Patents

Literature

32results about How to "Troubleshoot follow-up issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

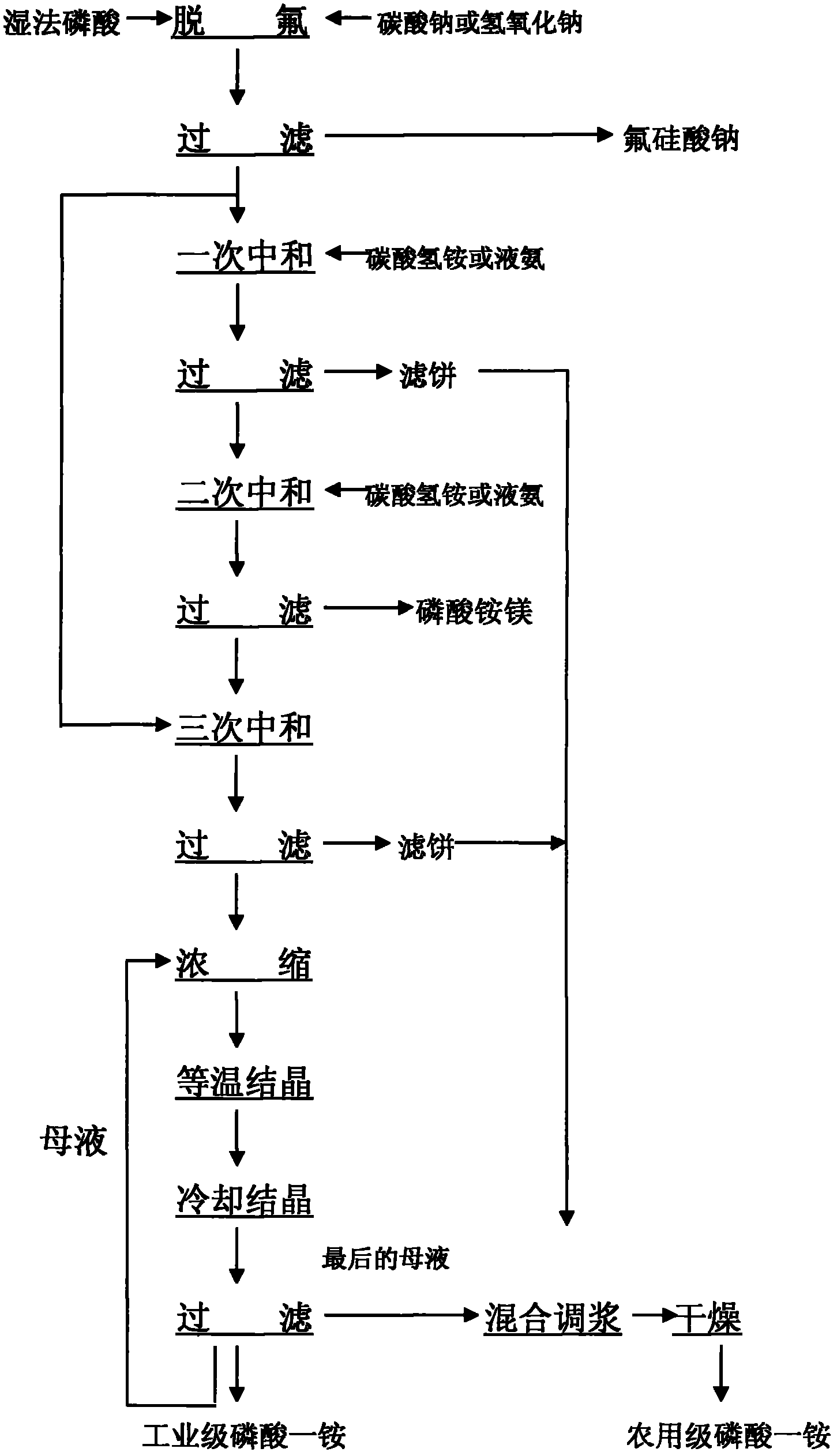

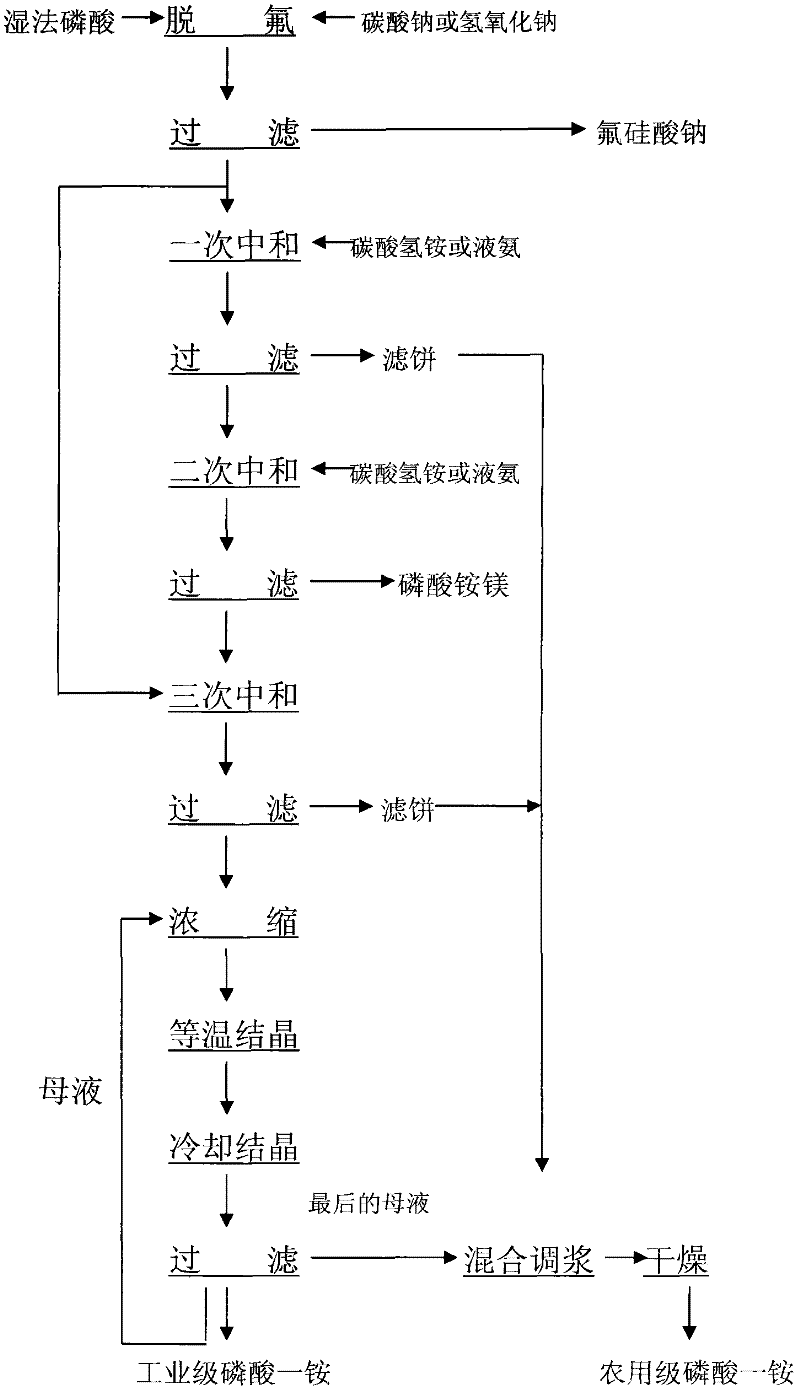

Method for producing industrial and agricultural monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid

ActiveCN102020256AImprove purification effectTroubleshoot follow-up issuesPhosphatesO-Phosphoric AcidAgricultural engineering

The invention provides a method for producing industrial and agricultural grade monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid. The wet-process phosphoric acid is taken as a raw material. Sodium fluosilicate, monoammonium phosphate solution, monoammonium phosphate filter cakes and magnesium ammonium phosphate are respectively obtained through defluorination and a three-section substep neutralization process, wherein the monoammonium phosphate solution is concentrated and crystallized to obtain high-quality water soluble industrial monoammonium phosphate, and the monoammonium phosphate filter cakes and the monoammonium phosphate mother solution subjected to repeated crystallization are subjected to size mixed and dried to obtain qualified agricultural monoammonium phosphate. The magnesium ammonium phosphate is a good slow release nitrogenous fertilizer per se. The process has the advantages of little investment of equipment, good adaptability of raw material, low production cost and good product quality. The water soluble industrial monoammonium phosphate with low cost can provide a cheap and good water soluble phosphatic fertilizer for modern facility agriculture.

Owner:昆明隆祥化工有限公司

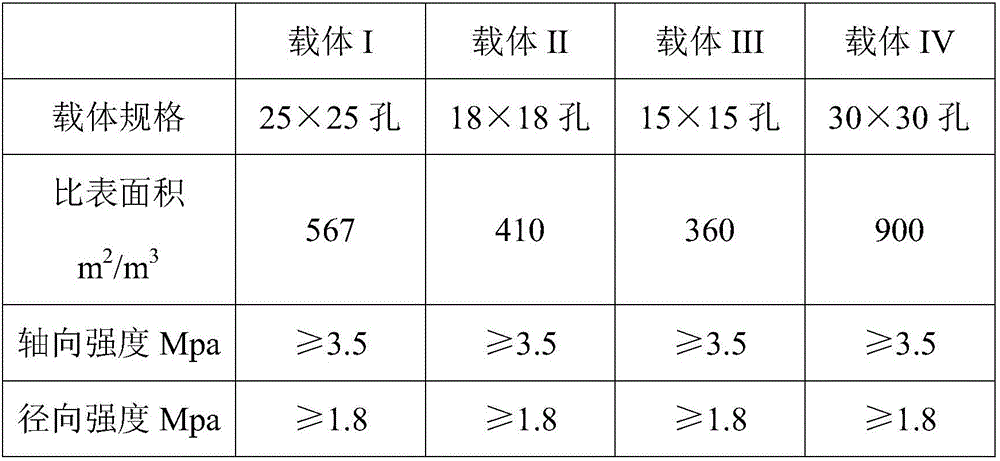

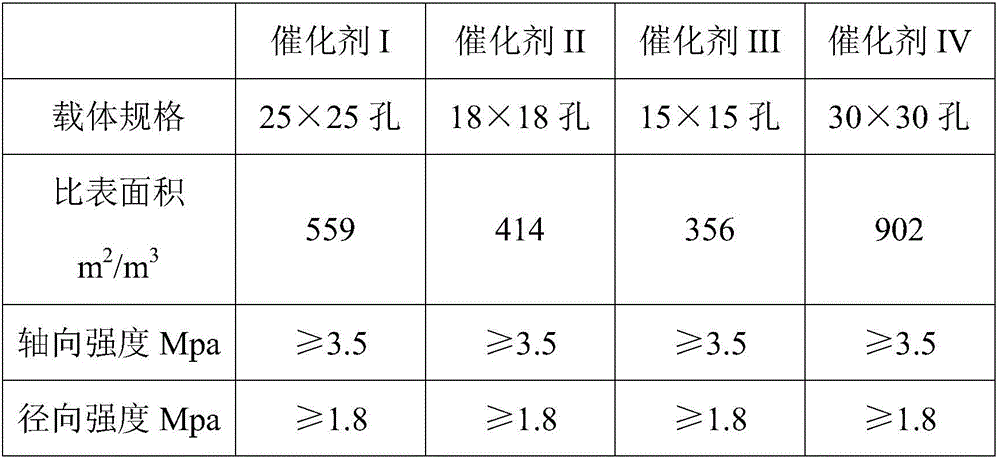

Method for forming fly-ash-based honeycomb type denitration catalyst ceramic carrier

The invention belongs to the technical field of SCR denitration catalyst preparation and discloses a method for forming a fly-ash-based honeycomb type denitration catalyst ceramic carrier. Cheap and non-toxic fly ash serves as a carrier, additives and water are added, and the finished carrier product is prepared through mixing, ageing, filtering, pre-extrusion, ageing, extrusion molding, drying and forging. The catalyst carrier prepared through the method is low in mass, high in strength and large in specific surface area, and can meet requirements of industrial application. A loaded catalyst has high activity. The fly ash takes the place of titanium dioxide to serve as a main component of the carrier, the subsequent treatment problem of solid waste in coal-fired power plants is solved, waste is turned into wealth, recycling is achieved, cost is reduced, pollution caused by use of titanium dioxide is also avoided, forming of the carrier and loading of active components of the catalyst can be achieved at a time, and industrialization is easy.

Owner:湖北思搏盈环保科技有限公司

Method for preparing amorphous FeOOH and FeOOH desulfurizer prepared thereby

ActiveCN101585556AAvoid generatingTroubleshoot follow-up issuesIron oxides/hydroxidesFerrous saltsPhysical chemistry

The invention relates to a method for preparing amorphous FeOOH, which comprises the following steps: (a) mixing solid soluble ferrous salt and solid hydroxid according to a molar ratio of iron to hydroxyl being between 1:2 and 1:3; (b) completing reaction of a mixed material prepared in step (a) by kneading, and controlling the temperature of the material not to exceed 70 DEG C in the kneading process; (c) drying a reaction product obtained in step (b) in air; (d) washing and filtering a material obtained in step (c); and (e) naturally drying or baking a solid obtained in step (d). On the basis, the invention further discloses an amorphous FeOOH desulfurizer prepared by the preparation method, and the desulfurizer has high sulfur capacity and high desulfurization efficiency.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

