Patents

Literature

14170results about How to "Simple manufacturing method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process of methanol conversion for preparing arene and catalyst and catalyst preparation method

InactiveCN1880288AHigh selectivityHigh flexibility in process operationMolecular sieve catalystsHydrocarbonsGas phaseAromatic hydrocarbon

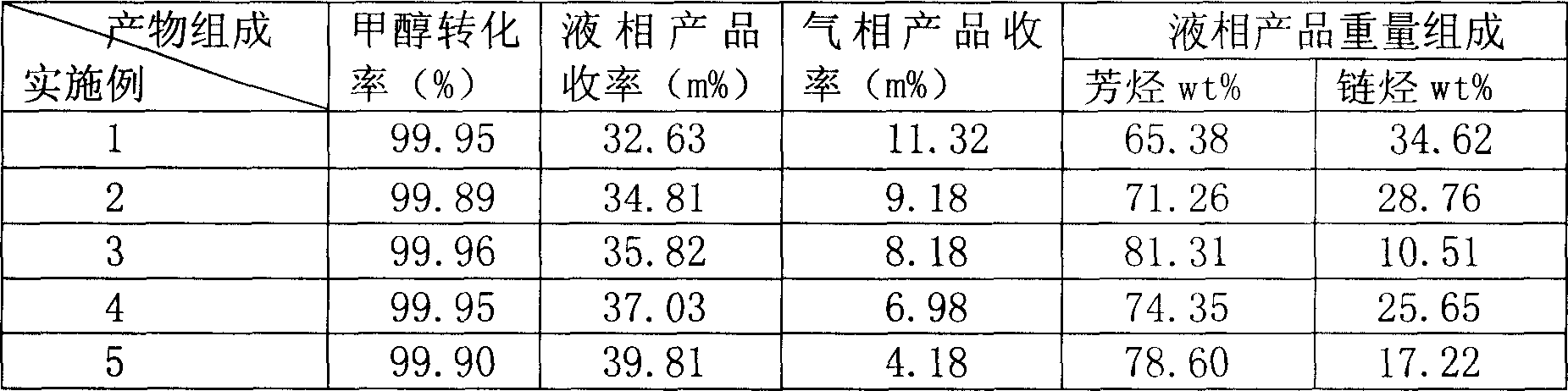

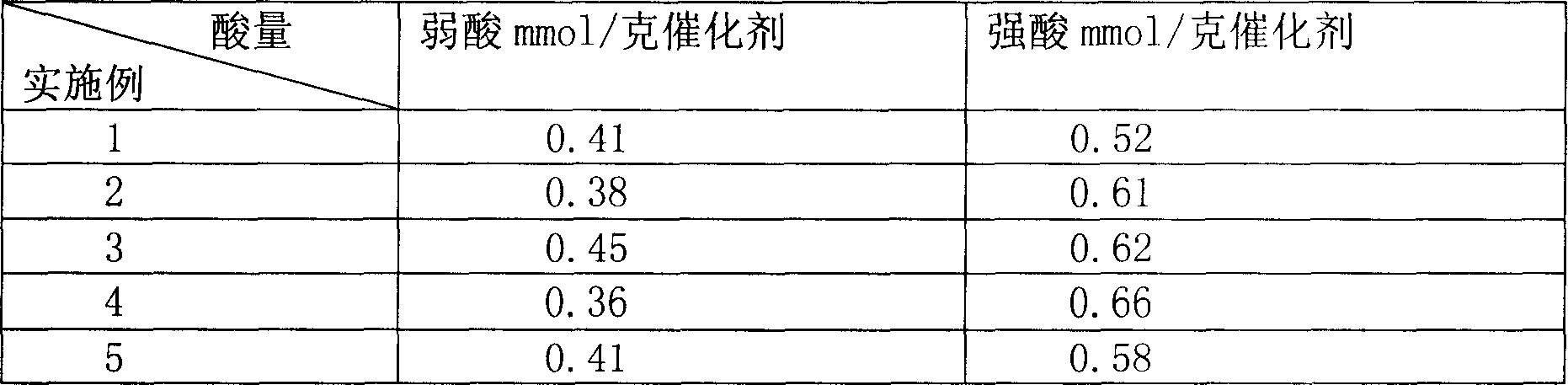

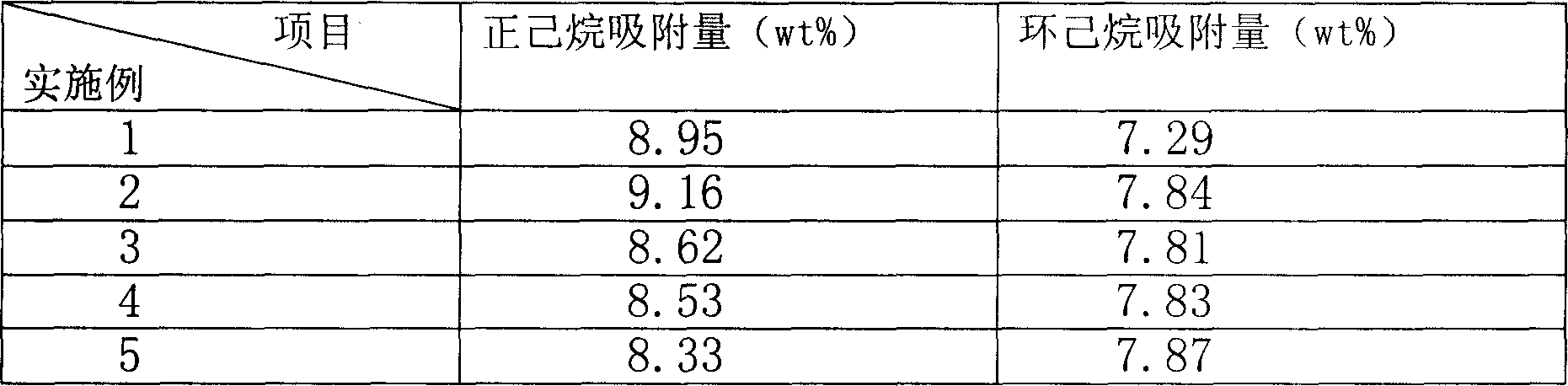

This invention relates to a process for transforming methanol to aromatic hydrocarbons, comprising: use methanol as raw material, with modified ZSM-5 molecular sieve as catalyst, under conditions of operation pressure 0.1-5.0Mpa, operation temperature 300-460Deg C, raw material liquid air speed 0.1-6.0h-1, transformed to products with aromatic hydrocarbons as main components; separate the gas-phase products lower carbon hydrocarbons from the liquid-phase C5+ hydrocarbons by cooling separation; the liquid-phase C5+ hydrocarbons then can be separated to be aromatic hydrocarbons and non-aromatic hydrocarbons by extracting separation. This invention is characterized of high total selectivity of aromatic hydrocarbons and flexible process operation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

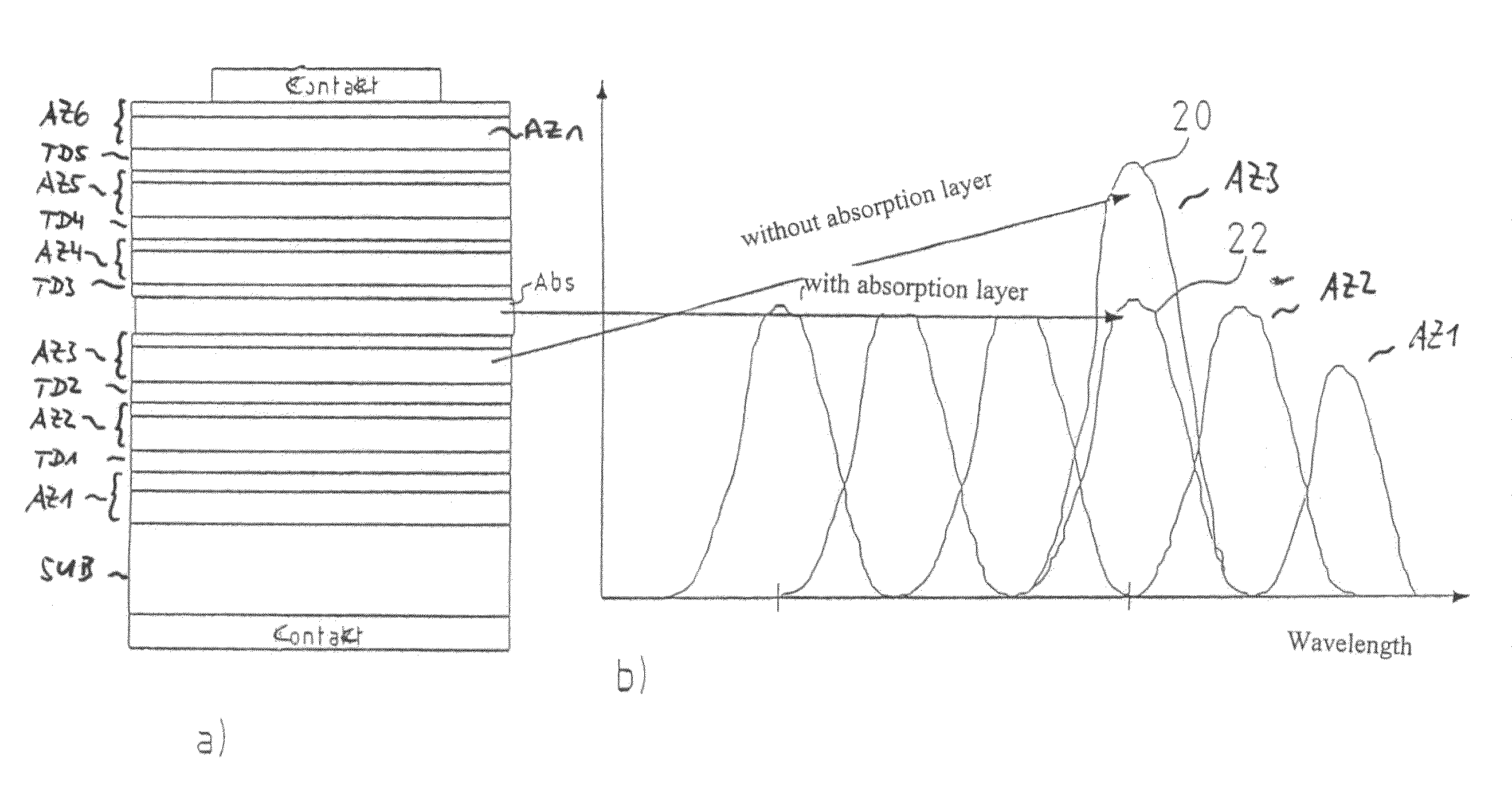

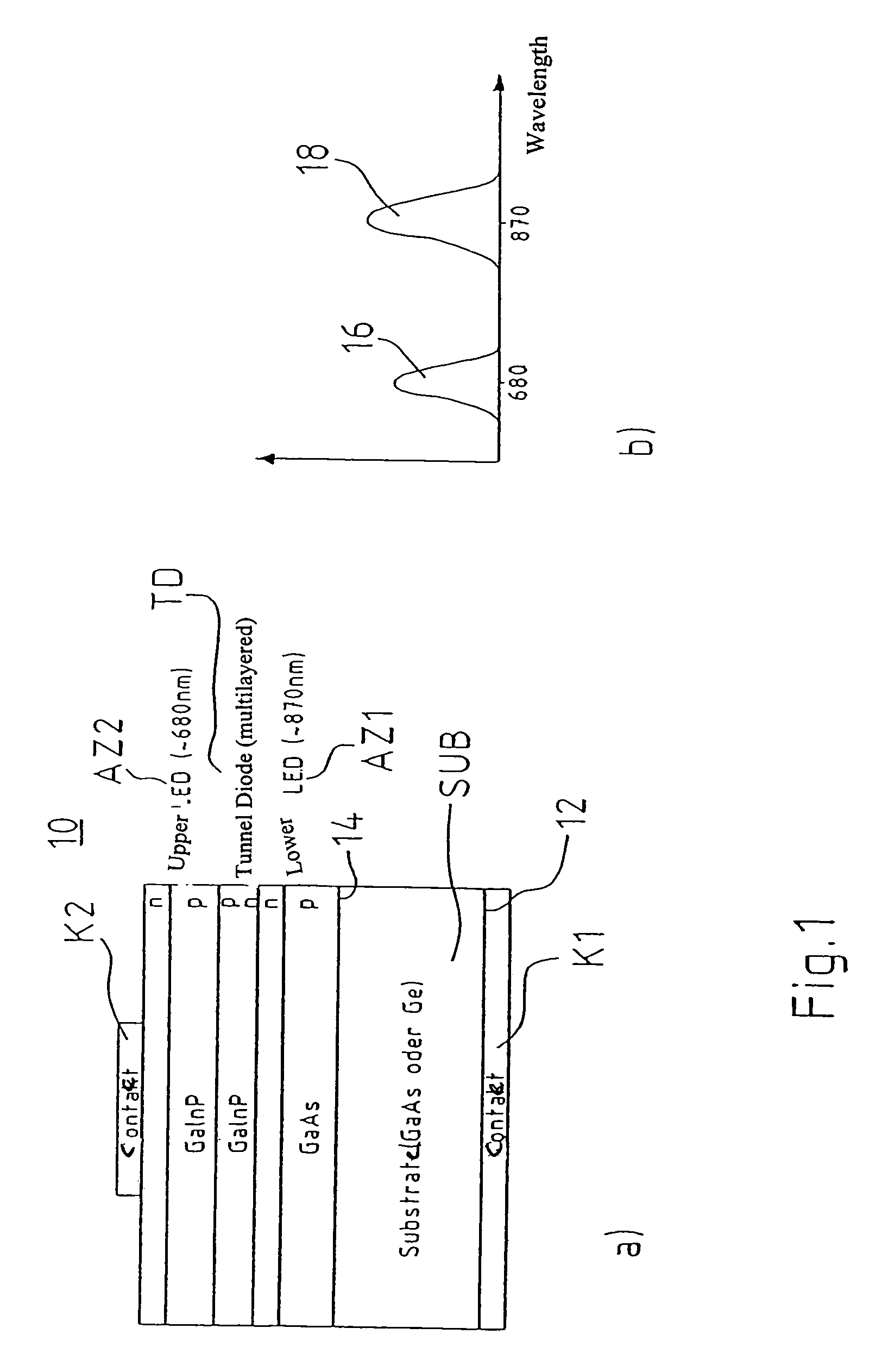

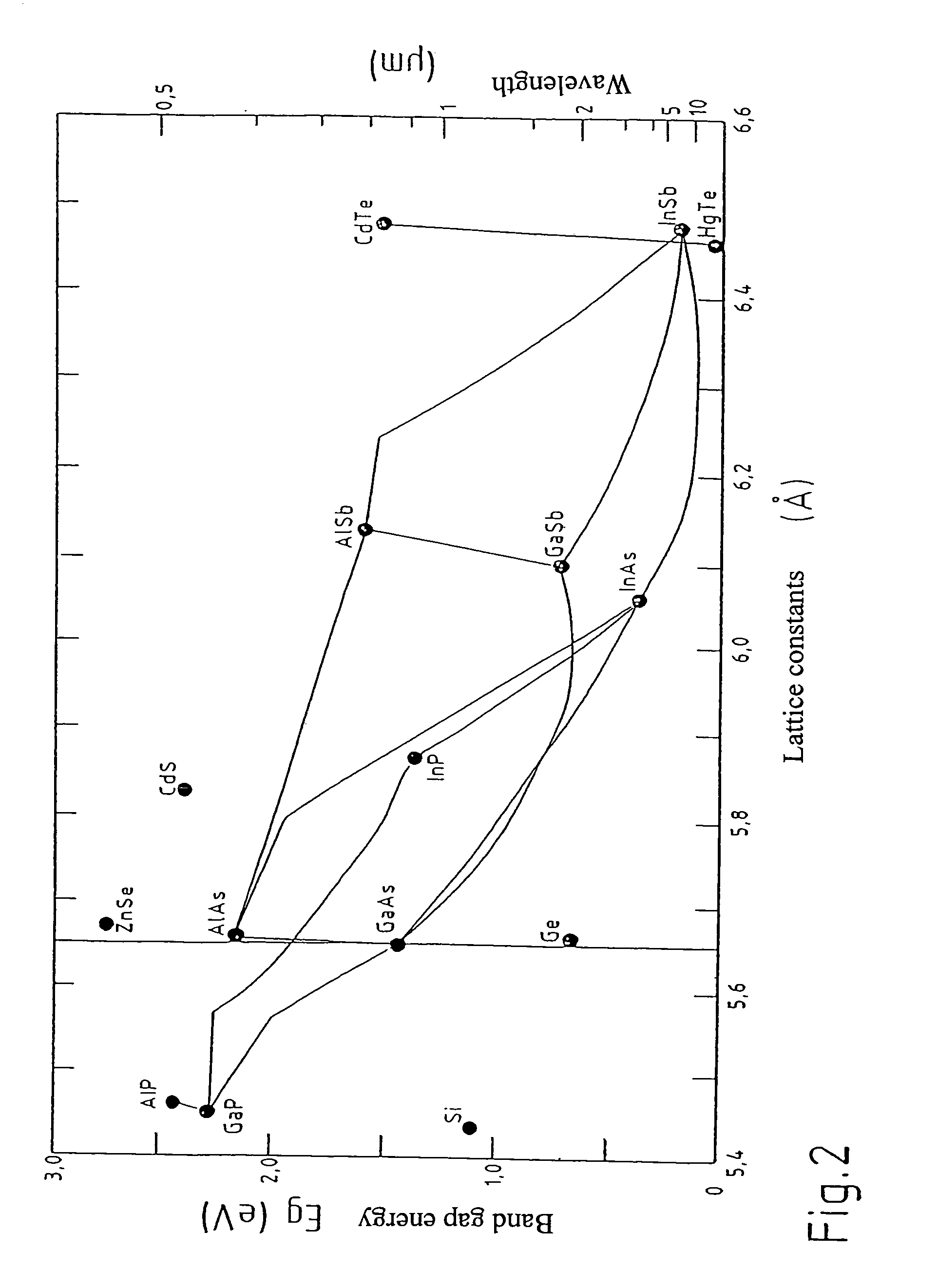

Semiconductor structure comprising active zones

InactiveUS7692202B2Improve light yieldSimplify manufacturing methodSolid-state devicesSemiconductor devicesMulti wavelengthTunnel diode

A semiconductor structure with active zones, such as light diodes or photodiodes, including a substrate (SUB) with at least two active zones (AZ1-AZn), each of which emits or absorbs a radiation of differing wavelength. According to the invention, a multi-wavelength diode may be achieved, in which a first (lower) active zone (AZ1) is grown on a surface of the substrate (SUB), with one or several further active zones (AZ1-Azn) epitaxially grown one on the other and the active zones (AZ1-AZn) are serially connected from the lower active zone (AZ1) to an upper active zone (AZn), by means of tunnel diodes (TD1-TDn), serving as low-impedance resistors.

Owner:AZUR SPACE SOLAR POWER

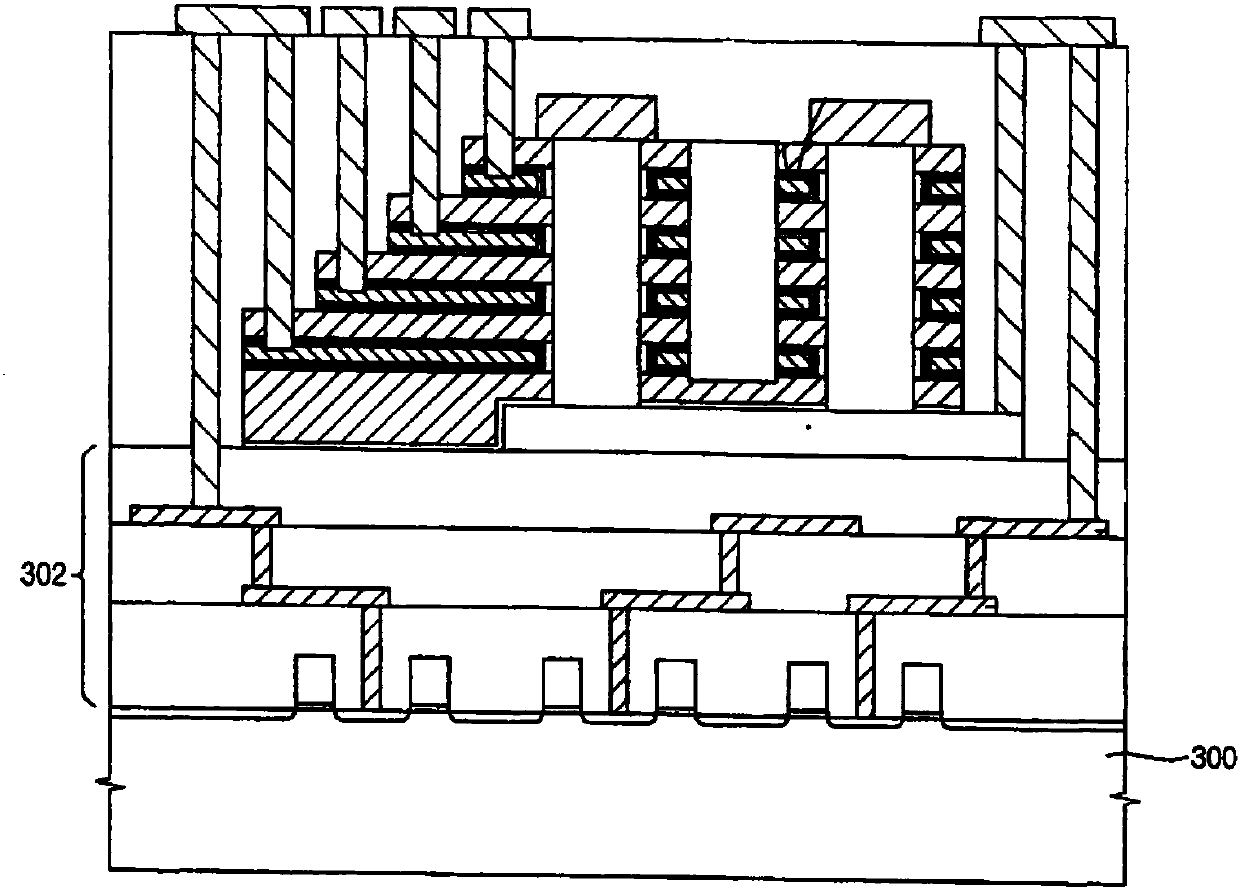

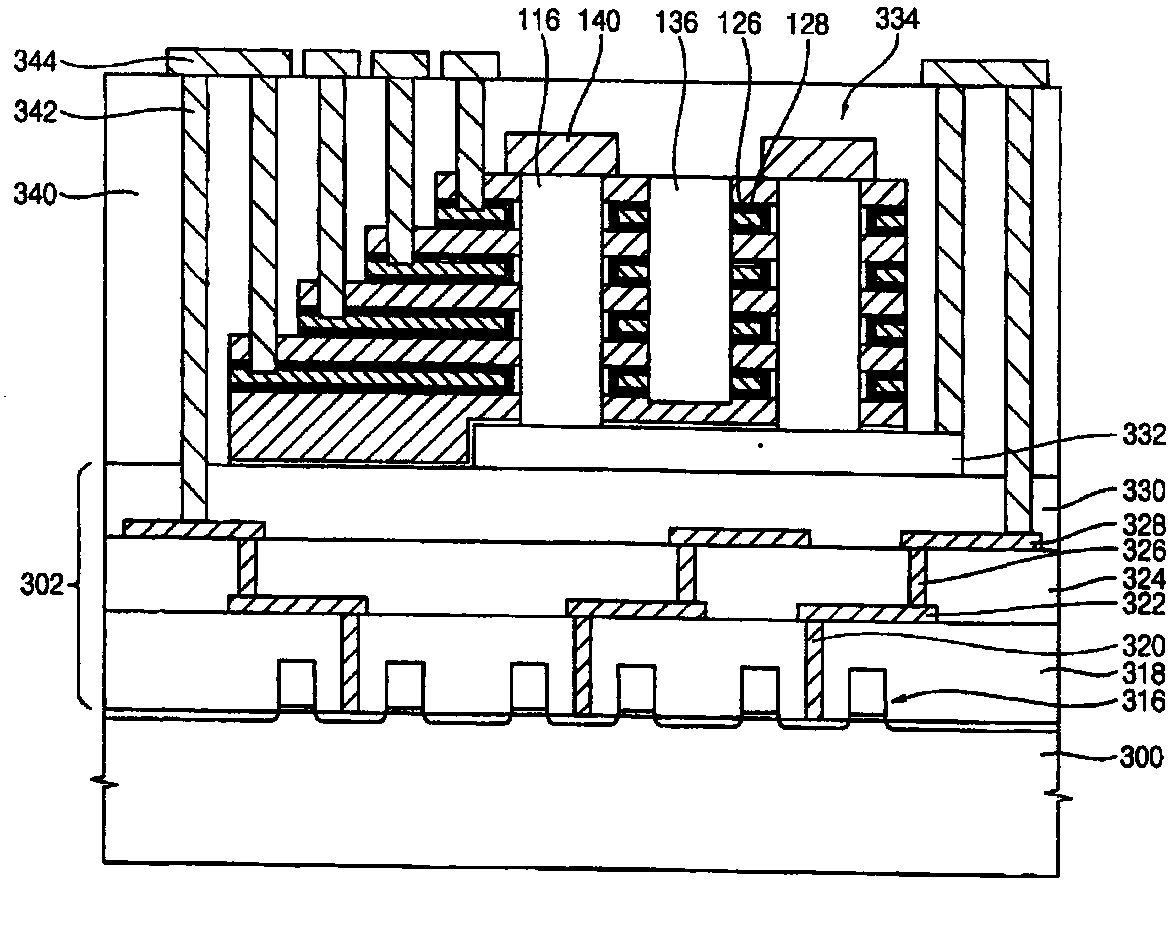

Semiconductor apparatus and preparation method therefor

ActiveCN107658315ASolve the problem of temperature limitAvoid mutual influenceSolid-state devicesSemiconductor devicesMutual influenceSemiconductor

The invention relates to an NAND memory and a preparation method therefor. The NAND memory comprises a silicon substrate, a plurality of peripheral devices, a plurality of NAND strings formed above the peripheral devices, a monocrystal silicon layer formed above the multiple NAND strings, and one or more first interconnection layers formed between the multiple peripheral devices and the multiple NAND strings, wherein the monocrystal silicon layer and the multiple NAND strings are in contact connection. By manufacturing array devices and peripheral devices separately, mutual influence to the processing process of the two devices in manufacturing can be avoided, so that the problem of limitation to the post layer manufacturing by the temperature of the former layer in the prior art can be solved, thereby obtaining high peripheral device performance; and in addition, the array devices are overlaid on the peripheral devices, so that high device density is realized.

