Patents

Literature

31results about How to "Improve bone formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porous composite containing calcium phosphate and process for producing the same

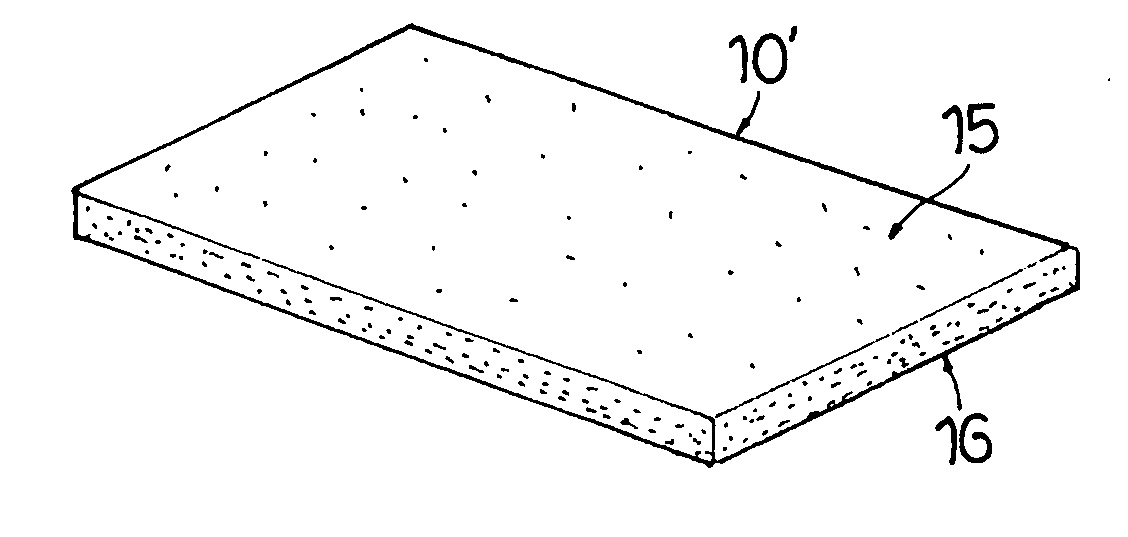

ActiveUS20060292350A1Small apertureImprove thermal conductivityImpression capsSynthetic resin layered productsLinking collagenCalcium biphosphate

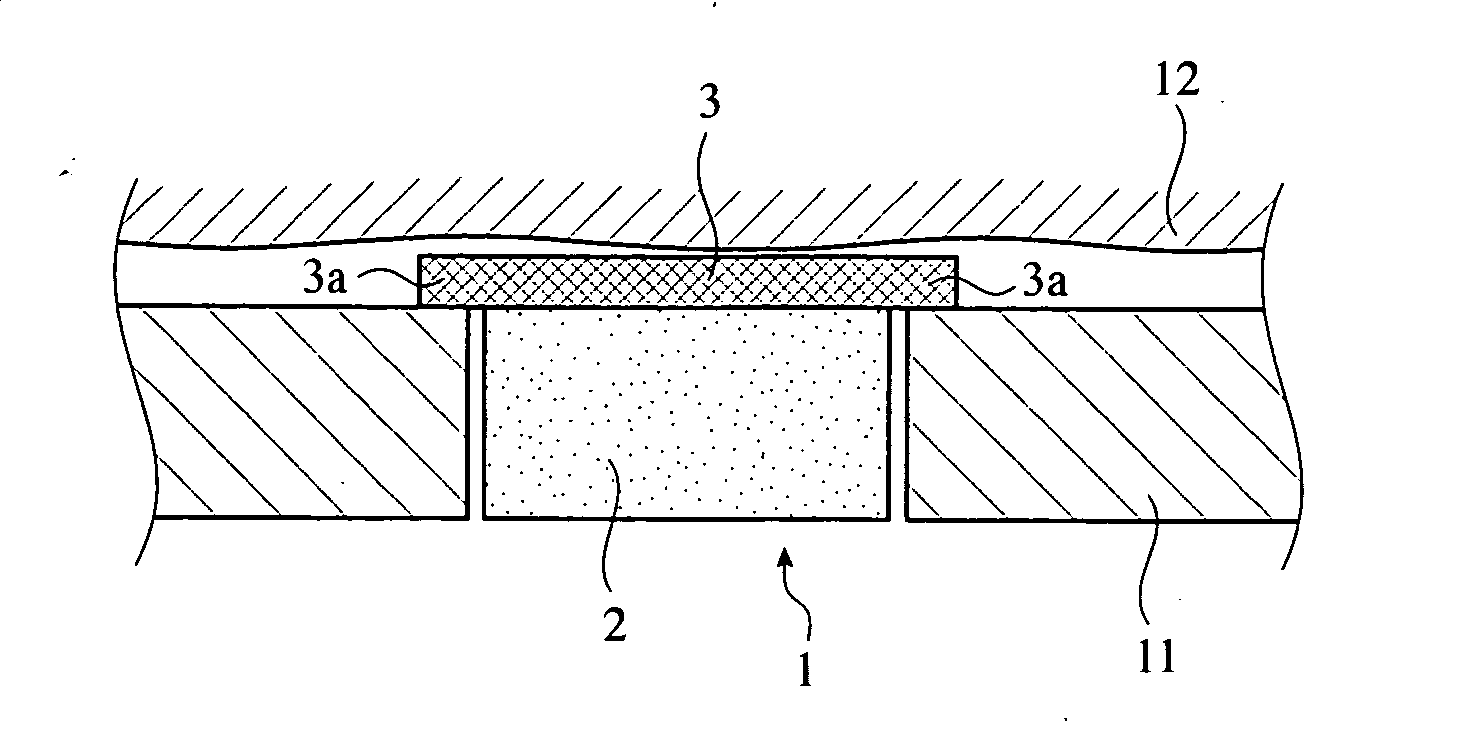

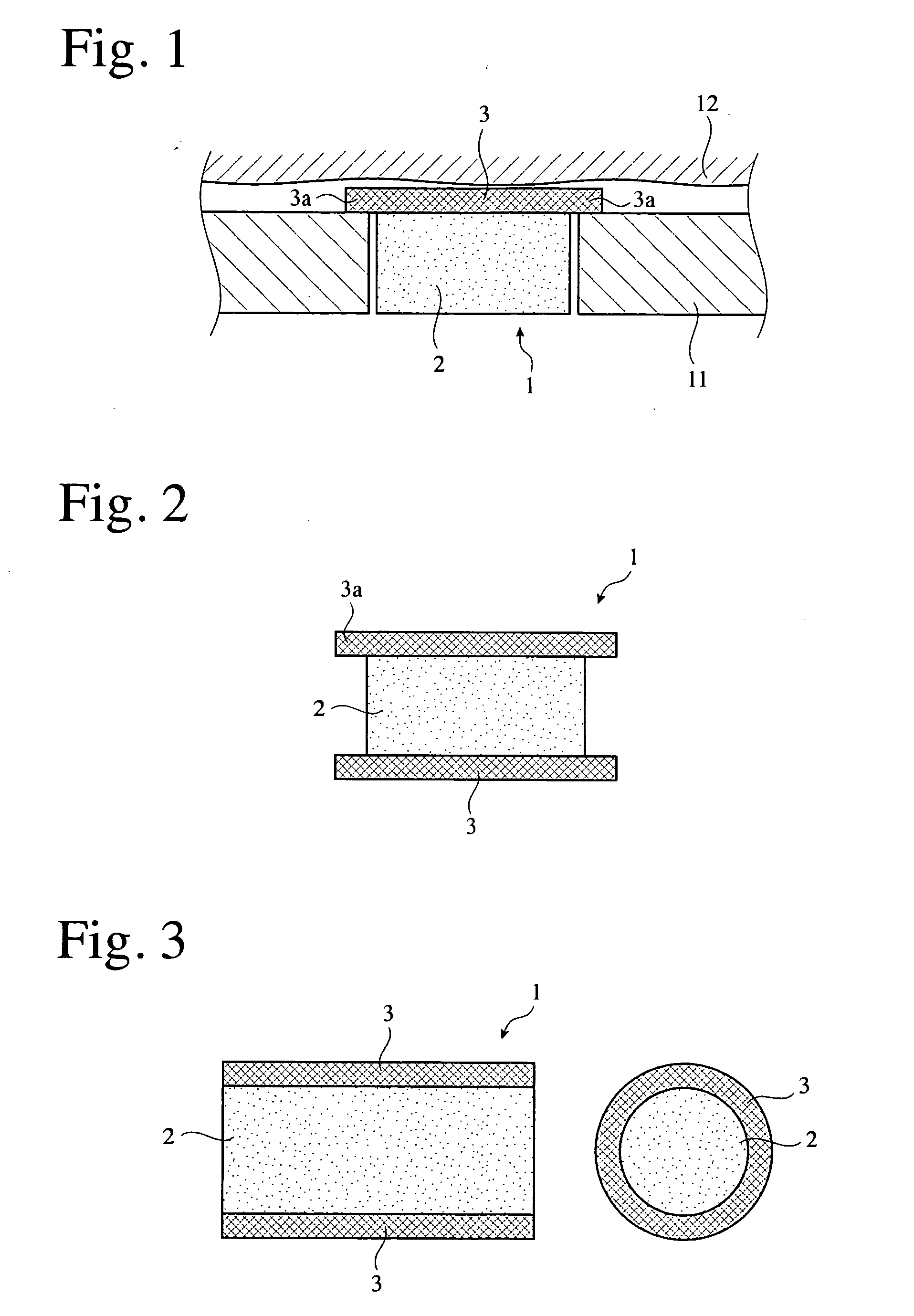

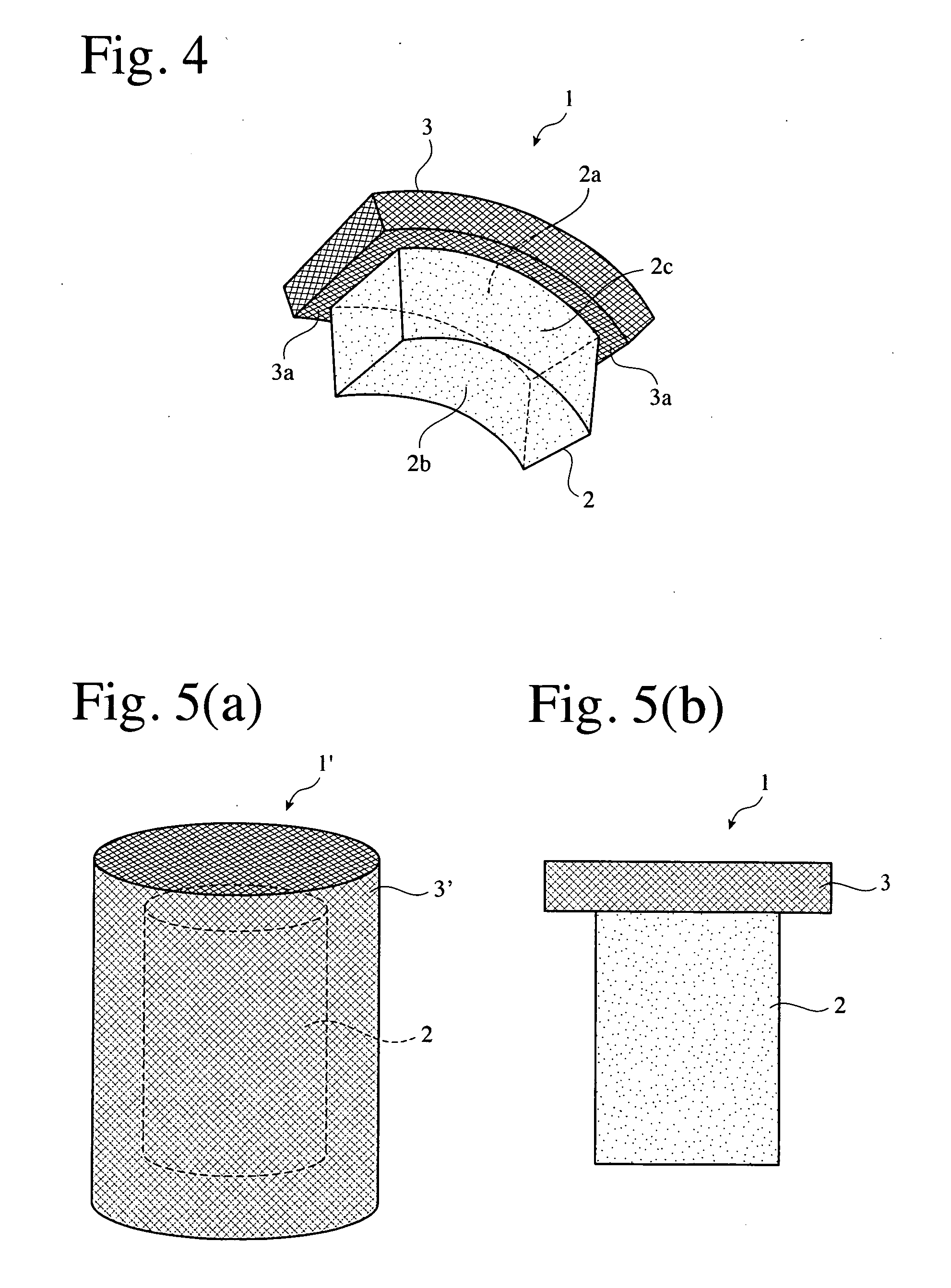

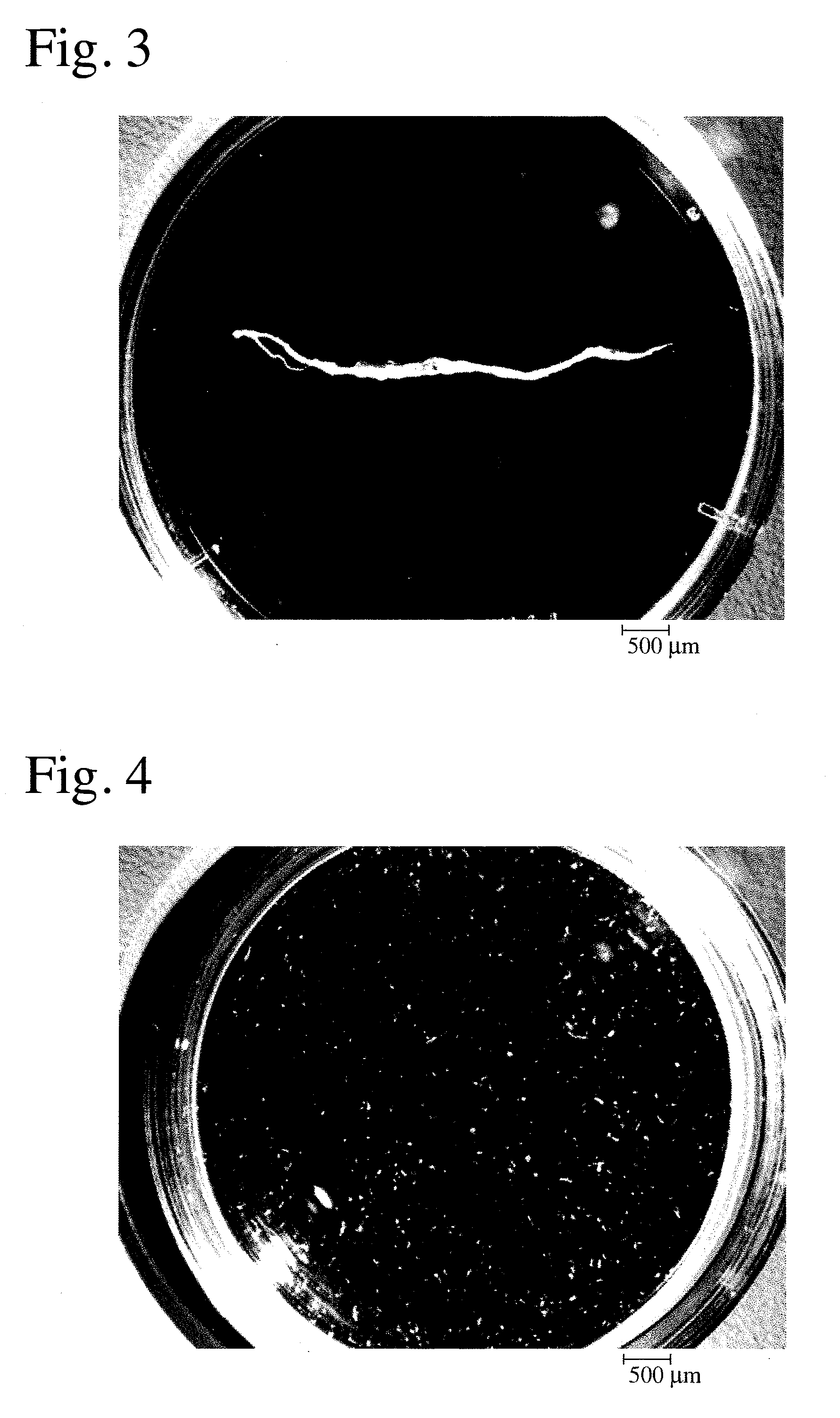

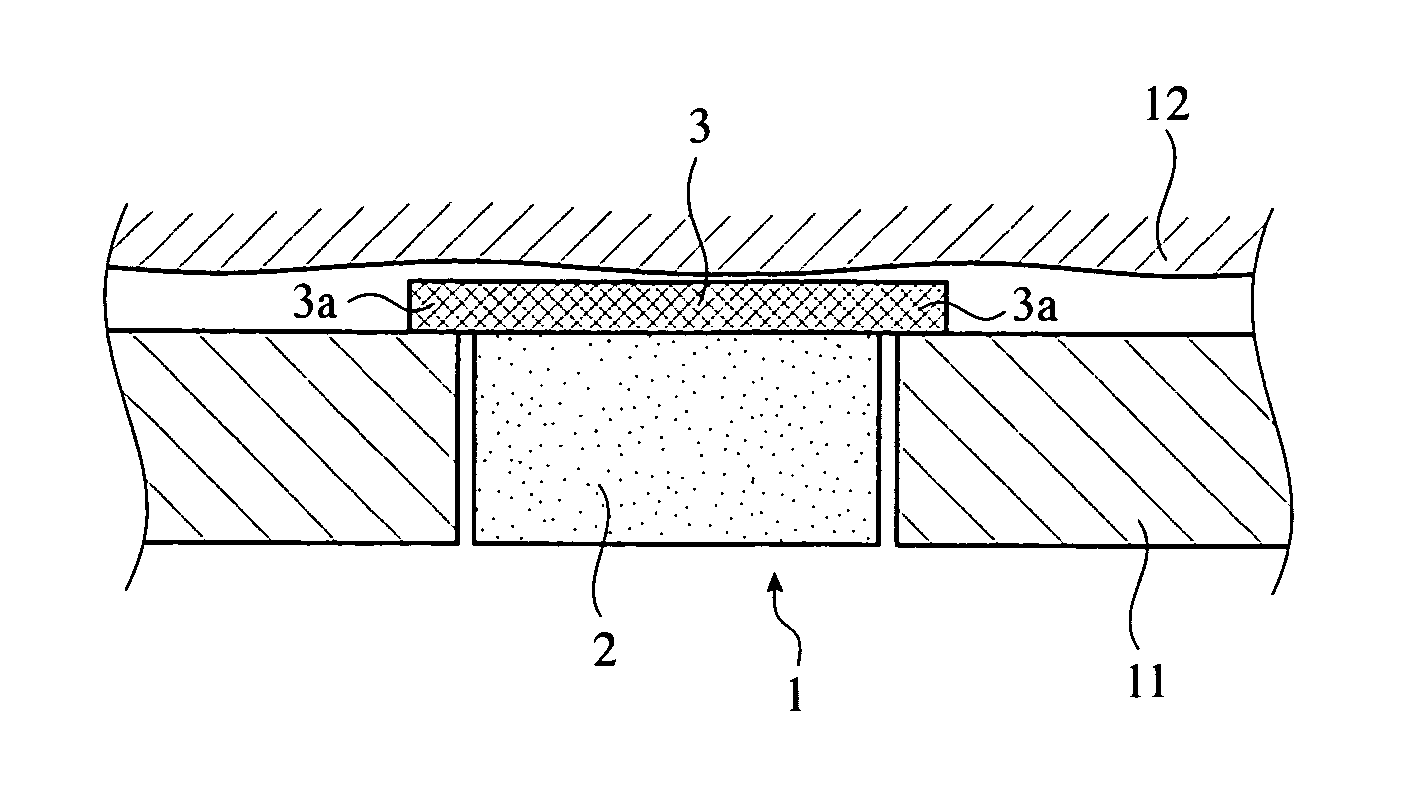

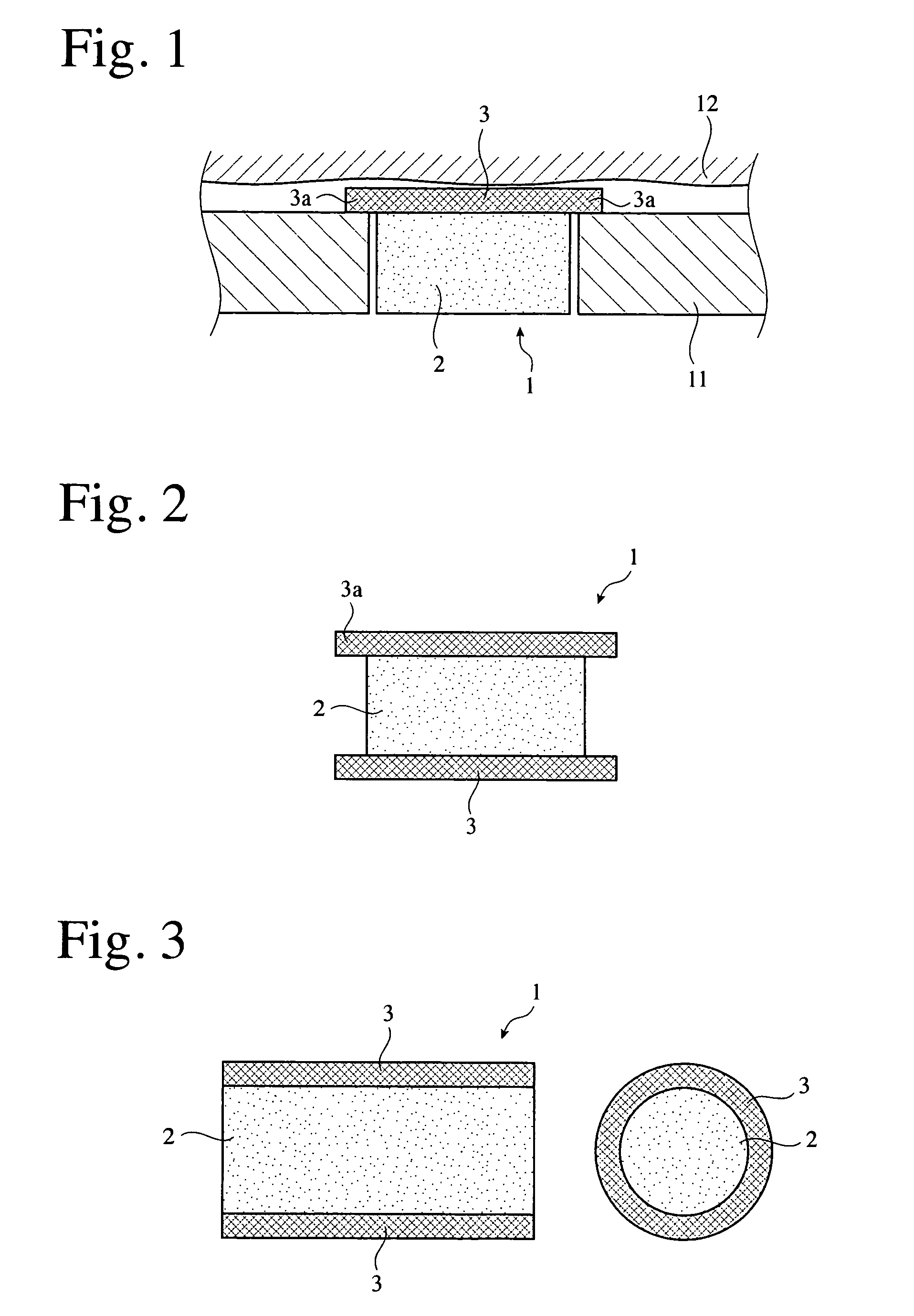

A porous composite comprising a porous layer containing a calcium phosphate ceramic, and a dense layer formed on part of the porous layer and having a smaller average pore size than that of the porous layer. The porous composite can be produced by (1) introducing a slurry containing a calcium phosphate ceramic / collagen composite and collagen into a molding die having a high thermal conductivity, (2) rapidly freezing and drying the slurry in the molding die, to form a porous body comprising a porous layer and a dense layer formed on the porous layer, (3) cross-linking collagen in the porous body, and (4) removing the dense layer except for a portion thereof on a surface coming into contact with a soft tissue when implanted in a human body, so that the porous layer is exposed.

Owner:NAT INST FOR MATERIALS SCI +1

Bone grafting material, method and implant

InactiveUS20050201987A1Broaden the formation processImprove bone formationBiocideTissue regenerationBone graftingGlass-ceramic

A bone grafting material, a method of producing the same, and an implant. The bone grafting material comprises a porous carrier of ceramic or glass ceramic or glass material and at least one pyrrolidone arranged in the carrier.

