Patents

Literature

967results about How to "Realize the load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

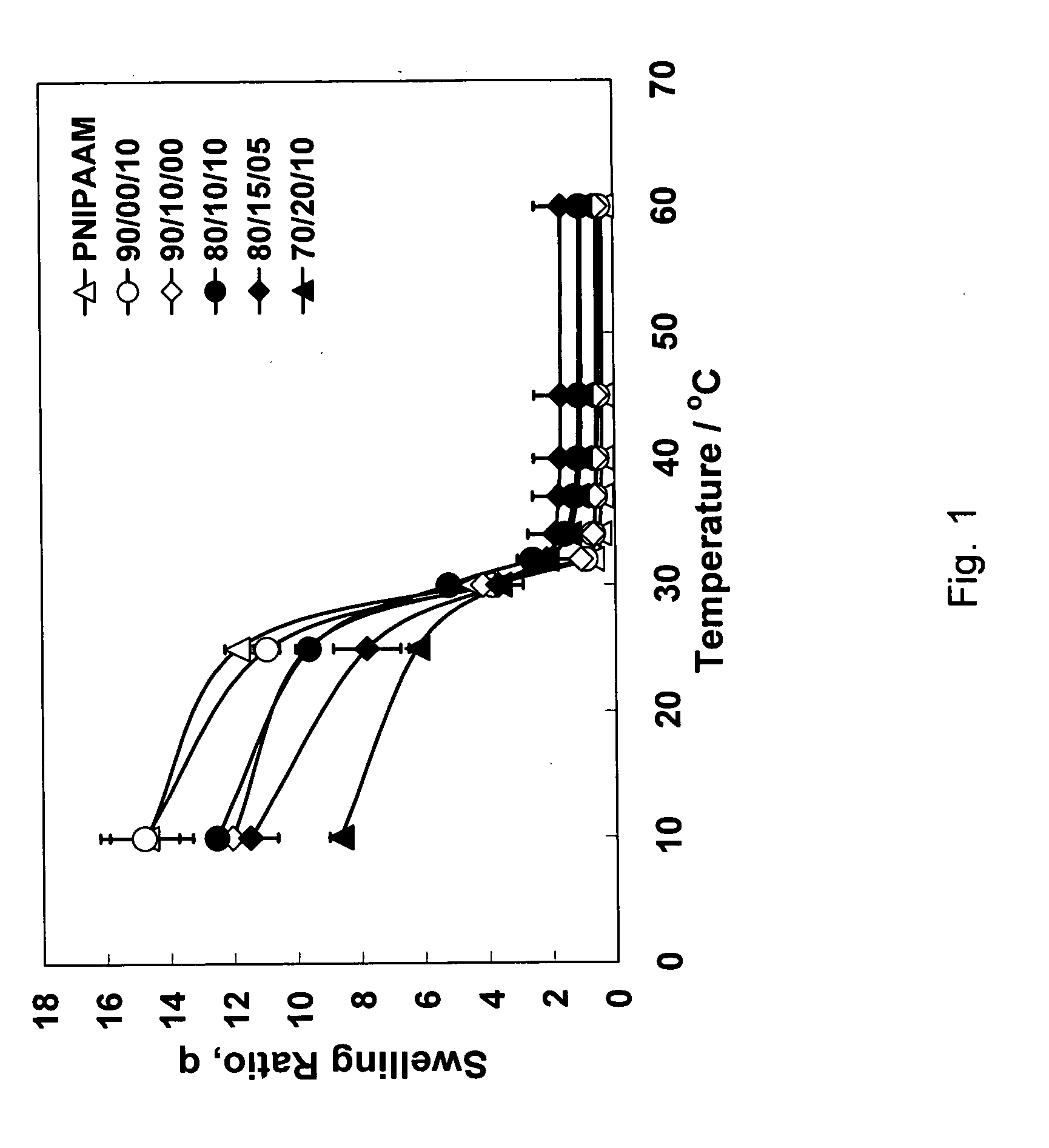

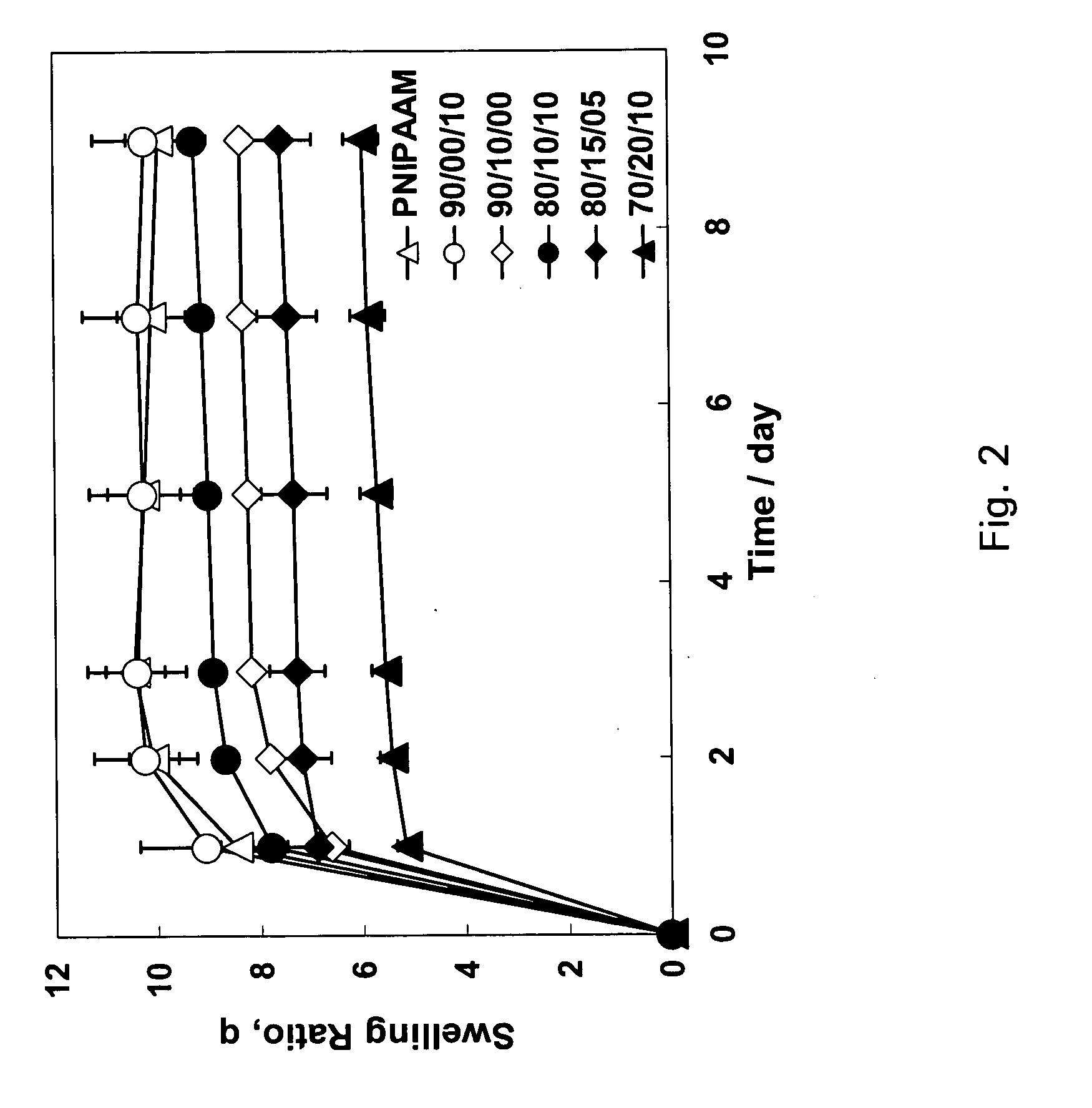

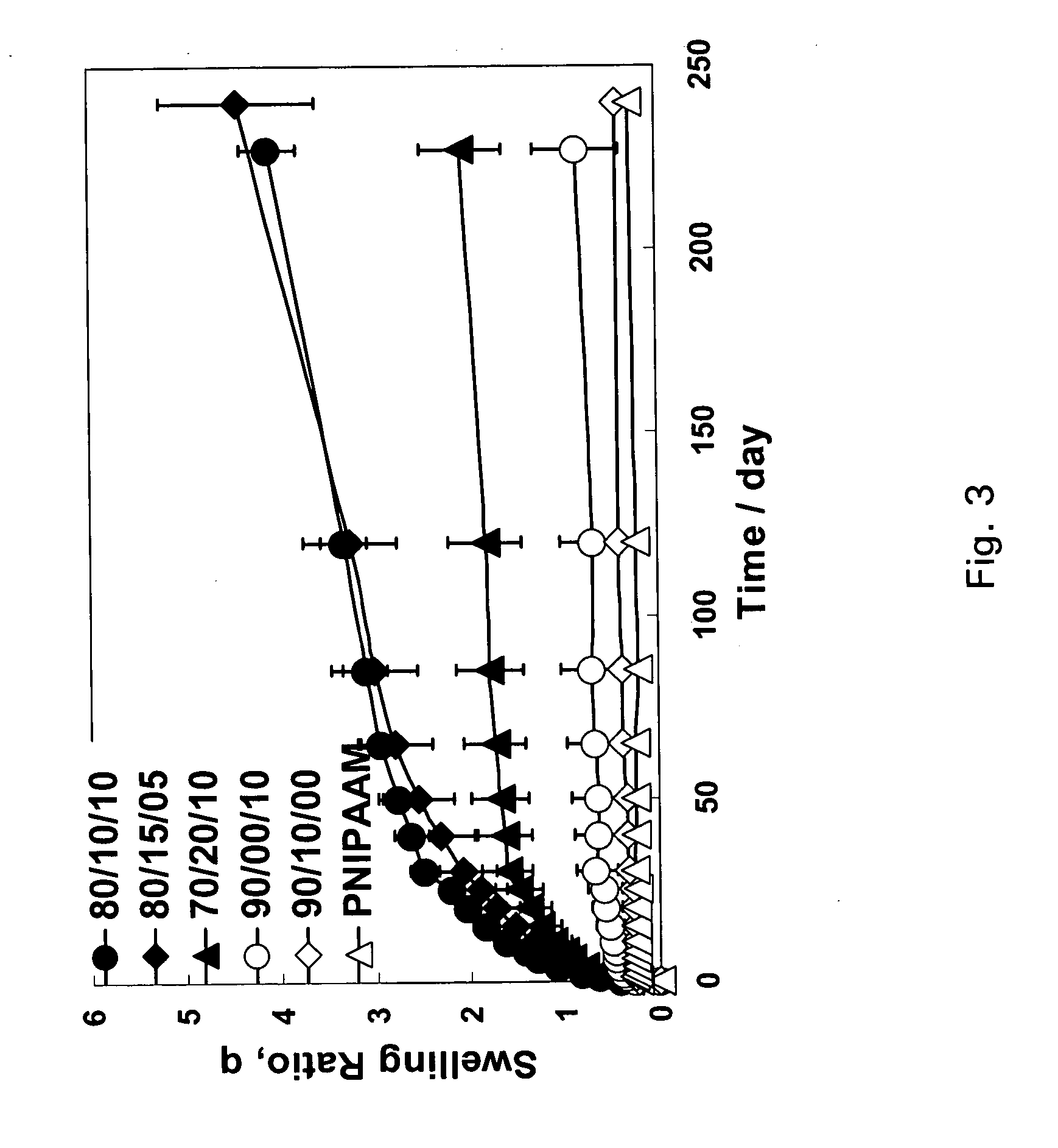

Multi-functional polymeric materials and their uses

InactiveUS20050169882A1Easy to controlReduce deliveryPowder deliveryMaterial nanotechnologyBiomedical engineeringPolymer

Multifunctional polymers are disclosed having a smart segment and a biodegradable segment. Advantageously, the biodegradable segment includes a hydrophilic segment and a hydrophobic segment. Embodiments include combining the multifunctional polymeric material with a biologically active substance in an aqueous loading environment and administering the composition as a drug delivery vehicle to a human subject.

Owner:HUANG XIAO +2

Composite photocatalyst prepared from stephanoporate mineral and method thereof

InactiveCN101322944ALow costReduce the risk of poisoningMolecular sieve catalystsWater/sewage treatment by irradiationPoisoning riskLight energy

The invention relates to the preparation of an inorganic functional material, in particular to a photochemical catalyst prepared by taking a porous mineral as a carrier for carrying an n-typed semiconductor with a large energy gap and a method thereof. The natural porous mineral and an artificial porous mineral are used for preparing the carrier to carry the n-typed semiconductor and a compound semiconductor with photochemical catalysis function; the catalyst prepared is applied to the degradation of organic pollutants by photochemical catalysis or to serving as the filling of paints which can reproduce after being poisoned. The carrier prepared by the invention has large specific surface area, strong adsorption capacity, good adhesive force and low environment cost, can remarkably improve the efficiency of the photochemical catalyst and lower the poisoning risk of the catalyst; the sol of the semiconductor or the compound semiconductor has a photoresponse range covering visible light area and ultraviolet light area, thus being capable of effectively utilizing the light energy and being beneficial to reduce the cost of the light sources; the sol-gel dipping method is adopted to realize loading, which has the advantages of mild condition, even distribution, simple technique and convenience for mass production.

Owner:JILIN UNIV

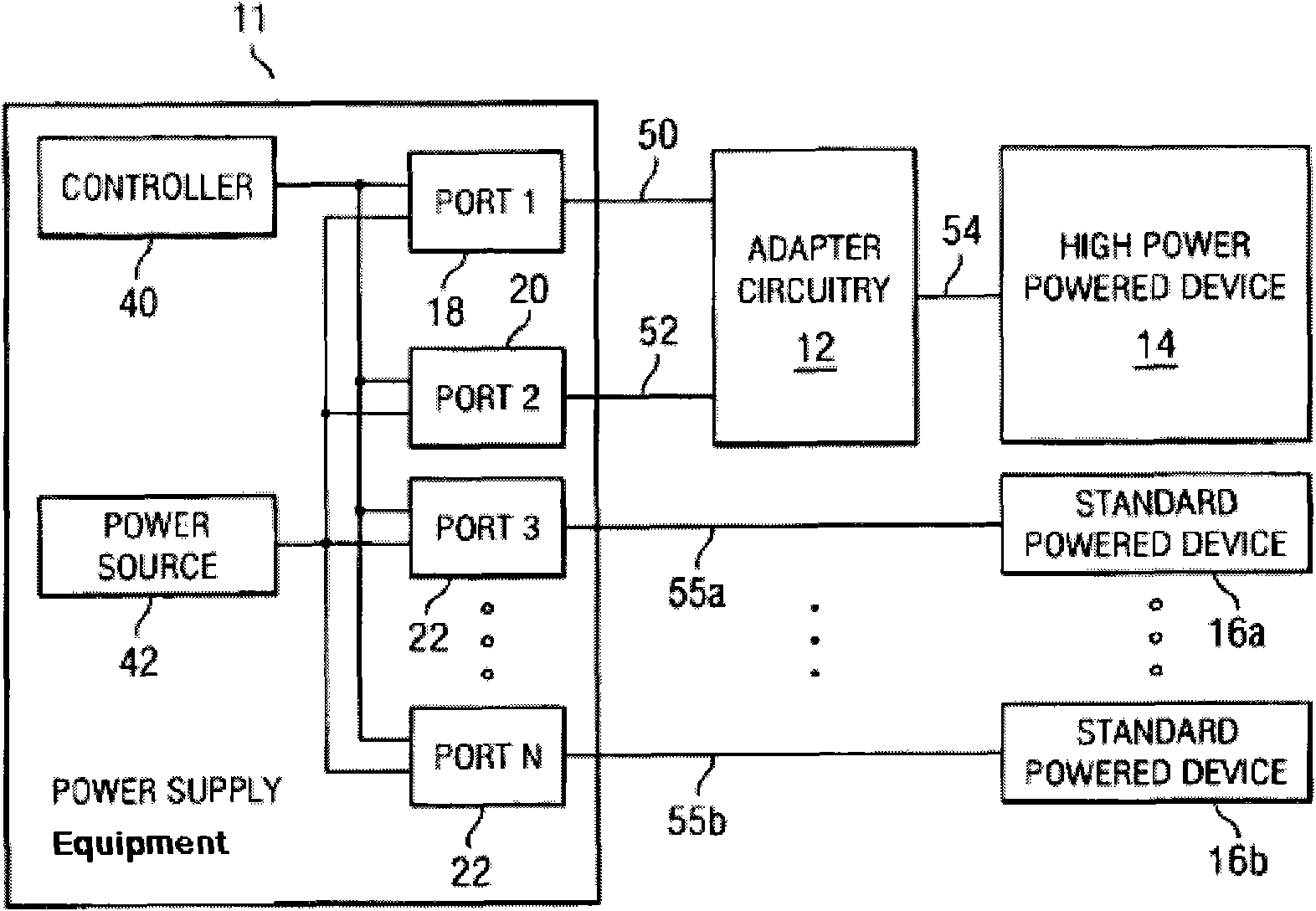

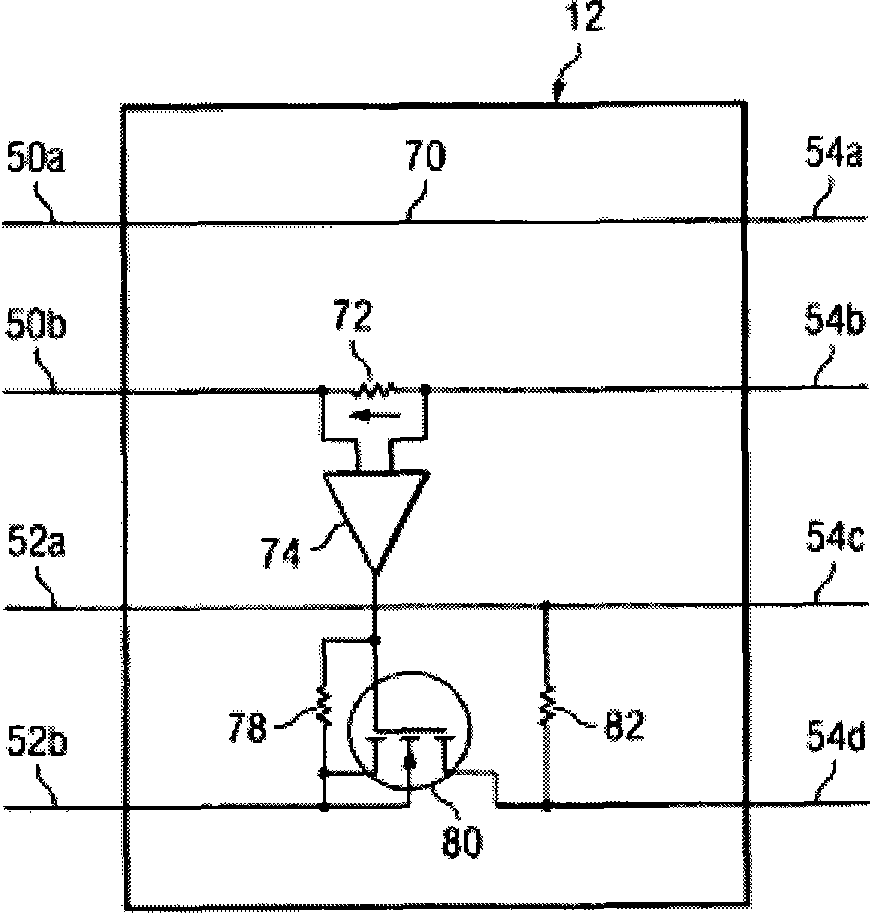

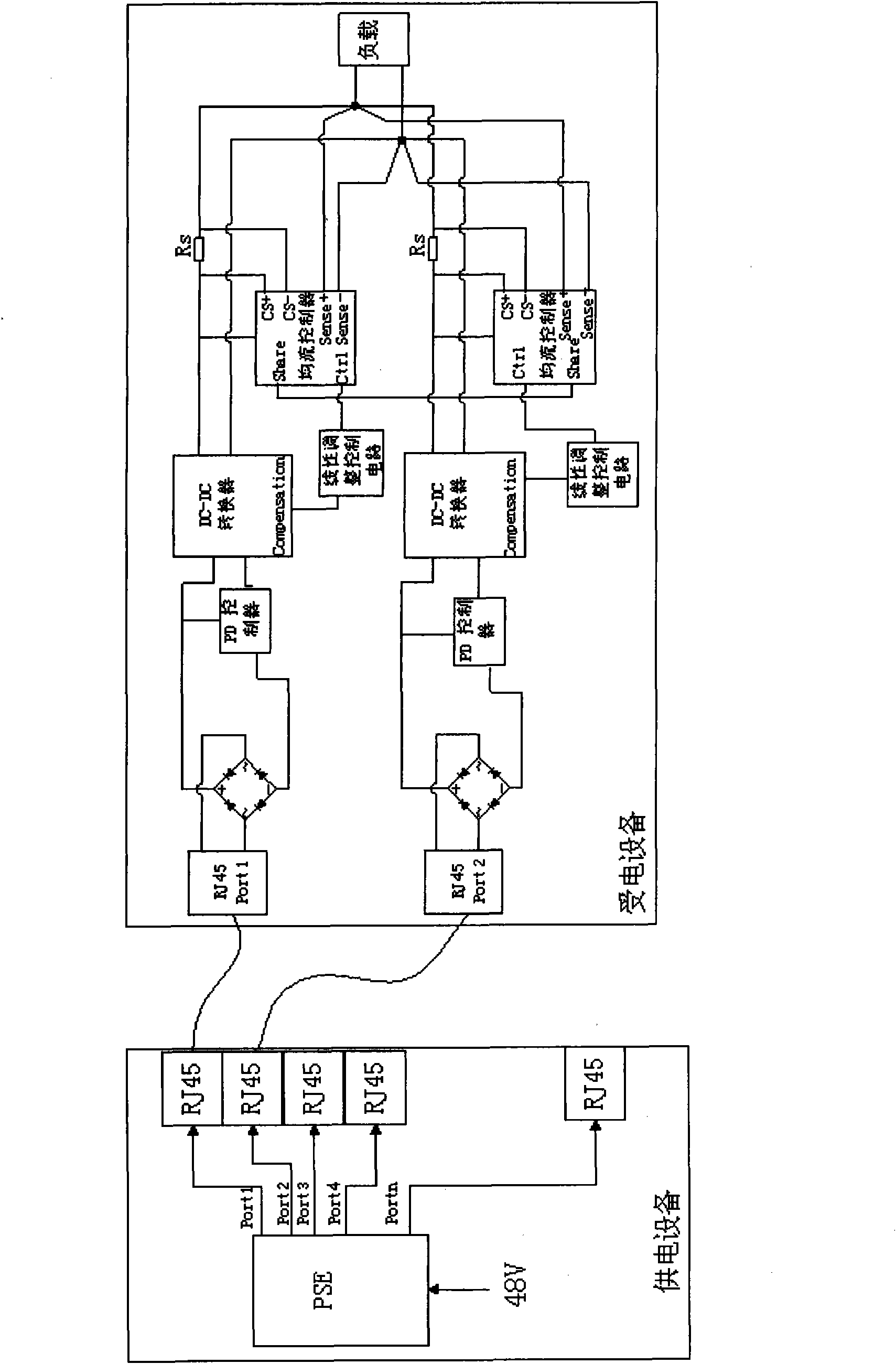

Method, device and system for realizing power over Ethernet (POE)

ActiveCN101594236ARealize the loadRealize functionDc network circuit arrangementsData switching current supplyElectricityEngineering

The invention discloses a method for realizing power over Ethernet (POE), which comprises the steps of: receiving direct current power supplies provided by power supply equipment (PSE) through at least two ports at a PD side of power receiving equipment; performing load balancing processing on a plurality of the direct current power supplies which enter from the at least two ports; and outputting the direct current power supplies which are subjected to load balancing processing to loads. The embodiment of the invention also provides a POE control device and a POE system. The direct current power supplies are received through multiple ports at a power receiving equipment side; and a plurality of the direct current power supplies are subjected to load balancing processing, so that the functions of load balancing and redundancy backup of the POE are realized, and the stability of system operation is improved.

