Method for forming fly-ash-based honeycomb type denitration catalyst ceramic carrier

A denitration catalyst, ceramic carrier technology, applied in catalyst carrier, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of reducing catalyst denitration activity, pollution, calcination temperature, etc., and achieve high value-added utilization and technology. Simple method and good denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Mix 500kg of primary fly ash (particle size 45μm), 450kg of water, 15kg of cellulose, 3kg of starch, 5kg of glycerin, 4kg of polyvinyl alcohol, 20kg of glass fiber, 2kg of activated carbon, and 1kg of lactic acid with a mixer , rotating at 800rpm, stirring for about 4 hours to obtain plastic clay, and then sealed and aged at room temperature for 12 hours.

[0040] (2) The aged mud material is passed through a filter screen, pre-extruded, and then sealed and aged at room temperature for 12 hours.

[0041] (3) The aged mud in step 2 is vacuum-extruded through an extruder with a honeycomb abrasive tool. Degree -0.1MPa, extrusion pressure 2.7MPa, extrusion temperature 25.3°C.

[0042] (4) The wet embryo of the honeycomb carrier was microwave-dried at 100° C. for 0.8 h to obtain a carrier with a water content of 2.5%.

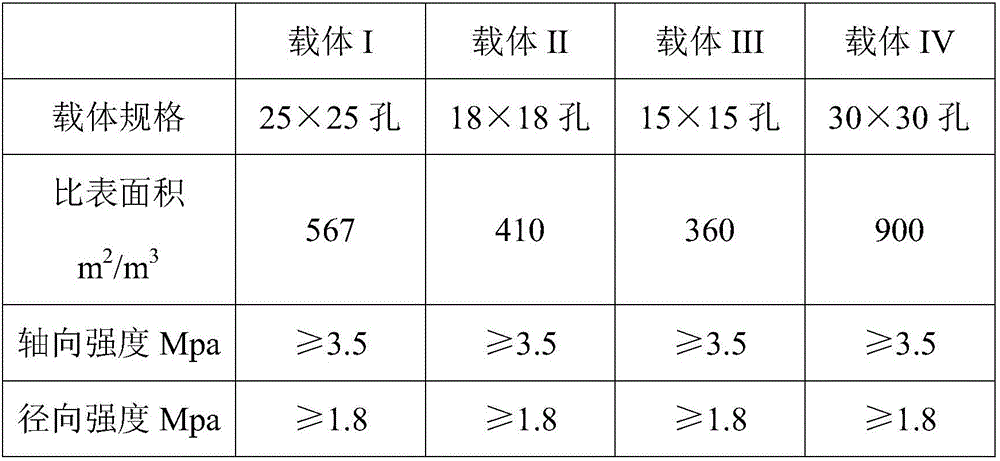

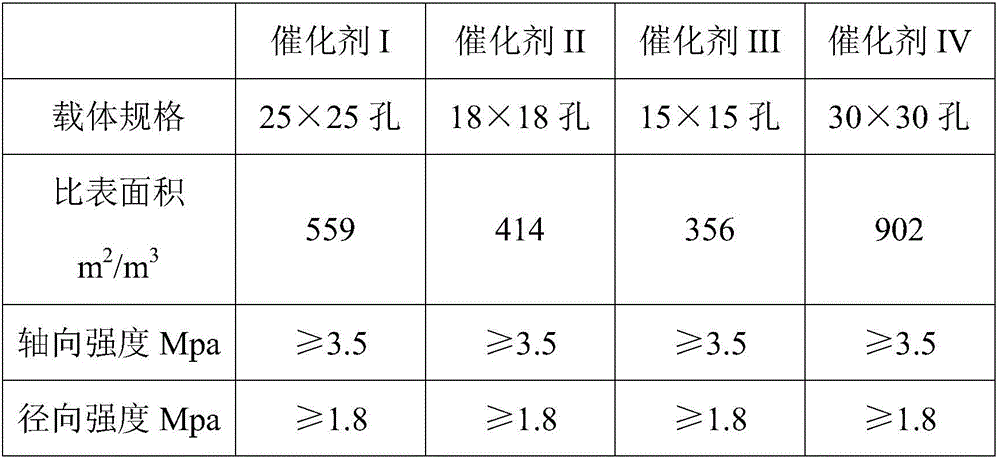

[0043] (5) The dried carrier was calcined at 550° C. for 5 hours to obtain a ceramic carrier I for a honeycomb denitration catalyst, represented by carri...

Embodiment 2

[0046] (1) 550kg of primary fly ash (particle size 45μm), 380kg of water, 10kg of cellulose, 3kg of pseudo-boehmite, 20kg of clay, 4kg of glycerin, 4kg of polyethylene oxide, 25kg of glass fiber, 2kg of refined cotton, 1kg of Lactic acid and 1 kg of stearic acid were mixed evenly with a mixer at a speed of 1000 rpm, and stirred for about 5 hours to obtain plastic clay, which was then sealed and aged at room temperature for 18 hours.

[0047] (2) The aged mud material is passed through a filter screen, pre-extruded, and then sealed and aged at room temperature for 18 hours.

[0048] (3) The aged mud in step 2 is vacuum-extruded through an extruder with a honeycomb abrasive tool. Degree -0.1MPa, extrusion pressure 3.0MPa, extrusion temperature 26.0°C.

[0049] (4) The wet embryo of the honeycomb carrier was microwave-dried at 120° C. for 0.5 h to obtain a carrier with a water content of 2.0%.

[0050] (5) The dried carrier was calcined at 700° C. for 4 hours to obtain a cerami...

Embodiment 3

[0053] (1) 600kg secondary fly ash (particle size 50μm), 350kg water, 3kg pseudoboehmite, 7kg gum arabic, 5kg clay, 5kg glycerin, 5kg polyethylene oxide, 20kg glass fiber, 2kg refined cotton, 1kg Lignin and 2kg of stearic acid were mixed evenly with a mixer at a rotation speed of 1200rpm, and stirred for about 7 hours to obtain plastic clay, which was then sealed and aged at room temperature for 22 hours.

[0054] (2) The aged mud material is passed through a filter screen, pre-extruded, and then sealed and aged at room temperature for 22 hours.

[0055] (3) The aged mud in step 2 is vacuum-extruded through an extruder with a honeycomb abrasive tool. Degree -0.1MPa, extrusion pressure 4.2MPa, extrusion temperature 26.5°C.

[0056] (4) The honeycomb-shaped carrier wet embryo is steam-dried at 30°C for 15 hours, heated to 50°C for 15 hours, then heated to 80°C for 25 hours, and finally dried at 100°C for 30 hours to obtain a water content of 2.2%. Carrier.

[0057] (5) The dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com