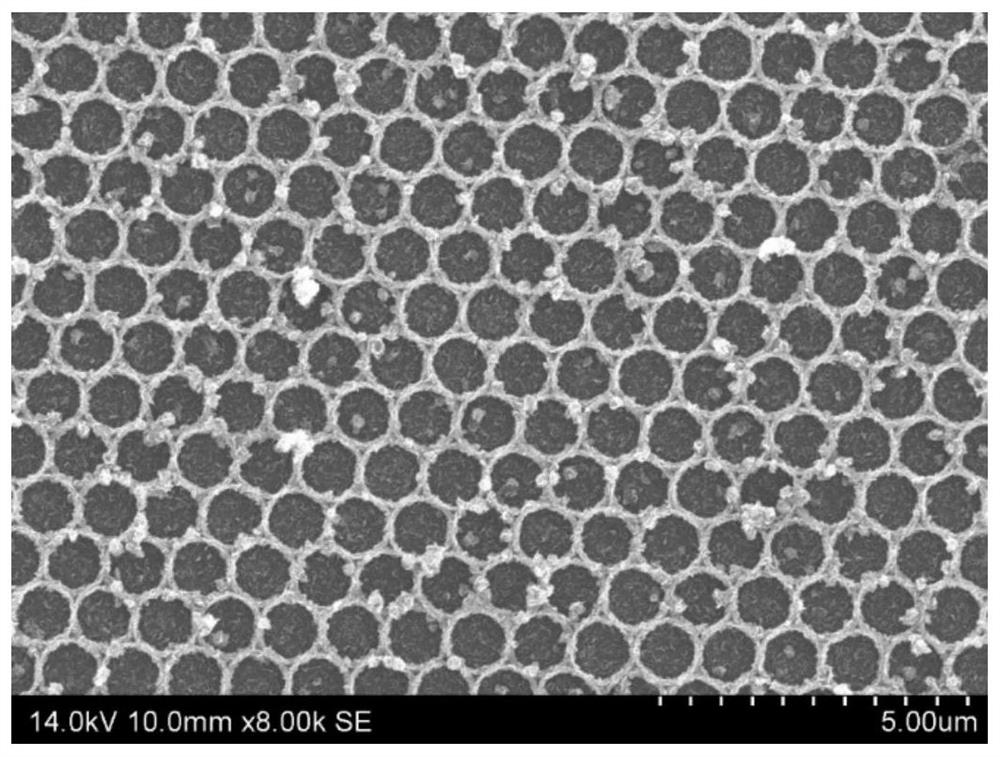

SnO2/MoS2 two-dimensional macroporous composite material film as well as preparation method and application thereof

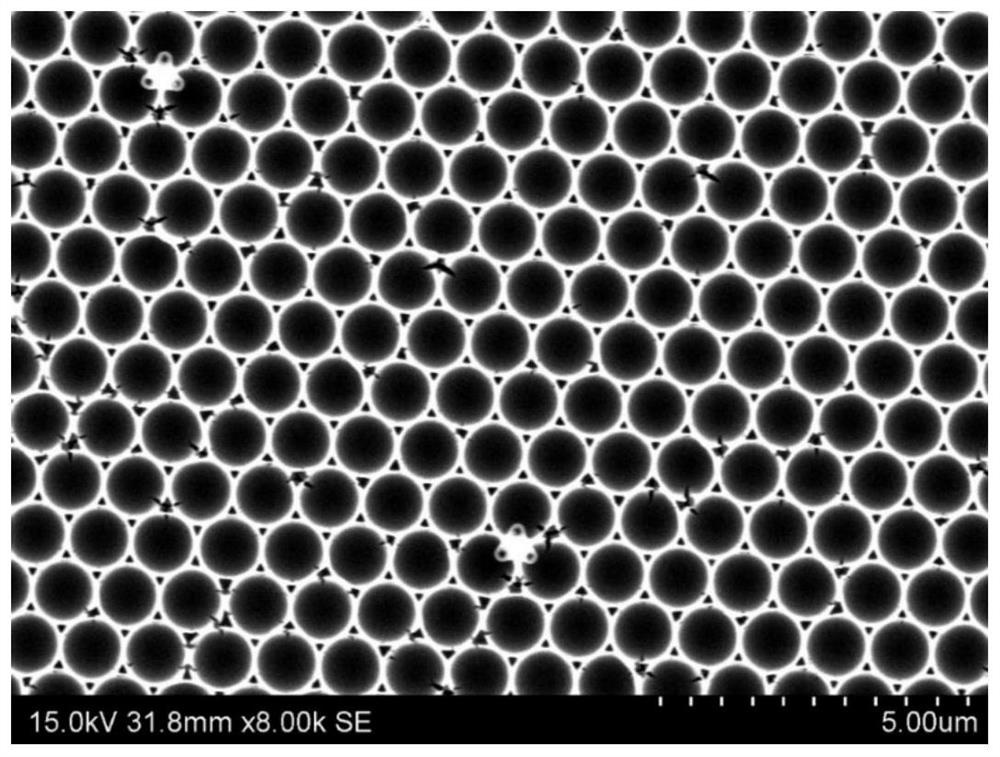

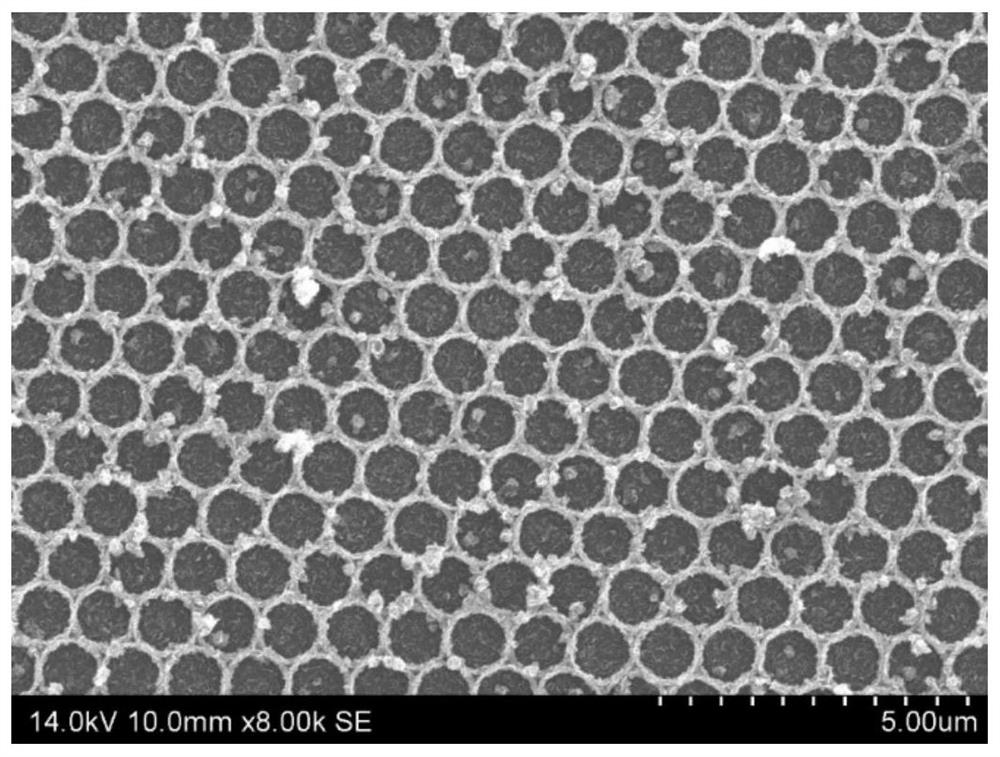

ActiveCN113354298AEasy dischargeIncrease surface active sitesMaterial nanotechnologyCoatingsComposite filmMicrosphere

The invention discloses a SnO2 / MoS2 two-dimensional macroporous composite material film as well as a preparation method and an application thereof, and belongs to the field of sensor material preparation. According to the invention,the preparation method comprises the following steps: soaking a PS template so that gaps among PS microspheres can be filled with a SnCl4. 5H2O solution, then annealing, gasifying the PS microspheres, and forming the SnO2 macroporous film; taking a PS template as a template, then carrying out hydrothermal reaction, introducing MoS2 nanosheets on the basis of keeping a regularly arranged SnO2 macroporous structure, and regulating to enable the PS template to pass through a SnO2 macroporous film to pass through a SnO2 / MoS2 macroporous film. According to the SnO2 / MoS2 two-dimensional macroporous composite film disclosed by the invention, the porous structure is beneficial to gas discharge, and the compounding of nanosheets enables the specific surface area of the film to be increased and the surface active sites to be increased, so that the gas-sensitive property is greatly improved, the gas-sensitive property is more excellent, and the SnO2 / MoS2 two-dimensional macroporous composite film has good gas-sensitive response to nitrogen dioxide gas.

