Patents

Literature

1392results about "Sludge processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS7465791B1Low viscosityNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

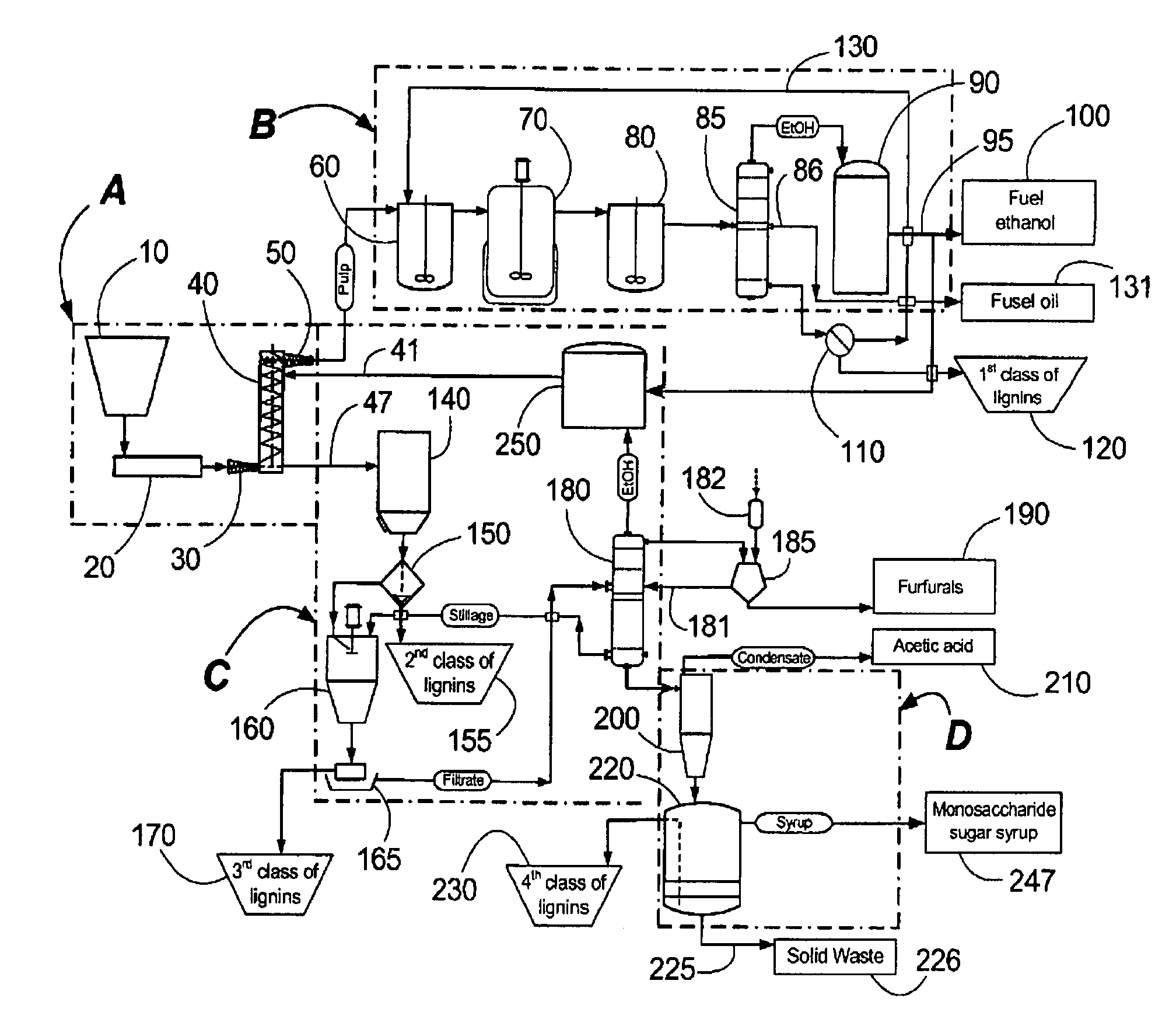

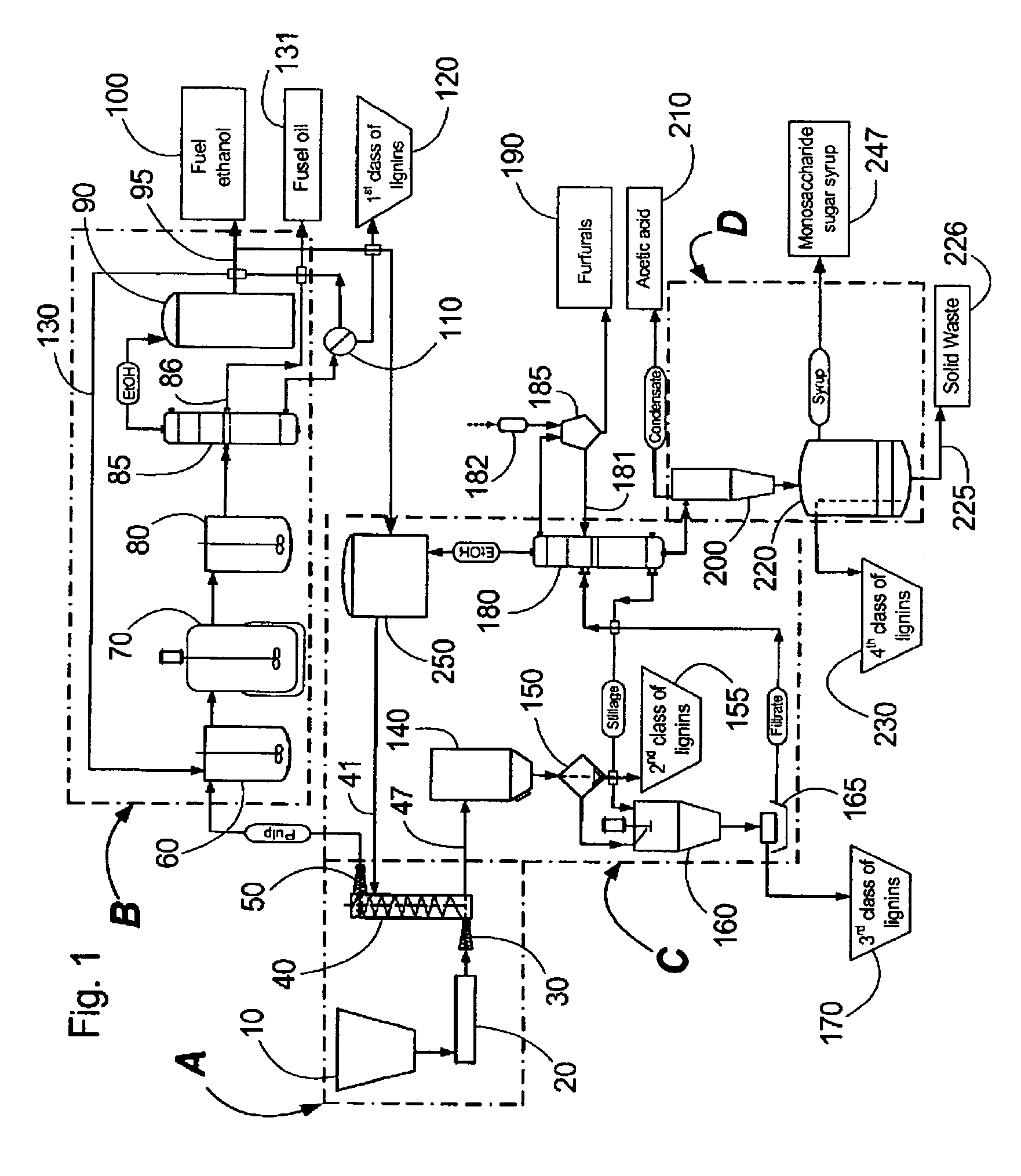

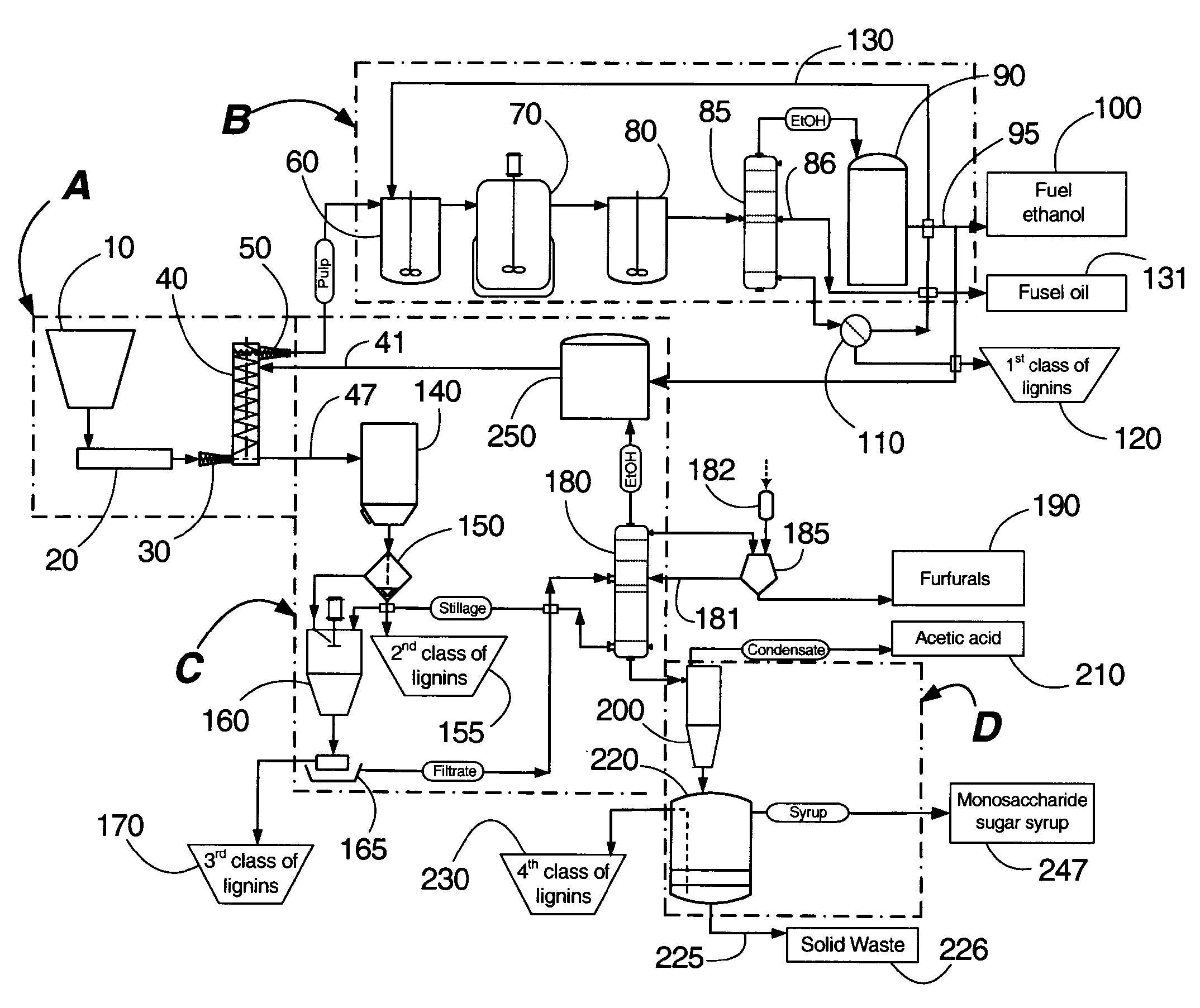

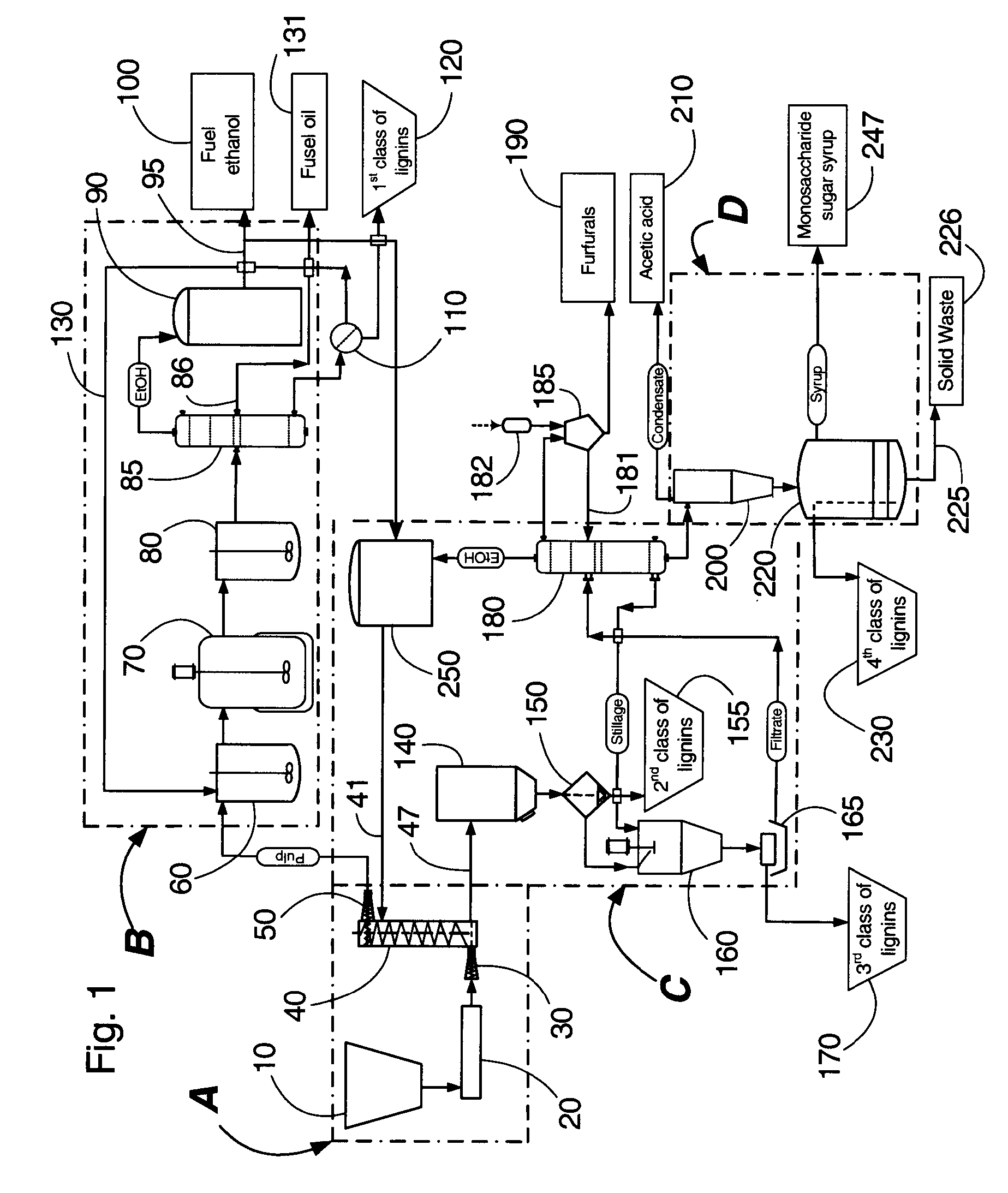

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:SUZANO CANADA INC

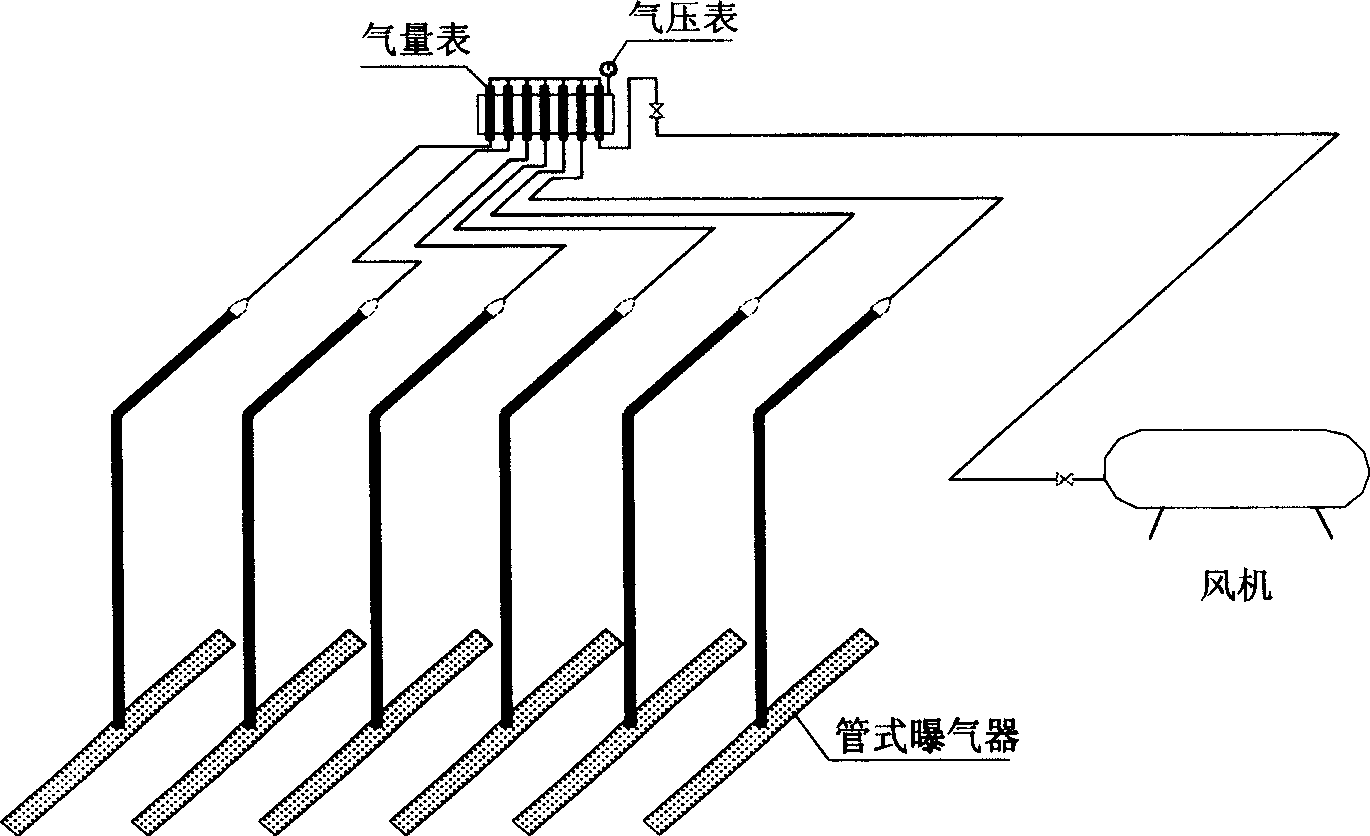

Black-odor river pollution treatment method

InactiveCN101417840AEfficient removalControl and reduce the total amount receivedTreatment using aerobic processesWater aerationMicrobial agentSelf purification

The invention discloses a method for managing town black and olid river pollution in situ by utilizing biological repair technology, which takes the steps and measures of aerating and oxygenizing in riverway, adding a complex microbial agent, biologically repairing bottom sediment, arranging a bio-nest system and the like, so as to control and eliminate the exogenous and endogenous pollution of the river, purify the water quality of the river, improve the self-purification ability of the water body and achieve the purpose of eliminating black and olid. The method does not need to build structures in the riverway or lead the river water out of the riverway to be treated, or dredge the bottom sediment in the river, therefore the method is generally applicable to incomplete sewage interception and dredging or the rivers which can not be intercepted sewage or dredged temporarily, and the in situ treatment to the riverway which is affected by tide and has complicated fluid variation. Therefore, the method which can lead the water body to recover normal ecological function provides the practical, economic and convenient treatment method for various town black and olid rivers.

