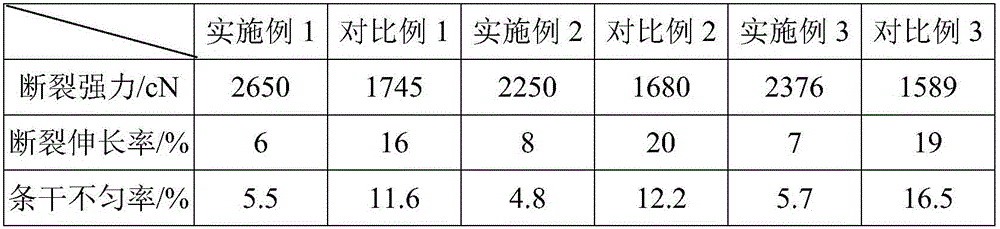

Patents

Literature

344results about How to "Improve breaking strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coated cemented carbide cutting tool

InactiveUS6293739B1Extended service lifeImproving flaking resistance of coating layerLayered productsTurning toolsCrystal structureAlloy

The invention is to prolong the life time of tools dramatically by (1) considerably improving the flaking resistance of the coating layer at the time of cutting, (2) increasing the wear resistance and crater resistance of the coating layer itself, and (3) enhancing the breakage strength of the coating layer in comparison with the conventional coating cutting tools. In order to achieve the object, the coated cemented carbide of the invention has the following structure in the coating layer on the surface of the cemented carbides: The outer layer has an Al2O3 layer practically having an alpha-type crystal structure. The Al2O3 layer has a region where alpha-type and kappa-type crystal grains coexist in the first row of the crystal grains that grow on the inner layer. In addition to that, the crystal grains of alpha-Al2O3 in the region include no pores.

Owner:SUMITOMO ELECTRIC IND LTD

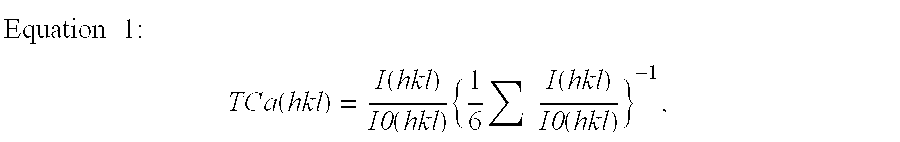

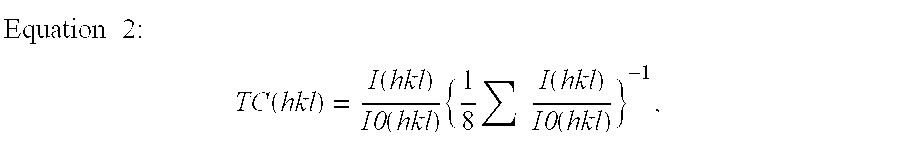

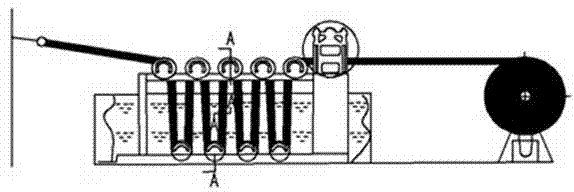

Orientation electro-spinning nanometer fiber spinning method and device thereof

InactiveCN103132194AHigh degree of axial orientationSuppress spinning instabilityDrafting machinesFilament/thread formingBobbinEngineering

The invention discloses an orientation electro-spinning nanometer fiber spinning method and a device thereof. A metal shower nozzle which exerts positive and negative high pressure is adopted to spin two strands of nanometer fibers with opposite charges, an electric field line of a spinning electric field, relative to a common spinning electric field, is straight, stability of spinning is effectively restrained, and the spinning nanometer fibers are straight. Two strands of the fibers surround the yarn tail and form a cone-shaped twisting trigonum on the upper portion of a metal twisting machine, and enable the nanometer fibers to be further oriented and twisted to form yarn through electric field force, tractive force of the yarn and acting force of the metal twisting force. The spinning nanometer fiber yarn is conducted heat shaping through a heat processing device under certain tensile force, degree of orientation of the nanometer fibers along the axial direction of the yarn, breaking force and yarn levelness are further improved, and the yarn after shaped is collected by a winding bobbin. The device can achieve the aim that orientation nanometer fiber yarn can be continuously prepared, is simple in device, convenient to operate, and good in resultant yarn continuity, yarn breaking strength and yarn levelness, and not only can spin pure nanometer fiber yarn, but also can spin nanometer fibers / filament core composite yarn. The orientation nanometer fiber spinning method and the device thereof have important application value in the fields, such as a biomedical field and a sensor field.

Owner:杨恩龙 +1

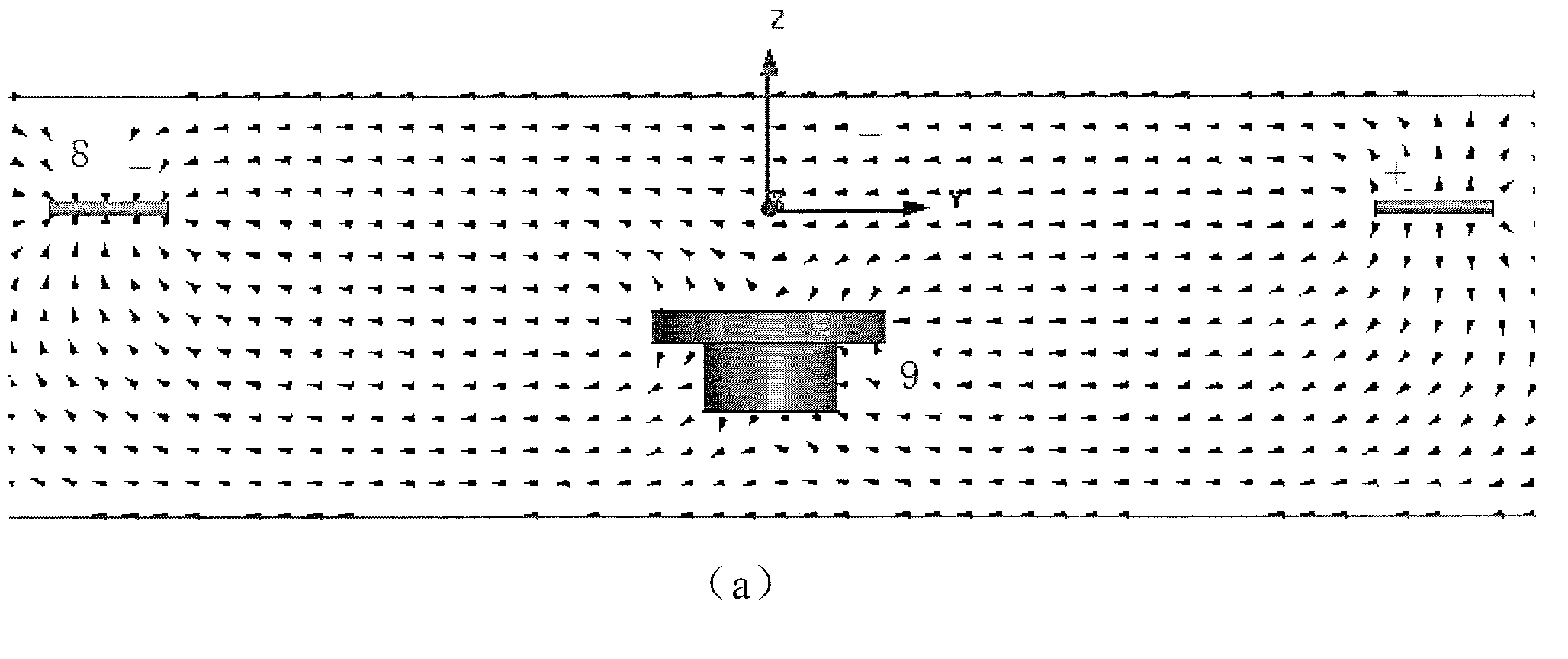

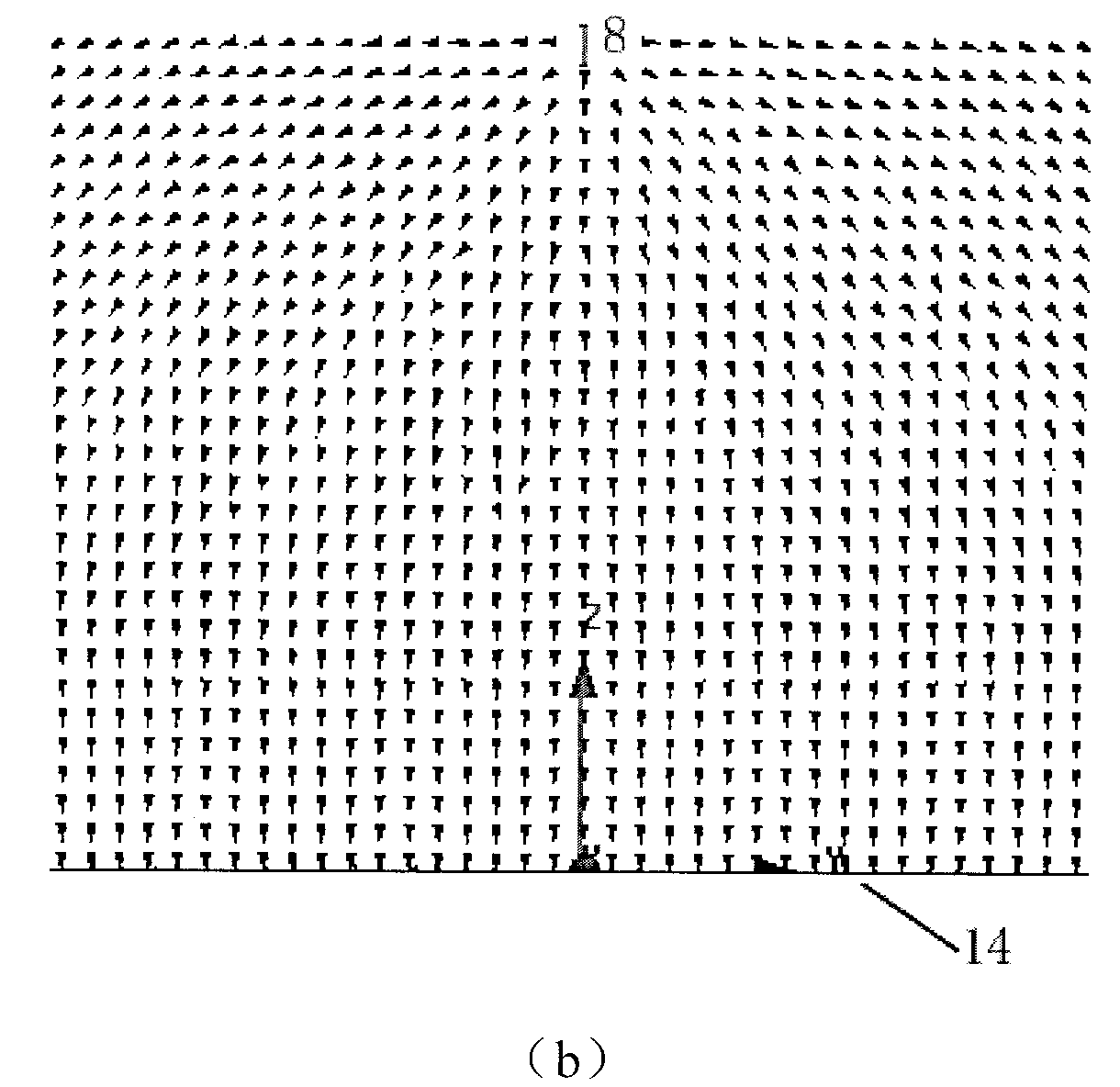

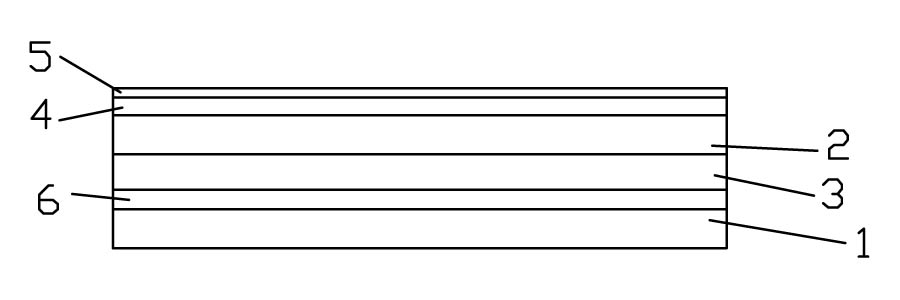

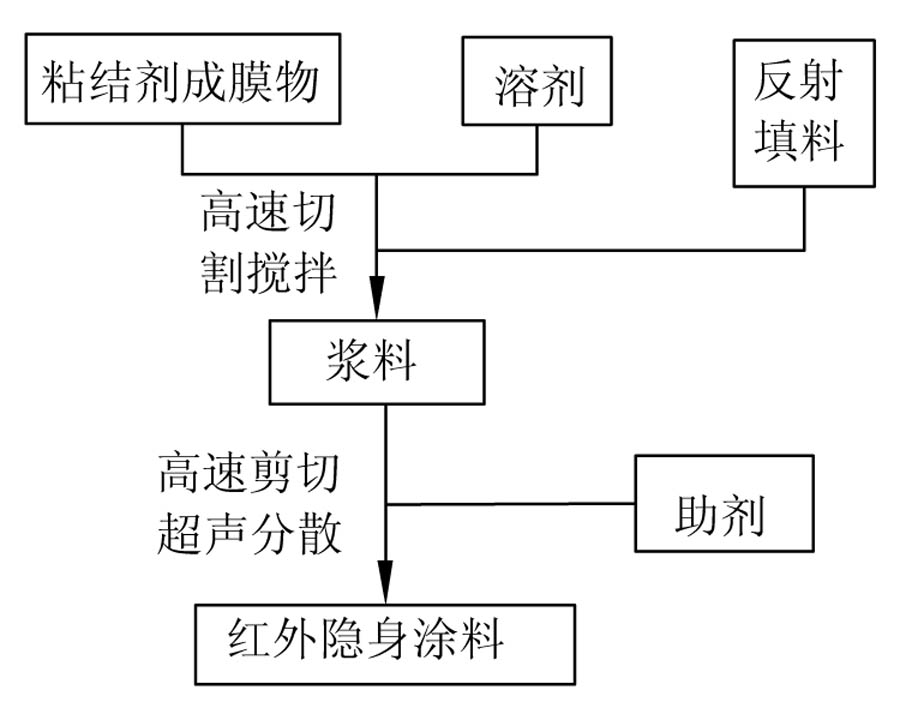

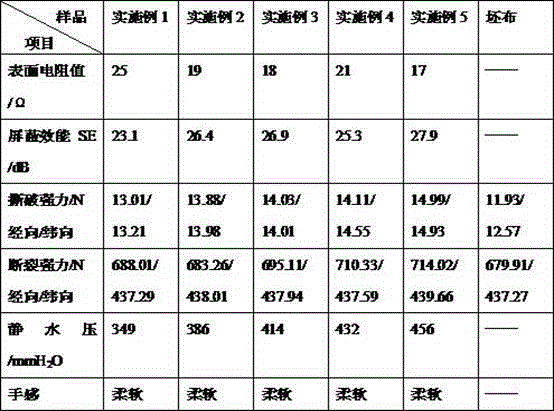

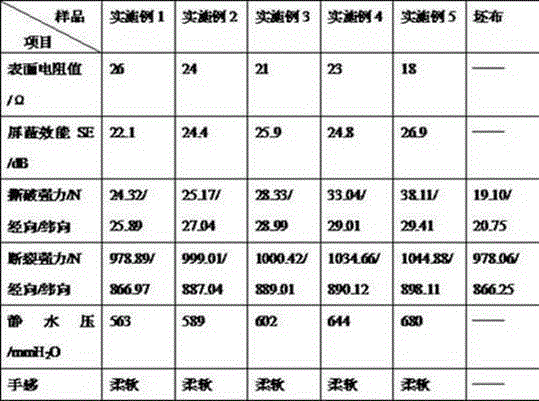

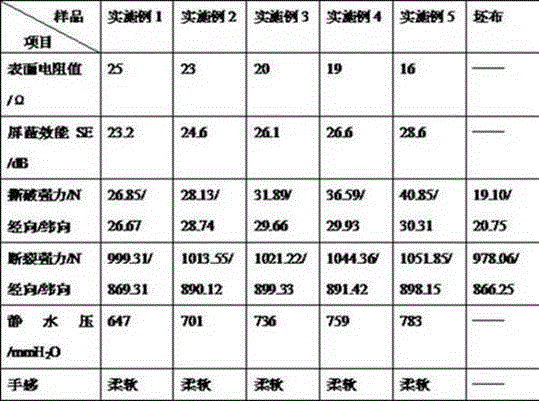

Novel infrared and radar integrated stealth fabric and preparation method thereof

InactiveCN101995187AOvercome crackingOvercome sheddingSynthetic resin layered productsPersonal protection gearBursting strengthCoated surface

The invention discloses a novel infrared and radar integrated stealth fabric and a preparation method thereof. The stealth fabric comprises an infrared camouflage surface layer and an antistatic bottom layer in turn from outside to inside; the infrared camouflage surface layer comprises an infrared stealth layer, a fabric layer and a radar wave absorption attenuation layer in turn from outside toinside; the infrared stealth layer is compounded by using a coating coated by an infrared stealth coating and a magnetron sputtering ITO (indium tin oxide) film arranged on the surface of the coating; the radar wave absorption attenuation layer comprises a sponge body; and a wave absorption material is adsorbed on the sponge body. The stealth fabric can realize radar stealth function and infraredstealth function at the same time, has good integral wave absorption effect and low surface density of materials, and has good effects on the aspects of breaking strength, bursting strength and the like. Moreover, excessive complex processes are not adopted for manufacturing the stealth fabric, and the stealth fabric can be produced by using a conventional fabric production method, so the stealthfabric is convenient for production and easy for implementation.