Owner:GUILIN UNIV OF ELECTRONIC TECH

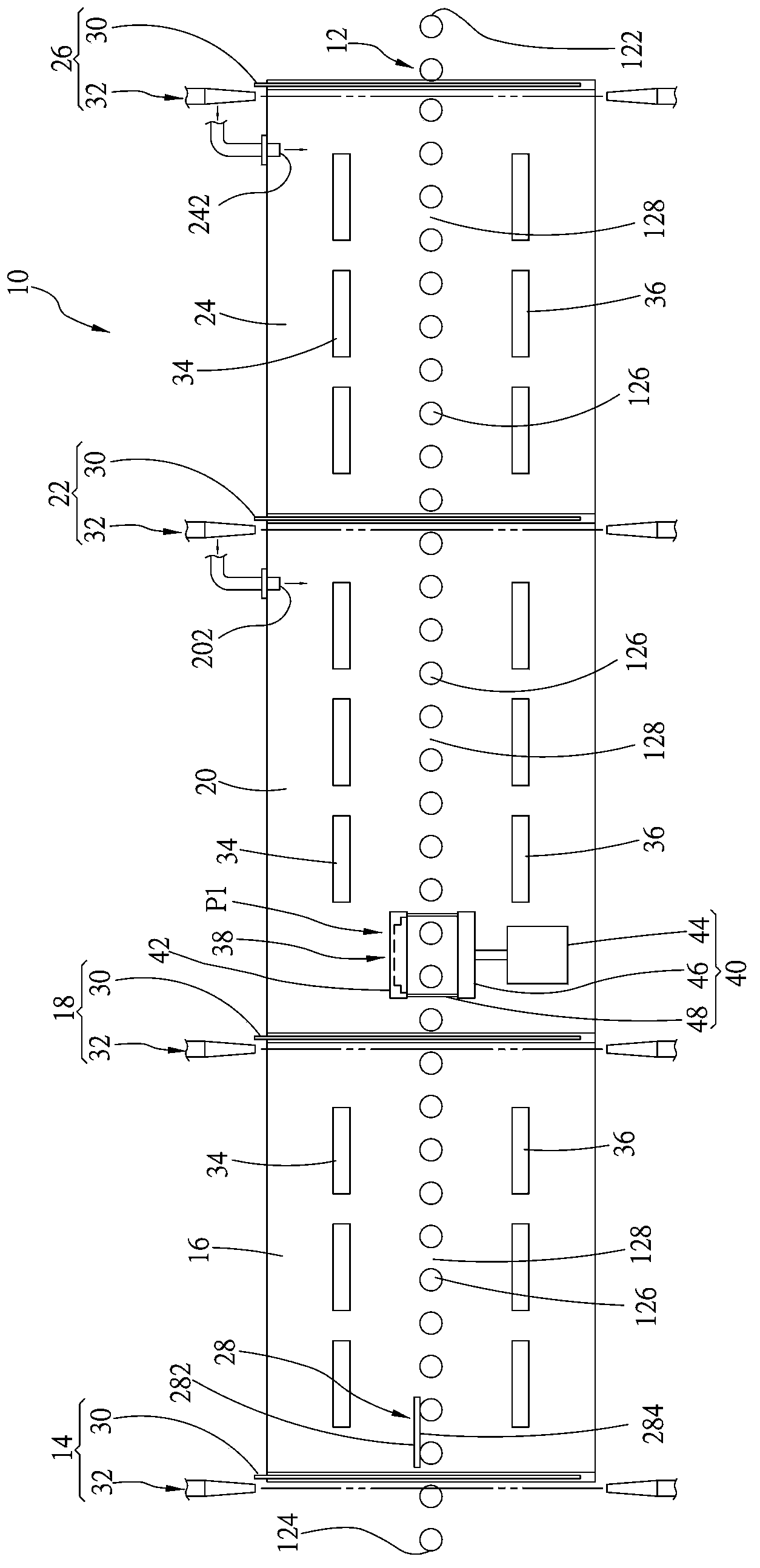

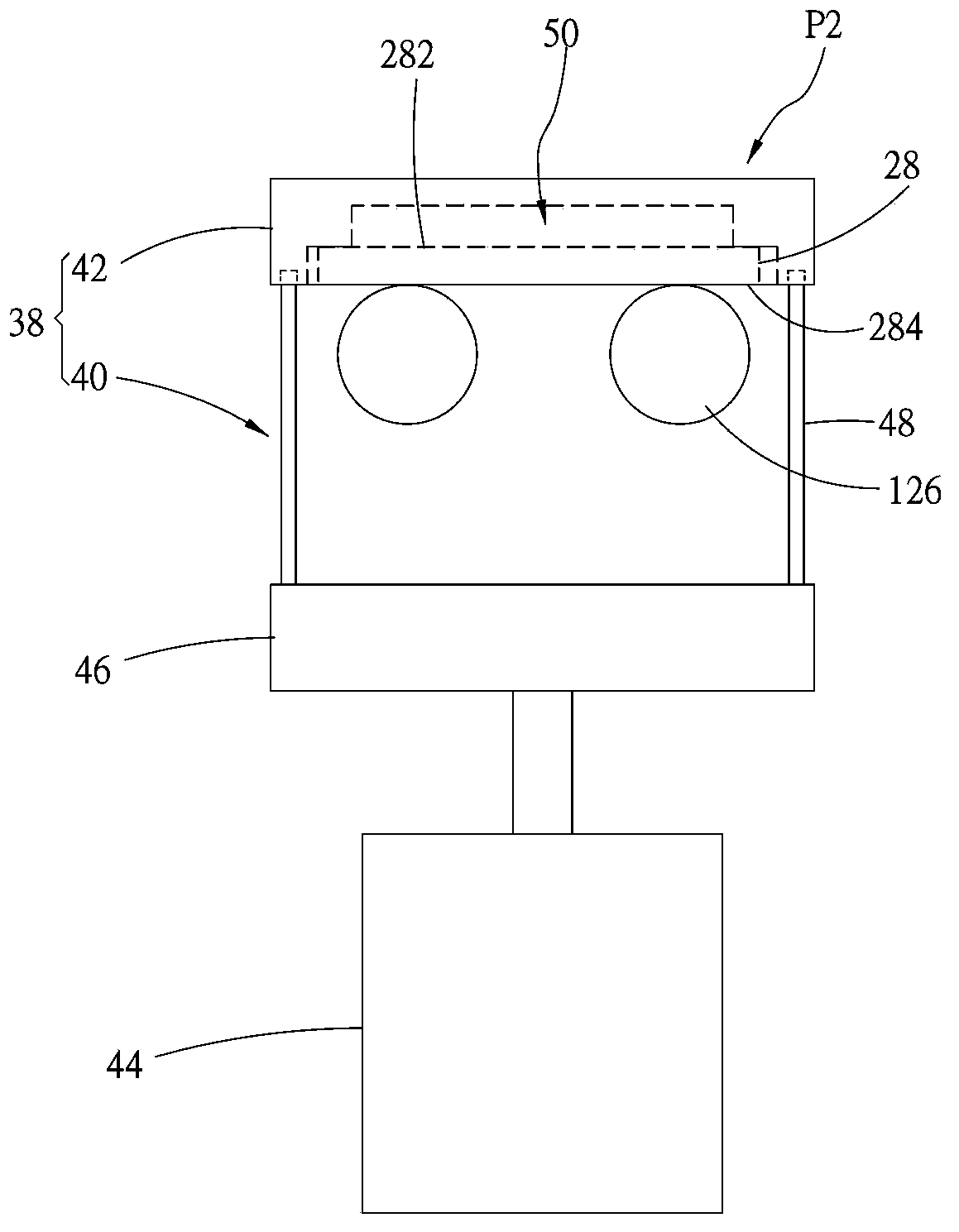

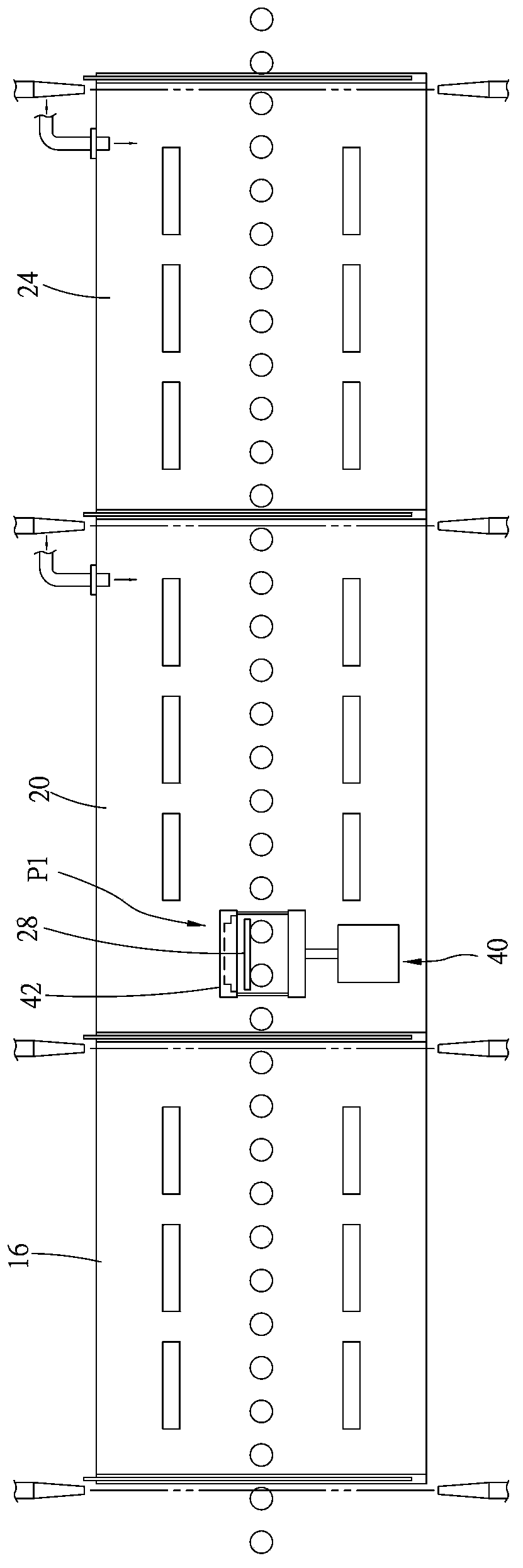

Gas reaction continuous cavity and gas reaction method

InactiveCN104233213AGood gas responsePrevent escapeVacuum evaporation coatingSputtering coatingCooling chamberReagent

The invention provides a gas reaction continuous cavity and a gas reaction method using the gas reaction continuous cavity. The gas reaction continuous cavity comprises a preheating chamber, a reaction chamber and a cooling chamber which are sequentially arranged, each of the chambers is positioned between two isolating devices, the plurality of isolating devices can ensure that the plurality of chambers are in an air-tight state, a conveying device is positioned in the plurality of chambers and the isolating devices and used for driving a reacted object to move so as to pass through the plurality of chambers, each of the plurality of chambers is provided with an upper heater which acts towards the top surface of the reacted object to adjust the temperature of the reacted object, and each of the reaction chamber and the cooling chamber is provided with a reaction gas input opening. Therefore, the gas reaction method provided by the invention can ensure the gas reaction of the reacted object and has good efficiency.

