Patents

Literature

720 results about "Biogas production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

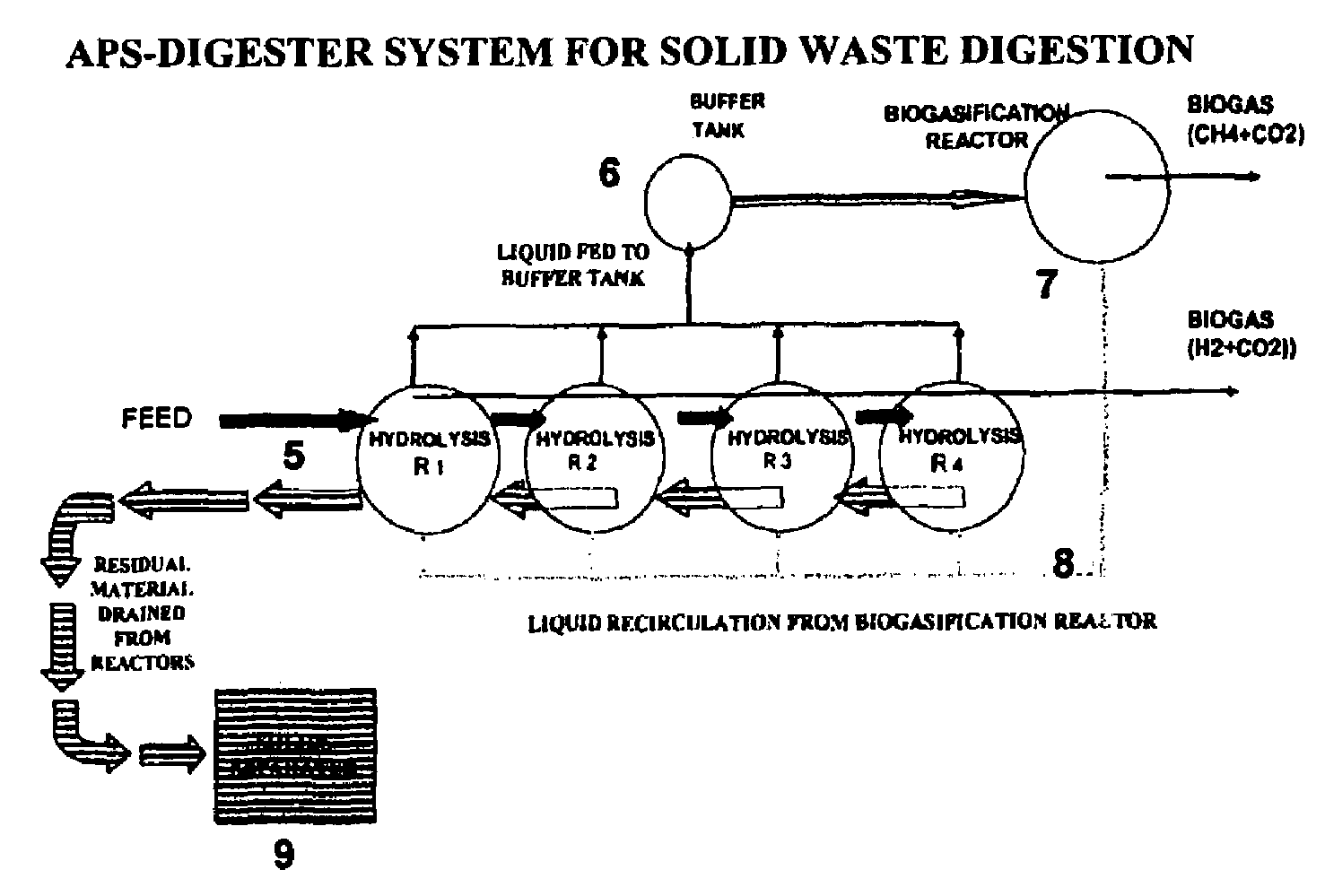

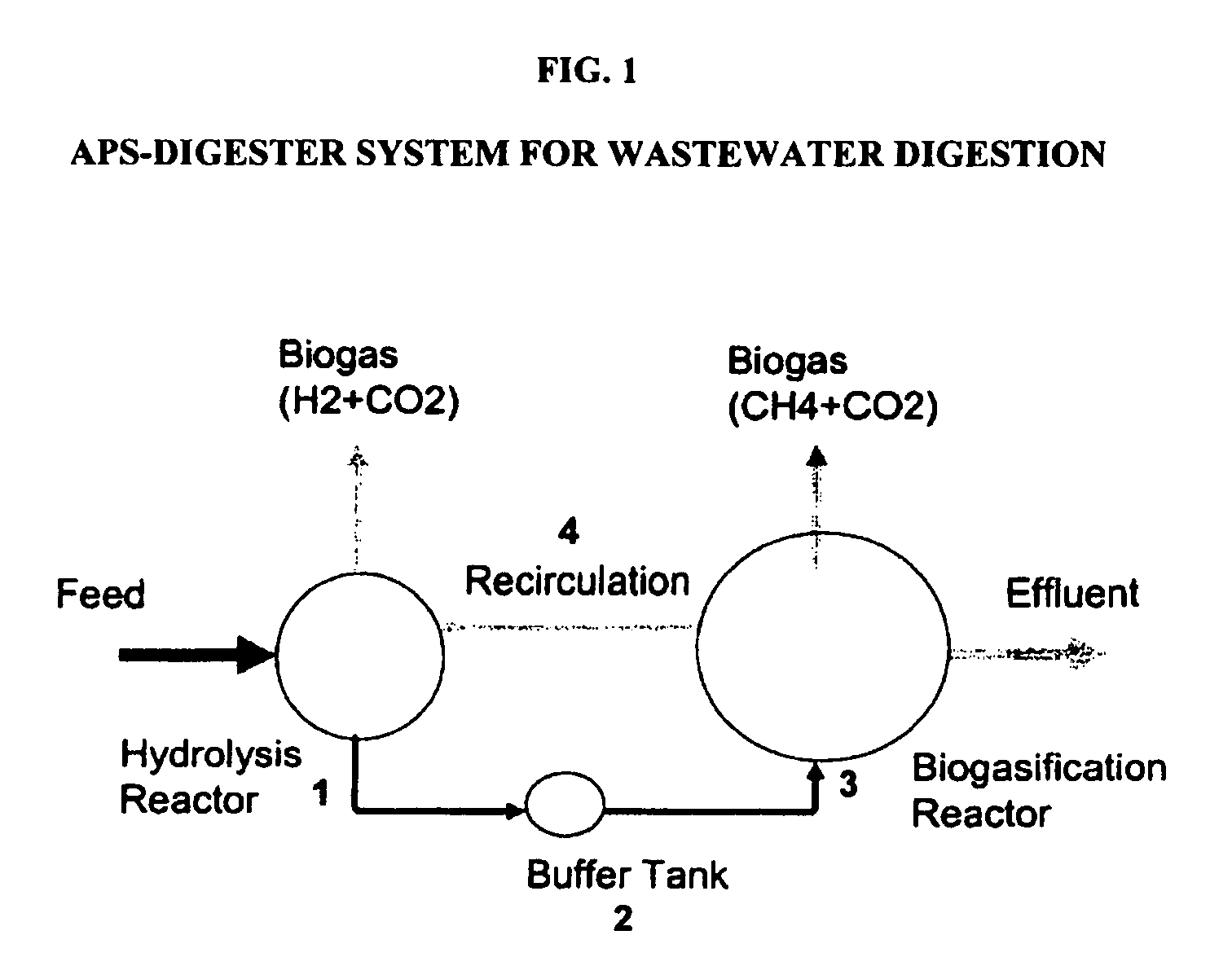

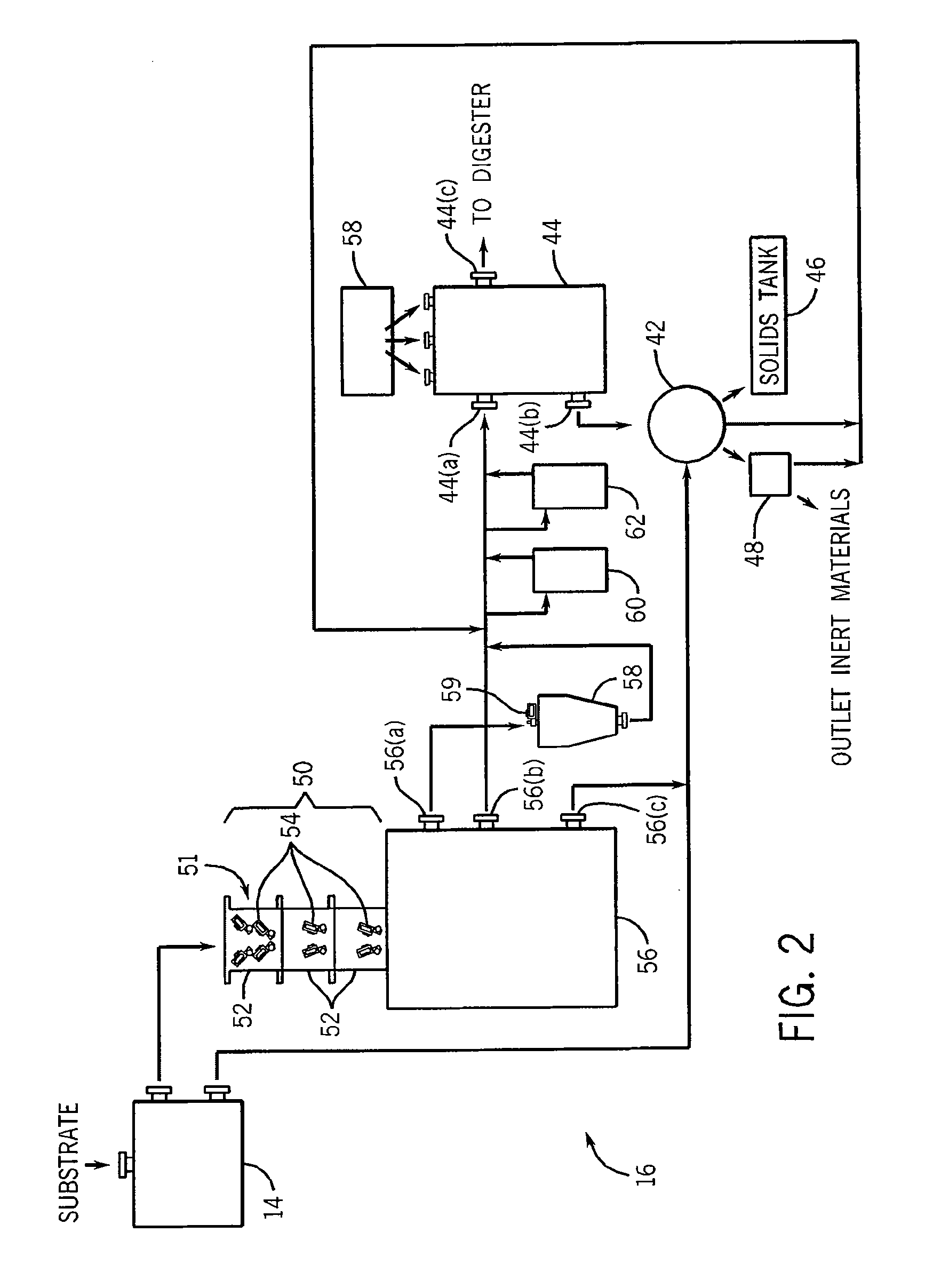

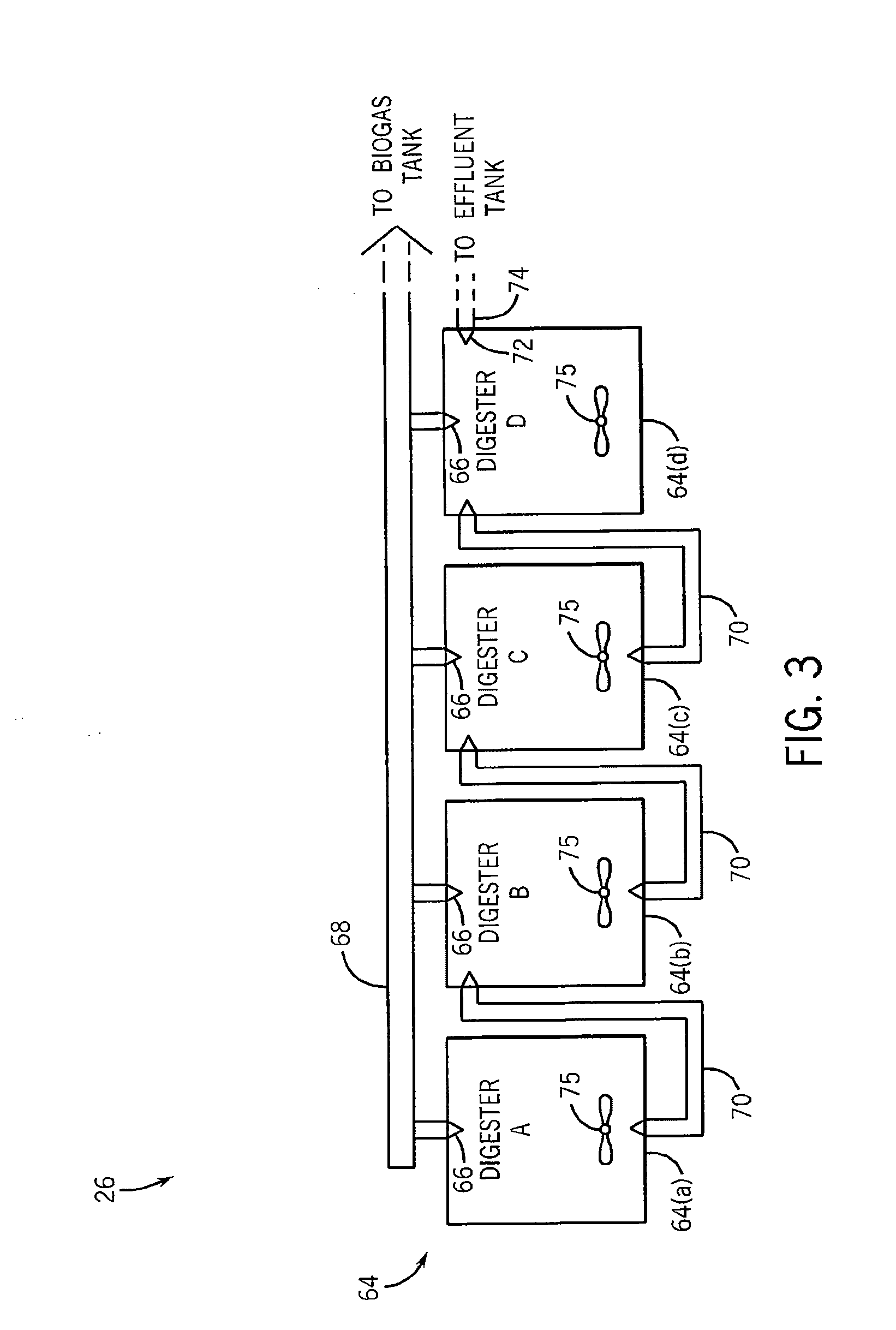

Anaerobic phased solids digester for biogas production from organic solid wastes

InactiveUS20070158264A1Improve energy conversion efficiencyLess air emissionLiquid degasificationBiological substance pretreatmentsHigh rateBuffer tank

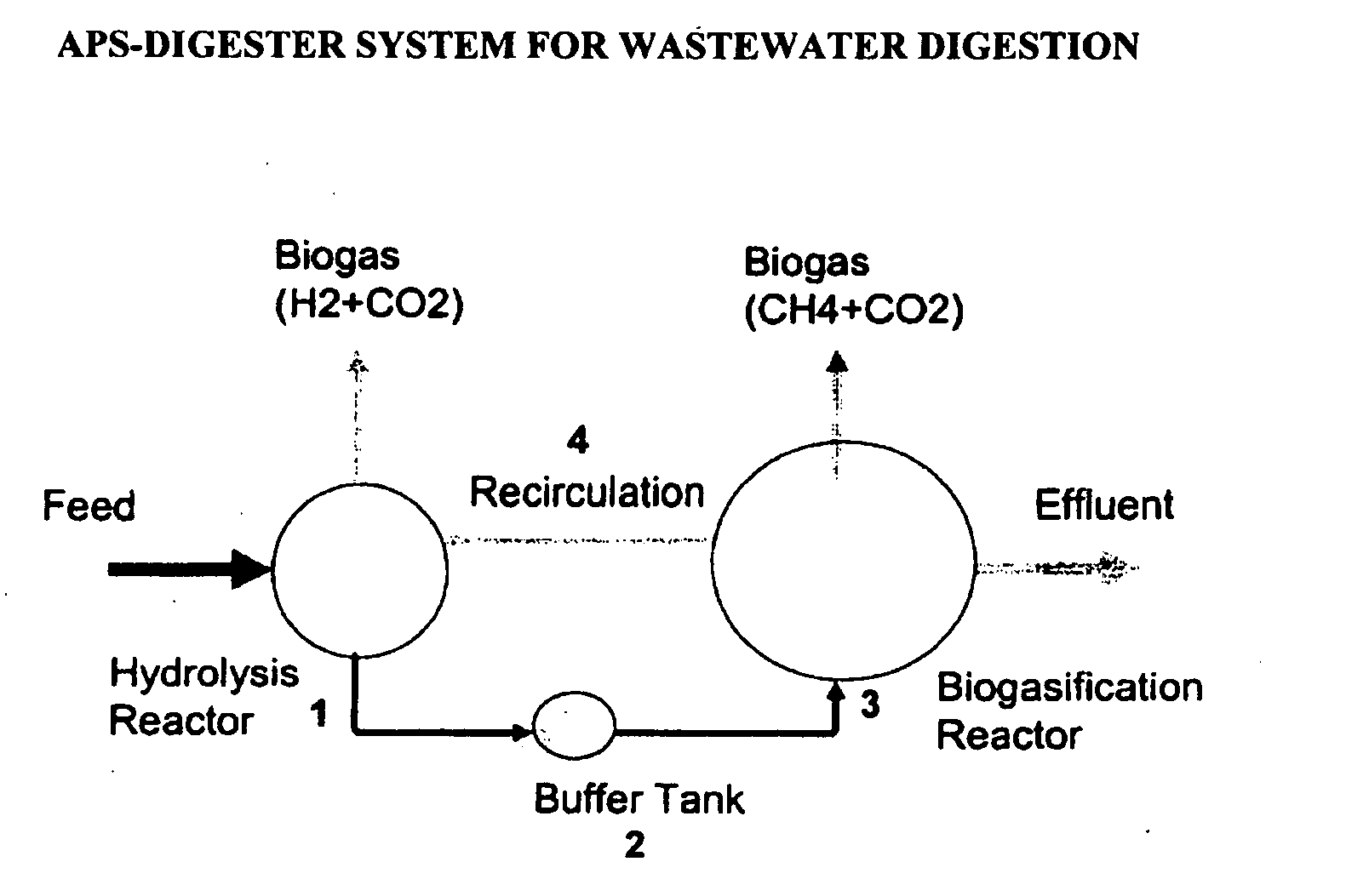

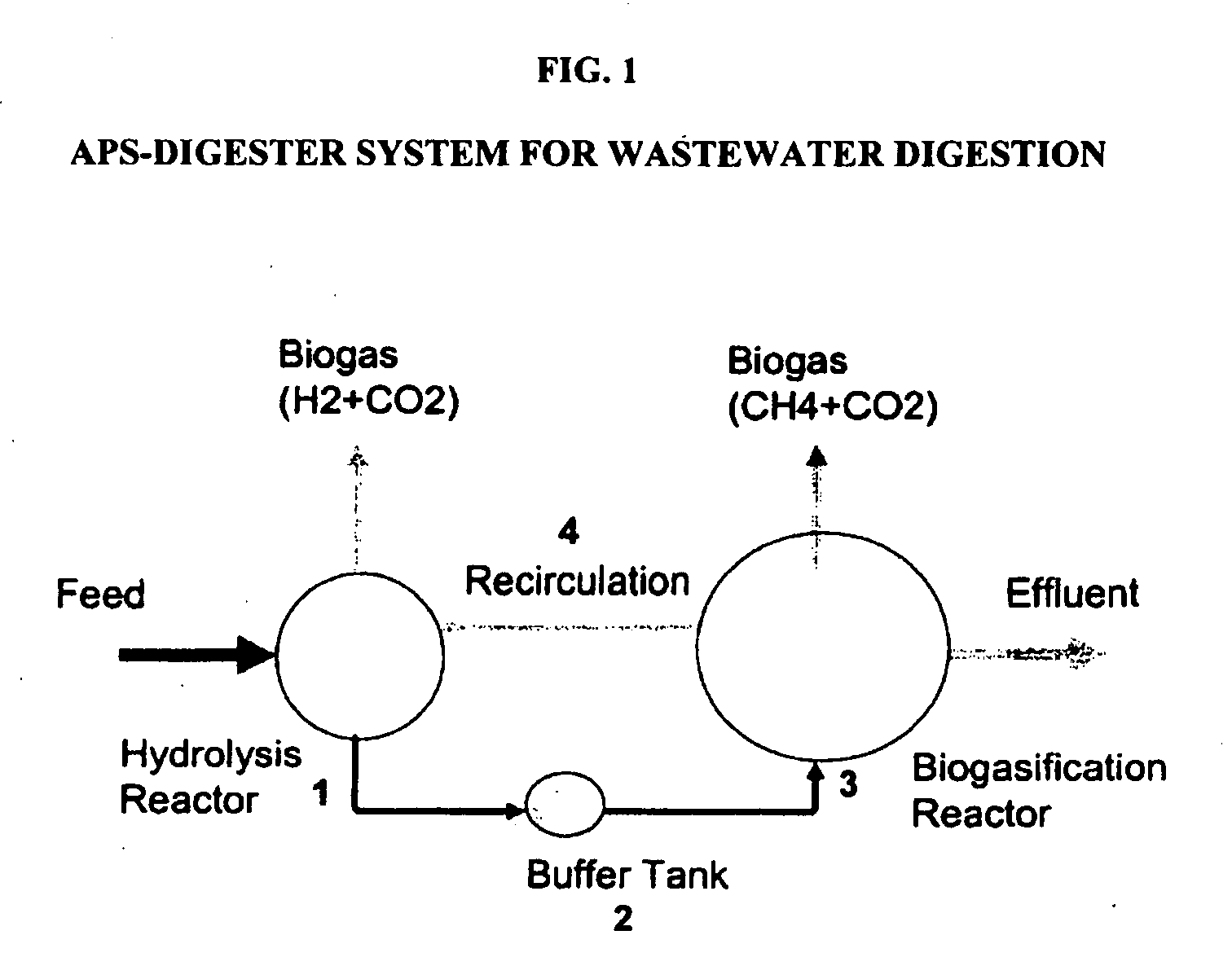

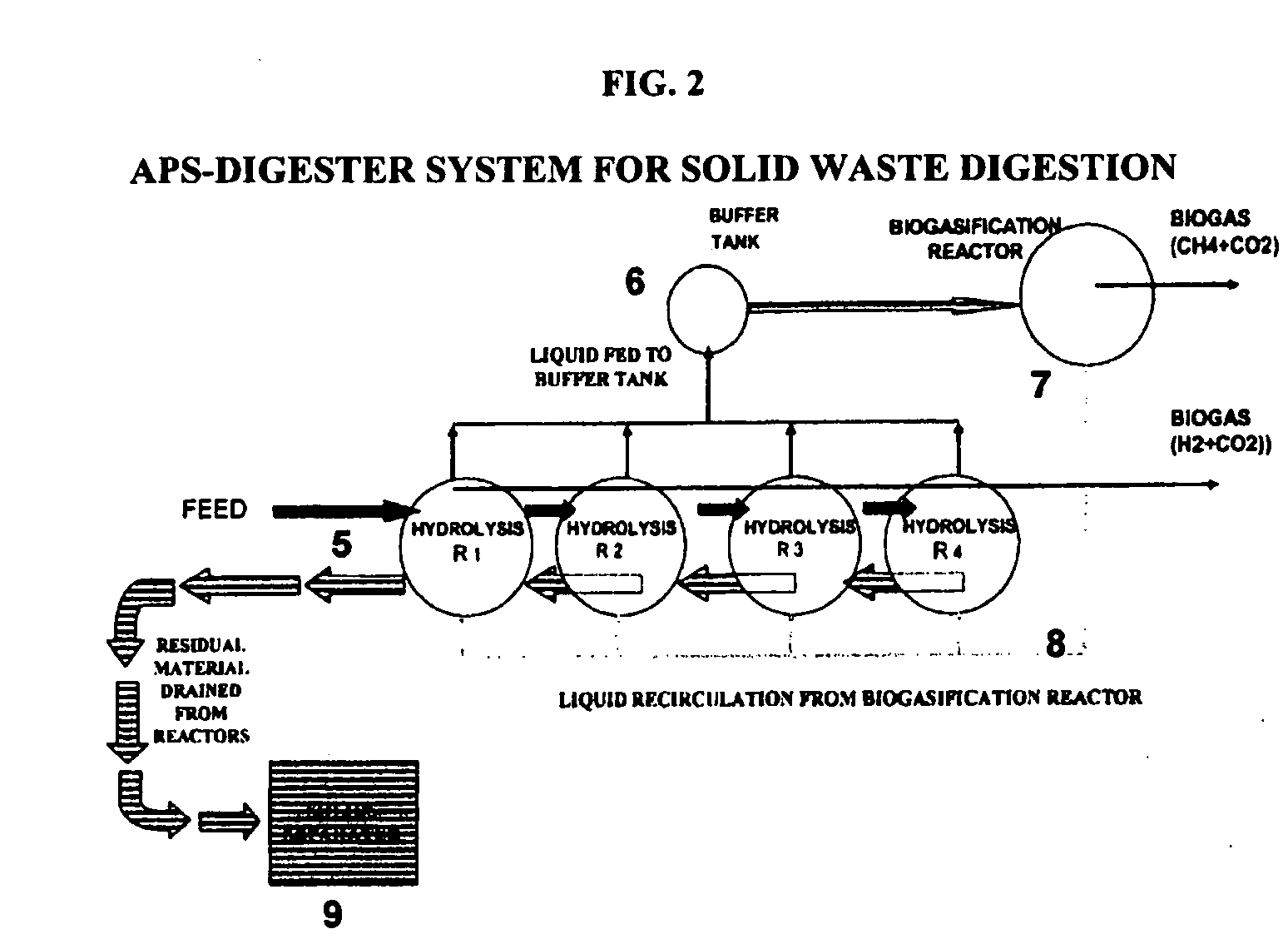

The present invention provides methods for the generation of methane by a two phase anaerobic phase system (APS) digestion of organic substrates. Also provided is a device for practicing the methods of the invention. The APS-digester system is a space-efficient, high-rate solids digestion system. The APS-digester system consists of one or more hydrolysis reactors, a buffer tank and one biogasification reactor.