Owner:INION

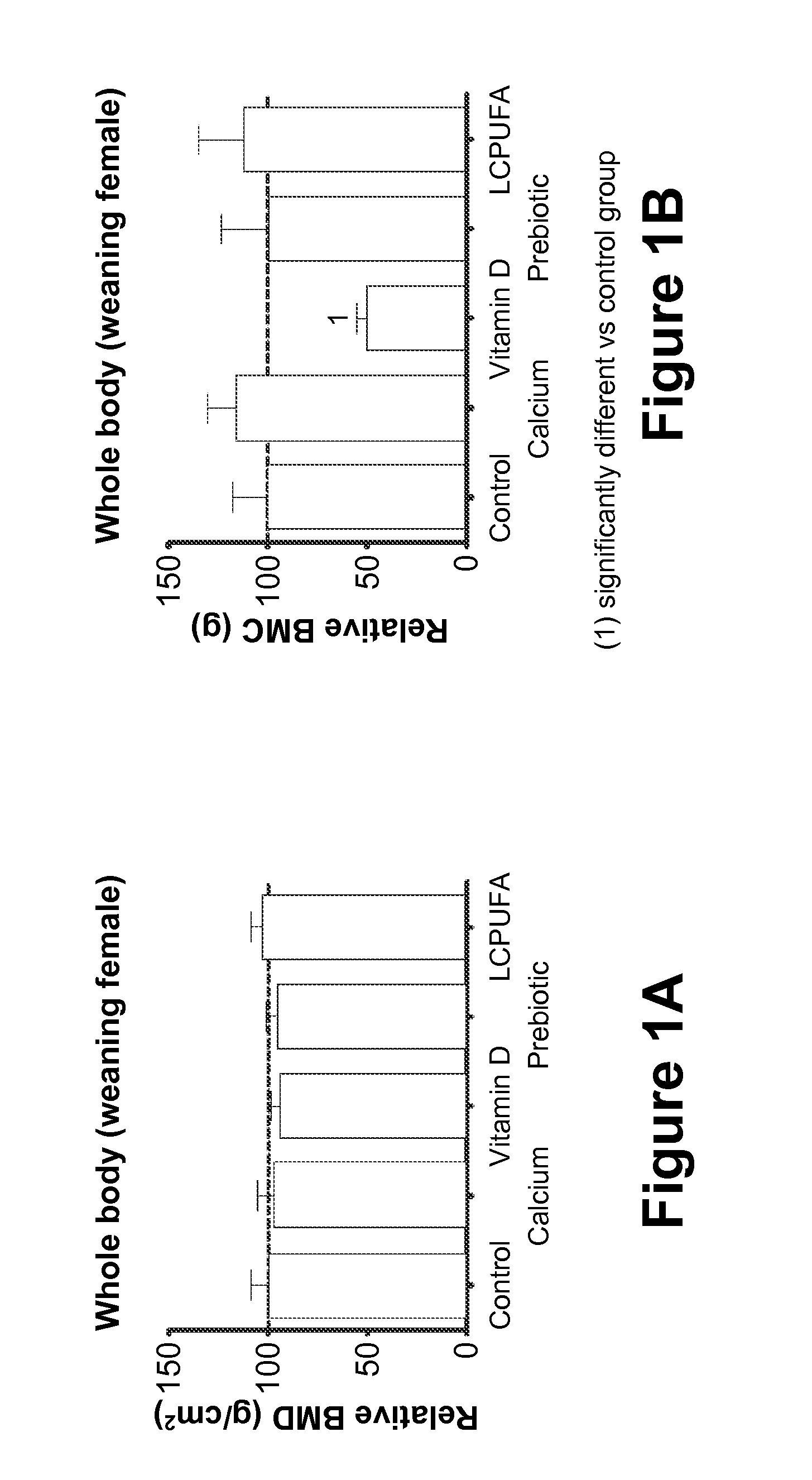

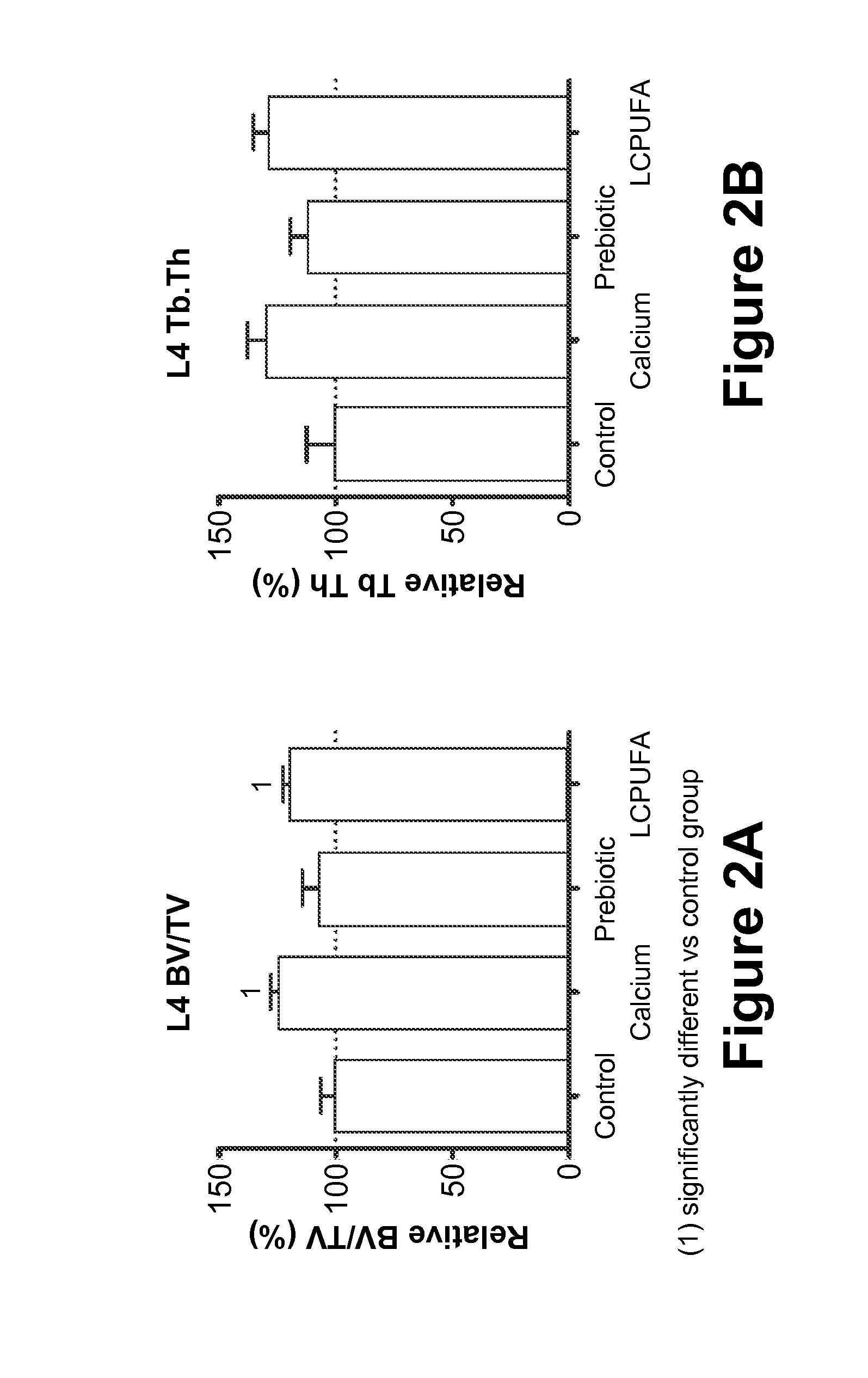

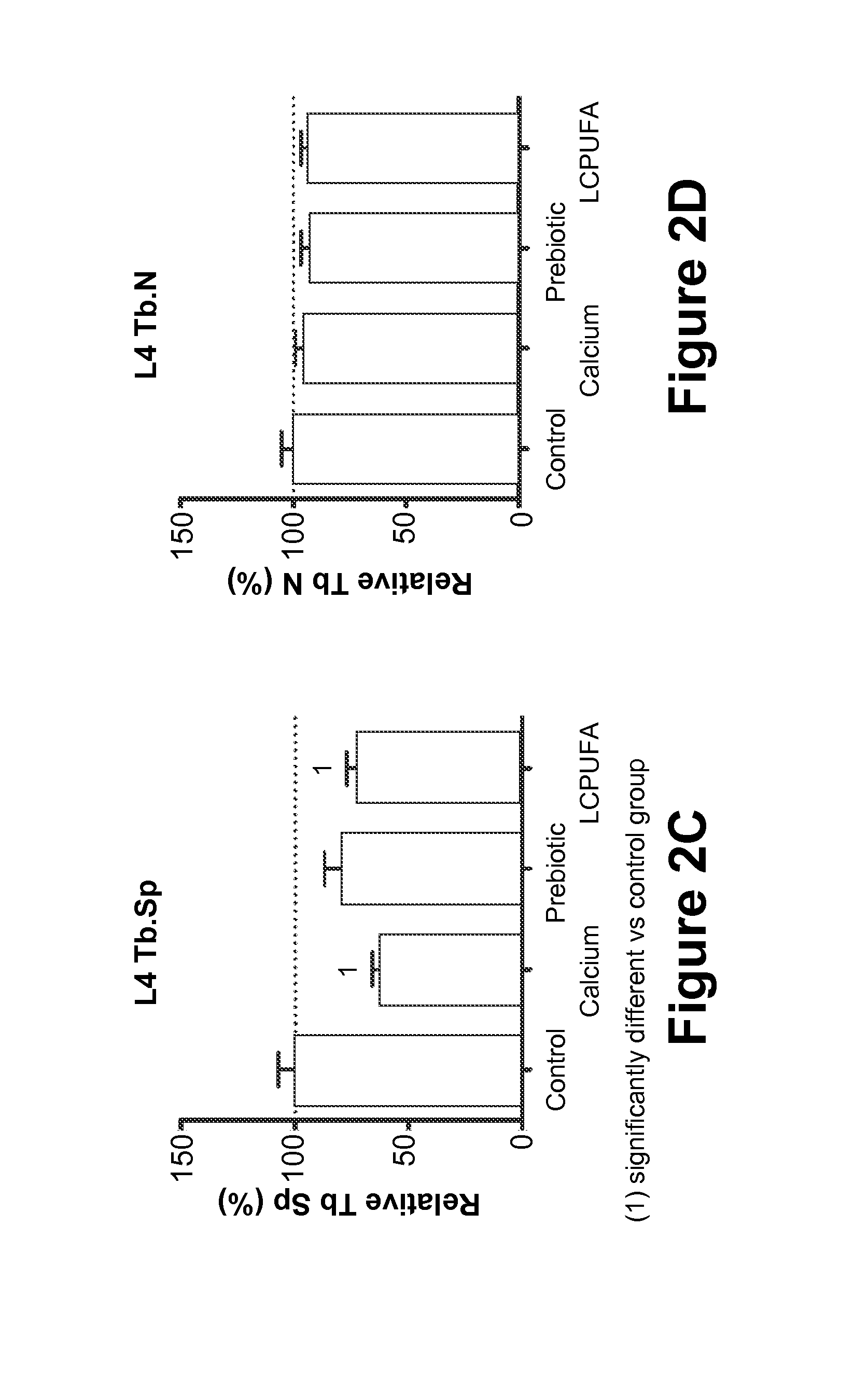

Methods for improving bone health in infants using long chain polyunsaturated fatty acids

InactiveUS20120245121A1Improved bone health bone boneImprove bone strengthBiocideVitamin food ingredientsBreastfeedingBone health

Disclosed are methods for improving bone health, strength and formation in an infant who may be susceptible to developing bone health issues from conception through adolescence. The methods include administration of a nutritional formulation including at least one LCPUFA to a woman during pregnancy and optionally during lactation and breastfeeding of an infant.

Owner:ABBOTT LAB INC

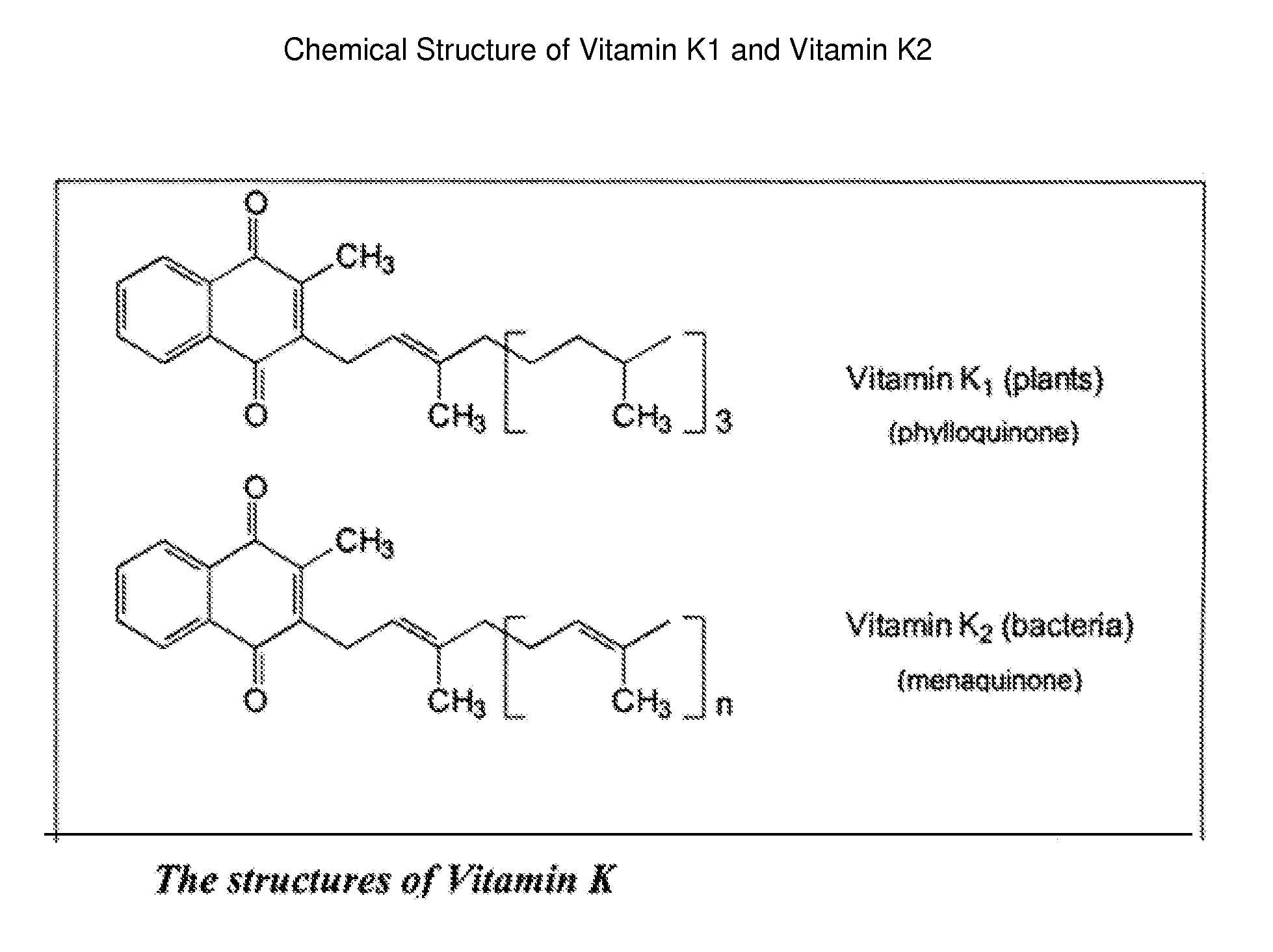

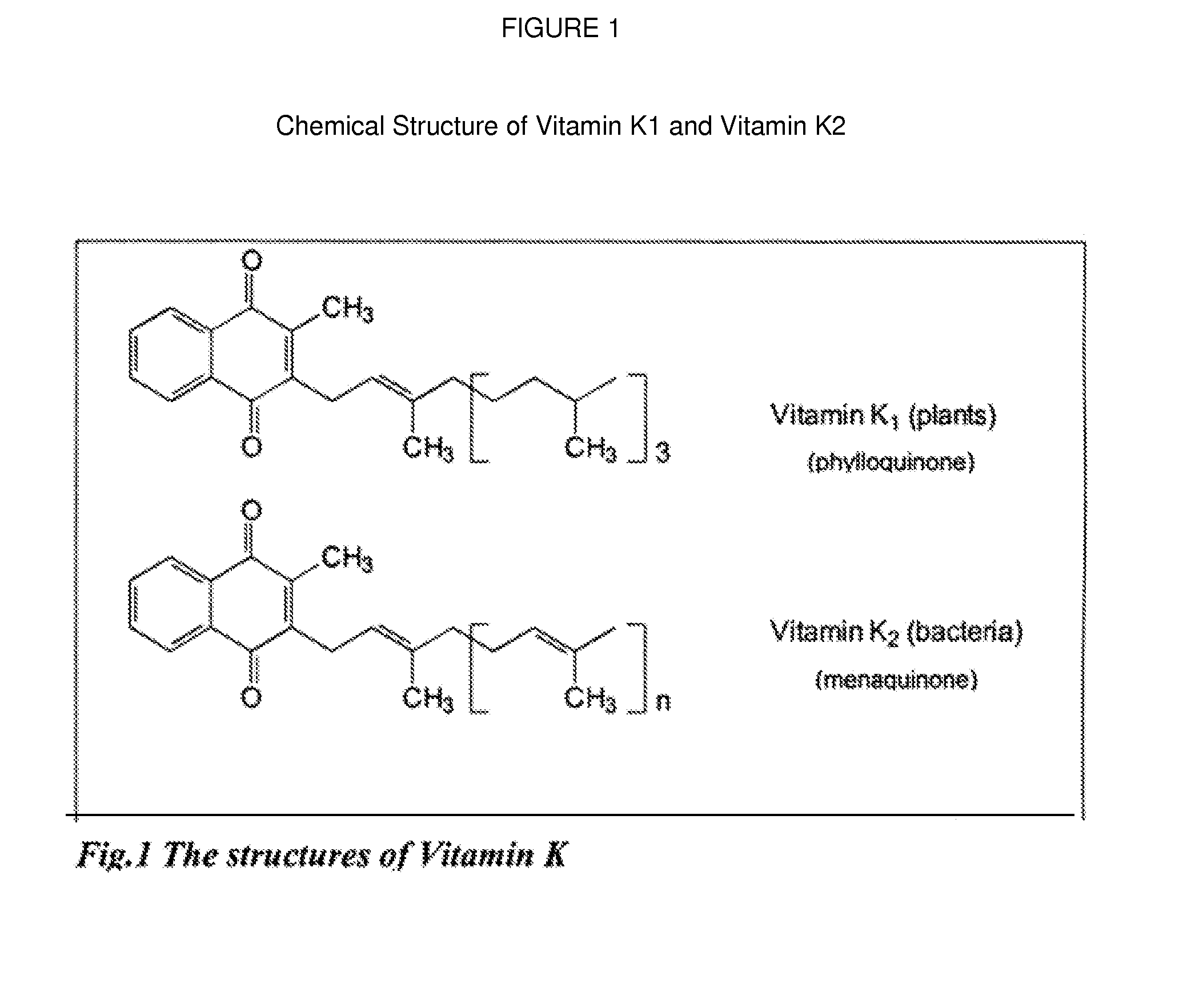

Compositions and methods for the treatment and/or prevention of osteoporosis

InactiveUS20080220094A1Prevention and reducing bone mineral density lossImprove bone formationBiocideKetone active ingredientsDysostosisBone formation

The invention of this application relates to compositions and methods for the treatment and / or prevention of osteoporosis; improving and / or enhancing bone formation; and prevention and / or reducing bone mineral density loss. More particularly, the invention relates to a composition comprising vitamin K, in any form and betacryptoxanthin. A further aspect of this invention is a composition comprising vitamin K, in any form, betacryptoxanthin, and / or vitamin D and / or calcium.

Owner:WYETH LLC

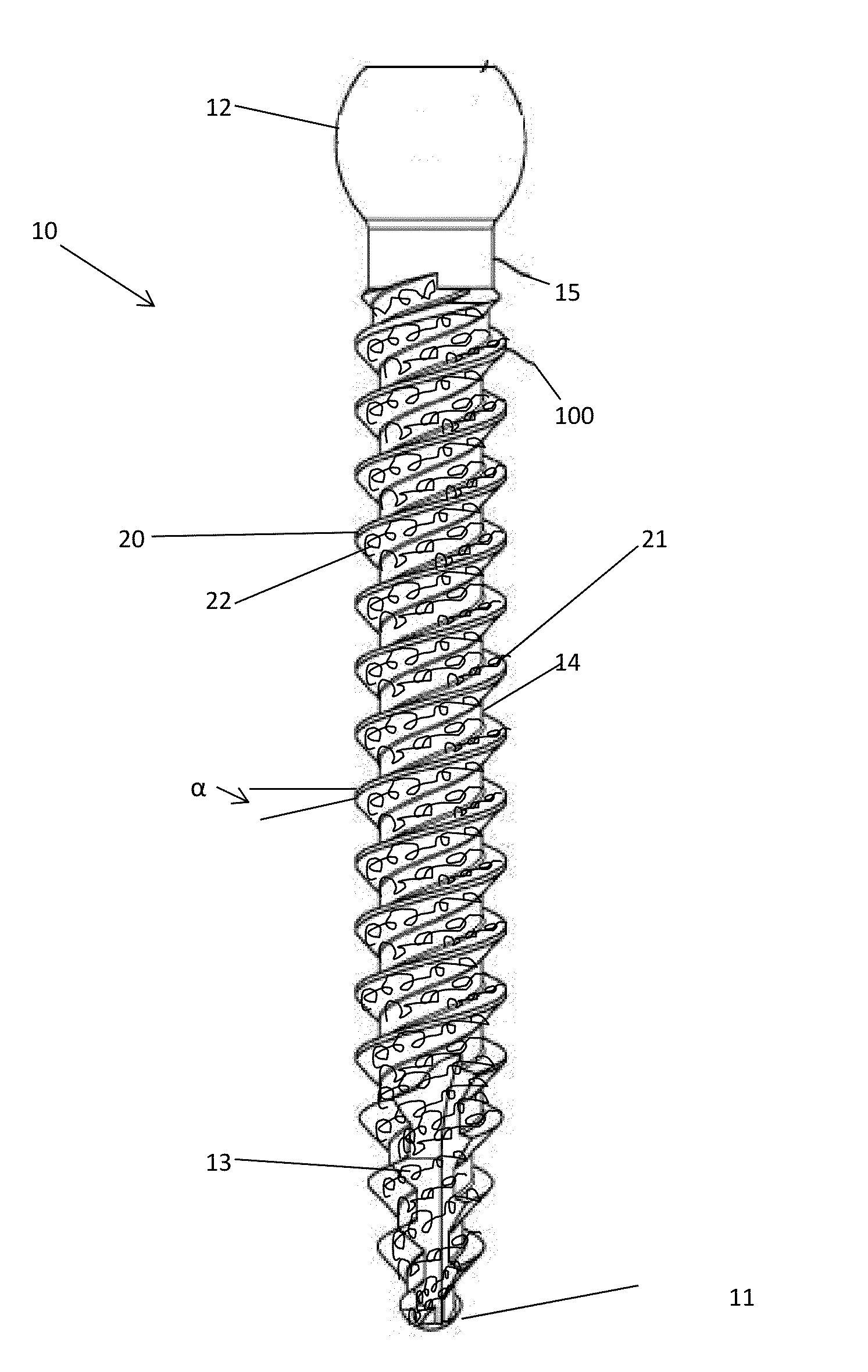

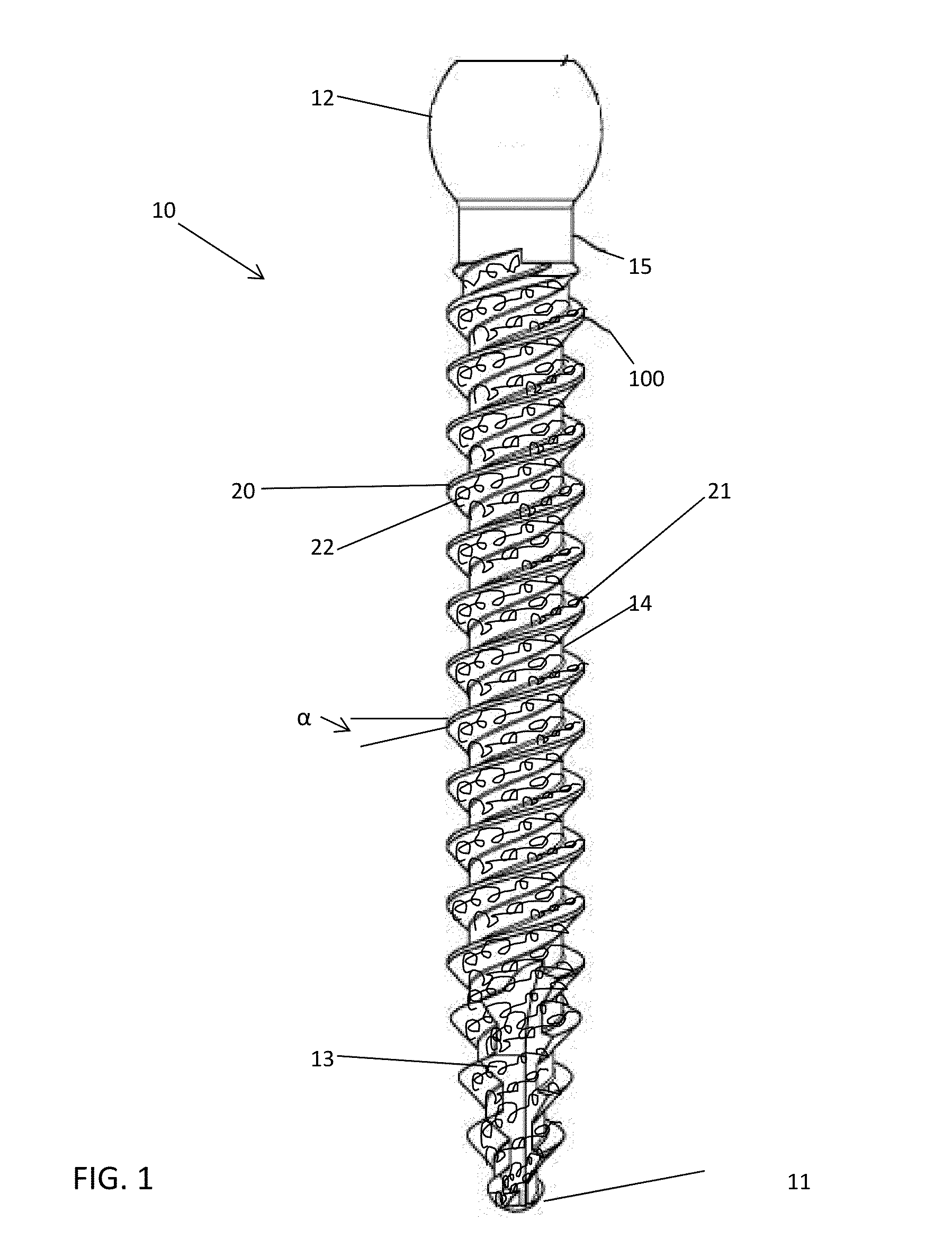

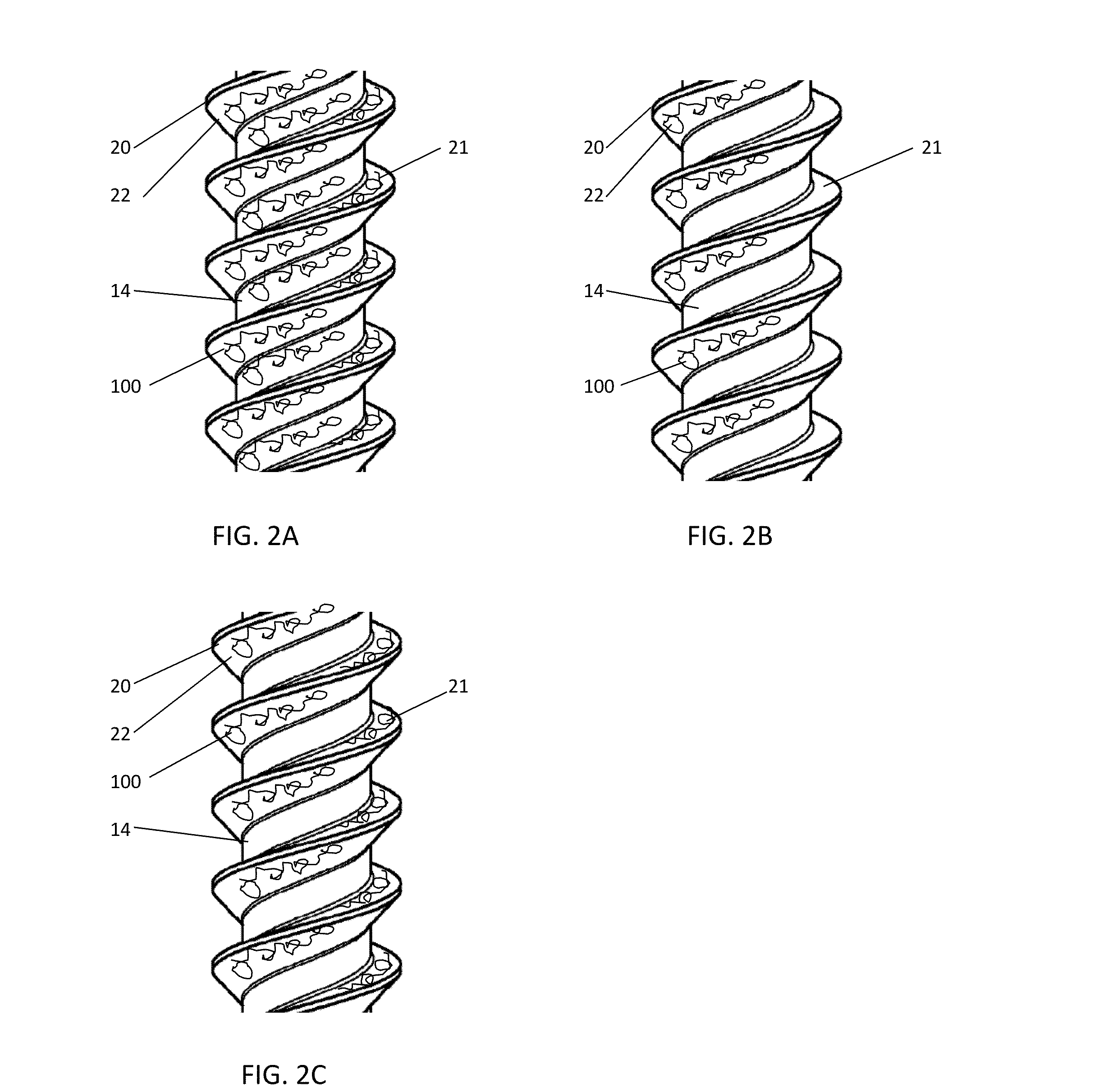

Bone screw fastener

ActiveUS20150127057A1Improve the immunityImprove bone formationSuture equipmentsDental implantsBone formationScrew thread

An improved bone screw for humans or mammals is a bone screw having exposed surfaces along a shank and threads extending from the shank with one or more selected portions of the exposed surfaces having a 3-dimensional pattern. The pattern provides enhanced resistance to thread loosening when affixed to bone. The exposed surface is on exterior portions of the threads or portions of the shank or both. The one or more selected portions of the exposed portions having a bone formation enhancing 3-dimensional patterns are in the external exposed thread surfaces or in the exposed shank surfaces or both.

