Patents

Literature

3114 results about "Sawdust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sawdust (or wood shavings) is a by-product or waste product of woodworking operations such as sawing, milling, planing, routing, drilling and sanding. It is composed of fine particles of wood. These operations can be performed by woodworking machinery, portable power tools or by use of hand tools. Wood dust is also the byproduct of certain animals, birds and insects which live in wood, such as the woodpecker and carpenter ant. In some manufacturing industries it can be a significant fire hazard and source of occupational dust exposure.

Two-stage method for pretreatment of lignocellulosic biomass

InactiveUS20100279361A1Reduce decreaseMaximize efficiencyOrganic compound preparationFood processingCelluloseFiber

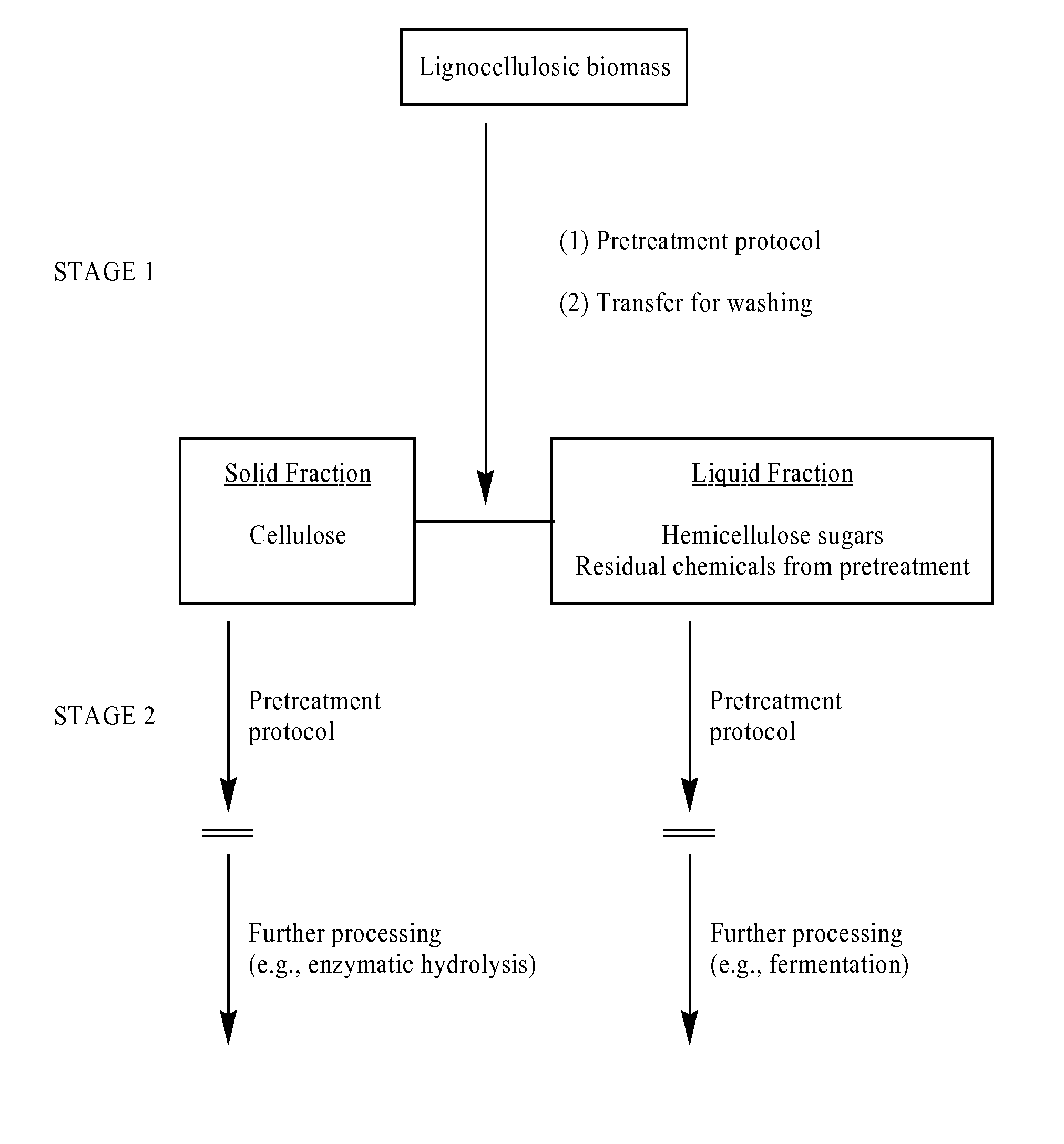

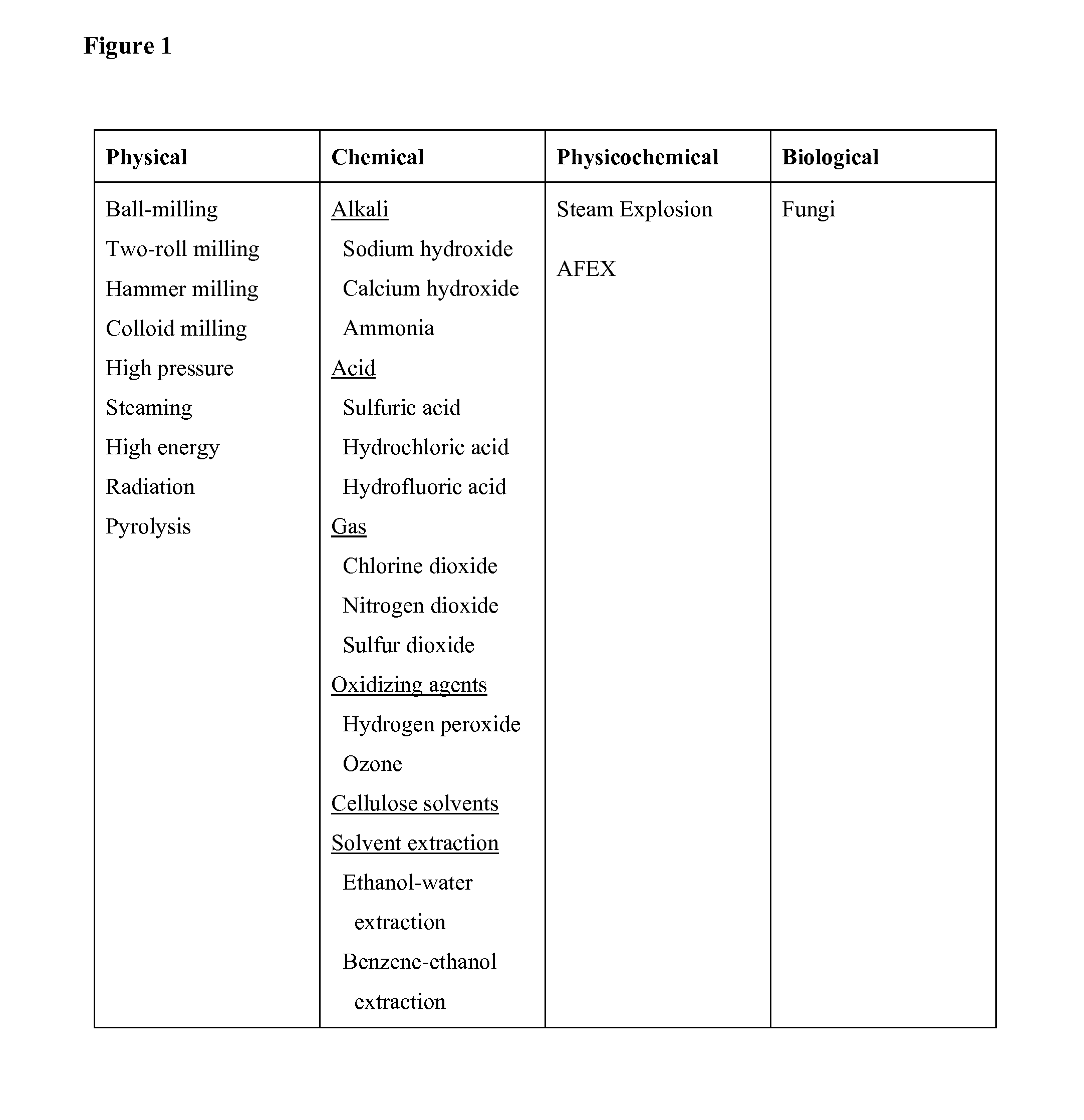

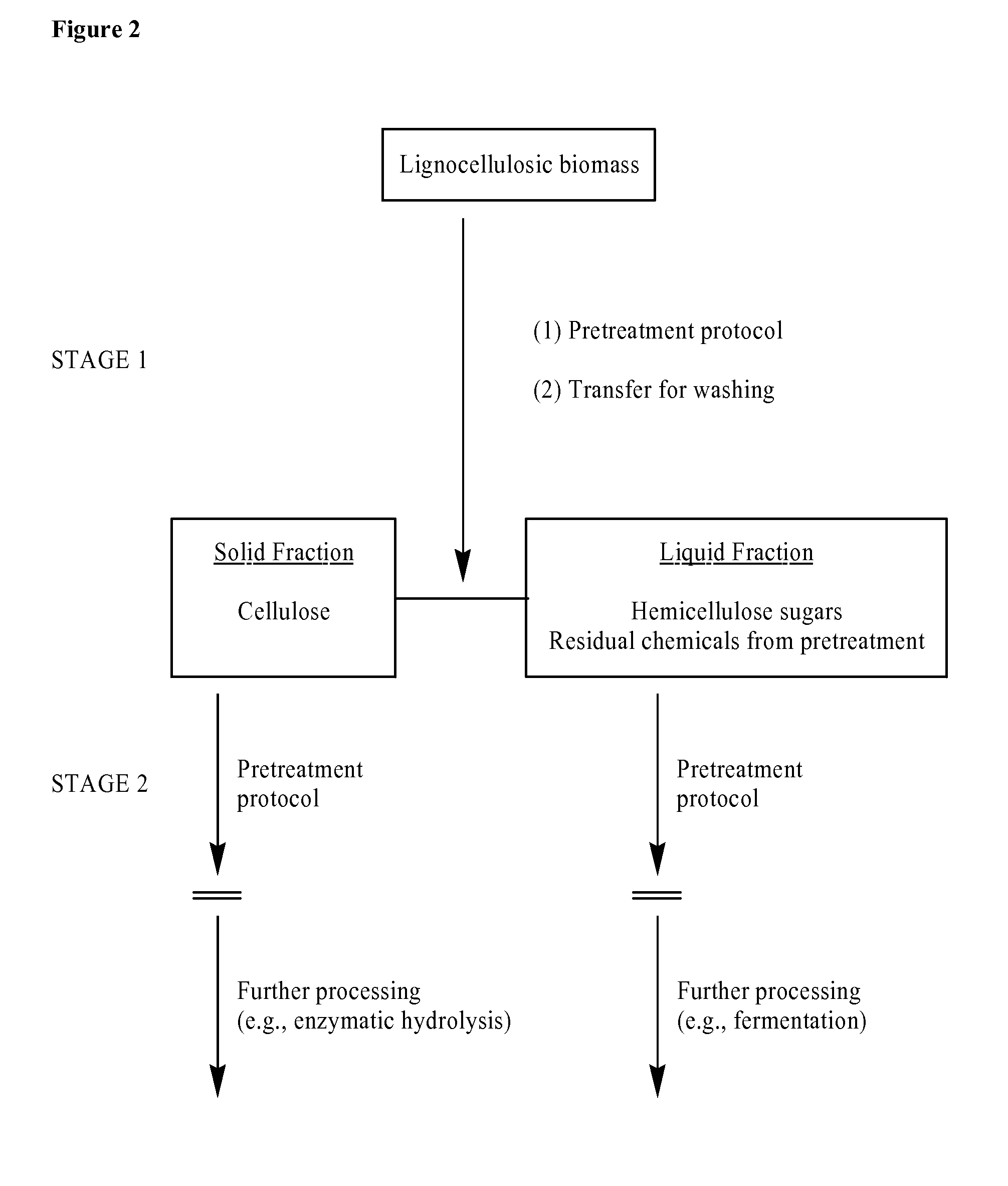

One aspect of the invention relates to a process, comprising treating lignocellulosic biomass according to a first pretreatment protocol, thereby generating a first product mixture; separating the first product mixture into a first plurality of fractions; and treating at least one fraction of said first plurality of fractions according to a second pretreatment protocol, thereby generating a second product mixture. In one embodiment, the lignocellulosic biomass is selected from the group consisting of grass, switch grass, cord grass, rye grass, reed canary grass, miscanthus, sugar-processing residues, sugarcane bagasse, agricultural wastes, rice straw, rice hulls, barley straw, corn cobs, cereal straw, wheat straw, canola straw, oat straw, oat hulls, corn fiber, stover, soybean stover, corn stover, forestry wastes, recycled wood pulp protocol protocol fiber, paper sludge, sawdust, hardwood, softwood, and combinations thereof.

Owner:MASCOMA CORPORATION

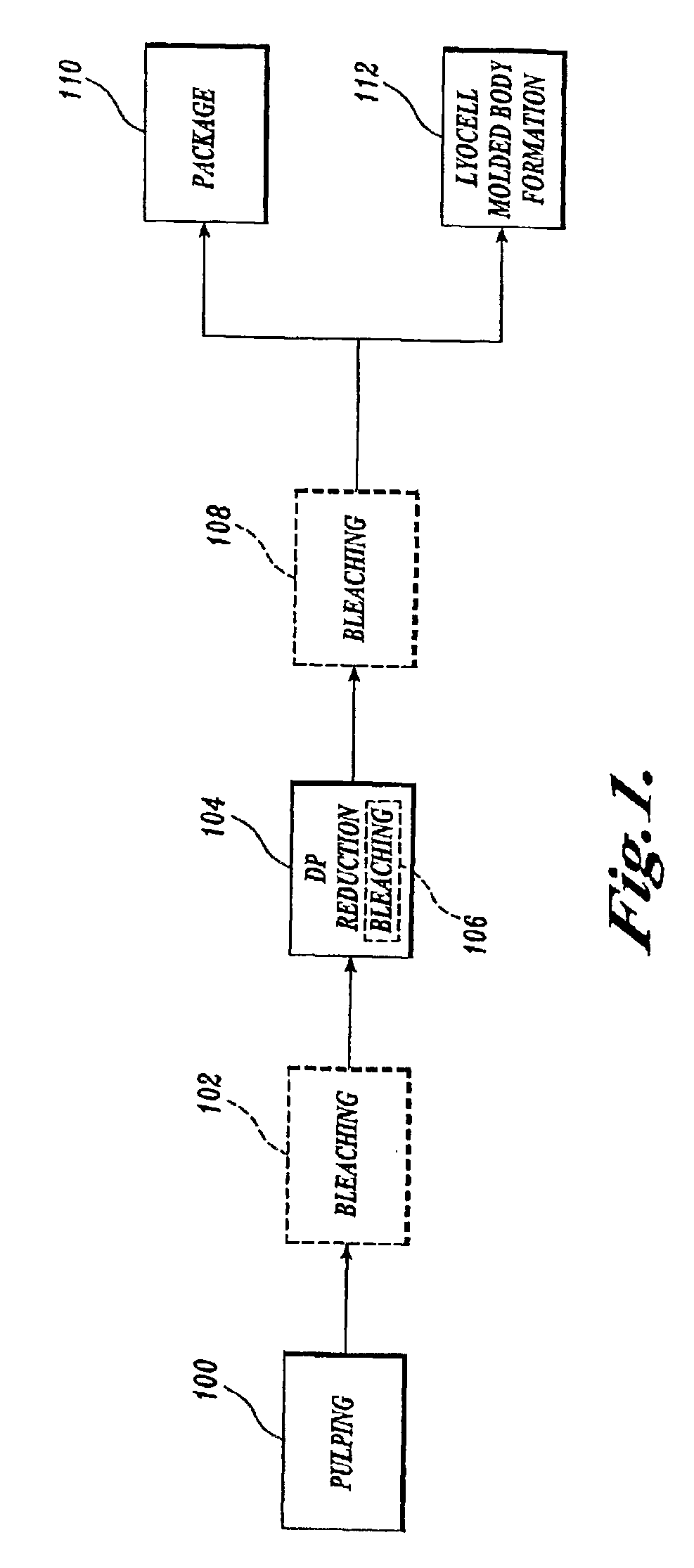

Clear-white gold needle mushroom cultivation method

InactiveCN101366346AAvoid pollutionNo diseaseBio-organic fraction processingOrganic fertiliser preparationSucroseSaccharum

