Patents

Literature

197results about How to "Broaden the formation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of modified biologically-activated filter fillings

InactiveCN101948166APromote growthSpeed up the formation processSustainable biological treatmentBiological water/sewage treatmentNutrientSewage treatment

The invention relates to a preparation method of modified biologically-activated filter fillings, comprising the following steps of: (1) cleaning an inorganic carrier with the grain diameter of 3-8 millimetres, sequentially carrying out acid cleaning, alkaline cleaning and drying to obtain dry fillings; (2) adding the dry fillings to a metal salt solution to carry out soaking and ultraphonic, drying and sintering to obtain sintering charges; (3) naturally cooling and drying the sintering charges to obtain dry sintering charges; (4) adding the dry sintering charges to a polymeric hydrogel solution containing trace elements and nutrient salts, carrying out soaking and ultraphonic and reacting in a saturated boric acid solution or a 3% calcium chloride solution so as to obtain crosslinked fillings; and (5) drying and naturally cooling the crosslinked fillings so as to obtain the modified biologically-activated filter fillings. The invention has the advantages of simple process and easy implementation; and in addition, the obtained modified biologically-activated filter fillings can increase the activity and the number of biomembranes, shorten the membrane-forming periods of biological aerated filter fillings and enhance the sewage treatment efficiency and the stability of a biological aerated filter.

Owner:GANSU GOLDEN BRIDGE GRP CO LTD +1

Composite amino acid ecological nutritious agent

InactiveCN1594232AApparently antiviralObvious antibacterialAnimal corpse fertilisersClimate change adaptationTrace elementFermentation

The invention provides a composite amino acid ecological nutritious agent, which comprises sea weed fermentation liquor, fermentation liquor of animal leftover bits and pieces, trace elements, and biological bacterium. The functions of the agent include stimulating growth, suppressing pathogenic agent and reinforcing immunization.

Owner:李长江

Halogen-free flame-retardant polypropylene master batch

The invention relates to a halogen-free flame-retardant polypropylene master batch. The halogen-free flame-retardant polypropylene master batch comprises the following components in percentage by weight: 20 to 40 percent of polypropylene pellets, 40 to 60 percent of ammonium polyphosphate, 0.5 to 3.0 percent of flame-retardant synergist, 6 to 25 percent of halogen-free charring agent, and 5 to 15 percent of compatibilizer. A method for preparing the halogen-free flame-retardant polypropylene master batch comprises the following steps of: weighing raw materials according to the weight proportion, drying, and extruding and granulating by a co-rotating or counter-rotating twin-screw extruder, wherein the rotating speed of a screw is 70 to 200rpm; and the temperature is 160 to 230 DEG C. The disadvantages that the atactic polypropylene (APP) is independently added, so flame-retardant efficiency is low, the mechanical properties of matrixes are greatly influenced, great inconvenience is brought to the drying treatment of the raw materials, dust pollution is caused and the like are overcome. The invention has the advantages that: the flame-retardant synergistic effect can be well realized among components of the master batch, mixing and drying processes of the raw materials in the production process are simplified, and the production efficiency is improved; the dust in the production process is reduced, and the production environment is improved; and a flame-retardant polypropylene material prepared from the master batch has a good flame-retardant effect and excellent mechanical properties.

Owner:YANGZHOU UNIV

Bone grafting material, method and implant

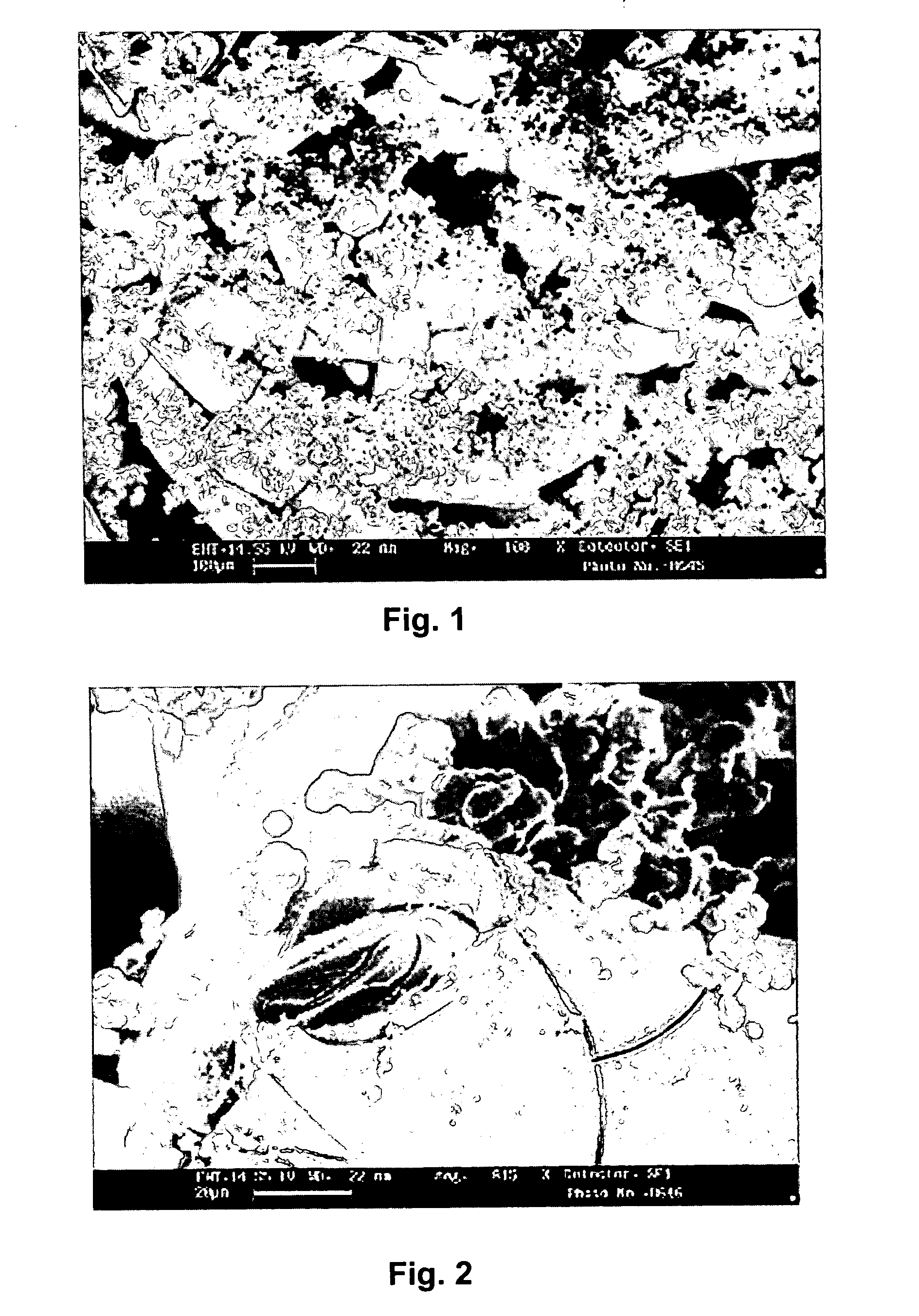

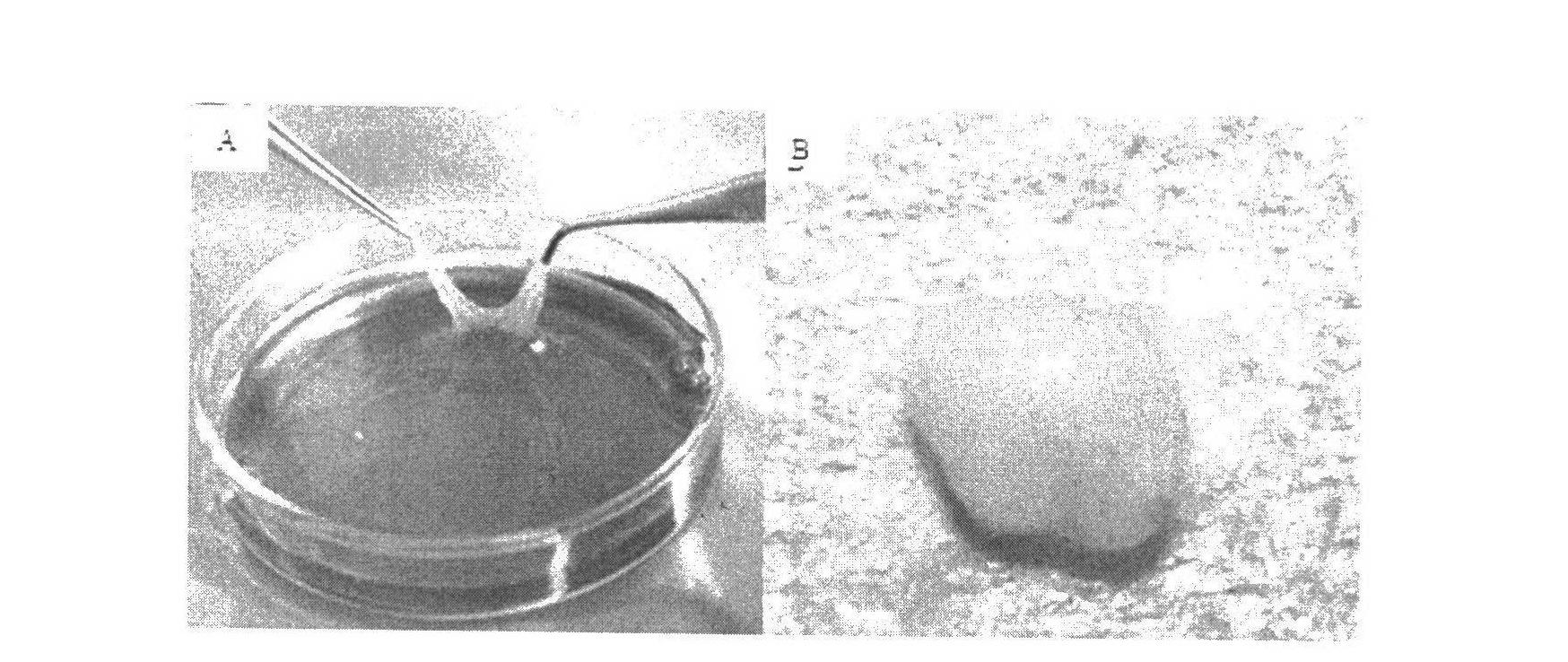

InactiveUS20050201987A1Broaden the formation processImprove bone formationBiocideTissue regenerationBone graftingGlass-ceramic

A bone grafting material, a method of producing the same, and an implant. The bone grafting material comprises a porous carrier of ceramic or glass ceramic or glass material and at least one pyrrolidone arranged in the carrier.

Owner:INION

Tissue engineering cartilage and preparation method thereof

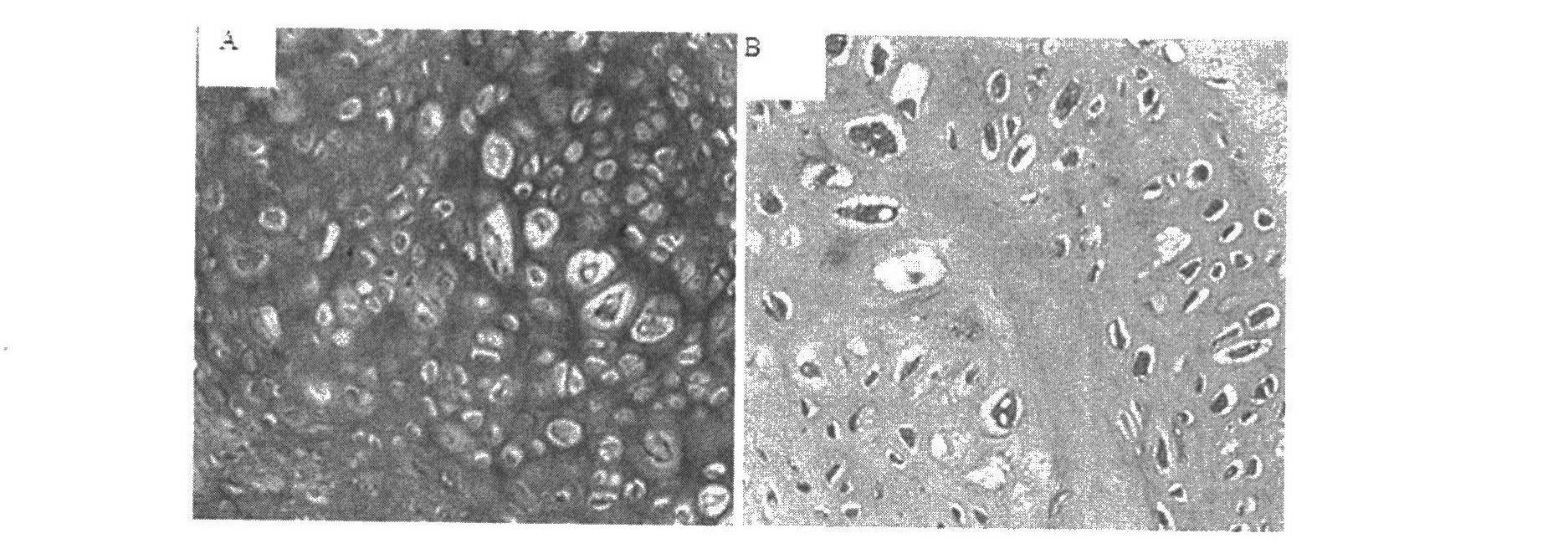

ActiveCN102526806AIncrease cell densityCell viability and microenvironment are goodBone implantTissue engineeringNormal cartilage

The invention discloses a tissue engineering cartilage and a preparation method thereof. The tissue engineering cartilage is cytoactive, consists of sequentially laminated cell patches including a surface layer, a middle layer, a deep layer and a calcified layer, and takes collagen matrix as a main component; the layers are compounded by collagen and hyaluronic acid, and the bordering integration of various layers of cartilage structures is promoted through hydrostatic culture; and the tissue engineering cartilage is prepared by preparing various layers of cartilage cell patches and assembling multiple structural layers. The prepared tissue engineering cartilage is in a layering arrangement of a natural cartilage, has a very good tissue structure and very good mechanical properties (frictional coefficient is 75-85 percent that of a natural cartilage tissue, and the elastic modulus is 80-90 percent that of the natural cartilage tissue.); the integration between different layers is good; experiments prove that the prepared tissue engineering cartilage can form the tidal line same as that of a normal cartilage tissue and has the same layering structure; and the prepared tissue engineering cartilage is capable of promoting regeneration and function recovery of a cartilage and obviously shortening the cycle of cartilage damage treatment and is applicable to cartilage defect restoration for a load-bearing part of a articular cartilage.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