Owner:BONE PHARM LLC

Method for producing porous body comprising apatite/collagen composite fibers

InactiveUS20090166580A1Improve bone formationPeptide/protein ingredientsPretreated surfacesFiberLinking collagen

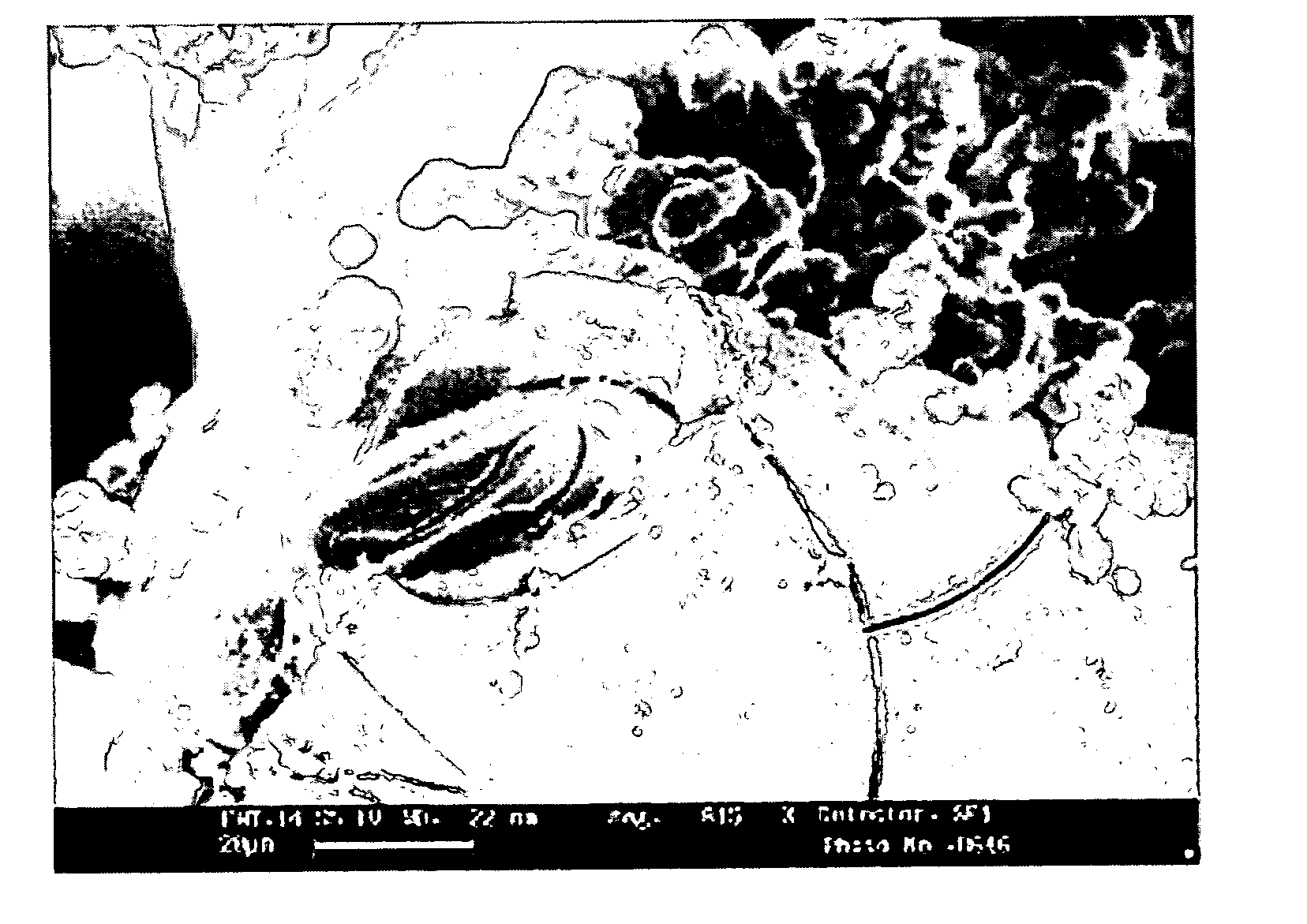

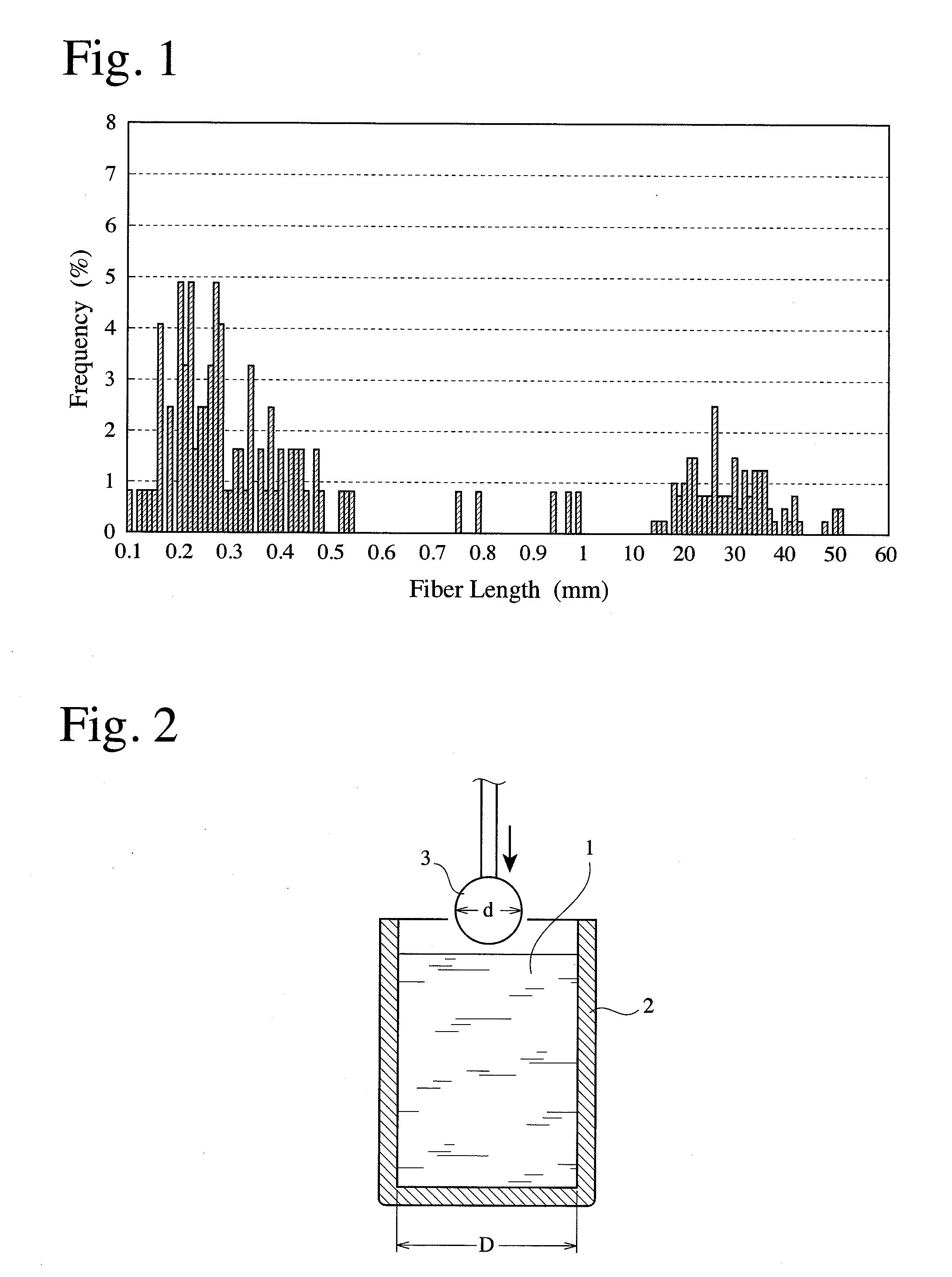

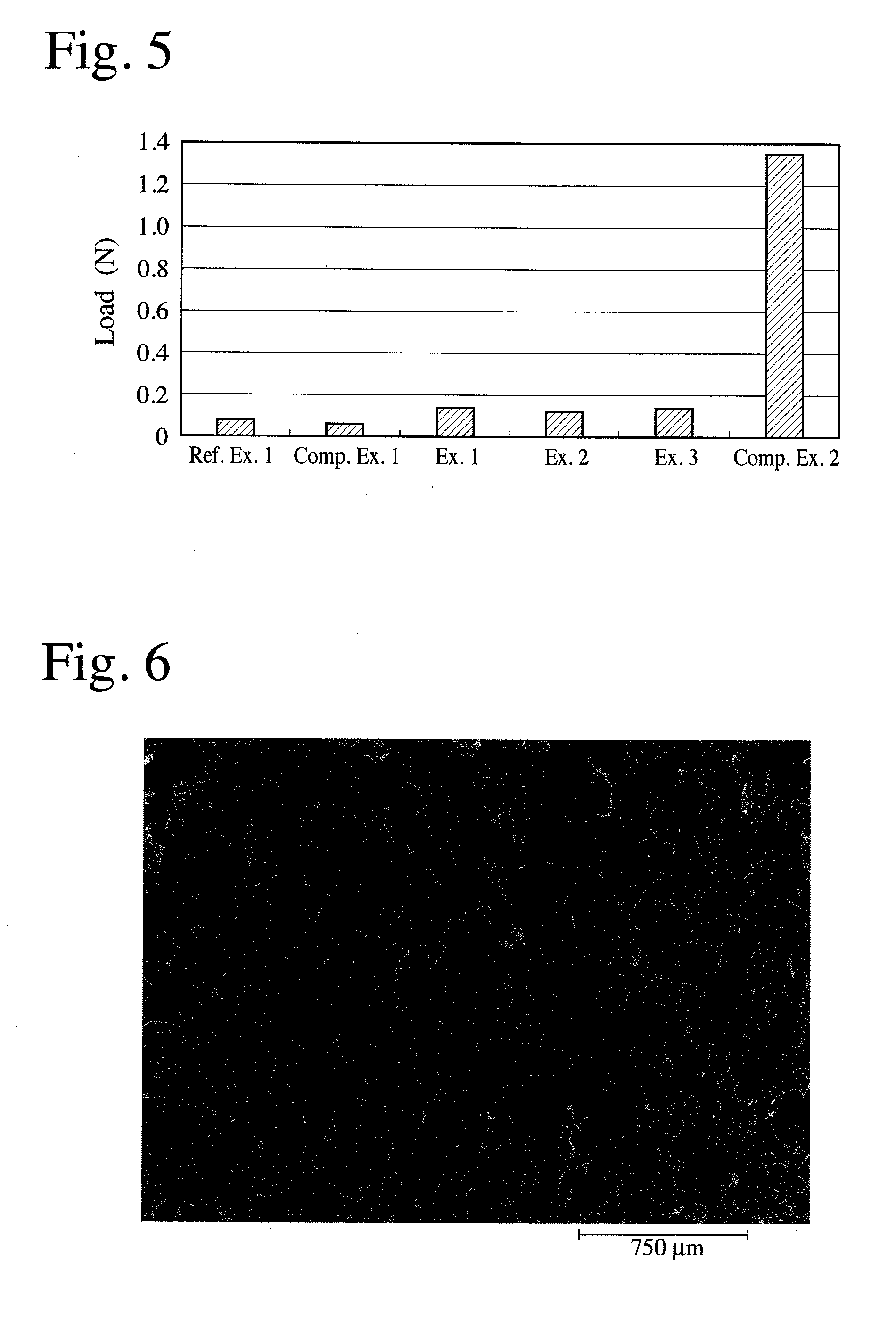

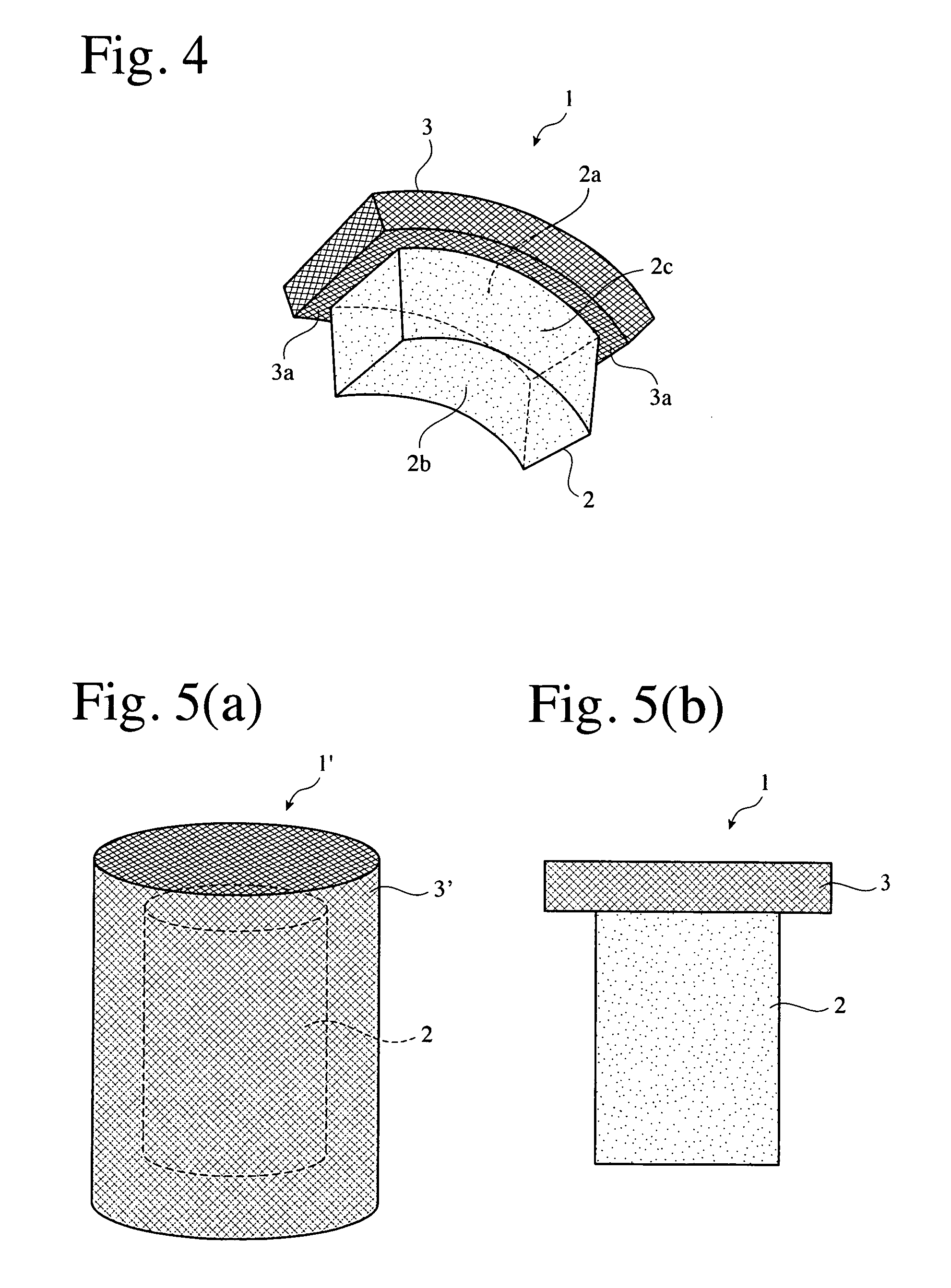

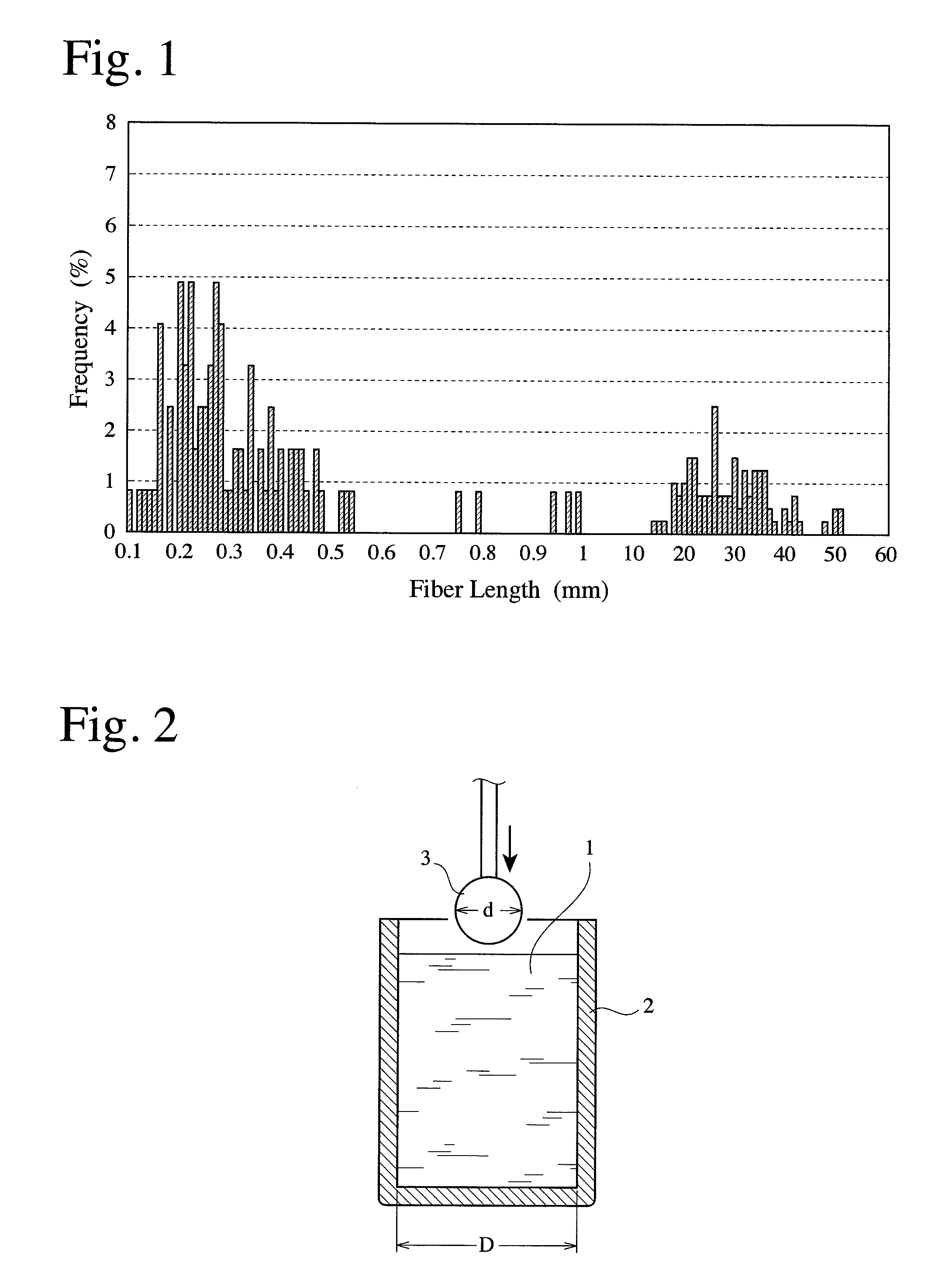

A method for producing a porous body comprising apatite / collagen composite fibers comprising the steps of gelling a dispersion comprising long apatite / collagen composite fibers having an average length of 10-75 mm, short apatite / collagen composite fibers having an average length of 0.05-1 mm, and a liquid; freezing and drying the resultant gel to form a porous body; and cross-linking collagen in the porous body.

Owner:NAT INST FOR MATERIALS SCI

Porous composite containing calcium phosphate and process for producing the same

ActiveUS8039090B2Improve bone formationInhibit growthImpression capsSynthetic resin layered productsCross-linkLinking collagen

A porous composite comprising a porous layer containing a calcium phosphate ceramic, and a dense layer formed on part of the porous layer and having a smaller average pore size than that of the porous layer. The porous composite can be produced by (1) introducing a slurry containing a calcium phosphate ceramic / collagen composite and collagen into a molding die having a high thermal conductivity, (2) rapidly freezing and drying the slurry in the molding die, to form a porous body comprising a porous layer and a dense layer formed on the porous layer, (3) cross-linking collagen in the porous body, and (4) removing the dense layer except for a portion thereof on a surface coming into contact with a soft tissue when implanted in a human body, so that the porous layer is exposed.

Owner:NAT INST FOR MATERIALS SCI +1

Method for producing porous body comprising apatite/collagen composite fibers

InactiveUS7732573B2Improve bone formationPeptide/protein ingredientsPretreated surfacesFiberCross-link

A method for producing a porous body comprising apatite / collagen composite fibers comprising the steps of gelling a dispersion comprising long apatite / collagen composite fibers having an average length of 10-75 mm, short apatite / collagen composite fibers having an average length of 0.05-1 mm, and a liquid; freezing and drying the resultant gel to form a porous body; and cross-linking collagen in the porous body.

Owner:NAT INST FOR MATERIALS SCI

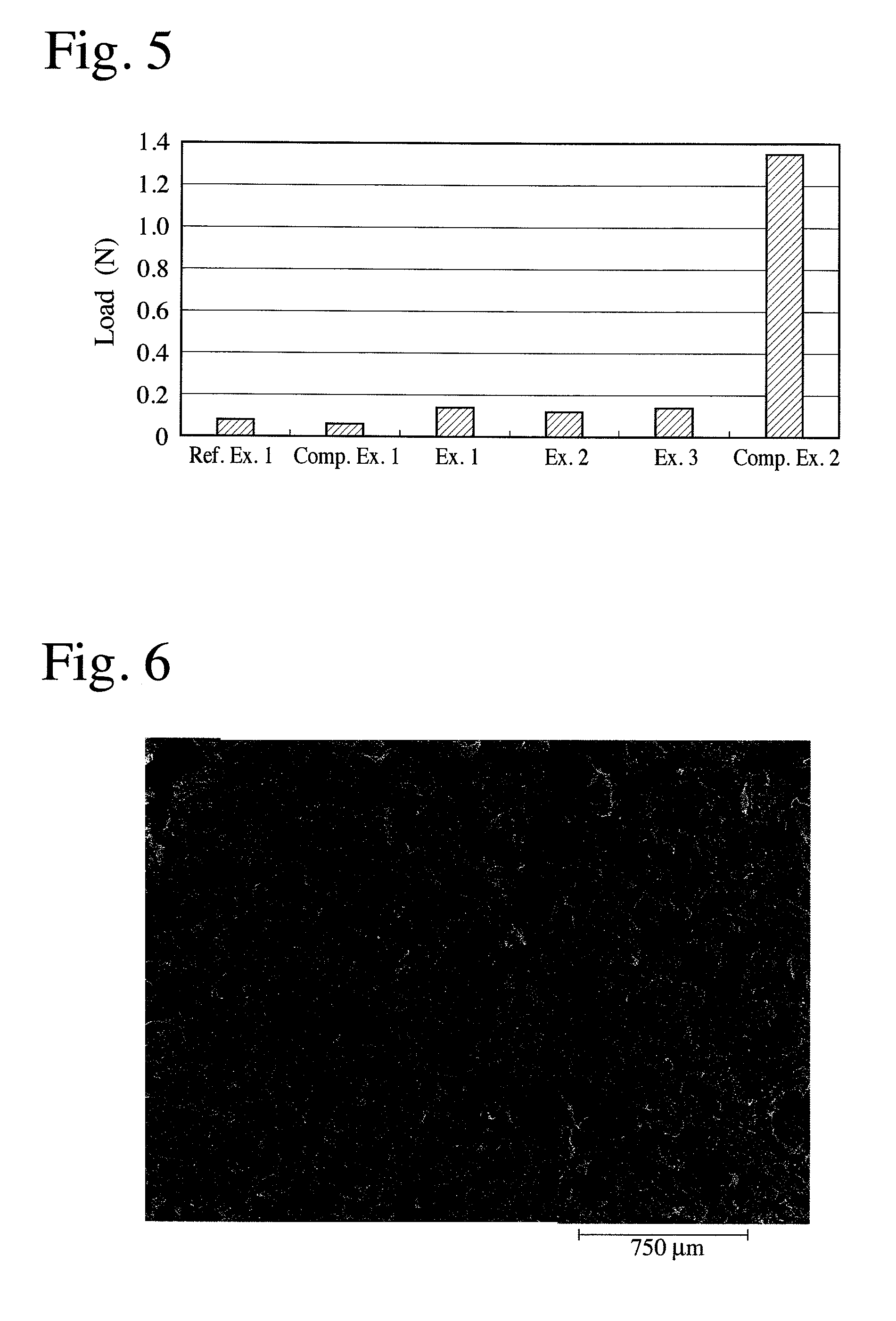

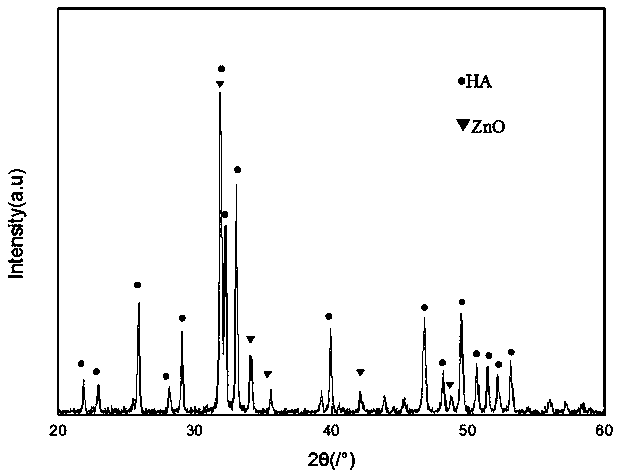

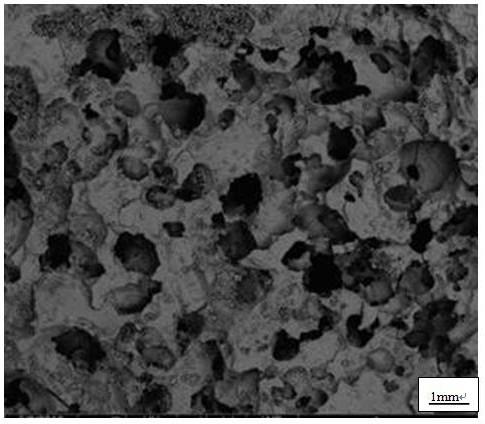

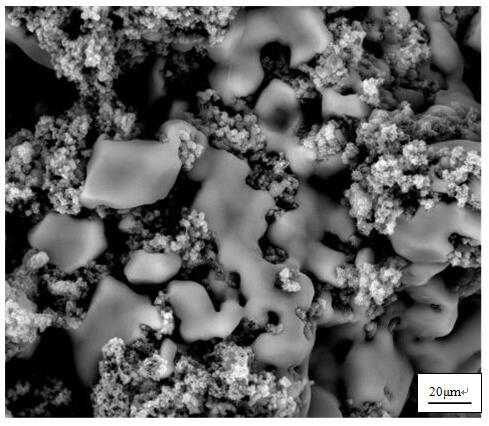

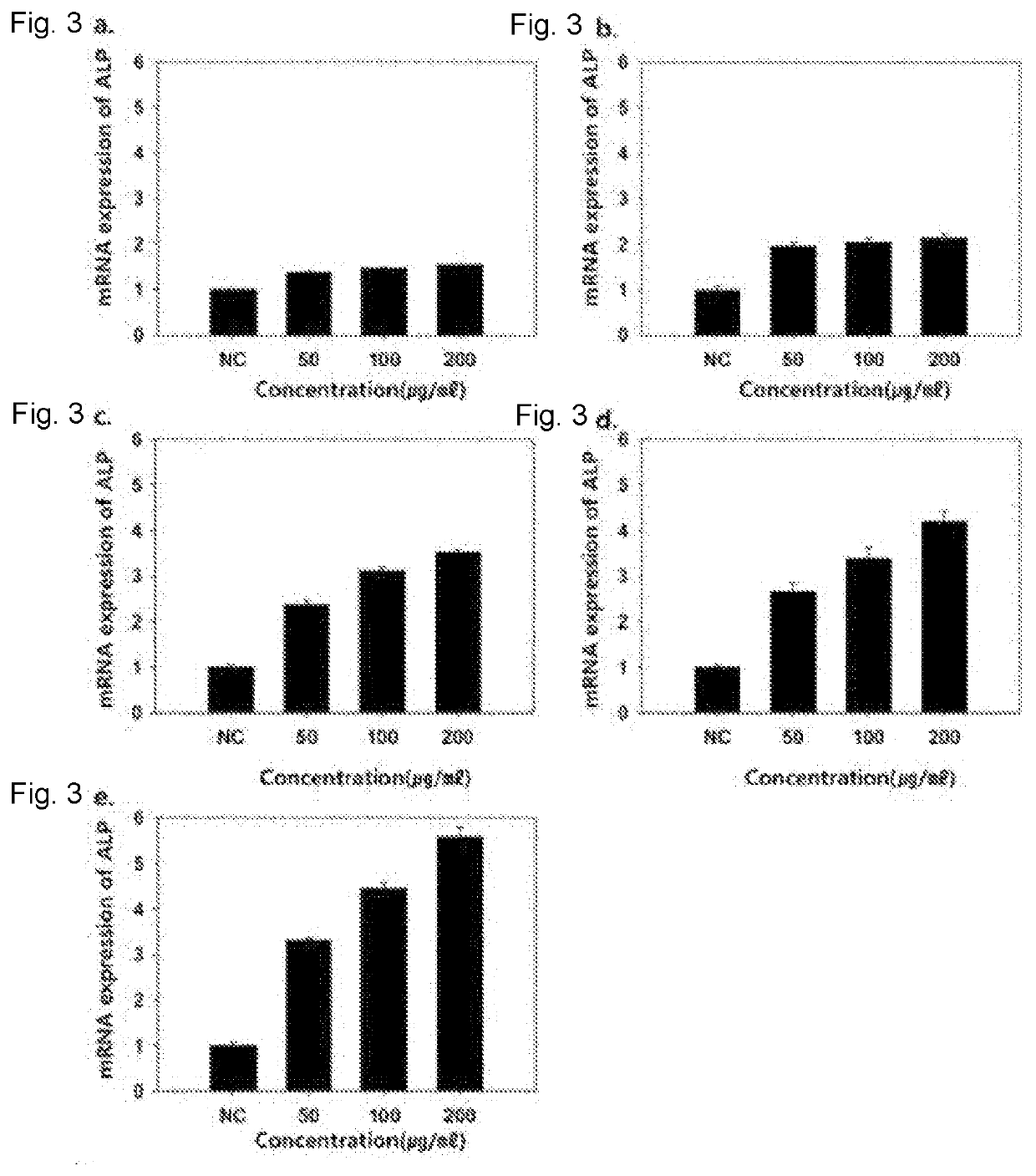

Preparation method of nano-zinc oxide-doped hydroxyapatite porous ceramic

ActiveCN110054491APure ingredientsAvoid churnPharmaceutical delivery mechanismTissue regenerationApatiteZno nanoparticles

The invention relates to a preparation method of a nano-zinc oxide-doped hydroxyapatite porous ceramic and belongs to the technical field of preparation of biomedical materials. The preparation methodtakes nano-zinc powder and hydroxyapatite powder as the raw materials and comprises weighing out ZnO and HA (hydroxyapatite) at a weight ratio of 1-7%:99%-93%, performing ball milling to obtain composite powder, uniformly mixing and pressing the composite powder and a pore forming agent of ammonium bicarbonate to obtain a blank, and then preparing the nano-zinc oxide-doped hydroxyapatite porous ceramic through a spark plasma sintering method. The prepared nano-zinc oxide-doped hydroxyapatite porous ceramic is pure in composition and achieves a controllable porosity of 40-70%, and added nano-zinc oxide can improve the osteogenic induction capacity of the nano-zinc oxide-doped hydroxyapatite porous ceramic and further improve the bone-forming capacity of parts around an implanted part; by controlling the porosity of the nano-zinc oxide-doped hydroxyapatite porous ceramic, the preparation method can prepare biological ceramics which meet different requirements and are applied to bone scaffold, filling and repair materials.

