Patents

Literature

202 results about "Coaxial electrospinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

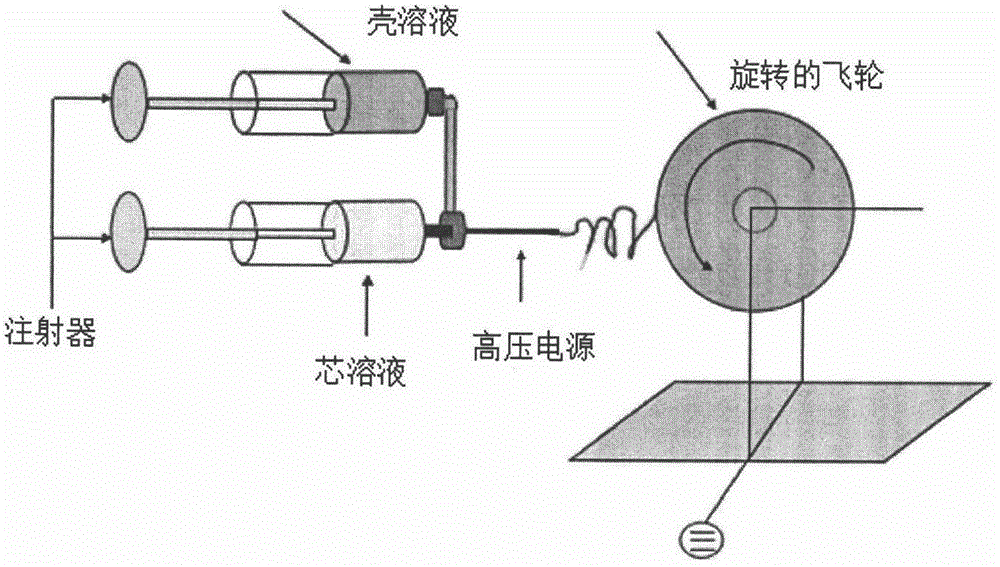

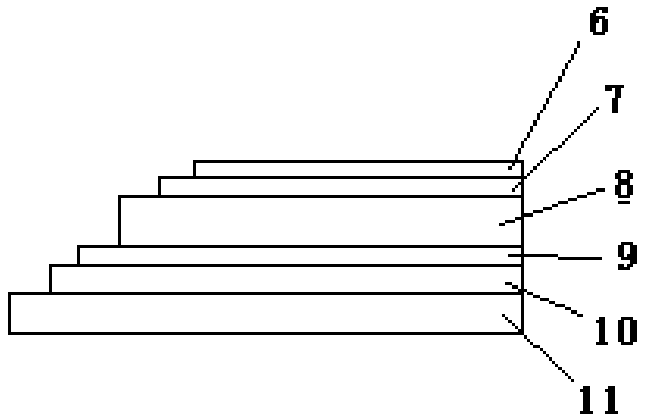

Preparation method of core-shell structured synthetic polymer-natural polymer composite fiber

InactiveCN102817105ASimple and fast operationMild reaction conditionsConjugated cellulose/protein artificial filamentsFilament/thread formingFiberPolymer science

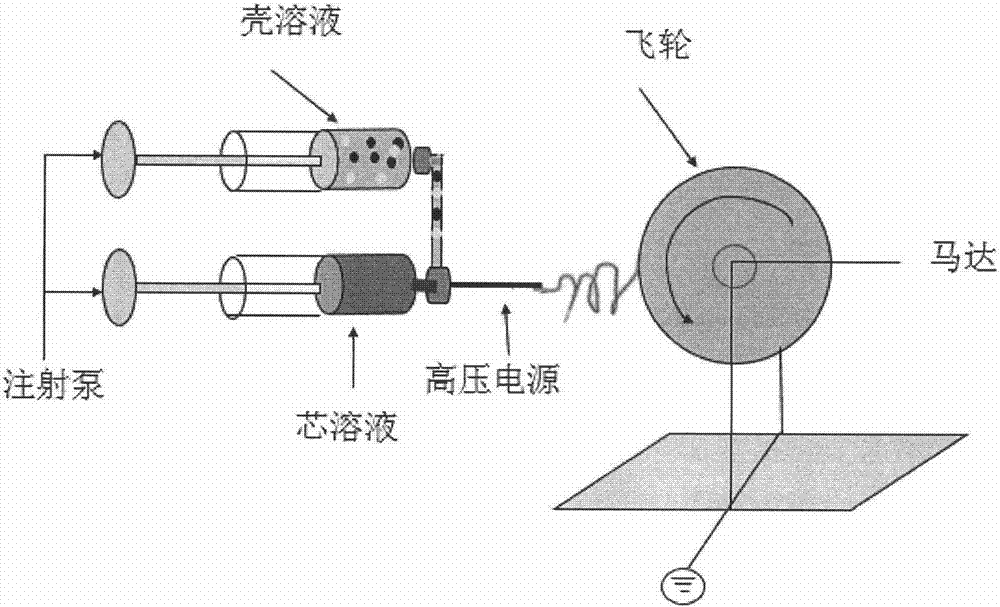

The invention discloses a preparation method of a core-shell structured synthetic polymer-natural polymer composite fiber, and the method comprises the steps of: (1) selecting one or several of synthetic polymers to dissolve in a solvent, and conducting stirring until complete dissolution; (2) selecting a natural polymer to dissolve in a solvent, or adding a spinning assistant, and carrying out stirring until complete dissolution; and (3) taking the solution prepared in step (1) as an outer tube spinning solution, adopting the solution prepared in step (2) as an inner tube spinning solution, injecting them into the inner tube and the outer tube of a coaxial spinneret, and performing coaxial electrospinning at room temperature. The core-shell structured nano-fiber prepared by the invention selects the synthetic polymer as the shell layer, and can inhibit water molecules from penetrating the natural polymer as the core layer. The natural polymer as the core layer can more effectively encapsulate active substances to avoid inactivation of the active substances in the presence of an organic solvent, so that the core-shell structured composite fiber can play a good drug sustained release role in the drug carrier field, and an integral activity can be maintained.

Owner:SHANGHAI JIAO TONG UNIV +1

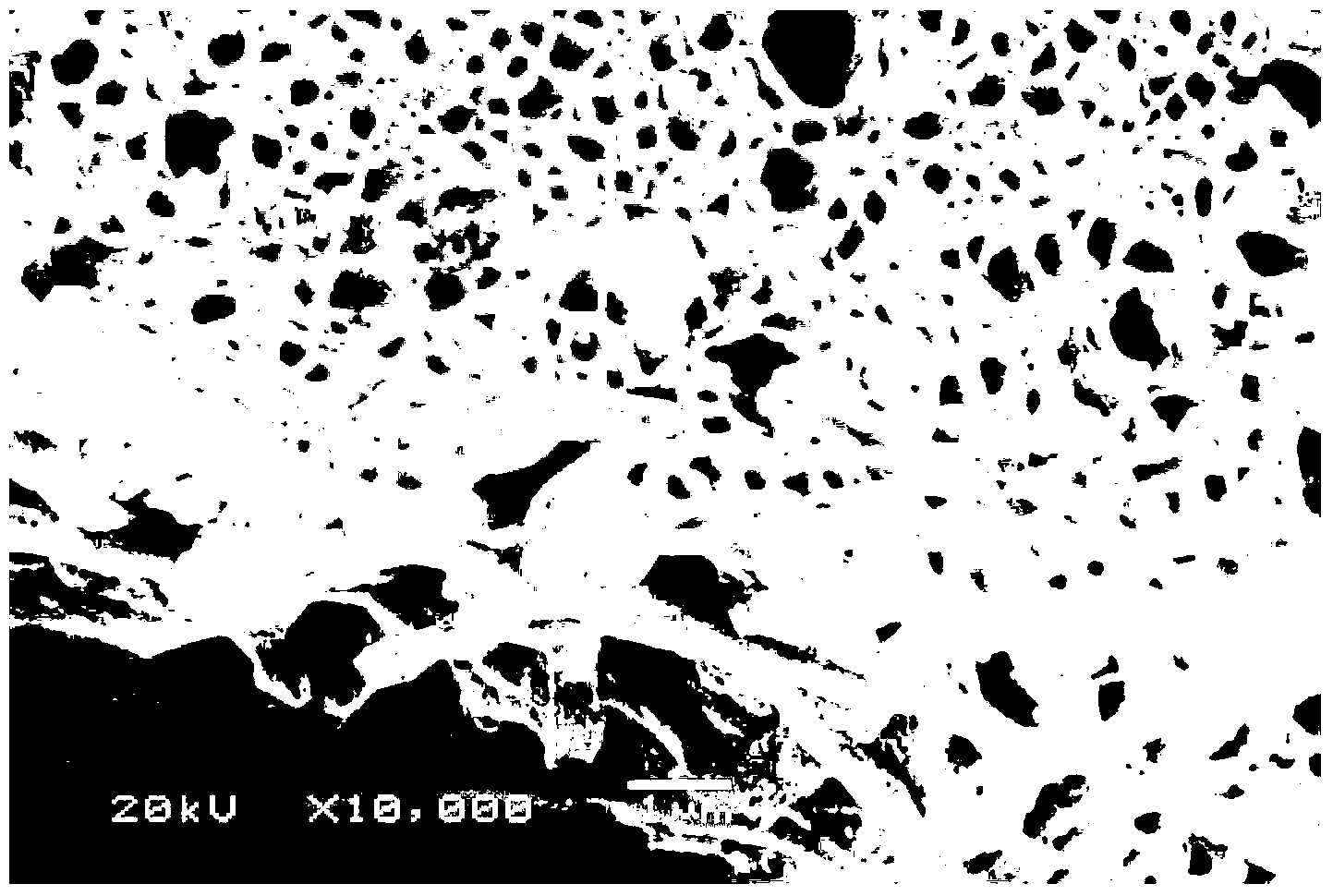

Method for preparing polyacrylonitrile-based porous hollow carbon fibers by coaxial electrospinning

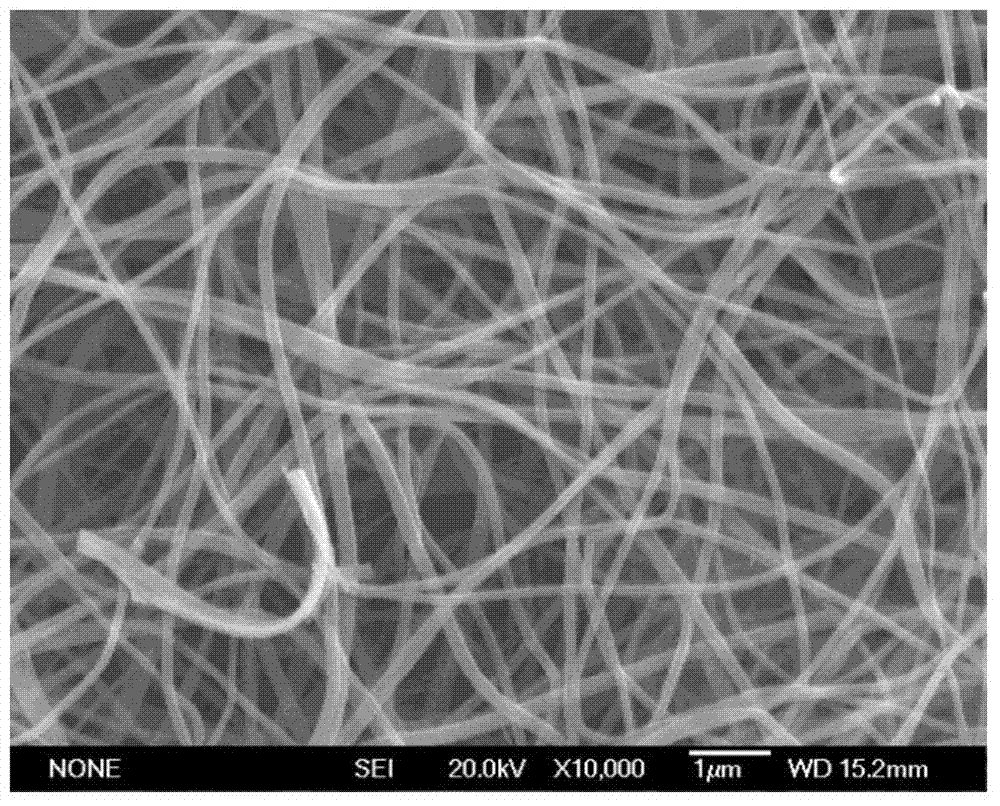

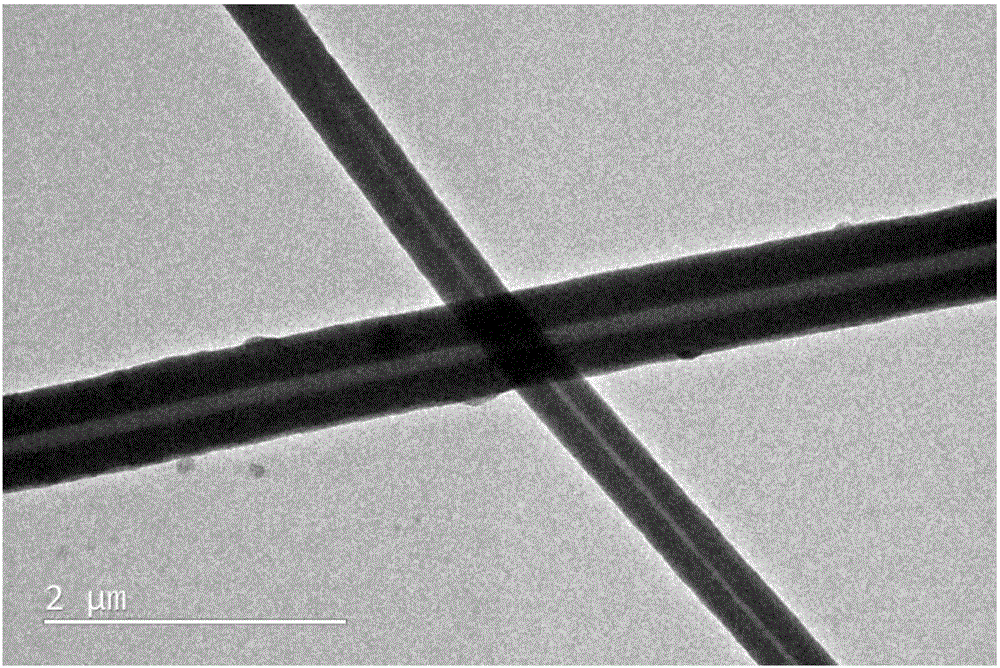

InactiveCN102691136ALarge specific surface areaImprove efficiencyCatalyst carriersOther chemical processesPolymer scienceCarbon fibers

The invention discloses a method for preparing PAN (polyacrylonitrile)-based porous hollow carbon fibers by coaxial electrospinning. The method includes the steps: mixing polyacrylonitrile with additives to serve as outer solution; taking inner polymer to serve as inner solution; inputting the outer solution and the inner solution into outer layers and inner layers of coaxial needles respectively at the constant flow velocity and in the constant velocity ratio for electrospinning so that PAN-based sheath-core composite fibers are obtained; and subjecting the PAN-based sheath-core composite fibers to washing, pre-oxidation and carbonization so that the PAN-based porous hollow carbon fibers are obtained. The PAN-based porous hollow carbon fibers combine structural characteristics of original porous carbon fibers and original hollow carbon fibers, the specific surface area of the fibers can be greatly increased, and use efficiency of materials is improved. When the PAN-based porous hollow carbon fibers prepared by the method are applied to gas adsorption, gas can enter hollow portions of the fibers more easily, so that adsorbability is enhanced while time required by adsorption is shortened.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Porous hollow carbon nanofiber as well as preparation method and application thereof

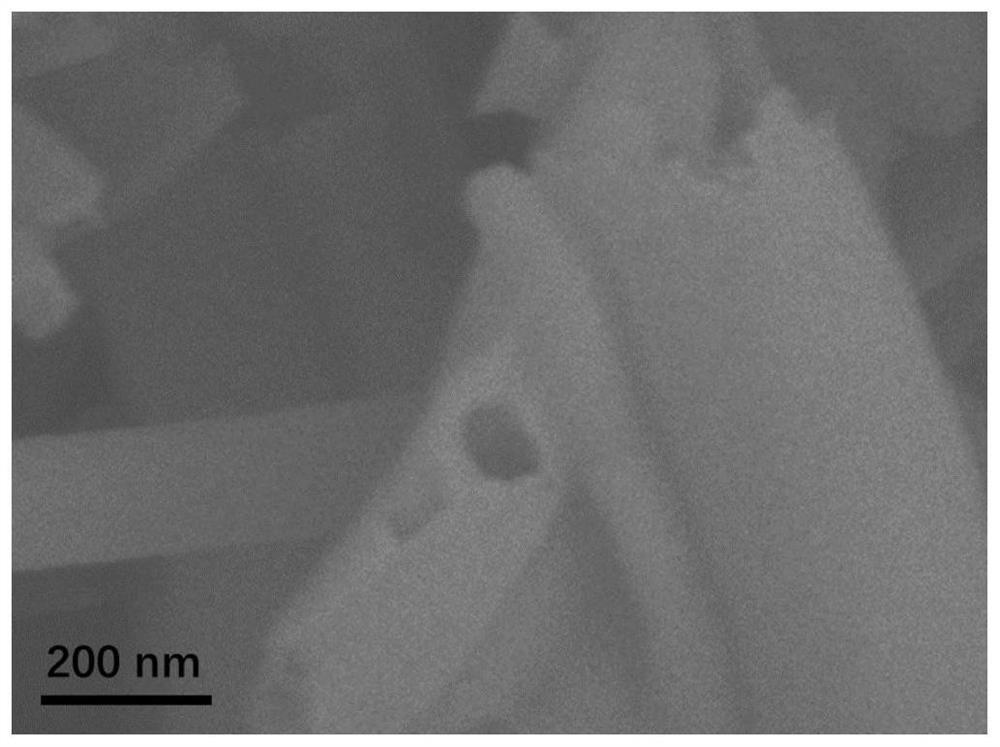

InactiveCN103233299AKeep shapeEasy hole makingHollow filament manufactureCarbonizationCarbon nanofiber

The invention discloses a method for preparing porous hollow carbon nanofiber by using metal salt pore-forming. The method comprises the following steps of: mixing metal salt with polyacrylonitrile to prepare outer-layer fluid; preparing inner-layer fluid by using soluble or volatile oil; respectively inputting the outer-layer fluid and the inner-layer fluid into the outer layer and the inner layer of a coaxial electrospinning spray head at a constant flow velocity and velocity ratio to carry out coaxial electrostatic spinning to obtain core-shell nano composite fiber; and carrying out ultrasonic washing, pre-oxidation, carbonization and ultrasonic pickling on the obtained core-shell nano composite fiber to obtain the porous hollow carbon nanofiber. The porous hollow carbon nanofiber prepared by using the preparation method has extremely wide application values in terms of gas adsorption, catalysis and battery electrode materials.