Owner:HUAWEI TECH CO LTD

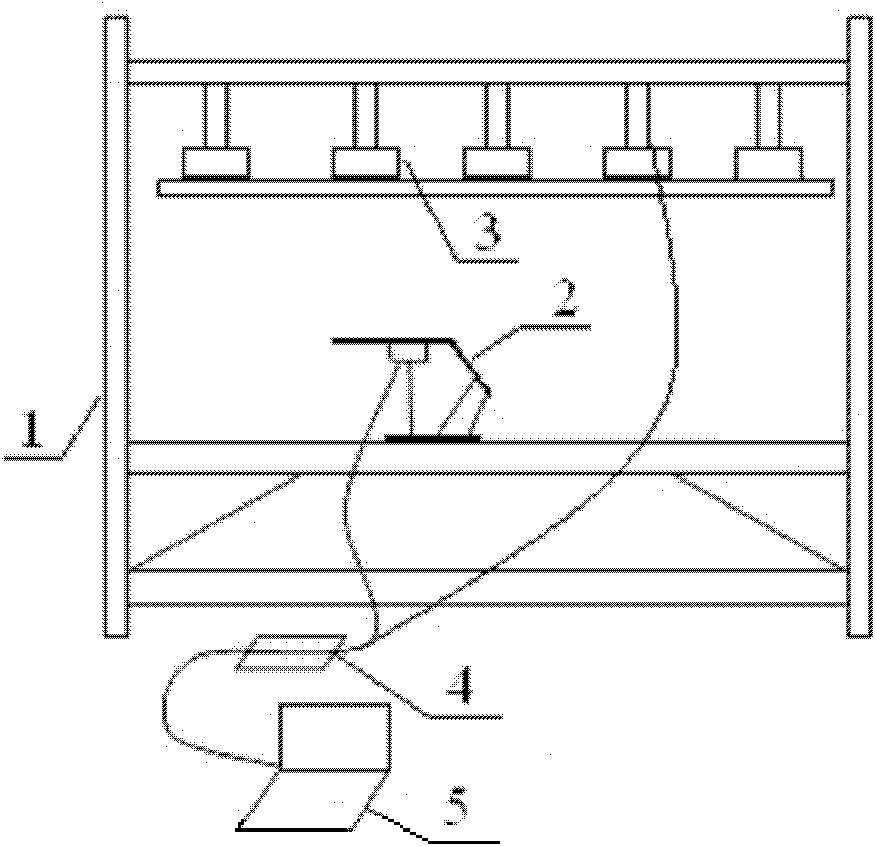

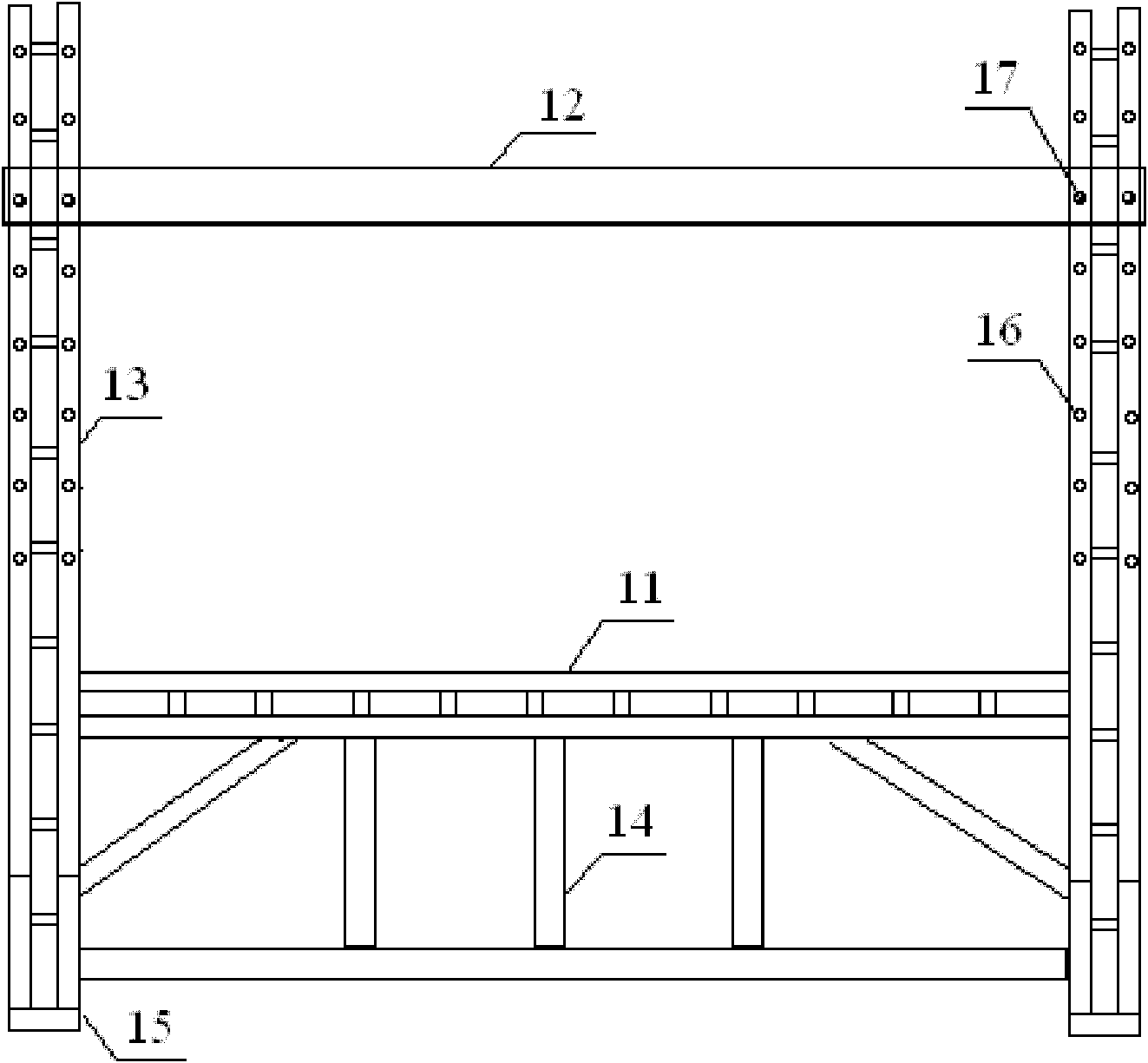

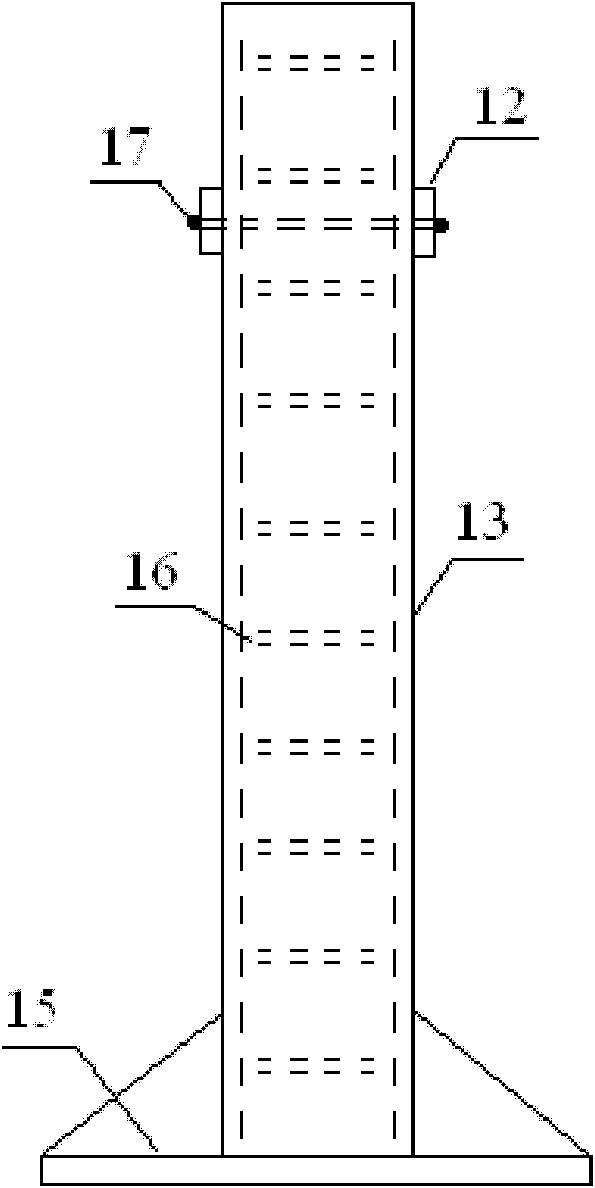

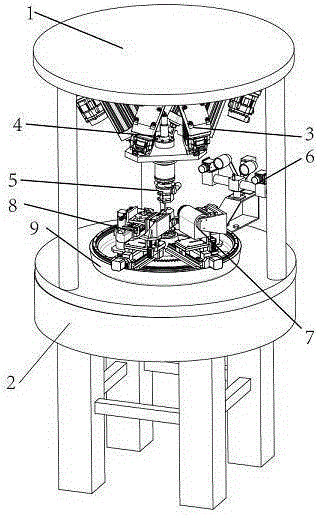

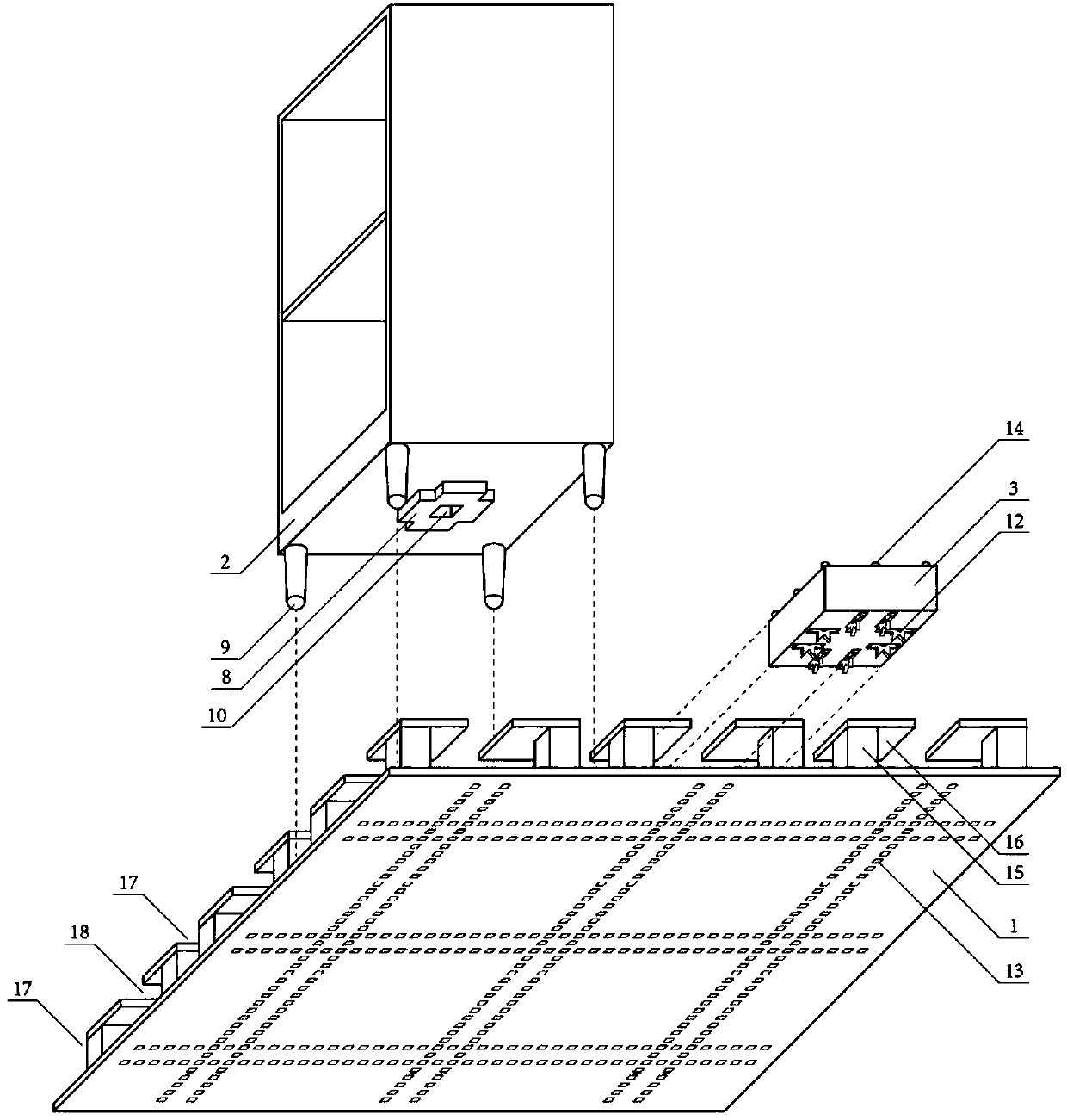

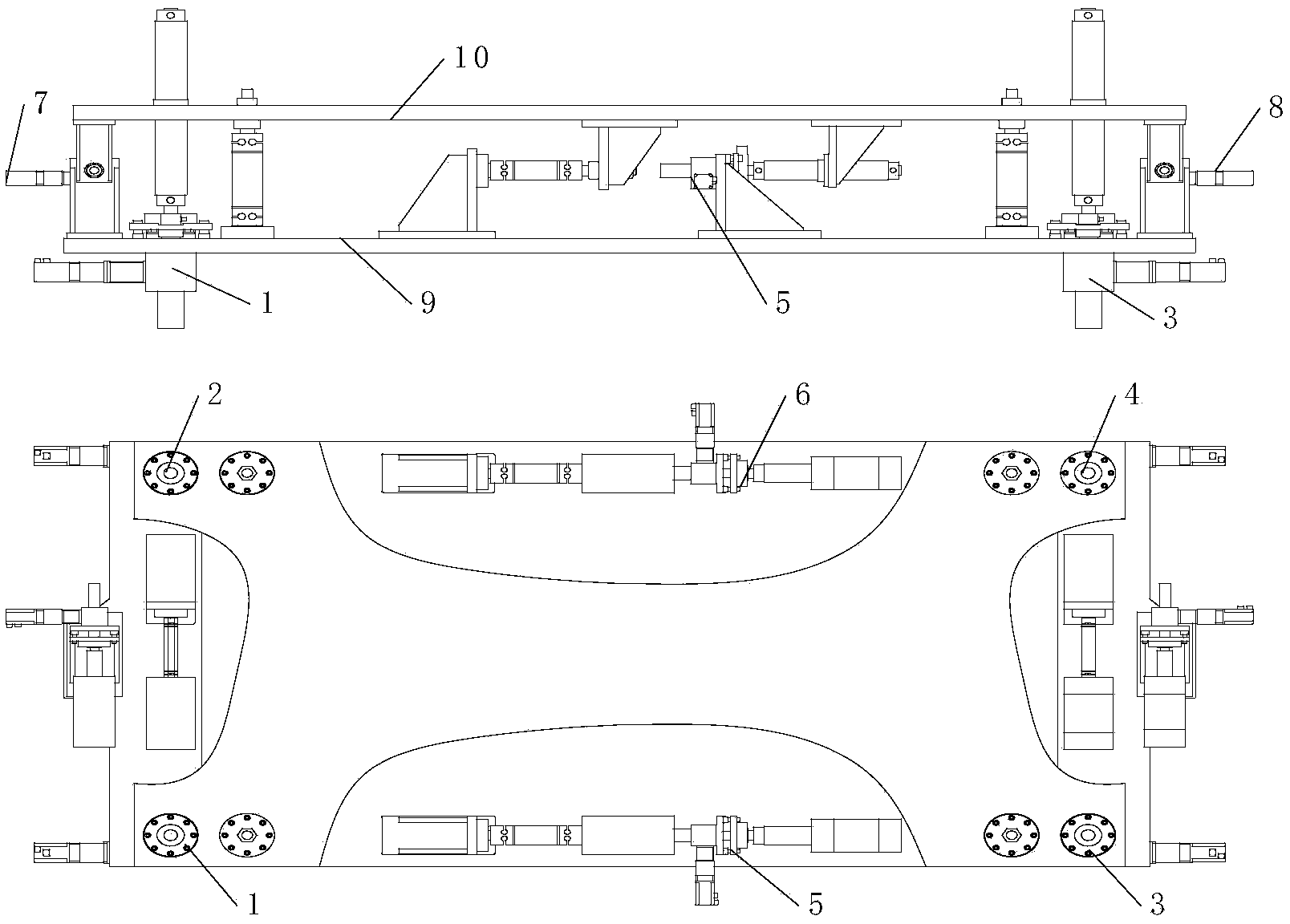

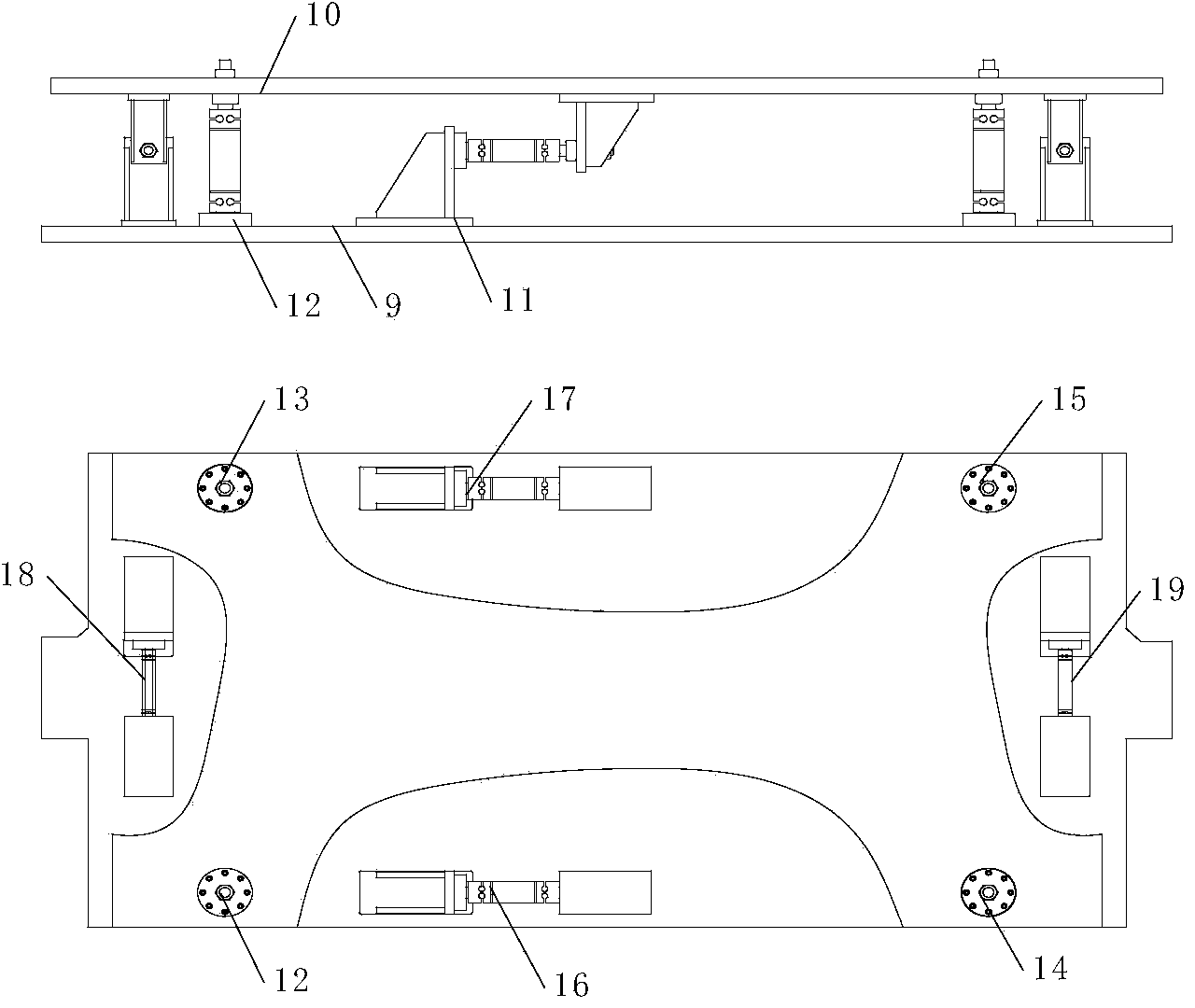

Coal mine fully mechanized mining support and surrounding rock relationship experimental platform

InactiveCN102261972ARealize the loadReal-time online monitoringStructural/machines measurementApparatus for force/torque/work measurementStress changeStrain gauge

The invention discloses an experimental platform for a relation between a mining fully-mechanized support and surrounding rocks. The experimental platform is used for researching an interaction relation between a hydraulic support in a mining fully-mechanized operating surface and the surrounding rocks. The platform comprises a loading experimental platform, a two-column shielding hydraulic support, a hydraulic loading system, a signal acquisition system and a data processing system, wherein the loading experimental platform comprises two experimental platform box body vertical grooves and a carrying bearing beam which is connected between the two experimental platform box body vertical grooves and used for paving an experiment material; and strain gauges are respectively embedded in different layers of the experiment material and used for monitoring the stress change of an overburden layer in a mining process. The experimental platform can load the overburden layer for complementing a ground stress. The two-column shielding hydraulic support is arranged on the operating surface and can perform real-time and on-line monitoring on loads of a top plate in the propelling process of the operating surface. The two-column shielding hydraulic support can realize high-frequency acquisition of support pressure signals and can monitor and record impact loads.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

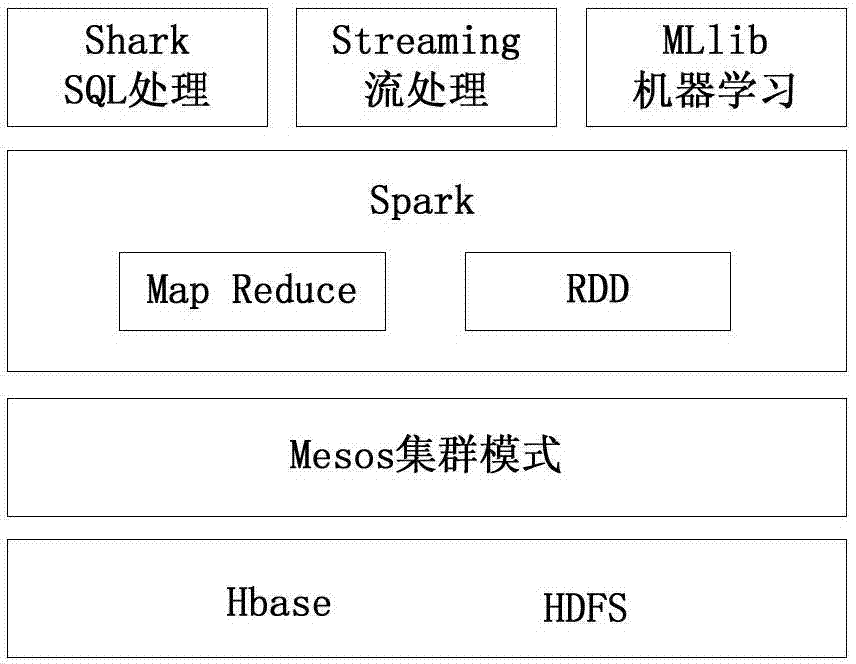

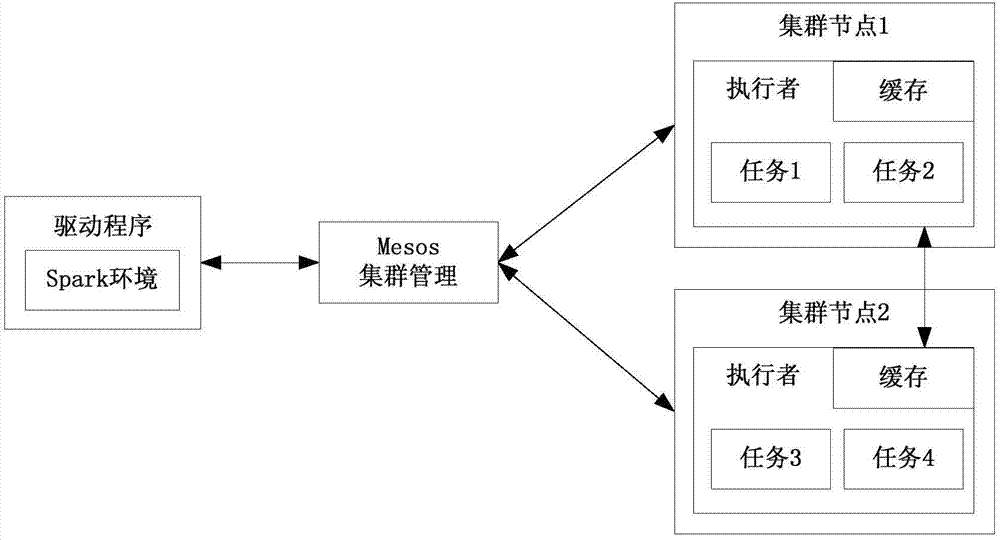

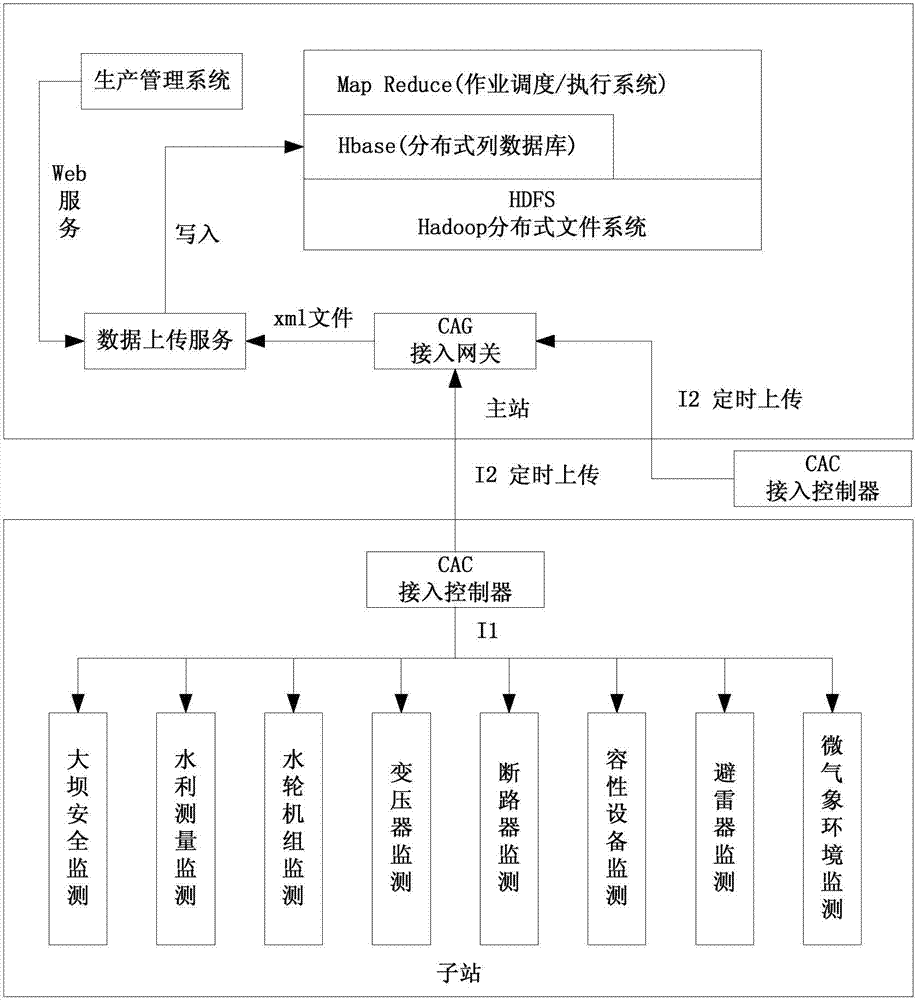

Hydroelectric equipment monitoring and fault diagnosis system based on big data technology

ActiveCN104281130ARealize unified accessRealize the loadTotal factory controlProgramme total factory controlRelevant informationDependability

The invention discloses a hydroelectric equipment monitoring and fault diagnosis system based on the big data technology. The hydroelectric equipment monitoring and fault diagnosis system comprises a visualization display module, an alarm management module, a query and statistics module and a fault diagnosis nodule. The visualization display module collects to-be-monitored information of a substation through a state access controller and uploads the information to a data uploading server through the state access controller, in this way, the data uploading server module can upload the equipment monitoring data to an Hbase database, query and statistics can be conducted on relevant information, and equipment monitoring information and equipment-related statistical information can be displayed. The alarm management module generates an alarm record through configuration of combined alarm conditions of an equipment monitoring point. The query and statistics module is used for achieving the functions for history query of the equipment monitoring data and general information query of equipment-related accounts. The fault diagnosis nodule adopts various fault diagnosis models or prediction models for conducting equipment fault diagnosis and early warning. By the adoption of the hydroelectric equipment monitoring and fault diagnosis system based on the big data technology, equipment diagnosis efficiency can be improved, the equipment diagnosis level can be increased, the basis is provided for equipment condition-based maintenance, the maintenance cost is reduced, and power supply reliability is improved.