Owner:KUNMING UNIV OF SCI & TECH

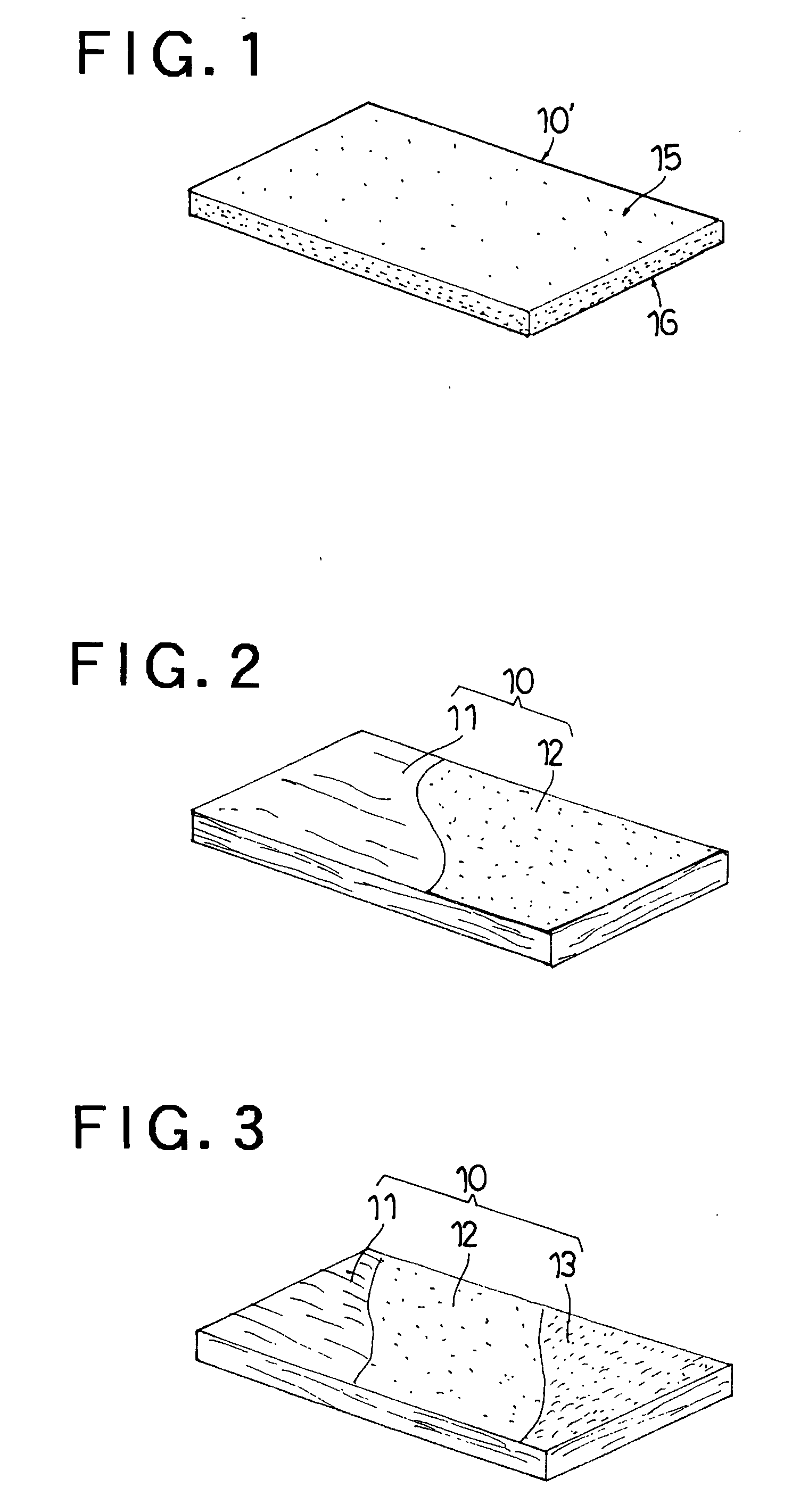

Dental Material And Composite Dental Material Formed By Using Hydroxy Apatite

InactiveUS20090004627A1Avoid contactImprove bone formationDental implantsImpression capsBioabsorbable membraneOsteoblast

It is intended to provide a dental material formed by using a hydroxy apatite, which is suitable for performing the guided bone regeneration (GBR) method in the implant therapy of dentistry. Also, it is intended to provide a composite dental material which is a bioabsorbable film provided integrally with hydroxy apatite, which is capable of rapidly attracting the osteoblast and blocking the fibroblast. The dental material is a membrane to be used for a guided bone regeneration method of guiding a bone formation by preventing invasion by anaplastic fibroblast by covering a bone developing site with a blocking membrane and filling the bone developing site with osteoblast, wherein a membrane main body of the blocking membrane is formed by using hydroxy apatite having osteoconductive capability of rapidly attracting osteoblast for the purpose of disposing the hydroxy apatite at a bone developing site side of the membrane main body. The composite dental material is a membrane to be used for a guided bone regeneration method of guiding a bone formation by preventing invasion by anaplastic fibroblast by covering a bone developing site with a blocking membrane and filling the bone developing site with osteoblast, wherein a membrane main body of the blocking membrane is formed by using a bioabsorbable membrane, and the bioabsorbable membrane is integrally provided with hydroxy apatite having osteoconductive capability of rapidly attracting osteoblast and a structure of being disposed at a bone developing site side of the membrane main body.

Owner:ISHIMOTO MITSUNORI +1

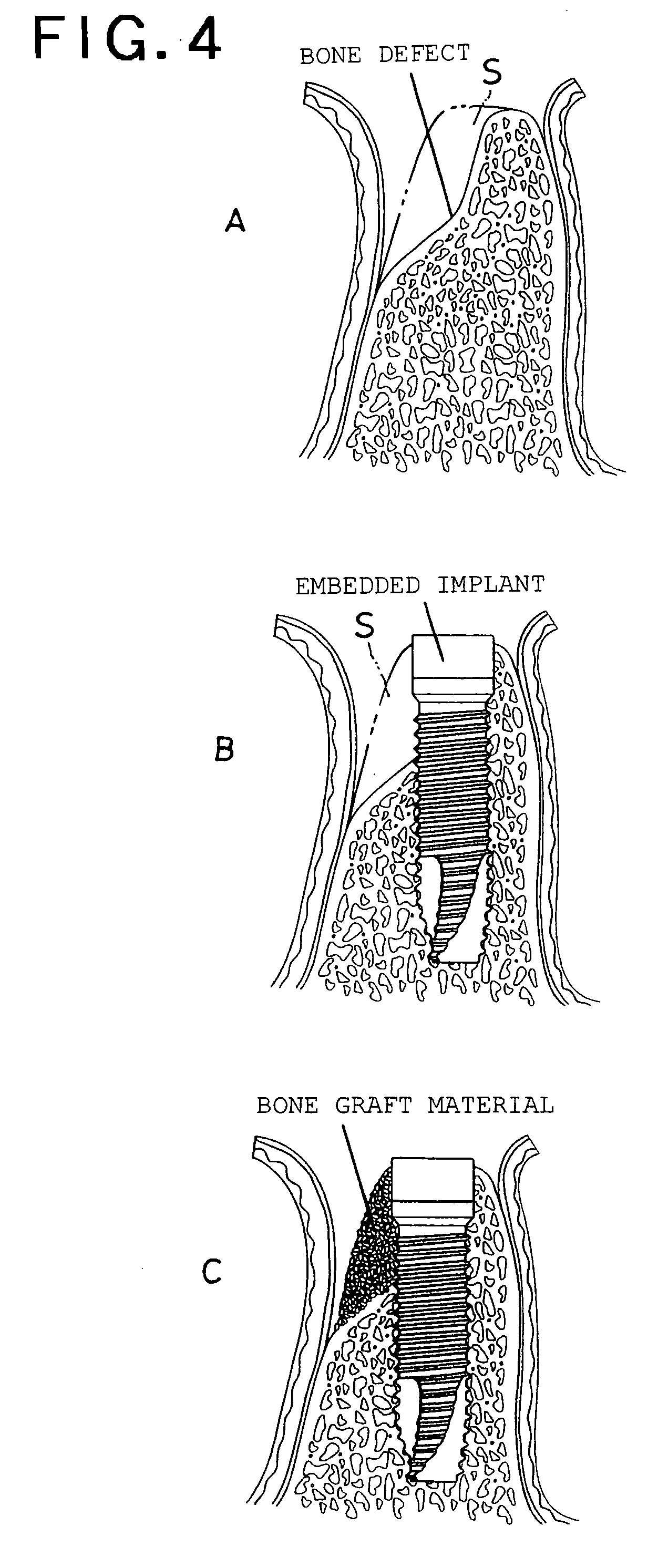

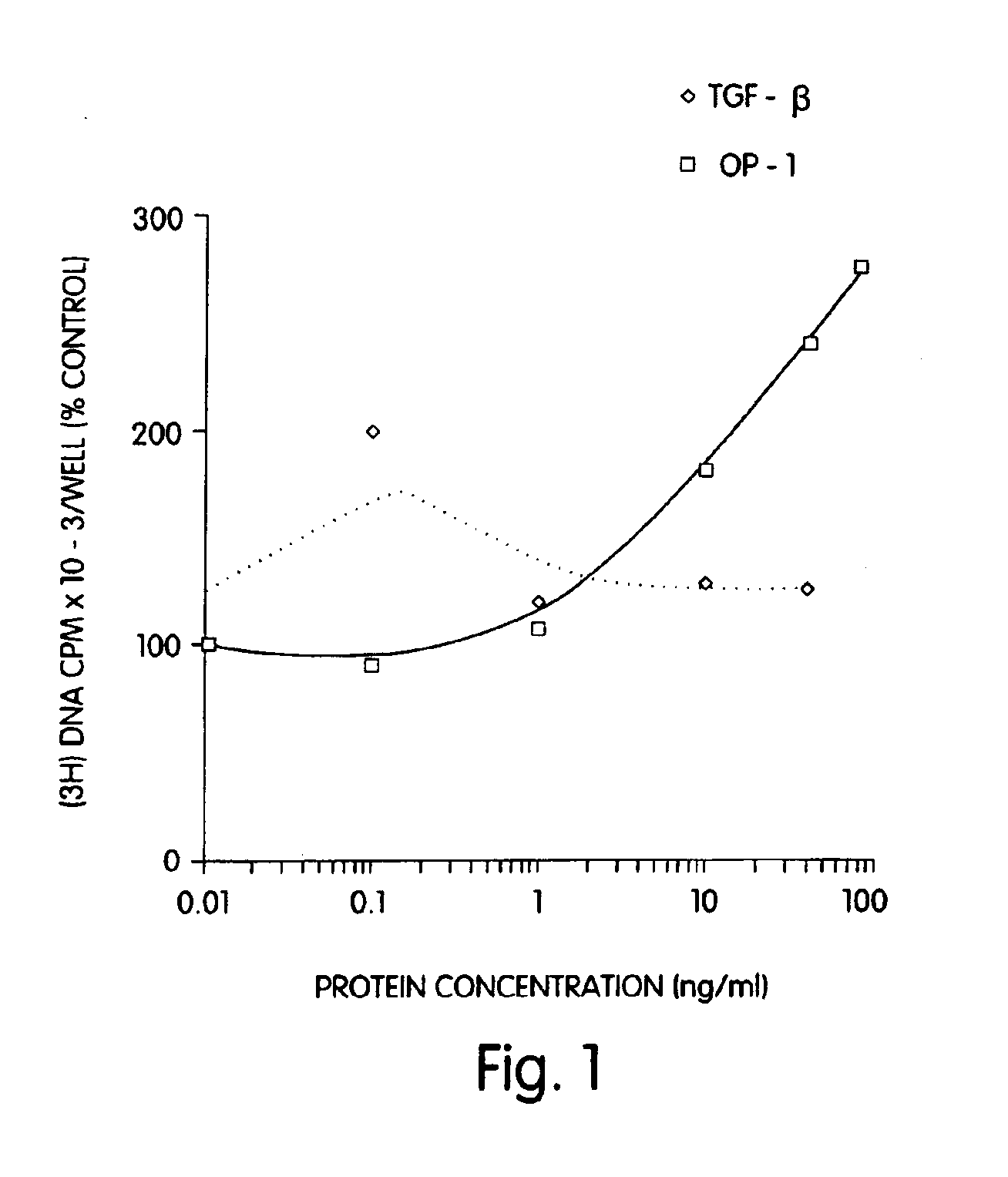

Treatment to prevent loss of and/or increase bone mass in metabolic bone diseases

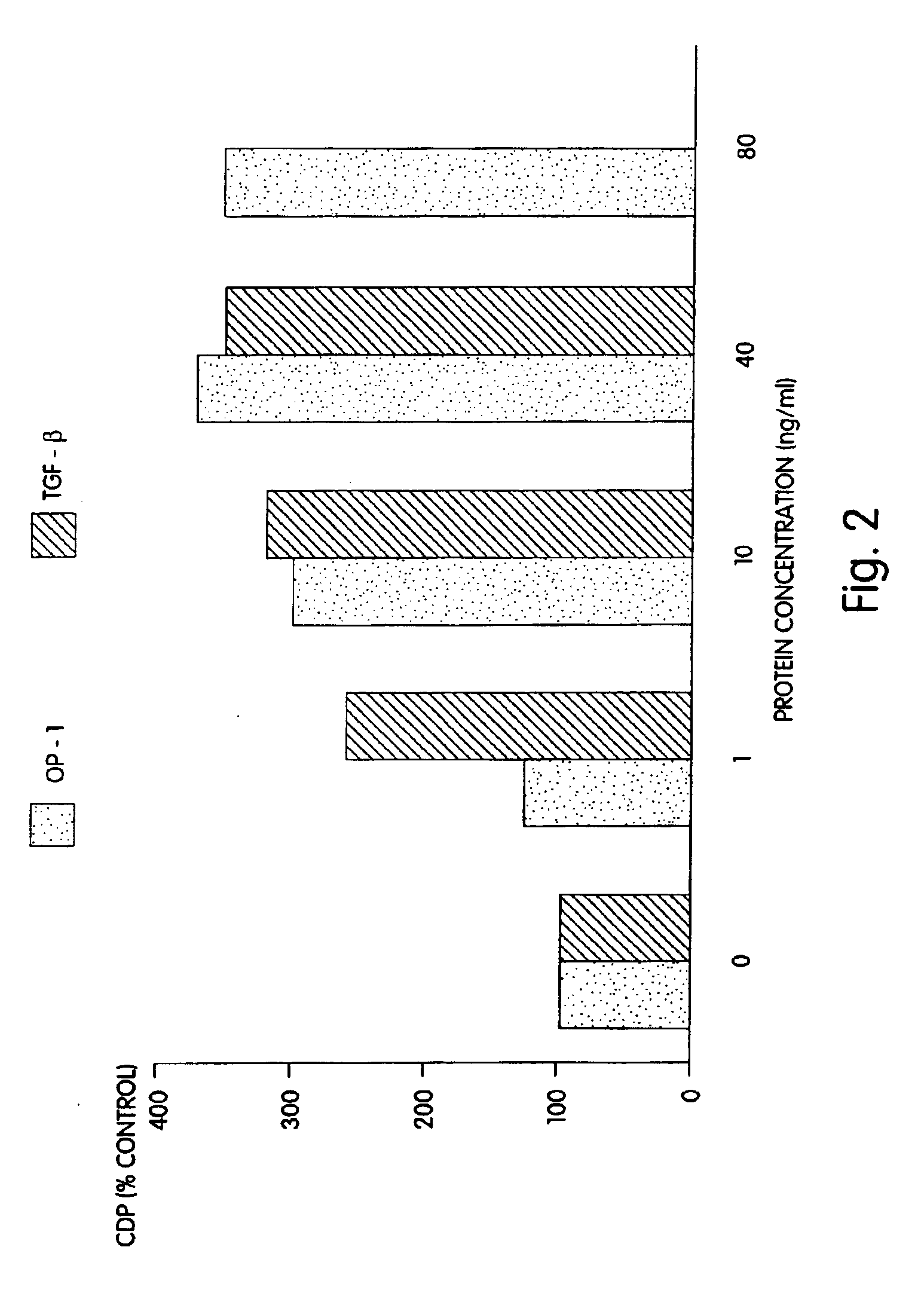

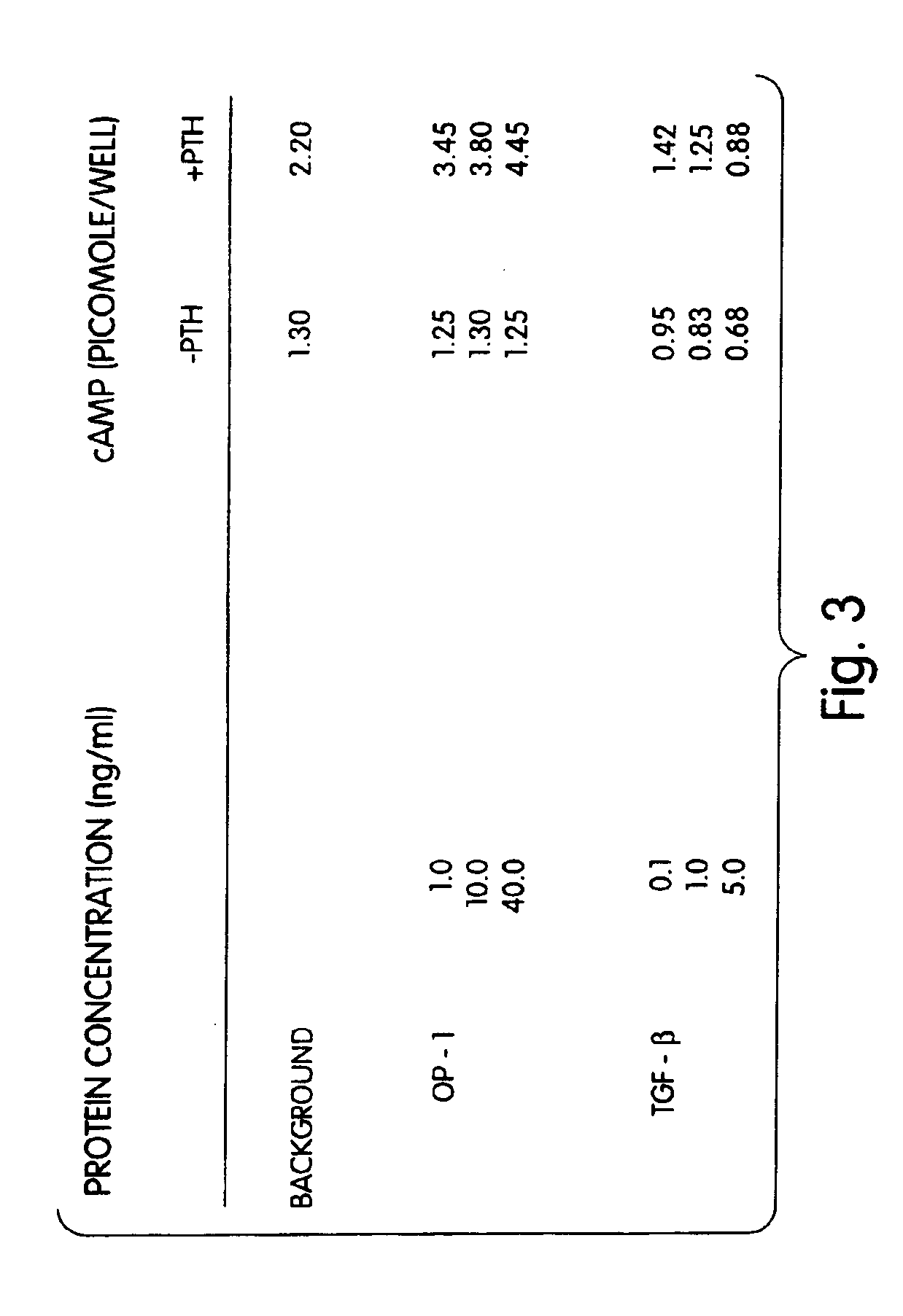

InactiveUS7056882B2Improve bone formationInhibiting abnormal bone deteriorationImpression capsPeptide/protein ingredientsMorphogenMorphogenesis

The invention is a treatment for increasing the bone mass or preventing bone loss in an individual afflicted with a bone disease which includes administering to the individual a morphogen in a therapeutically effective amount so as to maintain or stimulate bone formation.

Owner:STRYKER CORP

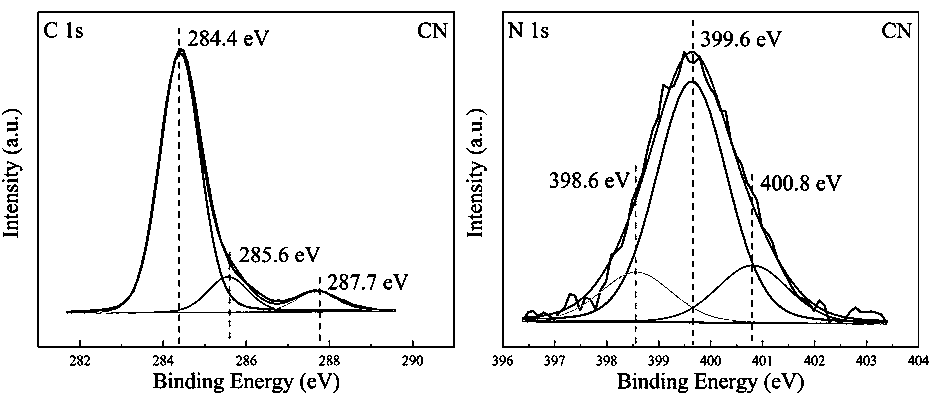

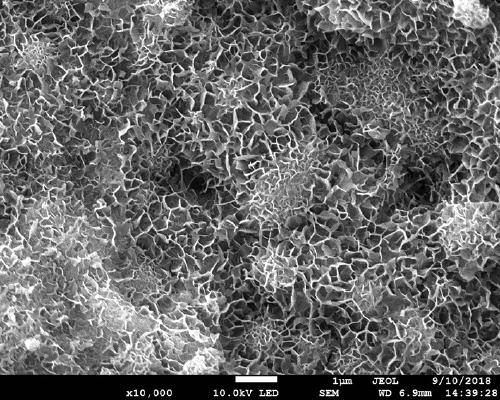

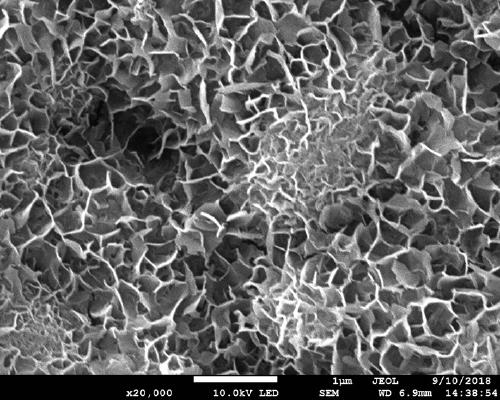

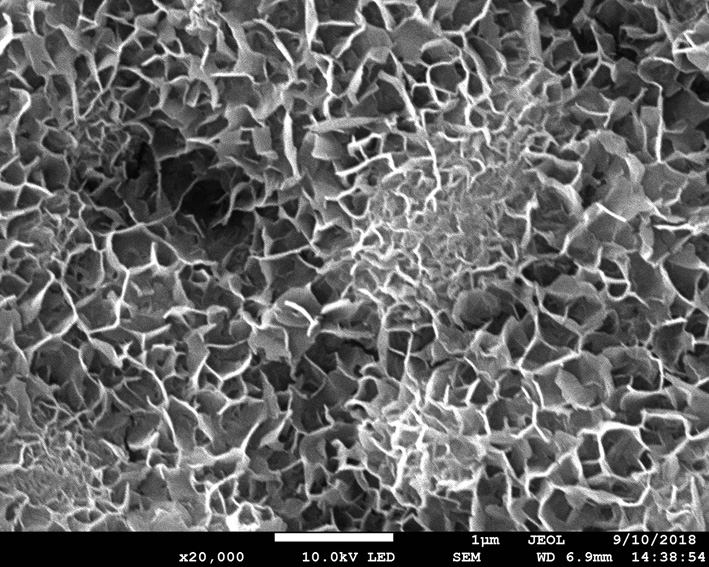

G-C3N4/ TiO2 coating with light-control and antibacterial functions and preparation method thereof

ActiveCN110327487AGood biological activityHigh bonding strengthTissue regenerationCoatingsHydrothermal synthesisAntibacterial coating

The present invention relates to a g-C3N4 / TiO2 coating with light-control and antibacterial functions and a preparation method thereof. The light-control antibacterial coating consists of TiO2 with athree-dimensional network structure and graphite-like phase carbon nitride (g-C3N4) deposited on the surface of the TiO2. The g-C3N4 / TiO2 coating with a three-dimensional network structure is combined with the surface of a titanium or titanium alloy substrate, rod-shaped nano-array sodium titanate is constructed on the surface of the substrate by a hydrothermal synthesis method, the nano-array sodium titanate is converted into titanium dioxide by a chemical vapor deposition technology, and the g-C3N4 is deposited at the same time. The preparation method comprises the following steps of: firstly, acquiring a rod-shaped nano-array sodium titanate biological coating on the surface of the substrate by adopting a hydrothermal synthesis method; and then converting the coating into titanium dioxide by using a high-temperature annealing technology, taking melamine as a raw material, and depositing g-C3N4 on the surface of the titanium dioxide through a chemical vapor deposition technology soas to finally obtain the g-C3N4 / TiO2 coating with the light-control and antibacterial functions.

