Patents

Literature

2604 results about "Rice hulls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rice hulls (or rice husks) are the hard protecting coverings of grains of rice. In addition to protecting rice during the growing season, rice hulls can be put to use as building material, fertilizer, insulation material, or fuel. Rice hulls are part of the chaff of the rice.

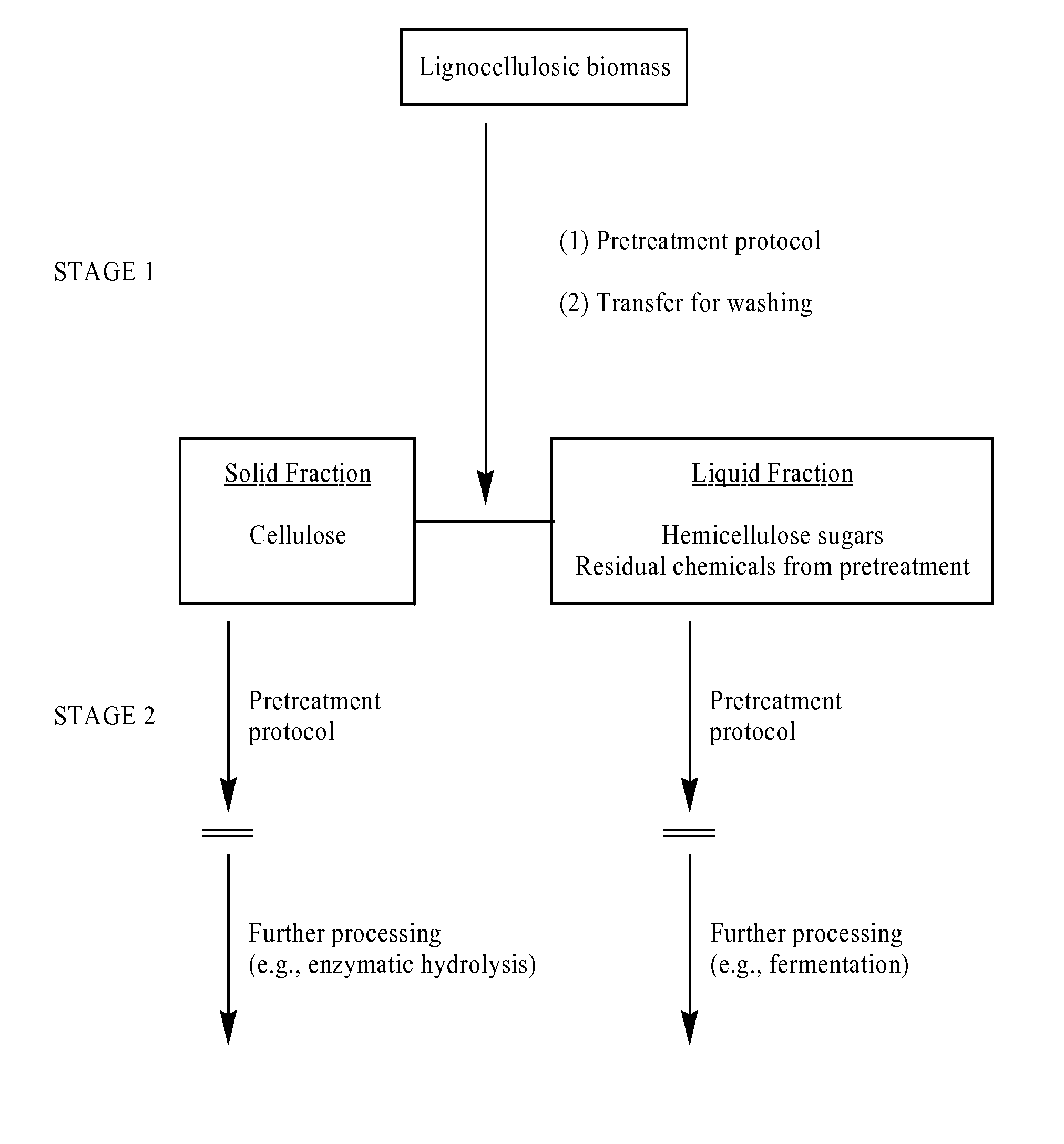

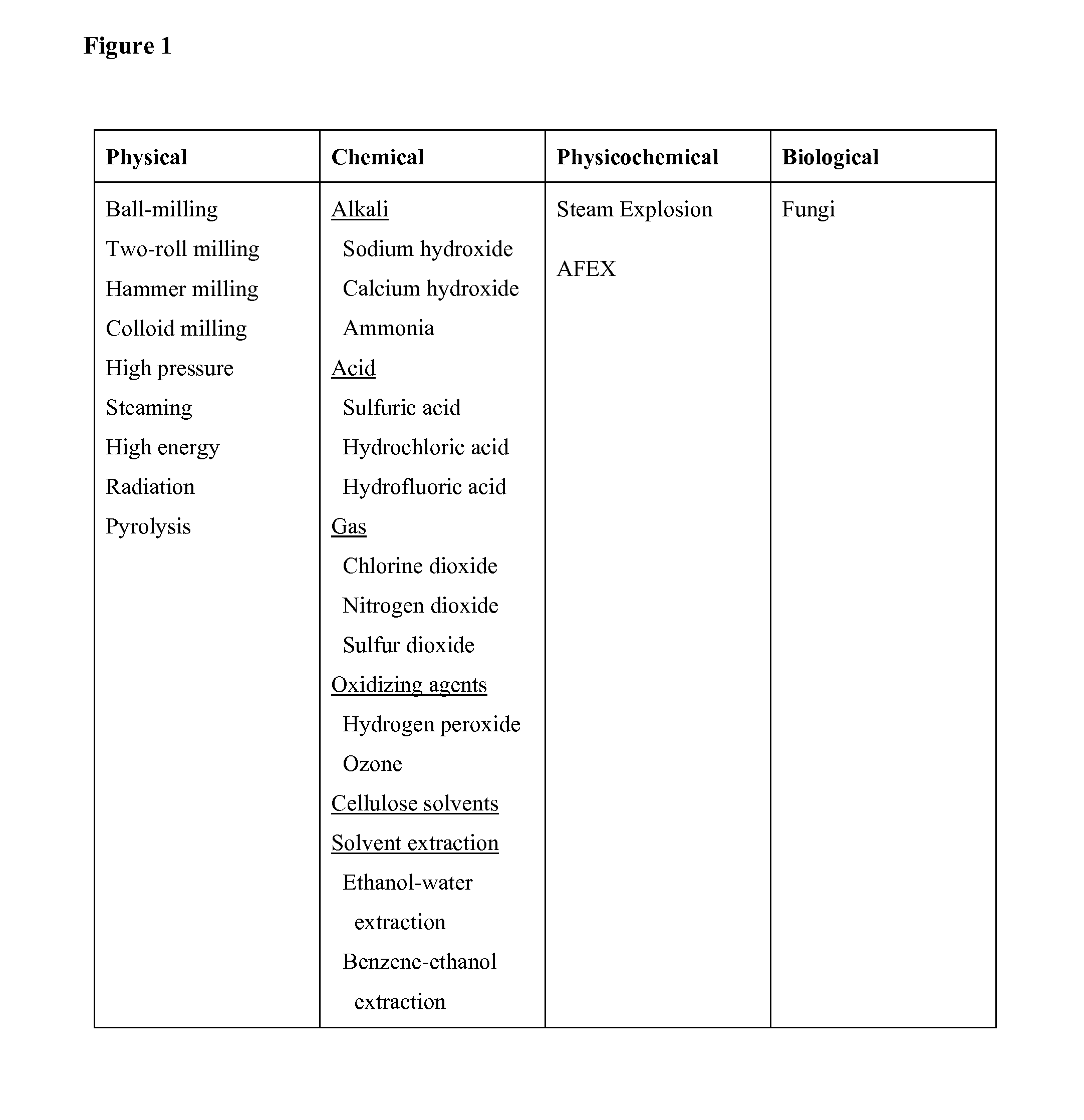

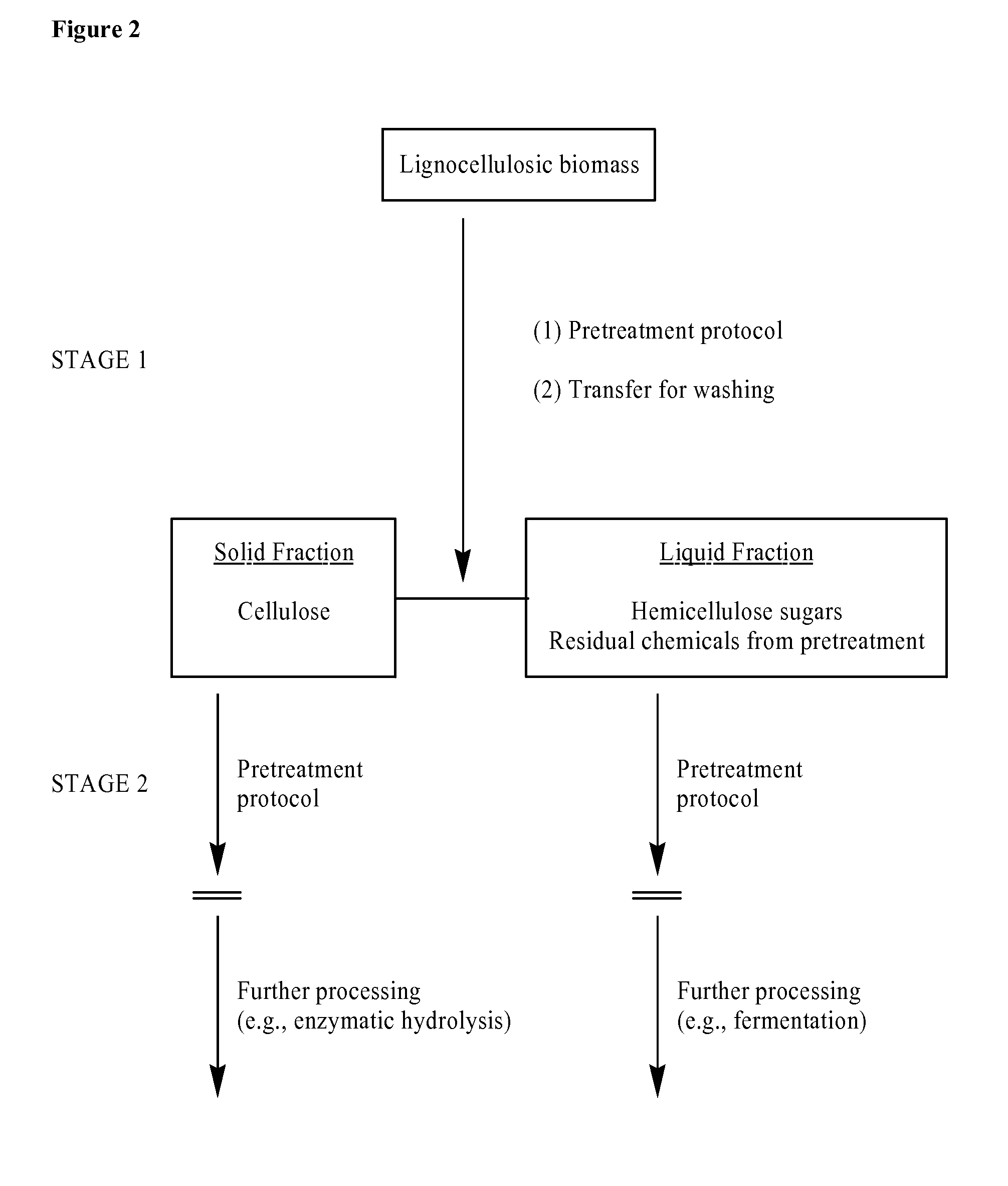

Two-stage method for pretreatment of lignocellulosic biomass

InactiveUS20100279361A1Reduce decreaseMaximize efficiencyOrganic compound preparationFood processingCelluloseFiber

One aspect of the invention relates to a process, comprising treating lignocellulosic biomass according to a first pretreatment protocol, thereby generating a first product mixture; separating the first product mixture into a first plurality of fractions; and treating at least one fraction of said first plurality of fractions according to a second pretreatment protocol, thereby generating a second product mixture. In one embodiment, the lignocellulosic biomass is selected from the group consisting of grass, switch grass, cord grass, rye grass, reed canary grass, miscanthus, sugar-processing residues, sugarcane bagasse, agricultural wastes, rice straw, rice hulls, barley straw, corn cobs, cereal straw, wheat straw, canola straw, oat straw, oat hulls, corn fiber, stover, soybean stover, corn stover, forestry wastes, recycled wood pulp protocol protocol fiber, paper sludge, sawdust, hardwood, softwood, and combinations thereof.

Owner:MASCOMA CORPORATION

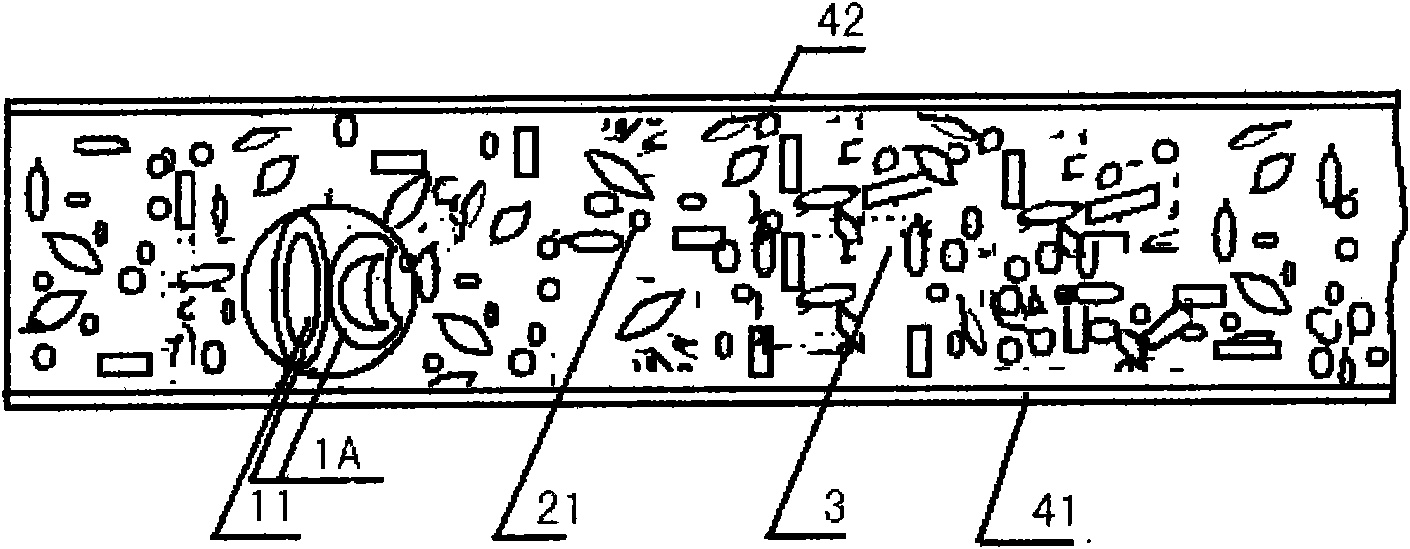

Environment-friendly light heat-insulating material and manufacturing method thereof