Owner:STATE GRID CORP OF CHINA +1

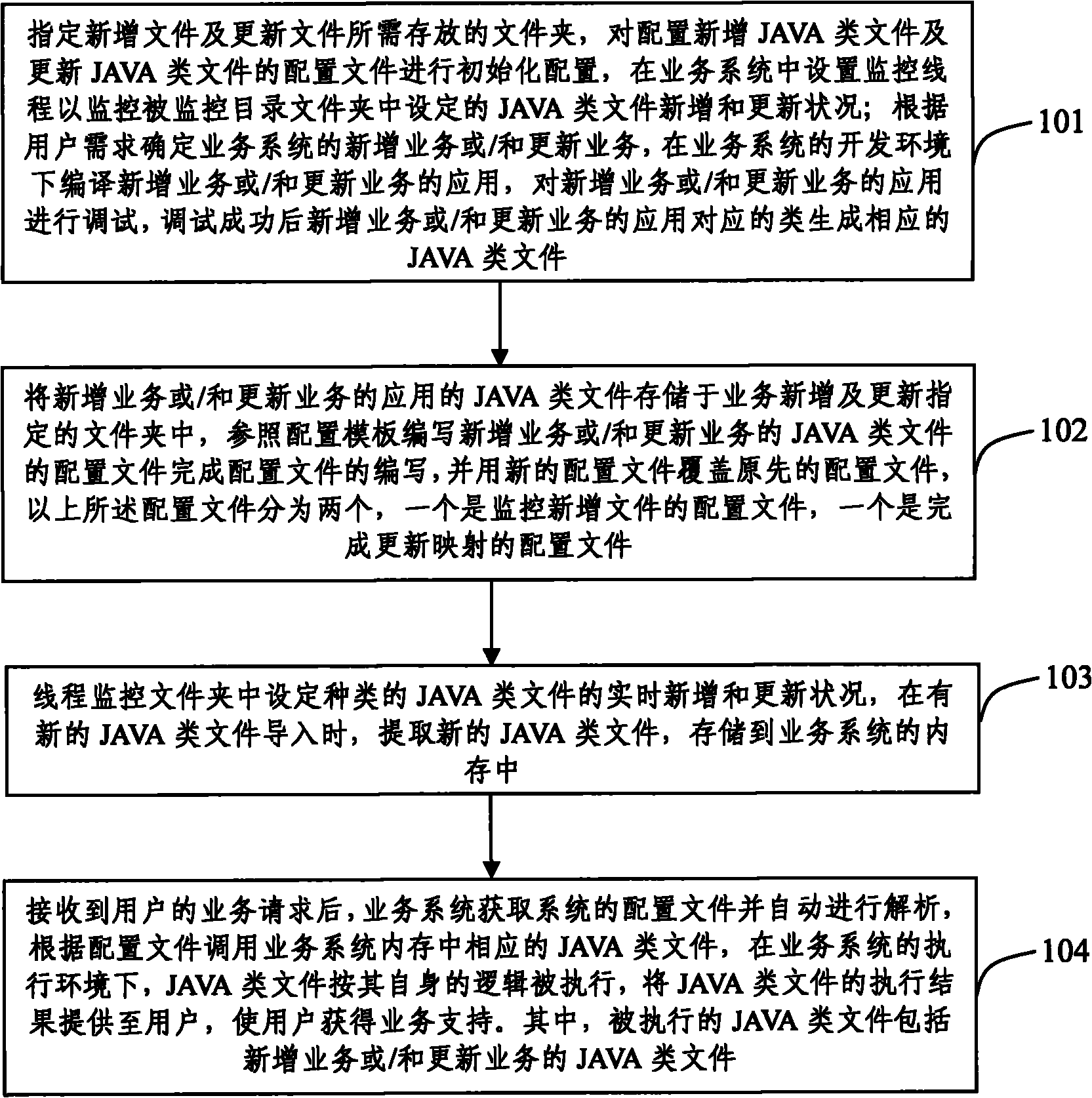

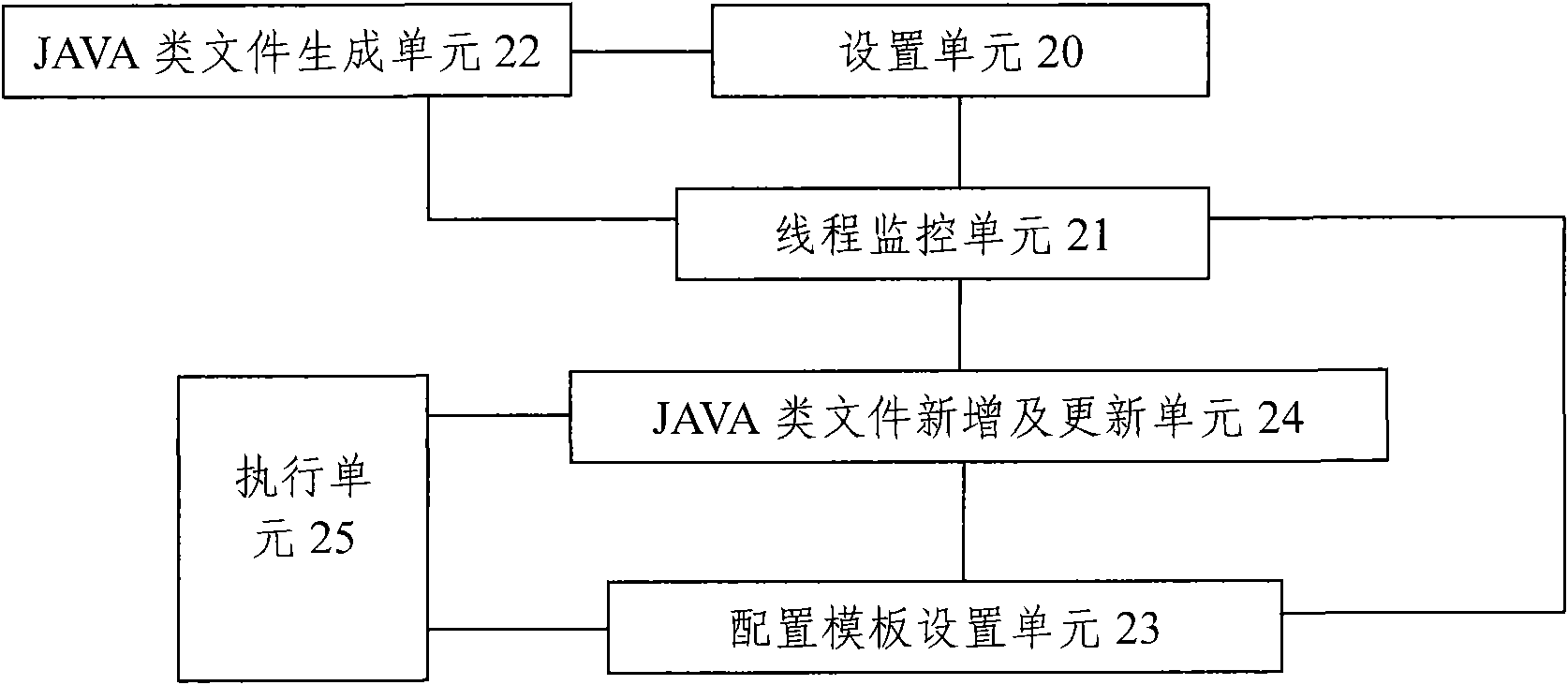

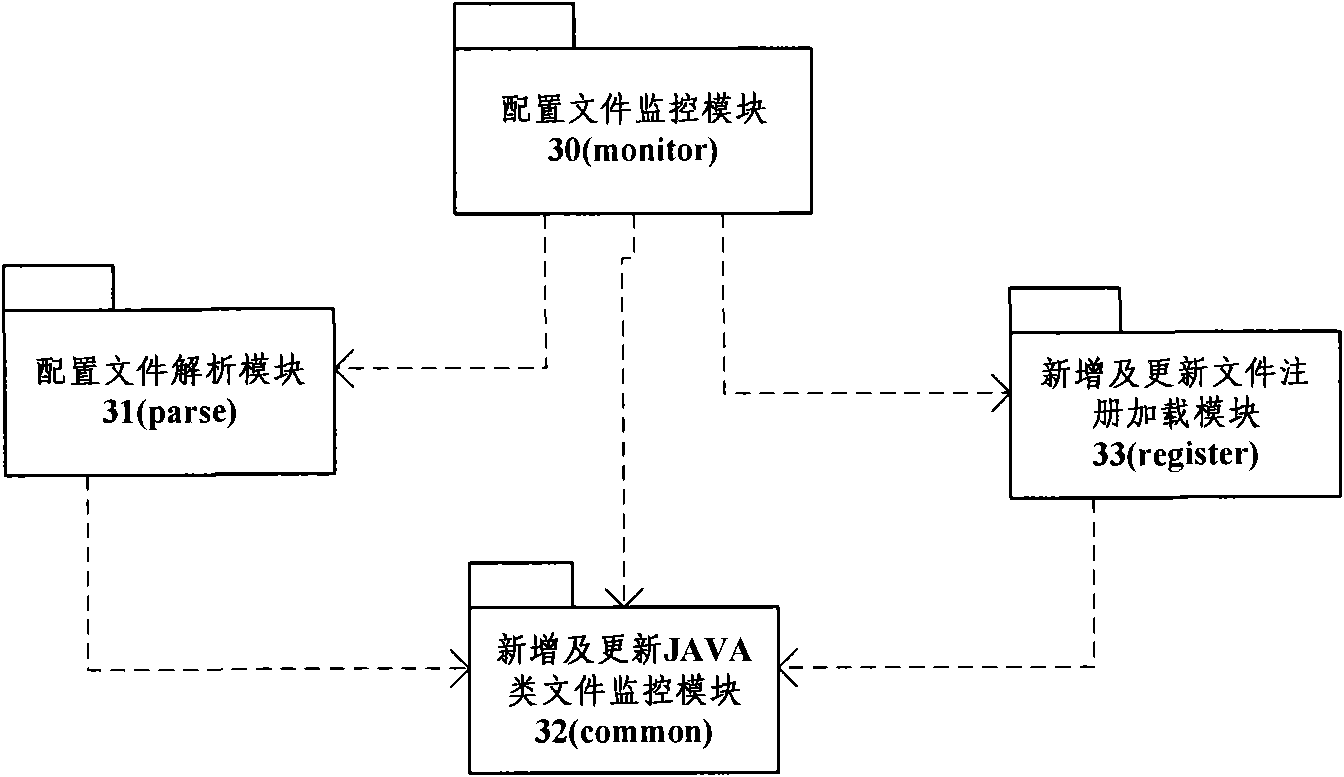

Method and system for dynamically loading services in service system

InactiveCN101771762ARealize the loadReduce lossesSpecial service for subscribersSupervisory/monitoring/testing arrangementsJava class fileJava classes

The invention discloses a method for dynamically loading services in a service system, which comprises the following steps: A, storing a JAVA type file applied by a new service or / and an updated service to a specified folder for the new service and the updated service, writing a configuration file of the JAVA type file of the new service or / and the updated service referring to a configuration template, and directly covering an old configuration file with the newly written configuration file; B, performing thread monitoring on the real-time new and update condition of the JAVA type file of the set type in the folder and extracting a new JAVA type file and storing the new JAVA type file to the memory in which the service system is positioned when the new JAVA type file is imported; and C, after the service system receives a service request of a user, acquiring and automatically resolving the configuration file of the system, calling a corresponding JAVA type file in the memory in which the service system is positioned according to the configuration file, executing the JAVA type file according to the logic of the JAVA type file, and providing an execution result to the user to make the service support available to the user. Simultaneously, the invention discloses a system for realizing the method. The method and the system realize the dynamic loading of the services.

Owner:BEIJING UNIV OF POSTS & TELECOMM

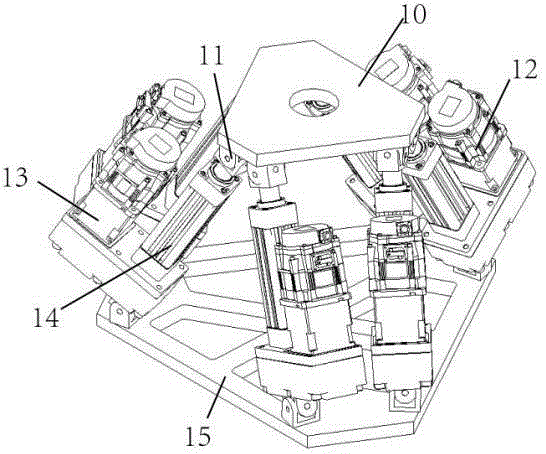

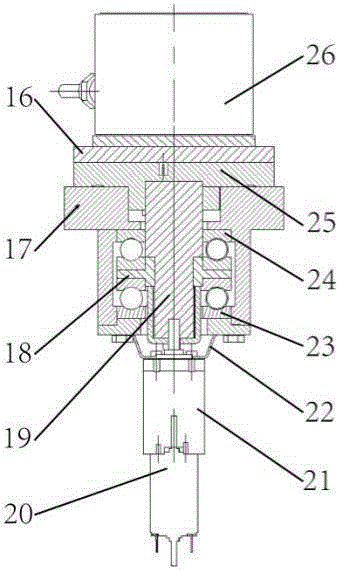

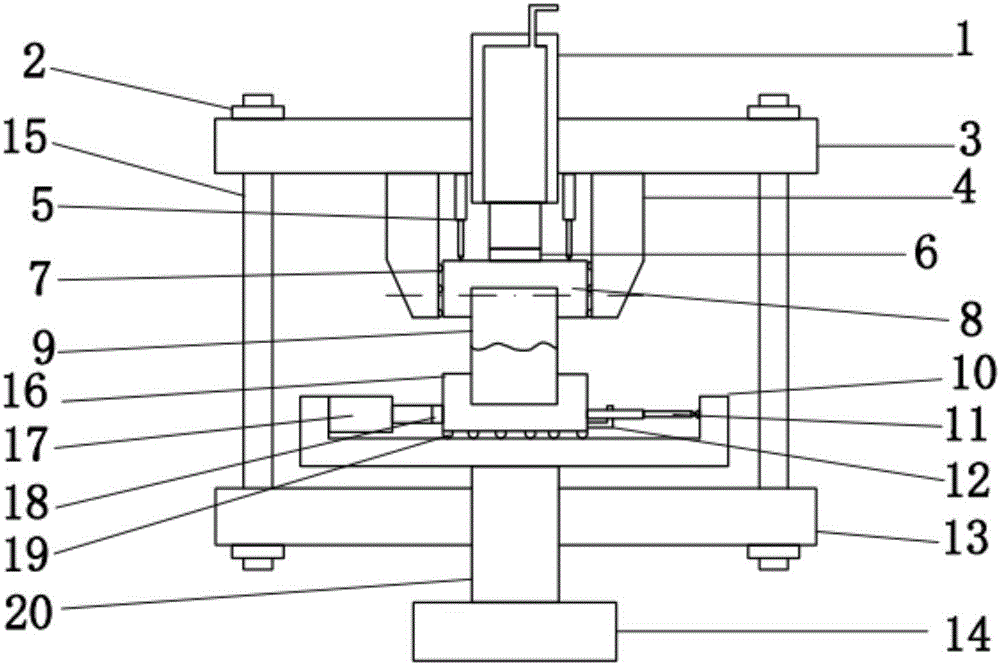

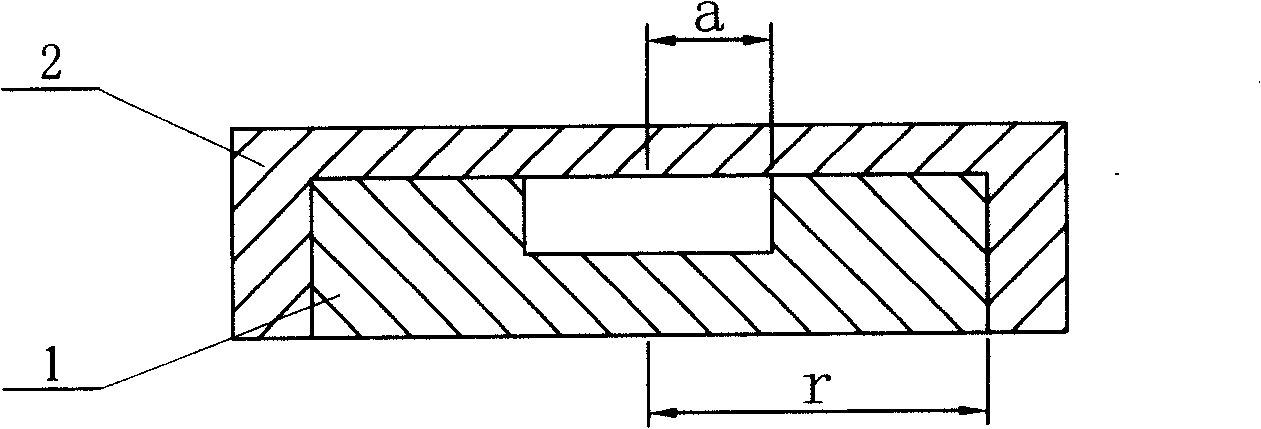

Material in-situ detection device and method under multi-load multi-physical field coupling service conditions

ActiveCN105223076ANovel structureCompact layoutMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesPhysical fieldScientific instrument

The invention relates to a material in-situ detection device and method under multi-load multi-physical-field coupling service conditions, and belongs to the field of precise scientific instruments. The material in-situ detection device is composed of a precise six-degrees-of-freedom composite load loading module, a precise torsion module, a precise indentation module, a clamp module and a control module which work together to complete a composite-load multi-physical-field coupling experiment, a digital speckle strain measurement and infrared thermal imaging module and a microscope observation module are integrated, and in-situ observation and quantitative characterization are carried out on material deformation behaviors and damage mechanism phenomena in a composite-load multi-physical-field loading process. The device and the method have the advantages that the composite-load loading can be realized, and a novel loading method such as 'cantilever type pure bending, cantilever type tensile / compression-torsion, and cantilever type bending-torsion' is carried out. Silicon nitride ceramic heating sheets, Peltier tiles and current loading are used for achieving simulation of cold / hot-electricity and other multiple physical fields, and an improvement innovative experimental testing method is provided for material micromechanical property tests close to the serving conditions.

Owner:JILIN UNIV

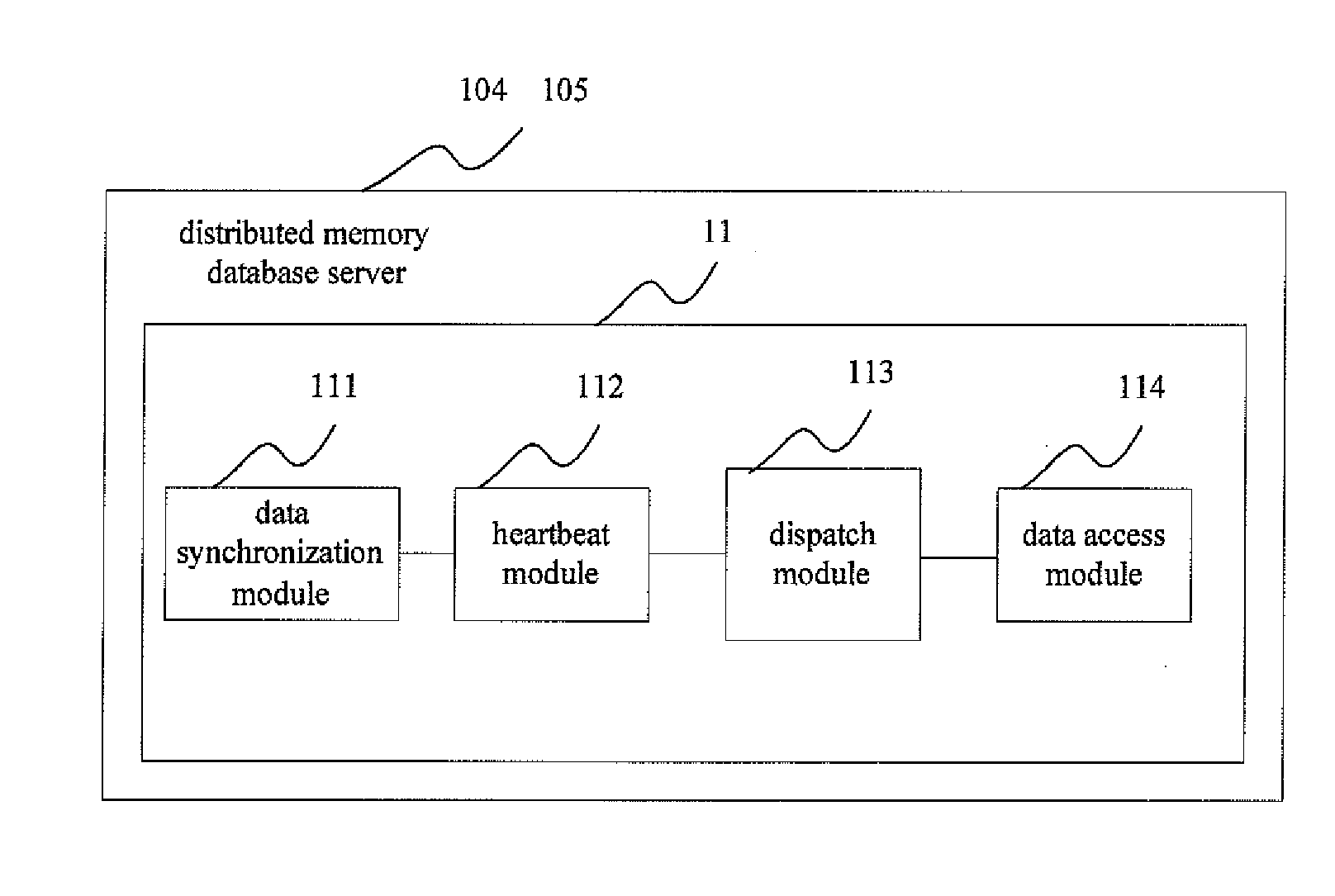

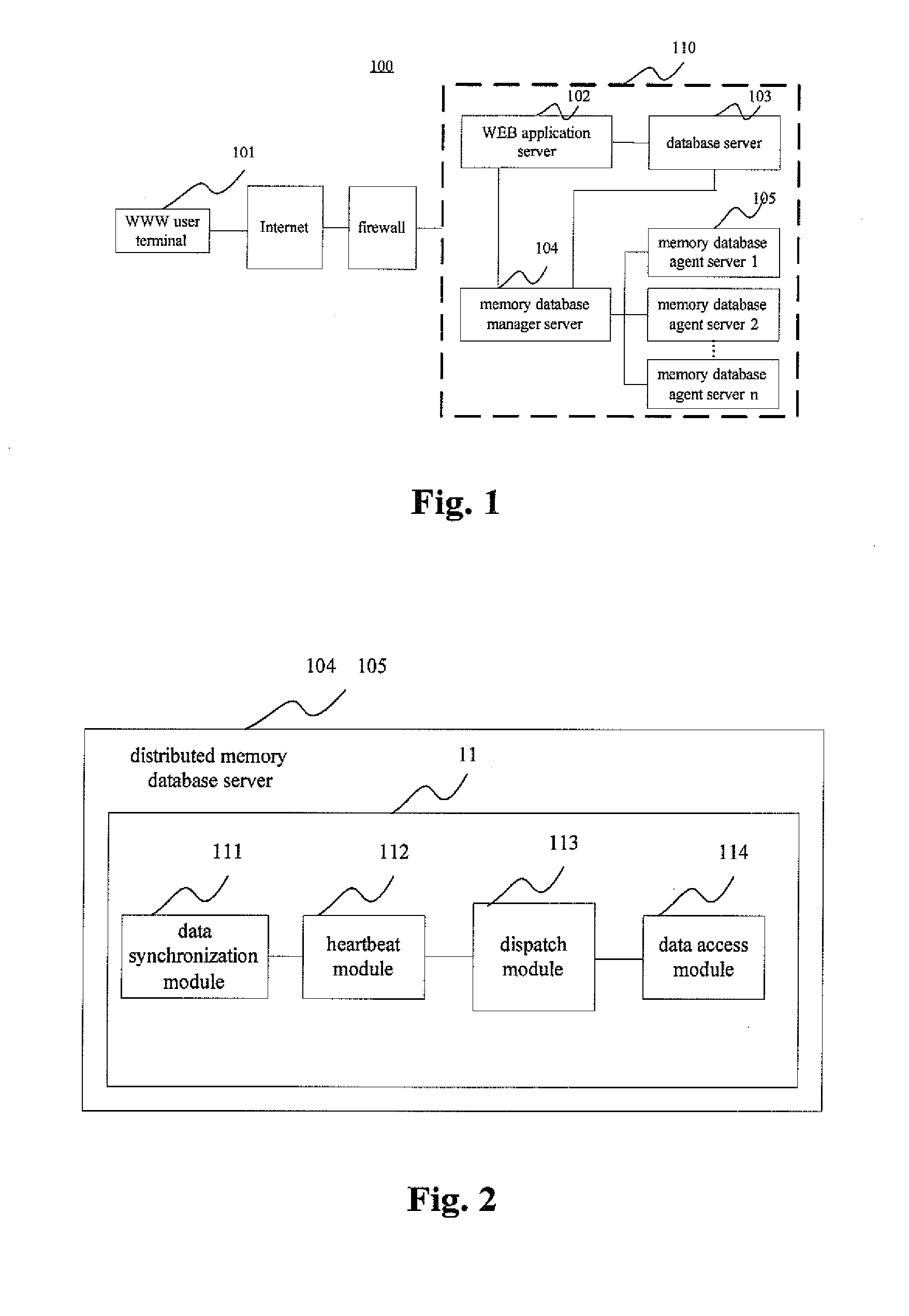

Database system based on web application and data management method thereof

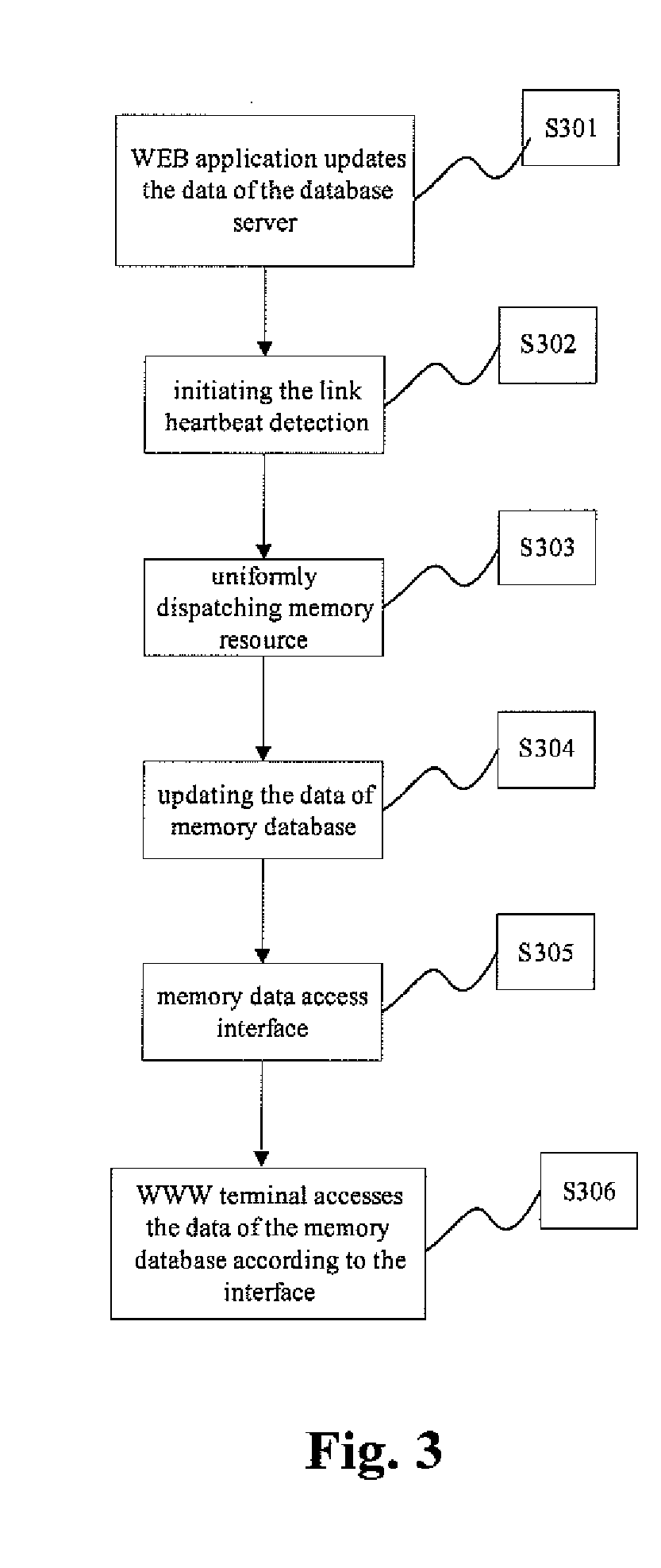

InactiveUS20110246420A1Lower capability requirementsLower performance requirementsDigital data processing detailsWebsite content managementData synchronizationIn-memory database

A database system based on a WEB application includes a database server (103) accessed by means of reading and writing a disk and a distributed memory database server (11), wherein the distributed memory database serve performs data synchronized with data read from the database server by a data synchronizing module (111); the distributed memory database server further includes a memory database Manager server (104) and more than one memory database Agent servers (105), wherein the memory database manager server performs uniform dispatch of memory resources, realizes the data synchronization between the database server and the distributed memory database, and provides the WEB application server (102) with a data access interface; and the memory database agent servers store specific data.

