Production process of natural gas by using paddy hull

A production process, natural gas technology, applied in the field of natural gas production using biological materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

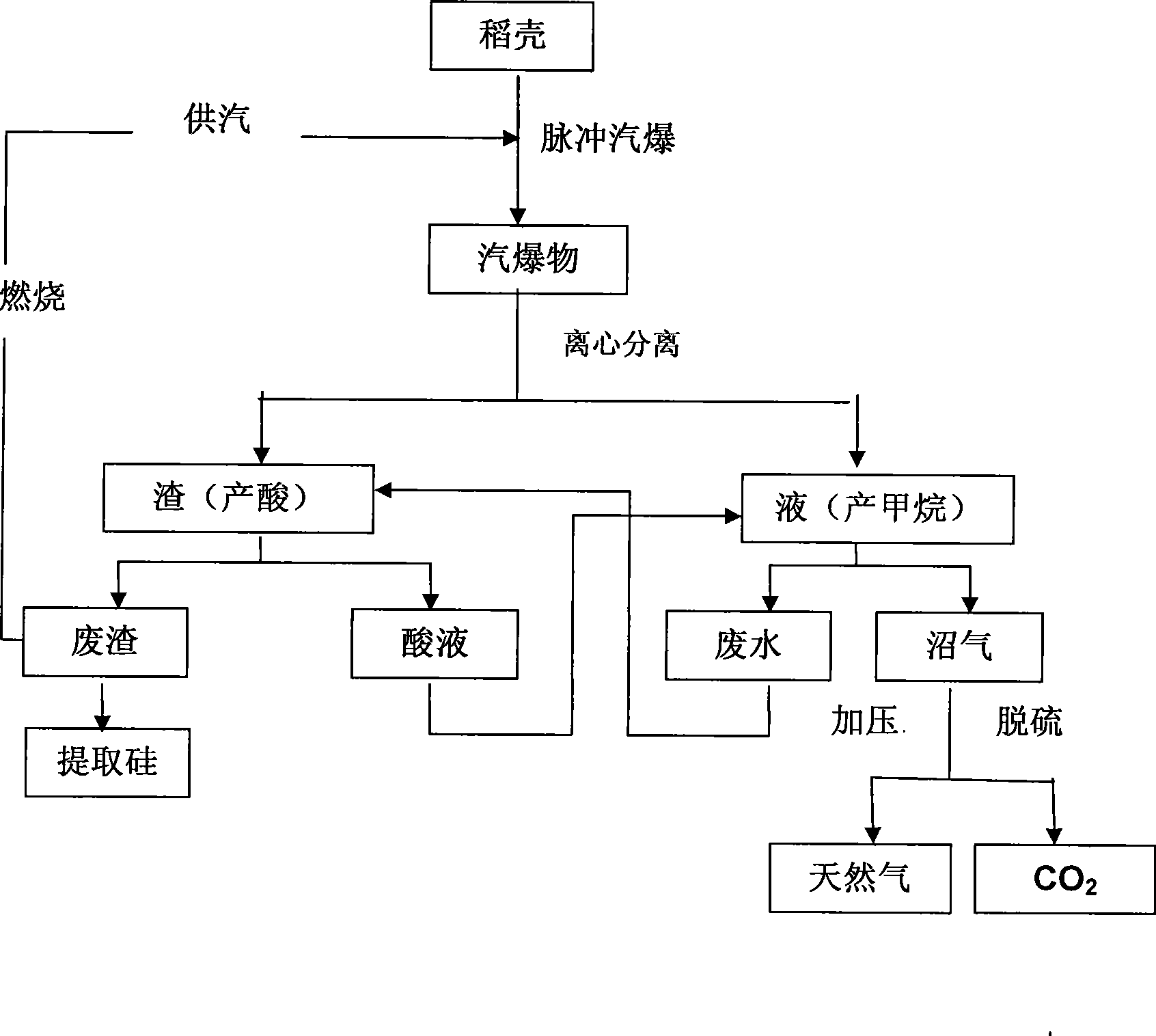

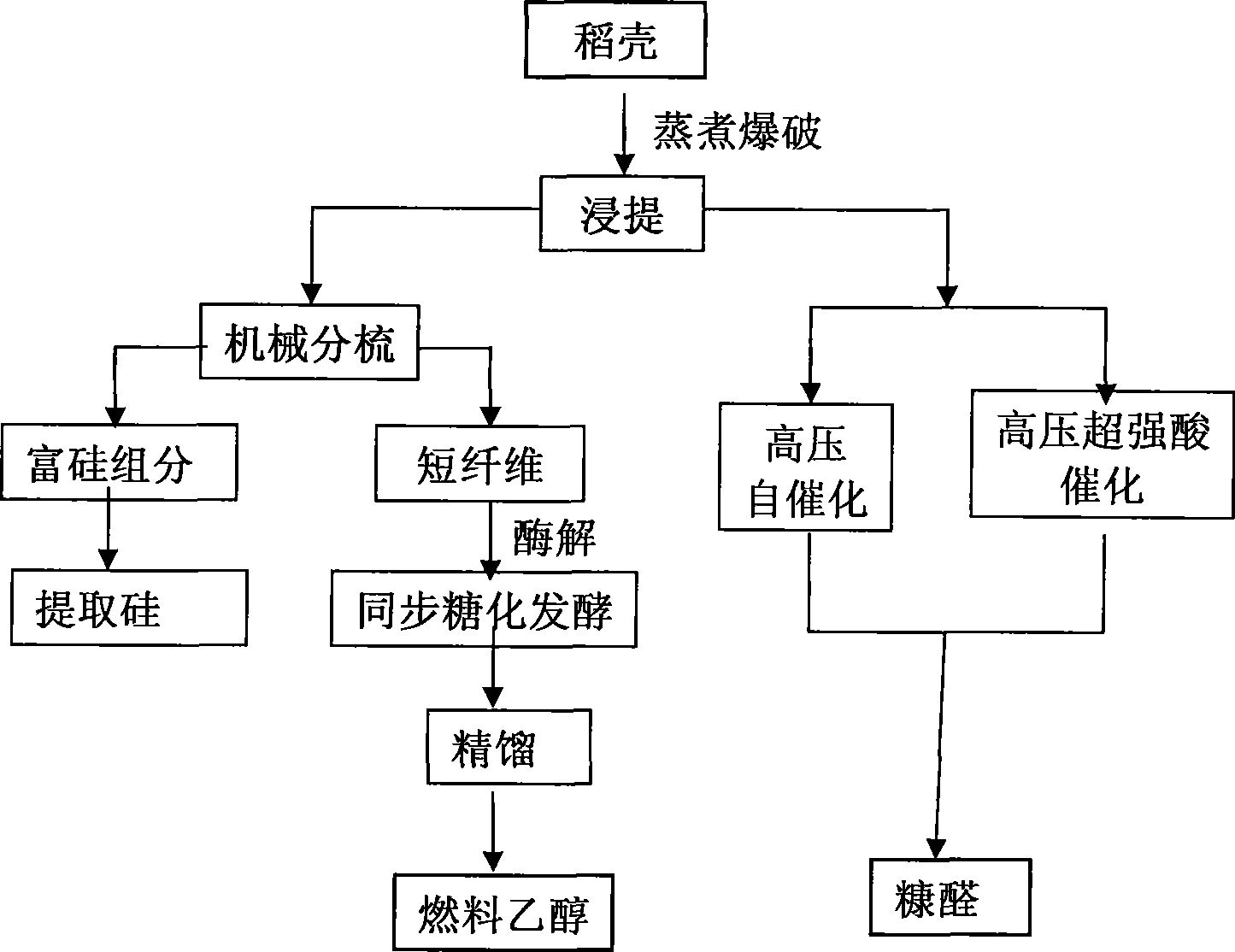

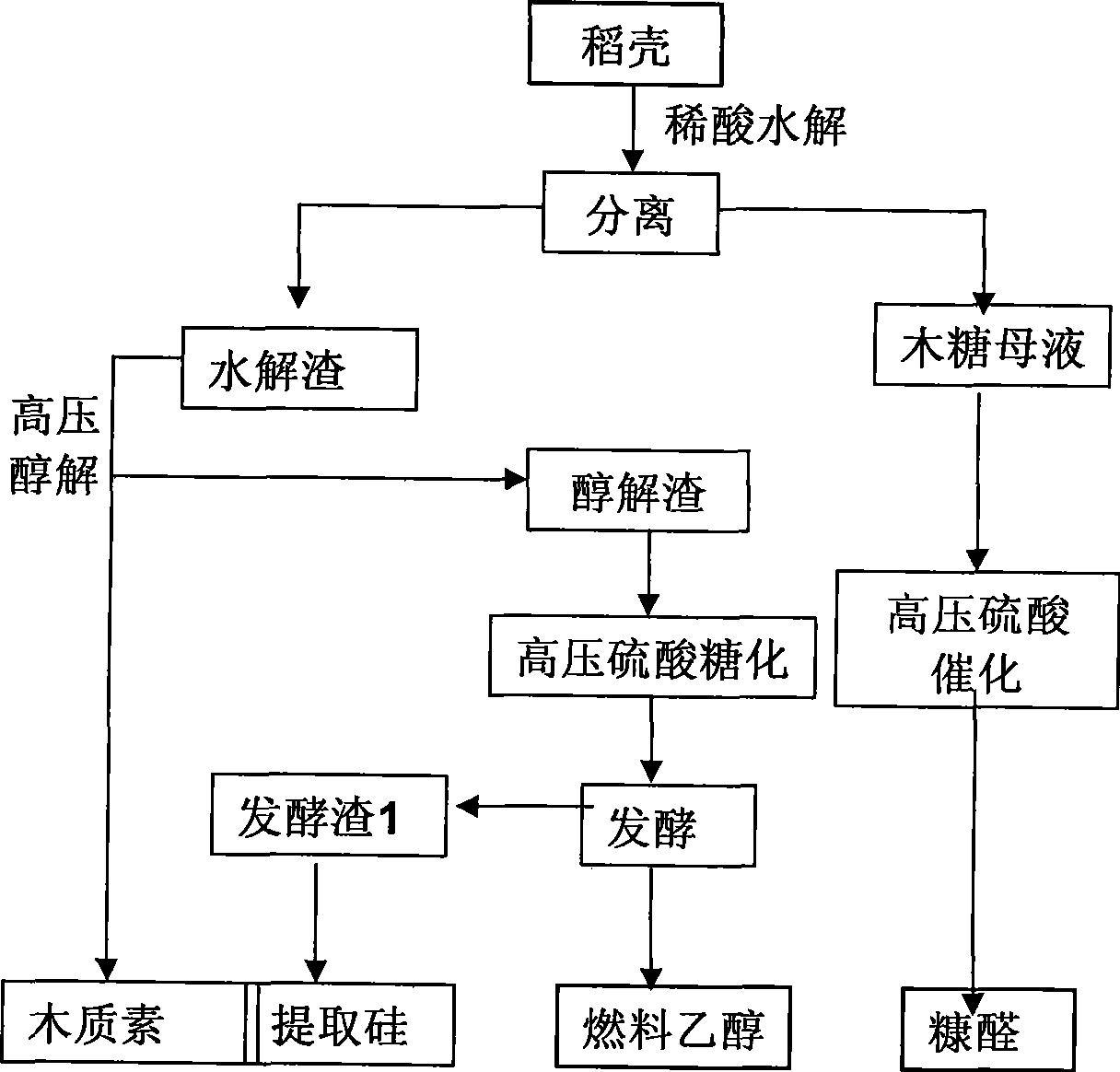

Method used

Image

Examples

Embodiment 1

[0055] Purchase rice husks from the grain processing factory in Yu'an District, Lu'an City. Its moisture content is about 11%, and its main components are 15% hemicellulose, 35% cellulose, 20% lignin, 18% silica and 12% husk. other ingredients;

[0056] Get 100kg of rice husks, hold the pressure for 180 seconds under the pressure of 1.5MPa, carry out steam explosion in the pulse steam explosion machine, the steam explosion pulse time is 0.00875 seconds, and the pH value of the obtained steam explosion material is 5.5;

[0057] According to the water ratio of 1:5 by weight, add water to the steamed substance for leaching, fully stir, and the leaching time is 10 minutes at room temperature to obtain the leaching substance, and centrifuge the leaching substance to obtain a solid phase and a liquid phase. ;