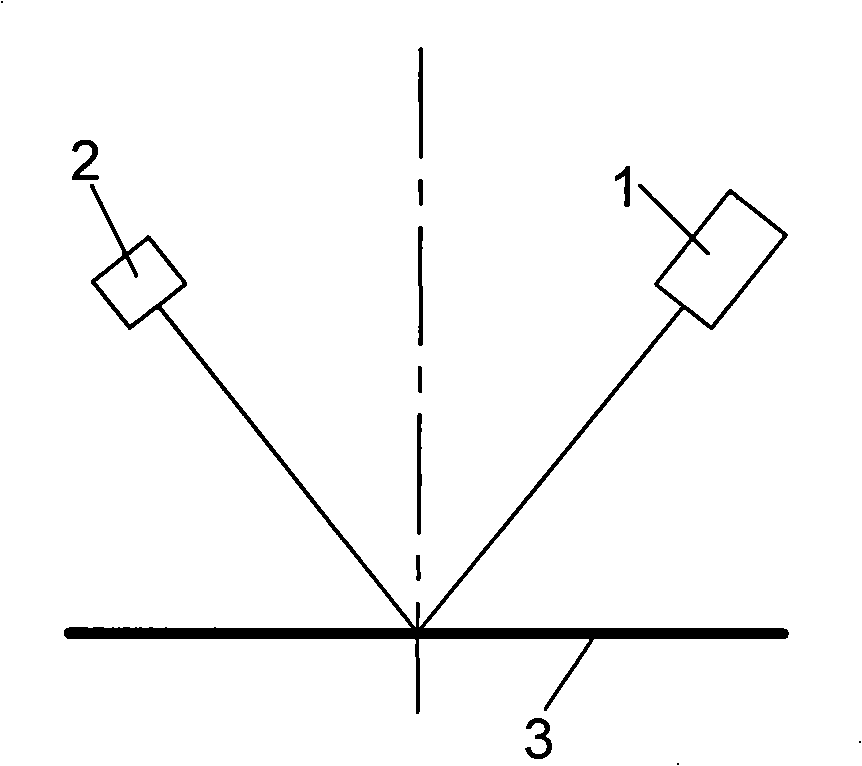

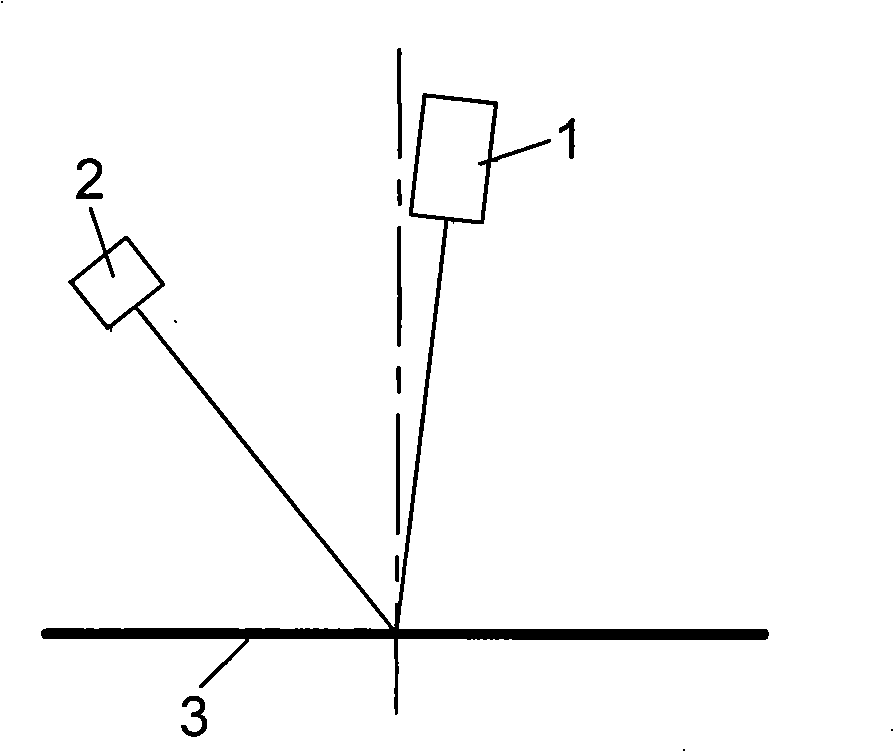

Detection imaging method and apparatus of strip surface flaw

InactiveCN101349652ALow costImprove accuracyOptically investigating flaws/contaminationSynchronous controlEngineering

The invention discloses an imaging method and a device for detecting band surface defects, wherein the method comprises establishing a sync signal generating unit to generate sync signals, synchronously controlling a switching unit and a camera shooting unit, establishing a light source switching unit, using the switching unit to switch and control the following two light sources, and using the two light sources to alternatively light the surfaces of bands, and respectively and only forming a single ground (a light field, a dark field) to image with the camera shooting unit in a scanning cycle, and obtaining total band surface defect images. The same defect on the band surface can be accurately matched with images which are formed on the same camera shooting unit and different illumination fields. The method avoids the post-treatment problem which is generated by the same defect which repeatedly images, greatly improves the accuracy of detecting the band surface defects, and in addition, and the method further lowers the production cost of the image device and the complexity of the structure.

Owner:BAOSHAN IRON & STEEL CO LTD

Concrete brick containing sludge burning ash residue

The invention discloses a concrete brick containing sludge burning ash residue, the preparation method of which comprises the following steps that: raw materials are uniformly mixed with water to be formed and to be demolded after the moisture is volatized; raw materials comprises 12 to 50 percent of cement, 0 to 30 percent of sand, 0 to 50 percent of stone, 10 to 50 percent of sludge burning ash residue and 0.1 to 0.5 percent of chemical chelating stabilizer (weight ratio); and the chemical chelating stabilizer is of complexone or organic polybasic phosphonic acid. The sludge burning ash residue which is produced in the sewage treatment plant is used for manufacturing the concrete brick, so not only the consumption of other fine aggregates is reduced without reducing the strength, but also the following processing problems of the sludge discharge reduction and sludge burning ash residue are saved, thereby saving the resource and being economical and envionrment-friendly.

