Patents

Literature

32results about How to "Change surface morphology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of modified biologically-activated filter fillings

InactiveCN101948166APromote growthSpeed up the formation processSustainable biological treatmentBiological water/sewage treatmentNutrientSewage treatment

The invention relates to a preparation method of modified biologically-activated filter fillings, comprising the following steps of: (1) cleaning an inorganic carrier with the grain diameter of 3-8 millimetres, sequentially carrying out acid cleaning, alkaline cleaning and drying to obtain dry fillings; (2) adding the dry fillings to a metal salt solution to carry out soaking and ultraphonic, drying and sintering to obtain sintering charges; (3) naturally cooling and drying the sintering charges to obtain dry sintering charges; (4) adding the dry sintering charges to a polymeric hydrogel solution containing trace elements and nutrient salts, carrying out soaking and ultraphonic and reacting in a saturated boric acid solution or a 3% calcium chloride solution so as to obtain crosslinked fillings; and (5) drying and naturally cooling the crosslinked fillings so as to obtain the modified biologically-activated filter fillings. The invention has the advantages of simple process and easy implementation; and in addition, the obtained modified biologically-activated filter fillings can increase the activity and the number of biomembranes, shorten the membrane-forming periods of biological aerated filter fillings and enhance the sewage treatment efficiency and the stability of a biological aerated filter.

Owner:GANSU GOLDEN BRIDGE GRP CO LTD +1

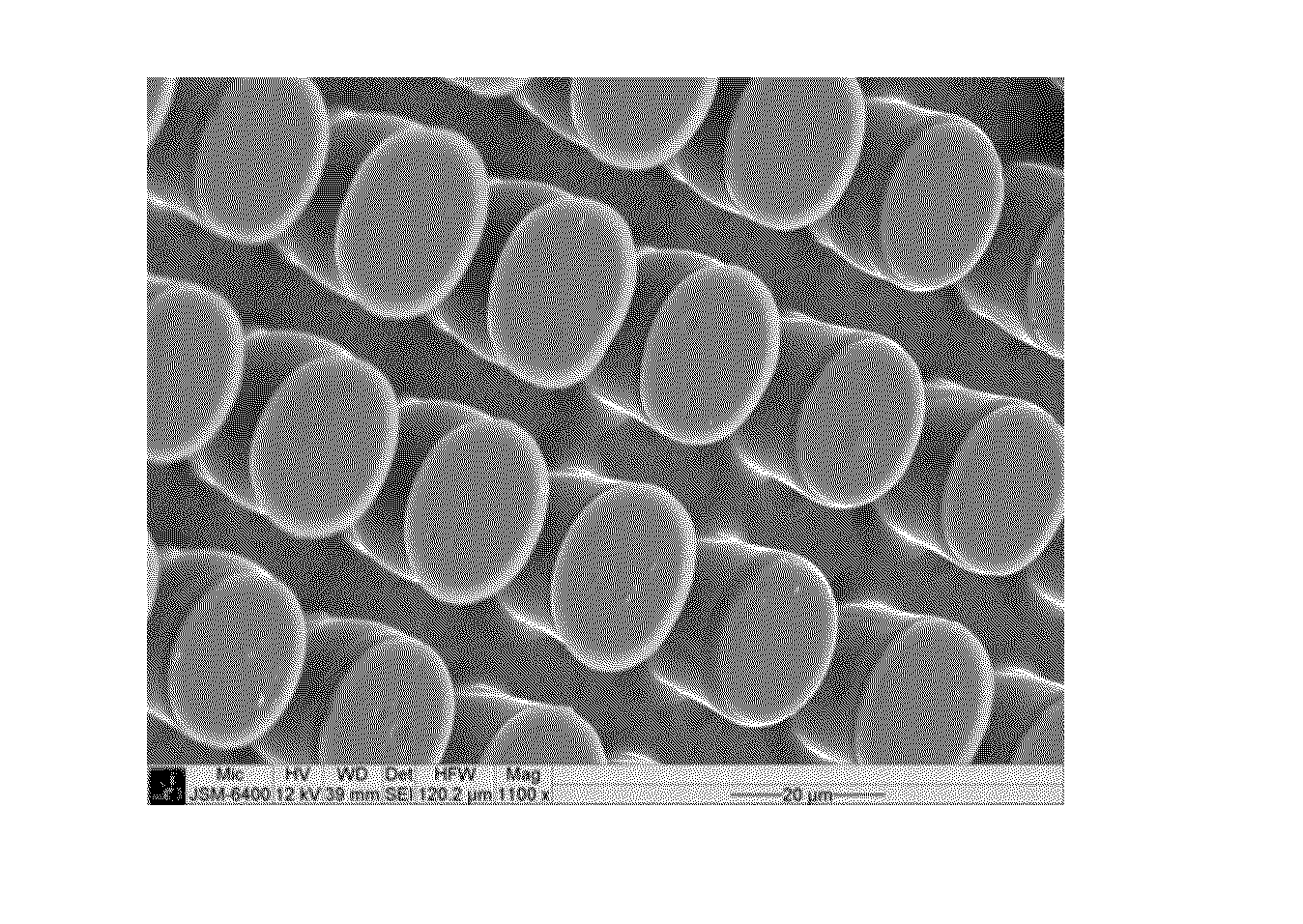

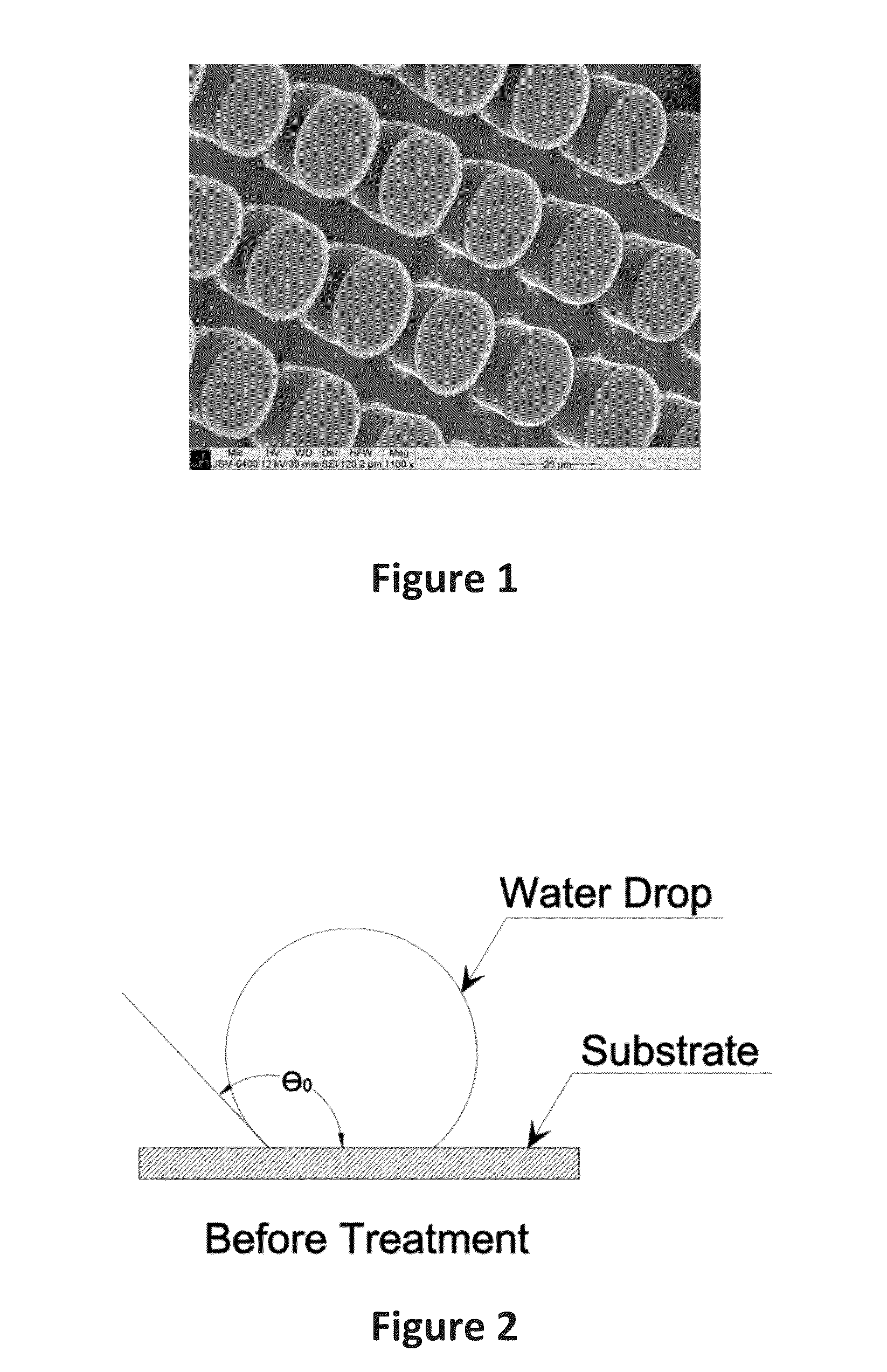

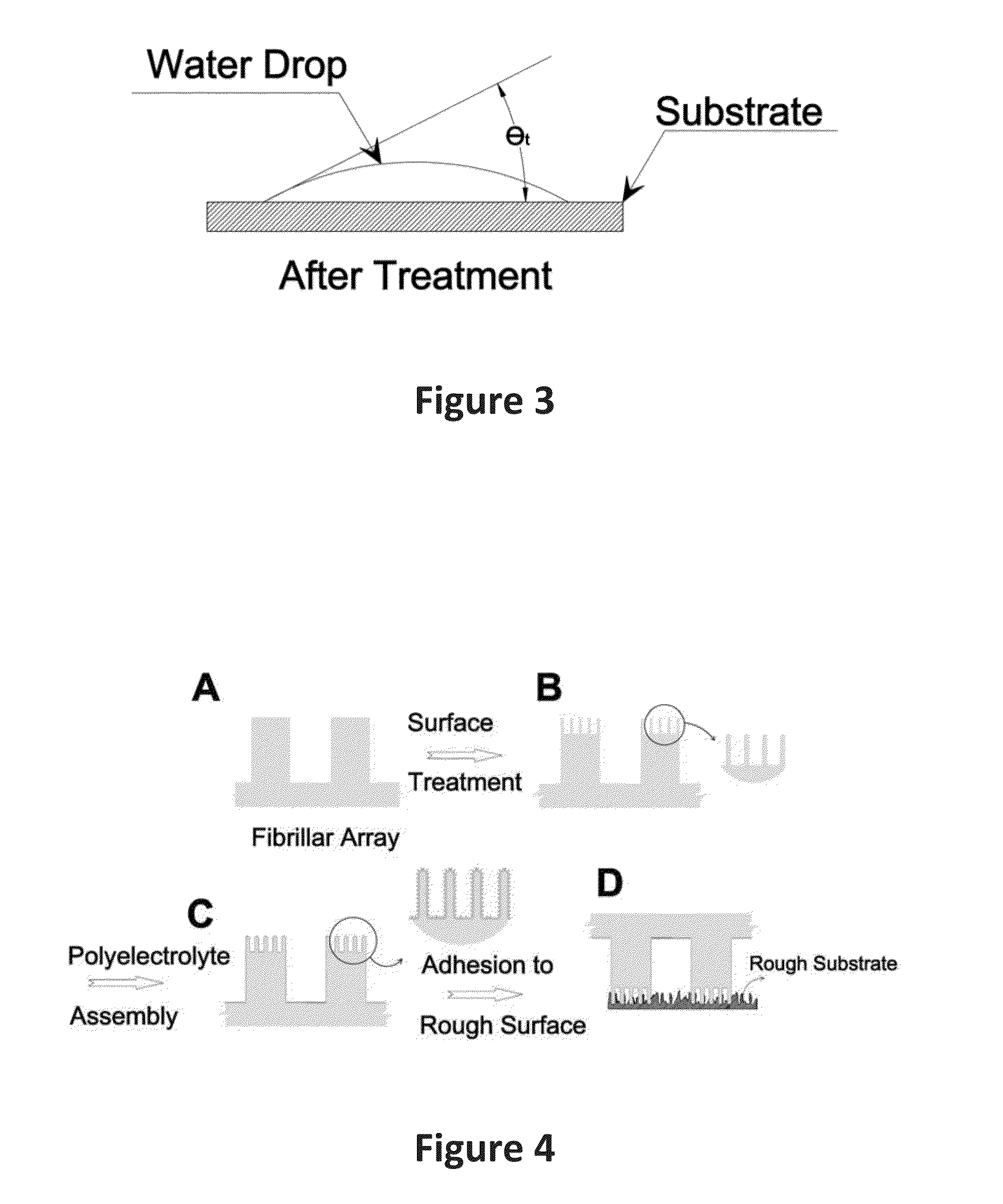

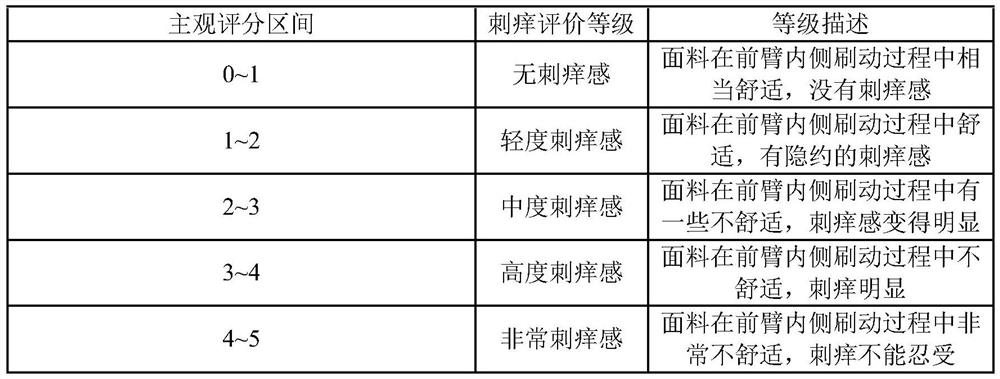

Durable Hydrophilic Dry Adhesives with Hierarchical Structure and Method of Making

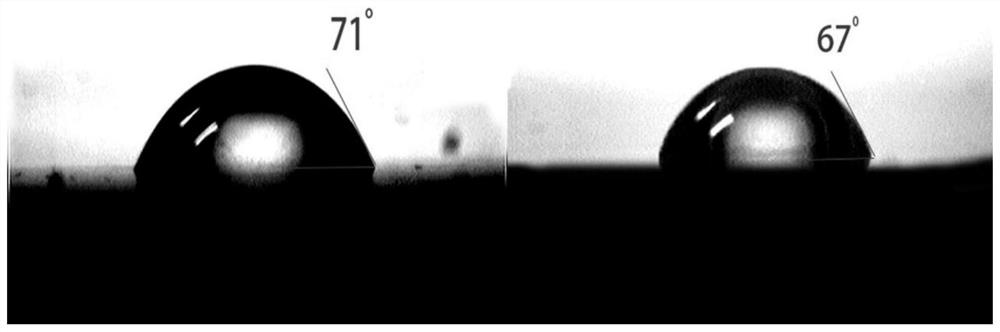

InactiveUS20140329061A1Improve wettabilityReduce contactFilm/foil adhesivesLayered productsFiberCrystallography

Provided is a method of making durable hydrophilic and hierarchical structures containing nano and micro features used as dry adhesives. The method includes introduction of hydrophilic, nanostructured features on the micro-scale tips of fibrillar arrays through UV / Ozone (UVO) and oxygen plasma treatment; the method also includes further coating of the hierarchical structure with a polyelectrolyte via electrostatically-driven self-assembly to improve the hydrophilic stability of the treated fibril tip surfaces.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV +1

Bacterial cellulose fermentation medium made from apple pomace and method for producing bacterial cellulose by utilizing medium

ActiveCN104031956AImprove solubilityReduce degradationMicroorganism based processesFermentationHydrolysateSugar

The invention discloses a bacterial cellulose fermentation medium made from apple pomace and a method for producing the bacterial cellulose by utilizing the medium, and belongs to the field of biotechnology. The bacterial cellulose fermentation medium comprises cane sugar, beef extract, disodium hydrogen phosphate, citric acid, ethanol and apple pomace hydrolysate. The method comprises the following steps: (1) activating and propagating gluconacetobacter xylinum to obtain gluconacetobacter xylinum seed solution, incubating the gluconacetobacter xylinum seed solution into a bacterial cellulose fermenting medium for fermenting to obtain bacterial cellulose fermenting solution; and (2) treating a bacterial cellulose in the bacterial medium fermenting solution to obtain bacterial cellulose. The method has the advantages of low cost, simple process and the like, is convenient for industrial production, is good in stability and reproducibility, and is suitable for large-scale production, wherein the yield of the fermented bacterial cellulose is more than 15g / L.