Owner:WUYI UNIV

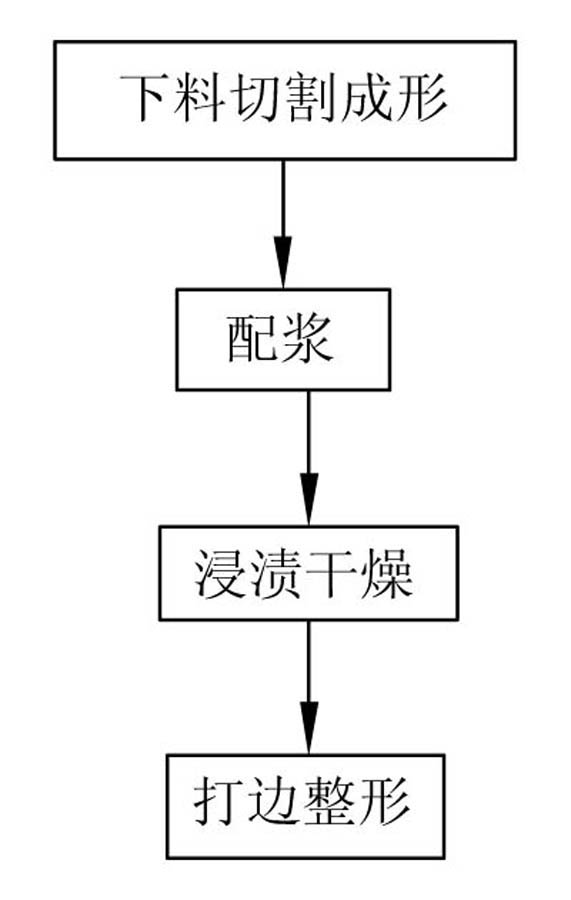

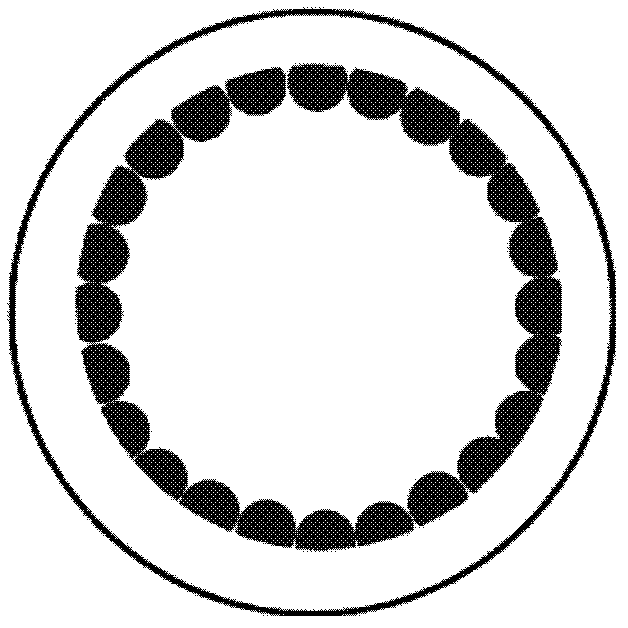

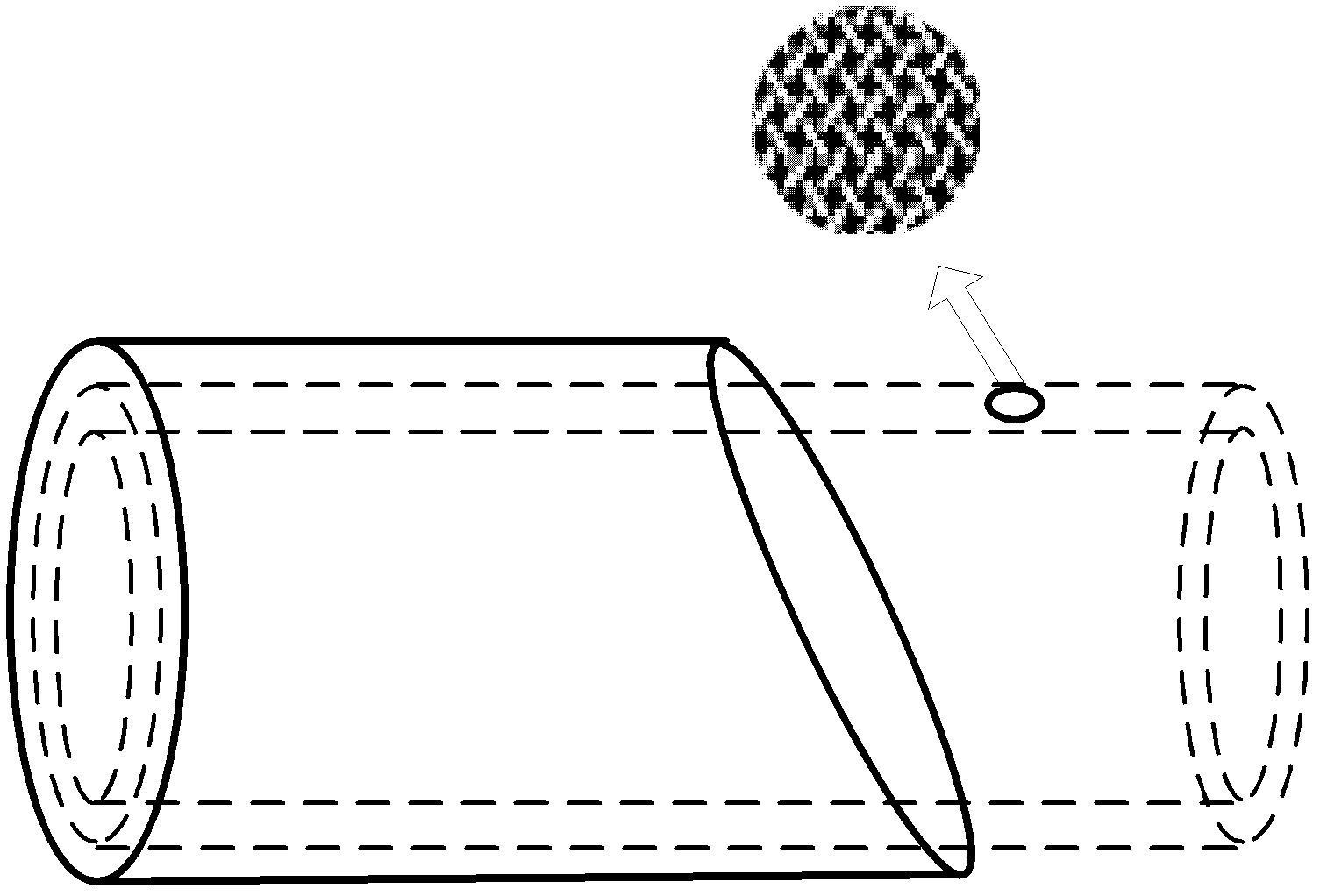

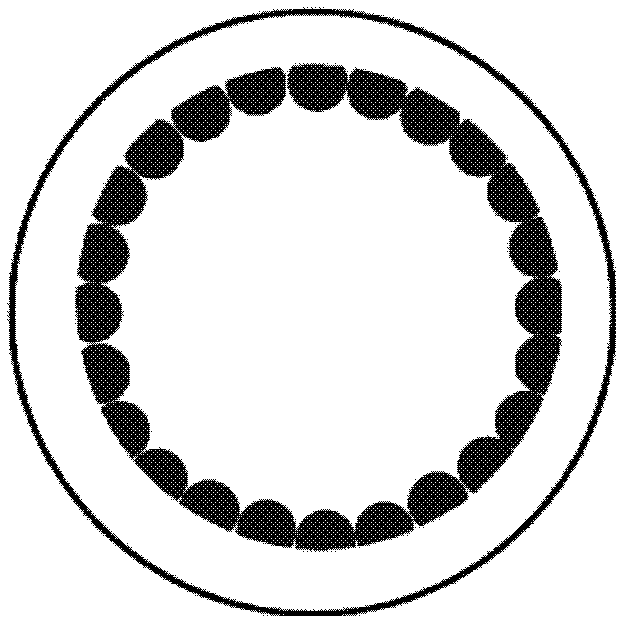

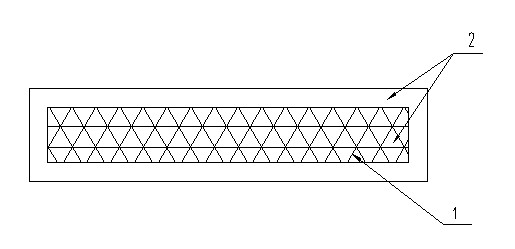

Preparation method of enhanced polyacrylonitrile hollow fiber membrane

InactiveCN102580577AImprove mechanical propertiesExtended service lifeSemi-permeable membranesMembranesHollow fibre membranePolymer science

The invention discloses a preparation method of an enhanced polyacrylonitrile hollow fiber membrane. The preparation method comprises the following steps of: (1) knitting a polyacrylonitrile fiber reinforcement body: knitting a polyacrylonitrile fiber hollow knitted tube by a two-dimensional knitting technology, wherein the polyacrylonitrile fiber hollow knitted tube is used as a reinforcement body of the hollow fiber membrane; (2) preparing polyacrylonitrile membrane casting liquid, wherein the polyacrylonitrile membrane casting liquid consists of the following components in percentage by mass: 3-25% of polyacrylonitrile resin, 50-95% of solvent and 2-30% of additive; (3) performing surface pretreatment of the reinforcement body: wetting the hollow knitted tube with low-polarity organic liquid for 1-60 seconds, wherein the low-polarity organic liquid is ethanol, glycerol, isopropyl alcohol or polyethylene glycol-600; and (4) preparing a hollow fiber membrane: co-extruding the hollow knitted tube and the membrane casting liquid through an annular spinning nozzle, and performing sufficient solidification in a coagulating bath to obtain the enhanced polyacrylonitrile hollow fiber membrane.