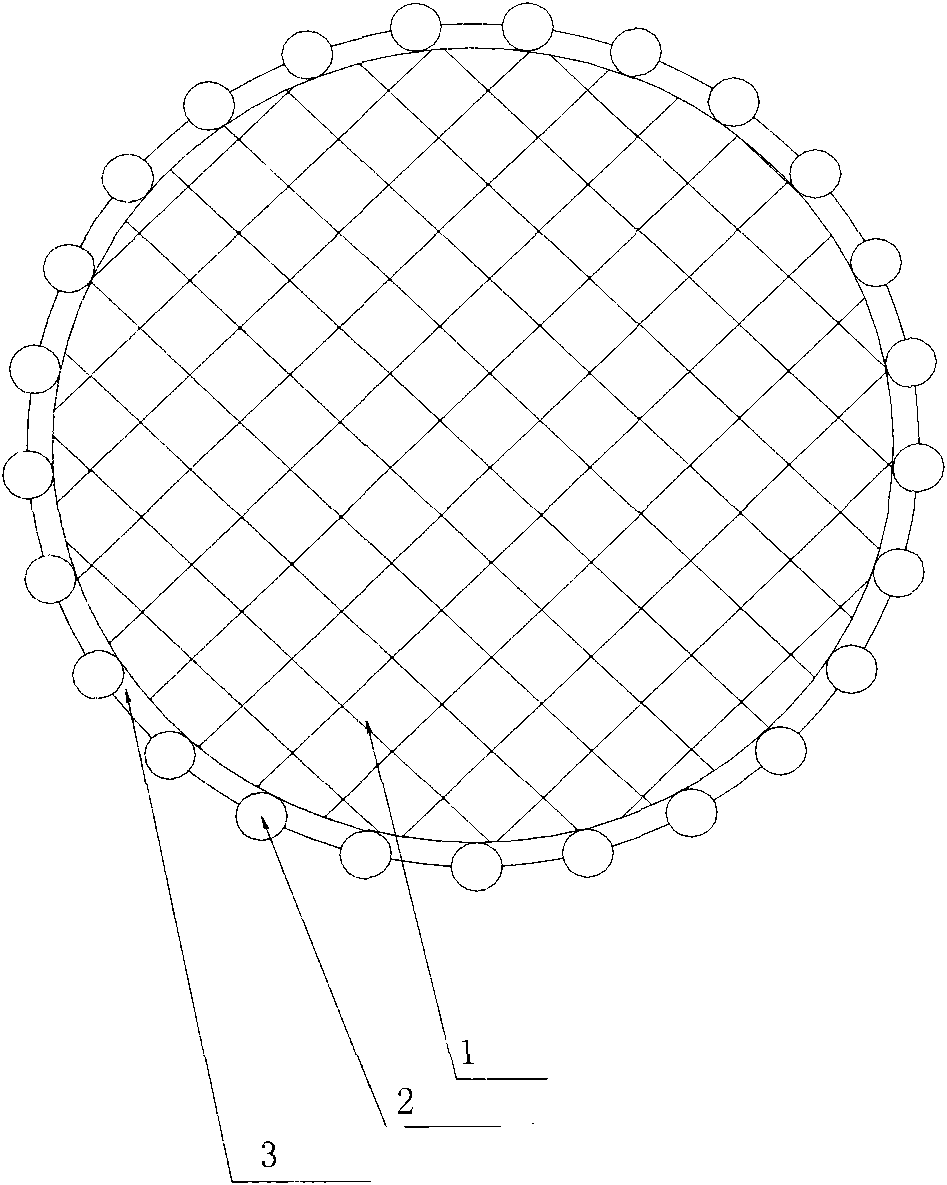

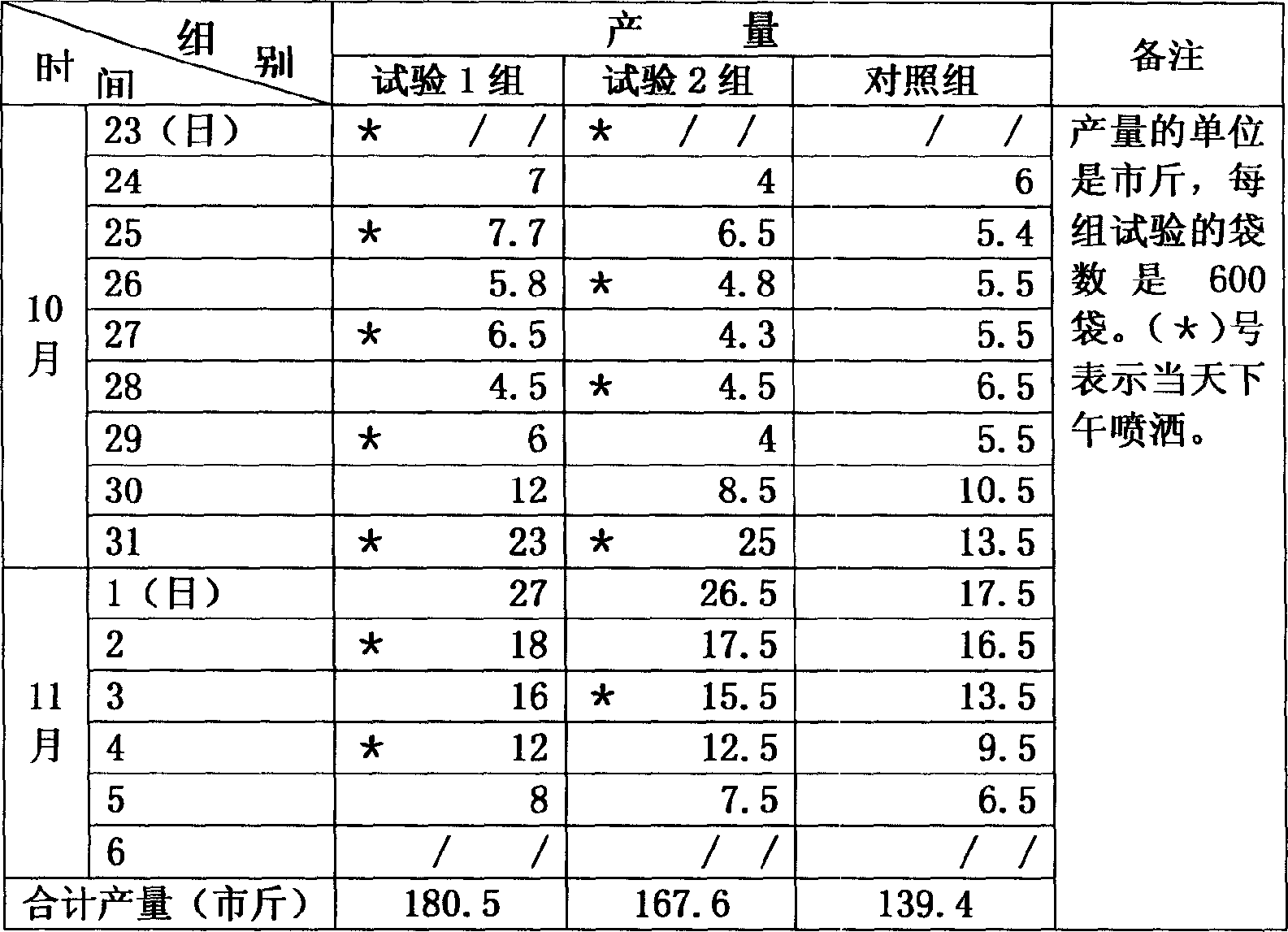

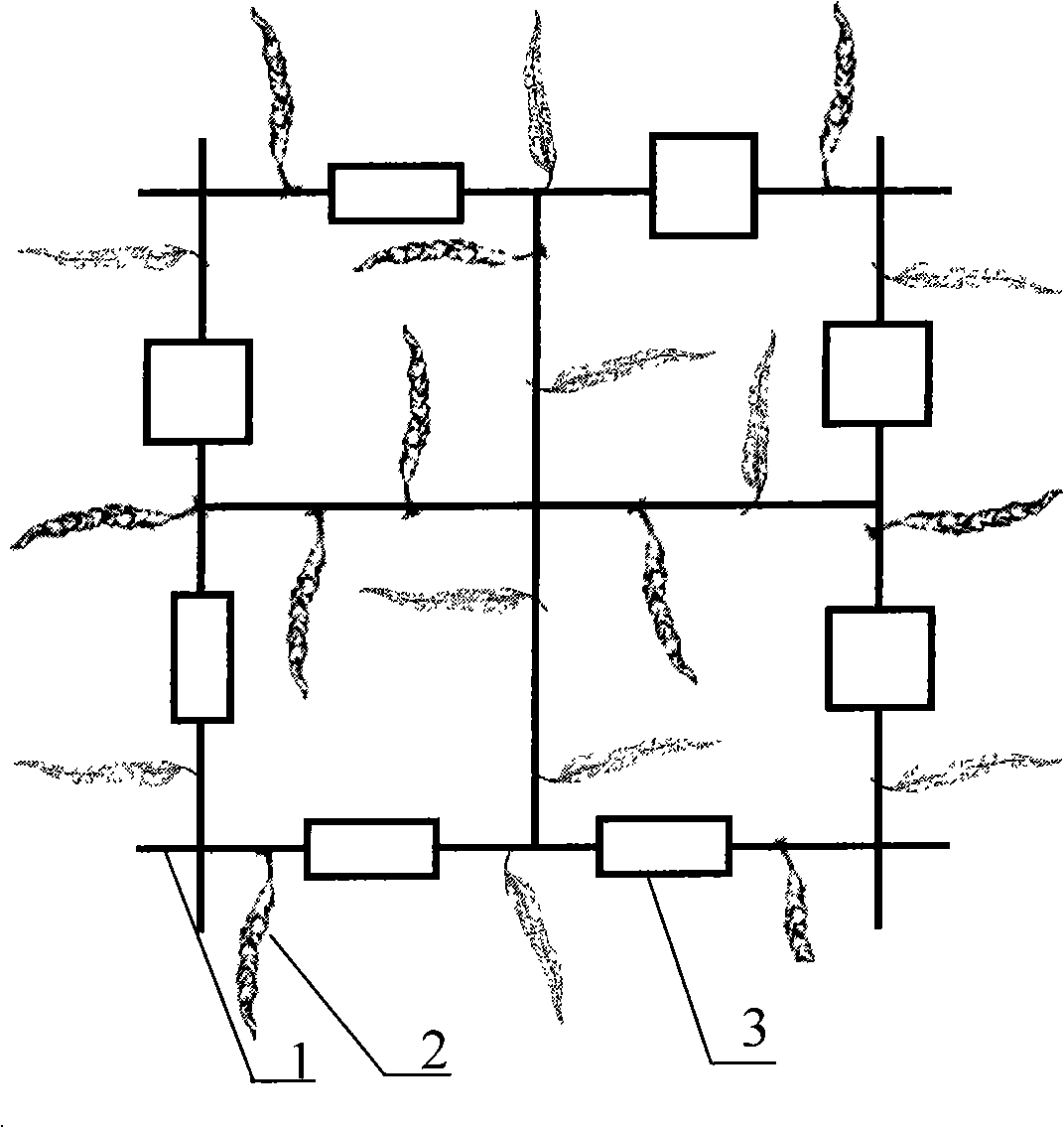

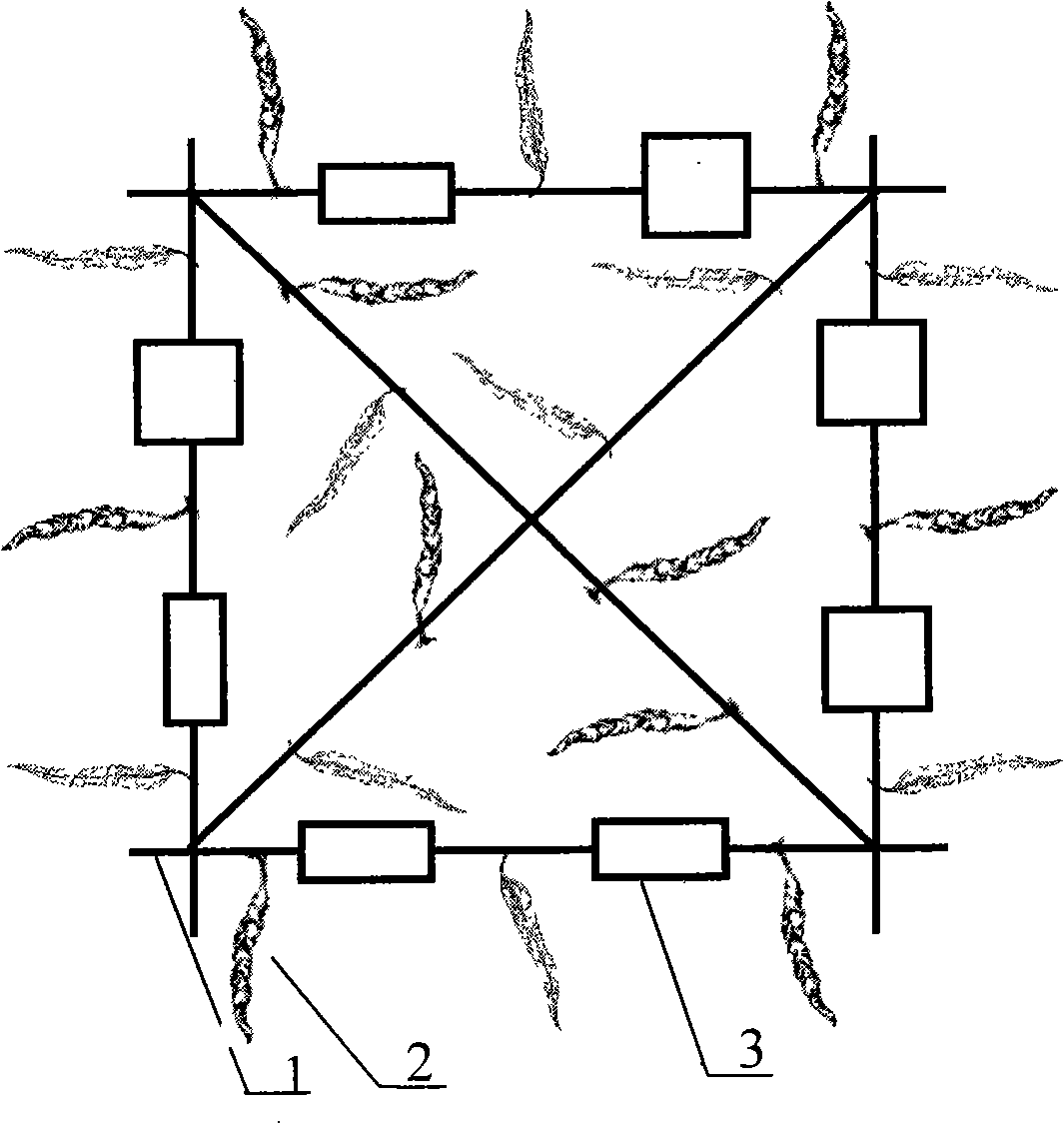

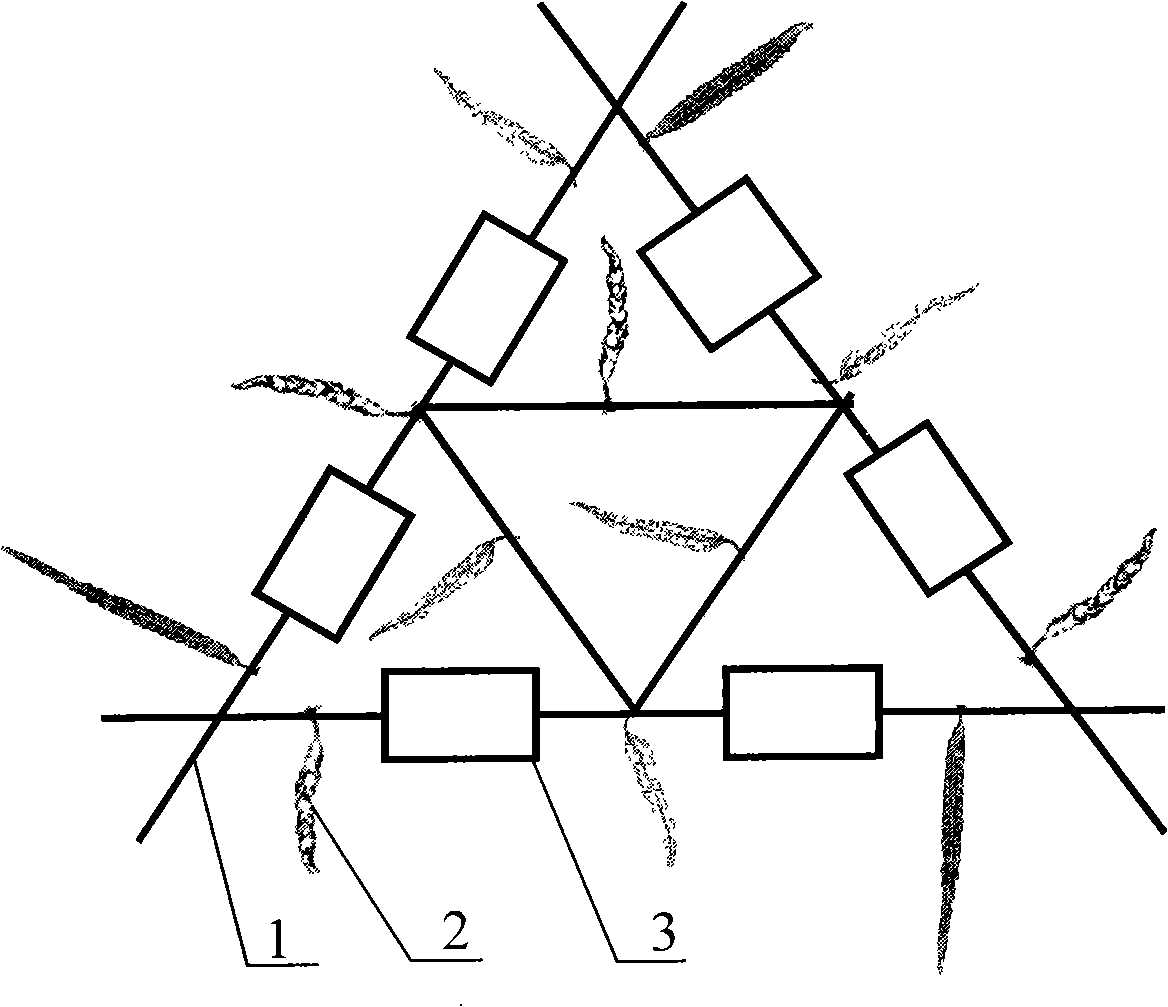

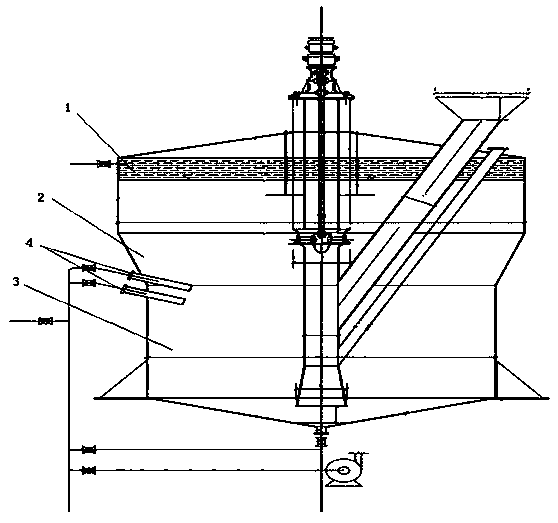

Artificial algae field and construction method thereof

InactiveCN101326894AIncrease chance of attachmentBroaden the formation processClimate change adaptationCultivating equipmentsEngineeringPolygon mesh

The invention relates to an artificial alga field and a construction method thereof. A regular polygon grid structure formed by ropes is taken as a unit grid; a heavy stone stabilizing the structure is arranged on each side of the unit grid, and at the equal-distant location of each side inside the unit grid, a crossed rope or a polygon structure is connected with other sides; marine alga is planted on the ropes to form a unit alga field; and a great many of such unit alga fields are woven by ropes to achieve a large area of artificial alga field. The invention is capable to construct an artificial alga field rapidly at low cost; as a result, the desertification of sea area is alleviated, the marine environment is purified, and a place for fish, shrimp and cuttle fish to spawn, seek food and inhabit is established, and the fishery resources are protected and increased; in addition, the artificial alga field can also be used to breed marine alga, and as a result, the income of fishermen is increased.