Owner:ZTE CORP

Network video recorder cluster video monitoring system and method

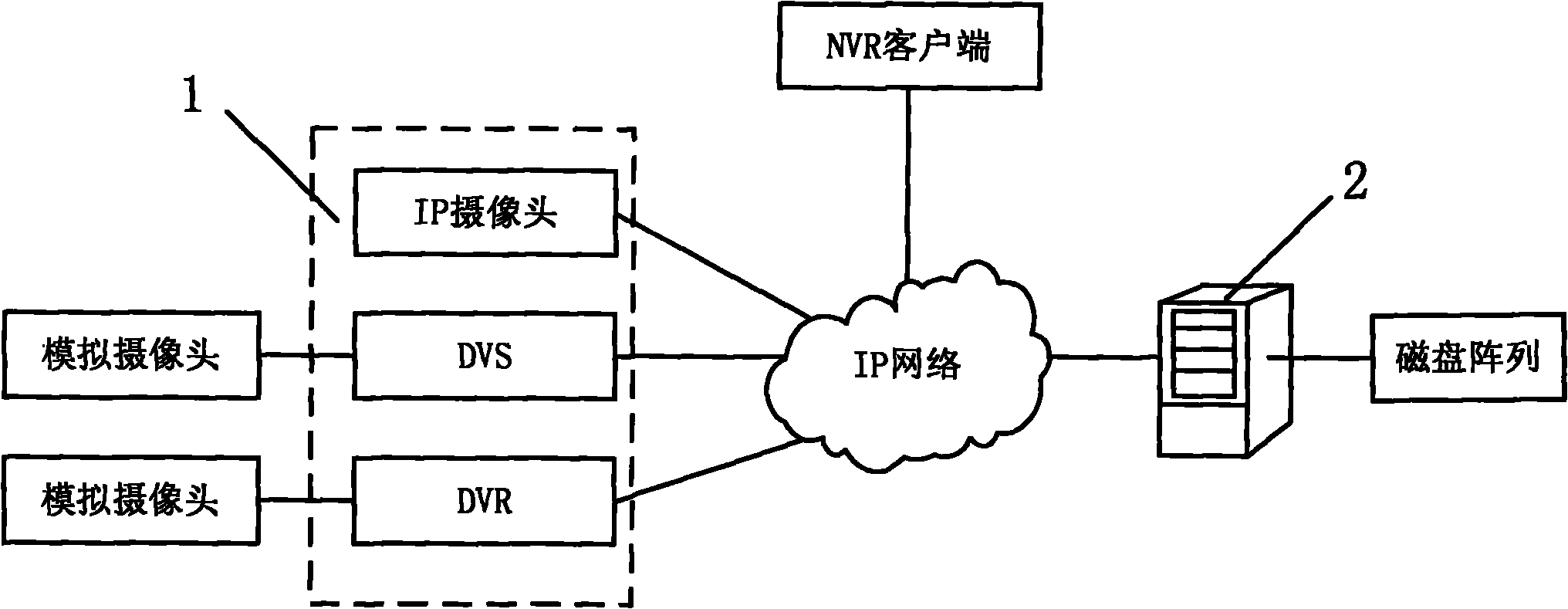

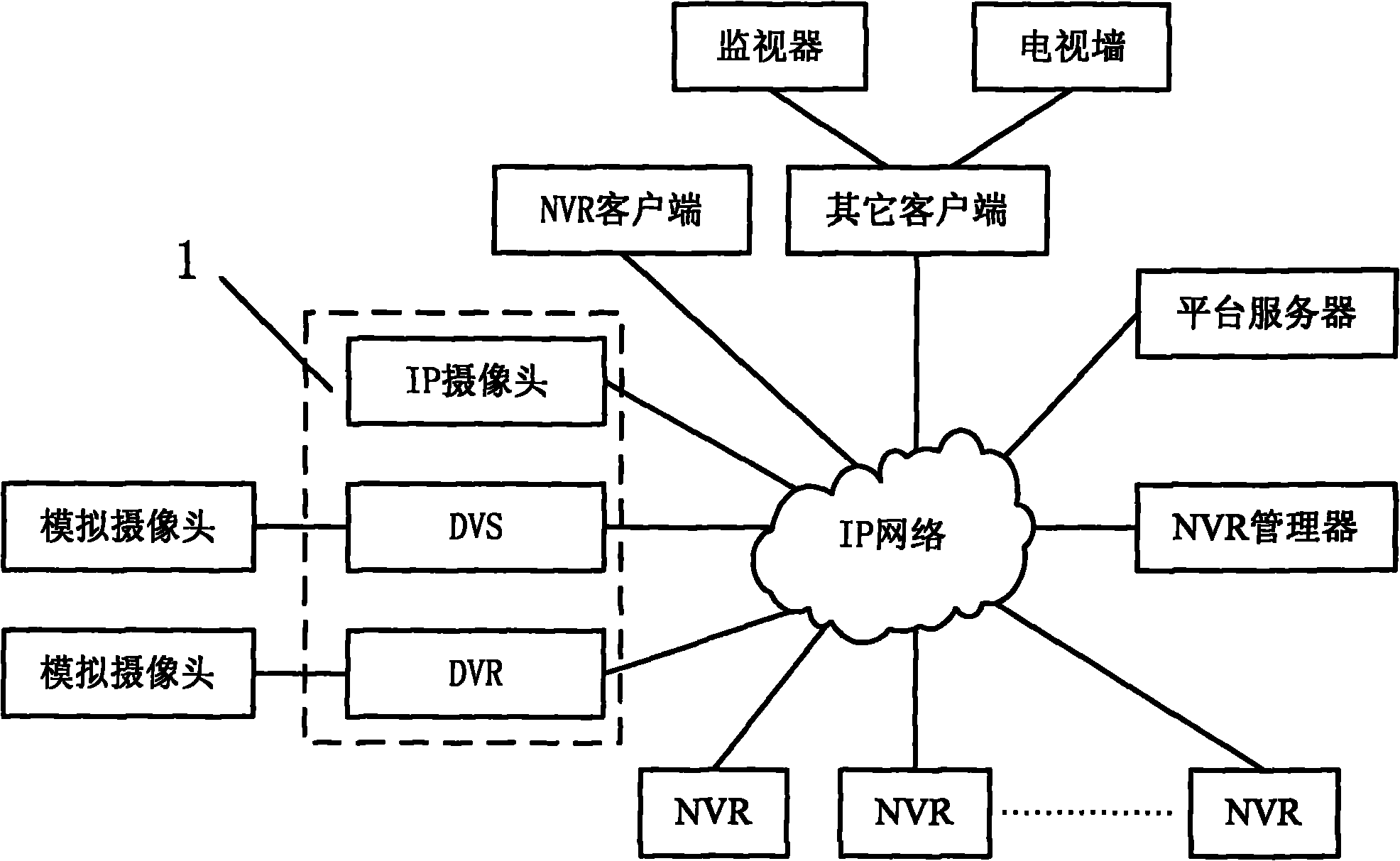

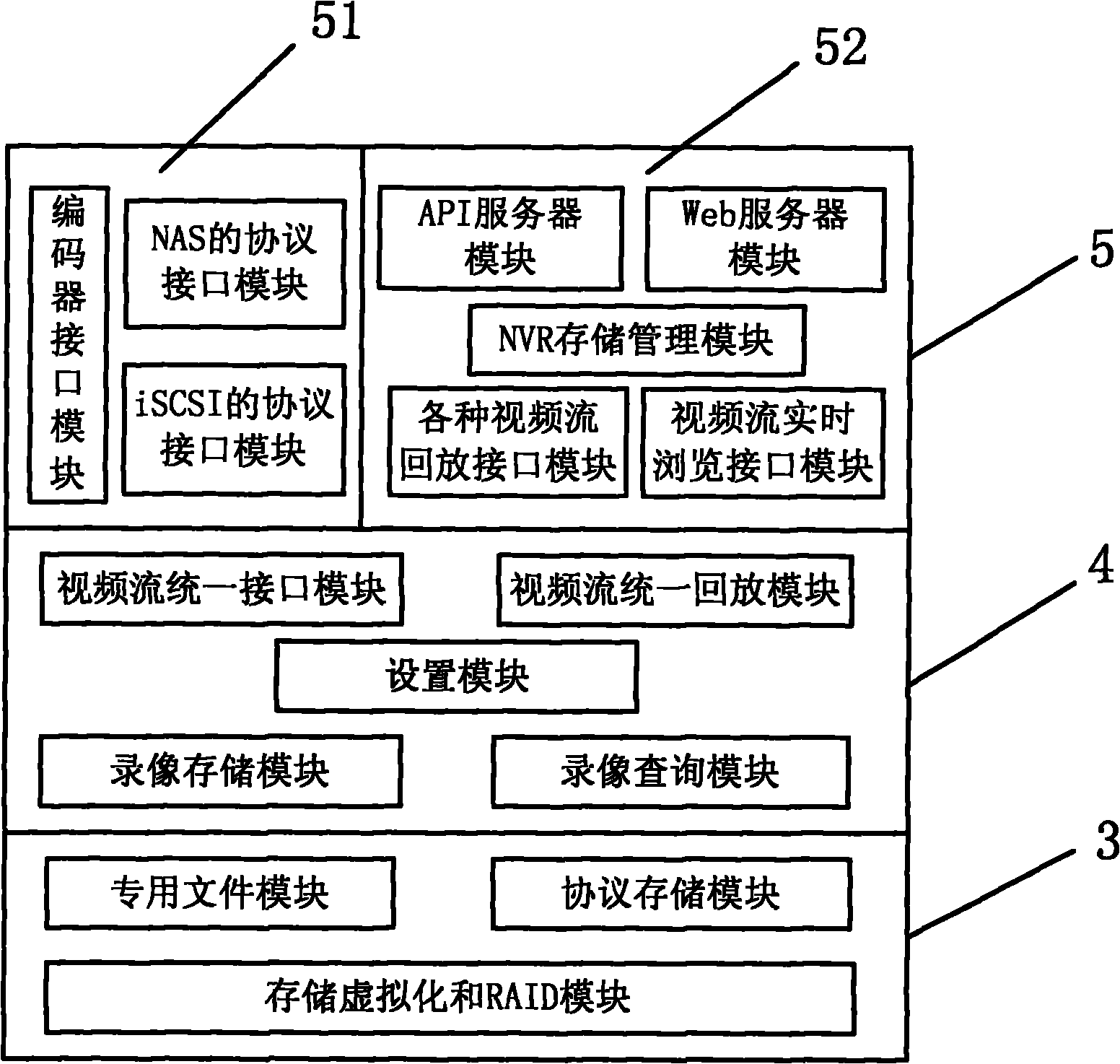

ActiveCN101877783ALow costMapping implementationClosed circuit television systemsData switching networksVideo monitoringVideo storage

The invention relates to a network video recorder cluster video monitoring system and a method. The system comprises a network encoder, a plurality of network video recorders (NVR) and an NVR manager, wherein the network encoder, the NVR manager and each NVR are all connected with an IP network; each NVR supports a network storage protocol that the network encoder can directly access to audio / video data thereon so as to directly store the audio / vide data output by the network encoder in an encoding manner in the NVR; the NVR manager is composed of a mapping module and a monitoring module, the mapping module is stored with the mapping relationship between the network encoder and each NVR, and the monitoring module monitors and manages the audio-video data received by each NVR; and each NVR receives the audio-video data encoded by the network encoder by the IP network under the control of the NVR manager, records, responses to access requests from a client side or the network encoder, and queries or replays or stores the recording data. The system can manage the NVR in a cluster manner, solves the problems of performance and storage bottlenecks simultaneously and improves the whole system performance.

Owner:HANGZHOU HIKVISION DIGITAL TECH +1

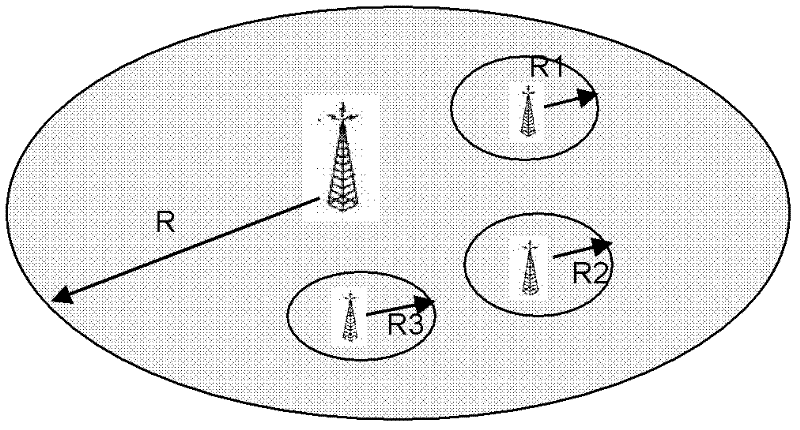

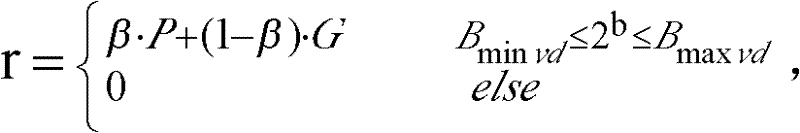

Method for managing heterogeneous network resources based on reinforcement learning

InactiveCN102238631AImprove resource utilizationRealize the loadNetwork traffic/resource managementBandwidth allocationSelf adaptive

The invention discloses a method for managing heterogeneous network resources based on reinforcement learning. In the method, reinforcement learning is adopted in the resource management of heterogeneous wireless network according to multiple business needs and various call types of the heterogeneous network, different call types is treated differently by assigning different processing priorities, different resource allocation policies for different business types, a bandwidth adaptive equalization factor based on load and a profit function based on bandwidth are given, the bandwidth adaptive equalization factor is combined with the profit function to form a reward function, load balance among different networks and adaptive bandwidth allocation in the same network is realized in the condition of meeting various requirements on business bandwidth as much as possible, and the resource utilization rate is improved.

Owner:NANJING UNIV OF POSTS & TELECOMM

Automatic container system

The invention discloses an automatic container system. The system comprises a rail frame, a plurality of containers, at least one container moving device, a connecting device, a movement device drive unit, a connecting device drive unit and a control unit, wherein the plurality of containers are movably arranged on the rail frame, at least one space which is used for moving and switching the container and is not less than the size of the container is left; the connecting device is used for connecting the container moving device with the container and drives the container to move. According to the automatic container system provided by the invention, the intensive arrangement of a plurality of rows of the containers without space can be realized by switching the positions of the containers, so that half of storage content can be promoted in comparison with a traditional technology; the automatic container system is matched up with an unloader so as to move out or in goods in any cell of any container, so that automatic goods entry and exit and refined goods management can be realized; and the containers and the rail frame can be freely spliced and assembled by adopting a standard cell design, so that the layout is flexible. The automatic container system is suitable for intensive storage centers, automatic storage racks in supermarkets, automatic storage cabinets, three-dimensional parking buildings, automatic container trucks, vending machines, automatic post cabinets and the like.

Owner:潘玉坤 +1

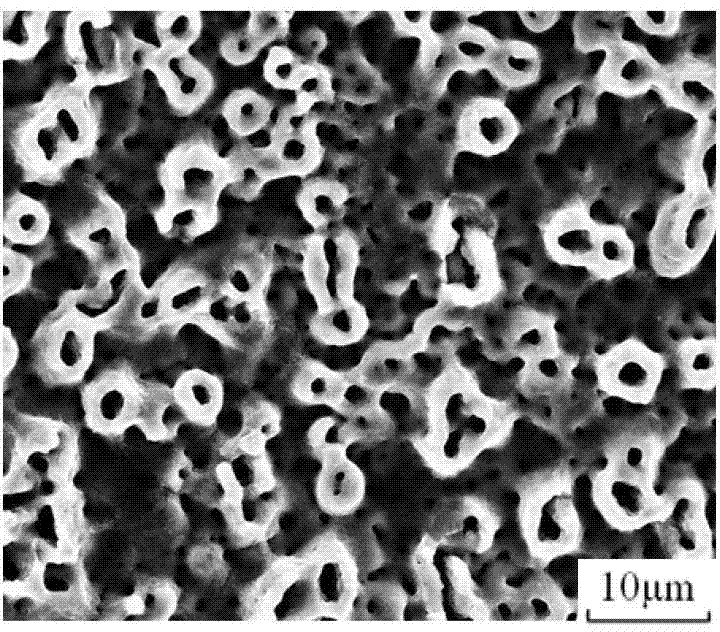

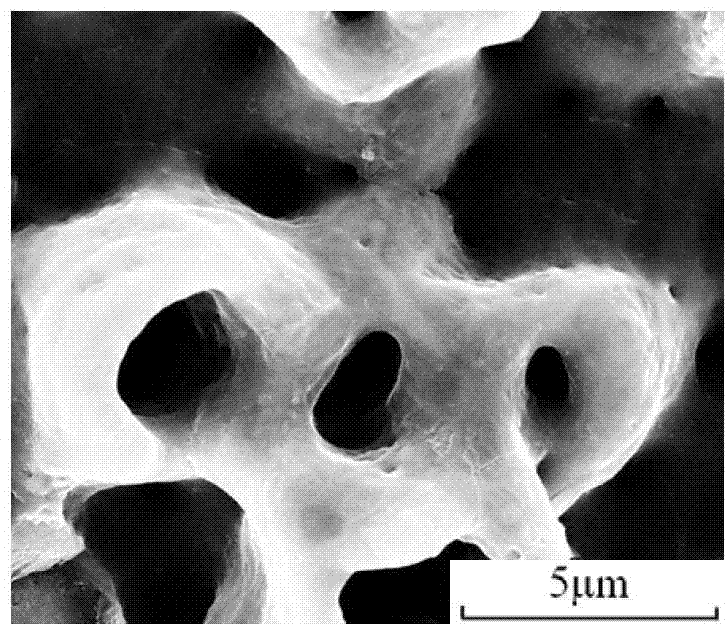

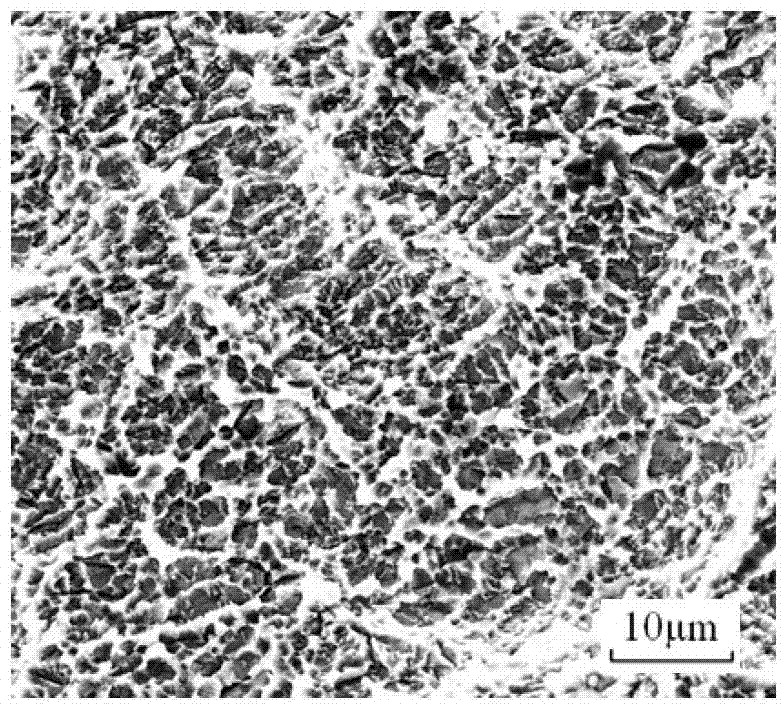

Method for preparing multistage micron structure on titanium implant surface

ActiveCN102921037ARich morphologyImprove the production operating environmentProsthesisTitanium implantImplant surface

The invention discloses a method for preparing a multistage micron structure on a titanium implant surface and relates to a titanium implant. The method includes polishing the titanium implant surface, performing oil removing treatment, and cleaning; subjecting the titanium implant which is subjected to the oil treatment and cleaning to acid dipping treatment in a mixed solution containing a nitric acid, a hydrofluoric acid and hydrogen peroxide; subjecting the titanium implant surface to sand blasting treatment; cleaning the titanium implant which is subjected to the sand blasting treatment; subjecting the cleaned titanium implant to acid etching post-treatment in an acid etching solution; and subjecting the titanium implant to heat treatment and cooling the titanium implant to the normal temperature to obtain the titanium implant with the surface in the multistage micron structure. According to the method for preparing the multistage micron structure on the titanium implant surface, the contact area between the titanium implant and bone tissues is increased, osteoblast ingrowth is facilitated, and thereby the forming of bone closure is facilitated; processing devices are easy to obtain, the operation process is simple, the environmental pollution is small, and the industrialization is easy to achieve; and the appearance is abundant, and the hydrophilic performance is excellent.

Owner:百齿泰(厦门)医疗科技有限公司

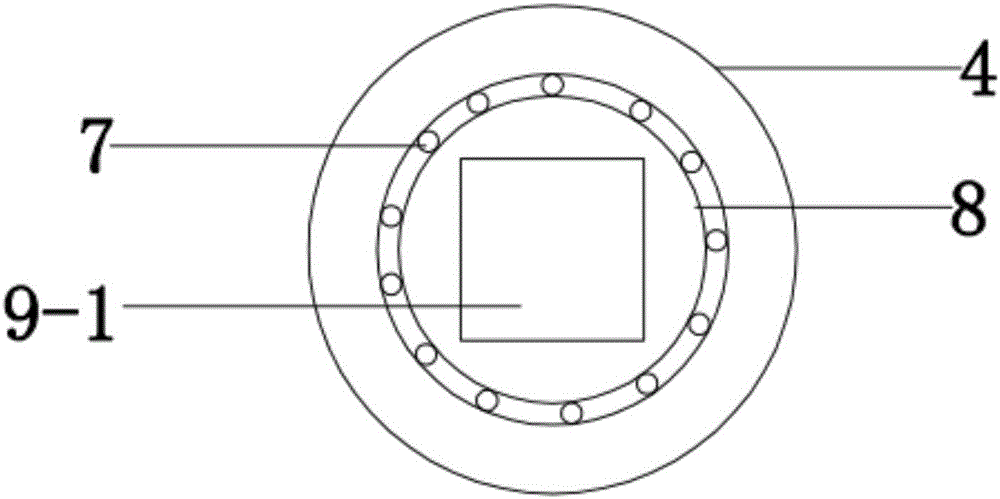

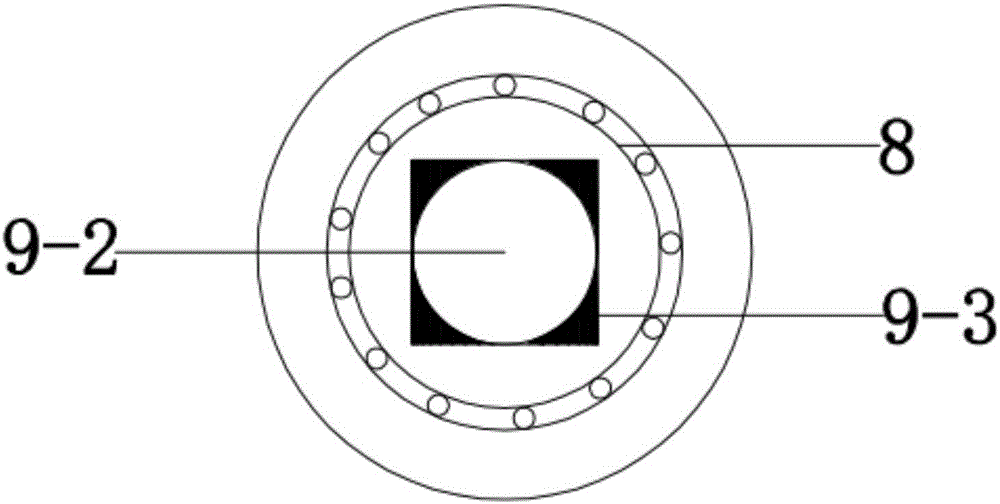

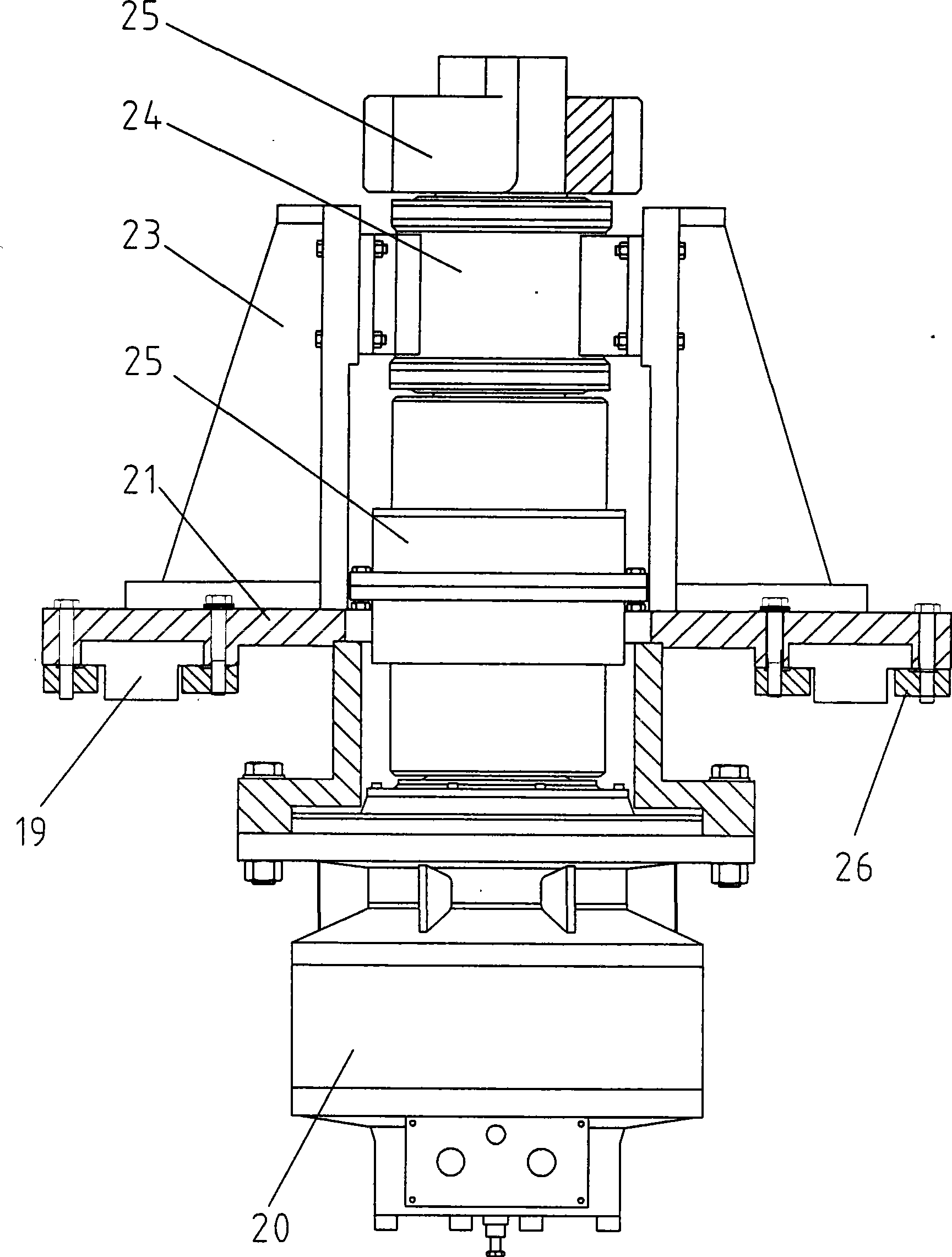

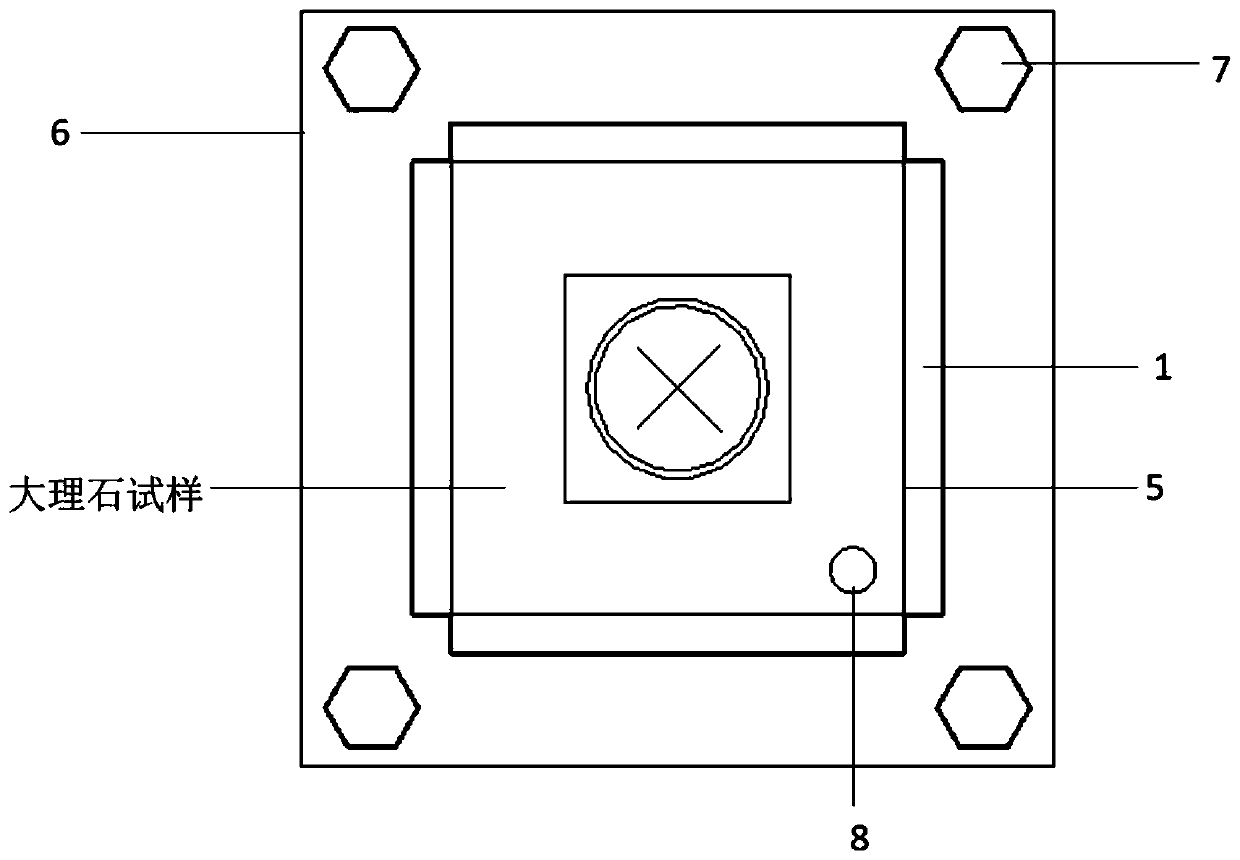

Rock joint direct shear test system suitable for CT three-dimensional real-time scanning

PendingCN106525575AGuaranteed StrengthHigh precisionMaterial strength using steady shearing forcesDirect shear testTransverse shear

The invention relates to a rock joint direct shear test system suitable for CT three-dimensional real-time scanning. The system includes a host frame, an upper shear box, a lower shear box, a rotating device and a CT scanner; a rock joint test piece is placed between the upper shear box and the lower shear box, the upper part of the upper shear box is connected to a rotary gasket, and the rotary gasket is connected to an action end of a normal loading device applying normal pressure to the rock joint test piece; the lower shear box is placed on a rotary bracket, a transverse loading device for applying transverse shear force to the rock joint test piece is fixed the rotary bracket, an action end of the transverse loading device abuts against the side of the lower shear box, and the rotary bracket is in connection with the action end of the rotating device; the rotary bracket, the upper shear box, the lower shear box and the rotary gasket are arranged coaxially; and the CT scanner includes a radioactive source and a detector disposed on two opposite sides of the shear box. The rock joint direct shear test system suitable for CT three-dimensional real-time scanning provided by the invention has good stability and realizes three-dimensional imaging.