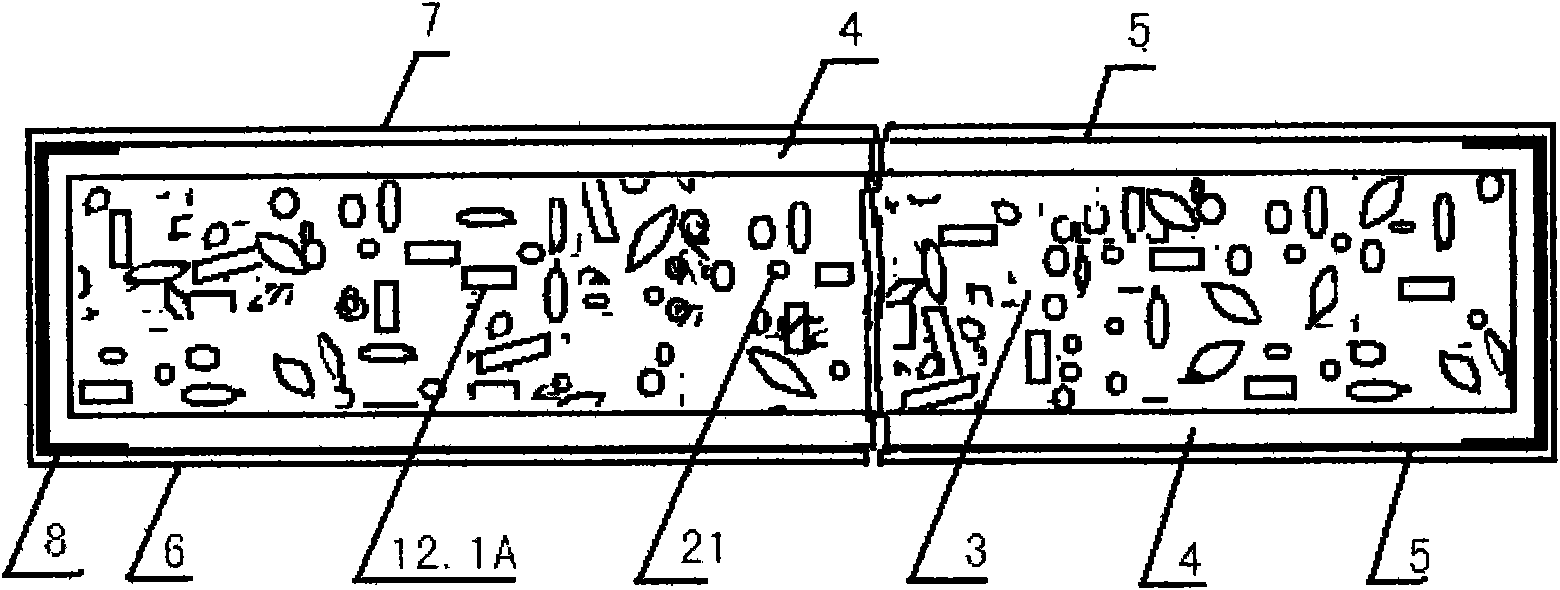

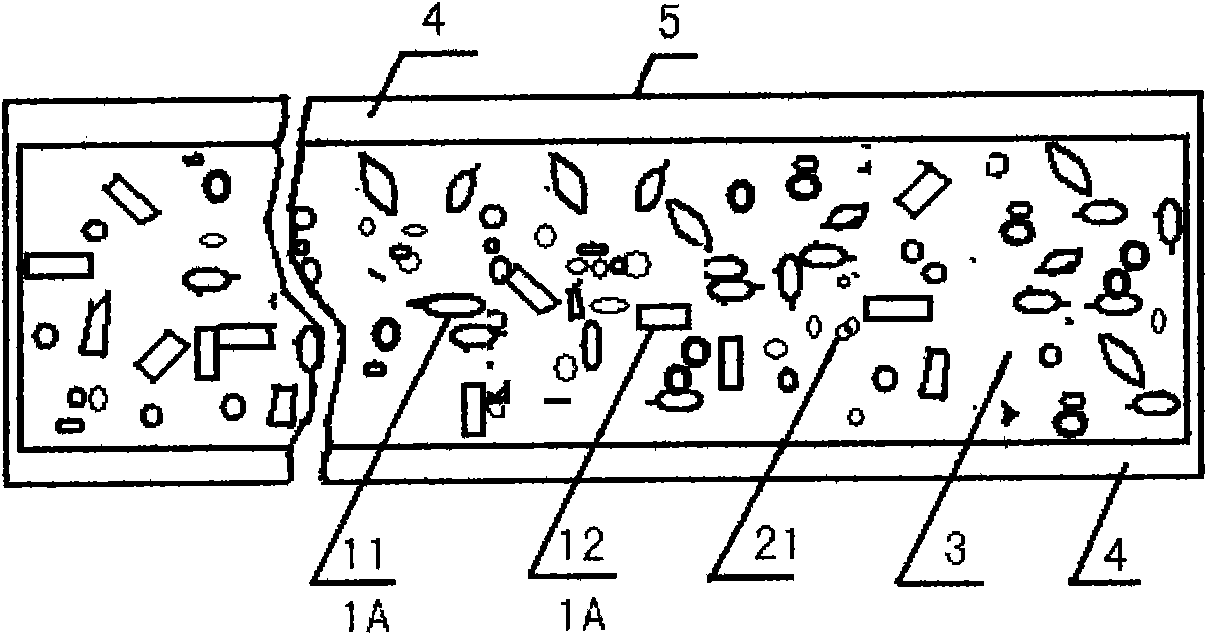

The invention relates to an environment-friendly light heat-insulating material for fireproof doors and buildings, and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: pretreating plant hollow core bodies and / or flexible porous fillers by using a water glass adhesive; mixing with inorganic fire-resistant hollow particles; and performing mould pressing, shaping and drying to obtain the environment-friendly light heat-insulating material. The hollow core bodies and the flexible porous fillers are arranged multidirectionally; one layer of water glass adhesive is arranged at least on the surfaces of the hollow core bodies and the flexible porous fillers; and discontinuous holes are reserved between the hollow core bodies and / or the flexible porous fillers and the inorganic fire-resistant hollow particles. Preferably, the hollow core bodies are rice husks and straw sections; and the flexible porous fillers are foam and fibers. Renewable plant resources and recovered foam and fiber waste are adopted, so the environment-friendly light heat-insulating material is energy-saving and environment-friendly; and a large number of sealed holes are formed among the material particles through the penetration and coating of the modified water glass adhesive, and a heat-insulating hydrophobic corrosion-resistant multi-effect protective layer is provided, so the environment-friendly light heat-insulating material has good fireproof, heat-insulating and heat-preserving effects, high weather resistance, combined rigidity and toughness, low density and low cost.

Owner:重庆恒宏致嘉全过程建设项目管理有限公司

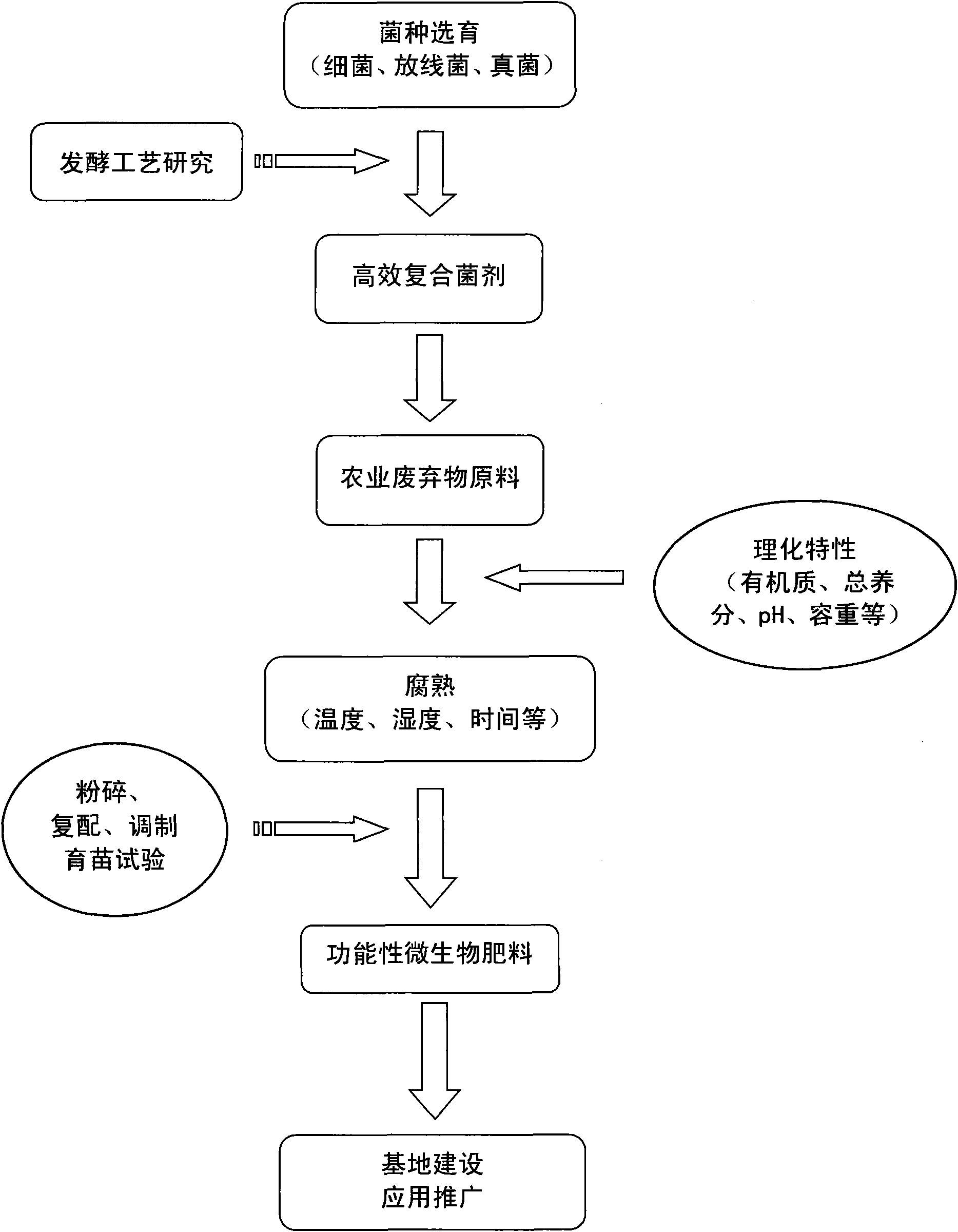

Functional microbial fertilizer production by utilizing agricultural wastes

InactiveCN101665374ASuitable physical and chemical propertiesPromote fermentation and maturityFungiBio-organic fraction processingBacillus licheniformisBiotechnology

The invention discloses a functional microbial fertilizer and a production method thereof. The production method comprises the following steps: grinding 60%-70% of mushroom residue and 15%-25% of livestock manure to 2-3mm to obtain the major material by a grinder, regulating water content to be 60%-65%; adding composite fermenting agent consisting of bacillus subtilis, bacillus licheniformis, trichoderma harzianum and trichoderma viride in accordance with 50g-100g / T; stacking, fermenting and maturing for 15-30d, and turning 5-10 times during the process; evenly mixing the major material prepared from fermentation with auxiliary materials consisting of 6%-10% humic acid and 6%-10% rice hull; adding arbuscular mycorrhiza agent in accordance with 50g-100g / T; and sieving with a 3mm sieve to obtain the fertilizer. The invention provides an economic and effective technological approach for the resource recycling of agricultural wastes in China, and has important application prospect on promoting the development of green agriculture, controlling and reducing rural environmental pollution, improving rural eco-environment and other aspects.

Owner:THE INST OF MICROBIOLOGY XINJIANG ACADEMY OF AGRI SCI

Process for production of high purity amorphous silica from biogenic material

The process for process for production of high purity amorphous silica from biogenic matter having a content of amorphous silica, particularly rice hulls, is characterized by use of a solution having an oxidizing solute to reduce the long-chain organic compounds of the biogenic matter prior to volatile removal of the organic compounds by heated oxidation. Prior to reduction of the hydrocarbons the biogenic matter may be finely divided, screened, subjected to surfactant wash, rinsed and soaked in water to accelerate and enhance penetration of the oxidizing solution. Following removal of the volatile impurities by heated oxidation the remaining silica may be rinsed with water, acid solution or other solutions to remove even trace impurities. At the end of the process herein disclosed a fine white amorphous silica of extreme purity can be produced.

Owner:KILT LLC

Organic fertilizer produced by comprehensively utilizing straw, and preparation method for organic fertilizer

InactiveCN102531756AIncrease profitImprove resistance to pests and diseasesFertilizer mixturesPhosphoric acidAmmonium chloride mixture

The invention discloses an organic fertilizer produced by comprehensively utilizing straw, and a preparation method for the organic fertilizer, and relates to the technical field of agricultural fertilizers. The organic fertilizer is prepared from composted straw, 34 to 44 parts of rice hulls, 20 to 30 parts of composted animal dung, 10 to 15 parts of potassium chloride, 10 to 15 parts of humic acid, 0.4 to 0.6 part of medium and trace elements, 0.4 to 0.6 part of microorganism, 10 to 15 parts of calcium superphosphate and 5 to 10 parts of ammonium chloride through mixing and granulating. The organic fertilizer has the characteristics of low production cost, high bioactivity, high fertilizer efficiency, wide sources of raw materials and the like, can serve as a fertilizer for rice and a fertilizer for dry crops, vegetables, melons, fruits and fruit trees, and also can serve as a fertilizer for flowers.

Owner:HUNAN ZHONGKE AGRI

Fermented feed additive, preparation method and application

ActiveCN102550815ASlow down digestionPromote digestion and decompositionFood processingAnimal feeding stuffMonosodium glutamateBacillus licheniformis

The invention discloses a fermented feed additive, a preparation method and application thereof. The fermented feed additive is prepared by fermenting mixed strains and mixed auxiliary materials consisting of monosodium glutamate protein, bean pulp, bran, cottonseed meal, corn fibers, rice bran and powdered rice hulls, wherein the mixed strains are obtained by mixing activated strains of lactobacillus acidophilus, lactobacillus planetarium, lactobacillus casei, saccharomyces cerevisiae, bacillus subtilis and bacillus licheniformis in a proportion of (1-5): (1-5): (1-5): (1-5): (1-5): (1-5); and the dosage of the fermented feed additive is 5 to 100 percent of the weight of the animal feed when used for the animal feed. According to the fermented feed additive, the bean pulp, the bran, the cottonseed meal and other raw auxiliary materials are sufficiently utilized, so that the food consumption in the animal feeding process is reduced; the fermented feed additive can be used to partiallyor completely replace the animal feed, and antibiotic medicaments can be reduced or prevented from being used; and no medicament is left, so that the feeding cost of farmers is reduced.

Owner:WEIFANG ZHONGKEJIAYI BIO FODDER TECH

Paddy hull burned gas and waste residue comprehensive utilization method

The invention discloses a comprehensive utilization method for rice hull combustion emissions and waste residue, in particular a method for preparing superfine silicon dioxide and active carbon with high specific surface area by using the emissions and waste residue generated by the pyrolysis and combustion of the rice hull, which comprises the following steps: the main raw material sodium carbonate (or potassium carbonate) is heated and hydrolyzed to be sodium bicarbonate (or potassium bicarbonate), OH<-> is released, the silicon dioxide in the rice hull ashes is dissolved, the sodium bicarbonate (or the potassium bicarbonate) is reduced to sodium carbonate (or potassium carbonate) after temperature reduction, and then the silicon dioxide precipitate is separated out. The method has the advantages that the silicon dioxide which only plays the role of catalyst in the process can be used circularly without consumption, the cost is reduced; the purified combusted tail gas can be used for preparing a precipitator of the silicon dioxide, thus avoiding the pollution brought by acid neutralization and precipitation in the traditional technology, reducing the cost, making full use of carbon dioxide and reducing green house gas emission; and the activating agent for preparing the active carbon can be recovered, which can be returned to the hydrolyzation process to be reused after adjusting the concentration of the sodium carbonate (or the potassium carbonate), thus reducing the cost.

Owner:JILIN UNIV

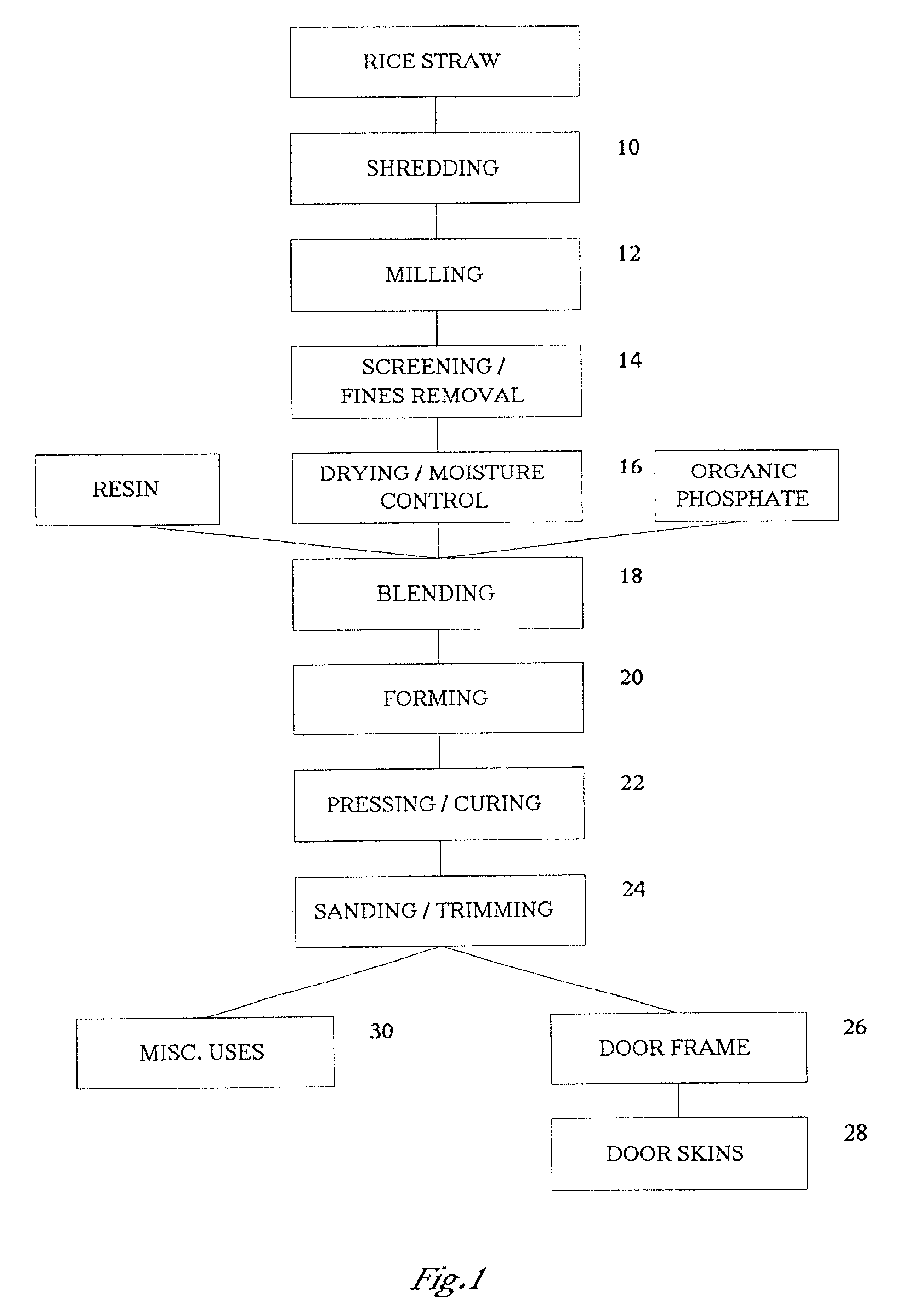

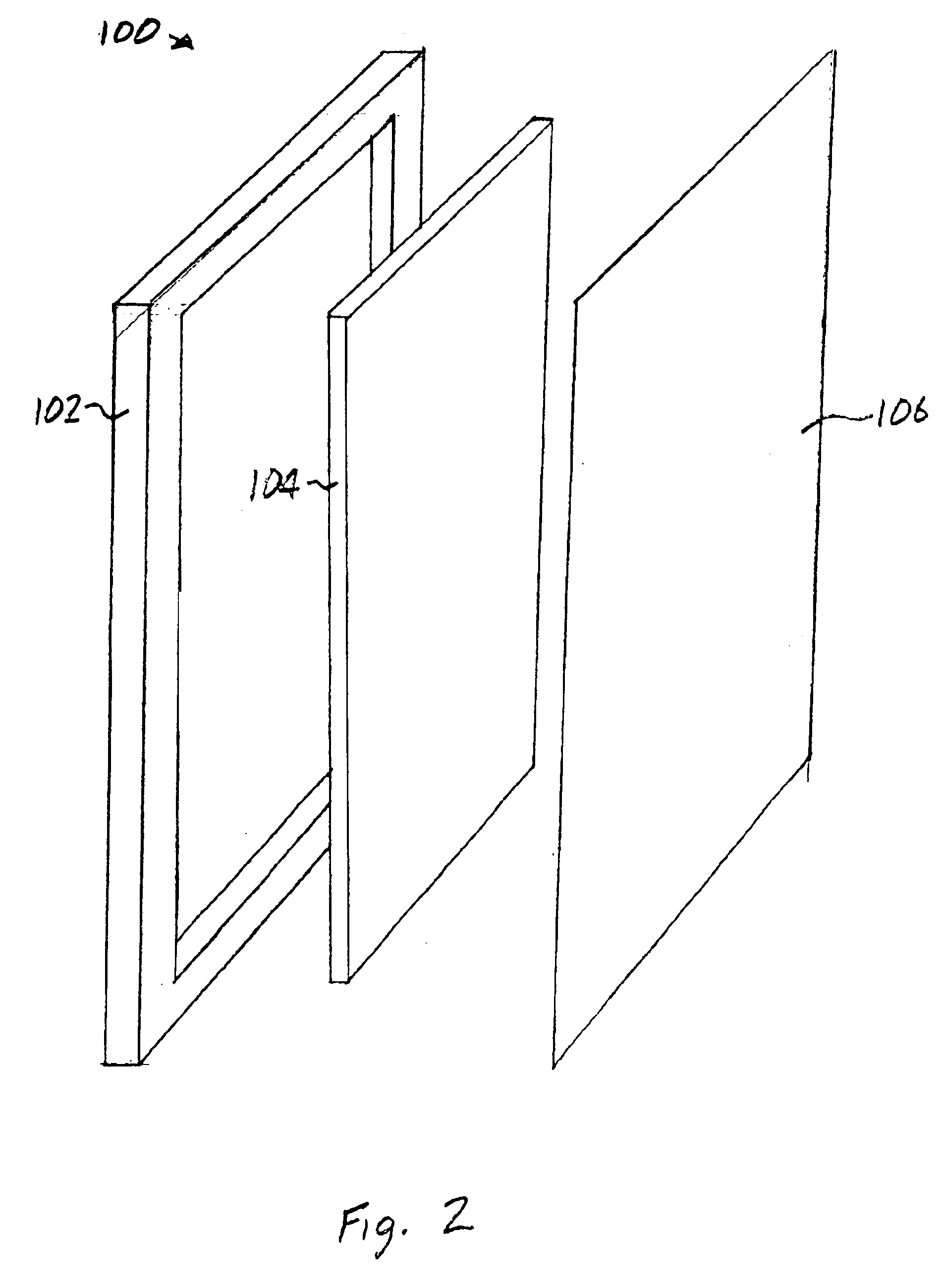

Fire-resistant material and method of manufacture

InactiveUS6886306B2Improve fire resistanceImprove the level ofConstruction materialClimate change adaptationCelluloseZinc borate