Owner:DALIAN JIAOTONG UNIVERSITY

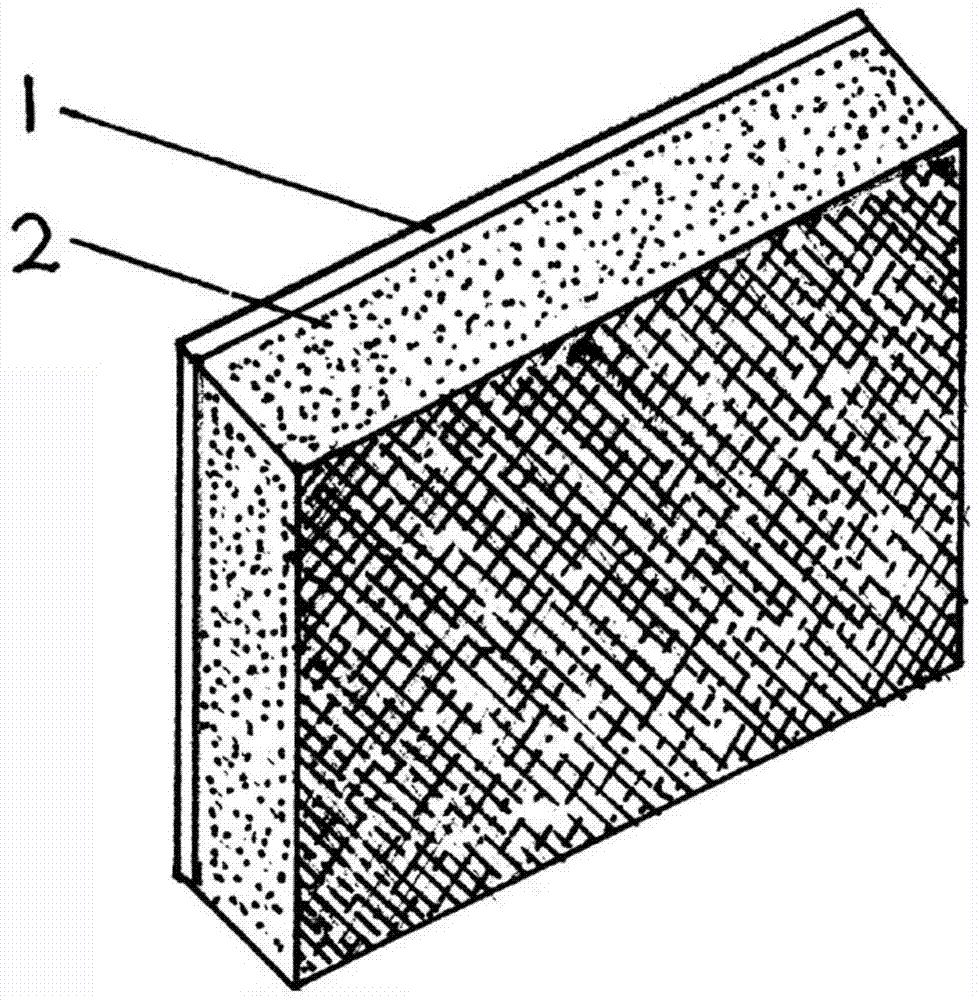

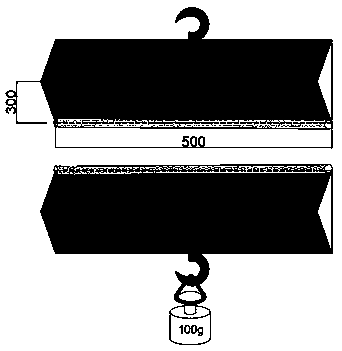

Phase-change heat-storage fabric prepared by using coaxial electrospinning technology

InactiveCN108374238ANo leaksAchieve functionalizationConjugated synthetic polymer artificial filamentsNon-woven fabricsPhysical chemistryPhase change

The invention provides phase-change heat-storage fabric prepared by using a coaxial electrospinning technology. A preparation method comprises the following steps that (1) phase change materials are added to a first solvent and stirred until the phase change materials are completely dissolved to obtain a core layer solution, wherein the mass concentration of the phase change materials in the corelayer solution is 30-90%; (2) polymer materials are added to a second solvent and stirred until the polymer materials are completely dissolved to obtain a shell layer solution, wherein the mass concentration of the molecular materials in the shell layer solution is 5-30%; (3) the core layer solution obtained in the first step and the shell layer solution obtained in the second step are injected into two solution channels of a coaxial electrospinning device respectively, and coaxial electrospinning parameters are adjusted for electrospinning to obtain the phase-change heat-storage fabric. The phase-change heat-storage fabric not only has the properties of phase change and heat storage, but also has the functions of intelligent temperature adjustment, intelligent color matching, anti-flame retardation, bacterium and virus resistance and the like.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

Efficient electrostatic spinning oil-water separation fiber membrane

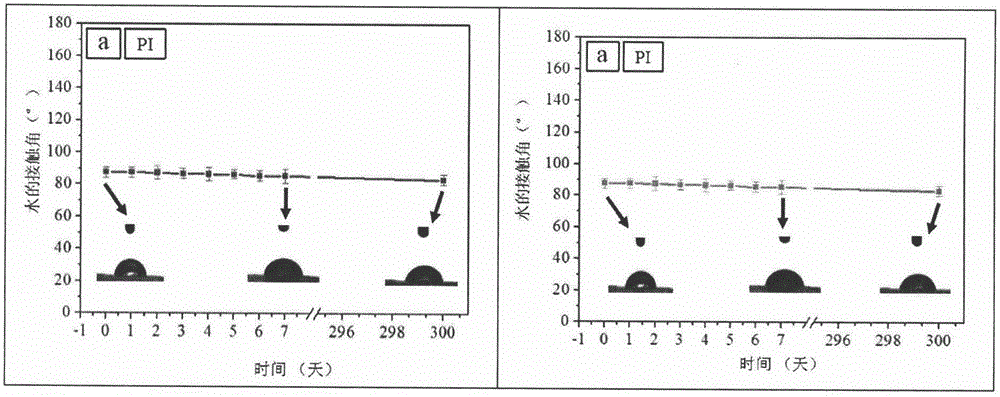

InactiveCN105603637AEasy to separateImprove separation efficiencyFatty/oily/floating substances removal devicesElectro-spinningFiberSilica nanoparticles

The invention discloses a preparation method of an efficient electrostatic spinning oil-water separation fiber membrane. The preparation method includes the steps that polyamic acid (PPA) is synthesized, a PPA nanofiber membrane is prepared in an electrospinning mode, and the PPA nanofiber membrane is imidized into a polyimide membrane (PI); a cellulose acetate (CA) nanofiber membrane is prepared; coaxial electrospinning is carried out on CA-PAA, and a product is imidized into CA-PI; benzoxazine monomers (BAF-tfa) are synthesized; in-situ immobilization is performed on the CA, PI and CA-PI nanofiber membranes with BAF-tfa and BAF-tfa / silica nanoparticles (SiO2NPs); an oil-water separation experiment is carried out. The preparation method has the advantages that by carrying out surface modification on the fiber membranes, the CA-PI nanofiber membrane which is biodegradable, low in cost, large in oil-water separation flow and high in separation efficiency is obtained; the high-performance membrane material has broad application prospects in oil-water separation, sewage treatment and deepwater oil leak.

Owner:NANJING FORESTRY UNIV

Preparation method for conduction and sustained release type nervous tissue engineering scaffold

ActiveCN104225685AGood cell compatibilityExtended highFilament/thread formingNon-woven fabricsConductive polymerDefect repair

The invention relates to a preparation method for a conduction and sustained release type nervous tissue engineering scaffold. The method comprises the following steps: silk fibroin Silk and lactic acid-caprolactone copolymer are dissolved in a solvent, dissolved and stirred to obtain a solution, then polyaniline and camphorsulfonic acid are added and stirred and mixed uniformly to obtain a cortex electrospinning solution, and NGF (nerve growth factors) are dissolved in ultrapure water completely to obtain a core electrospinning solution; and the cortex electrospinning solution and the core electrospinning solution are accommodated in an injector respectively for coaxial electrospinning, and then fumigation treatment and vacuum drying are performed to obtain the conduction type nervous tissue engineering scaffold. According to the prepared nanofiber scaffold, the nerve repair speed is increased from ways including external electrical stimulation (conductive polymer), biochemistry (NGFs), a topological structure required by nerve regeneration (orientation guide) and the like. The method is simple to operate, good in repeatability and high in economic benefit, and provides novel experimental thought for nerve defect repair in clinical application.

Owner:诺一迈尔(山东)医学科技有限公司

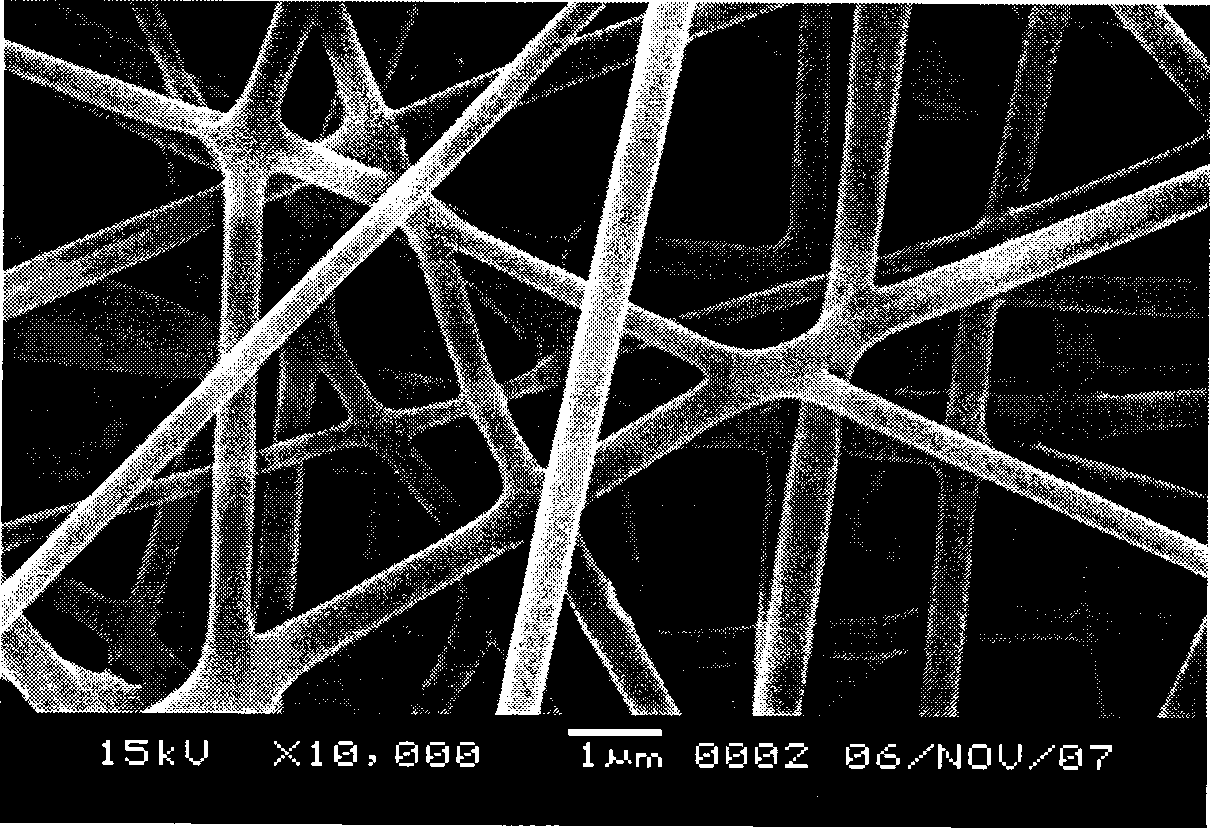

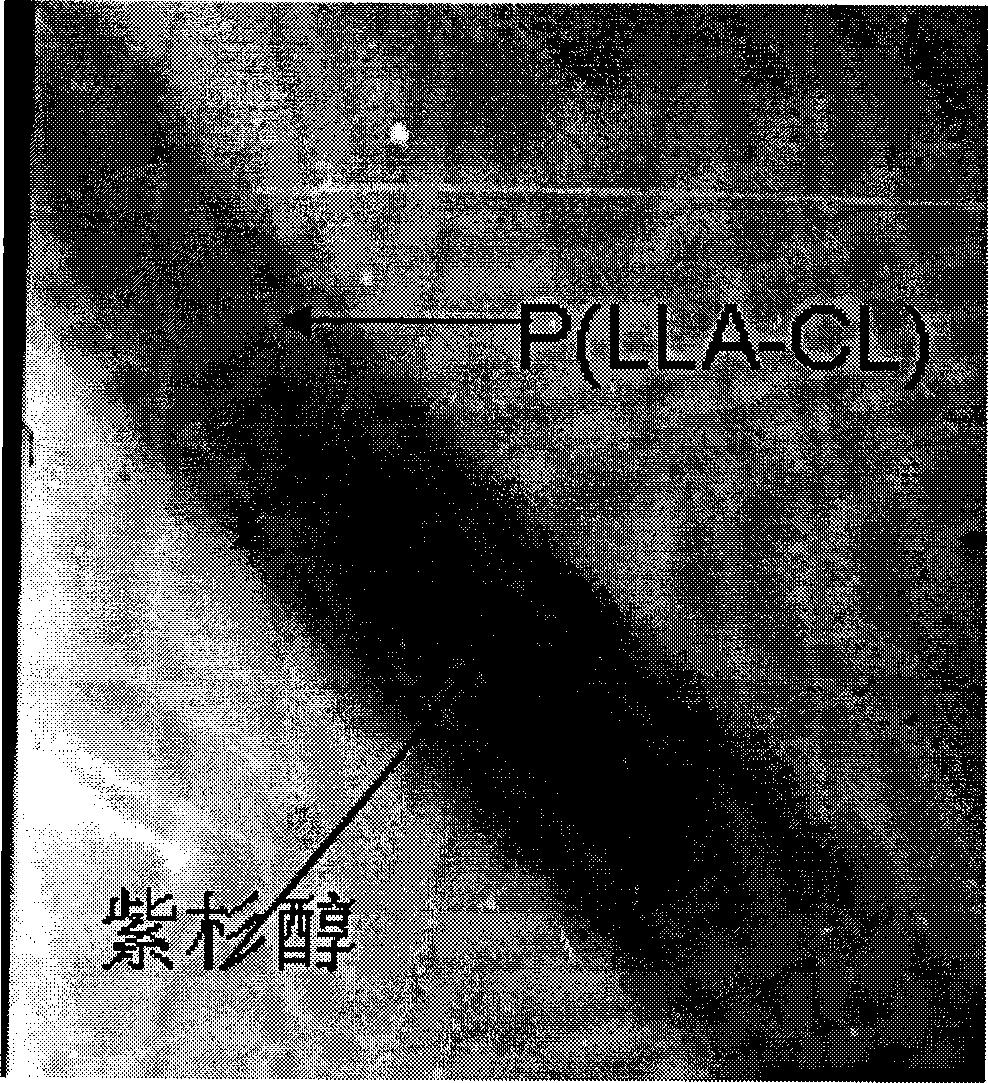

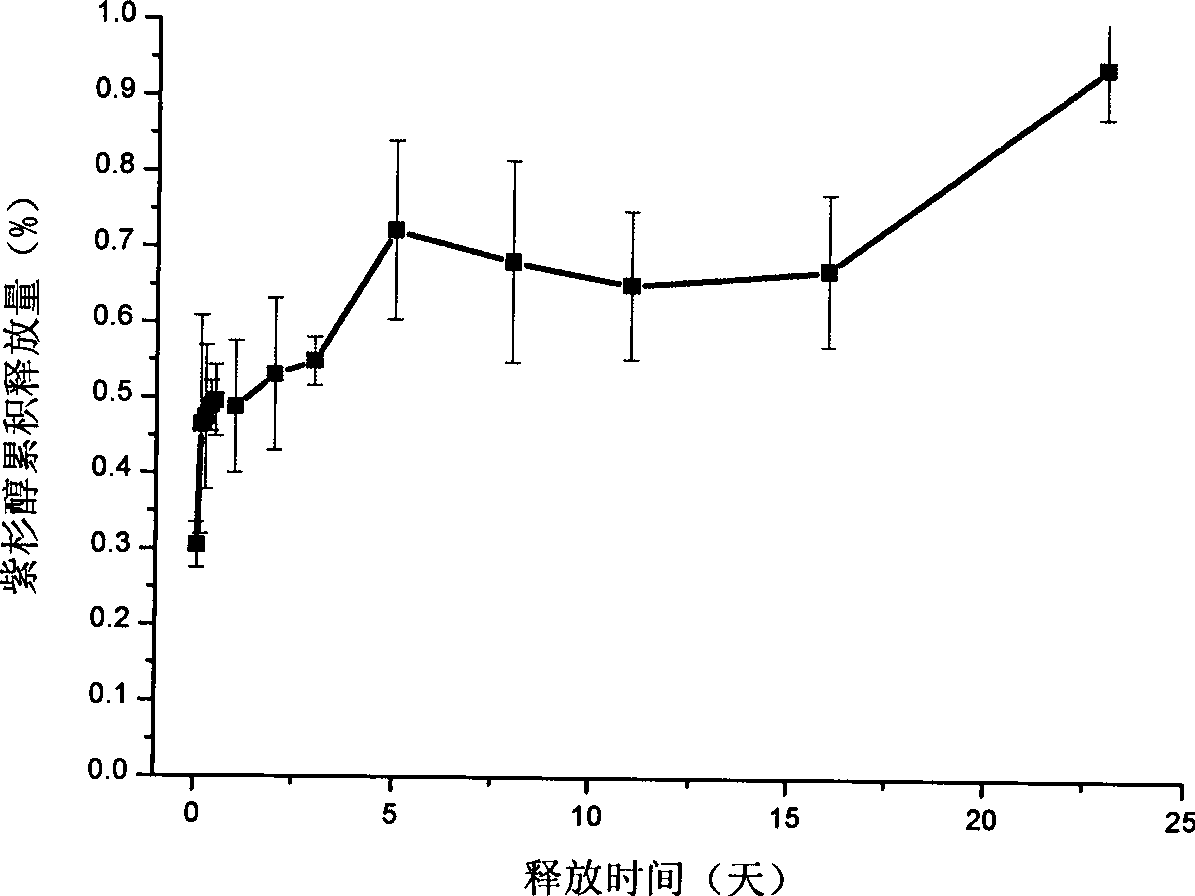

Paclitaxel loaded sustained release nano fiber and preparation method and use thereof

InactiveCN101396337AControlled slow releaseInhibition of value addedPharmaceutical delivery mechanismUnknown materialsFiberMicroinjections

The invention relates to a paclitaxel-loaded sustained release nano-fibre material which comprises the components of bio-degradable polymer material and pure paclitaxel, the mol ratio of which is 1.33 to 10. The diameter of the nano-fibre is 90nm to 1.44micrometer, and the drug-loading rate can be regulated within the range of 0 percent to 100 percent. The preparation of the nano-fibre comprises the steps as follows: (1) the bio-degradable polymer material is solved in organic solvent and stirred to be solved completely to obtain lamella spinning solution A; (2) the white pure paclitaxel powder is solved in trifluoroethanol and stirred to be solved completely to obtain core spinning solution B; (3) clear transparent solutions A and B are respectively added into two injectors; the speed of a microinjection pump, the voltage of a static generator and the receiving distance between a grounded aluminum foil and a spinning needle are adjusted, and unordered drug-loaded nano-fibre is obtained by a coaxial electrostatic spinning technology. A nanometer control release system composed by the drug-loaded nano-fibre effectively controls the sustained release of the drug and is applied to the preparation of the drug for remedying malignant tumor.