Owner:SHAOXING UNIVERSITY

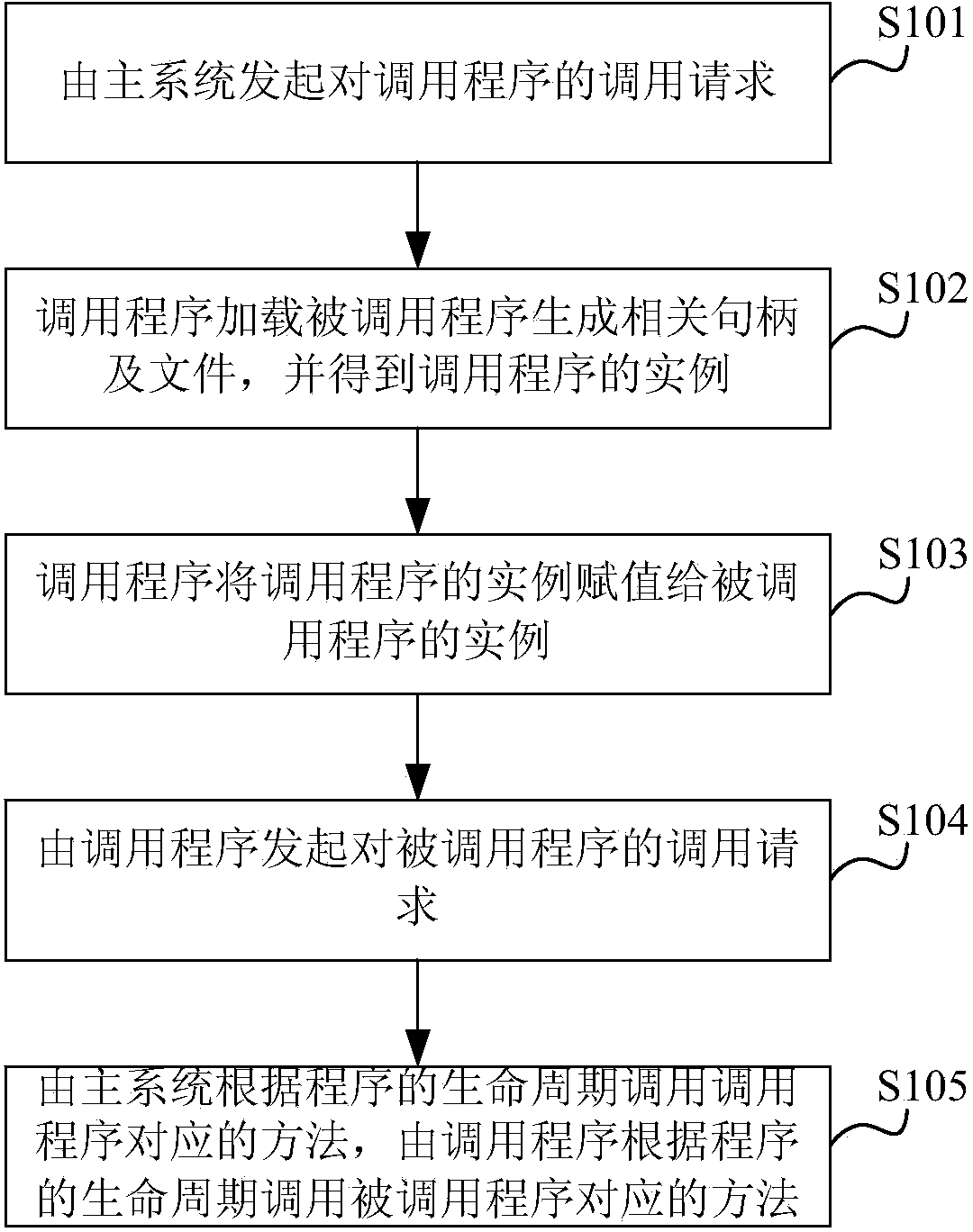

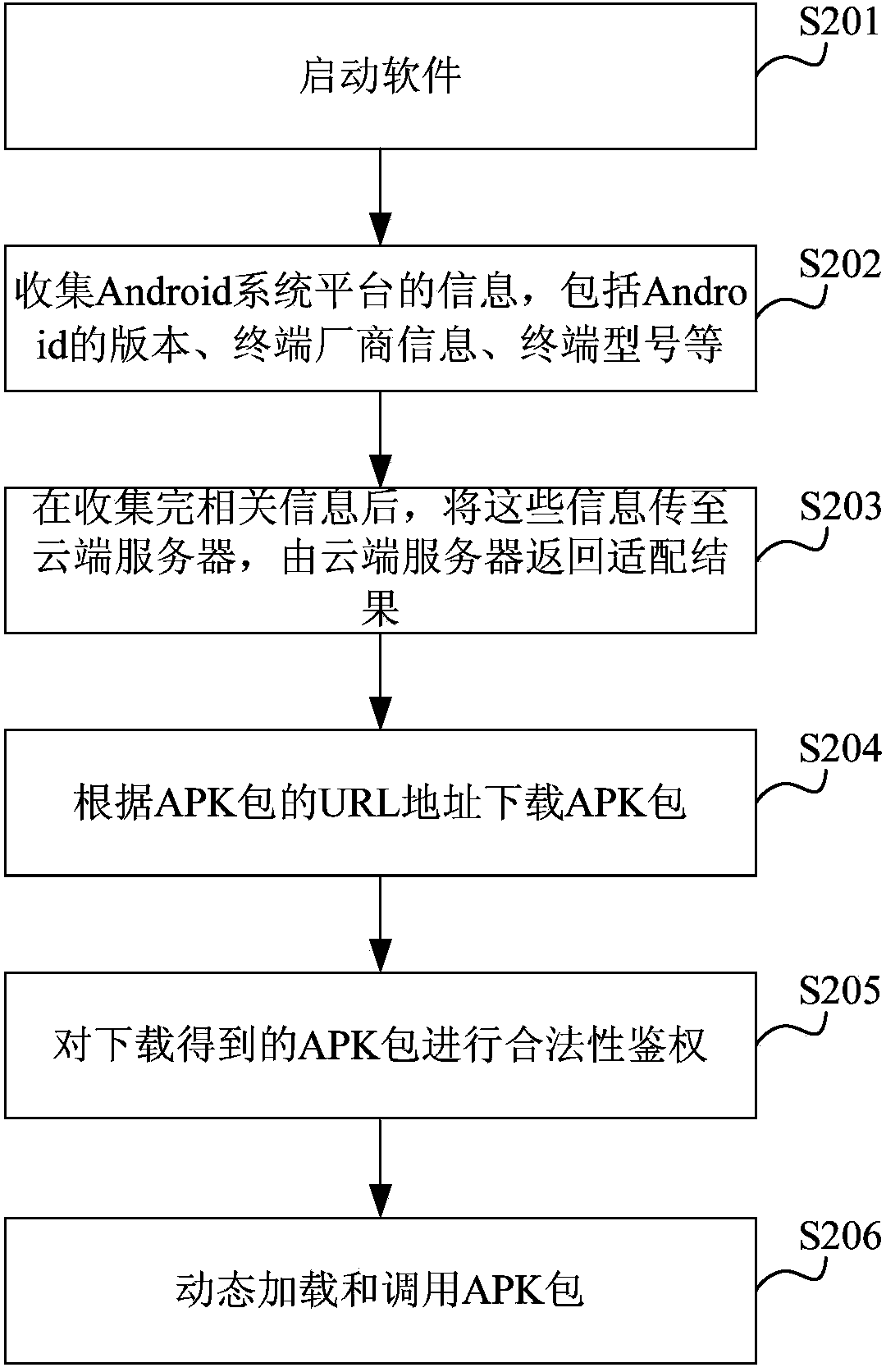

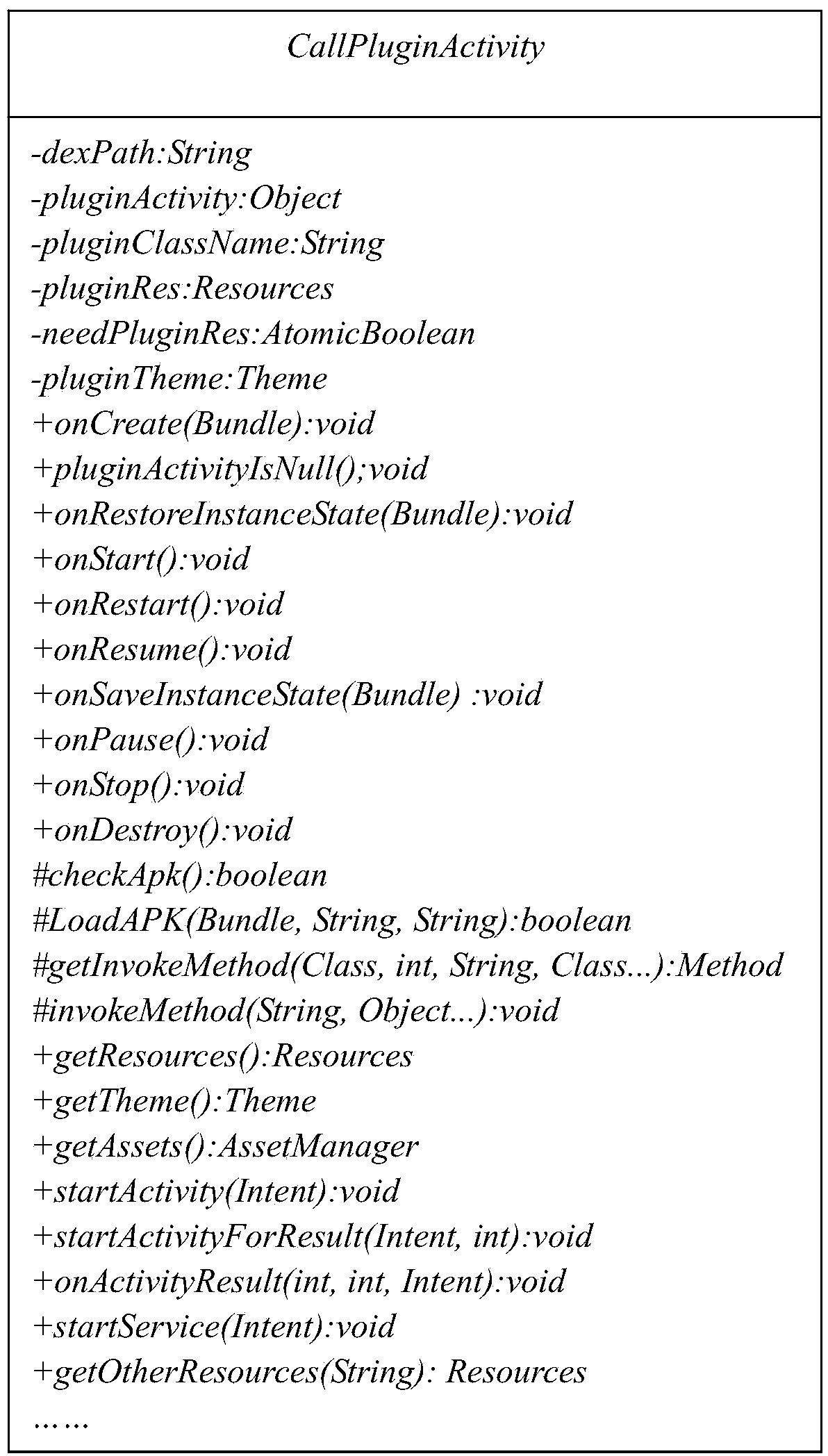

Method and device for dynamically loading and calling program

ActiveCN103530156ARealize the loadImplement the callProgram loading/initiatingSoftware engineeringSystem call

The invention discloses a method and device for dynamically loading and calling a program. The method comprises the steps that a main system initiates a calling request for a calling program, the calling program loads a called program to generate a relevant handle and a file, a living example of the calling program is obtained, the calling program assigns the living example of the calling program to a living example of the called program, the calling program initiates the calling request for the called program, the main system calls a method corresponding to the calling program according to the life cycle of the program, and the calling program calls a method corresponding to the called program according to the life cycle of the called program. By means of the scheme, the program can be loaded and called only by downloading a program package, and the mode for a user to use the program is simplified.

Owner:BEIJING QIHOO TECH CO LTD

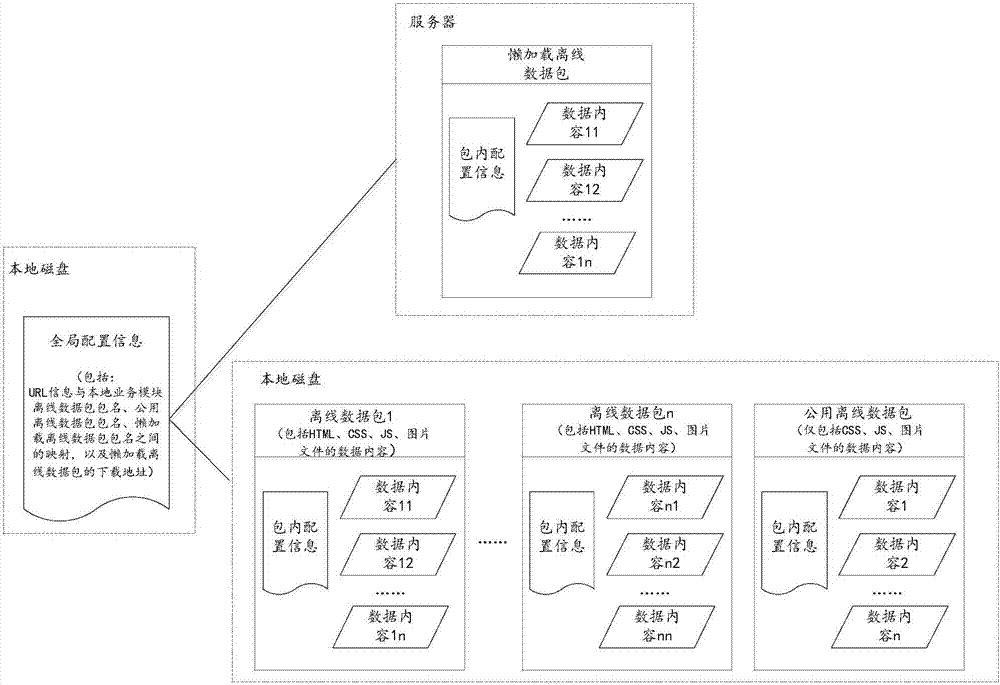

Page loading processing method and device

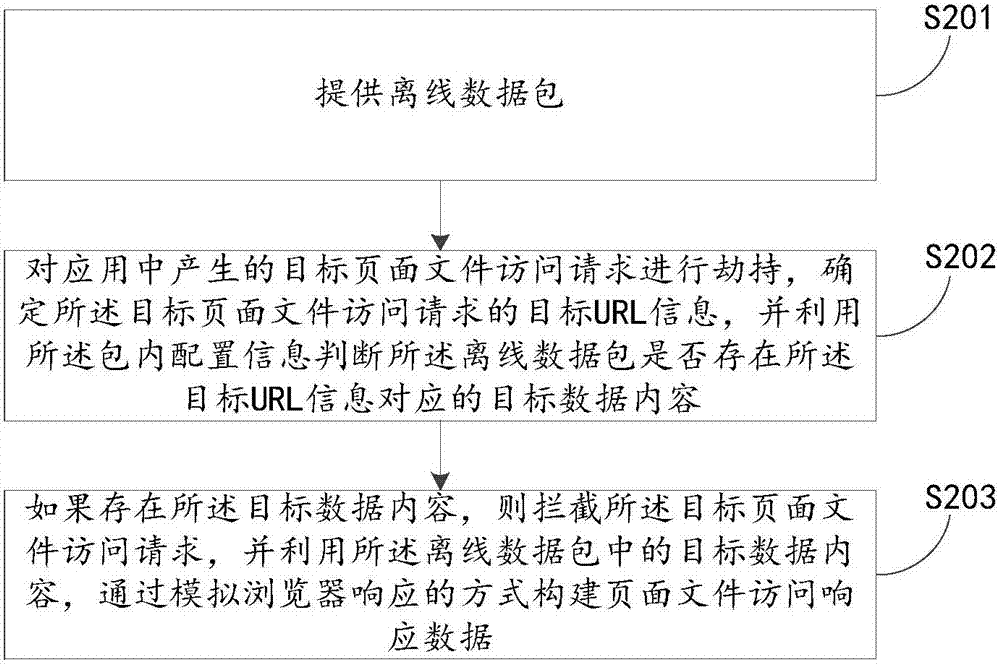

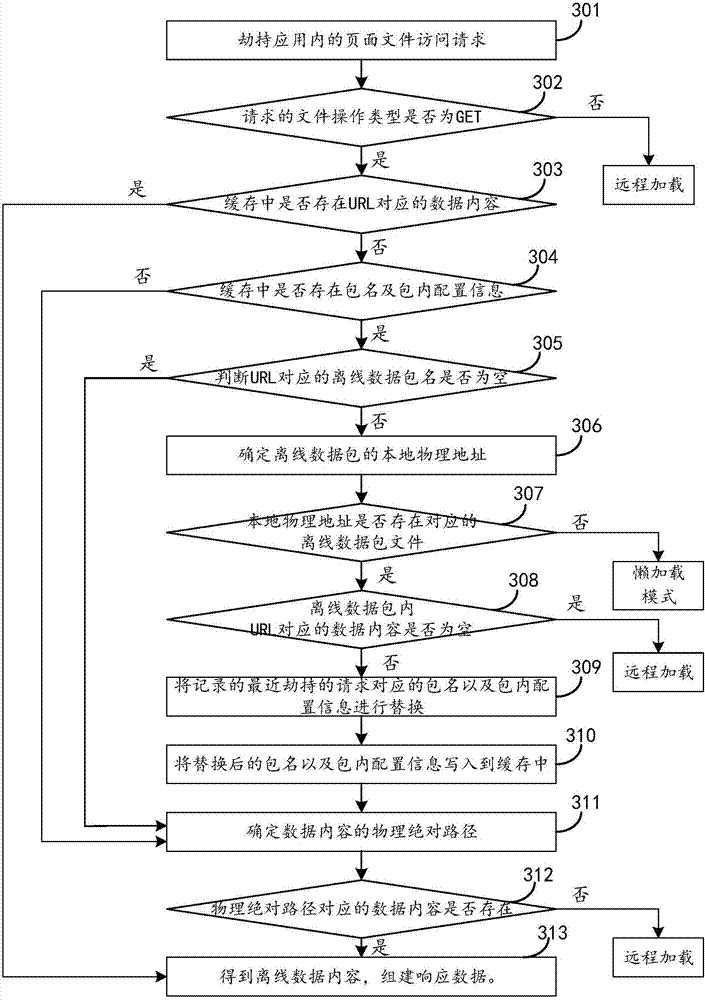

ActiveCN107203555ANo errorsSupport loadingSpecial data processing applicationsNetwork packetData content

The embodiment of the invention discloses a page loading processing method and device. The method includes the steps that an off-line data packet is provided, wherein the off-line data packet includes intra-packet configuration information and multiple parts of data content; a target page file access request generated in an application is intercepted, and whether or not target data content corresponding to target URL information exits in the off-line data packet is judged based on the intra-packet configuration information; if the target data content exists, the target page file access request is intercepted, a page file is constructed in a simulating browser response mode with the target data content in the off-line data packet to access response data, and the response data is returned to a built-in browser control of the application. By means of the page loading processing method and device, the loading speed is increased, and meanwhile the robustness of the scheme is improved.

Owner:ALIBABA GRP HLDG LTD

Clutch based on ultrasonic suspending force control

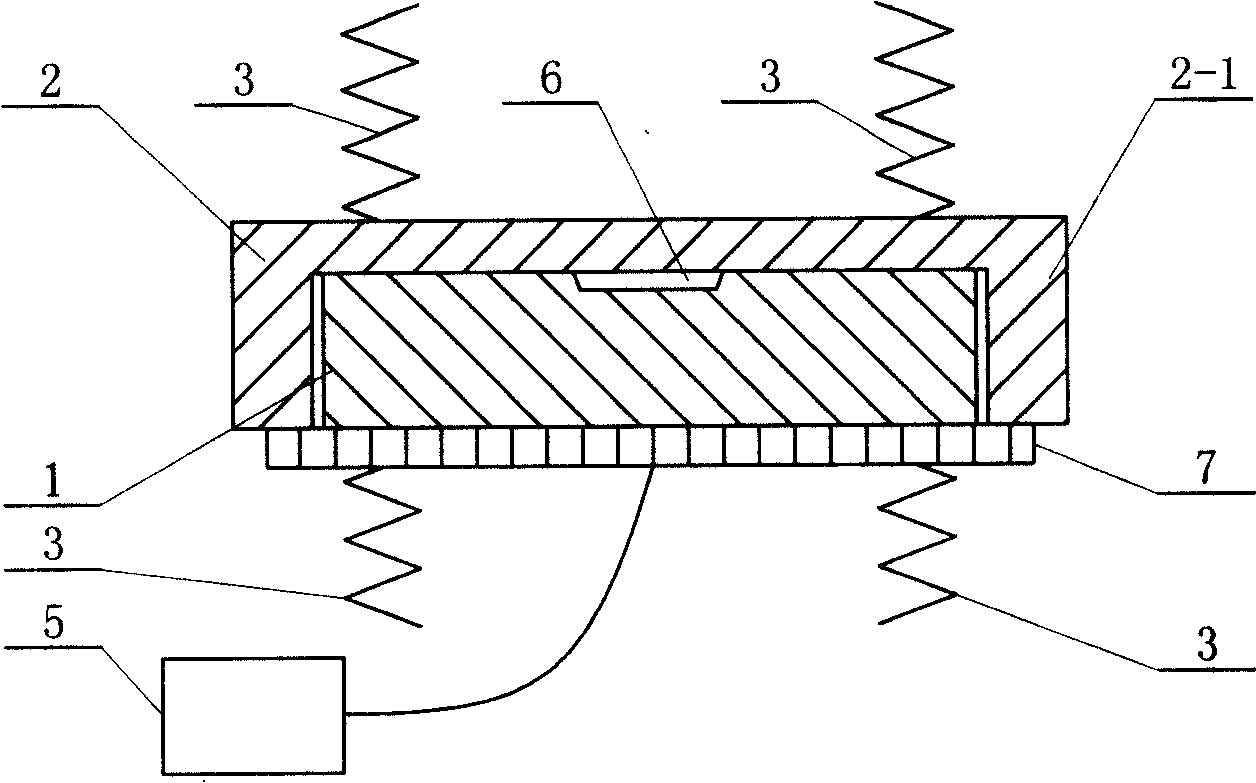

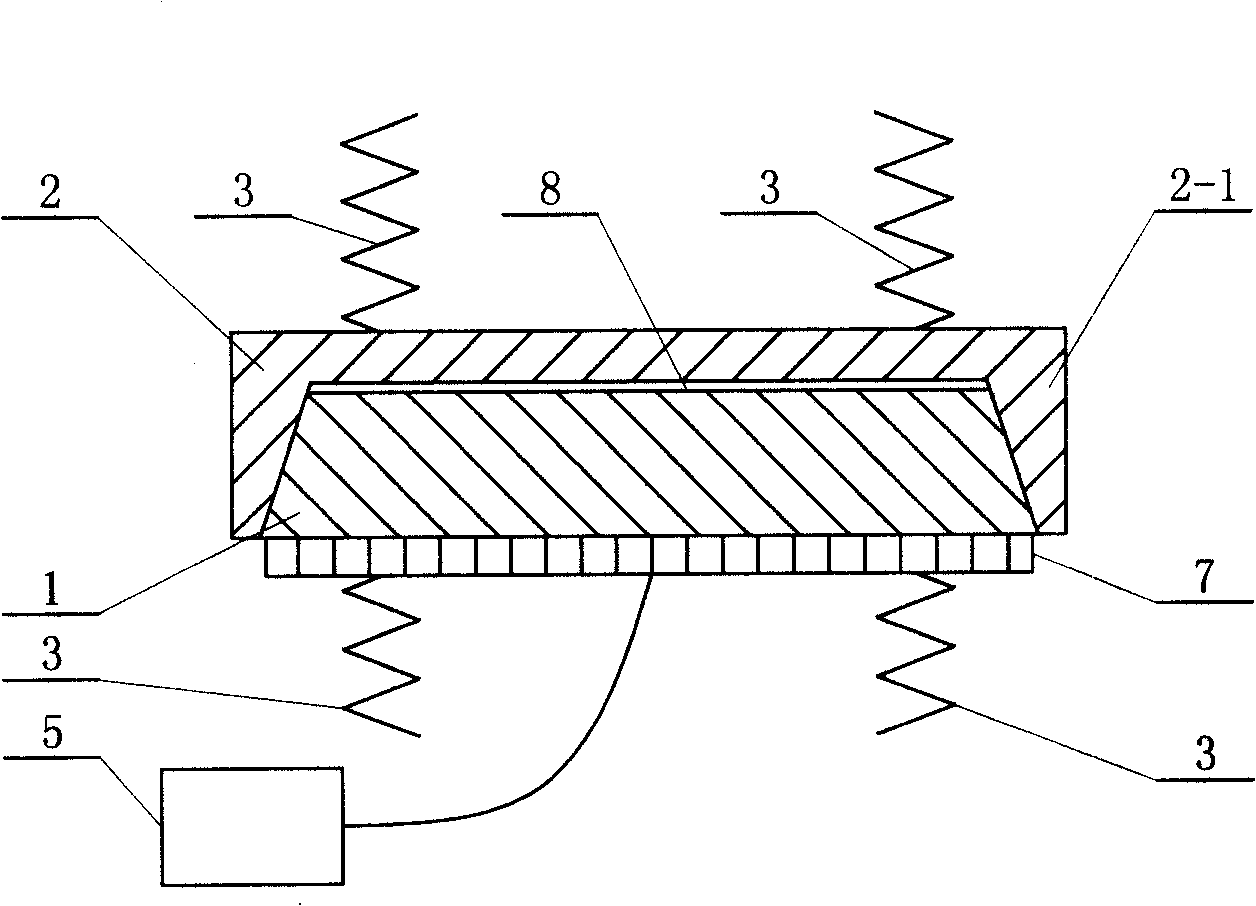

InactiveCN100424369CSimple structureOverall small sizePiezoelectric/electrostriction/magnetostriction machinesMagnetically actuated clutchesTransmitted powerElectromagnetic interference

The invention discloses a clutch based on ultrasonic suspending force control, which is composed of active rotating disc, passive rotating disc, piezoelectric ceramic piece, back-moving spring and high-frequency electric source. The passive rotating disc couples to the circular ring of the active rotating disc. The end face of the active rotating disc contacts to an end face of the passive rotating disc. The piezoelectric ceramic piece is fixed on the other end face of the passive rotating disc. The high-frequency electric source connects to the receiving terminal of the piezoelectric ceramic piece. The back-moving spring is set on active rotating disc or passive rotating disc to keep a certain distance between the active rotating disc and passive rotating disc. Another embodiment is that: the inner surface of the circular ring 2-1 is taper shaped; the flange of 1 is taper shaped; the inner surface of the 2-1 contacts to the flange of 1. The invention applies the ultrasonic suspending force as drive force for separation and applies friction moment to transmit power.