The present invention provides a building material derived from straw, such as rice straw, that has significantly improved fire-resistance properties over traditional cellulose-based materials. In one embodiment, the invention provides a method of fabricating a board from milled rice straw. The milled rice straw is blended with a binder to form a mixture. The mixture is then formed into a mat with sufficient size to achieve a predetermined board thickness and density. The mat is then pressed into the board. In another embodiment, the present invention provides a fire resistant board that includes milled rice straw, a resin binder, and a fire retardant material such as an organic phosphate, zinc borate, aluminum trihydrate, sodium silicate, or even rice hulls.

Owner:GREENCOR COMPOSITES

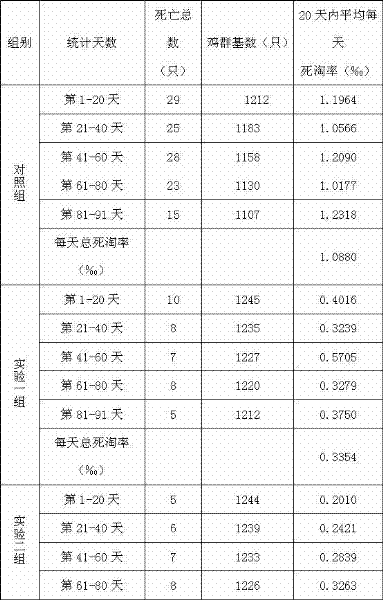

Fermenting bed bioactive padding and preparation and application methods thereof

ActiveCN103053432AEfficient degradationImprove pollutionBacteriaMicroorganism based processesMicroorganismArea source

The invention discloses fermenting bed bioactive padding and preparation and application methods thereof. The fermenting bed bioactive padding is made from, by weight percent, 20%-50% of sawdust, 20%-50% of rice hull, 20%-30% of crop straw, 2%-3% of accessories, and 0.1%-0.3% of fermenting agent. The fermenting bed bioactive padding has the main function of effectively degrading pen manure to improve pollution of rural environment in pig industry. The powerfully functional beneficial microorganisms in the fermenting bed padding are capable of absorbing, degrading and digesting excrement of pigs during breeding, so that pig manure is degraded in situ in a fermenting bed and area source pollution of the rural environment in the pig industry is eliminated.

Owner:湖南省微生物研究所

Process for preparing high-purity nano silicon dioxide from rice husk

The method for preparing nano silicon dioxide by utilizing rice husk includes the following steps: firstly, preparing inorganic acid treatment agent whose concentration is 1-20 wt%, according to the weight ratio of 2-50:1 adding rice husk, boiling for 0.5-3 hr., washing with water, drying, combusting rice husk for 15-180 min, at 600-900 deg.C, pulverizing combusted product to obtain the invented nano silicon dioxide whose grain size is 30-80 nm and purity is 98-99.9%. The used treatment agent is HCl or H2SO4, etc. The combustion heat or the rice husk can be recovered, and can be used as heat source for drying treated rice husk and also can be used as heat source for other application including heating and bathing pool.

Owner:JILIN UNIV

Method for preparing high mode number waterglass and active carbon by rice hull ash

The invention relates to a method for preparing high-mode water glass and activated carbon from rice husk ash, which is characterized by comprising: micro-milling, heating of an alkali liquor, reaction, filtration, washing by boiling water, acid leaching, filtration and washing, drying, secondary activation, water washing, drying, and crushing. The method has the advantages that the method adopts the rice husk ash as a raw material to prepare the activated carbon, and the rice husk ash not only has low cost but also dose not contain harmful substances, so that the method fully and comprehensively utilizes rice husks, and not only achieves the aim of using waste materials as resources but also protects the environment.

Owner:NANCHANG UNIV

Preparation method and application of magnesium oxide-rice husk biological carbon composite material

ActiveCN106669603AReduced bioavailabilityImprove the phenomenon of low pollution adsorption effectOther chemical processesContaminated soil reclamationCarbon compositesMixed materials

The invention belongs to the technical field of water and soil pollution restoration, and discloses a magnesium oxide-rice husk biological carbon composite material as well as a preparation method and application of the magnesium oxide-rice husk biological carbon composite material. The preparation method comprises the following steps: cleaning rice husks, drying the rice husks under a temperature of 80 to 90 DEG C for 10 to 16 hours, carrying out smashing and screening, heating to a temperature of 300 to 400 DEG C under a condition of feeding nitrogen and isolating oxygen at the rate of 3 to 8 DEG C per minute, carrying out thermal cracking for 2 to 4 hours, naturally cooling to a room temperature, cleaning the smashed rice husks, and drying the smashed rice husks to constant weight, so as to obtain rice husk biological carbon; adding the rice husk biological carbon into a magnesium oxide suspension with the mass percentage of 0.6 to 3 percent to obtain a mixed material; carrying out uniform stirring and mixing and then ultrasonic reaction for 1 to 2 hours, putting the mixed material under a condition of 85 to 105 DEG C for 20 to 24 hours, and carrying out thermal treatment at 300 to 400 DEG C for 20 to 60 minutes under a condition of feeding N2 to obtain the magnesium oxide-rice husk biological carbon composite material. The composite material can be applied to adsorbing and removing cadmium from cadmium polluted wastewater or cadmium polluted soil.

Owner:GUANGDONG UNIV OF TECH

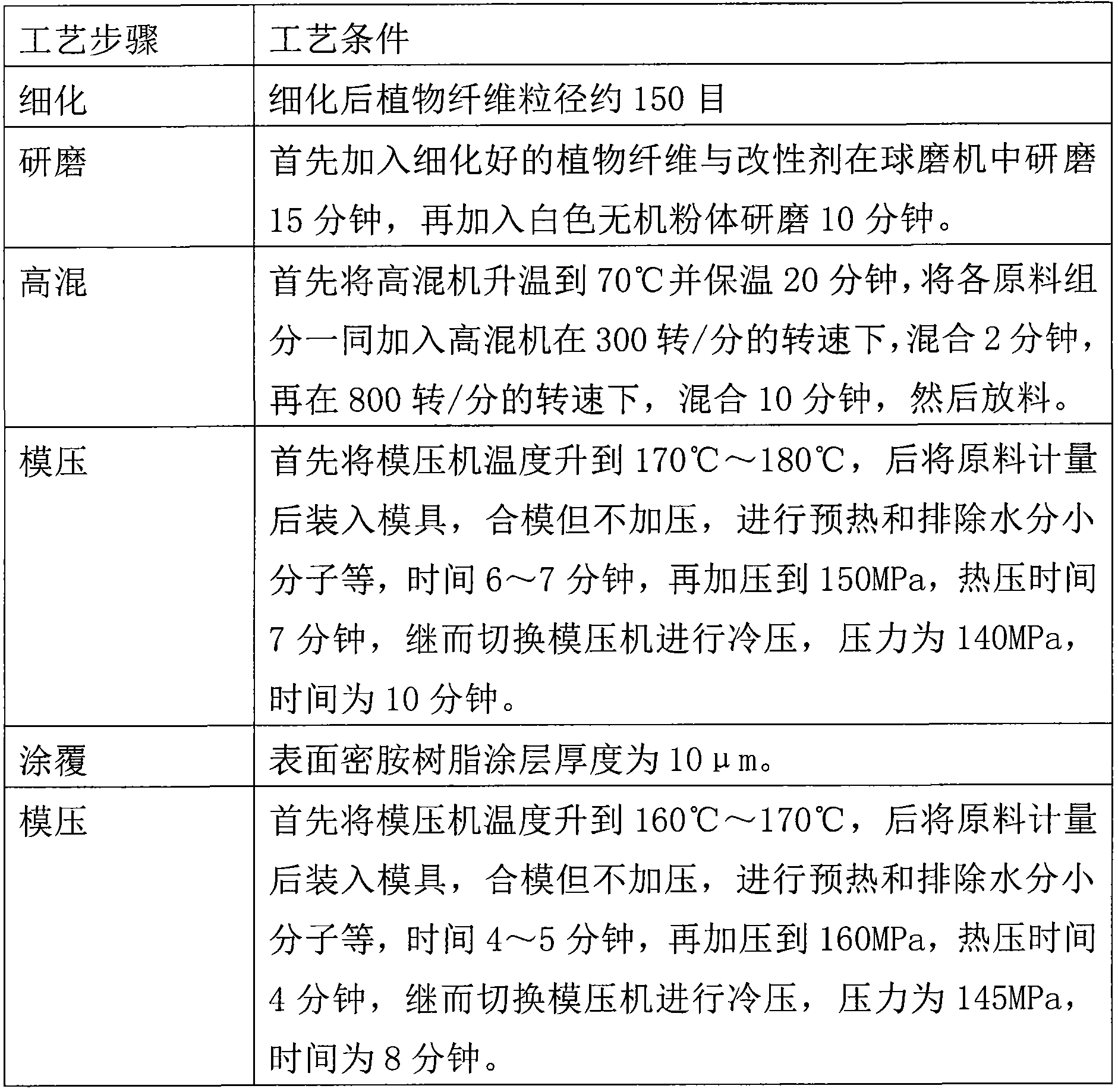

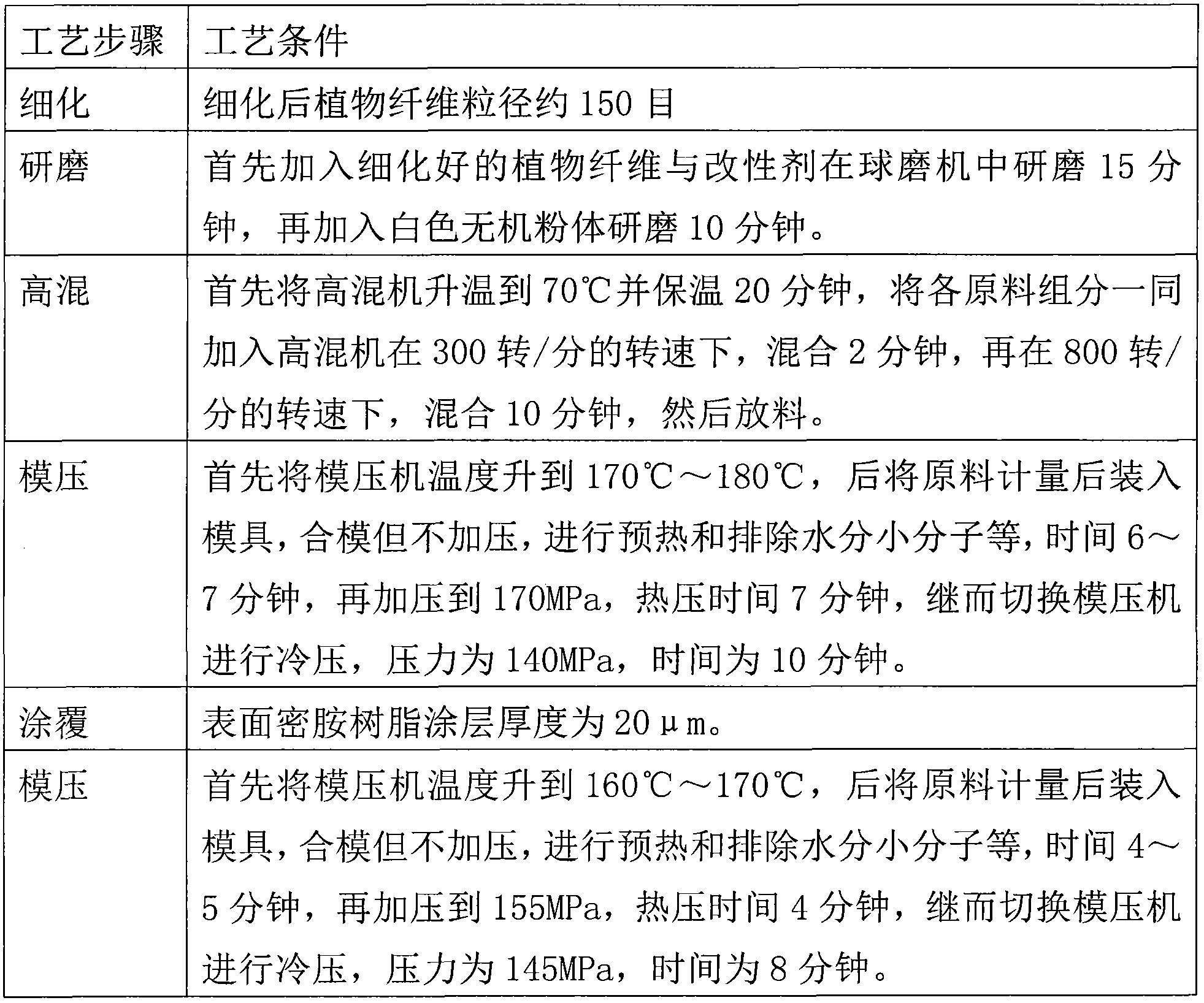

Manufacturing method for vegetable fiber compound tableware

ActiveCN102794803AControlled high temperature oxidative degradationControllable DurabilityWood compressionAviationHusk

The invention belongs to the technical field of vegetable fiber compound tableware and specifically relates to a manufacturing method for the vegetable fiber compound tableware. The manufacturing method specifically comprises seven steps. The production cost of the vegetable fiber compound tableware is obviously lower than that of the traditional metal, ceramic and melamine tableware; the traditional metal, ceramic and melamine tableware can be replaced by the vegetable fiber compound tableware; a large quantity of vegetable fibers, such as, crop straws, rice husks, cobs, sawdust, and the like, are effectively utilized; the atmospheric pollution caused by vegetable fiber burning is effectively prevented and the waste is turned into the wealth; the main products are as follows: basins, bowls, cups, dishes, trays, snack boxes, soup ladles, soup spoons, chopsticks, aviation meal boxes, and the like; and the products have the characteristics of high ceramic simulating strength, good natural texture, clear and gorgeous grains, and the like.

Owner:安徽绿之态秸秆制品有限公司

Method for producing nano-scale white carbon black with rice hull ash

The invention relates to a method for preparing nanometer level white carbon black by rice husk ash. The method is characterized in that the process method comprises the following steps: the rice husk ash is treated by an alkaline method to prepare soluble glass; and a soluble glass solution is subjected to condensation, heat insulation, acidic reaction, aging, rinsing, filtering, preparing, homogenizing, spraying and drying, and airflow pulverization. The method has the technical effects that the method reduces cost, improves corrosion resistance, high hardness and high toughness of the material, and has simple preparation process flow, low production cost and good stability.

Owner:NANCHANG UNIV

Process for preparing silicon dioxide aerogel using rice husk ash as raw material

InactiveCN1449997ALarge specific surface areaReduce manufacturing costSilicaSolid waste disposalHYDROSOLSilicon dioxide

The method for preparing silicon dioxide aerogel utilizing waste material rice husk ash obtained by combusting rice husk includes the following steps: soaking the rice husk ash in organic alkaline aqueous solution, using inorganic acid to neutralize alkaline solution to produce silicon dioxide hydrosol, ageing said hydrosol, substituting water content in the hydrosol with organic solvent, then substituting organic solvent with liquid CO2, then supercritical CO2 drying so as to obtain white silicon dioxide aerogel whose specific surface area is 297.3 sq.m / g, apparent density is 0.532 g / cu.cm and internal microporous average pore size is 22.3 nano.

Owner:TSINGHUA UNIV

Composite biological activated carbon and rapid preparation method thereof

InactiveCN101643208AExtended service lifeSolve the technical problems of long carbonization timeSpontaneous combustionBiological activated carbon

The invention discloses a composite biological activated carbon and a rapid preparation method thereof, raw materials thereof comprise coconut shell, bamboo, rice hull, sawdust, wheat straw or rice straw, or the raw materials thereof comprise the rice hull, the sawdust, the wheat straw or the rice straw, corn stalk or corn core, the raw materials are smashed to prepare columnar granules, the direct heating method of the spontaneous combustion type granules is adopted for preparing the carbon, a fixed layer is paved at the bottom of a furnace by taking the granules as the raw materials, the fixed layer is ignited by using ignition materials, the feeding is adopted at the upper part of the furnace and the air induction is carried out at the lower part of the furnace for accelerating carbonization of the granules, the air induction is stopped after the carbonization of the granules, the temperature in the furnace is kept at 430-700 DEG C, the spray cooling method is adopted for activatingand cooling the granular carbon, and a finished product is prepared after 20-30 minutes. A plurality of raw materials are mixed, and more pores are naturally formed, thereby expanding the specific surface area of the carbon, greatly increasing effective micropores, leading the absorption performance to be greatly better than the existing activated carbon of single material and reflecting the unique advantages of the composite material.