Owner:生阳新材料科技(宁波)有限公司

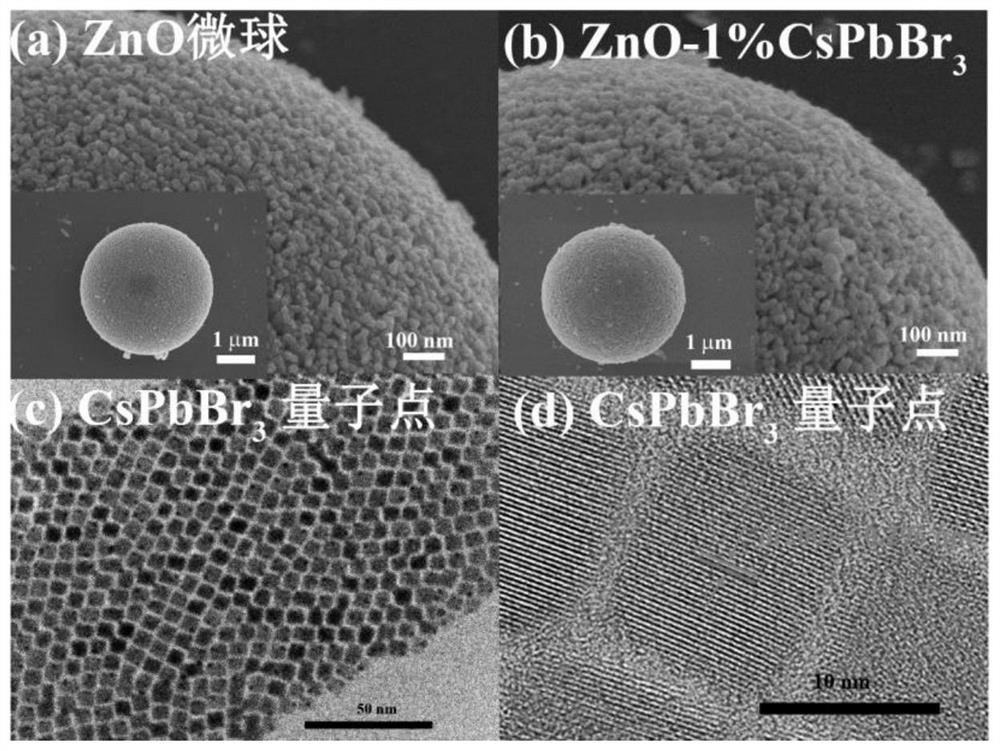

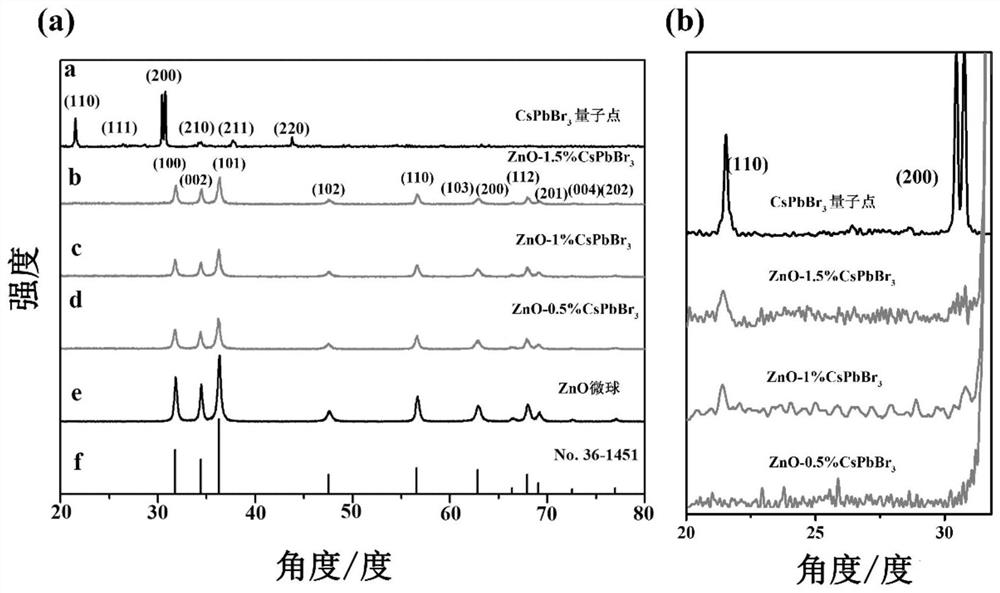

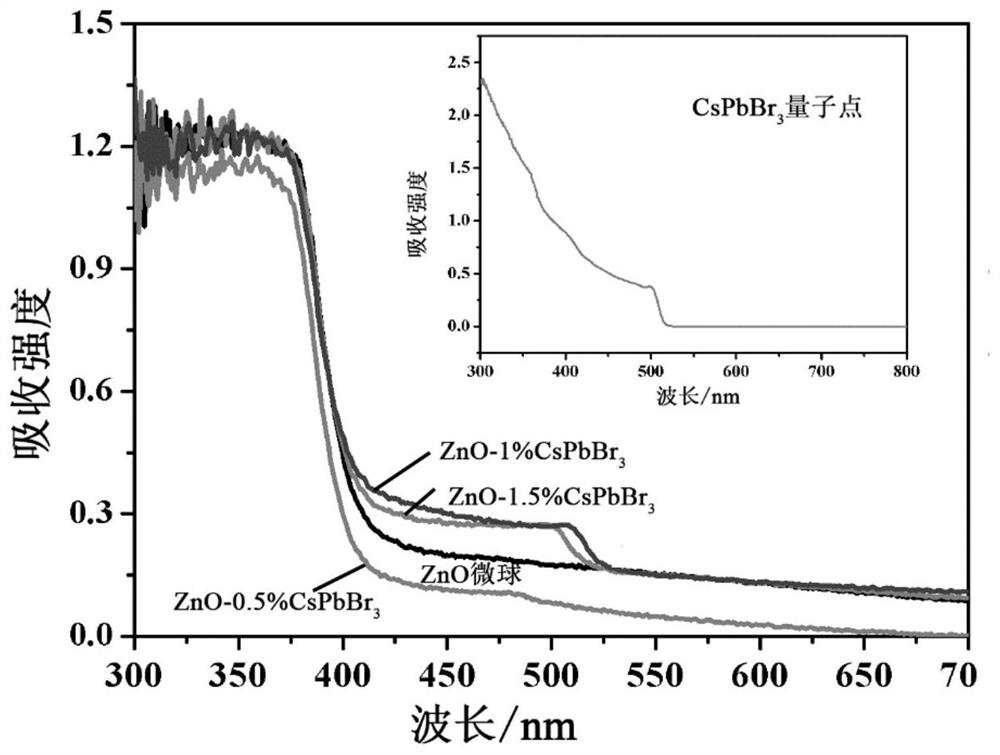

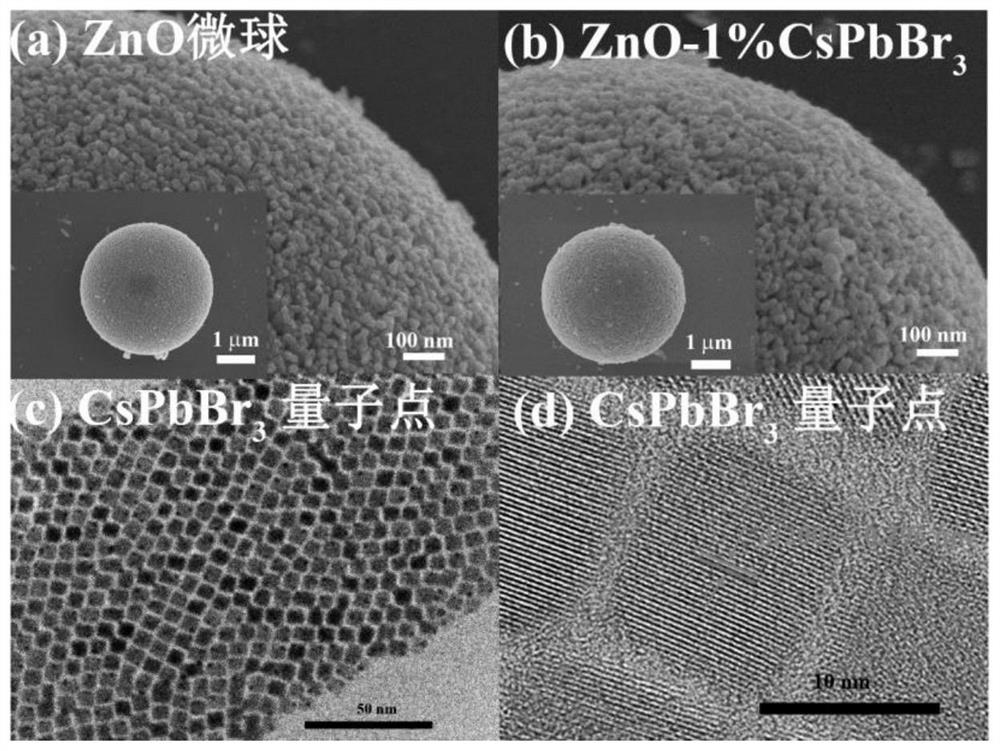

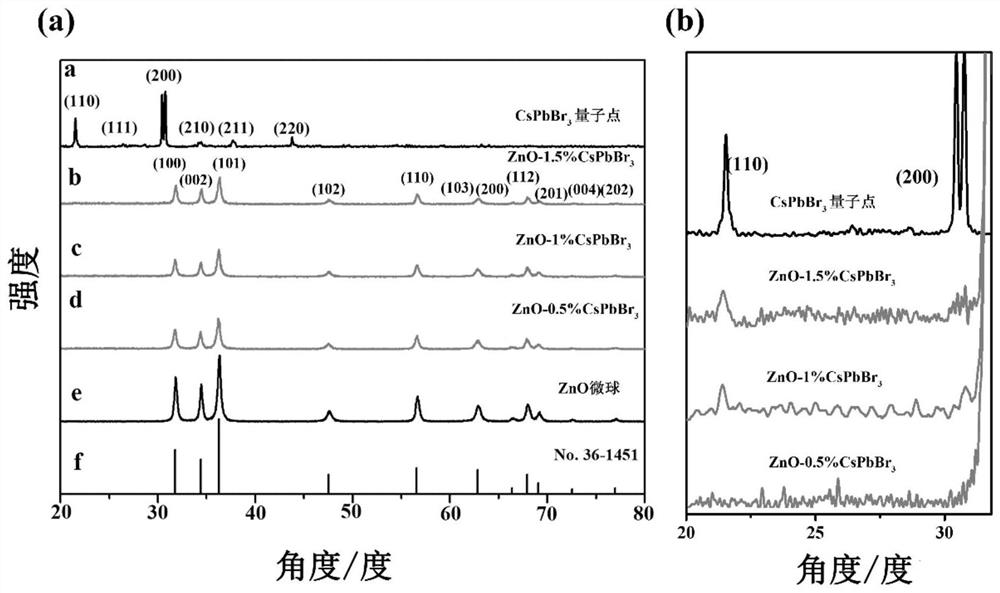

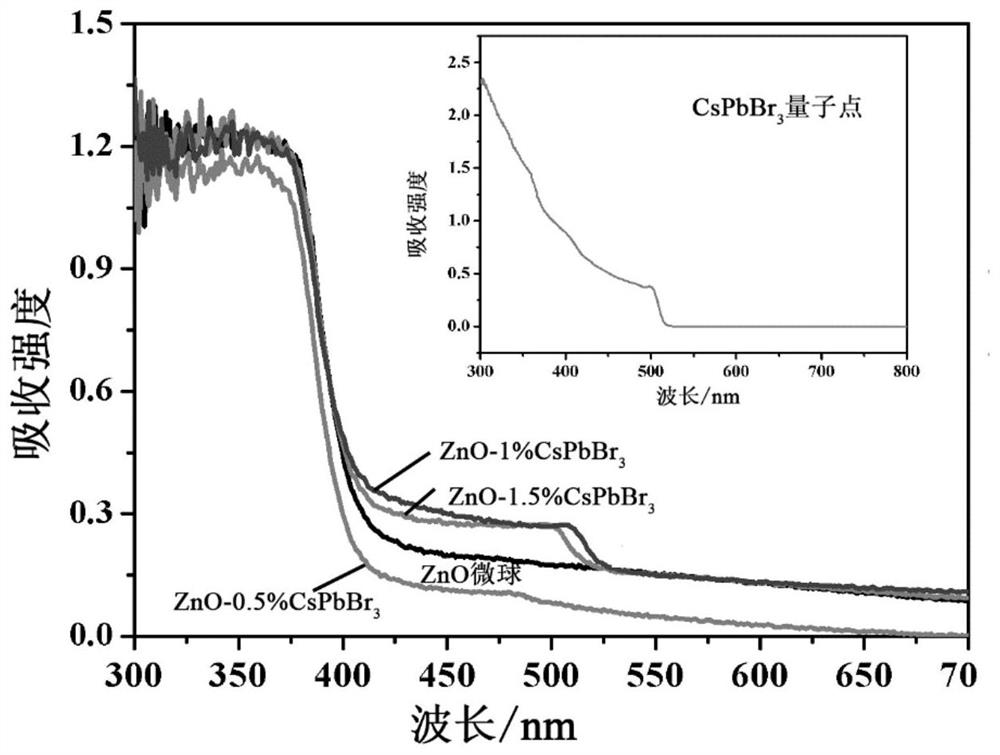

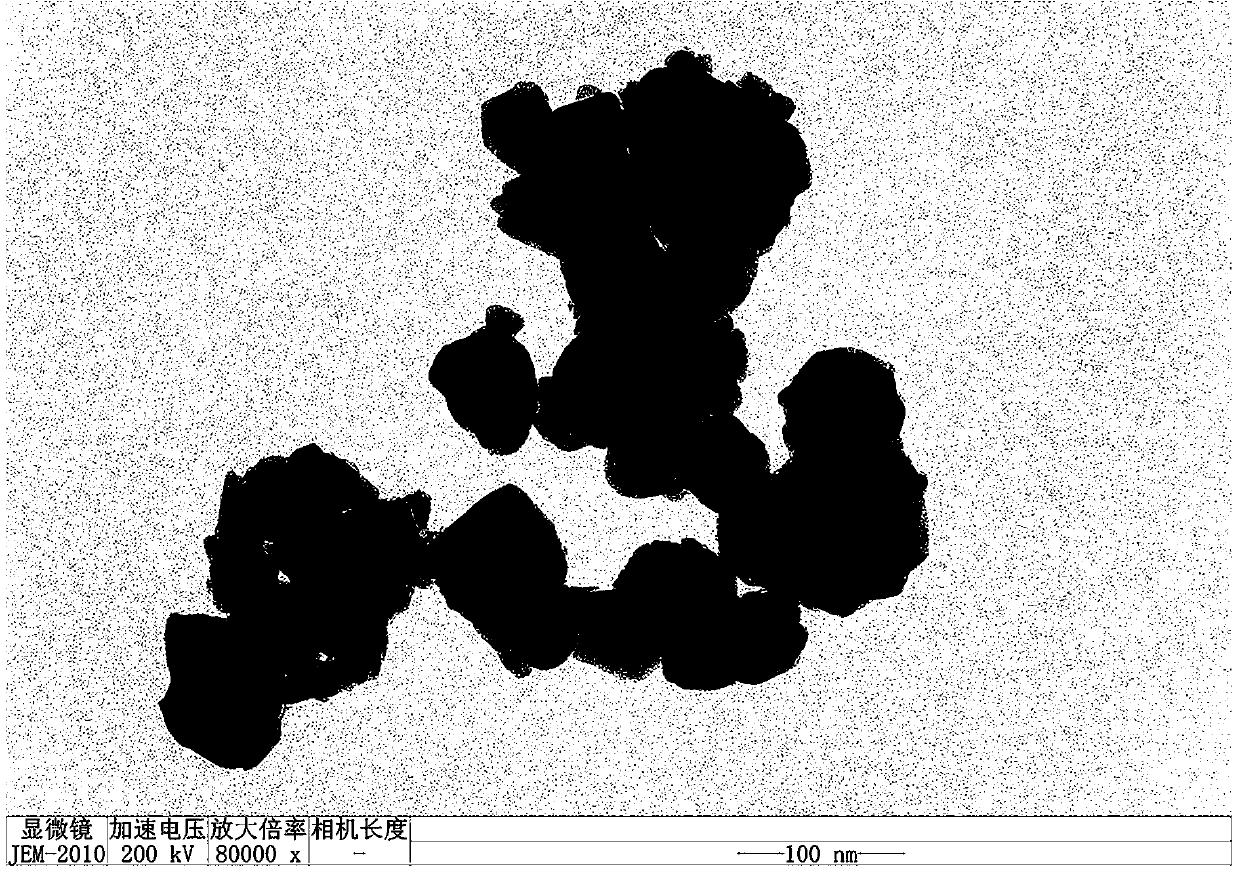

Room-temperature NO2 sensor based on ZnO microsphere and CsPbBr3 quantum dot composite material and preparation method thereof

ActiveCN112683963AThe synthesis method is simpleLow costMaterial resistanceChemistryComposite material

The invention discloses a room-temperature NO2 sensor based on a ZnO microsphere and CsPbBr3 quantum dot heterostructure composite material and a preparation method thereof, and belongs to the technical field of semiconductor oxide gas sensors. The sensor is composed of a ceramic chip substrate with a metal interdigital electrode and a ZnO microsphere and CsPbBr3 quantum dot heterostructure composite material sensitive layer coating the metal interdigital electrode. The morphology of zinc oxide is of a sphere structure, has a large specific surface area, and can provide more attachment sites, so that zinc oxide is in full contact with perovskite CsPbBr3 quantum dots with small sizes, and a gas sensitive element with good gas sensitive response and high response recovery speed is obtained. In addition, the CsPbBr3 quantum dots are used as an excellent photoelectric material and can absorb visible light, so that more photon-generated carriers are provided. The sensor provided by the invention adopts a planar structure, and is simple in process, short in manufacturing period and suitable for mass production.

Owner:JILIN UNIV

Gas-liquid interface processing method for a semiconductor gas sensor

ActiveCN106556623BImprove stabilityEasy to processMaterial resistanceBatch processingUltraviolet lights

The invention proposes a gas-liquid interface processing method for a semiconductor gas sensor comprising the following steps: preparing a precursor solution; irradiating the precursor solution with ultraviolet light to prepare a film on the surface of the solution; picking up the surface film with a clean glass sheet and transferring it to Wash the film on the surface of deionized water; pick up the film cleaned by deionized water with a ceramic