Owner:SHANGHAI NORMAL UNIVERSITY +1

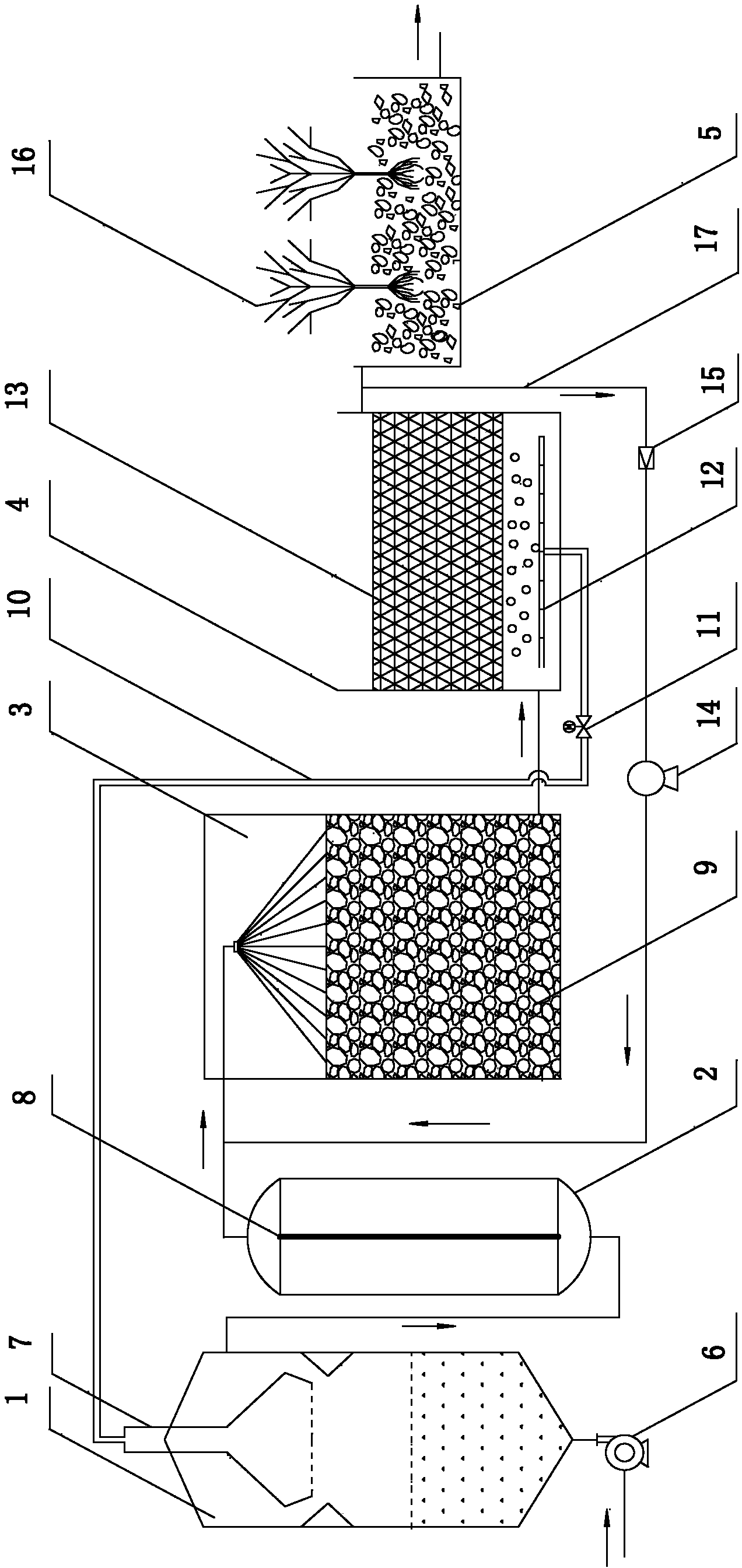

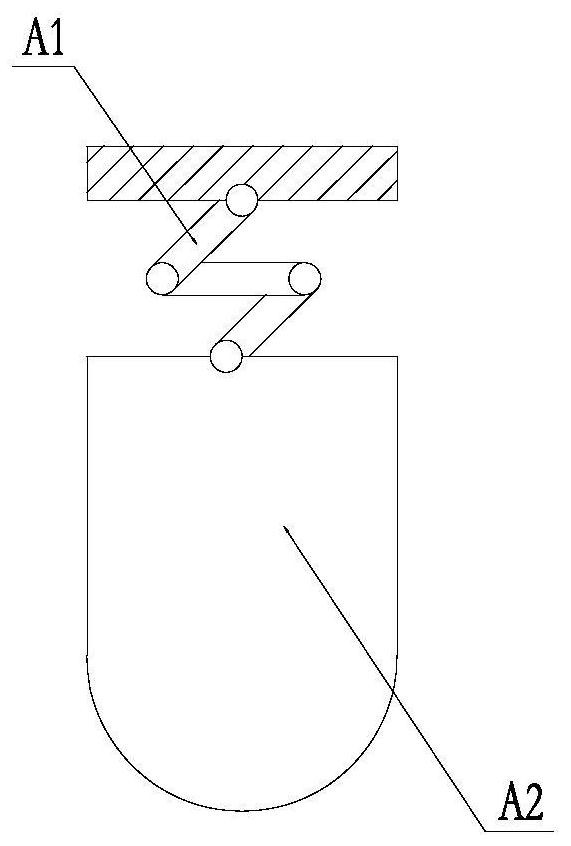

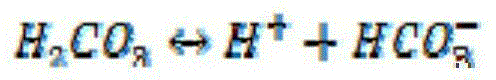

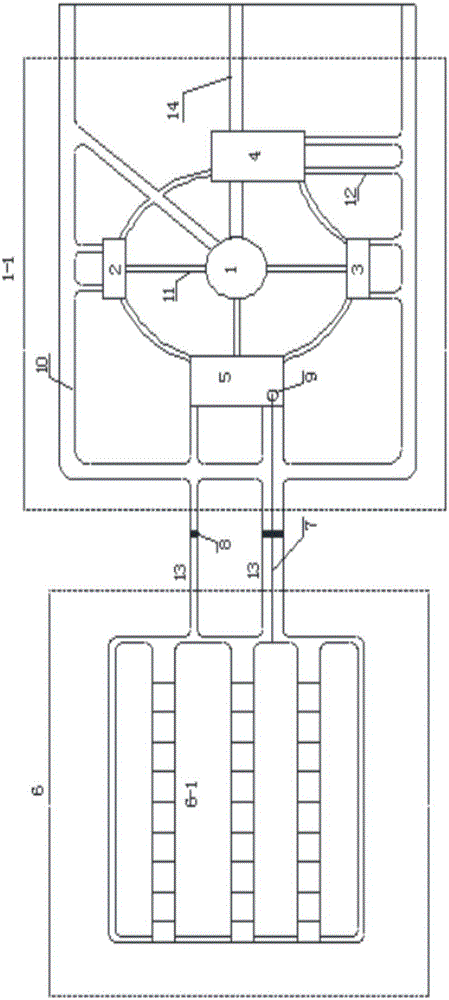

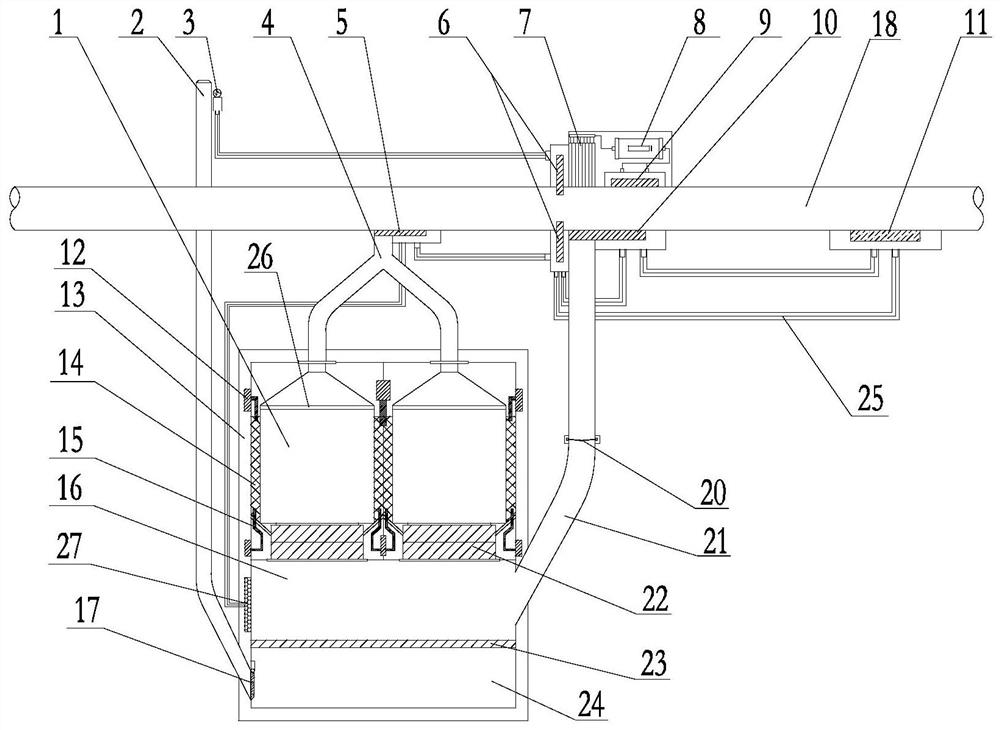

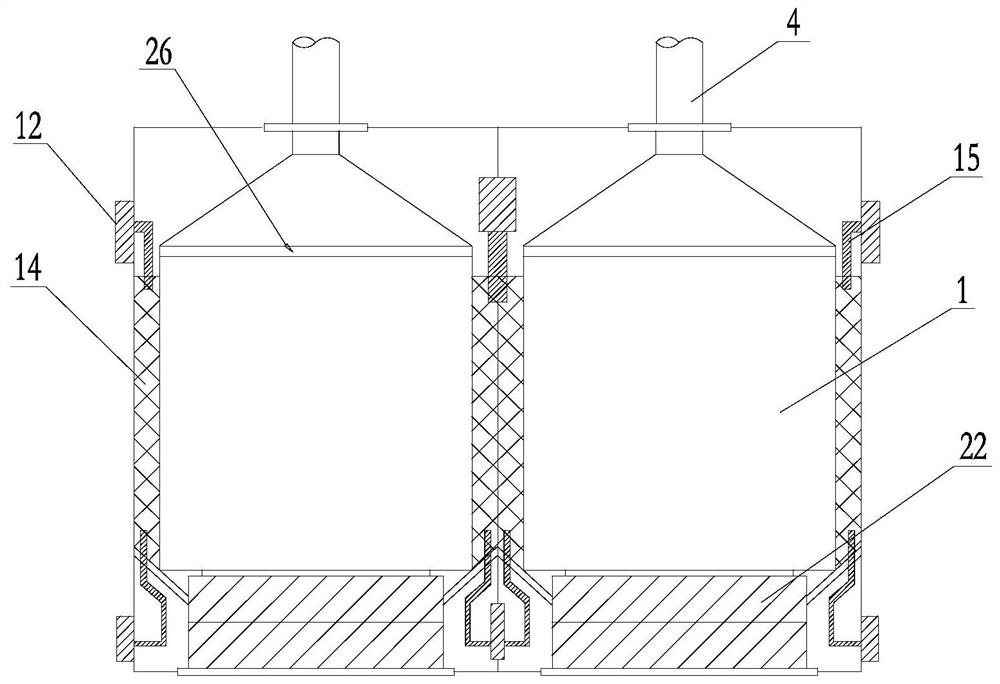

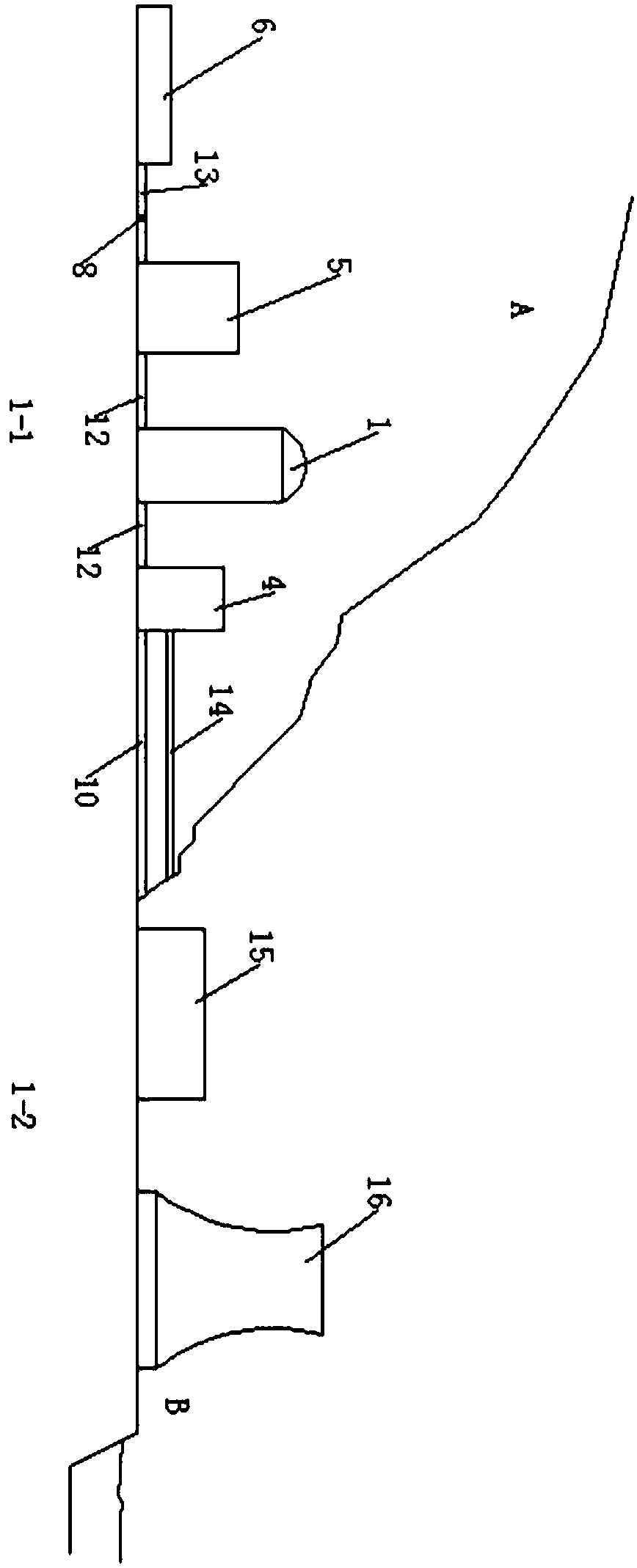

Processing device and processing method applicable to high-ammonia-nitrogen agricultural wastewater

InactiveCN103395937AEfficient purificationGood removal effectWater/sewage treatmentMultistage water/sewage treatmentWater qualityBiological filter

The invention discloses a processing device and a processing method applicable to high-ammonia-nitrogen agricultural wastewater, and belongs to the field of processing of agricultural wastewater. According to the processing device and the processing method, a cylindrical electrolytic bath is arranged between an anaerobic sludge bed and a tower-type biological filter, and has a significant buffer effect on pollution load of the agricultural wastewater; at the same time through the arrangement of a return system and a two-phase denitrifying tank, the water quality of effluent water and the stable operation of the system can be ensured; biogas produced by the anaerobic sludge bed can be reused into the two-phase denitrifying tank, not only carbon emissions to the environment can be reduced, but also the denitrification rate of the two-phase denitrifying tank can be improved through utilization of anaerobic denitrification effect of methane, recycling utilization of waste matters can be realized, and the concept of green environmental protection can be embodied. The processing device is convenient to operate and easy to maintain, has relatively low construction costs and maintenance costs, and has good popularization and application value.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

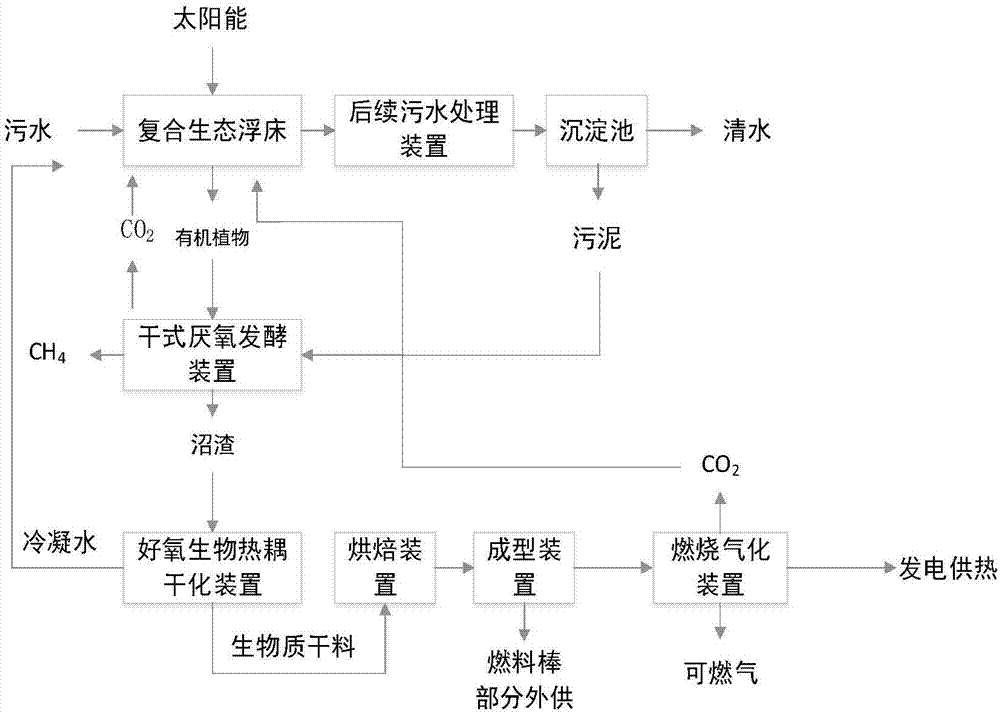

Energy output type sewage treatment process

ActiveCN106927635AImprove water qualityCompliance with emission standardsWater contaminantsGaseous fuelsWater dischargeWater quality

The invention provides an energy output type sewage treatment process, and belongs to the technical field of sewage treatment. The energy output type sewage treatment process adopts a composite biological floating bed, a subsequent sewage treatment device, a precipitation tank, a dry type anaerobic fermentation device, an aerobic biomass heat coupling drying device, a baking device, a molding device and a combustion gasification device. The process comprises the following steps: firstly, adsorbing a large amount of nitrogen and phosphorus nutrient elements and organic matters through the composite biological floating bed; and then carrying out secondary treatment through the subsequent sewage treatment process. Clear water discharged from the precipitation tank has good water quality and meets the comprehensive class A discharging standard of national sewage. The energy output type sewage treatment process has the characteristics of good sewage treatment effect and realization of zero emission of carbon dioxide and conversion from pollutants into energy.