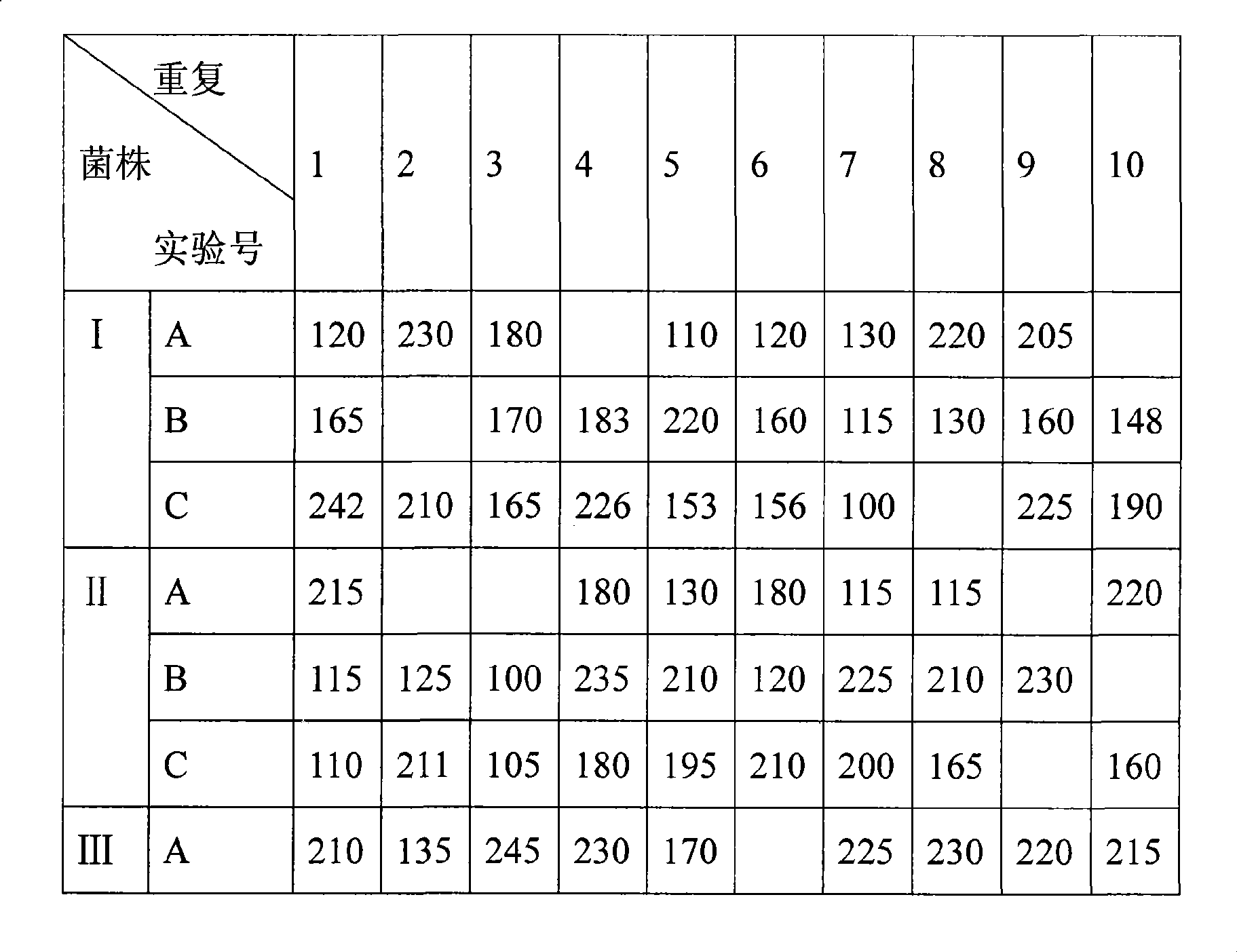

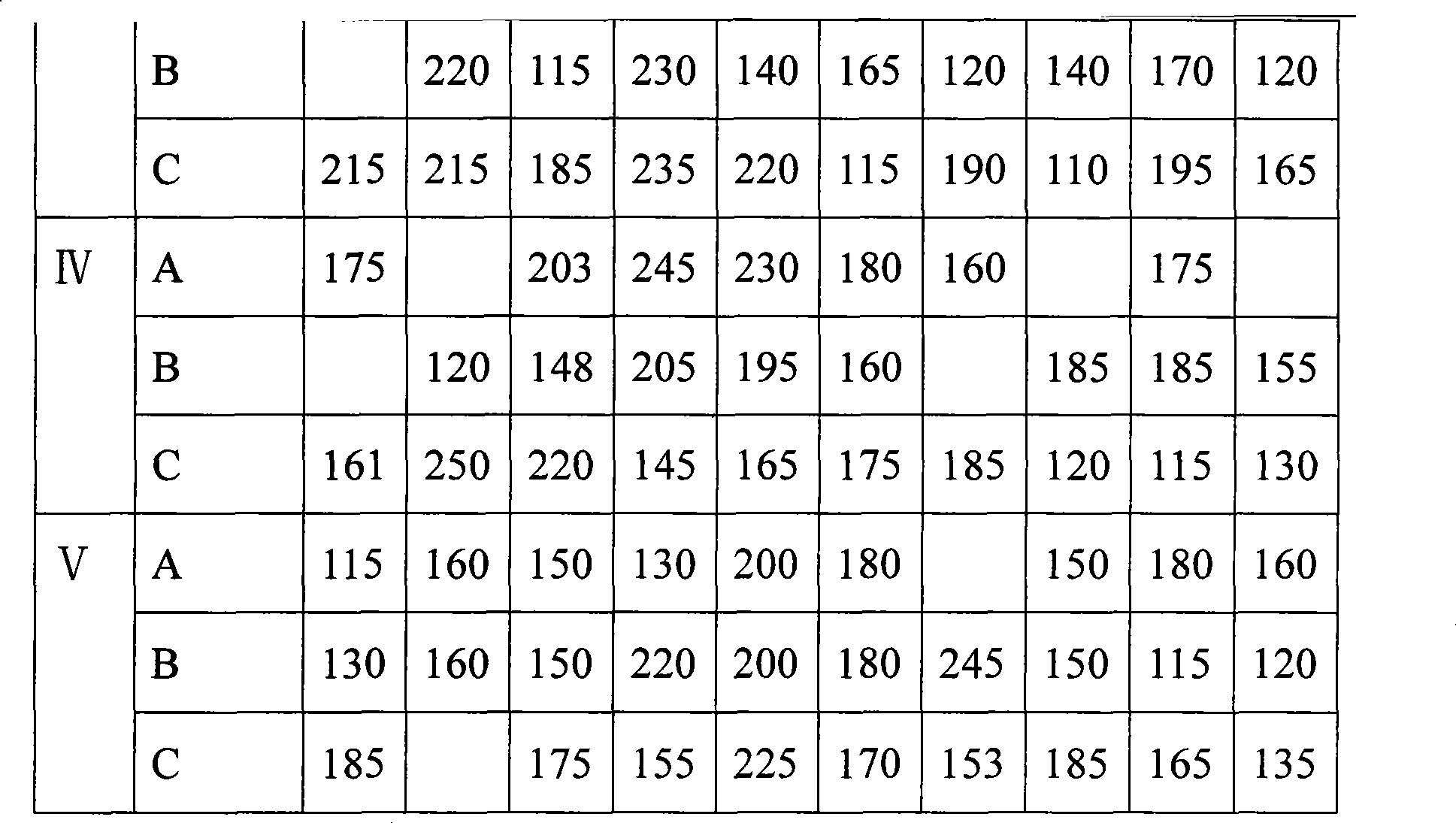

The invention discloses a method for cultivating pure white needle mushrooms. The method comprises the following steps: a strain is prepared; a culture material is prepared; bagging and sterilization are carried out; inoculation is carried out; a mycelium is cultured; nutrition, humidity, temperature, light, air and other culture conditions are strictly controlled during a fruiting period; and harvesting is carried out in an optimum period. the formulation of the culture material is 0 to 32 percent of weed tree sawdust, 0 to 93 percent of cotton seed hulls or wheat straw, straw, corncob and other crop straw, 0 to 20 percent of wheat bran, 0 to 10 percent of corn meal, 0 to 10 percent of soybean meal, 0 to 1 percent of calcium carbonate, 0 to 0.2 percent of monopotassium phosphate, 0 to 0.2 percent of magnesium sulfate, 1 to 1.2 percent of sucrose, 0 to 10 percent of rice bran, 0 to 1 percent of plaster and 0 to 0.02 percent of urea. Quicklime and wettable carbendazim are added during the preparation of the culture material so as to prevent the pollution of undesired bacteria. The technical proposal aims to select proper breeds, popularize local large scale planting and improve cultivation benefit.

