Method for finishing environment-friendly flame-retardant waterproof coating fabric

A technology of waterproof coating and flame retardant coating, which is applied in the directions of fiber treatment, textile and papermaking, fiber type, etc. The effect of increasing breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

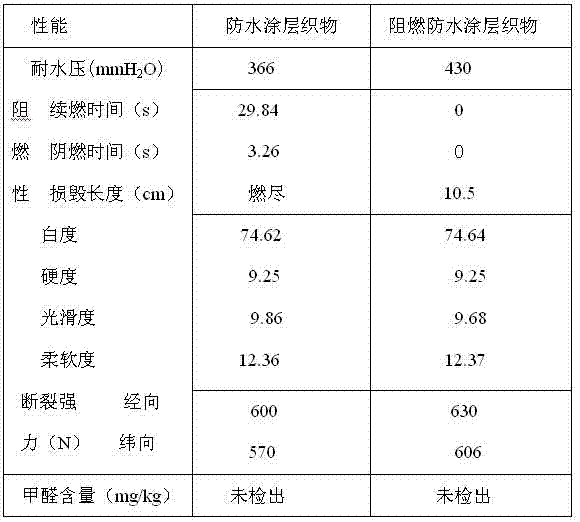

Examples

Embodiment Construction

[0015] The finishing method of the environmental protection flame retardant waterproof coating fabric of the present invention comprises the following steps:

[0016] 1. Polyester fabric preparation 。

[0017] 2. Front water repellency: Mix the water repellent agent with water to make a water repellent treatment agent. The dosage of the water repellent agent is 10g / L-50g / L. The padding process is adopted, the liquid rolling rate is 40%-70%, and the baking temperature is 160 ℃~180℃, time 20s~60s.

[0018] 3. Coating finishing: Mix 100 parts of coating agent, 2 parts of crosslinking agent and 5-10 parts of flame retardant and stir evenly to obtain an environmentally friendly flame retardant coating agent. Dry direct coating with an environmentally friendly flame retardant coating agent, the dry weight of the coating is 8g / m 2 ~20g / m 2 , Baking temperature 160 ℃ ~ 180 ℃, time 40s ~ 90s.

[0019] 4. Post-water repellency: Mix the water repellent agent with water to make a wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com