Owner:DONGHUA UNIV

Method for preparing dense micro/nano ceramic fiber by virtue of coaxial electrospinning technology

The invention discloses a method for preparing dense micro / nano ceramic fiber by virtue of a coaxial electrospinning technology. The method comprises the specific steps: carrying out coaxial electrospinning on a prepared spinning solution to obtain nascent fiber having a coaxial structure and then sintering the nascent fiber to obtain the dense micro / nano ceramic fiber. The ceramic fiber prepared by the method for preparing dense micro / nano ceramic fiber by virtue of the coaxial electrospinning technology has the advantages of dense structure, no holes in the fiber, small diameter of fiber and far lower preparation temperature than that of the existing preparation technology and has good economic benefits and broad application prospects in such industries as machinery, metallurgy, chemical engineering, petroleum, ceramics, glass and electronics.

Owner:XIAN UNIV OF TECH

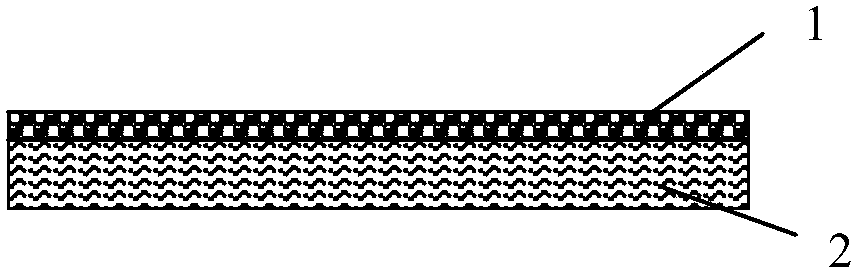

An alginate dressing for treating bedsore and a preparing method thereof

ActiveCN104758977APromote healingNo tissue proliferationAbsorbent padsBandagesPorosityComposite film

The invention relates to an alginate dressing for treating bedsore and a preparing method thereof. The dressing has a double-layer composite structure, namely the dressing comprises a base layer and a surface layer. The base layer is an alginate composite film layer. The surface layer is a natural rubber film layer. The preparing method includes following steps of: A) preparing a shark collagen solution, B) preparing a coaxial electrospinning outer layer solution, C) preparing a coaxial electrospinning core layer solution, D) spinning, E) crosslinking, F) dipping, G) preparing an epoxy natural rubber film, and H) compositing. The dressing has good biocompatibility, and has controllable growth regulation, good hygroscopicity, good anti-inflammation performance and good antibacterial performance of synthetic biological materials. The dressing is capable of improving local blood supply of wounds, promoting tissue growth and accelerating wound healing, shows good multifunctional properties, has good porosity, soft and comfort hand feeling, good compliance and using convenience, and can be used in the field of modern biomedicine, especially in the field of bedsore treatment and nursing, and the like.

Owner:HENAN YADU IND

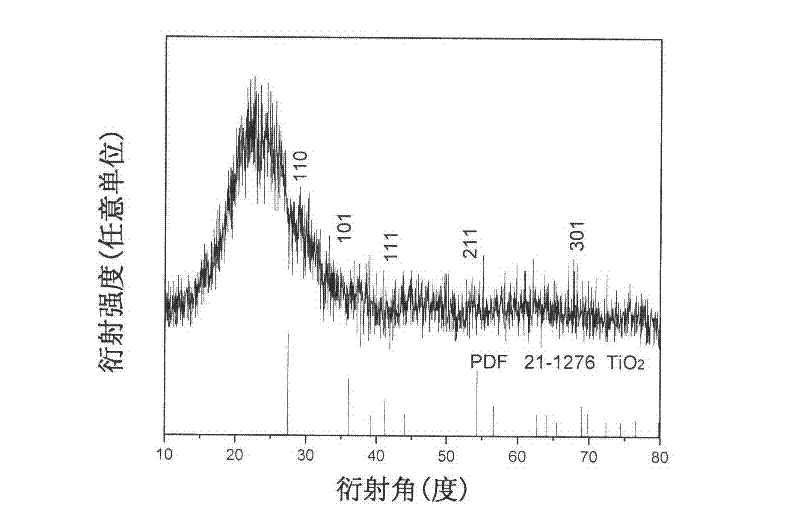

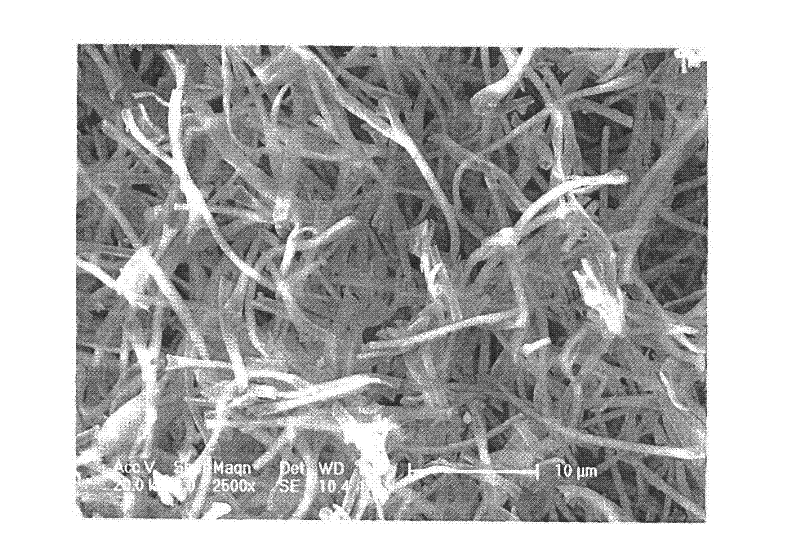

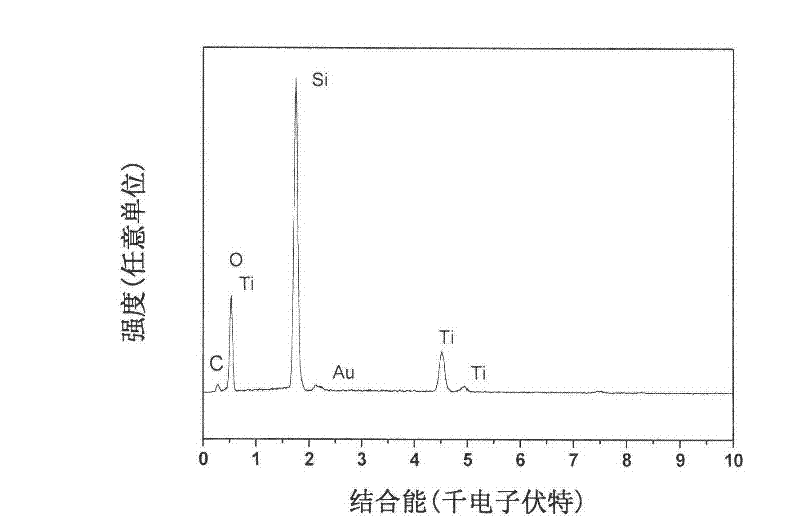

Method for preparing TiO2@SiO2 coaxial nanotube

Belonging to the technical field of nano-material preparation, the invention relates to a method for preparing a TiO2@SiO2 coaxial nanotube. The method comprises three steps: (1) spinning solution preparation: mixing polyvinylpyrrolidone, ethyl orthosilicate, absolute ethanol and chloroform so as to form a shell layer spinning solution, and mixing sesame oil, sorbitan oleate and butyl titanate soas to form an intermediate layer spinning solution; (2) preparation of a [sesame oil+Span-80+Ti(OC4H9)4]@[PVP+TEOS] coaxial hollow composite fiber: employing a coaxial electrospinning technology and using a three-layer coaxial spinning head, placing the shell layer spinning solution in an outer tube of the apparatus, putting the intermediate layer spinning solution in an intermediate tube of the apparatus, and leaving the inner tube empty and communicated with the atmosphere; (3) preparation of a TiO2@SiO2 coaxial nanotube: subjecting the coaxial hollow composite fiber to heat treatment so asto obtain the TiO2@SiO2 coaxial nanotube with an average diameter of 650nm. For the obtained TiO2@SiO2 coaxial nanotube, the hollow part has a diameter of 530nm, the inner wall is crystalline TiO2 and has thickness of 30nm, while the shell layer is non-crystalline SiO2 and has thickness of 30nm and length of over 20 micrometers. The method provided in the invention is simple and practicable, thusboasting wide application prospects.

Owner:CHANGCHUN UNIV OF SCI & TECH

Chitosan-nanofiber hemostatic material and preparation method thereof

InactiveCN103505758AImprove water absorptionGood fibrosisFilament/thread formingAbsorbent padsFiberBiological body

The invention provides a chitosan-nanofiber hemostatic material and a preparation method thereof. The chitosan-nanofiber hemostatic material is a core-shell nanofiber, wherein chitosan forms the shell of the nanofiber, polyvinyl alcohol forms the core of the nanofiber, and the diameter of the core-shell nanofiber is 100nm-20Mum. According to the invention, a coaxial electrospinning technology is adopted to prepare the nanometer material with a chitosan-polyvinyl alcohol (CS-PVP) core-shell structure, and the nanometer material has high chitosan content and a high specific surface and is used for hemostasis on living organisms. Experiments prove that the chitosan-polyvinyl alcohol nanofiber, provided by the invention, has good biocompatibility and excellent hemostasis performance, reserves the good water-absorption and fiber forming property of a PVP material, combines the excellent antibacterial hemostasis performance of a CS material, and can be clinically used for wound hemostasis. The preparation method is simple and fast, and has high efficiency.