Owner:SHAANXI UNIV OF SCI & TECH

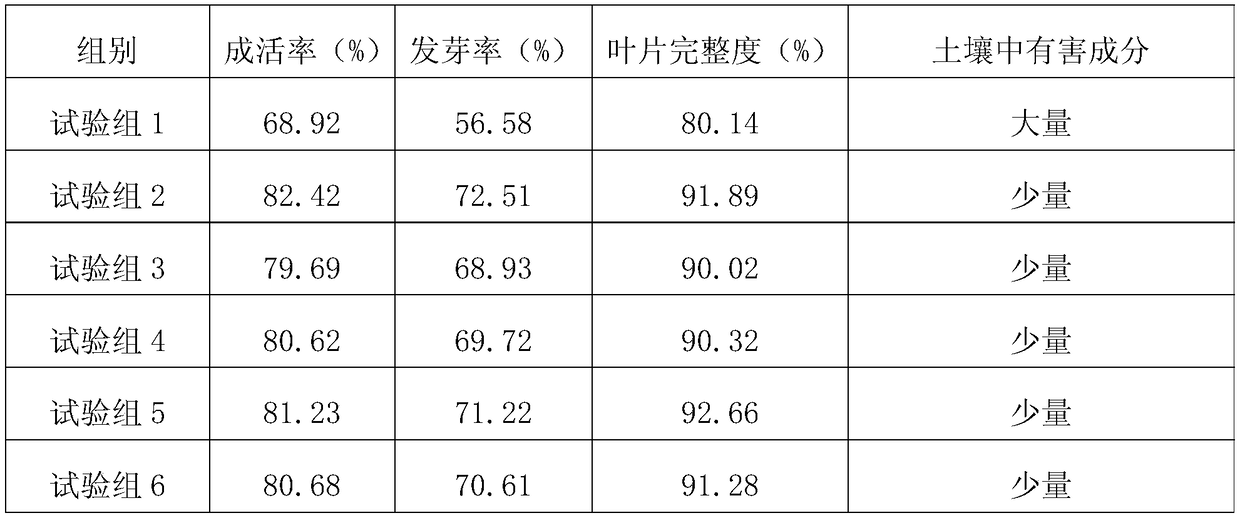

Seed tissue culture medium for root of subprostrate sophora

InactiveCN106508675APromote healthy and strongEnsure balancePlant tissue cultureHorticulture methodsSucroseSaccharum

The invention provides a seed tissue culture medium for the root of subprostrate sophora, and relates to the technical field of tissue culture. The seed tissue culture medium is formed by mixing a basal culture solution and a mother solution with the volume ratio being 3-5:0.03-0.08. The mother solution mainly contains hymexazol, brassinolide, alpha-naphthylacetic sodium salt, pyrimethanil and diethyl aminoethyl hexanoate. The basal culture solution mainly contains pineapple waste hydrolysate, cane sugar, agar, lactoalbumin hydrolysate, ABT rooting powder, zeatin, kinetin, isopentenylaminopurine and gibberellin. According to the seed tissue culture medium disclosed by the invention, the using quantity of culture medium raw materials like saccharose in a traditional process is reduced through utilization of pineapple waste in the basal culture solution, and preparation cost of the culture medium is reduced. In addition, by adding the formula of the mother solution, rooting of strong seedlings can be promoted quickly, and the rooting percentage can reach 99% or above. Moreover, the average plant number reaches 20-25 after the strong seedlings take roots.

Owner:潘克稳

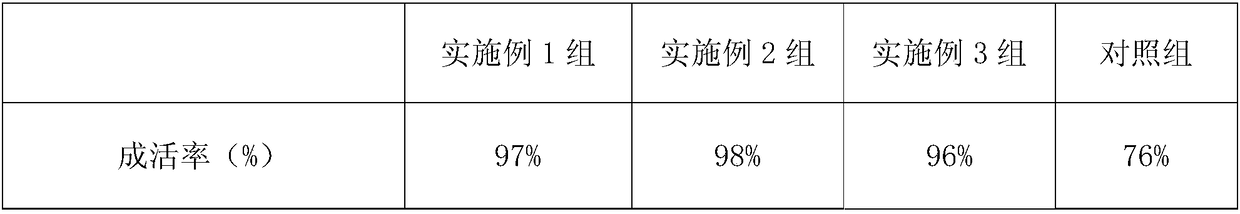

Fertilizer specially used for sugar oranges, and preparation method of fertilizer

InactiveCN108083869ASlow effectQuick resultsSuperphosphatesBiocideMicrobial agentHazardous substance

A fertilizer provided by the invention is prepared from the following raw materials in parts by weight: 10-18 parts of urea, 5-9 parts of powdered rock phosphate, 3-7 parts of calcium superphosphate,10-18 parts of fermented earthworm dung, 5-9 parts of orange residue, 8-16 parts of peanut shell, 6-12 parts of waste mushroom sticks of lentinula edodes, 5-12 parts of apple pomace hydrolysate, 12-20parts of a sterilized composition, 2-6 parts of a fermentation microbial agent and a right amount of water. Harmful substances are not added from the formulation process to the production process ofthe fertilizer; after the fertilizer is adopted, the problems that cannot be solved by the convertional fertilizer that the water retention, fertility keeping ability and permeability of the soil arereduced, the residual fertilizer in plants pollutes the environment, and the like can be solved; the fertilizer also can accelerate the growth speed of sugar oranges while promoting the increase of fruit granules of the sugar oranges, and achieves the aim of green agriculture.

Owner:宜州市横山泰顺种养专业合作社

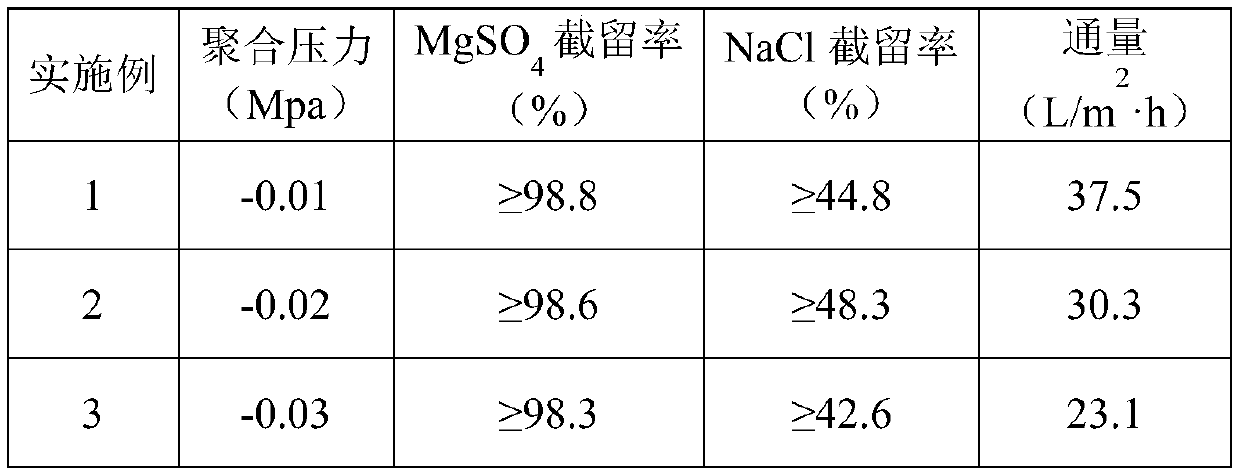

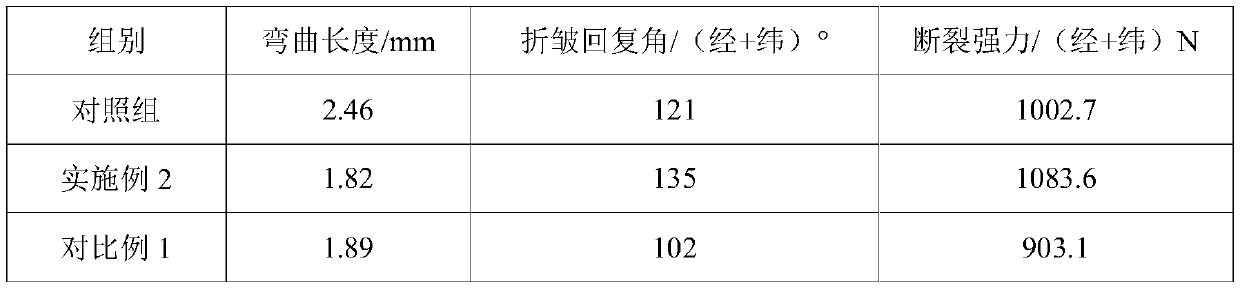

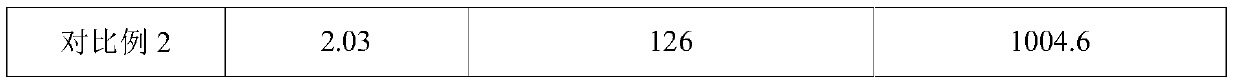

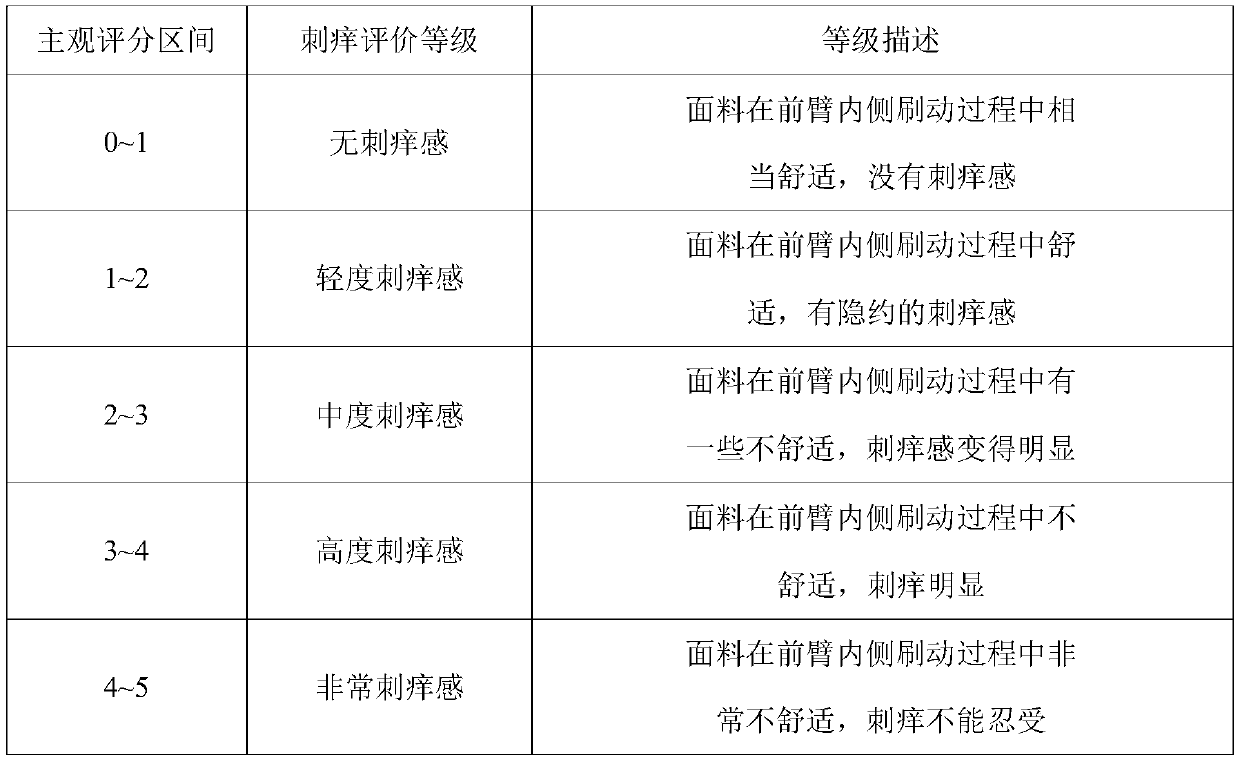

Anti-wrinkle ramie fabric with low itch

ActiveCN110253972BRelieve itchingIncrease elasticityPhysical treatmentLaminationPolymer scienceLanolin