Owner:OCEAN UNIV OF CHINA

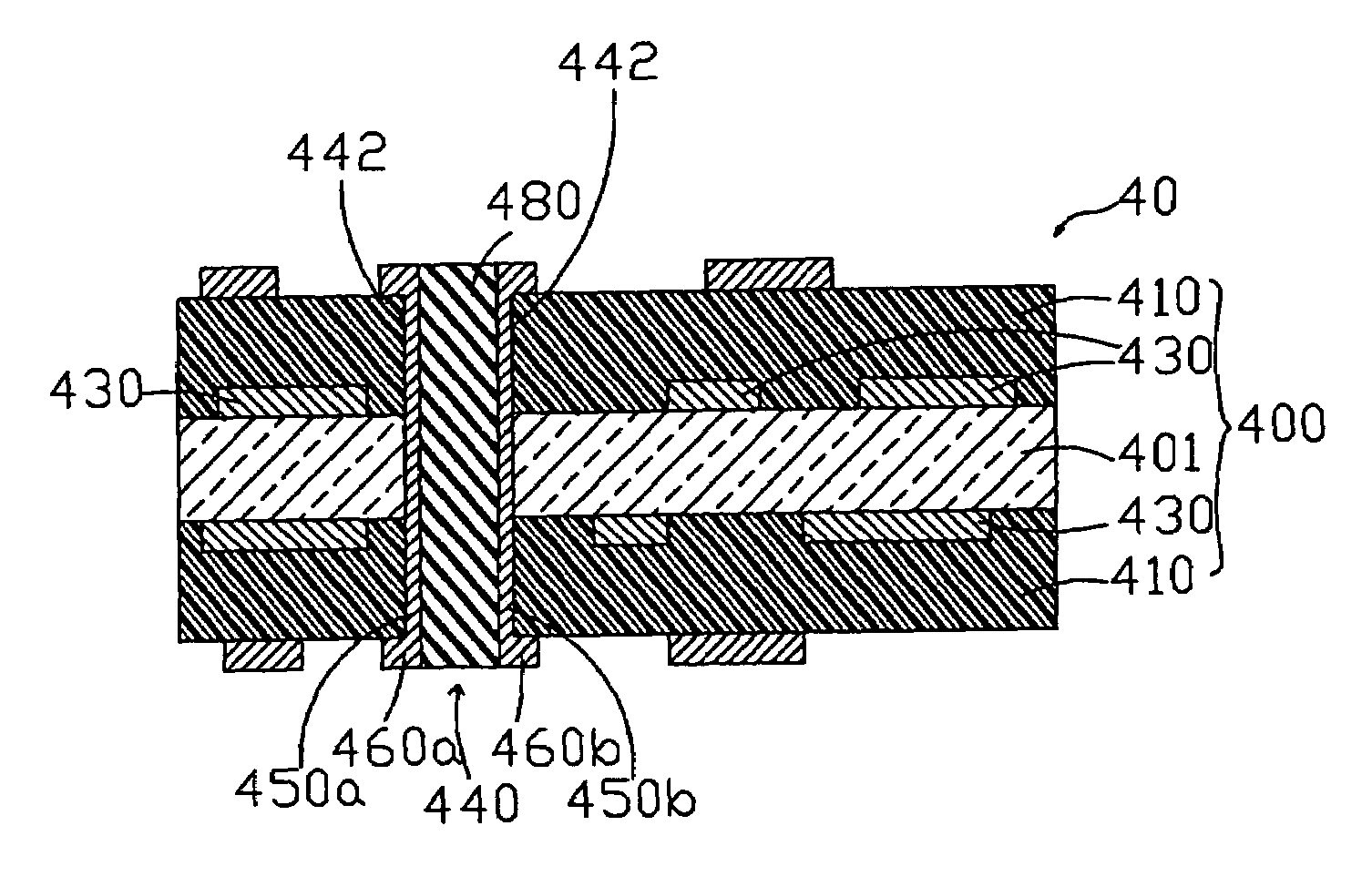

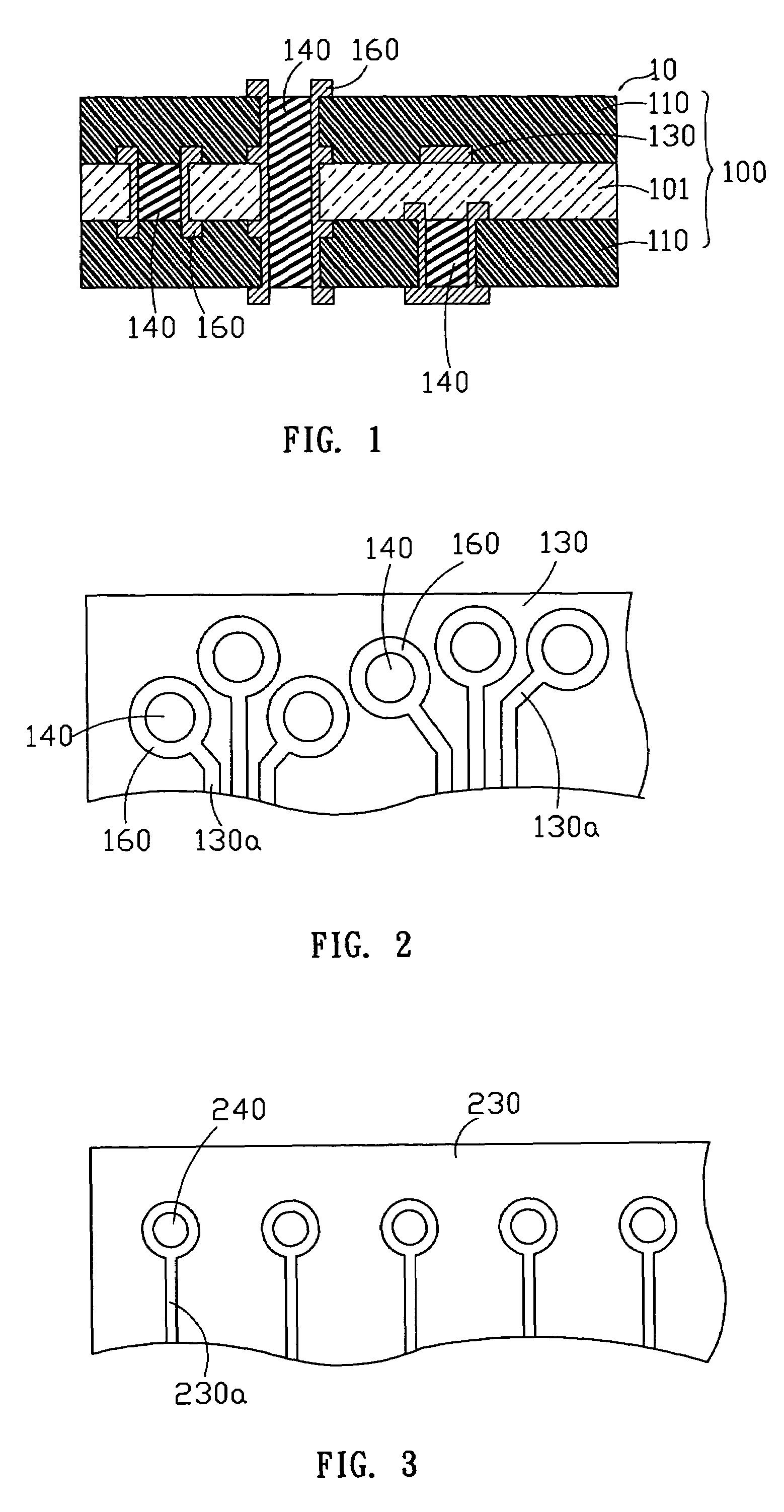

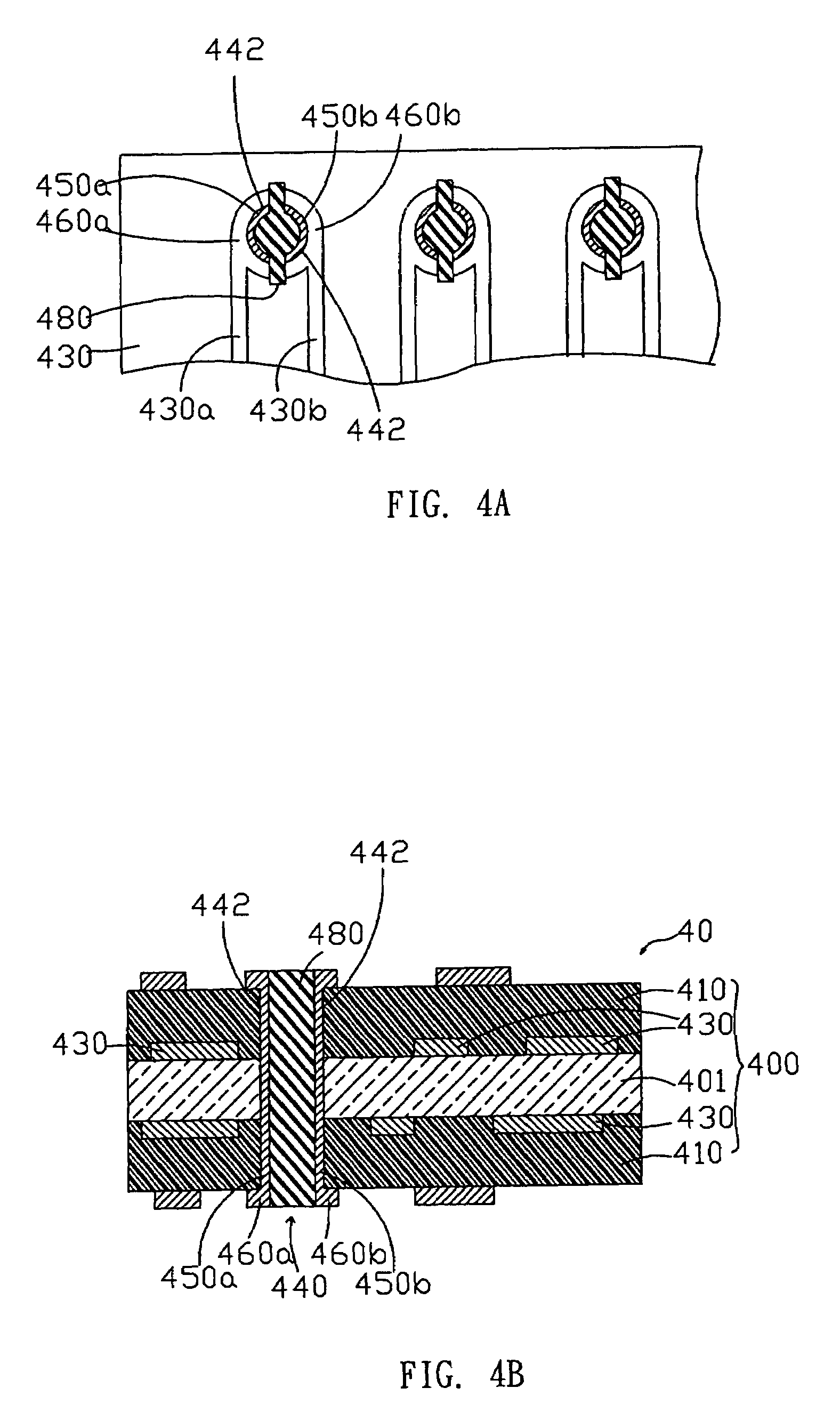

Circuit substrate and fabrication method thereof

ActiveUS7060595B2High densityReduce in quantitySemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringMetal

A circuit substrate includes a board, a plurality of metal layers and an insulator. The board has a plurality of conductive traces layers and a via formed therein. The metal layers are formed on the inner wall of the via and each of the metal layers is electrically connected to its corresponding conductive traces layer. The via is filled with the insulator so that each of the metal layers is electrically isolated from each other. In addition, this invention also provides a fabrication method of the circuit substrate.

Owner:ADVANCED SEMICON ENG INC

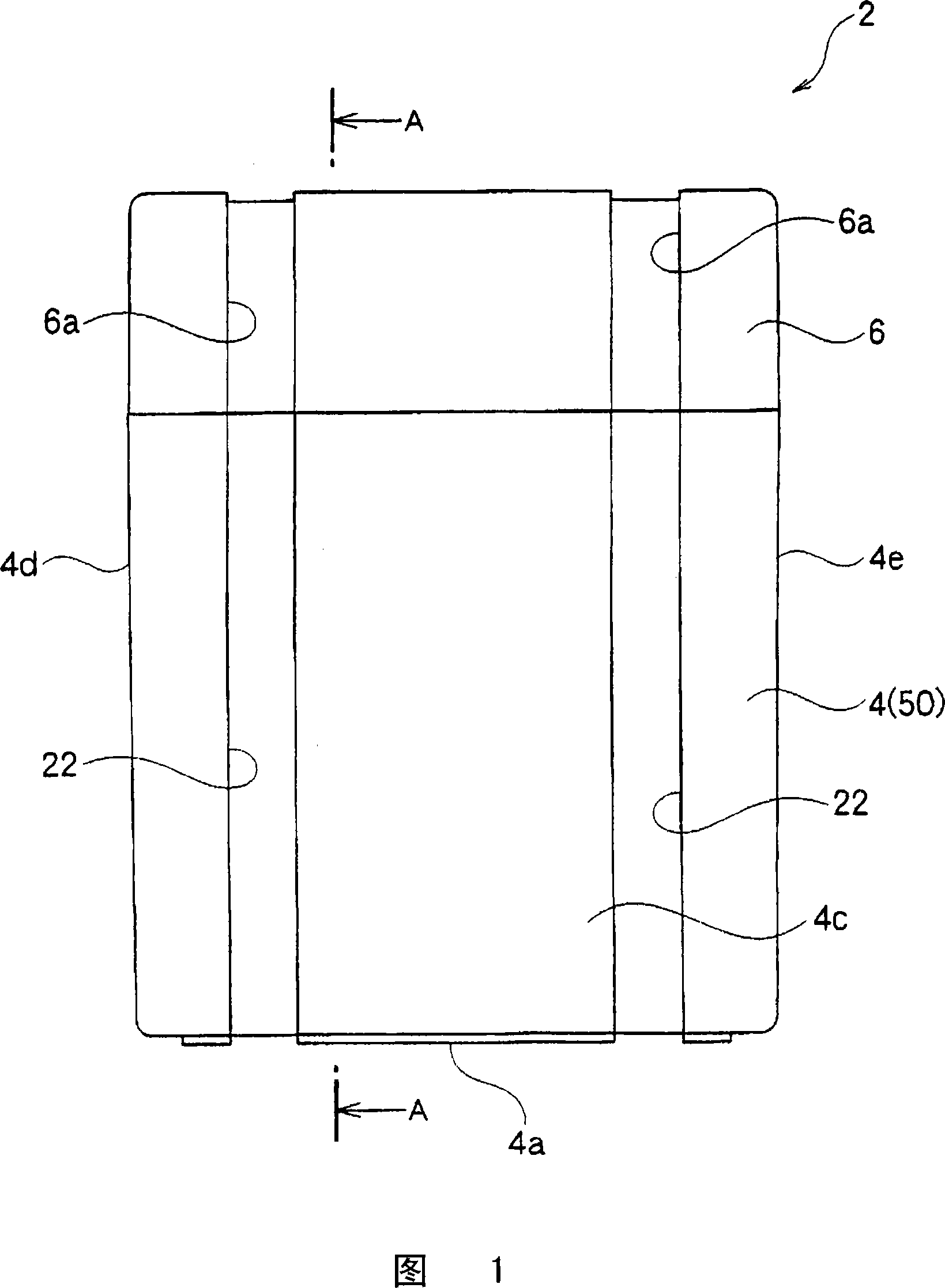

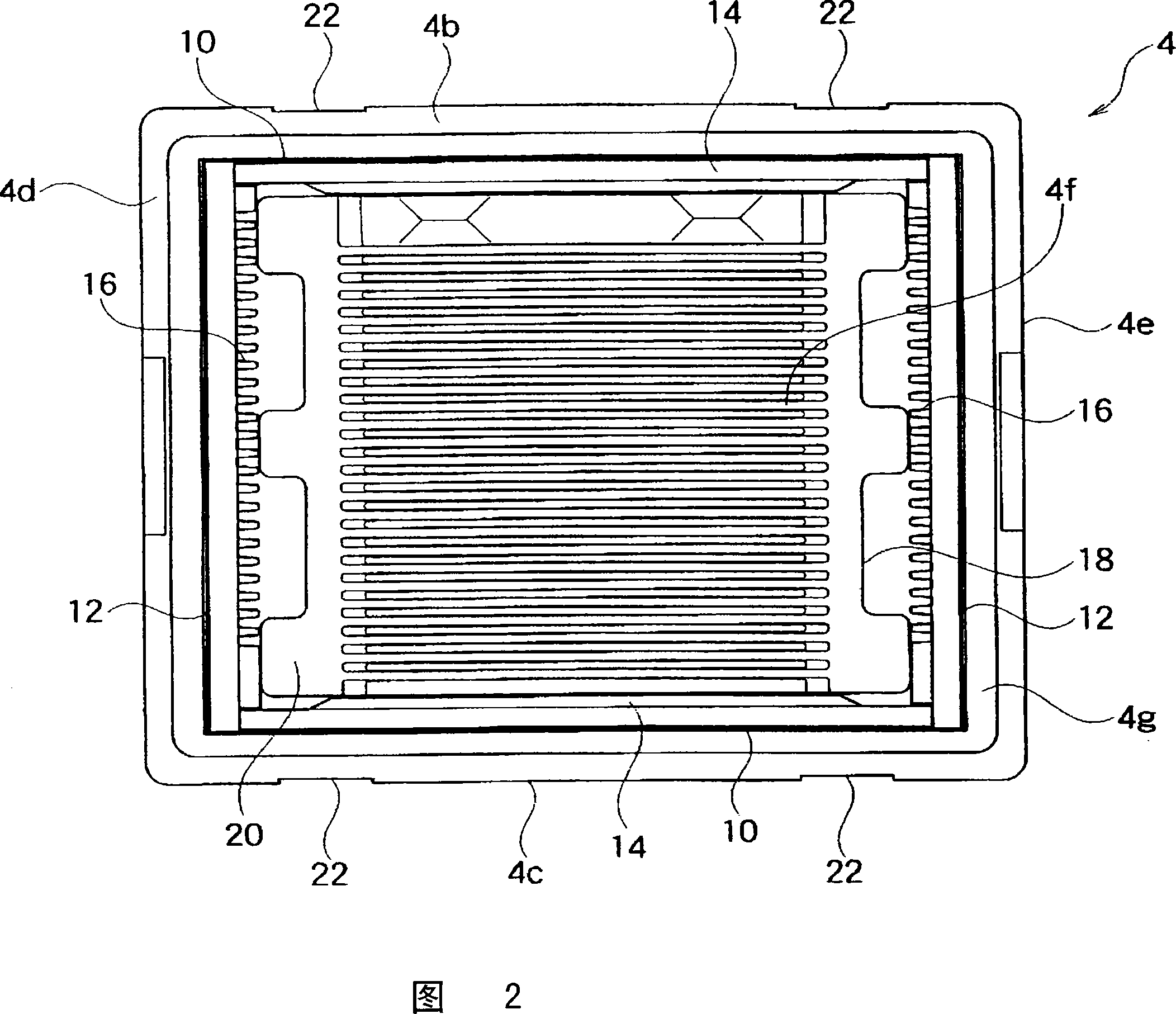

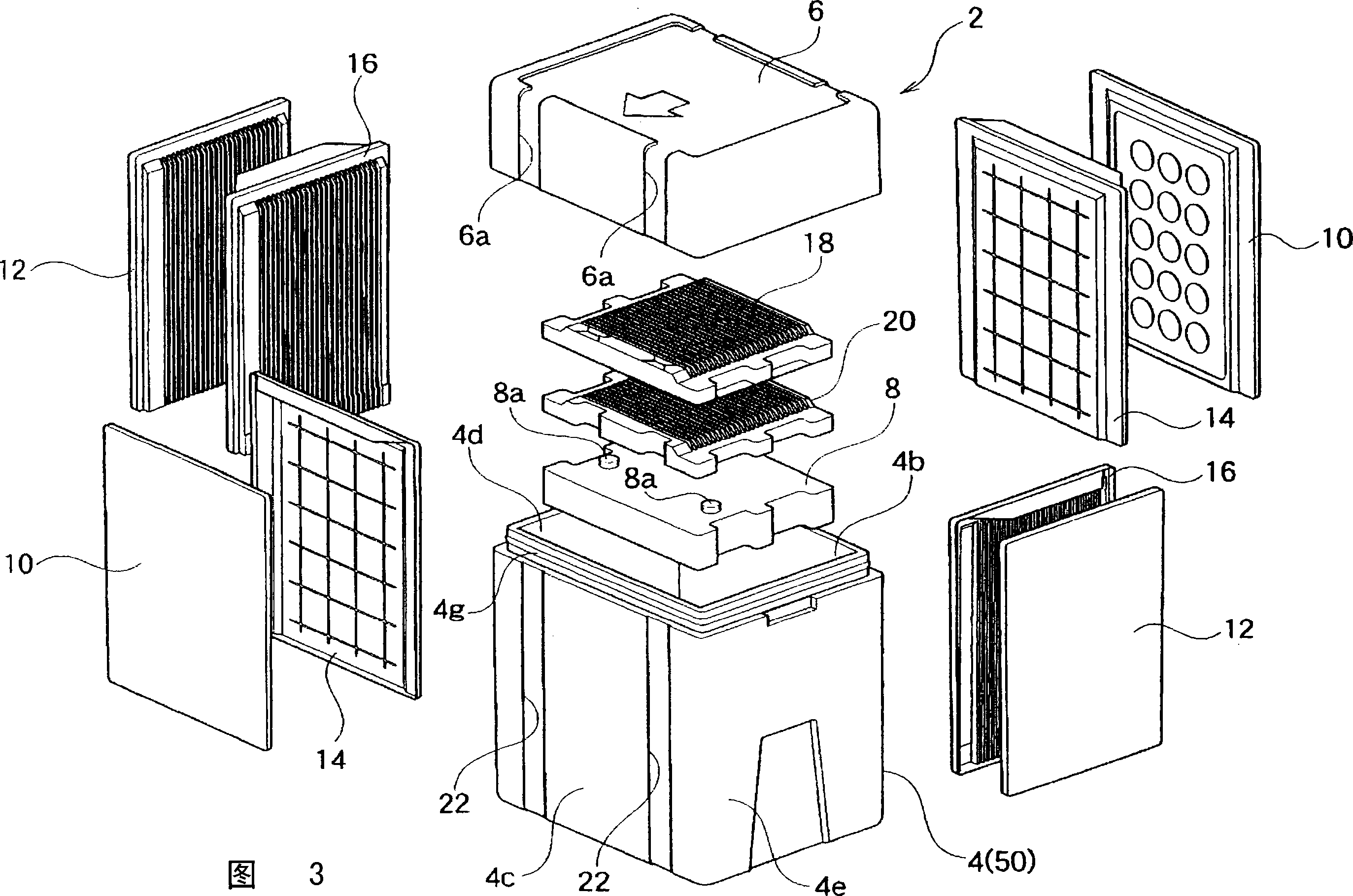

Container for conveying substrate, inner wall structure of the container, and bottom raising member used for the container

InactiveCN101035724AInstalledGood take out workabilityDomestic cooling apparatusLighting and heating apparatusDouble wallEngineering

A container for conveying a substrate, the main part of which container is made from a foamed synthetic resin. In the container, loading and unloading of a glass substrate into and out of a container body is facilitated and unexpected vertical movement of the substrate during conveyance is prevented, thereby the substrate is less likely to chip or crack. [MEANS FOR SOLVING PROBLEMS] A container body of a container for conveying a substrate is constructed from foamed synthetic resin inner heat insulators and sheet members so as to form double walls of the heat insulators, and the heat insulators and members are formed as separate bodies in advance. Vertically arranged inner heat insulators are provided with inclination where the thickness of the heat insulators gradually thins from the opening of the container body downward. Further, in an inner heat insulator provided on the bottom side of the container body, a recess is formed in the thickness direction, and a slit in which a drying agent can be inserted is formed in a sheet member placed on the recess.