Owner:HARBIN INST OF TECH

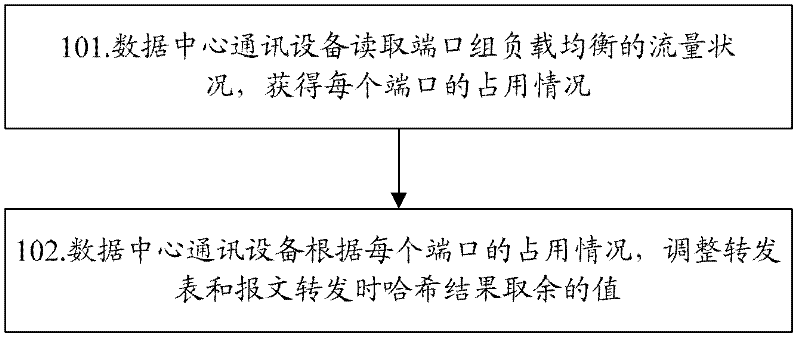

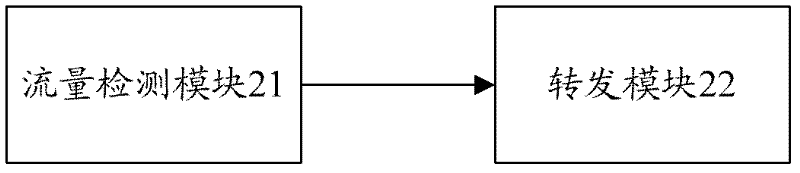

Load sharing method and device of data center communication equipment

InactiveCN102447636ALoad balancingEven load sharingStore-and-forward switching systemsTraffic capacityWire speed

The invention discloses a load sharing method of data center communication equipment, which comprises steps as follows: data center communication equipment regularly reads flow conditions of port group load balancing to acquire occupation conditions of each port; and a forwarding table and a Hash result modulo value in the message forwarding process are adjusted according to the occupation conditions. The invention also discloses a load sharing device of data center communication equipment. By using the scheme disclosed by the invention, static / dynamic combined load sharing of the data center communication equipment can be implemented, so that the ports can carry balanced loads and satisfy the requirements for linear speed.

Owner:ZTE CORP

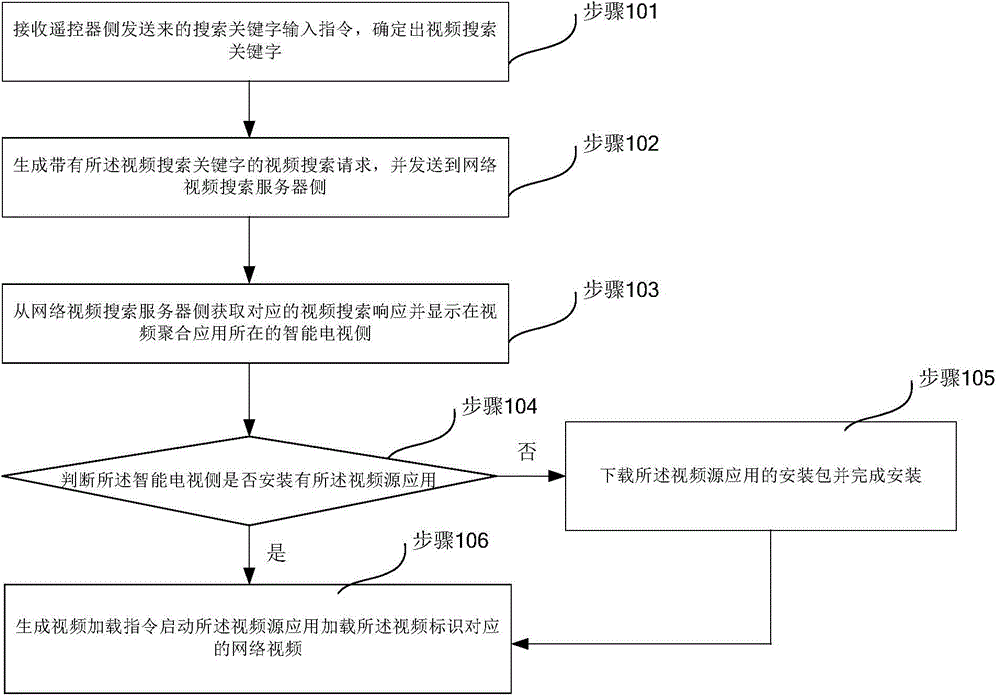

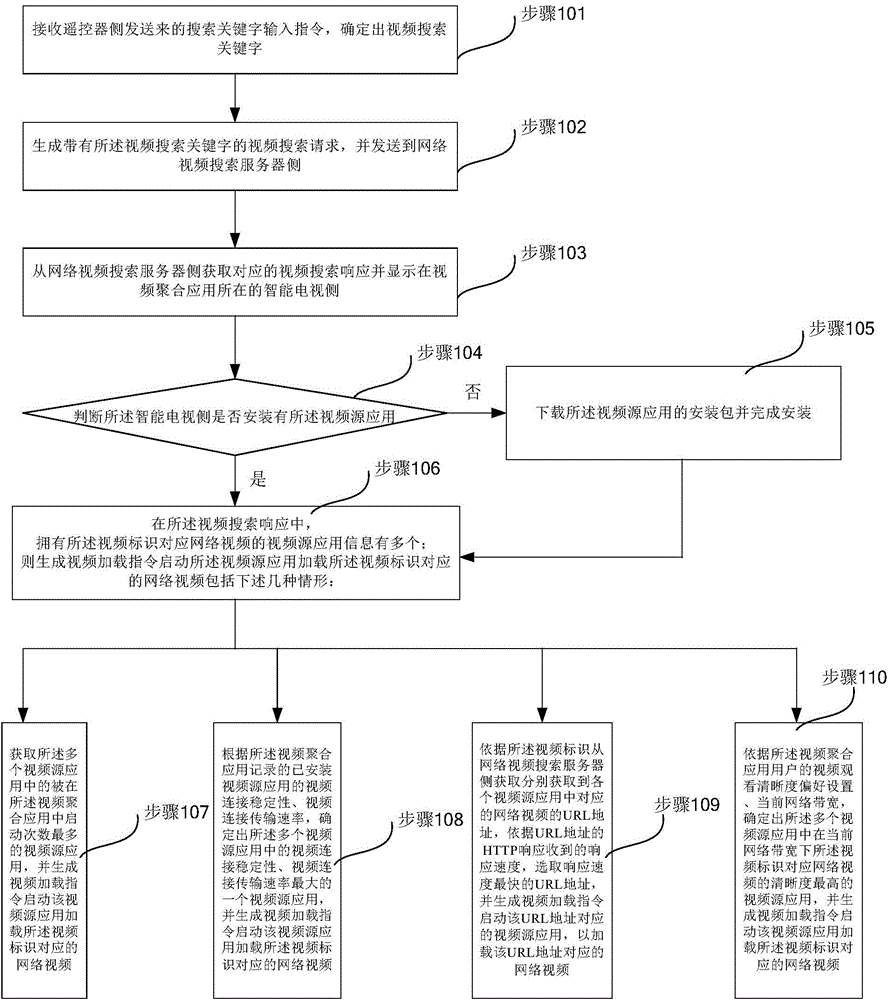

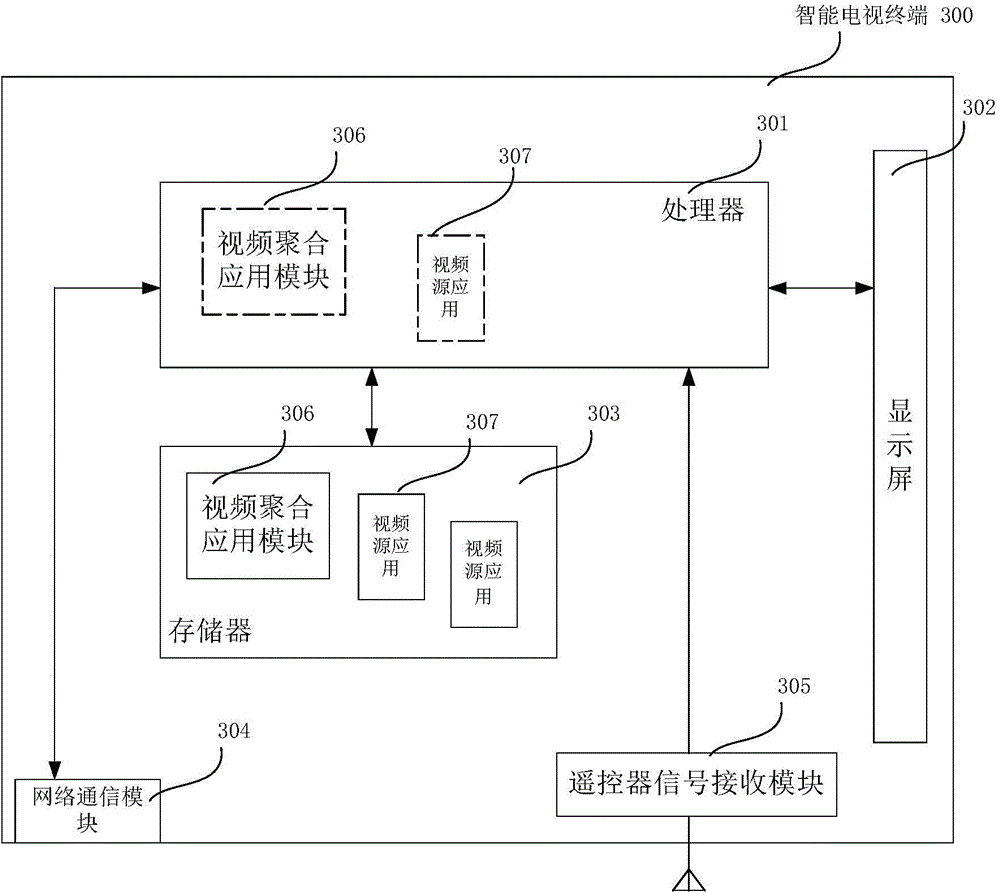

Method for loading network video by video polymerization application and intelligent television terminal

ActiveCN104954811AImplement responseRealize the display effectVideo data retrievalSelective content distributionComputer graphics (images)Computer terminal

The invention provides a method for loading a network video by a video polymerization application. The method comprises the following steps: receiving a search keyword input instruction sent by a remote controller side to determine video search keywords; generating a video search request with the video search keywords, and sending the video search request to a network video search server side; acquiring corresponding video search respond from the network video search server side, and displaying video search responds on an intelligent television side where the video polymerization application is placed, wherein the video search responds comprises a video identification and video source application information with a network video corresponding to the video identification; judging that a video source application is mounted on the intelligent television side, and generating a video loading instruction to start the video source application to load the network video corresponding to the video identification. Through the adoption of the method, video source across application can be conducted in the video polymerization application for video search, and the number of the polymerized videos is increased.

Owner:杭州当贝网络科技有限公司

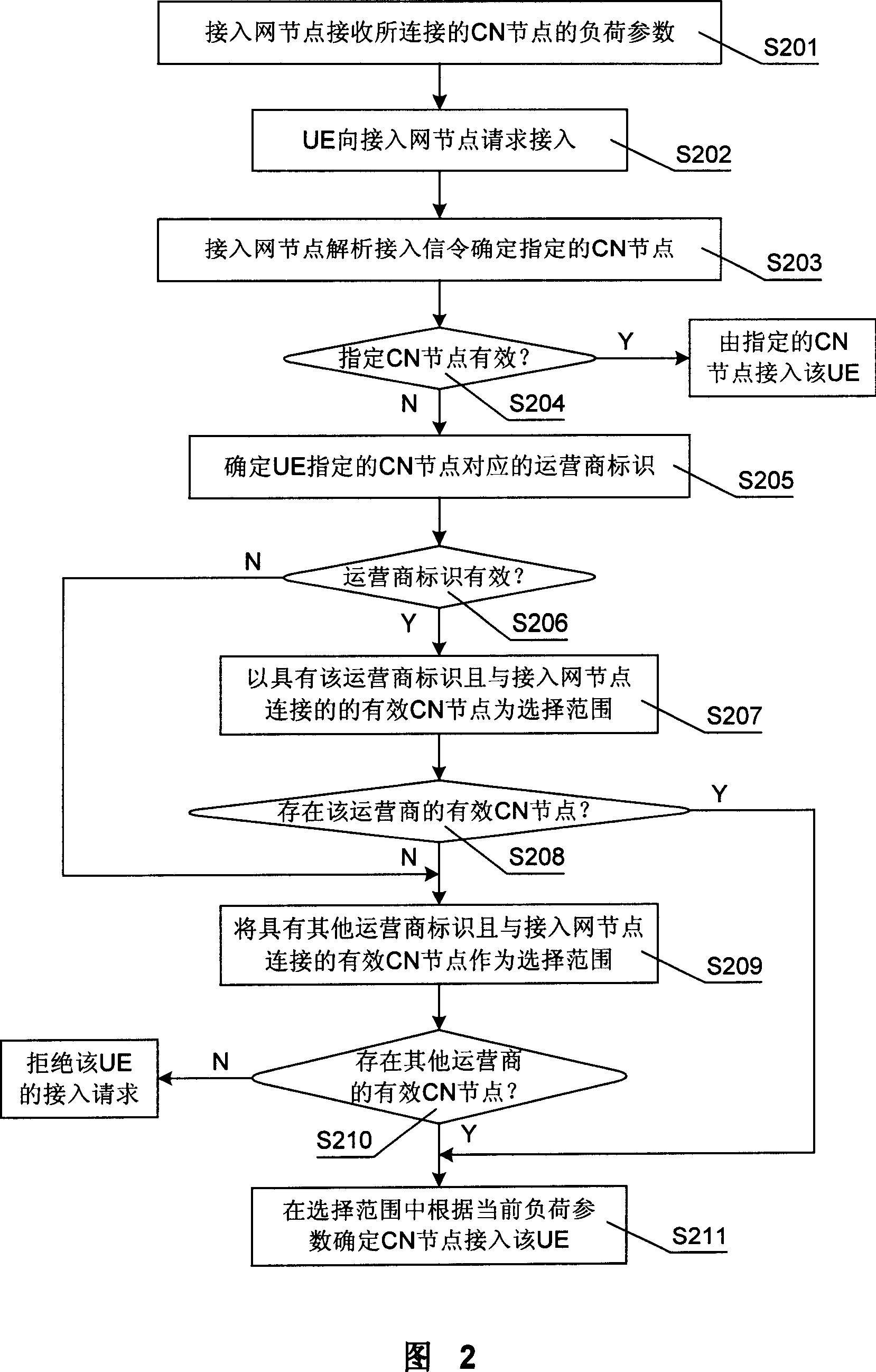

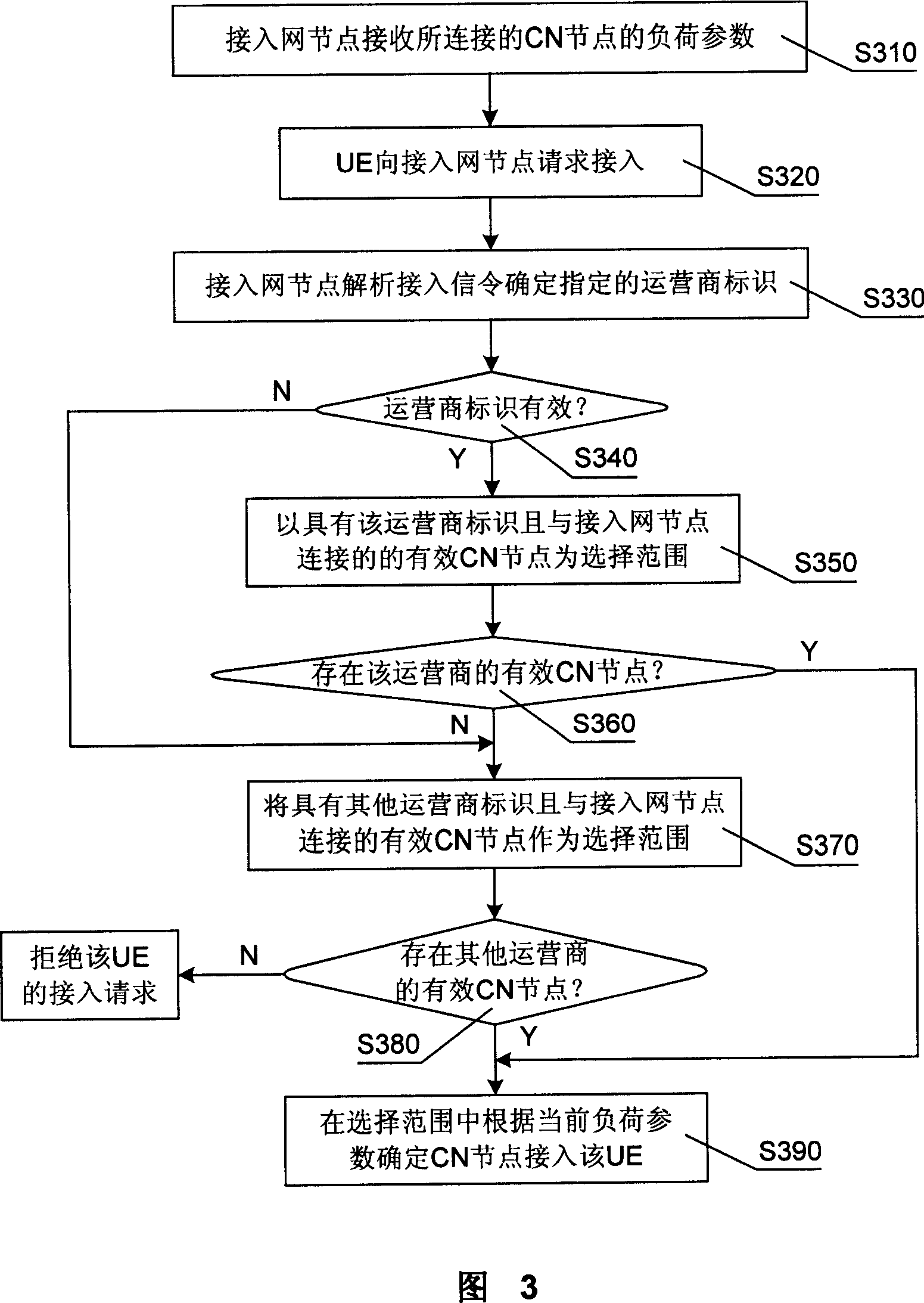

A method for balancing the loads in the mobile communication system and its communication equipment

InactiveCN101060698AImprove stability and reliabilityRealize the loadNetwork traffic/resource managementAssess restrictionSystem stabilityAccess network

The disclosed loading balance method comprises: the access network node determines the selection of UE CN-node; in the selection range, selects one of current loading parameter, and transmits the UE access signaling. This invention balances loading among all CN nodes efficiently, and improves system stability and reliability.

Owner:CHINA ACAD OF TELECOMM TECH

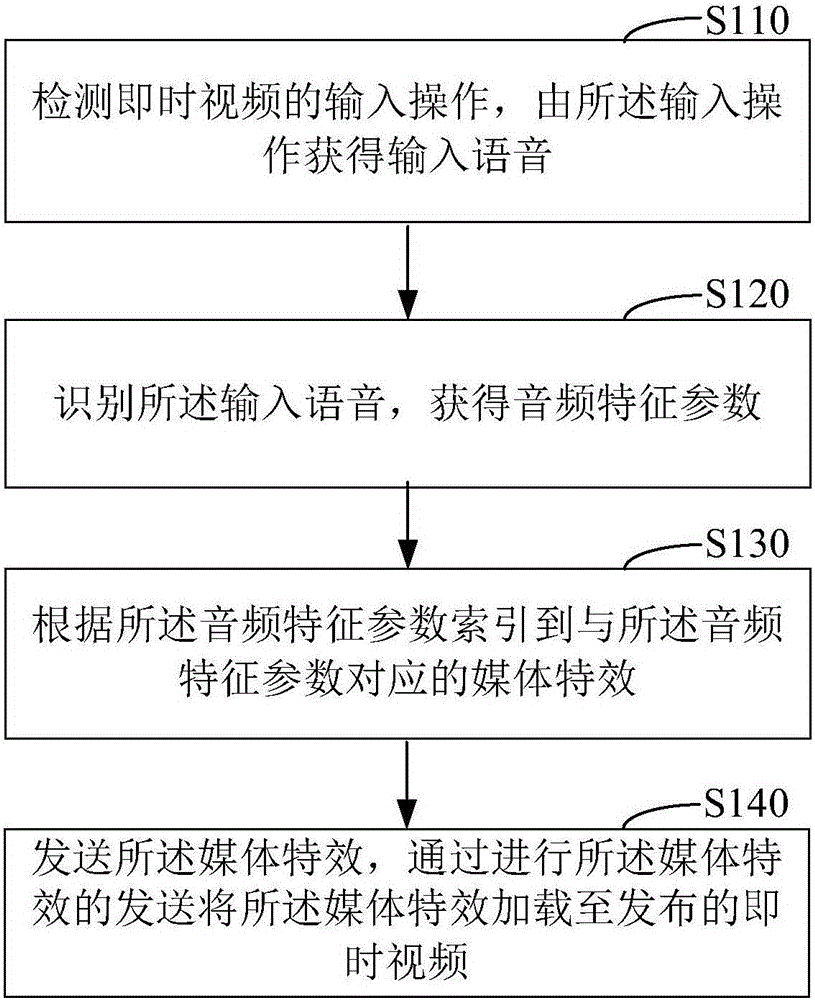

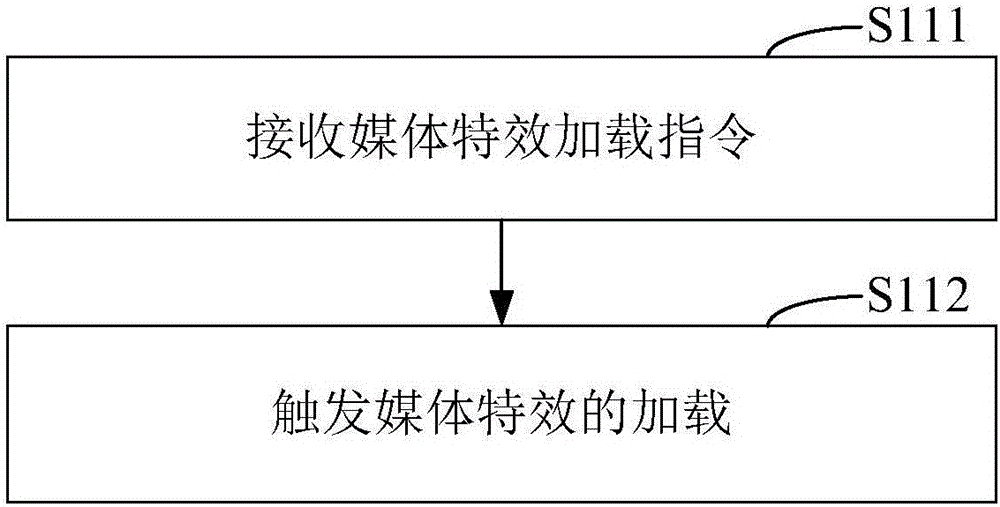

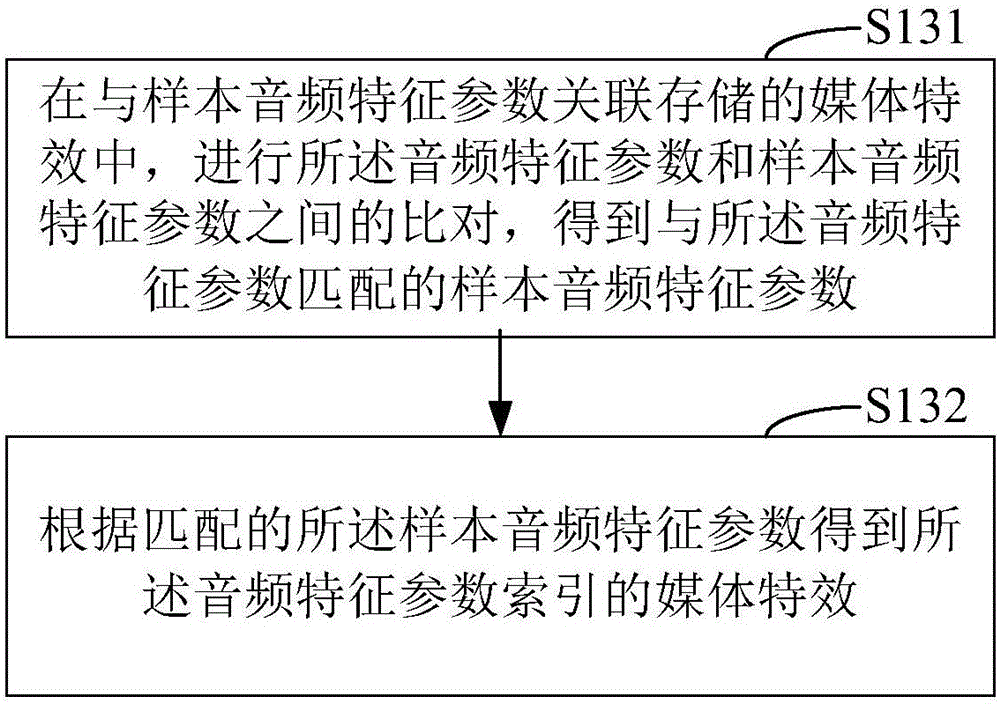

Sending method and device of special media effects of real-time videos

InactiveCN105872838ARealize the loadImprove sending efficiencySelective content distributionFeature parameterComputer science

The present invention provides a method for sending media special effects in real-time video, comprising: detecting an input operation of the real-time video, and obtaining an input voice through the input operation; recognizing the input voice, and obtaining audio feature parameters; according to the audio feature parameters, Index to the media special effect corresponding to the audio feature parameter; send the media special effect, and load the media special effect to the released instant video by sending the media special effect. In addition, a device for sending media special effects in instant video matching the method is also provided. The above method and device for sending media special effects in instant video can improve the sending efficiency of media special effects.