Owner:SOUTHWEST UNIVERSITY

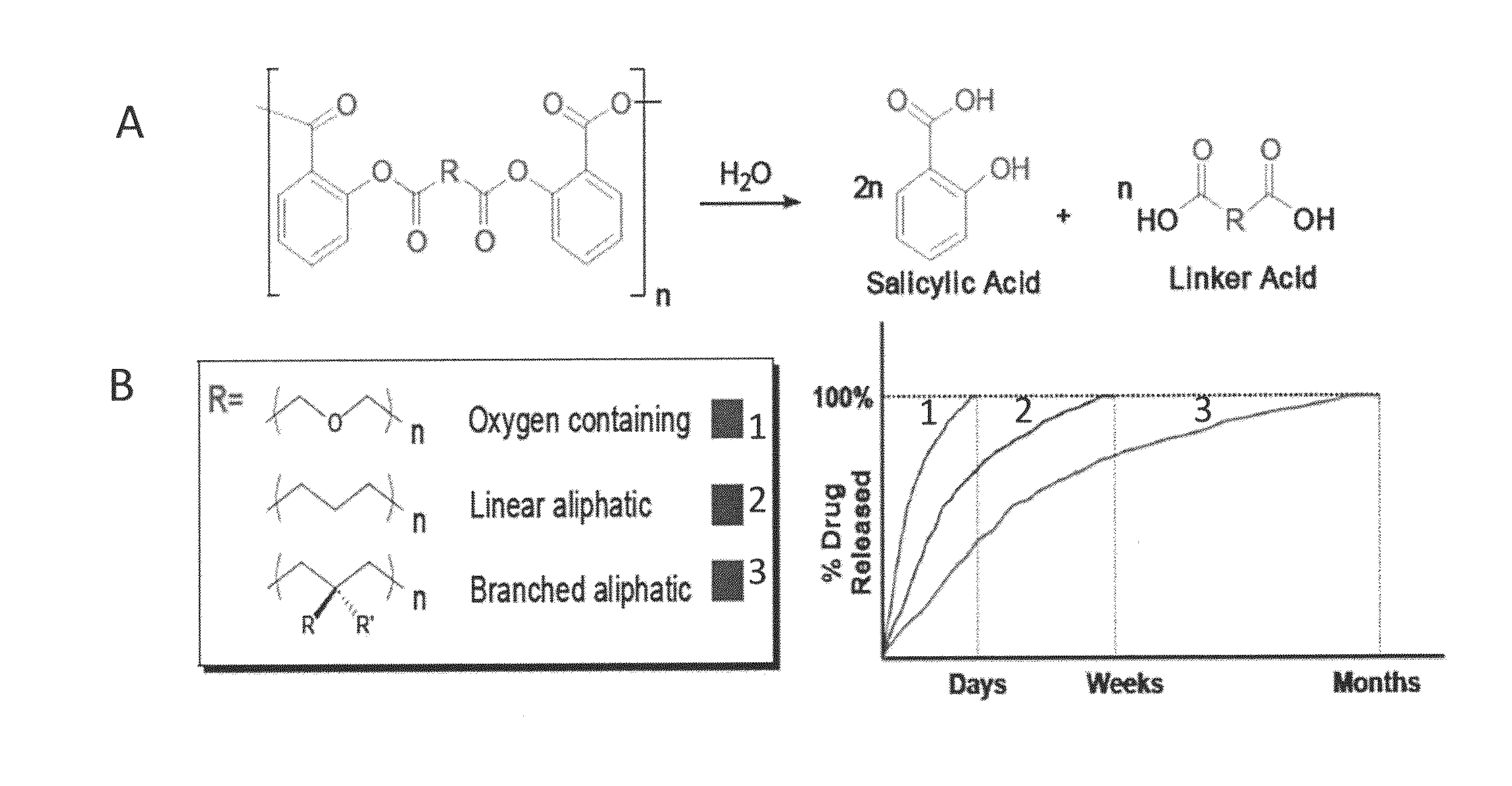

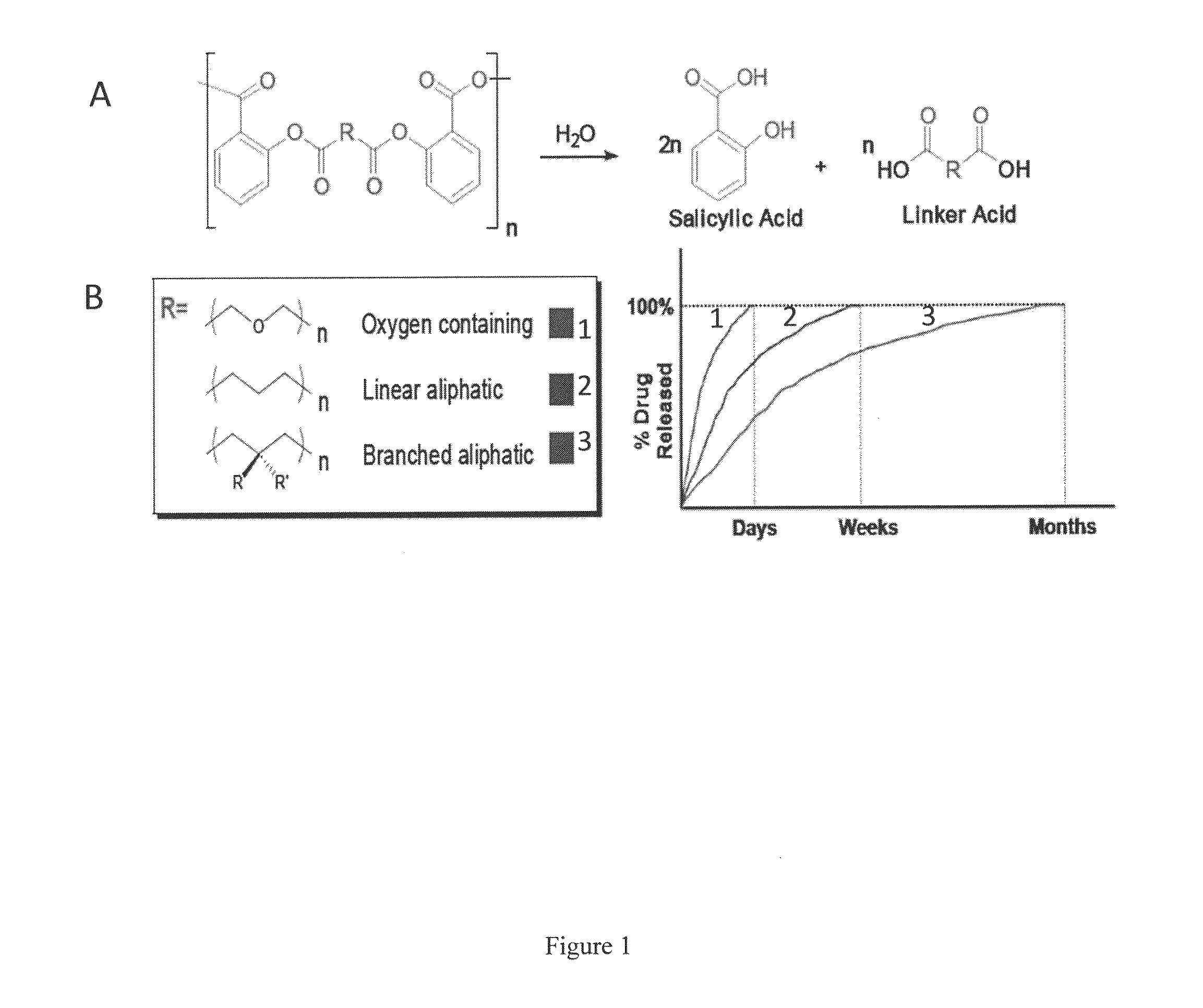

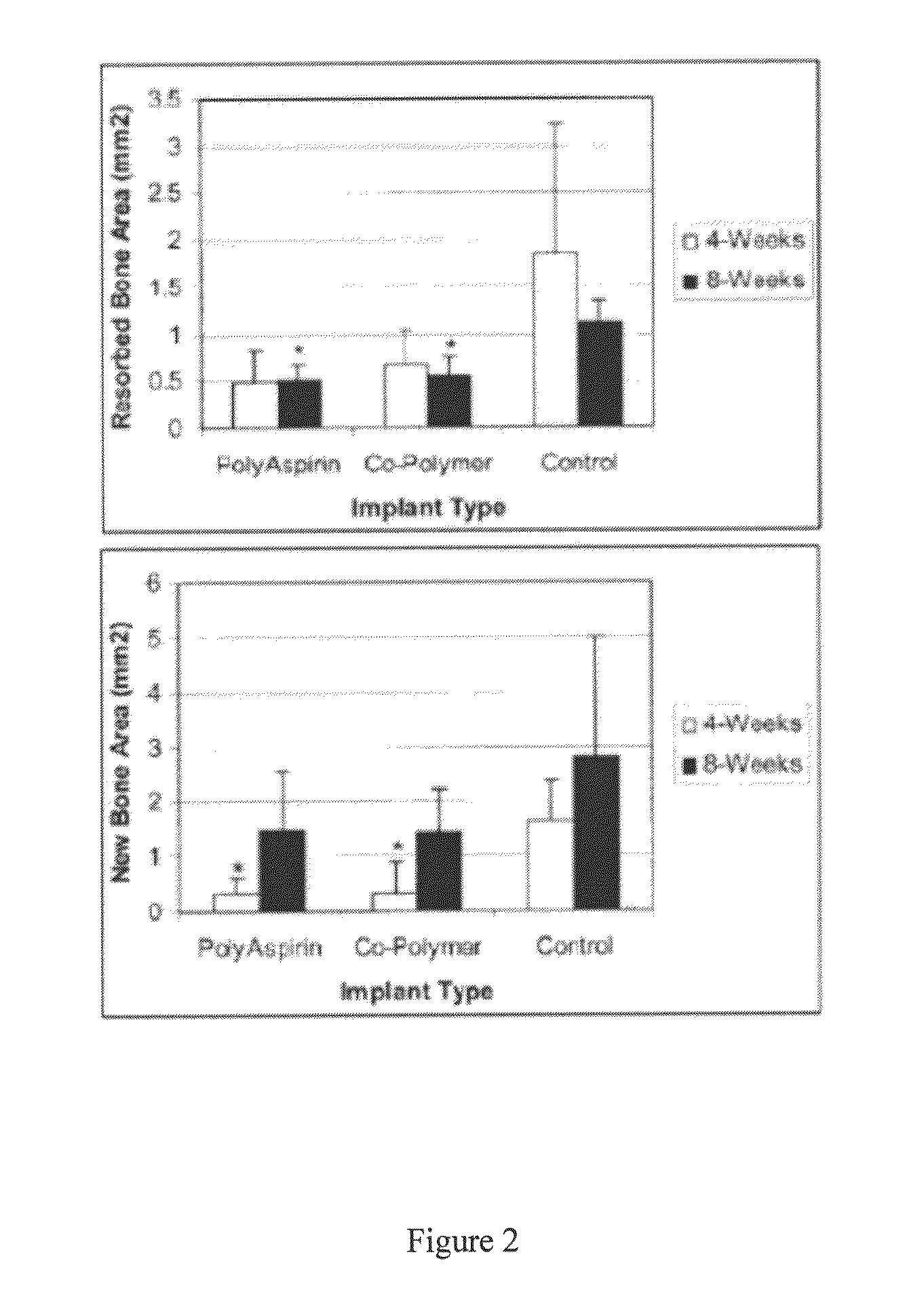

Therapeutic compositions for bone repair

ActiveUS20140271864A1Decreasing bone resorptionImprove bone formationPowder deliveryOrganic active ingredientsSalicylic acidPolyanhydrides

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA +1

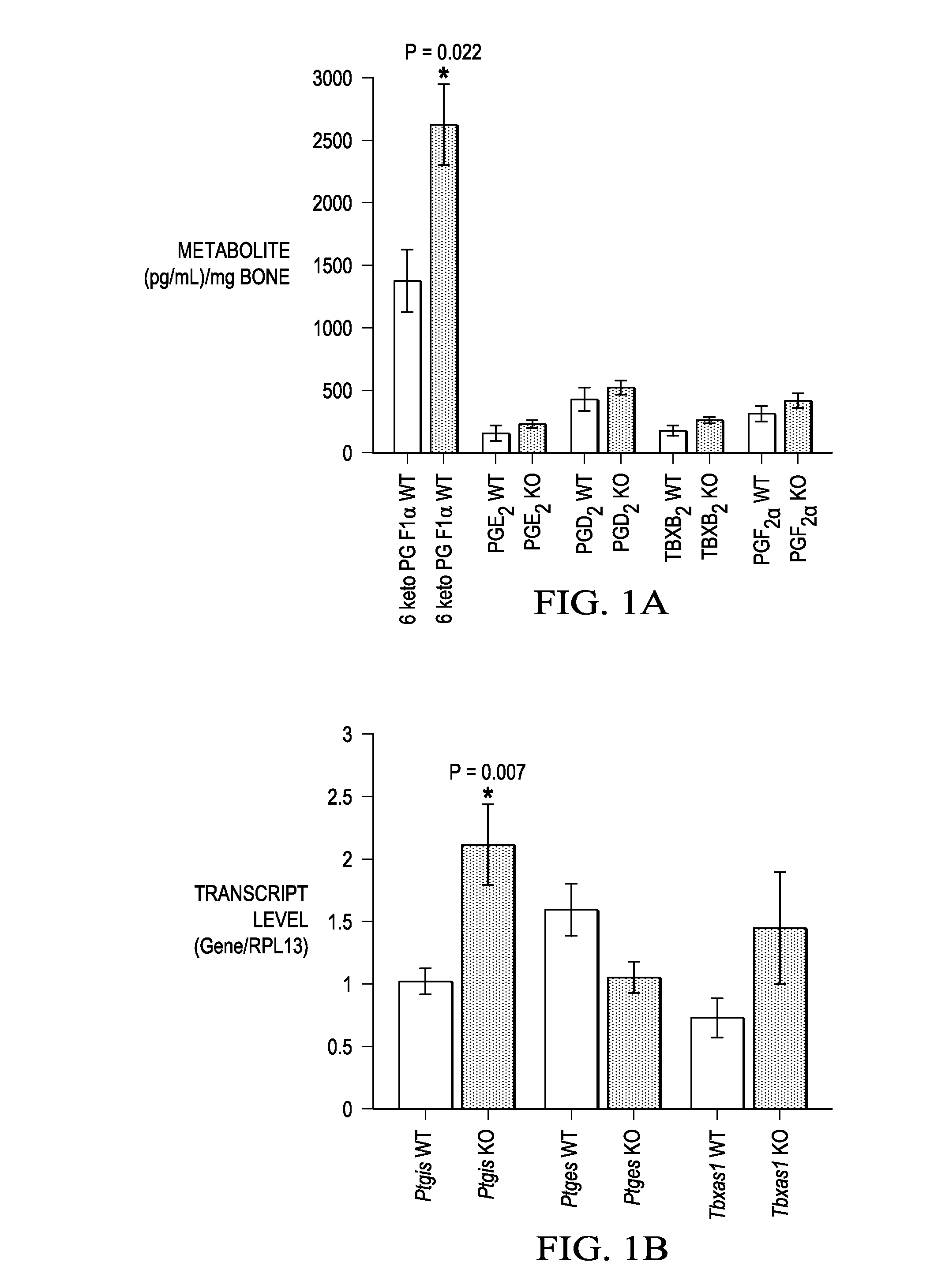

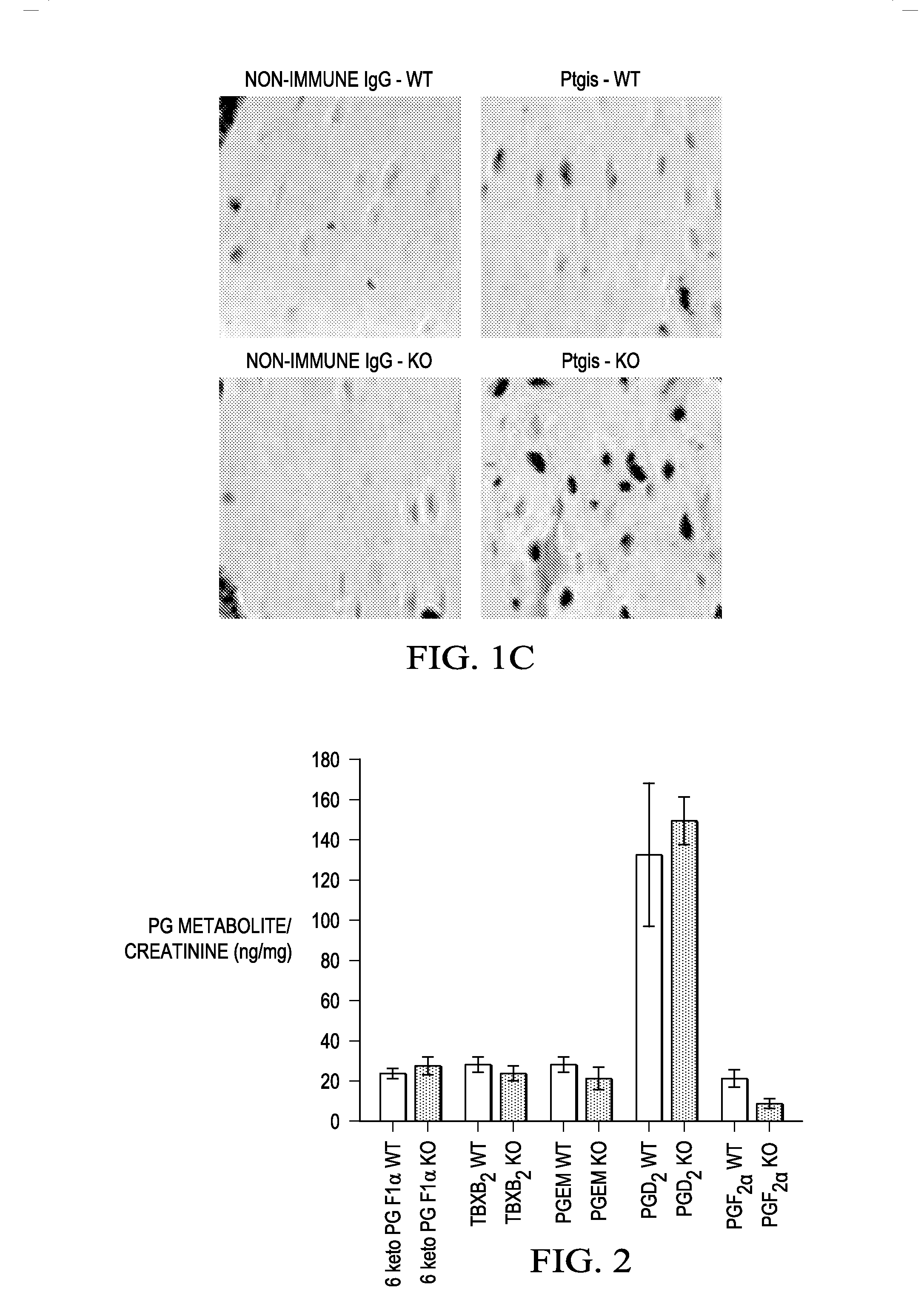

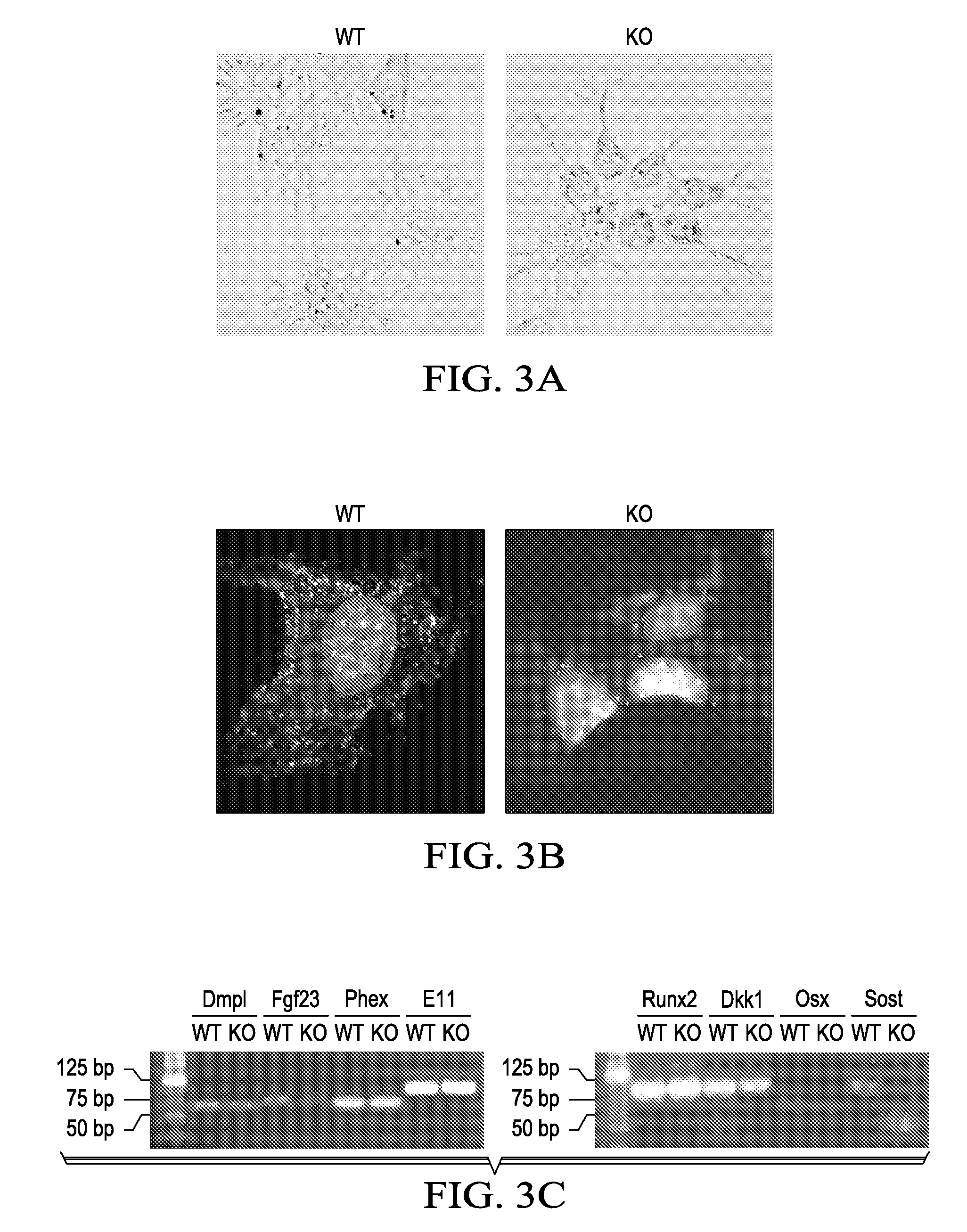

Prostacyclin compositions for regulation of fracture repair and bone formation

ActiveUS20150164853A1Improve bone formationEnhance fracture repairBiocideSurgeryProstacyclinBone formation

The present disclosure provides a prostacyclin coated implant to enhance fracture repair and bone formation comprising: an implant; and a prostacyclin coating comprising a prostacyclin compound disposed in a polymer coating the implant, wherein the prostacyclin coating releases the prostacyclin compound which enhances fracture repair and bone formation.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

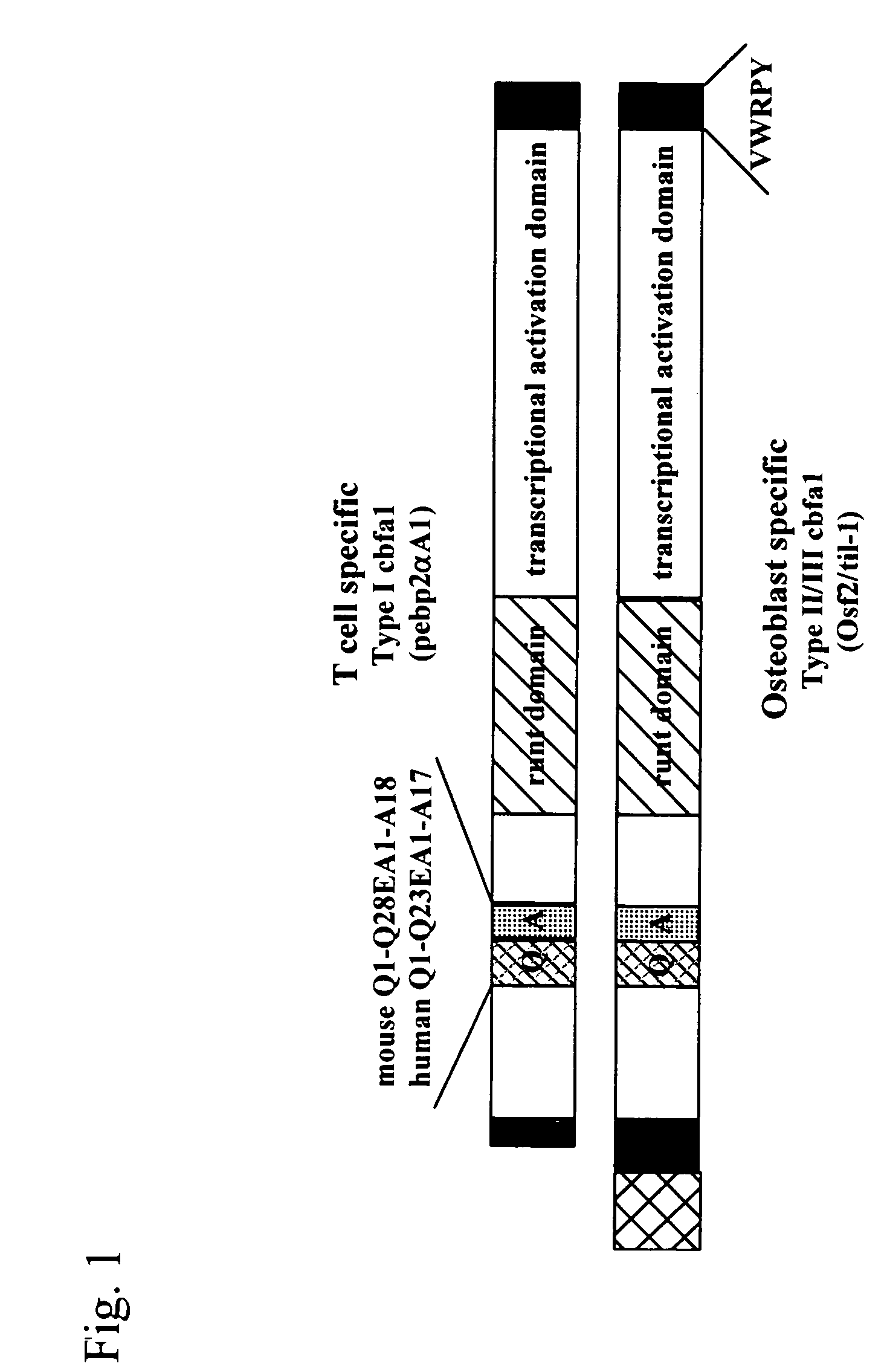

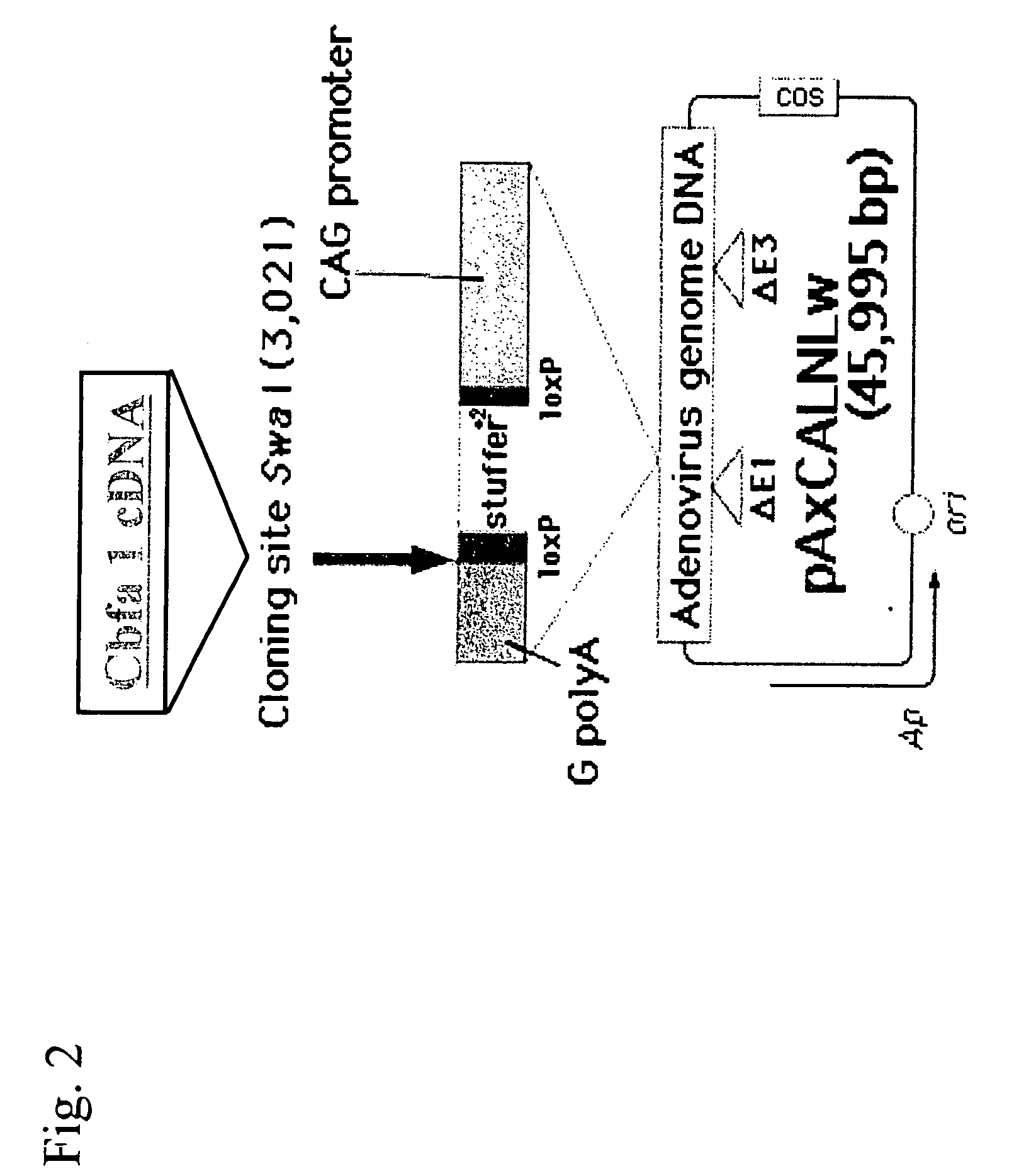

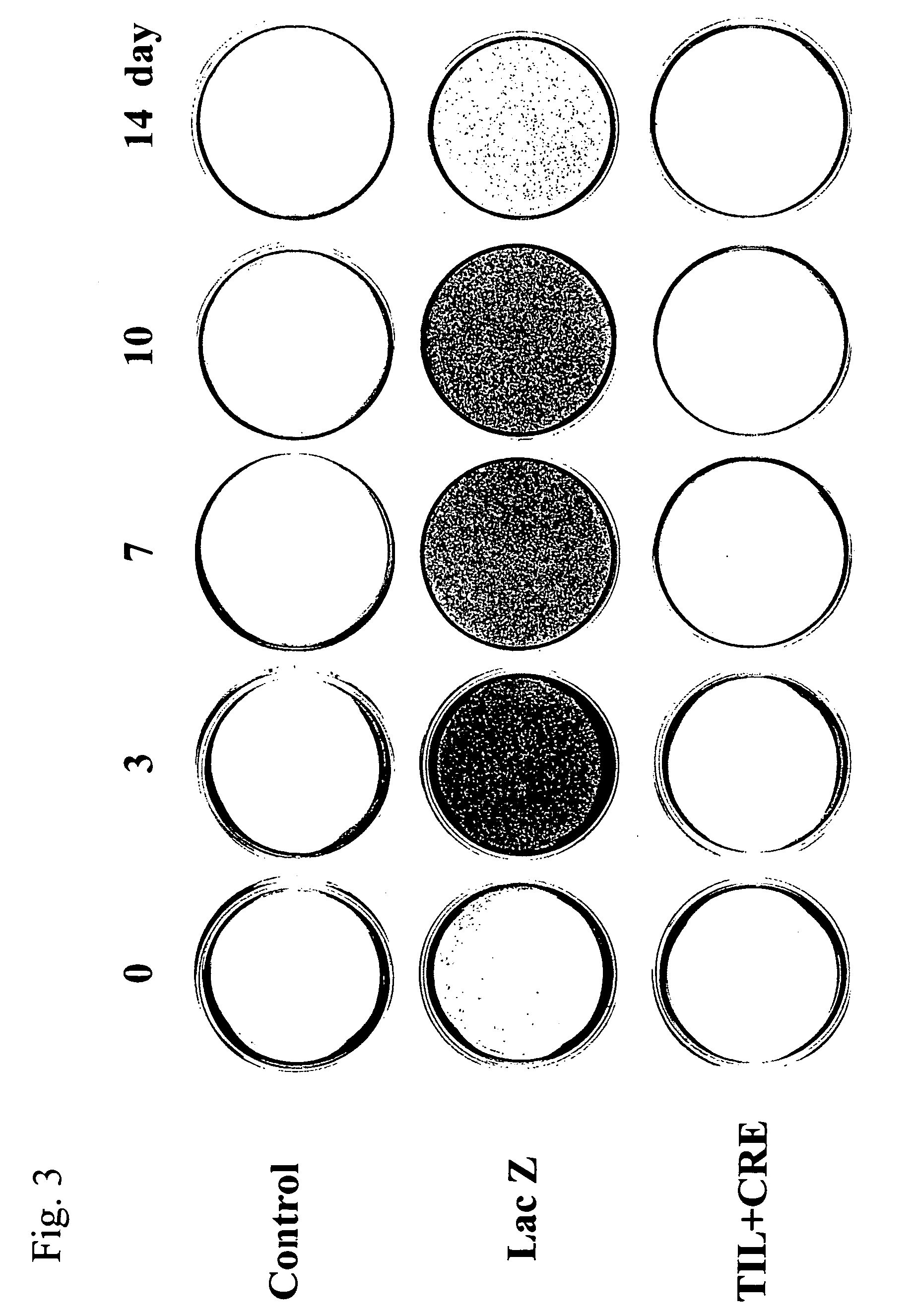

Method of regenerating bone/chondral tissues by transferring transcriptional factor gene