Owner:WUHU YESHULIN BIOTECH

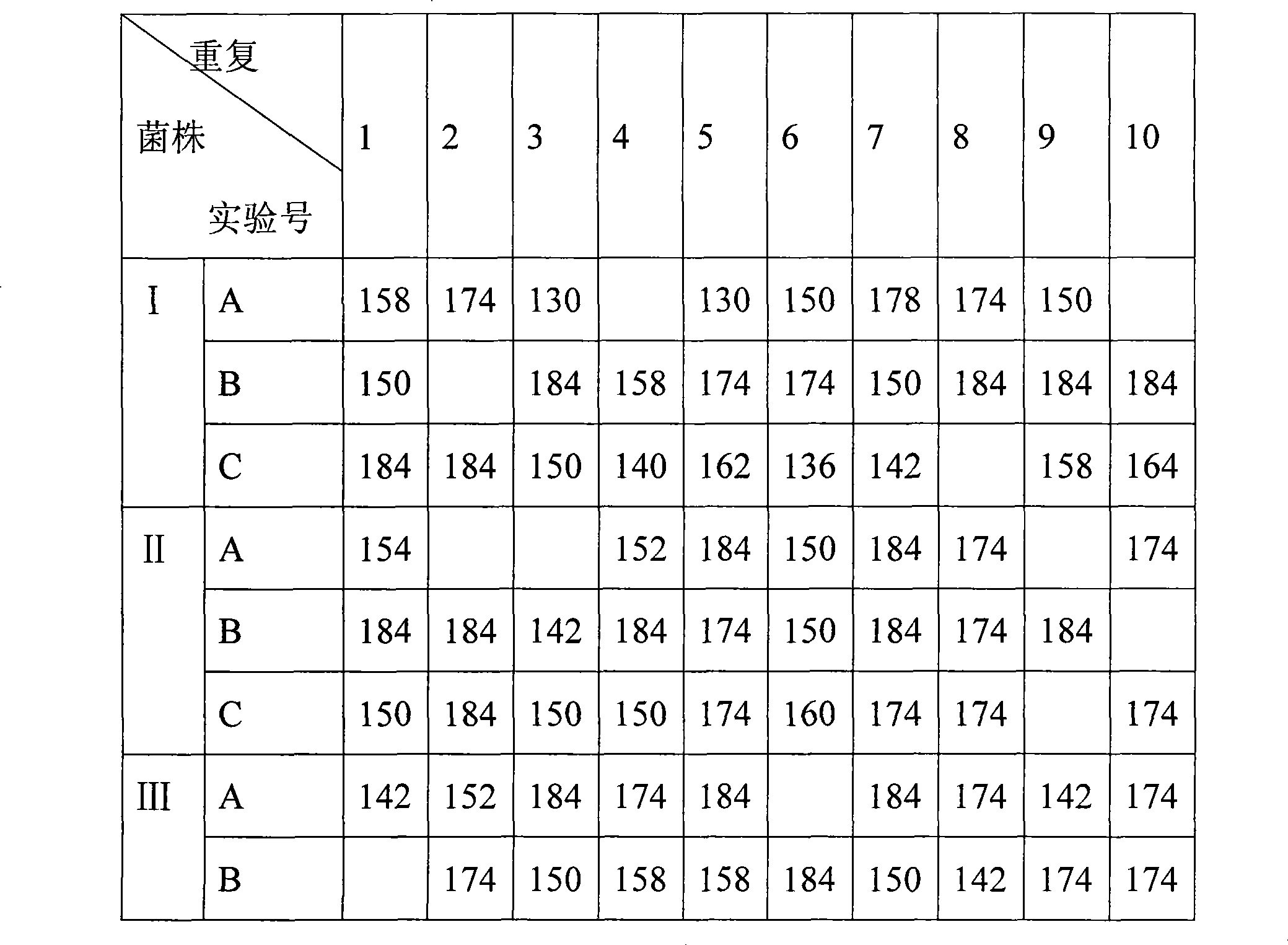

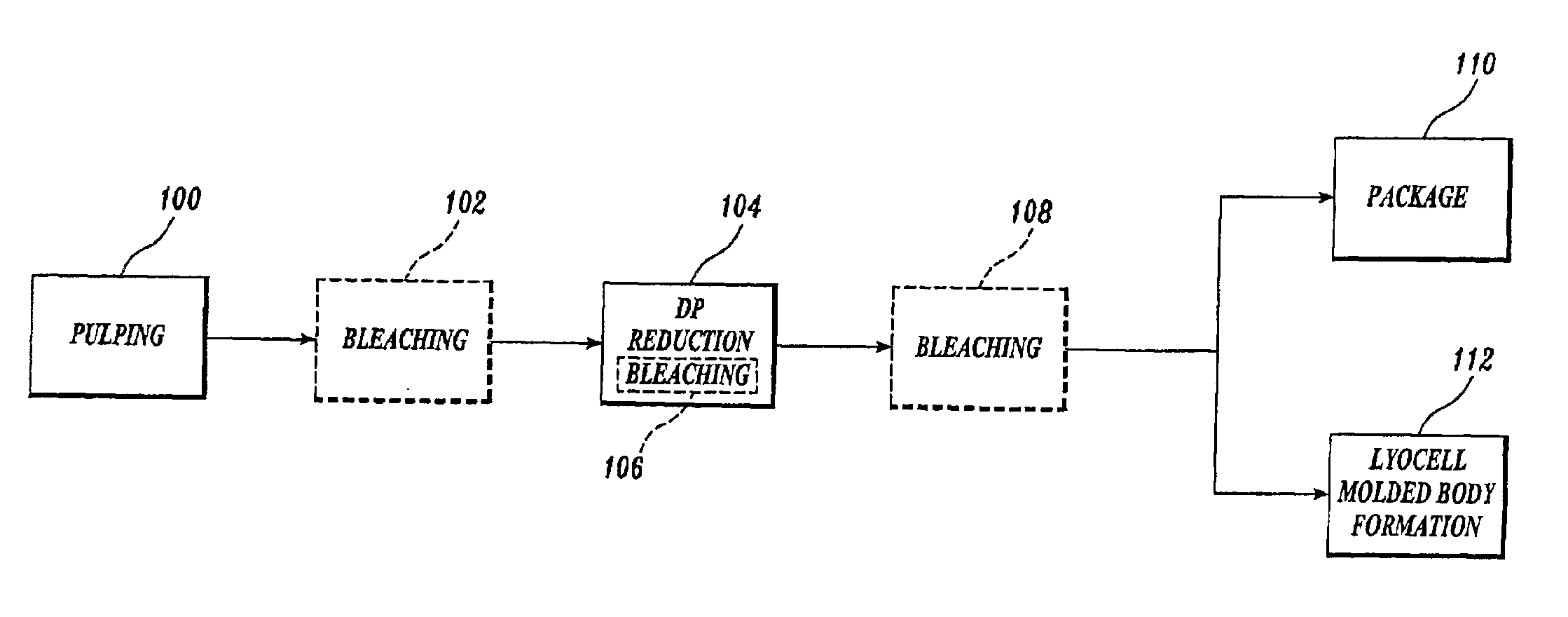

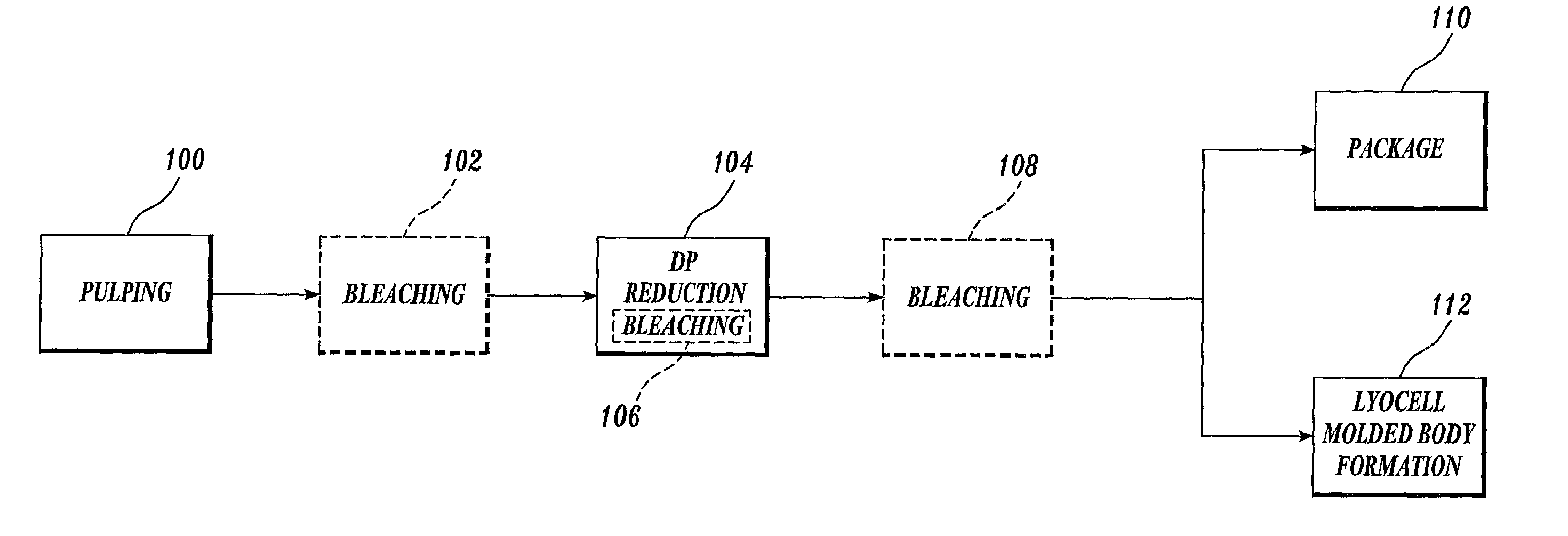

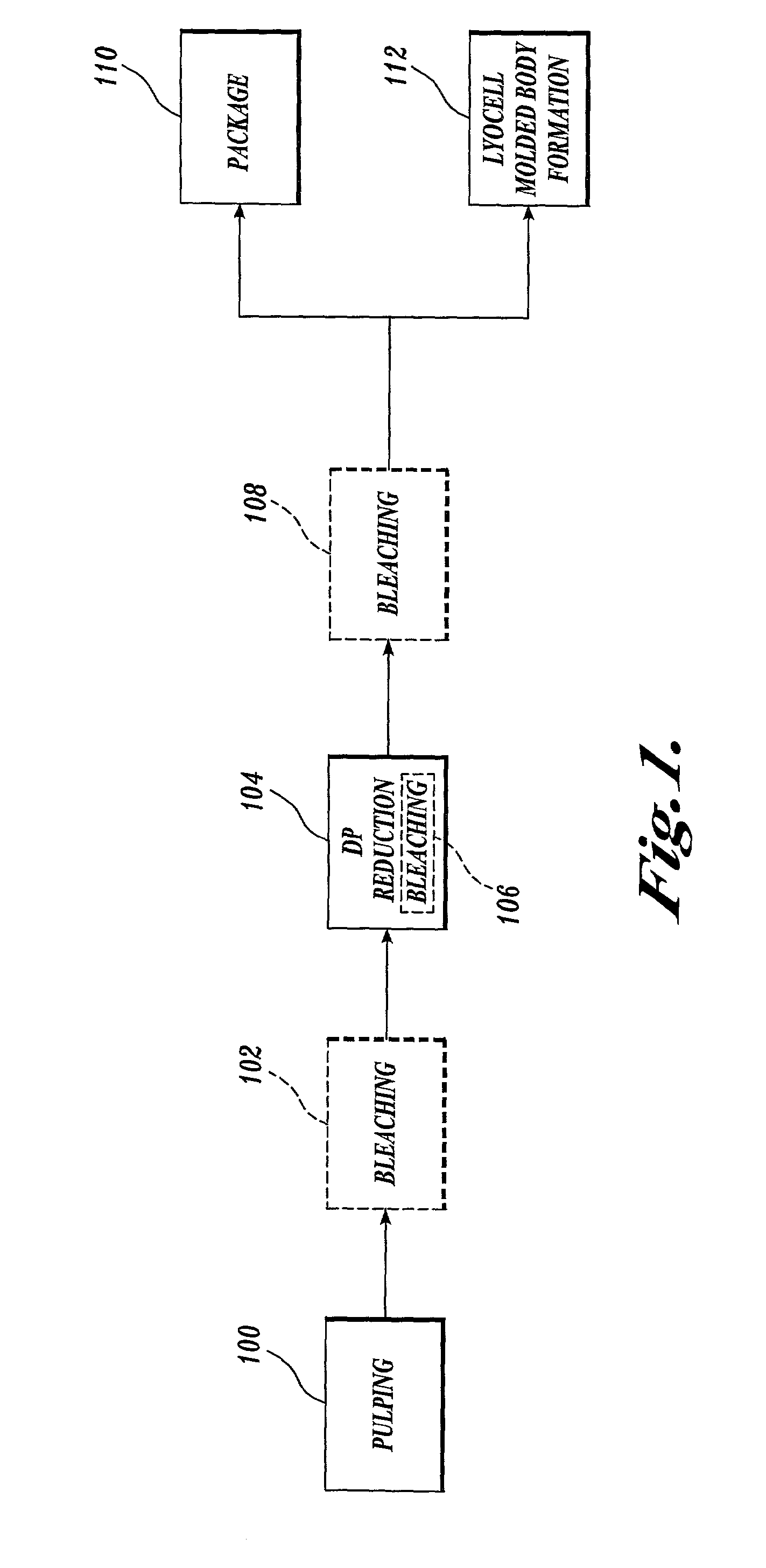

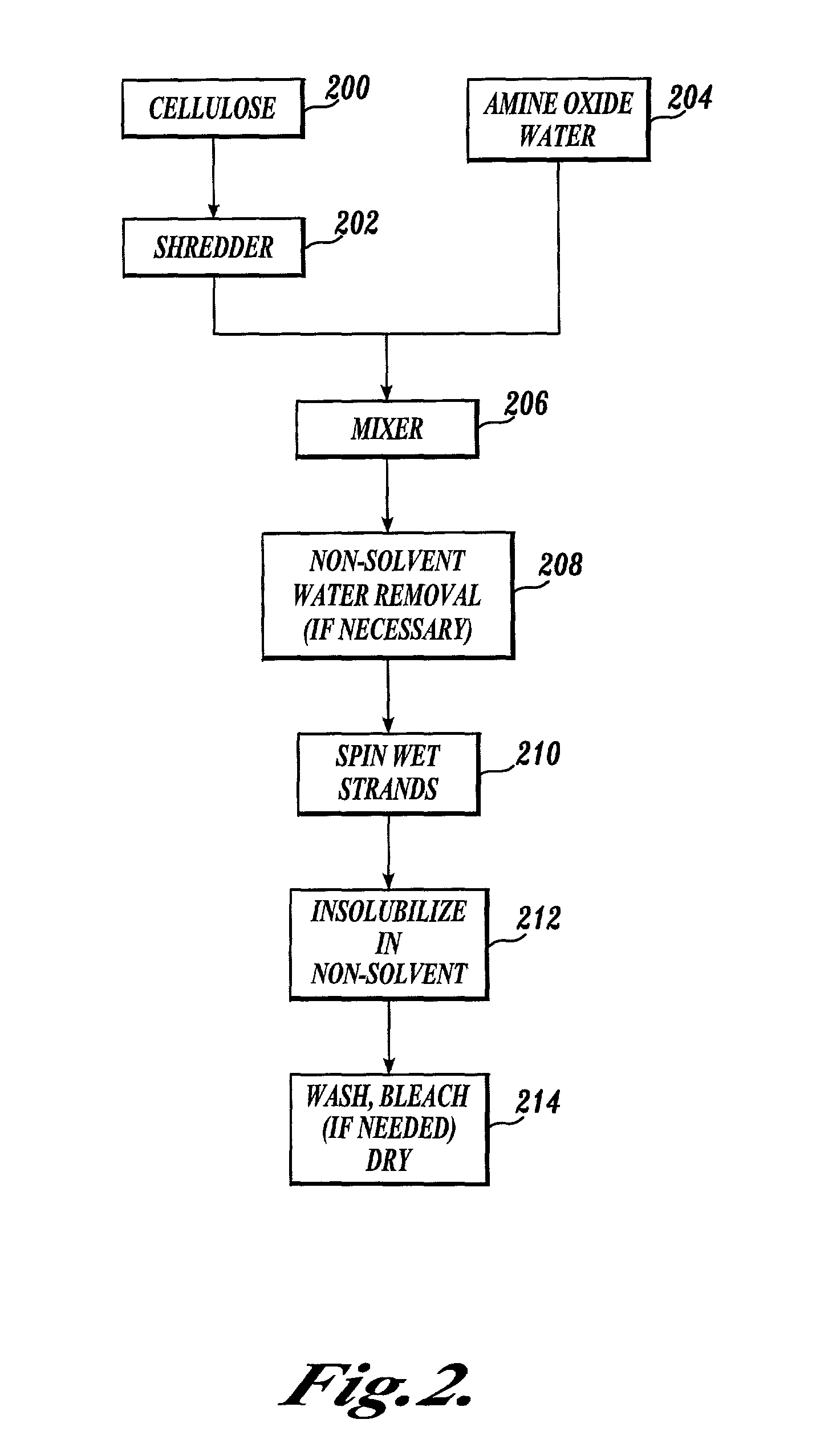

Process for making lyocell fiber from sawdust pulp

InactiveUS6861023B2Reducing average degree of polymerizationReduced hemicellulose contentPulp properties modificationArtificial filaments from cellulose solutionsCopperLyocell

A process for making lyocell fibers including the steps of pulping raw material in a digester to provide an alkaline pulp, wherein the raw material includes sawdust in an amount greater than 0% up to 100%; contacting the alkaline pulp including cellulose and at least about 7% hemicellulose under alkaline conditions with an amount of an oxidant sufficient to reduce the average degree of polymerization of the cellulose to the range of from about 200 to about 1100 without substantially reducing the hemicellulose content or substantially increasing the copper number of the pulp; and forming fibers from the pulp.

Owner:INT PAPER CO

Method for cultivating wood-rotting fungi

InactiveCN102415279AReduce dosageIncrease productionHorticultureFertilizer mixturesBiotechnologyGossypium

The invention discloses a method for cultivating wood-rotting fungi. The raw materials for cultivating the wood-rotting fungi comprise the following components of: 45-55 parts of cotton stalk crumb, 8-20 parts of fine sawdust, 8-20 parts of corncob, 5-20 parts of bran coat, 4-7 parts of bean dregs, 5-11 parts of pure chicken manure, 0.5-1.5 parts of phosphate fertilizer, 0.5-1.5 parts of plaster, 1-5 parts of lime and 8-20 parts of cotton seed hull. The raw materials in weigh ratio are cultivated to generate the wood-rotting fungi according to the steps of adding water in the raw materials and uniformly stirring, building pile and fermenting, producing an inoculation bacterial bag and generating mushroom. According to the method disclosed by the invention, the consumption of the cotton seed hull is reduced; and cotton straws are used to replace the cotton seed hulls and are simultaneously matched with the fine sawdust and the corncob to produce a cultivation raw material of the wood-rotting fungi. The method has the characteristics of ensuring quick material consumption by hypha during fingi fermentation, robust growth and white and density, compact produced fruiting body and rounding mushroom shape. According to the method, the labor and time are saved, the cost is reduced and the yield is increased.