Owner:南通南京大学材料工程技术研究院

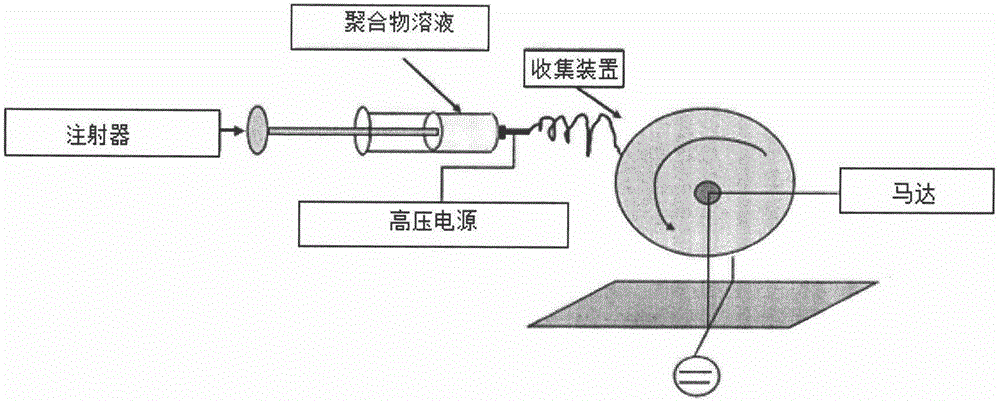

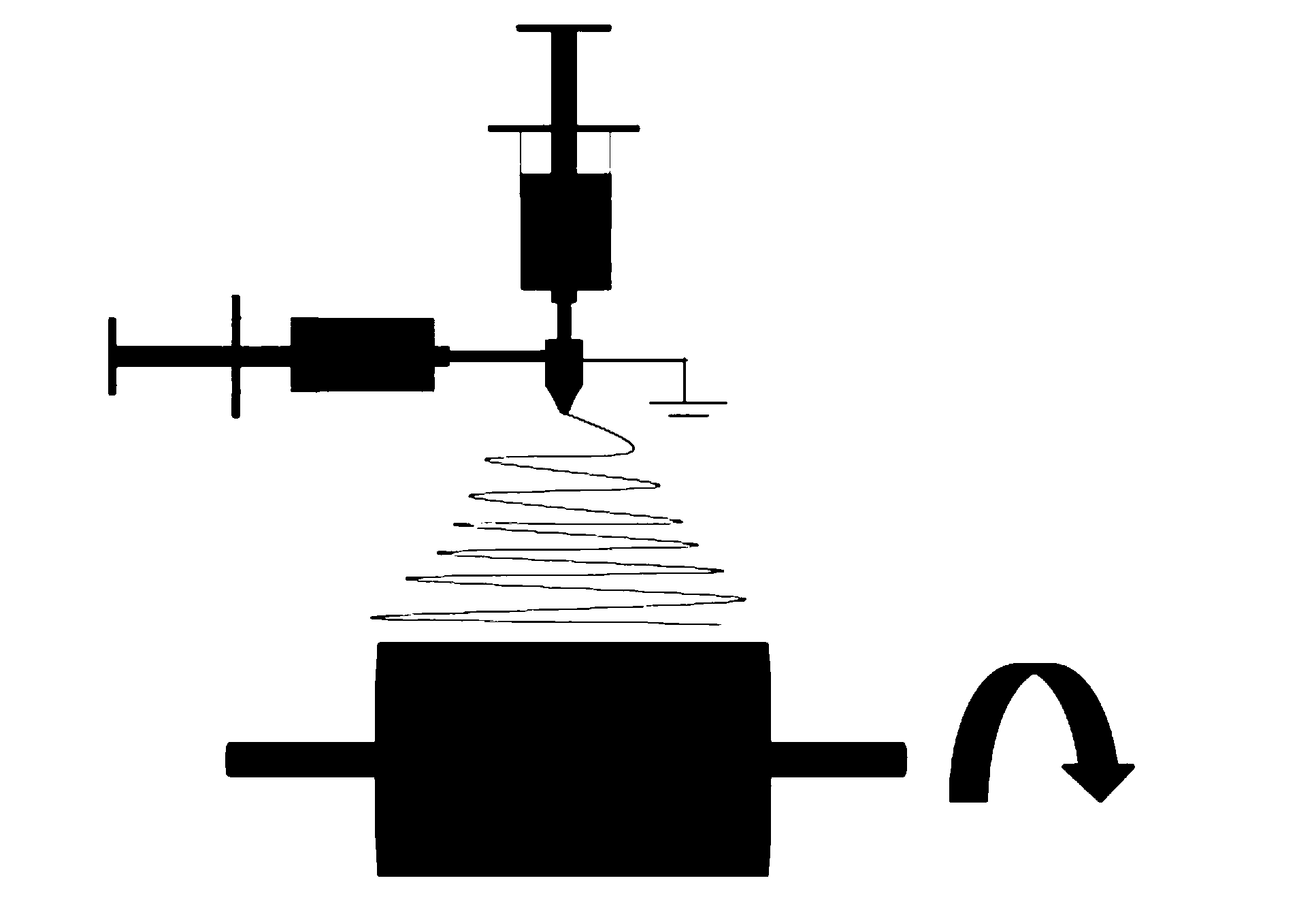

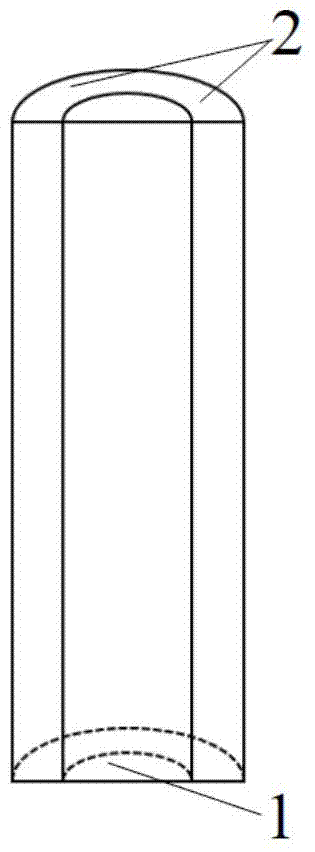

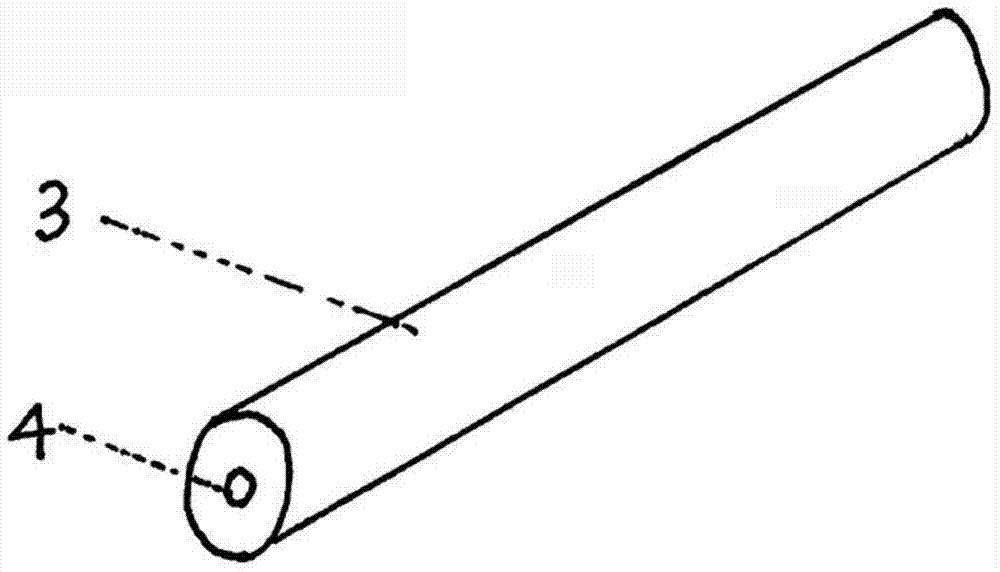

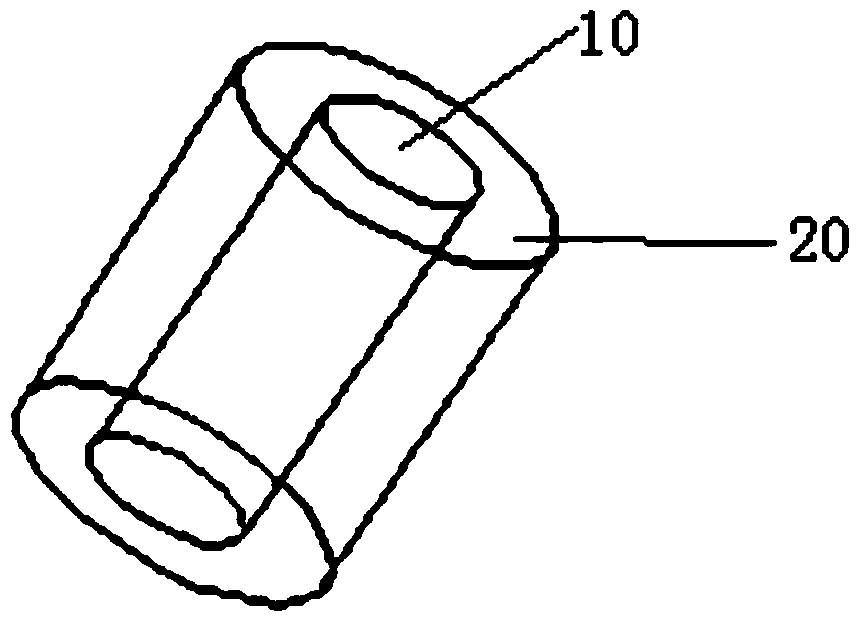

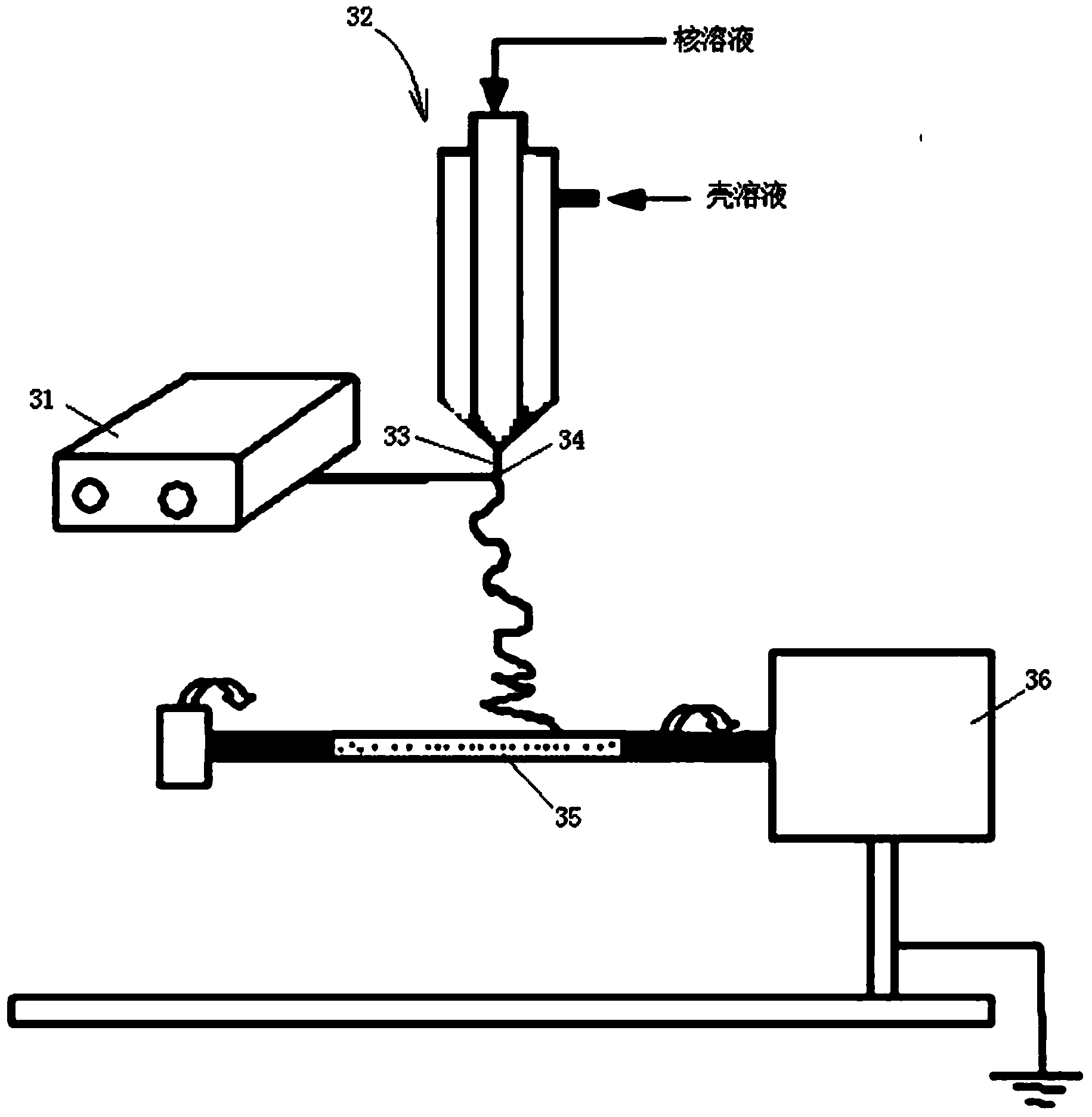

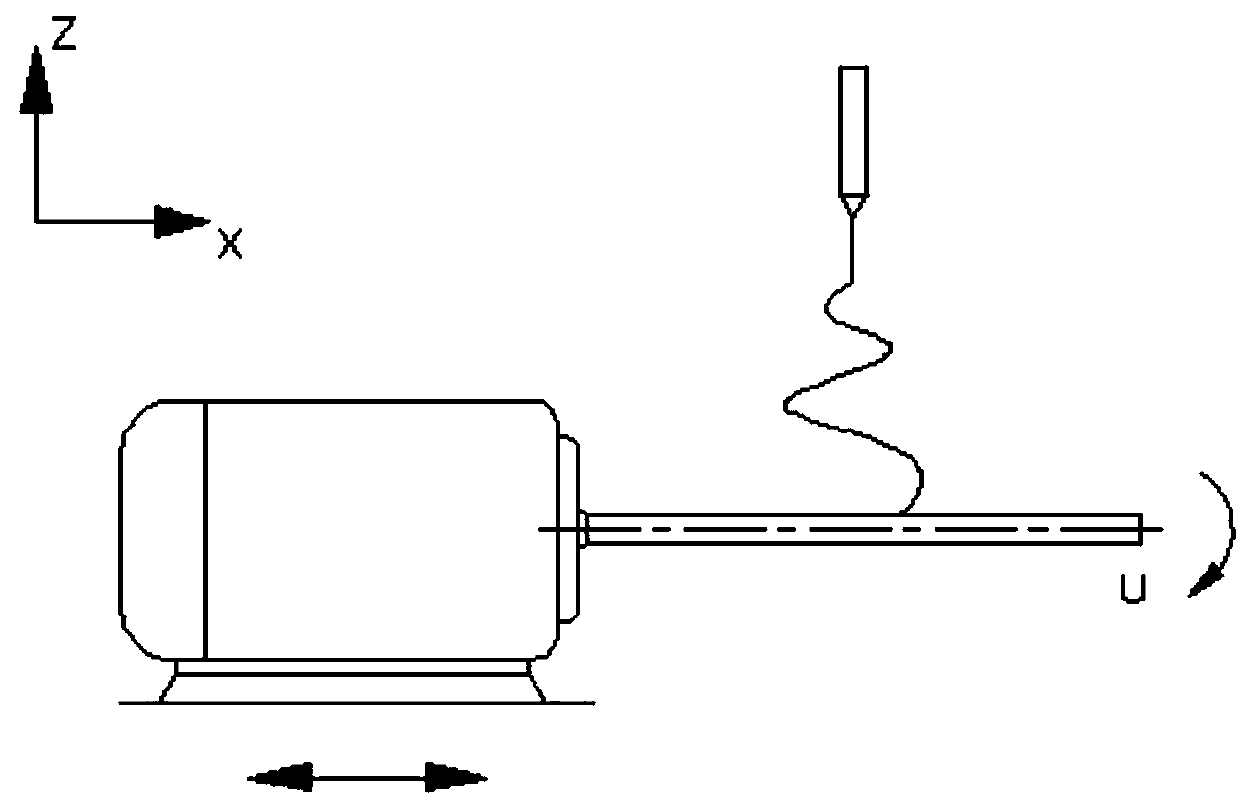

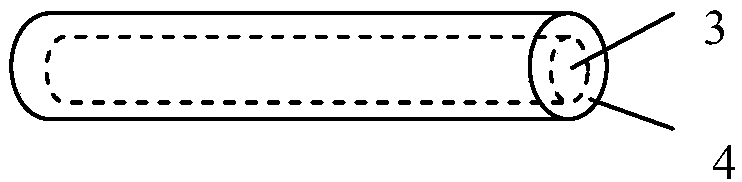

Preparation method of controlled-release oriented nanofiber nerve conduit

InactiveCN102091353AAbundant resourcesSimple manufacturing methodCatheterFiberBiocompatibility Testing

The invention relates to a preparation method of a controlled-release oriented nanofiber nerve conduit. The method comprises the following steps: preparing a core layer solution, preparing a skin layer solution, performing coaxial electrospinning, preparing a controlled-release oriented nanofiber membrane with a high-speed rotary drum receiving device and preparing the nanofiber nerve conduit. The preparation method in the invention has advantages of simple and practical, rich raw material sources, good biocompatibility and biodegradability, and is easy to realize industrial production. The prepared nerve conduit has wide application prospects in the clinical treatment of peripheral nerve damage.

Owner:JIAXING UNIV

Traditional Chinese medicine asiaticoside carrying core/shell structure nanometer fiber film preparation method and wound dressing use

The invention discloses a preparation method and use of a traditional Chinese medicine asiaticoside carrying core / shell structure nanometer fiber film. The traditional Chinese medicine asiaticoside carrying core / shell structure nanometer fiber film is prepared from a lactic acid / glycollic acid copolymer (PLGA) as a shell and polycaprolactone (PCL) as an inner core through a coaxial electrospinning method. The preparation method has the advantages of use of easily available raw materials, operation easiness, good controllability and large scale industrial production easiness. The traditional Chinese medicine asiaticoside carrying core / shell structure nanometer fiber film can be used for wound dressing and has the advantages of controllable drug loading amount, high drug utilization rate and excellent wound healing promoting effect.

Owner:杭州珈晟生物数字技术有限公司

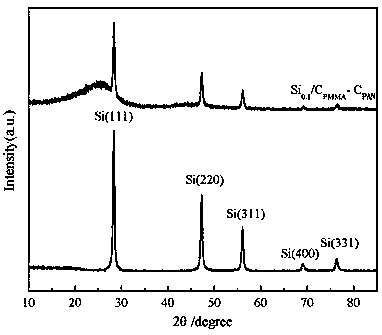

Preparation method of nanometer silicon-carbon composite negative electrode material for lithium ion battery

ActiveCN108923035AShorten the diffusion migration pathImprove electrochemical activityCell electrodesSecondary cellsCarbon compositesCarbon layer

The invention discloses a preparation method of a nanometer silicon-carbon composite negative electrode material for a lithium ion battery. The preparation method comprises: preparing fiber filamentsfrom an inner layer precursor emulsion and an outer layer precursor emulsion through a coaxial electrospinning technique, and carrying out load freeze-drying-load hot pressing-load heat treatment andtwo carbonization treatment processes to obtain the nanometer silicon-carbon composite negative electrode material. The nanometer silicon-carbon composite negative electrode material has small and even fiber diameters and a large specific surface area. The load heat treatment reduces the thickness of the carbon layer. The nanometer silicon carbon composite negative electrode material has a good specific capacity and cycle performances. The preparation method effectively shortens the diffusion path of lithium ions and solves the problem that the nanometer silicon particles are pulverized through the volume expansion effect and are easy to collapse. The preparation method has a good application prospect.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

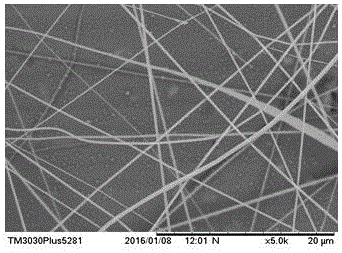

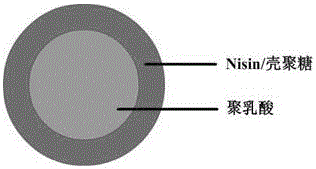

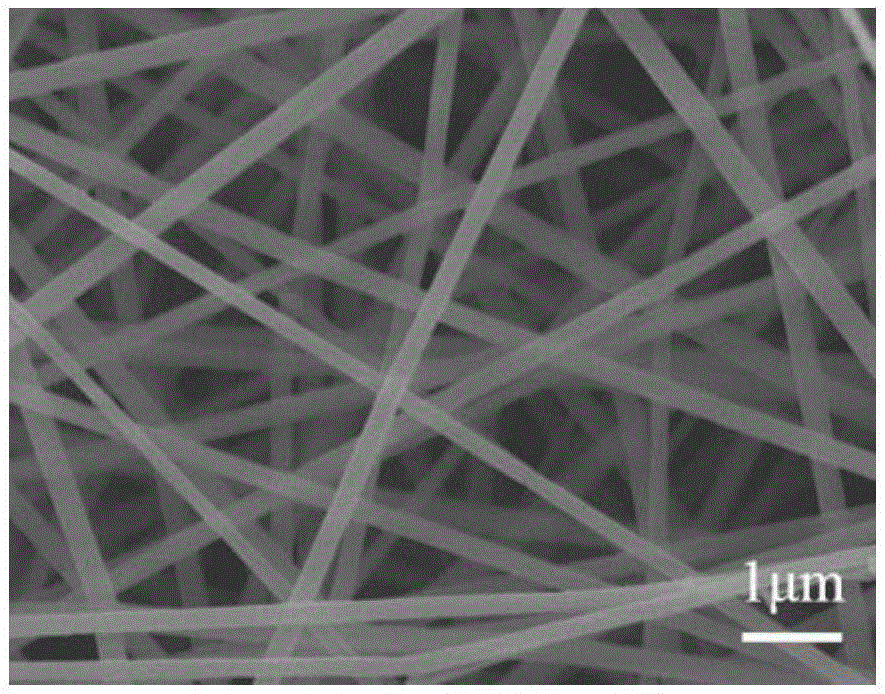

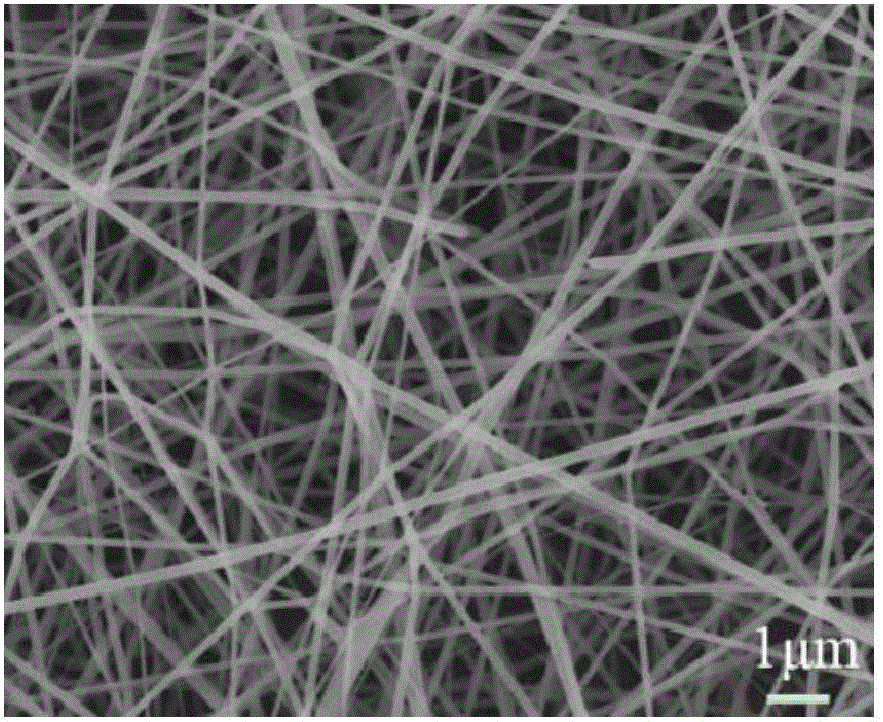

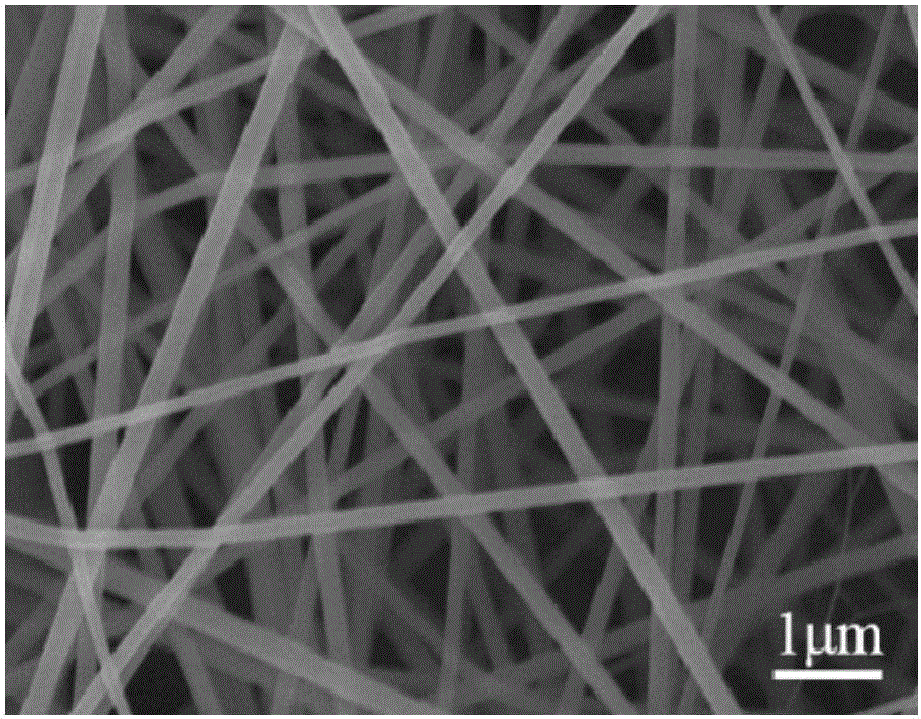

Method for preparing Nisin/chitosan/polylactic acid composite nanofiber mats by coaxial electrospinning

InactiveCN106668930ASpatial structure is stableImprove thermal stabilityFilament/thread formingAbsorbent padsWound dressingPolylactic acid

The invention discloses a method for preparing Nisin / chitosan / polylactic acid composite nanofiber mats by coaxial electrospinning. The method comprises the following steps: dissolving chitosan in an acetic acid solution, stirring and dissolving to prepare a chitosan solution; adding Nisin, stirring to prepare a Nisin / chitosan solution which is used as a shell spinning solution for coaxial electrospinning; dissolving polylactic acid in dichloromethane to prepare a polylactic acid solution which is used as a core spinning solution for coaxial electrospinning; and carrying out coaxial electrospinning on the shell spinning solution and the core spinning solution to prepare the Nisin / chitosan / polylactic acid composite nanofiber mat with Nisin and chitosan as the shell and with polylactic acid as the core. The method is simple and feasible, and cost is low. The prepared biodegradable bioactive antiseptic composite nanofiber mat can be used in the fields of wound dressing, tissue engineering and food package and the like, has excellent antibacterial effects, is safe and harmless, and will not cause drug resistance of bacteria.

