Polyurethane adhesive for compositing two-component PVC plate

A polyurethane adhesive, two-component technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of composite board deformation, low surface polarity, and reduced bond strength, etc., to achieve guaranteed Effects of dimensional stability, improvement of thixotropy, and improvement of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The special polyurethane adhesive of the two-component composite PVC sheet of the present embodiment is specifically as follows:

[0027] Component A: Weigh 18kg of castor oil, 12kg of polyether polyol, 5kg of silane coupling agent, 1kg of fumed silica, 56kg of calcium carbonate, and 8kg of 4A molecular sieve in a 200L reaction kettle. , -0.096Mpa dehydration until the moisture is below 500ppm, and the material is discharged.

[0028] Component B: Weigh 12kg of polyether polyol, 18kg of polyester polyol, 2kg of 1,4-butanediol, diphenylmethylene diisocyanate and polymethylene polyphenylisocyanate in a 200L reactor Respectively 50kg and 18kg, react at 80-100°C for 4-6h, control NCO% at 10-25%, and discharge.

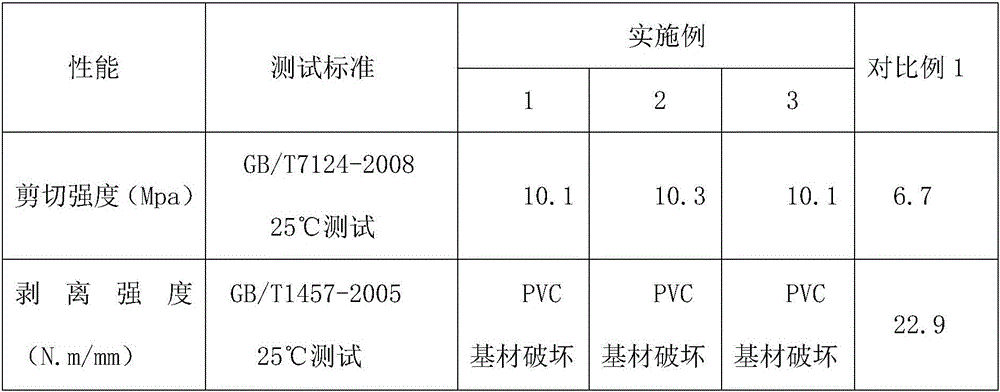

[0029] Mix components A and B at a mass ratio of 3:1 to make a stainless steel shear sample, and test the shear strength after 3 days at room temperature under the curing condition (GB / T7124-2008); use PVC / plate as the test sample, and cure under the condition of ...

Embodiment 2

[0031] The special polyurethane adhesive of the two-component composite PVC sheet of the present embodiment is specifically as follows:

[0032] Component A: Weigh 12kg of castor oil, 18kg of polyether polyol, 3kg of silane coupling agent, 2kg of fumed silica, 55kg of calcium carbonate and 10kg of 4A molecular sieve in a 200L reactor. ℃, -0.096Mpa dehydration until the water content is lower than 500ppm, and the material is discharged.

[0033] Component B: Weigh 5kg of polyether polyol, 15kg of polyester polyol, 4kg of 1,4-butanediol, diphenylmethylene diisocyanate and polymethylene polyphenylisocyanate in a 200L reactor Respectively 56kg and 18kg, react at 80-100°C for 4-6h, control NCO% at 10-25%, and discharge.

[0034] Mix components A and B at a mass ratio of 2:1 to make a stainless steel shear sample. The curing condition is normal temperature for 3 days and then test the shear strength (GB / T7124-2008); use PVC / plate as the test sample, and the curing condition is Tes...

Embodiment 3

[0036] The special polyurethane adhesive of the two-component composite PVC sheet of the present embodiment is specifically as follows:

[0037] Component A: Weigh 15kg of castor oil, 15kg of polyether polyol, 5kg of silane coupling agent, 2kg of fumed silica, 55kg of calcium carbonate and 8kg of 4A molecular sieve in a 200L reactor. ℃, -0.096Mpa dehydration until the water content is lower than 500ppm, and the material is discharged.

[0038]Component B: Weigh 6kg of polyether polyol, 18kg of polyester polyol, 3kg of 1,4-butanediol, diphenylmethylene diisocyanate and polymethylene polyphenylisocyanate in a 200L reactor Respectively 58kg and 15kg, react at 80-100°C for 4-6h, control NCO% at 10-25%, and discharge.

[0039] Mix components A and B at a mass ratio of 3:1 to make a stainless steel shear sample, and test the shear strength after 3 days at room temperature under the curing condition (GB / T7124-2008); use PVC / plate as the test sample, and cure under the condition of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com