Owner:徐文波

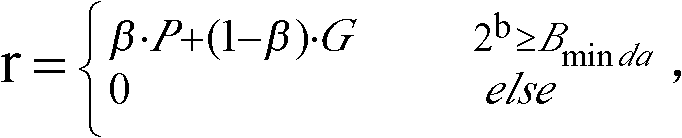

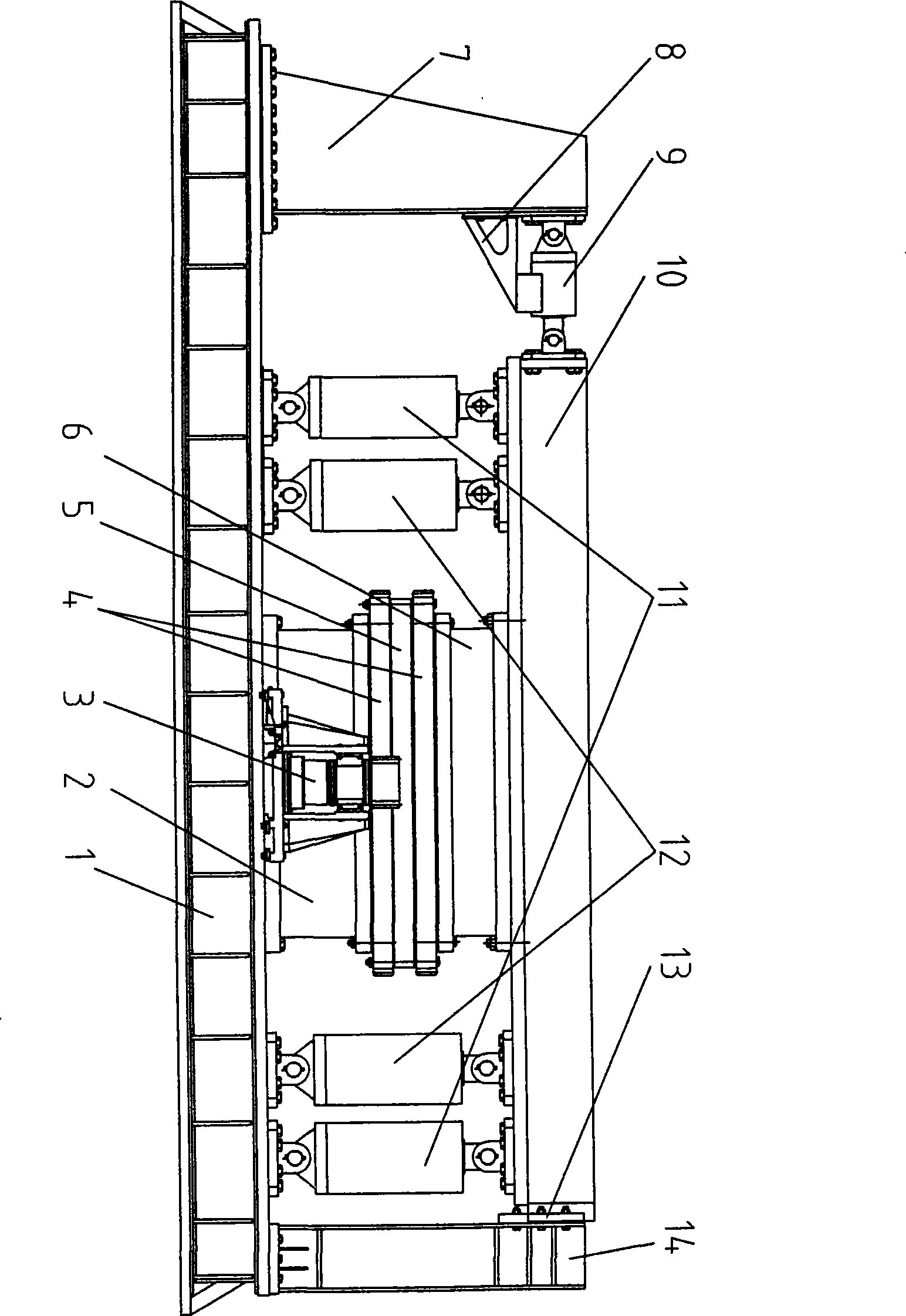

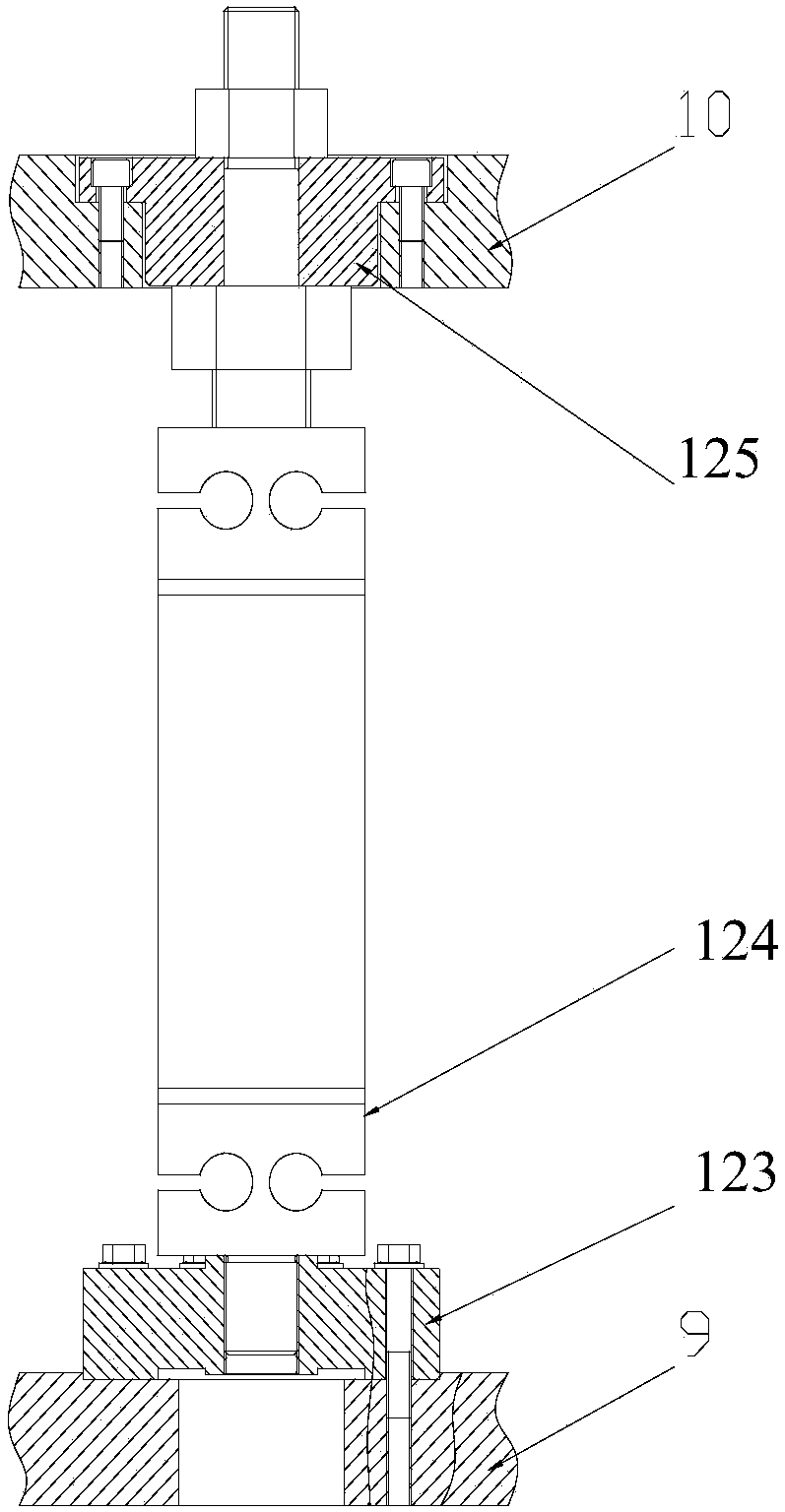

Wind-powered turntable bearing combination property bench

The invention relates to a comprehensive performance experiment table for wind power turntable bearings, which consists of a bottom plate (1), a lower adapter flange cylinder (2), a power assembly (3), the wind power turntable bearings (4), an upper adapter flange cylinder (6) and a loading cover (10), wherein at least one pair of wind power turntable bearings are connected to the lower adaptor flange cylinder (2) and are two wind power turntable bearings which have the same specification and adopt the mounting means of 'back to back'; a pinion (25) is arranged on the power assembly (3) and meshed with gear teeth of an inner ring or an outer ring of one wind power turntable bearing or gear teeth of inner rings or outer rings of two wind power turntable bearings; the upper adapter flange cylinder (6) is detachably connected to upper parts of the wind power turntable bearings (4); and the loading cover (10) is detachably connected to the upper part of the upper adapter flange cylinder (2). The comprehensive performance experiment table for the wind power turntable bearings has a compact structure, is convenient to assemble, can realize modularized adjustment according to different wind power turntable bearings, and can simultaneously realize loading of the axial force, the radial force and the capsizing moment.

Owner:NANJING GONGDA CNC TECH

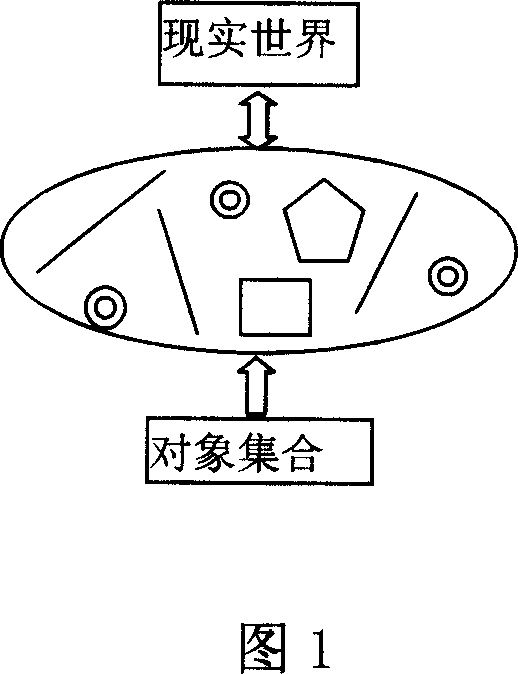

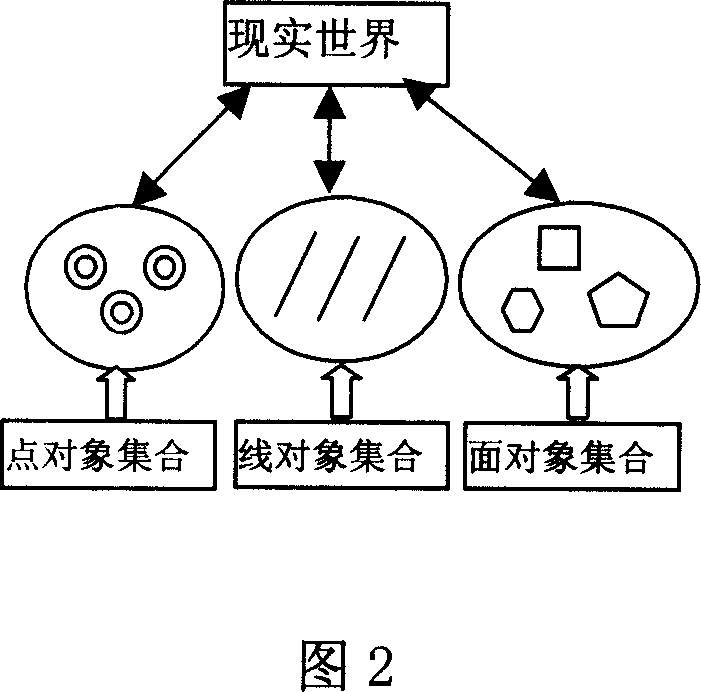

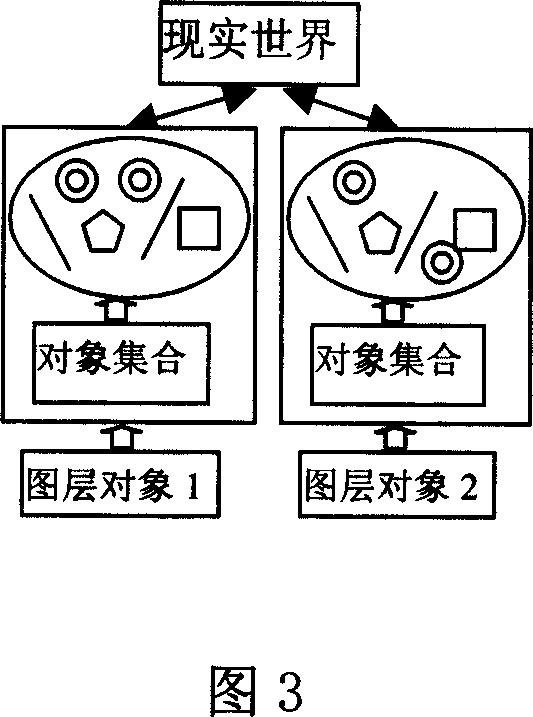

Satellite positioning, remote sensing and geographical in for mation integrating method based on mobile device

InactiveCN101051077ARealize the loadAchieve overlayPosition fixationSatellite radio beaconingOperational systemData acquisition

A method for integrating information of satellite positioning and remote sensing as well as geography based on mobile device utilizes embedded windows CE operation system built in mobile device and its provided-embedded development environment including embedded GIS data model and integration of GPS and GIS as well as integration of GIS and RS to realize position data collection and remote sensed image loading as well as superposition of remote sensed image with vector map.

Owner:上海市闸北区绿化管理局 +1

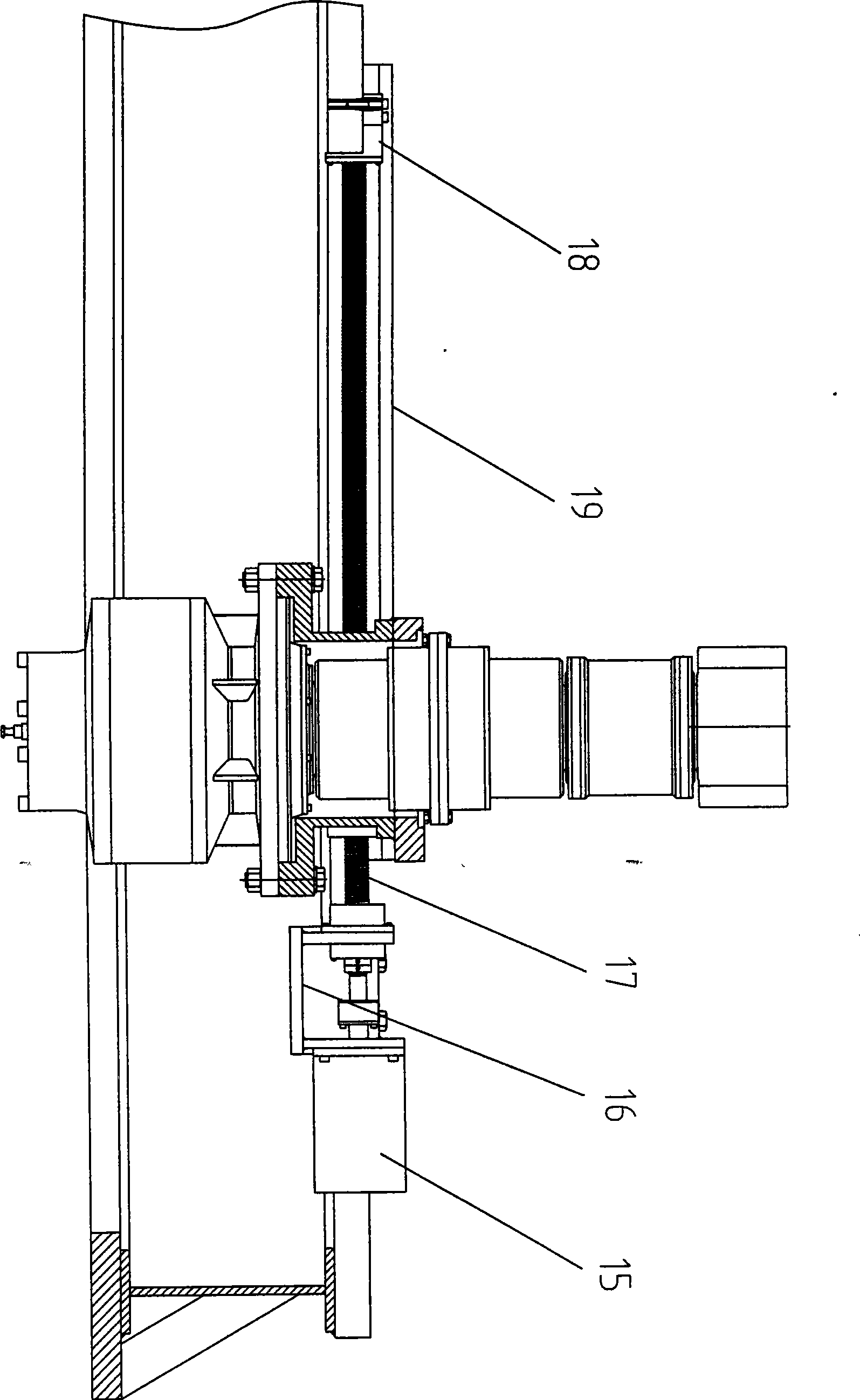

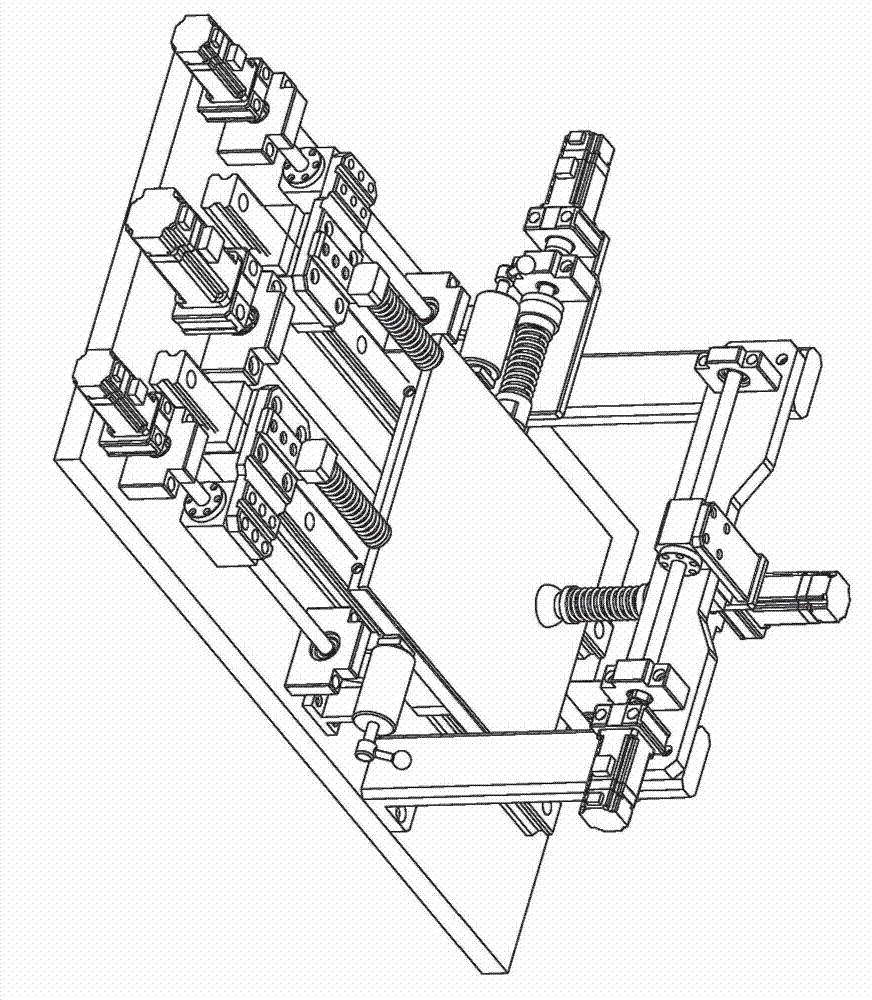

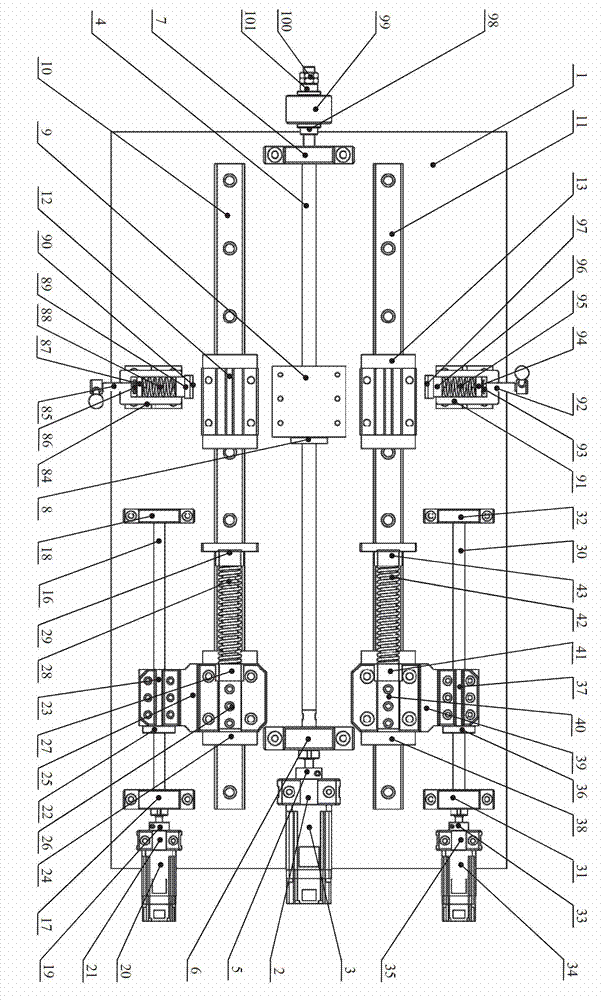

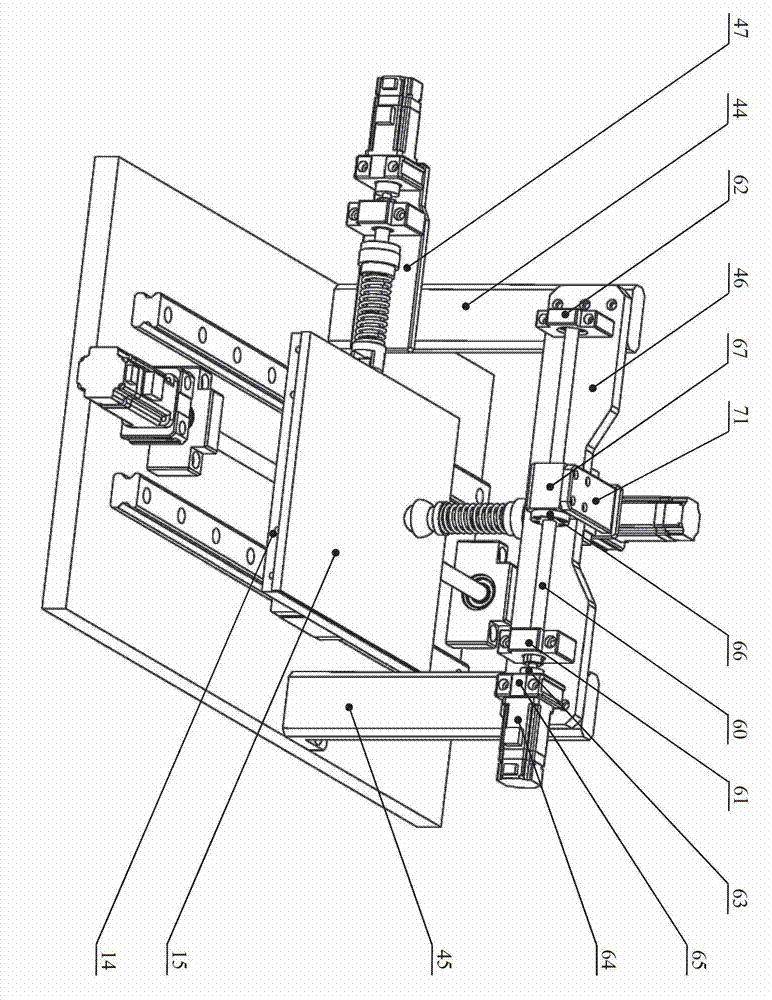

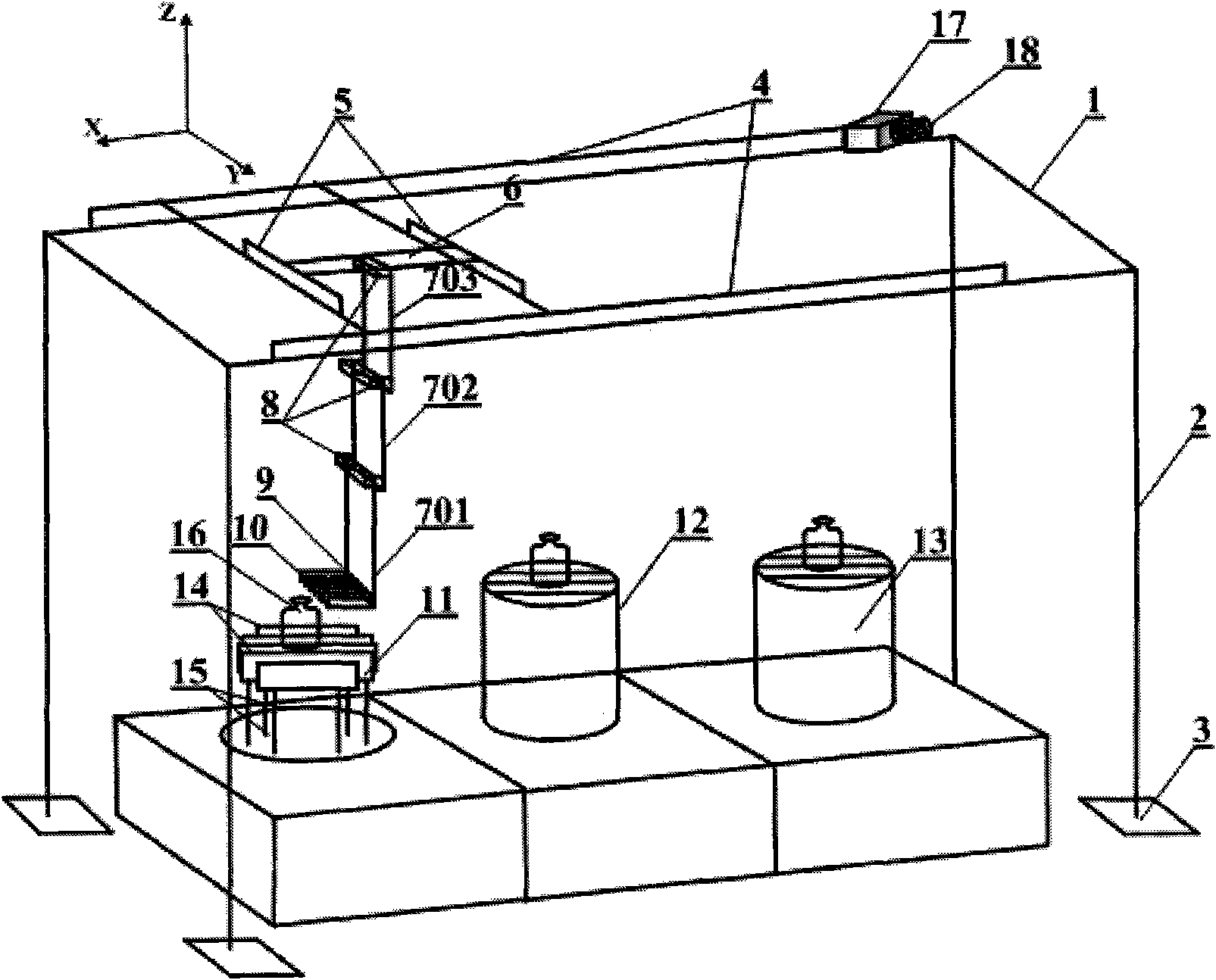

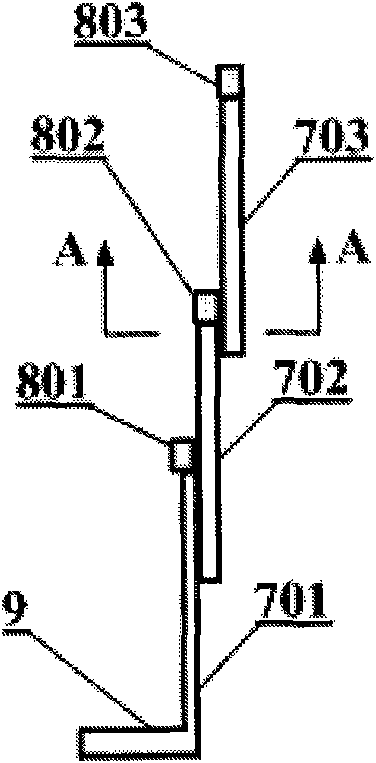

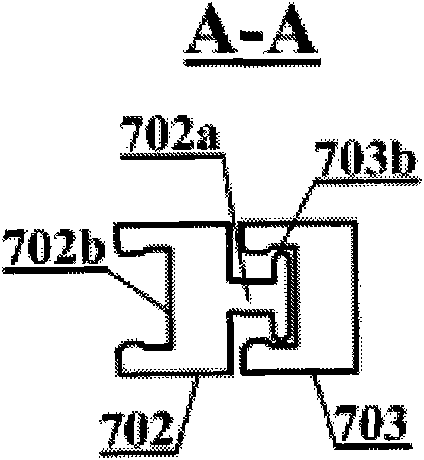

Experimental device for comprehensively testing dynamic characteristics of linear feeding system

InactiveCN102928220APrecise control of loading forceSimple structureMachine gearing/transmission testingSingle degree of freedomEngineering

The invention discloses an experimental device for comprehensively testing dynamic characteristics of a linear feeding system and belongs to the technical field of machinery manufacturing. The device comprises a single-degree-of-freedom servo feeding mechanism, a longitudinal loading mechanism, a gantry frame, a transverse loading mechanism, a vertical loading mechanism, a friction loading mechanism and an inertia matching mechanism, wherein the single-degree-of-freedom servo feeding mechanism controls the position of a worktable; the longitudinal loading mechanism controls amplitude and direction of longitudinal loading force; the transverse loading mechanism controls amplitude of transverse loading force; the vertical loading mechanism controls amplitude of vertical loading force; the friction loading mechanism controls application of a friction load; and inertia matching mechanism can research inertia matching characteristics. The device is reasonable and compact in structure, convenient to maintain and wide in application range, can simulate a longitudinal load, a transverse load, a vertical load, torque and a composite load at any position of the worktable and accurately controls the loading force.

