Bottom mud conditioning and pollutant blocking and controlling coupling treatment method

A treatment method and pollutant technology, applied in water/sludge/sewage treatment, sludge treatment, sludge treatment, etc., can solve the problem of reducing the adsorption performance of zeolite powder to ammonia nitrogen, high cost of bottom sludge treatment, and difficulty in utilizing residual sludge and other problems, to avoid subsequent processing problems and waste of resources, low cost, and improve dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

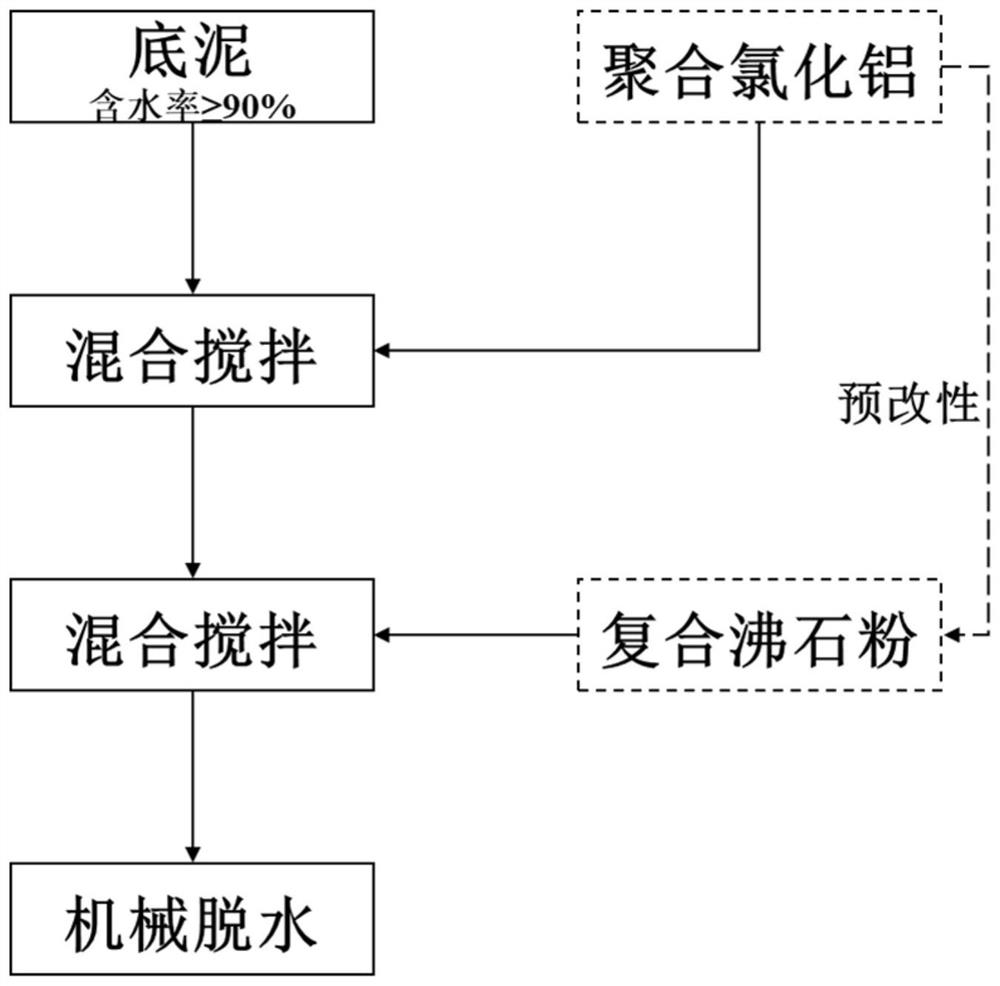

Method used

Image

Examples

Embodiment 1

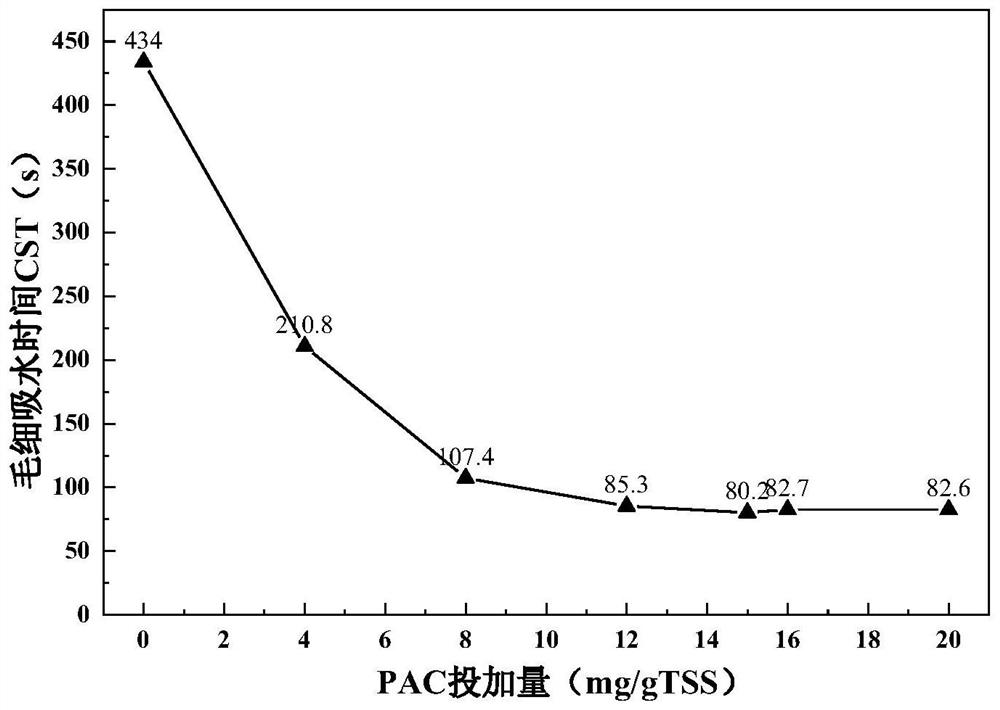

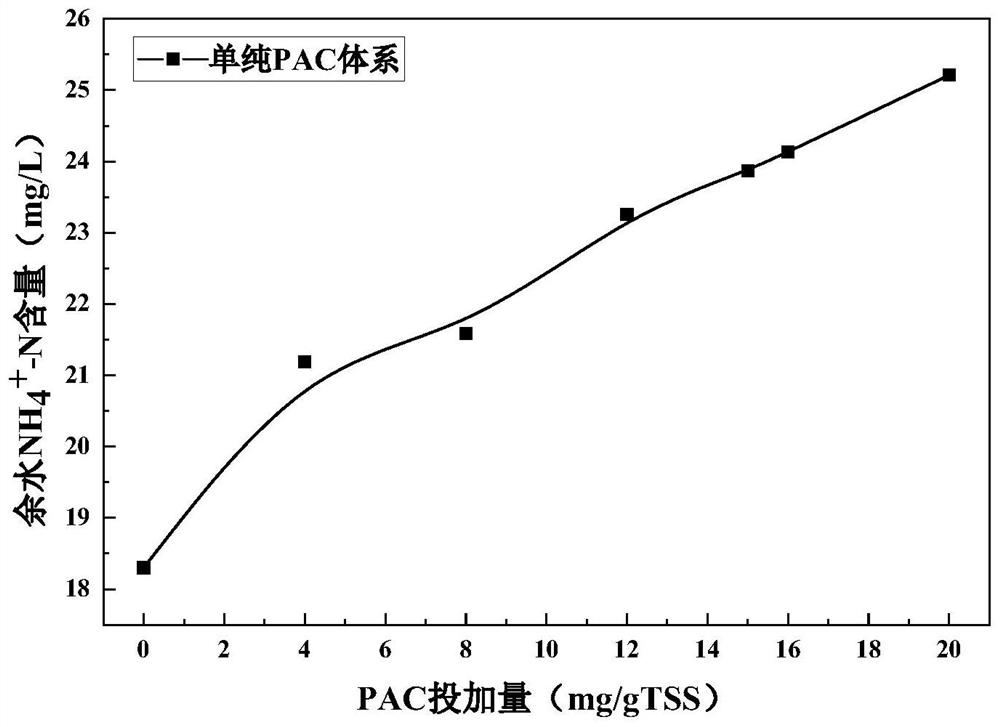

[0039] Simple PAC conditioning experiment

[0040] Weigh 300g of sampled sediment samples and place them in six beakers respectively; then add 0mL, 2.4mL, 4.8mL, 7.2mL, 9.6mL, 12mL of PAC solution with a concentration of 50g / L into the six beakers, respectively. The ratio of PAC solid to sediment dry basis mass (TSS) was 0mg / g, 4mg / g, 8mg / g, 12mg / g, 16mg / g, 20mg / g; the six samples were stirred at a constant speed of 300r / min for 3min , and then stirred at a constant speed for 12 minutes at 100 r / min, and after settling for 30 minutes, the CST and residual ammonia nitrogen (NH) were measured respectively. 4 + -N) concentration, which results as figure 2 and image 3 shown.

[0041] Depend on figure 2 It can be seen that when the mass ratio of PAC solids to the dry base of the sediment is 12 mg / g, the dewatering performance of the sediment is optimized to reach a balance. Under the optimal dosage, that is, 15mg / g TSS, CST decreased by 81.5%, PAC promoted the electrical n...

Embodiment 2

[0044]Coupling conditioning experiment of PAC and unmodified zeolite powder