Owner:DALIAN UNIV OF TECH

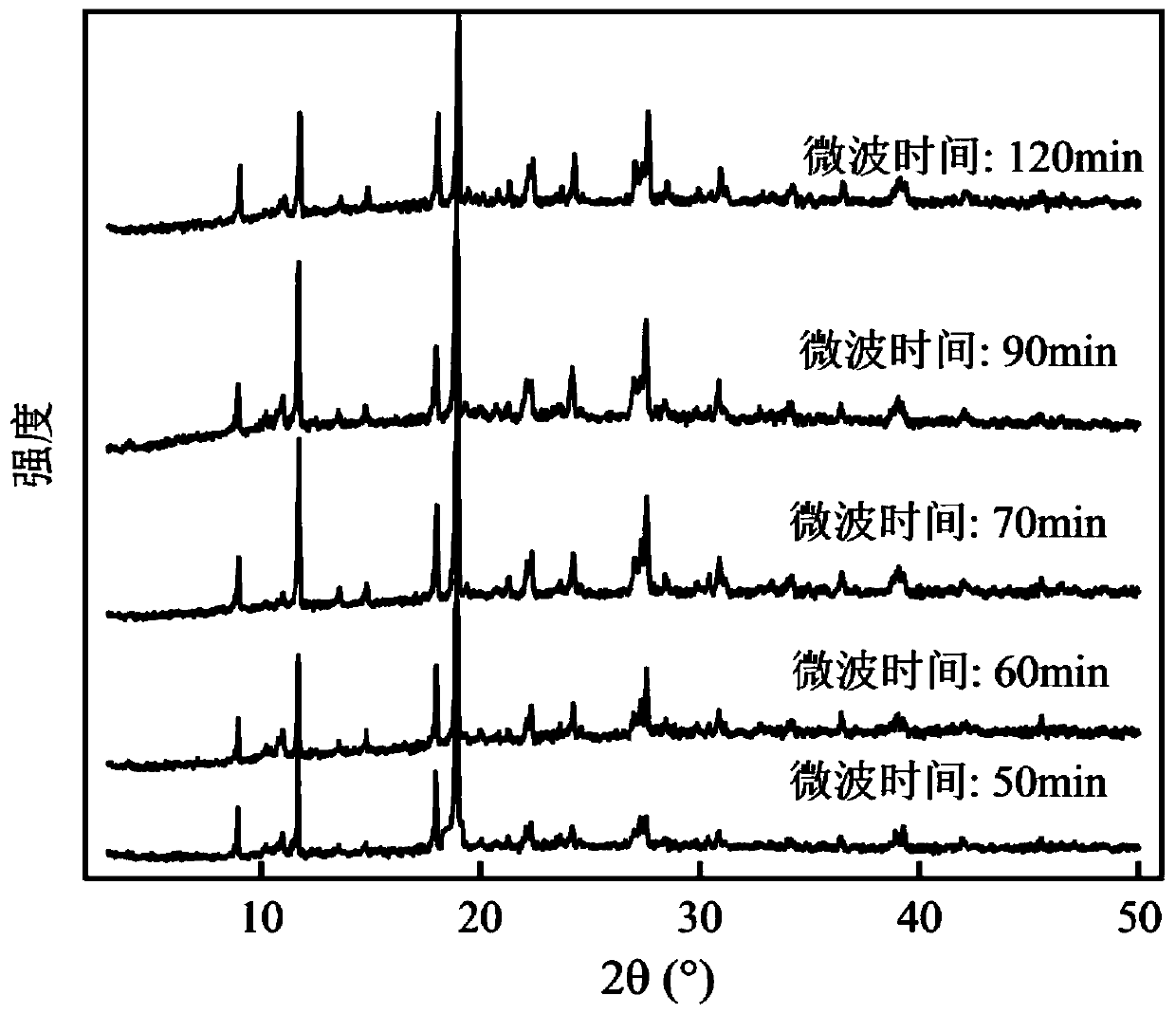

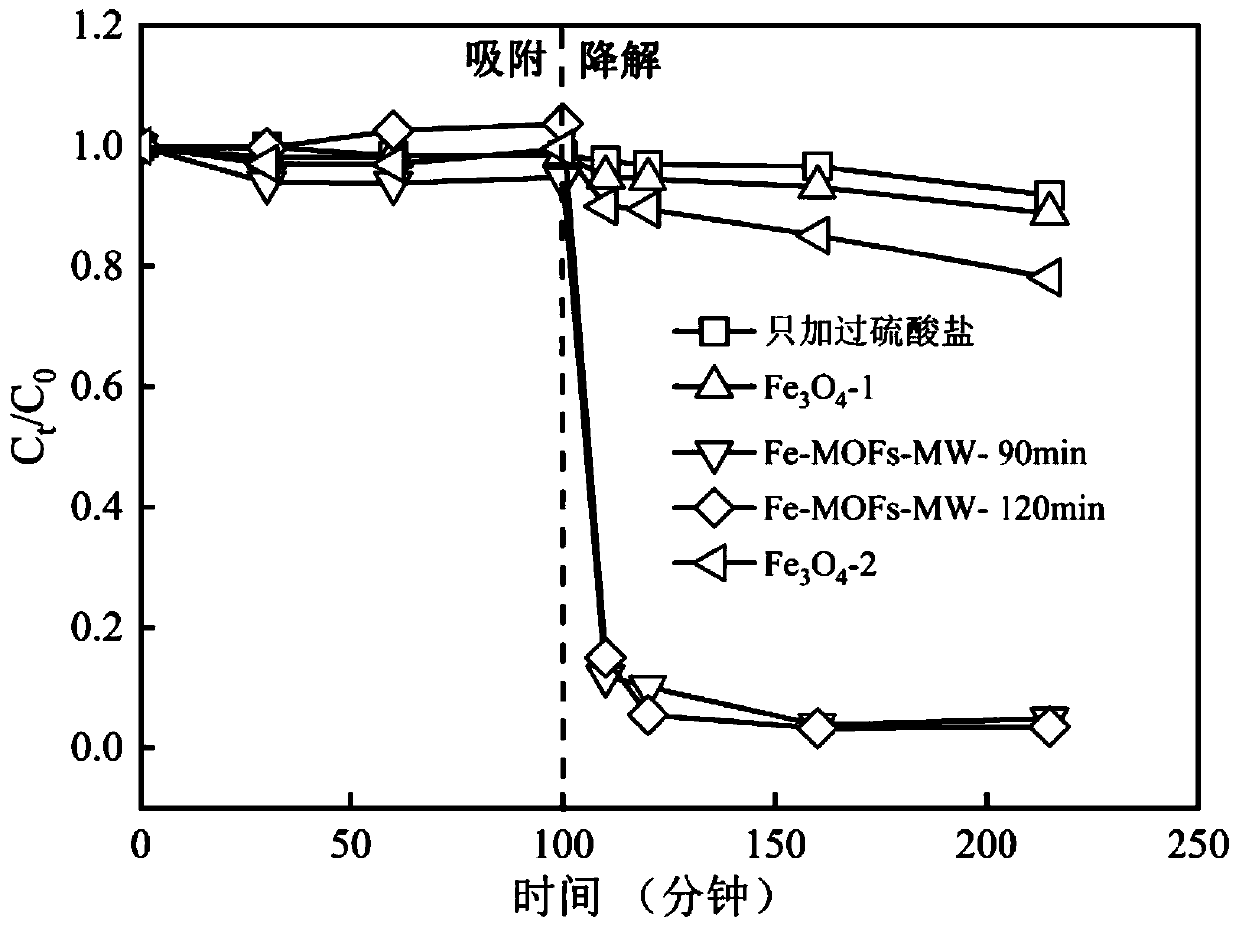

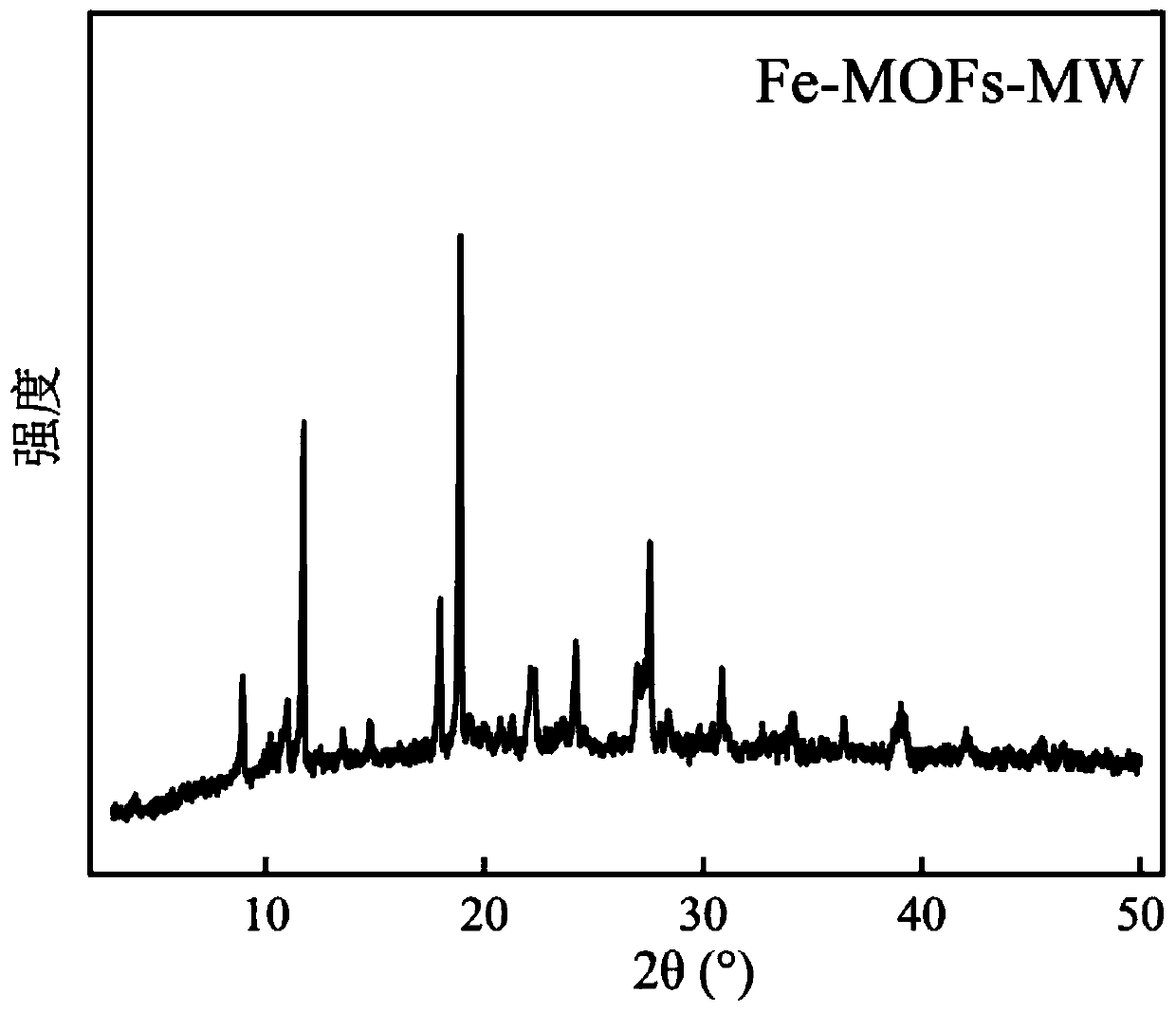

Iron oxide doped iron metal organic framework and green macro preparation method and application thereof

ActiveCN110548544ATo avoidImprove environmental qualityOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsMetal-organic frameworkVacuum drying

The invention discloses an iron oxide doped iron metal organic framework material and a green macro preparation method and an application thereof. The preparation method comprises the following steps:(1) grinding and mixing ferrous sulfate heptahydrate and trimesic acid evenly, adding a sodium hydroxide solution, transferring to a micro wave reaction kettle, carrying out ultrasonic treatment, heating, and cooling to room temperature to obtain a mixed liquid; and (2) washing the mixed liquid obtained in the step (1), centrifuging to obtain a solid, washing the obtained solid, and drying in vacuum to obtain the iron oxide doped iron metal organic framework material. A heterogeneous catalyst is synthesized by a microwave solid-phase co-crystallization method, the synthesis cycle is greatly shortened, the synthesis process is green, environmentally friendly and efficient, and the synthesized iron oxide doped iron metal organic framework material can make full use of an unsaturated metal site to efficiently activate persulfate to degrade organic pollutants, avoid the generation of iron mud, reduce the cost of synthesis of the heterogeneous catalyst material and the cost of degradationof organic pollutants, and improve water environment quality.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing industrial and agricultural monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid

ActiveCN102020256BImprove purification effectTroubleshoot follow-up issuesPhosphatesO-Phosphoric AcidAgricultural engineering

The invention provides a method for producing industrial and agricultural grade monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid. The wet-process phosphoric acid is taken as a raw material. Sodium fluosilicate, monoammonium phosphate solution, monoammonium phosphate filter cakes and magnesium ammonium phosphate are respectively obtained through defluorination and a three-section substep neutralization process, wherein the monoammonium phosphate solution is concentrated and crystallized to obtain high-quality water soluble industrial monoammonium phosphate, and the monoammonium phosphate filter cakes and the monoammonium phosphate mother solution subjected to repeated crystallization are subjected to size mixed and dried to obtain qualified agricultural monoammonium phosphate. The magnesium ammonium phosphate is a good slow release nitrogenous fertilizer per se. The process has the advantages of little investment of equipment, good adaptability of raw material, low production cost and good product quality. The water soluble industrial monoammonium phosphate with low cost can provide a cheap and good water soluble phosphatic fertilizer for modern facility agriculture.

Owner:昆明隆祥化工有限公司

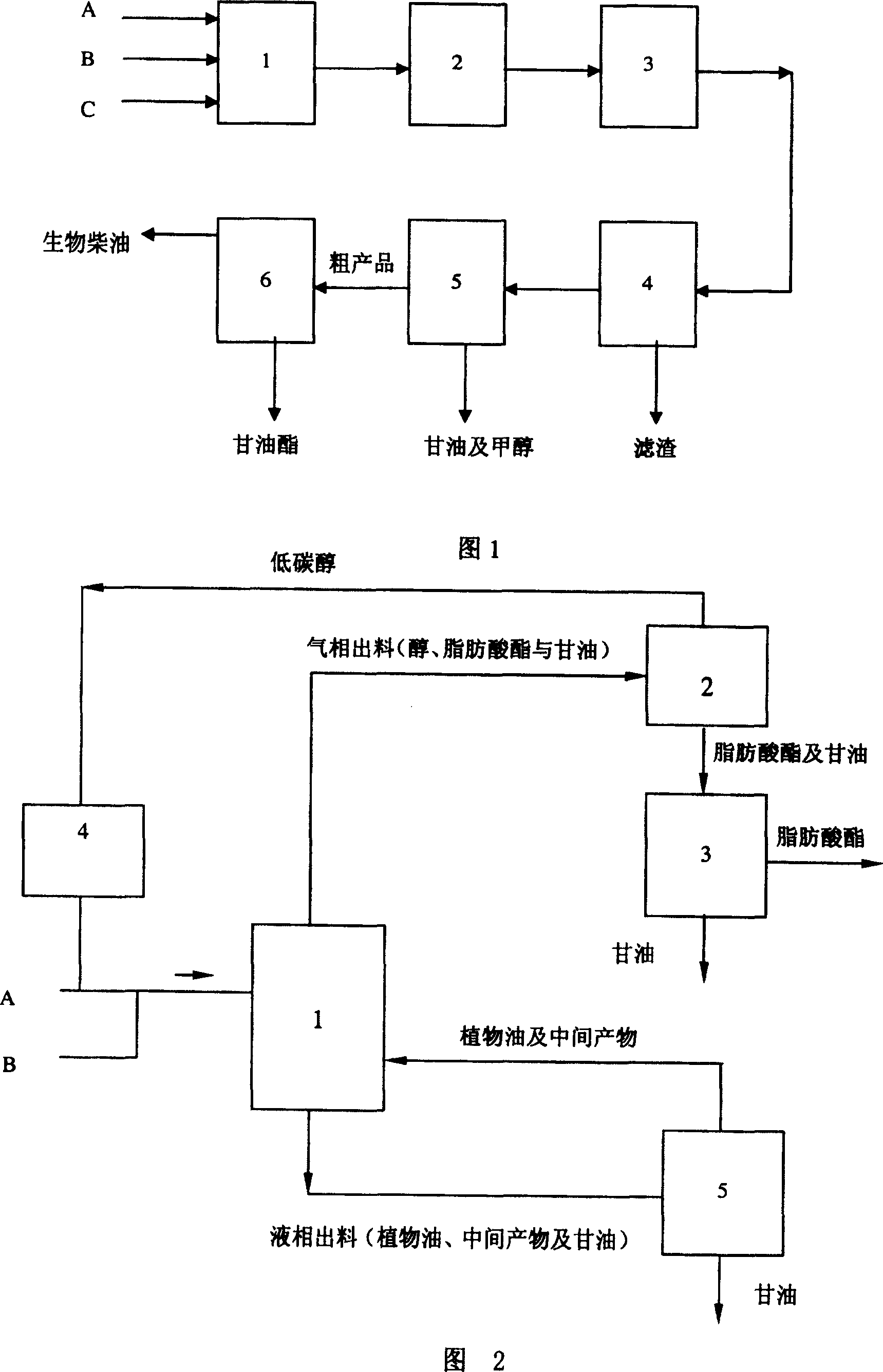

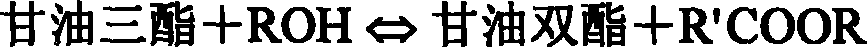

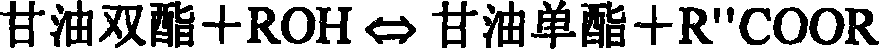

Technical method for preparing biodiesel using reactive separation process coupling technique

InactiveCN100375779CAchieve couplingAchieve separationBiofuelsLiquid hydrocarbon mixture productionChemical industryVegetable oil

This is the craft method of preparing biological diesel oil by using the coupling technology in reaction separating course. It relates to the new craft of preparing biology diesel oil (fatty diethylene glycol dinitrate) through the ester exchange reaction of vegetable oil and higher alcohols, and belongs to chemical industry craft technology field. It includes: the ester exchange reaction of vegetable oil and higher alcohols; the separation of product fatty diethylene glycol dinitrate, glycerol and reaction mixed liquid; the separation of product fatty diethylene glycol dinitrate, glycerol and higher alcohols; the separation of fat diethylene glycol dinitrate and glycerol; the condensation backflow of fatty alcohol; and the separation of glycerol. It makes the circumvolving higher alcohols carry out the product fatty diethylene glycol dinitrate and glycerol through higher reaction temperature, and realizes the separation of outcome and reactant; the non-homogeneous phase catalyst stays in the actor, and don't need to have following process to the catalyst. The invention realizes the coupling of reaction and separation courses, speeds up the speed of non-homogeneous phase reaction, and avoids the problem of the following process to catalyst in the homogeneous phase process. Besides it can save production cost, and improves the producing performance of biology diesel oil.