Owner:HAIYAN SHUOCHUANG CLOTHING RES INST

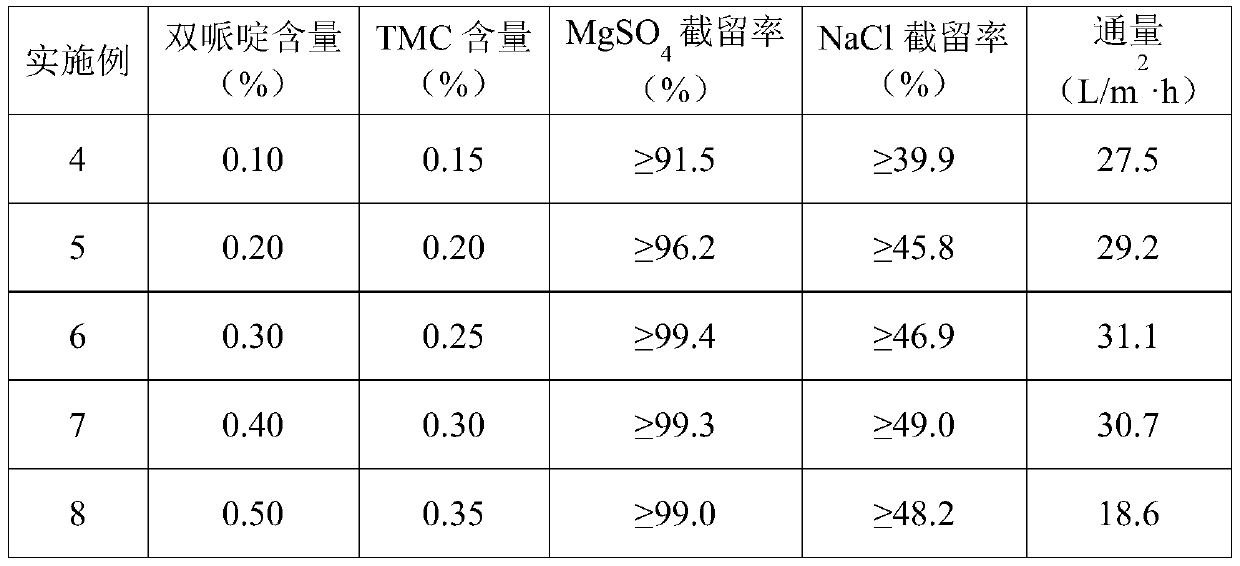

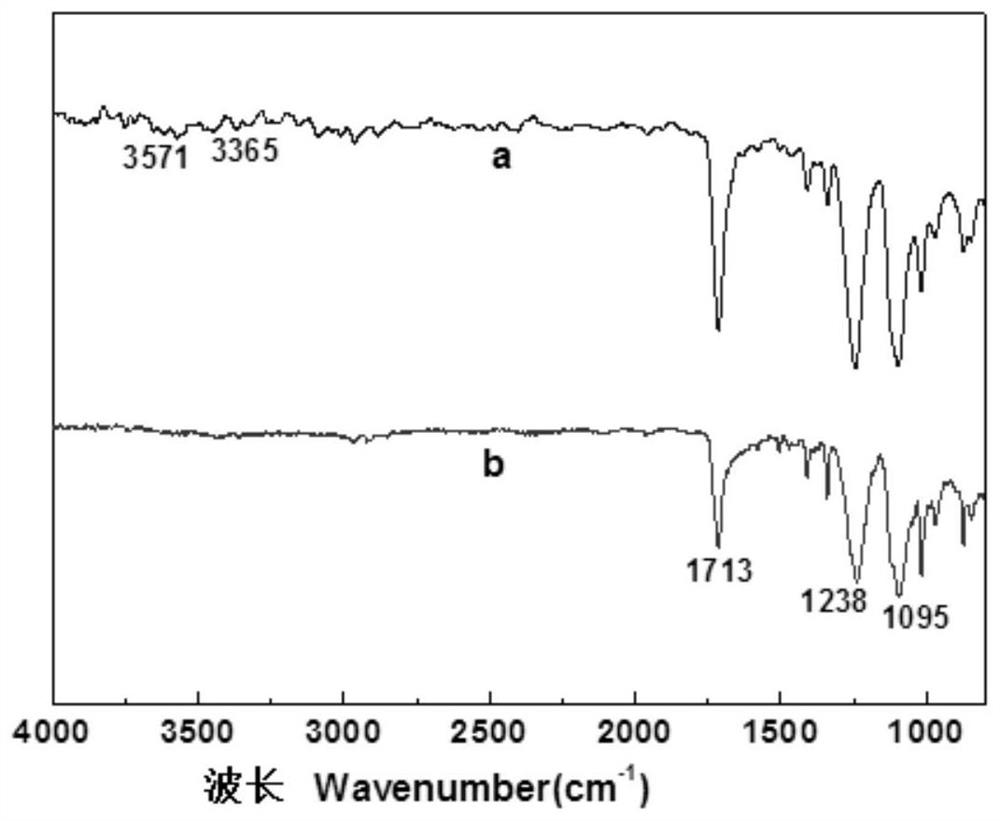

Preparation method of high-power interception reinforced nano-structure composite membrane

InactiveCN111467981AMinimized water flux decay rateWater flux decay rate increasedSemi-permeable membranesMembranesCarbonic acidComposite membrane

The invention belongs to the technical field of membranes, and relates to a preparation method of a high-power interception reinforced nano-structure composite membrane. According to the preparation method, an aqueous phase buffer system of interfacial polymerization is changed; adding of one or a combination of more of hydrosulfide radical, sulfite radical, bisulfite radical, bicarbonate radicaland carbonate radical is carried out, enough nanometer bubbles are generated in interfacial polymerization process, the nanometer polymerization structure is enhanced, the membrane surface morphologyis changed, and the nano-structure composite membrane with super high interception rate on inorganic high valence ions is obtained, and at the same time, the water flux attenuation rate of the membrane is minimized, and the pollution resistance and the hydrophilicity are significantly improved. According to the preparation method provided by the invention, through simpler and more convenient operation steps, a high-performance and low-cost preparation process is realized under the condition that raw materials and parameter variables are greatly reduced, and the application range of the composite membrane is greatly widened.

Owner:浙江迪萧科技有限公司

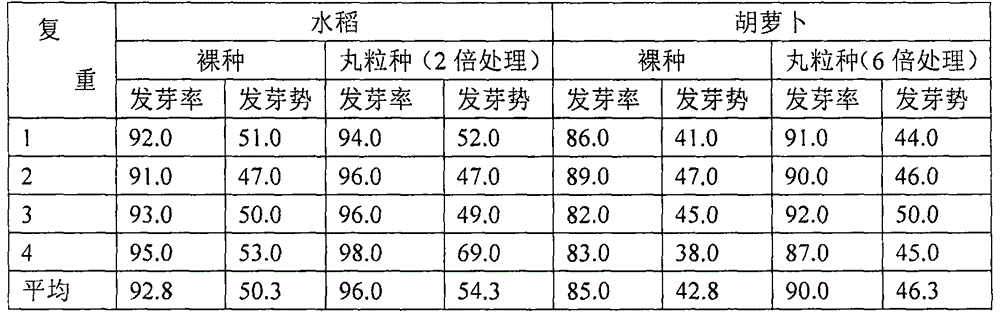

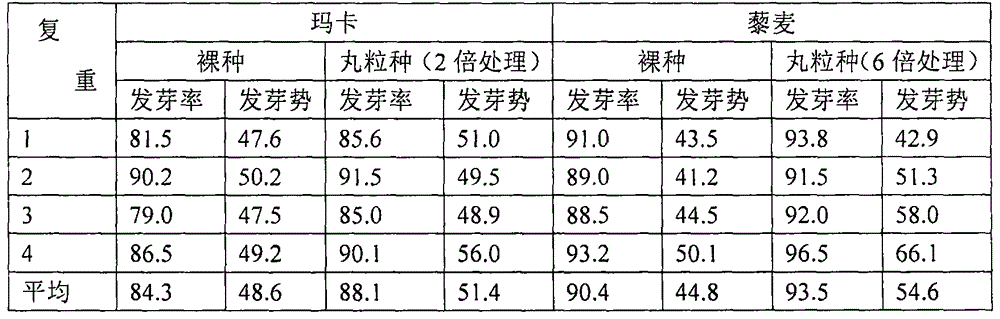

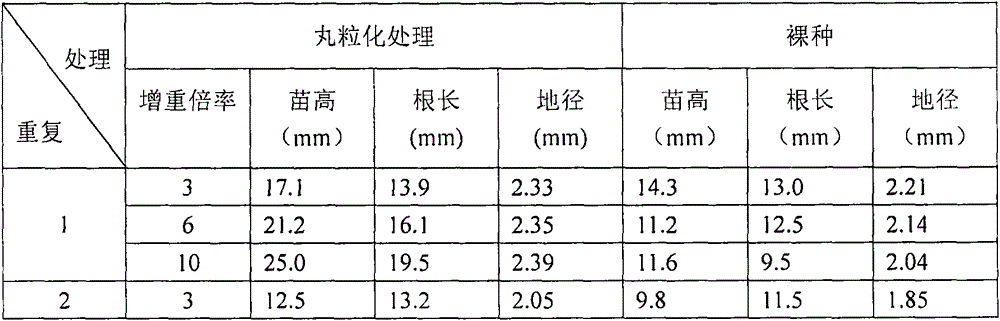

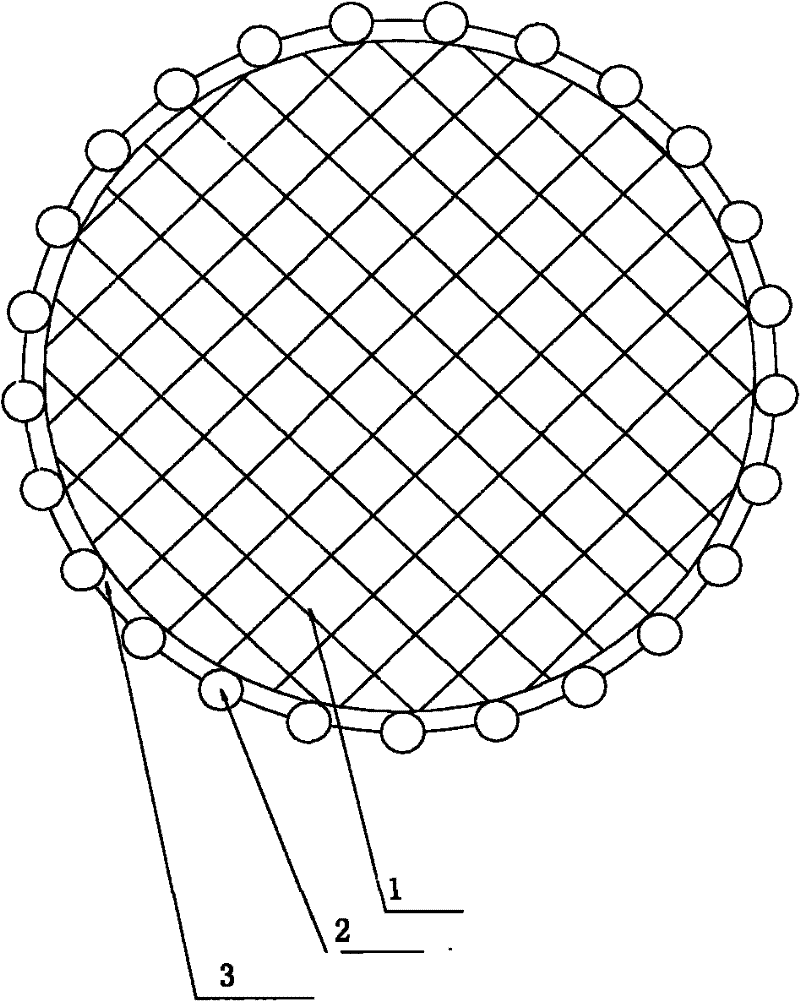

Pelleting powder used for wrapping special-shaped and micro seeds

InactiveCN105027746AImprove shear resistanceReduce stress deformationSeed coating/dressingFiberAmorpha fruticosa

The invention discloses a pelleting powder used for wrapping special-shaped and micro seeds and relates to the technical field of seed pelleting. The pelleting powder is formed by mixing powder A and powder B. The powder A comprises, by weight, 15-40 parts of tertiary red clay deposits, 10-50 parts of columnar loess, and 20-60 parts of biological rock powder. The powder B comprises, by weight, 5-20 parts of mixtures of three wormwood plants and two toxic plants. Each part of the mixtures of the three wormwood plants and the two toxic plants comprise 10-30 parts of artemisia capillaries dry powder, 5-20 parts of artemisia ordosica dry powder, 10-30 parts of Chinese mugwort dry powder, 20-50 parts of dry powder of radix euphorbiae lantu whole plants and 20-50 parts of amorpha fruticosa whole plants or seed dry powder. The surface morphology of the irregular or micro seeds can be remarkably improved, the irregular or micro seeds can be uniform, and mechanical precision sowing is facilitated. On the basis of the biological characteristic of the mixtures of the three wormwood plants and the two toxic plants, the capacity of the seeds for resisting outside biological violation is improved. Due to application of biological rock powder, columnar loess and plant fibers in the pelleting powder, the breathable water absorbing capacity of seed pelleting surface layers is enhanced, and the pelleting powder has great significance in fast water absorbing performance, breathing and germinating of multi-time pelleted seeds.

Owner:INNER MONGOLIA DONGSHENG SHENNONG CHEM CO LTD

A bacterial cellulose fermentation medium using apple pomace as raw material and a method for producing bacterial cellulose using the medium

ActiveCN104031956BImprove solubilityReduce degradationMicroorganism based processesFermentationGluconobacter sp.Gluconates

The invention discloses a bacterial cellulose fermentation medium using apple pomace as a raw material and a method for producing bacterial cellulose by using the medium, belonging to the field of biotechnology. The bacterial cellulose fermentation medium of the present invention contains sucrose, beef extract, disodium hydrogen phosphate, citric acid, ethanol and apple pomace hydrolyzate. The method for producing bacterial cellulose using the culture medium includes: 1) activating and expanding the gluconacetobacter xylosus to obtain the gluconacetobacter xylosacillus seed solution, and the gluconacetobacter xylosus seed solution Inserting bacterial cellulose fermentation medium for fermentation to obtain bacterial cellulose fermentation liquid; 2) taking the bacterial cellulose film in the bacterial cellulose fermentation liquid, and obtaining bacterial cellulose after treatment. The method has the advantages of low cost, simple process, convenient industrial production, etc., good stability and reproducibility, the yield of bacterial cellulose obtained by fermentation is greater than 15g / L, and is suitable for large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of reduced dye vat yellow 1

The invention discloses a preparation method of a reduced dye vat yellow 1. The preparation method comprises the following steps: grinding, kneading and extraction. Through pregrinding and segmented shearing actions, the prepared vat yellow 1 has good vibrance and tinting strength, and the quality of the product is obviously improved, so that the use values of the vat yellow 1 is enhanced.

Owner:安徽融创化工科技股份有限公司

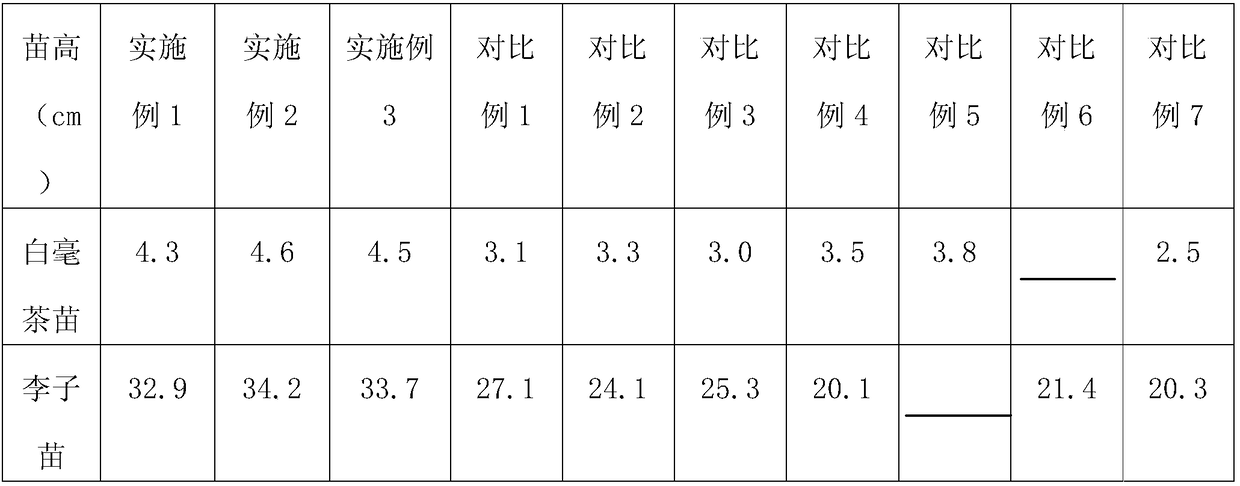

Interplanting method of Lingyun pekoe teaandprunussalicinalindl

InactiveCN108966985AImprove the ecological environmentPromote a virtuous circleBiocideBio-organic fraction processingEcological environmentPrunus

The invention provides an interplantingmethod of Lingyun pekoe tea and prunussalicinalindl, and relates to the technical field of planting. The interplanting method of Lingyun pekoe tea and prunussalicinalindl comprises the following steps of (1) land parcelpreparation, (2) cultivation for pekoe teaseedlings, (3) planting of the pekoe tea seedlings, (4) pre-treatment ofprunussalicinalindlseedlings, (5) interplanting of the prunussalicinalindl seedlings and (6) water and fertilizer management; by utilizing the height difference and required different illumination intensities of the prunussalicinalindl and the Lingyun pekoe tea, a stereoscopiccultivation mode is adopted,the Lingyun pekoe tea and the prunussalicinalindlare interplanted, prunussalicinalindl trees are planted in a pekoe tea garden, the ecological environment of the tea garden can be improved, the virtuous cycle of the ecological system of the tea garden is facilitated, and tea trees can promote the growth of the prunussalicinalindl trees, and the win-win result is achieved.