[0058] Transfer the solid phase to the acid producing tank, add 1:3 water and acid producing bacteria (10%), stir evenly, seal it to produce acid, keep the pH value of the a...

Embodiment 2

[0063] Take 100kg of rice husks and hold the pressure at 2.5MPa for 90s before performing pulse steam explosion. The pulse time of steam explosion is 0.008 seconds, and the resulting pH value is 4.0. Other treatments are the same as in Example 1. The liquid phase starts to produce gas after 12 hours of anaerobic fermentation. The initial daily gas production is 70-90L, and the daily gas production will increase every day. The peak of gas production is from the 7th to the 15th day, and the daily gas production is 2.5m 3 between, and then decrease day by day. After about 10 days, the acid production ended, and the gas production ended in about 30 days, with a total gas production of about 33.2m 3 , The composition of rice husk natural gas is 78.5% methane, 18.2% carbon dioxide, and the rest is impurity gas.

Embodiment 3

[0065] Take 100kg of rice husks and hold the pressure at 4.0MPa for 20s to perform pulse steam explosion. The steam explosion pulse time is 0.006 seconds, and the resulting pH value is 3.5. Other treatments are the same as in Example 1. The liquid phase starts to produce gas after 12 hours of anaerobic fermentation, and the initial daily gas production is 45-50L, and gradually increases every day thereafter. On the 15th-25th day, the daily gas production is 1.0-1.6m 3 After that, it will decrease day by day, and the gas production will end in about 36 days, with a total gas production of about 22.7m 3 , The composition of rice husk natural gas is 72.3% methane, 22.8% carbon dioxide, and the rest is impurity gas. The specific experimental data are shown in the table below.

[0066] Table 2 Data comparison table of three examples

[0067]

[0068]

[0069] According to the above examples, it can be seen that within the range of steam explosion pressure of 1.5MP-4MP and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com