Owner:YANGTZE MEMORY TECH CO LTD

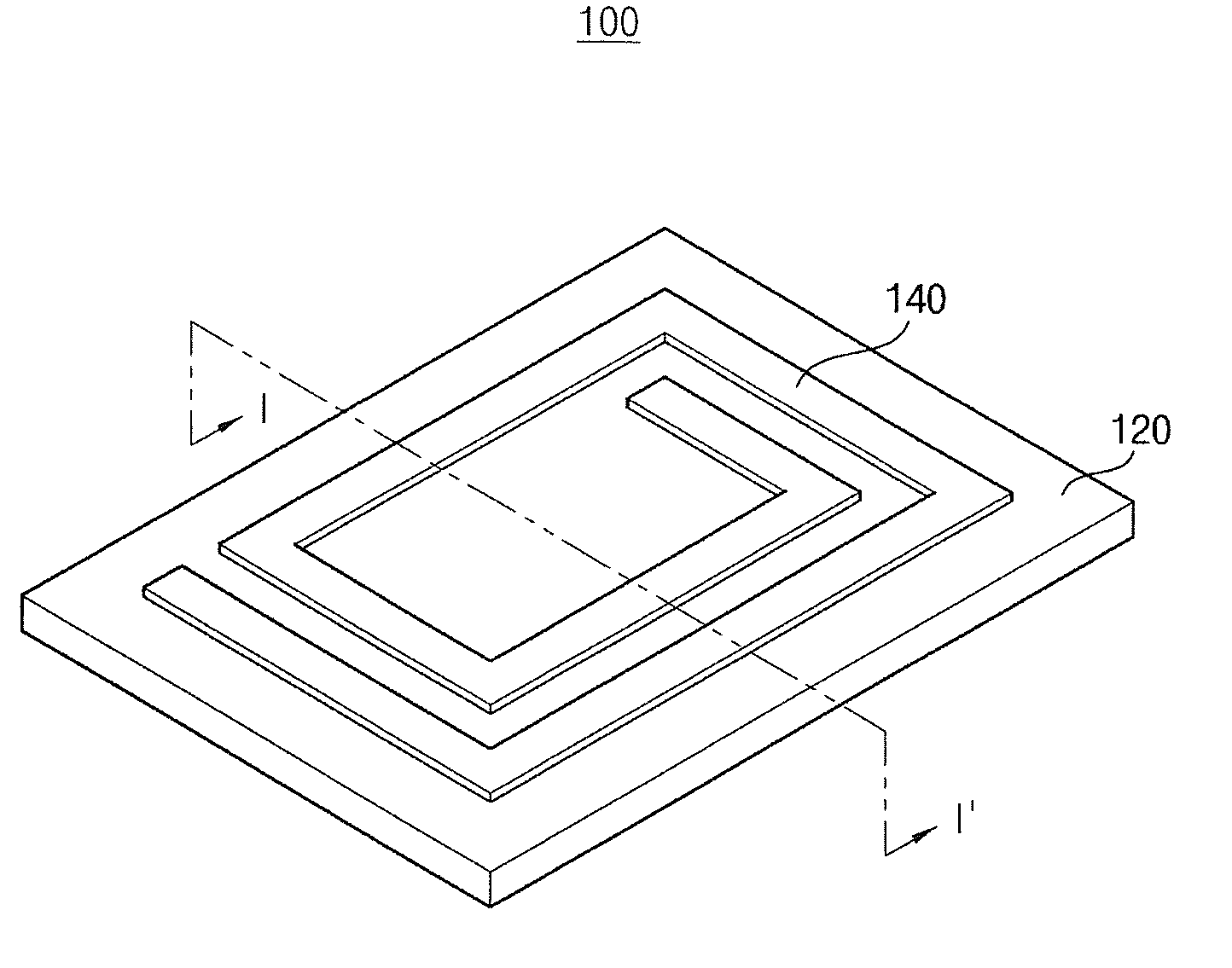

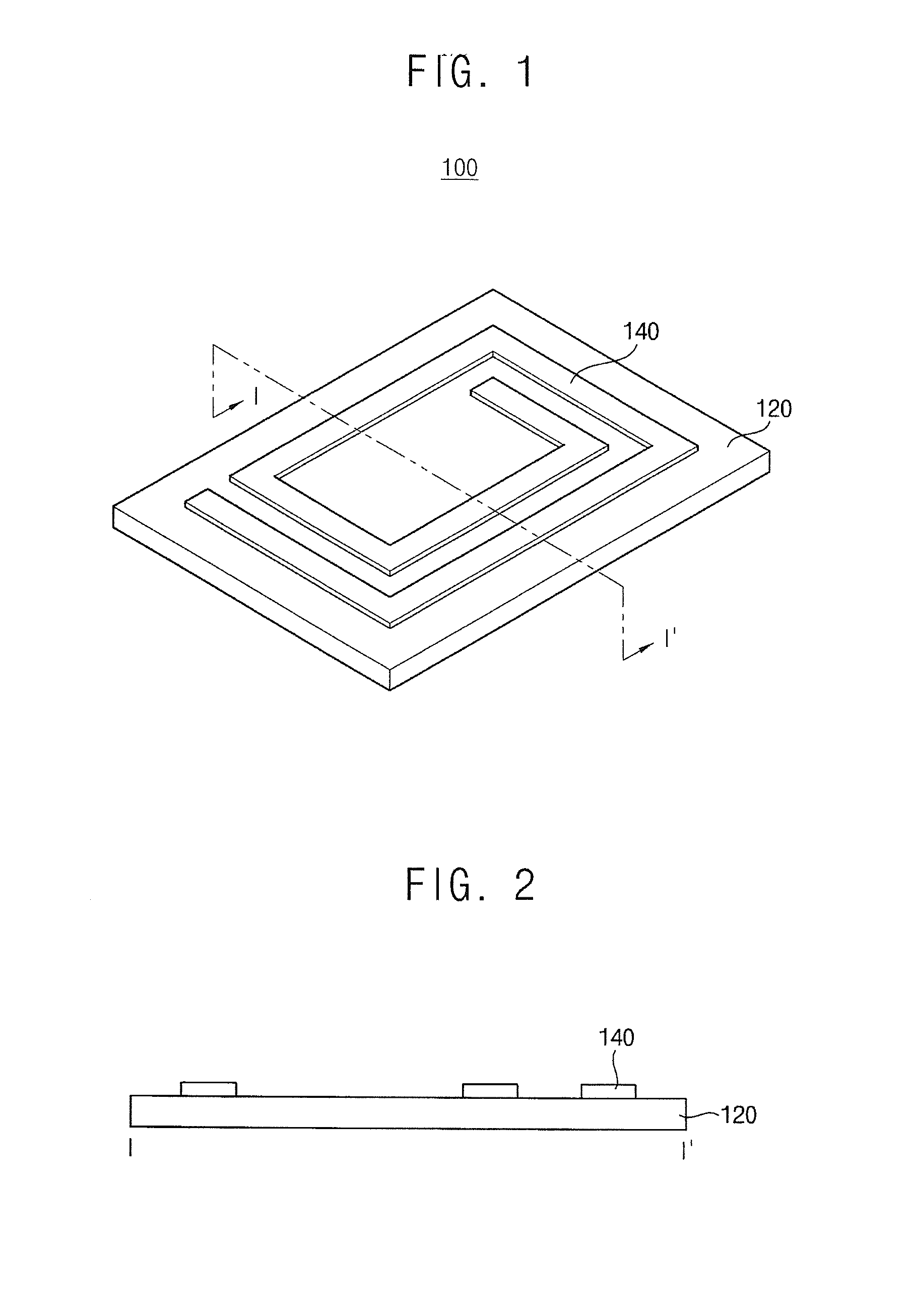

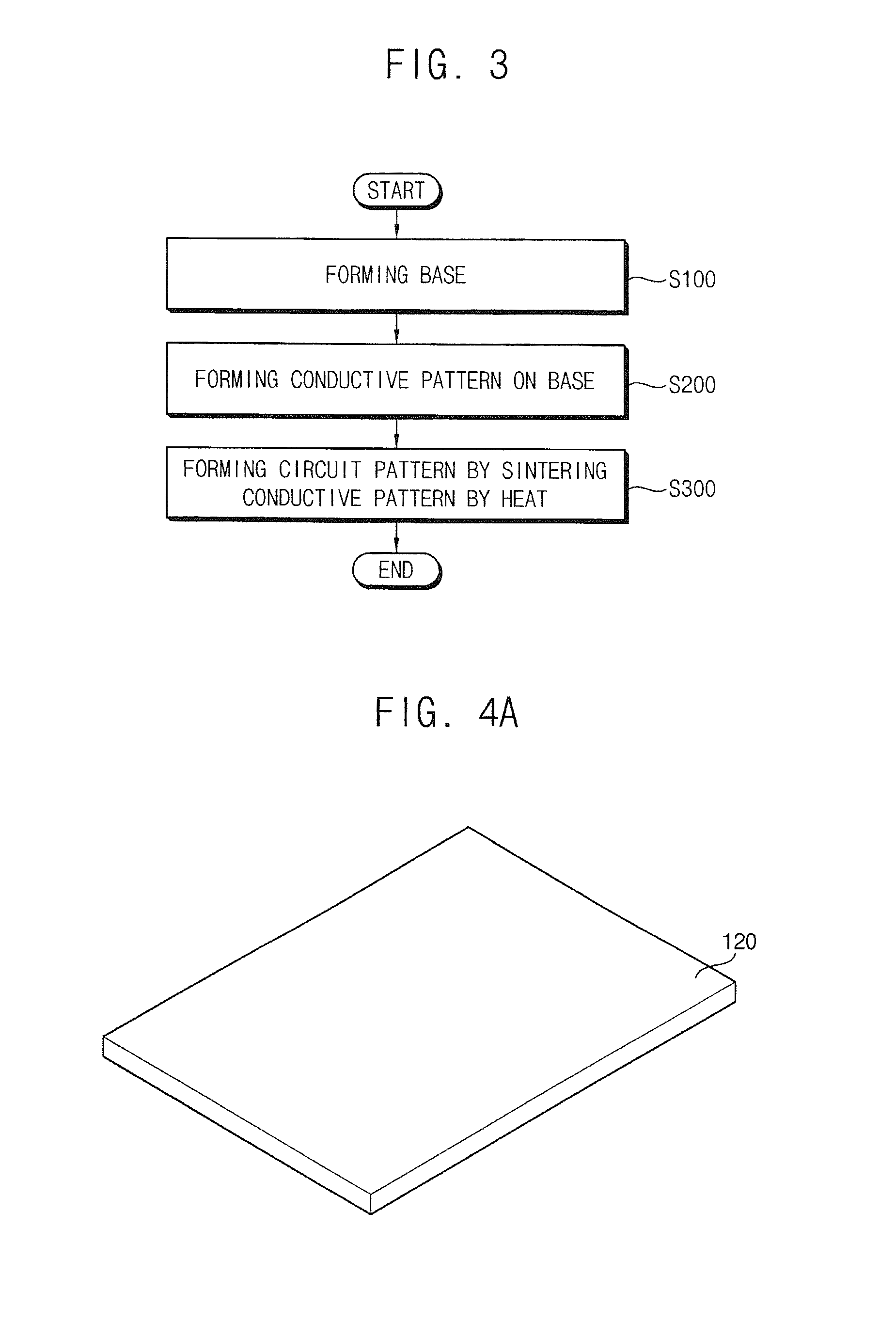

Method of manufacturing antenna using sintering of metal and antenna manufactured by the same

InactiveUS20120038514A1Reduce adverse effectsEasy to useSimultaneous aerial operationsPrinted electric component incorporationConductive pasteSynthetic resin

A method of manufacturing an antenna includes forming a base including a synthetic resin, forming a conductive pattern on the base and forming a circuit pattern by sintering the conductive pattern by applying heat. The conductive pattern includes a conductive paste and a binding material binding the base and the conductive pattern. The conductive paste includes a metal.

Owner:DYNATRON

Ion mineralization stabilizer for treating soil with heavy metal pollution and application method thereof

InactiveCN102766465AWide range of raw materialsEasy to obtainContaminated soil reclamationOrganic fertilisersSulfurPhosphor

The invention discloses ion mineralization stabilizer for treating soil with heavy metal pollution and an application method thereof. The ion mineralization stabilizer comprises, by weight percent, 5-30% of sulfur-based compound, 10-50% of phosphor-based compound, 10-50% of calcium-based compound, and 10-30% of silicon-based compound. The materials are respectively ground into powders with particle size not less than 200 meshes, and the powders are proportionally mixed well. The application method of the ion mineralization stabilizer for treating soil with heavy metal pollution includes: detecting arsenic content and leaching toxicity of the soil to be treated, placing the ion mineralization stabilizers in different proportions on the surface of the soil to be treated according to pollution level, well mixing to form mixed soil by ploughing and stirring, adding water to keep the water content of the mixed soil no less than 25%, covering the mixed soil with moisturizing material, curing for at least 5 days to keep heavy metals in the mixed soil to form stable minerals.

Owner:YONKER ENVIRONMENTAL PROTECTION

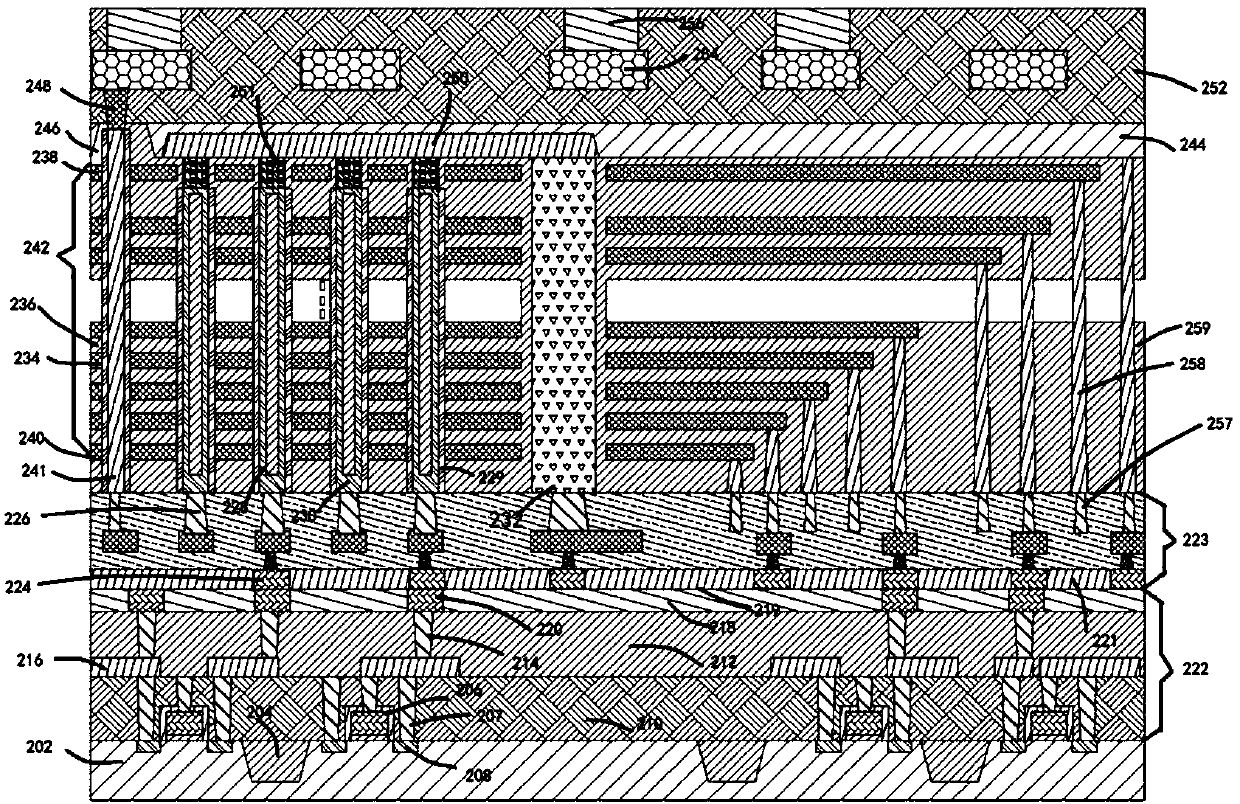

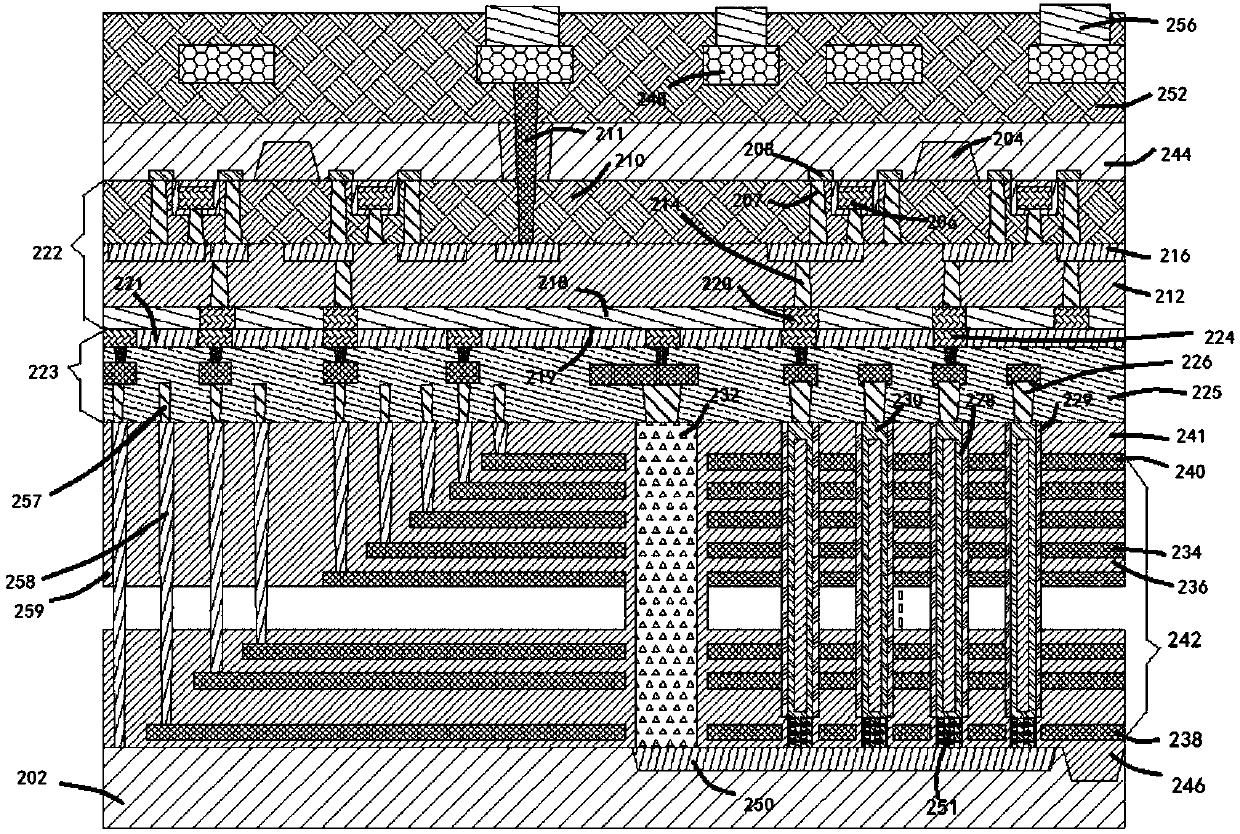

Semiconductor device and preparation method thereof

ActiveCN107658317ASolve the problem of temperature limitAvoid mutual influenceSolid-state devicesSemiconductor devicesPower semiconductor deviceBond interface

The invention discloses a semiconductor device and a preparation method thereof. The semiconductor device sequentially comprises a silicon substrate, one or more NAND strings formed at the upper partof the silicon substrate, one or more peripheral devices formed at the upper parts of the NAND strings, a monocrystal silicon layer formed at the upper parts of the one or more peripheral devices, andone or more first interconnection layers formed between the one or more peripheral devices and between the one or more NAND strings from bottom to top, wherein the peripheral devices are bonded withan array device through a bonding interface. The preparation process that two devices are affected by each other when prepared can be avoided through separating preparation of the array device and theperipheral devices, so that the problem of temperature limitation of preparation of the front layer to preparation of the back layer in the prior art is solved, thereby obtaining good performance ofthe peripheral devices. In addition, the peripheral devices are superposed on the array device, thereby achieving high device density.