tube; weld the ceramic tube with the film on the special base of the gas sensor, and there is a heating resistance wire in the ceramic tube; insert the base into the On the gas-sensing test system, apply a voltage to the resistance wire, and obtain a gas sensor after obtaining a film with stable composition. The invention achieves the attachment of gas-sensitive materials on the sensor substrate, improves the defects of multi-step operation, high-temperature processing, stability, repeated processing and batch processing in the current gas sensor processing process, and has the advantages of easy-to-obtain raw materials, simple process, It is characterized by easy operation and mass production, good gas response and recovery performance and excellent stability.

Owner:SOUTH CHINA NORMAL UNIVERSITY

A rare earth doped modified graphene composite material gas sensor for detecting NOx and its preparation method

InactiveCN104122305BImprove electrochemical performanceGood gas responseMaterial resistanceDoped grapheneRare earth

Owner:HEILONGJIANG UNIV

Room temperature no based on quantum dot composites 2 Sensor and its preparation method

ActiveCN112683963BThe synthesis method is simpleLow costMaterial resistanceMicrospherePerovskite (structure)

A based on ZnO microspheres and CsPbBr 3 Room temperature NO of quantum dot heterostructure composites 2 A sensor and a preparation method thereof belong to the technical field of semiconductor oxide gas sensors. A ceramic substrate with metal interdigitated electrodes and ZnO microspheres and CsPbBr coated on the metal interdigitated electrodes 3 Composition of sensitive layer of quantum dot heterostructure composite material. The morphology of zinc oxide is a sphere structure, which has a large specific surface area and can provide more attachment sites, so that it can be combined with the smaller perovskite CsPbBr 3 The quantum dots are in full contact, so that a gas sensor with better gas sensor response and faster response recovery speed can be obtained. In addition, CsPbBr 3 As an excellent photoelectric material, quantum dots can absorb visible light, thereby providing more photogenerated carriers. The sensor of the present invention adopts a planar structure, has simple process, short production period, and is suitable for mass production.