Owner:RGT UNIV OF CALIFORNIA

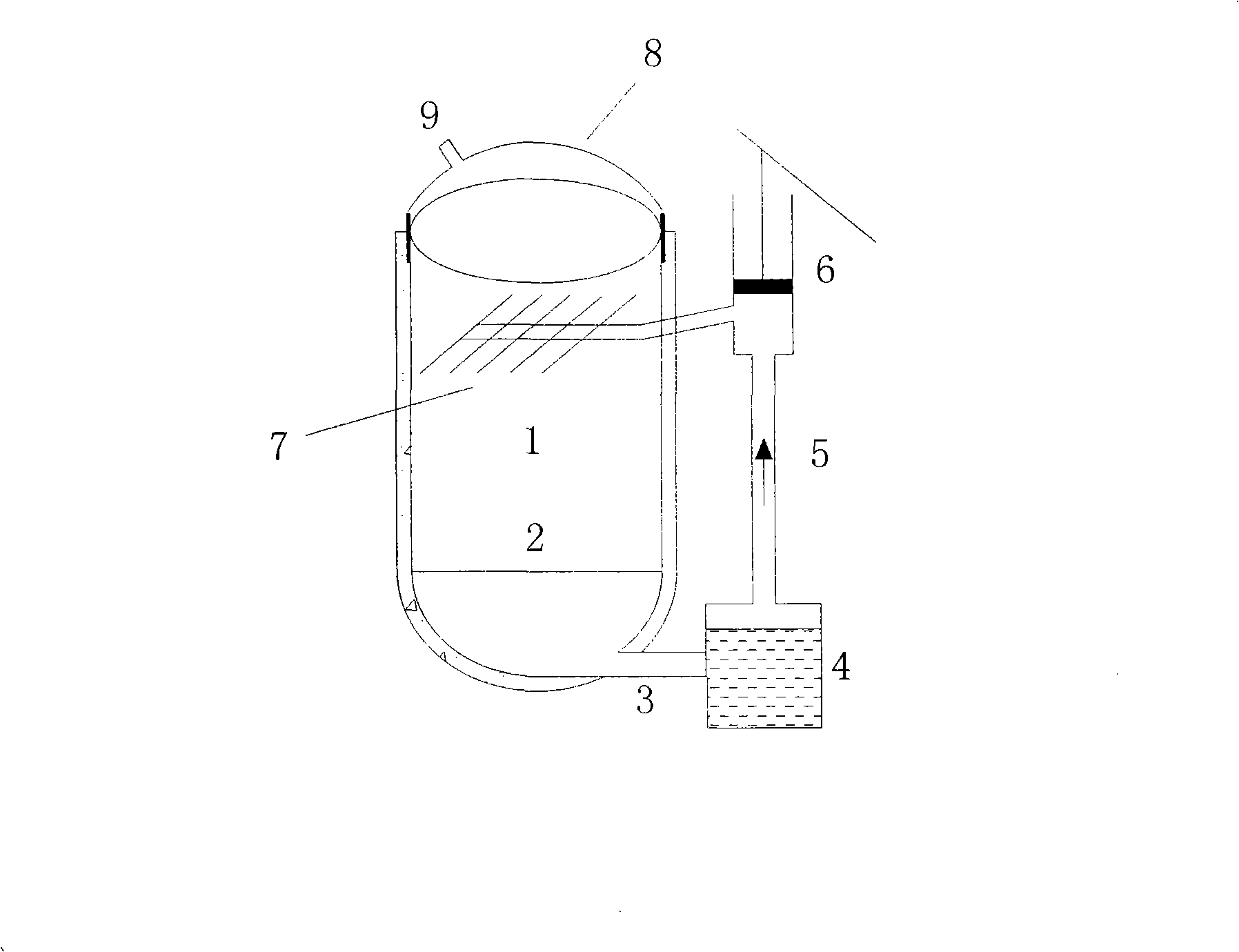

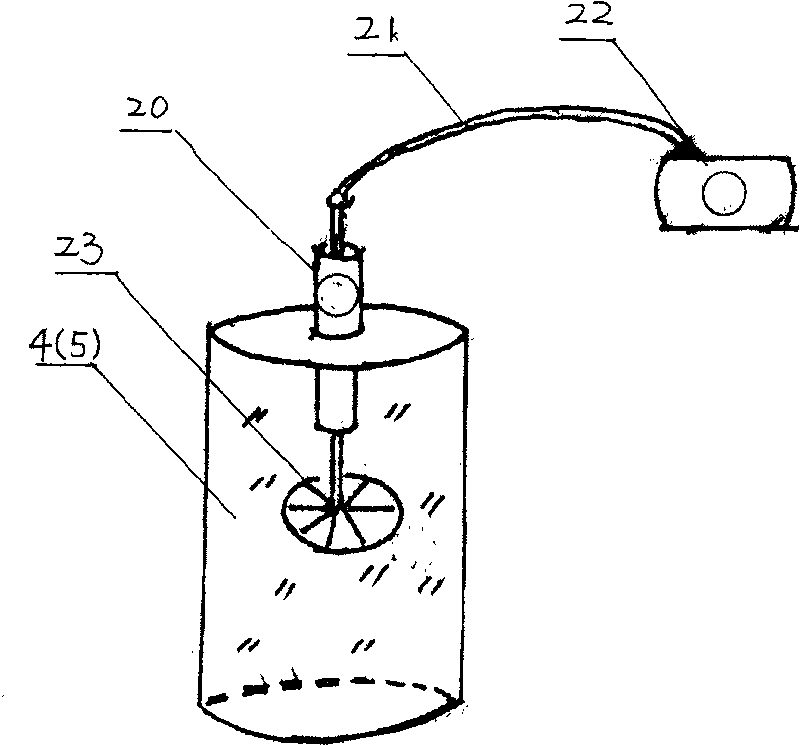

Efficient methane-generating pit using poultry excrement and methane generation process

InactiveCN102531310AReduce moisture contentEasy to produceWaste based fuelBiological sludge treatmentProcess engineeringBiogas production

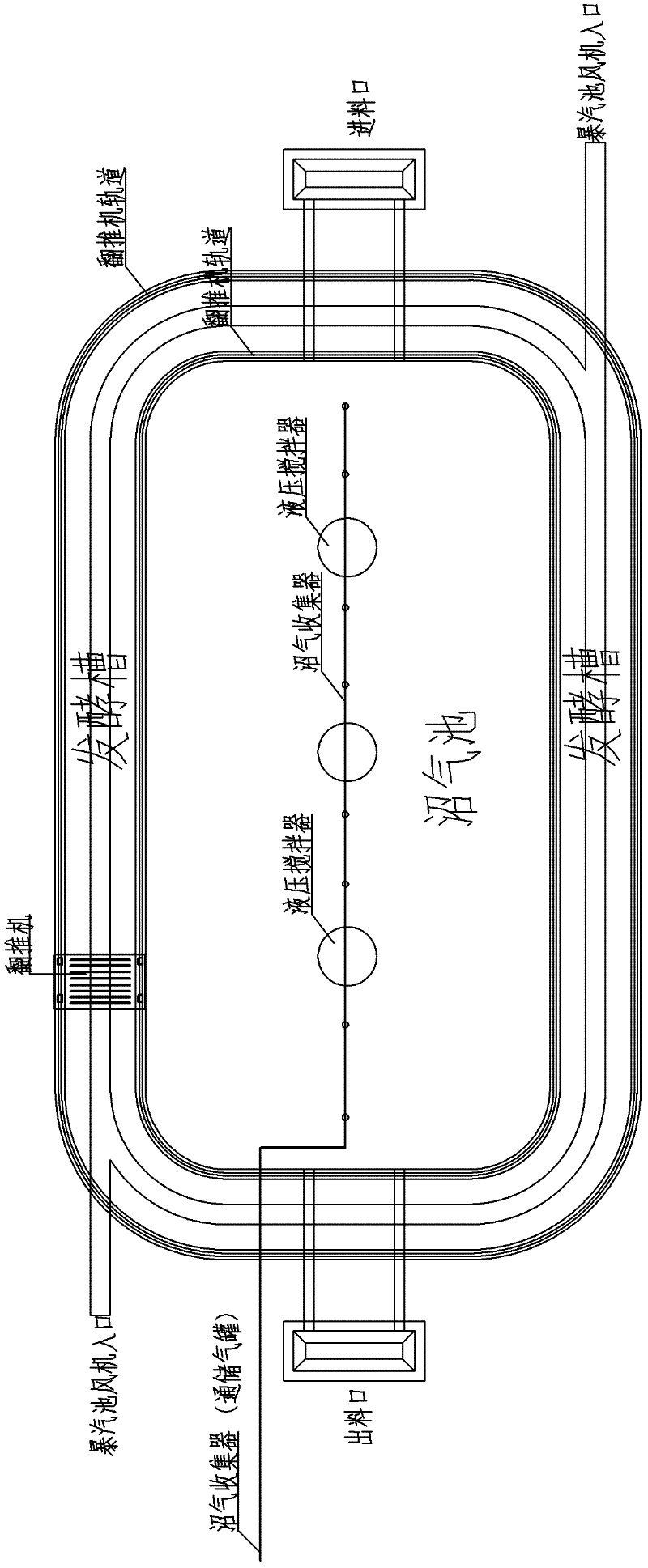

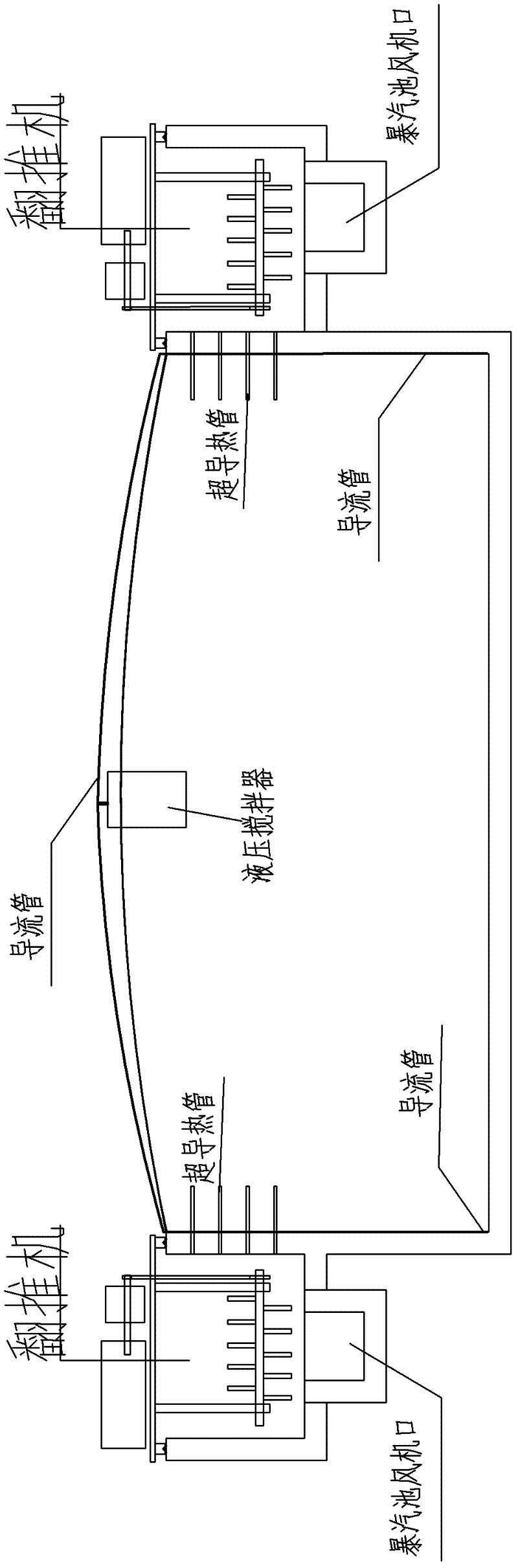

The invention relates to a methane-generating pit using poultry excrement, which is integrally horizontally placed under the water plane. Partition walls are arranged in the middle of the methane-generating pit for dividing the whole methane-generating pit into a plurality of unit methane-generating pits, and medium channels arranged on the partition walls are communicated with each other. An annular fermentation tank is arranged above the periphery of the methane-generating pit, a plurality of superconductive heat pipes are arranged on the inner side of the annular fermentation tank, and the superconductive heat pipes are inserted into the methane-generating pit. A material inlet and a material outlet are respectively arranged at two ends of the methane-generating pit and under the unit methane-generating pits at two ends of the methane-generating pit, a methane collector is arranged above each unit methane-generating pit, and the methane collectors are directly communicated with a gas storage tank through pipelines. The methane-generating pit has the advantages of being high in material concentration, integrating material inlet, deslagging, methane generating, stirring, temperature controlling, regulating and the like, being high in mechanization degree, large in treating quantity, fast in digesting rate and the like and can meet requirements for scale production, and concentration of inlet materials of a continuous methane-generating pit can reach about 15%.

Owner:范立河

Method of producing biogas through high-solid two-phase three-stage anaerobic digestion by using perishable organic wastes

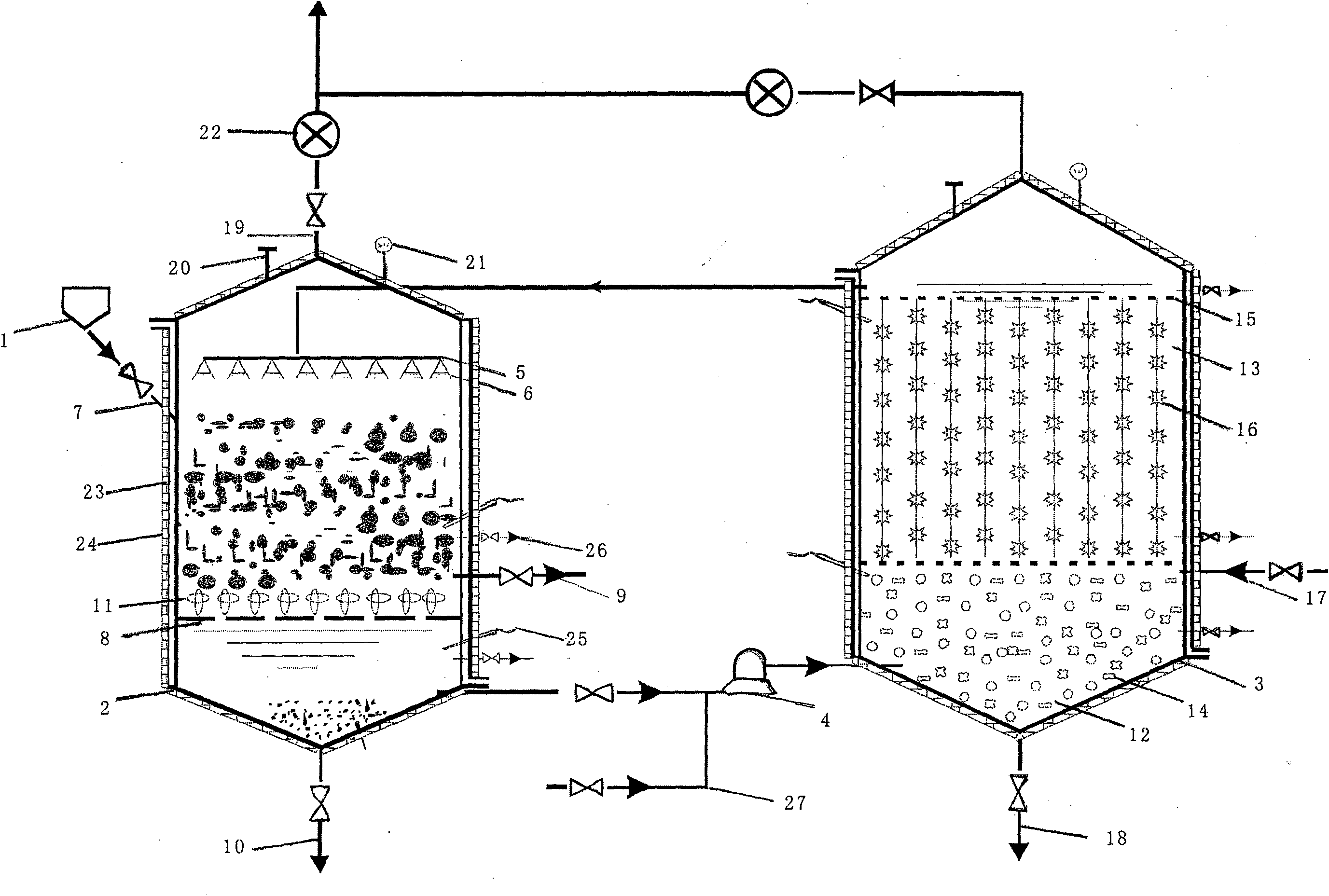

ActiveCN101805753AAvoid cloggingIncrease concentrationWaste based fuelFermentationAcetic acidOrganic acid

The invention provides a method for producing biogas through high-solid two-phase three-stage anaerobic digestion by using perishable organic wastes, which comprises the following steps: the perishable organic wastes are hydrolyzed in a hydrolysis acidogenic reactor, and a mixture obtained after hydrolysis is acidified to generate a large number of organic acid products with low molecular weight; the bottom of the hydrolysis acidogenic reactor is communicated with the bottom of a methanogenic reactor through a circulation pump and a pipeline; the top of the methanogenic reactor is communicated with the top of the hydrolysis acidogenic reactor; and the acetic acid producing reaction is carried out in the methanogenic reactor and the methane producing reaction is continuously carried out. The invention can separate the hydrolysis acidogenic process from the acetic acid and methane producing process in the anaerobic digestion process so as to prevent organic acids generated by the perishable organic wastes from inhibiting methanogenesis. The device has simple processing procedure, low cost, easy maintenance and stable and reliable performance, is suitable for anaerobic digestion treatment of various perishable organic wastes, and has highly efficient and stable biogas production capacity of the perishable organic wastes through the anaerobic digestion.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Kitchen waste disposal method and anaerobic fermentation reaction device

InactiveCN102703514ASpeed up the fermentation processHigh yieldBiological substance pretreatmentsGas production bioreactorsMicrobial transformationBiogas production

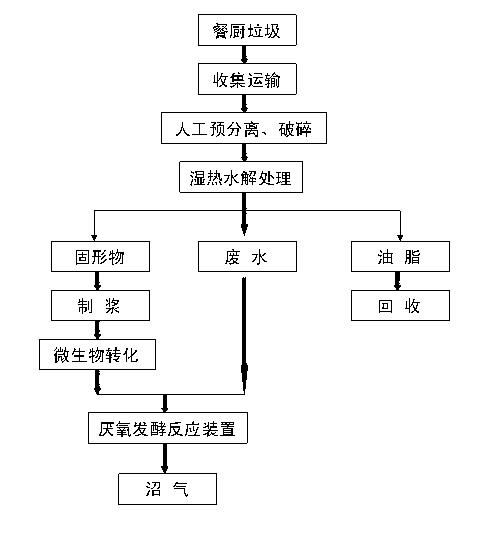

The invention discloses a kitchen waste disposal method, which comprises the following steps of: (1) screening and crushing kitchen waste; (2) carrying out damp and hot hydrolytic treatment; (3) carrying out solid-liquid separation; (4) carrying out fat separation; (5) pulping; (6) carrying out fermentation pretreatment, and (7) converting solid matter microorganism. According to the kitchen waste disposal method disclosed by the invention, from the view point of improving the biodegradation efficiency and the biogas production efficiency of the kitchen waste, the methane is prepared from compound microorganism bacterium agent and the processed kitchen waste by mixing and fermenting, and the microorganism bacterium agent fundamentally solves the problems of high saline matter and high fat of the kitchen waste and odour in a biological treatment process, and greatly improves the efficiency of producing the methane by anaerobic digestion.

Owner:无锡丰陆环保科技有限公司

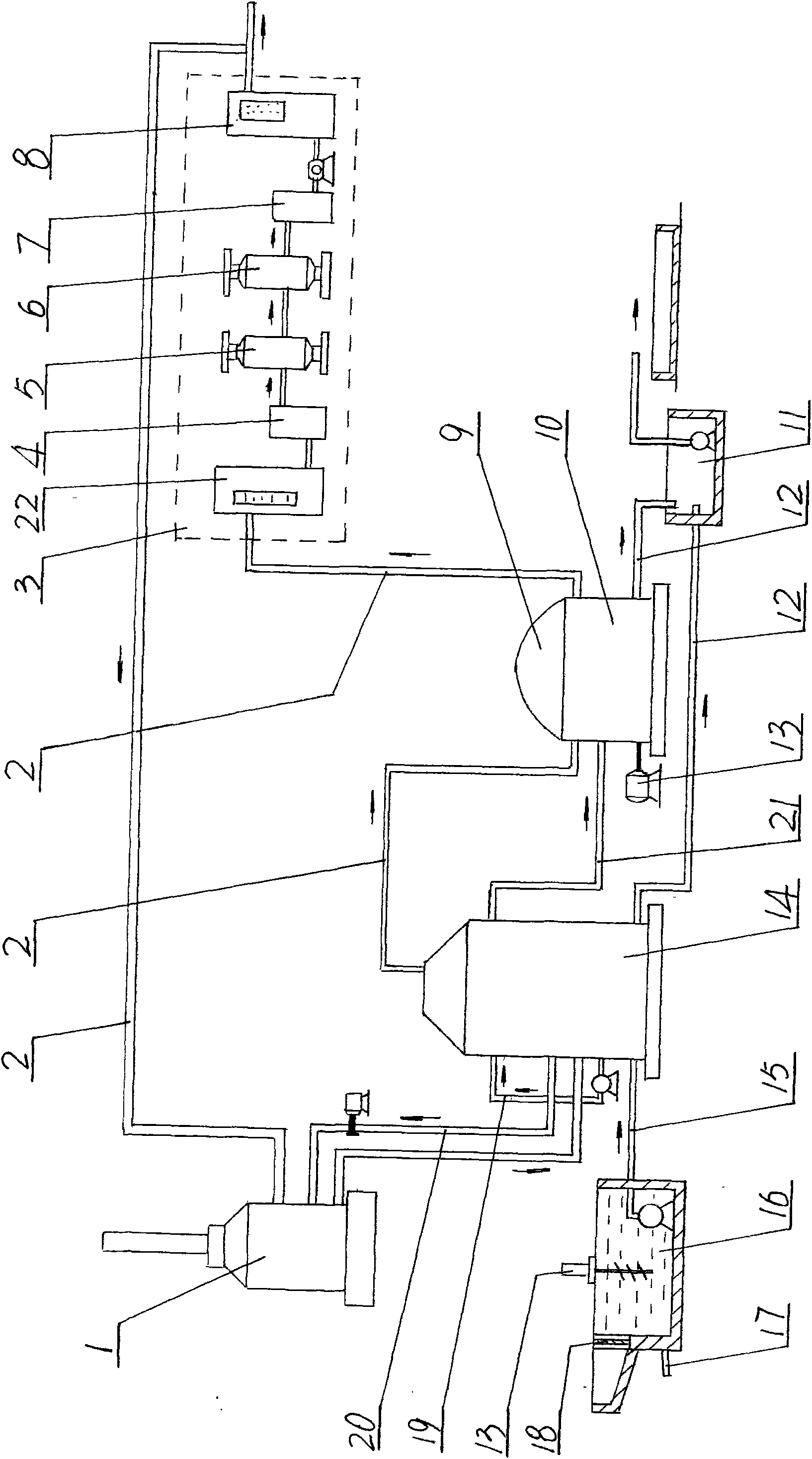

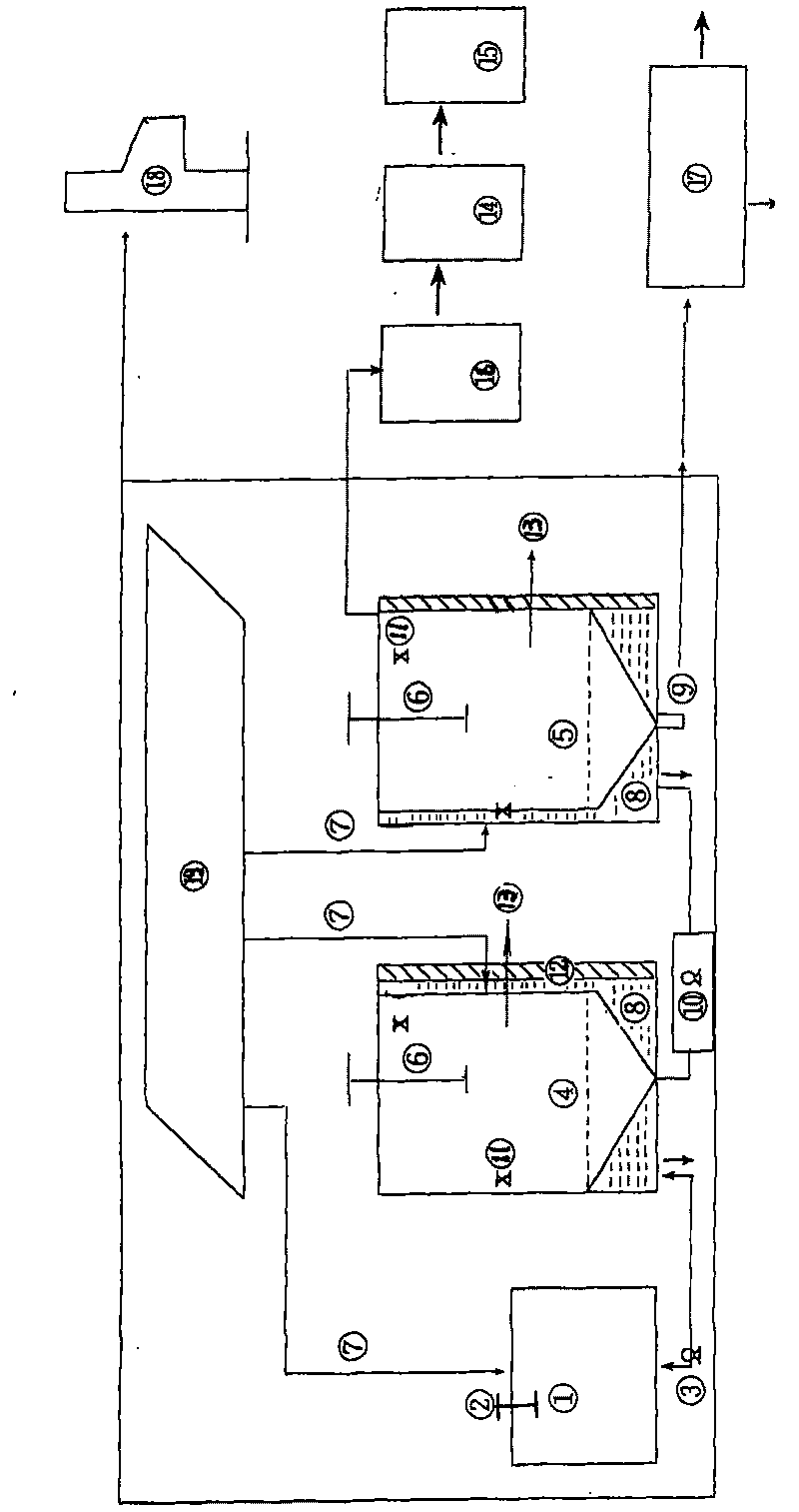

Secondary anaerobic fermentation and power generation system for large-middle scale biogas engineering

InactiveCN101597562AImprove processing efficiencyImprove gas production efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBiogas productionFermentation

The invention discloses a secondary anaerobic fermentation and power generation system for large-middle scale biogas engineering, which belongs to a biogas production device. The invention aims to provide a biogas production system which can be used for centralized power generation. The system comprises a pretreatment tank, a primary fermentation tank, a secondary fermentation tank and a biogas residue tank; the pretreatment tank (16) is communicated with a USR reactor (14) through a feeding pipe (15), the USR reactor is communicated with the secondary fermentation tank (10) through an overflow pipe (21) and a gas conduit (2), and the USR reactor (14) and the secondary fermentation tank (10) are communicated with the biogas residue tank (11) through a residue discharge pipe (12) respectively; and the secondary fermentation tank supplies biogas for a generator through a biogas purification device (3). The system realizes the conversion of biogas fermentation from a small-scale production mode to a centralized high-efficiency large-scale mode, and has the advantages of low cost, high efficiency of wastewater treatment, high gas yield and the like; and the system can be matched with large-scale livestock and poultry farms for construction, thereby achieving the aims of saving energy sources, reducing the emission, and protecting the agricultural ecological balance.