InactiveUS20050063959A1Improve compatibilityImprove bone formationBiocideGenetic material ingredientsBone Marrow-Derived CellCell biology

This invention provides a method of rapid and adequate culture of cells isolated from a body to effectively construct bone / cartilage tissues and implants containing the bone / cartilage tissues constructed by the aforementioned method. In this method, osteo- / chondro-inducible transcription factor genes are transfected into bone-marrow-derived cells isolated from a body using an adenoviral or a retroviral vector to grow on adequate scaffolds. The constructed bone / cartilage tissues are transplanted into a body together with the scaffolds. Thus, they can be used as substitutional bone / cartilage implants.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

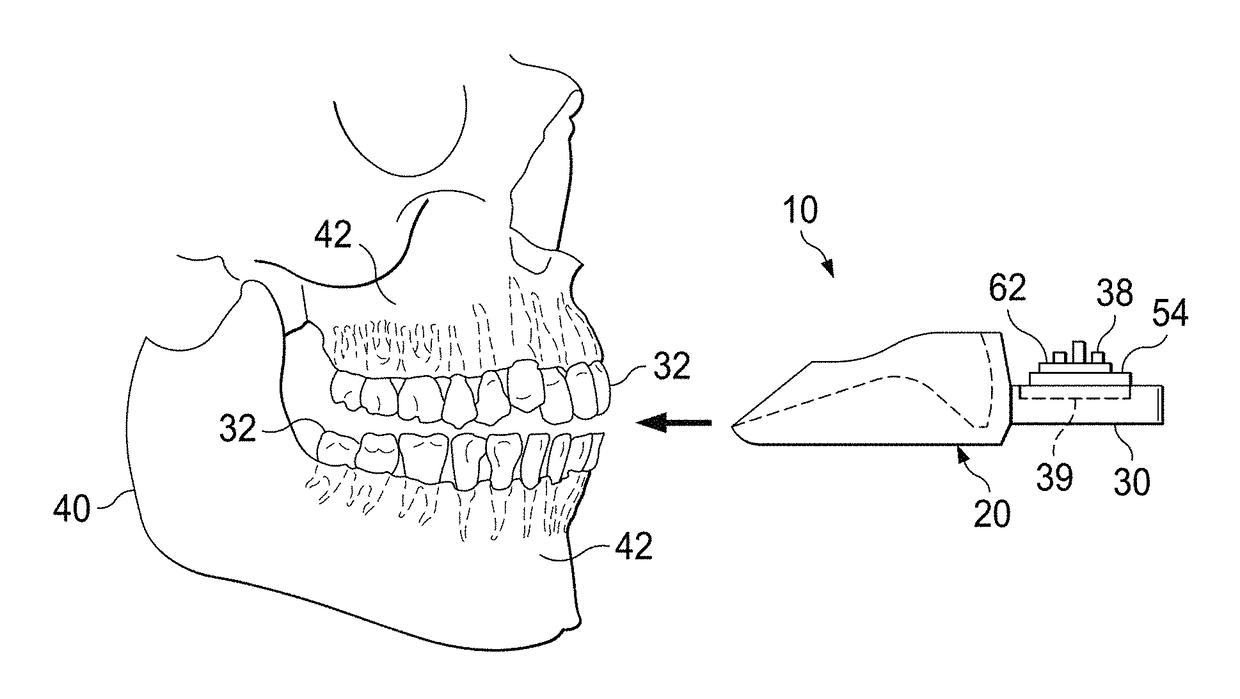

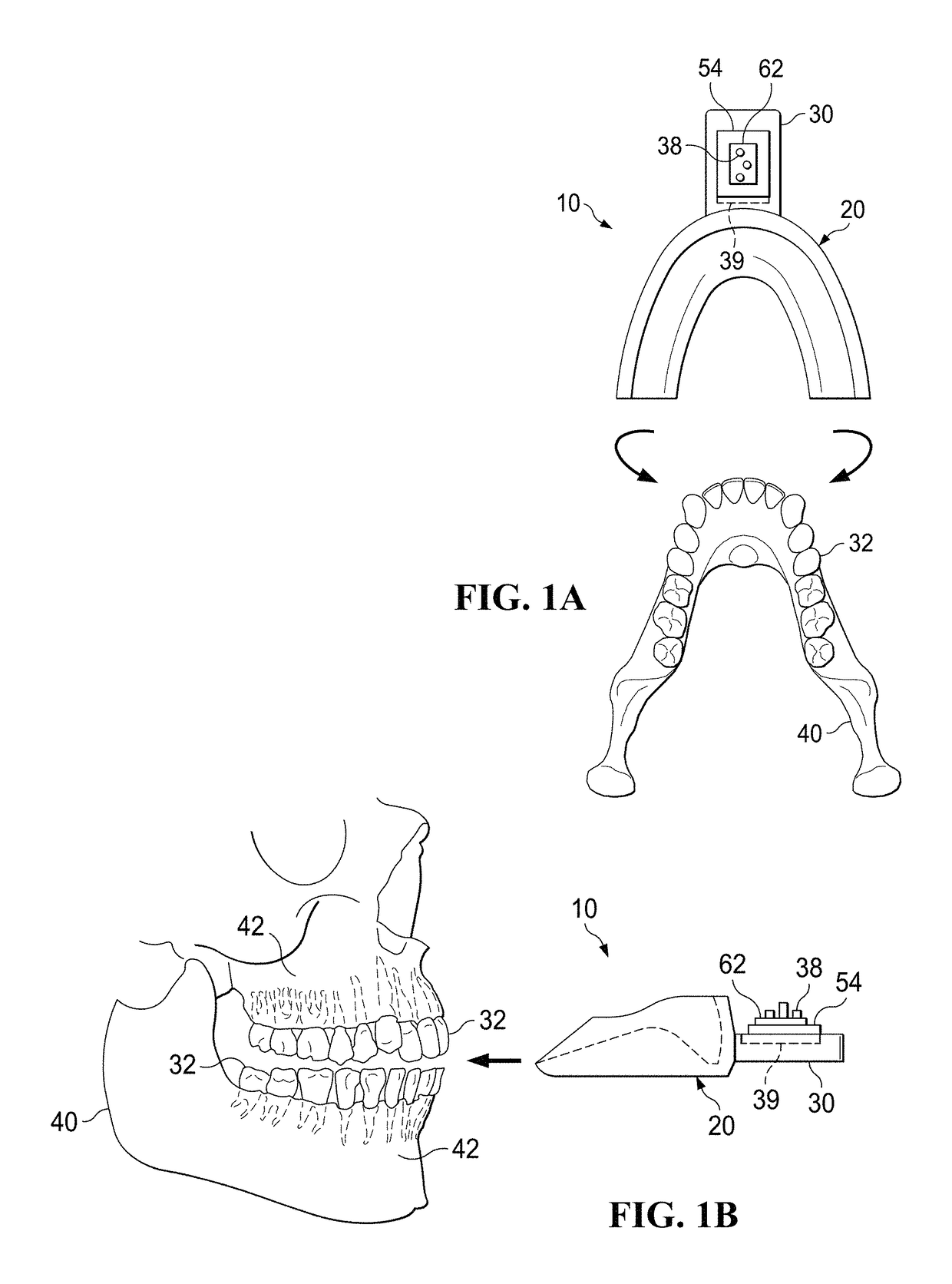

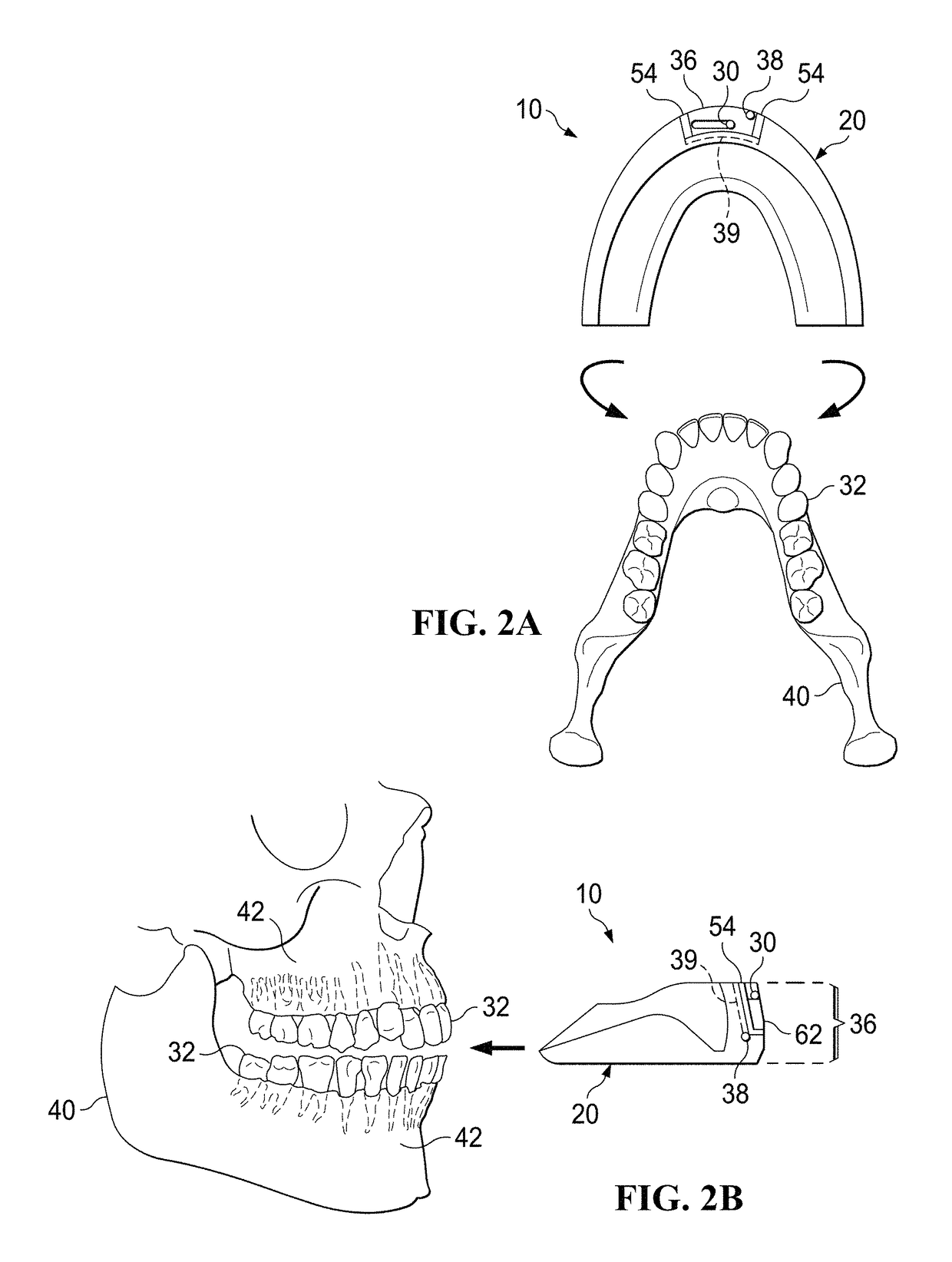

Orthodontic accelerator

ActiveUS9907626B1Improve bone formationImproved rate of bone formationBracketsMotor speedEngineering

An improved vibrating orthodontic device is provided wherein motor speed is controlled by capacitive sensor, and thus lacks moving parts that are required by encoder use. The improved device also uses a tungsten offset weight, reducing size by more than 50%, yet still produces the needed force. The device is thus smaller, lighter and more robust.

Owner:DENTSPLY LLC

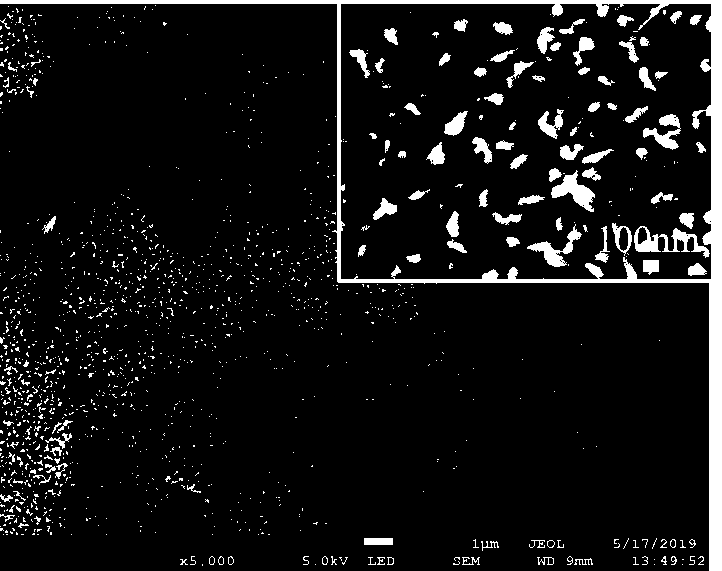

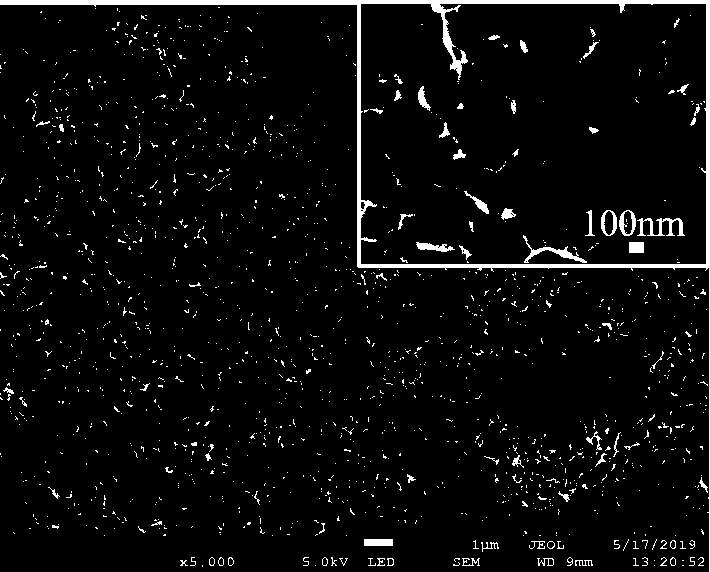

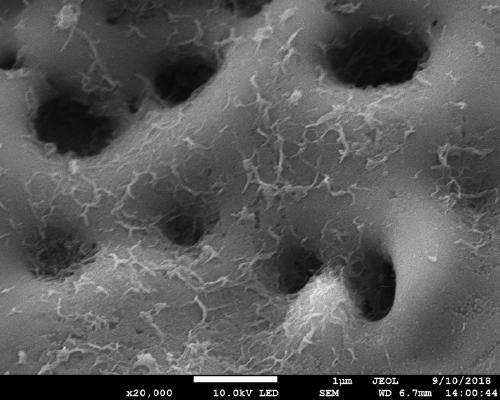

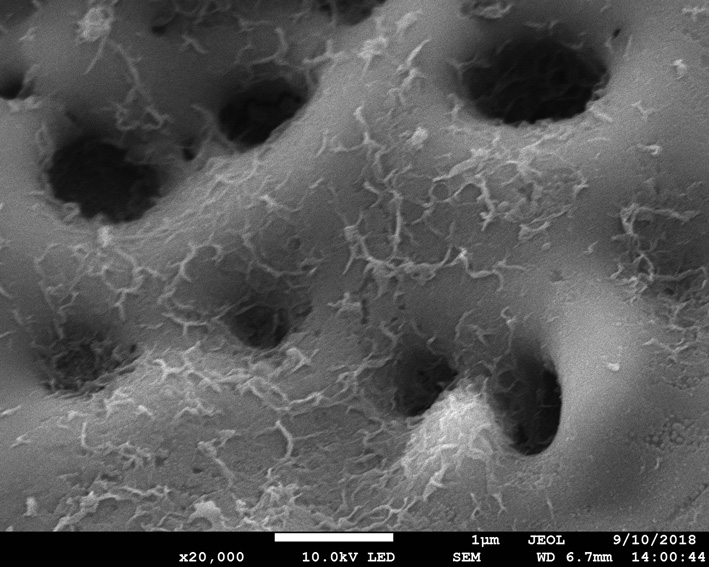

Degradable magnesium alloy bone nail with squamous bionic bone nanostructure coating and preparation method

ActiveCN109432514AImprove biological activityImprove antibacterialAnodisationSurgeryOxide ceramicMicro arc oxidation

The invention discloses a degradable magnesium alloy bone nail with a squamous bionic bone nanostructure coating and a preparation method thereof. The degradable bone nail consists of an AZ31B magnesium alloy bone nail matrix and a magnesium oxide bioceramic coating with a squamous bionic bone nanostructure loaded with PLGA-bone morphogenetic protein BMP. The magnesium oxide bioceramic coating with the squamous bionic bone nanostructure is combined with the surface of a metal matrix and the nano-sized squamous nanostructure is constructed on the surface of the matrix by using a micro-arc oxidation technology. The BMP is filled and loaded between magnesium oxide squamous bionic bone nanostructured laminates through centrifugal force and capillary action. The preparation method comprises thefollowing steps: firstly, selecting an AZ31B magnesium alloy and processing into the bone nail; then preparing the magnesium oxide ceramic coating with squamous bionic bone nanostructure characteristics on the surface of the matrix by adopting the micro-arc oxidation technology; finally, loading the PLGA-bone morphogenetic protein between the magnesium oxide squamous bionic bone nanostructured laminates by adopting a centrifugal load technology.

Owner:SOUTHWEST UNIVERSITY

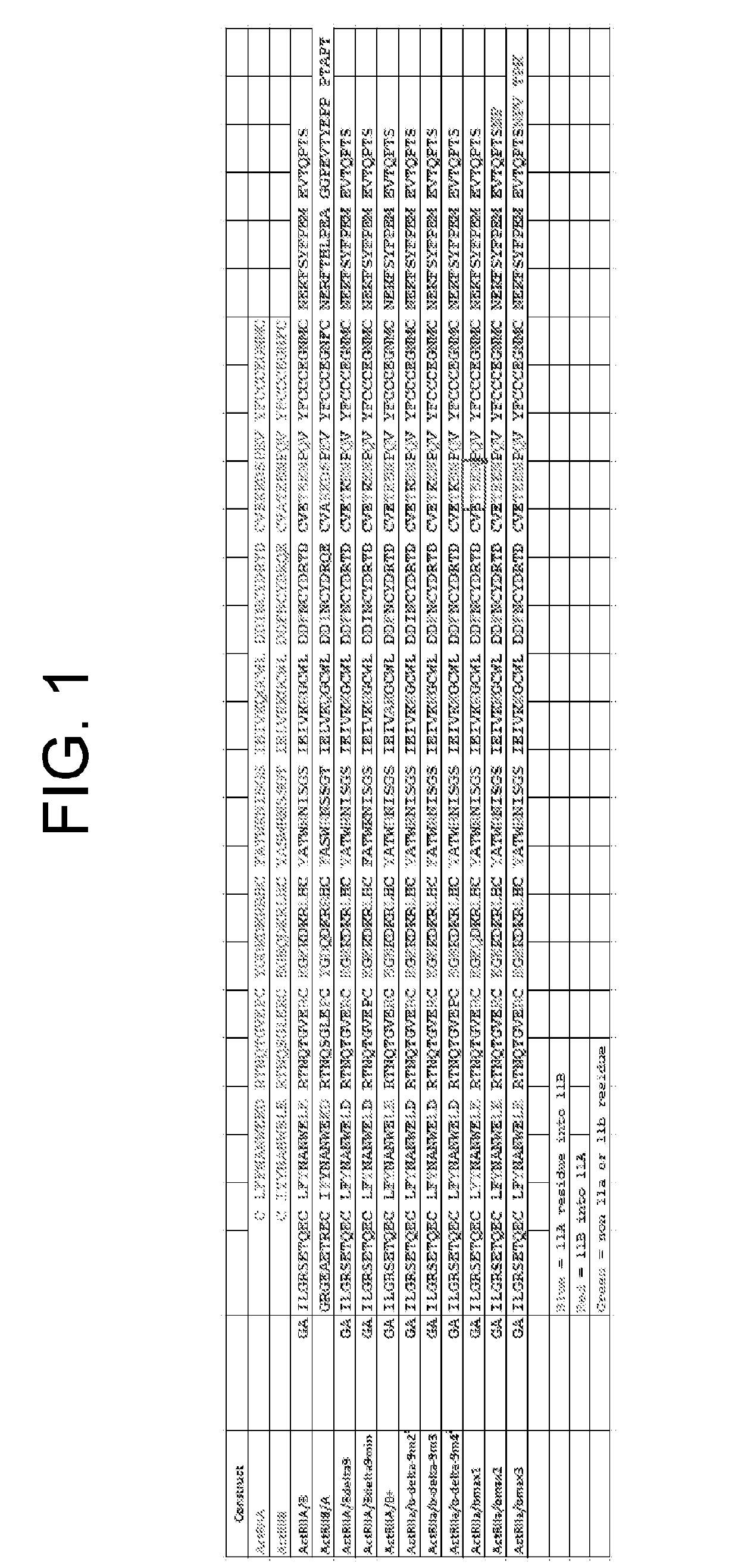

Activin receptor type iia variants and methods of use thereof

ActiveUS20190282663A1Improve bone formationDecrease bone resorptionPeptide/protein ingredientsAntibody mimetics/scaffoldsOsteopetrosisBone cancer

The invention features polypeptides that include an extracellular ActRlla variant. In some embodiments, a polypeptide of the invention includes an extracellular ActRlla variant fused to an Fc domain monomer or moiety. The invention also features pharmaceutical compositions and methods of using the polypeptides to treat diseases and conditions involving bone damage, e.g., primary osteoporosis, secondary osteoporosis, osteopenia, osteopetrosis, facture, bone cancer or cancer metastasis-related bone loss, Paget's disease, renal osteodystrophy, treatment-related bone loss, diet-related bone loss, bone loss associated with the treatment of obesity, low gravity-related bone loss, or immobility-related bone loss.

Owner:KEROS THERAPEUTICS INC

Methods, systems, and reagents for delivery to bone of an osteoinductive factor with a contrast agent

InactiveUS20070202048A1Improve bone formationNanotechPeptide/protein ingredientsOSTEOINDUCTIVE FACTORContrast medium

The present invention is directed to methods, systems and reagents for providing contrast media that are compatible with osteoinductive factor induced bone formation.