Owner:广西浪伏茶业股份有限公司

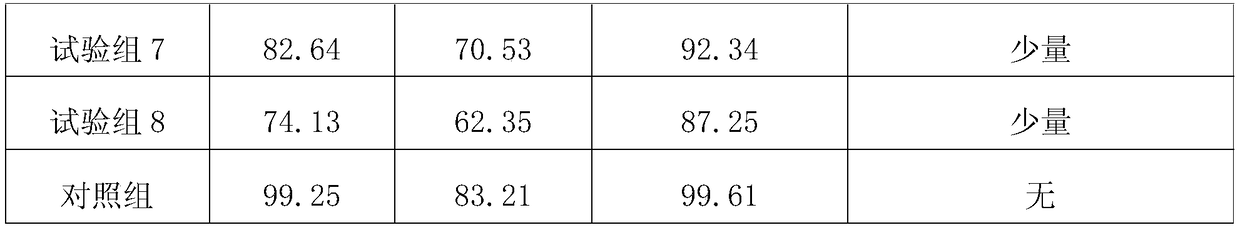

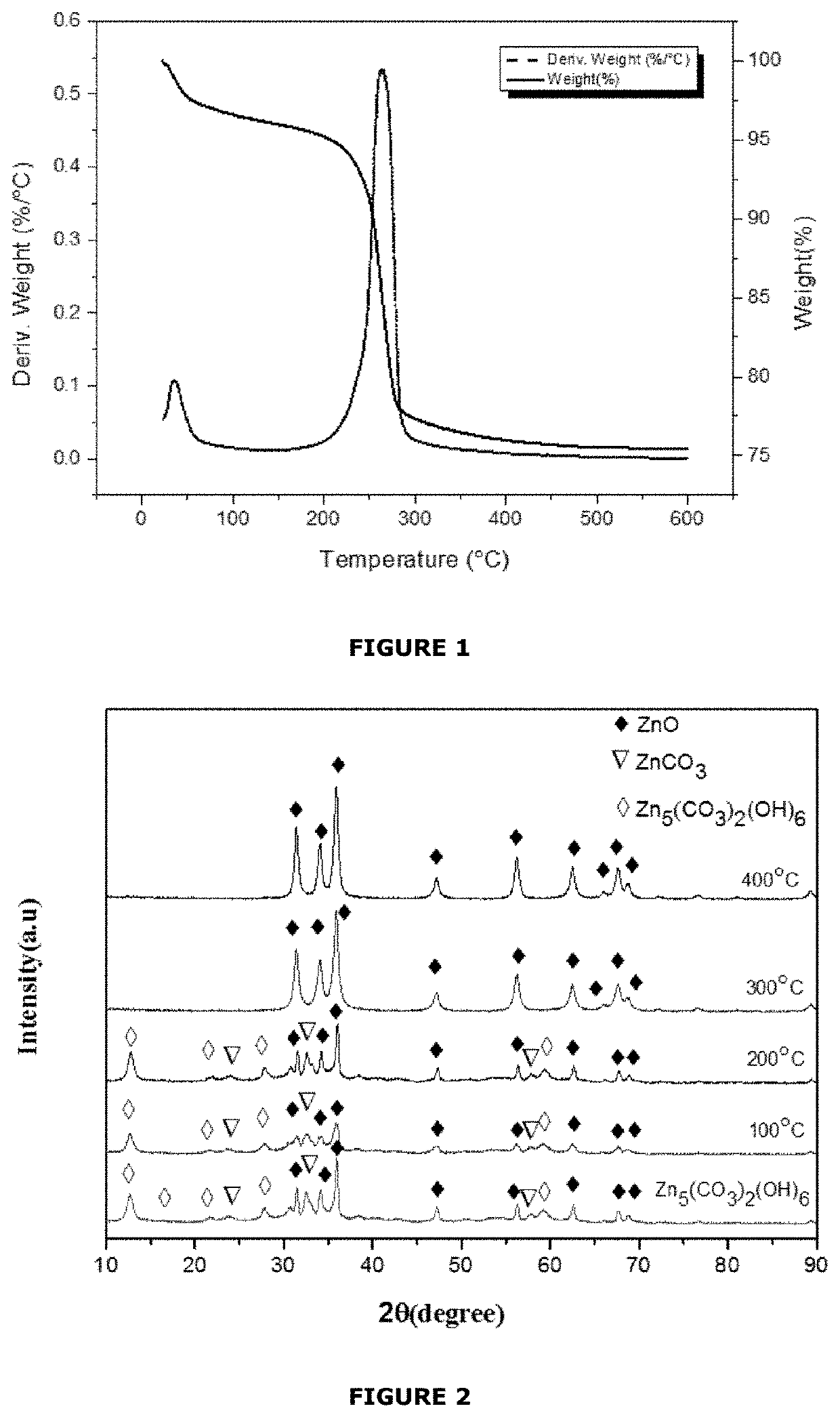

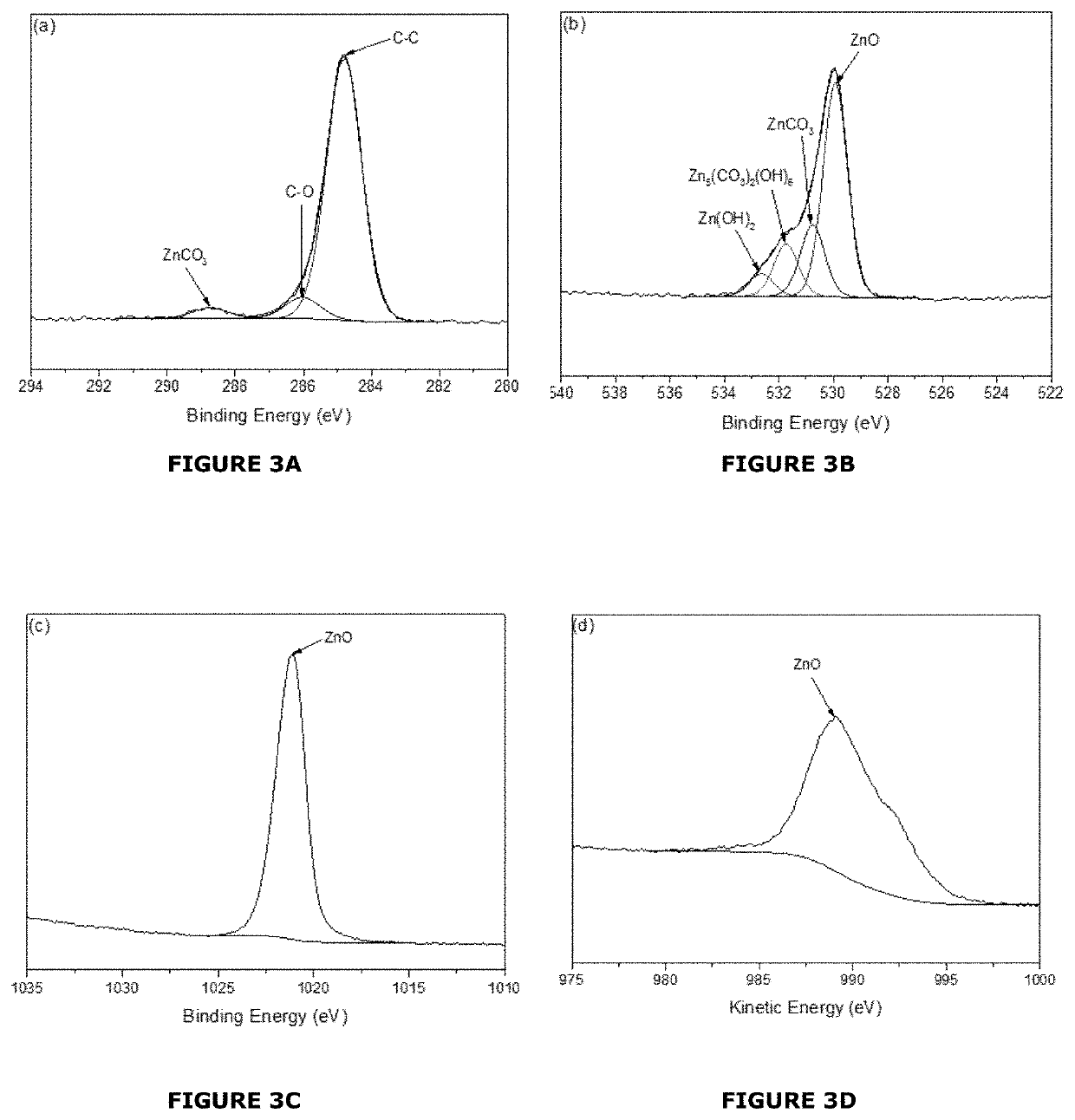

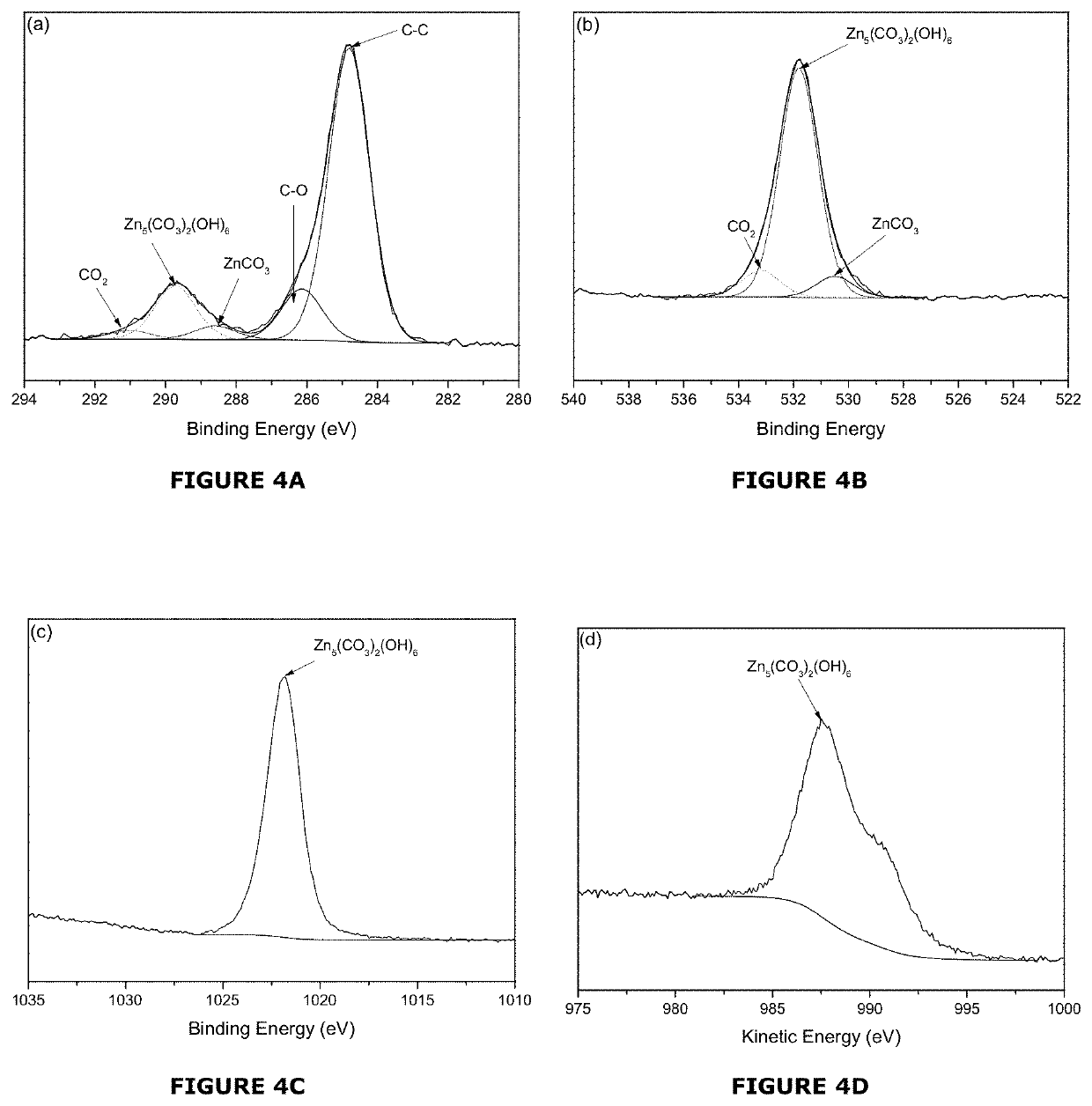

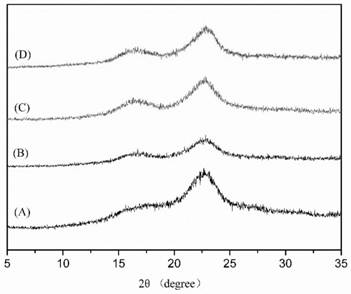

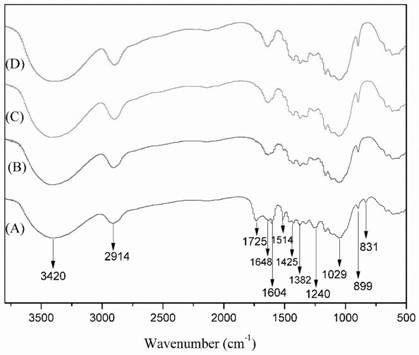

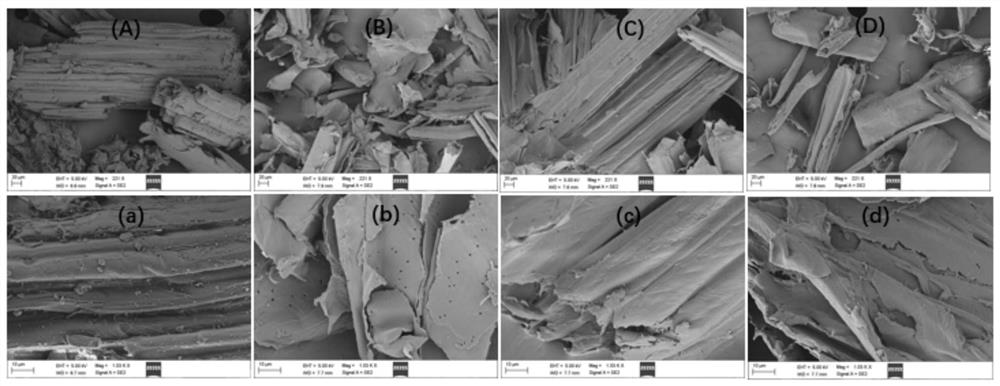

Methods of making polymers and metal-polymer composites

PendingUS20210317320A1Increase surface areaImprove surface energyAnti-corrosive paintsMetallic material coating processesPolymer sciencePolymer composites

The present invention relates to a method for producing a polymer, polymers and metal-polymer composites produced by the method. The method comprises providing one or more polymerisable monomers and providing a substrate comprising an activated metal surface, the activated metal surface comprising one or more compounds capable of initiating polymerisation of the one or more polymerisable monomers. The method comprises contacting the activated metal surface and the one or more polymerisable monomers to polymerise the one or more polymerisable monomers, thereby producing the polymer.