Owner:河北省农业环境保护监测站

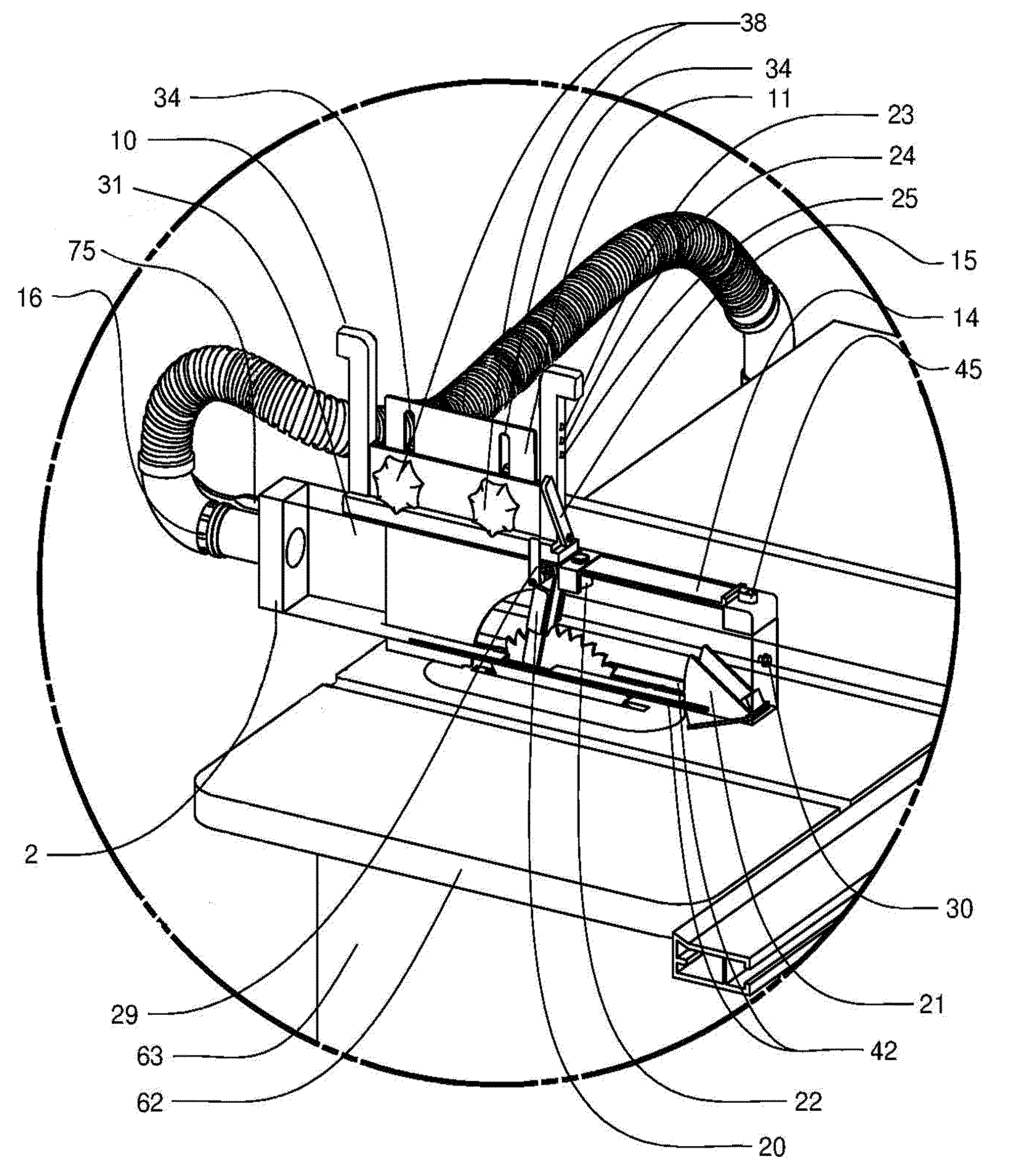

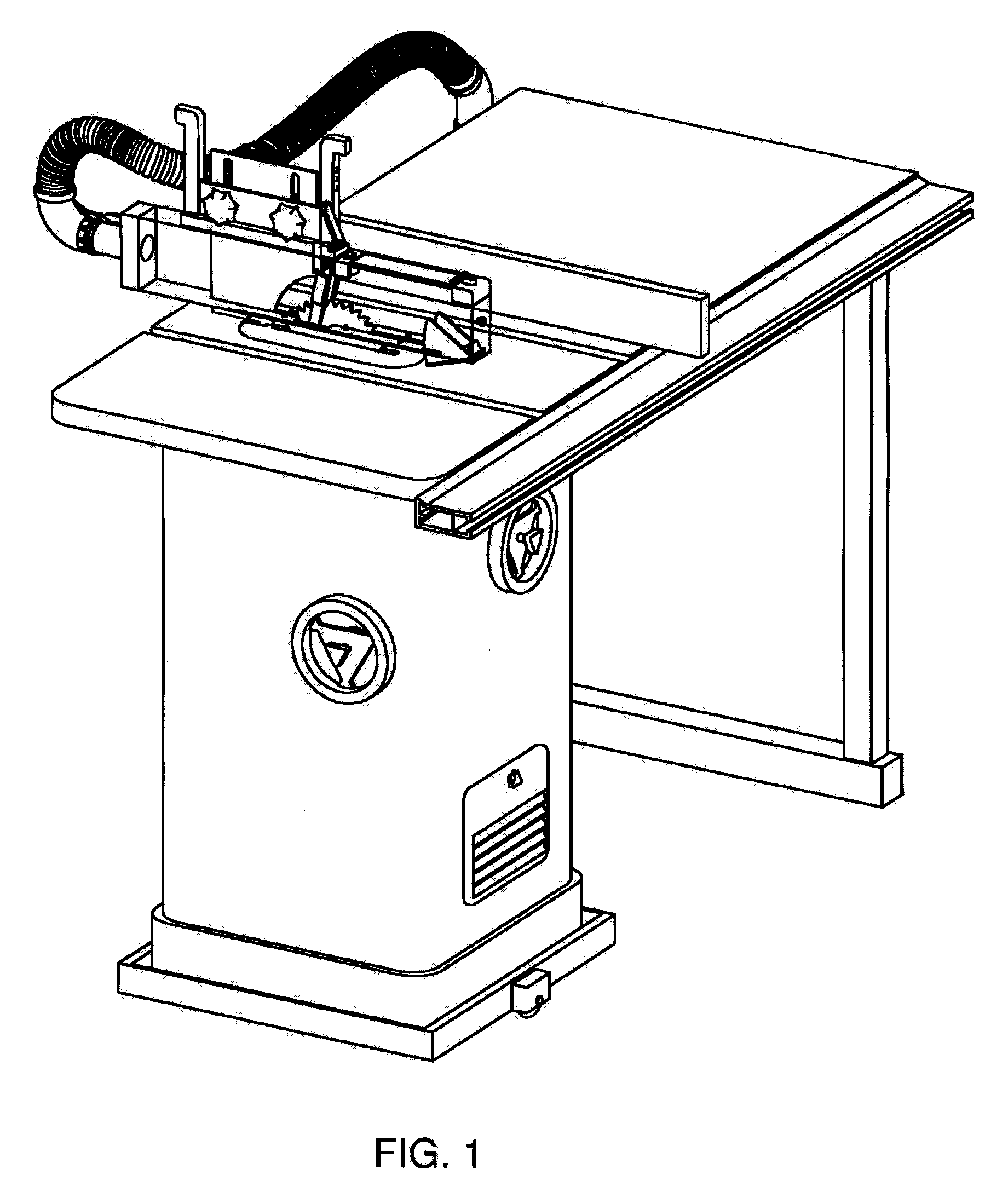

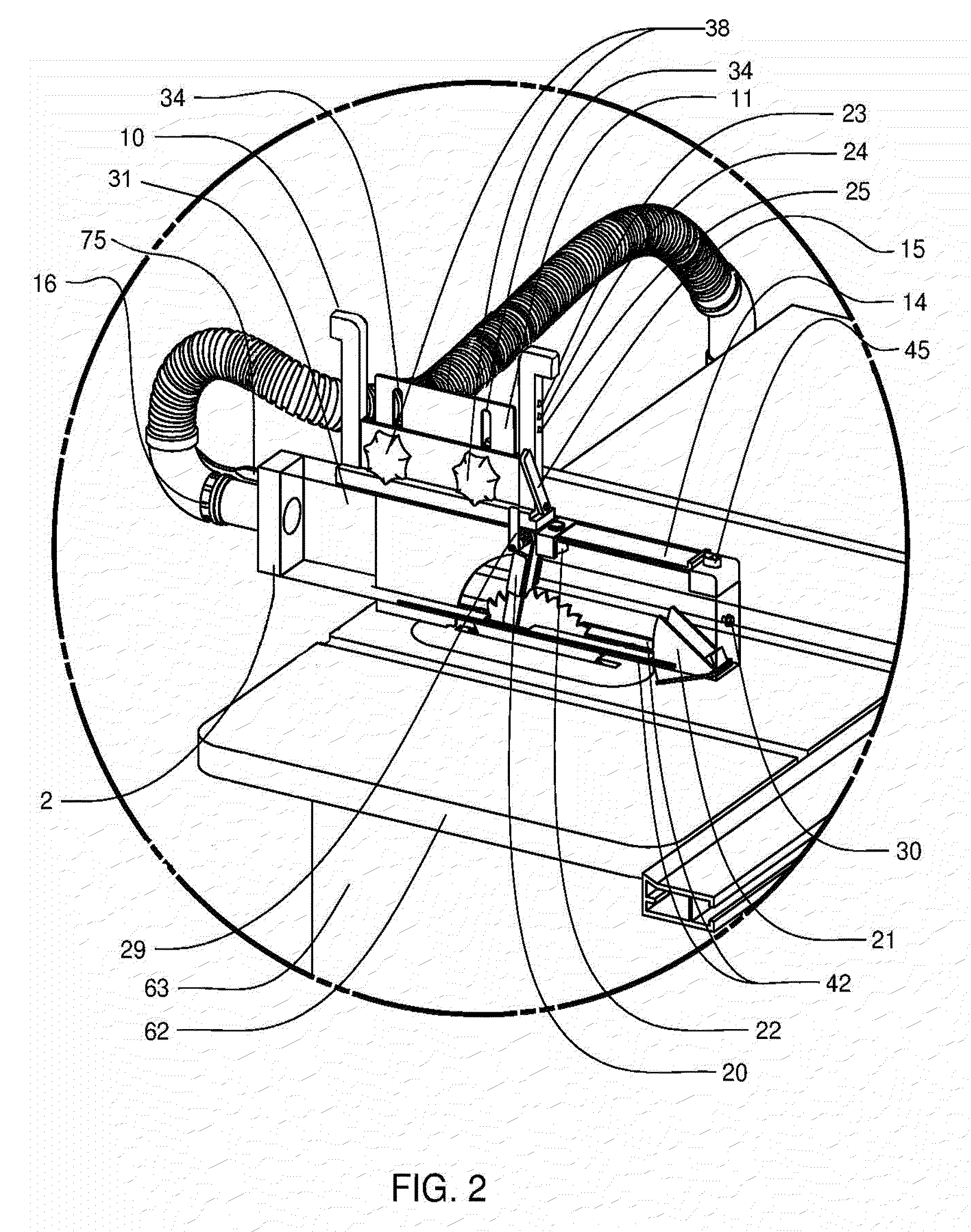

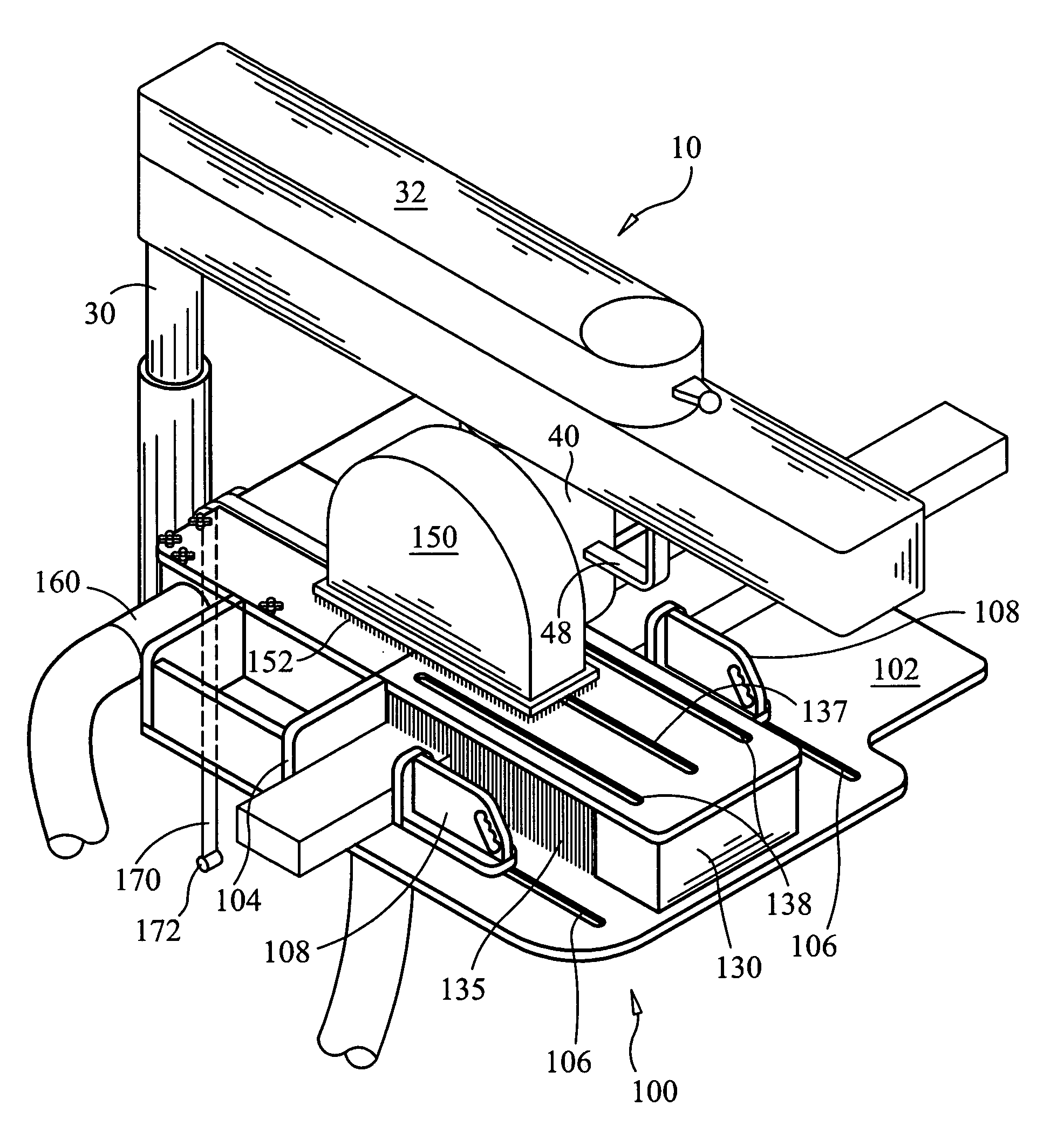

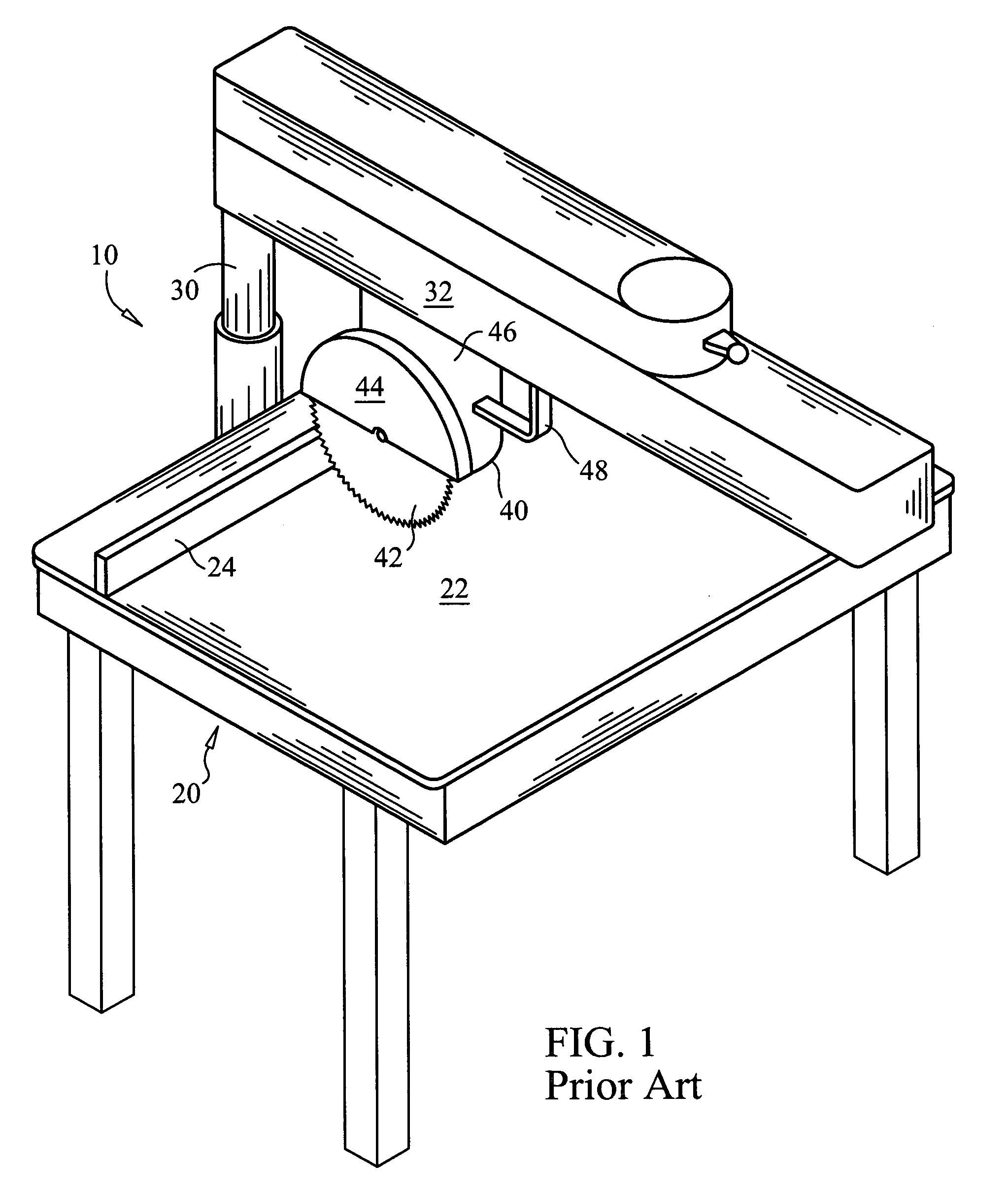

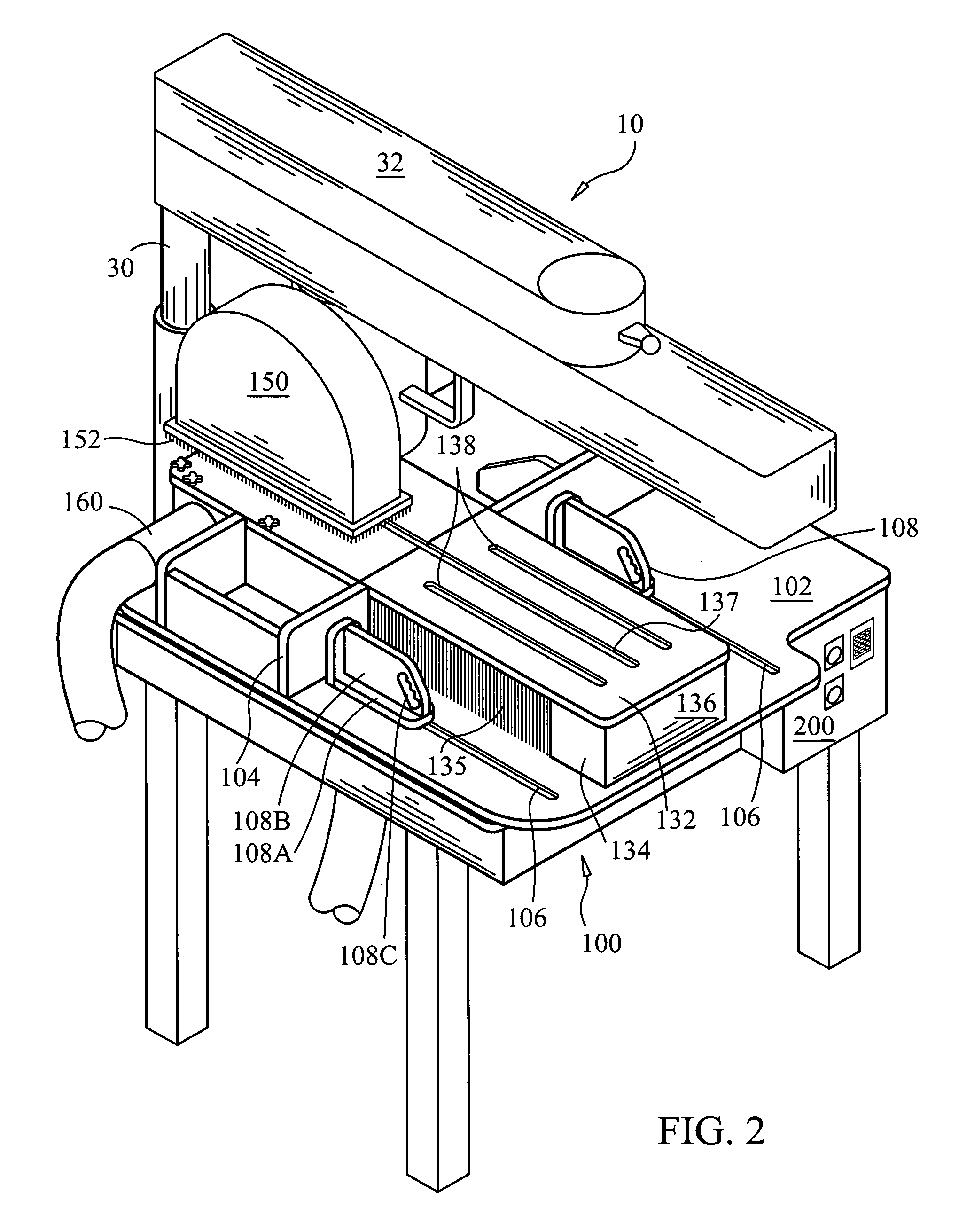

Health and safety system for a table saw

InactiveUS20100307307A1Reduces long-term riskEasy accessMetal sawing accessoriesGuide fencesInjury causeCollection system

An improved health and safety system for a table saw includes one or more of: a blade guard that protects the operator from the saw blade, and contains and collects sawdust; a proximity detector and emergency saw motor braking means for use in connection with such blade guard; an anti-kickback device for use in connection with such blade guard, a rip fence adapter for use in connection with such a blade guard, and hoses and fittings to connect the dust containment and collection system of said blade guard to a shop dust collection blower or vacuum system. The system protects the saw operator from potential traumatic injury to a hand, and from ingesting potentially carcinogenic sawdust.

Owner:BUTLER DAVID J

High efficient plugging agent for well drilling

InactiveCN102127403AWide coverage of pluggingImprove pressure bearing capacityDrilling compositionWell drillingLost circulation

The invention relates to a plugging agent during well drilling in oil and gas field, and particularly to a high efficient plugging agent for severe lost circulation. The components are, by weight: 18-25% of walnut shell powder, 8-10% of sawdust, 8-10% of cottonseeds, 10-15% of hull powder, 20-30% of active plugging agents, and 15-25% of elastic rubber granules, and the raw materials are mixed uniformly to obtain a high efficient plugging agent for well drilling. According to the invention, the fibrous plugging agent with granules is formed by mixing natural plant inert materials, a synergistic agent, and a reinforcing agent with a certain preparation ratio. The plugging agent of the invention has the advantages of wide covering area for leak stopping, high pressure bearing capacity, good plugging effect, high success rate for disposable leak stopping, simple on-site preparation process, and reliable and safe construction, which can achieve the purposes of reducing loss of lost circulation and saving comprehensive cost. The high efficient plugging agent of the invention is applicable to leak stopping operations under various lost circulation conditions with good leak stopping effect and high success rate, and is superior to other types of plugging agents.

Owner:浙江仁智股份有限公司

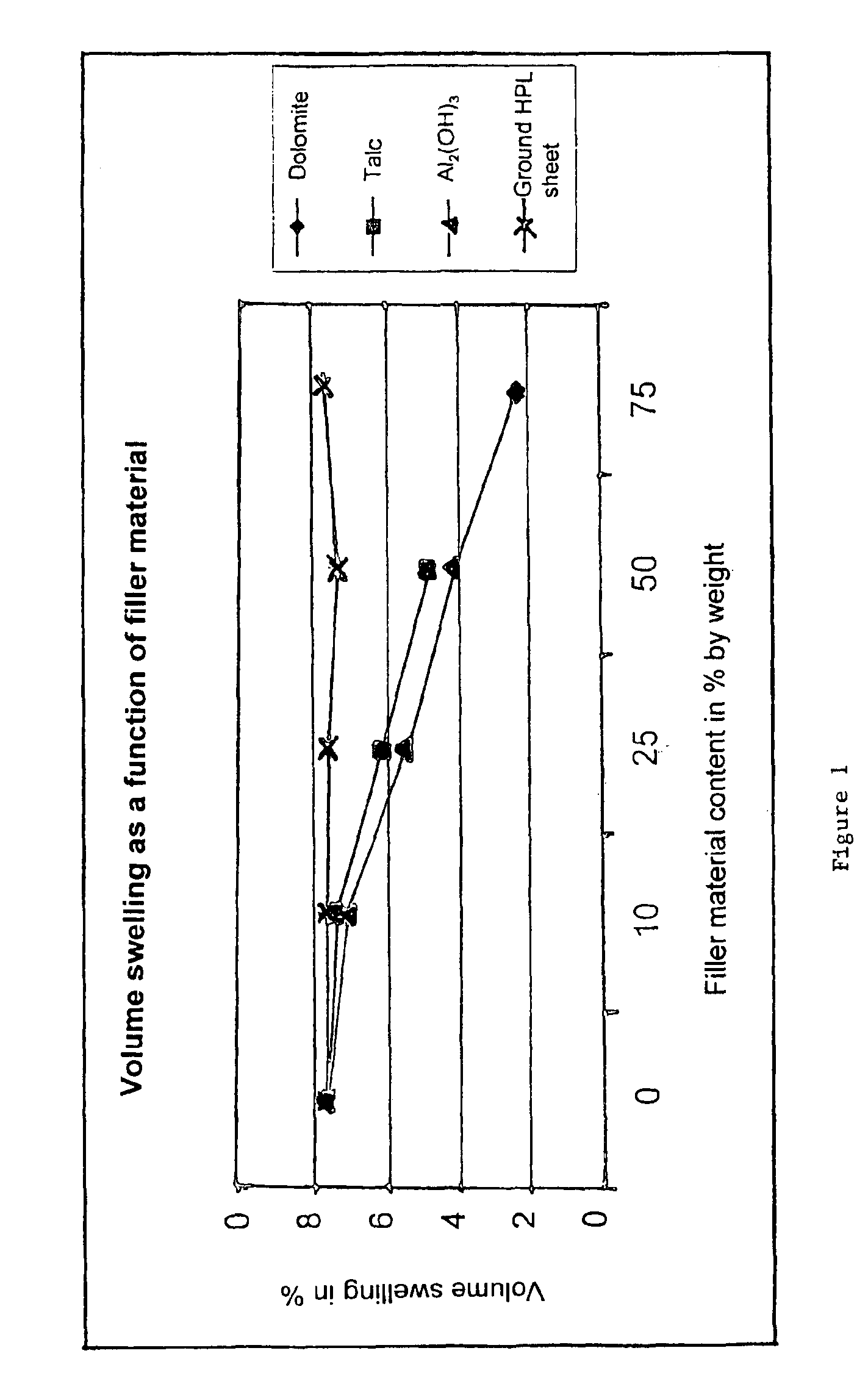

Decorative sheet or molding comprising fibers and fillers and process for its production

A decorative sheet or a molding, in particular suitable for indoor or outdoor applications on buildings, is in each case composed of a single- or multi-layer core, monolaterally or bilaterally laminated with decorative layer(s) The core layer(s) comprise(s) wood fibers, cellulose fibers, or timber sawdust products and also an organic or inorganic filler material, and a hot-curing resin. The particle size of the filler material is smaller than the thickness of the fibers or of the timber sawdust products in the core layer(s). These core layer(s) are composed of from 15 to 80% by weight of fibers or of timber sawdust products, from 10 to 75% by weight of filler material, and from 10 to 50% by weight of resin, based in each case on the total weight of the core layer(s).