Owner:徐克文

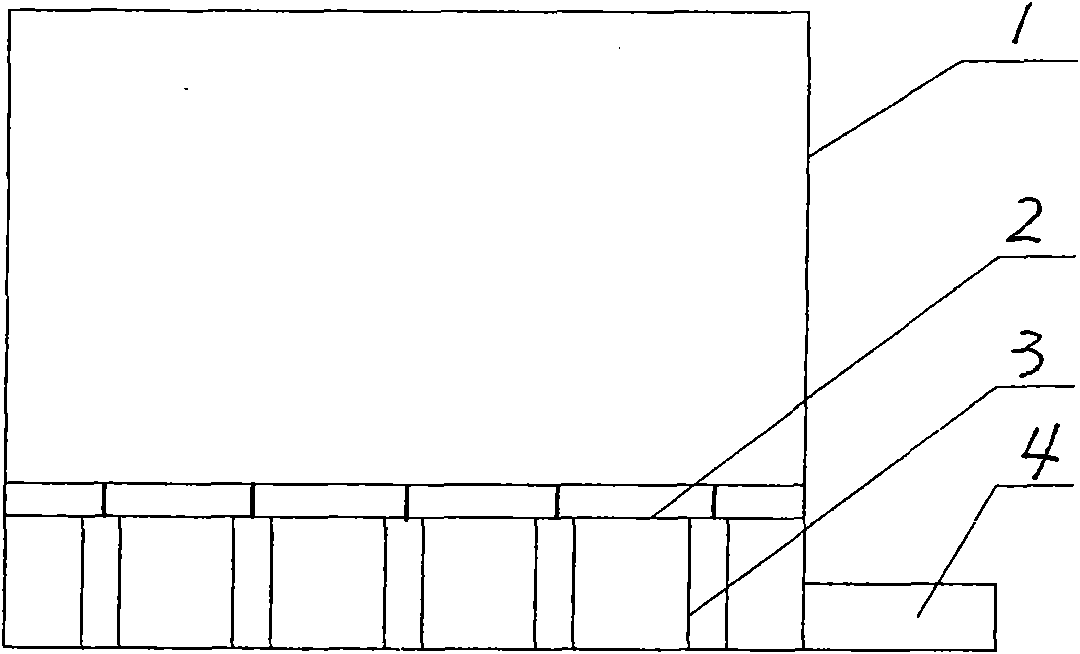

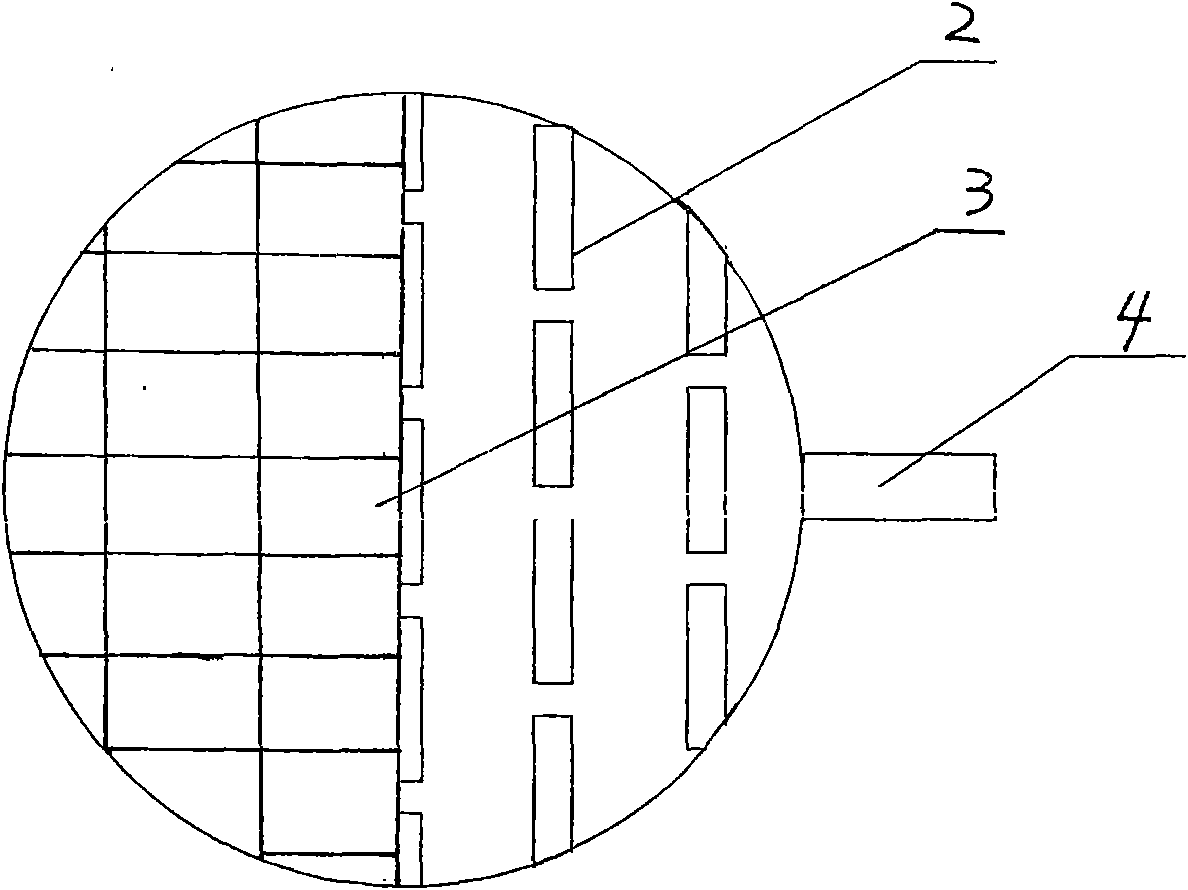

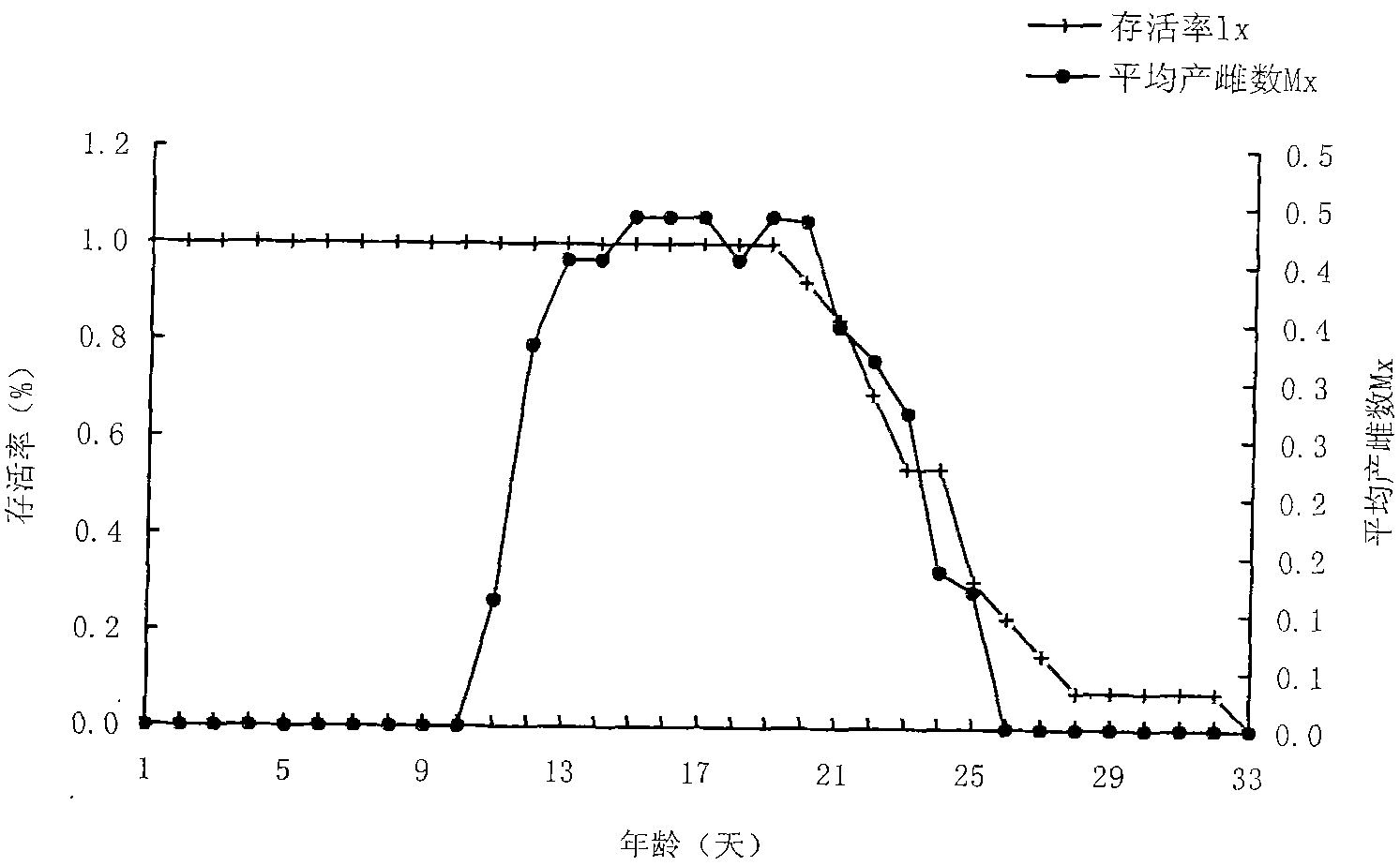

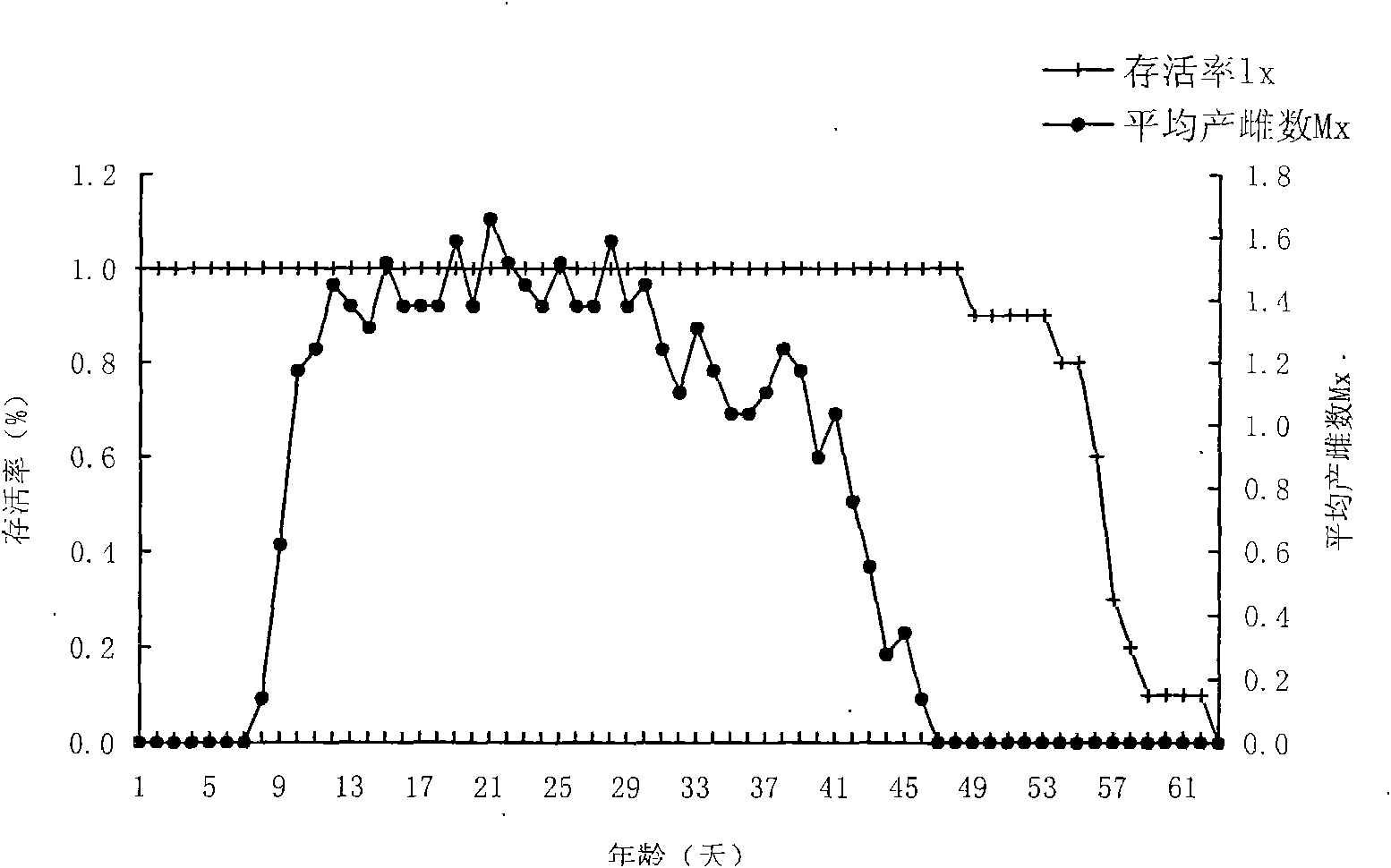

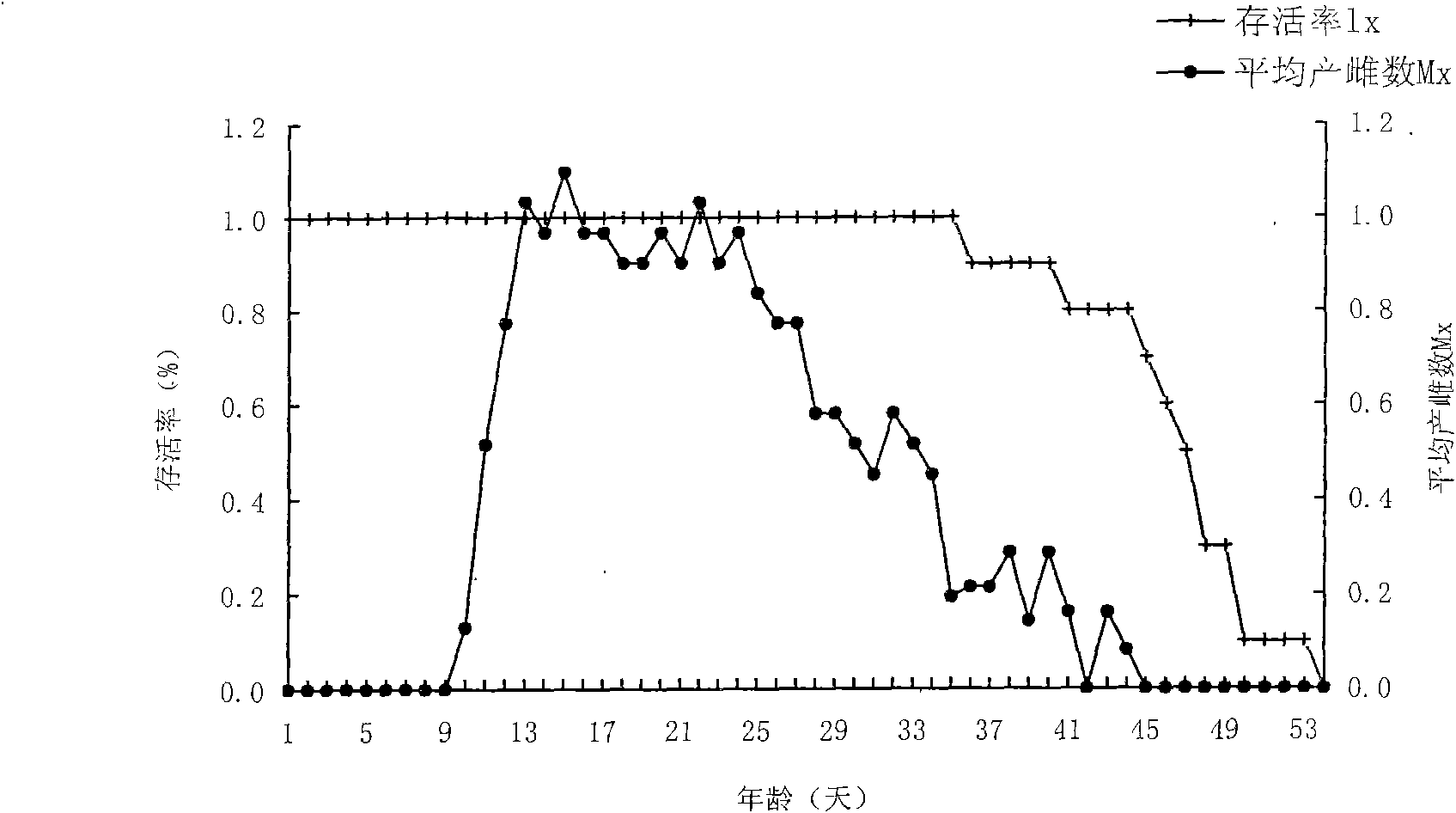

Method for artificial feeding production of Steinman small blind cucumeris

The invention discloses a method for artificial feeding production of small blind Steinman cucumeris, which comprises disinfecting wheat bran, rice bran, rice hulls or grain crops as off-cuts and using the off-cuts as a culturing material for alewrglyphus ovatus. The process flow of the method for artificial feeding production comprises the following steps: selecting standby health and disease-free alewrglyphus ovatus, disinfecting an artificial culturing material for the alewrglyphus ovatus, filling the disinfected culturing material into a special culturing container, adding 10-50ml of water into the culturing container, adding the alewrglyphus ovatus, then adding purified and rejuvenated new small amblyseius swirskii, sealing the opening of the culturing container with paper or cloth, adding the culturing container into a disinfected culturing room for culture with the culturing temperature being 10-38 DEG C, the relative humidity being 40-90 percent, the illumination being 8-10L: 14-16d, testing the product after culturing for 20-50 days, and finally packing finished products.