Owner:TSINGHUA UNIV

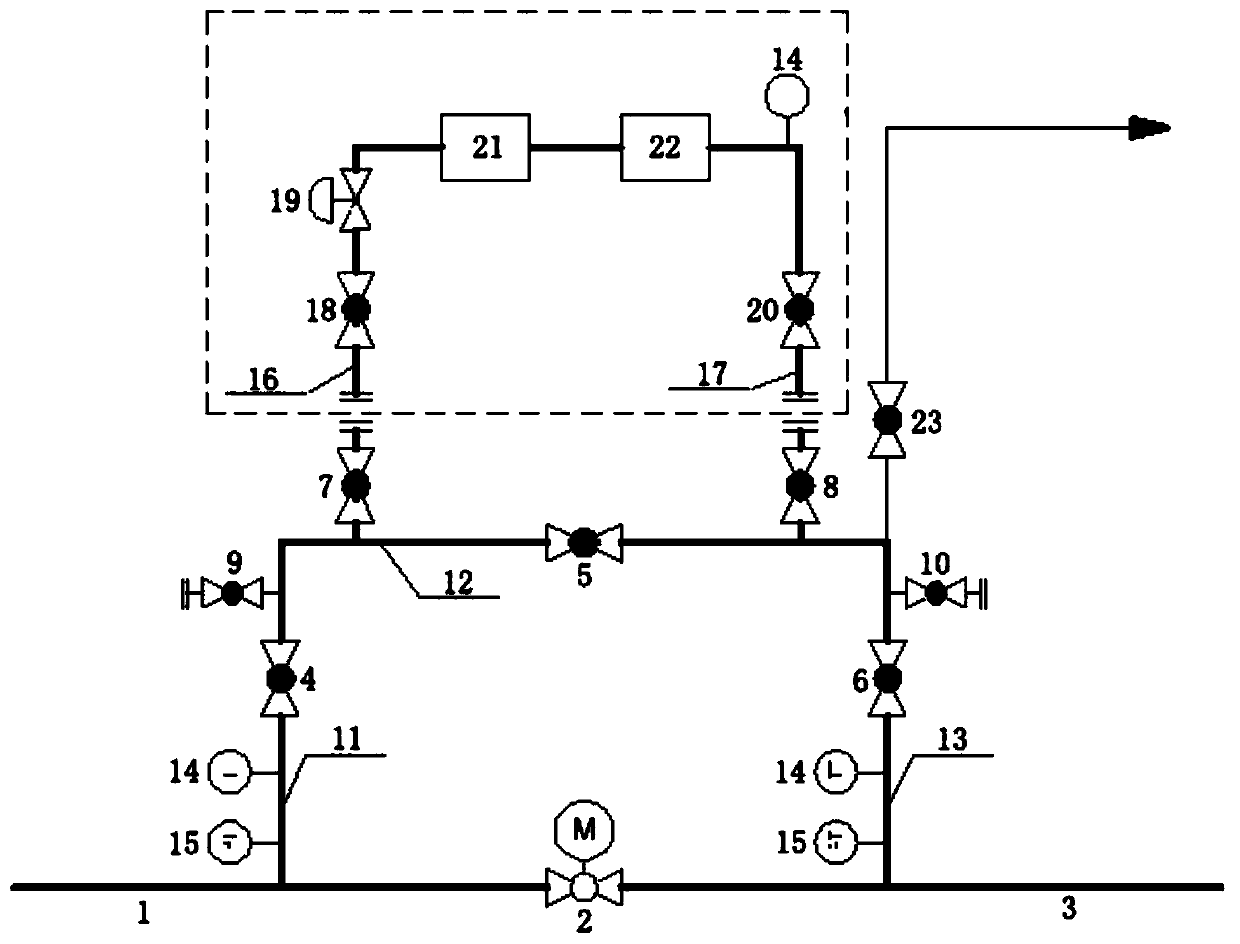

System and method for safe filling after liquid ethane pipeline overhauling

PendingCN111536420AGuarantee safe operationGuarantee the safety of operationPipeline systemsEngineeringEnvironmental geology

The invention discloses a system and method for safe filling after liquid ethane pipeline overhauling. The system comprises a trunk system, a trunk valve chamber system, an ethane filling system and apipeline temperature and pressure detection system, the trunk valve chamber system is responsible for emptying and reopening of upstream and downstream pipelines of a valve chamber and also providesa channel for replacing of a trunk pipeline, and the ethane filling system is used for introducing ethane from an upstream trunk line, heating the ethane for temperature adjustment and then feeding the ethane into a to-be-opened downstream trunk line before the downstream trunk line is reopened. According to the functional demand of reopening of a liquid ethane pipeline after overhauling and releasing, on the basis of the characteristic that the liquid ethane is vaporized under the low pressure to cause the low temperature, by adopting the measures that an upstream pipe section provides a medium filling channel through a valve chamber bypass, an initial-stage filled medium is externally connected with equipment for vaporization heating, and middle-and-later-stage filling, boosting and liquidation are conducted, the problem of low temperature of the medium in the filling process of an isolated and overhauled section of the liquid ethane pipeline is effectively controlled, safe operationof the liquid ethane pipeline is guaranteed, and the effective guarantee is provided for safe operation of the liquid ethane pipeline.

Owner:CHINA PETROLEUM ENG & CONSTR +1

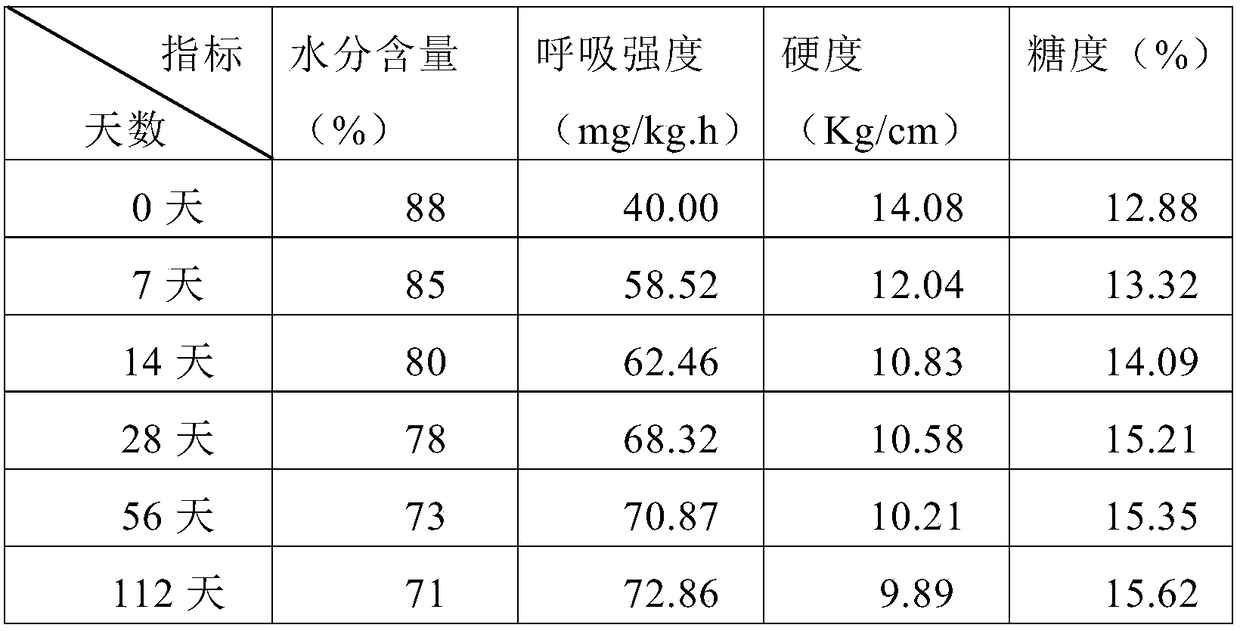

Apple fresh-keeping liquid as well as preparation method and application thereof

PendingCN108967530ATroubleshoot follow-up issuesGood environmental compatibilityNatural extract food ingredientsFruits/vegetable preservation by coatingPesticide residueFermentation

The invention relates to apple fresh-keeping liquid as well as a preparation method and application thereof. Effective components are dissolved into an acetic acid solution with the volume concentration of 1 to 5 percent to prepare a viscous colloidal solution with the mass concentration of 10 to 30 percent; the effective components comprise the following components in parts by weight: 15 to 30 parts of shenqinmycin fermentation filtrate, 5 to 10 parts of an eggplant peel extracting solution, 10 to 20 parts of chitosan, 5 to 10 parts of corn starch and 15 to 30 parts of distilled water. Compared with the prior art, the apple fresh-keeping liquid provided by the invention is safe, green and environmentally friendly; instruments and equipment are simple and utilized reagents are cheap and easy to obtain; industrialized production and popularization and application in the market are convenient to realize, and the potential safety hazard problems of pesticide residues, toxicity and the like; chemical pesticide or preservatives are not needed, and long-time fresh keeping can be realized.

Owner:洛川美域高生物科技有限责任公司 +1

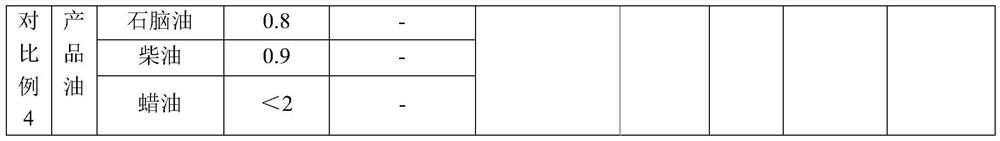

Method for preparing high-purity calcium nitrate by desulfurization and denitrification by-products

ActiveCN109110791BTroubleshoot follow-up issuesRaw materials are easy to getCalcium/strontium/barium nitratesOrganic solventAntioxidant