Owner:黎赓桓 +1

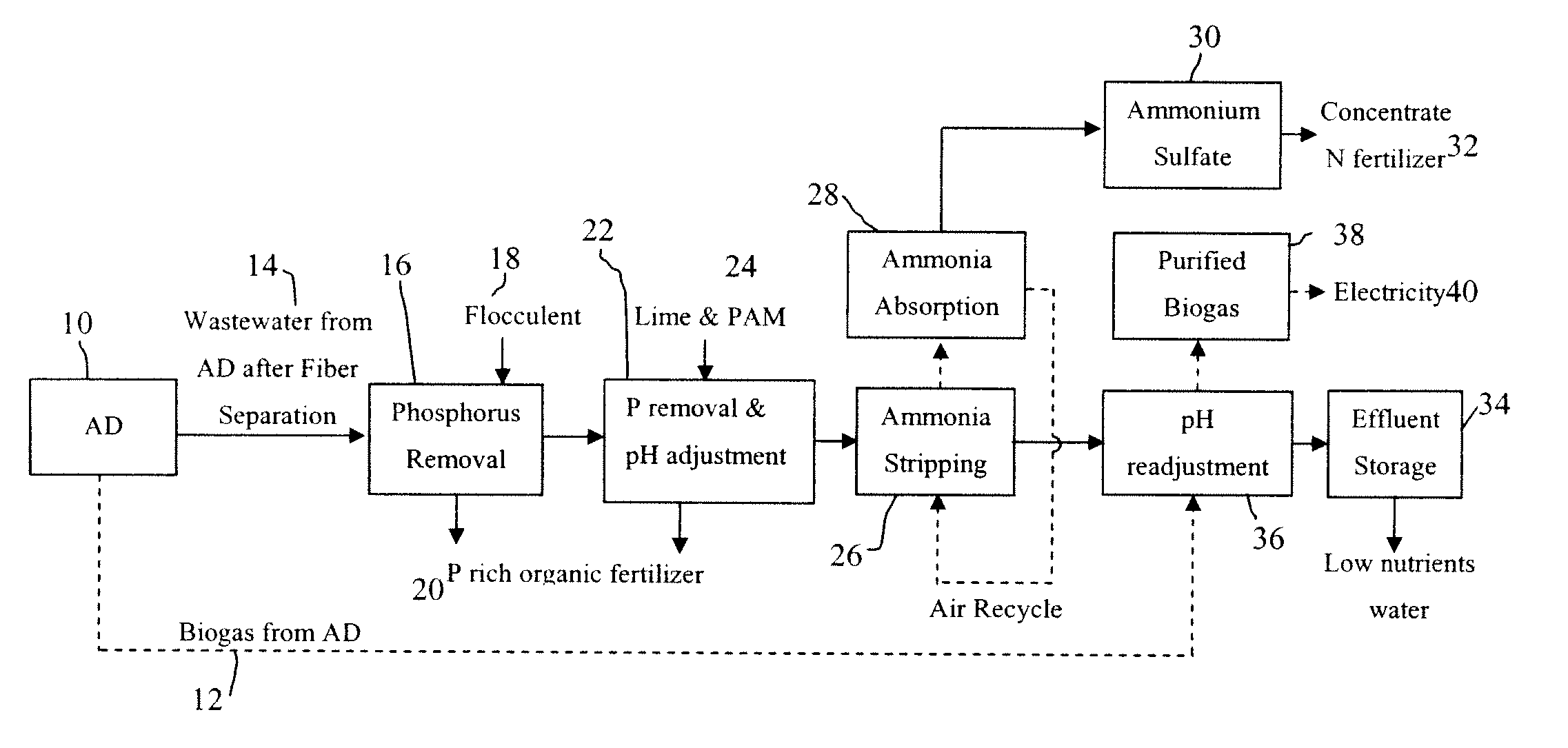

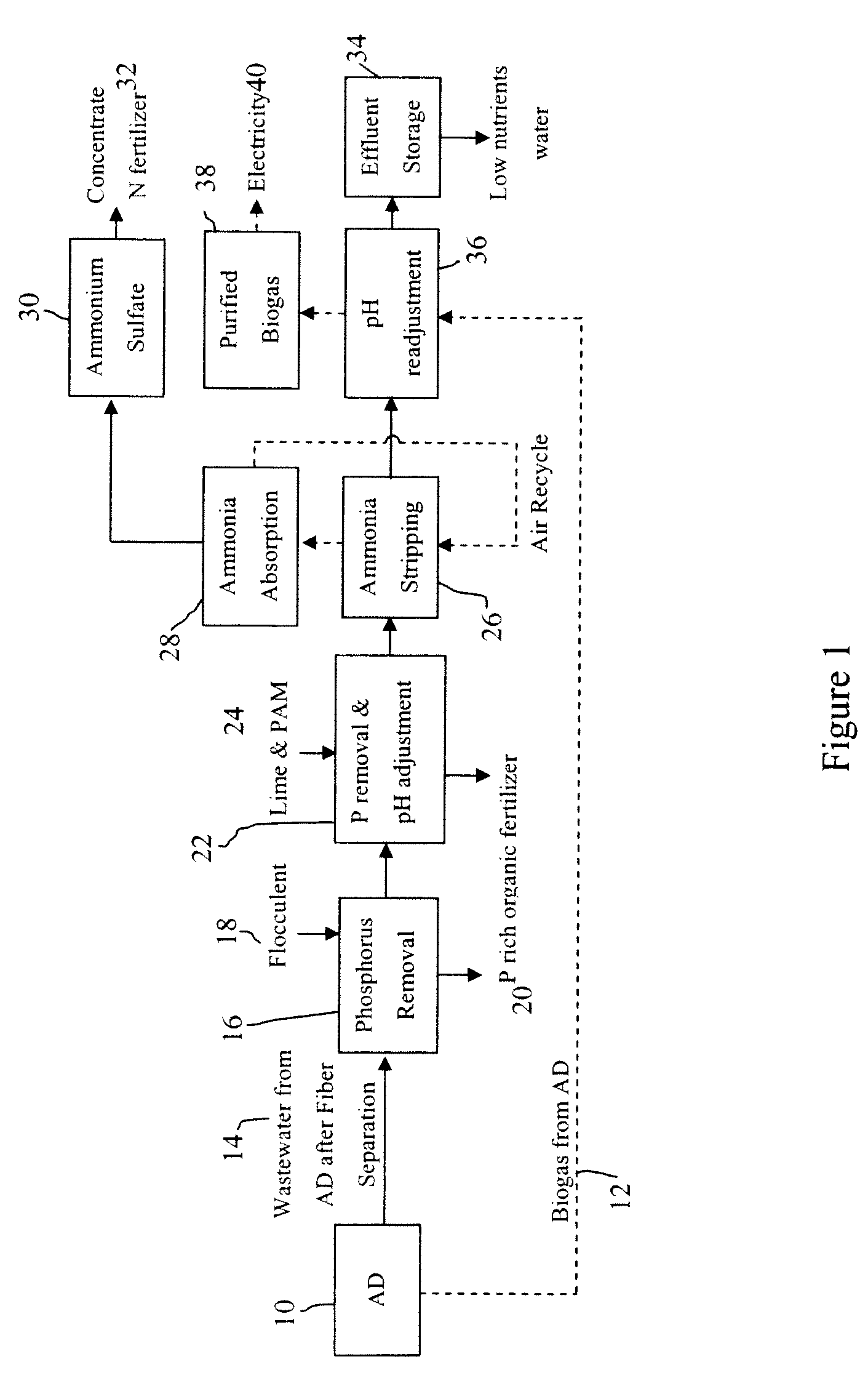

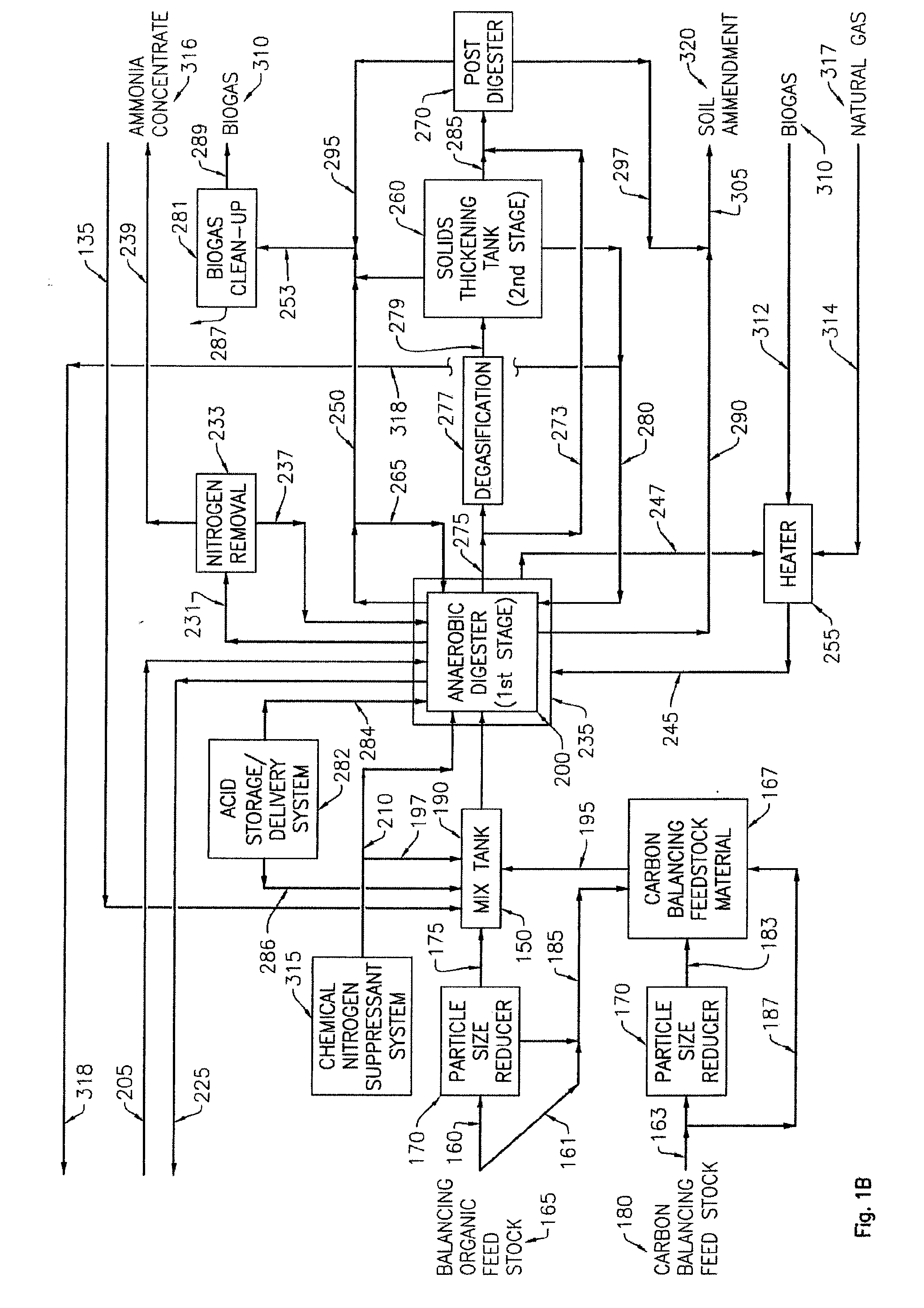

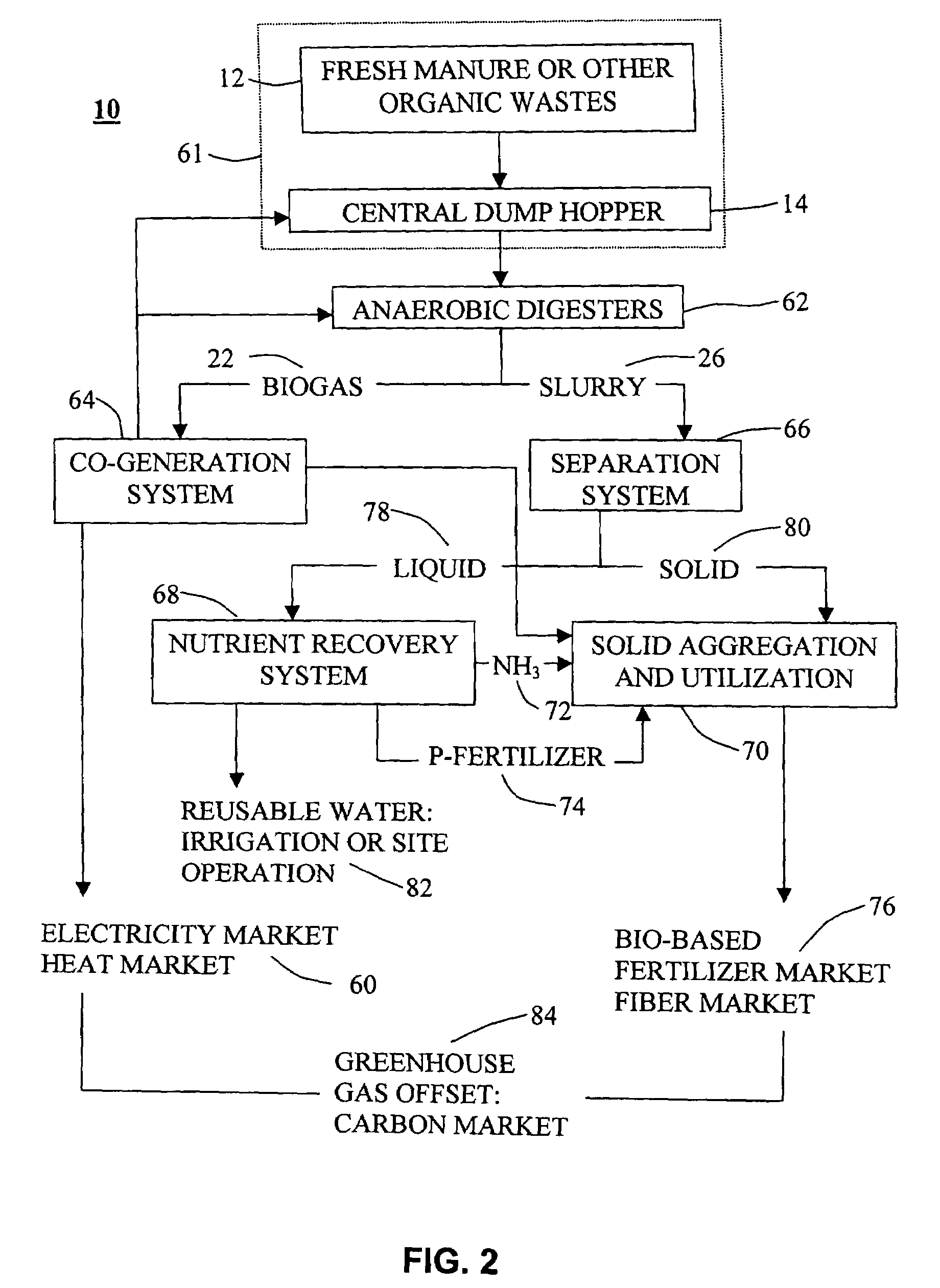

Combined nutrient recovery and biogas scrubbing system integrated in series with animal manure anaerobic digester

InactiveUS20090206028A1Inherent flexibilityIncrease flexibilityBio-organic fraction processingBiological substance pretreatmentsFecesNitrogen

An economical, integrated system works in series with anaerobic digestion of animal waste to recover nitrogen and phosphorous, while also scrubbing the produced biogas.

Owner:WASHINGTON STATE UNIV RES FOUND INC

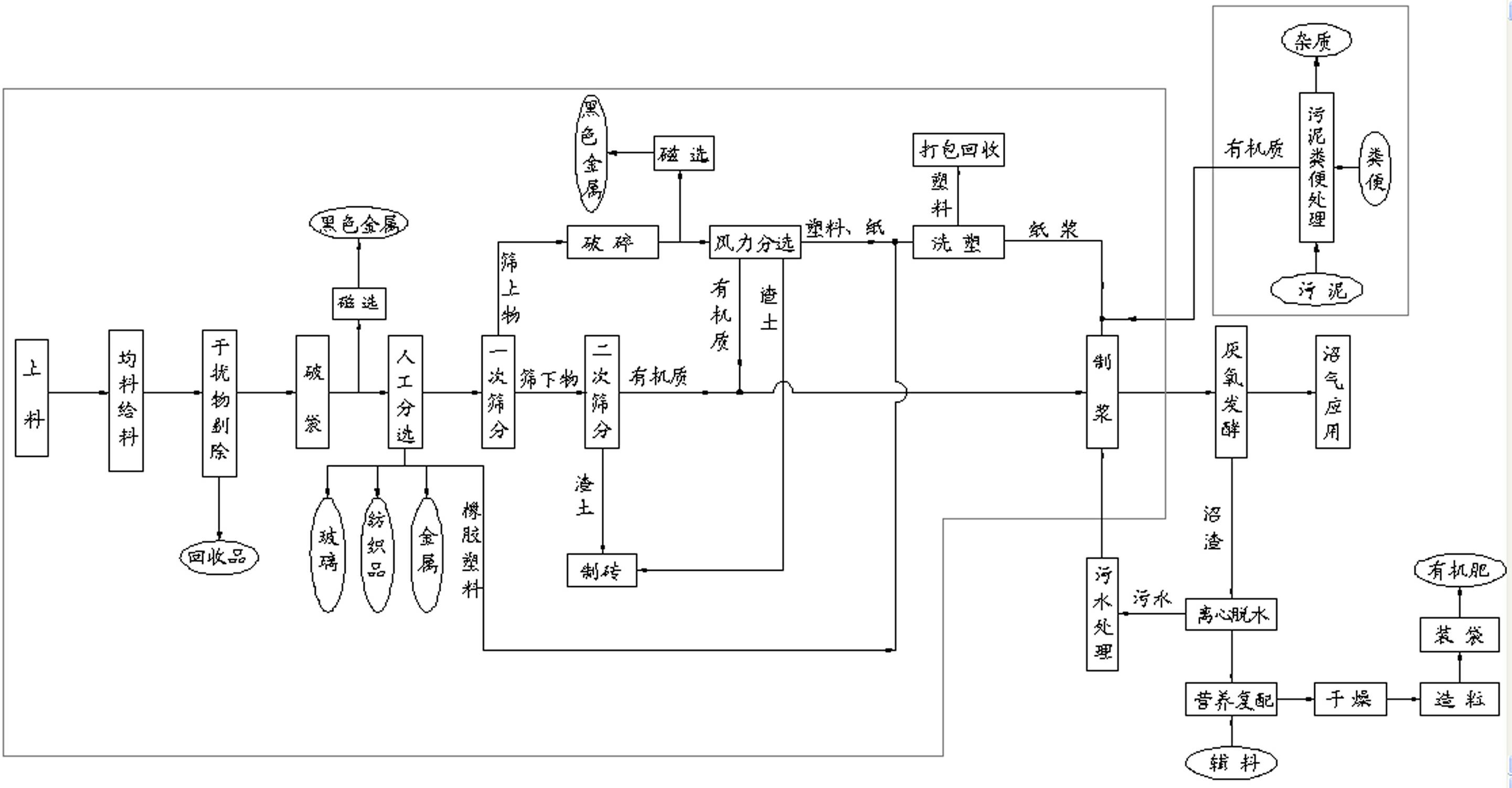

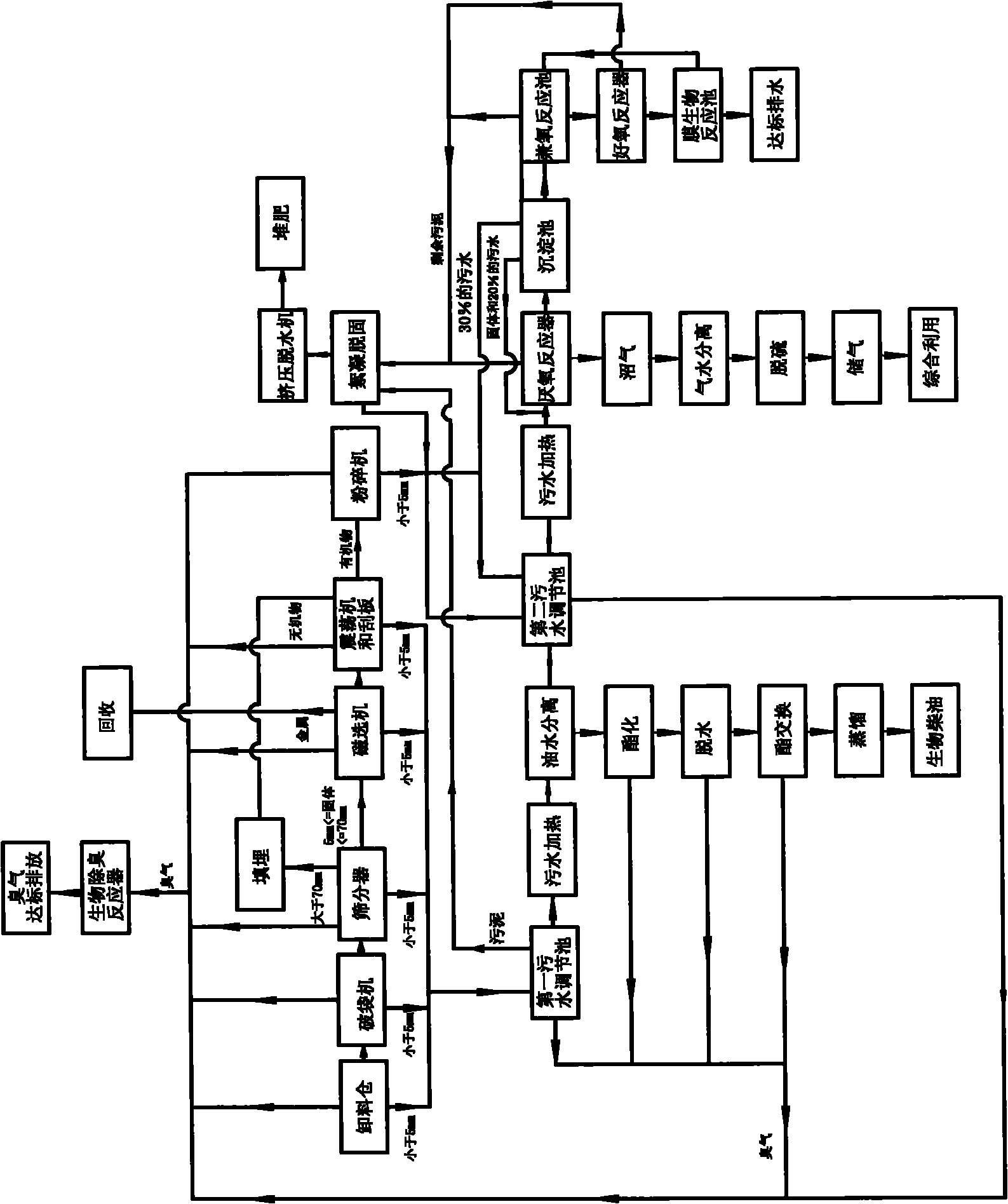

Comprehensive treating system for domestic wastes

InactiveCN102527701AIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

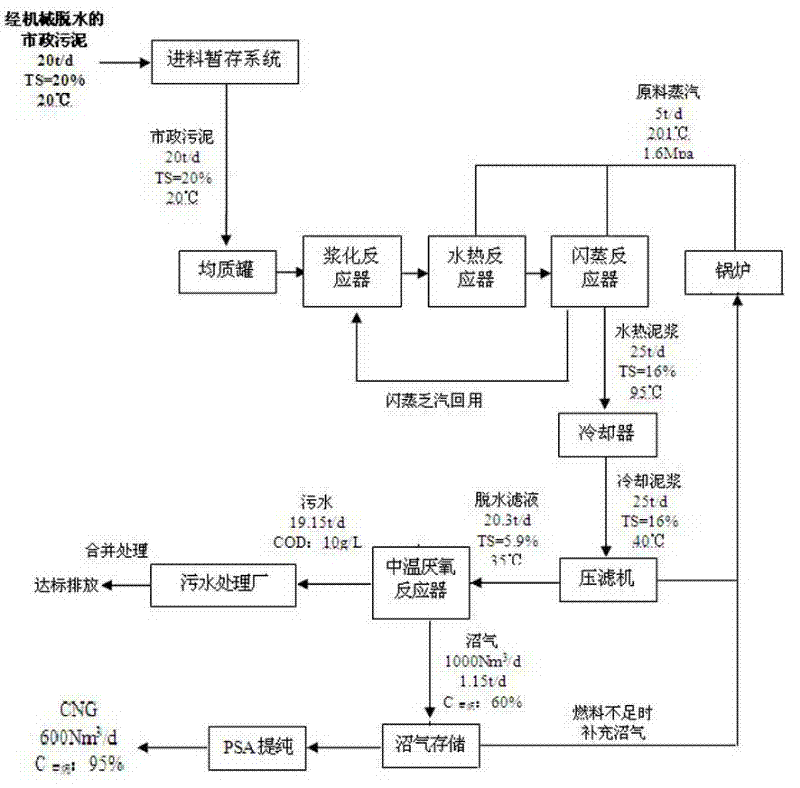

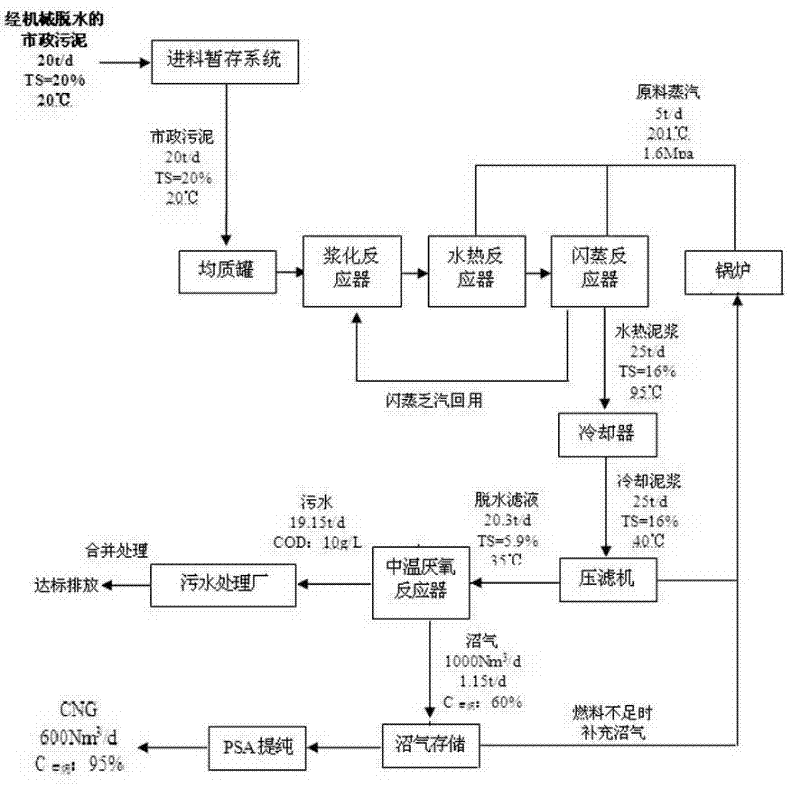

Sludge treatment process based on hydrothermal modification technology

InactiveCN102381820AAdvanced technologyHighlight energy savingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningAnaerobic reactorHigh pressure

The invention relates to a sludge treatment process based on a hydrothermal modification technology. The sludge treatment process is carried out by comprising the following steps of: (1) temporarily storing the sludge which is subjected to mechanical dehydration and has the water content of 70-85% to a pretreatment unit and deodorizing the sludge; (2) introducing to a homogeneous device, fully mixing and homogenizing, introducing the homogenized sludge to a slurrying device, introducing the slurried sludge to a hydrothermal reactor for hydrothermal reaction, and introducing the hydrothermal sludge to a flash evaporator for decompression and flash evaporation; (3) cooling to 35-45 DEG C by using a cooler, then introducing to a high-pressure diaphragm pressure filter for pressure filtering and dehydration to obtain a dehydrated mud cake with the solid content of 35-45% and dehydrated filtrate; (4) introducing the dehydrated filtrate to an intermediate temperature anaerobic reactor, wherein the residence time is for 5.5-7.5d, the inlet water temperature is controlled below 40 DEG C, and the anaerobic reaction temperature is 30-40 DEG C; and (5) preparing a biomass fuel rod by using the dehydrated mud cake, and introducing the biomass fuel rod to a boiler to provide steam for the hydrothermal reactor and the flash evaporator. The sludge treatment process has the advantages of goodtreatment effect, obvious volume reduction effect, high harmless degree, recycling of methane, good economic benefit and the like.

Owner:FUZHOU DEV ZONE SANSHUI ENVIRONMENTAL PROTECTION TECH

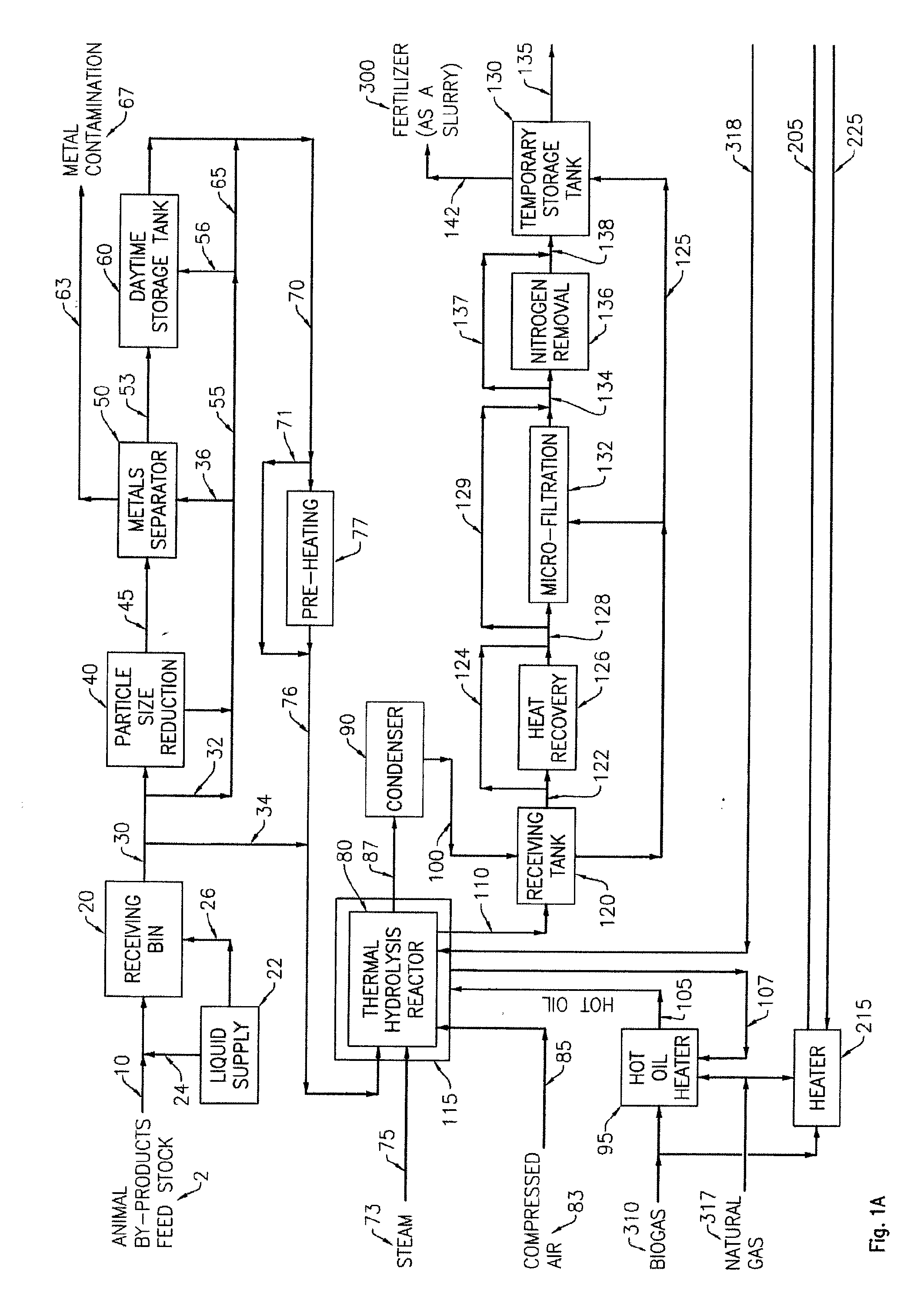

Apparatus and Process for Production of Biogas

ActiveUS20100021979A1Quick conversionDigesting retention timeBioreactor/fermenter combinationsBiological substance pretreatmentsHydrolysateSolid fraction

A process and an apparatus for the manufacture of biogas and a solids fraction from an organic waste feedstock is provided. The process involves thermal hydrolysis of the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours, to produce a hydrolysate. The hydrolysate undergoes anaerobic digestion at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce a biogas stream and a digestate. The digestate is separated into a solids fraction and a liquid fraction, and a portion of the solids fraction is recycled for further anaerobic digestion. The biogas stream, characterized as having a methane content from between 55 to 80% by volume, and the solids fraction, are recovered. The apparatus includes a receiving bin for receiving and supplying organic waste feedstock to a thermal hydrolysis reactor. The thermal hydrolysis reactor for processing the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours to produce a hydrolysate. An anaerobic digester for processing the hydrolysate at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce the biogas and a digestate, and a solids thickening tank for separating the digestate into the solid fraction, a liquid fraction and a secondary biogas fraction.

Owner:GEMINI CORP

Centralized kitchen waste treatment method

ActiveCN101837366ARealize harmless treatmentRecycling is possibleFatty oils/acids recovery from wasteBio-organic fraction processingResource utilizationOil water

The invention relates to a centralized kitchen waste treatment method which comprises the following steps of: (A) sorting kitchen waste; (B) separating oil from water; (C) treating oil; (D) treating sewage; and (E) treating odor. Compared with a traditional kitchen waste burying method, by using the centralized kitchen waste treatment method, a great amount of soil is saved and an available methane resource is generated, kitchen waste reaches 100 percent of harmlessness, more than 95 percent of resource utilization and more than 95 percent of quantitative reduction, and the harmless treatmentof waste and the recycle of resources are truly realized.