Owner:TIANJIN POLYTECHNIC UNIV

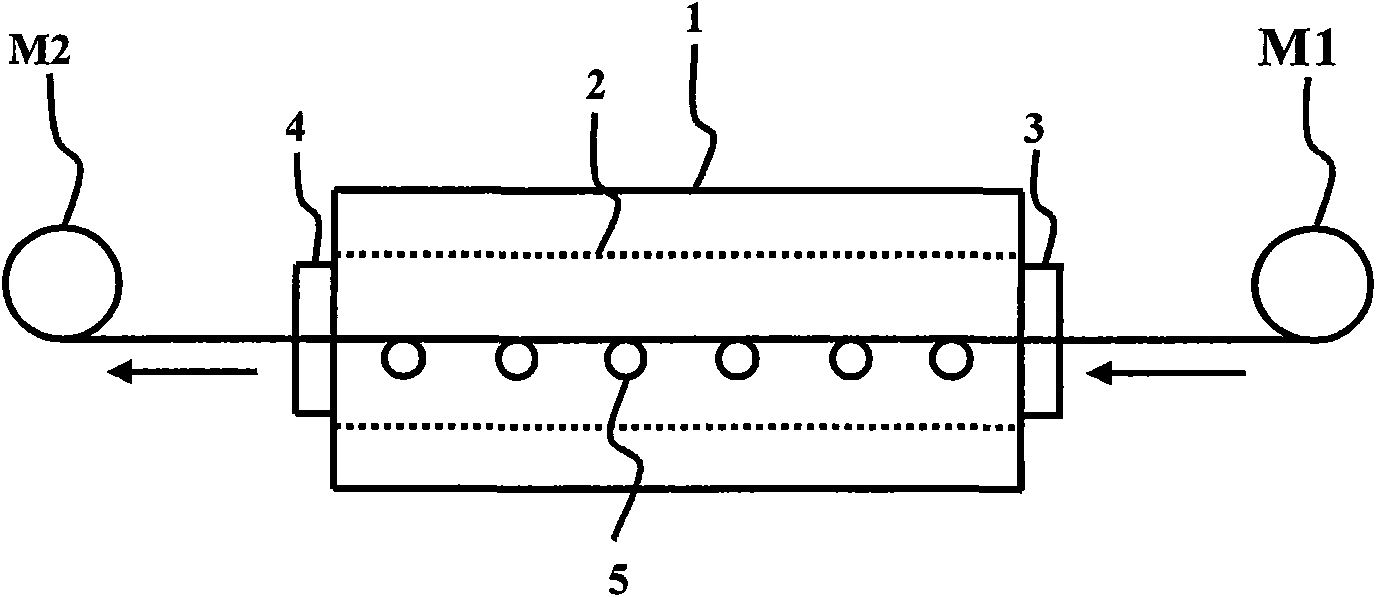

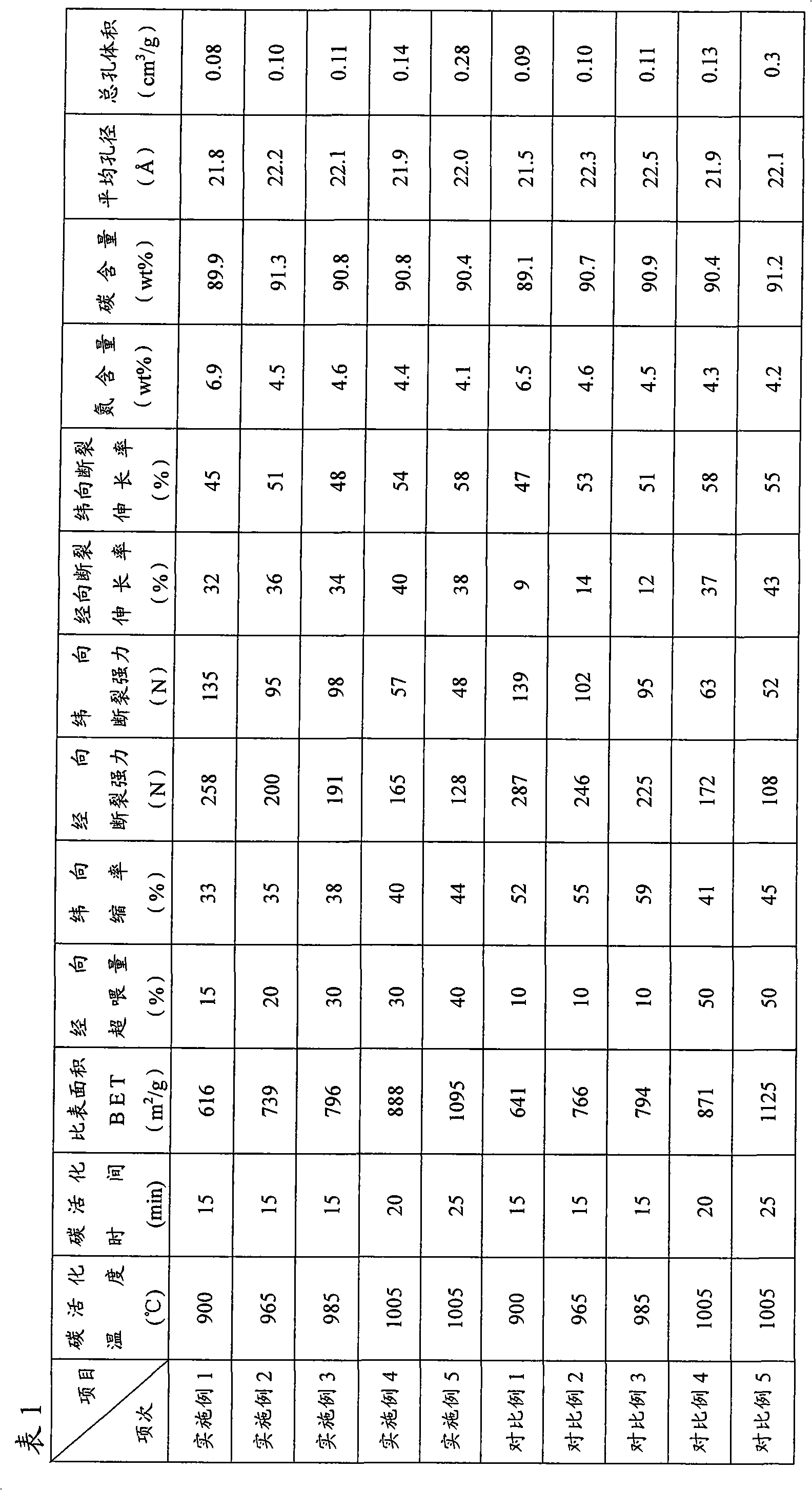

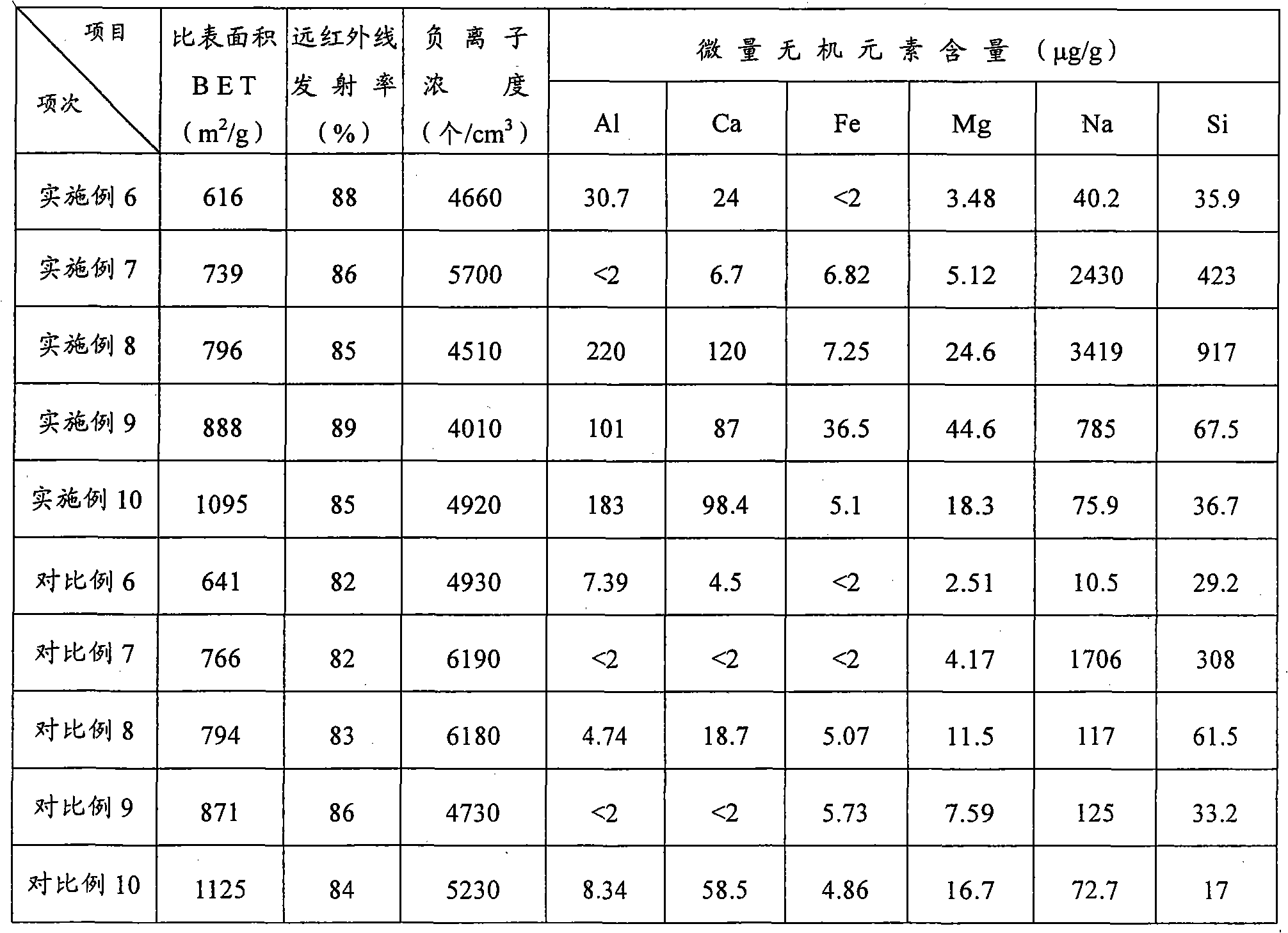

Continuous preparation method of activated carbon fiber cloth with high breaking strength and elongation at break

ActiveCN101660254AImprove breaking strengthHigh elongation at breakHeating/cooling textile fabricsActivated carbonCarbon dioxide

The invention discloses a continuous preparation method of activated carbon fiber cloth with high breaking strength and elongation at break, which comprises the following steps: (a) providing polyacrylonitrile oxidized fiber cloth; (b) providing a heat treating furnace which comprises at least four reaction regions and is provided with a feeding mechanism and a discharging mechanism; (c) providingactivated gas vapor and carbon dioxide; and (d) enabling the polyacrylonitrile oxidized fiber cloth to carry out the carbon activating reaction. The invention is characterized in that the feeding mechanism and the discharging mechanism are used for controlling the meridional overfeeding amount of the polyacrylonitrile oxidized fiber cloth in the carbon activating process to be 15-40%.

Owner:SHANGHAI TIANXIANG TEXTILE TECH

Method for improving antibacterial property of wool by bio-enzymatic method

InactiveCN101565894AHigh catalytic efficiencyReduce dosageBiochemical fibre treatmentYarnPre treatment

The invention provides a method for improving antibacterial property of wool by a bio-enzymatic method, which belongs to the field of textile biotechnology. The method utilizes the catalysis of transglutaminase (MTG) to graft some natural compounds which contain primary amine groups and have antibacterial property onto wool to improve the antibacterial property of the wool. The method comprises the following process flows: wool pretreatment, treatment with an MTG-containing antibacterial finishing agent, washing and drying. Wool yarn or fabric treated by the method not only has improvement on the antibacterial property but also correspondingly has improvement on some other properties and particularly has great improvement in low-temperature dyeing property. Meanwhile, the method improves the strength of the wool yarn or the fabric, thereby playing a role in restoring strength. The strength-restoring function is an outstanding advantage of the method compared with other antibacterial finishing agents or antibacterial finishing processes. In addition, compared with chemical finishing, the treatment process of the method is free from pollution, healthier and friendlier to environment by adopting a bio-enzyme technique.

Owner:JIANGNAN UNIV

Method for improving wool fire-retardancy with biological enzyme

InactiveCN101509193AConform to modern green environmental protection requirementsMild reaction conditionsBiochemical fibre treatmentAnimal fibresYarnBiotechnology

A method for improving flame retardance of wool by bioenzyme treatment is disclosed, belonging to the field of textile biotechnology. The invention utilizes a catalytic action of transglutaminase (MTG) to graft a type of compounds containing primary amino groups and a large number of phosphorus elements onto the wool so as to improve the flame retardance of the wool, the technological procedures comprise: pretreatment, treatment with a phosphoric finishing agent containing the MTG, water rinsing and drying. Wool yarns and fabrics treated by the inventive technology can not only be improved in the flame retardance, but also be enhanced in some other performances to a certain extent, in particularly the strength of the wool yarns and the fabrics is enhanced to play a role of powerful repair, which is outstandingly superior to other flame-retardant finishing agents or flame-retardant finishing technologies. In addition, in contrast to chemical finishing, the invention is healthier and more environmentally-friendly due to the employment of bioenzyme technique and the pollution-free treatment technology.

Owner:JIANGNAN UNIV

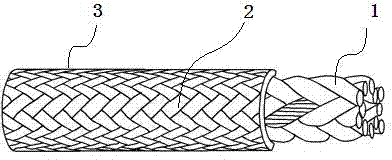

Wear-resisting high-strength cable and preparation method thereof

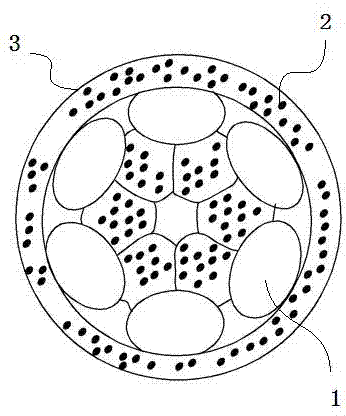

ActiveCN104762748AImprove performanceImprove breaking strengthRope making machinesCoatingsYarnPolyester

The invention discloses a wear-resisting high-strength cable produced by a non-single material and a preparation method of the wear-resisting high-strength cable. A cable body is an 8-strand structure core body which is prepared from ultra-high molecular weight polyethylene (UHMWPE) and high-strength polyester according to the amount ratio of 3 to 1; a high-toughness wear-resistant coating woven by adopting vectran fibers is arranged outside the core body; and a wear-resistant coating which is especially made of a wear-resistant material PTFE as a matrix coats the outer surface of the sleeve; the preparation method comprises the following steps: fabricating a cable body by the procedures of preparing roving, preparing rope yarns, infiltrating resin, preparing rope strands, braiding ropes, prestretching and drying; weaving a high-strength wear-resisting sleeve on the surface of the core body; and dipping and coating a wear-resisting coating which is especially prepared from PTFE as a matrix on the outer layer of the sleeve.

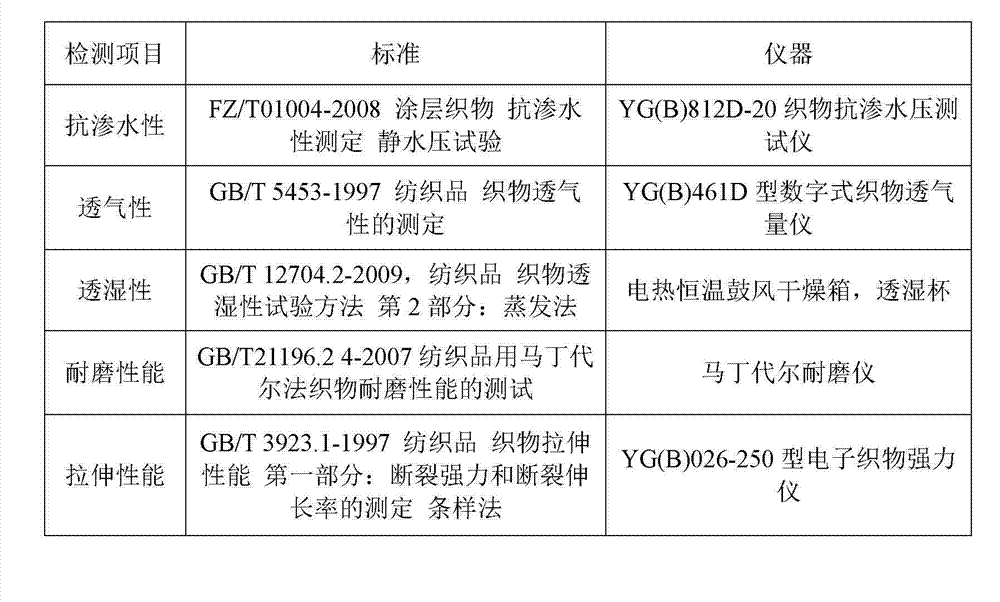

Method for producing textile coated with coating adhesive

InactiveCN102965907AImprove thermal stabilityGood weather resistancePhysical treatmentAdhesiveWater resistant

The invention relates to a method for producing textile coated with coating adhesive, comprising the following steps of: sheering double-stop end vinyl silicone oil, hydrogen-containing silicone oil, oily polyurethane resin, silane coupling agent, pentaerythritol triacrylate and nano-stage white carbon black by a high-shear homomixer at high efficiency under room temperature to prepare coating adhesive; and hot pressing a base cloth by a hot-press roller of a planishing mill, coating the coating adhesive onto the base cloth, putting the base cloth provided with the coating adhesive on a bundle transferring frame of a 200 KeV low-energy electron accelcrator through a driving roller to be cured in a radiation way to obtain the textile coated with the coating adhesive. The water permeability resistance of the textile is 17084-36483 Pa, the mean air permeability of the textile is 10.97-25.1L / M<2>.s, the moisture permeability rate of the textile is 5799-7832 g / m<2>.24h, the coating layer starts to be broken after being ground at 116-140 circles, the radial breaking strength of the textile reaches 802.7N, and the latitudinal breaking strength of the textile reaches 456.7N. The textile produced by the method can increase the humidity management, is free from wrinkle, easy to iron and press, good in tensile property and recovery property, elastic, flexible, smooth, comfortable in hand feel, nontoxic, sunshine-resistant, wind-resistant, water-resistant, and suitable for the clothes, the outdoors, the fashion fabric and the like.