Owner:JILIN UNIV

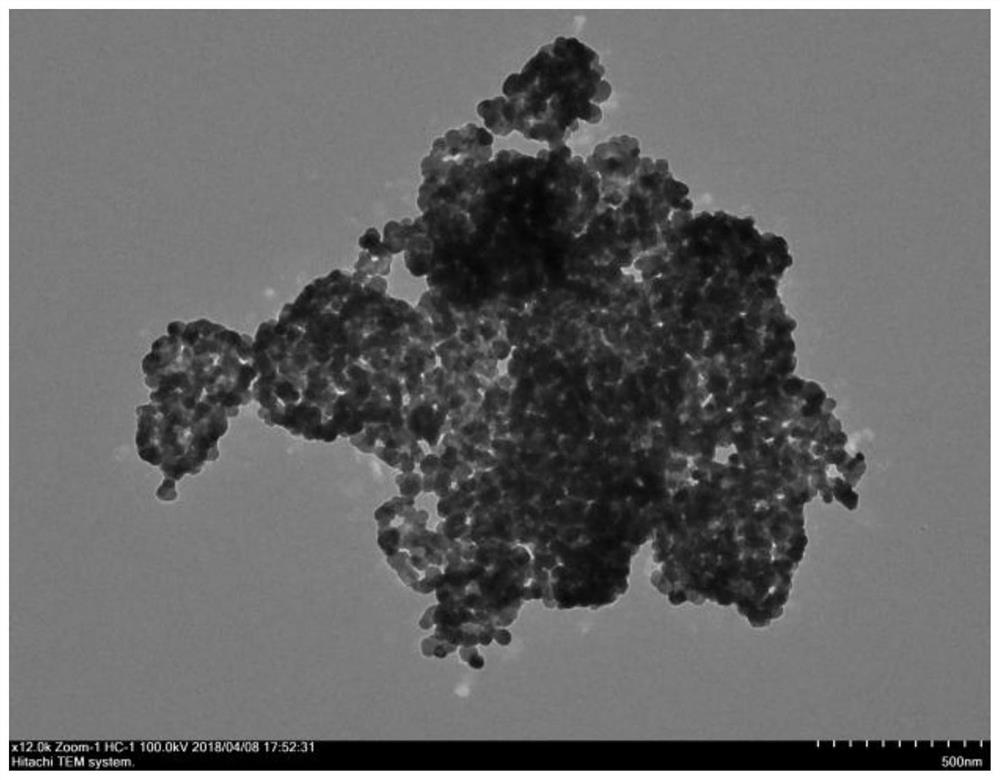

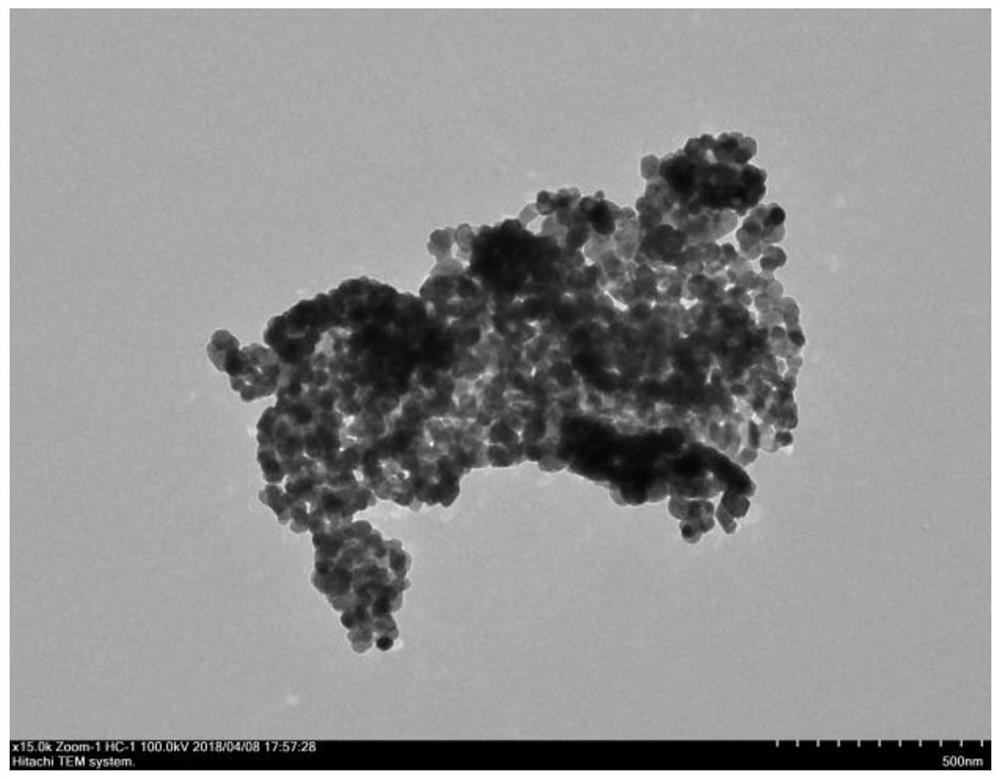

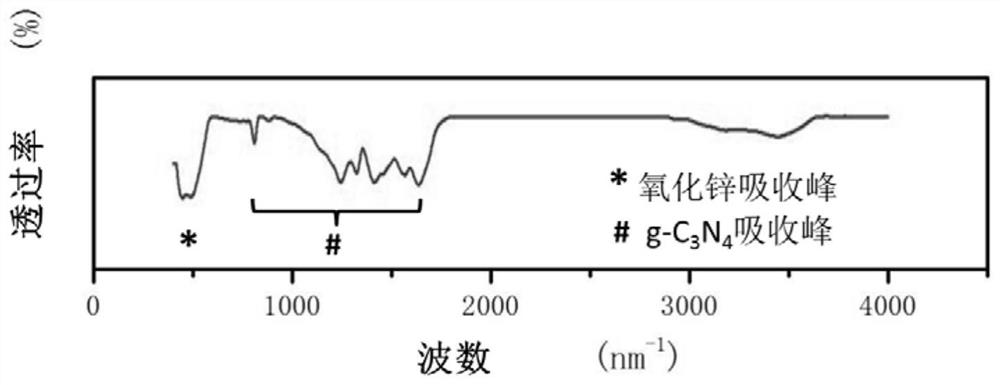

Use g-c for detecting vocs 3 no 4 Synthesis method of modified porous zinc oxide nanosheet composite gas-sensing material

ActiveCN108844999BGuaranteed permeabilityFacilitate conductionMaterial resistanceChemical synthesisBenzene

The present invention relates to the use of g-C for detecting VOCs 3 N 4 A method for synthesizing a modified porous zinc oxide nanosheet composite gas-sensing material, comprising the following steps: (1) preparing basic zinc carbonate and recrystallized commercialized melamine respectively, and grinding and mixing the two evenly according to a certain mass ratio; (2) The mixture obtained in step (1) is calcined under the protection of nitrogen to obtain a composite gas-sensitive material. In this method, the chemical synthesis method of precursors is used to synthesize g-C, which has a special interaction with gas molecules containing benzene rings. 3 N 4 Composite on porous zinc oxide nanosheets, with the help of the synergistic effect between the two porous two-dimensional semiconductor materials, the gas-sensing performance of zinc oxide is effectively improved. The material can be used for the gas-sensing detection of benzene-containing volatile organic pollutants and chlorobenzene-like gases. The gas-sensing response is good, the material synthesis method is green and simple, and the repeatability is good. It is easy to realize large-scale production and gas sensing detection applications. .

Owner:SHANDONG UNIV

A method and application for preparing formaldehyde gas-sensing material based on modification of tin sludge in tin plating process

ActiveCN108426923BGood gas responseImprove performanceMaterial resistanceTin platingToxic industrial waste

The invention belongs to the fields of comprehensive recycling and utilization of industrial waste tin, environmental protection and semiconductor oxide formaldehyde gas-sensitive sensors, and relates to a method and application of preparing formaldehyde gas-sensitive materials based on the modification of tin mud in the tin plating process. The formaldehyde gas-sensitive material of the present invention is obtained from the waste tin sludge existing at the bottom of the plating tank on the tin plating production line through acidification activation, washing and drying, noble metal doping and subsequent heat treatment. The manufactured gas sensor has excellent gas-sensing properties such as high sensitivity, fast response and recovery speed to formaldehyde. It achieves effective and rational utilization of tin resources, reduces economic costs, and reduces environmental pollution caused by waste. It is an environmentally friendly preparation method.

Owner:NORTHEASTERN UNIV LIAONING +1

A kind of electrodeless semiconductor gas sensor and its preparation method

ActiveCN104614413BGood gas responseImprove conductivityMaterial resistanceWorking temperatureNanocrystal

The invention discloses an electrodeless semiconductor gas sensor and a preparation method thereof. By adopting the electrodeless-type design, a gas sensitive layer is produced from a colloidal-state nano crystal composite material which is high in sensitivity and good in conductivity, the gas sensitive layer is smeared on an insulation substrate to form a device, no additional signal electrode is needed, the device structure and the process procedure are simple, the cost is reduced, and the mass production can be realized; moreover, the method is suitable for producing a flexible gas sensor. The gas sensor has characteristics of light weight, thinness, shortness, small size and good portability; moreover, the working temperature is low, and the application prospect is good.

Owner:HUAZHONG UNIV OF SCI & TECH

A boron-doped titanium dioxide photo-assisted gas sensor and its preparation method and application

ActiveCN107894448BGood gas responseConducive to preparation and applicationMaterial resistancePhysical chemistryUltraviolet lights