Owner:FUJIAN YANXUAN BIOLOGICAL CONTROL TECH CO LTD

Mould-proof mothproof non-woven fabric and preparation method thereof

InactiveCN103696142AHigh tensile strengthImprove adhesionSynthetic resin layered productsNon-woven fabricsPentachlorophenolJojoba oil

The invention provides a mould-proof mothproof non-woven fabric, which comprises a top surface layer, a back surface layer, and a fiber cotton layer sandwiched between the top surface layer and the back surface layer, wherein the top surface layer and the back surface layer are made of non-woven fabric materials; the non-woven fabric is prepared by the following active ingredients in parts by weight through adopting a melt-blowing method: 100 parts of isotactic polypropylene, 2-3 parts of molybdenum disulfide, 1-2 parts of copper sulfate, 1-2 parts of jojoba oil, 1-2 parts of pentachlorophenol, 3-4 parts of zinc stearate, 1-2 parts of antioxidant 168, 12-15 parts of dioctyl terephthalate, 10-12 parts of rice hulls, 2-3 parts of bamboo charcoals, 2-3 parts of coptidis rhizome, 1-2 parts of cogongrass rhizome, 1-2 parts of rust-coloured crotalaria herb with root, and 4-5 parts of auxiliaries. The non-woven fabric has the mould-proof mothproof properties, as well as aromatic fragrance and health-care function, can adsorb harmful gas and peculiar smell, is heat-resistant, corrosion-resistant, non-toxic and odorless, large in tensile strength, good in binding power and free from dust and chips.