Owner:北京昊业怡生科技有限公司

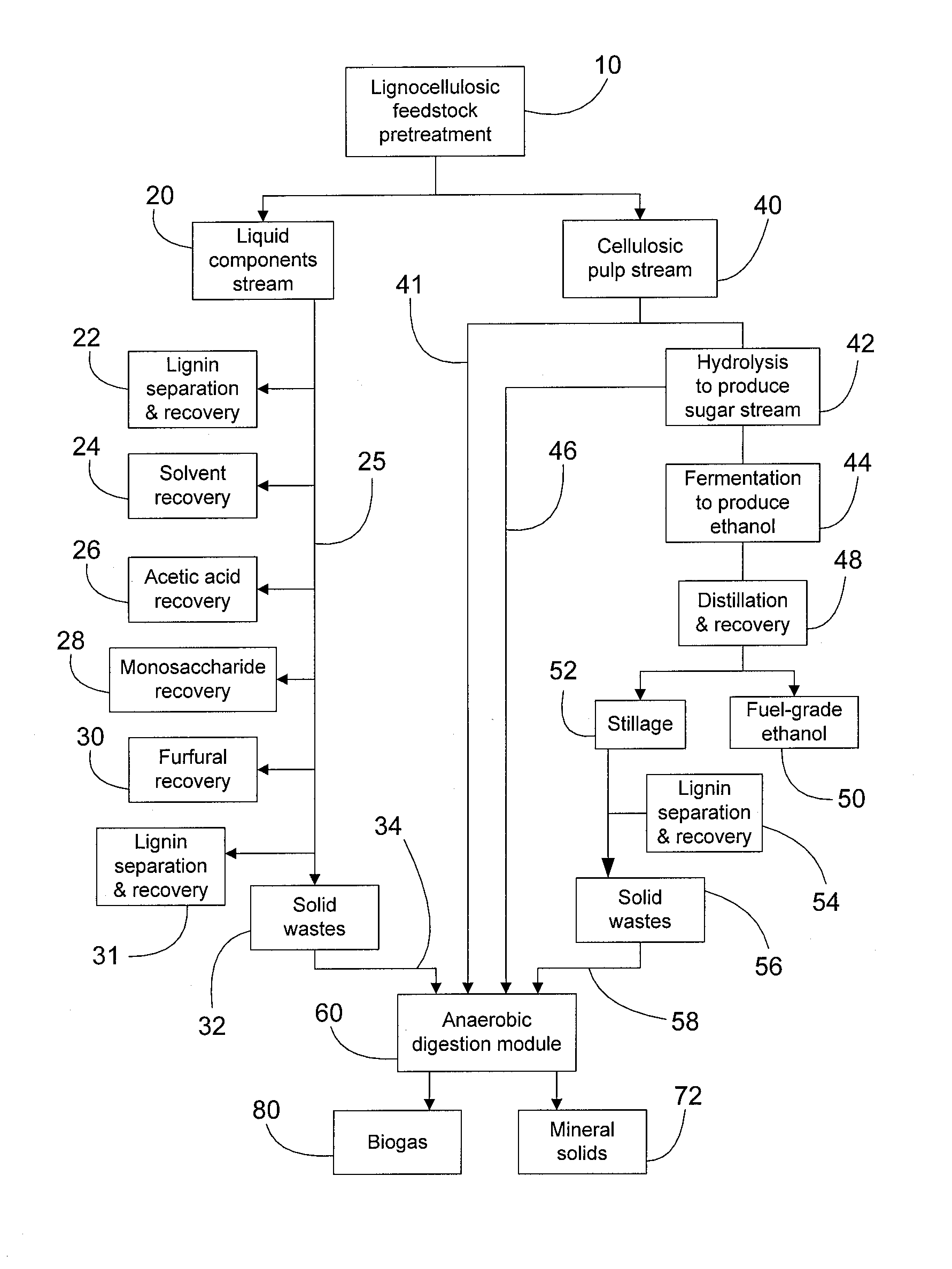

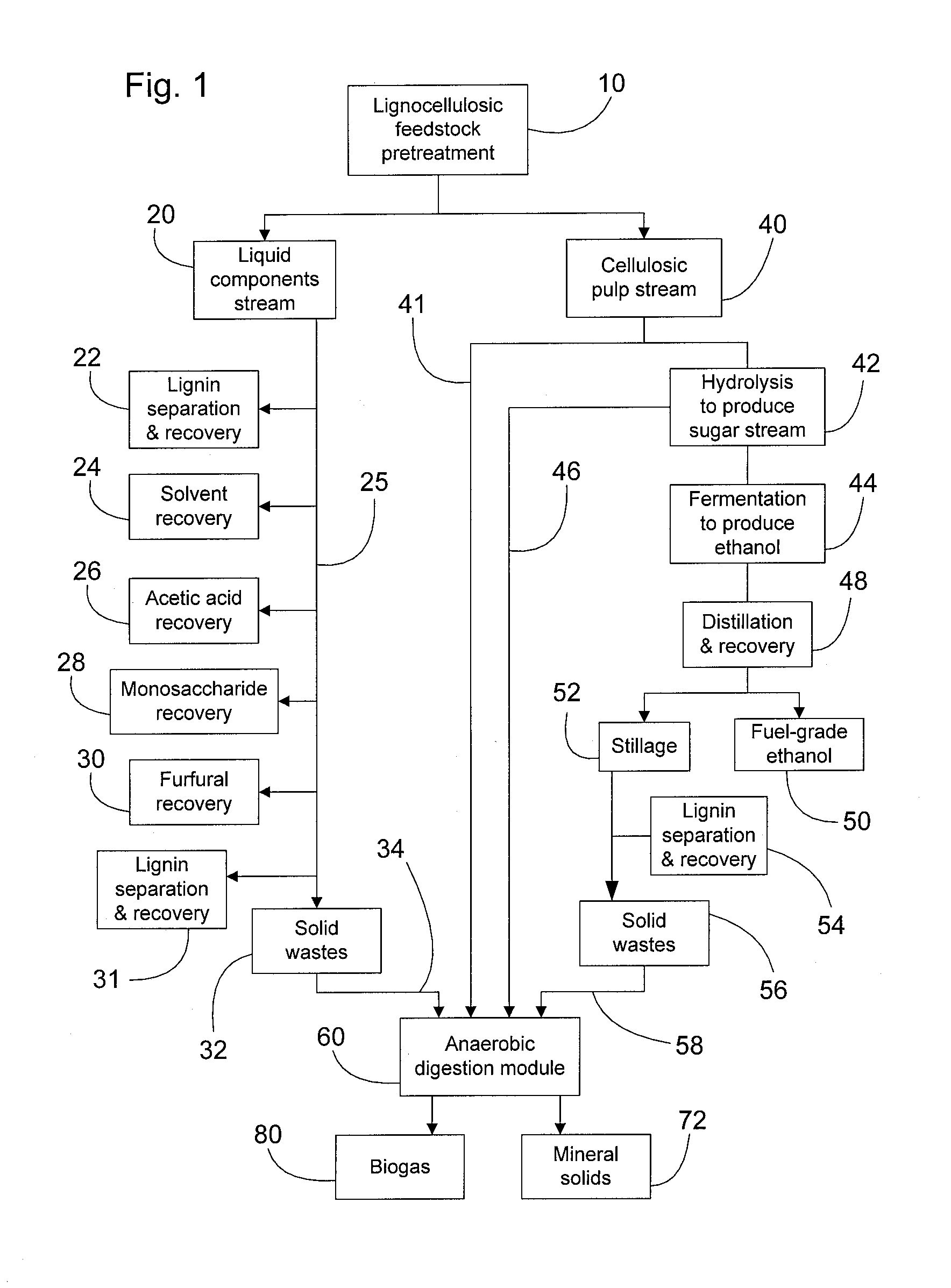

Concurrent Anaerobic Digestion and Fermentation of Lignocellulosic Feedstocks

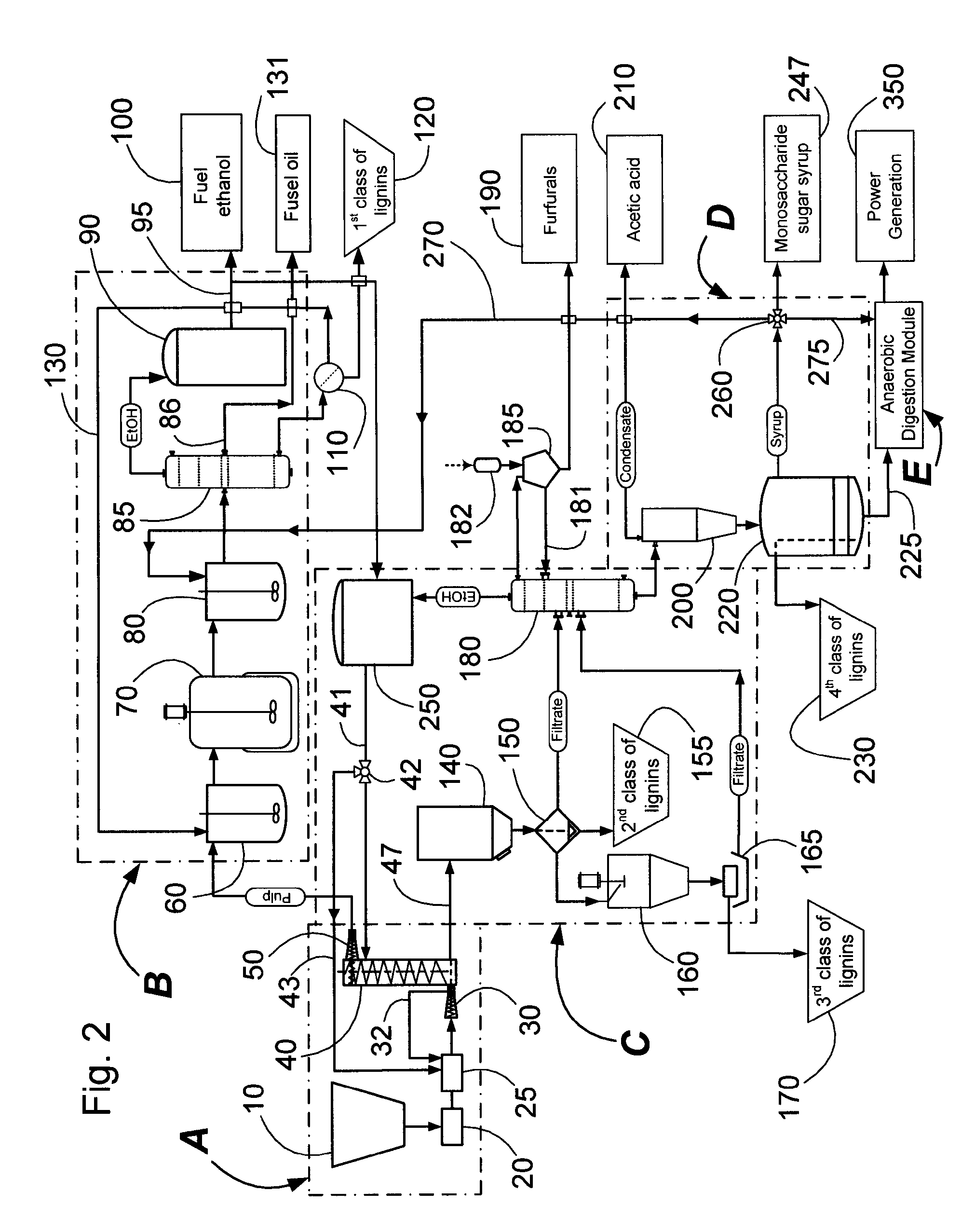

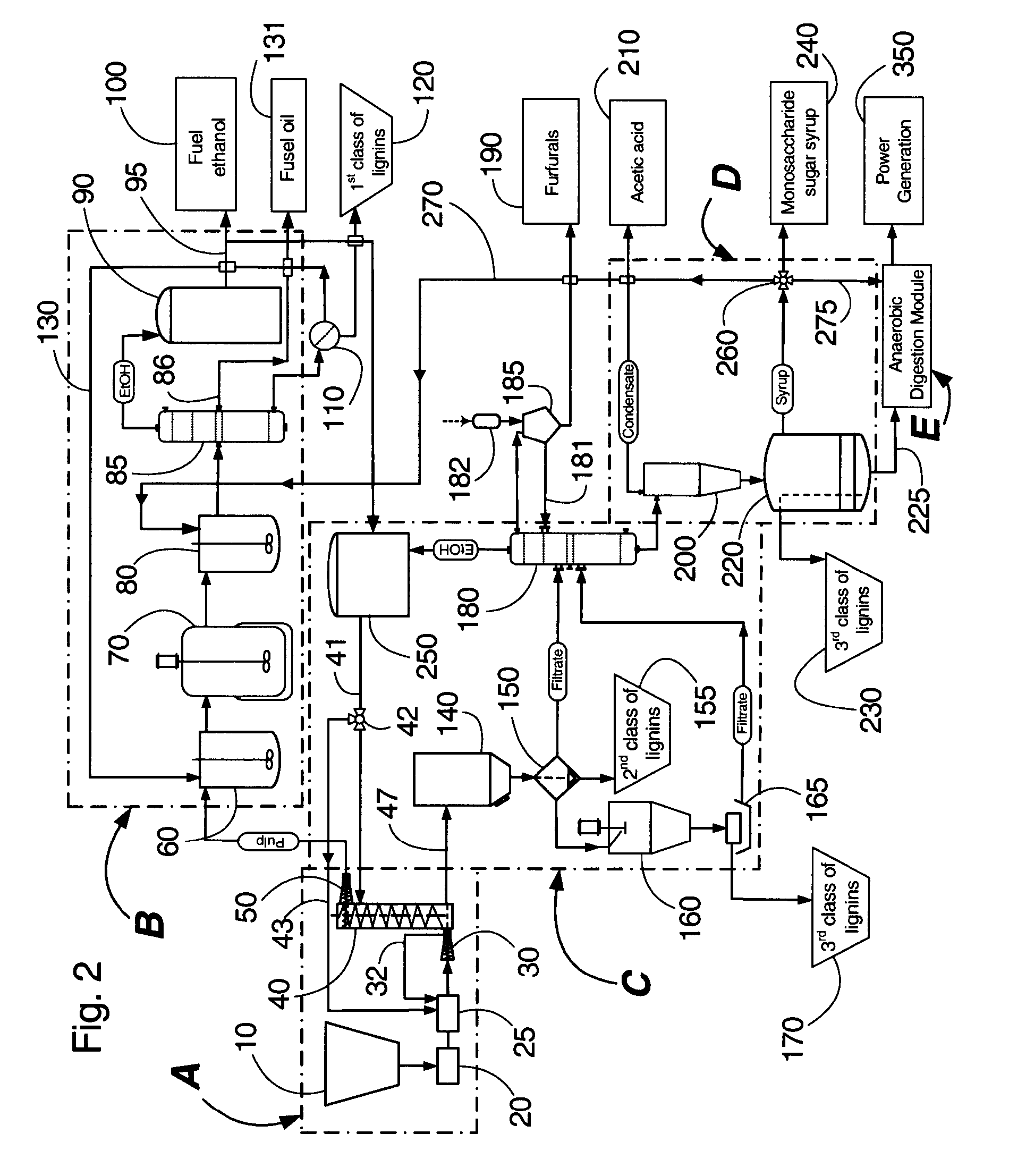

InactiveUS20110236946A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholSemi solid

A process for concurrent production of lignins, fuel alcohol, and biogas from lignocellulosic feedstocks. The process comprises: (1) pretreating a lignocellulosic feedstock to produce a solubilised liquid components stream comprising lignins, lignin-derived compounds, and a cellulosic pulp stream, (2) separating the liquid stream from the cellulosic pulp stream, (3) processing the liquid stream to separate and recover at least lignins, lignin-derived compounds, and semi-solid waste material, (b) processing the cellulosic pulp stream to saccharify and ferment the cellulose pulp to produce a beer which is then separated into fuel-grade alcohol and a waste stillage material, (4) anaerobically digesting the semi-solid waste material from the liquid stream and the waste stillage material to produce a biogas. The rate of anaerobic digestion can be manipulated by controllably supplying a portion of the monosaccharides produced from the cellulosic pulp. The cellulosic pulp stream may also be anaerobically digested.

Owner:LIGNOL INNOVATIONS

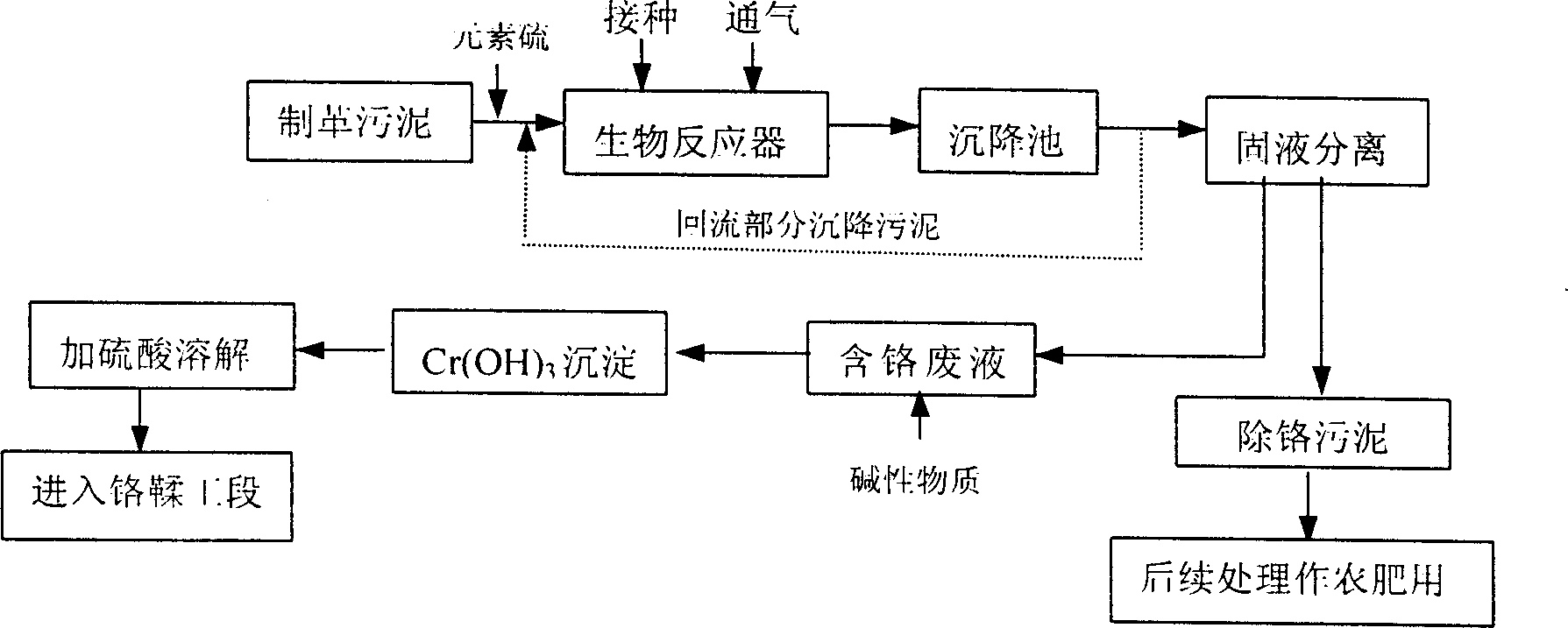

Thiobacillus thiooxidans and biological eliminating method of chromium in tanning sludge

InactiveCN1389564ALess value lossAchieve recyclingBacteriaSludge processingThiobacillus ferrooxidansSludge

The invention relates to sulfur oxide sulfur bacilli and biological eliminating method of chromium in tanning mud. Bacterial strain is named as TS6, preserve mark is CGMCCNO.0759. The method of eliminate chromium in tanning mud by above mentioned sulfur oxide sulfur bacilli is adding 1-3 g / L sulfur into tanning mud in biology reactor, inocualting 10-15% (v / v, the same below) TS6 bacteria strain, stirring, ventilating and subsiding; that 10-20% of subsiding mud backflow to reactor; dehydrating suprplus subsiding mud; adding basic material into liquid part to turn Cr3+ into Cr(OH)3 and subside, sediment is dissolved by sulfuric acid, then there is the tannage stage; solid part is neutralized to agriculture. The elimianting rate of Cr in mud is 95%-100%, reserving rate of nutrient in mud is above 80%.

Owner:周立祥 +1

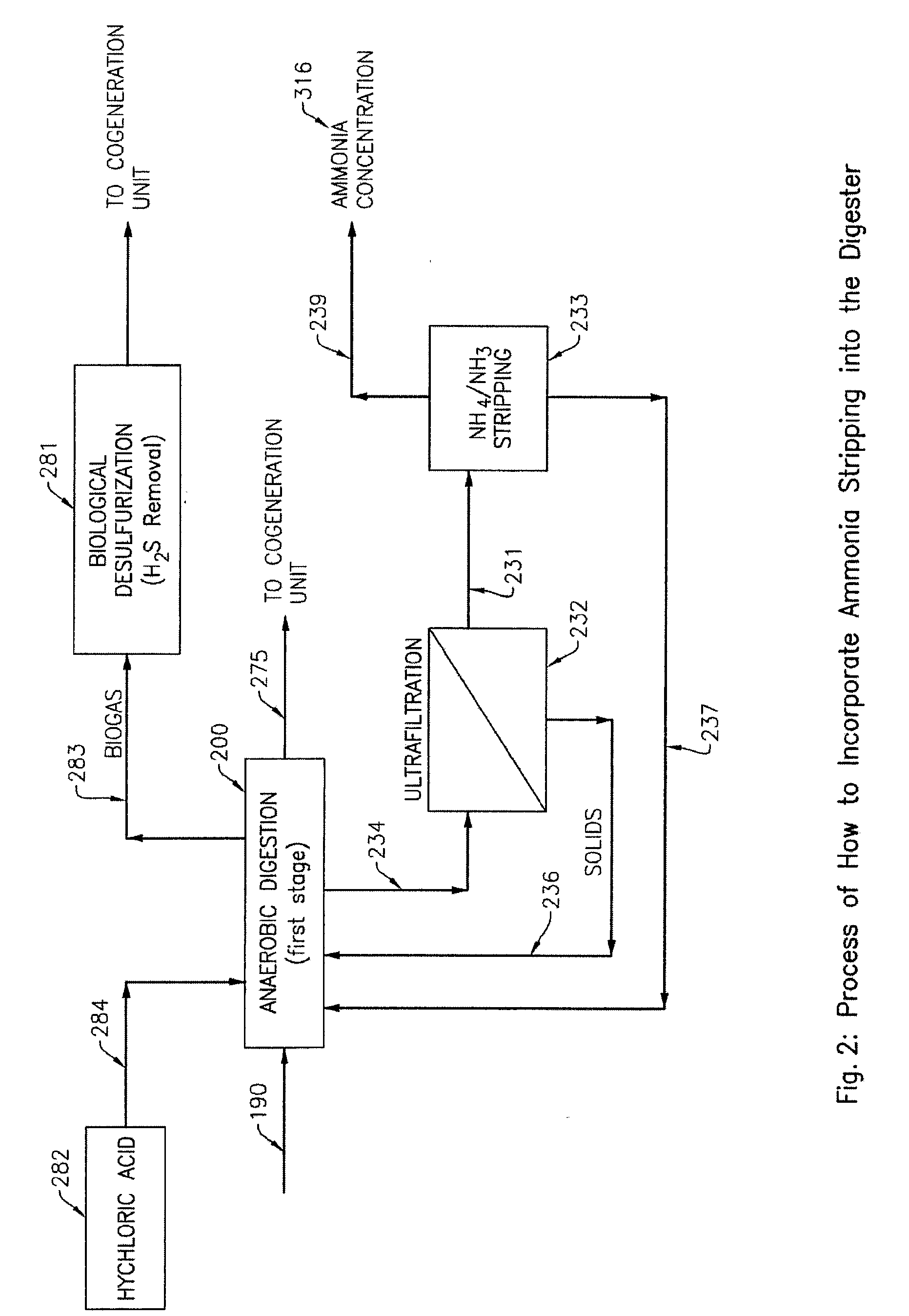

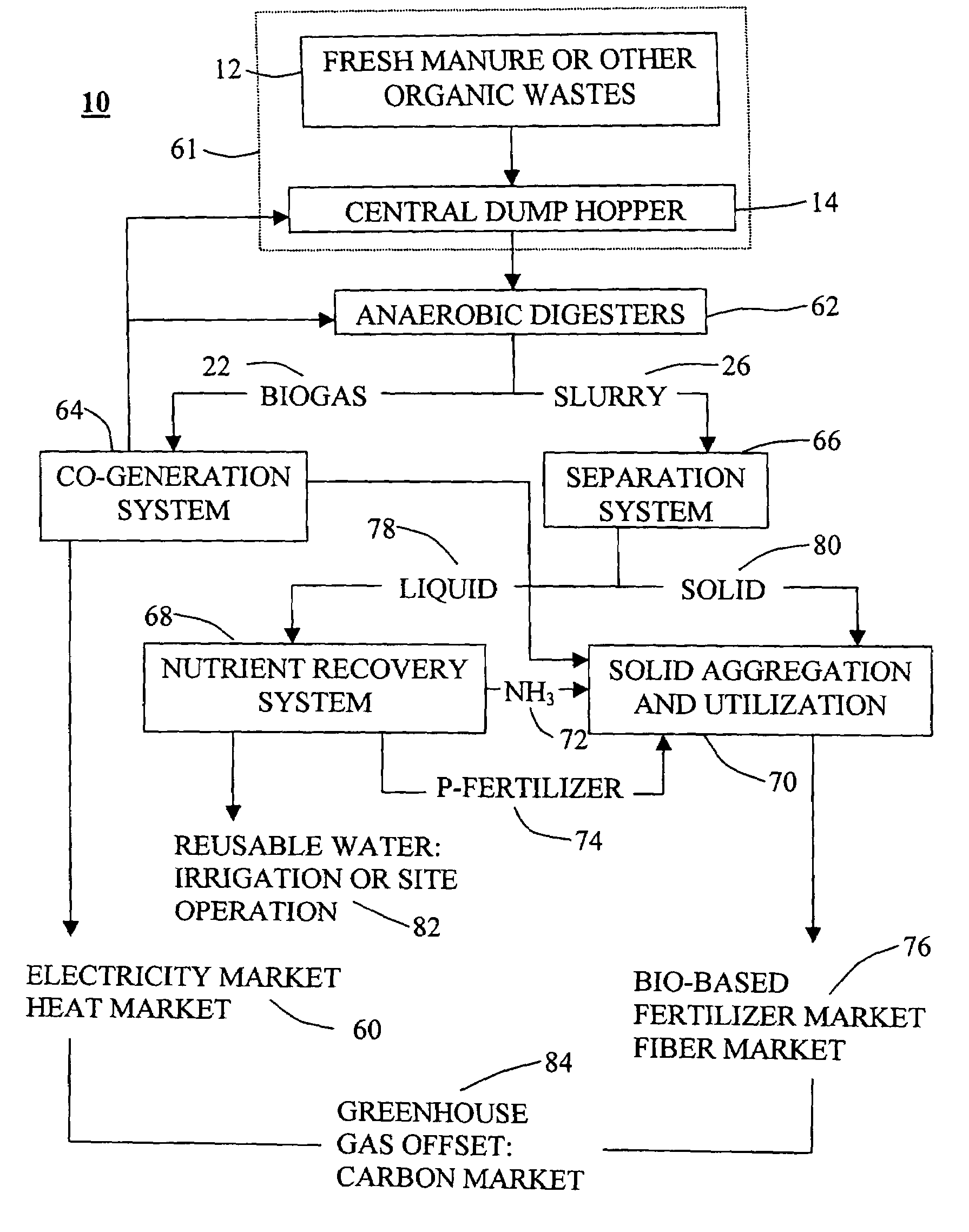

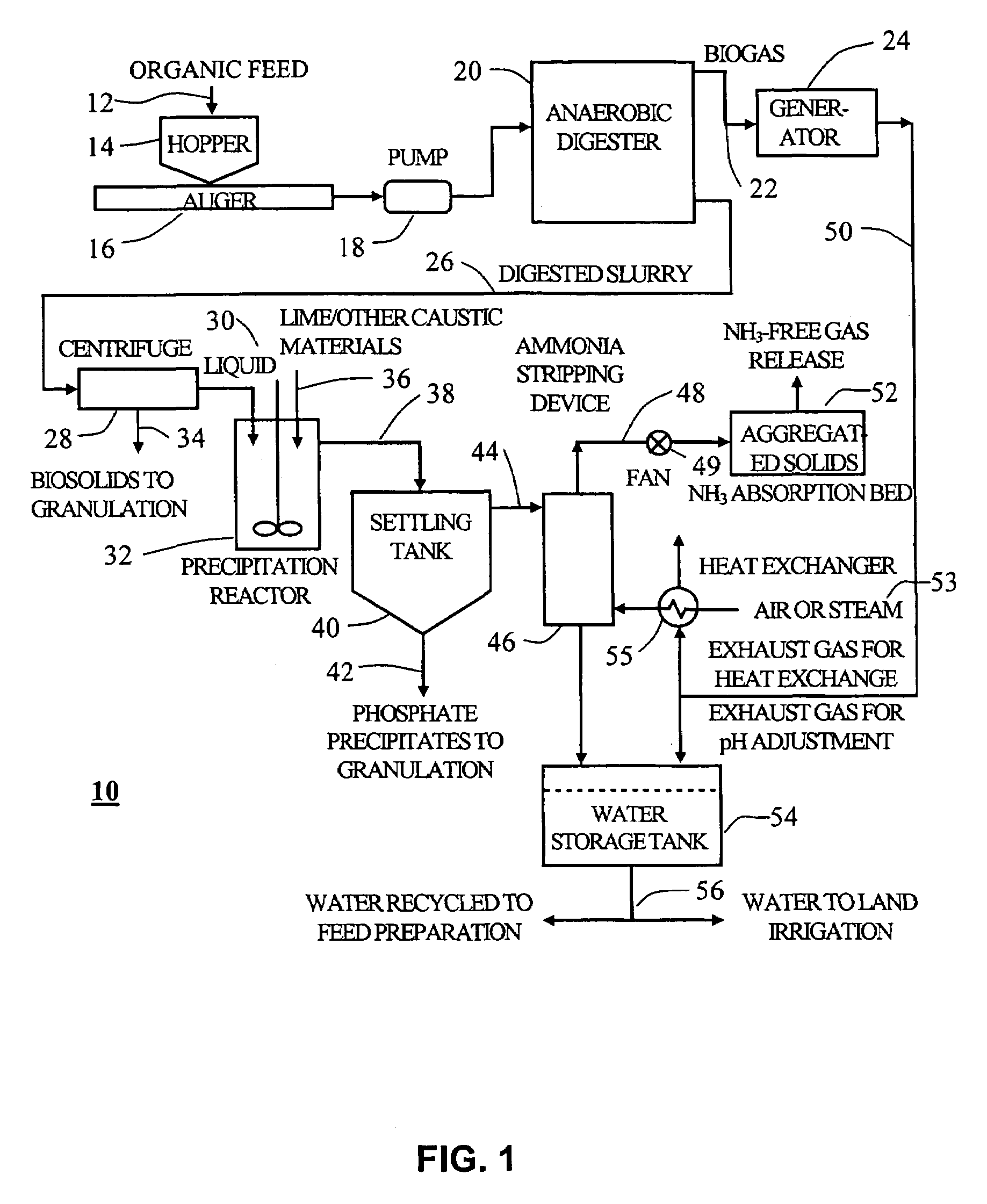

Process for removal and recovery of nutrients from digested manure or other organic wastes

InactiveUS7014768B2Eliminate the effects ofIncrease temperatureBioreactor/fermenter combinationsBio-organic fraction processingCogenerationNitrogen gas

A process for removal and recovery of nutrients and recycling of water from digested manure or other organic wastes. A first step involves separating waste from an anaerobic digester into digested liquids, digested solids, and biogas. A second step involves precipitating solids from the digested liquids. A third step involves stripping ammonia from the digested liquids. A fourth step involves injecting an exhaust stream of carbon dioxide drawn from the co-generator into the digested liquids to reduce the pH and raise the temperature of the digested liquid. A fifth step involves recycling the digested liquids back to the anaerobic digester for use in diluting in coming solid wastes. A sixth step involves passing the excess ammonia stripped from the digested liquid through the digested solids to recover nitrogen through aborption with the resultant digested solids being usable as a biofertilizer with a high nitrogen content. A seventh step involves capturing the biogas for use in a co-generation system.