Owner:FUZHOU UNIV

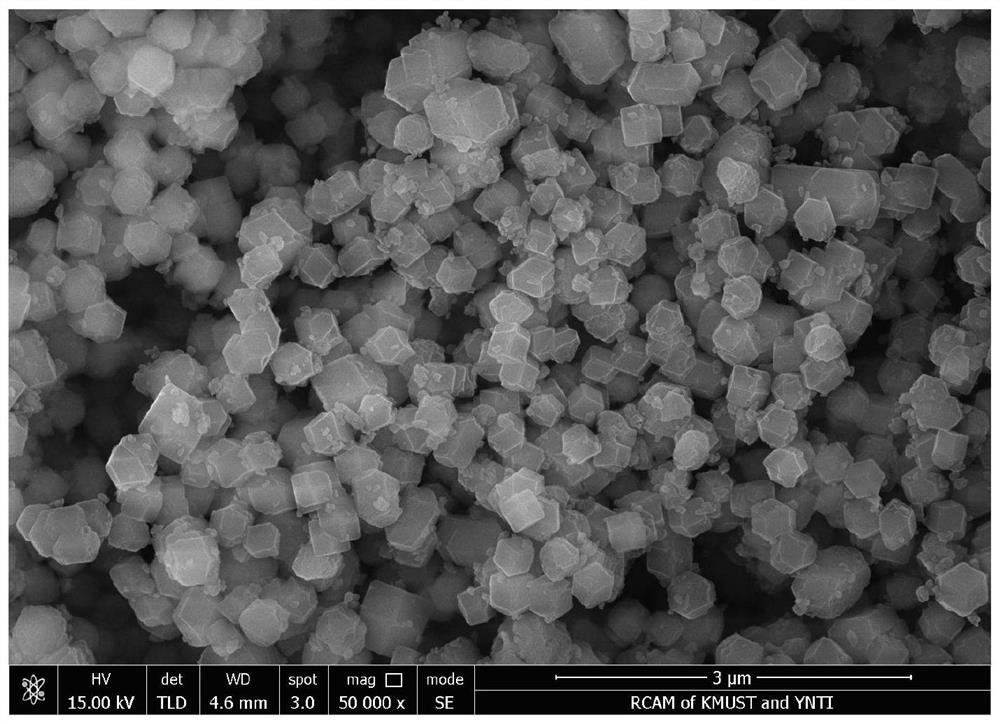

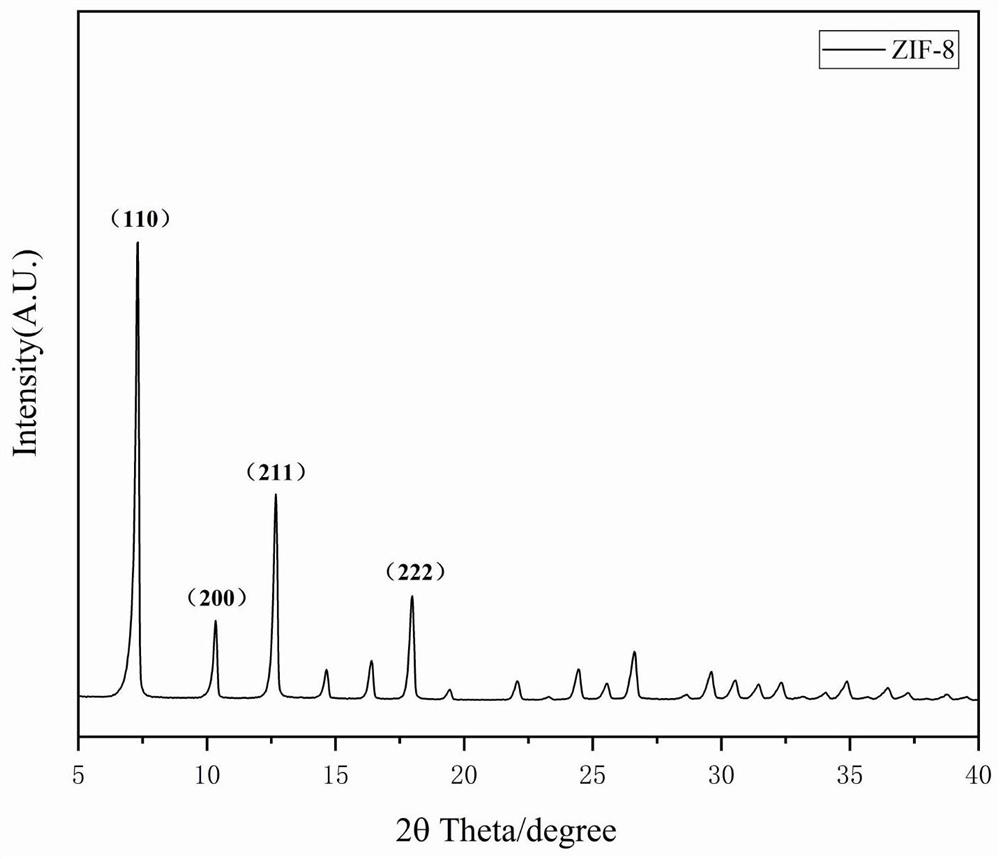

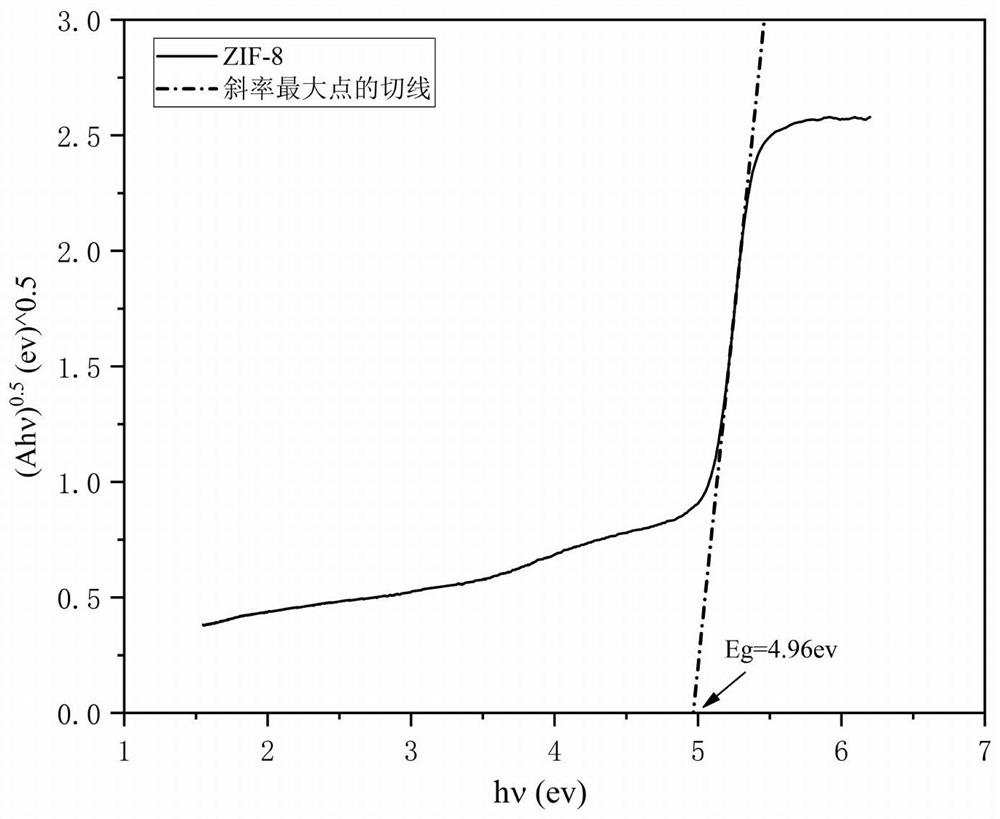

Method for improving gas-sensitive response performance of ZIF-8 to ethanol gas

PendingCN113237927ALower response temperatureGood gas responseMaterial resistancePhysical chemistryUltraviolet lights

The invention discloses a method for improving gas-sensitive response performance of ZIF-8 to ethanol gas, and belongs to the technical field of gas-sensitive materials.The method comprises the following steps that firstly, ultraviolet light excitation is conducted on ZIF-8, and then thermal excitation is increased under the condition that ultraviolet light excitation is kept; by adopting the method disclosed by the invention, the ZIF-8 has excellent gas-sensitive response to ethanol gas with the concentration of 100-300ppm under the low-temperature condition of 25-75 DEG C, the working temperature of the ZIF-8 porous wide-band gap material is reduced, the gas-sensitive response performance of the ZIF-8 porous wide-band gap material to the ethanol gas is improved, and the ZIF-8 porous wide-band gap material can be applied to an ethanol low-temperature gas sensor; and the method provided by the invention provides a thought for subsequent research on the application of the wide bandgap semiconductor gas-sensitive material to the low-temperature sensor.