Owner:藤原俊郎

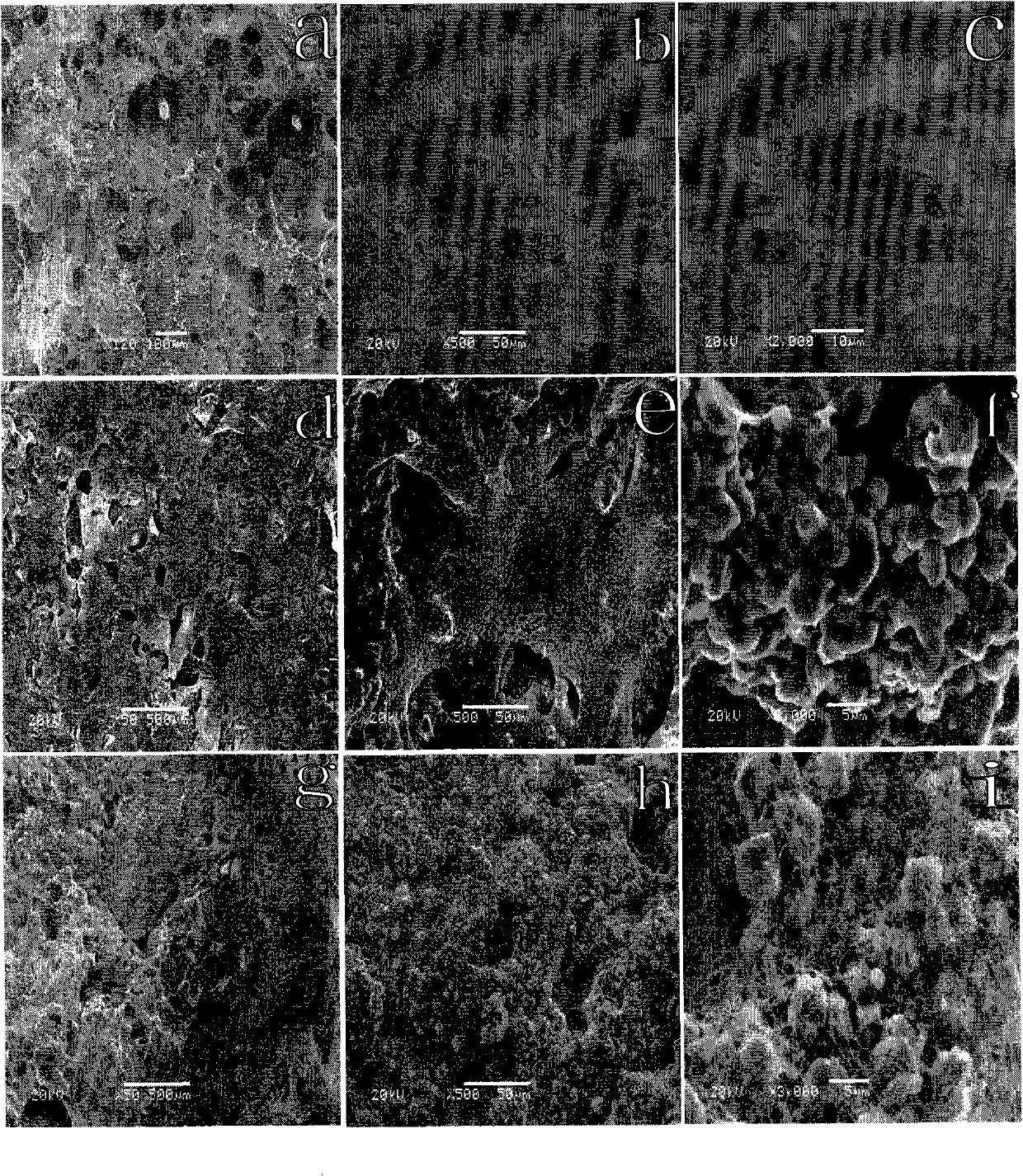

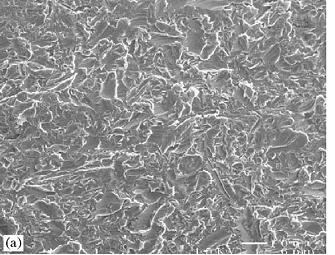

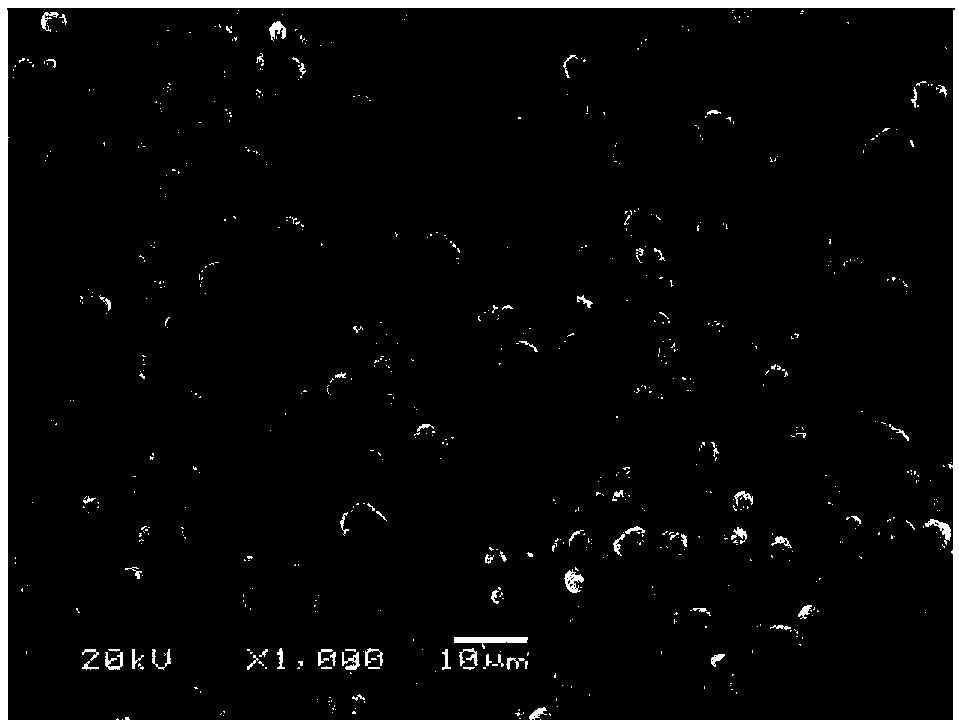

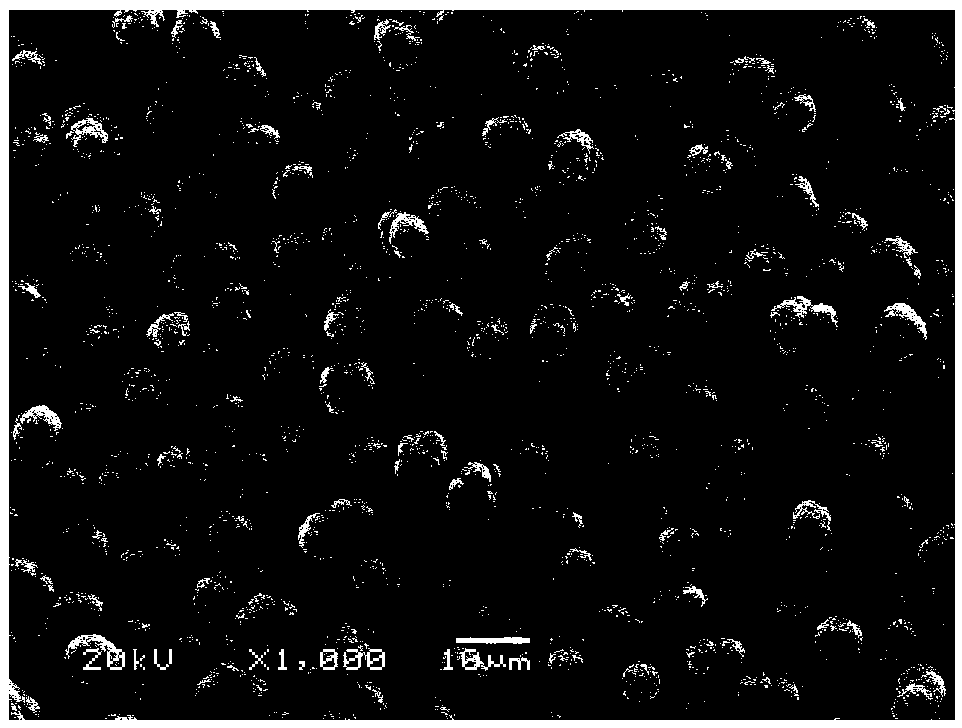

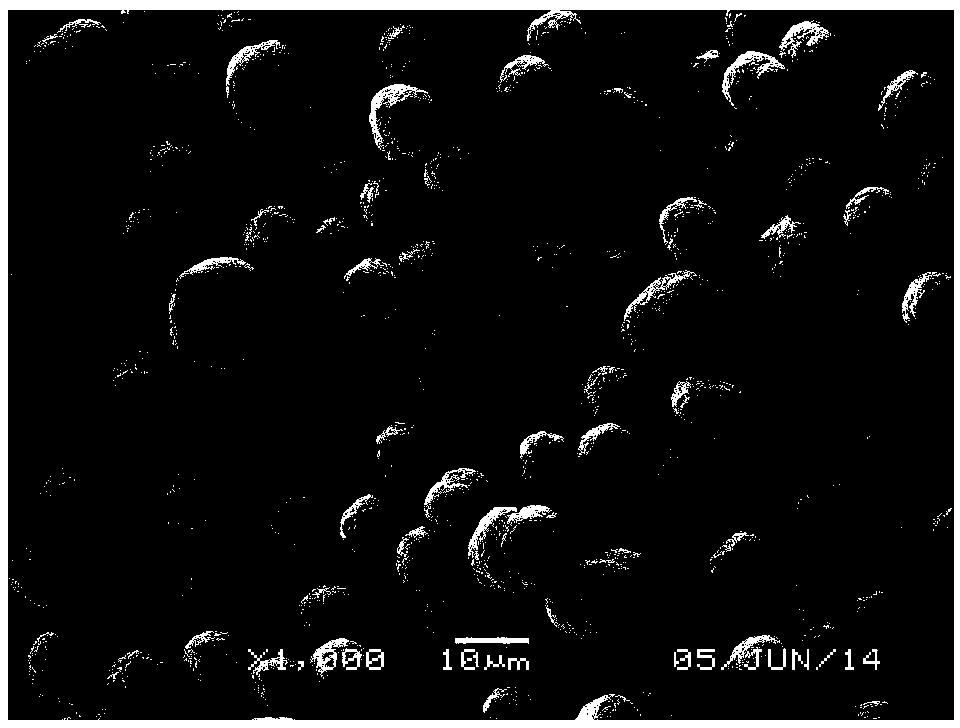

Dental implant with micron-nanometer multi-grade micro-surface structure and preparation method

InactiveCN101919741AHigh activityBroaden the formation processDental implantsArtificial teethDentistryDental implant

The invention provides a dental implant with a micron-nanometer multi-grade micro-surface structure and a preparation method. The homogenous and uniform dental implant with the micron-nanometer multi-grade micro-structure is etched by using titanium as a substrate in a short time period, so that working efficiency is greatly improved and the problem of lacking bonding force between the surface structure and the substrate is solved.

Owner:JILIN UNIV

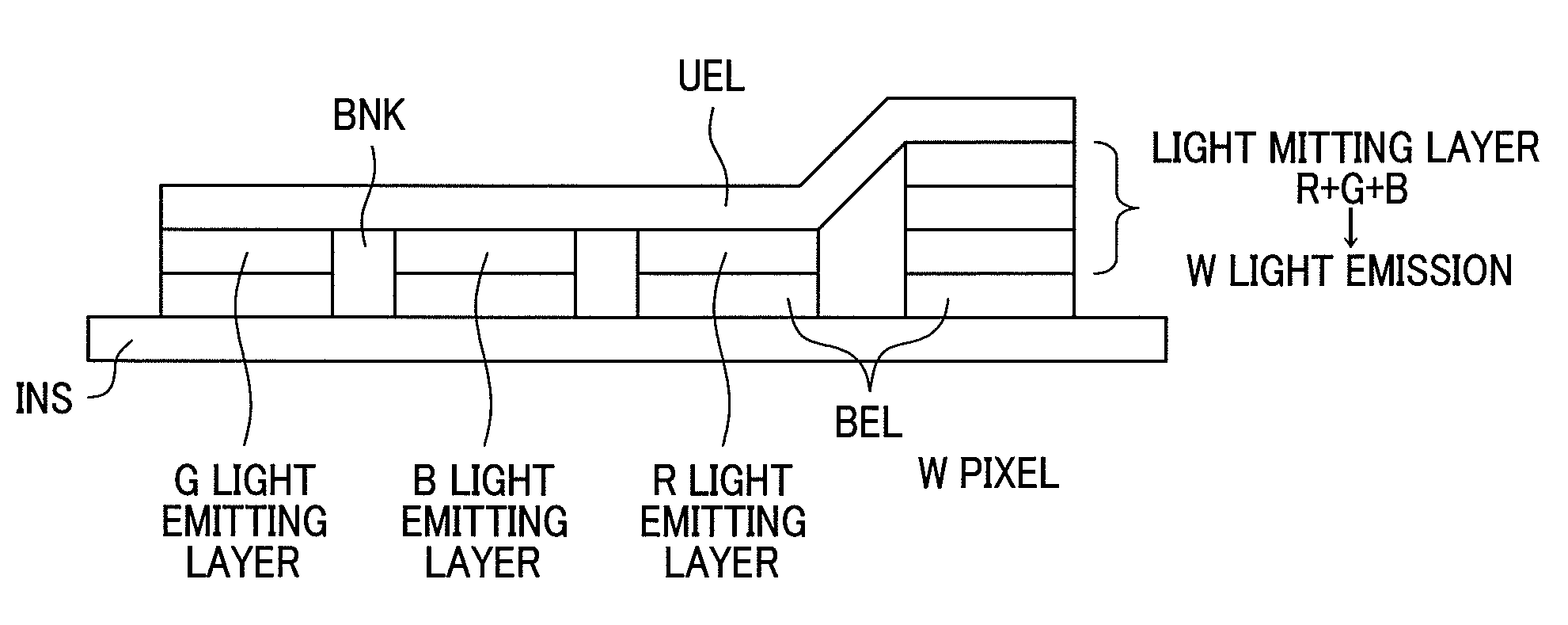

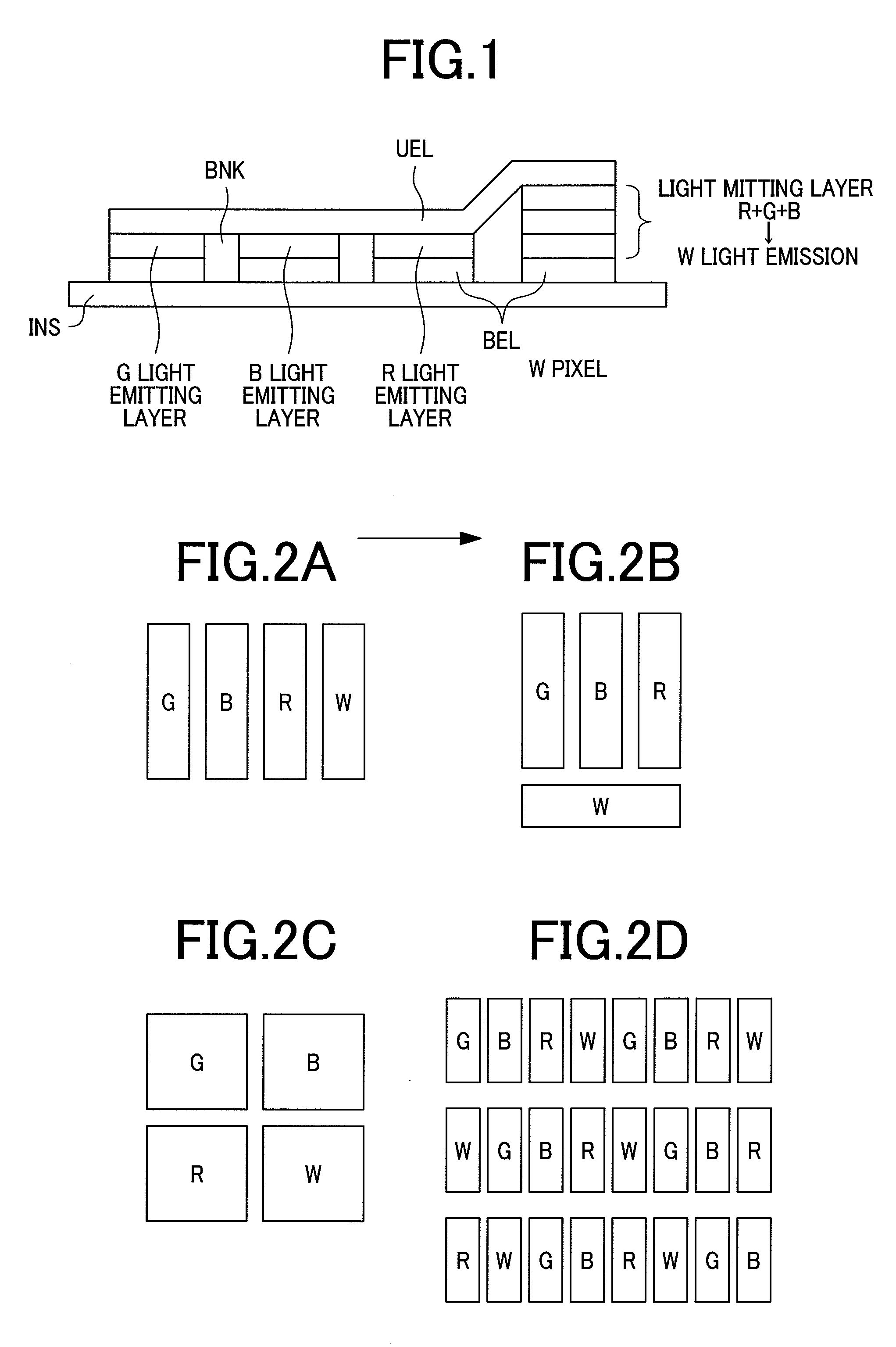

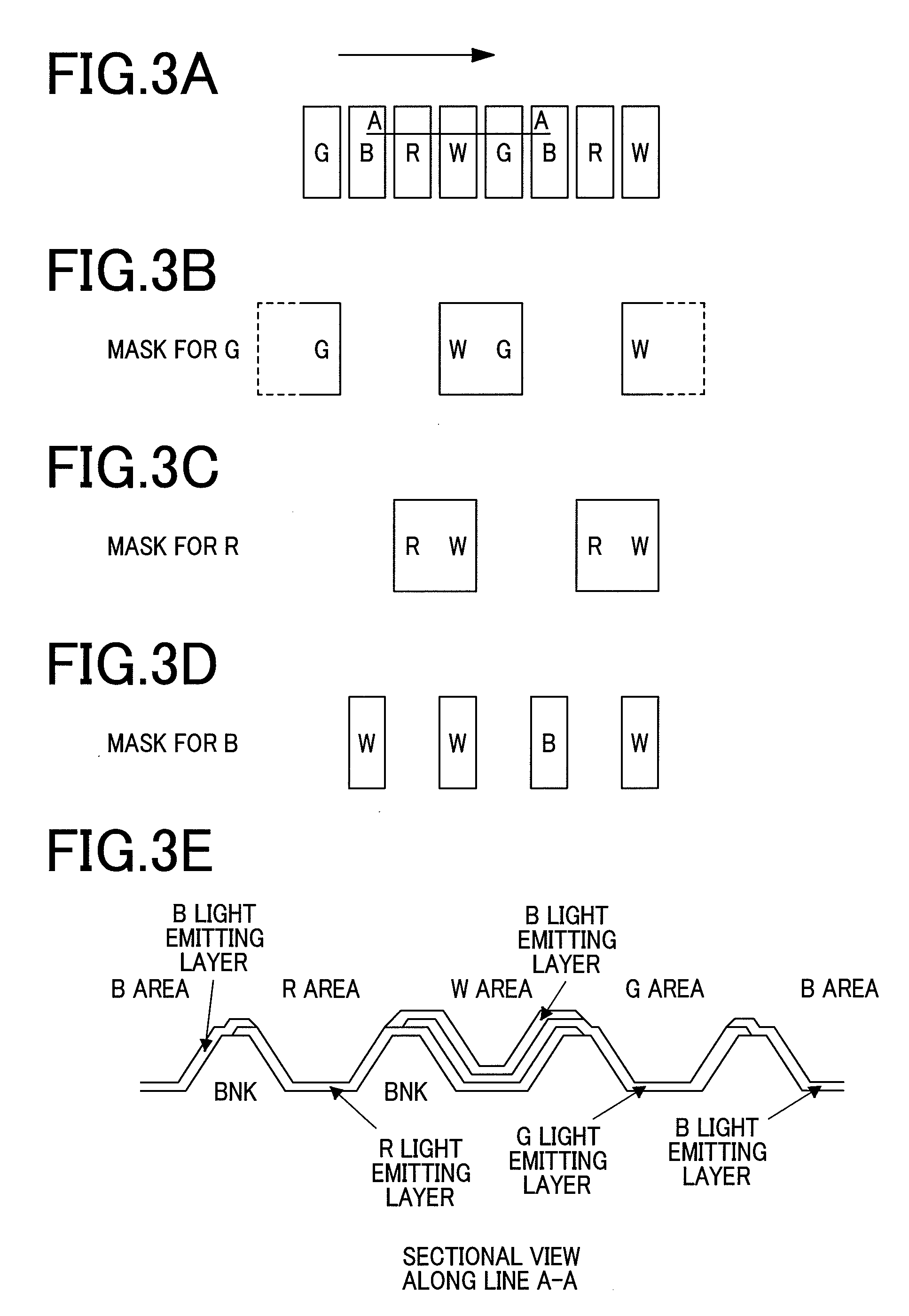

Organic electroluminescence display device

ActiveUS20070200495A1Increase pixel formation processColor purity can be easilyDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceGreen-light

The recent invention provide an organic electroluminescence display device with color purity adjustment, particularly white purity increased, without increasing formation processes. For each of unit pixels formed on an insulating film INS formed on a principal surface of a glass substrate, a bank BNK is provided on a bottom electrode BEL being a pixel electrode. The bank BNK has the shape of a bank that surrounds a pixel concerned, for each of pixels, and an organic electroluminescence light emitting layer is charged within a region surrounded by the banks BNKs. Between the banks BNKs, a green light emitting layer (G light emitting layer), a blue light emitting layer (B light emitting layer), and a red light emitting layer (R light emitting layer) are provided. At the same time as the formation of these color light emitting layers, light emitting layers of three colors, the green light emitting layer (G light emitting layer), the blue light emitting layer (B light emitting layer), and the red light emitting layer (R light emitting layer) are stacked on a region of a white pixel to form a white light emitting layer (G+B+R). An upper electrode UEL is formed over the green light emitting layer (G light emitting layer), the blue light emitting layer (B light emitting layer), the red light emitting layer (R light emitting layer), and the white light emitting layer (G+B+R light emitting layer).