Owner:HIGHMARK RENEWABLES RES PARTNERSHIP

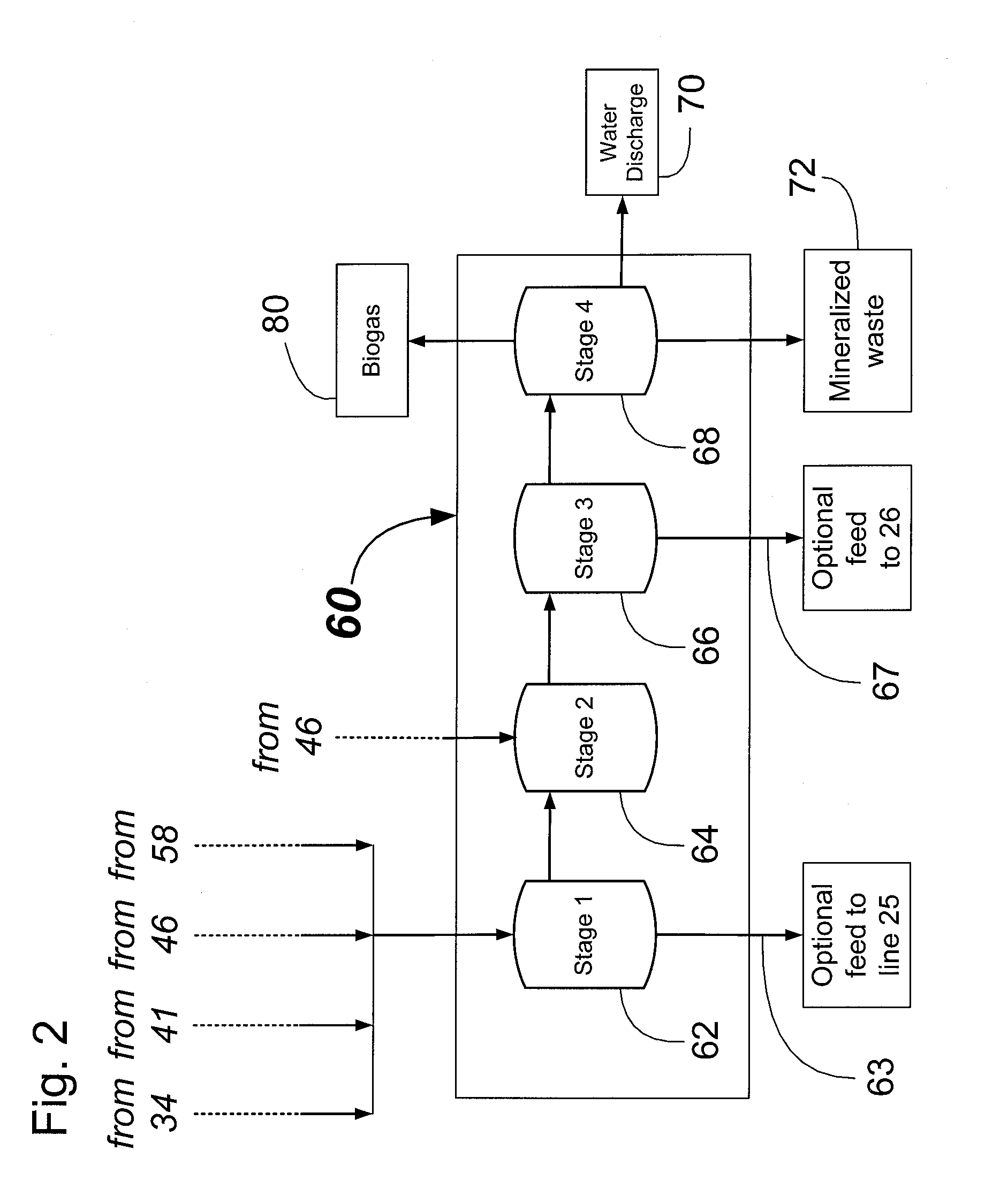

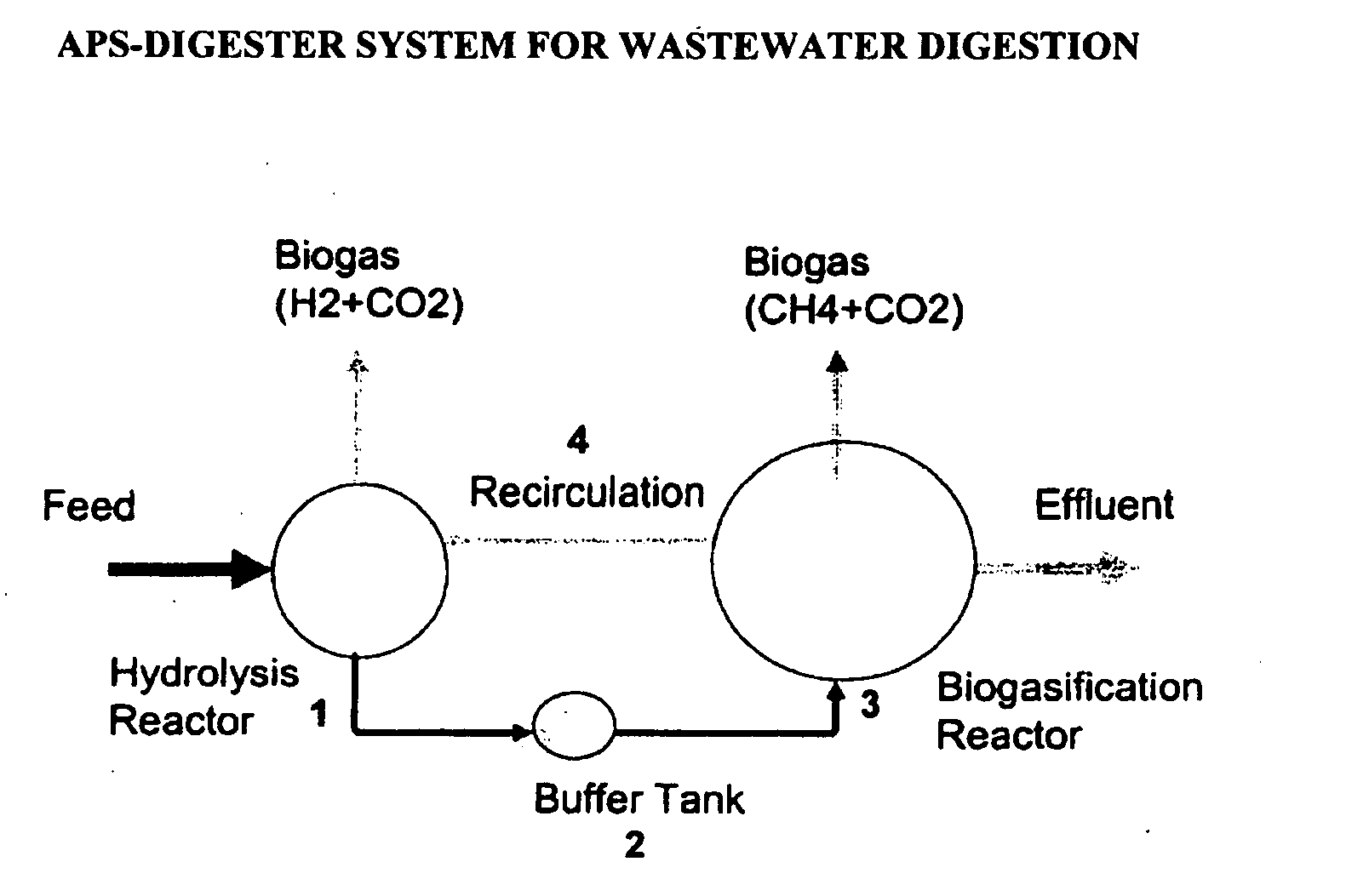

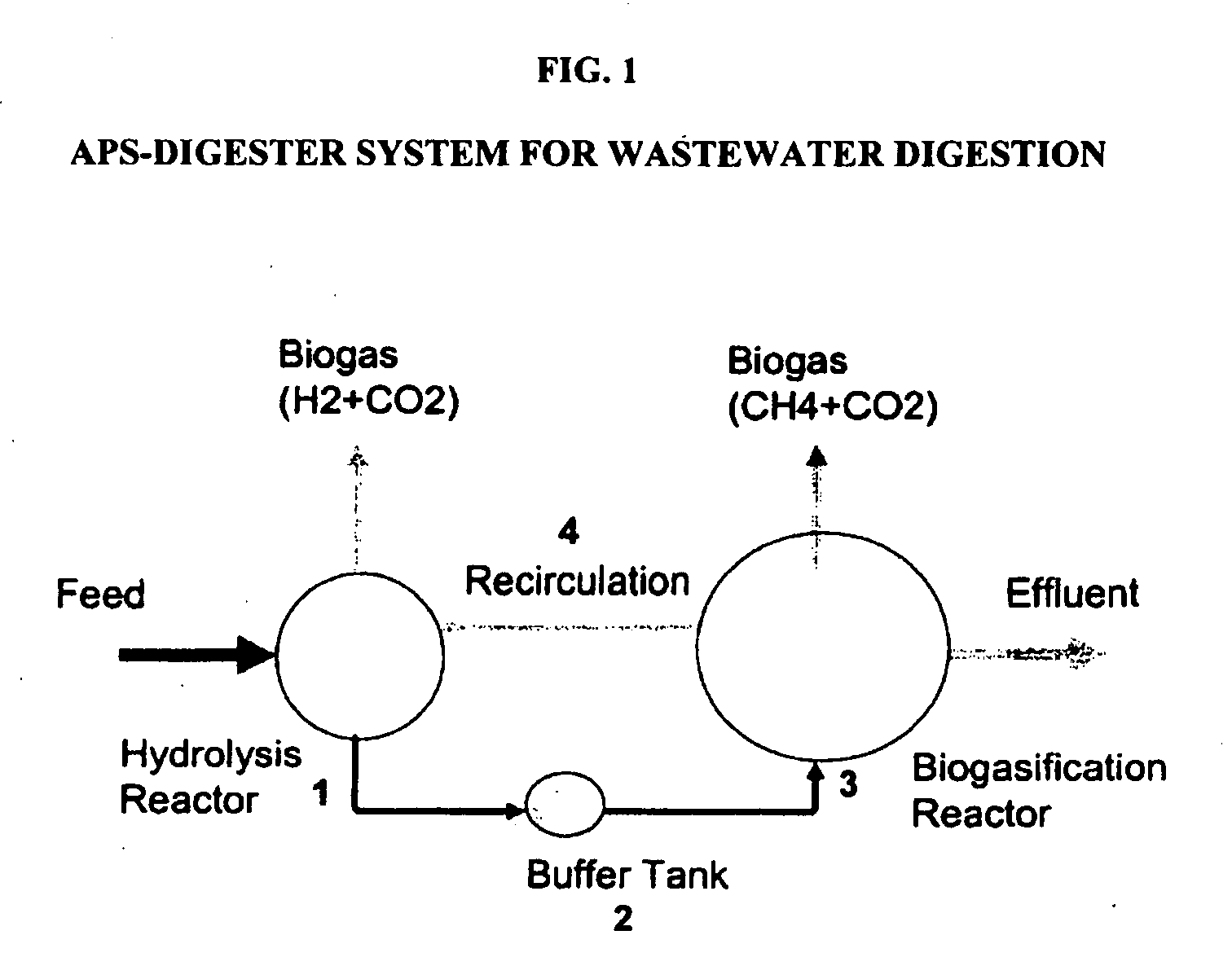

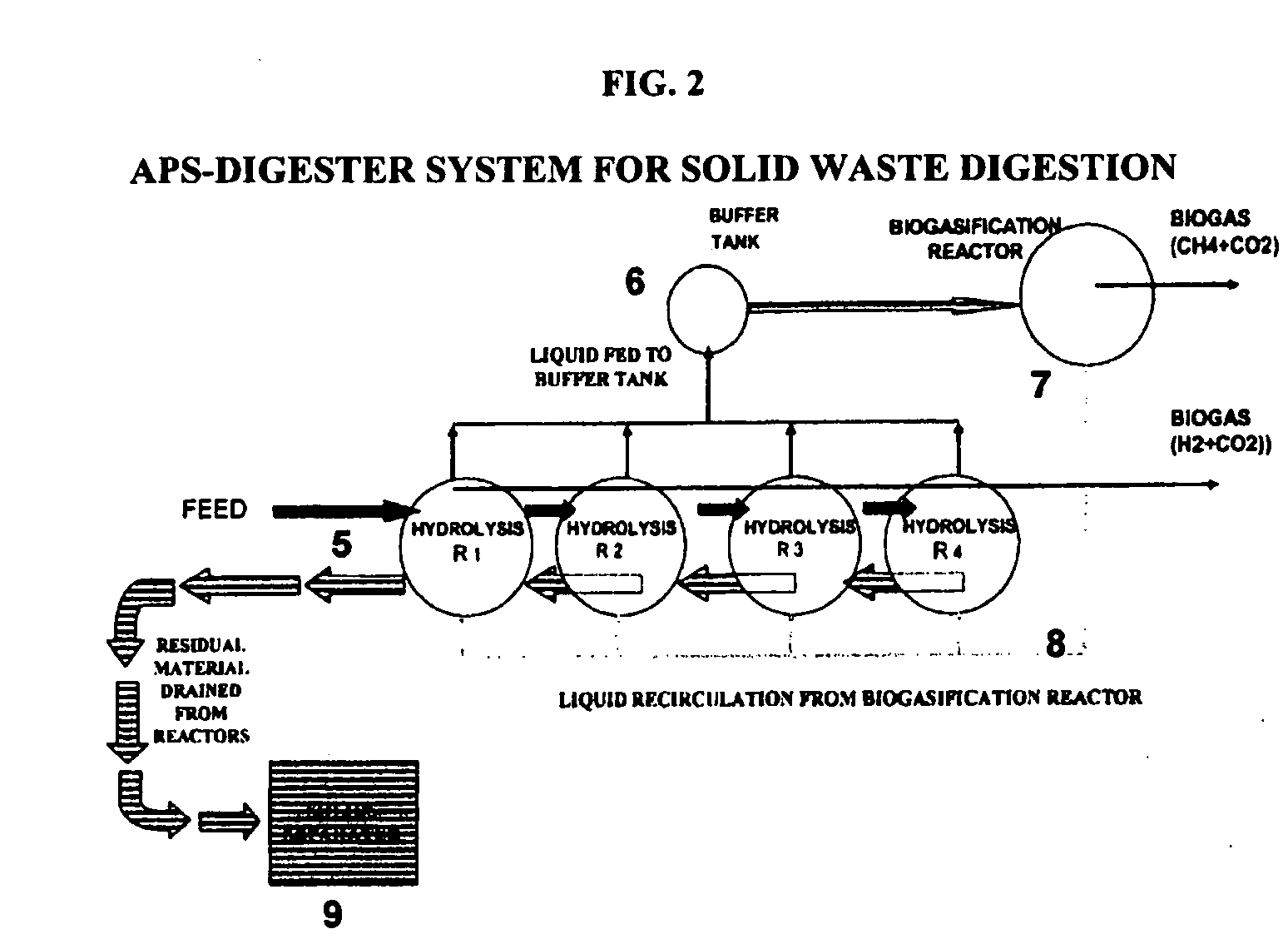

Anaerobic phased solids digester for biogas production from organic solid wastes

InactiveUS20070158264A1Improve energy conversion efficiencyLess air emissionLiquid degasificationBiological substance pretreatmentsHigh rateBuffer tank

The present invention provides methods for the generation of methane by a two phase anaerobic phase system (APS) digestion of organic substrates. Also provided is a device for practicing the methods of the invention. The APS-digester system is a space-efficient, high-rate solids digestion system. The APS-digester system consists of one or more hydrolysis reactors, a buffer tank and one biogasification reactor.

Owner:RGT UNIV OF CALIFORNIA

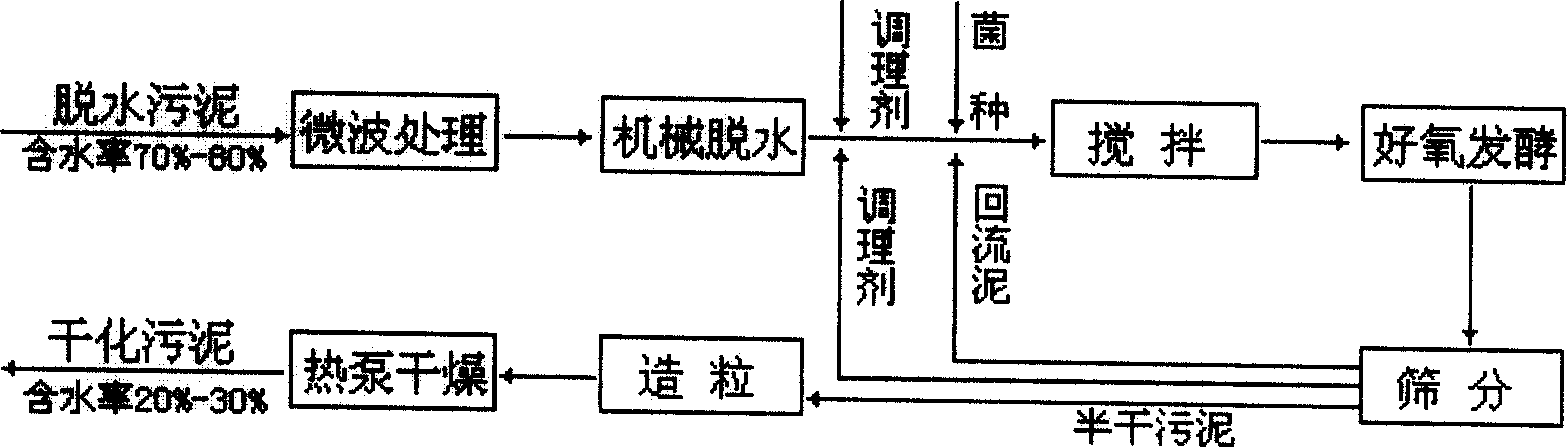

Sludge drying and resource disposal process

InactiveCN1762863AImprove processing efficiencyReduce energy consumptionSludge treatment by de-watering/drying/thickeningSolid waste disposalEutrophicationSludge

The present invention relates to environment protecting technology, and is especially one kind of sludge drying treatment process. The present invention is one low-cost combined sludge drying and utilizing process integrating microwave technology, aerobic fermentation technology and heat pump drying technology. The present invention is suitable for treatment of different kinds of sludge, and the sludge product has wide applications, including use as organic fertilizer, use as the material for composite organic fertilizer and building material, use as fuel for incinerating garbage and heating boiler, etc.

Owner:吴为中 +1

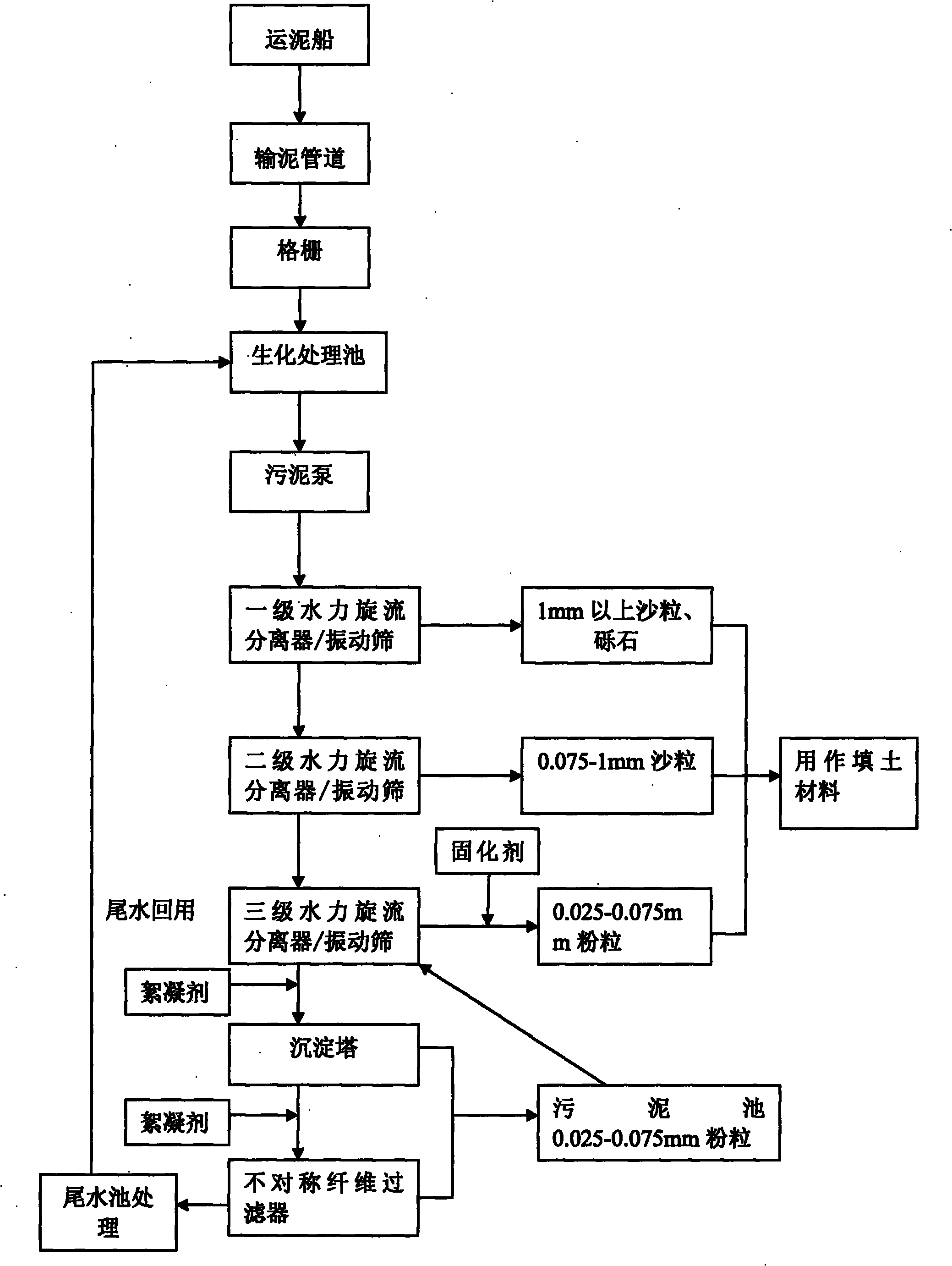

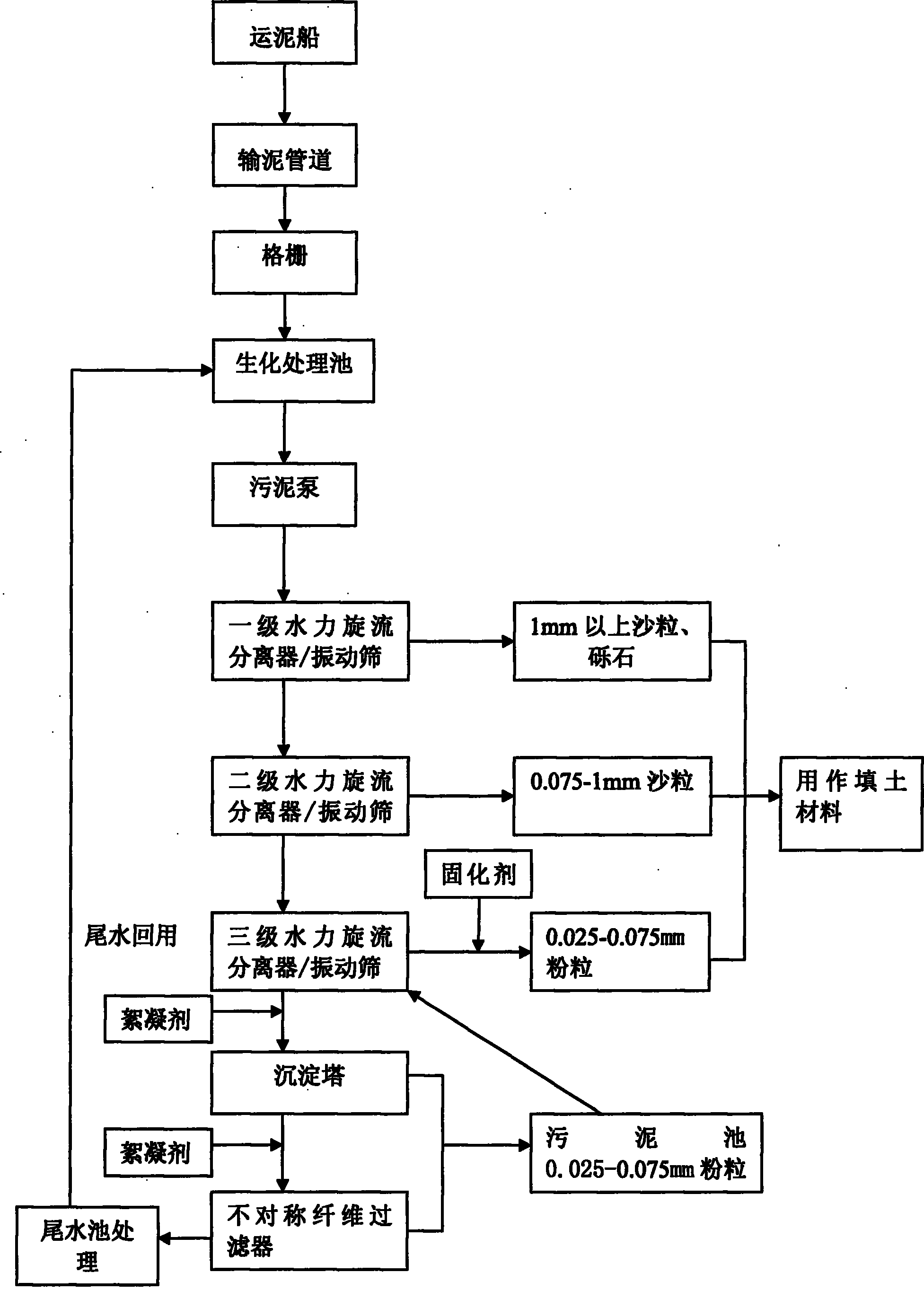

River surge silt harmless and recycling treatment method

InactiveCN101870546ALower redox potentialSmooth processSludge treatment by de-watering/drying/thickeningSolid waste managementFiberResource utilization

The invention provides a river surge silt d harmless and recycling treatment method. In the method, a dredger is utilized to suck silt, the silt is sent into a biochemical treatment pond from the ship through a silt transmission pipeline, compound enzyme is utilized to carry out bioremediation, gravels and sands with the particle size bigger than 1mm are filtered out by a primary hydrocyclone and a vibration screen, sands with the particle size of 0.075-1mm are filtered out by a secondary hydrocyclone and the vibration screen, powdery particles with the particle size of 0.025-0.075mm are filtered out by a third-level hydrocyclone and the vibration screen, powder particles are further separated out from outlet silt tail water through a sediment tower, sewage from the sediment tower is filtered by utilizing a fiber filter after flocculant is added into the sewage, and powdery particles are deposited from backflushing silt after being filtered by utilizing the sediment tower again, and the powdery particles are dehydrated by the third-level hydrocyclone and the vibration screen after entering a sludge pool and are cured by a curing agent after dehydration. The method has high resource utilization ratio, meets the requirements for the environmental protection, particularly carries out stage treatment on the silt, lowers the cost and enhances the efficiency.