Owner:KUNMING UNIV OF SCI & TECH

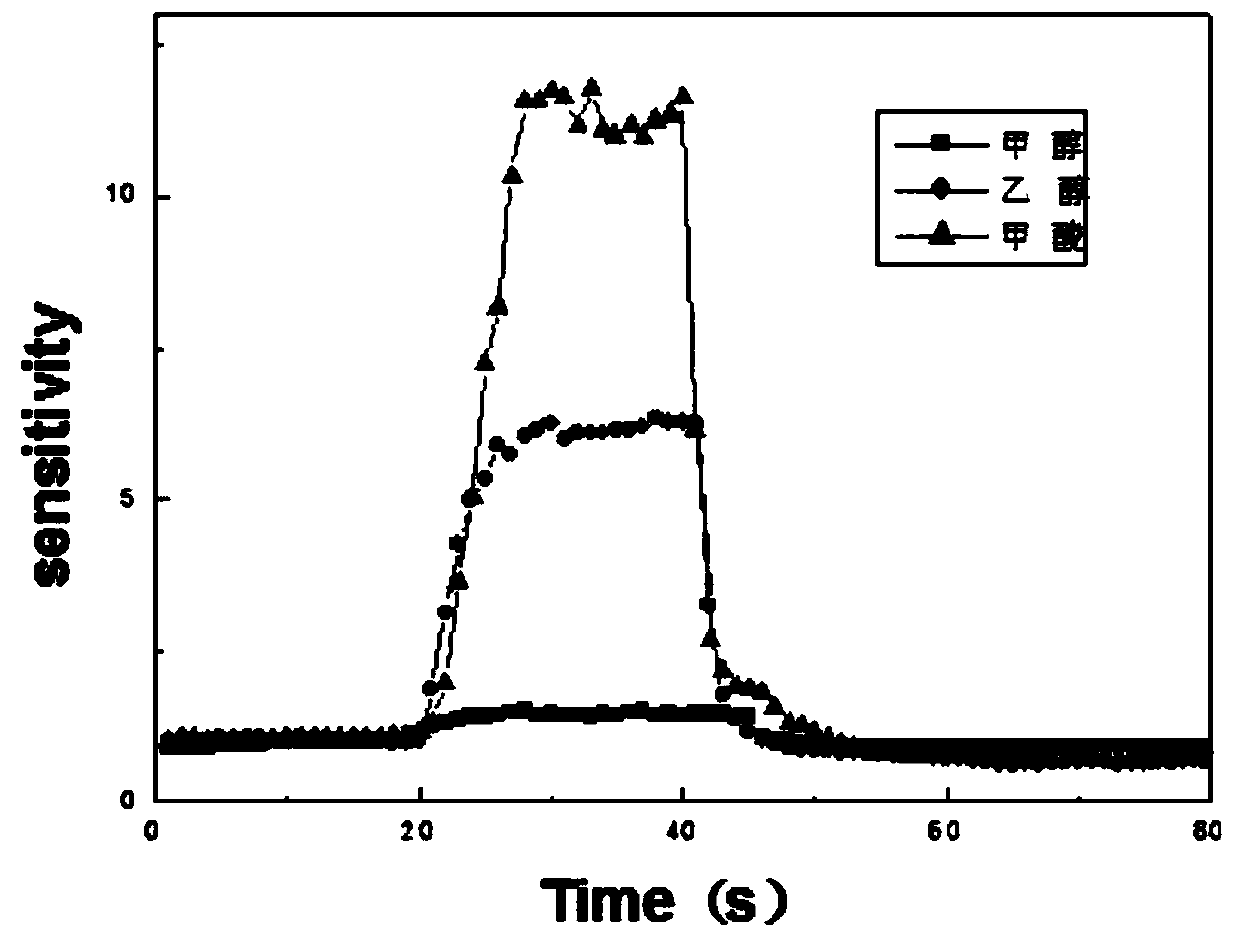

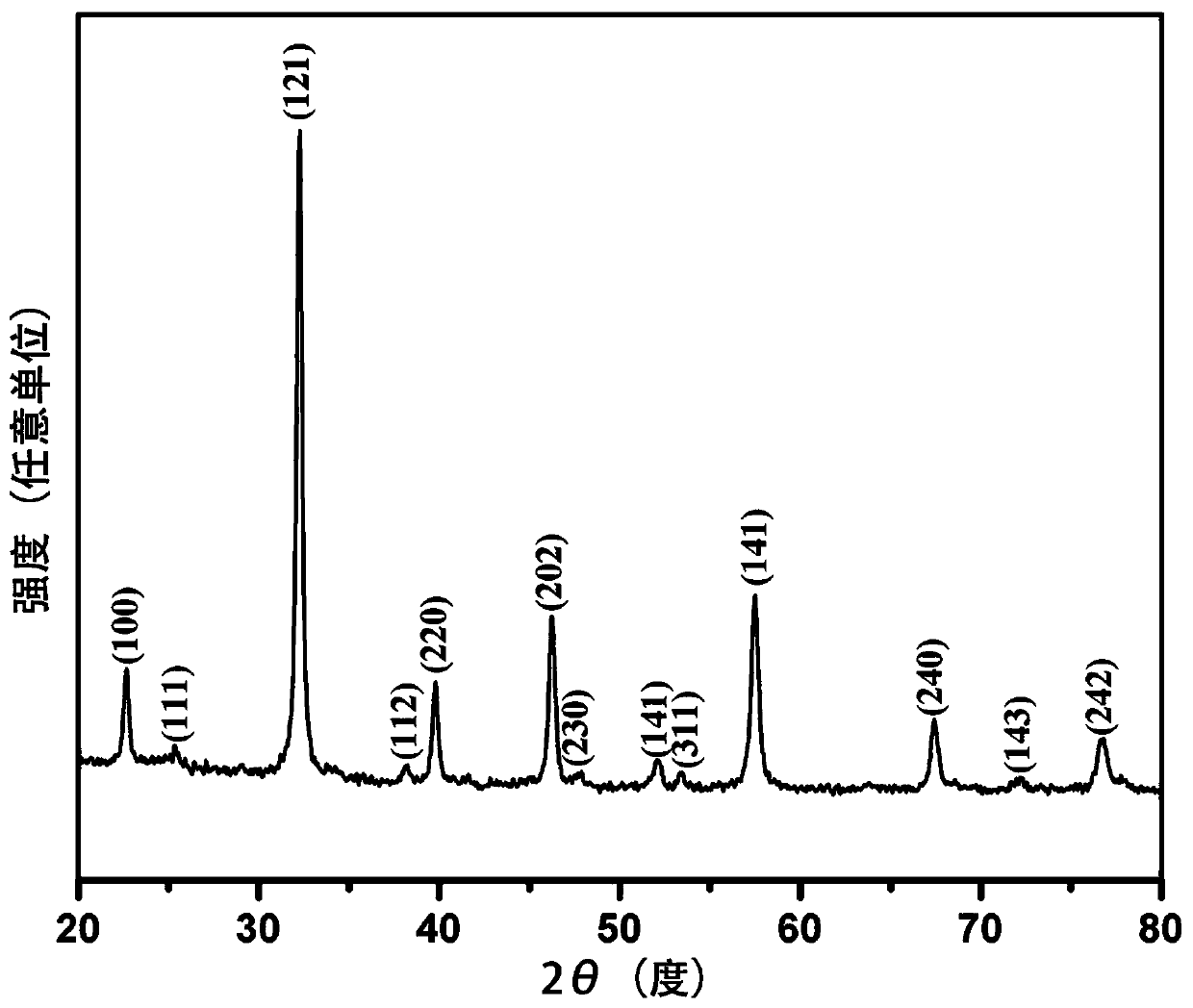

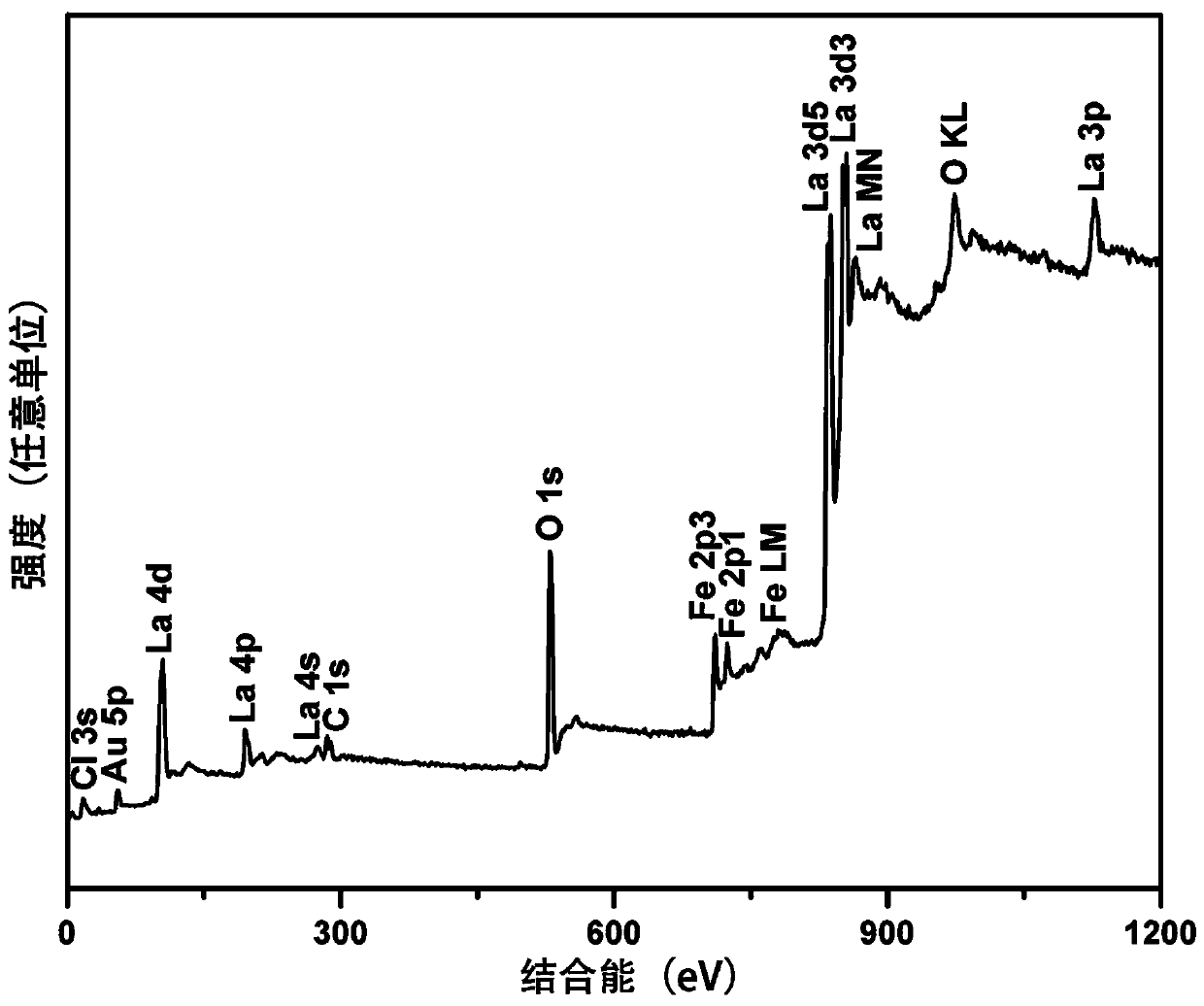

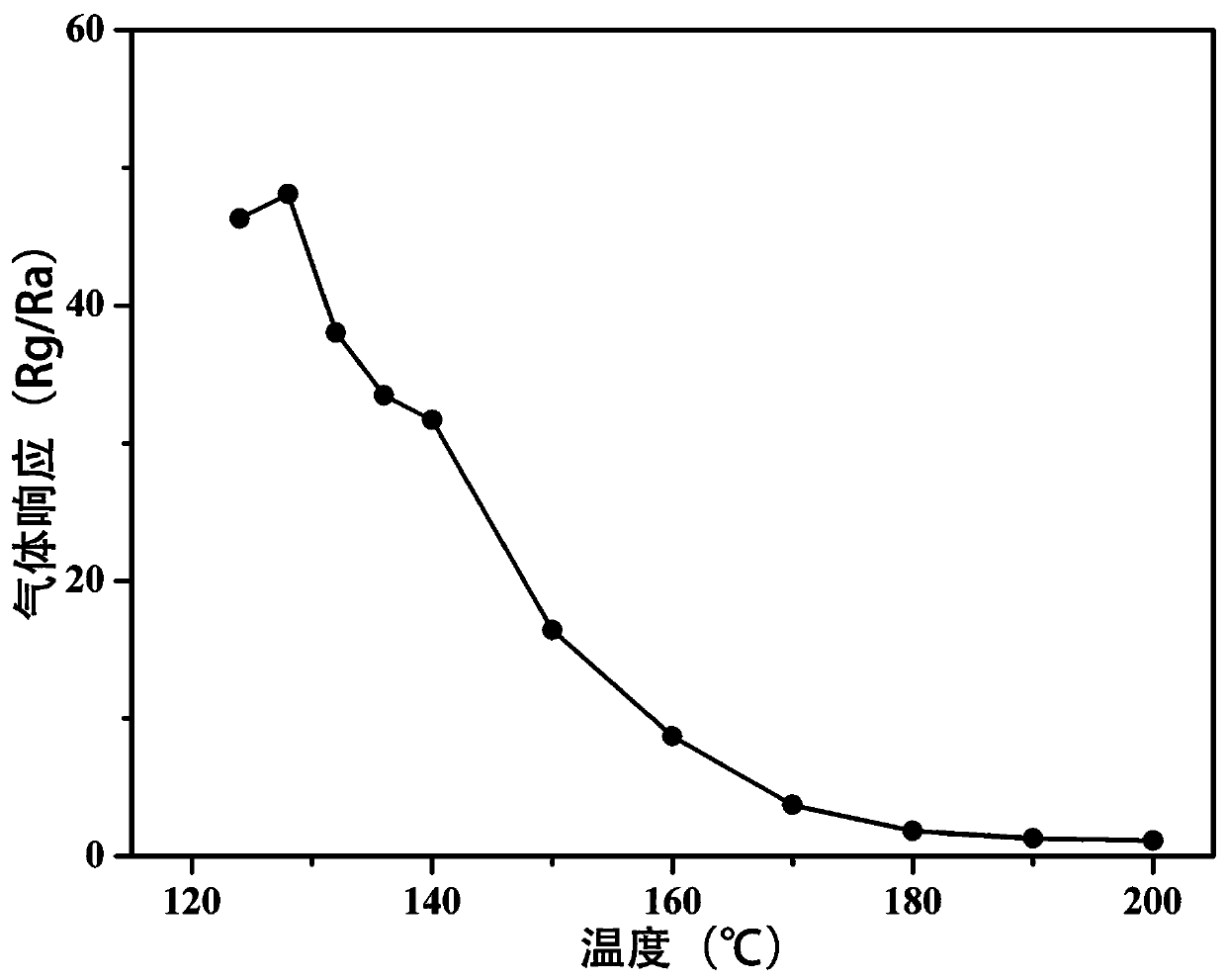

A lafeo co-modified with au and cl 3 Ethanol gas sensor and preparation method thereof

The invention belongs to the technical field of gas sensor production, and provides an Au and Cl co-modified LaFeO3-based ethanol gas sensor and a production method thereof. The method comprises the following steps: adding an aqueous HAuCl4 solution with the mass fraction being 1% into a LaFeO3 solution according to a mass ratio of the aqueous HAuCl4 solution to the LaFeO3 solution of 1:100, preparing Au and Cl co-modified LaFeO3 nano-powder through a sol-gel technology, and producing an indirectly-heated ceramic tube structure gas sensor element. The best working temperature of the produced gas sensor element to ethanol is 128 DEG C; the gas response to 100 ppm of ethanol at the best working temperature is 47.7, and has no much change 96 h later, so the gas sensor element has a good stability; the response to 100 ppm of DMF, dichloromethane, n-hexane, carbon dioxide, and hydrogen gases is 23.3 or less, and has a good selectivity; the gas response to 20 ppm of ethanol is 19.5, and thegas sensor element has a very high gas response to a low-concentration ethanol gas.

Owner:TAIYUAN UNIV OF TECH

A gas sensor based on metal molybdate nanocomposite material and its preparation method

ActiveCN109781800BGood gas responseImprove stabilityMaterial nanotechnologyNanosensorsMolybdateThiourea

The invention belongs to the technical field of gas sensors, and relates to a gas sensor based on a metal molybdate nanocomposite material and a preparation method thereof; the ring-shaped gold electrode of the sensor is coated with a metal molybdate nanocomposite film, and the metal The specific preparation process of molybdate nanocomposites is as follows: first, ammonium molybdate, thiourea and ammonium fluoride are prepared by hydrothermal synthesis of MoS 2 At the same time, the semiconducting metal oxide suspension is prepared by hydrothermal synthesis of the semiconducting metal salt; then the molybdenum sulfide powder and the semiconducting metal oxide suspension are hydrothermally synthesized into the molybdenum sulfide nanocomposite precursor, and the prepared molybdenum sulfide The metal molybdate nanocomposite material is obtained by calcining the precursor of the nanocomposite material in an atmosphere; the ethanol gas sensor has high selectivity to ethanol, high sensitivity, good stability, long service life, and short response time and recovery time to ethanol gas , excellent performance, quick and timely alarm for ethanol gas.

Owner:QINGDAO UNIV

a sno 2 /mos 2 Two-dimensional macroporous composite film, preparation method and application thereof

ActiveCN113354298BEasy dischargeIncrease surface active sitesMaterial nanotechnologyCoatingsComposite filmMicrosphere

The invention discloses a SnO 2 / MoS 2 The invention relates to a two-dimensional macroporous composite film, a preparation method and an application thereof, belonging to the field of sensor material preparation. In the preparation method of the present invention, the PS template is soaked so that the SnCl 4 ·5H 2 The O solution fills the gaps between the PS microspheres, followed by annealing to vaporize the PS spheres to form SnO 2 macroporous film; followed by hydrothermal reaction, the regular arrangement of SnO 2 Based on the macroporous structure, the introduction of MoS 2 Nanosheets, through regulation, make PS template → SnO 2 Macroporous film→SnO 2 / MoS 2 Macroporous film. SnO of the present invention 2 / MoS 2 Two-dimensional macroporous composite film, the porous structure is conducive to gas discharge, the compounding of nanosheets increases the specific surface area of the film, and increases the surface active sites, which greatly improves the gas-sensing performance, and the gas-sensing performance is more excellent. Nitrogen gas has a good gas sensitivity response.