Owner:ZHEJIANG UNIV +1

Nanofiber membrane and preparation method and application thereof

InactiveCN106676754AReduce releaseSmall and uniform fiber diameterOrganic active ingredientsFilament/thread formingFiberGenipin

The invention provides a nanofiber membrane and a preparation method and application thereof. The nanofiber membrane is formed by fibers of a core-shell structure and is characterized in that the core is formed by mixed fibers mixed by polylactic acid-hydroxyacetic acid and polycaprolactone, the shell is formed by fibers formed by gelatin crosslinking with genipin, and the core is loaded with chemical therapy medicine. The nanofiber membrane prepared by the coaxial electrospinning technology has an in-situ anti-cancer function and is implantable, good in biocompatibility, free of cytotoxicity to normal cells and good in curative effect on tumor. The preparation method is simple, mild in condition, low in cost and easy to popularize and apply.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Preparation method of photo-thermal response nanofiber oil and water separation membrane

InactiveCN107881649AEasy to separateImprove separation efficiencyMembranesSemi-permeable membranesFiberCarbon nanotube

The invention provides a preparation method of a photo-thermal response nanofiber oil and water separation membrane. The preparation method of the photo-thermal response nanofiber oil and water separation membrane includes the following steps that polymethyl methacrylate-b-poly-N- isopropylmethacrylamide (PMMA-b-PNIPAM) is synthesized; electrospinning is conducted on a polyurethane (PU) nanofibermembrane; a PMMA-b-PNIPAM membrane into which 1 wt% of carbon nanotubes and silver nanoparticles are added separately is subjected to electrospinning; a PU / PMMA-b-PNIPAM nanofiber membrane is subjected to coaxial electrospinning, wherein the carbon nanotubes and the silver nanoparticles are added into PMMA-b-PNIPAM separately; a contact angle experiment is adopted to represent the photo-thermal response performance of the PU / PMMA-b-PNIPAM nanofiber membrane; oil-water nano-emulsion separating experiments are conducted. The preparation method of the photo-thermal response nanofiber oil and water separation membrane has the advantages that by conducting surface modification on the fiber membrane, the PU / PMMA-b-PNIPAM nanofiber membrane which has biodegradability and photo-thermal response performance and is low in cost and free of toxicity is obtained; the high-performance PU / PMMA-b-PNIPAM nanofiber membrane has broad application prospects in oil and water separation, sewage treatment and deep-sea oil spill.

Owner:NANJING FORESTRY UNIV

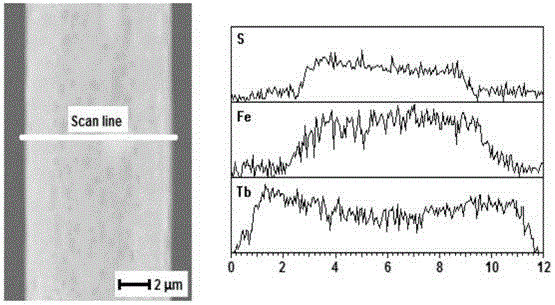

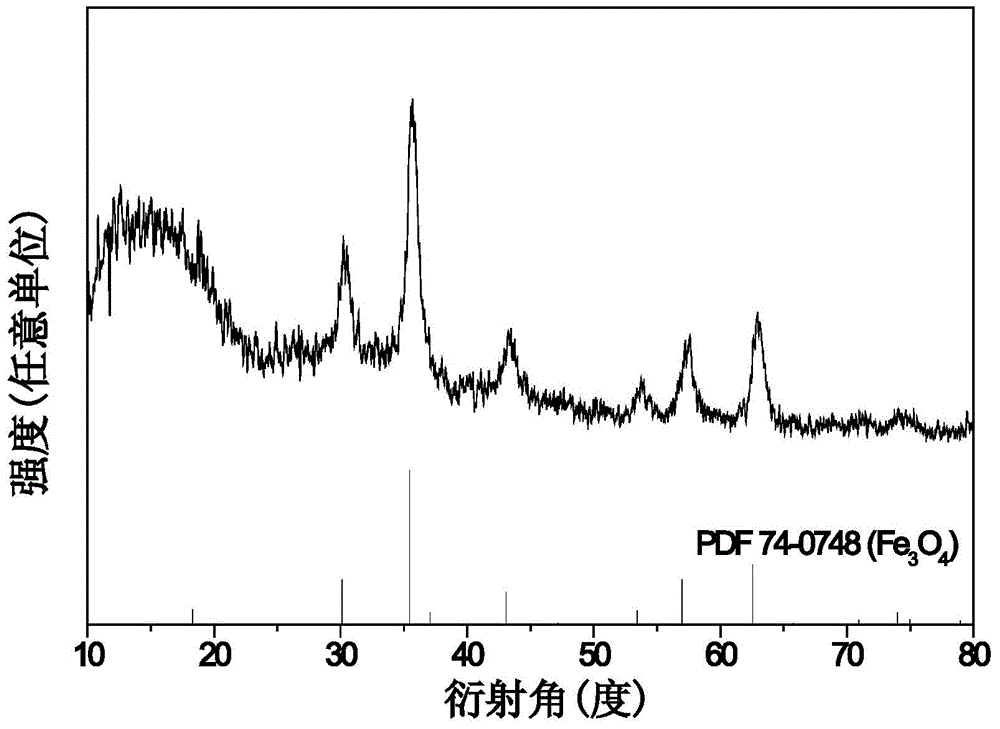

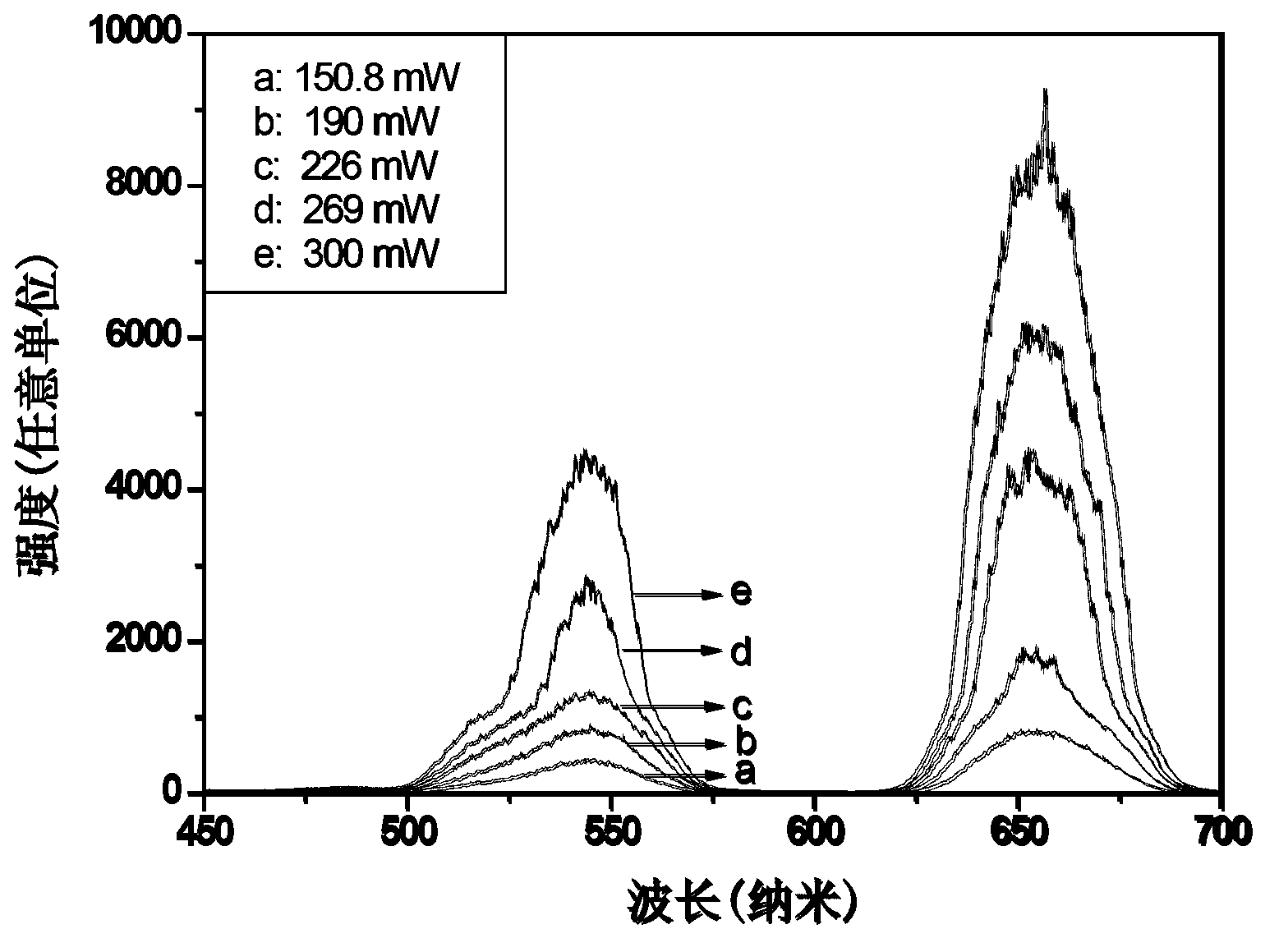

Photo-electro-magnetic three-function banded coaxial nano cable array and preparation method thereof

ActiveCN104538121AIndividual molecule manipulationFilament/thread formingMaterials preparationNano structuring

The invention relates to a photo-electro-magnetic three-function banded coaxial nano cable array and a preparation method thereof, belonging to the technical field of nanometer material preparation. The method comprises the following five steps: (1) preparing Fe3O4 nanocrystalline coated with oleic acid by precipitation; (2) preparing a Tb(BA)3phen complex by precipitation; (3) preparing polymethyl methacrylate; (4) preparing spinning solution; and (5) preparing a [Fe3O4 / PANI / PMMA]@[Tb(BA)3phen / PMMA] photo-electro-magnetic three-function banded coaxial nano cable array by a coaxial electrospinning technology. The prepared banded coaxial nano cable array has good luminescence, conductivity and magnetism. The width of a banded coaxial nano cable is 10 microns, the thickness is less than 1 micron, and the length is greater than 500 microns. The method of the invention is simple and easy, and supports mass production. The novel nano structure material has broad application prospects.

Owner:CHANGCHUN UNIV OF SCI & TECH

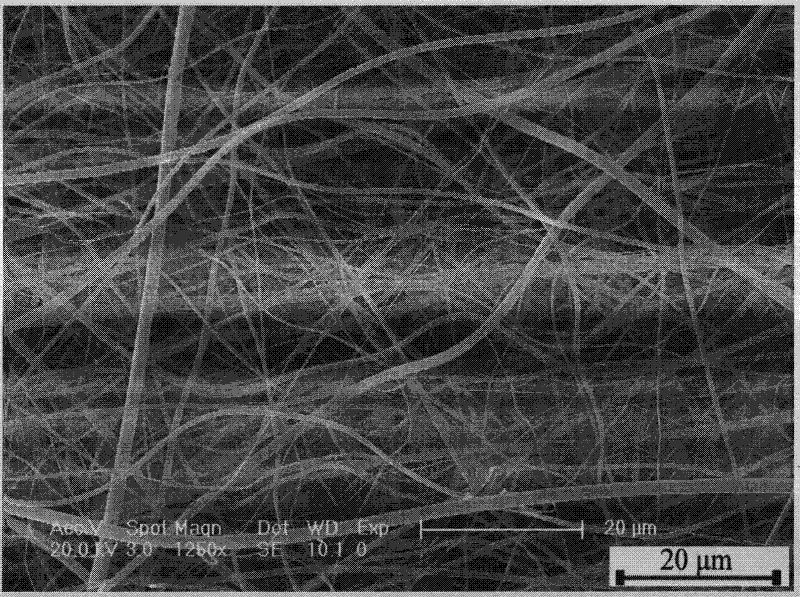

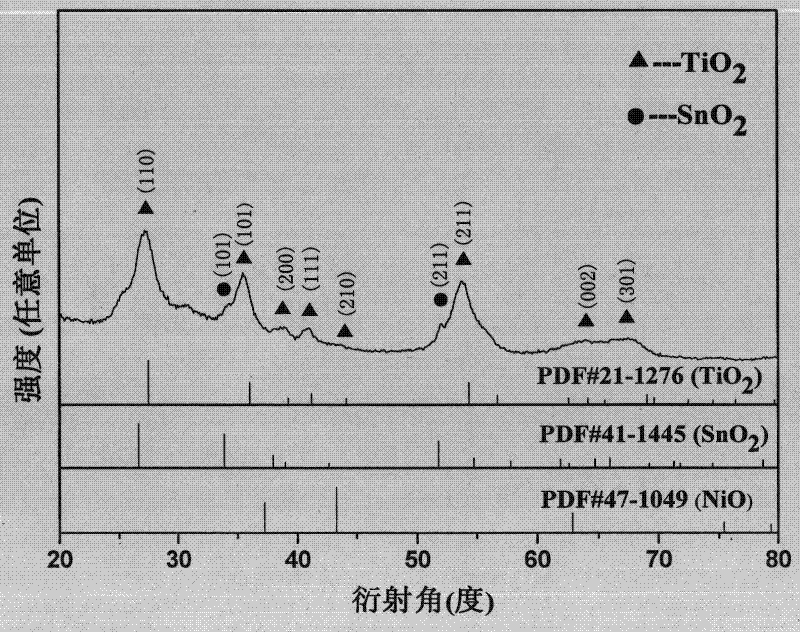

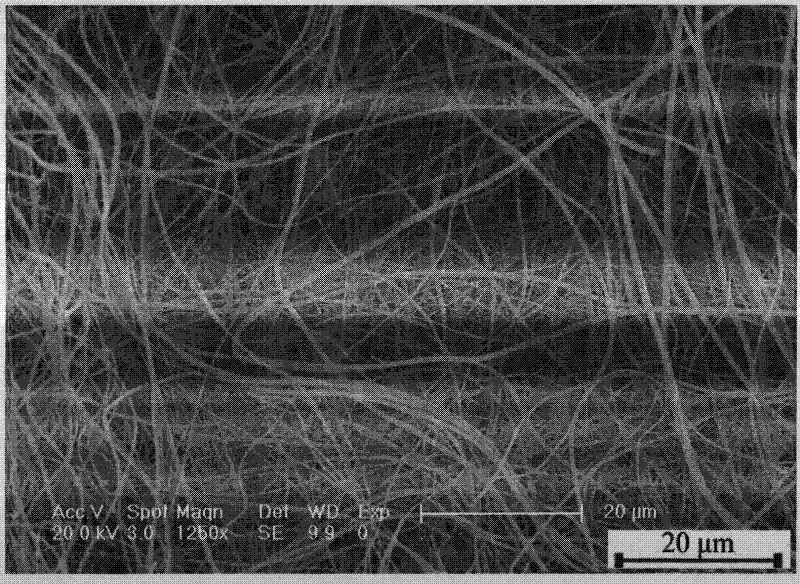

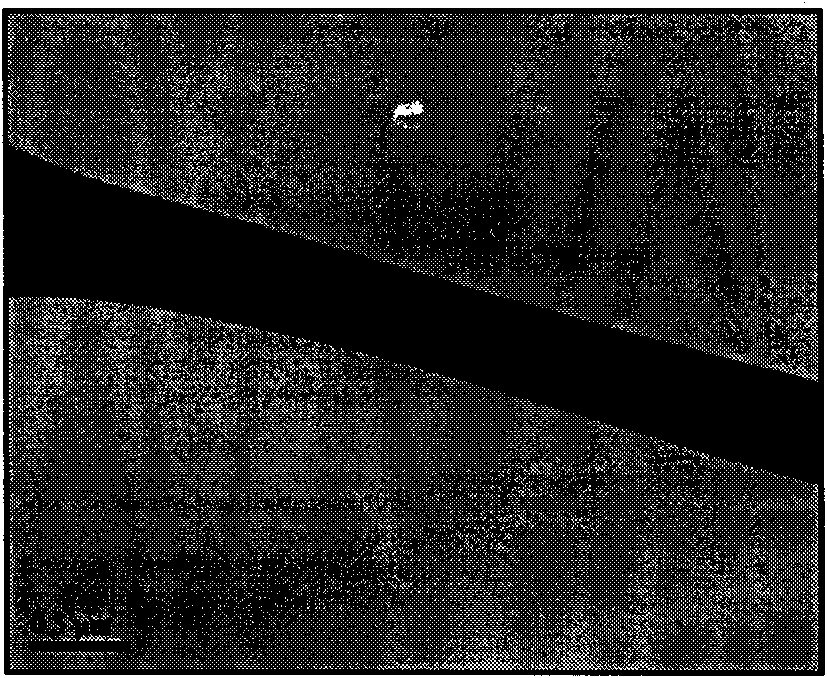

Preparation method of coaxial three-layer nano cable NiO@SnO2@TiO2

InactiveCN102191571AFilament/thread formingConjugated artificial filamentsN dimethylformamideNickel acetate tetrahydrate

The invention relates to a preparation method of a coaxial three-layer nano cable NiO@SnO2@TiO2, belonging to the technical field of preparation of nano materials. The method comprises the following three steps: (1) preparation of spinning liquids: adding nickel acetate tetrahydrate and polyvinylpyrrolidone (PVP) into N,N-dimethylformamide (DMF) to form a core layer spinning liquid, adding tin tetrachloride pentahydrate and PVP into DMF to form a middle layer spinning liquid, and adding tetrabutyl titanate, PVP and glacial acetic acid into ethanol to form a shell layer spinning liquid; (2) preparation of [Ni(CH3COO)2+PVP]@[SnCl4+PVP]@[Ti(OC4H9)4+CH3COOH+PVP] precursor composite cable: by using a coaxial electrostatic spinning technology and a coaxial three-layer spinning jet, curing at the room temperature of 22-25 DEG C under the voltage of 18kV, wherein the curing distance is 15cm, and the relative humidity 40-50%; and (3) preparation of coaxial three-layer nano cable NiO@SnO2@TiO2:carrying out heat treatment on the precursor composite cable to obtain the NiO (core layer)@SnO2 (middle layer)@TiO2(shell layer) coaxial three-layer nano cable of which the diameter is 340-434 nm and the length is greater than 300 mu m: heating at a rate of 1 DEG C / min, keeping the temperature of 600 DEG C for 8 hours, cooling at a rate of 1 DEG C / min to 200 DEG C, and naturally cooling to room temperature.