Owner:JIHUA 3509 TEXTILE

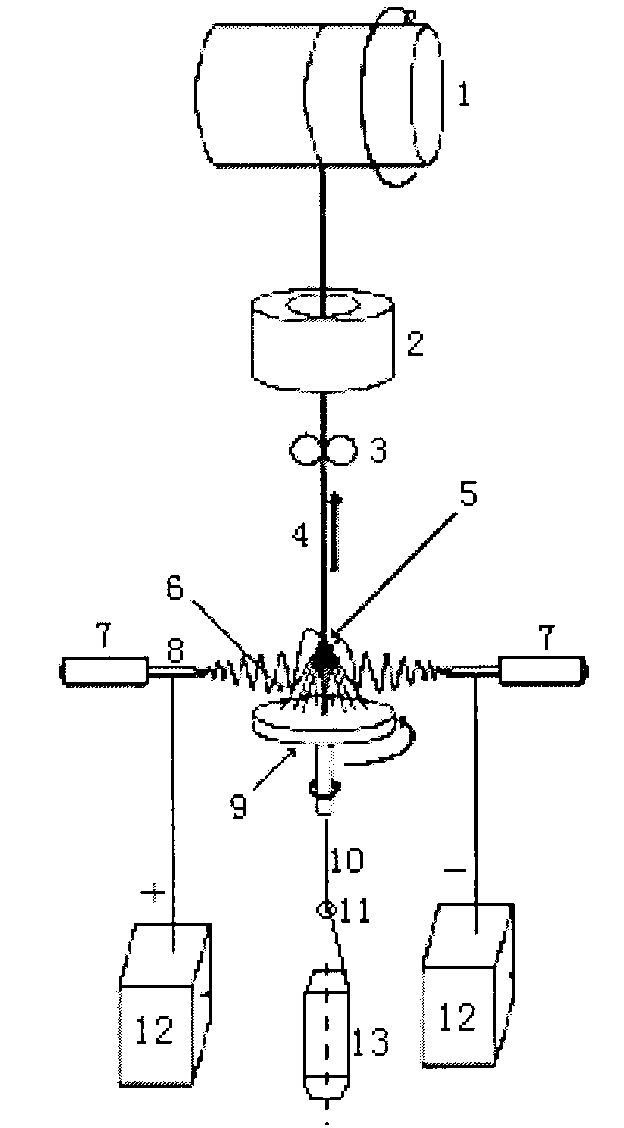

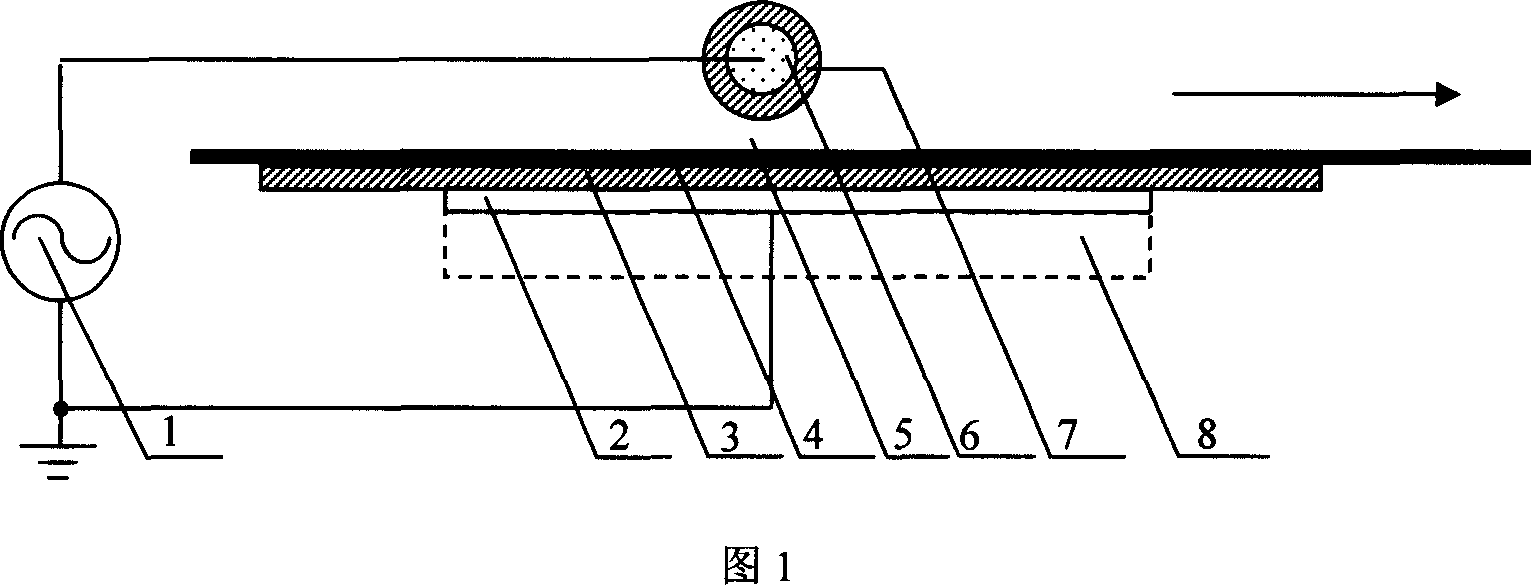

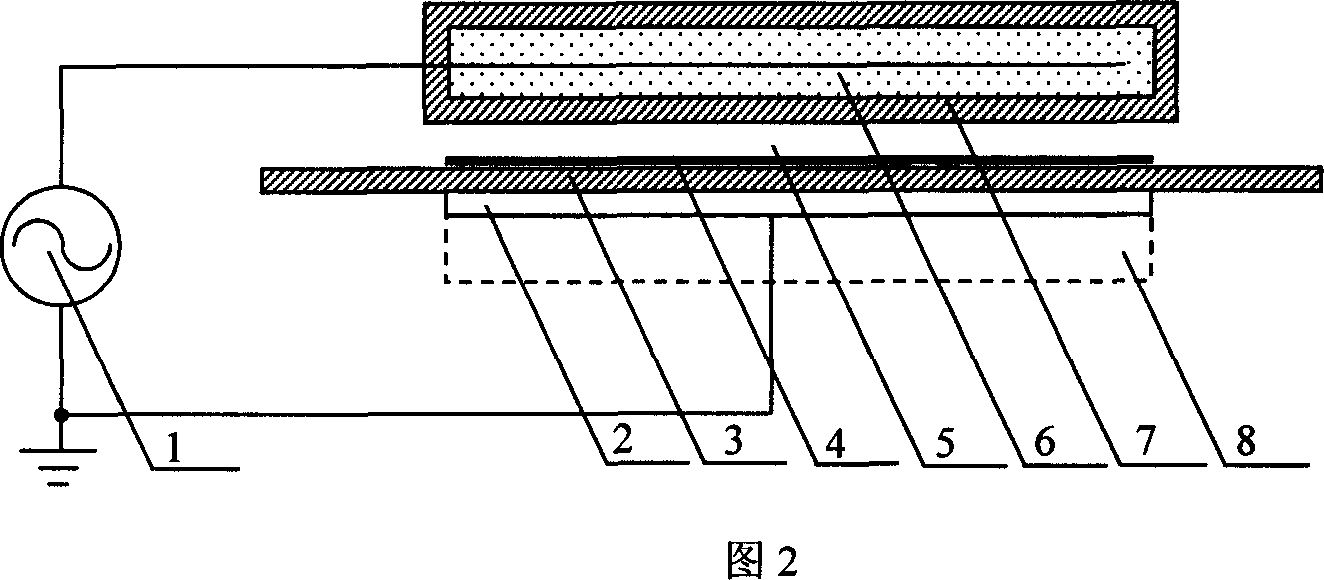

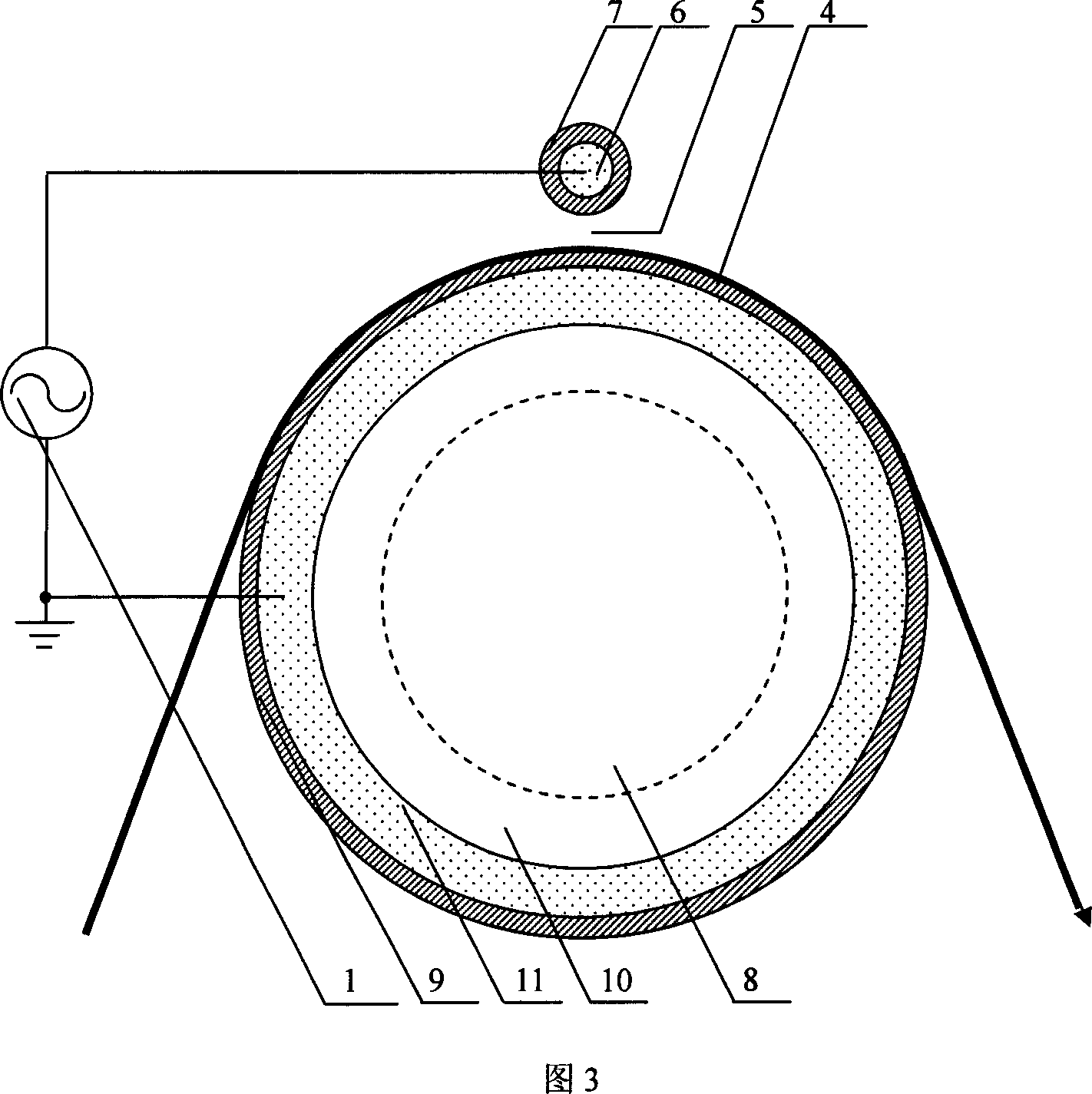

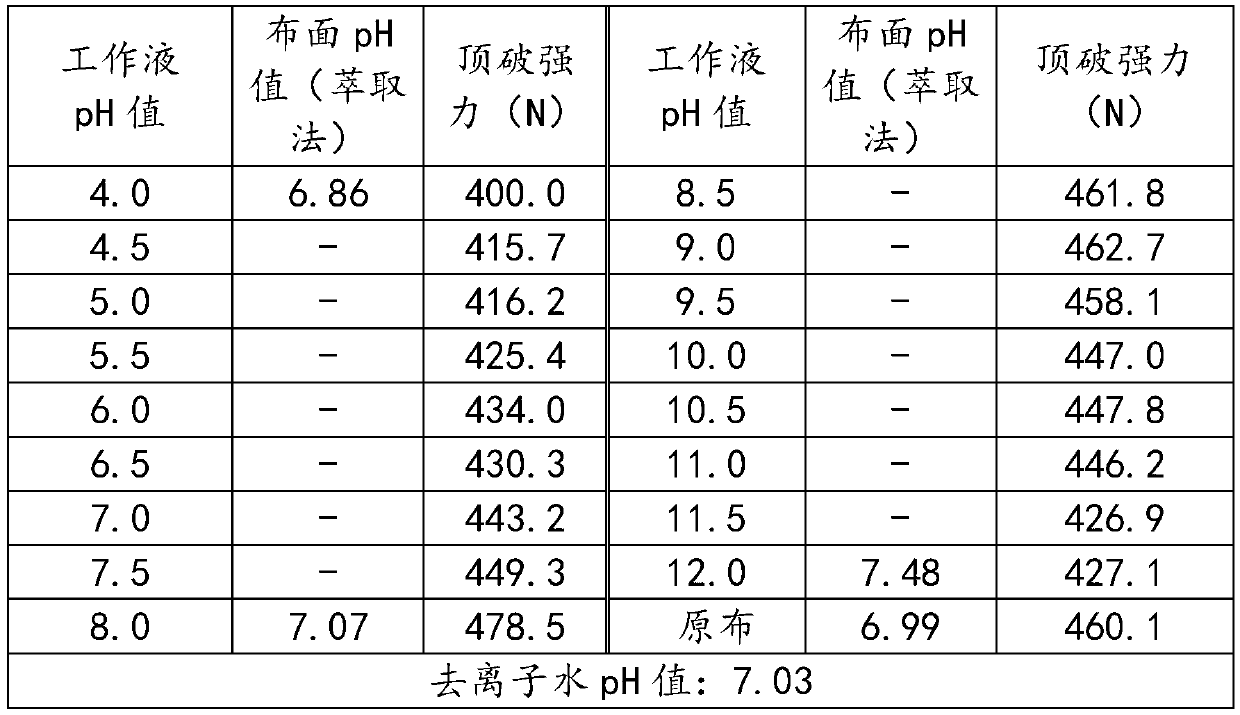

Textile and non-woven cloth plasma surface treating device

ActiveCN1932132AEvenly distributedSimple structurePhysical treatmentHigh frequency powerHigh pressure

The present invention belongs to the field of gas discharge technology, and relates to a plasma surface treatment equipment for textiles and non-woven fabric. Said plasma surface treatment equipment for textiles and non-woven fabric includes high-frequency power supply, high-voltage electrode and grounding electrode. The high-voltage electrode is at least one medium tube whose interior is filled with metal powder and sealed or one metal tube whose exterior is covered with silicone rubber, the high-voltage end of said high-frequency power supply is inserted into the medium tube interior by means of conducting wire, and the grounding electrode is a metal electrode covered with medium plate or a metal rod whose exterior is covered with silicone rubber tube, the grounding end of said high-frequency power supply is connected with metal electrode by means of conducting wire. Said invention can be used for making large-area plasma surface treatment of textiles, non-woven fabric and paper material, etc.