Owner:WARSAW ORTHOPEDIC INC

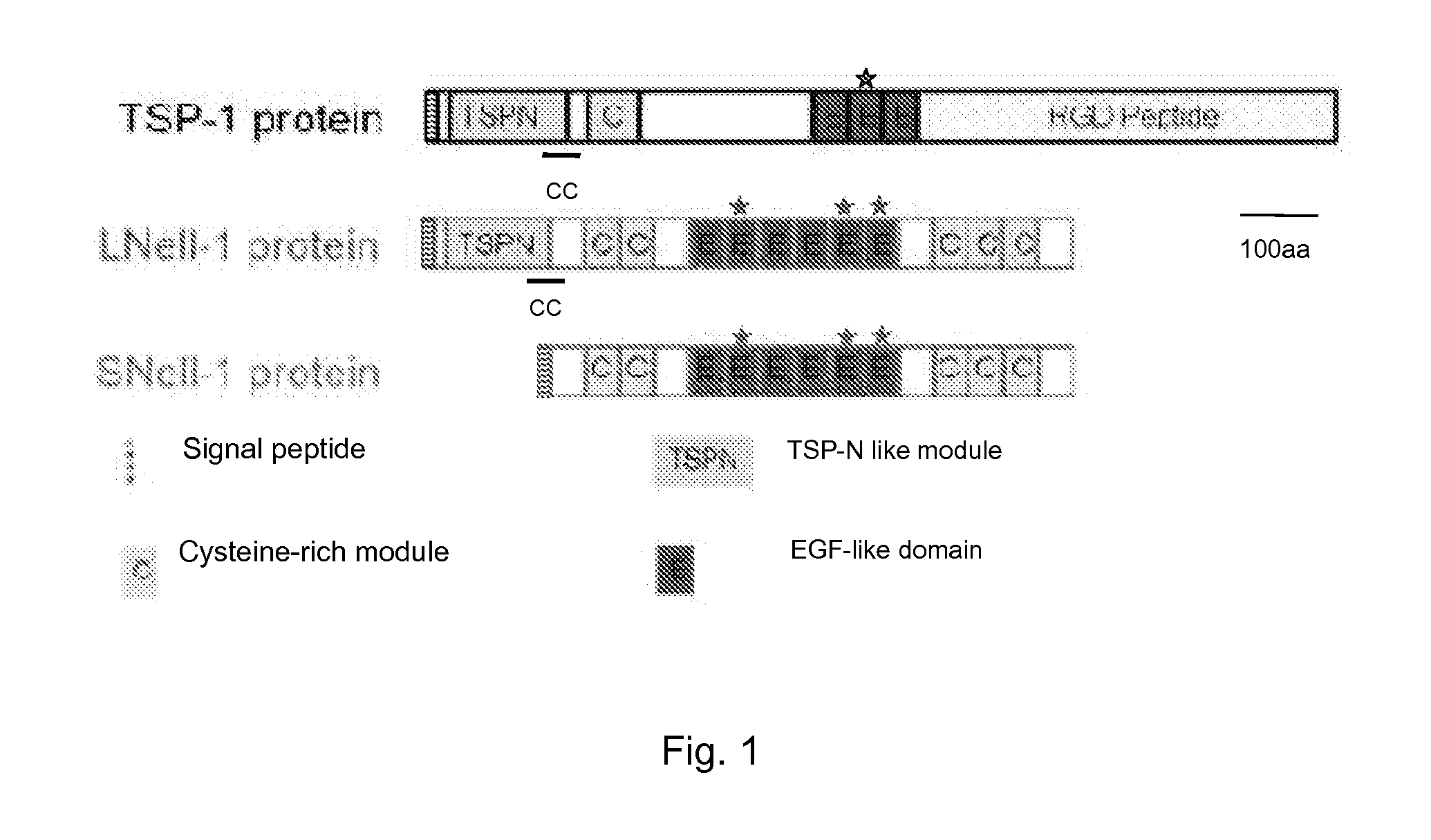

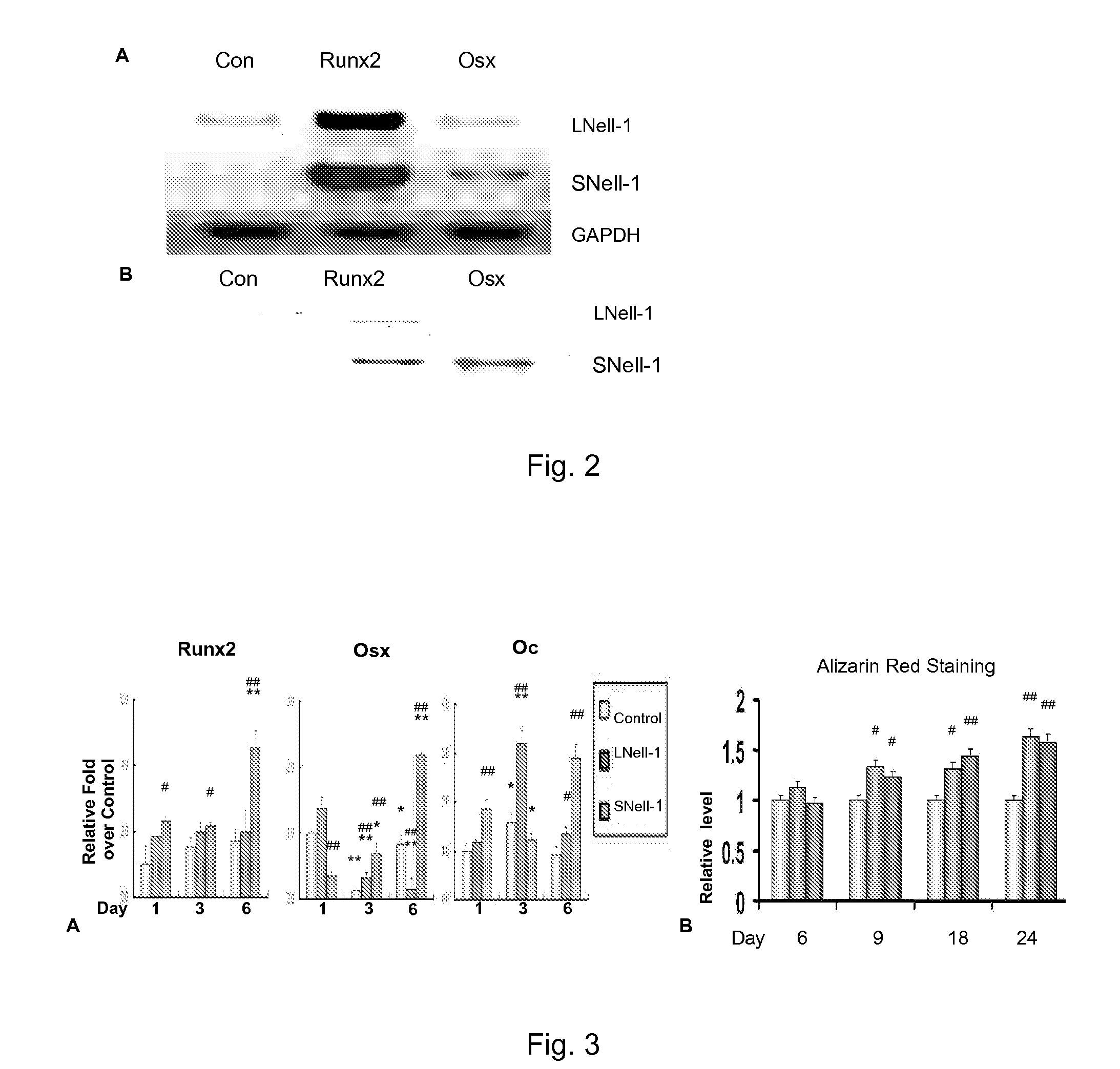

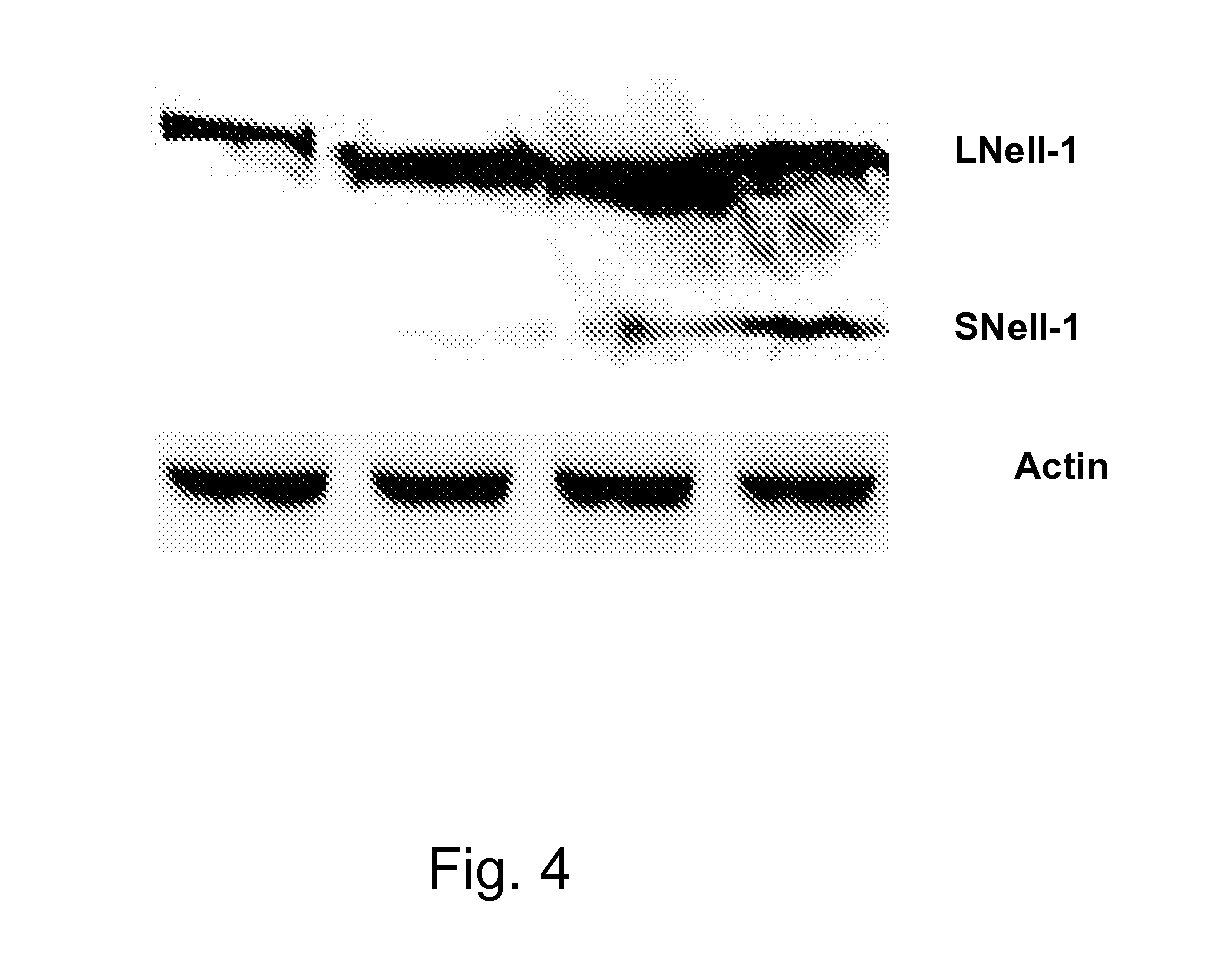

Isoform nell-1 peptide

ActiveUS20120065574A1Improve bone formationPromote regenerationPeptide/protein ingredientsAntipyreticBiologyPeptide

This application generally relates to an isoform Nell-1 peptide, compositions thereof, and methods of using the same.

Owner:RGT UNIV OF CALIFORNIA

Bacterial antigen induced bone morphogenesis

InactiveUS20060040878A1Induce bone growthPromote bone growthBacterial antigen ingredientsGenetic material ingredientsBacteroidesBone growth

Bone growth following a spinal fusion procedure is enhanced by packing the fusion site with a mixture of a bone material such as allograft or autograft, and an antigen produced from bacteria or parasitic organisms. A composition for inducing bone morphogenesis also is disclosed.

Owner:SUDDABY LOUBERT

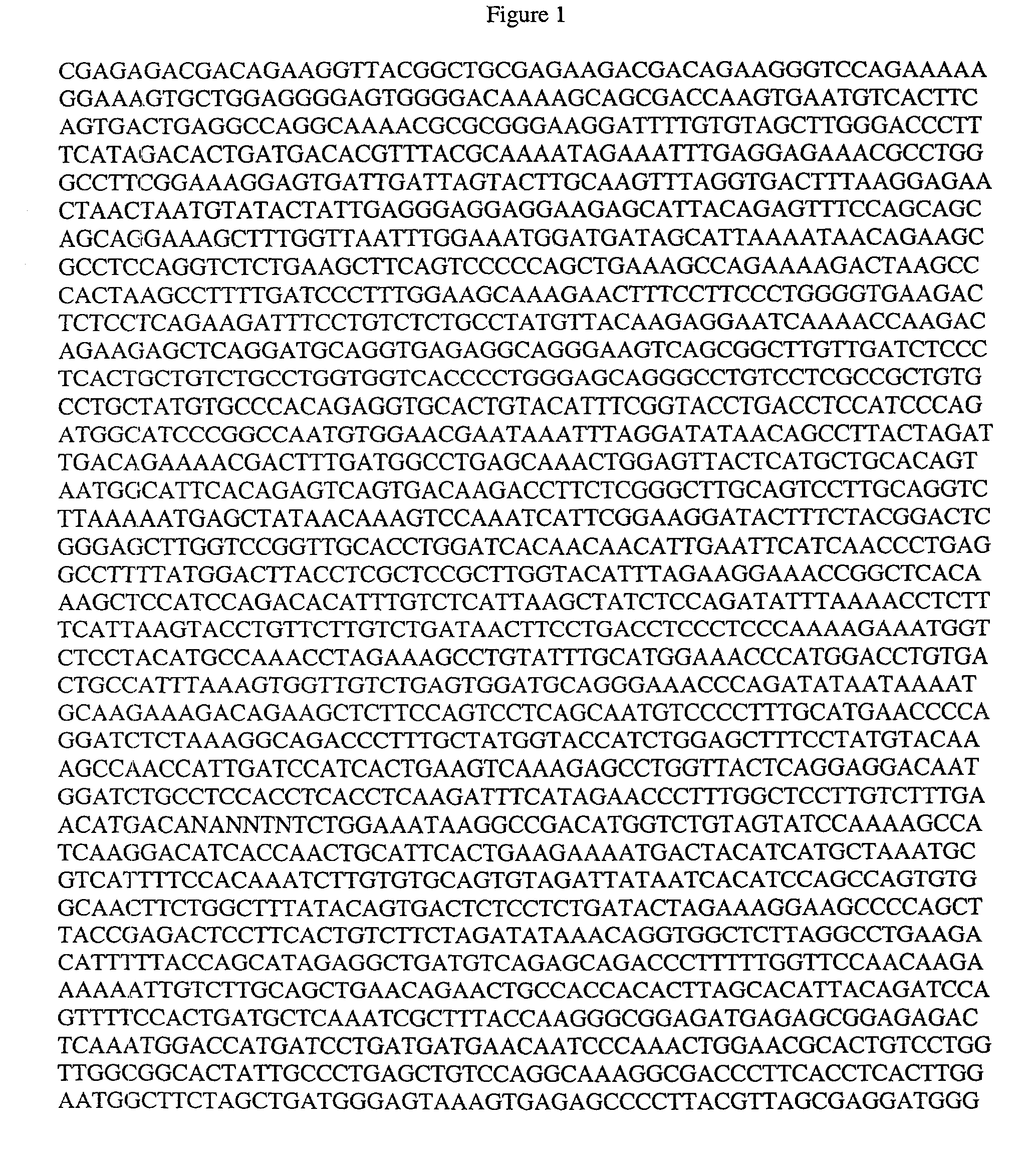

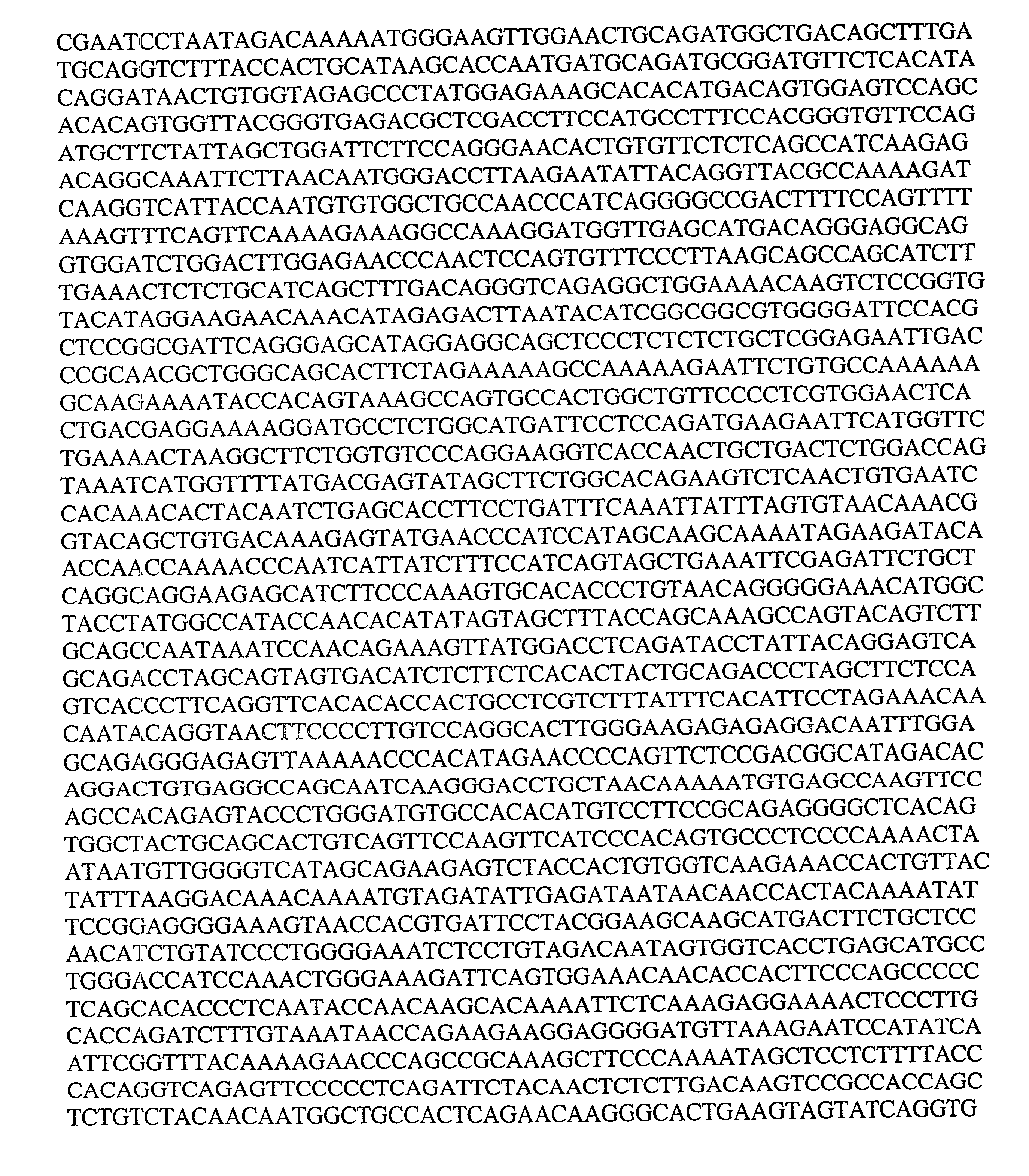

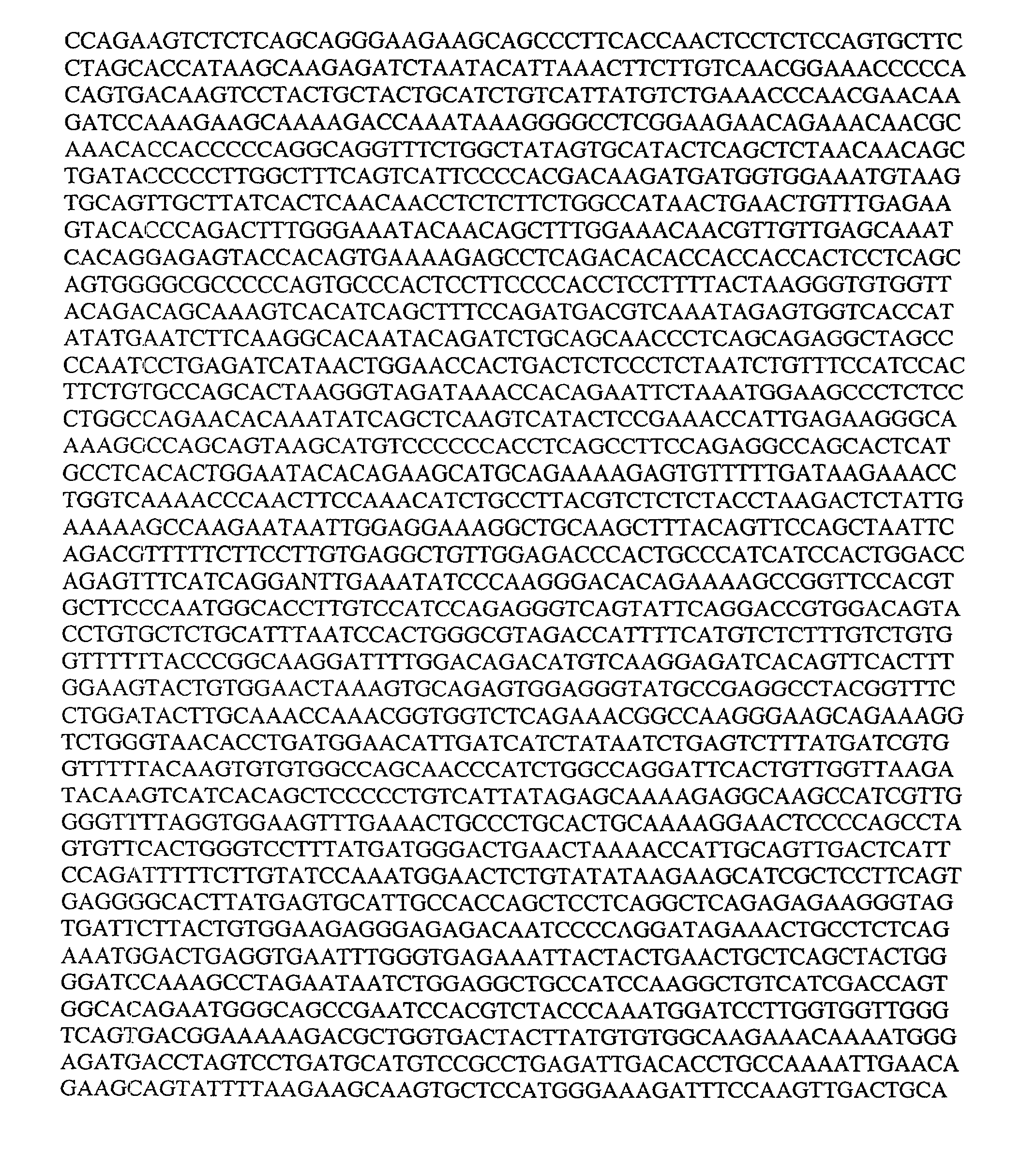

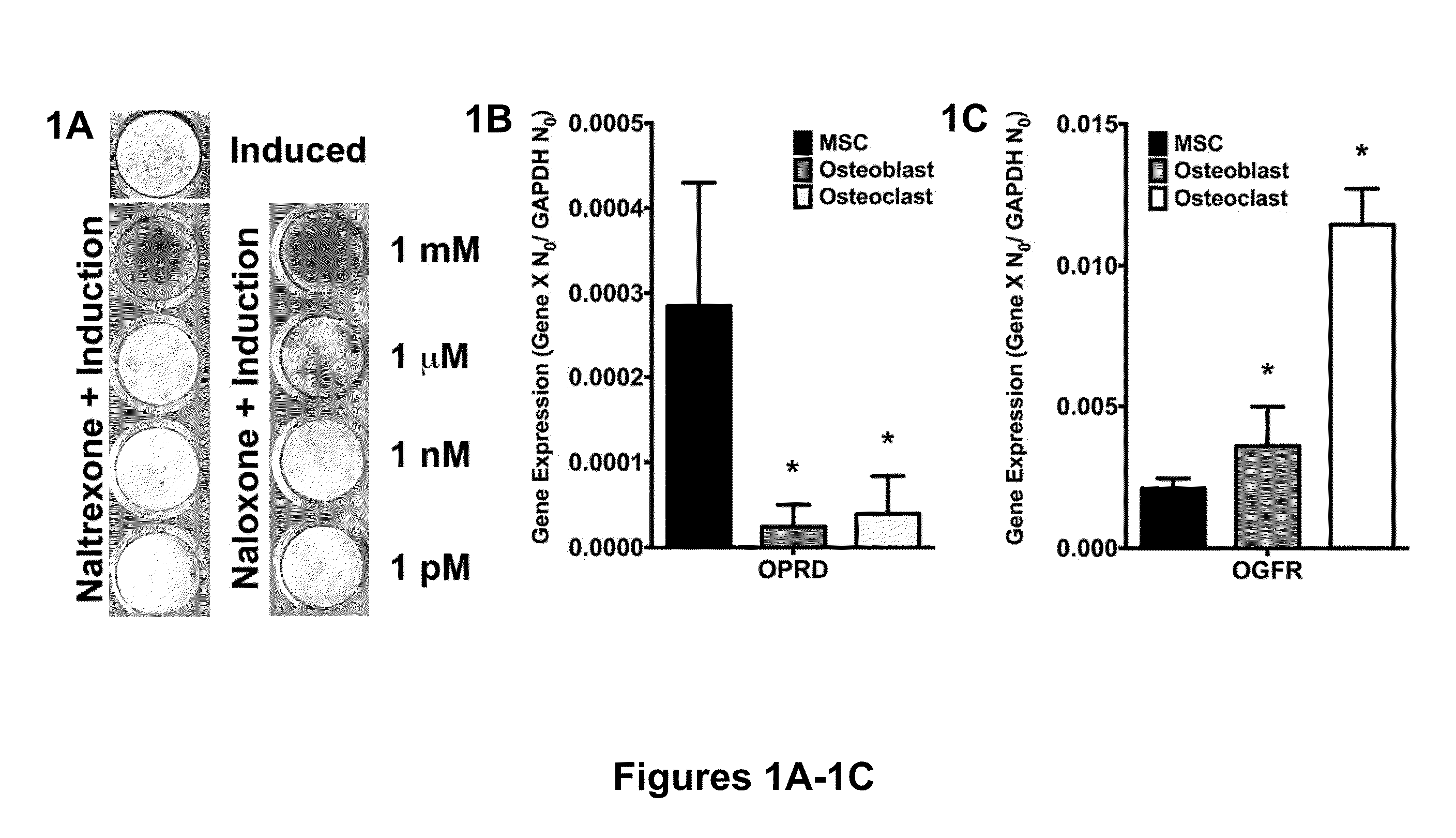

Genes associated with mechanical stress, expression products therefrom, and uses thereof

InactiveUS20020086825A1Enhance osteoblast proliferation/differentiationImprove bone formationPeptide/protein ingredientsGenetic material ingredientsStress inducedDysostosis

The disclosure relates to mechanical stress induced genes, such as those from human and from mice, probes therefor, tests to identify such genes, expression products of such genes, uses for such genes and expression products, e.g., in diagnosis (for instance risk determination), treatment, prevention, or control, of osteoporosis or factors or processes which lead to osteoporosis; and, to diagnostic, treatment, prevention, or control methods or processes, as well as compositions therefor and methods or processes for making and using such compositions.

Owner:EINAT PAZ +4

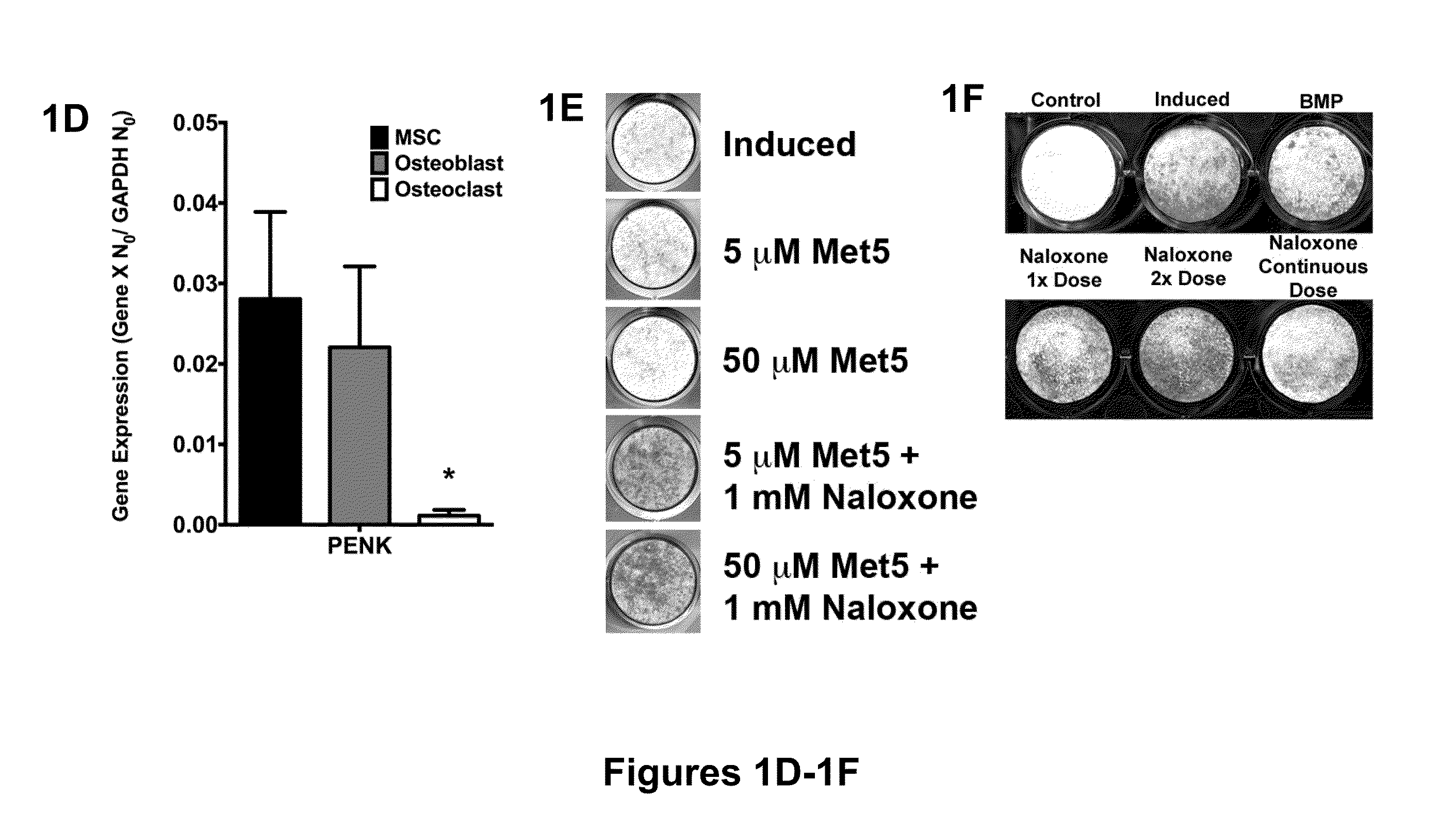

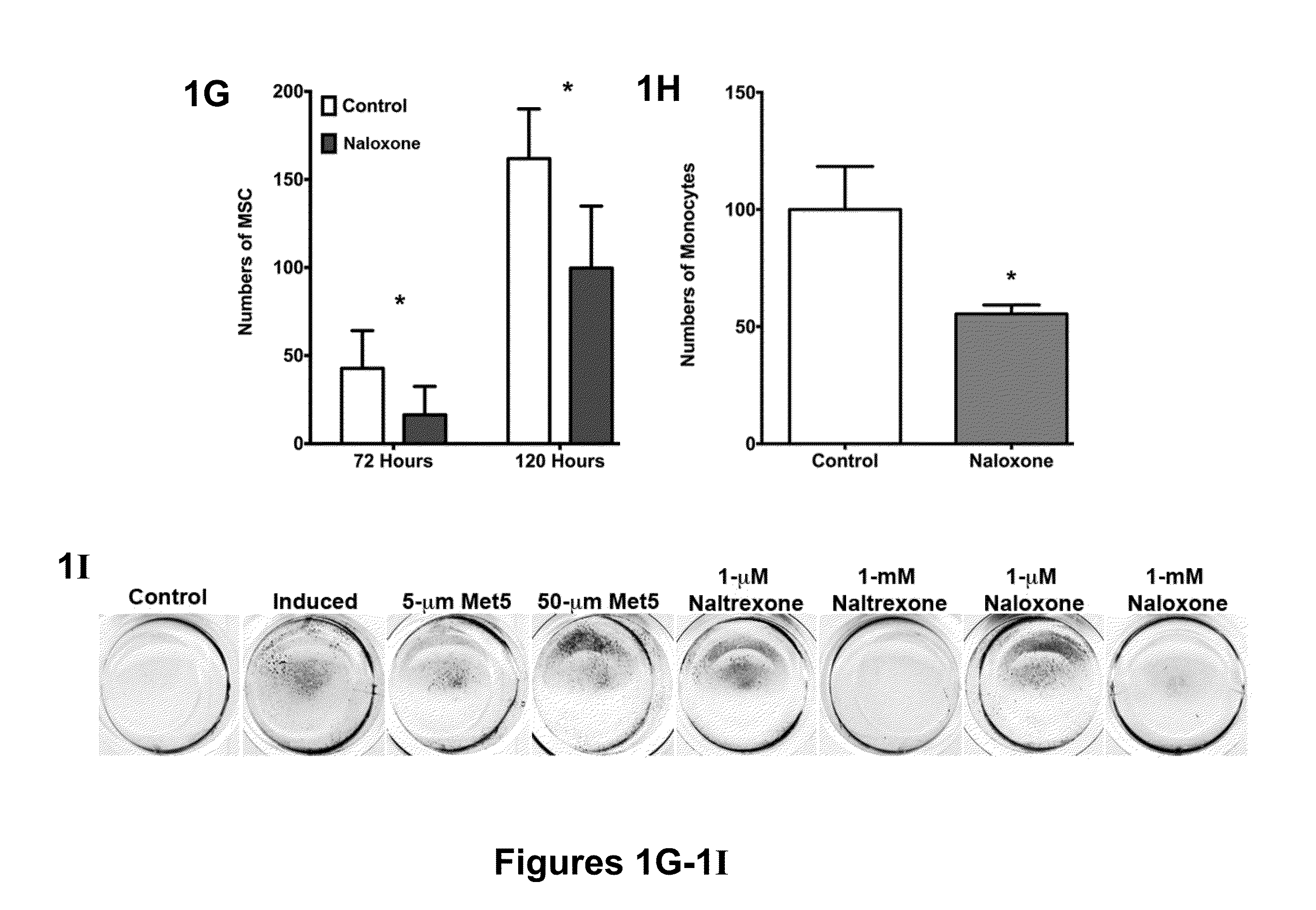

Compositions and methods to promote bone formation

ActiveUS20150344882A1Promotes bone formationReduce bone destructionBiocidePharmaceutical delivery mechanismDysostosisOsteoradionecrosis