Owner:CHANGCHUN UNIV OF SCI & TECH

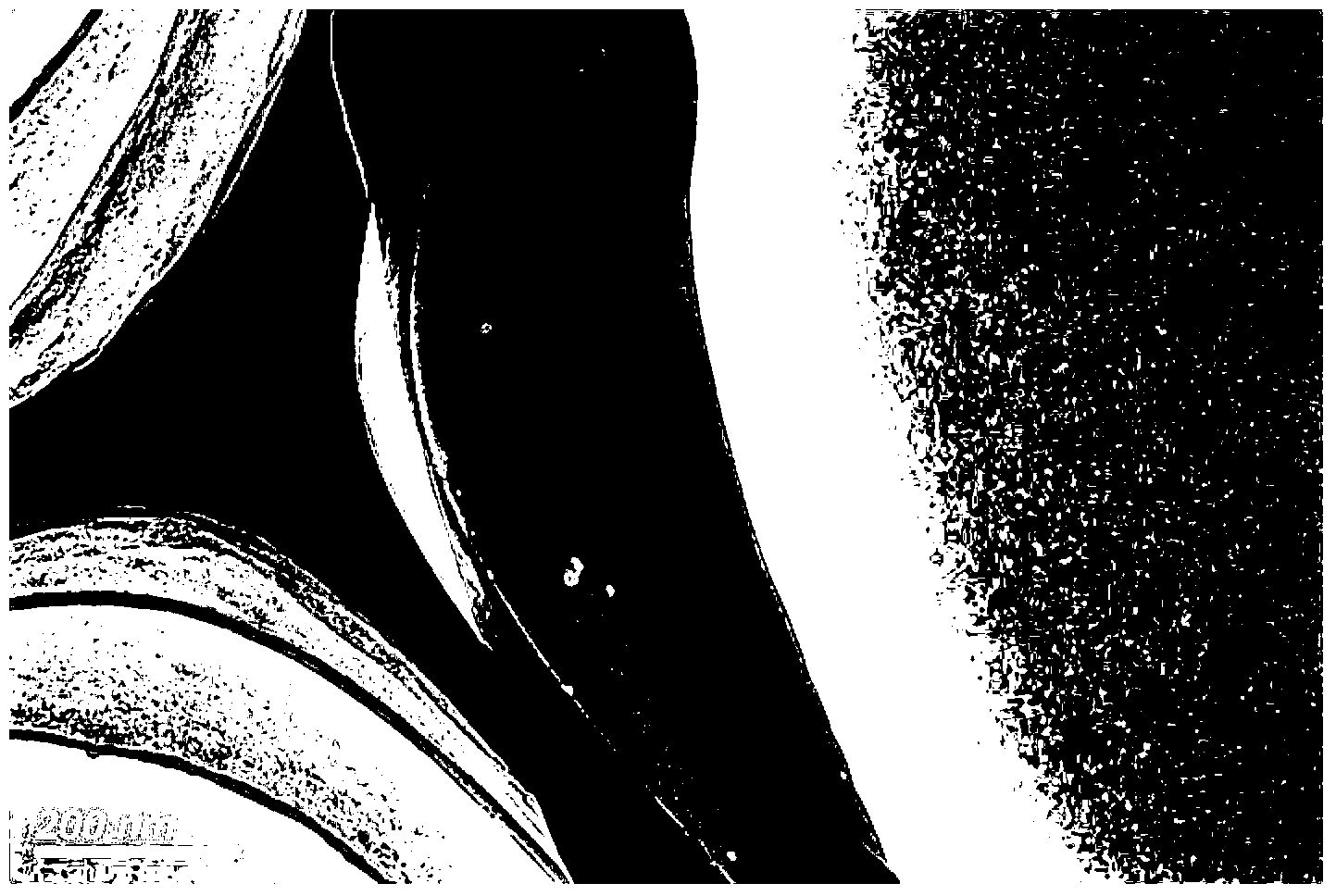

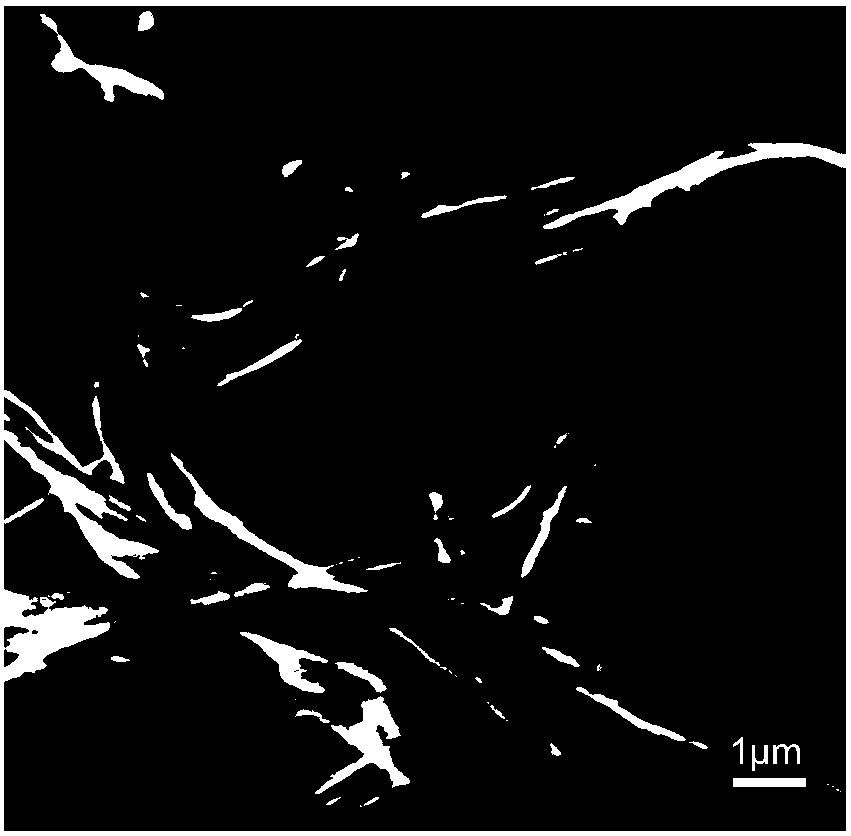

Emulsion core coaxial electrically spun ultrafine fibrous membrane with clad proteins and preparation method thereof

InactiveCN101892529AReduce burstConjugated cellulose/protein artificial filamentsFilament/thread formingFiberLactide

The invention relates to a method for preparing an emulsion core coaxial electrically spun ultrafine fibrous membrane with clad proteins, which comprises the following step of electrospinning by using a device the same with coaxial electrospinning by using an emulsion containing bovine serum albumin (BSA) as an inner core solution and using a polyethylene glycol-co-poly(lactide-co-caprolactone) solution as a shell solution. The preparation method of the emulsion comprises following steps of: using polyethylene glycol-co-poly(lactide-co-caprolactone) or the chloroformic solution of the polyethylene glycol-co-poly(lactide-co-caprolactone) as an oil phase, using 300-500 mg / mL of BAS aqueous solution as a water phase, adding the water phase into the oil phase and oscillating by a cyclone mixer for 5 min to prepare the emulsion. The electrospinning voltage is 16 kV; the reception distance is 20 cm; and the flow rate of the inner core solution is 0.05-0.1 mL / h. The cladding of the BSA in the fiber is determined by a transmission electron microscope. The electrically spun fiber prepared by using the method is also applicable for the cladding and the release of other proteins.

Owner:TIANJIN UNIV

Method for building three-dimensional enzyme electrode surface by using coaxial nanofibers

InactiveCN102645474AQuick responseImprove curing stabilityMaterial nanotechnologyCell electrodesCross-linkComputational chemistry

The invention provides a method for building a three-dimensional enzyme electrode surface by using coaxial nanofibers. The method comprises the following steps: preparing a coaxial electrospinning kernel material by dissolving a high molecular weight polymer and a high-orientation nano material into water; preparing a coaxial electrospinning shell material by dissolving enzymes or proteins with catalytic property and a high molecular weight polymer together into water; spinning nanofibers on an electrode surface by using a coaxial electrospinning method; and cross-linking by using a cross-linking agent to obtain a three-dimensional enzyme electrode. The conditions of the coaxial electrospinning method are that spinning voltage is 8-30kV, liquid flow rate is 0.5-2mL / h, and spinning interval is 10-100cm. According to the method, the coaxial electrospinning technology is used to prepare a coaxial nanofiber film electrode, the preparation of the enzyme electrode is finished by relatively simple steps, the surface enzyme immobilization stability of the enzyme electrode is improved, the response speed of the enzyme electrode is improved, and the output power of a fuel battery is increased.

Owner:HARBIN ENG UNIV

Nanofiber, organic solar cell using same, and a method for preparing organic solar cell

ActiveCN108511609AAct as a supporting structureRealize the purpose of electrospinning into silkMaterial nanotechnologyArtificial filament physical treatmentFiberOrganic solar cell

The invention discloses a nanofiber, an organic solar cell and a method for preparing an organic solar cell by using the nanofiber. A target material, which is less likely to be made into fibers, is made into fibers by using a novel coaxial electrospinning technology, thereby obtaining a nanofiber suspension of the target material. Then, the obtained target material nanofiber is processed and thenadded to the active layer of the organic solar cell. Therefore, negative influences on device performance due to the thickness increase of the active layer is eliminated by the characteristics of high crystallinity, large specific surface area and good structural continuity of the nanofiber, thereby significantly improving multiple optoelectronic performance parameters of the device and providinga possibility for breaking the battery efficiency bottleneck.

Owner:NANJING UNIV OF TECH

Preparation method for porous inorganic photocatalytic composite nanometer fiber

InactiveCN104032406ARealize the loadMaintain photocatalytic activityCatalyst carriersFilament/thread formingFiberPtru catalyst

A preparation method for porous inorganic photocatalytic composite nanometer fiber comprises the following steps: a) mixing a high-molecular spinning base material and an organic silicate, adding a solvent and stirring uniformly, so as to prepare a surface-layer spinning solution of a coaxial electrospinning solution, mixing a high-molecular spinning base material and an organic titanate, adding a solvent and stirring uniformly, so as to prepare a core-layer spinning solution of the coaxial electrospinning solution; b) respectively inputting the surface-layer spinning solution and the core-layer spinning solution into a coaxial syringe needle with constant flow velocity and a constant flow-velocity ratio for performing coaxial high-voltage electrospinning preparation, so as to obtain composite nanometer fiber; and c) performing high-temperature processing on the composite nanometer fiber at nitrogen atmosphere to remove a high-molecular spinning base material in the composite nanometer fiber, and then naturally cooling to room temperature, so as to obtain the porous inorganic photocatalytic composite nanometer fiber. According to the preparation method, the tradition that a photocatalyst is supported on the surface of a carrier is changed, instead, the catalyst is supported in a carrier material, so that the specific surface area for photocatalysis is relatively substantially increased, the photocatalytic activity of the composite photocatalytic material is improved, and the photocorrosion problem of the photocatalytic material to a base material is effectively solved.

Owner:ZHEJIANG SCI-TECH UNIV

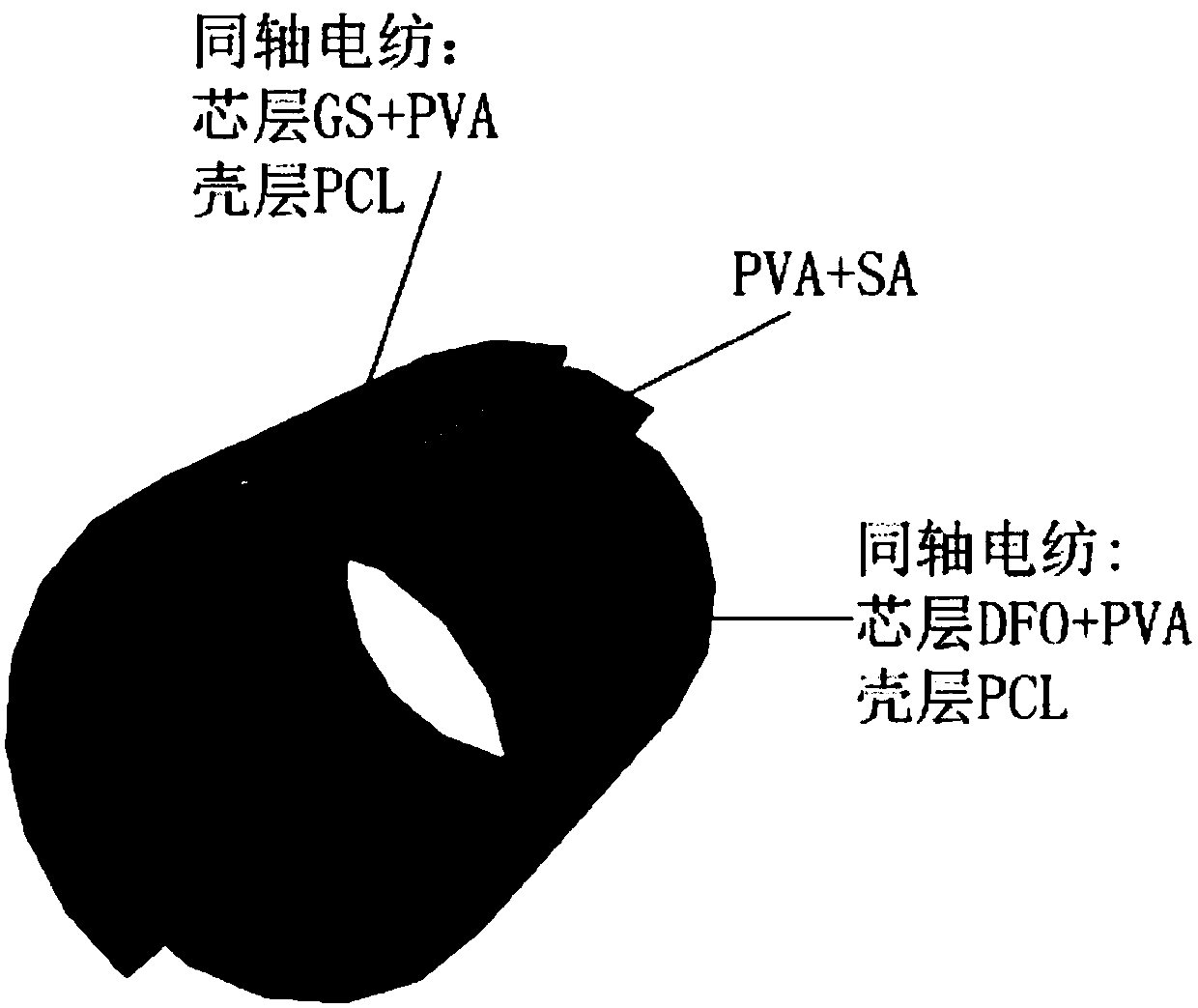

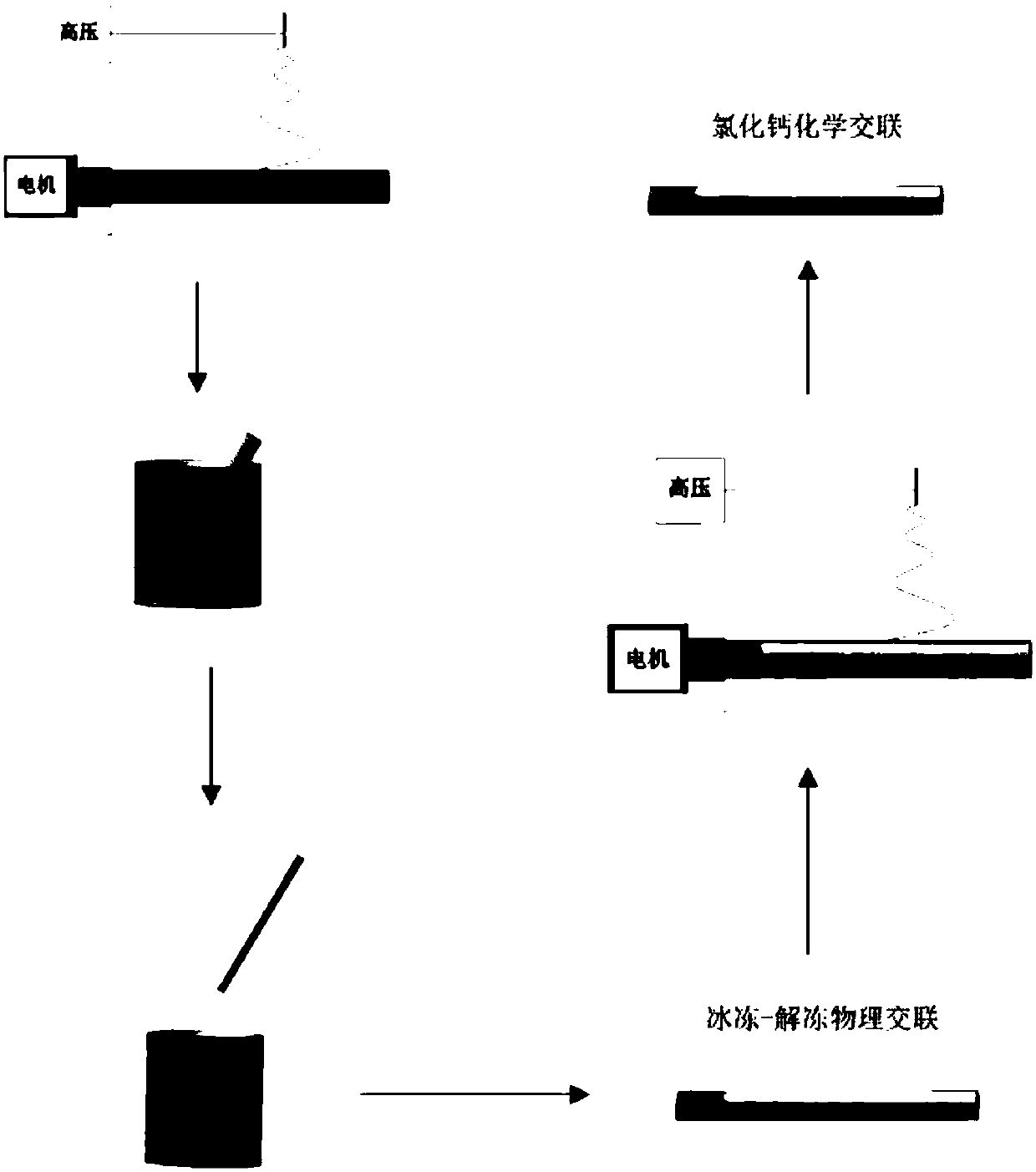

Artificial medicine carrying coaxial regenerated intravascular stent and compound process preparation method thereof