Owner:NANJING SUMAN PLASMA TECH CO LTD

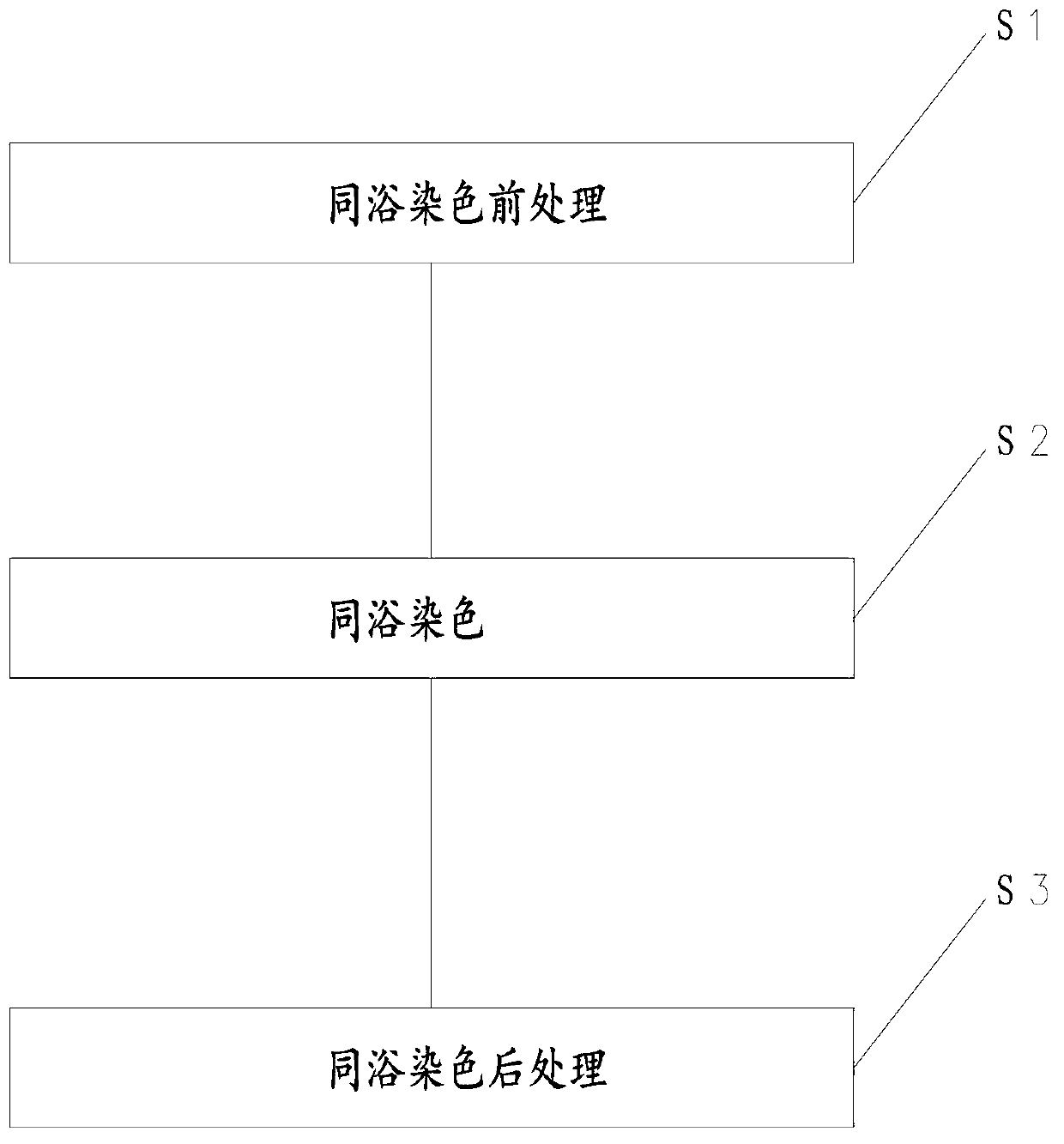

Acrylic fiber and viscose (cotton) fiber apposition dyeing method

The invention discloses an acrylic fiber and viscose (cotton) fiber apposition dyeing method relating to the technical field of blended yarn weaved fabric dyeing. The method comprises the following steps: (1) performing apposition dyeing pretreatment; (2) performing apposition dyeing; and (3) performing apposition dyeing post-treatment. The method has the advantages of simple production process, stable process control and energy conservation, and the related problems in the prior art can be solved.

Owner:GAOMI FUYUAN PRINTING & DYEING

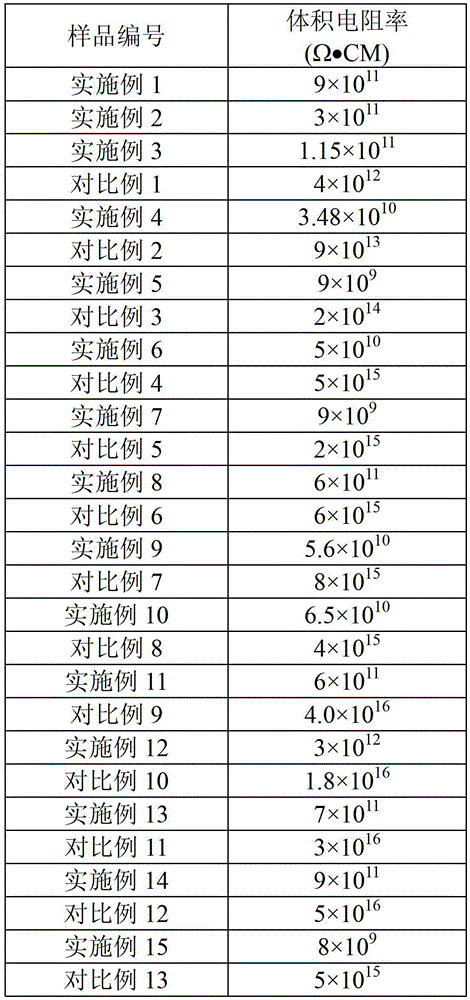

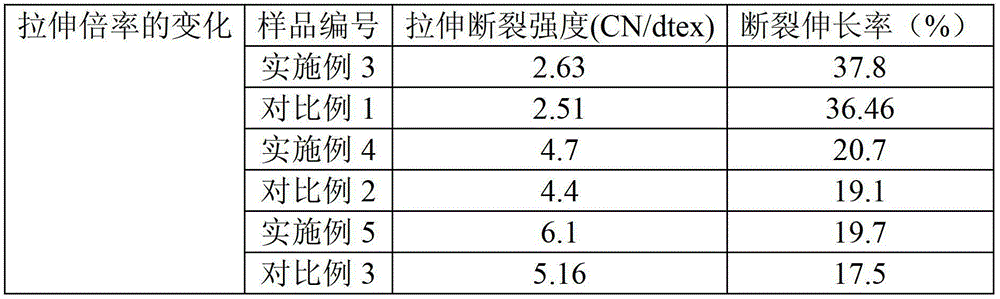

Polymer/filler/metal composite fiber and preparation method thereof

ActiveCN104099684AImprove breaking strengthElectrical properties are not affectedElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentFiberPolymer science

The invention relates to polymer / filler / metal composite fiber. The polymer / filler / metal composite fiber comprises polymer fiber containing metal short fiber and a filler, the metal short fiber is distributed in the polymer fiber as a dispersion phase and is in parallel distribution along the shaft of the polymer fiber, and the filler is dispersed in the polymer fiber and is distributed among the metal short fiber; the filler is not fused at a polymer processing temperature; a metal is a low-melting-point metal, is at least one selected from single-composition metals and metal alloy, and has the melting point between 20 DEG C and 480 DEG C and lower than the polymer processing temperature; the volume ratio of metal short fiber to polymer fiber is 0.01:100-20:100; and the weight ratio of the filler to the polymer is 0.1:100-30:100. By using the composite fiber, the volume resistivity is reduced, the wire fracture rate is reduced, and the surface of the fiber is smooth. The preparation method is simple, relatively low in production cost and easy for industrialized batch production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Impregnating compound special for single-filament plastic coated yarn and preparation method thereof

The invention relates to an impregnating compound special for single-filament plastic coated yarn and a preparation method thereof. The impregnating compound is prepared mainly by a main film former including water-solubility polyurethane and epoxy resin emulsion, and an assistant film former including water-solubility epoxy resin, as well as a coupling agent, a lubricating agent, a pH value adjusting agent and deionized water. The preparation method comprises the following steps: hydrolyzing the coupling agent in the deionized water; diluting the lubricating agent, and adding the diluted lubricating agent into the hydrolyzed coupling agent for stirring; adding the water-solubility polyurethane, the epoxy resin emulsion and the water-solubility epoxy resin for continuously stirring; and adding the deionized water and stirring uniformly. In the invention, the water-solubility polyurethane and the epoxy resin emulsion are taken as the film formers, so that the impregnating compound has the advantages of simple preparation process and low cost; and glass fiber yarn produced by the impregnating compound has extremely high breakage resistance and smaller fur containing amount, and the strength and the production efficiency of products are improved greatly, so that the impregnating compound is more suitable for promotion and application.

Owner:SHANDONG FIBERGLASS GRP

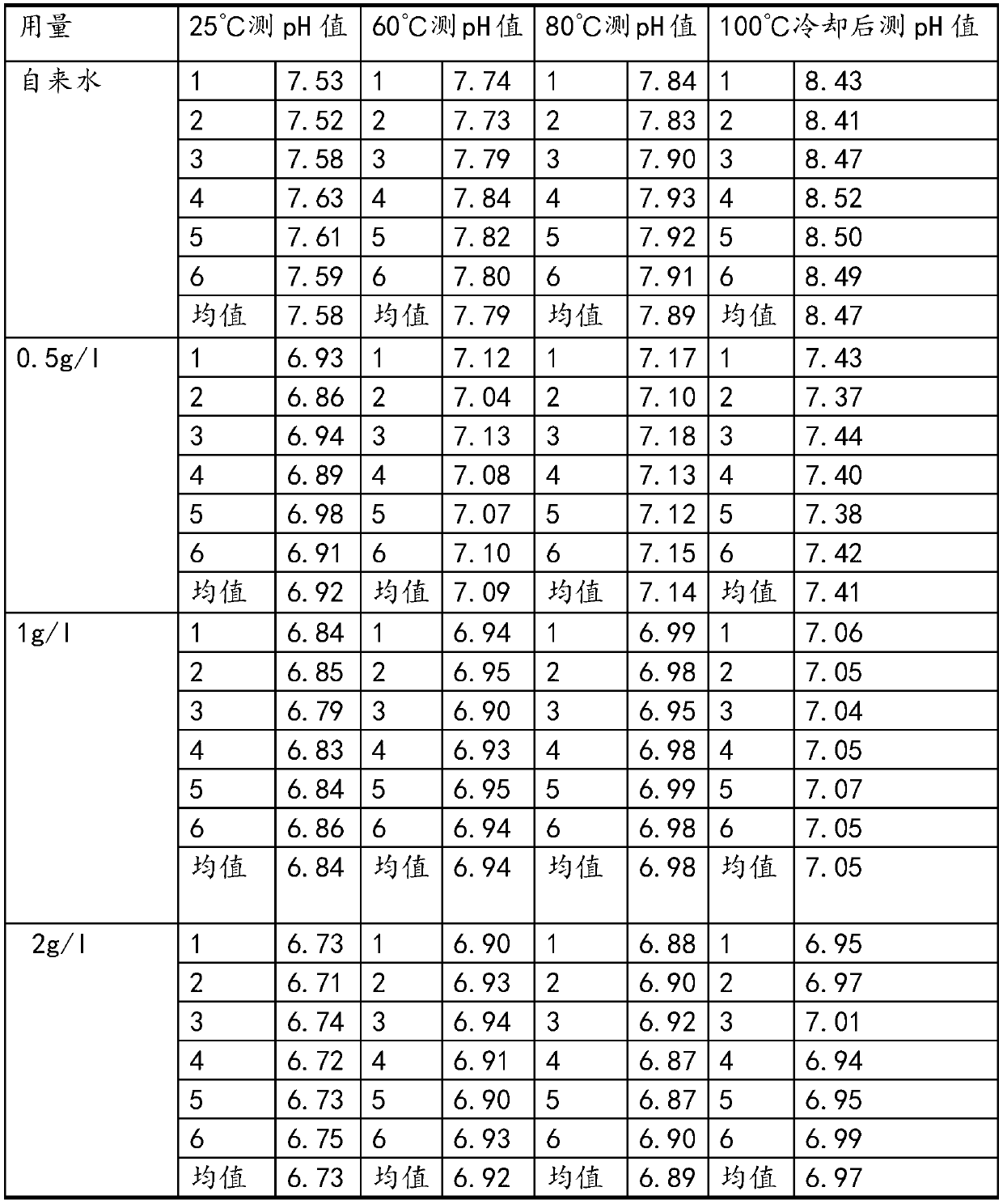

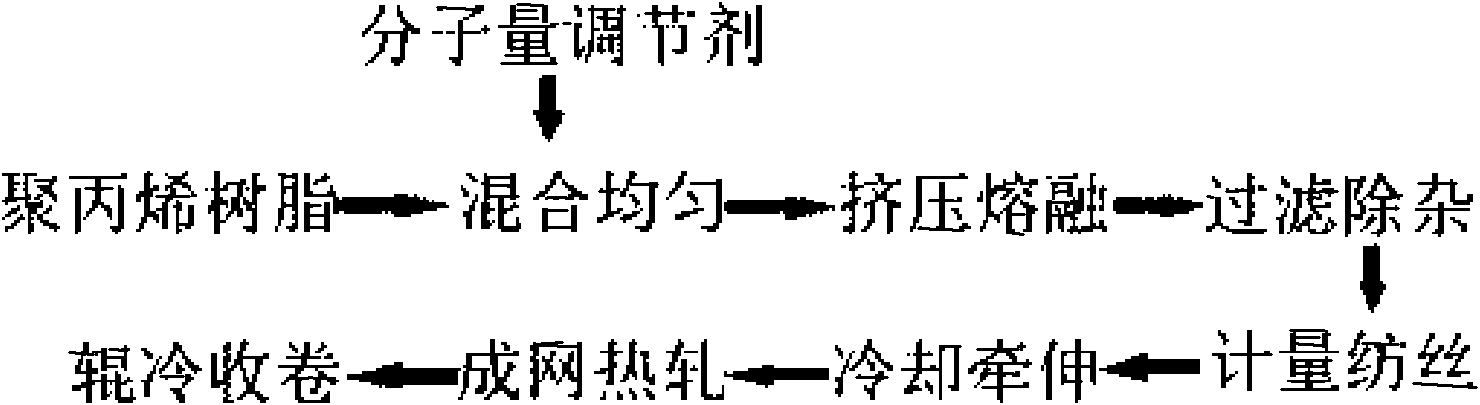

Non-woven fabric based on polypropylene non-woven fabric recycle and preparation method thereof

InactiveCN101624758AGood flexibilityImprove breaking strengthNon-woven fabricsMonocomponent polyolefin artificial filamentResidual deformationPolymer science

The invention discloses a polypropylene non-woven fabric and a preparation method thereof. The polypropylene non-woven fabric is prepared by taking polypropylene resin prepared from polypropylene non-woven fabric recycle material as the raw material and adding a molecular weight regulator, wherein the quantity of the molecular weight regulator is 0.1%-0.3% of the gross of the polypropylene resin. The polypropylene non-woven fabric is pliable, tough and light and has good flexibility, breathability and small residual deformation. The invention takes good advantages of the recycle material of polypropylene non-woven fabric, thereby saving resources and protecting the environment; and the prepared polypropylene non-woven fabric is a recyclable and environmentally friendly product which not only fits the development thougtht of circular economy, but also has low production cost and excellent product performance.