Owner:TSINGHUA UNIV

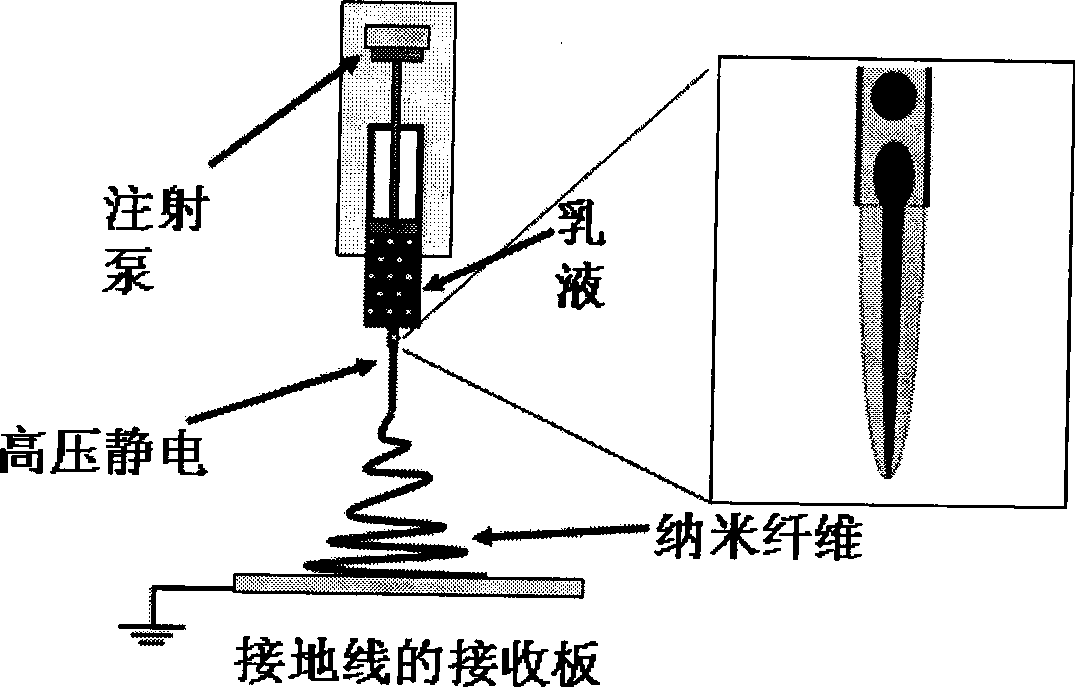

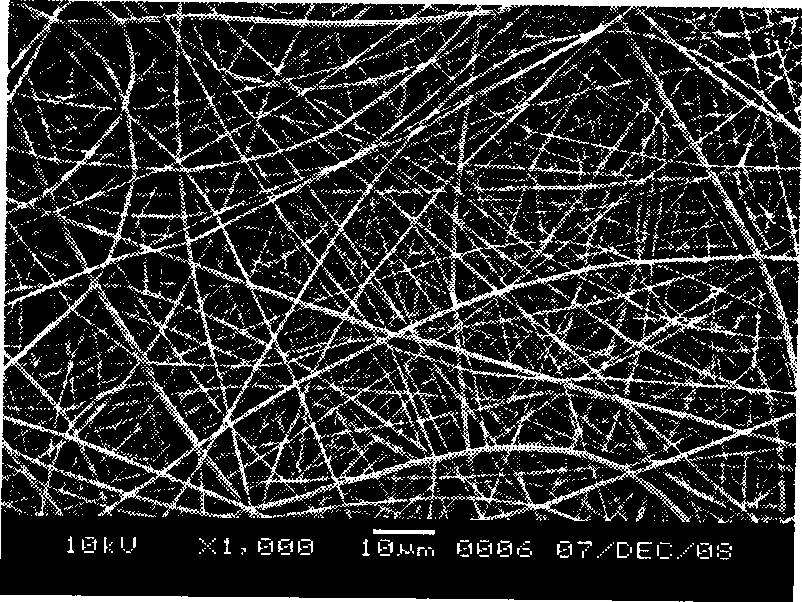

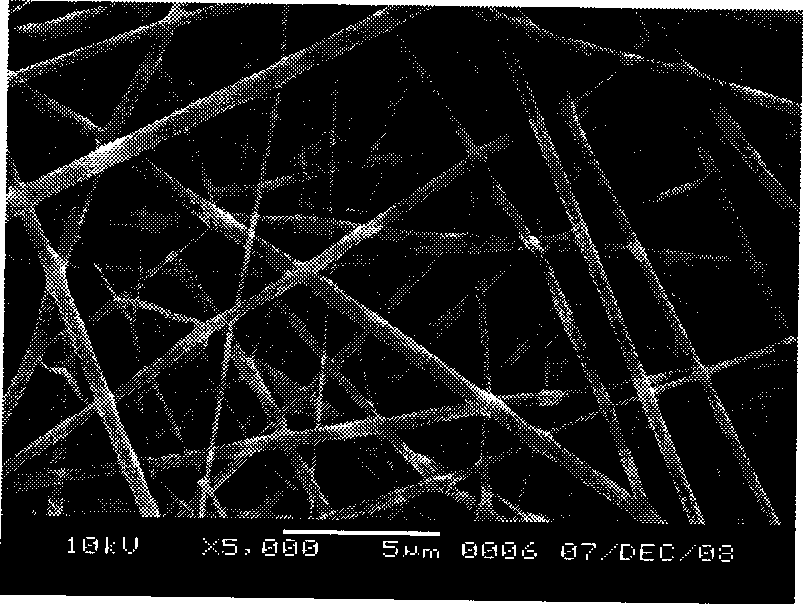

Method for producing shell-core structure medicament nano-fibre with emulsion electrostatic spinning technology

InactiveCN101509154AEasy to operateMild reaction conditionsFilament/thread formingPharmaceutical delivery mechanismWater in oilChemistry

The invention relates to a method for preparing shell-core structured medicament nano fiber by emulsion electrostatic spinning technology, comprising dissolving water soluble medicaments or active growth factors in super pure water to prepare uniform water phase solution; (2) dissolving high molecular polymers and oil soluble medicaments in organic solution, and adding emulsifier to prepare uniform oil phase solution; (3) dripping the water solution into the oil phase solution, and completely stirring the mixed solution to obtain uniform water-in-oil type W / O emulsion; and (4) carrying out electrostatic spinning on the emulsion, setting the spinning voltage at 15-25kv, the reception distance at 10-20cm, the spinning pushing speed at 0.5-1.5mL / h, and the spinning nozzle as 0.9mm, and obtaining the target product. The preparation method is simple in operation, mild in reaction condition, low in cost and favorable for economic benefit; and the prepared shell-core composite nano fiber not only has better mechanical property, but also can realize loading of oil soluble medicaments.

Owner:DONGHUA UNIV

Automatic handing system of weight and application thereof

InactiveCN101806612AConvenient automatic handlingCompact structureWeighing auxillary devicesPower controlManipulator

The invention belongs to the field of weighing apparatus metering, relating to an automatic handing device of a three-dimensional weight in quality measurement. The invention discloses an automatic handing system of weight and application thereof. The system comprises the weight, a power control part, a sliding assembly, a flexible assembly and a mechanical arm, wherein the sliding assembly and the flexible assembly are matched to operate under the driving of the power control component so as to control the mechanical arm to transport the weight. The automatic handing system of a three-dimensional weight in high-accuracy quality measurement provided by the invention can conveniently and automatically transport and load cylindrical weight, has compact structure, small occupation space, high transportation and loading speed and high working efficiency, and can automatically adjust speed and realize no-impact loading, thereby bringing great convenience for operating staff to operate, saving manpower.

Owner:NAT INST OF METROLOGY CHINA

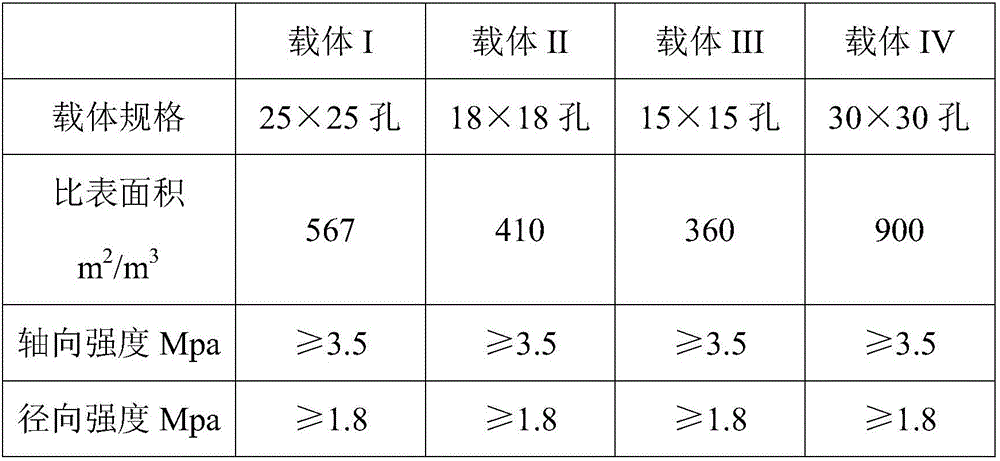

Method for forming fly-ash-based honeycomb type denitration catalyst ceramic carrier

The invention belongs to the technical field of SCR denitration catalyst preparation and discloses a method for forming a fly-ash-based honeycomb type denitration catalyst ceramic carrier. Cheap and non-toxic fly ash serves as a carrier, additives and water are added, and the finished carrier product is prepared through mixing, ageing, filtering, pre-extrusion, ageing, extrusion molding, drying and forging. The catalyst carrier prepared through the method is low in mass, high in strength and large in specific surface area, and can meet requirements of industrial application. A loaded catalyst has high activity. The fly ash takes the place of titanium dioxide to serve as a main component of the carrier, the subsequent treatment problem of solid waste in coal-fired power plants is solved, waste is turned into wealth, recycling is achieved, cost is reduced, pollution caused by use of titanium dioxide is also avoided, forming of the carrier and loading of active components of the catalyst can be achieved at a time, and industrialization is easy.

Owner:湖北思搏盈环保科技有限公司

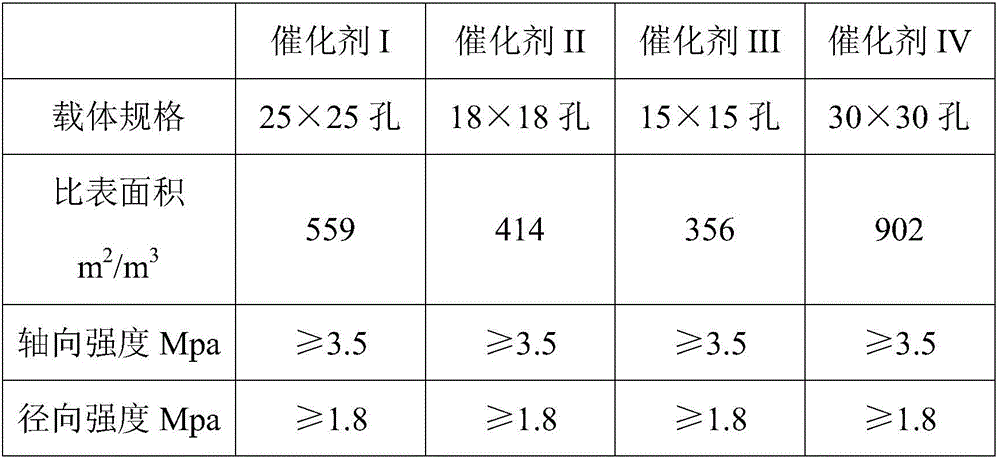

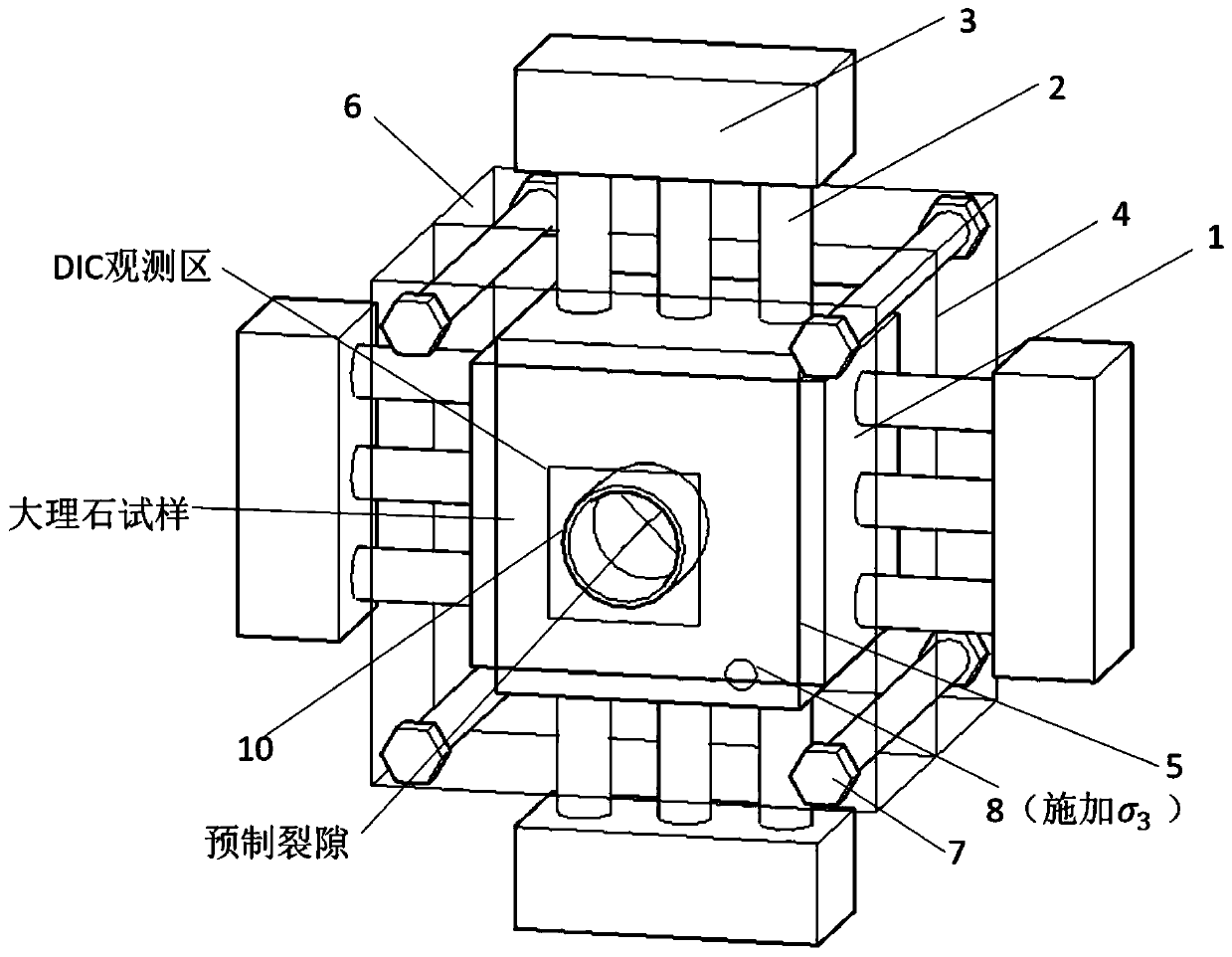

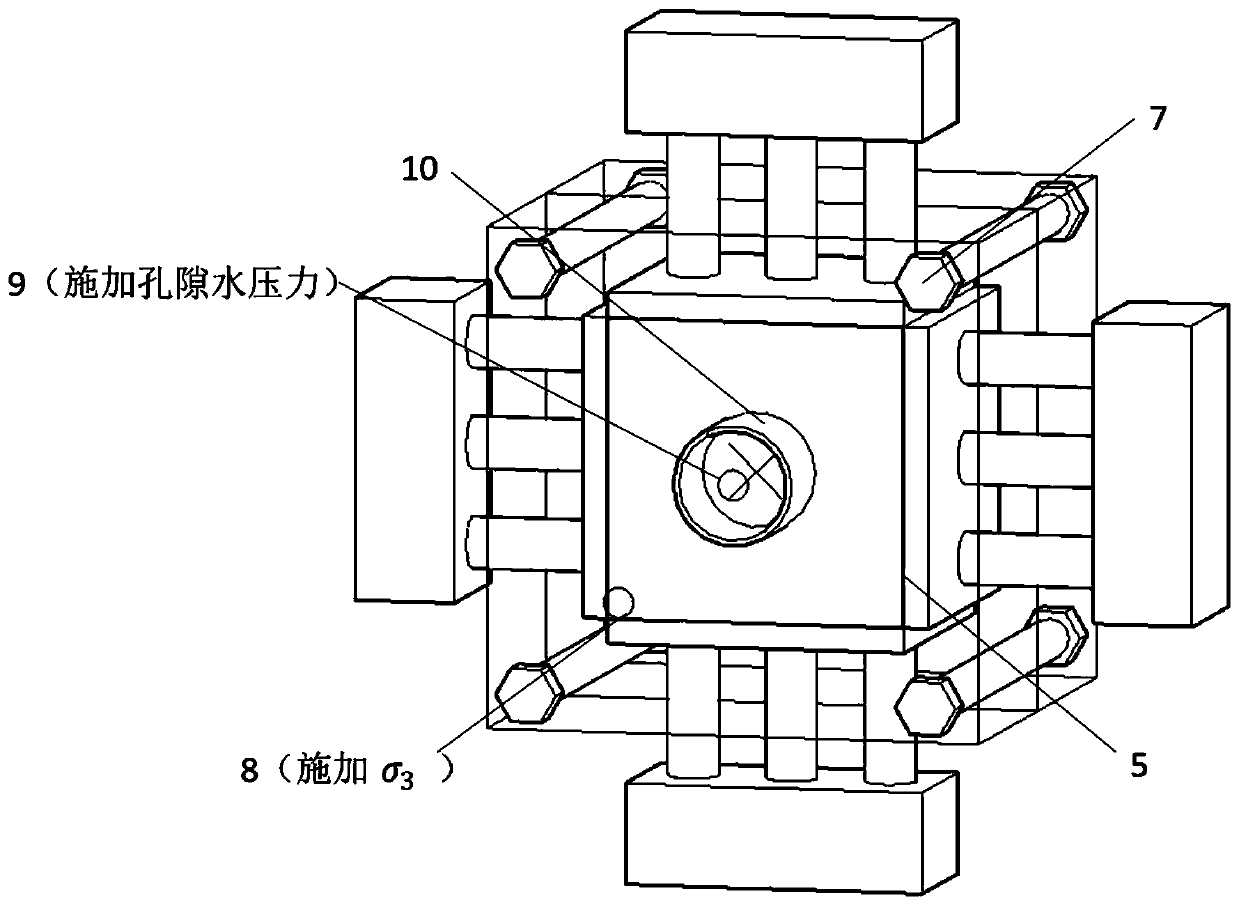

True triaxial hydraulic coupling test device for realizing visualization based on biaxial rheometer

ActiveCN110501232ARealize visual operationRealize the loadPreparing sample for investigationMaterial strength using tensile/compressive forcesCouplingButt joint

The invention relates to a true triaxial hydraulic coupling test device for realizing visualization based on a biaxial rheometer, thereby carrying out hydraulic coupling testing on a marble sample with front and rear surfaces having centers with penetrating cracks in a front-rear communication manner. The true triaxial hydraulic coupling test device comprises two modified polycarbonate plates thatare in a mutual butt joint manner to form square sealed inner space and a biaxial rheometer loading assembly for applying pressures on a marble sample in four directions. The marble sample is arranged in the sealed inner space; and the biaxial rheometer loading assembly applies pressures on the marble sample by the modified polycarbonate plates.. Compared with the prior art, the true triaxial hydraulic coupling test device has advantages of true three-axis loading, visual operation, and the like.

Owner:TONGJI UNIV

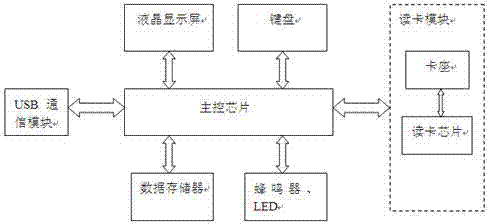

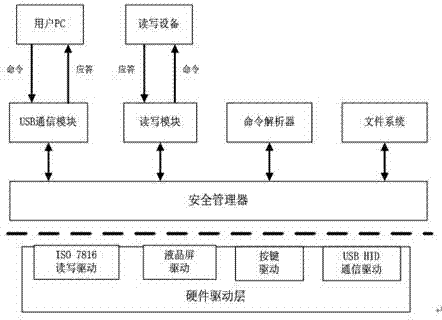

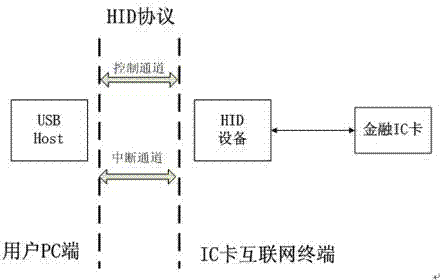

Financial IC (integrated circuit) card Internet terminal and trading method thereof

ActiveCN104217327AImprove security protectionSpecified in accordance withAutomatic card filesUser identity/authority verificationLiquid-crystal displayThe Internet

The invention discloses a financial IC card Internet terminal. The financial IC card Internet terminal comprises a card reading module, a liquid crystal display screen, a keyboard, a USB (universal serial bus) communication module and a master control chip. The card reading module comprises a card holder and a card reading chip, wherein the card holder is used for placing an IC card, and the card reading chip is used for reading and writing data of the IC card and performing data communication with the master control chip through the reading and writing driver of a hardware driving layer of the master control chip; the liquid crystal display screen, the keyboard and the USB communication module perform data communication with the master control chip through the liquid crystal layer driver, the key driver and the USB communication driver of the hardware driving layer of the master control chip. The invention also discloses a trading processing method of the financial IC card Internet terminal. The method is based on the bidirectional-authentication terminal security channel technology and authentication and encryption of domestic cryptographic algorithms.

Owner:SHANDONG ZHONGFU INFORMATION IND

Bone cartilage repair material and preparation method of scaffold for tissue engineering

InactiveCN109364302AEasy to prepareRealize the loadAdditive manufacturing apparatusTissue regenerationOsteoblastSolvent

The invention discloses a bone cartilage repair material and a preparation method of a scaffold for tissue engineering. The material comprises a subchondral bone layer, an interface layer and a cartilage layer arranged in sequence, wherein the interface layer is positioned between the subchondral bone layer and the cartilage layer; the material contains the following components in parts by weight:10-40 parts of oil-soluble high polymer materials, 10-50 parts of biological ceramic powder, 50-100 parts of oily solvents, 0.1-1 part of a water-soluble bio-active material, 2-30 parts of water, more than 0 and less than 1 part of an emulsifier, 10-30 parts of a hydrogel material, 0-10 parts of seed cells and 50-100 parts of a culture medium. The preparation method comprises the following steps:preparing printing ink according to the ratio of the materials, and transferring into 3D printing equipment for printing molding. The bone cartilage scaffold having a personalized appearance can be prepared, load and controlled release of different growth factors or peptides in different zones of the scaffold can be realized, and directional differentiation of bone marrow stem cells at differentparts to osteoblast and chondrocyte can be promoted.

Owner:王翀

Large-scale missile engine six-component dynamometry and calibrating device

ActiveCN104111138AMeasuring range can be changedReduce volumeMeasurement of force componentsForce/torque/work measurement apparatus calibration/testingFixed frameEngineering

A large-scale missile engine six-component dynamometry and calibrating device. Four force transmission assemblies are vertically mounted between a fixed frame and a floating frame and are arranged in a square shape. The other four force transmission assemblies are respectively fixed to the floating frame and the fixed frame though upper and lower support frames. Axes of the four force transmission assemblies are installed horizontally relative to the floating frame, and the installation positions are parallel to four edges of the above square shape. Four force generators are vertically installed on the fixed frame and the floating frame, the other four force generators are respectively horizontally fixed between the floating frame and the fixed frame through the support frames, and the installation positions are respectively parallel to four edges of the above square shape. During calibration, force generated by the force generators is transferred to a working force sensor through the floating frame, and calibration is realized according to information measured by the working force sensor. During dynamometry, the force generators do not work, measured force is transferred to the working force sensor through the floating frame, and force and moment which need to be measured are obtained according to information measured by the working force sensor.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com