Owner:SAMSUNG DISPLAY CO LTD +1

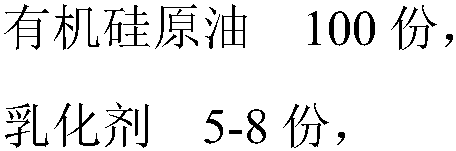

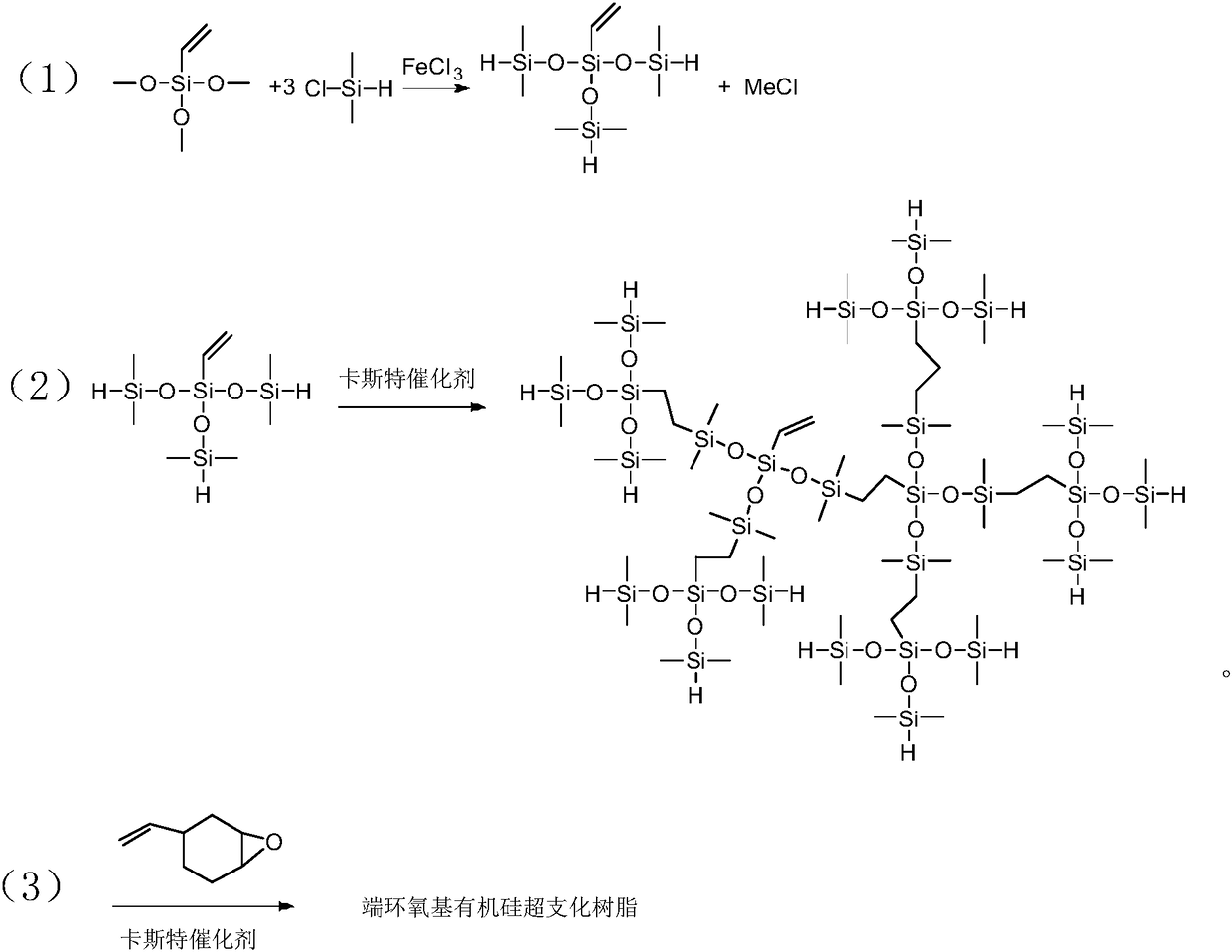

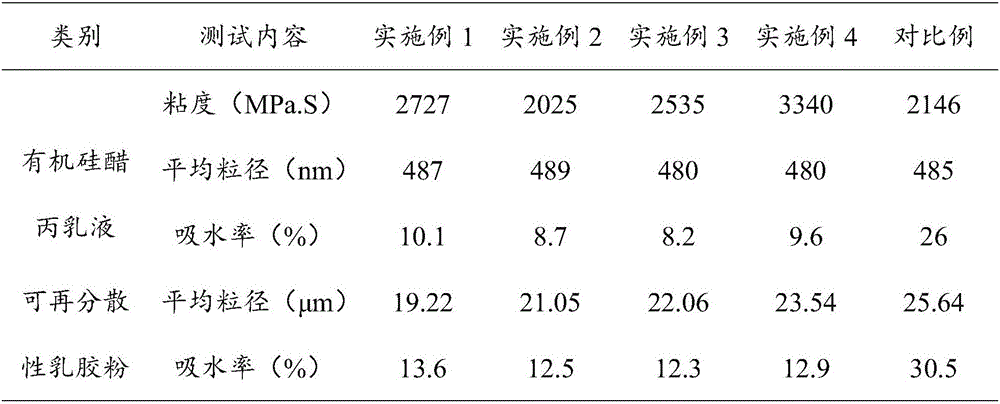

Organic silicone emulsion and production technology thereof

The invention relates to a polymer emulsion, and particularly relates to an organic silicone emulsion and a production technology thereof. The organic silicone emulsion comprises the following components in parts by weight: 100 parts of organic silicone crude oil, 20-35 parts of epoxy-terminated organic silicone hyperbranched resin, 10-18 parts of graphene oxide dispersion liquid, 5-8 parts of anemulsifying agent, 5-8 parts of a co-emulsifier, 0.5-3 parts of glacial acetic acid, and 50-75 parts of distilled water. The organic silicone emulsion has the following beneficial effects: (1) the preparation processes are simple; (2) all components are uniformly and stably mixed; and (3) emulsion cannot be broken during being stored and transported.

Owner:浙江科峰新材料有限公司

Low cover degree sand stabilizing method

InactiveCN101705679AGive full play to the advantages of side travelBroaden the formation processHorticultureSoil preservationNatural recoveryEngineering

The invention provides a low cover degree sand stabilizing method, comprising the steps of planting one row to four rows of arbor and / or bush and / or subshrub in parallel to form a sand stabilizing forest shelter belt, and reserving a vegetation natural restoration belt between the forest shelter belts; and the forest shelter belts play roles of biological barrier for stabilizing sand, protection the stabilization of sand surface and promoting natural restoration of vegetation in the vegetation natural recovering belt, wherein the cover area of the arbor and the bush is 15-25 percent and the cover area of the vegetation natural restoration belt is 75-85 percent. By adopting a row-belt sand stabilizing mode, when the cover degree is 15-25 percent, the effect of stand stabilizing forests distributed in a row-belt mode for reducing the wind speed is 25-50 percent higher than that of the stand stabilizing forests an evenly-distributed and randomly-distributed mode for reducing the wind speed, the border-row advantages of forests can be fully exerted; and after the sand surface is stabilized, wide enough interband is beneficial to the infiltration of rainfall and natural recovery of the vegetation, and forms complex sand stabilizing vegetation for promoting natural recovery at zonality vegetation occupying 85-75 percent of land under the protection of forest belt occupying 15-25 percent of the land.

Owner:RES INST OF FORESTRY NEW TECH CHINESE ACAD OF FORESTRY

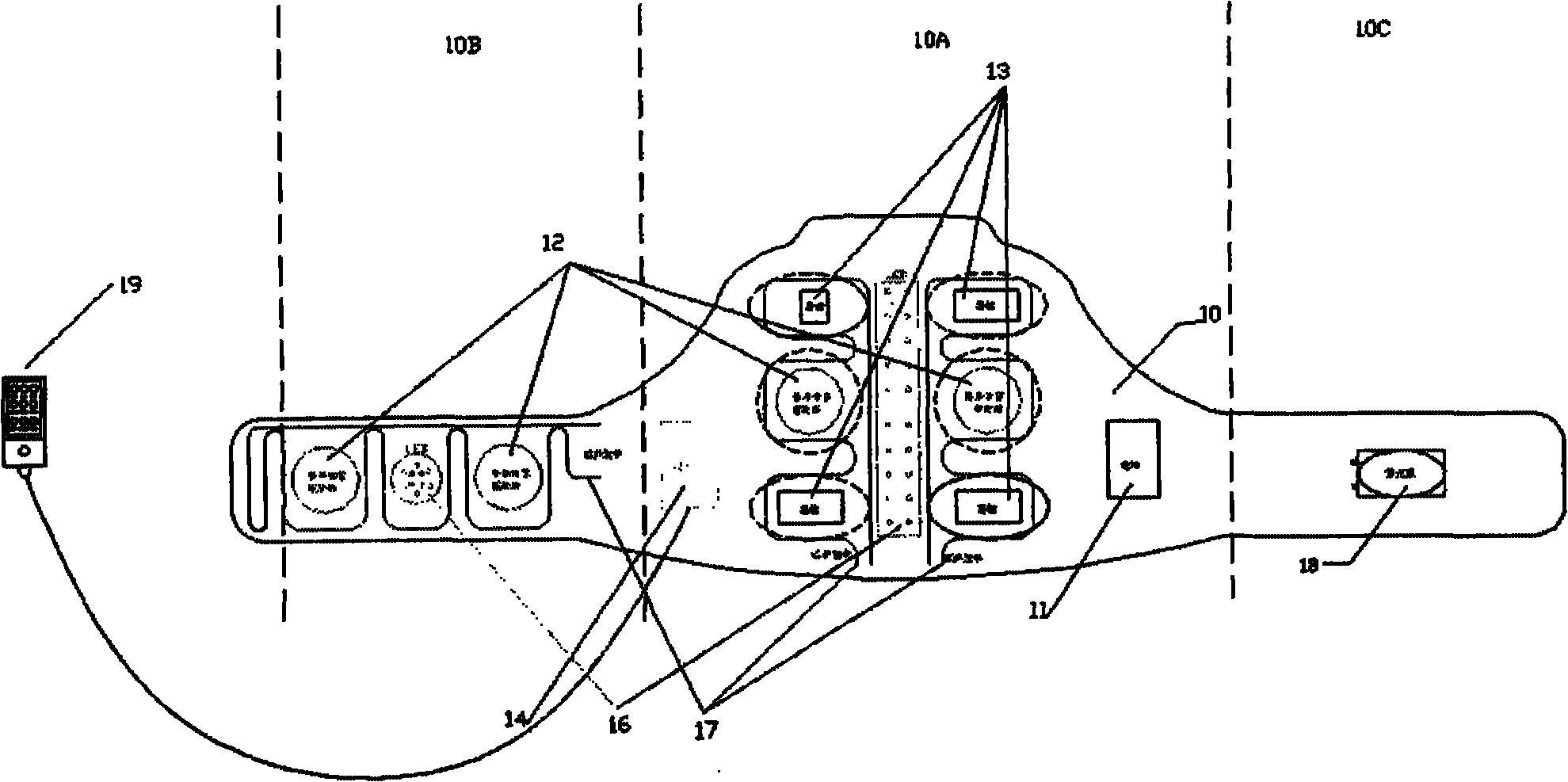

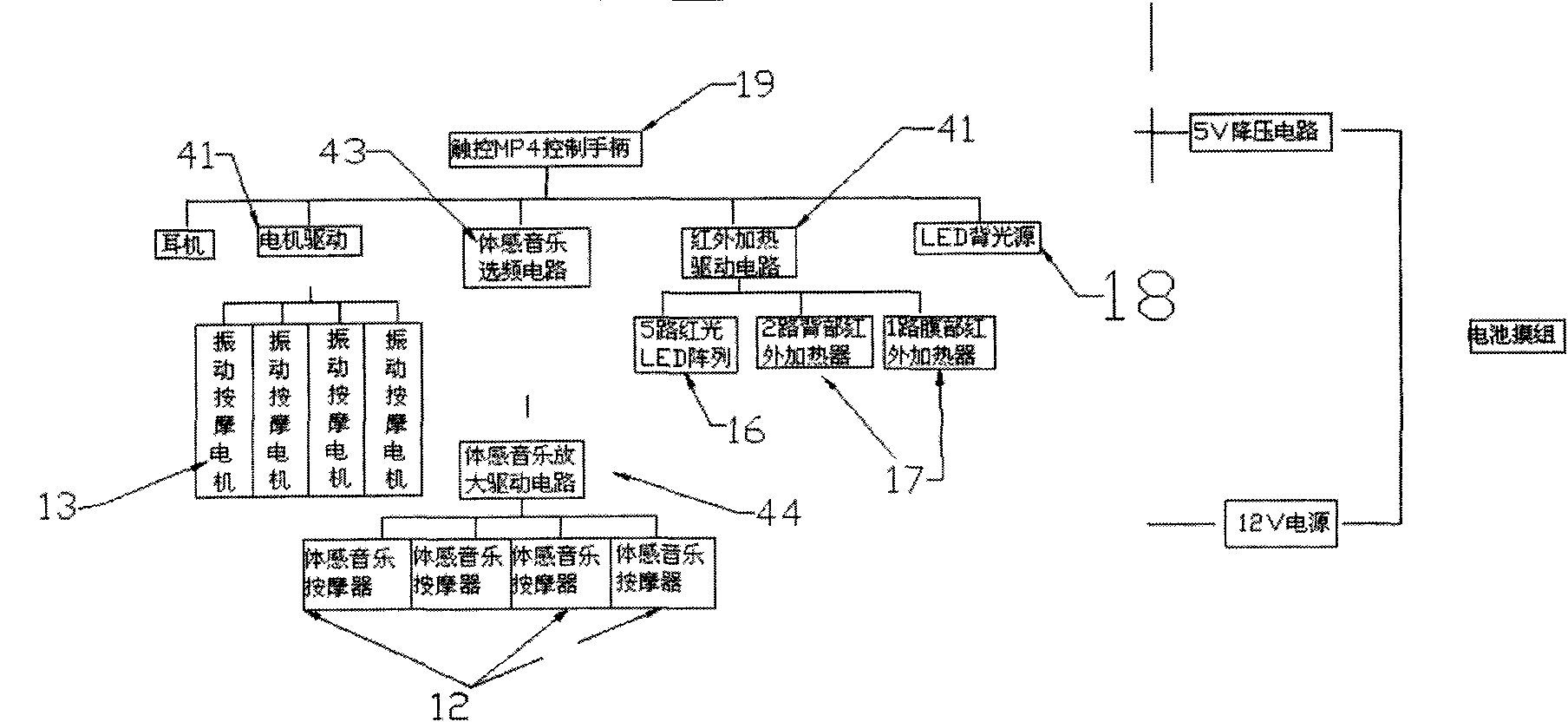

Movable back type multifunctional massager

InactiveCN102058472ATo promote metabolismPromote blood circulationVibration massageLight therapyAbdominal massageBlood circulation

The invention relates to a movable back type multifunctional massager, belonging to the field of massage and health care appliances. The movable back type multifunctional massager comprises a back massager, an abdomen massager and a manually-controlled touch controller. The back massager comprises four vibratory massage motors, four perceived music massagers, two infrared heaters, two phototherapy luminescent plates, a battery and a controller. The abdomen massager comprises two perceived music massagers, an infrared heater, and a visible light phototherapy luminescent plate. The back massager is used for promoting blood circulation, relieving pains, and achieving the purpose of treating back pains. The abdomen massager is used for treating constipation, and abdominal and gastrointestinal diseases.