Owner:GUIZHOU QIAN LIN ZHOU ENVIRONMENTAL PROTECTION ENERGY TECH +1

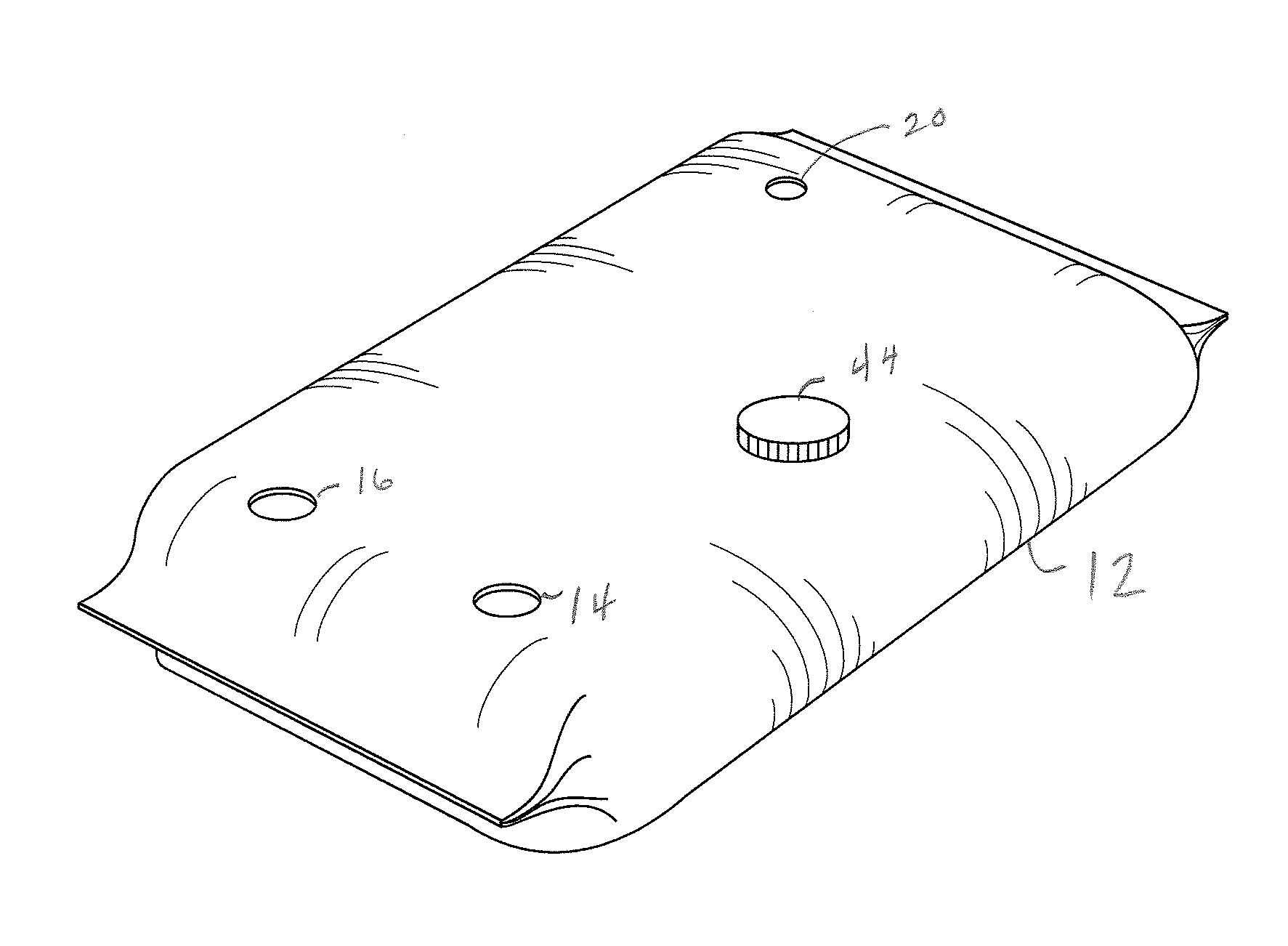

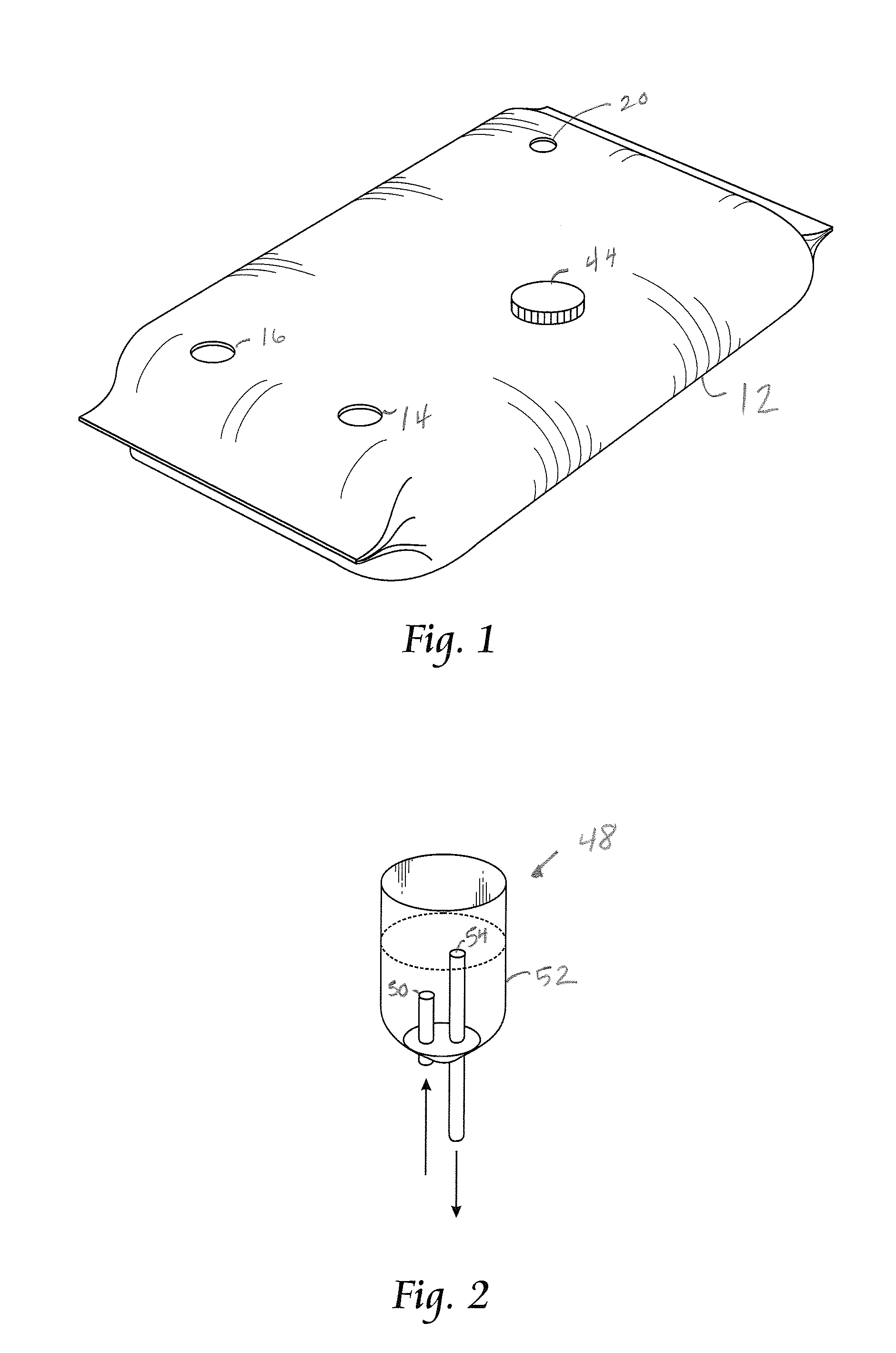

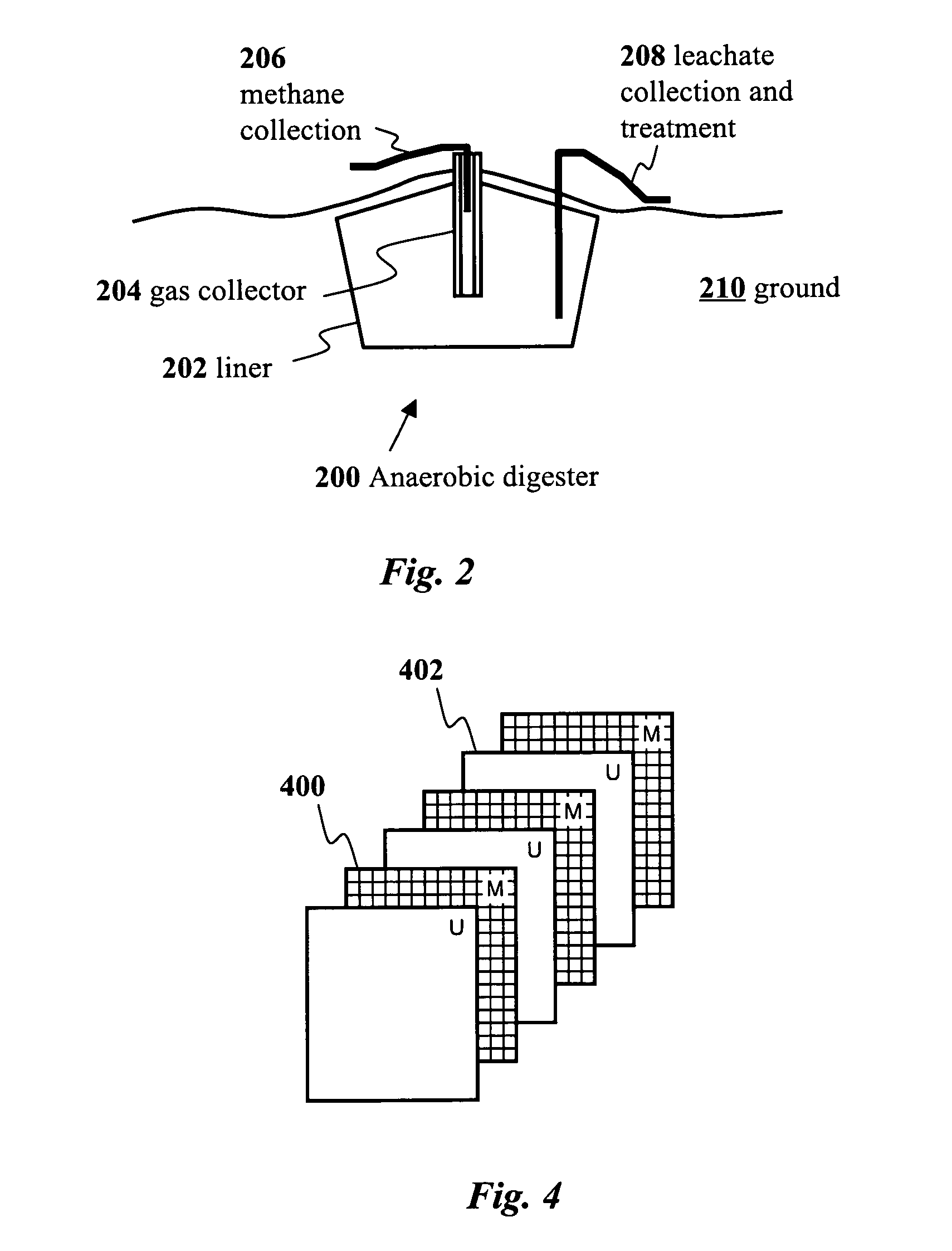

Anaerobic digester system for animal waste stabilization and biogas recovery

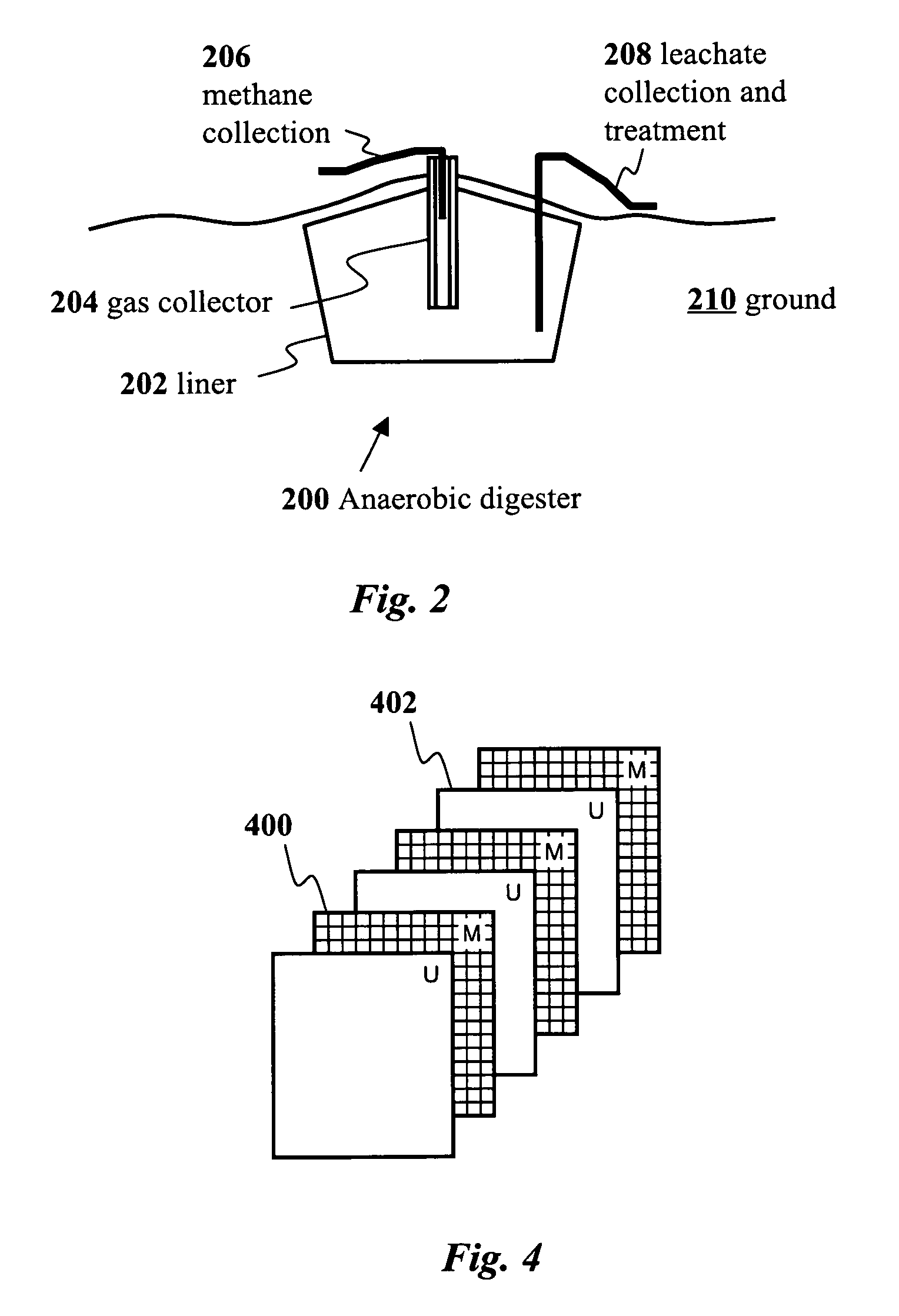

InactiveUS7186339B1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiogas productionEnergy expenditure

An ambient anaerobic digester system for anaerobic digestion of animal waste with biogas production and recovery is provided. The anaerobic digester system includes a substantially flexible bladder for anaerobically digesting the animal waste with biogas production and transmitting the biogas to at least one biogas storage container, biogas use device or a combination thereof. In a preferred form, the substantially flexible bladder has a waste inlet, a digester effluent outlet, one or more sludge access ports and a biogas outlet in a top surface thereof.The anaerobic digester system may inexpensively, simply, reliably, and effectively be used to treat animal waste without energy expenditure and little capital expense, thus minimizing pollution typically caused by animal waste.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