Owner:厦门创业人环保科技股份有限公司 +1

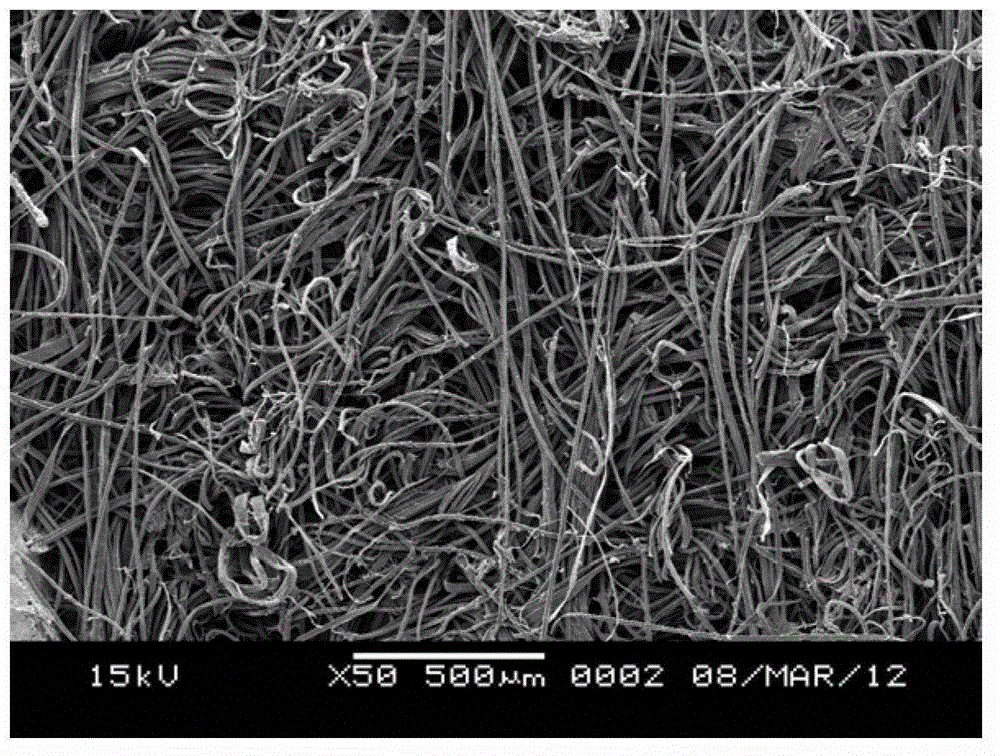

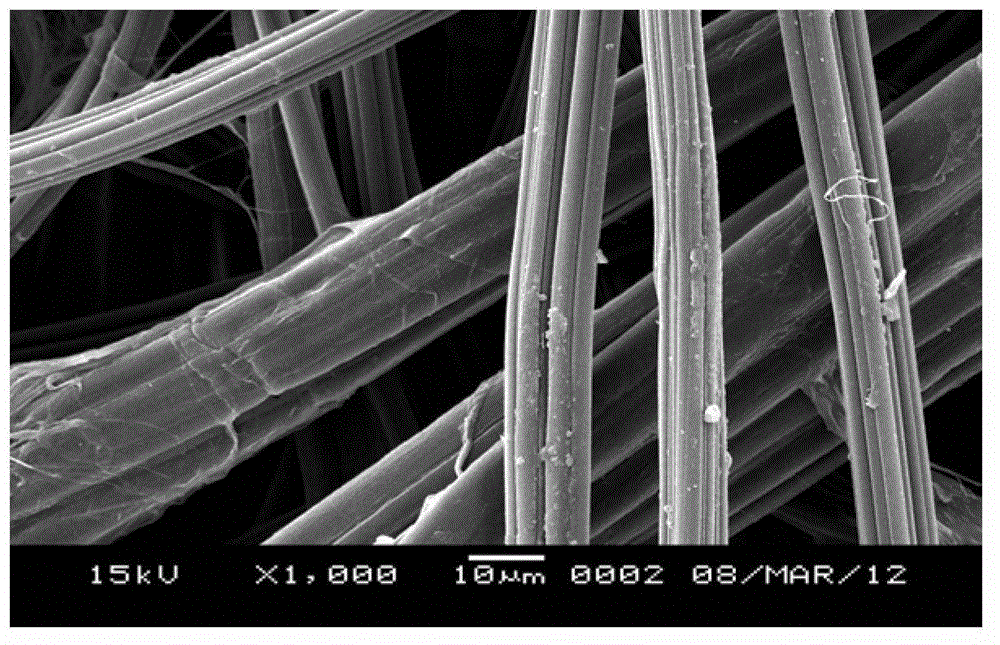

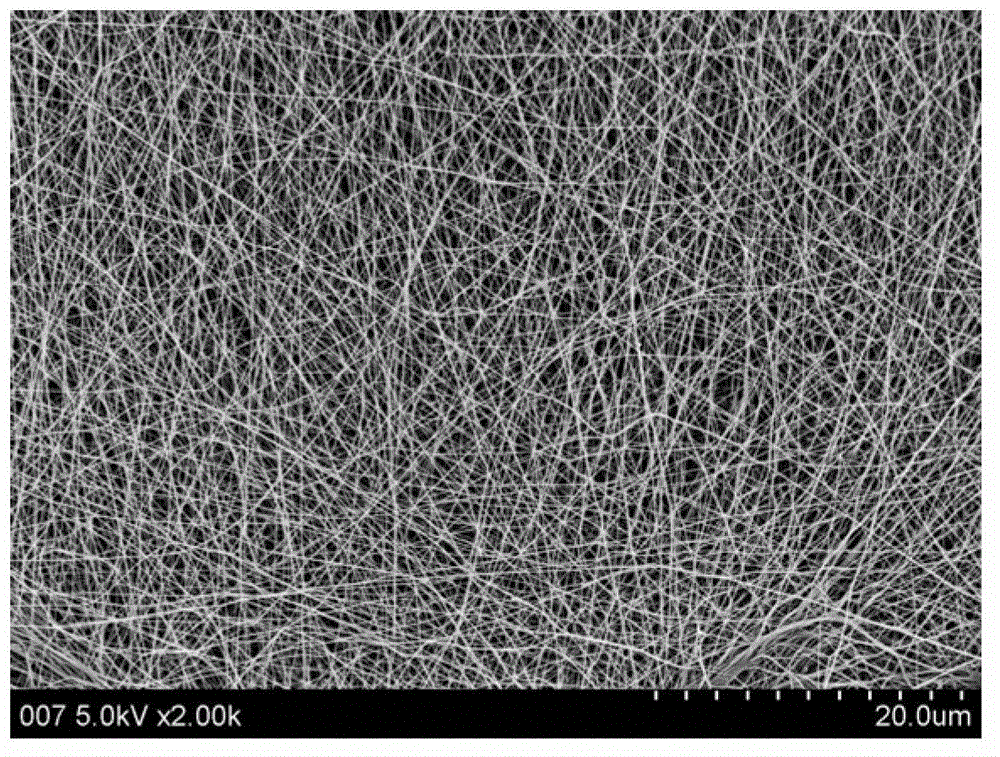

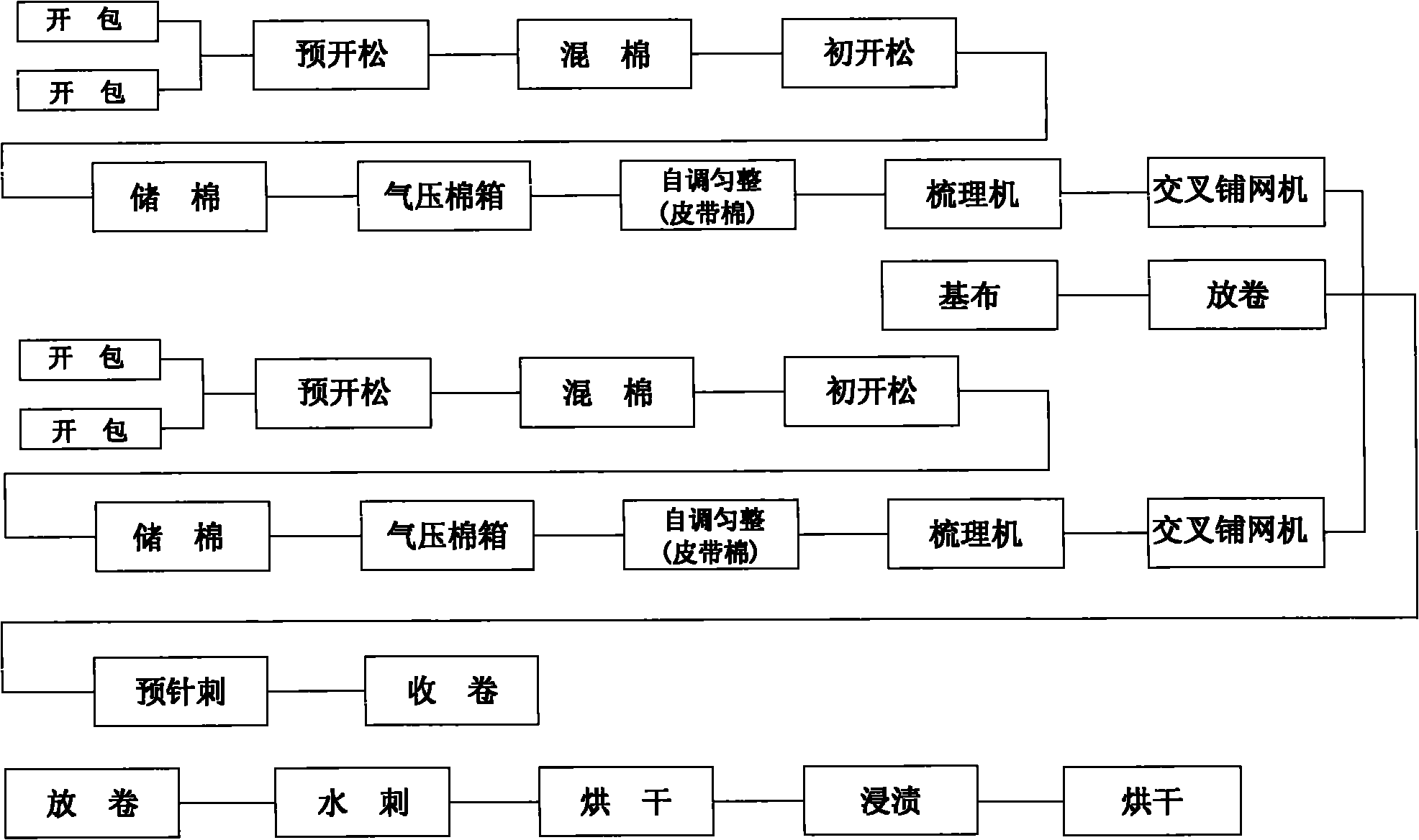

Hemp composite filter material and its preparation method

InactiveCN102743925AGood physical propertiesImprove breathabilityCellulosic plastic layered productsFiltration separationBreaking strengthMicrometer

The invention discloses a hemp composite filter material and its preparation method. The method comprises the following steps: 1, mixing a hemp fiber with a viscose fiber, and then sequentially carrying out steps of opening, carding, lapping, drafting, spunlace and drying to obtain a hemp / viscose spunlaced non-woven; and 2, preparing a nanometer fiber layer on the hemp / viscose spunlaced non-woven through electrostatic spinning to obtain the hemp composite filter material. The composite filter material provided by the invention is a two-layer composite material comprising the micrometer-diameter hemp / viscous spunlaced non-woven and the nanometer-diameter fiber, wherein the hemp / viscous spunlaced non-woven has the advantages of good physical performances, good permeability, small thickness and proportion, large breaking strength and good wear resistance; and a comparison between the base cloth of the hemp / viscous spunlaced non-woven and the two-layer composite filter material disclosed in the invention in filter performance and bore diameter indicates that the two-layer composite filter material provided by the invention has a better filter effect.

Owner:DONGHUA UNIV +2

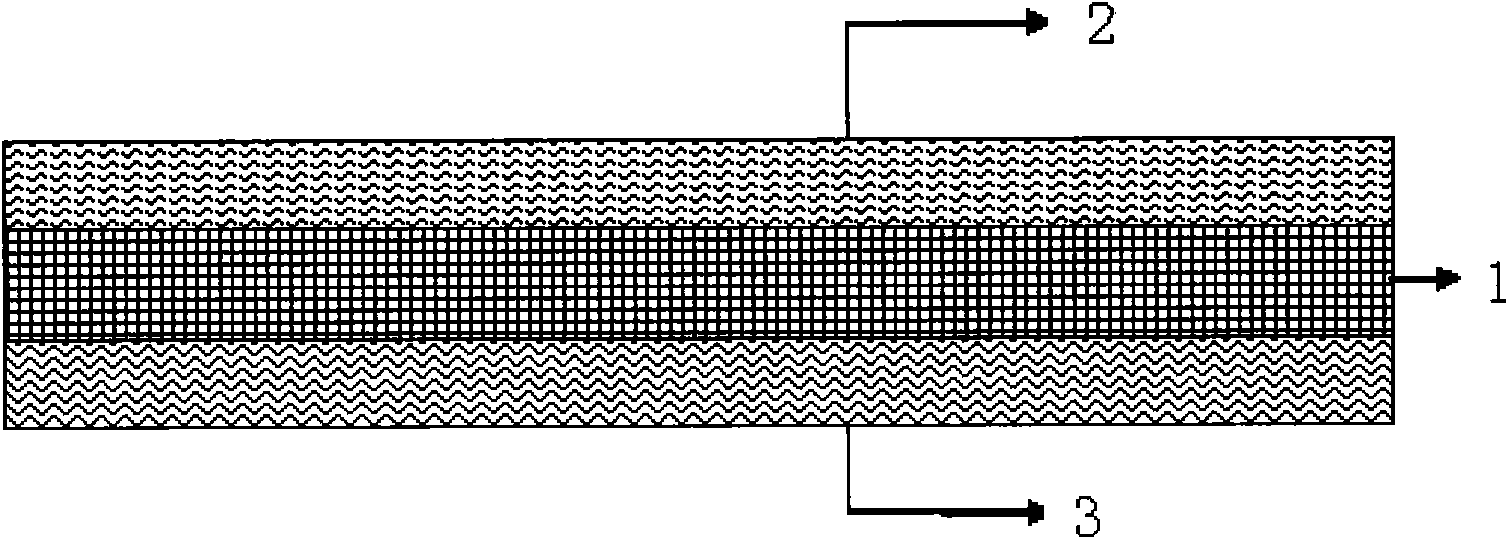

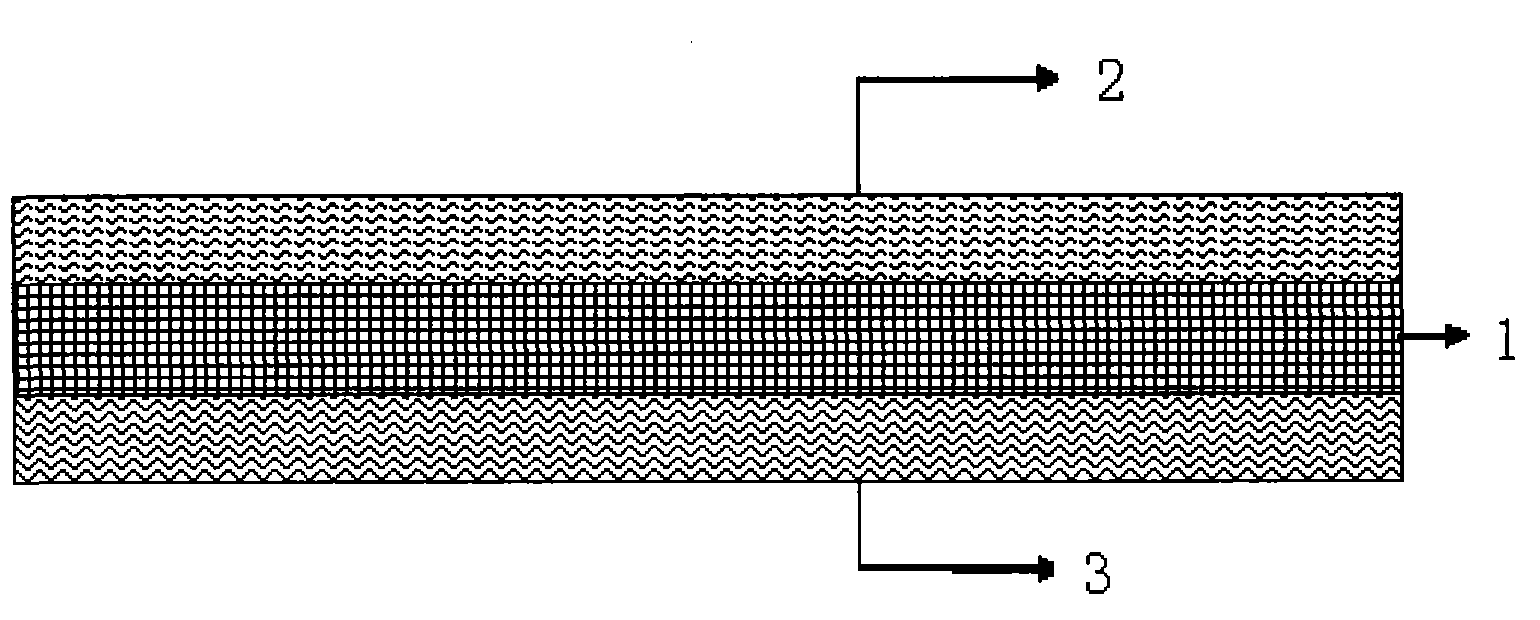

Specific composite filter material for coal-fired power plant electric bag integration project

InactiveCN101804273AImprove Oxygen LimitationStrong chemical resistanceCombination devicesLayered productsCompound (substance)Engineering

The invention discloses a specific composite filter material for a coal-fired power plant electric bag integration project; the composite filter material comprises base cloth, a dust facing surface and a bottom layer; the dust facing surface is arranged on the upper surface of the base cloth; the bottom layer is arranged on the lower surface of the base cloth; the dust facing surface is mixedly blended from PTFE fibers and PPS fibers, wherein the weight proportion of the PTFE fibers is 30 to 70 percent; the base cloth is interwoven from 100 percent PTFE long filaments in the longitudinal and latitude directions; and the bottom layer is mixedly blended from the PTFE fibers and the PPS fibers, wherein the weight proportion of the PTFE fibers is 30 to 70 percent. The fibers tangle through an acupuncture and spunlace composite process to form a plain blanket which is soaked into chemical solvent, so as to further improve the corrosion resistance and chemical performance resistance. The specific composite filter material for the coal-fired power plant electric bag integration project has smooth surface, improves the dust removing capability, reduces the operation resistance of equipment, prolongs the service life, can ensure the use for 35000h in the electric bag integration project, and is applicable to the coal-fired power plant electric bag integration project.