ActiveCN107898533ABiocompatiblePromote generationStentsPharmaceutical delivery mechanismCross-linkBlood vessel

The invention discloses an artificial medicine carrying coaxial regenerated intravascular stent and a compound process preparation method thereof. The intravascular stent is provided with a three-layer structure which is prepared through different process methods, an inner-layer material adopts a deferoxamine DFO+PVA core layer solution and a PCL shell layer solution, and a coaxial electrospinning forming process is adopted; a middle-layer material adopts a PVA+SA mixed solution, a dipping method forming process is adopted, and calcium chloride is adopted for cross linking after outer layer electrospinning is carried out; an outer-layer material adopts a gentamicin GS+PVA core layer solution and a PCL shell layer solution, and the coaxial electrospinning forming process is adopted. The three-layer medicine carrying intravascular stent is prepared through the two processes by compounding different materials, the three-layer structure of a natural blood vessel is simulated well, the time needed by in-vitro culture and transplantation is shortened, the success rate is increased, and the intravascular stent has wide prospects in clinical application.

Owner:SHANGHAI UNIV

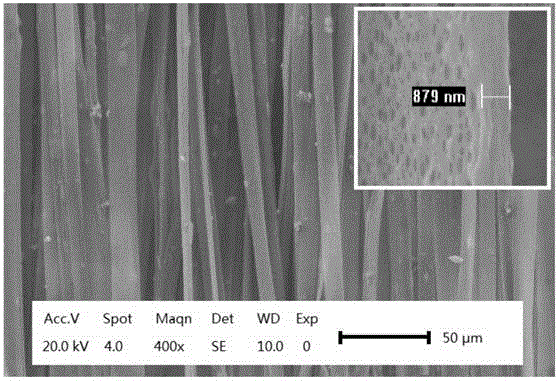

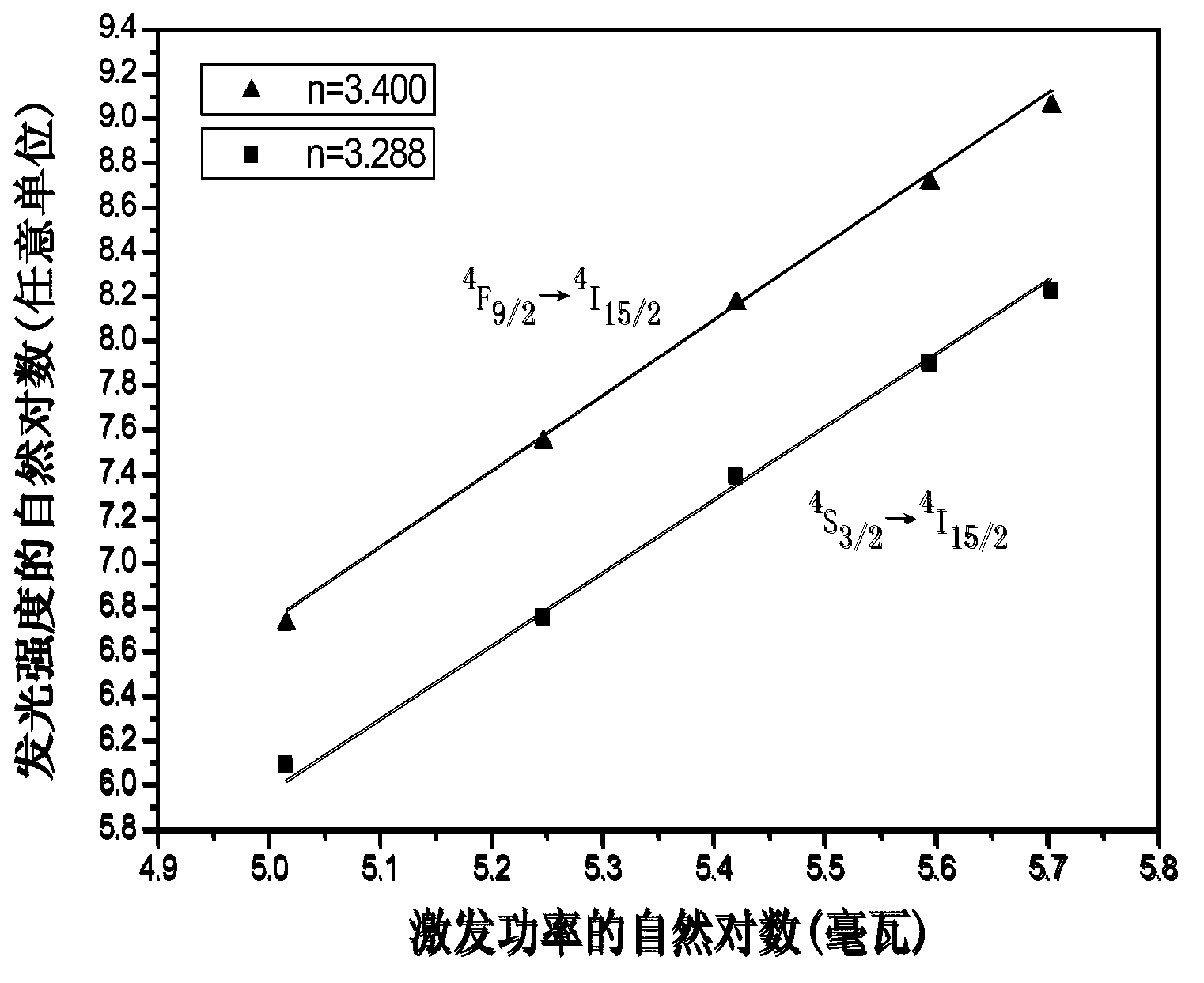

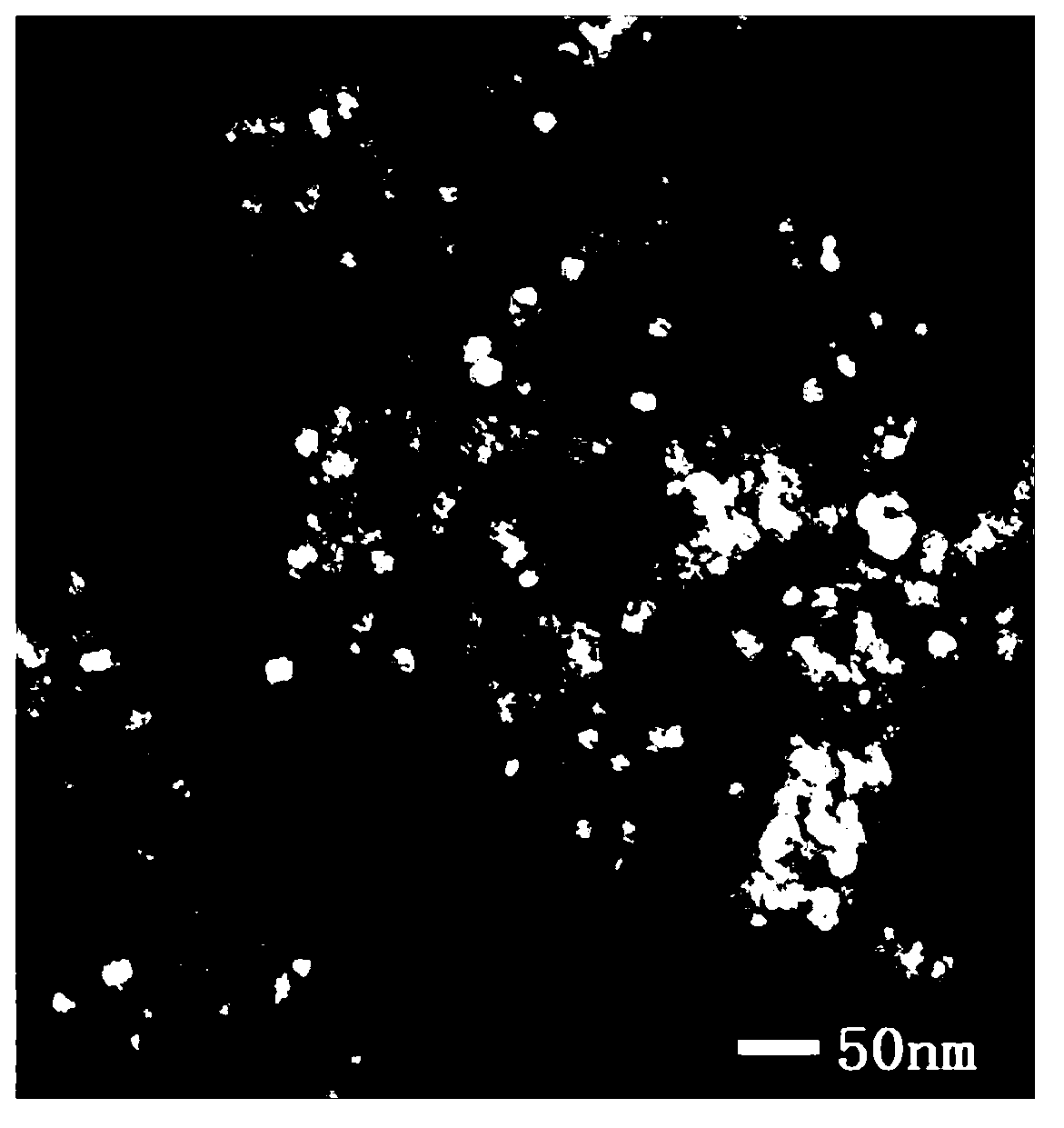

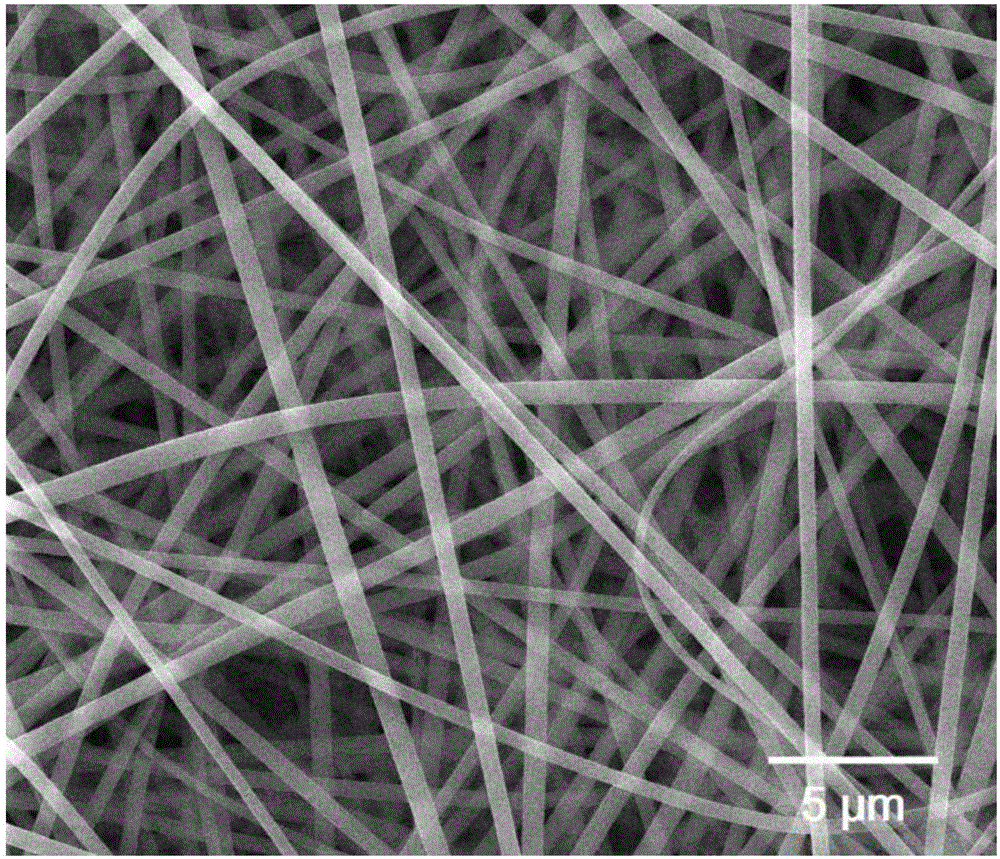

Magnetic up-conversion luminescence dual-functional coaxial composite nanofiber and preparation method thereof

InactiveCN103225121AFilament/thread formingConjugated artificial filamentsMaterials preparationUpconversion luminescence

The invention relates to magnetic up-conversion luminescence dual-functional coaxial composite nanofiber and a preparation method thereof, and belongs to the technical field of nano material preparation. The preparation method comprises four steps as follows: 1), an Fe3O4 nanocrystalline material is prepared with a precipitation method; 2), an NaYF4: Yb3+, Er3+ nanocrystalline material is prepared with the precipitation method; 3), a spinning solution is prepared; and 4), an [Fe3O4 / PVP]@[NaYF4: Yb3+, Er3+ / PVP] magnetic up-conversion luminescence dual-functional coaxial composite nanofiber is prepared by using a coaxial electrospinning technique, the average diameter of the coaxial composite nanofiber is 390 nm, the core layer diameter is 130 nm, the casing thickness is 130 nm, and the length is larger than 100 mu m. The coaxial composite nanofiber which has magneto-optical dual functions and novel structure can have an important application prospect. The method is simple and feasible, batch production can be achieved, and a wide application prospect is provided.