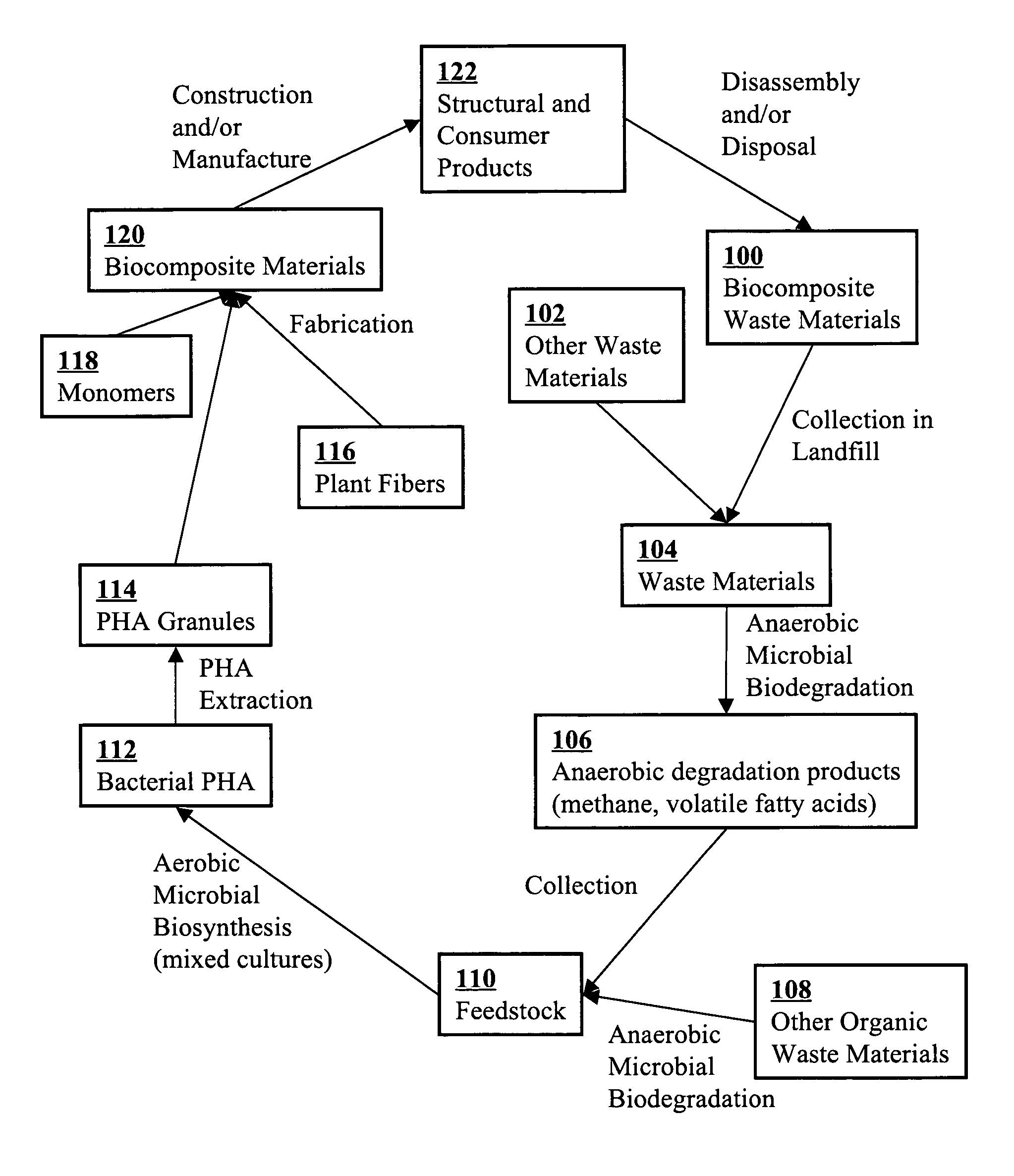

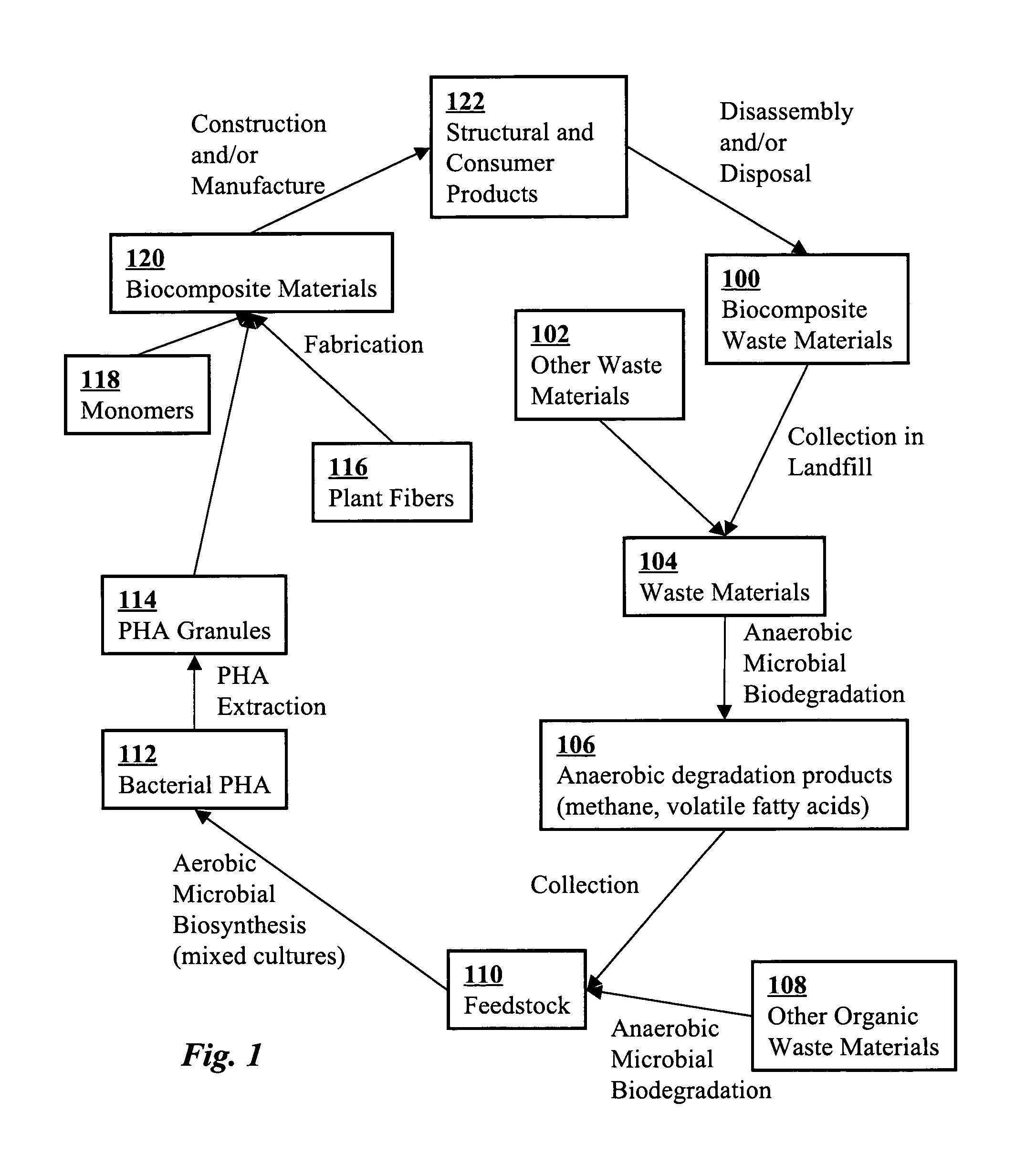

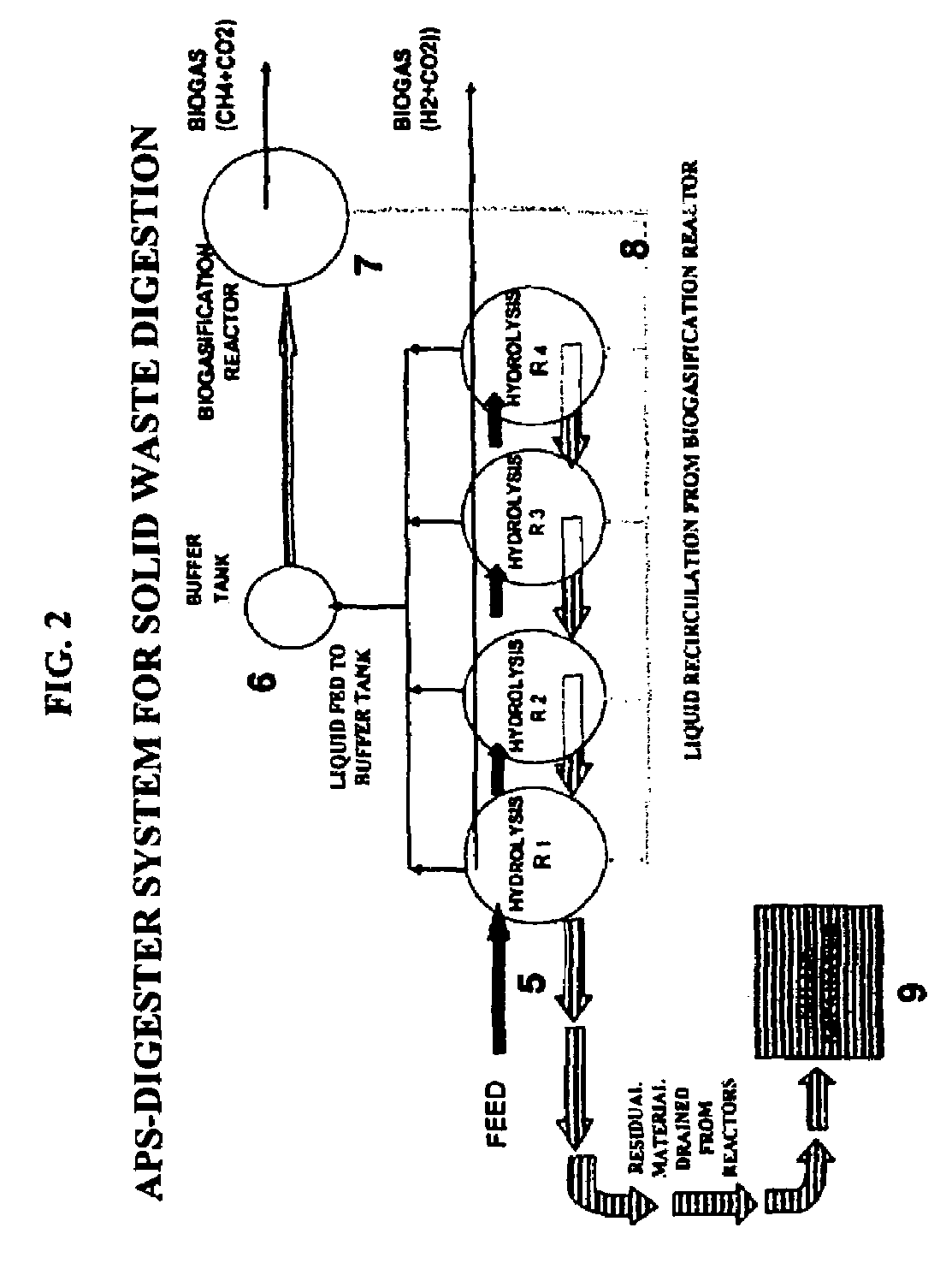

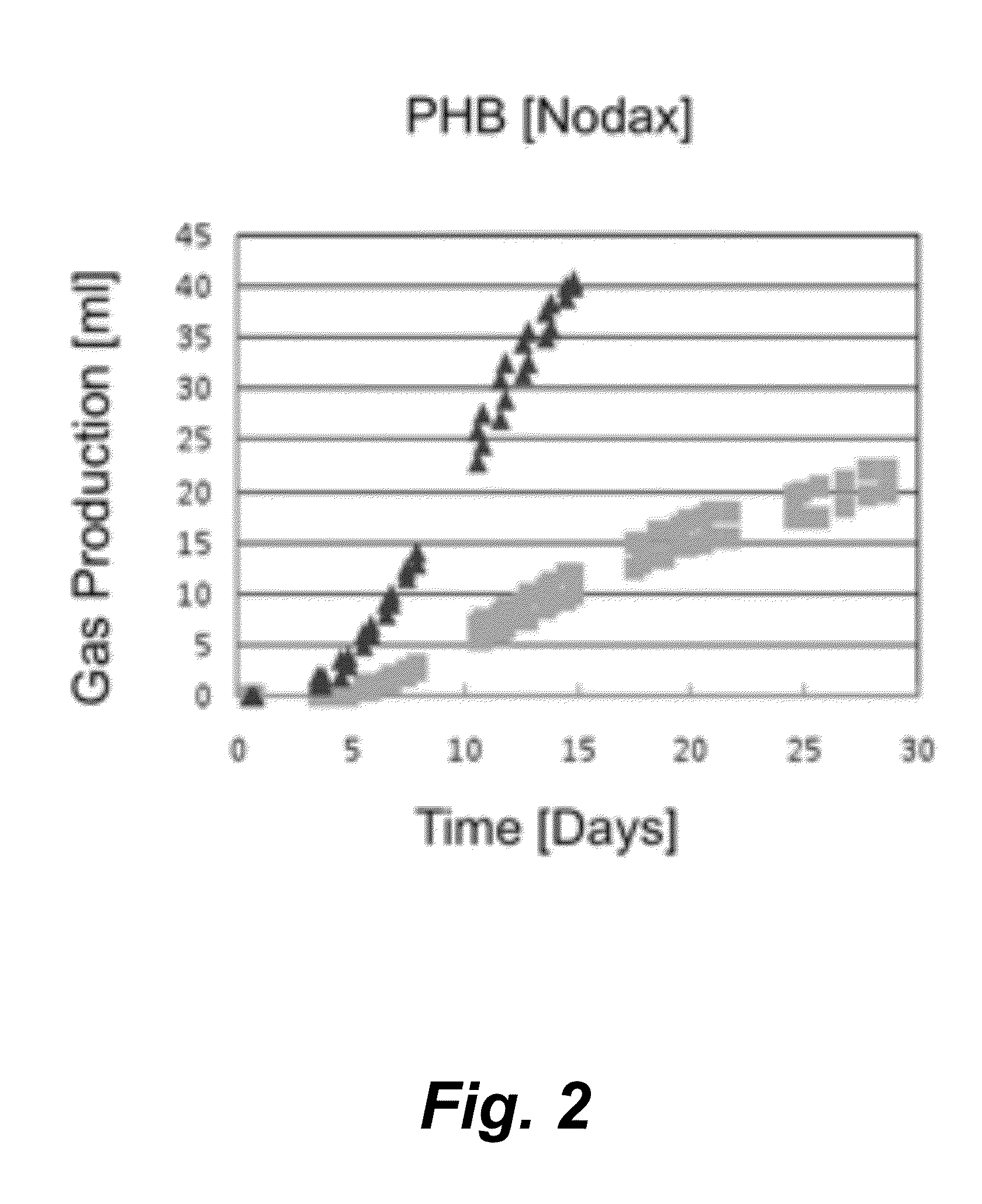

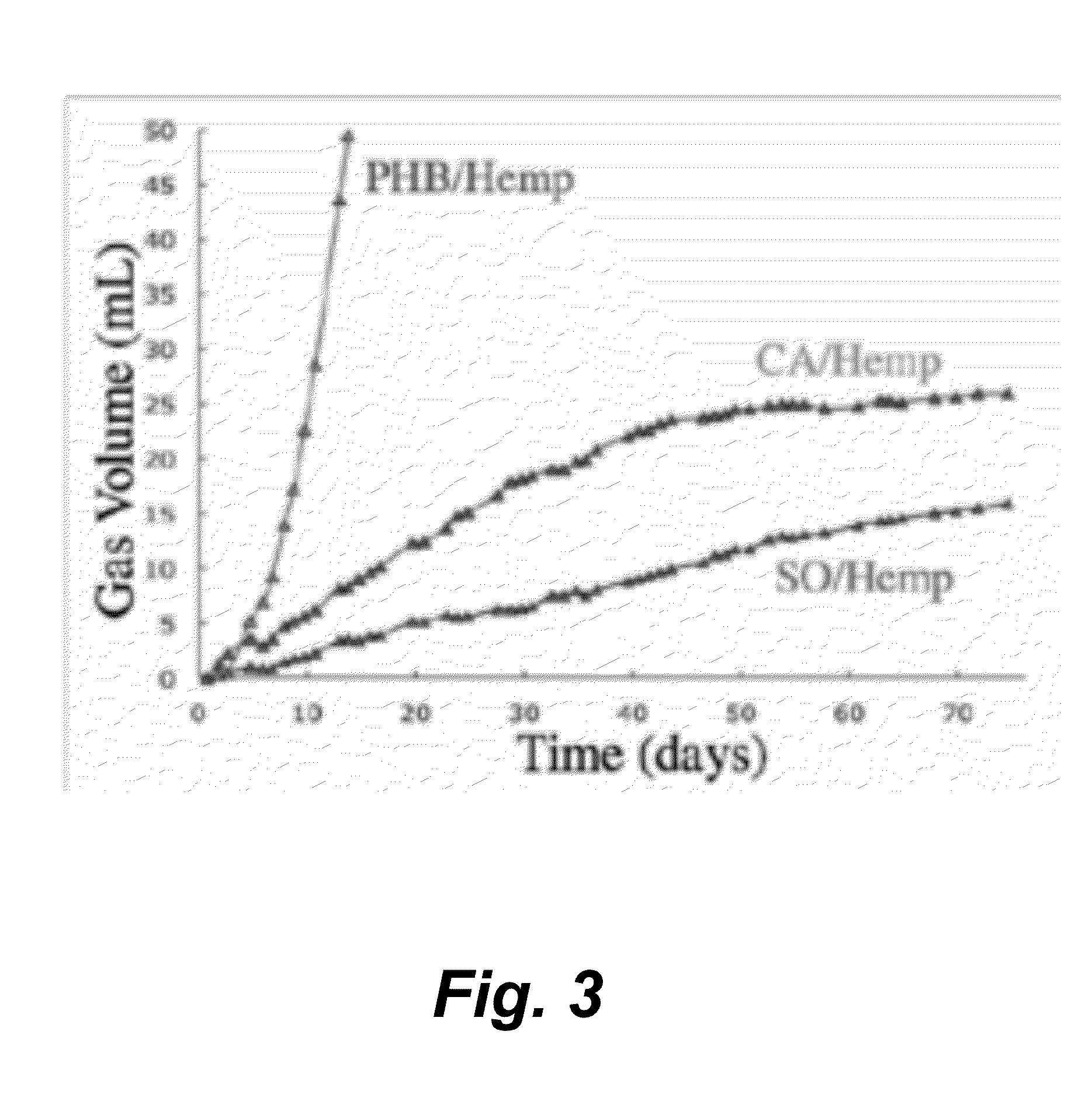

Bacterial poly(hydroxy alkanoate) polymer and natural fiber composites

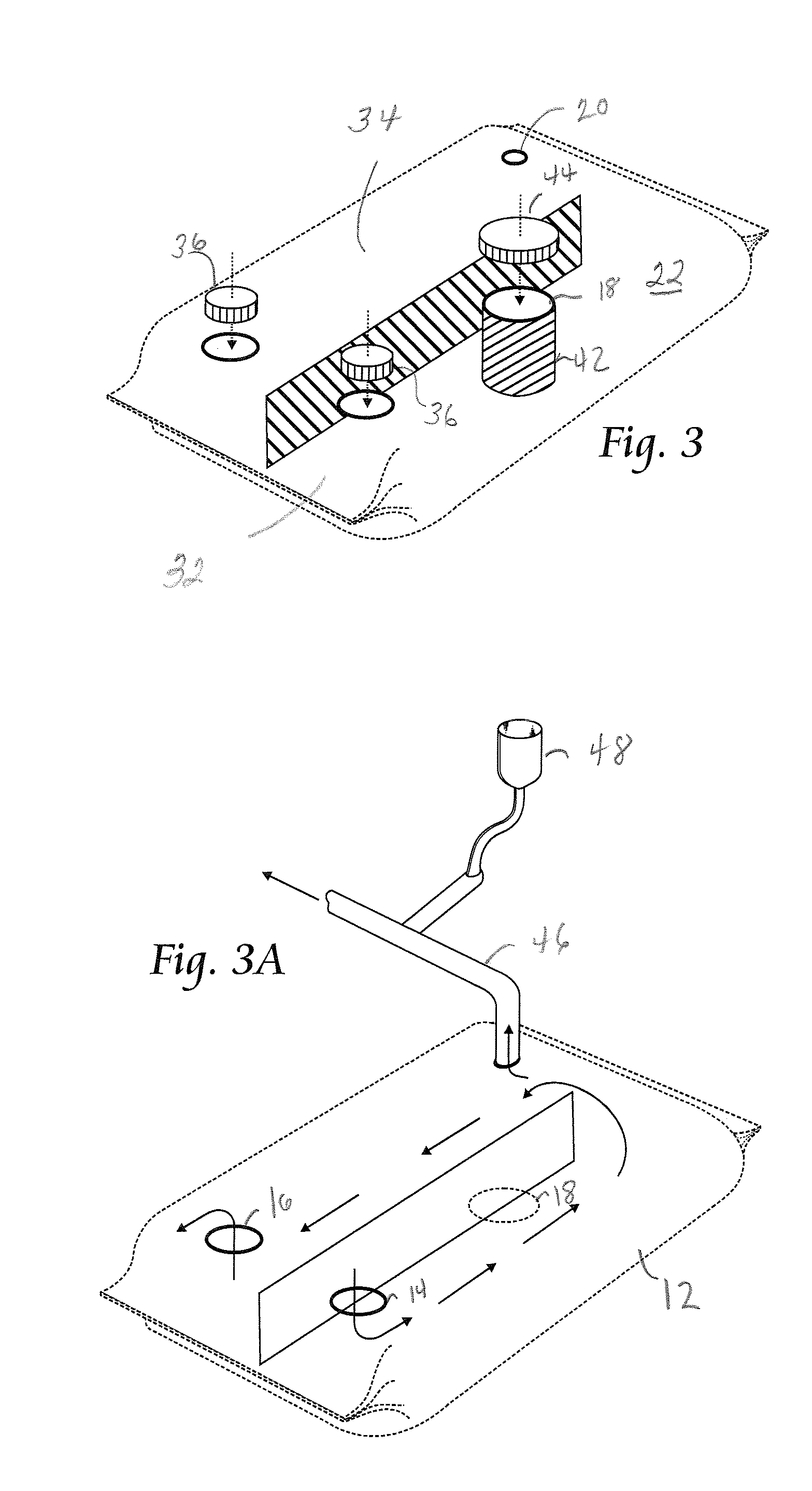

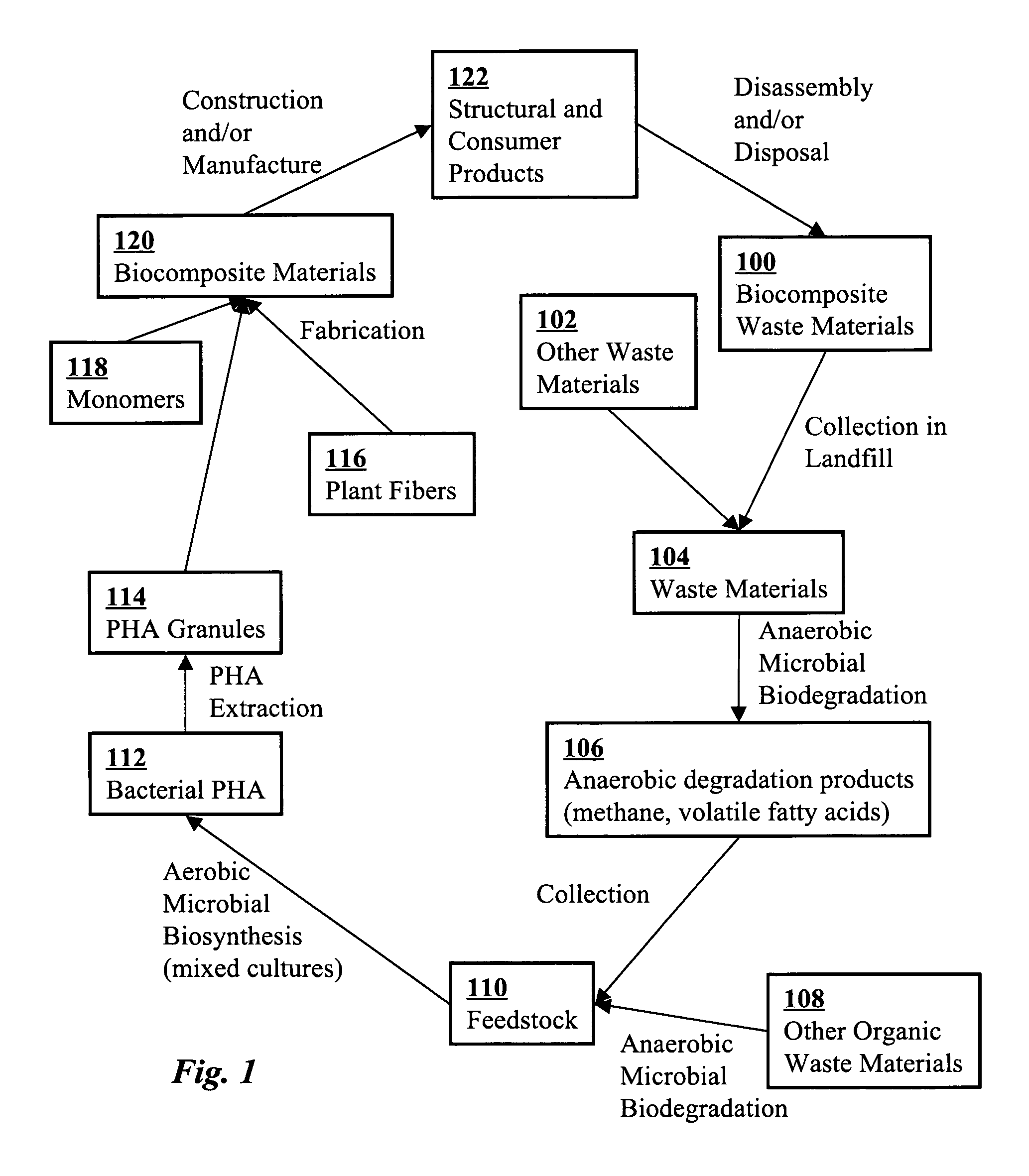

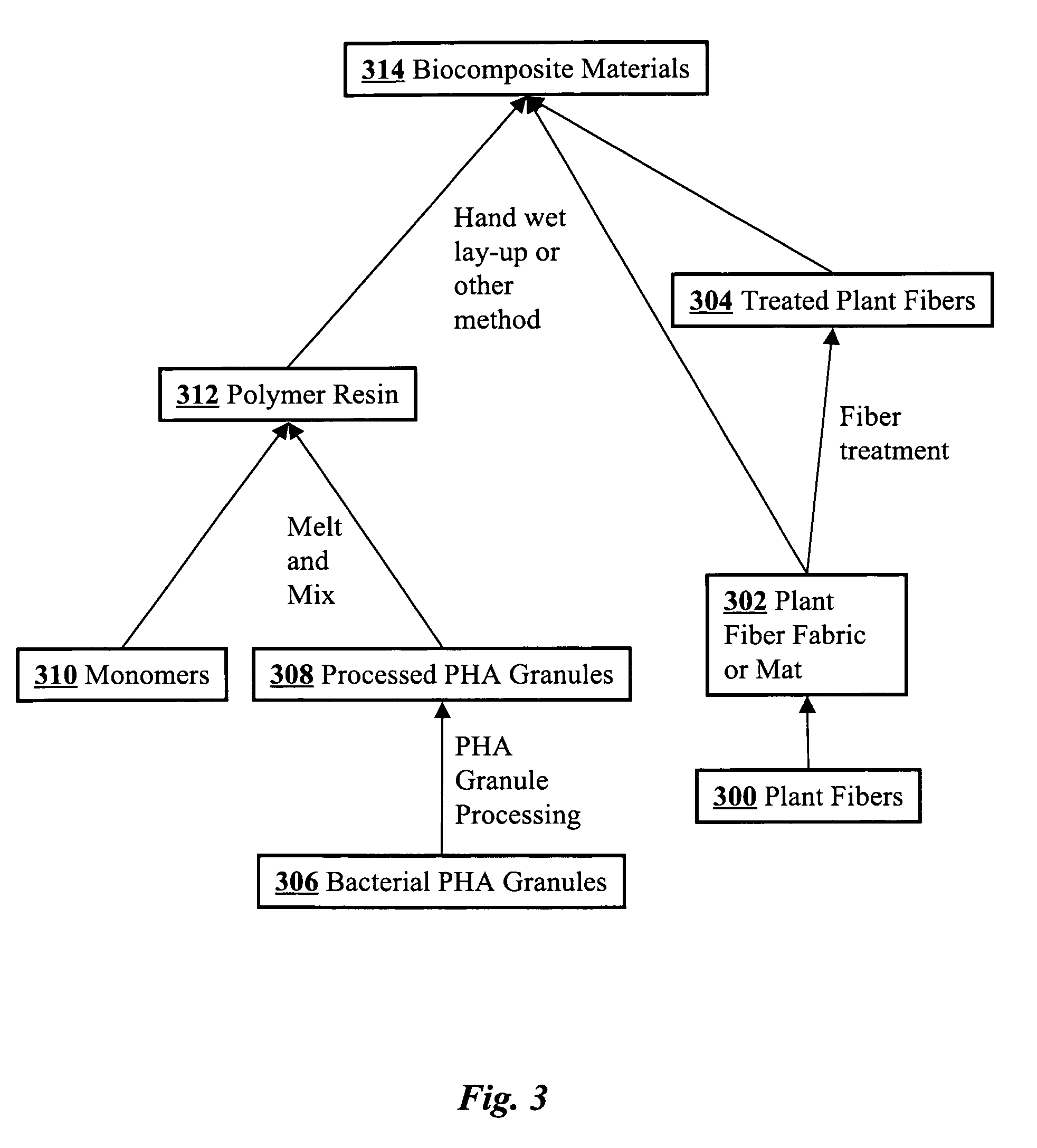

ActiveUS7887893B2Improve bindingImprove performanceLayered productsPedestrian/occupant safety arrangementVolatile fatty acidsResin matrix

A biocomposite is produced from natural fiber fabrics embedded in a matrix of biosynthetic polyhydroxy-alkanoate (PHA) polymers. The PHA is synthesized using aerobic microbial biosynthesis using mixed bacterial cultures and a feedstock containing anaerobic degradation products such as methane and volatile fatty acids derived from microbial biodegradation of organic waste materials, which may include waste biocomposites. Monomers may be added to the synthesized PHA polymer to control mechanical properties of the resulting biocomposite. The natural fibers and / or PHA may be pretreated using various techniques to improve the bond between the fibers and the PHA resin matrix and water absorption resistance of the fibers. The composite may be a laminate of treated and untreated fabric layers, or differently treated layers, to achieve good in-service performance as well as rapid and / or optimal biogas production when taken out of service and put in an anaerobic environment to degrade.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Water treatment plant for combined biomass and biogas production

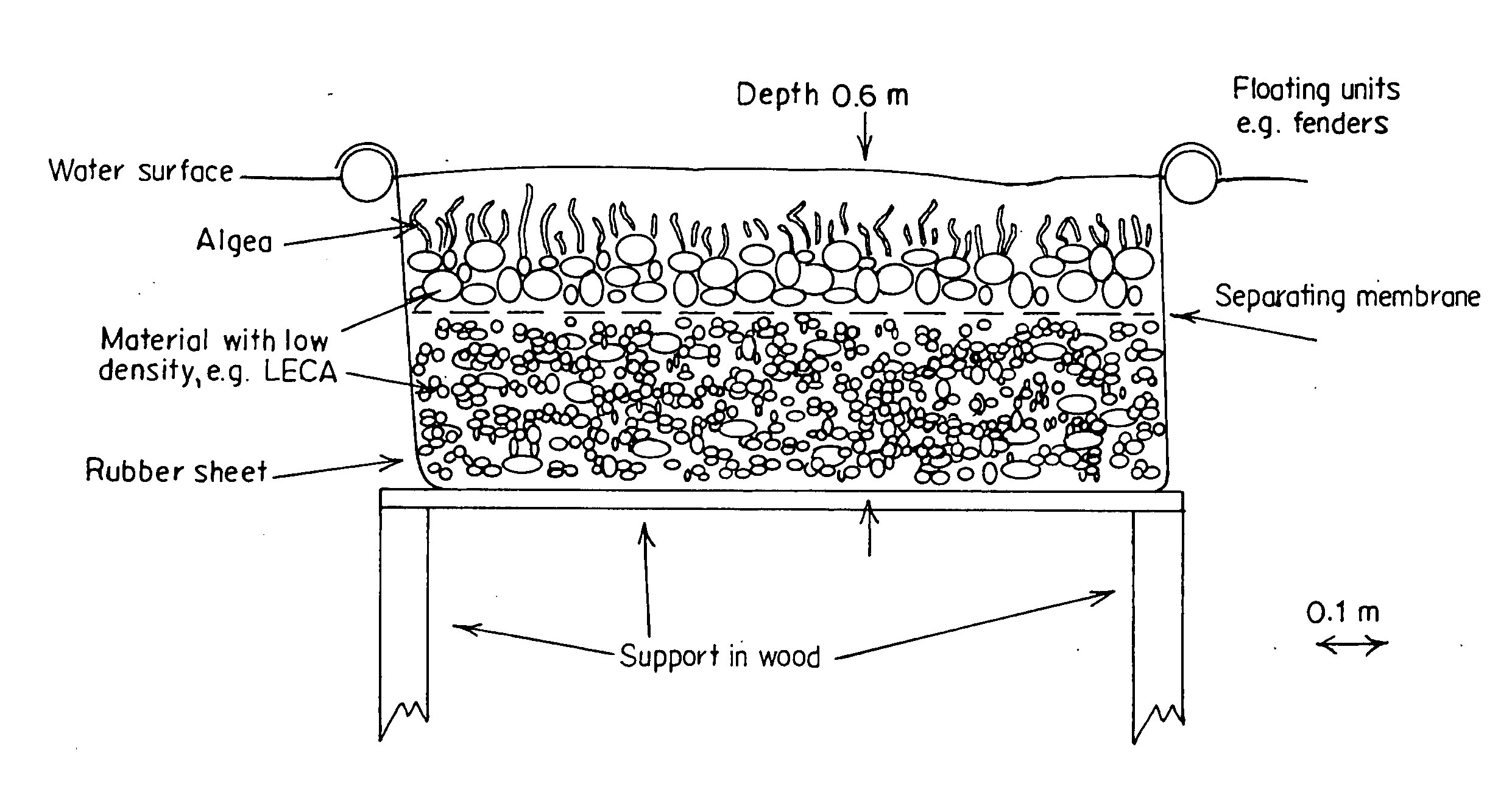

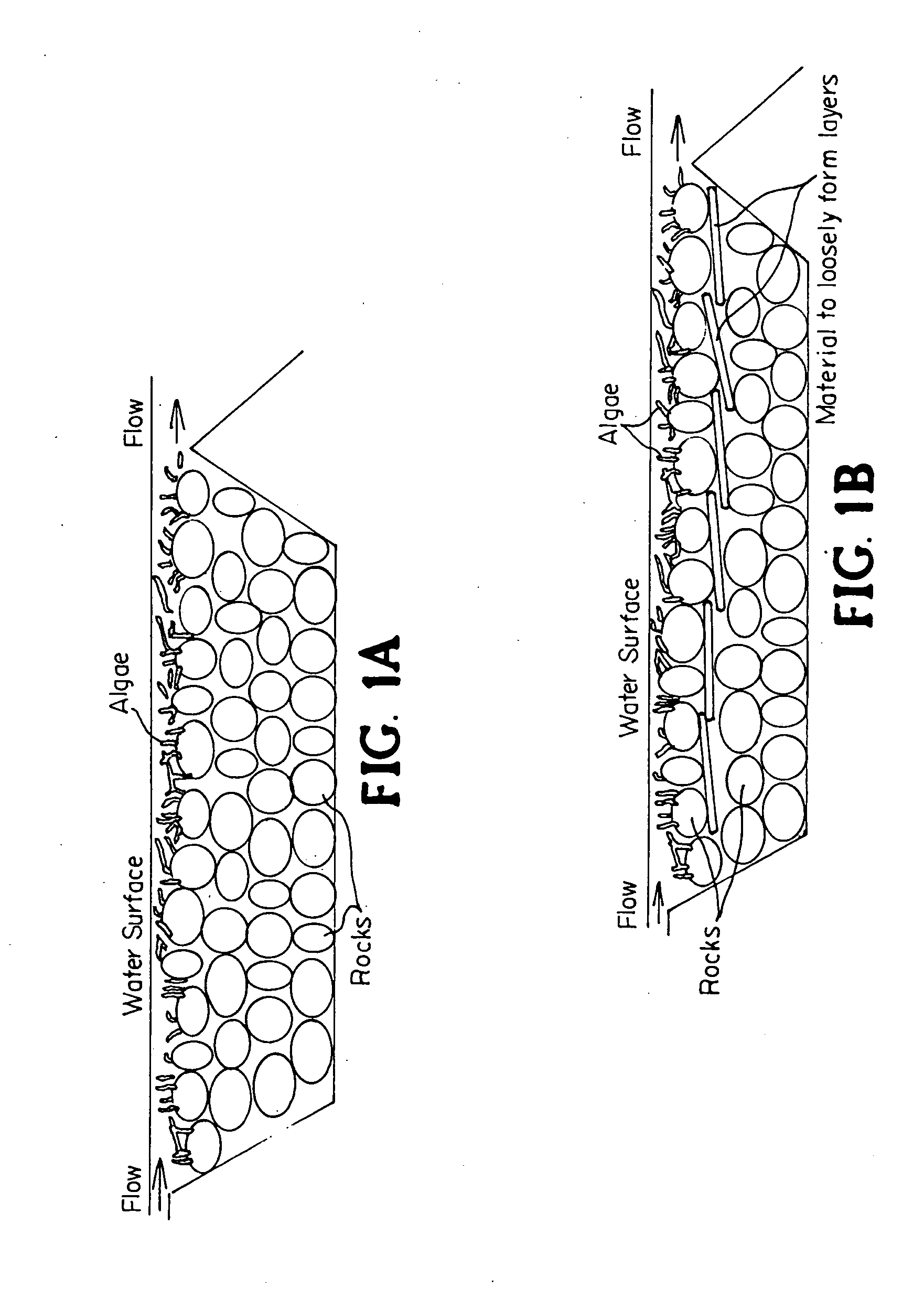

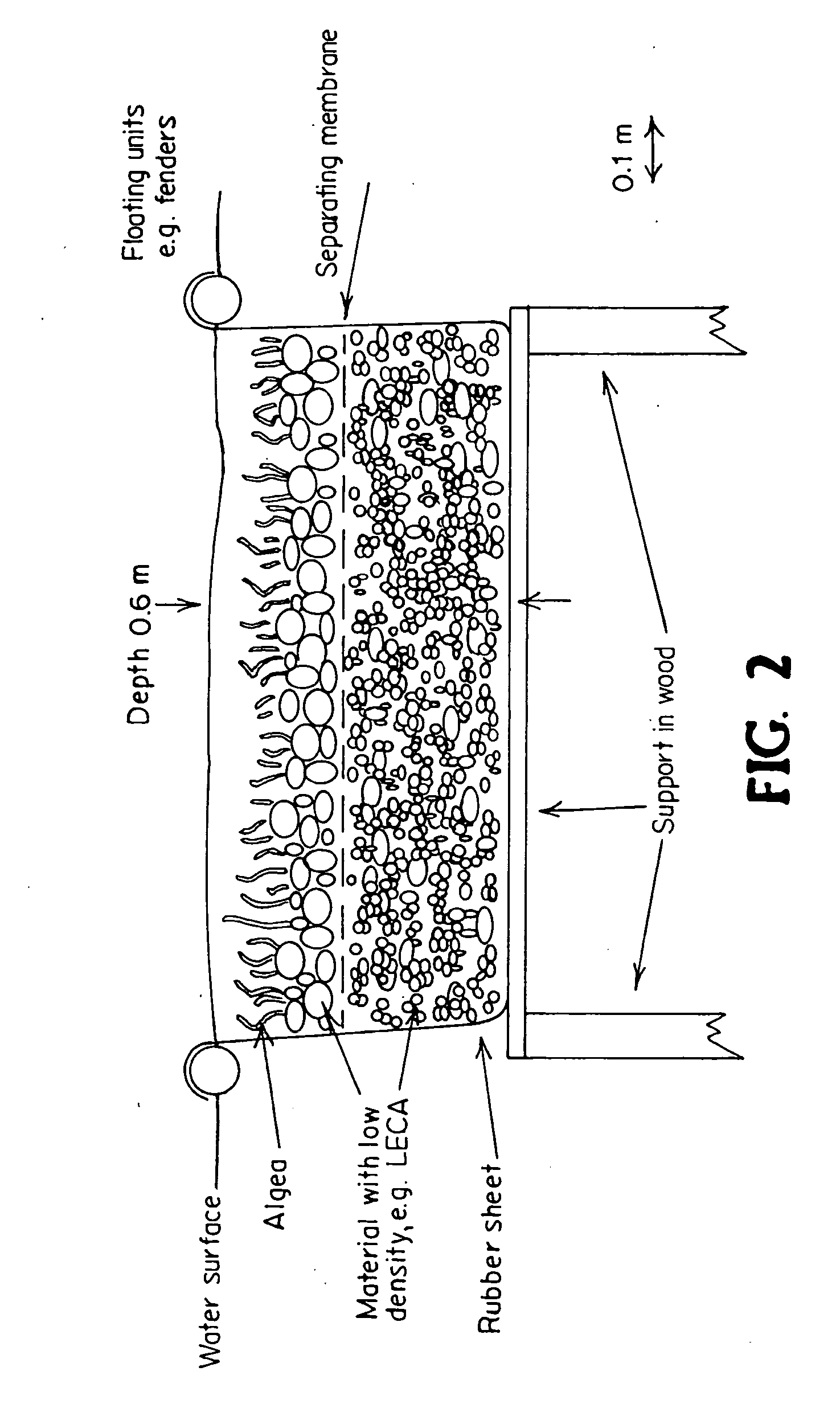

InactiveUS20120024780A1Easily harvested/collectedIncrease flexibilityBio-organic fraction processingWaste based fuelNitrifying bacteriaBiogas production

A waste water treatment system is provided that includes a basin for holding water; nitrifying and denitrifying bacteria; macroalgae; and a biobed having a at least one layer and being constructed of materials selected to provide sufficient level of pH for enabling bacterial growth. In the biobed de-nitrification and nitrification bacterial processes are separated. Oxygen produced by algae is used by the nitrifying bacteria. Water is provided continuously to the biobed at an inlet and exits the system downstream after having gone through the biobed. The system may be used with waste water in water treatment plants, domestic waste water (sewage), waste water from diverse industries, drain water from waste deposits, runoff water from roads, water waste treatment and recycling plants, agricultural and farm land and surrounding land of populated areas. The algae and bacteria are combined for symbiotic remediation of water that may be flexibly controlled to adapt to a broad range of applications.

Owner:CLEAR WATER ENERGY NORDIC

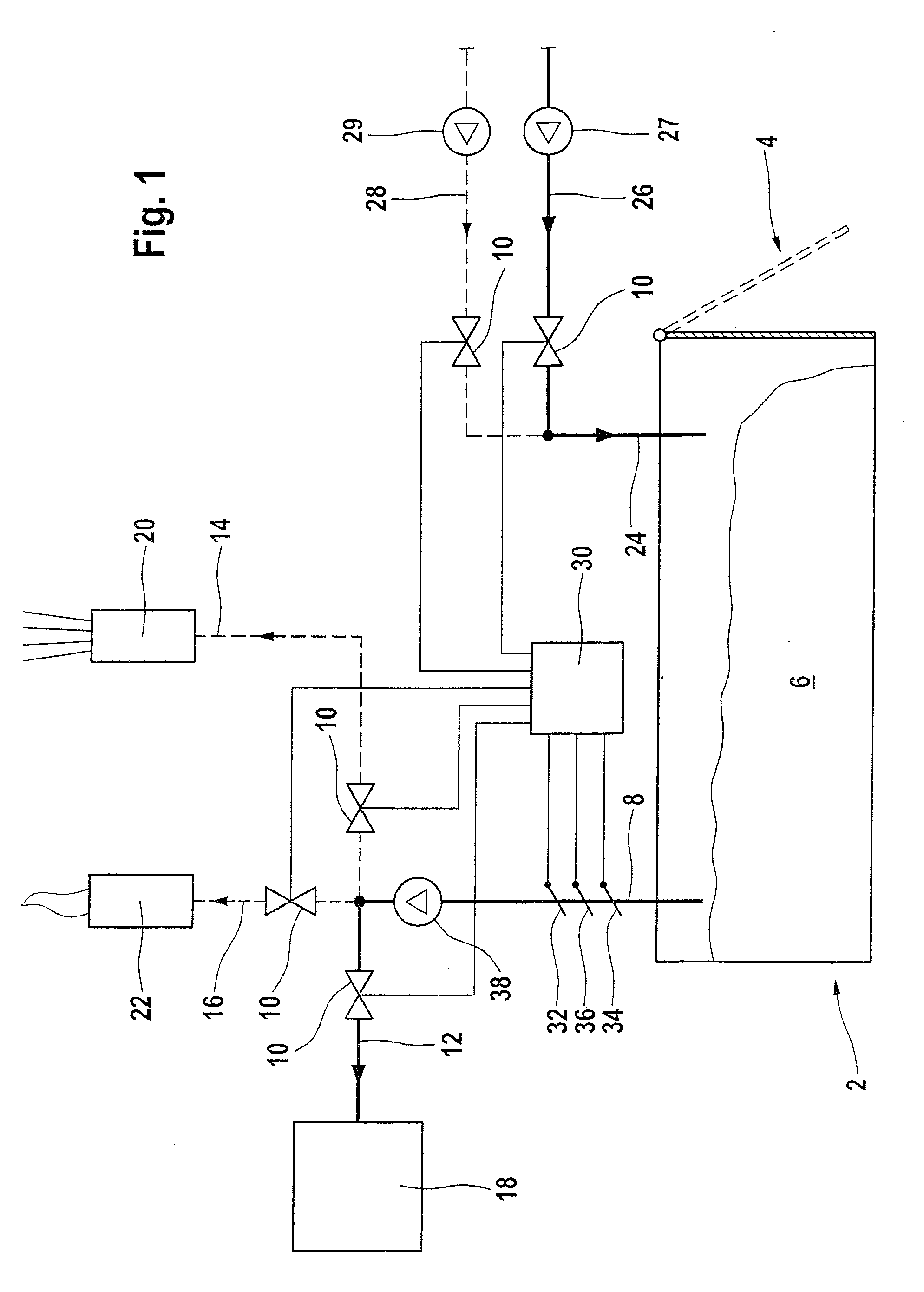

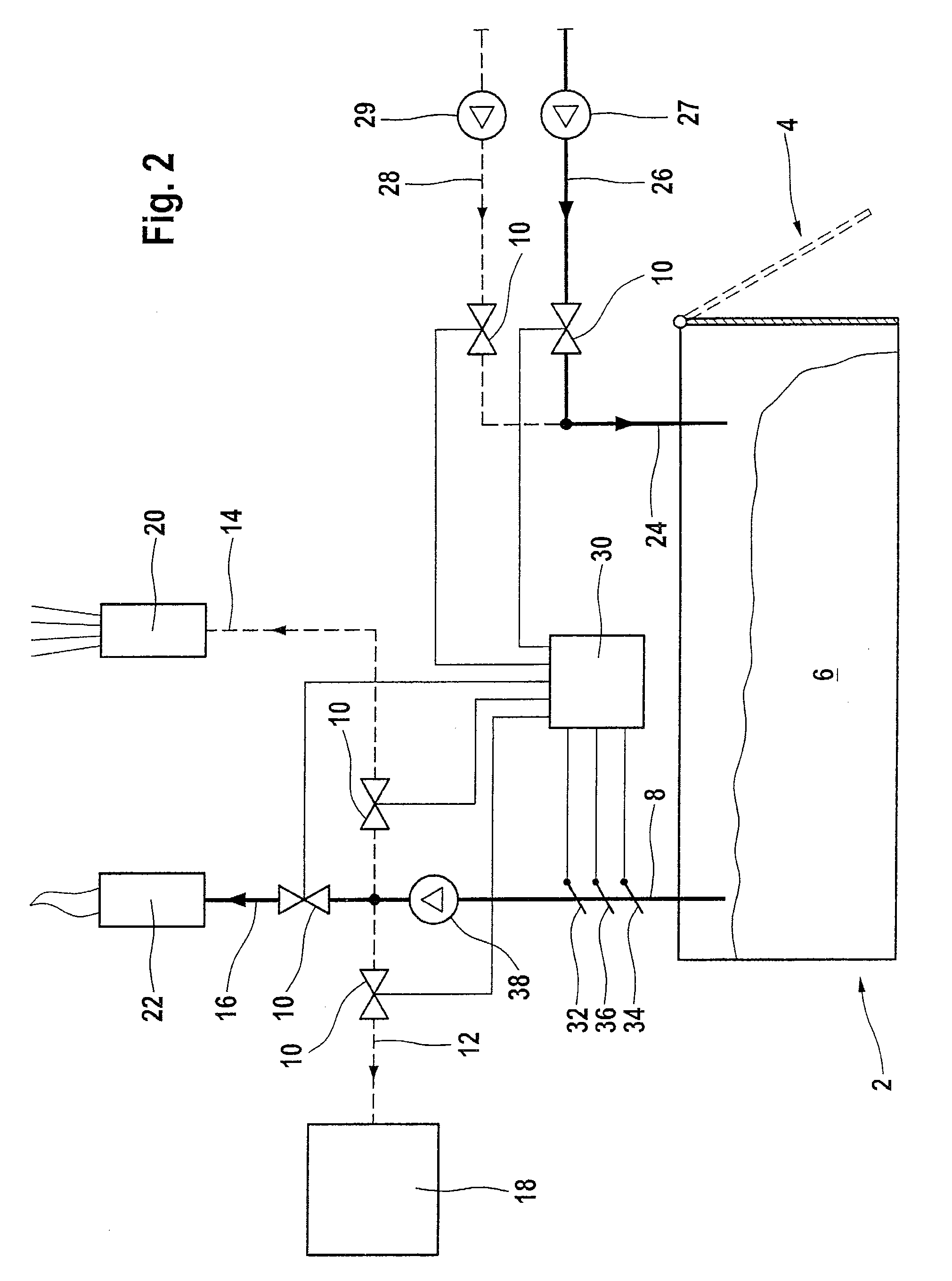

Biogas producing facility with anaerobic hydrolysis

InactiveUS20060275895A1Easy to operateReduce operating costsBioreactor/fermenter combinationsBiological substance pretreatmentsEnvironmental engineeringBiogas production

The present invention on relates to a method and a system for conversion of organic waste into biogas, i.e. a methane containing gas, with an improved efficiency and economy. The system comprises a reactor (3) for holding organic waste for production of biogas by digestion and having an output for digested waste, and an anaerobic tank (6) that is connected to the reactor (3) output for anaerobic hydrolysis of the digested waste and having an output for hydrolysed material that is connected to an input of the reactor for adding hydrolysed material to the content of the reactor. The anaerobic hydrolysis process makes the energy content of material that has not been digested in the reactor available for bacterial digestion and thus, the hydrolysed material is fed back into the reactor for further bacterial conversion into biogas.