Owner:GUANGZHOU BAOMINGLAI ENVIRONMENT SCI & TECH

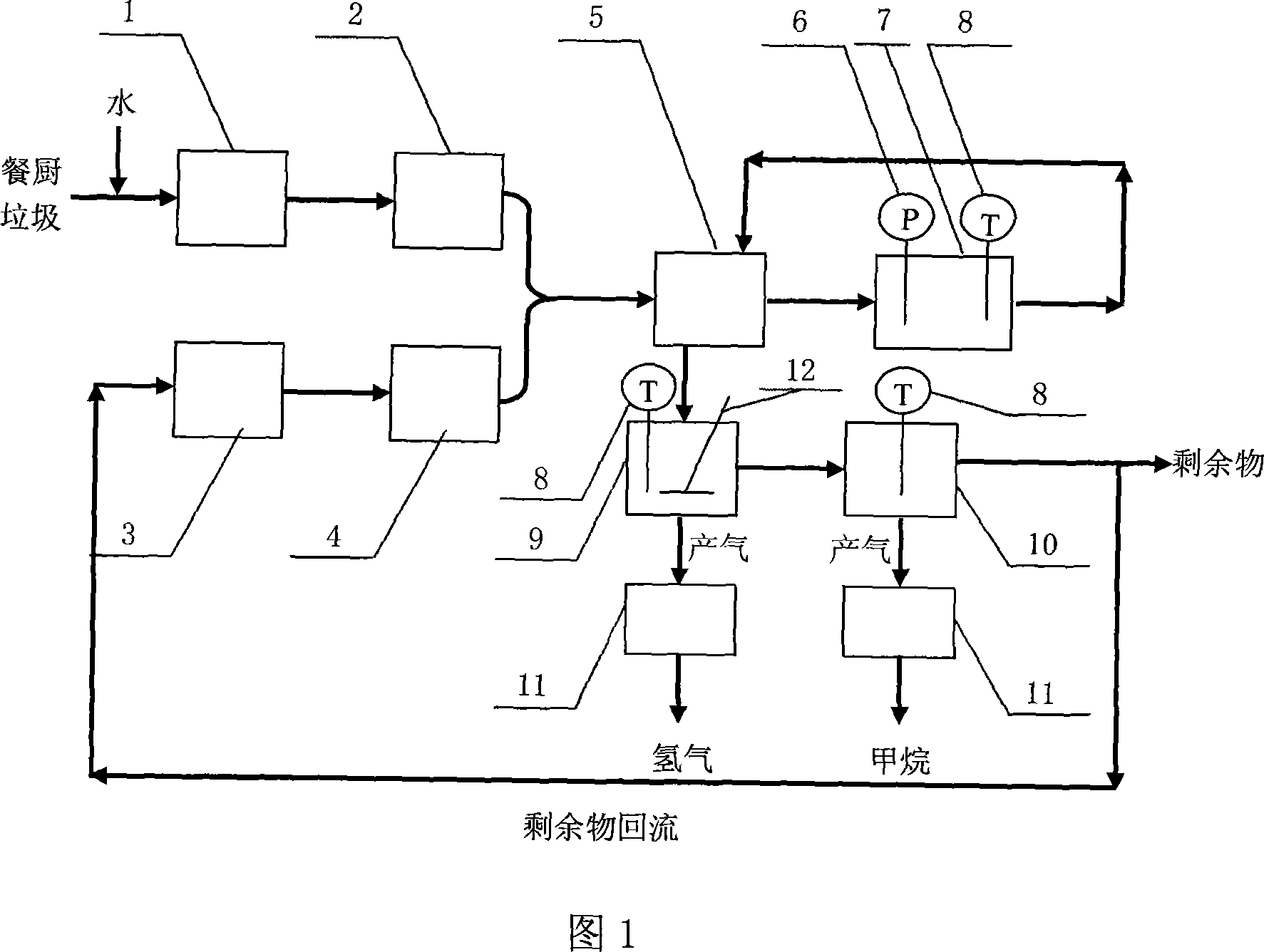

Method for producing hydrogen and methane by kitchen waste diphasic anaerobic fermentation

InactiveCN101134684APH controlLow running costBio-organic fraction processingClimate change adaptationHydrogenSludge

The biphase anaerobic fermentation process of kitchen refuse to produce hydrogen and methane includes the following steps: 1. sorting kitchen refuse and mixing with water in certain amount; 2. mixing with sludge from sewage treating yard and heat treatment; 3. heat exchange between heat treated mixture and mixture without through heat treatment; 4. anaerobic fermentation of the heat treated mixture in the first phase to produce hydrogen; 5. anaerobic fermentation of the residue from the first phase fermentation in the second phase to produce methane; and 6. using the residue from the second phase fermentation as fertilizer or returning to replace sludge serving as hydrogen producing bacteria source. The process is simple, can recover the biomass energy from kitchen refuse effectively, and has no secondary pollution.

Owner:DONGGUAN KECHUANG FUTURE ENERGY SOURCE TECHDEV

Ecological restoration and purification method for landscape water environment

InactiveCN104803570ARestore natural ecologyNo pollution in the processWater resource protectionSludge processingAquatic ecosystemPurification methods

The invention discloses an ecological restoration and purification method for landscape water environment which is characterized by comprising the following steps of (1) performing bottom mud sterilization and activation treatment; (2) splashing a microbial flora compound preparation; (3) reconstructing a submerged communities; (4) repairing an aquatic ecosystem food chain; and (5) performing aquatic ecosystem conservation management. According to the ecological restoration and purification method for the landscape water environment, a biological integrated control technology is applied, and the water purification effect is achieved by use of submerged plants; furthermore, decomposers, namely microorganisms in an ecosystem are fully utilized, and multiple types of aquatic animals are put in the aquatic ecosystem, so that the ecosystem food chain is perfected, various aquatic species promote and restrict one another, the whole riverway, lake, pond and wetland system is kept in dynamic balance for a long time, the original self-purification capability of the aquatic ecosystem is restored, and a long-term stable effect is achieved.

Owner:佛山五色时空生态环境科技有限公司

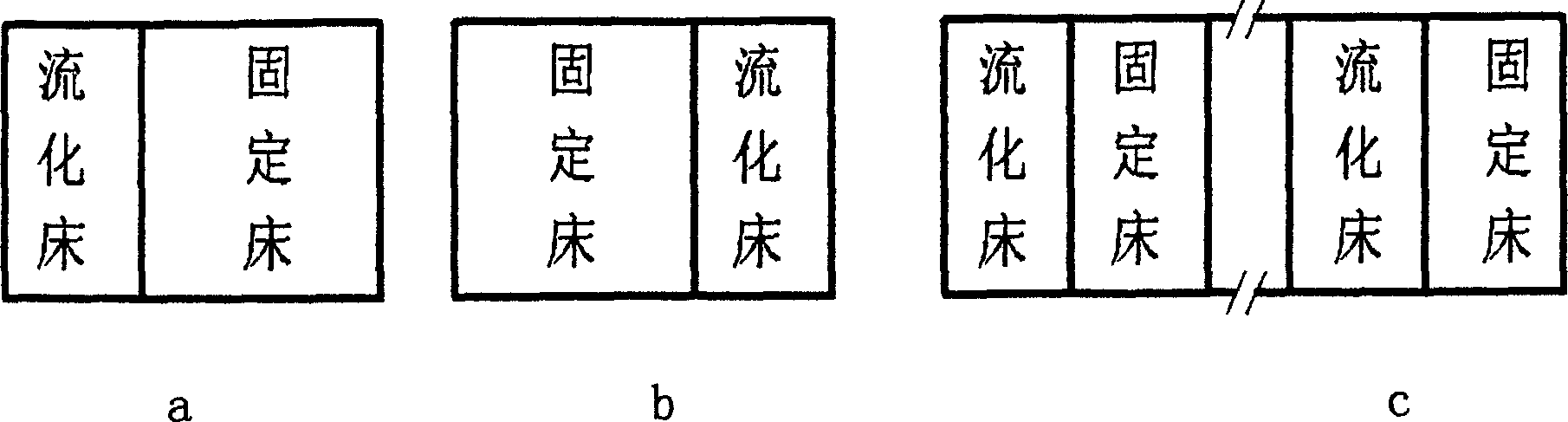

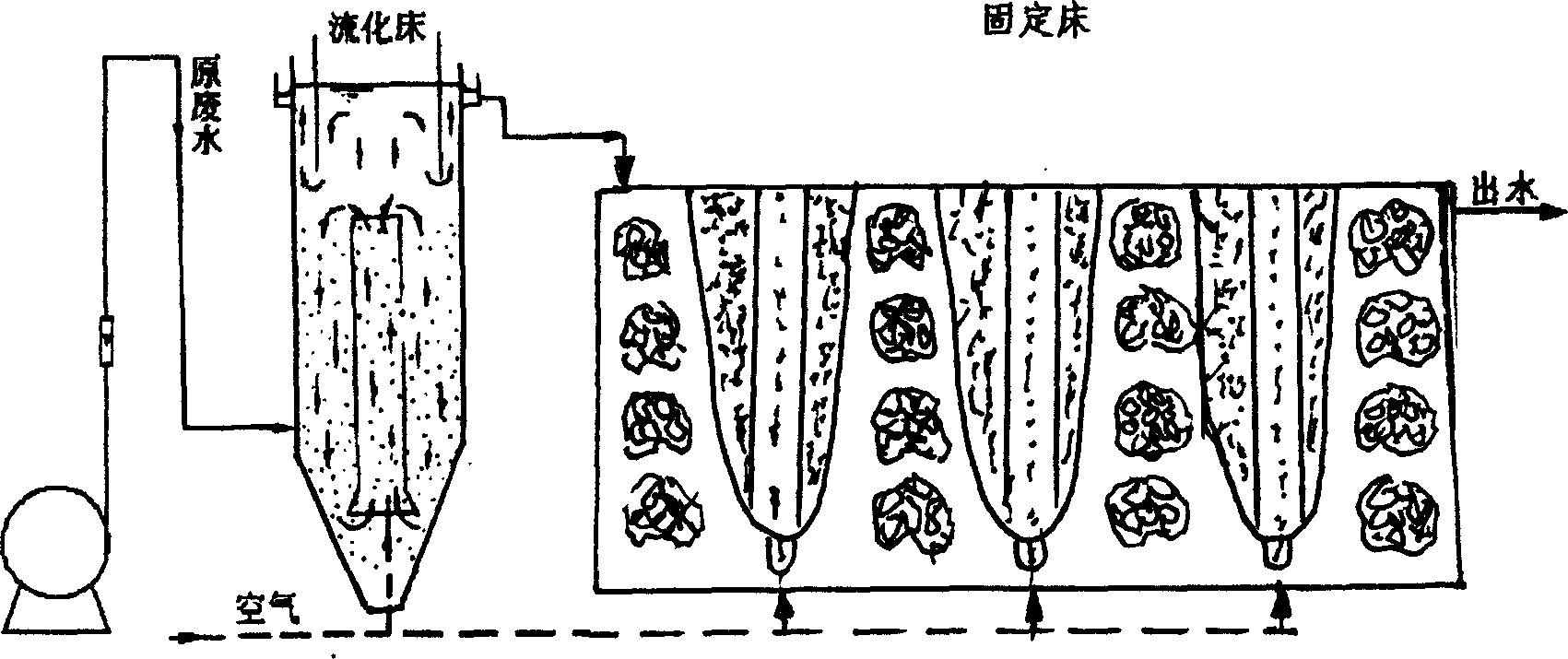

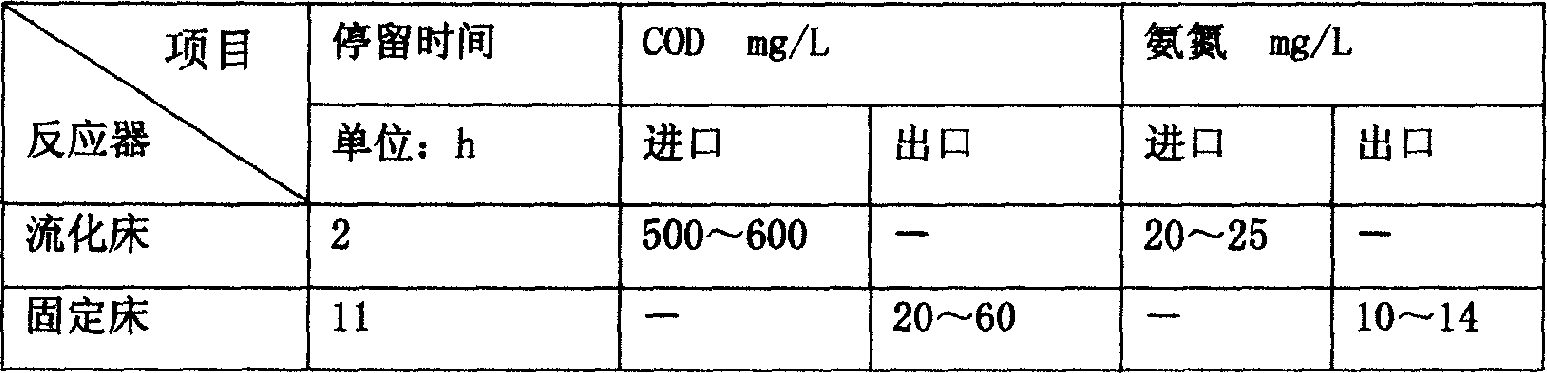

Process for treating waste water by aerobic-anaerobic microbic repeated coupling

ActiveCN1554599AEfficient removalAchieve decompositionSludge processingTreatment with aerobic and anaerobic processesSludgeDecomposition

The present invention belongs to the field of waste water treating technology, and is especially repeated aerobic-anaerobic microbe coupling process of treating waste water in environment protection. Biological fluidizing beds and biological fixed beds are connected serially with overflow partition boards and added with two different kinds of porous biological carriers. Via repeated aerobic-anaerobic microbe coupling in different layers, the present invention disposes organic matter and nitrogen compound in waste water while in-situ decomposing sludge. The present invention realizes the effective elimination of organic matter and nitrogen in waste water, the forced separation of the solid particles from water in the fixed beds and the digestion, degradation and final complete decomposition of solid matter. The present invention has high efficiency, low power consumption and low running cost.

Owner:TSINGHUA UNIV

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS20080295980A1Facilitate and enhance of fermentation and efficiencyFacilitate and enhance rateNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:LIGNOL INNOVATIONS

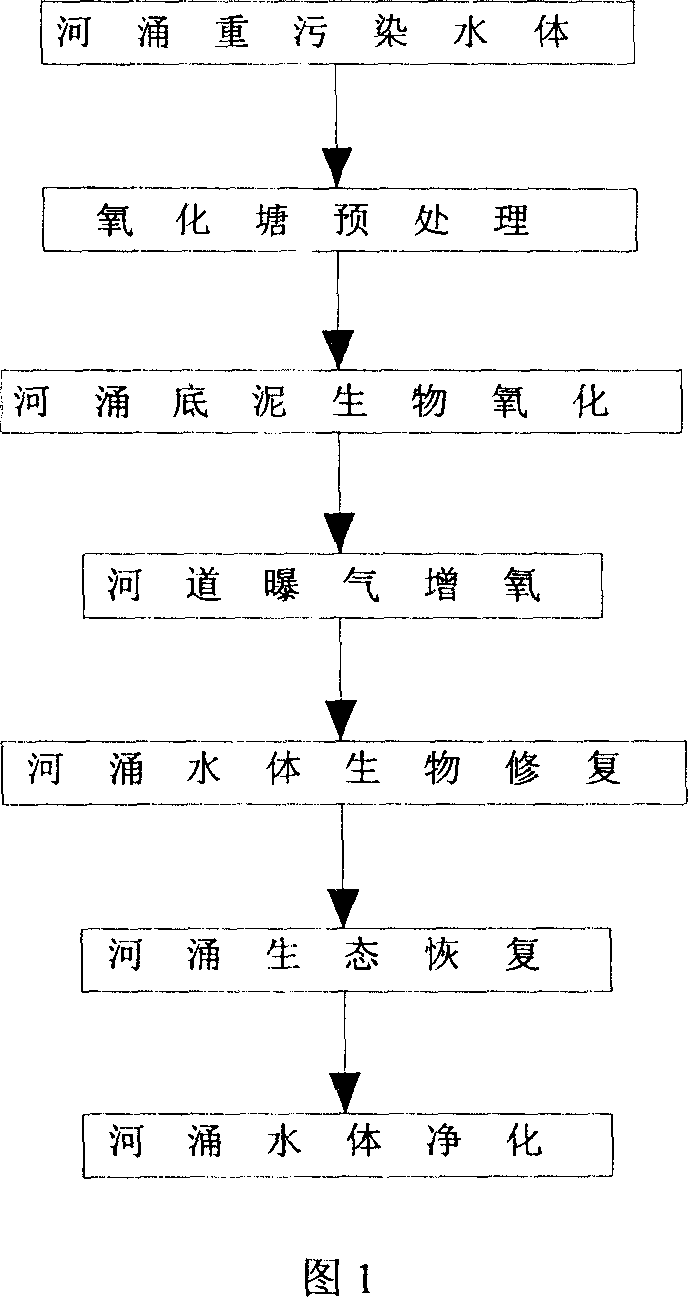

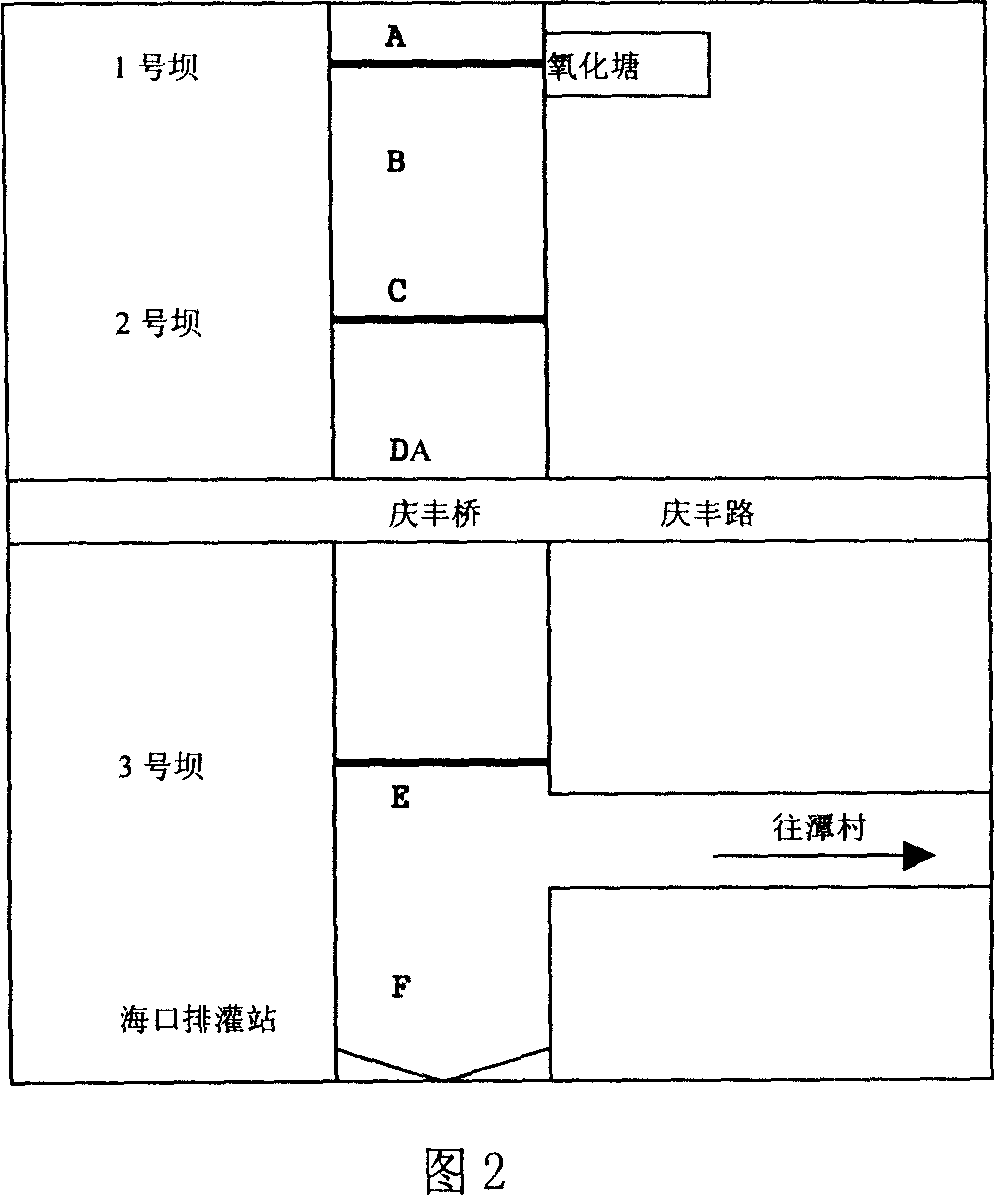

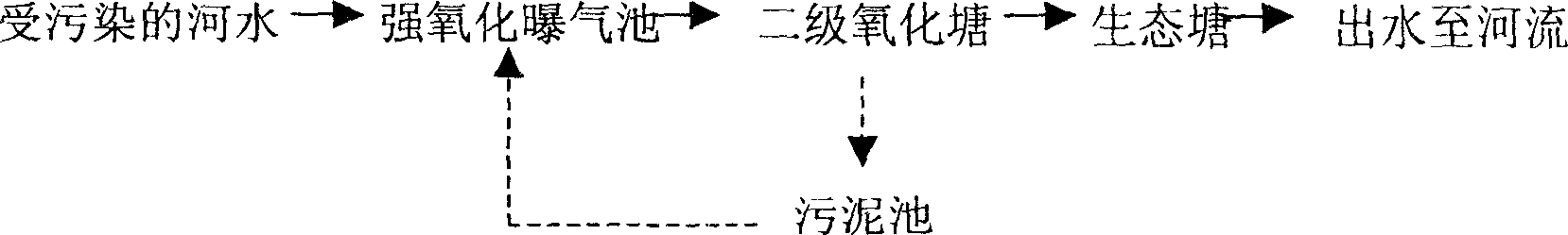

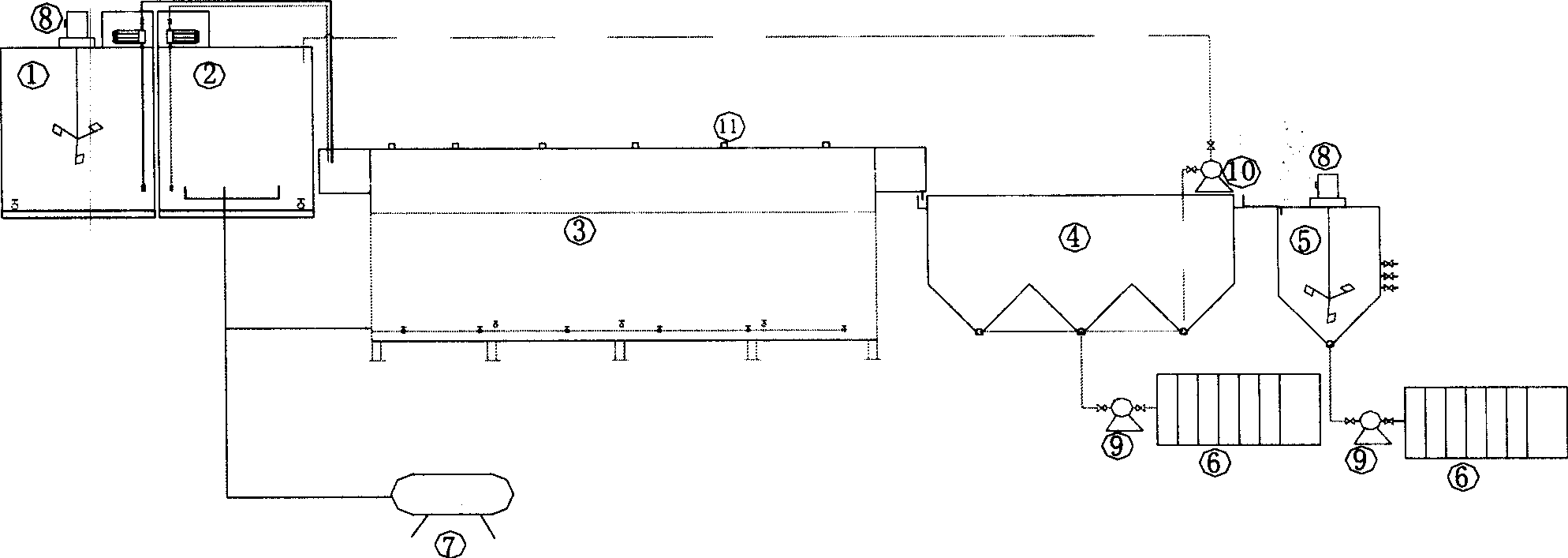

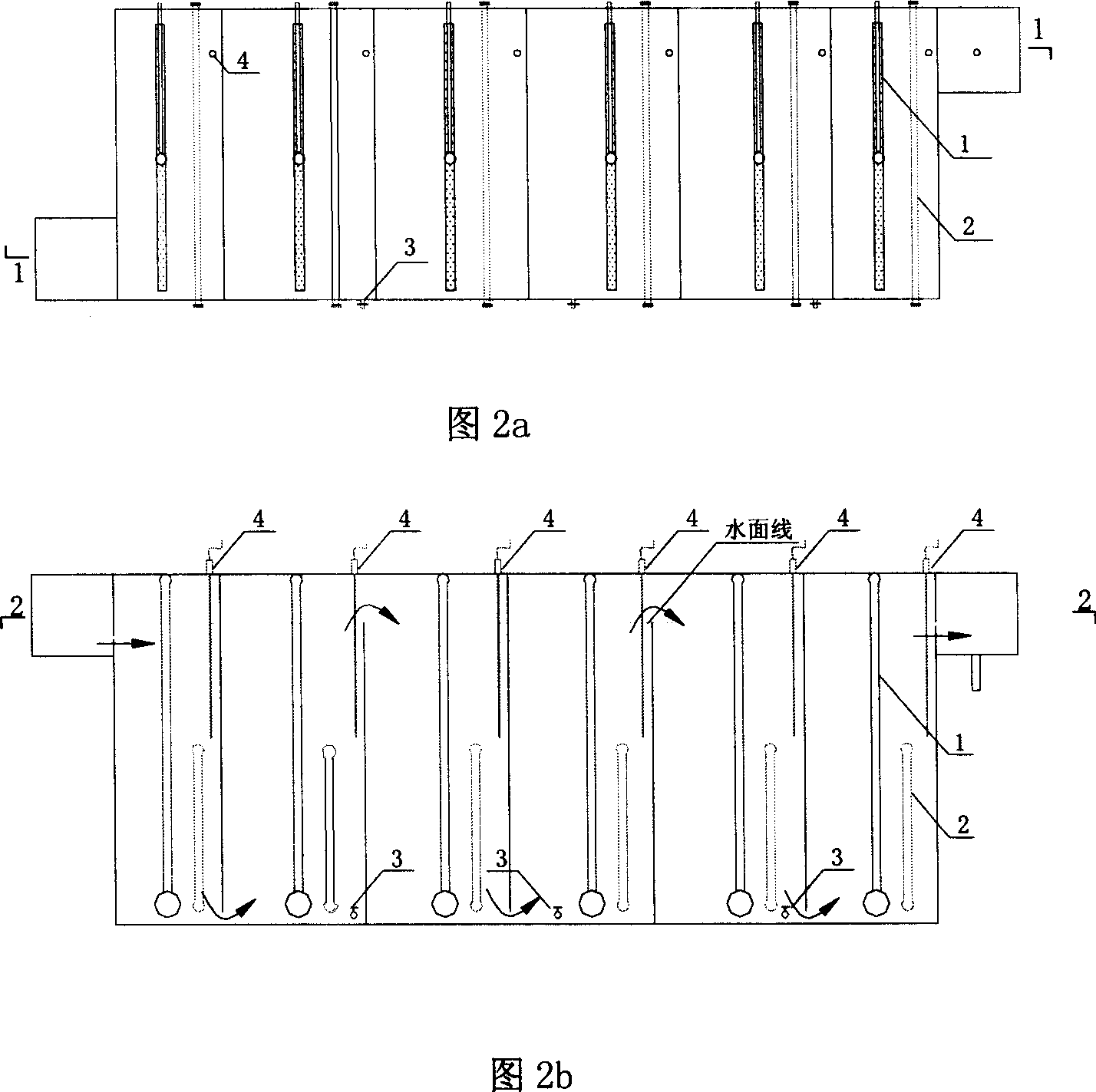

Method for governing pollution of river surge

InactiveCN101050041APurify waterEliminate black odorTreatment using aerobic processesSludge processingCombined methodWater quality

This invention provides a combined method for treating urban river surge with bioremediation as the major technique. The method comprises: pre-treating polluted water body of upstream urban river surge in an oxidation pool, performing biological oxidative remediation on bottom deposits in river, aerating river channel, performing bioremediation on middle reach water body, and performing ecological remediation on downstream water body. The method utilizes abandoned fishpond, vacant land or modified oxidation pool to perform pre-treatment on heavily polluted water body of urban river surge that cannot be treated by sewage interception. Then the method adopts biological oxidative remediation on bottom deposits to control internal pollution source of urban river surge, and artificial aeration, and biological-ecological remediation to effectively eliminate pollutants and odor of water body, improve water quality of urban river surge, and improve self-cleaning ability of urban river surge water body. The method is a feasible method in treating urban river surge.