Owner:NANJING JIHUA 3521 SPECIAL EQUIP

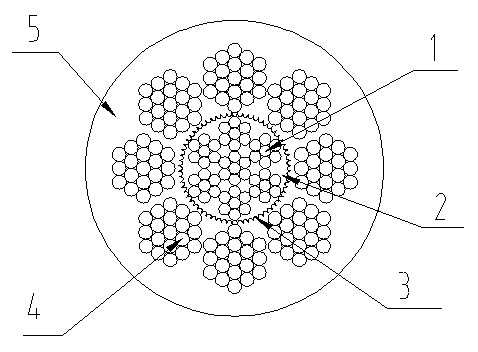

Carbon fiber bilayer plastic wrapped steel rope specially used for elevator

ActiveCN102635003AAvoid driftingAvoid conductive propertiesElevatorsBuilding liftsFiberCarbon fibers

The invention relates to a carbon fiber bilayer plastic wrapped steel rope specially used for an elevator and belongs to the technical field of elevators. The carbon fiber bilayer plastic wrapped steel rope specially used for the elevator is provided with a carbon fiber rope core, wherein a synthetic plastic inner protective layer is wrapped outside the carbon fiber rope core; a suction disc which is densely covered by ranks of micro ridges and slots is wrapped outside the inner protective layer; a braided steel wire rope is arranged outside the suction disc, and a synthetic plastic shell is extruded and wrapped outside the steel wire rope. The carbon fiber bilayer plastic wrapped steel rope disclosed by the invention has a scientific and reasonable structure; an intermediate sizing rope core adopts a carbon fiber plastic wrapped rope; a plastic wrapped surface imitates the mode of the suction disc of a wall gecko, and the suction disc which is densely covered by ranks of micro ridges and slots is arranged, so as to enhance the binding ability of the carbon fiber bilayer plastic wrapped steel rope with other materials; the shell is wrapped by the synthetic plastic; and the tensile strength of the carbon fiber resin composite material is 3500MPa or above and is 7-9 times that of a steel wire while the weight of the carbon fiber resin composite material is one fourth of the weight of the steel wire of the same class, thus the carbon fiber bilayer plastic wrapped steel rope disclosed by the invention has a prospect in application of the elevator and is a replacement product of an elevator hoisting rope.

Owner:SANXING ELEVATOR YANGZHOU ECONOMICAL DEV ZONE

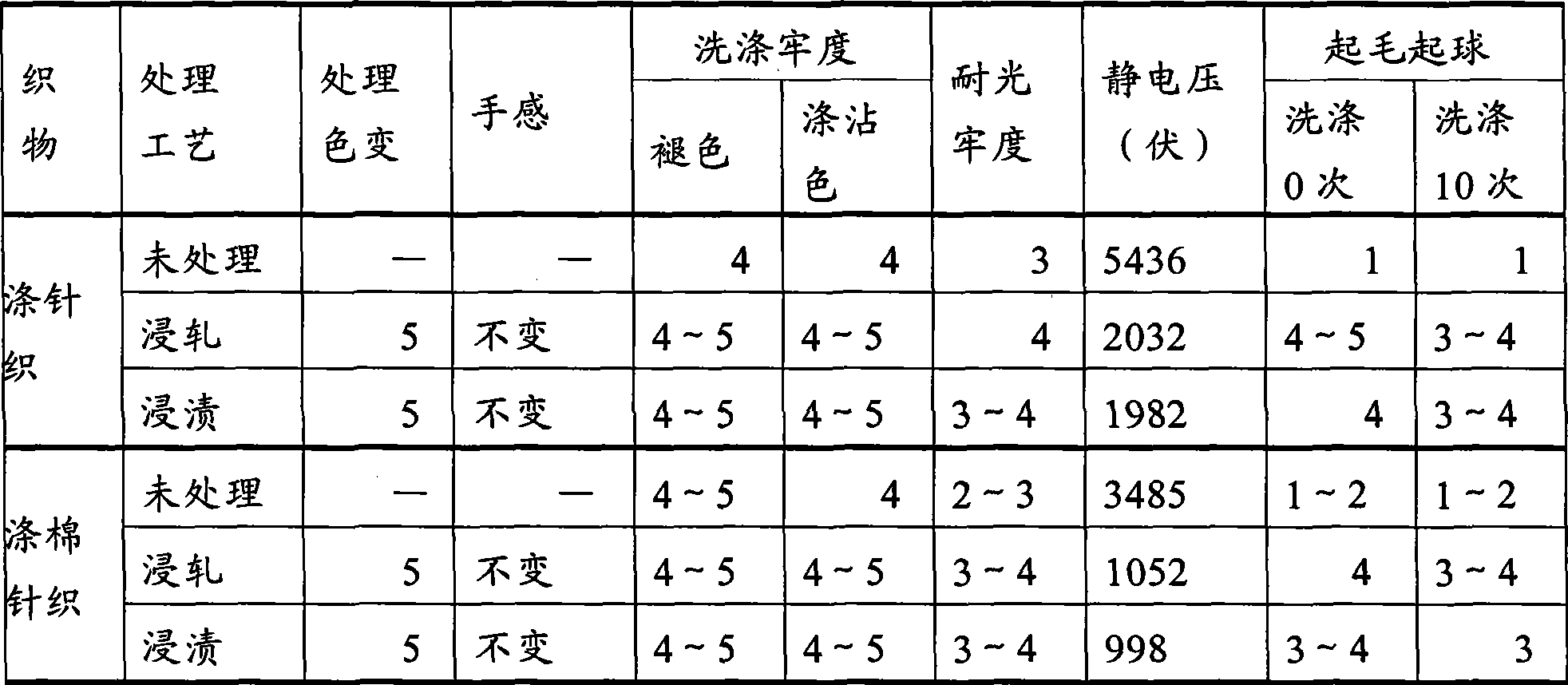

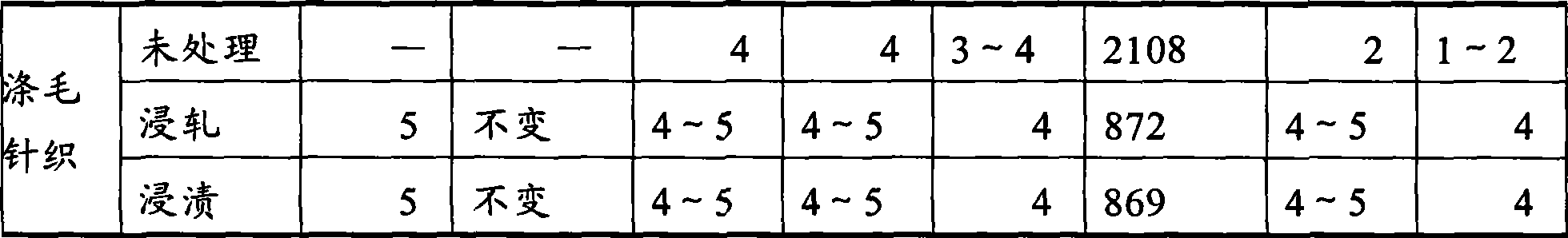

Anti-fuzzing and anti-pilling finishing agent for fabric

The invention relates to an auxiliary agent in the printing and dyeing industry, in particular to a surface finishing auxiliary agent for fabric. An anti-pilling finishing agent for the fabric is nonionic macromolecular polymer, and is characterized in that the anti-pilling finishing agent for the fabric is formed by copolymerizing 10 to 20 portions of high-hydro silicone oil, 30 to 50 portions of polyurethane prepolymer and 30 to 50 portions of polypropylene ester copolymer under the conditions of catalyst and heating; and the portion is weight portion. The fabric anti-pilling finishing agent is suitable for various fibers and fabrics; and in particular, polyester fabric treated by the anti-pilling finishing agent has basically unchanged tone and handfeel, improves the fastness to washing and light fastness, greatly improves the antistatic performance, has certain dust resistance and obviously improves the anti-pilling performance.

Owner:上海德桑精细化工有限公司

Preparation method of nano modified soaking agent used for basalt fiber

The invention discloses a preparation method of a nano modified soaking agent used for basalt fiber. The preparation method includes: adopting a mixed emulsion of the nano modified soaking agent prepared by film former, coupling agent, lubricant, modified nano SiO2 particle and water; taking the film former as a main material; using water to dilute binder; adding the coupling agent, the lubricant and the modified nano SiO2 particle; stirring after being fully mixed to obtain a finished nano modified soaking agent product. The nano modified soaking agent is mainly used for coating the basalt fiber, is high in impregnability and stability, has effect of improving clustering performance and wear resistance of the basalt fiber and can improve mechanical performance of the basalt fiber, and cracking strength, drawing performance and shearing strength are all improved.

Owner:SICHUAN AEROSPACE WU YUAN COMPOSITE

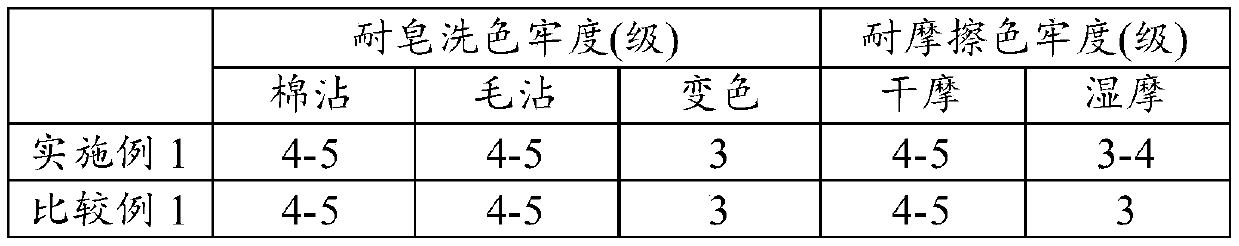

Ink-jet printing pretreatment agent and silk fabric surface pretreatment method

ActiveCN110029511AImprove the apparent color depth K/S valueImprove breaking strengthDyeing processSodium bicarbonateBreaking strength

The invention provides an ink-jet printing pretreatment agent which is prepared from sodium bicarbonate, urea, polyacrylamide and water. The mass ratio of the urea to the sodium bicarbonate to the polyacrylamide is (1-10) to 1 to (0.5-5); the mass concentration of the polyacrylamide in the ink-jet printing pretreatment agent is 0.1-3%. When a silk fabric is treated by using polyacrylamide as a surface treatment agent, the color shade and the vividness are increased, the apparent color depth K / S value of the printed fabric is improved, the width of printed lines is smaller (namely the anti-seepage effect is better), the permeability of dye molecules on the fabric is reduced, the breaking strength is slightly increased, and the color fastness index is almost unchanged. That is, the polyacrylamide as the pretreatment agent can not only improve the utilization rate of the dye molecules, but also effectively improve the image effect of ink-jet printing, the improvement of the technical level of ink-jet printing is facilitated. The invention also provides a surface pretreatment method of the silk fabric.

Owner:TIANJIN POLYTECHNIC UNIV

Polyurethane urea rubber composite elastic fiber and preparation method thereof

ActiveCN103898631AImprove high temperature resistanceAccelerated corrosionMonocomponent synthetic polymer artificial filamentConjugated synthetic polymer artificial filamentsRubber materialFiber

The invention discloses a polyurethane urea rubber composite elastic fiber and a preparation method thereof. According to the preparation method, a butadiene-acrylonitrile rubber material and polyurethane urea are uniformly mixed through a solution blending mode, lots of strong-polarity nitrile groups are introduced into the fiber, and the interaction force of the polymer molecular chain is increased, so that the fiber has high-temperature resistance and alkali and chemical corrosion resistance. Moreover, the operations of vulcanization cross-linking and stock solution fiber forming are simultaneously finished through a low-temperature low-speed spinning process, the limiting effect on the soft segment of polyurethane urea is increased by utilizing a mico-crosslinking network structure formed by a rubber phase in the fiber forming process, and the mechanical strength and thermal stability of the fiber are further improved.

Owner:ZHEJIANG HUAFENG SPANDEX

Preparation method of stable basalt continuous fiber impregnating compound

The invention discloses a preparation method of a stable basalt continuous fiber impregnating compound. The impregnating compound is a mixed emulsion prepared from a film-forming agent, a coupling agent, a lubricant, a PH modifier and water, wherein the film-forming agent serves as the main component. The preparation method comprises the following steps: diluting the film-forming agent by using the water, then adding the coupling agent, the lubricant and the like, fully mixing the components, and then performing stirring to obtain a finished impregnating compound product. The stable basalt continuous fiber impregnating compound is mainly used for a coating of a basalt fiber, has high impregnability and stability, and also has the functions of improving the bundling and the abrasion resistance of the basalt fiber; the mechanical property of the basalt fiber can be improved, and the breaking strength, the tensile property and the shear strength are improved.

Owner:SICHUAN AEROSPACE WU YUAN COMPOSITE

Polyester glass fiber geotextile and production method thereof

ActiveCN102358993AEvenly distributedImprove breaking strengthPaving reinforcementsNon-woven fabricsBreaking strengthPolyester

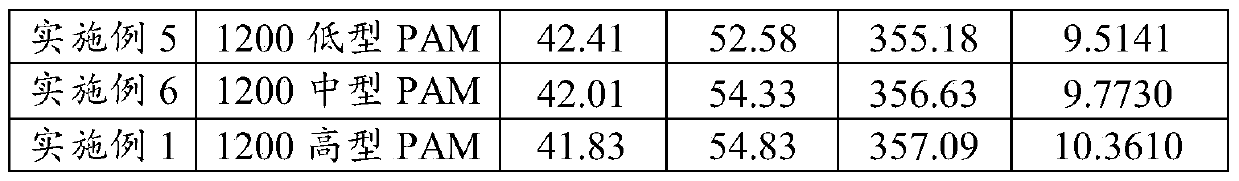

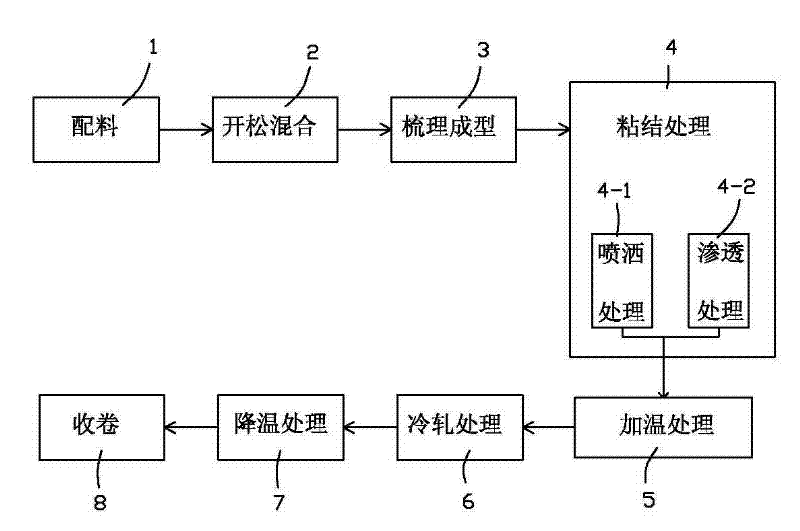

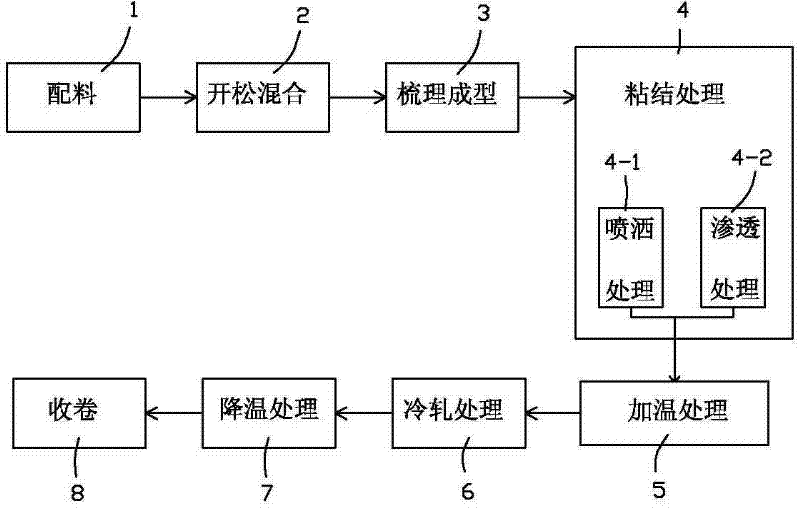

The invention relates to a polyester glass fiber geotextile and a production method thereof. The geotextile is prepared by uniformly mixing glass fibers and polyester fibers, bonding with a bonding agent and pressing, wherein the weight part ratio of the glass fibers to the polyester fibers to the bonding agent is (5-7):(2.5-4.0):(0.5-1). The production method of the polyester glass fiber geotextile comprises the following steps of: preparing glass fibers and polyester fibers according to the weight part ratio; opening and mixing; carding, molding and feeding into a conveying mesh belt; bonding; heating; performing cold rolling; cooling; and winding, wherein the bonding treatment comprises spreading treatment and permeating treatment. The polyester glass fiber geotextile has the advantages of uniform fiber distribution, high breaking strength, high breaking elongation consistence, remarkable waterproofing function and suitability for road surfaces; and by adopting a dry production method, water resource is saved, drainage of waste water is avoided, environmental pollution is avoided, bonding agent mixing equipment used in conventional production is eliminated, and the equipment investment is low.

