Low-scratchiness anti-crease ramie fabric

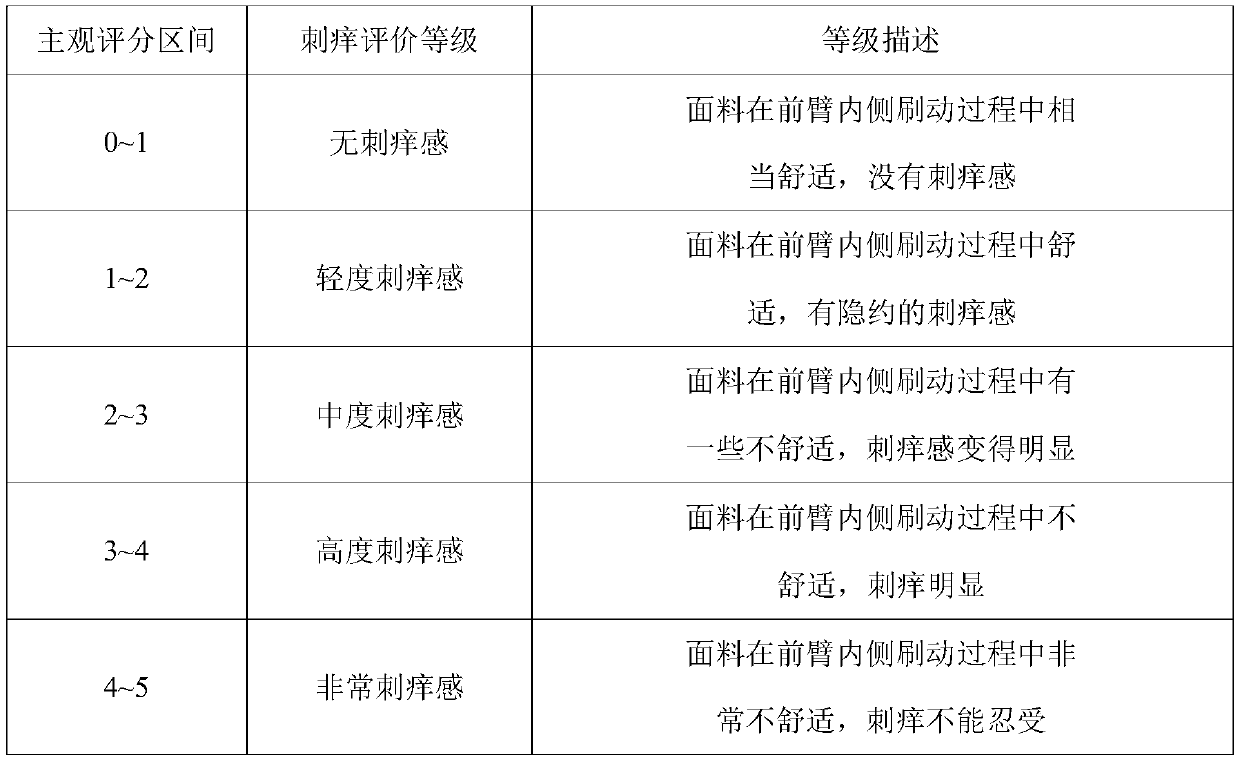

A tickling and fabric technology, applied in the field of garment processing, can solve problems such as affecting the quality and comfort of fabrics, affecting the appearance comfort, and easily yellowing shirts, so as to improve elasticity, improve anti-wrinkle performance, and reduce itchiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] In addition, the present invention provides a method for preparing a laminated fabric, comprising the following steps:

[0021] 1) preparing the fabric main body, the bottom fabric, and setting a vertically arranged hollow jacquard layer on the upper surface of the fabric main body;

[0022] 2) preparing the laminated fabric by heating the bottom fabric, the fabric main body and the hollow jacquard layer on the upper surface of the fabric main body, and then laminating each fabric in sequence;

[0023] 3) heating the laminated fabric;

[0024] 4) Electron irradiation of the laminated fabric.

[0025] Step 1) The processing method for the fabric main body, including: padding finishing solution, low temperature plasma treatment and electronic crosslinking;

[0026] Wherein, each component of the finishing liquid is sodium hydroxide, citric acid, sodium tetraborate decahydrate and glycerol mixed in a mass ratio of 5-9:0.5-1:1-3:4-7; the processing method is: The main bo...

Embodiment 1

[0043] A wrinkle-resistant ramie fabric with low itch feeling, comprising a fabric main body (1), the material of the fabric main body (1) is ramie; the upper surface of the fabric main body (1) is provided with a vertically arranged hollow jacquard layer (2), and the hollow jacquard layer (2) is provided with a polyurethane anti-wrinkle strip (3), and the polyurethane anti-wrinkle strip (3) has a memory function; the lower surface of the fabric main body (1) is the bottom fabric (4), and the bottom fabric (4) is made of thermoplastic resin Preparation of resin composition, degraded chitosan, lanolin and D-phenylglycinol;

[0044] The thickness of the fabric main body (1) is 1.2 mm; the thickness of the bottom fabric (4) is 0.03 mm; the cross-sectional size of the fabric main body (1) is larger than that of the hollow jacquard layer (2) and smaller than the cross-sectional size of the bottom fabric (4) ; The embossing density of the hollow jacquard layer (2) is 0.2g / cm 3 ;

...

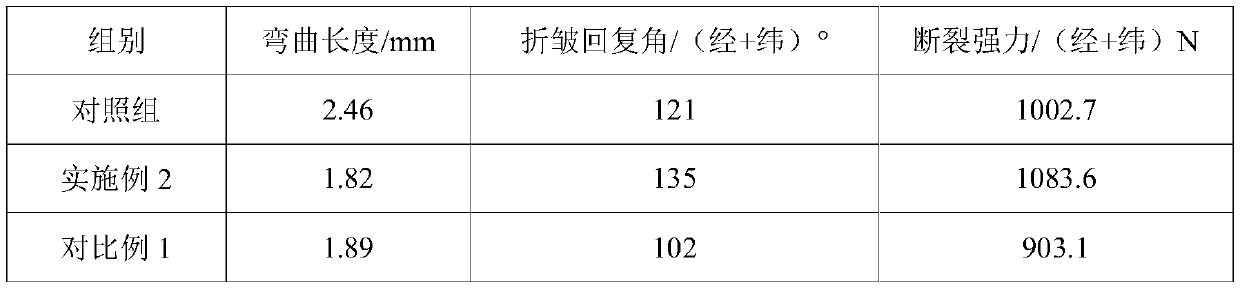

Embodiment 2

[0057] A wrinkle-resistant ramie fabric with low itch feeling, comprising a fabric main body (1), the material of the fabric main body (1) is ramie; the upper surface of the fabric main body (1) is provided with a vertically arranged hollow jacquard layer (2), and the hollow jacquard layer (2) is provided with a polyurethane anti-wrinkle strip (3), and the polyurethane anti-wrinkle strip (3) has a memory function; the lower surface of the fabric main body (1) is the bottom fabric (4), and the bottom fabric (4) is made of thermoplastic resin Preparation of resin composition, degraded chitosan, lanolin and D-phenylglycinol;

[0058] The thickness of the fabric main body (1) is 1.6mm; the thickness of the bottom fabric (4) is 0.03mm; the cross-sectional size of the fabric main body (1) is larger than that of the hollow jacquard layer (2) and smaller than the cross-sectional size of the bottom fabric (4) ; The embossing density of the hollow jacquard layer (2) is 0.5g / cm 3 ;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com