Owner:国家环境保护总局华南环境科学研究所

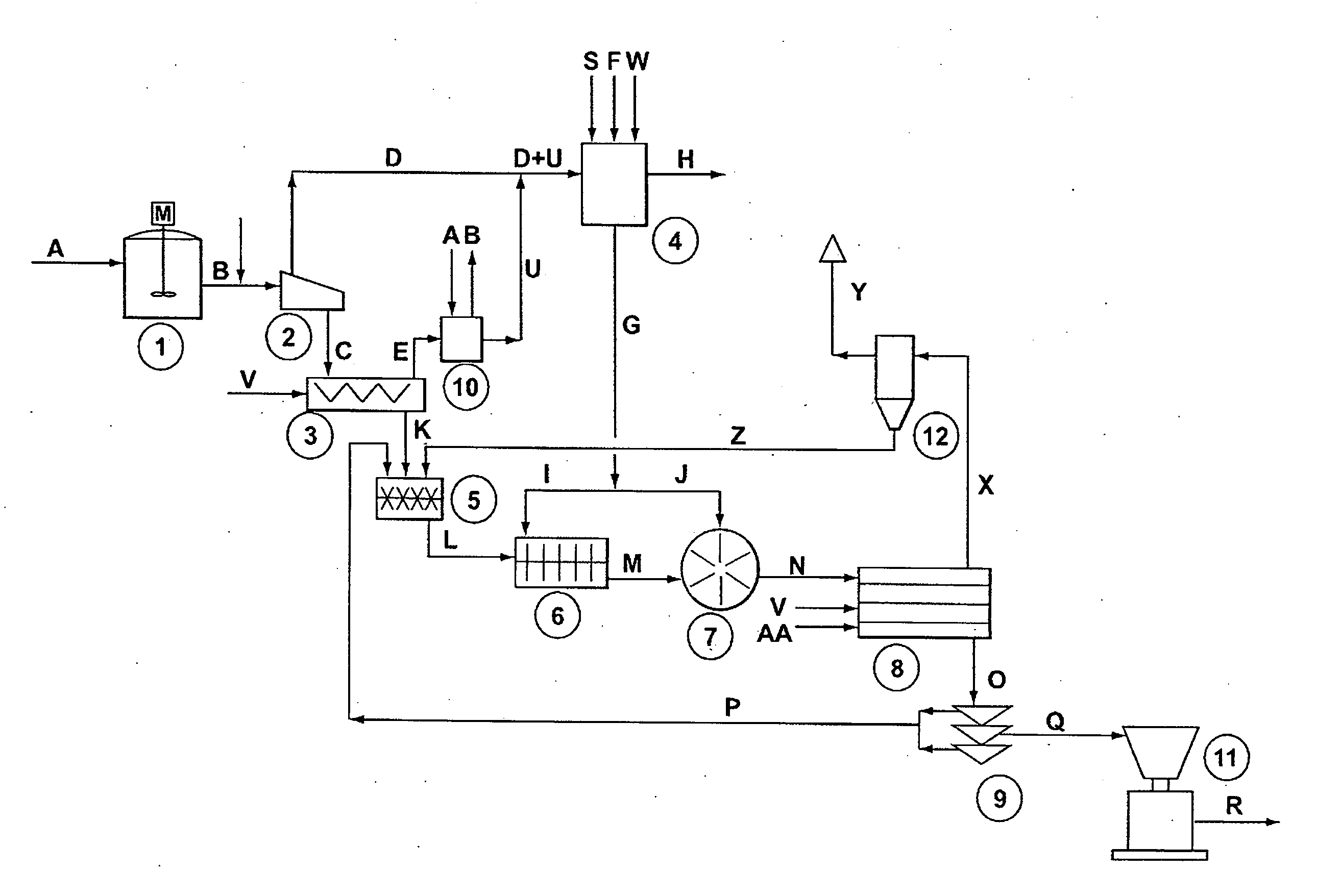

Plug flow type bioleaching process and apparatus for sludge treatment

InactiveCN101503269AStable productionLow investment costSludge treatment by de-watering/drying/thickeningSludge processingFluid phaseSludge

The invention provides a plug-flow type bioleaching treatment process for sludge treatment and equipment thereof. The equipment comprises a sludge regulating reservoir, an activating tank, a plug-flow type bioleaching reactor, an advection type sludge concentrated tank, a heavy metal recovery pond and other facilities, an aeration device, a heating device, a dehydration device, a stirring device and other devices. The process comprises the following steps that: a sludge system is acidified by a composite bacterium consisting of a thiobacillus and an acid resistant heterotrophic bacterium under conditions of aerobism and existence of sulfur powder and other composite nutriments, heavy metal in the sludge is massively dissolved in liquid phase, the sludge is regulated at the same time so as to facilitate sedimentation and dehydration; the sludge stays in the reactor for 2 to 4 days; discharged treated sludge enters the concentrated tank to be subjected to gravity thickening; 20 to 50 percent of concentrated bioleaching sludge flows back to the reactor, and the rest sludge is subjected to chamber filtration and dehydration without adding any flocculating agent until the water ratio is below 60 percent; and the heavy metal in the water is recycled by an alkali precipitation method. The method can remove massive heavy metals of the sludge, has over 99 percent of sludge pathogen kill ratio, and ensures that the treated sludge does not have malodor and is in khaki color, thereby realizing the aims of innoxiousness and minimization of the sludge.

Owner:NANJING AGRICULTURAL UNIVERSITY

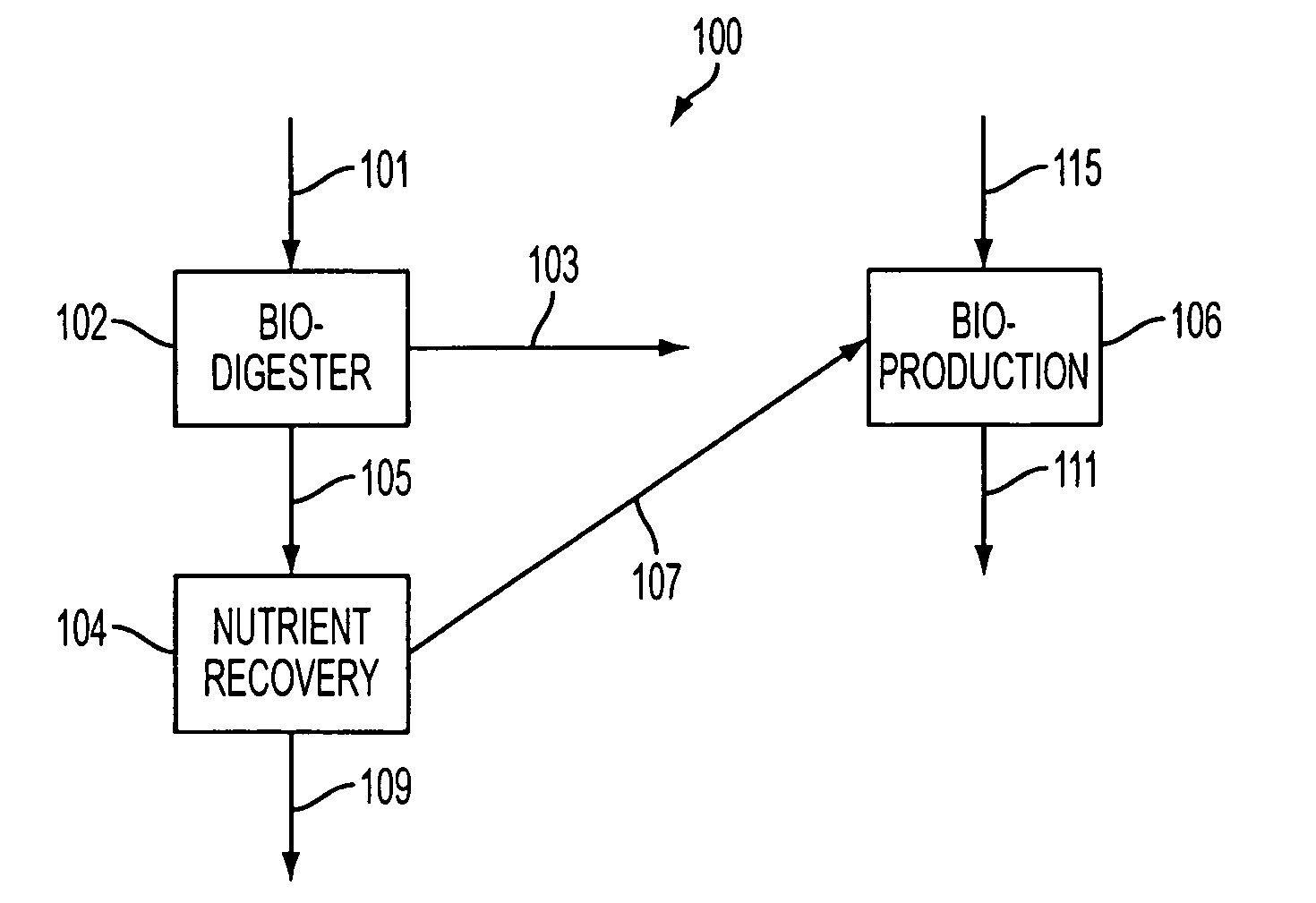

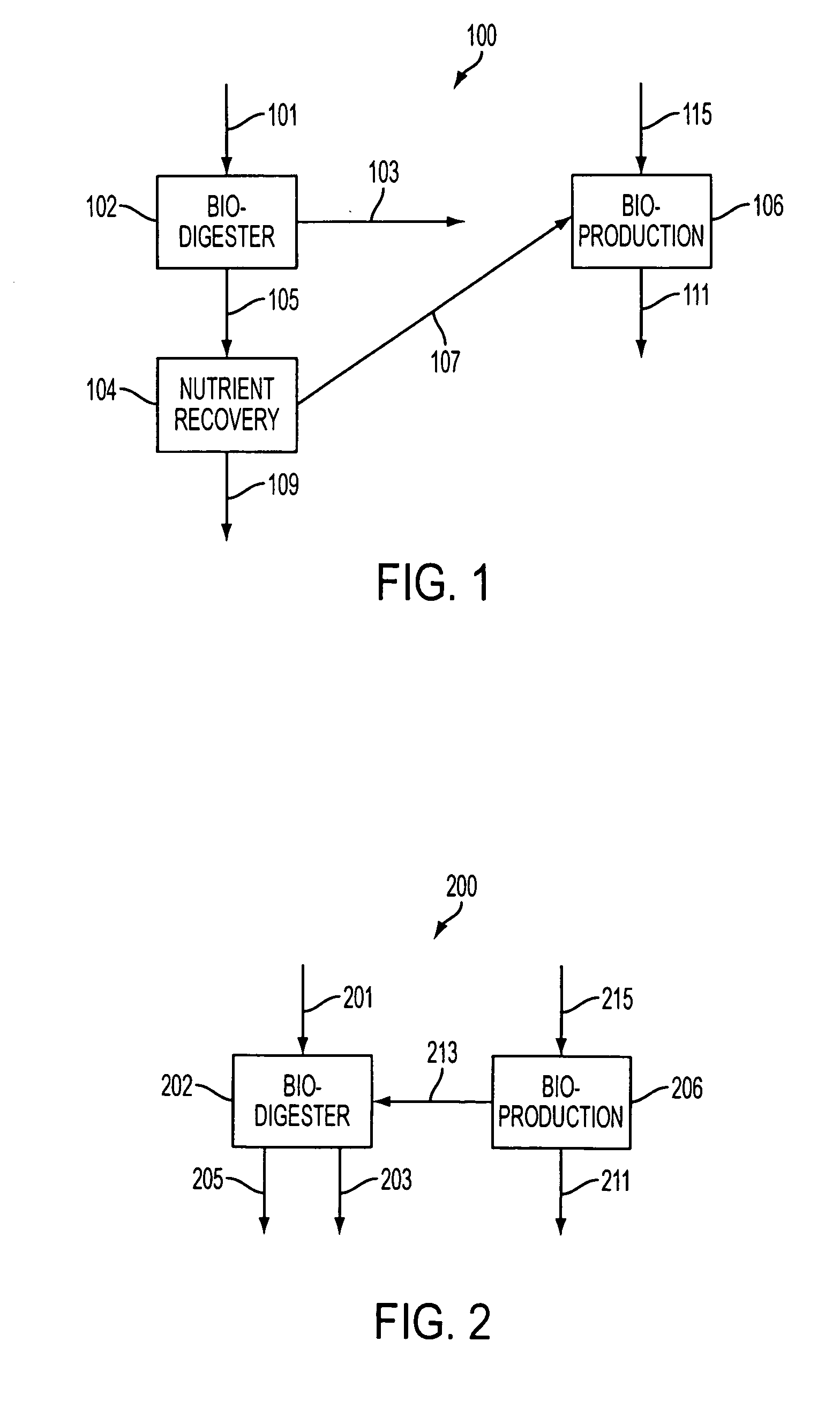

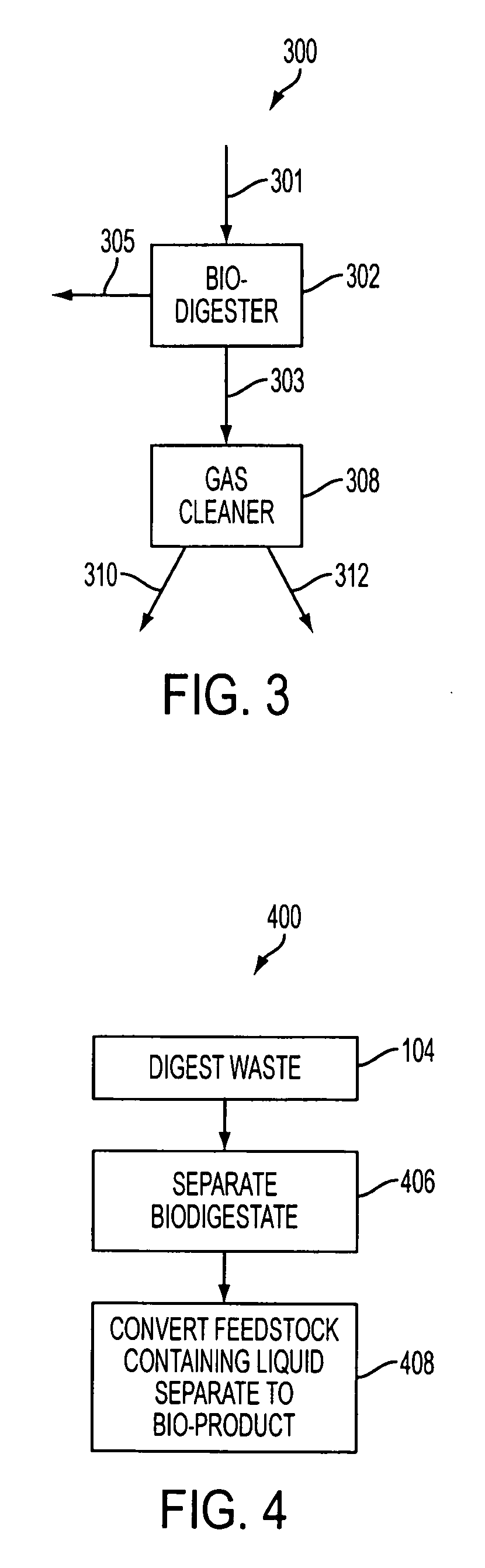

Integrated bio-digestion facility

InactiveUS20090250401A1Fatty acid esterificationAnimal corpse fertilisersEnvironmental engineeringDigestion

Methods and systems for processing organic waste material are provided. These methods and systems include integrating an anaerobic bio-digester and nutrient recovery module with a bio-production facility, which can locally provide feedstock for the bio-production facility, and can locally provide organic material for the anaerobic bio-digester. Methods and systems for integrating an anaerobic bio-digester with a gas cleaner are also provided, which can recover nutrients while cleaning the biogas produced by the anaerobic bio-digester.

Owner:HIGHMARK RENEWABLES RES PARTNERSHIP

Anaerobic process for treating organic material to generate biogas

InactiveUS20100078307A1Reduce volatile organic solidWater treatment compoundsWater contaminantsActive enzymeDigestion

The present invention provides an anaerobic digestion process for the treatment of organic waste materials, which process comprises a bacterial process that is carried out in the absence of oxygen and wherein said process comprises digestion, in which said waste is fermented in tanks at an elevated temperature, and wherein said process results in the production of biogas, which can be used in generators for electricity production and / or in boilers for heating purposes, the comprises treating an organic waste with a composition comprising a fermentation supernatant containing active enzymes from a Saccharomyces cerevisiae culture; and a non-ionic surfactant, wherein said nonionic surfactant may be selected from the group consisting of ethoxylated nonylphenol and ethoxylated octyl phenol.

Owner:NEOZYME INT

Prepn of microbial colony sludge for efficient treatment of sewage

InactiveCN1348987AComplex compositionStable structureMicroorganismsSludge processingMarshMicroorganism

This invention relates to a preparation method for microbial colony used for effectively treating urban living sewage and sewage sludge in river bend, lake, marsh enclosed or semi-enclosed water areas. The said method includes the following steps: collecting and culturing of engineering initial bacterial strain, enrich mixed culture of bacterial strain, acclimatized culture of engineering bacteria and expanding culture of acelimatized bacteria. It this invention found is from the microbial growth and metabolic mechanism a preparation method of microbial colony which can high-effectively and high-adaptively treat various sewage sludges.