Owner:MAANSHAN HUBIN NONWOVEN CLOTH TECH

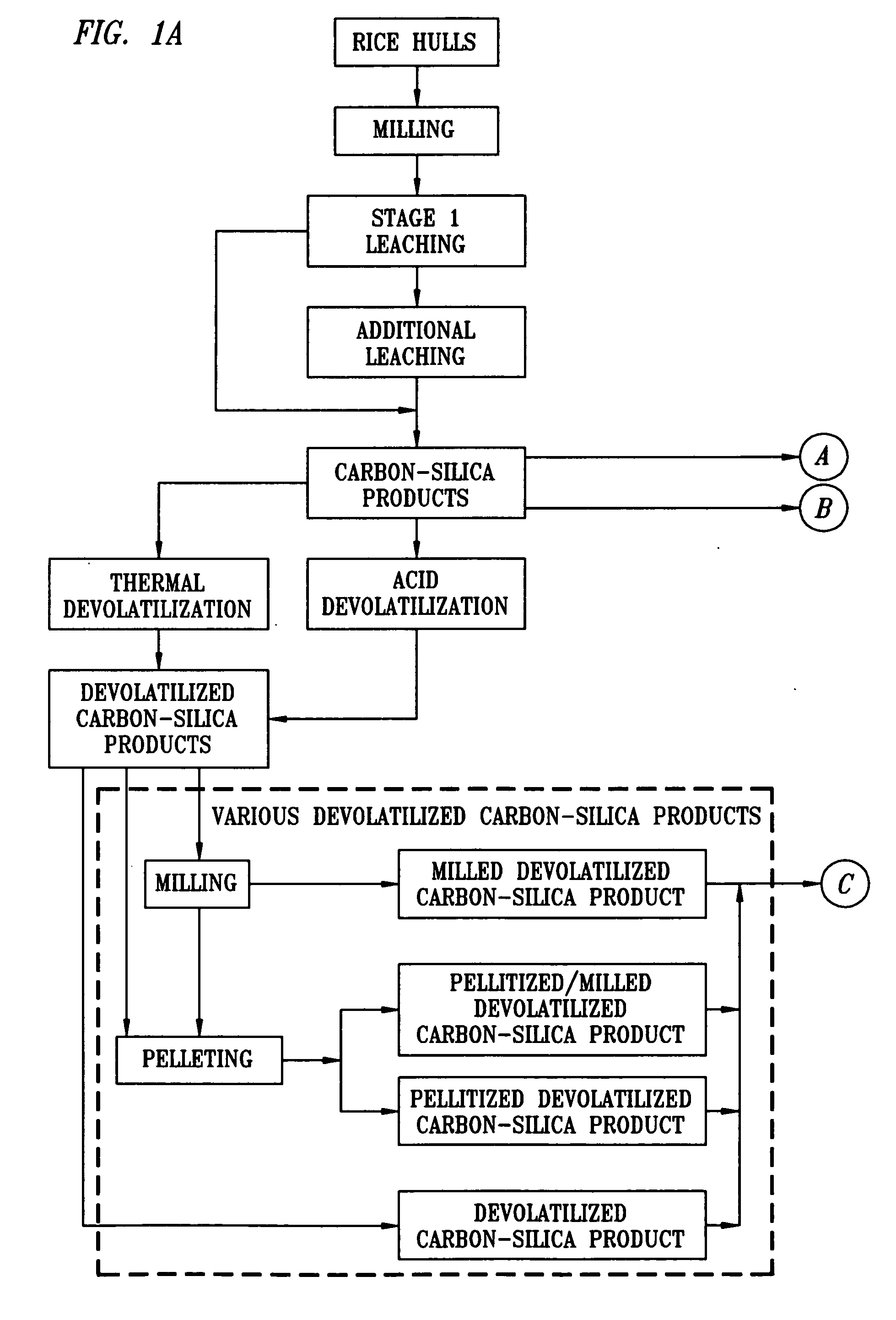

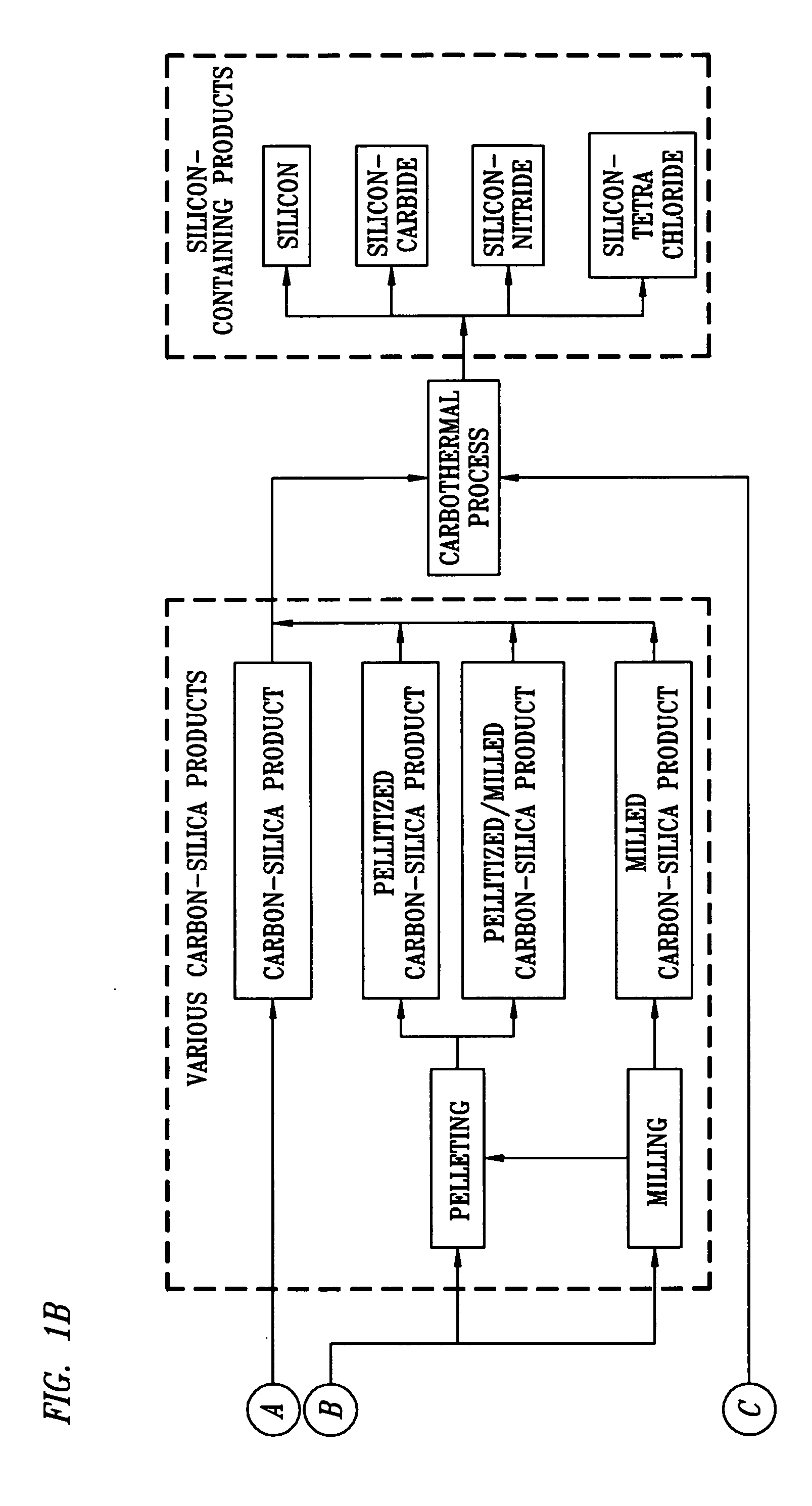

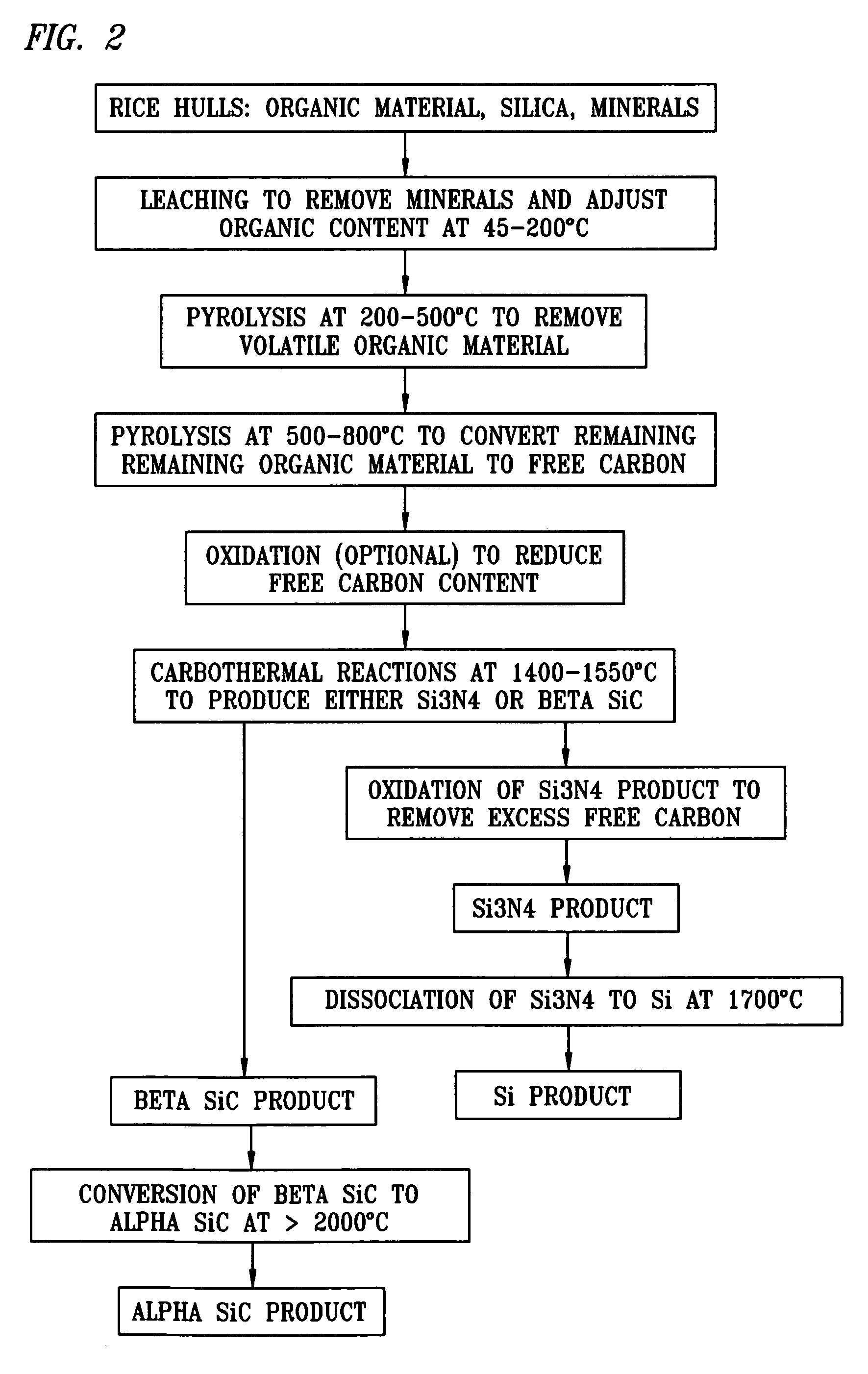

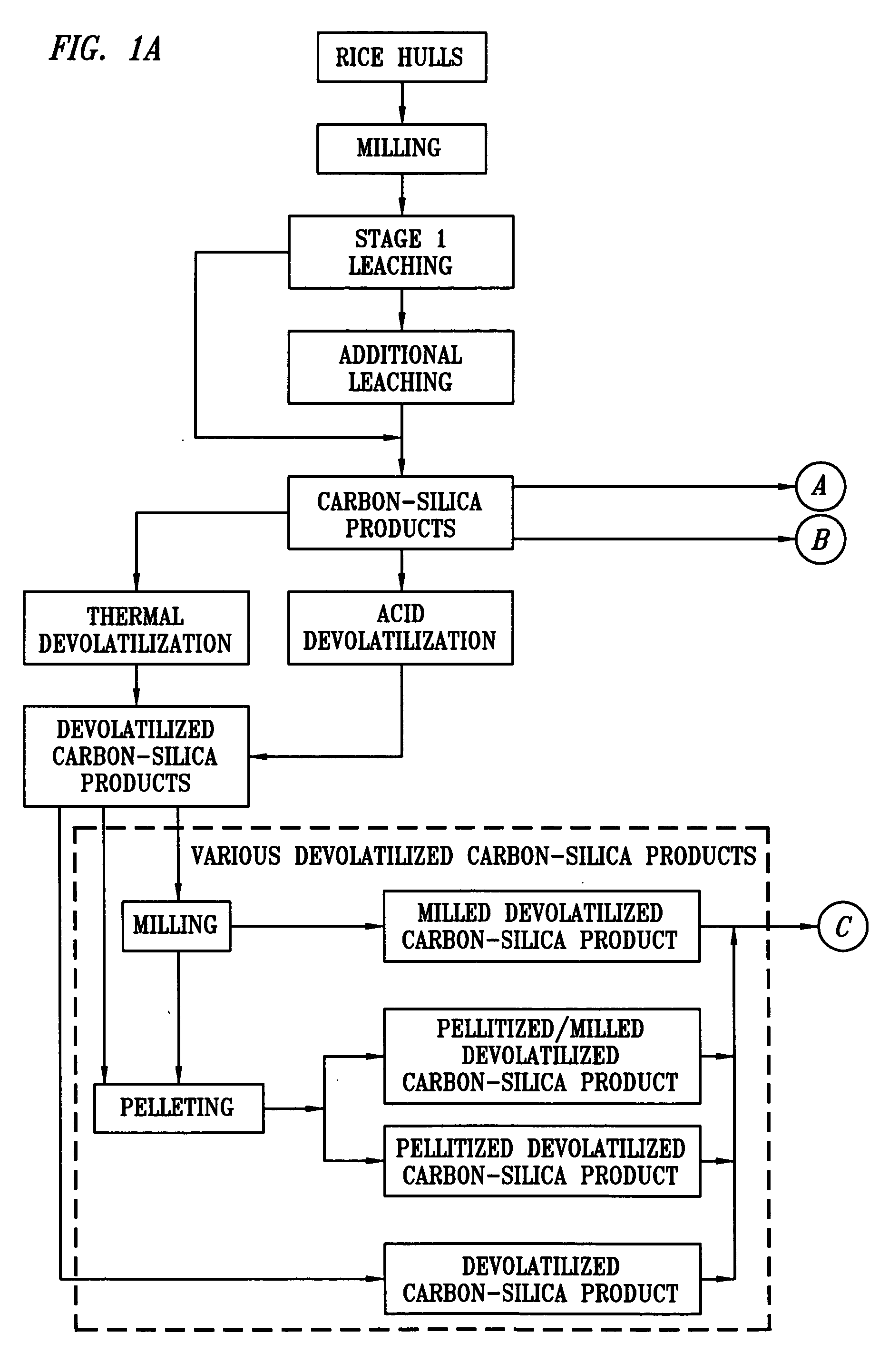

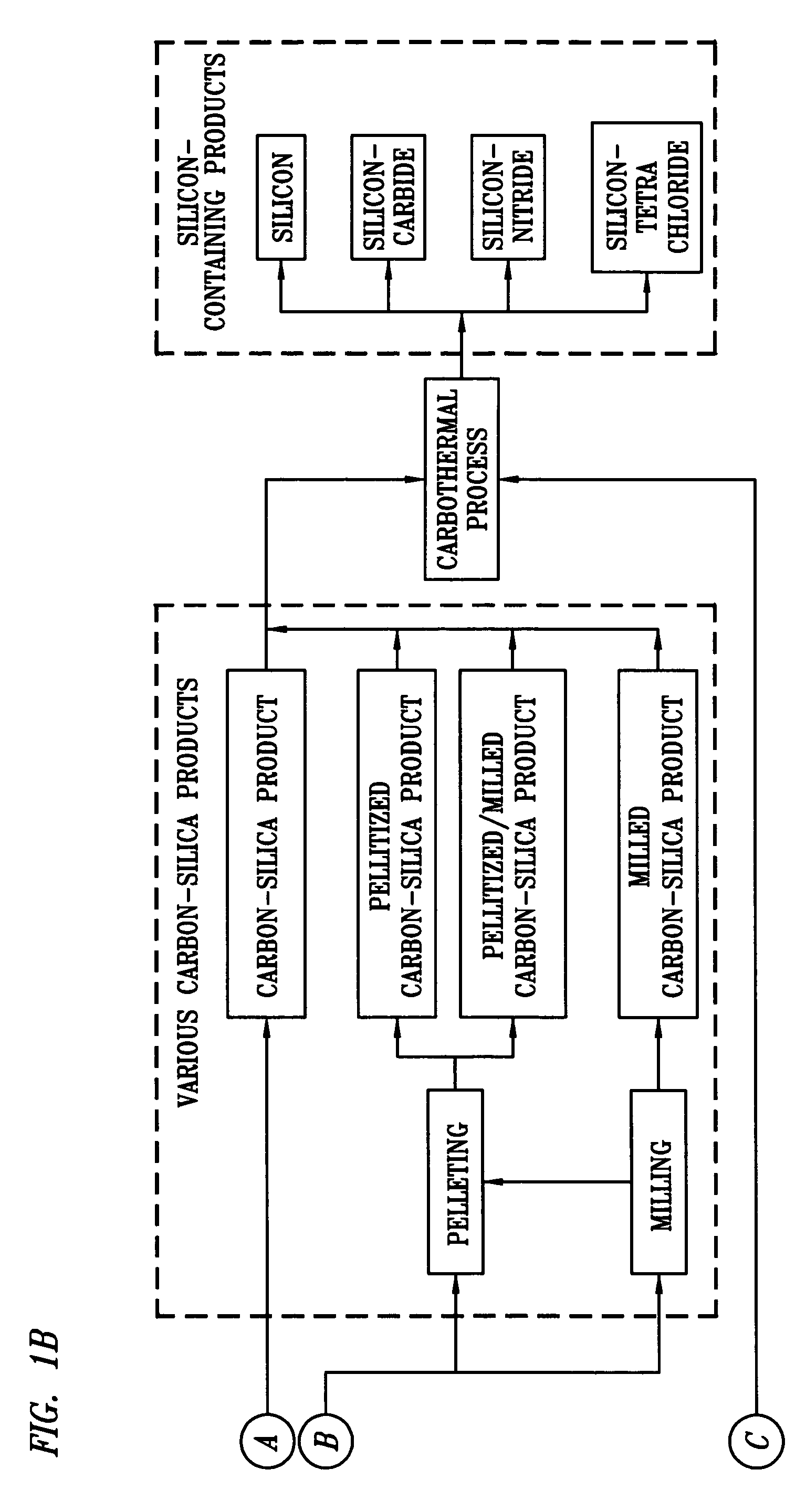

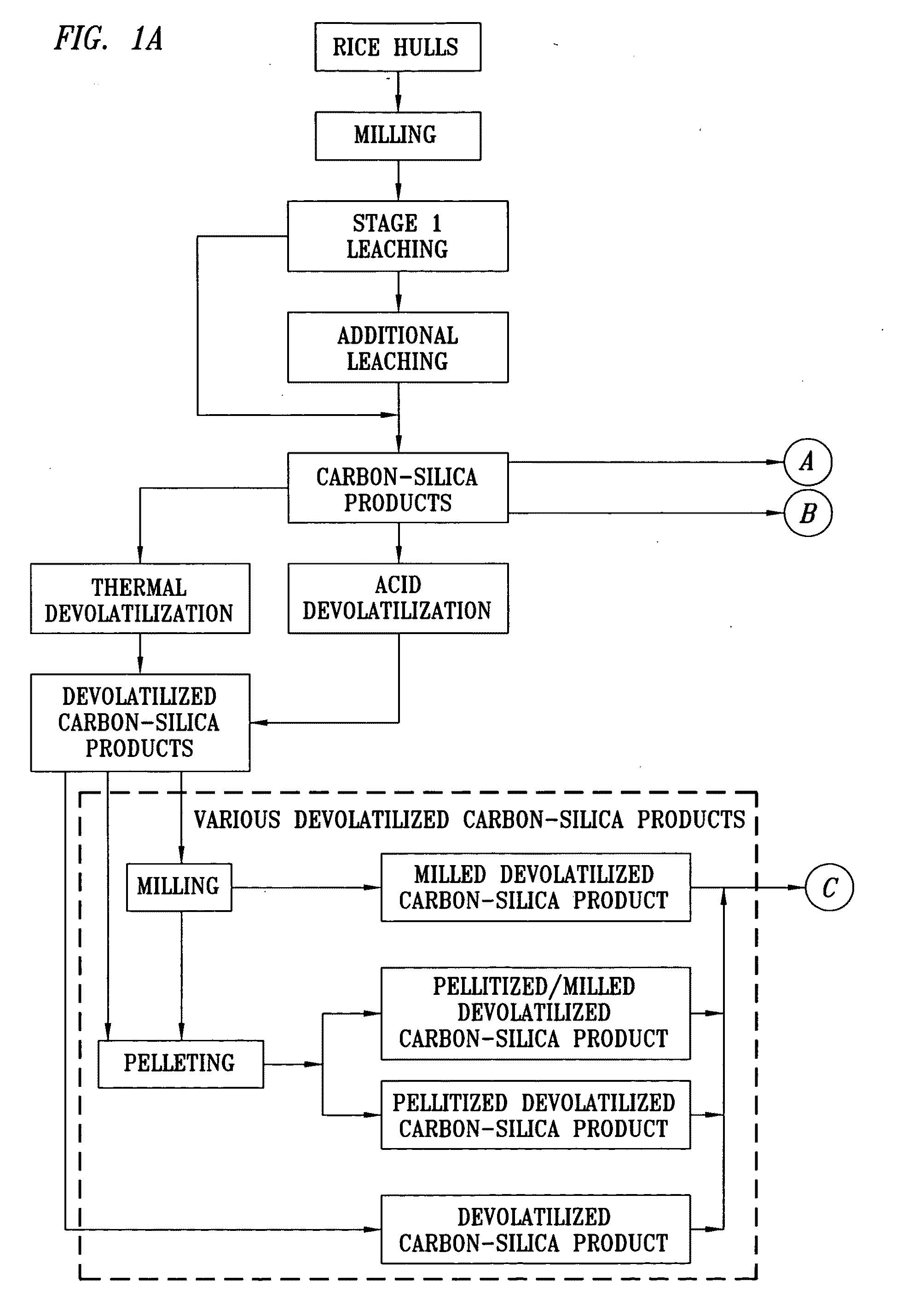

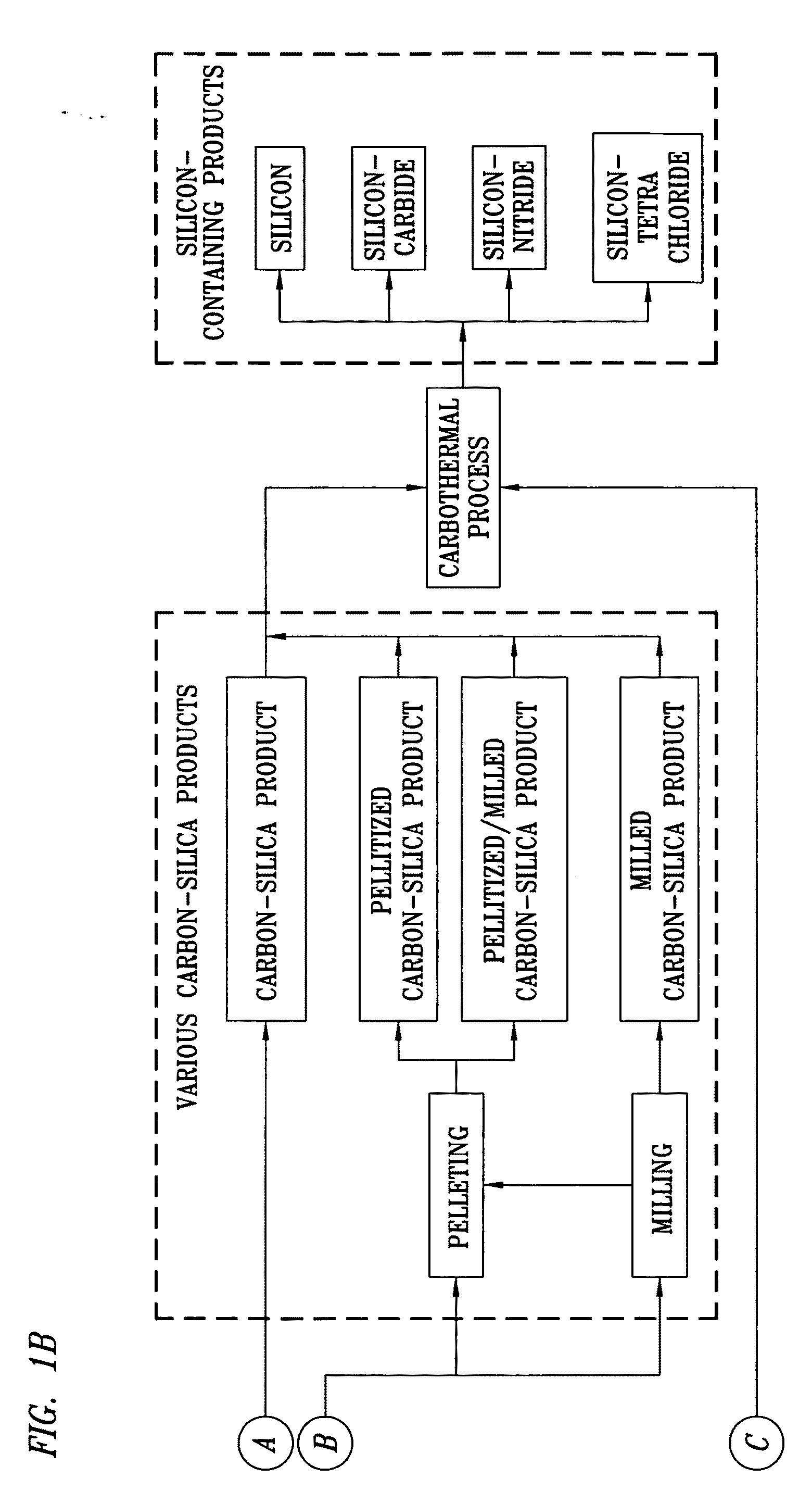

Composition and method for making silicon-containing products

Silicon-containing products, such as silicon, silicon carbide and silicon nitride, containing less than 0.01 weight percent total mineral impurities and selectively determined carbon-to-silicon ratios. The products are derived from plant matter, such as rice hulls and rice straw, containing at least three weight percent silica. Methods are provided for making such high purity silicon-containing products by leaching silica-containing plant matter with aqueous sulfuric acid under controlled temperatures, pressures and reaction times to remove minerals and metals while adjusting the mole ratio of fixed carbon to silica, and then thermally treating under controlled conditions to produce the desired product.

Owner:SI OPTIONS LLC

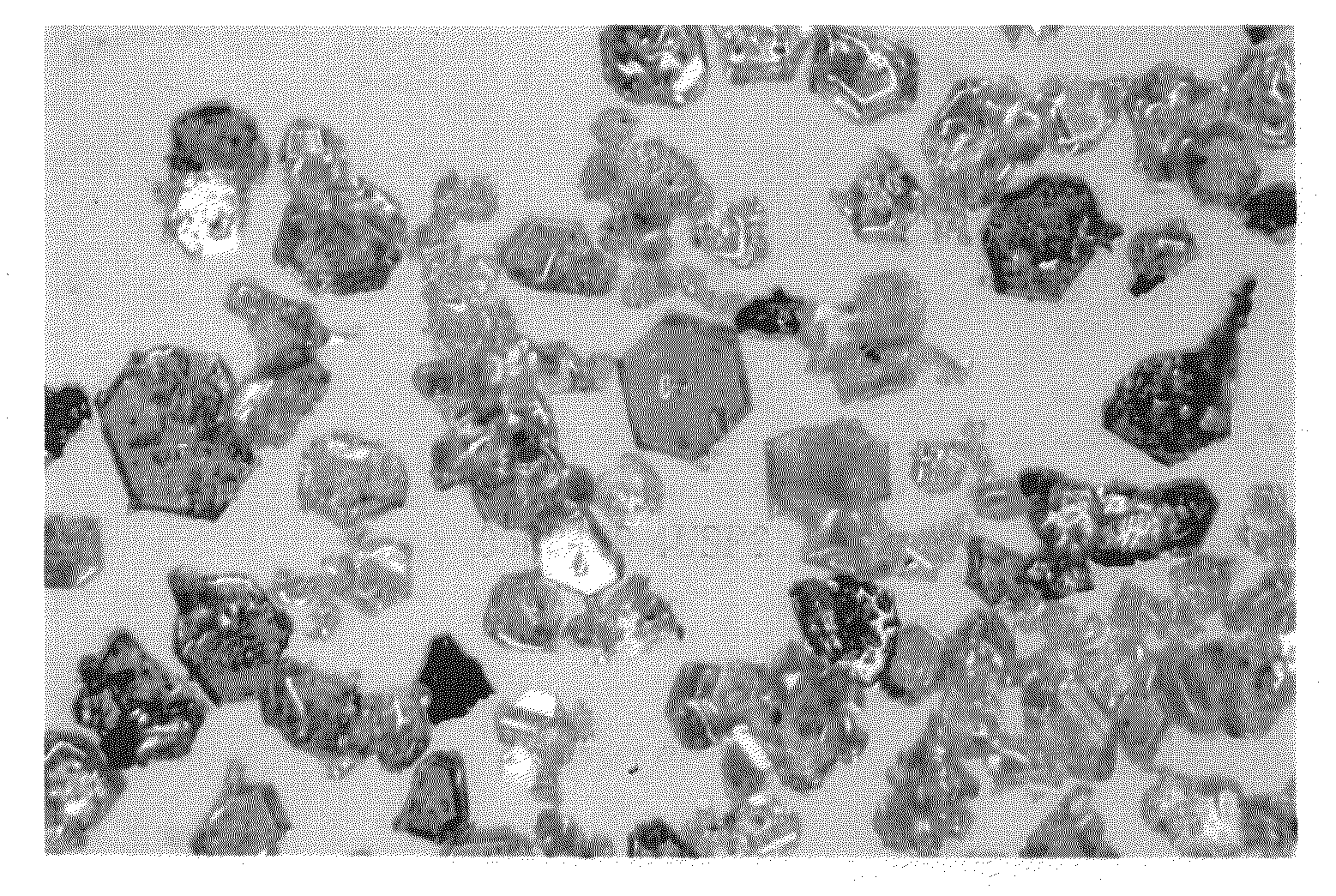

Composition and method for making silicon-containing products

ActiveUS20050227868A1Increase throughputSave energyNitrogen compoundsOther chemical processesPorositySilicon dioxide

A method for producing carbon-silica products from silica-containing plant matter such as rice hulls or straw by leaching with sulfuric acid to remove non-silica minerals and metal while adjusting the mole ratio of fixed carbon to silica in the resultant product. The carbon and silica are intimately mixed on a micron or submicron scale and are characterized by high purity and reactivity, small particle size, high porosity, and contain volatile carbon that can be used as a source of energy for the production of silicon-containing products from the carbon-silica products. High purity silicon-containing products made from the carbon-silica products of the invention are also disclosed.

Owner:SI OPTIONS LLC

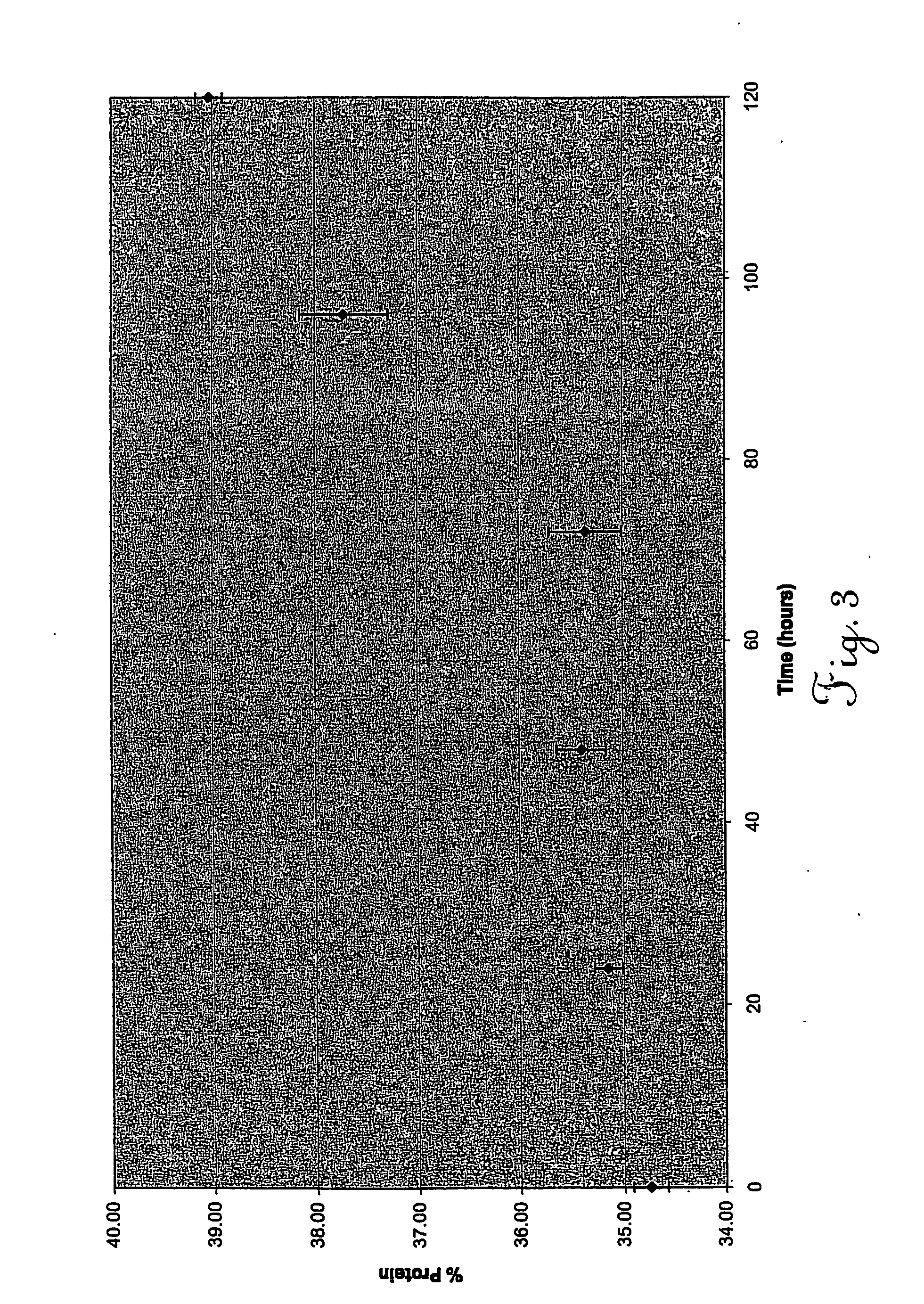

Methods for improving the nutritional quality of residues of the fuel, beverage alcohol, food and feed industries

InactiveUS20060233864A1Improve nutritional qualityIncreased rate of weight gainBy-product recoveryFood processingBeet pulpIngested food

A method is provided for improving the nutritional quality of a fibrous by-product or residue of a food manufacturing process, wherein the fibrous by-product or residue is inoculated with at least one filamentous fungus, and the fibrous by-product or residue is fermented thereby to decrease dry matter content, increase protein content, and decrease fat content of the by-product or residue. Suitable byproducts or residues include spent brewer's grains, dried distiller's grains, dried distiller's solubles, distiller's dried grains with solubles, residues of the cereal processing industry, wheat bran, soybean hulls, citrus pulp, beet pulp, rice husks or hulls, bagasse, apple pommace, and combinations thereof. Enzymes produced during the fermentation may also be used as valuable coproducts such as animal feed supplements, or may be used in primary fermentations for the brewing and distilling industry.