Owner:GUILIN UNIV OF ELECTRONIC TECH

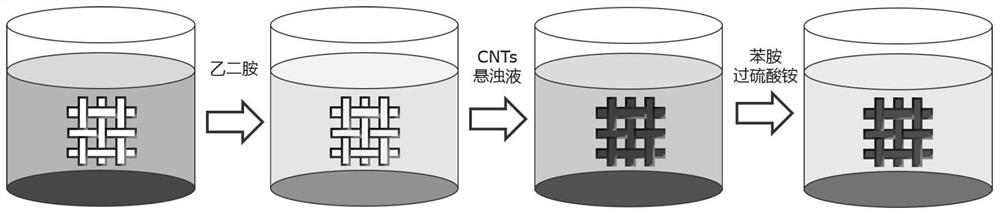

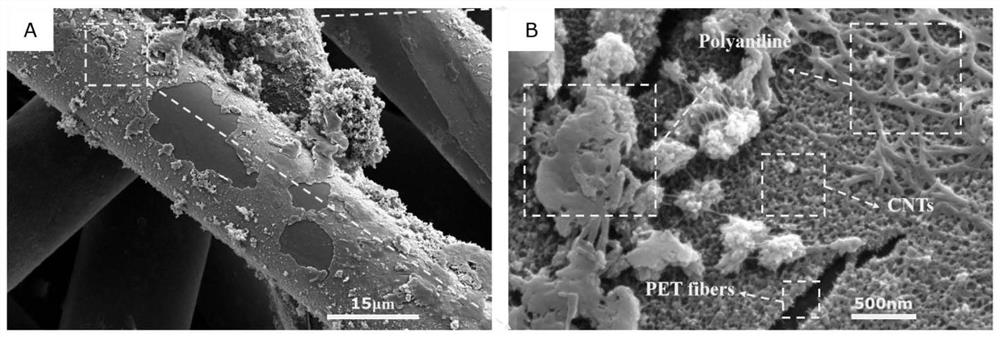

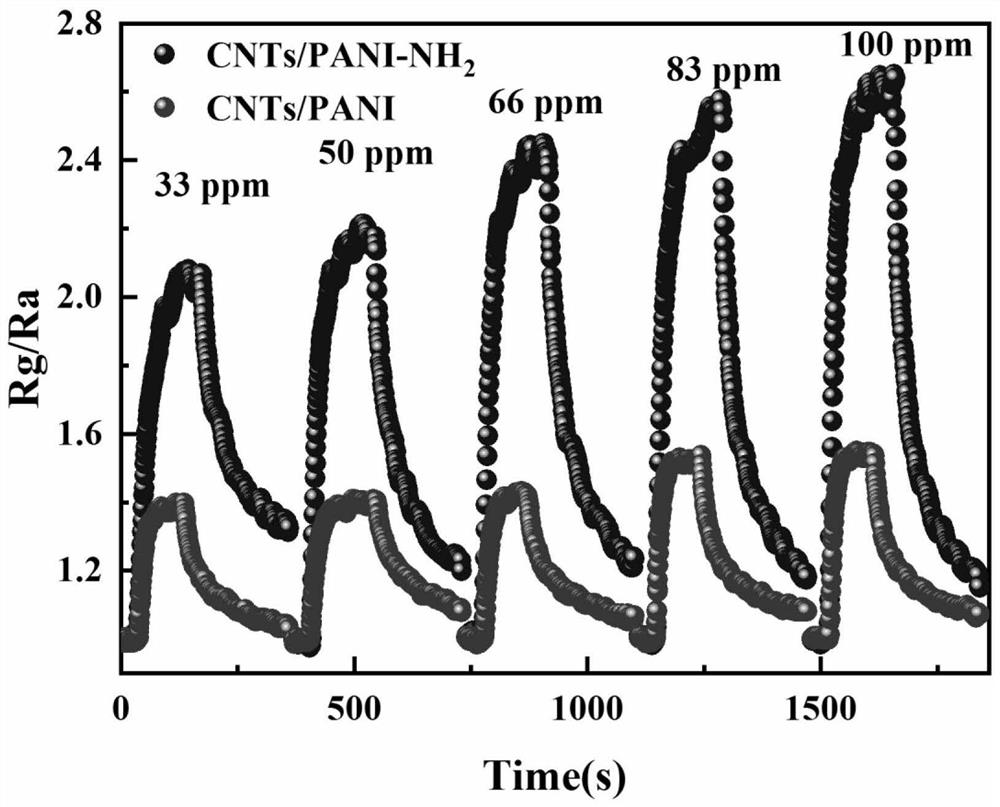

A kind of flexible ammonia sensing material and preparation method based on cnts/polyaniline

ActiveCN111254708BImprove gas sensing performanceIncrease loadFibre typesMaterial resistanceEthylenediaminePolymer science

The invention relates to a flexible ammonia sensing material based on CNTs / polyaniline and a preparation method thereof. The flexible PET fiber is used as the sensing material base, and the flexible PET fiber base is modified with amino functional groups on the surface, and attached to the surface of the flexible PET fiber. There are layers of CNTs and polyaniline. Among them, the surface of the PET fiber was impregnated with ethylenediamine solution to modify the amino functional group, the CNTs were combined with the surface of the PET fiber through an ultrasonic vibration adsorption process, and polyaniline was combined with the surface of the CNTs through in-situ polymerization. The invention adopts flexible PET fiber as a base, and modifies amino groups on the surface of the PET fiber to increase the load capacity of CNTs on the PET surface, thereby improving the gas-sensitivity of the CNTs / polyaniline material to ammonia. The ammonia gas sensing material obtained by the invention has good gas response and good ammonia gas selectivity.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

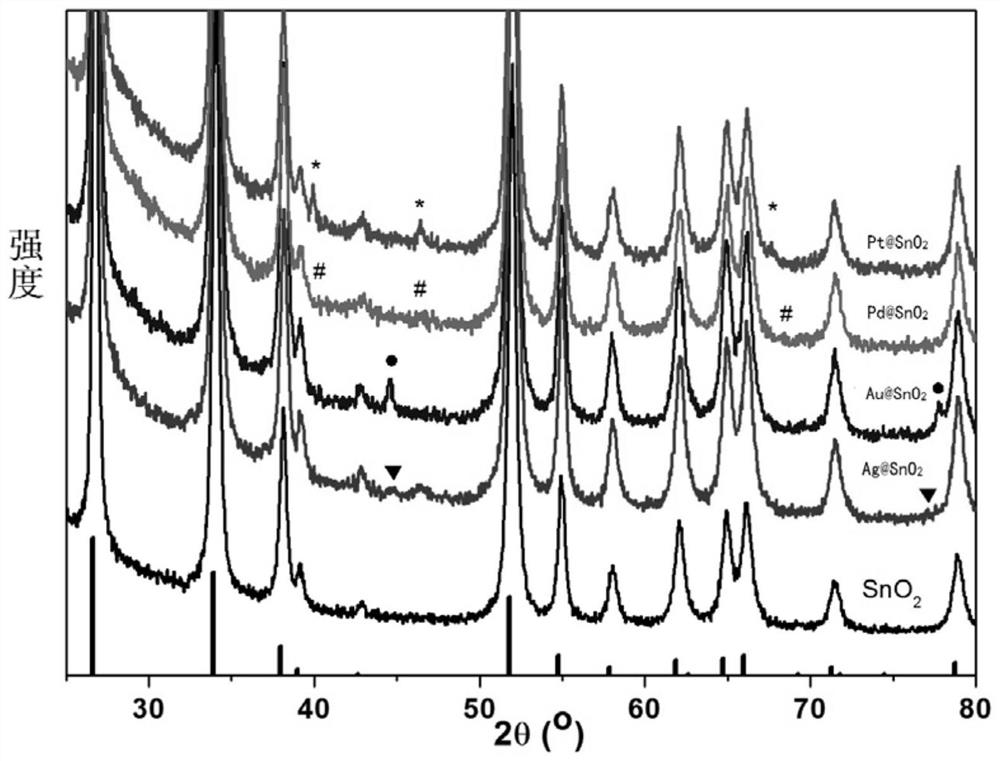

Gas sensing module and its preparation method and application

ActiveCN110161091BUniform assembly sizeLarge specific surface areaMaterial electrochemical variablesTin dioxideEngineering

The invention relates to the field of new functional materials, and discloses a gas sensing module and its preparation method and application. The gas sensing module includes a micro-sensor chip and a noble metal-loaded gas-sensitive sensing material loaded on the micro-sensor chip; wherein , the noble metal-loaded gas-sensitive sensing material includes a tin dioxide carrier and a noble metal supported on the tin dioxide carrier, and the noble metal is selected from one or more of the metal elements of Group IB and Group VIII. The gas sensing module provided by the invention has the characteristics of simple material preparation method, large output, simple way of loading precious metals, less dosage, good sensitivity and stability, low resistance and the like.

Owner:CHINA PETROLEUM & CHEM CORP +2

A lafeo with high gas sensitivity 3 Ethanol gas sensor and preparation method thereof

ActiveCN108152337BIncrease the ability to absorb oxygenLower working temperatureMaterial resistancePhysical chemistryHexane

The invention belongs to the technical field of preparation of gas sensors, and provides a LaFeO3-based ethanol gas sensor with high gas-sensitive property and a preparation method thereof. La2 / 3Ba1 / 3Fe2 / 3Ti1 / 3O3 nano-powder prepared with a sol-gel method is taken as a working mediumsubstance for preparing a nindirectly-heated heater-type ceramic tube constructed gas sensor element. In a LaFeO3 lattice, an equivalent quantity of Ba elements and Ti elements with an equivalent quantity are introduced at a La bit and an Fe bit, so that the surface oxygen adsorption performance of the nano-powderis improved, the ethanol gas sensor element is lower in working temperature under the condition of not adding heavy metals or rare earth precious metals, and is higher in gas response and selectivity.The high gas-sensitive property LaFeO3-based ethanol gas sensor with high gas-sensitive property is 128 DEG C in best working temperature specific to the ethanol, is 48.1 in gas response specific to100ppm ethanol at the best working temperature, is below 22.4 and below in gas response specific to 100ppm acetone, DMF (Dimethyl Fformamide), dichloromethane, n-hexane, carbon dioxide and hydrogen gas response, and is up to 15.1 in gas response specific to 20ppm ethanol.

Owner:TAIYUAN UNIV OF TECH

A lafeo with high gas response and selectivity 3 Ethanol gas sensor element and preparation method thereof

ActiveCN108205002BHigh originalityLower working temperatureMaterial resistanceAlcoholPhysical chemistry

The invention belongs to the technical field of gas sensors, and provides a high gas response and selective LaFeO3-based ethanol gas sensor element and a preparation method thereof. LaFeO3 and BaTiO3nano powder are prepared by a sol-gel method and mixed at a molar ratio of 2:1; the mixture is sintered for 2 h at 190-210 DEG C, a nano gas-sensitive material is obtained, and a side-heating ceramictube structure gas sensor element is obtained. The oxygen adsorption capability of the surface of the nano-gas sensitive material is enhanced, and the gas response and selectivity are significant improved at lower operating temperatures. The optimum operating temperature of the gas sensor element for ethanol is 128 DEG C; the gas response to 100 ppm ethanol at the optimum operating temperature is102.9, and good stability is achieved; for 100 ppm acetone, dichloromethane, n-hexane, carbon dioxide and hydrogen and the like, the gas response is 38 or below, and good selectivity is achieved; andthe gas sensor element has a very high gas response to low concentration ethanol gas.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com