Owner:BIO CIRCUIT

Bacterial poly(hydroxy alkanoate) polymer and natural fiber composites

ActiveUS20080160567A1Improve bindingGood in-service performanceLayered productsPedestrian/occupant safety arrangementVolatile fatty acidsResin matrix

A biocomposite is produced from natural fiber fabrics embedded in a matrix of biosynthetic polyhydroxy-alkanoate (PHA) polymers. The PHA is synthesized using aerobic microbial biosynthesis using mixed bacterial cultures and a feedstock containing anaerobic degradation products such as methane and volatile fatty acids derived from microbial biodegradation of organic waste materials, which may include waste biocomposites. Monomers may be added to the synthesized PHA polymer to control mechanical properties of the resulting biocomposite. The natural fibers and / or PHA may be pretreated using various techniques to improve the bond between the fibers and the PHA resin matrix and water absorption resistance of the fibers. The composite may be a laminate of treated and untreated fabric layers, or differently treated layers, to achieve good in-service performance as well as rapid and / or optimal biogas production when taken out of service and put in an anaerobic environment to degrade.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Anaerobic phased solids digester for biogas production from organic solid wastes

InactiveUS7556737B2Less air emissionImprove conversion efficiencyBiological substance pretreatmentsLiquid degasificationBuffer tankBiogas production

The present invention provides methods for the generation of methane by a two phase anaerobic phase system (APS) digestion of organic substrates. Also provided is a device for practicing the methods of the invention. The APS-digester system is a space-efficient, high-rate solids digestion system. The APS-digester system consists of one or more hydrolysis reactors, a buffer tank and one biogasification reactor.

Owner:RGT UNIV OF CALIFORNIA

Home device and method for producing methane by dry-type fermentation of stalks

InactiveCN101338273AReduce handling difficultiesSmall footprintGas production bioreactorsWaste based fuelSludgeSlag

The invention relates to a device for producing biogas by straw dry type fermentation and a method, belongs to the agriculture environmental protection and biomass energy source utilization field. The straw is chopped. Nitrogen fertilizers are added. C / N is adjusted. The mixture is arranged in a column shaped biogas digester built underground after the mixture is composted. Anaerobic fermentation outcomes are inoculated and sealed with red-sludge plastic. The biogas is produced in the process of anaerobic fermentation. When the biogas production is lowered, the straw is processed eluviation by biogas liquid which is pumped by manual pumping device. When the biogas production is obviously reduced, the new materials should be changed. The straw dry typed anaerobic biogas can be realized. The technical requirements that the straw is substituted the animal manure as the main raw materials are achieved. The straw dry typed fermentation technology is used, which can reduce the difficulties in treating biogas liquid and biogas slag of the wet typed anaerobic fermentation biogas. At the same time, the volumetric biogas production of the biogas digester is improved, and the biogas digester building cost is lowered and the biogas digester occupied area is reduced. The designed biogas fluid backflow system solves the difficulty of the exchange of mass flows and substances in the straw dry typed fermentation.