[0045] Weigh 300g of sampled sediment samples and place them in six beakers. First, add PAC to each beaker according to the optimal dosage (15mg / gTSS) in Example 1, and stir at a constant speed for 3min at 300r / min. , and then stir at a constant speed for 12min at 100r / min; then according to the mass ratio of zeolite powder and bottom mud dry base, 0.1g / g, 0.2g / g, 0.4g / g, 0.8g / g, 1g / g, 1.2 Add zeolite powder at g / g, stir at a constant speed for 10-15 minutes at 200 r / min, and measure the capillary water absorption time (CST) and residual water quality index (NH) after settling for 30 minutes. 4 + -N, COD). Another set of experiments was carried out in the order of adding zeolite powder first, followed by PAC, and the detection was performed after repeating the above steps. Figures 4 to 6 Both shows the comparison curves of conditioning experiment results when PAC and zeolite powder are added in d...

Embodiment 3

[0050] Coupling conditioning experiment of PAC and composite zeolite powder

[0051] In this example, the dosing order of "zeolite powder→PAC" was selected to study the conditioning effect of the modified zeolite powder. The specific experimental steps are as follows: Weigh PAC solid and zeolite powder and mix them uniformly to form composite zeolite powder, wherein the mass ratio of PAC solid and zeolite powder is 0mg / g, 1mg / g, 3mg / g, 5mg / g, 7mg / g and 9mg / g mixed to form composite zeolite powder with different mass ratios of PAC / zeolite powder.

[0052] Weigh 300g of sampling bottom mud samples and place them in six beakers respectively, and add the composite zeolite powder of different PAC / zeolite powder mass ratios into each beaker according to the optimum dosage (1g / gTSS) in Example 2, Stir at a constant speed for 10-15 minutes at 200 r / min; then add PAC to each beaker according to the optimal dosage (15 mg / g TSS) in Example 1, stir at a constant speed for 3 minutes at 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com