Owner:王瀛

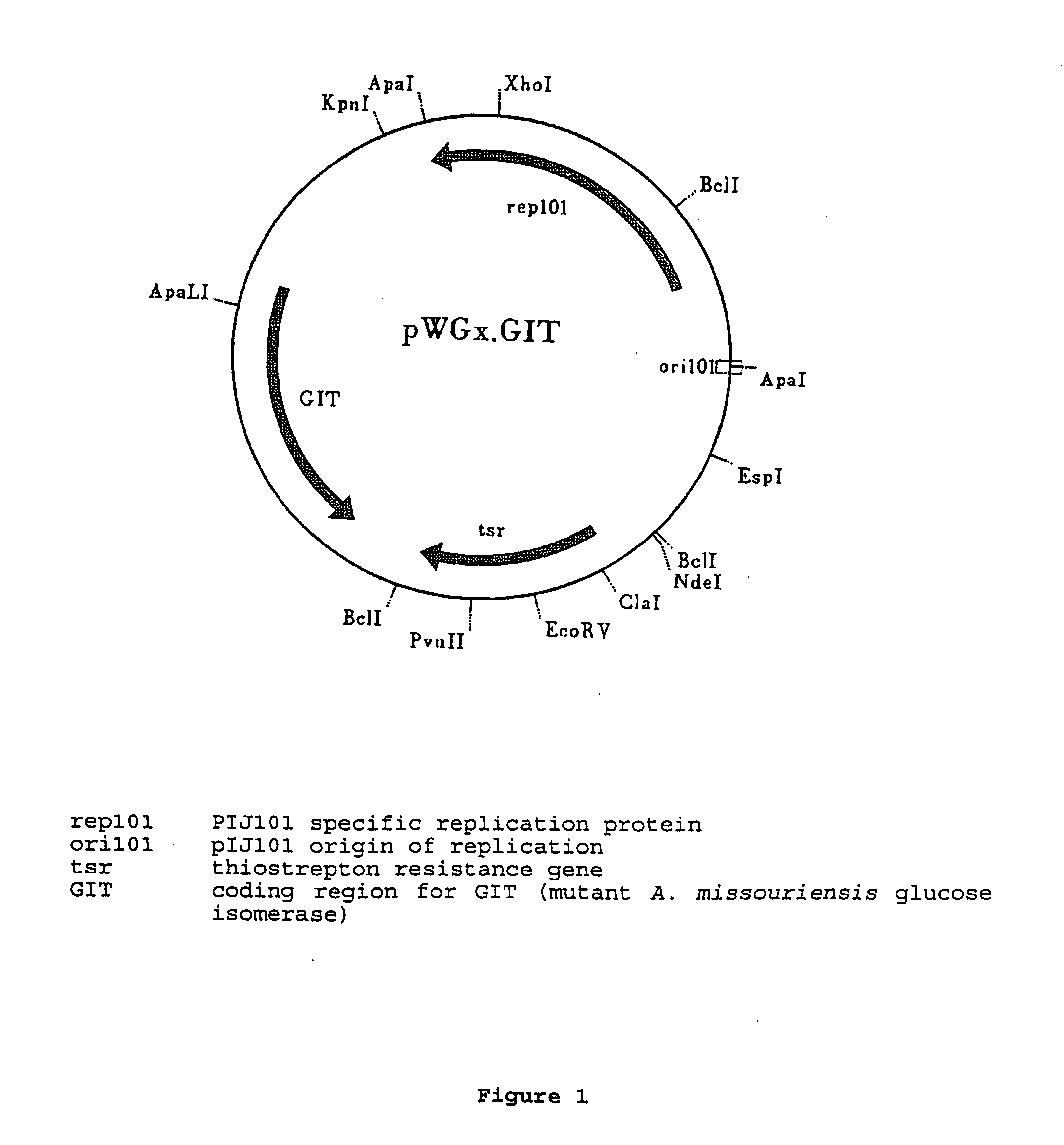

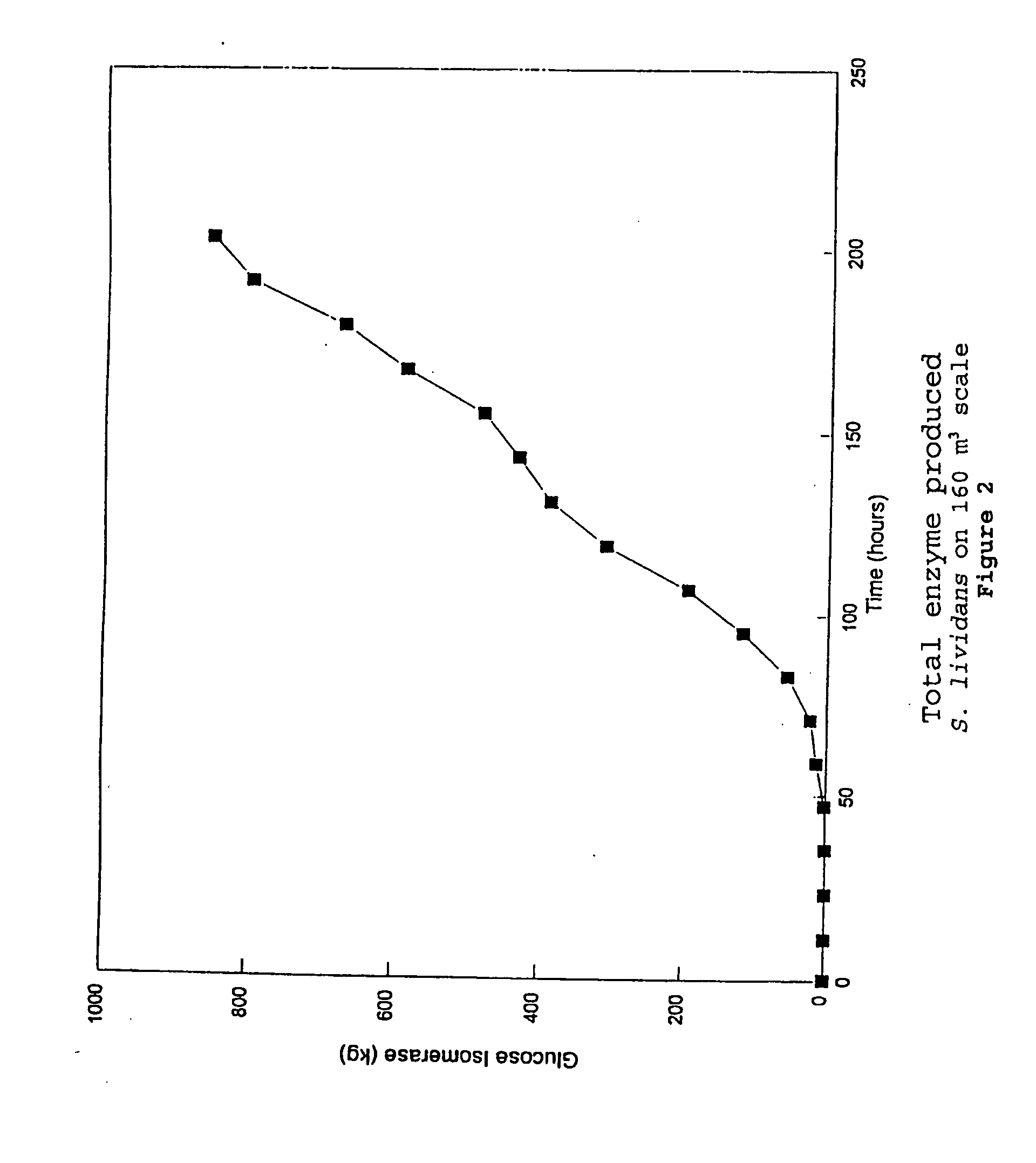

Fermentative production of lipids on an industrial scale using chemically defined media

InactiveUS20140342396A1Broaden the formation processIncrease probabilityFungiBacteriaBiotechnologySerum free media

Owner:DSM IP ASSETS BV

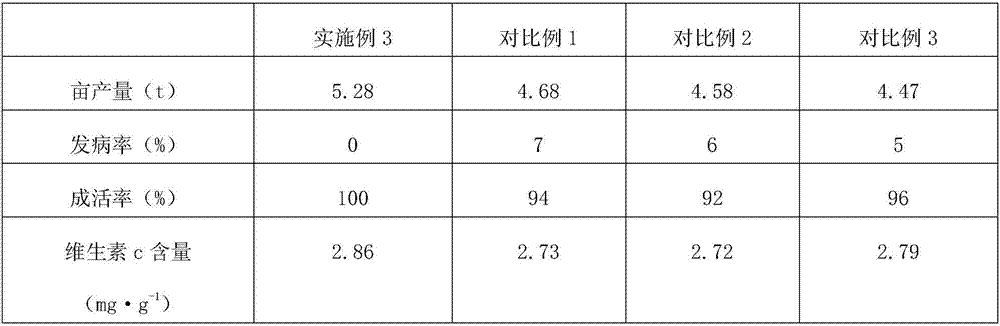

High-yield planting base fertilizer of psidium guajave and production method of high-yield planting base fertilizer

InactiveCN107235803AImprove survival rateSave fertilizerCalcareous fertilisersMagnesium fertilisersFertilizerAgriculture

The invention provides high-yield planting base fertilizer of psidium guajave and a production method of the high-yield planting base fertilizer, which belongs to the technical field of agriculture planting. The base fertilizer is prepared by fermenting the following raw materials in parts by weight: 30 to 35 parts of psidium guajave rotten branches, 20 to 25 parts of wheat straws, 10 to 15 parts of banana leaves, 10 to 12 parts of Sichuan pepper meal, 10 to 15 parts of pond sludge, 15 to 18 parts of pig manure, 10 to 15 parts of night soil 0.12 to 0.14 part of 5-nitroguaiacol sodium, 2 to 3 parts of plant extracting agent, and 0.011 to 0.013 part of rotten accelerator. The high-yield planting base fertilizer of the psidium guajave is used for planting the psidium guajave, so that the survival rate of the psidium guajave can be increased, the fertilizer can be saved, the yield can be increased, the disease can be prevented, the product nutritional value can be increased, the obtained psidium guajave is good in taste, and the high-yield planting base fertilizer is suitable for mass planting and can increase the yield and income of planters.

Owner:广西驰胜农业科技有限公司

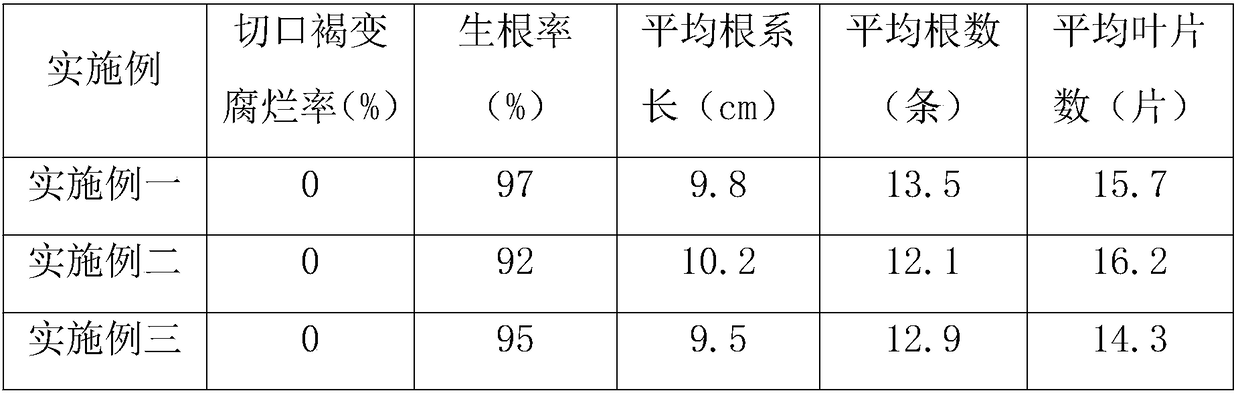

Filbert shoot cutting seedling raising method

The invention discloses a filbert shoot cutting seedling raising method. The filbert shoot cutting seedling raising method comprises, from middle June to early July, choosing robust, pest and disease-free plants as objects to cut, collecting one-year-old branches robust in growth and high in degree of lignification from the base of a tree, clipping out tender parts of the middle and upper portionsof the branches, performing scion cutting and immersion treatment and then planting the clipped parts in a nursery bed with a temperature of 25-28 DEG C, an air humidity higher than 90% and a substrate moisture content higher than 50%-60% for seedling raising. According to the filbert shoot cutting seedling raising method, tannin molecules can enter into amorphous regions of silk fibroin fiber and settle inside the fiber by being bonded with the silk fibroin fiber via hydrogen bonds, Van der Waals' force and the like, and are in multi-point bond in forms of hydrogen bonds with peptidyl-OH, -NH-CO-, -NH2 and-COOH of proteins of sericin to immobilize the sericin; immersion in acetic acid aqueous solution can extrude a large amount of tannin inside scion cells and absorb the tannin onto silks to reduce the content of tannin inside scions as well as the browning amount of tannin, to avoid browning and rotting of cuts of the scions due to oxidation of tannin, to promote rooting of the scions and further to improve the cutting survival rate.

Owner:贵州省核桃研究所

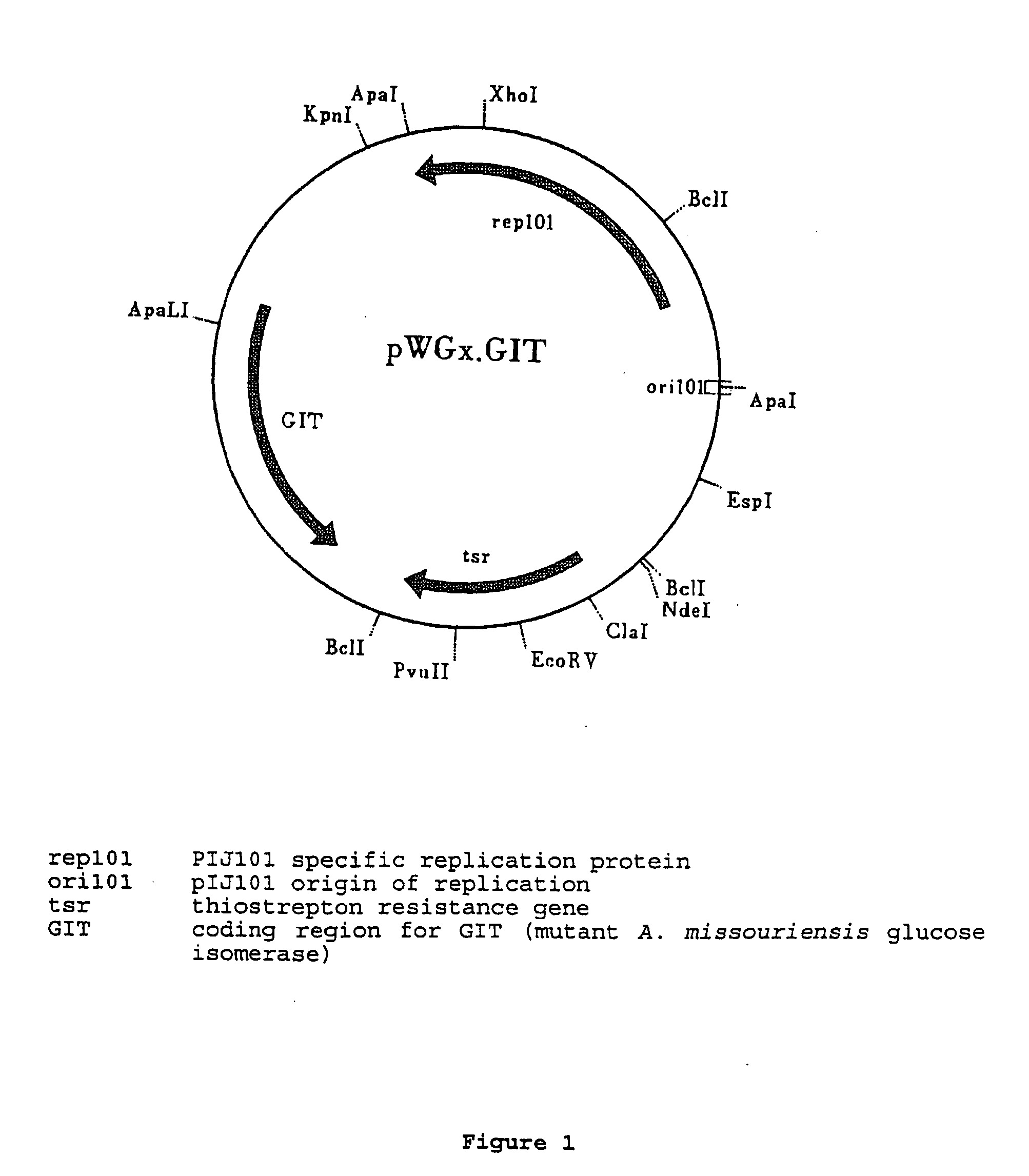

Fermentative production of lipids on an industrial scale using chemically defined media

InactiveUS20070092955A1Similar and improved growth performanceImprove the level ofFungiBacteriaIndustrial scaleWild type strain

We describe the use of chemically defined media for the fermentative production of valuable compounds on an industrial scale. Microbial strains which are suitable for fermentation on an industrial scale using a chemically defined medium include fungal, yeast and bacterial strains. Suitable strains can be obtained as wild type strains or by screening and selection after mutagenic treatment or DNA transformation.

Owner:DSM IP ASSETS BV

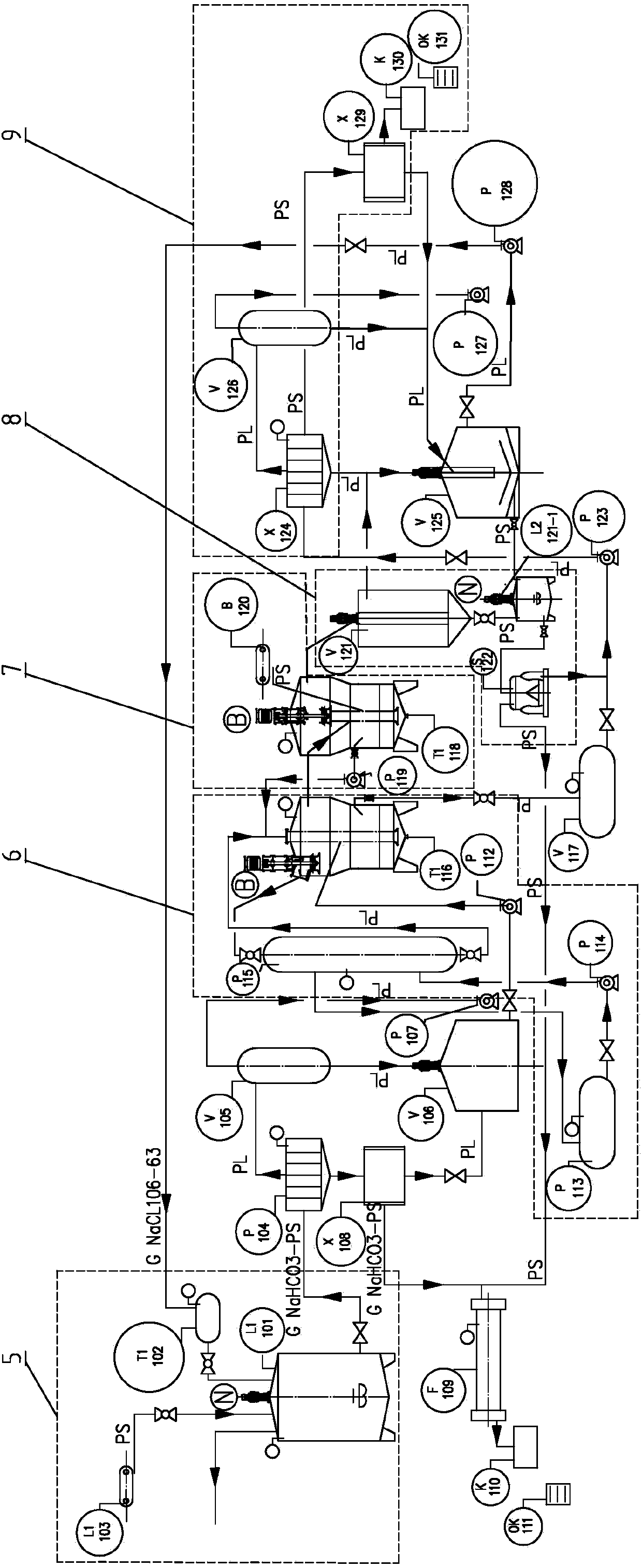

Cyclic manufacturing method for coproduction of baking soda and ammonium chloride

ActiveCN109534365APromote crystallizationReduce energy consumptionAmmonium chlorideCarbonate preparationEnergy consumptionPrecipitation

The invention relates to a cyclic manufacturing method for coproduction of baking soda and ammonium chloride. The cyclic manufacturing method comprises the steps of primary precipitating of baking soda, cold precipitation crystallization, salt precipitation crystallization and mother liquor cycling which are conducted sequentially; and the cyclic manufacturing method further comprises the step that the step of secondary precipitating of baking soda is arranged between the salt precipitation crystallization step and the mother liquor cycle step, and the step of secondary precipitating of bakingsoda is used for further precipitating the baking soda from baking soda mother liquor (I-II) generated after salt precipitation crystallization. By adopting the cyclic manufacturing method, energy consumption of ammonium chloride recovering through cold precipitation crystallization can be decreased, the baking soda and the ammonium chloride are efficiently produced, meanwhile, full cycle of motor liquor generated in a reaction in the production process is achieved, the process is easy, and the production cost is low.