Owner:TRESPA INT

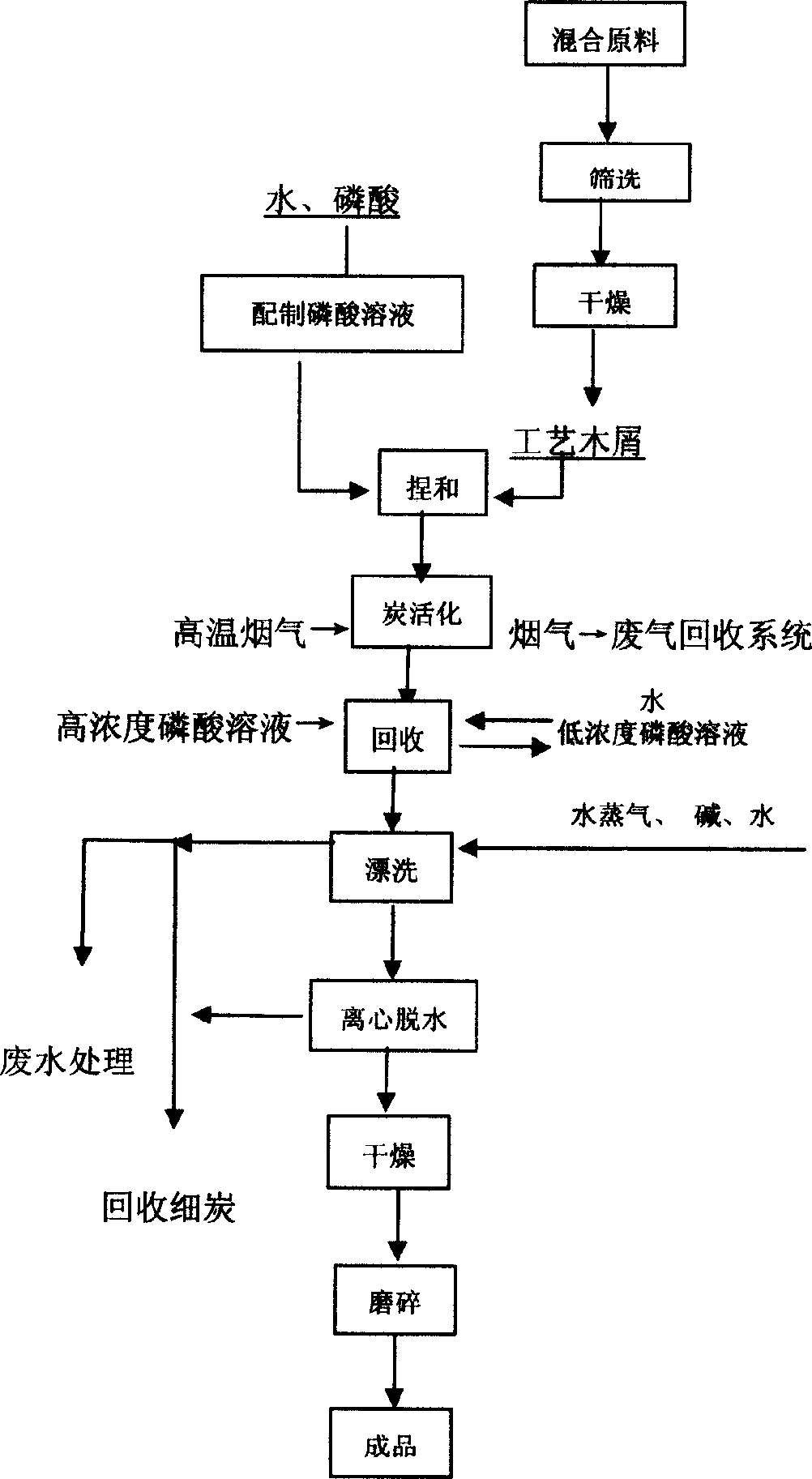

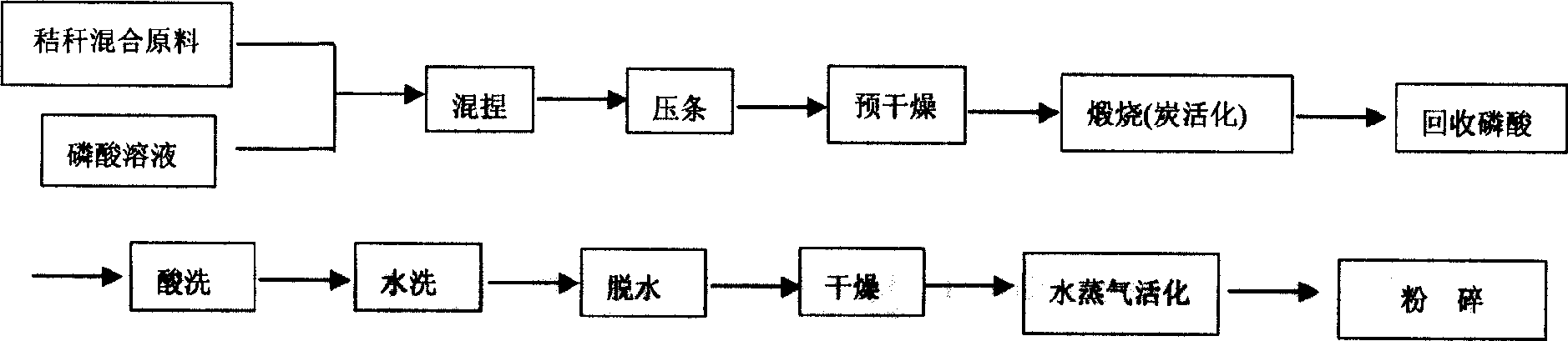

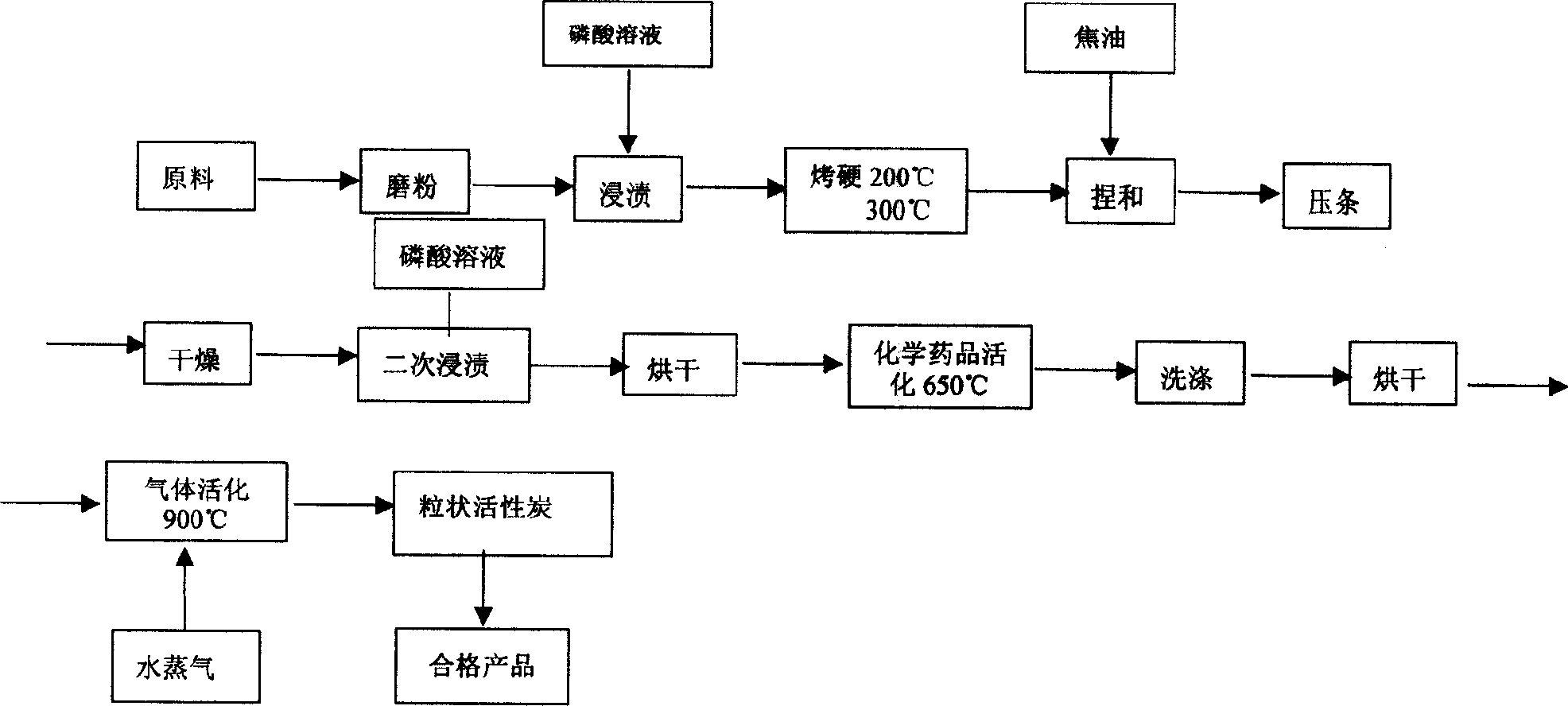

Active carbon producing process with mixed stalk material

The present invention discloses the active carbon producing process with mixed stalk material. The mixed stalk material of crop stalk, waste fruit branch and sawdust is produced into powdered or granular active carbon via phosphoric acid process and combined physical process. Or, the mixed stalk material is produced into powdered or granular active carbon in a chemical physical process with potassium hydroxide as activating agent and perchloric acid for pre-treatment of the material. The present invention has small investment scale, low cost, high utility and simple operation, and the product may be used widely.

Owner:NORTHWEST A & F UNIV

Radial arm saw safety top

InactiveUS7044039B2Overcome disadvantagesMetal sawing devicesMetal sawing accessoriesEngineeringMechanical engineering

A radial arm saw is adapted with a safety top configured with cutting box enclosure that contains and collects substantially all of the sawdust generated during use. A dust collection system is in fluid communication with the cutting box for removing the sawdust contained therein. Spring biased push blocks function to hold the work piece in place during the sawing process while maintaining the user's hands safely away from the saw blade. A laser alignment device projects a beam within the cutting box along the cutting plane. A control panel is provided to allow use by authorized users upon entry of an authorization code.

Owner:POWELL MICHAEL S

Fuel for firing into rotary kiln cement clinker

A fuel which is used for rotary kiln cement clinker firing is composed of raw materials with the following weight percentage: coal 3-80, straw substances 0-90, forest products wastes 0-95 and food industry by-product residues 0-70. The straw substances refer to rice straws, wheat straws, cotton stalks, sesame stalks, soybean straws, corn stalks, sorghum stalks, rice husks, peanut shells, soybean shells and corn sticks, the forest products wastes refer to defective bamboo, wood, tree branches, leaves, shrubs, faggot straws and sawdust and wood wool corner scrap materials in the bamboo and wood-processing industry, the food industry by-product residues refer to bran, wheat skin, squeezing meal cake, bean dregs and wine lees, and the coal refers to bituminite, anthracite and coke coal powder. The flue raw materials which are used for the rotary kiln cement clinker firing have wide selecting range, simple preparation, convenient use and rapid burning speed and are beneficial for protecting atmosphere circumstances.

Owner:吴飞龙

Cultivation medium for Pleurotus geesteranus and method for producing the same

InactiveCN101462900AImprove qualityBacteriaBio-organic fraction processingOrganic fertiliser preparationAgricultural scienceSucrose

The invention discloses a pleurotus geesteranus medium and a preparation method thereof. The recipe of the medium comprises (by weight) 60-75% of cotton seed hull or wheat straw or rice straw or corn cob, 7-15% of weed tree sawdust, 8-15% of wheat bran or rice bran, 3-8% of corn flour, 0.5-1.5% of sucrose, 1-1.5% of dried gypsum, 2-2.5% of quicklime, 0.1-0.3% of potassium dihydrogen phosphate and 0.1-0.2% of magnesium sulfate. The preparation method of the medium comprises the following steps: dissolving the quicklime, the dried gypsum, the potassium dihydrogen phosphate and the magnesium sulfate into water; adding the cotton seed hull or the wheat straw or the rice straw or the corn cob and the weed tree sawdust for prewetting; then adding the rice bran, the corn flour, the wheat bran and the sucrose and mixing evenly; and returning the medium having been used for planting the pleurotus geesteranus to field and soil in situ. The technical scheme can cause the pleurotus geesteranus to grow better and avoids the defect of no special medium for the growth of the pleurotus geesteranus in the prior art.

Owner:许忠

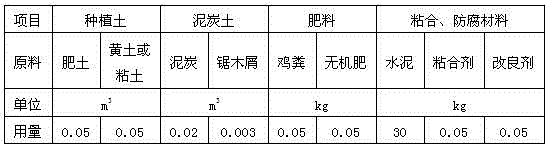

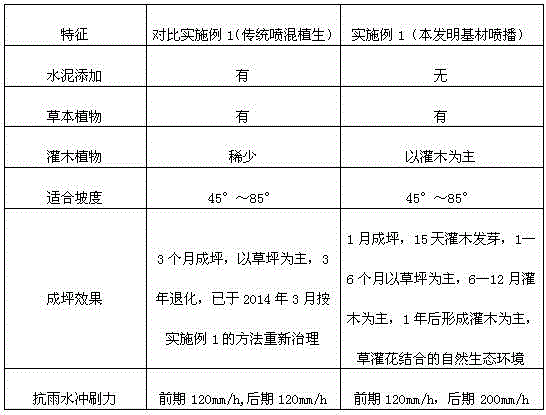

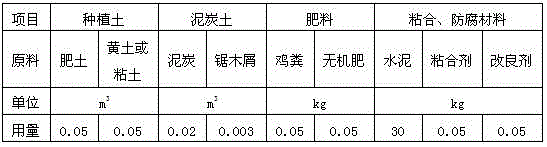

High and steep side slope ecological retrieved green spray-seeding base material and preparation method and application of base material

InactiveCN104782383AAvoid churn problemsEvenly distributedPlant cultivationCultivating equipmentsFiberCoreopsis

The invention relates to the technical field of side slope treatment, and discloses a high and steep side slope ecological retrieved green spray-seeding base material and a preparation method and application of the base material. The spray-seeding base material comprises the following raw materials in parts by weight: 330-420 parts of planting soil, 20-30 parts of peat soil, 1.5-5 parts of organic fertilizer, 1-3 parts of grass fibers, 1-3 parts of sawdust, 0.03-0.05 part of a water-retaining agent, 0.02-0.04 part of an adhesive, 0.1-0.5 part of inorganic fertilizer, 0.5-2 parts of a pH adjustment agent, 30-44 parts of hybrid seeds and 150-200 parts of water, wherein the hybrid seeds consists of the following plant seeds in parts by weight: 10-12 parts of rhizomes tall fescue, 2-4 parts of trifolium repens, 3-5 parts of alfalfa, 2-3 parts of bermuda grass, 2.5-4 parts of indigofera pseudotinctoria, 4-6 parts of magnolia multiflora, 3-5 parts of cassia corymbosa, 2-3 parts of amorpha fruticosa and 1-2 parts of coreopsis. The base material disclosed by the invention for spray-seeding can make a soil replacement base layer with the intensity higher than 0.25MPa; after 45 days when a turf is formed, the rainwash strength is higher than or equal to 120mm / h; within half a year to a year, an ecological plant colony with shrubs which grow with the rainwash strength higher than or equal to 200mm / h and serve as main plants is formed.

Owner:HUANGSHI GARDEN FLOWER & WOOD CO LTD

Fermenting bed bioactive padding and preparation and application methods thereof

ActiveCN103053432AEfficient degradationImprove pollutionBacteriaMicroorganism based processesMicroorganismArea source

The invention discloses fermenting bed bioactive padding and preparation and application methods thereof. The fermenting bed bioactive padding is made from, by weight percent, 20%-50% of sawdust, 20%-50% of rice hull, 20%-30% of crop straw, 2%-3% of accessories, and 0.1%-0.3% of fermenting agent. The fermenting bed bioactive padding has the main function of effectively degrading pen manure to improve pollution of rural environment in pig industry. The powerfully functional beneficial microorganisms in the fermenting bed padding are capable of absorbing, degrading and digesting excrement of pigs during breeding, so that pig manure is degraded in situ in a fermenting bed and area source pollution of the rural environment in the pig industry is eliminated.

Owner:湖南省微生物研究所

A method for cultivating high-quality Pleurotus eryngii with waste mushroom residue

The invention discloses a method for culturing high-quality pleurotus geesteranus by using waste pleurotus eryngii residue. The method is characterized in that: when raw materials are prepared and treated, the culture material composition for production, namely the formula composition of raw materials, comprises the following raw materials in part by weight: 400 to 700 parts of waste pleurotus eryngii residue, 200 to 300 parts of sawdust, 300 to 500 parts of corn straw, 100 to 200 parts of cotton seed hull, 200 to 350 parts of bran, 10 to 20 parts of gypsum, 15 to 15 parts of lime, and 10 to 1 5 parts of white sugar. A proper amount of sodium selenite serving as a clearing auxiliary agent is added into each 100 kilograms of dry culture material. By the method, the waste is utilized, the cost of the raw materials is lowered, the resource waste is reduced, environmental pollution is lightened, the sources of the raw materials are easily solved, the process is simple, labor and effort are saved in management, and stable yield and high yield are achieved; and by adding a little amount of sodium selenite (Na2SeO3) serving as the clearing auxiliary agent, the cadmium content of the pleurotus geesteranus finished product is reduced, and the production and the export scale are enlarged.

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI

Method for cultivating microbial strain of phellinus linteus and planting phellinus linteus

The invention relates to a method for cultivating microbial strains of phellinus linteus, which is characterized in that the culture media of microbial strains comprises the following components by weight percent: 75-85% of sawdust of poplar or willow or mulberry, 10-15% of bran, 5-8% of rice bran, 1-2% of plaster, 0.2-0.5% of monopotassium phosphate, 0.1-0.3% of magnesium sulfate, wherein, the sum of the weight percentage of the components is 100%. The microbial strains of phellinus linteus prepared in the invention has rapid growing of microbial strains of phellinus linteus, not easy ageing and yellow water occurred on surface hypha; and the strains can expand completely after 30-35 day cultivation. By adopting the method for cultivating a phellinus linteus forest land, forestry land resources can be fully utilized to plant phellinus linteus products; the method is simple and practicable; and the produced phellinus linteus with large volume can be artificially cultivated in great amounts, thus fully meeting the market demand.

Owner:SHANGHAI ACAD OF AGRI SCI +1

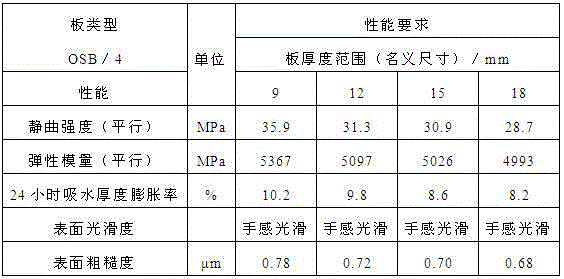

Surface-decorated oriented strand board and preparation process thereof

ActiveCN104626292AHigh strengthGood dimensional stabilityLaminationLamination apparatusFiberParticle board

The invention relates to a surface-decorated oriented strand board and a preparation process of the surface-decorated oriented strand board. The surface-decorated oriented strand board comprises a core layer and a surface layer. Rotary cut veneer leftovers left in the plywood production process are selected as raw materials of the core layer. Sawdust, wood shavings, waste fibers and sanding powder produced in the production process of glued-laminated timber, core-boards, particle boards or medium-density fiberboards are selected as raw materials of the surface layer. The raw materials are subjected to drying, screening, gluing, laying, plate blank sawing and cutting and hot-pressing, and then the surface-decorated oriented strand board can be manufactured. The static bending strength of the oriented strand board in the parallel direction can reach 22-30 MPa, the elasticity modulus of the oriented strand board can reach 3500-4800 MPa, and the surface roughness of the oriented strand board is less than 0.8 micron. The surface-decorated oriented strand board can be directly processed into a decorative surface and can also be widely used for replacing artificial boards such as plywood, the core-boards, the particle boards and the medium-density fiberboards.

Owner:寿光市鲁丽木业股份有限公司

A preparation method of carbonized adsorption particles for water body purification

InactiveCN102266752ATo overcome the poor adsorption effectPromote decompositionOther chemical processesWater/sewage treatment by sorptionInorganic materialsSawdust

The invention relates to the technical field of water treatment, in particular to a method for preparing carbonizing absorption grains used for purifying water. The method comprises the following steps: preparing organic materials, such as peat, sawdust, straw, bamboo dregs, and the like, and inorganic materials, such as diatomite, vermiculite, perlite, cement, and the like, according to proportion; and then mixing the organic materials and the inorganic materials with diatomite, kaolin, cement, slaked lime and the like; and adopting a high-temperature carbonizing process for forming the grains which are porous, high in absorption property, and different in sizes and shapes. The prepared grains are used for purifying polluted water.