Owner:重庆和润实业(集团)有限公司

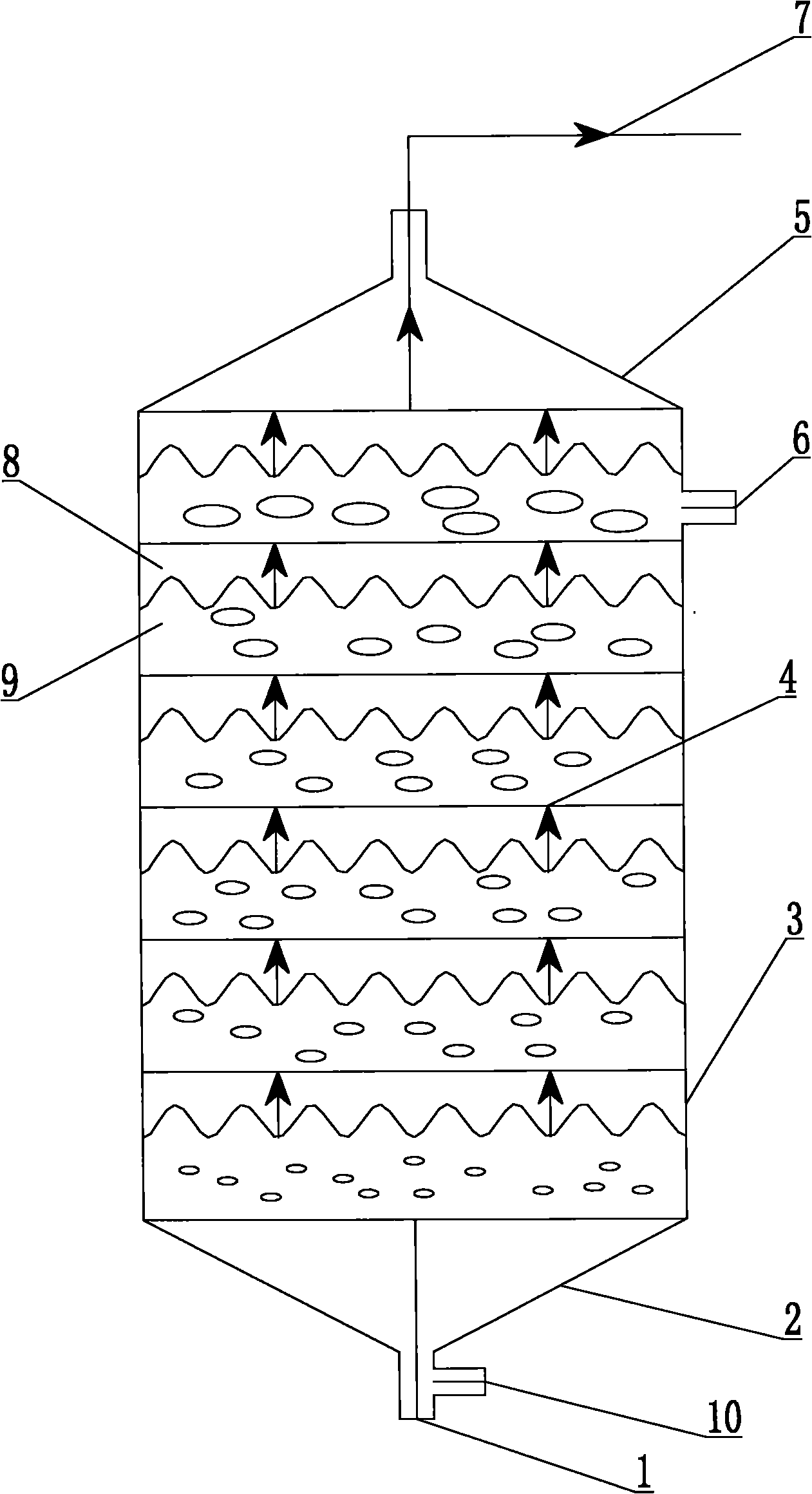

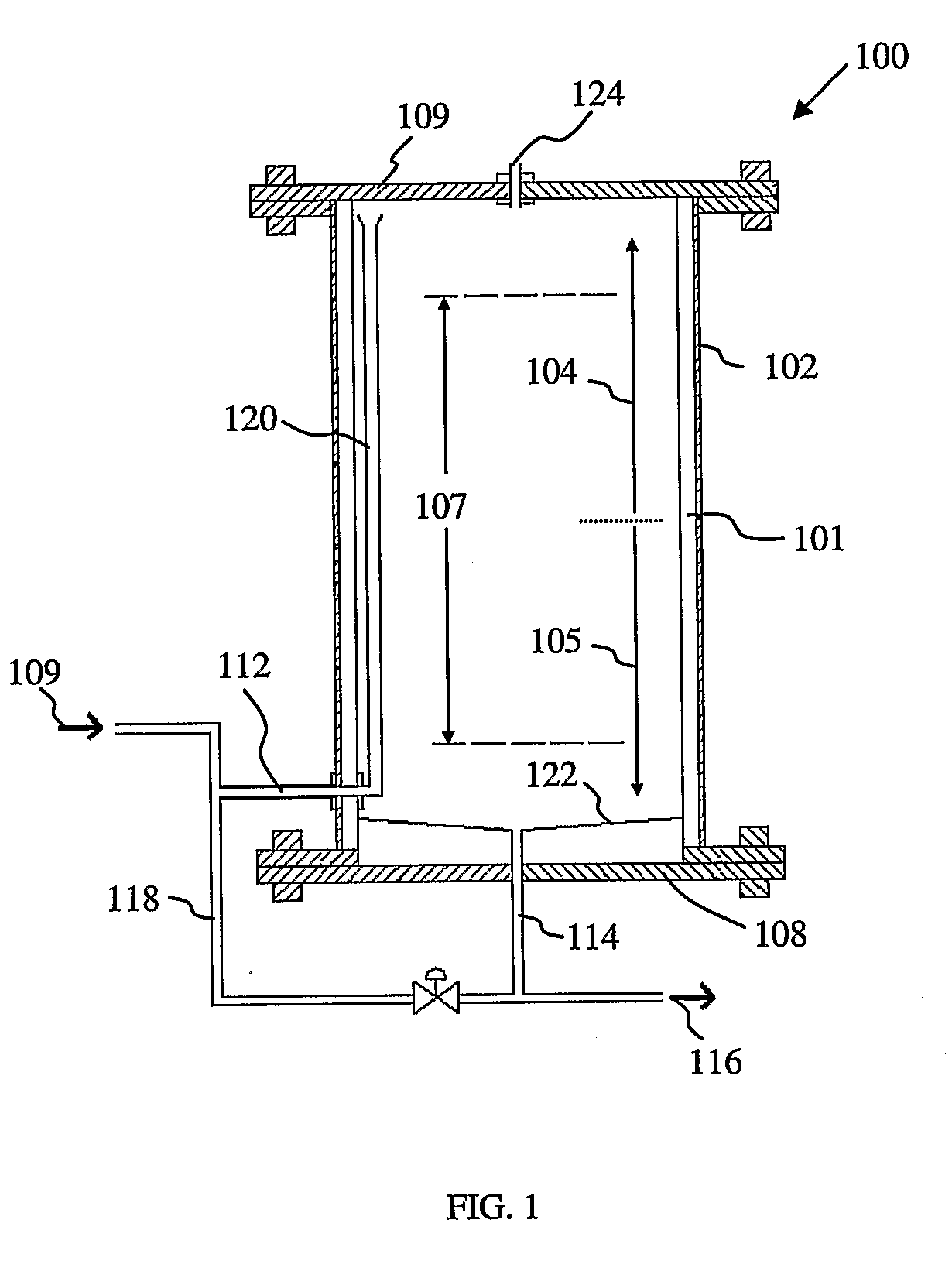

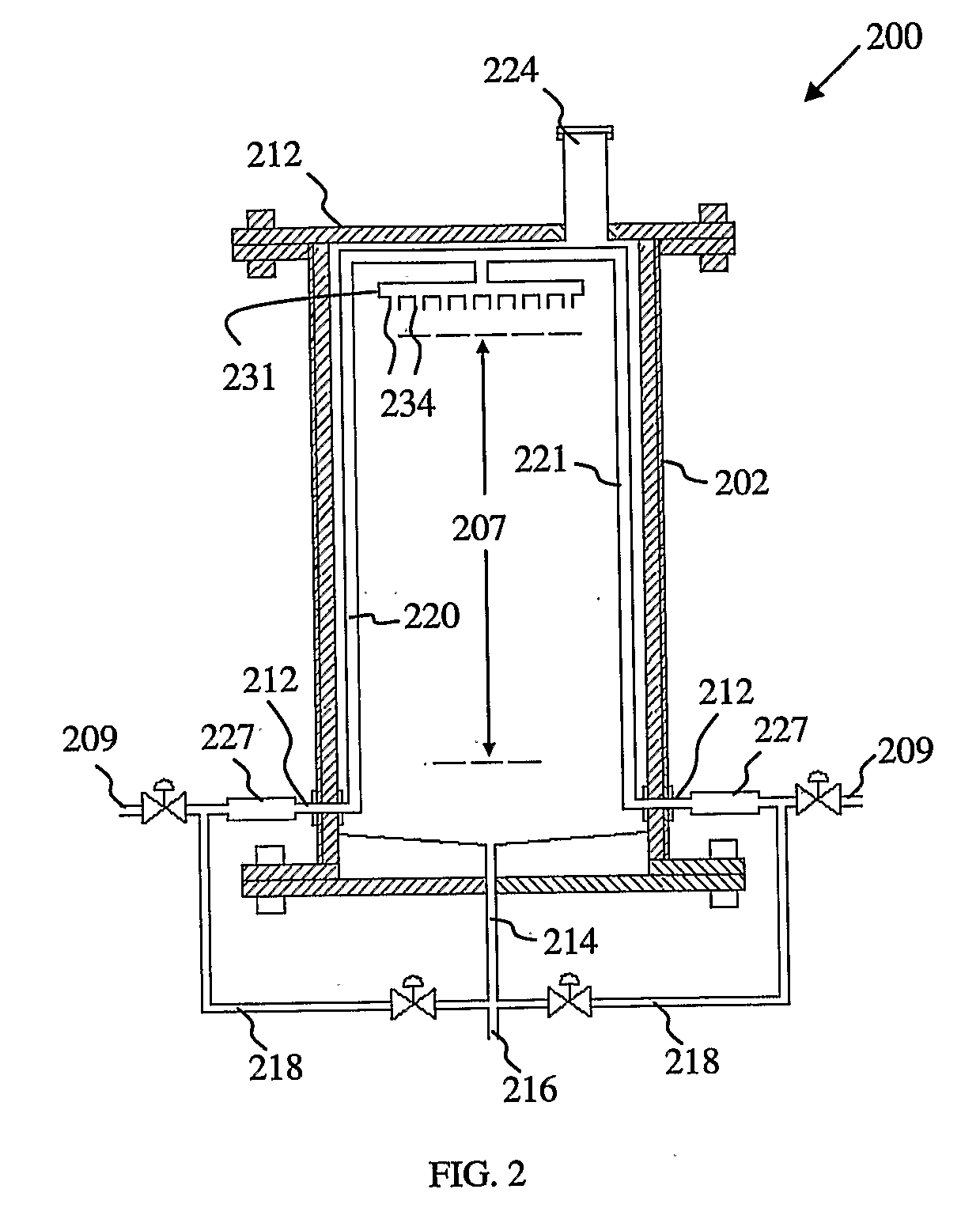

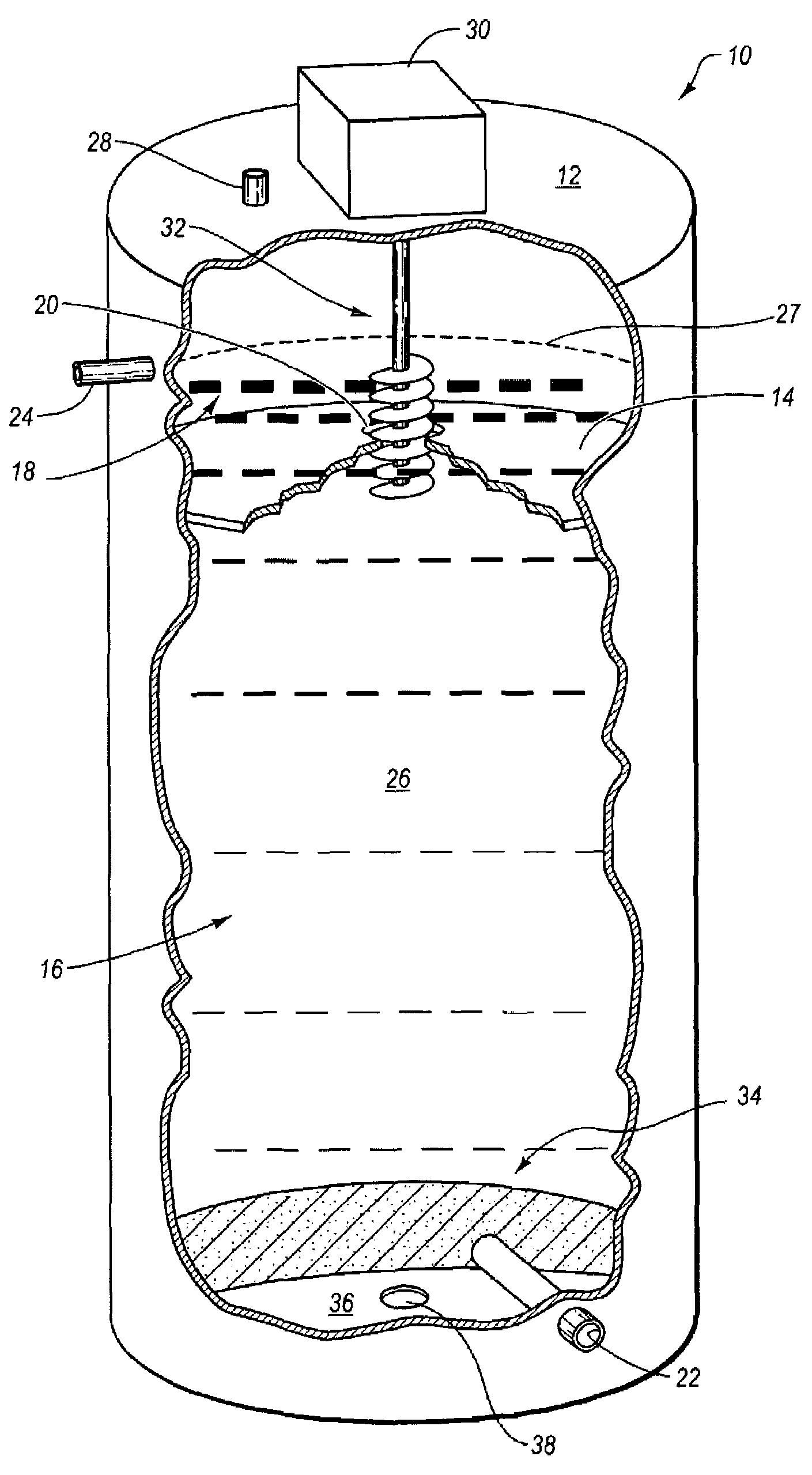

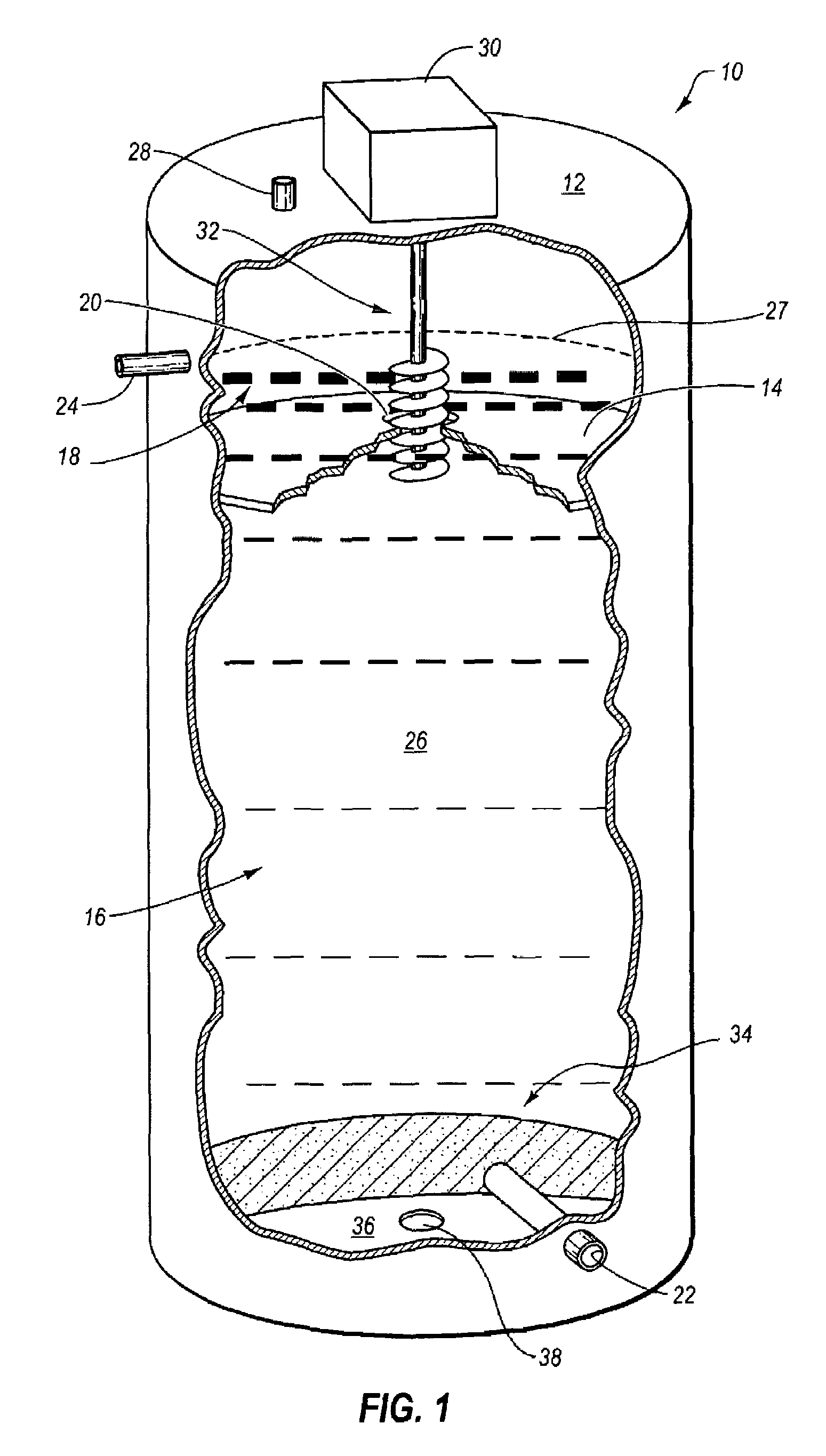

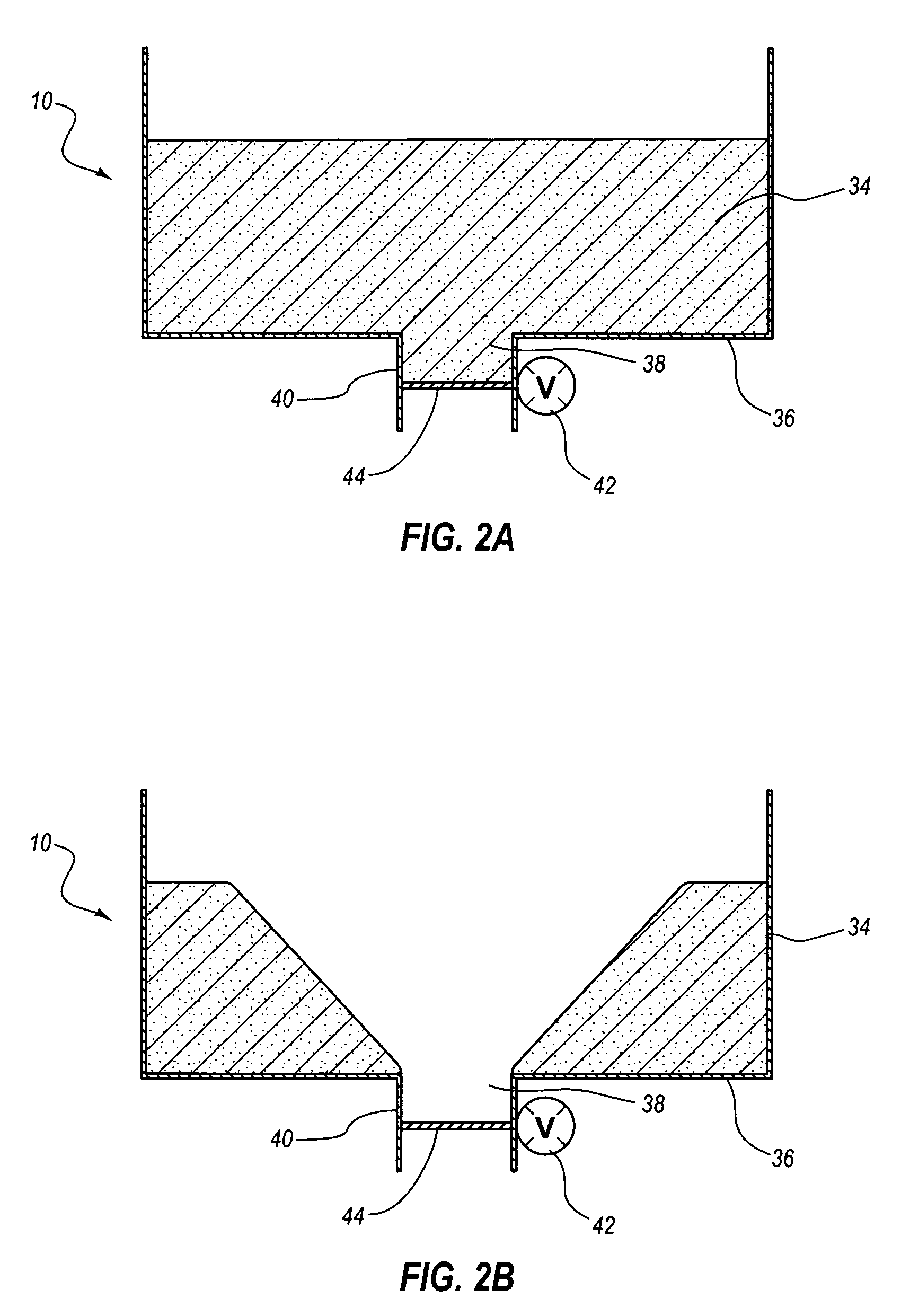

High solid thermophilic anaerobic digester

InactiveUS20090209025A1Small sizeFast dryingBioreactor/fermenter combinationsBiological substance pretreatmentsReaction chamberAnaerobic digestion

A device for digesting sludge anaerobically, comprising a digesting tank (100) having an upper region (104) and a lower region (105), and a reaction chamber (107) for converting raw sludge into matured sludge, an inlet (112) for introducing sludge (109) into the digesting tank, at least one transfer pipe (120) for channelling sludge from the lowe region of the digesting tank to the upper region of the digesting tank, said at least one transfer pipe being arranged within the digesting tank and having at least a part of its length thereof arranged within the reaction chamber so that least one transfer pipe is in contact with sludge moving through the reaction chamber, thereby resulting in heat transfer from sludge moving in at least on transfer pipe to sludge in the reaction chamber, and an outlet (114) arrange at the lower region of the digesting tank for discharging matured sludge (116) from the digesting tank.

Owner:IUT GLOBAL PTE

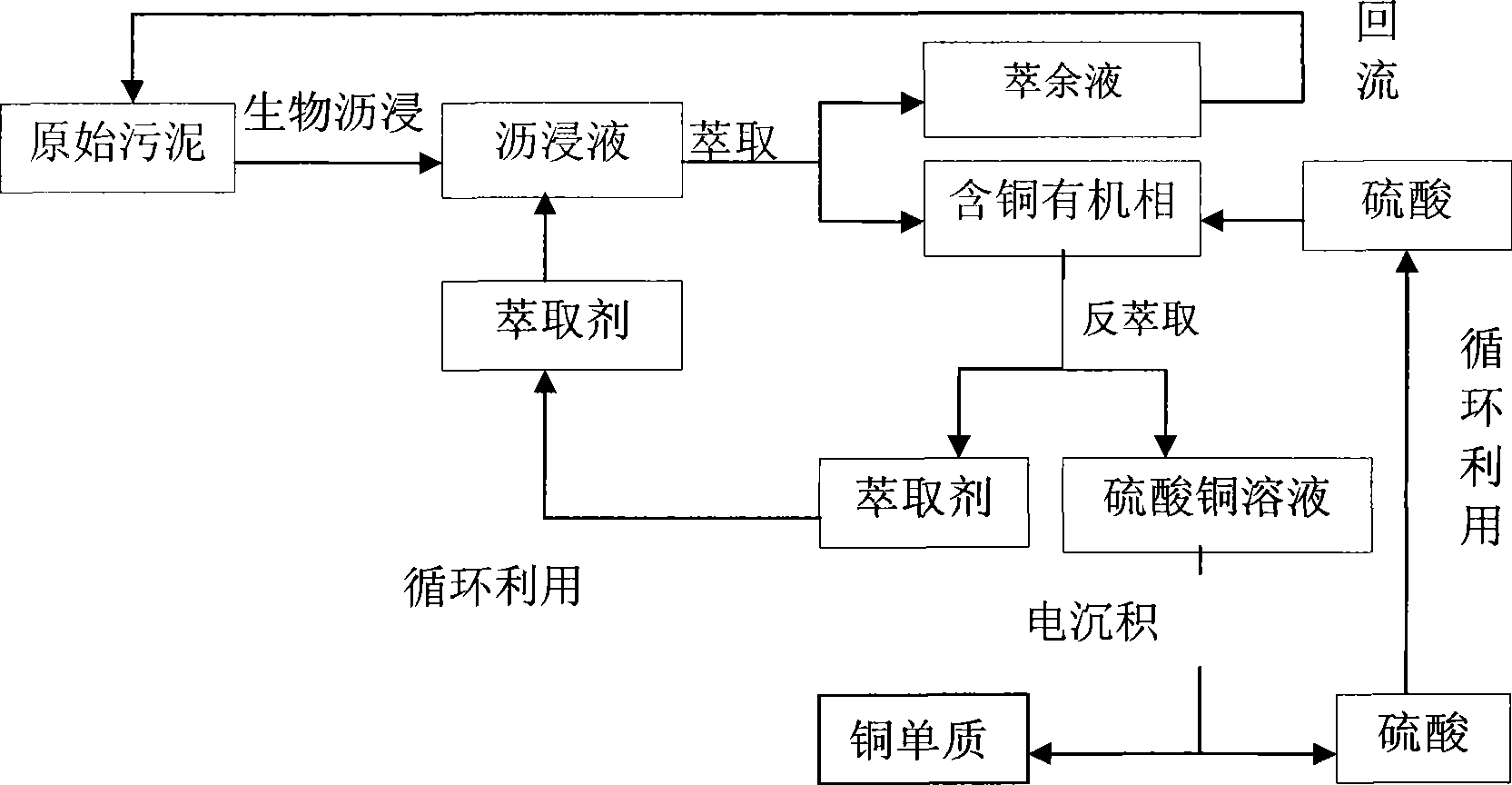

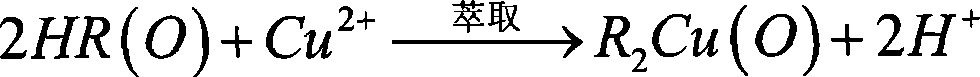

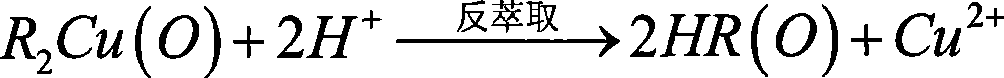

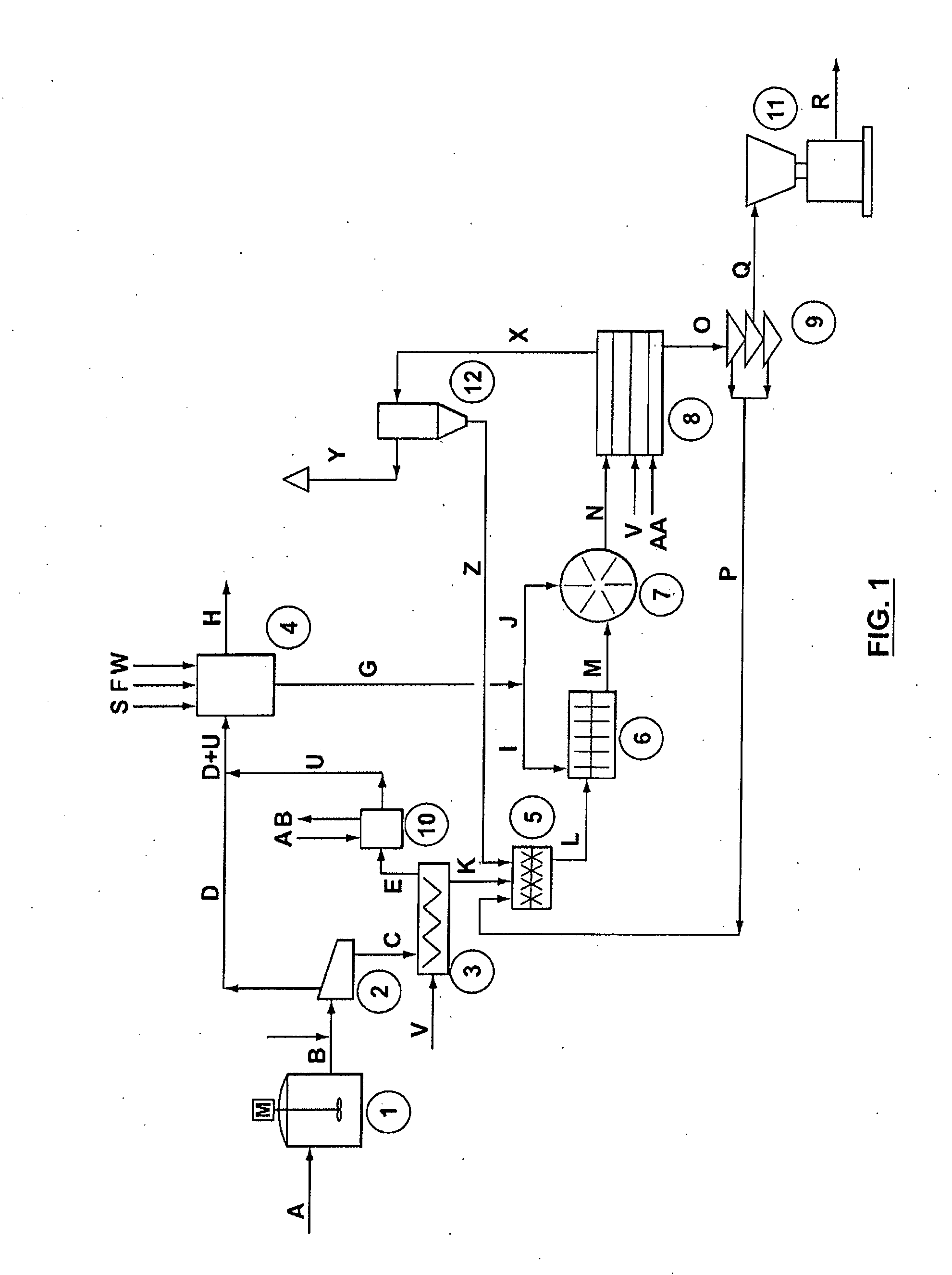

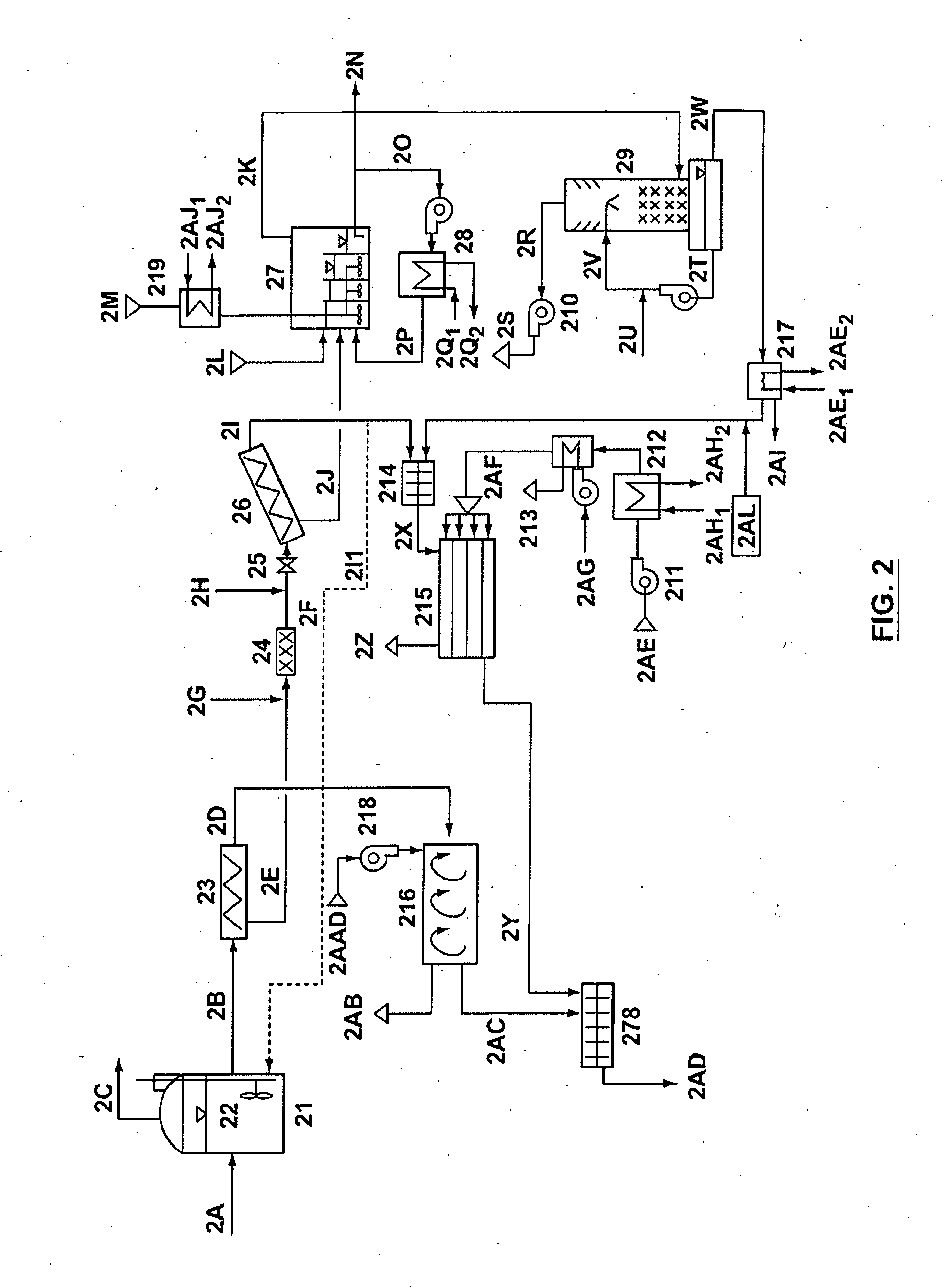

Biological leaching-solvent extraction-electrodeposition recovering method for heavy metal copper in sludge

InactiveCN101497942ANo pollution in the processLess investmentPhotography auxillary processesSludge processingRecovery methodSludge

The invention relates to a biological leaching, solvent extraction and electrowinning recovery method for heavy metal copper in sludge, and is a method of dissolving the copper from the sludge by biological leaching method, separating and enriching the copper in leaching solution by solvent extraction method, and recovering the metal coppe by electrowinning electroless plating copper technology, and is a harmless and resourceful treatment technology for municipal sludge and industrial sludge with higher copper content. Firstly, the biological acidization which lowers the ph value of a sludge system and oxygenizement of compound acidophilic thiobacillus under aerobic condition in the presence of energy matter are utilized to enable the heavy metal copper in the sludge to abundantly dissolved out from solid phase to liquid phase, so that the sludge can be harmless; secondly, the copper in the biological leaching solution is extracted by using a copper extractant M5640 so that the copper enters an organic phase, and then the copper is conducted back extractioin by using sulfuric acid so that the copper enters the water phase again so as to separate and enrich the copper; finally, the enriched copper solution is electrolyzed to causes the copper to be deposited, and the copper is recovered to be resourceful. The technique not only can remove the heavy metals in the sludge and kill pathogens, but also ensures that the treated sludge is easy to dehydrate and settle and the heavy metal copper dissolved out can be recovered to achieve the purposes of harmlessness, reduction and resource of the sludge.