Owner:衡阳爱洁科技股份有限公司

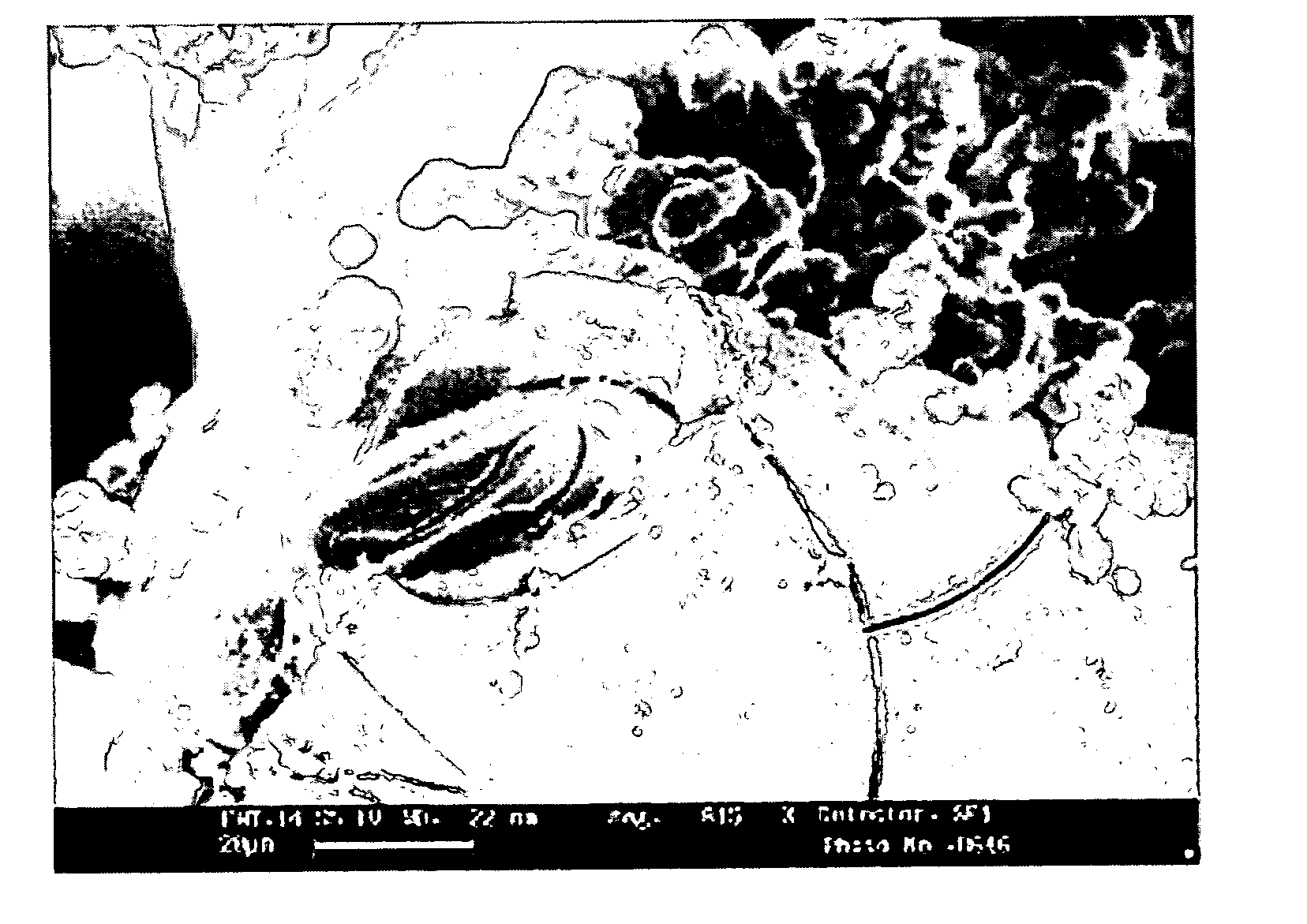

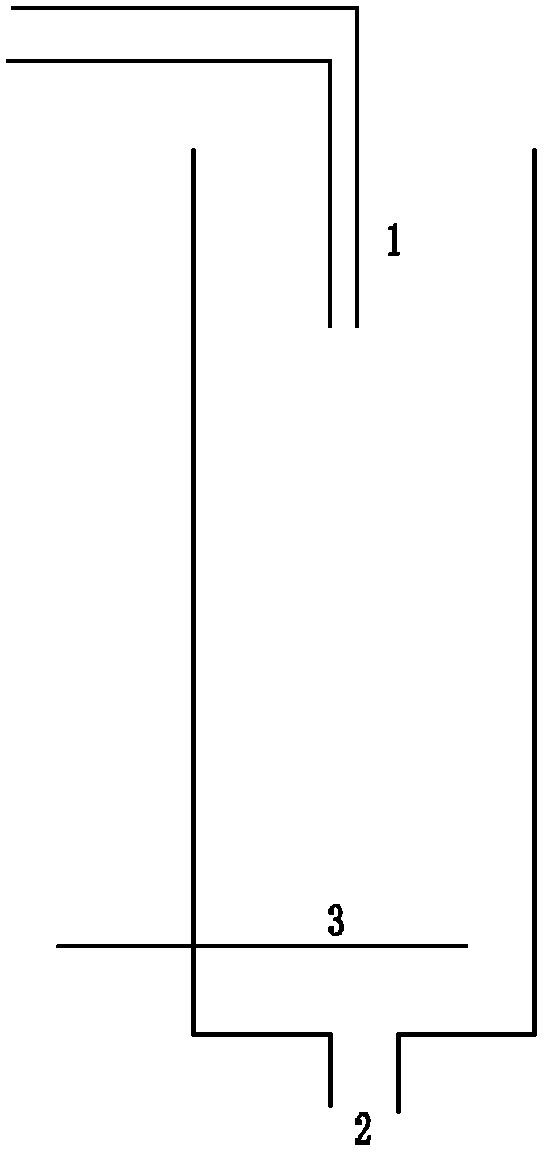

Application of hollow glass bead biological membrane carrier in wastewater treatment

ActiveCN102642919AThere is no problem of secondary pollutionCarrier is lightSustainable biological treatmentBiological water/sewage treatmentStart timeSludge

The invention discloses application of a hollow glass bead biological membrane carrier in wastewater treatment, which includes that a hollow glass bead is added in a biological membrane reactor for inoculating active sludge, the biological membrane reactor is started to intake water and aerate so as to enable the hollow glass bead to contact with microorganisms in the biological membrane reactor fully, a biological membrane is generated on the surface of the hollow glass bead, and the biological membrane is used for perform wastewater treatment. The weight of a single hollow glass bead is less than 0.001g, grain size of the single hollow glass bead is 0.01-0.075mm, and density of the single hollow glass bead is 180-190Kg.m-3. The hollow glass bead biological membrane carrier is light in weight, small in grain size and density, stable in chemical property and high in mechanical strength, has good sealing performance, wind pressure resistance and corrosion resistance, is not easy to break and good in mobility, can form a turbulence state with the microorganisms, simultaneously can resist strong hydraulic shear action, facilitates the wastewater treatment, and accelerates forming speed of the biological membrane and starting time of the reactor.

Owner:HANGZHOU NORMAL UNIVERSITY

Organosilicon vinyl acetate-acrylic emulsion and preparation method thereof and redispersible emulsion powder prepared from organosilicon vinyl acetate-acrylic emulsion

The invention discloses organosilicon vinyl acetate-acrylic emulsion and a preparation method thereof and redispersible emulsion powder prepared from the organosilicon vinyl acetate-acrylic emulsion. The emulsion is prepared from, by mass, 60-80 parts of vinyl acetate, 12-30 parts of butyl acrylate, 5-15 parts of a functional monomer, 1-6 parts of a crosslinking monomer, 0.2-3 parts of a silane coupling agent, 3-10 parts of protective colloid, 0.2-5 parts of an emulsifying agent, 0.2-0.6 part of a buffering agent, 0.2-0.6 part of a redox initiator and 90-120 parts of water. According to the organosilicon vinyl acetate-acrylic emulsion, by adopting a pre-emulsification method, the emulsion stability is greatly improved, the gelation phenomenon caused by instability of the emulsion in the polymerization process is effectively reduced, and the emulsion preparation success rate is increased; by introducing the crosslinking monomer, the functional monomer and the silane coupling agent into macromolecular chains of a polymer, crosslinking points on the polymer are increased, and a dense three-dimensional net is formed during the film forming process, so that the water resistance is improved, and then the application property of the redispersible emulsion powder in the application fields of building mortar, building waterproof paint and the like is promoted.

Owner:YOUNGWOO CHEMTECH

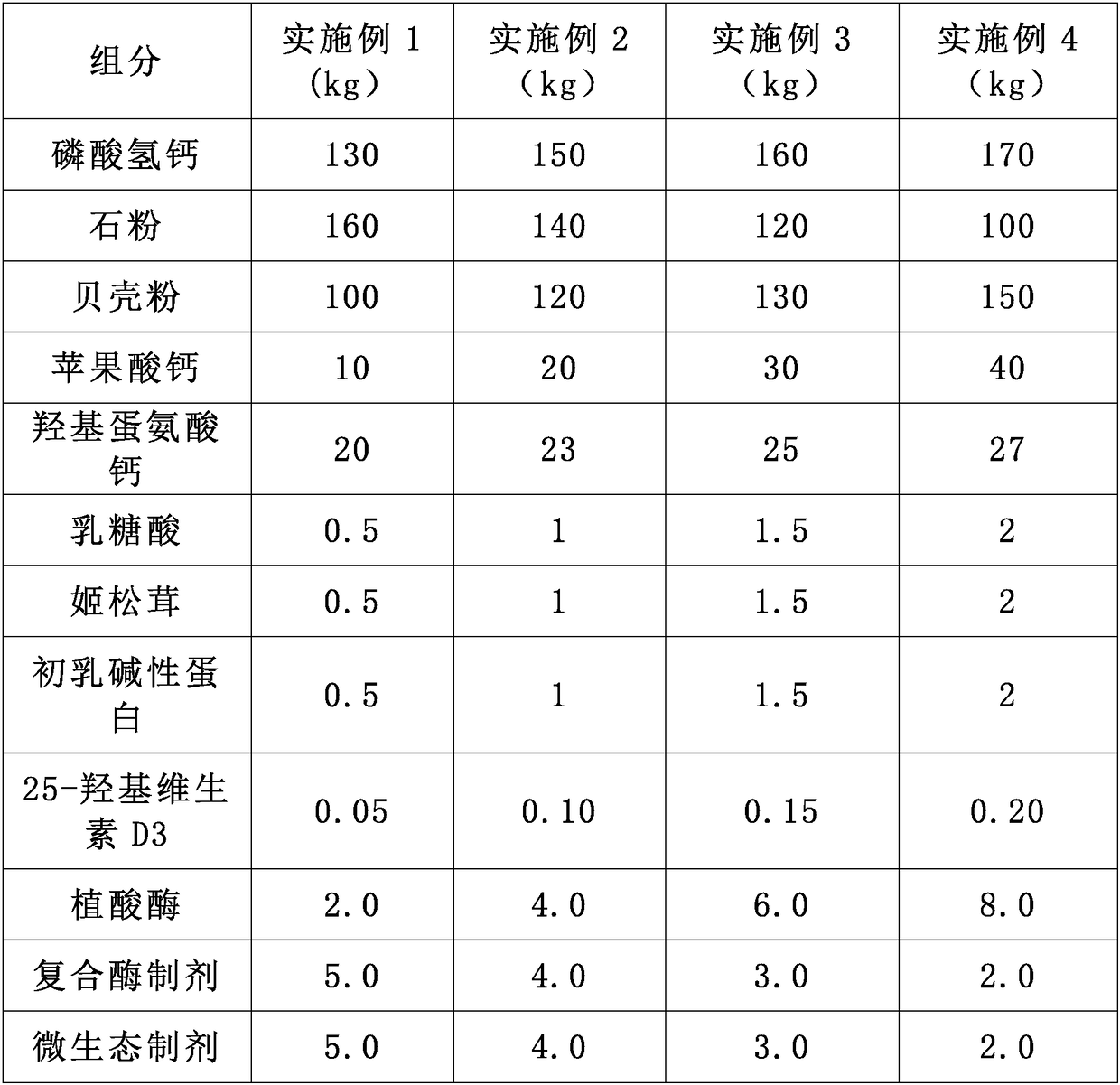

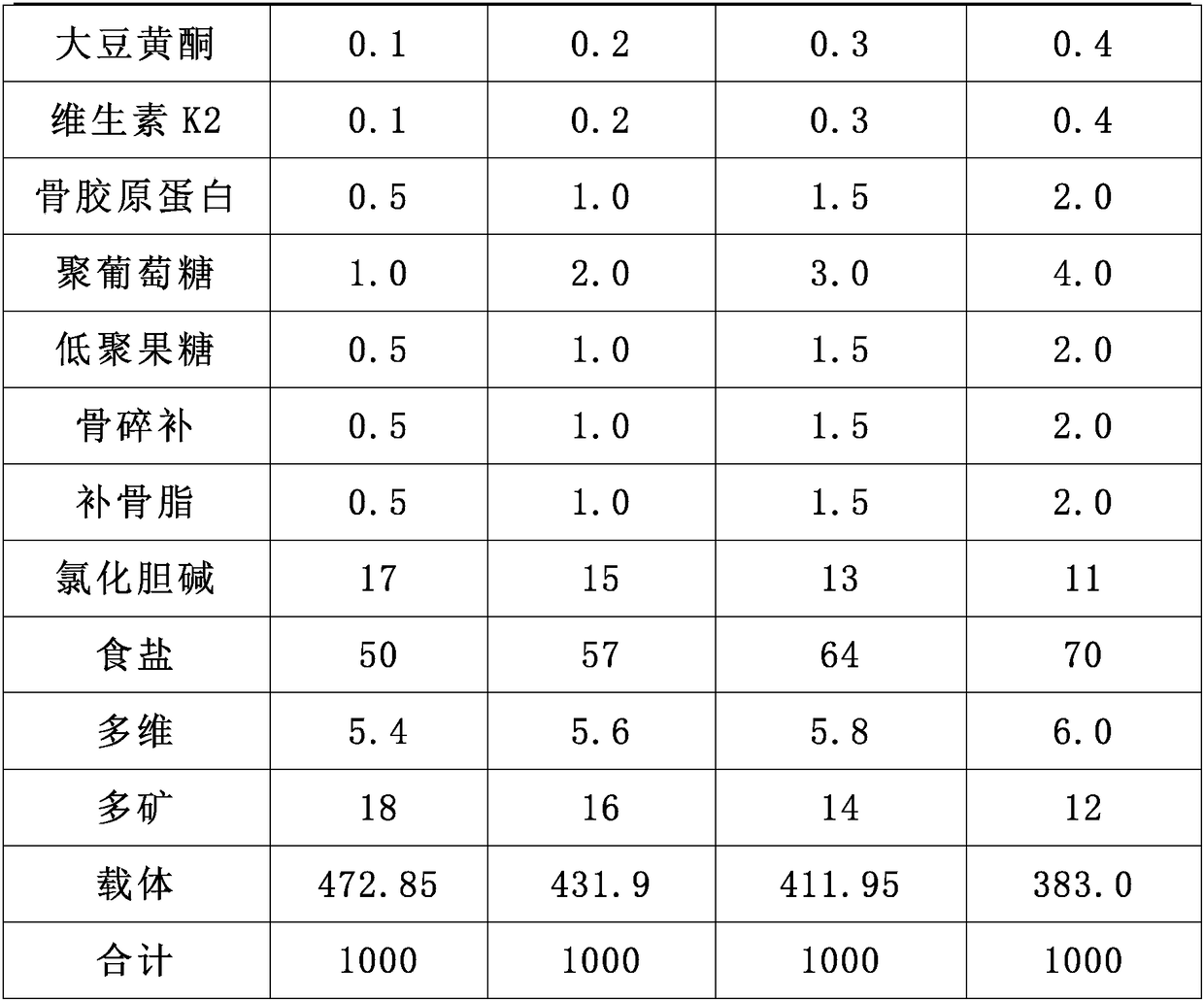

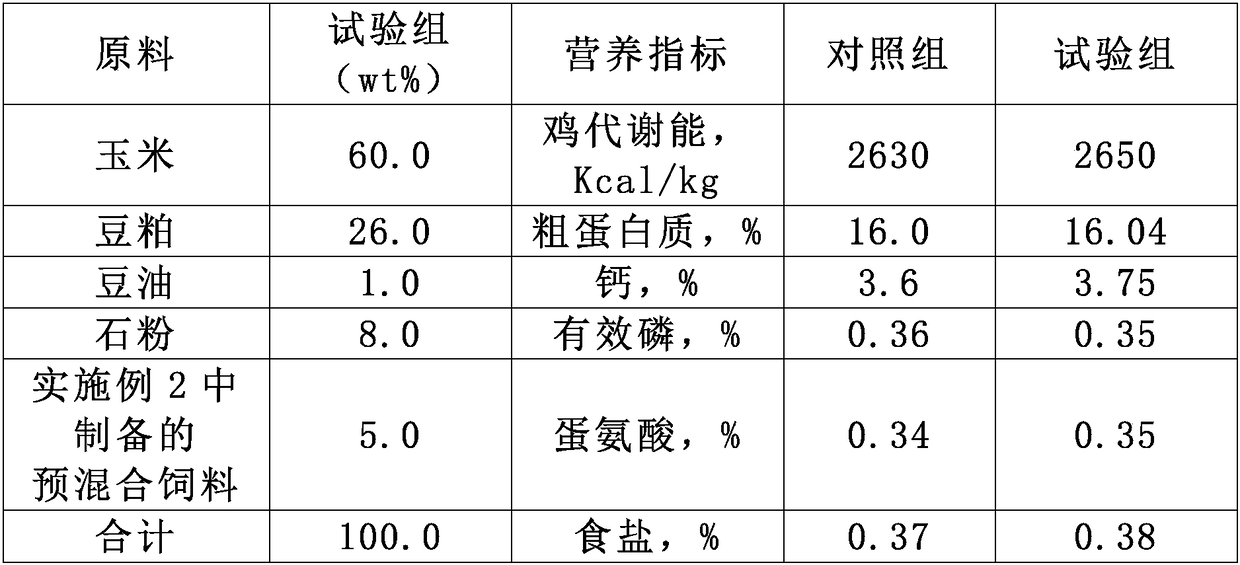

Pre-mixed feed for improving bone density and eggshell quality of laying hens and preparation method thereof

InactiveCN109123181APromote absorptionBroaden the formation processFood processingAnimal feeding stuffVitamin K2Eggshell

The invention provides a pre-mixed feed for improving the bone mineral density and eggshell quality and a preparation method thereof, belonging to the technical field of egg chicken feed. The method comprises the following components in parts by weight: 130-170 parts of calcium hydrogen phosphate, 100-160 parts of stone powder, 100-150 parts of shell powder, 10-40 parts of calcium malate, 20-27 parts of calcium hydroxymethionine, 0.5-2 parts of lactobionic acid, 0.5-2 parts of agaricus blazei and 0.5-2 parts of colostrum alkaline protein, 2-5 parts of hydroxyl vitamin D, 2-8 parts of phytase,2-5 parts of composite enzyme preparation, 2-5 parts of microecological agent, 0.1-0.4 parts of soybean flavone, 0.1-0.4 parts of vitamin K2, 0.5-2 parts of bone collagen, 1-4 parts of polydextrose, 0.5-2 parts of fructo-oligosaccharide, 0.5-2 parts of rhizoma drynariae, 0.5-2 parts of fructus psoraleae and the like. In order to improve the calcium utilization rate, a brand new idea of calcium utilization is provided, that is, three systems of the calcium supplement of the laying hens, that is, a calcium supplementing system, a calcium promotion absorption system and a health system of improving the gastrointestinal.