Owner:YANGTZE MEMORY TECH CO LTD

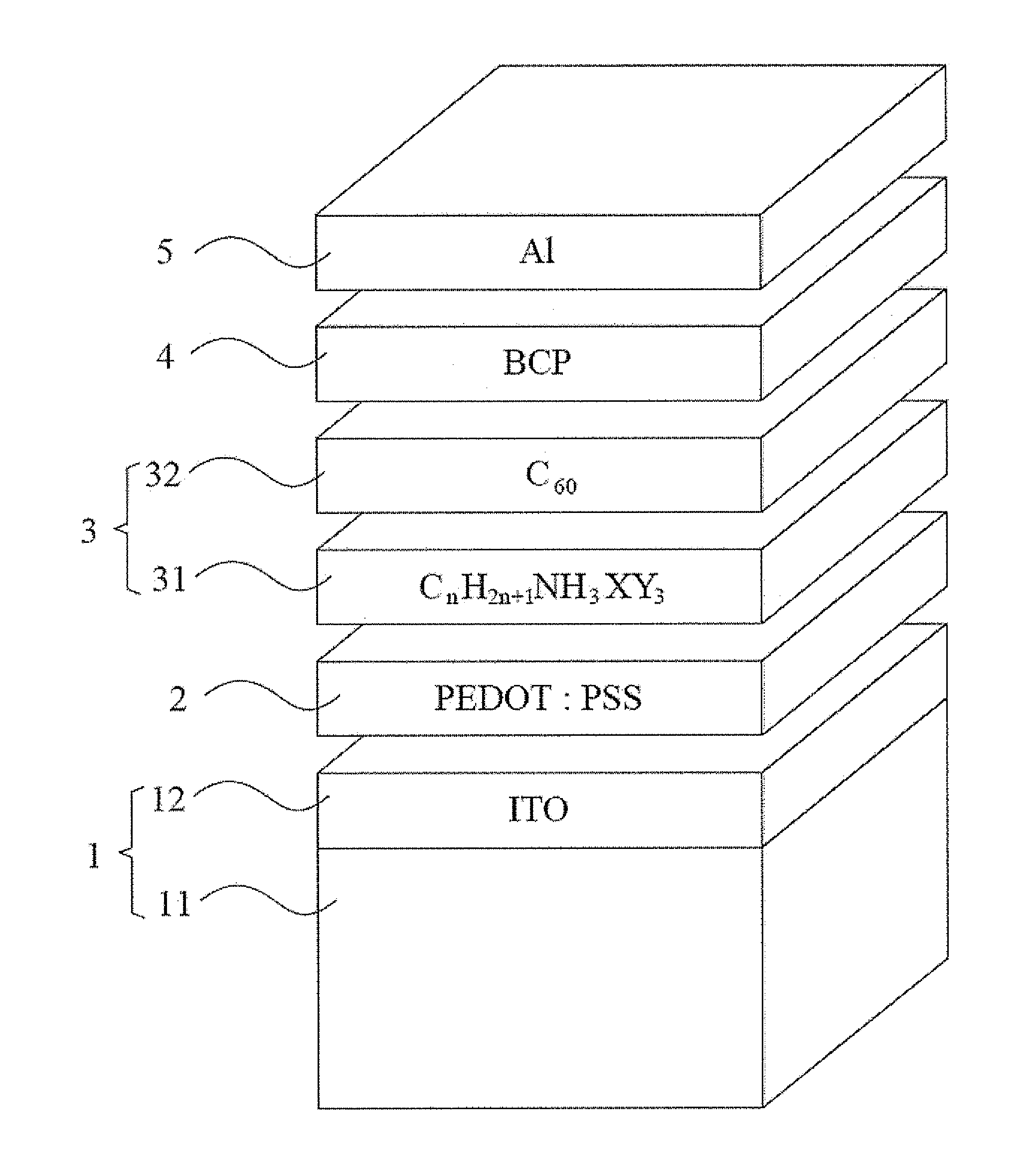

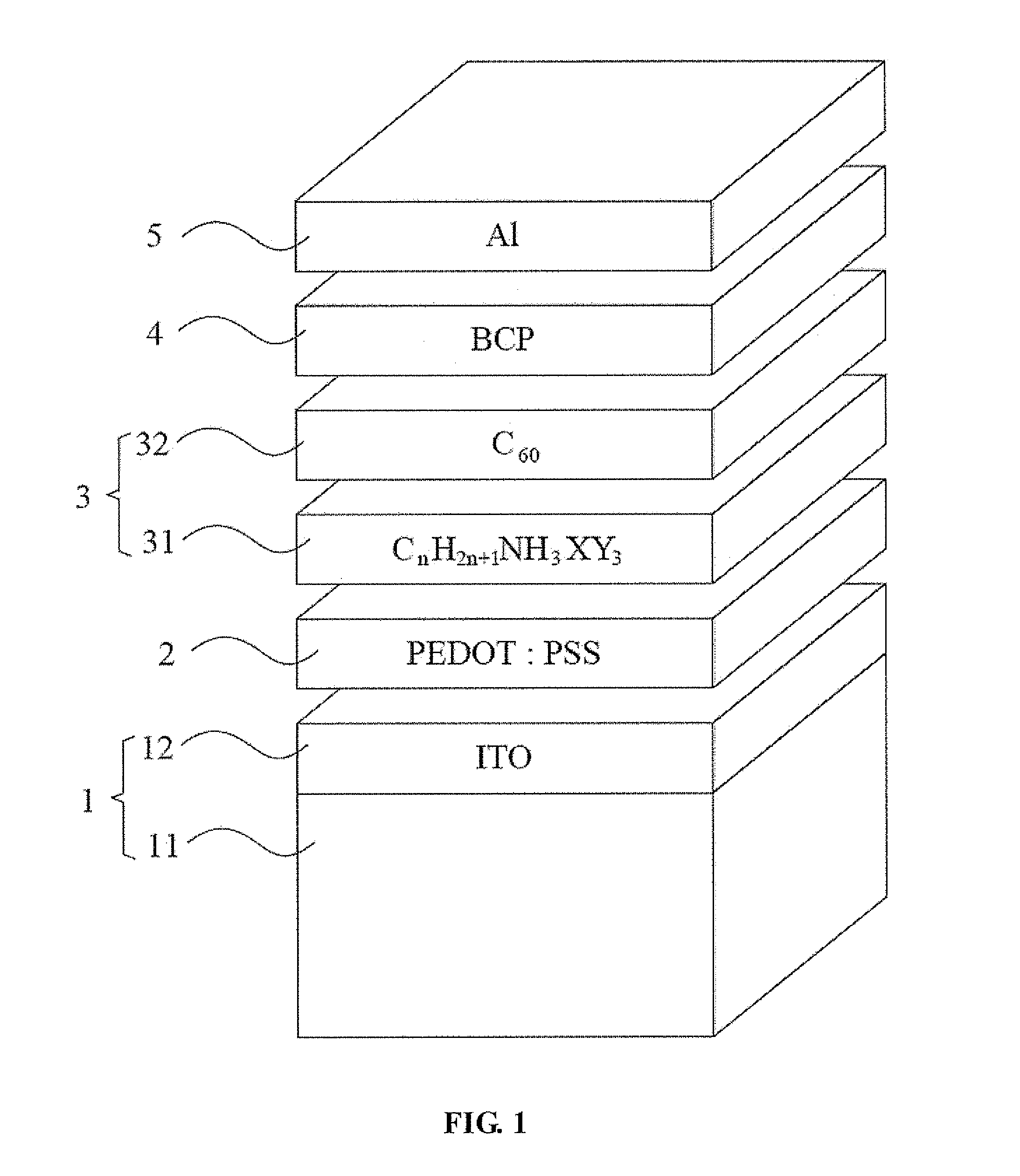

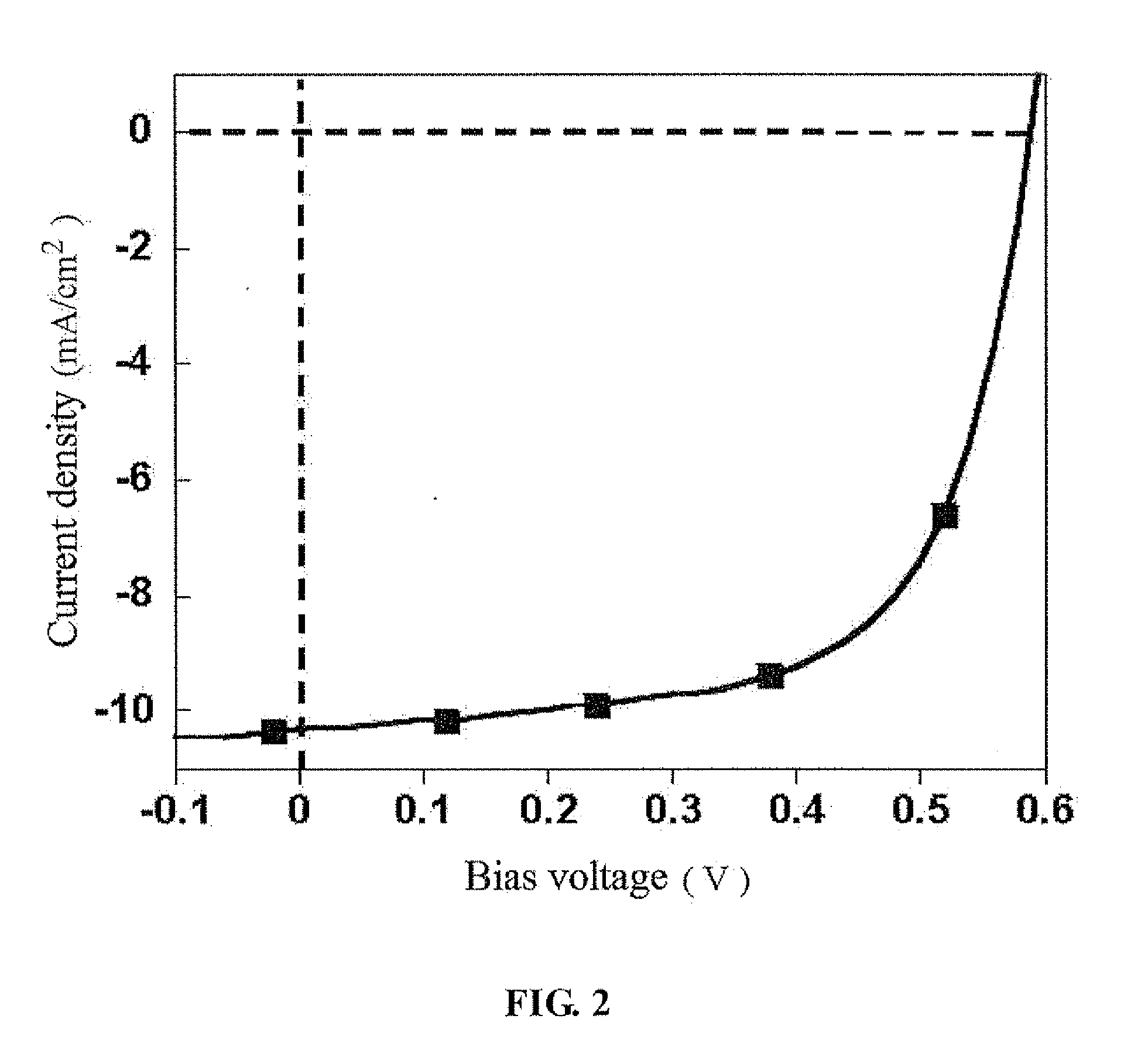

Hybrid organic solar cell with perovskite structure as absorption material and manufacturing method thereof

ActiveUS20140332078A1Low costSimple processFinal product manufactureSolid-state devicesHeterojunctionOrganic solar cell

A hybrid organic solar cell (HOSC) with perovskite structure as absorption material and a manufacturing method thereof are provided. The HOSC includes a conductive substrate, a hole transport layer, an active layer, a hole blocking layer and a negative electrode. The active layer has a light absorption layer (LAL) and an electron acceptor layer (EAL). The LAL is made of perovskite material represented by the following equation: CnH2n+1NH3XY3, n is positive integer form 1 to 9; X is Pb, Sn or Ge; and Y is at least one of I, Br or Cl. The EAL is made of at least one type of fullerene or derivatives thereof. A planar heterojunction (PHJ) is formed between the LAL and the EAL. The LAL has simple structure and fabricating process with relatively low cost, so that it is advantageous to carry out the mass production of HOSCs of flexible solid-state form.

Owner:NAT CHENG KUNG UNIV

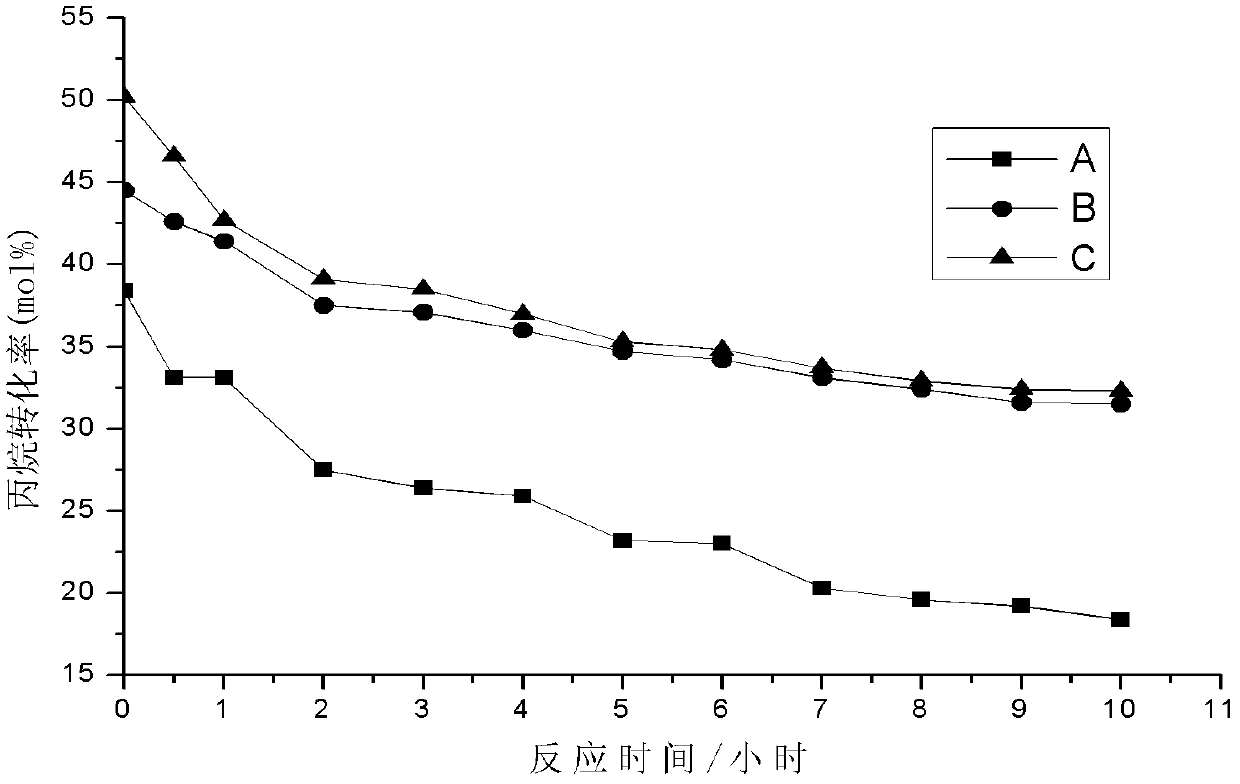

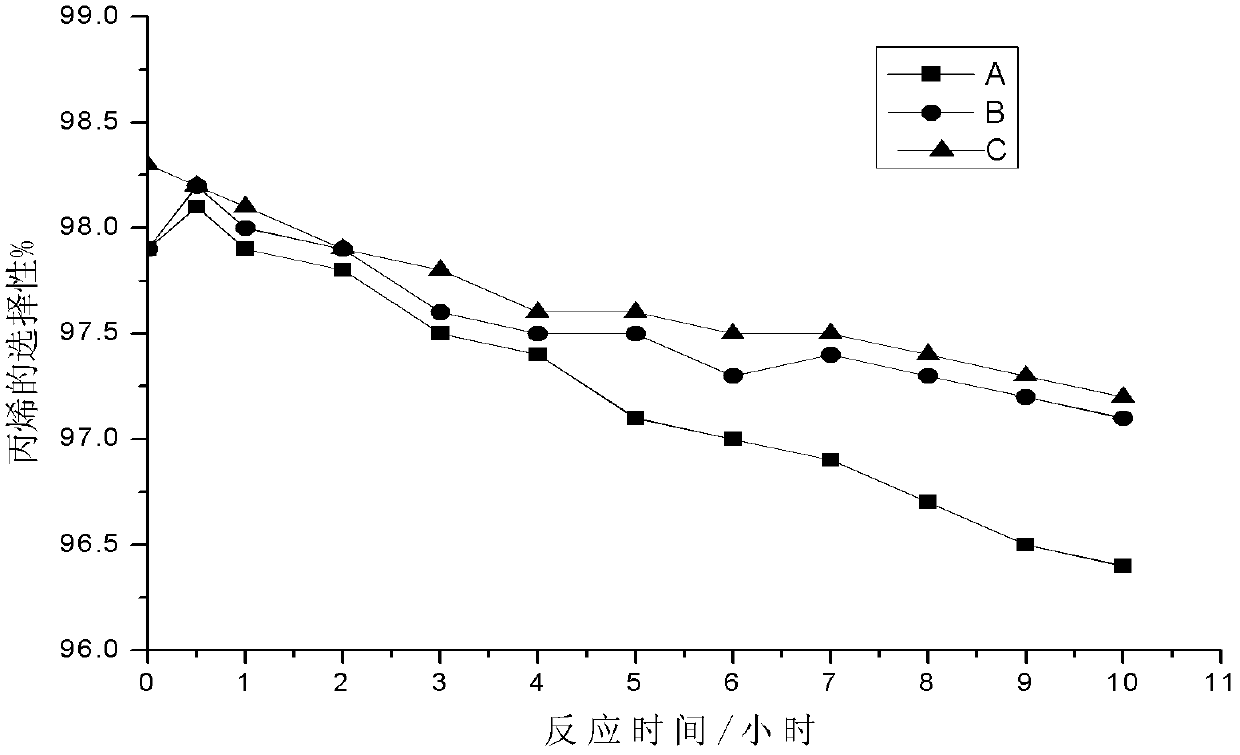

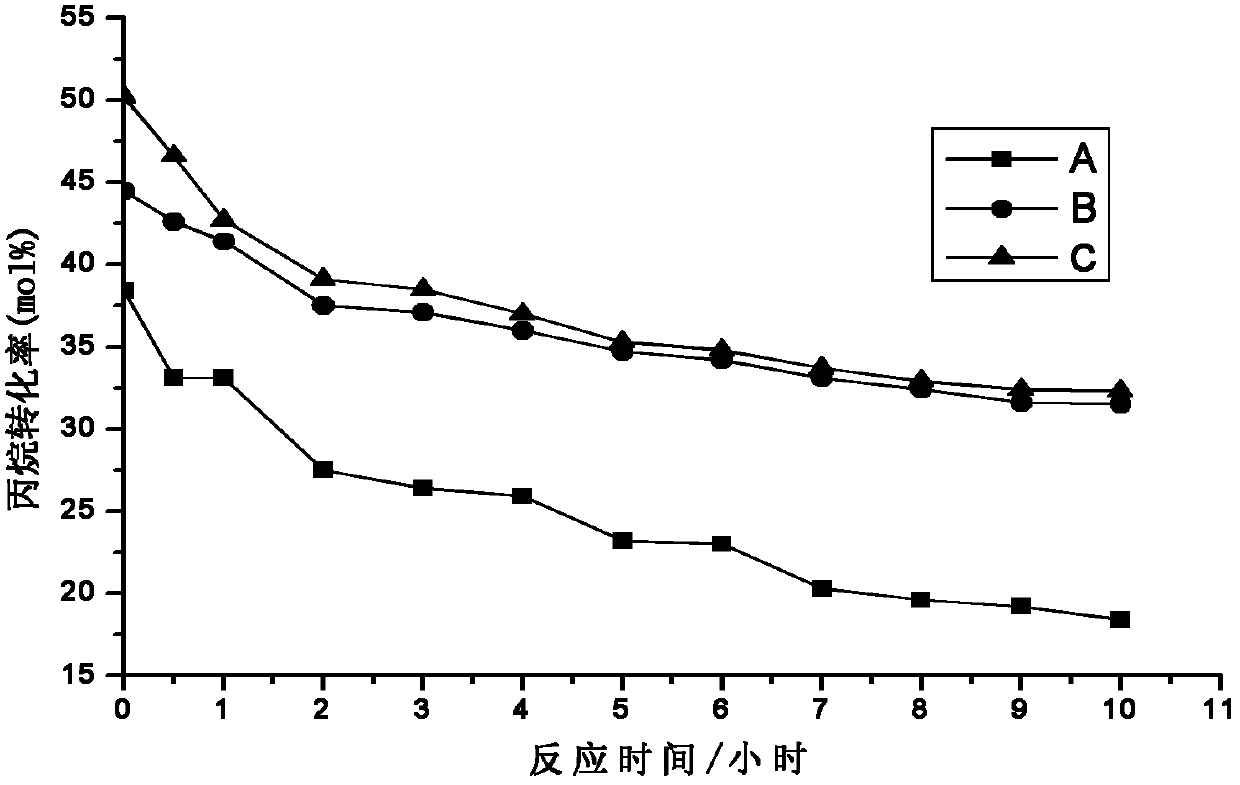

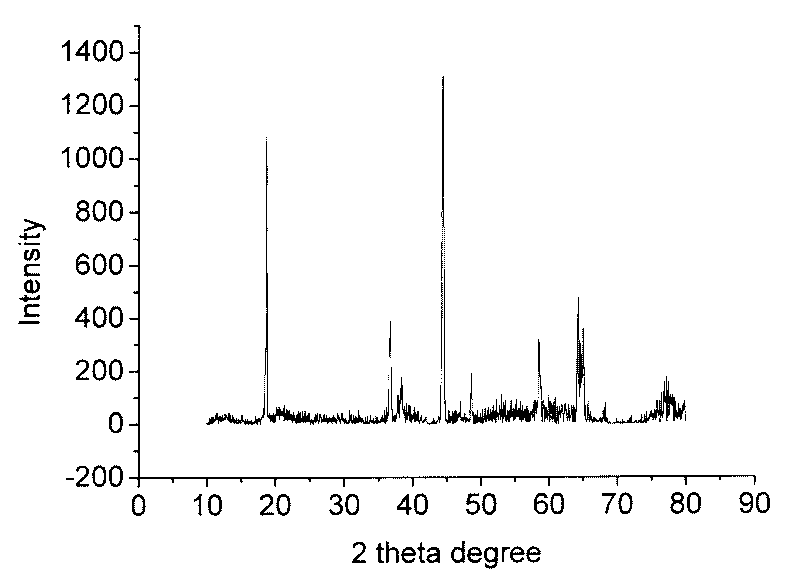

Catalyst for preparing propylene through propane catalytic dehydrogenation and preparation method thereof

InactiveCN102389831ALarge specific surface areaHigh catalytic activityMolecular sieve catalystsHydrocarbonsDehydrogenationEconomic benefits

The invention relates to a catalyst for preparing propylene through propane catalytic dehydrogenation, which is a load type platinum-based catalyst and is characterized in that home-made mesoporous molecular sieves MCM-41 are used as carriers, metal Pt is used as an active ingredient, and metals Sn, Sn-Ce or Sn-Ce-Ca are used as auxiliary agents. In a preparation method, an isovolumetric continuous immersion method is adopted for preparation. The catalyst and the preparation method have the advantages that the isovolumetric continuous immersion method is adopted for preparing multi-component catalysts, wherein the content of any one component is easy to control, the prepared catalyst has higher specific surface area (700 to 900m<2> / g) and has high catalytic activity, the propane conversion rate is high, the propylene selectivity is good, the one-path stability is good, in addition, the service life is longer, the preparation method of the catalyst carriers is simple and feasible, the economic benefit is obvious, and good industrial development and application prospects are realized.