Owner:NANJING AGRICULTURAL UNIVERSITY

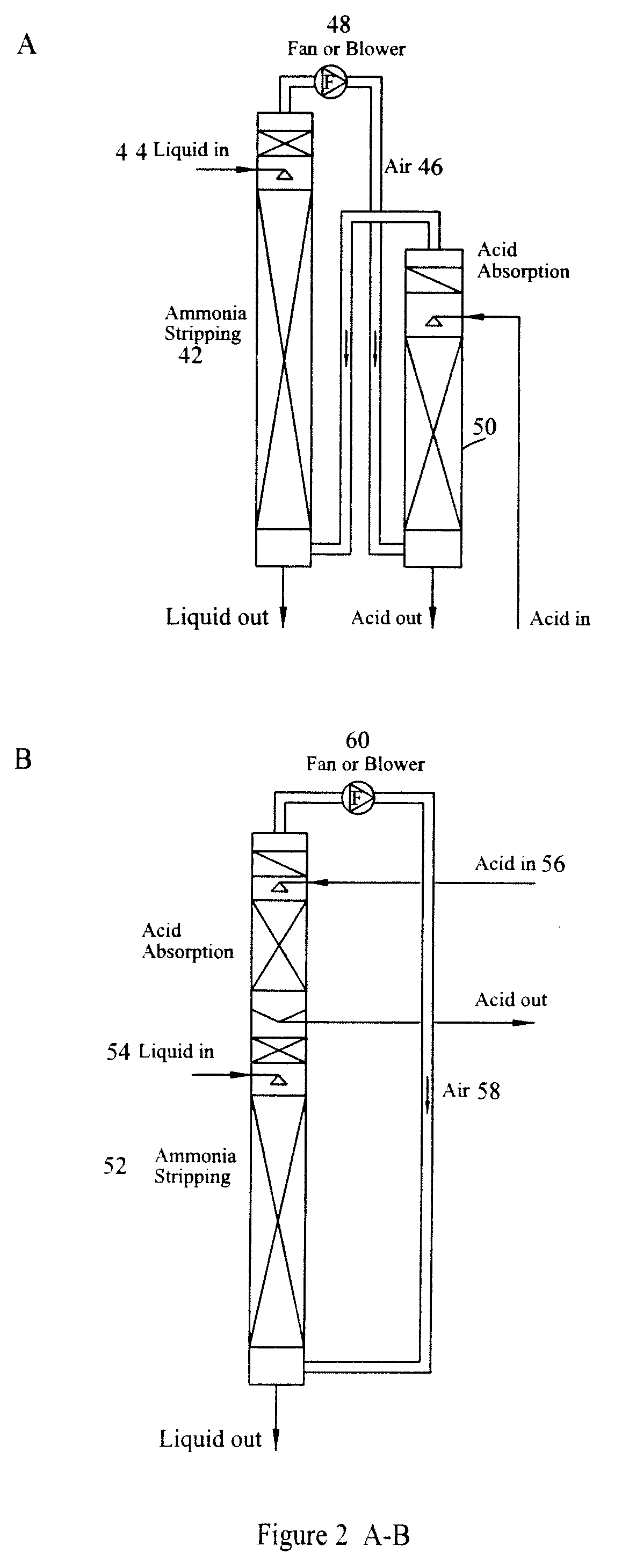

Organics and nutrient recovery from anaerobic digester residues

Sludge from an anaerobic digester is treated to recover one or more of fibers, or solids or liquids with a high nutrient content. The solids or liquids can be used as a fertilizer. The fibers can be used in a plant growing medium. Solids are separated from liquids in the sludge and dried. The solids may be dried to produce a flake or pellet. Ammonia in the liquids is recovered and used to produce a concentrated acidic ammonium salt solution. This solution may be mixed with the solids to produce a nitrogen enhanced solid. The fibers and solids or liquids can also be used in combination to produce an enhanced plant growing medium. A device and process for removing ammonia from a liquid can be used in the system or separately.

Owner:ANAERGIA

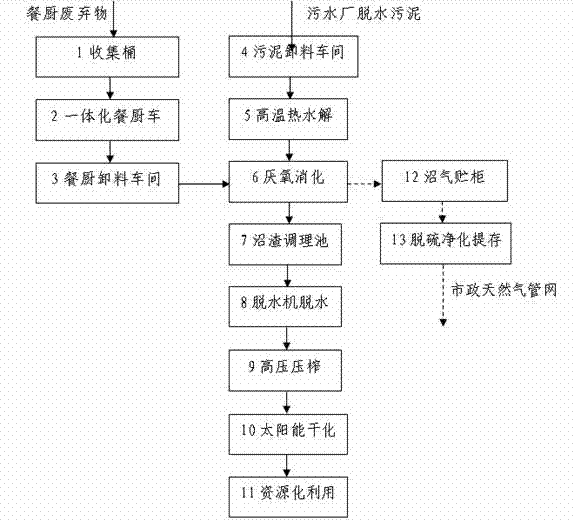

Cooperative treating method of kitchen waste and sludge of sewage plant

InactiveCN106964633AReduce the impactAvoid pollutionSludge treatment by de-watering/drying/thickeningWaste processingSolar dryingSewage

The invention discloses a cooperative treating method of kitchen waste and sludge of a sewage plant. The method comprises the following steps that A, a kitchen waste source is pretreated; B, the sludge is subjected to high-temperature hydrolysis cooperating with anaerobic digestion; C, biogas residues are dehydrated and pressed; and D, drying treatment is conducted to obtain finished products. The cooperative treating method has the advantages that after the comprehensive treating processes that the kitchen waste source is pretreated, the sludge is subjected to high-temperature hydrolysis cooperating with anaerobic digestion, the biogas residues are dehydrated through a dehydrator and pressed directly through a high-pressure filter press and subjected to solar drying, stabilization, harmlessness and reduction of the sludge can be achieved, and meanwhile waste is changed into treasures, specifically, available biogas and garden greening soil and forest land are produced.

Owner:江苏泓润生物质能科技有限公司

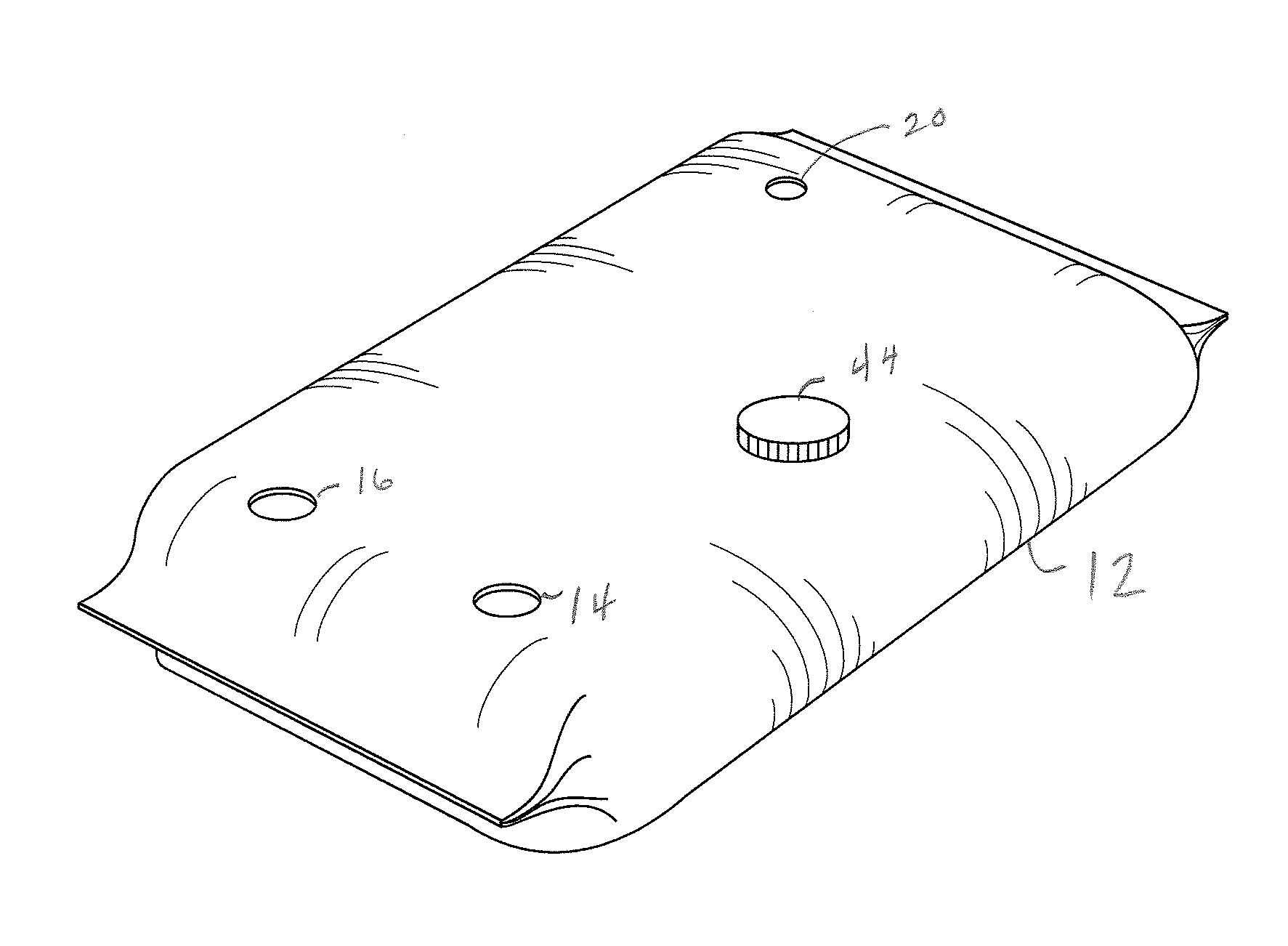

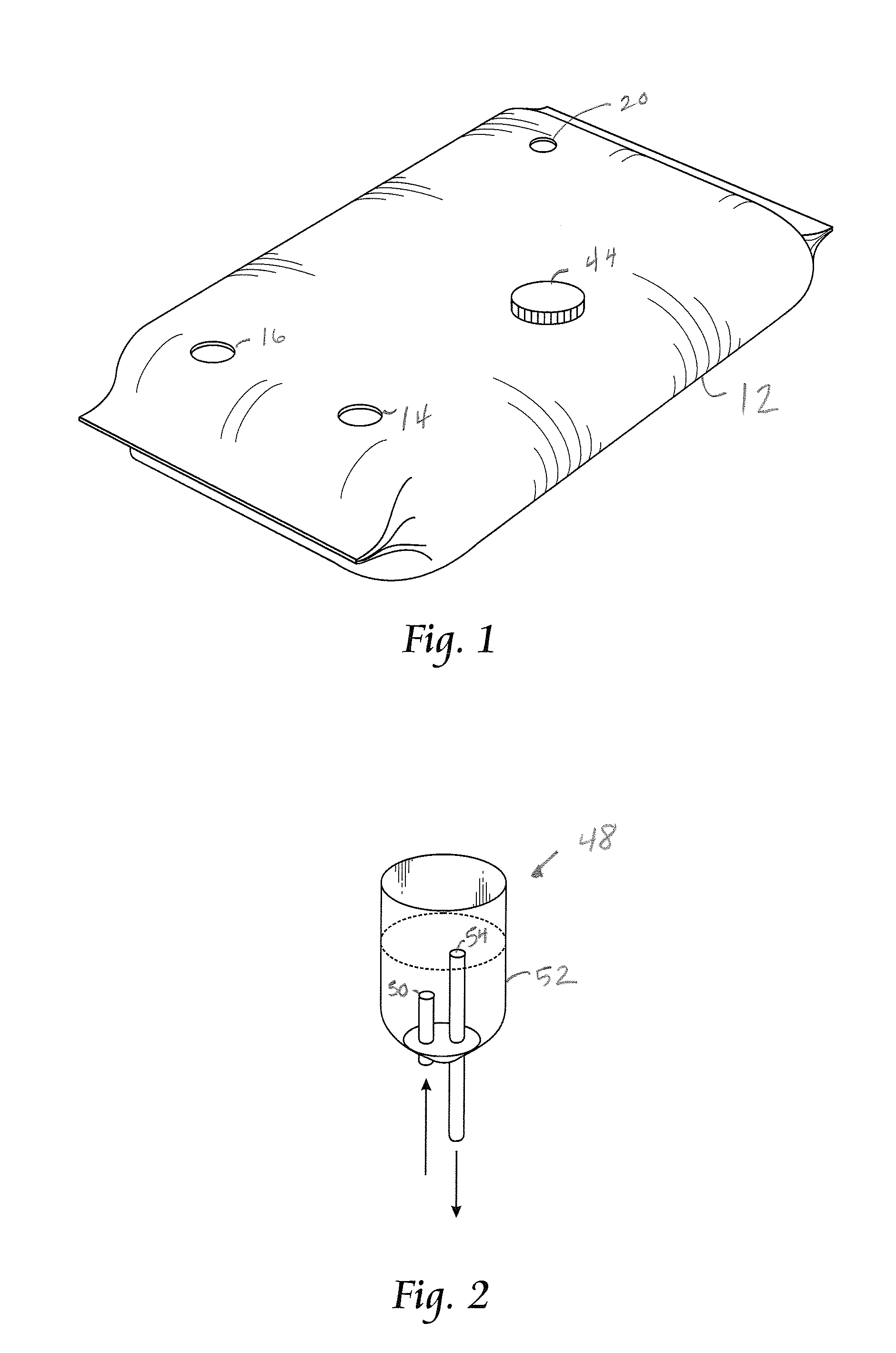

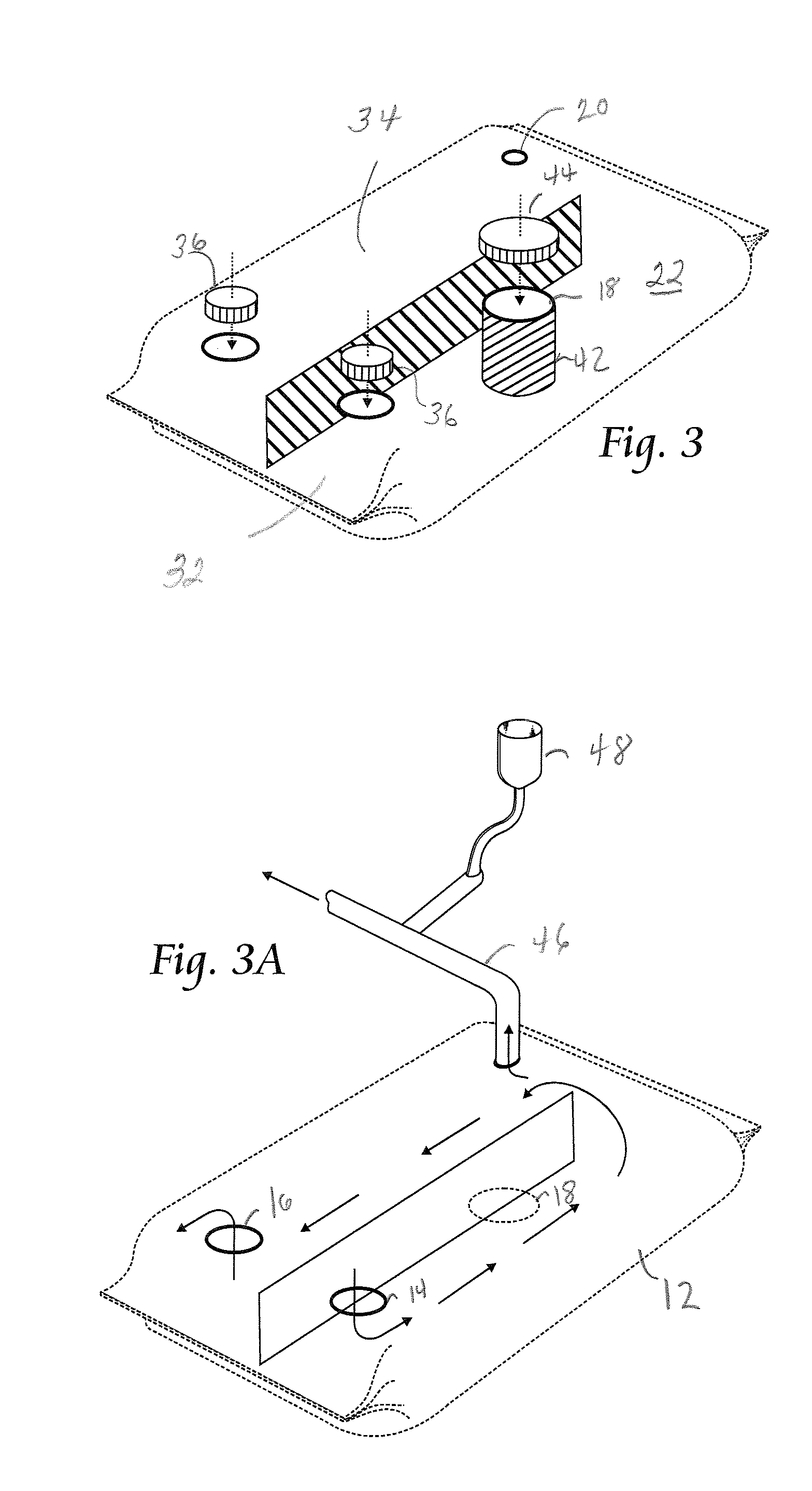

Anaerobic digester system for animal waste stabilization and biogas recovery

InactiveUS7186339B1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiogas productionEnergy expenditure

An ambient anaerobic digester system for anaerobic digestion of animal waste with biogas production and recovery is provided. The anaerobic digester system includes a substantially flexible bladder for anaerobically digesting the animal waste with biogas production and transmitting the biogas to at least one biogas storage container, biogas use device or a combination thereof. In a preferred form, the substantially flexible bladder has a waste inlet, a digester effluent outlet, one or more sludge access ports and a biogas outlet in a top surface thereof.The anaerobic digester system may inexpensively, simply, reliably, and effectively be used to treat animal waste without energy expenditure and little capital expense, thus minimizing pollution typically caused by animal waste.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

Methods for removal of non-digestible matter from an upflow anaerobic digester

ActiveUS7615155B1Preserving efficient operationBacterial population is relatively stableSolid waste disposalWaste water treatment from animal husbandryOrganic matterSteady state

Methods for steady state operation of an upflow anaerobic digester using organic matter that contains a portion of solid, non-digestible matter include (1) providing an upflow anaerobic digester, (2) providing a bacterial culture in the upflow anaerobic digester for the breakdown of organic matter, (3) introducing an influent into the upflow anaerobic digester, wherein the influent comprises a biodegradable component, a liquid component, and an amount of solid non-digestible matter, (4) operating the upflow anaerobic digester in a steady-state, (5) accumulating the solid, non-digestible matter in the upflow anaerobic digester, (6) and removing a portion of the accumulated solid, non-digestible matter from the upflow anaerobic digester through the bottom of the upflow anaerobic digester while maintaining steady-state operation of the upflow anaerobic digester. Steady-state operation of the upflow anaerobic digester is maintained by selecting a percentage of the total volume of the liquid and material that are flushed from the digester for a given period of time so as to preserve the steady-state of the bacterial culture.

Owner:UTAH STATE UNIVERSITY

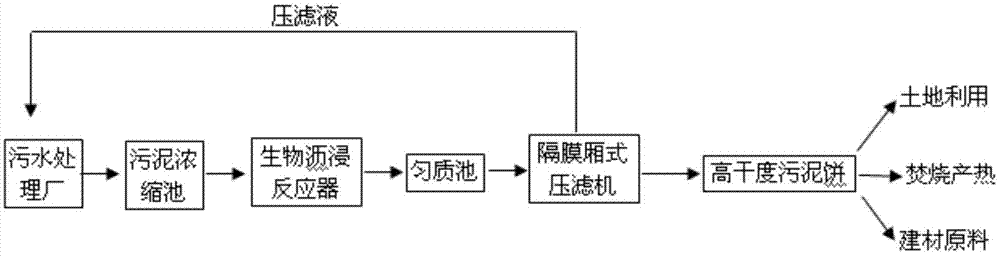

New method for deeply dewatering sludge through bio-leaching process rapid conditioning

ActiveCN103936246ASimple processLow running costSludge treatment by de-watering/drying/thickeningSludge processingSludge cakeResource utilization

The invention discloses a new method for deeply dewatering sludge through bio-leaching process rapid conditioning. The method comprises the steps of firstly performing bio-leaching conditioning on sludge, namely, directly pumping concentrated liquid sludge of a sewage treatment plant into a bio-leaching reactor which contains special composite microbial community, performing treatment for 1.5-2 days, changing bound water in the sludge into free water which can be removed relatively easily by virtue of the microbial substitution effect, biological oxidation effect and biological acidification effect, dissolving out heavy metals from the sludge at the same time, entering an aqueous phase, killing pathogens in the sludge, then collecting the sludge subjected to bio-leaching in a homogeneous pool, directly transporting to a common-pressure diaphragm chamber type filter press by virtue of a pump, and dewatering, wherein the moisture content of dewatered sludge cake is less than 60%, and no flocculant like PAM (polyacrylamide) is added during the preparation process. The method disclosed by the invention is performed under normal temperature and pressure, and has low cost; the dewatered sludge cake is low in moisture content, odorless, and yellowish-brown in color; and the organic matters, calorific values and nutrients of the dewatered sludge can not be reduced, thus facilitating the subsequent resource utilization.

Owner:NANJING AGRICULTURAL UNIVERSITY

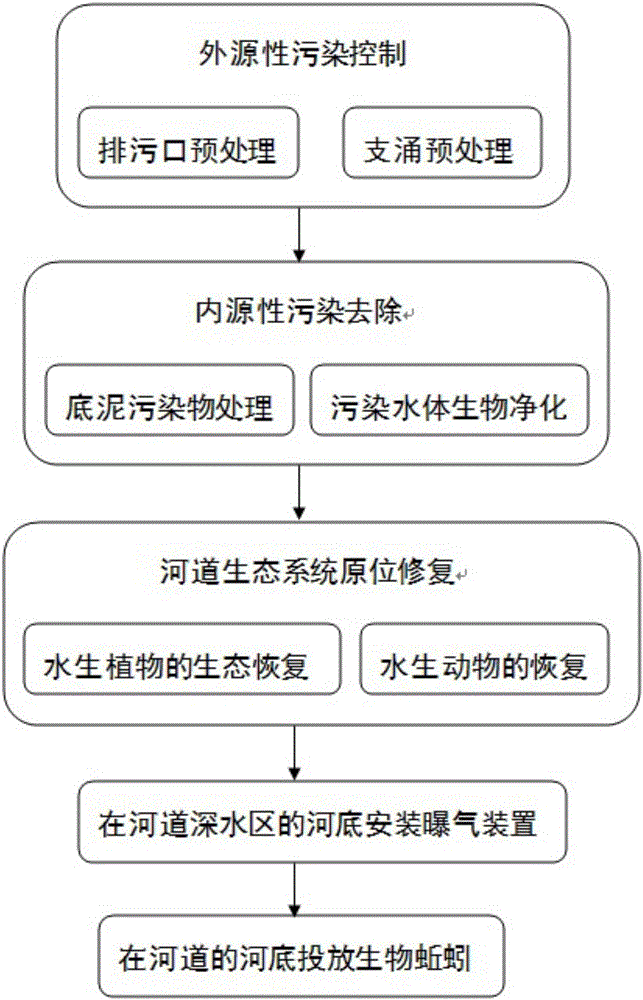

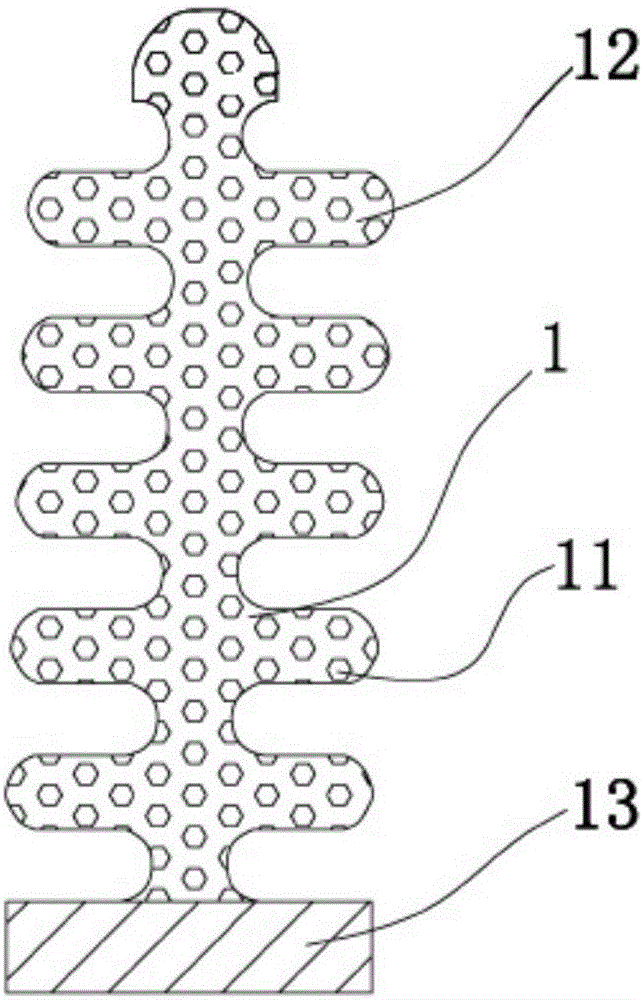

Method for comprehensive treatment of town river way

ActiveCN106186343AReduce pollutionAchieving a healthy water cycleWater resource protectionWater treatment parameter controlAquatic animalMicrobial agent

The invention discloses a method for comprehensive treatment of a town river way. The method comprises exogenous pollution control: sewage draining outlet pretreatment and branch surge pretreatment; endogenous pollution removal: bottom mud pollutant treatment and biological purification of polluted water; in-situ remediation of a river channel ecological system: ecological restoration of aquatic plants and restoration of aquatic animals; and supplemented feeding of an efficient microbial agent and ecological restoration monitoring of the river channel. A staged treatment principle is adopted for the method for comprehensive treatment of the town river way, conditions are created positively to gradually reduce river channel pollution; through the exogenous pollution control, the endogenous pollution removal, the in-situ remediation of the river channel ecological system, later period maintenance and ecological regulation and the like, a water system is made smooth, the river channel is made clean, the ecological system is established artificially, the self-cleaning capacity of the river channel is restored gradually, healthy water circulation of the river channel is achieved, biodiversity is promoted, and virtuous circle of the town and country environment and the ecological system is promoted.

Owner:广州市天瑞环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com