Owner:ALLTECH CO LTD

Method for producing silicon dioxide silica aerogel by drying in atmosphere pressure with rice hull as raw material

The invention discloses a drying preparation method of silicon dioxide aerogel under atmospheric pressure, using rice husk as raw material, which comprises the following procedures: (1) preparation of rice husk sol; (2) aging of gel; (3) solvent exchange; (4) surface modification of gel; (5) drying under atmospheric pressure. Instead of expensive toxicant organ silicon source, agricultural trashes rice husk is used as raw material, thus greatly reduce the cost; instead of super-critical drying, drying under atmospheric pressure greatly reduces the requirements for the whole process on the equipment, greatly improves the safety performance on one hand, also greatly reduces the running cost on the other. The method in the invention has the advantages of simple technology, easy operation, which is suitable for scale production.

Owner:纳诺科技有限公司

High Purity Silicon-Containing Products and Method of Manufacture

InactiveUS20110008236A1Lower energy requirementsImprove throughputSilicaNitrogen compoundsSilicon dioxideImpurity

Silicon-containing products, such as silicon, silicon carbide and silicon nitride, containing less than 0.01 weight percent total mineral impurities and selectively determined carbon-to-silicon ratios. The products are derived from plant matter, such as rice hulls and rice straw, containing at least three weight percent silica. Methods are provided for making such high purity silicon-containing products by leaching silica-containing plant matter with aqueous sulfuric acid under controlled temperatures, pressures and reaction times to remove minerals and metals while adjusting the mole ratio of fixed carbon to silica, and then thermally treating under controlled conditions to produce the desired product.

Owner:SI OPTIONS LLC

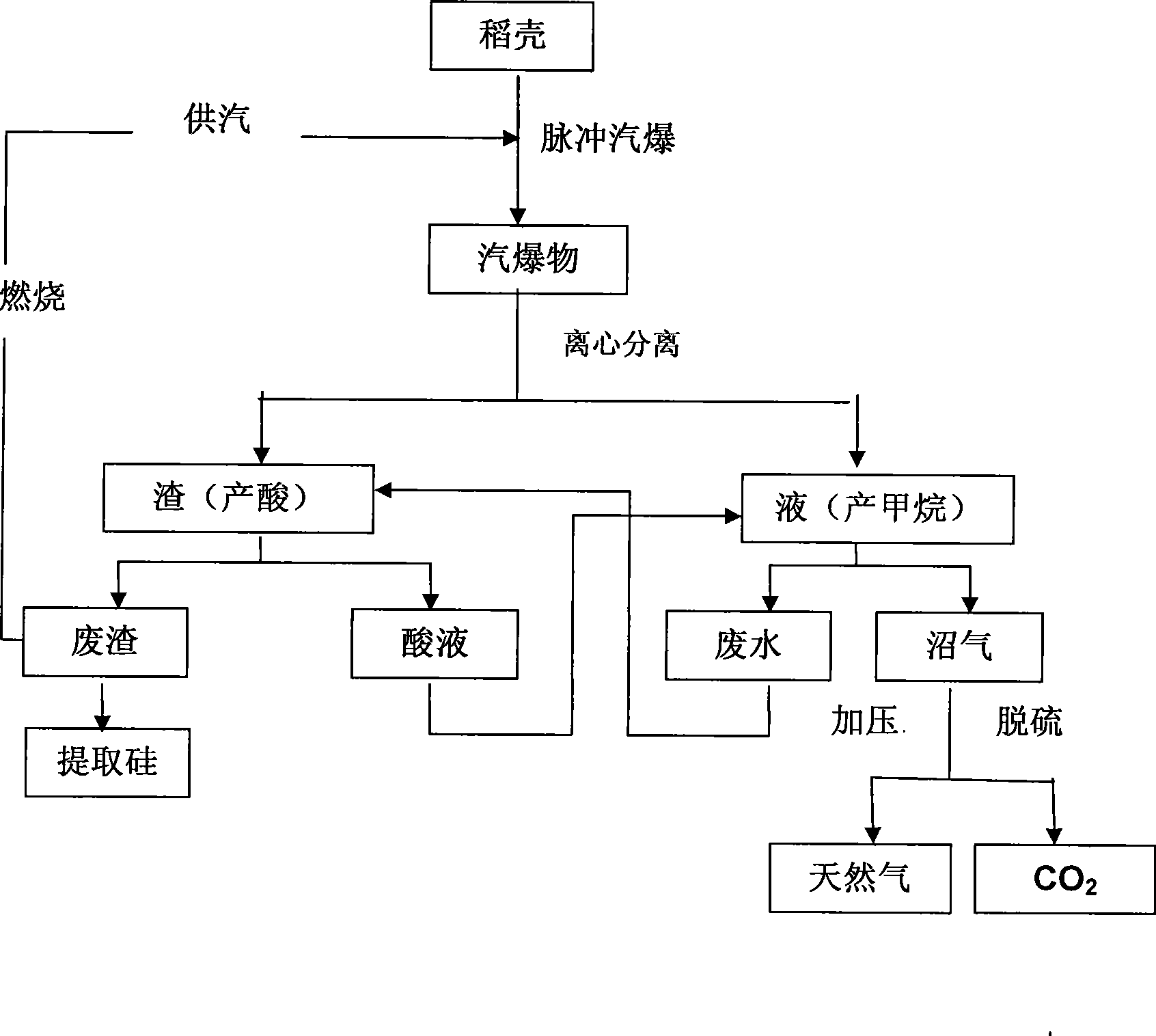

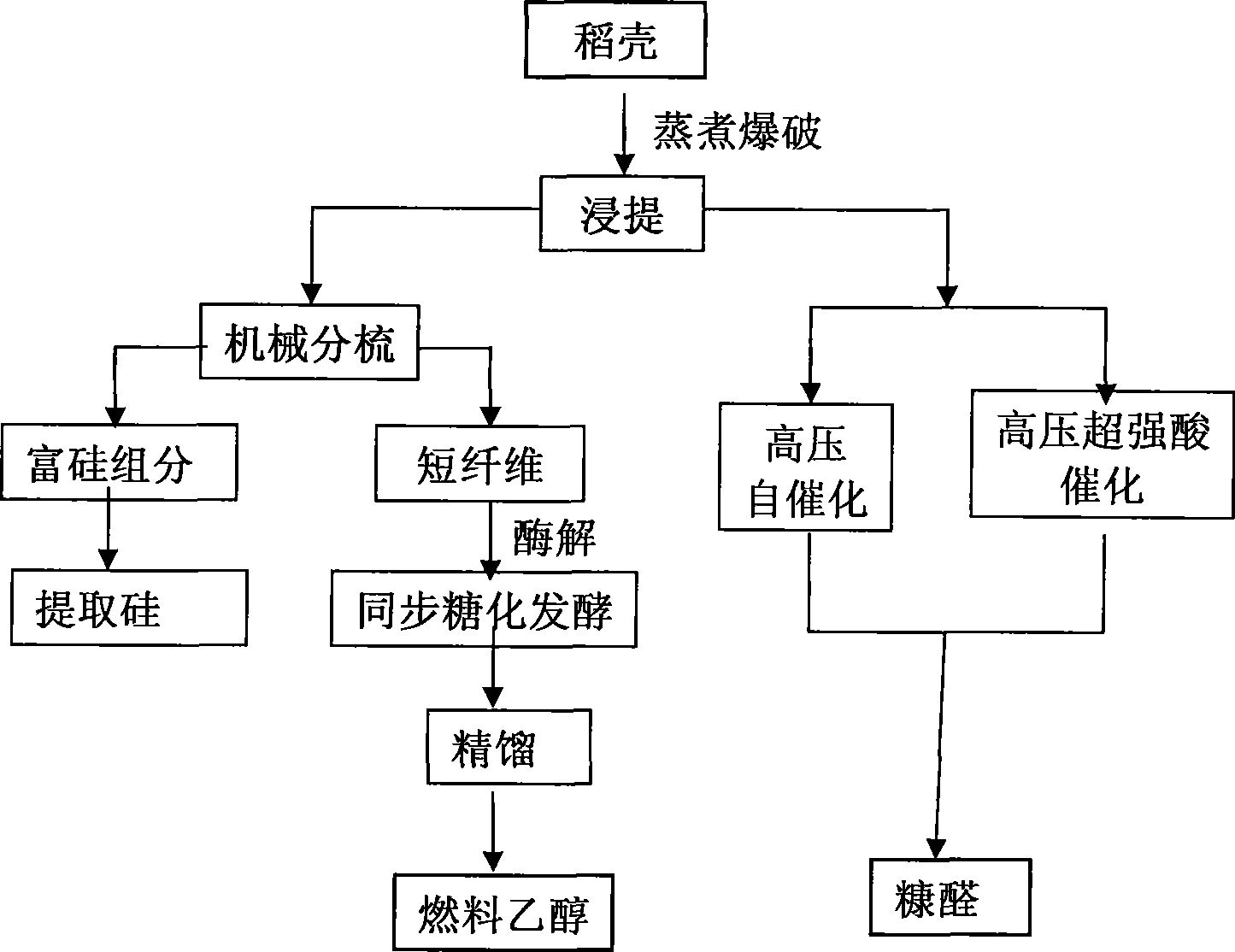

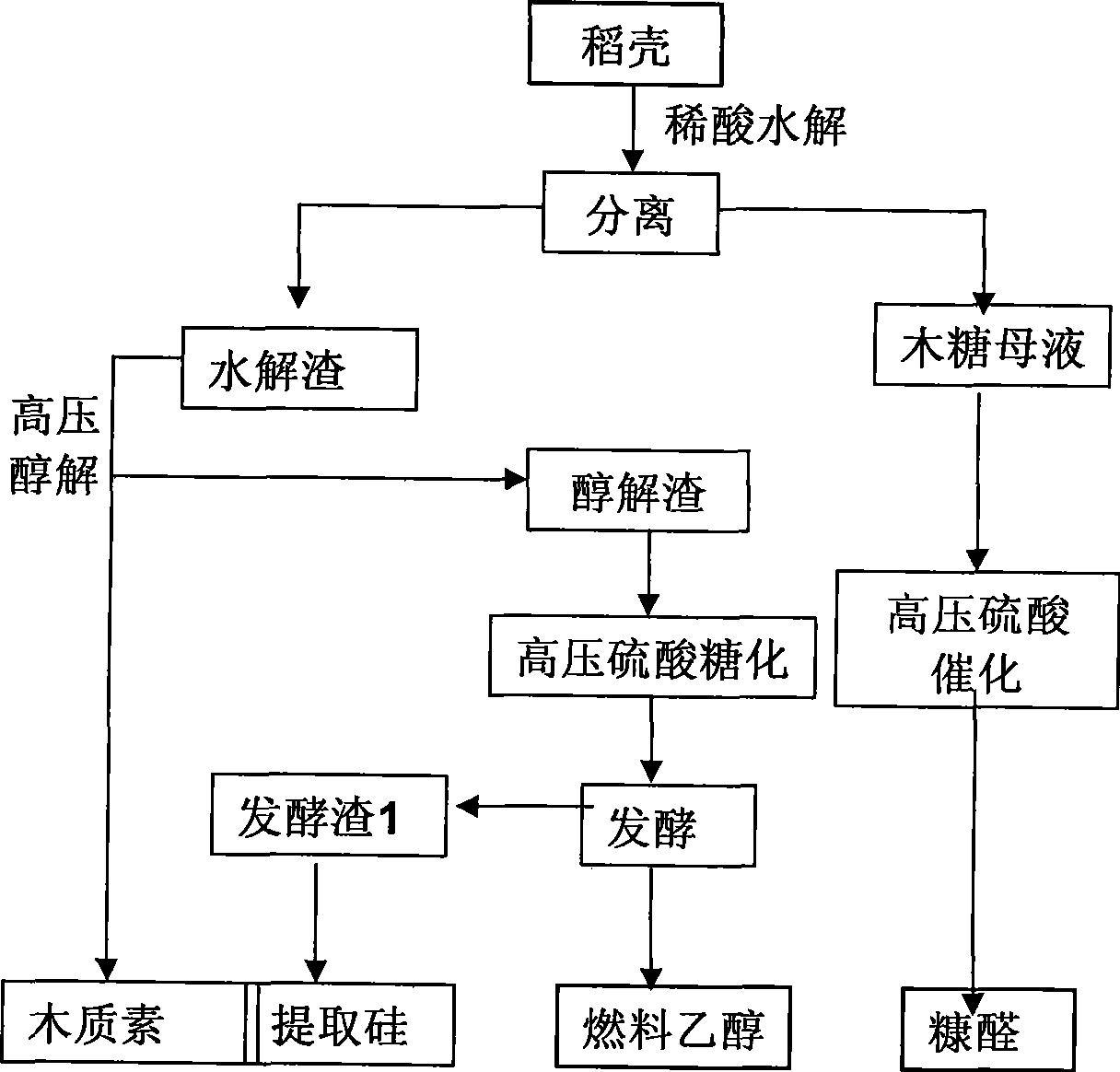

Production process of natural gas by using paddy hull

The invention relates to a production technique utilizing rice hulls to produce natural gas, which solves the problem of economically and effectively utilizing the rice hulls which are rich resources and biological materials. The technique of the invention essentially comprises the following steps: 1. Pulse gas explosion is carried out to the rice hulls and more than 90 percent of hemicelluloses in products of gas explosion are hydrolyzed while more than 85 percent of celluloses are isolated and puffed; 2. two-phase anaerobic fermentation is carried out to the products of gas explosion, thus respectively obtaining methane and acid liquor; and 3. desulfurization is carried out to the methane, thus obtaining the natural gas of the rice hulls. The technique of the invention pertains to anaerobic fermentation and has little manpower and low management cost; compared with the biomass heat energy transformation modes, such as cellulosic ethanol, biomass methanol, biological oil, pyrolytic bio-oil, biomass hydrogen production, wheat straw power generation, and the like, the transformable heat energy of biological natural gas is the highest; the technique of the invention pertains to a closed internal recycling system, which is environmentally friendly and has no pollution and high economic benefit.

Owner:浙江格义清洁能源技术有限公司

Method for preparing rice hull ash-natural rubber composite material

The invention provides a method for preparing a rice husk ash-natural rubber composite material. The method is characterized in that epoxidized natural rubber is taken as compatilizer of rice husk ash and natural rubber; the excellent compatibility of the epoxidized natural rubber and the natural rubber, as well as the chemical reaction of the epoxidized natural rubber and the rice husk ash are utilized to improve the dispersion effect of the rice husk ash in the natural rubber, and strengthen the interaction between the rice husk ash and the natural rubber, so as to prepare the rice husk ash-natural rubber composite material with high performance; the tensile strength of a vulcanized rubber sheet of the composite material is between 19 and 23 MPa; the tensile failure elongation of the vulcanized rubber sheet is between 750 and 900 percent; and the 300-percent stress at definite elongation of the vulcanized rubber sheet is between 4.0 and 6.0 MPa.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

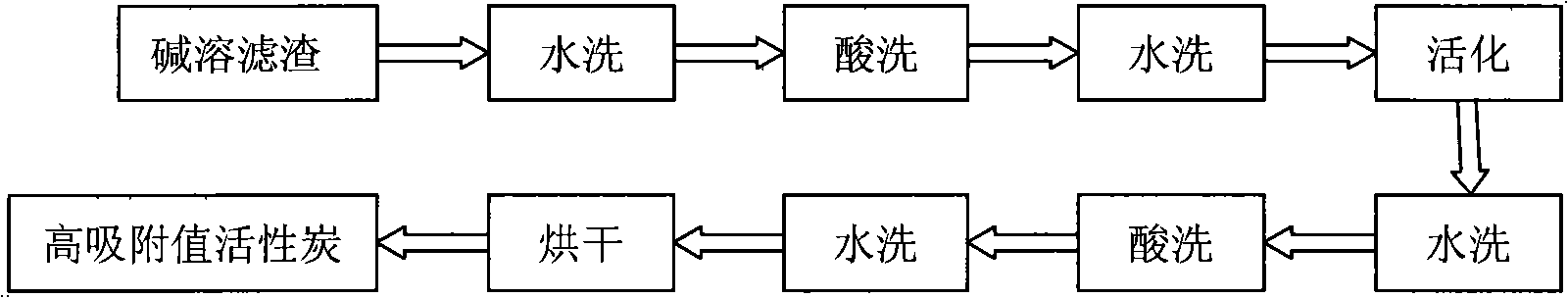

Method for preparing high grade activated carbon from rice husk ash

InactiveCN101264885AOvercoming the problem of excessive ash contentHigh modulusActivated carbonHigh absorption

The invention relates to a high quality active carbon production method using rice husk ash, belonging to active carbon manufacture technical field, which is characterized in that the water glass is made utilizing rice husk ash, and the alkali resolved filter residue is filtered and activated using potassium hydroxide as activator; the active carbon with high absorption value is made after rising and drying. The silicon dioxide in the alkali resolved filter residue is efficiently eliminated while in activation in the invention; the absorption performance of the obtained active carbon is good, and the methylene blue adsorption reaches to more than 20 mL / 0.1 g; each index meet national standard. The high quality active carbon is made utilizing the alkali resolved filter residue after the water class is made by rice husk ash; the produced active carbon has the advantages of good quality (the methylene blue adsorption reaches to more than 20 mL / 0.1 g and ash is lower than 3%) and low production cost; the pollution of rice husk ash alkali resolved filter residue to environment can be reduced.