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

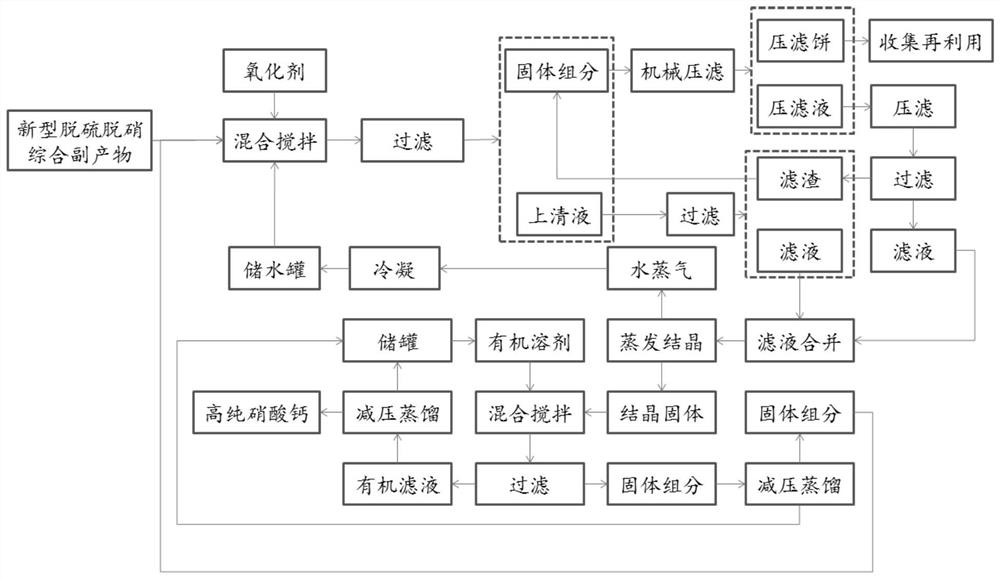

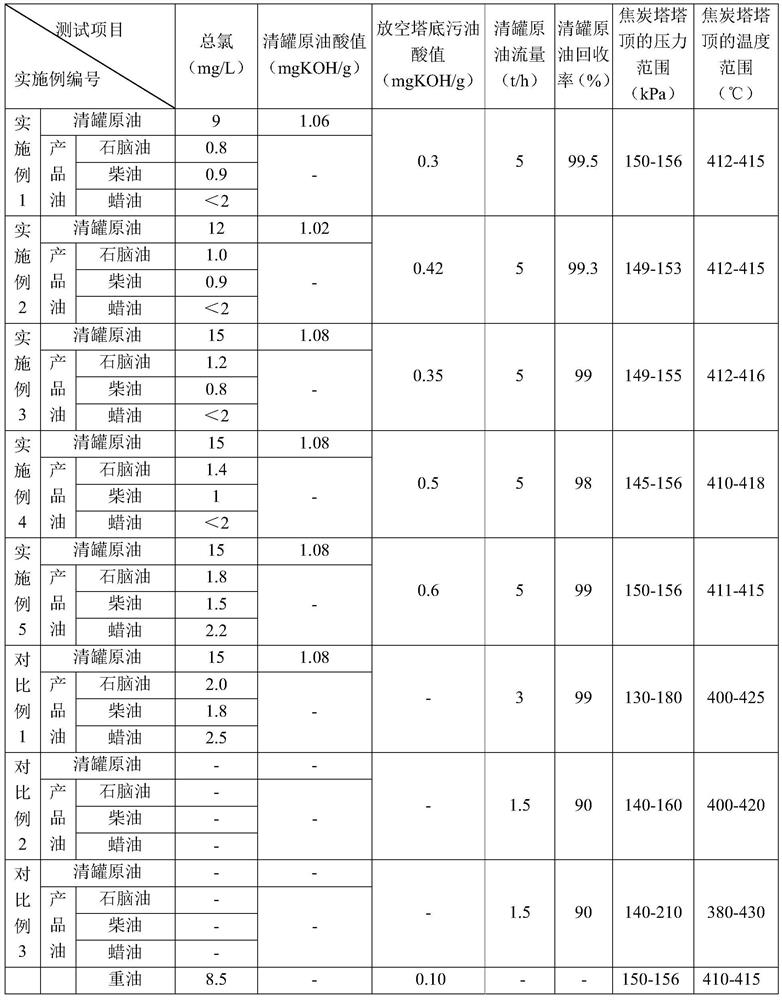

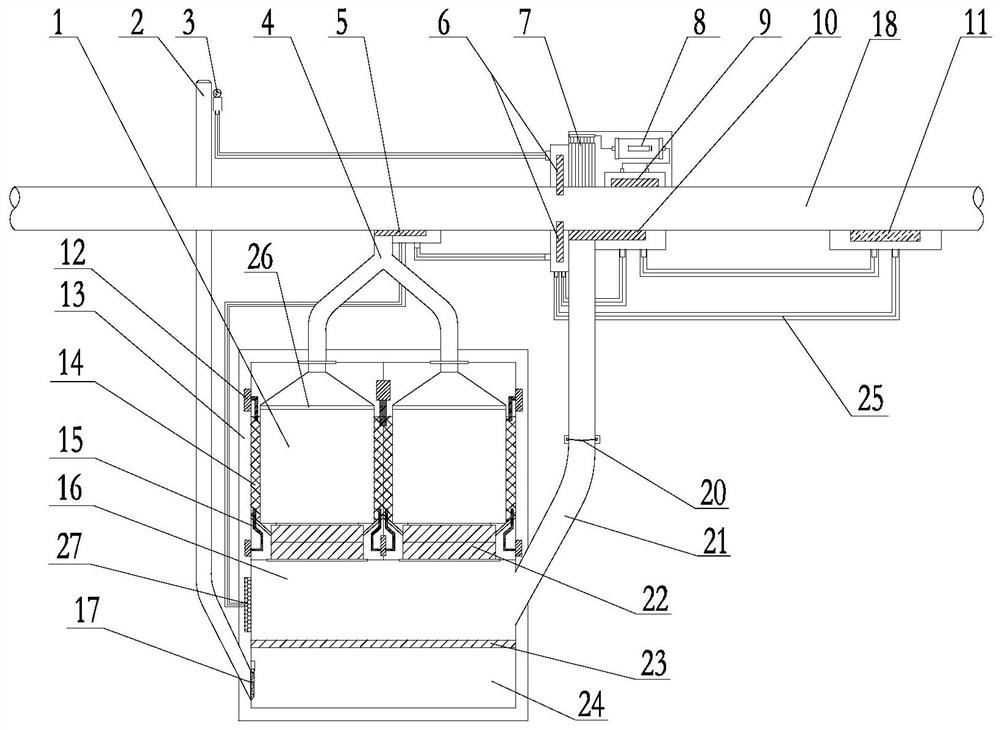

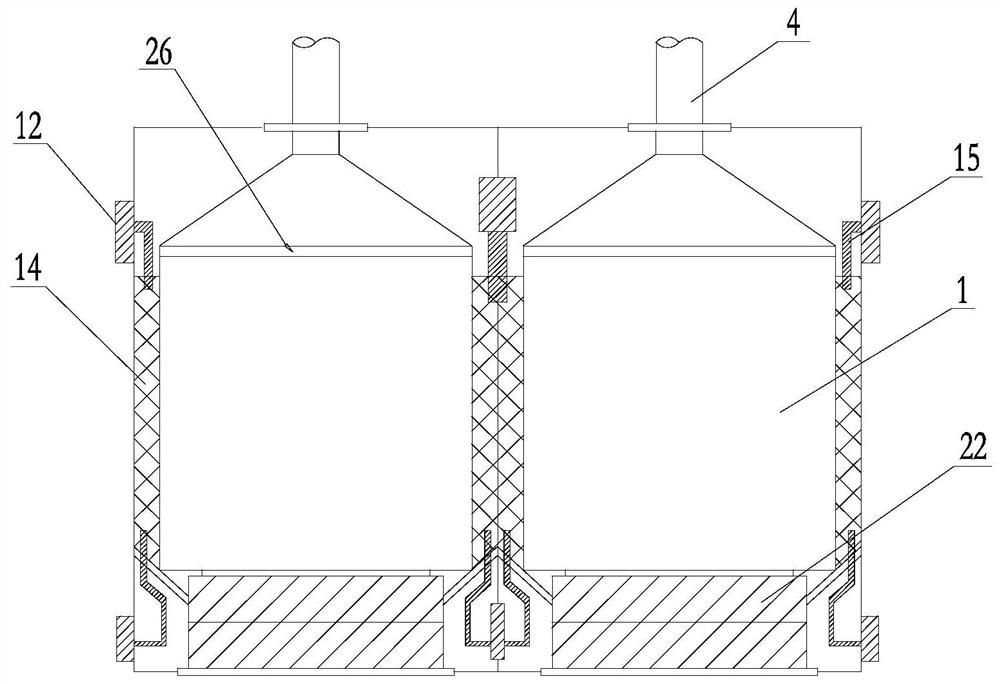

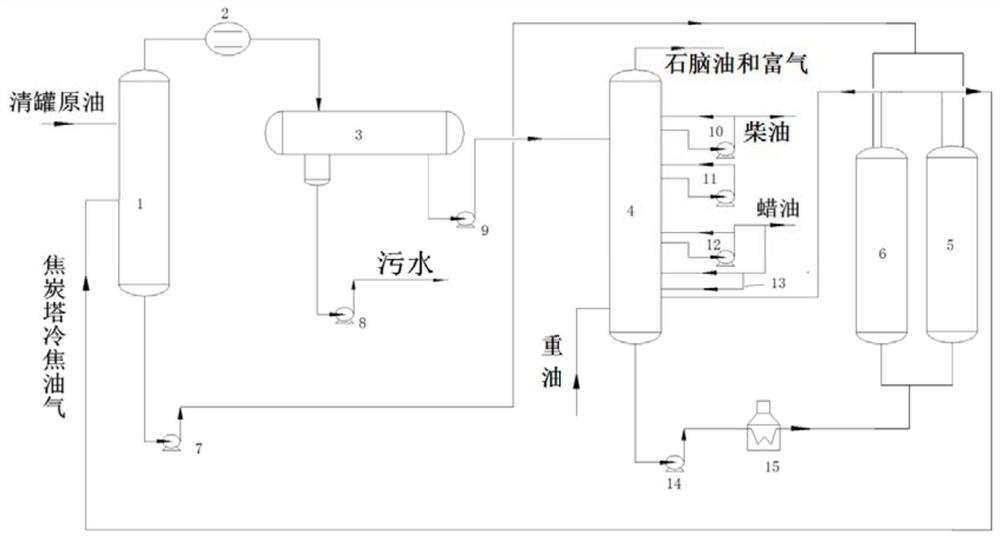

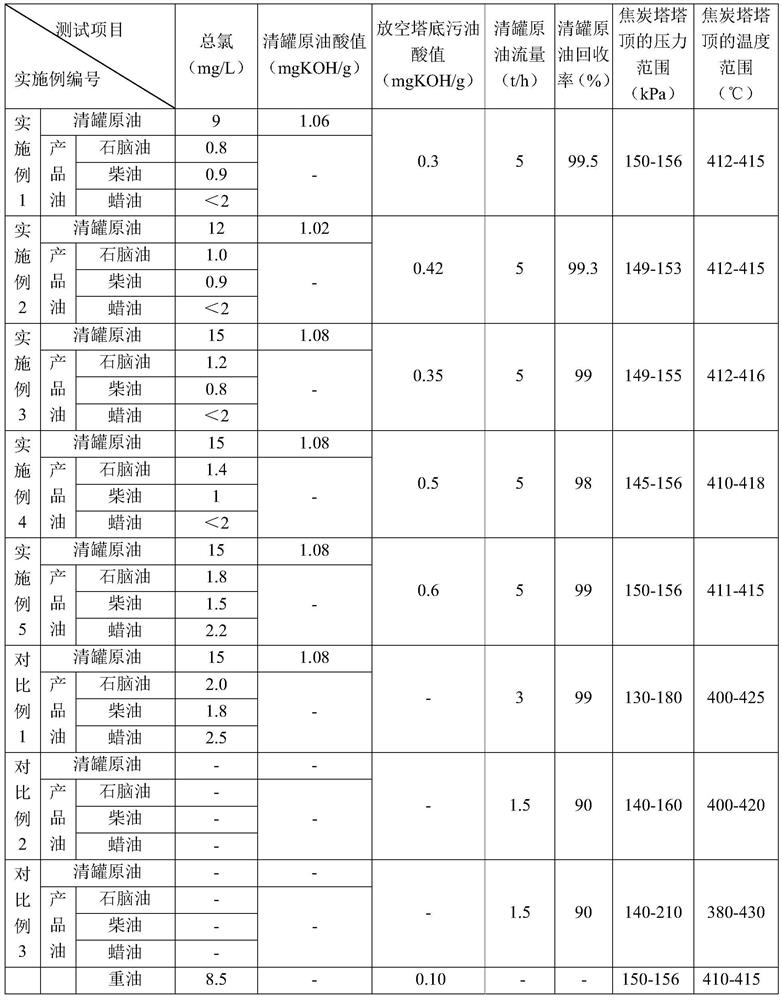

Cleaning treatment method for tank cleaning crude oil

ActiveCN111607427AEfficient separationTo achieve the purpose of green recyclingTreatment with plural serial refining stagesCoking carbonaceous materialsThermodynamicsNaphtha

The invention relates to the field of petrochemical sump oil etratment and discloses a cleaning treatment method for tank cleaning crude oil. The method comprises the following steps of: (1) introducing the tank cleaning crude oil into an emptying tower of a delayed coking device, and contacting the tank cleaning crude oil with second high-temperature oil gas generated during the coke cooling of adelayed coking coke tower for pretreatment to obtain a light liquid containing a light component and water, a first heavy component and a first mechanical impurity; (2) introducing the light component into a delayed coking fractionating tower for fractionation to obtain naphtha and diesel oil; (3) returning the first heavy component and the first mechanical impurity as quenching oil to the coke tower top of the delayed coking device. The method has the advantages of high recovery rate and low cost, and can achieve the purpose of green recovery.

Owner:CHINA PETROLEUM & CHEM CORP

Device for disposing solid blockages in natural gas hydrate slurry pipeline

ActiveCN112588737ATroubleshoot follow-up issuesEasy to operateHollow article cleaningIncinerator apparatusSlurry pipelinePetroleum engineering

The invention relates to a device for disposing solid blockages in a natural gas hydrate slurry pipeline. The device comprises a first decomposition bin for heating and decomposing the blockages intonatural gas, second decomposition bins for receiving the natural gas decomposed by the first decomposition bin, a heating bin for heating the first decomposition bin, a first sensor and a second sensor, wherein the first sensor and the second sensor are used for sensing the position of a pipe cleaner moving in a natural gas pipeline; the first decomposition bin is connected with a blockage feedingpipeline which communicates with or does not communicate with a natural gas pipeline, and pipeline blocking plates capable of moving in the radial direction to close or open the natural gas pipelineare further arranged; the upper ends of the second decomposition bins are connected with a natural gas discharging pipeline which communicates with or does not communicate with the natural gas pipeline; and a cutting device for crushing the blockages is mounted on the wall of the natural gas pipeline. According to the device, after being crushed, the blockages in the natural gas pipeline are decomposed into the natural gas in a heating manner and then is discharged into the natural gas pipeline again, so that the function of converting the blockages into the natural gas underground in the natural gas transportation process can be realized.

Owner:CHANGZHOU UNIV

A method for flue gas carbon fixation seawater decalcification

ActiveCN104108803BHigh feasibilityReduce processing costsSeawater treatmentDispersed particle separationSolid carbonFlue gas

The invention relates to a new method for removing calcium from seawater through flue gas carbon sequestration. The method comprises the following steps: 1, inducing seawater from a pump or a high level water tank into a premixing barrel, adding an alkali source into the seawater, and stirring for 10-30min for fully mixing the seawater with the alkali source; 2, allowing the alkali source-containing seawater to enter a calcium removal pool through a pump, and introducing flue gas into the calcium removal pool through an aeration head in order to make the flue gas contact with the seawater; and 3, allowing mass-transferred seawater to directly enter a settlement pool from the calcium removal pool, settling, filtering, and outputting the obtained clarified liquid at the upper portion of the settlement pool through a pipeline to obtain low calcium seawater. Alkali factory waste white mud is used to substitute sodium hydroxide as an alkali source, so the subsequent processing problem of the alkali factory white mud is solved, a continuous reaction is realized, industrial enforcement is benefited, and the calcium removal pretreatment cost of 1t of raw seawater is reduced by 1-2yuan.

Owner:HEBEI UNIV OF TECH

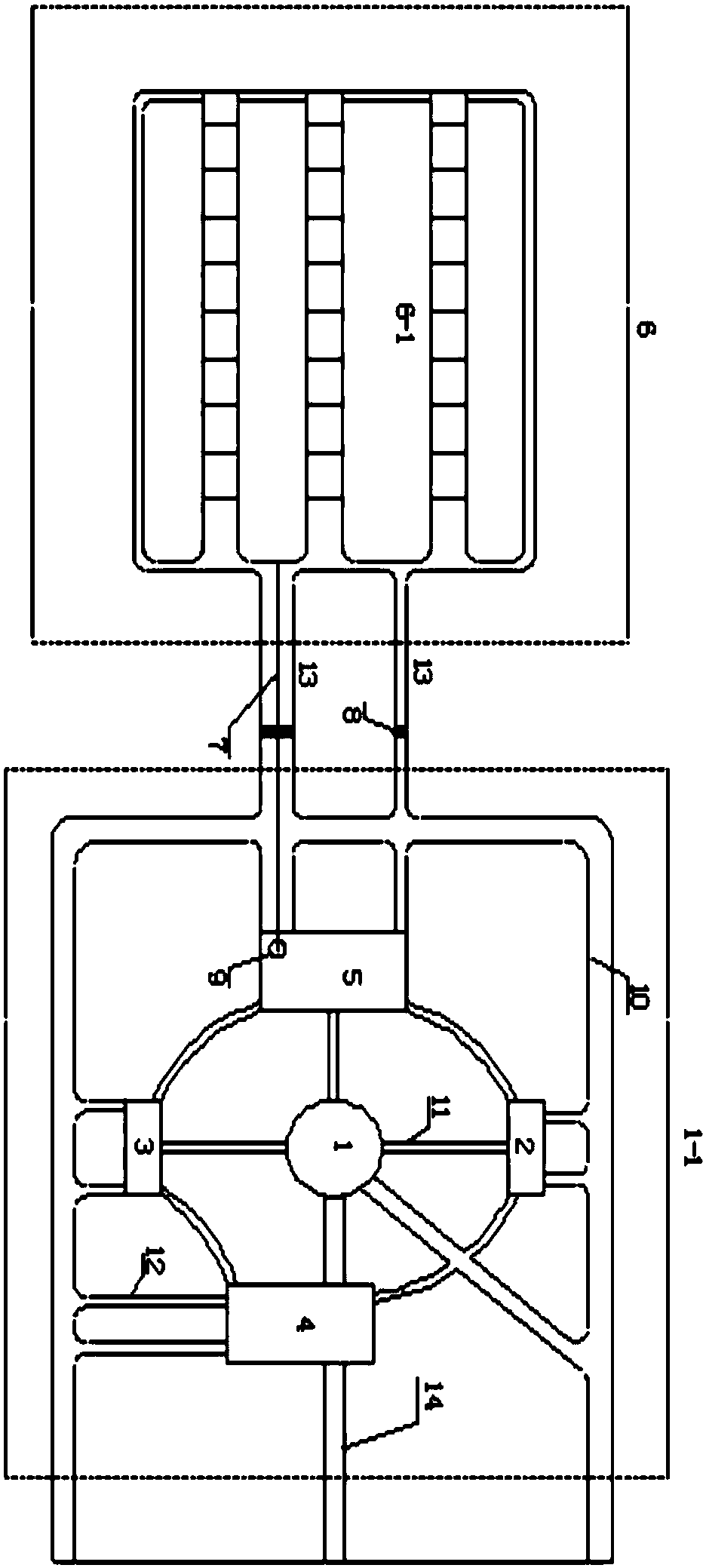

Underground nuclear power plant having low-and-intermediate-level radioactive waste disposal site

ActiveCN106128534ASave design and construction costsAvoid radioactive releaseNuclear energy generationFacility decommissioningNuclear plantCyclic process

The invention discloses an underground nuclear power plant having a low-and-intermediate-level radioactive waste disposal site. The underground nuclear power plant comprises a nuclear island arranged in an underground cavern group of a nuclear island of a mountain and a conventional island arranged on a ground platform at the outer side of the mountain. The nuclear island consists of a reactor workshop arranged at the center, a nuclear fuel workshop, a safety workshop, an electrical workshop, and a nuclear auxiliary workshop, wherein the nuclear fuel workshop, the safety workshop, the electrical workshop, and the nuclear auxiliary workshop encircle the reactor workshop. And the nuclear island also includes a low-and-intermediate-level radioactive waste disposal site arranged in the underground cavern group of the nuclear island of the mountain; and the low-and-intermediate-level radioactive waste disposal site is communicated with the nuclear auxiliary workshop of the nuclear island by a waste transport tunnel. According to the invention, on the basis of combination of characteristics of the underground nuclear power plant, the processing requirement of the low-and-intermediate-level radioactive waste can be met, the closed circulation of fuels can be realized, and the radioactive contamination possibly occurring during the fuel cycle process can be reduced; and the unified planning and building of the nuclear power plant and the disposal site can be realized and costs are saved.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