This disclosure relates to methods for promoting bone formation or reducing bone destruction. This disclosure also relates to methods for promoting the recruitment of mesenchymal stem cells (MSC) to a local site of injury or surgical intervention in bone to promote healing. In addition, this disclosure relates to methods for reducing or preventing mineral formation or bone growth, or reducing bone mass. The methods disclosed herein are useful for treating conditions such as osteoradionecrosis.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Composite bovine colostrum powder for improving bone mineral density

InactiveCN102763729BPromote acid-base balanceIncrease bone densityMilk preparationOrganic acidBone density

Owner:南京苏邦生物技术有限公司

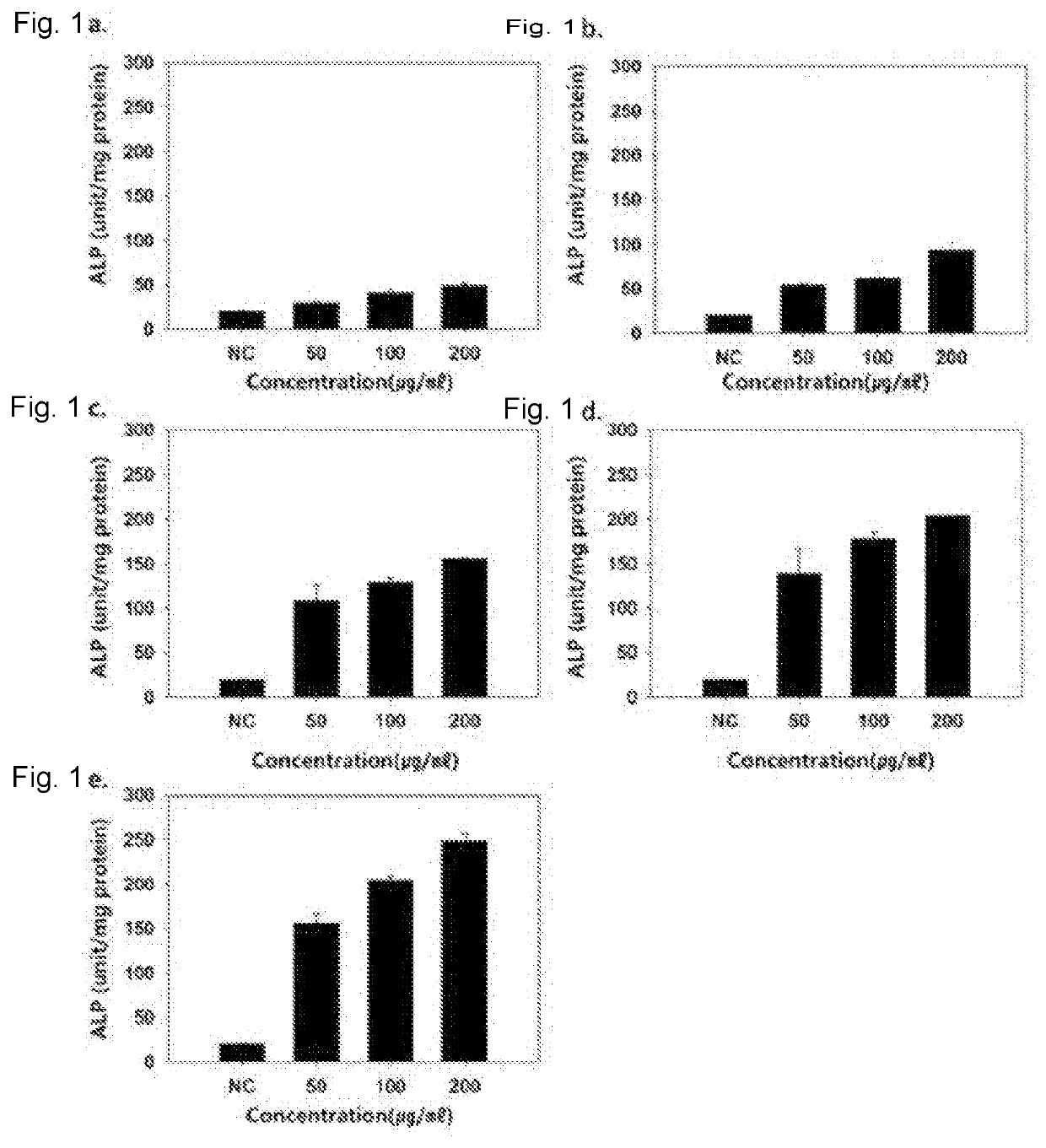

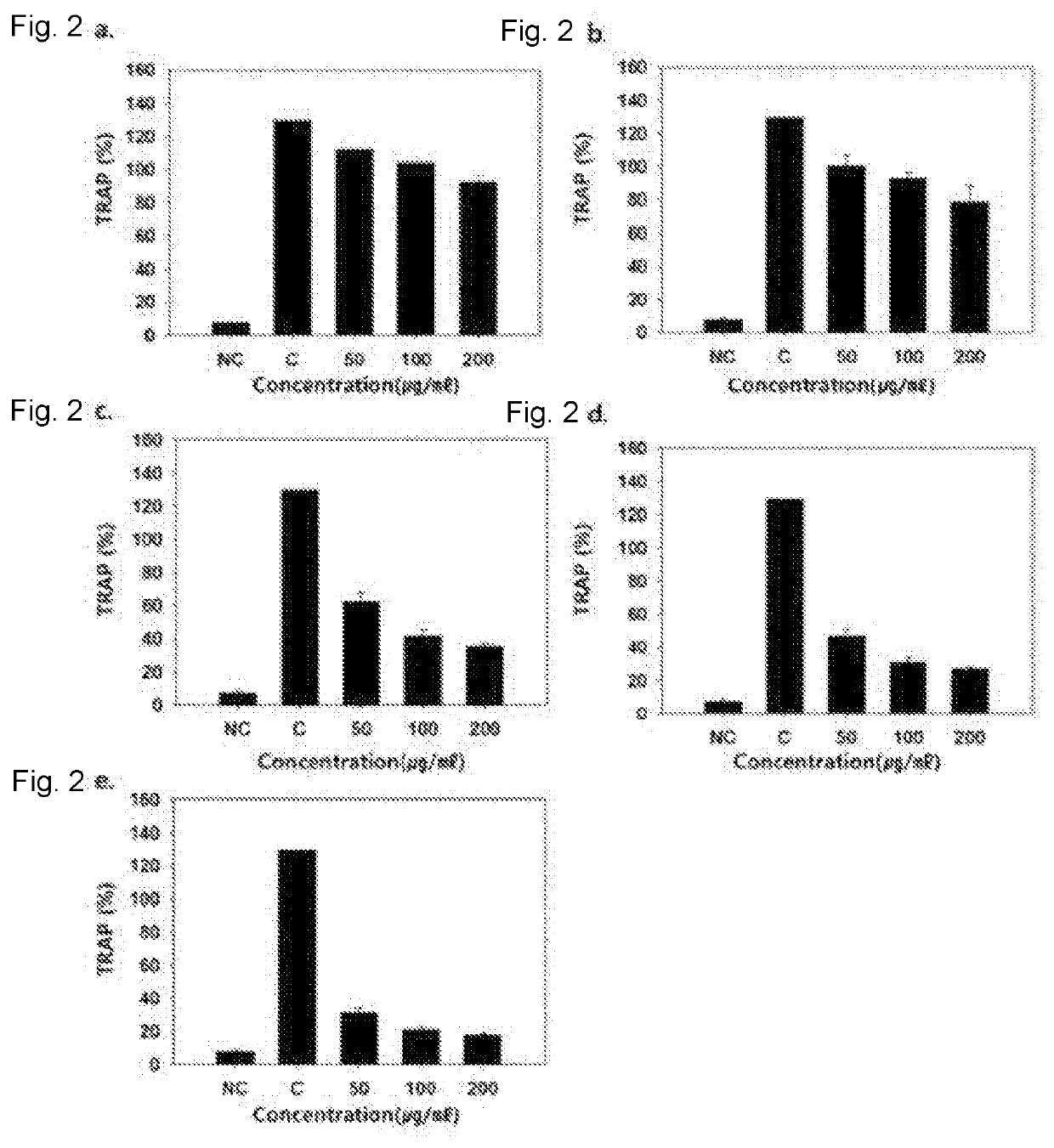

Compositon for preventing or treating osteoporosis

InactiveUS20210000900A1Improve bone formationInhibiting bone resorptionSkeletal disorderPlant ingredientsNatural productTraditional medicine

The present invention relates to a composition for preventing or treating osteoporosis, comprising a Gentiana scabra extract and a Sambucus williamsii extract, and it is an object of the present invention to provide the composition for preventing or treating osteoporosis, which is capable of increasing bone formation and inhibiting bone resorption. In addition, it is another object of the present invention to provide the composition for preventing or treating osteoporosis, which increases bioaffinity and has no side effects by comprising a Gentiana scabra extract and a Sambucus williamsii extract, which are natural products, thereby stably exhibiting an effect of preventing or treating osteoporosis.

Owner:PENS CO LTD +1

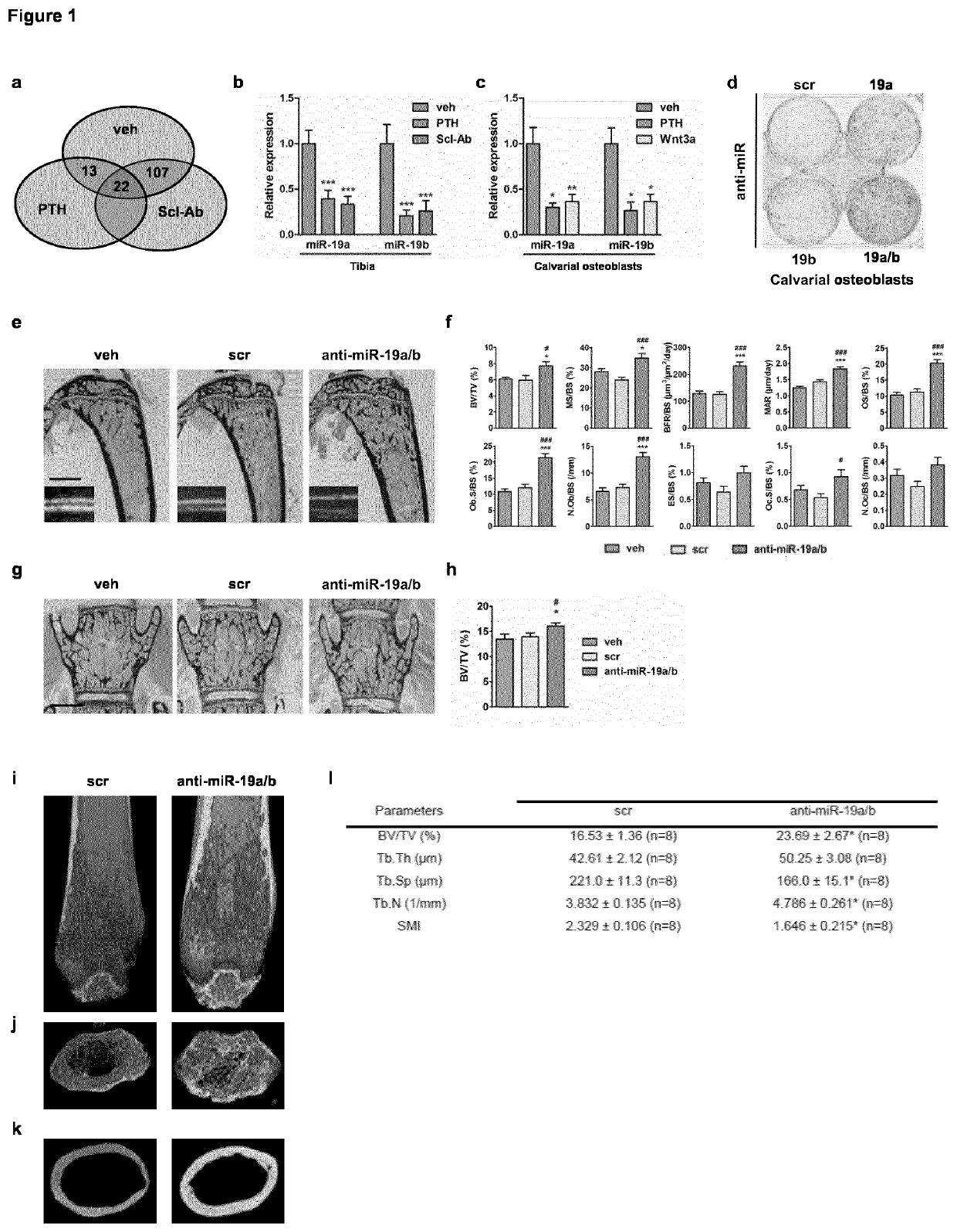

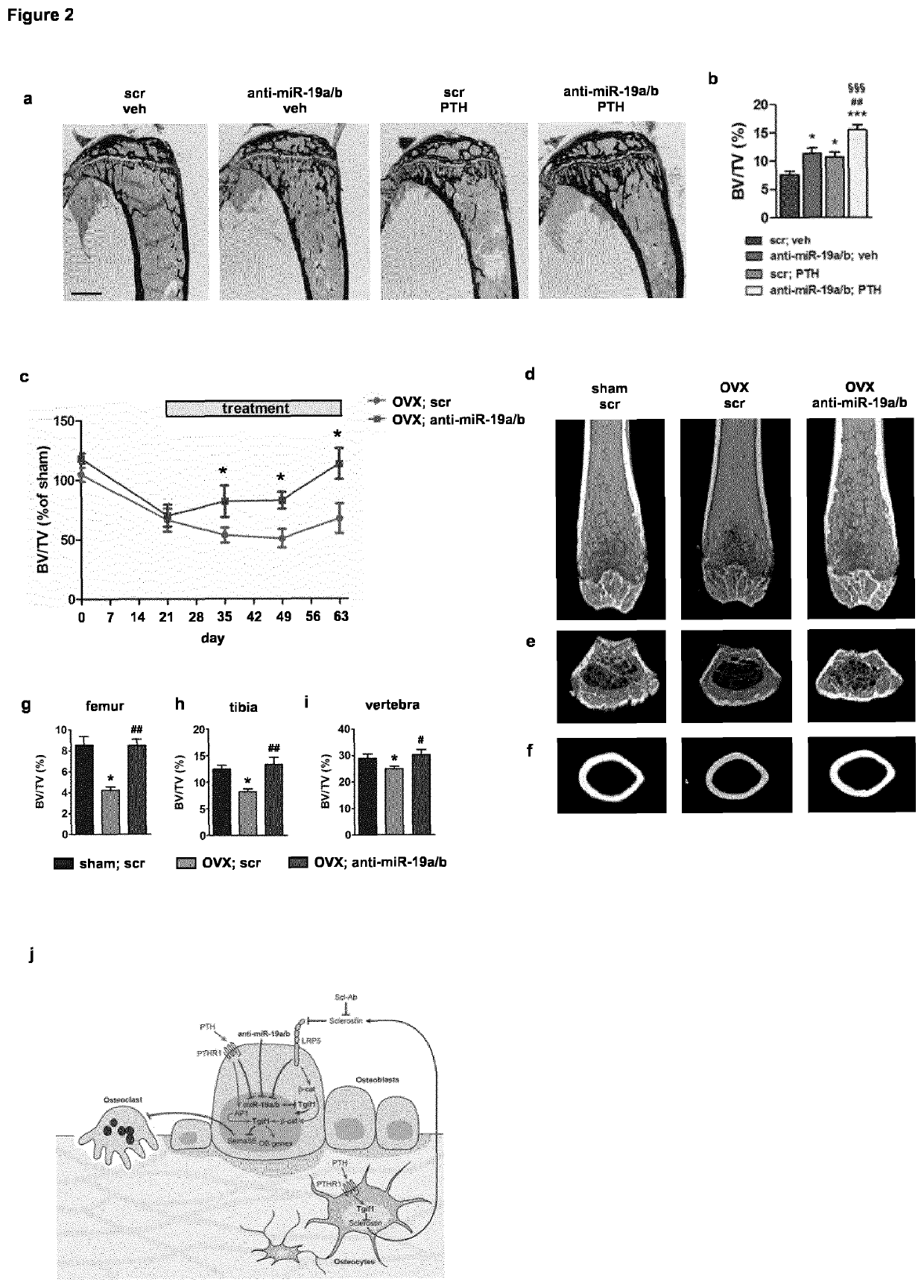

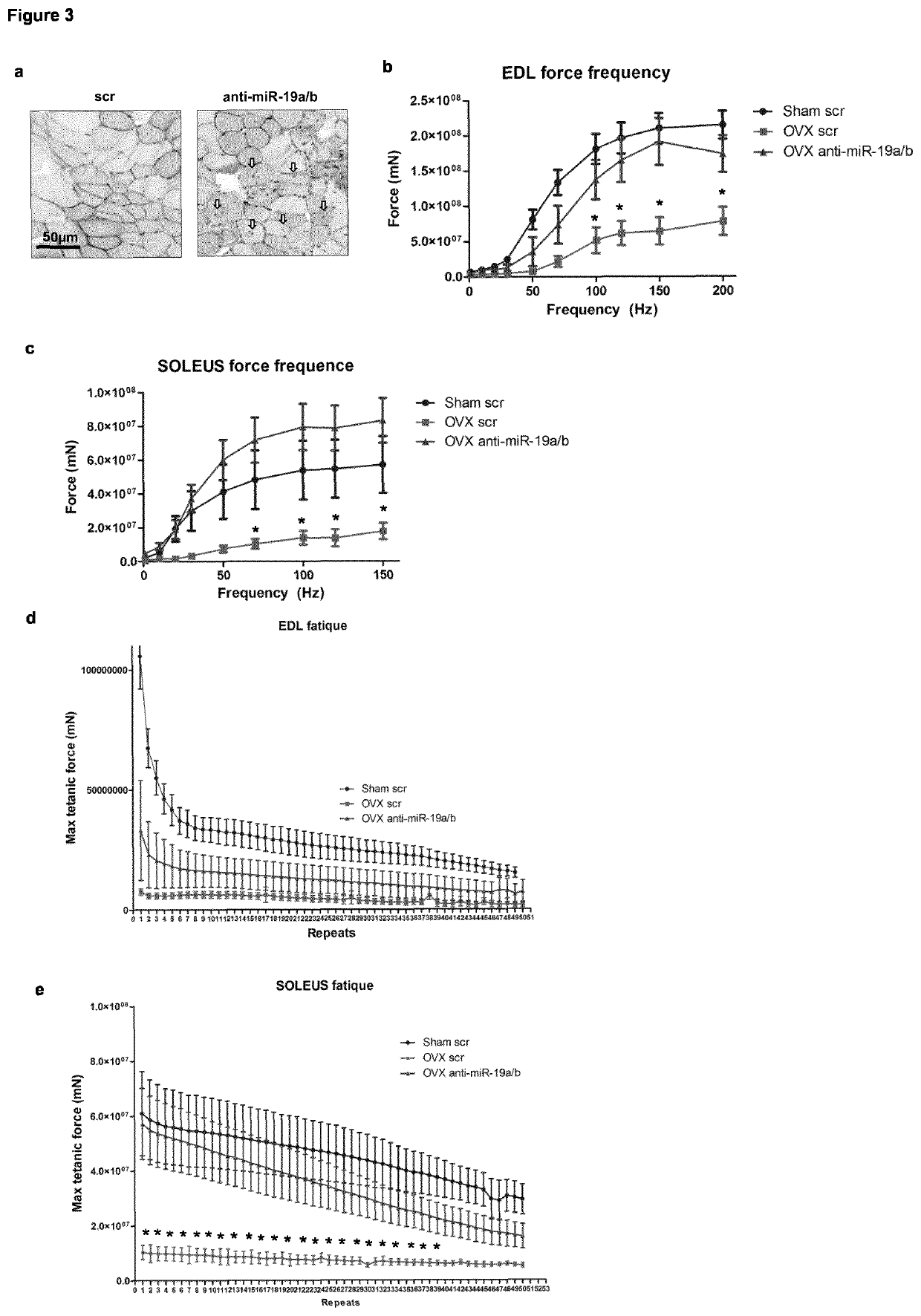

Microrna 19a/19b for use in treating a pathological condition associated with bone loss or reduced muscle function

ActiveUS20200038425A1Reduction of osteoclast-dependent bone resorptionIncrease bone massOrganic active ingredientsPeptide/protein ingredientsDecreased muscle functionDisease

The invention relates to inhibitors of microRNAs 19a and 19b and their use for treating or preventing conditions or diseases which are associated with bone loss, in particular osteoporosis and osteogenesis imperfect (01). The inhibitors are also useful for inducing an anabolic effect in bone, either alone or when administered in combination with parathyroid hormone or a recombinant fragment thereof. The invention further relates to inhibitors of microRNAs 19a and 19b and their use for treating or preventing conditions or diseases which are associated with reduced muscle function, in particular muscle degeneration and muscle atrophy. The inhibitors are also useful for stabilizing and / or strengthening muscle function. In addition, inhibitors of microRNAs 19a and 19b can be used for treating or preventing cancer-related bone destruction or bone metastasis.

Owner:UNIVERSITAETSKLINIKUM HAMBURG EPPENDORF

Anabolic compounds for treating and preventing bone loss diseases

InactiveUS20150126548A1Improve bone formationReduce the risk of fracturesBiocideOrganic chemistryDiseaseMedicine

Owner:JAFARI ABBAS +3

Degradable magnesium alloy bone nail with scaly bone-like nanostructure coating and preparation method thereof

ActiveCN109432514BImprove biological activityImprove antibacterialAnodisationPeptide/protein ingredientsOxide ceramicMicro arc oxidation

The invention relates to a degradable magnesium alloy bone nail with a scaly bone-like nanostructure coating on the surface and a preparation method thereof. The degradable bone nail consists of an AZ31B magnesium alloy bone nail base and PLGA-bone morphogenetic protein BMP loaded Squamous bone-mimicking nanostructures composed of MgO bioceramic coatings. The magnesium oxide bioceramic coating with a scaly bone-like nanostructure is combined with the surface of a metal substrate, and a nanoscale scaly nanostructure is constructed on the surface of the substrate by a micro-arc oxidation technique. BMP fills and loads between magnesium oxide squamous bone-like nanostructure layers through centrifugal force and capillary action. The preparation method is as follows: firstly, the AZ31B magnesium alloy is processed into a bone nail; then, a magnesium oxide ceramic coating with scaly bone-like nanostructure characteristics is obtained on the surface of the substrate by micro-arc oxidation technology; Loading of PLGA‑bone morphogenetic protein between layers of bone nanostructures.

Owner:SOUTHWEST UNIV

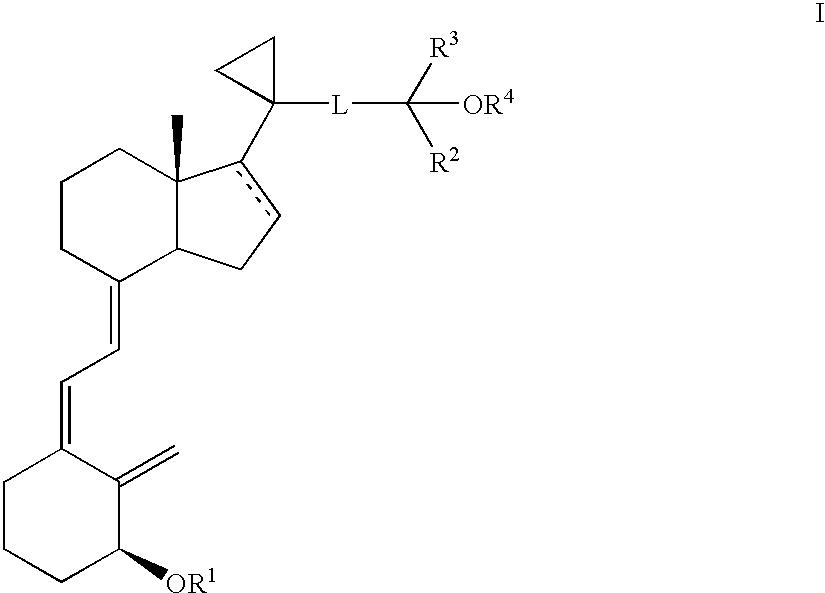

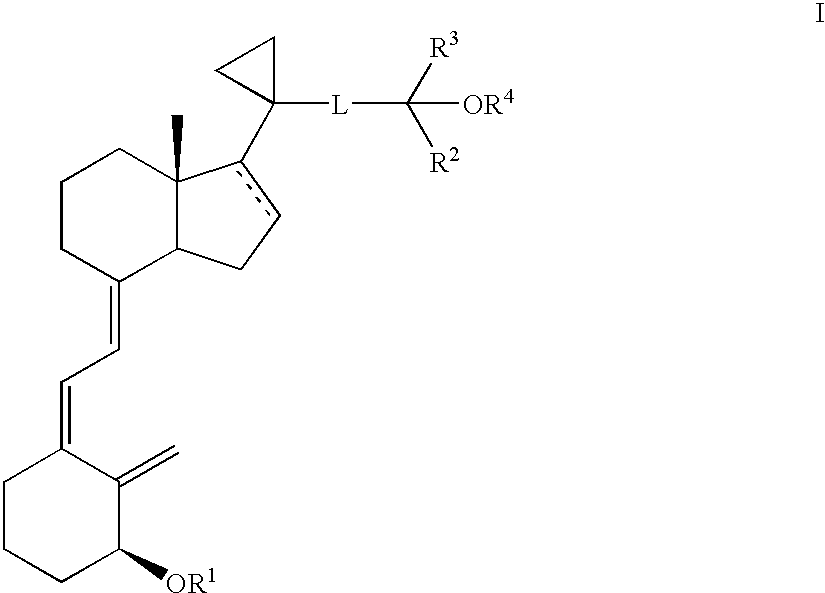

Methods of treatment using 3-desoxy vitamin D3 analogs

InactiveUS7491711B2Improve bone formationOrganic active ingredientsBiocideAutoimmune conditionMedicine

The present invention provides a method for treating osteoporosis, hyperparathyroidism or an autoimmune disease in a patient by administering to the patient a 3-desoxy vitamin D3 analog of the formula:a prodrug or a salt thereof, where the dotted line, R1, R2, R3, R4 and L are those defined herein. The present invention also provides methods for producing 3-desoxy vitamin D3 analog of Formula I.

Owner:SYNTEX (USA) INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com