Owner:JIANGSU ACAD OF AGRI SCI

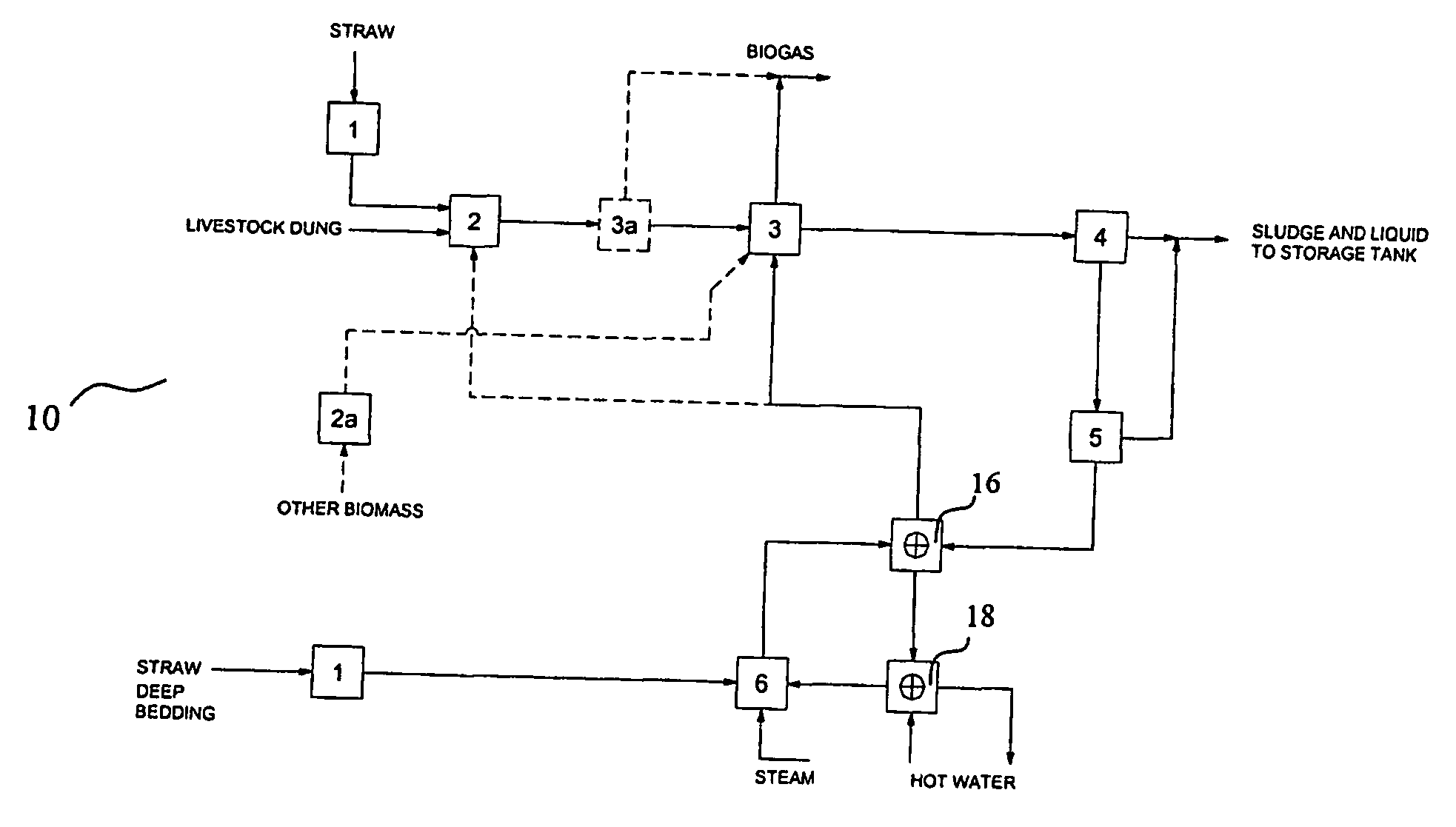

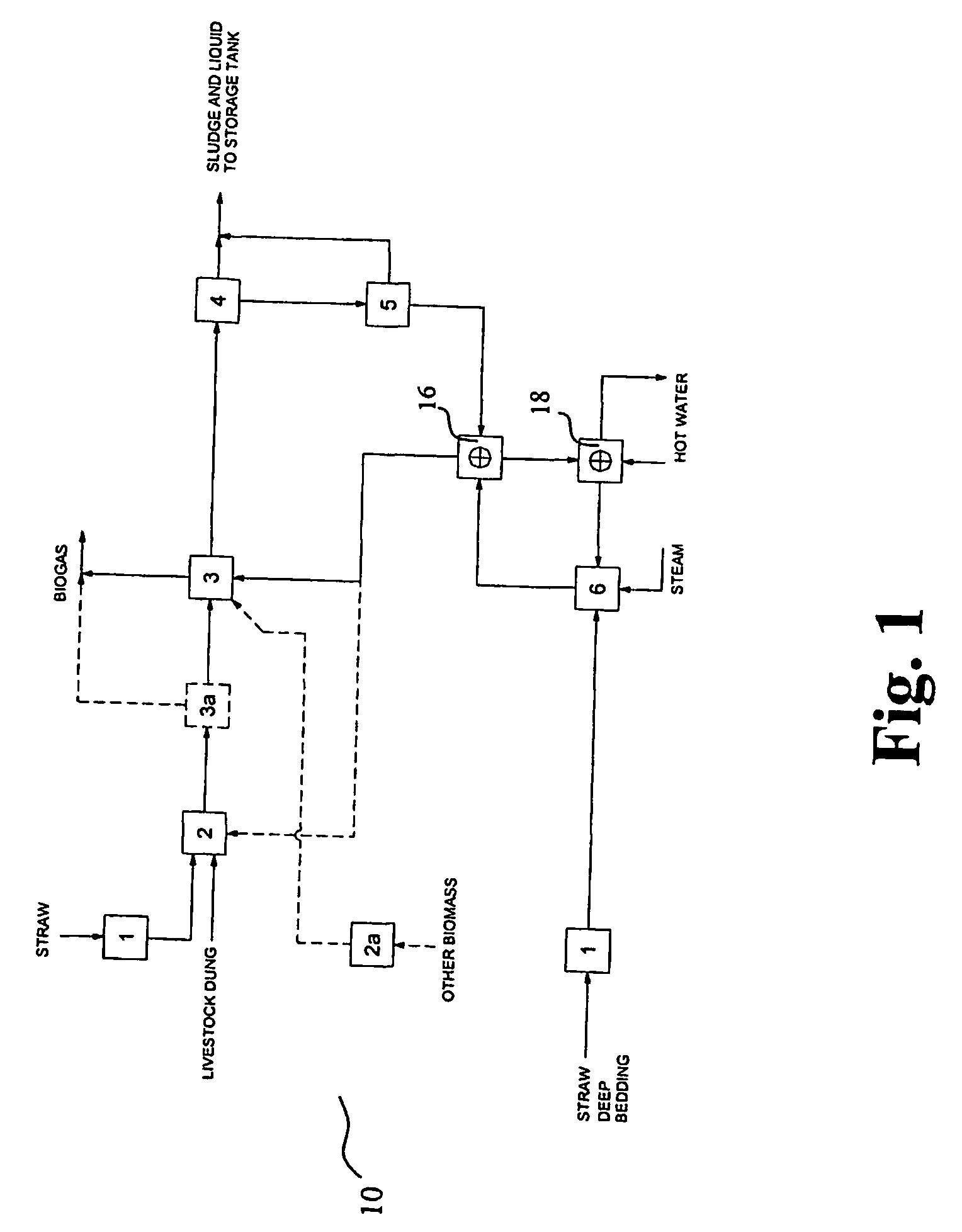

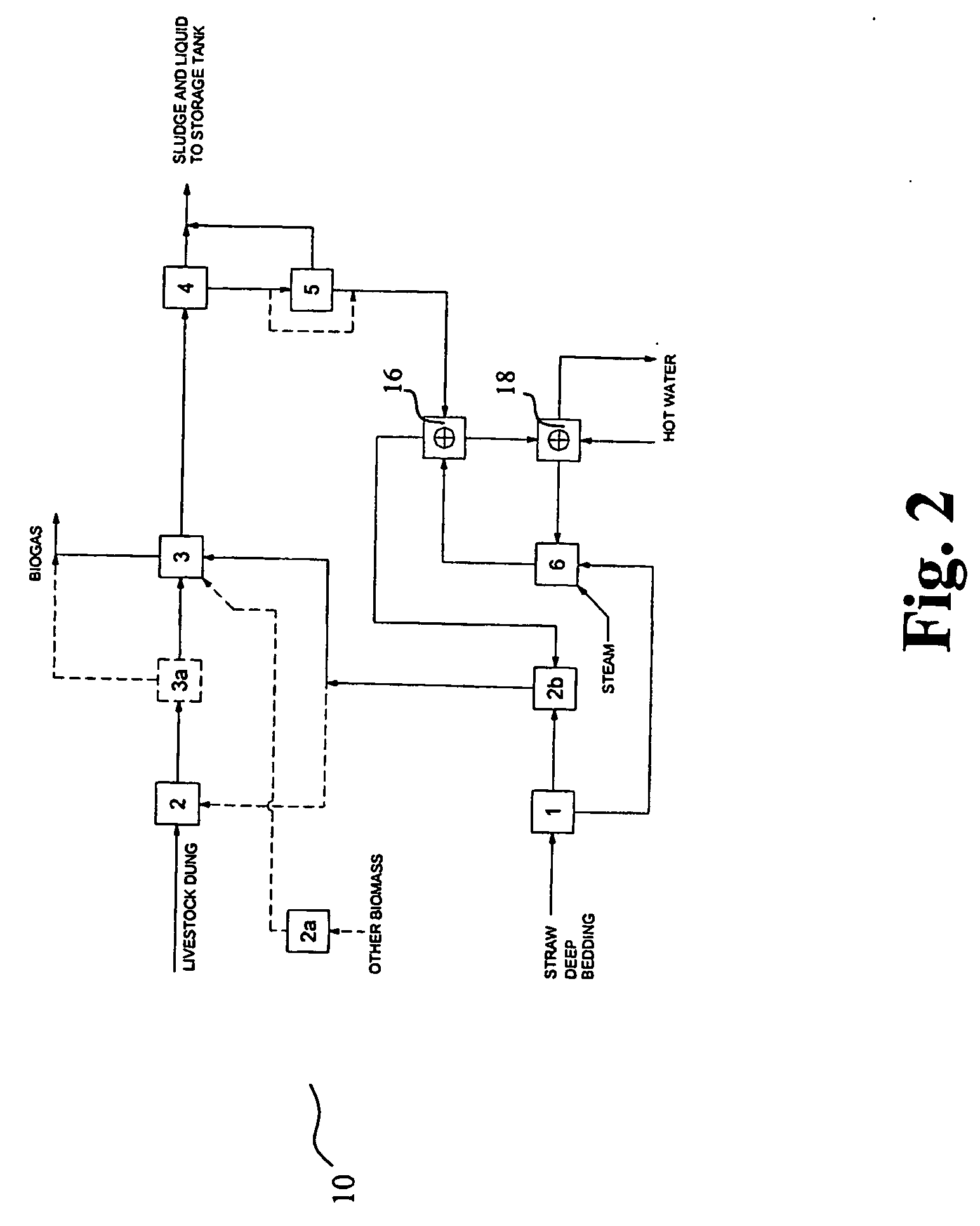

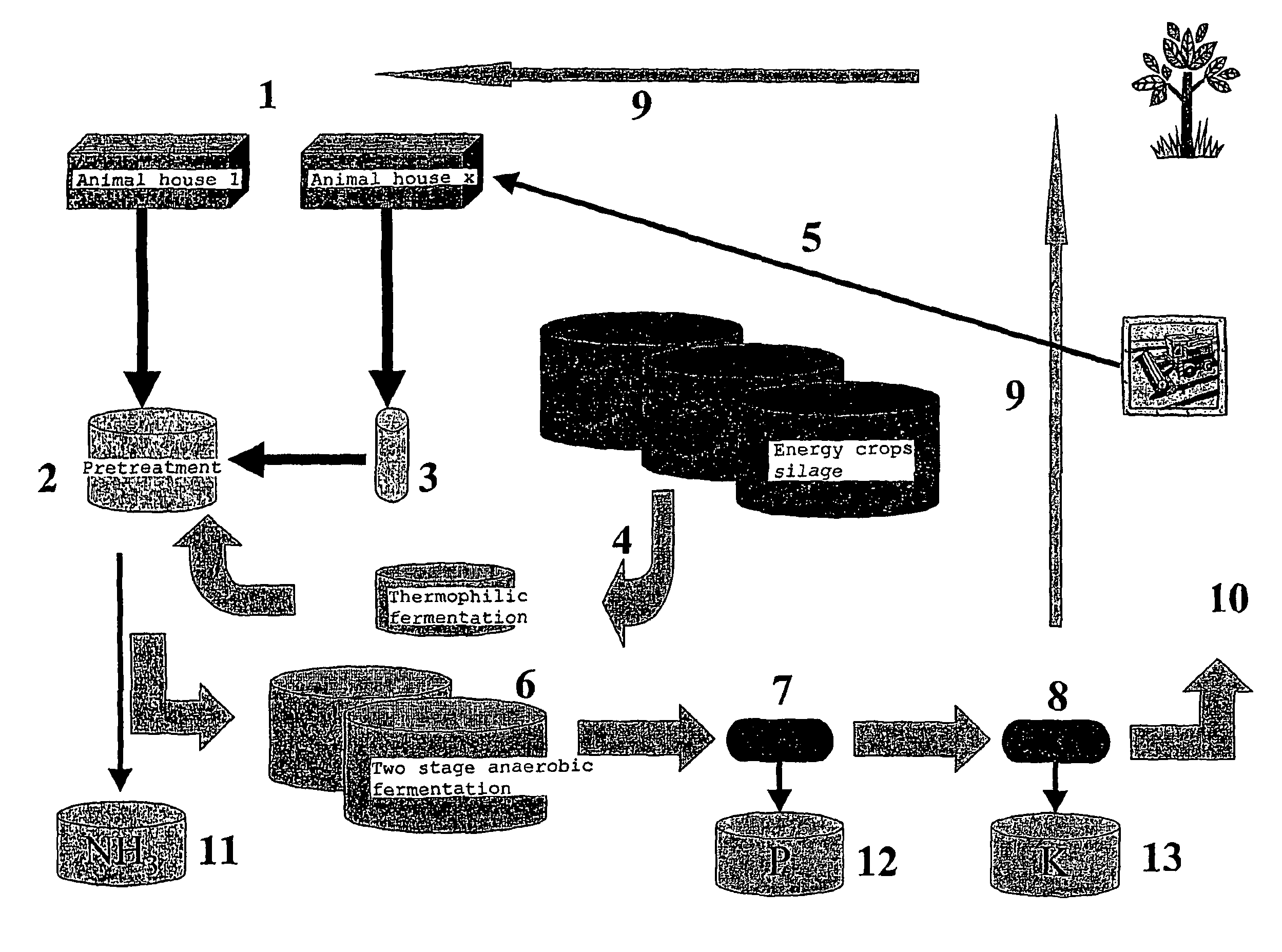

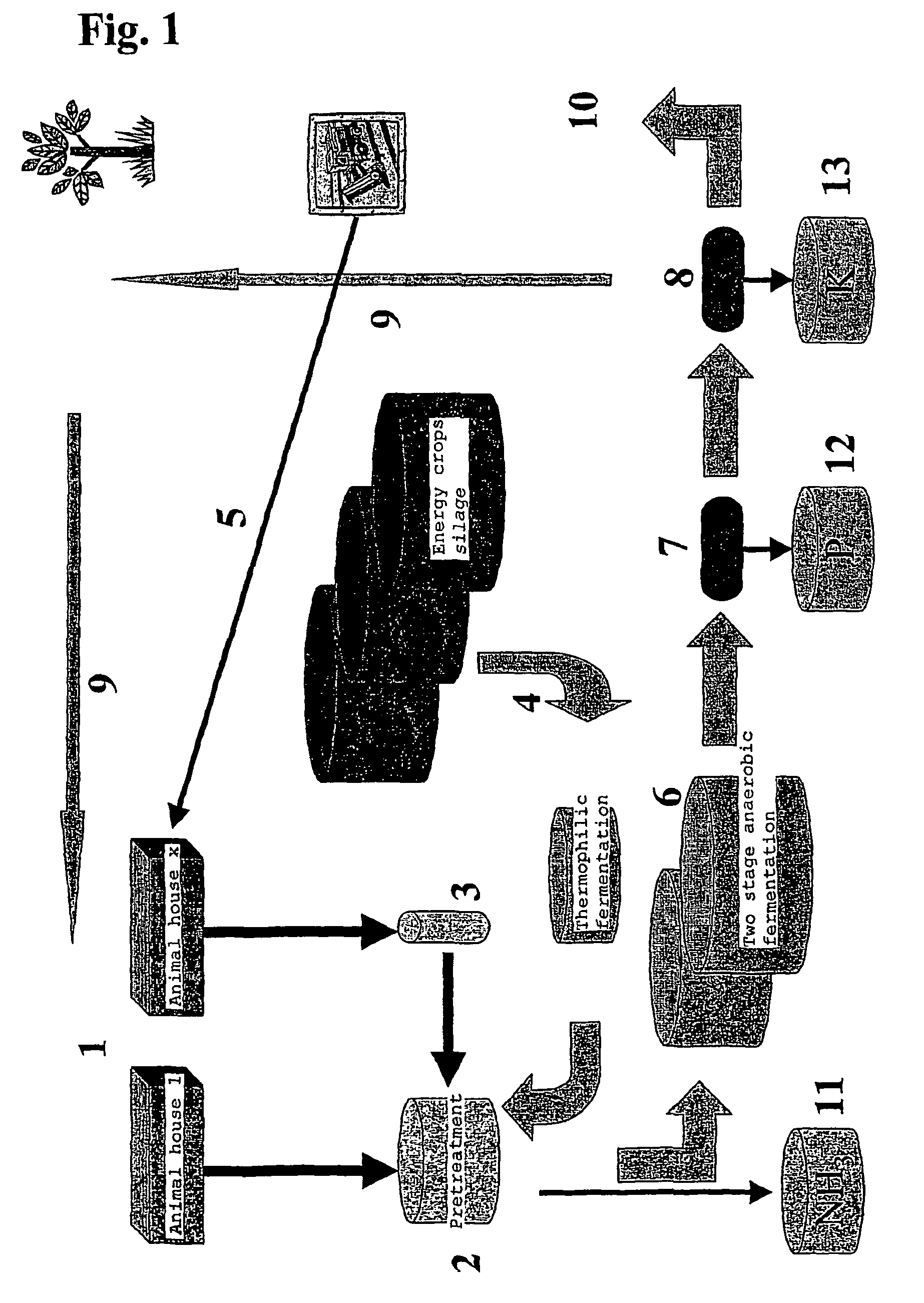

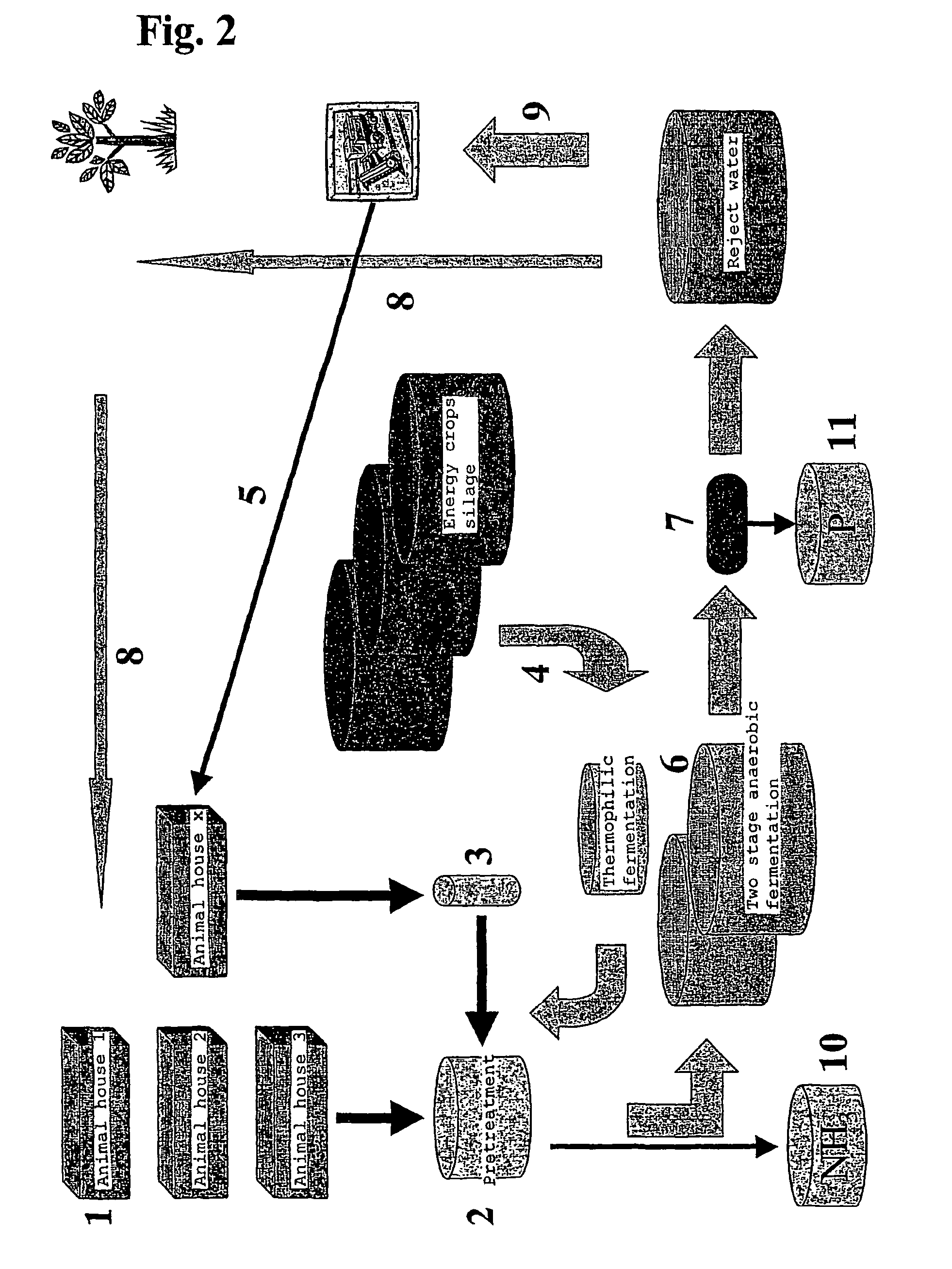

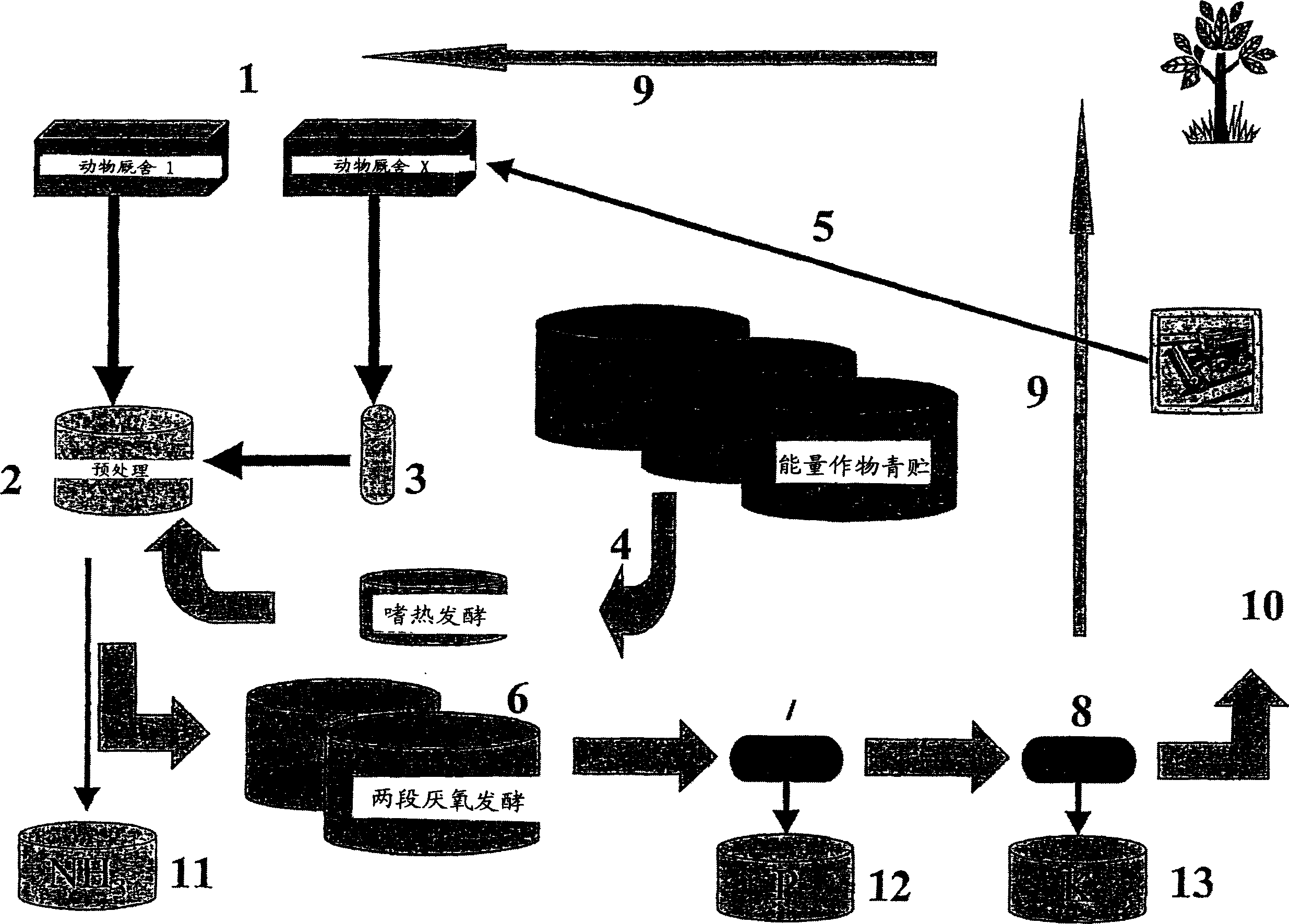

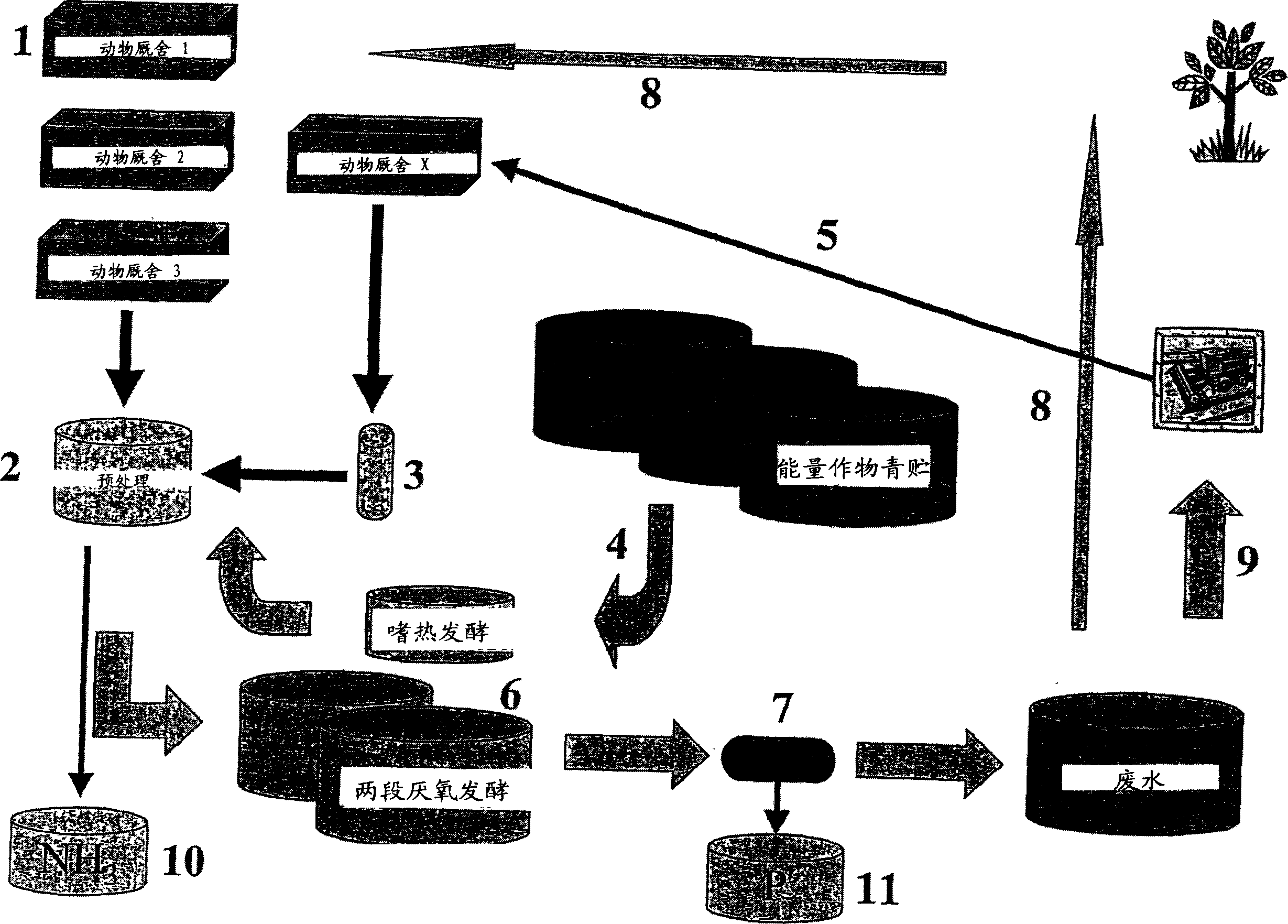

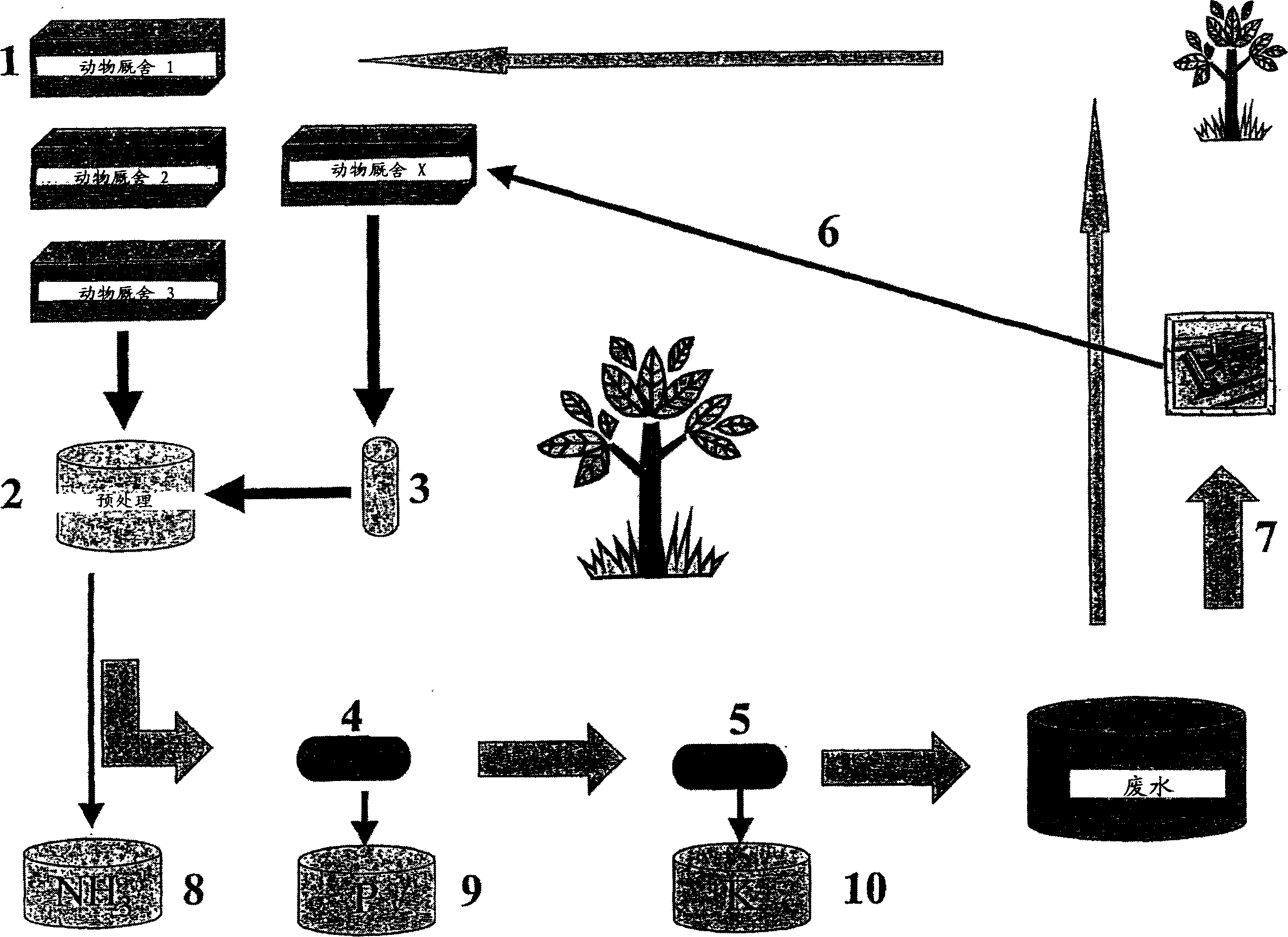

Concept for slurry separation and biogas production

InactiveUS7883884B2High yieldNot subsidisedBio-organic fraction processingAnimal corpse fertilisersEngineeringBiogas production

The present invention concerns an anaerobic digestion of animal manures, energy crops and similar organic substrates. The process is capable of refining nutrients comprised in the digested biomass to fertilizers of commercial quality. The invention also provides a method for oprocessing animal carcasses or fractions thereof including meat and bone meal etc., with the objective of providing an alternative means for processing the organic waste material of animal origin while at the same time facilitating the production of fertilizers. The risk of spreading BSE prions or any other prions to animals or humans is thus substantially reduced if not eliminated. The biogas and slurry separation system according to the present invention is preferably integrated with the operations of animal husbandries into a total concept in which the internal and external performances of animal husbandries are optimised. The internal performances concern quality aspects related to the management of the animal houses and include industrial hygiene, animal welfare, gaseous and dust emissions and food safety. The external performances concern mainly energy production and emissions to the environment of nutrients and greenhouse gases and the sale of high quality food product.

Owner:GFE PATENT AS

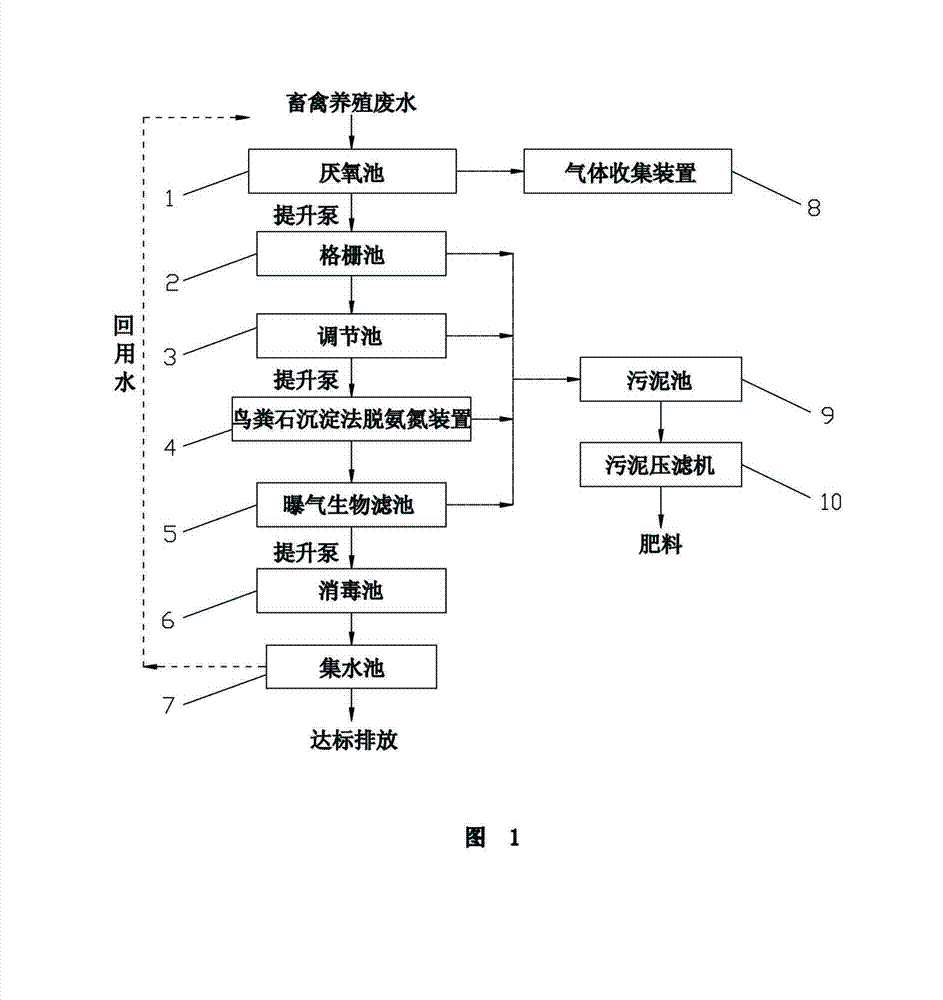

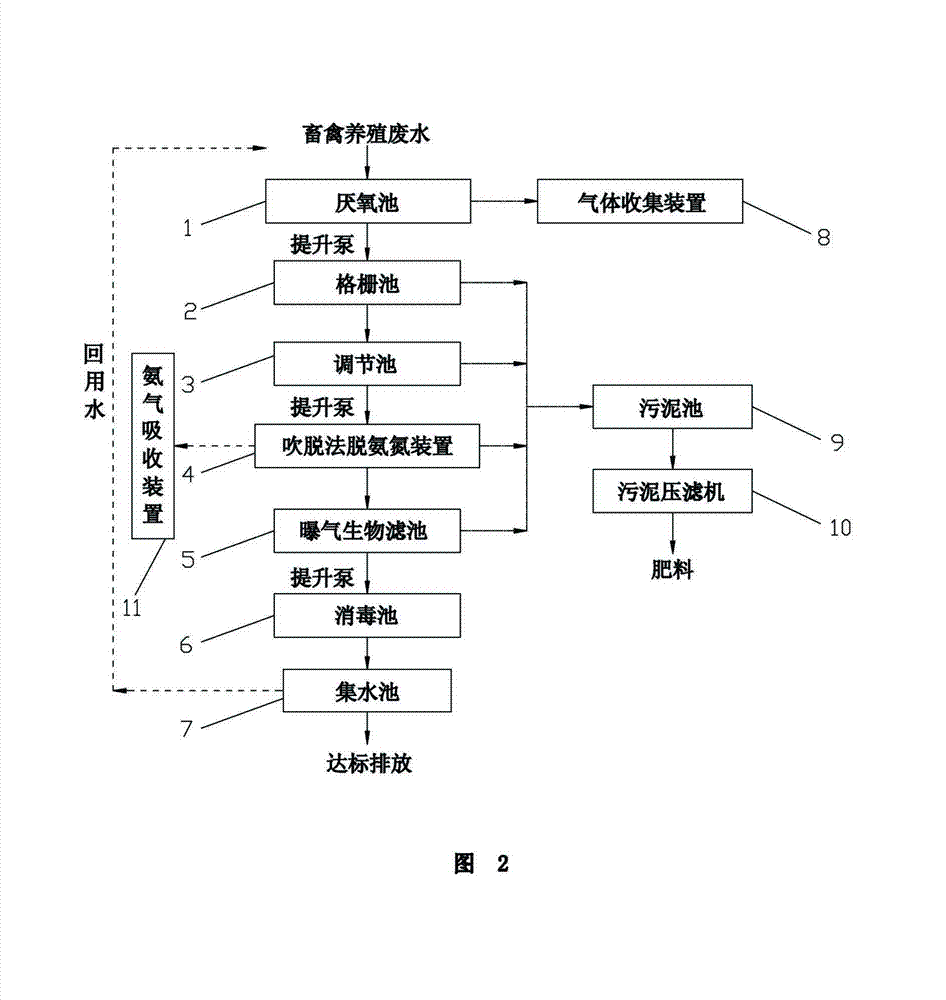

Livestock/poultry breeding wastewater resource utilization and regeneration recycling method

InactiveCN103288303AAnaerobicOvercome costsBio-organic fraction processingClimate change adaptationTreatment effectResource utilization

The invention discloses a livestock / poultry breeding wastewater resource utilization and regeneration recycling method which comprises the following steps of: (1) anaerobic digestion to produce biogas; (2) slag removal; (3) ammonia nitrogen removal; (4) biochemical treatment on a biological aerated filter (BAF); (5) disinfection; and (6) preparation of organic fertilizer. By combining the anaerobic technology, the denitrification technology, the BAF technology and the disinfection technology and adopting the livestock / poultry breeding wastewater as a resource, the method disclosed by the invention performs anaerobic fermentation treatment on the wastewater to produce biogas; the wastewater after the biogas production is subjected to solid-liquid separation; the solid slag is used as a raw material for producing organic fertilizer; the wastewater after the production of organic fertilizer is treated by the BAF technology and disinfected before recycling and up-to-standard emission; and the device realizes good treatment effect, low energy consumption and comprehensive utilization of resources while bringing economic benefits.

Owner:BOYING XIAMEN SCI & TECH

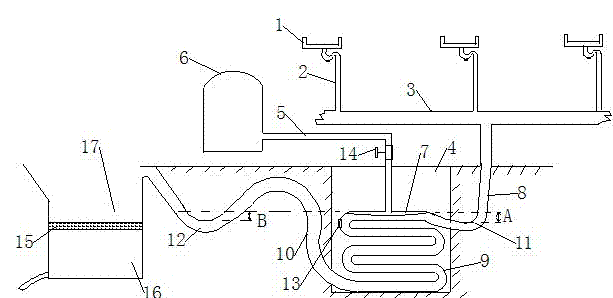

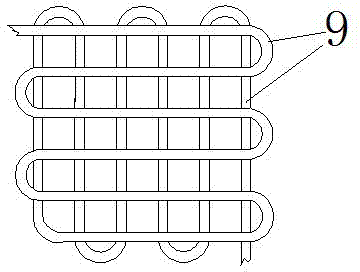

Intestinal-tract type biogas generating system

ActiveCN103289885AGuaranteed normal fermentationSmooth fermentationGas production bioreactorsWaste based fuelSlagBiogas production

The invention discloses an intestinal-tract type biogas generating system, and belongs to the field of biogas production devices. The intestinal-tract type biogas generating system comprises a multiple-entrance feeding device, an intestinal-tract type fermentation pipe path and a biogas collecting device. The multiple-entrance feeding device mainly comprises a plurality of sewage collectors which are arranged at a high place, collecting pipes connected with the sewage collectors and a total feeding pipe. The intestinal-tract type fermentation pipe path comprises a pipe storage chamber which is deeply digged underground, and multilayer-overlaying fermentation pipelines, wherein the fermentation pipelines are buried underground, and are bended and spiraled like the intestinal tract. A feeding port of the fermentation pipelines is connected with the total feeding pipe. The biogas collecting device comprises a plurality of biogas collecting pipes and a gas storage component, and the plurality of biogas collecting pipes are respectively leaded out from a plurality of gas taking ports of the uppermost fermentation pipeline. Through use of the intestinal-tract type biogas generating system, organic materials such as excrements and the like can be fully fermented, automatic feeding, automatic feed-discharging, automatic separating of the materials, and automatic conveying of the materials to the fields can be realized, and no caking and no slag is produced, so that the intestinal-tract type biogas generating system is energy saving and environmentally friendly.

Owner:广东永葆生机环保科技有限公司

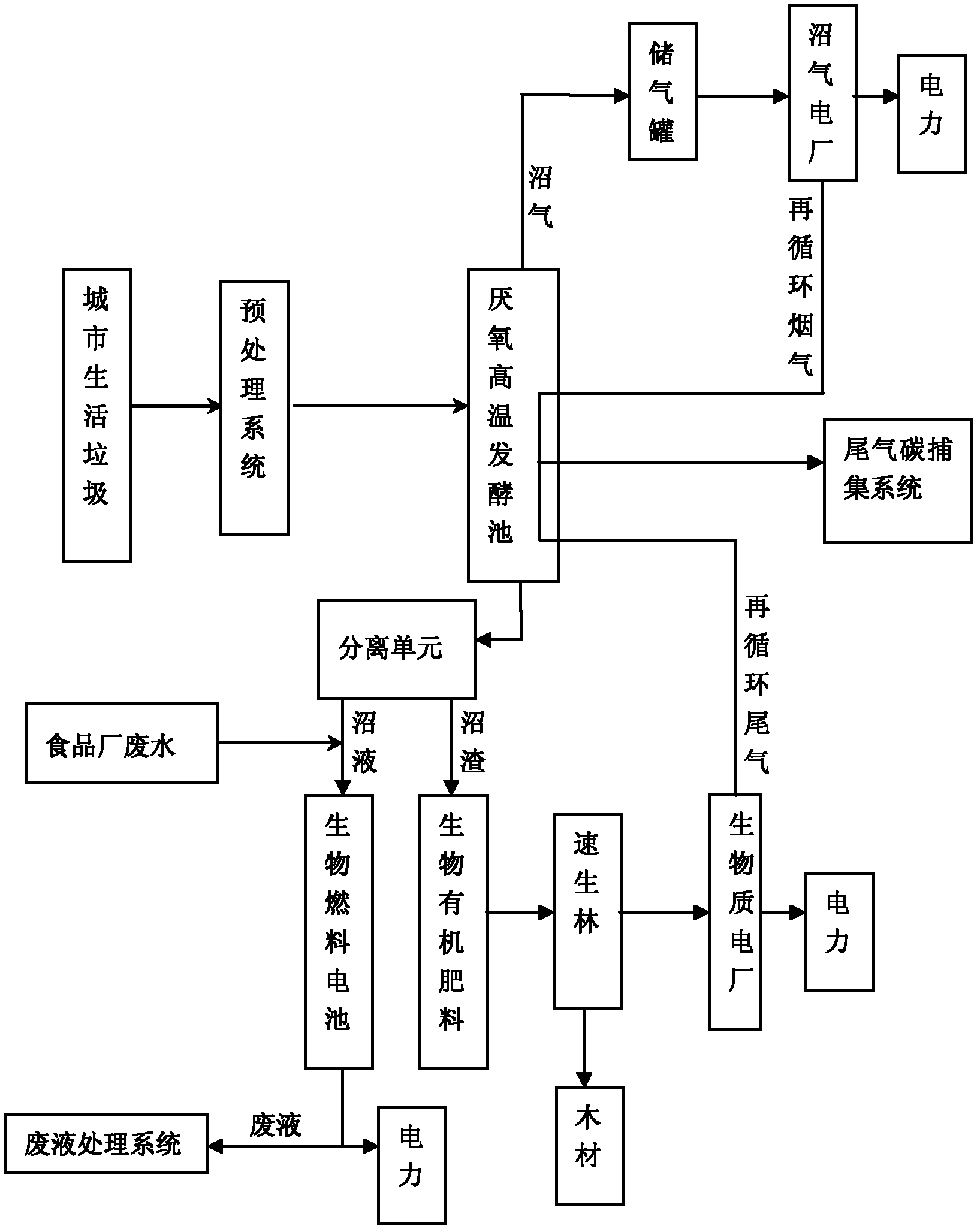

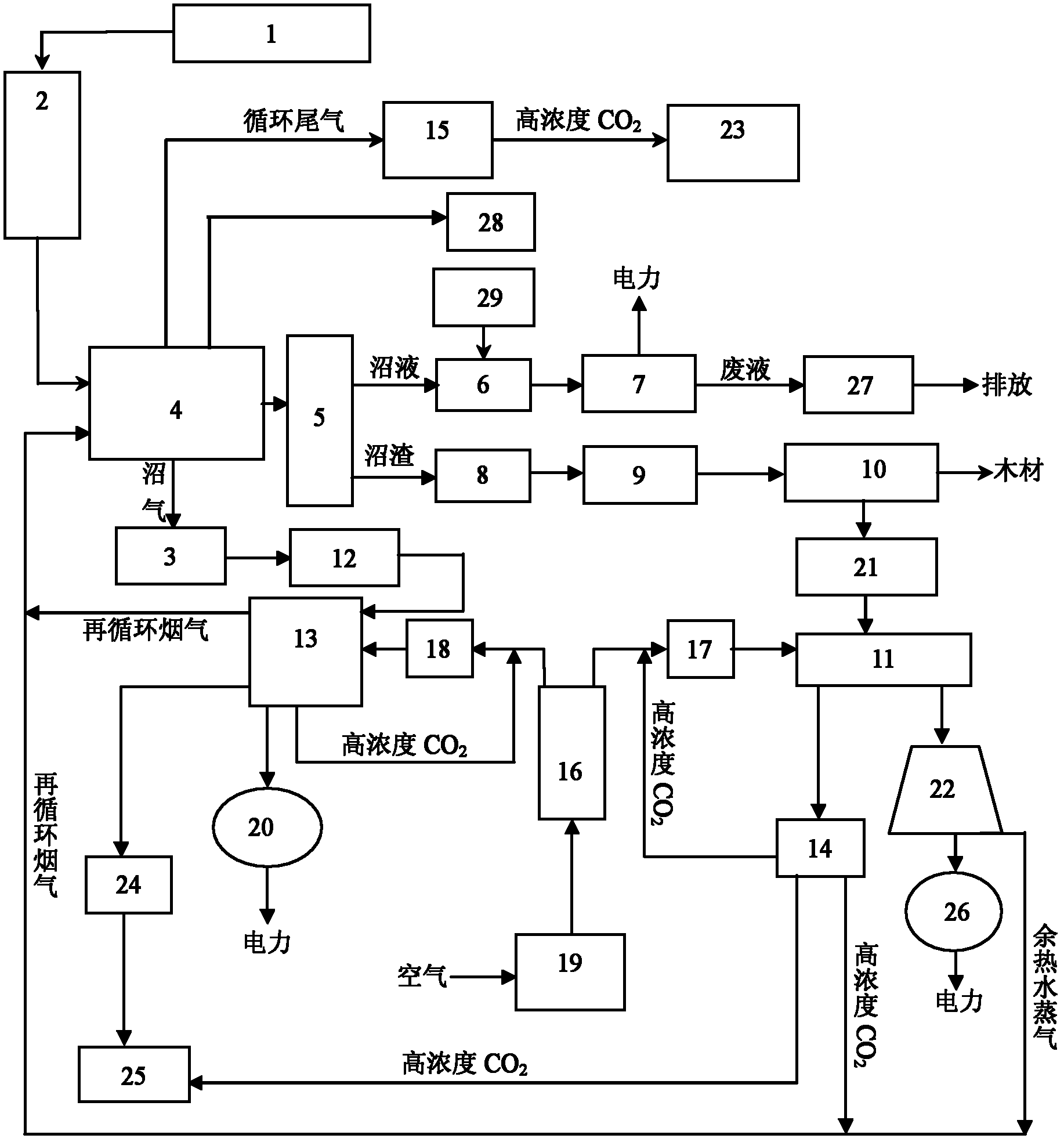

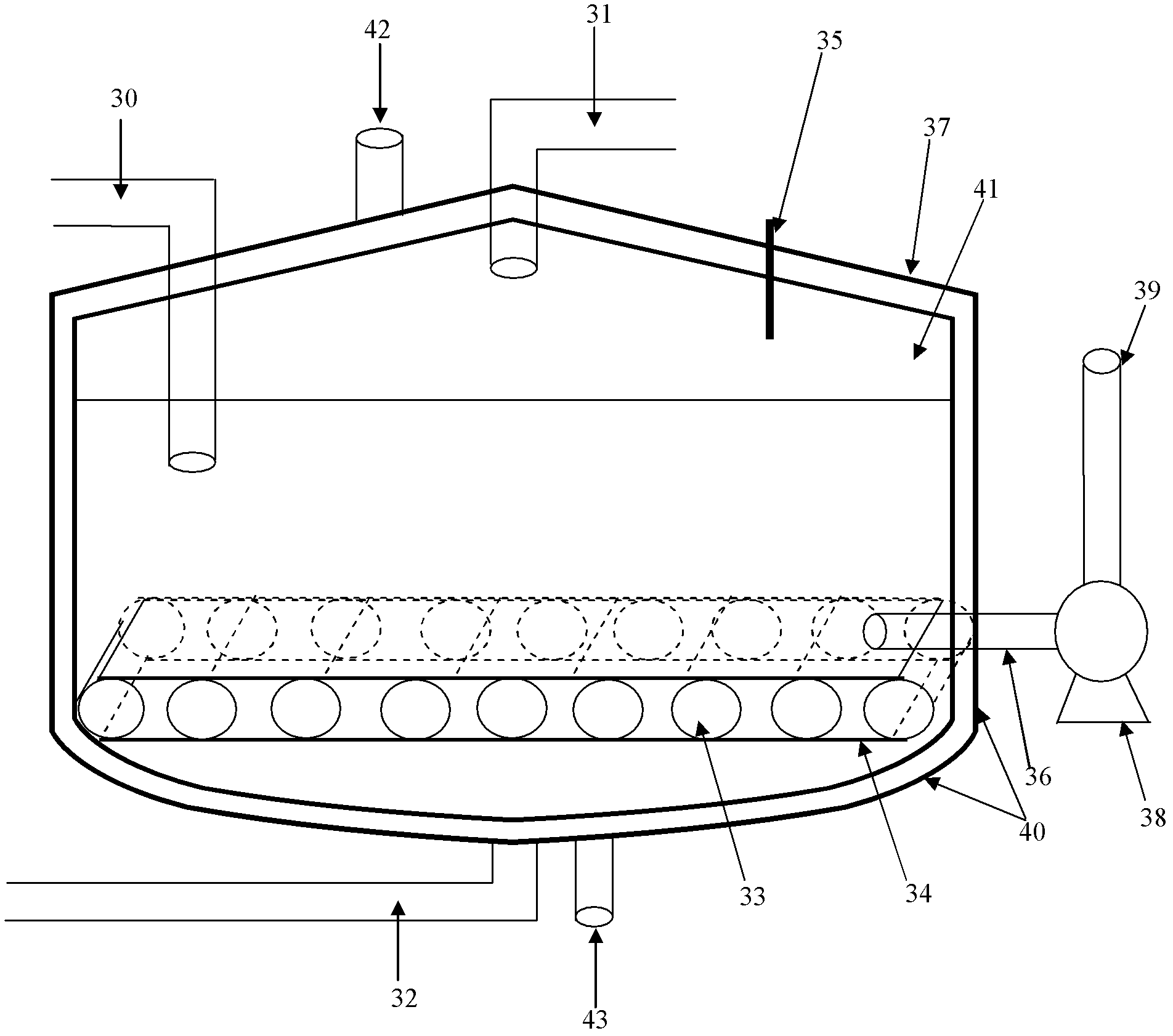

Household solid garbage recycling and renewable biological carbon circulating technology

ActiveCN102500604ARemarkable effectSignificant innovationWaste processingSolid waste disposalBiogas productionSlurry

The invention discloses household solid garbage recycling and renewable biological carbon circulating technology, which solves the problem that biogas generated from household garbage is difficult to ferment at places with low temperature, and realizes an integral circulating zero-carbon emission system and a large-size renewable biological carbon circulating system simultaneously. The technical scheme includes that pretreated household garbage is fed into a large-size biogas digester to ferment, biogas is supplied for oxygen-enriched combustion of a gas turbine gas to generate power, biogas slurry is used as a biofuel cell substrate and is cleaned and used for power generation, and biogas residue is used as biological organic fertilizer and used for growth of fast-growing trees for biomass fuel power plants. Flue gas generated in combustion in the power plants circulates to guarantee fermenting temperature of the biogas digester so as to realize biogas production stably and efficiently. Pure oxygen and recycled tail gas are used as combustion supporting gas of the power plants, and accordingly combustion efficiency can be improved while cost for treatment of tail gas is reduced. CO2 in the flue gas is captured according to the carbon capture technology, and accordingly the zero-carbon emission system is realized. In addition, the renewable biological carbon cycling system is realized by means of biological treatment to biogas slurry and biogas residue.