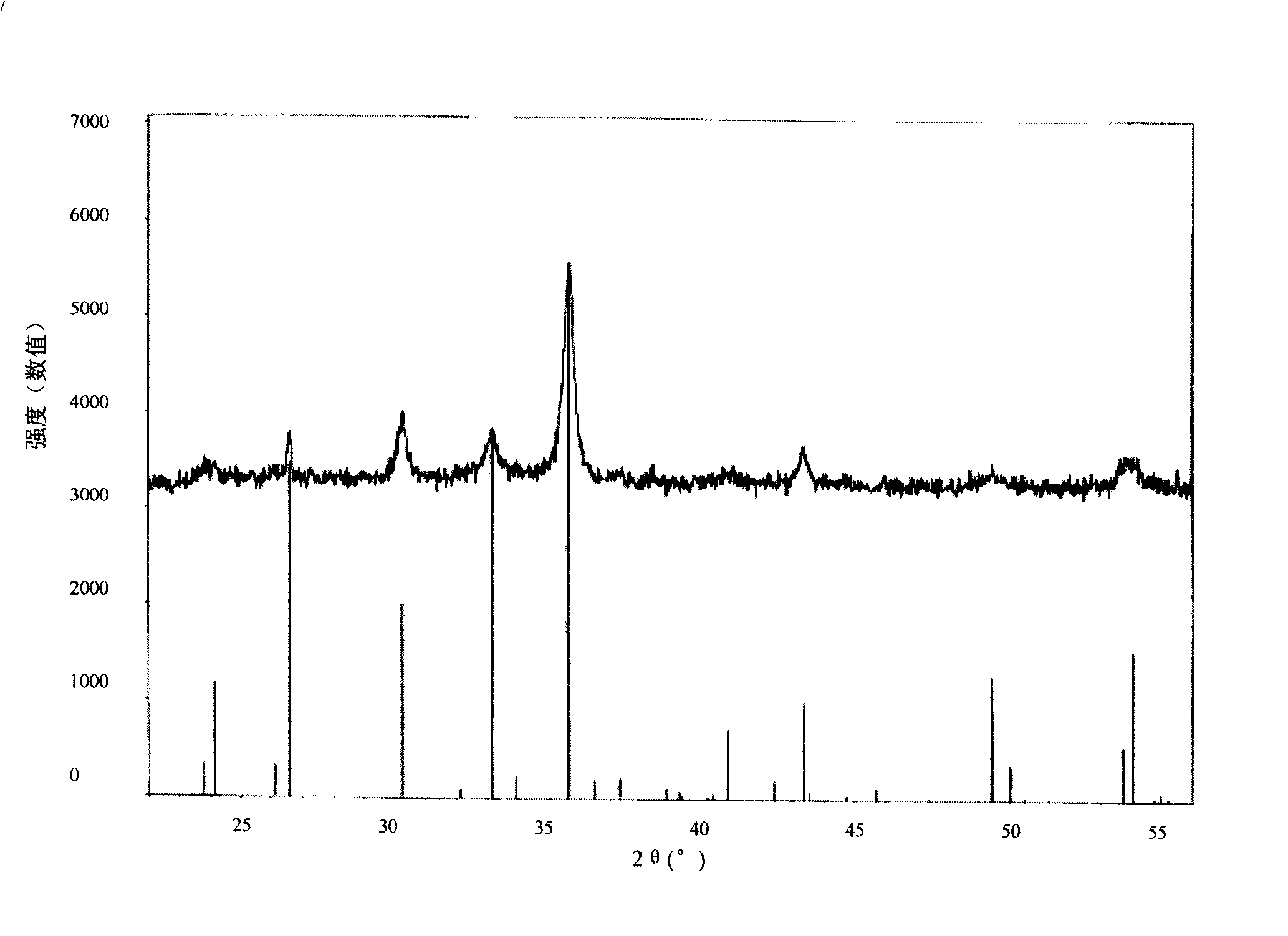

Method for preparing magnetic oxide iron and magnetic oxide iron desulfurizer prepared thereby

ActiveCN101585557BGuaranteed temperatureGuaranteed firing temperatureIron oxides/hydroxidesFerrous saltsSulfur

The invention relates to a method for preparing magnetic oxide iron Fe21.333O32, which comprises the following steps: (a) mixing solid soluble ferrous salt and solid hydroxid according to a molar ratio of iron to hydroxyl being between 1:2 and 1:3; (b) completing reaction of a mixed material prepared in step (a) by kneading, and controlling the temperature of the material not to exceed 70 DEG C in the kneading process; (c) drying a reaction product obtained in step (b) in air; (d) washing and filtering a material obtained in step (c); (e) naturally drying or baking a solid obtained in step (d); and (f) roasting a product obtained in step (e) at a temperature of between 150 and 500 DEG C. The invention further discloses a magnetic oxide iron Fe21.333O32 desulfurizer prepared by the preparation method. Tests show that the desulfurizer has high sulfur capacity reaching 62.0 percent.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

High-strength FeOOH desulfurizer and preparation method thereof

ActiveCN101584962BHigh mechanical strengthAvoid lostDispersed particle separationCarboxymethyl celluloseSulfur

The invention relates to a high-strength FeOOH desulfurizer, which consists of 50 to 95 weight percent of amorphous FeOOH, 0 to 45 weight percent of carrier and 5 to 50 weight percent of organic binder, wherein the carrier is one or more of aluminium oxide, diatomite, natural zeolite and catalytic cracking spent catalyst; and the organic binder is one or more of sodium carboxymethyl cellulose, sesbania powder and cellulose powder. The invention further discloses a preparation method for the desulfurizer on the basis. The FeOOH desulfurizer prepared by the preparation method has high sulfur capacity, high mechanical strength and wider applicable desulfurization range.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

A treatment device for solid blockages in natural gas hydrate slurry pipelines

ActiveCN112588737BTroubleshoot follow-up issuesEasy to operateHollow article cleaningIncinerator apparatusSlurry pipelinePetroleum engineering

The invention relates to a treatment device for solid blockages in natural gas hydrate slurry pipelines, comprising a first decomposition chamber for heating and decomposing the blockages into natural gas, a second decomposition chamber for receiving the natural gas decomposed by the first decomposition chamber, and a device for heating the first decomposition chamber The heating chamber, the first sensor and the second sensor that sense the position of the pig moving in the natural gas pipeline, the first decomposing chamber is connected with a blockage feed pipe that communicates with or closes the natural gas pipeline, and is also equipped with a radial Move the pipeline blocking plate that closes or opens the natural gas pipeline, and the upper end of the second decomposition bin is connected with a natural gas discharge pipeline that is connected or closed with the natural gas pipeline; a cutting device for breaking blockages is installed on the wall of the natural gas pipeline. The invention breaks the blockage in the natural gas pipeline, decomposes it into natural gas by heating and discharges it into the natural gas pipeline, thereby realizing the function of converting the blockage into natural gas underground during the transportation of natural gas.

Owner:CHANGZHOU UNIV

An underground nuclear power plant with a disposal site for low and intermediate radioactive waste

ActiveCN106128534BSave design and construction costsAvoid radioactive releaseNuclear energy generationFacility decommissioningCyclic processNuclear plant

The invention discloses an underground nuclear power plant with a disposal site for low and intermediate radioactive waste, which includes a nuclear island placed in the cavern group of the nuclear island of the mountain and a conventional island placed on the ground platform outside the mountain. The reactor building, the nuclear fuel building, the safety building, the electrical building and the nuclear auxiliary building arranged around the reactor building also include the low and intermediate level waste disposal site placed in the mountain nuclear island cavern group, and the low and intermediate level waste disposal site passes through the waste The transport tunnel is connected with the nuclear auxiliary plant of the nuclear island. Combining the characteristics of underground nuclear power plants, the present invention can not only meet the disposal requirements of low and intermediate radioactive wastes, realize closed cycle of fuel, reduce possible radioactive pollution in fuel cycle process, but also realize unified planning and construction of nuclear power plants and disposal sites, cut costs.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

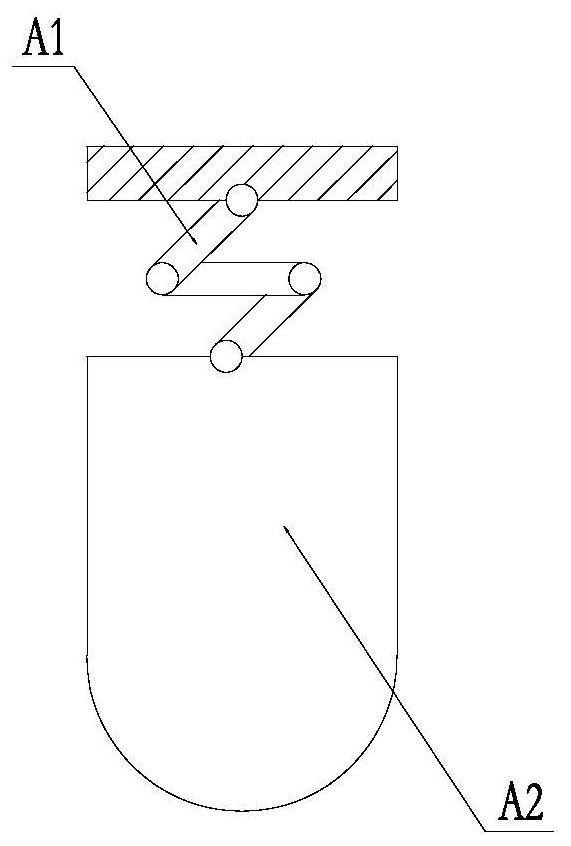

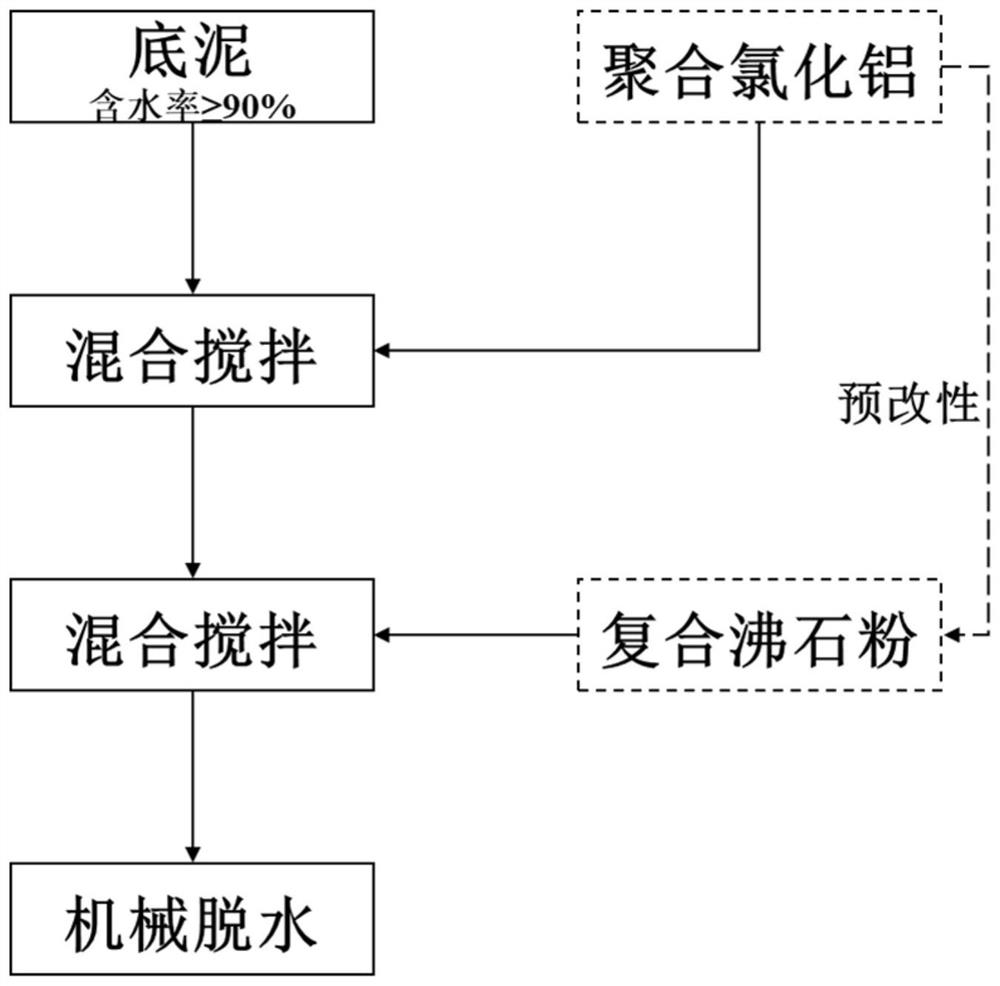

Bottom mud conditioning and pollutant blocking and controlling coupling treatment method