Owner:AUCKLAND UNISERVICES LTD

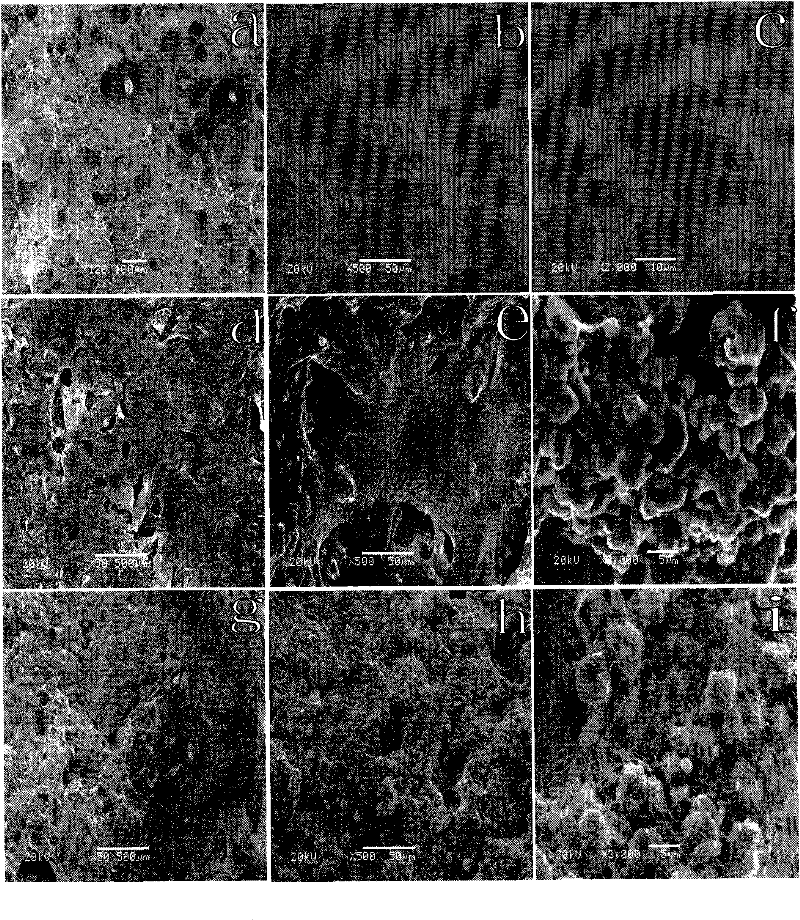

Method for pretreating bagasse by using sodium phosphate and hydrogen peroxide

InactiveCN111850070AReduce loadChange surface morphologyBiofuelsFermentationSodium phosphatesPre treatment

The invention relates to the technical field of bioengineering, and discloses a method for pretreating bagasse by using sodium phosphate and hydrogen peroxide. The method comprises the following steps: air-drying bagasse, pulverizing, screening, sealing, drying and storing; putting the treated bagasse into a mixed solution of sodium phosphate and hydrogen peroxide for one-step or step-by-step pretreatment; after the reaction is finished, cooling to room temperature, carrying out solid-liquid separation, washing a solid part to be neutral by using hot water, collecting solid residues, and drying to constant weight; the pretreatment liquid composed of hydrogen peroxide and sodium phosphate can significantly improve the enzymolysis efficiency and the lignin removal rate, the loading capacityof hydrogen peroxide in the mixed pretreatment liquid is lower, the pH of the system cannot be obviously reduced by adding hydrogen peroxide, and the surface morphology of bagasse can be better changed.

Owner:JINAN UNIVERSITY

Edible fungus cultivation base material and preparation method thereof

InactiveCN111357568ALow cost of preparationImprove economic efficiencyCultivating equipmentsMushroom cultivationNutrientEdible mushroom

The invention relates to the technical field of edible fungus cultivation, in particular to an edible fungus cultivation base material and a preparation method thereof. The edible fungus cultivation base material is prepared from the following raw materials in parts by weight: 10-20 parts of Chinese yam residues, 5-10 parts of pineapple residues, 8-16 parts of fungus residues, 3-8 parts of microcystin, 6-9 parts of agar and 3-5 parts of compound sodium nitrophenolate. According to the edible fungus cultivation base material, the Chinese yam residues, the fungus residues and the pineapple residues are utilized, the raw material consumption of the cultivation base material in a traditional technology is reduced, the preparation cost of the edible fungus cultivation base material is saved, meanwhile, the problems that food processing leftovers are improperly treated, and consequently environmental pollution is caused are solved, waste is turned into wealth, and economic benefits are high;meanwhile, no harmful substance is added in the cultivation base material from the formula to the production process, the obtained base material is scientific and reasonable, the preparation method is simple, and sufficient and reasonable nutrients can be provided for growth of edible fungi.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI +1

Red-heart honey-pomelo fertilizer and preparation method thereof

InactiveCN108456098ASlow effectQuick resultsExcrement fertilisersBioloigcal waste fertilisersHydrolysatePotassium

The invention provides a red-heart honey-pomelo fertilizer and preparation method thereof, and relates to the technical field of fertilizers. The fertilizer comprises, by weight, the following raw materials: 10-18 parts of urea, 5-9 parts of phosphate rock powder, 5-9 parts of potassium chloride, 3-8 parts of humic acid, 10-20 parts of organic compost, 7-14 parts of yellow ginger hydrolysate, 12-20 parts of mixed fungus bran, 2-6 parts of bacterial agent and a proper amount of water; The fertilizer solves the problems of reduction of soil water retention, fertilizer conservation and permeability caused by soil hardening, environmental pollution caused by residual fertilizer contained in plants and the like, which cannot be solved by the prior fertilizers. While promoting the enlargement ofred-heart honey-pomelo fruit, the fertilizer can also accelerate the growth rate. The aim of green agriculture is achieved.