Owner:NANKAI UNIV

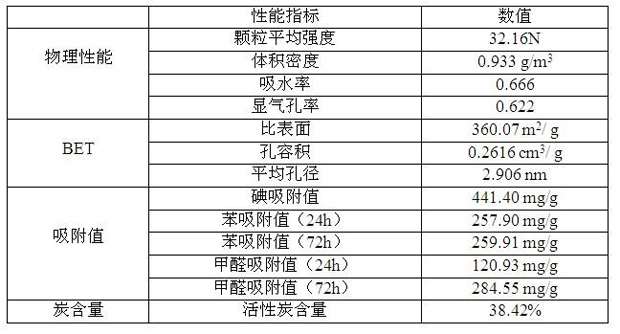

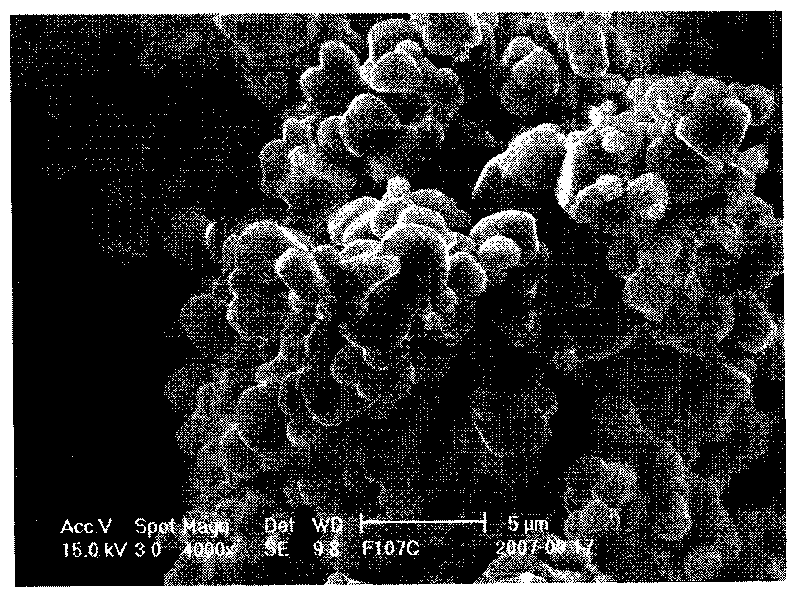

Activated alumina and activated carbon compounded material and preparation method thereof

InactiveCN101890336AAchieve the perfect combinationEasy to useCatalyst carriersOther chemical processesActivated carbonAir purification

The invention provides an activated alumina and activated carbon compounded material and a preparation method thereof. According to a formula, the material comprises the following raw materials in percentage by mass: 40 to 99 percent of aluminum hydroxide, 1 to 60 percent of activated carbon, and 15 to 35 percent of binder. The material is prepared by uniformly mixing, pelleting, ageing, molding, airing, sintering, rinsing, drying and the like. The invention aims to compound the activated carbon with the activated alumina; on the one hand, the material with a certain shape can be processed, the defects of loose shape, low strength, difficult recovery and the like of the activated carbon are overcome, and the material is easy to recycle; and on the other hand, the adsorption property of the activated alumina material is greatly improved. The method has the advantages of simpleness, practicality, readily available raw materials, low cost and suitability for industrial mass production, and can be widely applied to various fields such as industry, agriculture, environmental protection, air purification, water treatment and the like.

Owner:FUZHOU UNIV

Blend of fluorubber and silastic, and preparation thereof

InactiveCN101412835ASmall compression setThe preparation method is simple and feasibleTemperature resistancePolymer blend

The invention relates to a blend of fluorine rubber and silicone rubber, as well as a preparation method thereof. The composition in weight percentage of the blend of fluorine rubber and silicone rubber is as follows: 12 to 50 percent of fluorine rubber, 12 to 50 percent of silicone rubber, 2.5 to 10 percent of compatibilizer, 2.5 to 10 percent of acid-acceptor, 12 to 35 percent of reinforcing filler, 0.5 to 7 percent of constitution controller, 0.5 to 3 percent of vulcanizing agent and 0.5 to 4 percent of crosslinking additive. The blend of fluorine rubber and silicone rubber is prepared by a mechanical blending method and is vulcanized by use of peroxides. Vulcanized rubber has good mechanical properties, heat resistance, low-temperature resistance, oil resistance and low-compression permanent deformation performance, and can be used for producing and manufacturing high-performance rubber tubes, adhesive tapes, sealing elements, rubber linings and the like needed in automobile, mechanical, chemical, aerospace and other industries.

Owner:SOUTH CHINA UNIV OF TECH

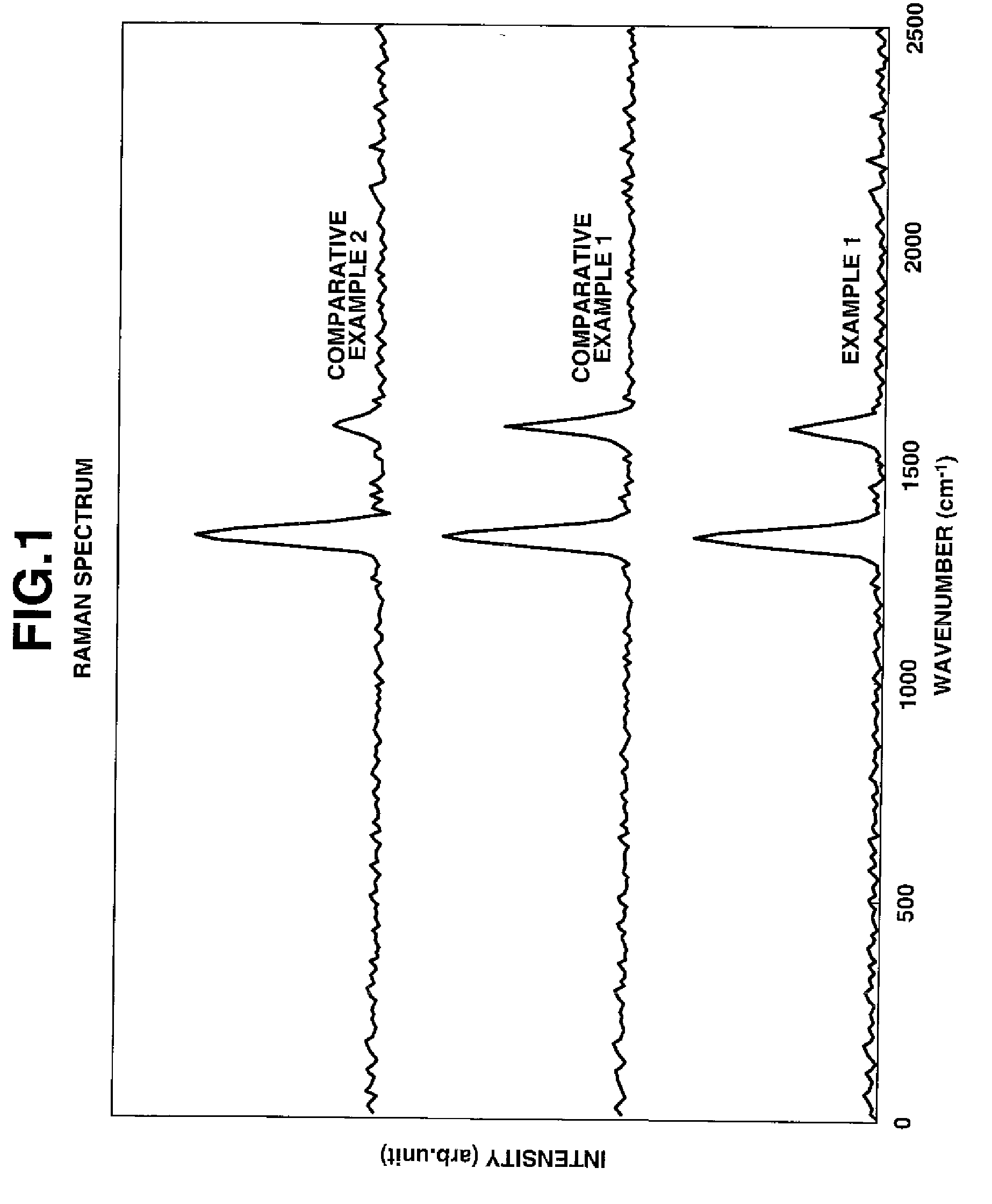

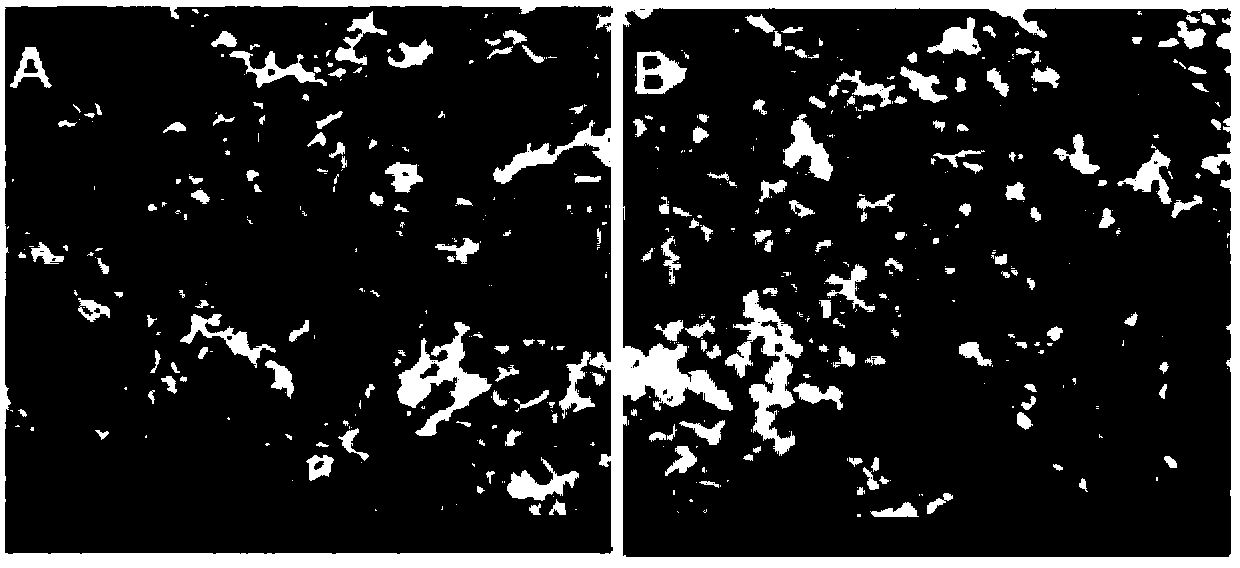

Non-aqueous electrolyte secondary battery negative electrode material, making method, lithium ion secondary battery, and electrochemical capacitor

InactiveUS20090202911A1Improve cycle performanceLarge capacityHybrid capacitor electrodesLiquid electrolytic capacitorsGraphiteCapacitor

A negative electrode material comprises a conductive powder of particles of a lithium ion-occluding and releasing material coated on their surface with a graphite coating. The graphite coating, on Raman spectroscopy analysis, develops broad peaks having an intensity I1330 and I1580 at 1330 cm−1 and 1580 cm−1 Raman shift, an intensity ratio I1330 / I1580 being 1.5<I1330 / I1580<3.0. Using the negative electrode material, a lithium ion secondary battery having a high capacity and improved cycle performance can be manufactured.

Owner:SHIN ETSU CHEM IND CO LTD

Composite natural polymer gel material

ActiveCN105837861ALarge specific surface areaImprove mechanical propertiesAerogel preparationColloidal chemistry detailsNon solventWater based

The invention discloses a composite natural polymer gel material with a cross-linking agent. The material comprises hydrogel, organogel, aerogel and bioplastics and mainly overcomes the problem of low mechanical strength of conventional natural polymer gel materials. According to the invention, a certain amount of the cross-linking agent is added into a natural polymer water-based solution or dispersion liquid, then stirring is carried out, the obtained mixture is placed in a non-solvent for physical cross-linking, and then washing is carried out so as to obtain composite natural polymer hydrogel; water in the composite natural polymer hydrogel is replaced with an organic solution so as to prepare composite natural polymer organogel; the composite natural polymer hydrogel or organogel is dried so as to prepare composite natural polymer aerogel; the composite natural polymer aerogel is subjected to hydrophobic treatment so as to obtain hydrophobic aerogel; the composite natural polymer aerogel is subjected to heat treatment so as to obtain carbon aerogel; and one or more selected from the above-mentioned gel materials are subjected to high-temperature pressing so as to prepare composite natural polymer bioplastics. The composite natural polymer gel material prepared in the invention has the advantages of excellent mechanical properties, a high specific surface area, high elongation at break, etc., and can be easily processed into molded products of a plurality of forms.

Owner:浙江绍兴万德福生物技术有限公司 +1

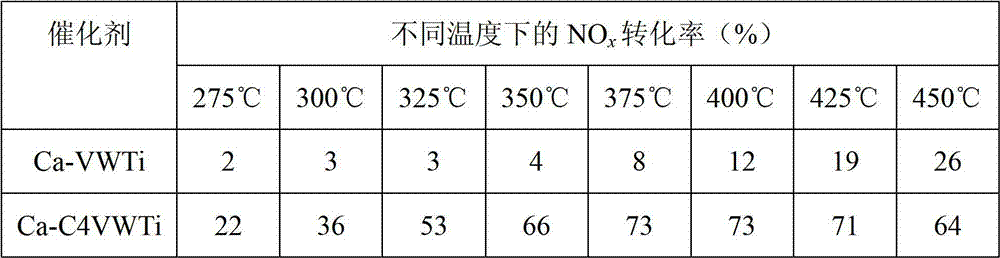

Vanadium-titanium oxide catalyst, and preparation method and application thereof

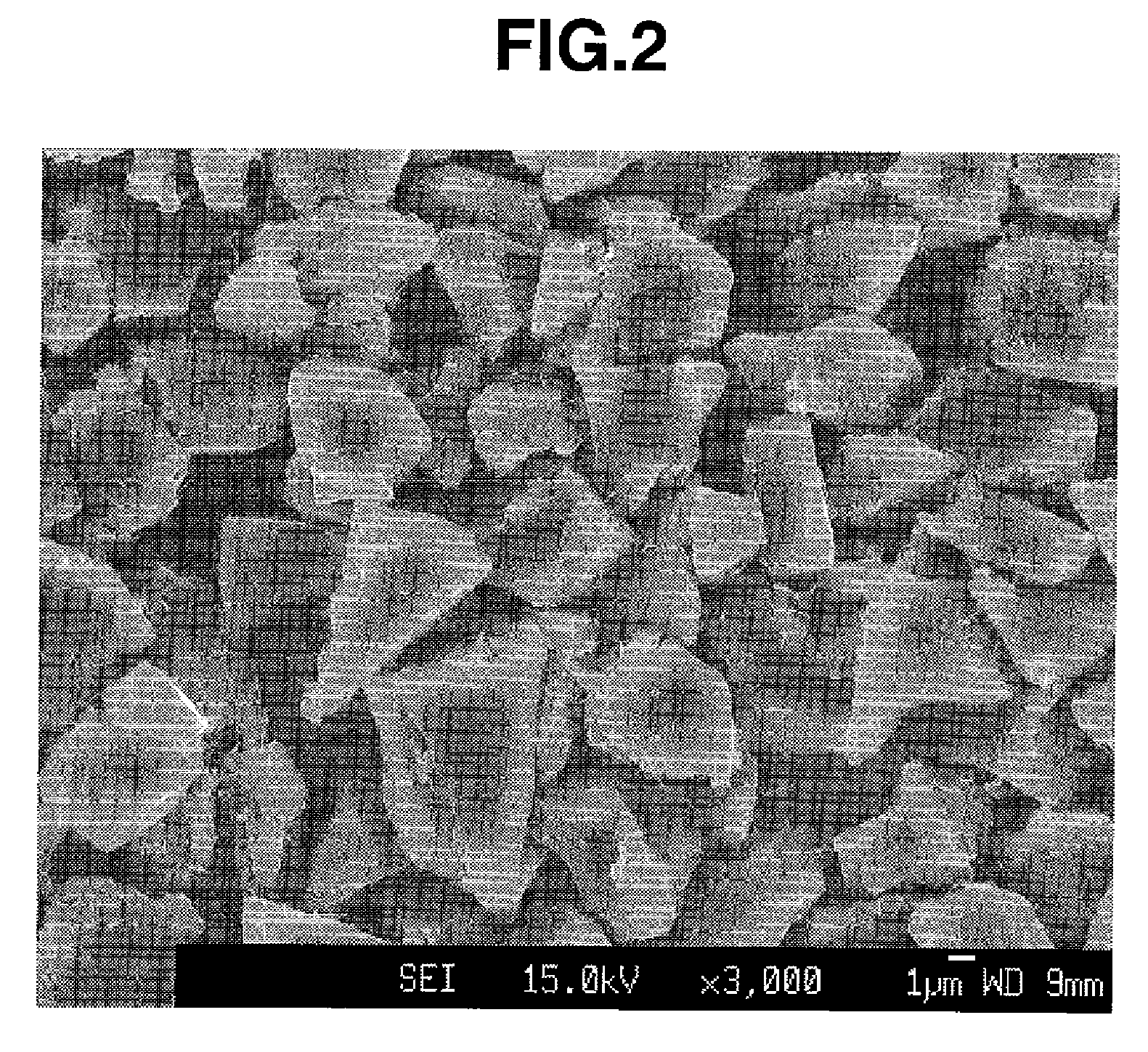

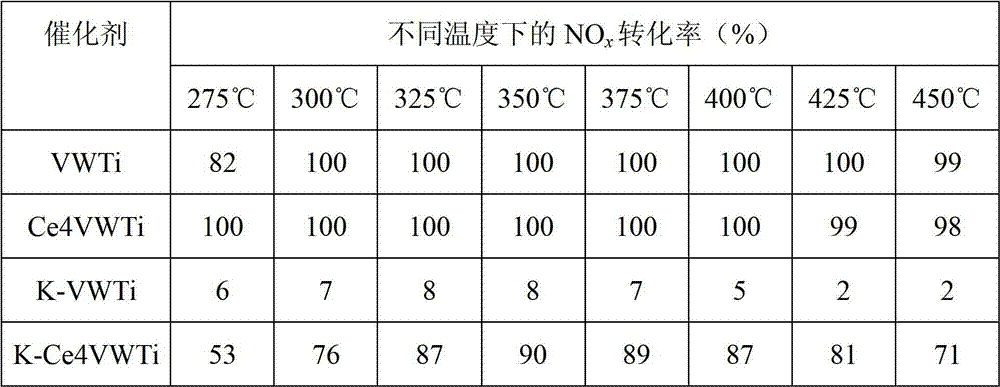

InactiveCN102764643ANo effect on activityDo not change the production processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMetal poisoningAlkaline earth metal

The invention relates to a vanadium-titanium oxide catalyst which can resist alkaline metal and alkaline earth metal poisoning. The catalyst is characterized in that the vanadium-titanium oxide catalyst is doped with an element Ce. The catalyst has fine resistance to alkaline metal poisoning, and above all, the doped cerium component has no influence on the activity of the SCR (selective catalytic reduction) catalyst while improving the resistance of the V2O5 / (MoO3)x(WO3)1-x-TiO2 catalyst to alkaline metal poisoning. The preparation method of the catalyst is simple and easy to implement and has very excellent N2 generation selectivity; and meanwhile, the Ce is a non-poisonous component and can not do harm to human health and ecological environment.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Non-aqueous electrolyte secondary battery negative electrode material, making method, and lithium ion secondary battery

ActiveUS20040106040A1Large capacityImprove cycle performanceNon-aqueous electrolyte accumulatorsNegative electrodesConductive coatingMaterials science

A non-aqueous electrolyte secondary battery negative electrode material is provided wherein a negative electrode active material containing a lithium ion-occluding and releasing material which has been treated with an organosilicon base surface treating agent is surface coated with a conductive coating. Using the negative electrode material, a lithium ion secondary battery having a high capacity and improved cycle performance is obtainable.

Owner:SHIN ETSU CHEM IND CO LTD

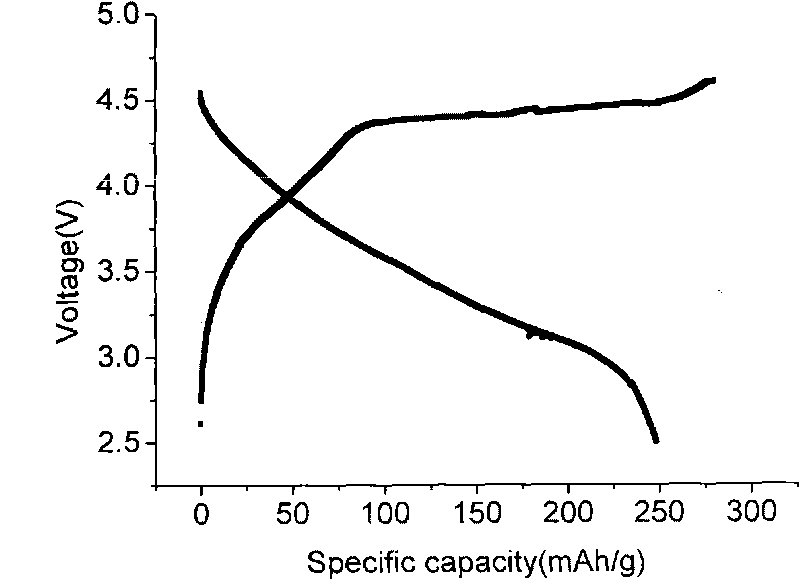

Lithium-rich manganese-based anode material and preparation method thereof

InactiveCN101694876AIncrease the charge cut-off voltageHigh specific capacityCell electrodesManganeseSpecific discharge

The invention relates to a lithium-ion secondary battery anode material technology, in particular to a lithium-rich manganese-based anode material Li(Li(1-2x) / 3Nix-aMyMn(2-x) / 3-b)O2 (M is Co, Al, Ti, Mg and Cu) and a preparation method thereof. A general formula of the lithium-rich manganese-based anode material is as follows: Li(Li(1-2x) / 3Nix-aMyMn(2-x) / 3-b)O2 (M is Co, Al, Ti, Mg and Cu), wherein x is more than 0 and less than or equal to 0.5, when M is Co and Al, y is more than 0 and less than 2x, a is equal to b, and b is equal to y / 2; when M is Ti, y is more than 0 and less than (2-x) / 3, a is equal to 0, and b is equal to y; and when M is Mg and Cu, y is more than 0 and less than x, a is equal to y, and b is equal to 0. The invention has high specific discharge capacity, excellent normal temperature and high temperature cycle performance, good safety, low raw material cost and production cost, and very high cost-performance ratio.