Owner:UNIV OF SCI & TECH LIAONING

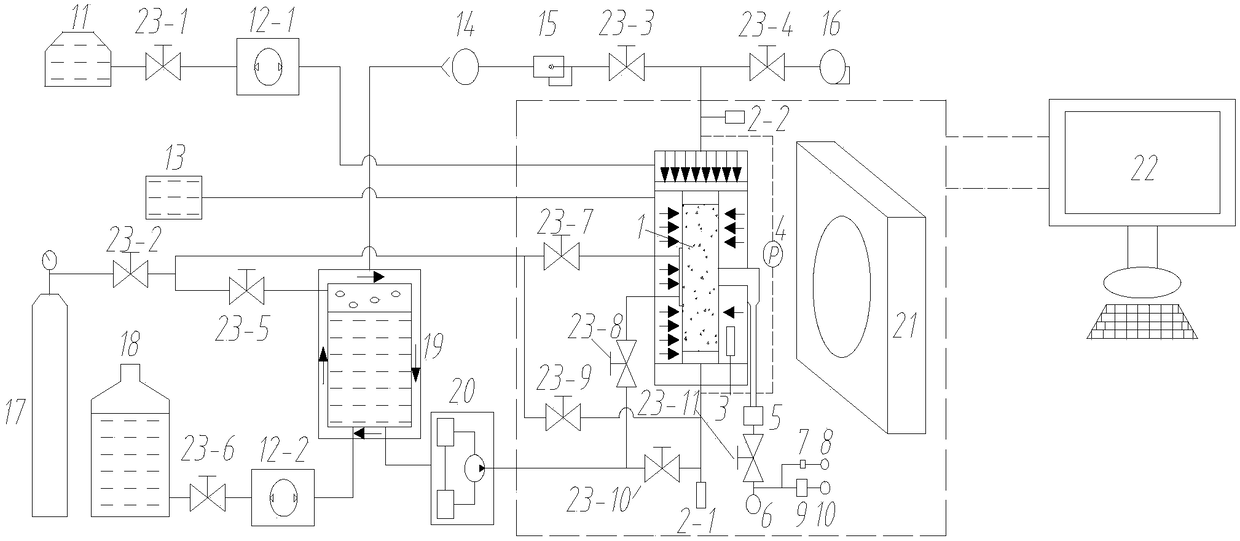

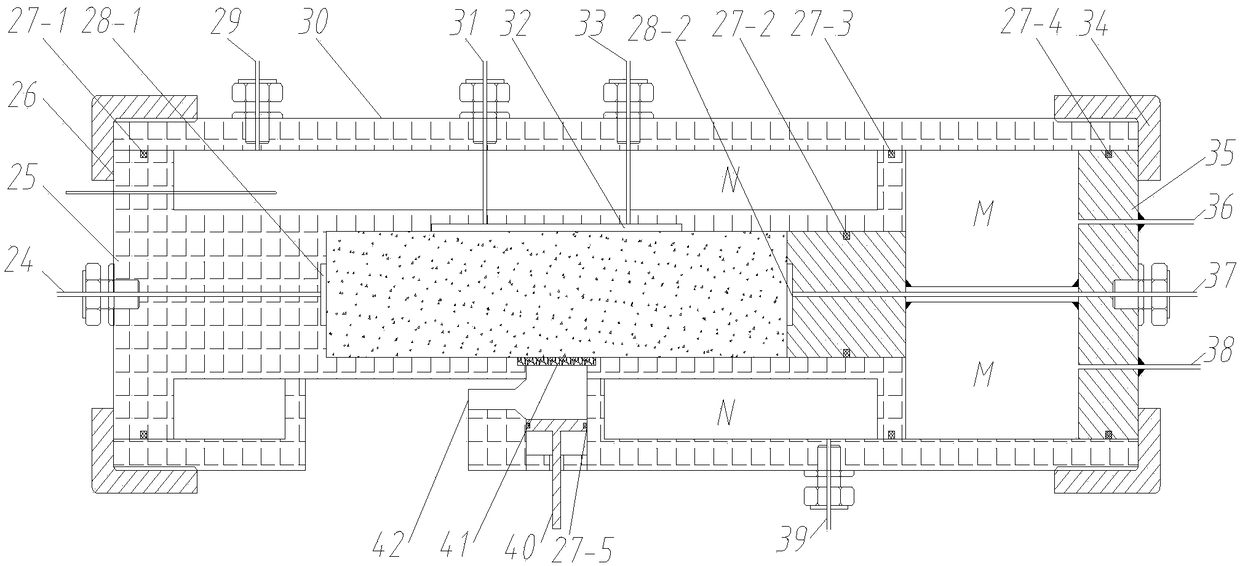

Hydrate sediment flow solid output measuring device combining X-CT technology and measuring method

ActiveCN109254137AImprove gas production efficiencyImprove the pressure reduction mining technology systemEarth material testingPermeability measurementsX-ray

The invention discloses a hydrate sediment flow solid output measuring device combining an X-CT technology and a measuring method. The measuring device comprises an X-ray penetration type reaction kettle, an X-CT scanning analysis system, a vacuum system, a temperature and pressure control system, a hydrate sample preparation system, a sand production monitoring system and a permeability measuringsystem, wherein through integrated application of a sand production-seepage system under the micro-scale multi-factor coupling effect, the coupling relationship of a reservoir structure and physicalspace-time evolution and flow solid output under the multi-factor collaborative action can be quantitatively described, different hydrate generation modes can be selected according to the experiment requirements, different hydrate occurrence states in natural sediments can be simulated and studied, and the device and the method can be used for researching the space-time evolution characteristics of a sediment pore structure under the hydrate convergence and divergence and effective stress conditions and an influence rule of the space-time evolution characteristics on sediment flow solid output, so that the theoretical bottleneck of the hydrate reservoir structure and a physical evolution and flow solid output mechanism in a hydrate production process is broken through, and the device and the method have important engineering significance to deeply understand a depressurizing production law of the South China Sea, practically improve the biogas production efficiency and perfect a depressurizing production technology system.

Owner:QINGDAO INST OF MARINE GEOLOGY

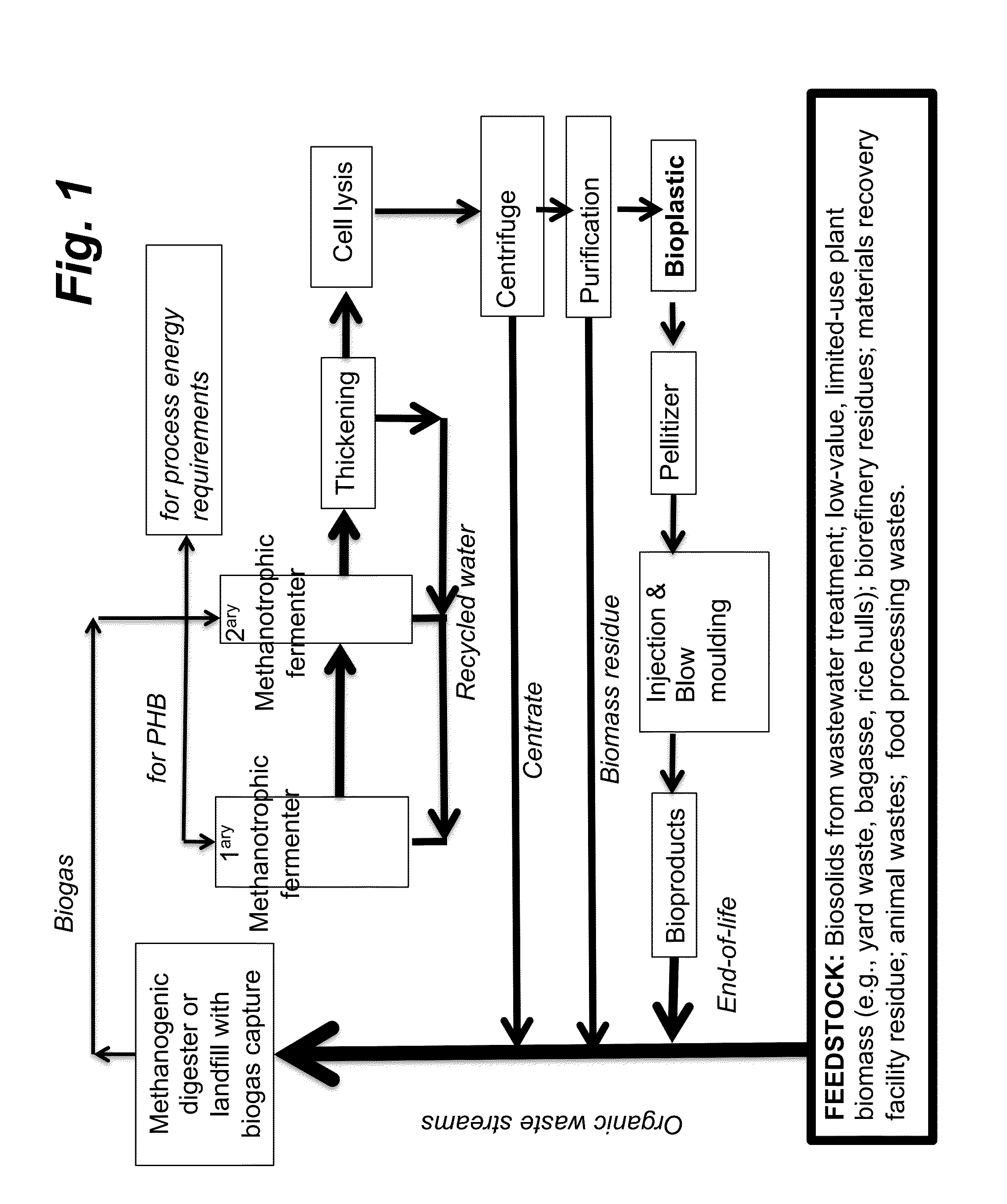

Production of PHA using Biogas as Feedstock and Power Source

InactiveUS20130071890A1Stable supplyQuality improvementOrganic chemistryPlastic recyclingPower gridProcess engineering

Methods for producing bioplastics from biogas include techniques for the production of PHB using a dirty biogas (e.g., methane from landfill, digester) as both a power source for the process and as feedstock. Biogas is split into two streams, one for energy to drive the process, another as feedstock. Advantageously, the techniques may be implemented off the power grid with no dependence upon agricultural products for feedstock.

Owner:CRIDDLE CRAIG S +7

Organic Substrate Treatment System

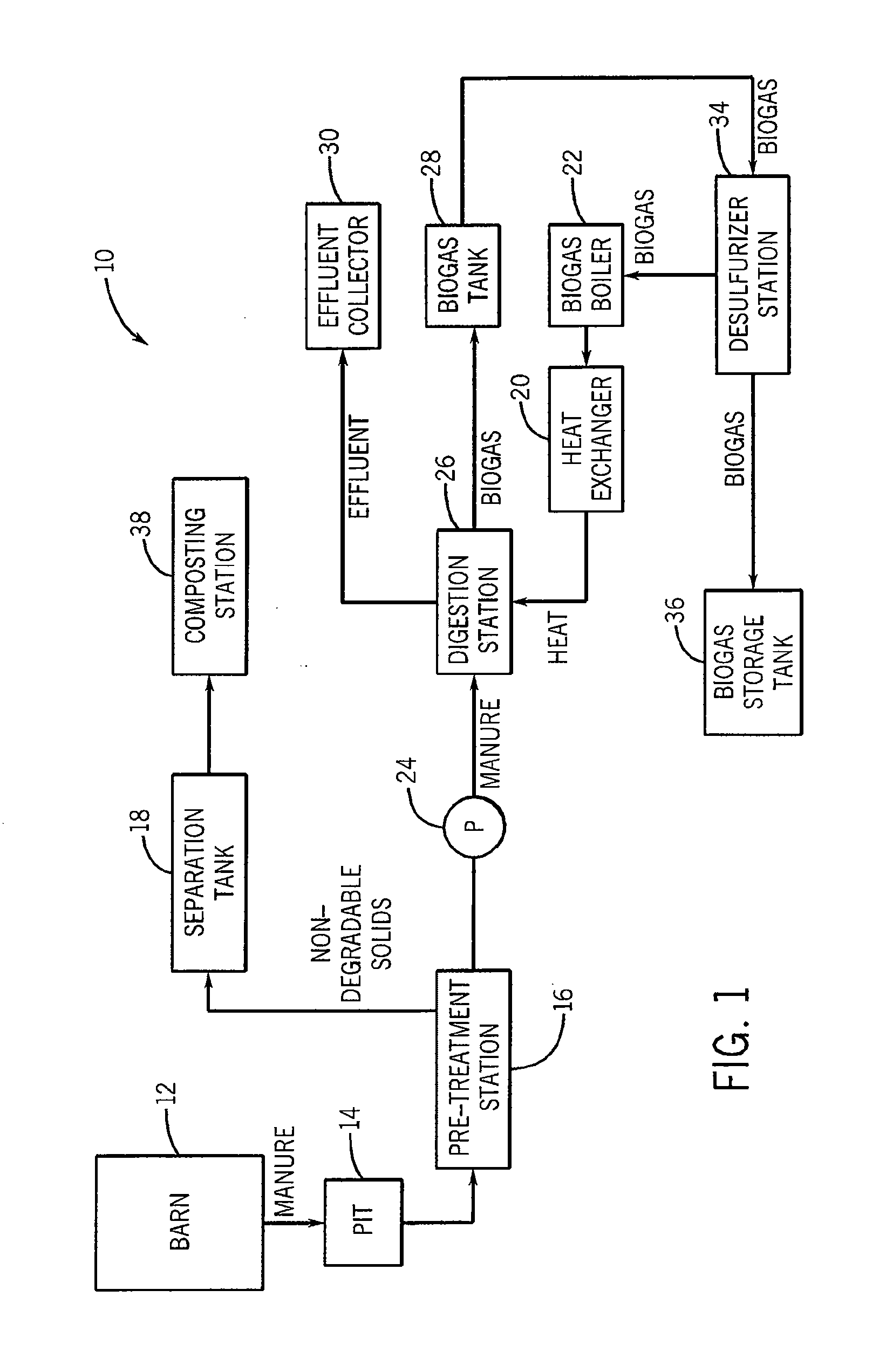

InactiveUS20110318778A1Easy injectionPromote degradationBioreactor/fermenter combinationsBio-organic fraction processingBiogas productionDigestion

The present invention is directed to an organic substrate treatment system that converts organic substrate and other organic materials to nutrient rich effluent and biogas. Using sequential degradation of the organic materials, biogas and effluent is efficiently produced with relatively short digestion times. Additives are added to the organic materials prior to anaerobic digestion to enhance biogas production. A desulfurizer may be used to clean the raw biogas so that it is suitable for use with gas engines and boilers.

Owner:ICS RENEWABLES

Concept for slurry separation and biogas production

InactiveCN1471409ADemonstrate Energy PotentialAttractiveBio-organic fraction processingAnimal corpse fertilisersAgricultural scienceAnimal feces

The present invention concerns an anaerobic digestion of animal manures, energy crops and similar organic substrates. The process is capable of refining nutrients comprised in the digested biomass to fertilizers of commercial quality. The invention also provides a method for processing animal carcasses or fractions thereof including meat and bone meal etc., with the objective of providing an alternative means for processing the organic waste material of animal origin while at the same time facilitating the production of fertilizers. The risk of spreading BSE prions or any other prions to animals or humans is thus substantially reduced if not eliminated. The biogas and slurry separation system according to the present ivnention is preferably integrated with the operations of animal husbandries into a total concept in which the internal and external performances of animal husbandries are optimised. The internal performances concern quality aspects related to the management of the animalhouses and include industrial hygiene, animal welfare, gaseous and dust emissions and food safety. The external performances concern mainly energy production and emissions to the environment of nutrients and greenhouse gases and the sale of high quality food product.

Owner:GFE PATENT AS

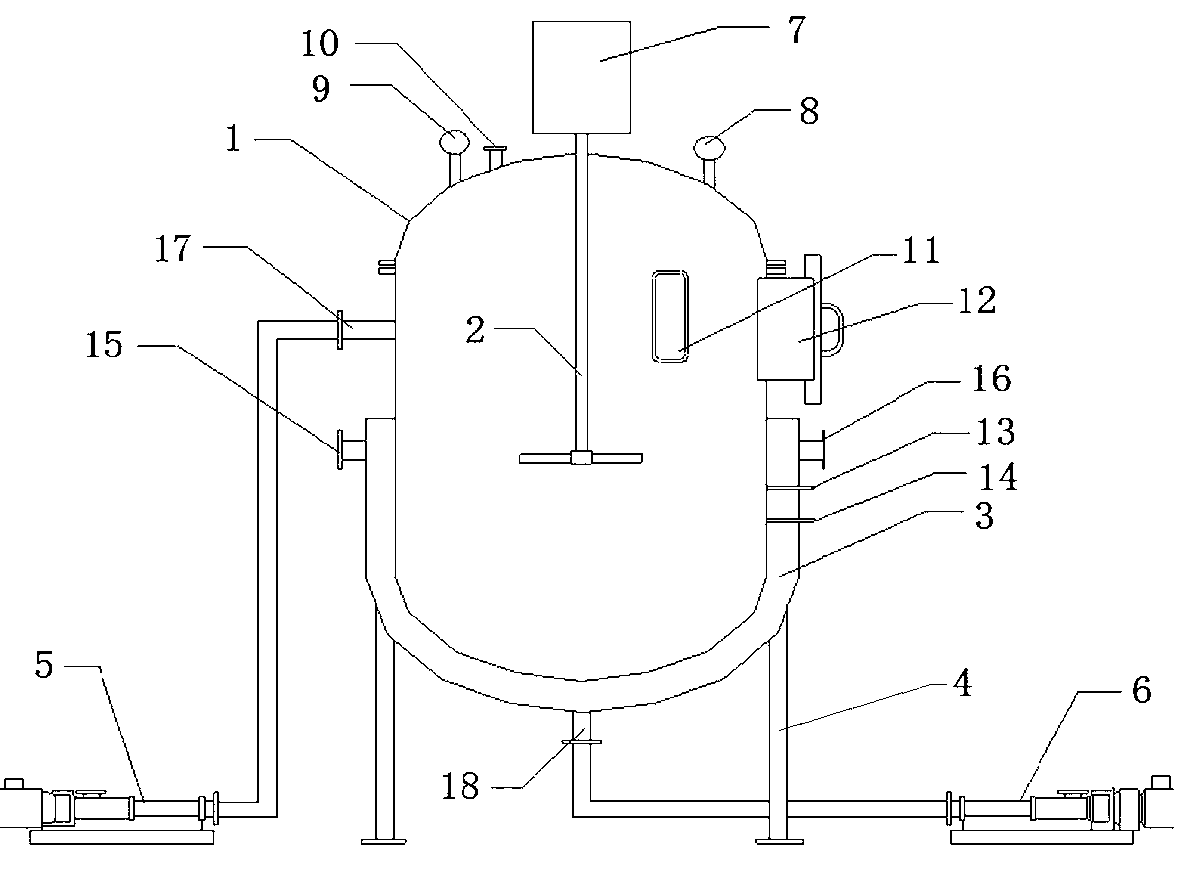

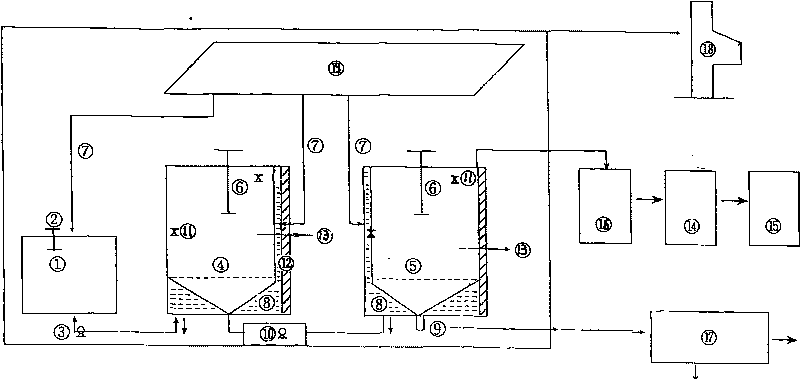

Automation solar energy biogas fermentation method and device

InactiveCN101704625AAutomatic feed controlAutomatic control of nestingWaste based fuelSludge processingAnimal fecesBiogas production

The invention relates to an automation solar energy biogas fermentation method, which belongs to the fields of environmental protection and chemical engineering. Aiming at the defects in the conventional biogas production process, the invention provides an automation solar energy biogas fermentation method and an automation solar energy biogas fermentation device, which can implement the steps of feeding, stirring, discharging, constant temperature and quantifying automatically in the north part of China in winter. The automation solar energy biogas fermentation method comprises the steps that: an automatic feeding delivery pump sends feces mixture in a feces collection pool into a material tank in a hydrolytic acidification treatment tank to carry out the hydrolytic acidification treatment; after being treated by the hydrolytic acidification treatment tank, the feces mixture is sent to a material tank in an anaerobic digestion tank by an automatic feeding pump; a solar thermal collector sends hot water into water collection interlayer of the hydrolytic acidification treatment tank and the anaerobic digestion tank by a temperature controlled pump and a solar energy hot water circulation system; and generated gas is injected into a gas holder for users to use after the treatment of desulfuration and solid-liquid separation. The automation solar energy biogas fermentation method and the automation solar energy biogas fermentation device are established on the basis of automatic program control of biogas feeding, stirring, discharging, constant temperature and quantity limitation, and correspond to the current development situation of the farmers of the animal breeding in China at present.