Owner:CHANGCHUN UNIV OF SCI & TECH

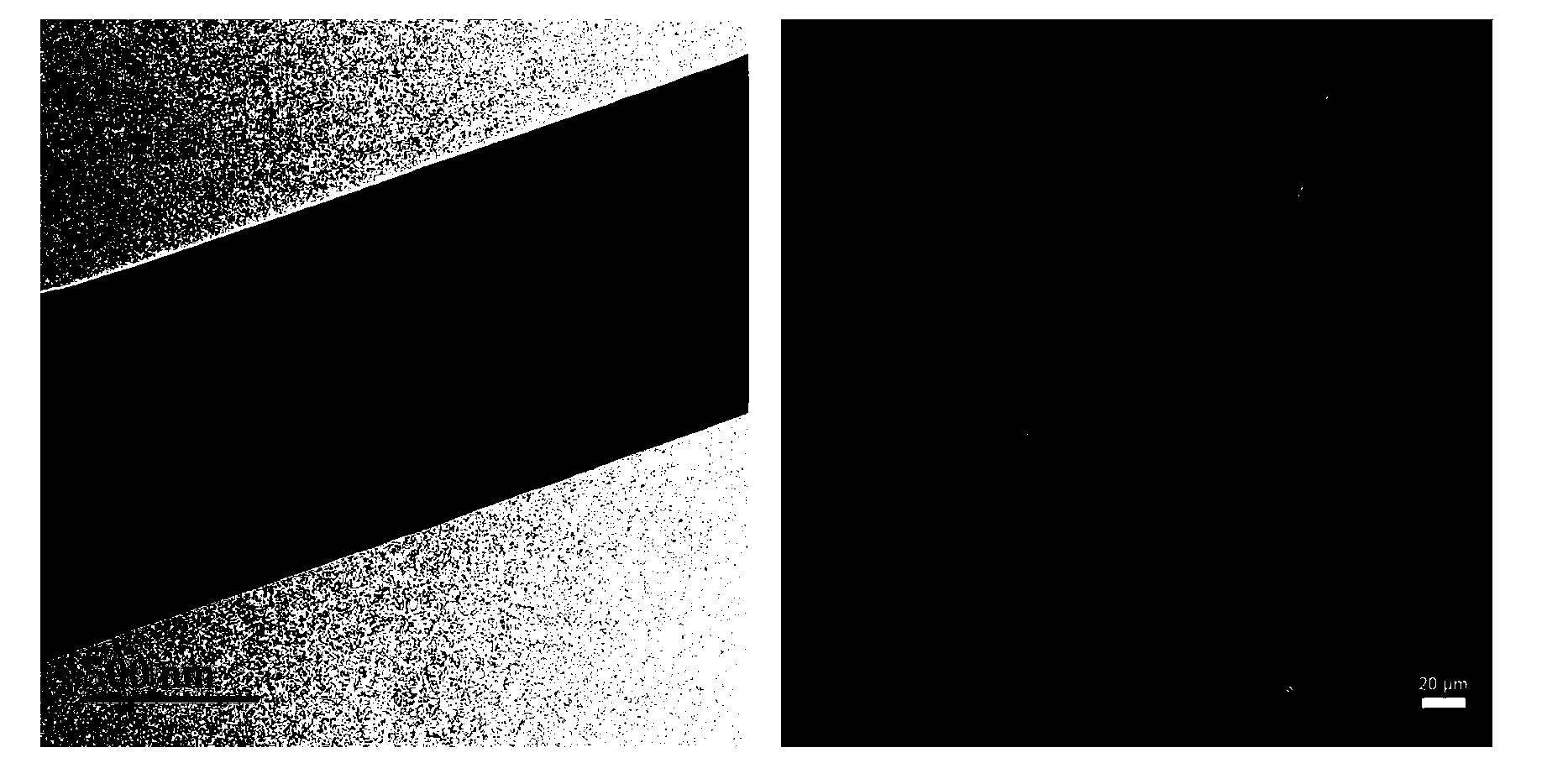

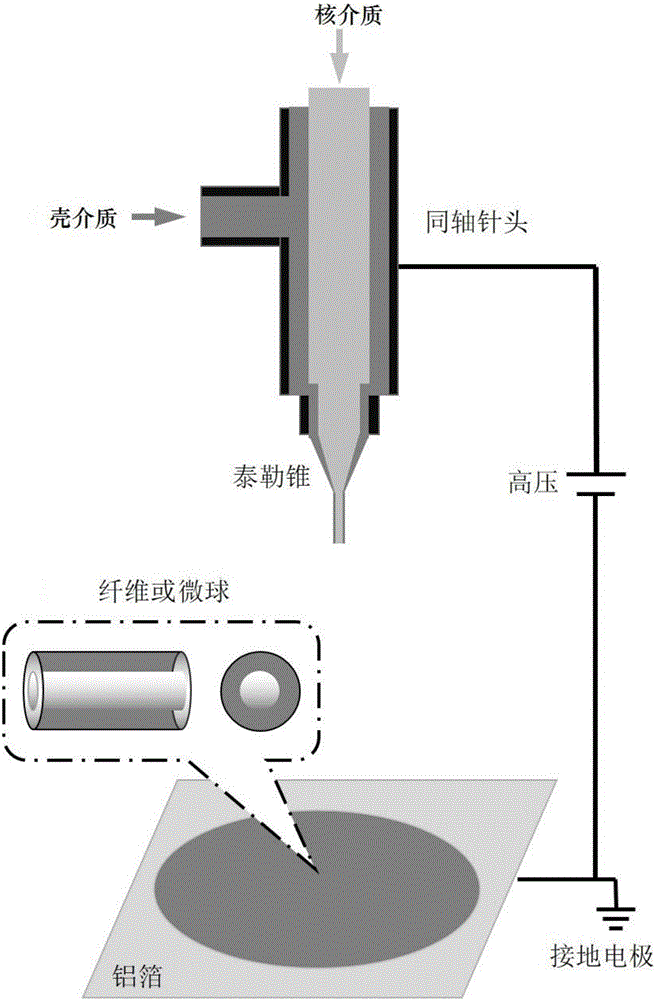

Coaxial electrospun polyimide micro/nano hollow structure material and preparation method thereof

ActiveCN106498558ASimple manufacturing processHigh yieldElectro-spinningConjugated synthetic polymer artificial filamentsFiberMicrosphere

The invention discloses a preparation method of a coaxial electrospun polyimide micro / nano hollow structure material. The preparation method uses a dimethylformamide solution of polyimide as a shell medium, uses a pore-forming agent solution as a core medium, prepares fibers of core-shell structure through coaxial electrospinning method, and then acquires the micro / nano hollow structure material after removing the core medium through post-processing. The preparation method is simple and quick in preparation process, high in yield, and capable of preparing fibers or microspheres of hollow structure.

Owner:BEIHANG UNIV

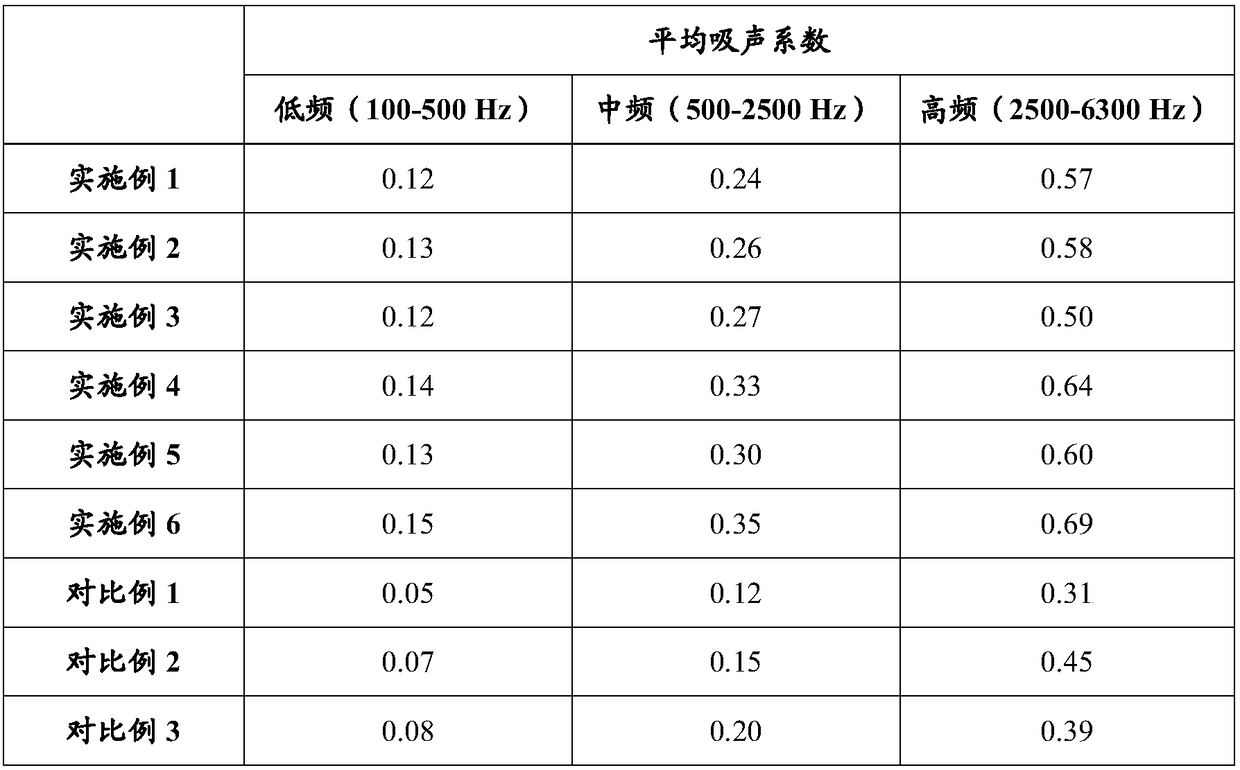

High-temperature-resistant sound-absorbing fiber membrane and preparation method

InactiveCN108085872AHigh porosityImprove performanceFilament/thread formingNon-woven fabricsFiberAviation

The invention provides a high-temperature resistant sound-absorbing fiber membrane and a preparation method. The fiber membrane is a polyimide piezoelectric composite nanofiber membrane with a hollowstructure; the preparation method particularly comprises the following steps that 1, a polyamide acid (PAA) solution of composite piezoelectric ceramic powder is prepared; 2, the PAA composite solution is a shell spinning solution, a polystyrene (PS) solution is a nuclear layer spinning solution, a coaxial electrospinning technology is adopted, and a PAA / PS nano composite fiber with a nuclear shell structure is obtained; 3, high-temperature imidization treatment is conducted, internal PS is removed through thermal decomposition, and a piezoelectric fiber membrane with a hollow structure is obtained; 4, polarization treatment is conducted, the polyimide nano fiber prepared through the method is uniform in size, the hollow structure is complete, the fiber membrane has the high porosity, thematerial has the light porous hollow structure facilitating sound wave dissipation and the piezoelectric effect generated by piezoelectric particles, the excellent sound absorption property is shown,the good high temperature resistant property and mechanical property are achieved, the sound absorption and noise reduction requirements in the high temperature environment can be met, and the high-temperature resistant sound-absorbing fiber membrane is applicable to the fields of aviation, spaceflight, military equipment and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Slow release type chitosan antibacterial dressing and preparation method thereof

PendingCN108498846ARich varietyGood compatibilityFilament/thread formingAbsorbent padsCuticleEffective action

The invention discloses a slow release type chitosan antibacterial dressing and belongs to the technical field of wound repair. The problems are solved that traditional dressings have low functionality and requirements of wound healing cannot be met. The dressing comprises a nanofiber membrane and a spunlaced non-manufactured substrate; the nanofiber membrane is composed of nanofibers having a structure of a shell layer and a core layer; the core layer is made of human epidermal growth factors and bovine serum albumin, and the shell layer is made of chitosan and polyvinyl alcohol. The invention also discloses a preparation method of the slow release type chitosan antibacterial dressing. On the basis of a coaxial electrospinning technology, by combining with on on-line deposition process, the slow release type chitosan antibacterial dressing made of the human epidermal growth factors is prepared; through slow release of the human epidermal growth factors, the effective action time of the human epidermal growth factors on partial wounds is prolonged, the synergistic healing and antibacterial effects of the human epidermal growth factors and chitosan can also be exerted, and the effect of accelerating wound healing is achieved.

Owner:NANTONG UNIVERSITY

Preparation method and application of iron-cobalt-loaded nitrogen-doped carbon fiber self-supporting membrane catalyst

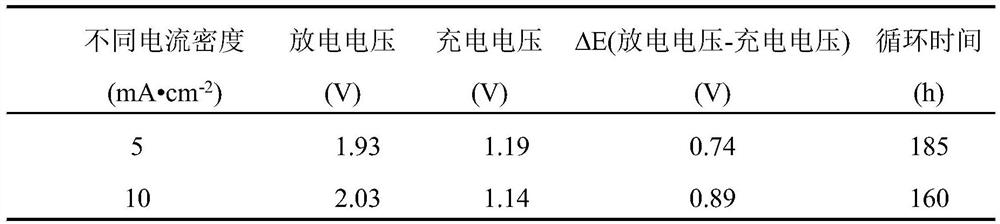

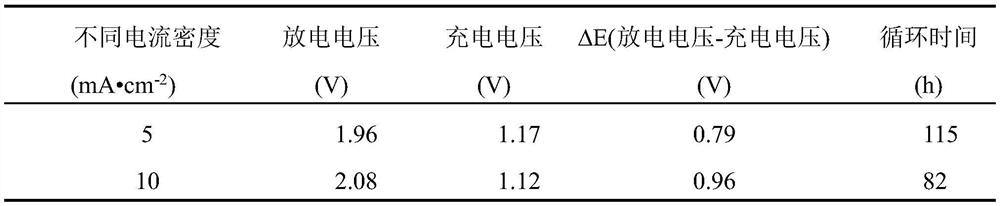

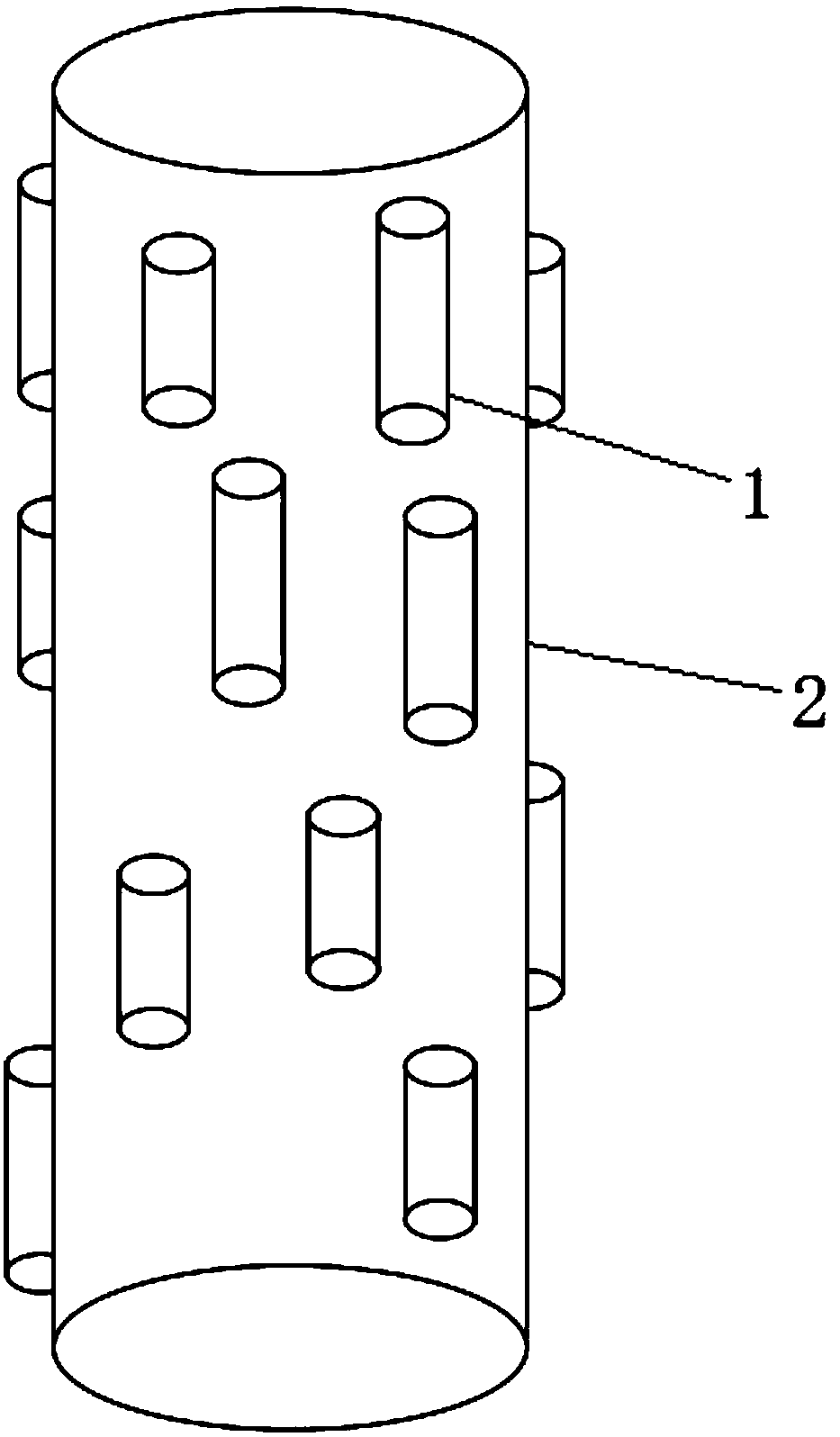

ActiveCN112397733AExcellent ORRExcellent OER performanceFuel and primary cellsCell electrodesFiberCarbon fibers

The invention discloses a preparation method and application of an iron-cobalt-loaded nitrogen-doped carbon fiber self-supporting membrane catalyst. The invention belongs to the technical field of zinc-air battery electrode materials. The transition metal electrocatalyst which can replace commercial Pt / C and RuO2 and is of a three-dimensional net-shaped hollow structure is synthesized through a coaxial electrostatic spinning technology, and a zinc-air battery with the catalyst as a cathode has high power density and stability. The method comprises the following steps: mixing a transition metalprecursor with a carbon source solution to obtain a shell precursor solution and a core precursor solution respectively, obtaining a nanofiber precursor through a coaxial electrostatic spinning technology, and carrying out heat treatment after coordination. An electrode material prepared from the iron-cobalt-loaded nitrogen-doped carbon fiber self-supporting membrane provided by the invention hasexcellent oxygen electro-catalysis capability and power density. The initial potential of the oxygen reduction reaction is 0.96 V, and the potential of the oxygen evolution reaction under the condition of 10mA. Cm<-2> current density is 1.68 V; and the limit power density of the assembled zinc-air battery can reach 205mW. Cm <-2>.

Owner:HEILONGJIANG UNIV

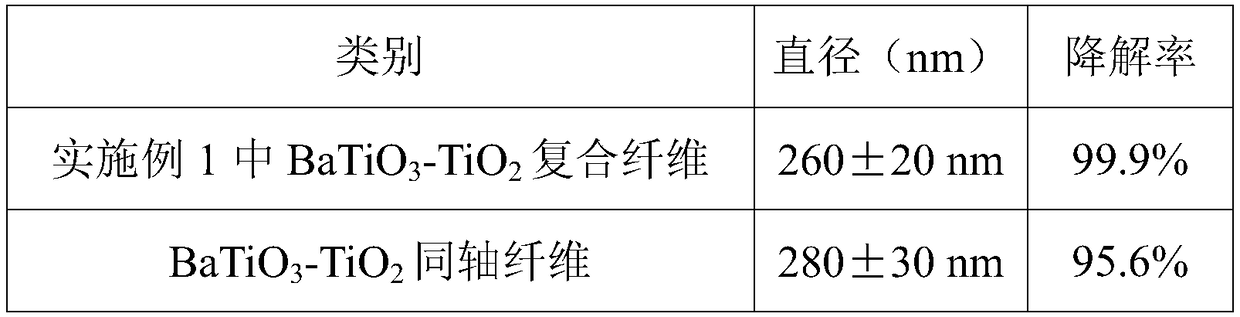

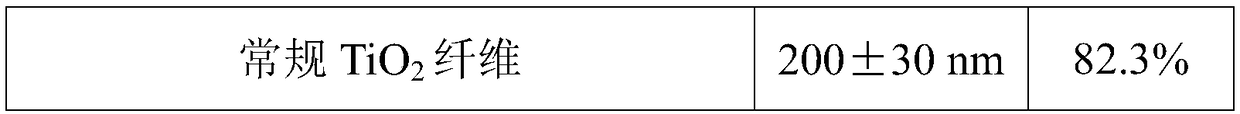

A kind of preparation method of piezoelectric photocatalytic composite fiber

ActiveCN108411406BImprove mechanical propertiesImprove photocatalytic reaction efficiencyHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsElectricityFiber

The invention discloses a method for preparing piezoelectric photocatalytic composite fibers, which includes the following steps: step 1, prepare raw materials; step 2, prepare spinning liquid; step 3, coaxial electrospinning; step 4, calcining treatment: 5. Fiber polarization treatment: This invention can obtain a high-density interface between the piezoelectric material exposed on the fiber surface and the photocatalyst, and make full use of the internal electric field at the interface between the piezoelectric material and the photocatalyst to effectively drive photogenerated electrons and holes. separation, thereby efficiently improving the photocatalytic reaction efficiency.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com