Owner:JIANGXI JIANGTE LITHIUM LON BATTERY MATERIAL +1

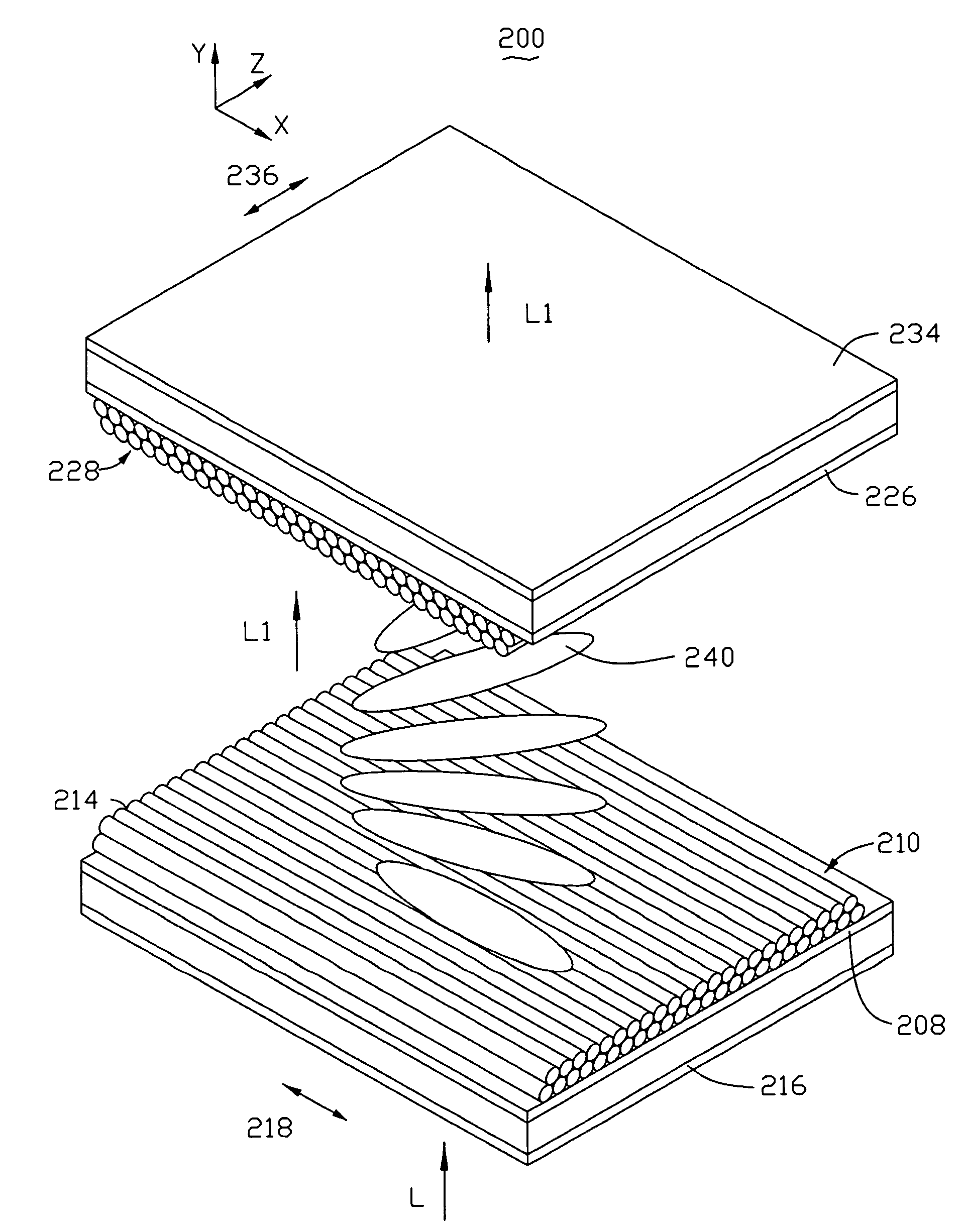

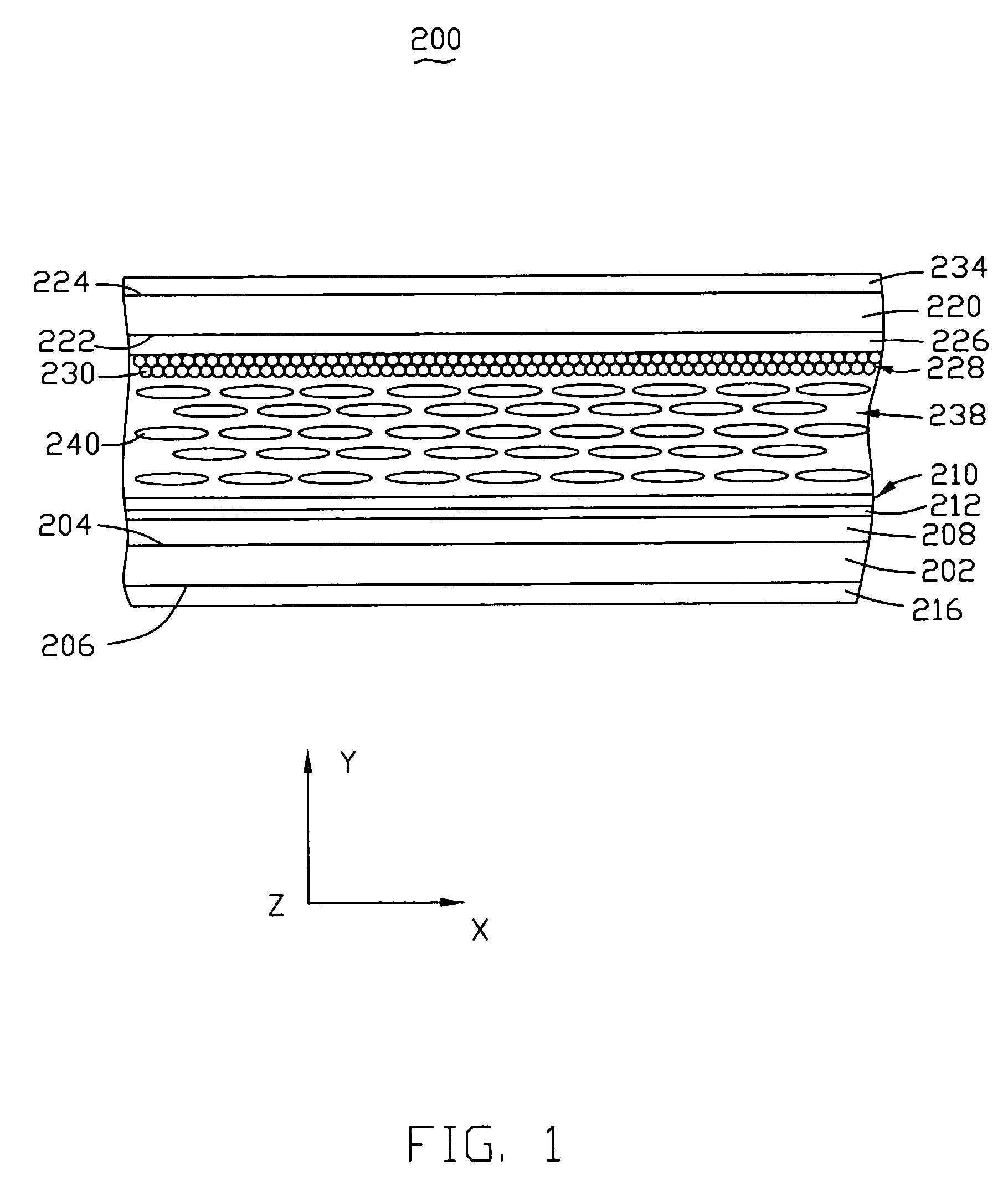

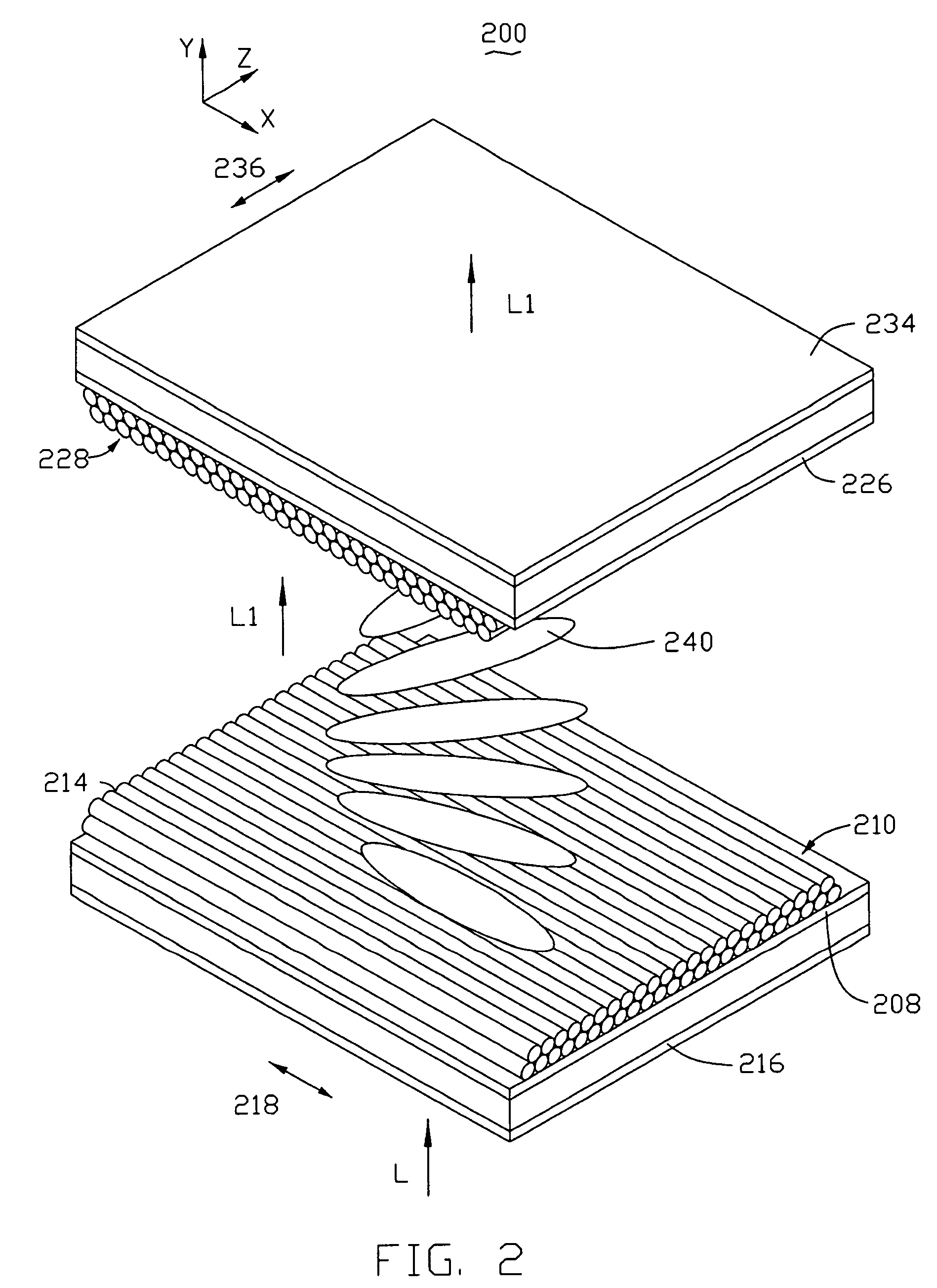

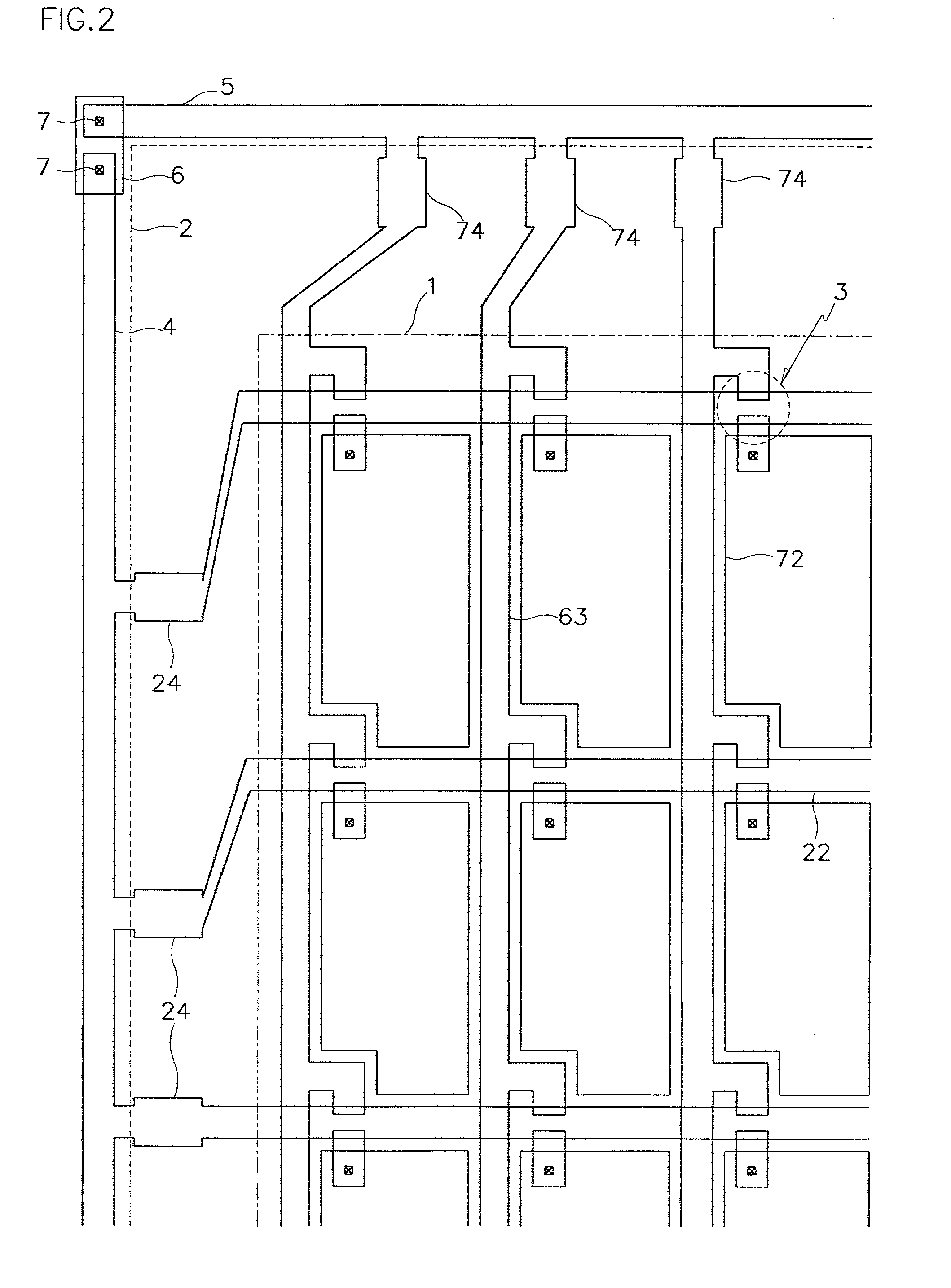

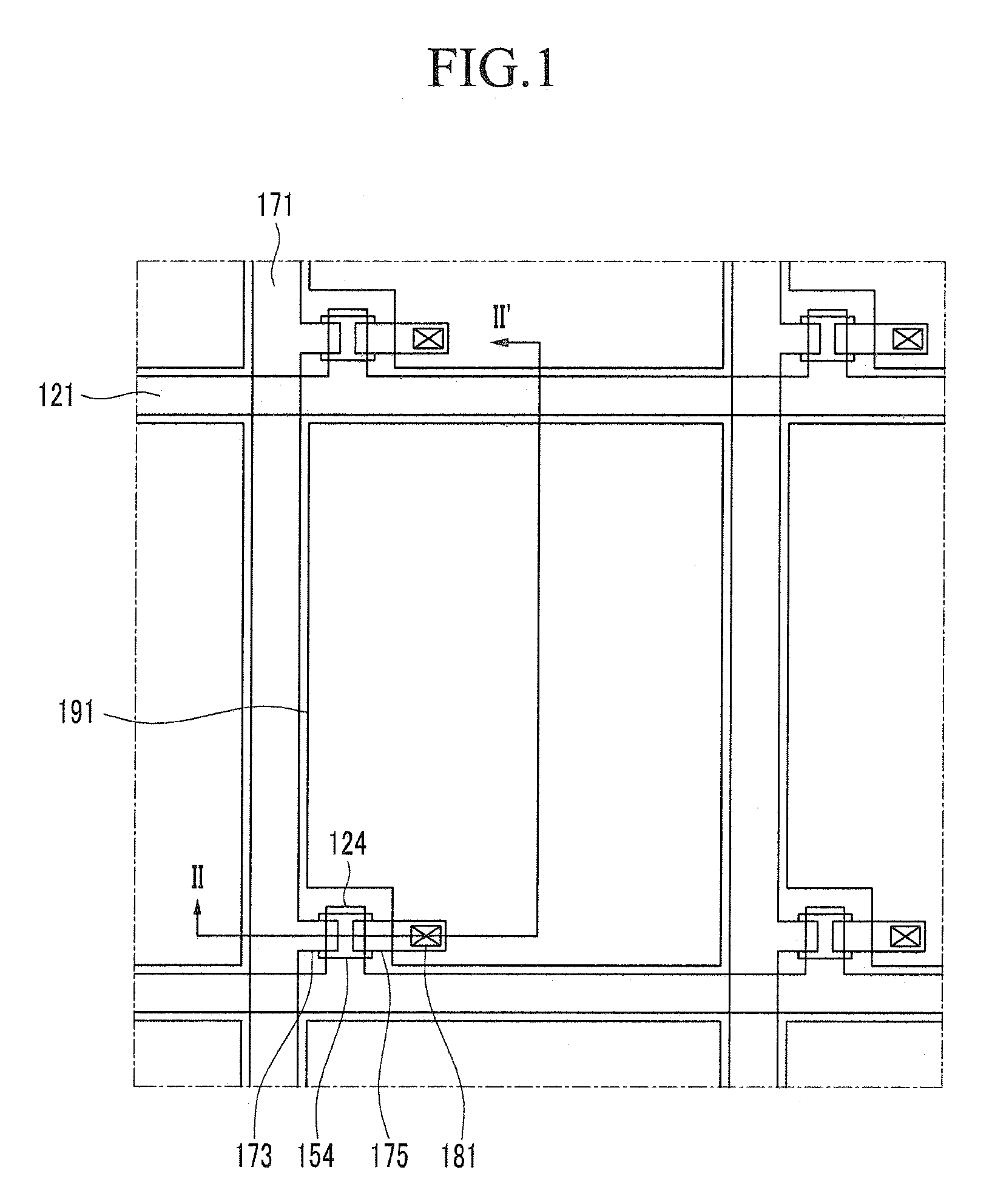

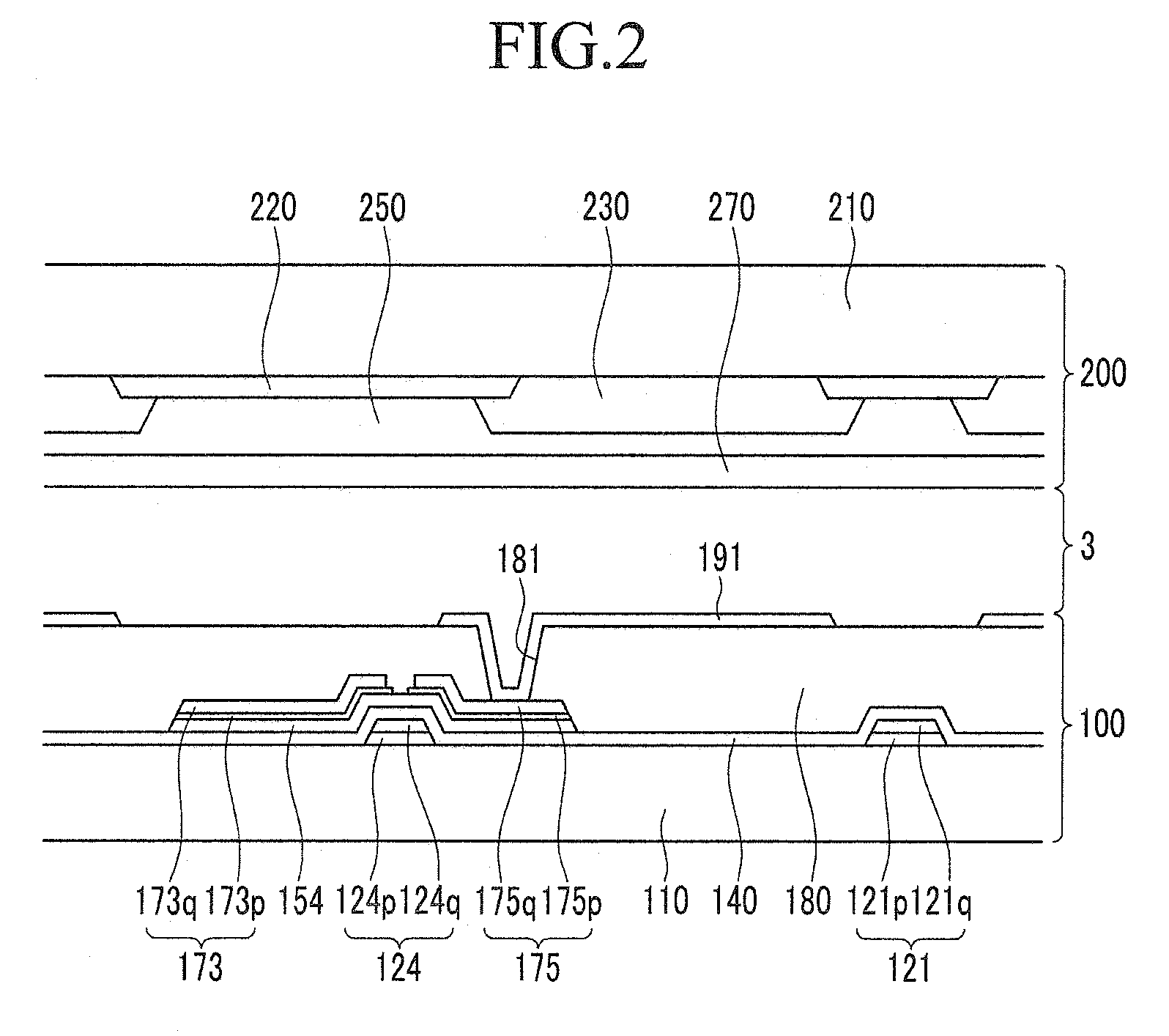

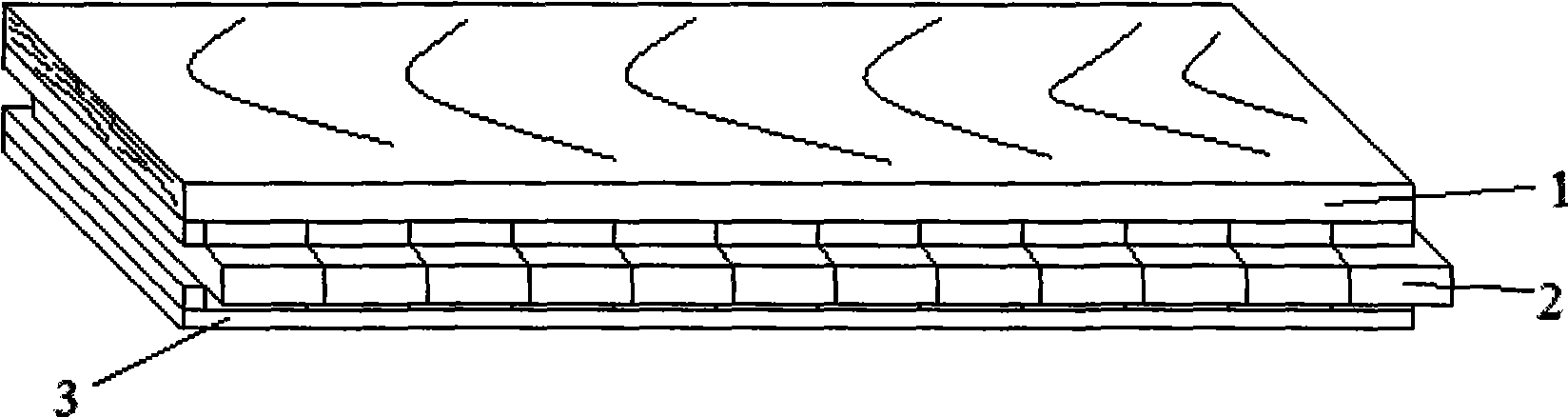

Liquid crystal display and manufacturing method therefor comprising alignment films of oriented carbon nanotubes

ActiveUS7630040B2Improve alignment qualitySimple manufacturing methodNanoopticsNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display (200) includes a first base plate (202), a second base plate (220), a liquid crystal layer (238) located between the first base plate and the second base plate, and two alignment films (210, 228). The two alignment films are respectively positioned on inner surfaces of the first base plate and the second base plate. Each alignment film is a film of oriented carbon nanotubes (212, 230). An oriented direction of the carbon nanotubes on the first base plate is perpendicular to that of the carbon nanotubes on the second base plate. A manufacturing method for the liquid crystal display is also disclosed.