Owner:JIANGNAN UNIV

Method for manufacturing active carbon by using rice hulls and stalks as main raw materials

The invention provides a method for manufacturing active carbon by using rice hulls and stalks as main raw materials. The method comprises the following steps of: (1) pretreatment of raw materials; (2) carbonizing treatment; (3) acid treatment; and (4) alkali treatment, and screening. After test performed by an active carbon test method specified in the national standards (GB / T 13803.2-1999), the iodine sorption value of the rice hull-stalk active carbon is over 1,000mg / g, and the adsorption rate of methylene blue is over 135mg / g; and the production cost is low.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Inorganic thermal-insulation mortar and production method thereof

The invention belongs to the technical field of building materials and particularly relates to inorganic thermal-insulation mortar and a production method thereof. The production method includes: using rice husks as the raw material, performing pickling preprocessing, calcining, using alkali dissolution to extract sodium silicate, removing impurities to obtain silicic acid, adding aluminum silicate fibers and tetraethyl silicate to serve as the framework of gel, performing condensation polymerization to deposit silicon dioxide composite hydrogel on the framework, cleaning with anhydrous ethanol and normal hexane, using trimethylchlorosilane to perform hydrophobic modification to obtain silicon dioxide aerogel, using the capillary force of the silicon dioxide aerogel adsorb paraffin, serving as the phase change thermal storage material, into pores to compact the aerogel, mixing the prepared silicon dioxide composite aerogel phase change material with expanded and vitrified small balls, silica fume and the like, and discharging to obtain the inorganic thermal-insulation mortar. The prepared inorganic mortar is small in heat conductivity coefficient, low in contractibility rate, high in strength, capable of effectively increasing the crack resistance and seepage resistance of the mortar and capable of prolonging building service life.

Owner:常州市天宁区鑫发织造有限公司

Water and energy saving domestic animal fermentation bed and preparation method thereof

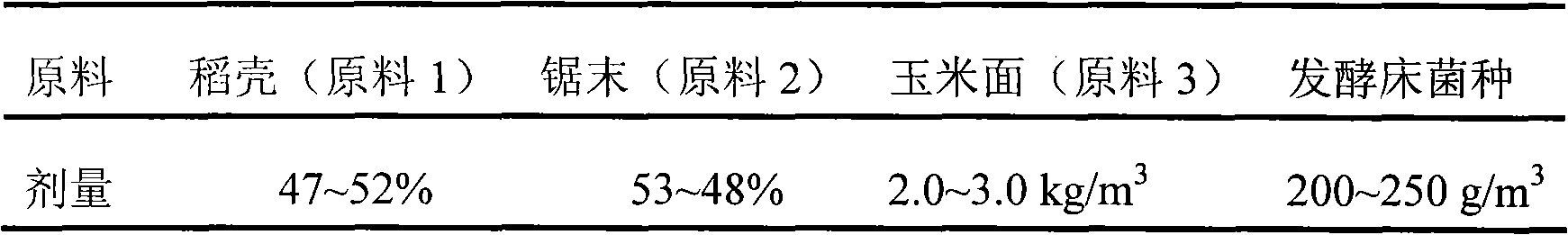

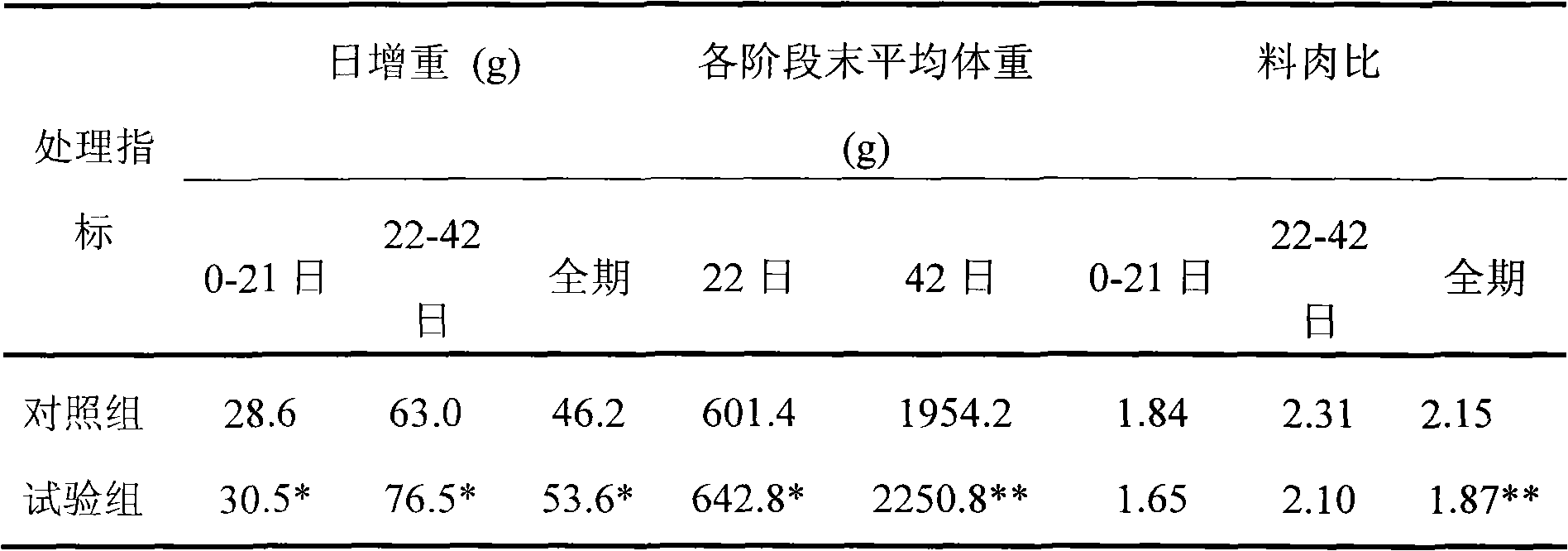

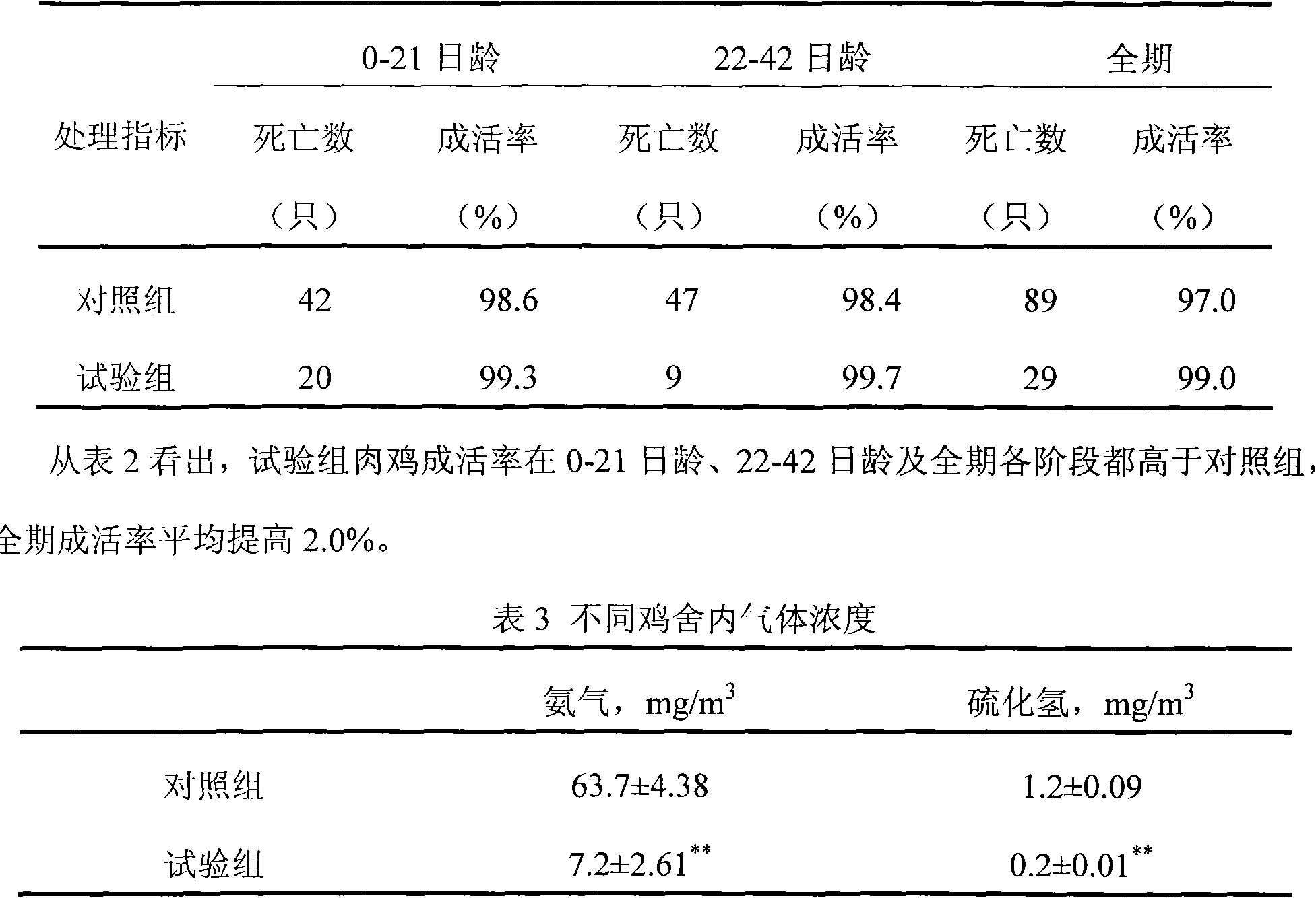

The invention discloses a water and energy saving domestic animal fermentation bed and a preparation method thereof. The fermentation bed is prepared from the following materials; material 1: rice husk or peanut shell or the like; material 2: sawdust or wood shavings or the like; and material 3: corn flour or rice bran or the like and fermentation bed strains. The method is as follows: firstly mixing the material 3 with the fermentation bed strains, laying the material 2 on the ground, laying the mixture of the material 3 and the fermentation bed strains on the material 1, then laying the material 1 on the mixture of the material 3 and the fermentation bed strains, and finally mixing the materials. The thickness of the padding of the fermentation bed is 20-40cm. The invention takes the physiological habits of poulards, meat ducks, broiler breeders, egg breeders, meat type breeding ducks and pigs into full consideration, reduces the thickness of the padding of the conventional fermentation bed and the cost of the padding of the fermentation bed and relieves the heat stress in summer; the padding is thoroughly mixed with the fermentation bed strains; the fermentation bed improves the dung degradation effect; the dung of the domestic animals is unnecessary to be added and pre-accumulated for fermentation, thus saving water and energy; and the operation is simple. The fermentation bed and the preparation method thereof are suitable for chickens, ducks and pigs and the application range is expanded.

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI

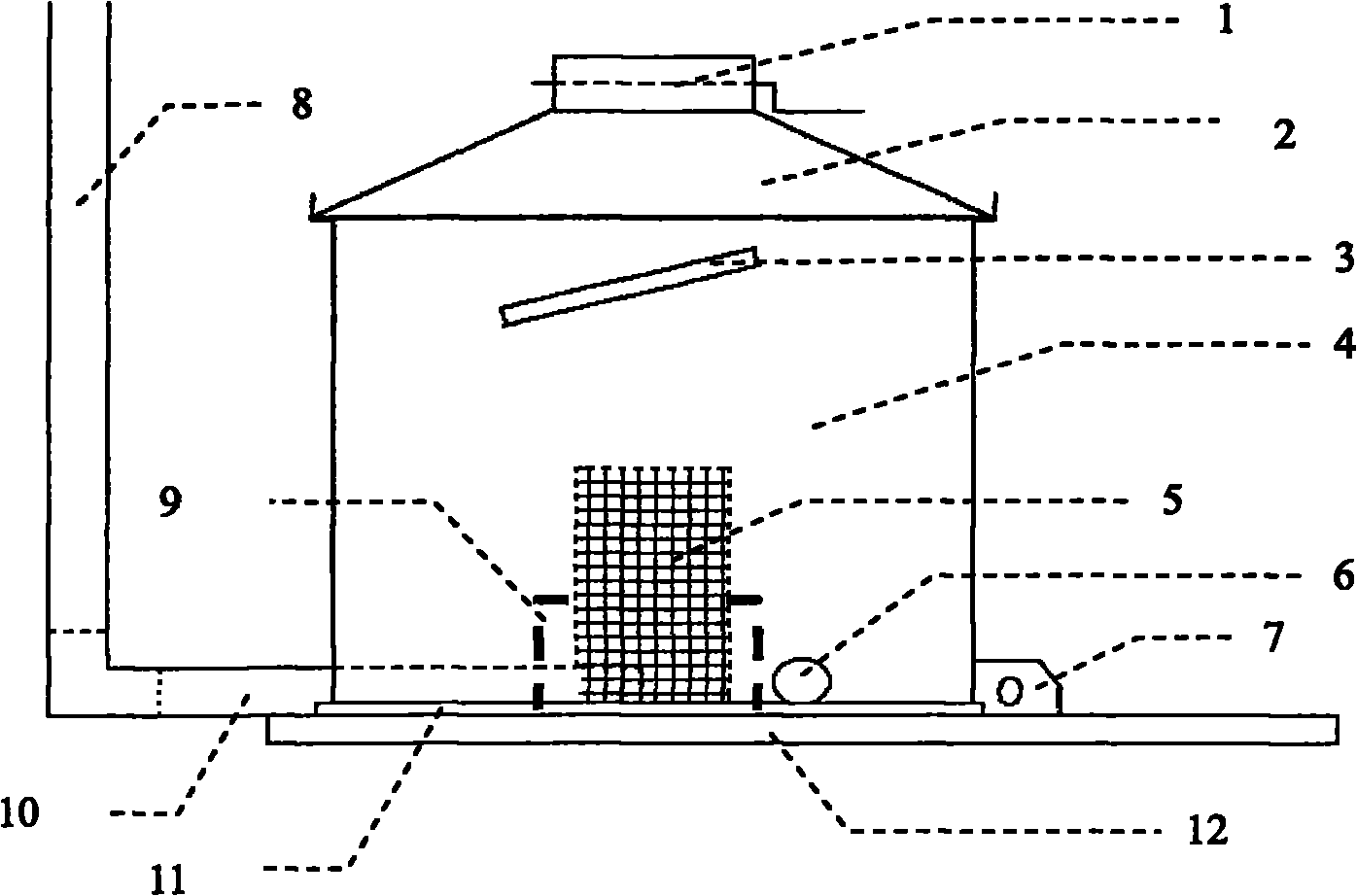

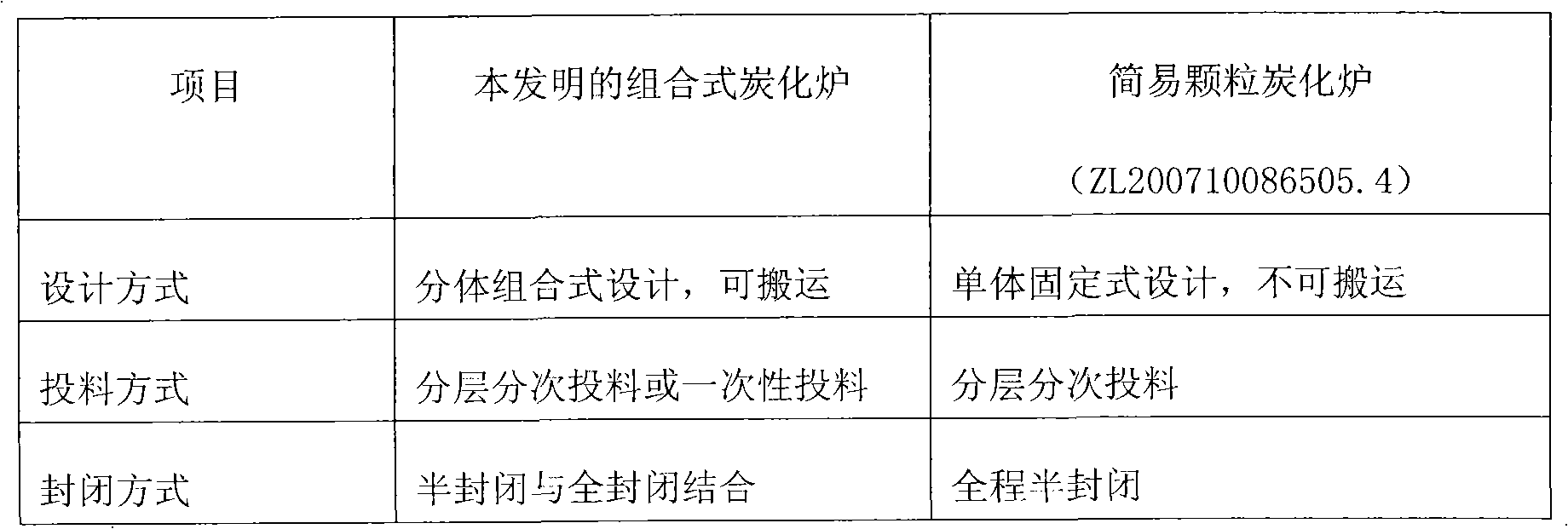

Combined biomass particle carbonization furnace and carbonizing method thereof

The invention relates to the field of agricultural machinery, in particular to a combined carbonization furnace which utilizes agricultural and forestry residue biomass particles to produce biomass carbon particles, and a carbonizing method thereof. The carbonization furnace contains a furnace body, a top cover, a burner, a swing door, a transverse exhaust pipe and a longitudinal exhaust pipe, wherein each component adopts the split-type design and the components are combined for use. The invention also provides a method which uses agricultural and forestry residue biomass as raw material and adopts the carbonization furnace to prepare biochar. The method comprises the following steps: selecting materials, processing the materials, assembling the furnace body, igniting the materials, filling the materials in the furnace, closing the cover, banking, etc. The agricultural and forestry residue biomass refers to corn stalks, corn cobs, peanut hulls, rice hulls, straws, waste edible mushroom medium for production or other wastes.

Owner:沈阳隆泰生物工程有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com