Circular production method for edible mushrooms

A production process and technology of edible fungi, applied in botany equipment and methods, horticulture, applications, etc., can solve the problems of waste of fungus chaff, pollution of the environment, low utilization rate of culture materials, etc., and achieve the effect of reasonable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

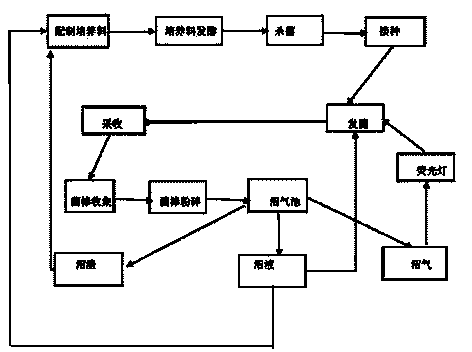

[0010] Example 1: Industrialized production of Flammulina velutipes circular production process.

[0011] The initial compost formula of Flammulina velutipes is 89% of cottonseed hulls, 10% of bran, and 1% of gypsum. The production process see figure 1 , After the preparation of Flammulina velutipes compost is completed, it is inoculated after fermentation and sterilization, and then the fungus is carried out under the suitable conditions artificially created. The stress resistance of the entity, the growth of Flammulina velutipes begins to produce about 35 days, and the fruiting body grows for about 35 days before harvesting. The harvested mushroom sticks directly enter the mushroom stick collection equipment, and then enter the mushroom stick crusher. After crushing, put it into the biogas digester. The crushed fungus chaff is fermented in the biogas digester to produce biogas, biogas slurry and biogas residue. The biogas is used to supply the fluorescent lamp lighting in...

example 2

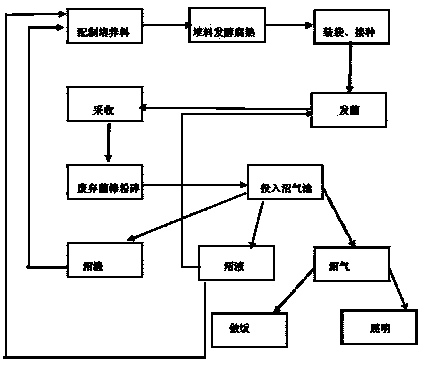

[0018] Example 2: The circular production process of shiitake mushrooms produced by farmers.

[0019] The initial compost formula of shiitake mushrooms in this example is 78% of sawdust, 15% of bran, 5% of corn flour, 1% of gypsum powder, and 1% of superphosphate. The production process is figure 2 After the cultivation and preparation of shiitake mushrooms is completed, mix well and put in water. The ratio of material to water is generally 1:1.5, and the pH value is controlled between 7.0-7.5. Add a certain amount of magnesium sulfate and urea in an appropriate amount. Generally, add 0.2kg of magnesium sulfate per 100kg of material , urea 0.15kg. After the stacking fermentation process, bagging and inoculation are carried out, and then put into the mushroom shed to grow bacteria. After about 35 days, the mushrooms start to grow, and the fruiting body grows for about 35 days, and the mushrooms are picked. After harvesting, discarded mushroom sticks are recycled, crushed ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com