Owner:播恩集团股份有限公司

Artificial algal reef and manufacturing method thereof

InactiveCN102972324AIncrease roughnessPromotes fixation and growthClimate change adaptationPisciculture and aquariaRebarHabitat

The invention discloses an artificial algal reef and a manufacturing method thereof, and relates to the artificial algal reef and a preparation method thereof. The artificial algal reef comprises an algal reef main body made from reinforcements and concrete; vegetable gum grains are arranged on the algal reef main body, and have the grain size of 1 to 60 mm; and the weight of the vegetable gum grains is 0.01% to 0.6% of the total weight of the artificial algal reef. The preparation method of the artificial algal reef comprises the following steps: 2 to 6 parts of cement, 3 to 10 parts of sand, 8 to 12 parts of stone and 0.001 to 0.008 part of vegetable gun grains are selected through proportioning in part by weight, wherein the grain sizes of the vegetable gum grains are 1 to 10 mm; the algal reef is prepared from cement, sand, stones and a reinforcement cage; and the vegetable gum grains are added before hardening. When the artificial algal reef is used, vegetable gum is dissolved in the water, a microcellular structure is formed on the surface of a reef, the roughness of the surface of the reef is increased, the adhesion possibility of algae spores is improved, a sessile substrate suitable for the adhesion and the growth of the algae spores is provided, and habitats for foraging, breeding, growing and the like are provided for aquatic organisms such as fishes.

Owner:山东大学(威海)

Preparation method of ternary precursor fine crystal nucleus

The invention discloses a preparation method of ternary precursor fine crystal nucleus, characterized by comprising the steps of S1, preparing nickel-cobalt-manganese soluble salt solution of certainconcentration, an alkaline solution and ammonia solution; S2, adding a mother liquor, which is composed of the ammonia solution and the alkaline solution, into a reactor, introducing nitrogen into thereactor, starting stirring, and adjusting pH of the mother liquor during stirring; S3, concurrently adding the nickel-cobalt-manganese soluble salt solution into the reactor, and allowing gradual reaction in the reactor to generate ternary precursor fine crystal nucleus. The preparation method has the advantages that the nucleating process is precisely controlled, the ternary precursor fine crystal nucleus of high compactness and good sphericity is prepared, and possible problems, such as cavitation, to the prepared nucleus are avoided.

Owner:DONGGUAN UNIV OF TECH

Soilless cutting seedling culture method of grapes

InactiveCN107318616AShorten rooting timeNutrient-rich substrateBiocideBio-organic fraction processingShootCallus formation

The invention mainly relates to the technical field of grape planting, and discloses a soilless cutting seedling culture method of grapes. The method includes the steps of clipping cutting slips, soaking the cutting slips, conducting cutting of the cutting slips, conducting post-cutting management, and exercising seedlings for cultivation. The method is simple and facilitates mass operation, the rooting time of the grape cutting slips is shortened to be 9-10 days, the rooting rate reaches 92%, the survival rate reaches 100%, the planting efficiency is obviously improved, and the economic income is increased by 9.6%; two-three-year-old grape shoots are clipped to serve as the cutting slips, many nutrients are accumulated in the cutting slips and can be supplied to callus formation of the cutting slips when external nutrients are not accumulated in the cutting slips yet, and the treating time and the rooting time are shortened.

Owner:JINZHAI XINTIANDI MODERN AGRI

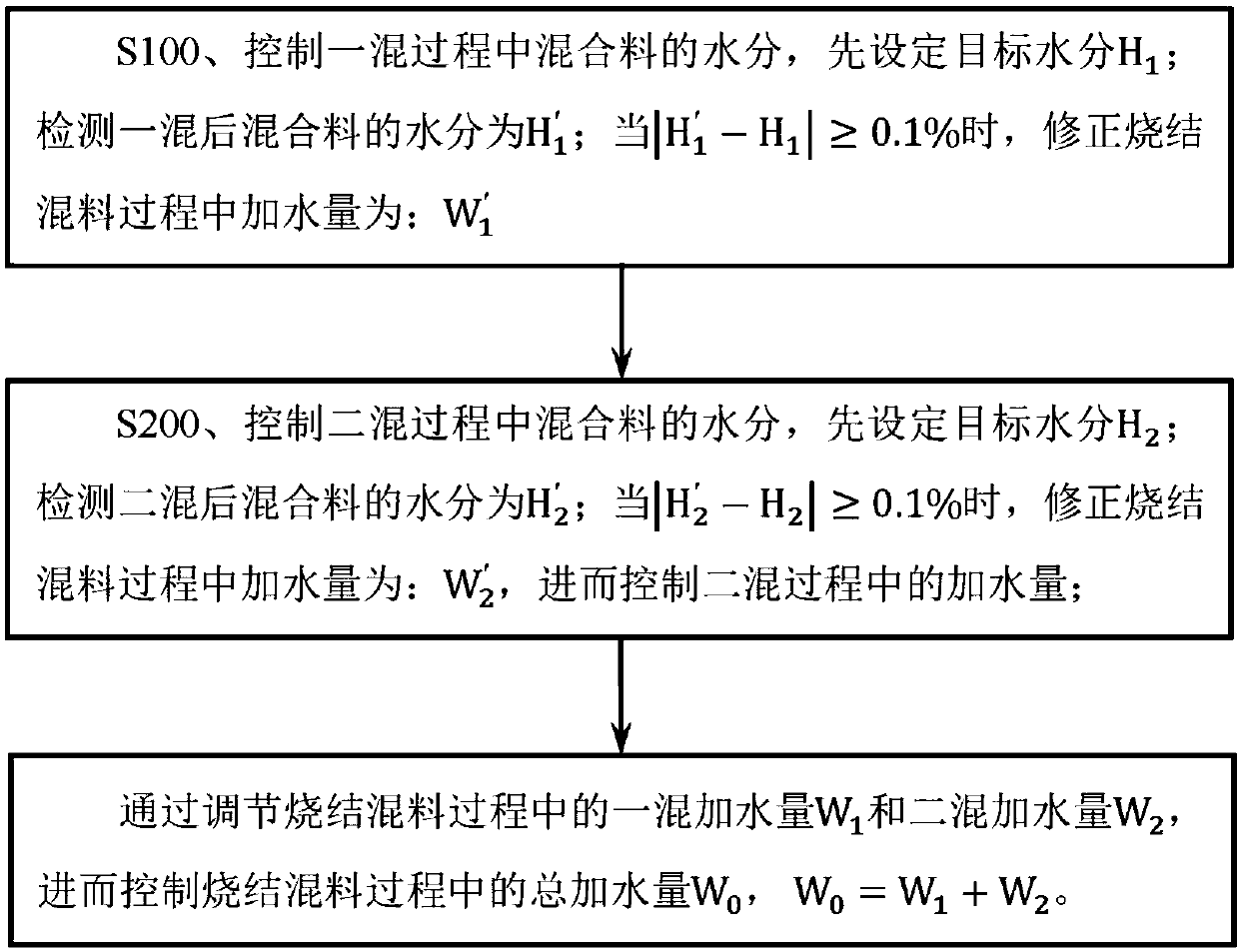

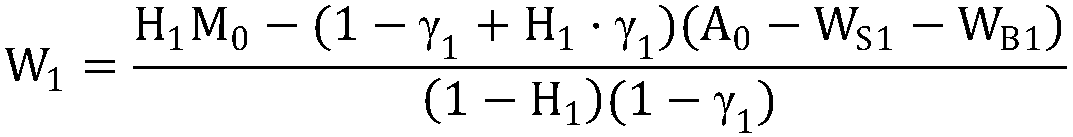

Automatic control method for water content of sintering mixture

ActiveCN108130417AImprove the accuracy of adding waterMoisture fluctuationsSpecial data processing applicationsAutomatic controlWater content

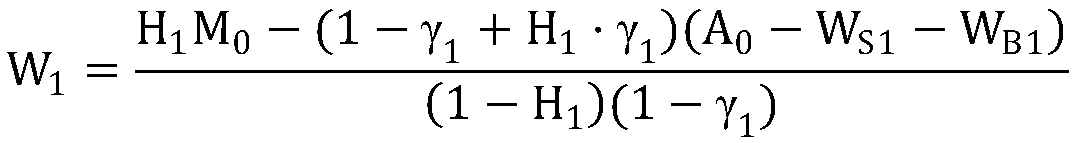

The invention discloses an automatic control method for the water content of a sintering mixture and belongs to the technical field of sintering. The automatic control method includes the specific steps that S100, the water content of a mixture in the first mixing process is controlled, and a target water content H1 is firstly set; it is detected that the water content of the mixture after first mixing is H'1; and when |H'1-H1|>=0.1%, the water adding amount in the mixture sintering correcting process is W'1; and S200, the water content of the mixture in the second mixing process is controlled, and a target water content H2 is firstly set; it is detected that the water content of the mixture after second mixing is H'2; and when |H'2-H2|>=0.1%, the water adding amount in the mixture sintering correcting process is W'2. By adjusting the water adding amount W1 during first mixing and the water adding amount W2 during second mixing in the mixture sintering process, the total water adding amount W0 in the mixture sintering process is controlled. According to the automatic control method for the water content of the sintering mixture, the accuracy and objectivity of operation are improved, and the water distribution precision of the sintering mixture is improved.

Owner:山东诺德能源科技有限公司

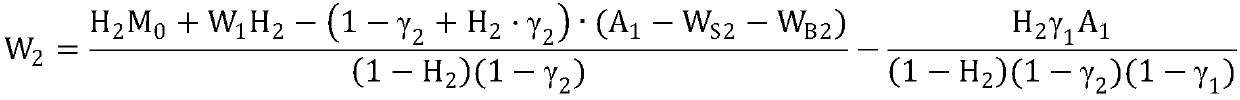

Composite conductive ink-jet ink and preparation method thereof

The invention relates to a composite conductive ink-jet ink. A mixture of nano-silver and graphite serves as the conductive component of the composite conductive ink-jet ink. The ink is prepared from, by mass, 10-20% of the conductive component, 1-5% of a dispersing agent, 1-15% of a resin joining agent, 1-4% of a surface active agent, 1-10% of other auxiliaries and 50-80% of a solvent. The invention further relates to a preparation method of the composite conductive ink-jet ink. According to the composite conductive ink-jet ink and the preparation method, nano-silver particles with a nano-scale particle size and graphite of a laminated structure are composited, and graphite of the laminated structure is used as a carrier of nano-silver, so that the degree of leaking from pores of coarse paper of nano-silver particles is reduced, the formation of a conductive path is promoted, and the conductivity of a conductive layer is improved. The composite conductive ink-jet ink is good in dispersity, high in stability, not likely to block a jet and good in ink jet continuity, and the formed conductive layer is good in film forming property and suitable for printing various types of paper.

Owner:山东中康激宏科技开发有限公司

Method for surface oxidation treatment of uranium oxide powder

InactiveCN101254950AImprove the O/U atomic ratioIncrease surface areaNuclear energy generationReactors manufactureUranium oxideSurface oxidation

The invention relates to a method of oxidation treatment of a surface of a uranium dioxide, which is characterized that the method comprises the following steps: (1) taking the UO2 powder and putting the UO2 powder into a tube type atmosphere oven, heating the UO2 powder under the condition of oxidation medium while the heating rate is 5 to 20 degree centigrade per minute, heating the UO2 powder to 250 degree centigrade to 400 degree centigrade and insulating for 2 to 6 hours; (2) when the UO2 powder is cooled to 100 degree centigrade to the room temperature in the oven, taking the UO2 powder out and cooling the UO2 powder in the air, so as to obtain the uranium dioxide powder with the oxidized surface. The method puts the UO2 in different oxidation medium and the UO2 is insulated at a certain temperature, then the surface oxygen content is increased, the surface area is increased, and the O / U atomic ratio of uranium dioxide and the surface area of the UO2 powder are enhanced. The oxidation medium obtained by the method has rich resources, low oxidation temperature and less consumption and has the advantages of simple fabrication process and low cost.

Owner:CHONGQING UNIV

Method for working fermenation raw liquid for distilling black liquor

InactiveCN1502684APromote decompositionSpeed up the conversion processAlcoholic beverage preparationYeastWhite liquor

The present invention relates to a fermented raw liquor processing method for producing distilled black liquor. Said method includes the following steps: (1). selecting material and pulverizing: using grain for making general white liquor as raw material, in which the black grain content is above 35%, pulverizing and sieving; (2) moistening: adding 35-40% of water into the pulverized and sieved raw material for moistening it; (3). steaming the above-mentioned raw material for 18-22 min, at normal pressure; (4). taking out steamed raw material from steamer, placing it into vat and adding water, uniformly stirring them to form raw material liquor; (5) adding saccharifying enzyme and distiller's yeast; (6). adding humics; and (7). sealing vat and making fermentation at least for 7 days at 40-20 deg.C so as to obtain the fermented raw liquor for producing black liquor.

Owner:刘广新

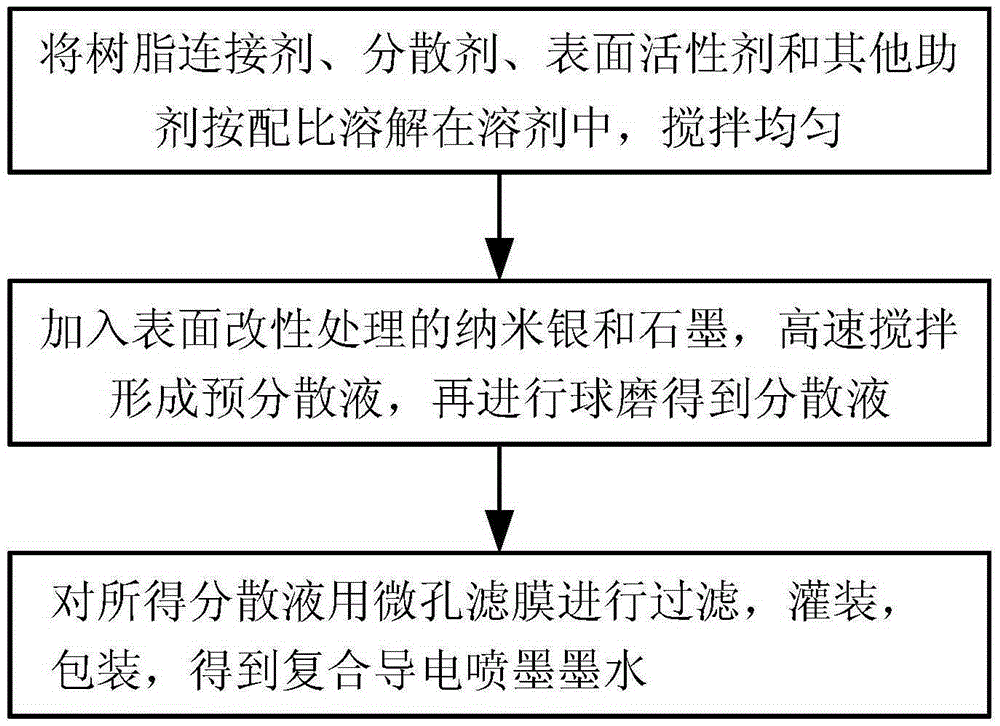

Method for estimating moisture content of mixture on sintering machine according to water addition volume

ActiveCN108133106AWater adjustmentEasy to add waterDesign optimisation/simulationSpecial data processing applicationsProcess conditionsMoisture

The invention discloses a method for estimating the moisture content of a mixture on a sintering machine according to the water addition volume, and belongs to the technical field of sintering. The estimated moisture content of the mixture on the sintering machine is H3 which is calculated according to a formula which is shown in the description. By means of the method, the moisture content of themixture on the sintering machine in the later period can be estimated according to the water addition volume of the mixing process in the former period, operating personnel conveniently adjust the water addition volume in the sintering and mixing process according to the technological conditions of the moisture content of the sintering mixture, and then the water addition volume is conveniently optimized in the sintering and mixing process.

Owner:山东诺德能源科技有限公司

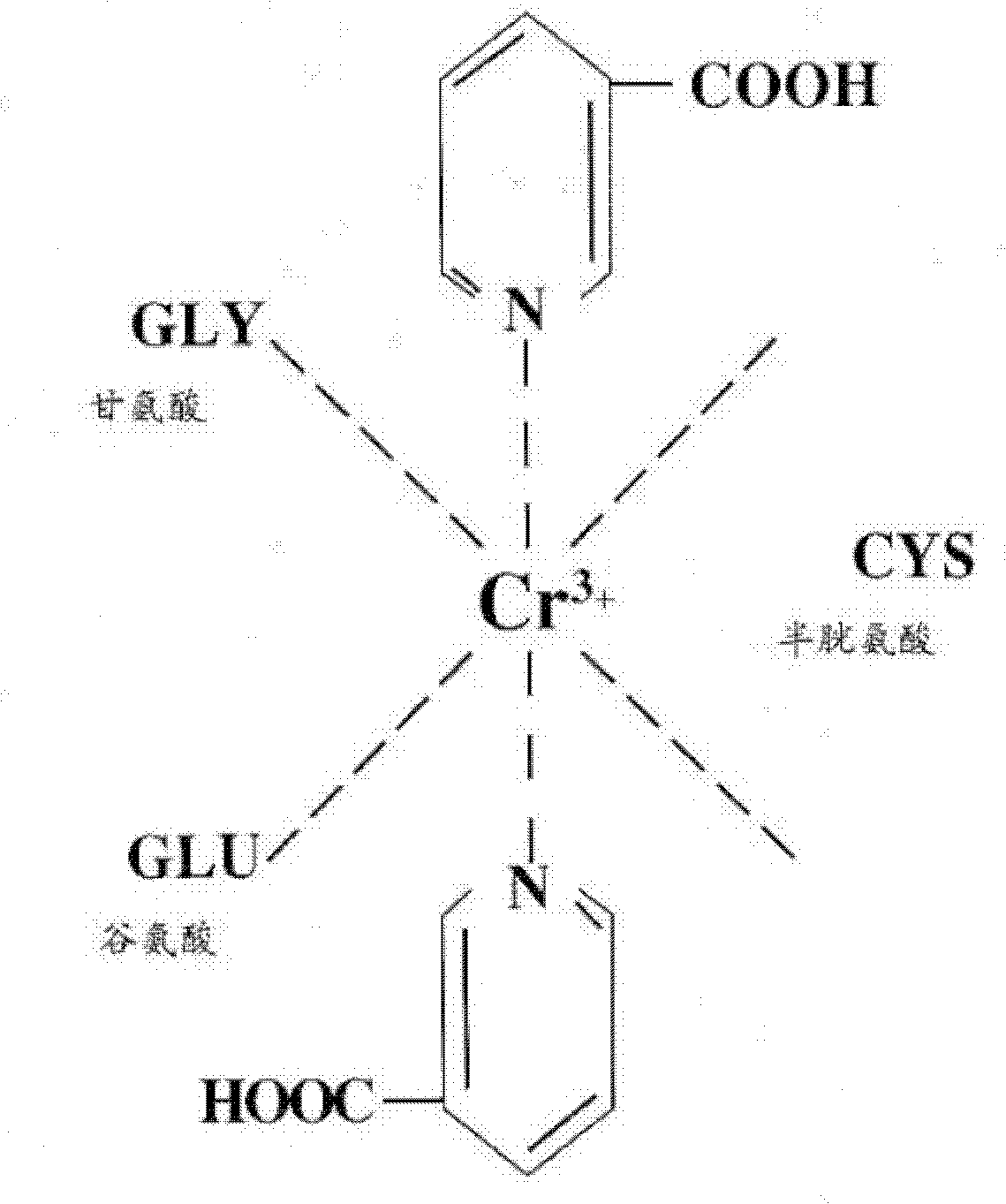

Production method of egg with low cholesterol, rich selenium, and rich chromium

ActiveCN102423005AProportional balanceSufficient contentAnimal feeding stuffAnimal scienceTrace element

The invention relates to a production method of eggs with low cholesterol, rich selenium, and rich chromium, which comprises the following steps: well mixing 50 parts of laying hen complete feed and 0.5-1 parts of Chinese herbal medicine compositions on a weight basis to prepare feed A, feeding 60-day-old laying hens with the feed A, continuing to feed till the laying hens are 125 days old; well mixing 50 parts of laying hen complete feed and 0.5-1 parts of nutritional compositions on a weight basis to prepare feed B, feeding 125-day-old laying hens with the feed B, continuing to feed throughout the whole process of the laying period. When the egg of the invention is eaten, trace elements such as selenium and chromium can be supplemented simultaneously, and metabolic syndrome can be effectively prevented when 1-2 eggs are eaten every day.

Owner:TIANJIN SELENIUM AIGE BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com