Owner:肥城三合工程材料有限公司

Anti-electromagnetic radiation fabric coating adhesive and preparation method thereof

ActiveCN104452298AShort production processSimple and fast operationVegetal fibresIsooctyl acrylatePolyester

The invention discloses an anti-electromagnetic radiation fabric coating adhesive and a preparation method thereof. The anti-electromagnetic radiation fabric coating adhesive is prepared from the following raw materials in parts by weight: 8-10 parts of sodium dodecyl benzene sulfonate, 5-6 parts of fatty alcohol-polyoxyethylene ether, 25-30 parts of butyl acrylate, 85-90 parts of 2-ethylhexyl acrylate, 9-10 parts of cyclohexyl methacrylate, 3.5-4 parts of acrylamide, 4-5 parts of acrylic acid, 1.5-2 parts of trimethylolpropane triacrylate, 10-20 parts of styrene, 1.5-2 parts of glycidyl methacrylate, 1.0-1.6 parts of ammonium persulfate and 250-330 parts of deionized water. The method comprises the following steps: synthesizing an emulsion by emulsification and initiated polymerization; and adding a mixed liquid of 3-6 parts of conductive polyaniline and 15 parts of N,N-dimethyl formamide, 30-35 parts of a carbon nanotube dispersion liquid and 3-4 parts of an associative polyurethane flatting rheological agent, and compounding, so as to obtain the anti-electromagnetic radiation fabric coating adhesive. The anti-electromagnetic radiation fabric coating adhesive is suitable for pure cotton and polyester fabrics, and has good conductive property, anti-electromagnetic radiation property, binding strength, water-fastness, tearing strength, breaking strength, hydrostatic pressure resistance and hand feeling.

Owner:DANDONG UNIK TEXTILE

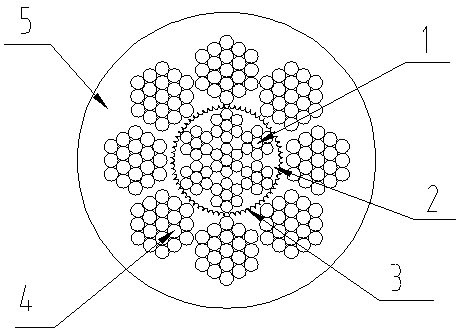

Special flat dragging tape for plastic-wrapping carbon fiber elevator

The invention relates to a special flat dragging tape for a plastic-wrapping carbon fiber elevator and belongs to the technical field of an elevator. The special flat dragging tape is prepared according to the following steps: firstly, weaving multi-strand carbon fiber thin ropes into a carbon fiber flat tape with meshes; performing injection molding on the synthetic plastics and carbon fiber flat tape; wrapping the carbon fiber flat tape in the synthetic plastics; and forming an integrated body by the synthetic plastics in the meshes of the carbon fiber flat tape and the synthetic plastics wrapped on the upper, lower and peripheral surfaces of the carbon fiber flat tape. The special flat dragging tape provided by the invention has the advantages that the tensile strength is 7-10 times of that of a steel tape with the same cross section; the weight is light; the density is only 1 / 4 of that of a common steel wire; the cross section of the dragging tape is reduced by 65%; the anti-breaking tensile force is increased by 70%; the durability is excellent; compared with the steel tape of the common elevator, the service life of the special flat dragging tape is increased by 4 times; the plastic-wrapping dragging tape is in tight contact with a wheel; a contact surface pressure ratio is low; no dragging abrasion exists; the bending capacity of rope is increased; a diameter of a dragging wheel is reduced; the driving power of a host machine is lowered; the cost is saved; and the special flat dragging tape is an ideal dragging transmission tape for elevator.

Owner:施凤鸣

Jute/terylene/cotton blended yarn

A jute / polyester / cotton blended yarn comprises three types of fiber of jute, polyester and cotton and is characterized in that the weight of the polyester fiber accounts for 10-40 percent by weight of the total weight of the jute, the polyester and the cotton fiber. The fineness difference between the polyester fiber and the jute fiber and the fineness difference between the polyester fiber and the cotton fiber are both small. When being blended, the polyester fiber of the blended yarn can be cohered with the jute fiber and can also be cohered with the cotton fiber, thereby enhancing the cohesion among different types of fiber; and the spun blended yarn has better breaking strength. The invention discloses the content range of the added polyester fiber which can lead the breaking strength of the yarn to be more satisfactory during the blending of the jute fiber / cotton fiber with different weight percentages.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Polytetrafluoroethylene filament as well as preparation method and application thereof

InactiveCN107177893AImprove evennessImprove breaking strengthMonocomponent halogenated hydrocarbon artificial filamentStretch-spinning methodsFlue gasIncineration

The invention discloses a polytetrafluoroethylene filament as well as a preparation method and an application thereof. The preparation method comprises the following steps: (1) performing superposition and oil removal on a plurality of layers of single-layer polytetrafluoroethylene rolling base tapes so as to form a multilayer superposed base tape; (2) longitudinally heating and drafting twice; (3) slitting into ribbon-like filaments; (4) sintering and drafting the ribbon-like filaments; and (5) twisting the ribbon-like filaments to obtain round filaments, setting, and performing shock cooling so as to obtain the product; or setting the ribbon-like filaments, performing shock cooling, twisting, thereby obtaining the product. The filament made by the method disclosed by the invention is low in unevenness, high in breaking strength and low in elongation, the overall strength of a filter material can be improved, and the service life of the filter material is prolonged; meanwhile, the breakage can be reduced due to high strength, and the production efficiency is improved; the polytetrafluoroethylene filament can be directly produced by using the conventional production equipment, is low in production cost and smooth and even in filament surface and contributes to weaving, and the woven base cloth can be widely applied to framework materials of high-temperature flue gas dust-removing filter materials in industries such as steel, waste incineration, cement, power plants and the like.

Owner:上海灵氟隆新材料科技有限公司 +1

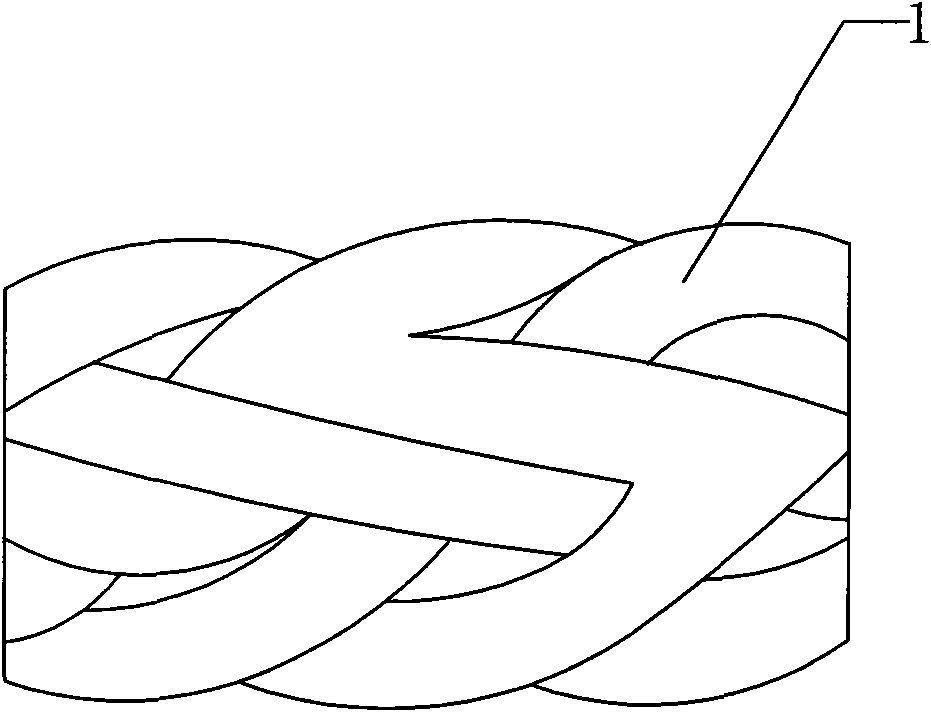

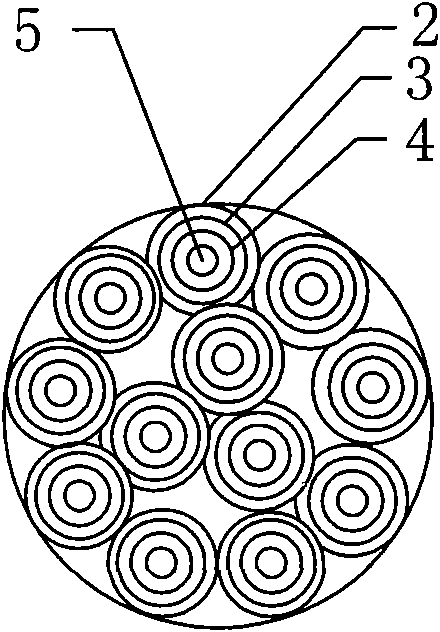

Polyester and polypropylene compound mooring rope and preparation process thereof

The invention relates to a polyester and polypropylene compound mooring rope and a preparation process thereof. The polyester and polypropylene compound mooring rope comprises twelve strands which are knitted into a whole, wherein six strands are used as left twisted strands and other six twisted strands are used as right twisted strands; the strands comprise outer layers, intermediate layers, inner layers and core layers which are formed by twisting and other polyester and polypropylene fiber twisting wires; the preparation process comprises the following steps: (1) selecting raw materials; (2) twisting wires; (3) producing strands; and (4) forming ropes. The invention has the beneficial effects that the mooring rope not only has the characteristics of low density, light weight, high strength, favorable specific modulus and impact resistance and the like which are the same as the characteristics of like products, but also has the performances of corrosion resistance, fatigue resistance, wear resistance, heat resistance, high melting point, ultraviolet ray resistance and the like; the wear resistance is about 8 percent higher than that of the like products, the fracture strength is 10 percent higher than that of the like products, the compressive strength is high and the structure is reasonable, attractive and practical.

Owner:浙江四兄绳业有限公司

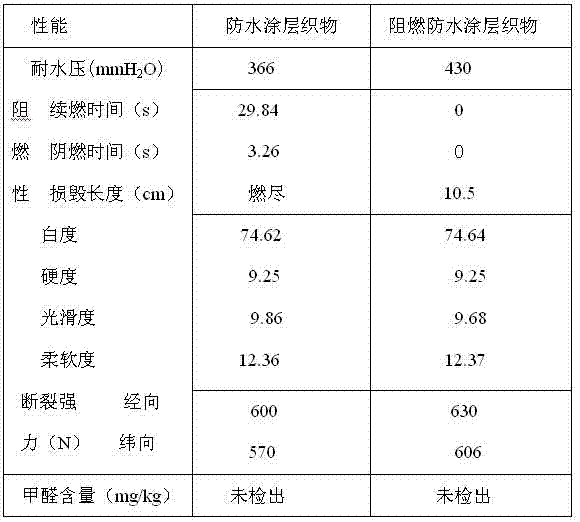

Method for finishing environment-friendly flame-retardant waterproof coating fabric

The invention discloses a method for finishing an environment-friendly flame-retardant waterproof coating fabric, comprising the following steps of: preparing a polyester fabric, carrying out pretreatment of water repellence, finishing a coating, carrying out after-treatment of water repellence and producing a finished product. The flame retardant adopted by the method is a layered anion inorganic magnesium-aluminium hydrotalcite which is similar to the magnesium hydroxide and the aluminum hydroxide in structure and composition. The layered anion inorganic magnesium-aluminium hydrotalcite can release a large amount of water and carbon dioxide after being heated to decompose and absorb a large amount of heat at the same time so that the temperature of a combustion system is reduced. The water vapour and the carbon dioxide released after the layered anion inorganic magnesium-aluminium hydrotalcite is heated to decompose have the functions of diluting and blocking combustible gases. The aluminum and magnesium oxides generated from thermal decomposition and the carbide formed during the combustion of polymer materials can form a protective film on the surface of the material so that the further intrusion of oxygen is blocked and the flame-retarding effect is achieved. The solid product generated from the decomposition of hydrotalcite particles has a very large specific surface area and strong alkalinity and can absorb the acidic gases and the smoke released during the thermal decomposition of the material to fulfill the function of suppressing and abating smoke.

Owner:ZHEJIANG SCI-TECH UNIV

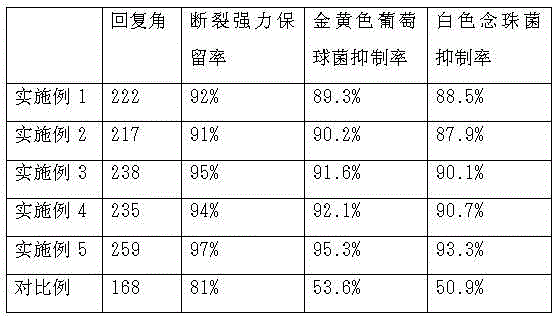

Anti-wrinkle antibiotic finishing agent as well as preparation method and application thereof

ActiveCN104695219AImprove wrinkle resistanceEnhanced inhibitory effectVegetal fibresBiotechnologyCyclodextrin

The invention discloses an anti-wrinkle antibiotic finishing agent as well as a preparation method and application thereof. The anti-wrinkle antibiotic finishing agent comprises 0.8-2.6wt% of azelaic acid, 1.6-3.2wt% of sodium hydrogen phosphate, 2.5-4wt% of carboxymethyl chitosan, 3.3-5.6wt% of hydroxypropyl-beta-cyclodextrin, 3-6wt% of a perilla frutescens ethyl acetate extract, 3.5-7wt% of a rhizoma kaempferiae ethanol extract, 6-12wt% of polyglycerol monooleate and the balance of water. The preparation method comprises the following steps: (1) preparing the perilla frutescens ethyl acetate extract; (2) preparing the rhizoma kaempferiae ethanol extract; and (3) mixing and stirring the components according to the percentage by weight, and shearing, thereby obtaining the anti-wrinkle antibiotic finishing agent. The anti-wrinkle antibiotic finishing agent has the advantages of good anti-wrinkle effect, good antibiotic effect and wide application range.

Owner:SUZHOU INST OF TRADE & COMMERCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com