Owner:TSINGHUA UNIV +1

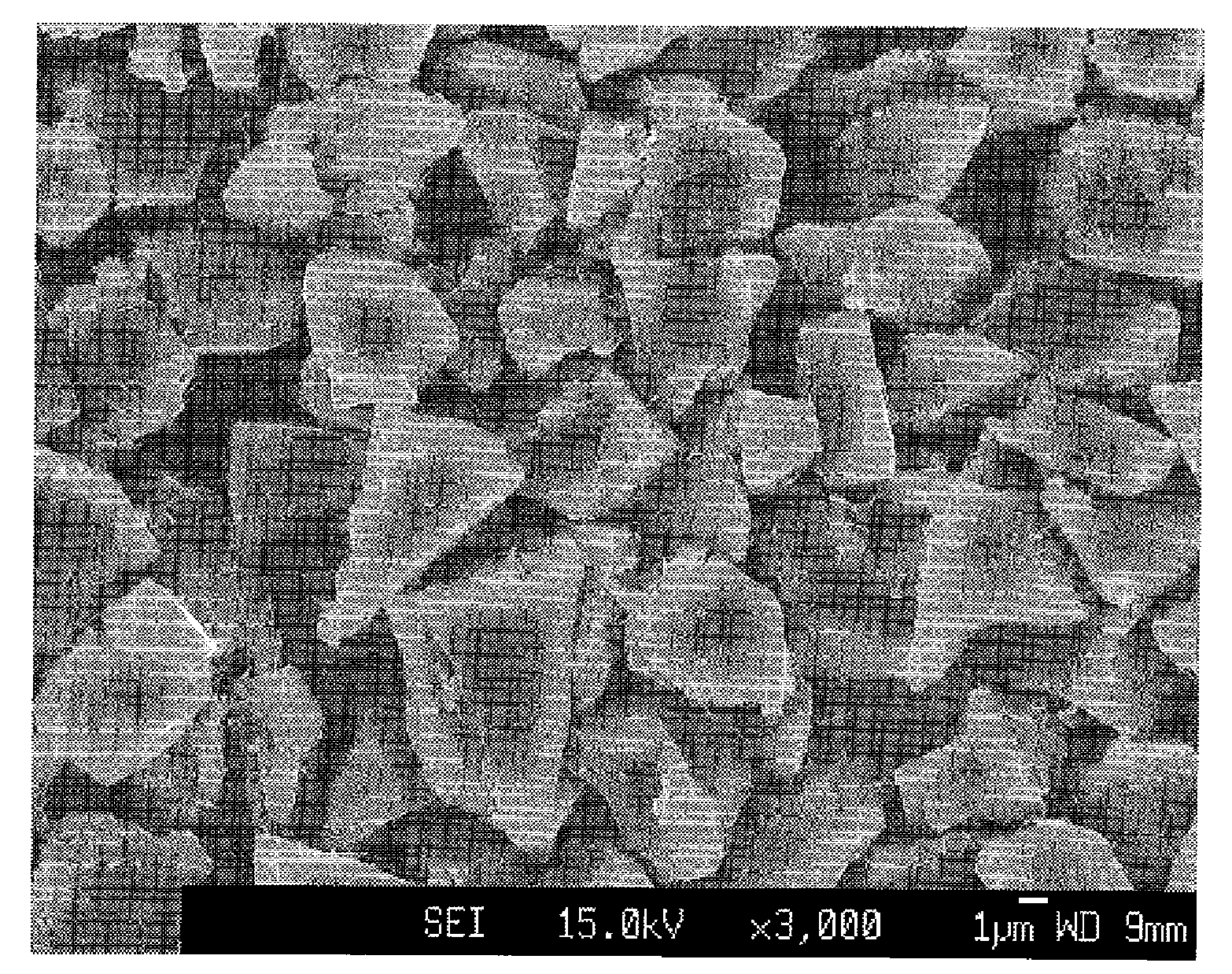

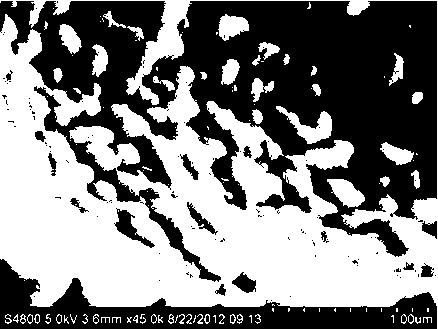

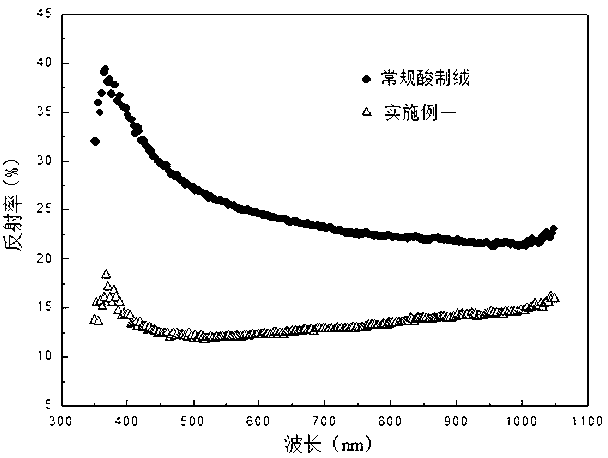

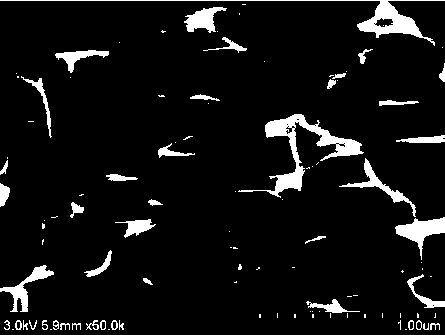

Textured structure of crystalline silicon solar cell and preparation method thereof

ActiveCN103219428AImprove conversion efficiencySimple manufacturing methodPhotovoltaic energy generationSemiconductor devicesMicrometerSpins

The invention discloses a preparation method of a textured structure of a crystalline silicon solar cell. The method includes the steps of (1) cleaning and texture preparation, (2) soaking a silicon wafer in a solution containing metal ions to enable the surface of the silicon wafer to be coated with a layer of metal nanometer particles, (3) corroding the surface of the silicon wafer to form a nanometer-grade texture, (4) cleaning to remove the metal particles, (5) carrying out microstructure amendment etching in second chemical corrosive liquid, and (6) cleaning and spin-drying. As is proved by a test, the size of the textured structure is between 100nm-500nm; the textured structure is of a nanopore shape with a large hole diameter and a small depth, or a nanometer pyramid with edge angles, or of a nanometer pit shape structure with an edge angle nanometer cone body or with an edge angle; and compared with a nanometer-micrometer composite textured structure disclosed in CN102610692A, the textured structure enables conversion efficiency of a cell piece to be improved by about 0.2%-0.5%, and an unexpected effect is achieved.

Owner:SUZHOU UNIV +1

Manufacturing method for crystallized fruit

The invention relates to a manufacturing method for crystallized fruit, which comprises the following steps: (1) preparing the following raw materials by weight percent: 20-67.7% of fruit embryos, 32.05-53.0% of sugar crops, 0.1-5% of filling materials, 0-5% of medicinal and food homologous traditional Chinese medicines, 0.05-10% of seasoning spices, 0.1-2.0% of preservatives and 0-5% of pigments; (2) pre-treating the raw materials by preparing liquid sugar, filling material liquid, traditional Chinese medicine extracts and preservative solution; (3) soaking: adding the liquid sugar material,the seasoning spices, the pigments, the liquid sugar, the filling material liquid and the traditional Chinese medicine extracts into a soaking cylinder and mixing uniformly to form the mixed materialliquid, adding the fruit embryos into the soaking cylinder, increasing the temperature of the mixed material liquid to 50-60 DEG C and keeping the temperature for 10-15 hours; (4) leaching and drying; and (5) drying to obtain the crystallized fruit. The manufacturing method for crystallized fruit is easily performed, the full utilization of fruit resource is realized, and the manufactured crystallized fruit is full of nutrition and tastes fresh and cool.

Owner:汕头市天悦轻工技术科技有限公司 +3

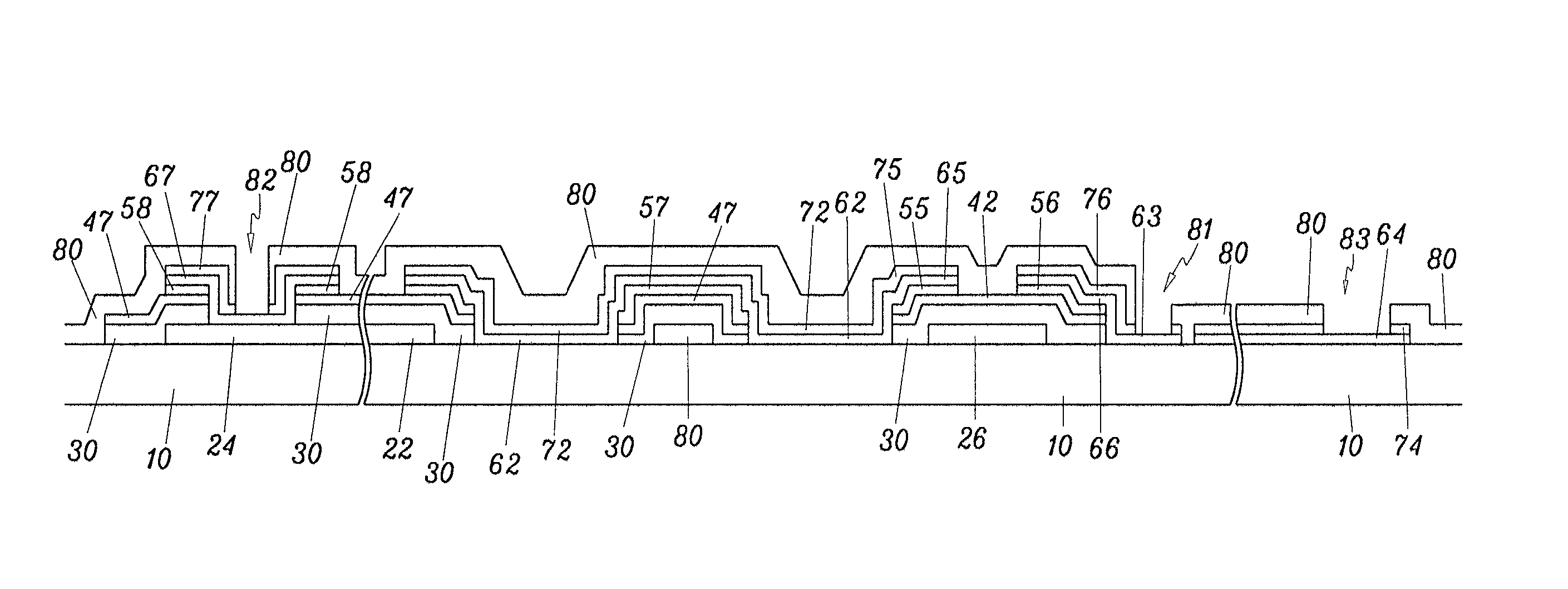

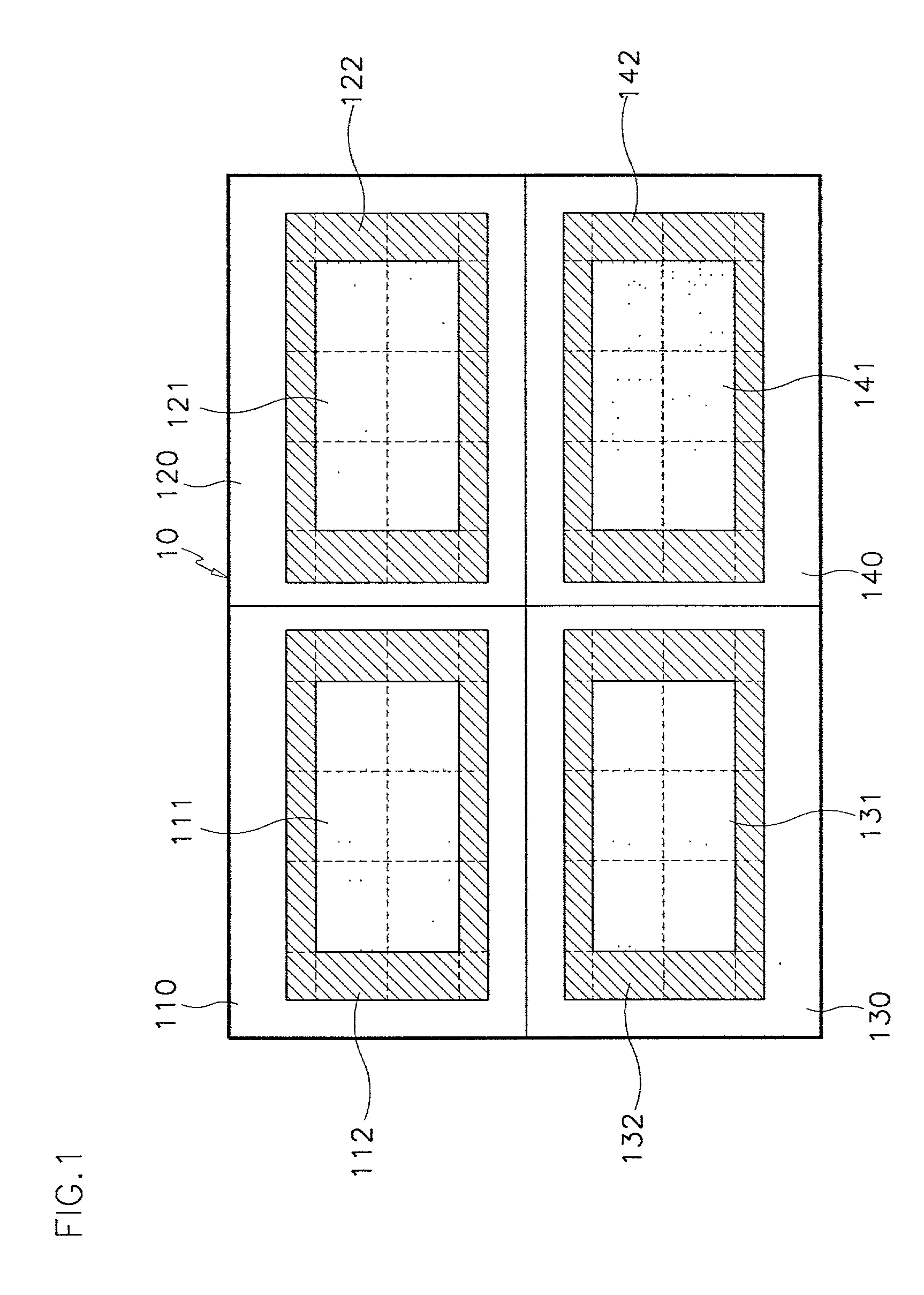

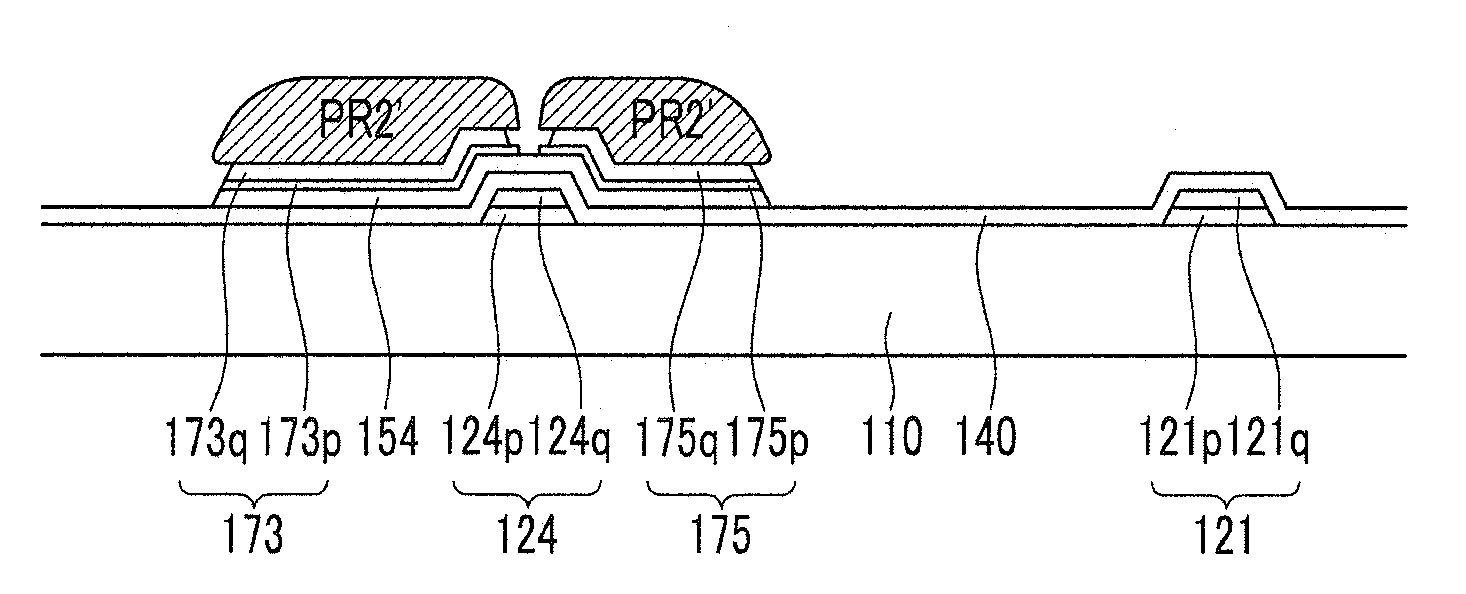

Thin film transistor array panel for a liquid crystal display and methods for manufacturing the same

InactiveUS20020130324A1Reduces contact resistivitySimple manufacturing methodSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsLiquid-crystal display

Owner:SAMSUNG DISPLAY CO LTD

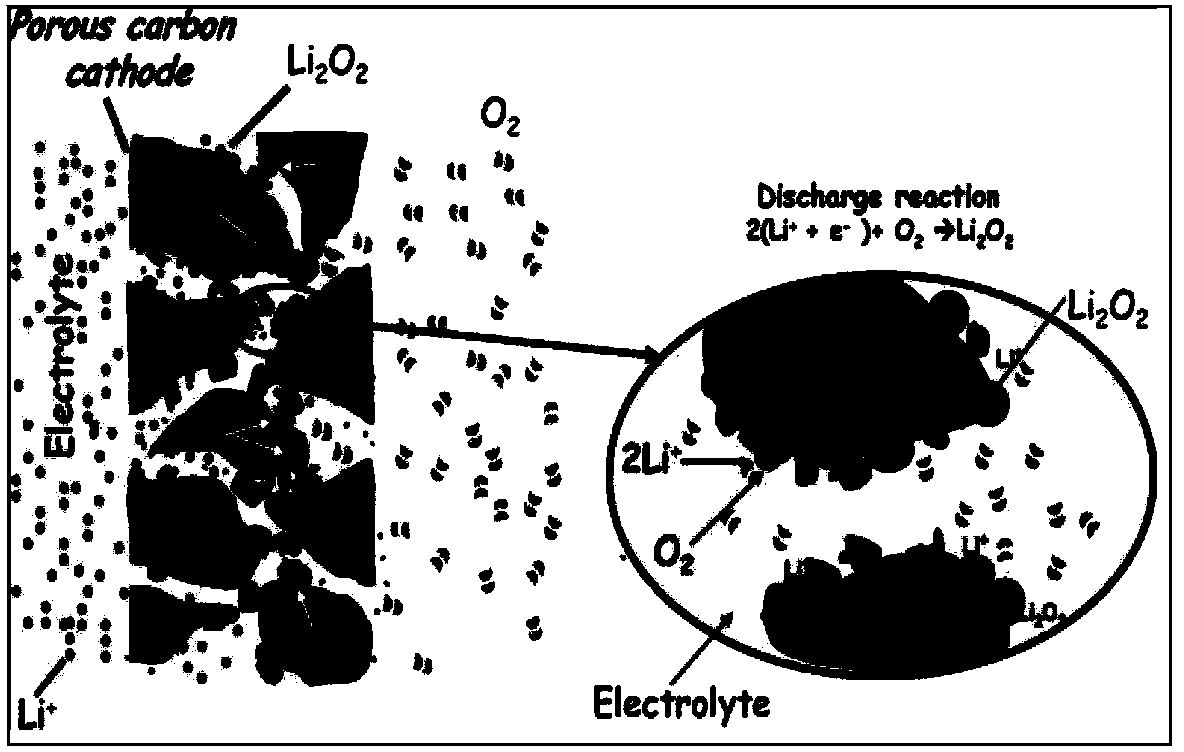

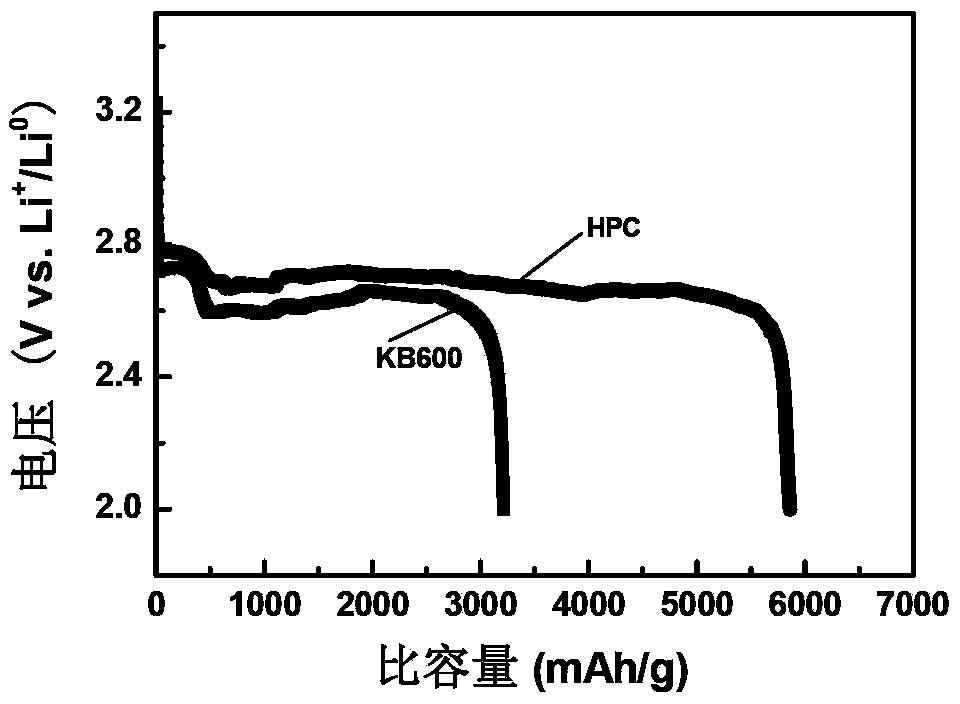

Nitrogen-doped porous carbon material for lithium-air battery positive electrode

ActiveCN103855366AHigh discharge specific capacityHigh voltage platformFuel and secondary cellsCell electrodesPorous carbonCharge discharge

The present invention relates to a nitrogen-doped porous carbon material for a lithium-air battery positive electrode, wherein the nitrogen-doped porous carbon material has an interconnected graded pore structure, N is uniformly doped in the C skeleton, N accounts for 0.2-15% of the carbon material atomic ratio, the graded pores comprise mass transfer pores and deposition holes, the deposition holes account for 40-95% of the total pore volume, and the mass transfer pores account for 4-55% of the total pore volume. According to the present invention, with application of the carbon material as the lithium-air battery electrode material, the space utilization rate of the carbon material during the charge-discharge process can be increased at a maximum, and the energy density and the power density of the lithium-air battery can be effectively increased; and the preparation process is simple, the material source is wide, the pore structure of the graded pore carbon material can be regulated, the regulation manner is diverse, and the nitrogen doping manner is easily achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Thin film transistor array panel and method of manufacturing the same

InactiveUS20100051934A1Simple manufacturing processReduce manufacturing costTransistorSolid-state devicesOxide semiconductorPhotolithography

A thin film transistor array panel and a method of manufacturing the same are provided according to one or more embodiments. In an embodiment, a method includes: forming a gate line on an insulation substrate; stacking a gate insulating layer, an oxide semiconductor layer, a first barrier layer, and a first copper layer on the gate line; performing a photolithography process on the oxide semiconductor layer, the first barrier layer, and the first copper layer and forming a data line including a source electrode, a drain electrode, and an oxide semiconductor pattern; forming a passivation layer having the contact hole that exposes the drain electrode on the data line and the drain electrode; and forming a pixel electrode that is connected to the drain electrode through the contact hole on the passivation layer, wherein the forming of a data line, a drain electrode, and an oxide semiconductor pattern includes wet etching the first copper layer and then wet etching the first barrier layer and the oxide semiconductor layer.