Owner:宜州市横山泰顺种养专业合作社

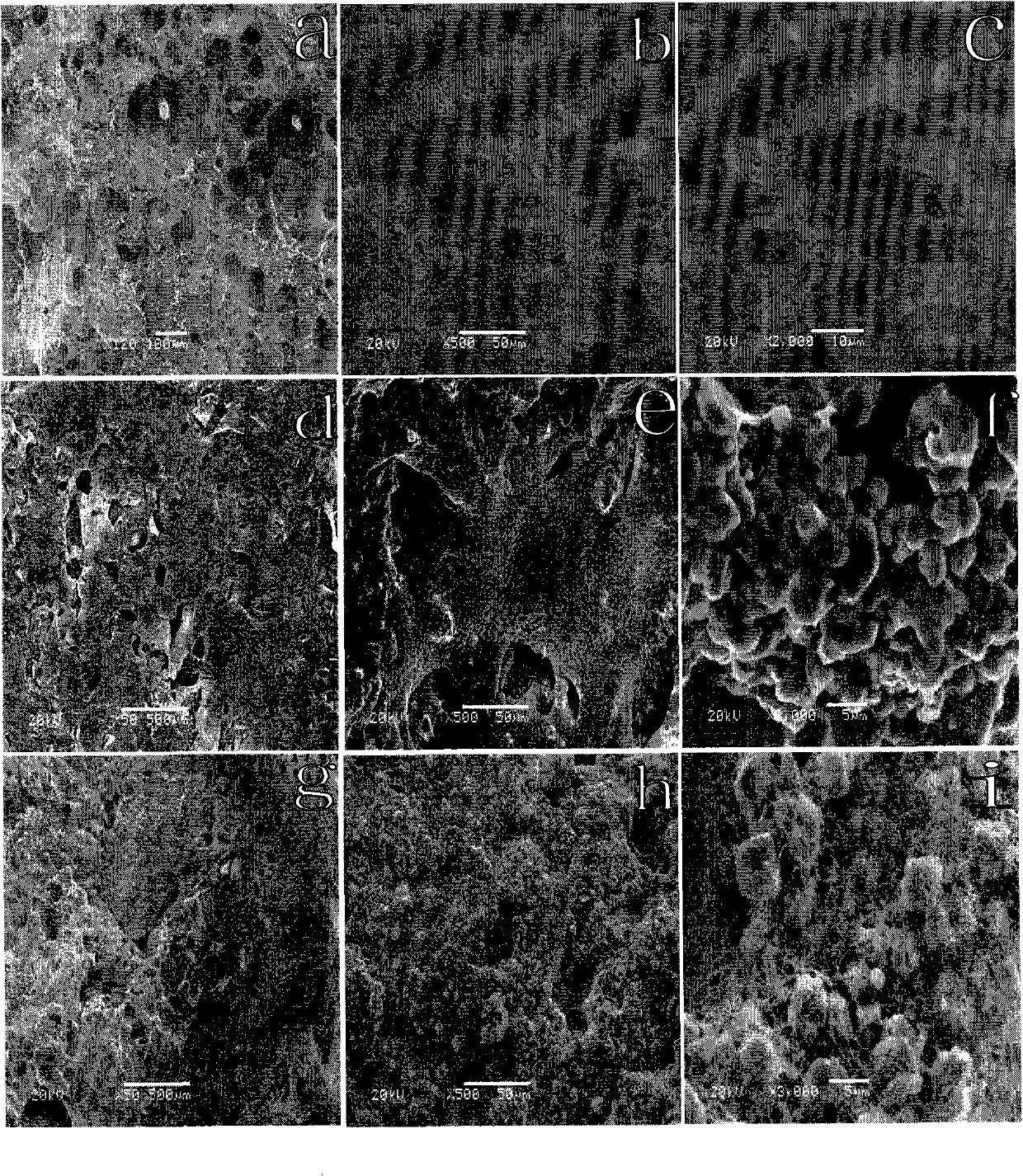

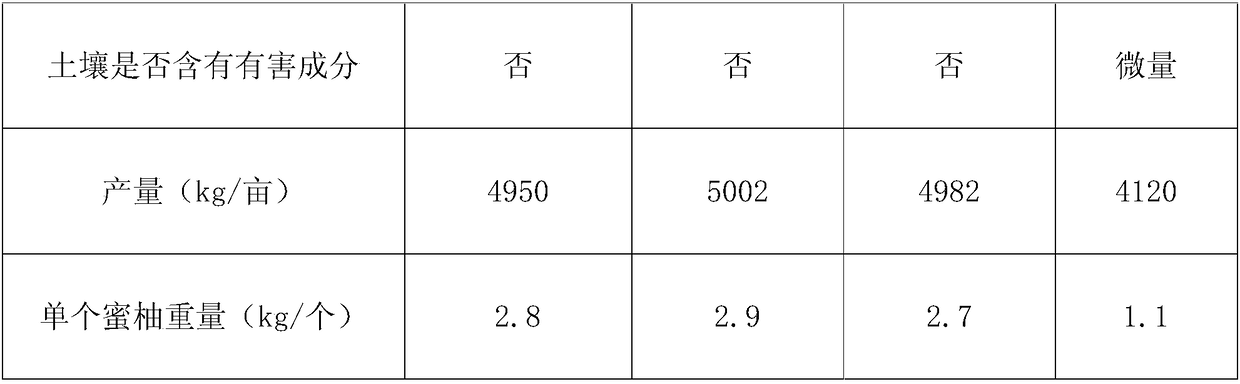

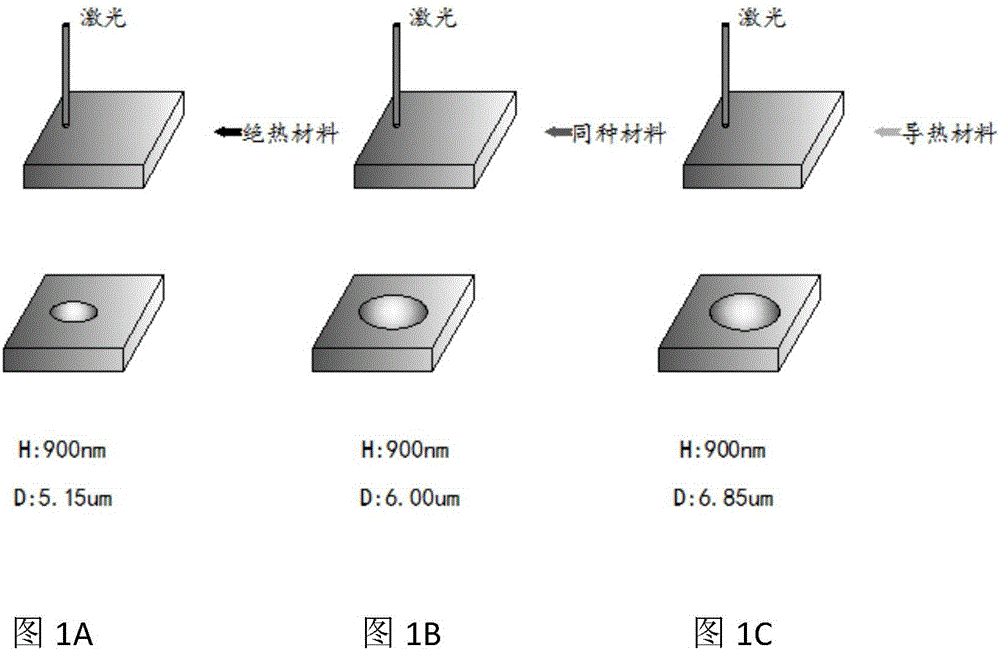

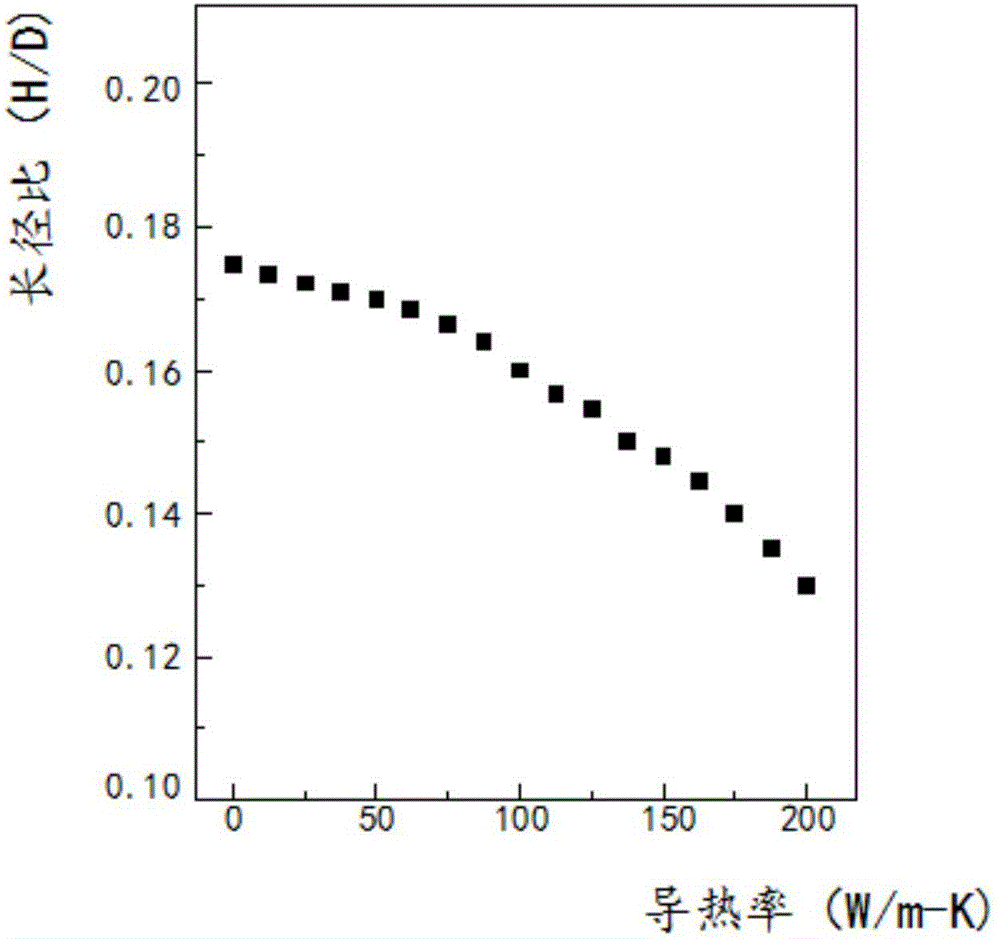

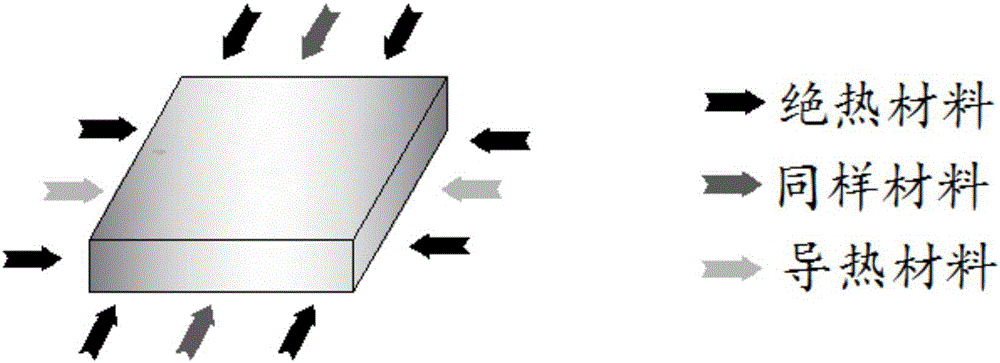

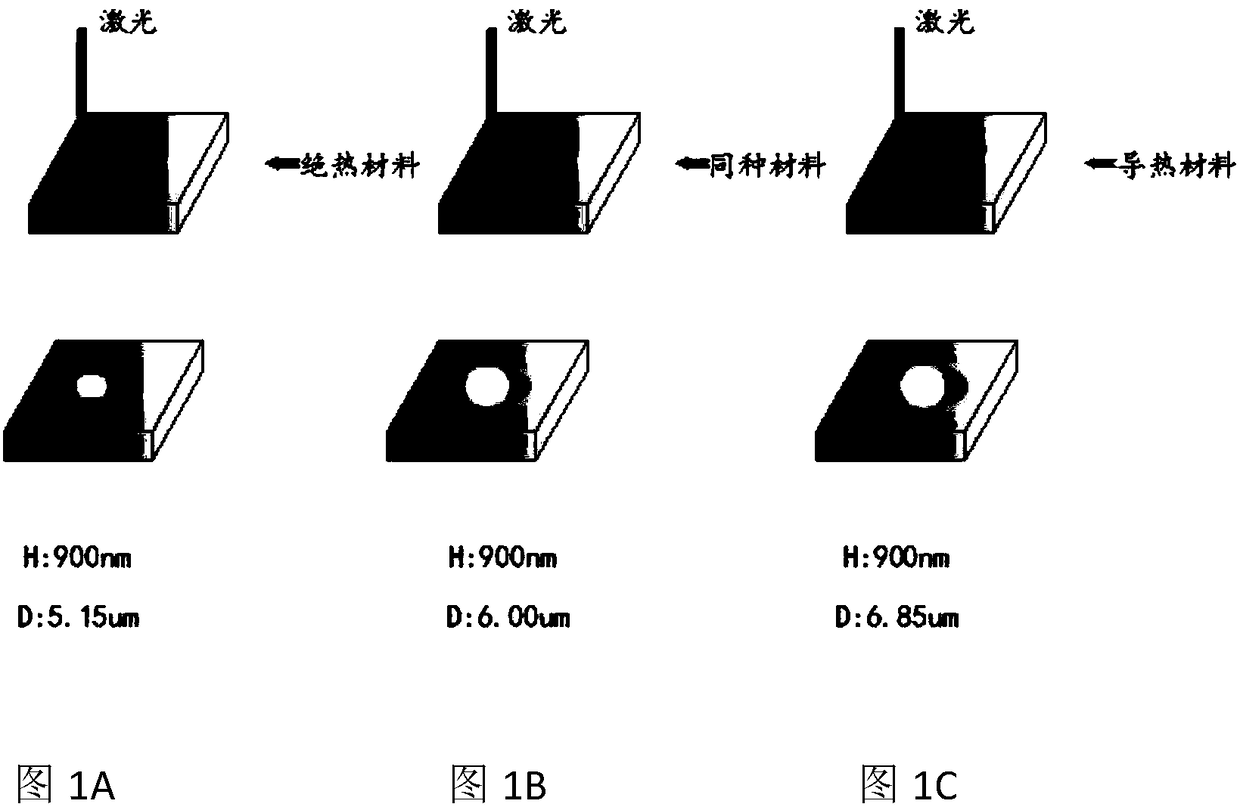

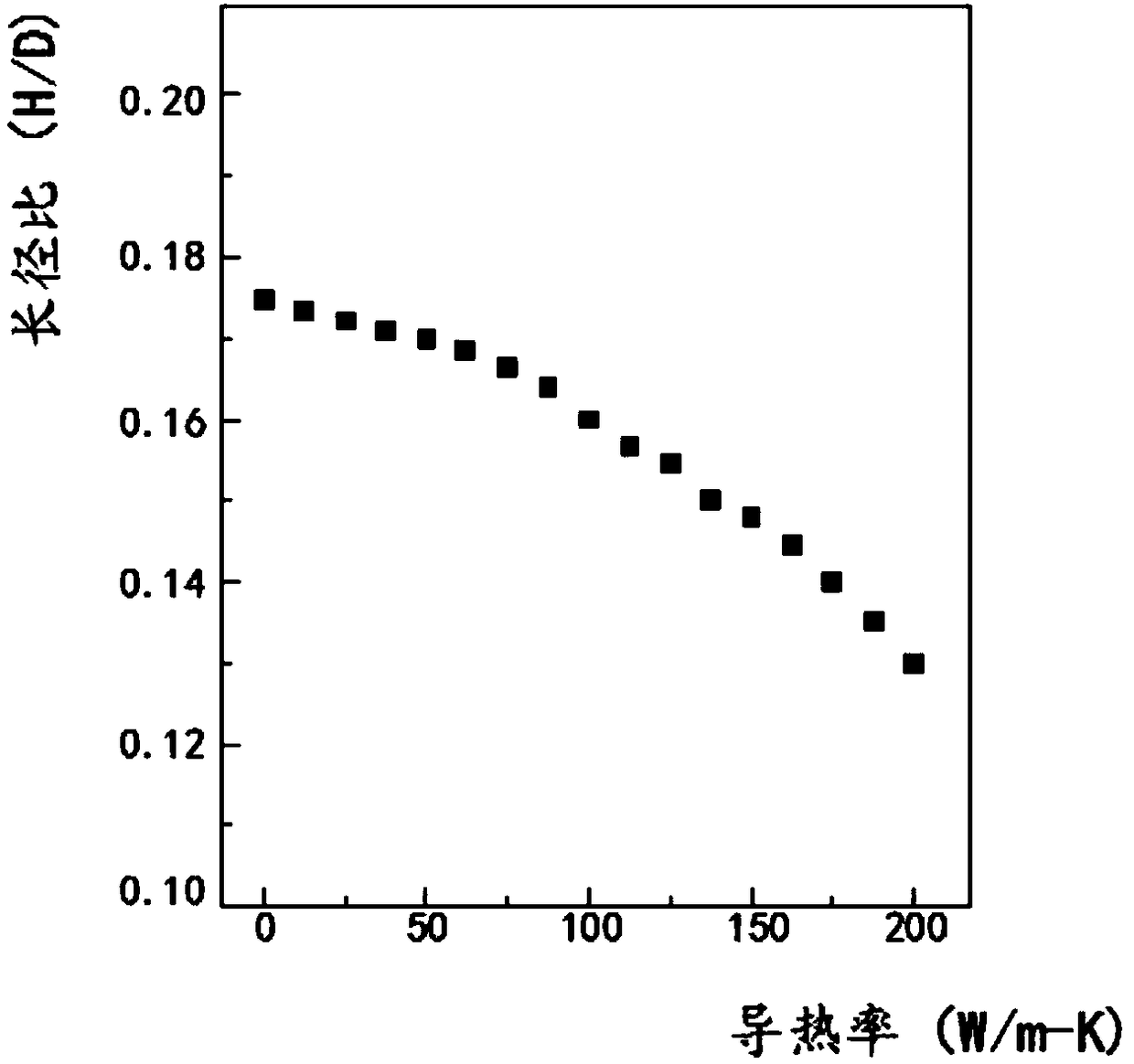

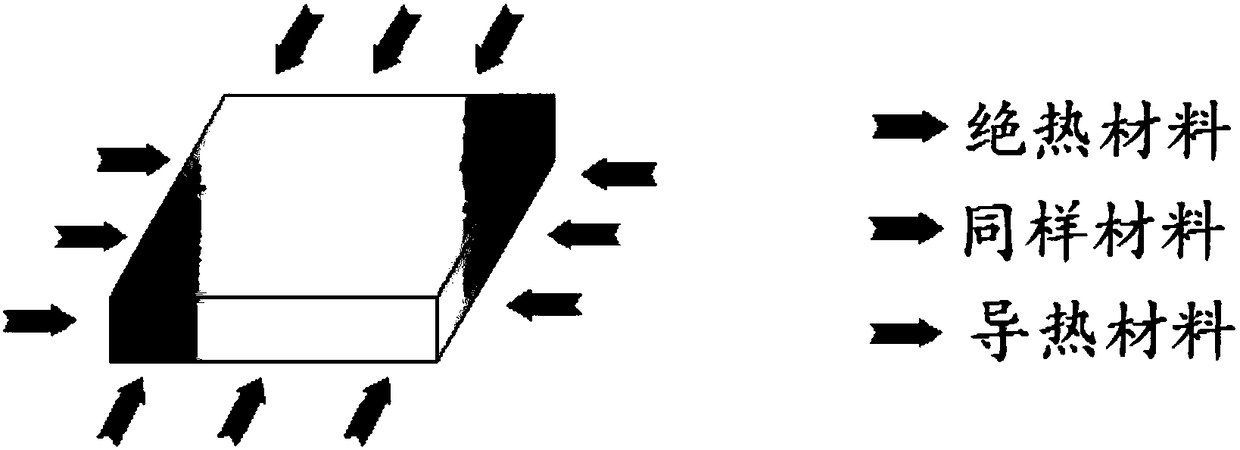

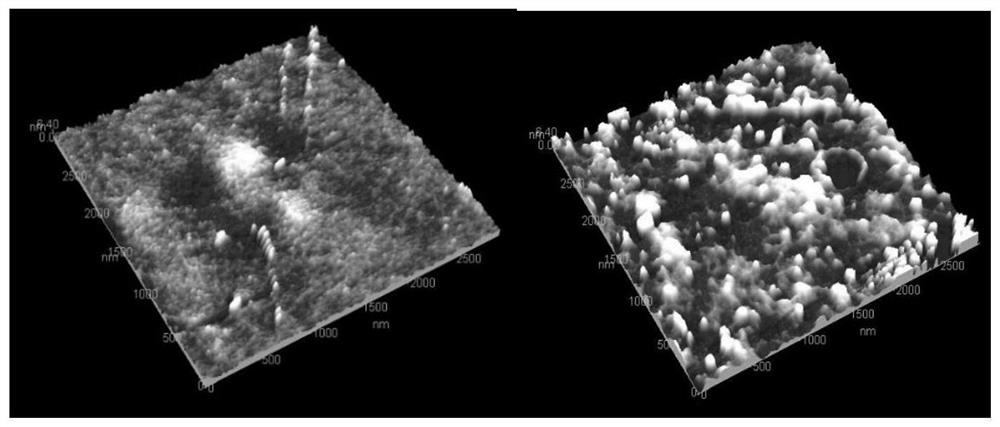

Research method silicon substrate surface morphology based on laser control nanostructure

ActiveCN106744659ANo pollution in the processShorten the timeDecorative surface effectsNanotechnologyStudy methodsNanostructure

The invention discloses a research method silicon substrate surface morphology based on a laser control nanostructure. The method comprises the following steps: 1, separately contacting a silicon substrate of a nanostructure by using materials with different thermal conductivities; 2, irradiating the surface of the silicon substrate of the silicon substrate via laser; 3, observing the surface morphology of the silicon substrate, and measuring a draw ratio of a projection on the surface of the silicon substrate; and 4, summarizing the change rule of the surface morphology of the silicon substrate. The research method disclosed by the invention has the following features: firstly, the surface morphology of the silicon substrate of the nanostructure is changed by the thermal conductivity of the contact material; secondly, the silicon substrate of the nanostructure is irradiated by the laser, thereby being clean and environmentally friendly, and generating no pollution; and thirdly, the time necessary for changing the surface morphology of the silicon substrate of the nanostructure is short, and the efficiency is high.

Owner:芜湖数字信息产业园有限公司

Low-scratchiness anti-crease ramie fabric

The invention provides a low-scratchiness anti-crease ramie fabric, and belongs to the field of clothing processing. The fabric comprises a fabric body (1), and the material of the fabric body (1) is ramie; the upper surface of the fabric body (1) is provided with a longitudinally arranged hollow-out jacquard layer (2), anti-crease polyurethane strips (3) are arranged in the hollow-out jacquard layer (2), and the anti-crease polyurethane strip (3) have a memory function; and the lower surface of the fabric main body (1) is a bottom fabric (4), and the bottom fabric (4) is prepared from a thermoplastic resin-containing resin composition, degraded chitosan, lanolin and D-phenylglycinol. The fabric of the invention is a laminated fabric, the surface of the fabric is provided with the anti-crease polyurethane strips, the main body undergoes low temperature plasma treatment, and the anti-crease bottom fabric is produced, so the anti-crease effect of the main body ramie fabric is enhanced; the low temperature plasma treatment is used to reduce the scratchiness of the fabric; and the ramie fabric is soft and comfortable, resists crease, is not prone to deform, and also has anti-shrinkage, antistatic, easy cleaning and decontaminating effects.