Owner:NORTHEAST NORMAL UNIVERSITY

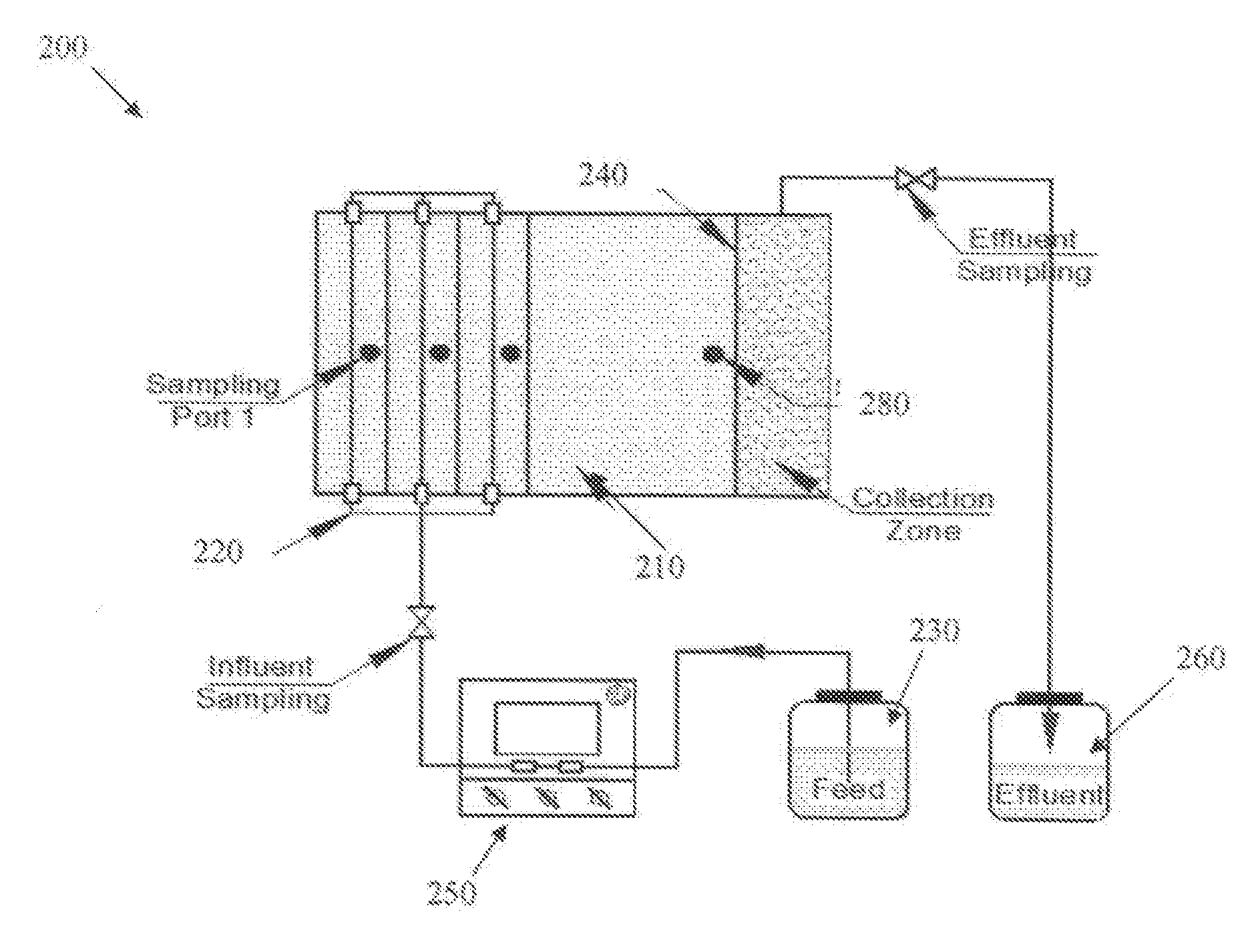

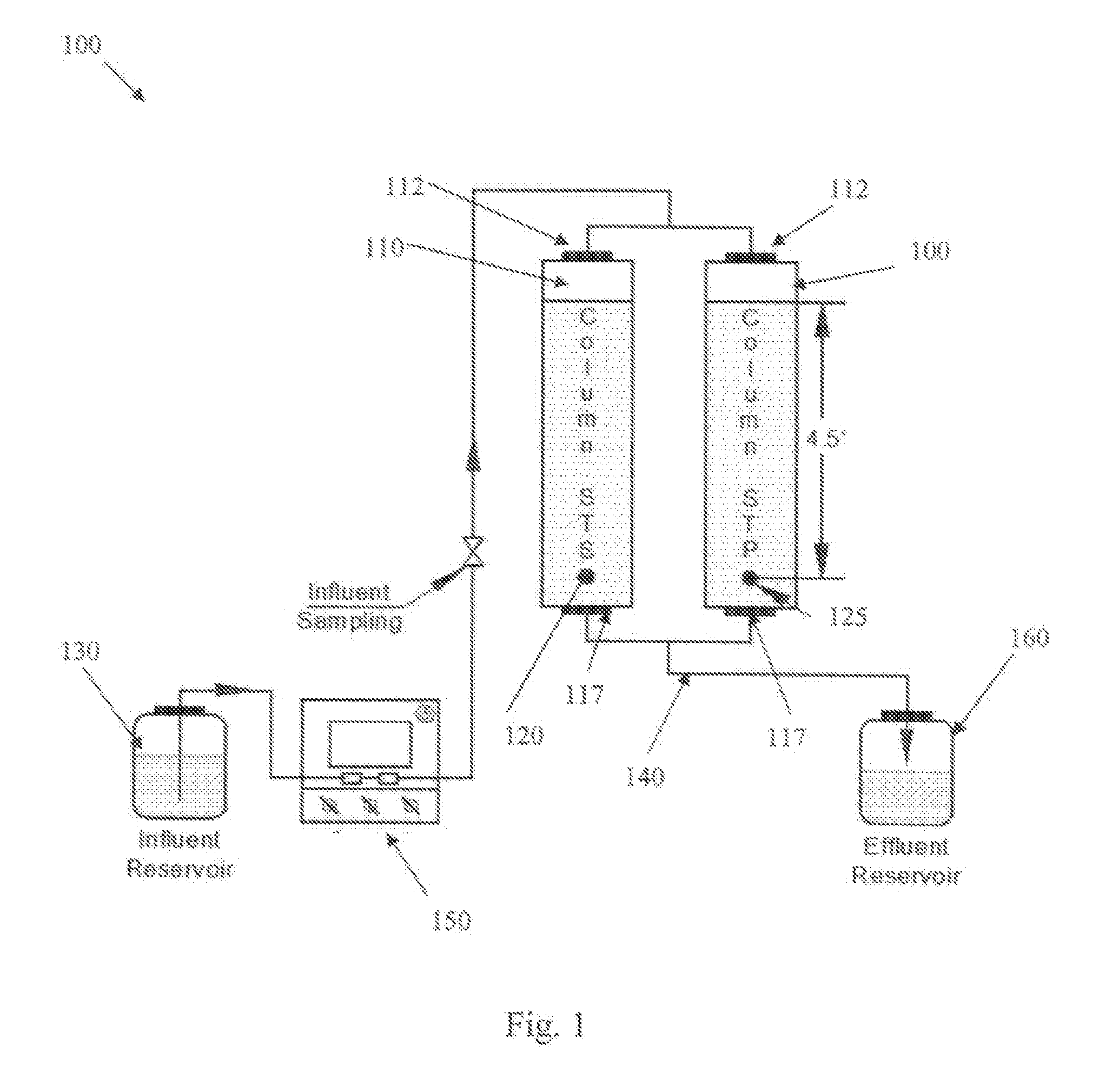

Green sorption material mixes for water treatment

ActiveUS8002984B1Low costRaise the ratioCalcareous fertilisersClimate change adaptationFiltrationStormwater treatment

Media compositions for use in wastewater treatment, stormwater treatment, CSO treatment and greenroof stormwater management systems as filtration media, plant growth media or pollutant retention media. Media composition includes at least one of a recycled material selected from a group consisting of tire crumb, wood sawdust and paper and a naturally occurring material selected from a group consisting of sand, limestone, sandy clay, expanded clay, organics used for processing geothermal water, organics used for agricultural drainage basins and filtration, and organics for aquaculture drainage and organics used for silviculture and forest drainage, and organics used as growing media.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Flower nutrient soil and preparation method thereof

InactiveCN103553767AImprove the cultivation effectRich in nutrientsFertilizer mixturesActivated sludgeMicroorganism

The invention belongs to the technical field of soil, and specifically relates to flower nutrient soil and a preparation method thereof. The flower nutrient soil comprises the following components in parts by mass: 30-35 parts of leaf mold, 25-30 parts of garden soil, 25-30 parts of river sand, 10-15 parts of activated sludge, 5-10 parts of bone meal, 10-15 parts of decayed farmyard manure, 10-15 parts of sawdust and 2-5 parts of active microorganisms. By using the technical scheme, the flower nutrient soil disclosed by the invention is rich in nutrient substances and short in fermentation time; leaf mold, garden soil, river sand and activated sludge are mixed, so that the flower nutrient soil is good in water retention and nutrient preserving capability, good in soil permeability, and low in cost; and by using the flower nutrient soil, flowers are robust and good cultivation effect is achieved.

Owner:DANYANG RUIQING GARDEN ENG

High-adsorptivity modified activated carbon and preparation method thereof

ActiveCN103566882ALarge specific surface areaBig gapOther chemical processesHazardous substancePotassium hydroxide

The invention relates to high-adsorptivity modified activated carbon which is prepared from the following raw materials in parts by weight: 30-40 parts of grape vine, 40-50 parts of sawdust, 100-120 parts of activated carbon, 30-40 parts of corn cob, 6-9 parts of potassium hydroxide, 7-10 parts of sodium lauryl sulfate or polyethylene glycol, 7-10 parts of urea, 2-5 parts of zinc nitrate, 2-5 parts of nickel nitrate, 10-14 parts of Arabic gum or sodium alginate, 7-10 parts of modified attapulgite and a right amount of water. According to the invention, the grape vine, sawdust and corn cob are subjected to high-temperature heat treatment, and the prepared activated carbon has large specific surface area, realizes new application of wastes and achieves the effects of convenient carbonization activation process and less pollutant discharge; and by using the potassium hydroxide, urea, zinc nitrate and nickel nitrate substances for modification, the activated carbon increases the gap and enhances the adsorption capacity. Besides, the high-adsorptivity modified activated carbon is accessible in raw materials, simple in process, low in cost and suitable for industrial production, causes no generation of harmful substances and has favorable application prospects.

Owner:安徽金叶碳素科技有限公司

Black fungus cultivation method and cultivation material thereof

InactiveCN101723759AImprove commoditySave agricultural facilitiesHorticultureFertilizer mixturesSawdustRaw material

The invention discloses a technology for cultivating black fungi in bags by utilizing a piece of woodland. The black fungi belong to crepuscular fungi, woods can just shade the black fungi, and CO2 released by the black fungi during growing adds carbon fertilizers for the woods. The black fungi and the woods are organically combined so as to ensure that the woodland is comprehensively utilized. The invention also discloses a black fungus cultivation material which changes a traditional formula using sawdust and cotton seed hulls as main materials and provides a new raw material with lower price and more environmental protection.

Owner:SHANDONG FANGLV AGRI SCI & TECH

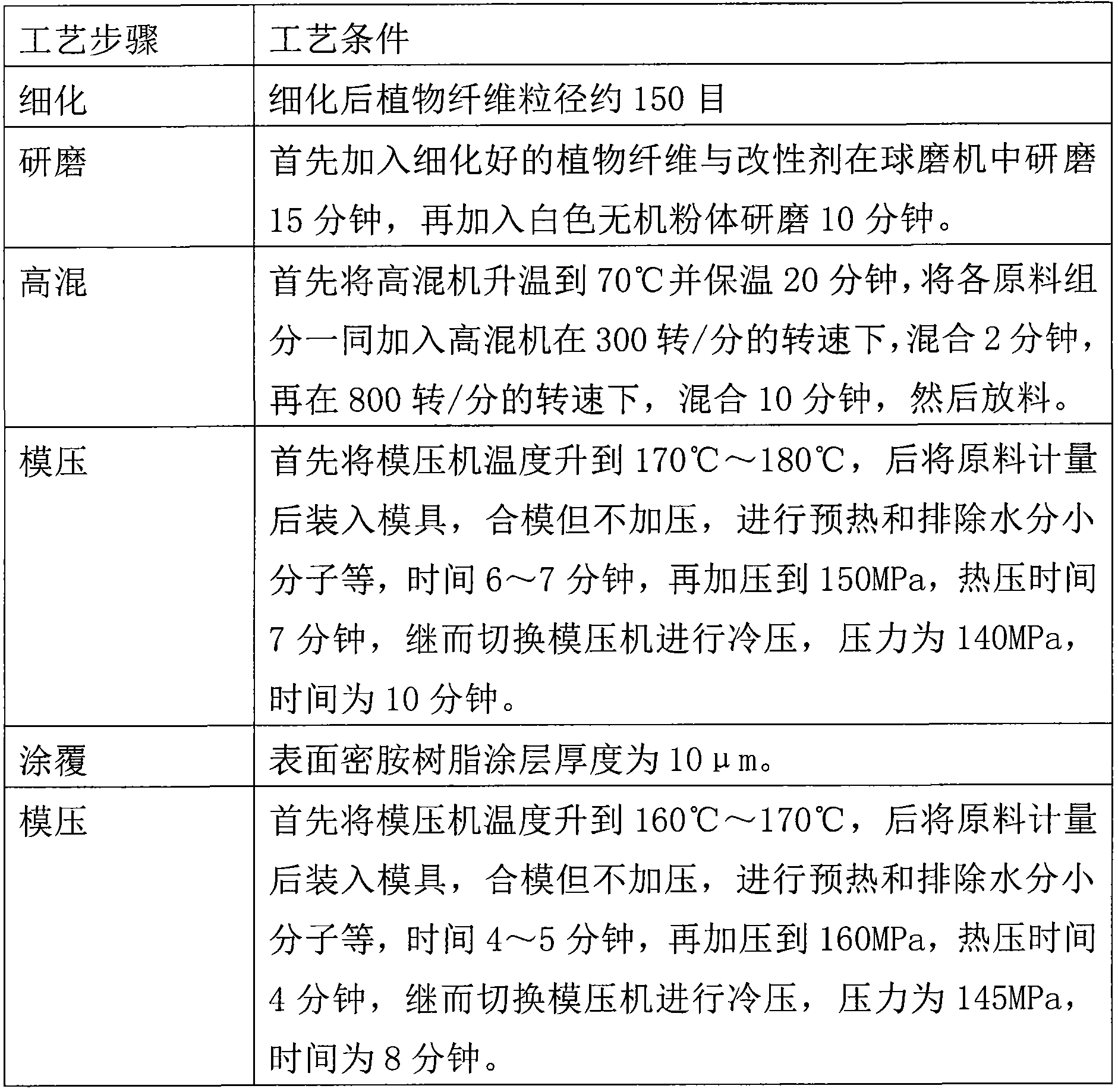

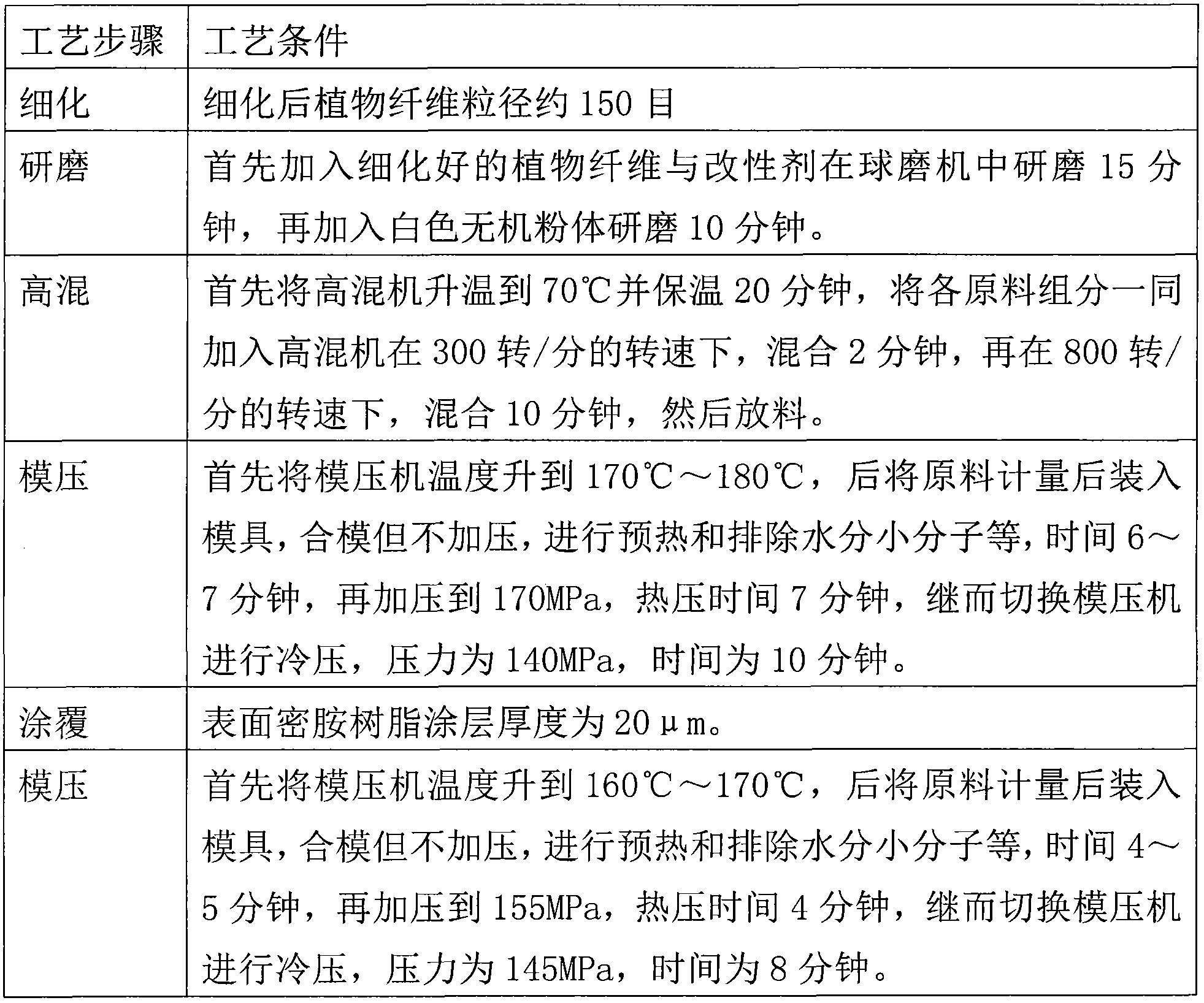

Manufacturing method for vegetable fiber compound tableware

ActiveCN102794803AControlled high temperature oxidative degradationControllable DurabilityWood compressionAviationHusk

The invention belongs to the technical field of vegetable fiber compound tableware and specifically relates to a manufacturing method for the vegetable fiber compound tableware. The manufacturing method specifically comprises seven steps. The production cost of the vegetable fiber compound tableware is obviously lower than that of the traditional metal, ceramic and melamine tableware; the traditional metal, ceramic and melamine tableware can be replaced by the vegetable fiber compound tableware; a large quantity of vegetable fibers, such as, crop straws, rice husks, cobs, sawdust, and the like, are effectively utilized; the atmospheric pollution caused by vegetable fiber burning is effectively prevented and the waste is turned into the wealth; the main products are as follows: basins, bowls, cups, dishes, trays, snack boxes, soup ladles, soup spoons, chopsticks, aviation meal boxes, and the like; and the products have the characteristics of high ceramic simulating strength, good natural texture, clear and gorgeous grains, and the like.

Owner:安徽绿之态秸秆制品有限公司

Method for preparing formed fuel by using agriculture castoff

A process for producing molded fuel by using agricultural waste belonging to a solid-fuel technology field and the objective is to resolve the problem of waste utilization. The technical scheme is showed as follows: straw, sawdust, wood chips, rice crust, bagasse and other agricultural waste and liquid waste of paper are used as raw materials to produce molded fuel by drying, grinding, mixing, and so on. The invention produces molded fuel with agriculture waste and liquid waste of paper as raw materials, not only saving raw materials costs, but also reducing pollution emissions. And the adhesion of some materials in liquid waste of paper are used without heating block, thus no heating loss, but also reducing the abrasion of mechanical equipment and heat loss of raw materials caused by heating. In addition, liquid waste of paper contains 3 to 5 percent of alkaline substances, which can enhance the activity of combustion. Molded fuel produced by using the process provided by the invention which is characterized in flammability, high heat value, non-polluting, low cost, and so on.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Cultivation method of black fungus

InactiveCN101548623AImprove the growing environmentSmall earsHorticultureFertilizer mixturesBiotechnologyAgaric

A cultivation method of black fungus adopts common PDA culture medium to cultivate mother seeds, takes sawdust and wheat bran as the culture material to cultivate original seeds and cultivated seeds, and uses straw grindings such as sawdust, wheat bran, cotton seed peel, wheat straw and the like as the growing material for growing. The cultivation method comprises the steps of bagging, sterilizing, inoculating, running spawn, forcing fungus, arranging fungus bags, managing grown fungus and harvesting. In the fungus forcing period, three sides of the fungus bags are thickly needled with inclined holes and the fungus bags are arranged vertically to ensure the fungus to grow out, the temperature is kept between 18 to 24 DEG C, the humidity is 85 to 90 percent, and the fungus bags can be moved into the fungus-growing field after the leaf diameter reaches 1 to 2cm so as to be managed; in the fungus-growing period, the fungus bags are arranged horizontally in the end-to-end way in the fungus-growing field, and the surface of the fungus bags without the holes is contacted with the ground; the arranged fungus bags are sprayed with water and covered with acupuncturing cotton to preserve moisture, the temperature of the fungus bed is 18 to 24 DEG C, and the humidity is 90 to 95 percent. The invention provides a novel, fast and green cultivation mode of black fungus, wherein the mode has the advantages of labor-saving, short period and high efficiency, and the method is especially suitable for industrialized production and scale production.

Owner:伍宗文

Special fertilizer for oil tea

InactiveCN102816015APromote growthImprove disease resistanceBio-organic fraction processingOrganic fertiliser preparationPaulowniaCamellia oleifera

The invention discloses a special fertilizer for oil tea. The fertilizer is prepared from the following components according to a certain weight ratio: an oil tea cake, peanut bran, sawdust of paulownia, bone meal, Chinese herbal medicine residue, humic acid, a nitrogen-phosphorus-potassium fertilizer, a biological bacterial preparation, a biological insecticide, zinc sulfate, magnesium sulfate, sodium molybdate and borax. According to the invention, long-term demands of oil tea for nutrients can be completely satisfied when the special fertilizers for the oil tea with different proportions of N, P and K are applied in different growth stages of the oil tea, and the special fertilizer provided by the invention has the advantages of a reasonable formula, balanced nutrition, safety, no pollution and capacity of promoting better growth of the oil tea, enhancing soil environment and improving quality and oil output of the oil tea.