Owner:SAMSUNG ELECTRONICS CO LTD

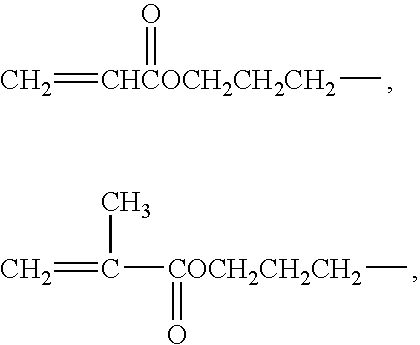

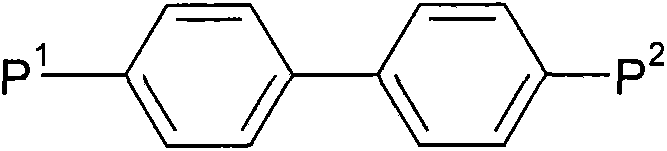

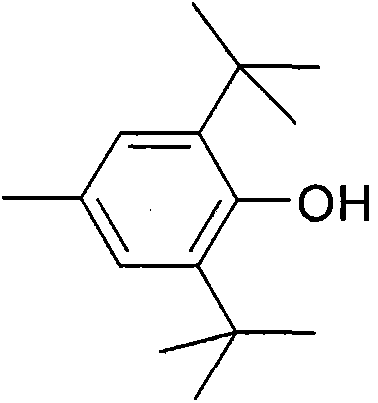

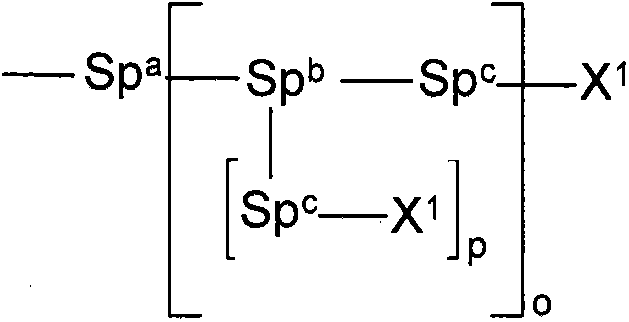

Liquid crystalline media with homeotropic alignment

ActiveCN105001879ASimple manufacturing methodShort response timeLiquid crystal compositionsOrganic compound preparationDielectric anisotropyLiquid crystalline

The present invention relates to liquid-crystalline media (LC media) having negative or positive dielectric anisotropy, comprising a low-molecular-weight component and a polymerizable component. The polymerizable component comprises self-aligning, polymerizable mesogens (polymerizable self-alignment additives) which effect homeotropic (vertical) alignment of the LC media at a surface or the cell walls of a liquid-crystal display (LC display). The invention therefore also encompasses LC displays having homeotropic alignment of the LC medium without alignment layers. The invention discloses novel structures for self-alignment additives which have a certain position of the functional groups.

Owner:MERCK PATENT GMBH

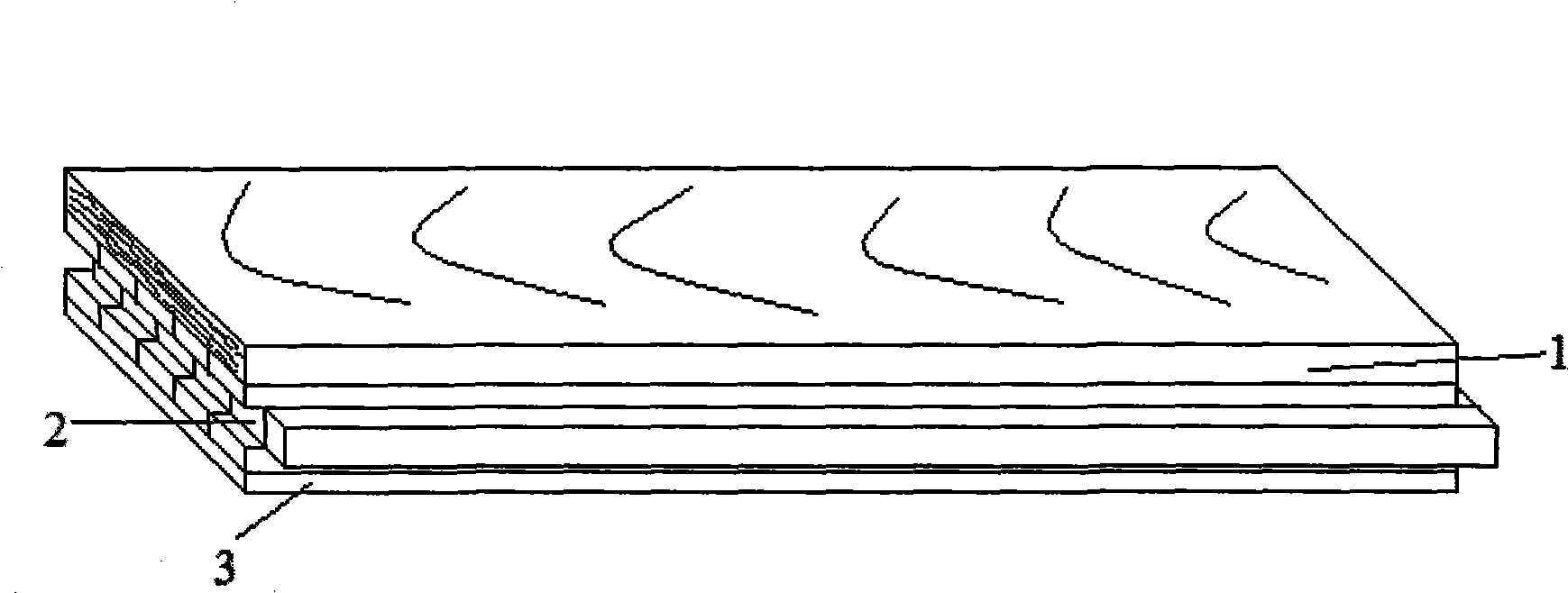

Method for producing compressed charing poplar three-layer wood composite flooring

InactiveCN101486212ALow costHigh densityWood treatment detailsWood veneer joiningSolid woodSurface layer

The invention discloses technology for producing compressed and carbonized poplar three-layer solid wood composite floor fully through utilization of a fast-growing material of poplar. A poplar sheet obtained by a special densification process is used as a surface layer; a common poplar core veneer is used as a core layer; a poplar veneer is used as a bottom layer to manufacture three-layer solid wood composite floor; each performance reaches the requirement of national standard GB / T 18103-2000 on the solid wood composite floor; the technology totally adopts the fast-growing material of the poplar as a raw material, does not add any chemical reagent in the special densification process of the poplar sheet, and does not cause any pollution to environment; after the poplar sheet is subjected to compaction treatment, the density and the hard sense of the wood are strengthened; the late high-temperature carbonization treatment solves the problem of rebounding after the poplar is compressed, changes luster of the wood, and strengthens high grade; and the technology is simple and feasible and has low manufacturing cost.

Owner:NANJING FORESTRY UNIV

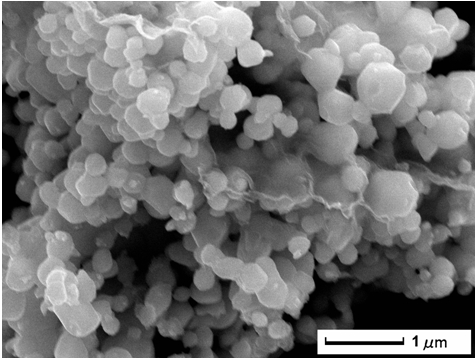

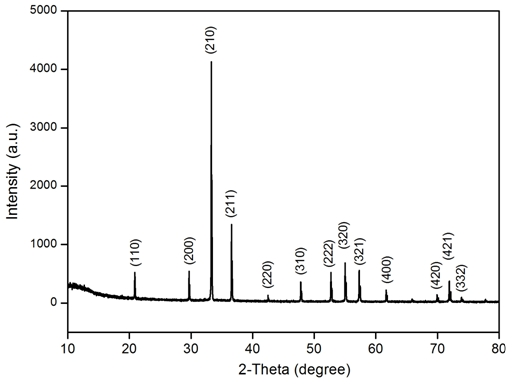

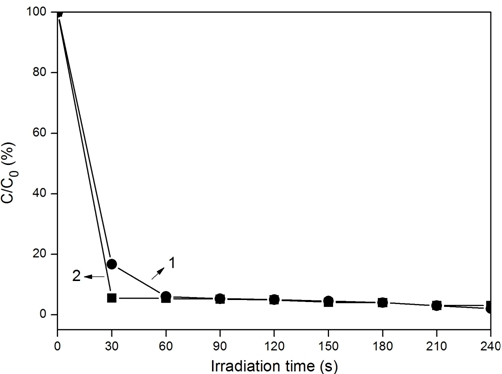

Graphene/silver phosphate composite visible light photocatalyst and preparation method thereof

InactiveCN102631939ALarge specific surface areaEfficient assemblyPhysical/chemical process catalystsWater/sewage treatment by irradiationOrganic dyePhosphoric acid

The invention discloses a high-efficiency graphene / silver phosphate composite visible light photocatalyst and a preparation method thereof, belonging to the technical field of composite materials and environmental management photocatalysis. The preparation method comprises the following steps: dissolving graphene oxide in water, and carrying out ultrasonic treatment to obtain a graphene oxide dispersed liquid; dissolving silver nitrate in deionized water, gradually and dropwisely adding into the graphene oxide dispersed liquid while stirring to obtain a mixed solution, uniformly stirring, and aging; dropwisely adding a prepared disodium hydrogen phosphate or sodium dihydrogen phosphate solution into the graphene oxide-silver nitrate mixed solution, continuing stirring, transferring into a hydrothermal reaction kettle, carrying out hydrothermal reaction, and cooling to room temperature; and washing the reaction product, and carrying out vacuum drying to obtain the visible light photocatalyst. The invention has the advantages of wide material sources and simple preparation process; and the obtained composite material has the advantages of controllable structure and regular pattern, and has high-efficiency degradation effect on organic dyes rhodamine B and methylene blue with certain concentration under the visible light irradiation.

Owner:JIANGSU UNIV

Composite epoxy anticorrosive paint and preparation method thereof

ActiveCN104231857AHigh glass transition temperatureGood flexibilityConjugated diene hydrocarbon coatingsAnti-corrosive paintsEpoxyPolymer science

The invention discloses composite epoxy anticorrosive paint and a preparation method thereof. The composite epoxy anticorrosive paint is composited by a component A and a component B at a ratio of 2:1, wherein the component A comprises constituents as follows: organosilicon modified epoxy resin, a pigment, filler, a plasticizer, a dispersant, a coalescing agent and a antifoaming agent; the component B comprises constituents as follows: polyphenyl ether resin powder, styrene-butadiene rubber, toluene, a plasticizer, a coupling agent, auxiliary materials and a flame retardant; and the components A and B are mixed respectively for preparation, and B is sprayed on A to form the composite epoxy anticorrosive paint. The composite epoxy anticorrosive paint is prepared by two components, has superior high-temperature resistance and abrasion resistance as well as good adhesion and low shrinkage simultaneously, has good corrosion resistance and penetration resistance to water, medium acid, alkali and other solvents and further has superior flexibility and paint application simultaneously; and the preparation method of the composite epoxy anticorrosive paint is simple and low in cost.

Owner:JIANGSU MARINE VICTORY COATING

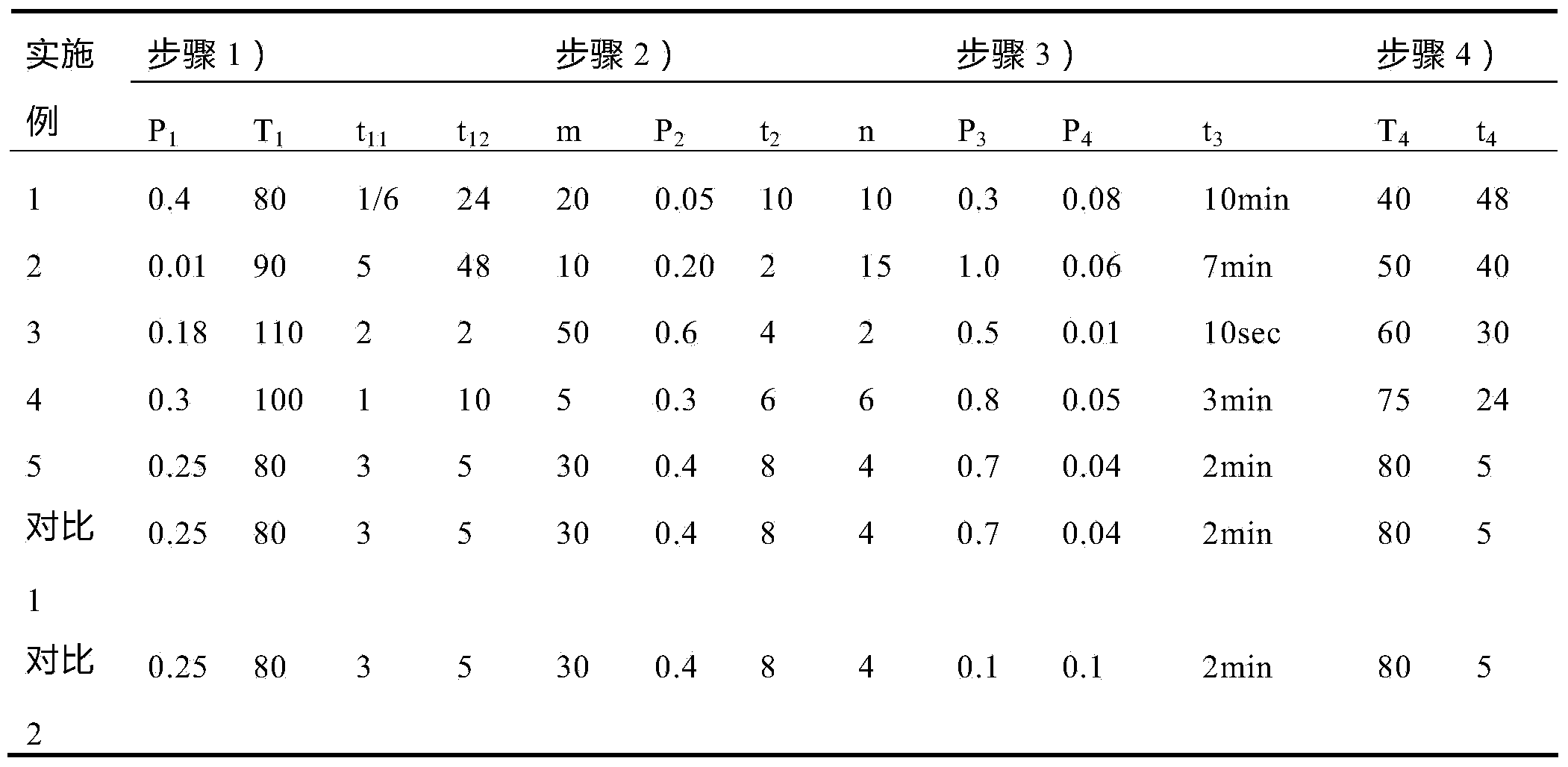

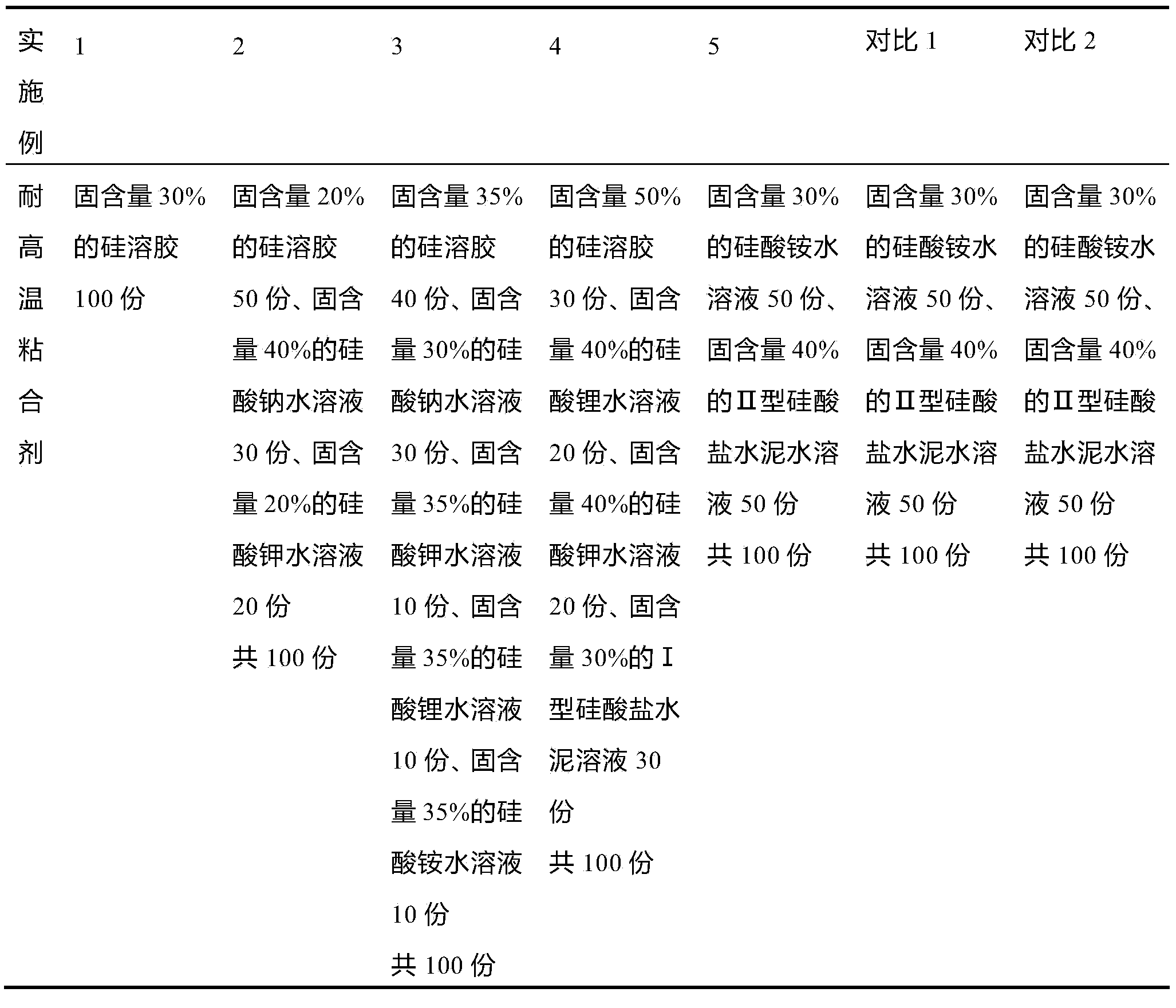

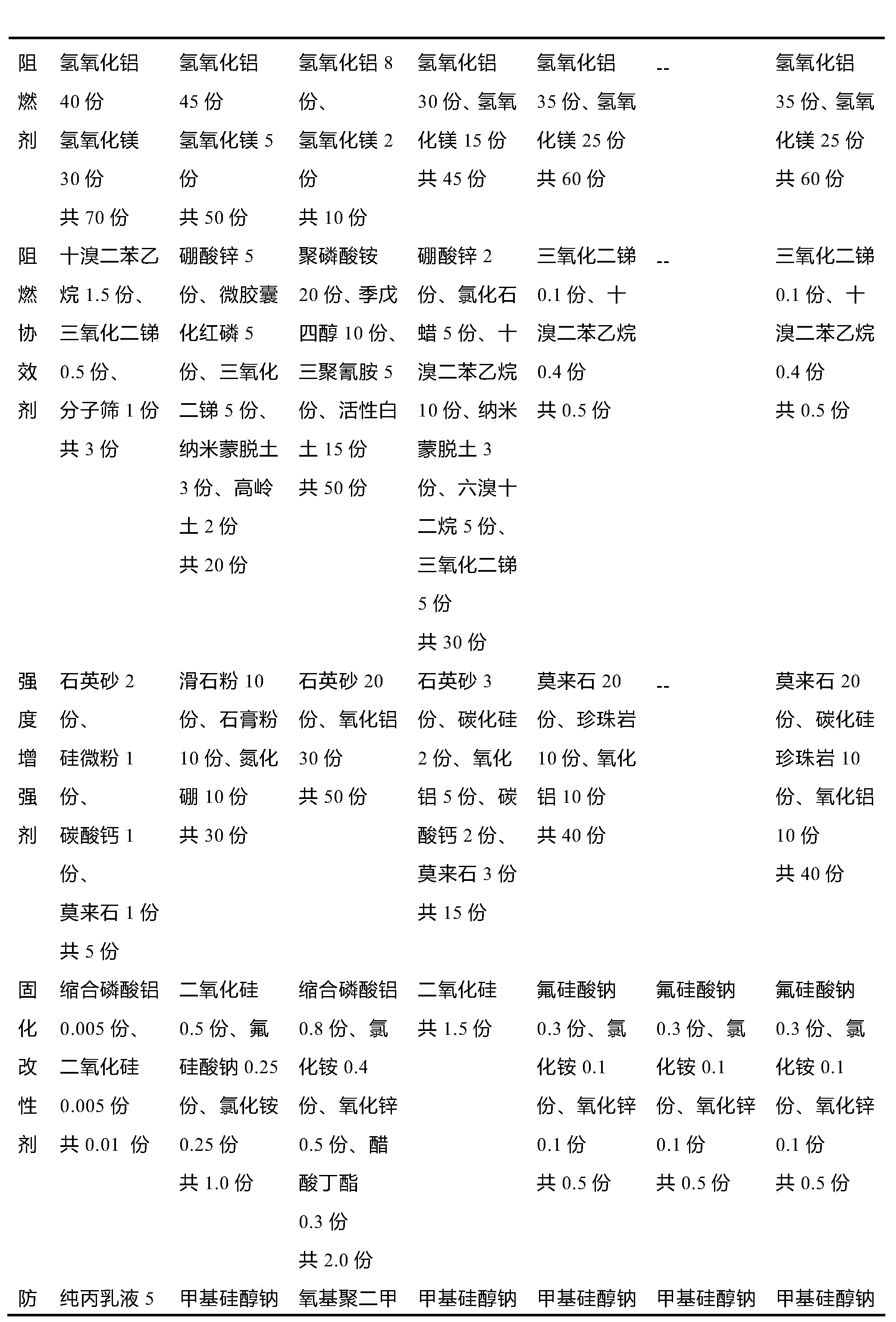

Fire-proof adhesive and application thereof

ActiveCN104099028AReduce total calorific valueImprove thermal conductivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCombustionAdhesive

The invention discloses a fire-proof adhesive and application thereof. The fire-proof adhesive comprises the following components by parts: 100 parts of high-temperature bonding agent, 10-70 parts of fire retardant, 0.5-50 parts of flame retardant synergist, 5-50 parts of strength enhancer, 0.05-20.0 parts of water-proof modifying agent and 0.01-2.0 parts of curing modifying agent. By adopting the fire-proof adhesive and a preparation method of a fire-retardant EPS (Expandable Polystyrene) foam heat-insulating plate, the combustion performance and physicochemical performance of the fire-retardant EPS foam heat-insulating plate can be improved remarkably. For example, the heat-conducting coefficient can be lowered below 0.055w / m.k, the specific gravity can be lower than 150Kg / M<3>, the compressive strength is higher than 150KPa, and the heat value is less than 3MJ / kg.