Owner:HAIYAN SHUOCHUANG CLOTHING RES INST

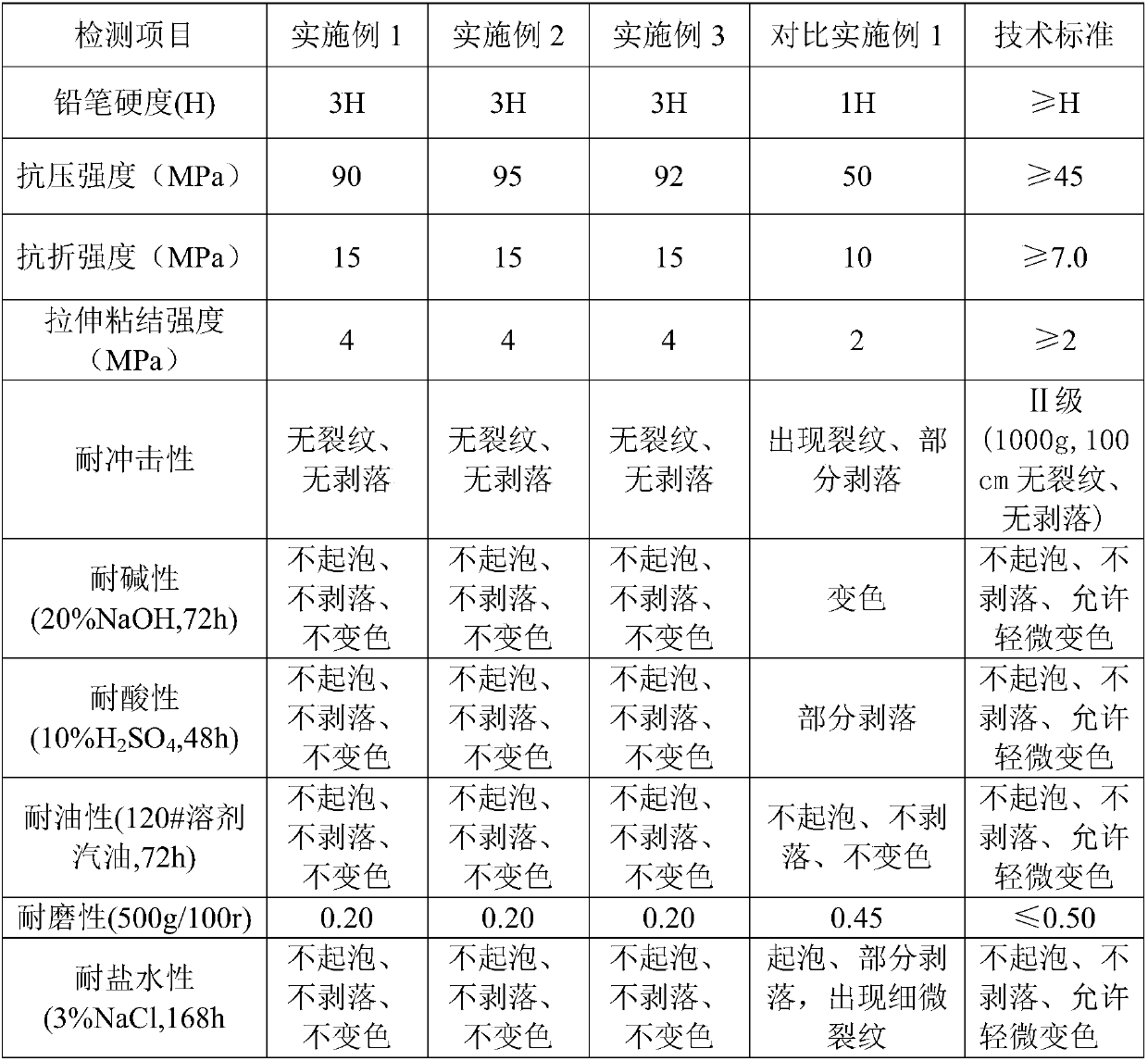

Furfural-acetone epoxy cement terrace coating

InactiveCN109554074AImprove crack resistanceImprove adhesionFireproof paintsAntifouling/underwater paintsSalicylic acidResin-Based Composite

The invention discloses a furfural-acetone epoxy cement terrace coating. The furfural-acetone epoxy cement terrace coating is prepared through mixing of a component A, a component B and a component Cat a weight ratio of 5:1:1, wherein the component A comprises the following raw materials: in parts by weight, 60-70 parts of E-51 epoxy resin, 45-55 parts of furfural-acetone resin, 2.5-3.5 parts oflong-chain alkyl glycidyl ether, 10-15 parts of butyl glycidyl ether, 0.5-0.8 part of EFKA-2040, 0.3-0.6 part of EFKA-3650 and 0.2-0.7 part of EFKA-4310, the component B comprises the following raw materials: in parts by weight, 10-15 parts of modified fatty amine, 5-6 parts of salicylic acid and 1-3 parts of quaternary ammonium salts, and the component C comprises the following raw materials: inparts by weight, 60-70 parts of cement and 12-15 parts of toner. The terrace coating which is prepared through combination of two-component composite resin with a cement material has excellent chemical resistance, impact resistance, compressive strength, scratch resistance, anti-cracking properties, easy maintenance and washing and environmental protection.

Owner:FUZHOU ROYAL FLOOR

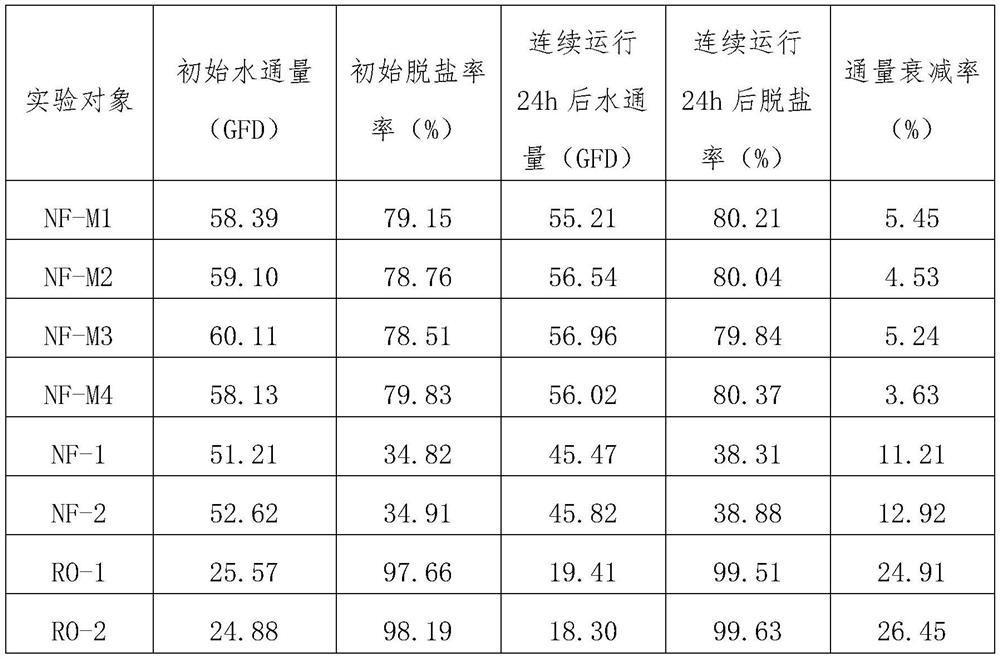

High-flux and inorganic-scaling-resistant medium-desalination nanofiltration membrane and preparation method thereof

PendingCN113908705AImproves resistance to inorganic foulingReduce poor solubilitySemi-permeable membranesGeneral water supply conservationProcess engineeringNanofiltration

The invention belongs to the technical field of preparation of nanofiltration membrane materials, and particularly relates to a high-flux and inorganic-scaling-resistant medium-desalination nanofiltration membrane and a preparation method thereof. An amine water-phase solution, an oil-phase solution and a dimethylformamide solution are adopted to treat a polymer-based membrane, and through the special component proportion in the amine water-phase solution and the oil-phase solution, compared with a traditional nanofiltration membrane and a reverse osmosis membrane, the prepared high-flux and inorganic-scaling-resistant medium-desalination nanofiltration membrane has higher water yield under the same operation pressure, can moderately desalt, and has improved inorganic scaling resistance.

Owner:VONTRON TECH CO LTD

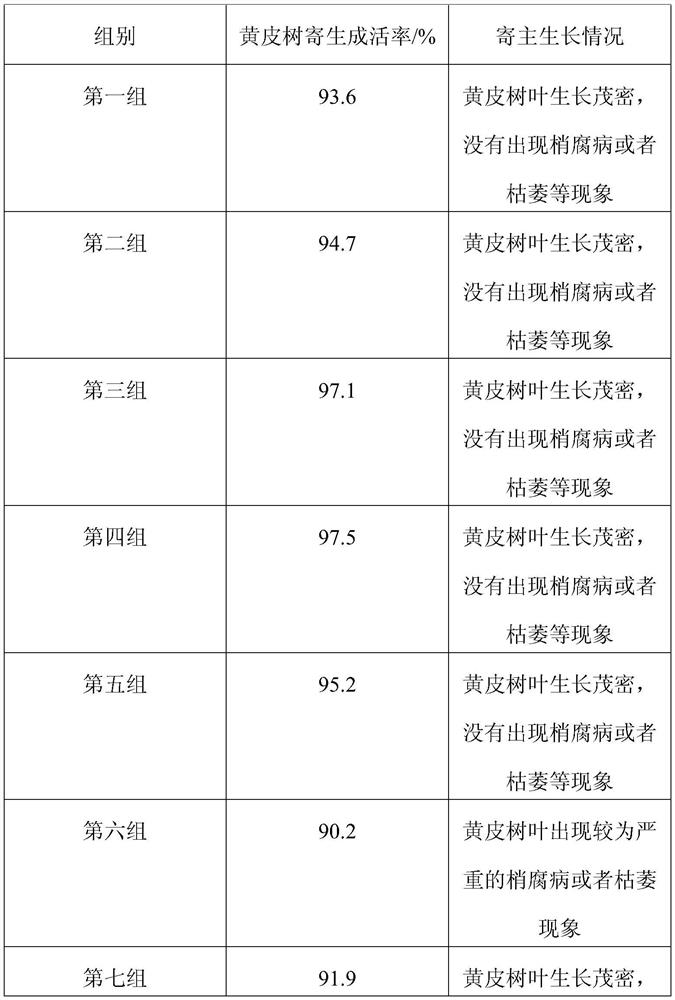

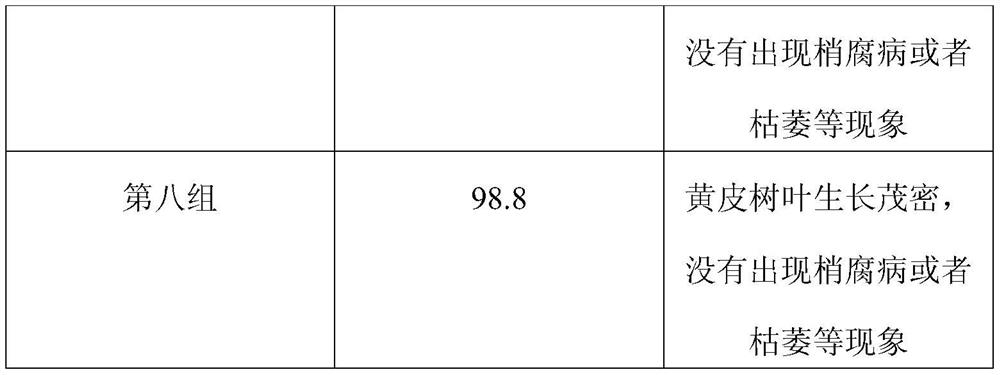

Method for increasing parasitic yield of Phellodendron sinii Y.C Wu

The invention provides a method for increasing the parasitic yield of Phellodendron sinii Y.C Wu, and relates to the technical field of planting. The method for increasing the parasitic yield of the Phellodendron sinii Y.C Wu comprises the following steps: (1) cultivating hosts, (2) preparing parasitic bud ears of the Phellodendron sinii Y.C Wu, (3) treating branches of the Phellodendron sinii Y.C Wu, and (4) grafting and the like. The method for increasing the parasitic yield of the Phellodendron sinii Y.C Wu is provided for the first time, so that the vacancy of the prior art is made up; parasitic leaves of the Phellodendron sinii Y.C Wu can be used for making tea, parasitic wood can be used as a traditional Chinese medicine, and the parasitic wood has the effects of clearing liver and improving vision and reducing uric acid, and can also be used for dispelling wind and cold, resolving qi and relieving dyspepsia and treating influenza and other symptoms; Through the method for increasing the parasitic yield of the Phellodendron sinii Y.C Wu, the parasitic yield of the Phellodendron sinii Y.C Wu can be increased, and meanwhile damage to the hosts can be reduced.

Owner:广西金韶农业开发有限公司

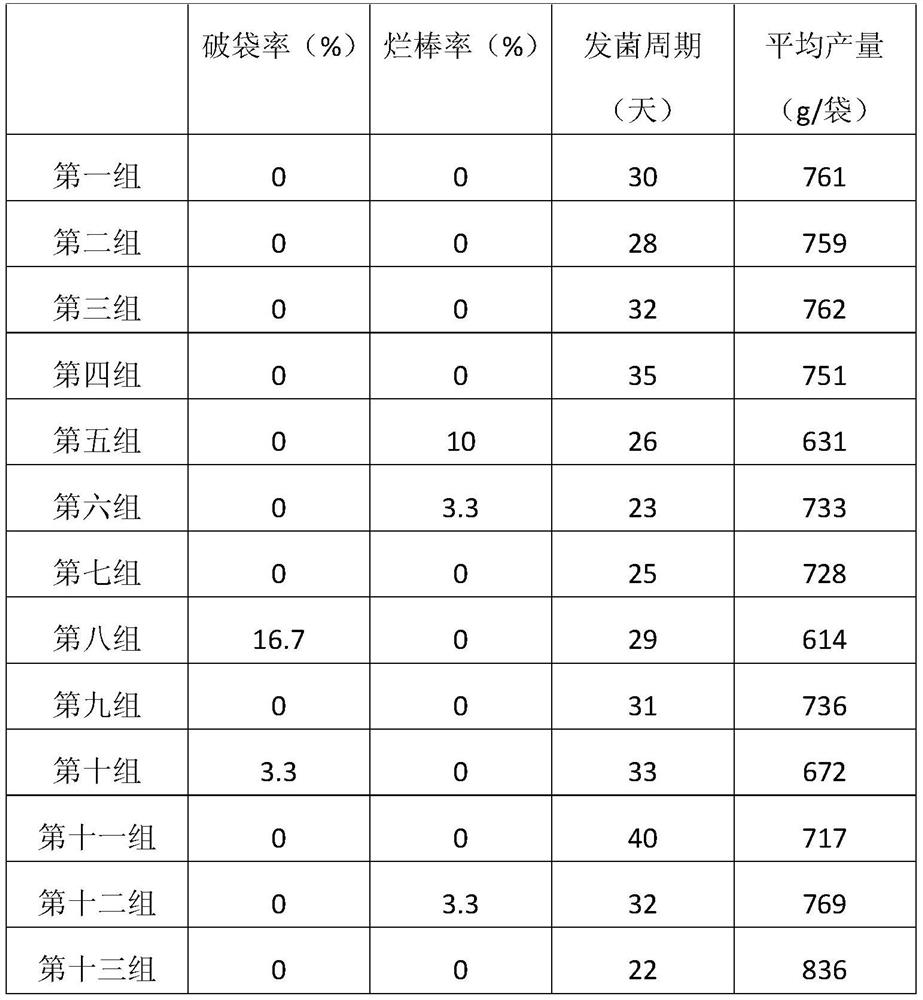

Preparation method of shiitake mushroom stick

PendingCN112352626AEasy to prepareSolve pollutionCultivating equipmentsMushroom cultivationBiotechnologyEconomic benefits

The invention relates to the technical field of edible fungus production, in particular to a preparation method of a shiitake mushroom stick. The preparation method of the shiitake mushroom stick comprises the following steps of (1) culture material preparation; (2) material mixing; (3) bagging; and (4) sterilization. The shiitake mushroom stick solves the problem of environmental pollution causedby improper treatment of food processing leftovers, waste is turned into wealth, the economic benefit is high, meanwhile, no harmful substance is added from the formula to the production process of the shiitake mushroom stick, the obtained mushroom stick is scientific and reasonable, the preparation method is simple, sufficient and reasonable nutrients can be provided for growth of shiitake mushrooms, the spawn running period can be shortened, and the yield can be increased.

