A kind of flexible ammonia sensing material and preparation method based on cnts/polyaniline

A sensing material, polyaniline technology, applied in the direction of analysis of materials, material resistance, material analysis by electromagnetic means, etc., can solve the problems of poor gas selectivity and low gas response, achieve good ammonia gas selectivity, improve gas Sensitivity, good gas response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

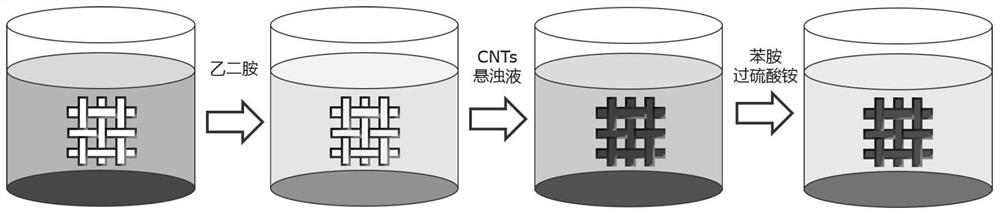

[0022] The preparation method of the flexible ammonia sensing material based on CNTs / polyaniline is characterized in that the steps are as follows:

[0023] Step 1: Amino groups are modified on the surface of PET by immersing PET fibers in ethylenediamine solution.

[0024] Step 2: Adsorb the CNTs layer on the surface of the PET fiber by using an ultrasonic vibration adsorption process.

[0025] Step 3: Prepare polyaniline on the CNTs layer by in-situ polymerization.

[0026] Wherein, the process of modifying amino groups on the surface of PET fibers described in step 1, the experimental raw materials and parameters are: ethylenediamine solution for surface modification of amino groups, the concentration of ethylenediamine is 50-70wt%, and the dipping temperature is 40-70°C , The soaking time is 10-30min.

[0027] The specific preparation process of the amino group modified on the surface of the PET fiber is as follows: After the PET fiber is ultrasonicated in absolute ethan...

Embodiment

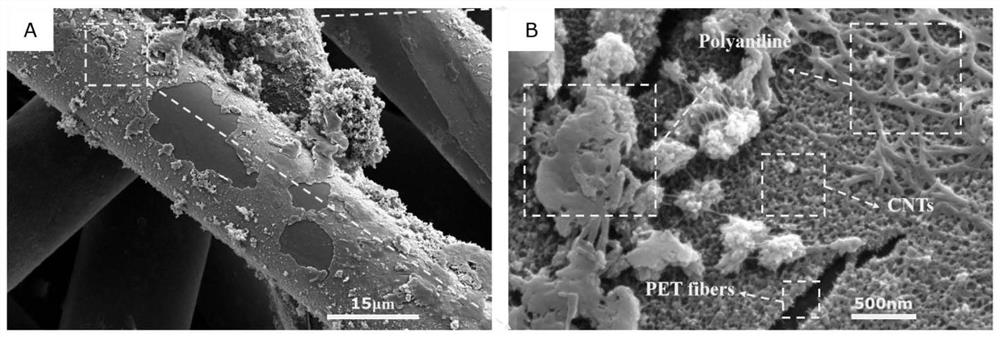

[0035] Such as figure 1 As shown, the PET fiber is used as the material substrate, the PET fiber is modified with amino functional groups, and the CNTs layer and polyaniline are adsorbed on the surface of the PET fiber.

[0036] The preparation method of the flexible ammonia sensing material based on CNTs / polyaniline has the following steps:

[0037] Step 1: Amino groups are modified on the surface of PET by immersing PET fibers in ethylenediamine solution.

[0038] Step 2: Adsorb the CNTs layer on the surface of the PET fiber by using an ultrasonic vibration adsorption process.

[0039] Step 3: Prepare polyaniline on the CNTs layer by in-situ polymerization.

[0040] Wherein, the technology of amino group modification on the surface of PET fiber described in step 1, its experimental raw materials and parameters are: carry out the ethylenediamine solution of surface modification amino group, its ethylenediamine concentration is 50wt%, immersion temperature is 50 ℃, and immer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com