Owner:BEIFANG SOLAR ENERGY BIOGAS RES INST OFGONGZHULING NAT AGRI SCI & TECH PARK

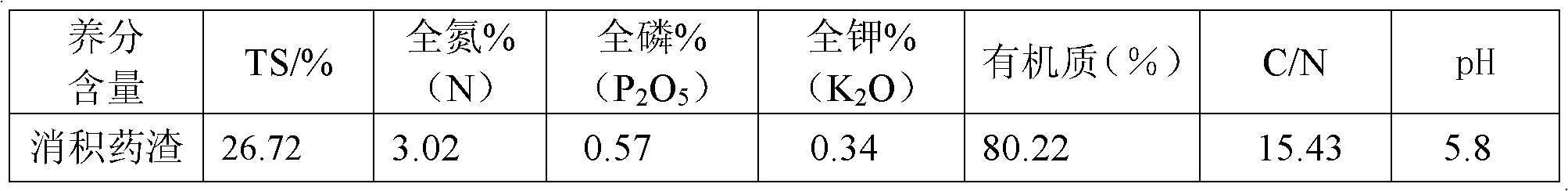

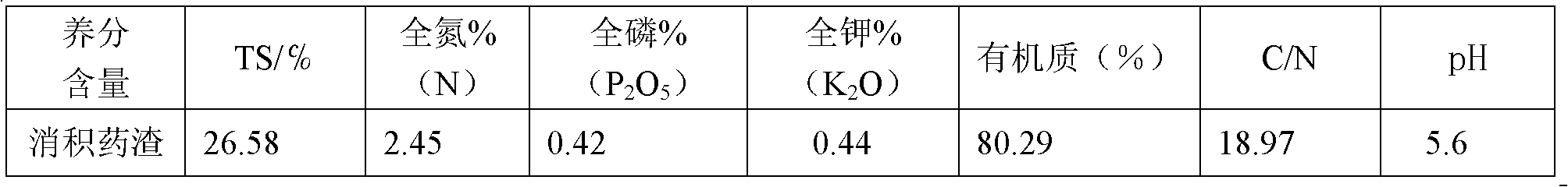

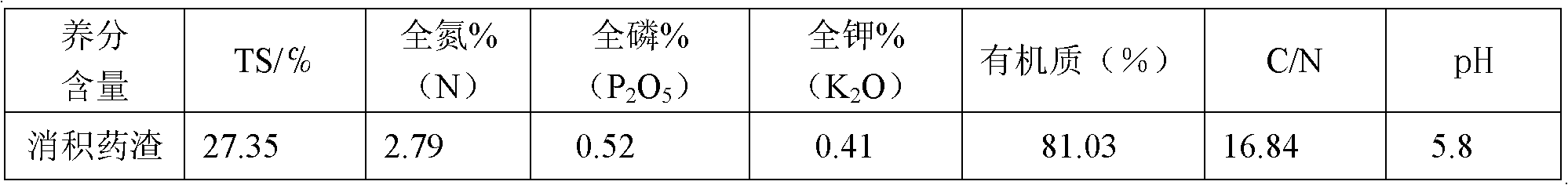

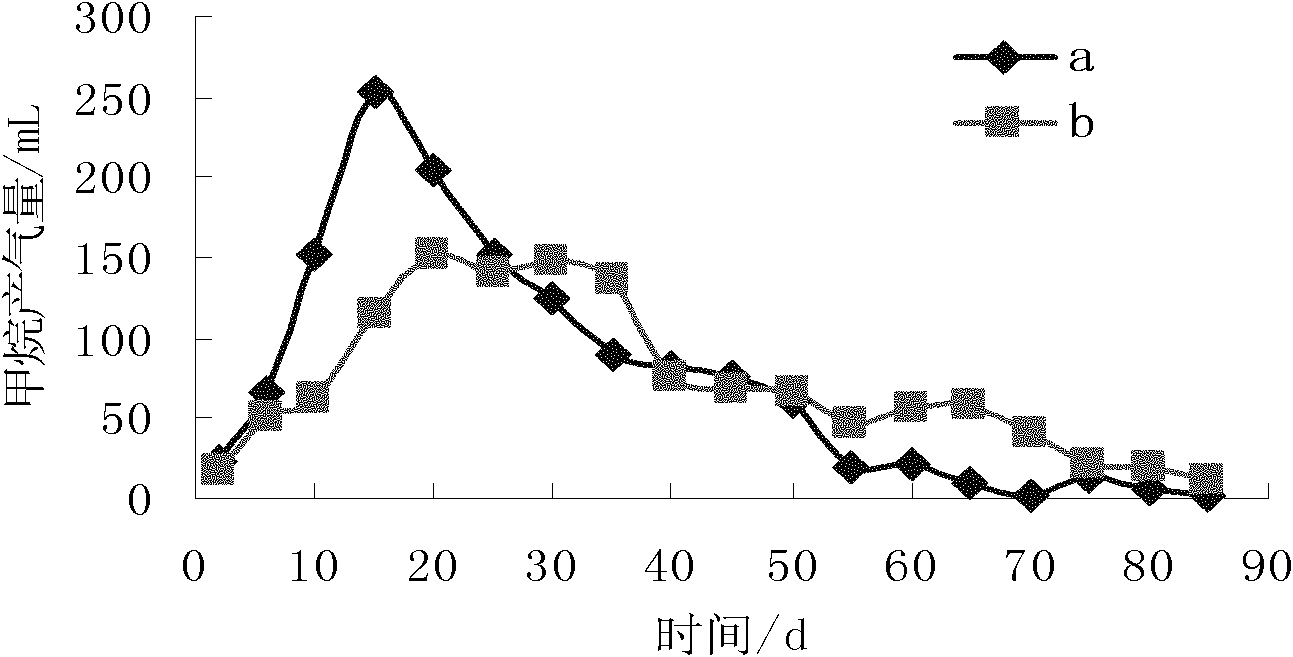

Method for generating biogas through anaerobic fermentation by taking traditional Chinese medicine dregs as raw materials

ActiveCN102382859AEasy to operateSuitable for useWaste based fuelFermentationProduction effectMedicine

The invention relates to a method for generating biogas through anaerobic fermentation by taking traditional Chinese medicine dregs as raw materials. Medicine dregs produced in a pharmaceutical factory of traditional Chinese medicine are used as fermentation raw materials, are united with waste water of the pharmaceutical factory for anaerobic fermentation, and are properly proportioned with biogas slurry and water for composting pretreatment, a proper amount of NaOH is added after the mixture enters a pool, the TS (total solid) concentration of the fermentation raw materials is 7-9%, 10-15% of biogas slurry is added as an inoculum so as to realize quick start, and the biogas production efficiency is high. Partial biogas slurry flows back after normal operation so as to ensure the concentration of microorganisms in an anaerobic tank. The traditional Chinese medicine dregs are taken as main raw materials for fermentation to produce the biogas, cow dung and other fermentation raw materials do not need to be added, the operation is simple, the gas production effect is good, the utilization ratio of the raw materials is high, the problem of environment pollution caused by the medicinedregs and the waste water can be solved, and simultaneously biogas energy sources can be recycled.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

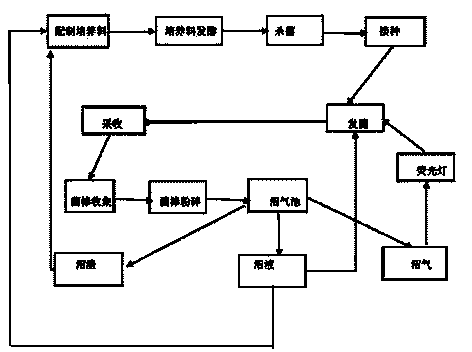

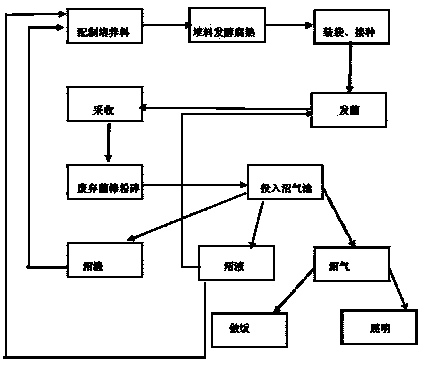

Circular production method for edible mushrooms

The invention discloses a circular production method for edible mushrooms. The circular production method is characterized in that: after edible mushroom compost is subjected to primary production of edible mushrooms, generated mushroom residue is put into a methane tank to generate methane, the generate methane is supplied to edible mushroom manufacturing enterprises or mushroom farmers for cooking, lighting, warming and the like, generated biogas residue is used as the main component of the edible mushroom compost to put into the production of edible mushrooms again, and biogas slurry can be directly added into the compost and also can be sprayed in the production of edible mushrooms; thereby, nutritional ingredient content of the edible mushroom compost is improved, and stress resistance of hyphae or sporocarps in the production of edible mushrooms are also improved. The method can be used for producing 350 kinds of known and naturalized edible mushrooms which can be artificially cultivated, and thus the purpose of comprehensively utilizing resources, saving cost and improving economic performance can be achieved.

Owner:黑龙江昌林盛业生物科技有限公司

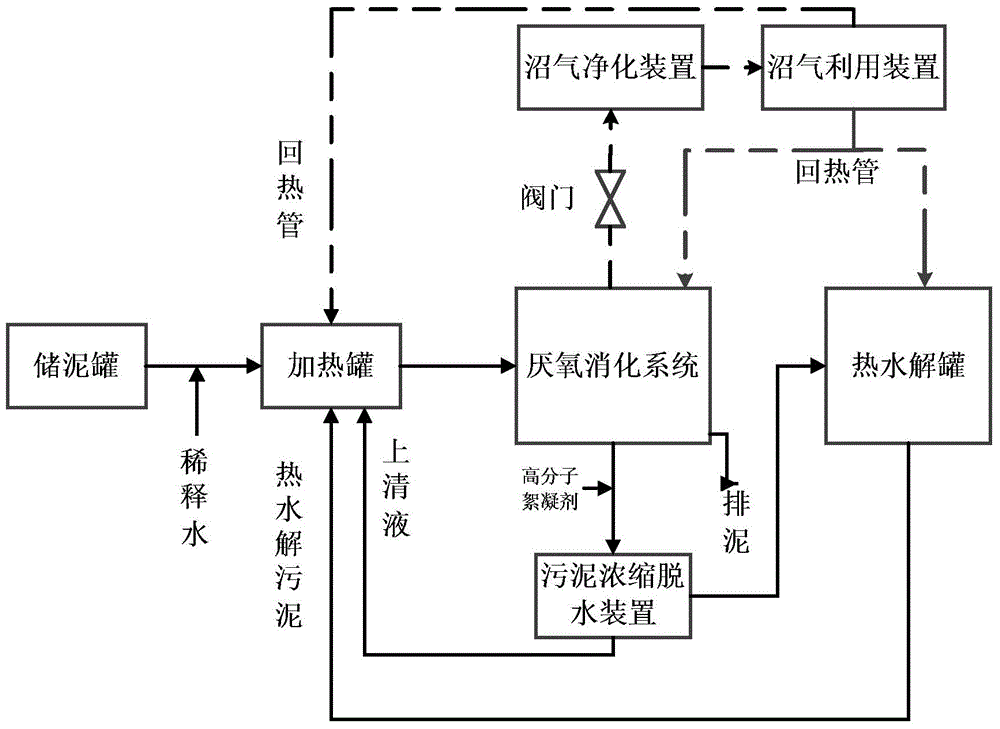

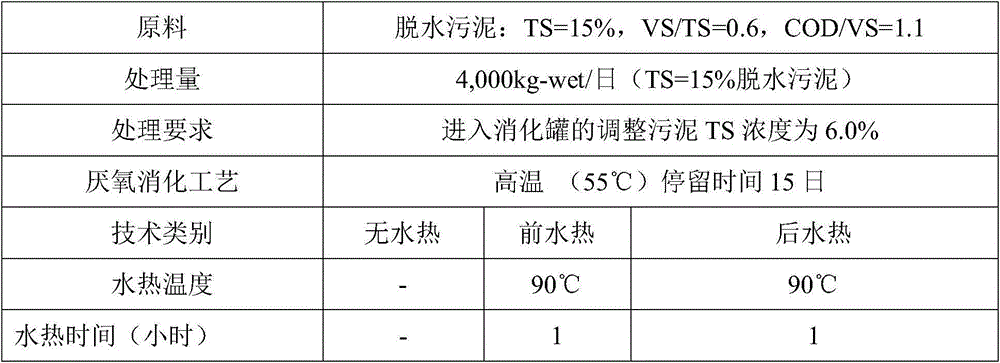

Anaerobic digestion sludge conditioning system and method

InactiveCN104909530AImproved Anaerobic Digestion PerformanceAchieve reductionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisEnergy transferBiogas production

The invention provides an anaerobic digestion sludge conditioning system. The anaerobic digestion sludge conditioning system comprises a sludge storage tank, a heating tank, an anaerobic digestion system, a methane purification device, a methane utilization device, a sludge concentration dewatering device, and a pyrohydrolysis reaction tank; the sludge storage tank, the heating tank, and the anaerobic digestion system are communicated successively; the anaerobic digestion system is communicated with the methane purification device and the sludge concentration dewatering device respectively; the sludge concentration dewatering device is communicated with the heating tank and the pyrohydrolysis reaction tank respectively; the methane purification device is communicated with the methane utilization device; the methane utilization device is communicated with the anaerobic digestion system and the pyrohydrolysis reaction tank respectively; and the pyrohydrolysis reaction tank is communicated with the heating tank. According to the anaerobic digestion sludge conditioning system, postposition pyrohydrolysis is adopted, so that energy consumed on the part of sludge easy for biodegradation in the prior art is transferred to the part of sludge difficult for biodegradation, biogas production efficiency is increased, energy utilization efficiency is increased greatly, and a large amount of operation cost is reduced for practical engineering.

Owner:SOUTHEAST UNIV

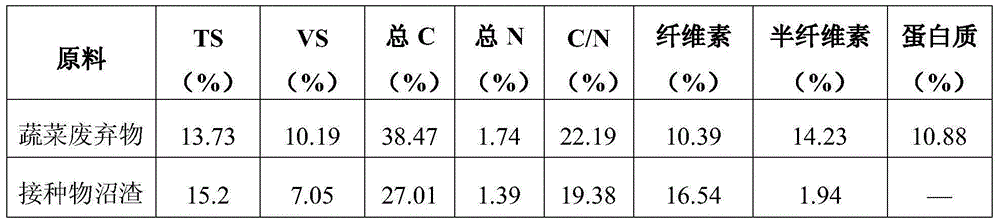

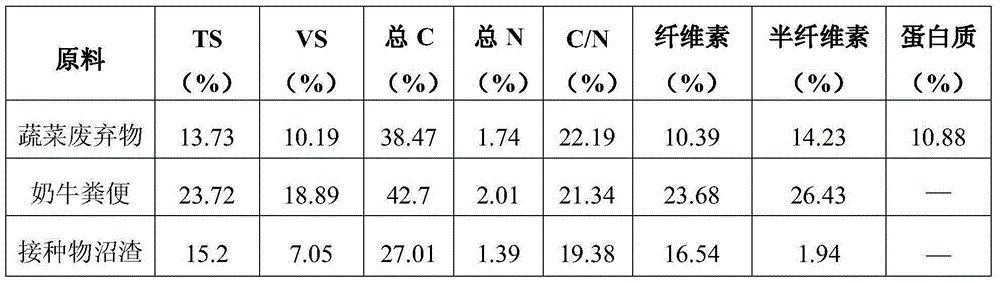

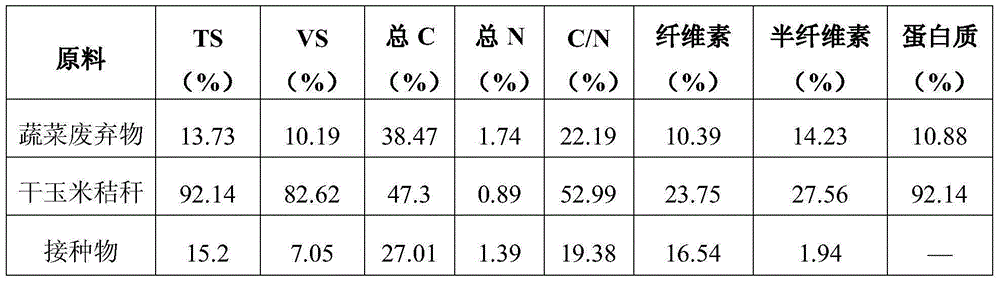

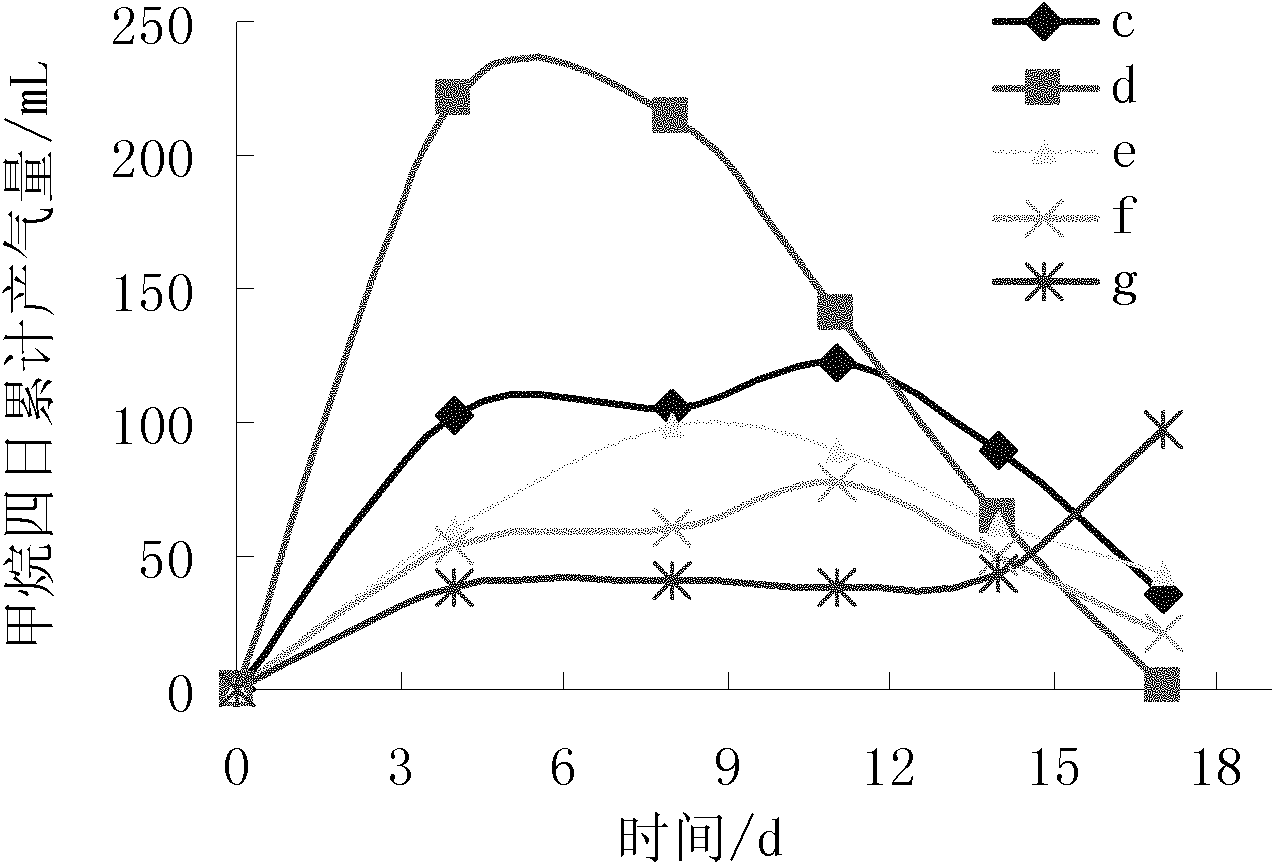

Method for producing biogas through high-efficiency anaerobic fermentation of organic waste resource in intensive vegetable area

ActiveCN105002221AReduce planting costsAvoid the problem of random stacking and polluting the environmentWaste based fuelFermentationFungicideMicrobial agent

The invention relates to a method for producing biogas through the high-efficiency anaerobic fermentation of an organic waste resource in an intensive vegetable area. According to the method, an acidification-inhibiting microbial agent is directly added in crushed vegetable wastes to be mixed with the crushed vegetable wastes. Or, one or more than two components selected from fresh cow manure, fresh swine manure and straws processed by a fungicide are added in crushed vegetable wastes to be mixed with the crushed vegetable wastes. After that, water is added and stirred evenly and the C / N ratio and the water content of the obtained mixture are adjusted to be (20-30):1 and 88-90% correspondingly. In this way, a mixed material is obtained. Then an inoculum is added. The TS and the pH value of the obtained material are adjusted to be 8-12% and 7.7-8.0 correspondingly, so that a fermentation material is obtained. The fermentation material is subjected to anaerobic fermentation at the temperature of 35-38 DEG C. According to the technical scheme of the invention, vegetable wastes, adopted as a resource, are subjected to anaerobic fermentation to generate biogas. In this way, the problem that vegetable wastes are randomly piled to pollute the environment can be avoided. Meanwhile, the biogas production efficiency through the anaerobic fermentation process of vegetable wastes can be improved at the same time.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Methane-producing composite microbial inoculum and preparation method thereof

InactiveCN101705199AReasonable designBreed fastBacteriaMicroorganism based processesBiogas productionLiquid methane

The invention relates to a methane-producing composite microbial inoculum and a preparation method thereof, which can solve the long-standing difficult problems that the existing biogas digester is lack of high-efficient methane-producing bacteria, thereby resulting in long initial start-up time of biogas production and poor stability of the biogas production. Methanosarcina acetoacidophilum DSM-N0.2834, methanobacterium formicicum DSM-No.1535, methanobrevibacter arboriphilicus DSM-No.1125, methanolobus tindarius DSM-No.2278 and methanothrix concilii DSM-No.6752 collected in German collection of microorganisms and cell cultures are adopted and inoculated in a liquid methane bacterial culture medium under the anaerobic condition, the independent enlarged culture is carried out grade by grade respectively, and bacterial liquid after the cultured methane bacteria is mixed together according to the volume ratio, thereby preparing a liquid methane-producing composite microbial inoculum; and the liquid methane-producing composite microbial inoculum can also be prepared into a solid methane-producing composite microbial inoculum. The method has reasonable design and adopts the high-efficient strains with the optimal combination and the rapid propagation technology, and the developed high-efficient methane-producing composite microbial inoculum can significantly accelerate the start-up time of the biogas production when in new construction of the biogas digester and large material change, and improve the efficiency and the stability of the biogas production of the biogas digester.

Owner:北京合百意可再生能源技术有限公司 +1

Method for increasing methane production efficiency in organic waste anaerobic process

ActiveCN102140001APromote hydrolysisImprove metabolic activityGas production bioreactorsWaste based fuelGeneration rateFeces

The invention discloses a method for increasing methane production efficiency in organic waste anaerobic process. The method is characterized in that powder containing no less than 15% of free ferric iron oxides is added into an anaerobic biochemical system to be uniformly blended, wherein the anaerobic biochemical system produces methane by utilizing organic wastes; and ferric ions released when microbes reduce the ferric iron oxides in the anaerobic process can promote the activity of anaerobic bacteria such as methane bacteria and the like, thus increasing the production rate and yield of methane by utilizing organic wastes. The method can be widely used for increasing the methane production rate and yield of an energy utilization system for biogas production of municipal domestic waste, agriculture product processing wastes, excess sludge of sewage treatment plants, feces of intensifying raising farms and the like and improves the utilization rate of renewable energy sources of organic wastes.

Owner:HEFEI UNIV OF TECH

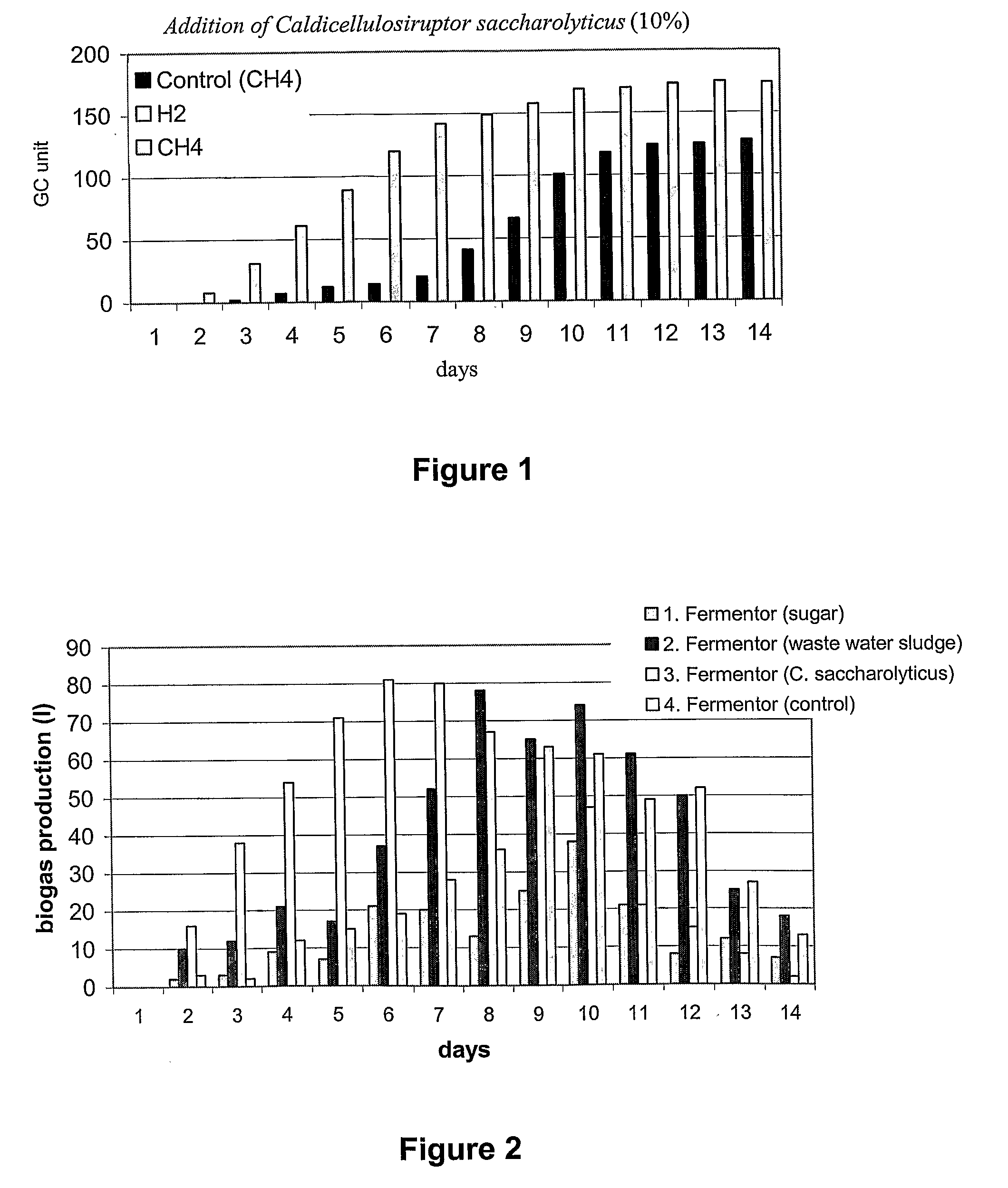

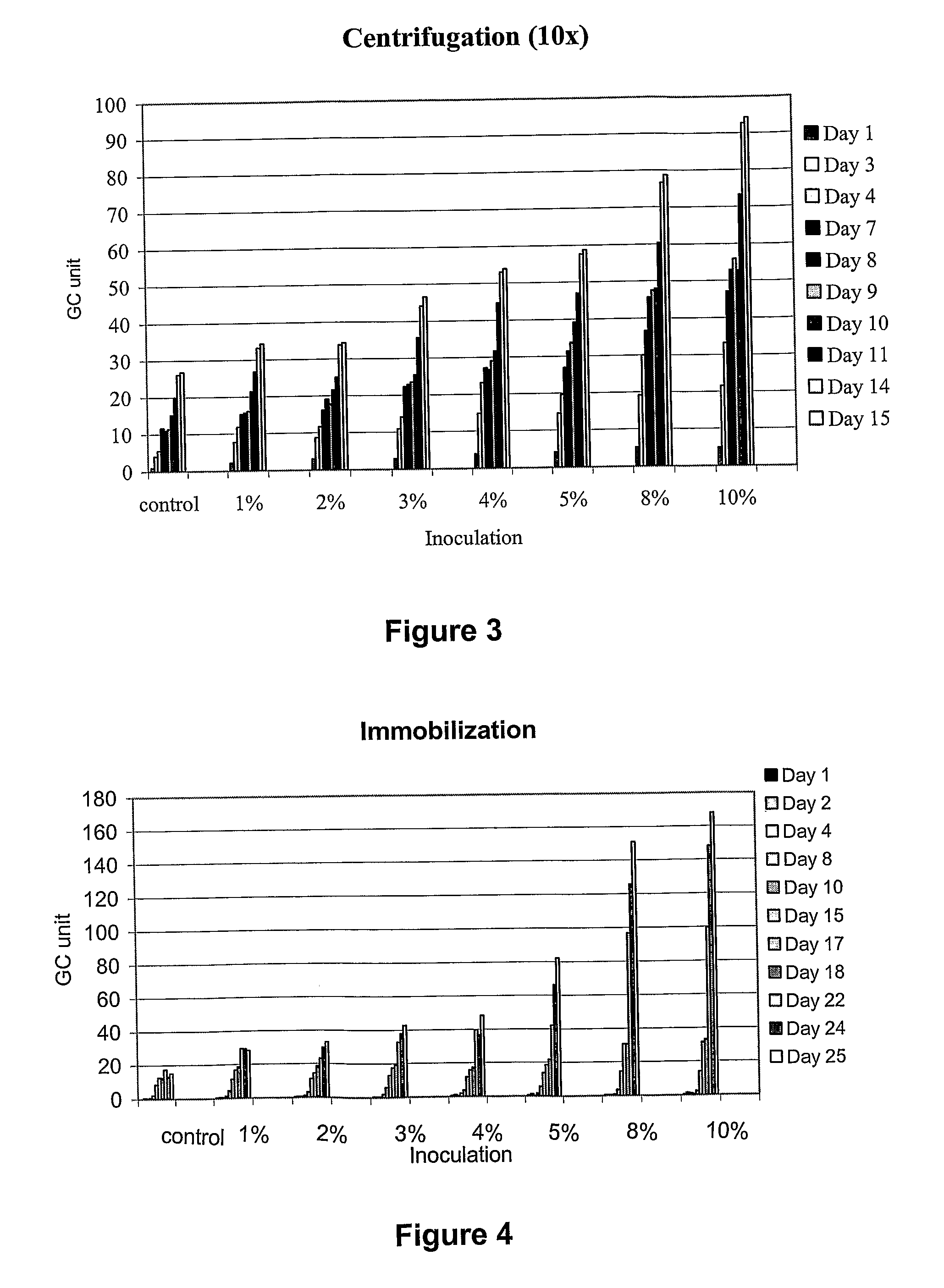

Method for Increased Production of Biogas

InactiveUS20080124775A1Improve overall utilizationGood curative effectManure treatmentMicrobiological testing/measurementMicroorganismAcetic acid

The invention relates to a method for increasing biogas production of thermophilic anaerobe systems. More closely, a biomass containing a consortium comprising polymer-degrading, acetogenic and methanogenic microorganisms is inoculated with a microorganism culture before the start of or during biogas production. Said microorganism is a thermophilic, acetogenic, hydrogen producing bacterium. As an example, Caldicellulosiruptor saccharolyticus is applied. According to the invention production if methane containing biogas is significantly increased.The invention is useful for intensifying biogas production and thereby increasing its feasibility.

Owner:SCHMACK BIOGAS GMBH

Combined installation for the production of biogas and compost, and method of switching a fermenter in a like installation between biogas production and composting

InactiveUS20090239209A1Maintain normal productionLong productionBioreactor/fermenter combinationsBio-organic fraction processingFresh airBiogas production

A combined installation is disclosed for the production of biogas and compost, including a dry fermentation fermenter for producing biogas in a batch mode, a biogas outlet, a purging gas inlet, a biogas line connected to the biogas outlet, a waste gas line, a waste gas chimney connected to the biogas outlet via a first biogas / waste gas line, a waste gas flare connected to the biogas outlet via a second biogas / waste gas line, a fresh air line connected to the purging gas inlet, a control means for connecting the biogas outlet to the biogas line or the biogas / waste gas chimney via the first biogas / waste gas line or the waste gas flare via the second biogas / waste gas line and for connecting the purging gas inlet to the waste gas line or the fresh air line, and a measurement means connected to the control means for detecting methane and carbon dioxide concentrations.

Owner:BEKON ENERGY TECH GMBH & CO KG

Method for simultaneously improving sludge anaerobic digestion efficiency and reducing ecotoxicity of heavy metals

ActiveCN110127972ALower pHIncrease productionWater contaminantsBiological sludge treatmentChemical reactionMicrowave

The invention relates to a method for simultaneously improving sludge anaerobic digestion efficiency and reducing the ecotoxicity of heavy metals. According to the method, after straws are activated with a ZnCl2 solution, straw biochar is prepared under a 550 DEG C high-temperature anaerobic condition, and further modification is performed by using an HCl solution and microwave; and by using modified biochar as carrier, a zero-valent nano-iron loaded modified biochar composite material HCl-FBC is prepared through a chemical reaction. According to the present invention, by adding the modified biochar composite HCl-FBC to the anaerobic digestion reactor at the initial stage of sludge anaerobic digestion, the organic matter conversion rate of sludge can be significantly increased, and the cumulative gas production of methane can be increased; HCl-FBC can easily increase the microbial diversity and the activity of the digested sludge and change the microbial community structure; and with the method, the sludge anaerobic digestion efficiency can be significant increased, the biogas production can be increased, the biological toxicity of the heavy metal in the digested sludge is effectively reduced, and the great significance is provided in the resource utilization of sludge and the reduction of the risk of sludge land use.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com