Owner:安徽金农生态农业科技发展有限公司

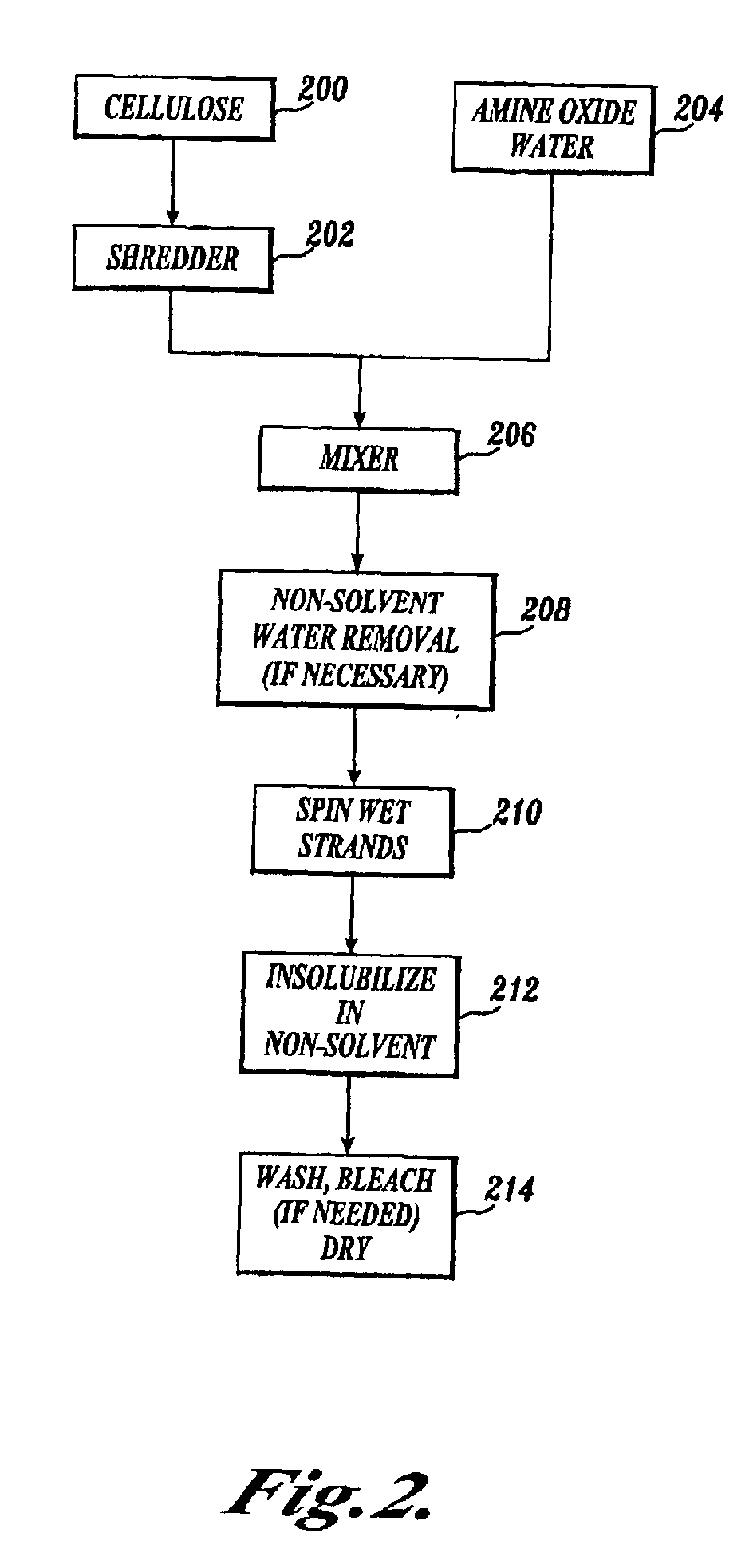

Process for making composition for conversion to lyocell fiber from sawdust

InactiveUS7090744B2Reduce the degree of polymerizationReduce contentPulp properties modificationMonocomponent cellulose artificial filamentCopperHemicellulose

A process for making a composition for conversion to lyocell fiber where the process comprises pulping a raw material in a digester to provide an alkaline pulp, wherein the raw material comprises sawdust in an amount greater than 0 % up to 100 %; and contacting the alkaline pulp comprising cellulose and at least about 7 % hemicellulose under alkaline conditions with an amount of an oxidant sufficient to reduce the average degree of polymerization of the cellulose to within the range of from about 200 to about 1100, without substantially reducing the hemicellulose content of the pulp or substantially increasing the copper number.

Owner:INT PAPER CO

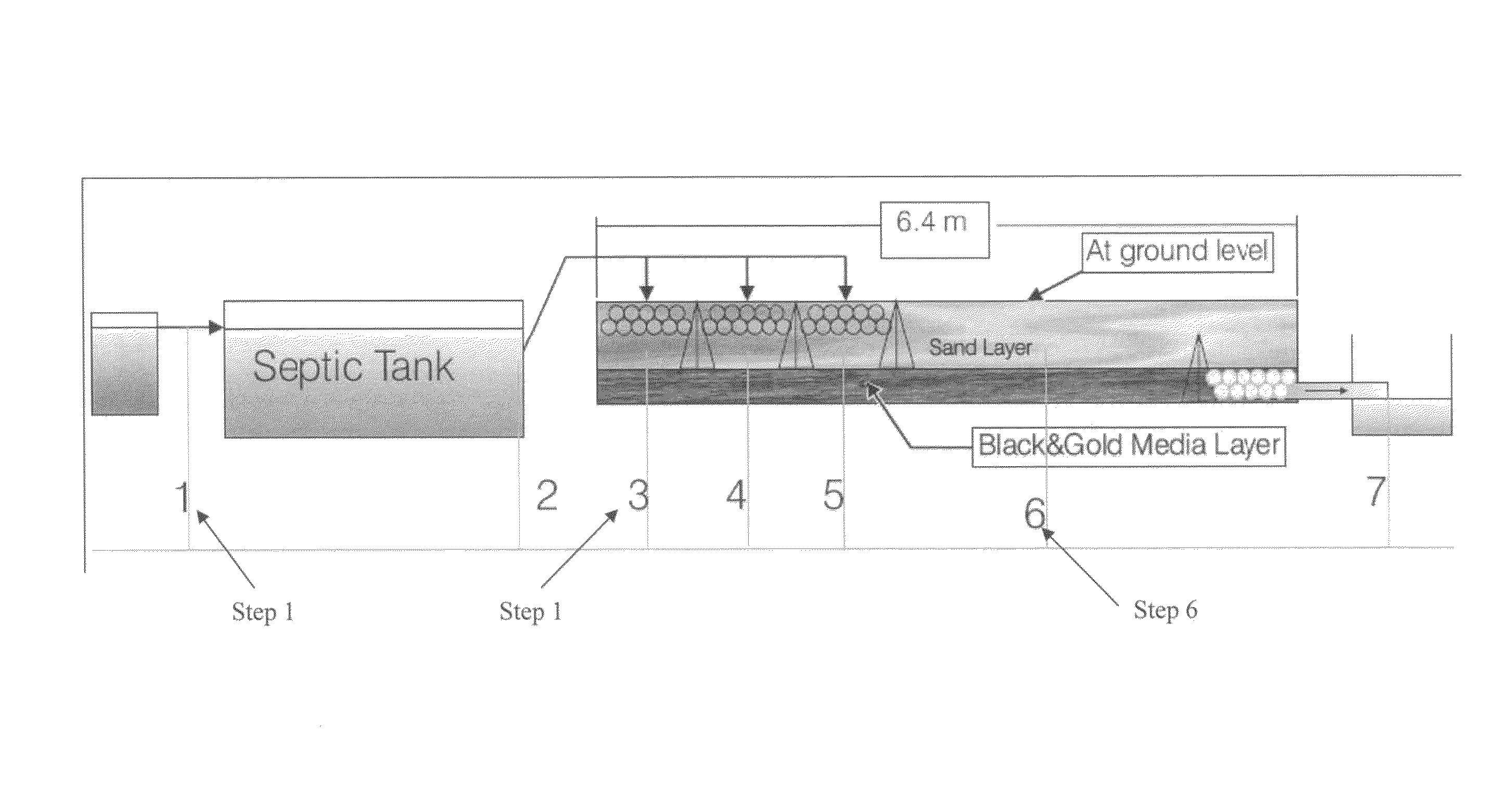

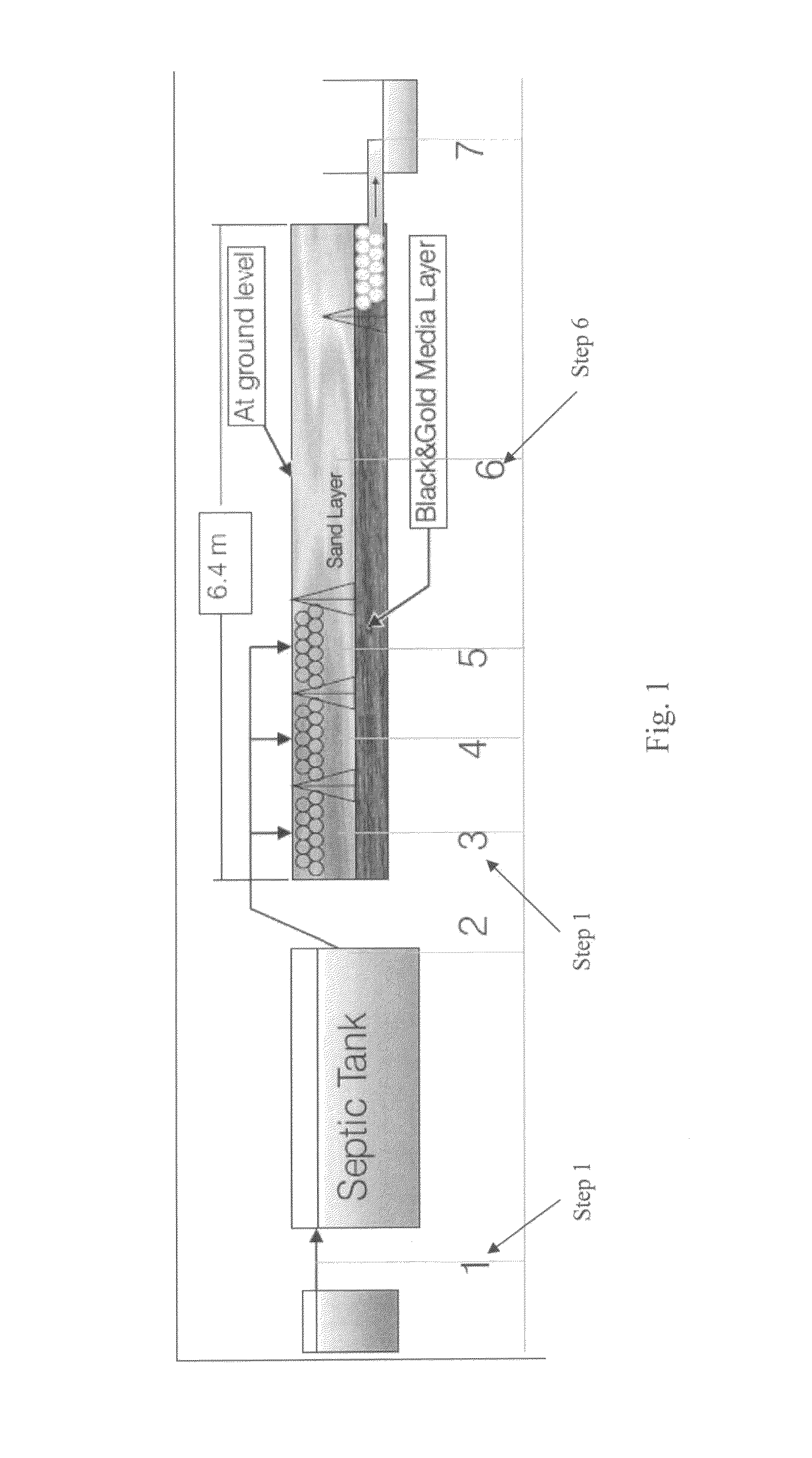

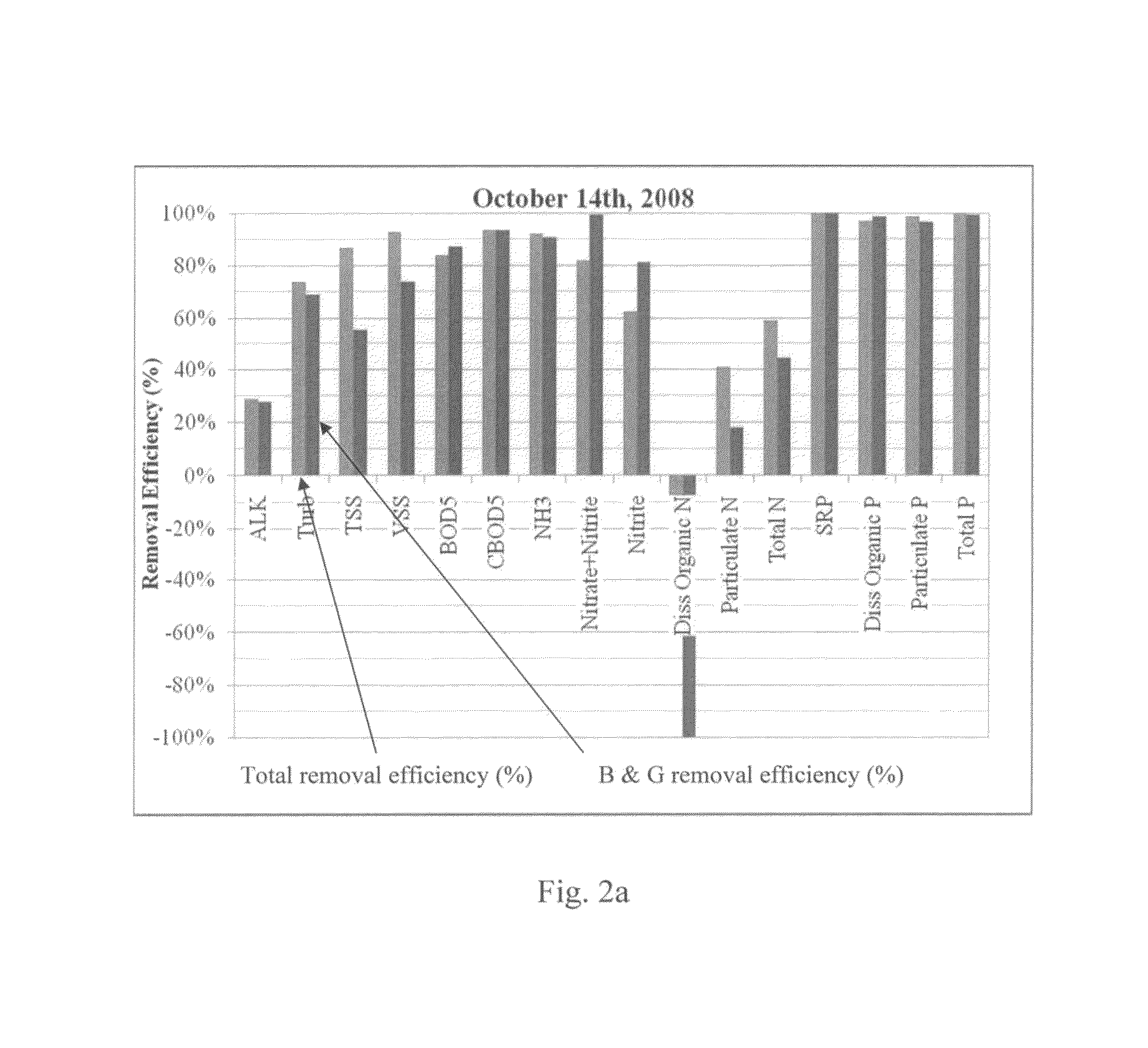

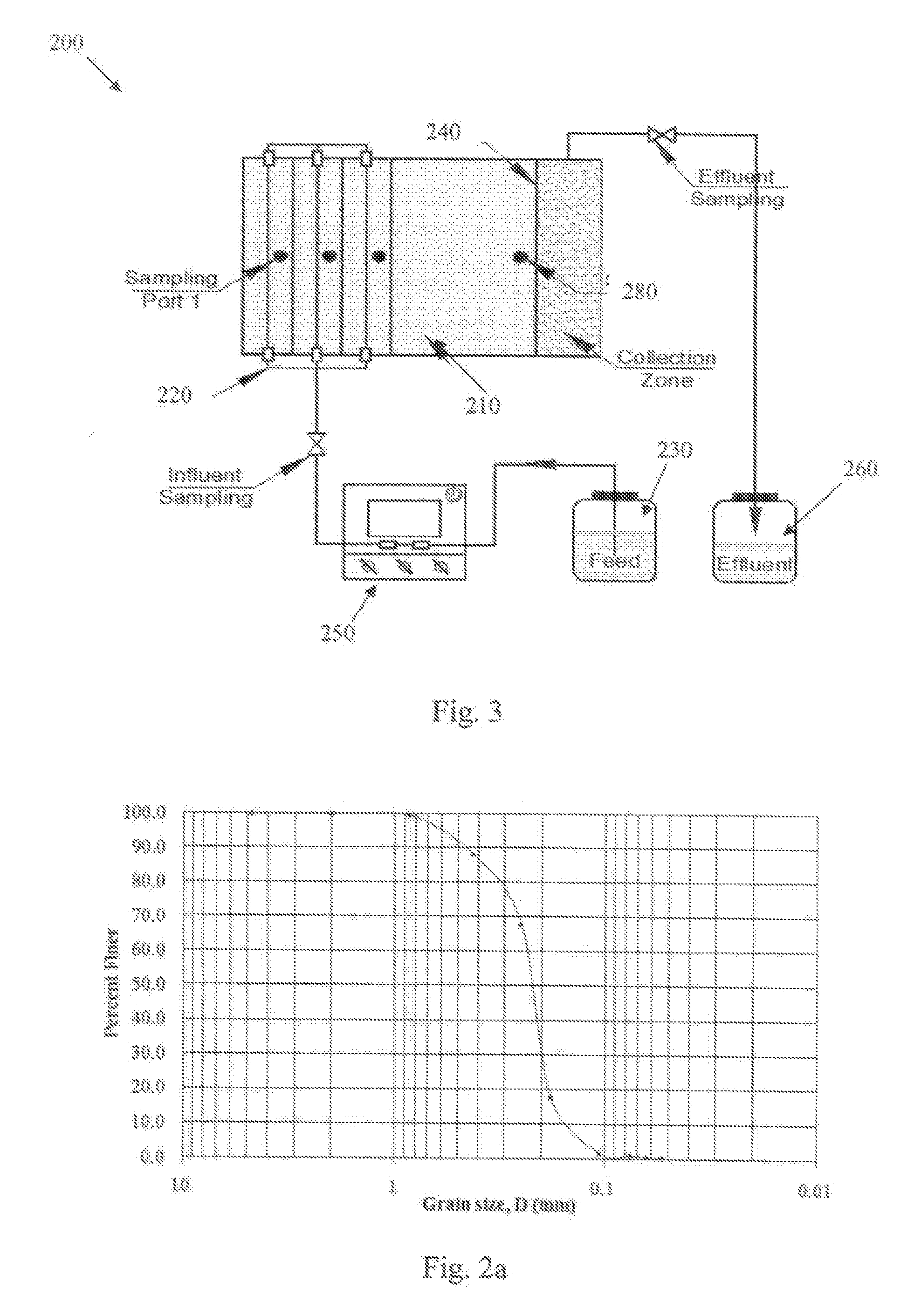

Passive Underground Drainfield For Septic Tank Nutrient Removal Using Functionalized Green Filtration Media

ActiveUS20100059437A1Improve sustainabilityImprove applicationWater cleaningContaminated soil reclamationSubsurface drainageOyster

Methods, systems and compositions for a green sorption media for bioretention soil amendments in drainfields for on-site waste water systems filled with the green sorption media to foster an anaerobic or anoxic environment saturated. The green sorption media includes one or more recycled materials, including tire crumb, sawdust, orange peel, coconut husks, leaf compost, oyster shell, soy bean hulls and one or more naturally occurring materials including peat, sands, zeolites, and clay. The wastewater filtration system for a passive drainfield includes the green sorption material mixture, a cell including baffled compartments and a riser, the cell filled with green sorption material mixture to provide an alternating cycle of aerobic and anoxic environments, an influent distribution system to distribute the influent over the cell, and a piping system arranged for dosing the cell to sustain the functionality of the green sorption material mixture to remove nutrient content in wastewater.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