Owner:GUANGXI HEMEI ECOLOGICAL AGRI CO LTD

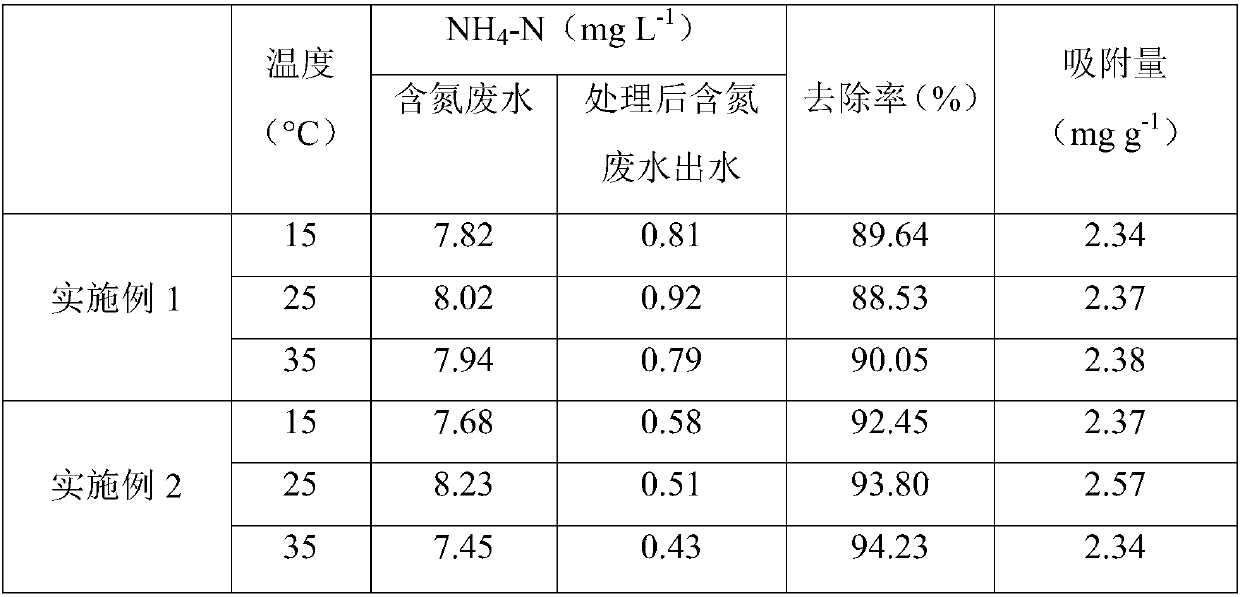

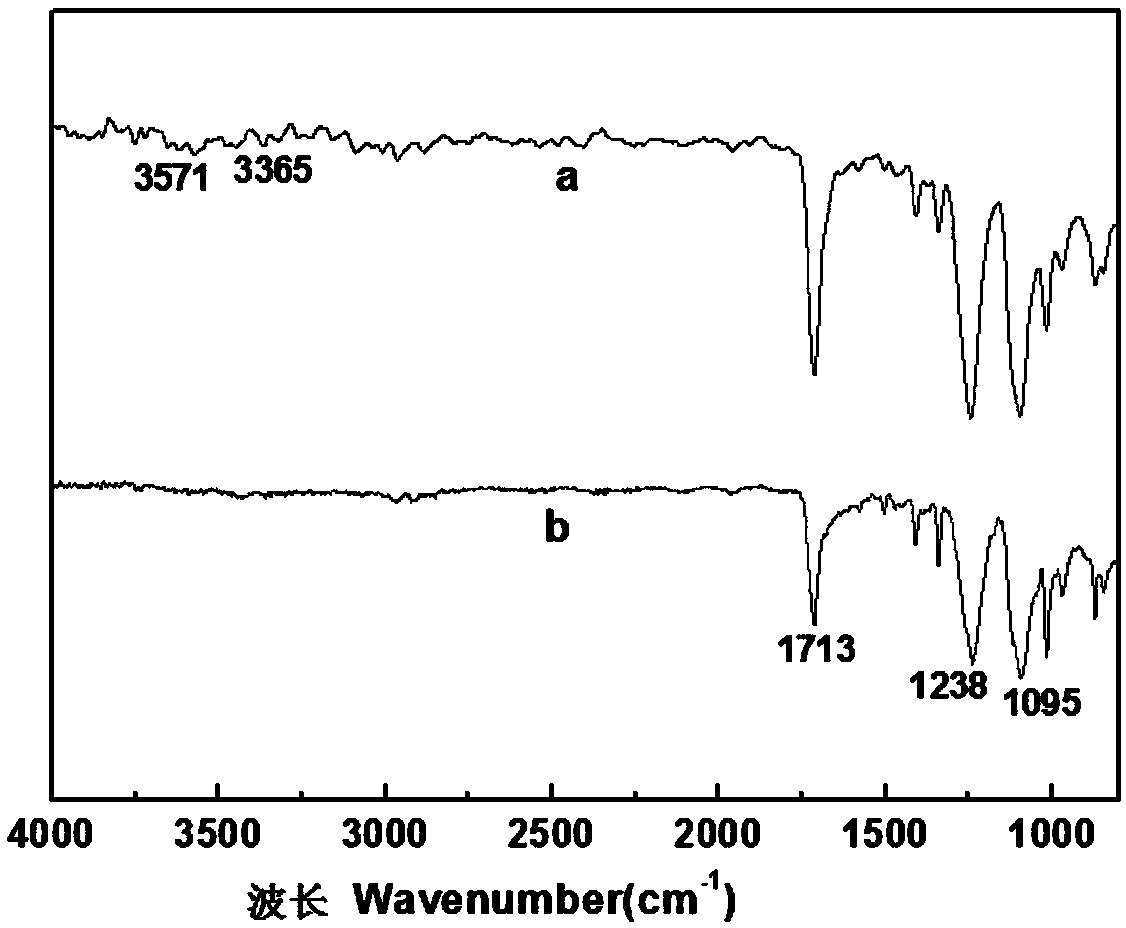

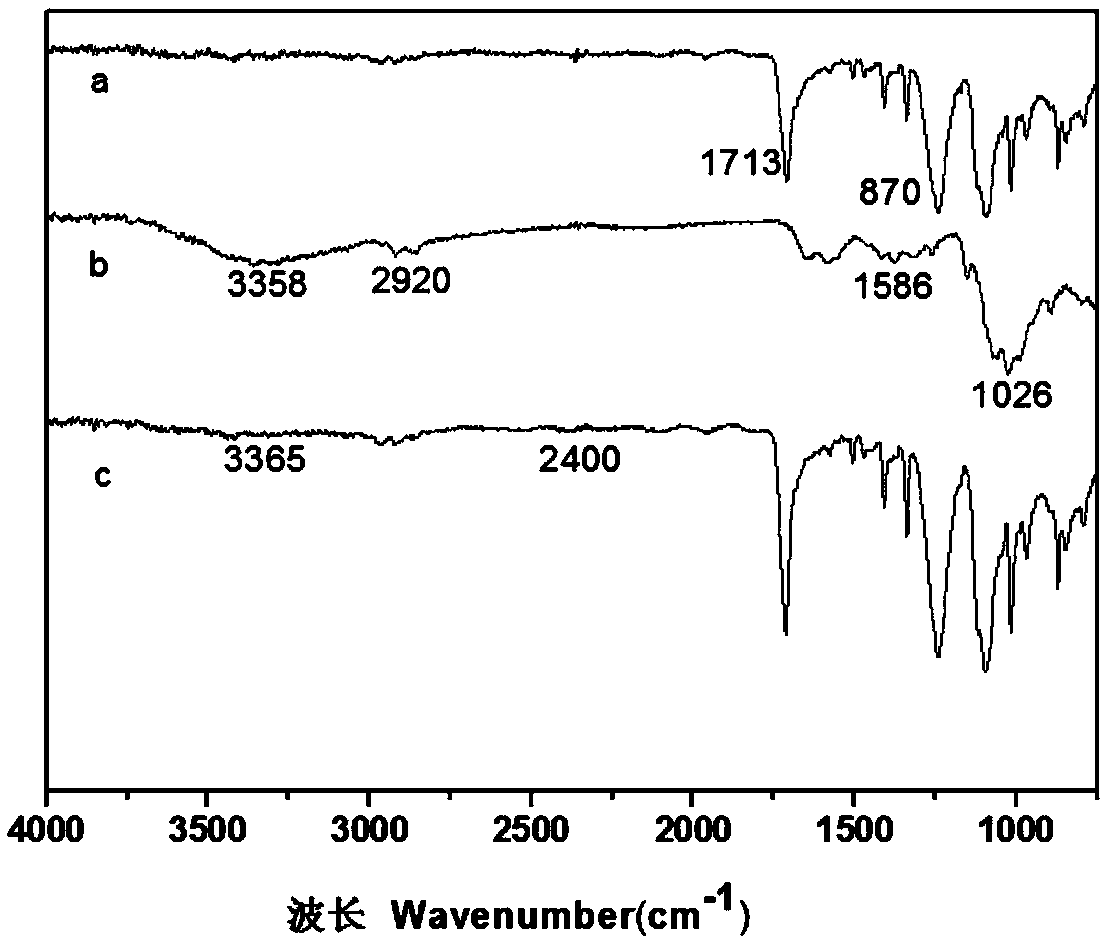

Denitrifying agent prepared by using river sediment as well as preparation method and application thereof

InactiveCN107684897AImprove resource utilizationChange surface morphologyOther chemical processesWater contaminantsResource utilizationNitrogen

The invention discloses a denitrifying agent prepared by using river sediment as well as a preparation method and application of the denitrifying agent. The method comprises the following steps: 1) drying the river sediment, grinding and sieving; then, performing acid pickling, grinding, cleaning and drying to obtain sediment particles; 2) calcining the sediment particles to obtain a porous sediment material; 3) mixing the porous sediment material with a sodium salt solution, adjusting the pH to 2.5-3.5, shaking, filtering and drying to obtain the denitrifying agent. The denitrifying agent disclosed by the invention can reduce the pressure on resource utilization of river sediment and has the advantages of easiness in operation, perfect preparation conditions, strong operability and high denitrifying efficiency.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Polyethylene antibacterial film and preparation method and application thereof

The invention discloses a polyethylene antibacterial film, which is composed of a polyethylene film, an acrylic film and at least one layer of chitosan-lime essential oil composite film. The inventionalso discloses a preparation method of the polyethylene antibacterial film, and an application of the polyethylene antibacterial film in a package material having antibacterial efficacy and in chilled meat fresh-keeping.

Owner:ZHONGKAI UNIV OF AGRI & ENG

A kind of polyethylene antibacterial film and its preparation method and application

ActiveCN109021271BChange surface morphologyImprove hydrophilicityFlexible coversWrappersPolymer scienceAnti bacteria

The invention discloses a polyethylene antibacterial film, which is composed of a polyethylene film, an acrylic film and at least one layer of chitosan-lemon essential oil composite film. Also disclosed are a preparation method of the polyethylene fresh-keeping film and an application of the polyethylene fresh-keeping film in preparing packaging materials with antibacterial effects and in keeping fresh meat fresh.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Laser-Based Control of Surface Morphology of Nanostructured Silicon Substrates

ActiveCN106744659BChange surface morphologyNo pollution in the processDecorative surface effectsNanotechnologyNano structuringThermal conductivity

The invention discloses a research method for controlling the surface morphology of nanostructured silicon based on laser: 1. Using materials with different thermal conductivity to contact the nanostructured silicon substrate; 2. Laser irradiation on the surface of the nanostructured silicon substrate; 3. Observing the silicon substrate The morphology of the substrate surface and the aspect ratio of the protrusions on the silicon substrate were measured. 4. Summarize the change law of the silicon-based surface morphology. The invention has the following characteristics: firstly, the nanostructure silicon base surface morphology is changed through the thermal conductivity of the contact material. Second, the nanostructured silicon substrate is irradiated with a laser, which is clean, environmentally friendly, and does not produce any pollution. Third, the time required to change the surface morphology of the nanostructured silicon base is short and the efficiency is high.

Owner:芜湖数字信息产业园有限公司

A kind of preparation method of vat dye vat yellow 1

The invention discloses a preparation method of a reduced dye vat yellow 1. The preparation method comprises the following steps: grinding, kneading and extraction. Through pregrinding and segmented shearing actions, the prepared vat yellow 1 has good vibrance and tinting strength, and the quality of the product is obviously improved, so that the use values of the vat yellow 1 is enhanced.

Owner:安徽融创化工科技股份有限公司

A kind of polyethylene preservative film and its preparation method and application

The invention discloses a polyethylene preservative film. The polyethylene preservative film consists of a polyethylene film, an acrylic acid film and at least one layer of titanium dioxide-chitosan composite film sequentially from bottom to top. The invention also discloses a preparation method of the polyethylene preservative film as well as application of the polyethylene preservative film to preparation packaging materials with antibacterial effect and to preservation of chilled fresh meat.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Preparation method of modified biologically-activated filter fillings

InactiveCN101948166BBroaden the formation processHigh activitySustainable biological treatmentBiological water/sewage treatmentMillimeterMaterials science

The invention relates to a preparation method of modified biologically-activated filter fillings, comprising the following steps of: (1) cleaning an inorganic carrier with the grain diameter of 3-8 millimetres, sequentially carrying out acid cleaning, alkaline cleaning and drying to obtain dry fillings; (2) adding the dry fillings to a metal salt solution to carry out soaking and ultraphonic, drying and sintering to obtain sintering charges; (3) naturally cooling and drying the sintering charges to obtain dry sintering charges; (4) adding the dry sintering charges to a polymeric hydrogel solution containing trace elements and nutrient salts, carrying out soaking and ultraphonic and reacting in a saturated boric acid solution or a 3% calcium chloride solution so as to obtain crosslinked fillings; and (5) drying and naturally cooling the crosslinked fillings so as to obtain the modified biologically-activated filter fillings. The invention has the advantages of simple process and easy implementation; and in addition, the obtained modified biologically-activated filter fillings can increase the activity and the number of biomembranes, shorten the membrane-forming periods of biological aerated filter fillings and enhance the sewage treatment efficiency and the stability of a biological aerated filter.

Owner:GANSU GOLDEN BRIDGE GRP CO LTD +1

A preparation method and application of paper-making reconstituted tobacco leaf filler

Owner:CHINA TOBACCO YUNNAN IND

Surface pore filling method for rock model structural surface

ActiveCN104792588AEasy to fillEasy to integratePreparing sample for investigationMaterial strength using steady shearing forcesSurface moistureStructure of the Earth

The invention discloses a surface pore filling method for a rock model structural surface. The surface pore filling method comprises the following steps: (1) cleaning and maintaining the model structural surface; (2) filling surface pores of the model structural surface at one time, (2.1) after maintenance, completely moistening the structural surface under the heat-preservation maintenance state, enabling the surface pores to be filled with moisture, then using a dry towel to wipe off the surface moisture, and only enabling the surface pores to retain the moisture, (2.2) filling the pores on the surface, and (2.3) till the coagulation cycle, using the dry towel to slightly wipe off a part of powdered binding material powder on the surface again, covering the surface of the structural surface with a maintenance tool, and enabling the structural surface to be under the water retention state; (3) filling the pores on the model structural surface for the second time: till the filling cycle, repeating the steps (2.1) to the step (2.3), filling the pores which are not completely filled up for the second time, and completing the pore filling of the structural surface. The surface pore filling method disclosed by the invention can effectively fill the pores and promote the roughness coefficient measurement accuracy of the structural surface.

Owner:SHAOXING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com