Owner:应急管理部四川消防研究所

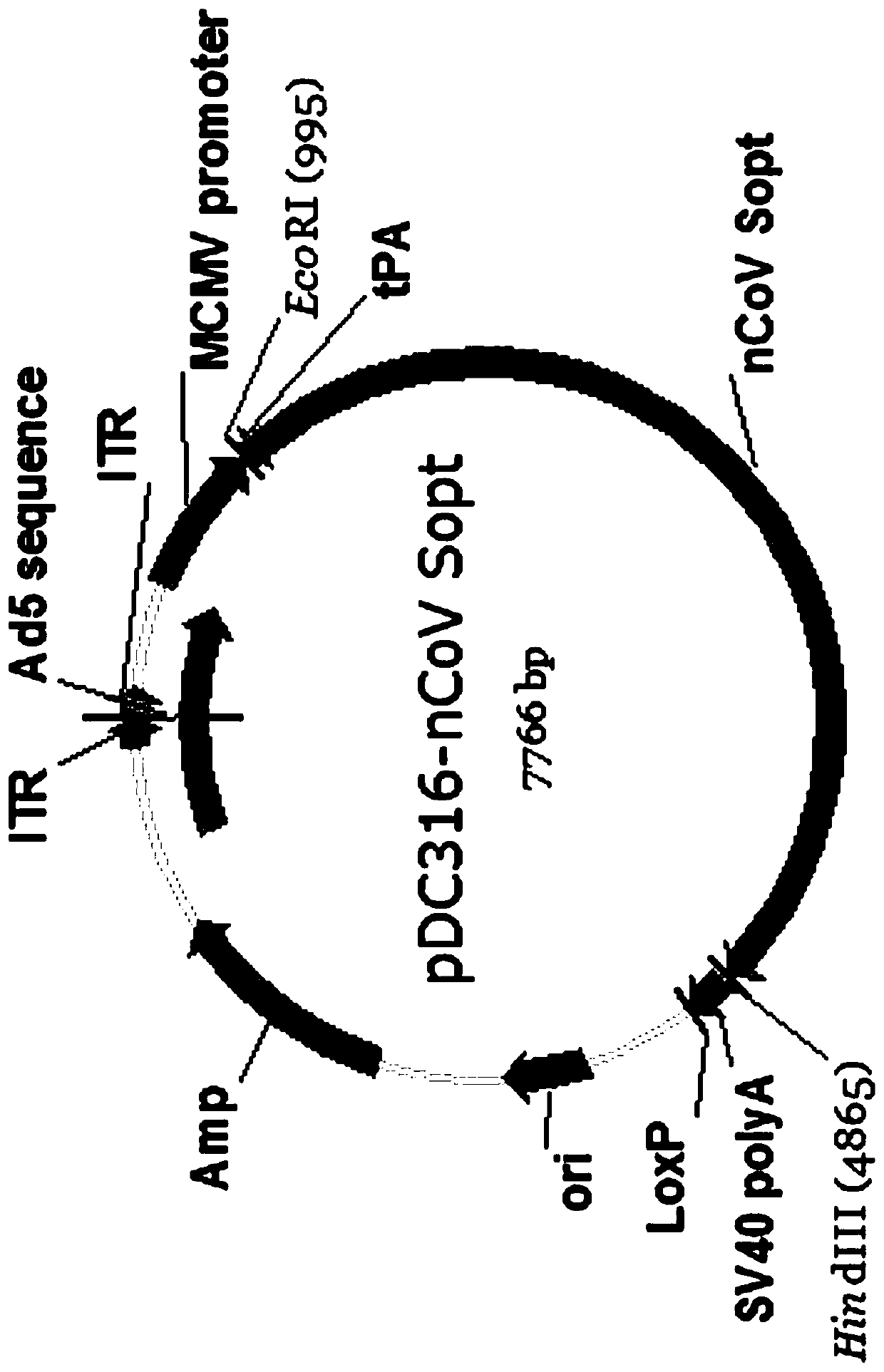

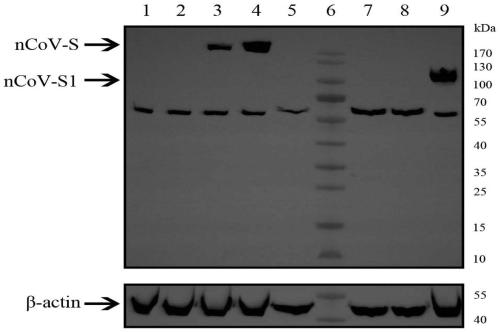

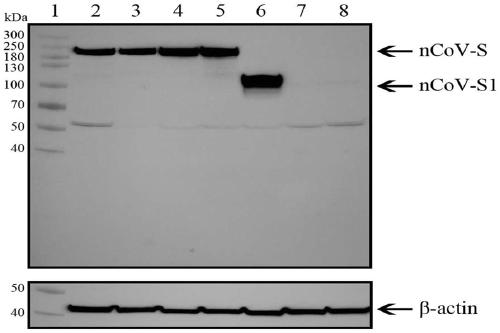

Recombinant SARS-CoV-2 vaccine using human replication-defective adenovirus as vector

ActiveCN111218459AReduce loadSimple manufacturing methodSsRNA viruses positive-senseViral antigen ingredientsProtective antigenCoronavirus vaccination

The invention provides a SARS-CoV-2 vaccine using human type-5 replication-defective adenovirus as a vector. The vaccine uses E1 and E3 to be combined with replication-defective human type-5 adenovirus as the vector and HEK293 cells integrating adenovirus E1 gene as a packaging cell line, and a protective antigen gene carried is the 2019 SARS-CoV-2 S protein gene (Ad5-nCoV) which is subjected to optimization design. After the S protein gene is optimized, the expression level in transfected cells is increased significantly. The vaccine has good immunogenicity in mouse and guinea pig models, andcan induce a body to produce a strong cellular and humoral immune response in a short time. Studies on the protective effect of hACE2 transgenic mice show that after 14 days of single immunization ofAd5-nCoV, the viral load in lung tissue can be significantly reduced, and it is indicated that the vaccine has a good immunoprotective effect on the 2019 SARS-CoV-2. In addition, the vaccine is quick, simple and convenient to prepare, and can be mass-produced in a short period of time to respond to sudden outbreaks.

Owner:ACADEMY OF MILITARY MEDICAL SCI +1

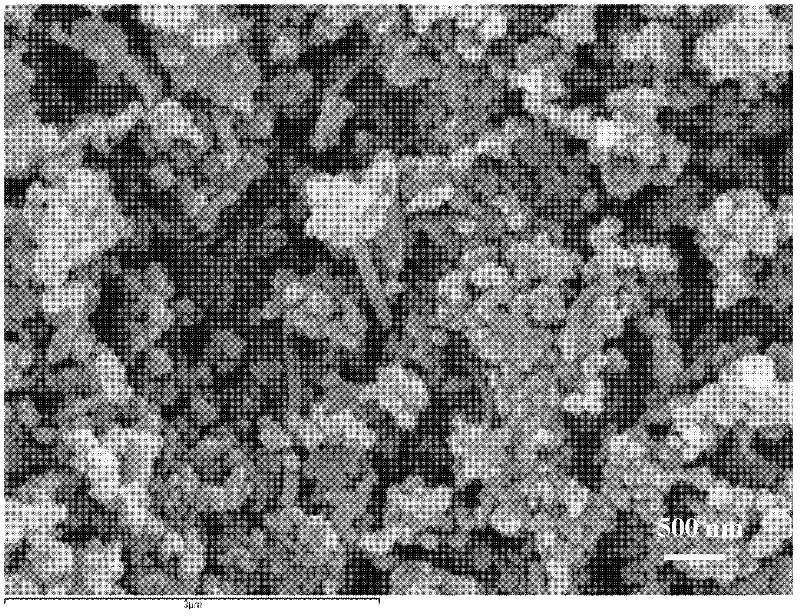

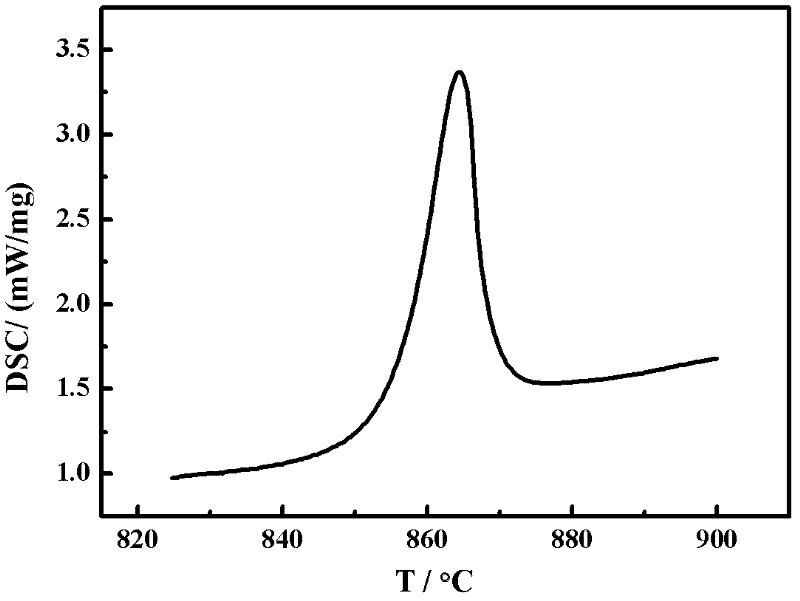

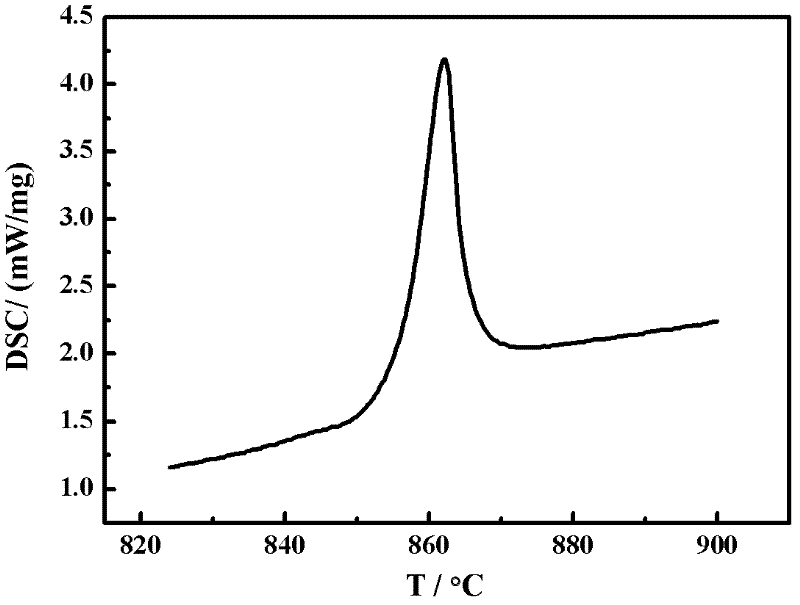

High-temperature composite phase change heat storage material and preparation method thereof

ActiveCN102585775ANo preprocessing requiredSimple manufacturing methodHeat-exchange elementsElectricityHeat conducting

The invention relates to a preparation method of a high-temperature composite phase change heat storage material, and relates to a high-temperature composite phase change heat storage material and a preparation method thereof. The method can be used for preparing high-temperature composite phase change heat storage material with high heat conductivity, so that the heat conductivity of the heat storage material is greatly improved, and the heat storage / release rate is greatly improved; and the preparation method is easy to control and simple to operate. The heat storage material can be directly obtained by sintering, without need of any bonding agent or other protectants, so that the heat-conducting property of the heat storage material is greatly improved, and the utilization ratio of the heat storage material is improved; the preparation method is simple to operate; and the prepared product can also be used for other intermediate-temperature low-temperature composite heat storage materials, as well as light heat utilization, heat-cold-electricity combined use, composite material synthesis and other many fields.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

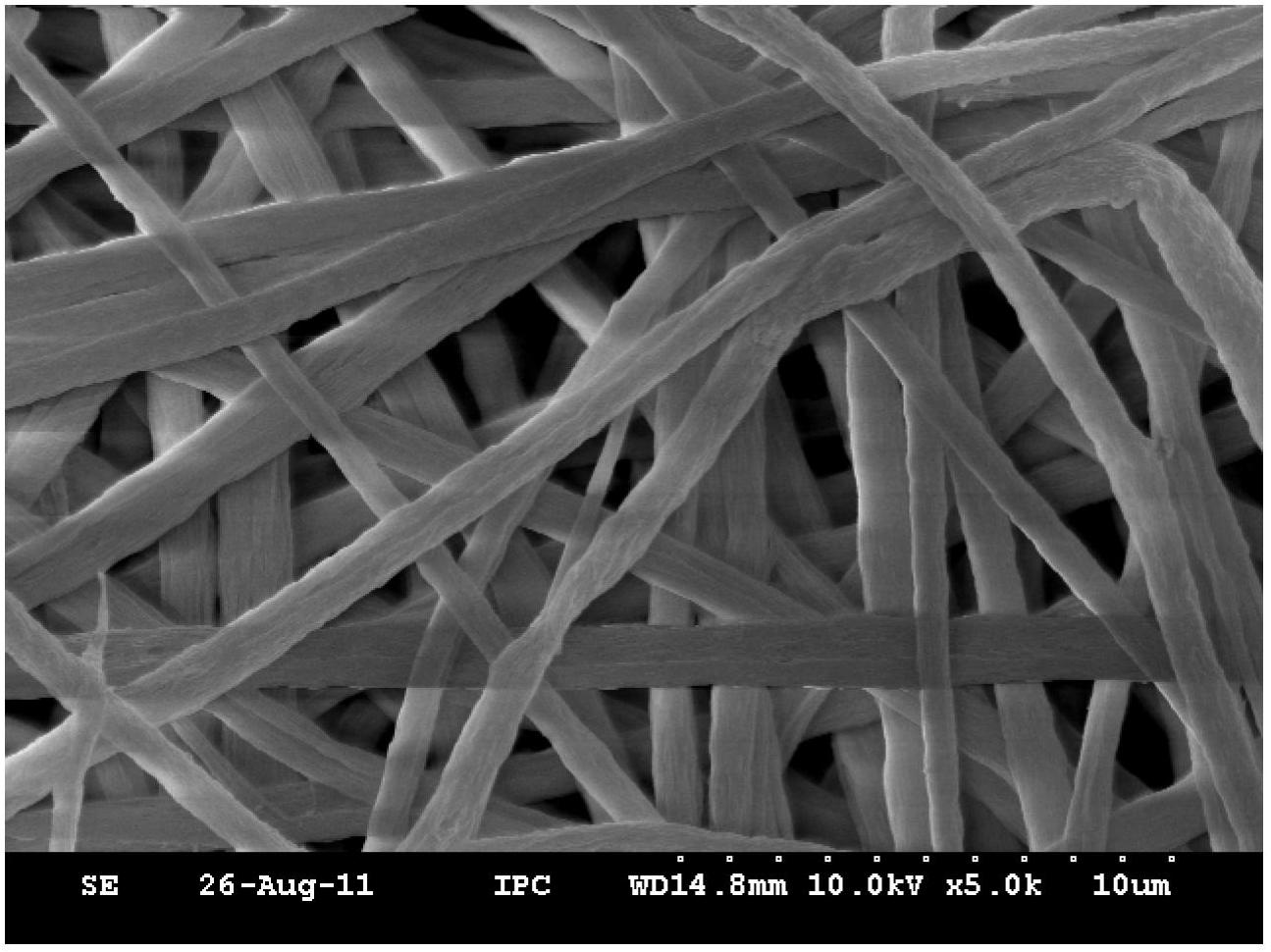

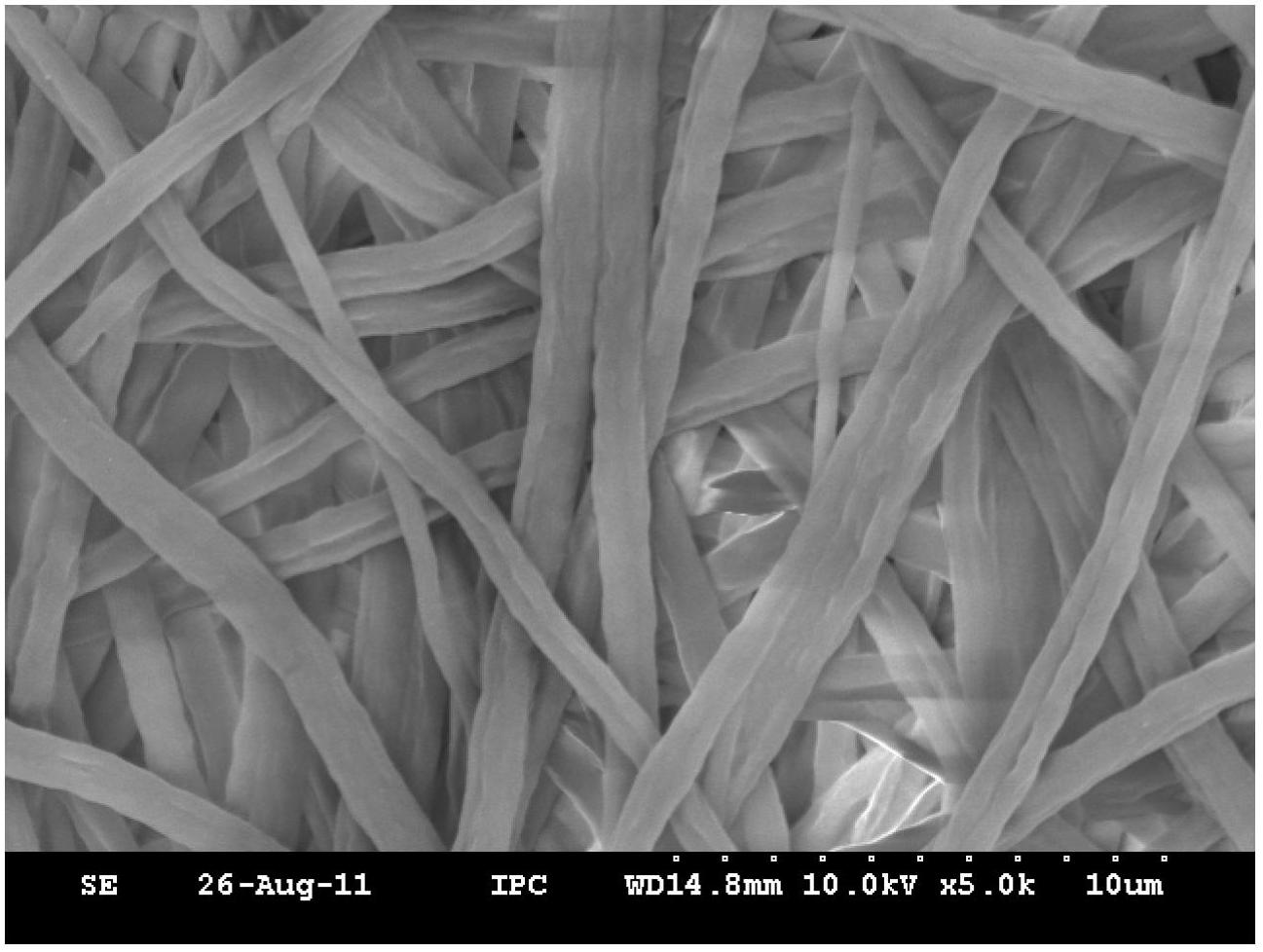

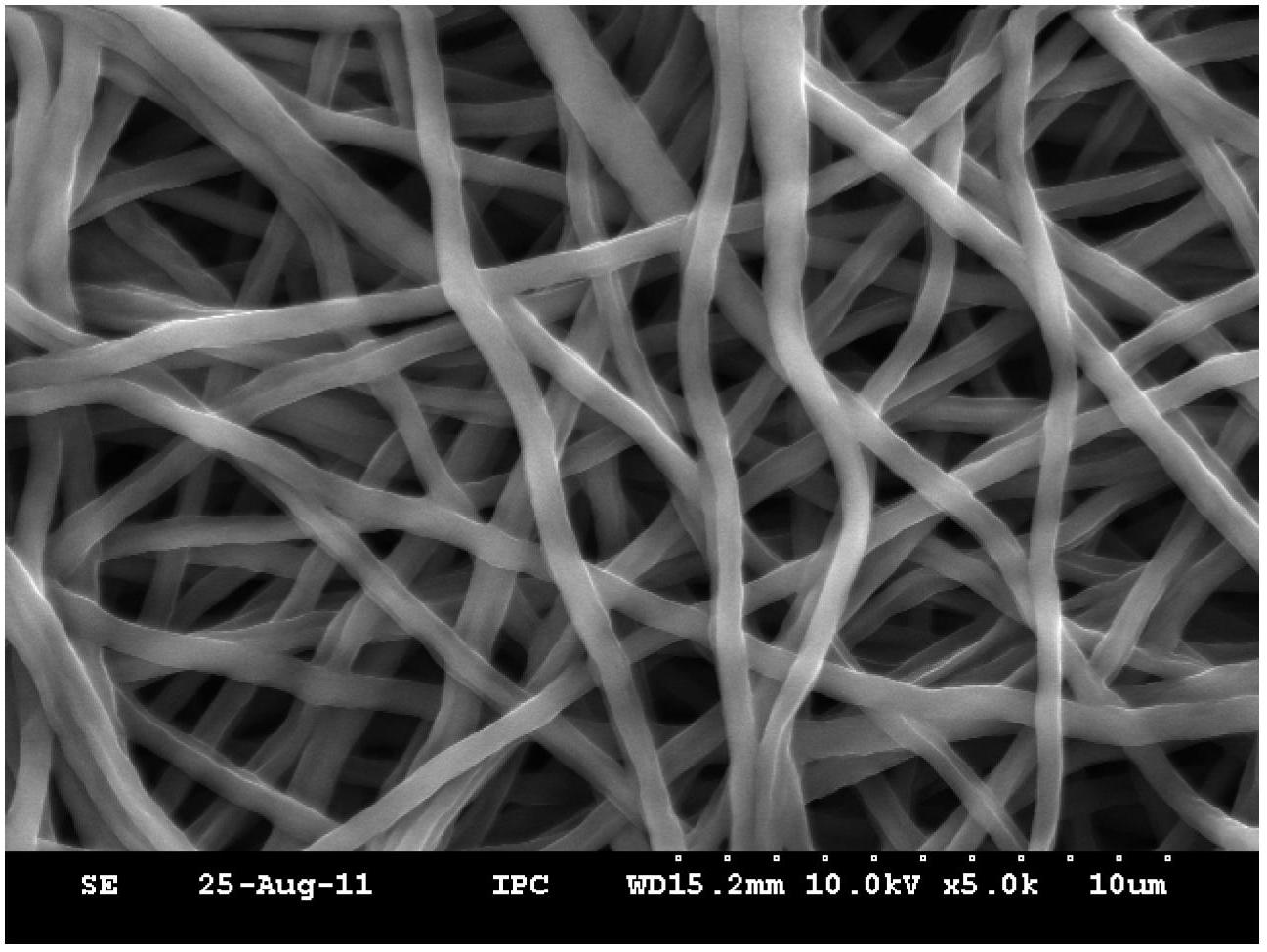

Method for preparing polyacrylonitrile-based porous hollow carbon fibers by coaxial electrospinning

InactiveCN102691136ALarge specific surface areaImprove efficiencyCatalyst carriersOther chemical processesPolymer scienceCarbon fibers

The invention discloses a method for preparing PAN (polyacrylonitrile)-based porous hollow carbon fibers by coaxial electrospinning. The method includes the steps: mixing polyacrylonitrile with additives to serve as outer solution; taking inner polymer to serve as inner solution; inputting the outer solution and the inner solution into outer layers and inner layers of coaxial needles respectively at the constant flow velocity and in the constant velocity ratio for electrospinning so that PAN-based sheath-core composite fibers are obtained; and subjecting the PAN-based sheath-core composite fibers to washing, pre-oxidation and carbonization so that the PAN-based porous hollow carbon fibers are obtained. The PAN-based porous hollow carbon fibers combine structural characteristics of original porous carbon fibers and original hollow carbon fibers, the specific surface area of the fibers can be greatly increased, and use efficiency of materials is improved. When the PAN-based porous hollow carbon fibers prepared by the method are applied to gas adsorption, gas can enter hollow portions of the fibers more easily, so that adsorbability is enhanced while time required by adsorption is shortened.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Process method for preparing ultra-hydrophobic surface by electrochemical method

ActiveCN101665968AEndows the superior performance of "self-cleaning"Apparent nanostructureAnodisationSpecial surfacesPhysical chemistryElectrochemistry

The invention discloses a process method for preparing an ultra-hydrophobic surface by the electrochemical method. The process adopts two processing steps: forming the micro nanometer double-structurerough surface by first electrochemical etching and then oxalic acid anodic oxidation; and preparing the ultra-hydrophobic surface by modifying the surface with fluorosilane. The method is simple andpractical, uses mature electrochemical etching and anodic oxidation technology, allows for easy mass production and avoids environmental pollution.

Owner:甘肃中安瑞科科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com