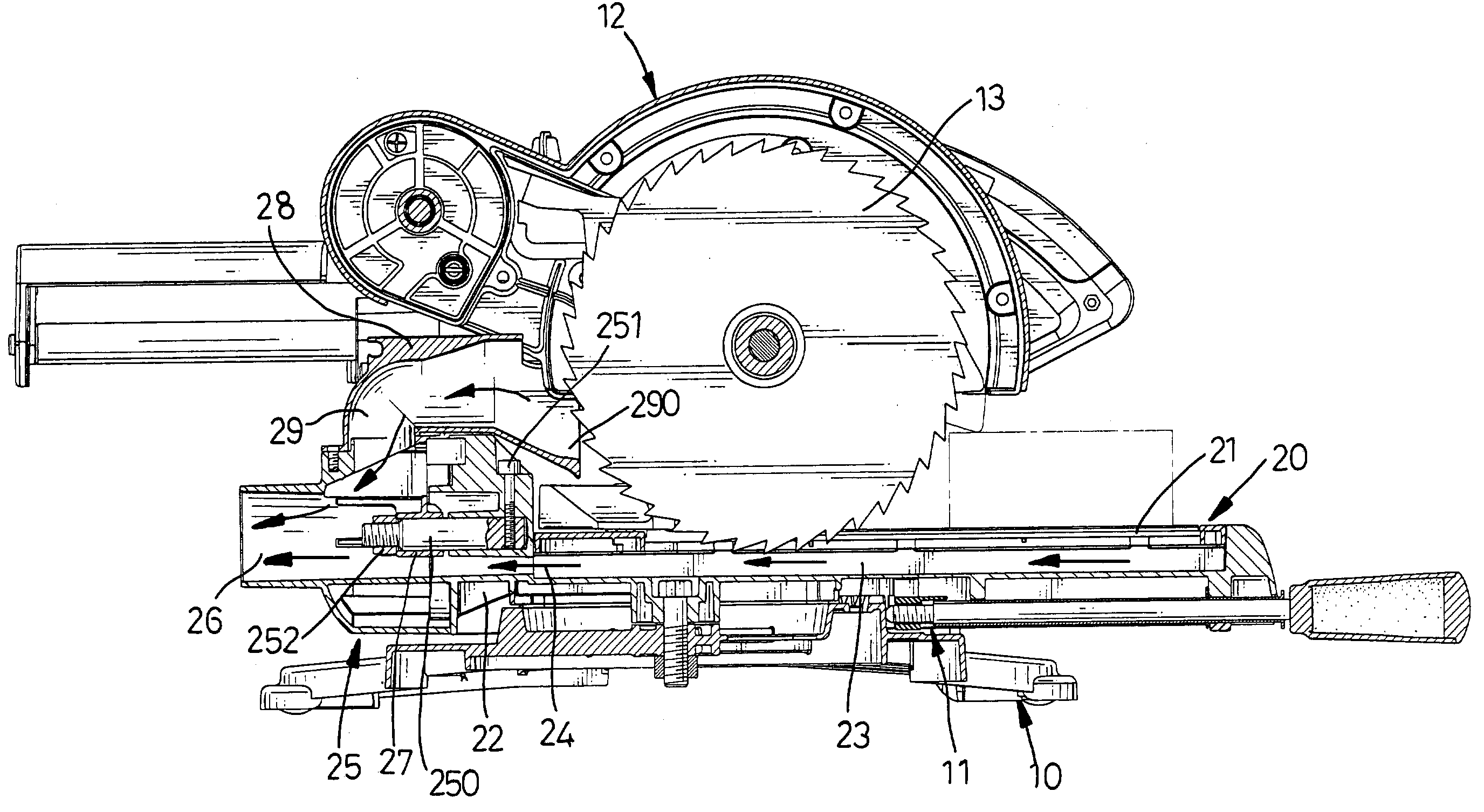

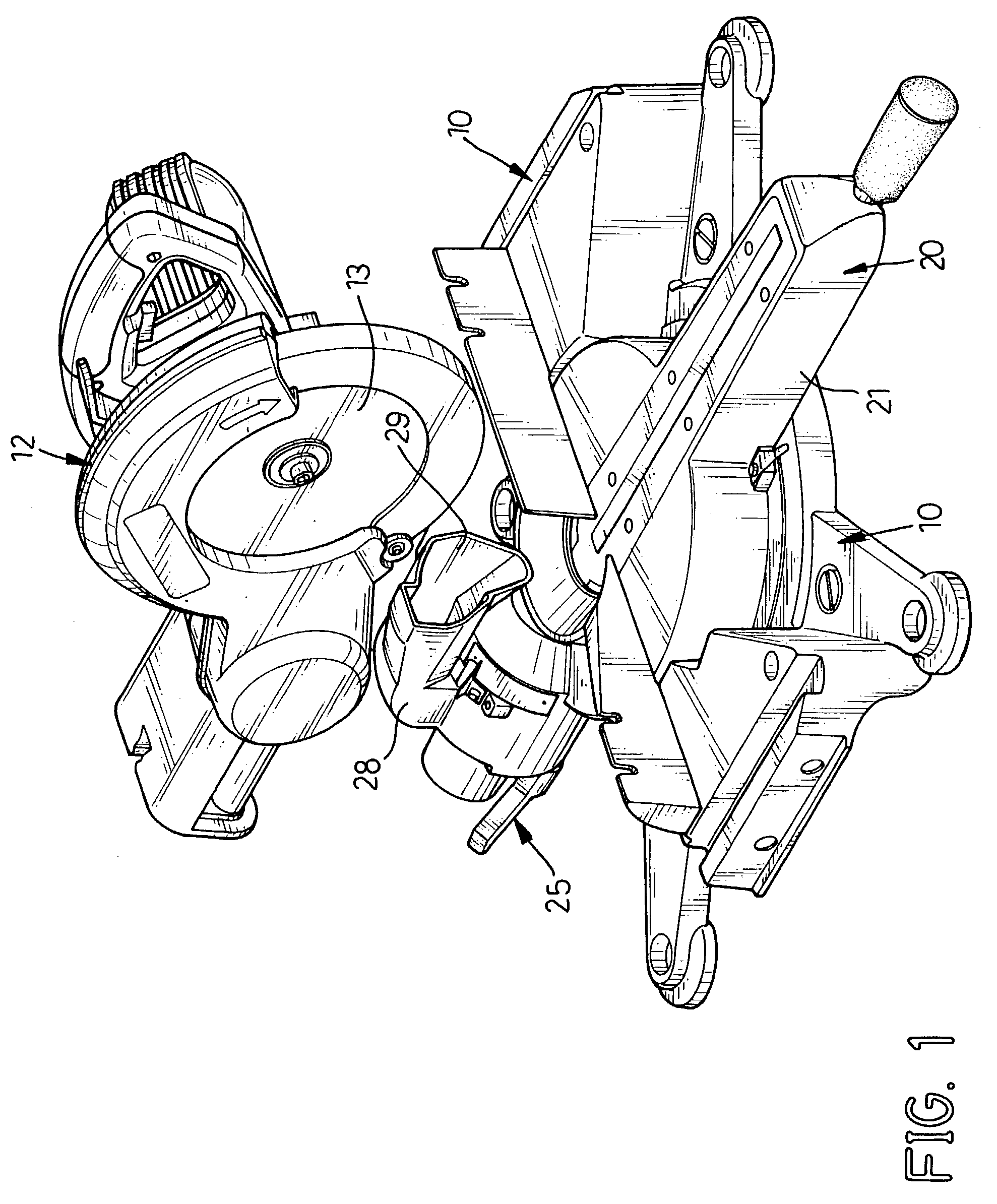

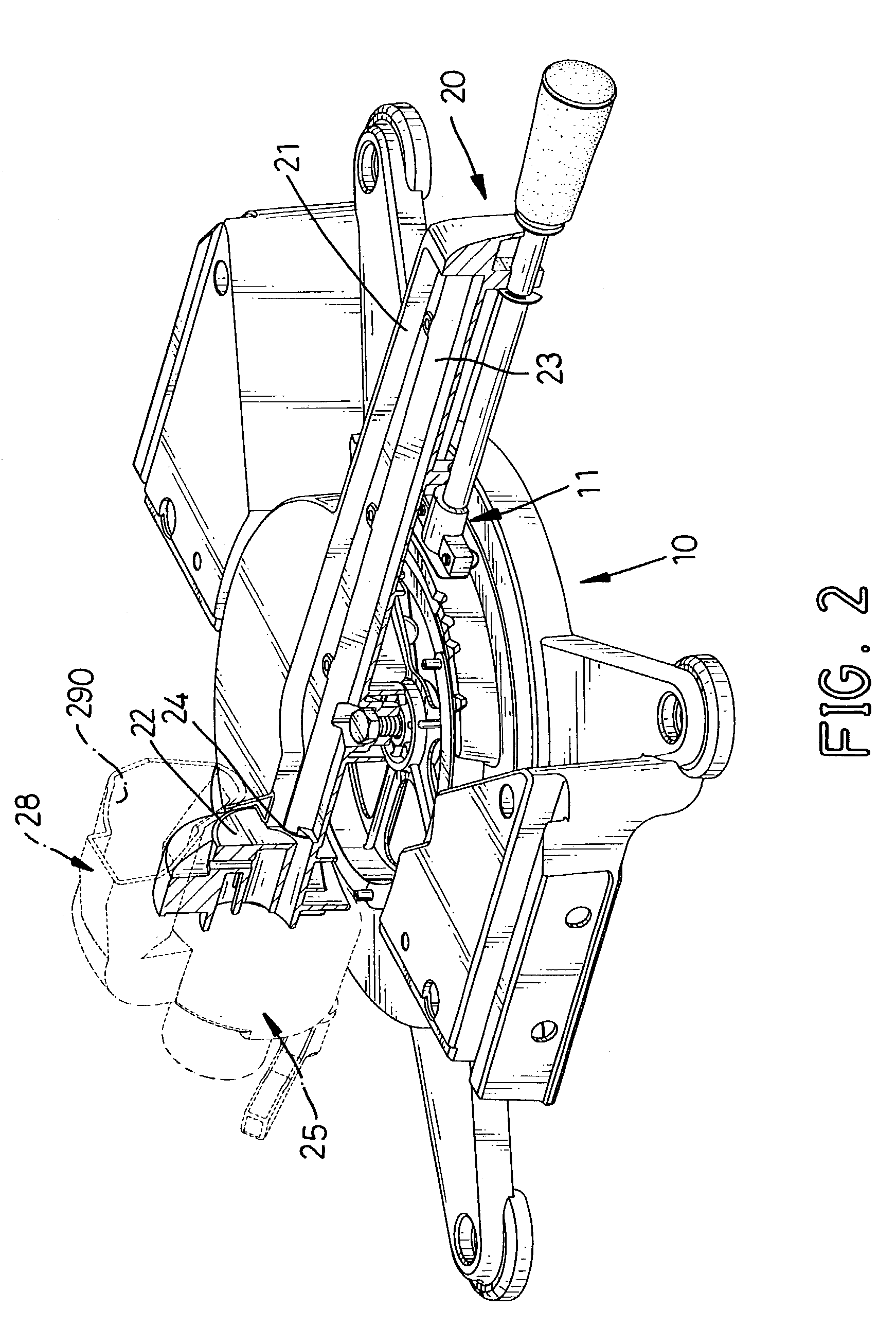

Sawdust collection assembly for a compound miter saw

InactiveUS20040060405A1Metal sawing devicesMetal sawing accessoriesEngineeringMechanical engineering

A sawdust collection apparatus for a compound miter saw includes a turntable and a sawdust collection assembly. The turntable is rotatably mounted on a base and has a cutting groove defined in the turntable and a sawdust guide communicating with the cutting groove. The sawdust collection assembly has a hollow sawdust duct with a sawdust channel communicating with the sawdust guide and a hollow sawdust entry duct with a sawdust entry port to receive sawdust and debris and a sawdust passage to communicate with the sawdust entry port. The sawdust channel is connected to a vacuum cleaner to efficiently pull sawdust and debris out of the miter saw through the sawdust channel and the sawdust passage.

Owner:P & F BROTHER INDAL

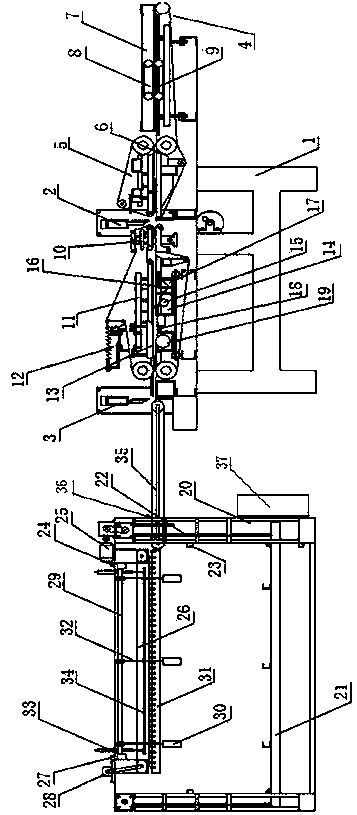

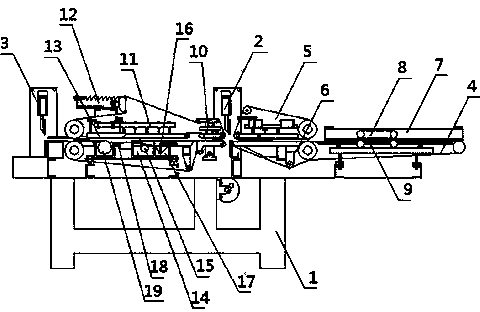

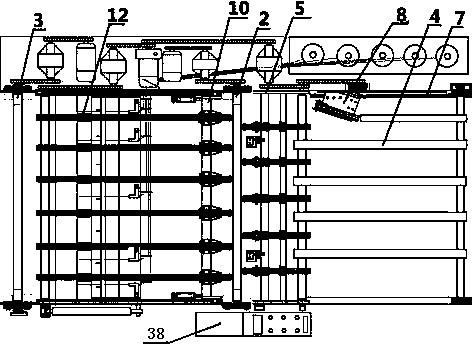

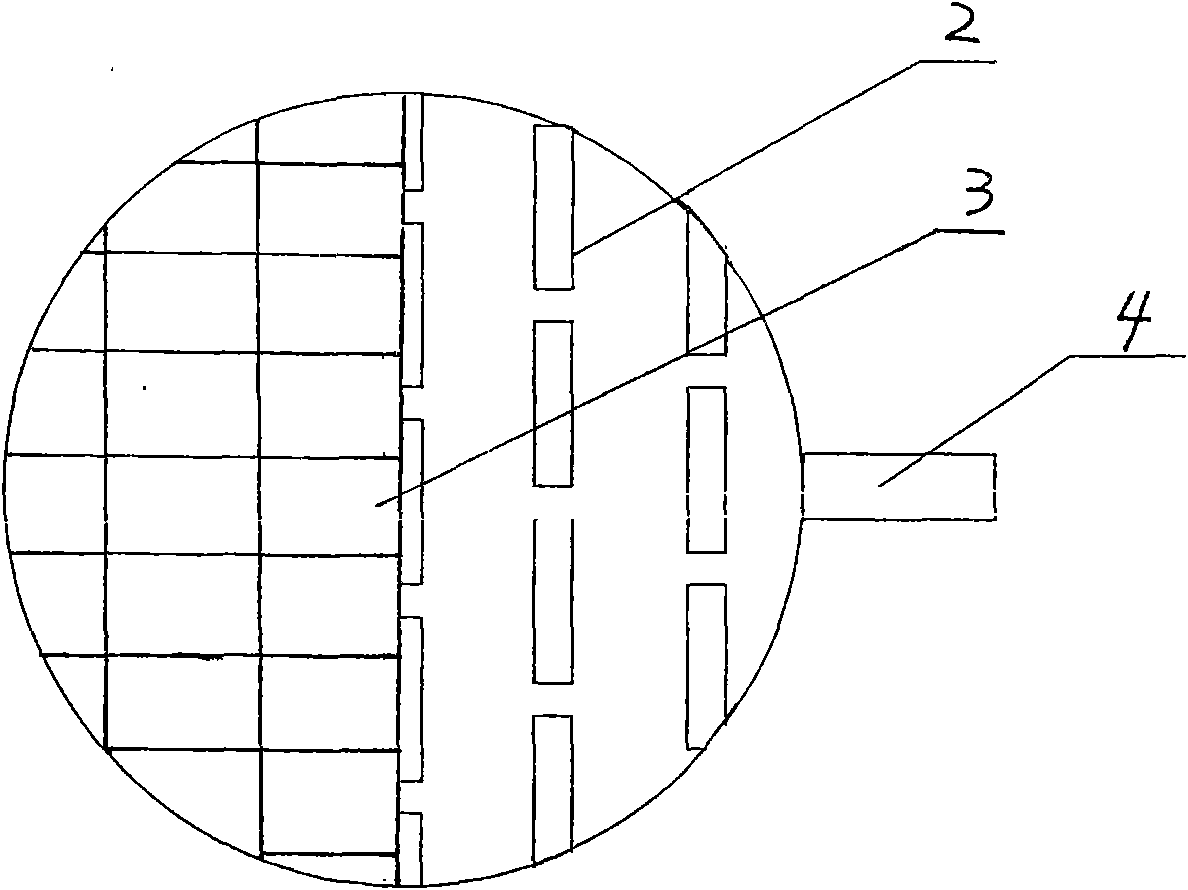

Medium plate splicing machine

ActiveCN103846985AFully automatedRealize fully automatic controlOther plywood/veneer working apparatusWood veneer joiningEngineeringMechanical engineering

The invention discloses a medium plate splicing machine. The medium plate splicing machine comprises a front rack, a feeding belt, a correction mechanism, an edge trimming cutter, a sawdust removing, material receiving and conveying mechanism, a sol tank, a finished product cutting mechanism, a transmission mechanism, a pneumatic mechanism, a coil table, a splicing mechanism and a plate collection device, wherein the splicing mechanism is arranged at a middle-to-rear position of the front rack, a feeding mechanism is arranged at the front end of the front rack, the edge trimming cutter is arranged at the tail end of the feeding mechanism, the correction mechanism is arranged on a conveying rack on one side of the feeding mechanism, and a line adding mechanism, a plate splicing mechanism and the finished product cutting mechanism are sequentially arranged at the middle-to-rear end of the front rack; the plate collection device comprises a rear rack, a lifting mechanism, a plate feeding mechanism, a plate collection device conveying mechanism, a plate receiving mechanism and a plate pressing mechanism. The medium plate splicing machine has the advantages that the design is reasonable, the medium plate splicing machine is integrated with functions of edge cutting, butting, line adding and plate collection, the process is finished in one step, the working efficiency is effectively improved, the labor cost is reduced, the waste small leftovers can be spliced together and the maximum utilization of resources is realized.

Owner:李东生

Composite biological activated carbon and rapid preparation method thereof

InactiveCN101643208AExtended service lifeSolve the technical problems of long carbonization timeSpontaneous combustionBiological activated carbon

The invention discloses a composite biological activated carbon and a rapid preparation method thereof, raw materials thereof comprise coconut shell, bamboo, rice hull, sawdust, wheat straw or rice straw, or the raw materials thereof comprise the rice hull, the sawdust, the wheat straw or the rice straw, corn stalk or corn core, the raw materials are smashed to prepare columnar granules, the direct heating method of the spontaneous combustion type granules is adopted for preparing the carbon, a fixed layer is paved at the bottom of a furnace by taking the granules as the raw materials, the fixed layer is ignited by using ignition materials, the feeding is adopted at the upper part of the furnace and the air induction is carried out at the lower part of the furnace for accelerating carbonization of the granules, the air induction is stopped after the carbonization of the granules, the temperature in the furnace is kept at 430-700 DEG C, the spray cooling method is adopted for activatingand cooling the granular carbon, and a finished product is prepared after 20-30 minutes. A plurality of raw materials are mixed, and more pores are naturally formed, thereby expanding the specific surface area of the carbon, greatly increasing effective micropores, leading the absorption performance to be greatly better than the existing activated carbon of single material and reflecting the unique advantages of the composite material.

Owner:徐克文

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com