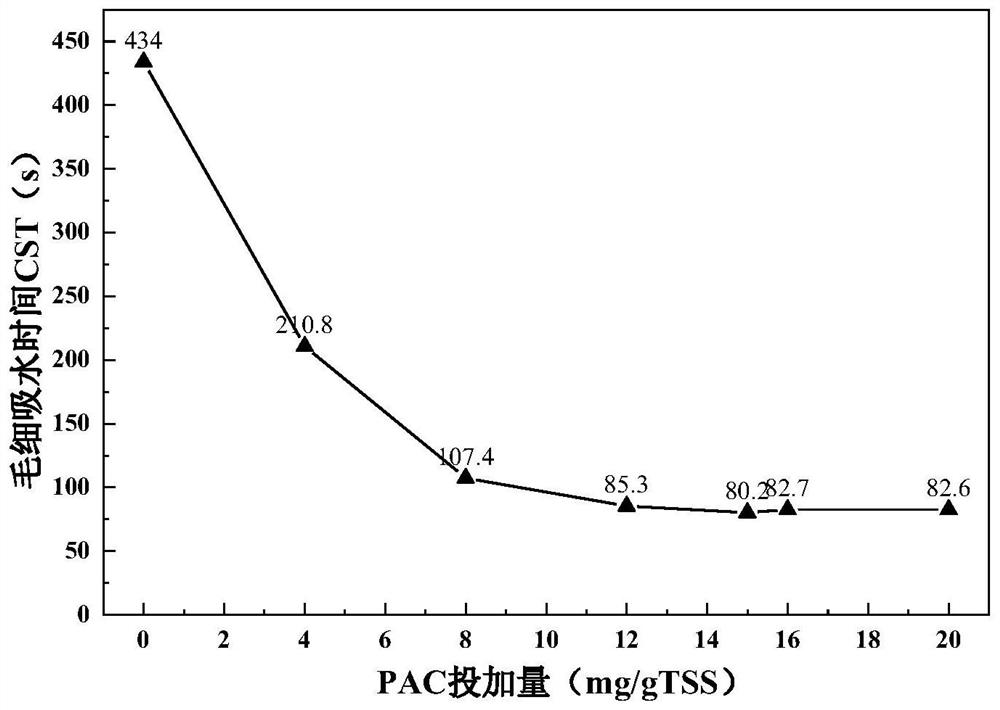

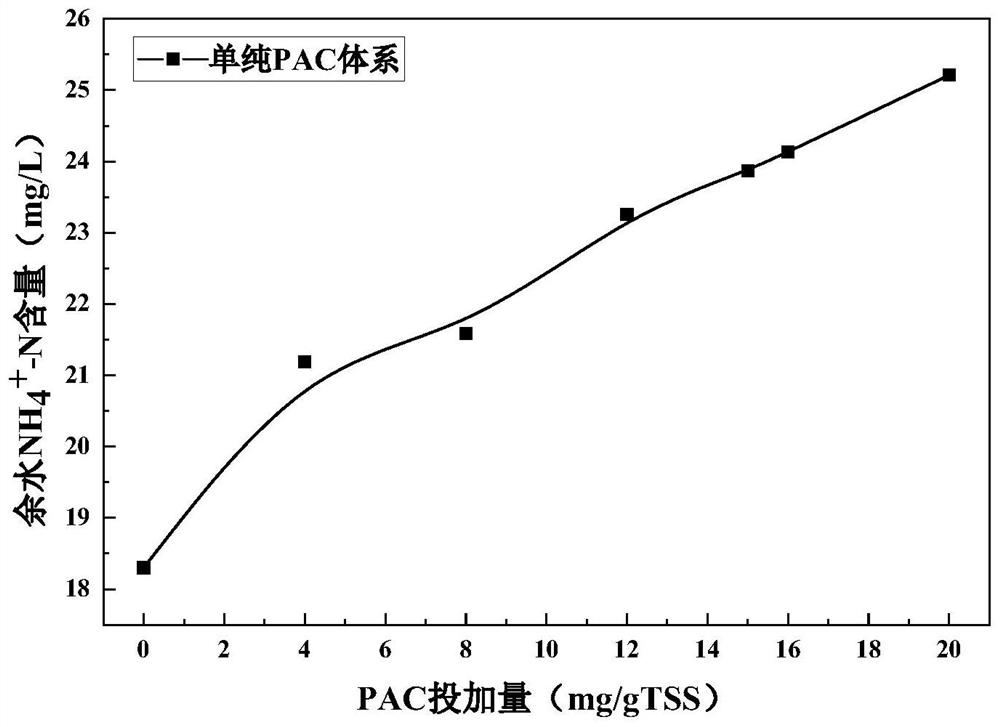

PendingCN114716119ASimple componentsLow costSludge treatmentWater contaminantsAmmoniacal nitrogenOrganic matter

The invention provides a coupled treatment method for conditioning bottom mud and blocking and controlling pollutants. The coupled treatment method comprises the following steps: (1) putting bottom mud to be treated into a reaction container; (2) preparing a PAC solution; (3) preparing composite zeolite powder; (4) adding the PAC solution and the composite zeolite powder into the reaction container according to the mass ratio of the PAC solid to the bottom mud dry basis of 10-20mg / g and the mass ratio of the composite zeolite powder to the bottom mud dry basis of 0.8-1.2 g / g, stirring at a constant speed, and fully mixing; and (6) carrying out filter pressing after standing. According to the method, the dehydration performance of the bottom mud is improved, and nutrient substances such as ammonia nitrogen and organic matters released in the dehydration process of the bottom mud are adsorbed.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

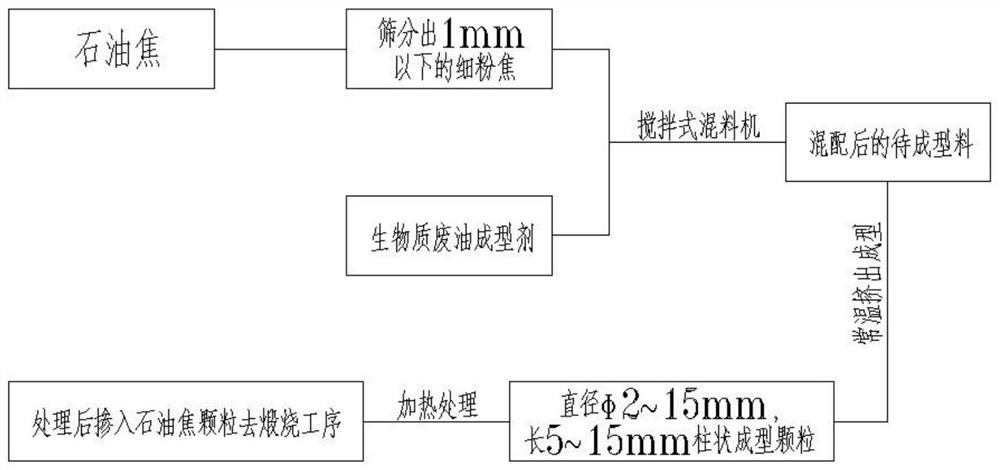

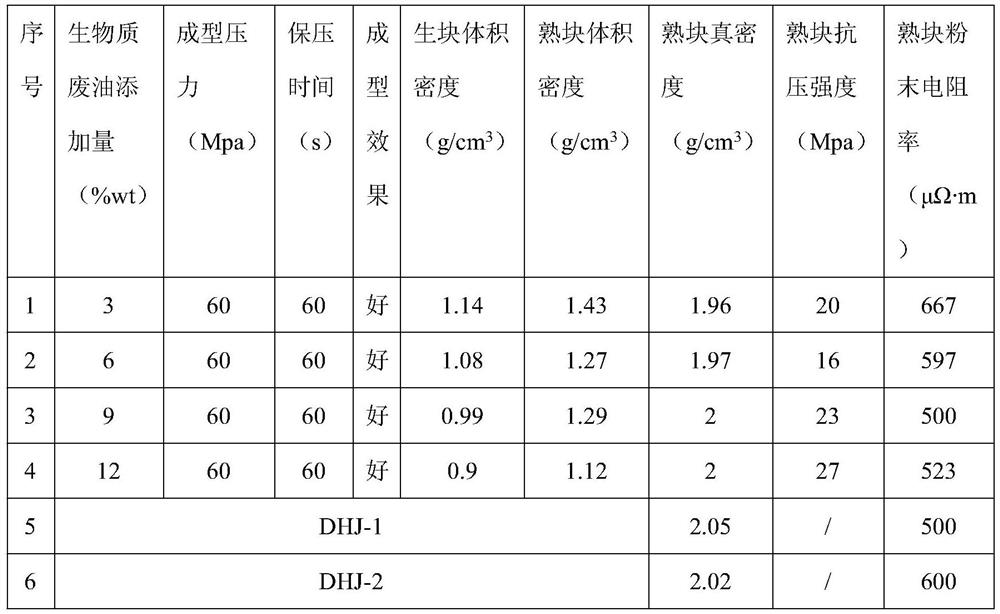

Petroleum coke fine powder coke forming process

PendingCN114506840AHigh resistivity of powderMeet the requirements of prebaked anode productionCarbon preparation/purificationWaste oilThermal treatment

The invention discloses a forming process of petroleum coke fine powder coke. The forming process comprises the following steps: taking fine powder coke which is screened from raw materials and has the moisture content of less than 10wt% as a forming raw material; biomass waste oil obtained by simply refining kitchen waste oil is adopted as a forming agent; mixing the fine coke powder with the biomass waste oil; after uniformly mixing, carrying out normal-temperature extrusion forming on the mixture through an extrusion forming machine to obtain columnar granules with the diameter of 2-15mm and the length of 5-15mm; the formed granules are placed in a sintering furnace to be dried and sintered, the sintering finishing temperature is 200-300 DEG C, the heating rate is 20-30 DEG C / min, and high-temperature heat preservation is conducted for 0.5-1 h; mixing the molded granules subjected to heating treatment into the screened petroleum coke granules, and carrying out a petroleum coke calcining process; and finally calcining to obtain finished product particles. The casting yield of the petroleum coke is increased, the production quality of the anode is guaranteed, and the problem that the anode raw material formula is limited by the fine coke powder amount is solved.

Owner:GUIYANG AL-MG DESIGN & RES INST

Recyclable desulfurizer and preparation method thereof and regeneration method

ActiveCN101898108BHigh sulfur capacityLoose structureOther chemical processesIron oxides/hydroxidesPhysical chemistryEnvironmental engineering

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Crude oil cleaning treatment method

ActiveCN111607427BEfficient separationTo achieve the purpose of green recyclingTreatment with plural serial refining stagesCoking carbonaceous materialsThermodynamicsPetroleum naphtha

The invention relates to the field of petrochemical waste oil treatment, and discloses a method for cleaning crude oil in tanks. The method includes the following steps: (I) passing the crude oil in tanks into the vent tower of a delayed coking device, and coking with the coke produced in the delayed coking tower The second high-temperature oil-gas contact is carried out for pretreatment to obtain light liquid containing light components and water, the first heavy component and the first mechanical impurities; (II) passing the light components into a delayed coking fractionator for fractionation to obtain petroleum Naphtha and diesel oil; (III) the first heavy component and the first mechanical impurity are returned to the top of the coke tower of the delayed coking unit as the quenching oil. This method has high recovery rate, low cost and can achieve the purpose of green recovery.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing material containing amorphous iron oxide hydroxide and methods for regenerating the same

ActiveCN101767828BHigh sulfur capacityImprove stabilityIron oxides/hydroxidesWater/sewage treatmentPhysical chemistryEngineering

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Tio2 nanotube drug sustained release material with pha coating and its application

The invention relates to a TiO2 nano-tube drug sustained-release material with a PHA (phytohematoagglutinin) coating and application thereof. The drug sustained-release material is a TiO2 nano-tube of which a polyhydroxyalkanoate polymeric membrane is coated on the outer surface, and can be used for drug loading. Compared with the prior art, the PHA polymeric membrane is coated on the surface of the drug-loaded TiO2 nano-tube, so that the speed of a drug release process can be controlled, and the drug release time can be prolonged; and the method has the advantages of simple process, reliable effect, safe process and low cost.

Owner:SHANGHAI JIAOTONG UNIV +1

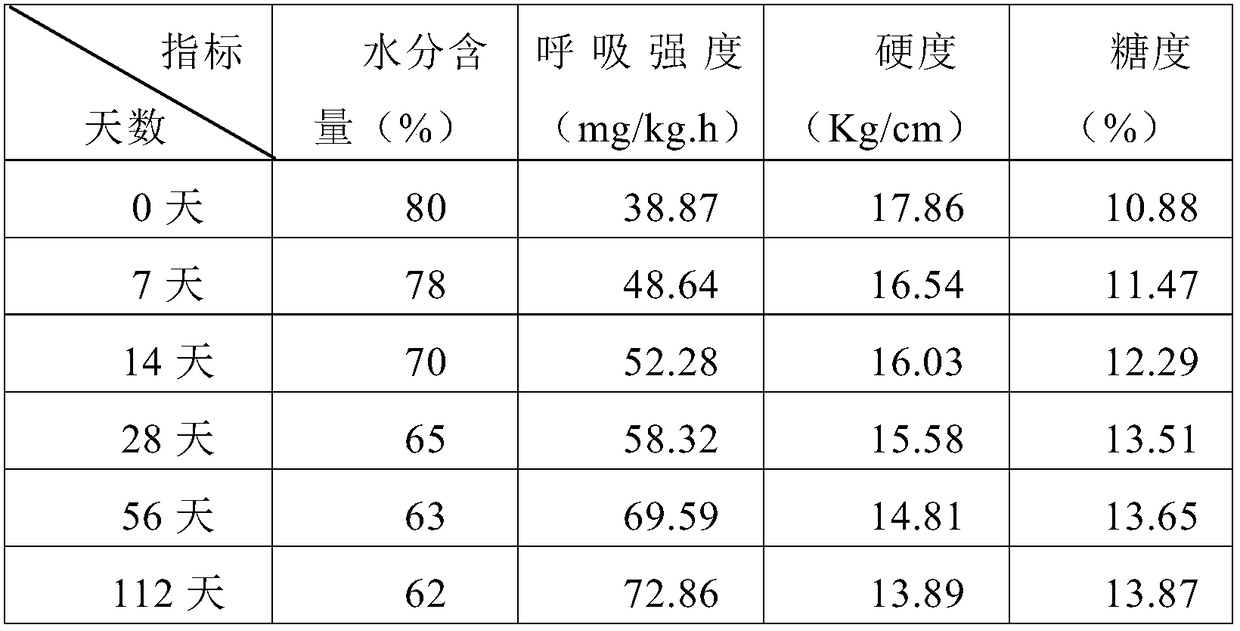

Method for preparing high-purity calcium nitrate by desulfurization and denitrification byproducts

ActiveCN109110791ATroubleshoot follow-up issuesRaw materials are easy to getCalcium/strontium/barium nitratesSolid componentOrganic solvent

The invention discloses a method for preparing high-purity calcium nitrate by desulfurization and denitrification byproducts. The method comprises the following steps: S1, mixing the desulfurization and denitrification byproducts, water and an antioxidant according to a certain ratio, and performing solid-liquid separation on a mixed solution; S2, mixing a second filtrate and a third filtrate in S1, evaporating, concentrating, cooling, crystallizing and drying; S3, mixing and stirring an obtained crystallizing solid in S2 and an organic solvent, and performing solid-liquid separation to produce a second solid component and an organic solvent filtrate; performing reduced pressure distillation on the organic solvent filtrate, wherein the organic solvent is recycled, and a crystallizing product is the high-purity calcium nitrate solid. The method for preparing the high-purity calcium nitrate by the desulfurization and denitrification byproducts has the advantages that by using the desulfurization and denitrification byproducts as the raw materials, the high-purity calcium nitrate is prepared by stepped extracting and oxidizing; the raw materials are easy to obtain, the corresponding technological process is safe and reliable, and the problem of subsequent treatment difficulty of the desulfurization and denitrification byproducts is solved.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Concrete brick containing sludge burning ash residue

Owner:SHANGHAI NORMAL UNIVERSITY +1

Method for preparing amorphous FeOOH and FeOOH desulfurizer prepared thereby

ActiveCN101585556BAvoid generatingTroubleshoot follow-up issuesIron oxides/hydroxidesFerrous saltsPhysical chemistry

The invention relates to a method for preparing amorphous FeOOH, which comprises the following steps: (a) mixing solid soluble ferrous salt and solid hydroxid according to a molar ratio of iron to hydroxyl being between 1:2 and 1:3; (b) completing reaction of a mixed material prepared in step (a) by kneading, and controlling the temperature of the material not to exceed 70 DEG C in the kneading process; (c) drying a reaction product obtained in step (b) in air; (d) washing and filtering a material obtained in step (c); and (e) naturally drying or baking a solid obtained in step (d). On the basis, the invention further discloses an amorphous FeOOH desulfurizer prepared by the preparation method, and the desulfurizer has high sulfur capacity and high desulfurization efficiency.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com