Preparation method of modified biologically-activated filter fillings

A kind of biological and active technology, applied in the field of preparation of modified biological active filter filler, to achieve the effect of strengthening, shortening the film hanging period, and enhancing the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

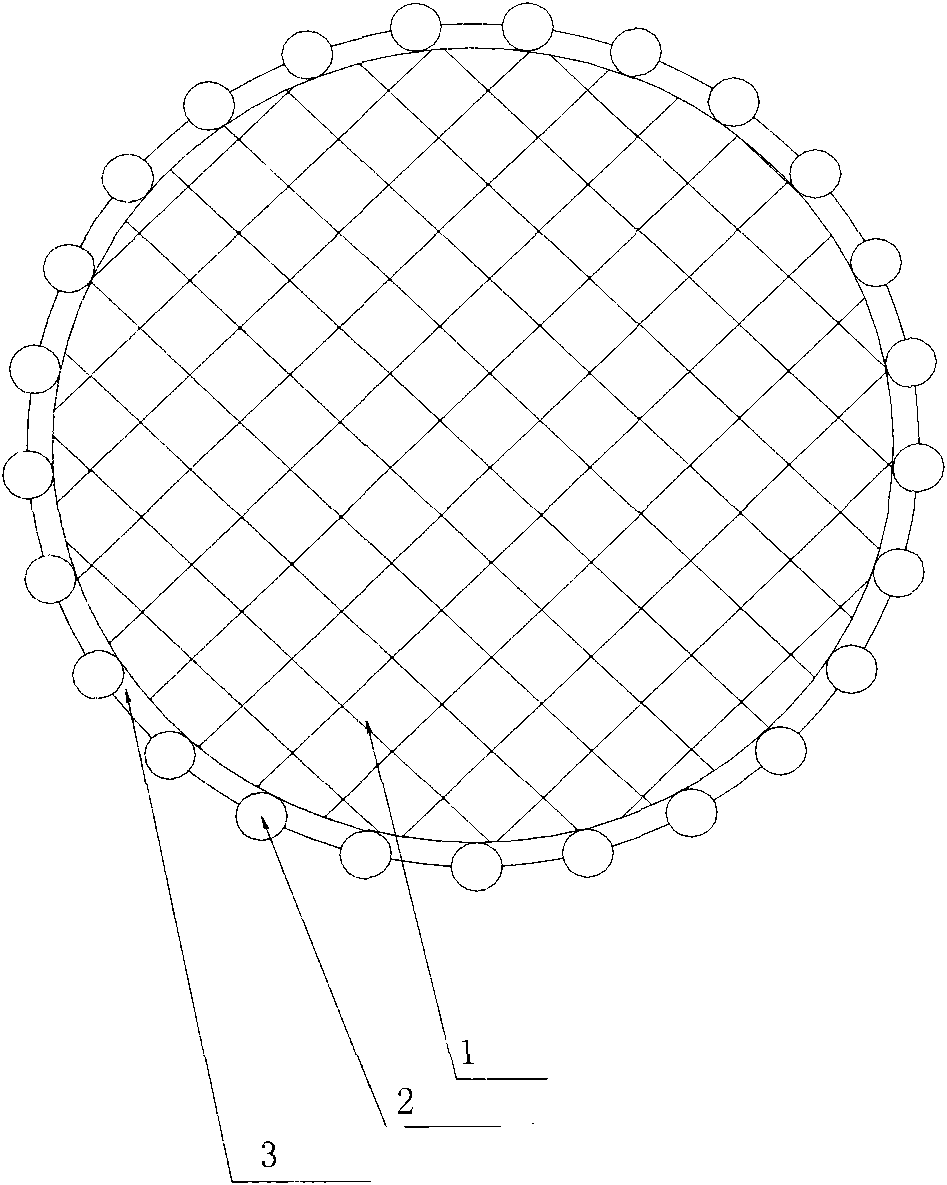

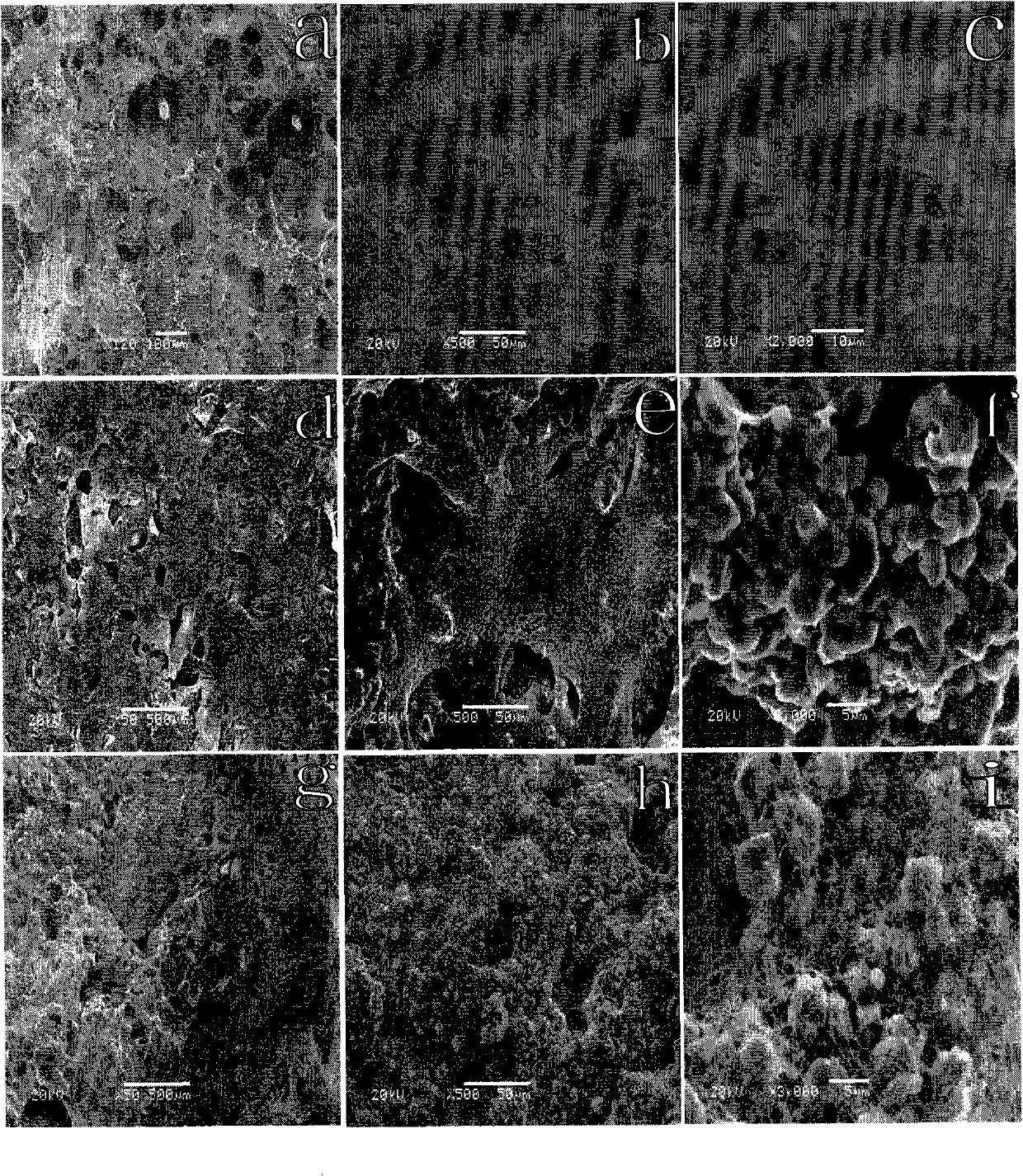

Image

Examples

Embodiment 1

[0028] The preparation method of embodiment 1 modified bioactive filter tank filler, comprises the following steps:

[0029] (1) Wash the inorganic carrier ceramsite with a particle size of 3 to 8 mm, first soak it with hydrochloric acid with a molar concentration of 0.5mol / l for 24 hours, and wash with water until neutral; then oxidize it with a molar concentration of 0.5mol / l Soak in sodium for 24 hours, wash with water until neutral; then dry at 100°C for 5 hours to obtain a dry filler.

[0030] (2) Put the dry filler into FeCl with a molar concentration of 1.0mol / l 3 In metal salt solution, immerse and sonicate for 1-2 hours, dry at 100°C for 6 hours, and then sinter in a muffle furnace at 550°C for 5 hours to obtain a sintered material.

[0031] (3) Wash the sintered material after natural cooling, and dry it at 100° C. for 3 hours to obtain a dry sintered material.

[0032] (4) Put the dry sintered material into the macromolecule hydrogel-polyvinyl alcohol solution wit...

Embodiment 2

[0036] The preparation method of embodiment 2 modified bioactive filter tank fillers, comprises the following steps:

[0037] (1) Wash the inorganic carrier porous ceramic particles with a particle size of 3 to 8 mm, soak them in hydrochloric acid with a molar concentration of 2.0 mol / l for 12 hours, wash with water until neutral; then use hydrogen with a molar concentration of 2.0 mol / l Soak in sodium oxide for 12 hours, wash with water until neutral; then dry at 110°C for 3 hours to obtain a dry filler.

[0038] (2) Put the dry filler into AlCl with a molar concentration of 3.0mol / l 3 In metal salt solution, immerse and ultrasonic for 1-2 hours, dry at 110°C for 4 hours, and then sinter at 750°C for 3 hours in a muffle furnace to obtain a sintered material.

[0039] (3) Wash the sintered material after natural cooling, and dry it at 110° C. for 2 hours to obtain a dry sintered material.

[0040] (4) Put the dry sintered material into the polymer hydrogel containing trace e...

Embodiment 3

[0044] The preparation method of embodiment 3 modified bioactive filter tank fillers, comprises the following steps:

[0045] (1) Wash the inorganic carrier ceramsite with a particle size of 3 to 8 mm, first soak it with hydrochloric acid with a molar concentration of 1.0mol / l for 18 hours, and wash with water until neutral; then oxidize it with a molar concentration of 1.0mol / l Soak in sodium for 18 hours, wash with water until neutral; then dry at 105°C for 4 hours to obtain a dry filler.

[0046] (2) Put the dry filler into Fe(NO with a molar concentration of 2.0mol / l 3 ) 3 In metal salt solution, immerse and sonicate for 1-2 hours, dry at 105°C for 5 hours, and then sinter in a muffle furnace at 650°C for 4 hours to obtain a sintered material.

[0047] (3) Wash the sintered material after natural cooling, and dry it at 105° C. for 2.5 hours to obtain a dry sintered material.

[0048] (4) Put the dried sintered material into the polymer hydrogel-carrageenan solution with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com